Patents

Literature

615results about How to "Reduce glitches" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

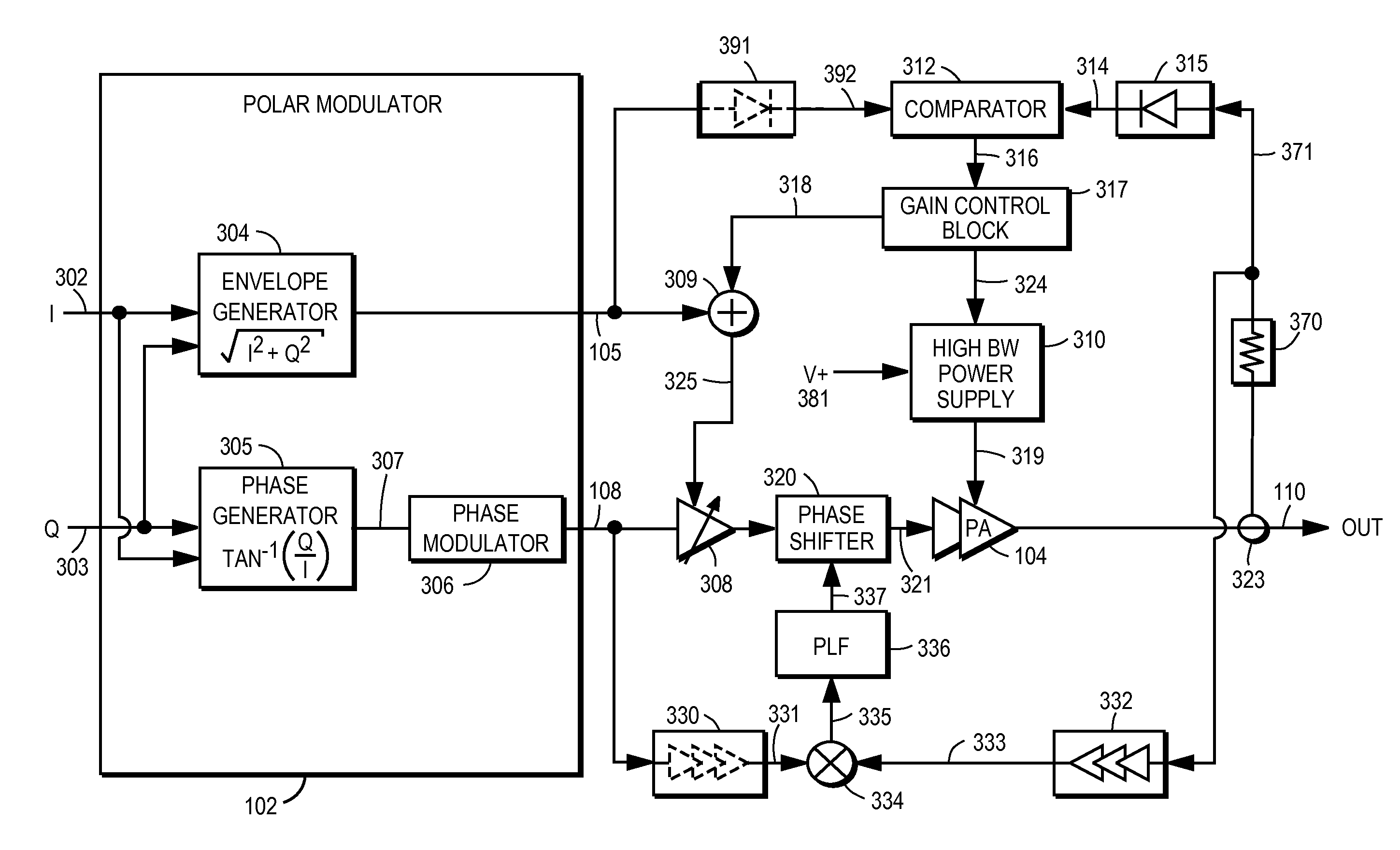

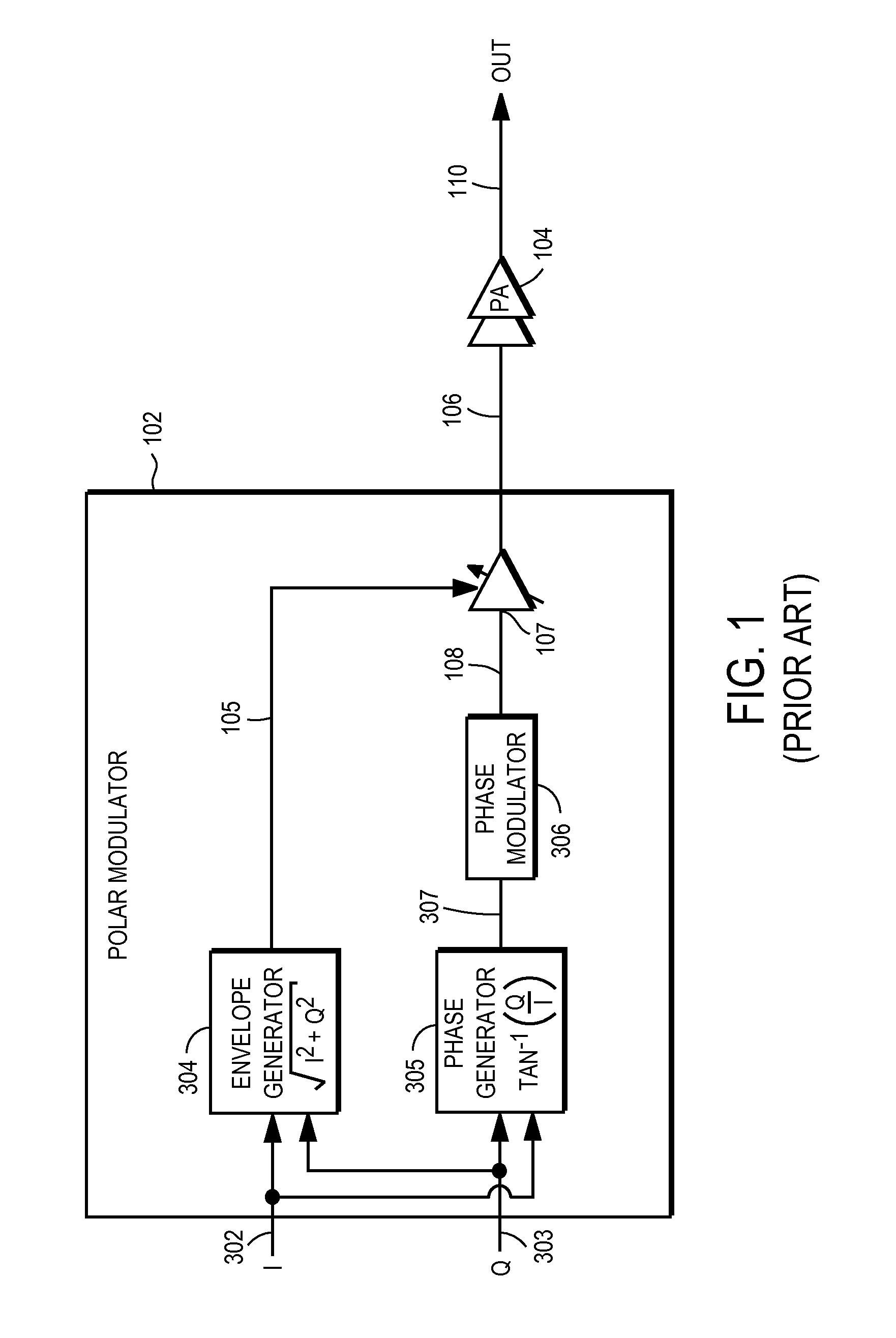

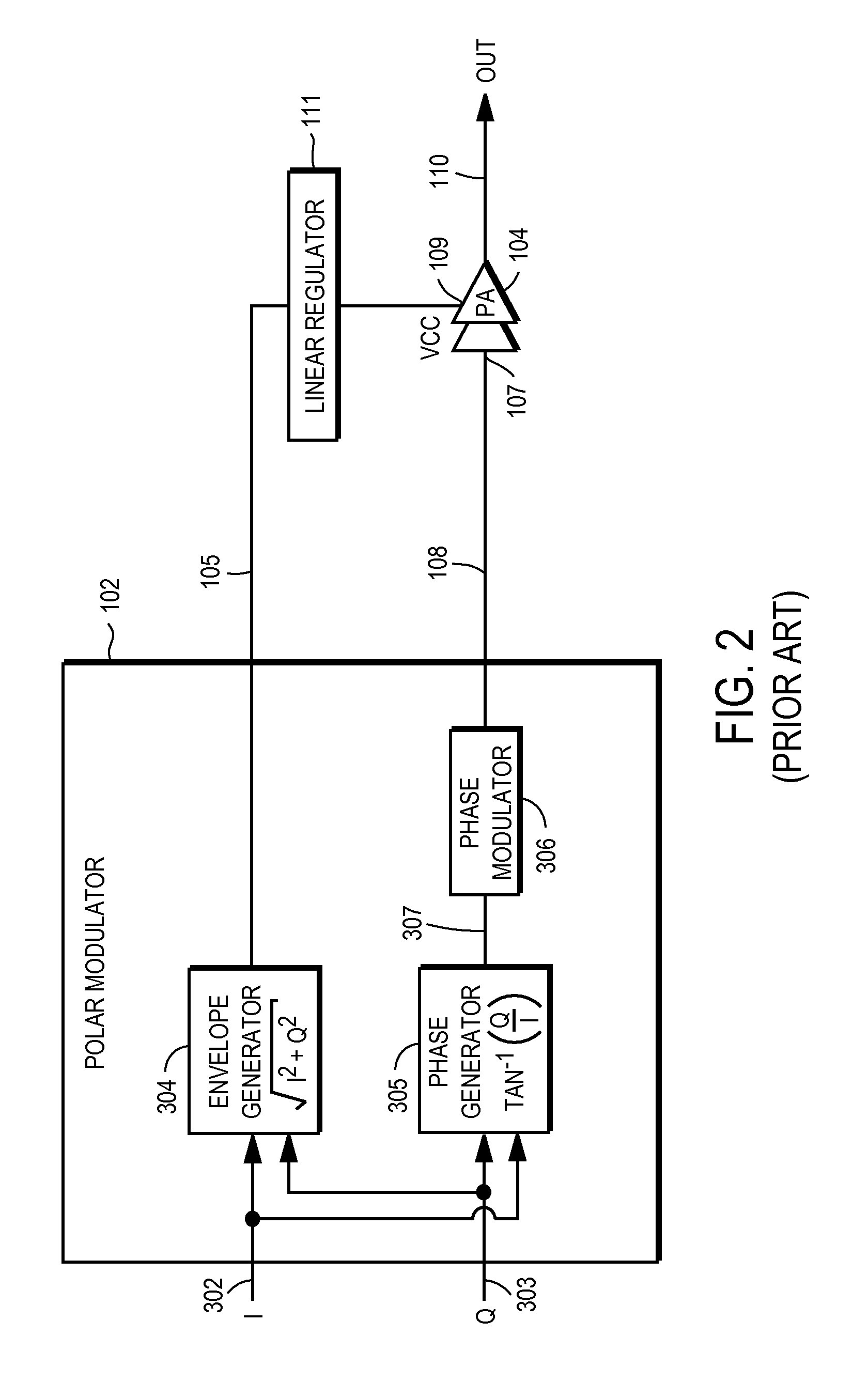

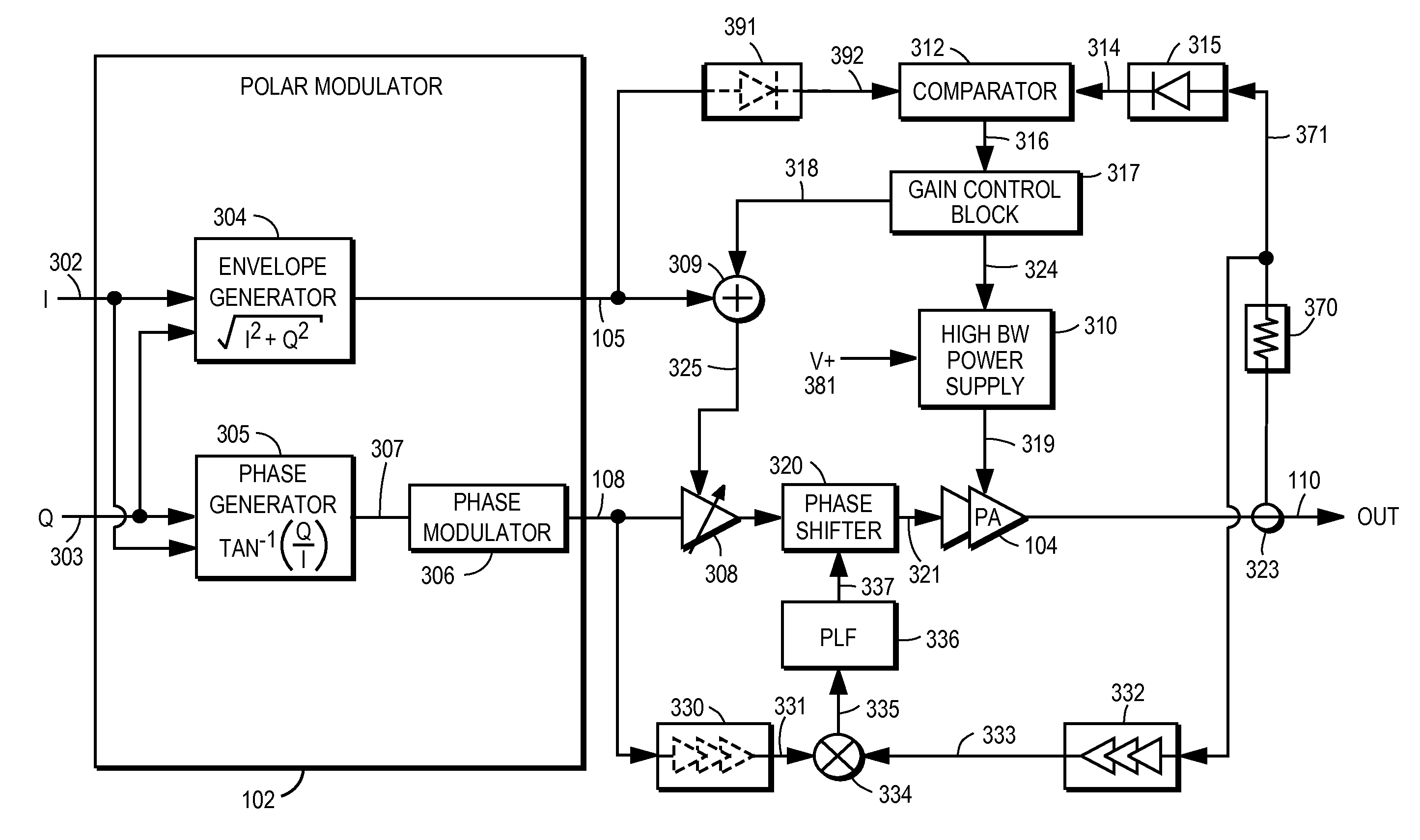

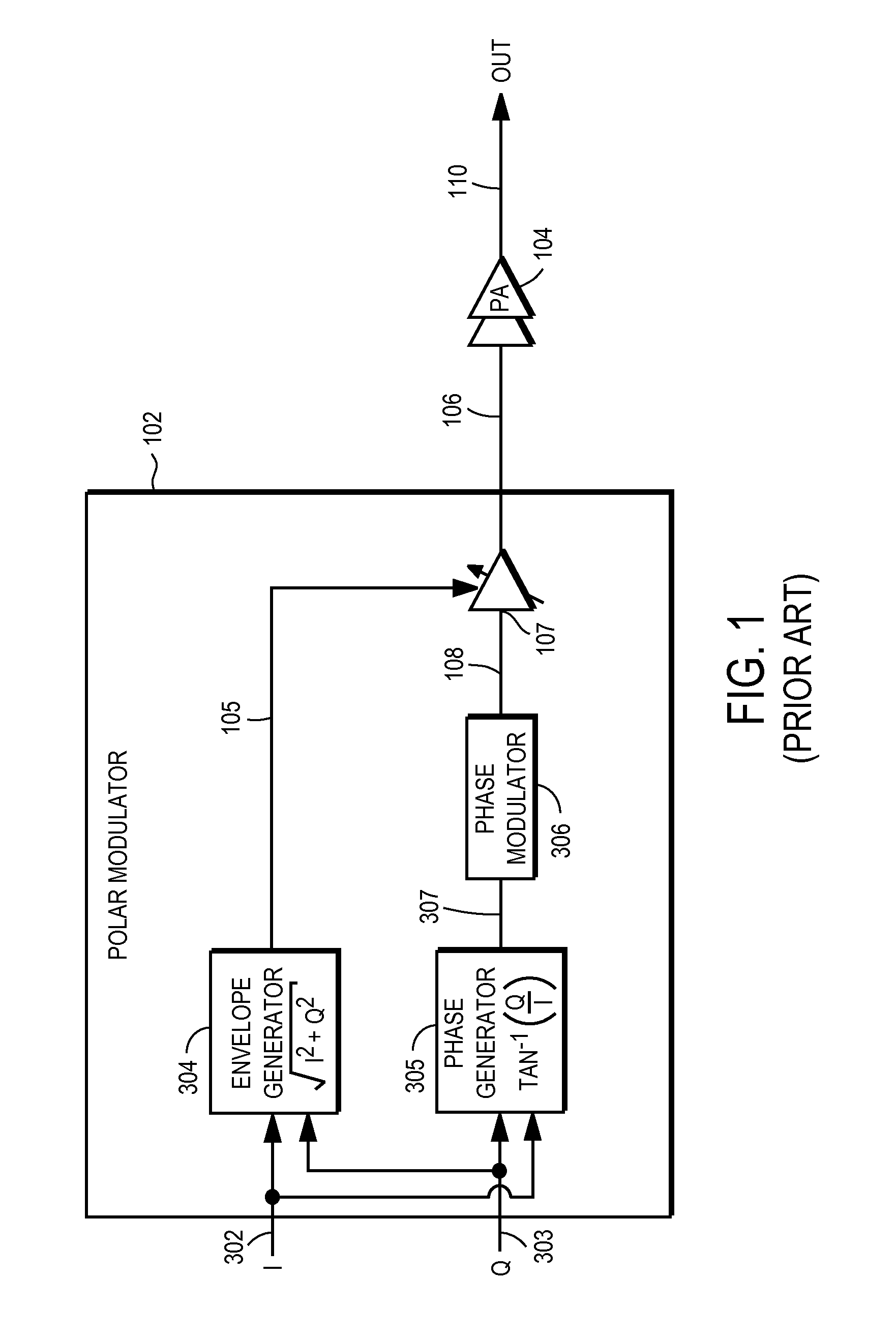

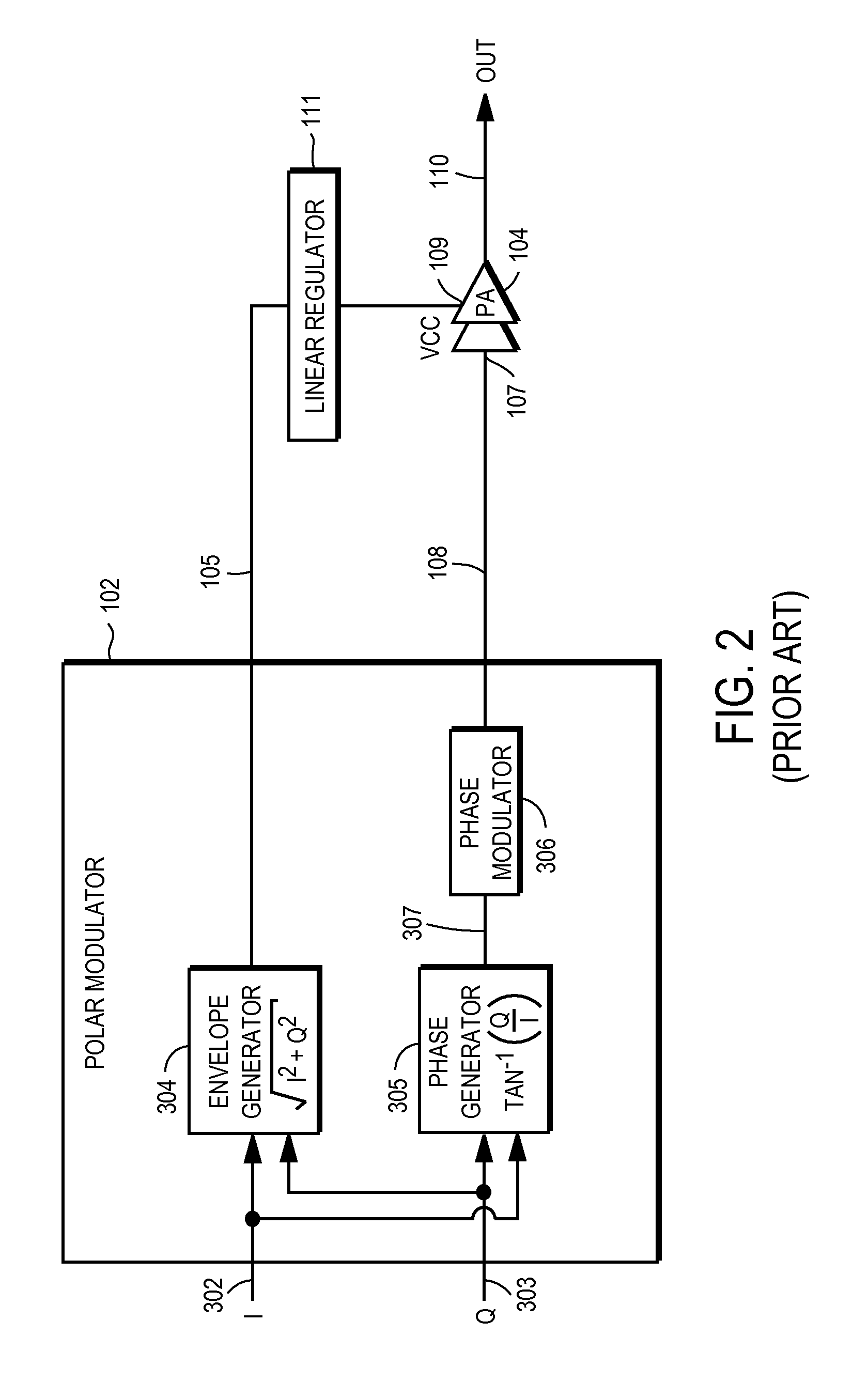

Power Amplifier Controller With Polar Transmitter

ActiveUS20100311365A1Reduce phase distortionMinimize the differenceAmplifier modifications to reduce non-linear distortionResonant long antennasAudio power amplifierEngineering

A power amplifier controller controls a power amplifier and is coupled to a polar modulator. The polar modulator generates an amplitude component and a phase-modulated component of the desired RF modulated signal, and outputs to the power amplifier controller. The power amplifier controller regenerates a combined phase and amplitude modulated RF signal to generate an input signal to a power amplifier by adjusting the gain of a VGA based on the amplitude component of the desired RF modulated signal. Concurrently, the power amplifier controller both controls an adjusted supply voltage to the PA and adjusts the gain of the VGA based upon an amplitude correction signal or amplitude error signal.

