Patents

Literature

343 results about "Soluble glass" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Soluble glass is a popular name for sodium silicate or potassium silicate.

Formula and method for manufacturing ceramic tile blank bodies and glazed tiles by utilizing polished waste residues

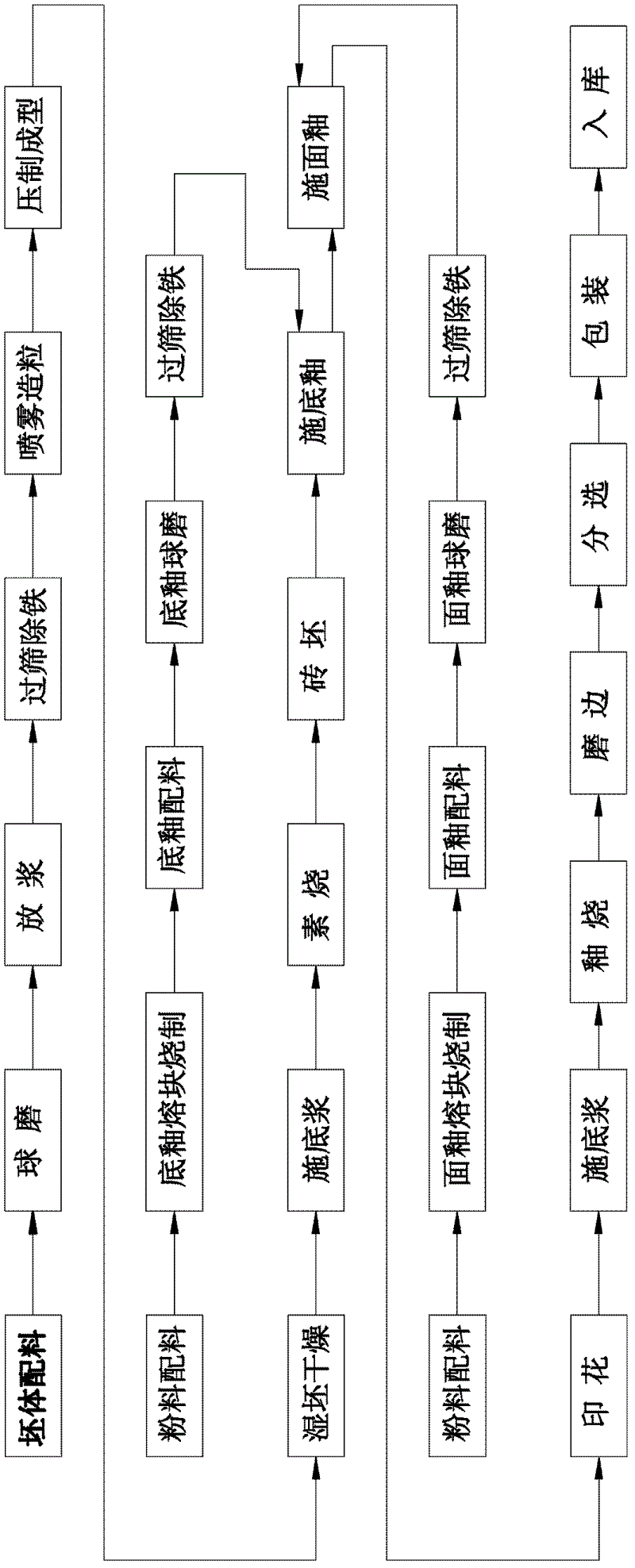

The invention discloses a formula and a method for manufacturing ceramic tile blank bodies by utilizing polished waste residues. The formula adopts ingredients by weight portions: porcelain clays account for 18 to 40 parts, clays account for 20 to 30 parts, limestone grains account for 1 to 10 parts, wollastonite grains account for 3 to 15 parts, glazed tile sludge residues account for 3 to 10 parts, ceramic polished waste residues account for 15 to 45 parts, soluble glass accounts for 1 to 2 parts, thinners account for 0.15 to 0.4 parts, sodium tripolyphosphate accounts for 0.05 to 0.2 parts, and a proper amount of water is adopted. A manufacturing method of the ceramic tile blank bodies comprises the steps as follows: a. raw materials are put in a ball grinder for ball milling after being blended so as to form sizing agents with proper fineness and screen tailings through milling, and the sizing agents are processed through deferrization, sieving and spray drying so as to form powders; and b. the powders are put in a die cavity of a press forming machine to form waterish blanks through pressing, the waterish blanks are dried in a drying kiln, the dried waterish blanks are applied with base pulp and then enter a biscuit firing kiln, biscuit firing is carried out under the temperature ranging from 1080 to 1160 DEG C, heat preservation is carried out in an area with the temperature ranging from 1040 to 1060 DEG C, the sintering time of the area is prolonged, and the sintering process for oxidizing atmosphere can be enhanced at the same time so as to obtain the ceramic tile blank bodies.

Owner:GUANGDONG WINTO CERAMICS +1

Aluminum alloy surface strengthening method using laser melting and coating

InactiveCN101012561APrevent excessive meltingPrevent collapseMetallic material coating processesLaser beam welding apparatusSoluble glassWavelength

The invention discloses a reinforcing method of aluminium alloy surface fused and covered by laser, which comprises the following steps: 1. predisposing aluminium alloy base; 2. allocating laser fusing and covering material with the bulk rate of Al-Si alloy powder and SiC ceramic powder at 1:(4-2); setting the Si content in the Al-Si alloy at 10-15(wt%) with grain size at - 140-+325; setting the grain size of SiC at -200; 2. modulating evenly blended fusing and covering material into paste through soluble glass; coating on the surface of aluminium alloy with thickness at 0.8-1.2mm; drying at 100-150 deg.c for 0.5-2h; 4. adopting crossflow CO2 laser to irradiate the coated layer on the surface of aluminium alloy base; setting the output power of laser at 3-4kW and optical beam scanning velocity at 2-5mm / s and optical spot dimension at 1-4mm; protecting fusing pond through high-purity argon in the laser fusing and covering course with argon flow at 20-30L / min.

Owner:TIANJIN POLYTECHNIC UNIV

Construction material produced by utilizing industrial residue

The invention discloses a construction material produced from industrial residue, aims to provide a construction material having the advantages of light weight, sound insulation, heat insulation, low cost, fire resistance, dense products, high rigidity and the like, and solves the problems with land occupation and pollute environment of phosphate slag and phosphogypsum at the same time. the invention is realized through the following technical scheme: phosphate slag and phosphogypsum are used as raw materials for producing the construction material, which comprises the following components by the weight part: 35 to 65 parts of phosphate slag, 10 to 40 parts of phosphogypsum, 5 to 15 parts of lime, 15 to 28 parts of cement, 0.1 to 0.4 part of light aggregate, 0.02 to 0.05 part of soluble glass, 0.02 to 0.05 part of water-reducing agent, 0 to 0.004 part of retarding agent, 0 to 0.005 part of early-strength admixture, and 0 to 0.008 part of foam killer; the components are weighed by the formula weight part and added to a blender; water is added to the blender with the water-to-material proportion being 4 to 10 and mixed evenly with the materials; and the solution is cast into a die and natural air dried after molding. Dies with different structures can be used according to purposes to conduct cast molding. The construction materials such as wall plates, guardrail decoration pillars, door and window sleeves, vase sleeves and the like can be produced.

Owner:张勇飞

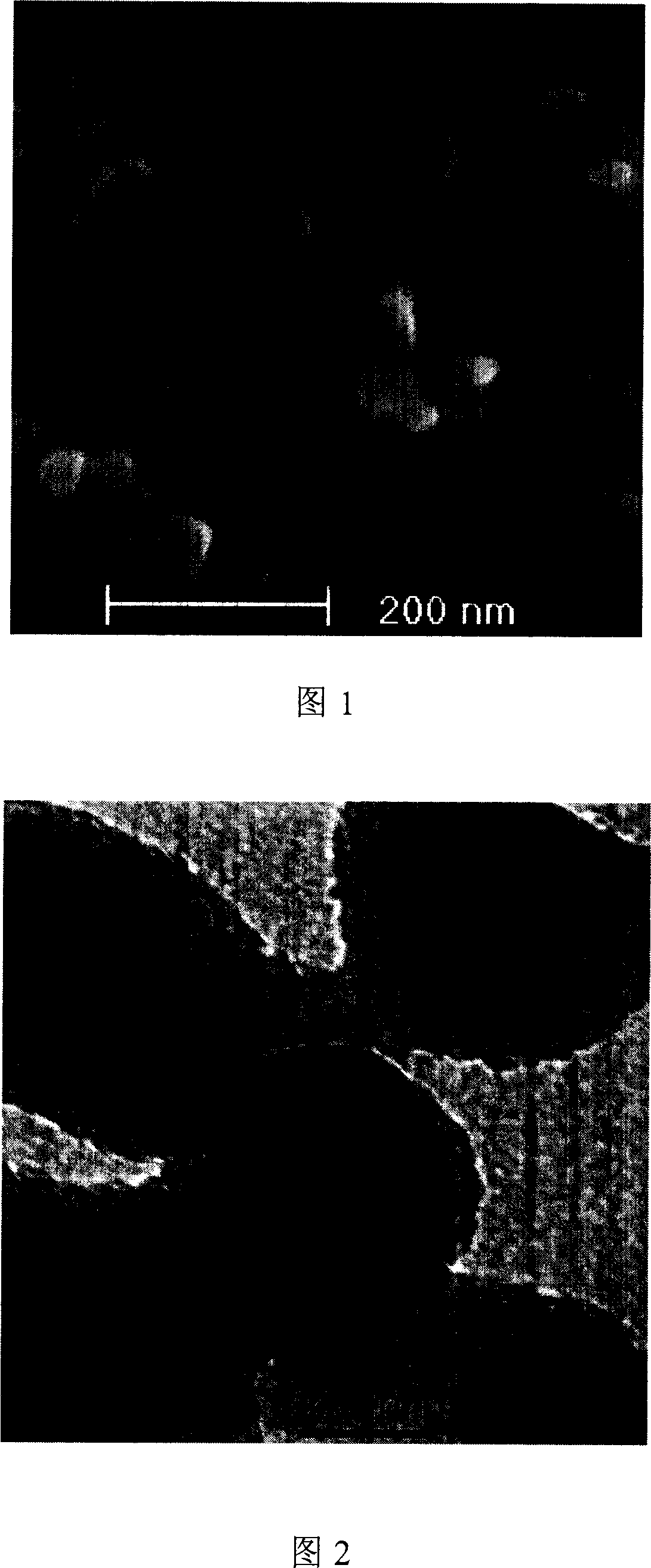

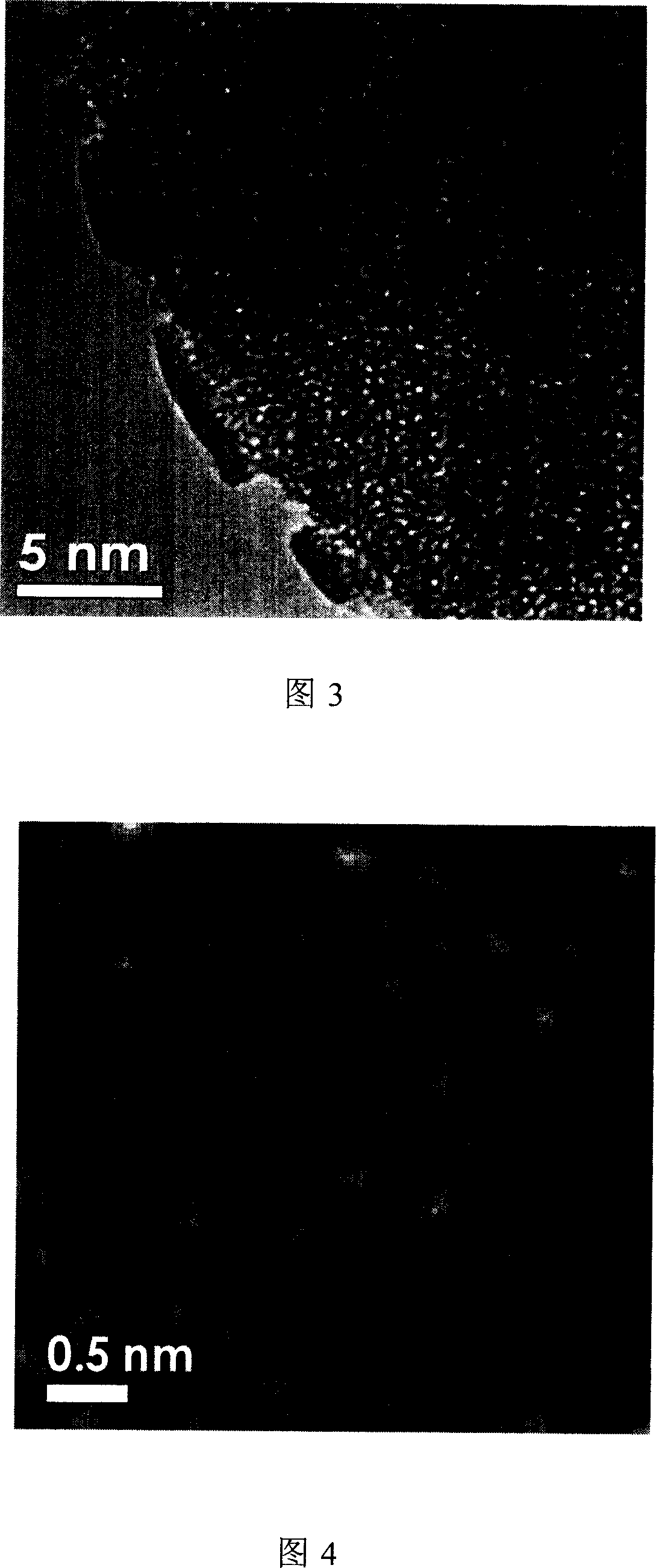

Method for synthesizing nano ZSM-23 molecular screen

InactiveCN101214971AShort production processLow costCrystalline aluminosilicate zeolitesSoluble glassIsopropylamine

A synthetic method of Nanosized ZSM-23 zeolites belongs to the technical field of synthesis of inorganic chemistry. Firstly preparing reaction mixture from sodium metaaluminate or aluminum sulfate, silicasol or soluble glass, sodium hydroxide and isopropylamine, then hydrothermal crystallizing the reaction mixture, at last obtaining the Nanosized ZSM-23 zeolites through conventionally filtering, washing, drying and sintering the hydrothermal crystallized reaction mixture. The synthetic method has the advantages that average diameter of the cross sections of crystal grains of the synthesized ZSM-23 zeolites is not more than 100 nm, the specific surface area is comparatively high, production flow is short, the cost is low, and the method is favorable for industrial production and application.

