Patents

Literature

389results about How to "High blackness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

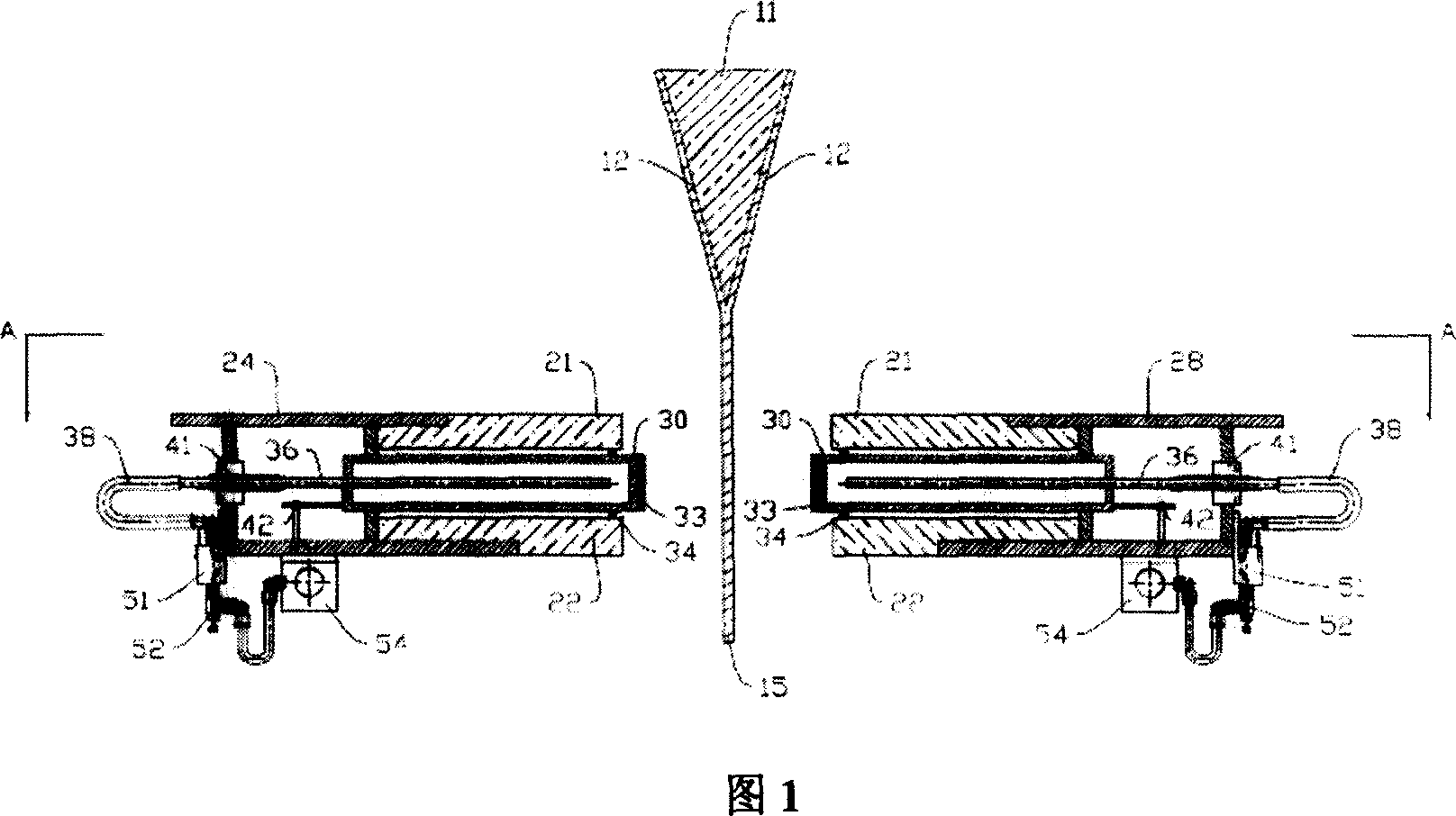

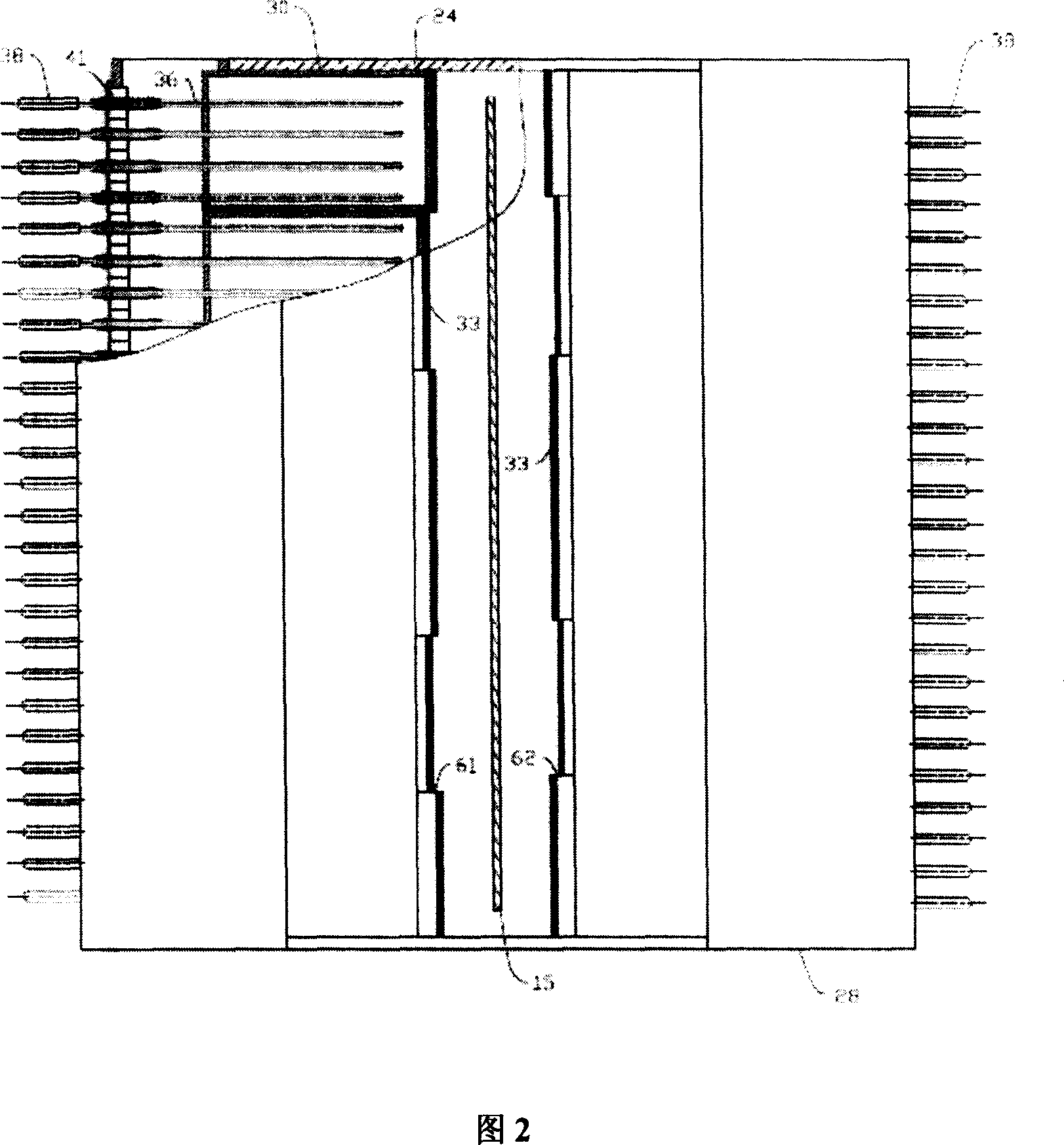

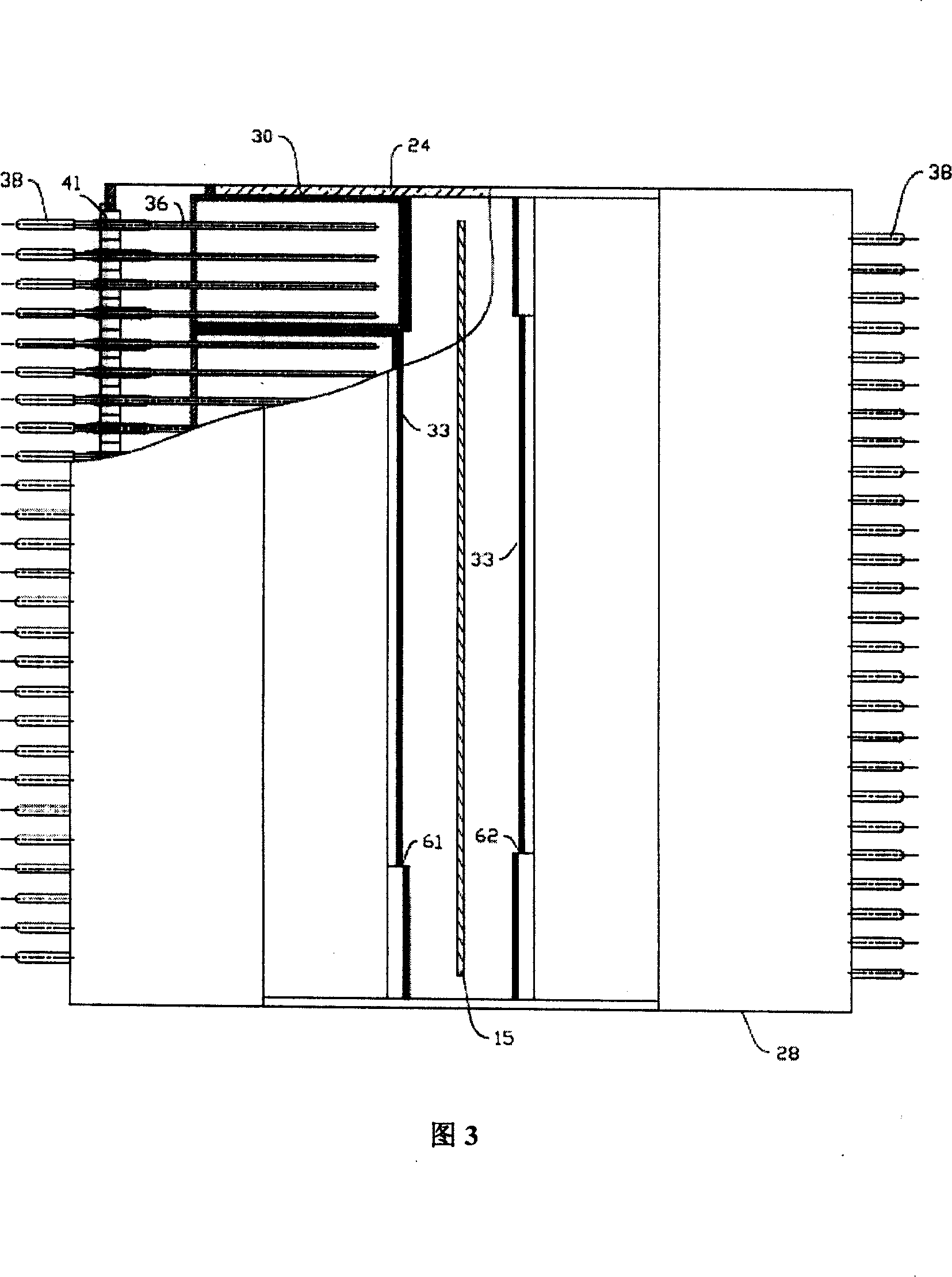

Device and method for controlling glass-board thickness evenness

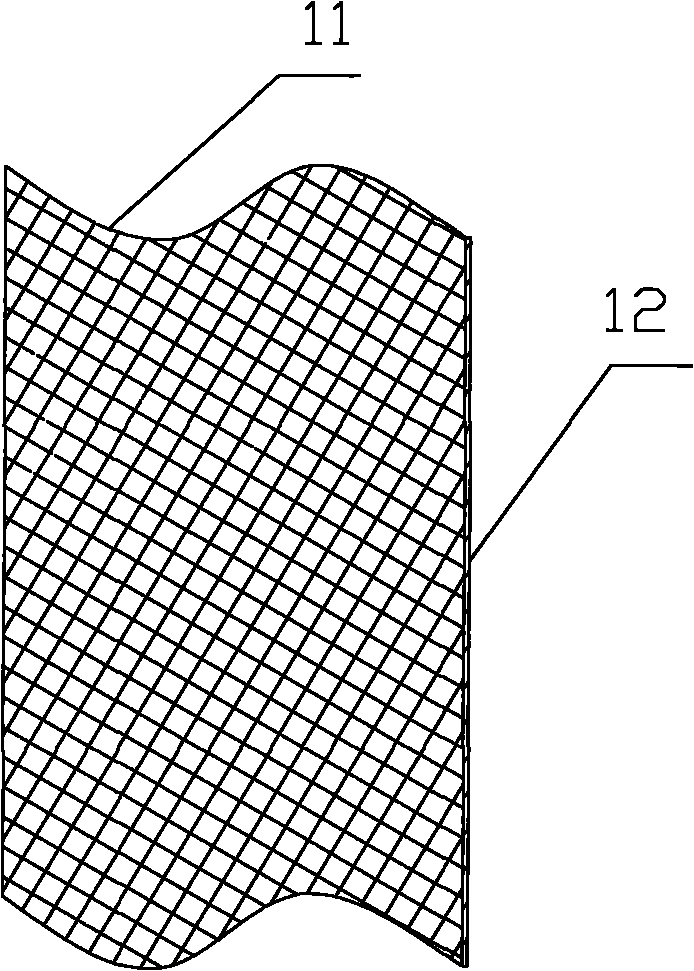

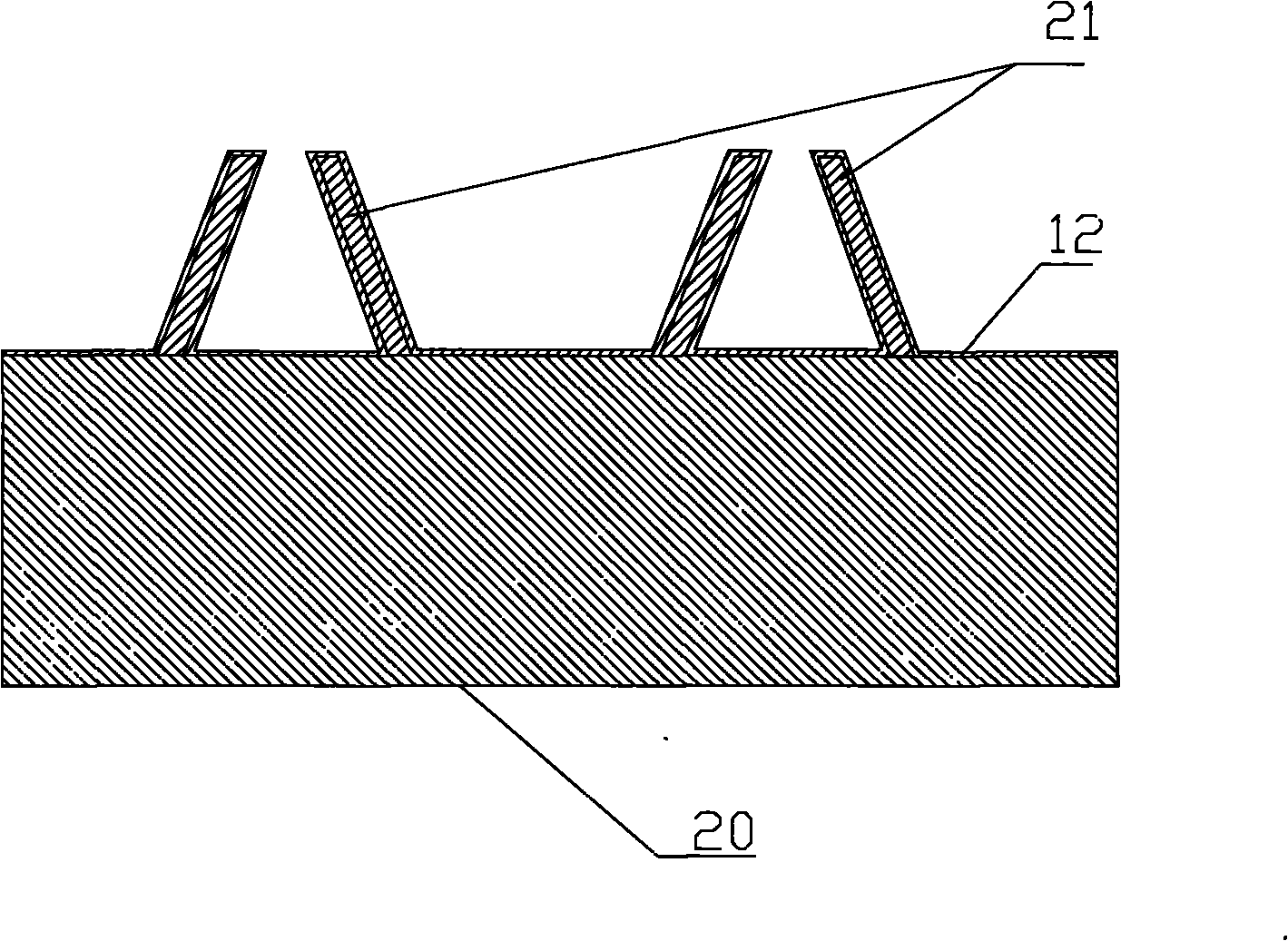

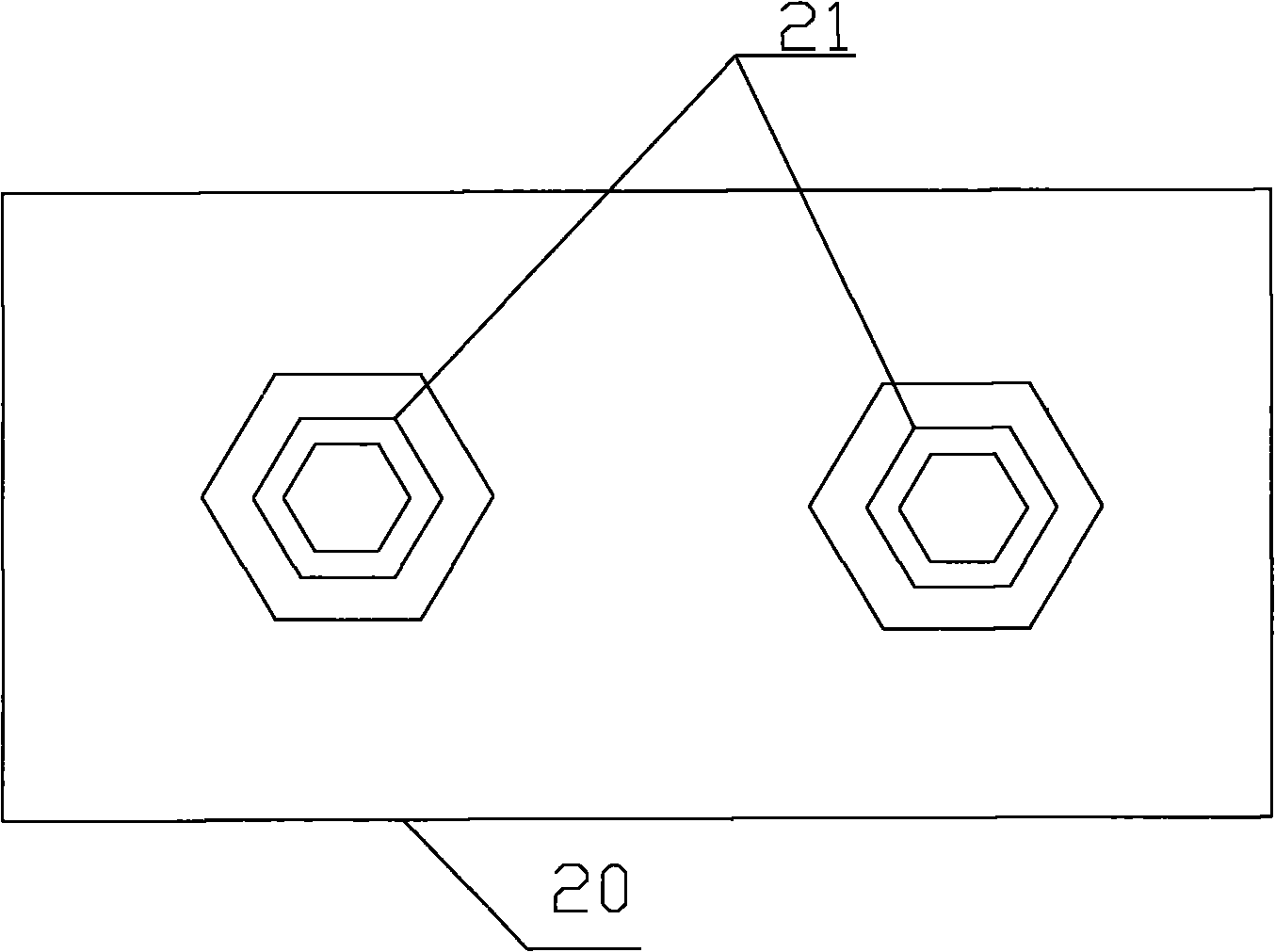

InactiveCN101028964AControl the degree of heat transferHigh blacknessGlass forming apparatusThermal energyBrick

An apparatus for controlling the thickness uniformity of glass plate is composed of supporting frame, the upper, lower, left and right insulating refractory brick layers for enclosing whole apparatus, and two closed cavities containing at least one fluid tube and arranged at both sides of glass plate for collecting the heat to heat the fused glass in irradiation mode. Its method features that the distance between said apparatus and fused glass and the relative position between fused glass and heating element are regulated for controlling the temp of fused glass.