Owner:QUANTANCE

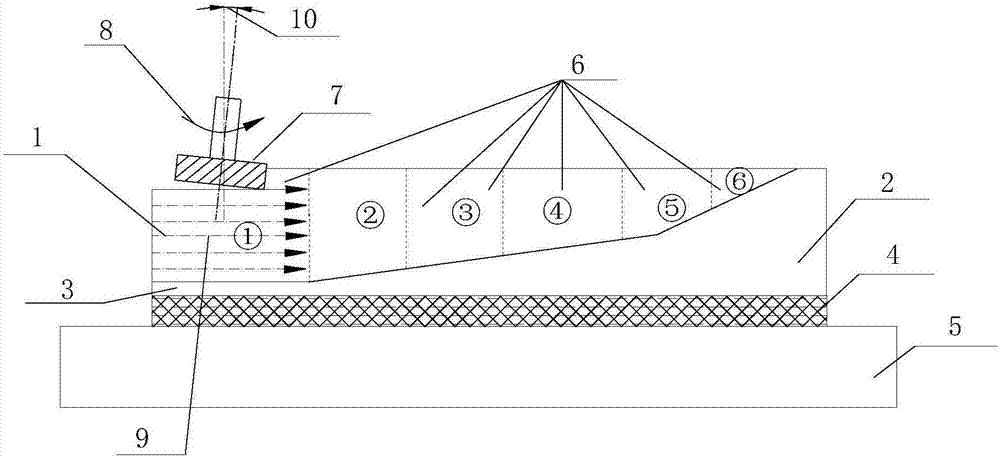

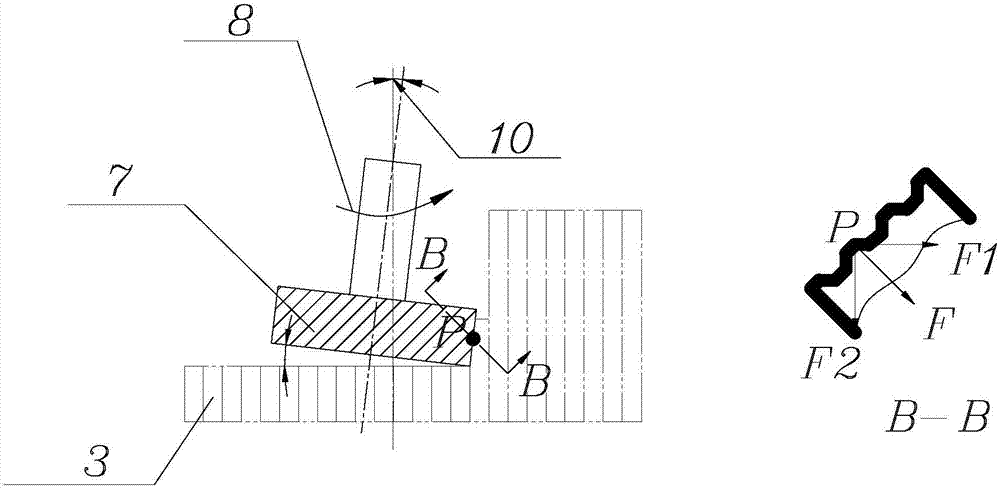

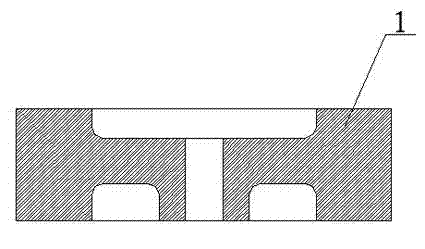

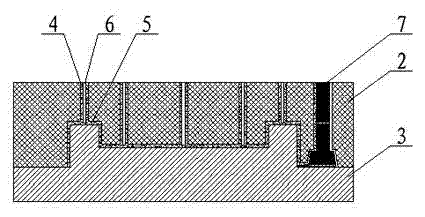

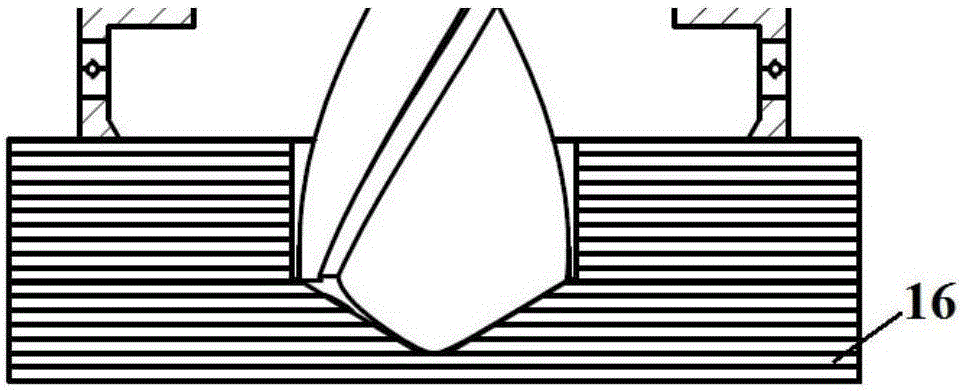

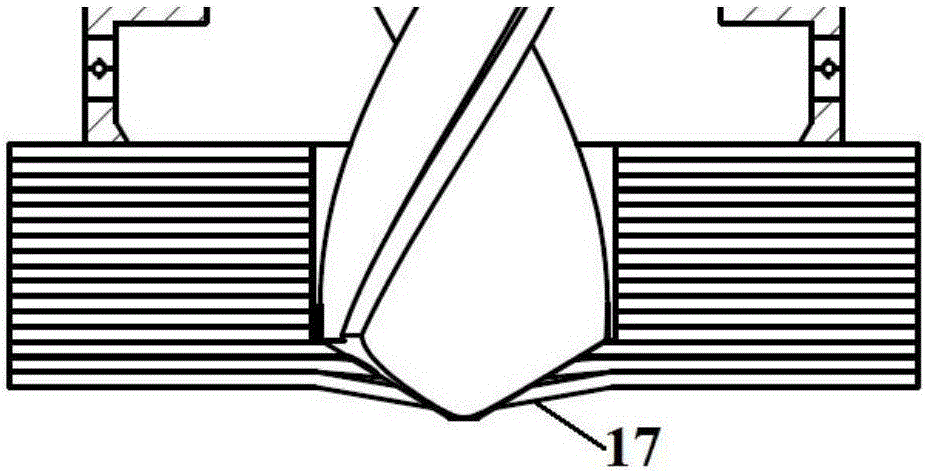

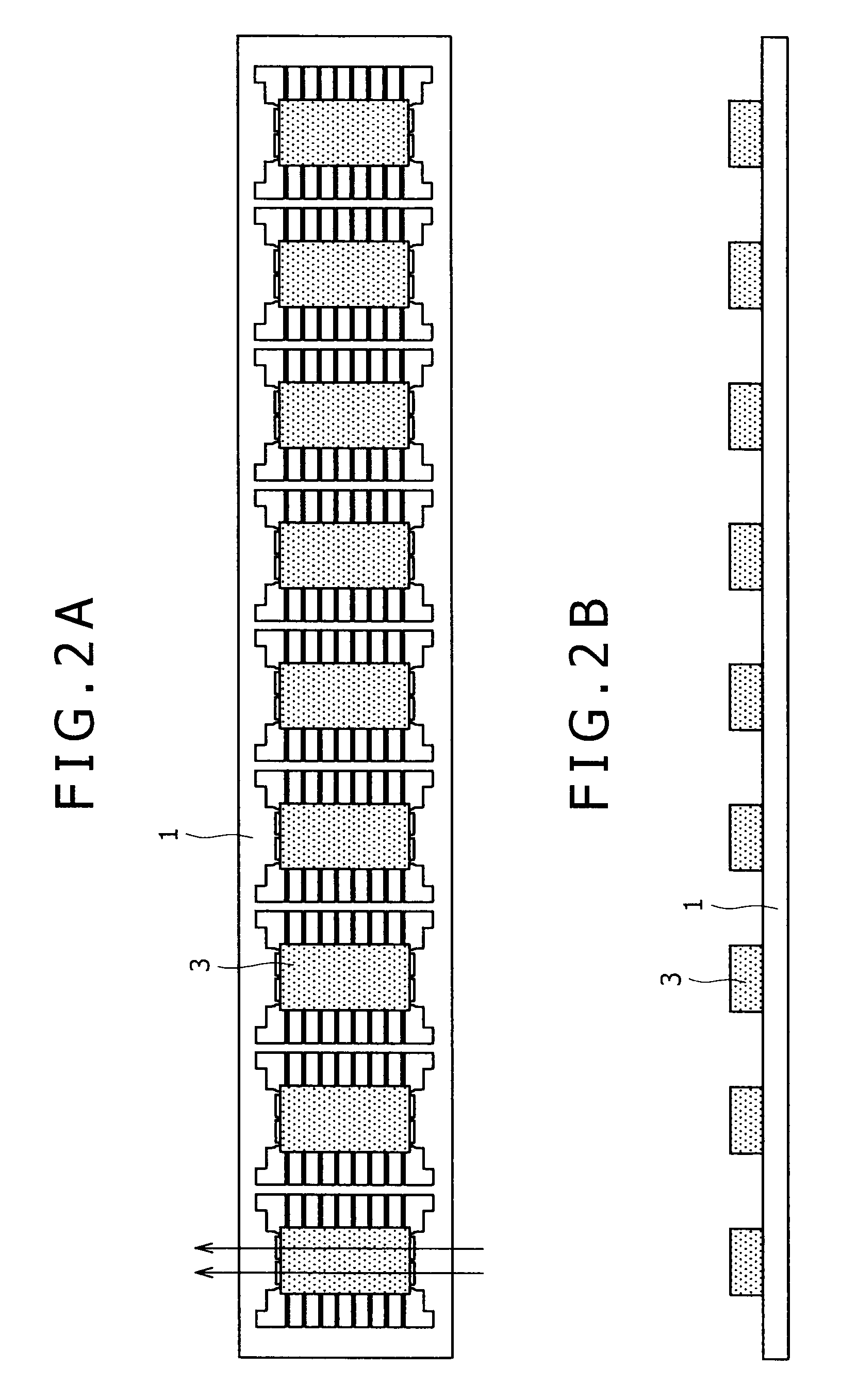

Machining method of thin-wall honeycomb core material curve machining molded surface

ActiveCN106903357AImprove milling efficiencyImprove machining accuracy and surface qualityWorkpiecesMilling equipment detailsThin walledHoneycomb

The invention discloses a machining method of a thin-wall honeycomb core material curve machining molded surface, and aims to provide a honeycomb machining method with high milling efficiency and capable of prolonging the life of a special honeycomb combined milling tool. The machining method is realized through the following technical scheme: when a double sided tape fixing state at the earlier stage of honeycomb machining is good, the special honeycomb combined milling tool with a conical disc return milling tool is changed for cutting; the rotating direction of the special honeycomb combined milling tool is changed; the conical disc return milling tool for feeding by a wedged angle of 30-45 degrees through high-speed rotation is used for cutting roughing; according to an anticlockwise tool rotating mode in the tool rotating direction, the downward pressure is applied to a honeycomb thin-edge area (1) through anticlockwise rotation; the part, easy to be pulled and damaged, of the thinnest honeycomb edge of the honeycomb bottom cutting profile is firstly machined; and after the honeycomb thin-edge area (1) of a NOMEX honeycomb part blank is machined, the sequential gradient machining is performed in (2-6) thickness direction of the thick-edge area cutting profile layer by layer, and the other parts are machined.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

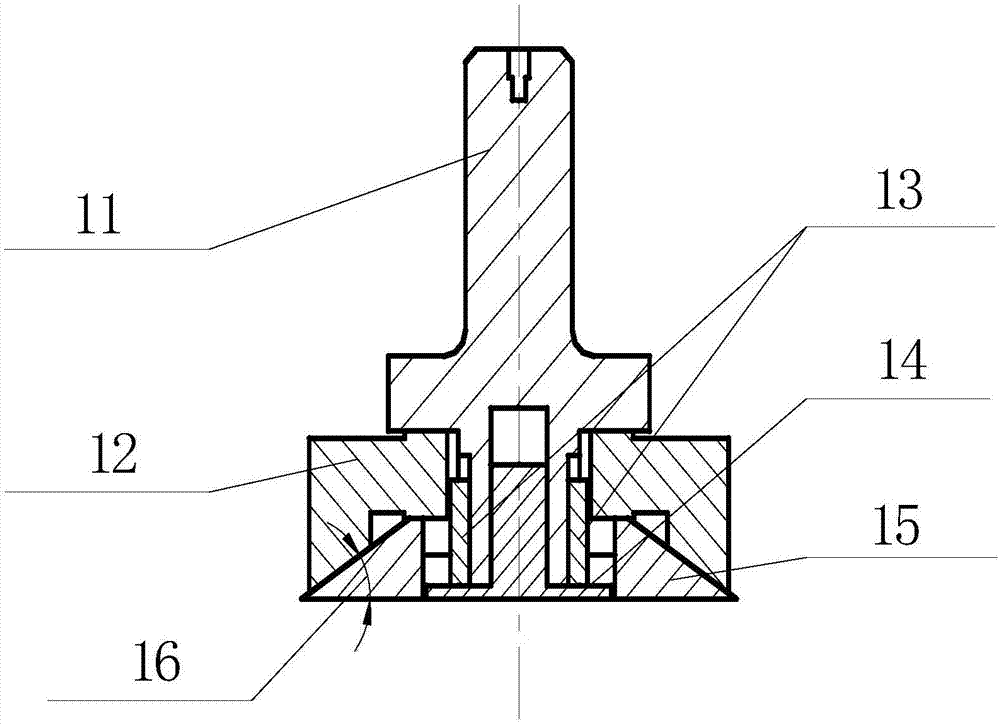

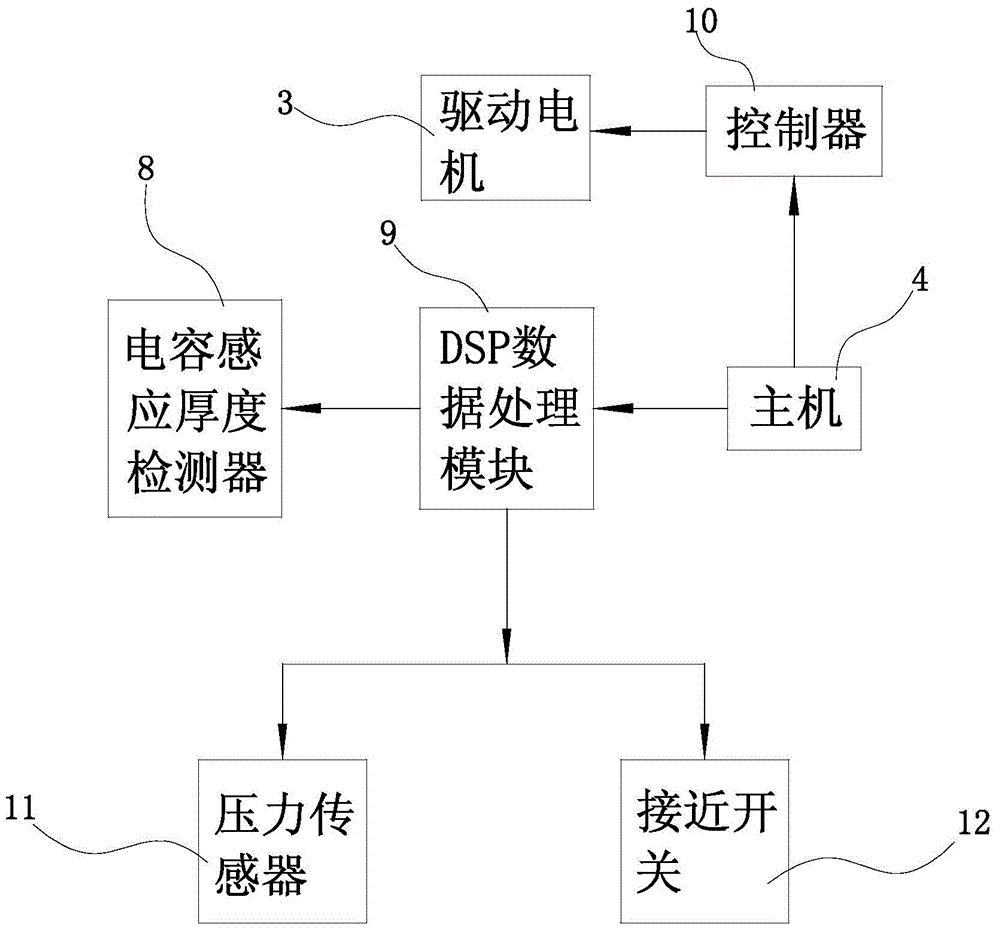

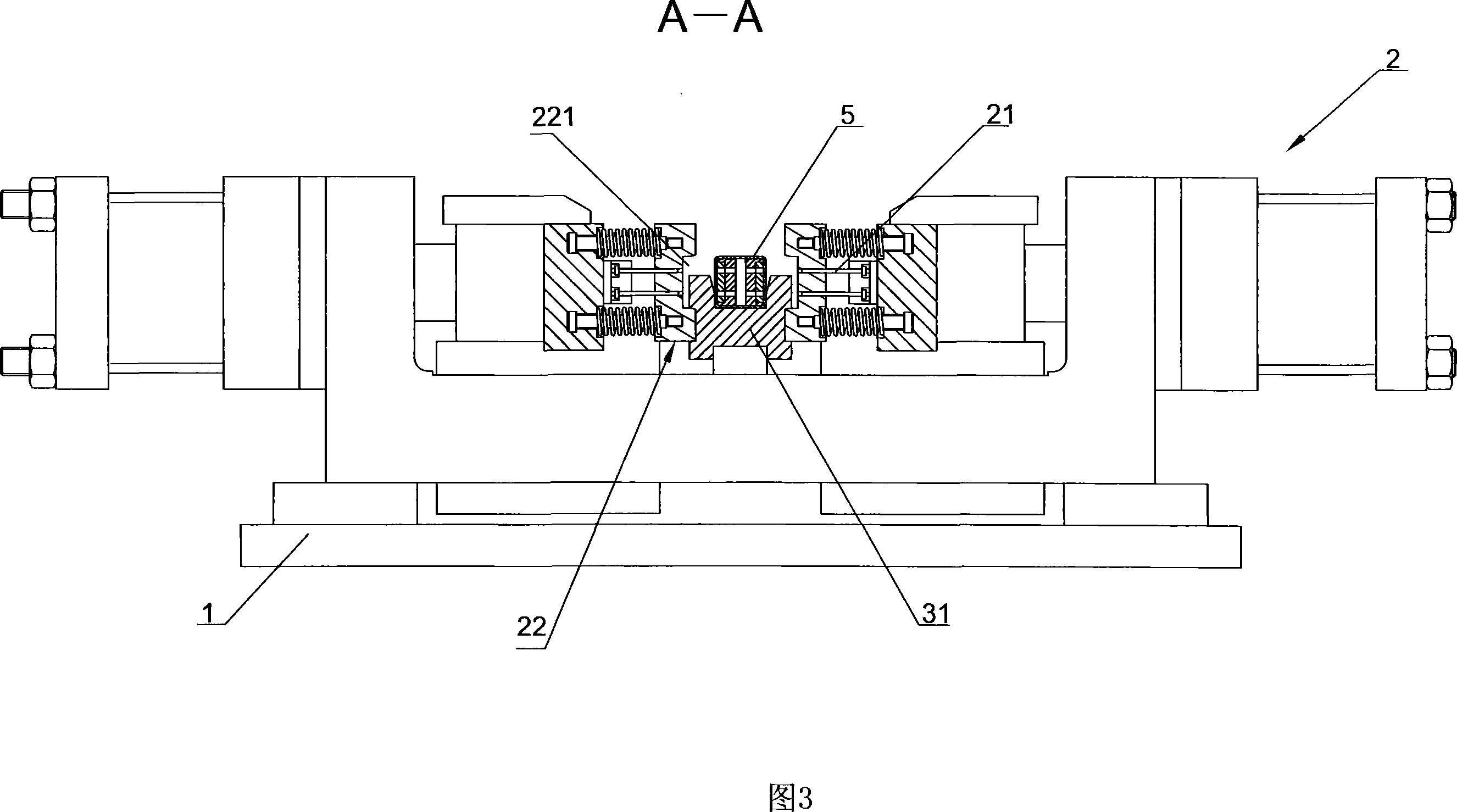

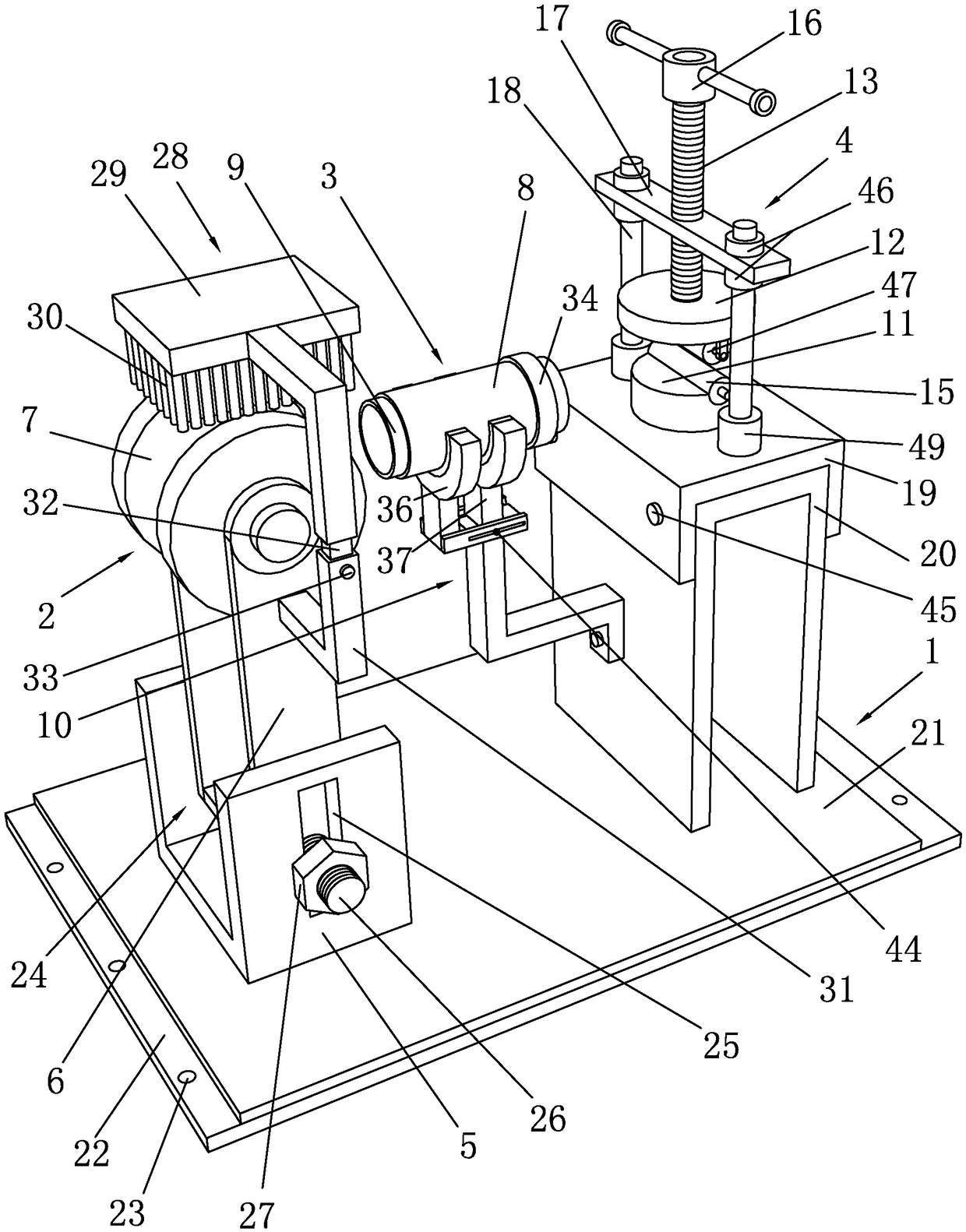

Bending machine controlling torque adjustment and roll bending through PLC and method

InactiveCN104624737APrevent looseningPrevent excessive deformationMetal-working feeding devicesMetal working apparatusCapacitanceAutomatic control

The invention relates to a bending machine controlling torque adjustment and roll bending through a PLC and a method. The bending machine comprises a driving motor, a clamping-fixing seat and a PLC mainframe, wherein the driving motor, the clamping-fixing seat and the PLC mainframe are arranged on a machine frame, a bending shaft is installed on the driving motor, and a machined part is arranged on the clamping-fixing seat. The bending machine further comprises a capacitive sensing thickness detector installed on the machine frame through a support, a proximity switch installed on the clamping-fixing seat, a pressure sensor and a rolling shaft, wherein the rolling shaft is connected to the upper end face of an adjusting plate, and the lower end face of the adjusting plate is installed in an installing groove formed in the clamping-fixing seat by means of a rotary shaft and a spring. The bending machine adopts the pressure sensor to control clamping force, and excessive deformation and looseness of boards are avoided. Bending is performed by utilizing most suitable torque, and machining quality is improved. The bending machine automatically controls a bending angle through the arranged proximity switch and prevents excessive bending. The inner concave face of the machined part is rolled through the rolling shaft, and cracks and burrs at the position of the concave face are decreased.

Owner:DONGGUAN ZHENGQIANG HARDWARE ELECTRONICS

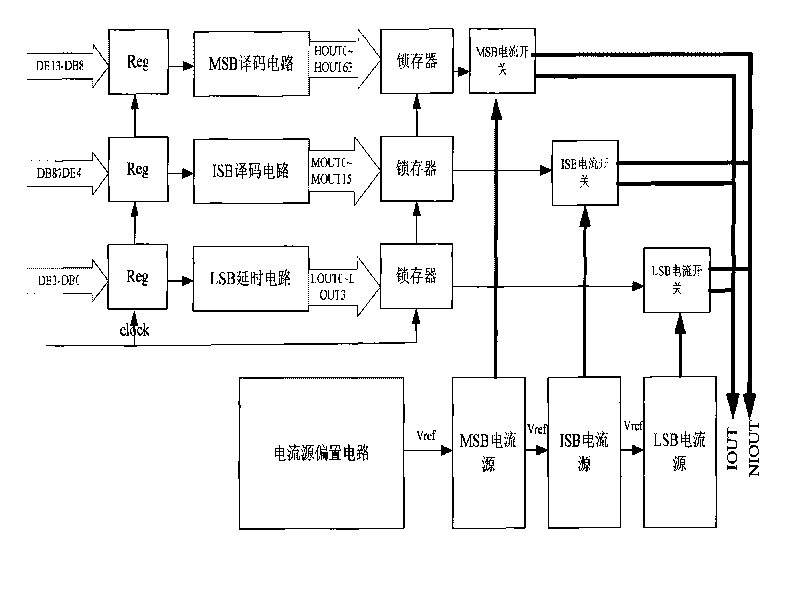

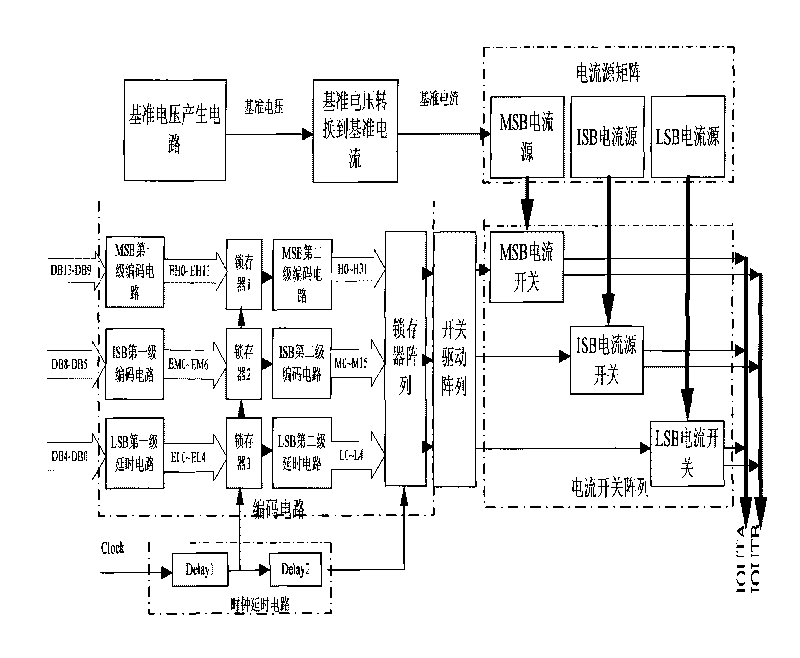

Segmented current-steering digital-to-analog converter

InactiveCN101741389AReduce areaReduce power consumptionDigital-analogue convertorsDriver circuitCommunications system

The invention discloses a high-speed high-accuracy digital-to-analog conversion circuit. The circuit comprises a reference voltage generation circuit, a reference voltage-to-reference current conversion circuit, a coding circuit, a current source matrix and a switch array, wherein the coding circuit has a two-stage water-flowing type coding structure, a switch driving circuit array is connected between the two-stage water-flowing type coding circuit and the switch array, and a two-stage clock delay circuit is connected between a clock input signal and the two-stage coding circuit and provides a clock signal to the two-stage water-flowing type coding circuit; and the current source matrix, a current switch and the coding circuit have a '5+4+5' segmental structure, namely high 5 bits and middle 4 bits have a thermometer code structure, and low 5 bits have a binary code structure. The high-speed high-accuracy digital-to-analog conversion circuit effectively reduces the area and the power consumption of chips, reduces the complexity of the coding circuit, increases conversion rate, reduces burrs, and improves the dynamic characteristics of a digital-to-analog converter. The high-speed high-accuracy digital-to-analog conversion circuit is used for digital processing systems, audio / video conversion systems and communication systems.