Owner:EAST CHINA NORMAL UNIV

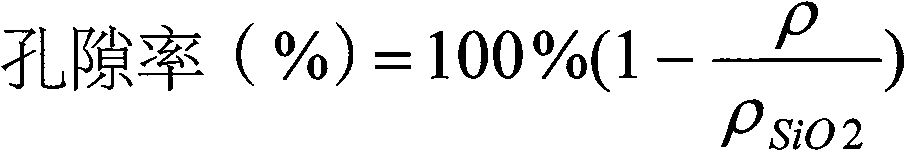

Method for simultaneously preparing SiO2 aerogel and zeolite by utilizing fly ash

InactiveCN101538046AGood workmanshipHigh porositySilicaCrystalline aluminosilicate zeolitesResource utilizationSoluble glass

The invention relates to a method for simultaneously preparing SiO2 aerogel and zeolite by utilizing fly ash, belonging to the technical field of the high-efficiency resource utilization of solid wastes and chemical material preparation. The method is as follows: the fly ash is firstly processed by high-temperature activation and then carries out hydro-thermal synthesis reaction with a sodium hydroxide water solution, soluble glass is catalyzed by a sulphuric acid with certain concentration, or the solution carries out cation exchange resin and is then processed by base catalysis to obtain SiO2 gel; aquagel is processed by solvent exchange / surface modification by utilizing a mixed solution of alcohols / alkanes solvent and trimethylchlorosilane, and the SiO2 aerogel is obtained under the condition of normal pressure and dryness; the fly ash is reacted with NaOH and then filtered to obtain filter residue, and the filter residue is further reacted with the NaOH so as to synthesize fly ash zeolite. The invention is not only a new way of the high-efficiency recycling of the solid wastes, but also a new technical method of the low-cost preparation of the SiO2 aerogel and the zeolite.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Method for producing nano-scale white carbon black with rice hull ash

The invention relates to a method for preparing nanometer level white carbon black by rice husk ash. The method is characterized in that the process method comprises the following steps: the rice husk ash is treated by an alkaline method to prepare soluble glass; and a soluble glass solution is subjected to condensation, heat insulation, acidic reaction, aging, rinsing, filtering, preparing, homogenizing, spraying and drying, and airflow pulverization. The method has the technical effects that the method reduces cost, improves corrosion resistance, high hardness and high toughness of the material, and has simple preparation process flow, low production cost and good stability.

Owner:NANCHANG UNIV

Preparation method of high dispersed white carbon black

ActiveCN102229758AIncreased dispersionReduce forcePigment treatment with organosilicon compoundsPigment treatment with non-polymer organic compoundsDispersityFiltration

The invention discloses a preparation method of high dispersed white carbon black. According to a new method and technology, a synthesis reaction of liquid soluble glass and concentrated sulfuric acid is carried out in two steps by first preparing fine seeds, and then carrying out a synthesis reaction, wherein the synthesis reaction is a precipitation reaction carried out under effects of an organic surfactant SDS and a composite silane coupling agent. The high dispersed precipitated white carbon black specially used in high-performance tyres is obtained through particle surface cladding, modification treatment, press filtration, washing, pulping and pressure drying. The method improves a traditional white carbon black production technology of a precipitation method by optimizing technological parameters and using an optimized auxiliary agent to meet a requirement of enhanced product dispersiveness; besides the method overcomes defects of an ordinary precipitation method, such as crude particles, wide distribution, strong hydrophilism and weak mixing dispersion. A prepared product has characteristics of fine primary particles, low surface hydroxyl content, increased lipophilicity,high bonding force with rubber high molecules and high wettability, and is an ideal reinforcing filling material specially used in high-performance tyres.

Owner:FUJIAN ZHENGSHENG INORGANIC MATERIAL

Preparation of methyl vinyl MQ resin for LED encapsulated strengthening

The invention discloses a preparation method of organic resin, in particular to a preparation method of a methyl vinyl MQ resin used for LED encapsulation and reinforcement. The method is that a soluble glass aqueous solution is added into concentrated hydrochloric acid (36.5 percent); after the reaction, the anhydrous ethanol solution of phenyl alkoxy silicane, vinyl alkoxy silicane and methyl alkoxy silicane is added; an extraction is carried out after cohydrolysis; the upper oil layer is removed; the reactants are washed to be neutral and dried; the low-boiling substances are removed; the colorless and transparent product of MQ resin is obtained. The preparation method of the invention has the advantages of accessible and cheap raw materials, simple and easy operation, and is convenient to industrialized with good effect. The products of the invention are especially suitable to be used as reinforcement materials in the LED encapsulation materials, also be expected as a reinforcing agent for other organosilicon materials and used in aspects of anchoring agent, surface treating agent, mold discharging agent, anti-blowing agent, adhesion preventives, brightening agent and other additives, etc.

Owner:HANGZHOU NORMAL UNIVERSITY

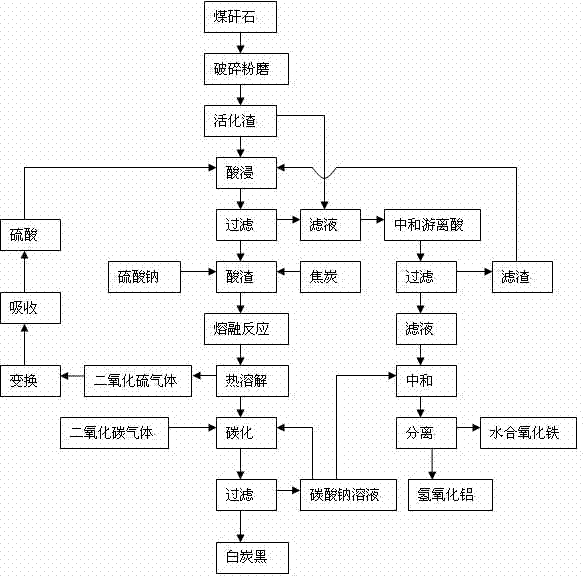

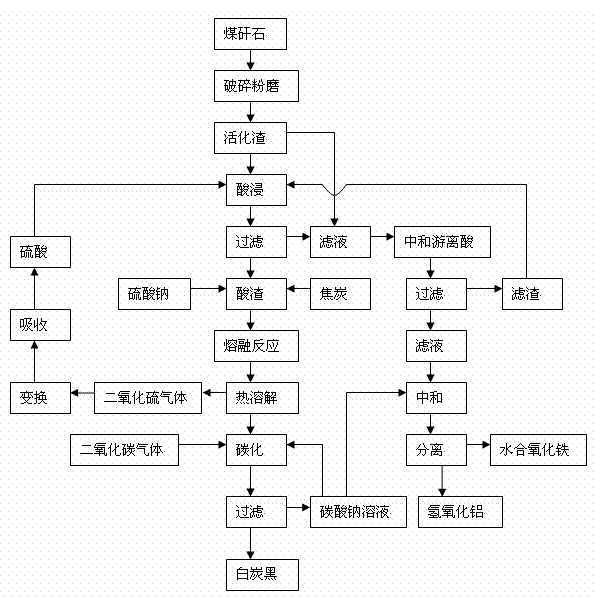

Comprehensive extraction method of ferro-silico-aluminum in gangue

ActiveCN102515279AGood slag activityMeet operating conditionsSilicaIron oxides/hydroxidesAluminium hydroxideSlag

The invention discloses a comprehensive extraction method of ferro-silico-aluminum in gangue, comprising the following steps of: using gangue as a raw material, crushing, grinding, activating, carrying out acid leaching, filtering, neutralizing free acid in the acid leaching filtered solution by the use of active slag, filtering to obtain a neutralized acid leaching solution, adding a sodium carbonate solution into the neutralized acid leaching solution, adjusting pH value, separating iron and aluminium to obtain hydrous iron oxide, aluminium hydroxide and a by-product sodium sulphate, adding sodium sulphate and coke into the acid leaching slag which has undergone acid leaching and filtration, carrying out a high-temperature melt reaction to recover silicon so as to prepare soluble glass, simultaneously recovering sulfur dioxide to prepare sulfuric acid, reusing sulfuric acid for the acid leaching treatment, diluting the soluble glass by the use of a sodium carbonate solution, carrying out carborization to obtain white carbon black, and reusing the carbonating solution for iron-aluminium separation. The method provided by the invention has characteristics of wide application range of the raw material gangue, high comprehensive recovery rate, no output of by-products, less residue amount and the like, provides a novel technological process for high-efficiency recovery of ferro-silico-aluminum from gangue, and expands the ways of gangue application.

