Patents

Literature

184 results about "Open tube" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

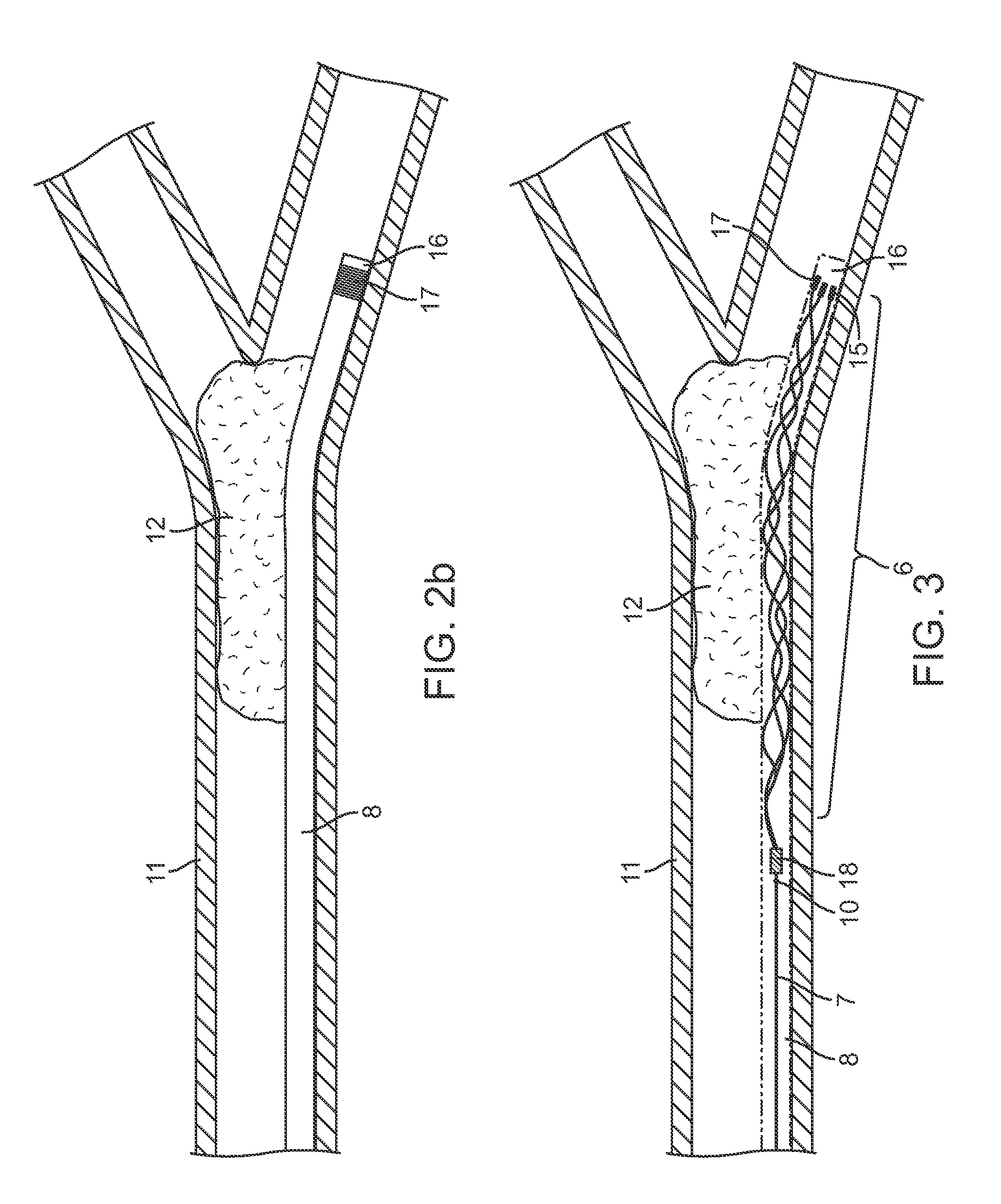

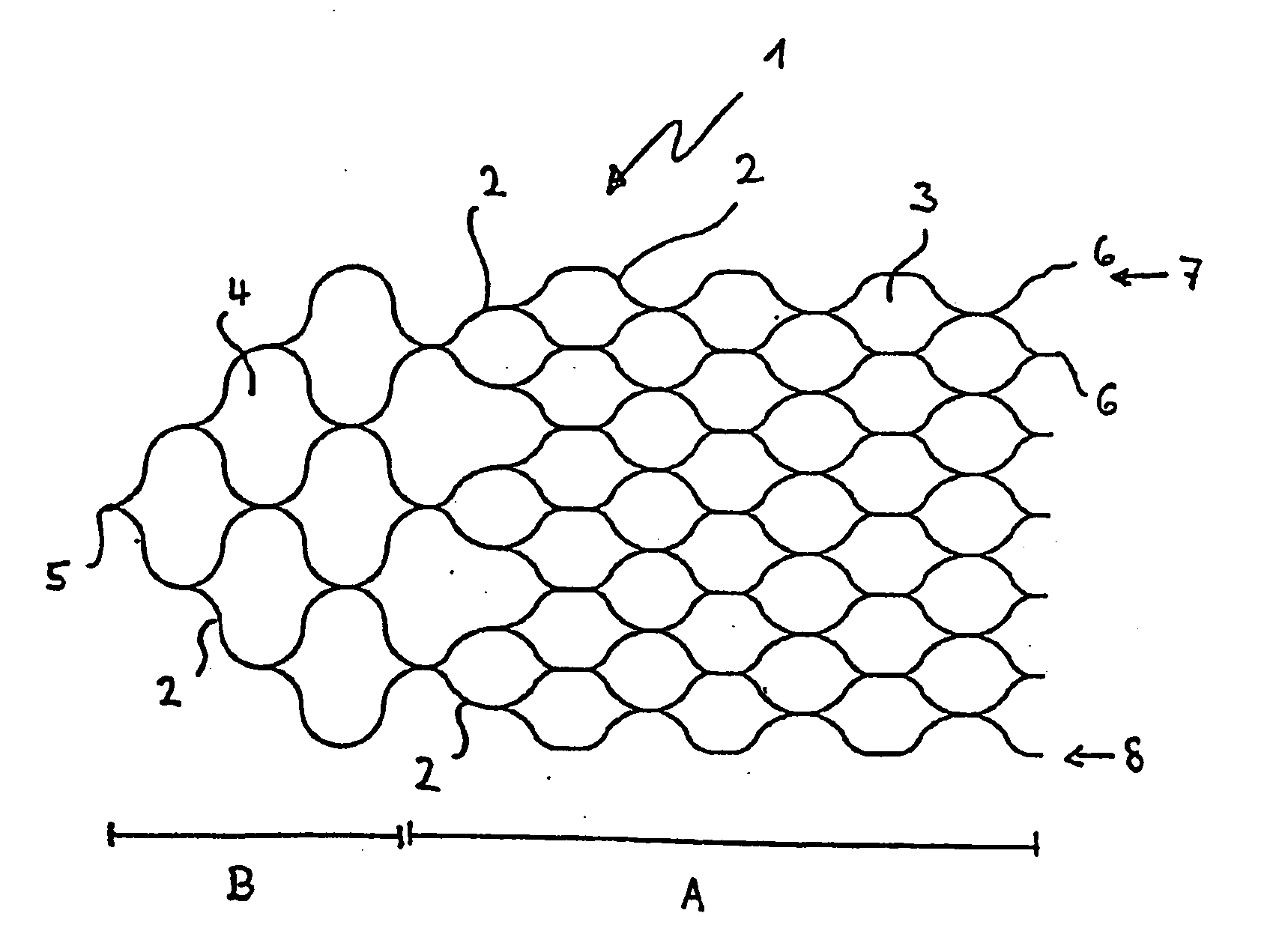