Owner:XIDIAN UNIV

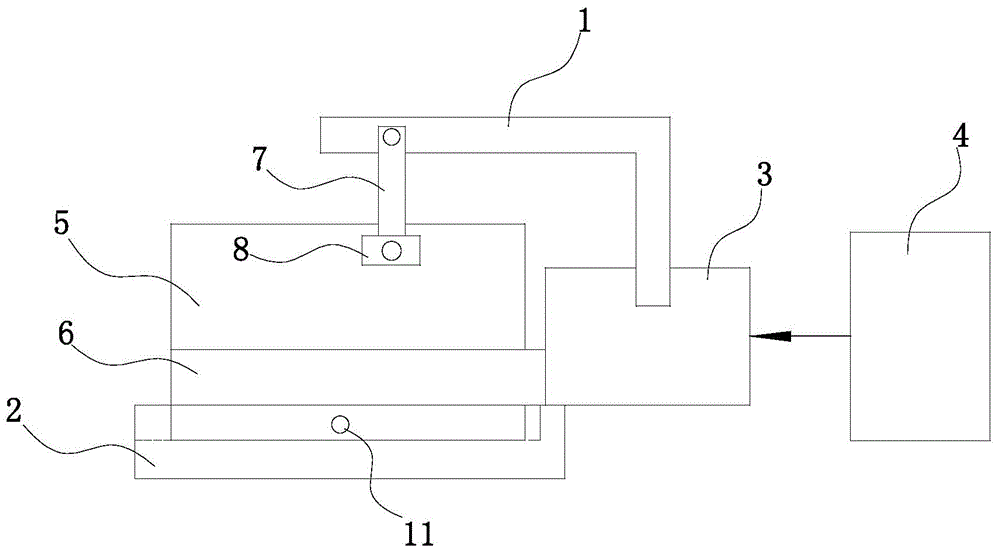

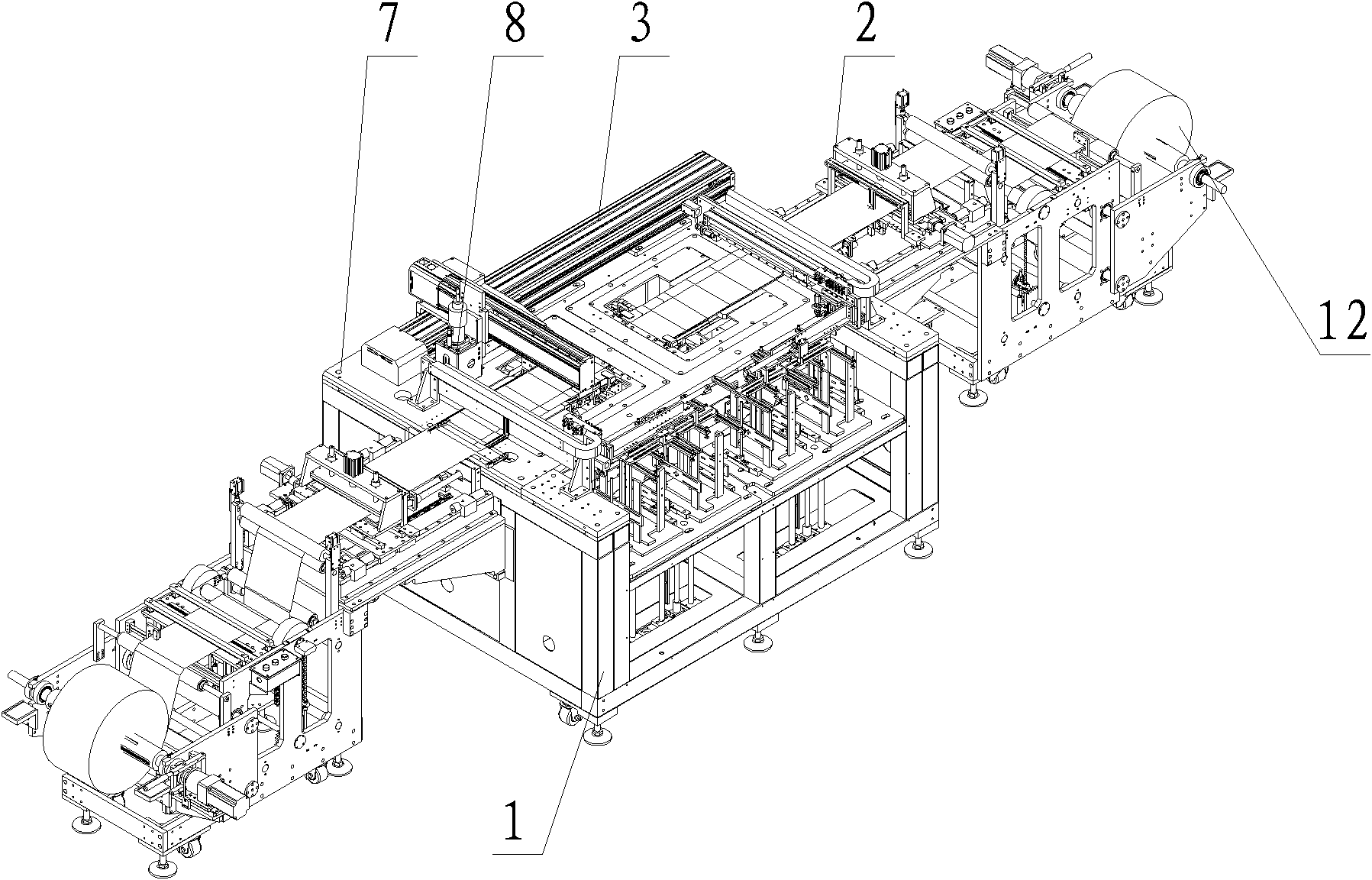

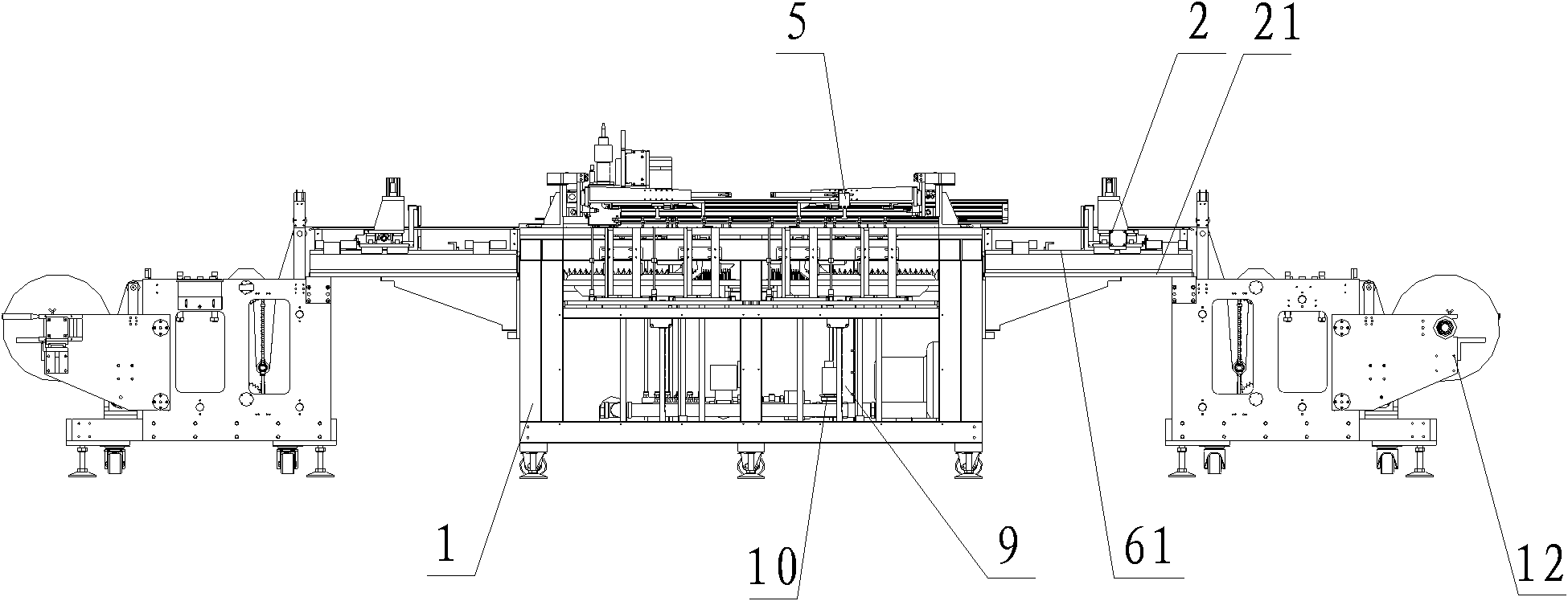

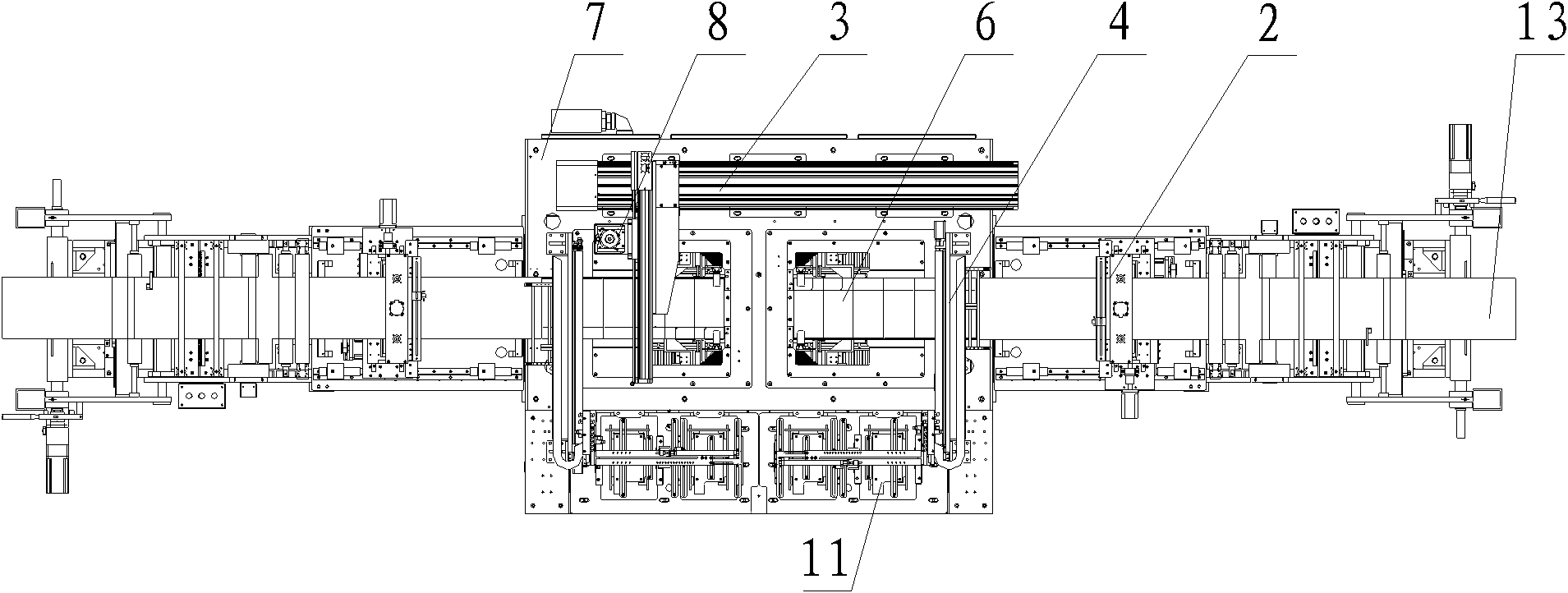

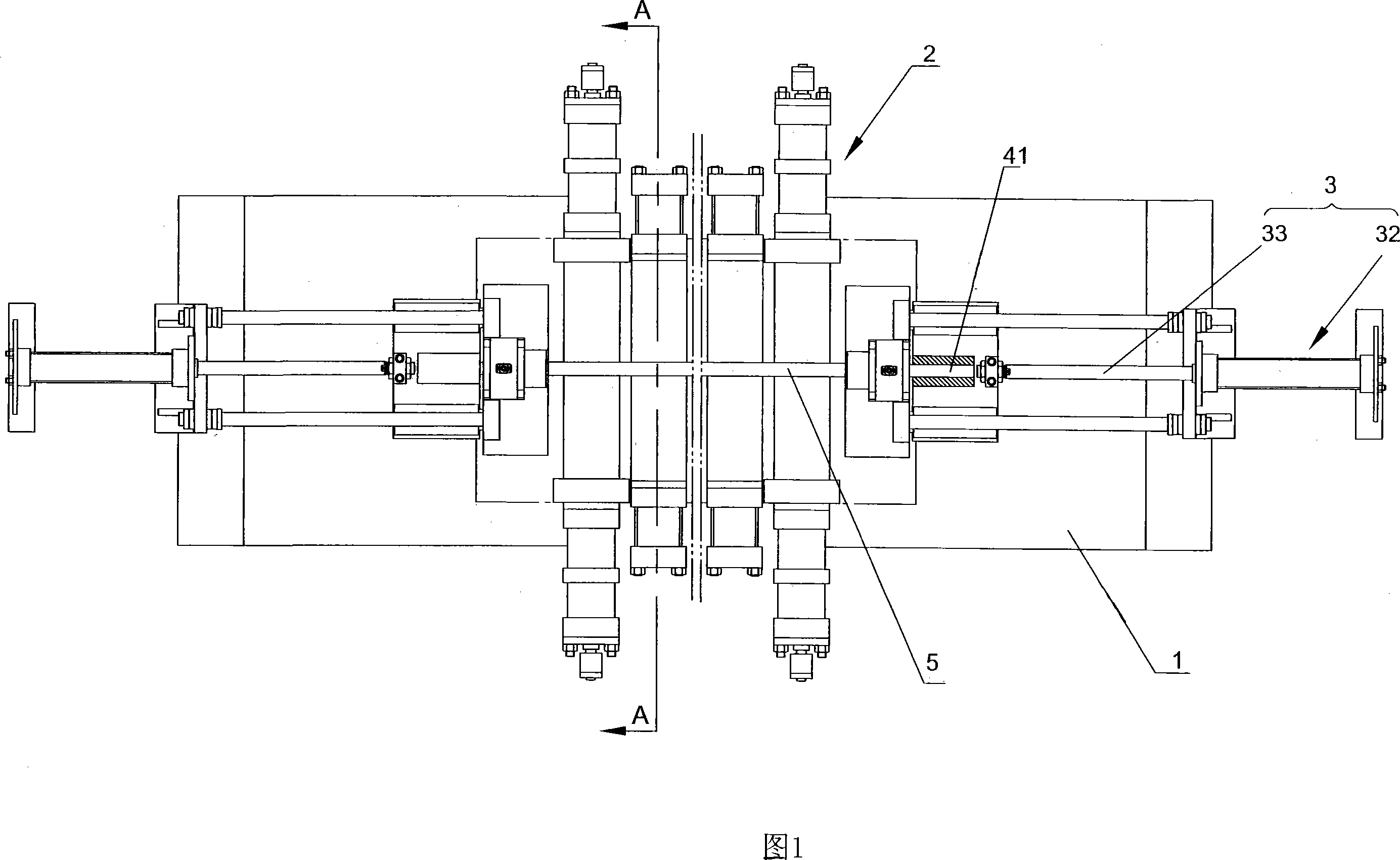

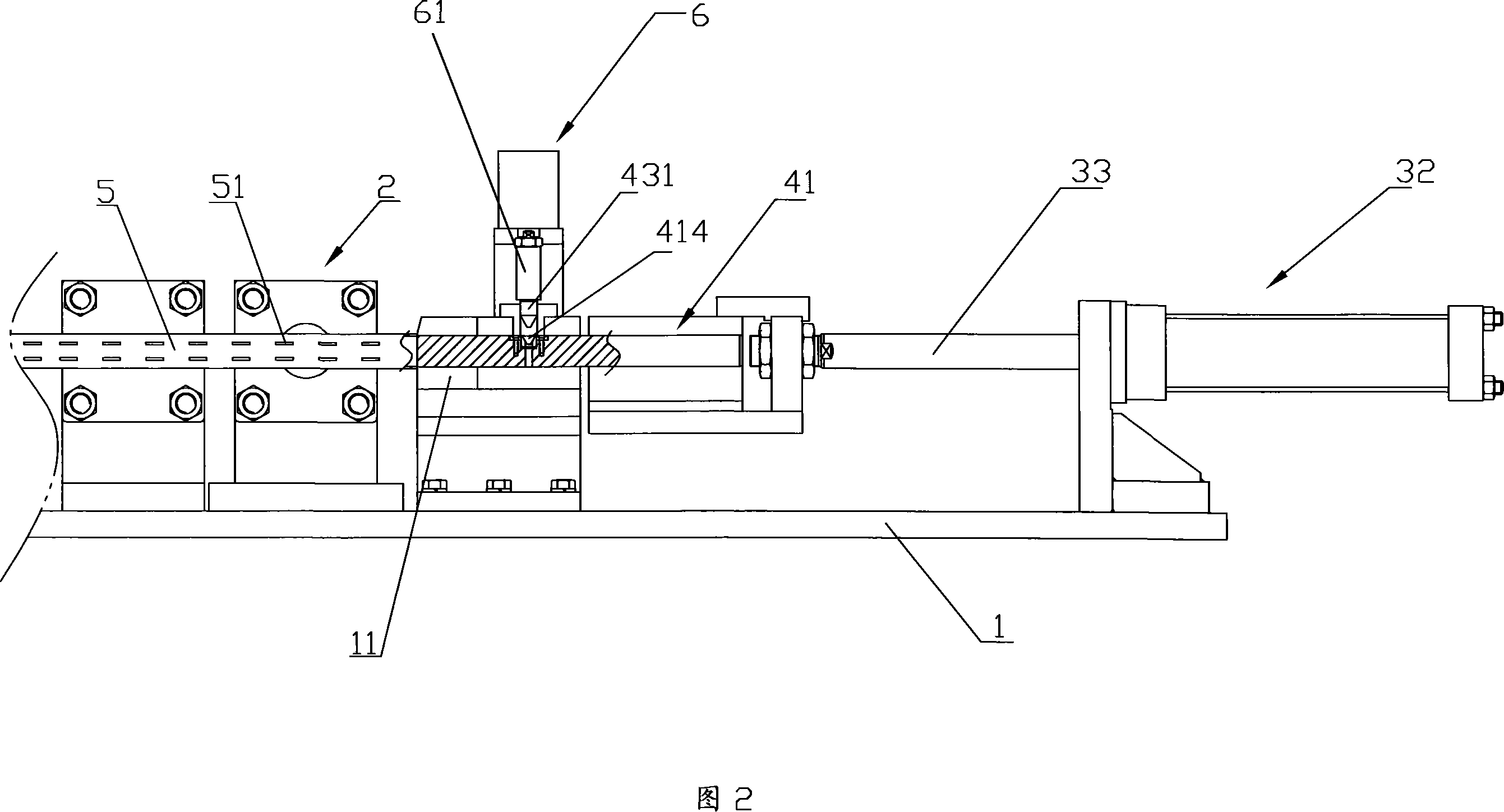

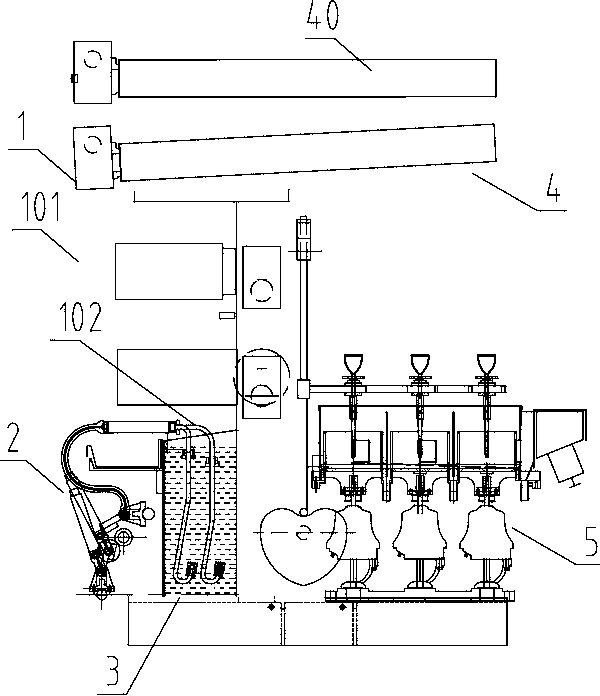

Pole piece laser cutting machine

ActiveCN102642089AOvercome deformationSmall size errorProgramme-controlled manipulatorElectrode manufacturing processesCapacitanceLaser technology

The invention discloses a pole piece laser cutting machine. The machine comprises a base frame part, a laser cutter, a cutting manipulator part, a control system and at least a piece feeding component, wherein the cutting manipulator part is used for driving the laser cutter; each piece feeding component comprises a material clamping manipulator part, a feeding fixed-length part and an emptying part; the cutting manipulator part and the material clamping manipulator part are installed on the base frame part; the feeding fixed-length part is arranged between the material clamping manipulator part and the emptying part; and the control system is connected with the cutting manipulator part, the material clamping manipulator part and the feeding fixed-length part. The machine has the following beneficial effects: the machine realizes the piece preparation processes of the lithium ion batteries or super capacitors by adopting the laser technology, can solve the problem that the pole pieces are easy to deform and have bigger burrs as the traditional cutting processes are adopted in the prior art, simultaneously improves the piece preparation process quality under the control of the control system and increases the yield.