Owner:KUNMING UNIV OF SCI & TECH +1

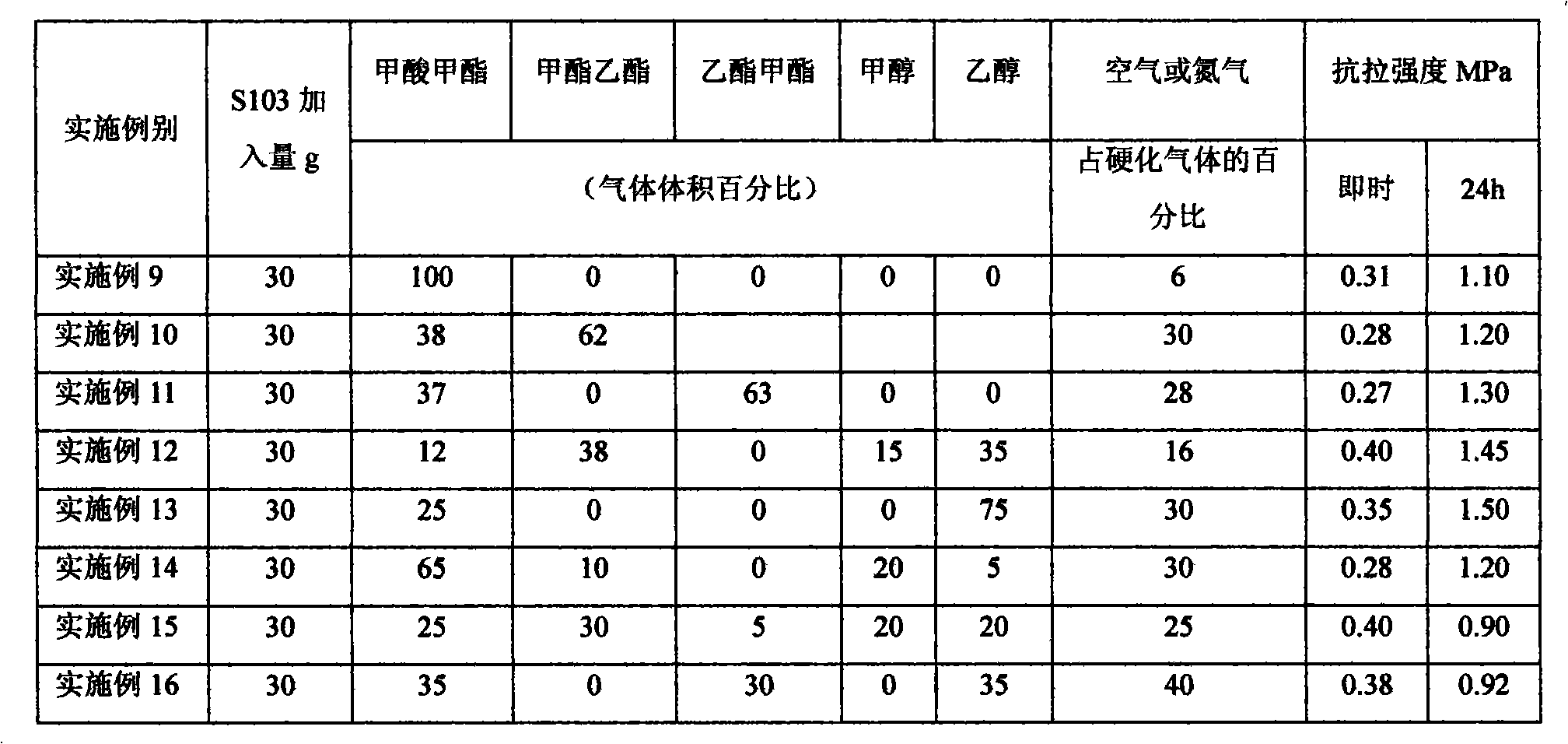

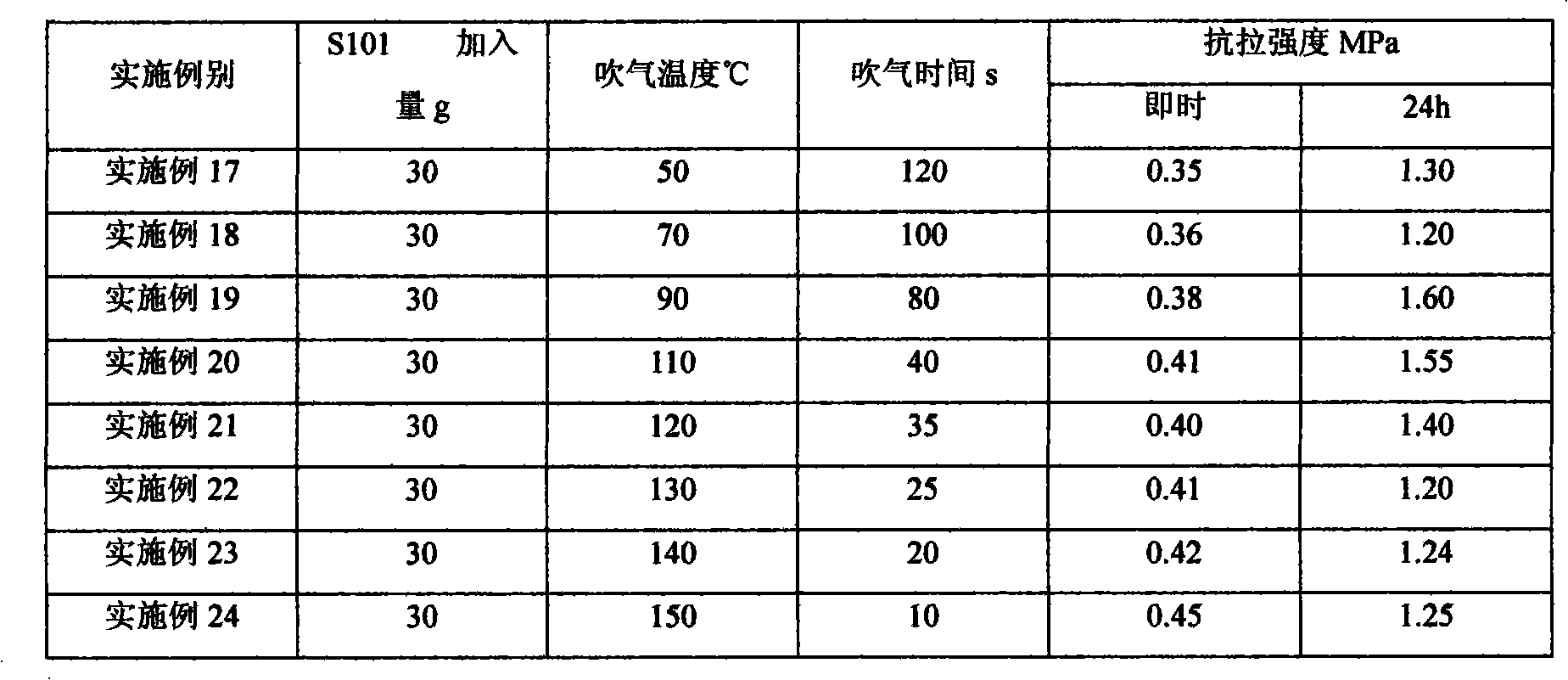

Method for making core with aeration ossification

InactiveCN101293271AWide variety of sourcesLow priceFoundry mouldsFoundry coresSoluble glassGlycerol

The invention discloses a core making method by gas-blowing hardening, which is characterized in that the mass percentage of mixing materials of the making core sand is as follows: 0.9-7.0 percent of soluble glass, 0.1-1.0 percent of moisture absorption resistant agent and raw sand for the rest; the used moisture absorption resistant agent can be triacetyl glycerine, diacetin, glycerol mono acetate bulk, diethylene glycol acetic ester, propylene glycol acetic ester, other polylol organic acid ester or the mixture thereof; the volume percentage of the blowing gas for hardening is as follows: 25-100 percent of C2-C4 organic ester and 0-75 percent of C1-C2 alcohols. The method of the invention has no toxicity and odor in production process, and the produced cores have better stripping strength.

Owner:SHENYANG HYATON FOUNDRY MATERIAL

Method of comprehensively utilizing serpentine

InactiveCN101235440ATake advantage ofFull controlSilicon oxidesProcess efficiency improvementFerric hydroxideSoluble glass

The invention relates to a method for comprehensively utilizing serendipities, which comprises: magnetically separating the serpentinites in a strong magnetic field, obtaining amorphous silica powder which contains silicon dioxide more than 90% through filtering acid dipping solution, dissolving the amorphous silica powder through using caustic soda under high temperature, which is used for manufacturing soluble glass with medium high modulus or taken as raw materials for producing white carbon black, then, mixing sulphuric acid and hydrochloric acid or nitric acid or mixing the sulphuric acid, the hydrochloric acid and nitric acid, adding acid dipping additive to carry out compound alternative and circulating acid dipping for ore powder which is magnetically separated and processed, fractionally depositing, filtering, and removing impurity for magnesium sulfate solution which is filtered through the acid dipping and contains the impurity, through adjusting the pH value, obtaining inorganic industrial dyes which mainly contain iron oxide yellow, ferric hydroxide and aluminum hydroxide, enriching the nickel, which is convenient for abstracting the nickel from the serpentinites, finally obtaining high purity magnesium oxide through refining refined magnesium sulfate solution whose impurity is removed after ammonium hydrogen carbonate and ammonial solution or sodium sulfide is used to deposit, and also obtaining ammonium sulfate or sodium sulfate which contains magnesium and calcium after liquid which is filtered is evaporated.

Owner:刘湘霖 +1

Method for preparing nano Fe-ZSM-5 zeolite molecular sieve

InactiveCN101121526ASynthetic safetyEasy to synthesizeNanostructure manufactureMolecular sieve catalystsSoluble glassPetrochemical

The present invention relates to the technical field of a zeolite molecular sieve synthesis, concretely speaking, relating to a preparation method of a zeolite molecular sieve of a nano heteroatom. A sodium silicate or a soluble glass, an inorganic acid, an inorganic ferric salt, an organic amine and deionized water serve as the material. After the steps of liquor preparation, two variable temperature crystallizations, washing-up centrifugalization, drying and roasting, the zeolite molecular sieve of nano Fe-ZSM-5 is produced with a grain size less than 100nm. The present invention can be used in the petrochemical industry, fine chemical industry and the environmental protection field.

Owner:CHINA PETROLEUM & CHEM CORP +1

Antimicrobial resin composition

The present invention provides a resin composition having excellent dispersibility, discoloration resistance and antimicrobial properties by blending a resin (A) with an antimicrobial agent (B) in which at least one kind of metal ion selected from the group consisting of silver, copper, zinc, and tin is supported on zeolite, and an antimicrobial agent (C) that includes a silver ion-containing phosphate as an active ingredient, or an antimicrobial agent (D) made of a soluble glass powder containing silver ion.

Owner:FUJI CHEM IND CO LTD

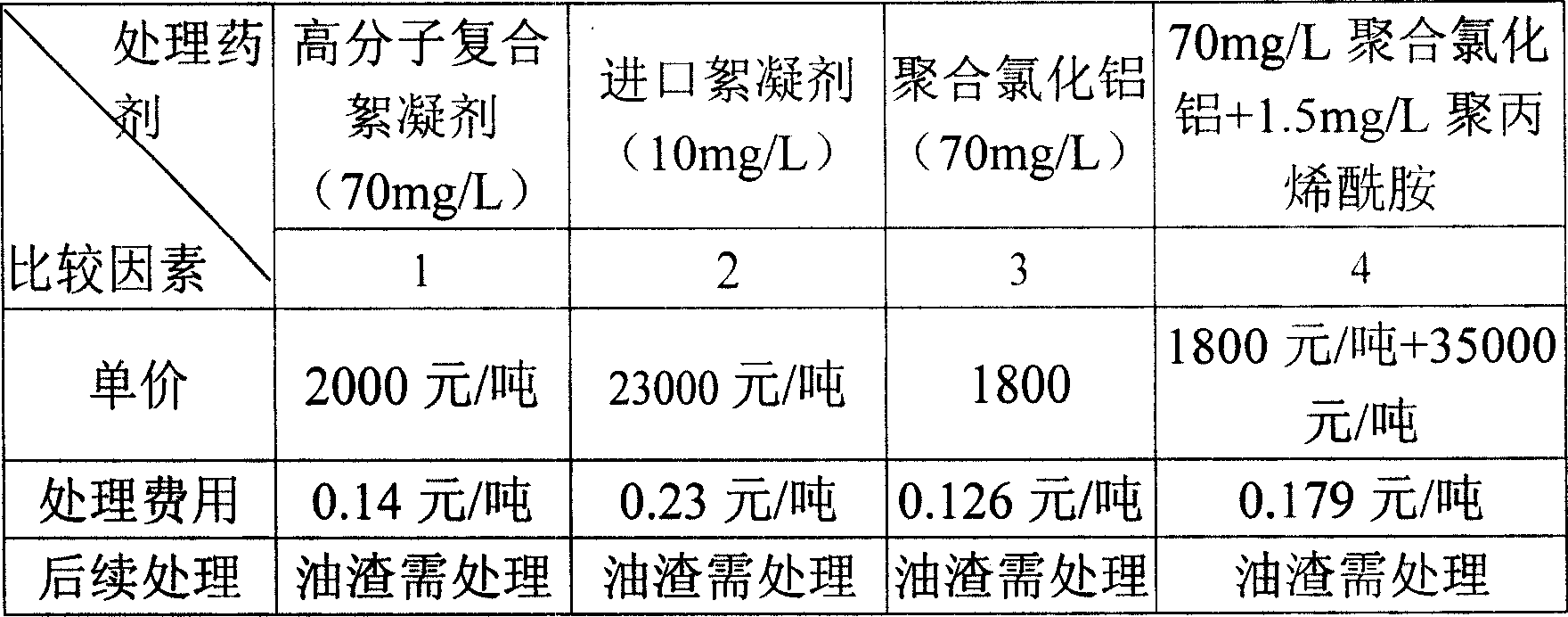

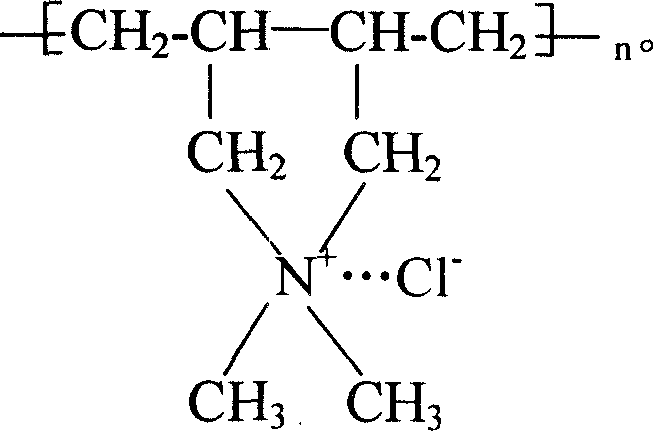

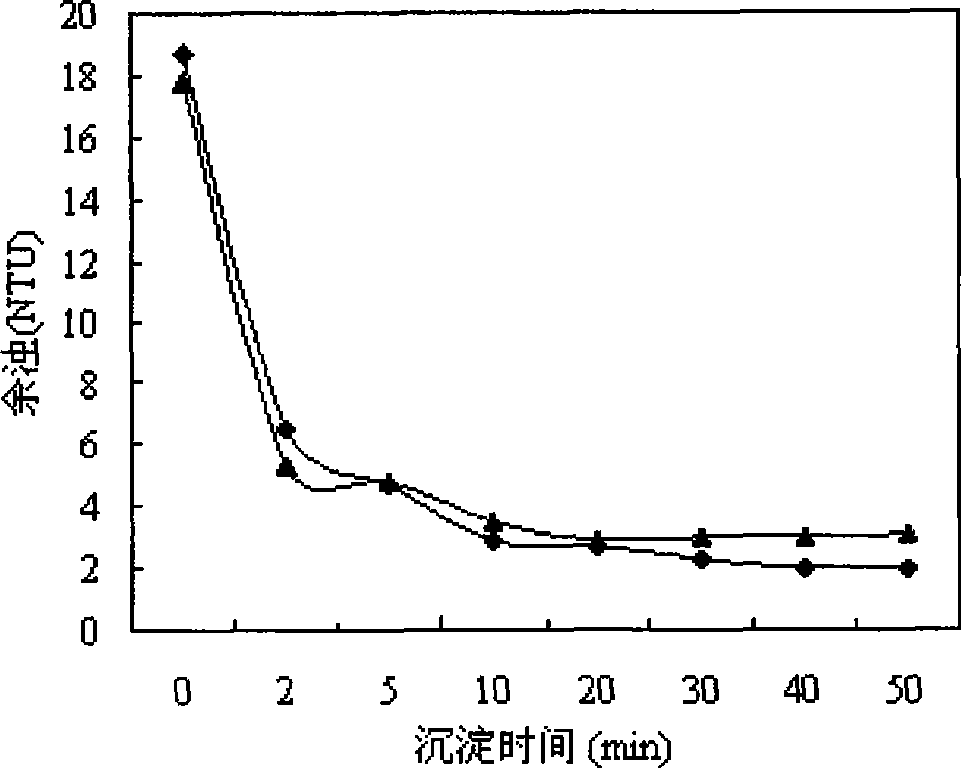

High polymer composite coagulant for treatment of oily waste water and making method thereof

InactiveCN101041495AEasy to handleLess one-time investmentWater contaminantsWater/sewage treatment by flocculation/precipitationAluminium chloridePolymer science

The invention discloses a high polymer composite coagulant for disposing oily wastewater and preparing method, which comprises the following steps: setting ingredient and weight ratio of high polymer composite coagulant with polymeric aluminium chloride : polymeric ferric sulfate : soluble glass : polydiene propyl dimethyl amchlor : water = 39.00:(1.90-2.10):(0.26-0.31):(1.04-1.52):(57.80-57.10); setting 0.02% basic ion polyacrylamide in polydiene propyl dimethyl amchlor; preparing finite density water solution with raw material as first step; preparing flocculant intermediate with polyaluminium chloride, polymeric ferric persulfate and sodium silicate as second step; proceeding mixed reaction with flocculating agent intermediate of the second step and polydiene propyl dimethyl amchlor of 0.02% positive ion polyacrylamide; controlling condition as temperature at 70-90 deg.c, pH value at 4-7; stirring intensity at 50-70r / min and ripening time at 6-24h.

