Carbon nanotube ultra-black coating and preparation method thereof

A technology of carbon nanotubes and coatings, which is applied in the field of carbon nanotube ultra-black coatings and its preparation, can solve the problems of high reflectivity of ultra-black coatings, and achieve the effects of increasing black chroma, improving flexibility, and increasing absorbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

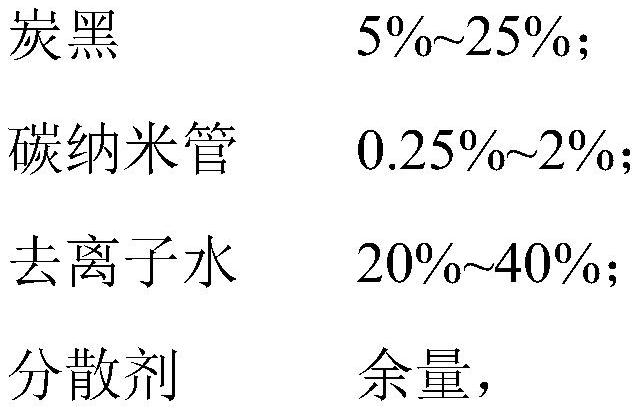

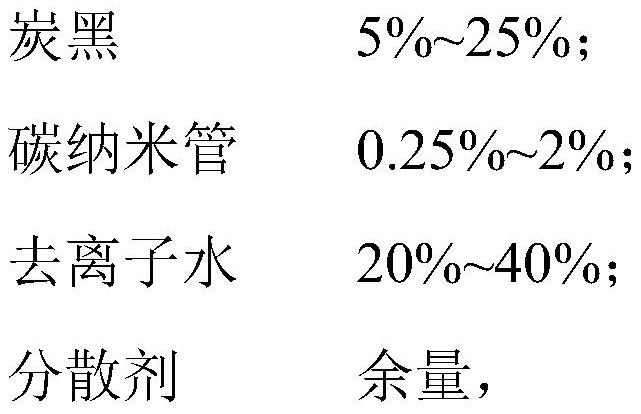

[0045] The first aspect of the present application provides a method for preparing a carbon nanotube super black coating, the method may further comprise the steps:

[0046] S01. Carbon black is dispersed in the first dispersion liquid of the first dispersant, organic auxiliary agent and deionized water to obtain the first mixed system, and the first mixed system is mechanically ground to obtain the carbon black dispersion liquid, wherein, the first mixed system A dispersant is an aqueous dispersion resin;

[0047] S02. Configure the second dispersion liquid mixed with the second dispersant and deionized water, and disperse the carbon nanotubes in the second dispersion liquid to obtain the second mixed system. After the second mixed system is ground, add deionized Diluted with water to obtain a carbon nanotube dispersion;

[0048] S03. Mixing the carbon black dispersion and the carbon nanotube dispersion to obtain a carbon nanotube super black coating.

[0049] The preparati...

Embodiment 1

[0095] A preparation method of carbon nanotube ultra-black paint, comprising the following steps:

[0096] (1) Add 40g water-based polyacrylate, 5g ethylene glycol into 10g deionized water and stir to obtain the first dispersion liquid, add 6g carbon black in batches to the first dispersion liquid and stir and mix, the obtained first dispersion liquid The mixed system was sand milled and dispersed for 5 hours.

[0097] (2) 10g sodium hydroxymethyl cellulose is added into 9g water to carry out dispersion treatment to obtain the second dispersion liquid, disperse treatment after adding 0.6g carbon nanotubes in the second dispersion liquid, obtain the second mixed system, the second mixed system Grind under a three-roll mill, add 5 g of water and stir evenly to form a carbon nanotube dispersion. Wherein, the method for grinding the second mixed system under the three-roll mill is as follows: the roller gap of the three-roll mill is adjusted to be 20 μm, and the three-roll mill i...

Embodiment 2

[0100] A preparation method of carbon nanotube ultra-black paint, comprising the following steps:

[0101] (1) Add 40g water-based polyacrylate, 5g ethylene glycol into 10g deionized water and stir to obtain the first dispersion liquid, add 6g carbon black in batches to the first dispersion liquid and stir and mix, the obtained first dispersion liquid The mixed system was sand milled and dispersed for 5 hours.

[0102] (2) 10g sodium hydroxymethyl cellulose is added into 9g water and carry out dispersion treatment to obtain the second dispersion liquid, disperse treatment after adding 1g carbon nanotube in the second dispersion liquid, obtain the second mixing system, the second mixing system is in Grind under a three-roll mill, add 5 g of water and stir evenly to form a carbon nanotube dispersion. Wherein, the method for grinding the second mixed system under the three-roll mill is as follows: the roller gap of the three-roll mill is adjusted to be 20 μm, and the three-roll mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com