Owner:SHENZHEN GEESUN INTELLIGENT TECHNOLOGY CO LTD

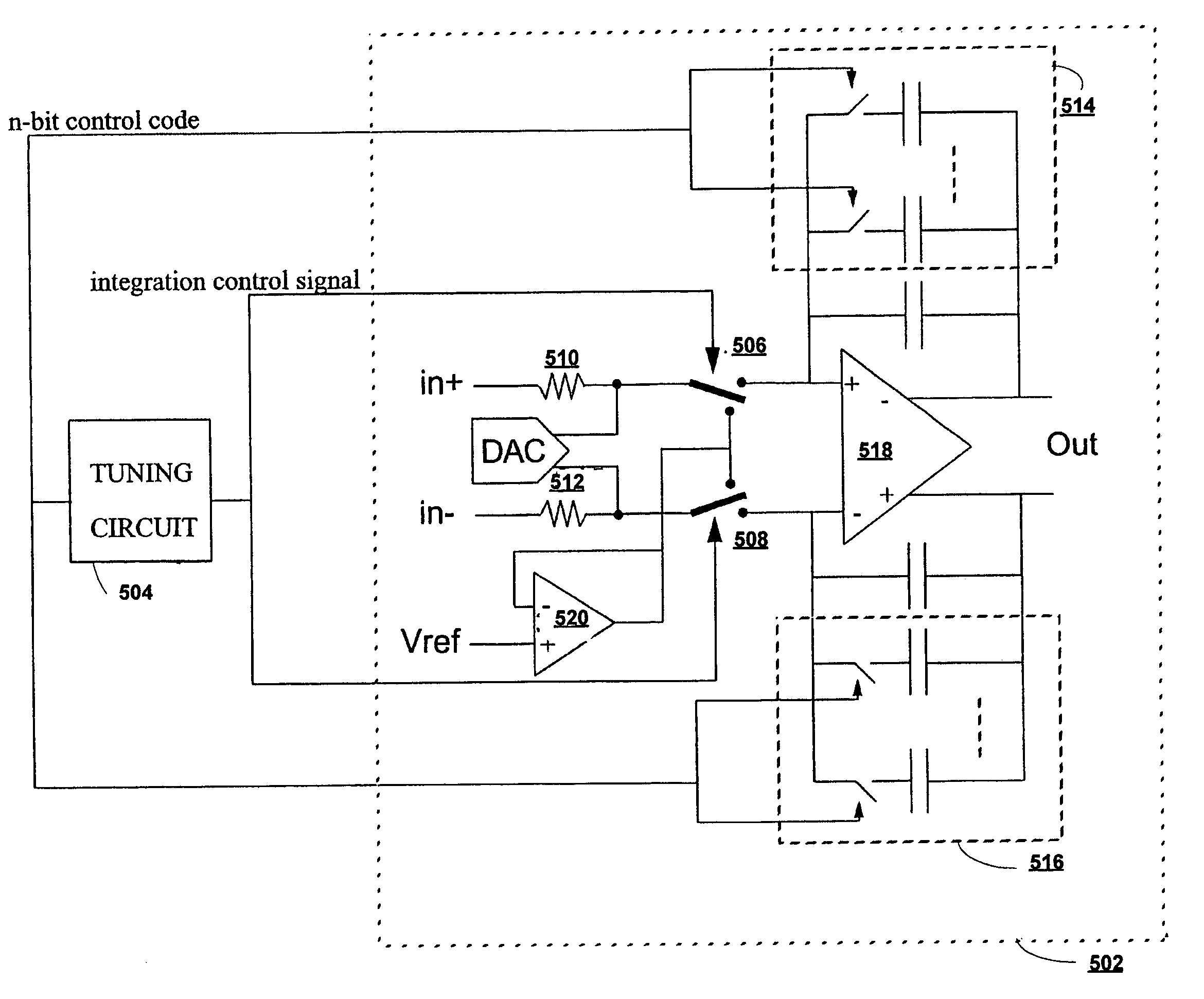

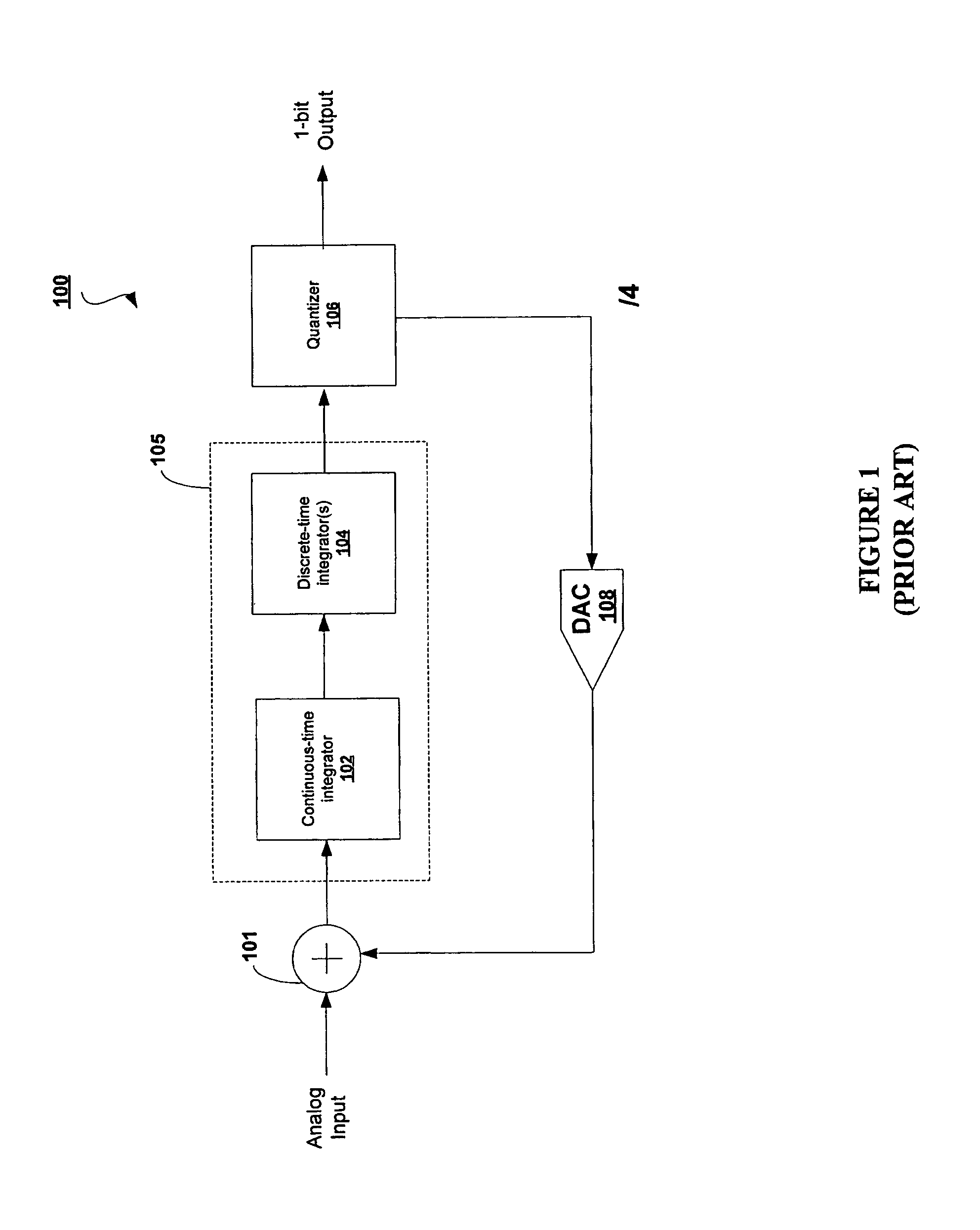

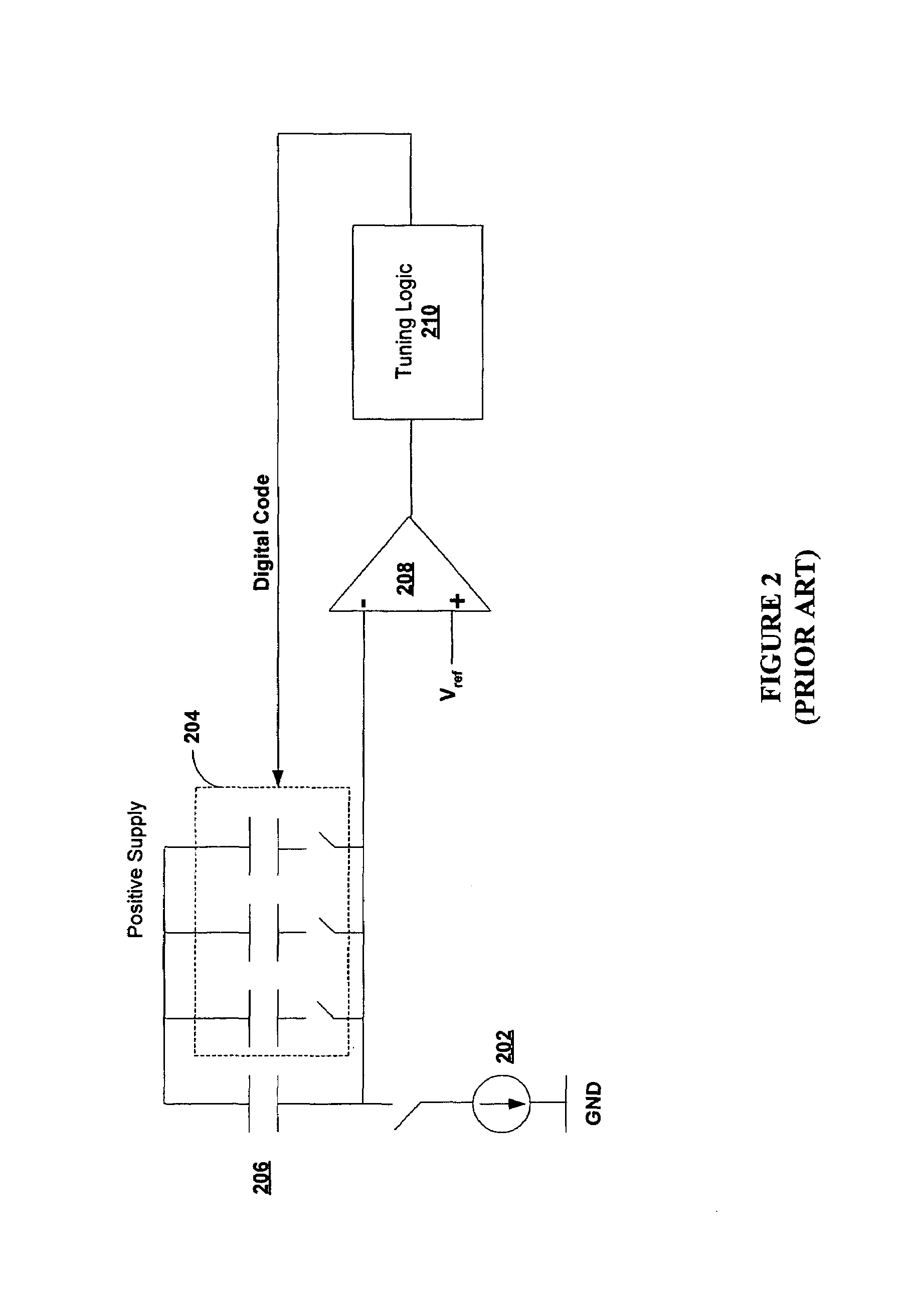

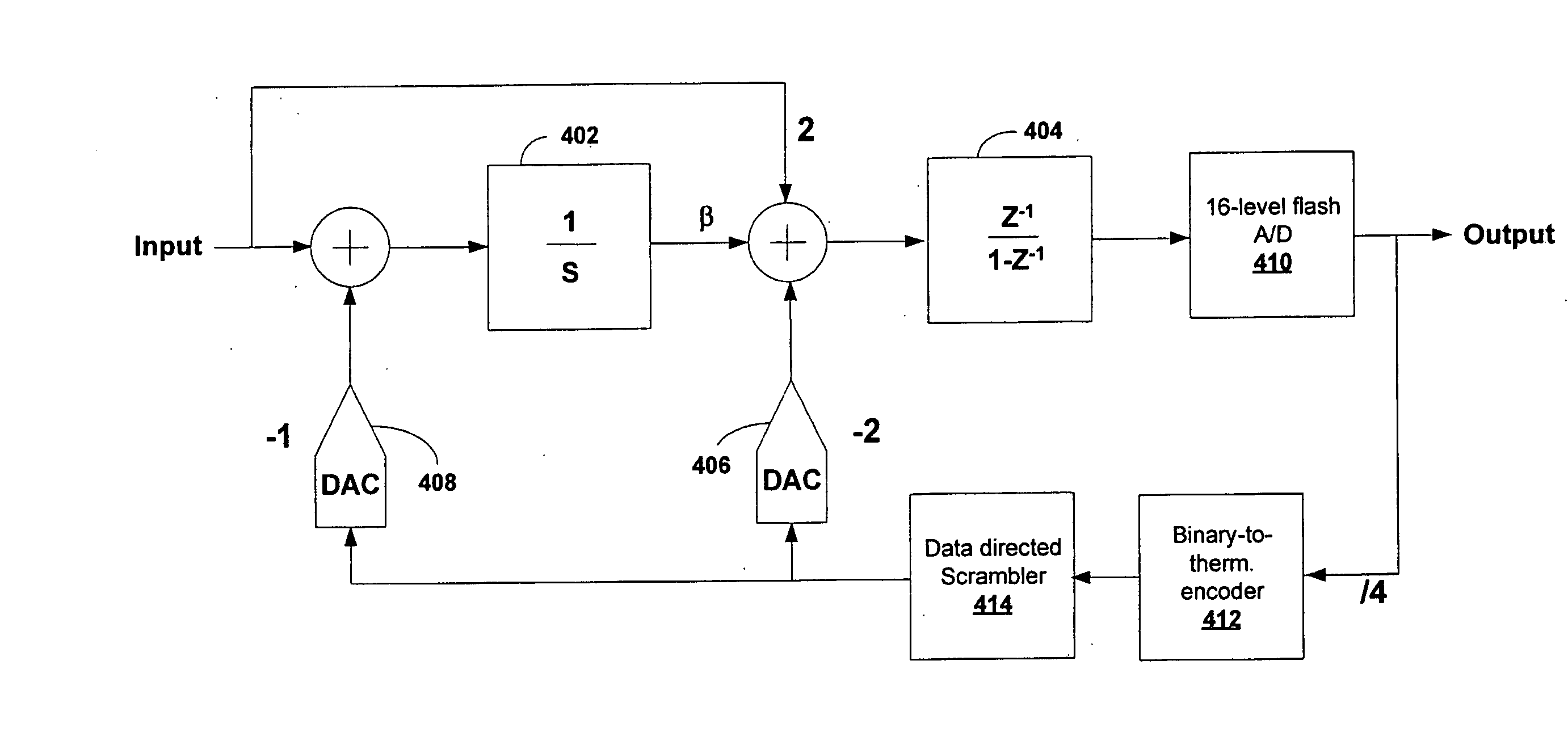

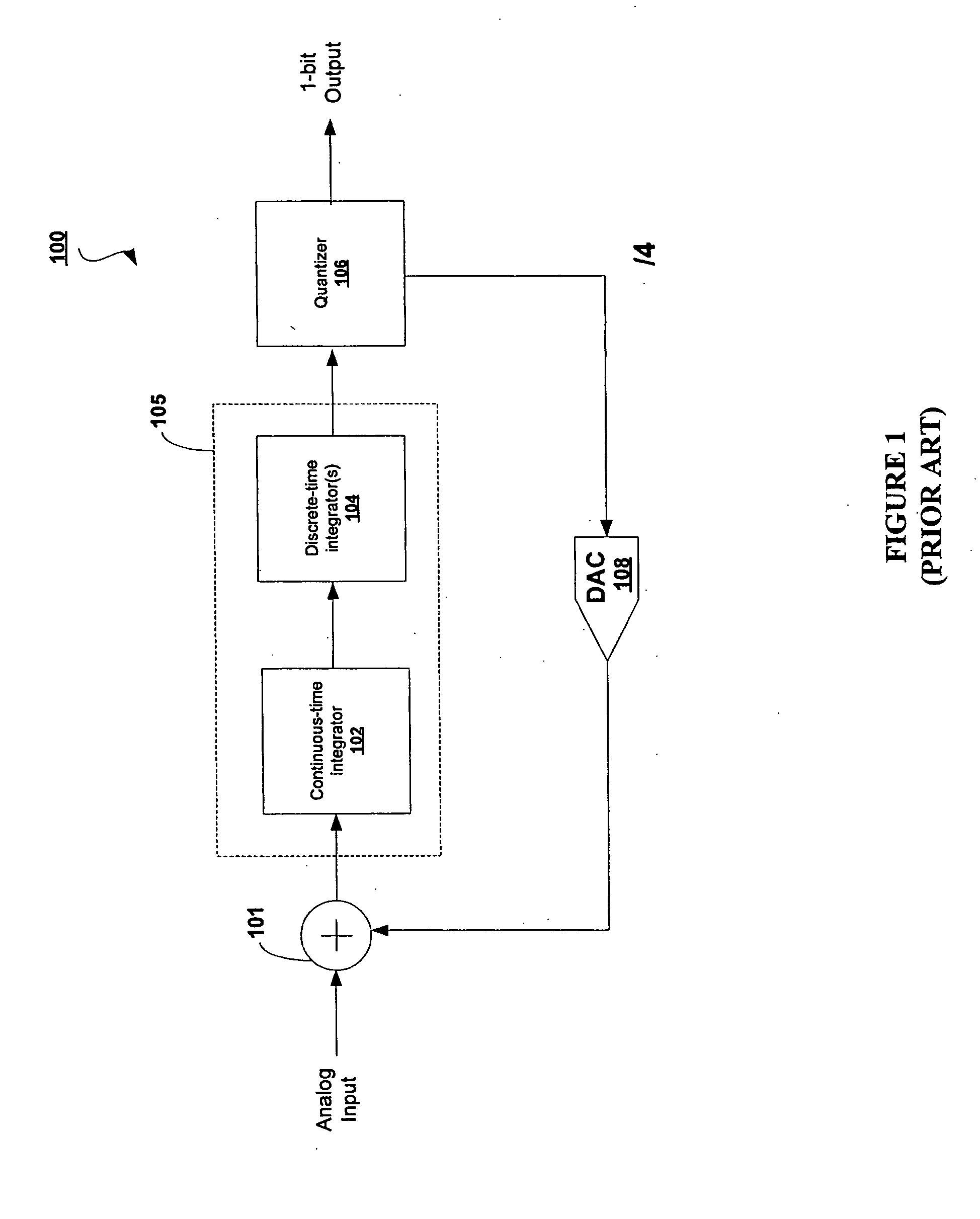

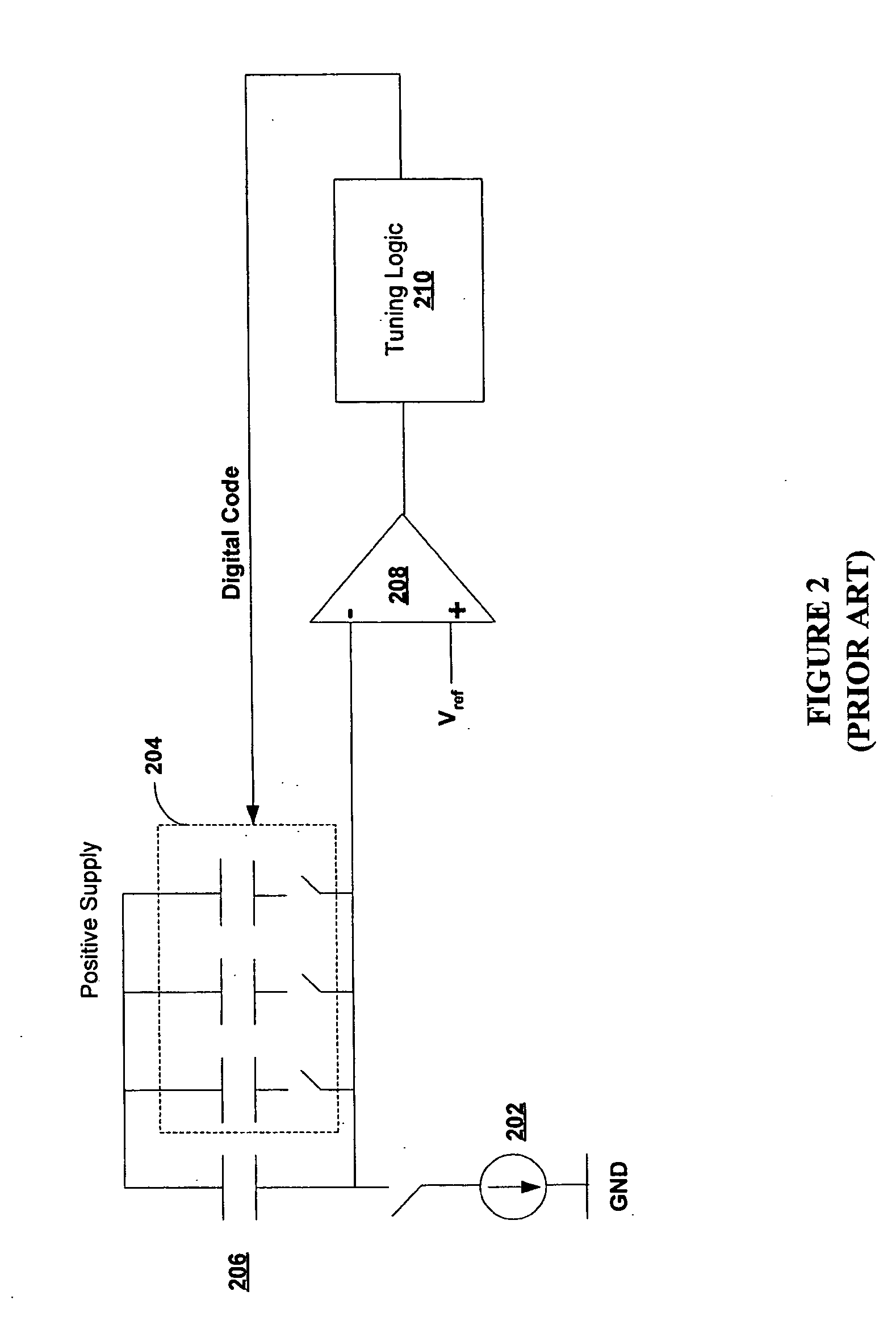

Hybrid tuning circuit for continuous-time sigma-delta analog-to-digital converter

ActiveUS7095345B2Eliminate the problemReduce glitchesElectric signal transmission systemsResonant circuit detailsDigital down converterIntegrator

A hybrid tuning circuit is used consisting of a digital finite state machine and an analog tuning circuit to effectively keep the RC product of the continuous time integrator constant across process, temperature, supply, and sampling rate variations. Since the implementation is continuous, the tracking is more accurate than traditional techniques. Using a carefully chosen clocking scheme, the technique gets rid of inter-symbol interference in the feedback DAC. The technique does not use a reference frequency, thereby eliminating the need for a user to identify a reference frequency.

Owner:ANALOG DEVICES INC

Sand-line iron mould casting process for grey cast iron flywheel housing of diesel engine

ActiveCN102728790AGood size consistencyPut an end to the phenomenon of sand swellingFoundry mouldsFoundry coresDieselingSurface roughness

The invention discloses a sand-line iron mould casting process for grey cast iron flywheel housings of diesel engines. In the invention, upper and lower sand-line iron mould processes are used, so that produced grey cast iron flywheel housing blanks have favorable geometric size precision which can be up to CT8 grade, favorable surface roughness which can be up to 12.5 microns and favorable mechanical properties, the blank processing has small allowance which can be controlled in 3mm, small flashing distortion which can be controlled in 0.5mm and small cleaning workload, so that the labor environment is improved, the environmental protection is improved, the yield is high and can be up to 95%, and the national policies of energy conservation, environmental protection and sustainable development are met.

Owner:JIANGSU SONGLIN AUTOMOBILE PARTS

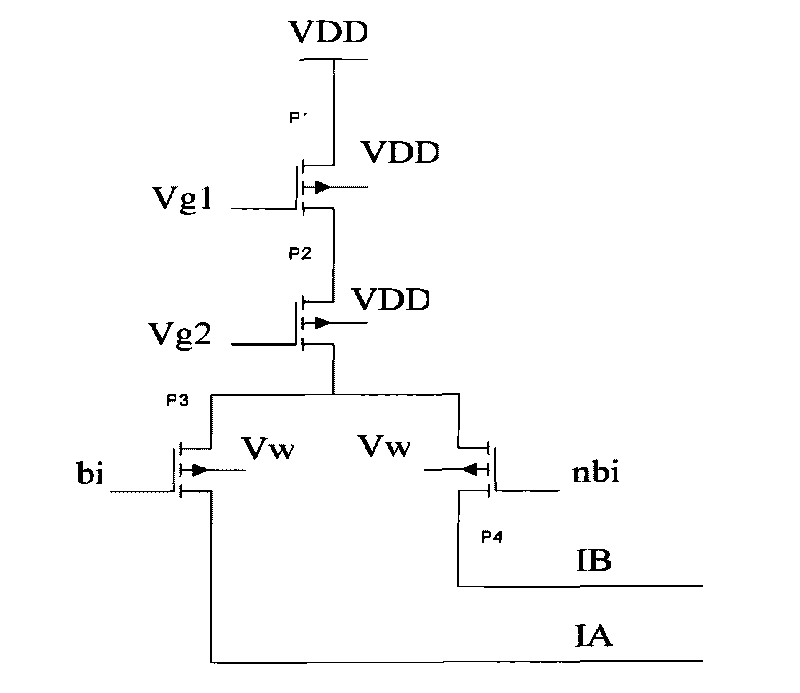

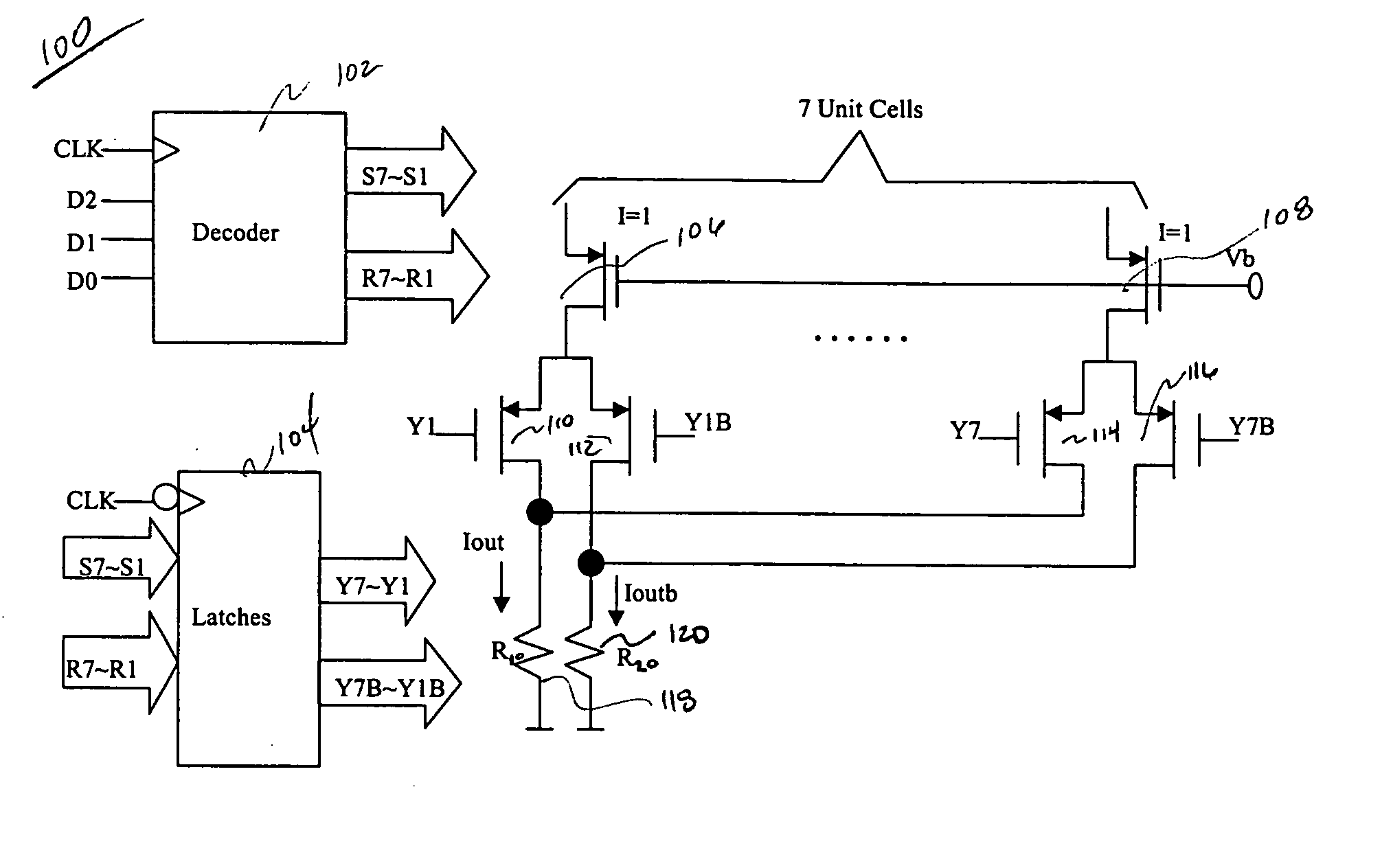

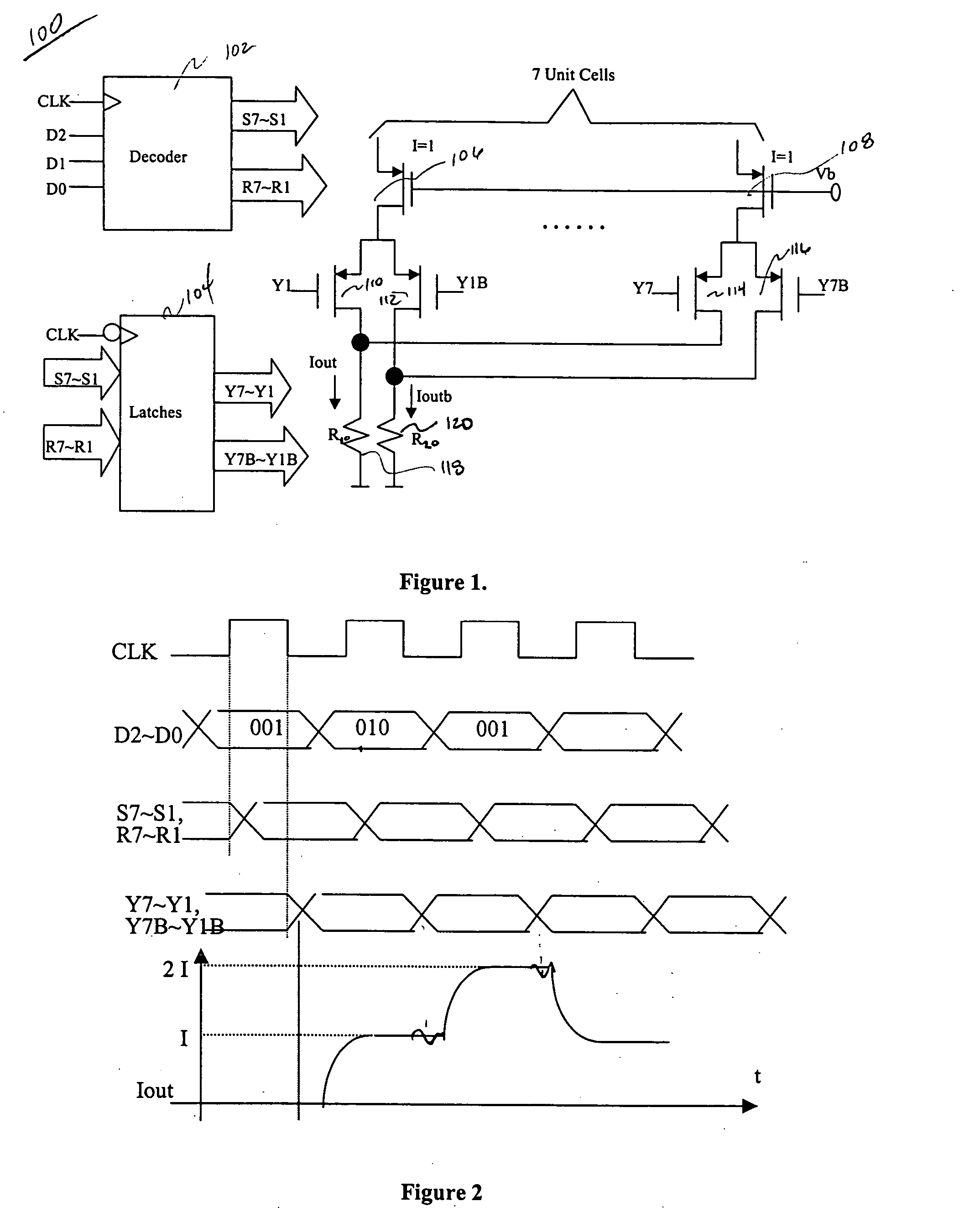

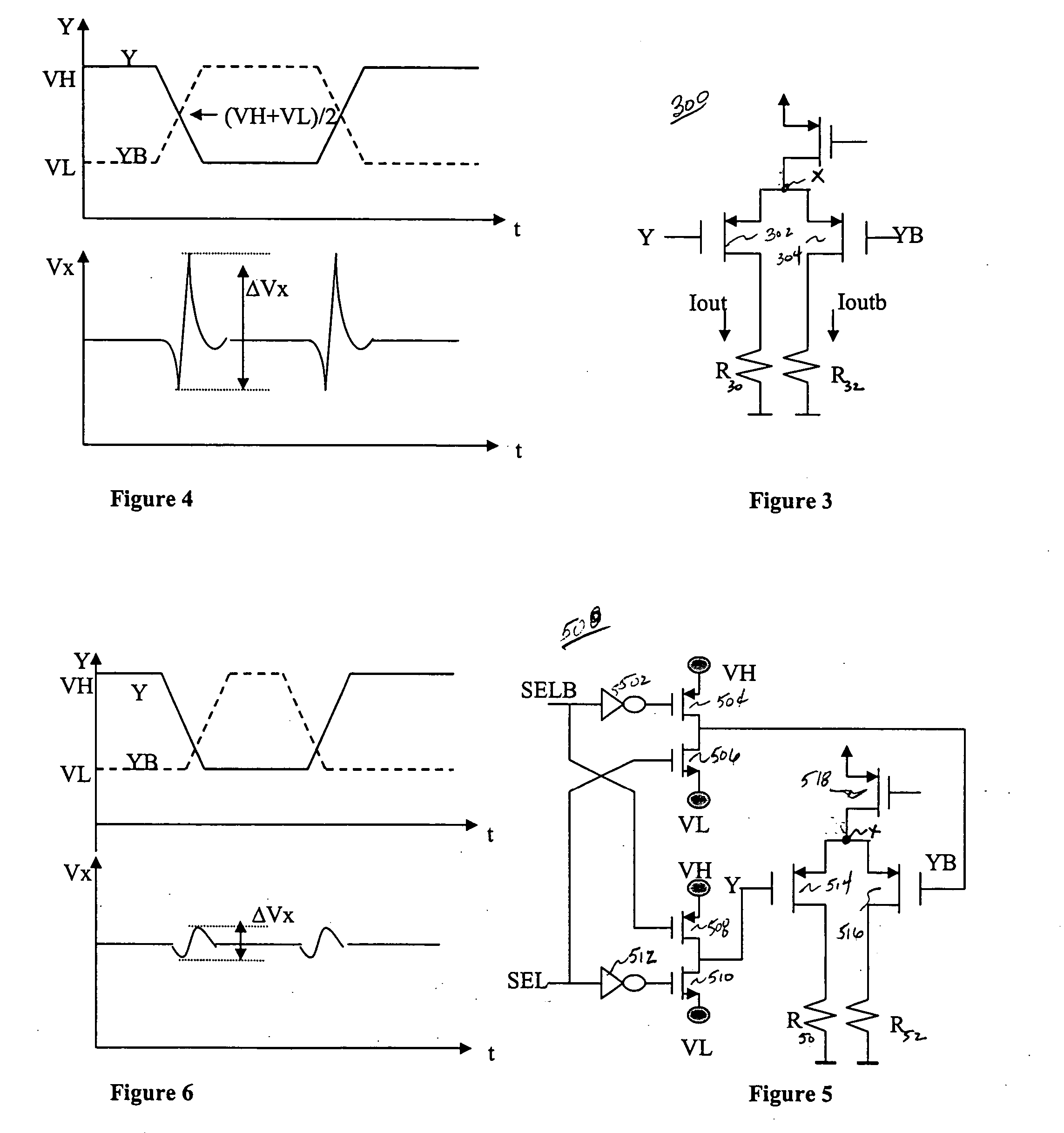

Current-steering digital-to-analog converter having a minimum charge injection latch

ActiveUS20050225465A1Reduce couplingReduce voltage variationElectric signal transmission systemsDigital-analogue convertorsCurrent cellControl signal

A latch architecture for driving unit current cell of a current-steering digital-to-analog converter (DAC) which reduces the drain-source voltage variation of the output current-source transistors and reduces the coupling of unwanted injection of input digital signals as well as clock signals is presented herein. Moreover, this latch helps to achieve lower glitch during code transition with improved dynamic performance. The latch effectively uses the intrinsic RC delay of most transistors within the latch architecture in order to achieve optimal crossing points of complementary control signals. Unwanted input injection or cross-talk is reduced by introducing transistors (904, 906, 932 and 934) that are off during code transitions without compromising the DAC update speed. Conflicts between currently held and new inputs are avoided in an effort to reduce the harmonic distortion. Furthermore, the distortion as a result of the clock signal fed through each transistor in the first and second subcircuit portions cancel each other.

