Patents

Literature

122results about How to "Guaranteed sharp" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

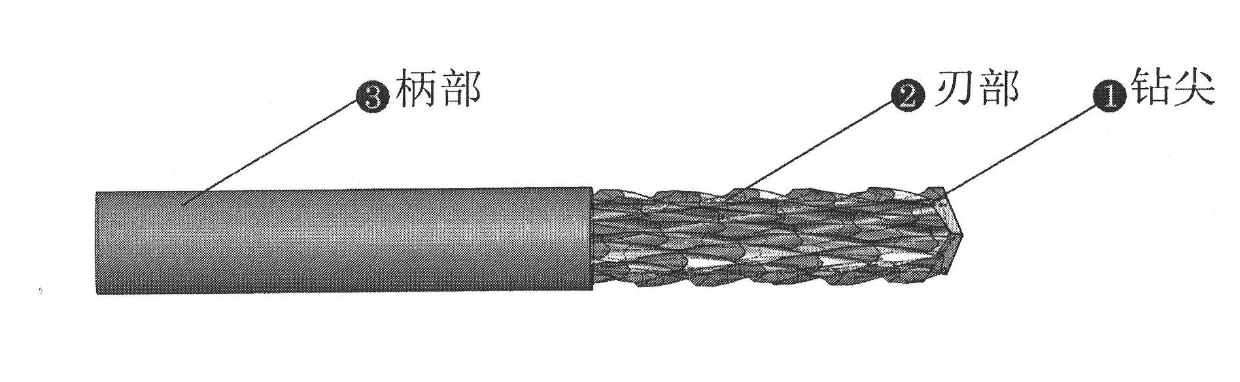

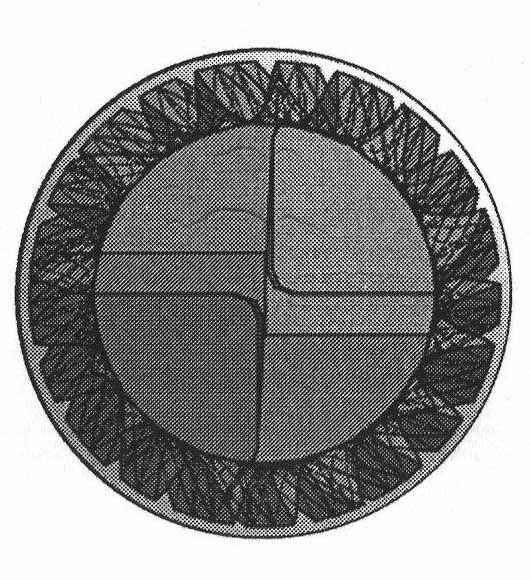

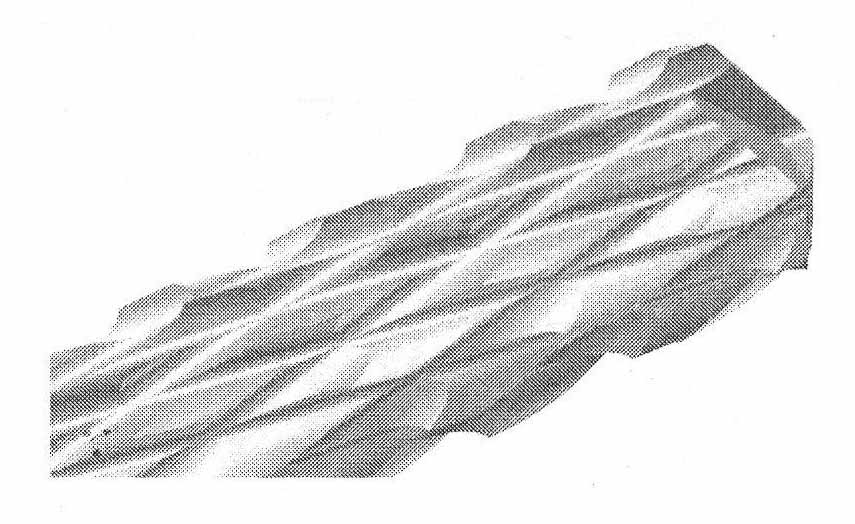

Diamond coated cutter and application thereof to processing of fiber composite material

InactiveCN102211218AImprove performanceGuaranteed sharpTransportation and packagingMilling cuttersSurface layerAlloy substrate

The invention relates to a diamond coated cutter, which comprises a drill tip, an edge part and a handle part, and is characterized in that: (1) a substrate material is a hard alloy with less than 6 mass percent of Co; (2) the drill tip and the edge part of the cutter are coated with a diamond coating; (3) the head part of the cutter has a drilling and milling integrated structure, the apex angleof the drill tip is double apex angles of 135 degrees and 90 degrees or a disc angle of 5 to 10 degrees, and the thickness of the coated diamond coating is 10 to 30mu m. The coated cutter is manufactured by the following steps of: (1) selecting an appropriate hard alloy substrate material; (2) forming the cutter; (3) pretreating a cutter coating; and (4) preparing the diamond coating on the drilltop and the edge part of the cutter through hot filament chemical vapor deposition (CVD). The phenomena of burrs and obvious surface layer peeling when the coated cutter processes a fiber composite material are avoided.

