Patents

Literature

893 results about "Free acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

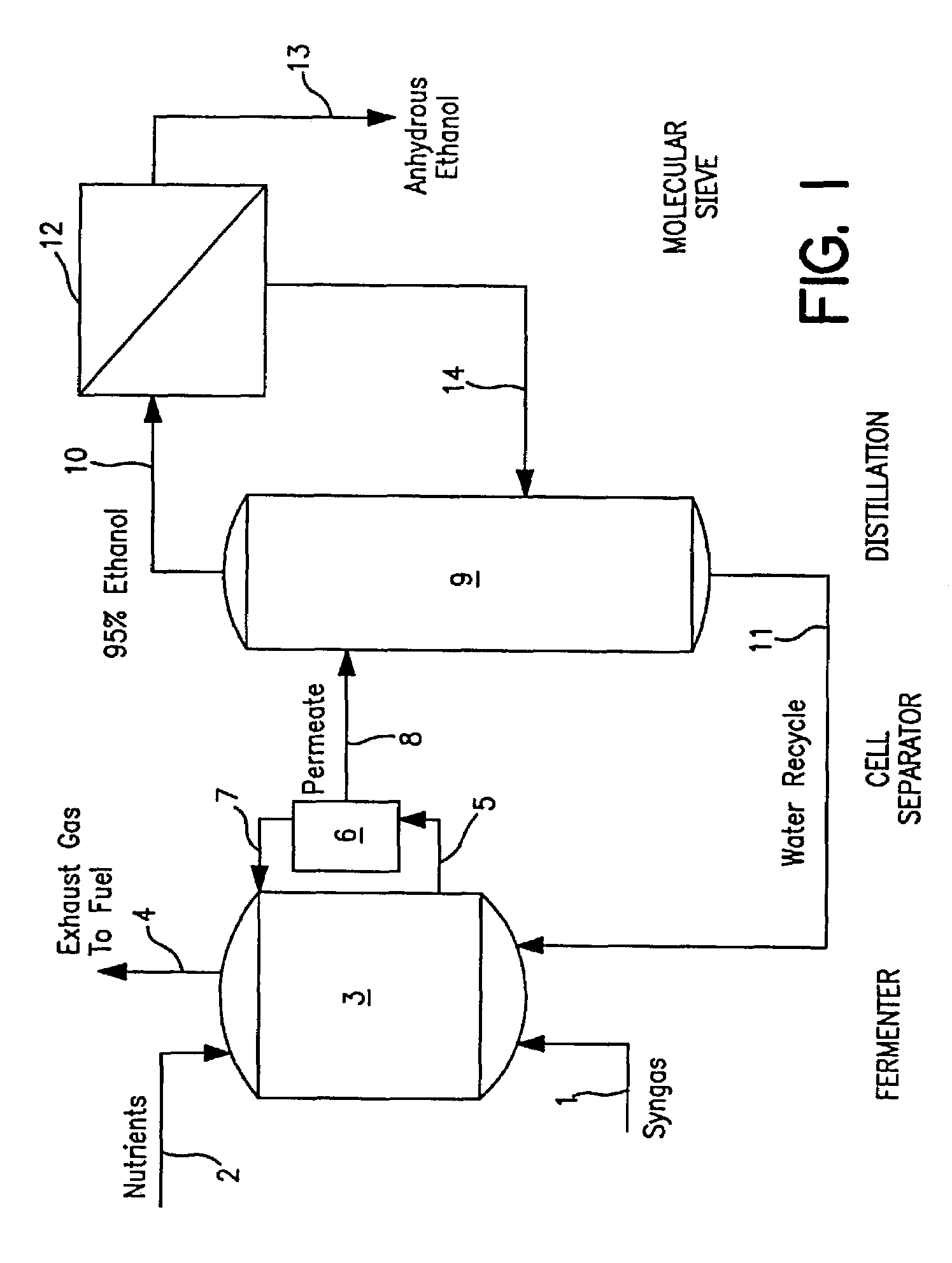

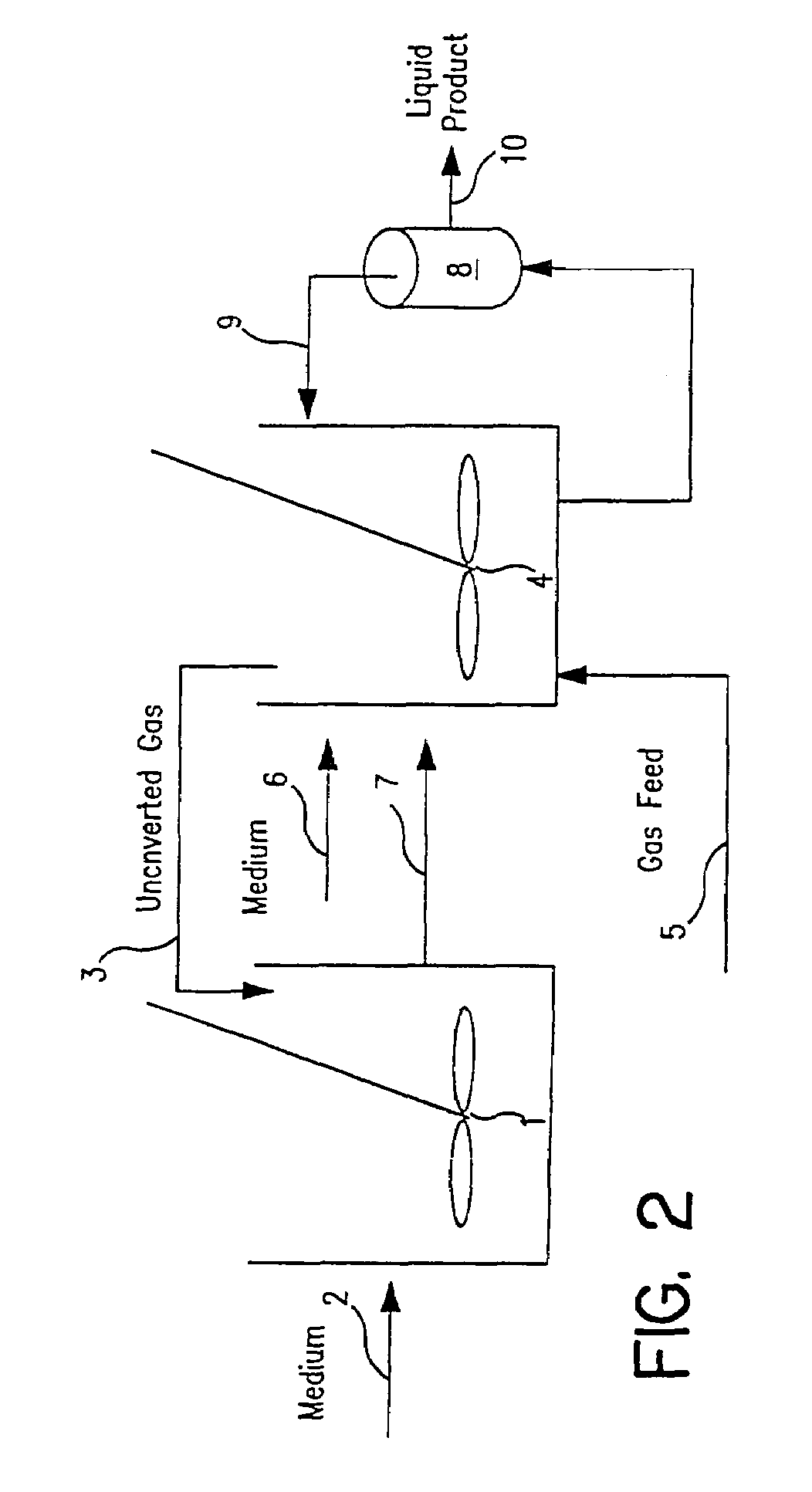

Methods for increasing the production of ethanol from microbial fermentation

InactiveUS7285402B2Good culture stabilityPermit growthBioreactor/fermenter combinationsSolid waste disposalBioreactorNutrient

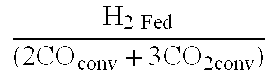

A stable continuous method for producing ethanol from the anaerobic bacterial fermentation of a gaseous substrate containing at least one reducing gas involves culturing a fermentation bioreactor anaerobic, acetogenic bacteria in a liquid nutrient medium; supplying the gaseous substrate to the bioreactor; and manipulating the bacteria in the bioreactor by reducing the redox potential, or increasing the NAD(P)H TO NAD(P) ratio, in the fermentation broth after the bacteria achieves a steady state and stable cell concentration in the bioreactor. The free acetic acid concentration in the bioreactor is maintained at less than 5 g / L free acid. This method allows ethanol to be produced in the fermentation broth in the bioreactor at a productivity greater than 10 g / L per day. Both ethanol and acetate are produced in a ratio of ethanol to acetate ranging from 1:1 to 20:1.

Owner:JUPENG BIO HK LTD

Method of using hydroxycarboxylic acids or related compounds for treating skin changes associated with intrinsic and extrinsic aging

A composition comprising an amphoteric or pseudo-amphoteric agent and a polyhydroxy alpha hydroxyacid existing as a free acid, lactone, or salt, and isomeric or non-isomeric forms thereof is provided. The amphoteric or pseudo-amphoteric agent can be selected from amino acids, dipeptides, aminoaldonic acid, aminouronic acid, lauryl aminoproplyglycine, aminoaldaric acid, neuraminic acid desulfated heparin, deacetylated hyaluronic acid, hyalobiuronic acid, chondrosine, deacetylated chondroitin, creatine, creatinine, hydroxyproline, homocysteine, homocystine, homoserine, ornithine, citrulline, phosphatidylserine, and sphingomyelin. The composition may contain other additives, including cosmetic or pharmaceutical agents for topical treatment of dermatological disorders.

Owner:TRISTRATA TECH

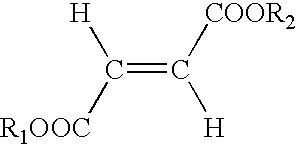

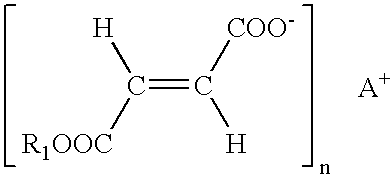

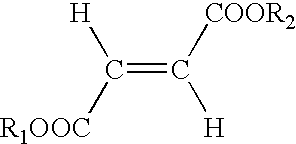

Use of fumaric acid derivatives for treating mitochondrial diseases

The present invention relates to the use of individual fumaric acid derivatives or mixtures thereof for preparing a pharmaceutical composition for treating mitochondrial diseases, especially for treating Parkinson's syndrome, Alzheimer's disease, Chorea Huntington disease, retinopathia pigmentosa and mitochondrial encephalomyopathy. Preferably, the fumaric acid derivative(s) is / are those selected from the group consisting of fumaric acid dialkyl esters or fumaric acid monoalkyl esters in the form of the free acid or a salt thereof.

Owner:BIOGEN INT

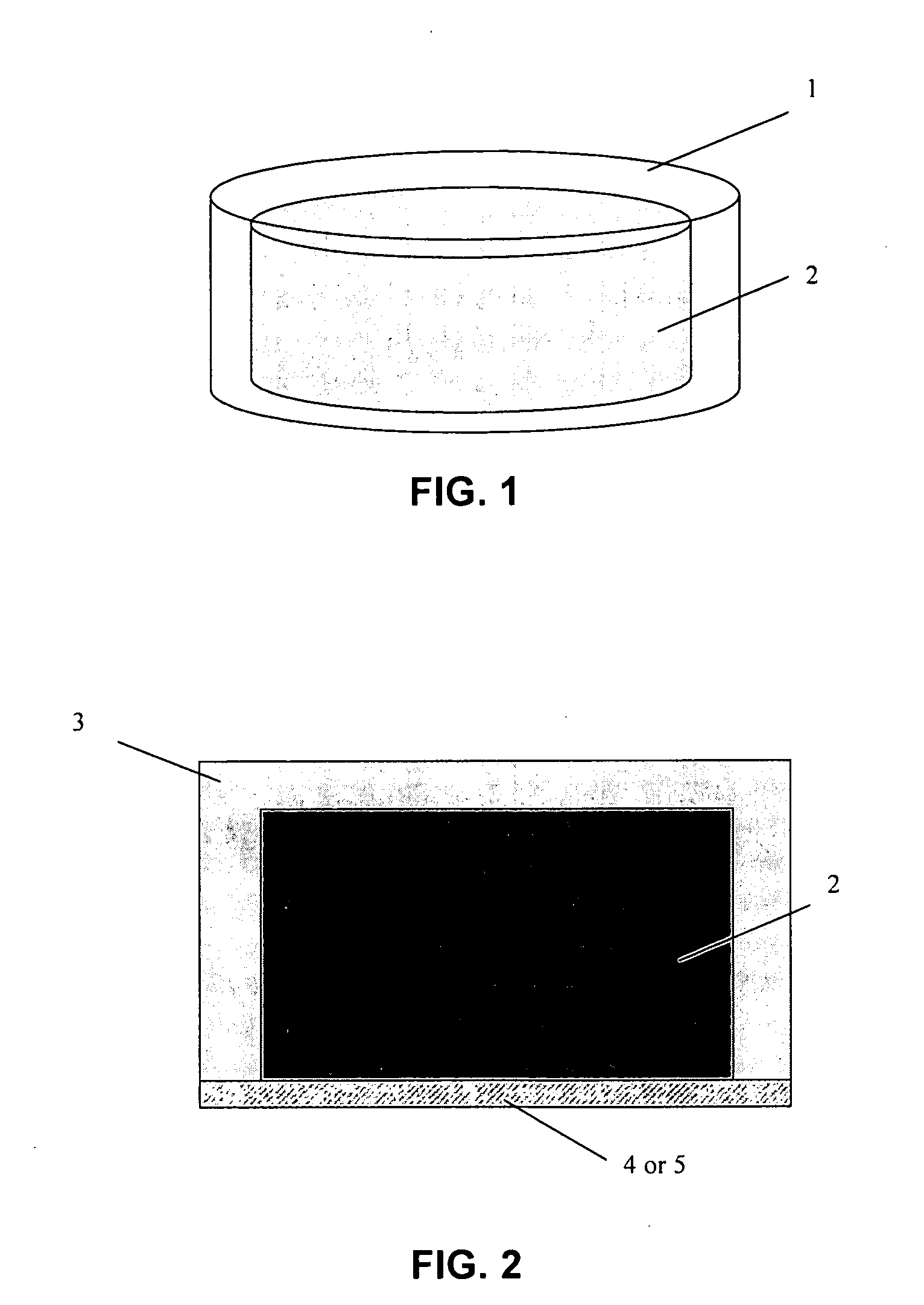

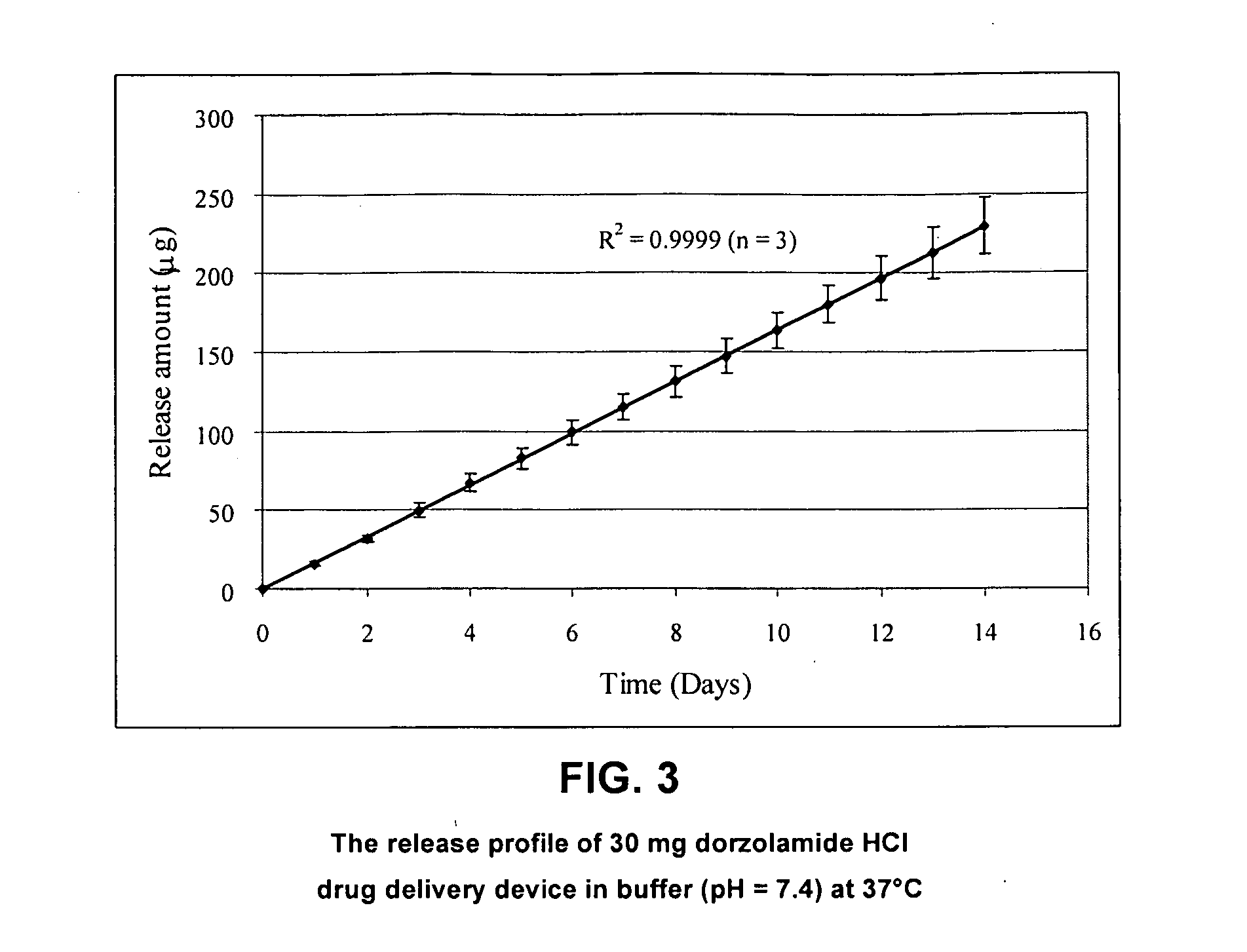

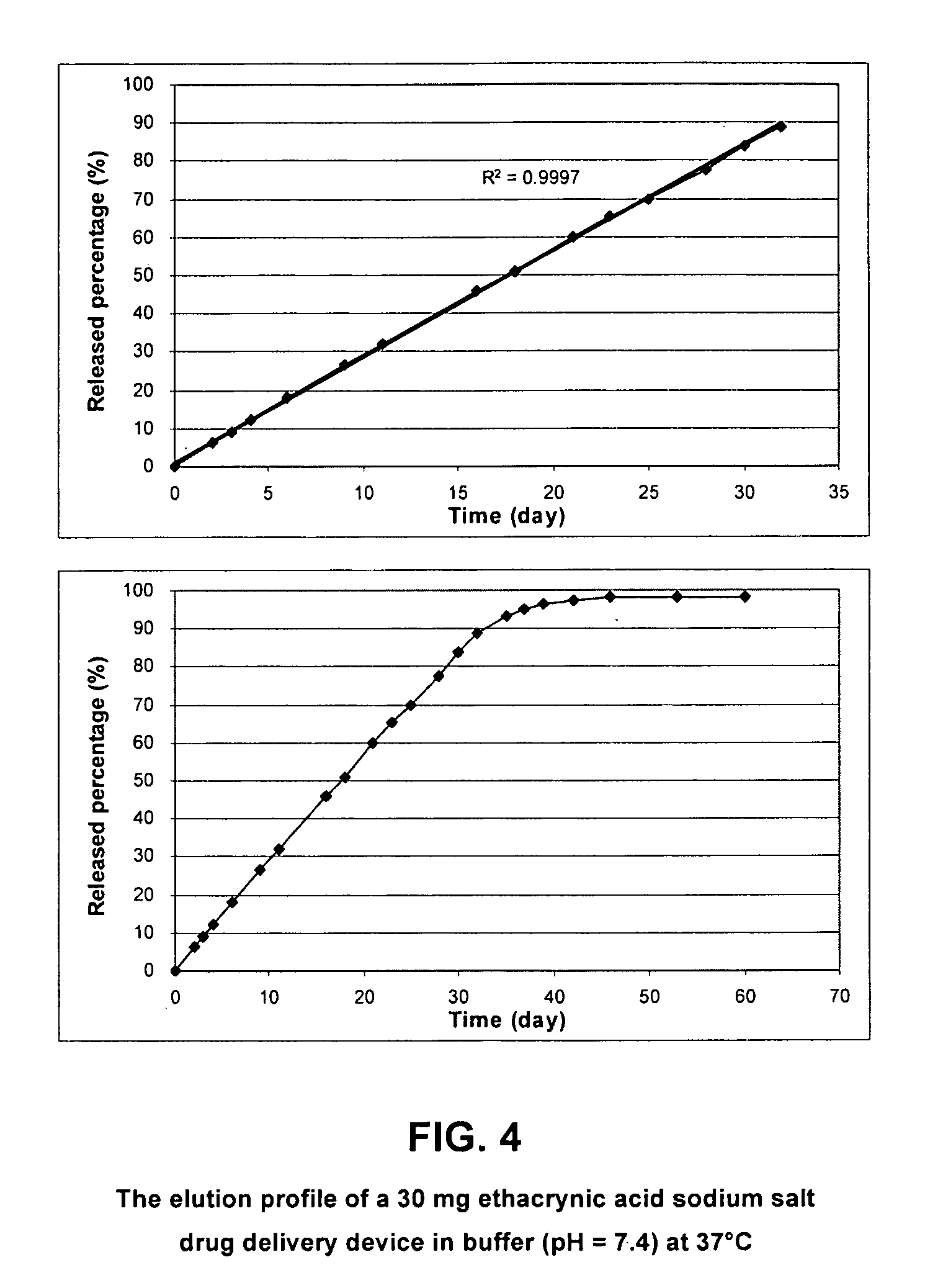

Drug delivery devices for delivery of therapeutic agents

Drug delivery devices comprising a non-bioabsorbable polymer structure and a composition comprising an active agent have been discovered. The drug delivery devices may be used to treat ocular conditions, among other diseases and conditions. In addition, a method of treating an ocular condition has been discovered comprising implanting a drug delivery device which releases the active agent at a rate ofQ=0.001×N×C wherein C is the topical effective concentration (in milligram / mL) of the active agent and N=0.01 to 0.5 for prostaglandins in their ester, amide, free acid or salt form, and N=0.5 to 5 for any active agent other than prostaglandins in their ester, amide, free acid or salt form.

