Toner for charged image developing and its preparing method and imaging method, imaging device and toner box

A toner, electrostatic latent image technology, applied in the field of electrostatic image developing toner, can solve the problems of difficult to control particle size, difficult to control aggregation rate, difficult to obtain particle stability and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

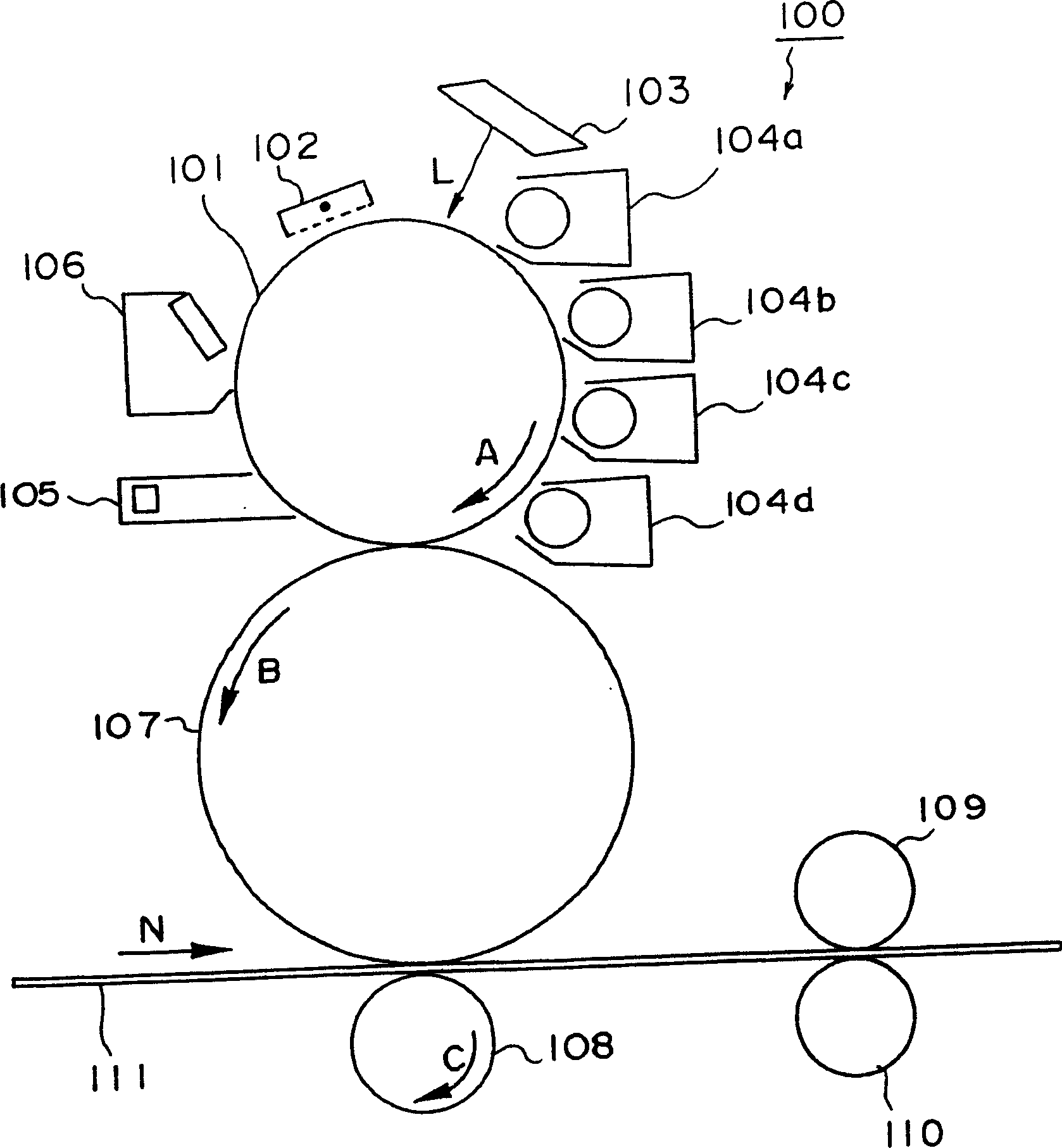

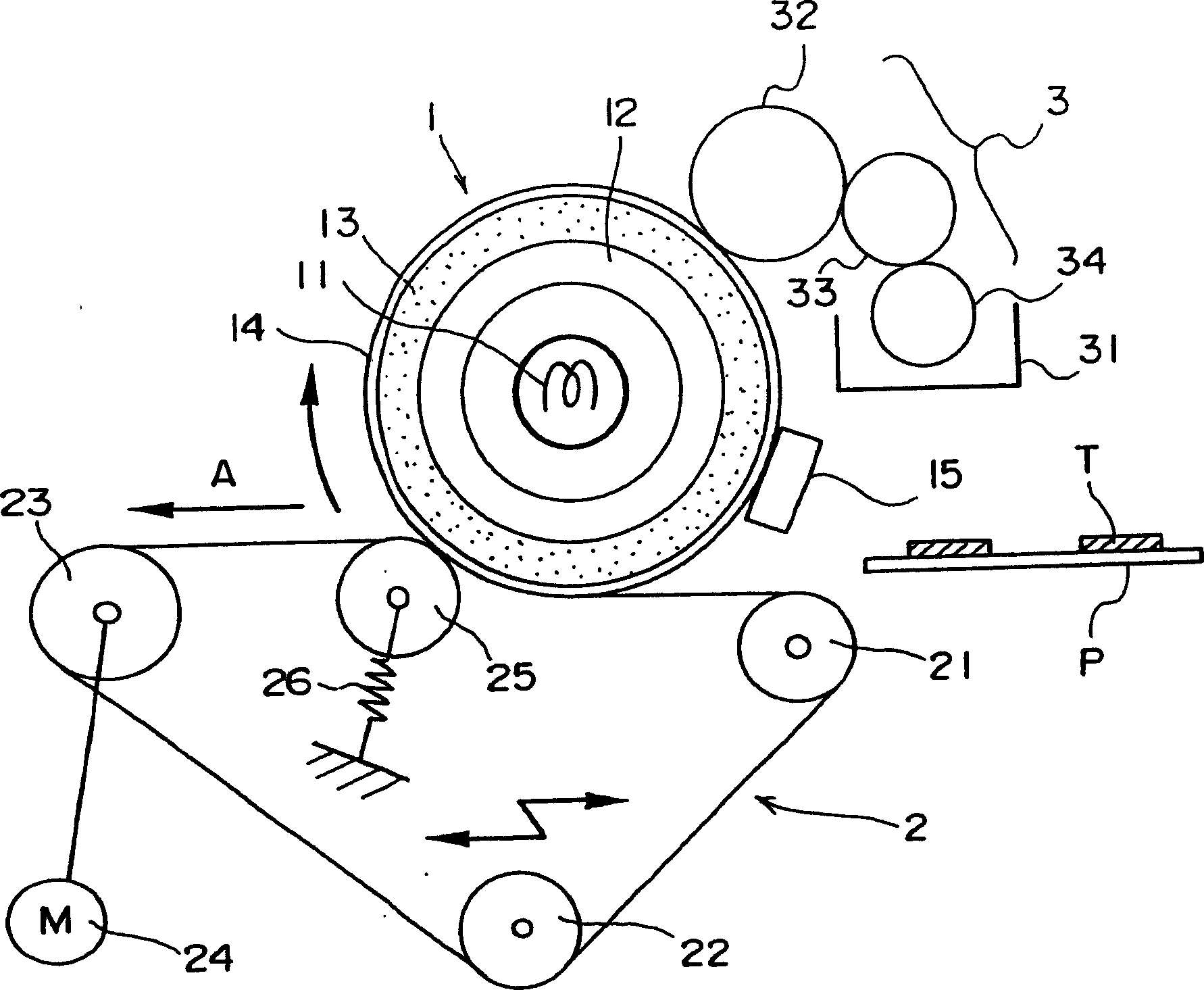

[0363] By adjusting the carrying amount of toner to 4.5g / m 2 , using toner 1, forming an image with a modified laser press 4161 (manufactured by Fuji Xerox Co., Ltd.), and using figure 2The shown high-speed / low-pressure / low-power-type fixing device was fixed at a nip width of 6.5 mm and a fixing speed of 200 mm / sec. The imaging method is an imaging method comprising the steps of: charging step, charging the surface of the image-bearing element; electrostatic latent image forming step, forming an electrostatic latent image corresponding to image information on the surface of the charged image-bearing element; developing step , developing the electrostatic latent image formed on the surface of the image bearing member with a developer containing at least one toner to form a toner image; and a fixing step of fixing the toner image on the surface of the recording medium. In addition, toner 1 was filled into a toner cartridge of a laser press 4161 (manufactured by Fuji Xerox Co.,...

Embodiment 2

[0367] By adjusting the carrying amount of toner to 4.5g / m 2 , using toner 2, forming an image with a modified laser press 4161 (manufactured by Fuji Xerox Co., Ltd.), and using figure 2 The shown high-speed / low-pressure / low-power-type fixing device was fixed at a nip width of 6.5 mm and a fixing speed of 200 mm / sec.