Owner:WUHAN IRON & STEEL (GROUP) CORP +1

Method for preparing alumina in fire resistant and high specific surface

InactiveCN1562753ASimple processLarger than surfacePhysical/chemical process catalystsAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationSoluble glassSilicon oxide

In the invention, meta-aluminate and soluble glass are used as raw materials to preparate aluminum oxide with high-temp. resistant and high specific surface by techonlogy that using sol-gel process to prepare aluminium oxide humidity gel and using supercritical fluid drying method to prepare aluminum oxide xerogel. The aluminum oxide contains silicon oxide (wt% is 0.1-10), the aluminum oxide xerogel is processed for 4h on 500 deg.c temp., its specific superficial area is more than 365 m2 / g, then it is processed for 4h, its specific superfical area is more than 165 m2 / g.

Owner:ZHEJIANG UNIV

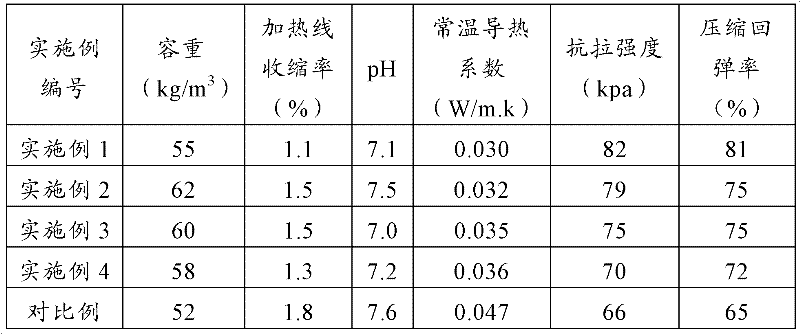

Composite heat-insulating material and preparation method thereof

The invention relates to a composite heat-insulating material, comprising the following ingredients: 0.4-10 wt% of sepiolite, 0-5 wt% of brucite, 0-15 wt% of alumina silicate fiber, 5-10 wt% of asbestos fiber, 0.5-8 wt% of aerogel, 0-12 wt% of diatomite, 0-3 wt% of bentonite, 1-5 wt% of perlite, 0.5-5 wt% of dispersant, 0.1-1 wt% of polyvinyl alcohol, 0-1 wt% of soluble glass, 0-0.015 wt% of sodium cetanesulfonate, and the balance consisting of clear water. The invention also discloses a preparation method of the composite heat-insulating material. The composite heat-insulating material disclosed herein has low heat-insulating coefficient, good flexibility, and high tensile strength, and is difficult to pulverization. In addition, the method has the advantages of simple process, high production efficiency, and low energy consumption.

Owner:张永武

Hard surfacing sintered flux and manufacturing method thereof

InactiveCN101564804AMeet different requirements of hardnessImprove performanceWelding/cutting media/materialsSoldering mediaMaterials preparationThermal fatigue

The invention relates to a hard surfacing sintered flux and a manufacturing method thereof. The sintered flux comprises MgO of 30 percent to 50 precent, CaO of 2 percent to 10 percent, Al2O3 of 10 percent to 20 percent, CaF2 of 18 percent to 28 percent, SiO2 of 10 percent to 20 percent, SiC of 0 percent to 1.5 percent and other components of 0 percent to 5 percent such as ferroalloy mainly playing a role of desoxidation and the like. Material preparation, dry mixing and wet mixing by adding soluble glass into a blender are conducted until granules which have the required sizes are formed, then the granules are dried in a rotary drying way at the low temperature of 200 DEG C to 250 DEG C, and then finished products are obtained by high-temperature sintering in a rotary drying oven at the high temperature of 700 DEG C to 750 DEG C, sieving and packaging. The invention has low flux cost so as to meet the requirements of different hardness, excellent technique and good high-temperature slag detachability; the deposited metal has no gas hole, no crackle but adjustable hardness; and the high-temperature wear-resistance, oxide etch resistance and cold and thermal fatigue resistance of a hot roll are greatly improved.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

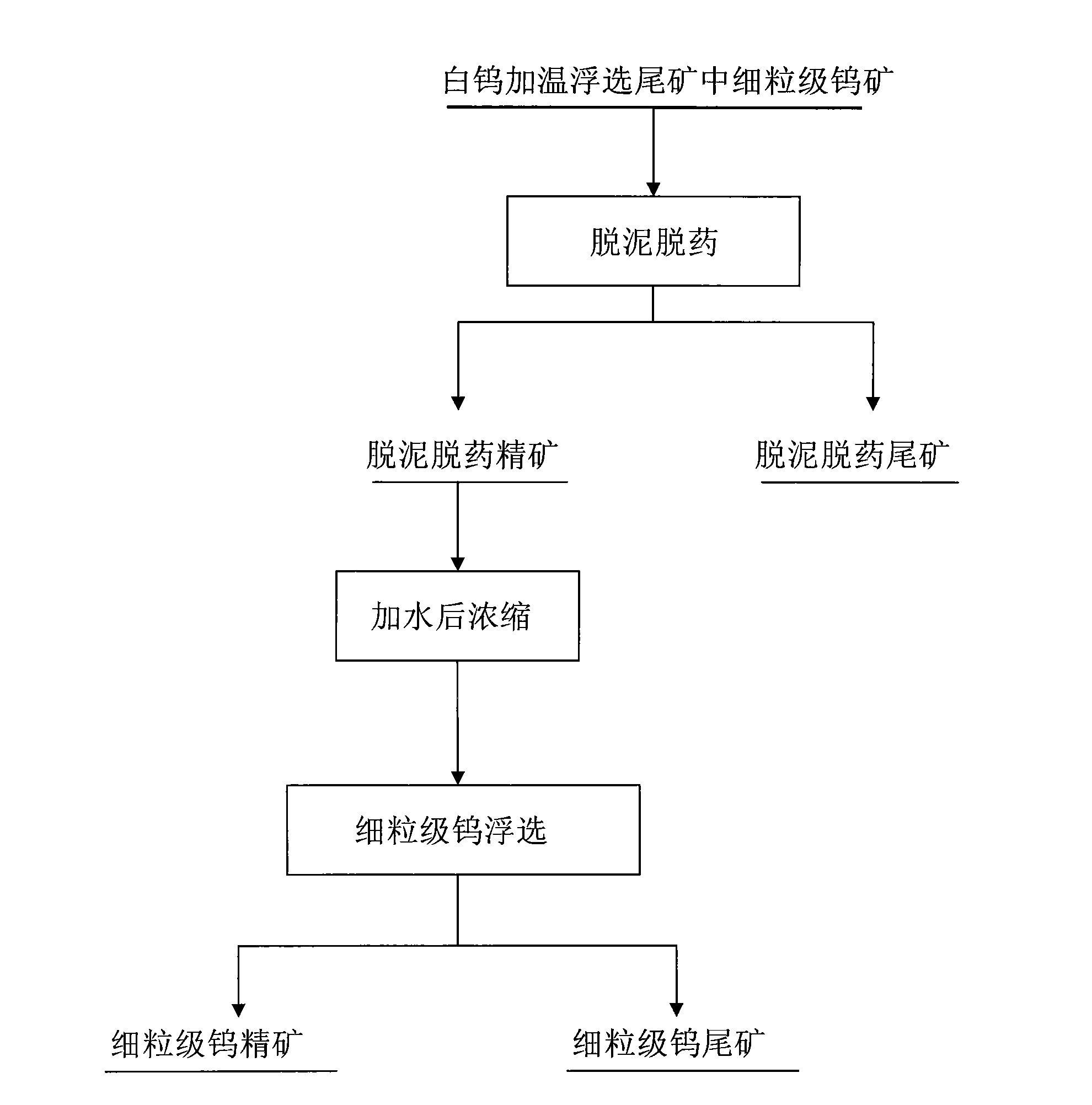

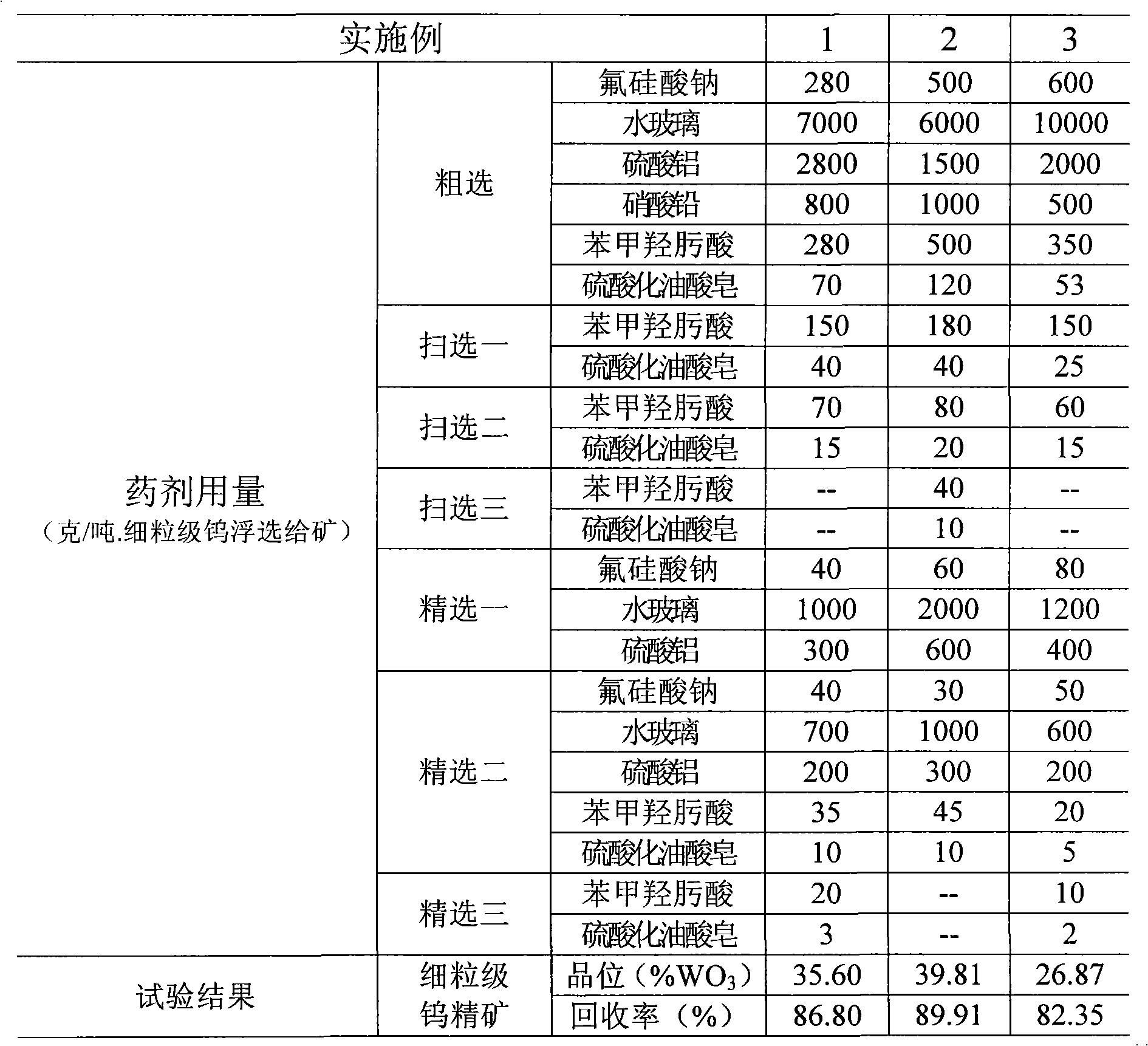

Benefication method for concentrating fine tungsten ore in tailings by warming scheelite

InactiveCN101579653ASimple recycling processThe beneficiation process is stableFlotationWet separationLead nitrateSoluble glass