Owner:HENAN ANCAI HI-TECH +1

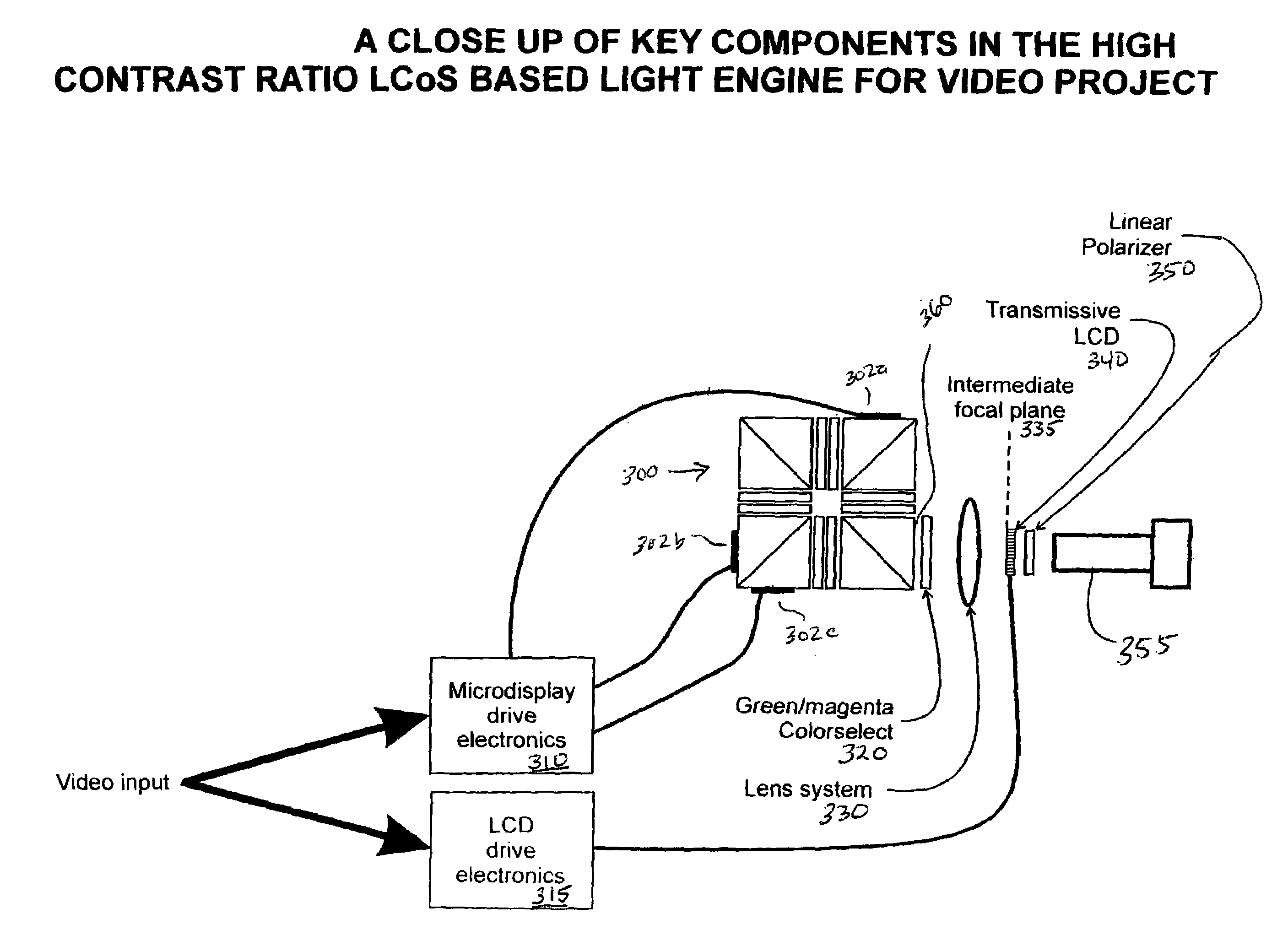

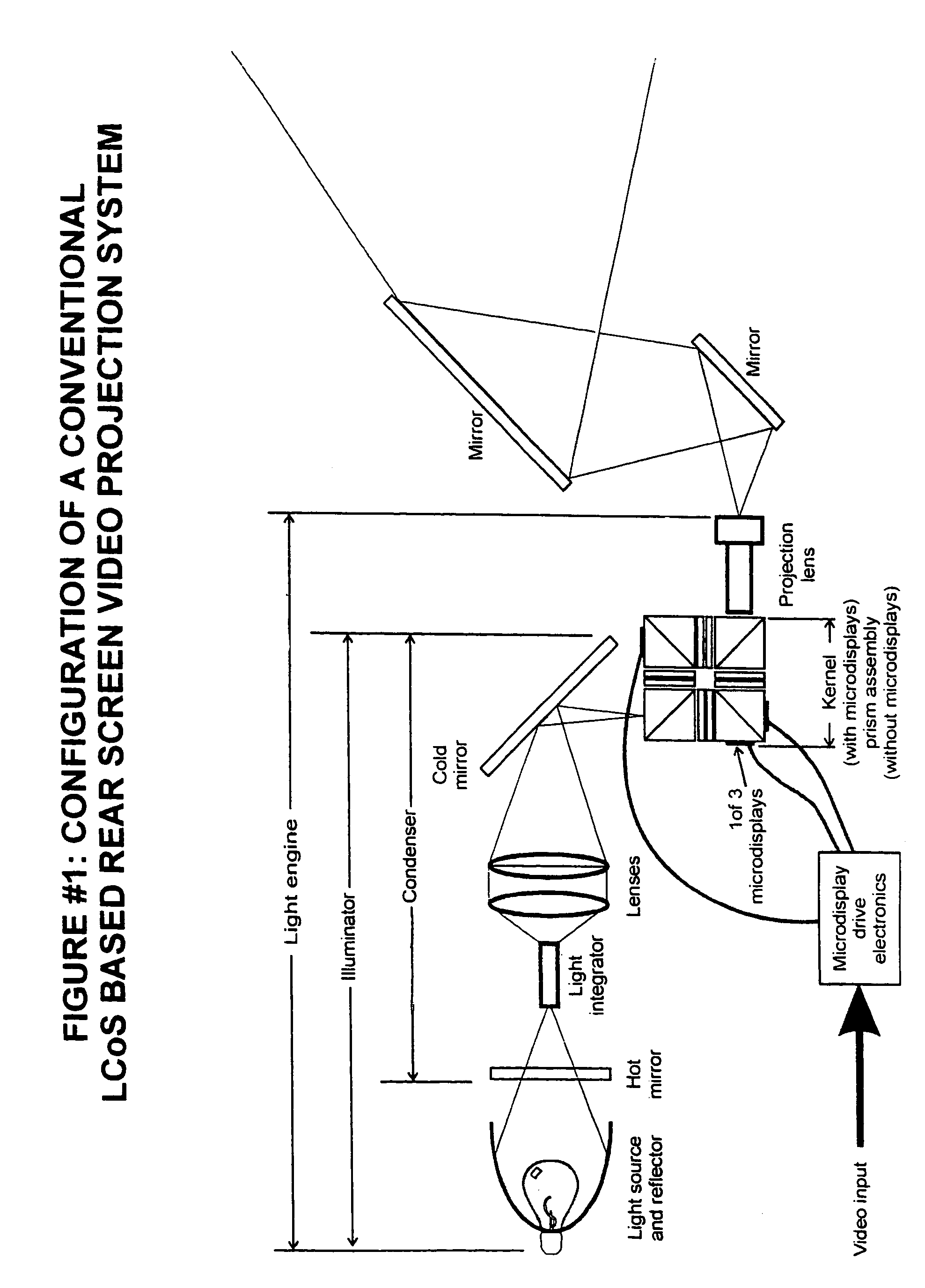

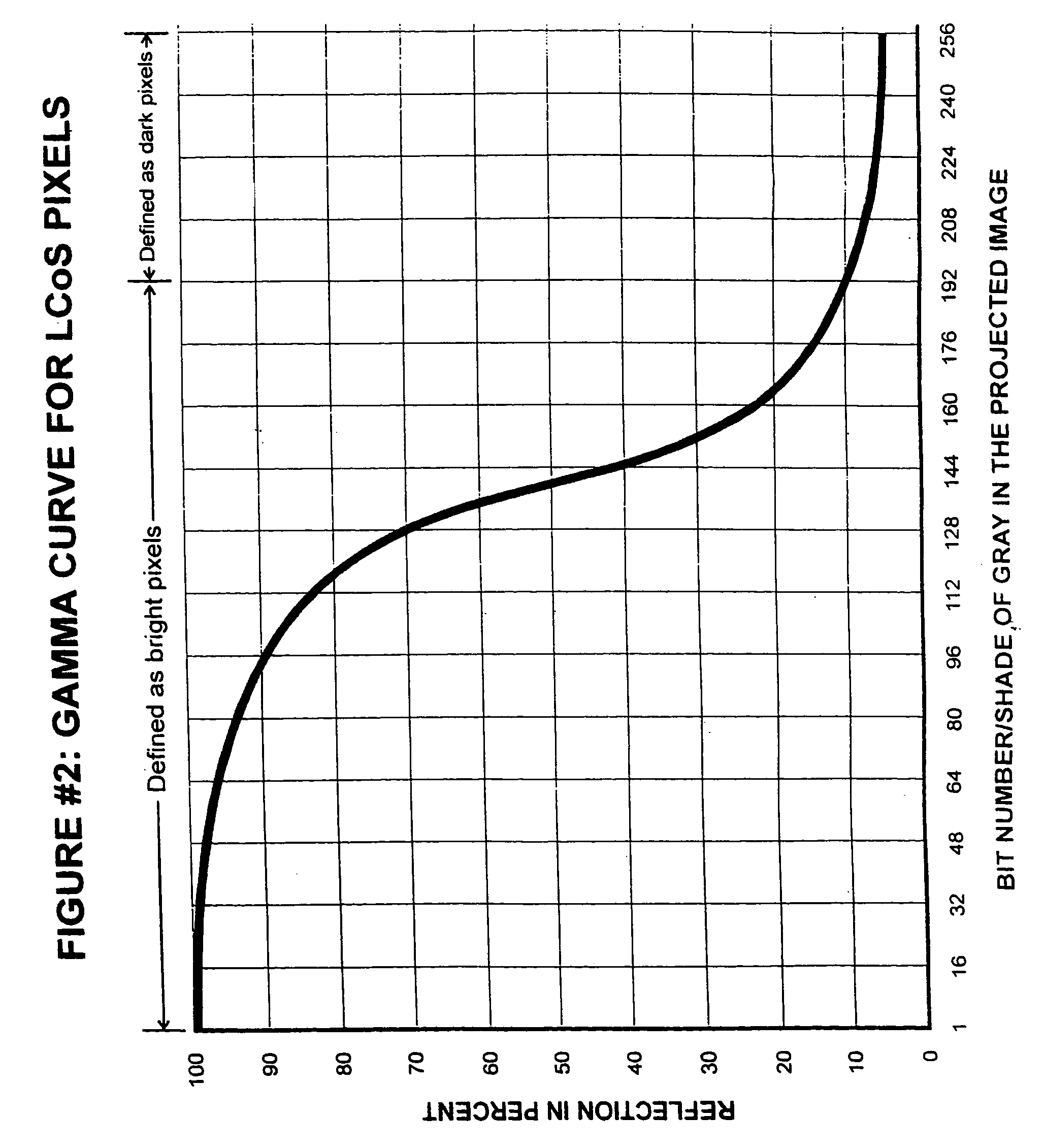

Method and apparatus to increase the contrast ratio of the image produced by a LCoS based light engine

InactiveUS7175281B1Increase contrastReduce transmissionTelevision system detailsStatic indicating devicesTransmittanceComputer vision

A transmissive LCD is placed in optical series with pixels of an image. The transmissive LCD is set to full transmissivity when bright pixels of the image pass through the transmissive LCD. Transmissivity is decreased where pixels darker than a darkening threshold pass through the transmissive LCD. A darkening curve representative of an amount of darkening performed by the transmissive LCD provides an amount of darkening to be performed on each pixel. Preferably, the darkening curve gradually darkens pixels more as the pixels themselves are darker. The darkening curve may be implemented as a formula or a look-up table in software or drive electronics that energize the transmissive LCD. Both the darkening threshold and the darkening curve may be user selectable.

Owner:LIGHTMASTER SYST

Coating compositions that transmit infrared radiation and exhibit color stability and related coating systems

ActiveUS20120308724A1High blacknessRadiation-absorbing paintsElectrostatic spraying apparatusCoating systemPigment

A coating composition suitable for producing coatings that are transparent to infrared radiation and can exhibit color stability, such as a jet black color. The coating compositions include a first tint having a low haze and a second tint having a high haze. The tints include visibly absorbing infrared transparent pigments.

