Sand-line iron mould casting process for grey cast iron flywheel housing of diesel engine

A technology for sand-coated iron mold casting and gray cast iron, which is applied in the directions of molds, mold components, and manufacturing tools. Improved strength and working environment, good surface quality, good dimensional consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

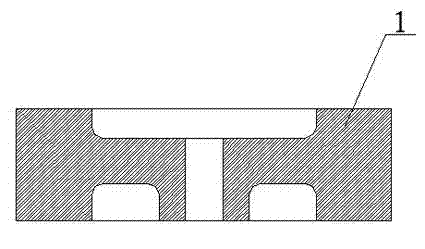

[0045] figure 1 Shown is a schematic cross-sectional structure diagram of a gray iron flywheel housing casting 1 for a diesel engine.

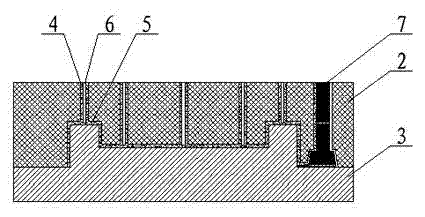

[0046] figure 2 As shown, a schematic diagram of the upper iron mold sand-coated structure of the iron mold sand-coated casting process of the gray iron flywheel housing of a diesel engine, including the upper iron mold 2, the runner mold 7 and the upper mold 3, the surface structure of the upper mold and the flywheel housing casting The upper surface structure is the same, and there is a sand-covered cavity between the upper iron mold and the upper mold. There are multiple sand-covering holes 4 connected to the sand-coating cavity on the top. Through the multiple sand-shot holes on the upper iron mold, the sand-coating cavity between the upper iron mold and the upper mold is filled with coated sand by compressed air to form a sand-coated mold. Layer 5, pierce an air hole 6 into the sand-covered layer from each sand shooting hole.

[0047]...

Embodiment 1

[0049] Embodiment one; Casting process of the present invention comprises steps as follows:

[0050] (1) Manufacture of iron molds and molds: Make upper and lower molds according to the size of flywheel shell castings, and make upper and lower iron molds corresponding to the size of upper and lower molds with sand-covered cavities, and set casting system and multiple molds on the upper iron molds Sand shooting holes, set multiple sand shooting holes on the lower iron mold;

[0051] (2) Upper and lower casting shapes:

[0052] (2a) Preheat the upper iron mold and the upper mold, and the lower iron mold and the lower mold on the sand coating machine respectively. The iron mold preheating temperature is 240°C, and the mold preheating temperature is 240°C; Mold, spray release agent on the outer walls of the upper and lower molds, and then fit;

[0053] (2b) Fill the sand-covered cavity between the upper iron mold and the upper mold, the lower iron mold and the lower mold with co...

Embodiment 2

[0072] Embodiment two; Casting process of the present invention comprises steps as follows:

[0073] (1) Manufacture of iron molds and molds: Make upper and lower molds according to the size of flywheel shell castings, and make upper and lower iron molds corresponding to the size of upper and lower molds with sand-covered cavities, and set casting system and multiple molds on the upper iron molds Sand shooting holes, set multiple sand shooting holes on the lower iron mold;

[0074] (2) Upper and lower casting shapes:

[0075] (2a) Preheat the upper iron mold and the upper mold, and the lower iron mold and the lower mold on the sand coating machine respectively. The iron mold preheating temperature is 260°C, and the mold preheating temperature is 260°C; Mold, spray release agent on the outer walls of the upper and lower molds, and then fit;

[0076] (2b) Fill the sand-covered cavity between the upper iron mold and the upper mold, the lower iron mold and the lower mold with co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com