The invention discloses a benefication method for concentrating fine tungsten ore in tailings by warming scheelite, which is characterized by comprising the following steps in turn: performing desliming and reagent removal; condensing concentrate after desliming and reagent removal, which is added with water, into 26 to 44 percent of pulp density, and controlling the pH of pulp at about 8.5; performing floatation on the fine tungsten ore; adding regulators of sodium fluosilicate, soluble glass, aluminium sulphate and lead nitrate; and adding collecting agents of benzohydroxamic acid and sulfated oleate soap, and performing rough concentration, concentration and scavenging to obtain the fine tungsten ore concentration and fine tungsten tailings. The method has simple recovery process flow, stable benefication process, high tungsten recovery rate, and low cost of reagents; the used benefication reagents do not pollute environment; and tailing water can meet the emission requirement. The method is suitable for the fine tungsten ore, of which the WO3 content is 0.95 to 5.10 percent, the ratio of peanut ore to the scheelite is between 1:9 to 9:1, and the occupancy rate of WO3 metal smaller than 30 microns is more than or equal to 60 percent, and which is subjected to concentration of the tailings by warming the scheelite and then reconcentration of the tailings by a shaker.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

Normal-pressure rapid preparation method for hydrophobic silica aerogel powder

The invention discloses a normal-pressure rapid preparation method for hydrophobic silica aerogel powder. The method comprises the following steps: preparing gel particles at first; then carrying out exchanging and modification with a non-polar solvent, alcohols and a silane coupling agent as modifier solutions; and drying modified wet silica aerogel so as to obtain the hydrophobic silica aerogel powder. According to the invention, industrial soluble glass is used a silicon source for formation of the gel particles with a uniform size in a dispersion phase under the action of an emulsifier and a catalyst, then the gel particles are modified by using a one-step solvent exchange and surface modification method, and finally, drying at normal pressure is carried out so as to directly obtain the silica aerogel powder. The normal-pressure rapid preparation method for the hydrophobic silica aerogel powder substantially reduces time for sol exchanging and surface modification; the prepared silica aerogel powder has a uniform size; and a great amount of energy is saved in normal pressure drying compared with supercritical drying.

Owner:ECONANO TECH LTD BEIJING

Pyrophillite lost foam casting coating and preparation method thereof

InactiveCN101444827AGood suspensionImprove thixotropyFoundry mouldsFoundry coresSoluble glassOctanol

The invention discloses a pyrophillite lost foam casting coating and a preparation method thereof. The coating comprises the following components by the mass percentage: 90% to 95.8% of pyrophillite refractory powder, 0.2% to 0.7% of sodium carboxymethyl cellulose, 1.9% to 4.4% of swell soil, 1.9% to 5.3% of soluble glass, 0.1% to 0.18% of polyethylene alkyl polyol ether, and 0.05% to 0.1% of N-octanol, and the mass percentage of the components is 100% in total, wherein, pyrophillite refractory powder is pyrophillite or mixture of pyrophillite and other refractory materials. The invention has the advantages that the pyrophillite lost foam casting coating has favorable suspension property and thixotropy, as well as excellent ventilation property and relatively high surface strength; and the preparation technology is simple, the operation is convenient, the raw material is abundant and the production cost is low. The invention is mainly used for producing refractory material on the surface of foam plastic mould of lost foam pieces.

Owner:HAIAN HENGYE SILK

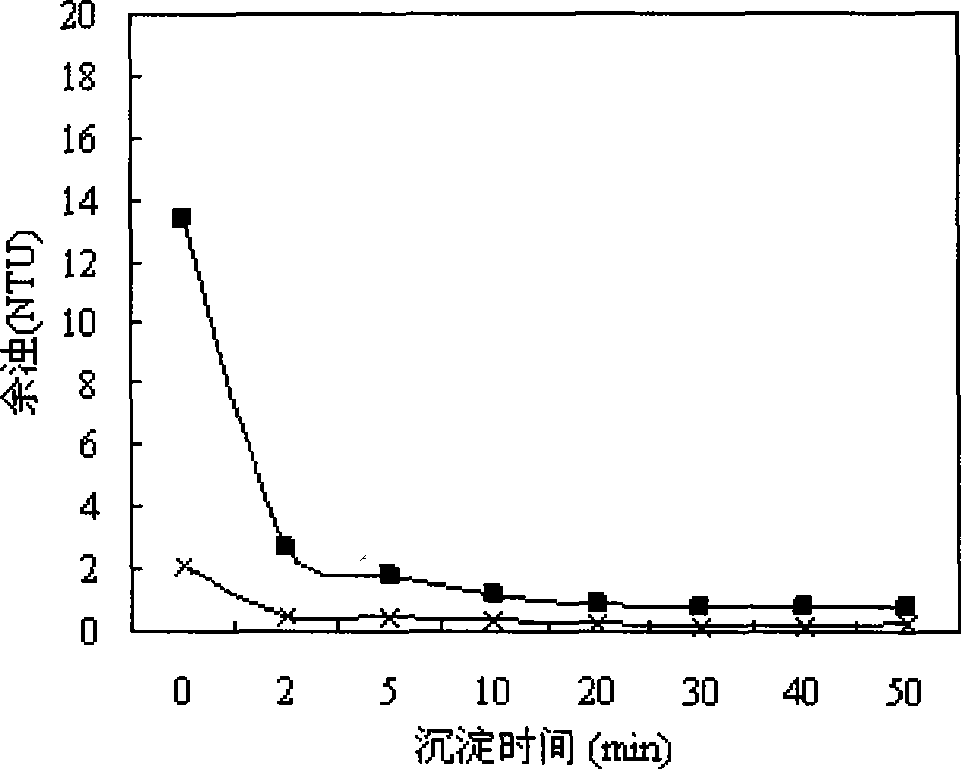

Poly ferrosilicium coagulant and preparation method thereof

ActiveCN101386435AReduce turbidityReduce CODWater/sewage treatment by flocculation/precipitationSodium chlorateSulfate

The invention discloses a poly silicon iron coagulating agent and a preparation method thereof, relates to an inorganic polymer coagulating agent and a preparation method thereof and solves the disadvantages of poor adaptability to low temperature and low turbidity water quality, high production cost, complex preparation technique and secondary pollution to the environment in the existing preparation process of poly silicon iron coagulating agent. The poly silicon iron coagulating agent of the invention is made from soluble glass, soluzione leggermente acida, ferrous sulfate and sodium chlorate. The preparation method of the poly silicon iron is as follows: step 1. raw materials are weighted; step 2. the soluble glass is added into the soluzione leggermente acida and activated silicic acid is prepared after the reaction; 3. the ferrous sulfate and the sodium chlorate are added into the rest soluzione leggermente acida and then the activated silicic acid obtained in step 2 is added, thus obtaining the poly silicon iron coagulating agent. The poly silicon iron coagulating agent is applicable to low temperature and low turbidity water quality and has the advantages of low preparation cost, simple preparation method and no pollution during the preparation process.

Owner:HARBIN INST OF TECH

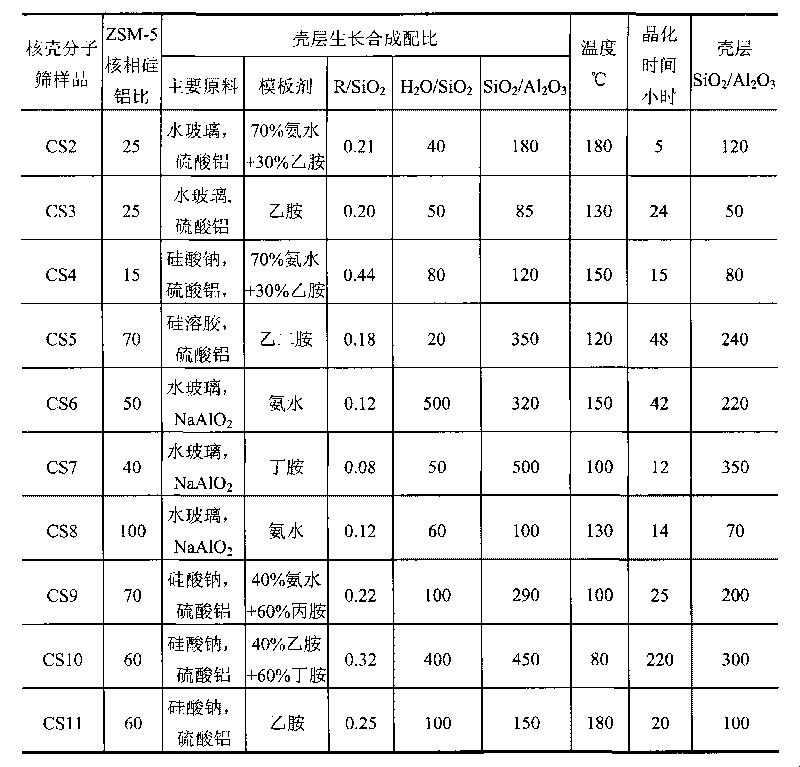

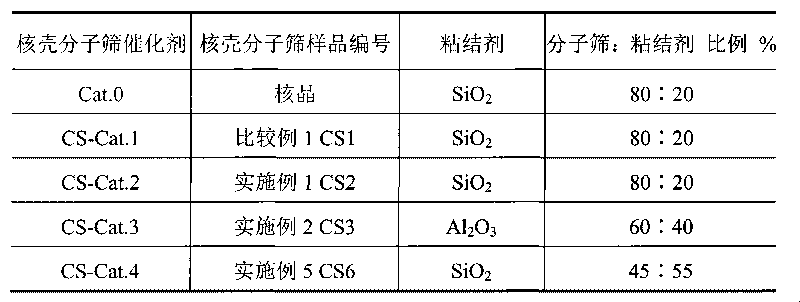

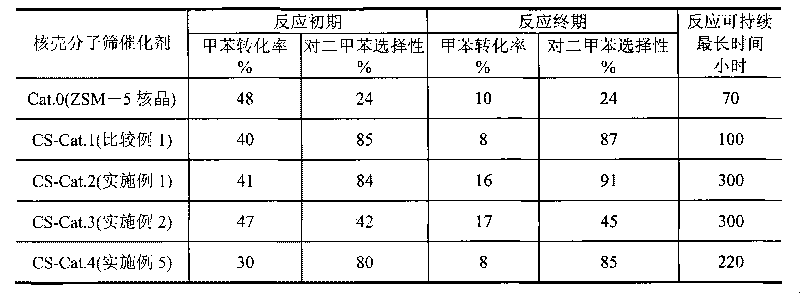

Method for synthesizing core-shell type zeolite molecular sieve

ActiveCN101723402APromote formationEvenly dispersedMolecular sieve catalystsPentasil aluminosilicate zeoliteSoluble glassPropylamine

The invention relates to a method for synthesizing ZSM-5 / ZSM-5 core-shell type zeolite molecular sieve, mainly solving the technical problems of expensive used raw materials, great environment pollution of template agent, high difficulty of industrial amplification and synthesis, difficult industrial production and the like of the core-shell type zeolite molecular sieve in the prior art. The invention adopts the following technical scheme: the core-shell zeolite molecular sieve is prepared by adopting ZSM-5 core phase molecular sieve with a relatively low silica alumina ratio as a seed crystal, using at least one of soluble glass, silica solution, sodium silicate, white carbon black or atlapulgite which are cheap and easily obtained as a silicon source, and taking at least one organic amine from ethylamine, ethanediamine, propylamine and butylamine or the mixture of the organic amine and inorganic amine as a template agent so as to better solve the above technical problems. The invention can be used in industrialized synthetic production of core-shell type molecular sieve.

Owner:CHINA PETROLEUM & CHEM CORP +1

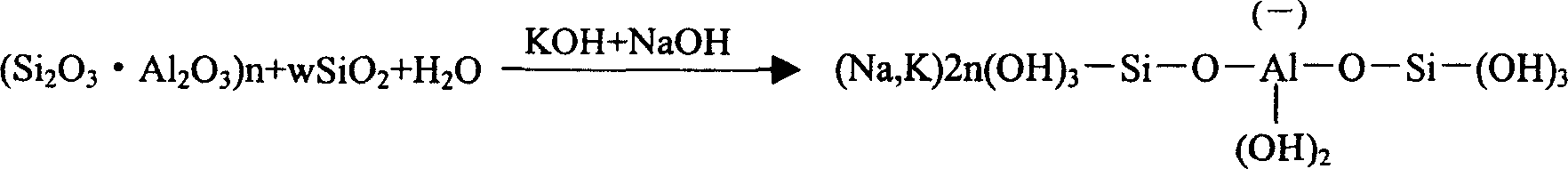

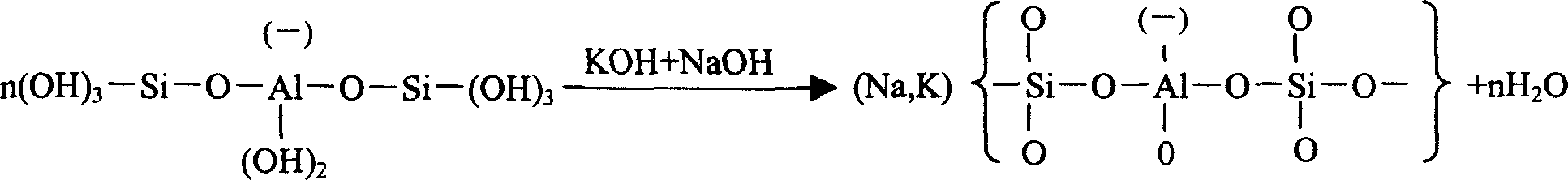

Method for preparing geopolymer adsorption material by using Bayer process red mud

ActiveCN103920457AUniform stomataHigh strengthOther chemical processesAluminium silicatesSoluble glassKaolin clay

The invention discloses a method for preparing geopolymer adsorption material by using Bayer process red mud. According to the invention, kaolin and red mud are respectively dried, kaolin is calcined after ball milling, then red mud and calcined kaolin are mixed according to mass ratio of 3: 7-6: 4, placed in a stirring pan, a soluble glass solution with 1.5 of modulus is added for uniformly stirring until the sodium oxide mass in the soluble glass solution accounts for 8% of total mass of a mixture of the calcined kaolin and red mud, the water cement ratio of the slurry is 0.35-0.38; a proper amount of aluminum powder and powdered soap are placed in a few water, and uniformly dispersed and then added in the obtained slurry, uniformly stirred; after waiting for 3-5 minutes, the expanded slurry is filled in a die, and the expanded slurry is placed in a baking oven with the die or placed in the baking oven without die for maintenance, so that the geopolymer adsorption material is prepared. The method has the advantages of simple equipment, low cost, easy popularization and little environmental influence, the prepared geopolymer adsorption material has the advantages of uniform pore and high strength, and can be reused after being processed by an acid solution.

