Patents

Literature

110results about How to "Synthetic safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

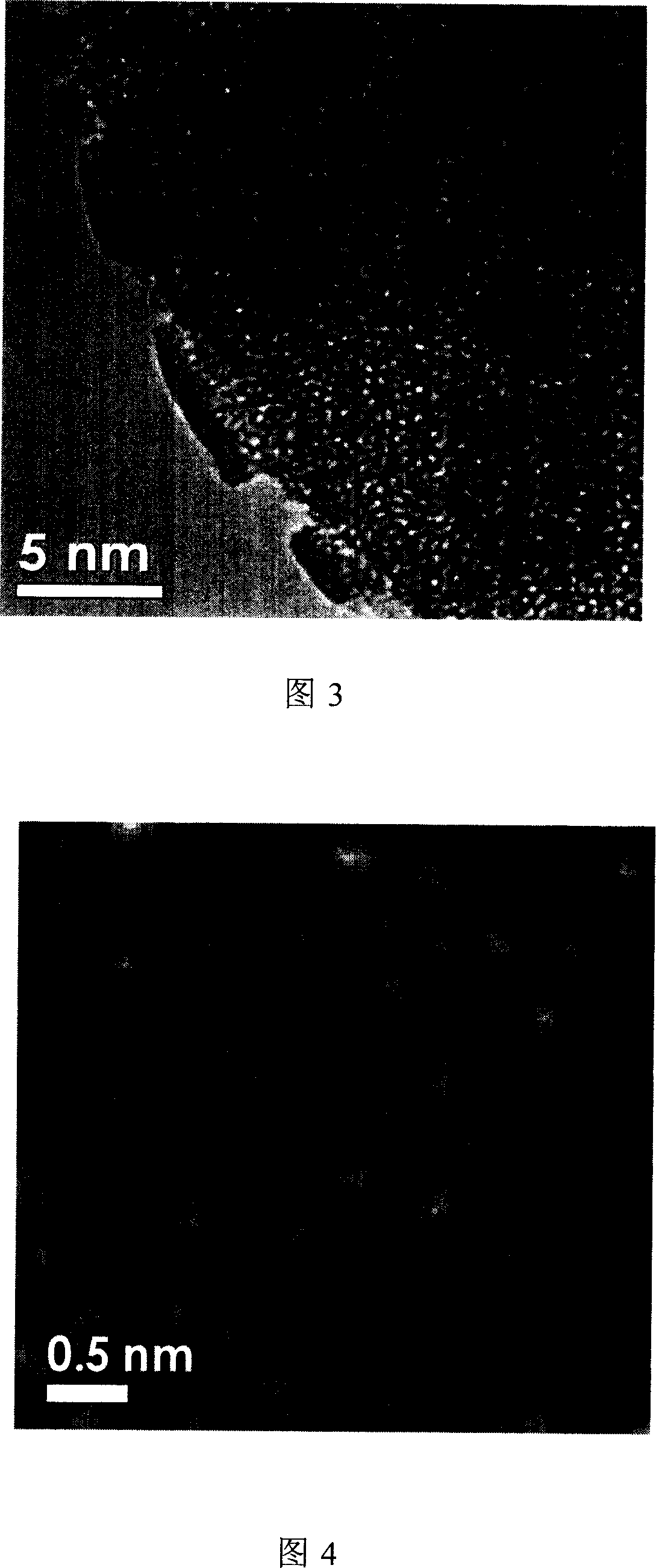

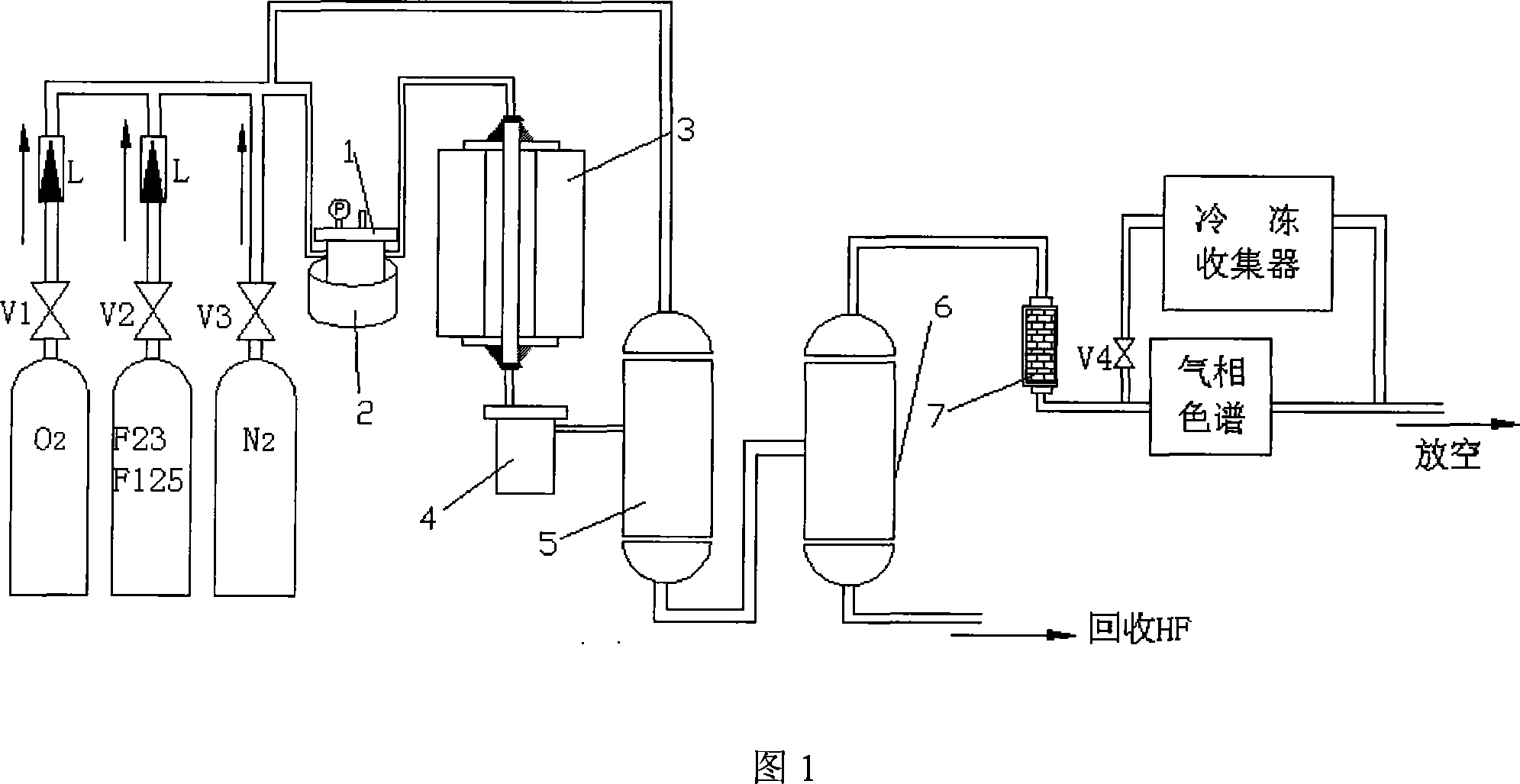

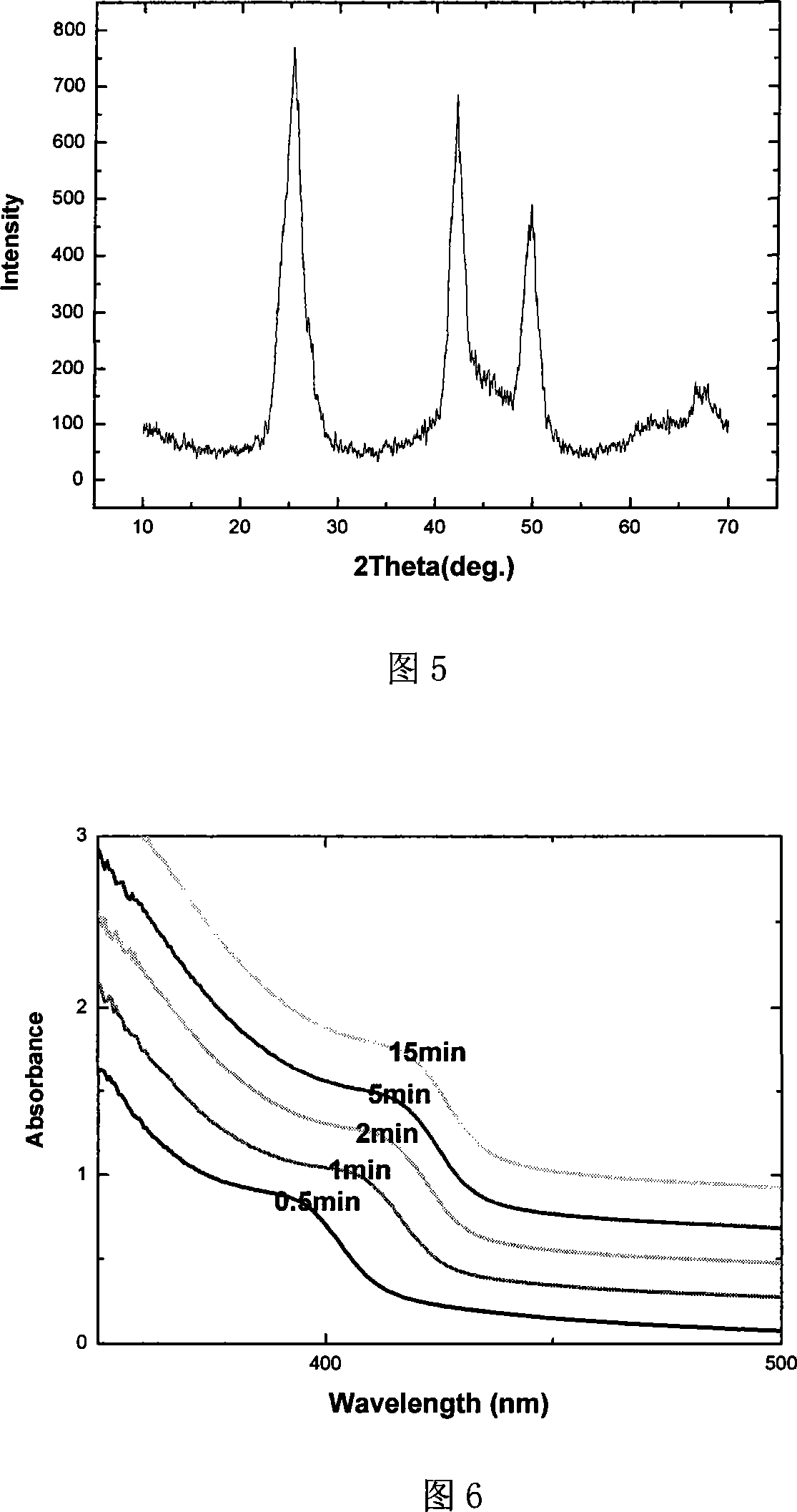

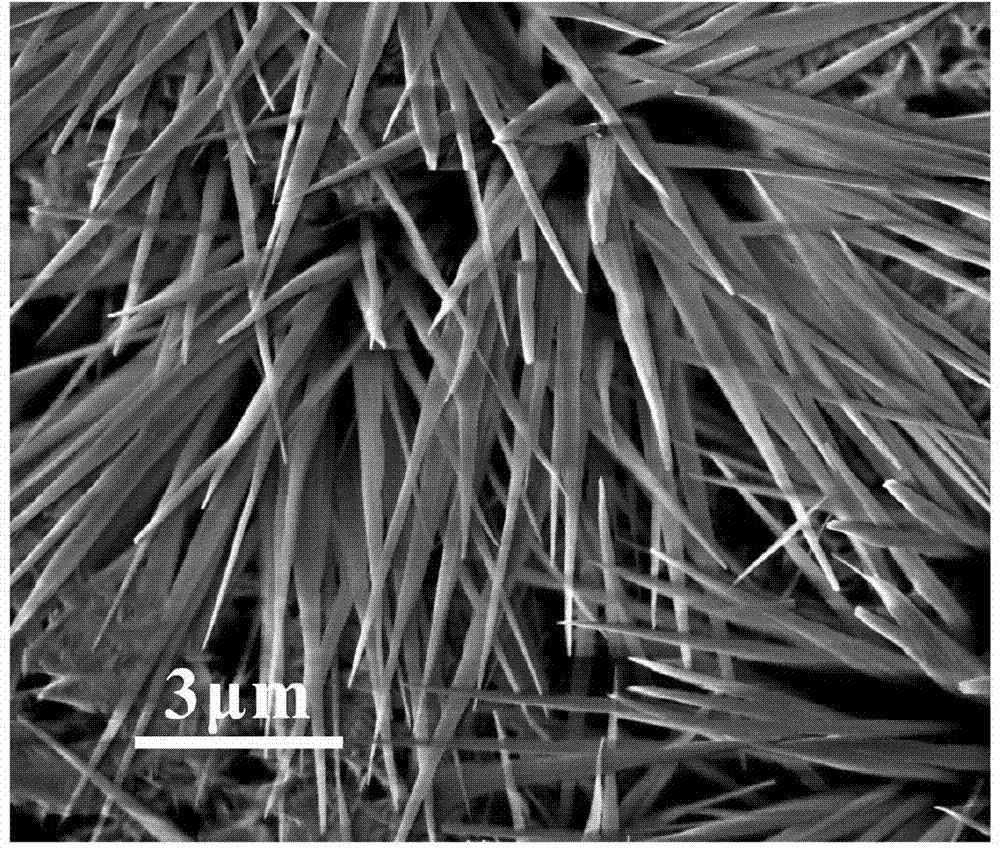

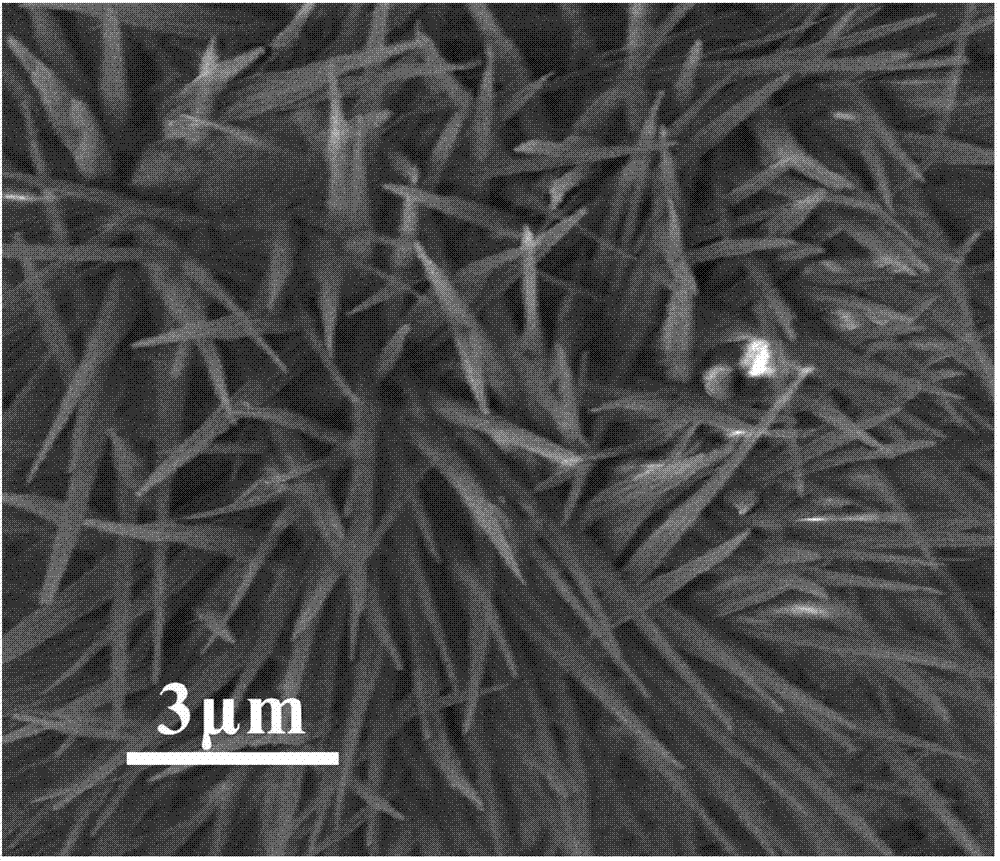

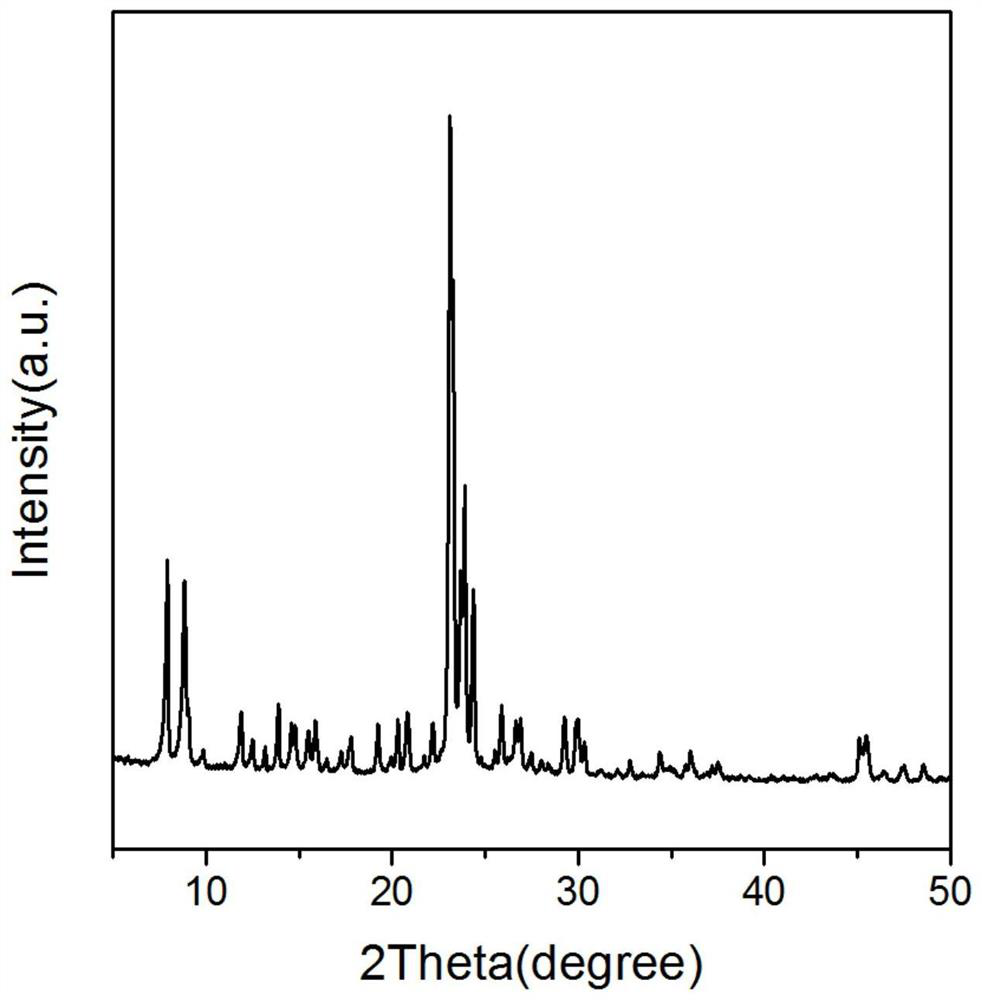

Method for preparing nano Fe-ZSM-5 zeolite molecular sieve

InactiveCN101121526ASynthetic safetyEasy to synthesizeNanostructure manufactureMolecular sieve catalystsSoluble glassPetrochemical

The present invention relates to the technical field of a zeolite molecular sieve synthesis, concretely speaking, relating to a preparation method of a zeolite molecular sieve of a nano heteroatom. A sodium silicate or a soluble glass, an inorganic acid, an inorganic ferric salt, an organic amine and deionized water serve as the material. After the steps of liquor preparation, two variable temperature crystallizations, washing-up centrifugalization, drying and roasting, the zeolite molecular sieve of nano Fe-ZSM-5 is produced with a grain size less than 100nm. The present invention can be used in the petrochemical industry, fine chemical industry and the environmental protection field.

