Low-L value inflaming retarding ABS modified resin and preparation method thereof

A technology of modified resin and L value, which is applied in the field of flame-retardant ABS modified resin and its preparation, can solve the problems of increasing the risk of flame-retardant ABS smoldering, affecting the physical properties of flame-retardant ABS, and increasing the cost of flame-retardant ABS. Achieve high blackness, stable product quality, and increase tinting strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

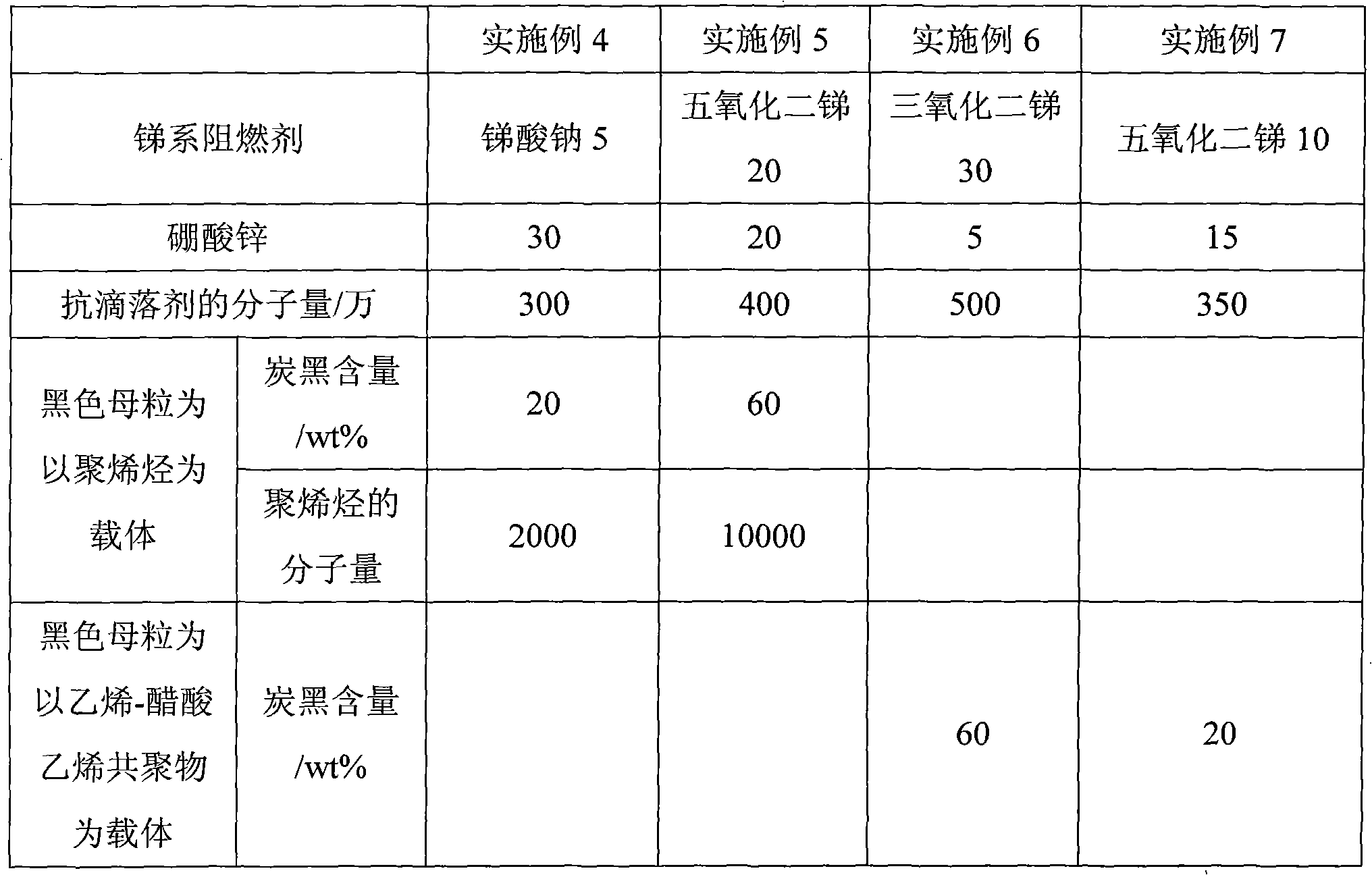

Examples

Embodiment 1

[0056] Embodiment 1 comprises embodiment 1-1 and 1-2, and its formula is as shown in table 2; The formula of comparative example 1,2,3 is also as shown in table 2;

[0057] In Table 2:

[0058] ABS resin is PA757, Taiwan CHIMEI company;

[0059] Brominated epoxy, bromine content 52%-55%, Kaimei Chemical;

[0060] FR245, bromine content 67%, Shandong Shouguang Weidong;

[0061] Antimony trioxide 1, 0.8 μm, Hunan Shanxing;

[0062] Antimony trioxide 2, 3.2 μm, Hunan Shanxing;

[0063] Zinc borate, 7μm, Zibo Dongzuan Chemical;

[0064] Antioxidant is Irganox 1076, Ciba;

[0065] The light stabilizer is UVP, Ciba;

[0066] The anti-dripping agent is PTFE, Guangzhou Entropy Energy Polymer Co., Ltd.;

[0067] Lubricant EBS (ethylene bis stearic acid amide), commercially available;

[0068] Black masterbatch: carbon black content is 50%, polyethylene wax is used as carrier, commercially available.

[0069] The performance tests of Examples 1-1, 1-2 and Comparative Examples 1...

Embodiment 2

[0076] Embodiment 2 comprises embodiment 2-1, 2-2, and its formula with comparative example 4 is as shown in table 4;

[0077] The raw and auxiliary materials are the same as in Example 1, but the preparation method is the above-mentioned two-step masterbatch method, rather than the one-step process in the embodiment. Among them, the inorganic flame retardant masterbatch is ABS carrier, and the contents of antimony trioxide 2 and zinc borate are 15% and 10% respectively.

[0078] The performance tests of Examples 2-1, 2-2 and Comparative Example 4 are shown in Table 5.

[0079] The formula table of table 4 embodiment 2-1, 2-2 and comparative example 4

[0080]

Example 2-1

Example 2-2

Comparative example 4

ABS

78.5

78.5

100

FR245

20

19

19

Inorganic Flame Retardant Masterbatch

30

30

/

/

/

4.5

Zinc borate

/

/

3

Irganox 1076...

Embodiment 3

[0084] Example 3 includes Examples 3-1, 3-2, 3-3 and 3-4, and its formulation is shown in Table 6; its preparation method is as in Example 2.

[0085] in:

[0086] Polyethylene wax, Honeywell;

[0087] Oxidized polyethylene wax, Honeywell;

[0088] Ethylene-vinyl acetate copolymer wax, Honeywell;

[0089] Ethylene-acrylic acid copolymer wax; Honeywell;

[0090] All the other raw and auxiliary materials are the same as in Example 1.

[0091] The performance tests of Examples 3-1, 3-2, 3-3 and 3-4 are shown in Table 7.

[0092] The formula table of table 6 embodiment 3-1, 3-2, 3-3 and 3-4

[0093]

Example 3-1

Example 3-2

Example 3-3

Example 3-4

ABS

78.5

78.5

78.5

78.5

FR245

19

19

19

19

Inorganic Flame Retardant Masterbatch

30

30

30

30

Irganox 1076

0.5

0.5

0.5

0.5

UVP

0.3

0.3

0.3

0.3

PTFE

0.3

0.3

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com