Owner:SHANGHAI XIANGREN NEW MATERIALS

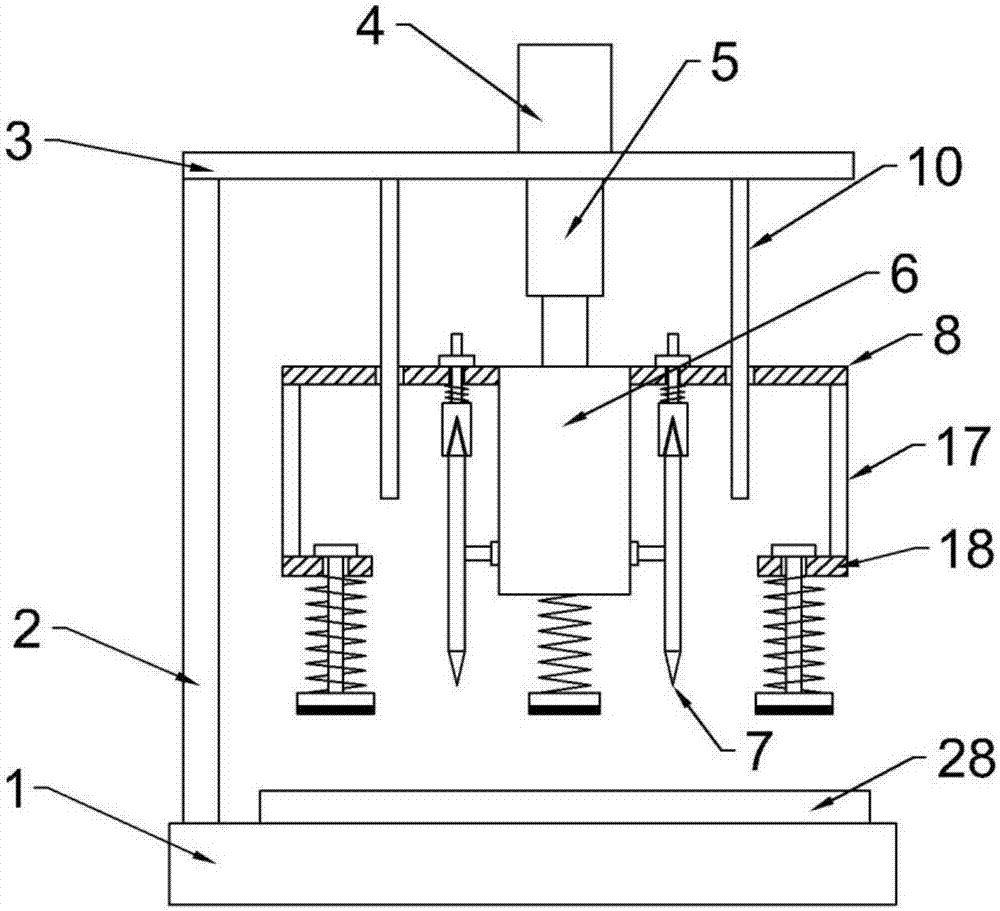

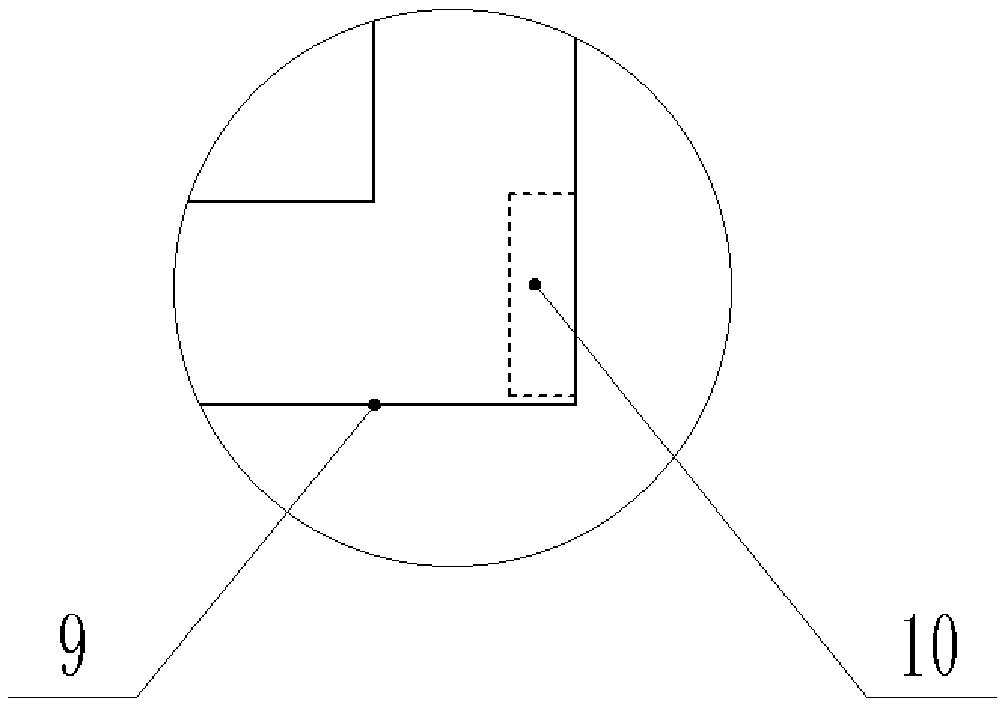

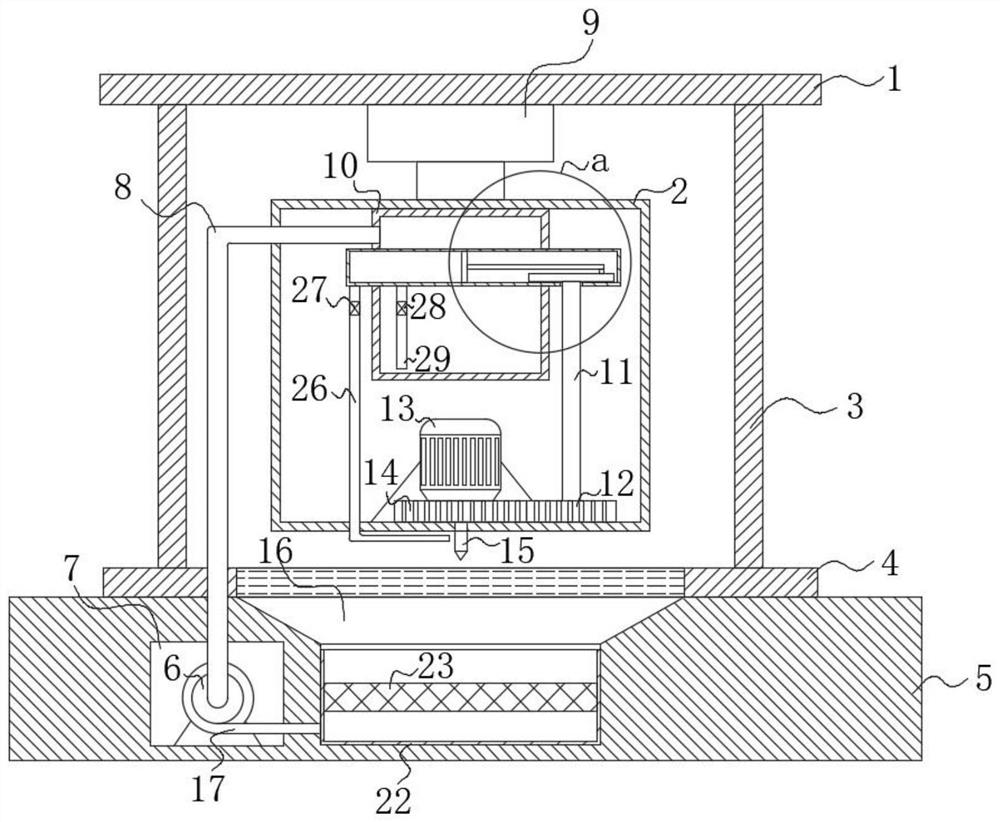

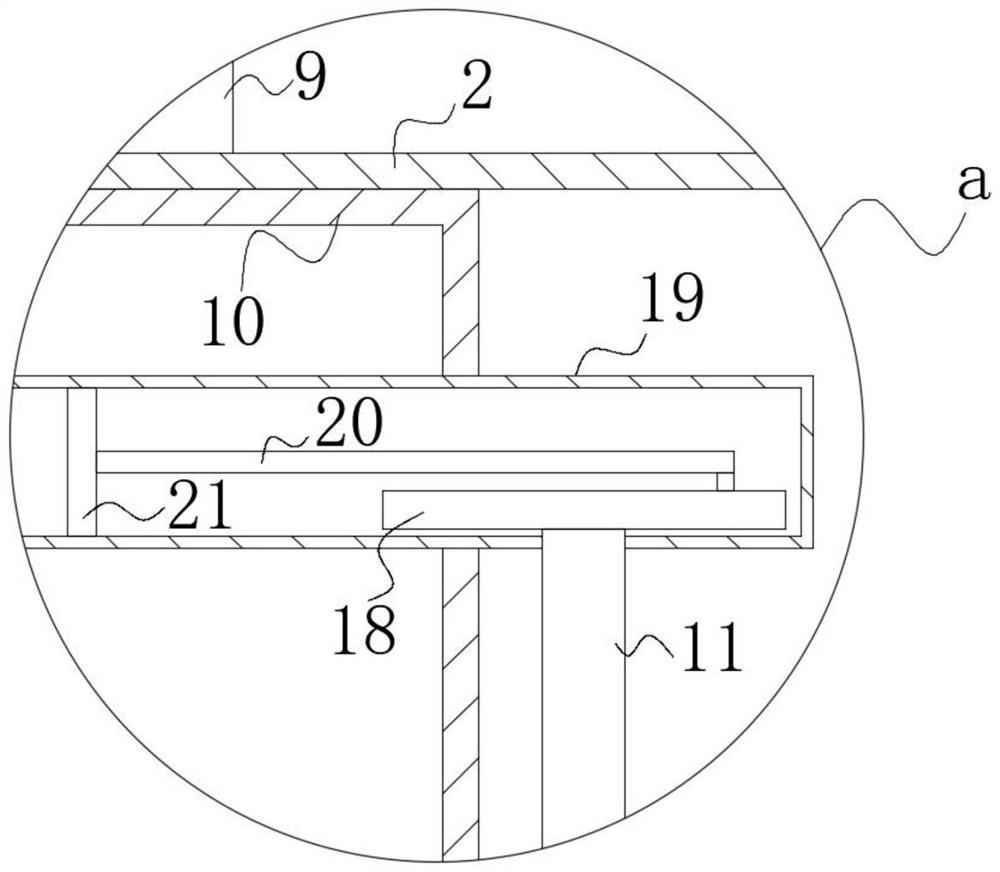

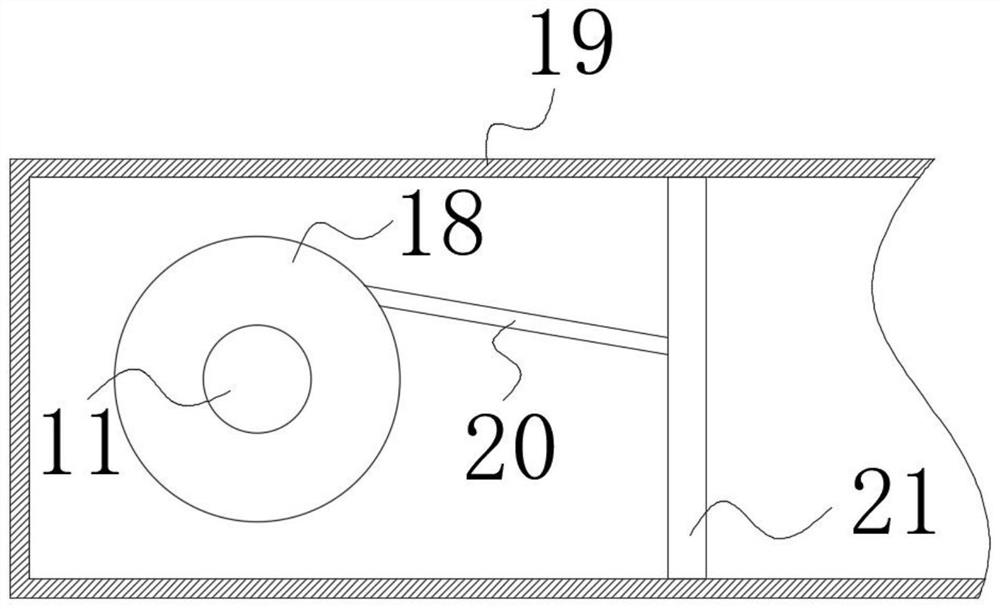

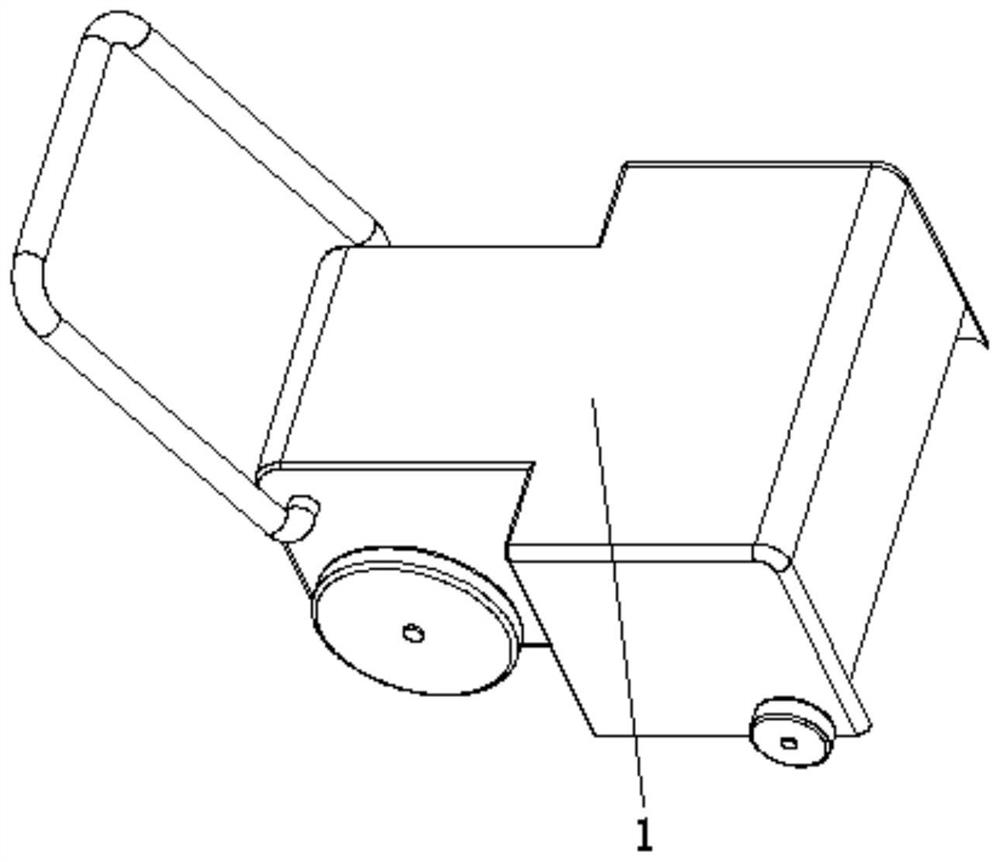

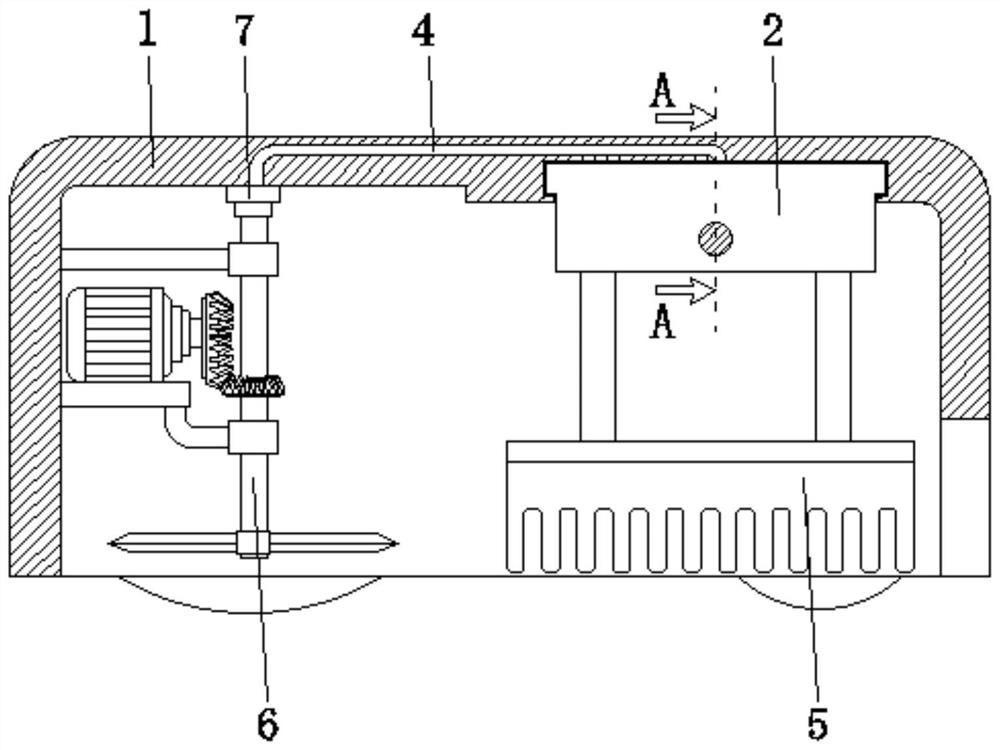

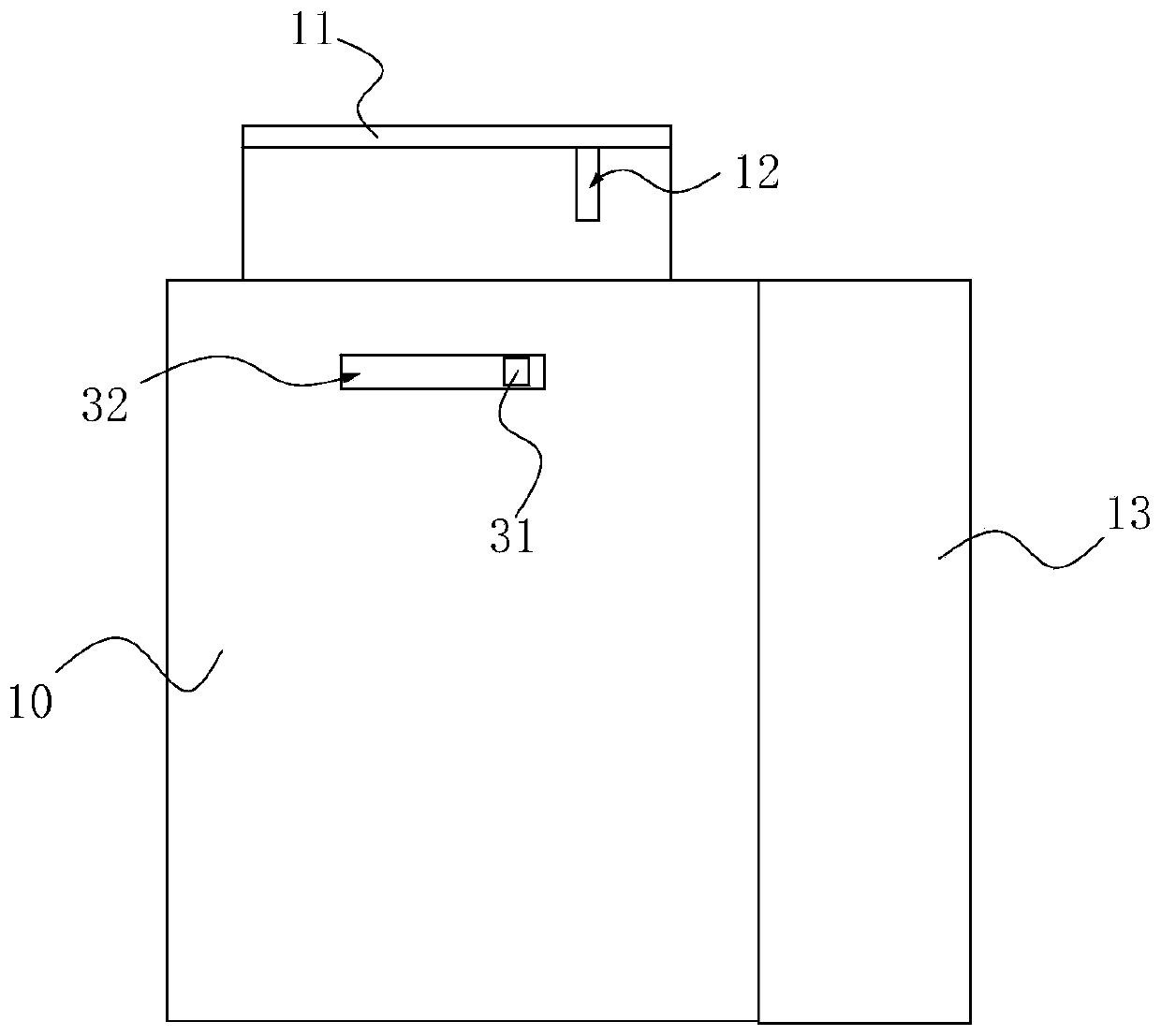

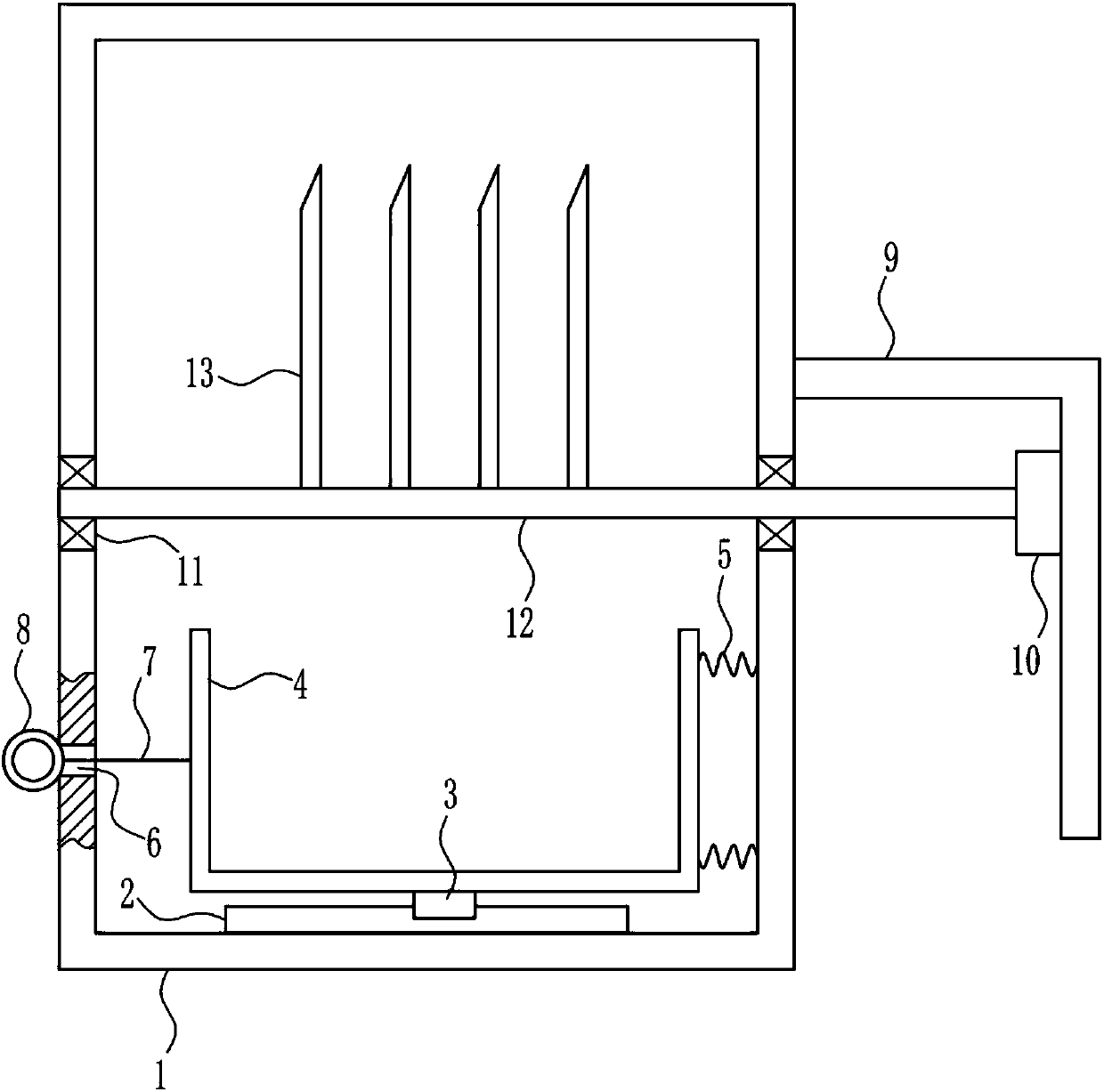

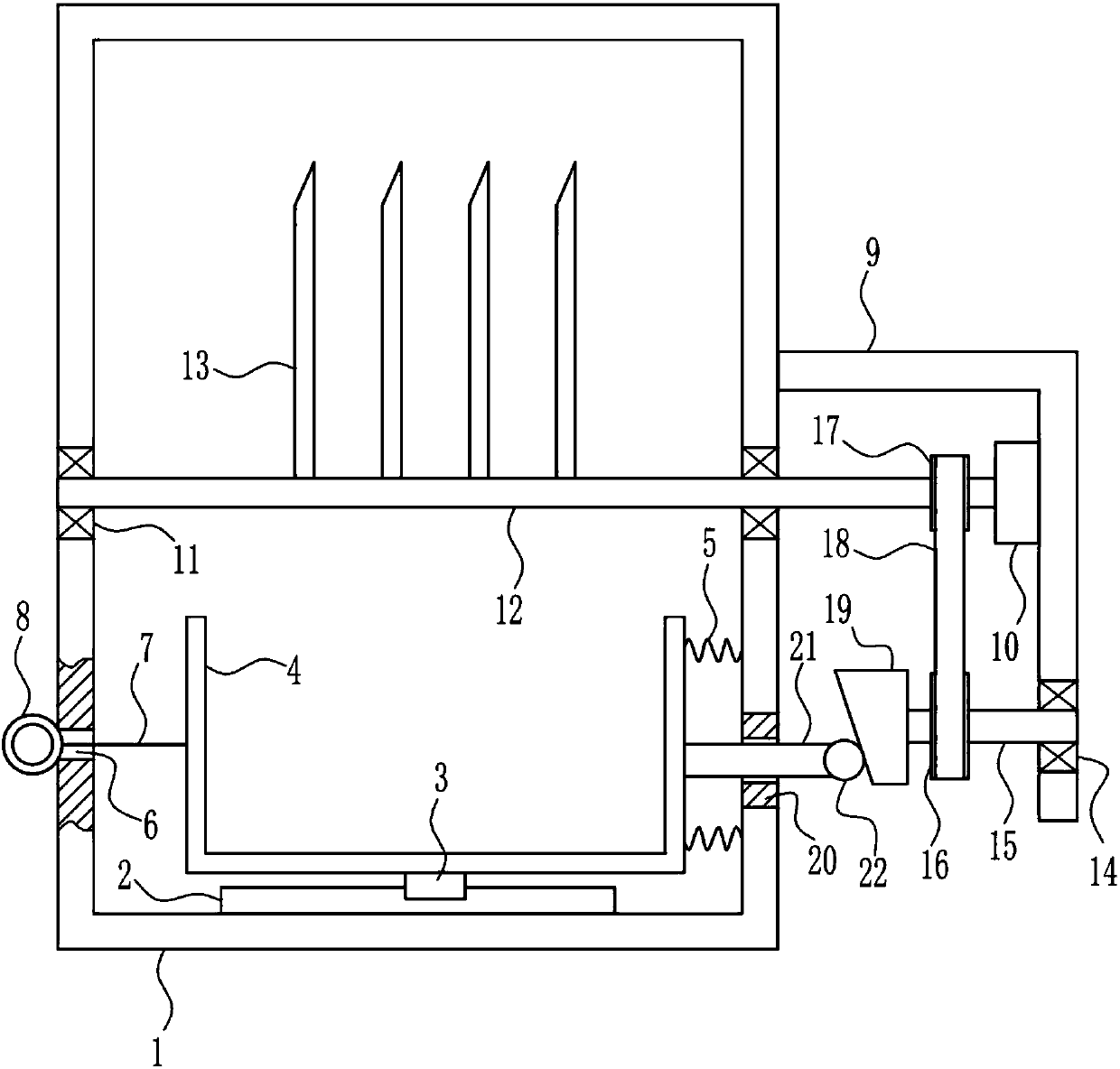

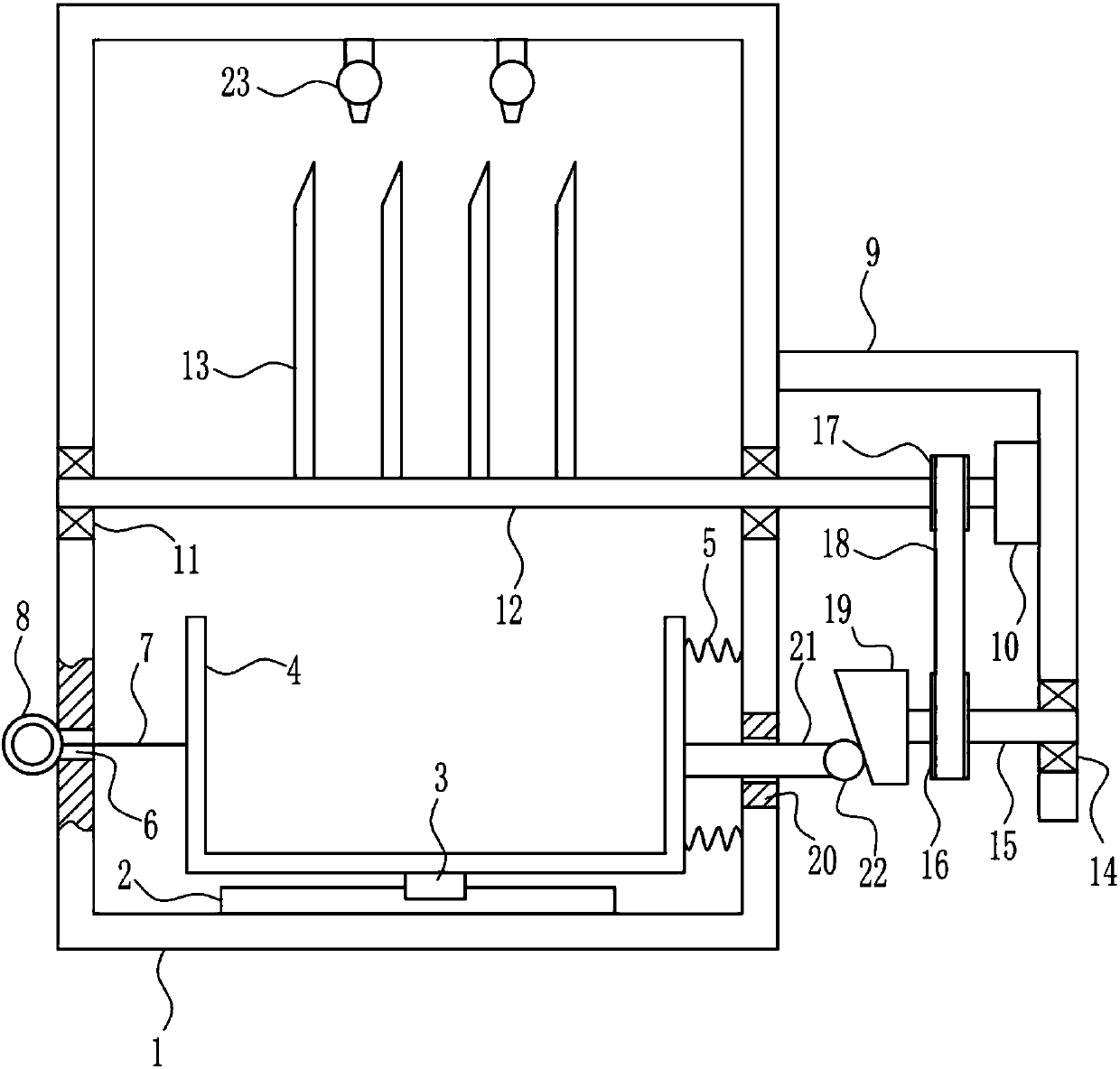

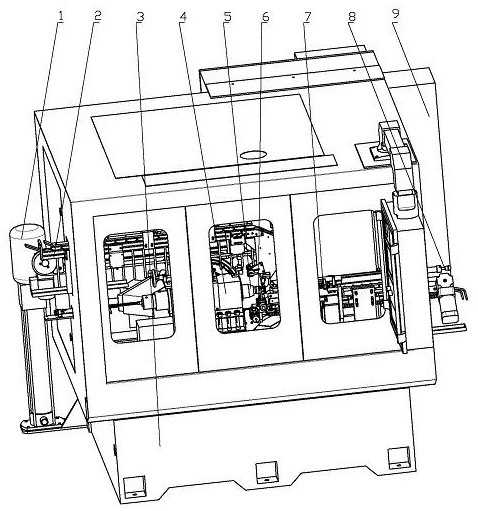

Double-cutter cutting device for packing plates

ActiveCN107876855ASame speedGuaranteed sharpMachine tool componentsShearing machinesDrive shaftCoupling

The invention discloses a double-cutter cutting device for packing plates. The double-cutter cutting device comprises a base, a supporting column, a transverse plate, a first motor, a feed mechanism,a cutting mechanism and an extension plate, and the cutting mechanism comprises a shell, a second motor, a driving shaft, a driving bevel gear, a driven bevel gear, a rotating shaft, a coupling and aconnecting shaft; cutting wheels are mounted at the end, away from the coupling, of the connecting shaft, and mounting holes are formed in the side, close to the shell, on the extension plate; threaded columns are arranged in the mounting holes, and friction blocks are mounted at the lower ends of the threaded columns; and a first spring is further arranged on each threaded column in a sleeving mode, and the first springs are located between the extension plate and the friction blocks. According to the double-cutter cutting device for the packing plates, single power is adopted to drive the double cutting wheels, the same rotational speed of the two cutting wheels can be achieved, neat cutting is ensured, by arranging the friction blocks, the cutting wheels can be grinded while being cut,so that the cutting wheels is ensured to be sharp, the plates can be pressed and fixed while feeding of the cutting mechanism is conducted by arranging pressing blocks, and a separate control fixtureis not required to be arranged.

Owner:宣城大天新材料科技股份有限公司

Thread turning process

The thread turning process includes the following steps: 1. rough machining of workpiece with rough turning tool; and 2. correcting thread form and eliminating the accumulated error of thread to obtain the required machining precision with finishing tool. The present invention has reduced wear of the finishing tool and raised thread machining precision.

Owner:祁宝栋

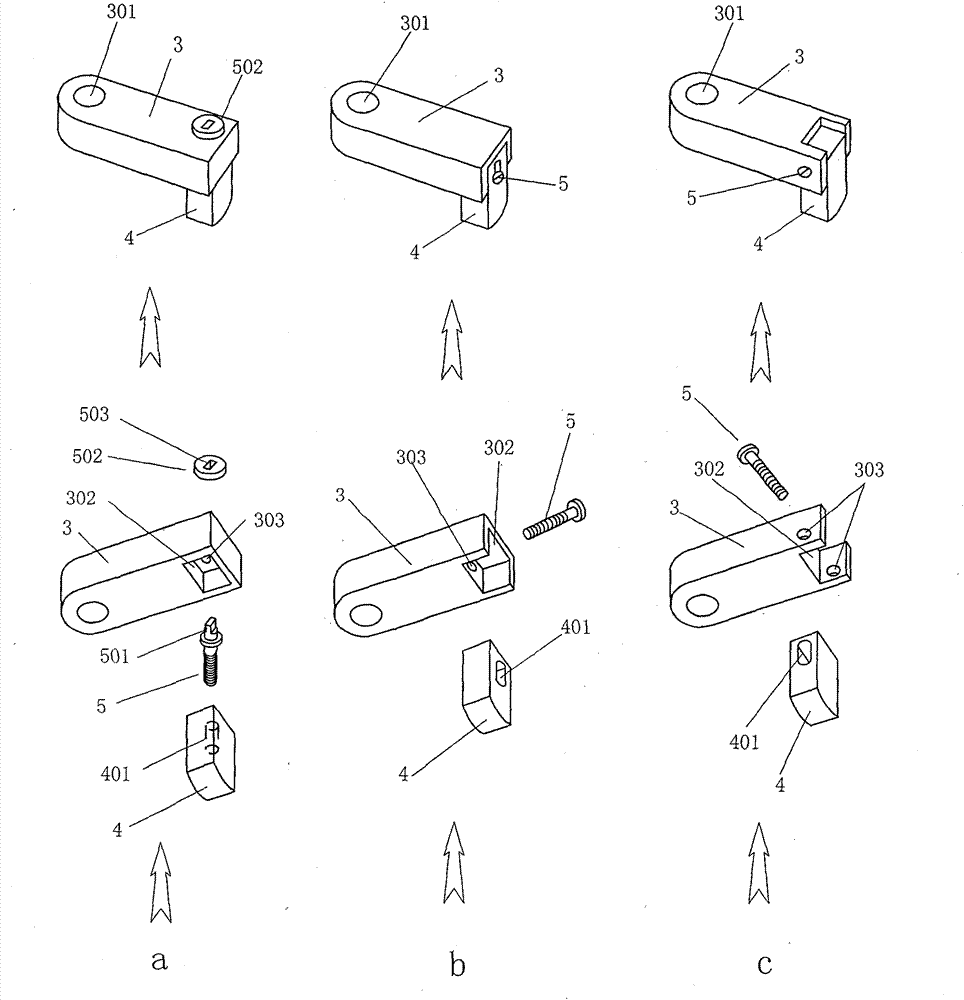

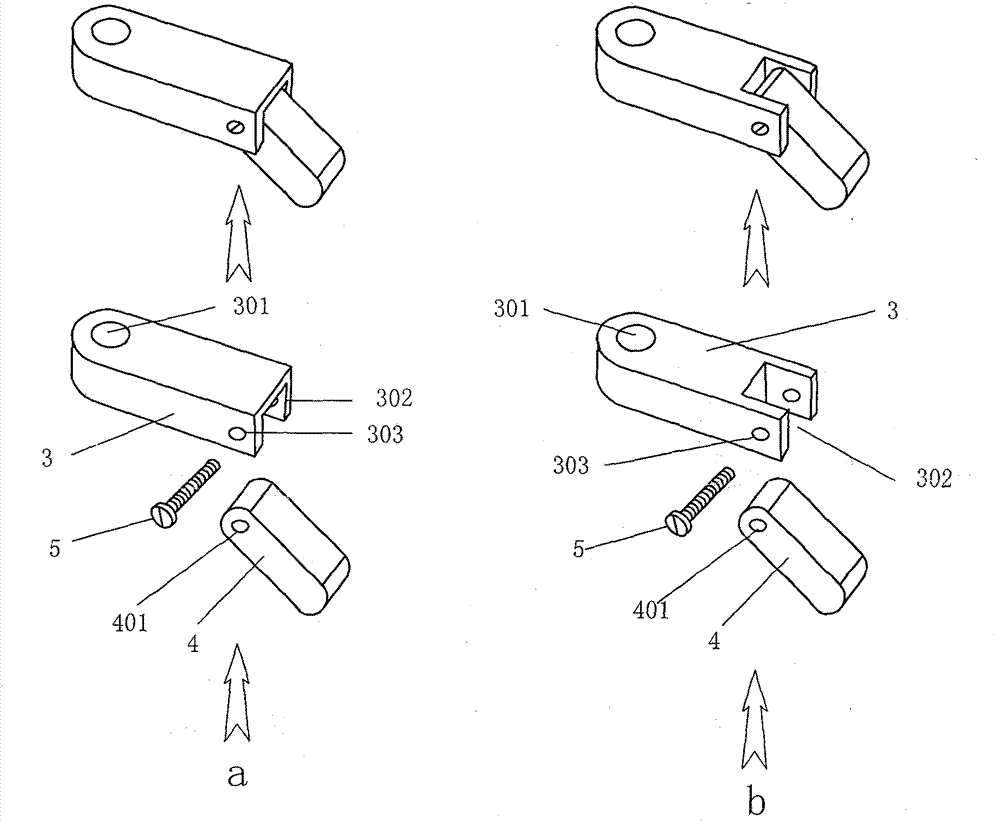

Diode pin cutting mechanism

ActiveCN109127956ASolve the problem of easy splashing aroundFacilitate orderly processingMetal stripsEngineering

The invention relates to the field of semiconductor device pin cutting machining, and discloses a diode pin cutting mechanism. The diode pin cutting mechanism comprises a cutter and a cutting platform, the cutting platform comprises a conveying platform and a rotating platform which are fixedly connected, a gap is formed between the conveying platform and the rotating platform to form a cutting seam, grooves used for containing metal strips are formed in the conveying platform and the rotating platform, a fixing plate is arranged over the groove of the conveying platform in a crossed mode, anarc-shaped plate is arranged over the groove of the rotating platform in a crossed mode, the arc-shaped plate and the fixing plate are both used for fixing the metal strips, and a rotating platform driving mechanism is connected to the rotating platform. According to the diode pin cutting mechanism, the problem that splashing occurs after a pin is cut by the cutter can be solved.

Owner:泸州龙芯微科技有限公司

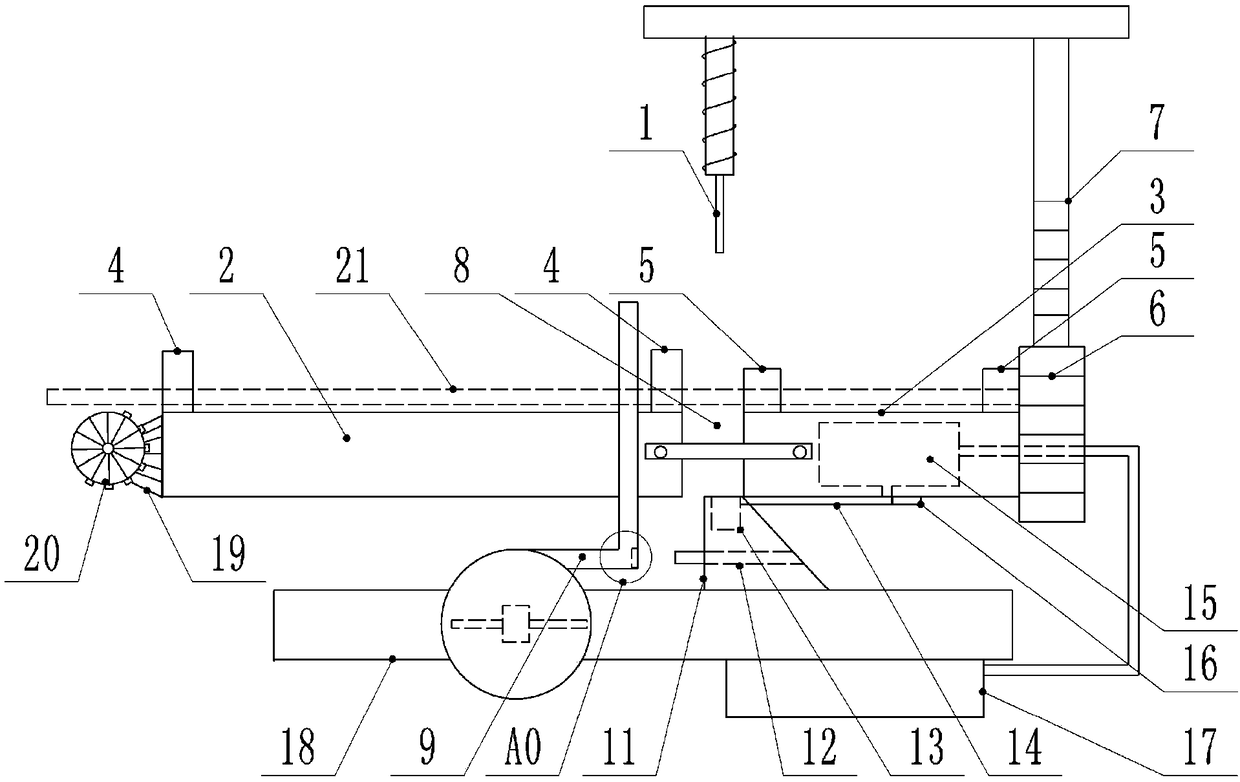

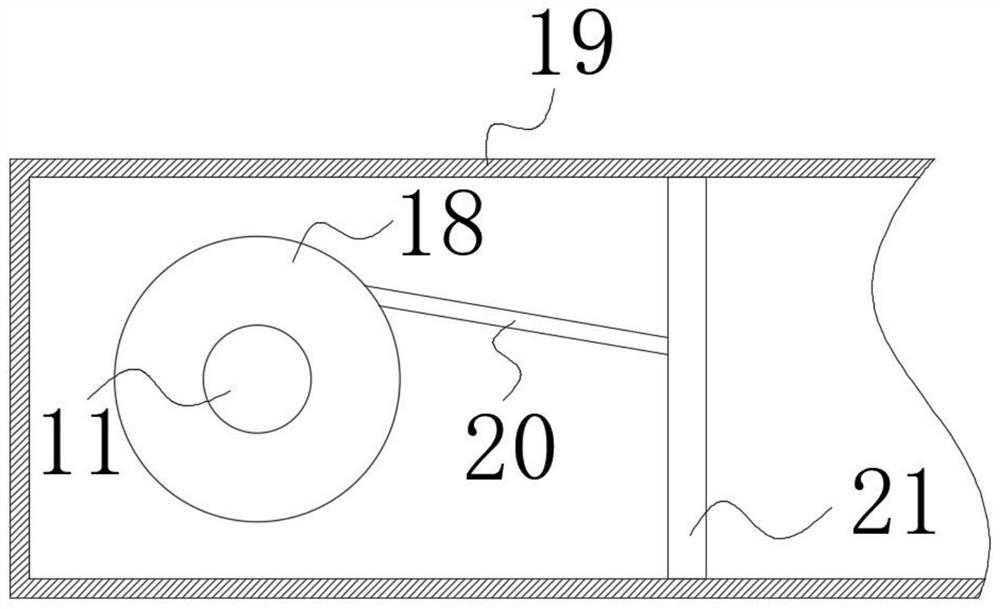

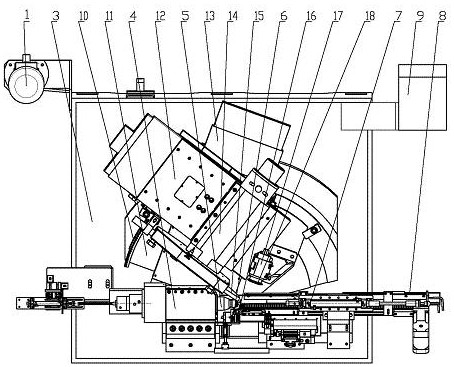

Transparent adhesive tape processing die cutting machine and die cutting method

ActiveCN110576462AReduce bending deformationConsistent widthMetal working apparatusMechanical engineeringTransparent adhesive tape

The invention relates to a transparent adhesive tape processing die cutting machine and a die cutting method. The transparent adhesive tape processing die cutting machine comprises a mounting table, adriving device, a clamping rotating device and a dividing device, wherein the driving device is mounted on the left side of the upper end of the mounting table in a welding manner, the clamping rotating device is arranged on the left side of the driving device, the dividing device is arranged above the clamping rotating device, and the driving device and the clamping rotating device are located inside the dividing device. According to the transparent adhesive tape processing die cutting machine and the die cutting method, the problems can be solved that when the large-volume transparent adhesive tape is subjected to segmentation processing, due to the fact that a cutting tool causes a certain pressure on a roller column, the roller column generates bending deformation, so that the width of the divided tape is inconsistent, in the cutting process, the cutting edge of the cutting tool is easily adhered with glue, so that the side surface of the adhesive tape which is divided by the cutting tool is rough, and even a part of the adhesive tape is torn off.