Owner:CHINA PETROLEUM & CHEM CORP +1

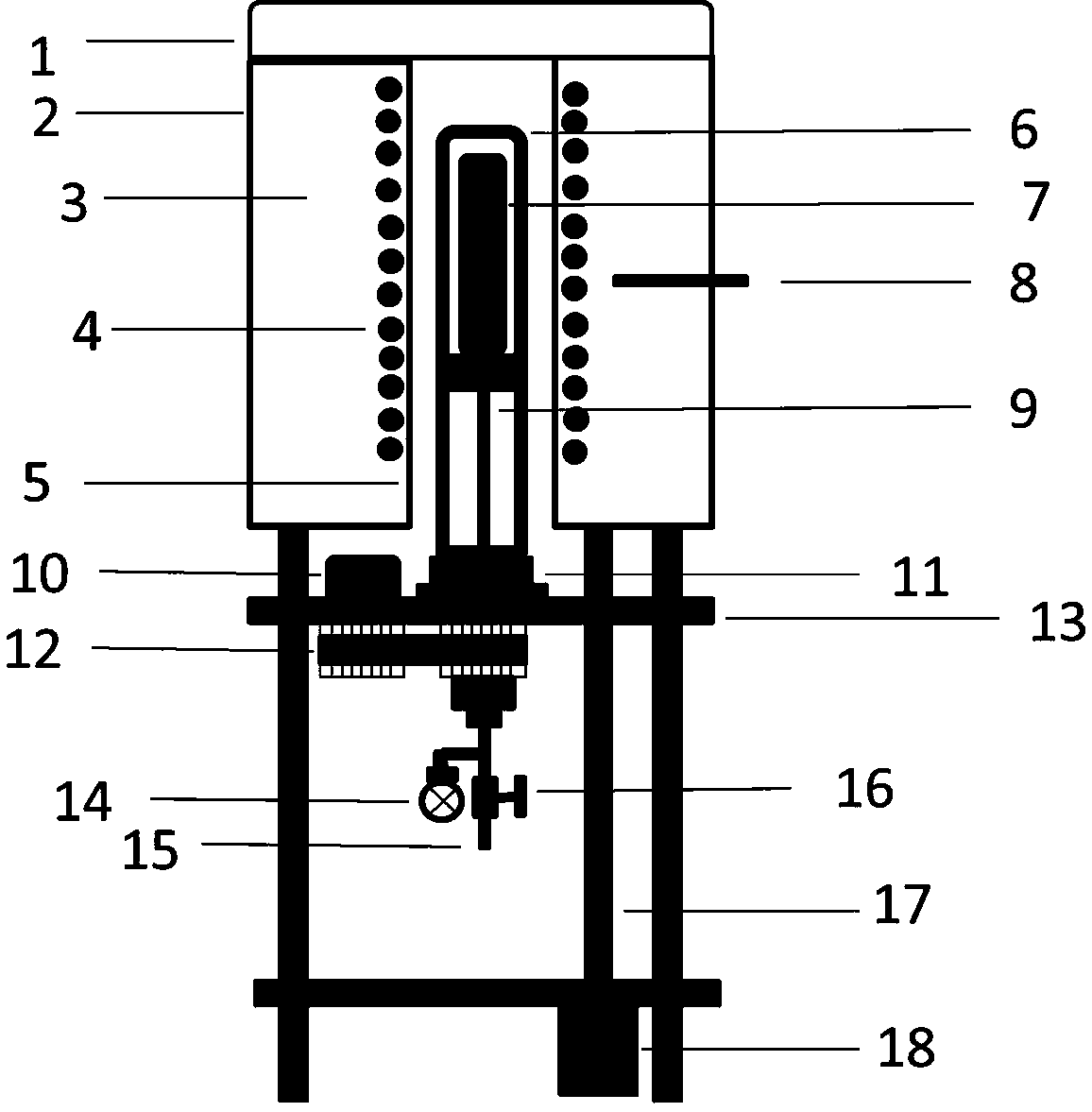

Method for synthesizing trifluoroiodomethane and pentafluoroethyliodide meanwhile

ActiveCN101219925AConvenient sourceImprove stabilityHalogenated hydrocarbon preparationChemical synthesisAlkaline earth metal

The invention relates to a method of synthesizing CF_3I and C2F5I simultaneously, which belongs to the filed of organic chemical synthesis. The method of synthesizing CF_3I and C2F5I simultaneously is characterized in that a alkali metal salt, a alkali earth metal salts or / and a copper salt are taken as a catalyst to be attached to a porous carrier; an oxygen or mixed gas of oxygen and an inert gas is pumped; a CHF3 and / or a HFC_125 are taken as a raw material; an iodine is taken as an iodinating agent; then iodination occurs in a reactor under high temperature to generate the C2F5I and the CF_3I. The porous carrier is a fluoride or an oxyfluoride. The raw material of the invention is nontoxic and is convenient to get; the catalyst does not react with a reaction medium and has good stability. The synthesis process is safe and suitable for technical production.

Owner:泉州宇极新材料科技有限公司

Method for synthesizing hexafluoro-1,3-butadiene

ActiveCN104844411ASave raw materialsConvenient sourceChemical recyclingHalogenated hydrocarbon preparationChemical synthesisHydrogen fluoride

The invention relates to a method for synthesizing hexafluoro-1,3-butadiene, and belongs to the field of organic chemistry synthesis. The method for synthesizing hexafluoro-1,3-butadiene comprises the following steps: removing hydrogen fluoride from tetrafluoro ethane (HFC-134a) under the action of a catalyst to generate trifluoroethylene; rapidly reacting trifluoroethylene with liquid bromine to generate 1,2-dibromo-1,1,2-trifluoroethane, and removing hydrogen bromide under alkaline conditions to obtain trifluorobromoethylene; and reacting trifluorobromoethylene with activated zinc powder and N,N-dimethyl formamide to generate trifluorovinylzinc, and carrying out a coupling reaction on trifluorovinylzinc under the action of Fe<3+> to generate hexafluoro-1,3-butadiene. A solvent can be recovered after above reactions. The method has the advantages of low price and convenient source of raw materials, good stability and long service of the catalyst, simple separation and purification of the above product, and easy industrial production.

Owner:泉州宇极新材料科技有限公司

Device and method capable of increasing synthesizing stability of cadmium zinc telluride polycrystals

ActiveCN107904662AReduce pressure difference between inside and outsideAvoid explosive situationsPolycrystalline material growthSingle crystal growth detailsShielding gasCadmium zinc telluride

The invention discloses a device and method capable of increasing the synthesizing stability of cadmium zinc telluride polycrystals and aims to solve the problem that quartz tube explosion occurs easily during the synthesizing of cadmium zinc telluride, and the tube cracking accident is caused. The device and method is characterized in that protective gas is filled into a pressure-maintaining inner container, the internal and external pressure difference of a quartz crucible is balanced or lowered by regulating the gas filling pressure in the pressure-maintaining inner container, raw materialreaction rate is controlled by crystal material distribution, temperature gradient setting or furnace tube ascending and descending, and crystal growth is performed through the temperature gradient setting and the furnace tube ascending and descending. The device and method has the advantages that crucible explosion can be avoided effectively, reaction conditions are mild, phenomena such as tube cracking are avoided effectively, corresponding preparation requirements can be satisfied, and the device and method is promising in application prospect.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Composite metal product of carbon nano material and low melting point metal and method of producing the same

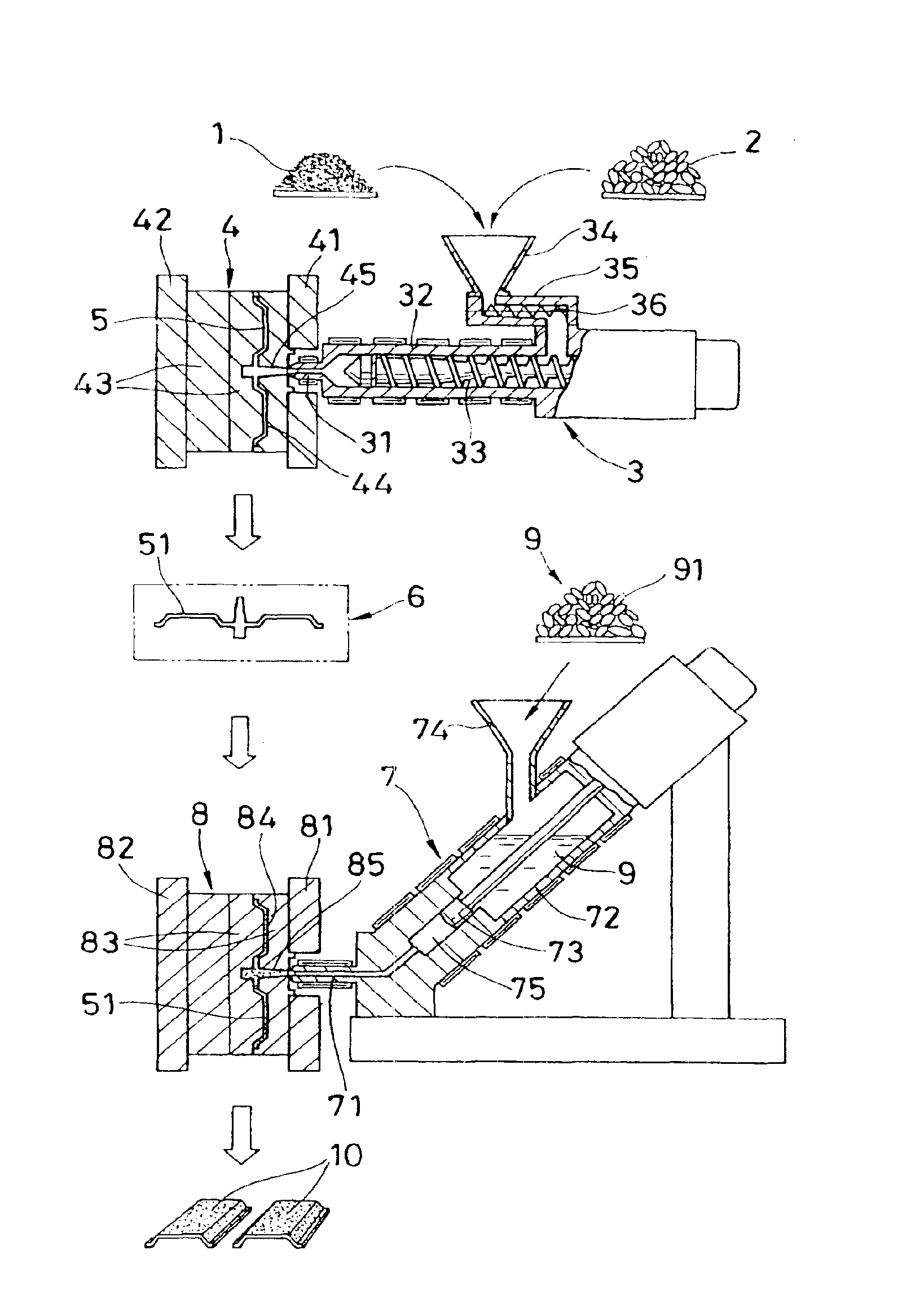

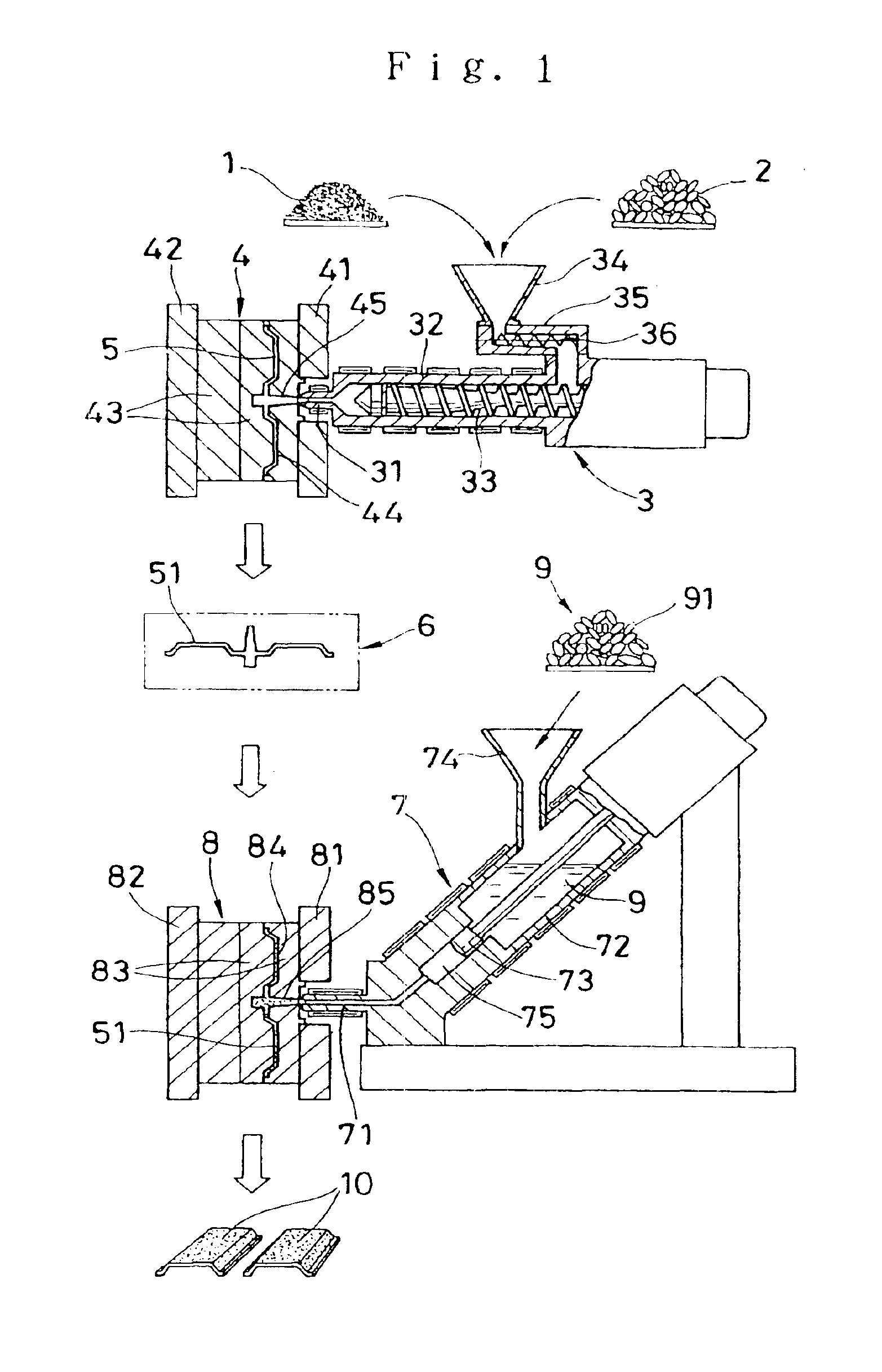

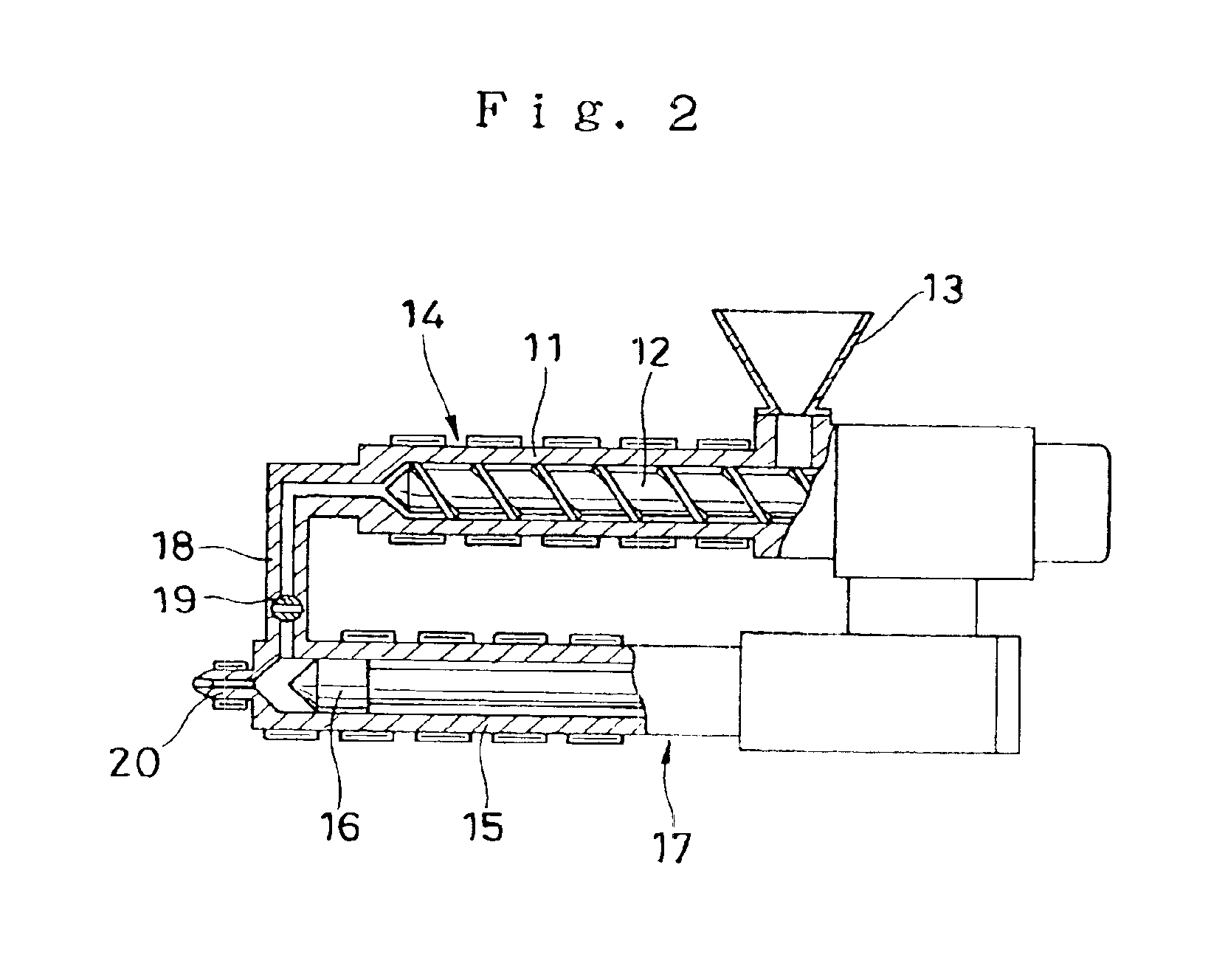

InactiveUS6874563B2Synthetic safetyLow melting pointGearingCylindersInjection pressureCarbon nanomaterials

A carbon nano material and a resin binder are plasticized and injection molded to form a preliminarily molded member. The preliminarily molded member is degreased by a heat treatment and made to a preliminarily molded porous member composed of the carbon nano material. The preliminarily molded porous member is inserted into a cavity of a product mold. A molten low melting point metal is injected into and fills the cavity. The preliminarily molded porous member is impregnated with the low melting point metal by injection pressure, thereby a composite metal product composed of the low melting point metal material integrally composited with the carbon nano material is molded. With the above arrangement, the characteristics of the carbon nano material are applied to the composite metal product to improve the functions thereof.