Owner:TEXAS INSTR INC

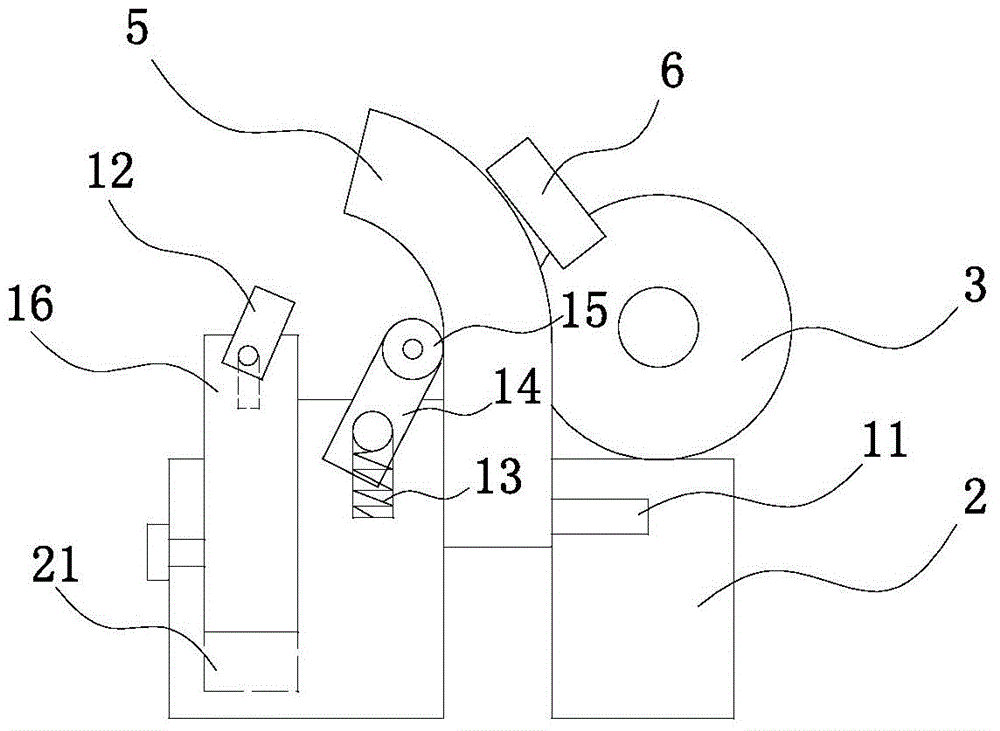

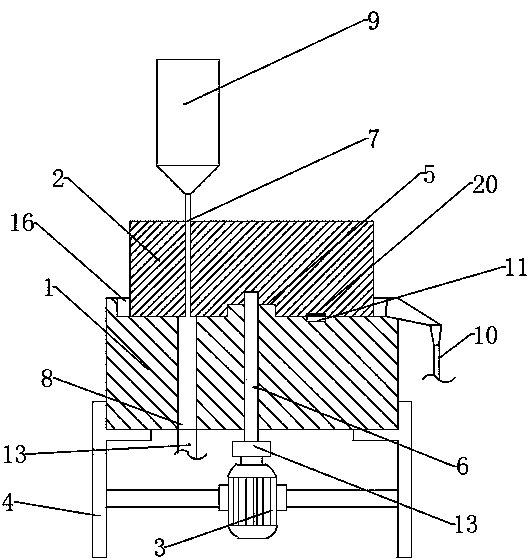

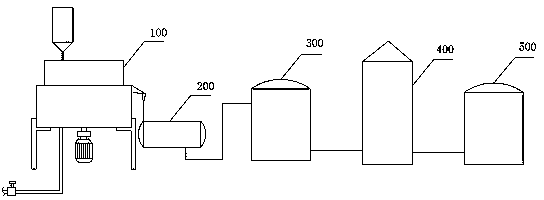

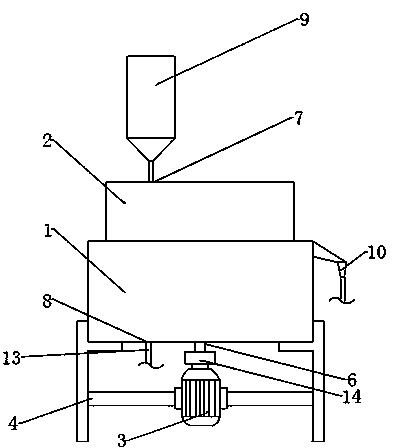

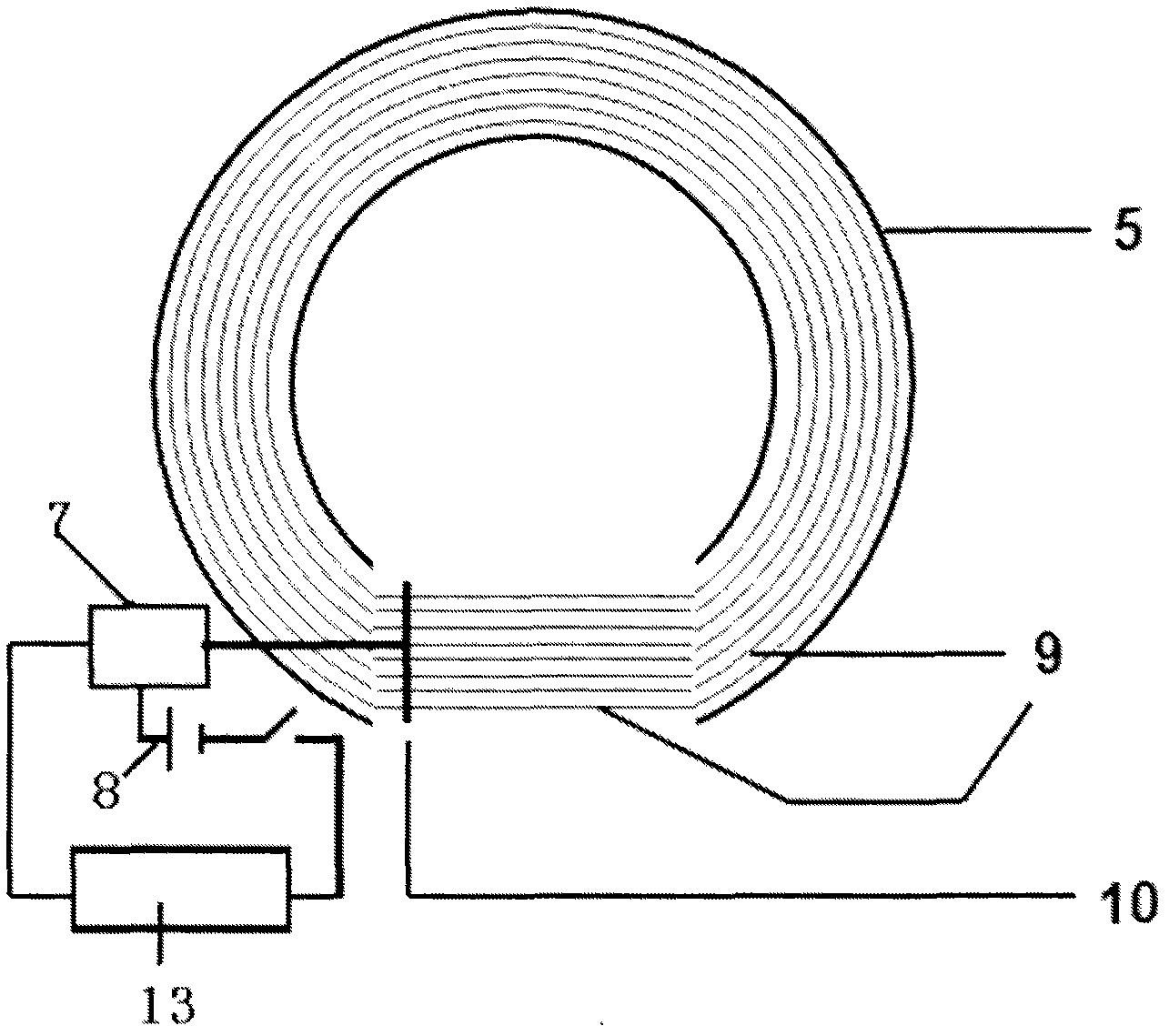

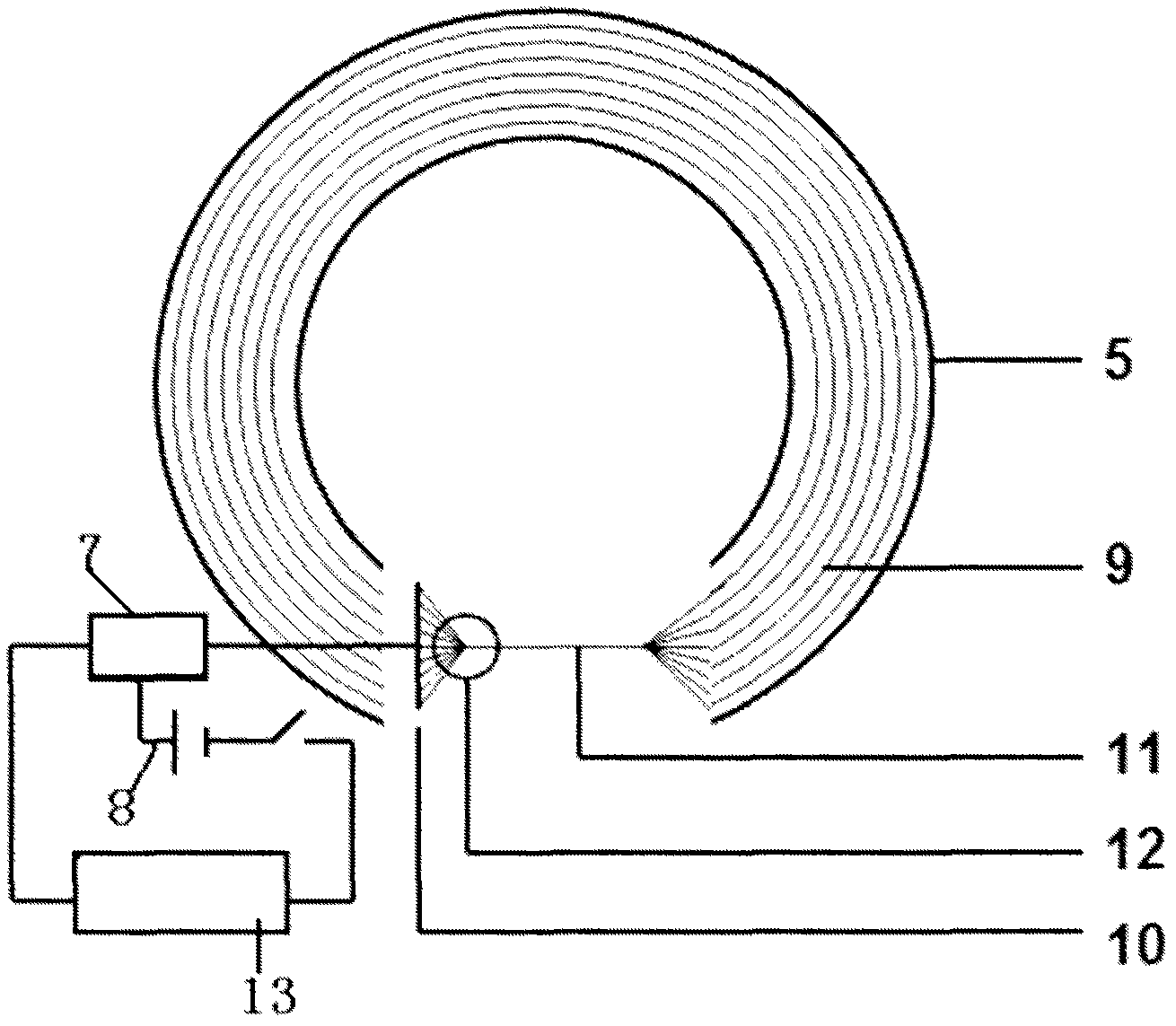

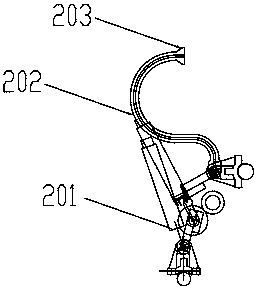

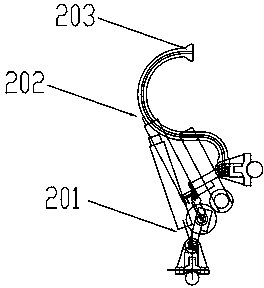

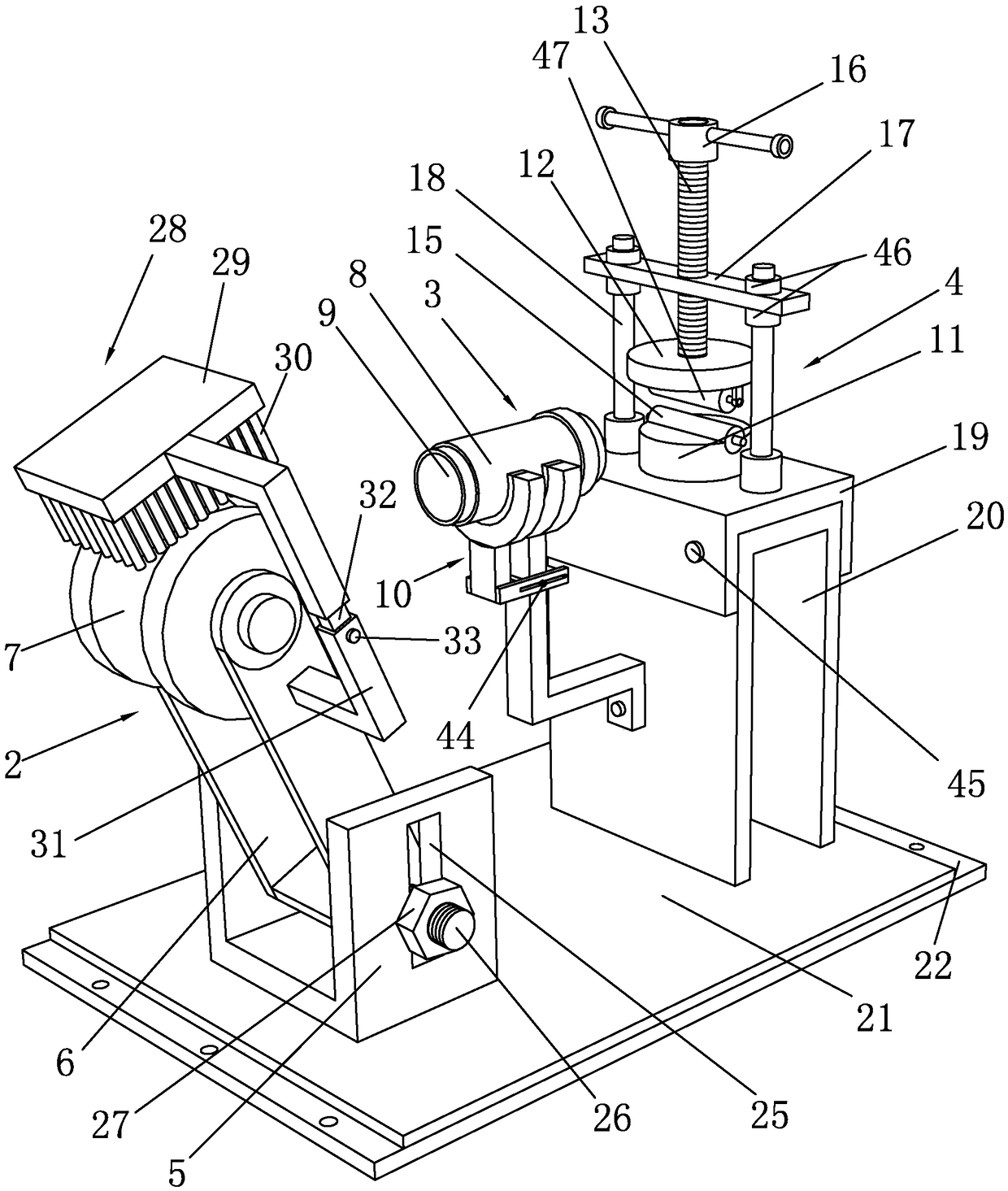

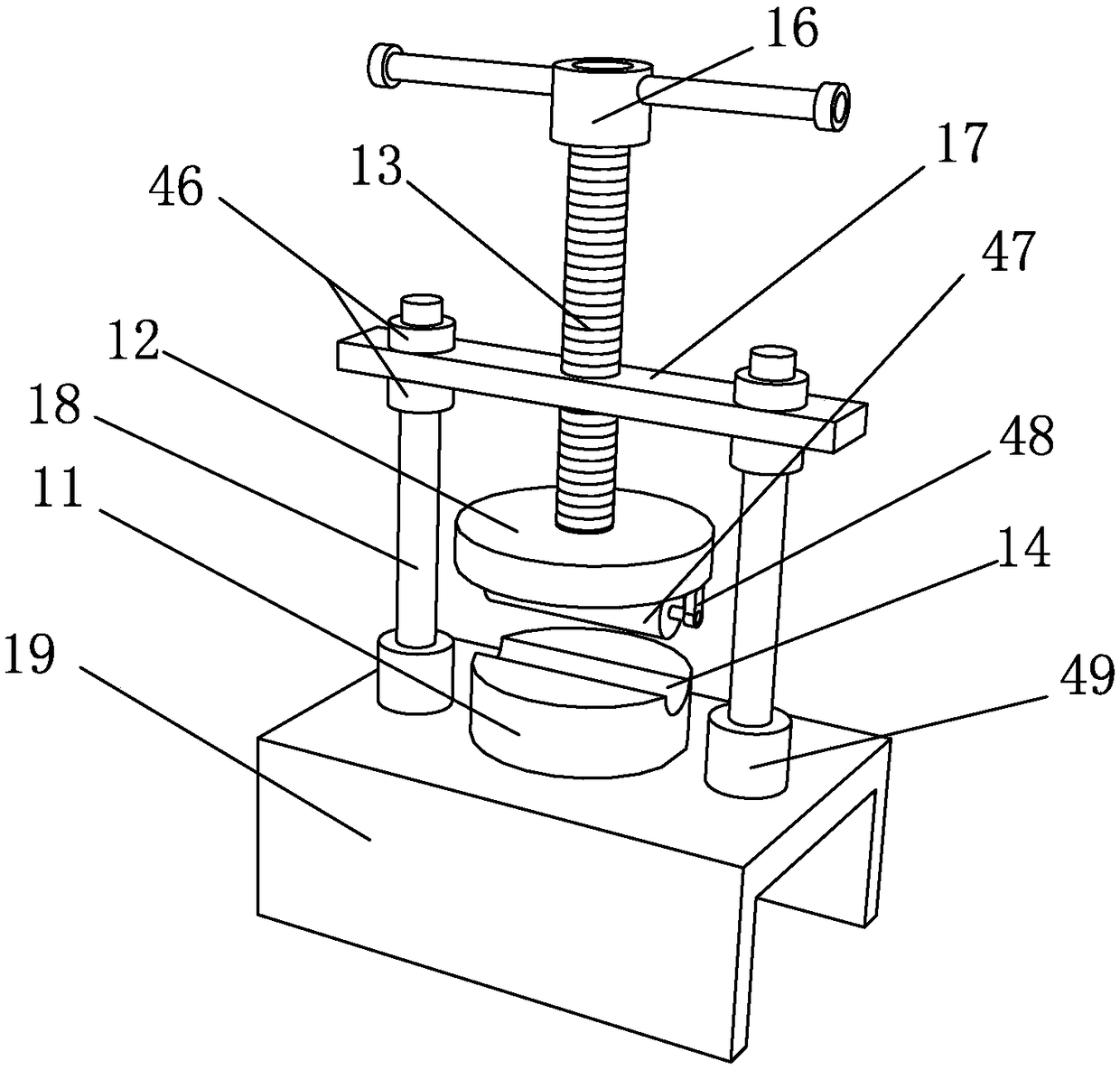

Graphene grinding and stripping device, graphene production system and production method

ActiveCN104401971AKeep the natural plane sizeReduce the chance of crushingCvd grapheneMechanical engineering

The invention discloses a graphene grinding and stripping device which comprises an upper grinding disc, a lower grinding disc, a driving mechanism for driving the upper grinding disc to rotate, and a material collection mechanism for collecting a product after grinding, wherein the upper grinding disc and the lower grinding disc are matched with each other; a horizontal contact surface is formed between the upper grinding disc and the lower grinding disc, the upper grinding disc is provided with an upper feed inlet, the lower grinding disc is provided with a lower feed inlet, the upper feed inlet and the lower feed inlet are both connected with the contact surface between the upper grinding disc and the lower grinding disc, and the lower end of the lower feed inlet is in sealed connection with one water inlet tube; moreover, the upper end face of the lower grinding disc is provided with a groove, and an annular region formed by rotary surrounding of the lower end of the upper feed inlet is surrounded in the groove. The graphene grinding and stripping device can realize large-size successful stripping of graphene. The invention also relates to a graphene production system containing the graphene grinding and stripping device and a graphene production method.

Owner:江苏碳谷二维世界科技有限公司

Hybrid tuning circuit for continuous-time sigma-delta analog-to-digital converter

ActiveUS20050285763A1Eliminate the problemInterference problemElectric signal transmission systemsResonant circuit detailsIntegratorA d converter

A hybrid tuning circuit is used consisting of a digital finite state machine and an analog tuning circuit to effectively keep the RC product of the continuous time integrator constant across process, temperature, supply, and sampling rate variations. Since the implementation is continuous, the tracking is more accurate than traditional techniques. Using a carefully chosen clocking scheme, the technique gets rid of inter-symbol interference in the feedback DAC. The technique does not use a reference frequency, thereby eliminating the need for a user to identify a reference frequency.

Owner:ANALOG DEVICES INC

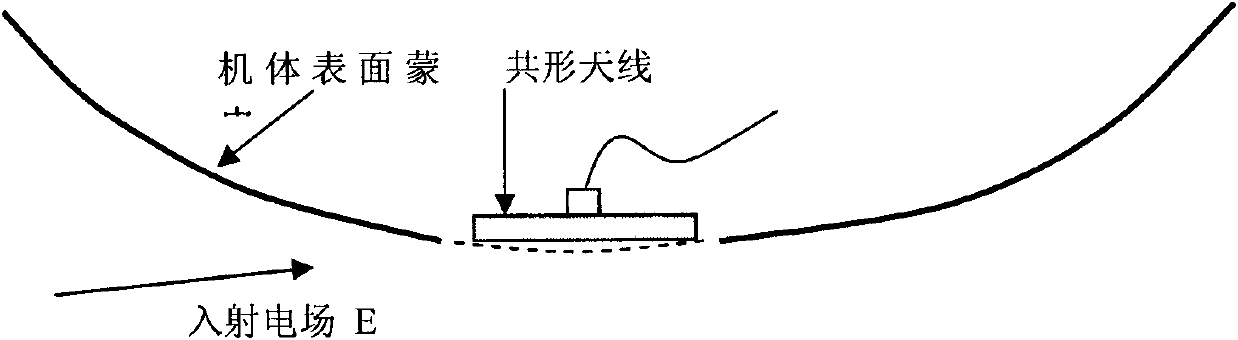

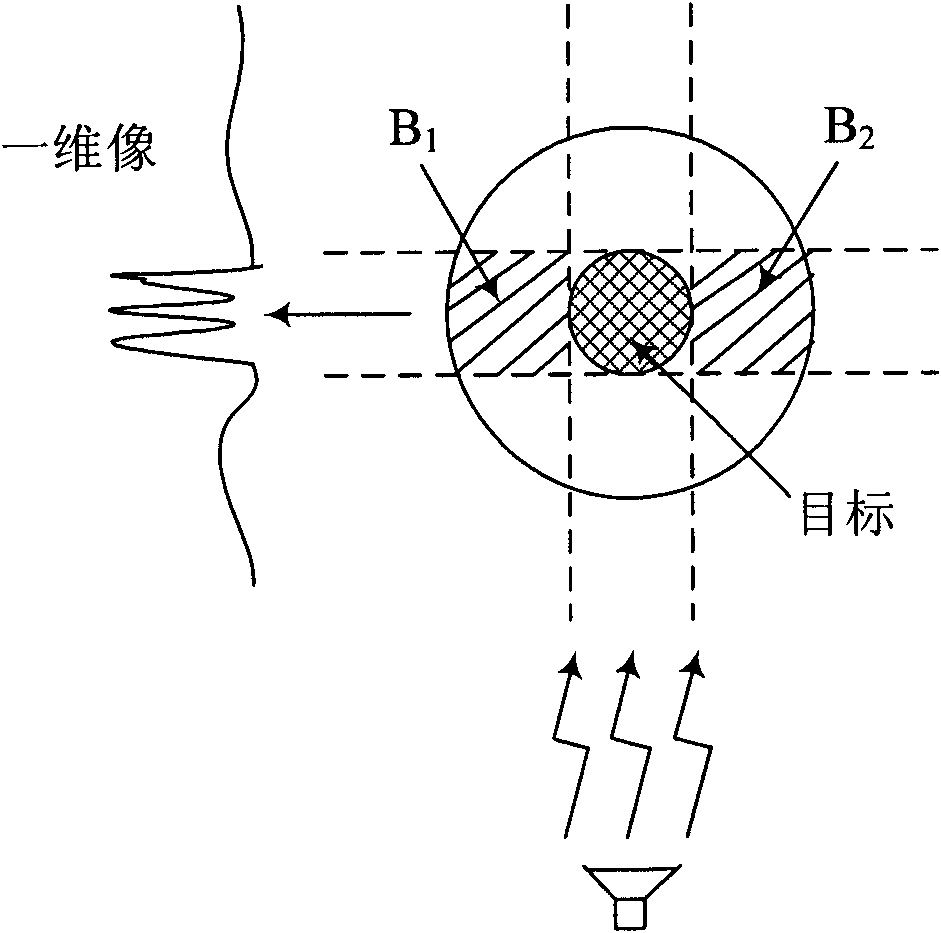

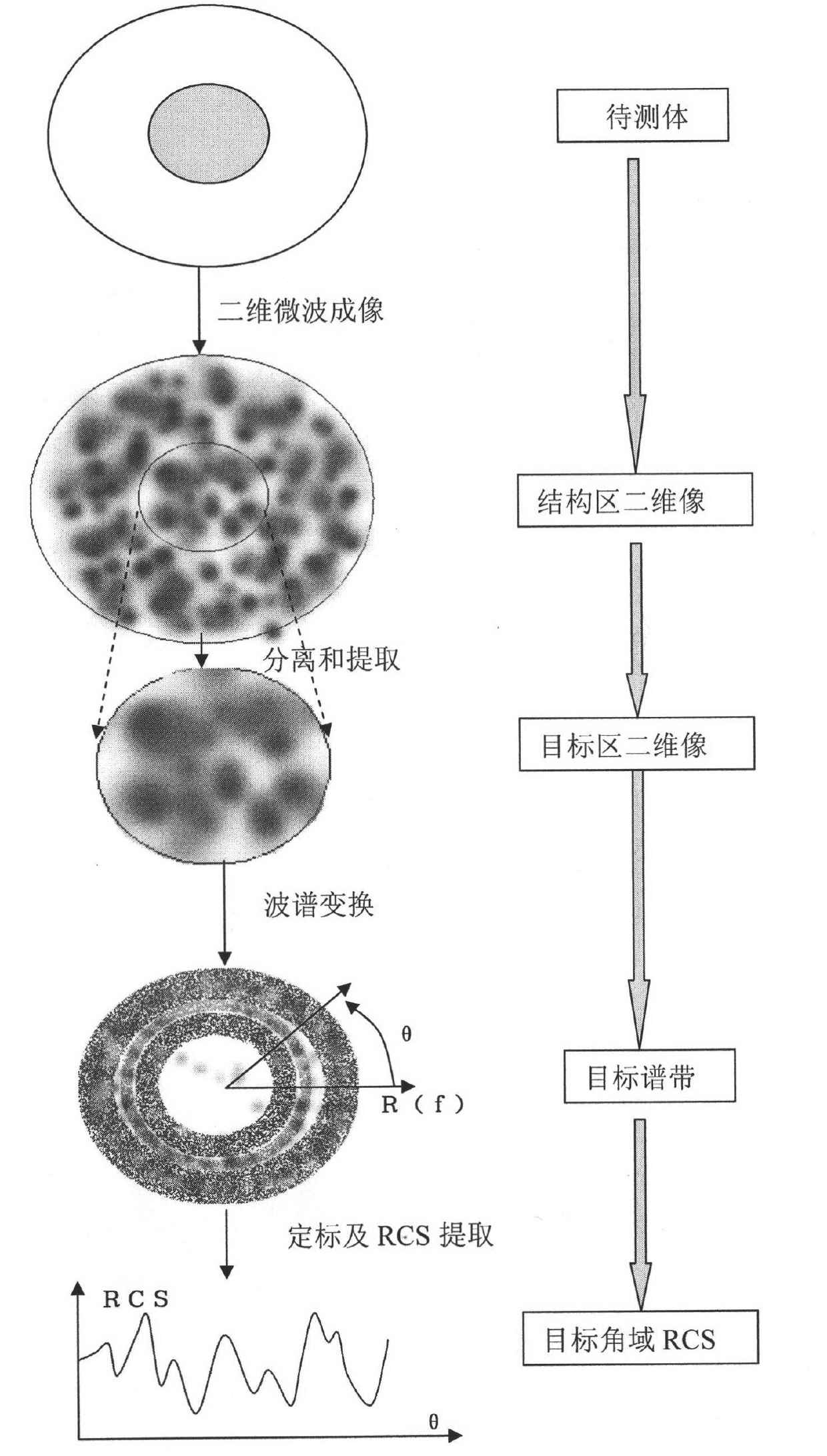

Method for testing RCS (radar cross section) of low-scattering conformal antenna based on two-dimensional microwave imaging