Owner:PPG IND OHIO INC

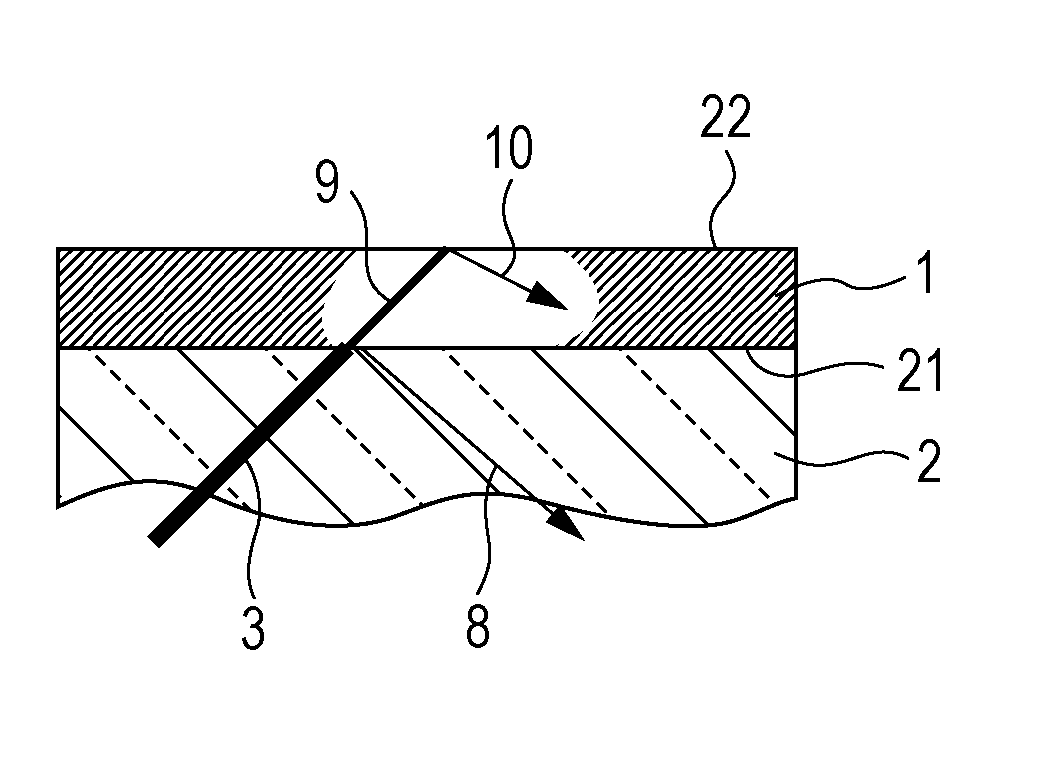

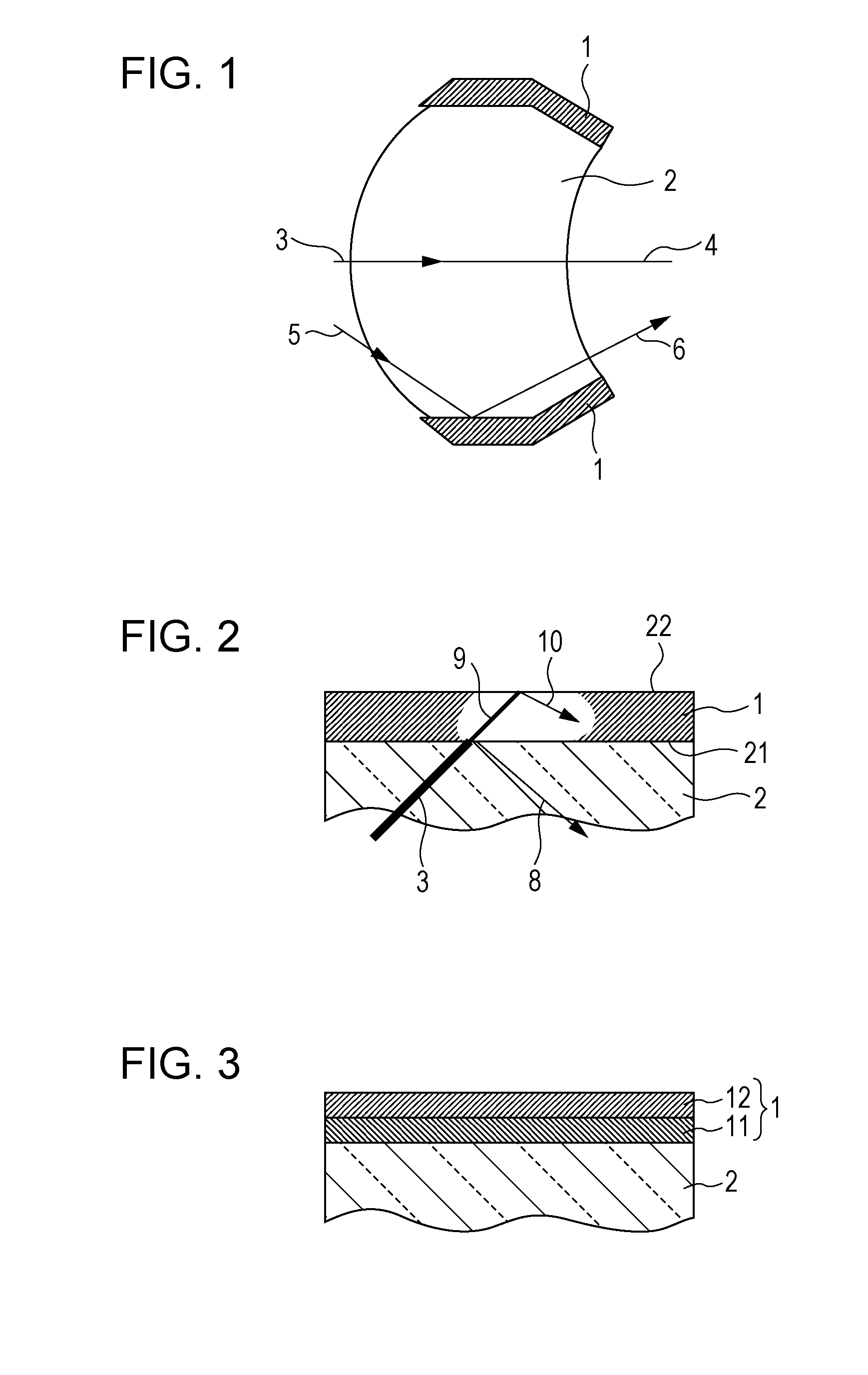

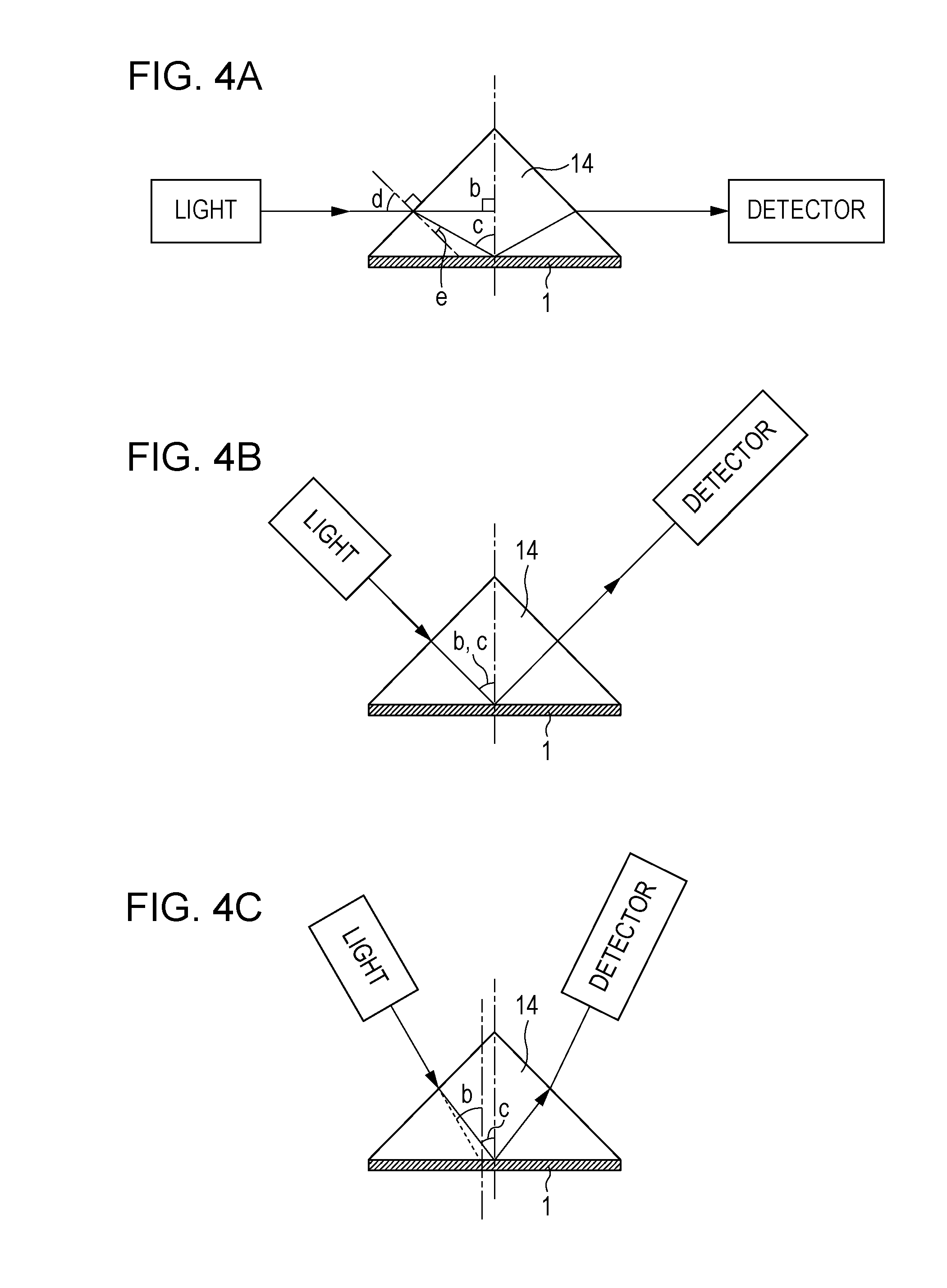

Light-shielding film for optical element and optical element having light-shielding film

InactiveUS20110200810A1Relieve pressureReduce distortionPrismsOther chemical processesWavelength range

A light-shielding film for optical element includes at least a resin and a colorant. The light-shielding film for optical element has an average extinction coefficient of 0.03 or more and 0.15 or less as an average of extinction coefficients of the whole light-shielding film for light having wavelengths ranging from 400 to 700 nm.

Owner:CANON KK

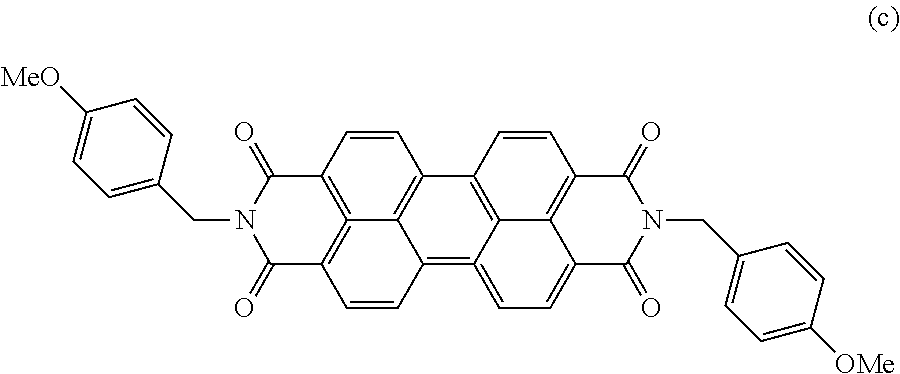

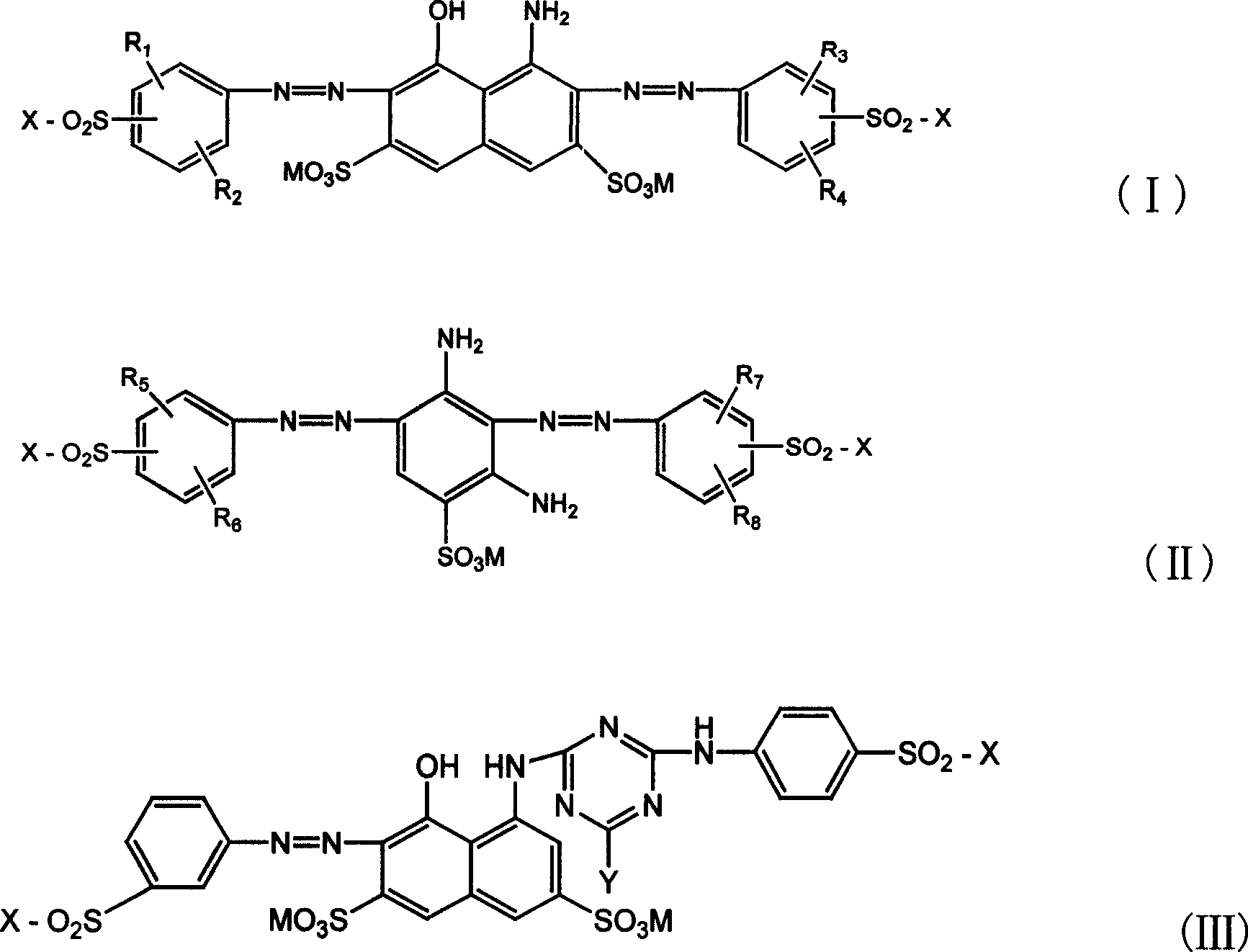

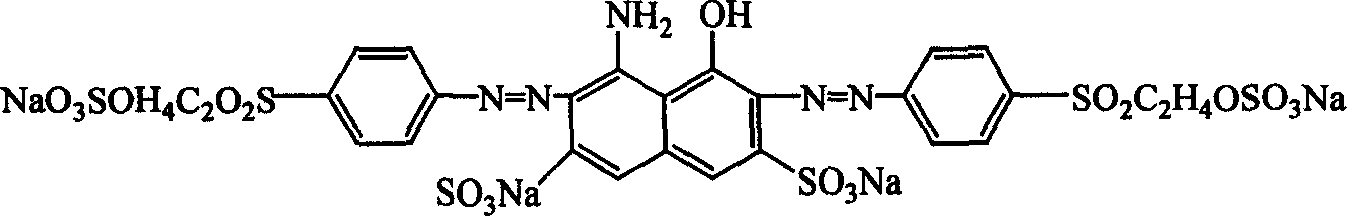

Composite active black dye

The present invention relates to a kind of disazo dyestuffs composition, the described composite active blank dyestuff mainly contains four dyestuffs, said invention also provides their structure formulas. The described composite dyestuff is suitable for dyeing dark colour fabrics, such as cellulose fibre, cotton fibre and synthetic fibre, etc., and has good level-dyeing property, repeatability, high dyeing fastness, fastness to washing and wet rubbing fastness.

Owner:SHANGHAI KEHUA DYESTUFF IND

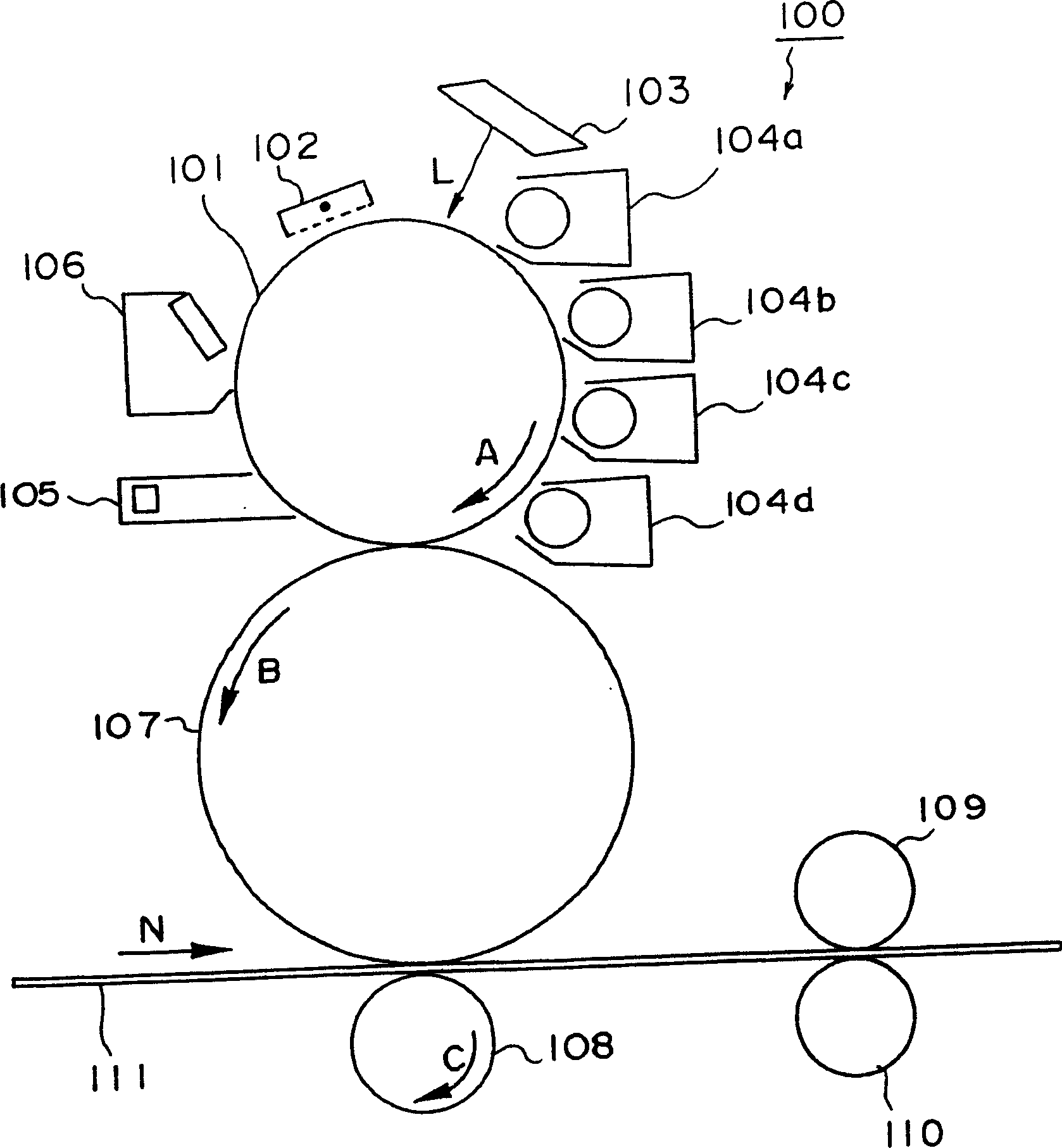

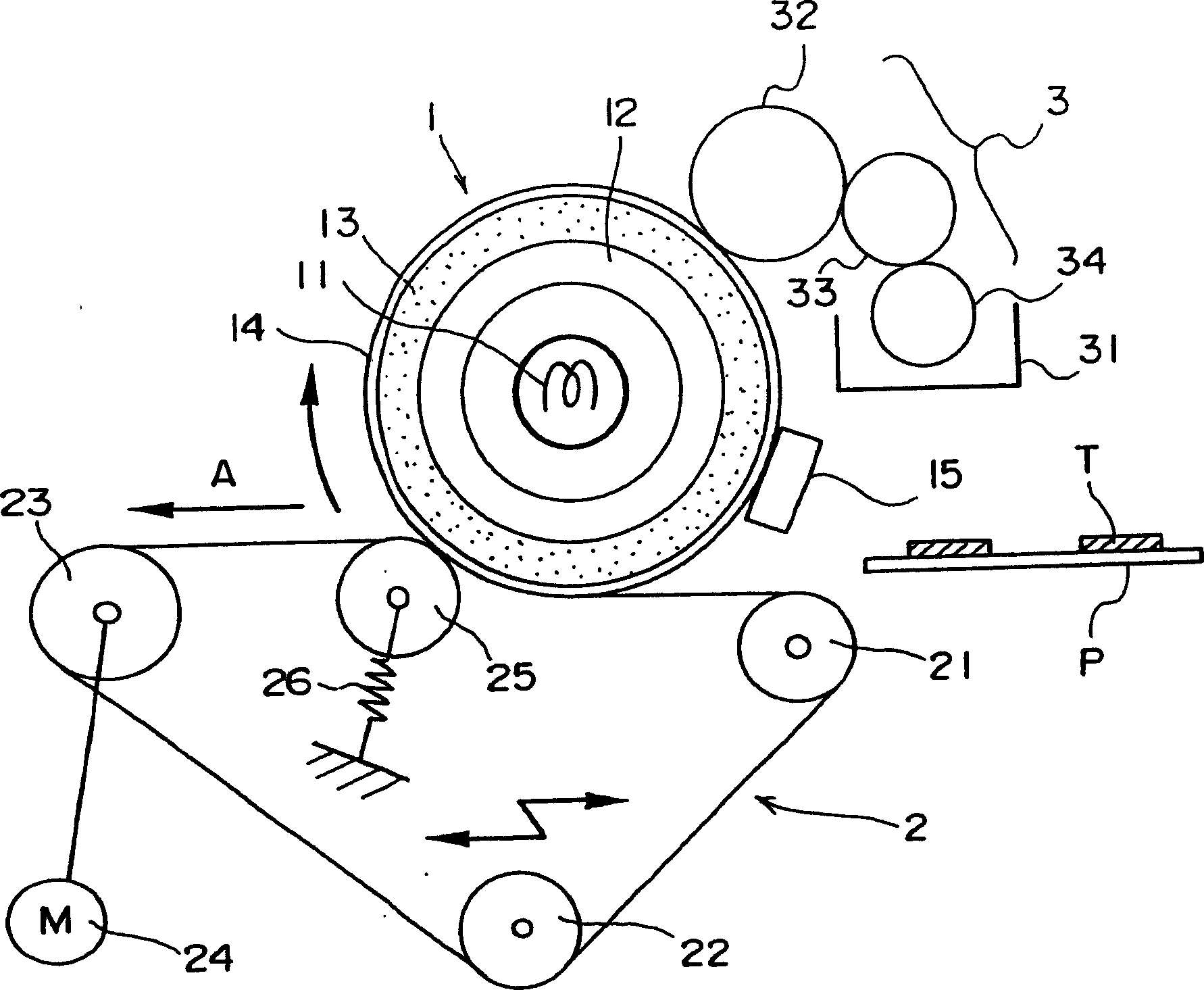

Magnetic toner

To provide a magnetic toner which is excellent in durability and developability even in the case of being applied to high-speed developing process or being used in a large-capacity process cartridge amount of toner in which is increased, and which has high degree of blackness. Provided is a magnetic toner having magnetic toner particles containing at least a binder resin and magnetic material particles each comprising a predetermined amount of a titanium compound, characterized in that:1) the magnetic material particles have a predetermined amount of adsorbed moisture at a relative vapor pressure of 50%; and2) a difference between the amount of moisture adsorbed to the magnetic material particles in an adsorbing process for increasing a relative vapor pressure and the amount of moisture adsorbed to the magnetic material particles in a desorbing process for reducing a relative vapor pressure is reduced.