Owner:NOVAER HLDG

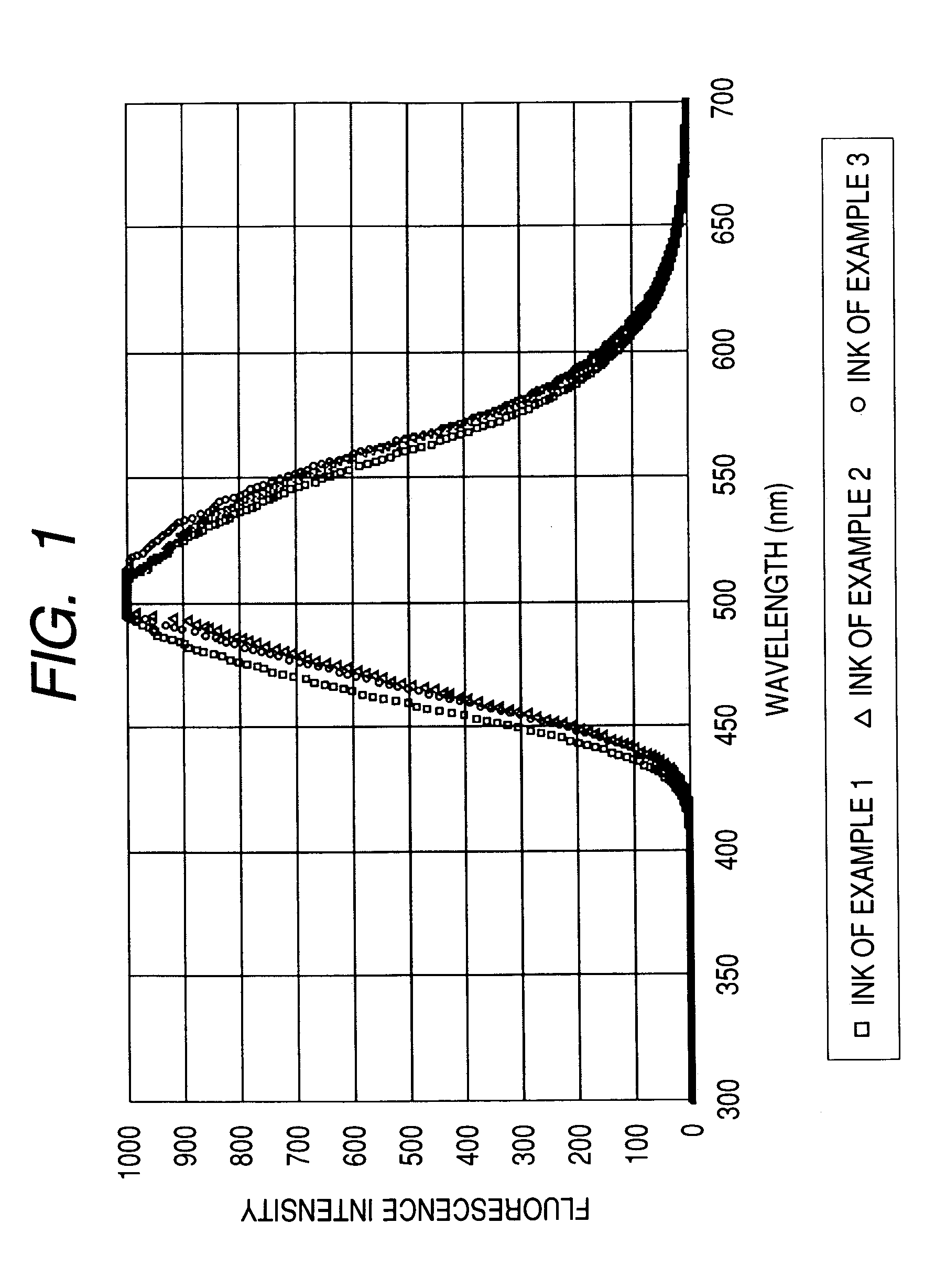

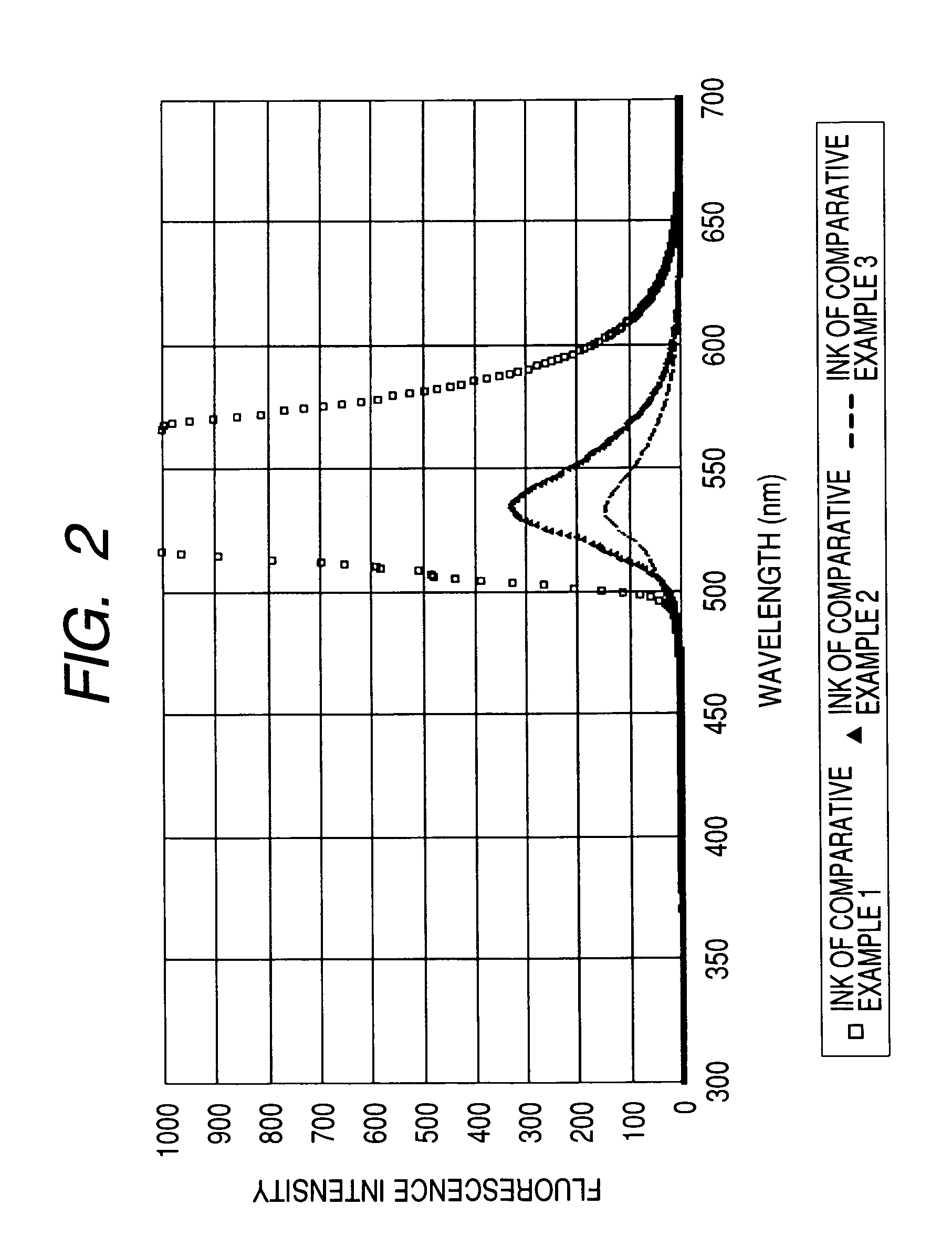

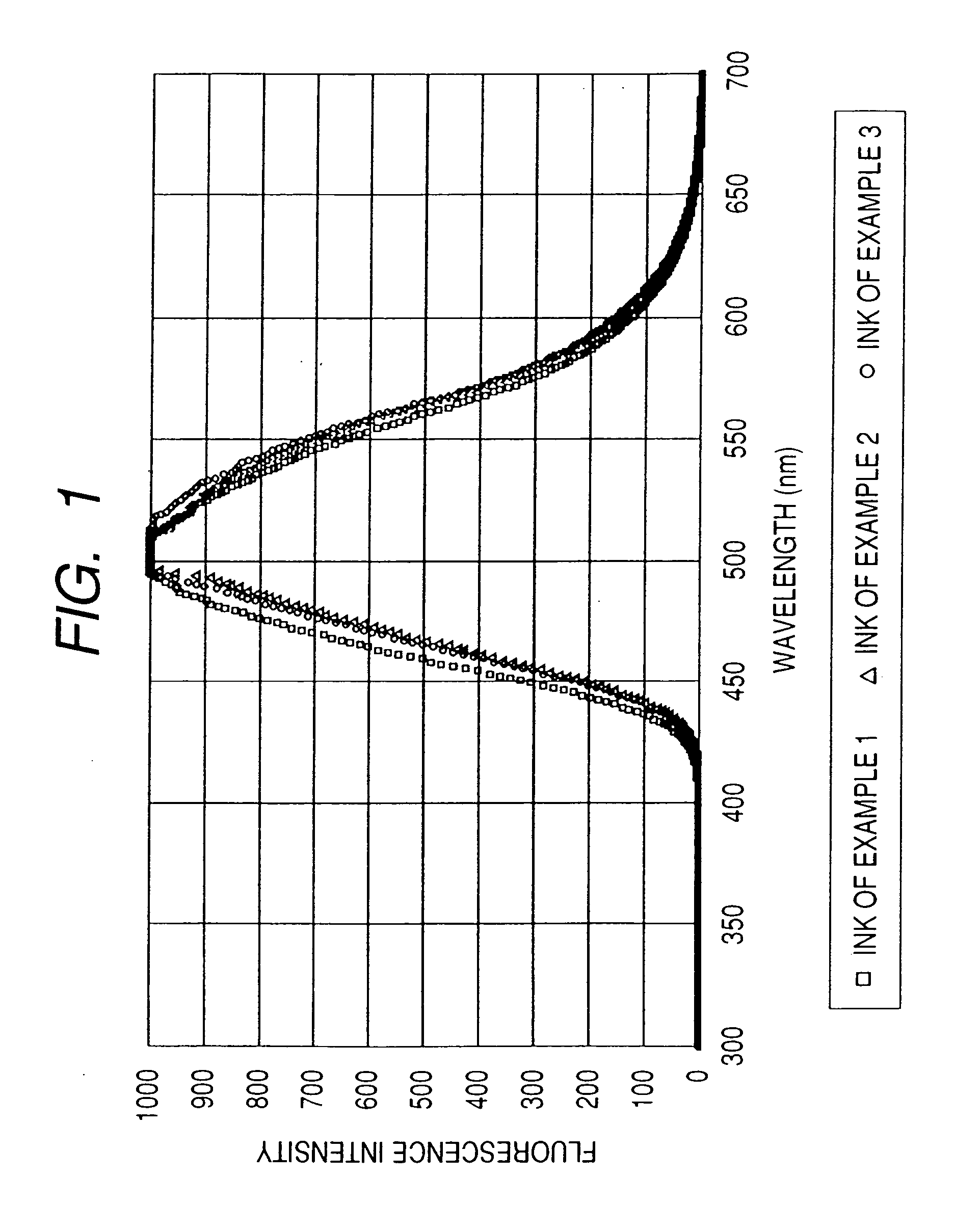

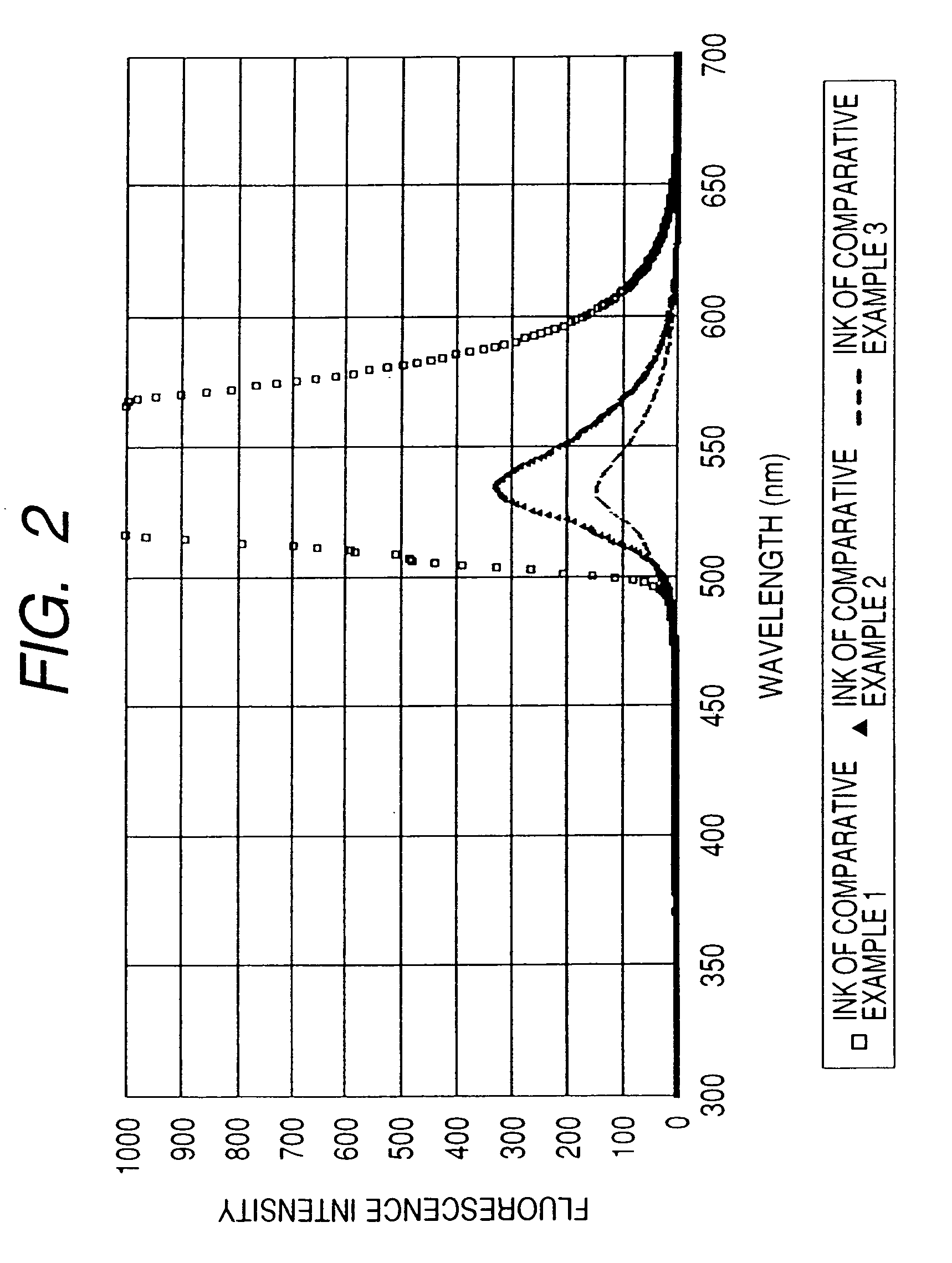

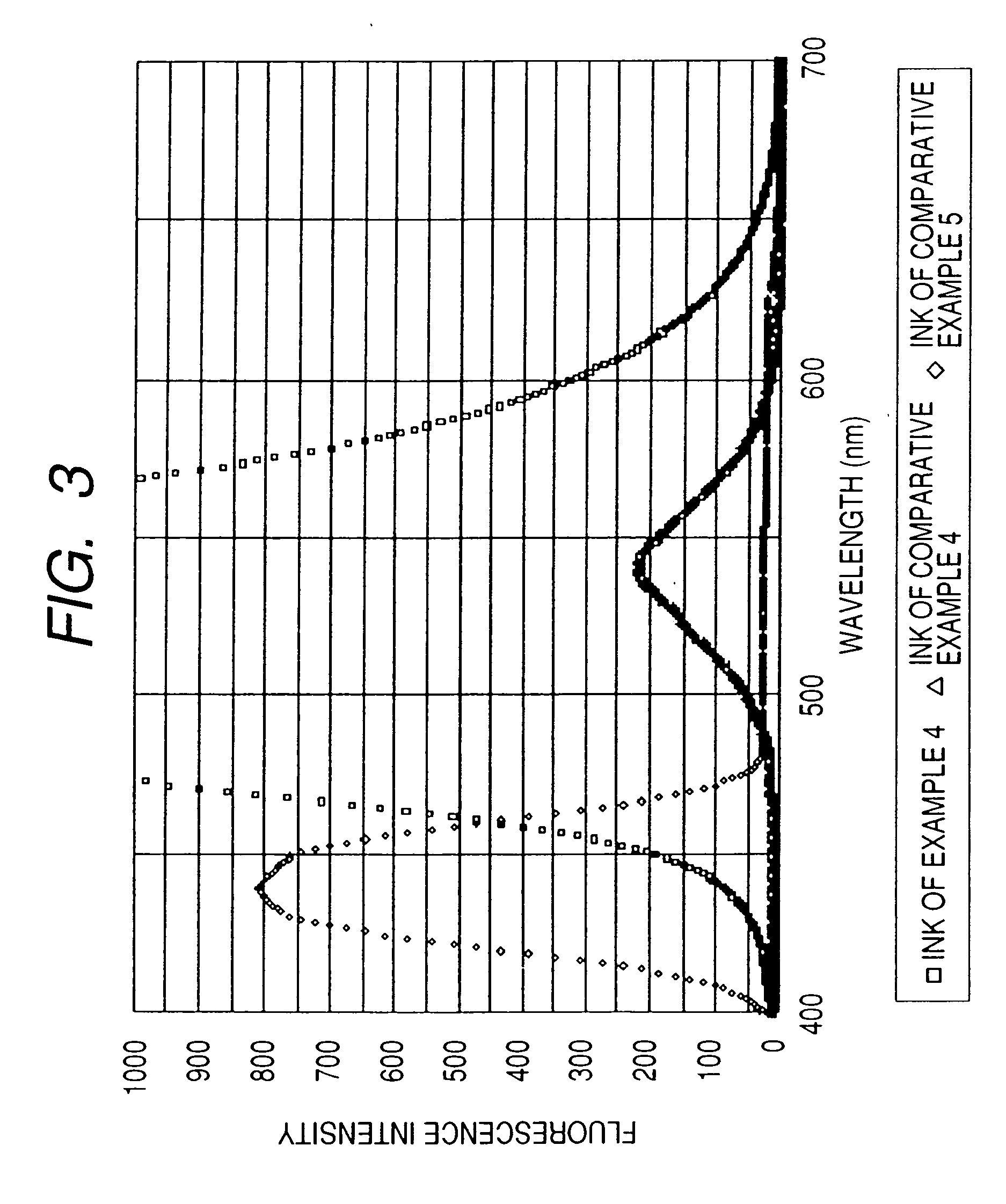

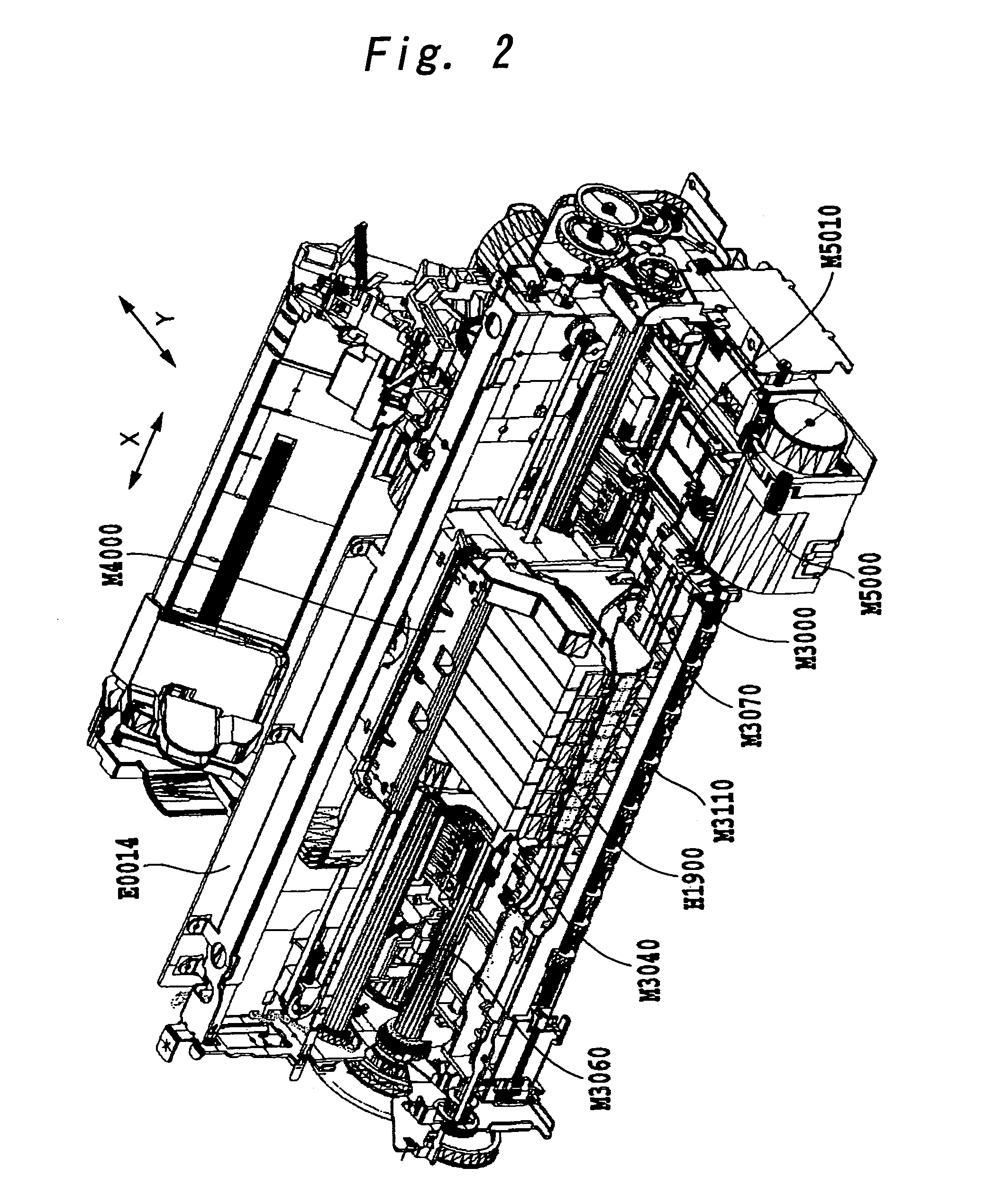

Water-based fluorescent ink, recorded image using the same, and judging method

The present invention relates to a water-based fluorescent ink for the purpose of measurement or judgment of the fluorescence emission in a visible light region by an excitation wavelength in a predetermined ultraviolet range, containing water, a coloring material dissolved or dispersed in water, and an organic solvent, having a plurality of fluorescent groups in the coloring material structure of the coloring material, and using a water-soluble coloring material having a sulfonic acid group as the water-soluble group in the state of a free acid, capable of improving the water resistance and the light resistance, dramatically increasing the content of the fluorescent coloring material in the ink, which has conventionally been included only by a small amount in the ink due to the concentration quenching problem, obtaining preferable fluorescence emission and water resistance of the recorded image, and providing preferable adhesion resistance to the recording medium of the coloring material and reliability.

