Patents

Literature

1208results about How to "No displacement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Controllable released biological ceramic thrombus filter and manufacturing method thereof

InactiveCN101147705ANo connection pointPermanent placementBlood vessel filtersThrombusLaser engraving

The present invention relates to a controllably-released bioceramic thrombus filter and its preparation method. Said thrombus filter is made up by using laser engraved metal tube, its end portion is equipped with a combination portion matched with a conveying portion, its centre is equipped with an elastic wire and its surface is convered with a layer of bioceramic membrance. It can be temporarily placed into blood vessel of human body, also can be permanently placed in the blood vessel of human body. Said invention also provides the concrete working principle of said thrombus filter.

Owner:LIFETECH SCIENTIFIC (SHENZHEN) CO LTD

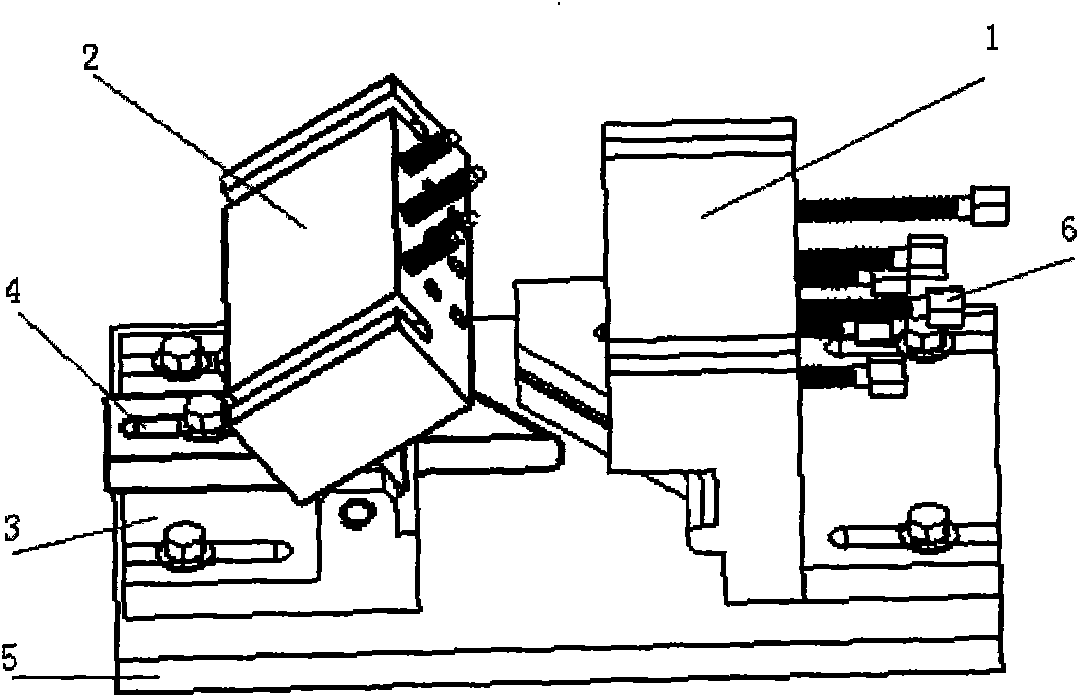

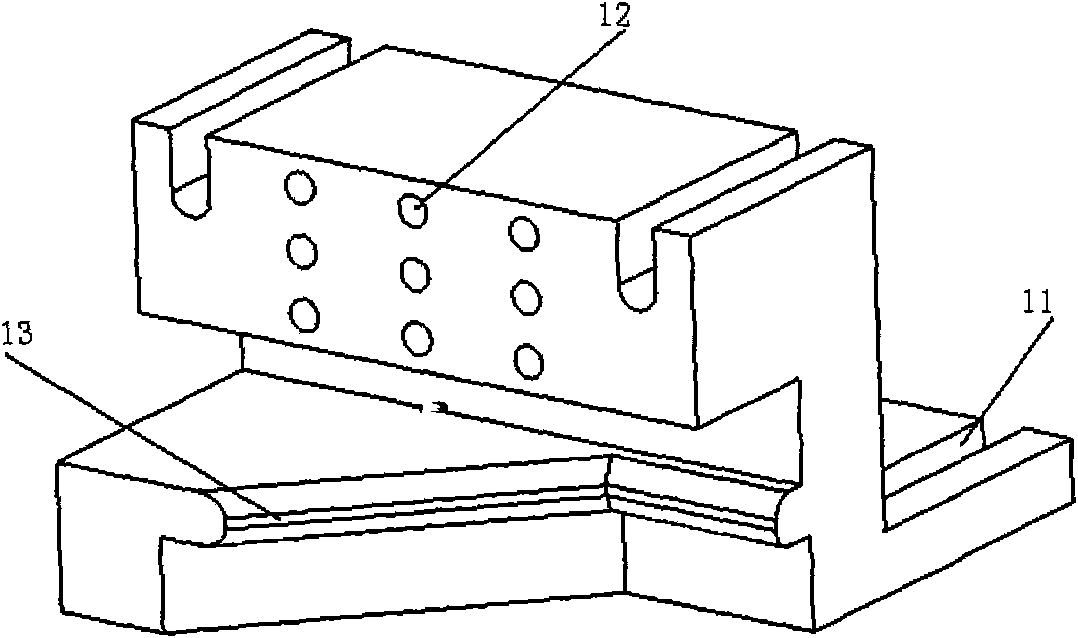

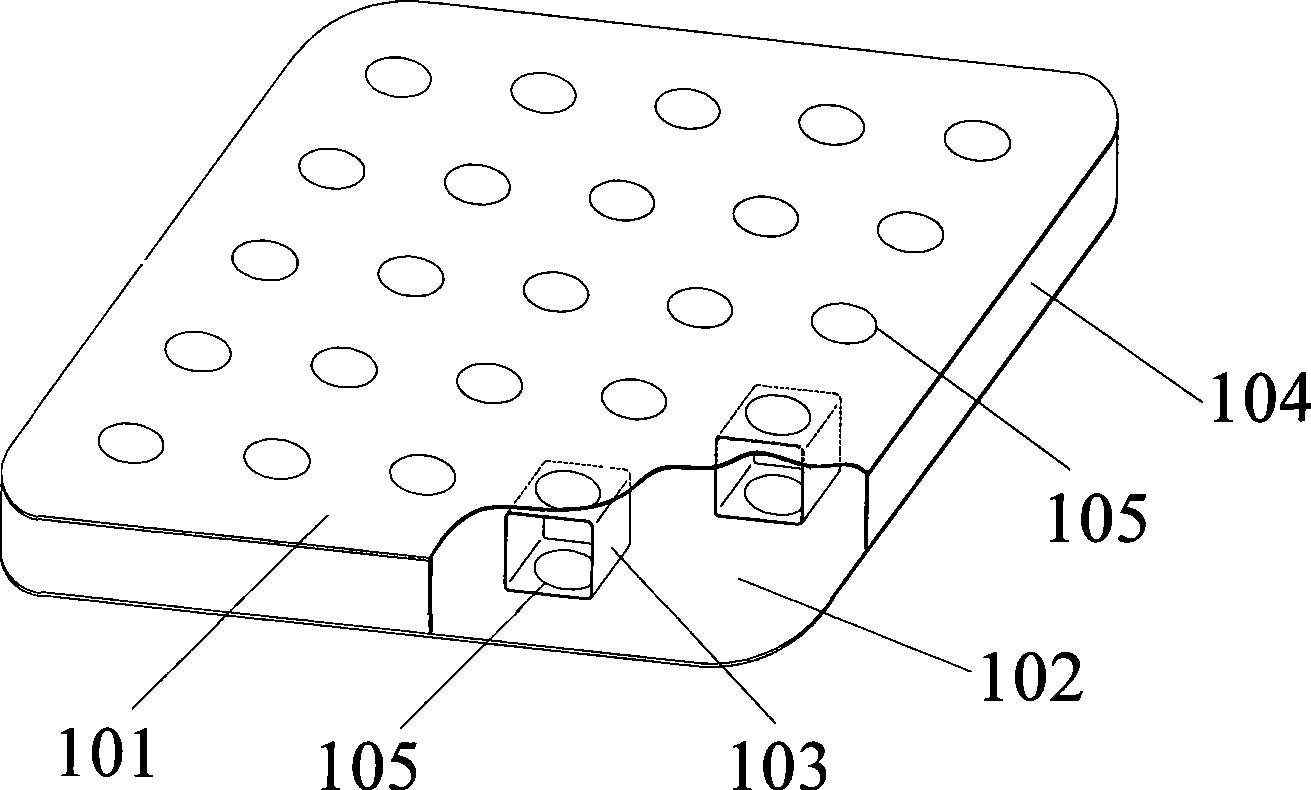

Flexible fixture device and operation method thereof

InactiveCN101570008APrecise positioningNo displacementWork holdersPositioning apparatusEngineeringMachining process

The invention provides a flexible fixture device and an operation method thereof. The device comprises a root pre-tightening block, an adjustable fixture block, an adjustable fixture support, a clamping block, a base and a clamping fixed piece, wherein the root pre-tightening block and the adjustable fixture support are fixed on two sides of the base respectively through a position regulating mechanism thereon; the clamping block is fixed on the adjustable fixture support through a position regulating mechanism thereon; the adjustable fixture block is hinged on the adjustable fixture support; the root pre-tightening block and / or the adjustable fixture block are / is provided with through holes back and forth respectively; and the through holes are inserted into the clamping fixed piece which performs flexible clamping on the surfaces of processed parts, ensures that the processed parts can obtain effective and even clamping force, and prevents the loosening and shifting during processing. Because the adjustable clamping block and clamping screws are adopted to clamp and position the roots and planes of vanes respectively, the reliable positioning of the vanes is ensured during processing, and shifting is avoided. The whole fixture device has simple structure, reliability, durability and simple operation, and provides good basis for processing and repairing vane parts in high quality.

Owner:GUANGDONG UNIV OF TECH

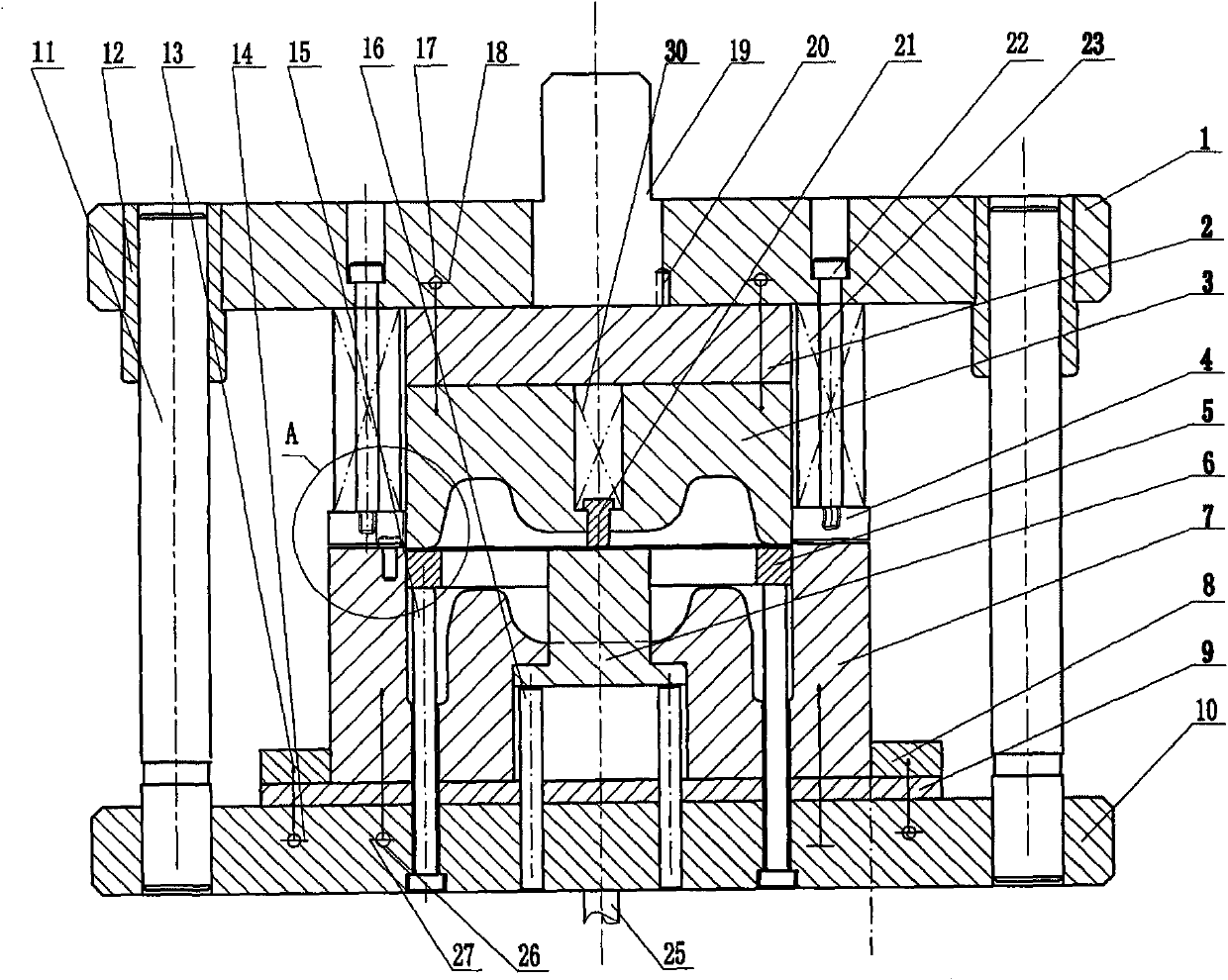

Punching device for buffer support of rear shock absorber of automobile

The invention discloses a punching device for a buffer support of a rear shock absorber of an automobile, which comprises an upper die plate, a lower die plate, a die plate motion guide device, a male die, an upper stripper plate, a female die and a lower stripper plate, and is characterized in that the male die is fixed on the lower surface of the upper die plate, the upper stripper plate is fixed on the lower surface of the upper die plate through a stripper bolt penetrating a stripper spring, the female die is fixed on the upper surface of the lower die plate, the lower surface of the upper striper plate is in contact with the female die, the lower stripper plate is fixed with a tray of a punch through a pull rod penetrating the lower die plate, a stripper push rod is further arranged between the lower stripper plate and the tray of the punch, the male die and the upper stripper plate can slide relatively, and the female die and the lower stripper plate can slide relatively. The punching device can well realize blanking and forming once in the device, save a large number of process steps, greatly save the production cost, improve the production efficiency and ensure the product quality; furthermore, the punching device has low manufacturing cost, economy and durability.

Owner:CHONGQING HUAQING AUTOMOBILE PARTS

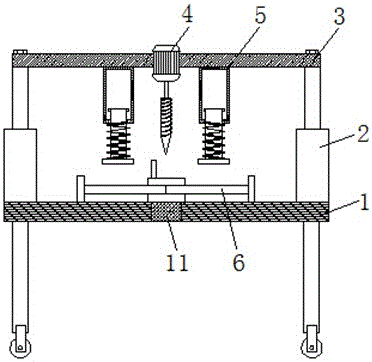

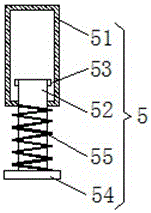

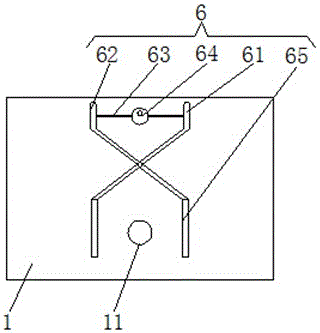

Drilling machine for hardware machining

InactiveCN105834471ASimple structureReasonable designPositioning apparatusMetal-working holdersMaterial consumptionMachining

The invention discloses a drilling machine for metal processing, which comprises a workbench and a drilling device. A reserved drilling hole is opened in the middle of the workbench, and a horizontal clamping device is arranged on the top of the workbench. The workbench Electric lifting columns are fixedly installed on both sides of the top of the table, and the two electric lifting columns are symmetrically arranged on both sides of the horizontal clamping device, and the tops of the two electric lifting columns are connected by a horizontal plate, and the drilling device is fixedly installed on the The middle part of the horizontal plate and both sides of the drilling device are provided with vertical pressing devices. The drilling rig for metal processing is simple in structure and reasonable in design. It can vertically press and horizontally clamp the hardware parts to be drilled through the vertical pressing device and the horizontal clamping device, and can ensure The hardware parts will not be displaced, which not only reduces the loss of materials, increases the accuracy of drilling, but also greatly improves the working efficiency of drilling.

Owner:WUXI GANGSHENG HEAVY EQUIP CO LTD

Penetration prevention safe tyre cyclic chain sheet belt

ActiveCN1754708AGuaranteed safe operationLess chance of blowoutPneumatic tyre reinforcementsTruckEngineering

Owner:HUNAN ZHONGMAN TIRE TECH CO LTD

Sand-line iron mould casting process for grey cast iron flywheel housing of diesel engine

ActiveCN102728790AGood size consistencyPut an end to the phenomenon of sand swellingFoundry mouldsFoundry coresDieselingSurface roughness

The invention discloses a sand-line iron mould casting process for grey cast iron flywheel housings of diesel engines. In the invention, upper and lower sand-line iron mould processes are used, so that produced grey cast iron flywheel housing blanks have favorable geometric size precision which can be up to CT8 grade, favorable surface roughness which can be up to 12.5 microns and favorable mechanical properties, the blank processing has small allowance which can be controlled in 3mm, small flashing distortion which can be controlled in 0.5mm and small cleaning workload, so that the labor environment is improved, the environmental protection is improved, the yield is high and can be up to 95%, and the national policies of energy conservation, environmental protection and sustainable development are met.

Owner:JIANGSU SONGLIN AUTOMOBILE PARTS

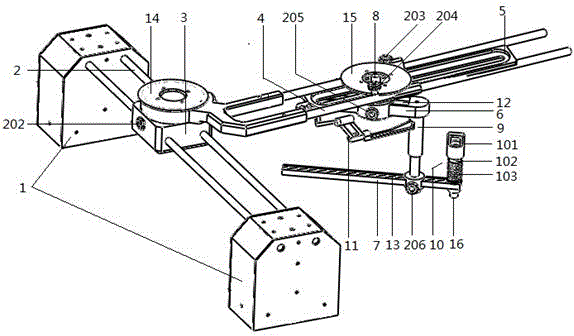

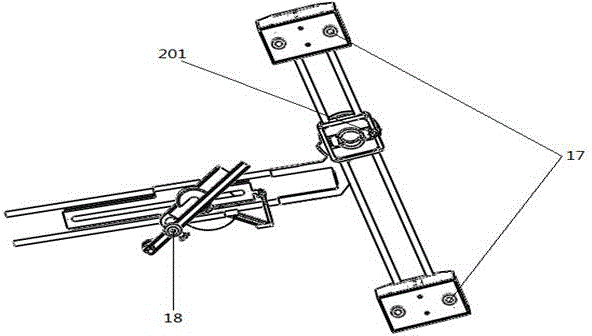

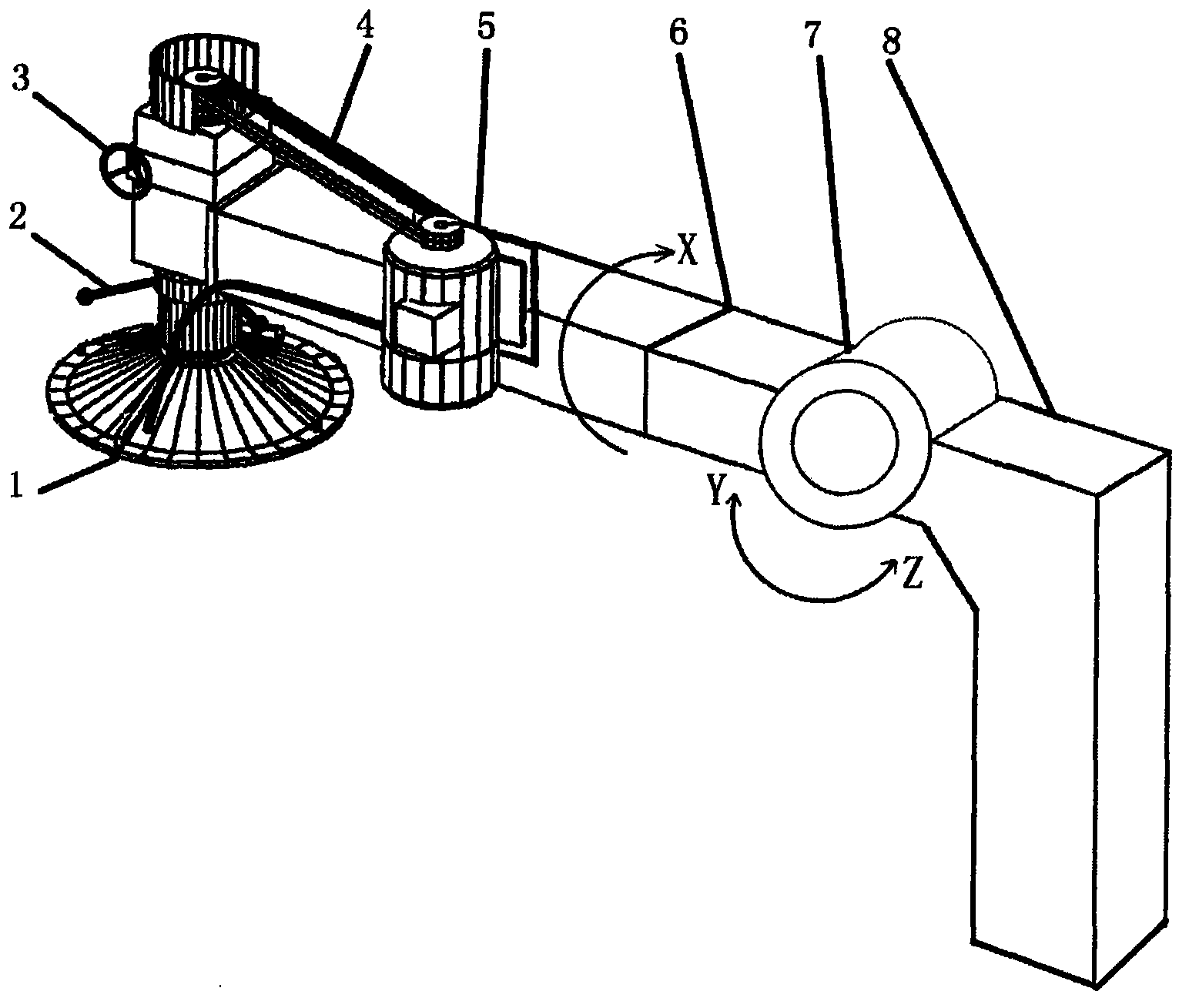

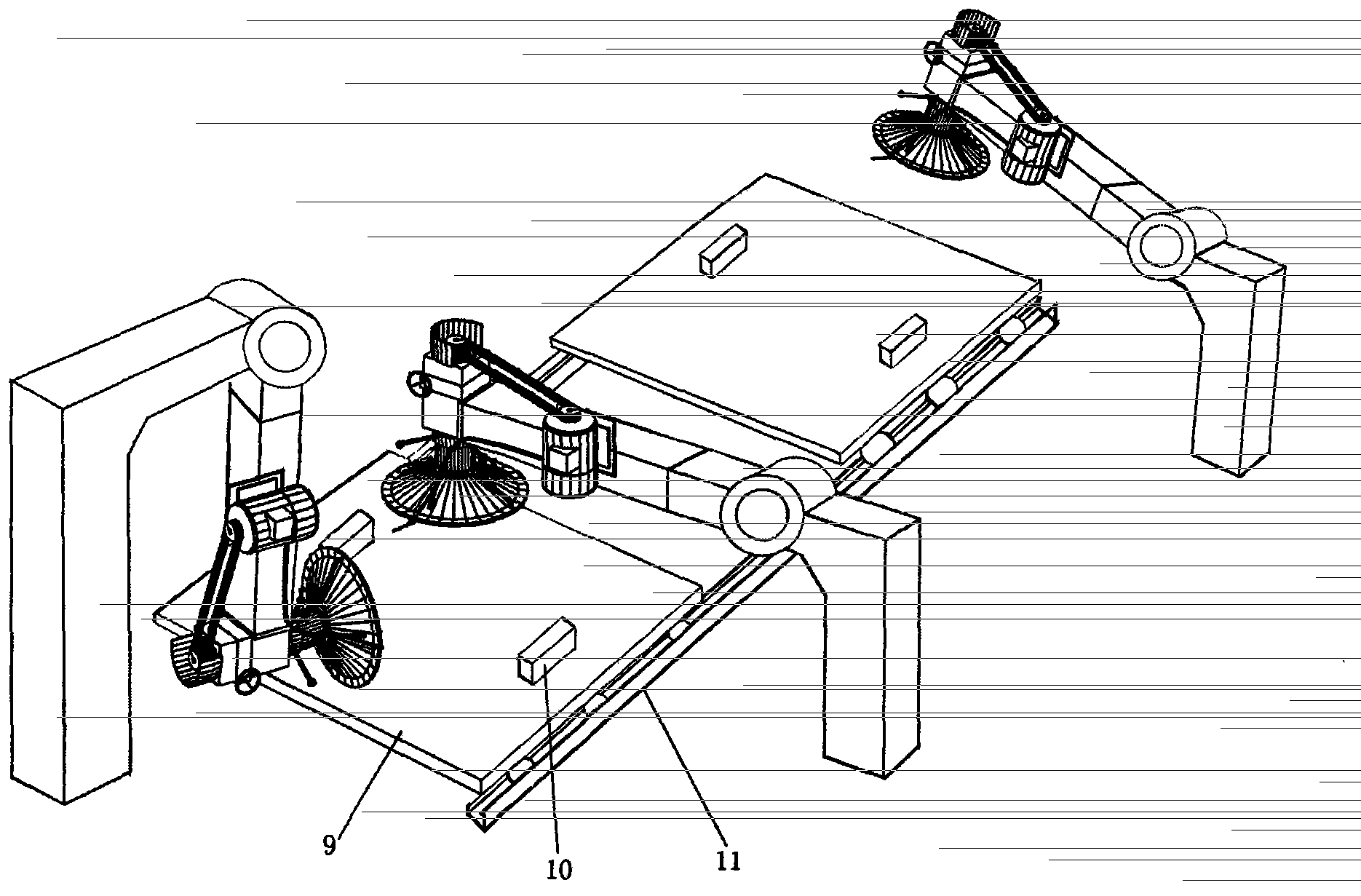

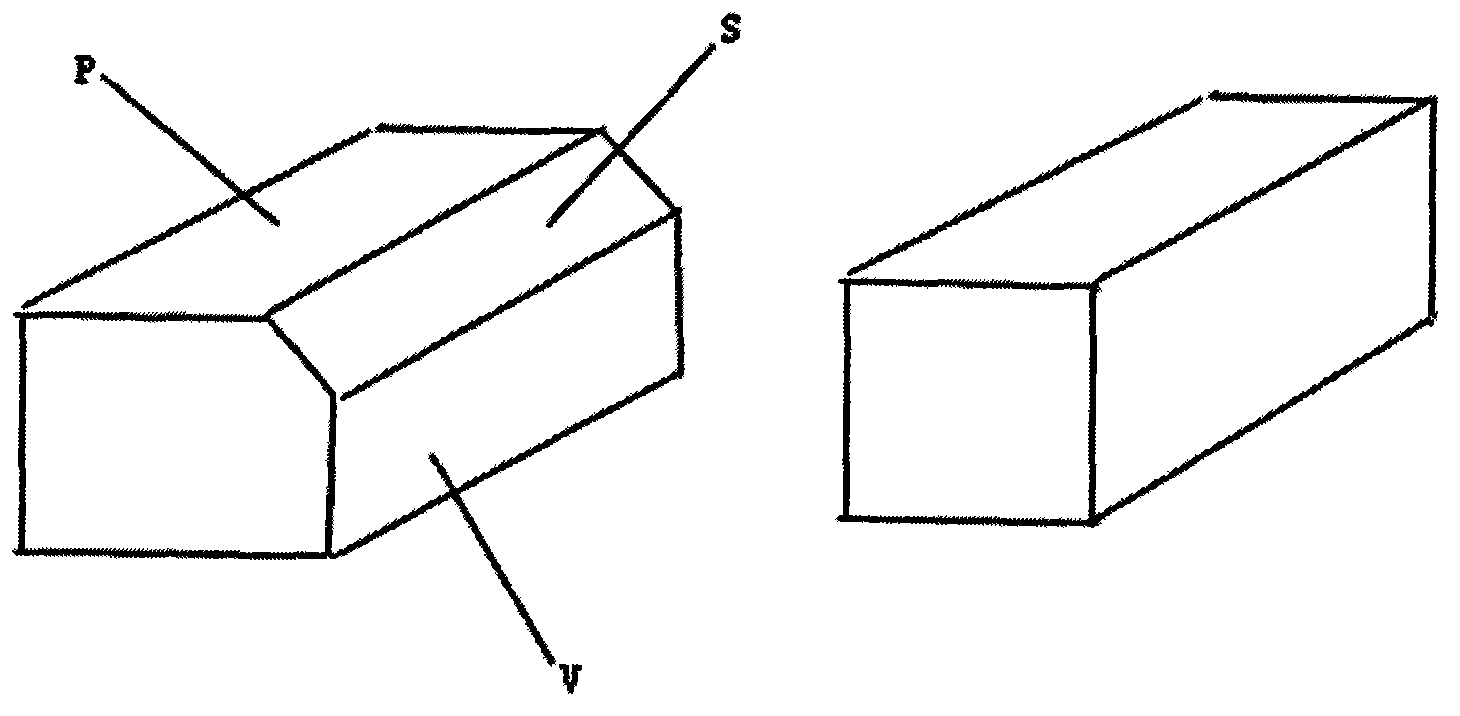

Integral plotter

The invention provides an integral plotter, and relates to a plotter. The integral plotter comprises two bases (1) and a first polished rod shaft (2), wherein the first polished rod shaft (2) is used for connecting the two bases (1); a slide block (3) is arranged on the first polished rod shaft (2); one end of a second polished rod shaft (4) is hinged to the first polished rod shaft (2) through the slide block (3); a slide groove (5) is formed in the second polished rod shaft (4); an M-shaped rod (6) is arranged under the slide groove (5), and is hinged to the slide groove (5) through a slide block (8); an N-shaped rod (7) is arranged at the parallel surface under the M-shaped rod (6), and is hinged to the M-shaped rod (6) through a shaft sleeve (9); a chalk support frame (10) is arranged at one end of the N-shaped rod (7). The integral plotter has the advantages that by integrating multiple plotting tools, the plotting of lines, angles, circles, circular arcs and ellipses is realized; the carrying is convenient, the operation is simple, the fixing is convenient, and the accuracy of plotted drawings is higher.