Owner:CANON KK

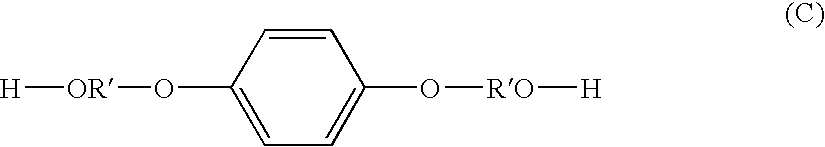

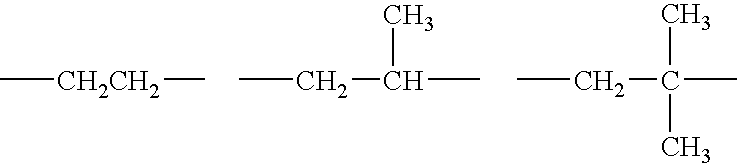

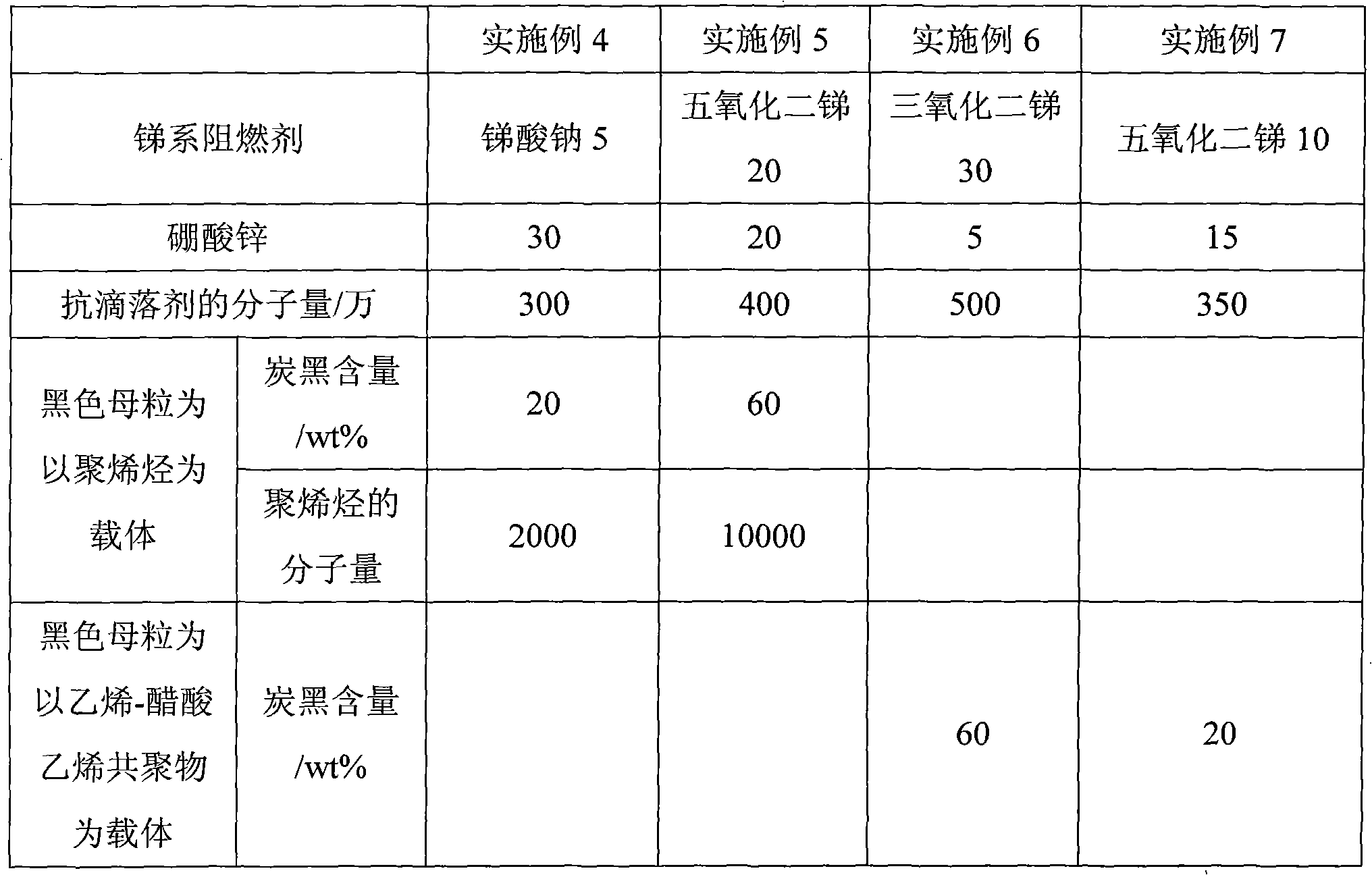

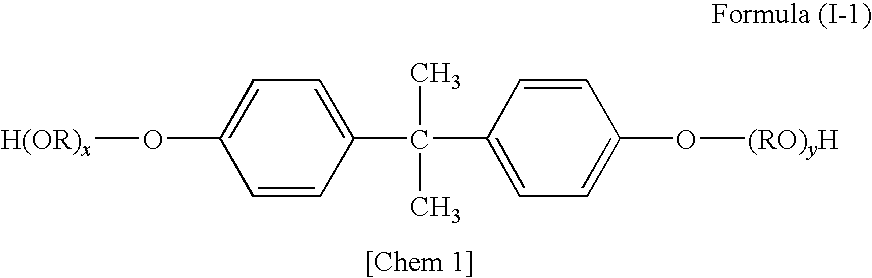

Low-L value inflaming retarding ABS modified resin and preparation method thereof

The invention relates to a low-L value (less than 27) inflaming retarding ABS modified resin and a preparation method thereof. The resin comprises the components with the content (based on parts by weight): 100 parts of ABS resin, 10-25 parts of brominated flame retardant, 20-40 parts of inorganic inflaming retarding master batch, 0.1-0.5 part of anti-dripping agent, 0.2-1 part of antioxidant, 0.1-0.5 part of light stabilizer, 1-3 parts of lubricating agent and 1-4 parts of black master batch. Compared with the prior art, the invention has reasonable technique, overcomes the defect of high L value (namely, low degree of blackness) of the existing inflaming retarding ABS resin, and adopts the novel high-efficiency inflaming retarding synergistic effect technology. The invention leads the resin has higher degree of blackness by reasonably selecting the grain diameter of antimony trioxide, a carbon black lubricating dispersion system and the processing technique of a master batch method on the basis of maintaining the excellent performance of the inflaming retarding ABS resin, and has wide application prospect in the field of the requirement of high degree of blackness.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Treatment method of black hard microarc oxidation ceramic membrane on surface of magnesium alloy

InactiveCN102021631AUniform colorImproved color stabilityAnodisationElectrolysisPlasma electrolytic oxidation

The invention belongs to the treatment technology of a black hard ceramic membrane on the surface of magnesium alloy, in particular relating to a treatment method of a black hard microarc oxidation ceramic membrane on the surface of magnesium alloy. The invention mainly solves the technical problems that the colour of a ceramic membrane treated by magnesium alloy microarc oxidation is white or grey white mostly and the deep colour and even black ceramic membranes can not be obtained in the prior art. The method provided by the invention comprises the steps that sodium phosphate, sodium fluoride, sodium hydroxide, sodium molybdate, potassium carbonate, sodium tungstate, copper sulphate and potassium dichromate are added into water and prepared into an alkaline electrolytic solution, and the solution is stirred for later use; and then magnesium alloy and a stainless steel plate are immersed into the alkaline electrolytic solution, the magnesium alloy is taken as an anode, the stainless steel plate is taken as a cathode, and microarc oxidation treatment is carried out until a compact black hard ceramic membrane grows in situ on the surface of the magnesium alloy.

Owner:杭州意来客电器设备有限公司

High-temperature glaze coating, preparation method thereof, binder and using method of coating

The invention discloses a high-temperature glaze coating, a preparation method thereof, a binder and a using method of the coating, and aims at solving the problems of poor high-temperature resistance, low emissivity and absorptivity in a high-temperature zone, instability, and easiness of attenuation of the existing far-infrared energy-saving coating. The high-temperature glaze coating has the characteristics of good radiation heat transfer effect, high external blackness (the emissivity is greater than 0.95) and the like, and has the advantages of stable emissivity and absorptivity, non-attenuation performance and long service life in a long-term use process. Meanwhile, the coating can be tightly combined with a basal body by matching with the binder disclosed by the invention; the adhesive force is increased; a glazed ceramic polymer can be formed on the basal body after high-temperature sintering; the high-temperature glaze coating has the advantages of hardness, abrasive resistance, and long service life, and does not fall off; and the coating disclosed by the invention can also evenly coat the surface which cannot be covered by general coatings.

Owner:四川科达节能技术有限公司

Magnetic toner

ActiveUS7544455B2Improve development performanceHigh blacknessDevelopersDielectric lossAqueous solution

A magnetic toner having magnetic toner particles each containing at least a binder resin and a magnetic iron oxide particle, in which: when a solution is prepared by dissolving the magnetic iron oxide particles in an acidic aqueous solution and an Fe element amount in a solution in which all the magnetic iron oxide particles are dissolved is defined as a total Fe element amount, a ratio X of the amount of Fe(2+) in a solution in which the magnetic iron oxide particles are dissolved to a state where 10 mass % of the total Fe element amount is present in the solution (solution having an Fe element-dissolving ratio of 10 mass %) to an Fe element amount in the solution having a specific Fe element-dissolving ratio; and the dielectric loss tangents of the magnetic toner measured at a temperature of 40° C. satisfy specific conditions.

Owner:CANON KK

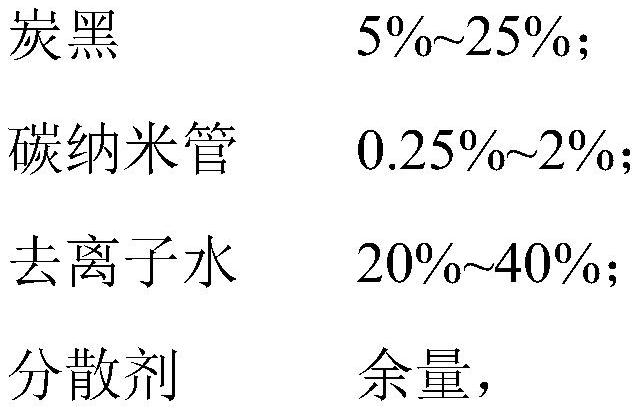

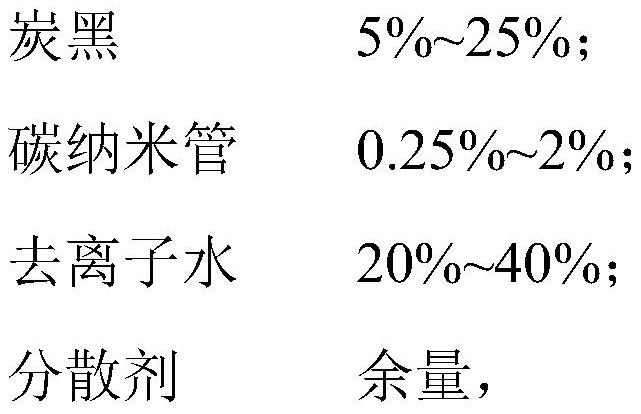

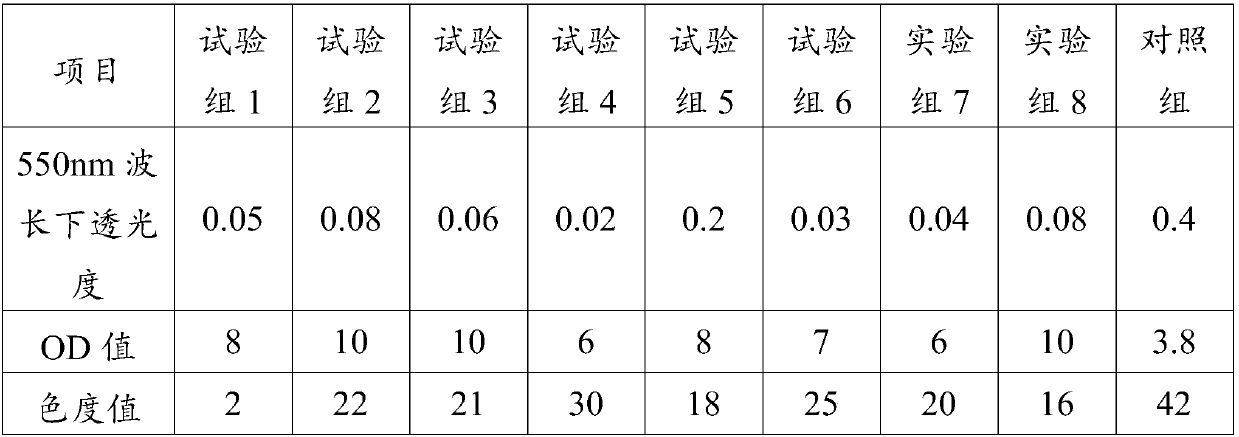

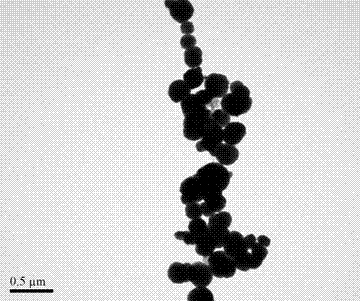

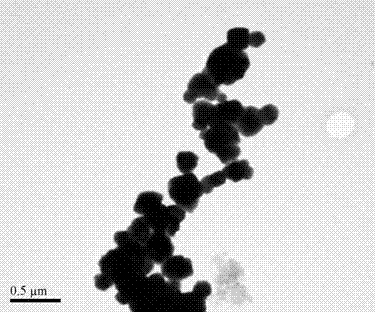

Carbon nanotube ultra-black coating and preparation method thereof

ActiveCN112011232AIncreased reflex difficultyIncrease black chromaRadiation-absorbing paintsChemistryCarbon black

The invention relates to the technical field of coating materials, and provides a carbon nanotube ultra-black coating and a preparation method thereof. The preparation method of the carbon nanotube ultra-black coating provided by the invention comprises the following steps: dispersing carbon black in a first dispersion liquid containing a first dispersing agent, an organic auxiliary agent and deionized water to obtain a first mixed system, and mechanically grinding the first mixed system to obtain a carbon black dispersion liquid, wherein the first dispersing agent is aqueous dispersion resin,preparing a second dispersion liquid mixed with a second dispersant and deionized water, dispersing carbon nanotubes in the second dispersion liquid to obtain a second mixed system, grinding the second mixed system, adding deionized water for dilution to obtain a carbon nanotube dispersion liquid, and carrying out mixing treatment on the carbon black dispersion liquid and the carbon nanotube dispersion liquid to obtain the ultra-black coating. Compared with an ultra-black coating singly taking carbon black as a pigment, the reflectivity of the carbon nanotube ultra-black coating provided by the invention is reduced.

Owner:SHENZHEN XIWAN TECH CO LTD

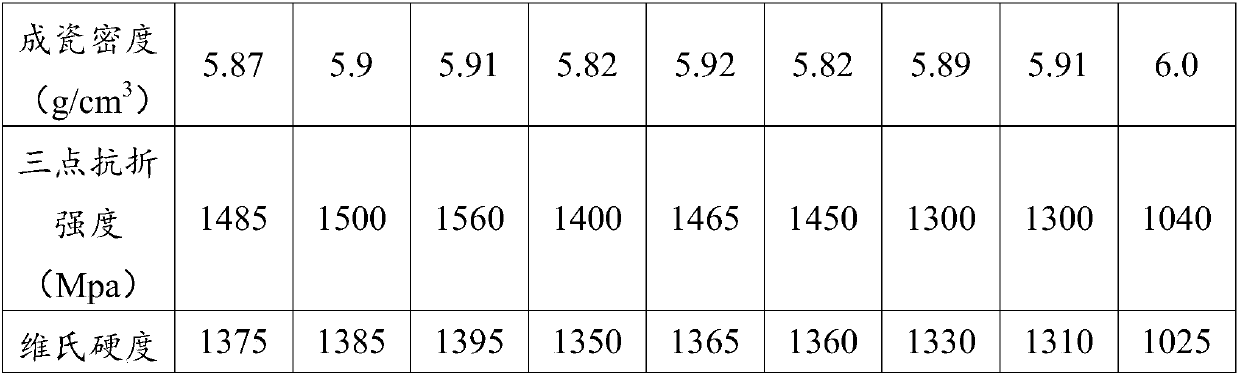

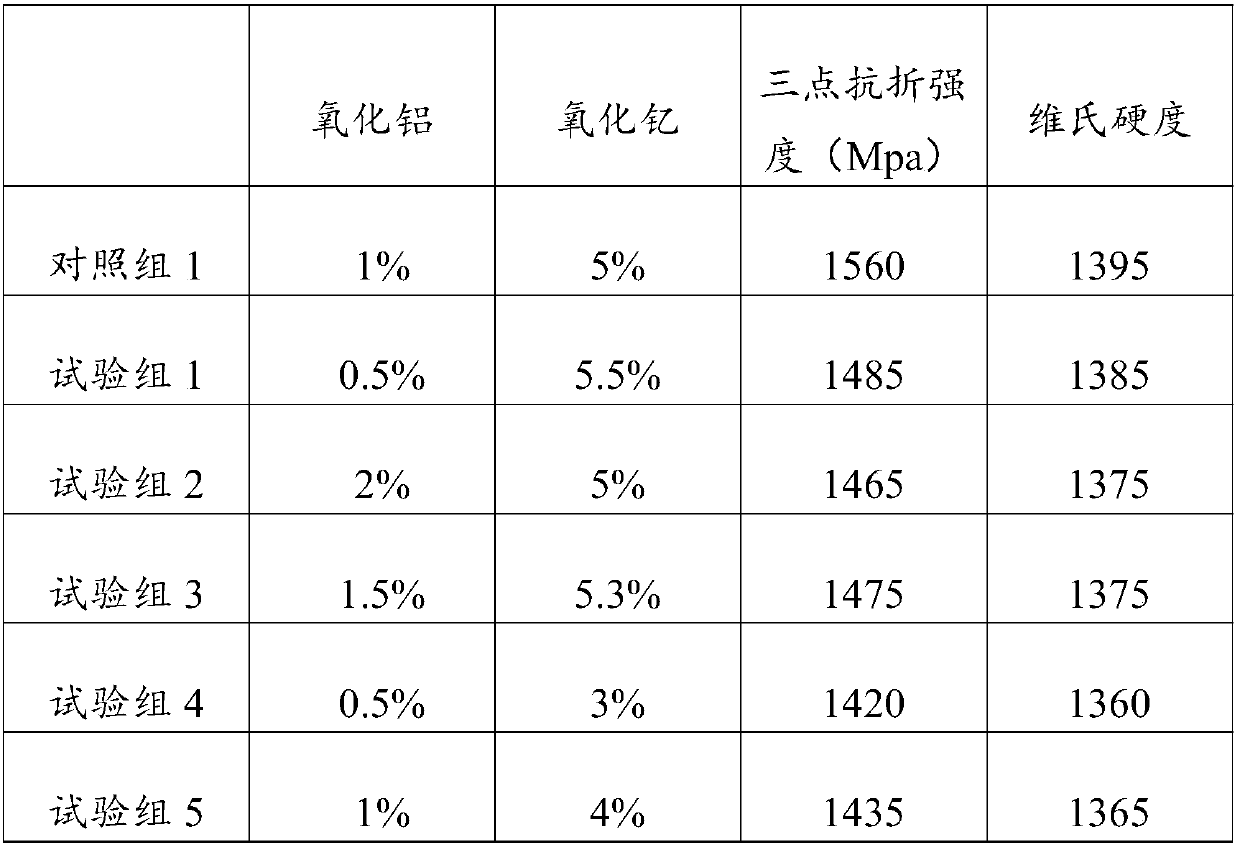

Black zirconia ceramic and preparation method thereof

The invention discloses a black zirconia ceramic material composition. The black zirconia ceramic material composition is prepared from the following ingredients in percentage by mass: 0.01-4% of ferric oxide, 0.01-3.5% of cobaltous oxide, 0.01-3.5% of chromic oxide, 0.01-15% of aluminum oxide, 0.01-4% of nickel oxide, 0.01-3.5% of manganese oxide, 0-3.5% of zinc oxide, 2-7% of yttrium oxide, 0-4%of titanium oxide, 0-3% of silicon dioxide, 0-5% of cerium oxide and the balance of hafnium oxide-containing zirconium oxide. The black zirconia ceramic material composition disclosed by the invention is small in powder particle size and uniform in dispersion, and a black zirconia ceramic containing the black zirconia ceramic material composition has relatively high strength and rigidity, relatively high covering power and relatively low transmittance. Meanwhile, the invention further discloses the black zirconia ceramic prepared by adopting the black zirconia ceramic material composition anda preparation method of the black zirconia ceramic.