[0368] The obtained image was evaluated, and it was confirmed that the blackness of the image was better, and accurate patterns were obtained. In addition, it was confirmed that toner migration and image blurring were not observed, and good chargeability was exhibited.

[0369] In addition, it was confirmed that the peelability from the fixing device was good, and peeling was performed without any resistance, and no offset occurred. In addition, no image defect was observed after the fixed image was bent into two parts, and stretched again. In addition, when forming an image, toner migration and image blurring were not observed.

Embodiment 3

[0371] By adjusting the carrying amount of toner to 4.5g / m 2 , using toner 3, forming an image with a modified laser press 4161 (manufactured by Fuji Xerox Co., Ltd.), and using figure 2 The shown high-speed / low-pressure / low-power-type fixing device was fixed at a nip width of 6.5 mm and a fixing speed of 200 mm / sec.

[0372] The obtained image was evaluated, and it was confirmed that the blackness of the image was better, and accurate patterns were obtained. In addition, it was confirmed that toner migration and image blurring were not observed, and good chargeability was exhibited.

[0373] In addition, it was confirmed that the peelability from the fixing device was good, and peeling was performed without any resistance, and no offset occurred. In addition, no image defect was observed after the fixed image was bent into two parts, and stretched again. In addition, when forming an image, toner migration and image blurring were not observed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com