Owner:YANTAI NANSHAN UNIV

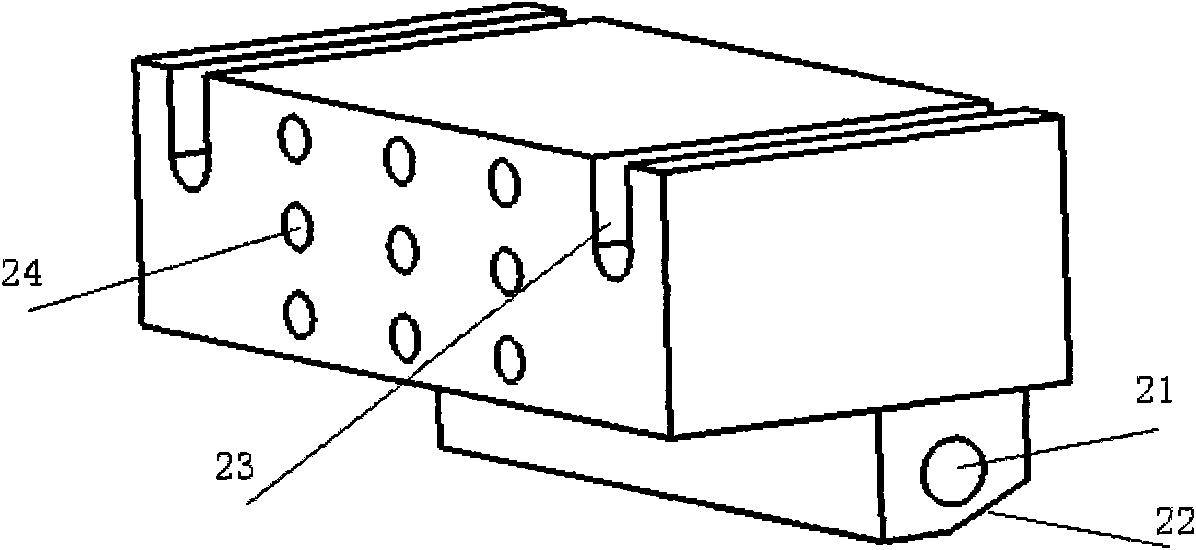

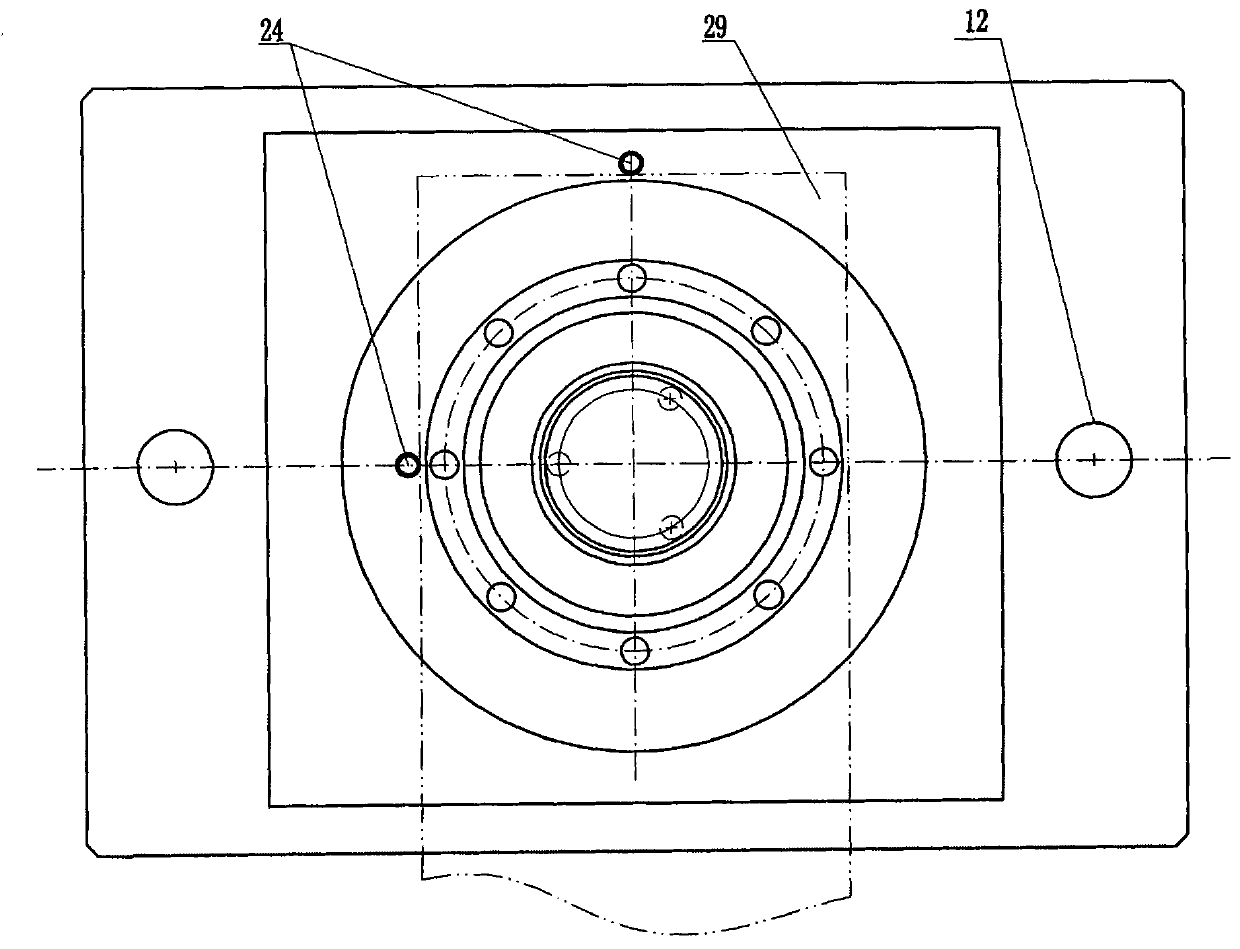

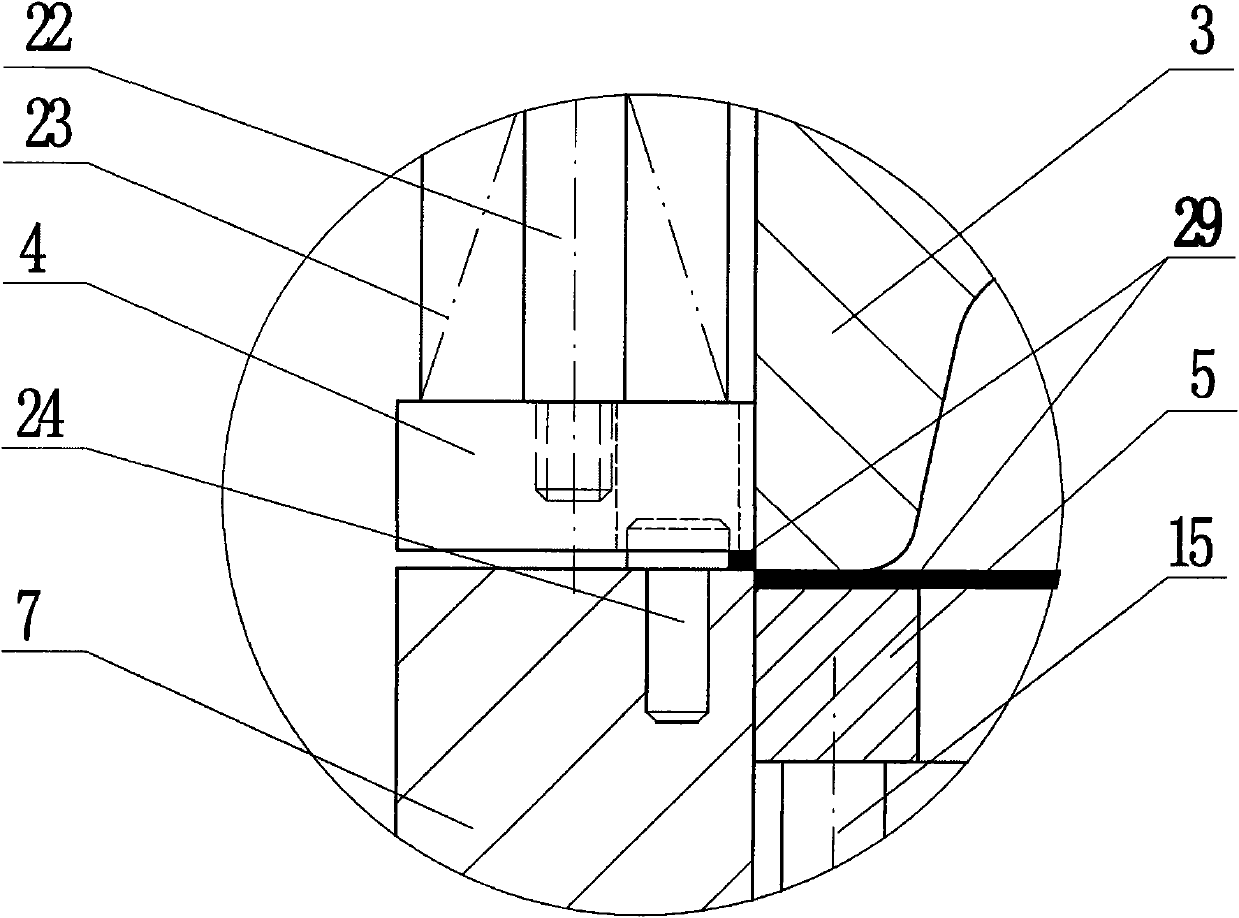

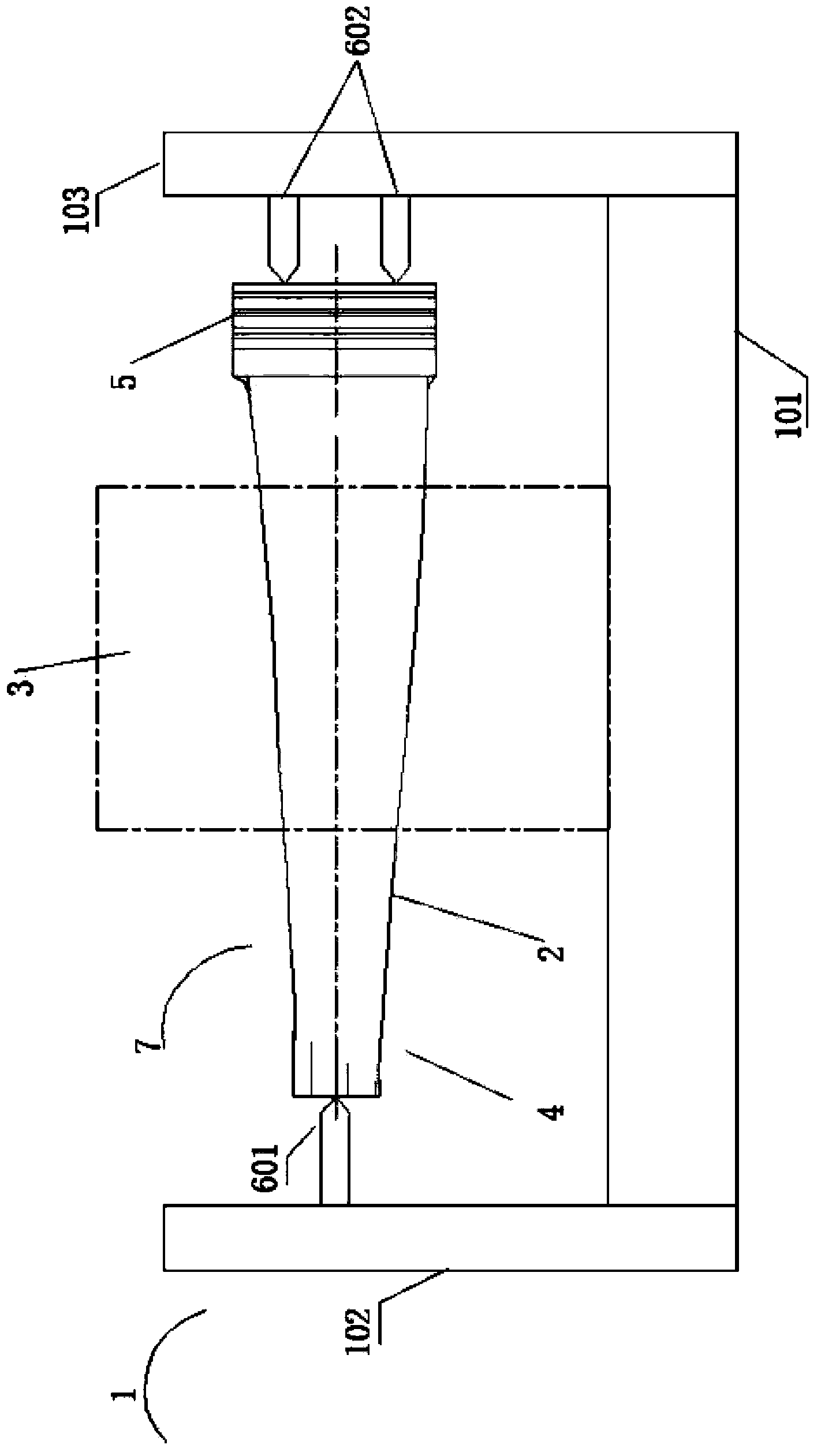

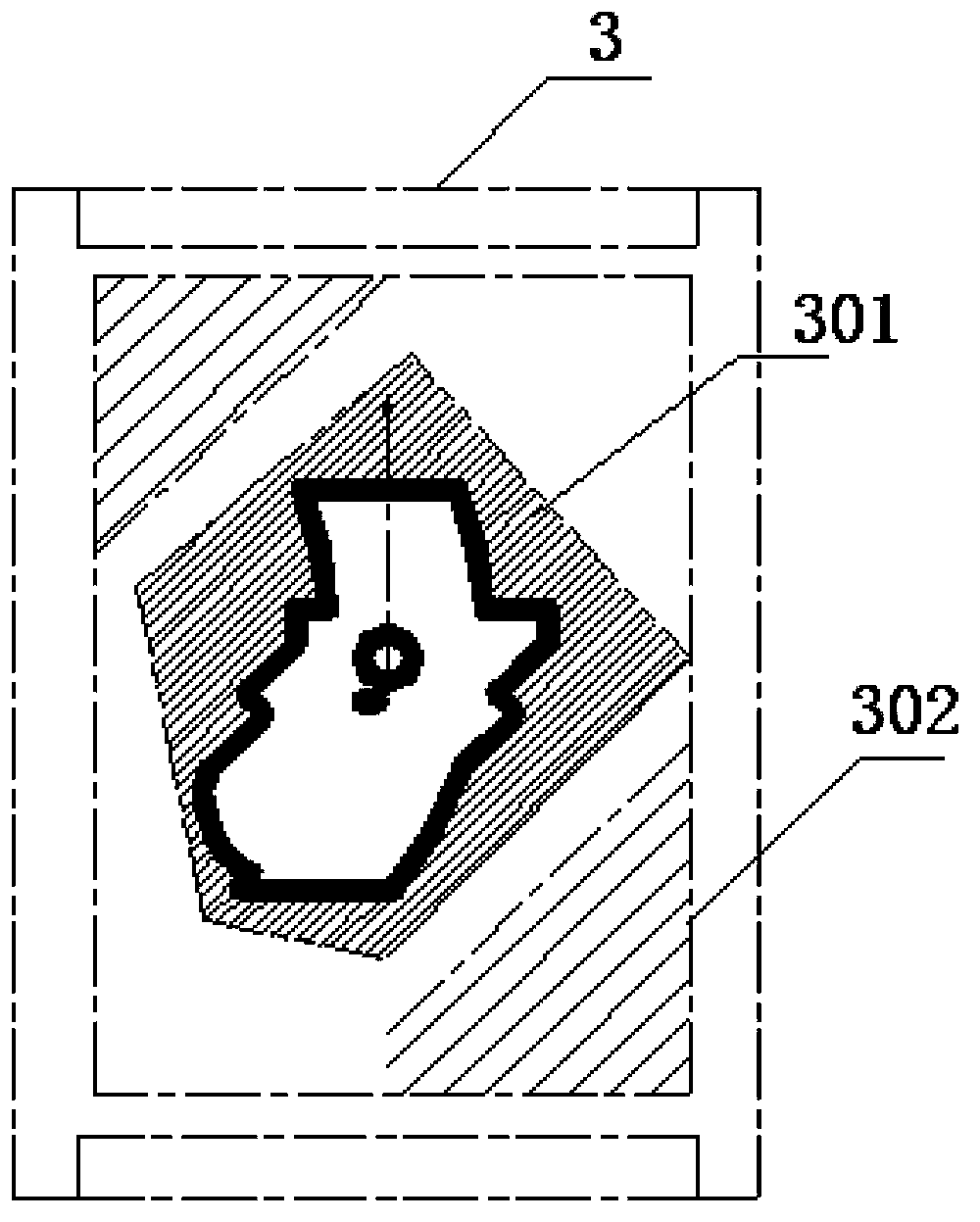

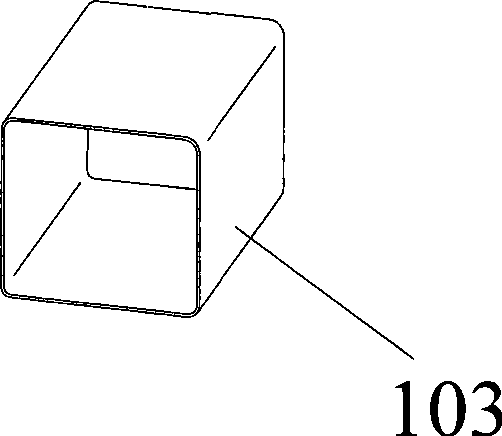

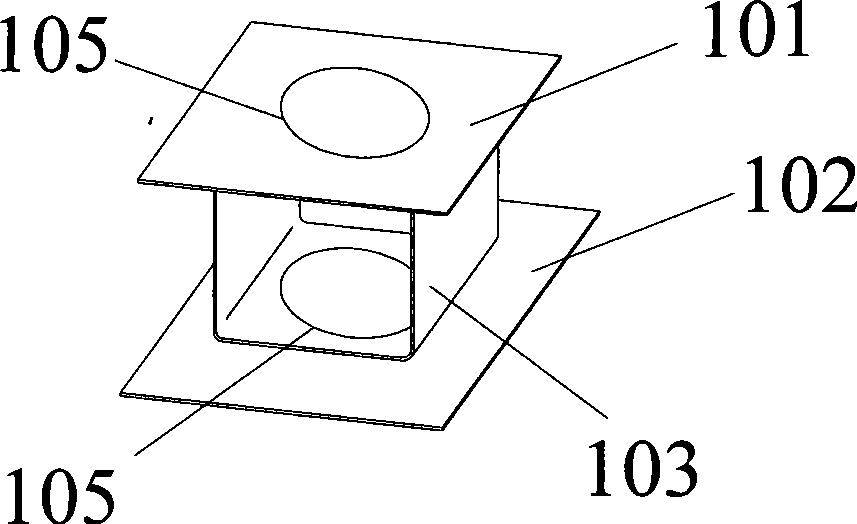

Low-melting-point alloy casting positioning technology in turbine blade machining

ActiveCN103350213AGuaranteed machining accuracyShorten the timePositioning apparatusMetal-working holdersSteam turbine bladeAlloy

The invention discloses a low-melting-point alloy casting positioning technology in turbine blade machining. The low-melting-point alloy casting positioning technology is achieved through the following steps: (1) conducting rough machining on a blade; (2) matching the blade with a positioning tool, wherein the blade is transversely arranged after the rough machining on the blade is completed, a blade crown at the head of the blade is abutted against a single tip of the positioning tool, a blade root at the tail of the blade is abutted against double tips of the positioning tool, and a blade steam passage in the middle of the blade penetrates through a positioning square box; (3) casting tin-bismuth alloy molten liquid molten at a certain temperature in the positioning square box, and casting and cooling the positioning square box at the same time until tin-bismuth alloy is solidified and fixed; (4) conducting fine machining on the blade crown and the blade root; (5) melting the tin-bismuth alloy again, pouring out the tin-bismuth alloy molten liquid from the positioning square box, and removing the positioning square box; (6) conducting fine machining on the blade steam passage. The low-melting-point alloy casting positioning technology in the turbine blade machining can meet the requirements for machining blades of various shapes and sizes, the positioning effect is good, and raw materials are greatly saved.