Owner:CHAOZHOU THREE CIRCLE GRP

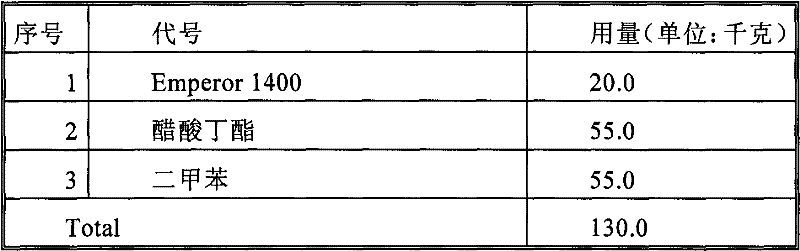

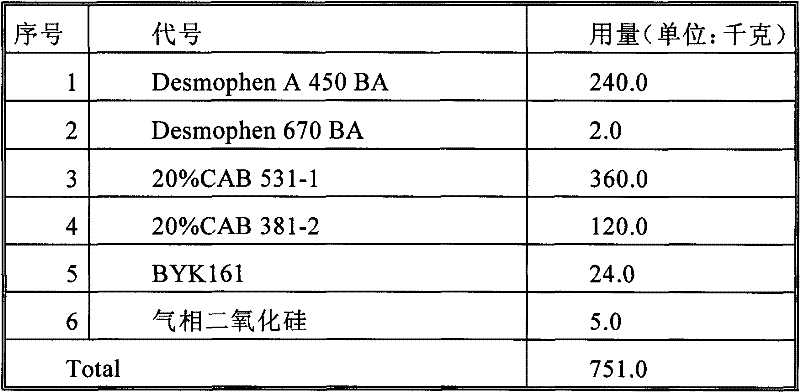

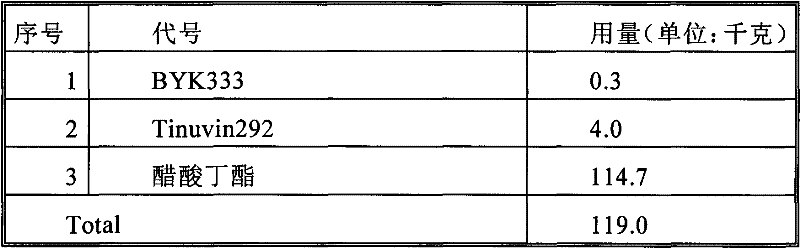

Black single-component solid color paint for automobile repair and preparation method thereof

InactiveCN102391726AGood storage stabilityGood flexibilityPolyester coatingsWeather resistanceUltraviolet lights

The invention relates to black single-component solid color paint for automobile repair and a preparation method thereof. The black single-component solid color paint is prepared from the following components in parts by weight: 2.0-4.0 parts of carbon black pigment, 20.0-25.0 parts of resin, 18.4-21.4 parts of solvent, 45-50.0 parts of cellulose acetate butyrate, 2-8 parts of dispersing agent, 0.3-0.5 part of rheological aid, 0.02-0.05 part of flatting agent and 0.4-1 part of ultraviolet light absorbing agent. Compared with the prior art, the blackness of the solid color paint prepared by the method provided by the invention is greatly improved, and the hue of the prepared solid color paint is more partial to blue phase; and the prepared solid color paint has the advantages of excellent storage stability, flexibility, impact resistance, weather resistance and interlayer adhesive force, high drying speed and the like, and is more suitably used as automobile repair paint.

Owner:DONGLAI COATING TECH SHANGHAI

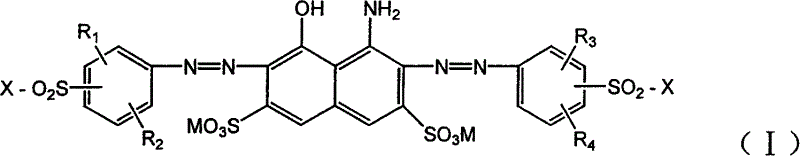

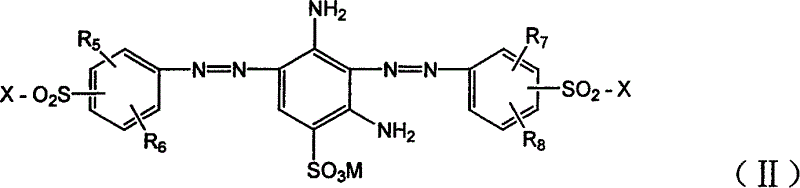

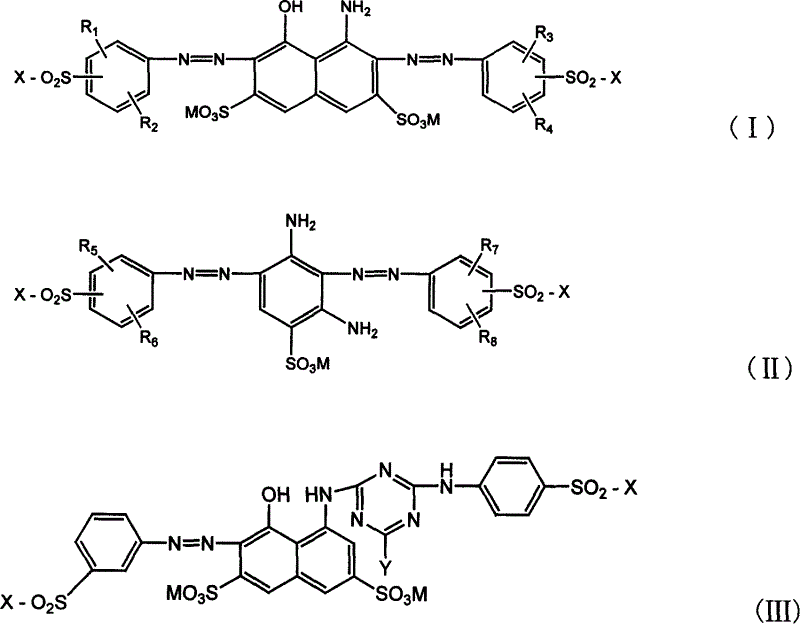

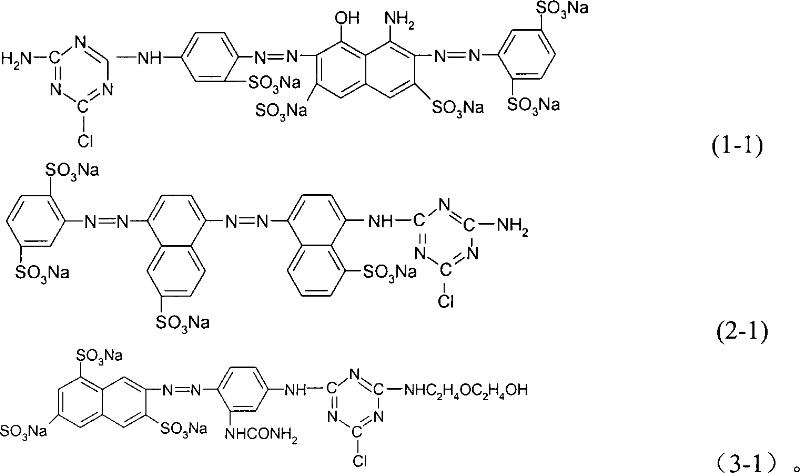

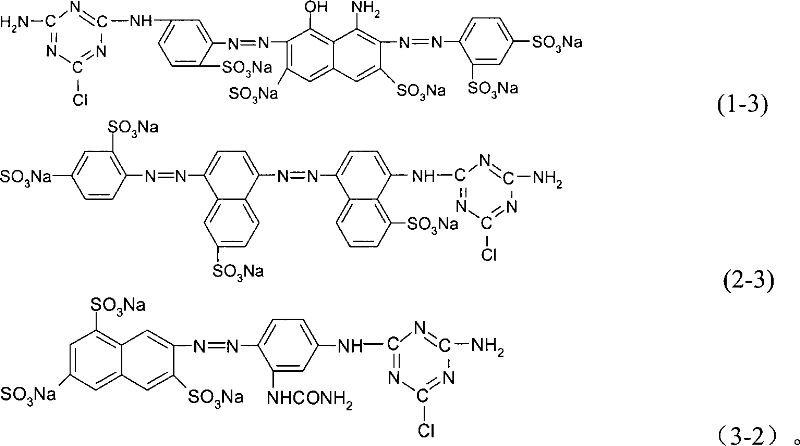

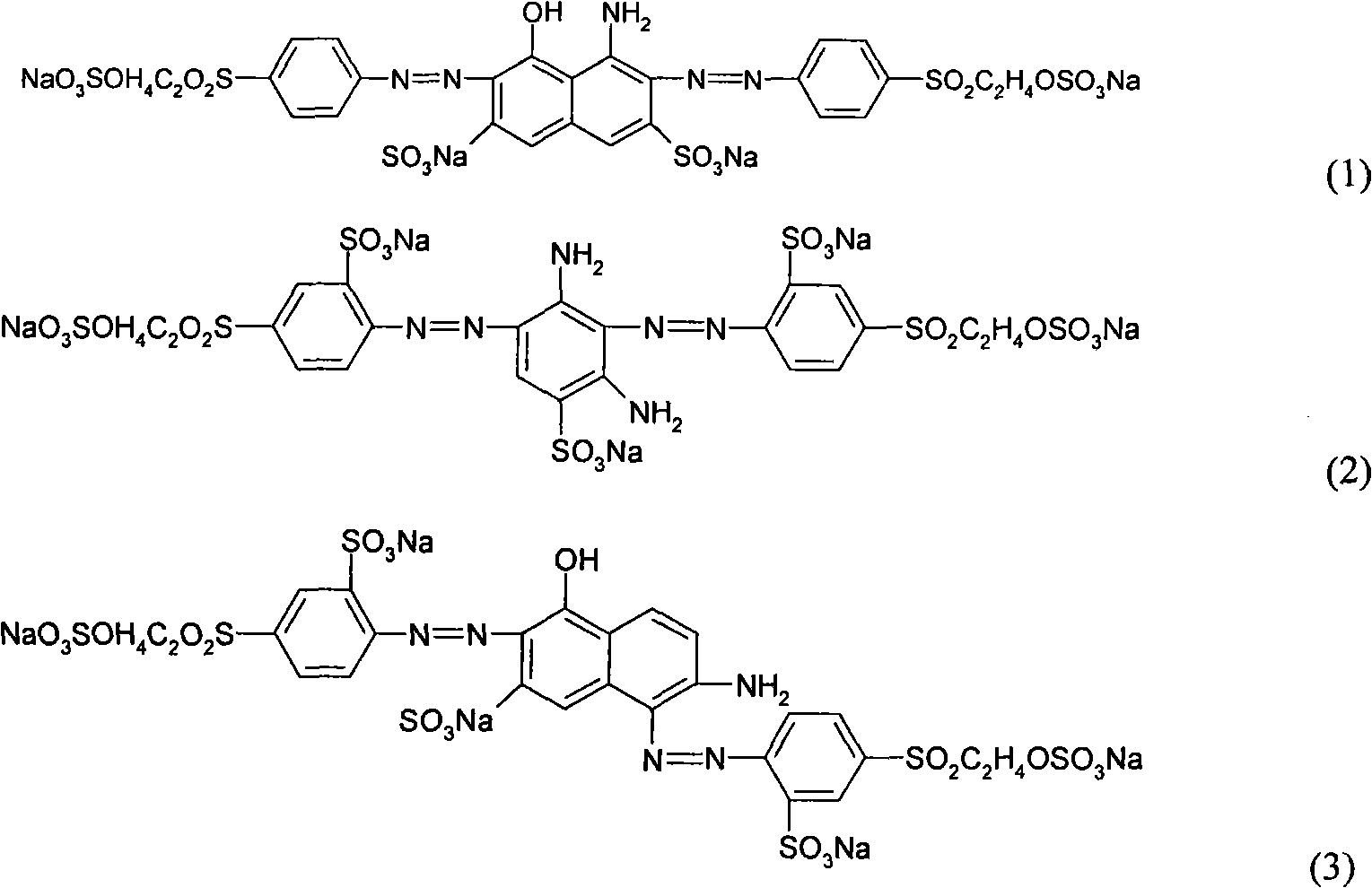

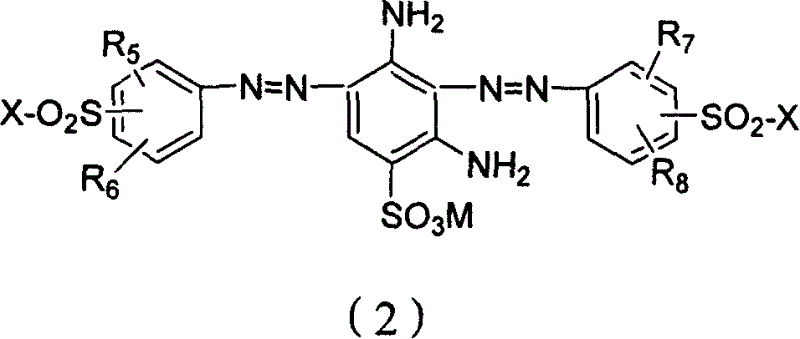

Composite active black dye

InactiveCN1616551AHigh color fastnessHigh blacknessOrganic dyesDyeing processSynthetic fiberHydroxyl radical

The composite active black dye includes dye A in 40-70 wt%, dye B in 15-35 wt% and dye C IN 8-30 wt%. The composite active black dye is especially suitable for dyeing fiber material containing hydroxyl radical or carboxyl radical, such as cellulose fiber, cotton fiber, synthetic fiber, etc. and is one kind of ecological active black dye with high color fastness, high blackness and other features.

Owner:SHANGHAI KEHUA DYESTUFF IND

Extra-black environment-friendly tempered glass ink and preparation method thereof

The invention discloses extra-black environment-friendly tempered glass ink and a preparation method thereof. The extra-black environment-friendly tempered glass ink comprises the following components in percentage by weight: 18-30% of a coloring agent, 50-60% of glass-base glaze, 18-30% of varnish and 0.1-1% of an additive, wherein the coloring agent mainly comprises copper-chromium oxide. The extra-black environment-friendly tempered glass ink disclosed by the invention is not only efficient and environmental friendly, but also has the excellent characteristics of high blackness, high hardness, super wearing resistance, high acid and alkali resistance and the like.