Owner:徐州星皓乐器有限公司

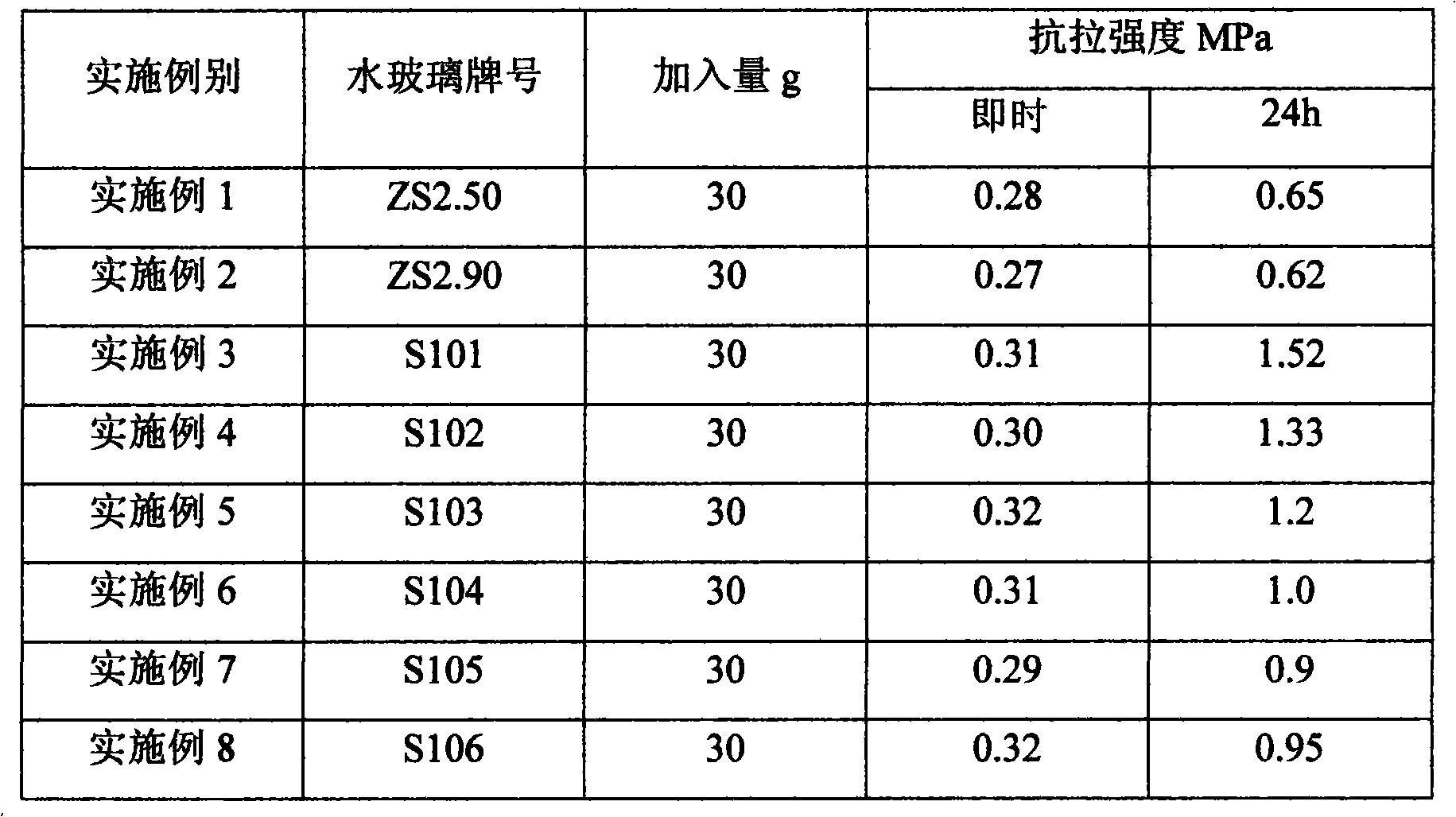

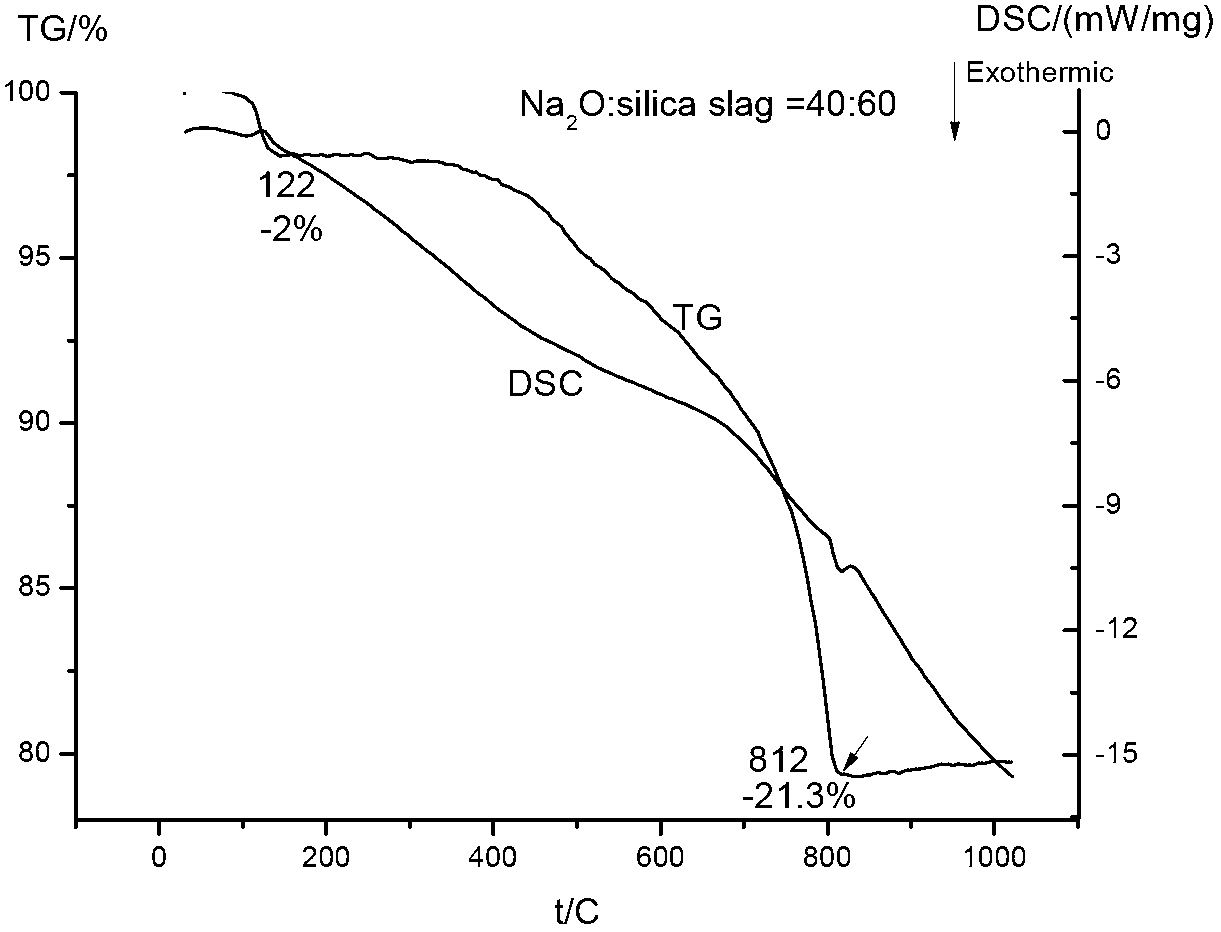

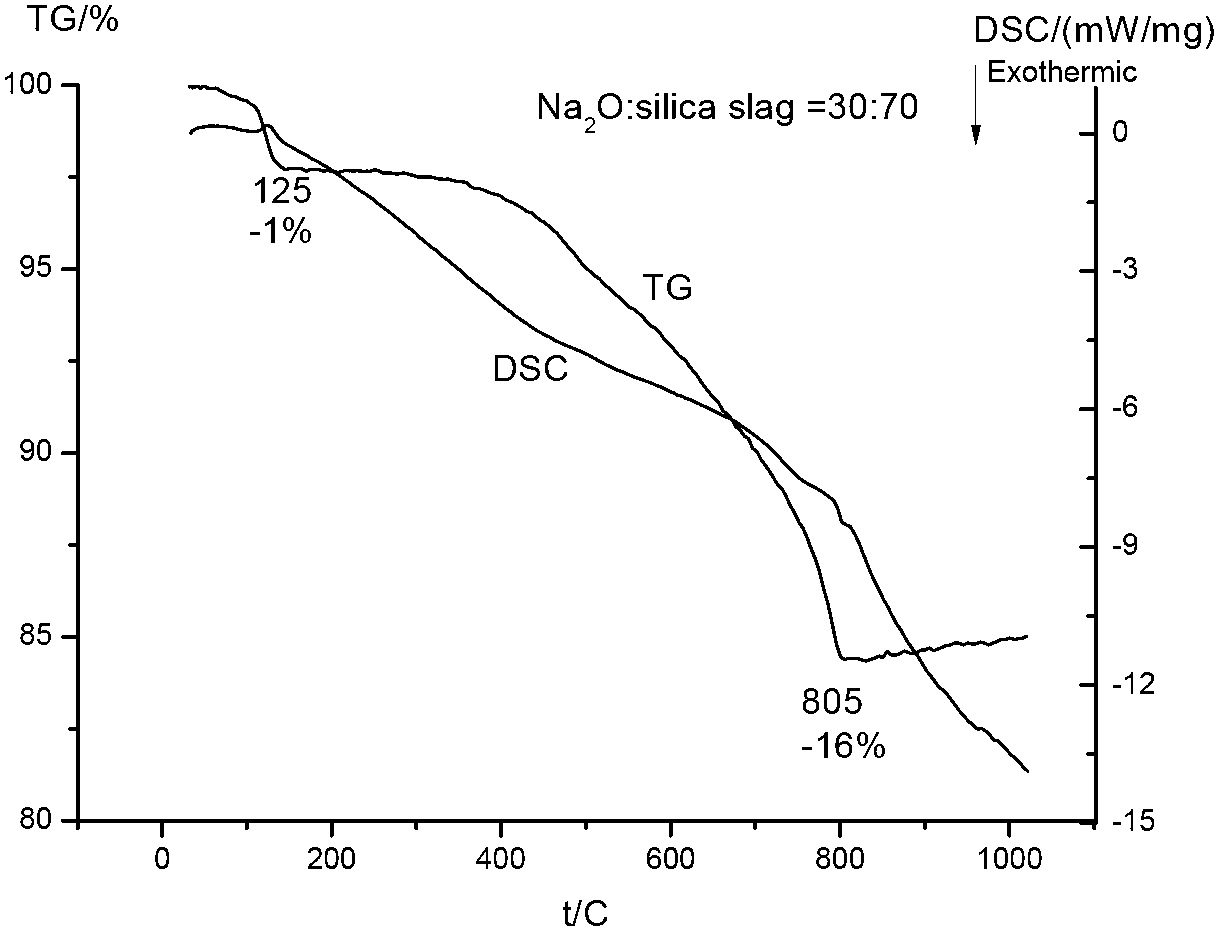

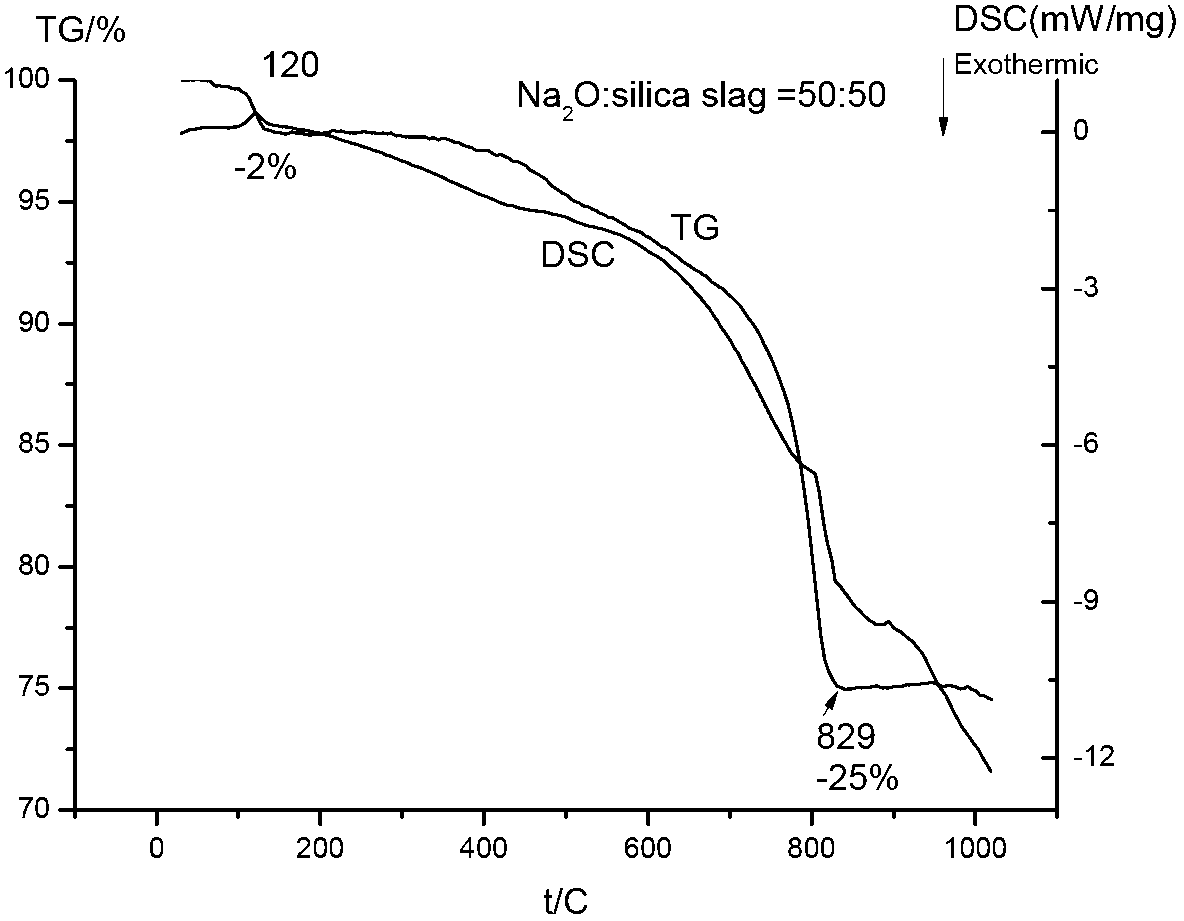

Method for preparing soluble glass by using waste residues with aluminum extracted by coal gangue

ActiveCN102936016AReduce the temperatureAvoid strong corrosionSolid waste disposalAlkali metal silicatesCongruent meltingSoluble glass

The invention relates to a method for preparing soluble glass by using waste residues with aluminum extracted by coal gangue. The method comprises firstly mixing and grinding the waste residue with aluminum extracted by coal gangue and sodium carbonate to be 1-50mu m particles, then conducting temperature programming in a muffle furnace, conducting low temperature congruent melting reaction for 1-5 hours at the temperature of 500-850 DEG C, and conducting water quenching to obtain coarse sodium silicate solid; and placing the coarse sodium silicate solid in a high pressure reactor, adding distilled water, heating to be 150 DEG C, stirring and dissolving for 5 hours, cooling to be room temperature, filtering and separating to obtain a colorless and transparent sodium silicate solution, and crystallizing to be the soluble glass. The method lowers the temperature for preparing sodium silicate by using a traditional soda ash method by about 600 DEG C, greatly reduces energy consumption, and simultaneously avoids highly corrosive of a traditional caustic soda alkali-dissolution method on production facilities and alkali pollution on the environment.

Owner:SHANXI UNIV

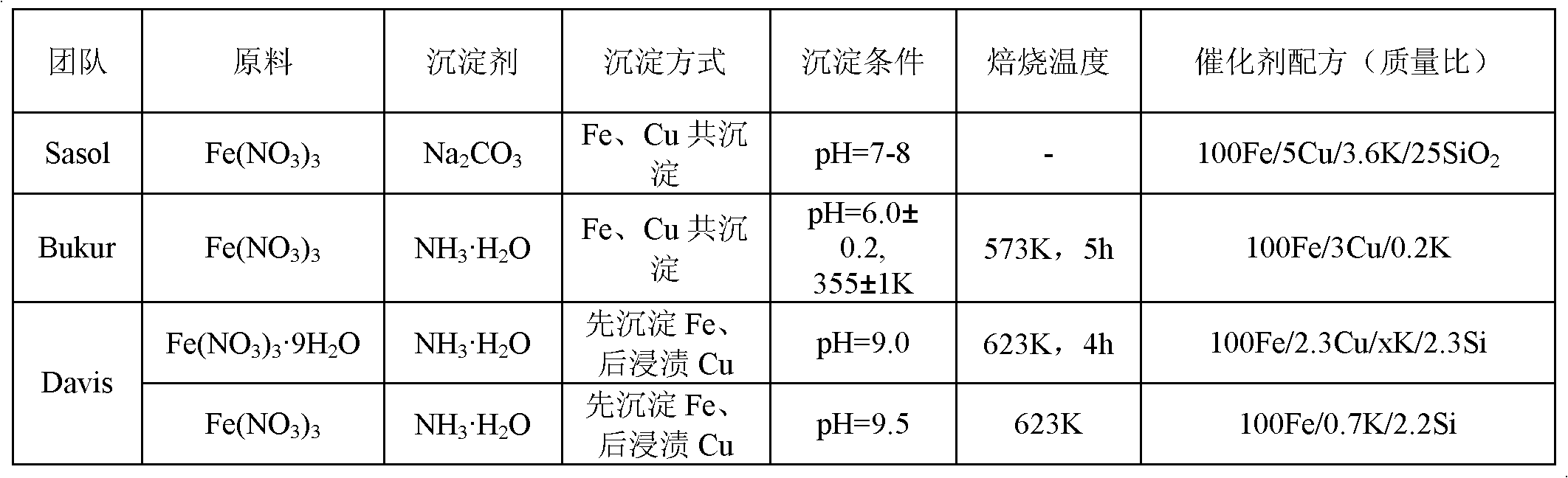

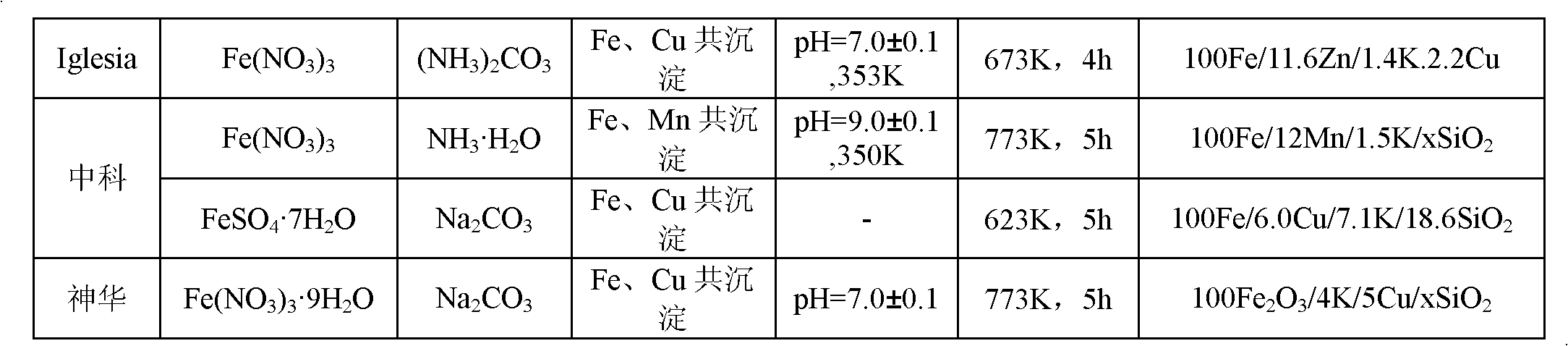

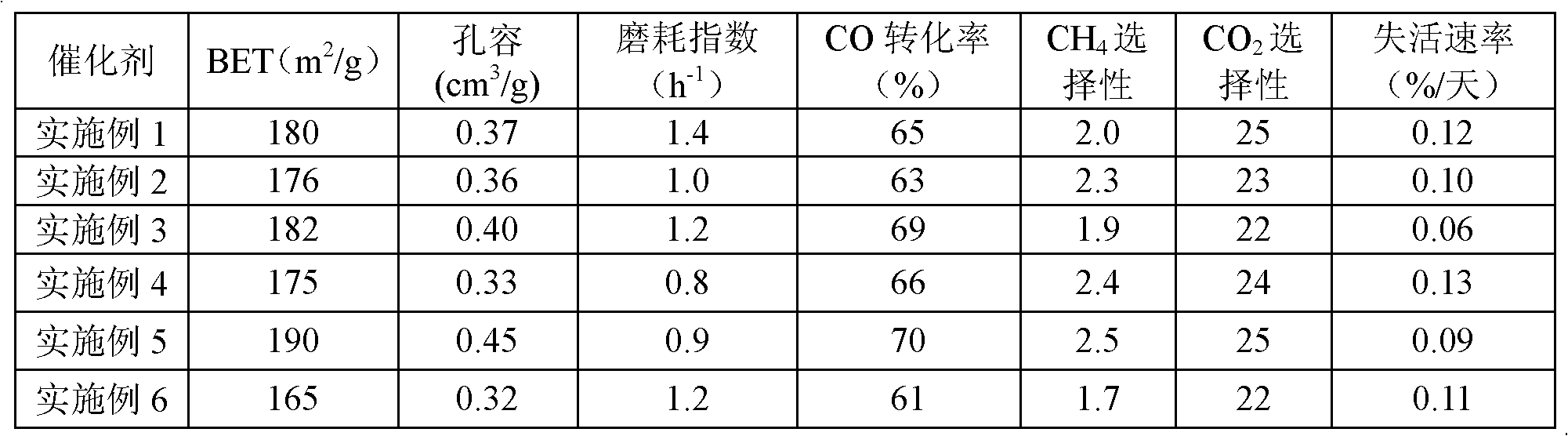

Fischer-Tropsch synthesis iron-based catalyst and preparation method thereof

ActiveCN102658148ALess distracting factorsHigh activityCatalyst activation/preparationLiquid hydrocarbon mixture productionIron saltsSoluble glass

The invention discloses a Fischer-Tropsch synthesis iron-based catalyst and a preparation method thereof. The preparation method comprises the following steps: 1, carrying out a coprecipitation reaction on an aqueous solution of an iron salt, a copper salt and a cobalt salt, and an aqueous solution of potash to obtain a precipitation slurry; 2, ageing the precipitation slurry, adding