Owner:CANON KK

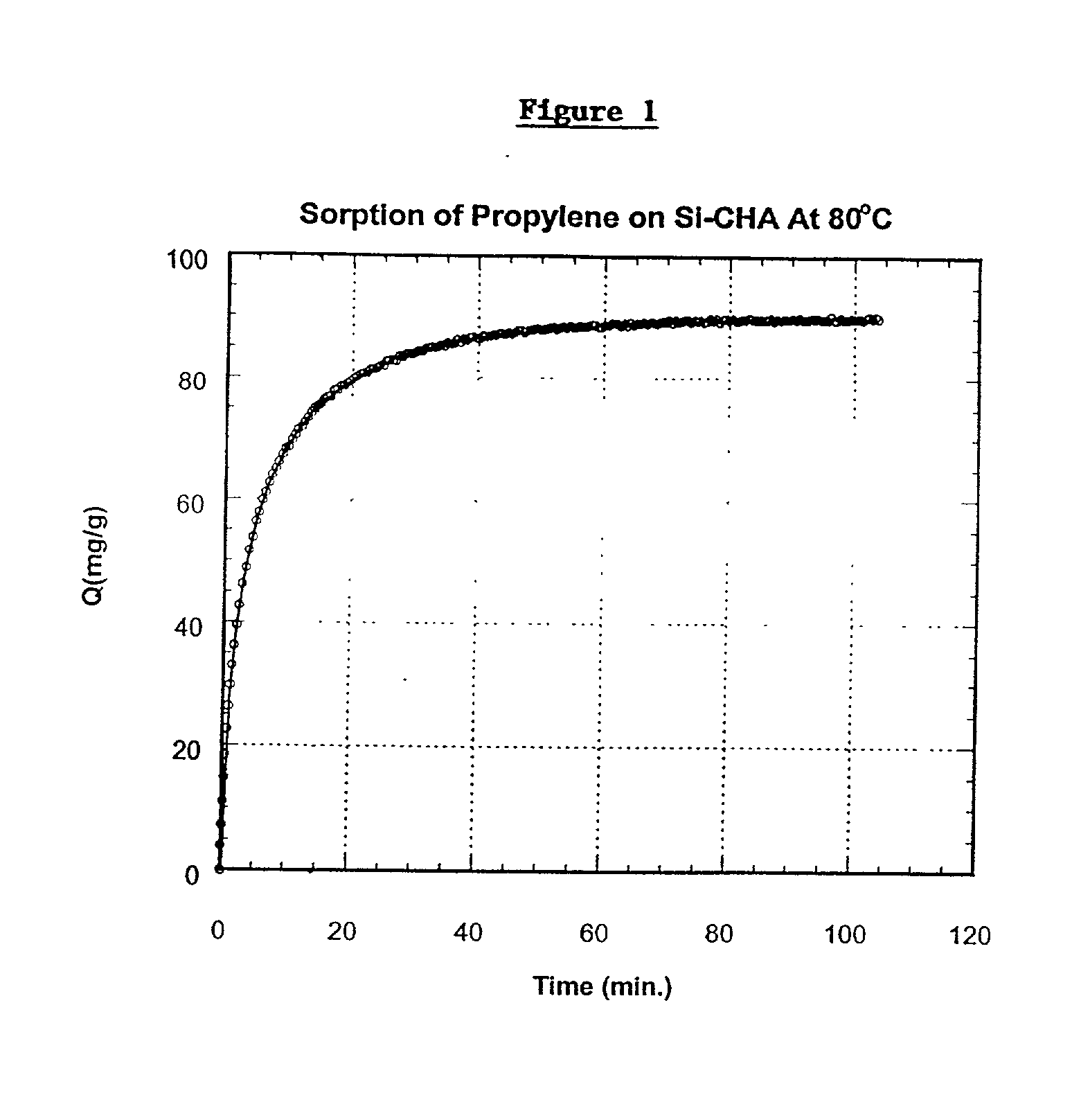

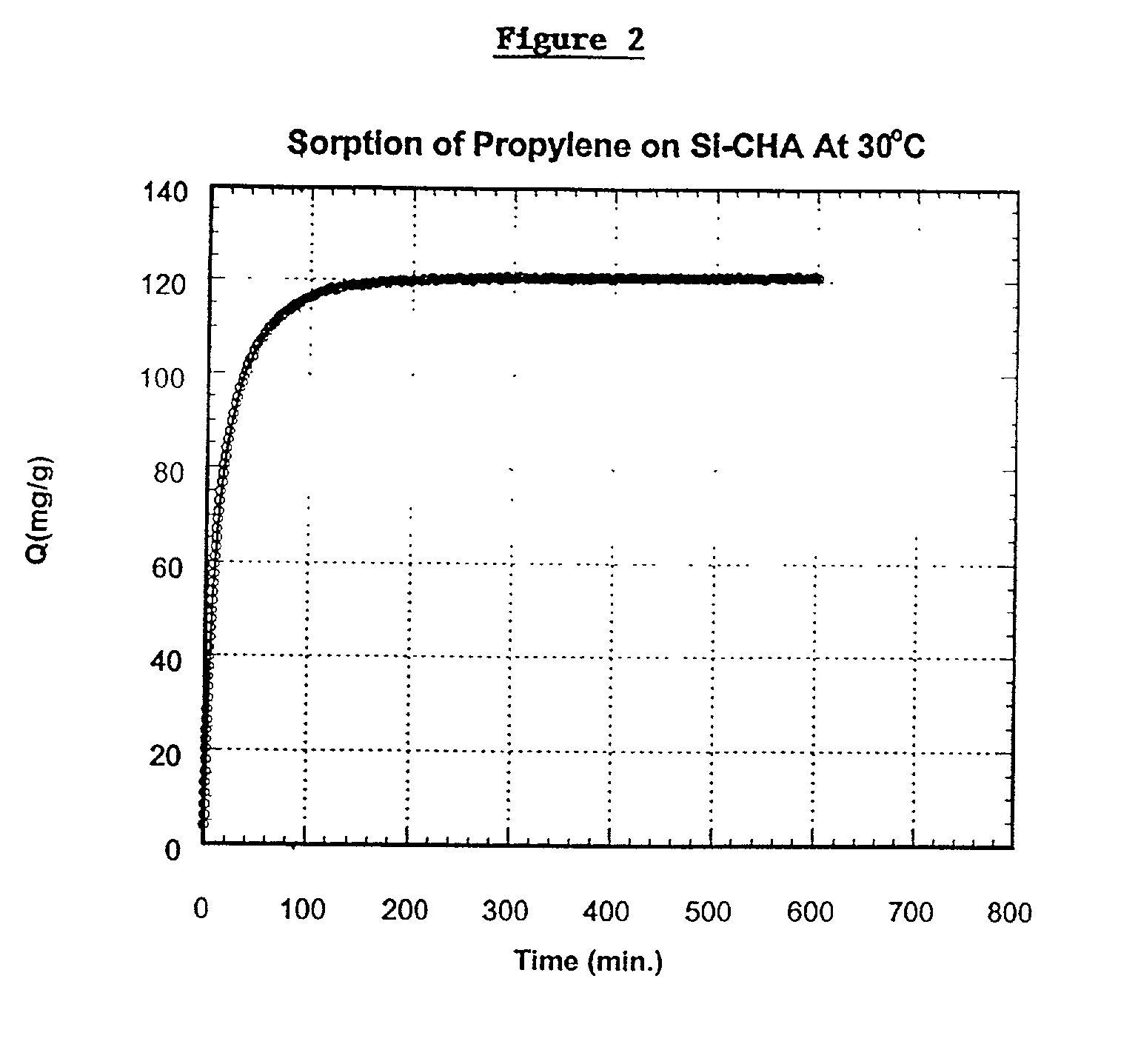

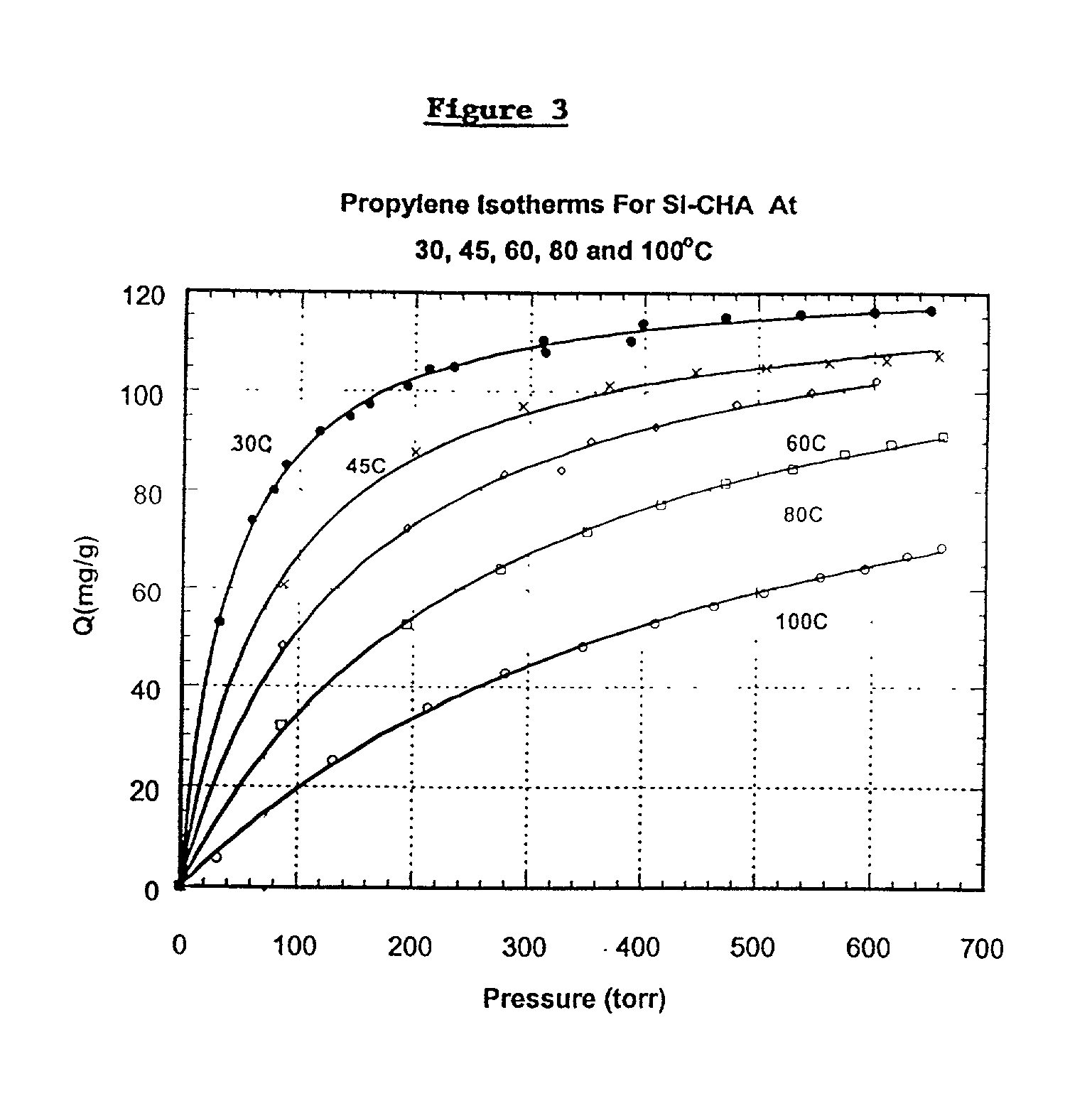

Light hydrocarbon separation using 8-member ring zeolites

InactiveUS6488741B2Improve efficiencyImprove diffusivityGas treatmentIsotope separationSorbentPropane

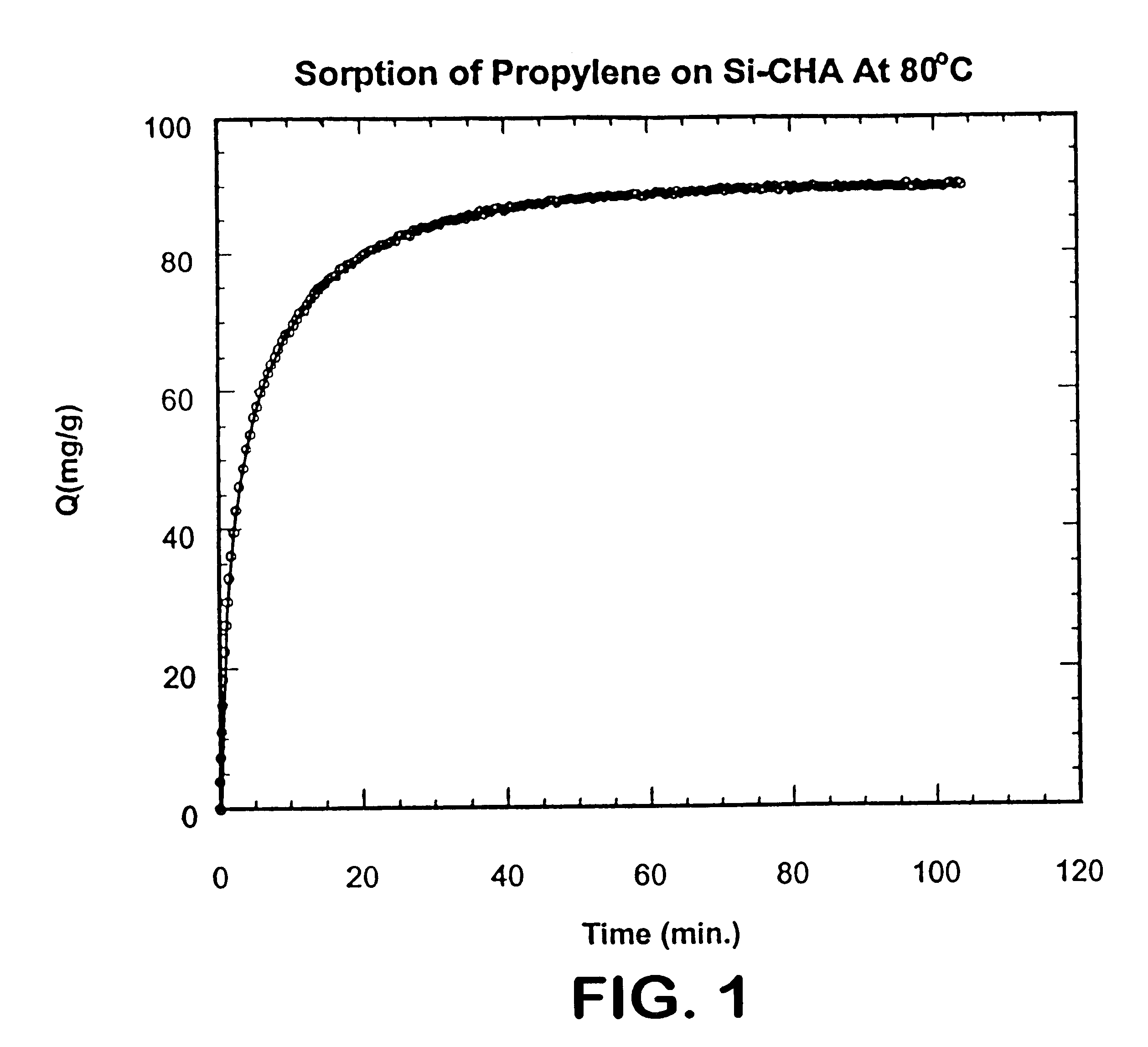

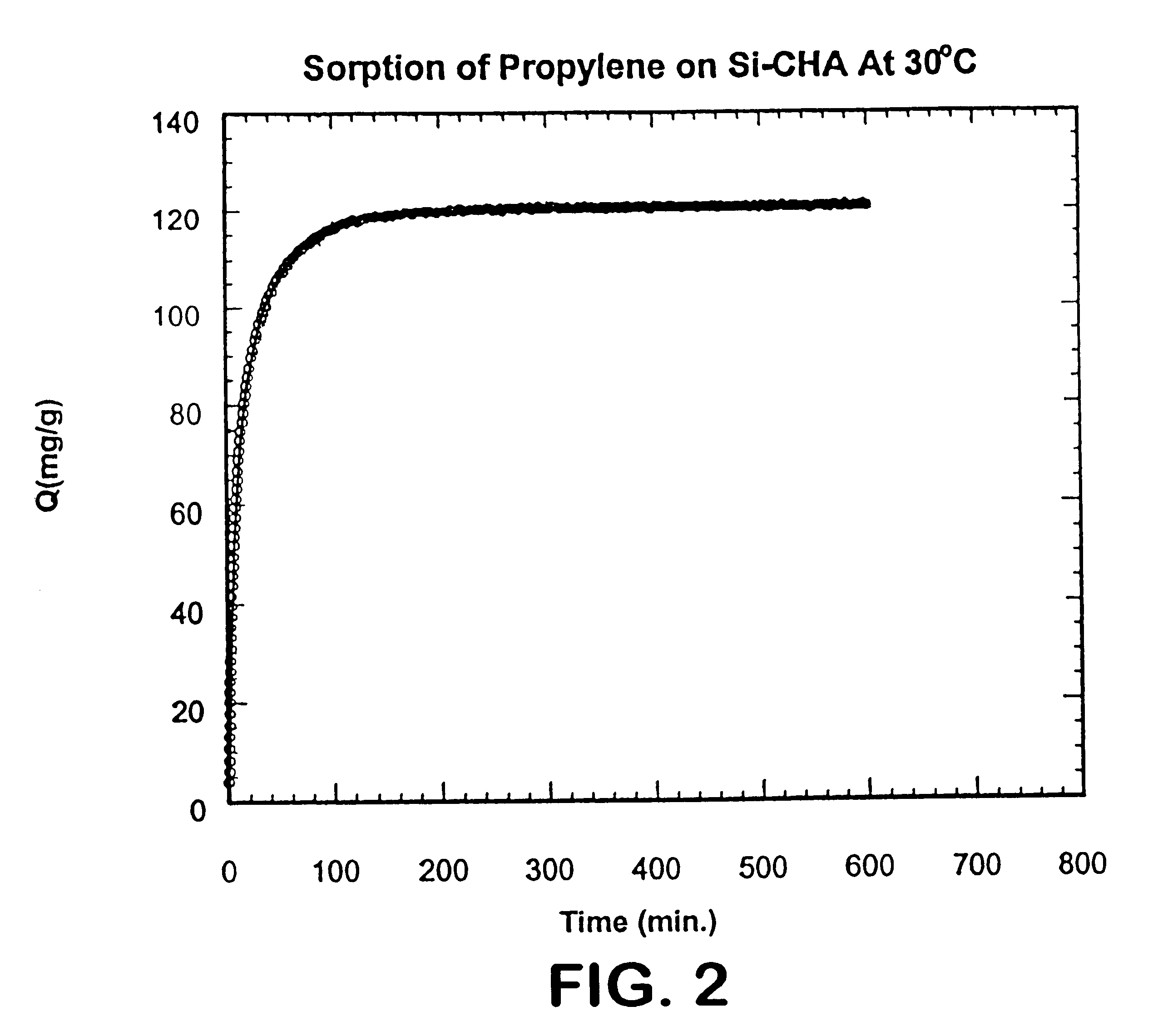

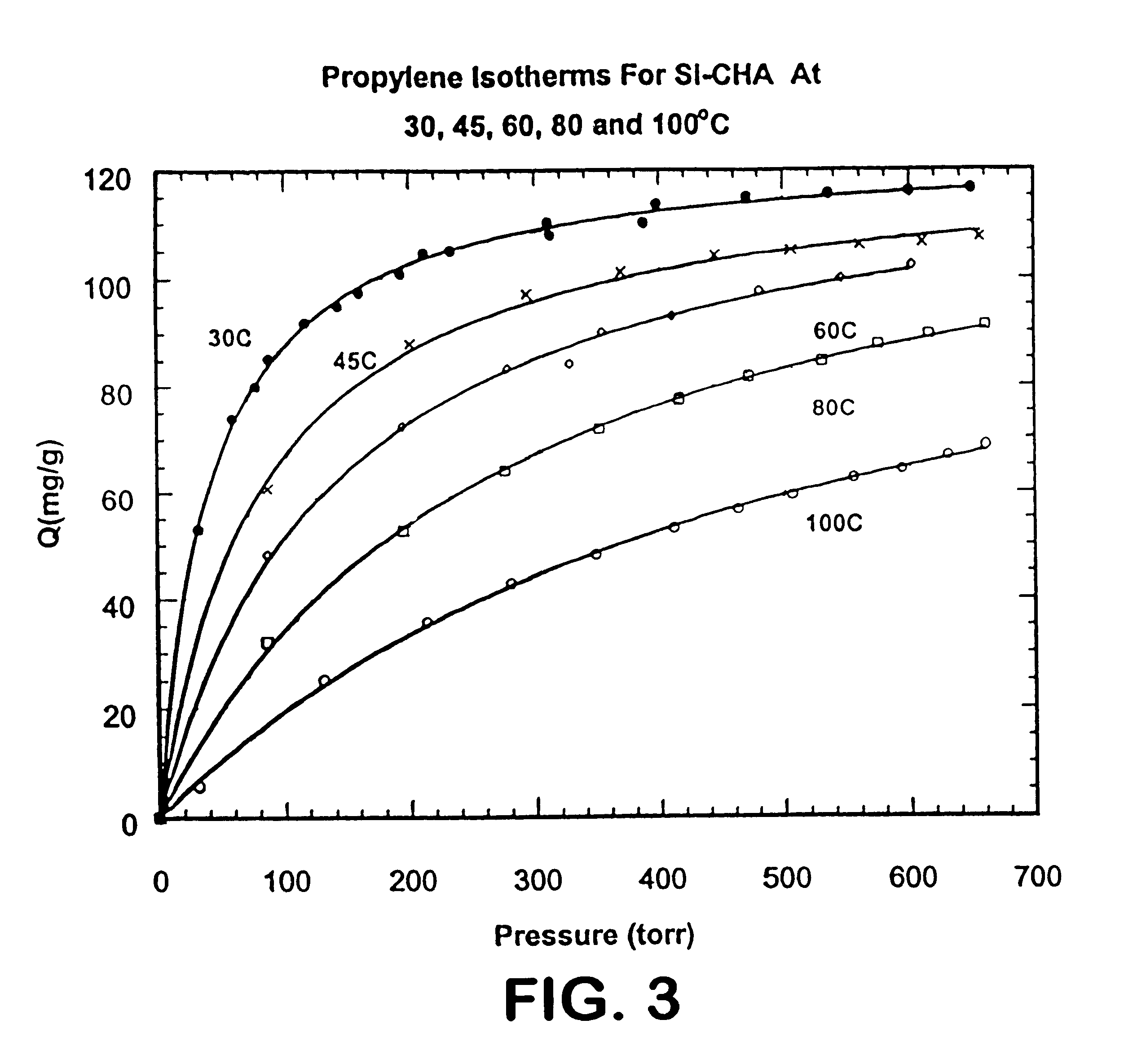

A method of selectively adsorbing propylene in mixtures of propylene / propane and propylene / olefins through the use of zeolites having structures with a maximum of 8-member rings of tetraheda controlling the diffusion rate. Suitable zeolite adsorbents are those having the CHA and ITE structure types. Other 8-member ring zeolites, including aluminosilicates, with a Si:Al molar ratio of at least about 200 and having substantially no free acid are also suitable adsorbents.

Owner:THE TRUSTEES OF THE UNIV OF PENNSYLVANIA

Method of Administering beta-hydroxy-beta-methylbutyrate (HMB)

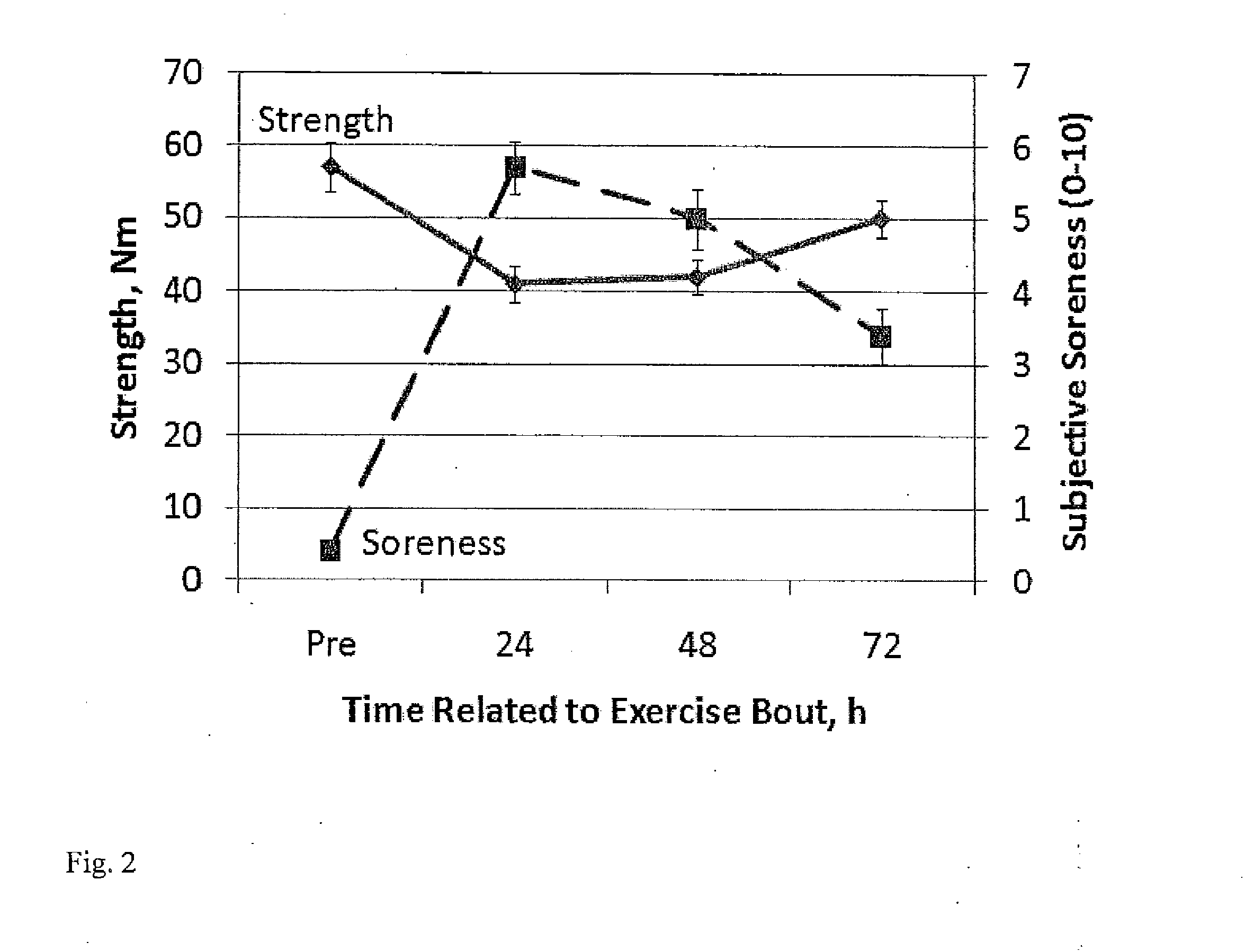

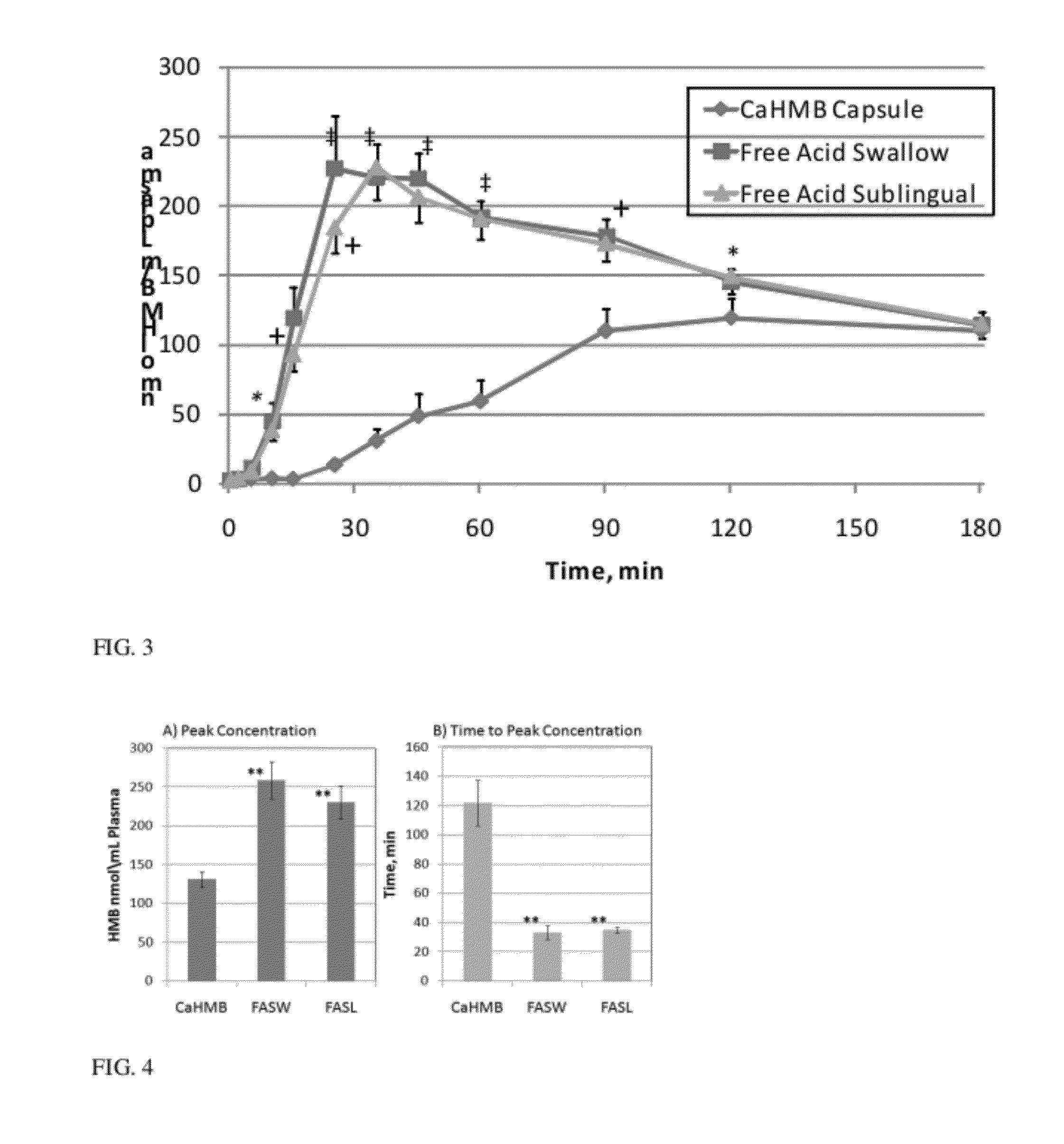

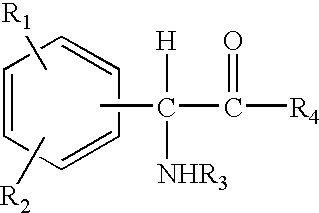

InactiveUS20120053240A1Improves HMB availabilityFast wayBiocideNervous disorderBlood plasmaBeta-Hydroxy beta-methylbutyric acid