Owner:NISSEI PLASTIC IND CO LTD

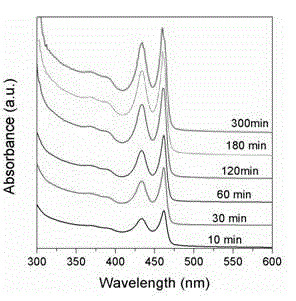

Selenium precursor fluid and method for preparing cadmium selenide or zinc selenide quantum dots by using the same

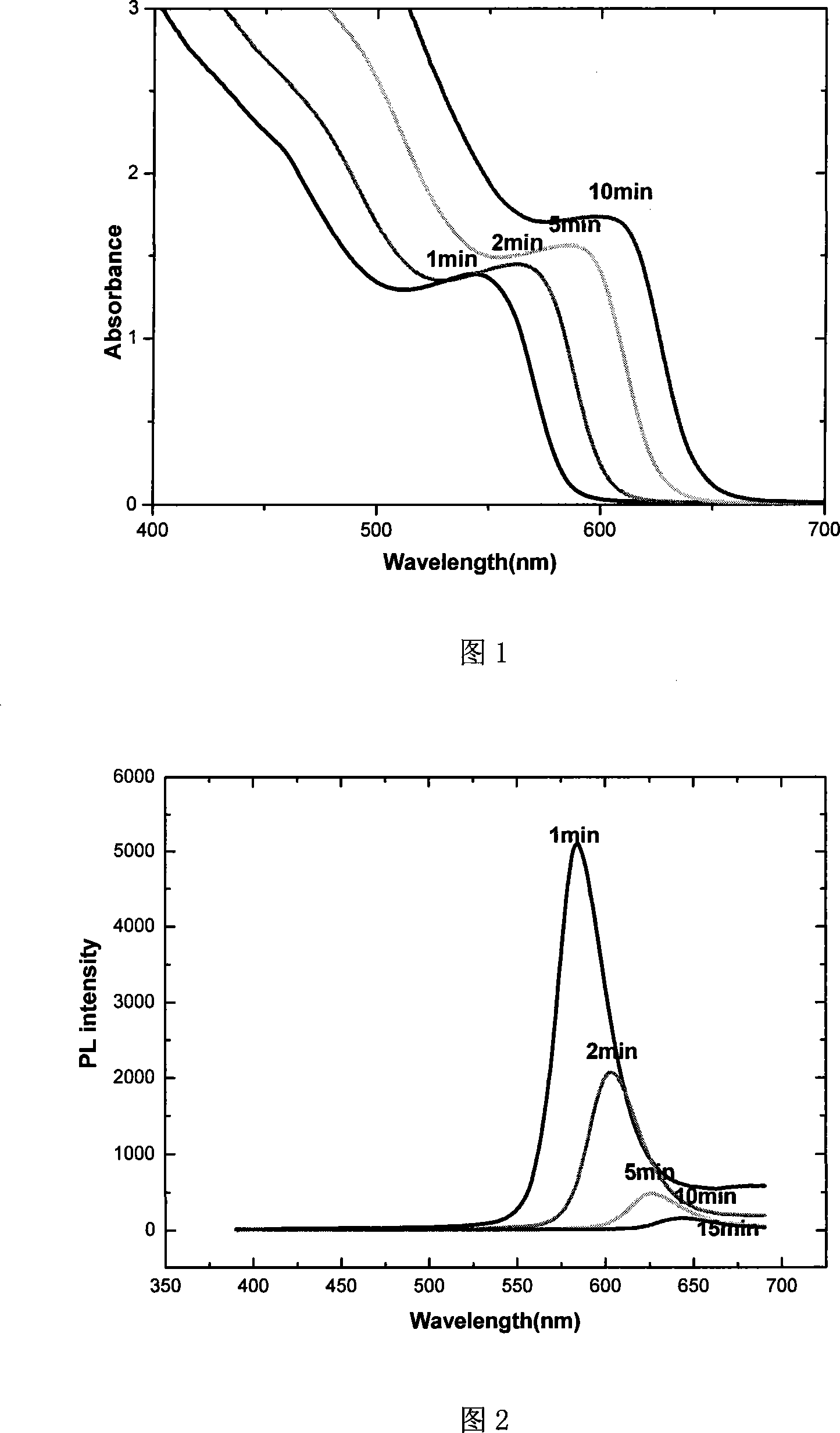

InactiveCN101186825ANarrow size distributionGood monodispersityLuminescent compositionsZinc selenideMorpholine

Provided is a selenium precursor liquid which is achieved by the preparation of heating and dissolving the elemental selenium in oleoyl morpholine under the protection of inert gas. The process for the preparation of cadmium selenide or zinc selenide quantum dots with the selenium precursor liquid is to generate pyrolytic reaction by stirring and mixing the selenium precursor liquid and fatty acid cadmium or fatty acid zincum precursor liquid under the protection of inert gas at a temperature of 150 DEG C to 330 DEG C, and the last is to separate and purify the mixture with low carbon alcohols. The dissolving capacity of the oleoyl morpholine for the elemental selenium is strong, the compatibility of the oleoyl morpholine with other green common solvents is perfect, which can increase the volume productivity of selenide nanocrystalline, thereby achieving quantum dots with relatively narrower size and higher quality.

Owner:HEFEI UNIV OF TECH

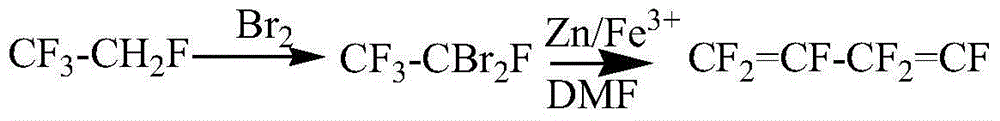

Method for synthesizing hexafluoro-1,3-butadiene

ActiveCN104829415AEasy to separateHigh yieldChemical recyclingHalogenated hydrocarbon preparationChemical synthesisGas phase

The invention relates to a method for synthesizing hexafluoro-1,3-butadiene, and belongs to the field of organic chemistry synthesis. The method comprises the following steps: carrying out gas phase bromination on tetrafluoroethane HFC-134a to generate dibromotetrafluoroethane CF3CBr2F, and carrying out a coupling reaction on dibromotetrafluoroethane, activated zinc powder and N,N-dimethyl formamide under the action of Fe<3+> to generate hexafluoro-1,3-butadiene. A solvent after the above reactions can be recycled. The method has the advantages of low price and convenient source of raw materials, high product yield, simple separation and purification of the above product, and easy industrial production.

Owner:泉州宇极新材料科技有限公司

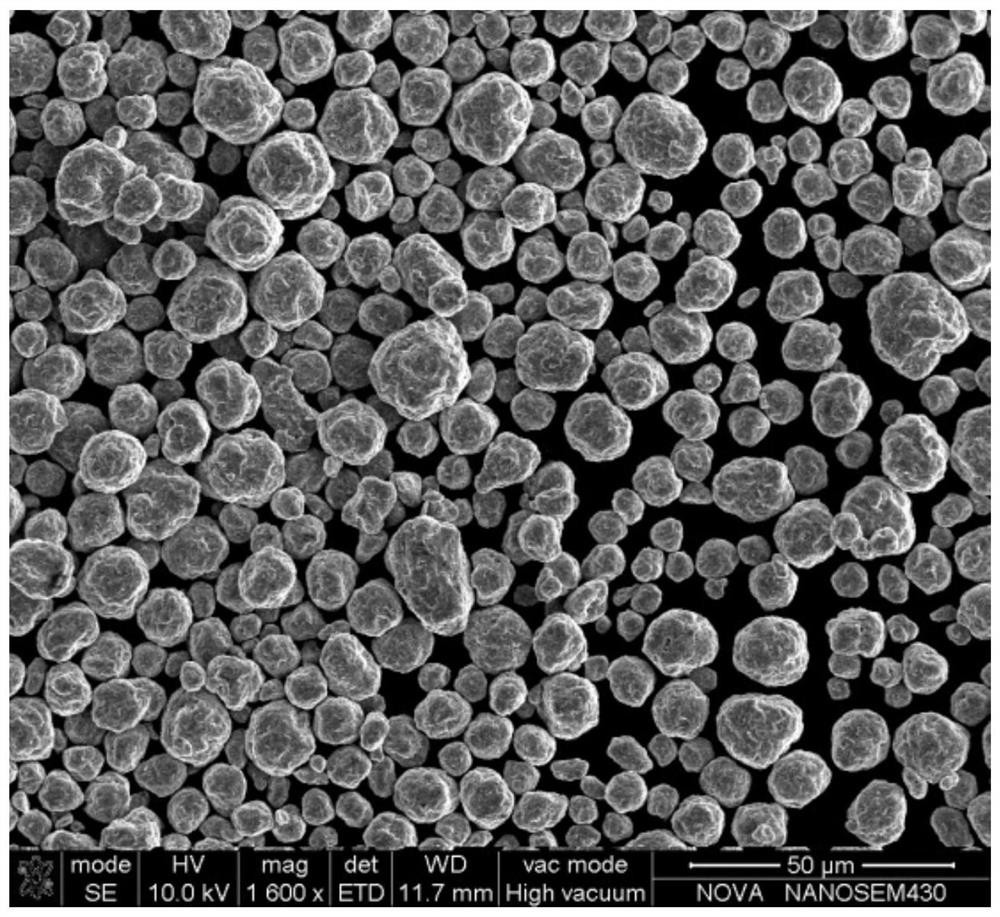

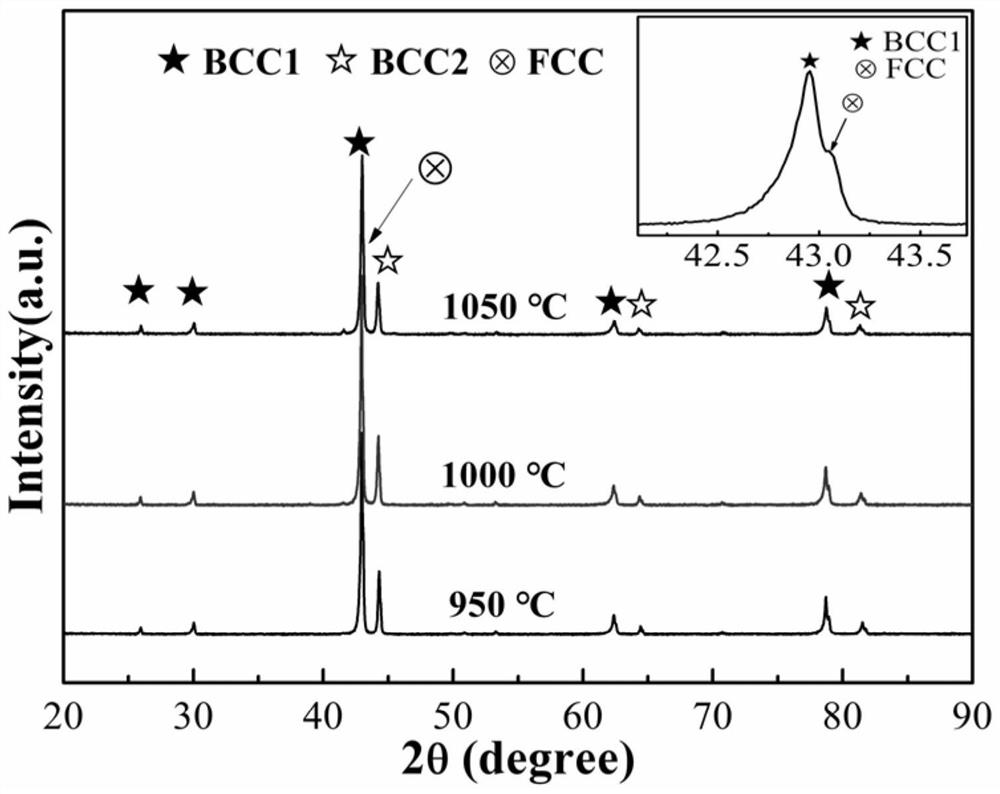

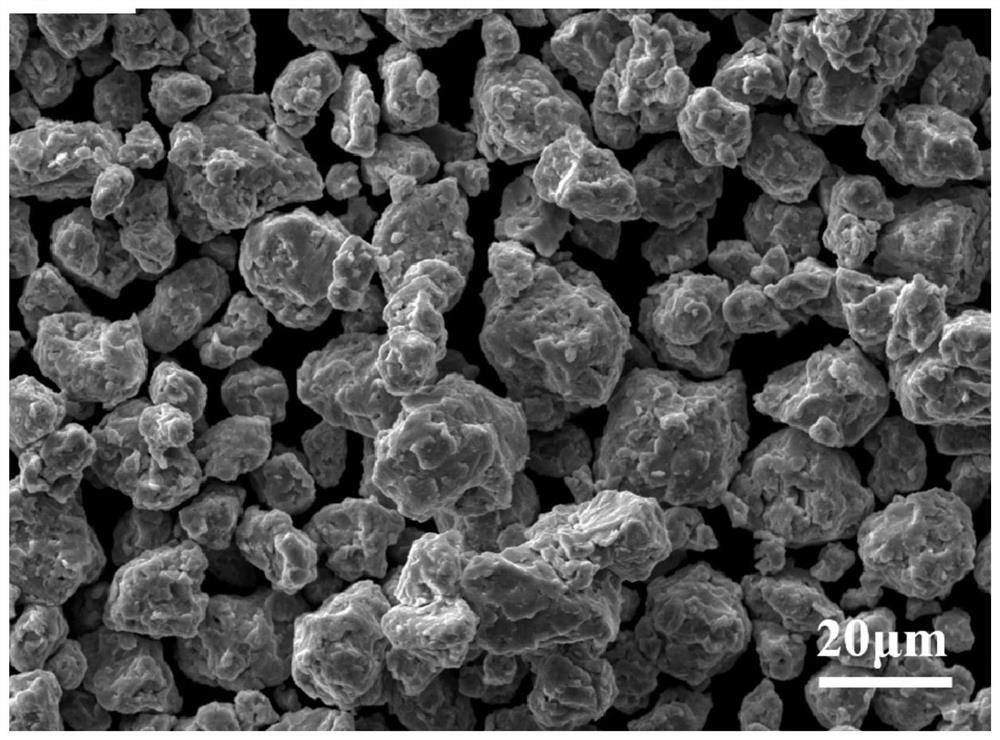

Low-density biphase high-entropy alloy powder suitable for 3DP technology and preparation method of low-density biphase high-entropy alloy powder

InactiveCN112692275ALow densityAdjustable densityAdditive manufacturing apparatusHigh entropy alloysLow density

The invention discloses low-density biphase high-entropy alloy powder suitable for a 3DP technology and a preparation method of the low-density biphase high-entropy alloy powder. The alloy powder comprises, in molar ratio, 0-30% of Al, 0-30% of Ti, 0-20% of V, 0-20% of Cr, 0-30% of Mg, 0-20% of Ni, 0-20% of Cu, 0-30% of Si and 0-30% of B. The method comprises the steps that the above element powder is uniformly mixed to obtain mixed powder; and ball milling is conducted, screening is conducted under vacuum, powder with the particle size being 10-100 micrometers is taken, and the low-density biphase high-entropy alloy powder suitable for the 3DP technology is obtained. The high-entropy alloy material has an FCC / BCC or FCC / HCP biphase structure, has high strength and high hardness, also has good plasticity of an FCC structure and is suitable for being used for 3DP.

Owner:SOUTH CHINA UNIV OF TECH

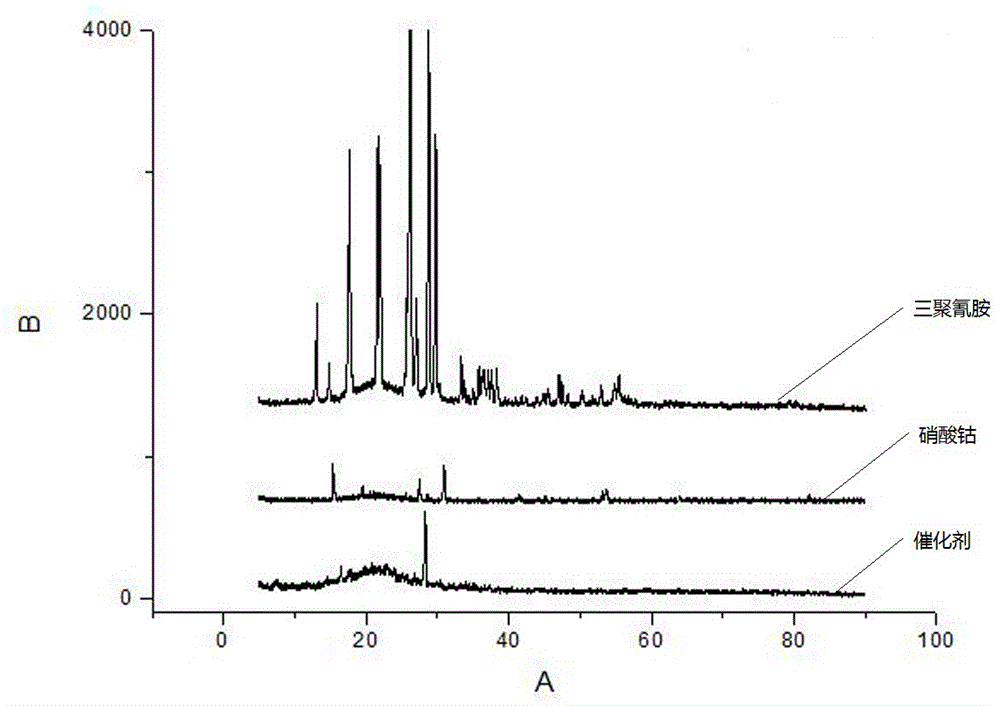

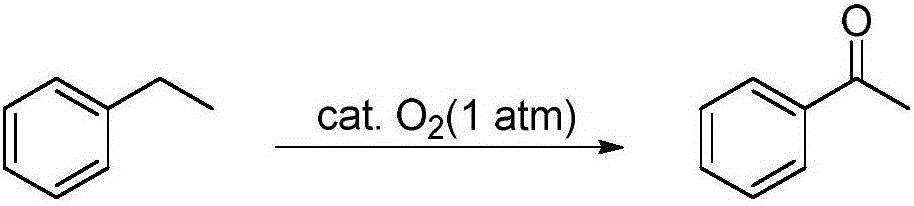

Co-N-C catalyst, and preparation method and applications thereof

ActiveCN106391082AEasy to synthesizeSynthetic safetyOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsRoom temperatureCobalt salt

The invention discloses a Co-N-C catalyst. According to a preparation method of the Co-N-C catalyst, the Co-N-C catalyst is prepared at room temperature via grinding, or ball milling, or grinding-sintering of a cyanamide compound and a cobalt salt at a mass ratio of (1-20):1. The invention also discloses applications of the Co-N-C catalyst. In applications, the Co-N-C catalyst is mainly used for selective oxidation of the benzyl positions of aromatic hydrocarbons and the allyl position C-H bonds of olefins. The synthesis process of the Co-N-C catalyst is simple, is easy to control, and is safe; and at the same time, coordination of the cyanamide compound with the cobalt salt is firm, the cost of metal Co is relatively low, requirements on equipment used in catalyst synthesis are simple, the equipment is easily available; efficiency is high; no additive is added; no solvent is added; conditions of the Co-N-C catalyst in application process are mild; and cycling performance is excellent.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Phenolic resin for environment-friendly thermoplastic refractory material and preparation method thereof

The invention relates to phenolic resin for an environment-friendly thermoplastic refractory material and a preparation method thereof, and the material comprises the following components: 100 parts of phenol, 20-25 parts of solid paraformaldehyde, 0.2-0.4 part of acid catalyst, 0.2-2.0 part of alkaline solution and 20-30 parts of solvent. The phenol and the acid catalyst are added into a reactor, the temperature is raised to 90 DEG C, then all the solid paraformaldehyde is slowly and completely added into the reactor within 2.5-3.5 hours, and the solution temperature is controlled to be 90-108 DEG C; after the solid paraformaldehyde is added completely, the solution temperature is controlled to be 95-110 DEG C, and then the constant temperature is kept for 3-4 hours for performing phenolic aldehyde polycondensation reaction; after the reaction is finished, the alkaline solution is further added into the solution, and the pH value of the solution is regulated to 6.5-7.5; and a solvent is simultaneously added into the solution, and the phenolic resin for the refractory material is finally obtained. The production process is safe and reliable, vacuum dehydration is unnecessary, sewage discharge can be avoided, an ecological environment can be protected, and the production efficiency can be improved.