water, uniformly stirring, and concentrating to remove partial water; 3, adding potassium silicate soluble glass or a silicon sol to the concentrated precipitation slurry, uniformly stirring, and allowing the obtained mixture to stand for 0-180min; and 4, carrying out spray drying and roasting on the slurry obtained in step 3 to obtain the Fischer-Tropsch synthesis iron-based catalyst. The preparation method of the Fischer-Tropsch synthesis iron-based catalyst of the invention selects potash as a precipitating agent, and potassium is one component for composing the catalyst, so no impurity ions are introduced, the washing process is omitted, and a large amount of a water resource is saved; the preparation technology is simplified, so interference factors in the catalyst preparation process are reduced; and the atomic utilization rate of raw materials in the catalyst preparation process is improved.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Fly ash/bentonite ceramsite concrete hollow insulation block and preparation method thereof

ActiveCN103253906ALightweight and low densityCorrosion resistantSolid waste managementCeramicwareSoluble glassNano al2o3

The invention discloses a fly ash / bentonite ceramsite concrete hollow insulation block and a preparation method thereof. The block is prepared from the following raw materials by weight: 100 to 150 parts of ordinary Portland cement grade 42.5, 500 to 600 parts of stone chippings, 30 to 40 parts of fly ash, 10 to 15 parts of bentonite, 5 to 10 parts of paper pulp waste liquid, 2 to 4 parts of nanometer alumina, 3 to 6 parts of light calcium carbonate, 20 to 30 parts of soluble glass, 10 to 15 parts of straw powder, 4 to 6 parts of a foaming agent, 1 to 2 parts of foots, 2 to 3 parts of a glass fiber, 0.5 to 1.5 parts of a redispersible latex powder and 150 to 210 parts of water. The boron fly ash / bentonite ceramsite concrete hollow insulation block produced in the invention has the advantages of high strength, low density, good heat insulation performance, good impact resistance, small possibility of water absorption, fire resistance, flame retardation, good weatherability, environment-friendliness, energy conservation and the like and has great market space and development prospects in the application field of building energy conservation in China.