Owner:江苏双成新材料有限公司

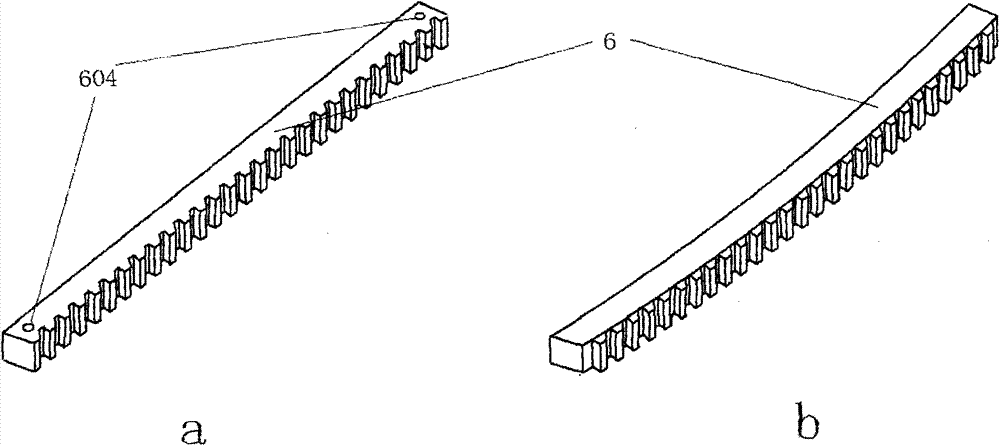

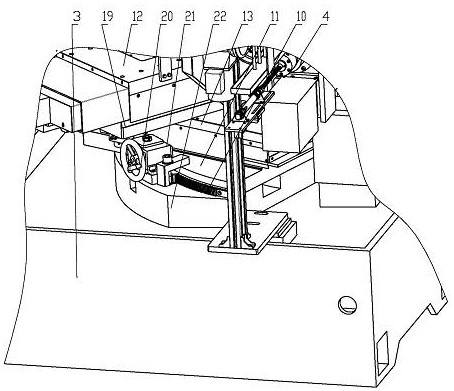

Gear grinding head and guide rail type manual knife sharpener

InactiveCN103659474ASolve the problem of partial wearUniform wearGrinding machine componentsOther manufacturing equipments/toolsLinear motionGear grinding

The invention discloses a gear grinding head and a guide rail type manual knife sharpener. The guide rail type manual knife sharpener mainly comprises the gear grinding head which is composed of a grinding body and a stem gear, a grinding head fixing part, a connecting rod, an adjustable tailstock, a tailstock positioning screw rod and a rack type guide rail, wherein the grinding body is a cylinder, one end face of the grinding body is a grinding surface, the other end face of the grinding body is an installation surface, a gear is arranged in the middle of the stem gear, a center positioning pillar is arranged at one end of the stem gear, the end, provided with the center positioning pillar, of the stem gear is bonded with and fixed to the grinding body, the other end of the stem gear is a grinding head shaft which is mounted at one end of the connecting rod, a tailstock installation groove is formed in the other end of the connecting rod, the adjustable tailstock is mounted in the groove, the adjustable tailstock is stretchable or foldable entirely, the rack type guide rail is linear or arc-shaped, a tooth row is arranged on one lateral side of the guide rail and can drive the gear on the gear grinding head in a rubbing mode to enable the gear to rotate proactively and limit the linear motion of the gear grinding head so that the grinding surface of the gear grinding head can be abraded evenly and be prevented from deforming, and meanwhile, the sharpening efficiency is improved remarkably.

Owner:郭广仁

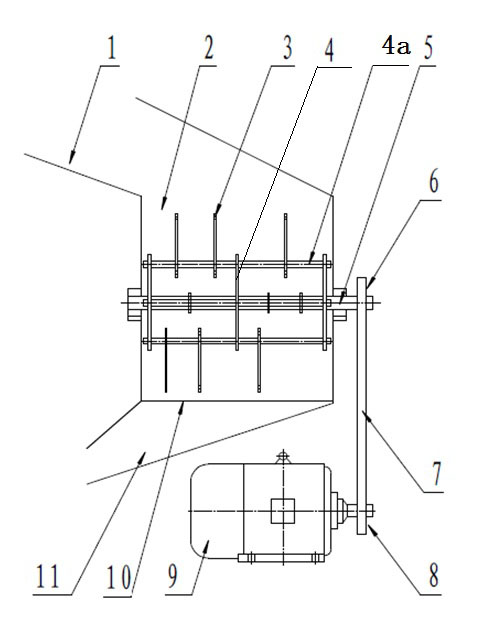

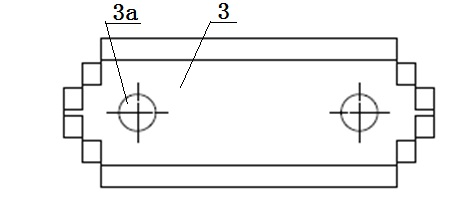

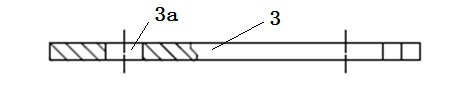

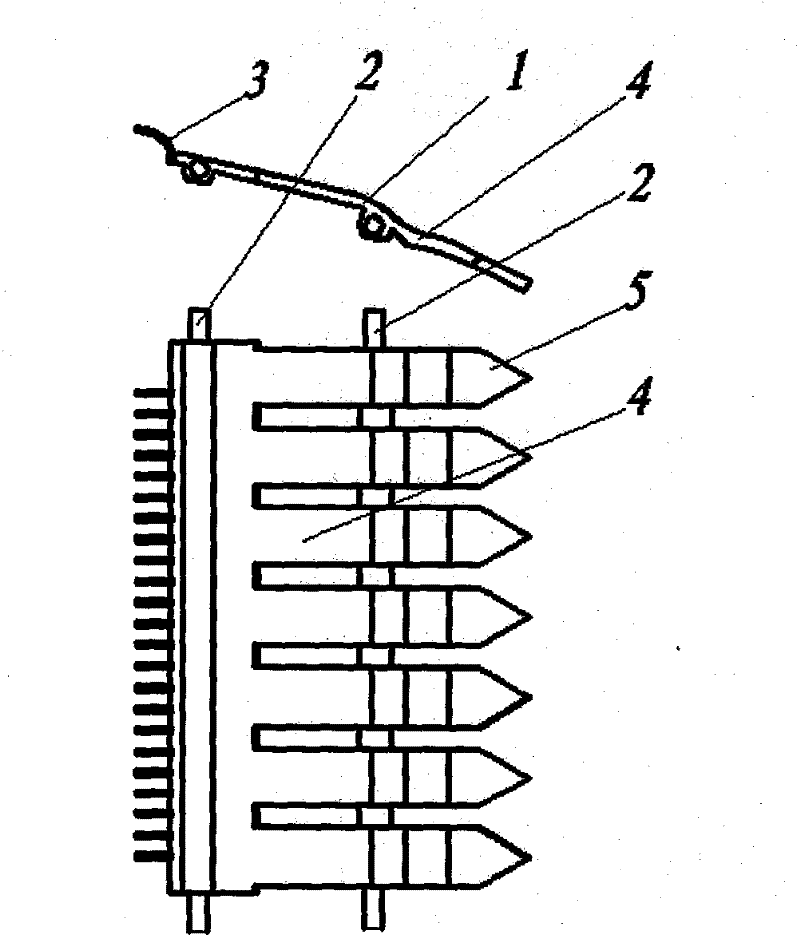

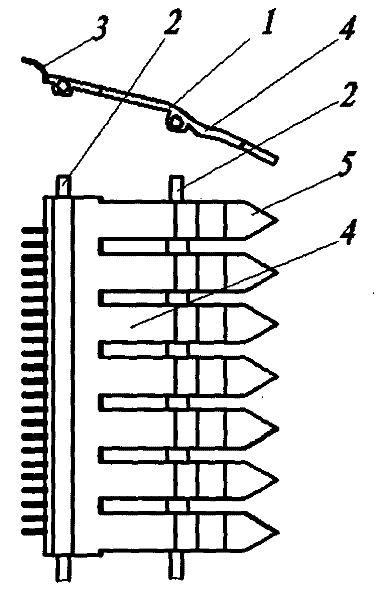

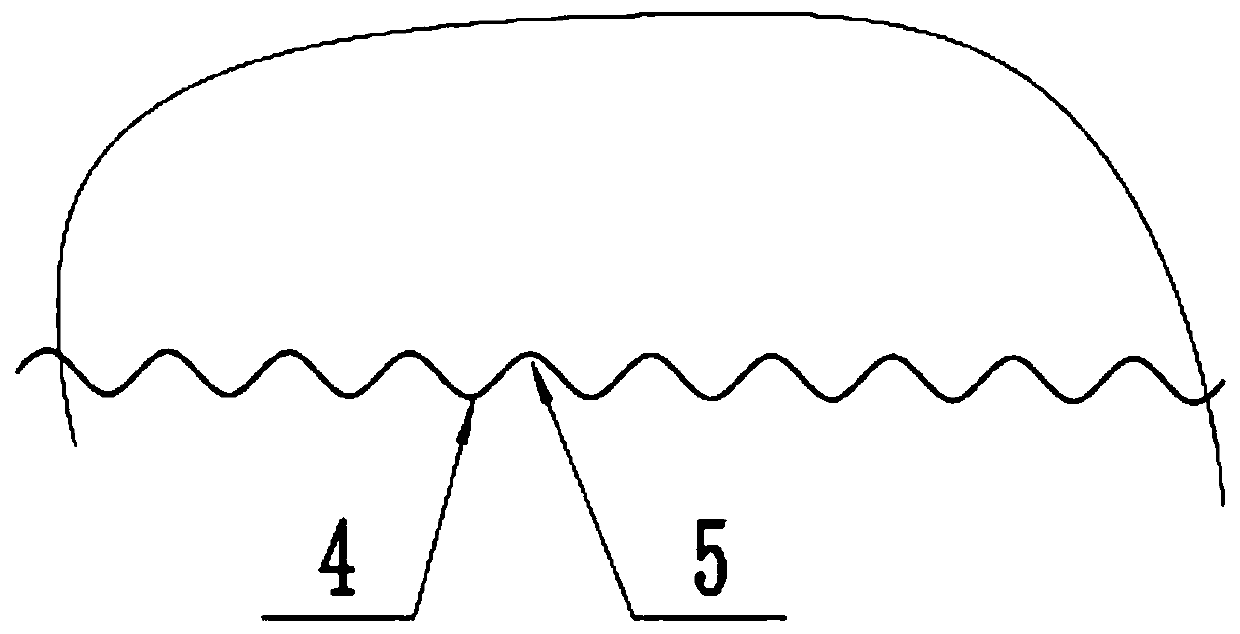

Hammer type shearing granulator

A hammer type shearing granulator comprises a granulating cabin (2) provided with a feeding port (1) and a discharging port (11), a blade support (4) and shearing blades (3) installed on the blade support, wherein the blade support (4) is installed in the granulating cabin and can rotate around a horizontal central shaft (5). The outer end of the central shaft of the blade support is connected with a power transmission device. The blade support is of a transversely arranged cylindrical-cage-shaped structure, cylindrical-cage-shaped strips (4a) are evenly distributed on the outer circumferential face of the blade support, each blade is of a structure with a single side or double sides provided with edges, installation holes (3a) capable of being freely sleeved on the cage strips (4a) are arranged at one ends or two ends of the blades, at least two blades are evenly installed on each cage strip, the blades on two adjacent cage strips are arranged in staggered mode, and a screen net (10) is arranged at the position of the discharging port of the granulating cabin. Expansion tobacco stalk granulation is performed by means of the hammer type shearing granulator, particle shape of ternary porous particles of expansion tobacco stalk is changed, production yield is improved, a product filling value is improved, and service life of the blades is prolonged.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

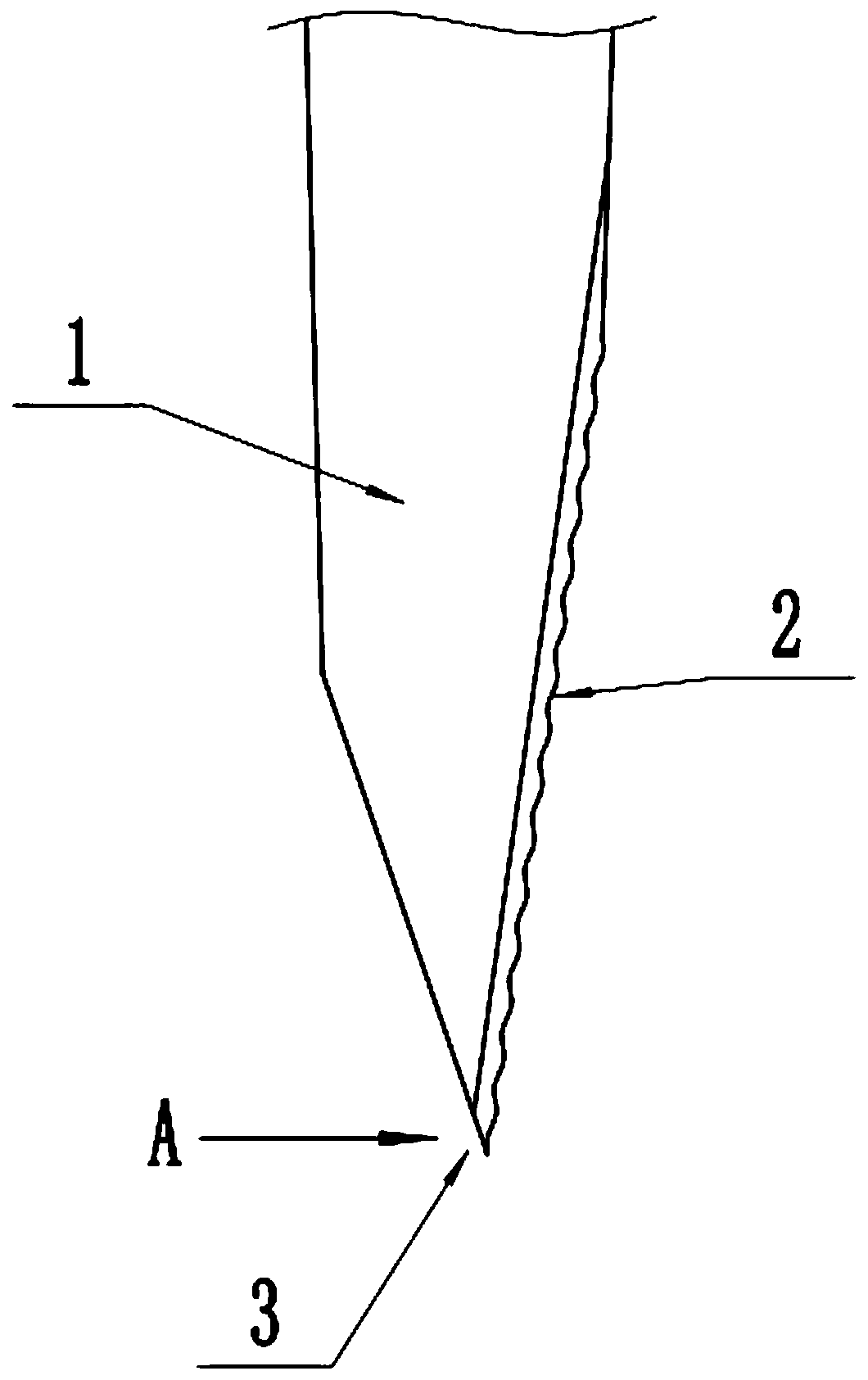

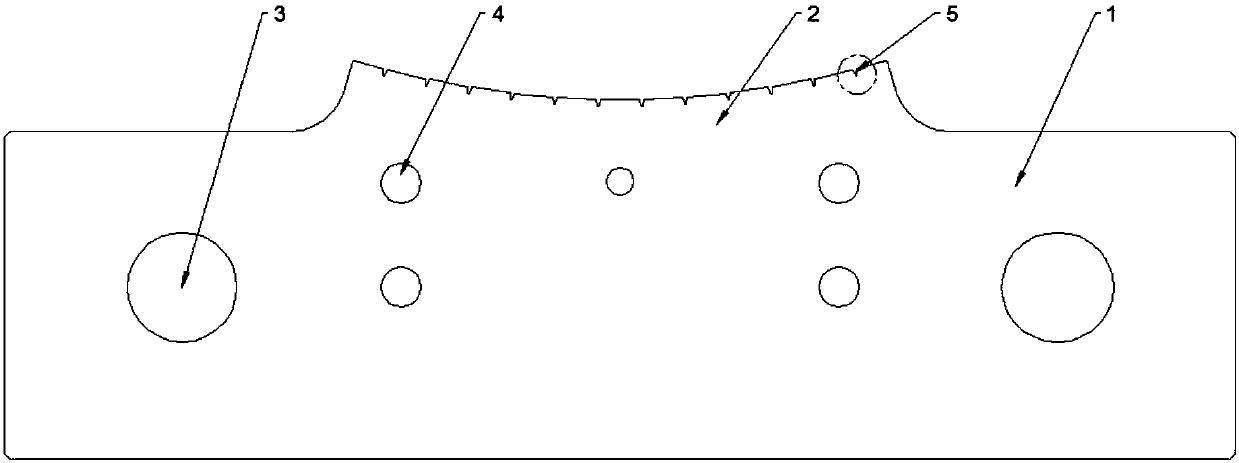

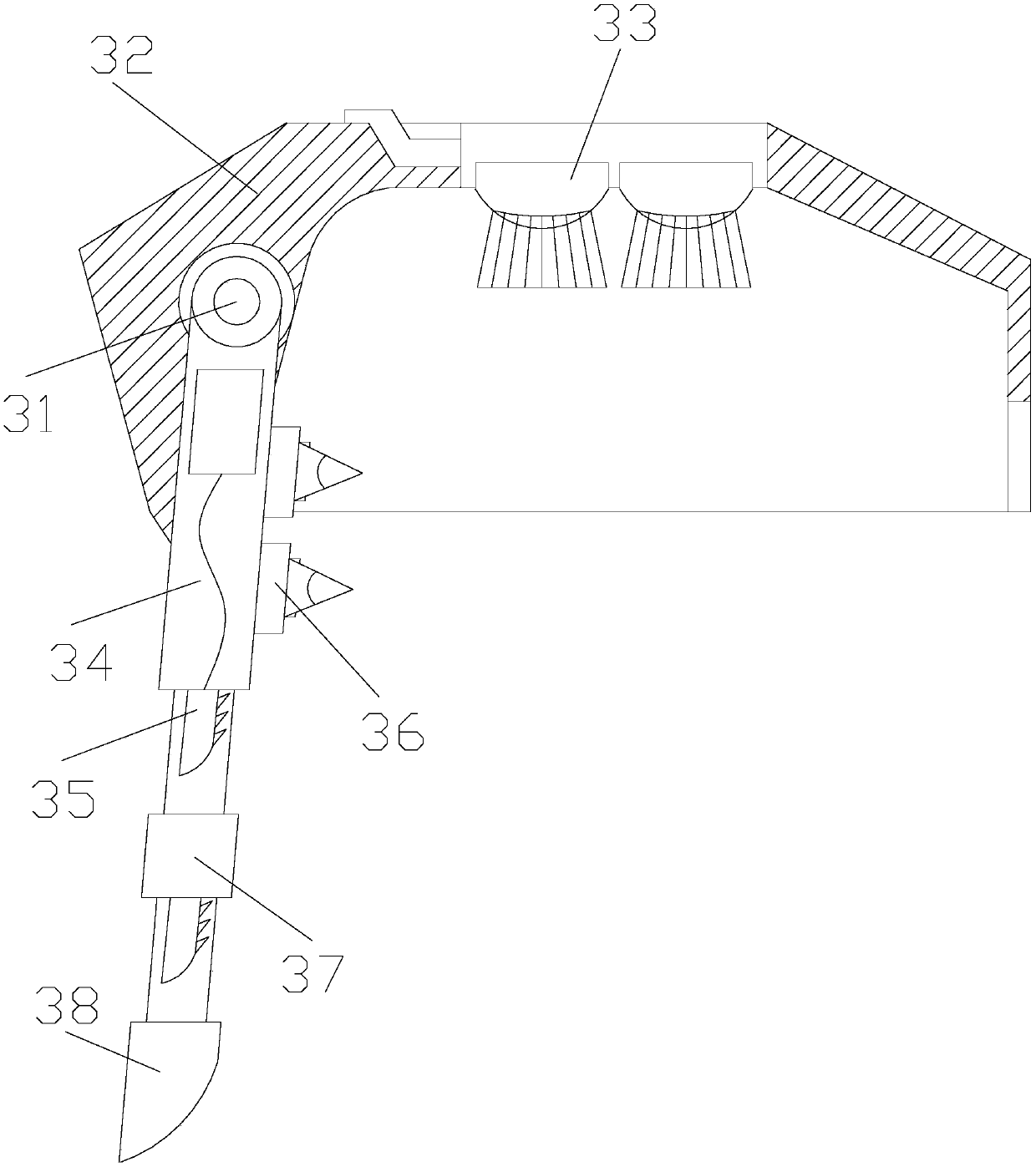

Potato lifter ladder-shaped digging shovel

The invention relates to a digging shovel used for a potato lifter, belonging to the technical field of agricultural machinery. The invention provides a ladder-shaped digging shovel, aiming at solving the problems that the traditional digging shovel has poor soil crumbling capability during operation, consumed traction force is high and the shovel is obtuse owning to abrasion of shovel point. The ladder-shaped digging shovel is mainly composed of a shovel body (1), a connecting shaft (2) and a soil potato dredging rod (3), the upper surface and the lower surface of the shovel body are formed by combining different materials, and hardness and abrasive resistance of the materials of the lower surface of the shovel body are required to be higher than those of the materials of the upper surface of the shovel body. The shovel body is divided into an interring section and a crumbling and conveying section according to function. An interring angle of the interring section is 25 degrees, which is relatively larger, the interring angle of the crumbling and conveying section of the shovel body is 13 degrees, and oblique angle of a shovel edge of a shovel point is 50-65 degrees. The shovel provided by the invention is applicable to soil which is seriously hardened and has the characteristics of small interring resistance, strong soil crumbling performance, smooth conveying, no blocking, autogenous grinding sharp function of the shovel point and the like.