Owner:JINAN LUDONG REFRACTORY CO LTD

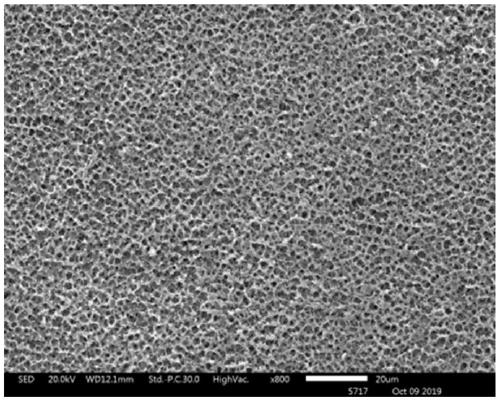

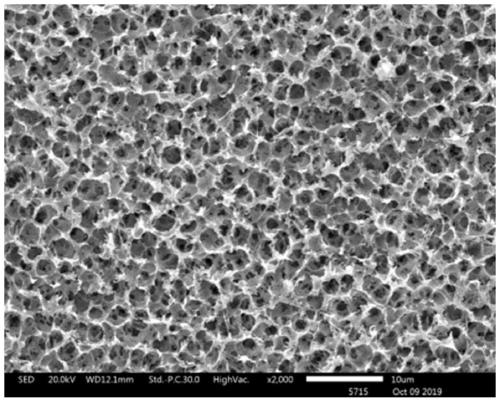

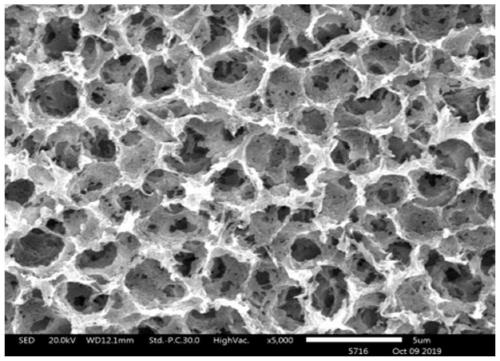

Polyvinyl alcohol-ethylene copolymer honeycomb porous membrane and preparation method thereof

ActiveCN111346522AImprove controllabilityImprove uniformitySemi-permeable membranesMembranesPolyvinyl alcoholPorous membrane

The invention provides a polyvinyl alcohol-ethylene copolymer honeycomb porous membrane and a preparation method thereof. The preparation method comprises the following steps: firstly, a polyvinyl alcohol-ethylene copolymer is dissolved in a mixed solvent of isopropanol and water in a mass ratio of (1: 2)-(2: 1) to prepare a polyvinyl alcohol-ethylene copolymer solution with the mass fraction of 7%-12%; then, after a polyvinyl alcohol-ethylene copolymer film is prepared through spin coating, heat treatment is conducted at the temperature 1 to 10 DEG C lower than the boiling point of an azeotrope of isopropanol and water, a solvent phase is removed, and a honeycomb-shaped porous film is formed; and finally, annealing treatment is carried out to obtain the polyvinyl alcohol-ethylene copolymer honeycomb porous membrane. The molecular chain of the selected polyvinyl alcohol-ethylene copolymer comprises a hydrophilic polyvinyl alcohol chain segment and a hydrophobic polyethylene chain segment, and the honeycomb porous membrane with uniform distribution, small pore diameter and uniform pore diameter is prepared through multi-stage solvent volatilization by utilizing the difference of solubility and boiling points of isopropanol and water on the polyvinyl alcohol-ethylene copolymer.

Owner:武汉维晨科技有限公司

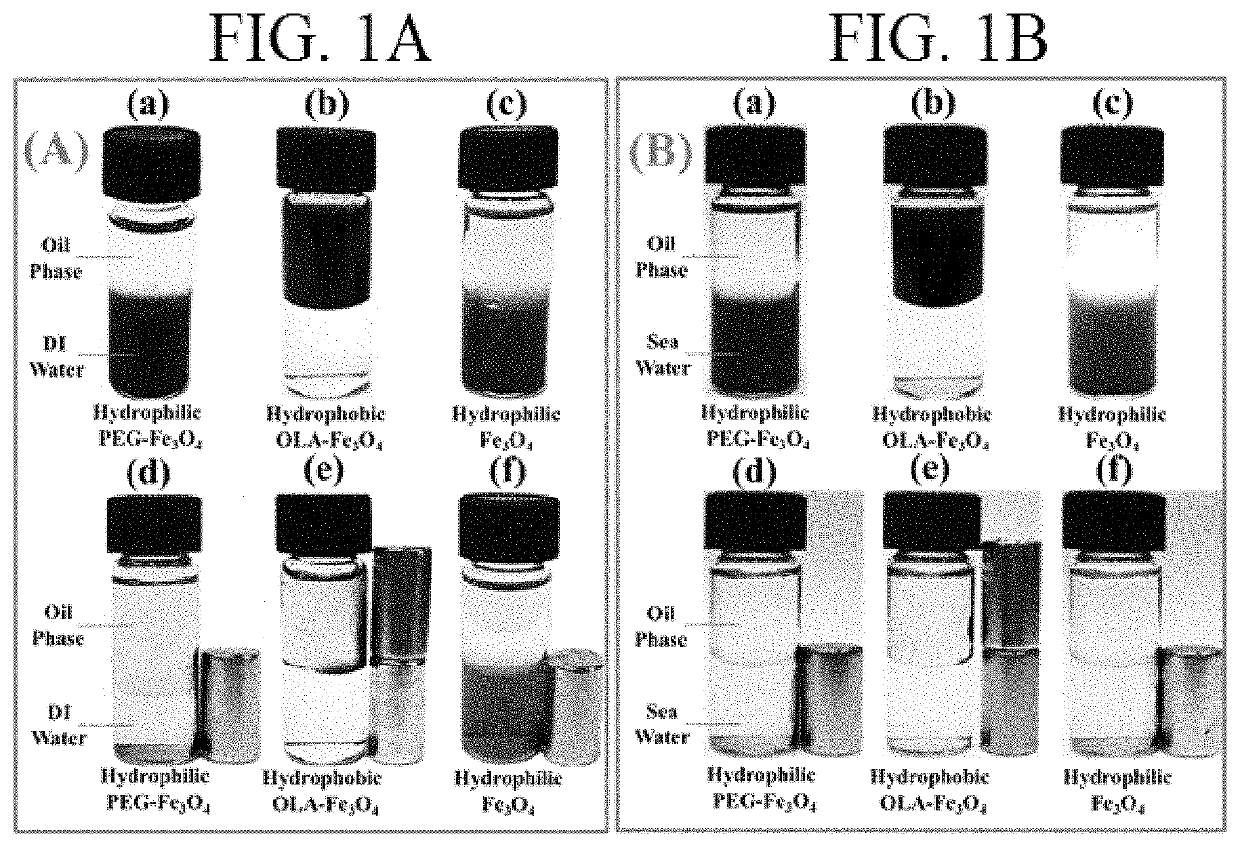

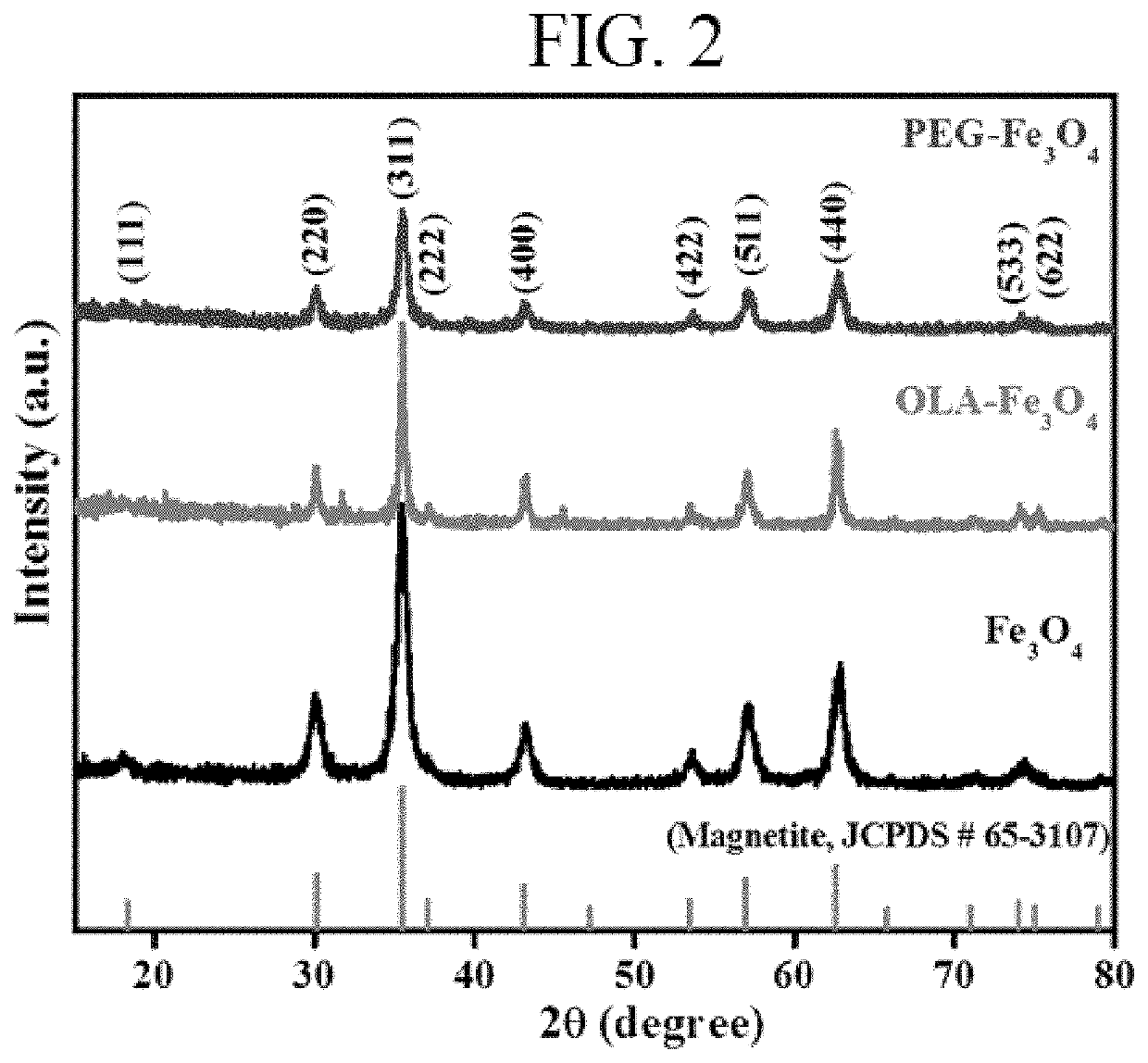

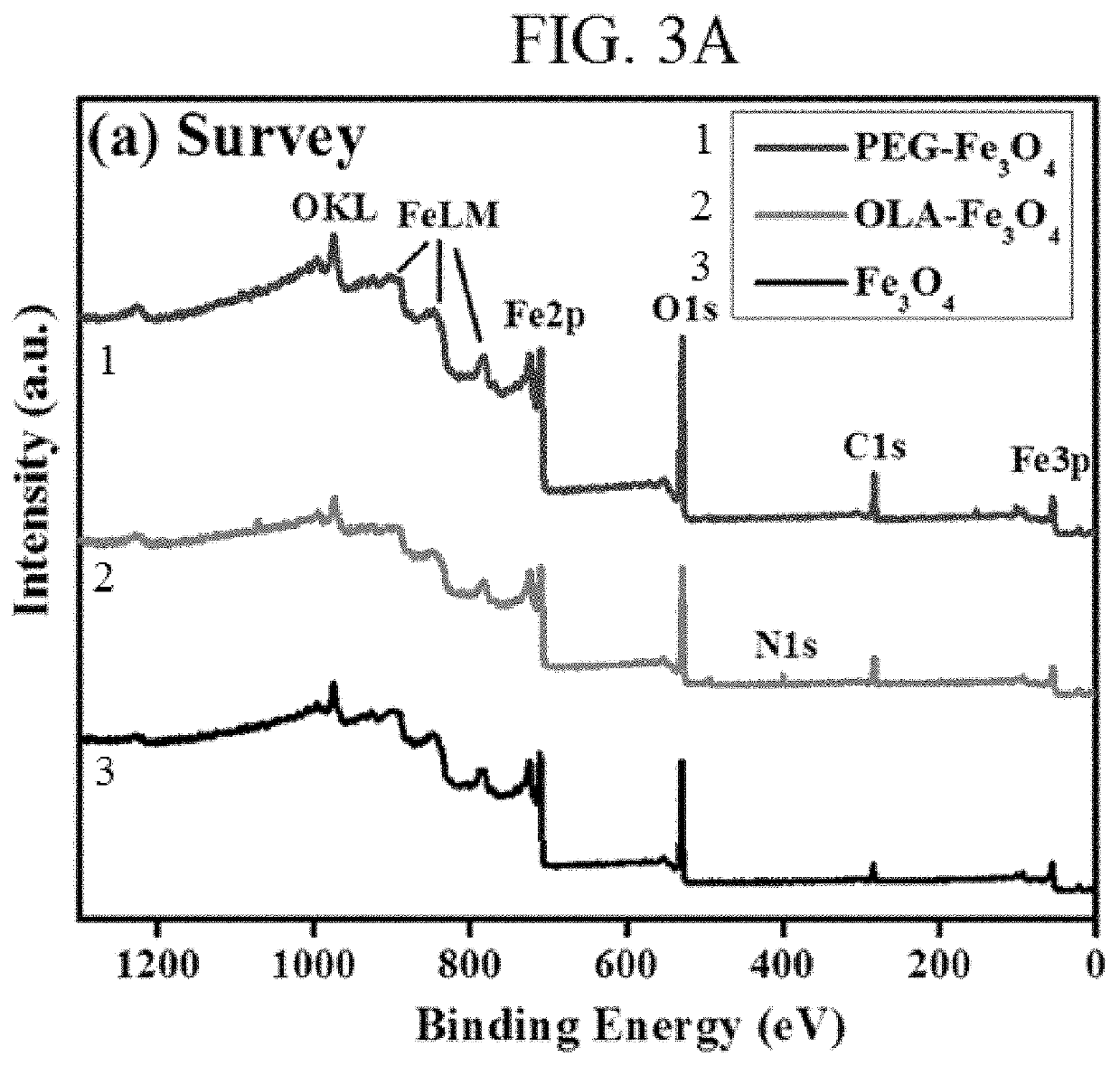

Hydrophilic and hydrophobic superparamagnetic fe3o4 nanoparticles as t2-contrast agents for oil reservoir applications

ActiveUS20200231858A1Enhance T contrast propertySafer and more controlledMaterial nanotechnologySurveyWell loggingPhysical chemistry

The invention is directed to hydrophilic and hydrophobic superparamagnetic nanoparticles and their use as contrast agents for NMR including agents that distinguish oil and water in NMR logging of geological formations containing oil or water. Methods of making these SPIONs are also described.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