Owner:FOSHAN CITY GREEND CHEM

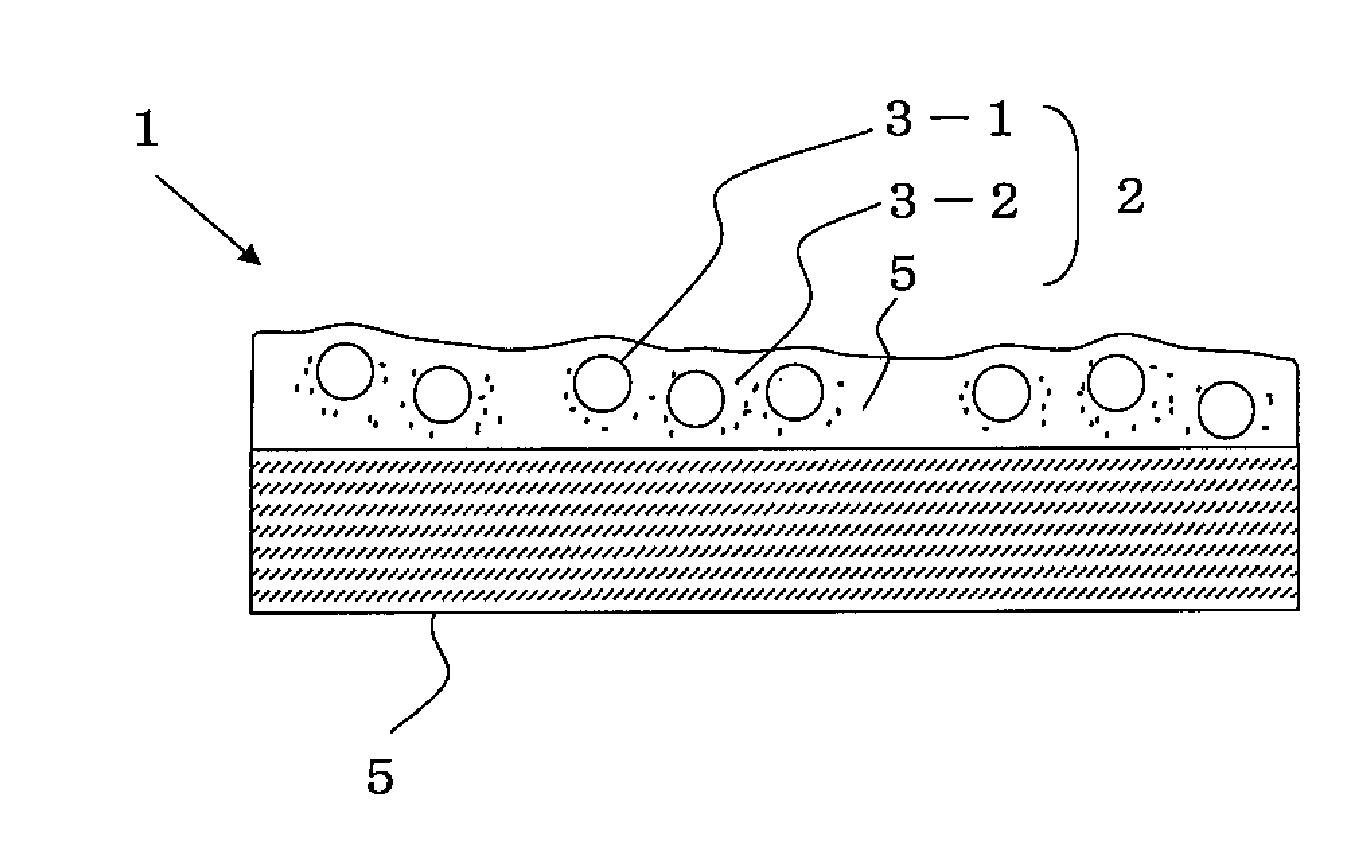

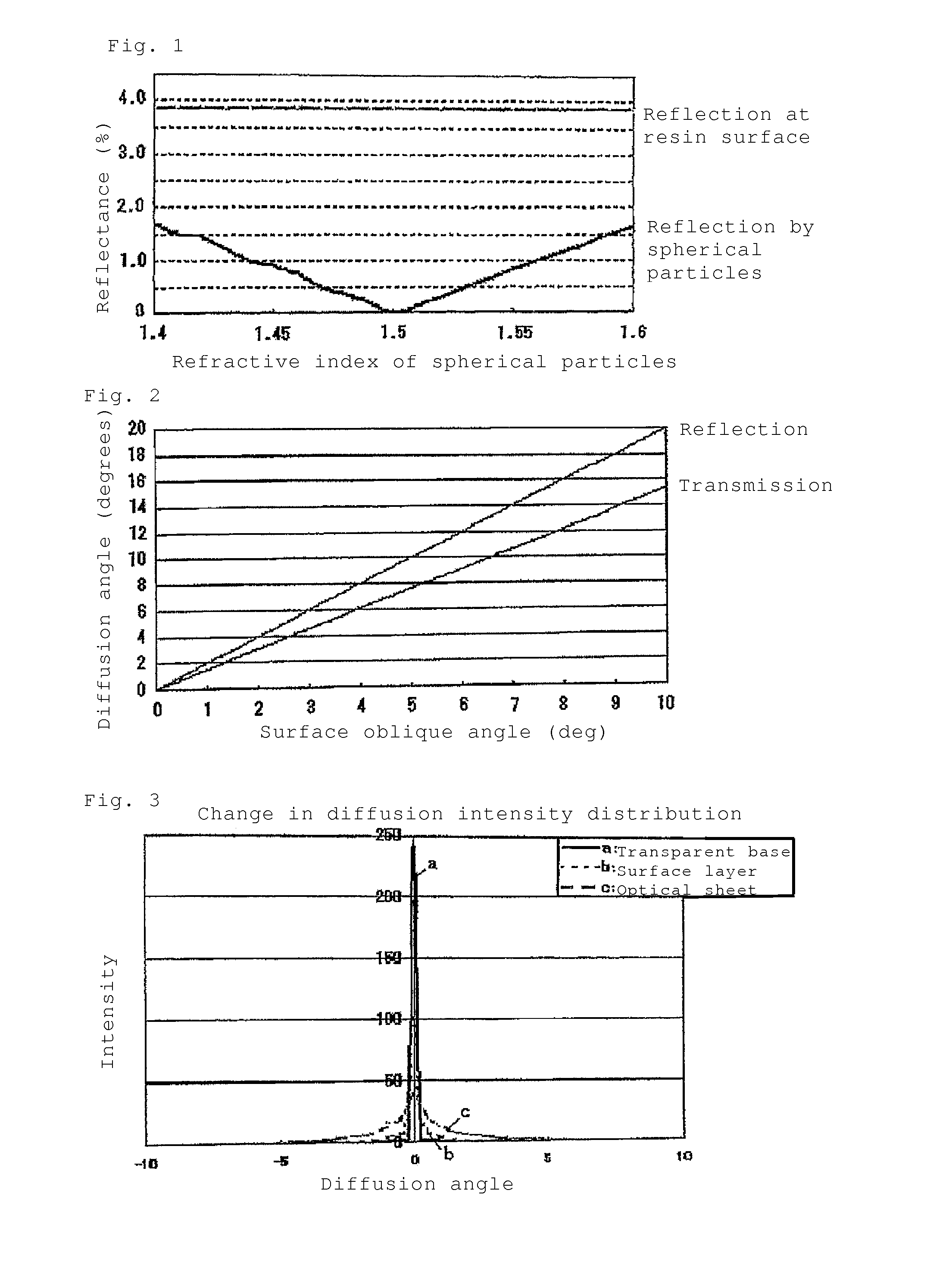

Anti-glare sheet for image display device

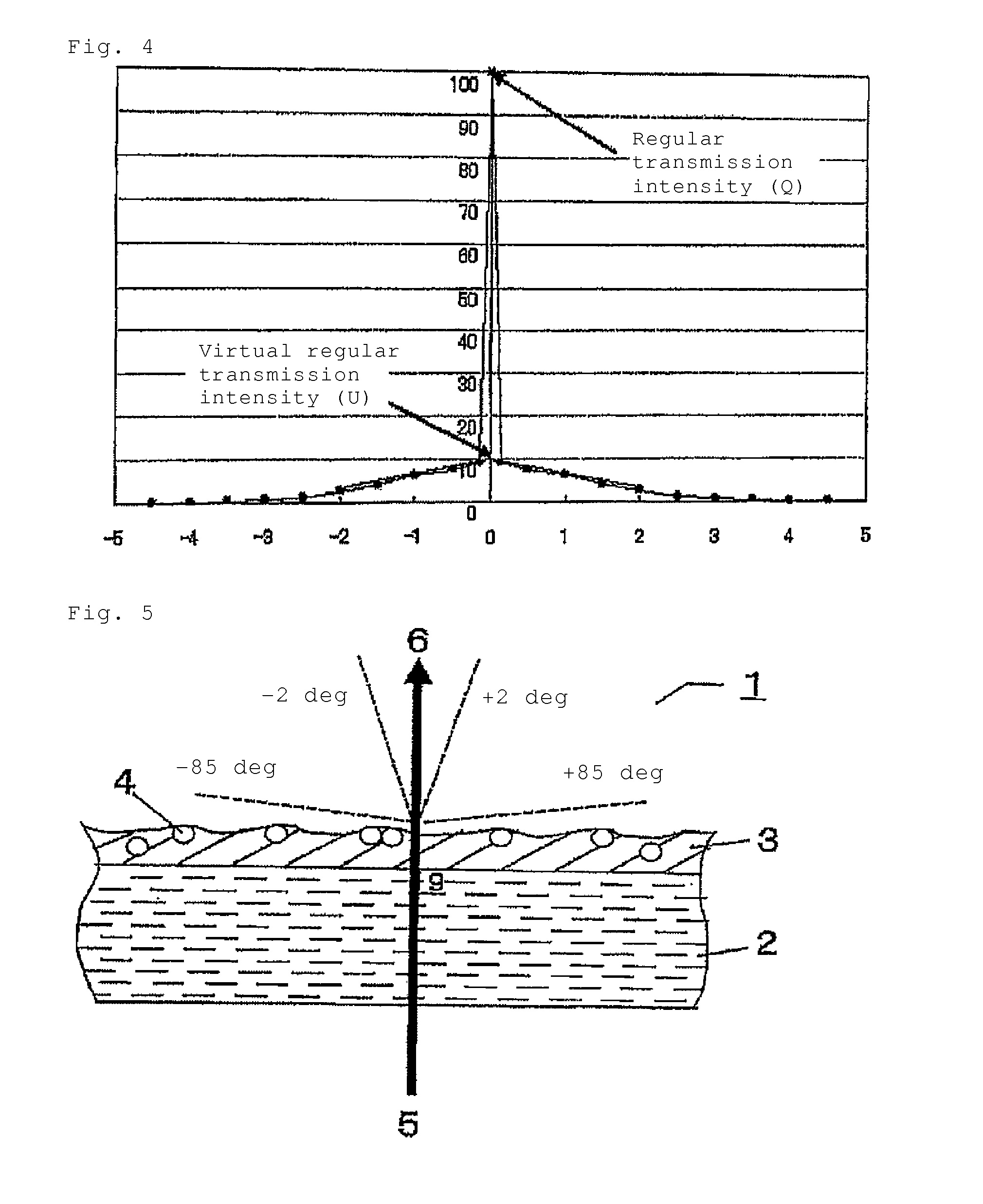

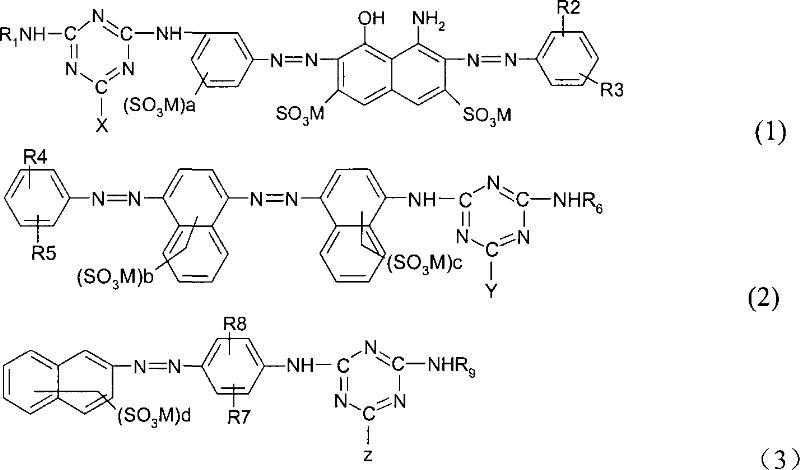

ActiveUS20140211316A1High blacknessExcellent vivid complexionDiffusing elementsSynthetic resin layered productsParticulatesVolumetric Mass Density

An anti-glare sheet that exhibits excellent glossy black textures, blackness in dark locations, and anti-glare properties for dynamic images, and that is suited to the implementation of high quality images. The anti-glare sheet has, on at least one surface of a transparent substrate, an anti-glare layer comprising binder resin, diffusion particles, and binder particulates. The anti-glare sheet is characterized by the anti-glare layer having protrusions and recesses on the surface on the opposite side thereof to the transparent substrate, the protrusions and recesses being formed by protrusions based on agglomerations of the diffusion particles and / or diffusion particles having in the vicinity thereof a localized layer in which the density of binder particulates is high, and equation (1) and equation (2) being satisfied where Q is the luminance in the direction of regular transmission when visible light is perpendicularly irradiated on the anti-glare sheet from the transparent substrate side, Q30 is the luminance in a direction 30 degrees from regular transmission; and U is the average value of the transmission intensity obtained by respectively extrapolating, to a regular transmission, a straight line joining the luminance in a direction +2 degrees from regular transmission to the luminance in a direction +1 degree from regular transmission, and a straight line joining the luminance in a direction −2 degrees from regular transmission to the luminance in a direction −1 degree from regular transmission.10<Q / U<36 Equation (1)Log10(Q30 / Q)<−6 Equation (2)

Owner:DAI NIPPON PRINTING CO LTD

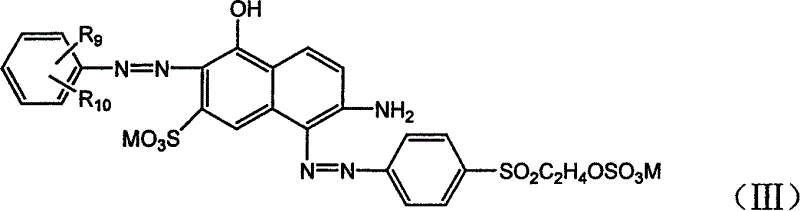

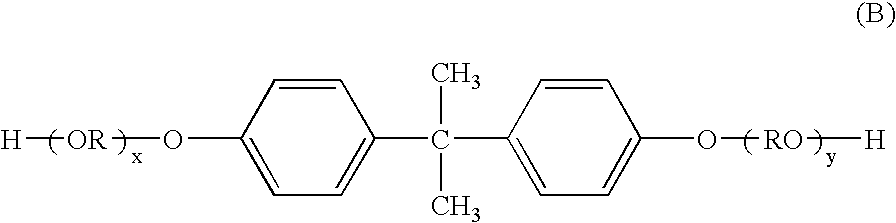

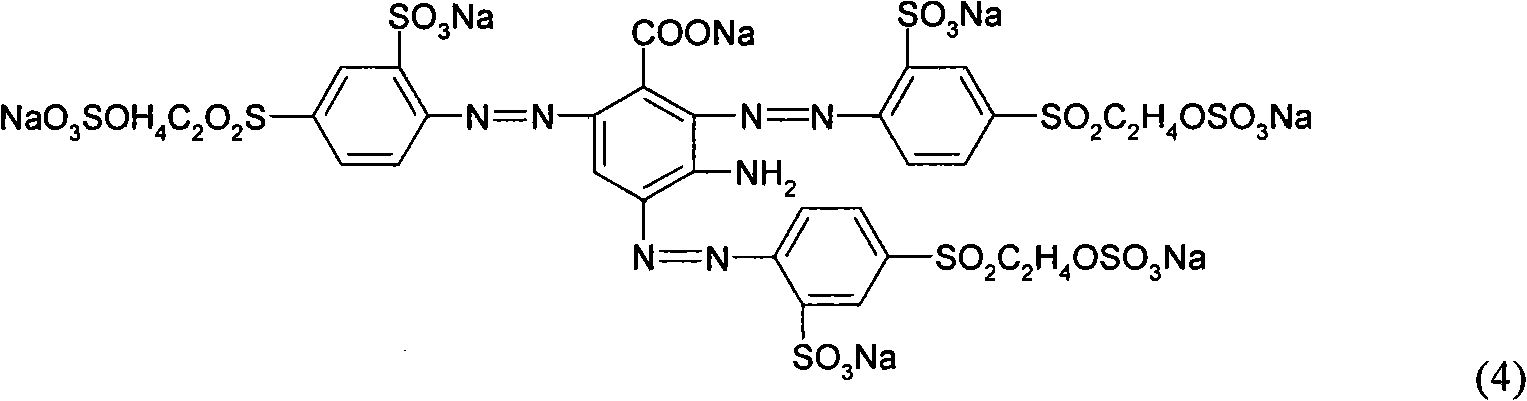

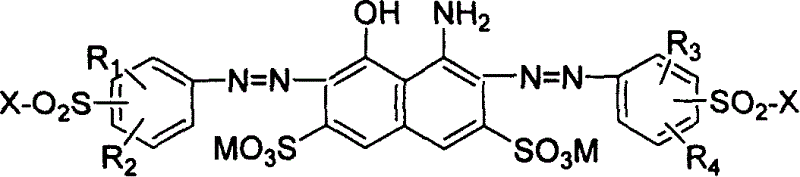

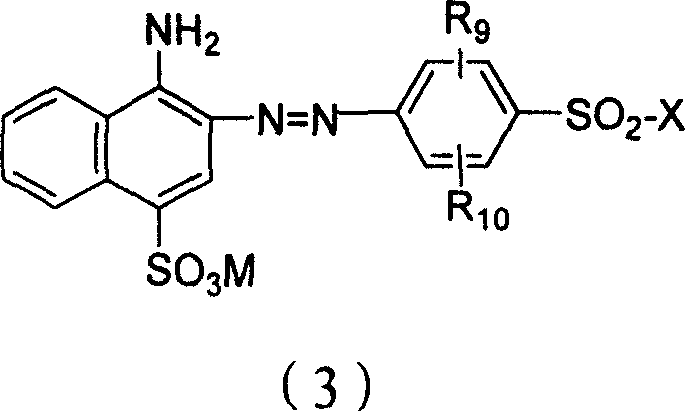

Black dye mixer and preparation method and application thereof

The invention provides a black dye mixture, which is mixed by (counted by weight quotient): dye shown by formula (1) of 50-80 quotient, dye shown by formula (2) of 9-30 quotient and dye shown by formula (3) of 4-20 quotient. The black dye mixture owns property of high level-dyeing property, high fixation yield and high jet black degree, and can combine with cotton, hemp, yarn, thread, hair and polyamide to form covalent bond. Moreover, the black dye contains no harmful arylamine and heavy metal element and does not decompose harmful matter to human body during using process.

Owner:佛山市焱基化工染料有限公司 +1

High-permeability super black decorated base paper and preparation method thereof

ActiveCN103614949AImprove permeabilityImprove breathabilitySpecial paperPaper/cardboardTitaniumWet strength

The invention relates to high-permeability super black decorated base paper and a preparation method of the high-permeability super black decorated base paper, and belongs to the technical field of decoration base paper. The preparation method is characterized by comprising the following steps: taking pulp mixed from bleached softwood pulp and bleached hardwood pulp according to the mass ratio of 1:(3.6-4.4) as a main raw material; reducing the beating degree of bleached wood pulp to 32 SR, enabling the mass concentration to reach 4%, and then pumping into a repulping pond for later use; directly adding a black pigment to the repulping pond, wholly substituting kaoline for titanium dioxide to prepare the decorated base paper with a black and shiny color, the fluorescent whiteness of 6%-8%, the basis weight of 70-90g / m<2>, the ash content of 10%-15%, the wet strength of 6.5-9N, the dry strength of 35-50N, the water absorption of 20-35mm / 10 minutes and the air permeability of 15-20s / 100ml. The high-permeability super black decorated base paper disclosed by the invention has the advantages of uniformity in coloring, good covering power, high air permeability, low basis weight and high paper output ratio; a processed decorating plate is high in stereoscopic impression, pure and bright in color and luster, green and environmental-friendly without white patterns.

Owner:ZIBO OU MU SPECIAL PAPER

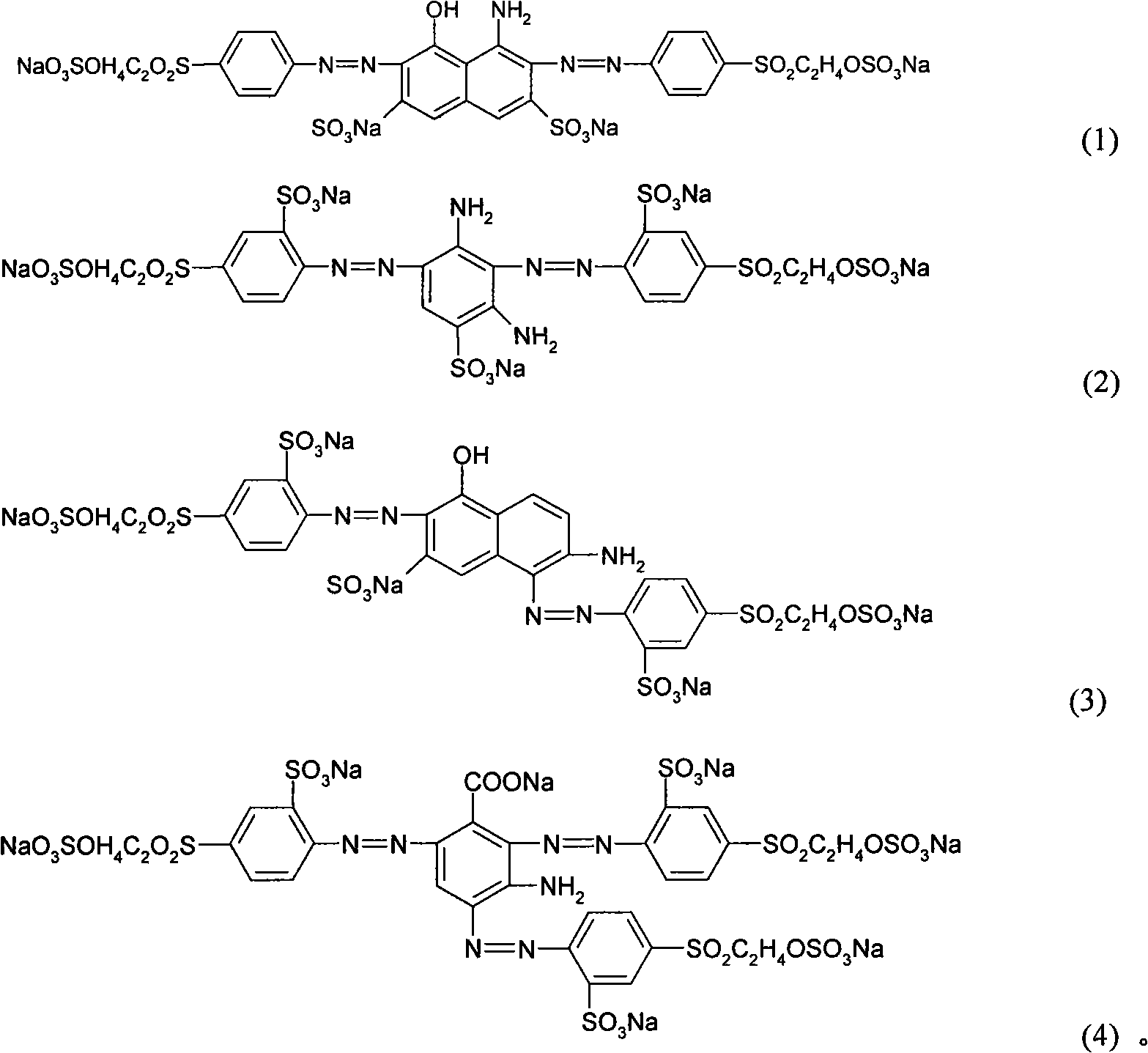

Composite active black dye

ActiveCN101580649AStrong color fixing abilityExcellent color depthOrganic dyesDyeing processDyeingFiber

The invention relates to a composite active black dye, which is characterized in that the dye is compounded by four dyes shown in formula (1), formula (2), formula (3) and formula (4) according to parts by weight of 80-84, 6-10, 1-3 and 6-10, has high responsiveness, good color fixing capability and excellent deep dyeing property, and is suitable for dyeing cotton fiber.

Owner:HUBEI HUALI DYESTUFF INDAL

Method for darkening treatment of black polyester fabrics

ActiveCN102677470APromote absorptionIncrease the black depth valueFibre typesHeating/cooling textile fabricsPolyesterPolymer science

The invention provides a method for darkening treatment of black polyester fabrics. The method comprises a first-stage darkening posttreatment procedure and a second-stage darkening posttreatment procedure, wherein the first-stage darkening posttreatment procedure comprises the following steps of: padding black polyester fabrics in treating liquid of 10 to 60g / l organic fluorine-type polymer finishing agent or acrylic ester-type polymer finishing agent, keeping the padding residue rate at 55 to 175 percent, performing infrared drying, roasting the polyester fabrics, performing baking setting treatment at the temperature of between 175 and 215 DEG C for 30 to 90 minutes; and the second-stage darkening posttreatment procedure comprises the following steps of: padding the polyester fabrics obtained by the first-stage darkening posttreatment procedure in treating liquid of 10 to 85g / l hydrophilic linear organosilicon finishing agent, keeping the padding residue rate at 45 to 150 percent, performing infrared drying, roasting the polyester fabrics, performing baking setting treatment at the temperature of between 180 and 220 DEG C for 30 to 90 minutes. By the technical scheme of the invention, the black depth value of the black polyester fabrics is increased by over 20 percent, and the test data obtained by the Datacolor instrument show the L value of the ultra-black polyester fabrics can reach 9.59.