InactiveCN102253376AGood effectPromotion value of large projectsWave based measurement systemsSpectral domainFourier transform on finite groups

The invention relates to a method for testing an RCS (radar cross section) of a low-scattering conformal antenna based on two-dimensional microwave imaging, which is characterized by comprising the following steps: carrying out an RCS test on a metal envelope and a low-scattering conformal antenna in an installed state so as to obtain a two-dimensional microwave image; carrying out two-dimensional Fourier transform on the obtained new two-dimensional microwave image so as to obtain the data of a target spectral domain; carrying out an RCS test on a metal ball (the RCS of the metal ball is known) so as to obtain a two-dimensional microwave image, then carrying out two-dimensional Fourier transform on the obtained two-dimensional microwave image so as to obtain the data G0 (f, theta) of a scattered field of the metal ball, wherein the data of the scattered field varies with frequency and angle; and finally, obtaining the RCS of the conformal antenna, wherein the RCS of the conformal antenna meets the following formula: RCS= G1 (f, theta) (of the conformal antenna) - G0 (f, theta) (of the metal ball) + RCS (of the metal ball). The method provided by the invention is a method for testing an RCS (radar cross section) of a low-scattering conformal antenna in an installed state based on the two-dimensional microwave imaging technology, and after practicing, the obtained effect is good, therefore, the method provided by the invention has great engineering popularization value.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

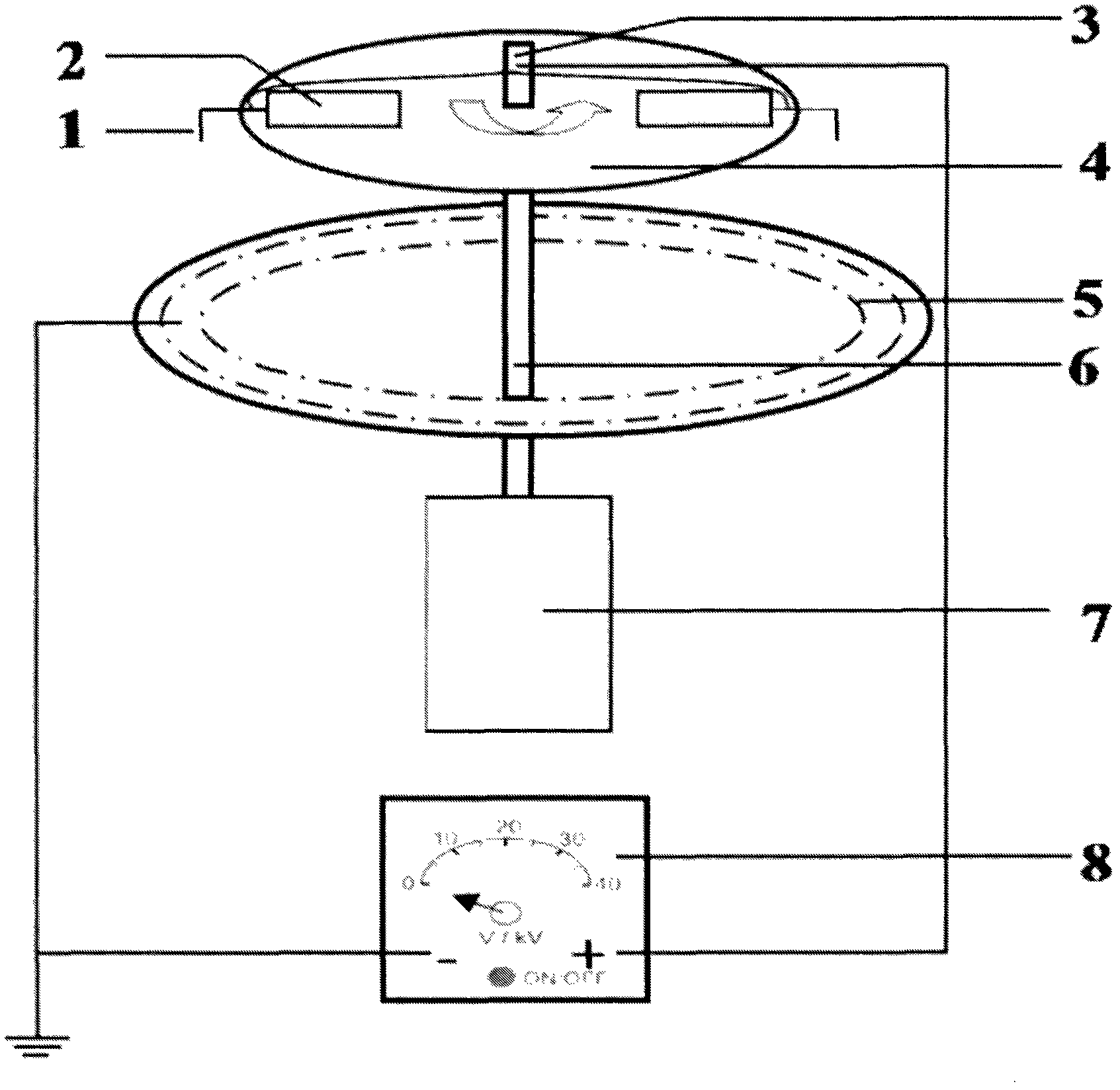

Device for preparing nano fiber twisted structure

InactiveCN102212893AThe number is accurate and controllableStranded wire structure and shapeArtificial thread manufacturing machinesFilament/thread formingMicro nanoVoltage

The invention belongs to the technical field of nano fiber twisted structure or micro-nano rope preparation, and particularly relates to a device for preparing a nano fiber twisted structure by using a centrifugal electrostatic spinning technology. A metal rod is placed in the vertical direction at the central line of an annular aluminum foil collector, a metal rod bracket passes through the center of the annular aluminum foil collector and is used for supporting and stabilizing the metal rod, and the bottom end of the metal rod is butted against and linked with the output shaft of a motor; and the upper part of the metal rod is provided with a circular insulated turntable vertical to the axis of the metal rod, two spinning solution containers are placed on the upper lateral surface of the insulated turntable and symmetrical to the central line of the metal rod, and the spinning solution containers are provided with communicated needle openings aligned with a spinning nozzle of the annular aluminum foil collector. The spun fiber number is accurate and controllable, the twisted structure is good, the lapping sequence is high, the voltage is low, burrs are not caused, and the deviceis convenient for measuring the mechanical property of single fibers.

Owner:QINGDAO UNIV

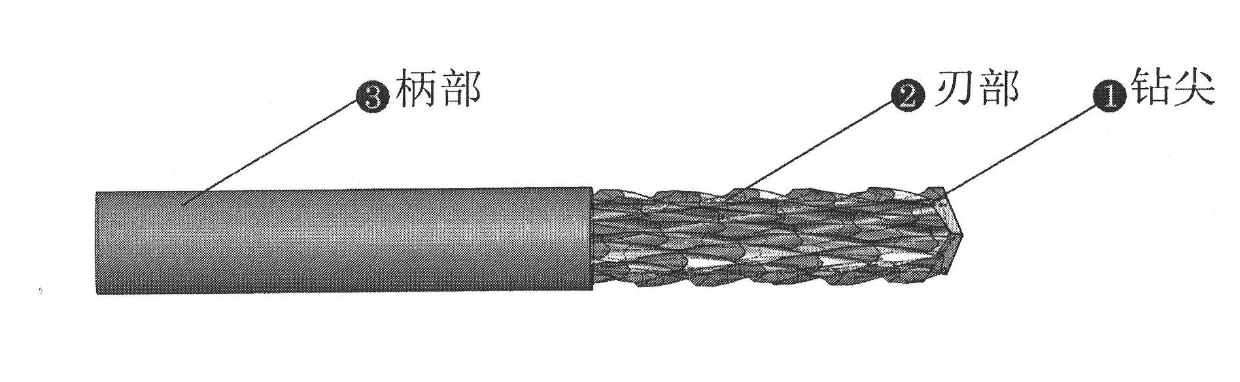

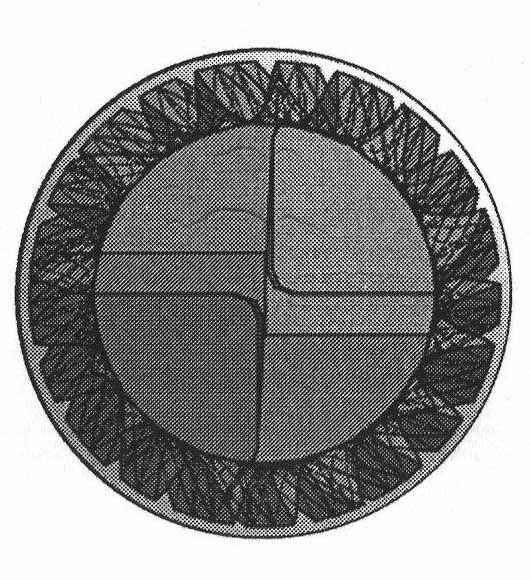

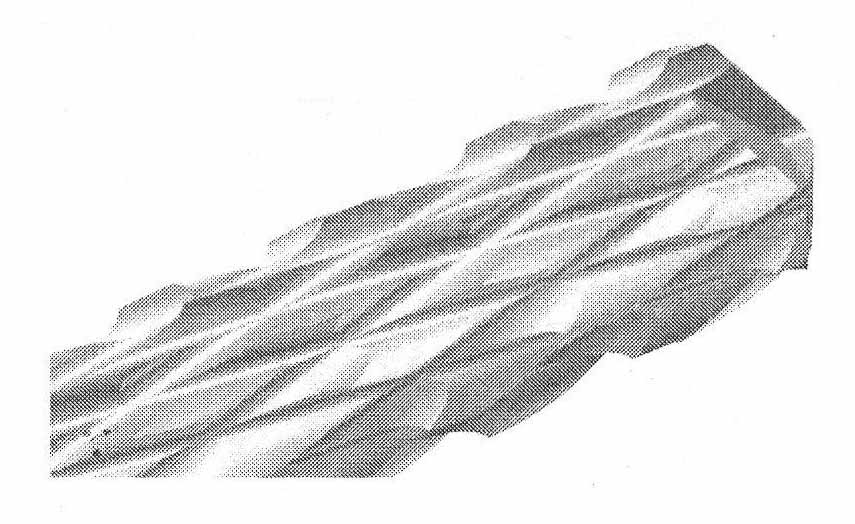

Diamond coated cutter and application thereof to processing of fiber composite material

InactiveCN102211218AImprove performanceGuaranteed sharpTransportation and packagingMilling cuttersSurface layerAlloy substrate

The invention relates to a diamond coated cutter, which comprises a drill tip, an edge part and a handle part, and is characterized in that: (1) a substrate material is a hard alloy with less than 6 mass percent of Co; (2) the drill tip and the edge part of the cutter are coated with a diamond coating; (3) the head part of the cutter has a drilling and milling integrated structure, the apex angleof the drill tip is double apex angles of 135 degrees and 90 degrees or a disc angle of 5 to 10 degrees, and the thickness of the coated diamond coating is 10 to 30mu m. The coated cutter is manufactured by the following steps of: (1) selecting an appropriate hard alloy substrate material; (2) forming the cutter; (3) pretreating a cutter coating; and (4) preparing the diamond coating on the drilltop and the edge part of the cutter through hot filament chemical vapor deposition (CVD). The phenomena of burrs and obvious surface layer peeling when the coated cutter processes a fiber composite material are avoided.