Owner:池州市新蕾绿色建材有限公司

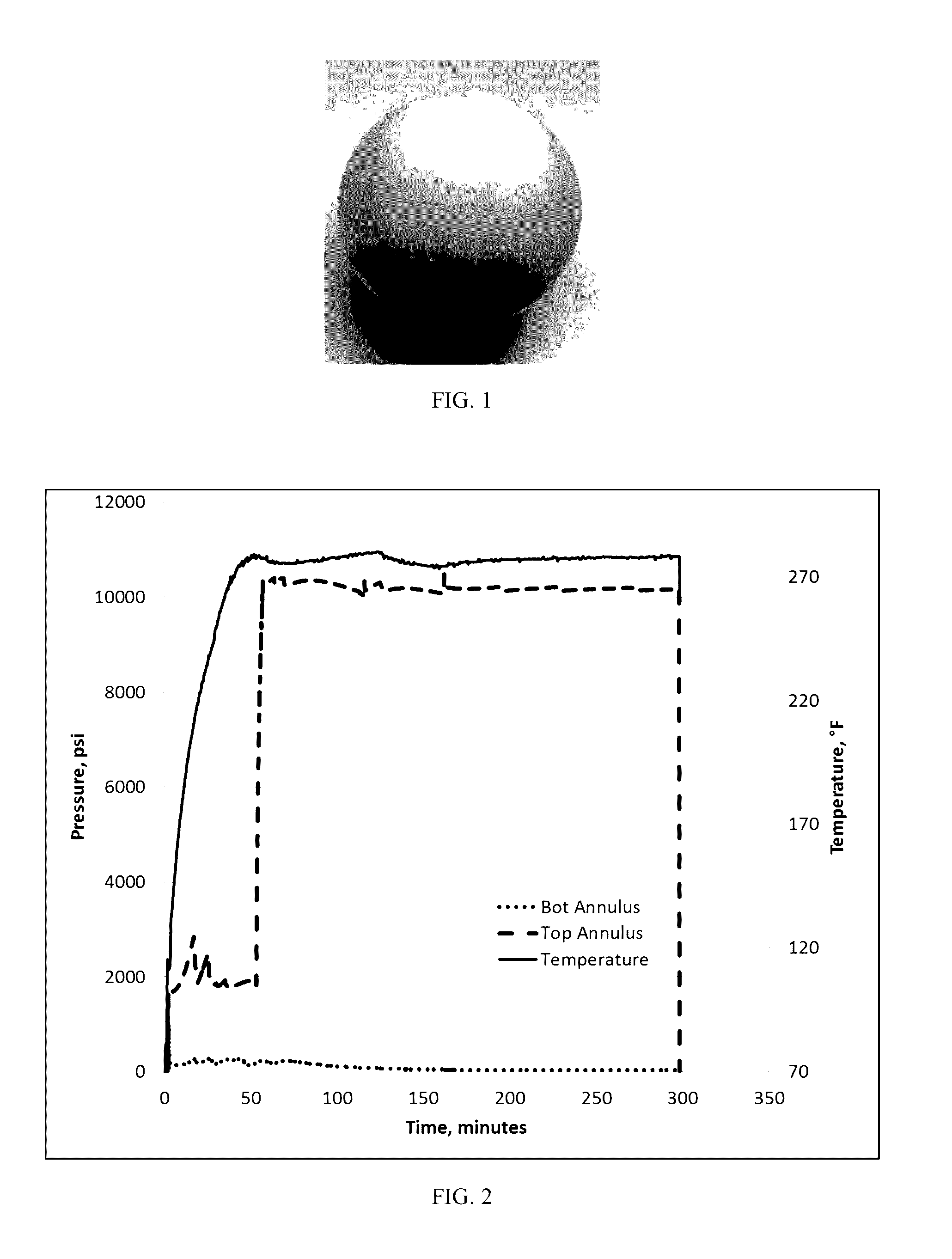

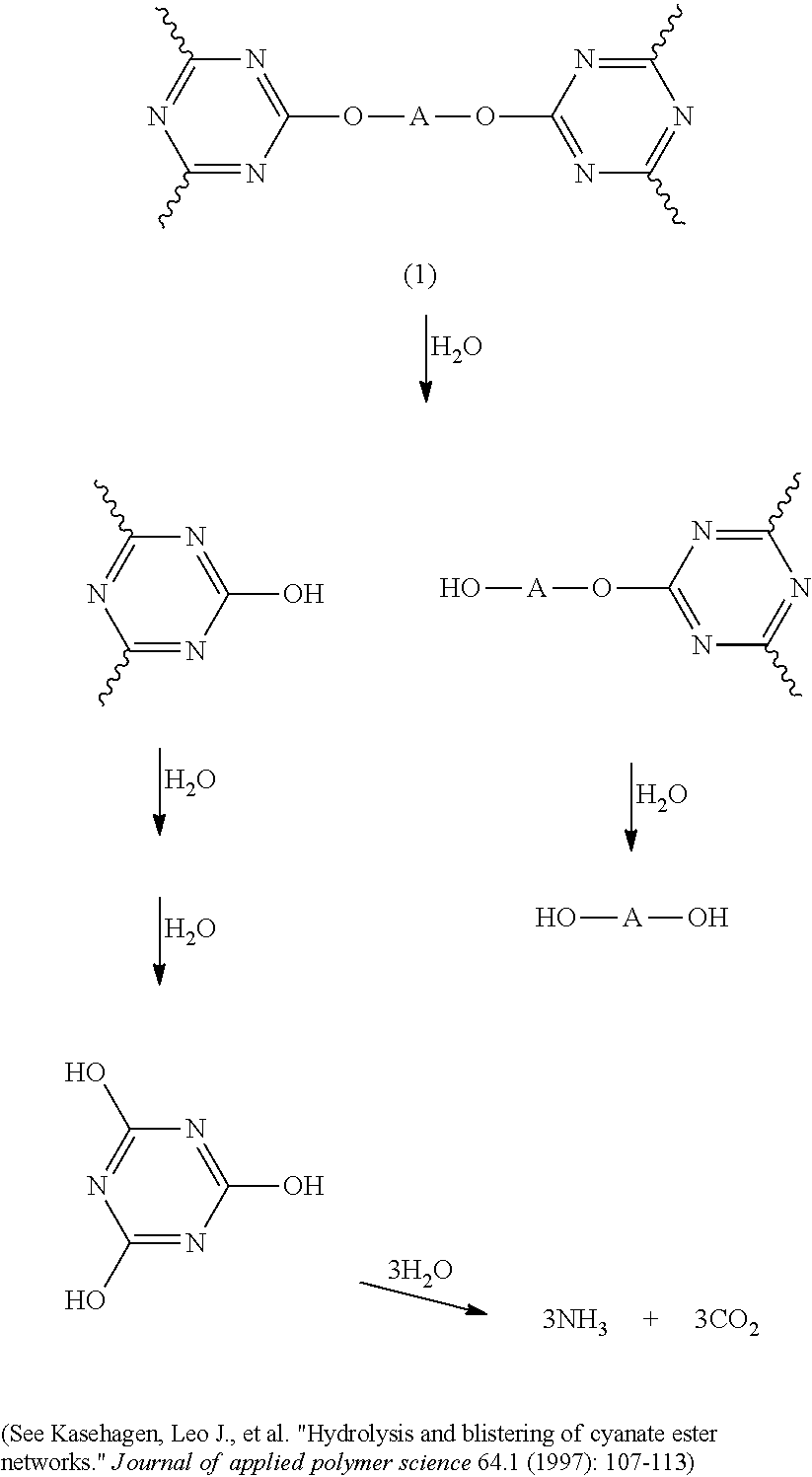

Disintegratable polymer composites for downhole tools

A disintegrable polymer composite comprises: a polymer component comprising one or more of the following: a cured cyanate ester; a crosslinked unsaturated polyester; or a crosslinked vinyl ester resin; and dissolvable glass comprising about 55 to about 80 wt. % of SiO2, 0 to about 35 wt. % of Na2O, 0 to about 35 wt. % of K2O, 0 to about 20 wt. % of CaO, 0 to about 10 wt. % of MgO, provided that the sum of the weights of Na2O and K2O is about 20 wt. % to about 40 wt. %, wherein each weight percent is based on the total weight of the dissolvable glass.

Owner:BAKER HUGHES INC

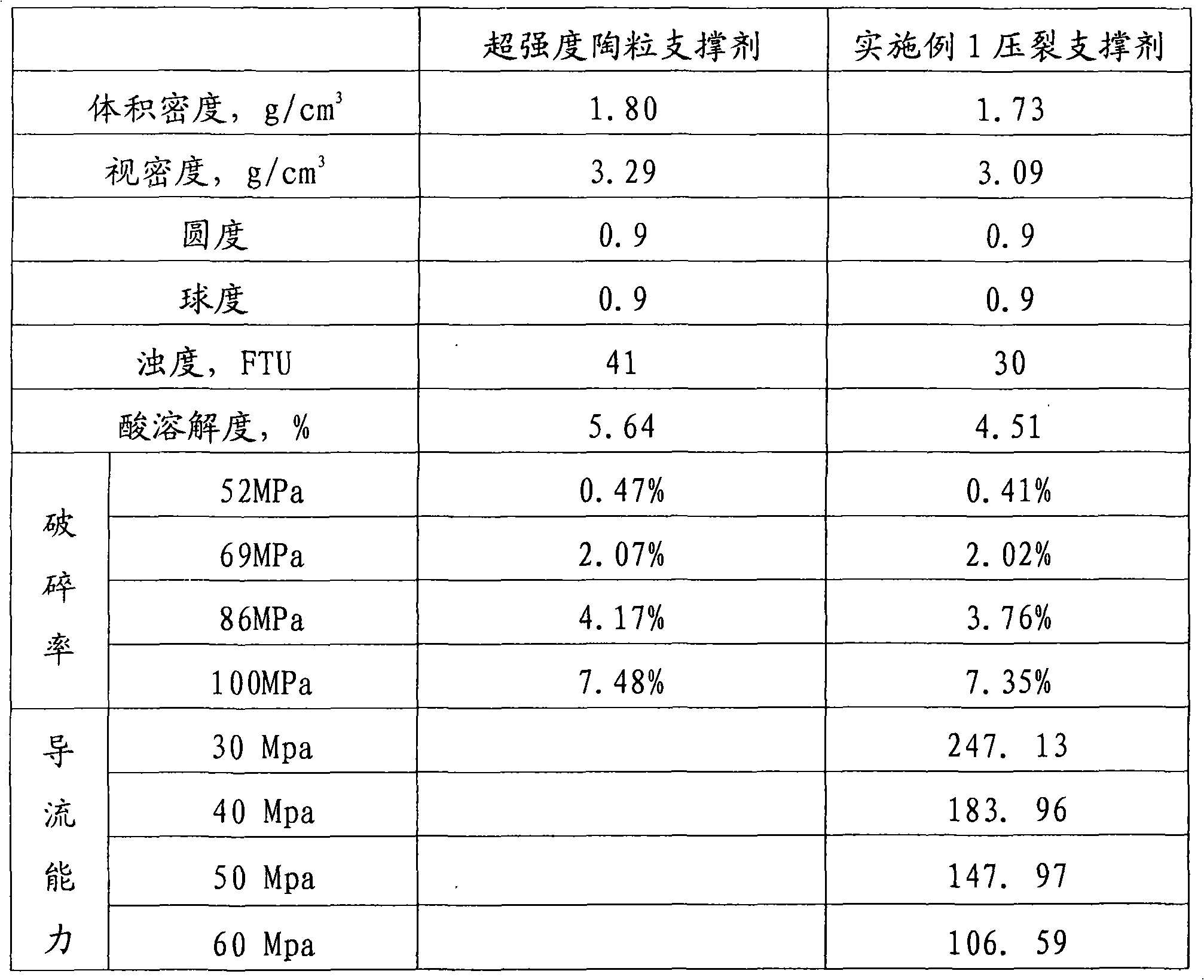

Fracturing propping agent for oil gas well and preparation method thereof

ActiveCN101270280AImprove product qualityHigh breakage resistanceFluid removalSoluble glassAcid corrosion

The invention relates to a fracturing proppant used for oil and gas wells, which is prepared with the following materials by weight: 80 to 88 portions of low content bauxite, 1 to 4 portions of manganese ore, 2 to 3 portions of potash feldspar, 2 to 4 portions of solid soluble glass, 1 to 5 portions of calcium mountain meal, and 1 to 5 portions of French chalk. The quality of the fracturing proppant is stable; the break resistance is high; the acid corrosion resistance is high; the volume density is low; the fracturing proppant can effectively prop up fracture, and significantly improve the permeability in the fracture so that oil and gas flow smoothly, and the oil productivity is improved. In addition, the raw materials and the preparation method are simple, and low requirements are proposed about the raw materials, and the fracturing proppant is prepared simply.

Owner:XINMI WANLI IND DEV

Steel slag-metakaolin compound gel material and preparation method thereof

Disclosed is a steel slag-metakaolin compound gel material which comprises steel slag, metakaolin, soluble glass solution, sodium sulfate, and sodium fluoride by the mass proportion of steel slag : metakaolin : soluble glass solution : Na2SO4 : NaF = 1:0.1-9:0.66-8:0.033-0.3:0.022-0.2.

Owner:WUHAN UNIV OF TECH

High temperature far infrared insulated energy-saving paint and method for preparing same

ActiveCN1844277AImprove general performanceImprove energy savingCellulose coatingsSoluble glassRare earth

The invention provides a high temperature far infrared insulation energy-saving coating material and its preparing process, wherein the coating material comprises zircon sand, aluminium oxide, porcelain clay, rare-earth oxide, boron nitride, silicasol, phosphoric acid, soluble glass, cellulose methyl or cellulose glycolate. The preparing process consists of batching, immersing, agitating, mixing, filtering and loading.

Owner:娄底市华晟节能材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com