Polishing liquid for stainless steel material and use thereof

A polishing liquid and stainless steel technology, applied in the direction of water-based dispersant, etc., can solve the problems of sticking knife, burns, etc., and achieve the effect of reducing sticking phenomenon, keeping sharpness, and avoiding burns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

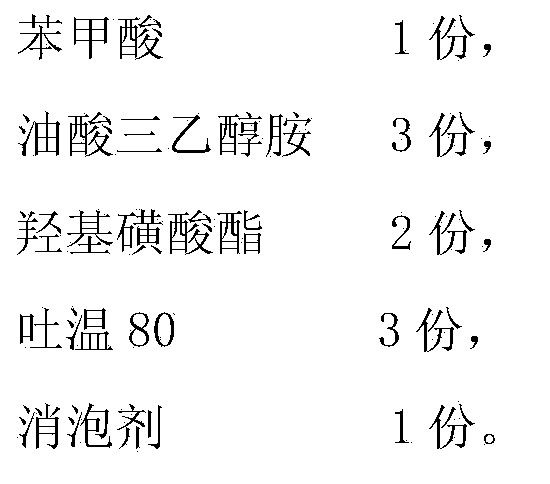

[0028] This embodiment relates to a stainless steel material polishing liquid. The polishing liquid formula contains 1 part of benzoic acid, 3 parts of triethanolamine oleate, 2 parts of hydroxysulfonate, 3 parts of Tween 80 (polyoxyethylene sorbitan monooleate), 1 part of defoaming agent (simethicone).

[0029] Wherein, benzoic acid is a crystal with the smell of benzene or formaldehyde, slightly soluble in water, easily soluble in ethanol, and is a commonly used preservative to protect the metal surface. Triethanolamine oleate has excellent emulsifying and dispersing properties, strong temperature resistance in acidic and alkaline media, and good washing, lubricating and antirust capabilities. The disadvantage is that it is easy to foam. The full name of Tween 80 is polyoxyethylene sorbitan monooleate, which is easily soluble in water and ethanol. Tween 80 can be used as a dispersion and suspending agent. It should be dispersed in the solution, so that the material particl...

Embodiment 2

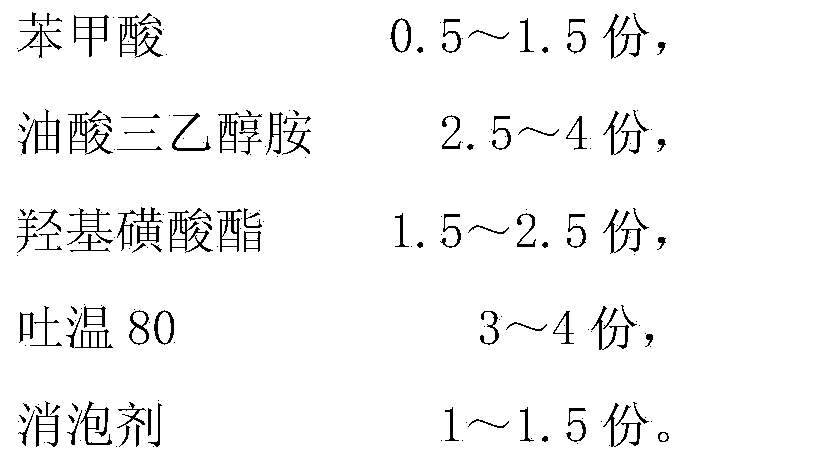

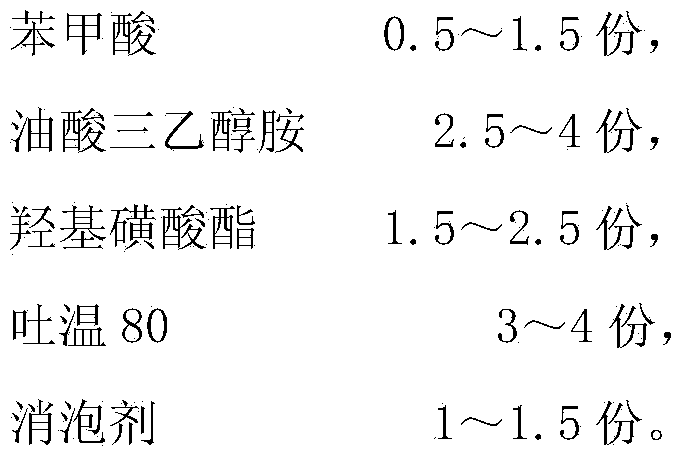

[0035] This embodiment relates to a stainless steel material polishing liquid. The components contained in the polishing liquid formula are the same as in Example 1, and the amounts of the components are different, specifically: 0.5 parts of benzoic acid, 2.5 parts of triethanolamine oleate, 1.5 parts of hydroxysulfonate, Tween 80 (polyoxyethylene Sorbitan monooleate) 3 parts, defoamer (simethicone) 1 part.

[0036] The polishing liquid of the present embodiment is specifically used with embodiment 1:

[0037] Blend the stock solution of the polishing solution at a ratio of 1:4.5, that is, 1 unit of the stock solution of the polishing solution is mixed with 4.5 units of pure water. This polishing fluid is only used when using sandpaper for mechanical rough polishing and semi-finish polishing, not when using other methods (such as abrasive paste) for polishing. When using this polishing fluid, you can refer to the use of cutting fluid on the machine tool, and use the nozzle t...

Embodiment 3

[0039] This embodiment relates to a stainless steel material polishing liquid. The components contained in the polishing liquid formula are the same as in Example 1, and the amounts of the components are different, specifically: 1.5 parts of benzoic acid, 4 parts of triethanolamine oleate, 2.5 parts of hydroxysulfonate, Tween 80 (polyoxyethylene Sorbitan monooleate) 4 parts, defoamer (simethicone) 1.5 parts.

[0040] The specific use of the polishing liquid in this embodiment is the same as that in Example 1: the polishing liquid stock solution is blended, and the blending ratio is 1:5.5, that is, 1 unit of polishing stock solution is mixed with 5.5 units of pure water. This polishing fluid is only used when using sandpaper for mechanical rough polishing and semi-finish polishing, not when using other methods (such as abrasive paste) for polishing. When using this polishing fluid, you can refer to the use of cutting fluid on the machine tool, and use the nozzle to spray the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com