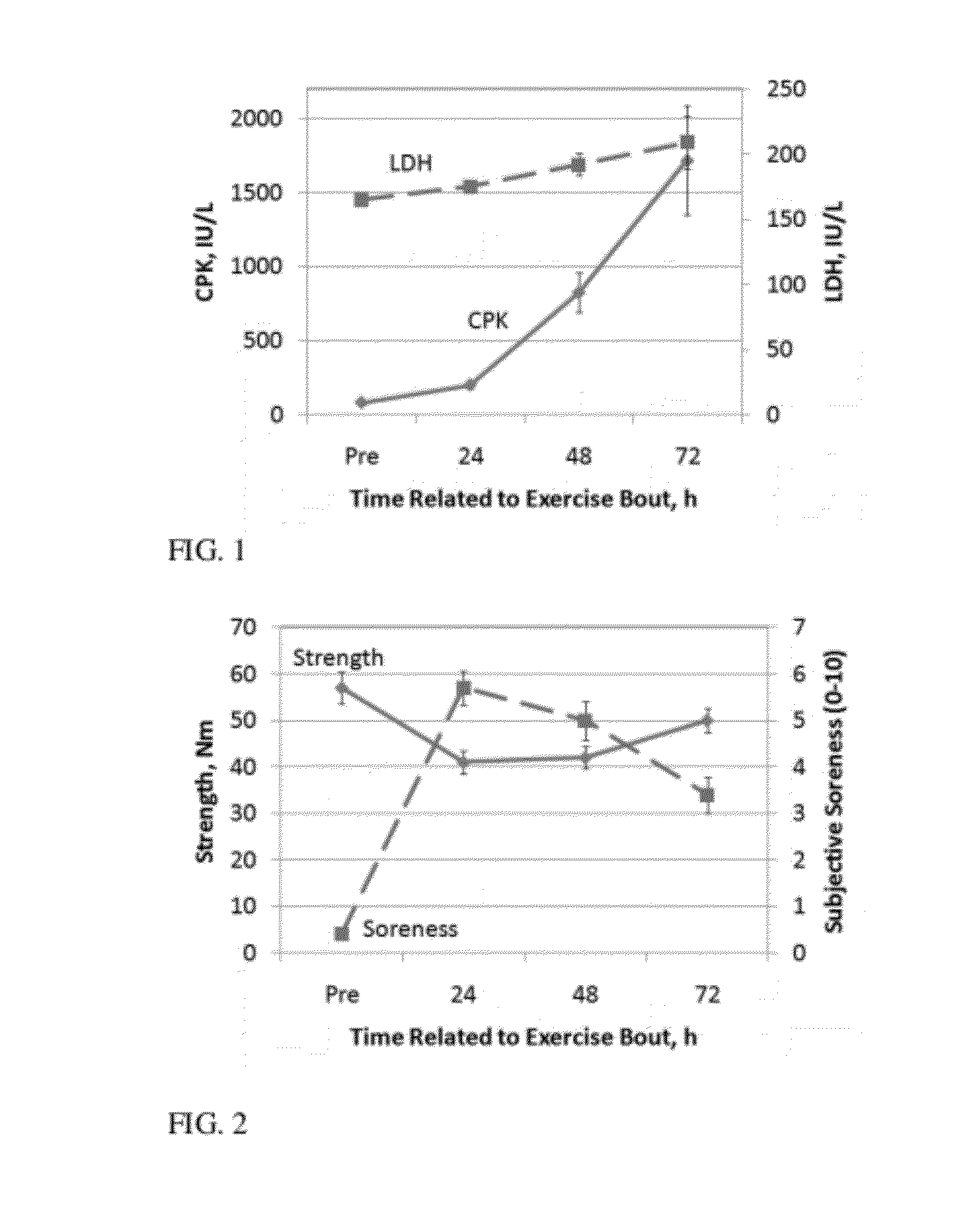

A method of administering beta-hydroxy-beta-methylbutyric acid (HMB) is described, and specifically administering HMB-acid to a person such that the administration of free acid HMB results in an increase in effectiveness of HMB over administration of other forms of HMB, including a calcium salt HMB composition is described. Administration of HMB-acid results in an increase in the peak level of HMB in plasma compared with administration of a similar dose of a calcium salt HMB composition. Administration of HMB-acid results in a faster time to reach peak plasma levels of HMB relative to administration of a similar dosage of a calcium salt HMB composition.

Owner:METABOLIC TECH

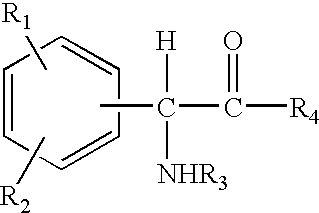

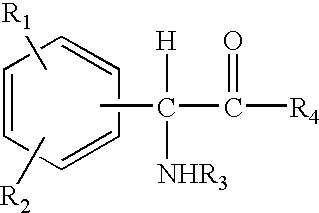

Compositions comprising phenyl-glycine derivatives

The invention relates to compositions and methods useful for treating a variety of cosmetic conditions and dermatological disorders, where the composition includes a phenyl glycine derivative represented by the following formula:wherein, R1 and R2 are independently H, I, F, Cl, Br, OH, SH, NH2, NHNH2, alkyl, aralkyl, alkoxy, acetoxy, acyloxy group having 1 to 9 carbon atoms, and being attached at the 2, 3 or 4 position of the phenyl group, whereby when R1 and / or R2 are OH, SH, NH2, they may be acetylated or acylated with 1 to 9 carbon atoms; R3 is H, formyl, acetyl, propanoyl, acyl, alkyl, aralkyl or an aryl group having 1 to 9 carbon atoms; R4 is OH, NH2, NHOH, NHNH2, or OR; where R is an alkyl, aralkyl or aryl group having 1 to 9 carbon atoms; the H attached to any carbon or nitrogen atom may be substituted by I, F, Cl, Br, OH, SH, NH2, NHNH2, an alkyl, aralkyl, alkoxy or acyl group having 1 to 9 carbon atoms. Phenyl-glycine and its derivatives may be present as isomeric D or L, non-isomeric or racemic DL, as a free acid, salt, lactone, amide or ester form.

Owner:YU RUEY J +1

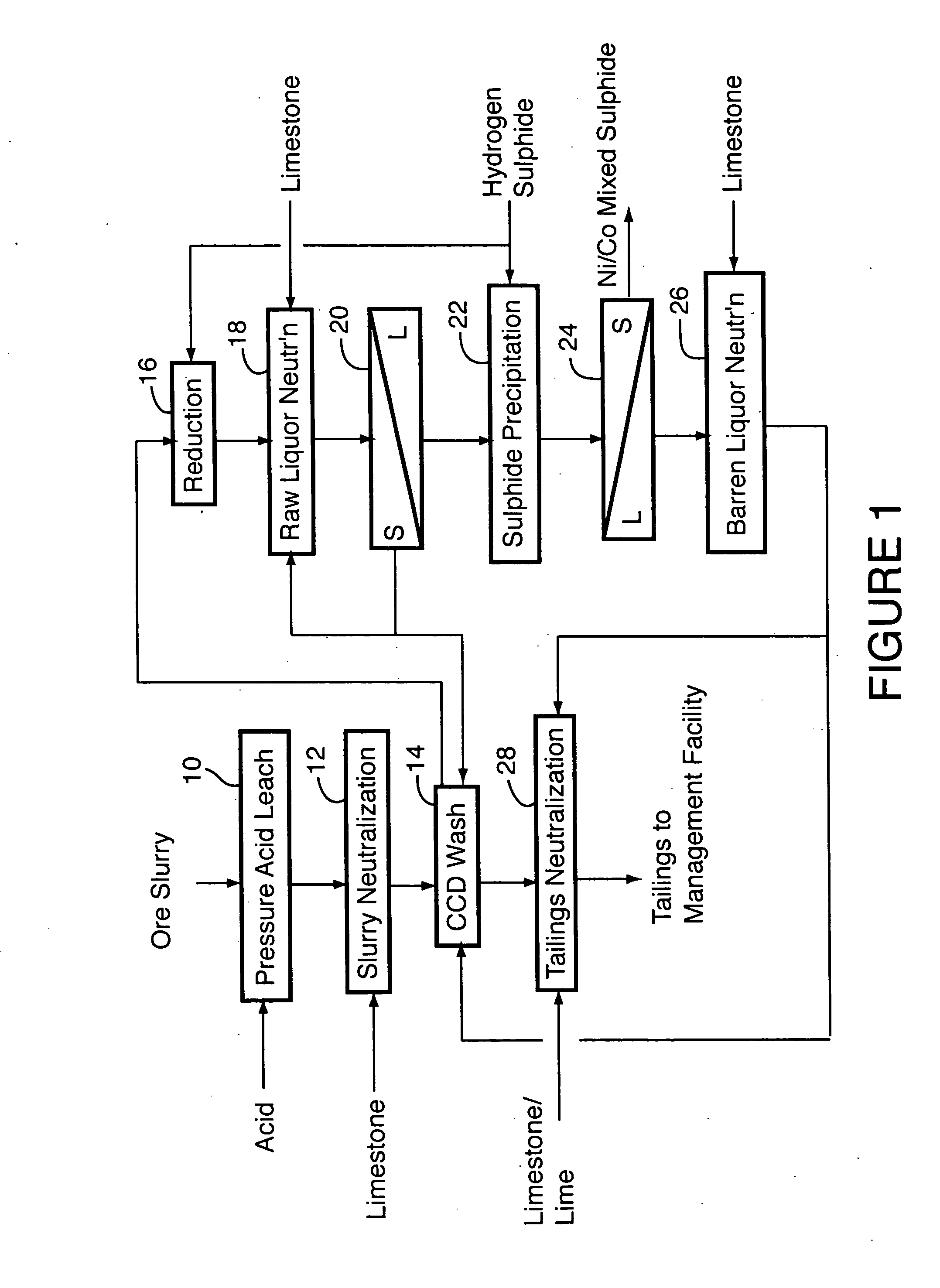

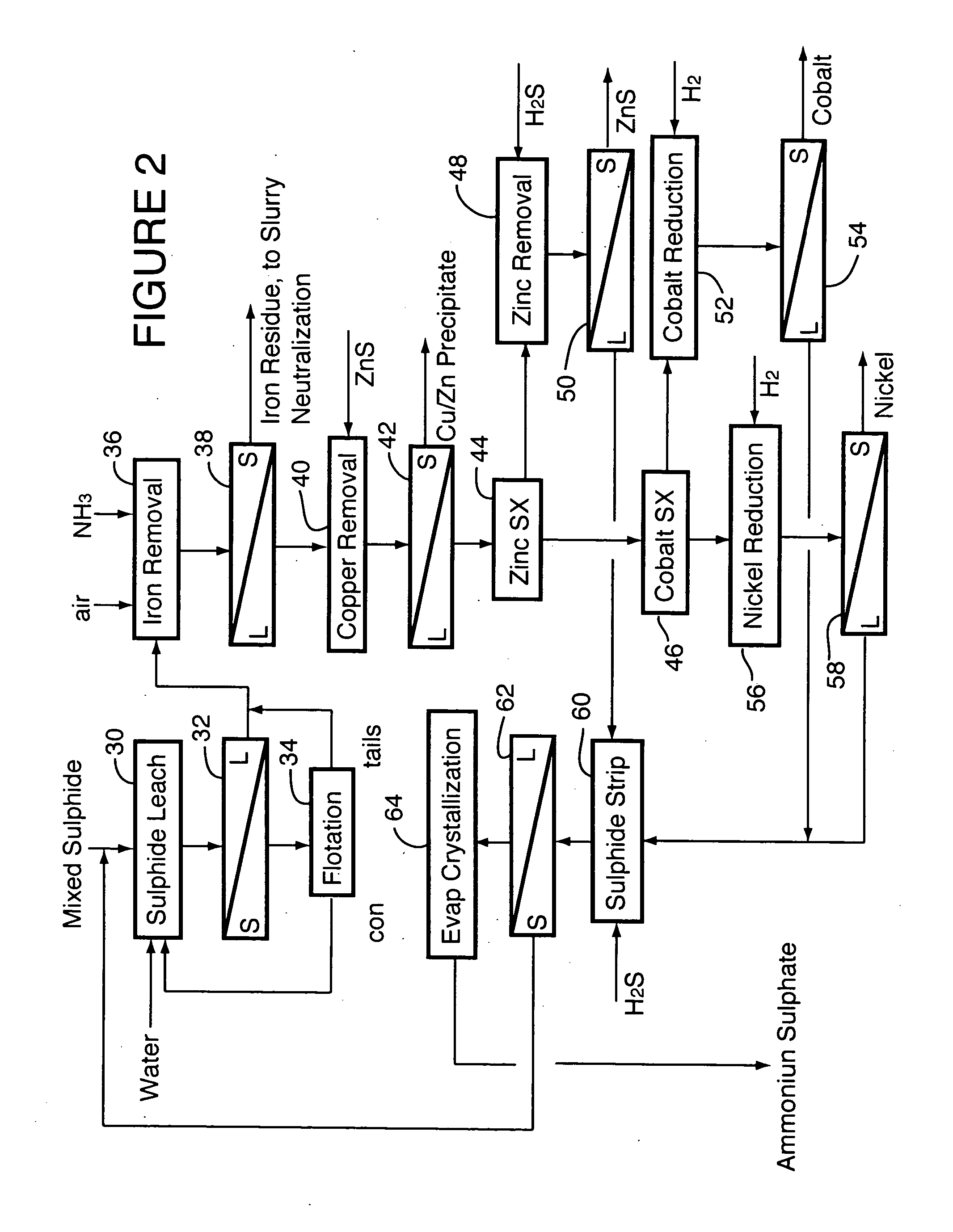

Process for recovery of nickel and cobalt from laterite ore

ActiveUS20060228279A1Efficient separation and recoveryHigh purityCobalt sulfidesSolvent extractionFree solutionSlurry

A process for recovering nickel and cobalt values from nickel- and cobalt-containing laterite ores as an enriched mixed nickel and cobalt sulphide intermediate and for producing nickel and cobalt metal from the nickel and cobalt sulphide intermediate. The laterite ore is leached as a slurry in a pressure acid leach containing an excess of aqueous sulphuric acid at high pressure and temperature, excess free acid in the leach slurry is partially neutralized to a range of 5 to 10 g / L residual free H2SO4 and washed to yield a nickel- and cobalt-containing product liquor, the product liquor is subjected to a reductant to reduce any Cr(VI) in solution to Cr(III), the reduced product liquor is neutralized to precipitate ferric iron and silicon at a pH of about 3.5 to 4.0, and the neutralized and reduced product liquor is contacted with hydrogen sulphide gas to precipitate nickel and cobalt sulphides. The precipitated nickel and cobalt sulphides can be leached in a water slurry in a pressure oxidation leach, the leach solution subjected to iron hydrolysis and precipitation, the iron-free solution contacted with zinc sulphide to precipitate copper, the iron- and copper-free solution subjected to zinc and cobalt extraction by solvent extraction to produce a nickel raffinate, the nickel raffinate contacted with hydrogen gas to produce nickel powder and the cobalt strip solution from the solvent extraction step contacted with hydrogen gas to produce cobalt powder.

