Diamond coated cutter and application thereof to processing of fiber composite material

A technology of diamond coating and cutting tools, which is applied in the direction of metal material coating technology, metal processing equipment, coating, etc., can solve the problems of low processing efficiency, poor cutting performance of processing tools, and tool wear, so as to improve processing efficiency and Accuracy, reduced dispersion of cutting force, and reduced tool change time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

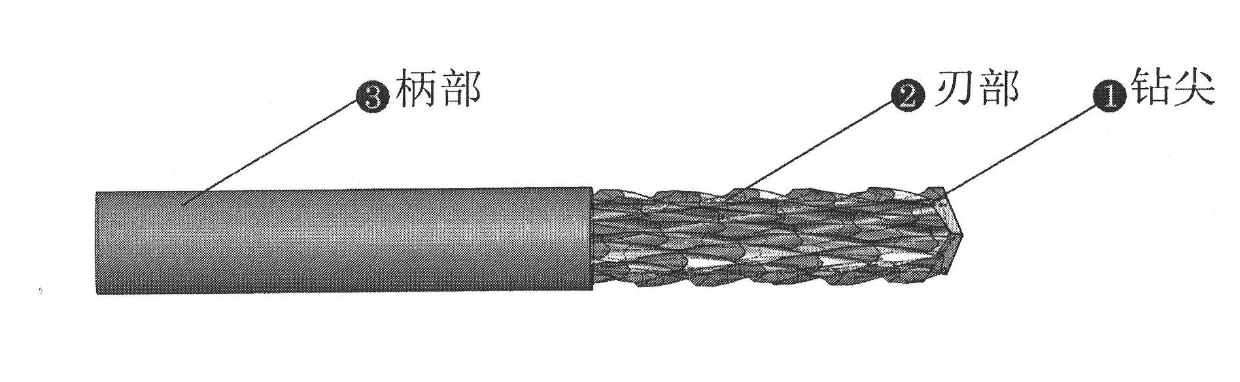

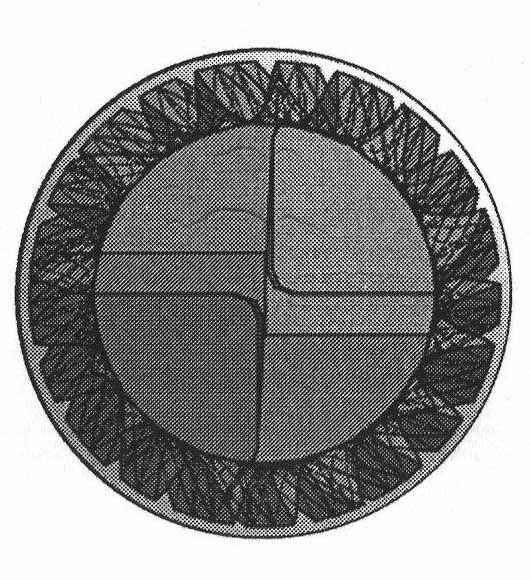

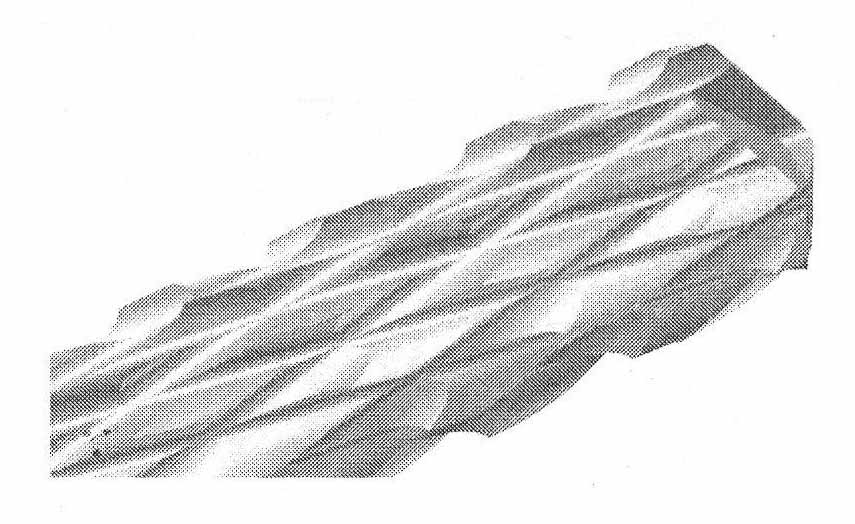

[0024] The substantive features and significant progress of the present invention will be further clarified below through the accompanying drawings and the preparation process of the diamond-coated cutting tool.

[0025] The making of embodiment 1 diamond-coated cutting tool

[0026] Step 1: Select the appropriate cemented carbide substrate material

[0027] Since the coating process is carried out above 800°C, neither copper-plated tools nor high-speed steel tools can be coated with diamonds, and the selected base material should be cemented carbide. Before the coating process, selecting the appropriate cemented carbide substrate material for surface treatment has an important impact on the coating effect and the adhesion of the diamond film. Since the presence of Co will have a negative impact on the formation of diamond films, the mass percentage of Co should be controlled within 6%, the cemented carbide substrate and the particle size of the material should be between 1 a...

Embodiment 2

[0037] In the processing of carbon fiber composite materials, diamond-coated cutters have obvious advantages, especially compared with the currently used PCD (polycrystalline diamond) cutters, diamond-coated drills can drill more holes in the production process, and The advantages are more obvious in the processing of glass fiber composite materials. Diamond-coated milling cutters are also widely used in cutting carbon fiber composites, reducing processing costs and reducing delamination between composite layers. This is mainly due to the ability of the CVD coating process to coat all complex shapes of drill and milling cutter surfaces. However, most of the currently used PCD tools are welded to the PCD template into the groove of the tool. The preparation process is long, the shape of the tool is more restricted, and the cost is relatively high. The price of PCD tools is 3 to 5 times that of other coated tools and 10 times that of uncoated tools.

[0038] The laser Raman sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com