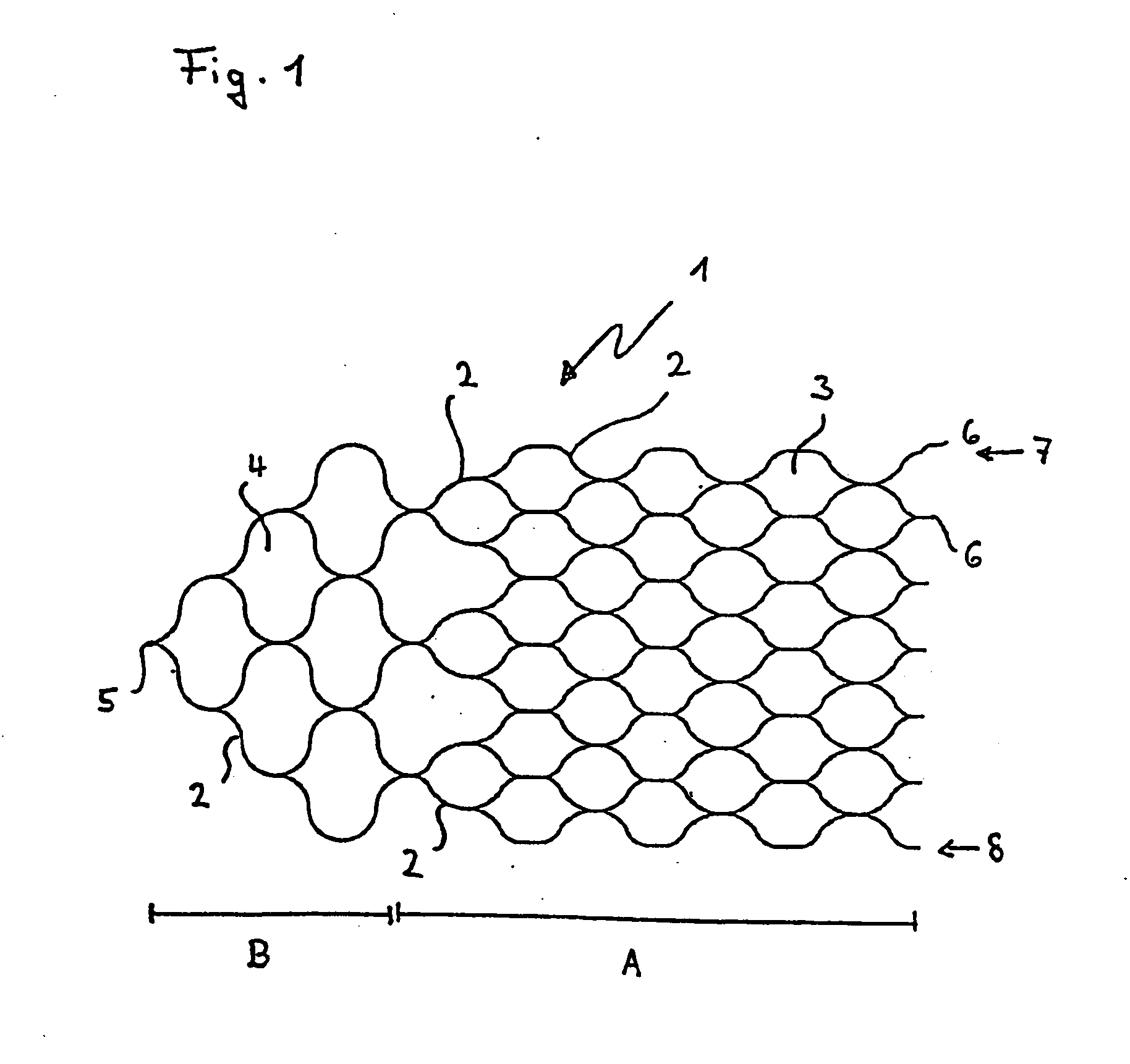

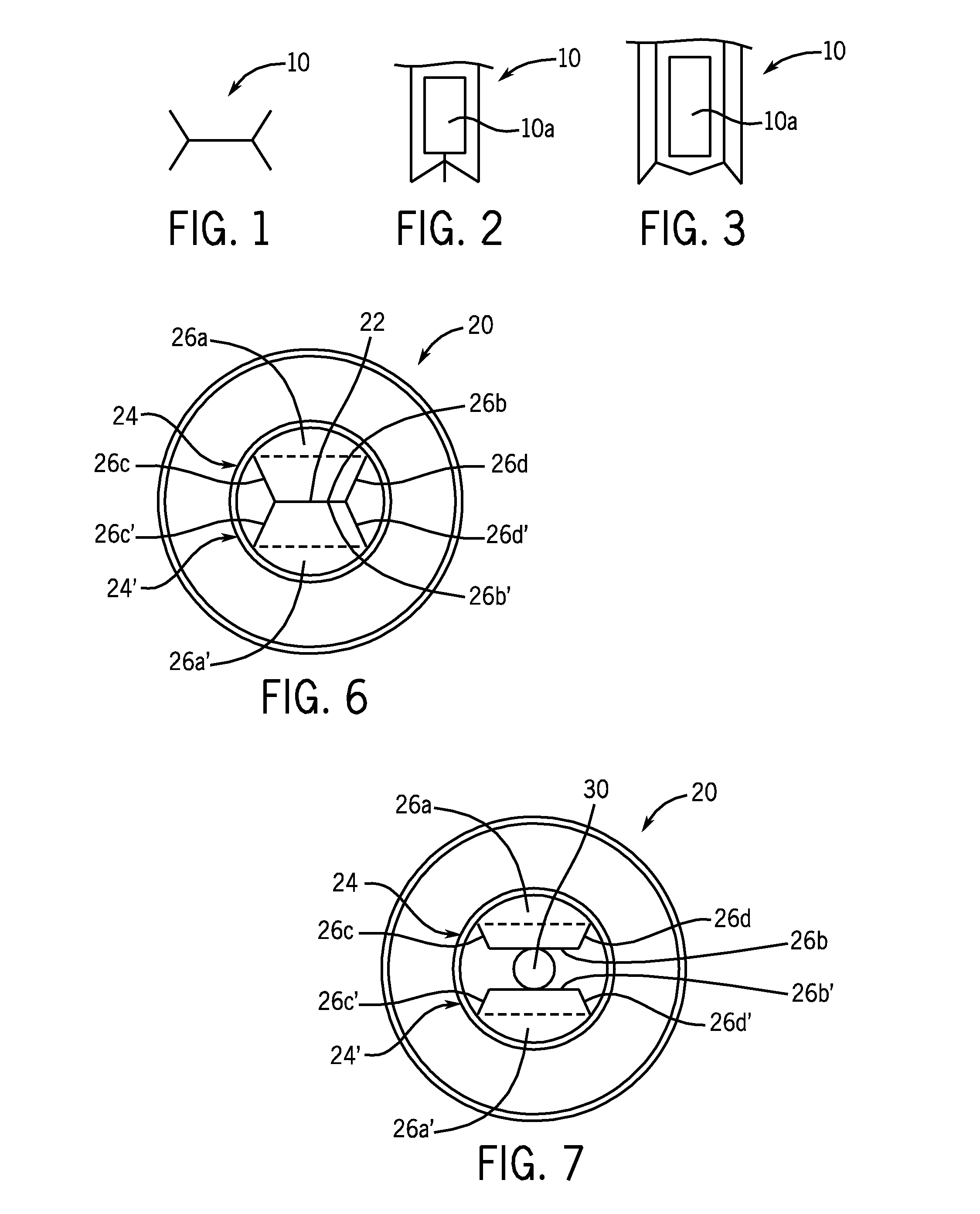