Owner:GANSU AGRI UNIV

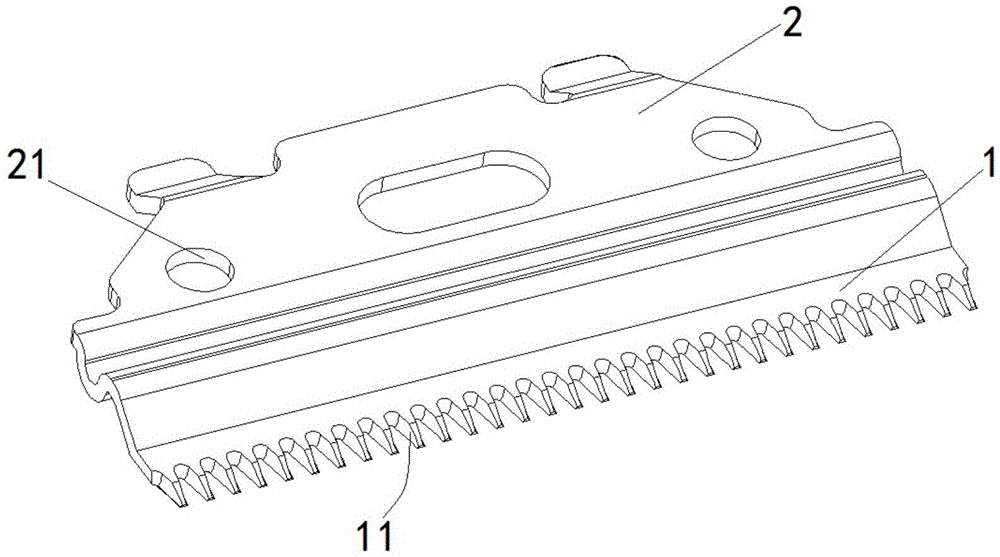

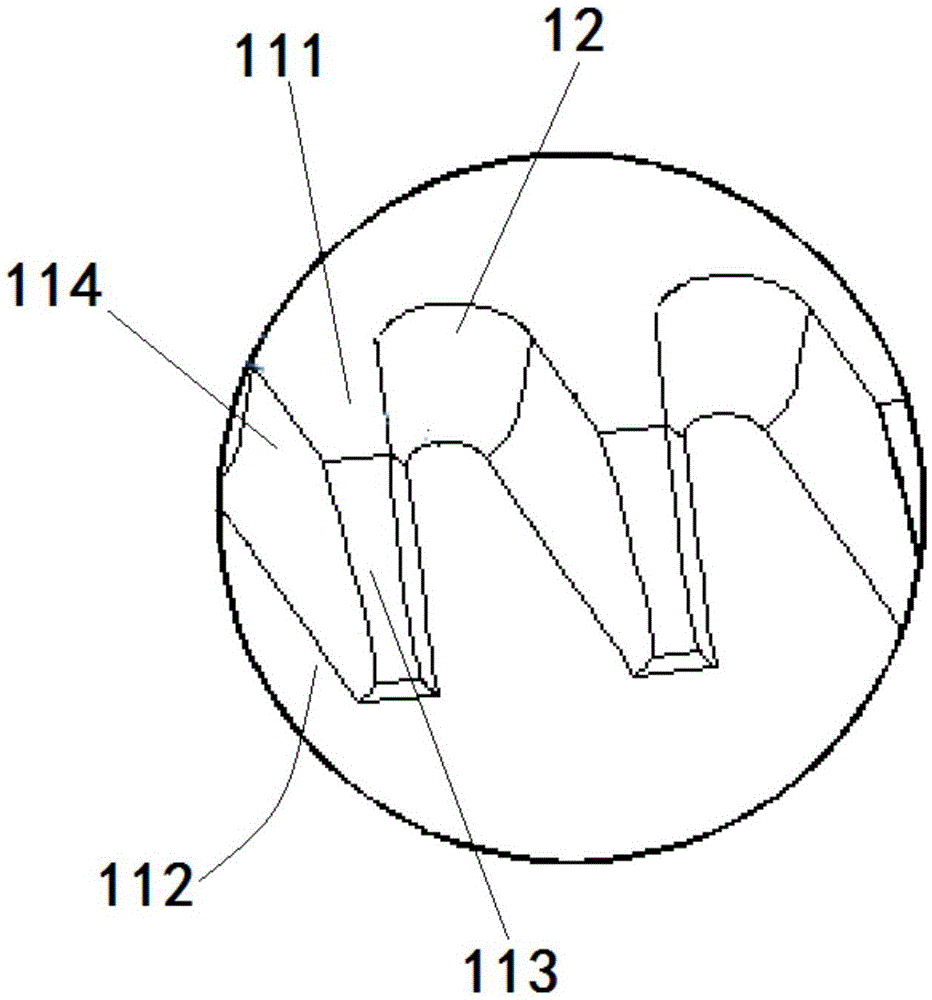

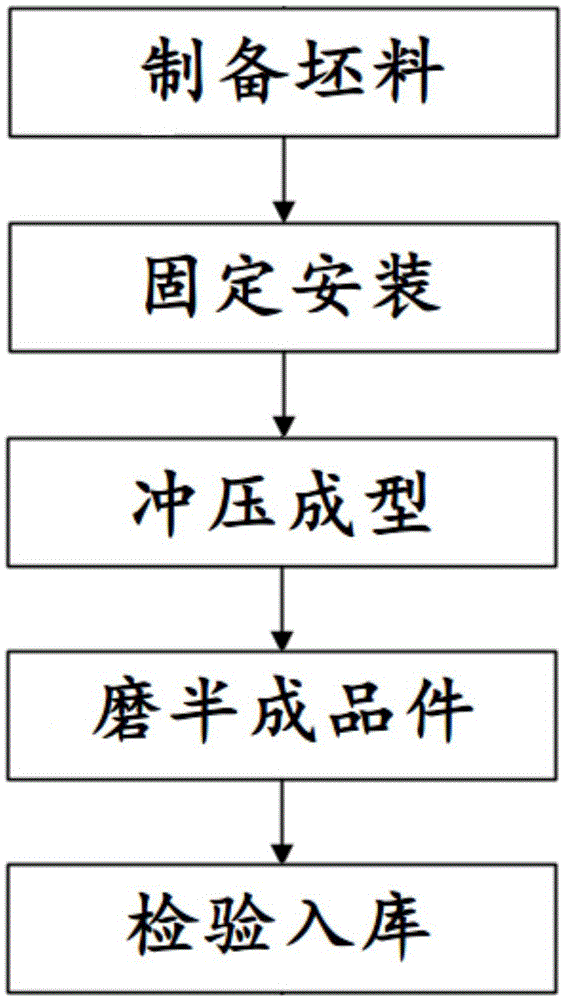

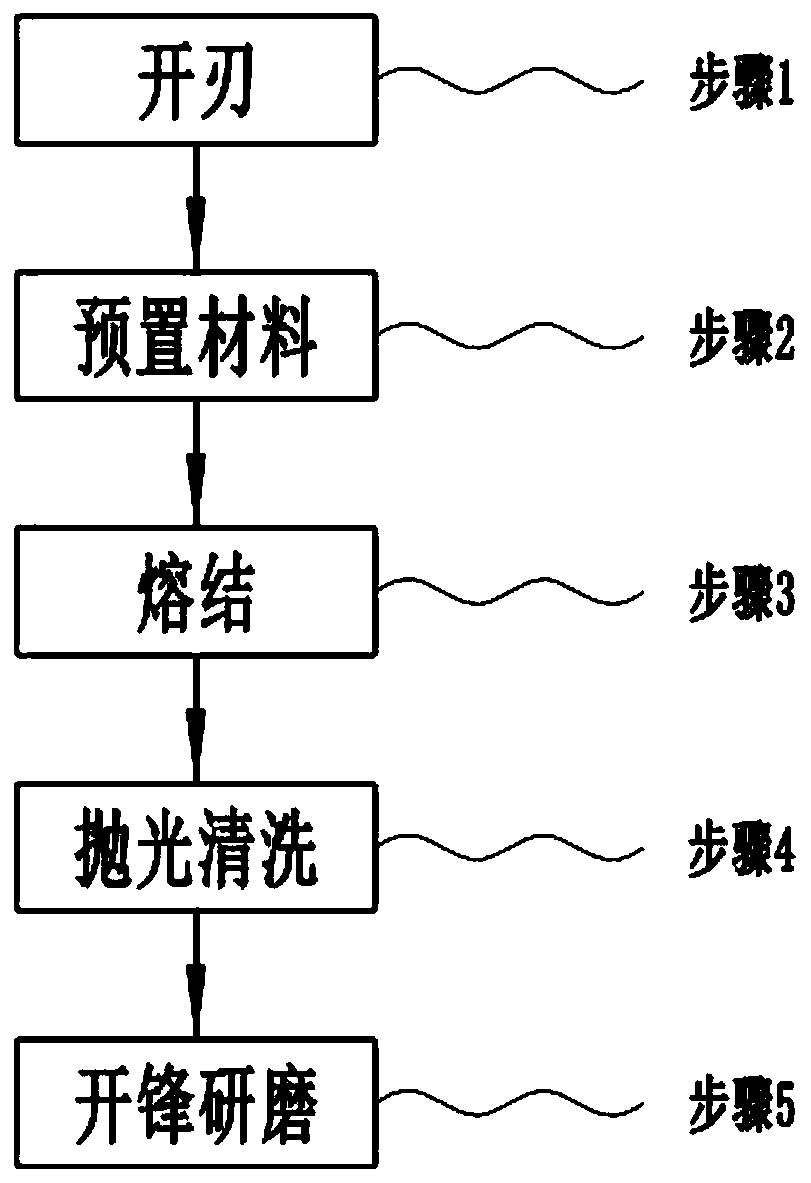

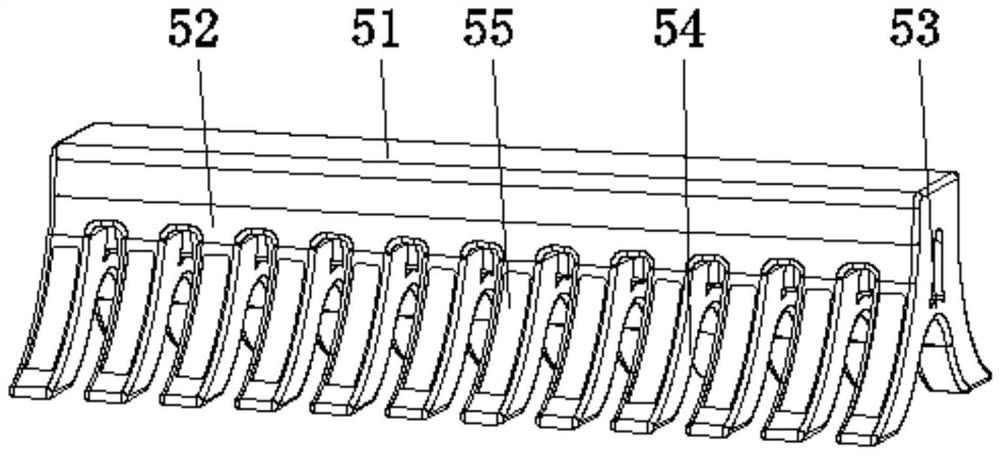

Personal care trimmer with high-reliability cutting edges and manufacturing method for personal care trimmer

ActiveCN105522596AImprove reliabilityReasonable structural designMetal working apparatusPersonal careEngineering

The invention relates to the field of personal care articles, and discloses a personal care trimmer with high-reliability cutting edges. The personal care trimmer with the high-reliability cutting edges comprises a cutting tool and a cutting head arranged at the end portion of the cutting tool; the cutting head is evenly provided with comb-shaped cutting teeth in the length direction. Each cutting tooth comprises a top face, a bottom face, an end face, an oblique face and two side faces, wherein the side faces and the top face intersect to form one first cutting edge; the side faces and the bottom face intersect to form one second cutting edge; the oblique face extends from the top face to the end face; the oblique face and the side faces form one third cutting edge. A connection face is arranged between every two adjacent cutting teeth, each connection face and the upper surface of the cutting head form one fourth cutting edge, and each connection face and the lower surface of the cutting head form one fifth cutting edge. The invention further discloses a manufacturing method for the personal care trimmer with the high-reliability cutting edges. The cutting head is formed in a punch forming mode, the sharp cutting edges are formed in the intersecting position of the arc faces and the bottom faces of the cutting teeth by polishing semi-finished parts, and the trimming efficiency and production efficiency of products are greatly improved.

