Continuous casting monolithic stopper and method of manufacture thereof

A technology of integral stopper rod and continuous casting, which is used in manufacturing tools, casting equipment, casting melt containers, etc., can solve the problems that stopper rods have not yet been used, and achieve good thermal shock resistance, high temperature strength, and erosion resistance. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

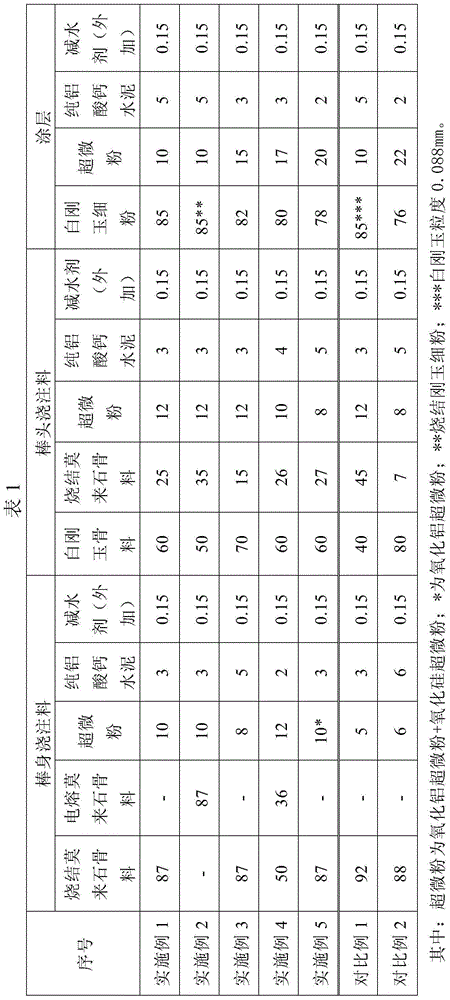

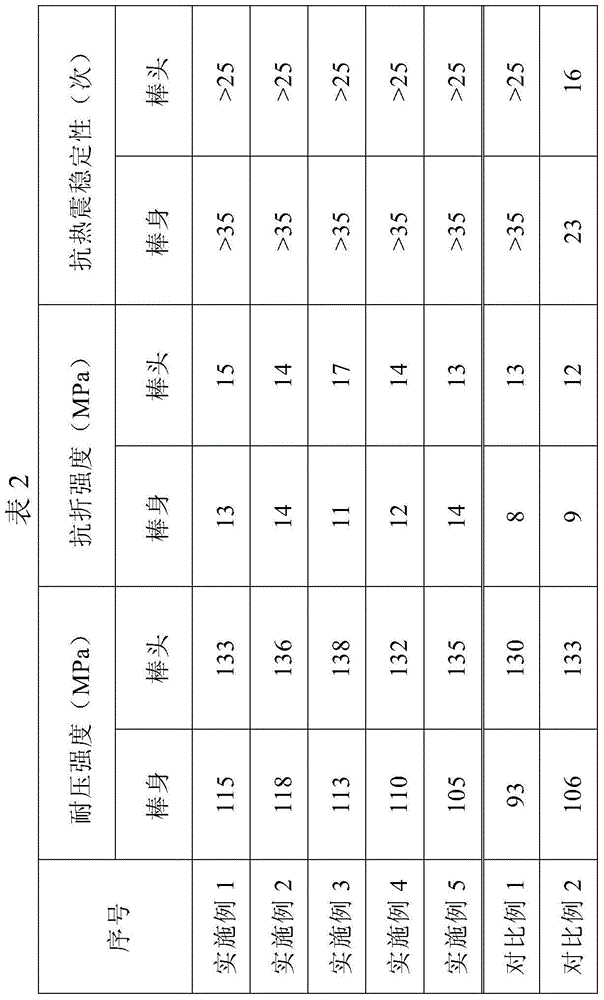

[0052] The rod castables, rod head castables and Al of Examples 1-5 of the present invention 2 o 3 The composition of the coating is shown in Table 1, wherein the content of each component is expressed in mass percentage (wt.%).

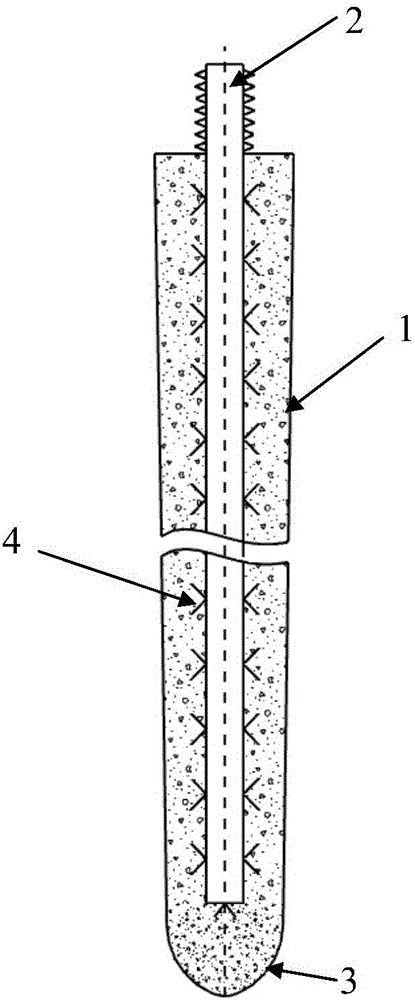

[0053] Embodiment 1-5 of the present invention has a body diameter of 140-160 mm as a whole stopper rod, steel core adopts a steel pipe with an outer diameter of 40-55 mm, the lower port of the steel pipe is welded and sealed with a steel plate, and a downward anchor is provided.

[0054] The production method of integral stopper for continuous casting of the present invention comprises the steps:

[0055] 1) Molding

[0056] Fix the steel core at the center of the stopper mold, and brush the inner wall of the stopper mold with machine oil;

[0057] 2) Pouring molding

[0058] First add a water reducing agent to the casting material for the rod head prepared according to the ratio in Table 1, add water and stir evenly, pour it into the stopper mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com