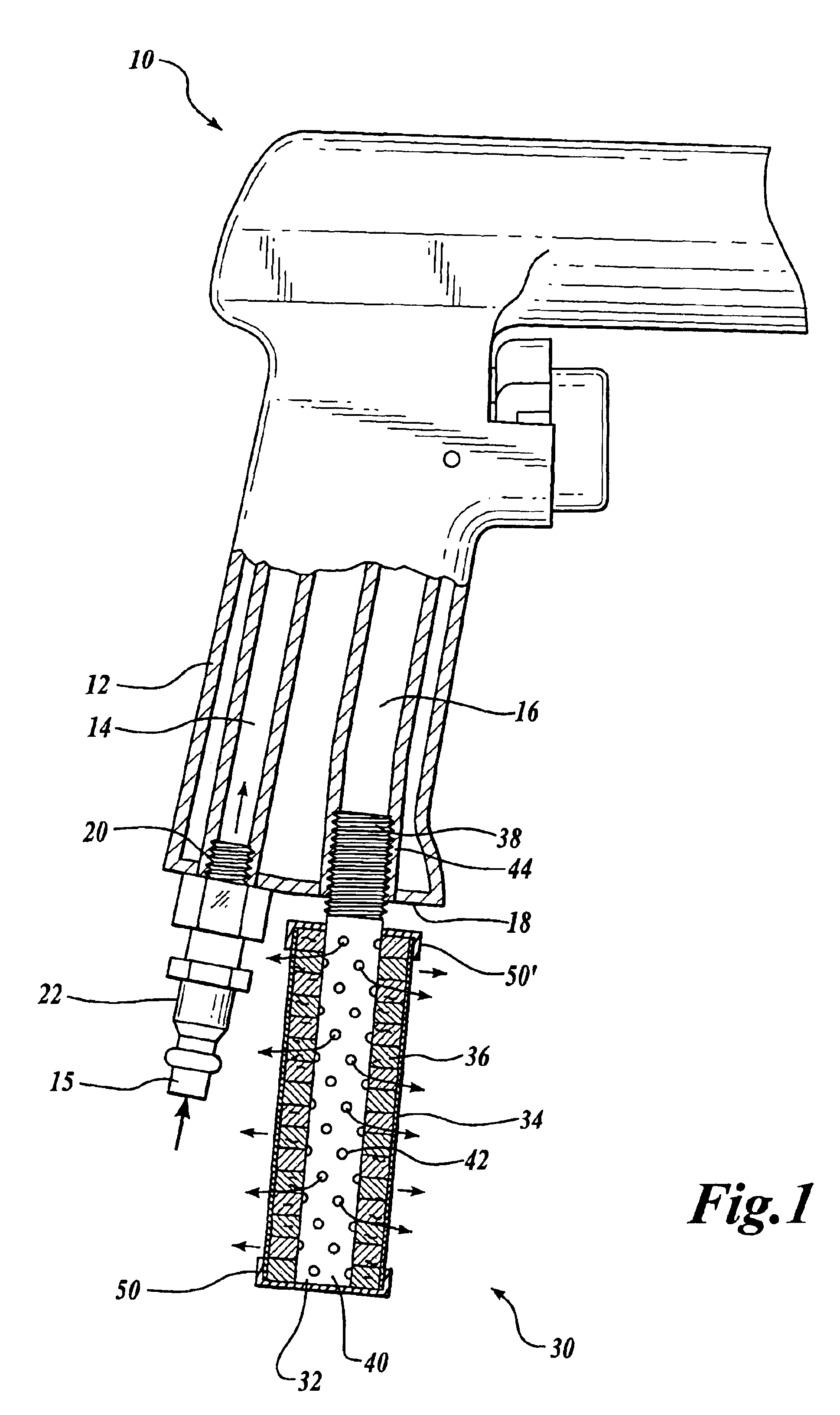

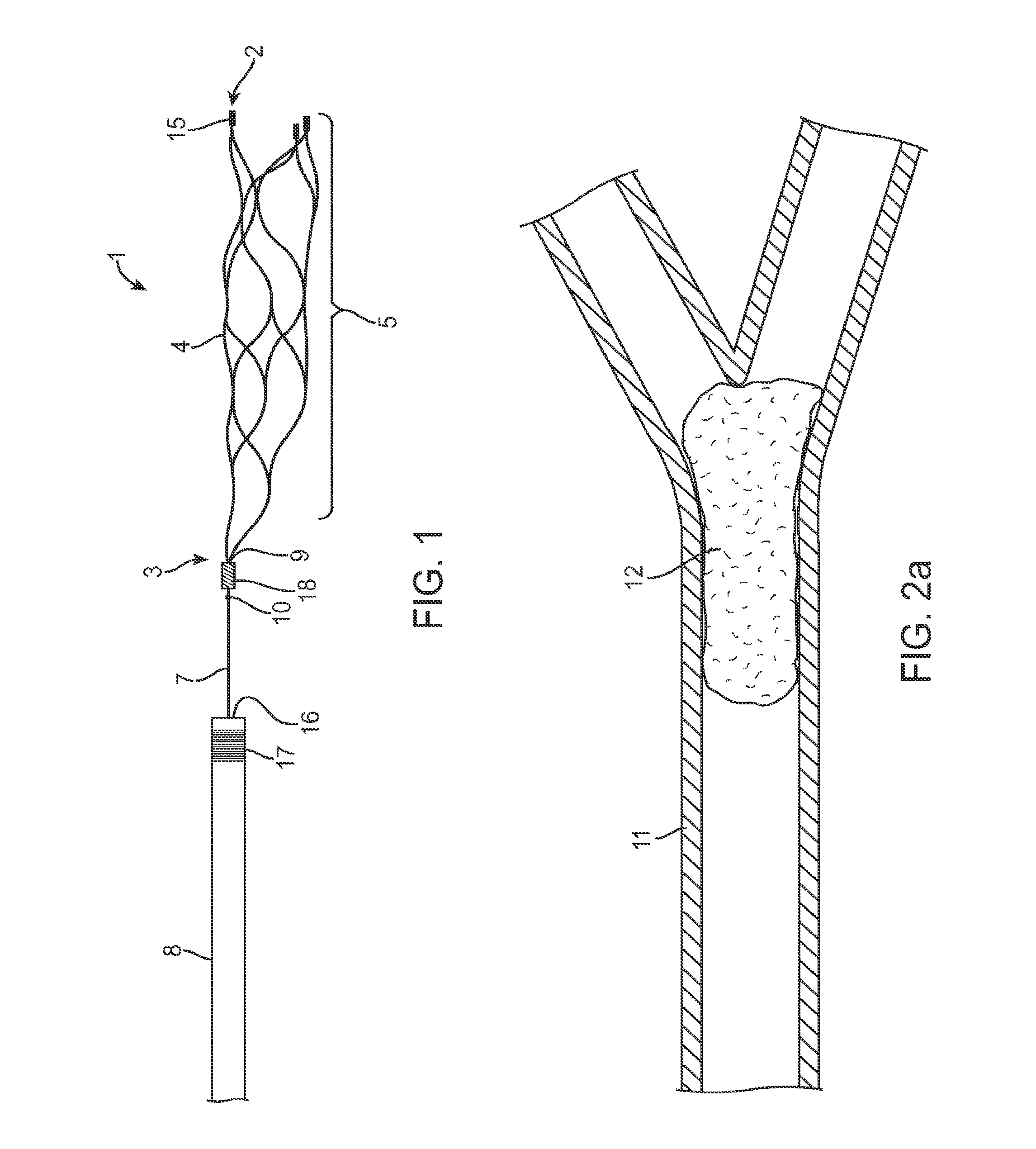