Owner:SHANGHAI XIANGREN NEW MATERIALS

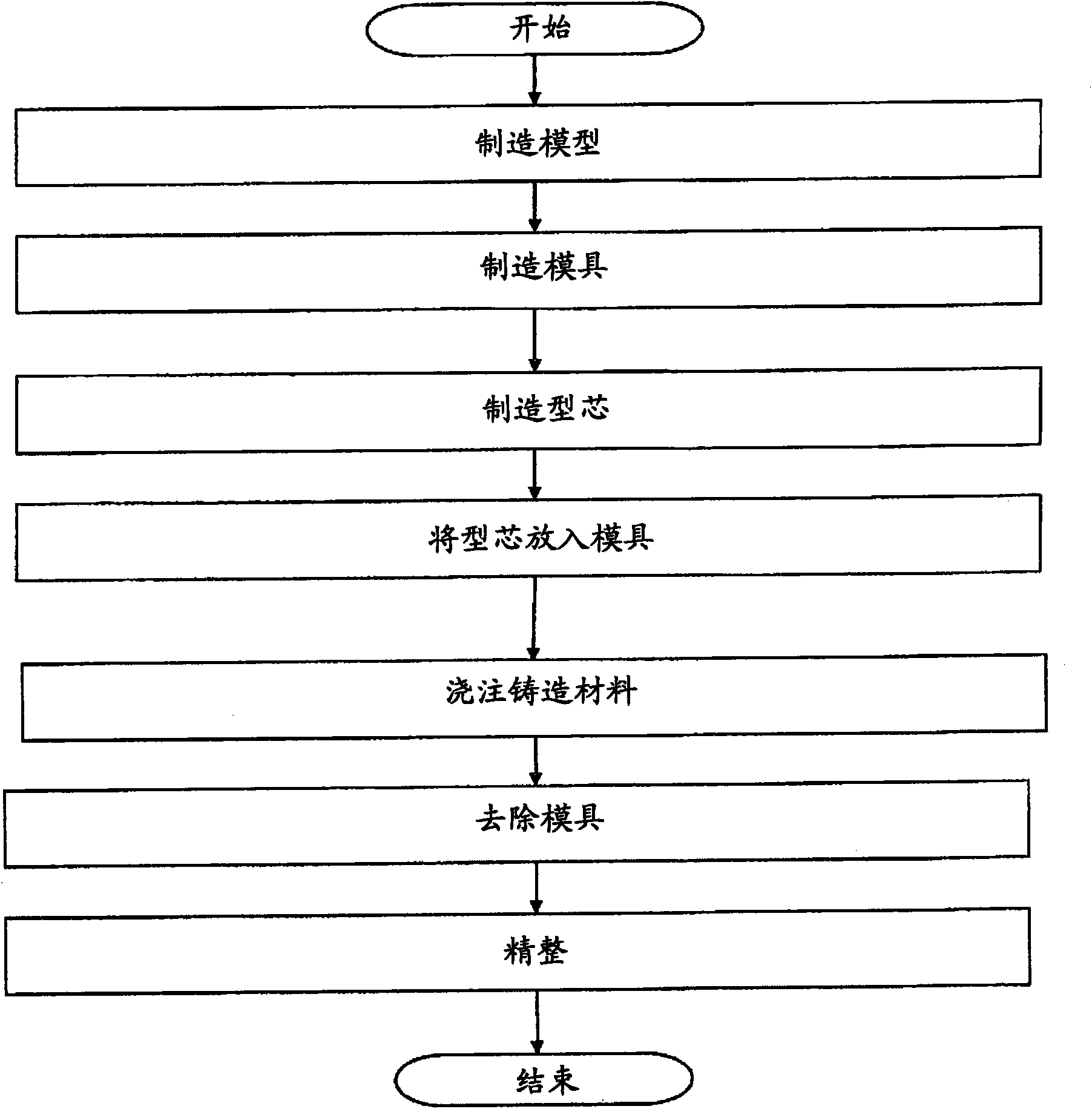

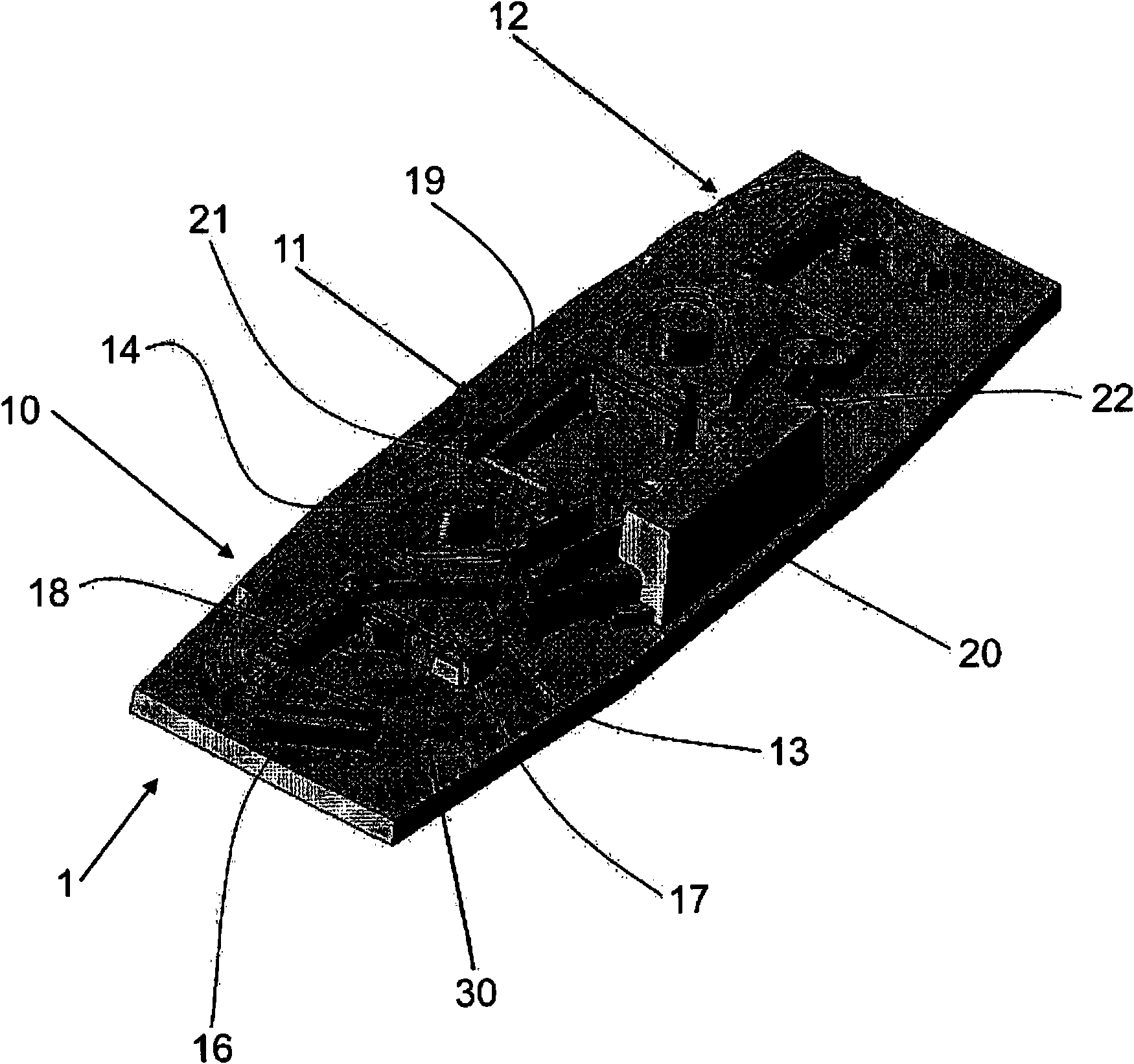

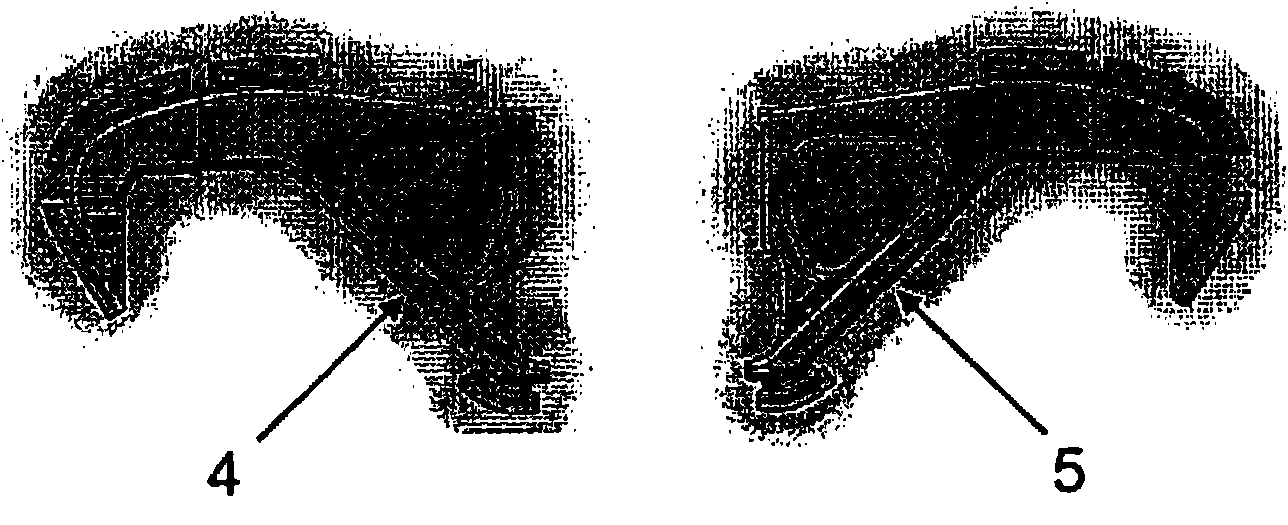

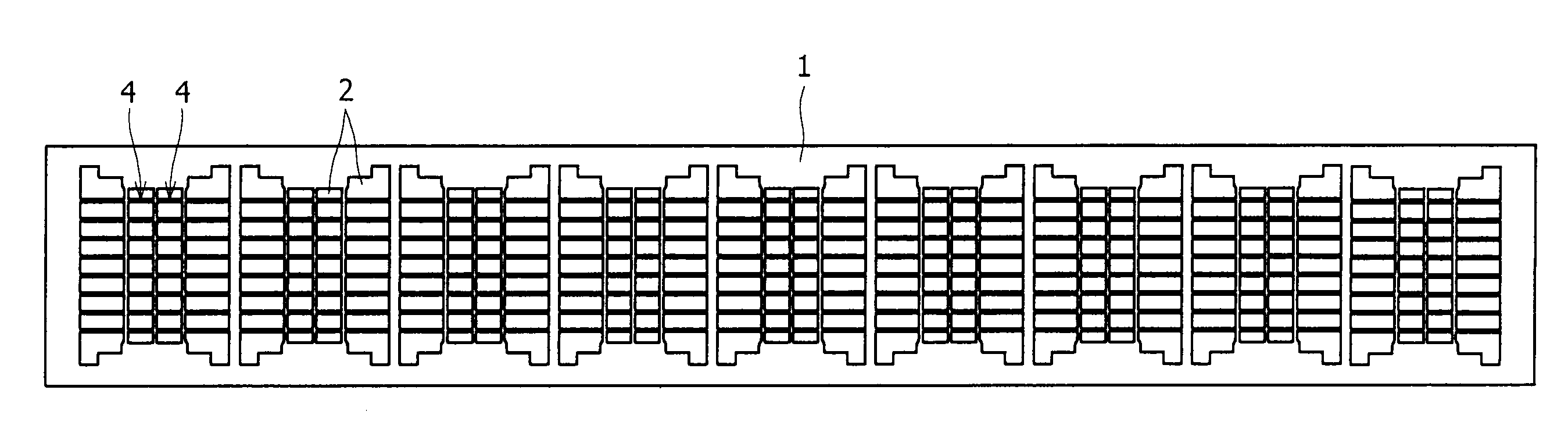

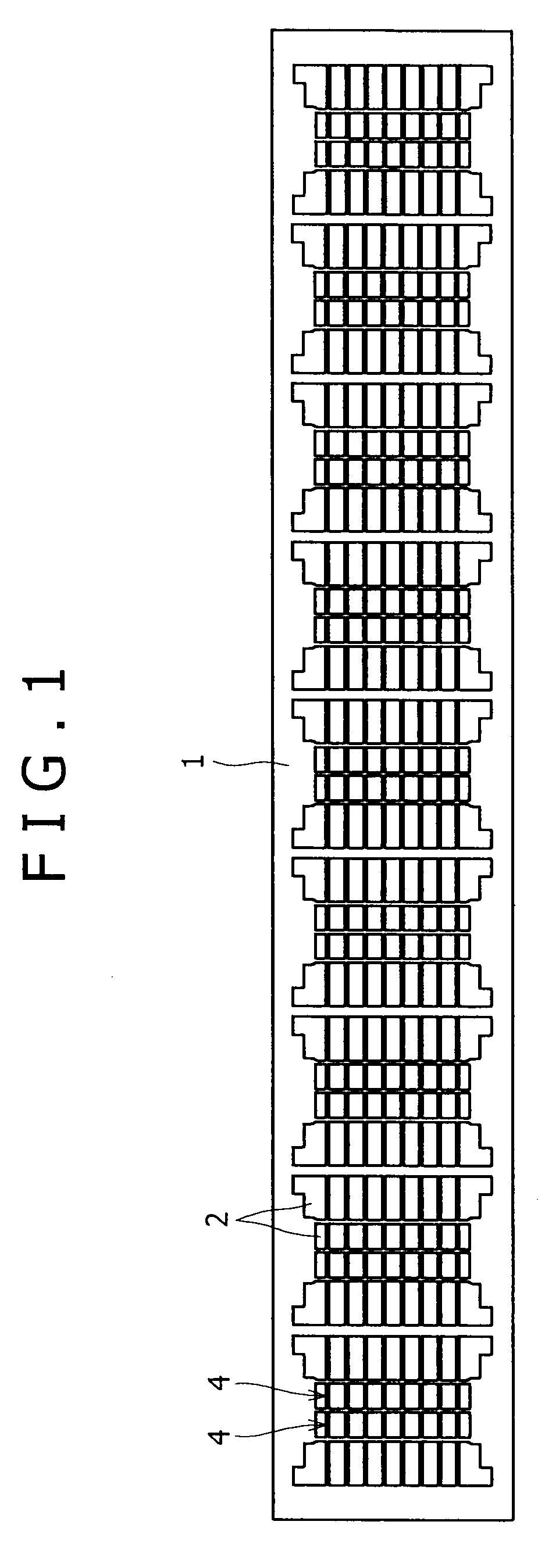

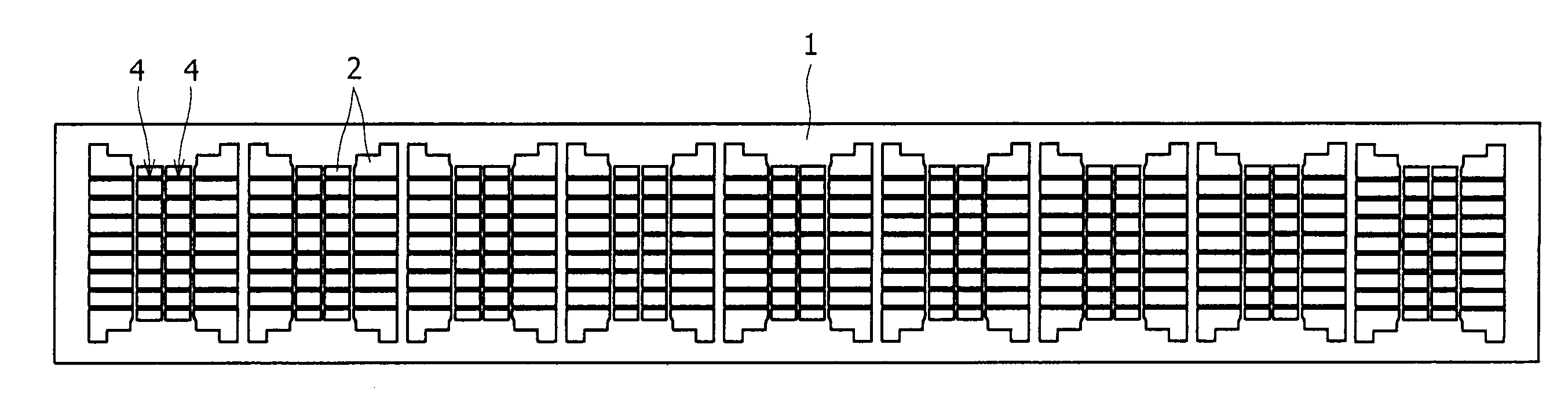

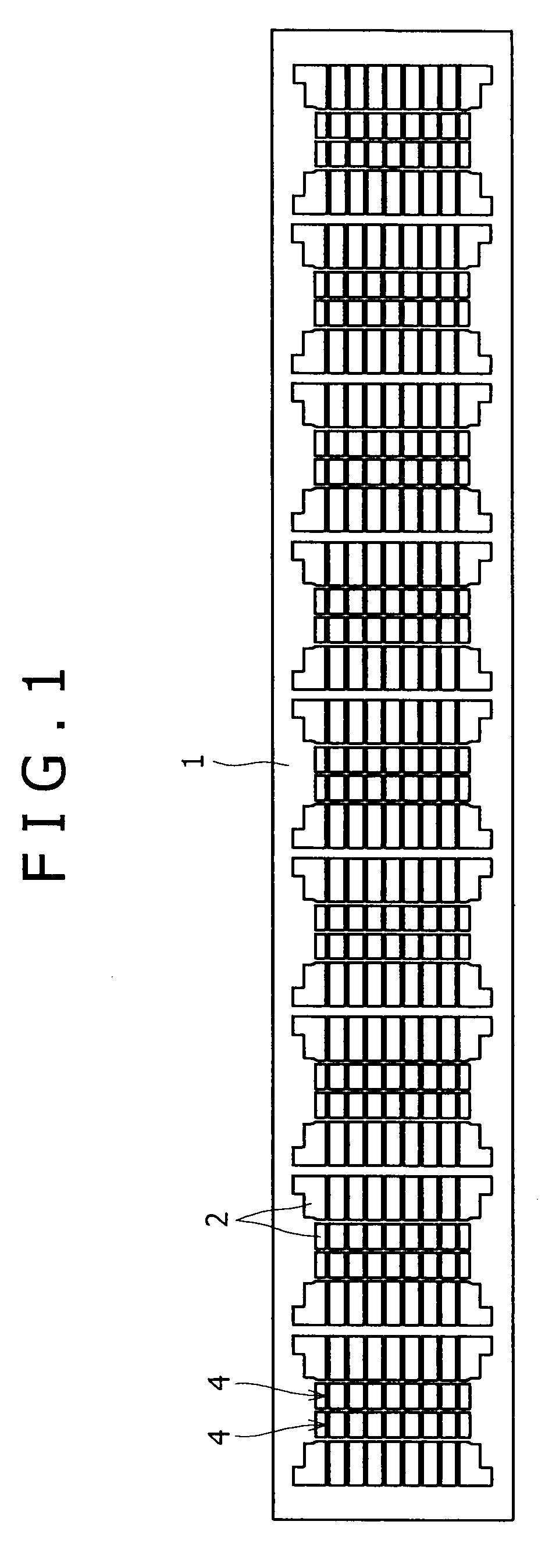

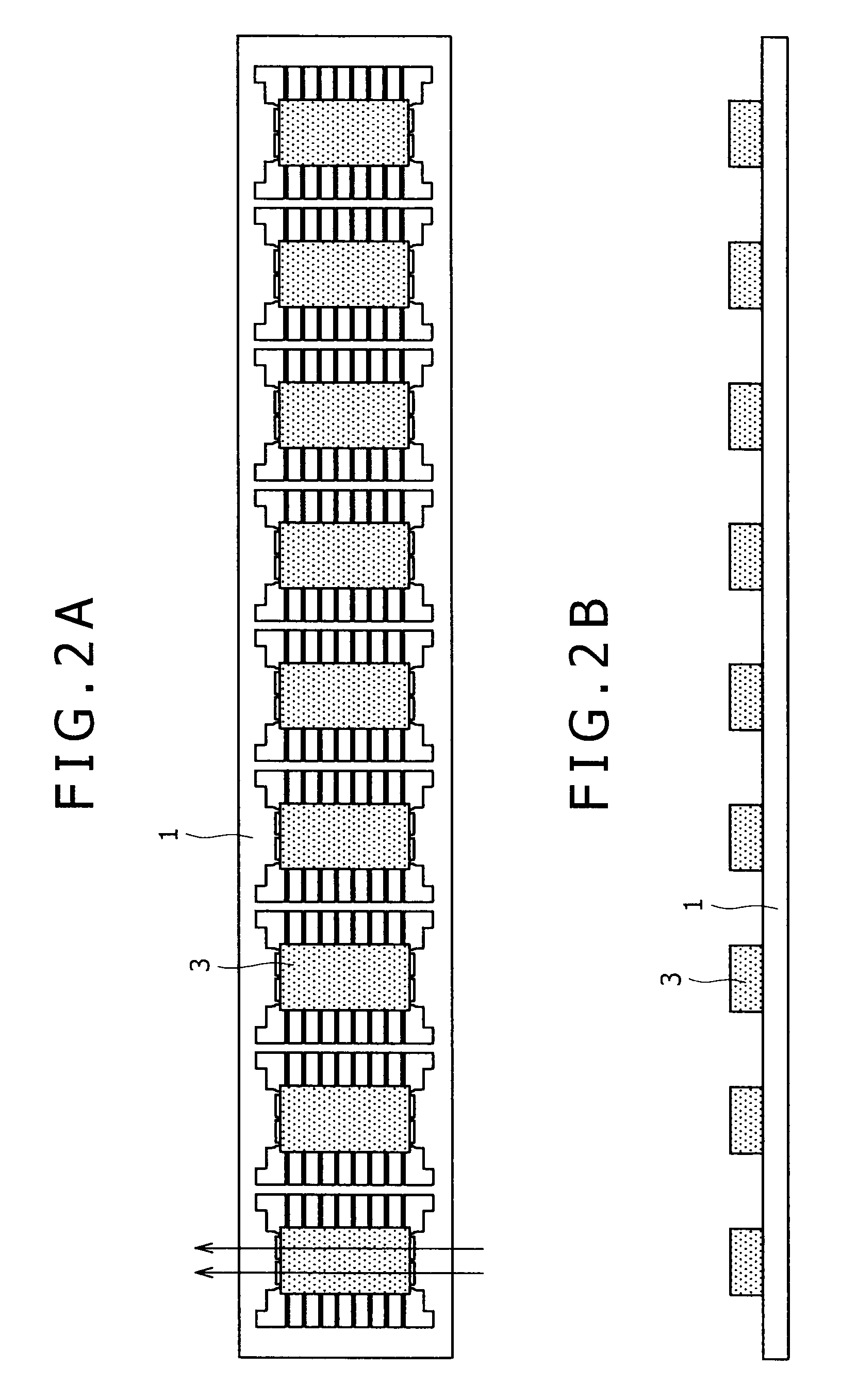

Casting process of a truck sideframe, casting model, railway car truck sideframe, railway car truck and railway car

The present invention refers to a casting process for a railway truck sideframe comprising the stages of: (i) manufacture of the model; (ii) manufacture of the mold; (iii) manufacture of the cores; (iv) placement of the cores into the mold; (v) pouring of the casting material; (vi)removing mold and (vii) finishing. The cores of the bases and the central section of the truck sideframe are eliminated in this process. The present invention also refers to a casting model (1 ), comprising a first sideframe section (10) connected by a central section (11 ) to a second sideframe section (12). The sideframe sections (10 and 12) have a base (30), with their respective space (18) in their free extremities, and a central section (11) has a central space (21). The cavity formation elements positioned in the base (18) and central (21 ) spaces are eliminated in the casting model of the present invention (1 ), so that the central and base cores are not required in the casting process. The housing (23) avoids the placement of the core of the brake guide (9) in the mold. Finally, the present invention describes a railway car truck sideframe whose principal characteristic is the fact that it is produced in accordance with the casting process of the present invention.

Owner:AMSTED MAXION FUNDICAO E EQUIPAMENTOS FERROVIARIOS

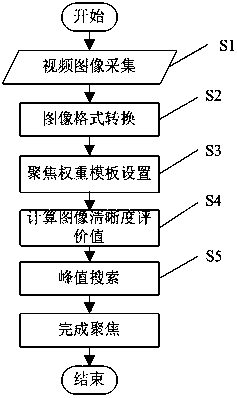

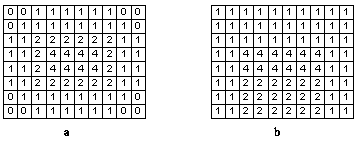

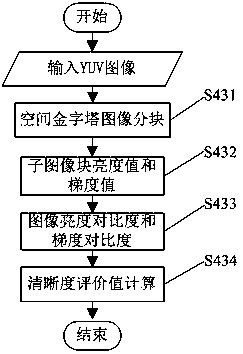

Method and device for improving automatic focusing accuracy and speed of camera

PendingCN110166692AEvenly distributedOffset the effect of sharpness evaluation valueTelevision system detailsColor television detailsBrightness contrastHill climbing

The invention relates to the field of image processing and food monitoring, and particularly discloses a method and a device for improving the automatic focusing accuracy and speed of a camera. The method for improving the automatic focusing accuracy and speed of the camera is characterized by sequentially comprising the steps of video image collection, image format conversion, focusing template setting, night vision low-illumination scene definition evaluation value calculation, daytime scene definition evaluation value calculation, peak searching and motor-driven lens focus finding. The threshold value of the change of the definition evaluation value in the hill climbing algorithm is adaptively adjusted according to the brightness contrast, the gradient contrast and the ISO value, the change trend of the current evaluation value can be effectively judged, the peak value can be found more quickly, and the automatic focusing speed and accuracy of night vision and low-illumination scenes are improved.

Owner:JINAN JOVISION TECH CO LTD

Power amplifier controller with polar transmitter

ActiveUS8050638B2Reduce phase distortionMinimize the differenceAmplifier modifications to reduce non-linear distortionResonant long antennasAudio power amplifierPolar transmitter

A power amplifier controller controls a power amplifier and is coupled to a polar modulator. The polar modulator generates an amplitude component and a phase-modulated component of the desired RF modulated signal, and outputs to the power amplifier controller. The power amplifier controller regenerates a combined phase and amplitude modulated RF signal to generate an input signal to a power amplifier by adjusting the gain of a VGA based on the amplitude component of the desired RF modulated signal. Concurrently, the power amplifier controller both controls an adjusted supply voltage to the PA and adjusts the gain of the VGA based upon an amplitude correction signal or amplitude error signal.

Owner:QUANTANCE

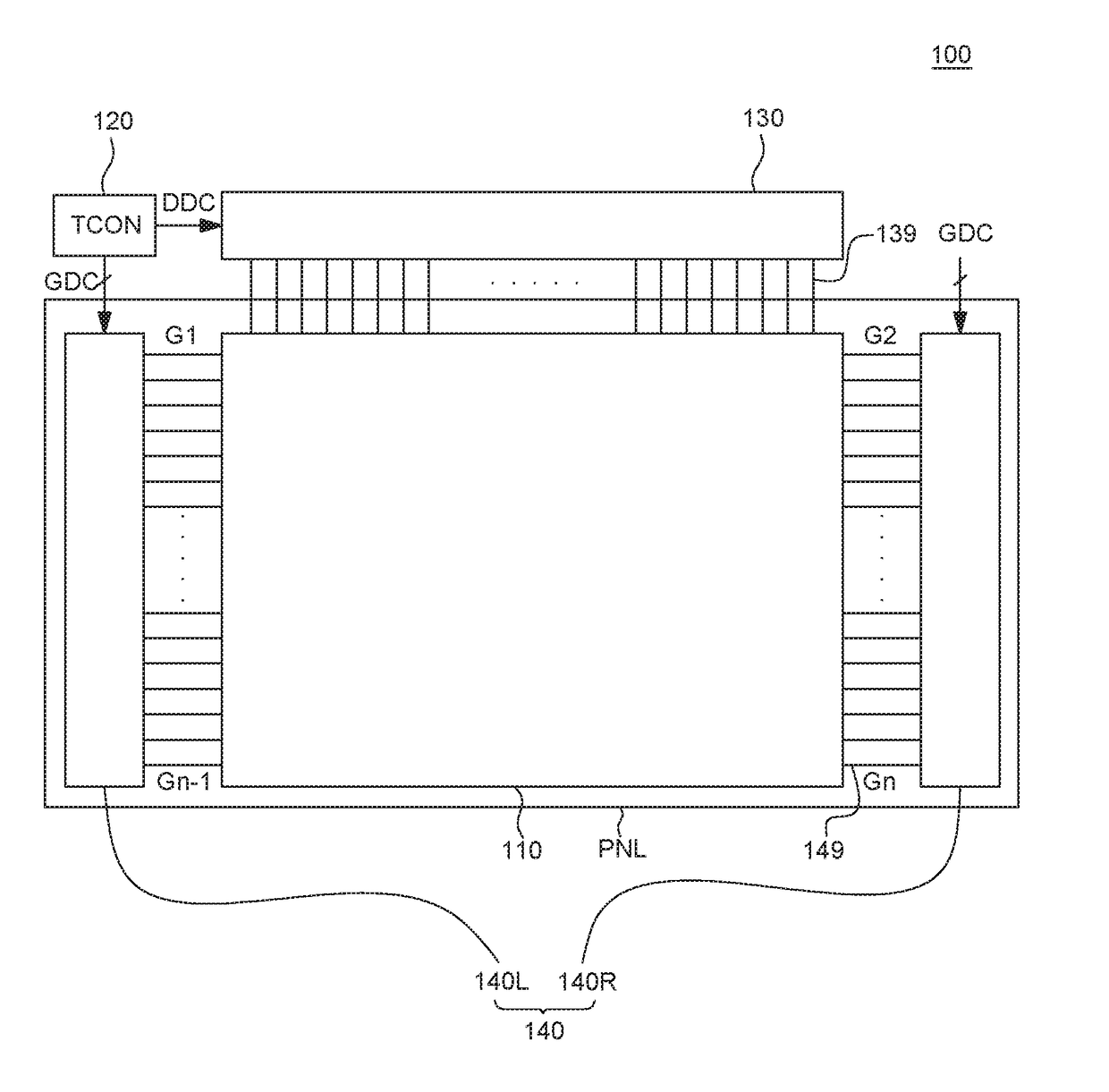

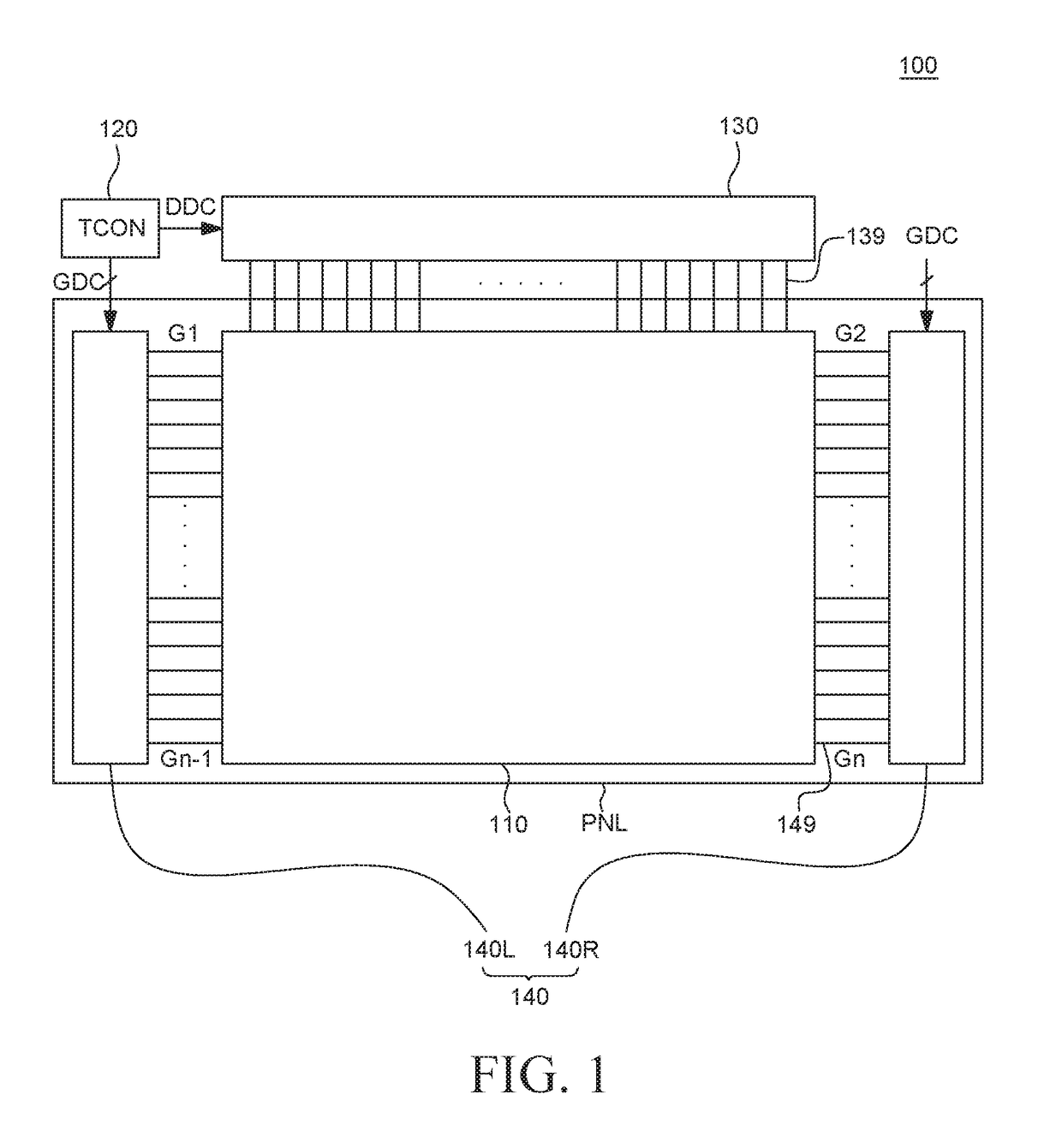

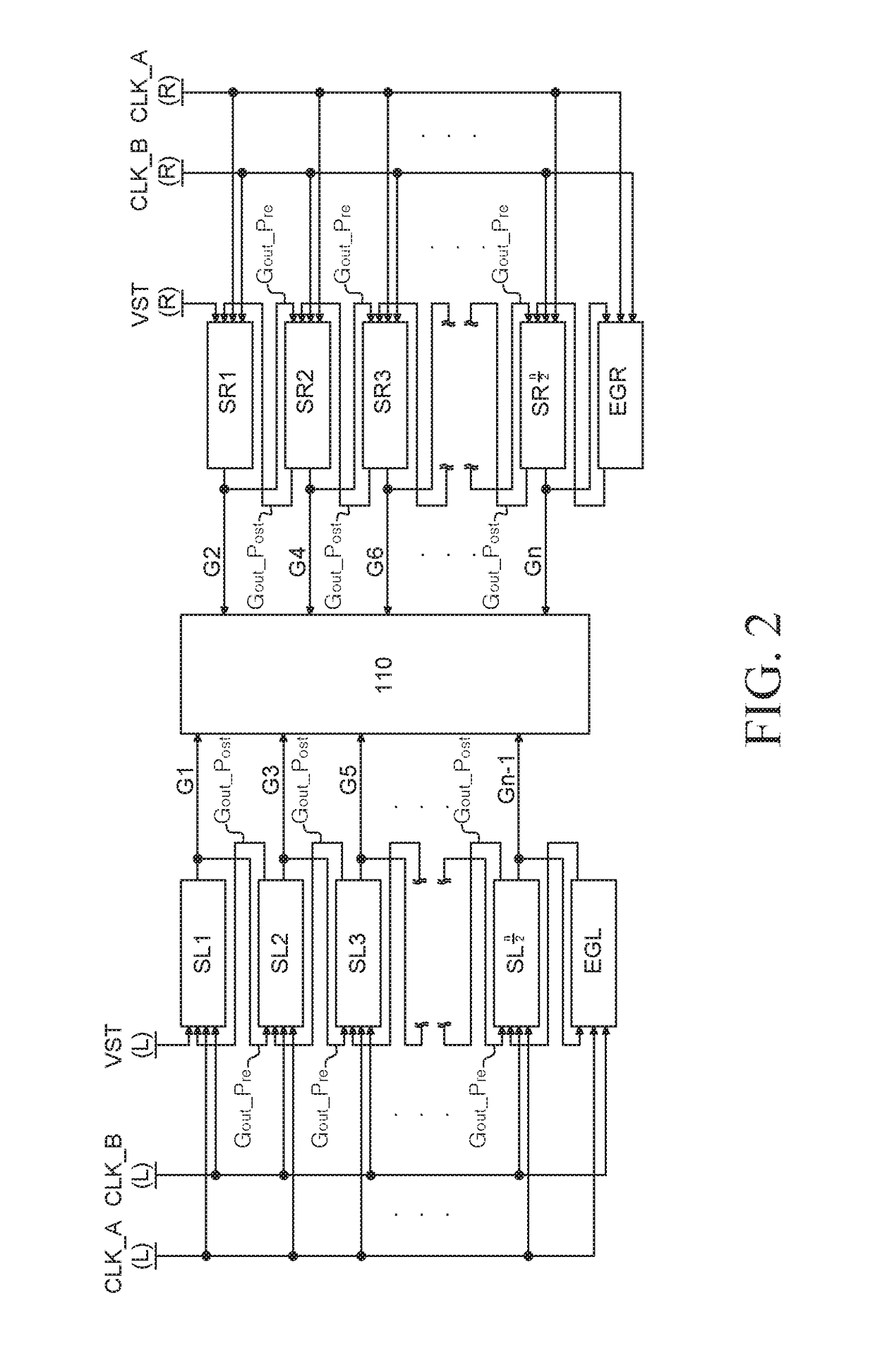

Gate driving circuit and display device including the same

ActiveUS20170169757A1Reduce glitchesOutput maximizationStatic indicating devicesDigital storageShift registerTransmission gate

Provided are a gate driving circuit and a display device including the same. The gate driving circuit according to an embodiment includes a shift register including a plurality of stages. An nth stage of the stages includes a latch control circuit including a first NMOS transistor connected to a QB node, a second NMOS transistor connected to a Q node, and a third NMOS transistor having a gate electrode to which a first clock is input and connected to the first and second NMOS transistors, where n is a positive integer. A latch is connected between the Q and QB nodes. A transmission gate is connected to the Q and QB nodes. In the gate driving circuit, output signals of a previous stage and a following stage are controlled so as to be synchronized with the first clock to suppress a glitch.