Owner:SPECIALIFE ZHUHAI

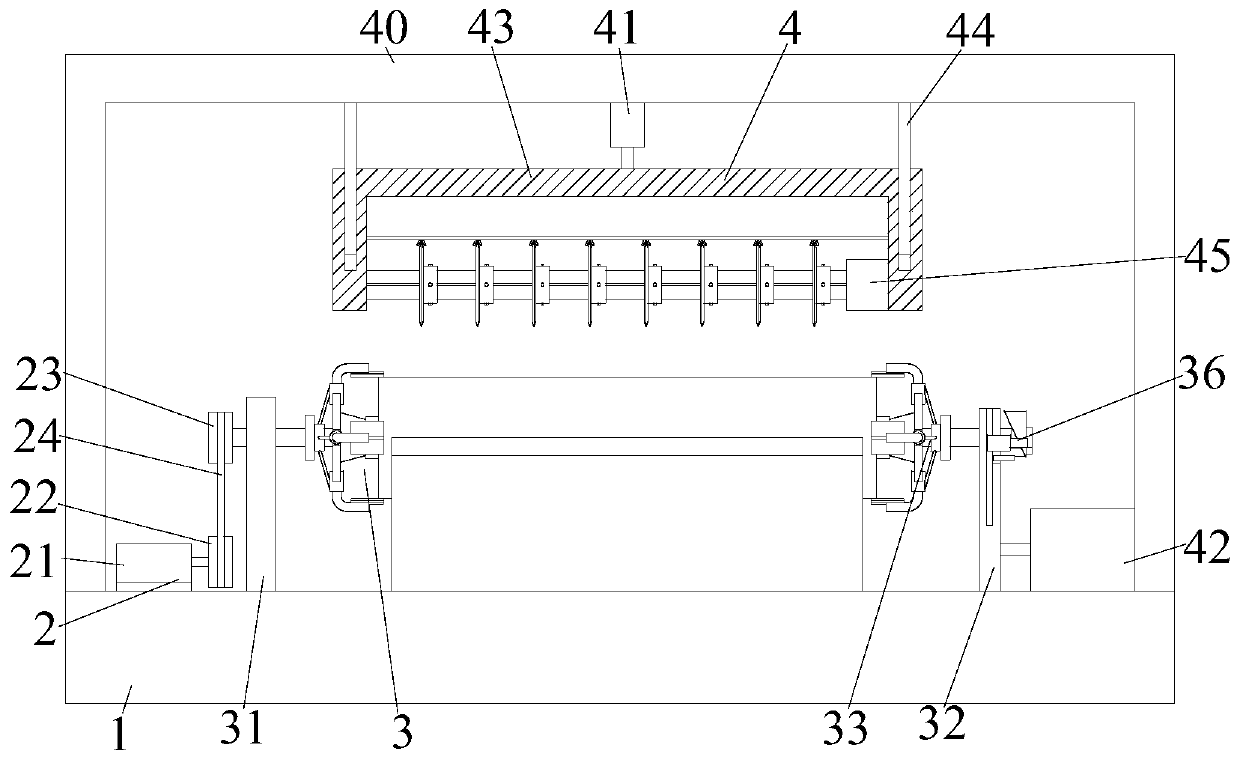

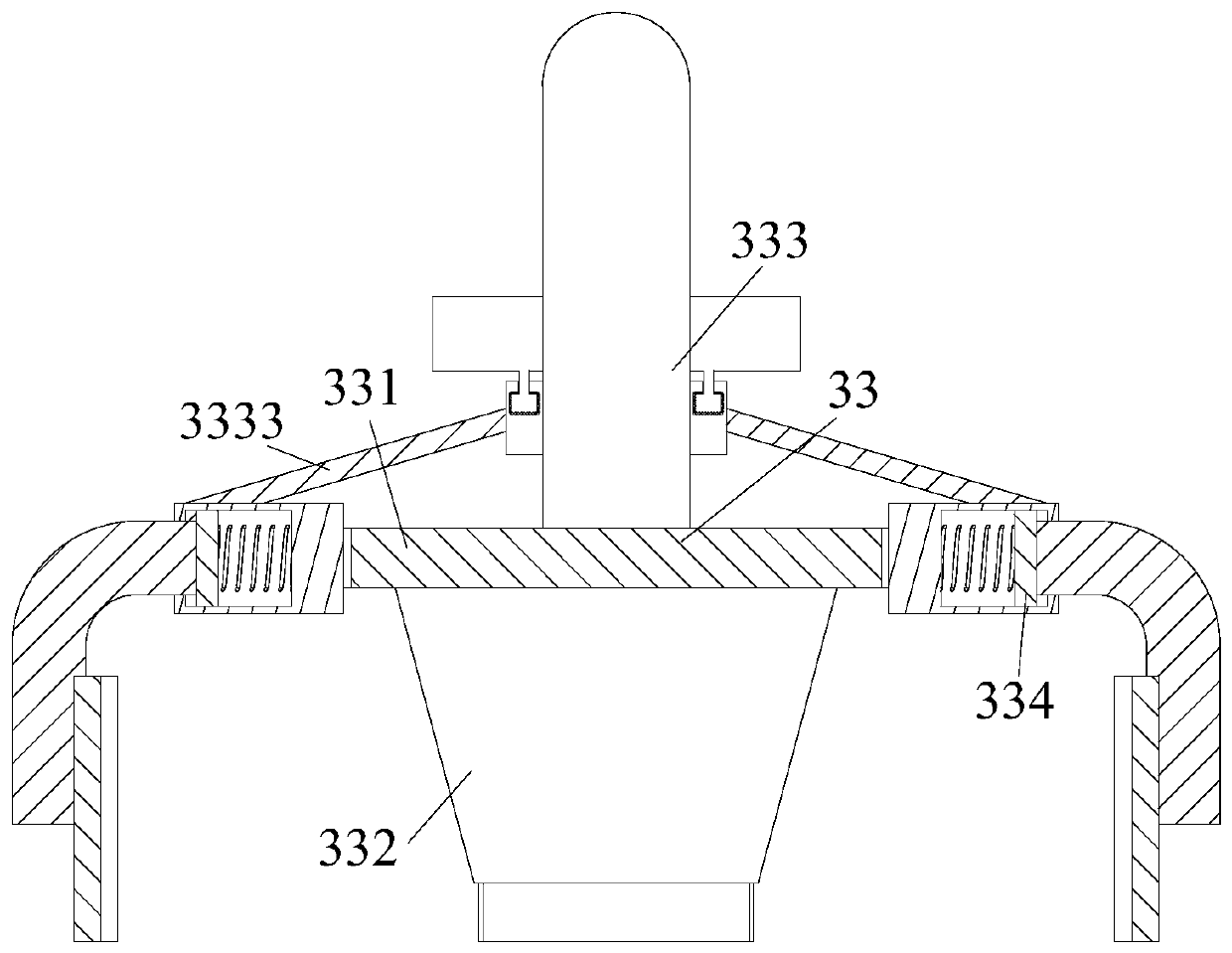

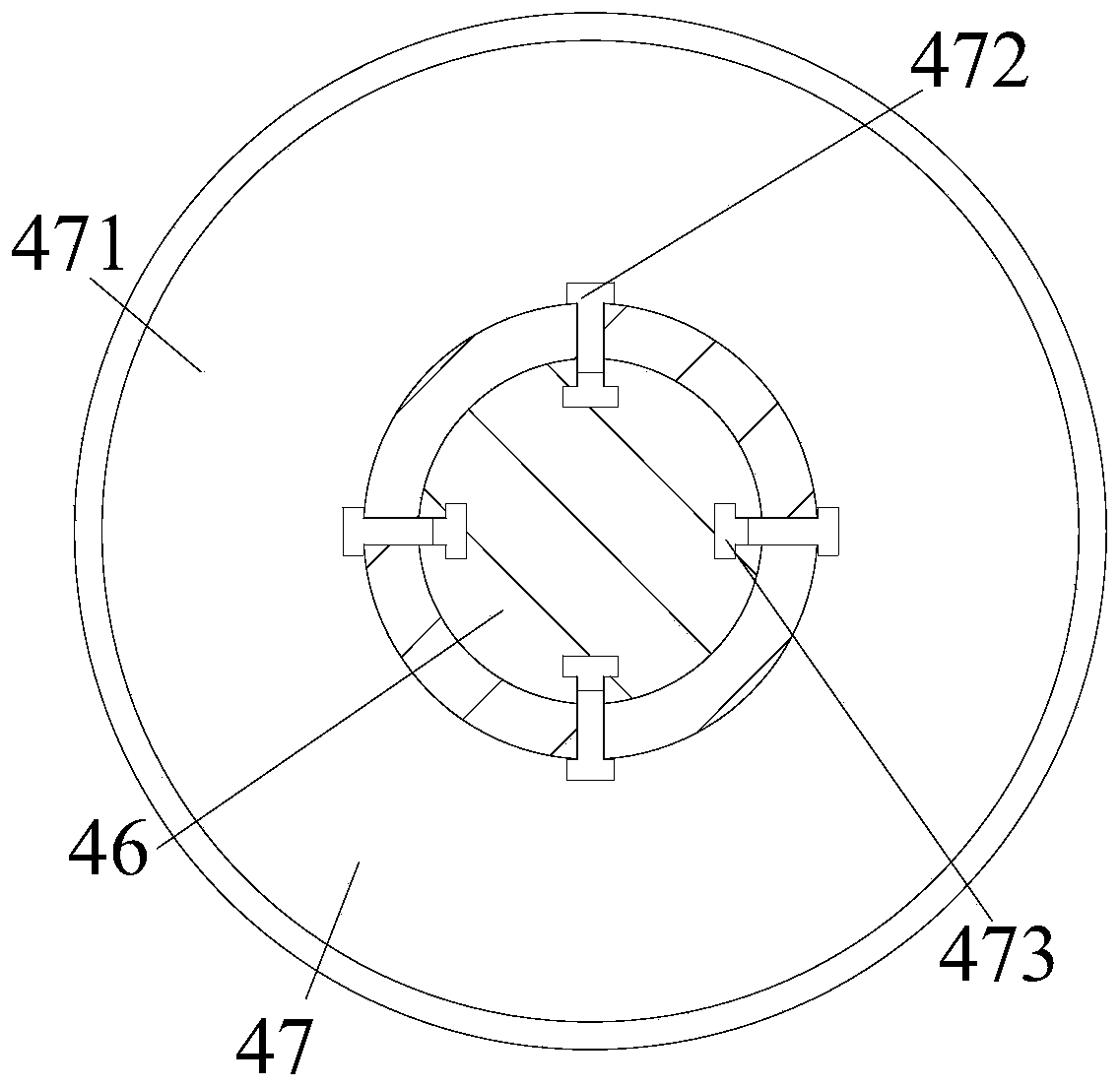

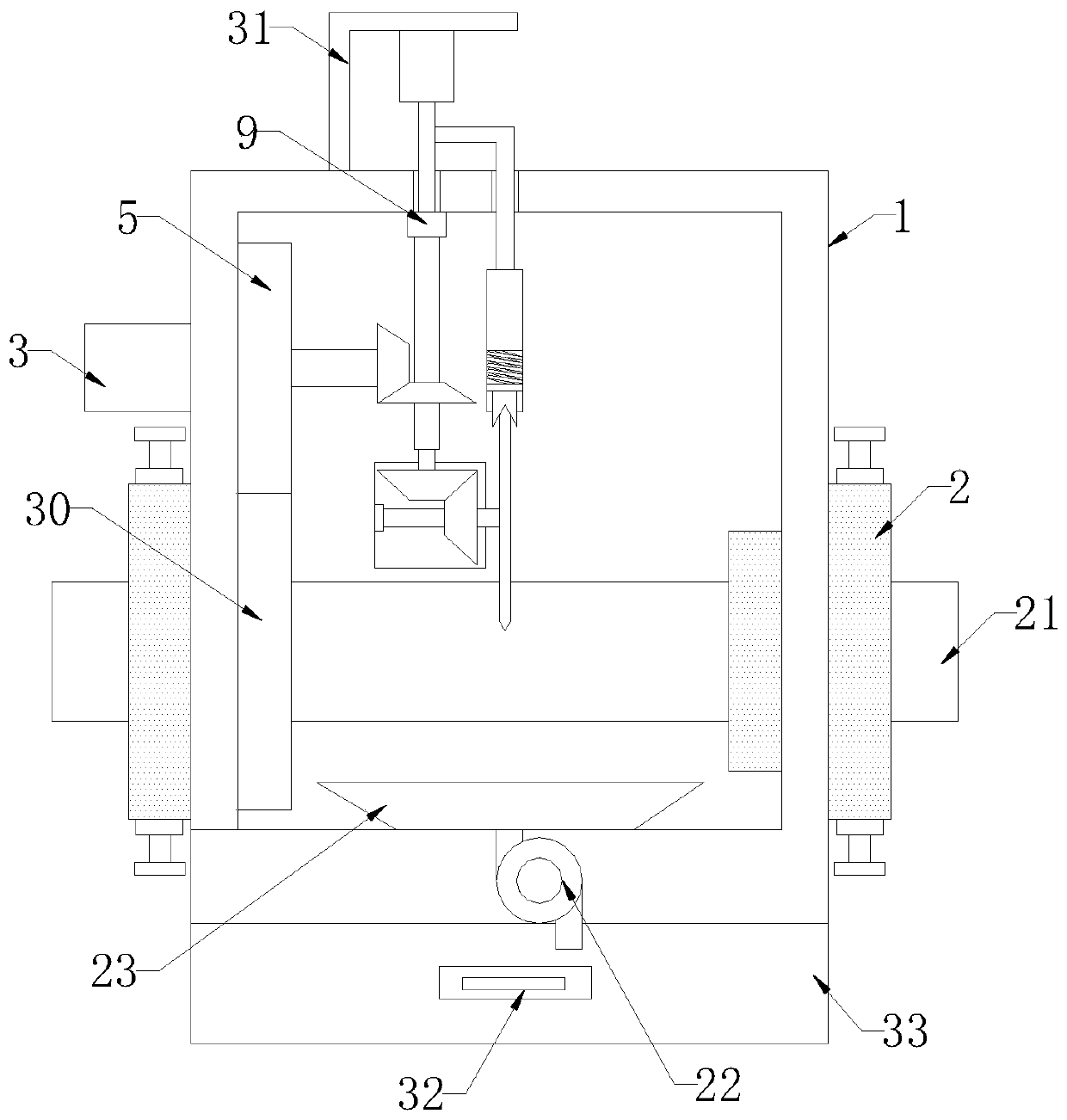

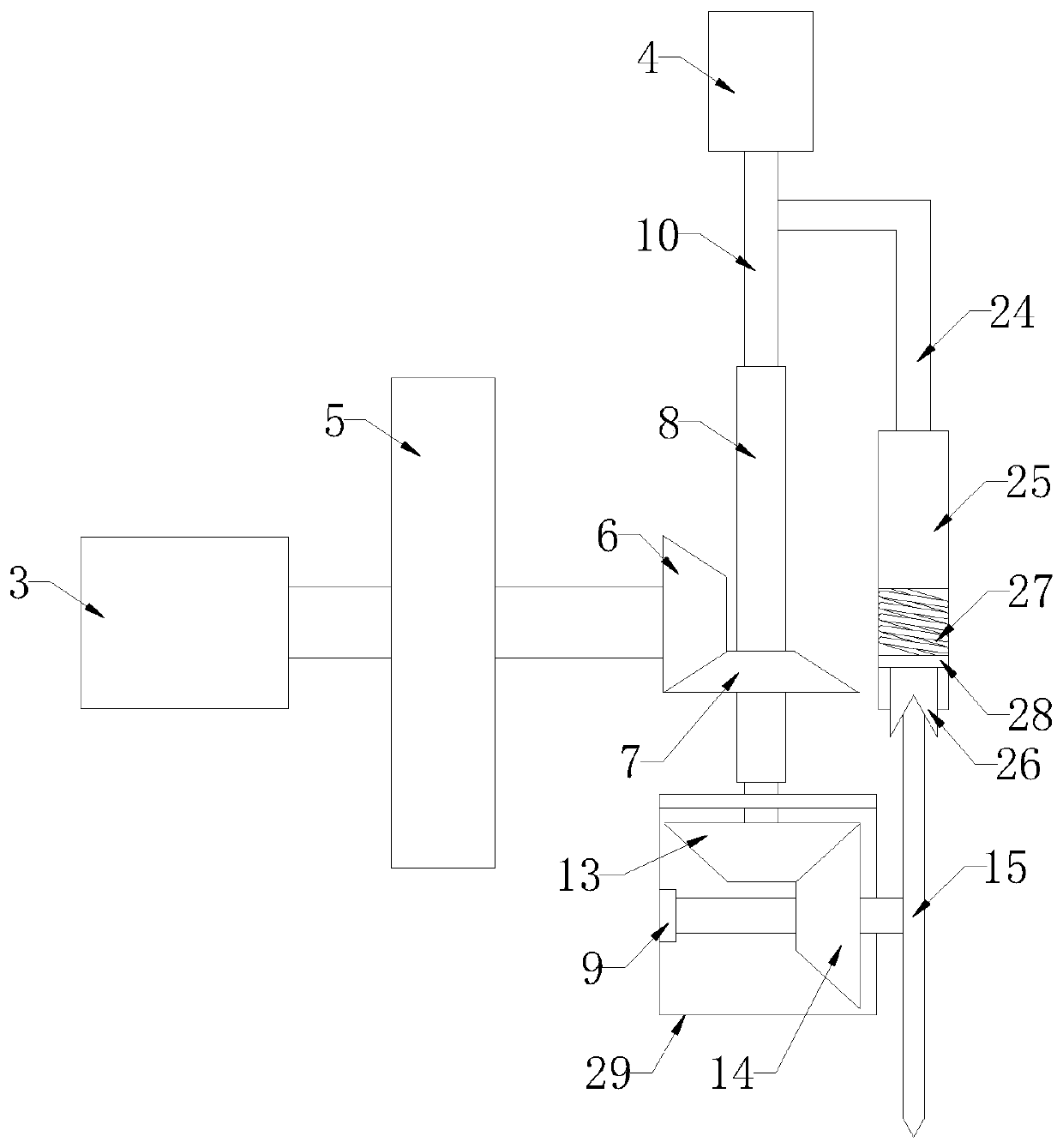

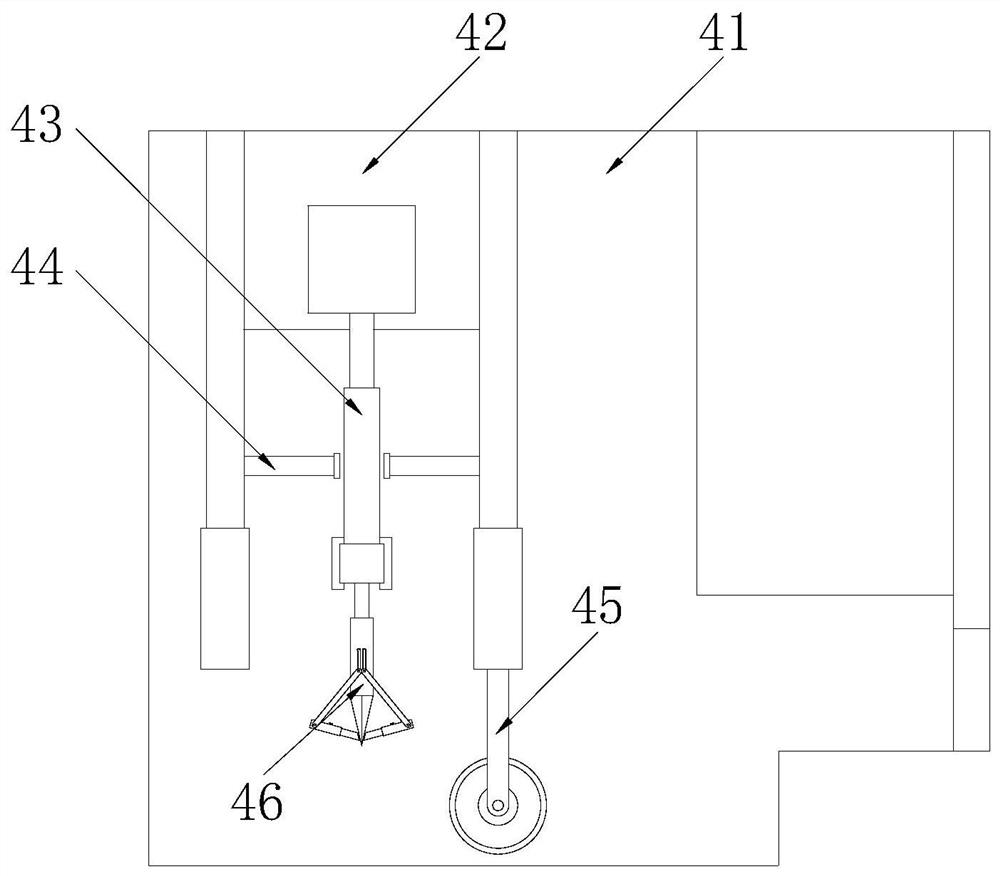

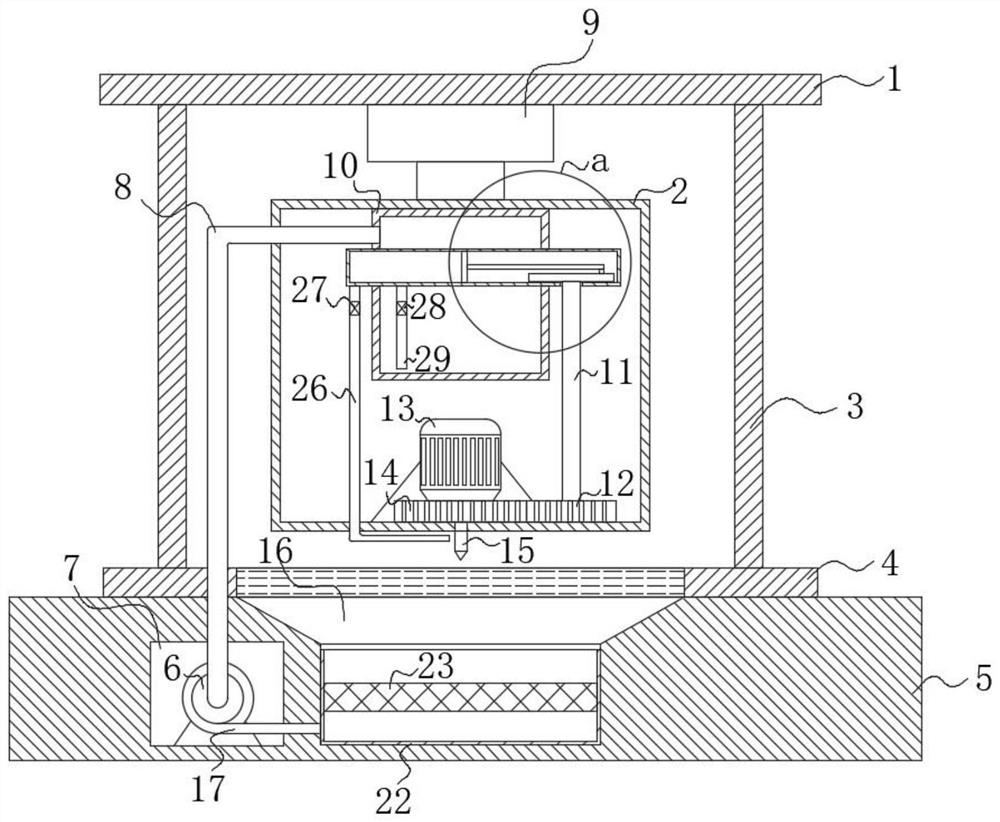

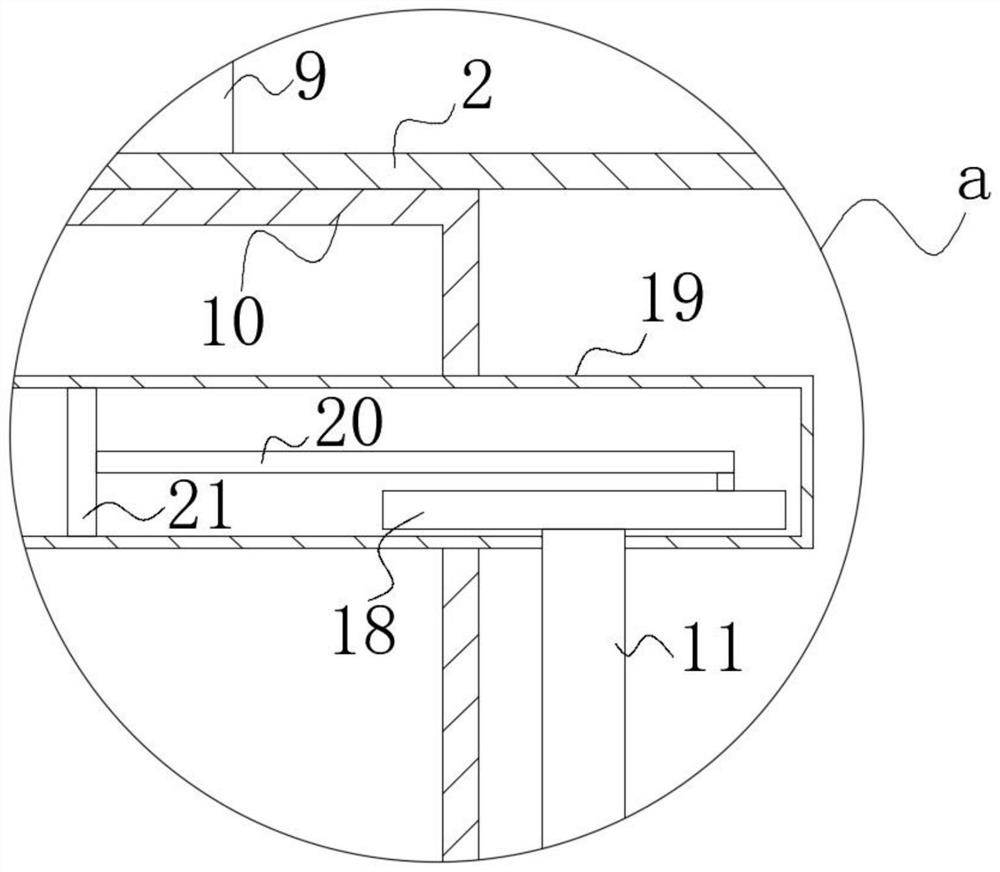

Chipless full-automatic pipe cutting machine

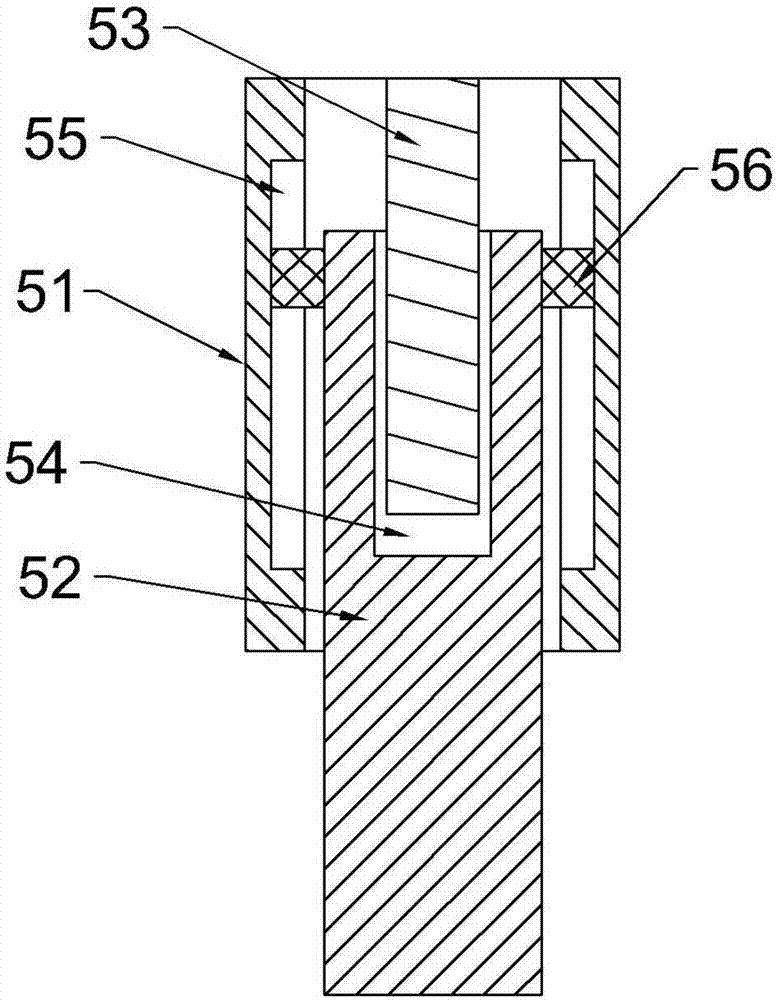

ActiveCN111037628ARealize moving up and downEasy maintenanceMetal working apparatusDrive wheelElectric machinery

The invention discloses a chipless full-automatic pipe cutting machine. The chipless full-automatic pipe cutting machine comprises a rack, a cutting mechanism suspended in the rack and clamping sleeves arranged at the two ends of a feeding port of the rack in parallel, wherein the cutting mechanism comprises a motor, an air cylinder and a grinding assembly; a motor shaft is connected with a driving wheel and a first conical wheel; the first conical wheel is engaged with a second conical wheel; the second conical wheel is fixedly arranged outside a spline shaft sleeve in a sleeving manner; thespline shaft sleeve is rotationally suspended on the top wall of a rack operation cavity through a bearing; the output end of the air cylinder is connected with a telescopic shaft; the telescopic shaft is fixedly connected with a connecting piece; a spline shaft is rotationally arranged at the bottom of the connecting piece; the end, penetrating the spline shaft sleeve, of the spline shaft is fixedly sleeved with a third conical wheel; the third conical wheel is engaged with a fourth conical wheel; the fourth conical wheel is in shaft connection with a round cutter; each clamping sleeve is composed of a thick sleeve and a thin sleeve; the thick sleeve communicates with the thin sleeve; a clamping block for fixing a charging roller is arranged in the thick sleeve and connected with a bolt;and the bolt is sleeved with a nut.

Owner:珠海大勇科技有限公司

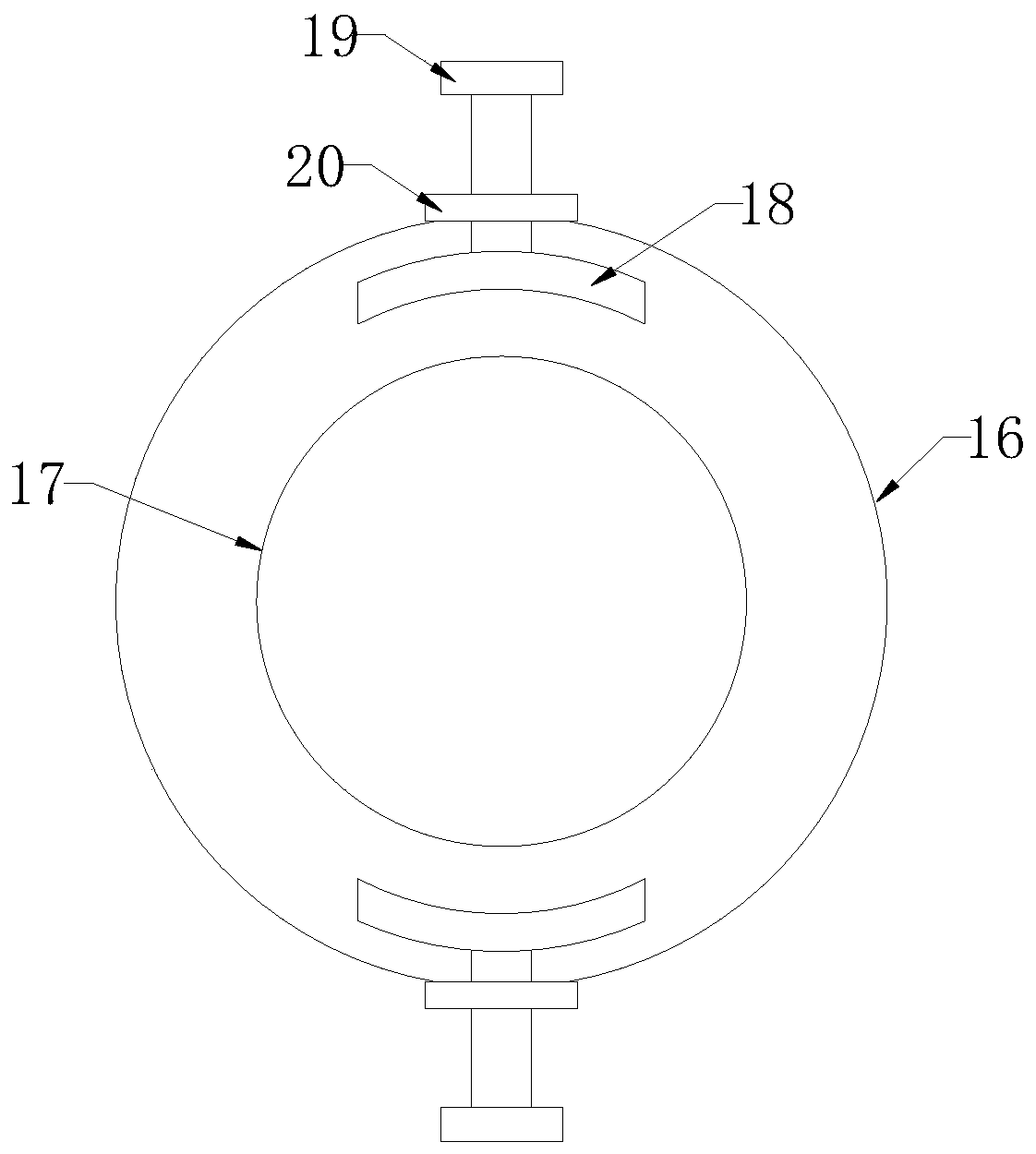

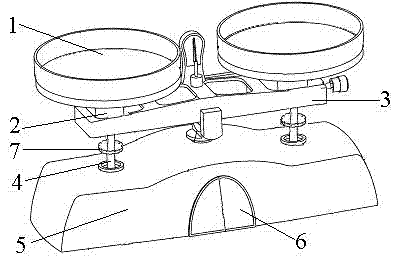

Counter balance capable of protecting knife edge of balance

InactiveCN102778273AGuaranteed sharpAvoid getting dirtyWeighing apparatus using counterbalanceWeighing apparatus detailsEngineeringMechanical engineering

Owner:昆山旭虹精密零组件有限公司

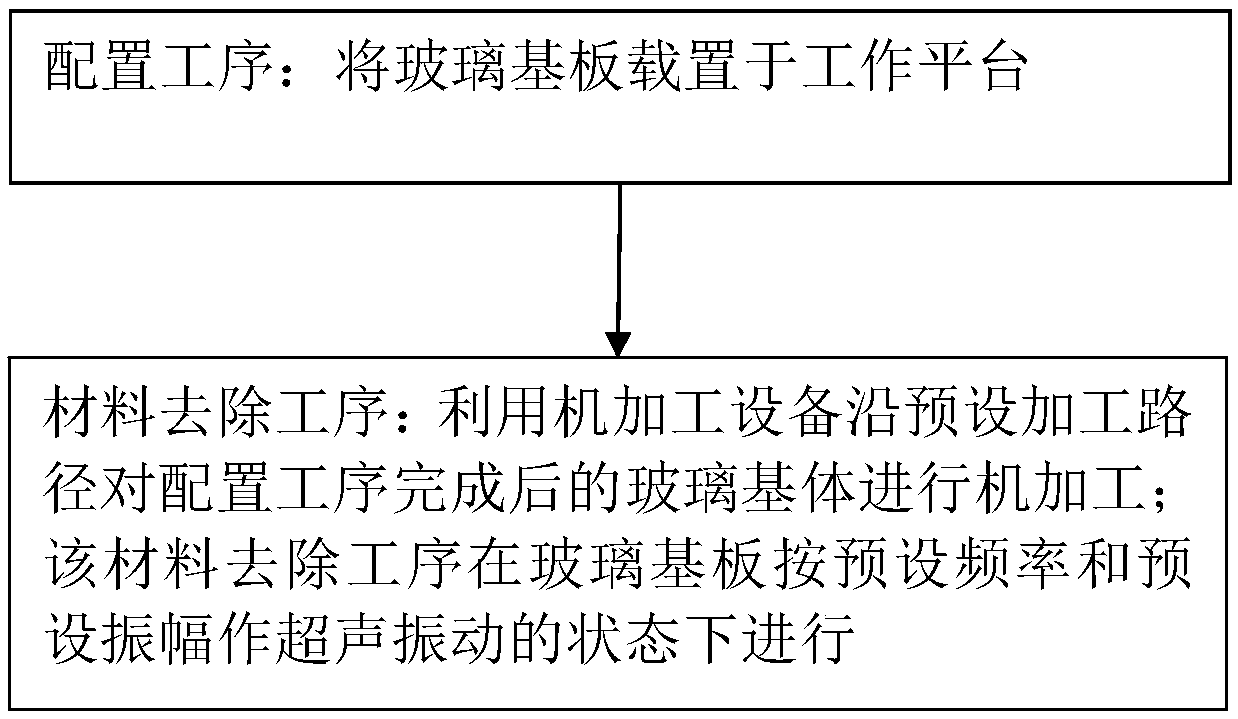

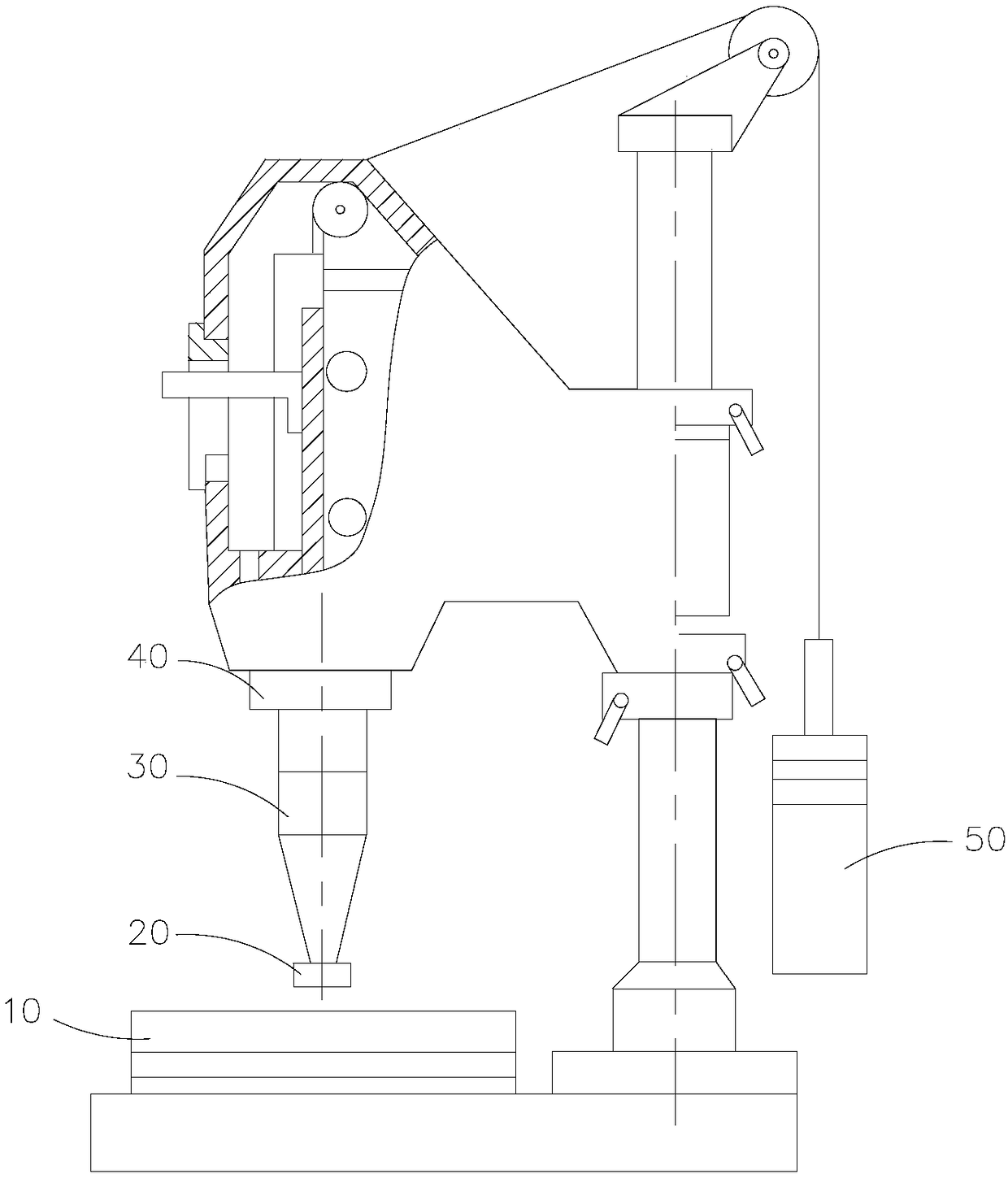

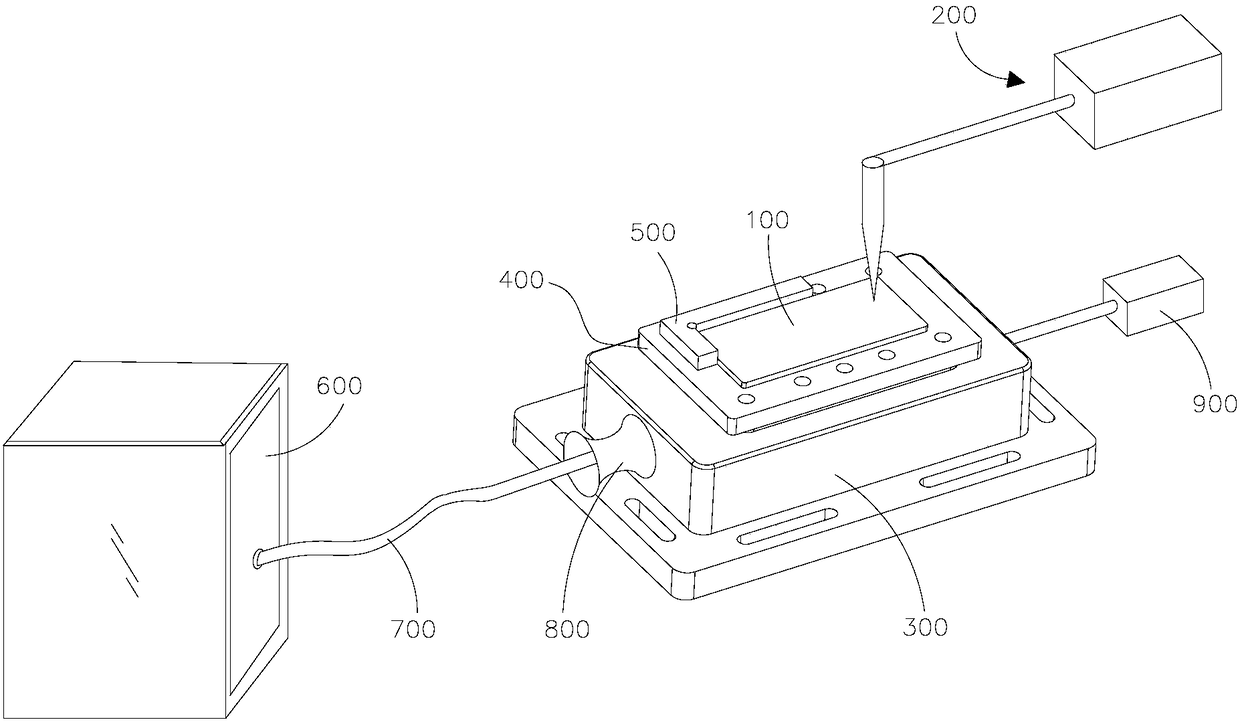

Ultrasonic machining method and device for glass substrates

InactiveCN108326640AReduce cutting forceImprove removal efficiencyGrinding work supportsStone-like material working toolsUltrasonic machiningEngineering

The invention provides an ultrasonic machining method for glass substrates. The method comprises a preparation step in which a glass substrate is placed on a worktable and a material removing step inwhich the glass substrate which is subjected to the preparation step is machined by utilizing machining equipment along a preset machining path; and the material removing step is performed at a statethat the glass substrate does ultrasonic vibration according to a preset frequency and preset amplitude. According to the method, vibration impact is formed between the glass substrate and a tool of the machining equipment by virtue of ultrasonic vibration of the glass substrate, and miniature cracks can be formed at a contact surface between the glass substrate and the tool; then machining is performed with the rotary tool; not only is cutting force greatly lowered, but also machining efficiency is improved; and surface quality of the product can also be improved through the effects of hammering, cavitation, uncontinuous cutting and the like of ultrasonic vibration, and notches, edge burning, cracking and other defects are reduced, so that the yield of the product is improved, and the service life of the tool is prolonged. The invention further provides a glass substrate ultrasonic machining device which can be applied in the method.