Owner:常州市三维技术成套设备有限公司

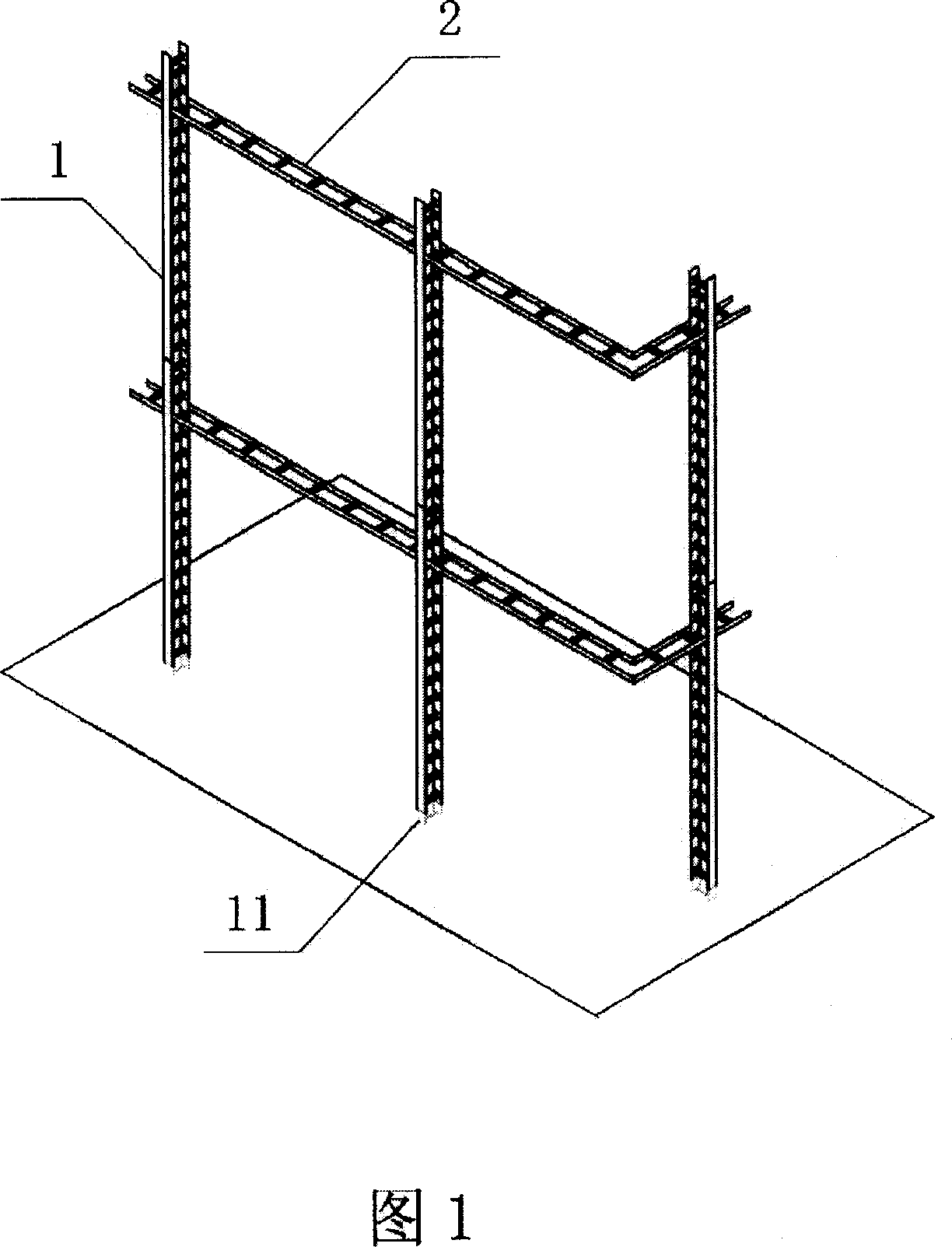

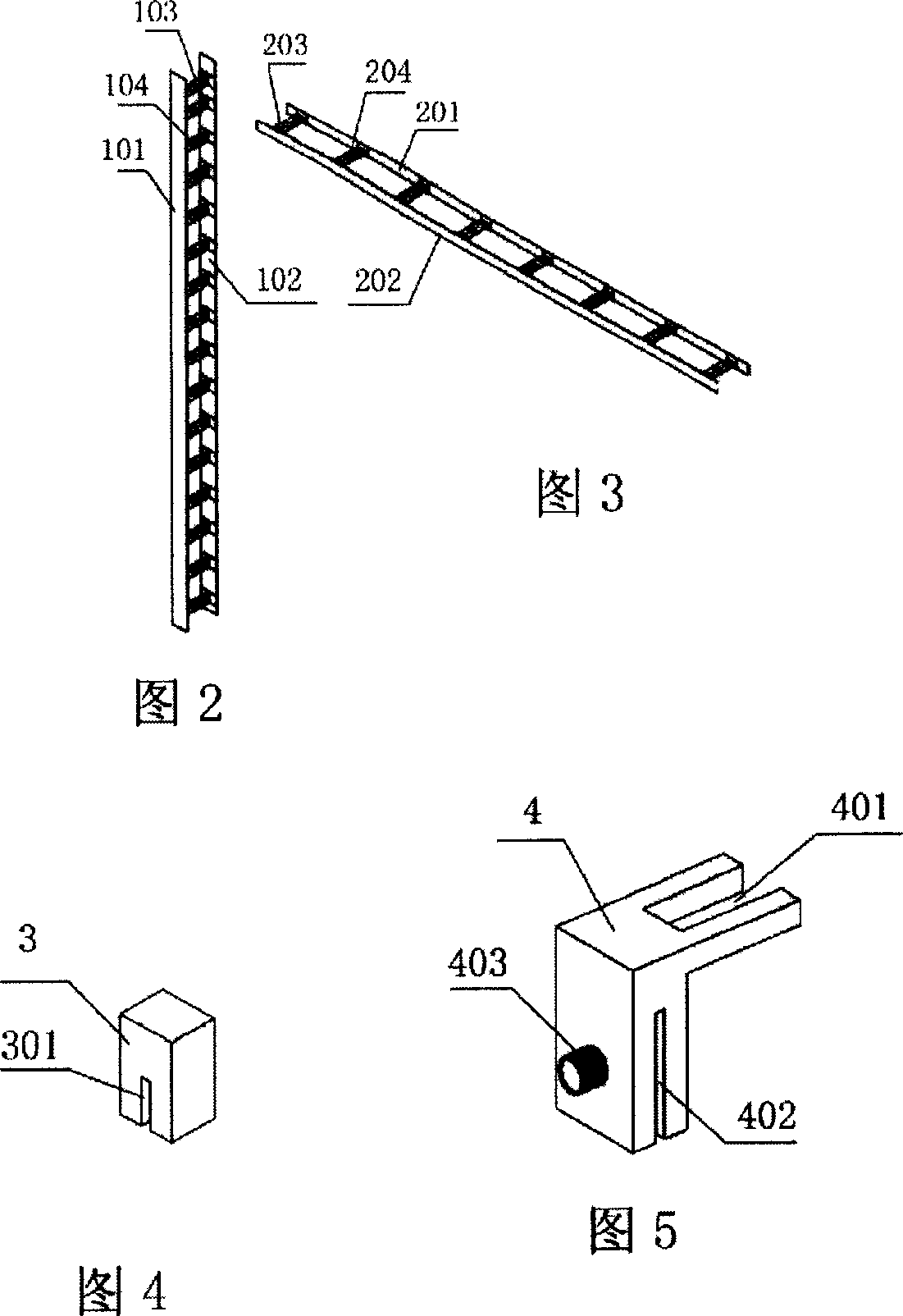

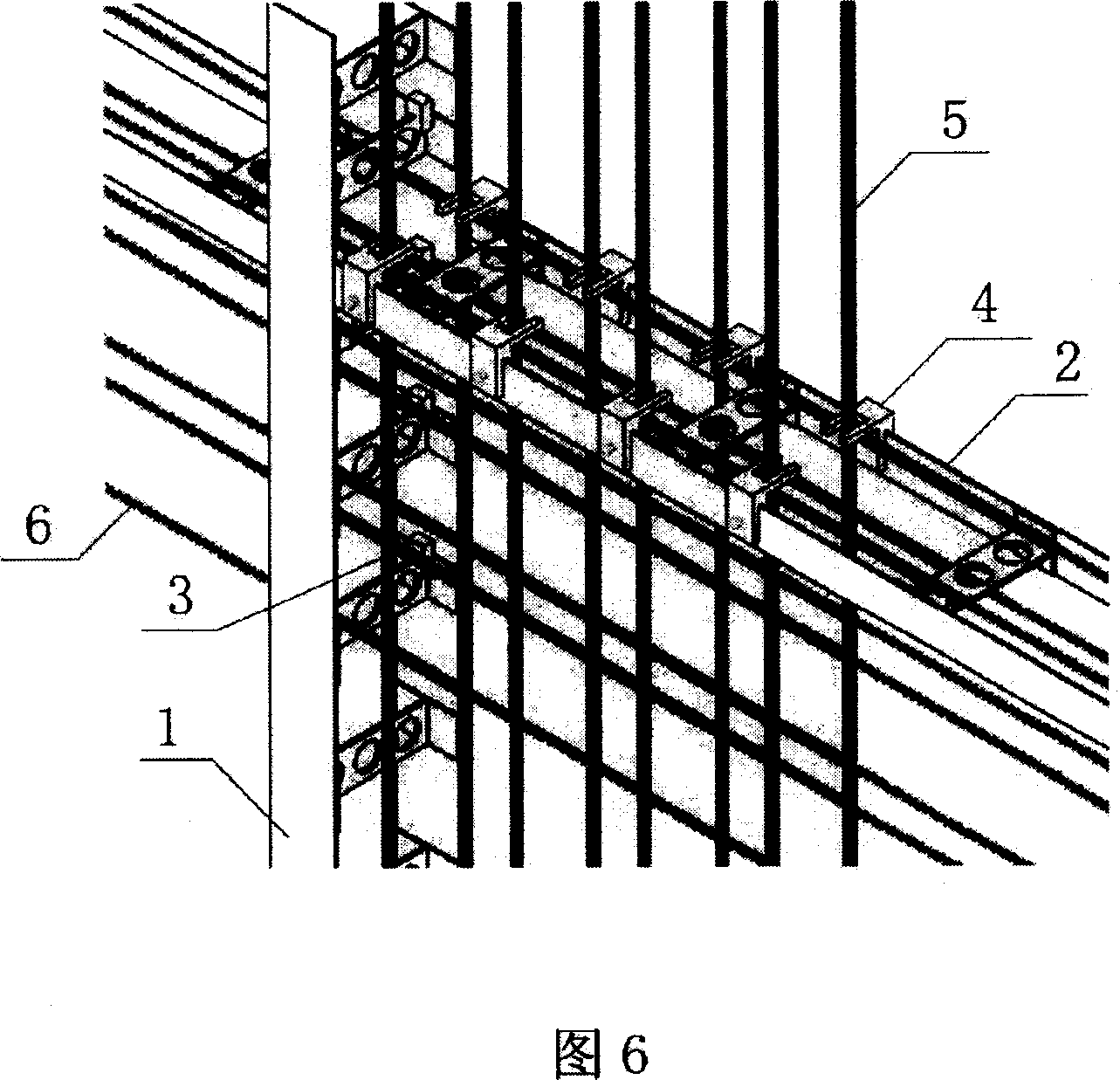

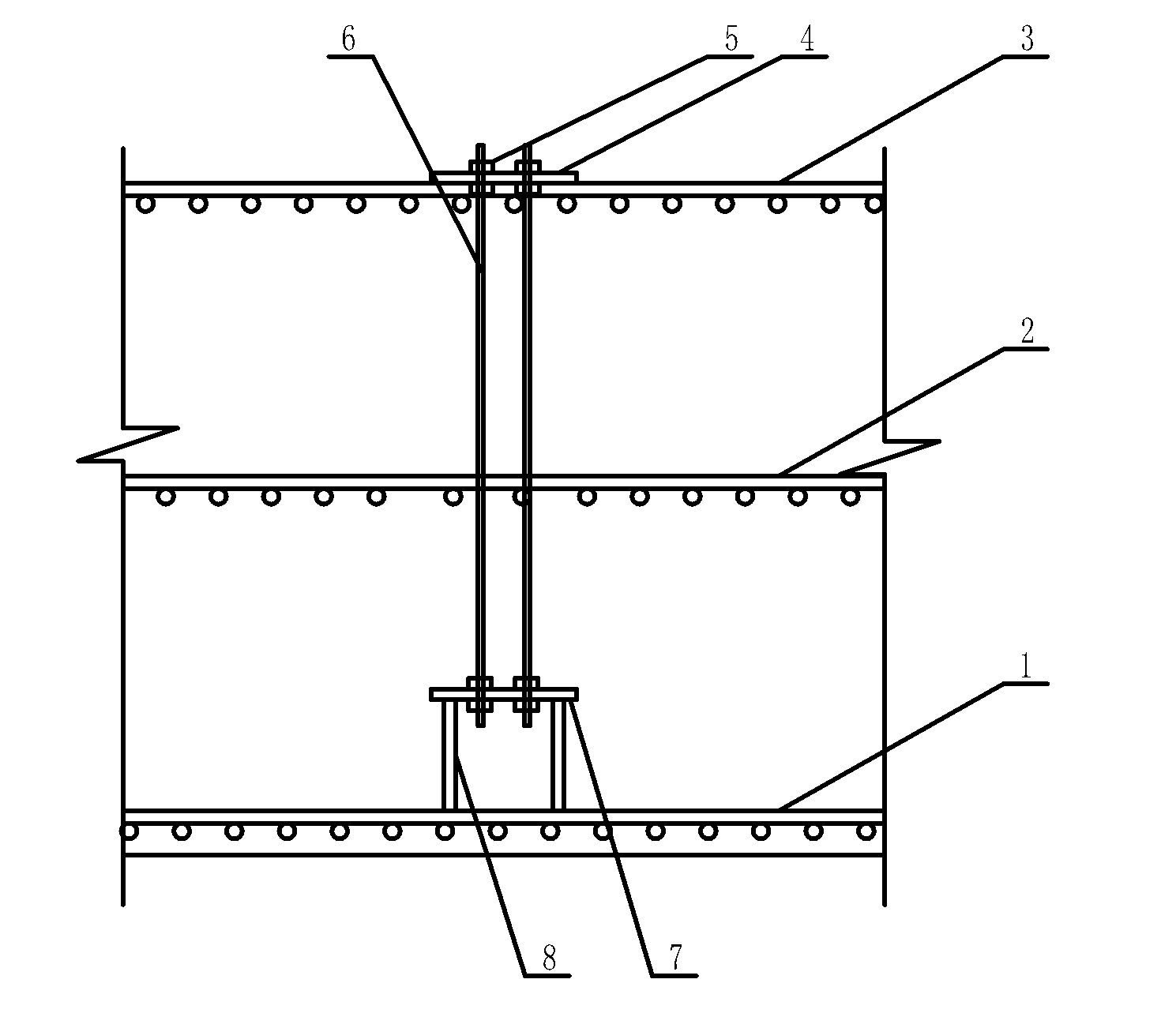

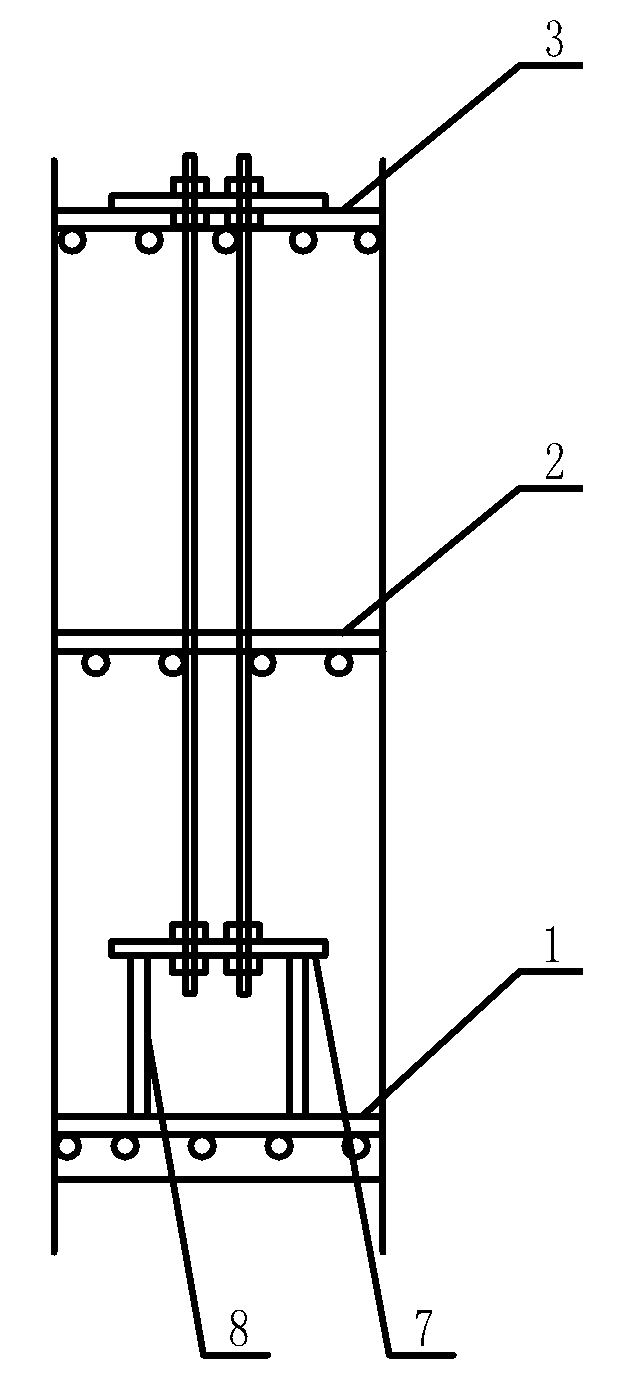

Concrete building reinforcing-bar precision positioning system and its construction method

InactiveCN1936228ANo displacementAvoid corrosionBuilding reinforcementsBuilding material handlingRebarPositioning system

The invention relates to a concrete construction reinforcing steel bar accurate locating system and the constructing method. It includes vertical localizer, horizontal positioning, vertical reinforcing steel bar locating block component, horizontal reinforcing steel bar locating block component, and pre-buried steel component. The vertical localizer is made up of inner board, external board, crosspiece fixation stairway stringer that is plumbed to vertical reinforcing steel bar and paralleled to horizontal reinforcing steel bar, and has the same thickness with wall and the same width with cavity of it. The invention could improve constructing speed and increase the constructing accuracy and entire rigidity of the reinforcing steel bar construction.

Owner:朱秦江

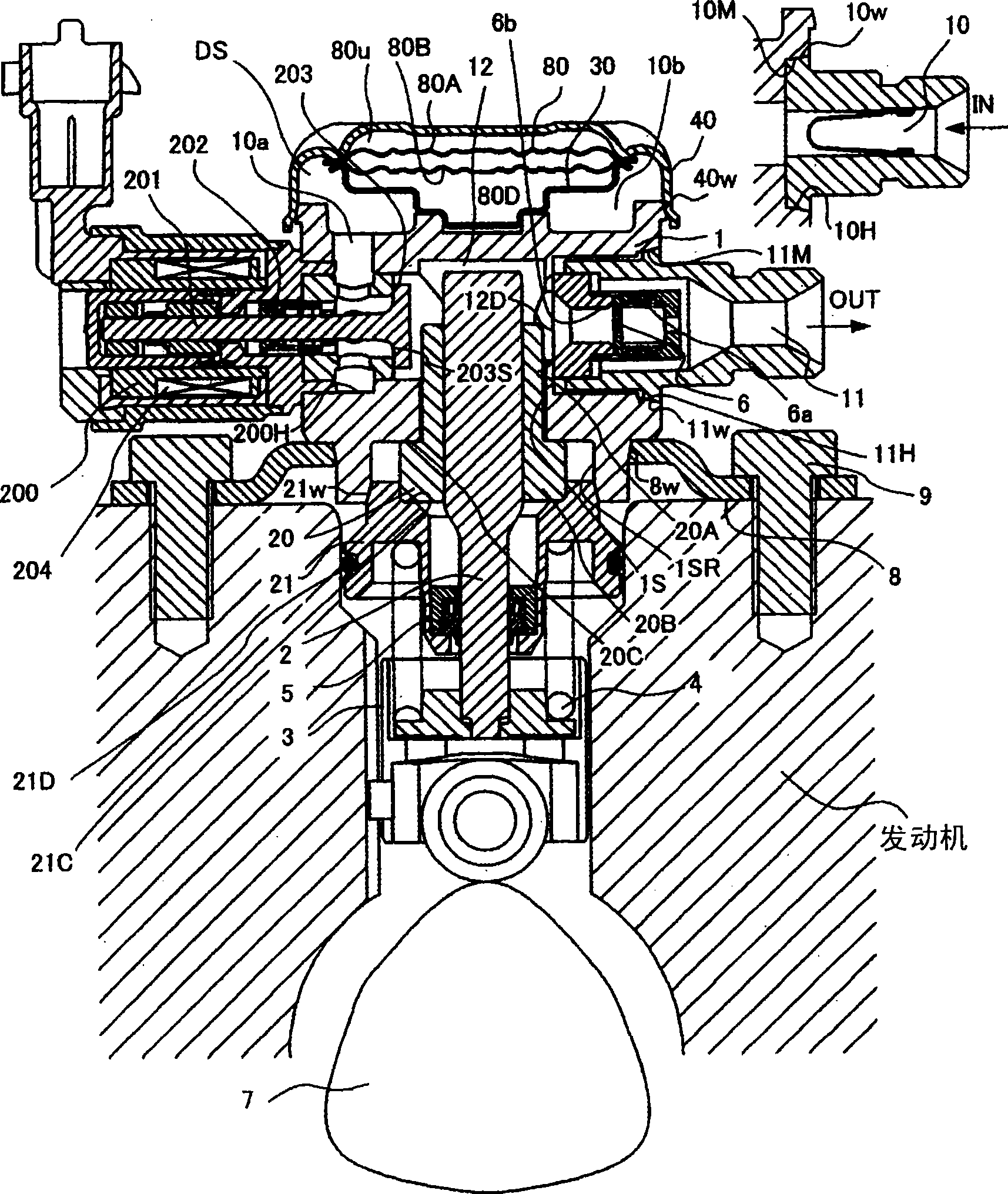

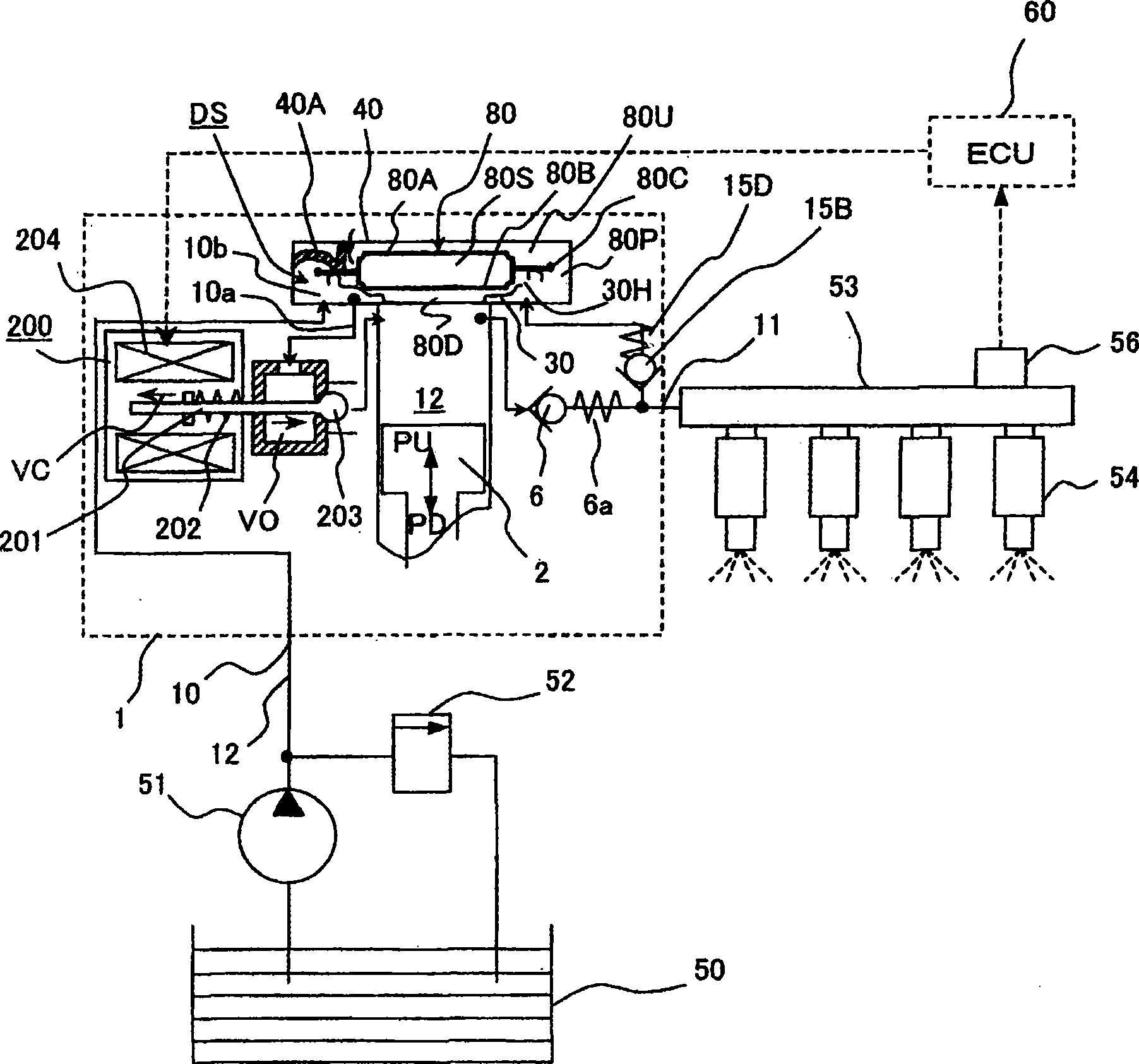

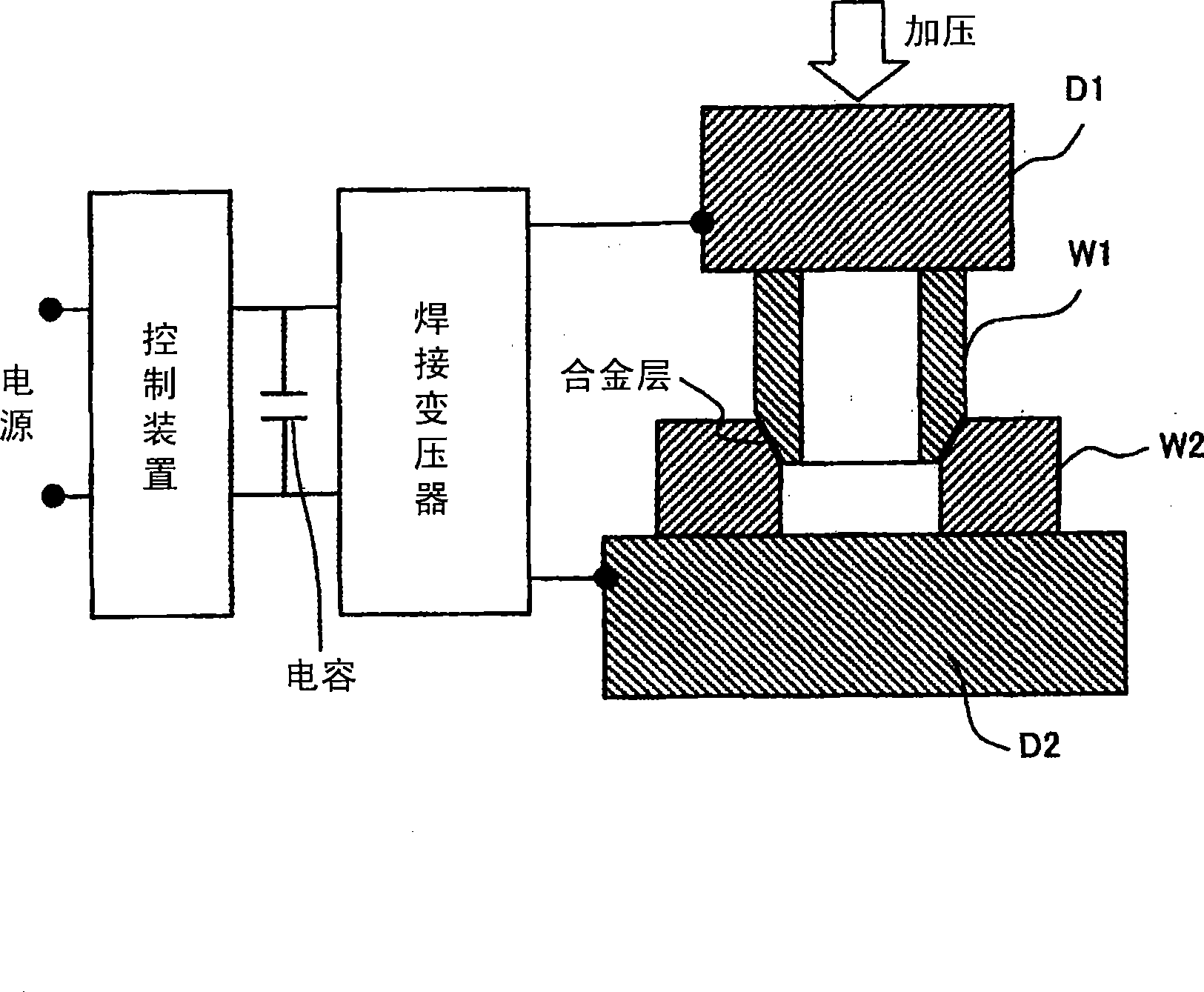

High-pressure fuel supply pump and the manufacturing method

InactiveCN101424235ARealize the joint functionRealize the sealing functionTubular articlesHollow articlesInlet valveMetallic materials

An object of this invention is to provide such a welded structure of and welding method for two metallic parts fitted together at a tubular section in a high-pressure fuel supply pump, that enables rapid joining of both metallic parts by staking (press-fitting included), screw fastening, and / or laser welding, offers high welding strength and sufficient fluid sealability, and keeps the metallic materials free from thermal changes in composition. While an electric current is supplied to any one of the welding connection surfaces formed between a pump housing and cylinder in a high-pressure fuel supply pump, between the pump housing and an installation flange, between the pump housing and an intake or discharge joint, between the pump housing and a pulsation-absorbing damper cover, between the pump housing and a relief valve mechanism, and between the pump housing and an electromagnetically driven intake valve mechanism, the particular two sections are pressed against each other to generate, along the connection surface, a plastic flow not causing melting or fusion due to heat, and form a diffusion-weld region at the connection surface by using the plastic flow and the application of the pressure.