Owner:绍兴柯桥中侨置业有限公司

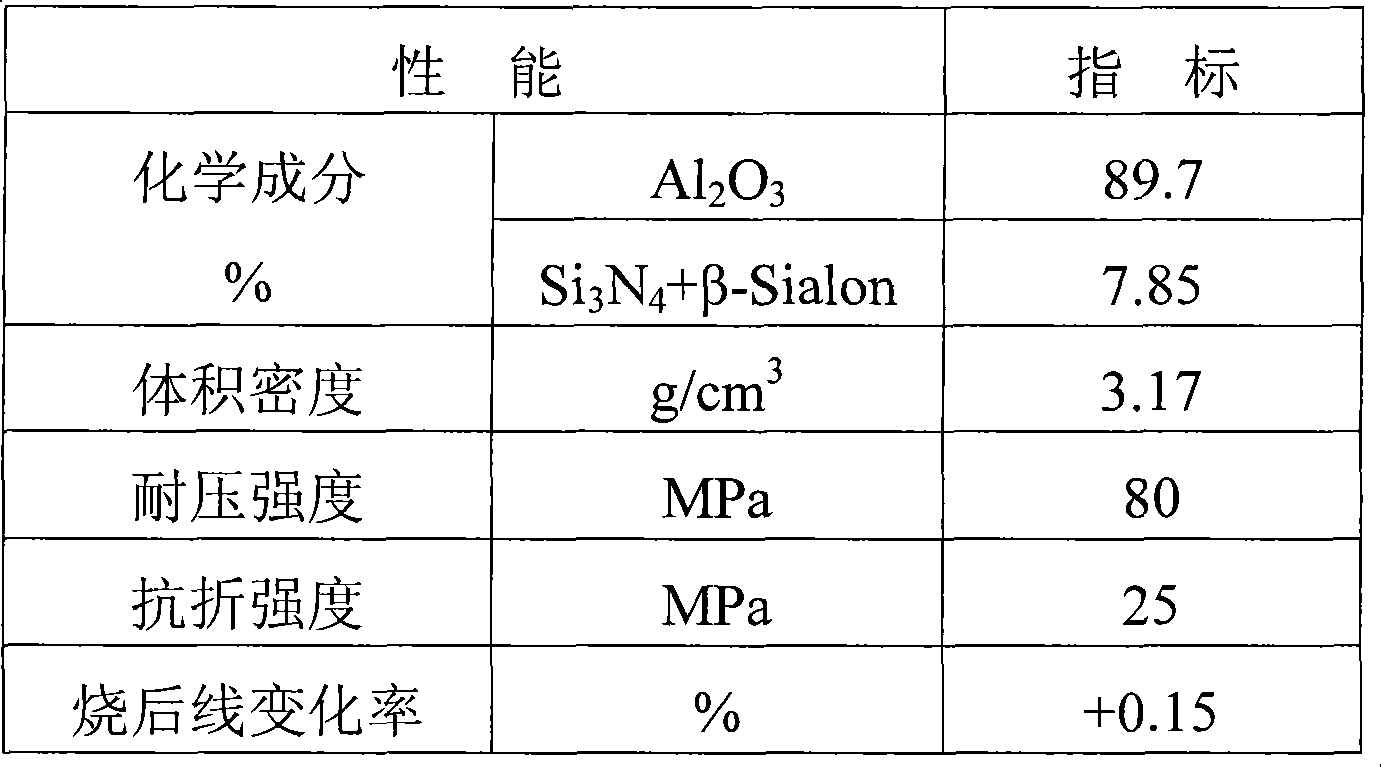

Aluminum oxide pure black ceramic material and processing method thereof

The invention discloses an aluminum oxide pure black ceramic material. The aluminum oxide pure black ceramic material comprises the following components in percentage by weight: 77.5 to 95.0 percent of alpha-aluminum oxide, 2.5 to 7.5 percent of ferric oxide, 2.0 to 10.0 percent of manganese dioxide and 0.5 to 5.0 percent of nickel oxide. The invention also discloses a formula and a processing method of the aluminum oxide pure black ceramic material. The ferric oxide, the manganese dioxide, the nickel oxide and the alpha-aluminum oxide are mixed according to the design ratio, so that the internal and external consistency of the ceramic material is greatly improved and the ceramic material is pure black. The sintered product has low shrinkage ratio and good consistency.

Owner:XINHUA COUNTY XINTIAN ELECTRONICS CERAMICS

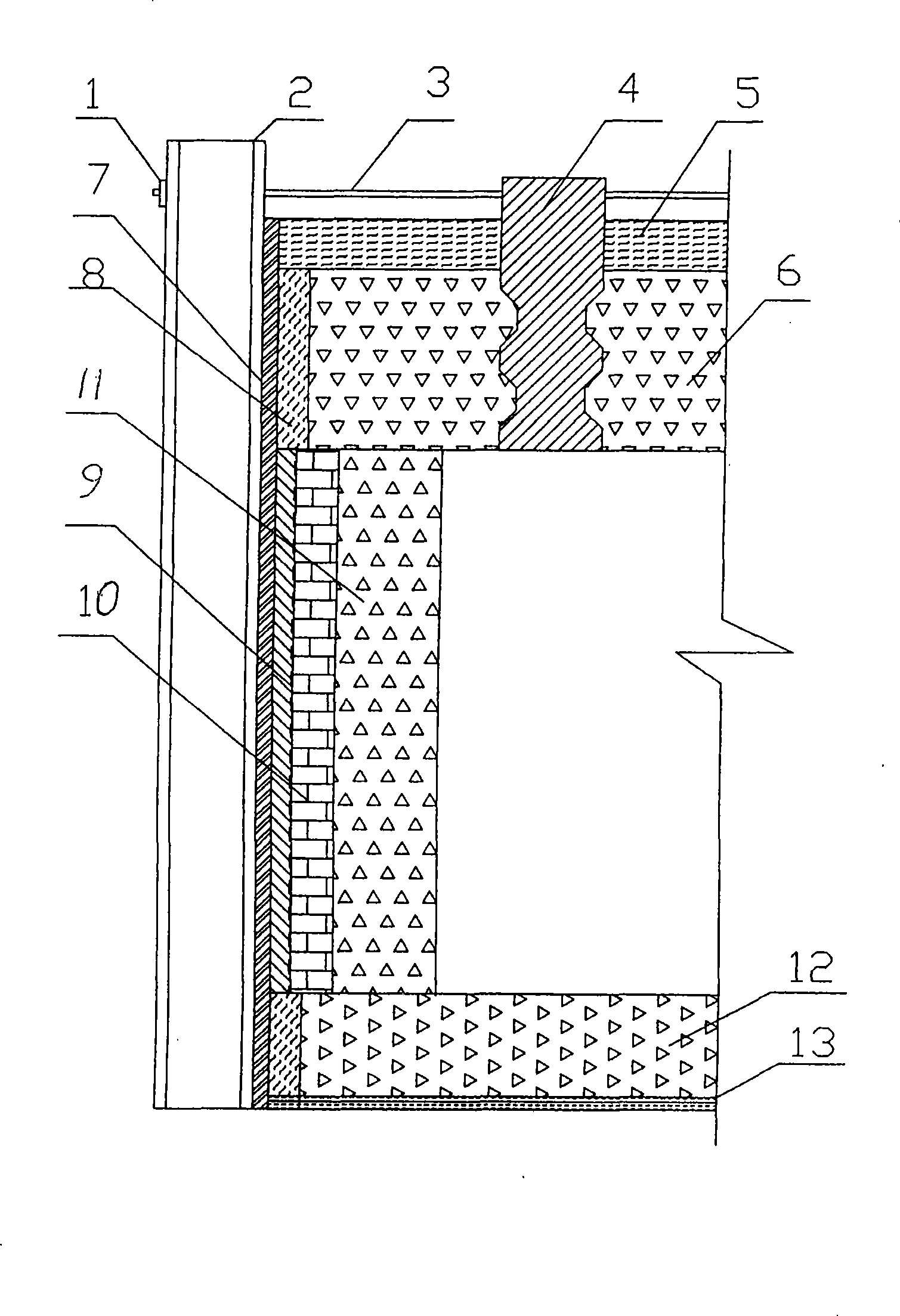

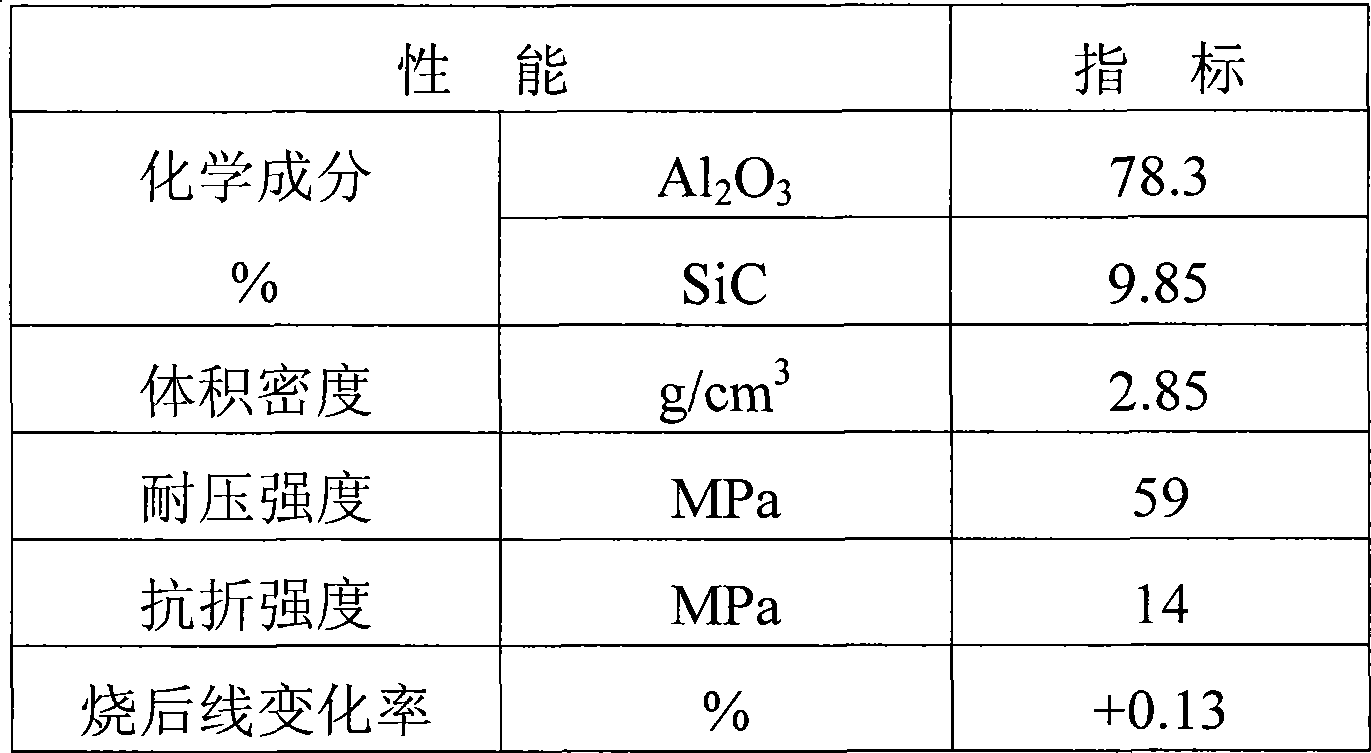

Aluminum melting furnace capable of improving service life and thermal efficiency

InactiveCN101413757AImprove heat radiation abilityGood energy saving effectMonolithic liningsHeating efficiencyThermal efficiency

An aluminum melting furnace capable of increasing service life and heat efficiency comprises a shell body and a lining layer covered on the inner wall of the shell body. The furnace is characterized in that work layers in the lining layer, namely the work layers of the furnace bottom, the furnace wall and the furnace top, are integrally cast from castable refractory and constructed; wherein, the furnace top is in a flattopping structure as well as the integral cast structure with hanging anchorage bricks, the furnace wall is in a composite structure belonging to a straight vertical surface structure. Being fully cast, the lining of the aluminum melting furnace has no seam, smooth surface, high integral strength, good air tightness and stable structure in use, and can greatly reduce radiation loss and improve the heat efficiency; with nonoxides used in the lining casting material, the material does not shrink, crack, aluminize, uneasily adhere with slag and is not eroded by aluminum alloy melt with high thermal shock stability in the state of smelting operation. Compared with the service life of a traditional brick structure, the service life is improved more than 3 times.