Owner:雷索智能科技(苏州) 有限公司

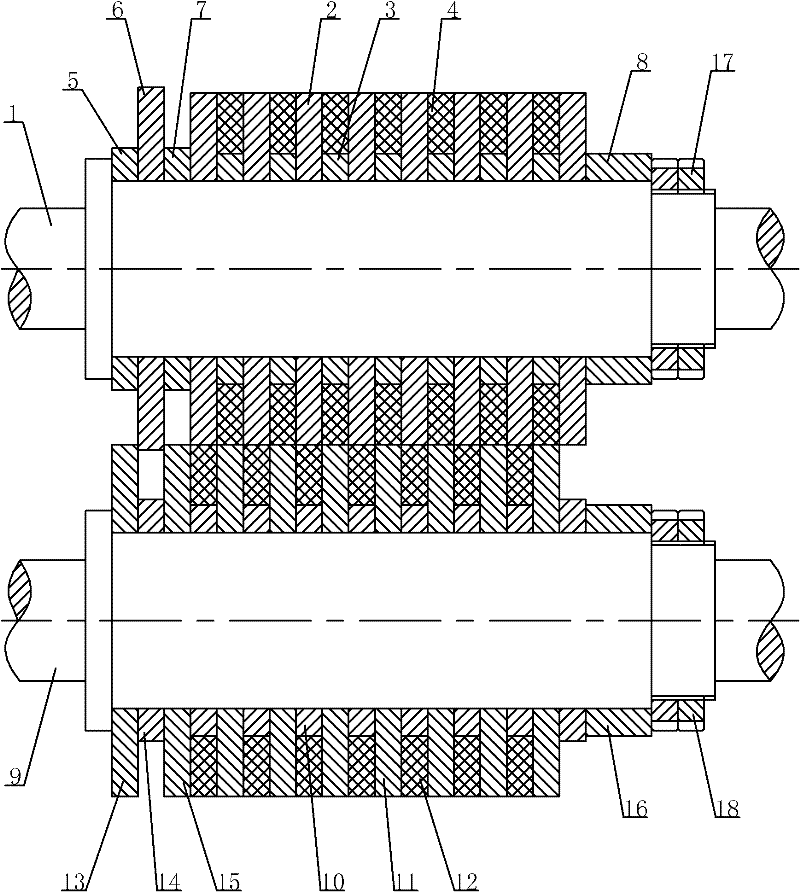

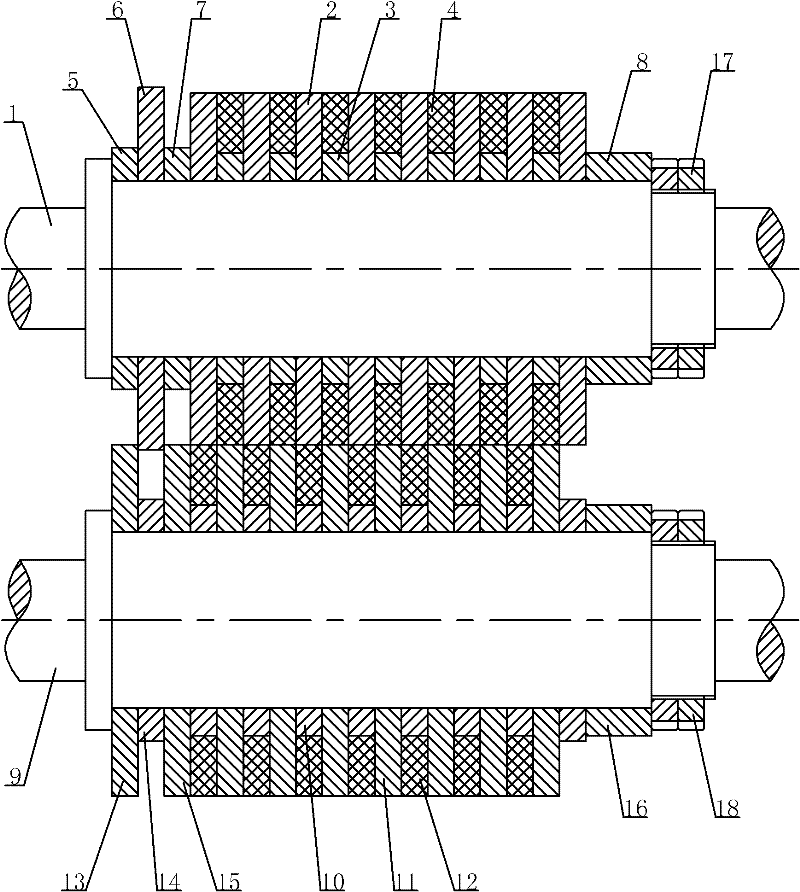

Fixing cutter group with positioning device

The invention discloses a fixed cutter group with a positioning device. The fixed cutter group comprises an upper cutter part and a lower cutter part, wherein the upper cutter part comprises an upper cutter shaft, and a cutting disc I and a cutter pad I which are arranged on the middle part of the upper cutter shaft at a uniform interval; the lower cutter part comprises a lower cutter shaft, and a cutter pad II and cutting disc II which are arranged on the middle part of the lower cutter shaft at a uniform interval; a guide cutter pad I, a guide cutter I and a positioning cutter pad are arranged on the left part of the upper cutter shaft; the guide cutter pad I is positioned on the left side of the guide cutter I; the positioning cutter pad is positioned on the right side of the guide cutter I; the cutting disc I, the cutter pad I, the guide cutter pad I, the guide cutter I and the positioning cutter pad are fixedly connected into a whole; a guide cutter II, a guide cutter pad II and a positioning cutter are arranged on the left part of the lower cutter shaft; the guide cutter II is positioned on the left side of the guide cutter pad II; the positioning cutter is positioned on the right side of the guide cutter pad; and the cutter pad II, the cutting disc II, the guide cutter II, the guide cutter pad II and the positioning cutter are fixedly connected into a whole. The fixed cutter group has a reasonable design, high processing accuracy and high processing efficiency, and is convenient to detach and use.

Owner:THE NORTHWEST MACHINE

Intelligent new textile material cutting-off equipment for textile

InactiveCN111893743AHigh strengthImprove wear resistanceDrying solid materials without heatDrying gas arrangementsFiberMechanical engineering

The invention discloses intelligent new textile material cutting equipment for textile. The equipment structurally comprises a fixed seat, an unwinding device, a placement table, a cutting-off main machine, a motor and a stacking table, wherein the unwinding device is arranged at the right front end of the fixed seat. A rotating roller makes close contact with the surface of viscose fiber cloth, and a heating wire carries out heating to generate hot air while a roller body rotates, so that the viscose fiber cloth is heated and dried, the strength and abrasion resistance of the viscose fiber cloth are improved, and it is guaranteed that the viscose fiber cloth cannot be torn in the cutting-off process; linkage rods slide upward inside sliding rails, at the moment, the ends, close to a cutter, of flattening plates shift upwards in a linkage mode, at the moment, the flattening plates on the two sides flatten the surface of the viscose fiber cloth, and it is guaranteed that a notch is keptflat; and meanwhile, a wiping block and knife stone make contact with the surface of the cutter, the wiping block wipes residual water on the surface of the cutter at the moment, and the knife stonegrinds and shovels away rust blocks on the surface of the cutter, so that it is guaranteed that the cutter is kept sharp.

Owner:李龙泉

Cutting edge structure, manufacturing method of cutting edge and kitchen knife

InactiveCN111055308AImprove wear resistanceHigh hardnessMetallic material coating processesMetal working apparatusStructural engineeringHigh wear resistance

Relating to the technical field of cutters, the embodiment of the invention discloses a cutting edge structure, a manufacturing method of the cutting edge structure and a kitchen knife. The cutting edge structure comprises a cutter body and a composite material layer, the composite material layer is arranged on one side face of the cutter body, the composite material layer and the cutter body forman integral structure through three times of high-temperature sintering, the surface of the composite material layer is in an uneven concave-convex shape, and the thickness of the composite materiallayer is 20-30 micrometers. The cutting edge structure provided by the embodiment of the invention integrally has the advantages of high wear resistance, high cutting performance, high toughness and high hardness.

Owner:黄发强

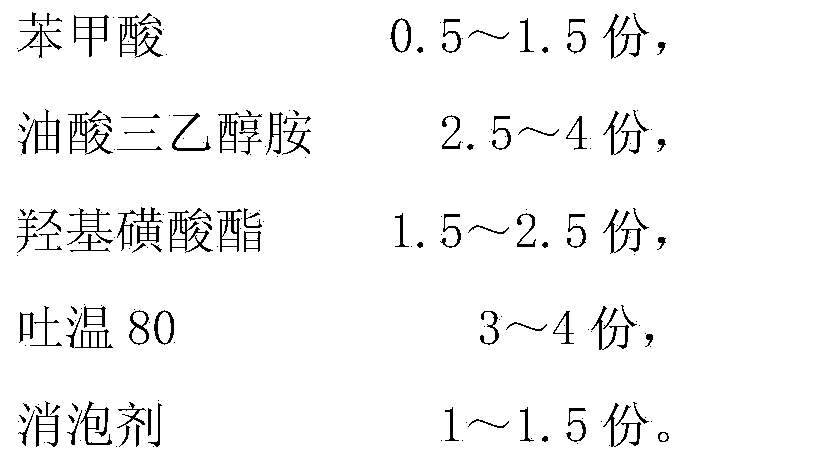

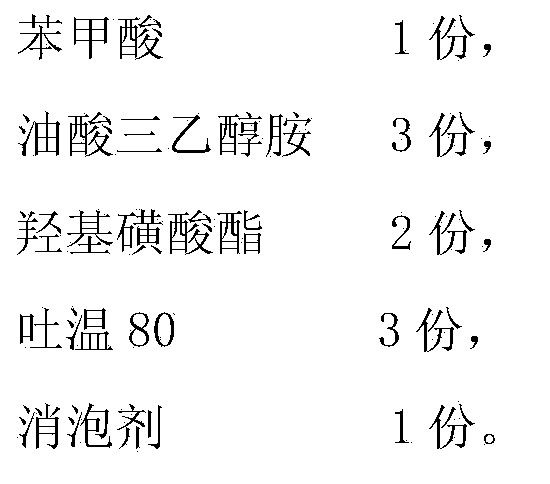

Polishing liquid for stainless steel material and use thereof

ActiveCN103642398AReduce stickingAbility to maintain continuous polishingAqueous dispersionsWater basedTriethanolamine oleate

The invention discloses a polishing liquid for a stainless steel material and use thereof. The polishing liquid comprises the following components in parts by weight: 0.5-1.5 parts of benzoic acid, 2.5-4 parts of triethanolamine oleate, 1.5-2.5 parts of hydroxyl sulphonate, 3-4 parts of Twain 80 and 1-1.5 parts of defoamer. The polishing liquid disclosed by the invention is added to mechanically polish the stainless steel material. The use specifically comprises the step of adding the polishing liquid on a polishing part when the stainless steel material is mechanically polished by using abrasive paper after the polishing liquid is blended by water. According to the polishing liquid disclosed by the invention, the phenomenon that the adhesive paper is bonded to a removed material during polishing is greatly reduced, the sharpness of the adhesive paper polishing edge is maintained, and the continuous polishing capacity of the adhesive paper is maintained. Meanwhile, the polishing liquid belongs to a water-based polishing liquid, so that the temperature caused by friction during polishing can be greatly reduced, the burning phenomenon on the surface of the material is avoided, and the polishing liquid has a good cooling effect.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

Plate drilling machine

ActiveCN111906339AAvoid cleaning difficultiesAvoid wastingDrilling machinesMaintainance and safety accessoriesThermodynamicsHydraulic ram

The invention discloses a plate drilling machine which comprises a cross beam, a supporting rod, a base plate and a base. A hydraulic oil cylinder is fixedly installed at the bottom of the cross beam,the piston end of the hydraulic oil cylinder is fixedly connected with a working box, a cooling box is fixedly installed in the working box, liquid pumping mechanisms penetrate through the side wallsof the two ends of the cooling box, and a collecting cavity is formed in the base; and a processing mechanism is movably connected into the collecting cavity, a cavity is formed in one side of the processing mechanism, and a recycling mechanism is fixedly installed in the cavity. By the arrangement of a chipping and cooling liquid collecting device, a large number of chippings generated in the drilling process and used cooling liquid are collected and recycled, so that the problem that the chippings are difficult to clean can be solved, and the cooling liquid can be recycled; and meanwhile, by the arrangement of a drill bit cooling mechanism, cooling liquid is sprayed to a drill bit when the drill bit works, the temperature of the drill bit is reduced, and cutting edges can be kept sharp.

Owner:芜湖腾飞信息科技有限公司

Hand-push type mower

The invention discloses a hand-push type mower. The mower comprises a mower body, a contraction air bag is arranged at the top of the inner wall of the mower body and located between the top of the surface of a sliding push plate and the two corresponding sides of the inner wall of the mower body, an air flow channel is formed at the position, close to the top, in the mower body, and one end of the air flow channel communicates with the end of the contraction air bag; and a carding device is fixed to the bottom of the sliding push plate through a connecting rod, a cutting device is arranged at the side, away from the carding device, of the mower body, and the end, away from the contraction air bag, of the air flow channel is connected with the top end of the cutting device in a matched manner through a rotary connector. The invention relates to the technical field of electric tools. According to the hand-push type mower, the purposes of preventing hard objects and adhesion are achieved, the hard objects can be cleaned in time, rigid collision on a cutter head is avoided, safety and reliability are achieved, meanwhile, moist chippings or grass leaves are prevented from adhering to a cutting edge, sharpness of a cutter is guaranteed, cutting is rapid and thorough, and the working efficiency and the using performance are improved.

Owner:LIAOCHENG YULIN IND DESIGN CO LTD

Plate drilling machine and using method thereof

InactiveCN113145888AAvoid cleaning difficultiesAvoid wastingDrilling machinesMaintainance and safety accessoriesThermodynamicsHydraulic ram

The invention discloses a plate drilling machine and a using method thereof. The plate drilling machine comprises a cross beam, supporting rods, a base plate and a base, wherein a hydraulic oil cylinder is fixedly installed at the bottom of the cross beam, the piston end of the hydraulic oil cylinder is fixedly connected with a working box, a cooling box is fixedly installed in the working box, liquid pumping mechanisms penetrate through the side walls of the two ends of the cooling box, and a collecting cavity is formed in the base; and a treatment mechanism is movably connected into the collecting cavity, a cavity is formed in one side of the treatment mechanism, and a recycling mechanism is fixedly installed in the cavity. A large amount of chippings generated in the drilling process and used cooling liquid are collected and recycled through a chipping and cooling liquid collecting device, so that the problem that the chippings are difficult to clean can be solved, and the cooling liquid can be recycled; and meanwhile, a drill bit cooling mechanism is arranged, and the cooling liquid is sprayed to a drill bit when the drill bit works, so that the temperature of the drill bit is reduced, and the cutting edge can be kept sharp.

Owner:芜湖腾飞信息科技有限公司

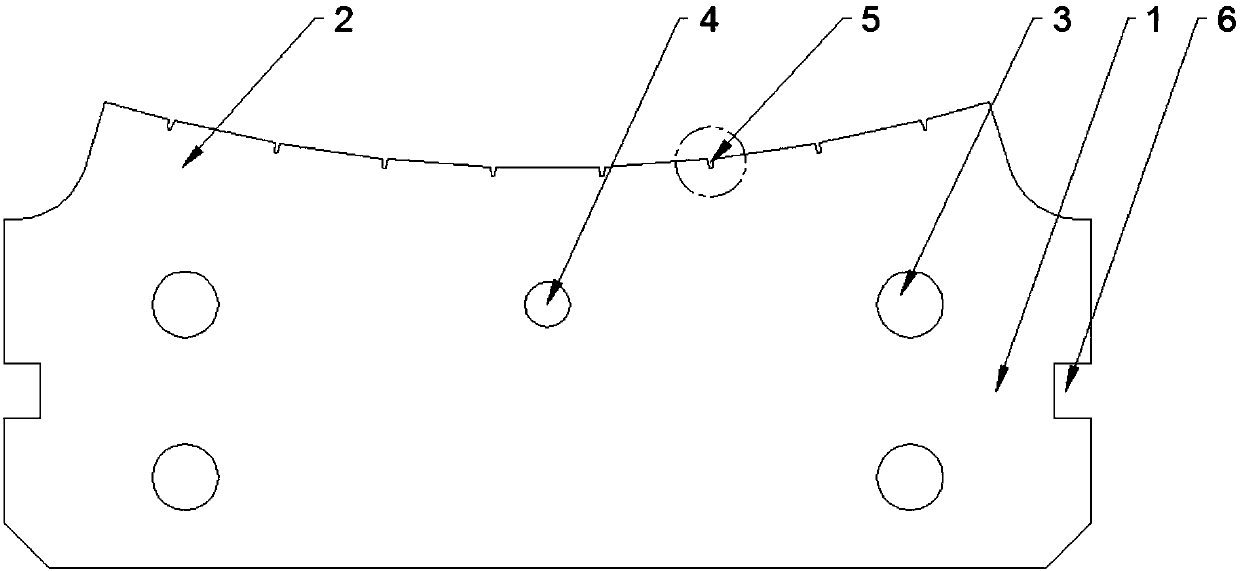

Involute cutter set and edge parameter calculating method thereof

ActiveCN107755718AReduce manufacturing costReduce wearTurning toolsMetal working apparatusEdge structureEngineering

The invention discloses an involute cutter set and an edge parameter calculating method thereof. The involute cutter set comprises a cutter head; a blade is arranged at the upper end of the cutter head; guide column holes are formed in the left and right ends of the cutter head; a fixed hole is formed in the middle part of the cutter head; the blade is provided with an edge; and two sides of the edge are of arc structures. The involute cutter set comprises cutter types of an A type cutter, a B type cutter, a C type cutter and a D type cutter. The involute cutter set has the following beneficial effects: the matching of a traditional involute cutting machine can be realized through replacing the cutter set; the batch production can be achieved; and each cutter is not needed to singly open molds, so that the production cost is reduced. Through improvement of the edge structure, the wear of the edge is reduced, the sharpness of the edge is guaranteed, and the service life is prolonged.

Owner:天津锐溥精密模具有限公司

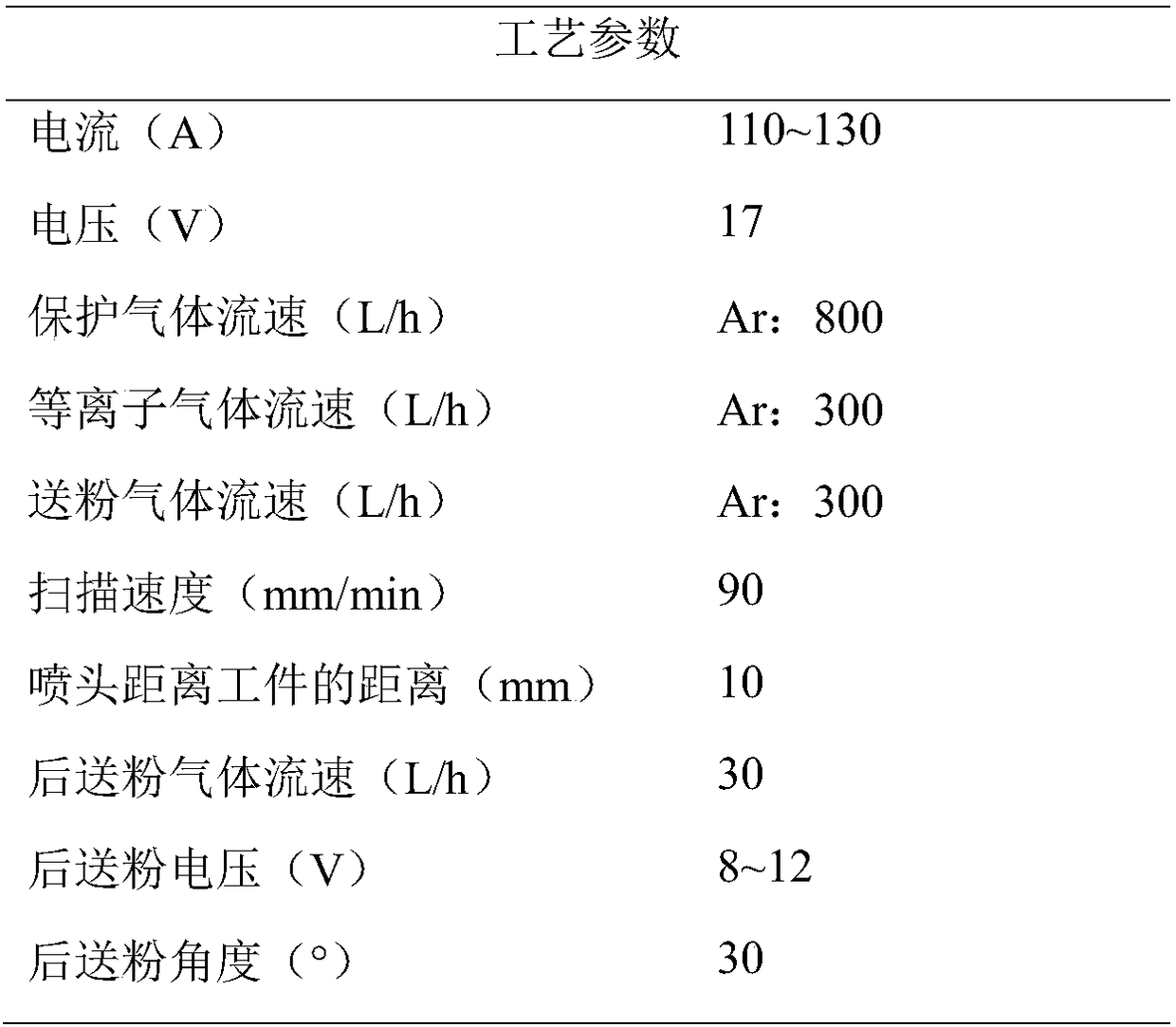

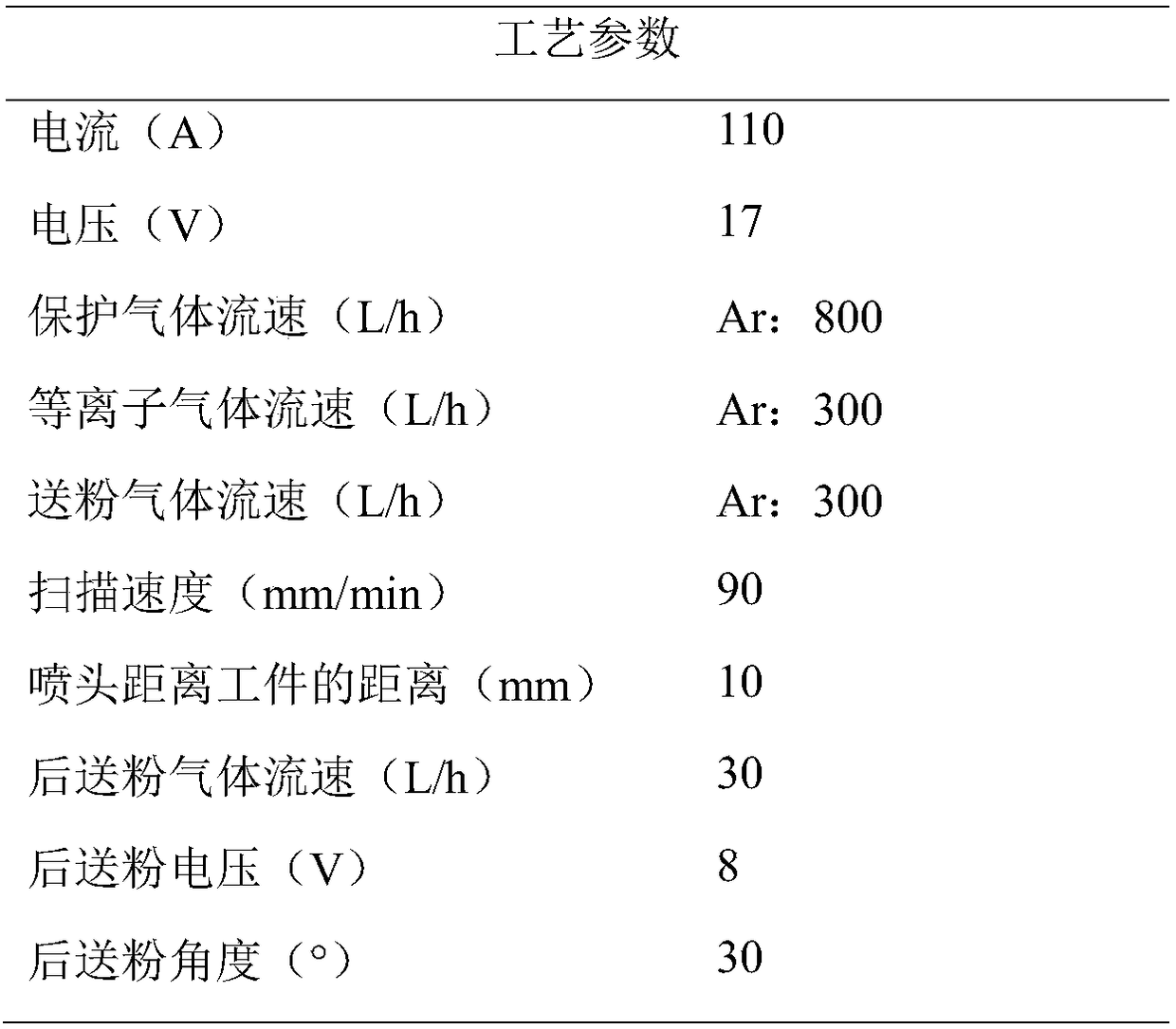

Preparation process of wear-resistance kitchen knife

InactiveCN108311854AExtended service lifeImprove hardness and wear resistanceMolten spray coatingMetal working apparatusFe basedHardness

The invention discloses a preparation process of a wear-resistance kitchen knife. A 45# steel, high-carbon steel or stainless steel blank is used as a knife body material; a WC particle reinforced Febase composite coating layer is prepared on the surface of the steel blank by using a plasma spray welding technology; then, a linear cutting technology is used for machining the steel blank as rectangular sheets with thicknesses of 2 mm, wherein the parts, with the coating layer, of the sheets are used as edges; finally, the edge parts are roughly sharpened and sharpened; and a shank is mounted on the knife body part. The edge material of the wear-resistance kitchen knife is a WC particle reinforced Fe base composite material to achieve higher hardness and wear resistance; the microscopic hardness of the edges is 501-2218 HV, and is far higher than the hardness of edges produced by general kitchen knife production processes; and through higher hardness, wear resistance is excellent, so that sharpness of the edges of the kitchen knife can be maintained for a long time, and the knife is hardly sharpened in daily use.