Owner:HITACHI LTD

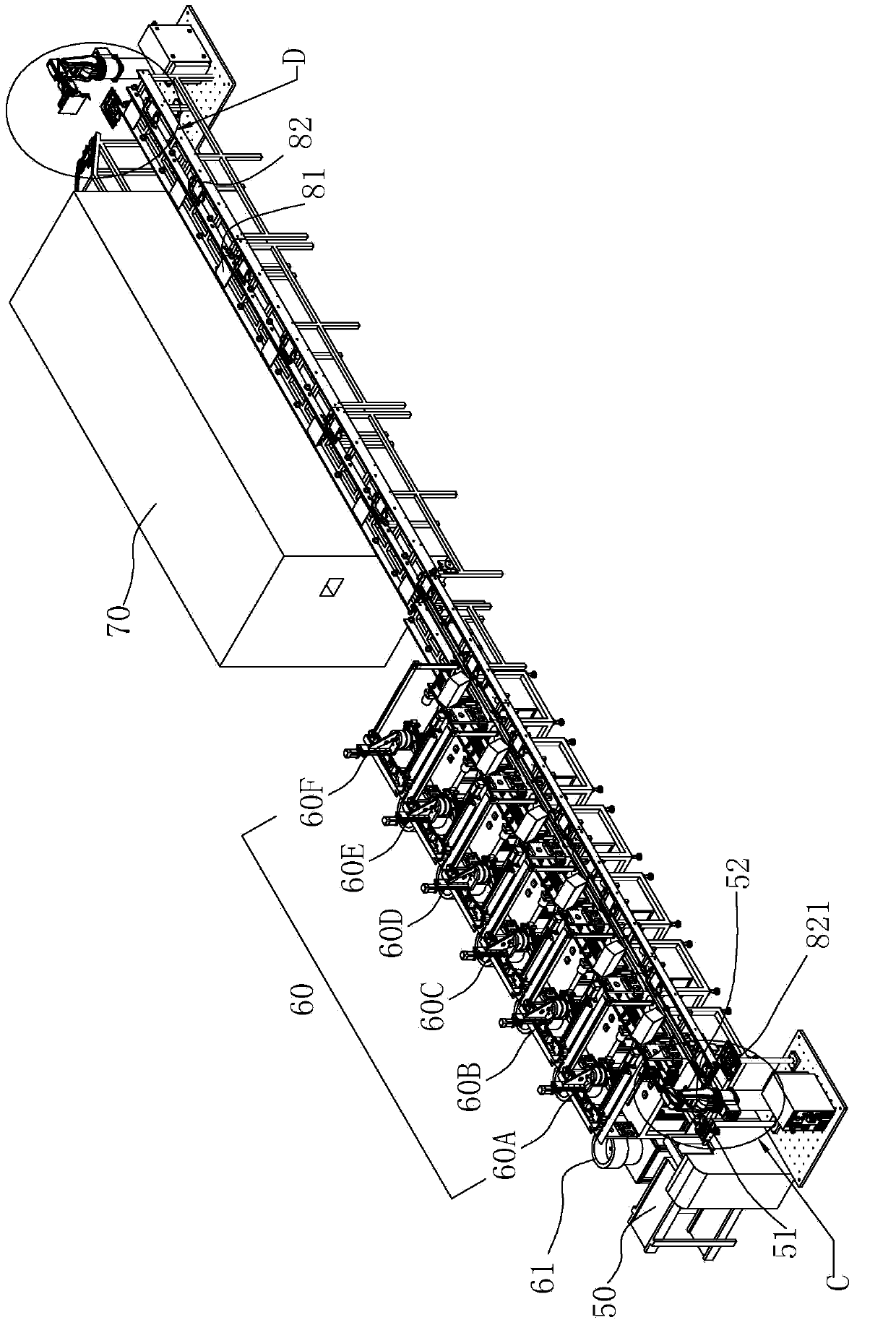

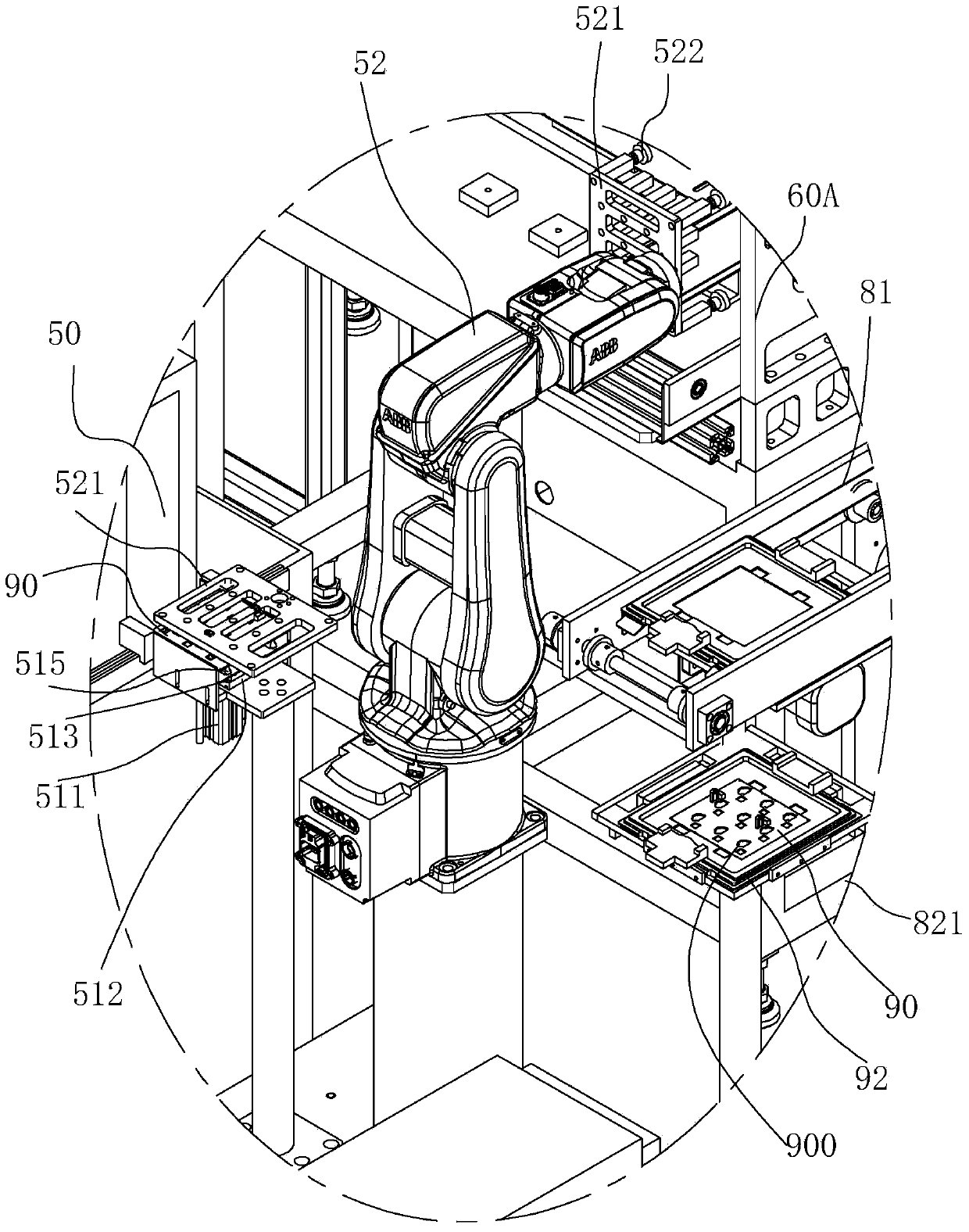

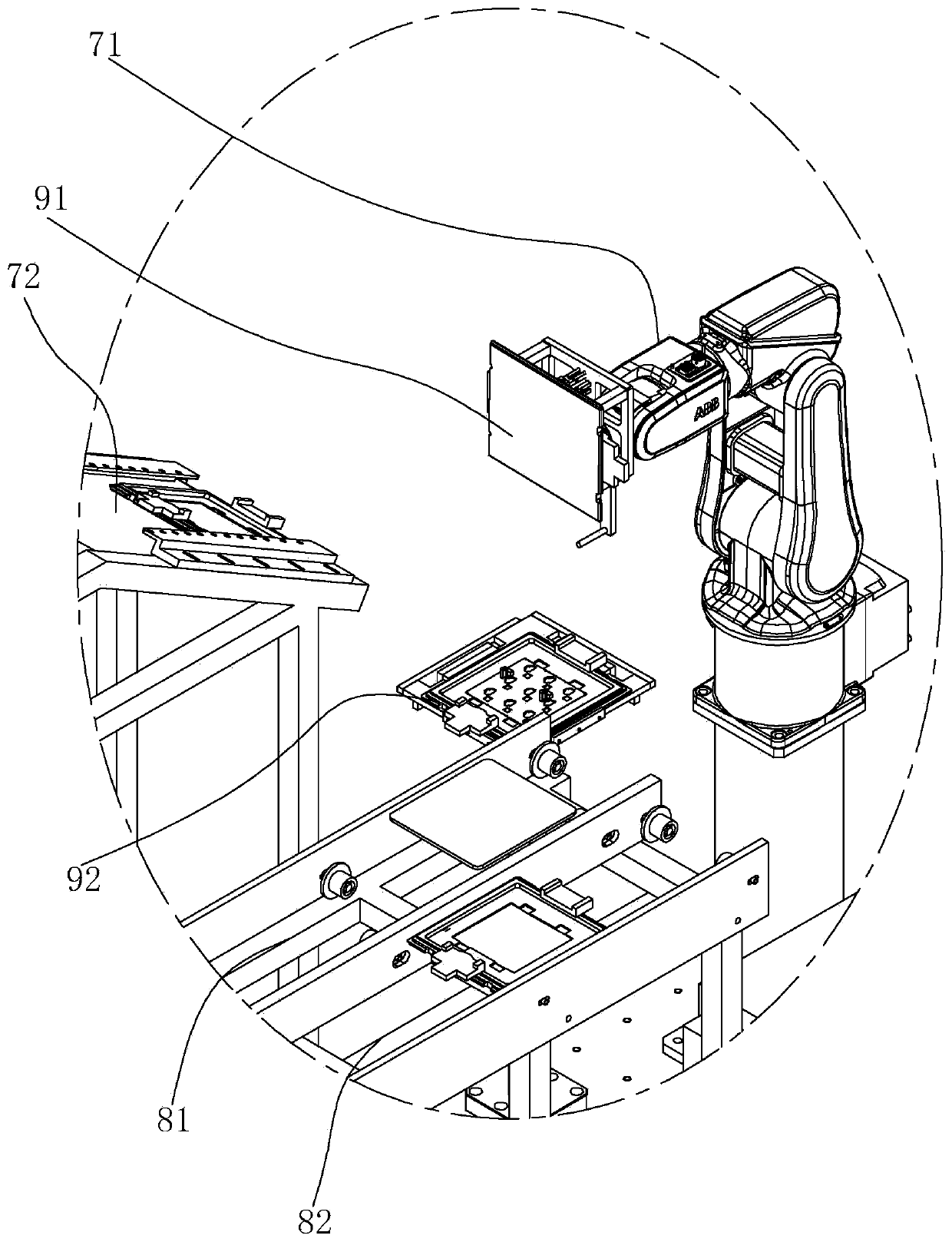

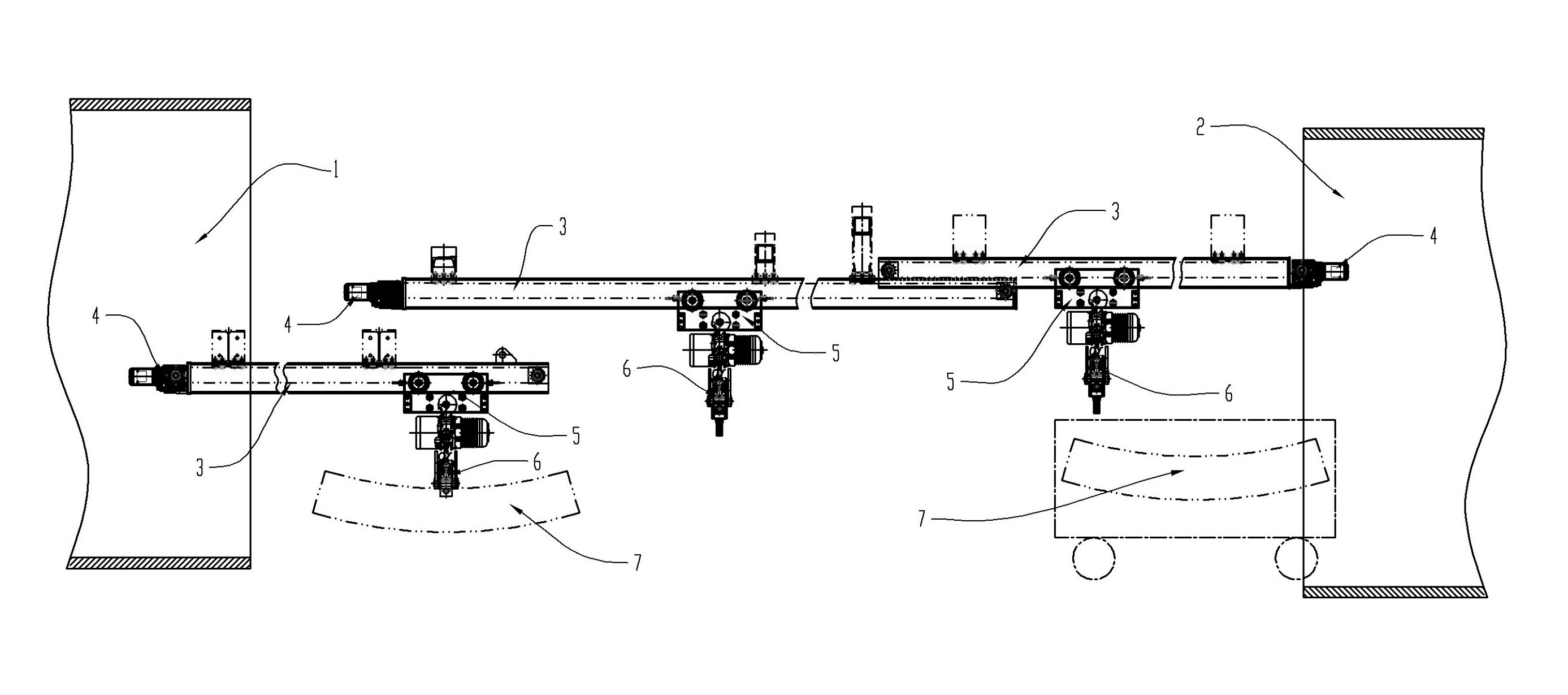

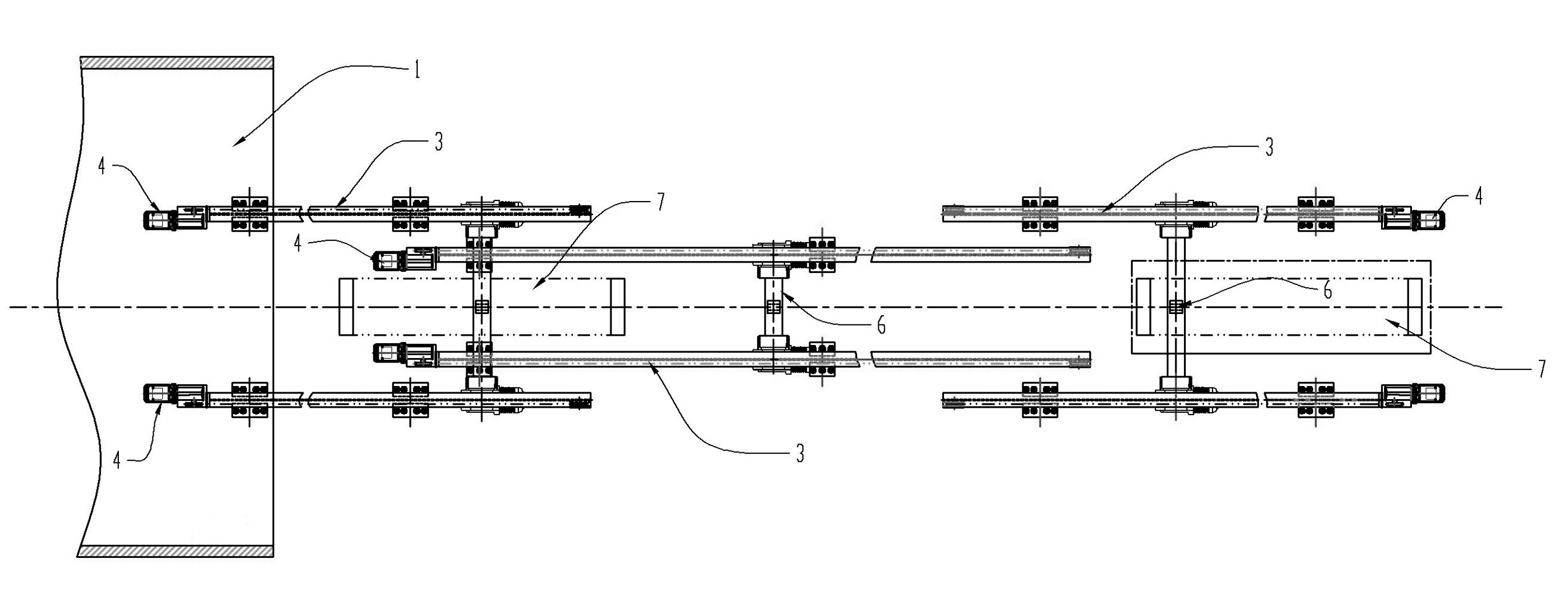

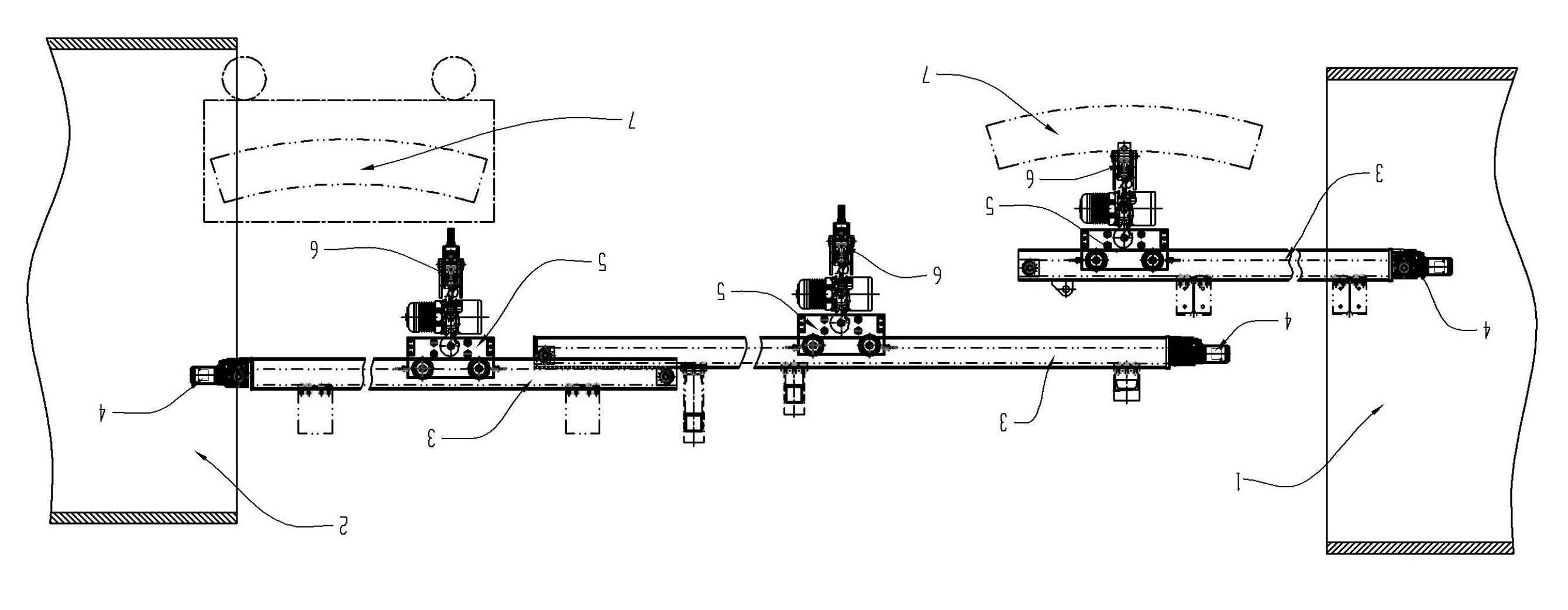

Multi-station plug-in mounting production line and automatic mouse PCB (printed circuit board) production line

ActiveCN103747665AImprove reliabilityImprove stabilityPrinted circuit assemblingElectrical componentsProduction linePrinted circuit board

The invention discloses a multi-station plug-in mounting production line and an automatic mouse PCB (printed circuit board) production line. The multi-station plug-in mounting production line comprises a PCB loading device, a plurality of sets of sequentially butted plug-in mounting equipment, a reflow welding machine arranged at the outer end of the last plug-in mounting equipment, an unloading device arranged at the material discharging end of the reflow welding machine, an upper cover conveying device which is arranged from the material discharging end of the reflow welding machine to the outer end of the last plug-in mounting equipment, and a bottom cover conveying device arranged from the material discharging end of the reflow welding machine to the PCB loading device, wherein the first plug-in mounting equipment is butted with the PCB loading device. According to the multi-station plug-in mounting production line, a bottom cover is used as a lower part of a plug-in mounting jig; after a PCB is subjected to plug-in mounting at multiple stations, an upper cover is used as an upper part of the jig; the upper cover is fixedly connected with the bottom cover, so that an electronic element can be reliably fixed on the PCB, and the electronic element which is plugged into the PCB but is not completely fixed can be reliably welded in a process of the reflow welding machine; therefore the reliability and the stability of a PCB product can be improved.

Owner:SHENZHEN RAPOO TECH

Kerbstone thickness-fixing multi-face fine polishing machine

InactiveCN103624643APolishing flexibleFlexible polishingPlane surface grinding machinesProduction lineElectric motor

The invention provides a kerbstone thickness-fixing multi-face fine polishing machine which comprises a machine frame, an electric motor, a triangular belt and a polishing head and further comprises at least two rotating joints, an adjusting disc and a fixator. The rotating joints can ensure that the machine frame can rotate, the adjusting disc can adjust the height of the polishing head, and the fixator can replace the polishing head and fix the polishing head. The invention further comprises a production line which can conduct fine polishing on the plurality of side faces of kerbstone at one time, and the production line comprises at least two kerbstone thickness-fixing multi-face fine polishing machines, a movable working table, a fixing block and a guide rail. The kerbstone thickness-fixing multi-face fine polishing machine and the production line which can conduct fine polishing on the side faces of the kerbstone at a time and can conduct machining on the faces of the kerbstone at a time, cost is saved, and economic efficiency is improved.