3C-sic nanowhisker and synthesizing method and 3c-sic nanowhisker

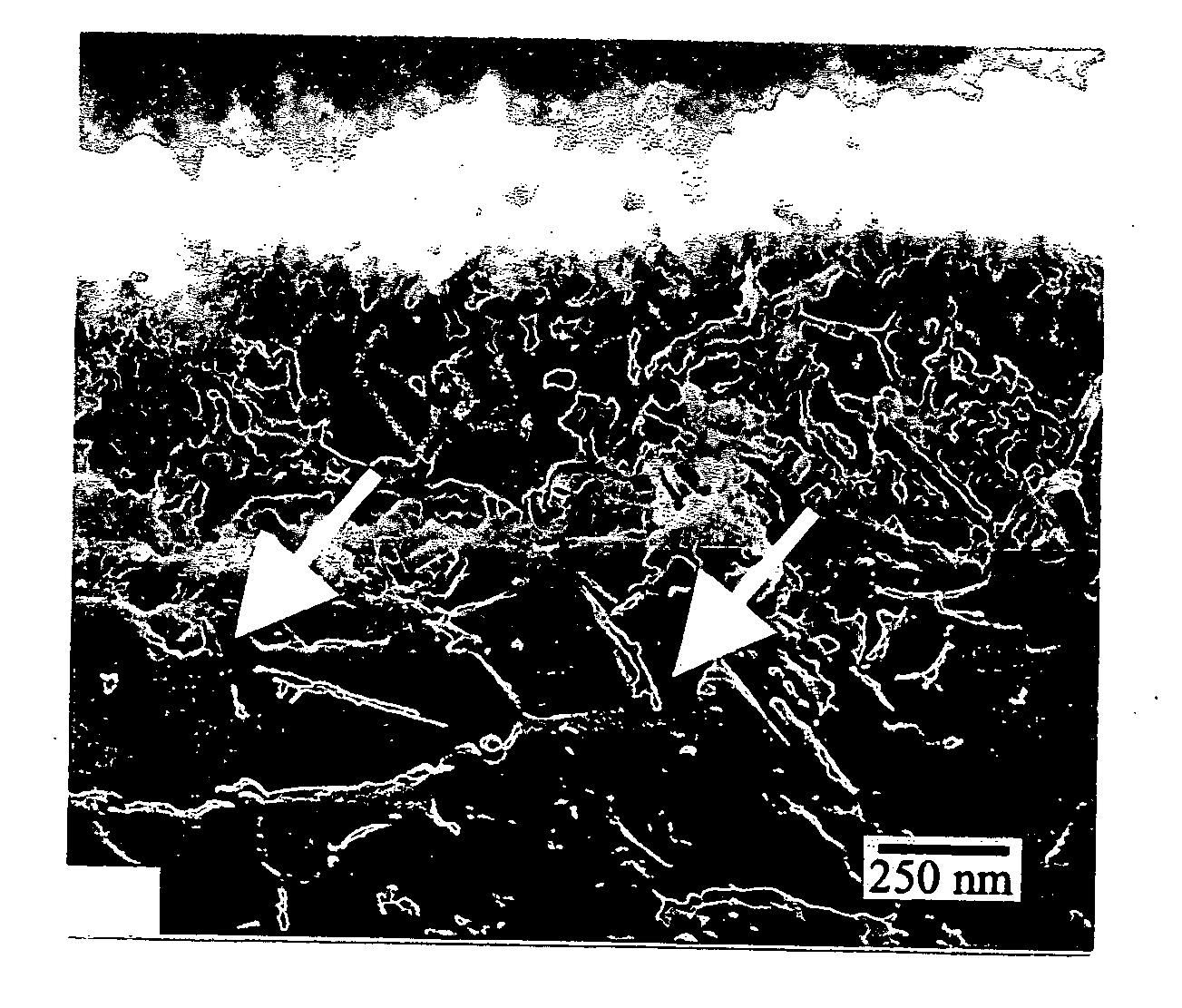

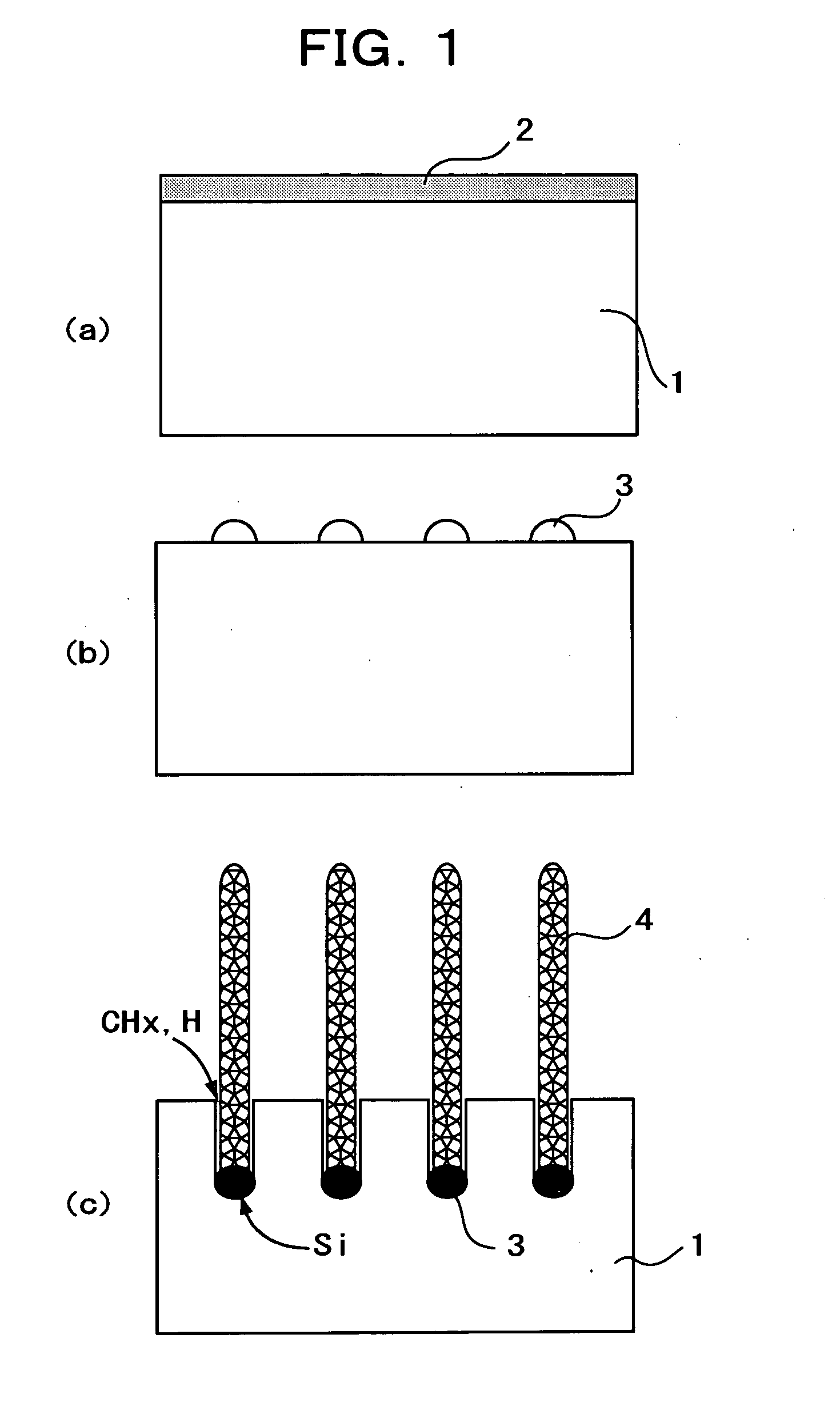

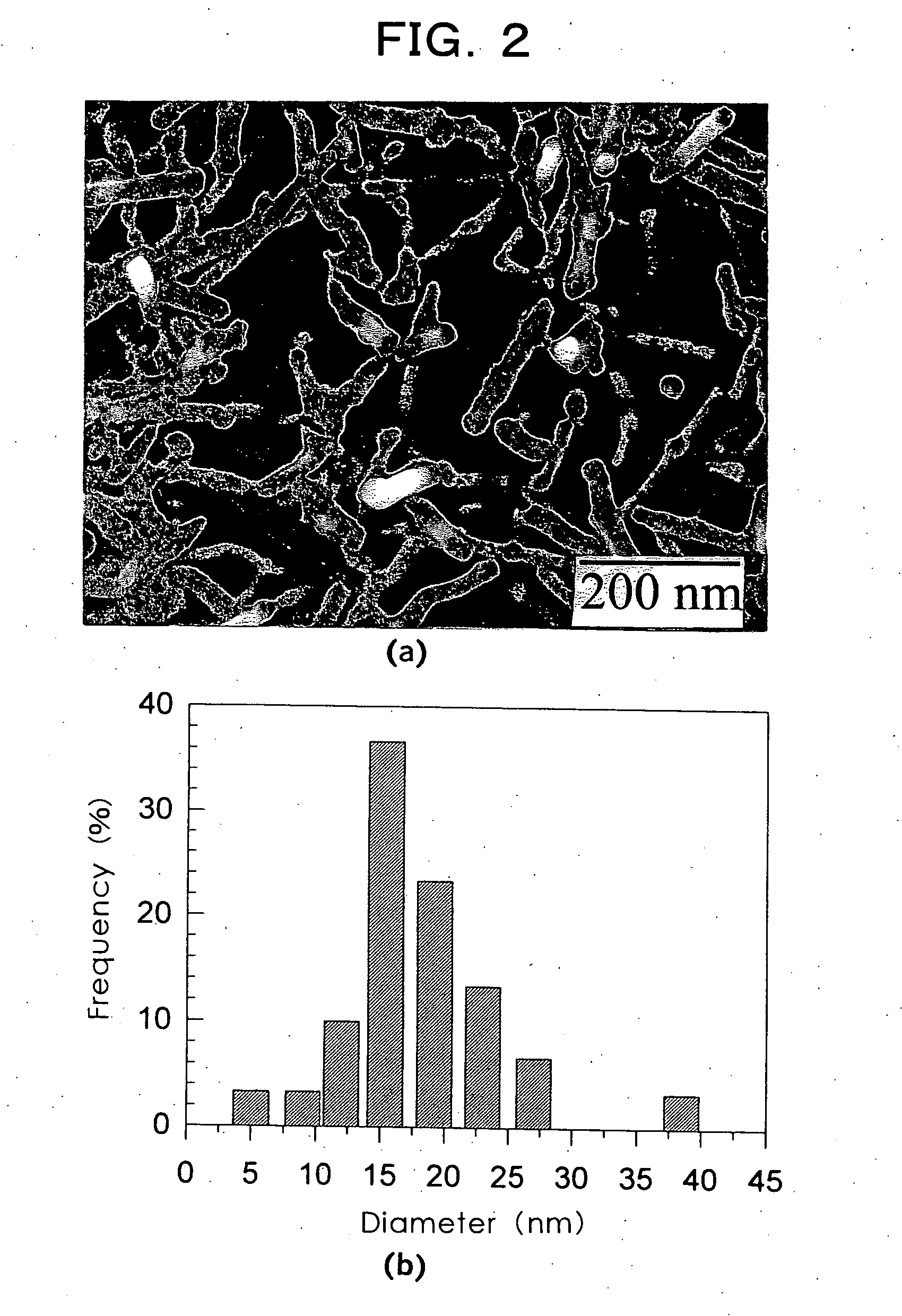

InactiveUS20050089680A1Low costSynthesize 3C—SiC single crystal nanowhisker quite safelyMaterial nanotechnologyFrom frozen solutionsHydrogenWhiskers

The present invention offers a synthesizing method of 3C—SiC: nanowhisker wherein its diameter anid length can be controlled, it can grow on Si substrate, and wherein said method is safe and its cost is low. and said whisker cart emit visible light of various wravelength. 3C—SiC nanowhisker is formed by depositing thin film (2) made of a metal element on Si substrate (1), placing this Si substrate (1) into a plasma GVD apparaturi and by holding it for predetermined time at predetermined substrate temperature in the plasma consisting of hydrogen and hydrocarbon. Si of Si substrate 1) and C in plasma dissolve at supersaturation into metal liquid particle (3), 3C—SiC nanowhisker (4) grows on the metal liquid particle (3), whisker surface is terminated with H so to maintain the diameter constant, and the metal liquid particle (3) at whisker root takes in Si from Si substrate (1) and penetrates into Si substrate (1). This 3C—SiC nanowhicker cani be used as light-emitting material suitable to Si process, and 3C—SiC nanowhisker device which can emit light boased on quantum confinement effect and Si device can, if mixed together, form very useful device.

Owner:JAPAN SCI & TECH CORP +1

Method for synthesizing 1,1,2,2-tetrafluoroethane

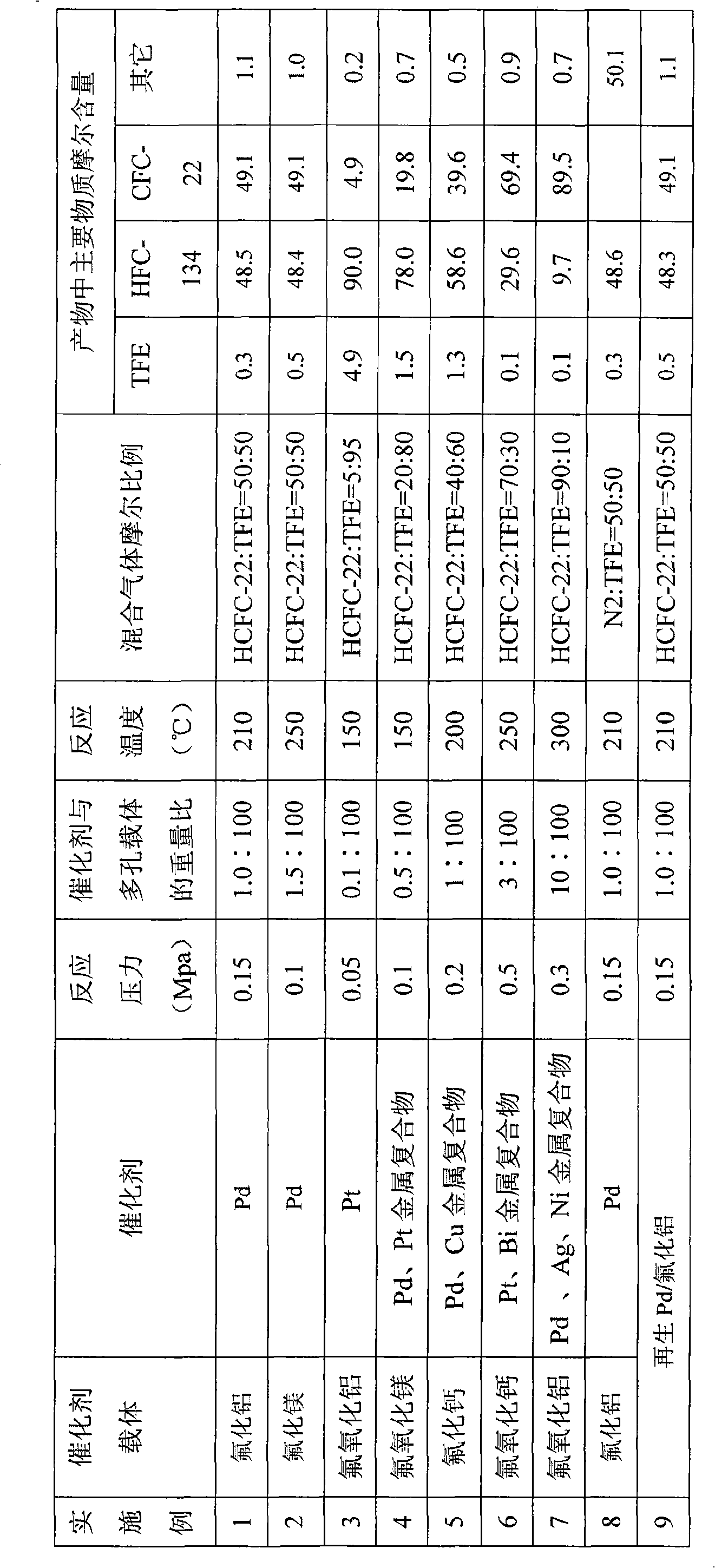

ActiveCN101591218AEasy to recycle and recycleExtended service lifeCatalyst carriersHalogenated hydrocarbon preparationHydrogen fluorideHydrogen

The invention relates to a method for synthesizing 1,1,2,2-tetrafluoroethane, which belongs to the field of preparation of refrigerants. TFE-containing mixed gas and hydrogen pass through a porous carrier supported hydrogenation catalyst bed to generate HFC-134; the TFE-containing mixed gas is a mixture formed by TFE and inert gas; the inert gas is gas which does not react with the TFE and the hydrogen under reaction conditions; and a porous carrier material is fluoride or oxyfluoride. An inert component in the method does not participate in the reaction, but can take away the heat generated by the reaction to ensure that the temperature of the catalyst bed is relatively steady and the service life of a catalyst is prolonged; and the adopted porous carrier is the fluoride or the oxyfluoride, does not react with hydrogen fluoride removed during the reaction, improves the service life of the catalyst and is easy to recycle at the same time. The synthesis method has good stability and safe synthesis process, and is suitable for technologized production.

Owner:泉州宇极新材料科技有限公司

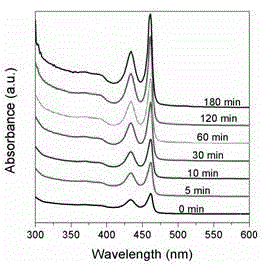

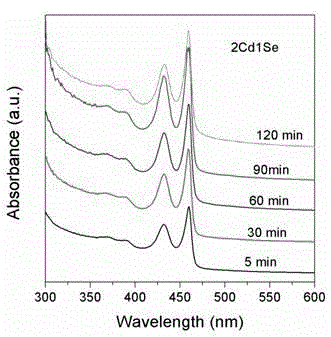

Method for synthesizing super small-size CdSe nanocrystalline through one-pot process

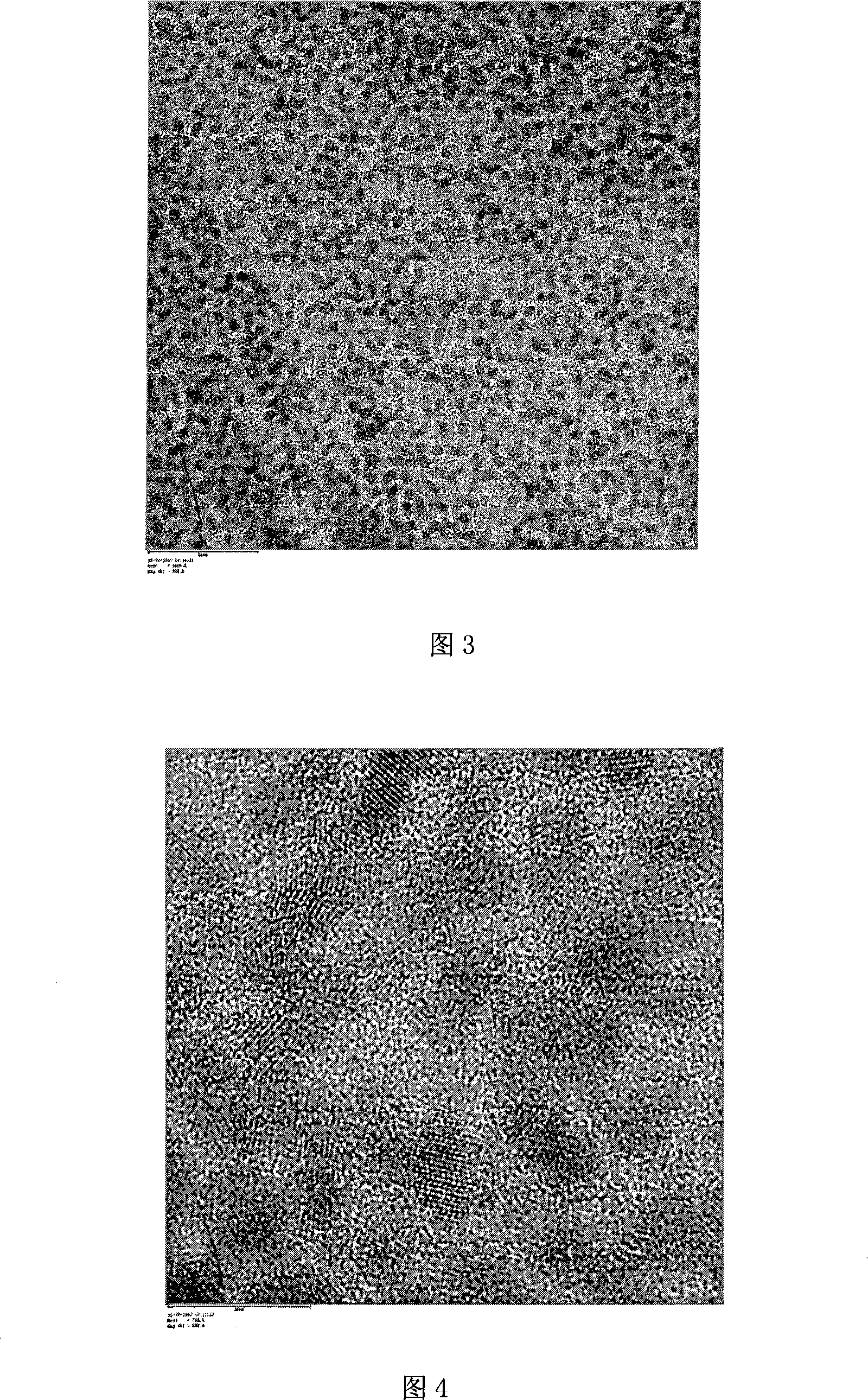

InactiveCN103553001ASynthesis process safetyGood operability and repeatabilityNanoopticsLuminescent compositionsSemiconductorMaterials science

The invention discloses a method for synthesizing super small-size CdSe nanocrystalline through a one-pot process, relating to the technical field of a preparation method of semiconductor nanocrystalline. The method comprises the following synthesis steps of respectively preparing a Se precursor solution and a Cd precursor solution; mixing the two precursor solutions, stirring, heating, and rapidly raising the temperature to be 150-240 DEG C at a speed of 10 to 20 DEG C per minute; synthesizing for 10-300 minutes at a growth temperature, thereby preparing the super small-size CdSe nanocrystalline. Compared with the prior art, the method has the advantages that the synthesized super small-size CdSe nanocrystalline is simple in synthesis operation and environment-friendly and has high repeatability, the synthesis cost is low, and the obtained super small-size CdSe nanocrystalline is single in size, high in quality and stable in performance.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

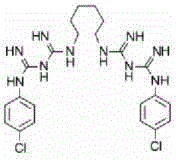

Antibacterial polymer and material prepared therefrom and use thereof

The invention discloses an antibacterial polymer and a product prepared therefrom and use thereof. An antibacterial agent in the antibacterial polymer with chlorhexidine slow-release function and a polymer are mainly hydrogen-bonded, the antibacterial polymer is prepared by a method as follows: during the preparation process of the polymer, the antibacterial agent such as chlorhexidine is added in the stage of formation of a polymer intermediate; the antibacterial polymer also can be prepared by a method as follows: the antibacterial agent is added after the polymer is melted by heating. The antibacterial polymer can be used for preparing plastic materials, rubber materials, textile materials, non-woven materials, oxygen masks, medical dressings or surgical sutures, and has the characteristics of high efficiency, slow release, long effic, broad spectrum, nontoxicity, safety, no stimulation, low cost of synthesis, easy synthesis and secondary use and so on.