Owner:HEFEI UNIV OF TECH

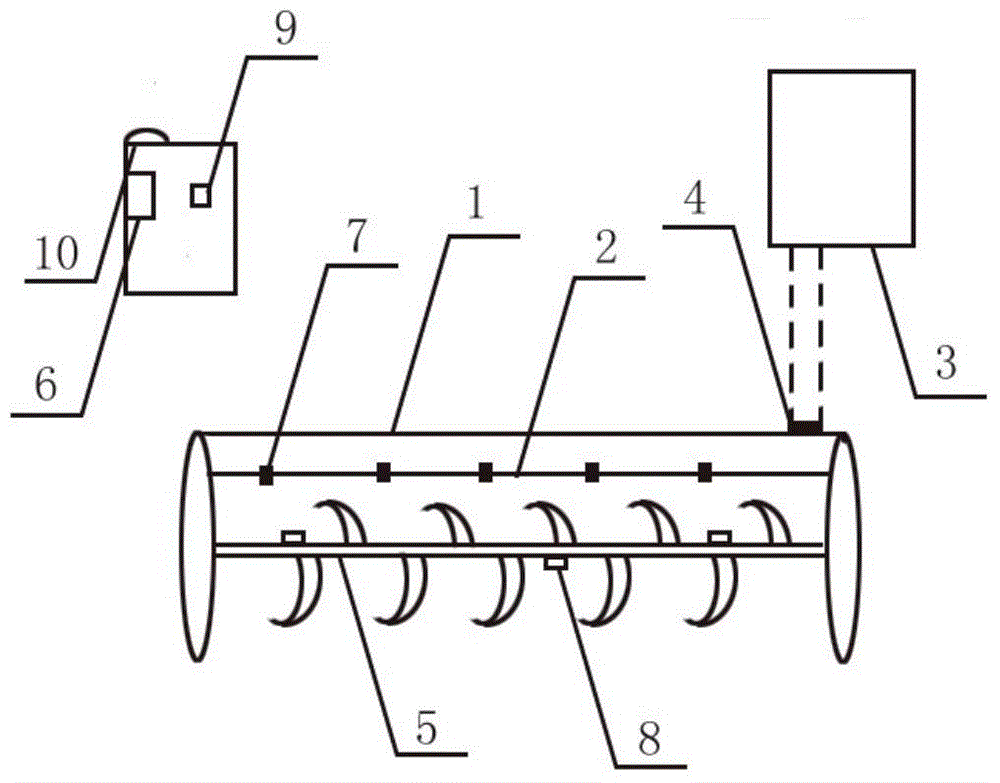

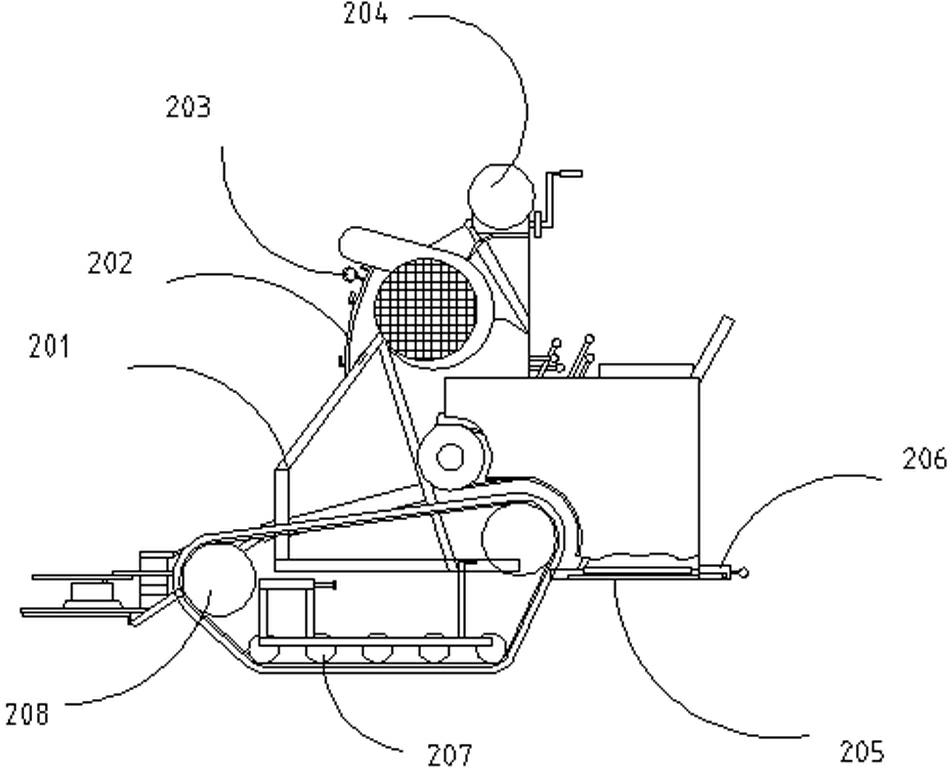

Rotary cultivator device with cleaning function

A rotary cultivator device with a cleaning function comprises a coulter rotation machine body (1). A first hollow pipeline (2) is arranged on the lower portion of a top facing of the machine body (1) and connected with an external water collection device (3). A pressure water pump (4) delivers water into the pipeline. A second hollow pipeline (5) is arranged on the side face of a coulter rotation spindle and connected with a water tank. In cleaning, the second hollow pipeline and the spindle rotate at the same frequency. A water outlet is set to be in an automatic opening and closing mode to prevent sludge blocking, an operation module (6) is connected with a control room, and cleaning is regulated manually. A lower water outlet of the first hollow pipeline (2) is a pressure sprayer (7), high-strength cleaning is conducted, and sludge is removed; a detection module (8) is arranged on the side face of the second hollow pipeline (5) and used for monitoring the cleaning state, and the observation time is saved; the cleaning effect is remarkable through the pressure water pump, secondary manual cleaning is avoided, it is guaranteed that a coulter is sharp, manual controllability is strong, and the service life of the machine body is prolonged through real-time cleaning.

Owner:ANQING LINGKANG ELECTROMECHANICAL PROD DESIGN

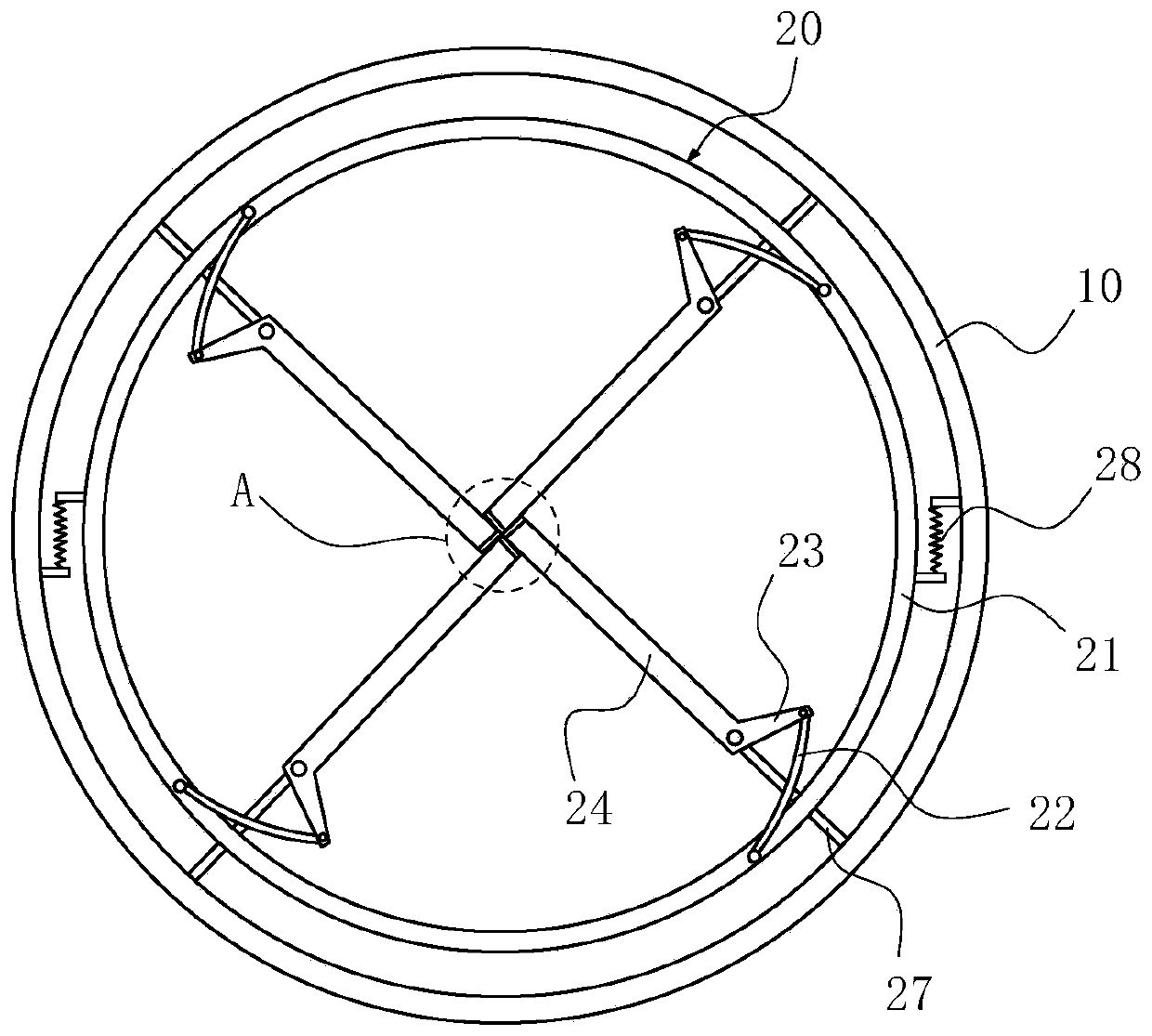

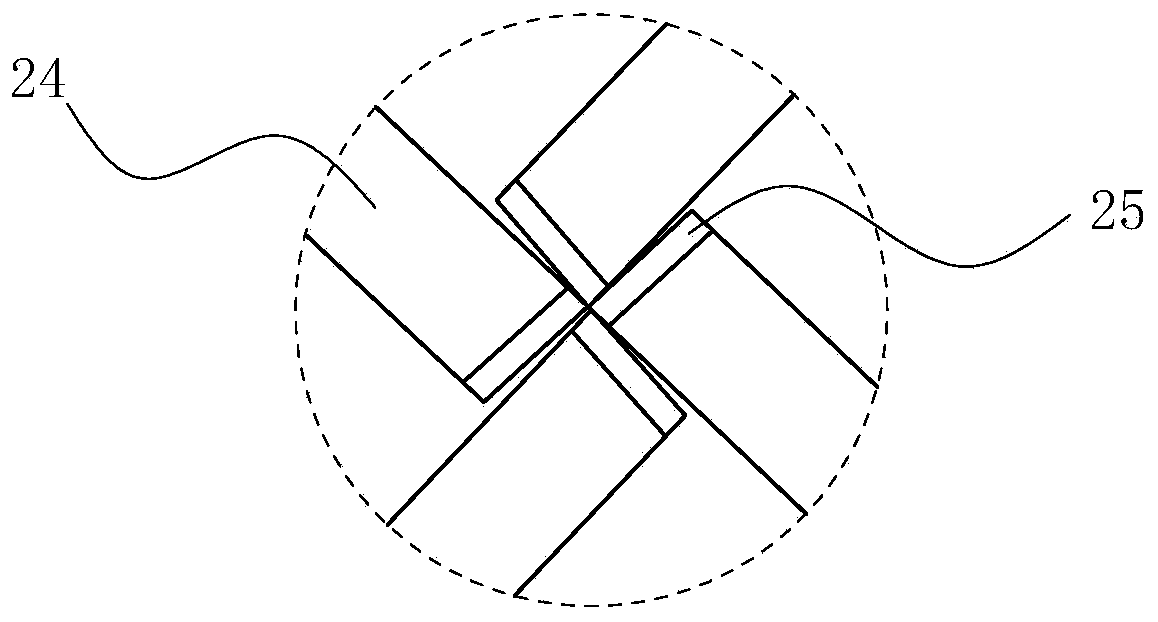

Rubbish barrel capable of separating rubbish bag

PendingCN111377168AAchieve separationEasy to sort and recycleWaste collection and transferRefuse receptaclesKnife bladesStructural engineering

The invention discloses a rubbish barrel capable of separating a rubbish bag and belongs to the technical field of rubbish barrels. The rubbish barrel comprises a barrel body, the top of the barrel body is provided with an input mouth, the rubbish barrel is characterized in that the barrel body is internally provided with a bag cutting device, the bag cutting device is located below the input mouth, is connected with a driving mechanism used for driving the bag cutting device to act and comprises an annular rack connected with the driving mechanism and four swing arms evenly hinged to the annular rack, the ends, located at the central position of the annular rack, of the swing arms are provided with cutter blades, and when the driving mechanism drives the annular rack to rotate, the cutterblades move to the direction away from the central position of the annular rack. According to the rubbish barrel capable of separating the rubbish bag, the bag cutting device can cut the bottom of the rubbish bag into a cross opening, so that rubbish and the rubbish bag are separated in the case of not dirtying hands, and the rubbish barrel is convenient to use.

Owner:孙新宇

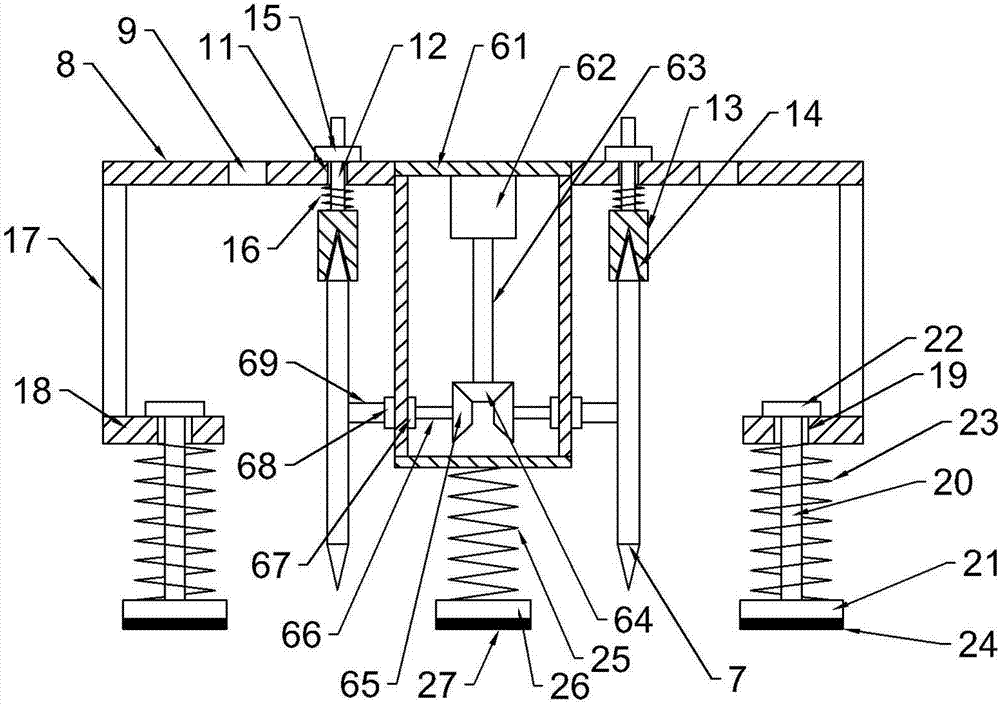

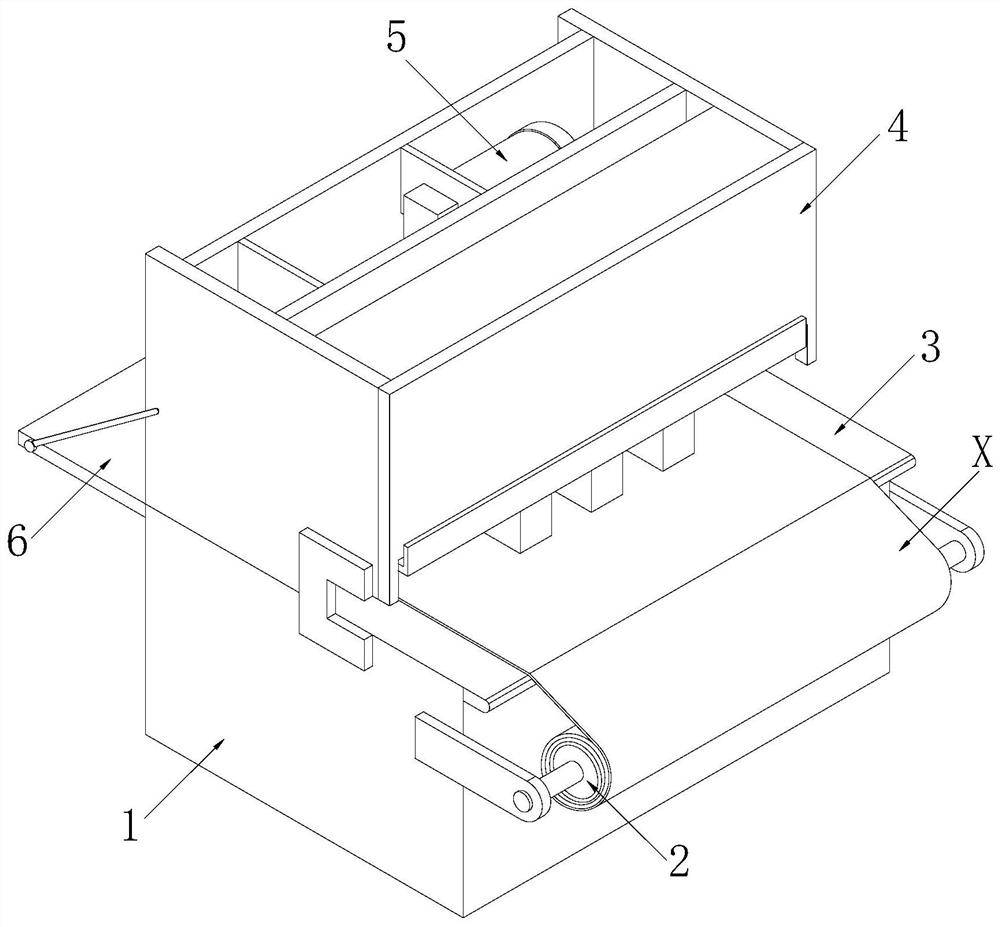

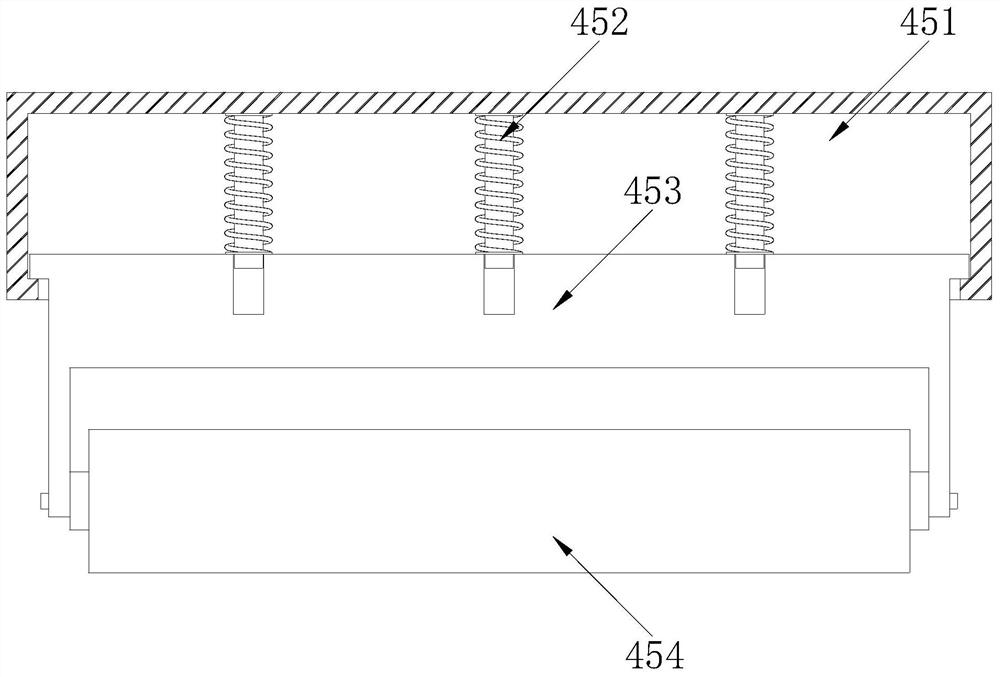

Upper and lower cutting device for full-automatic soft material cutting equipment

PendingCN108839077AGuaranteed sharpImprove efficiencyMetal working apparatusUniversal jointSoft materials

The invention discloses an upper and lower cutting device for a full-automatic soft material cutting equipment. The device comprises an eccentric lifting device which is arranged on a cutting machinehead, the eccentric lifting device is connected with a lifting rod, the lower end of the lifting rod is connected with a lifting base through a universal joint, the lifting base is connected to thecutting machine head in a sliding mode, a rotating device is installed on the lifting base, a cutter head is connected to the lower end of the rotating device, a cutting tool is arranged on the cutterhead, and the eccentric lifting device and the rotating device are jointly connected with a circuit control panel. The cutting device is reasonable in design, the cutting tool can be lifted and rotated, the design of the eccentric wheel ensures that the lifting stroke is fixed, the rotary motor can realize the rotation of the cutter, the cutting edge can be cut by being matched with the knife grinding stone, the sharpness of the knife edge is guaranteed, so that the cutting efficiency is greatly improved, the efficiency is improved, the benefits of enterprises are increased, and the device issuitable for popularization.

Owner:无锡易玛卡机械科技有限公司

Smashing device for recycling waste papers

InactiveCN107841897ASave human effortSmash thoroughlyPaper recyclingFibrous raw materialsMoving frameLeft wall

The invention relates to a smashing device, and particularly relates to a smashing device for recycling waste papers. The technical problem to be solved is to provide a smashing device for recycling the waste papers, which can completely smash waste papers and is convenient to collect waste papers. For solving the technical problem, the invention provides the smashing device for recycling the waste papers, which comprises an installing frame, a slide rail, a side block, a moving frame, a spring, a pull rope, a pull ring, an L-shaped bracket, and others; the slide rail is arranged in the middleof the inner bottom part of the installing frame, and the slide block is glidingly arranged in the slide rail; the upside of the slide block is provided with the moving frame, upper and lower parts of the outside of the right wall of the moving frame are symmetrically connected with springs; the right ends of the springs are connected to the lower part of the inside of the right wall of the installing frame, the left side of the left wall of the installing frame is provided with a through hole. The smashing device for recycling the waste papers can completely smash waste papers and is convenient to collect waste papers; through cross movement of the moving frame, the waste papers can be more completely smashed, and waste papers can be collected through the collecting box.

Owner:王静娴

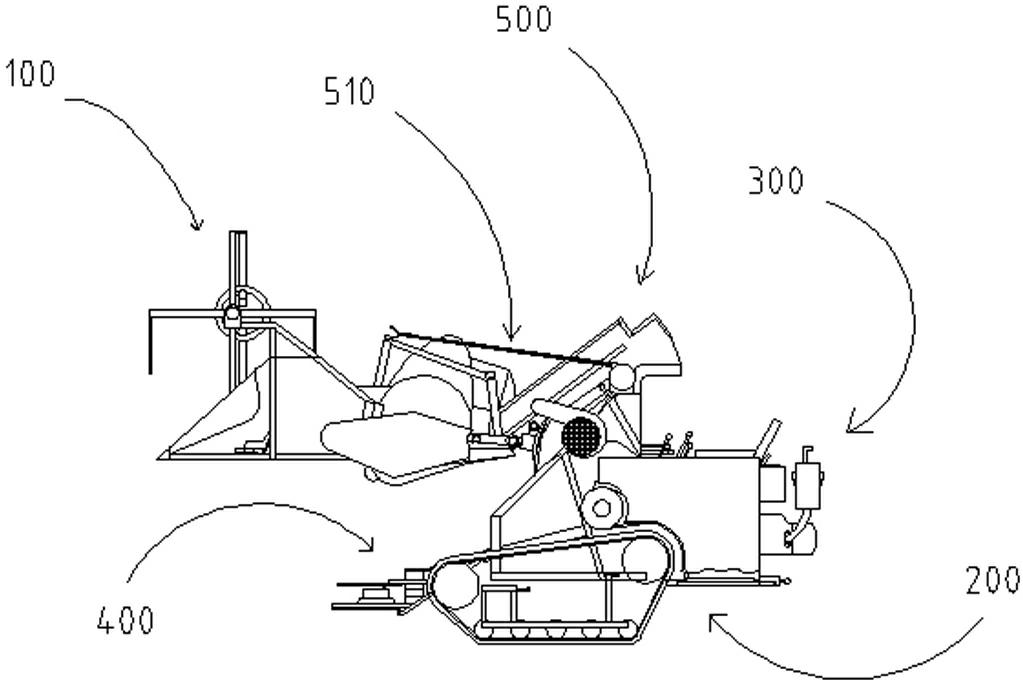

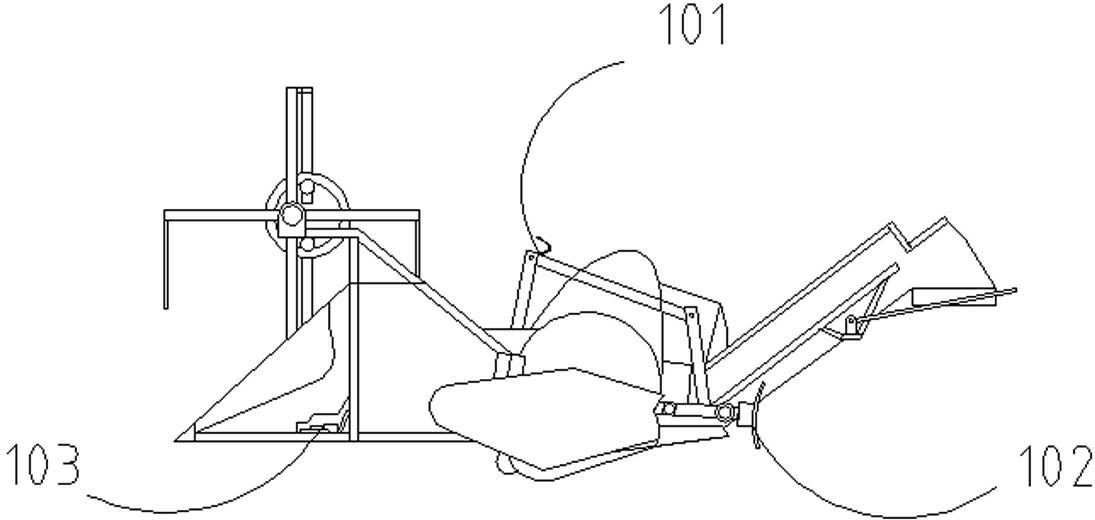

Light and small elevating quick assembling and disassembling rice and wheat harvester

The invention discloses a light and small elevating quick assembling and disassembling rice and wheat harvester comprising a harvesting assembly, a chassis assembly, a power assembly and a straw cutting cutter row assembly, wherein an ear outlet of a shear and an ear inlet of a threshing barrel are directly connected to form an integral harvesting assembly; the straw cutting cutter row assembly is positioned on the front end of the lower underframe of the chassis assembly; the rear part of the harvesting assembly is provided with an affiliated embedding spile assembly; the upper end of the chassis assembly is provided with an affiliated embedding socket assembly; the rear lower part of the chassis assembly rack is provided with a spile slot and a tensioner; the top of the chassis assembly is provided with a cord drawing device; the lower part of the power assembly is provided with a spile; and the movable cutter bar of the straw cutting cutter row assembly is provided with a left grass feeding huge-tooth assembly, a right grass feeding huge-tooth assembly and a grass separator. The harvester can be free from the limitation of hills, montanic field narrow roads or single bridge. During harvesting, the harvester is free from limitation of muddy feet depth and abnormity, small plots and bent and narrow fields. The working efficiency of the harvester is higher than any rice and wheat harvester which can be carrier by two people for times.