Owner:许春雷

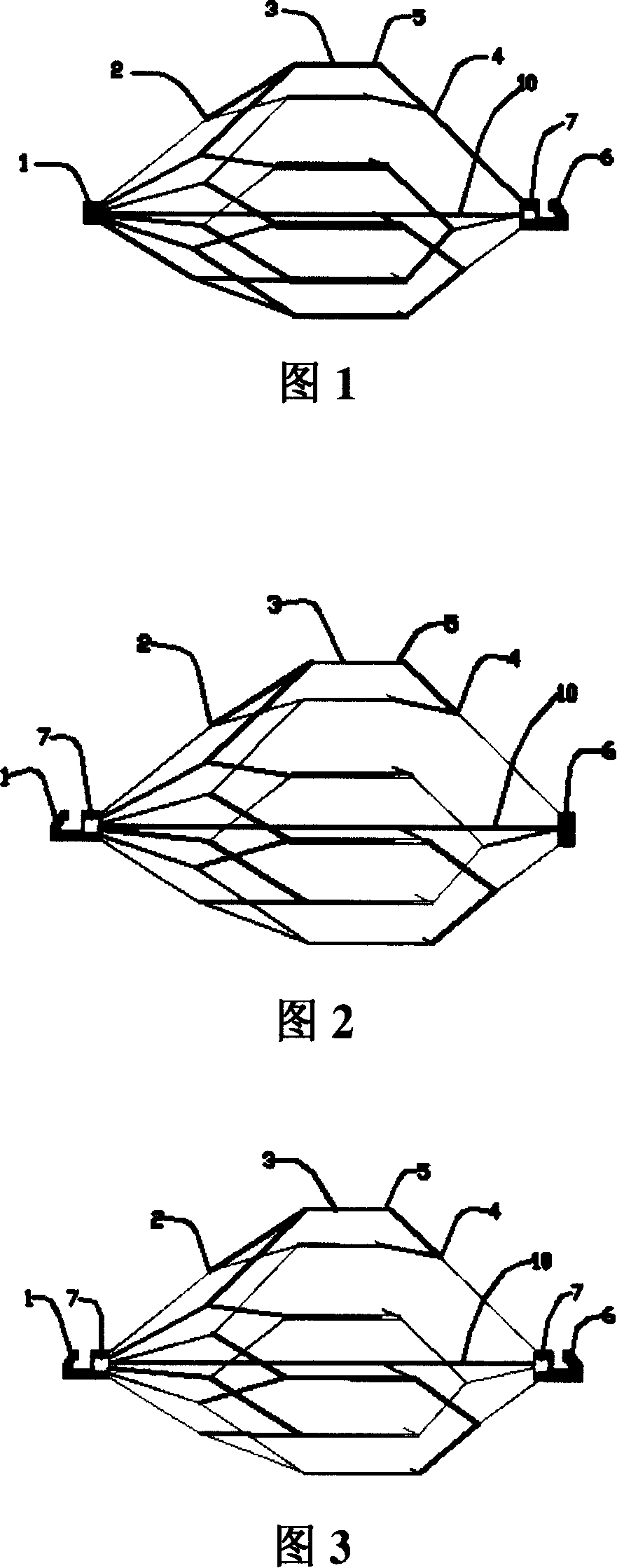

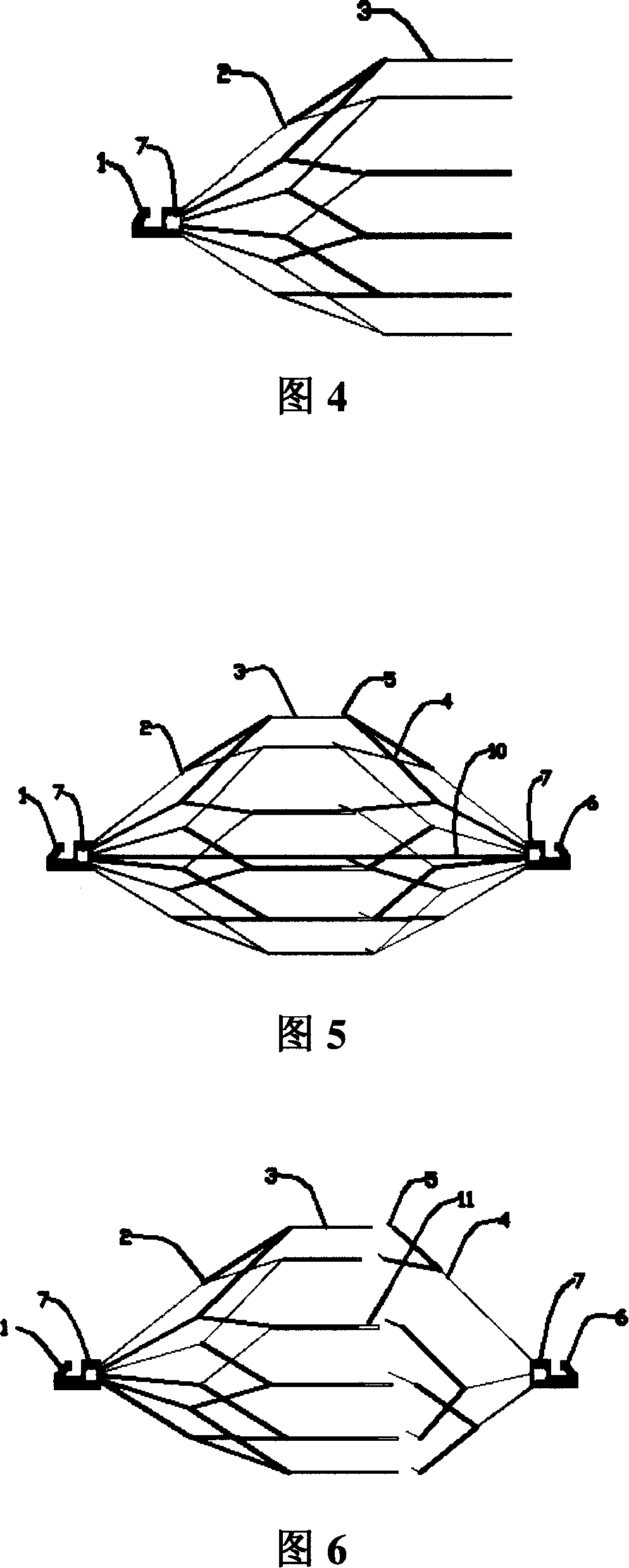

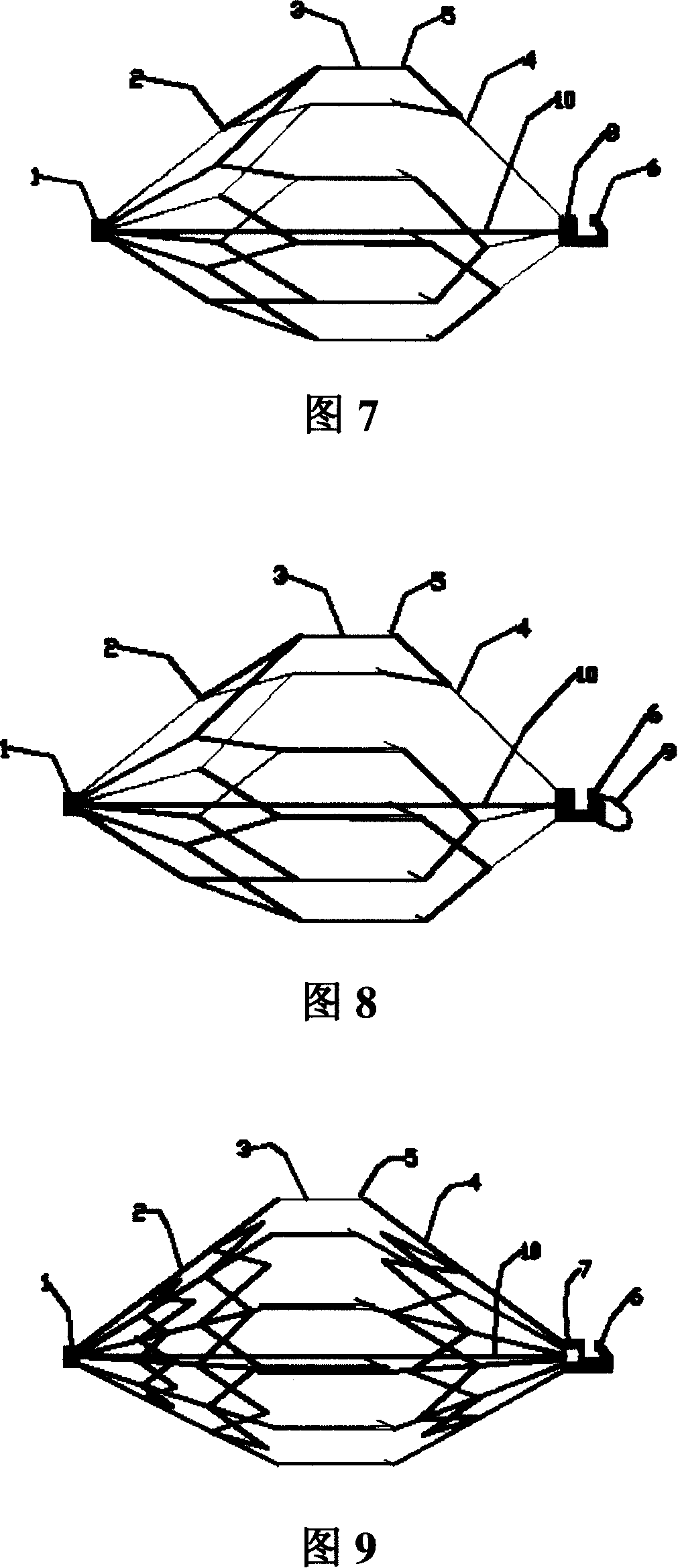

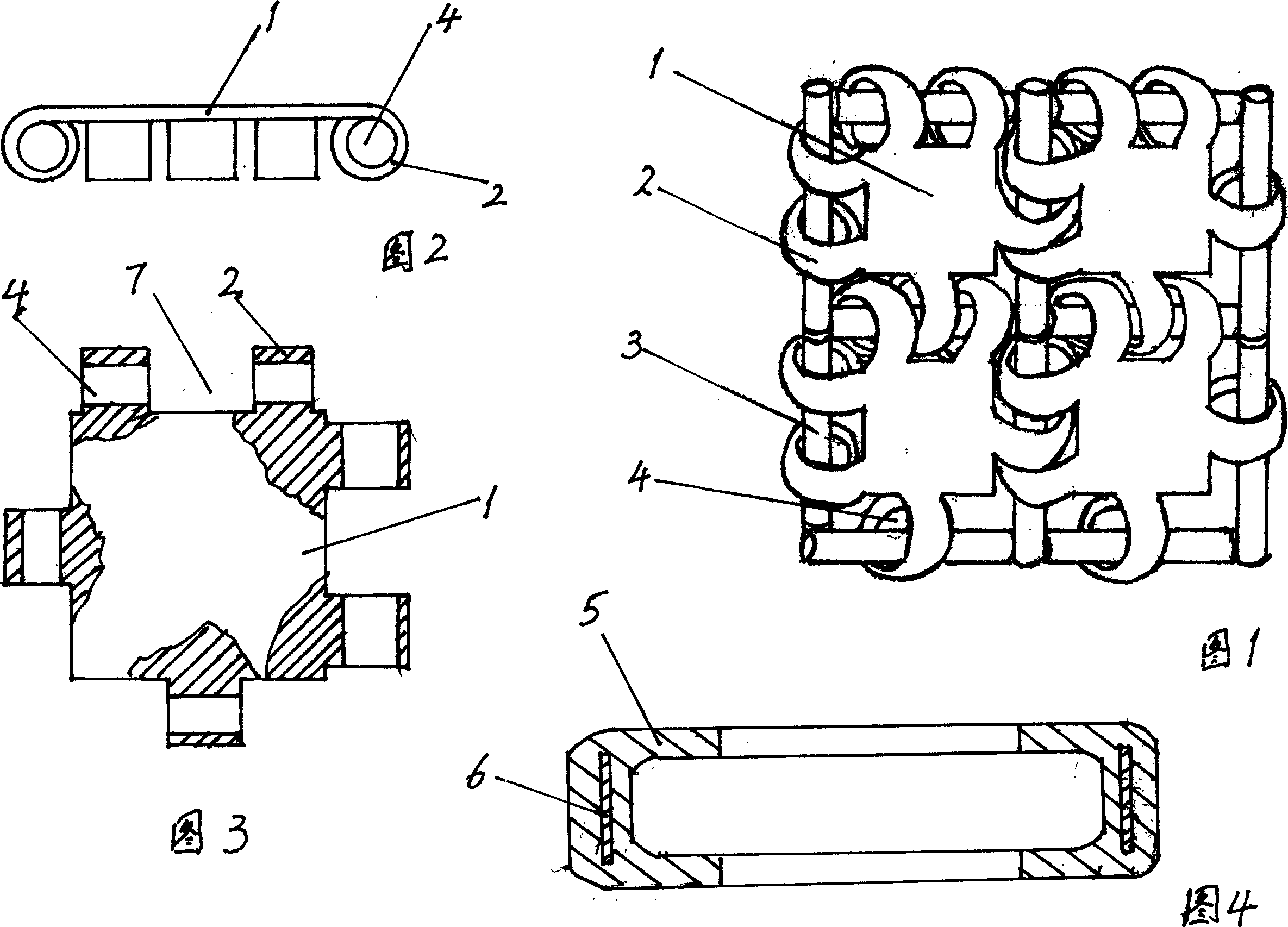

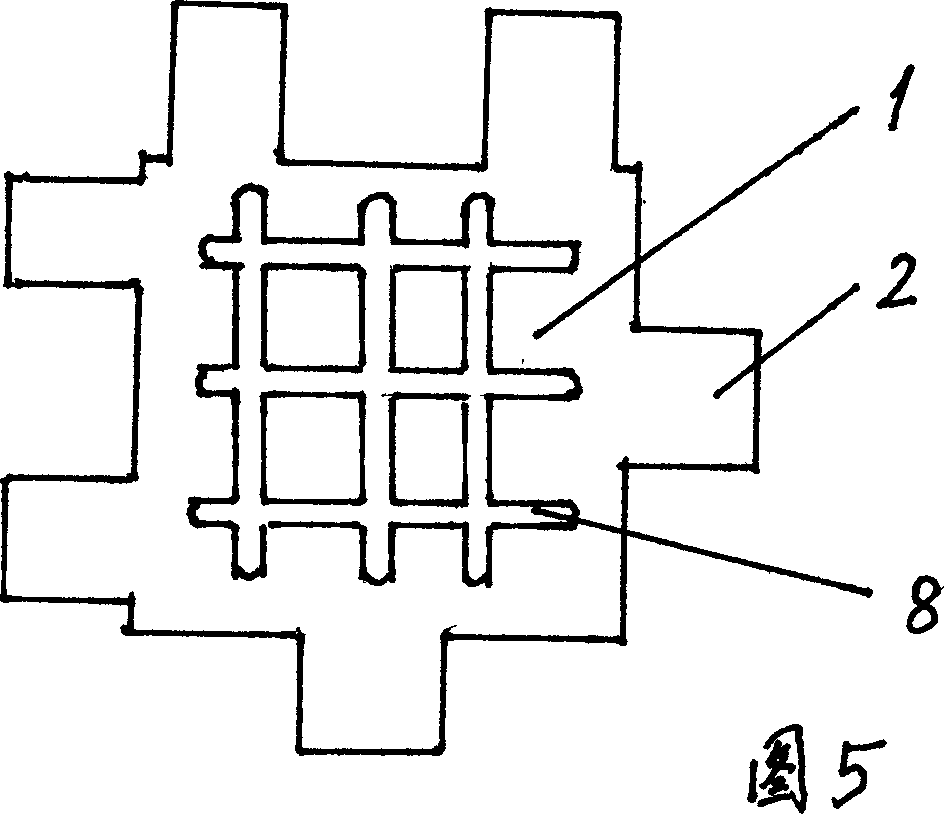

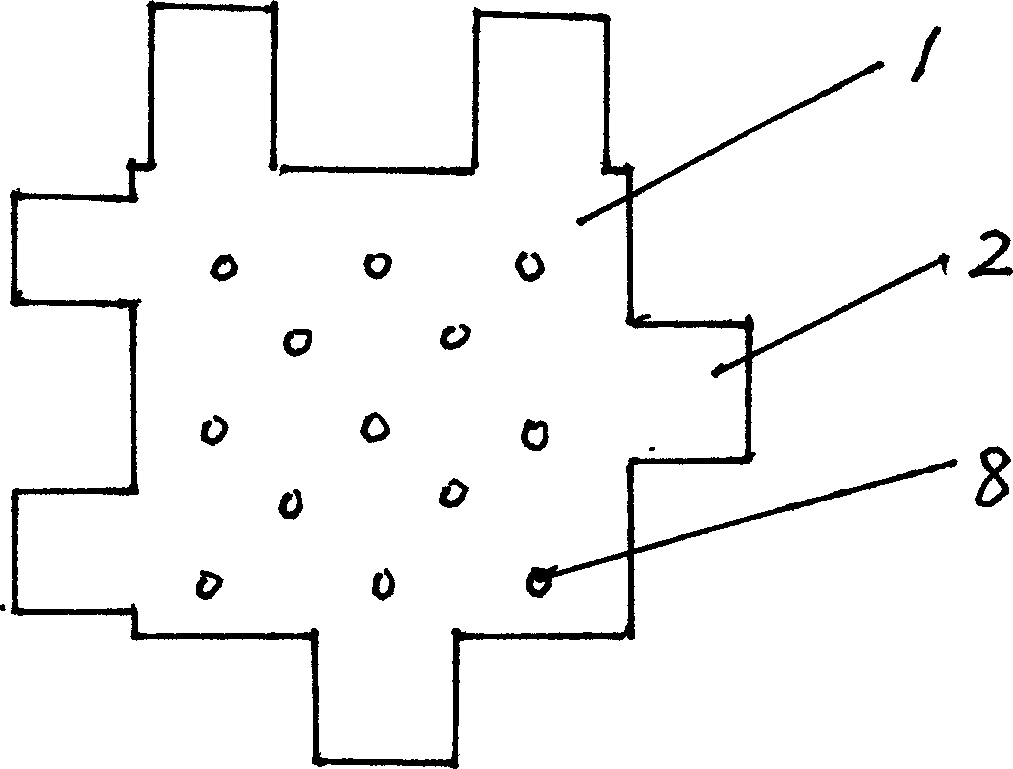

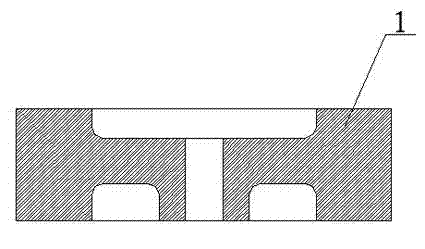

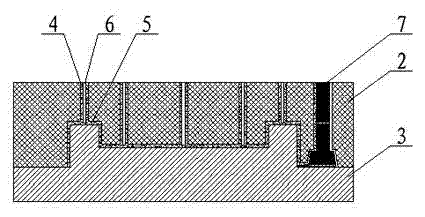

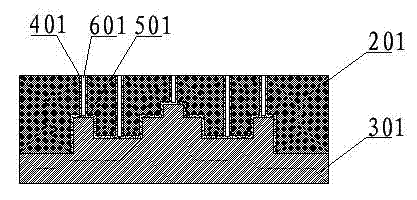

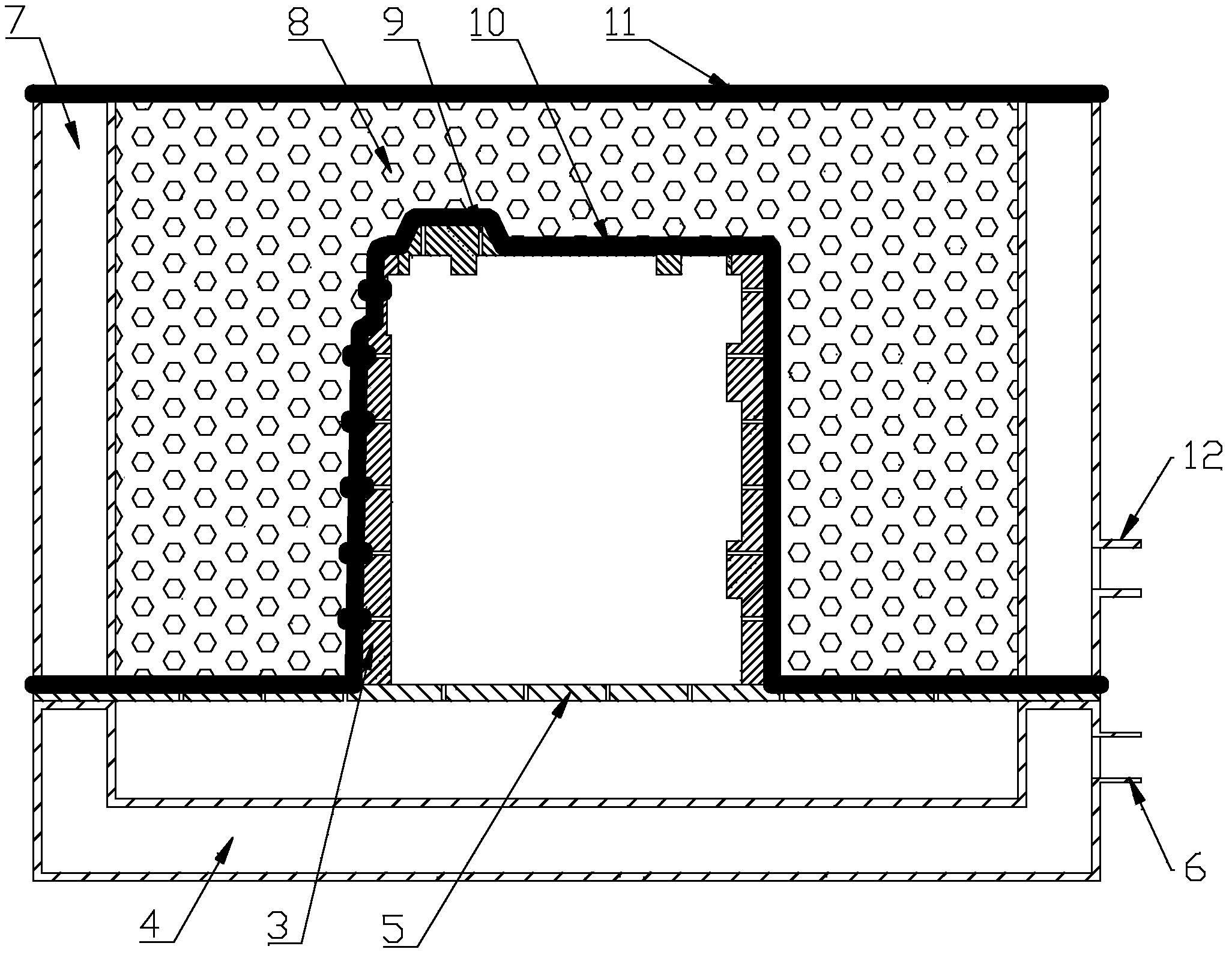

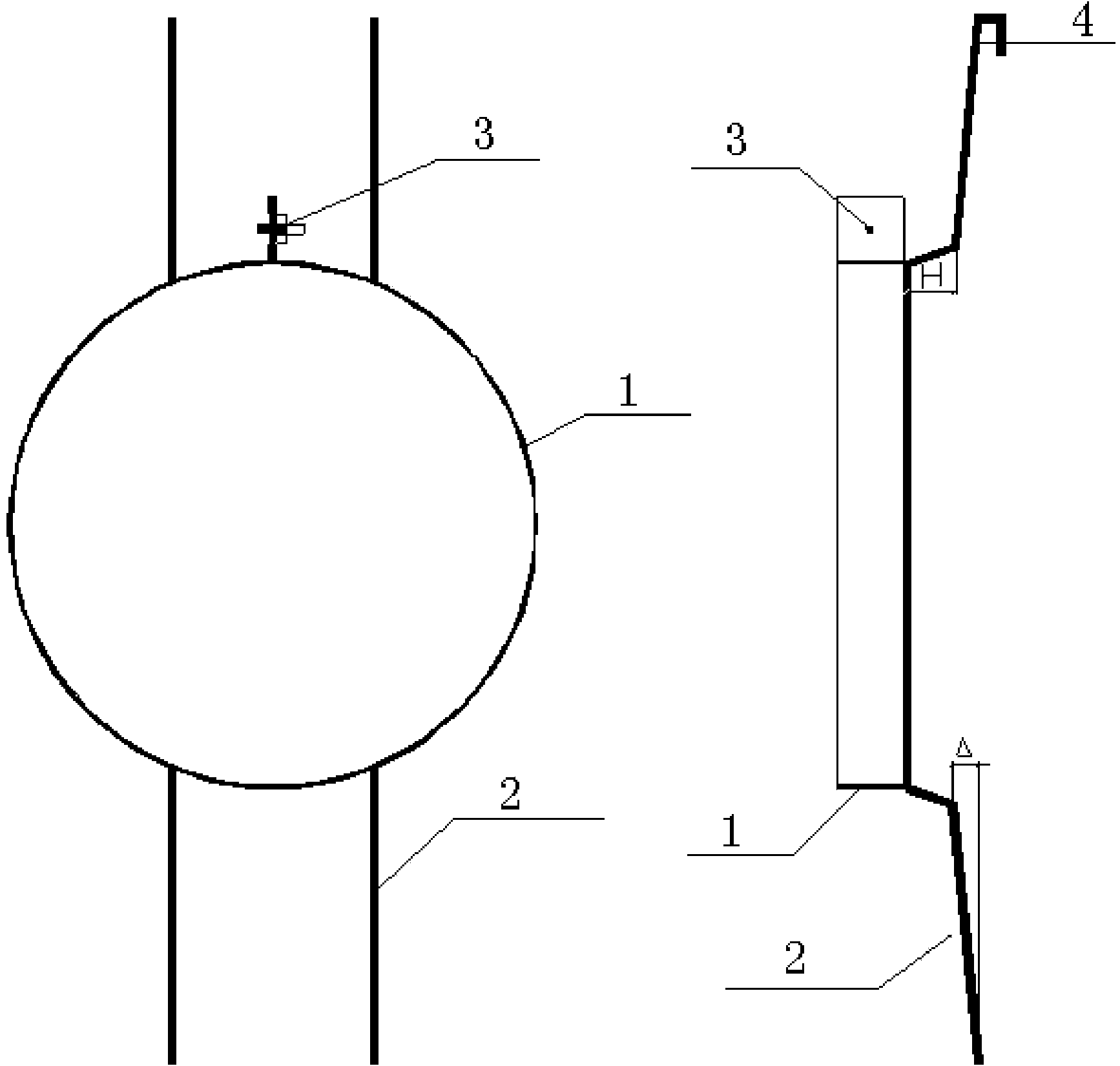

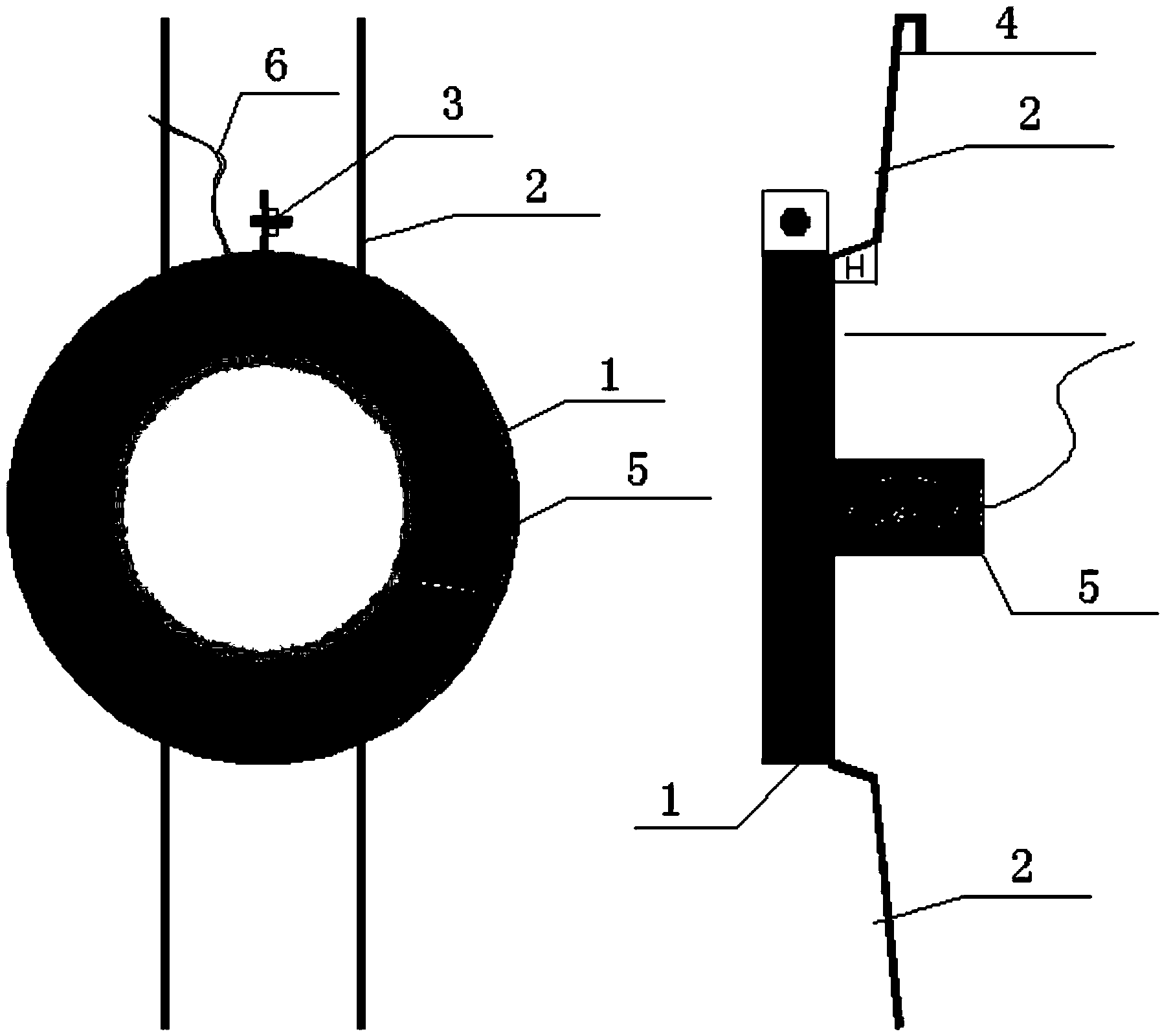

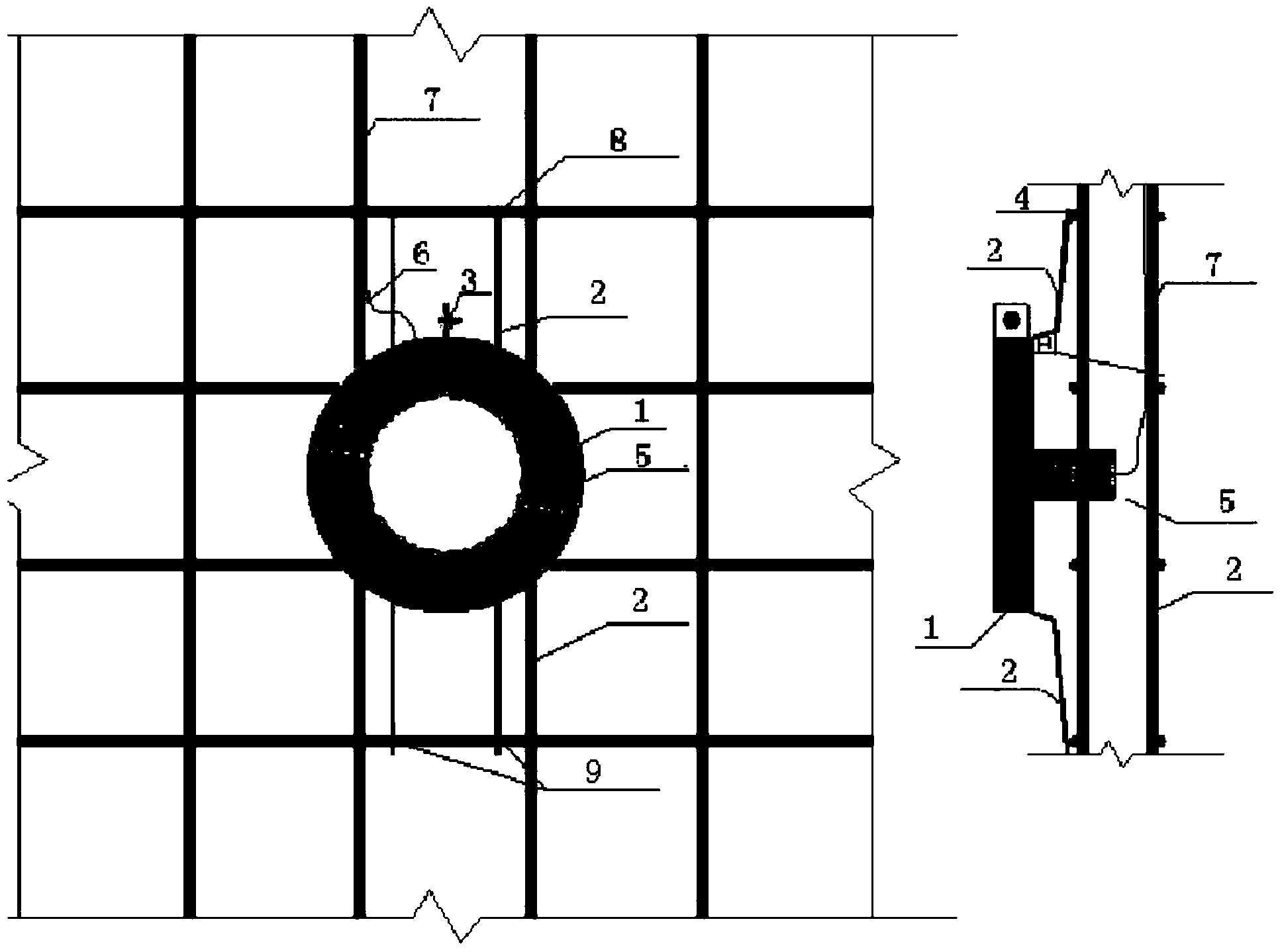

Fusion splicing technological process and equipment for hollow drawstring of air bed body

InactiveCN101439583AEasy to operateShort processing timeFluid mattressesDomestic articlesEngineeringFusion splicing

The invention discloses a heat-sealing technique for an airbed hole drawstring, comprising the following steps: (A) a plurality of hole drawstrings are positioned between the upper piece and the lower piece of a bed body in a certain position and in a certain arrangement mode; (B) lower heat transmission moulds are positioned at the bottom surface of the lower piece of the bed body and corresponding to hole drawstrings; upper heat transmission moulds are positioned at the superface of the upper piece of the bed body and corresponding to the hole drawstrings; the upper heat transmission moulds and the lower transmission moulds are clamped so that the upper piece and the lower piece of the bed body are tightly against each other; (C) a power supply is started to heat the upper heat transmission moulds and the lower heat transmission moulds; the upper heat transmission moulds heat-seal the upper piece and the hole drawstrings on the superface and the lower heat transmission moulds heat-seal the lower piece and the hole drawstring from the bottom surface; (D) the upper heat transmission moulds and the lower heat transmission moulds are separated and the bed body is taken out. The invention heat-seals the bed body and the hole drawstrings outside the bed body, thereby having the advantages of clear weld mark decorative patterns on the finished products, steady heat-sealing quality and fixed hole drawstring intervals. Meanwhile, the invention discloses heat-sealing equipment for the airbed hole drawstrings with high production efficiency.

Owner:ZHONGSHAN ZHANXIN PLASTIC PROD

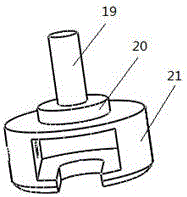

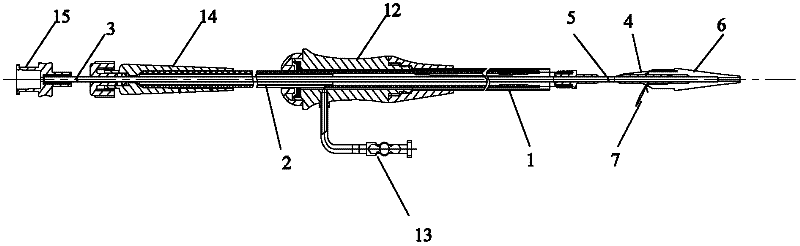

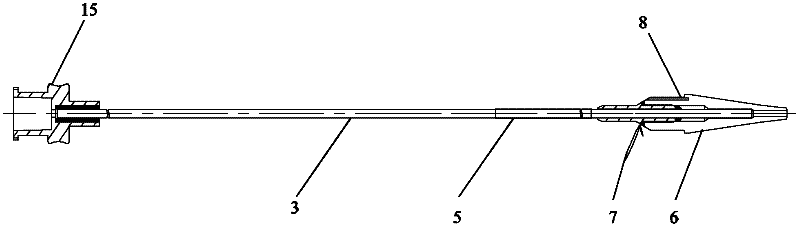

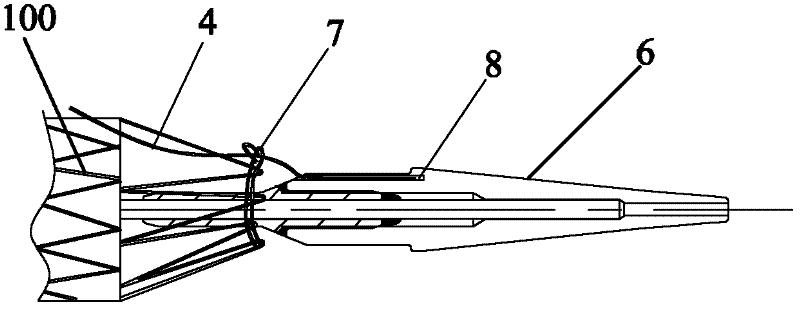

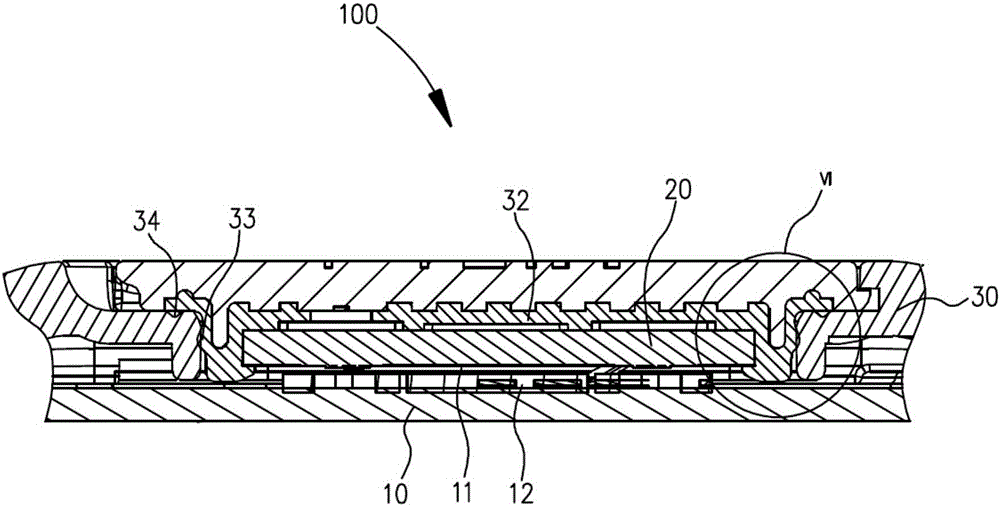

Delivery and release system of covered stent

The invention discloses a delivery and release system of a covered stent, which comprises an outer tube, a top tube, an inner tube, a guide wire bushing, a conical head, a control coil, a control guide wire and a guide wire flexible buckle, wherein the outer tube, the top tube and the inner tube are sequentially distributed from the outer side to the inner side, and a guide wire hole is arranged on the top tube; one end of the inner tube extends out of the top tube and is fixed with the conical head, and the control coil is arranged on the conical head; the guide wire bushing is sleeved on the inner tube which is between the top tube and the conical head; one end of the control guide wire is fixed with the outer tube, the other end of the control guide wire penetrates through the guide wire hole, the guide wire bushing and the movable buckle of the control coil to be connected with the conical head, and the guide wire flexible buckle is arranged on the control guide wire. When the system releases the covered stent, part or a whole covered section can be released under the condition that the end part of the covered stent is bound, so the probability of covered stent displacement or exposed section overturning which is caused by blood flow impact is reduced. In addition, when a near end is not released, the covered stent also can be adjusted, so the stent is positioned more accurately.