Owner:SHERRITT INTERNATIONAL

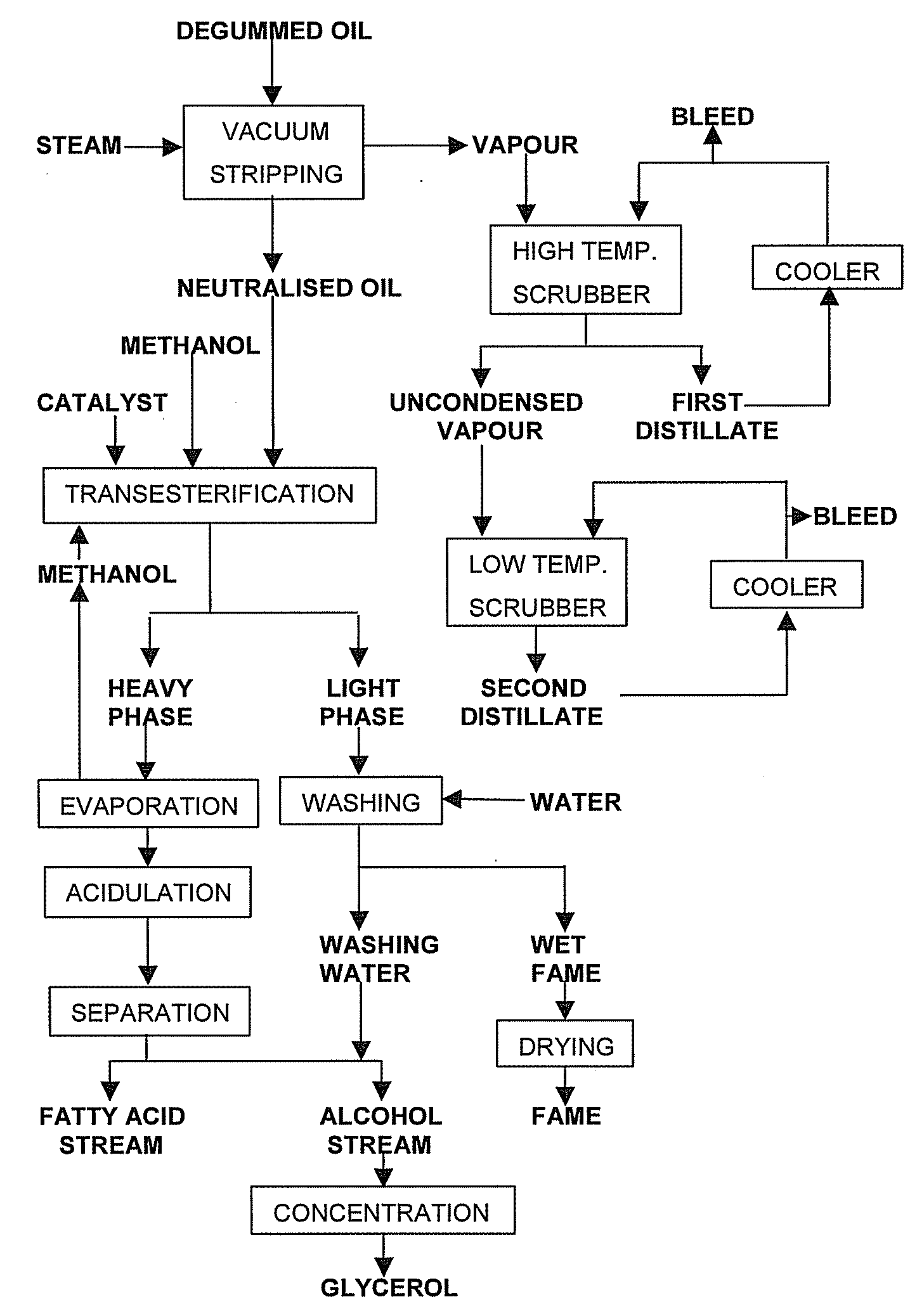

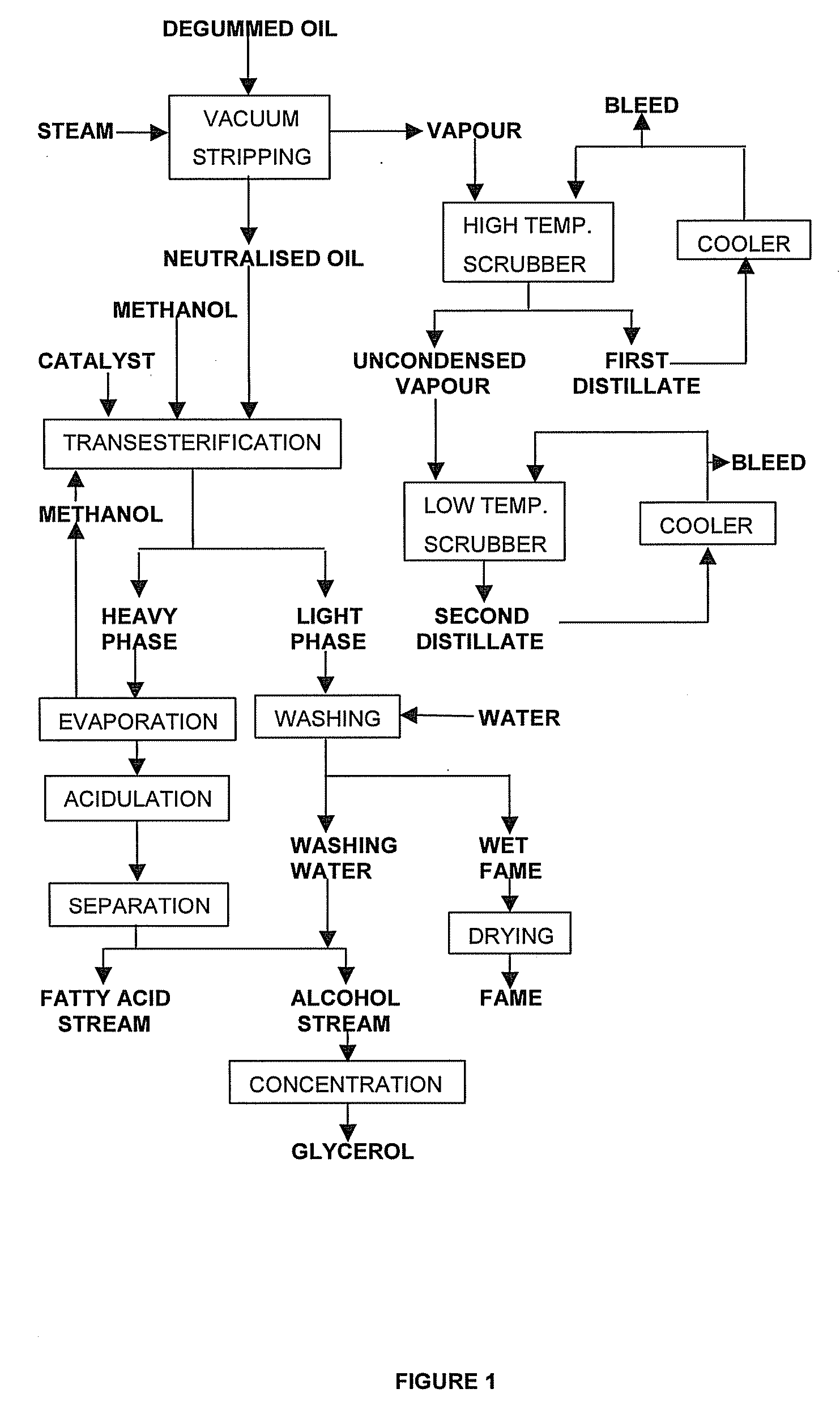

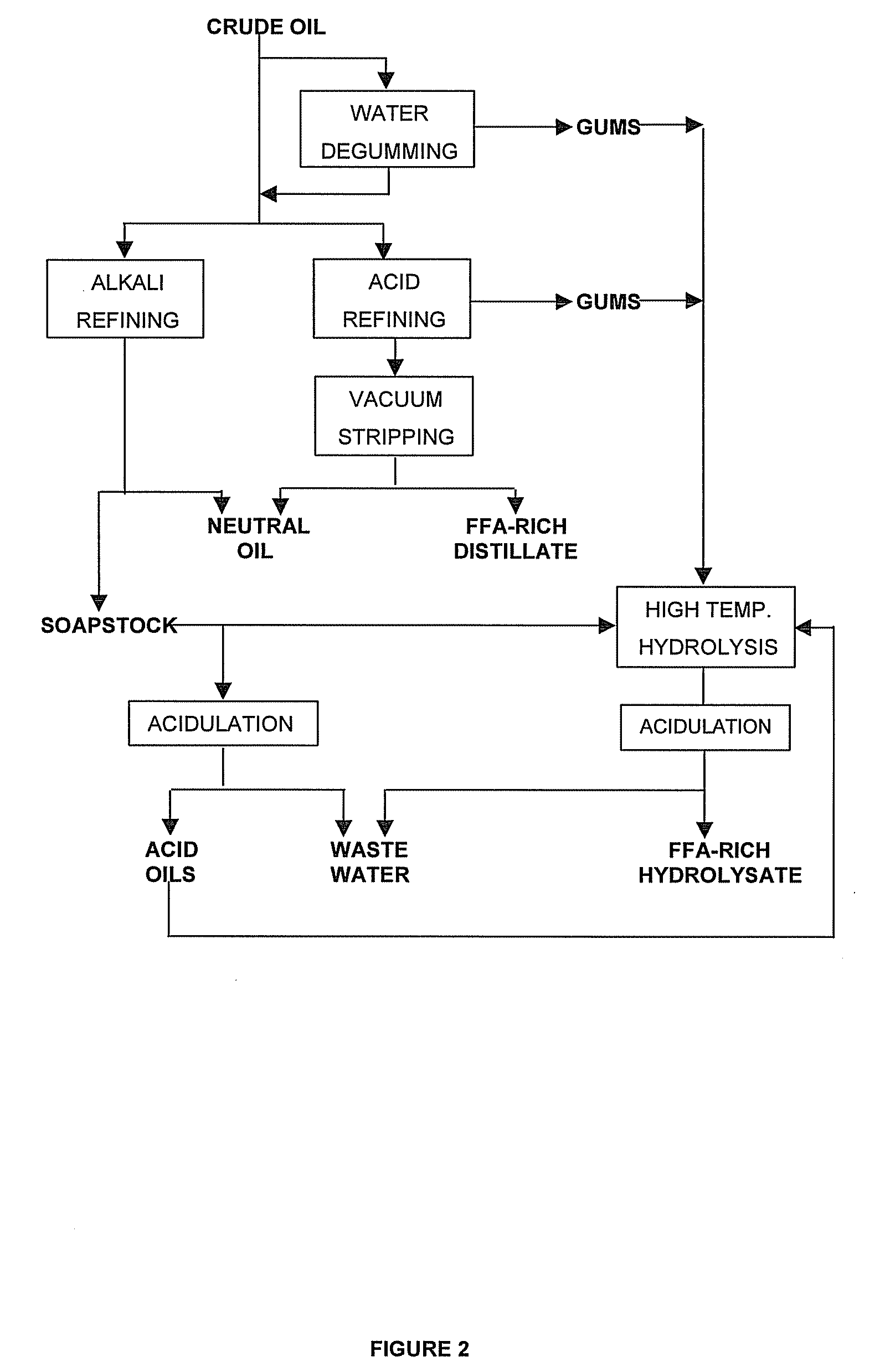

Production of esters of fatty acids and lower alcohols

InactiveUS20080051599A1Impurity can be harmfulBroad processingFatty acid esterificationFatty acids production/refiningTrans esterificationPtru catalyst

Process for the production of esters of fatty acids and C1-C5 alkyl alcohols comprising the steps of: (a) providing a fatty feed comprising a triglyceride oil or fat, partial glycerides and / or free fatty acids, (b) neutralising said fatty feed by vacuum stripping at a temperature from 200° C. to 280° C., thus providing a vapour stream and a residue, (c) collecting a distillate by scrubbing said vapour stream, (d) transesterifying said residue with a C1-C5 alkyl alcohol while using an alkaline catalyst, (e) separating the transesterification reaction mixture from step (d) into a fraction comprising C1-C5 alkyl esters of fatty acids and an alcoholic fraction (a) wherein at least part of free acids obtained as side products in step (a) and / or (c) and / or (e) are esterifyed with an alcohol using an acid catalyst, the product of this esterification being added to said fatty feed or said residue.

Owner:DESMET BALLESTRA OLEO

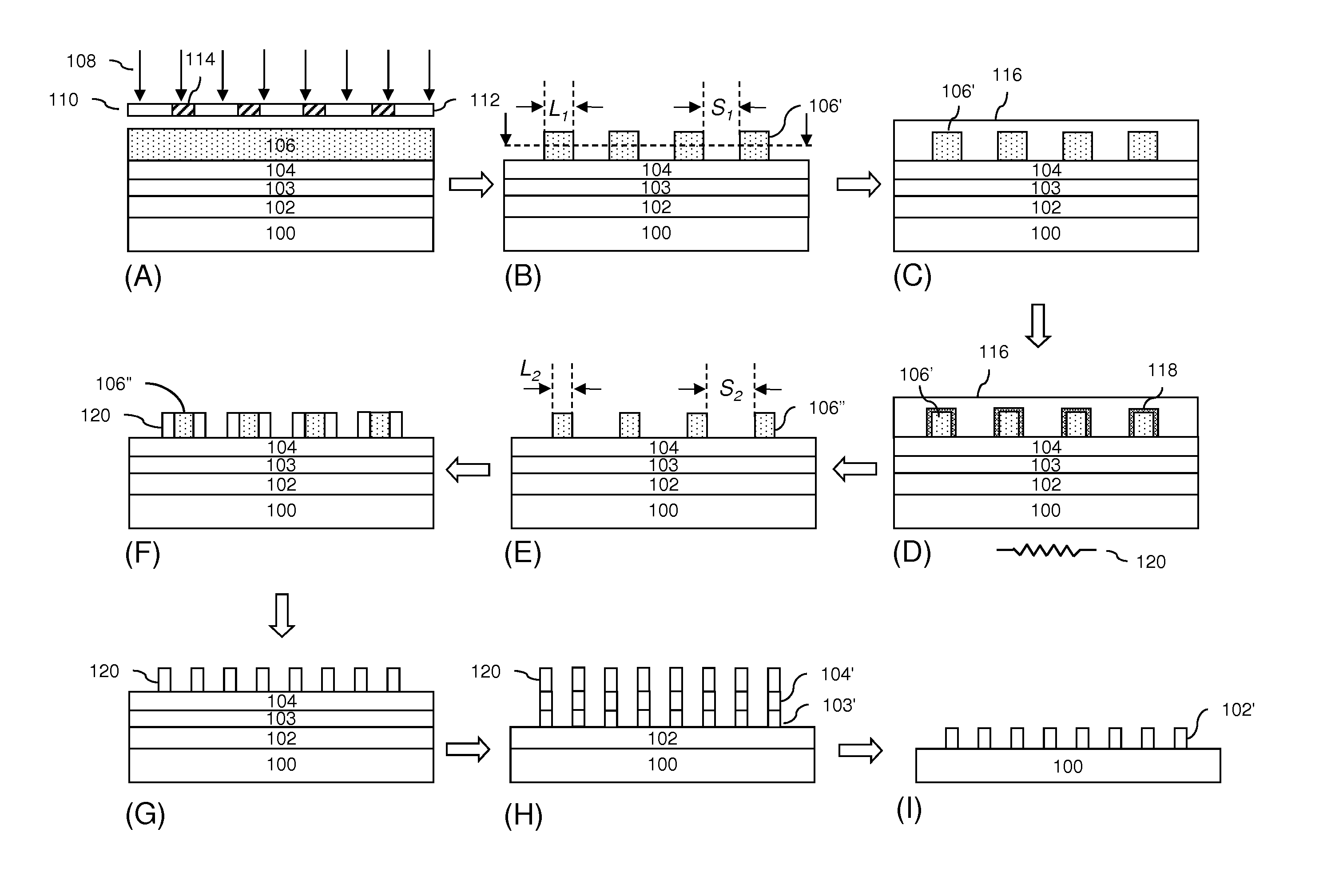

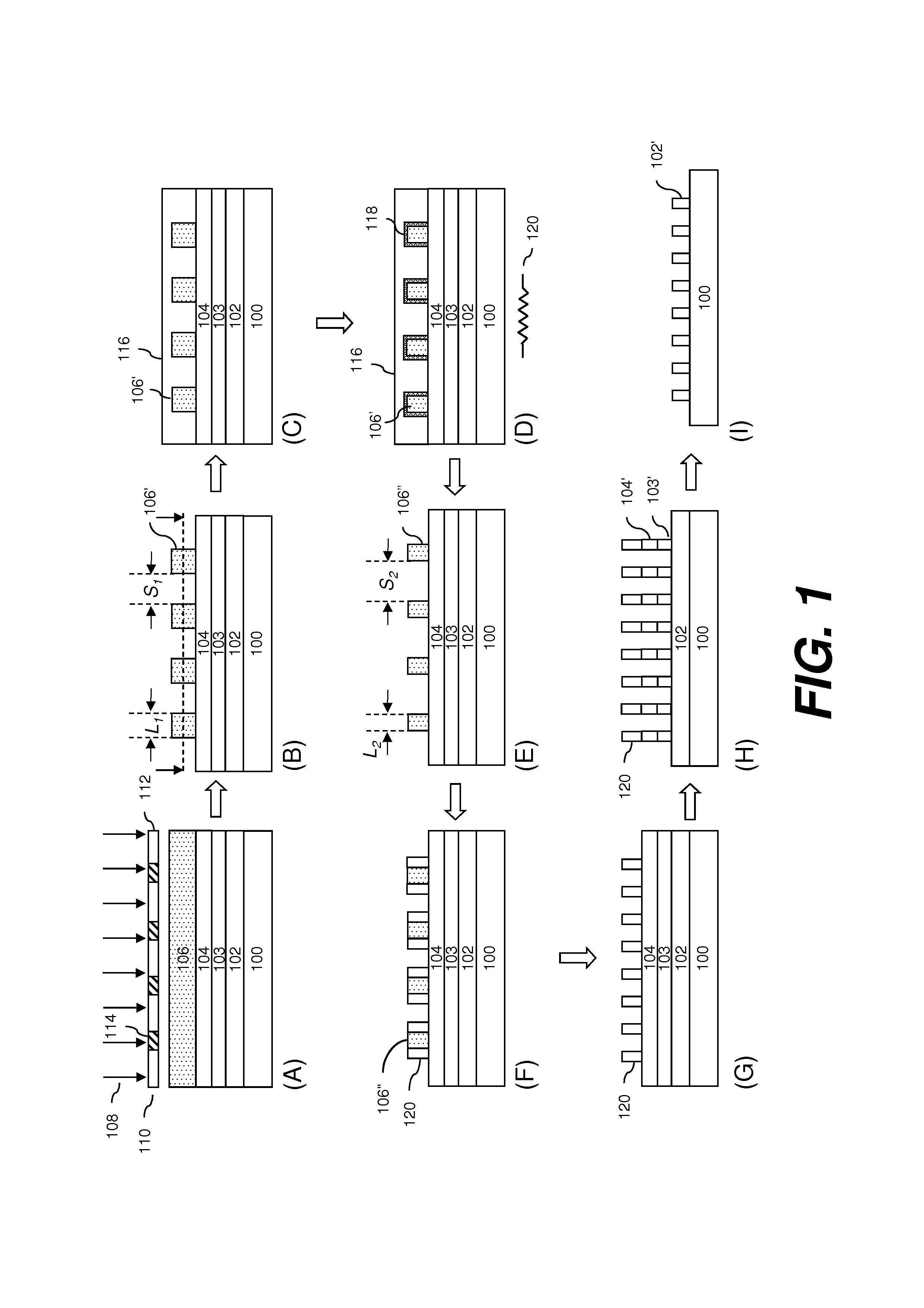

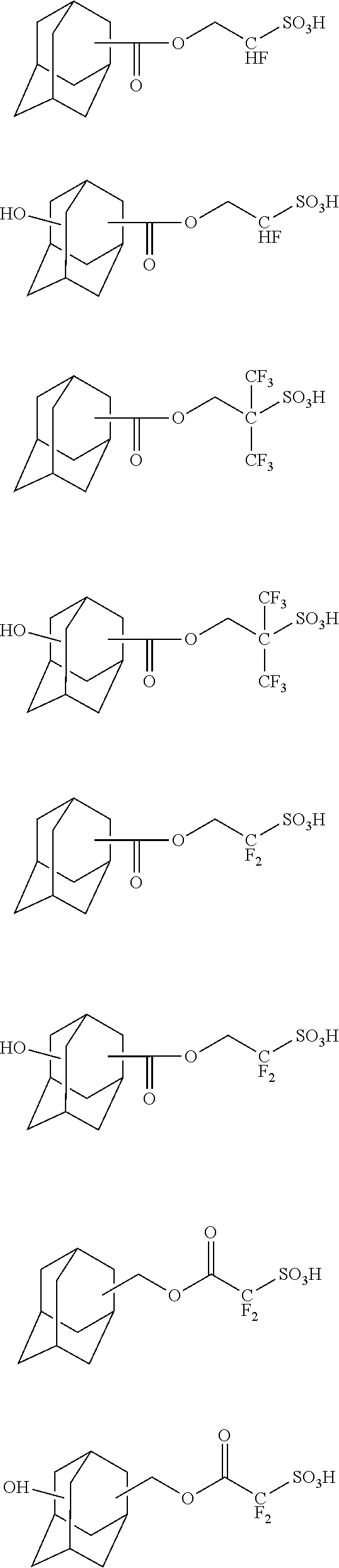

Photoresist pattern trimming methods

InactiveUS20130171574A1Increased process windowSemiconductor/solid-state device manufacturingPhotosensitive material processingResistPolymer science

Provided are methods of trimming photoresist patterns. The methods involve coating a photoresist trimming composition over a photoresist pattern, wherein the trimming composition includes a matrix polymer, a free acid having fluorine substitution and a solvent, the trimming composition being free of cross-linking agents. The coated semiconductor substrate is heated to cause a change in polarity of the resist polymer in a surface region of the photoresist pattern. The photoresist pattern is contacted with a developing solution to remove the surface region of the photoresist pattern. The methods find particular applicability in the formation of very fine lithographic features in the manufacture of semiconductor devices.

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

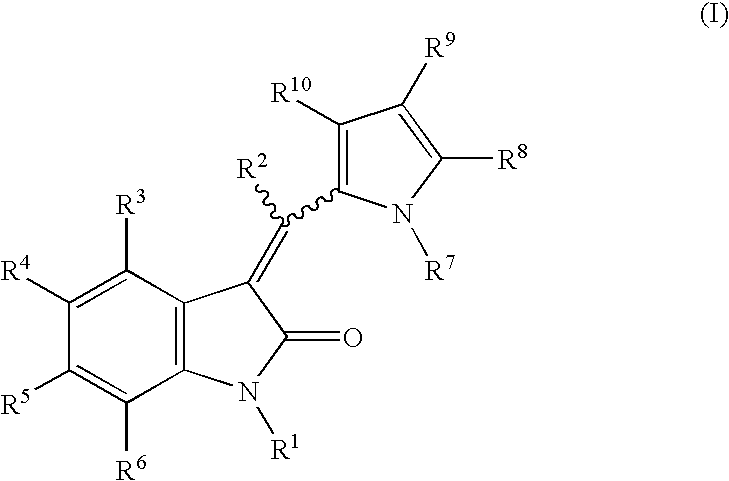

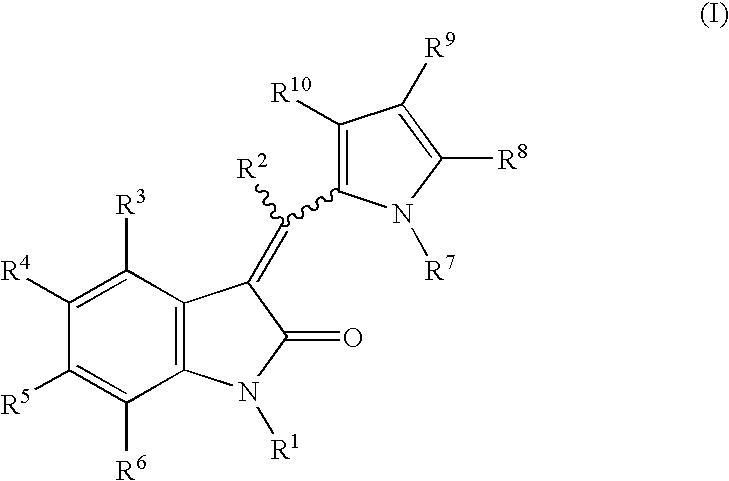

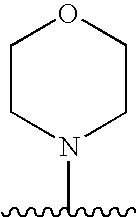

Formulations for pharmaceutical agents ionizable as free acids or free bases

InactiveUS6878733B1Sufficient tenacityHigh affinityBiocidePharmaceutical non-active ingredientsOral medicationMedicinal chemistry

The present invention features formulations of indolinones which compounds are ionizable as free acids or free bases. The formulation is suitable for parenteral or oral administration, wherein the formulation comprises an ionizable substituted indolinone, and a pharmaceutically acceptable carrier therefor. The term “ionizable substituted indolinone” includes pyrrole substituted 2-indolinones which, in addition to being otherwise optionally substituted on both the pyrrole and 2-indolinone portions of the compound, are necessarily substituted on the pyrrole moiety with one or more hydrocarbon chains which themselves are substituted with at least one polar group. The formulations and the compounds themselves are useful for the treatment of protein kinase related disorders as discussed herein.

Owner:SUGEN INC

Stabilizing agent-free acid protein beverage composition and process for making same

This invention is directed to a suspension stable protein containing acid beverage composition, comprising; (A) at least one protein material, (B) at least one flavoring material, (C) at least one sweetener, (D) at least one food grade acid, and (E) water; wherein the suspension stable protein containing acid beverage composition is free of a stabilizing agent, has a pH of from 3.0 to 3.7, and wherein for a 3 gram protein per 8 ounce composition has a viscosity at 25° C. of from 2 to 3 centipoise, less than 3% sediment and less than 1% serum, or wherein for a 6.5 gram protein per 8 ounce composition has a viscosity at 25° C. of from 3 to 5 centipoise, less than 5% sediment and less than 1% serum, or wherein for a 11 gram protein per 8 ounce composition has a viscosity at 25° C. of from 4 to 6 centipoise, less than 10% sediment and less than 1% serum.

Owner:SOLAE LLC

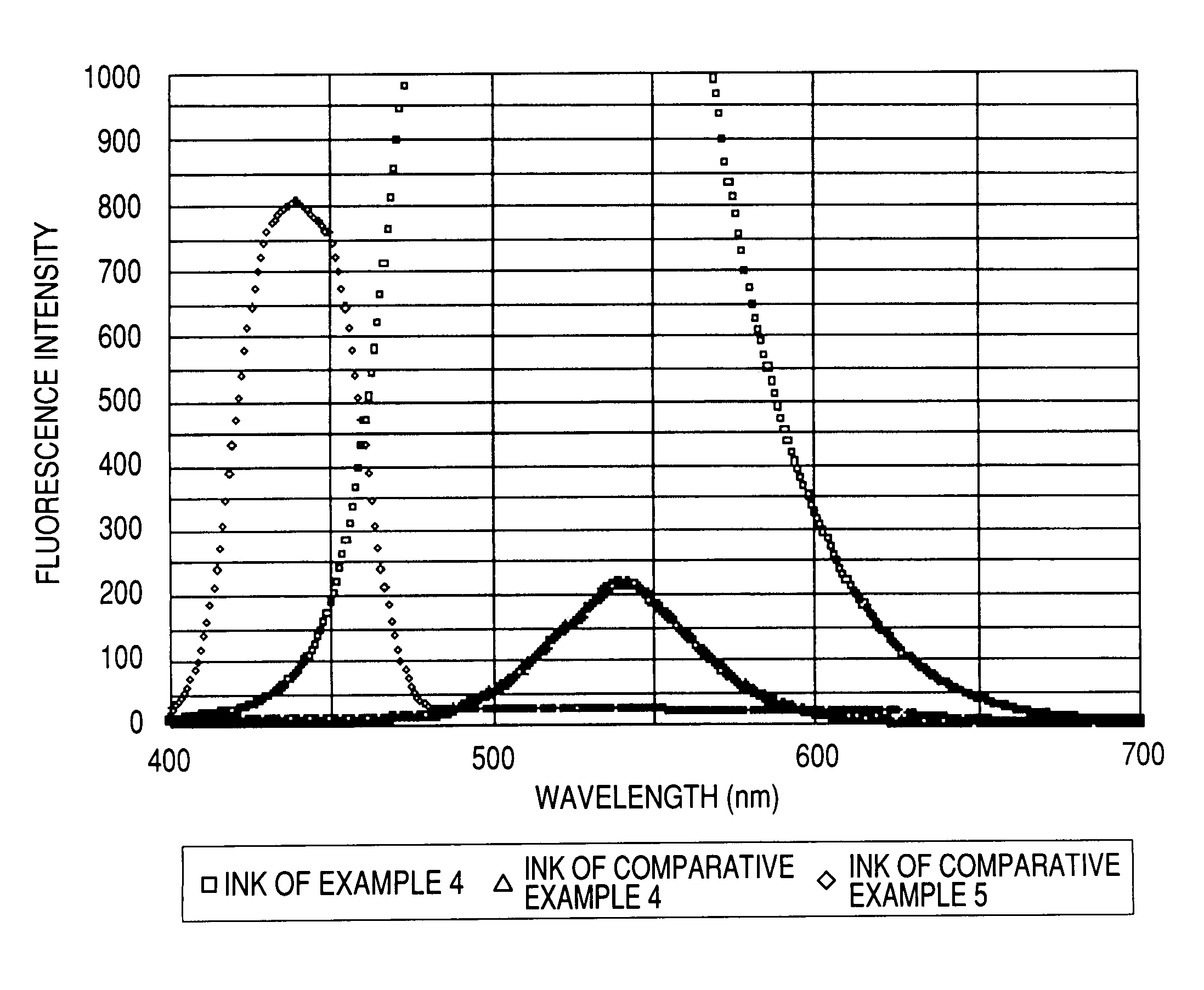

Water-based fluorescent ink, recorded image using the same, and judging method

InactiveUS20070034114A1Improve propertiesIncrease resistancePattern printingInksWater basedUltraviolet

The present invention relates to a water-based fluorescent ink for the purpose of measurement or judgment of the fluorescence emission in a visible light region by an excitation wavelength in a predetermined ultraviolet range, containing water, a coloring material dissolved or dispersed in water, and an organic solvent, having a plurality of fluorescent groups in the coloring material structure of the coloring material, and using a water-soluble coloring material having a sulfonic acid group as the water-soluble group in the state of a free acid, capable of improving the water resistance and the light resistance, dramatically increasing the content of the fluorescent coloring material in the ink, which has conventionally been included only by a small amount in the ink due to the concentration quenching problem, obtaining preferable fluorescence emission and water resistance of the recorded image, and providing preferable adhesion resistance to the recording medium of the coloring material and reliability.

