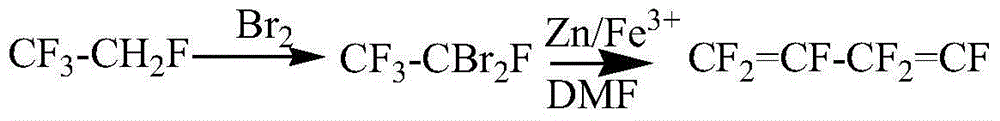

Method for synthesizing hexafluoro-1,3-butadiene

A technology of butadiene and tetrafluoroethane, which is applied in the field of synthesizing hexafluoro-1,3-butadiene, can solve the problems of restricting the industrial production of hexafluorobutadiene, and achieve safe synthesis process, cheap raw materials and high product quality. Simple effect of separation and purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) 20ml of activated carbon catalyst [the purpose of activated carbon is to increase the reaction contact time, can also be considered as catalyst] into the fixed bed reactor, and the fixed bed reactor is heated with an open tube heating furnace. Under the protection of 50ml of nitrogen, the catalyst was first dried at a rate of 10 °C / min to 400 °C for 2 hours, and then dried at a rate of 10 °C / min to 600 °C for 2 hours. This completes the catalyst activation process.

[0036] Heat the reactor to 450°C, then, 30ml / min tetrafluoroethane and 30ml / min liquid bromine enter the mixing chamber together and mix well. After that, it goes through the reactor until the buffer bottle, water washing bottle, concentrated lye, and cooling collector. After the experiment, the product is mainly distributed in the cooling collector. The collected product was subjected to GC analysis. GC results showed that the collected product contained 27% dibromotetrafluoroethane and 18% monobrom...

Embodiment 2

[0040] (1) 20ml activated carbon catalyst is packed into a fixed-bed reactor, and the fixed-bed reactor is heated with an open-type tube heating furnace. Under the protection of 50ml of nitrogen, the catalyst was first dried at a rate of 10 °C / min to 400 °C for 2 hours, and then dried at a rate of 10 °C / min to 600 °C for 2 hours. This completes the catalyst activation process.

[0041] Heat the reactor to 550°C, then, 30ml / min tetrafluoroethane and 30ml / min liquid bromine enter the mixing chamber together and mix well. After that, it goes through the reactor until the buffer bottle, water washing bottle, concentrated lye, and cooling collector. After the experiment, the product is mainly distributed in the cooling collector. The collected product was subjected to GC analysis. GC results showed that the collected product contained 19% dibromotetrafluoroethane and 15% monobromotetrafluoroethane.

[0042] (2) In a 150ml three-neck flask, add 2.0g of activated zinc powder and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com