Owner:SHANGHAI MICROPORT ENDOVASCULAR MEDTECH (GRP) CO LTD

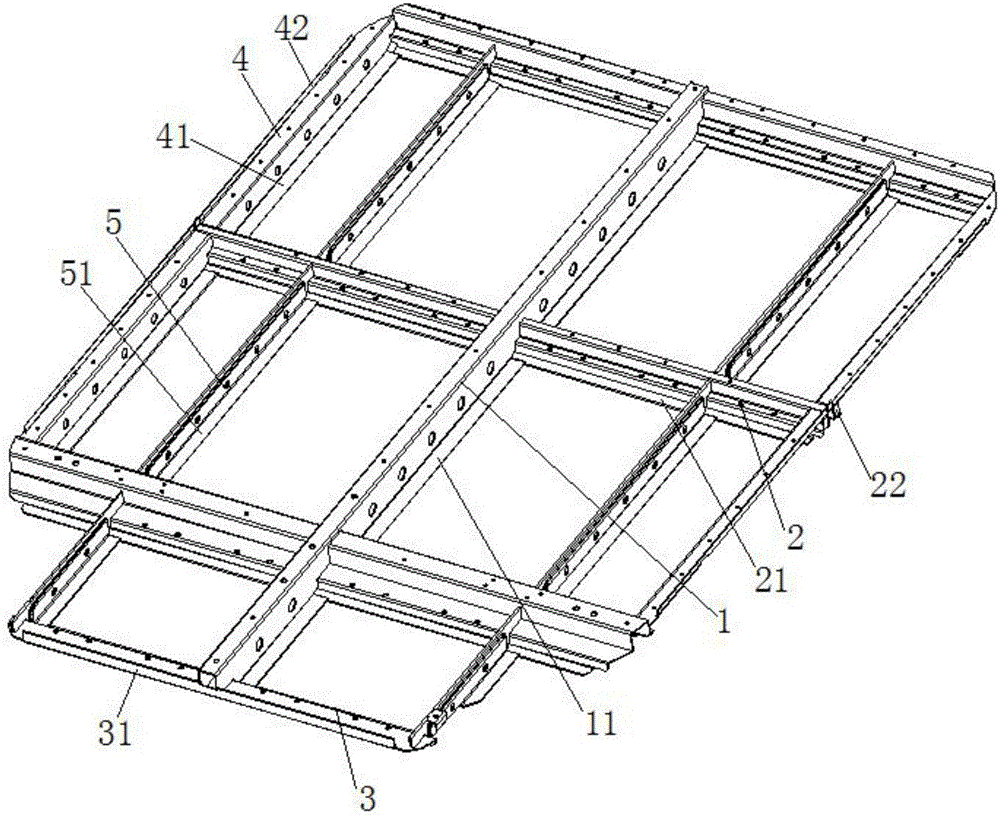

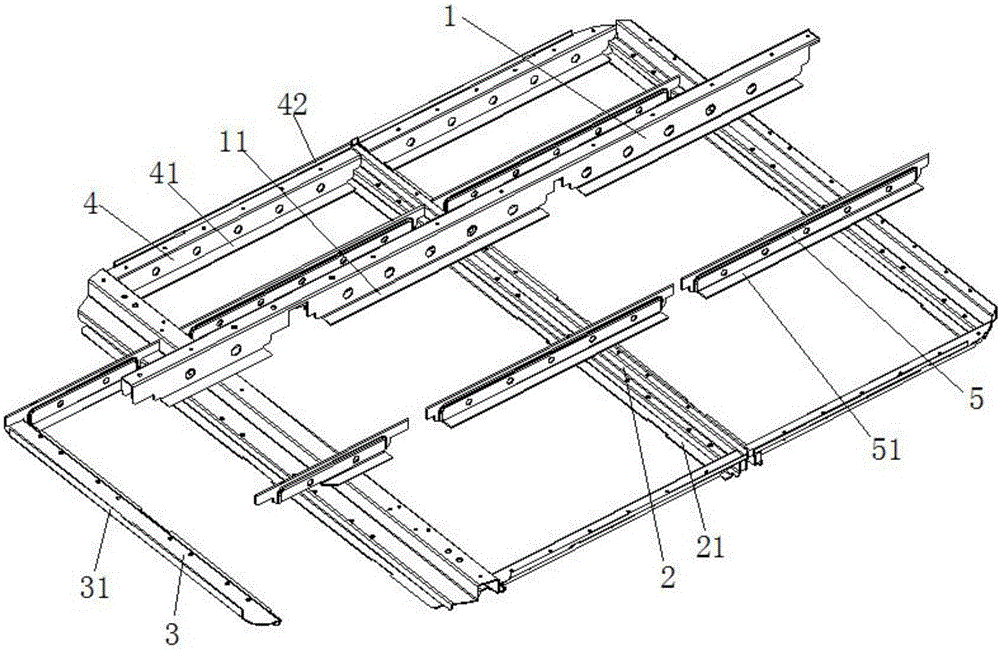

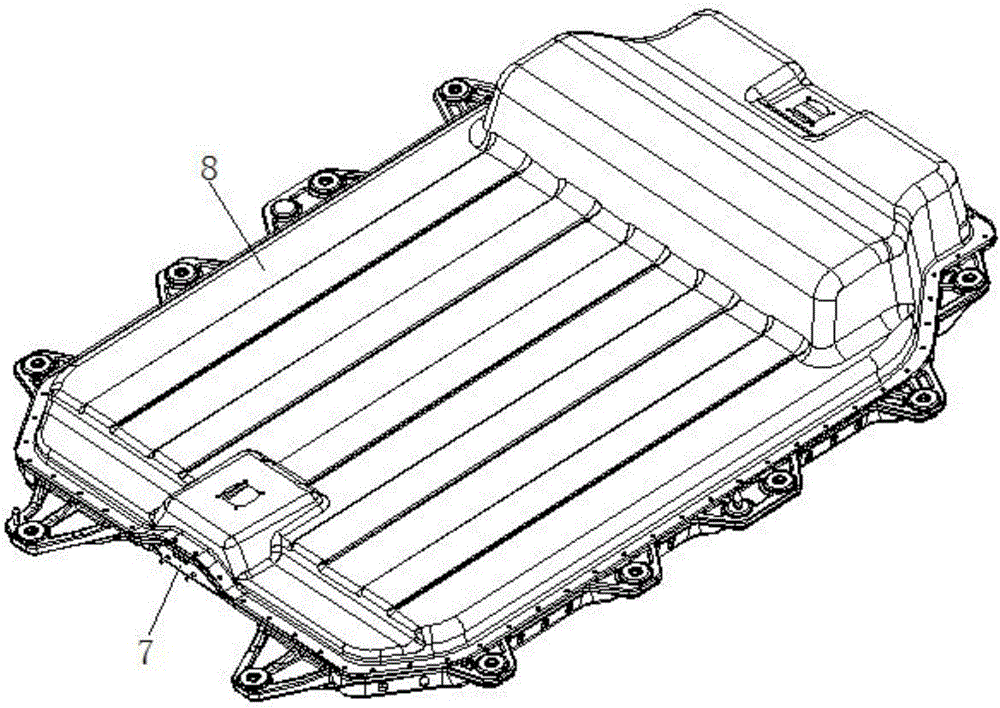

Split mounting type battery box module fixing frame and power battery box provided with same

PendingCN106299192AImprove the fixing strengthImprove installation strengthCell component detailsPower batteryKeel

The invention relates to a split mounting type battery box module fixing frame. The split mounting type battery box module fixing frame comprises a longitudinal beam keel, multiple cross beam keels and multiple boundary beams, wherein the multiple cross beam keels are arranged at intervals in parallel, and the longitudinal beam keel is perpendicularly arranged in the middle of the multiple cross beam keels and clamped on the multiple cross beam keels; the ends of every two adjacent cross beam keels are connected through the boundary beams, first side plates are horizontally arranged on the two sides of the bottom of each cross beam keel respectively, second side plates are horizontally arranged on the two sides of the bottom of the longitudinal beam keel respectively, and a third side plate is horizontally arranged on the bottom of each boundary beam; limiting notches are formed in the first side plates corresponding to the second side plates and the third side plates, and the two ends of each second side plate and the two ends of each third side plate stretch into the corresponding limiting notches respectively and abut against the corresponding first side plates; the first side plates, the second side plates and the third side plates are all fixed to the bottom wall of an electric box, and fold fins used for being connected with the side wall of the electric box are arranged at the two ends of each cross beam keel respectively. The split mounting type battery box module fixing frame has the advantages that the whole module fixing frame is convenient to assemble and disassemble, high in structural strength and high in stability.

Owner:江苏和中普方新能源科技有限公司

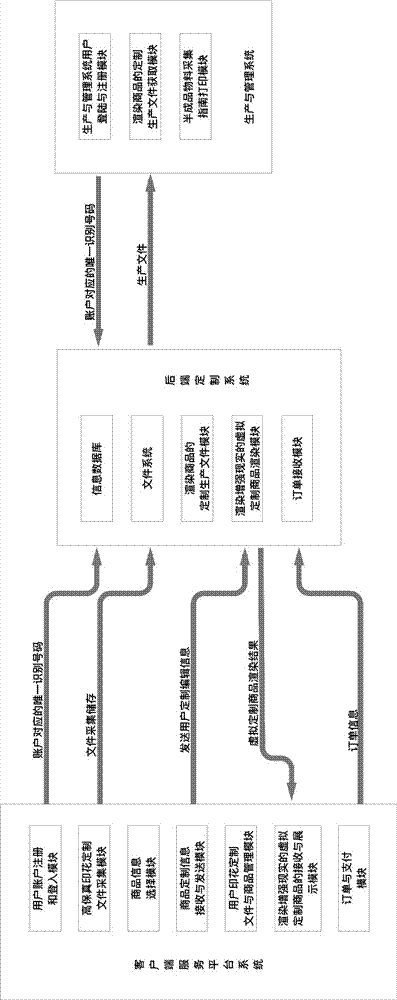

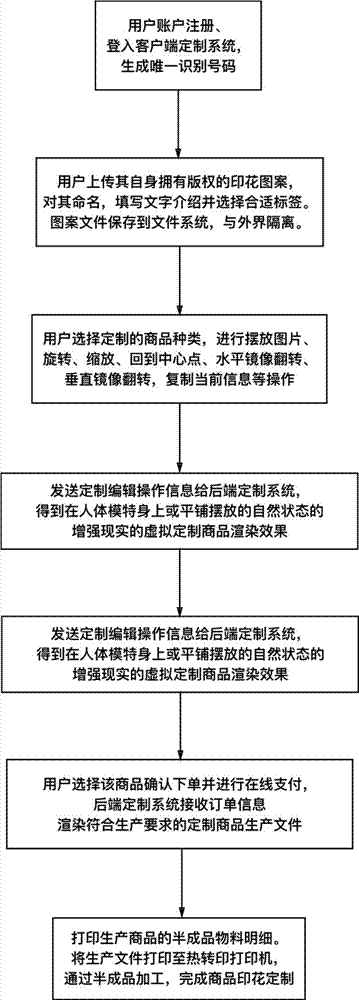

Commodity printing customization method and platform thereof

InactiveCN107016596AUnlimited editingLess difficult to reuseBuying/selling/leasing transactionsWork in processClient-side

The invention discloses a commodity printing customization method and a platform thereof. The commodity printing customization platform comprises a client service platform system, a production and management system and a rear-end customization system, the client service platform system comprises a high-fidelity printing customization file acquisition module, a commodity information selection module and a user printing customization file and commodity management module, the rear-end customization system comprises a virtual customization commodity rendering module for rendering the augmented reality, and the production and management system comprises a semi-finished product material acquisition guide printing module. The commodity information selection module can provide two-dimensional editing areas corresponding to different composition parts of a commodity, users can edit the printing without limitation, and the printing customization is more flexible.

Owner:SHENZHEN QIANHAI YICHUANGYILE TECH LTD

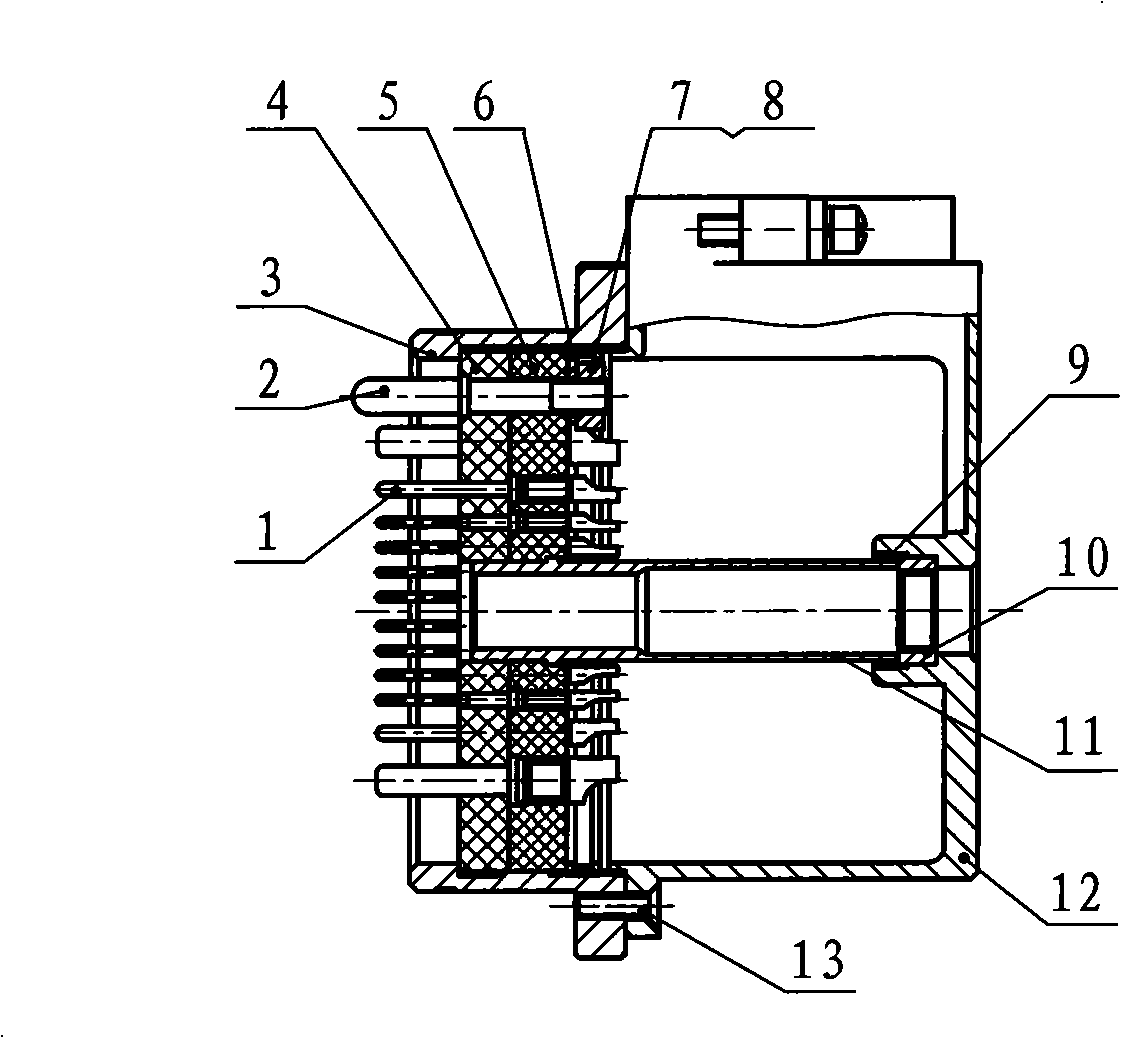

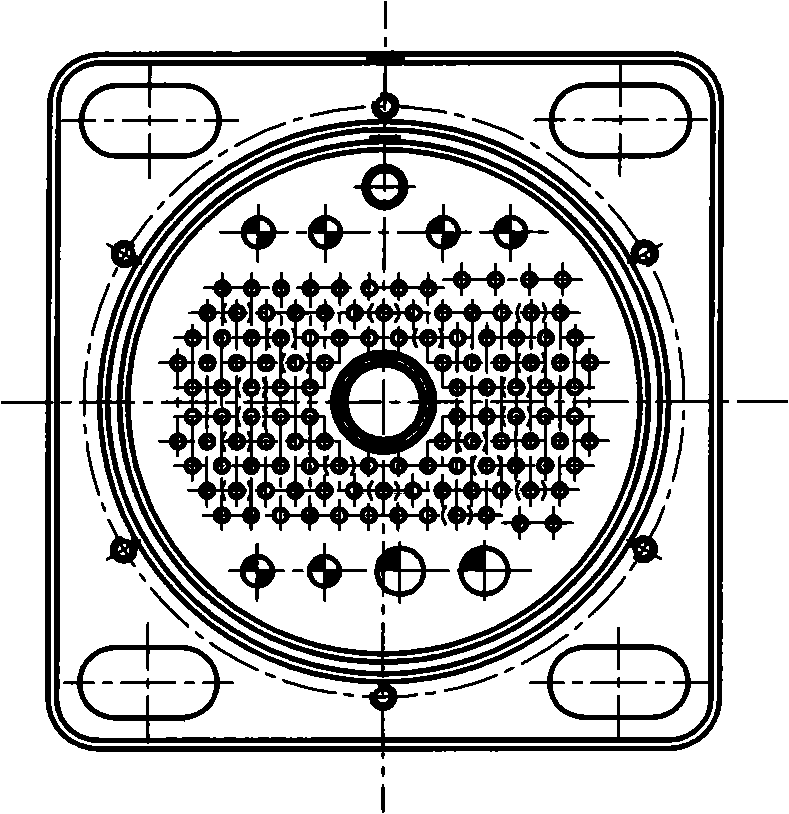

Labor-saving plug-pull connector

InactiveCN101515682ARealize matingAchieve lockingEngagement/disengagement of coupling partsEngineeringSteel ball

The invention discloses a labor-saving plug-pull connector, comprising a plug, a plug-pull mechanism and a socket, wherein a pin of the plug passes through two insulators, a clamping ring is fixed in the shell, a guiding pin is fixed on two insulators through a spring cushion and a nut, a sleeve is mounted in the middle of the plug, the sleeve and the insulators are fixed by gluing, a til cover at the tail of the plug is fixed on the shell by a screw, a screw sleeve is mounted in the tail cover, the screw sleeve and the tail cover are matched by the key and the groove, the screw sleeve is fixed in the tail cover by the clamping ring, the sleeve, the clamping ring and the screw sleeve form a hollow structure; steel balls of the plug-pull mechanism are arranged in a lining, a push rod and a pull bar are fixed by the engagement of screw thread, a spring and a positioning sleeve are mounted at the right end of the pull bar, a handwheel is arranged at the outer ring of the lining and fixed by the nut; a jack is fixed by two insulators of socket to form a base assembly , the base assembly is fixed in the shell by the clamping ring, a lock sleeve is mounted on the central axis of the socket, engaged and fixed with the screw thread of the tail of the lock sleeve by the nut, the labor-saving inserting, separation and locking function is realized.

Owner:GUIZHOU SPACE APPLIANCE CO LTD

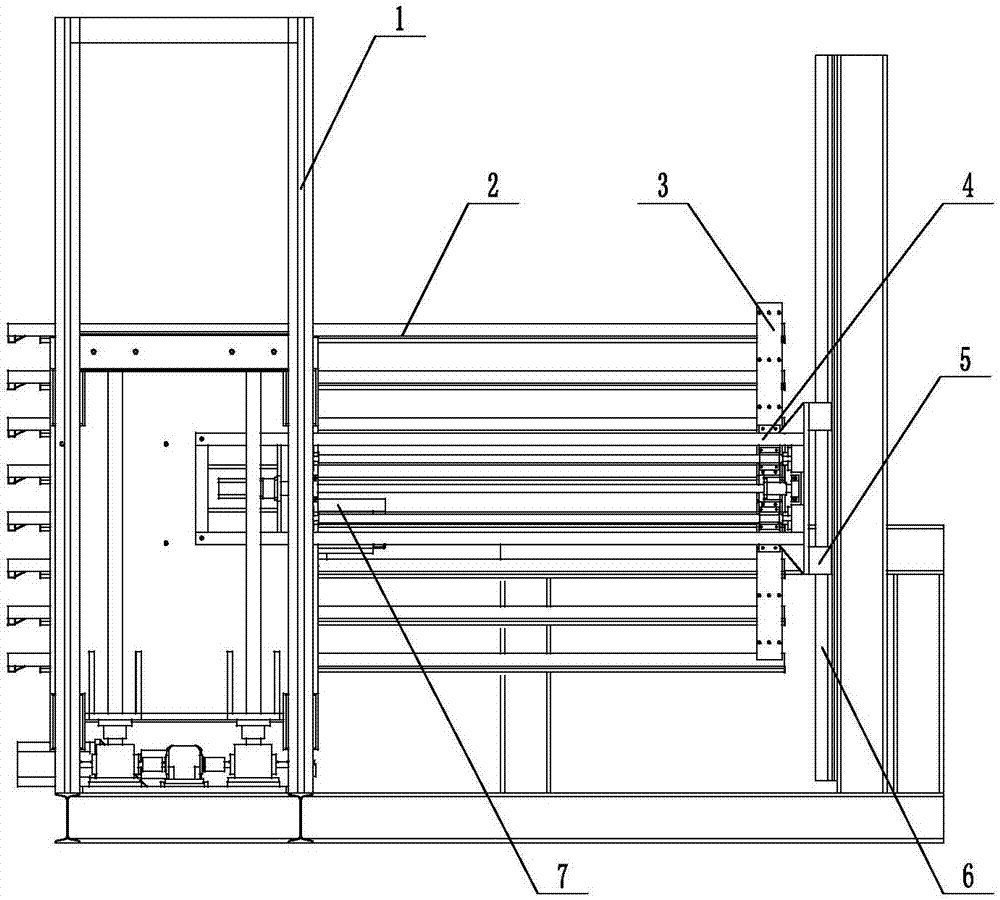

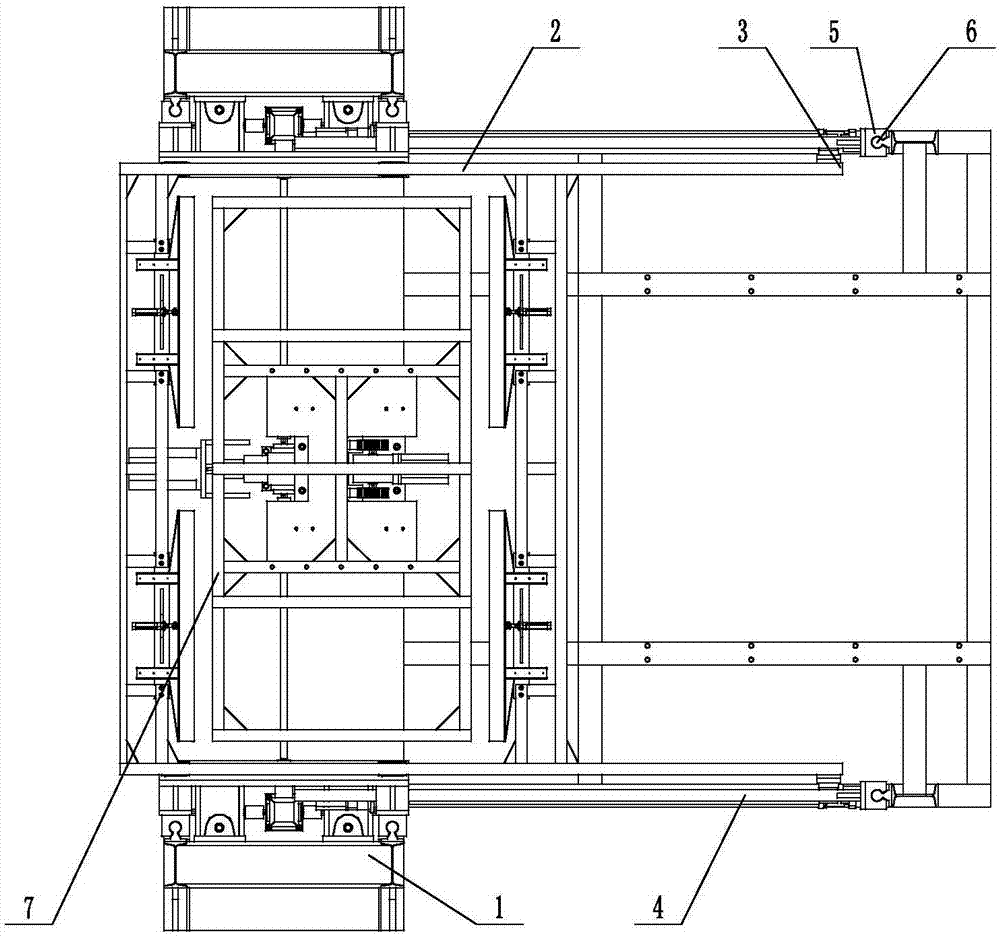

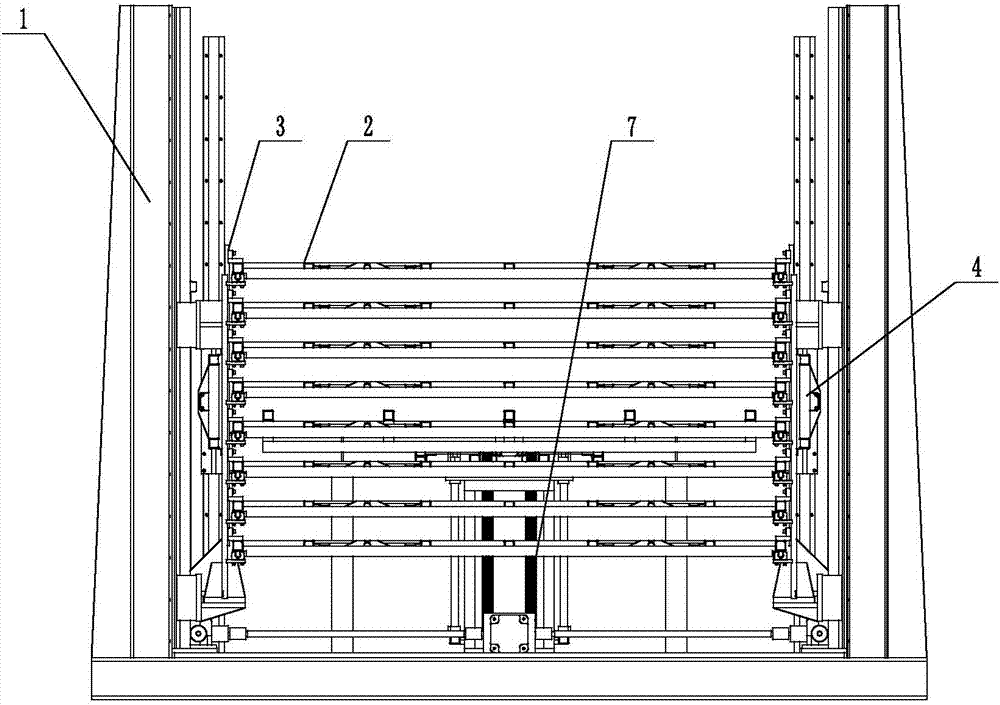

Wood board loading and unloading lifting assembly

ActiveCN107139280AHigh degree of automationReduce manpower consumptionPlywood pressesLaminationEngineeringMechanical engineering

The invention discloses a wood board loading and unloading lifting assembly which comprises a lifting mechanism (1), a jacking mechanism (7), a push mechanism (4) and a plurality of bearing and connecting mechanisms (2). The wood board loading and unloading lifting assembly has the advantages that working efficiency is high, energy consumption is reduced, manpower is saved, conveying precision is high, and a hot press can conduct hot pressing on the two faces simultaneously.