Owner:CANON KK

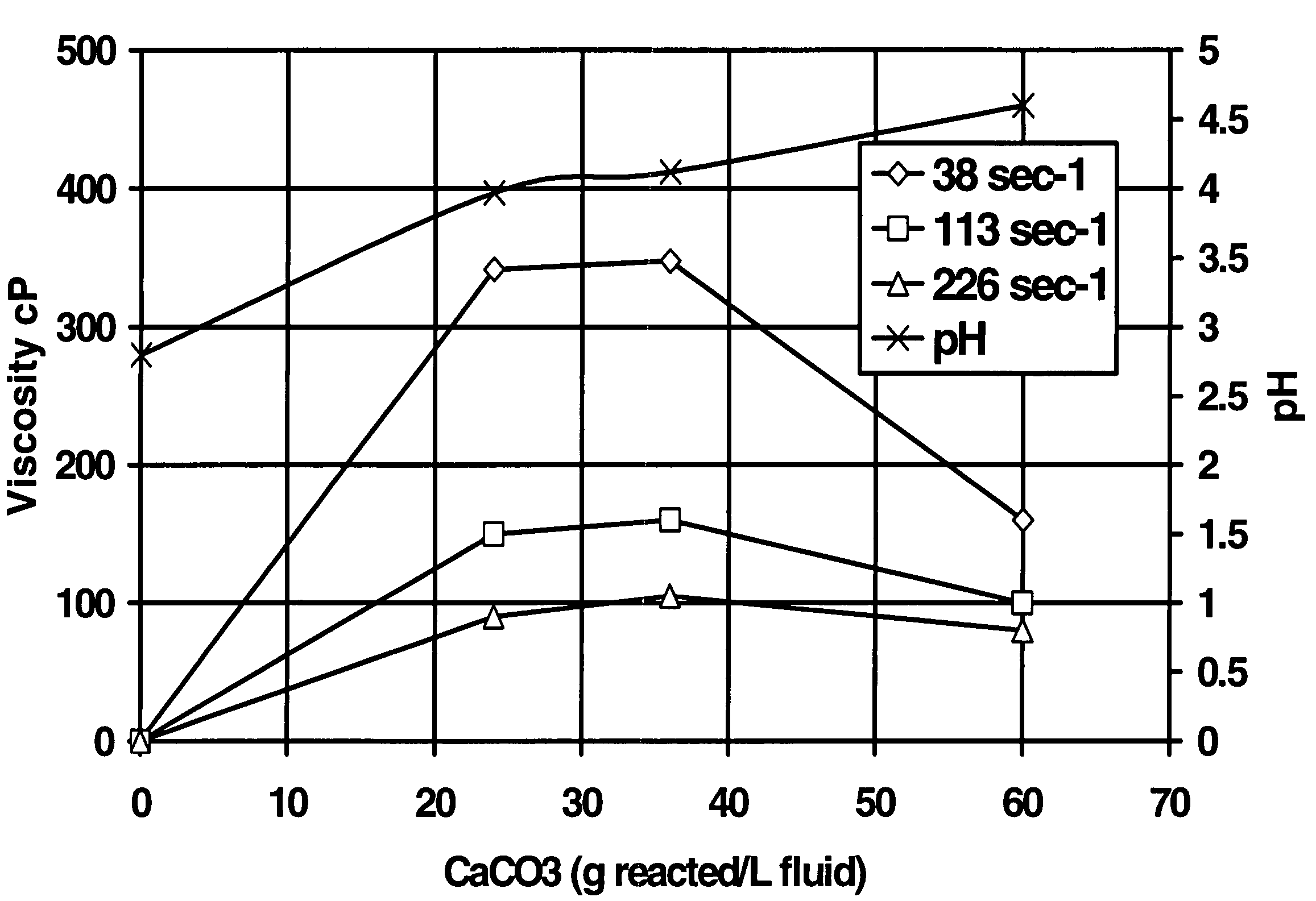

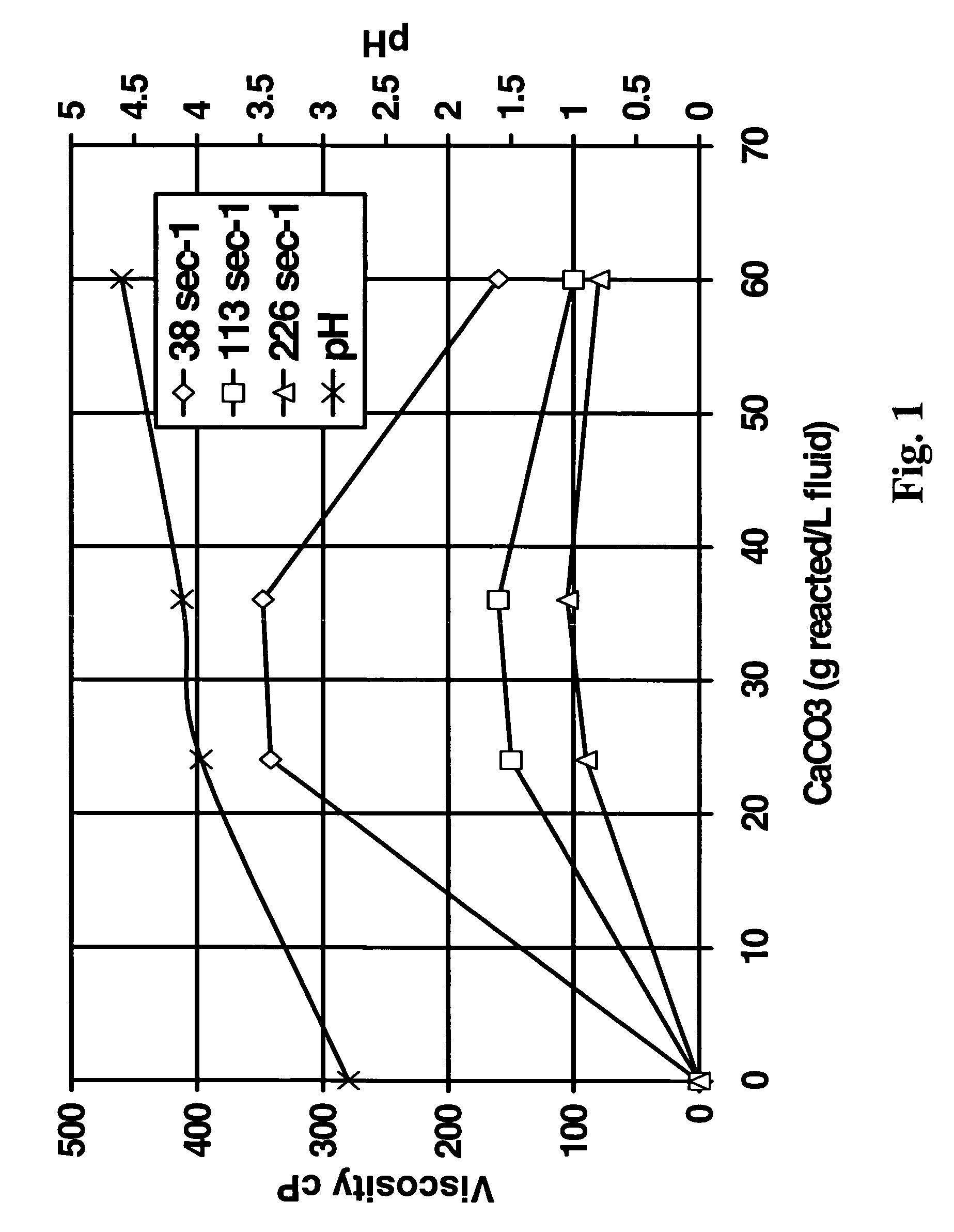

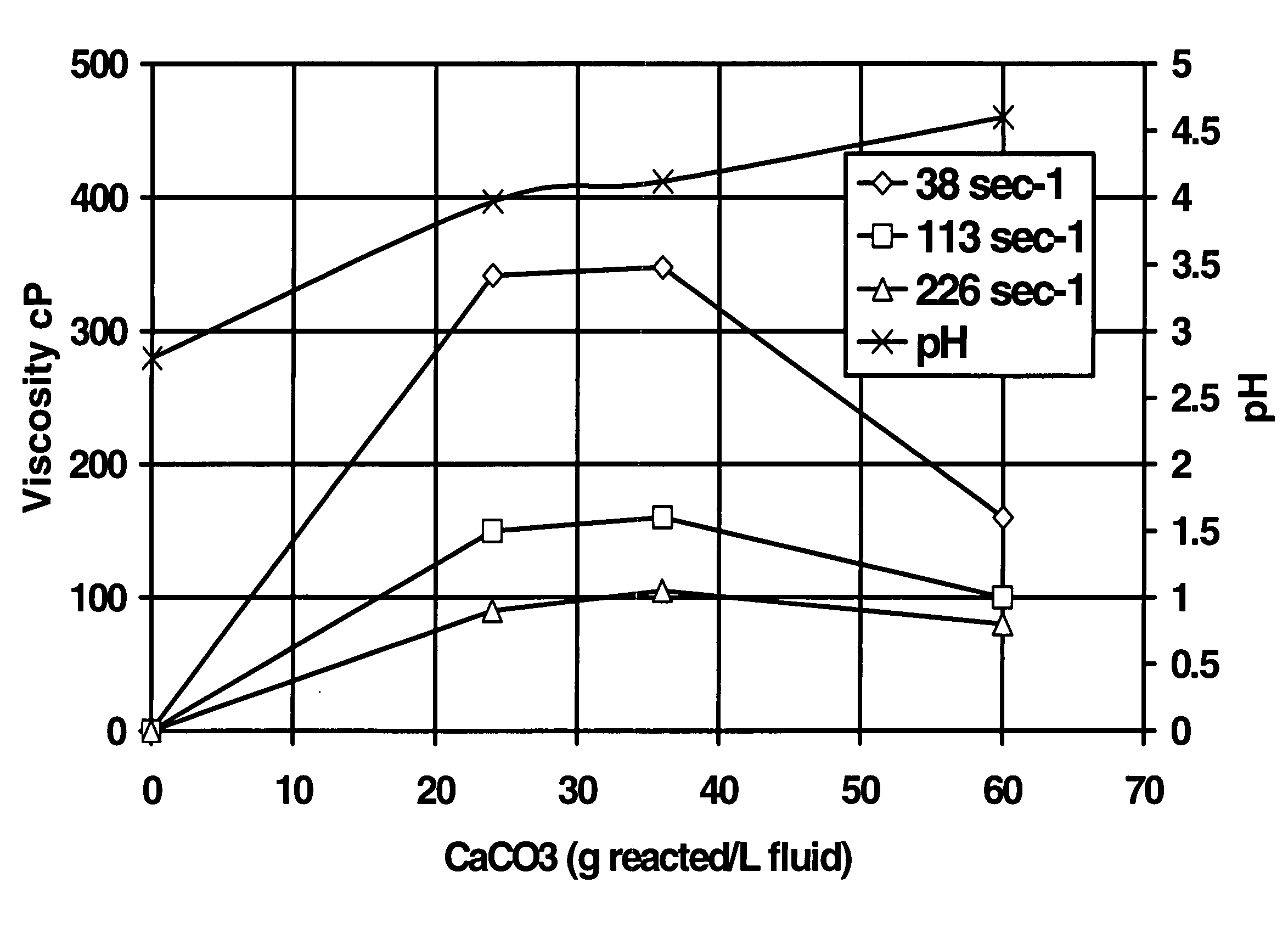

Composition and method for treating a subterranean formation

InactiveUS7380602B2Reduce friction pressureEasy to controlFluid removalDrilling compositionAcid fracturingSURFACTANT BLEND

A method of treating a subterranean formation with a retarded self-diverting fluid system. The method includes contacting the formation with a mixture of acid, chelating agent, and betaine surfactant in which the betaine surfactant is mixed with an aqueous solution of the chelating agent in which the pH has been adjusted to a pH of below about 3.0, but above the pH at which the free acid of the chelating agent precipitates, and the resulting fluid system is utilized for both acid fracturing and matrix stimulation, as well as workover procedures such as scale and filter cake removal, especially in high temperature formations.

Owner:SCHLUMBERGER TECH CORP

Composition and method for treating a subterranean formation

InactiveUS20060102349A1Reduce friction pressureFacilitate leak off controlFluid removalFlushingAcid fracturingSURFACTANT BLEND

A method of treating a subterranean formation with a retarded self-diverting fluid system. The method includes contacting the formation with a mixture of acid, chelating agent, and betaine surfactant in which the betaine surfactant is mixed with an aqueous solution of the chelating agent in which the pH has been adjusted to a pH of below about 3.0, but above the pH at which the free acid of the chelating agent precipitates, and the resulting fluid system is utilized for both acid fracturing and matrix stimulation, as well as workover procedures such as scale and filter cake removal, especially in high temperature formations.

Owner:SCHLUMBERGER TECH CORP

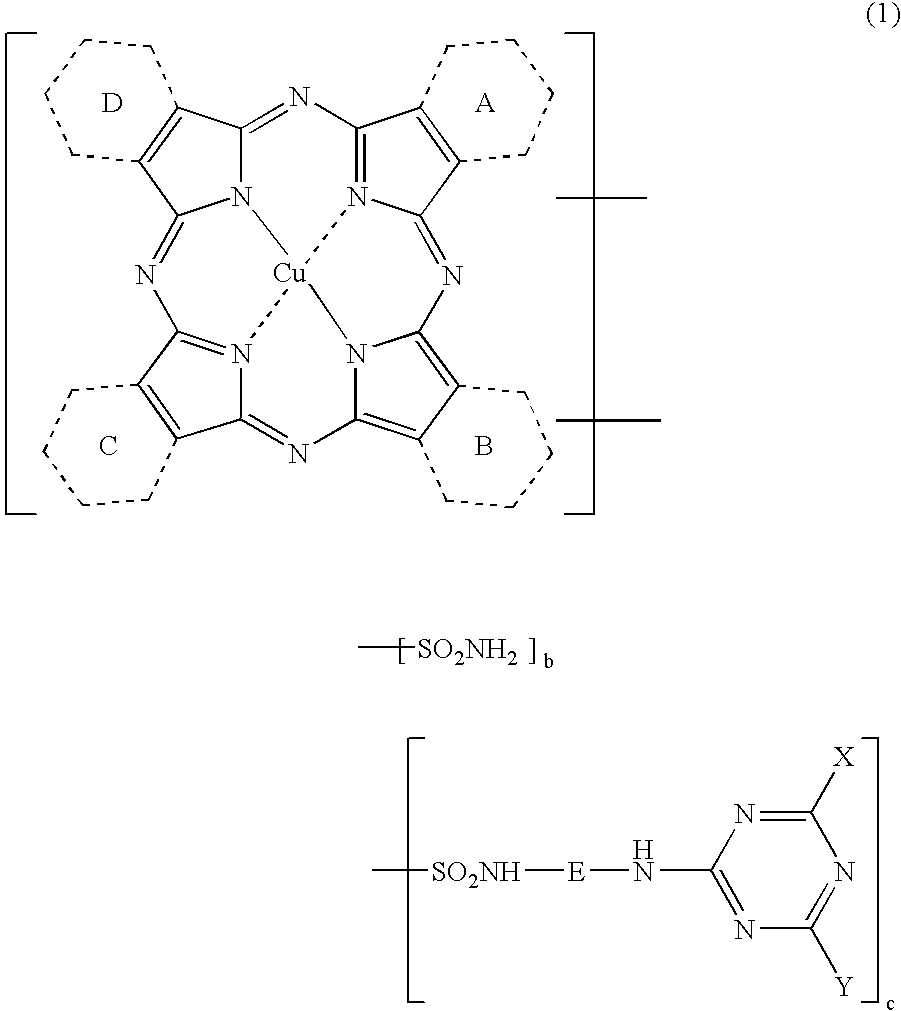

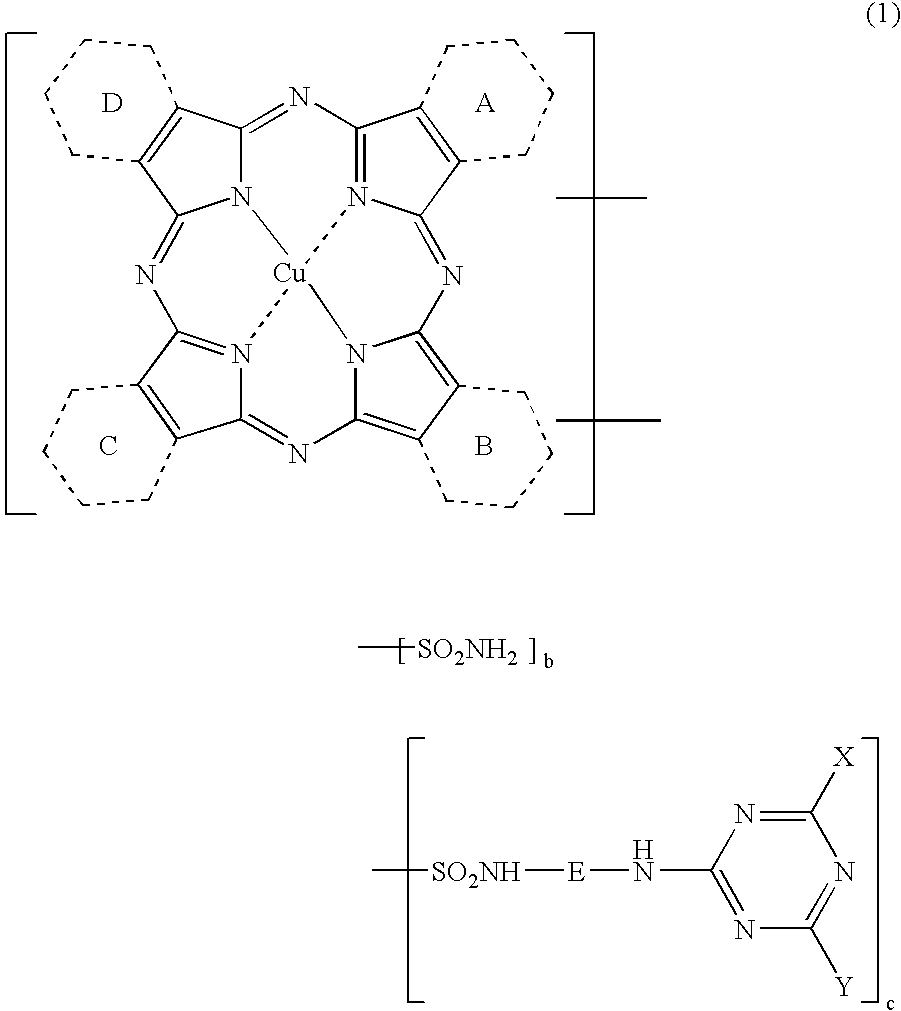

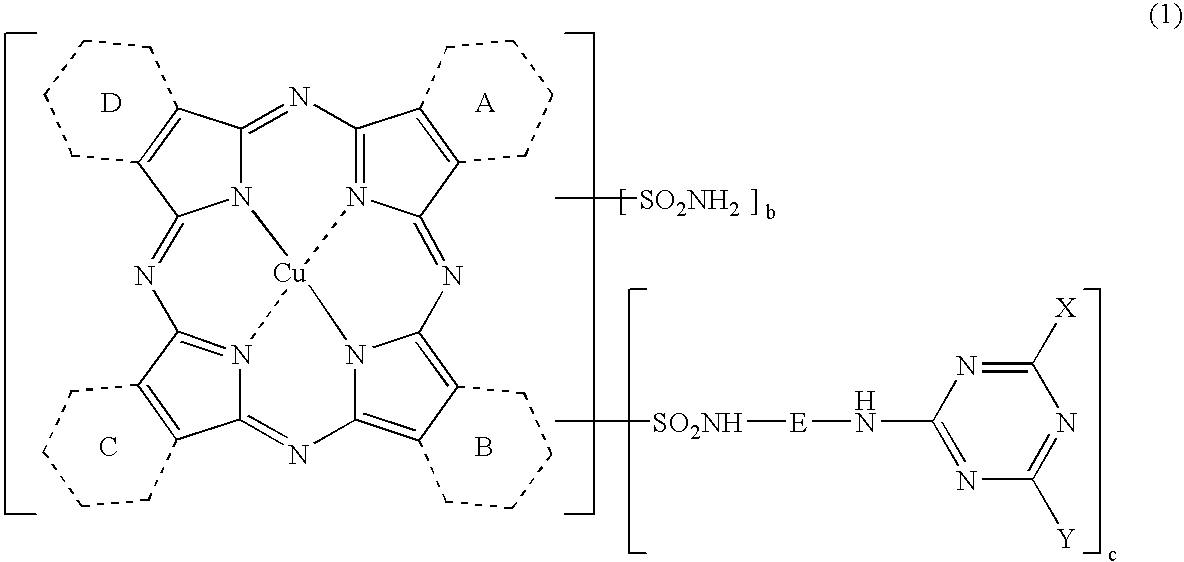

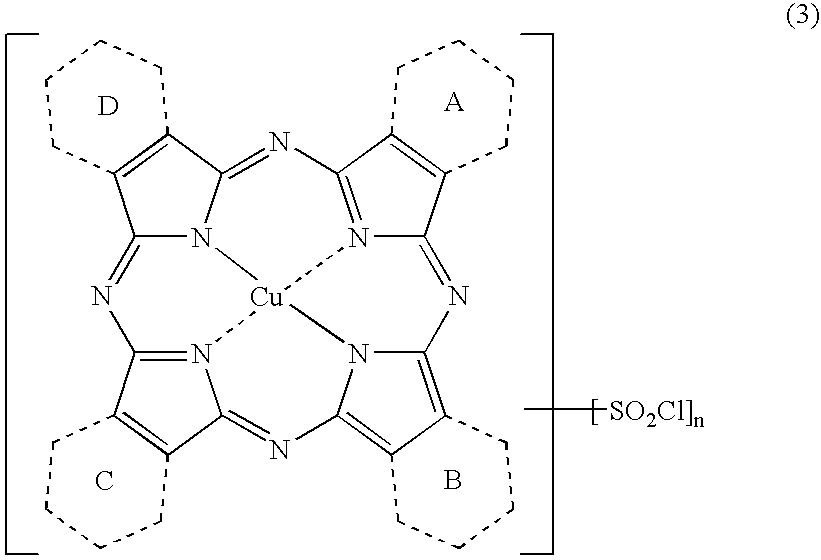

Porphyrazine coloring matter, ink, ink set and colored article

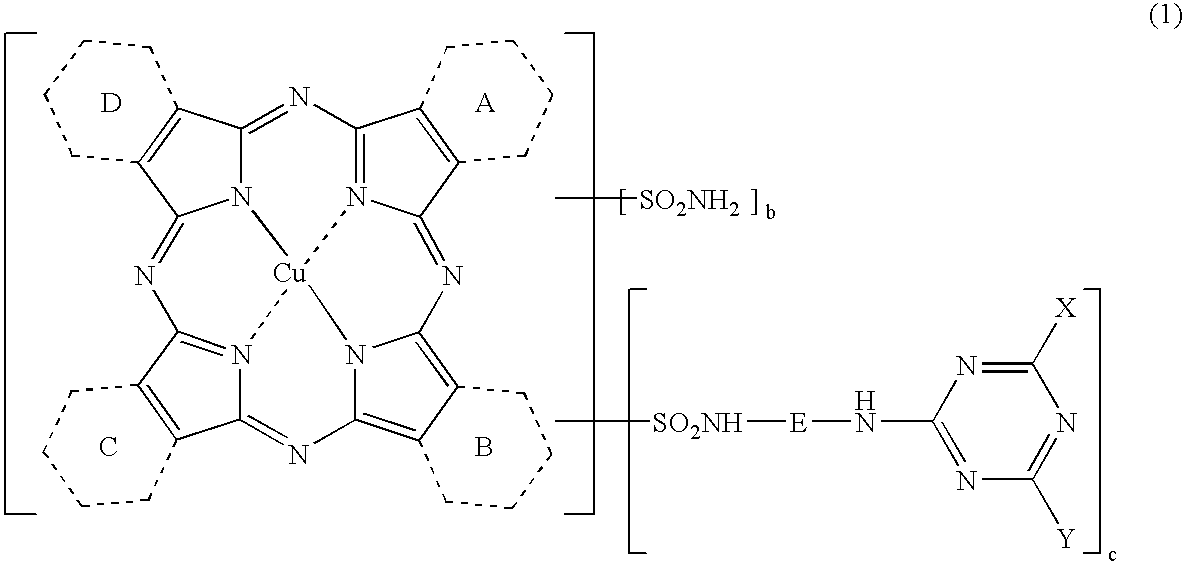

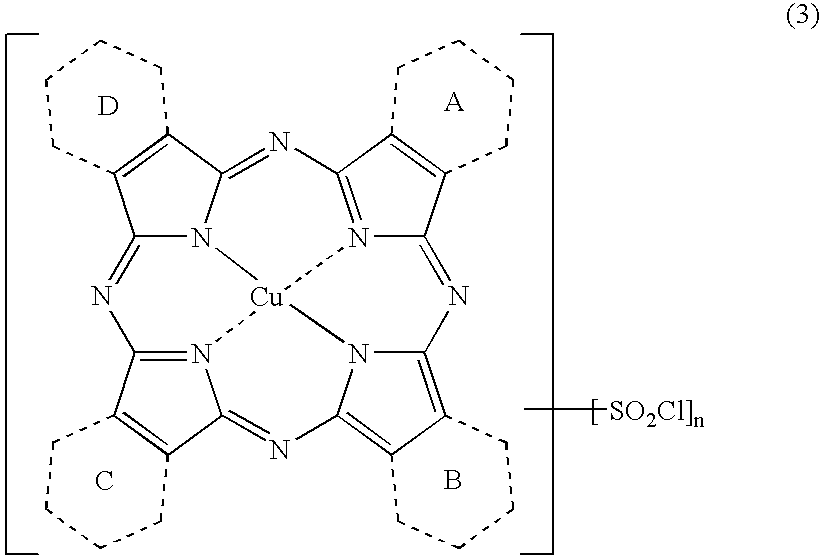

ActiveUS7591888B2Excellent toneGood light fastnessLiquid surface applicatorsOrganic chemistryPorphyrazineNitrogen

The present invention relates to a porphyrazine coloring matter represented by the following formula (1):(wherein, A, B, C and D independently represent a 6-membered ring having aromaticity, at least one or more of them are benzene rings and at least one or more of them contain nitrogen-containing heteroaromatic rings; E represents alkylene, X is a substituted anilino group and have at least one or more of sulfo group, carboxy group and phosphono group as a substituent, Y represents a hydroxy group or an amino group, b is respectively 0 to 2.9, c is 0.1 to 3, and the sum of b and c is 1 to 3) in free acid form, which is suitable for inkjet recording because it has good hue as a cyan ink, is excellent in light fastness, ozone fastness and moisture fastness, and does not cause bronzing phenomenon.