Owner:巩义市嘉丰耐火材料有限公司

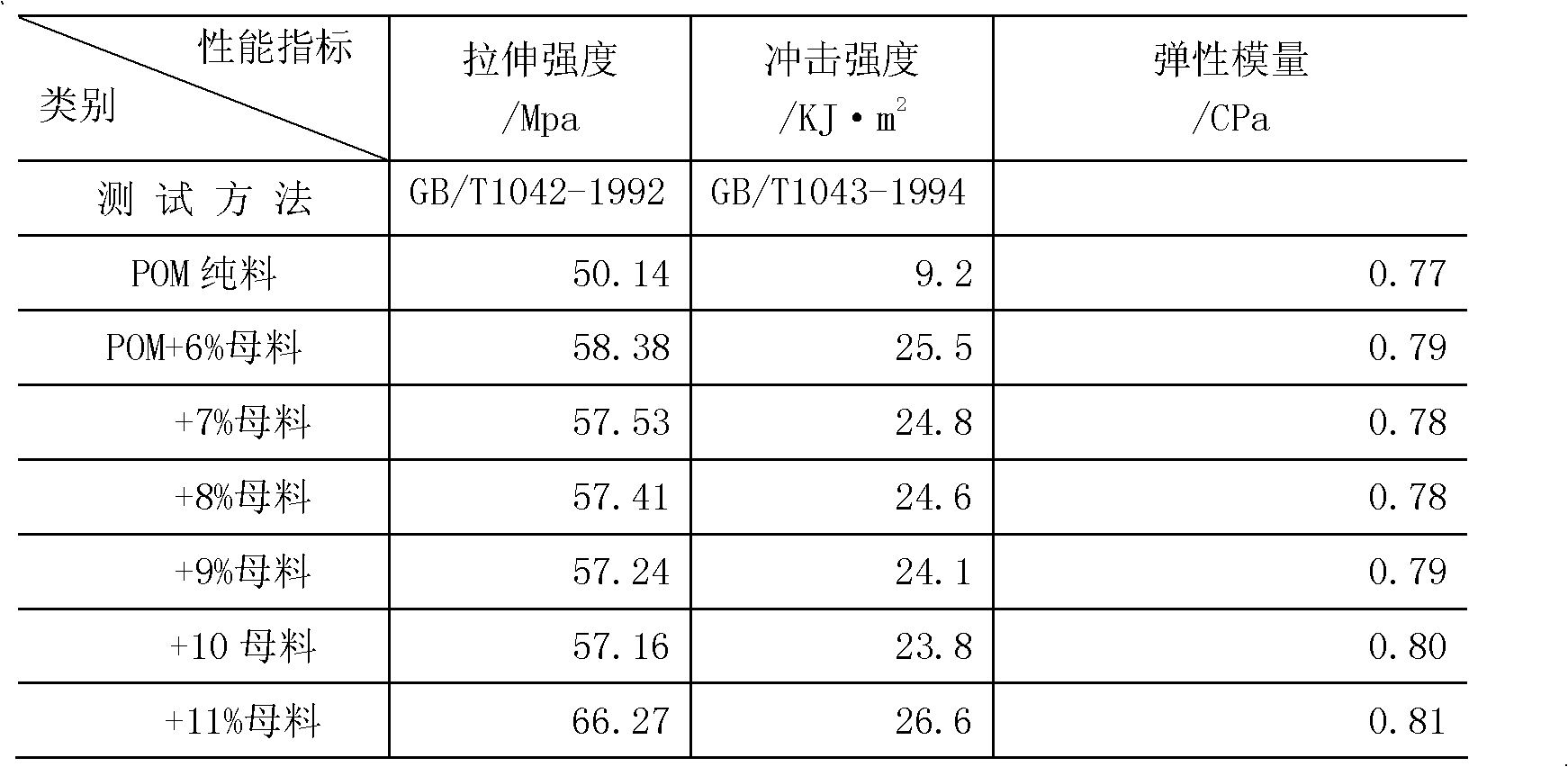

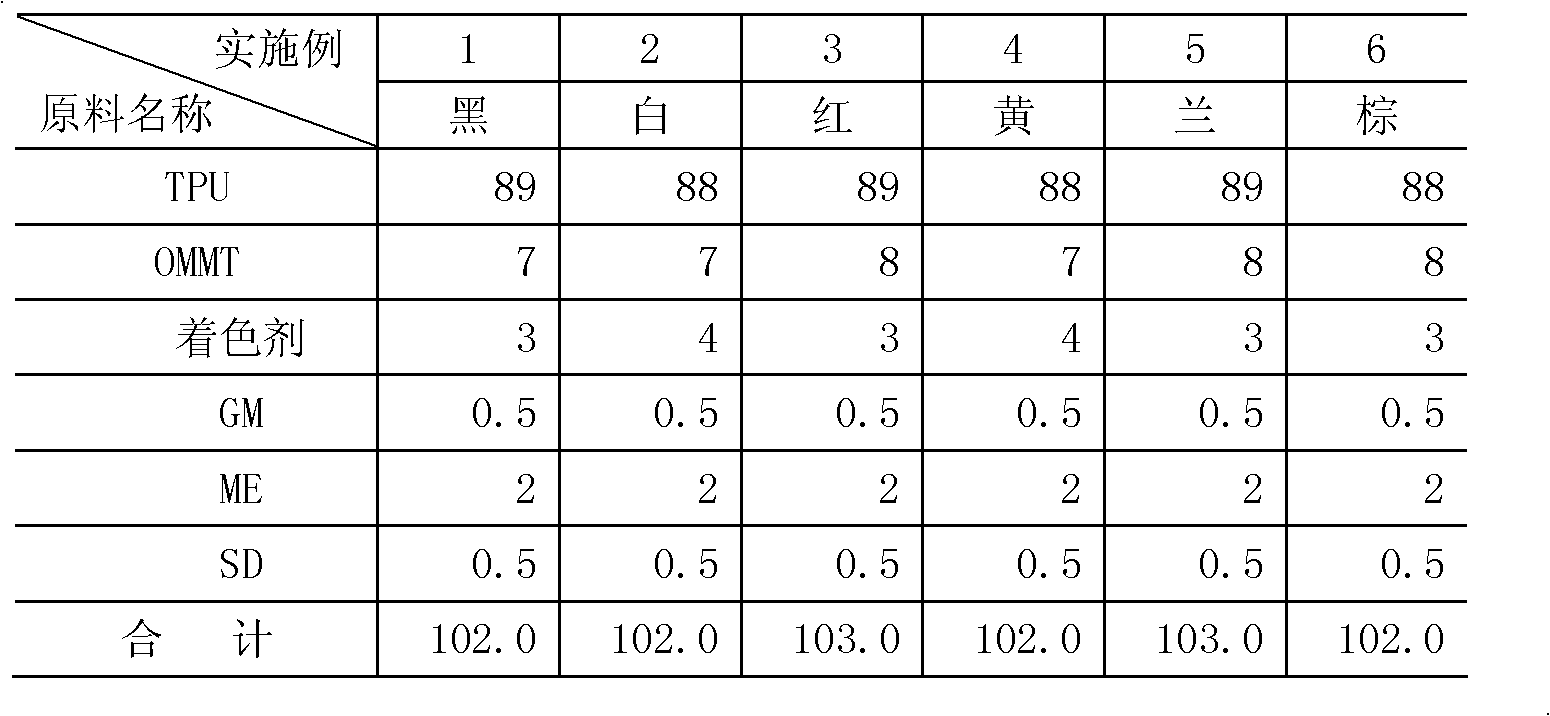

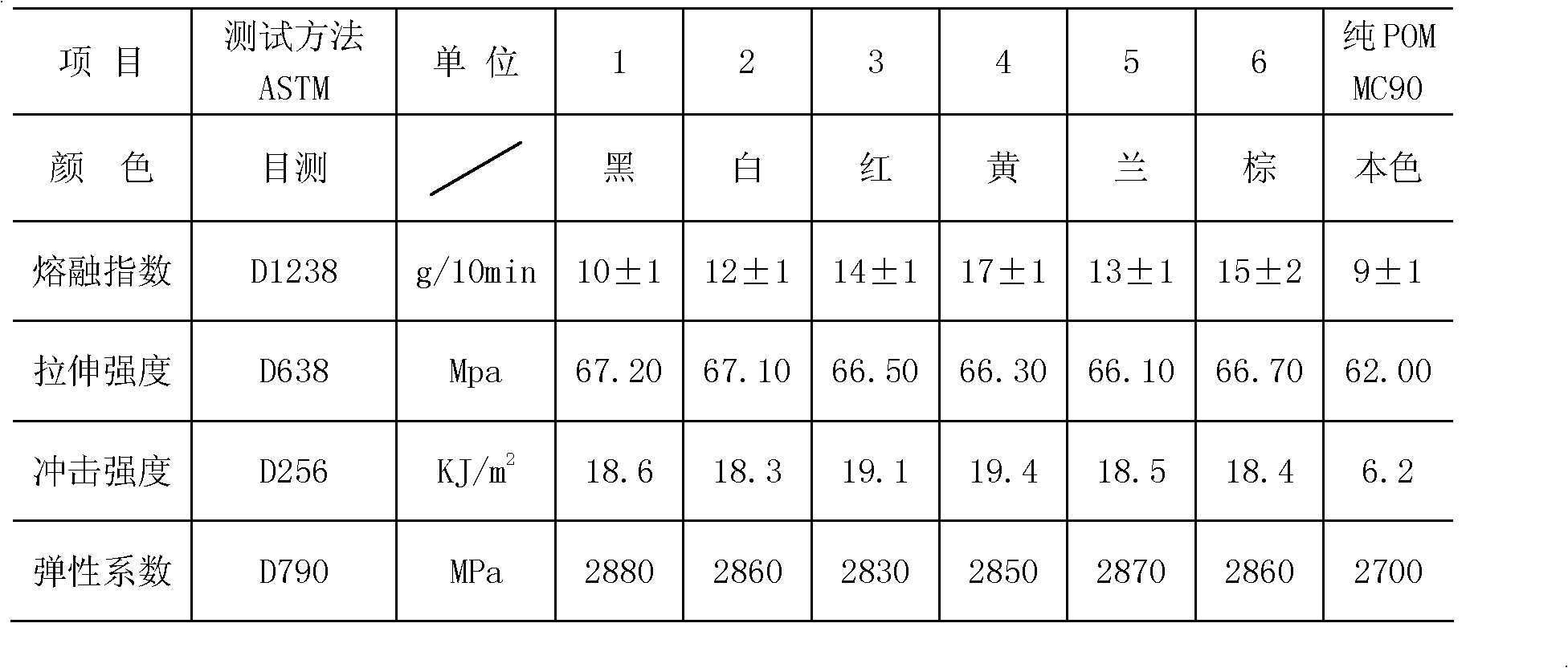

Polyformaldehyde masterbatch with double-function of toughening and coloring, and preparation method thereof

In the prior art, due to the structure characteristics of the polyformaldehyde, the coloring and the toughening of the polyformaldehyde are difficult compared to other plastics so as to provide a worldwide exploration problem. The present invention relates to a polyformaldehyde masterbatch with double-function of toughening and coloring, and a preparation method thereof. The polyformaldehyde masterbatch comprises, by weight, 70-90% of a thermoplastic polyurethane elastomer, 7-9% of nano-scale silicate, 0.8-2.5% of a nano-scale coloring agent, 1-3% of melamine, 0.3-0.8% of a surfactant polysiloxane, and 0.2-0.5% of an anti-aging agent, wherein the anti-aging agent is a mixture comprising styrenated phenol and diphenyl-p-phenylenediamine. The polyformaldehyde masterbatch of the present invention has the double functions of toughening and coloring, such that the strength and the stiffness of the material are not reduced while the notched impact strength of the POM is substantially improved, and the processing fluidity and the thermal deformation resistance are improved.

Owner:ZHEJIANG QISELU MASTERBATCH

Toner for charged image developing and its preparing method and imaging method, imaging device and toner box

The toner for electrostatic charged image development of the present invention is characterized in that it contains at least a binder resin, a mold releasing agent and magnetic metal particles, and the solubility of the magnetic metal particles in a 1 mol / l aqueous HNO3 solution at 50 DEG C. is 500 mg / g.l or less.

Owner:FUJIFILM BUSINESS INNOVATION CORP

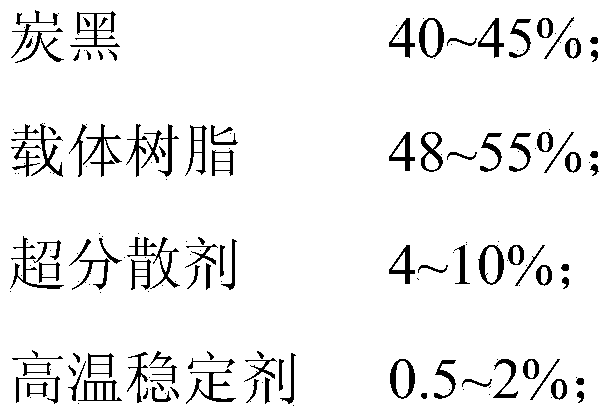

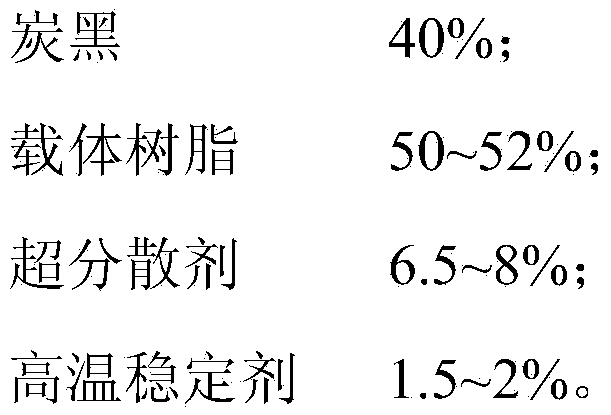

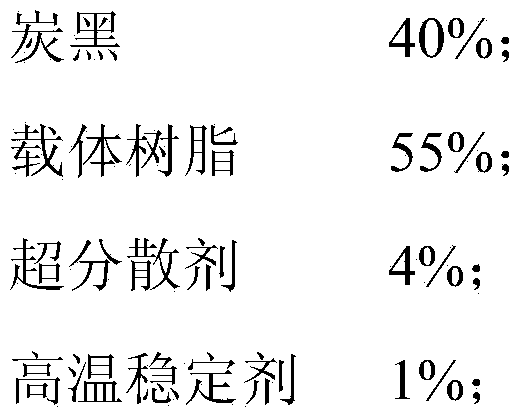

High-lightness and high-brightness black masterbatch and preparation method thereof

The invention belongs to the technical field of plastic coloring, and discloses high-lightness and high-brightness black masterbatch and a preparation method thereof. The high-lightness and high-brightness black masterbatch comprises components in percentage by weight as follows: 40%-45% of carbon black, 48%-55% of carrier resin, 4%-10% of hyperdispersant and 0.5%-2% of a high-temperature stabilizing agent. The preparation method comprises steps as follows: the carbon black, the carrier resin, the hyperdispersant and the high-temperature stabilizing agent are prepared according to content of a formula, the components of raw materials are totally put in a low-speed mixer for pre-mixing treatment, and then the obtained mixture is transferred to a pressurizing mixer for pressurizing mixing; materials obtained through pressurizing mixing are sliced and placed in a double-roll extruding machine for extrusion forming; materials obtained through extrusion are broken and transferred into a spiral granulator for granulation; and obtained materials are cooled, dried and sub-packaged to obtain the high-lightness and high-brightness black masterbatch. The high-lightness and high-brightness black masterbatch has high carbon black content, high blackness degree and good dispersity.

Owner:HUIZHOU HAOYING NEW MATERIAL TECH

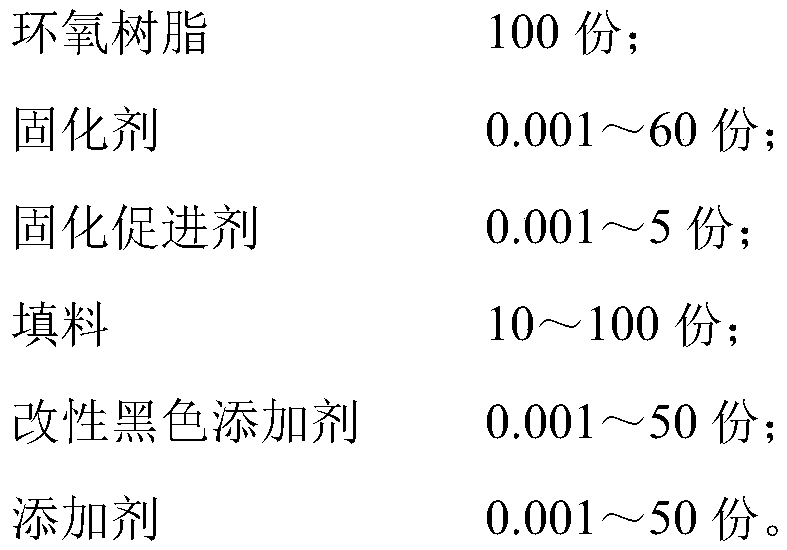

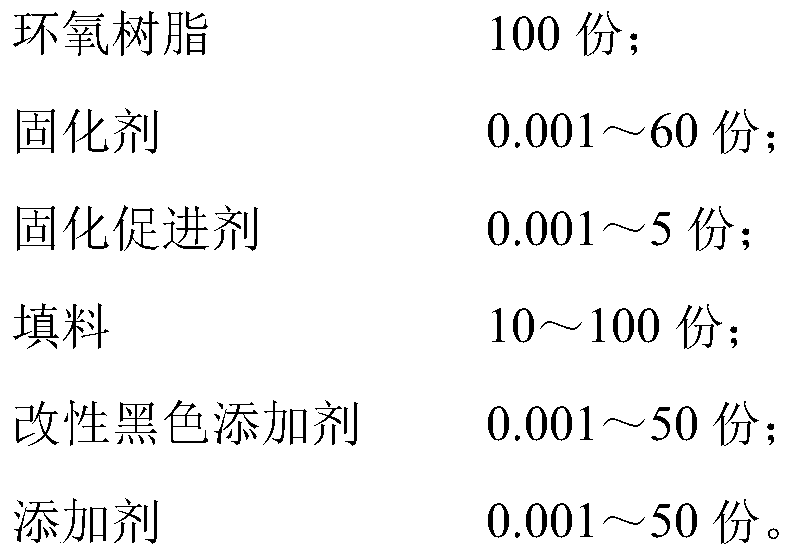

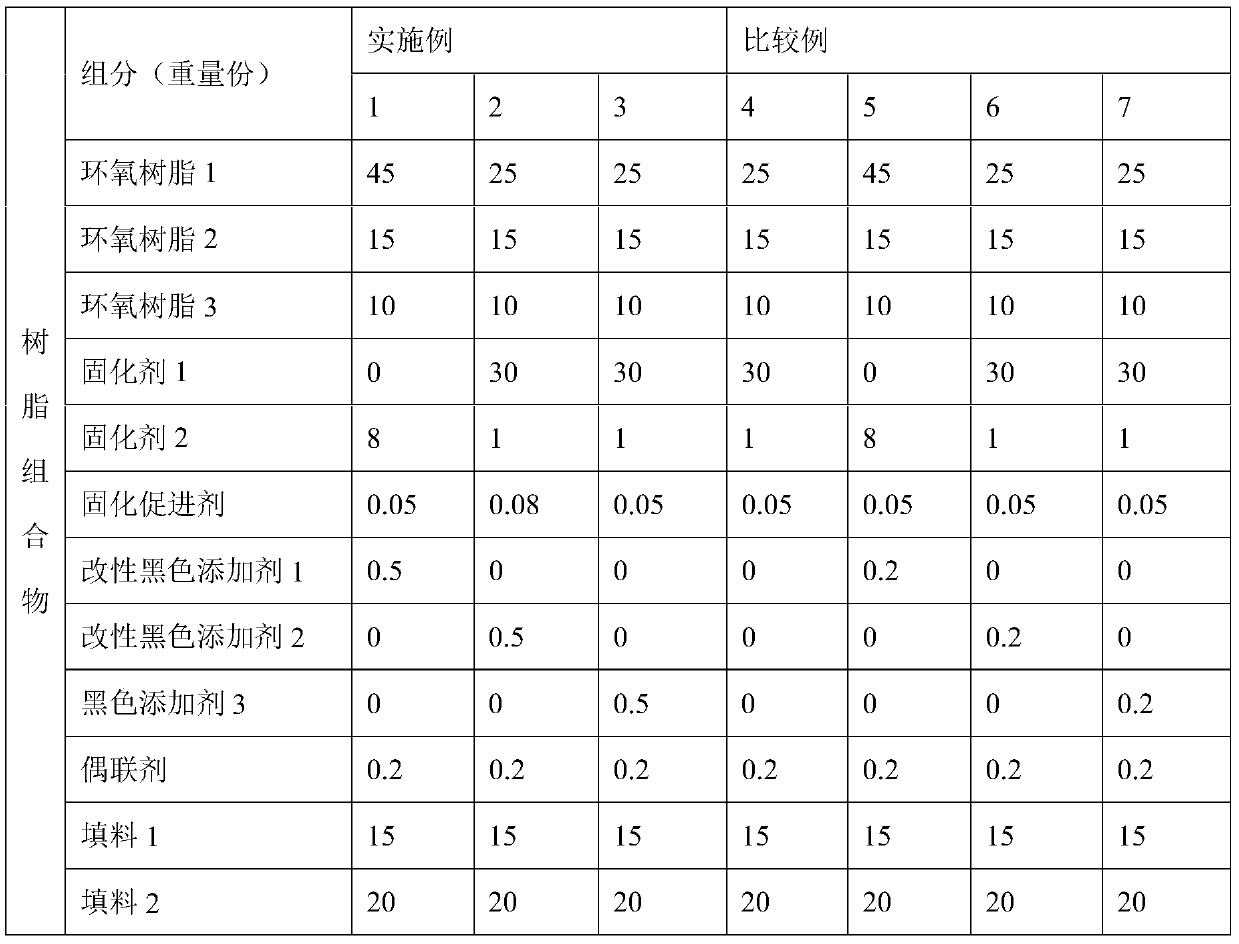

Black resin composition, prepreg and laminated plate

InactiveCN110305445AImprove Difficult DispersionHigh strengthSynthetic resin layered productsElectrical equipmentEpoxyPrinted circuit board

The invention belongs to the field of resin materials for printed circuit boards, in particular to a black resin composition, a prepreg and a laminated plate, wherein the black resin composition comprises the following components in parts by weight: 100 parts of epoxy resin; 0.001-60 parts of curing agents; 0.001-5 parts of curing accelerators; 10-100 parts of fillers; 0.001-50 parts of modified black additives; and 0.001-50 parts of additives. The resin composition improves the defects of difficult dispersion of the resin system, weak light shielding strength of the prepreg and the laminatedplate and large dust adsorption by modifying the black additive, and has good processability.

Owner:ZHEJIANG WAZAM NEW MATERIAL CO LTD +1

Thermal-radiating material and fire-resisting material using same

InactiveCN101973768AReduce heat lossHigh thermal efficiencyChemical industryHeat-exchange elementsHeat lossesHearth

The invention discloses a fire-resisting material using a thermal-radiating material, comprising a fire-resisting material body, wherein a furnace thermal-radiating element is arranged on the fire-resisting material body, and the thermal-radiating material is coated on the outer surfaces of the fire-resisting material body and the furnace thermal-radiating element. The invention also discloses a thermal-radiating material. Aiming at the defects of various traditional industrial heating furnaces, the thermal-radiating material is sprayed and arranged on the inner wall of a furnace to reduce the thermal loss of an industrial heating stove, thereby increasing heat efficiency and achievingthe purposes of saving energy and reducing emission.

Owner:BEIJING ENJI ENERGY SAVER TECH

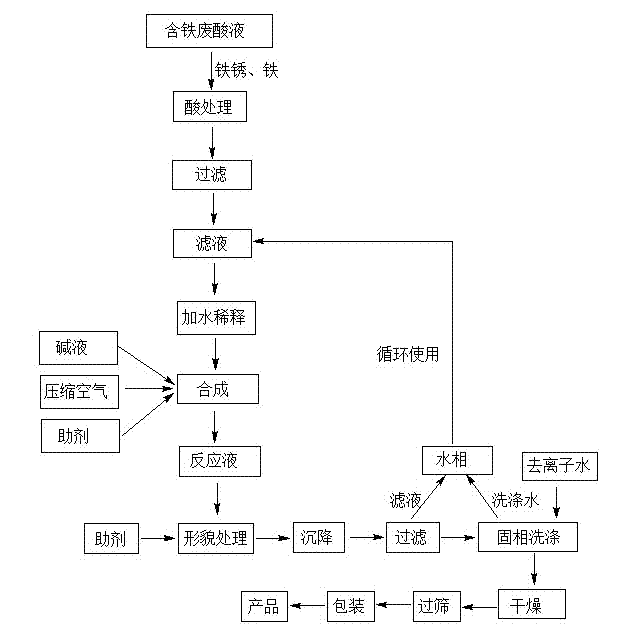

Process for producing high magnetic ferroferric oxide by galvanized pickle liquor

ActiveCN102757099ARealize resource processingSolve the emission problemFerroso-ferric oxidesMultistage water/sewage treatmentPtru catalystIndustrial engineering

The invention discloses a process for producing high magnetic ferroferric oxide by a galvanized pickle liquor. The process includes the steps of (1) directly reacting an iron containing pickle liquor produced by a galvanizing factory and an iron containing excess rust to consume a free acid; (2) filtering by a filter cloth with 800 meshes; (3) using a filter liquor containing ferrous chloride as a raw material, diluting, heating, stirring, neutralizing until potential of hydrogen (pH) of a system reaches to 5.0 to 10.0, then adding an auxiliary, using a nitrite as a catalyst, feeding air, and when the molar ratio between Fe3+ and Fe2+ in the system is in a range from 1.8 to 2.2, stopping reacting; (4) adding an alkaline liquor to control the pH of the system in a range from 10 to 12, performing a heat preservation, stirring, adding the auxiliary, placing naturally, performing a solid-liquid separation, and recycling the filter liquor; and (5) washing, drying, sieving and packaging to obtain the product. The process for producing the high magnetic ferroferric oxide by the galvanized pickle liquor has the advantages that the investment is small, the production costs are low, the efficiency is high, the product quality is good, the complete resource-recovering processing of an iron containing acid pickle can be achieved, and the like.

Owner:QINGDAO XINZHONGJI ENVIRONMENTAL PROTECTION TECH

Super black and misty leather surface treatment agent and preparation method thereof

The invention relates to a super black and misty leather surface treatment agent which is prepared by mixing the following components in parts by weight: 100 parts of solvent type PU, 10-20 parts of flatting powder, 5-10 parts of wax and 200-250 parts of solvent, wherein the solvent type PU is prepared by reaction of diisocyanate, polylol, chain extenders, catalysts and light stabilizers under the condition of existence of organic solvents. Compared with the original common black and misty leather surface treatment agent, the super black and misty leather surface treatment agent obviously increases the blackness and the haze of coatings, improves the crumpling resistance, the wear resistance and the scratch resistance of coatings, and enables leathers to have waxy effect.

Owner:JIAXING HEXIN CHEM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com