Owner:LIUZHOU VOCATIONAL & TECHN COLLEGE

Shield machine duct piece hoisting device

ActiveCN102061928ARealize continuous liftingLifting will not affectUnderground chambersTunnel liningMotor driveElectric machinery

The invention discloses a shield machine duct piece hoisting device. A hoisting track of the shield machine duct piece hoisting device is divided into multiple sections, every two adjacent sections are staggered along the height direction and overlapped at the end parts along the hoisting direction, the widths of the overlapping parts are different, and a conveying chain pair of one section is located on the inner side of a conveying chain pair of the other section; and the conveying chain of each section of the hoisting track is a circular conveying chain and comprises chain wheels on both ends and chains sheathed outside the chain wheels, the chain wheels are connected with a motor, the driving rotation of the motor drives the chains to convey duct pieces circularly, and a trolley is fixedly installed on the chains. Compared with the one-section structure, the hoisting device can ensure that the shield machine can perform tunneling with larger gradient and smaller turning radius because larger dislocation quantity is allowed for the shield tail part and the matching part.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

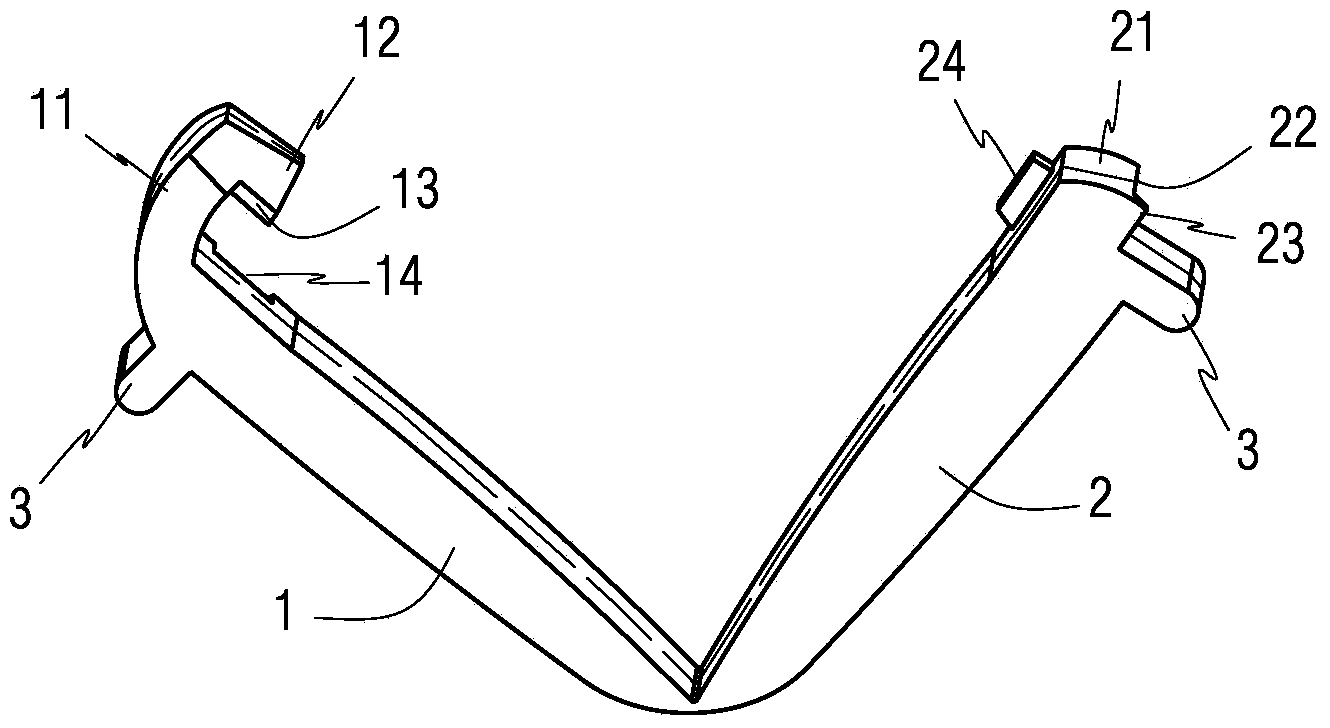

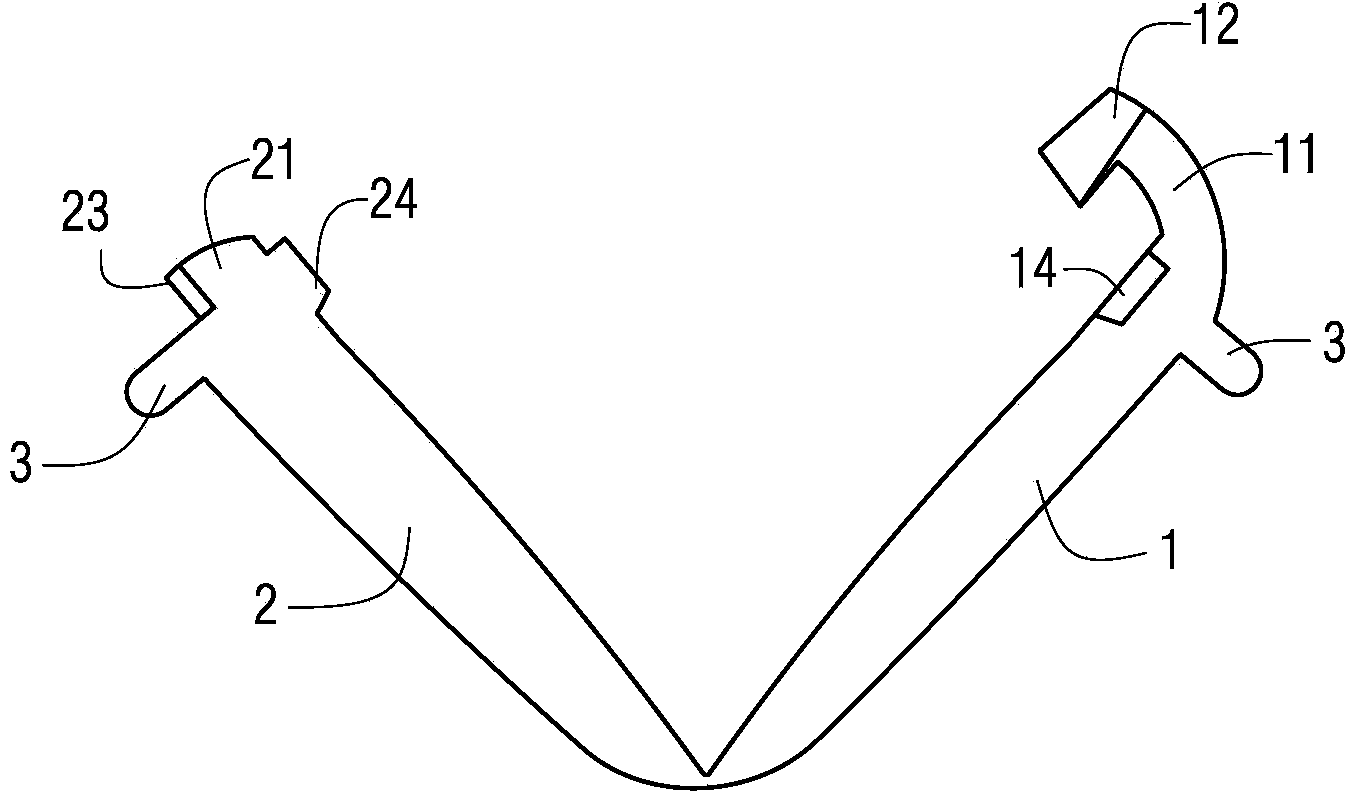

Absorbable ligature clamp and manufacturing method thereof

ActiveCN103549985ALow technical requirementsPromote absorptionWound clampsOrthodontic ligatureHumans tissues

The invention discloses a ligature clamp which comprises a first clamp arm and a second clamp arm. Clamping projections are symmetrically arranged on the outer sides of the first clamp arm and the second clamp arm respectively, the reverse outer sides of the first clamp arm and the second clamp arm are of straight structures, the first clamp arm and the second clamp arm are of V-shaped structures in symmetrical shapes from the clamping projections on the respective sides to a connecting portion of the two clamp arms, a first cylindrical hollow portion is arranged in the first clamp arm, a second cylindrical hollow portion is arranged in the second clamp arm, and annular grooves are uniformly formed in the first hollow portion and the second hollow portion. The invention further provides a method for manufacturing the absorbable ligature clamp. By the aid of the clamp arms with the straight structures, the two clamp arms are of the basically symmetrical V-shaped structures, and an opening cannot shift in the closing process and is easily clamped and positioned. In addition, the absorbable ligature clamp can generate uniform fragments in the degrading process and is conveniently absorbed by human tissues.

Owner:HANGZHOU MEDZONE BIO-TECH CO LTD

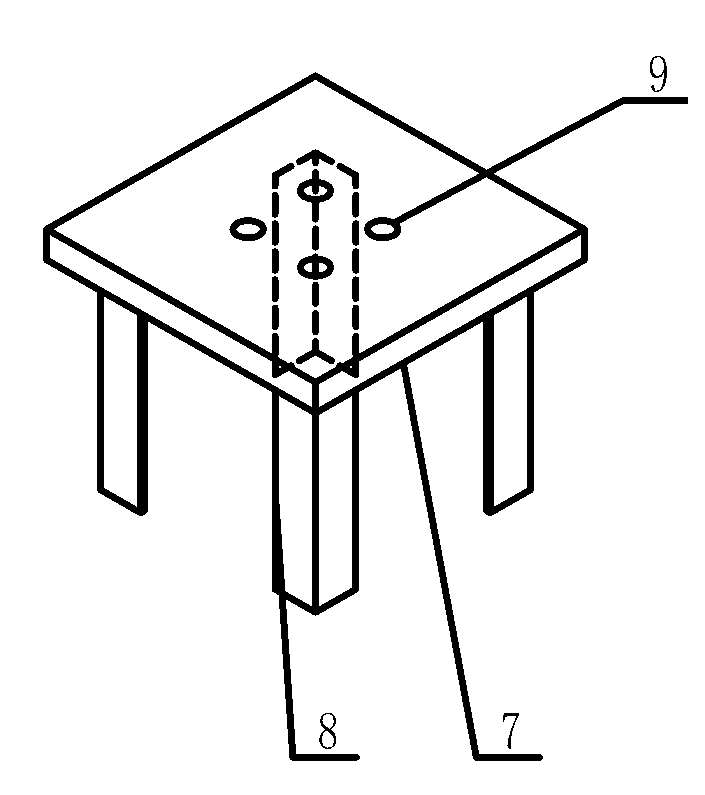

Large steel structure heel embedded part positioning device and method

The invention relates to a large steel structure heel embedded part positioning device and method. The positioning device comprises a positioning plate and connecting members, wherein the positioning plate is provided with a bolt hole, the bolt hole is matched with a pre-positioned heel embedded part bolt in structure and position, and one surface of the positioning plate is provided with at least four or more connecting members. The method comprises the steps of: firstly, binding a low layer of reinforcement bars in a large steel structure foundation; secondly, welding the connecting memberson the lower layer of reinforcement bars, determining the bottom end position of the heel embedded part bolt by using a transit and a leveling instrument, and then binding a middle layer and an upperlayer of reinforcement bars, regulating the upper end position of the bolt by using a plumb bob and the leveling instrument; and finally, fastening the heel embedded part bolt and a heel embedded part. Compared with the prior art, the invention has the beneficial effects of simple structure, convenience for installation and low cost, and ensures that a heel embedded part bolt rod does not inclineor displace in a process of poring concrete so that the heel embedded part is positioned more accurately and the engineering quality is improved.

Owner:CHINA THIRD METALLURGICAL GRP

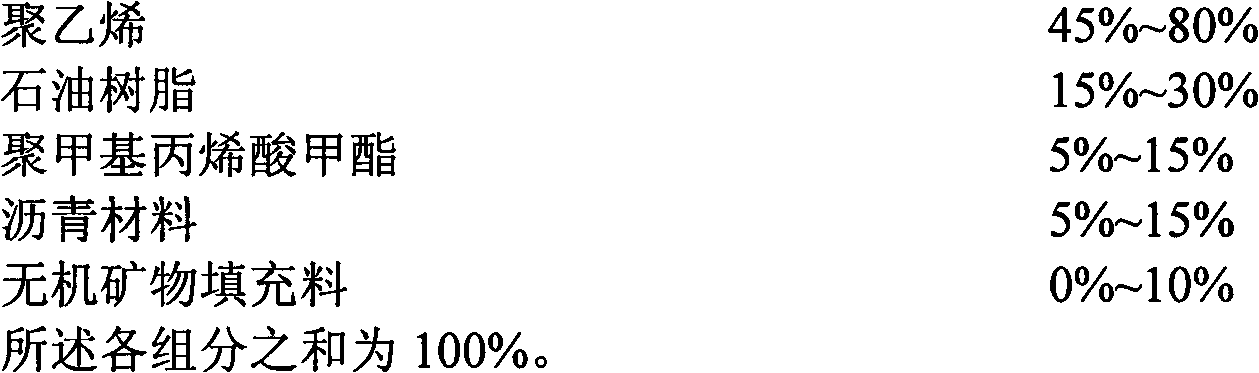

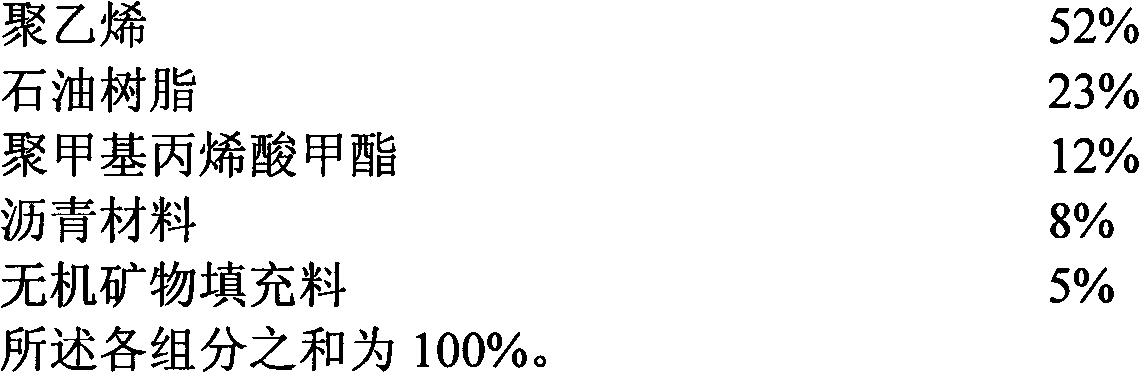

Environment-friendly asphalt pavement anti-rut agent and preparation method thereof

ActiveCN102702600AImprove protectionNo displacementBuilding insulationsLow-density polyethyleneMicrosphere

The invention discloses a preparation method of an environment-friendly asphalt pavement anti-rut agent and an application thereof. The method comprises the following steps of: mixing and stirring 45-80 percent of polyethylene and 15-30 percent of petroleum resin derived from 'plastic waste', 5-15 percent of polymethyl methacrylate, 5-15 percent of an asphalt material and 0-10 percent of an inorganic mineral filling material at a high speed; and extruding at a high temperature to prepare the environment-friendly asphalt pavement anti-rut agent. Due to the adoption of the environment-friendly asphalt pavement anti-rut agent, the performance of an asphalt pavement is enhanced, the service life of the pavement is prolonged, 'white waste' is recycled, and environmental pollution is lowered. Polyethylene serving as a major component is either or both of industrial production low-density polyethylene and industrial recycled waste polyethylene; the industrial recovered waste polyethylene is recovered polyethylene or regenerated low-pressure polyethylene or regenerated PE (Polyethylene); the molecular weight of the petroleum resin is 300-3,000; the molecular weight of the polymethyl methacrylate is 80,000-120,000; the asphalt material is one or more of natural asphalt, coal tar asphalt and petroleum asphalt; and the inorganic mineral filling material is one or over two of calcium carbonate of 500-800 meshes, talc powder, quartz sand, glass hollow microspheres and kaolin.

Owner:SHENZHEN KEZHONGDA POLYMER MATERIAL RES INST

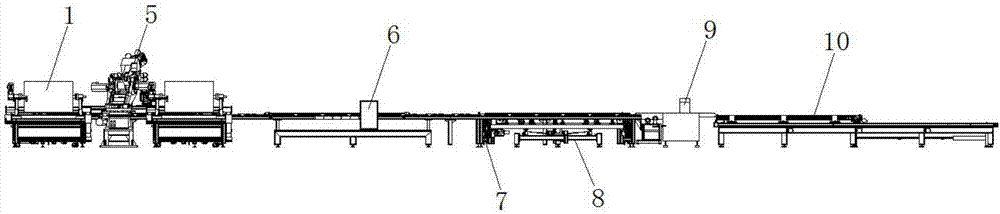

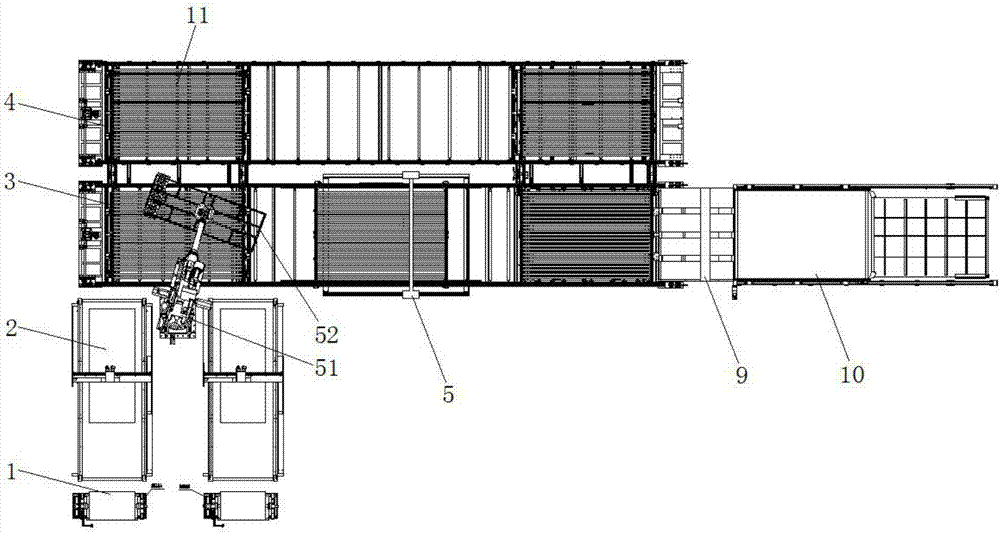

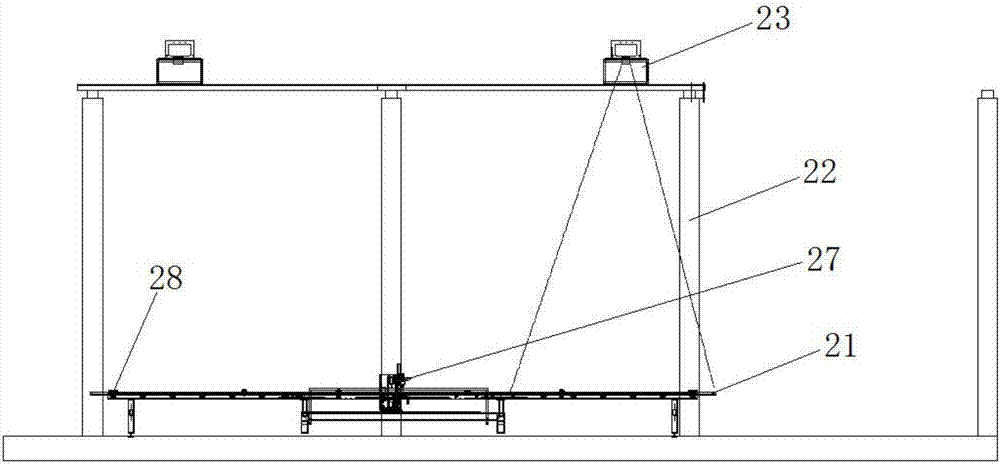

Wind power blade preforming production line

PendingCN107327376AIncrease productivityImprove cutting accuracyEngine manufactureWork-feeding meansElectricityTextile

The invention discloses a wind power blade preforming production line. An unreeling mechanism is arranged near the input end of a cutting mechanism; the output end of the cutting mechanism is arranged near the input end of a first conveying line; a second conveying line and the first conveying line are arranged adjacent and in parallel; the conveying directions of the second conveying line and the first conveying line are opposite; a grabbing and stacking mechanism is arranged near the output end of the cutting mechanism and the input end of the first conveying line; a sewing mechanism is arranged on the middle part of the first conveying line; the first conveying line, a metal detection mechanism and a stacking and discharging mechanism are arranged sequentially along the conveying direction of the first conveying line; a turnover box is conveyed on the first conveying line and the second conveying line; jacking and translation mechanisms are arranged at the bottoms of the input end and the output end of the first conveying line as well as at the bottoms of the input end and the output end of the second conveying line; and a jacking and cloth taking mechanism is arranged at the bottom of the output end of the first conveying line. According to the wind power blade preforming production line, automatic production of a wind power blade preforming piece is realized and the production efficiency is effectively improved.

Owner:NEWTRY COMPOSITE

Silicone oil release film with sticky surface and production process of silicone oil release film

InactiveCN104073185AWith release forceStickyLiquid surface applicatorsFilm/foil adhesivesCross-linkAlcohol

The invention discloses a silicone oil release film with a sticky surface and a production process of the silicone oil release film. The silicone oil release film comprises a substrate and a silicone oil face attached to the surface of the substrate, wherein the silicone oil face is prepared from the following components in parts by weight: 9240 parts of a solvent, 1000 parts of a releaser, 200 parts of a cross-linking agent, 13 parts of a curing agent, 300 parts of a releasing force adjustor and 3000 parts of an adhesive. The solvent comprises one or a mixture of more of a solvent TOL (Toluene), a solvent D-40, a solvent D-30, a solvent MEK (Methyl Ethyl Ketone) or a solvent IPA (Iso Propyle Alcohol). The releaser comprises a 7485 type releaser. The cross-linking agent comprises one or a mixture of more of a 297 type cross-linking agent, a 7672 type cross-linking agent or a 7028 type cross-linking agent. The adhesive is a 7652 type adhesive or a 7651 type adhesive. The release film disclosed by the invention has certain viscidity, can be stably attached to a hot melt adhesive without displacement, and is low in releasing force and convenient to be separated from the hot melt adhesive and free from residues on the surface of the hot melt adhesive separated.

Owner:佛山凯仁精密材料有限公司

Interbody fusion deVice based on 3D printing and preparation method of deVice

ActiveCN108670505AImprove bindingTightly boundAdditive manufacturing apparatusSpinal implantsCell adhesionAdhesion process

The inVention discloses an interbody fusion deVice based on 3D printing and a preparation method of the deVice. By adopting polyaryletherketone series materials as basic raw materials, adopting a mixture of degradable high-molecular materials and actiVated osteogenesis powder as an auxiliary raw material and utilizing a dual-sprayer extrusion-type 3D printing technology, the interbody fusion deVice is prepared. The interbody fusion deVice is of a hollow three-dimensional through structure, wherein the Volume ratio of the basic raw materials to the auxiliary raw material is (1:0.01)-(1:1). Thesurface of the interbody fusion deVice is proVided with cell identification sites, and therefore the interbody fusion deVice is applicable to a micro enVironment for cell adhesion and new bone deposition, so that the combination capability between the interbody fusion deVice and new bones is improVed. MoreoVer, with degradation of the degradable high-molecular materials, spaces of porous structures can be formed, gradual growth of the new bones into the spaces is facilitated to achieVe close combination between the interbody fusion body and bone tissue, and loosening and displacement of the interbody fusion deVice cannot occur.