Owner:NIPPON KAYAKU CO LTD

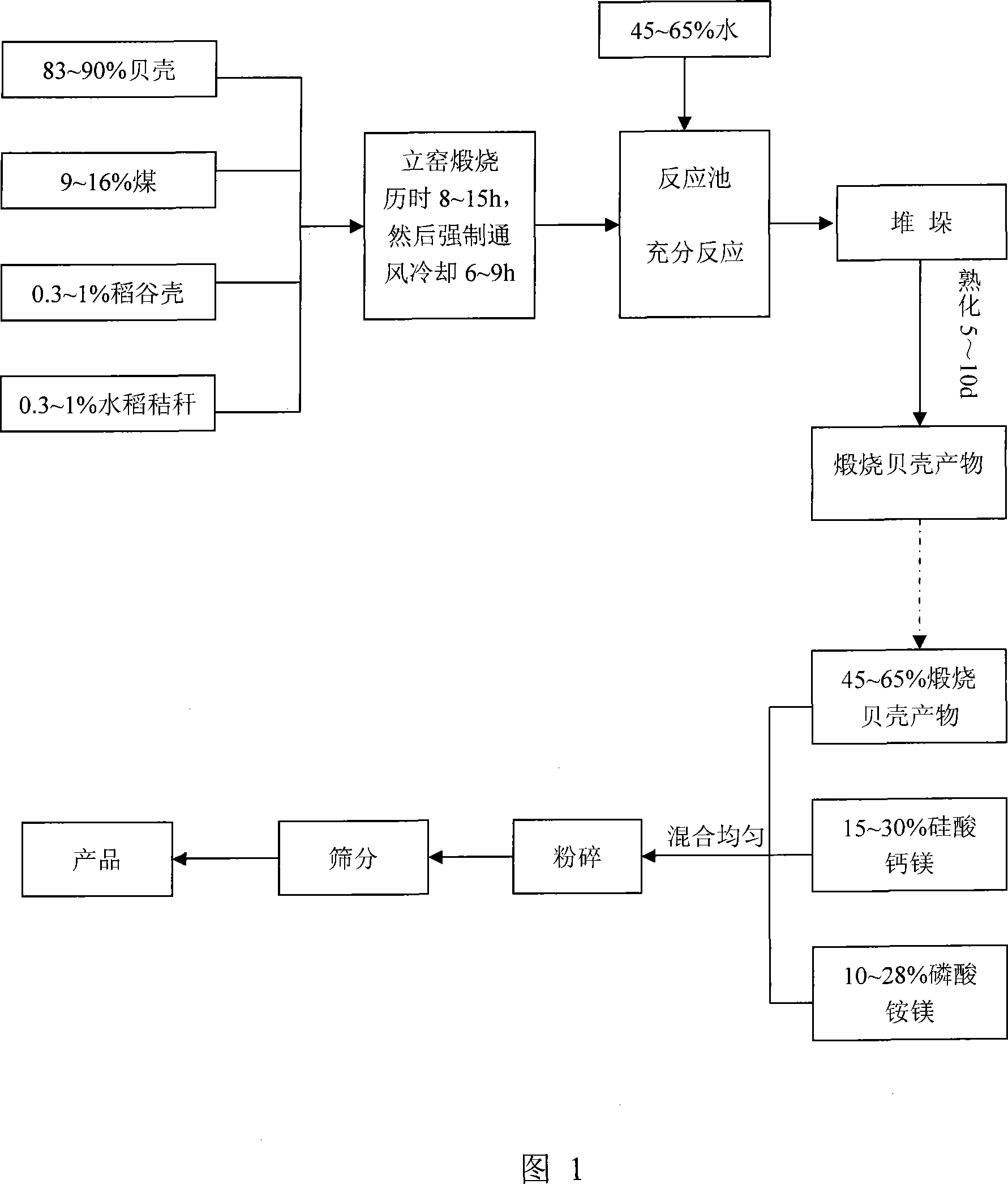

Method for preparing southern dry land acidic soil conditioner

ActiveCN101085920AImprove aggregate structurePrevent compactionOther chemical processesOrganic fertilisersPhosphateEnzyme function

The invention discloses a method for preparing soil amendment for southern dry and acid soil. It comprises following steps: mixing calcinated shell product of 40- 64% (proportion by weight), calcium magnesium silicate of 15- 30% and ammoniomagnesium phosphate of 10- 28%, getting mixed material; disintegrating mixed material, sifting, and getting soil amendment. The product can improve cluster structure for soil, reduce water loss and fertilizer loss problem in southern dry and acid soil, prevent soil consolidation; it can moderate the pH value for southern dry and scid soil, neutralizing free acid, inactivating the activity of active aluminium, improve microenvironment for root soil and increase microbe diversity in southern sry and acid soil, increase the enzyme functions, improve nutrition supply of magnesium and calcium and other microelement, and provides good basis for high crop productivity.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT GUANGDONG ACADEMY OF AGRI SCI

Light hydrocarbon separation using 8-member ring zeolites

InactiveUS20020144597A1Improve efficiencyImprove diffusivityGas treatmentIsotope separationSorbentPropane

A method of selectively adsorbing propylene in mixtures of propylene / propane and propylene / olefins through the use of zeolites having structures with a maximum of 8-member rings of tetraheda controlling the diffusion rate. Suitable zeolite adsorbents are those having the CHA and ITE structure types. Other 8-member ring zeolites, including aluminosilicates, with a Si:Al molar ratio of at least about 200 and having substantially no free acid are also suitable adsorbents.

Owner:THE TRUSTEES OF THE UNIV OF PENNSYLVANIA

Novel Porphyrazine Coloring Matter, Ink, Ink Set and Colored Article

ActiveUS20090029120A1Excellent toneGood light fastnessLiquid surface applicatorsMeasurement apparatus componentsFree acidCarboxylic group

The present invention relates to a porphyrazine coloring matter represented by the following formula (1):(wherein, A, B, C and D independently represent a 6-membered ring having aromaticity, at least one or more of them are benzene rings and at least one or more of them contain nitrogen-containing heteroaromatic rings; E represents alkylene, X is a substituted anilino group and have at least one or more of sulfo group, carboxy group and phosphono group as a substituent, Y represents a hydroxy group or an amino group, b is respectively 0 to 2.9, c is 0.1 to 3, and the sum of b and c is 1 to 3) in free acid form, which is suitable for inkjet recording because it has good hue as a cyan ink, is excellent in light fastness, ozone fastness and moisture fastness, and does not cause bronzing phenomenon.

Owner:NIPPON KAYAKU CO LTD

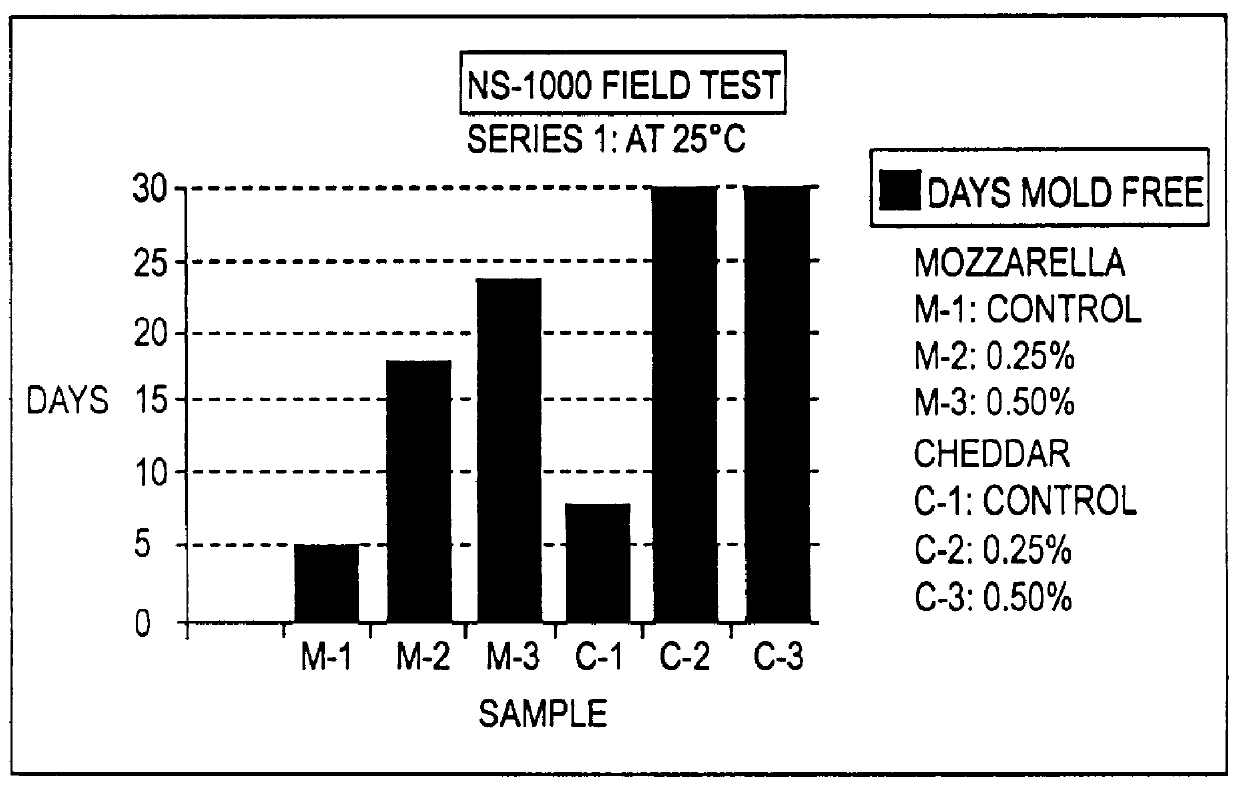

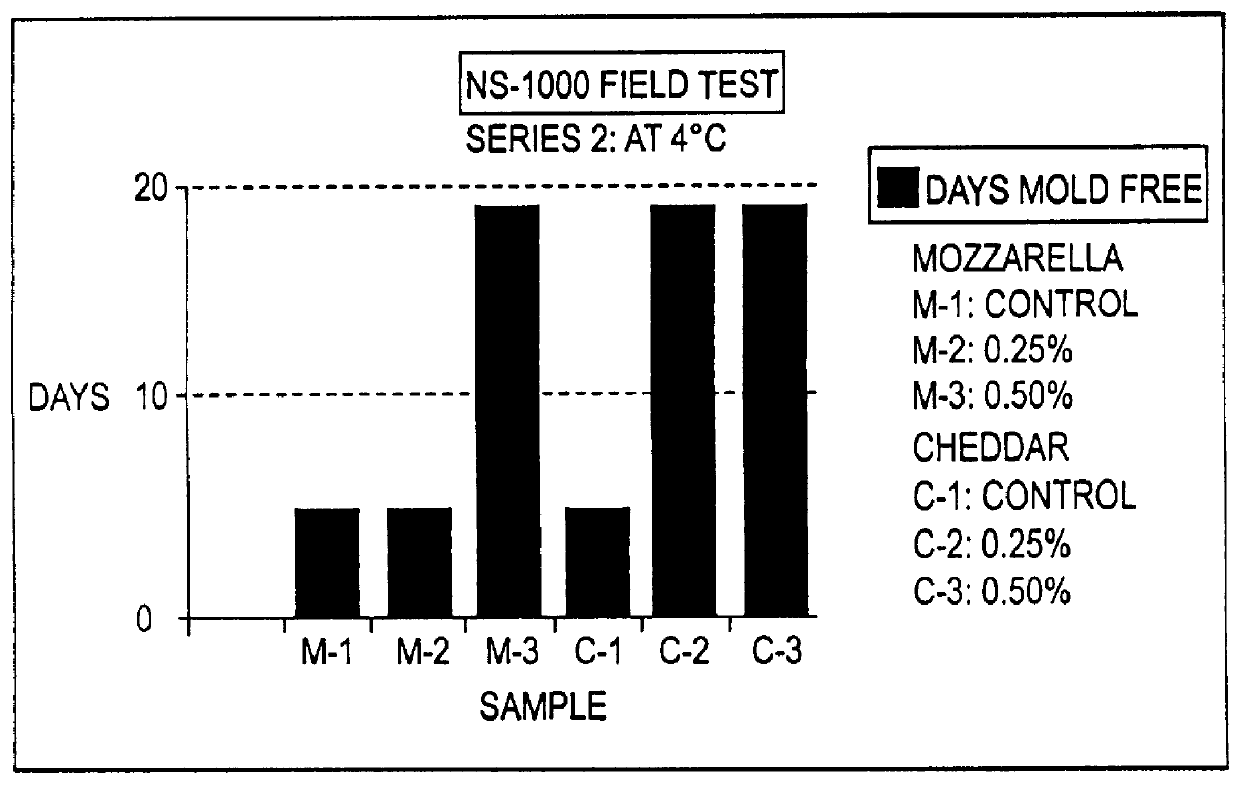

Methods of preparation and using antimicrobial products

InactiveUS6123973AEliminate bad tasteLower decomposition temperatureBiocideDough treatmentPropanoic acidSodium sorbate

Novel antimicrobial products and methods of making and using the same are shown, whereby the products can be used in the same or greater percentages as conventional microbial growth inhibitors without imparting an off-flavor, taste, color or odor to the products in which they are used. The antimicrobial products are formed by reacting azodicarbonamide or an ammonia gas with a compound selected from the group consisting of benzoic acid, sodium benzoate, calcium benzoate, potassium benzoate, acetic acid, sodium diacetate, paraben, niacin, calcium acetate, calcium diacetate, citric acid, lactic acid, fumaric acid, sorbic acid, sodium sorbate, calcium sorbate, potassium sorbate, propionic acid, sodium propionate, calcium propionate, potassium propionate and mixtures thereof. In one embodiment, the product is prepared by placing a layer of azodicarbonamide on a substrate and covering the layer with a gas permeable separator. The antimicrobial compound is then added on top of the separator, and the combination is heated to form the final product. In another embodiment, the product is prepared by exposing the antimicrobial compound to an ammonia gas. The ammonia gas reacts with free acids in the antimicrobial compound to convert the free acids into ammonium salts, thereby eliminating off-flavor and off-odor of the resulting antimicrobial product. The antimicrobial products prepared according to the present invention are suitable for use in foodstuffs, sanitation products, cosmetics, pharmaceuticals, and so forth.

Owner:TILLIN

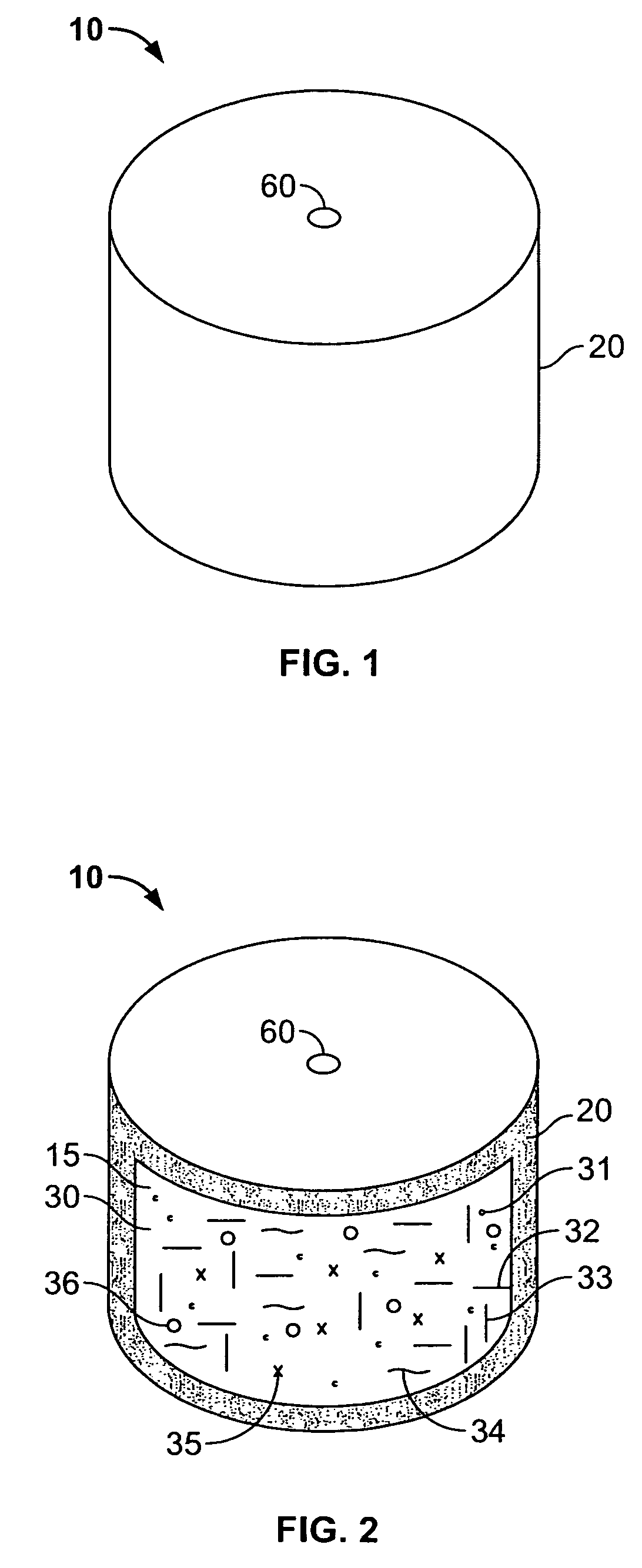

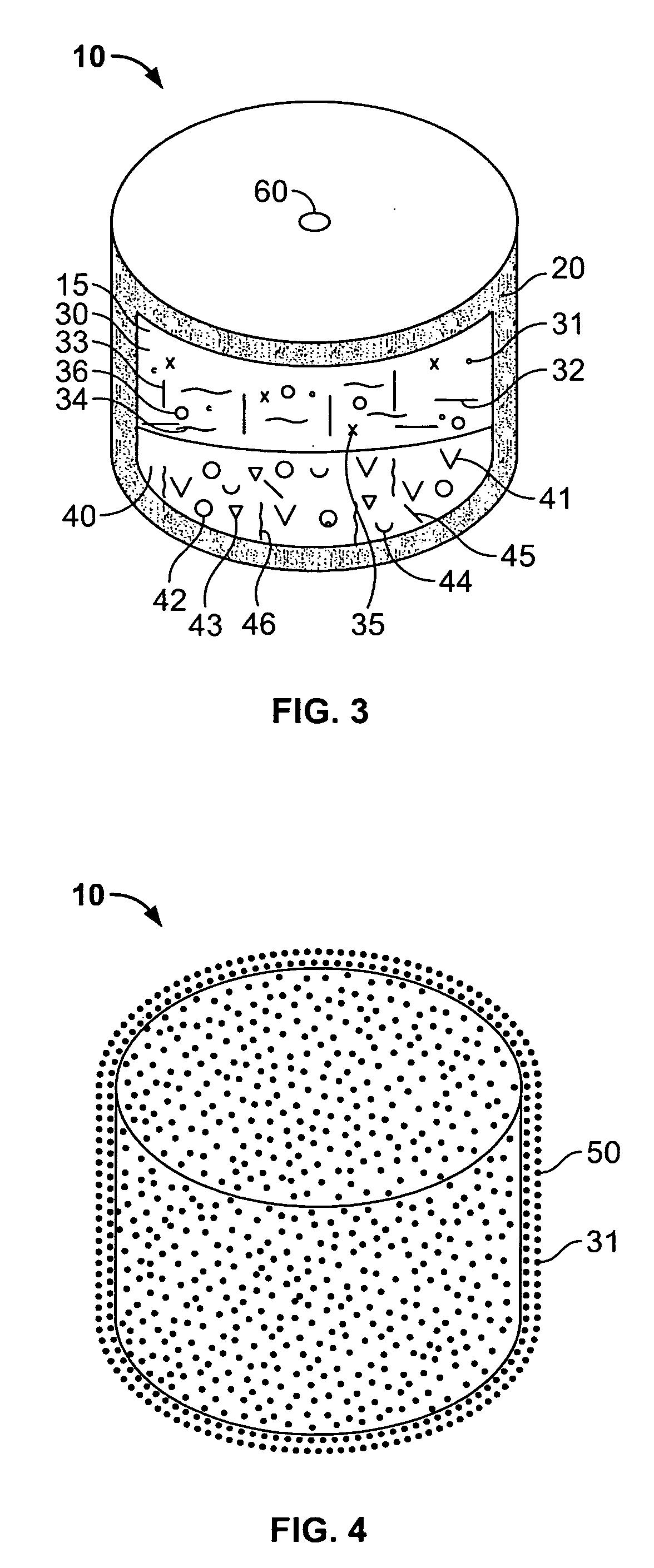

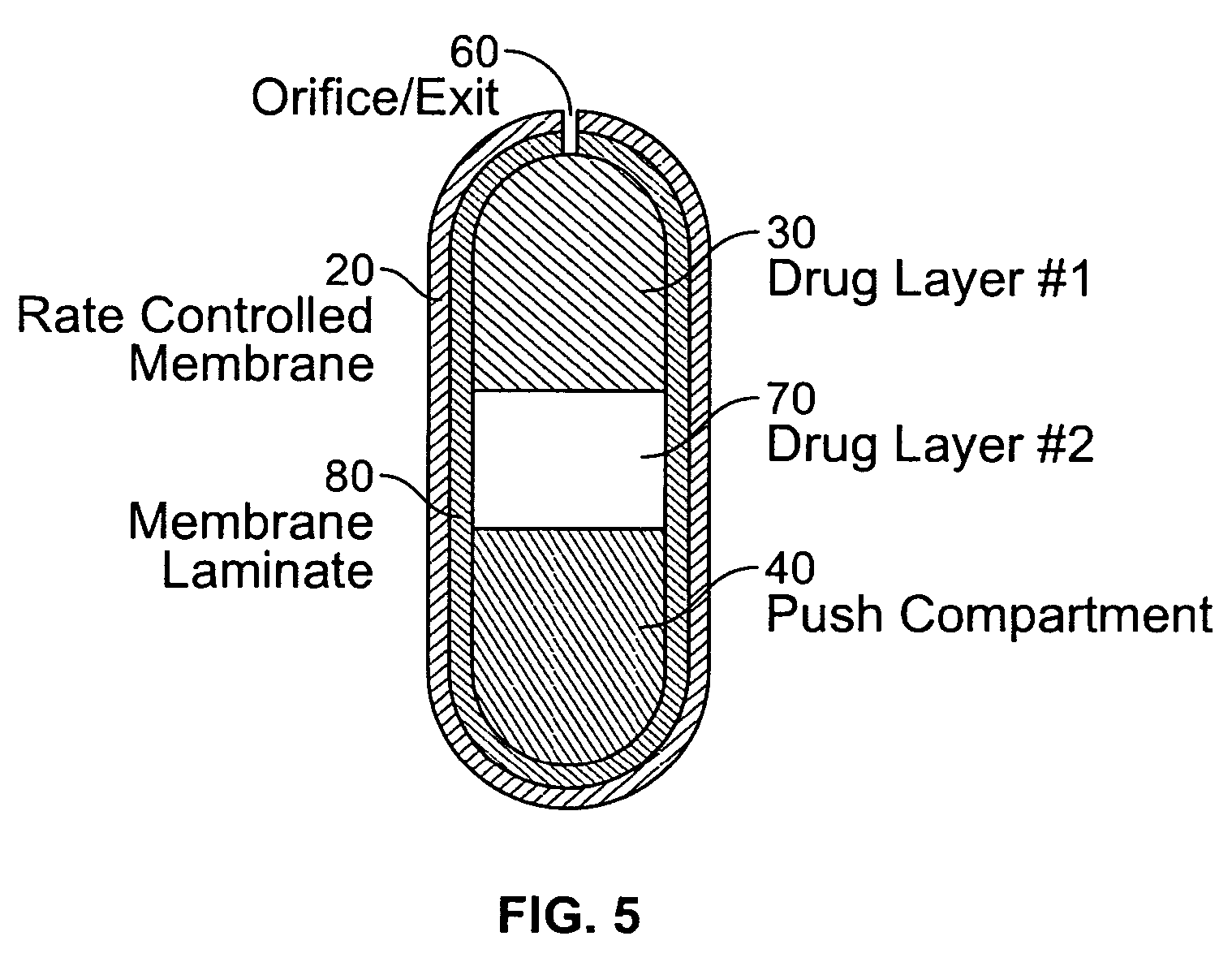

Dosage forms for low solubility and or low dissolution rate free acid pharmaceutical agents

InactiveUS20050287213A1Reduce solubilityLow dissolution ratePill deliveryAnhydride/acid/halide active ingredientsSolubilityTopiramate

An osmotic controlled release dosage form is described comprising a core comprising a first drug composition, wherein the first drug composition comprises topiramate and / or its pharmaceutically acceptable salt; a semi-permeable wall surrounding the core; and an exit orifice through the semi-permeable wall for releasing the first drug composition from the dosage form over a prolonged period of time.