Owner:福州维亚多国际贸易有限公司

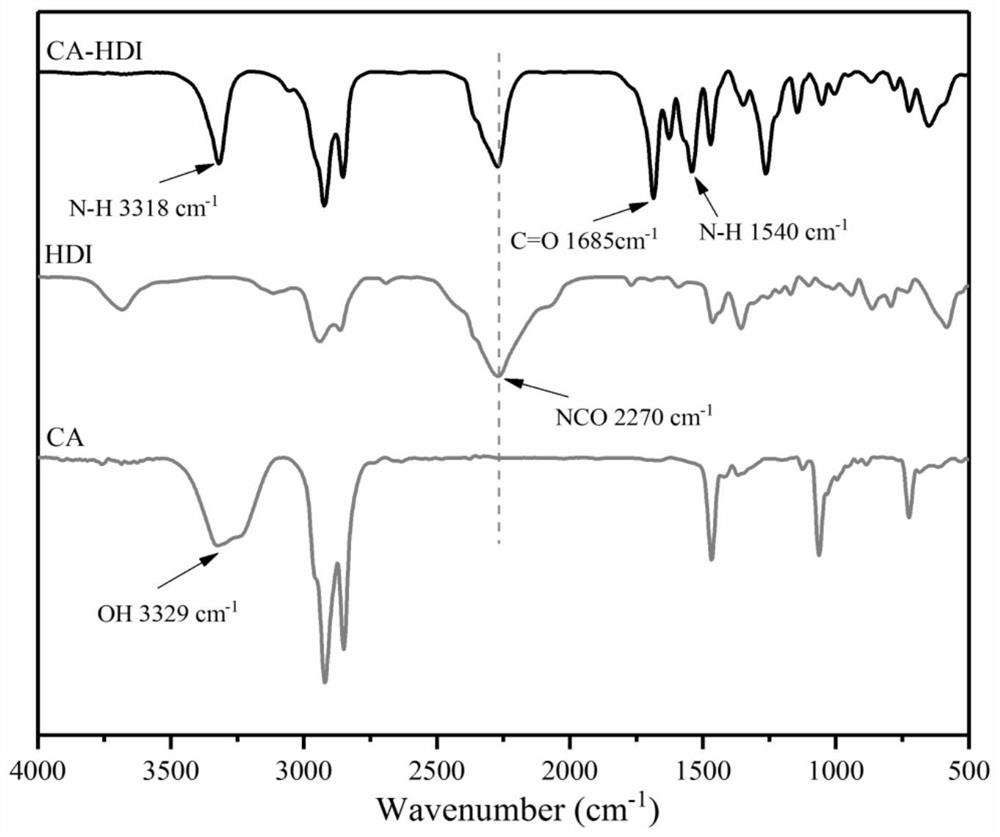

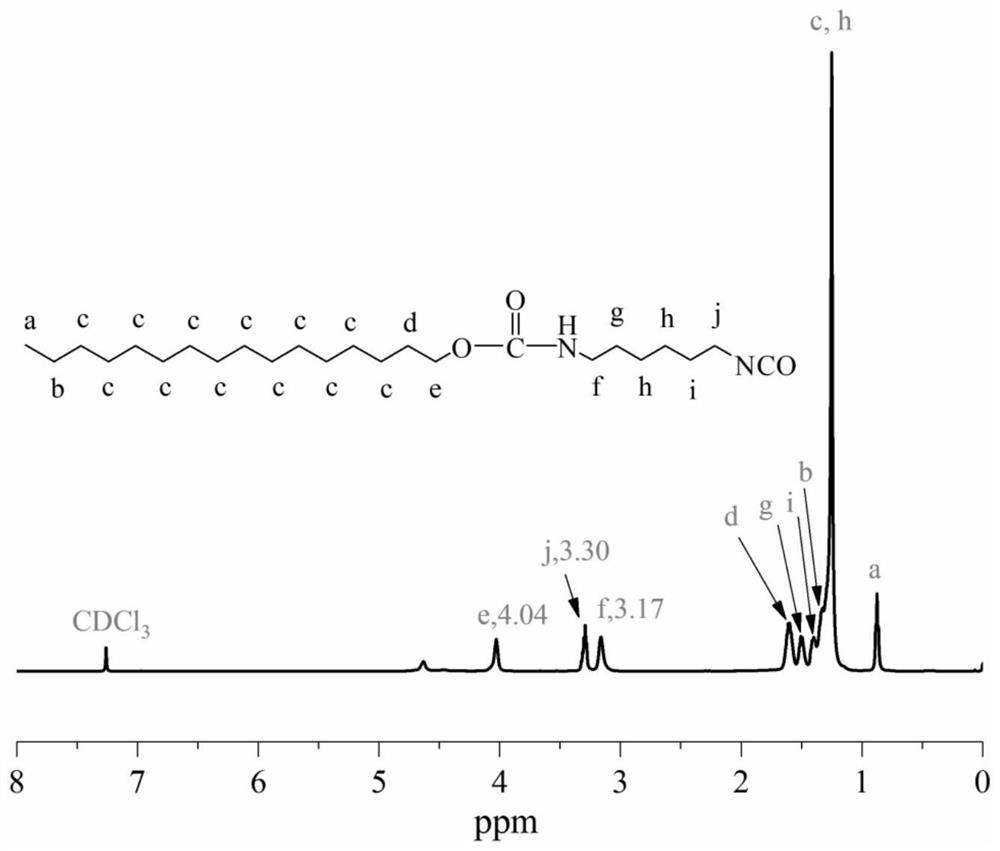

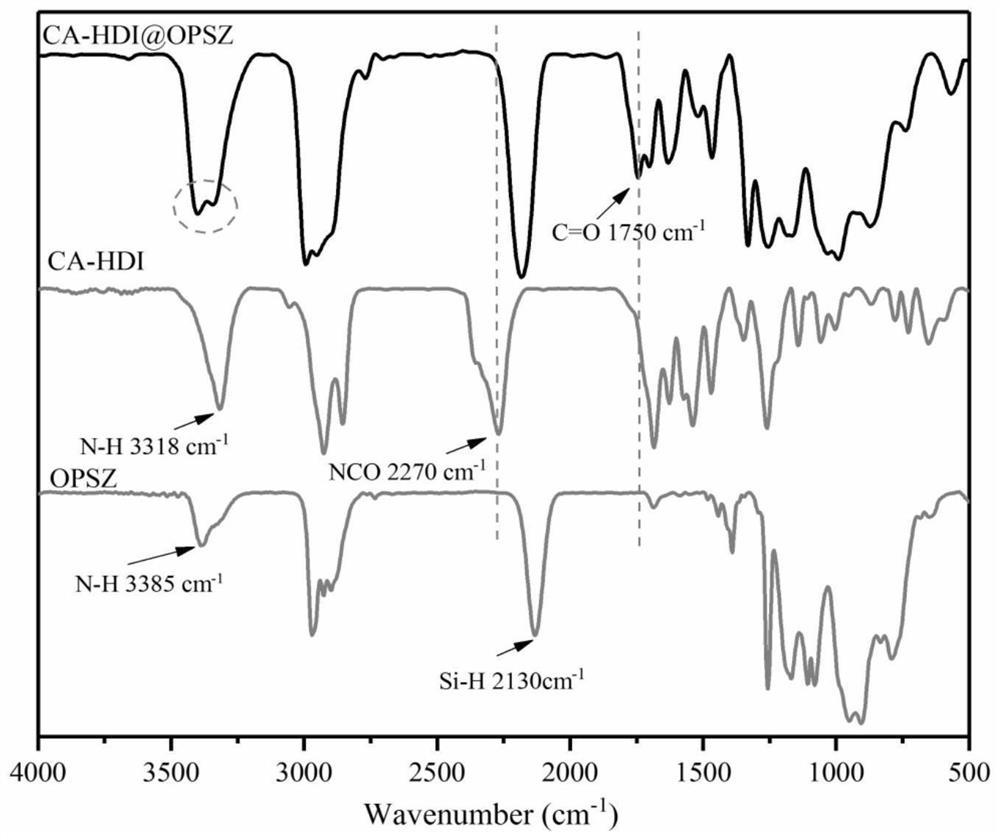

Modified organic polysilazane based on long-chain alkyl compound modification, preparation method and application thereof

ActiveCN113174049ASolve common problems that are difficult to attach firmlyHigh reactivityCoatingsPolymer sciencePtru catalyst

The invention discloses modified organic polysilazane based on long-chain alkyl compound modification, a preparation method and application thereof. The preparation method comprises the following steps: uniformly mixing an alcohol monomer and a diisocyanate monomer under the protection of inert gas, adding a catalyst, and reacting at 30-90 DEG C for 2-12 hours to obtain a long-chain alkyl compound containing 2-50 carbons; and uniformly mixing the synthesized modified substance long-chain alkyl compound with the organic polysilazane, and reacting at a temperature of 20-60 DEG C for 1-8 hours to obtain the organic polysilazane modified by the long-chain alkyl compound. The modified organic polysilazane prepared by the invention not only has lower surface energy, but also retains the excellent anchoring characteristic of polysilazane, and can be firmly adhered to different types of substrates, thereby greatly simplifying the process for constructing an easy-to-clean coating. The modified organic polysilazane coating and the modified organic polysilazane / micro-nano material composite coating prepared by the invention have good hydrophobic performance, easy cleaning performance, chemical resistance, wear resistance and weather resistance, and show excellent durability.

Owner:SOUTH CHINA UNIV OF TECH

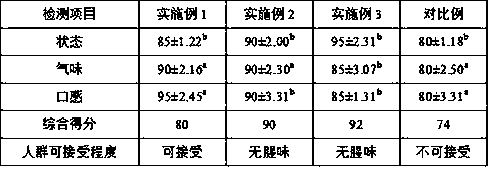

Preparation method of fish oil soft capsules

InactiveCN108208685ASynthetic safetySynthetic noneFood ingredient as antioxidantFatty substance preservation using additivesHazardous substanceFish oil

The invention relates to the technical field of health-care products, in particular to a preparation method of fish oil soft capsules. According to the preparation method disclosed by the invention, glyceride components in unsaturated fatty acid in salmon livers are extracted under mild condition by an enzyme catalysis method, lipase hydrolyzes saturate fatty acid and low unsaturated fatty acid onglyceride of fish oil firstly, hydroxyls are exposed, and then an ester bond synthesis reaction is generated with free EPA and free DHA, so that enriched EPA and enriched DHA are obtained, and the problems of polymerization, oxidation, conjugation, transformation and the like of polyunsaturated fatty acids caused by high temperature are solved; saturated fatty acids in ethyl ester fish oil are removed in a urea adduction manner in the process; and vacuum deodorization is adopted, fishy smell in the fish oil is removed, the palatability is improved, the preparation method is safe, and hazardous substances are not generated.

Owner:丁玉琴

Production process of ferrous disulfide

The invention provides a production process of ferrous disulfide, and belongs to chemurgy. The following raw materials including sodium disulfide, ammonium disulfide, potassium disulfide, ferrous sulfate, ferrous ammonium sulfate and ferrous chloride are required in a synthesis process. The sodium disulfide, the ammonium disulfide, the potassium disulfide, the ferrous sulfate, the ferrous ammonium sulfate and the ferrous chloride are respectively dissolved into water at the normal temperature of 25 DEG C to be made into a saturated solution; the sodium disulfide, the ammonium disulfide and the potassium disulfide can be sequentially matched with the ferrous sulfate, the ferrous ammonium sulfate and the ferrous chloride, and can also be respectively combined and matched to obtain a ferrous disulfide suspension solution. Vacuum suction filtration, drying and drying are performed, and then, crushing is performed to obtain ferrous disulfide powder. The synthesized ferrous disulfide suspension solution and the ferrous disulfide powder have wide purposes on agriculture; good market prospects are realized; a promotion effect is achieved on promoting the agriculture modernization construction in China; certain economic benefits and social benefits can be achieved on agricultural means of production enterprises and the society.

Owner:刘长福

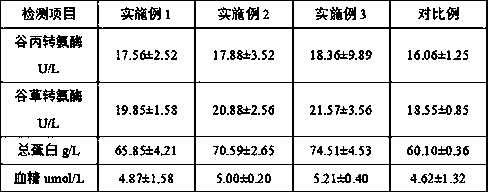

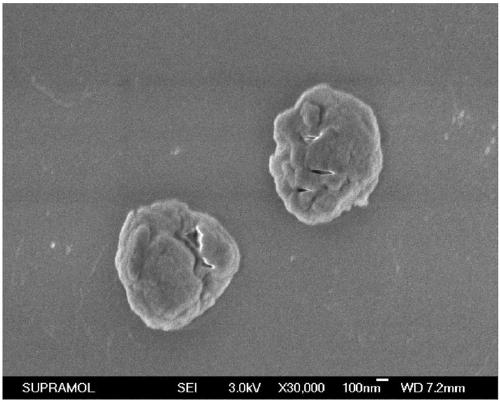

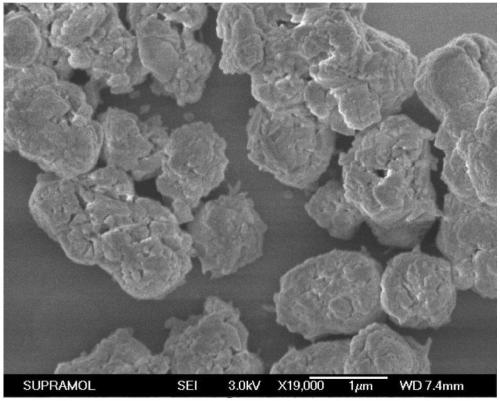

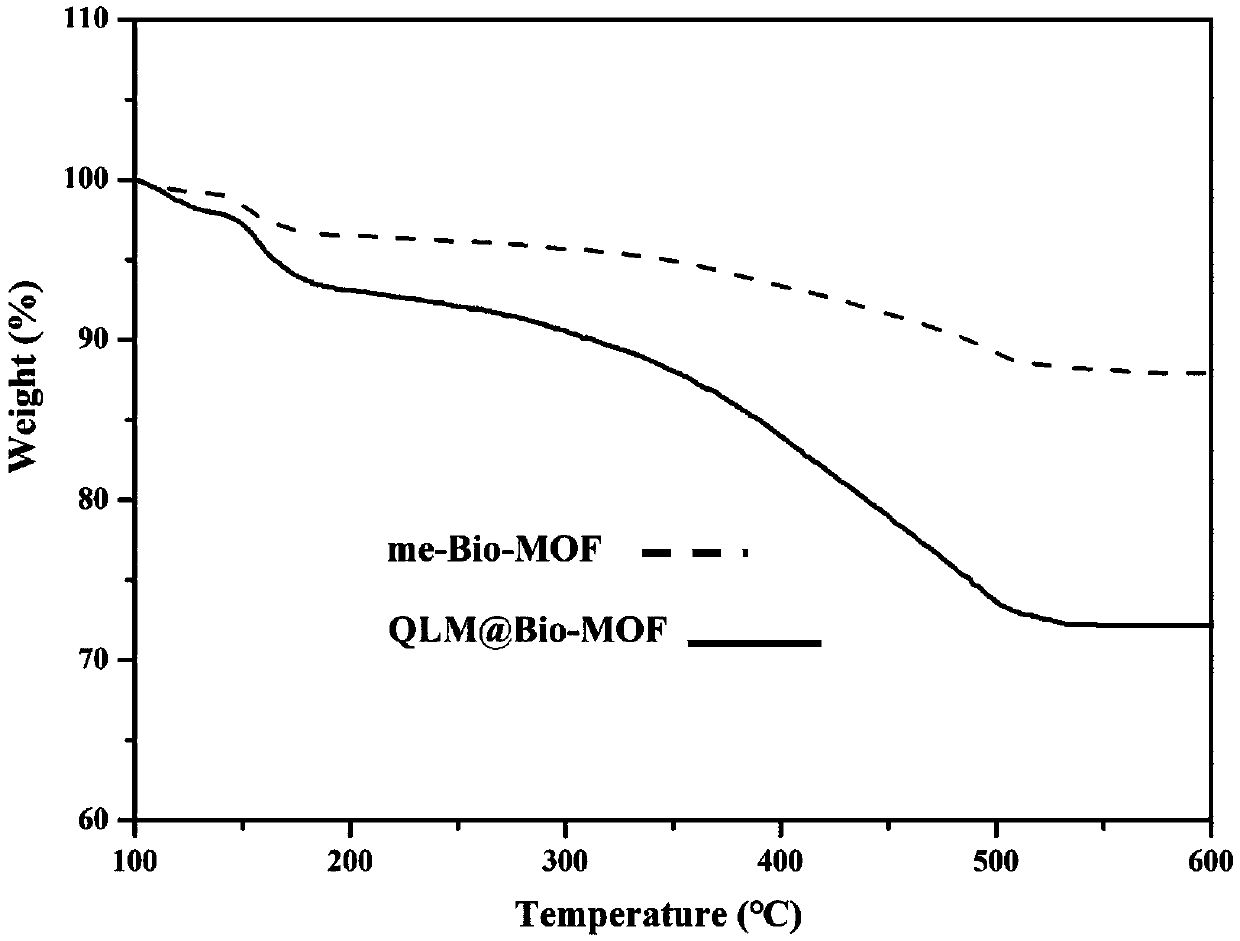

Bio-based metal organic framework assembly esterase catalyst, preparation method and application of catalyst in biodiesel synthesis

InactiveCN109569728AReduce environmental pollutionGood biocompatibilityFatty acid esterificationOrganic-compounds/hydrides/coordination-complexes catalystsMetal-organic frameworkImmobilized enzyme

The invention relates to a bio-based metal organic framework assembly esterase catalyst, a preparation method and application of the catalyst in biodiesel synthesis, belonging to the biotechnologicalfield. Thermophilic esterase QLM is immobilized into a bio-based MOF material, and the esterase immobilized into the MOF is discovered to still have good catalytic activity through activity detection,and can successfully catalyze the hydrolysis of ester p-NPC (4-nitrophenyl caprylate); the esterase-MOF assembly serves as a catalyst to catalyze the transesterification of sunflower oil and methanol, and successfully synthesizes biodiesel with good performance. After loaded with an enzyme and entering the bio-based MOF, the thermophilic esterase QLM has better thermal stability and pH tolerance;the immobilized enzyme serves as a catalyst, can successfully achieve the synthesis of biodiesel, has higher catalytic efficiency than a free enzyme at a high oil / methanol proportion, and simultaneously has good operational stability and recyclability.

Owner:JILIN UNIV

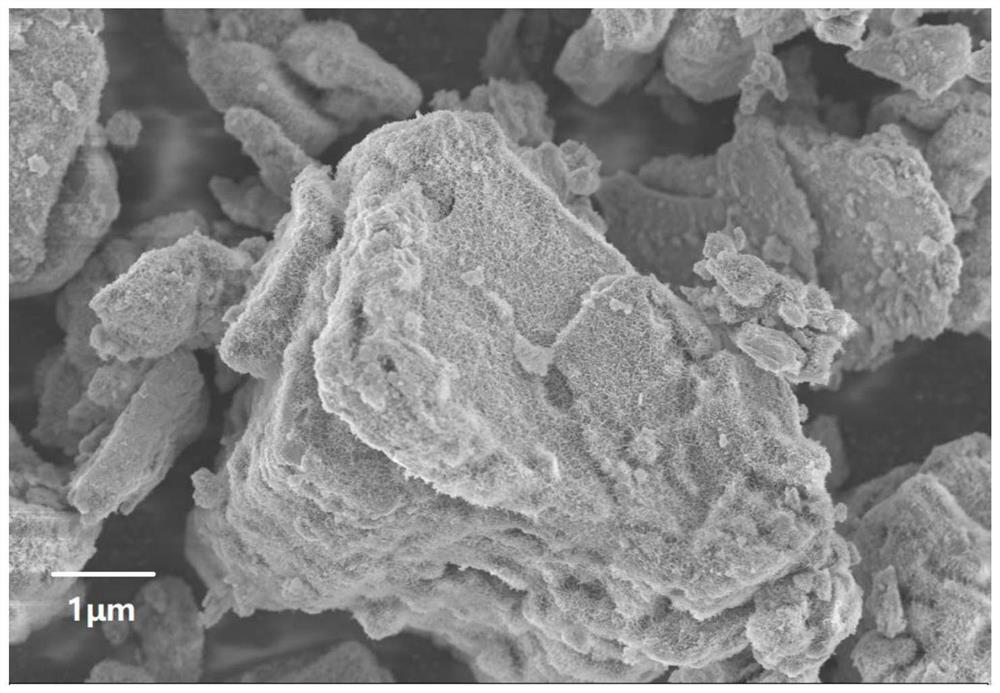

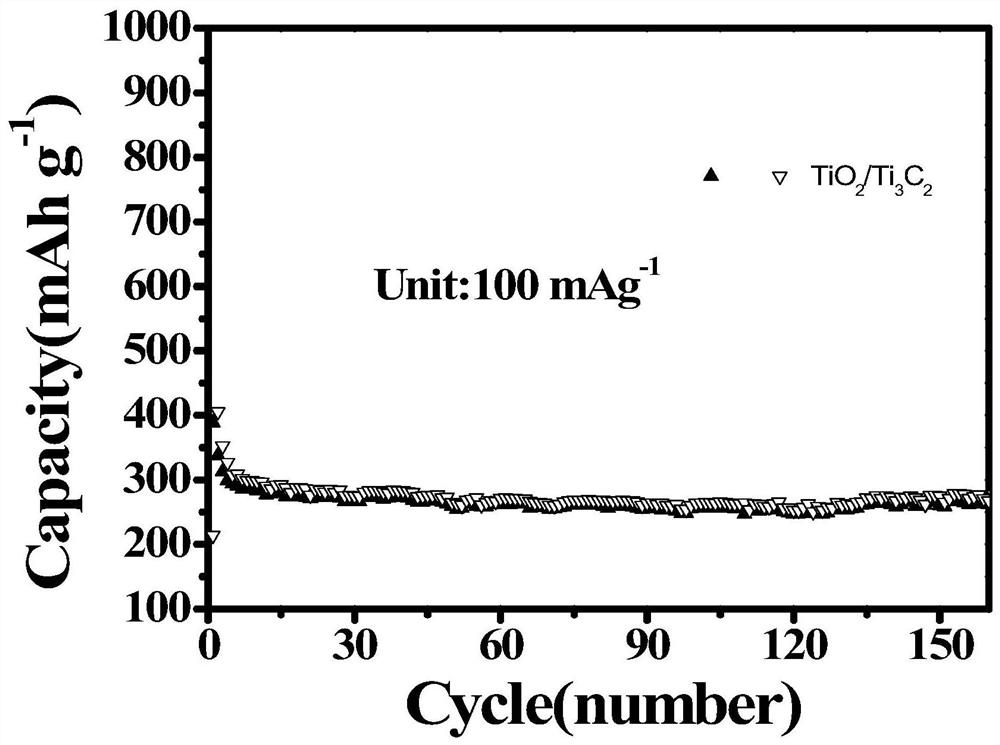

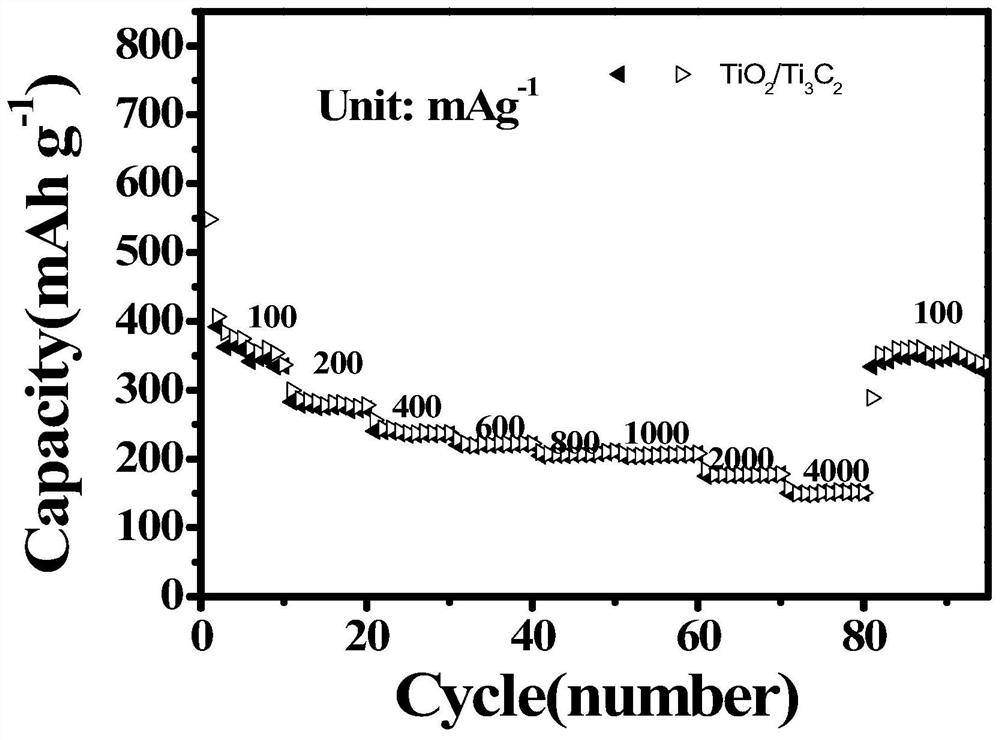

Preparation method of three-dimensional TiO2 nanowire/MXene composite material

The invention relates to a lithium battery negative electrode material, in particular to a preparation method of a three-dimensional TiO2 nanowire / MXene composite material. The method comprises the following steps: S1, adding Ti3AlC2 into hydrofluoric acid, and etching and stripping an aluminum layer; S2, carrying out the centrifugal drying on the reaction liquid obtained in the step S1 to obtain Ti3C2MXene; S3, ultrasonically dispersing the Ti3C2MXene obtained in the step S2 into a sodium hydroxide solution, and performing magnetic stirring to obtain a composite material precursor; S4, centrifuging and drying the composite material precursor obtained in the step S3 to obtain the composite material. Compared with the prior art, the preparation method has the advantages that MXene is alkalized through the sodium hydroxide solution, so that the interlayer spacing of MXene can be enlarged, the storage and transportation of lithium ions are facilitated, and the composite material has higher reversible capacity, better rate capability and good cycling stability and conductivity and is suitable for being applied to lithium ion batteries.