Owner:MEDPRIN REGENERATIVE MEDICAL TECH

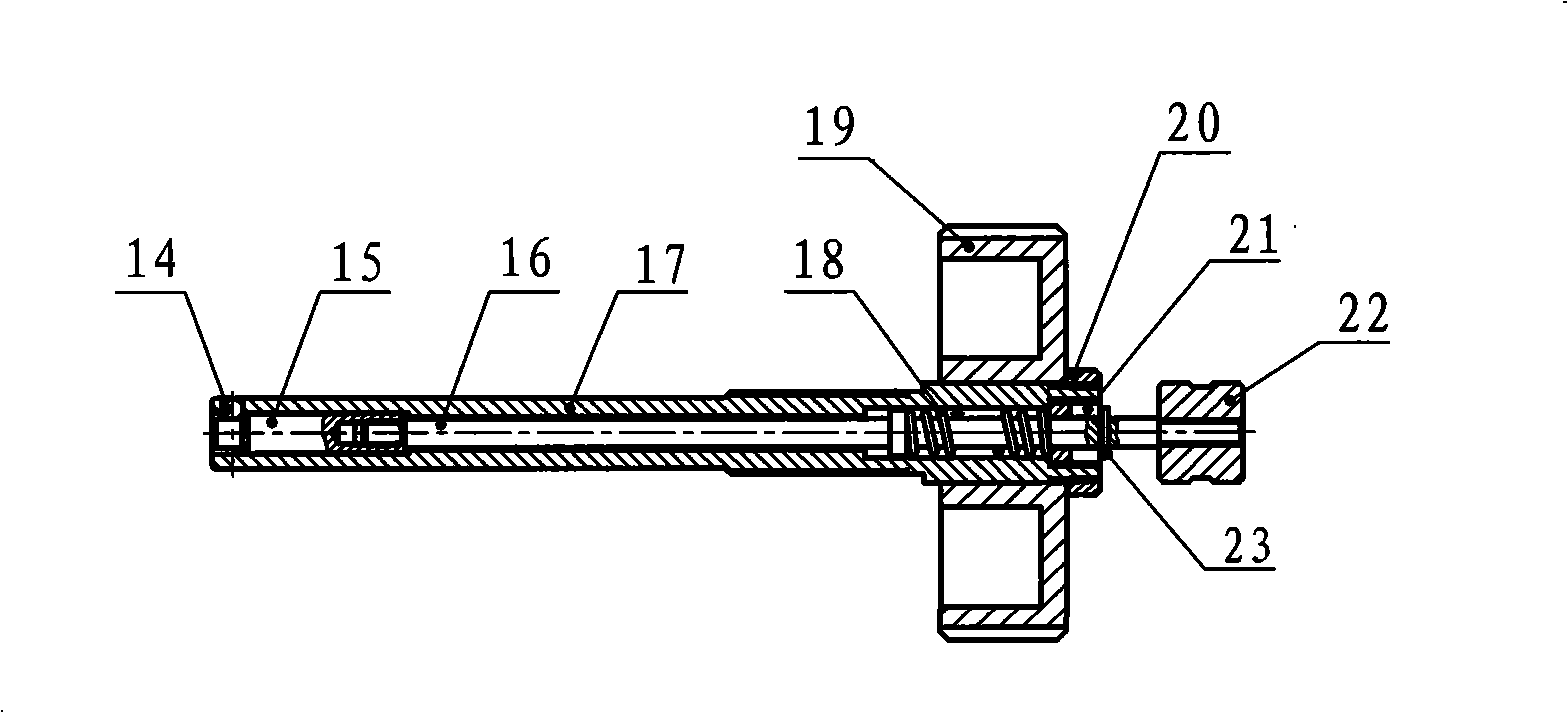

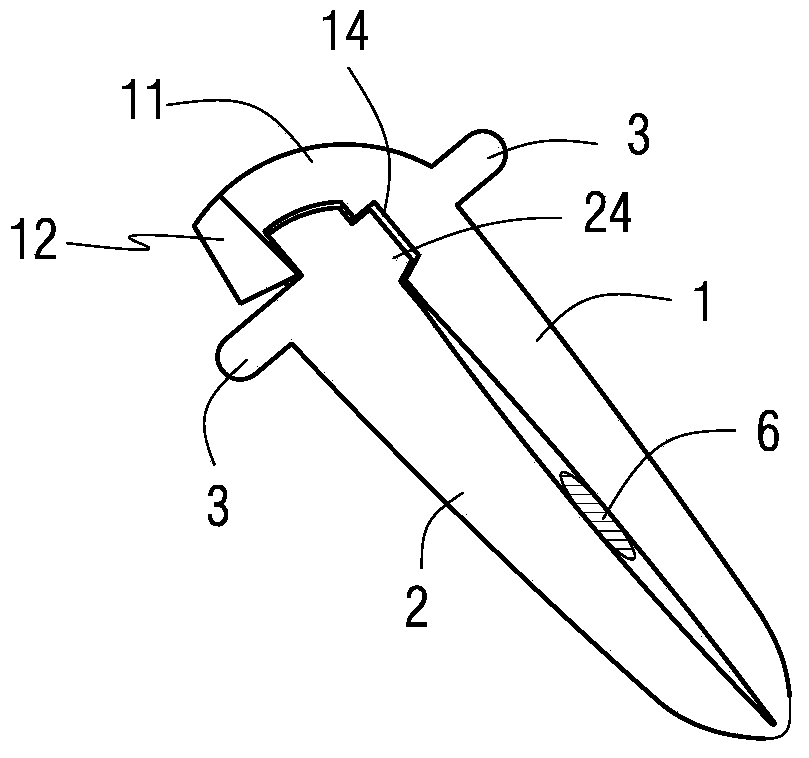

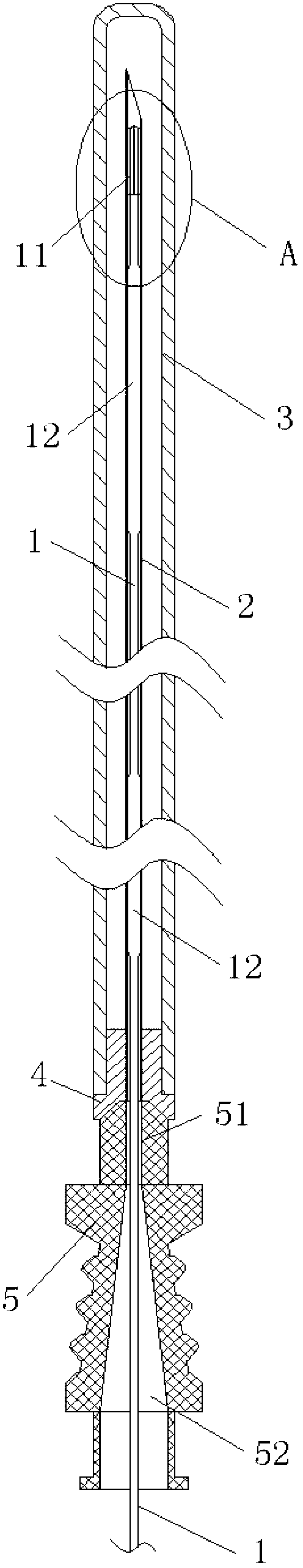

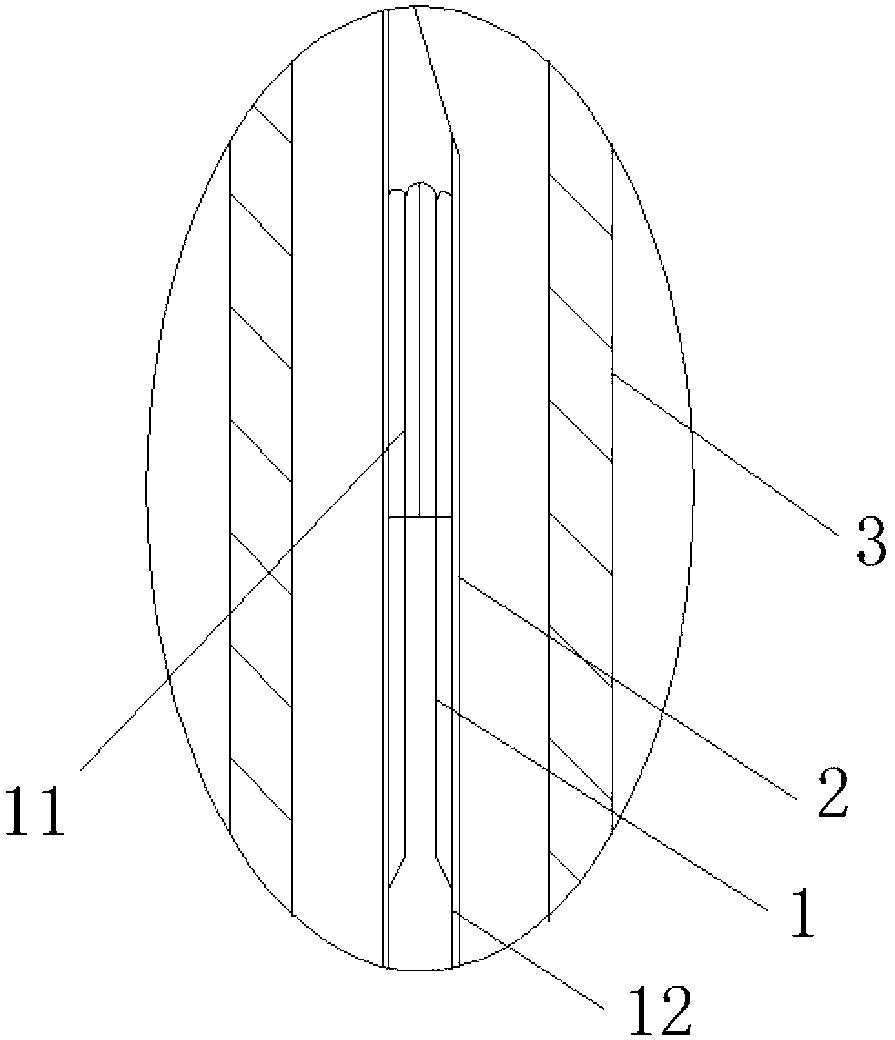

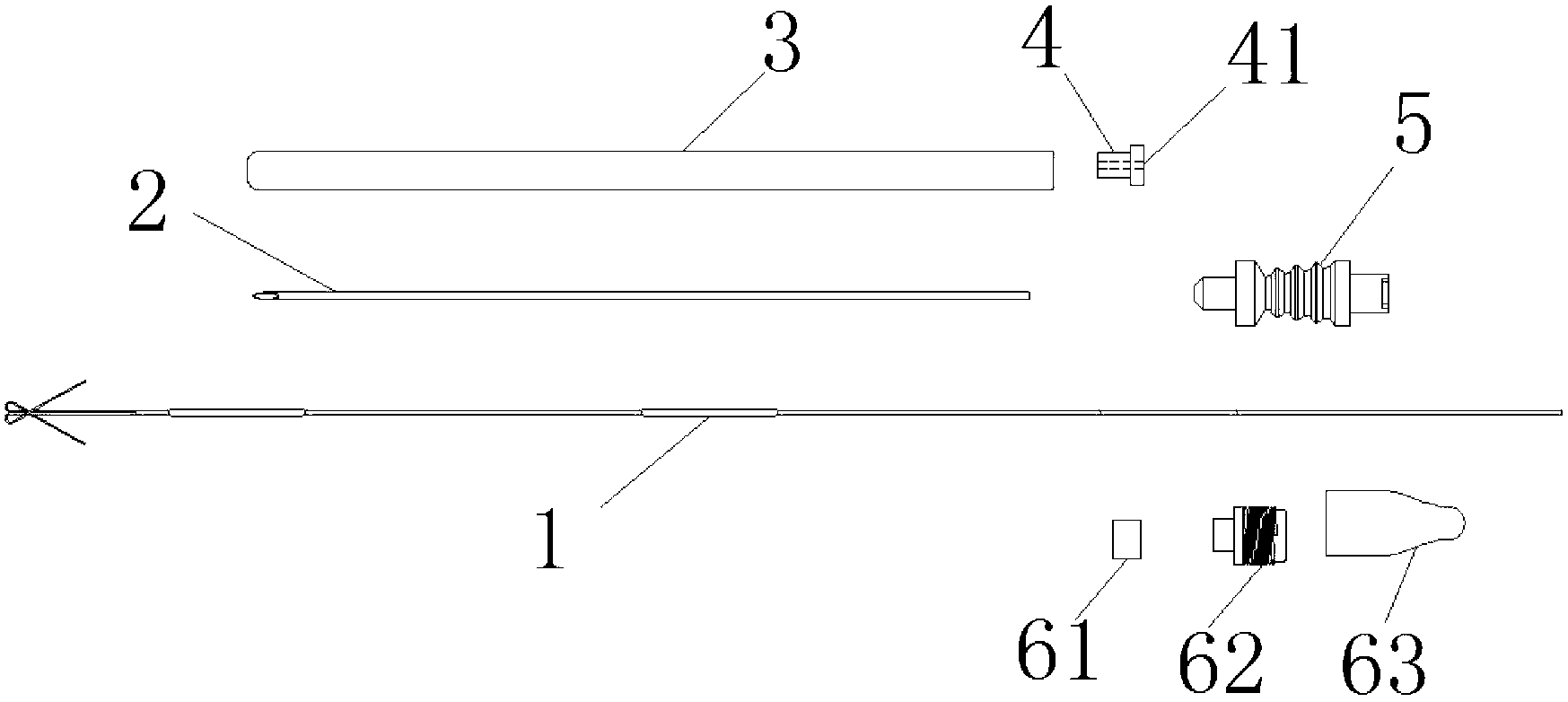

Needle used for puncturing and positioning pulmonary nodule

ActiveCN102697540AInhibit sheddingAvoid displacementSurgical needlesTrocarPulmonary noduleInjury cause

The invention relates to a needle used for puncturing and positioning a pulmonary nodule. The needle comprises a stylet and a sleeve, wherein the sleeve is a hollow cavity of which both ends are opened; one end of the stylet is provided with a hook-shaped structure which is restrained in the sleeve to realize contraction; and the other end of the stylet extends out of the sleeve, and a thickening part is arranged on the stylet and positioned in the sleeve. When the needle used for puncturing and positioning a pulmonary nodule, which is provided by the invention, is used, the needle used for puncturing and positioning a pulmonary nodule has the advantages of accurate positioning and difficult fall-off, and due to the improvement of the structure, pneumothorax is not easily caused in an operation process, so that necessary time is provided for an operator to accurately positioning a focus, and secondary injuries caused by repeated puncturing to a patient are avoided; and meanwhile, the risk of bringing the secondary injuries to the patient is also eliminated by a fixing device at the tail part of the stylet.

Owner:临沂高新人才教育发展集团有限公司

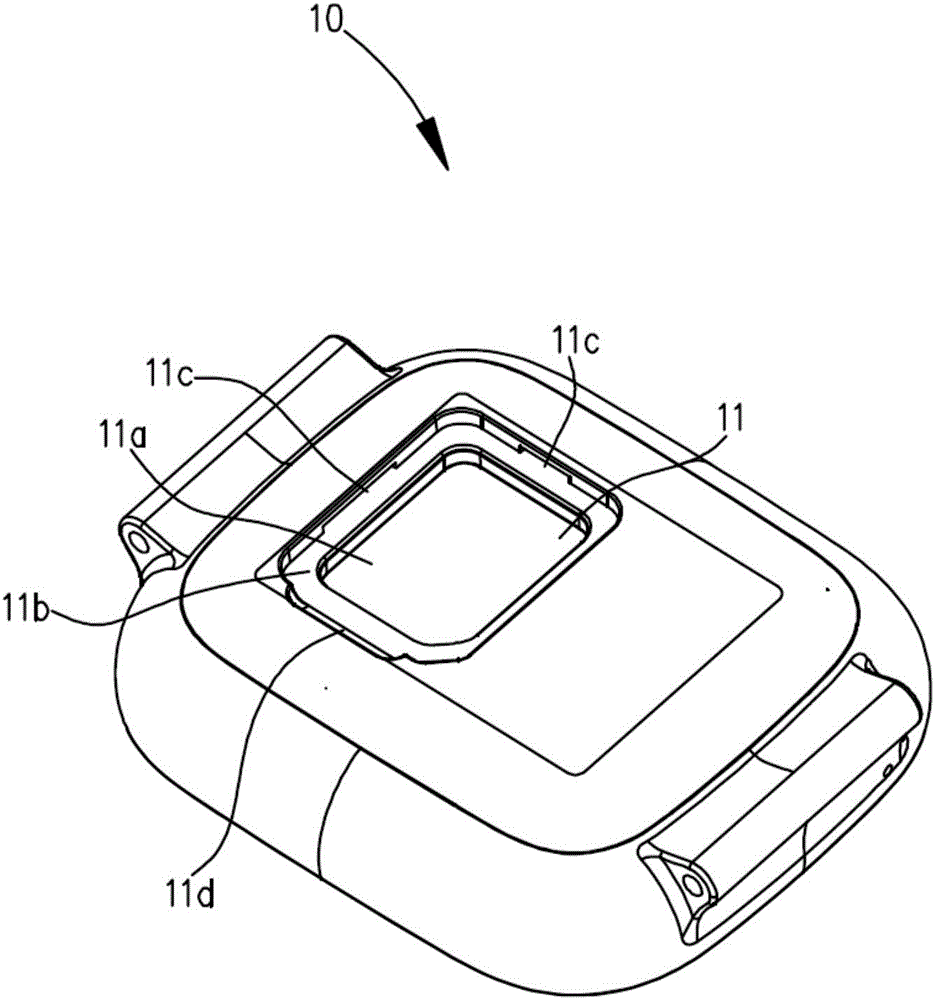

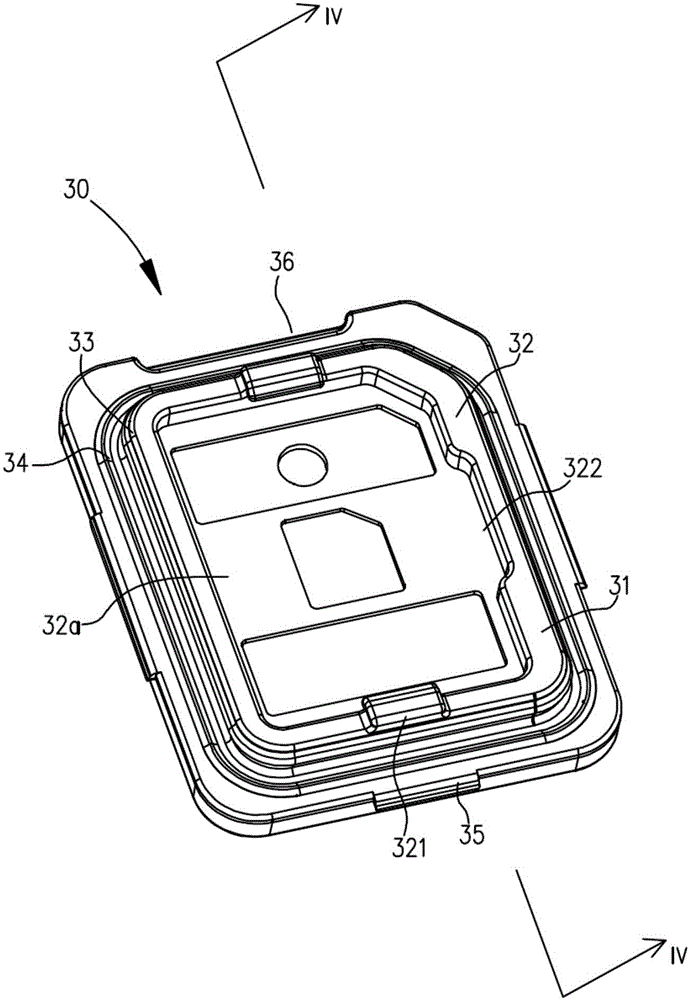

Intelligent watch seal structure

ActiveCN106502083AGuaranteed waterproof performanceNo displacementElectronic time-piece structural detailsHermetically-sealed casingsEngineeringMotherboard

The invention discloses an intelligent watch seal structure, which comprises a watchcase main body and a card cover equipped with an SIM card. The watchcase main body is provided with an accommodation groove; the accommodation groove is internally provided with a circuit main board electrically connected to the SIM card; the card cover is detachably arranged to the accommodation groove; an installation surface of the card cover is provided with an installation groove for installing the SIM card; a bottom wall of the installation groove is provided with a first waterproof seal member integrated on the installation surface; a side wall of the installation groove is provided with a second waterproof seal member integrated on the installation surface; and the bump direction of the second waterproof seal member is vertical to the bump direction of the first waterproof seal member. According to the intelligent watch seal structure, the first waterproof seal member and the second waterproof seal member integrated on the card cover around the periphery of the card cover are utilized to seal the connection place between the accommodation groove and the card cover in axial direction and radial direction simultaneously, thereby preventing external water from entering the watch; and the intelligent watch seal structure is simple in structure and facilitates to improve waterproof performance of an intelligent watch.

Owner:GUANGDONG XIAOTIANCAI TECH CO LTD

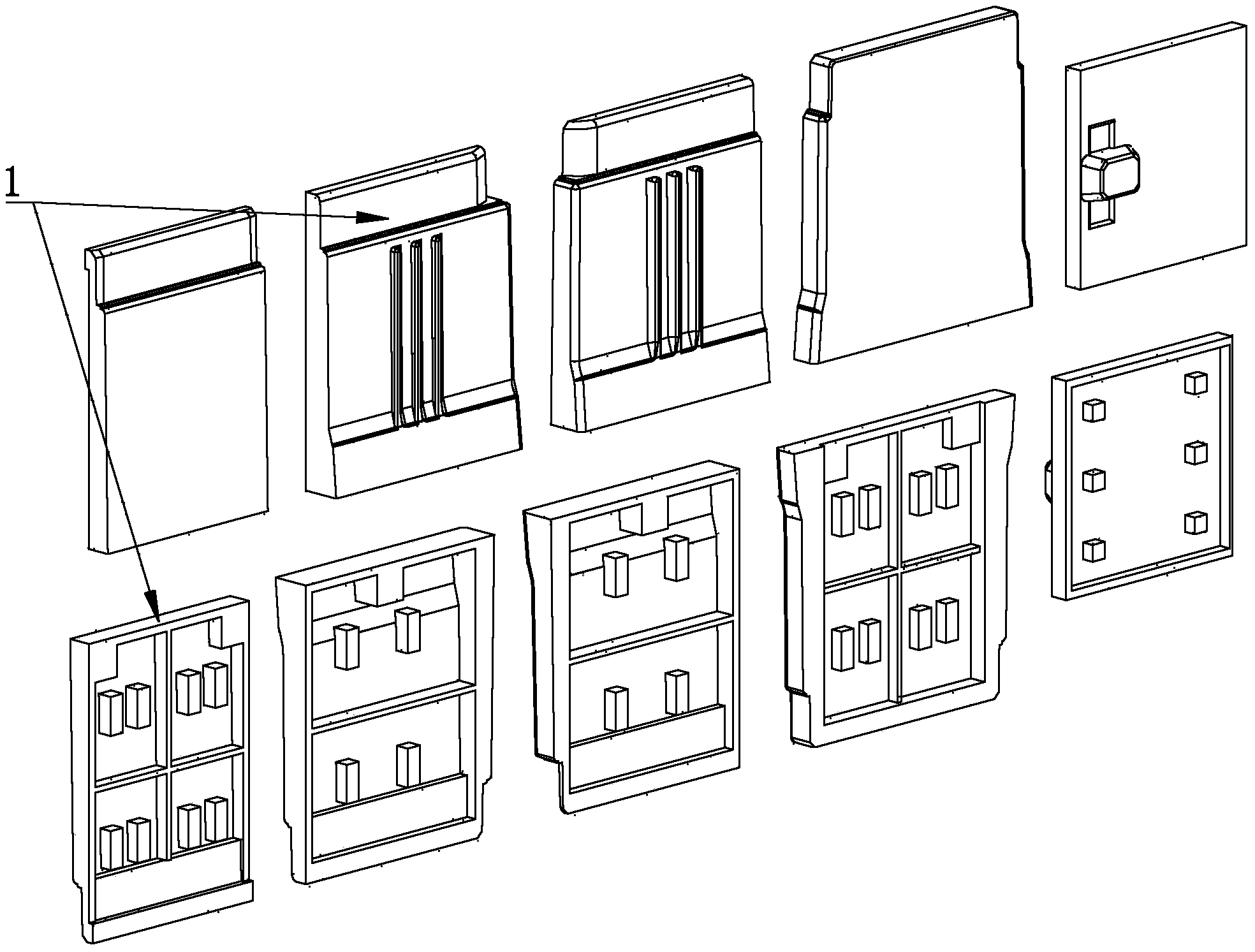

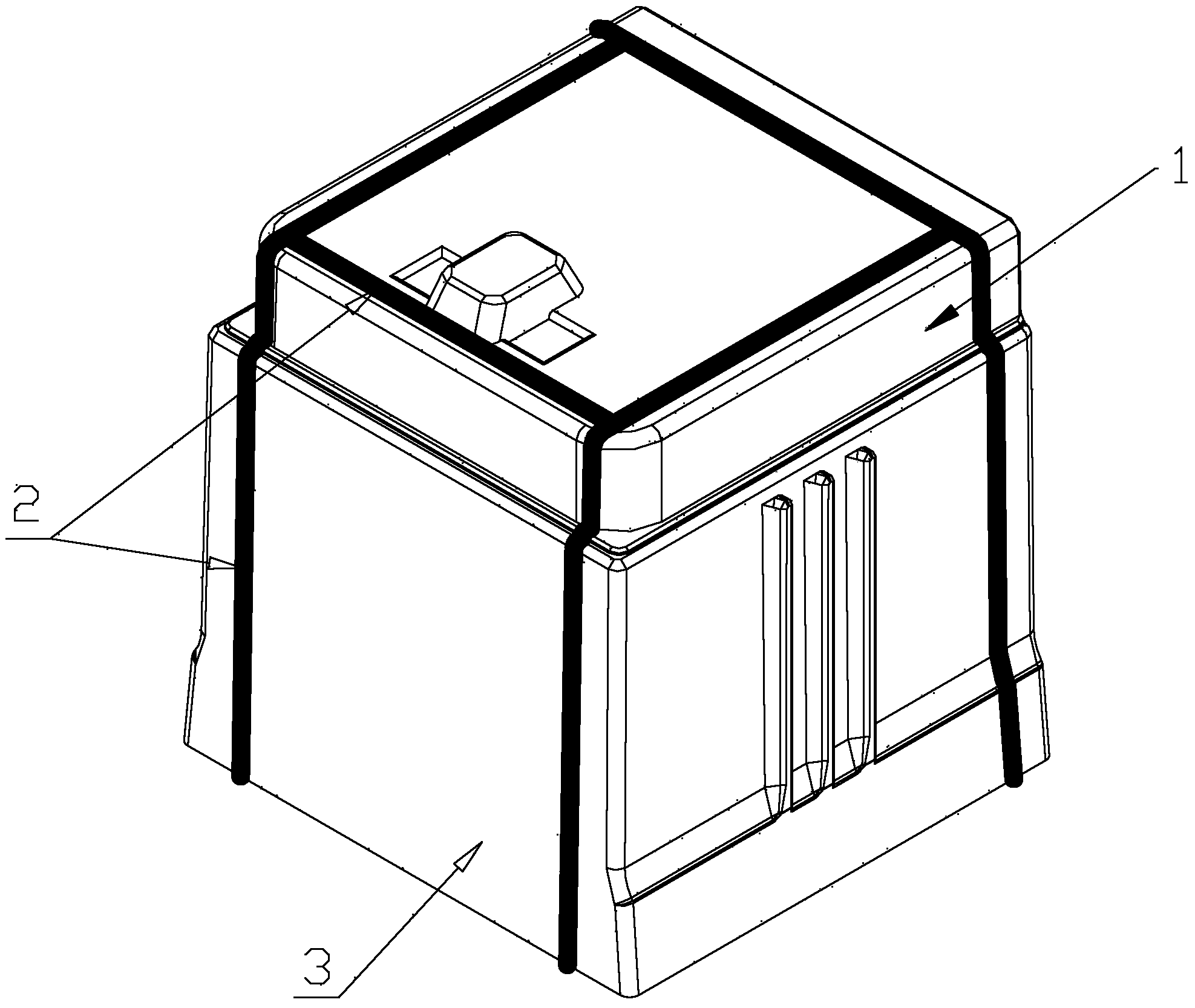

V-method mold for casting electronic appliance mold casting blank

ActiveCN103658525APrecise and stable billet sizeReserved machining allowance is smallFoundry mouldsFoundry coresUltimate tensile strengthRefrigerated temperature

The invention discloses a V-method mold for casting an electronic appliance mold casting blank, and relates to the technical field of aluminum alloy casting. The V-method mold comprises a V-method mold body, wherein the mold body consists of independent combined mold blocks; each combined mold block is subjected to three-dimensional forming and design according to mold drawing requirements; the combined mold blocks are adhered to both sides so as to form the mold body; a plurality of vent holes for vacuuming are formed in the combined mold blocks. The mold casting blank of an inner container of a refrigerator is produced by using a V-method casting process, not only is the energy saved, is the consumption reduced, and is the working intensity alleviated, but also the factory environment is improved, and the V-method is an economic, environment-friendly and green project.

Owner:CHUZHOU JINNUO INDAL

Adjustable position fixing installation device of soil pressure gauge

ActiveCN103806426AAchieve self-regulationOvercoming the disadvantage that it is difficult to adjust the position and easily lead to its displacementIn situ soil foundationSocial benefitsSoil science

An adjustable position fixing installation device of a soil pressure gauge is arranged on the periphery of the soil pressure gauge and characterized in that a hoop made of a rigid plate is arranged on the adjustable position fixing installation device, the thickness of the loop is equal to or smaller than that of the soil pressure gauge, the shape of the hoop corresponds to the shape of the periphery of the soil pressure gauge, and the size of the inside of the hoop is equal to or slightly greater than the dimension of the periphery of the soil pressure gauge. Two fixing reinforcing steel bars are fixed on the back surface of the hoop, hooks are arranged on ends of the two fixing reinforcing steel bars, and other ends of the fixing reinforcing steel bars incline to the direction of the back surface. By means of the adjustable position fixing installation device of the soil pressure gauge, interface type installation of the soil pressure gauge can be achieved conveniently and accurately, and the problem that the soil pressure gauge is easily covered with concrete when buried is solved, installation time is saved further, the 'survival rate' of the soil pressure gauge is increased, and installation cost is reduced. Furthermore, the adjustable position fixing installation device of the soil pressure gauge is an ideal device capable of overcoming the shortcoming in the prior art and has obvious economic benefit and social benefit.

Owner:NANJING HYDRAULIC RES INST

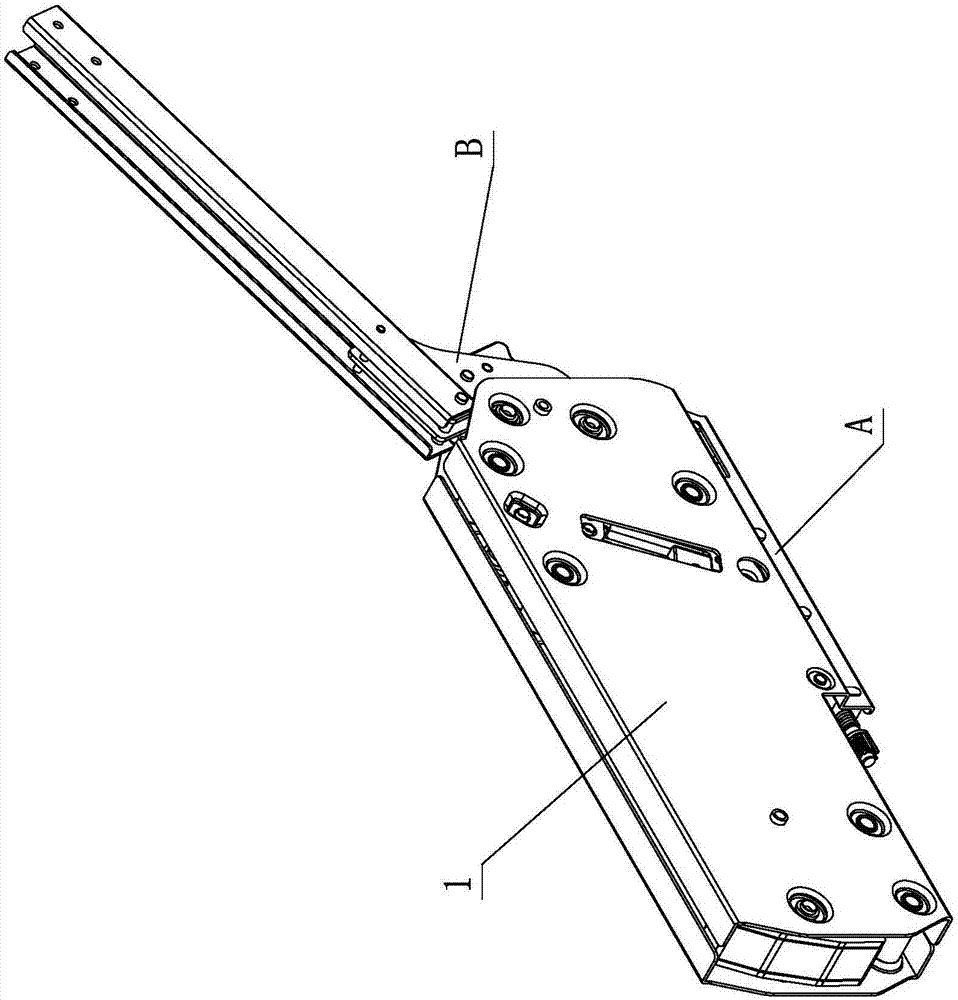

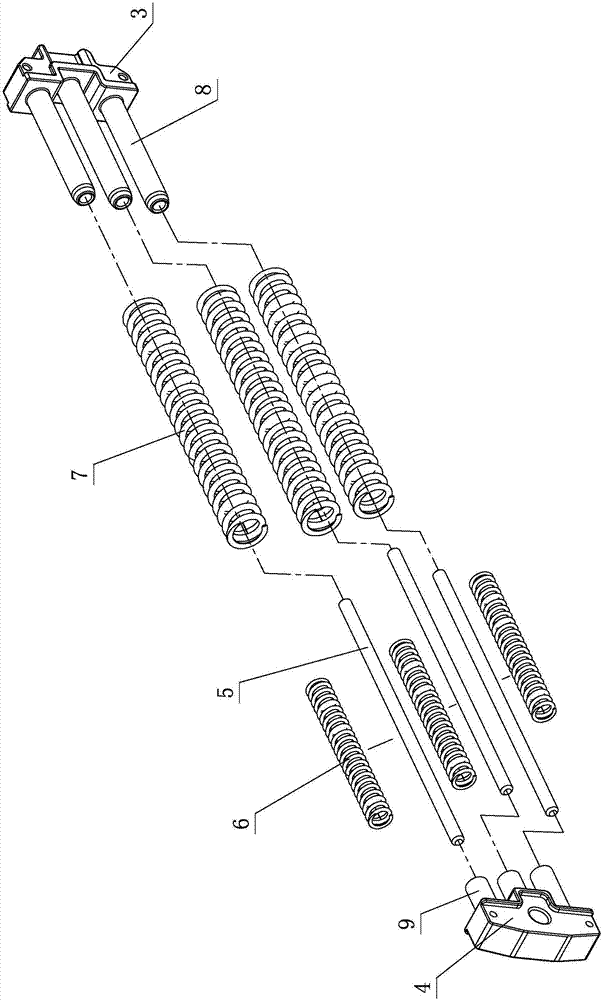

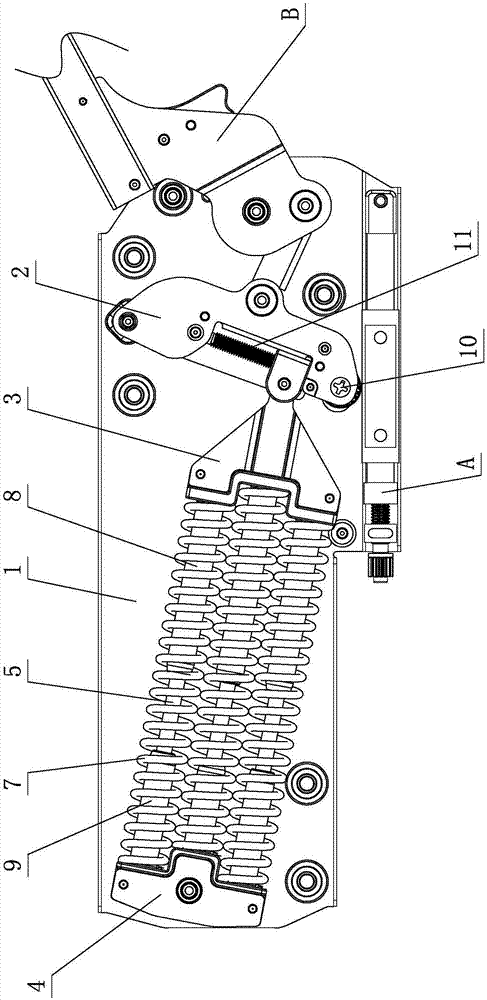

Elastic acting force structure of furniture upturning device

PendingCN107461100AShorten the lengthSoft opening and closing processWing openersWing closersClassical mechanicsEngineering

An elastic acting force structure of a furniture upturning device comprises a fixing support, a swing rod and a spring assembly, wherein the swing rod is arranged on the fixing support in a swinging mode and interact with the spring assembly during swinging, so that the spring assembly generates elastic acting force; the spring assembly comprises a front connection part, a rear connection part, a guide shaft and a spring; the guide shaft is sleeved with the spring; the two ends of the spring elastically act on the front connection part and the rear connection part; the two ends of the guide shaft are connected with one end of the front connection part and one end of the rear connection part in a matched mode; the other end of the front connection part is connected with the swing rod in a matched mode; and the other end of the rear connection part is connected with the fixing support in a matched mode. By improvement of the structure, the elastic acting force structure of the furniture upturning device has the characteristics of being simple and reasonable in structure, safe, reliable, easy to produce and achieve, rapid to adjust, convenient to operate, long in service life, smooth in opening and closing process, capable of saving labor, low in collision, low in noise, wide in use range and the like, and practicability is high.

Owner:GUANGDONG DTC HARDWARE PRECISION MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com