Owner:ALZA CORP

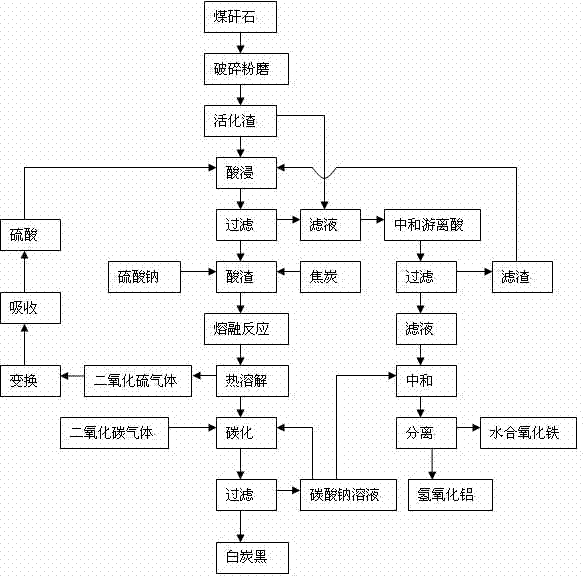

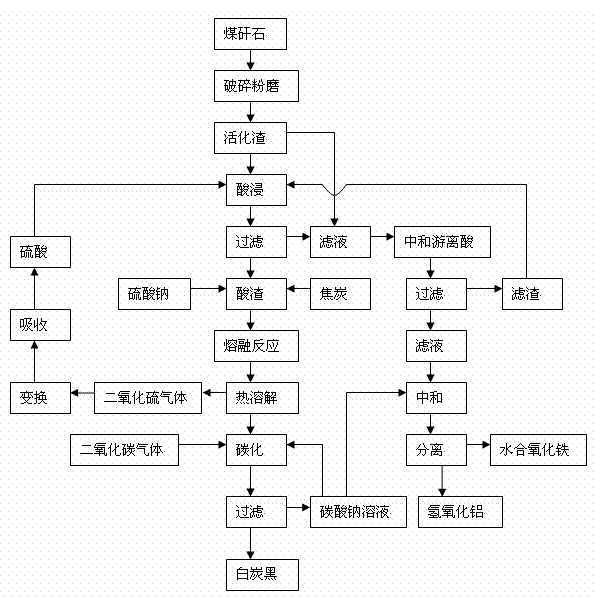

Comprehensive extraction method of ferro-silico-aluminum in gangue

ActiveCN102515279AGood slag activityMeet operating conditionsSilicaIron oxides/hydroxidesAluminium hydroxideSlag

The invention discloses a comprehensive extraction method of ferro-silico-aluminum in gangue, comprising the following steps of: using gangue as a raw material, crushing, grinding, activating, carrying out acid leaching, filtering, neutralizing free acid in the acid leaching filtered solution by the use of active slag, filtering to obtain a neutralized acid leaching solution, adding a sodium carbonate solution into the neutralized acid leaching solution, adjusting pH value, separating iron and aluminium to obtain hydrous iron oxide, aluminium hydroxide and a by-product sodium sulphate, adding sodium sulphate and coke into the acid leaching slag which has undergone acid leaching and filtration, carrying out a high-temperature melt reaction to recover silicon so as to prepare soluble glass, simultaneously recovering sulfur dioxide to prepare sulfuric acid, reusing sulfuric acid for the acid leaching treatment, diluting the soluble glass by the use of a sodium carbonate solution, carrying out carborization to obtain white carbon black, and reusing the carbonating solution for iron-aluminium separation. The method provided by the invention has characteristics of wide application range of the raw material gangue, high comprehensive recovery rate, no output of by-products, less residue amount and the like, provides a novel technological process for high-efficiency recovery of ferro-silico-aluminum from gangue, and expands the ways of gangue application.

Owner:KUNMING UNIV OF SCI & TECH +1

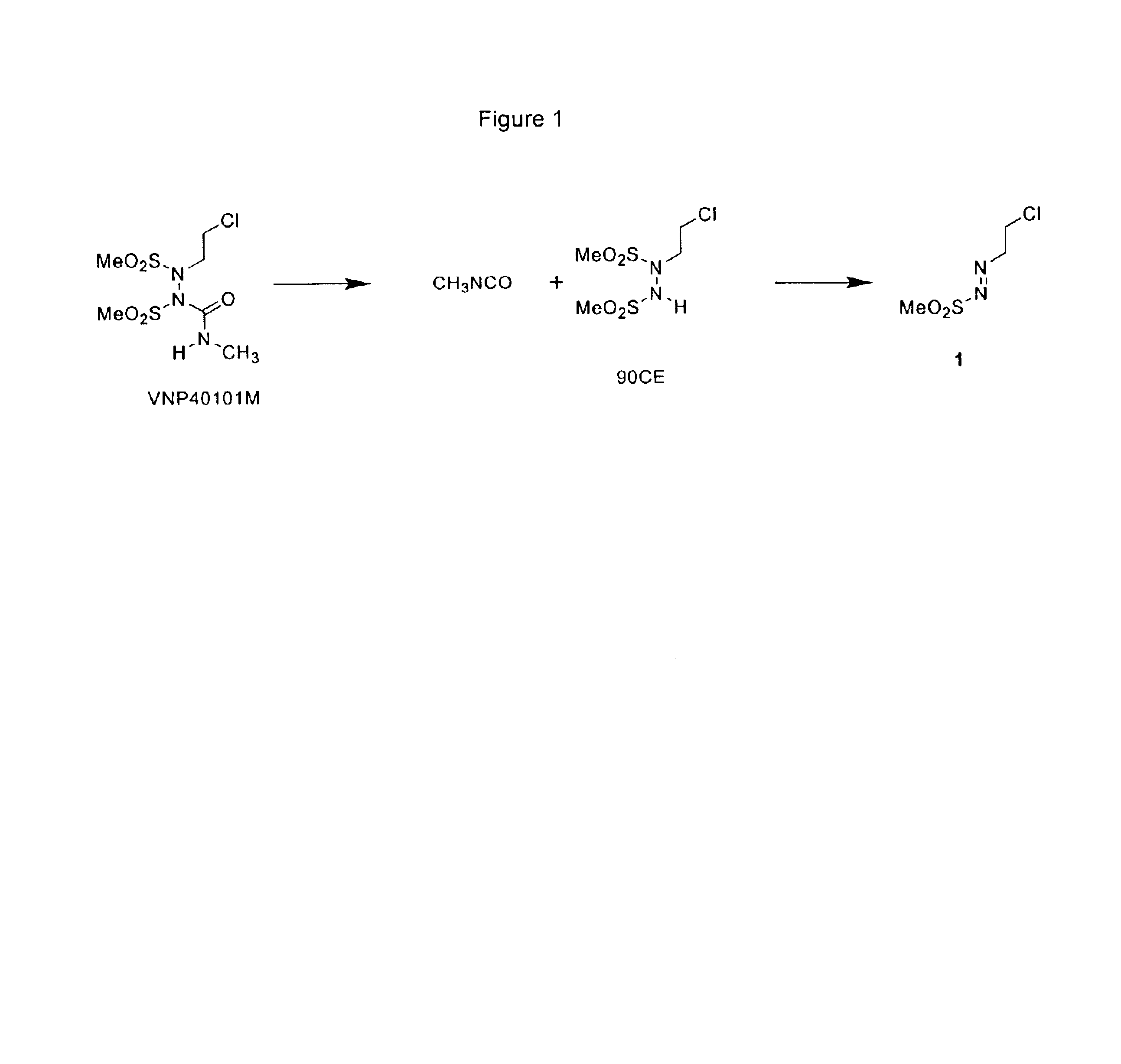

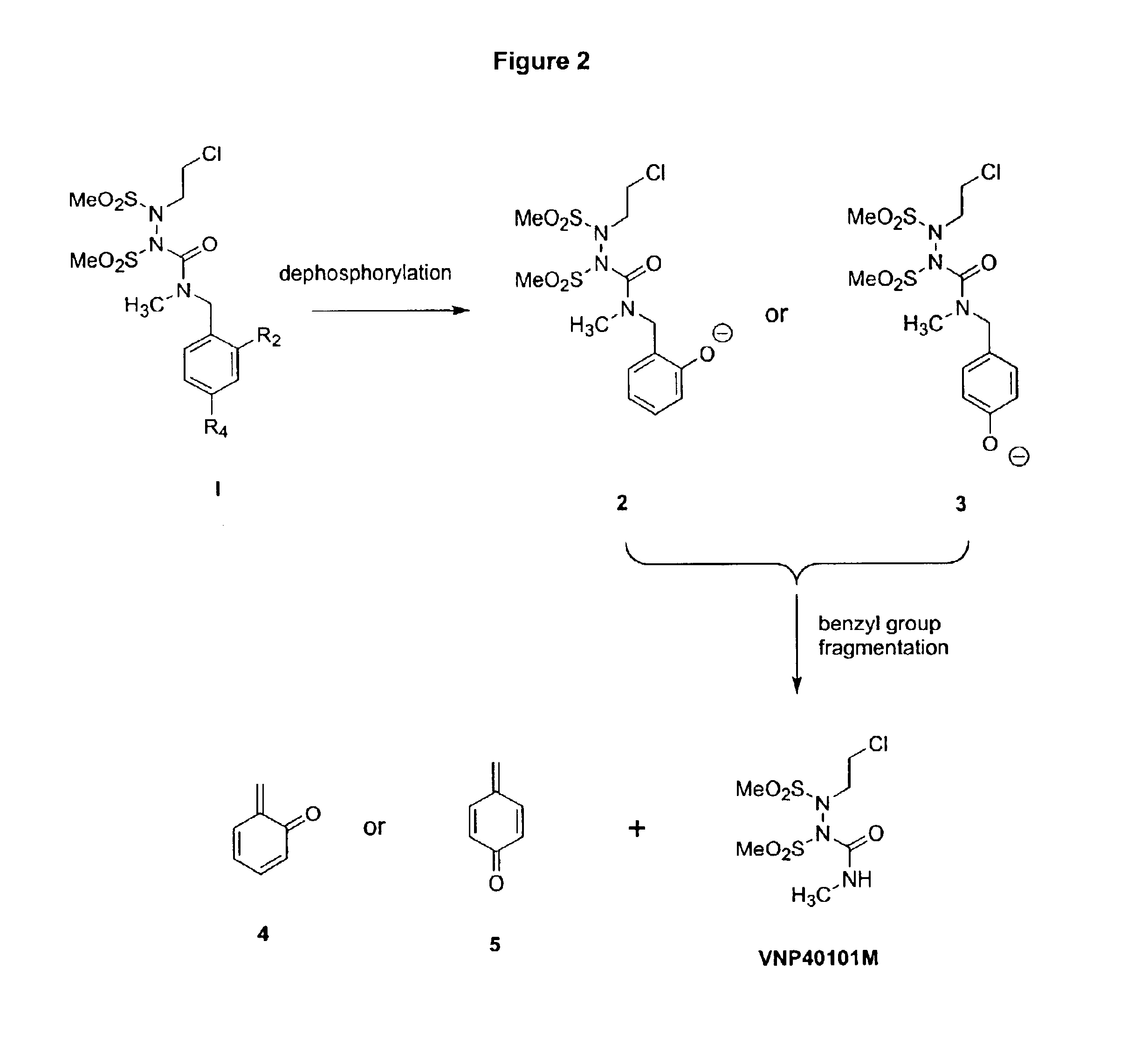

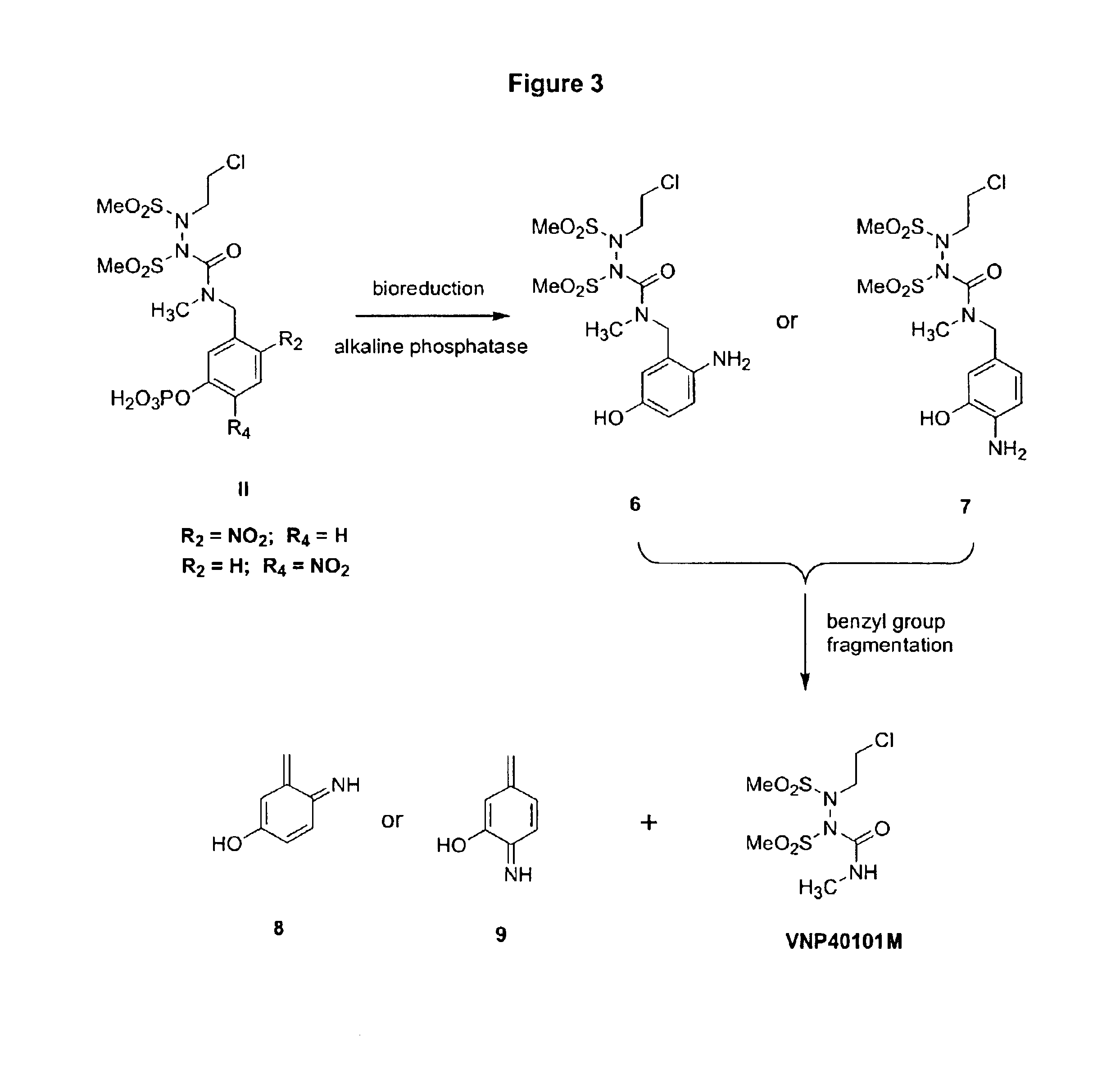

Water-soluble SHPs as novel alkylating agents

InactiveUS6855695B2Favorable enhanced characteristicLow toxicityOrganic active ingredientsBiocidePhosphoric acidWater soluble

Owner:NANOSHIFT LLC

Vinyl alcohol copolymers for use in aqueous dispersions and melt extruded articles

A product comprising a cold water soluble film wherein: a) the film comprises a copolymer of vinyl alcohol (VOH) with a minor amount of 2-acrylamido-2-methyl propane sulfonic acid in free acid form or as a salt of the free acid (AMPS); and b) the film has a harsh chemical dissolution time of less than about 80 seconds measured by the harsh chemical dissolution test method after 8 weeks.

Owner:SEKISUI SPECIALTY CHEM AMERICA

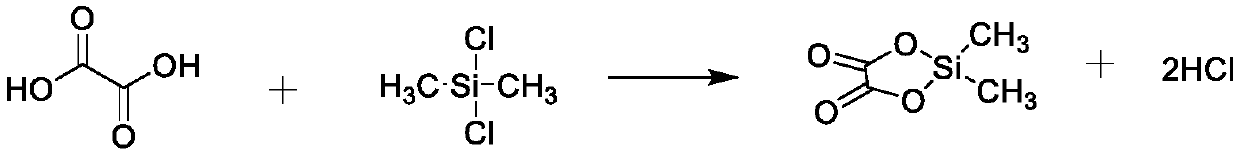

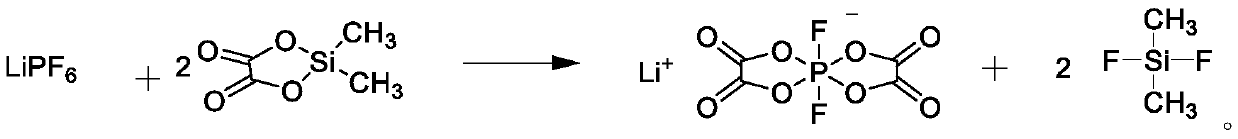

Preparation method of lithium difluorobisoxalate phosphate solution

The invention provides a preparation method of a lithium difluorobisoxalate phosphate solution. The preparation method of the lithium difluorobisoxalate phosphate solution comprises the following steps that (1) dichlorodimethylsilane and oxalic acid are reacted in the presence of a non-aqueous solvent to generate dimethyl silicon-based oxalate; and (2) lithium hexafluorophosphate is added into thereaction solution in the step (1), and reacting is carried out to obtain the lithium difluorobisoxalate phosphate solution. The preparation method is simple and practical, and industrial production can be achieved; the prepared lithium difluorobisoxalate phosphate solution can be directly used as an additive of a non-aqueous electrolyte battery; and the prepared lithium difluorobisoxalate phosphate solution has few chlorine compounds and free acids, wherein the chlorine compounds in terms of chlorine concentration are less than 5 mass ppm, and the free acids in terms of acid concentration converted from hydrofluoric acid are less than 200 mass ppm.

Owner:JIANGSU GUOTAI SUPER POWER NEW MATERIALS

Ink, recording method, recording unit, ink cartridge, and recording apparatus

InactiveUS7025817B2Small molecular weightGood moisturizing effectMeasurement apparatus componentsDuplicating/marking methodsSolubilityOrganic solvent

Owner:CANON KK

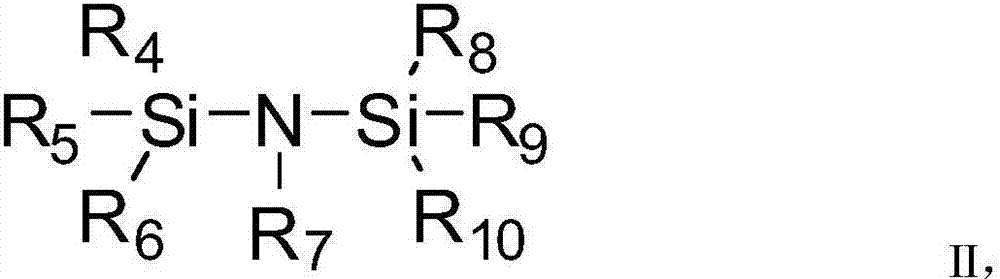

Non-aqueous electrolyte and high-nickel ternary cathode material battery

InactiveCN107293792AImprove stabilityImprove high temperature storage performanceSecondary cellsHigh temperature storageLithium-ion battery

The invention provides an electrolyte, and the electrolyte comprises a lithium salt, an organic solvent and an additive A; the additive A comprises one or more kinds of alkylamine compounds, silicon nitrogen compounds and siloxane compounds. In order to improve the electrolyte, the non-aqueous electrolyte has one or more kinds of the alkylamines, compounds with Si-N bonds (the silicon nitrogen compounds) and the siloxane compounds. The non-aqueous electrolyte has extremely low free acid content, is applied to a lithium-ion battery with a high-nickel ternary cathode material and can effectively improve the circulation performance, high-temperature circulation performance and high-temperature storage performance of the lithium-ion battery.

Owner:THE UNIV OF NOTTINGHAM NINGBO CHINA

Method for preparing silica aerogel composite material by adopting chloride-free and alcohol-free process

The invention discloses a method for preparing a silica aerogel composite material by adopting a chloride-free and alcohol-free process. The method comprises the following steps: S1, adopting a water-based silicon source as a raw material, regulating the pH value of sol with a chloridion-free acid, adding an additive after desalting, and uniformly stirring to obtain a first mixed solution; S2, immersing a fiber reinforced material into the first mixed solution, and completing gel curing; S3, standing the obtained composite gel material so as to obtain an aged composite gel material; S4, placing the aged composite gel material in a chloride-free and alcohol-free displacer to realize uniform solution infiltration; S5, performing surface methylsilane modification on the composite gel by usinga chloride-free surface modifier; S6, drying the modified composite gel, thereby obtaining the silica aerogel composite material. The invention provides a method for preparing the silica aerogel composite material without any chloride ion or alcohol substance in the formula.

Owner:SHENZHEN AEROGEL TECH CO LTD

Production of polymerized ferric-aluminum chloride composite coagulating agent

InactiveCN101074128AReduce manufacturing costLow costWater/sewage treatment by flocculation/precipitationPhosphateChlorate salt

Production of inorganic polymer coagulating agent is carried out by controlling Fe2+ concentration between 75-90g / L in hydrochloric acid pickling effluent, taking it as ferric source, taking calcium aluminate powder as aluminum source with Al2O3 content 47-56 wt%, putting two kinds of raw material into reactor in proportion of calcium aluminate powder: hydrochloric acid pickling effluent=0.05-0.10, reacting while agitating at 50-80 degree for 1-3 hrs, adding into minor chlorate oxidant and phosphate stabilizer, heating, reacting while agitating, and cooling to room temperature to obtain final product. It's simple and can be used for domestic sewage and industrial effluent treatment.

Owner:SHANGHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com