Owner:SHANGHAI INST OF TECH

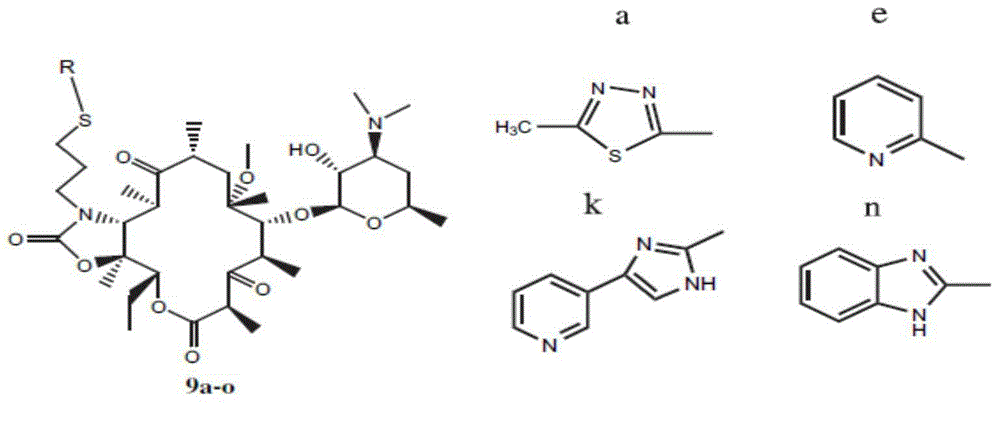

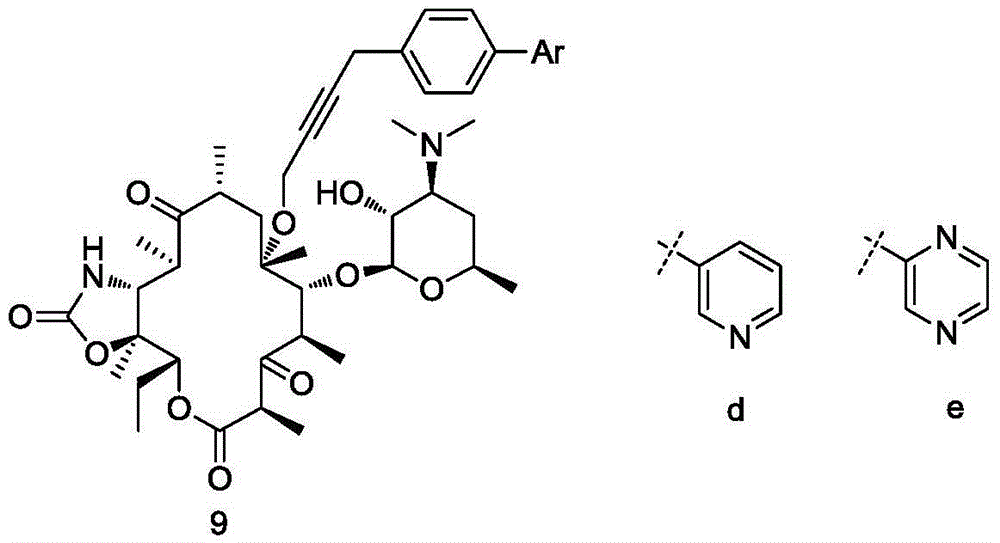

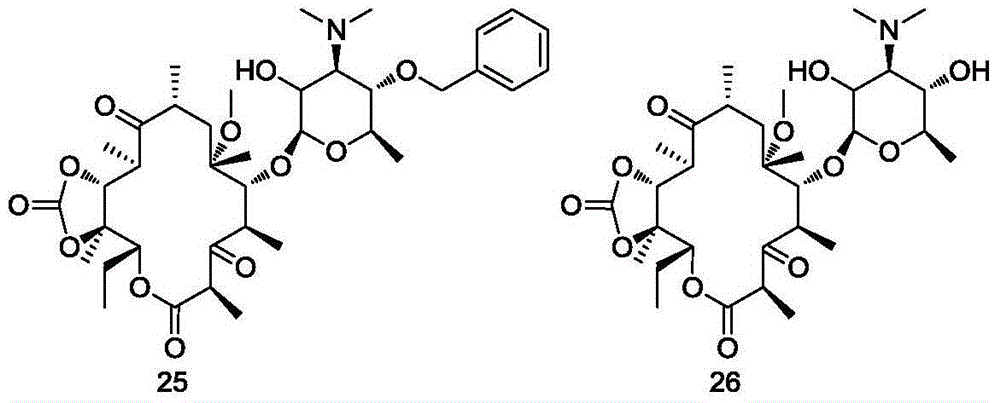

Erythromycin A ketolide antibiotic derivatives containing quinoline substituent group, and preparation methods and applications thereof

ActiveCN105524132ASynthetic safetyProductivityAntibacterial agentsOrganic active ingredientsSynthesis methodsSide chain

The invention discloses a series of erythromycin A ketolide antibiotic derivatives containing quinoline substituent group, represented by a formula I. The invention also provides preparation methods and applications of the derivatives, and side-chain intermediates of the compounds and synthesis methods thereof. The key point of the invention is that the compounds represented by the formula I have the efficacy of broad-spectrum antibiotics, and have outstanding antibacterial activity and anti-resistance activity in inhibiting Gram-positive bacteria and Gram-negative bacteria. The compounds provided by the invention can be used as broad-spectrum antibiotics, and also have antibacterial and antiviral activities in inhibiting Gram-positive bacteria and Gram-negative bacteria.

Owner:INST OF MATERIA MEDICA AN INST OF THE CHINESE ACAD OF MEDICAL SCI

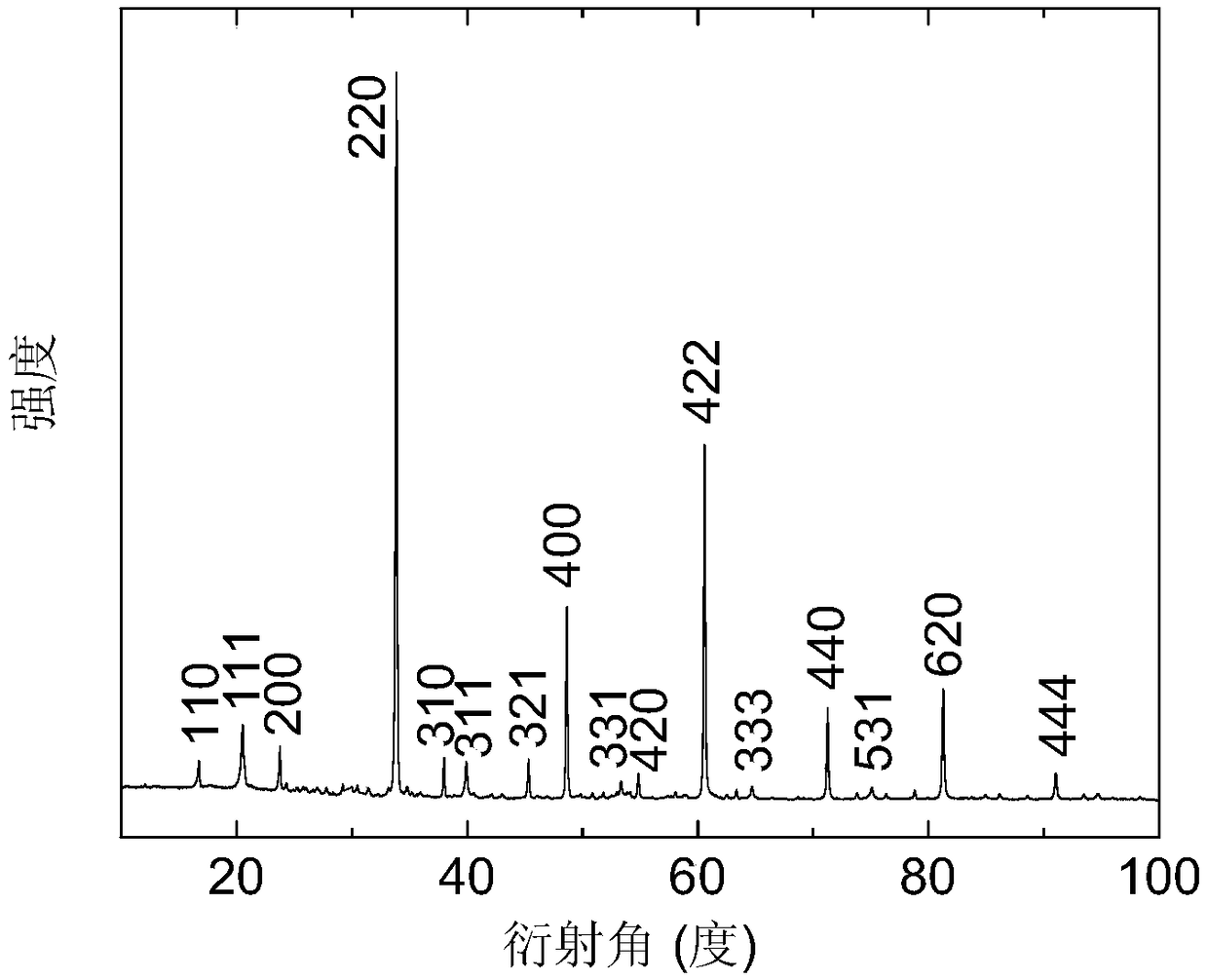

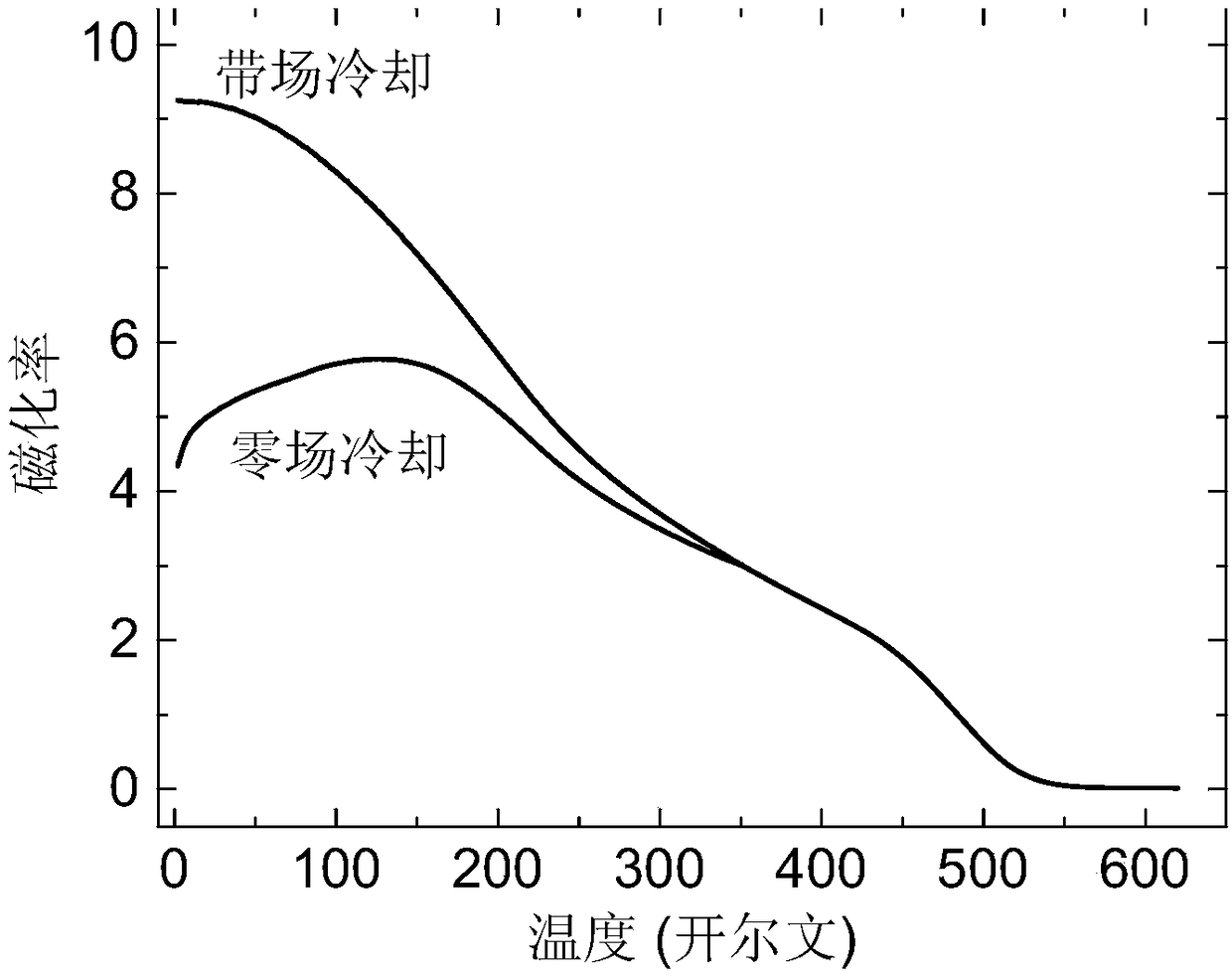

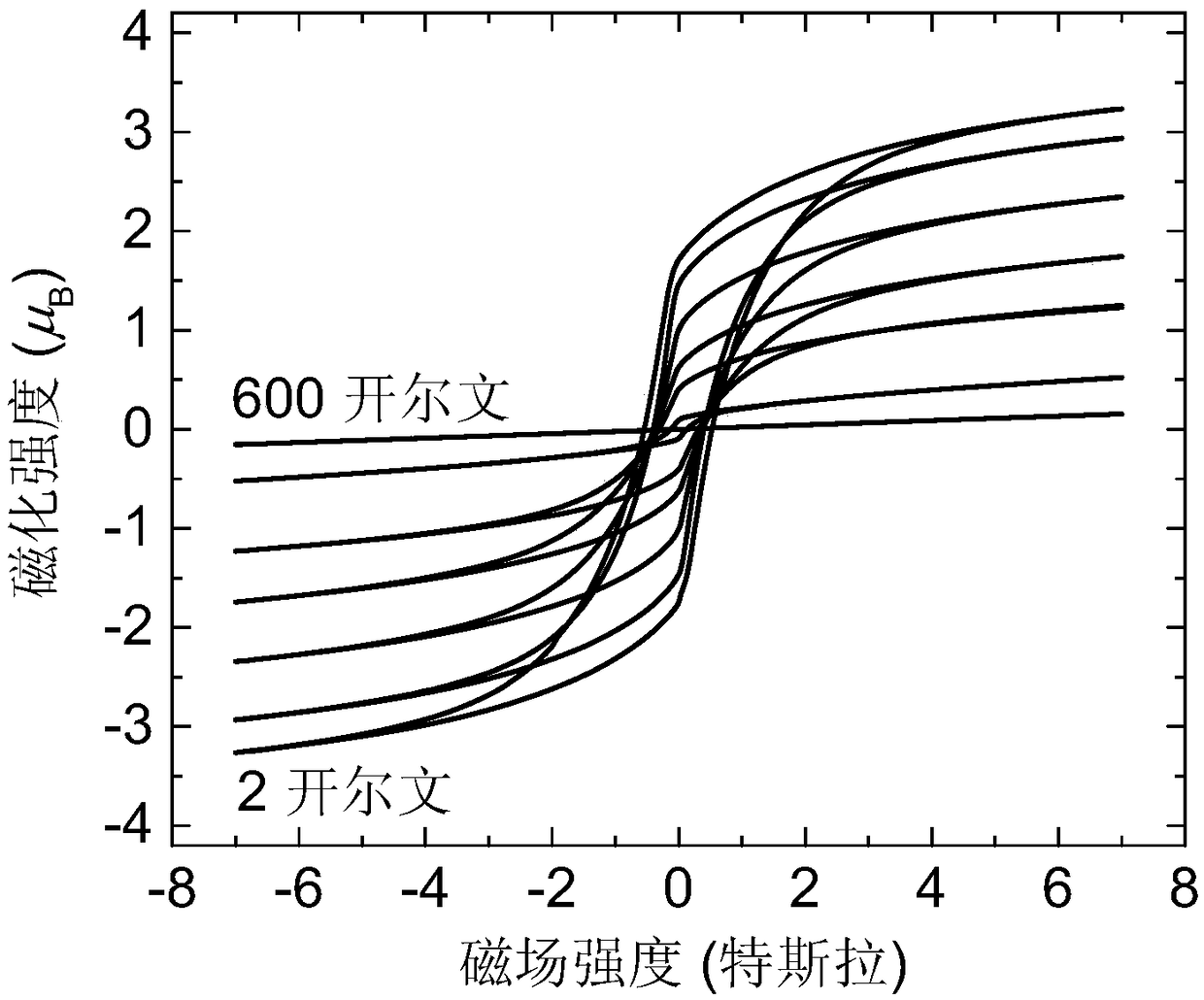

A LaCu3Fe2Os2O12 ferromagnetic semiconductor and a preparation method thereof

ActiveCN109166686AReduce air pressureLess quantityInorganic material magnetismInductances/transformers/magnets manufactureSpace groupCurie temperature

The invention provides a ferromagnetic semiconductor, which has the chemical formula LaCu3Fe2Os2O12 and the space group Pn-3, that lattice constant is shown in the description the Curie temperature is520K, and the band gap width is about 0.2 eV. The invention also provides a method for preparing the ferromagnetic semiconductor, comprising: (1) grinding and mixing La2O3, Fe2O3, CuO, Os and an oxygen source to obtain a mixture; 2, fill that mixture into a gold capsule or a platinum capsule and sealing; (3) treating the gold capsule or the platinum capsule under the pressure of 6-10GPa and the temperature of 1000-1200 DEG C; And (4) cooling the reaction product obtained in the step (3) to room temperature, relieving pressure, taking out from the gold capsule or the platinum capsule, grindingand cleaning to obtain a ferromagnetic semiconductor LaCu3Fe2Os2O12. The ferromagnetic semiconductor LaCu3Fe2Os2O12 of the present invention has potential value in the future magnetic semiconductor integrated circuit device, infrared-far-infrared sensors and multifunctional integrated devices.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

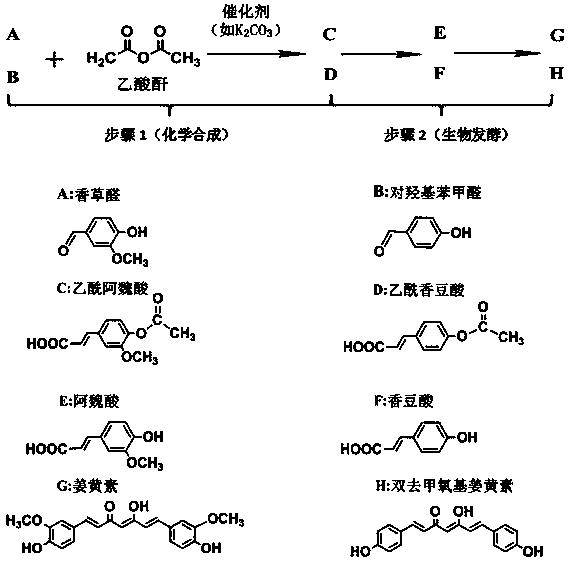

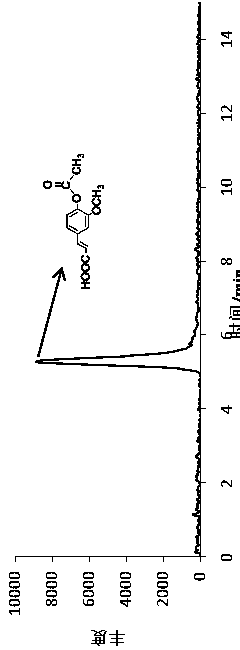

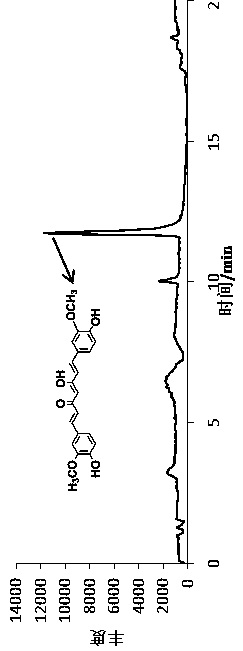

Method for preparing curcumin from vanillin and related analogues

PendingCN109182398ASynthesis fastSynthetic safetyOrganic compound preparationCarboxylic acid esters preparationBiotechnologyChemical synthesis

The invention relates to a method for preparing curcumin by using vanillin and related analogues, belonging to the technical field of combining chemical industry and bioengineering. The method comprises the following steps: preparing biological fermentation substrate by chemical synthesis of vanillin and its analogues, and carrying out biological fermentation on the biological fermentation substrate to prepare curcumin. The invention combines the chemical synthesis and the biological conversion path and utilizes the cheap raw materials to prepare curcumin, which not only realizes the rapid andsafe synthesis of curcumin, but also has very important engineering significance.