Owner:贺炳松

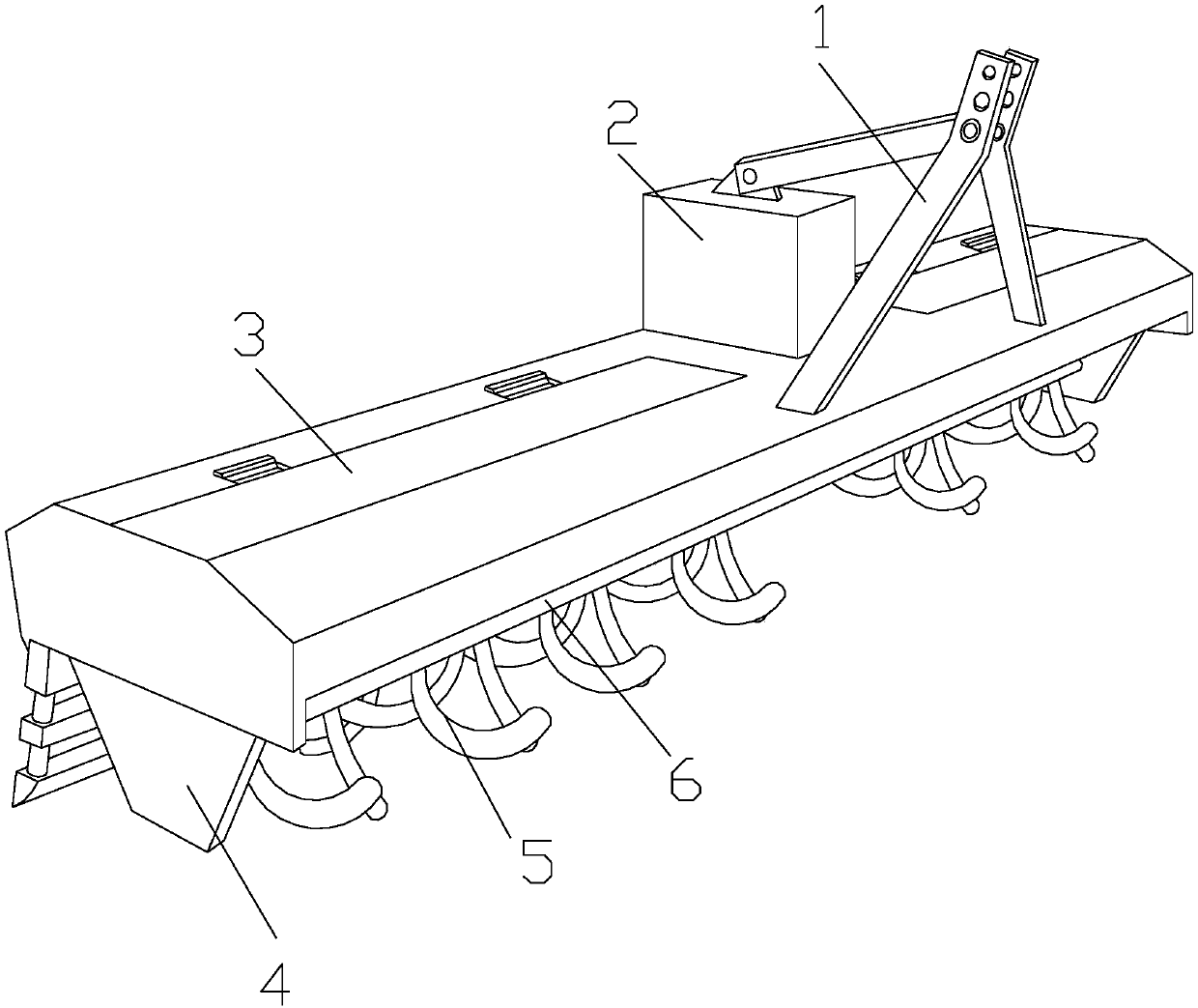

Anti-piling-compact deep-ploughing rotary cultivator through scraping

The invention discloses an anti-piling-compact deep-ploughing rotary cultivator through scraping. The anti-piling-compact deep-ploughing rotary cultivator through scraping structurally comprises a connecting frame, a driver, a soil-loosening leveling device, baffles, cutters and a rotating shaft; the connecting frame is connected with the upper surface of the driver, and the connecting frame is installed on the soil-loosening leveling device and connected with the soil-loosening leveling device in a bonding mode. According to the anti-piling-compact deep-ploughing rotary cultivator through scraping, an angle is adjusted through an adjusting shaft, a supporting rod is controlled by a valve port to move along a guide core to adjust the length of the rotary cultivator, the rotary cultivator adapts to deep ploughing of different depths, a cusp rod and a scraping rod enter soil, and through the upward action force on soil at the upper portion of the rotary cultivator when the rotary cultivator advances, the soil is soft and not compacted; meanwhile, breaking blocks are used for secondary smashing, smashing blocks carrying out primary smashing on soil blocks thrown backwards under the centrifugal force effect, impact force is reduced through buffering pads and extrusion blocks, it is avoided that a cover shell is impacted and damaged, wet surplus soil stuck on the surfaces of the cutters is cleaned through brushing heads driven by rotating discs, the sharp degree of the cutters is kept.

Owner:惠安铁邦五金制品有限公司

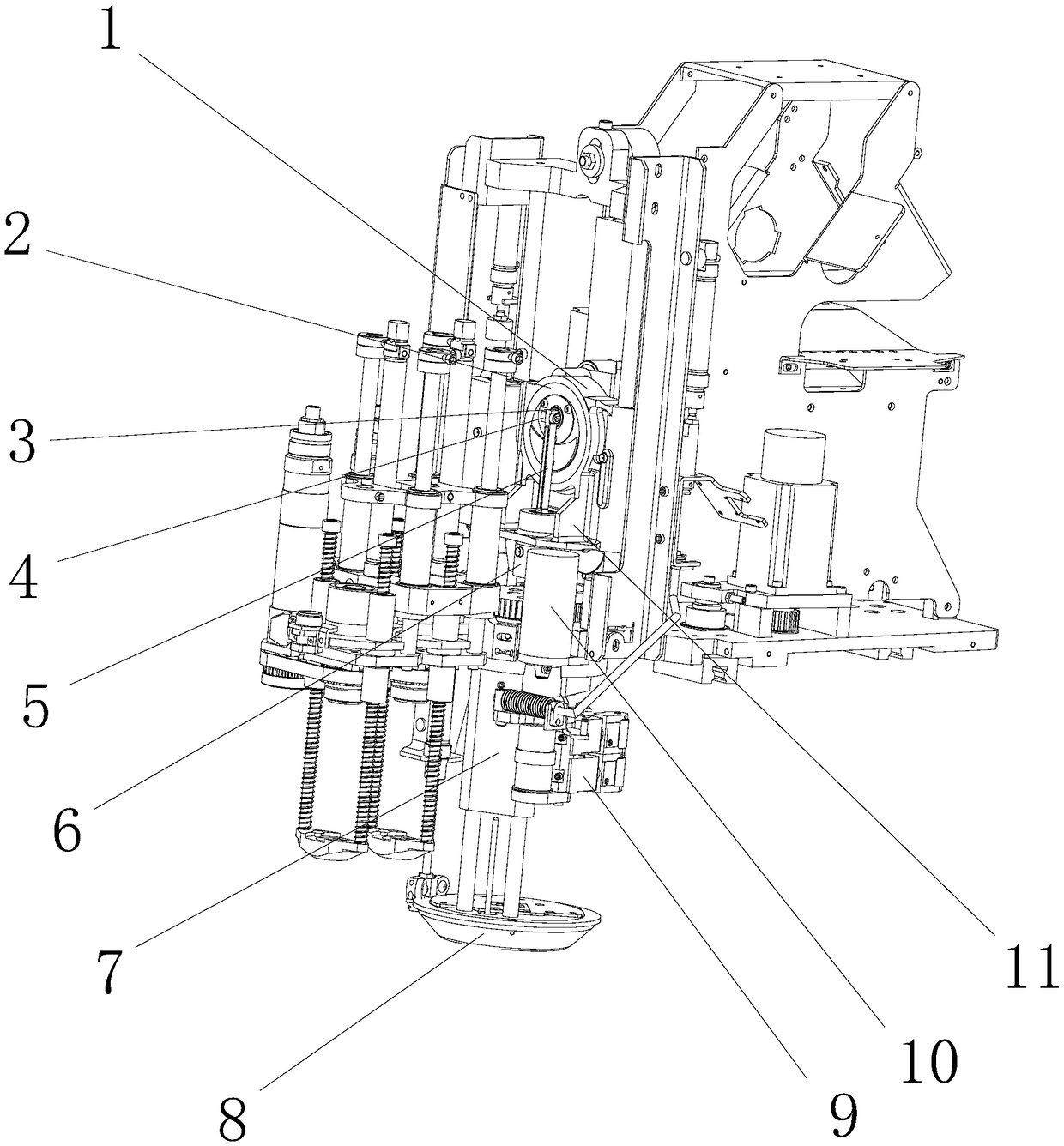

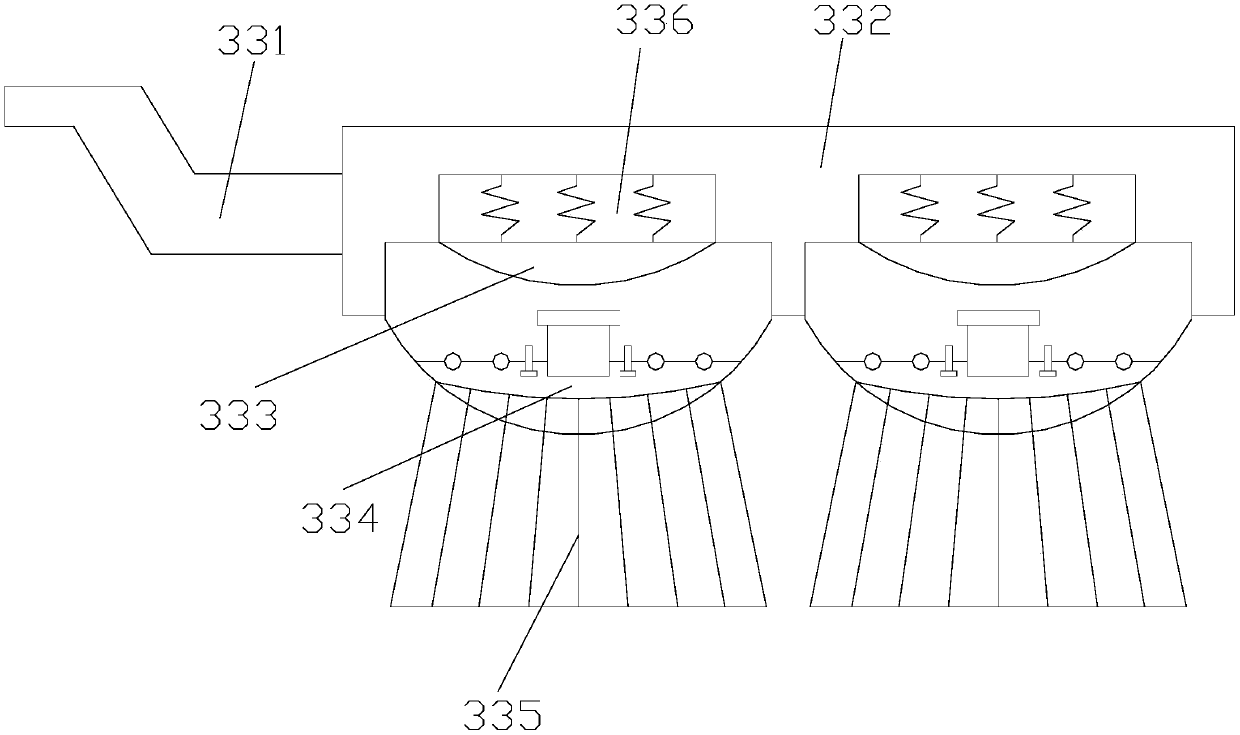

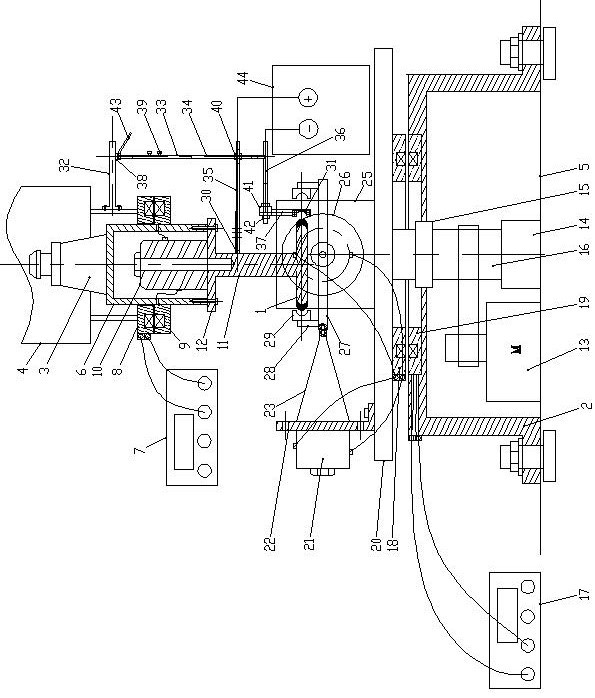

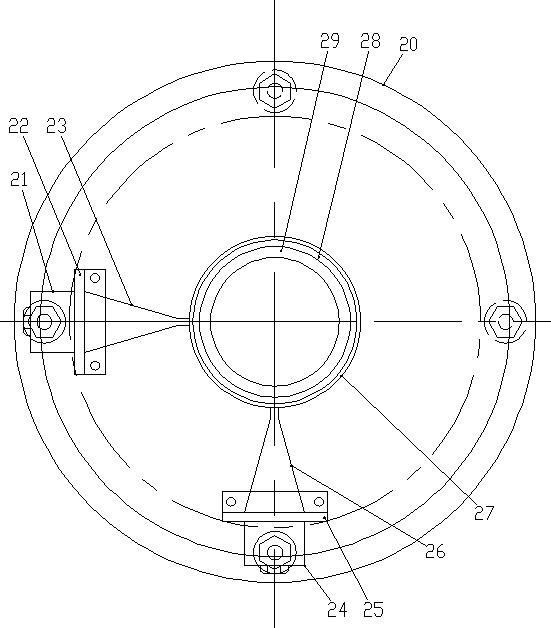

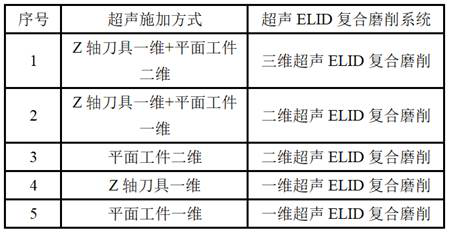

Multi-dimensional ultrasonic ELID grinding machining device for inner raceway of bearing

PendingCN114750005AGuaranteed sharpness and contourImprove fatigue lifeAbrasive surface conditioning devicesGrinding work supportsKnife handlesManufacturing engineering

A multi-dimensional ultrasonic ELID grinding machining bearing inner raceway device comprises a cutter ultrasonic part, an ELID finishing part, a workpiece ultrasonic part, a workpiece clamping part and a forming grinding wheel. The cutter ultrasonic part is connected with a machine tool spindle through a cutter handle, the machine tool spindle is arranged vertically downwards, and a forming grinding wheel is fixedly arranged at the lower end of the cutter ultrasonic part to achieve additional ultrasonic vibration on the forming grinding wheel. Two electrodes of the ELID dressing part are connected with the center and the circumferential edge of the formed grinding wheel correspondingly, and online electrolytic dressing of the formed grinding wheel is achieved. The workpiece ultrasonic part is fixed to a machine tool workbench, and the workpiece clamping part is arranged on the workpiece ultrasonic part to achieve addition of workpiece ultrasonic vibration. The precise grinding of the inner raceway of the bearing can be completed, and meanwhile, the machining efficiency and the machining quality of the workpiece can be greatly improved through the addition of the multi-dimensional ultrasonic action of the cutter and the workpiece, so that the super grinding machining of the precise inner raceway of the bearing is realized.

Owner:PINGDINGSHAN UNIVERSITY

Grinding machine for fine conical surface of air valve

PendingCN112935949APlay a limiting rolePrevent slipping outGrinding carriagesRevolution surface grinding machinesSpray nozzleEngineering

The invention discloses a grinding machine for a fine conical surface of an air valve. The grinding machine comprises a machine body, a workpiece main shaft assembly, a grinding wheel shaft assembly and a finishing shaft assembly, wherein an online dynamic balance device is arranged in the grinding wheel shaft assembly, a sound wave monitoring device is arranged in the finishing shaft assembly, and an air valve auxiliary supporting device opposite to the grinding wheel shaft assembly is arranged on one side of the workpiece main shaft assembly on the machine body; an air valve positioning device provided with a universal positioning head is arranged at the position opposite to the workpiece spindle assembly, a grinding fluid spray nozzle in communication with a grinding fluid booster pump is arranged at the position opposite to the valve grinding position, and a fire extinguishing device is arranged on the lathe bed; and the fire extinguishing device comprises a temperature inductive sensor and a fire extinguishing spray nozzle of which the mounting positions are opposite to the air valve grinding part. The grinding machine for the fine conical surface of the air valve can maintain the dynamic balance precision of the grinding wheel shaft for a long time, automatically monitors the grinding wheel dressing quality, improves the air valve positioning precision and reduces the bending deformation of the air valve in the grinding process, and is high in grinding efficiency and safe and reliable to use.

Owner:江苏吉斯特科技有限公司

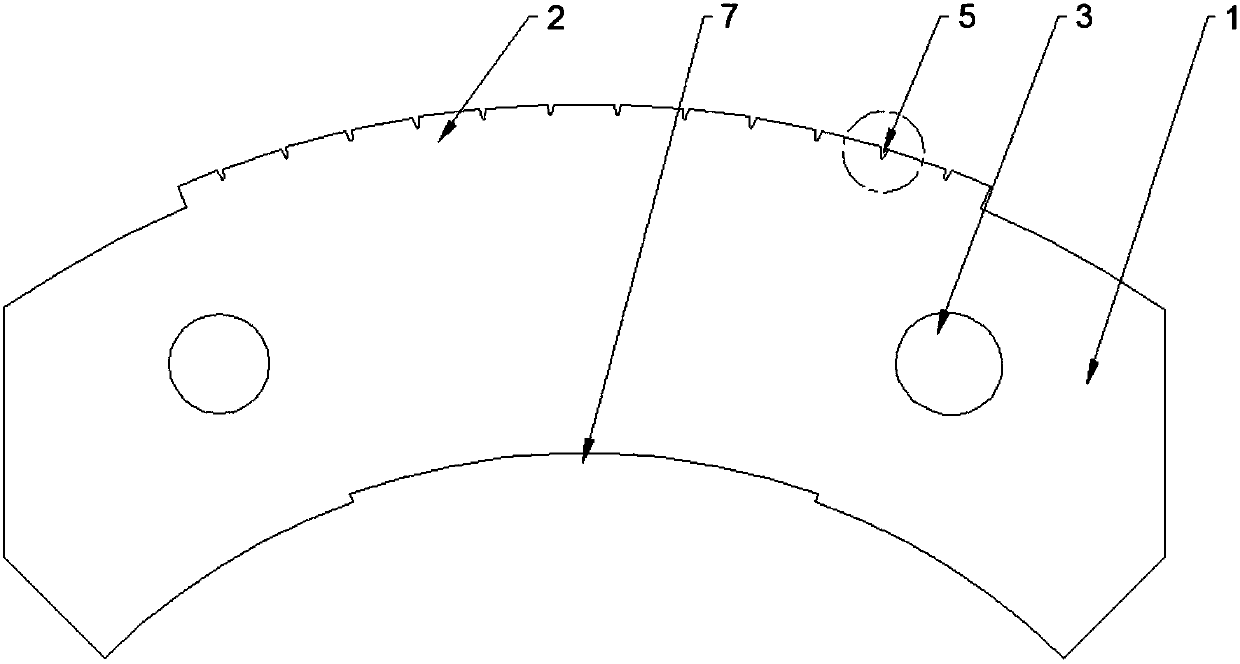

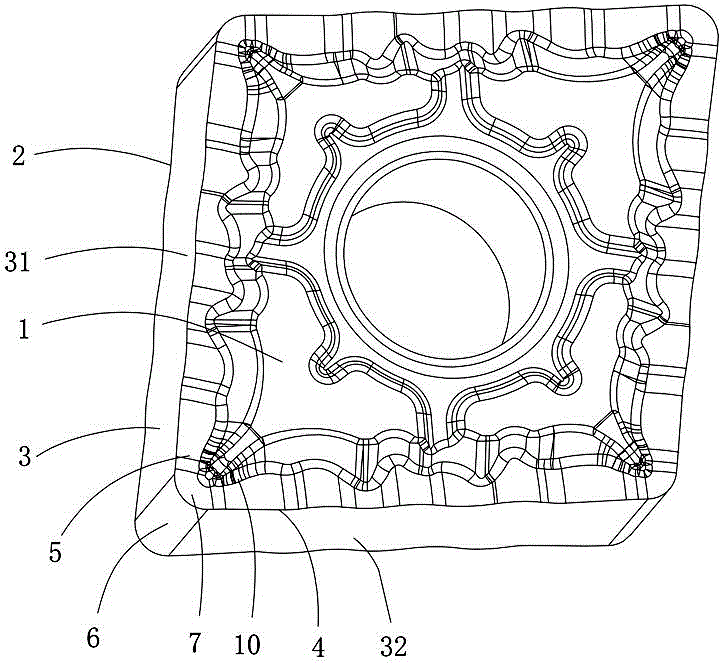

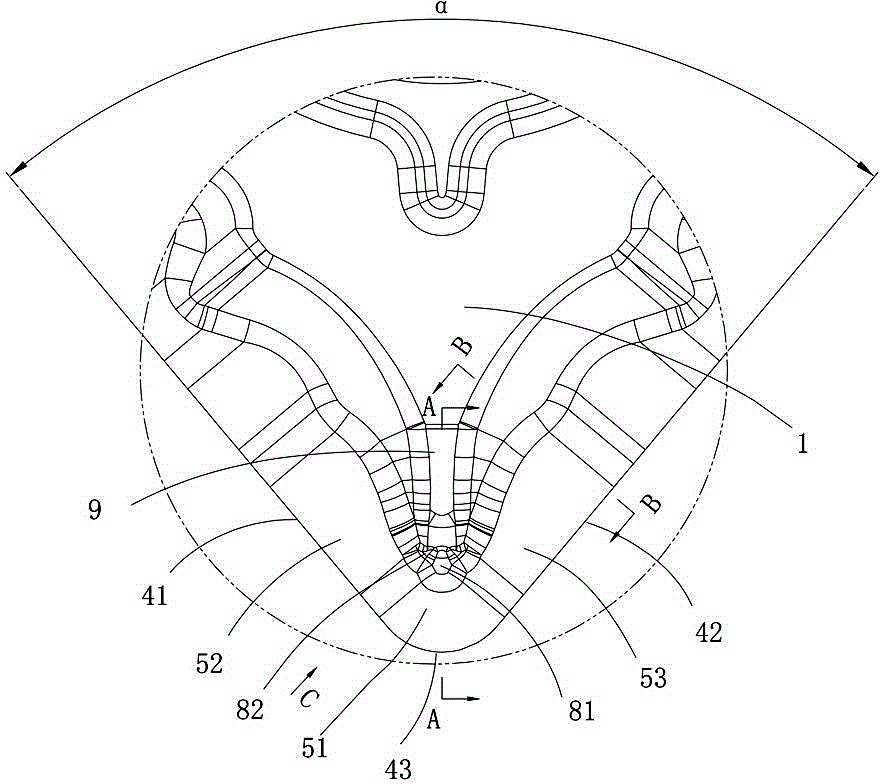

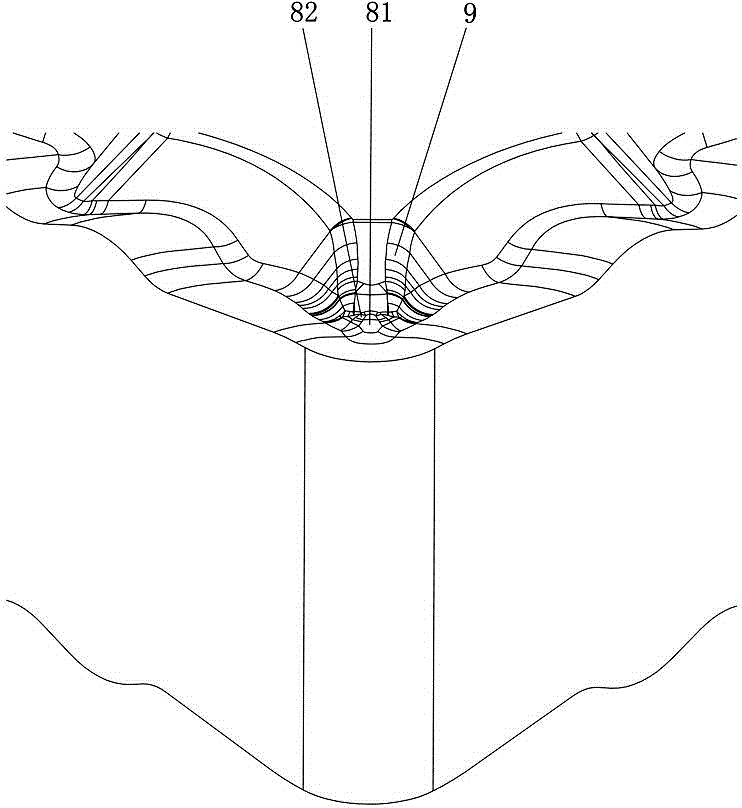

Rotary turning blade

ActiveCN104858460AGuaranteed sharpImprove surface qualityCutting insertsTurning toolsEllipseKnife blades

The invention discloses a rotary turning blade; the upper surface of the blade at a guiding surface formed on a cutting edge is a front blade surface; two adjacent sidewalls transit through the connection of a cylindrical surface; the upper surface, the sidewalls and the cylindrical surface intersect to form the point of a knife; the front blade surface corresponding to a blade tip edge and two side edges are divided into the front blade surface of the blade tip edge and the front blade surfaces of two side edges; the front blade surfaces of two side edges transit toward the front blade surface of the blade tip edge, and the included angle between the front blade surfaces of two side edges and the front blade surface of the blade tip edge grows big gradually, and the width of the edges grows small gradually; a chip breaker groove is set at the center of the top of the blade tip; the chip breaker groove comprises an oval large protruding ball, two oval small protruding balls and a T-shaped boss; the oval large protruding ball and the two oval small protruding balls distribute in a radiation way; the boss is set at one side of the oval small protruding balls far from the blade tip; and the bottom of the chip breaker groove transits in a smooth way. The blade has the blade tip and has the advantages of sharpness and intensity, controllable chip flow and shape. The blade is suitable for fine finishing and semi-finishing etc.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com