Owner:LG DISPLAY CO LTD

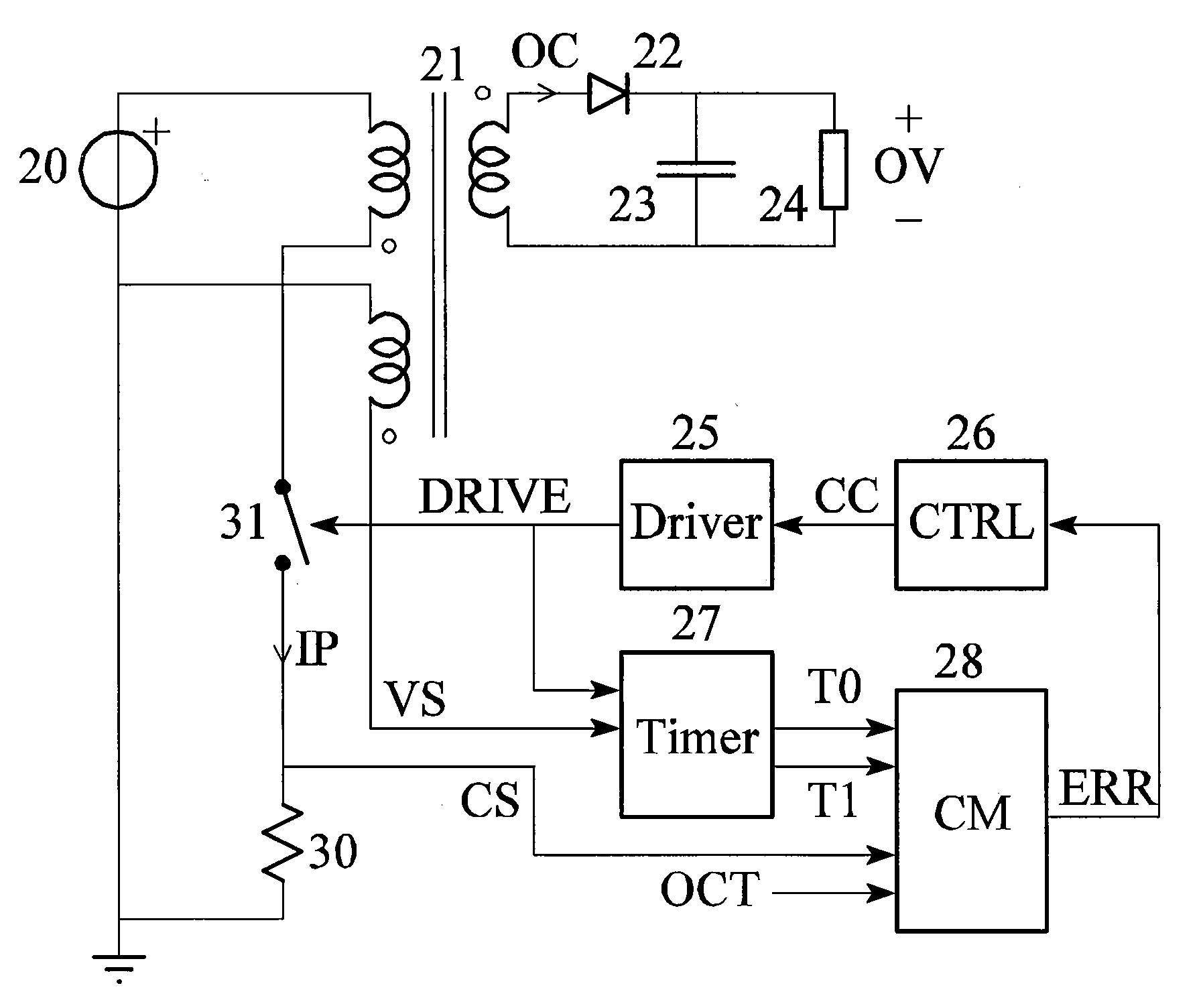

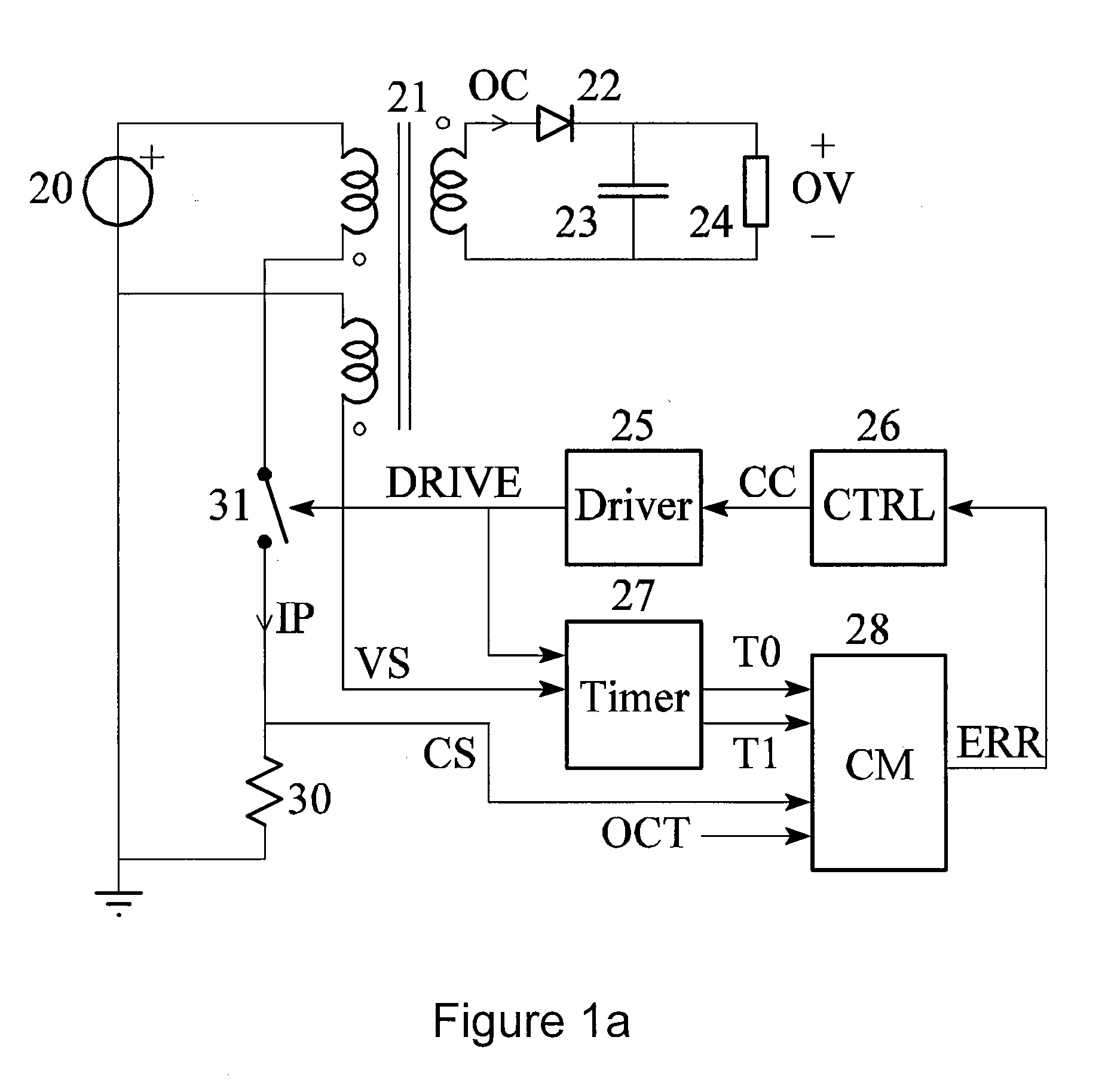

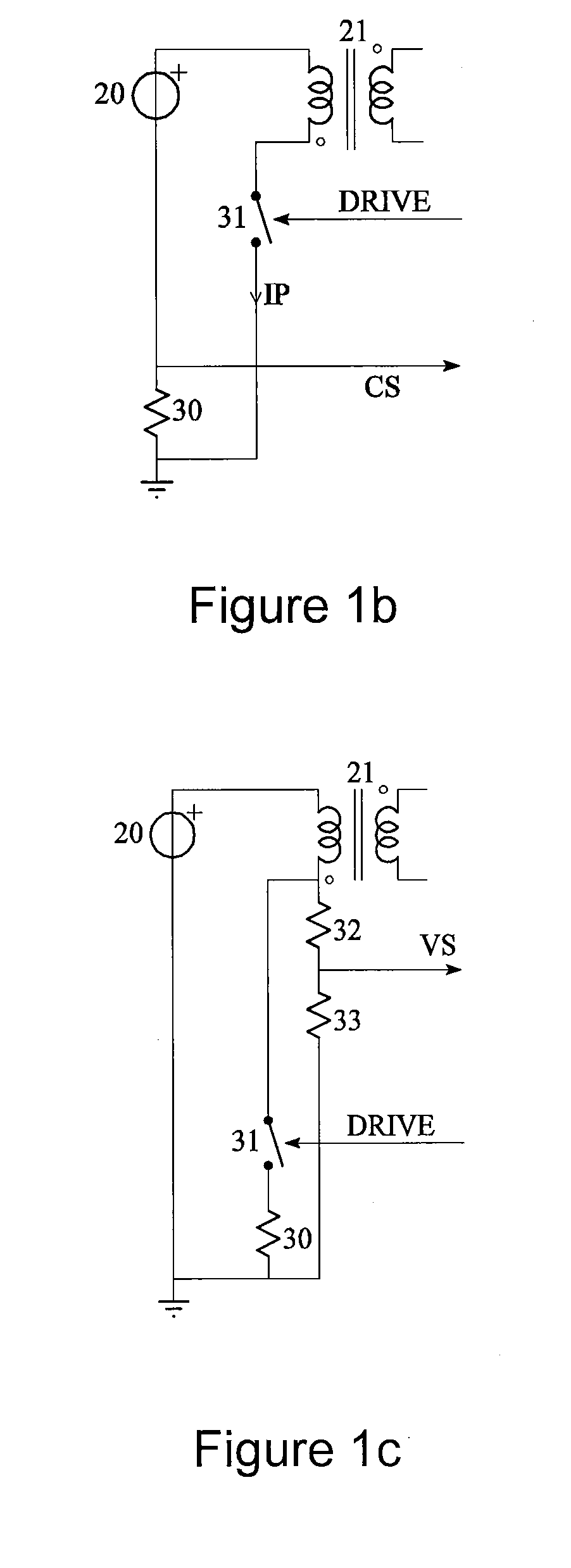

Switched mode power supply systems

ActiveUS20090290390A1Accurate estimateReduce glitchesDc-dc conversionElectric variable regulationEngineeringSignal generator

We describe a switch mode power supply (SMPS) current regulation system comprising: a current sense signal input sensing a primary current of the SMPS; a voltage sense input to receive a voltage sense signal from a primary or auxiliary winding; a switch drive signal input to receive a drive signal; a timing signal generator coupled to said voltage sense input and to said drive signal input to generate a timing signal T0 indicating a duration of a period for which current is flowing through said primary winding and a timing signal T1 indicating a duration of a period for which current is flowing through said secondary winding; and a regulator to provide an output current regulation signal responsive to an average of the current sense signal multiplied by a ratio of T1 to T0, and wherein T0 and / or T1 are generated responsive to the voltage or current sense signal.

Owner:POWER INTEGRATIONS INC

Square-pipe punching machine

InactiveCN101069911ADie-cut surface smoothReduce glitchesPerforating toolsMetal working apparatusPunching

The present invention relates to a square pipe punching machine. It includes machine frame, several tool seats which are respectively oppositely-placed on two sides of said machine frame, positioning mechanism for defining punching position of workpiece and holding mechanism. On every tool seat a mobile punching needle is set, and the positioning mechanism includes a piercing rod which can be passed through the workpiece interior, in the middle portion of said piercing rod several positioning holes are cut, said several positioning holes are correspondent to the punching needles. Besides, said invention also provides the working principle of said square pipe punching machine and its concrete operation method.

Owner:庄添财

Anodic phosphorous copper balls and preparation method thereof

InactiveCN101914801AImprove qualityPhosphorus is evenly distributedElectrodesCopper platingInduction furnace

The invention discloses anodic phosphorous copper balls and a preparation method thereof. The method comprises the following steps of: (1) after yellow phosphorus or red phosphorus and oxygen-free copper are melted by adopting a medium-frequency induction furnace, stirring the melt uniformly through a magnetic stirring tank to obtain phosphorous copper solution; (2) producing a phosphorous copper bar with a diameter of 20 to 50 millimeters by using the phosphorous copper solution prepared in the step (1) and an up-draw process, and continuously stamping the phosphorous copper bar to obtain copper balls of different sizes in different dies; and (3) performing polishing, burr removal, cleaning and drying treatment on the copper balls obtained in the step (2) in turn to obtain the anodic phosphorous copper balls. The anodic phosphorous copper balls have the advantages of compact crystal, thin and small crystal grain, high phosphorous copper film generating speed, exquisite and firm phosphorous copper film texture and dropping resistance, and can reduce the cleaning frequency of an anode, effectively improve the utilization rate of the anode and remarkably improve the copper plating effect.

Owner:金峰电路(惠州)有限公司

Preparation method for flake-like aluminium powder pigment

The invention discloses a preparation method for a flake-like aluminium powder pigment, and the method comprises the following steps: putting 1-1.5 tons of steel balls of which the diameter is 0.8-1.5mm, 1-10mu m of spherical aluminium powder, 150#or 200# solvent oil and accessory ingredients into a ball mill at a certain ratio; introducing nitrogen for protection; after the ball mill carries outball milling at a higher speed for 5-7 hours, slowing the revolving speed to carry out ball milling for 1.5-3 hours; after ball milling is finished, adding 80-120kg of 150# or 200# solvent oil for diluting; pressing out the diluted aluminium slurry by virtue of an air pump; screening and grading by virtue of a vibrating screen; carrying out filter pressing by a use of a plate and frame type filter press; separating solid and liquid to obtain a filter cake of which the solid content is 70-80%; adding a 150#or 200# diluted phenolic antioxidant; kneading in a kneader for 40-60 minutes; and packaging. By utilizing the preparation method disclosed by the invention, silver dollar type flake-like metal particles with even particle diameter can be obtained, the product performance is improved, the coating effect of the aluminium particle is improved, the phenomenon of silver drop can be solved, the surface of the aluminium particle is smooth and flat, and the welding, burr and the like of thealuminium particle can be reduced.

Owner:HEFEI SUNRISE PIGMENTS

Spinning technology of two-spinning-roller semicontinuous high-speed spinning machine

InactiveCN103409824AReduce in quantityReduce manufacturing costArtificial thread manufacturing machinesWet spinning methodsSpinningMachine

The invention relates to a spinning technology of a two-spinning-roller semicontinuous high-speed spinning machine, and belongs to the technical field of semicontinuous spinning machines. The spinning technology comprises the steps of glue supplying, thread-line forming, spinning and winding, wherein the spinning is carried out through a spinning device. The spinning device comprises two spinning rollers which are transversely arranged relative to an operating surface of a spun surface, thread lines surround the spinning rollers, and drafting, solidifying and deacidification in the spinning steps are achieved when the spinning rollers rotate. The spinning technology solves the problems that thread lines of a semicontinuous spinning machine in the prior art are insufficient in reaction, the spinning process cannot be accelerated, and production efficiency and the product quality cannot be taken into consideration. The arrangement direction of the spinning rollers is changed so that the thread lines can walk for a longer distance while the spinning process of the spinning machine is accelerated and the structures of other components of original equipment are not changed, the thread lines can be reacted with acid bath more fully, and both production efficiency and product quality are taken into consideration.

Owner:YIBIN HIEST FIBER +2

Safe lithium ion battery

InactiveCN102208678AImprove securityImprove cycle performanceElectrode carriers/collectorsSecondary cellsElectrical batteryThermistor

The invention discloses a safe lithium ion battery, which comprises an anode system, a cathode system, a membrane spaced between an anode and a cathode, and an electrolyte system, wherein the anode system comprises an anode current collector and a membrane attached to the anode current collector and containing an anode active substance; the cathode system comprises a cathode current collector and a membrane attached to the cathode current collector and containing a cathode active substance; an organic conductive film is used as the current collector in one or both of the anode system and the cathode system; and a polymer matrix with positive temperature coefficient (PTC) thermistor property is adopted in the organic conductive film. The organic conductive film has the PTC thermistor property. The lithium ion battery can avoid the safety problems of battery combustion and even explosion and the like caused by over charge and battery temperature rise due to external short circuit.

Owner:CENT SOUTH UNIV +1

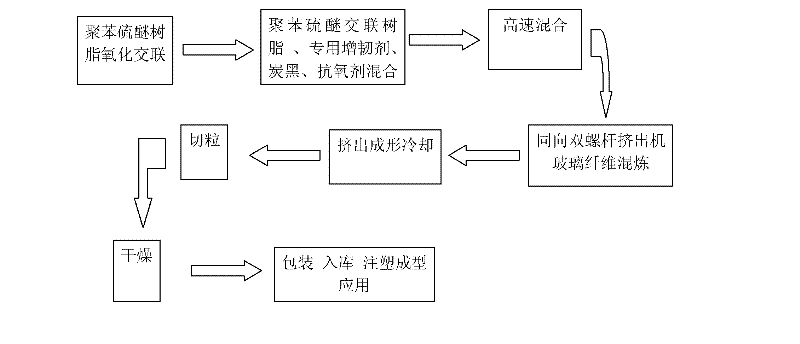

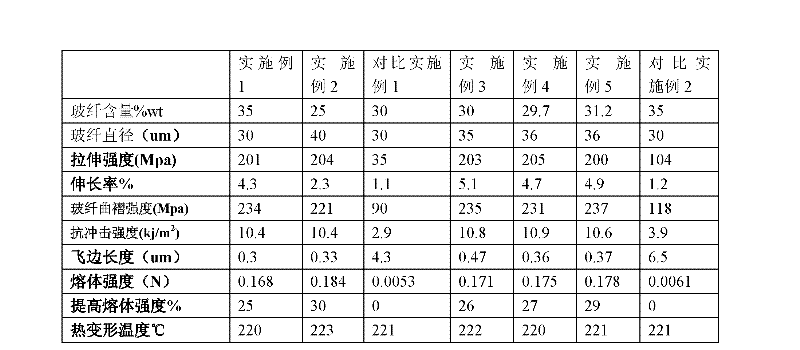

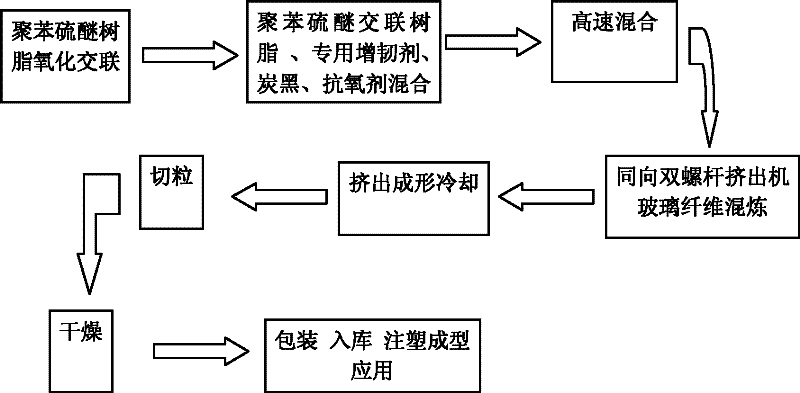

Preparation method of high-toughness polyphenyl thioether alloy

The invention discloses a preparation method of high-toughness polyphenyl thioether alloy. The preparation method comprises the following steps: adding an antioxidant, an ethylene-methyl acrylate-glycidyl methacrylate special ternary random copolymer toughening material and carbon black in a linear polyphenylene sulfide (PPS) resin subjected to oxidative thermal crosslinking, and then fully and evenly mixing in a high-speed mixer so as to obtain a PPS resin premix, wherein the weight percentage of PPS to glass fiber to special toughening material to carbon black to antioxidant is (59.8-65.2):(25-35):(3-8):(1-2):(0.2-0.8); and carrying out mixing, extrusion molding, cooling and chopping to obtain finished alloy. The alloy obtained by using the preparation method has the advantages of high thermal denaturation stability, high tensile strength and low metal corrosion rate, and can be widely applied to the fields of electronic appliances, machinery, chemical industry, petroleum, military industry and aerospace, especially used as an enclosure material or packaging material for all types of batteries.

Owner:SICHUAN DEYANG CHEM +1

Negative pressure reverse cooling-adopted high-quality processing method for fiber reinforced composite

ActiveCN105835120AEasy to cutReduce heat damageMetal working apparatusPositive pressureFiber-reinforced composite

The invention discloses a negative pressure reverse cooling-adopted high-quality processing method for a fiber reinforced composite, belongs to the technical field of cutting processing, and relates to a processing method for high-quality drilling and hole making of the fiber reinforced composite. The method is characterized in that different cooling technologies are implemented when different positions of the fiber reinforced composite formed through laying and curing a plurality of layers of prepregs are drilled. The method comprises the steps that firstly, a negative pressure cover is attached to the surface of the composite during the fiber reinforced composite hole making process; negative pressure is generated in the negative pressure cover and a drilling hole cavity through utilizing an air pump; drilling dust and cuttings are quickly collected; positive pressure is generated around a drill internal cooling hole through utilizing a cutter air pump, as as to help cooling the cuttings; and when the last layers of the material are drilled, the drill internal cooling hole performs negative pressure suction instead of positive pressure ventilation, relatively high negative pressure is generated for the material at the outlet part, support is provided for the drilling process, and a drill cutting edge is enabled to cut fibers. According to the method, defects such as burrs and delamination are effectively reduced, and the fiber reinforced composite is drilled and processed at high quality.

Owner:DALIAN UNIV OF TECH

Copper alloy sheet and qfn package

ActiveUS20090224379A1Suppress abrasionImprove qualitySemiconductor/solid-state device detailsSolid-state devicesHardnessCopper alloy

A QFN package is provided with a lead frame formed by processing a copper alloy sheet containing 0.01 to 0.50% by mass Fe, 0.01 to 0.20% by mass P, and Cu and inevitable impurities as other components, having a micro Vickers hardness of 150 or above, a uniform elongation of 5% or below and a local elongation of 10% or below, or a copper alloy sheet containing 0.05 to 2% by mass Ni, 0.001 to 0.3% by mass P, 0.005 to 5% by mass Zn, and Cu and inevitable impurities as other components, having a micro Vickers hardness of 150 or above, a uniform elongation of 5% or below and a local elongation of 10% or below. Lead burrs formed during the dicing of the QFN package are short, and a dicing blade used for dicing the QFN package is abraded at a low wear-out rate.

Owner:KOBE STEEL LTD

Yarn guiding device for textile product production

InactiveCN109281021AReduce mechanical vibrationEasy to assemble and disassembleYarnYarnPulp and paper industry

The invention discloses a yarn guiding device for textile product production. The device comprises a fixing bottom plate, a guiding assembly, a burr removing assembly and an adjusting assembly, the burr removing assembly comprises a guiding tube, a heating sleeve tube and a supporting frame, the heating sleeve tube is sleeved with the guiding wire, a heating wire is arranged in the heating tube, the adjusting assembly comprises a fixing plate, an adjusting plate and a pressurizing screw rod, the fixing plate is located on the limiting frame, a tensioning roller is arranged below the bottom ofthe adjusting plate, and the pressurizing screw rod is sleeved with the limiting plate. According to the yarn guiding device, yarns can be welled guided to prevent the yarns from breaking in the conveying process, the adjustment of the angle of the yarns can be conducted according to the conveying angle of the yarns, the using range of the guiding device is expanded, burrs, impurities and the likeon the yarns are removed through the burr removing mechanism to improve the quality of the yarns, and tensioning force in the yarn conveying process can be conducted by the adjusting assembly according to the conveying demands of the yarns to help the conveying of the yarns.

Owner:SHENGZHOU WENDA TEXTILE CO LTD

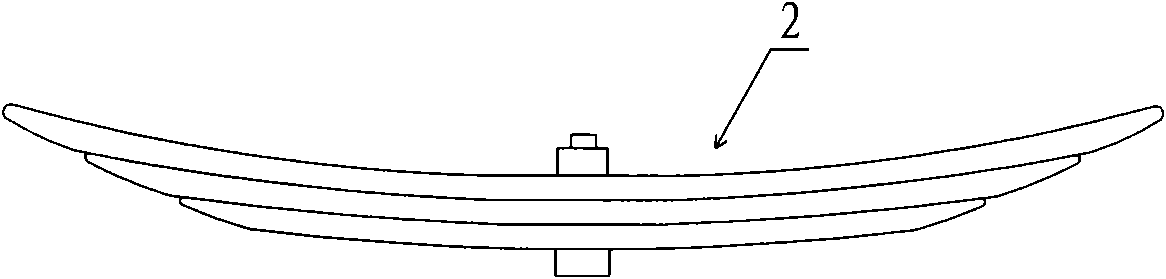

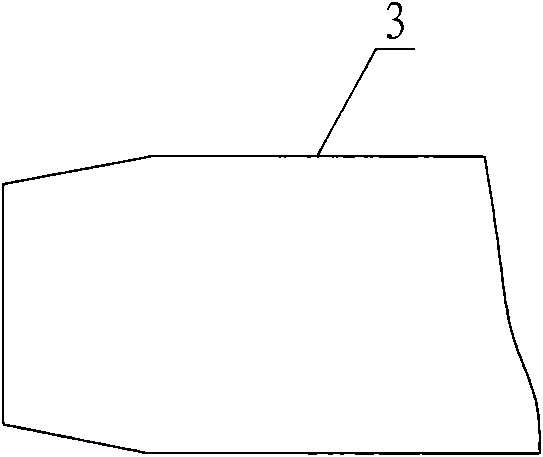

Non-cutting variable cross-section steel plate spring and end forming manufacturing technology and device thereof

InactiveCN101561023AImprove fatigue lifeImprove noiseLeaf springsManufacturing technologySheet steel

The invention discloses a non-cutting variable cross-section steel plate spring, which is an arc-shaped plate spring and consists of a plurality of variable cross-section steel plate spring strips overlapped mutually. The radian of each steel plate spring strip takes a steel plate center as a symmetric point and the arcs of both ends are completely same. A straight section is arranged in the middle part of each steel plate spring strip, the exterior at the end of the steel plate spring strip presents a convex arc and both sides thereof present a concave arc. The invention further discloses a manufacturing technology and a manufacturing device of the steel plate spring. The steel plate spring and the technology thereof, on the basis of keeping the property of an original variable cross-section steel plate, can effectively reduce the generation of early fatigue sources at ends among steel plate spring strips due to corner cut burr, increase the anti-fatigue life of the plate spring, improve the utilization rate of materials, reduce mold consumption during the plate manufacturing process, reduce the labor quantity of operators and effectively reduce the production cost of the plate spring.

Owner:QINGDAO SHUAICHAO IND

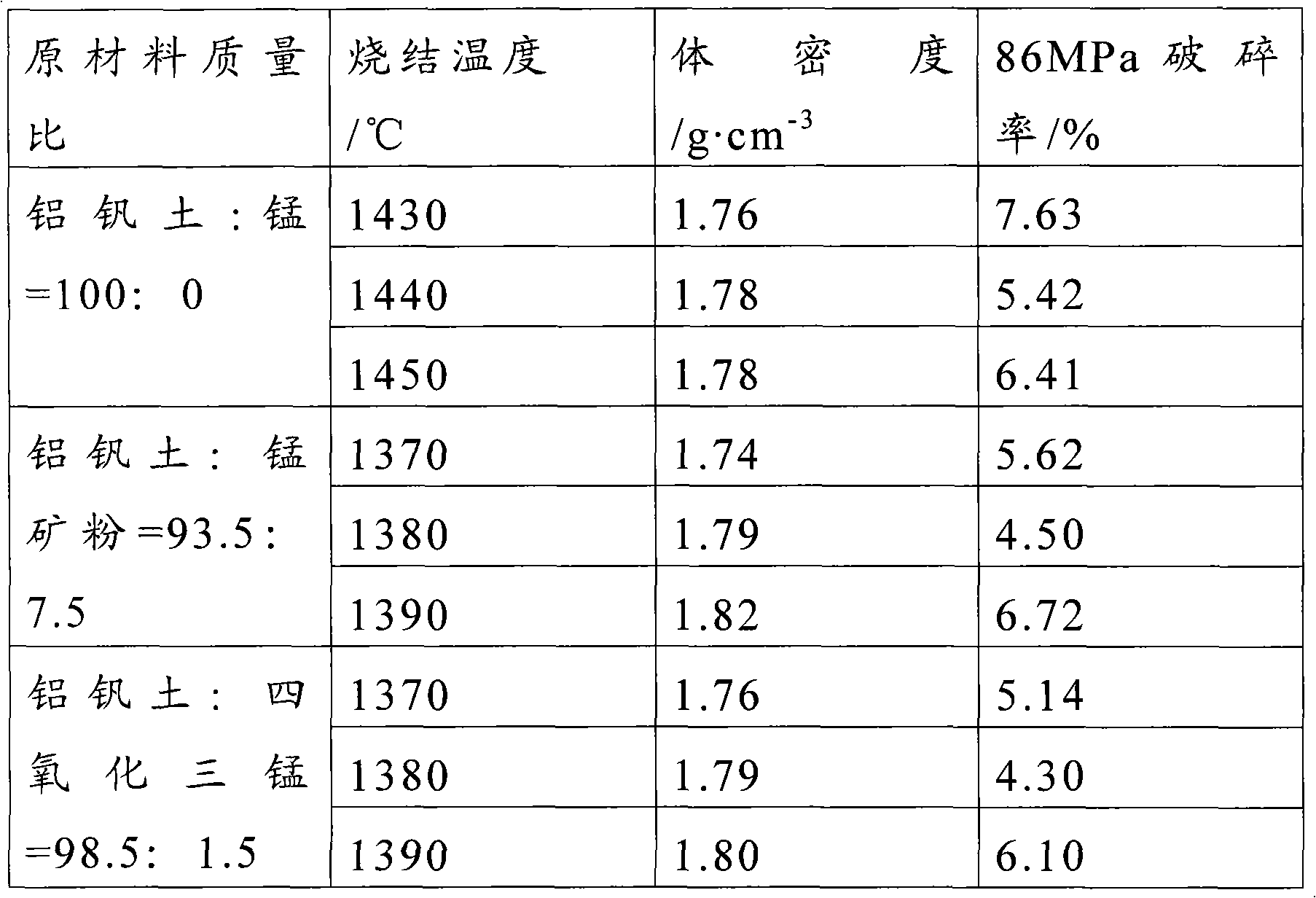

Ceramic proppant and preparation method thereof

The invention relates to a ceramic proppant and a preparation method thereof. The ceramic proppant comprises bauxite and trimanganese tetroxide and is characterized by comprising a water-based organic binder; and the mass ratio of the bauxite, the trimanganese tetroxide and the water-based organic binder is as follows: 93-99 mass proportion of bauxite; 1-7 mass proportion of trimanganese tetroxide, 8-15 mass proportion of water-based organic binder and total mass of bauxite and trimanganese tetroxide based on 100 mass proportion. The ceramic proppant has the advantages of lower rate of sintering temperature and low broken rate.

Owner:阳泉市长青石油压裂支撑剂有限公司

Copper alloy sheet and QFN package

ActiveUS7928541B2Abrasion of a dicing blade employed in the dicing process can be suppressedProductivitySemiconductor/solid-state device detailsSolid-state devicesMetallurgyLead frame

Owner:KOBE STEEL LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com