Black single-component solid color paint for automobile repair and preparation method thereof

A one-component, black technology, used in coatings, polyester coatings, etc., can solve problems such as difficult preparation, and achieve the effects of interlayer adhesion, fast drying speed, and excellent storage stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

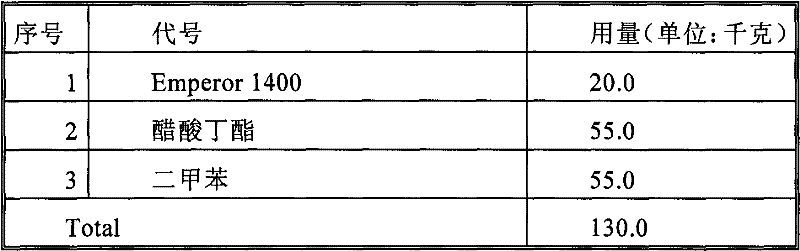

[0032] mixture a

[0033]

[0034] (a) First add the carbon black pigment into the small bucket according to the formula requirements, add the solvent, stir evenly, and store it for more than 16 hours;

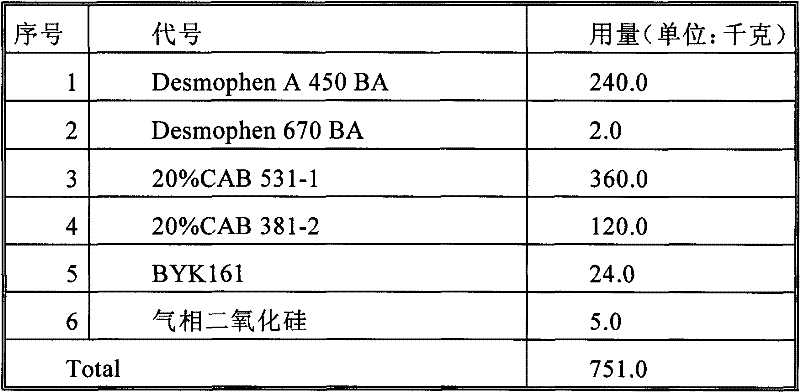

[0035]

[0036] (b) Add resin, 20% CAB, dispersant, and rheological additives into the large tank according to the formula requirements, and add mixture a, 300 rpm, stir for 15 minutes, keep the temperature at 40°C, and obtain mixture b, then Grind with a sand mill to a fineness <10 μm;

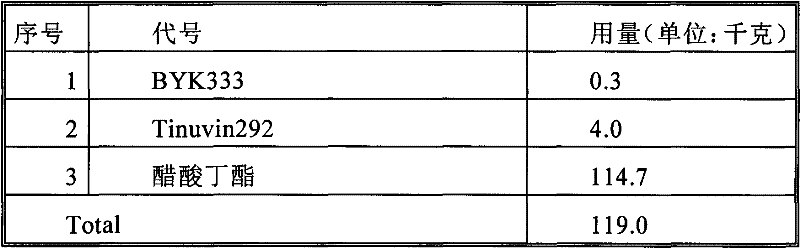

[0037]

[0038] (c) Add the leveling agent, UV absorber, and solvent into the mixture b according to the above amount, stir at 500 rpm for 30 minutes, and adjust the viscosity to 160 seconds.

[0039] (d) pack after filtering for subsequent use, and obtain the black one-component solid color paint for automobile repair.

Embodiment 2

[0041] mixture a

[0042]

[0043] (a) First add the carbon black pigment into the small bucket according to the formula requirements, add the solvent, stir evenly, and store it for more than 16 hours;

[0044]

[0045] (b) Add resin, 20% CAB, dispersant, and rheological additives into the large tank according to the formula requirements, and add mixture a, 300 rpm, stir for 15 minutes, keep the temperature at 40°C, and obtain mixture b, then Grind with a sand mill to a fineness <10 μm;

[0046]

[0047] (c) Add leveling agent, ultraviolet light absorber and solvent into mixture b according to the above amount, stir at 400-600 rpm for 25-30 minutes, and adjust the viscosity to 140-200 seconds.

[0048] (d) pack after filtering for subsequent use, and obtain the black one-component solid color paint for automobile repair.

Embodiment 3

[0050] mixture a

[0051]

[0052] (a) First add the carbon black pigment into the small bucket according to the formula requirements, add the solvent, stir evenly, and store it for more than 16 hours;

[0053]

[0054] (b) Add resin, 20% CAB, dispersant, and rheological additives into the large tank according to the formula requirements, and add mixture a, 300 rpm, stir for 15 minutes, keep the temperature at 40°C, and obtain mixture b, then Grind with a sand mill to a fineness <10 μm;

[0055]

[0056] (c) Add leveling agent, ultraviolet light absorber and solvent into mixture b according to the above amount, stir at 400-600 rpm for 25-30 minutes, and adjust the viscosity to 140-200 seconds.

[0057] (d) pack after filtering for subsequent use, and obtain the black one-component solid color paint for automobile repair.

[0058] The table below sets out the methodological criteria for each performance test execution.

[0059]

[0060]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com