Comprehensive extraction method of ferro-silico-aluminum in gangue

A comprehensive extraction and coal gangue technology, applied in the direction of chemical instruments and methods, silicon oxide, sulfur compounds, etc., can solve the problems of high impurity content in products, low total recovery rate of valuable elements, etc., to reduce reaction heat consumption and raw material selection Wide range and good activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

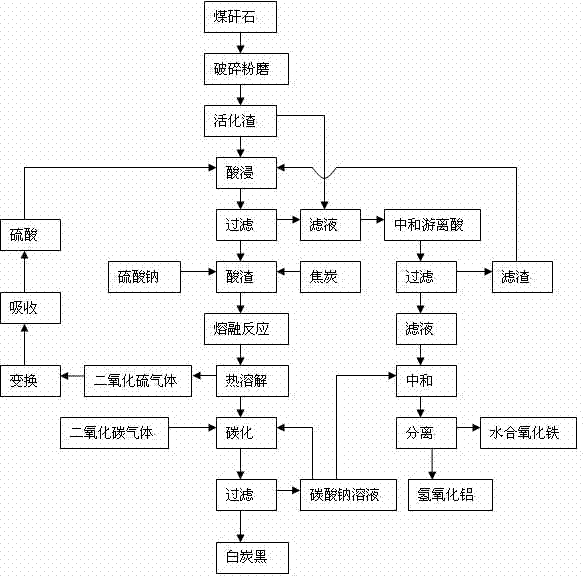

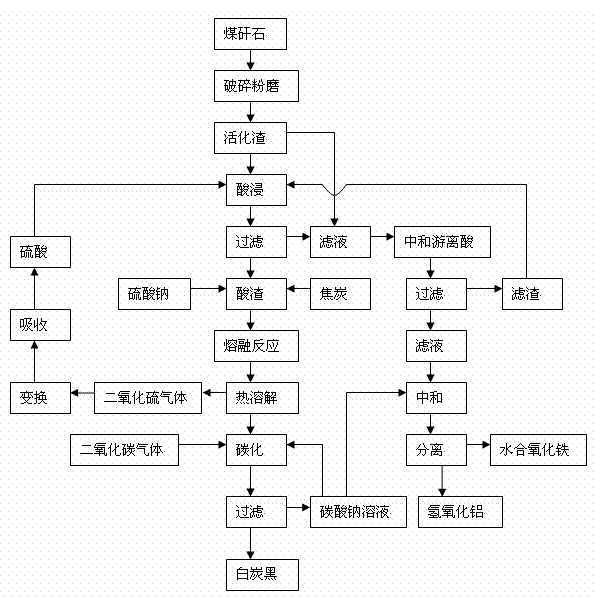

Image

Examples

Embodiment 1

[0032] Embodiment 1: the method for comprehensively extracting ferrosilicon in coal gangue, concrete operations are as follows:

[0033] Take 10kg of coal gangue and grind it with a Φ500×600 ball mill. The particle size is required to be less than 5% after passing through a 60-mesh sieve. The grinding material is placed in a circulating fluidized bed and activated at 850°C for 5 minutes. SiO in gangue ash 2 、Al 2 o 3 , TFe content are 56.20%, 38.57% and 2.35% respectively, take activated coal gangue slag 1000g and put it into a 5L three-neck flask, add 4000g mass percent concentration of 30% sulfuric acid solution under stirring state, the reaction temperature is 90 ℃, the reaction After 4 hours, filter to obtain the acid leaching filtrate.

[0034] Add activated slag to neutralize free acid in the above acid leaching filtrate, the reaction temperature is 90°C, when the pH value of the solution is 2, filter while it is hot, when the filtrate is heated to 90°C, slowly add 8%...

Embodiment 2

[0037] Embodiment 2: the method for comprehensively extracting ferrosilicon in coal gangue, concrete operations are as follows:

[0038] Take 10kg of coal gangue and grind it with a Φ500×600 ball mill. The particle size requirement is that the sieve residue of 60 mesh sieve is less than 5%. SiO in gangue ash 2 、Al 2 o 3 , TFe content are 54.27%, 32.42% and 6.17% respectively, take activated coal gangue slag 1000g and put in the three-necked flask of 5L, add 3500g mass percent concentration and be 50% sulfuric acid solution under stirring state, reaction temperature is 92 ℃, reaction After 4 hours, filter to obtain the acid leaching filtrate.

[0039] Add activated slag to the above acid leaching filtrate to neutralize free acid, the reaction temperature is 93°C, when the pH value of the solution is 1.5, filter while it is hot, when the filtrate is heated to 90°C, slowly add Soda ash solution, when the pH is 3.9, keep it warm at the operating temperature for 1 hour, filter ...

Embodiment 3

[0042] Embodiment 3: the method for comprehensively extracting silicon-aluminum-iron in coal gangue, concrete operations are as follows:

[0043] Take 10kg of coal gangue and grind it with a Φ500×600 ball mill. The particle size is required to be less than 5% after passing through a 60-mesh sieve. The grinding material is placed in a circulating fluidized bed and activated at 750°C for 20 minutes. SiO in gangue ash 2 、Al 2 o 3 , TFe content are 50.50%, 27.51% and 8.43% respectively, take activated coal gangue slag 1000g and put it into a 5L three-necked flask, add 3000g mass percent concentration of 70% sulfuric acid solution under stirring state, the reaction temperature is 95 ℃, the reaction After 4 hours, filter to obtain the acid leaching filtrate.

[0044] Add activated slag to neutralize free acid in the above acid leaching filtrate, the reaction temperature is 95°C, when the pH value of the solution is 1.0, filter while it is hot, when the filtrate is heated to 95°C,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com