Owner:NORTHEAST DIANLI UNIVERSITY

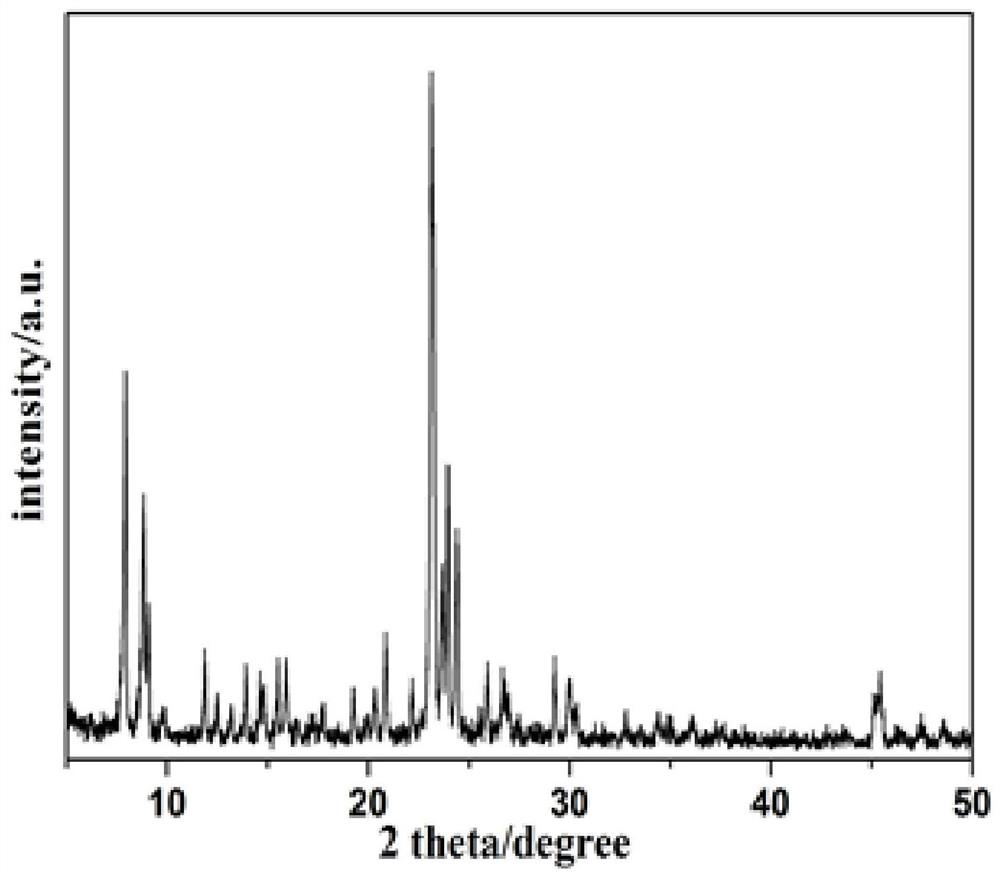

Synthesis method of barium titanate nano-needles

InactiveCN103771501ANot easy to reuniteShape controllableMaterial nanotechnologyTitanium compoundsSynthesis methodsBarium titanate

The invention discloses a synthesis method of barium titanate nano-needles, belonging to the technical field of preparation of nano-materials. The synthesis method comprises the following steps: taking barium acetate and tetrabutyl titanate as raw materials, and taking water as a solvent, wherein the molar ratio of barium acetate to tetrabutyl titanate is 1: 1; uniformly mixing barium acetate, tetrabutyl titanate and water, then placing into a reaction container, sealing, and performing heat preservation at the temperature of 120-180 DEG C for 0.5-24h, wherein the amount of barium acetate and tetrabutyl titanate is not more than 10% of the weight of water, and the amount of barium acetate, tetrabutyl titanate and water is not more than 50% of the filling degree of the container; finally obtaining a barium titanate nano-needle-like white flocculent product. The barium titanate nano-needles synthesized by the synthesis method disclosed by the invention have excellent ferroelectric, dielectric and thermoelectric properties, and can be applied to capacitors, transducers, semiconductor ceramics, ferroelectric and piezoelectric devices and other fields.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Method for synthesizing esterthio tin stabilizer

InactiveCN101704837AReduce extractionSkip the extraction stepTin organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsOrganic solventChange color

The invention discloses a method for synthesizing esterthio tin stabilizer. Firstly, the bichloride of intermediate compound tin is synthesized, and then the bichloride of tin reacts with isooctyl thioglycolate, phase transfer catalyst, organic solvent and inorganic alkaline solution to synthesize the esterthio tin stabilizer with stable quality and superior performance. The method better solves the problem that the esterthio tin stabilizer under long term standing is easy to deposit, change color, have severe odour and the like, has mild and simple synthesis condition and is easy to realize industrialized production.

Owner:SHANGHAI UNIV OF ENG SCI

Novel preparation method of beta-tricalcium phosphate/chitosan composite bionic hydrogel

The invention relates to a novel preparation method of a composite bionic hydrogel. The described material is a beta-tricalcium phosphate / chitosan composite bionic hydrogel. The method comprises the steps of firstly dissolving chitosan by using a dilute acetic acid solution, dissolving beta-sodium glycerophosphate (beta-GP) into tri-distilled water, putting two parts of solutions into a refrigerator at 4 DEG C for storage overnight; adding beta-tricalcium phosphate to the chitosan solution under continuous stirring, carrying out ice-bath, adding a beta-GP solution, dropwise adding a little of glyoxal in a pH neutral environment, pacing the mixed solution at 37 DEG C overnight to form the hydrogel; and storing the hydrogel into the refrigerator at 4 DEG C to obtain the beta-tricalcium phosphate / chitosan composite bionic hydrogel material. According to the provided material, the part, requiring quick skeleton filling and bone tissue repairing, of an existing bone repair material is complicated, or an application limitation during minimally invasive therapy is overcome, and the preparation method is simple in process, low in cost and safe in synthesis, and has important application value in the field of biomedical engineering.

Owner:JIANGNAN UNIV

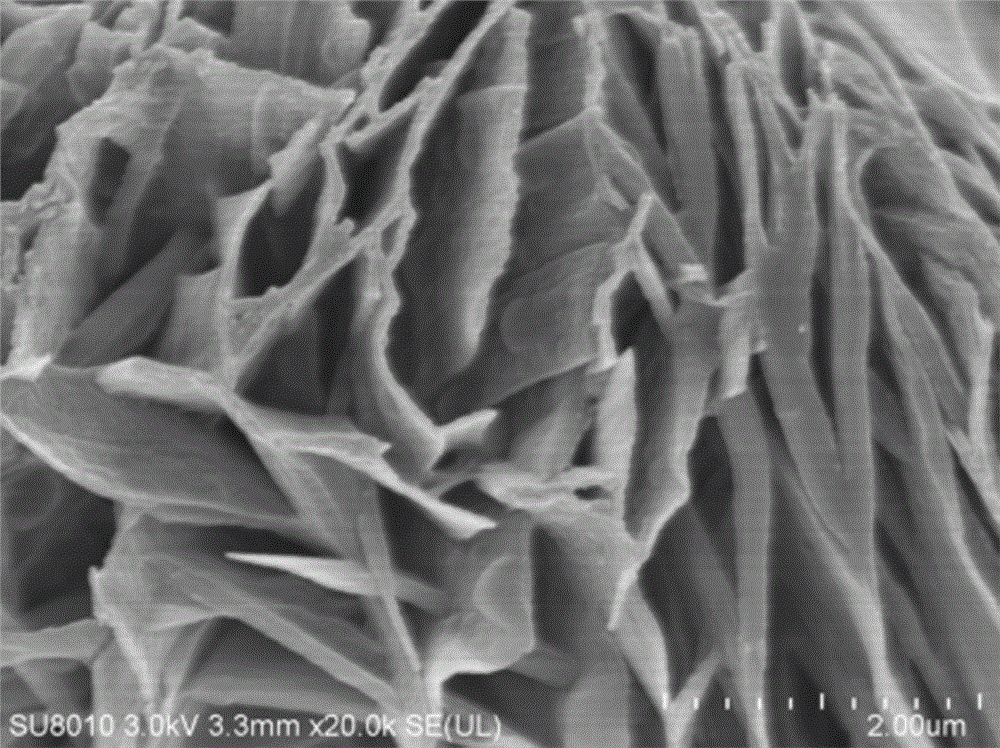

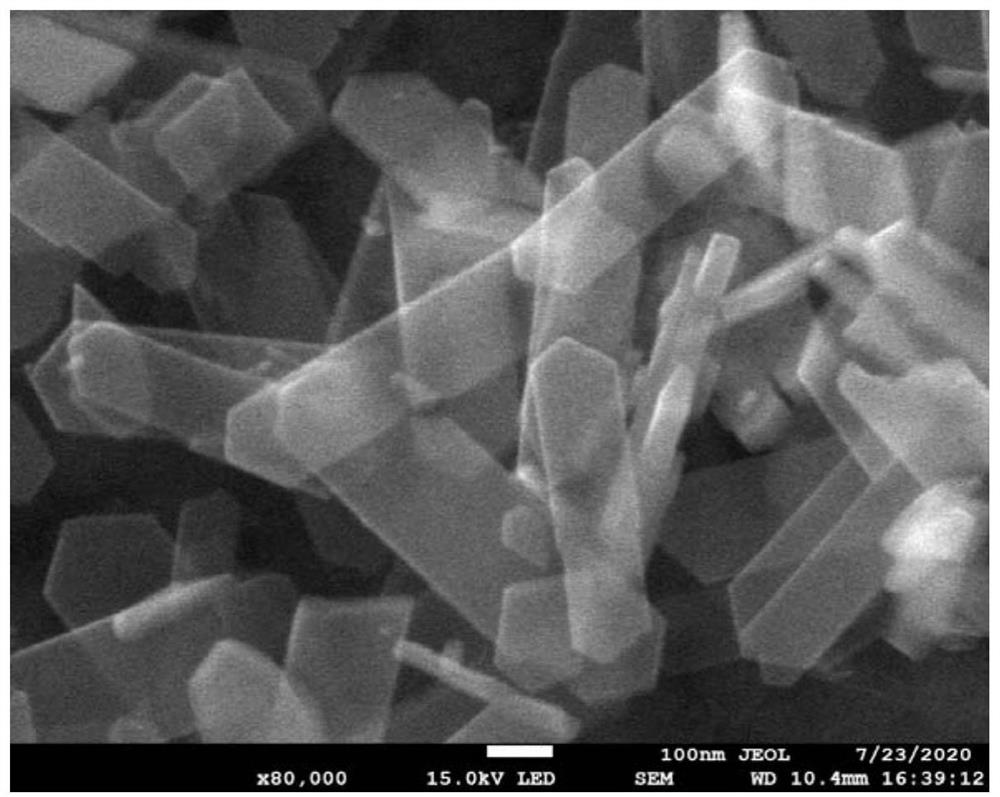

Synthesis method of MFI molecular sieve nanosheet

PendingCN112624145ASolve the problem of high synthesis temperatureSynthetic safetySilicaNanotechnologyMolecular sieveFiltration

The invention discloses a synthesis method of an MFI molecular sieve nanosheet. The method takes a small amount of template agent, silicon source and aluminum source as raw materials for hydrothermal synthesis, and is characterized by comprising the following steps: firstly, uniformly stirring the template agent, the silicon source and a certain amount of water, then selectively adding the aluminum source, adjusting the pH value of the system, stirring and pre-crystallizing for 1-50 hours at 40-100 DEG C, and then crystallizing for 1-10 days at 80-150 DEG C; and after the crystallization is finished, cooling the reaction kettle to room temperature, and then carrying out suction filtration / centrifugation, washing and drying on the product. According to the method, the synthesis temperature is low, the synthesis pressure is low, a fluorine-containing reagent does not need to be used, the yield exceeds 80%, and the thickness of the nanosheet can be regulated and controlled through the pH value of the system and the dosage of a template agent. The synthesized MFI molecular sieve nanosheet is high in crystallinity and controllable in thickness, more synthesis energy consumption is saved under the low-temperature and low-pressure conditions, industrial scale-up production is facilitated, and the MFI molecular sieve nanosheet has a good industrial popularization prospect.

Owner:NANKAI UNIV

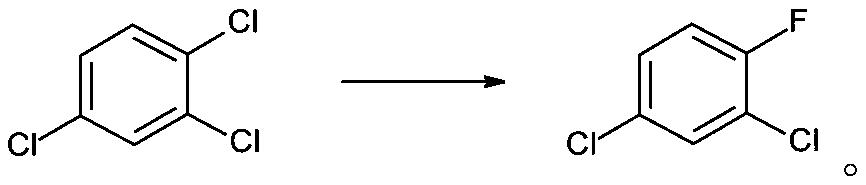

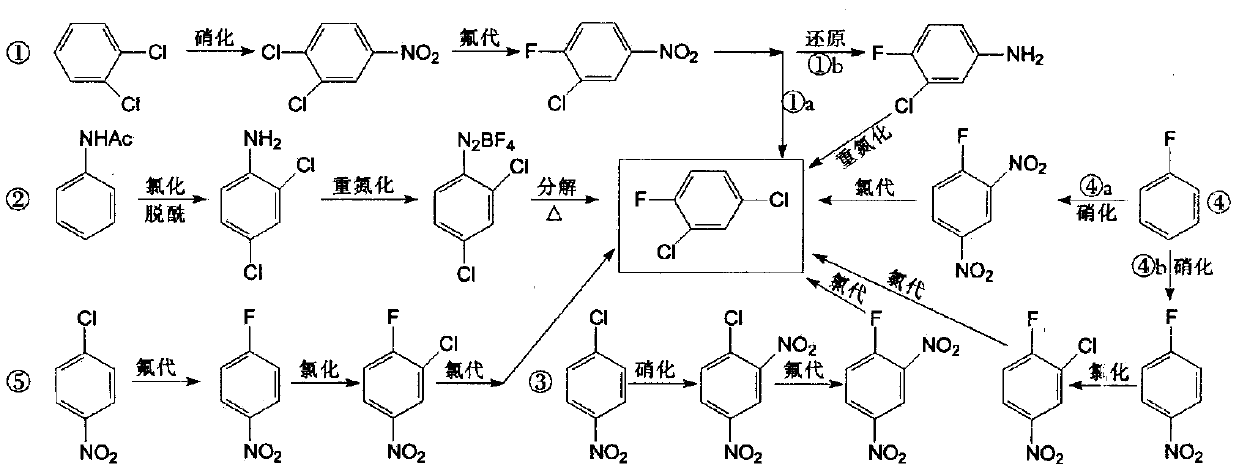

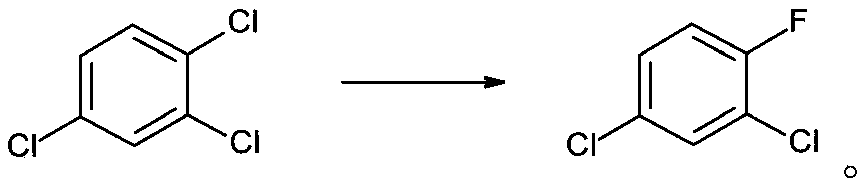

Synthesis method of 2, 4-dichlorofluorobenzene

ActiveCN109851471AFacilitate exchange reactionsFacilitated ionizationPreparation by halogen replacementSulfolaneSynthesis methods

The invention discloses a synthetic method of 2, 4-dichlorofluorobenzene. The method comprises the following steps: 1,2,4-trichlorobenzene is used as a raw material, a calix[6]arene and trimethylolpropane borate compound is used as a phase transfer catalyst, spray-dried potassium fluoride is used as a fluorinating agent, and the 2,4-dichlorofluorobenzene is produced through one step of reaction; herein, the molar ratio of trimethylolpropane borate to potassium fluoride is 1:10-1:20, preferably 1:15; the molar ratio of the potassium fluoride to the 1,2,4-trichlorobenzene is 1:1.1; the calix[6]arene is p-tert-butyl calix[6]arene; and the molar ratio of the p-tert-butyl calix[6]arene to the 1,2,4-trichlorobenzene is 0.001:1-0.05:1, preferably 0.02:1. By using the calixarene and trihydroxymethyl borate composite catalyst, the catalytic efficiency is greatly improved, and the product yield is as high as 92%. The boiling point of the 2,4-dichlorofluorobenzene is 168-169 DEG C, the boiling point of the raw material 1,2,4-trichlorobenzene is 214 DEG C, and the boiling point of the solvent sulfolane is 285 DEG C, so that the product is simple to separate and purify. The method has the advantages of one-step synthesis, short reaction route, avoidance of nitrification and high-temperature chlorination, safer synthesis process and suitability for industrial production.

Owner:ZHEJIANG BENLI TECH CO LTD

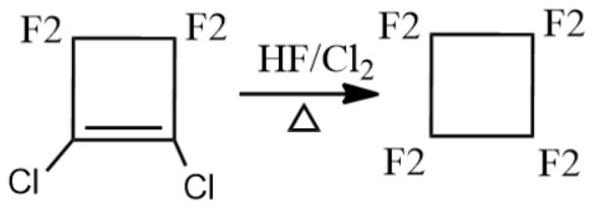

A method for synthesizing fire extinguishing agent octafluorocyclobutane

ActiveCN107721810BSave raw materialsConvenient sourcePreparation by halogen replacementCatalyst activation/preparationChemical synthesisPtru catalyst

The invention relates to a method for synthesizing a fire extinguishing agent octafluorocyclobutane, and belongs to the field of organic chemical synthesis. The method for synthesizing octafluorocyclobutane is characterized in that the octafluorocyclobutane is generated from dichlorotetrafluorocyclobutene, hydrogen fluoride and chlorine gas in the presence of a fluorination catalyst. FORMULA is shown in the description. According to the method, raw materials are cheap, the raw material source is convenient, product separating and purifying is simple, industrial production is easy, and a littlethree industrial wastes (waste solid, waste water and waste gas) is generated.

Owner:天津航大翼安科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com