Medical implant having a curlable matrix structure

InactiveUS7300458B2Reduce the overall diameterEasy to slideStentsCatheterReticular formationGuide wires

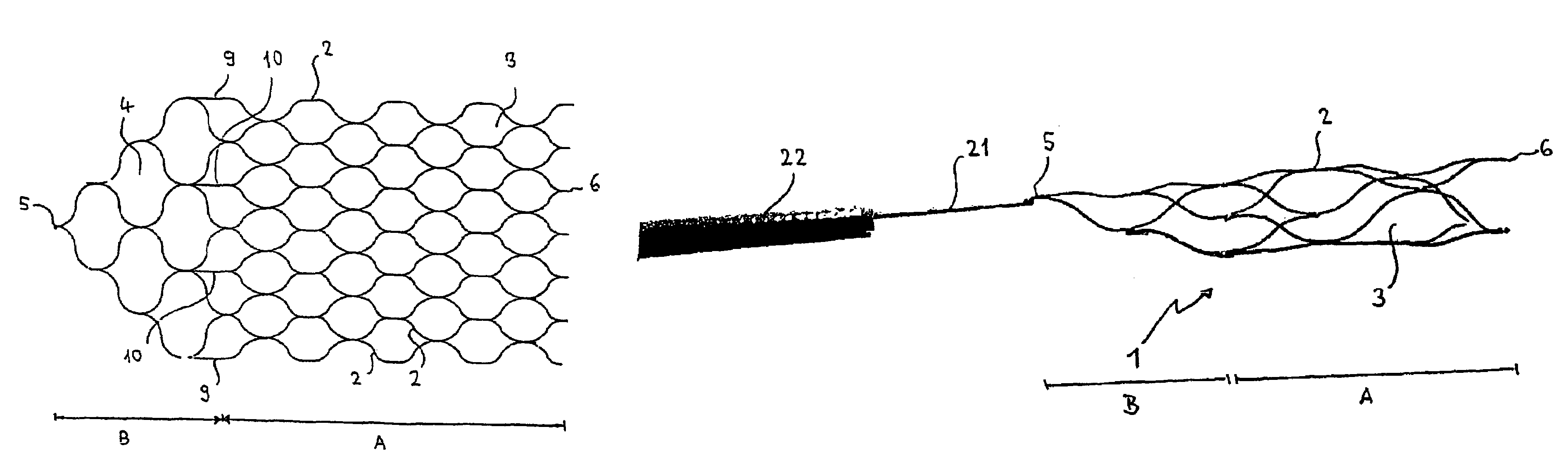

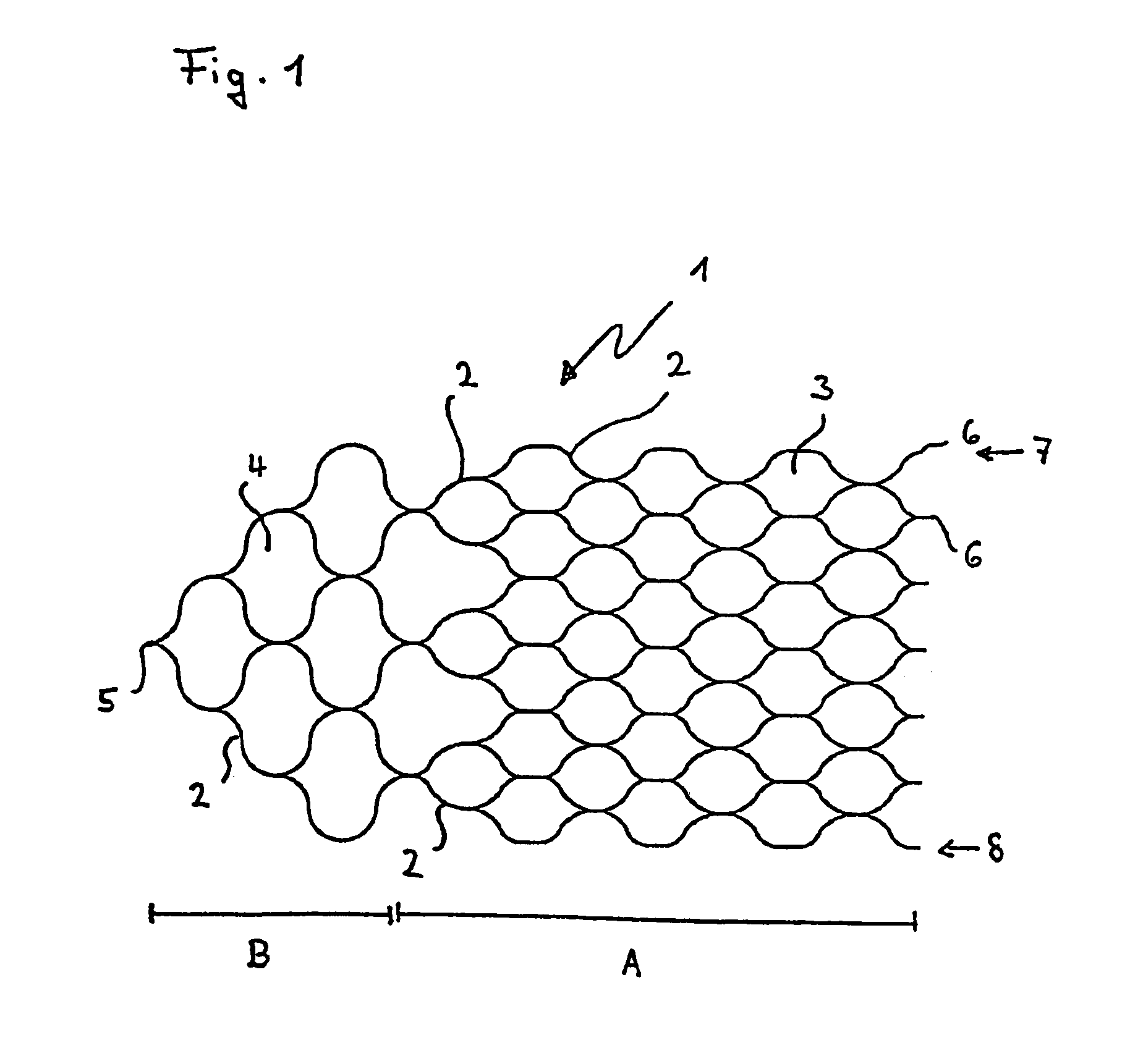

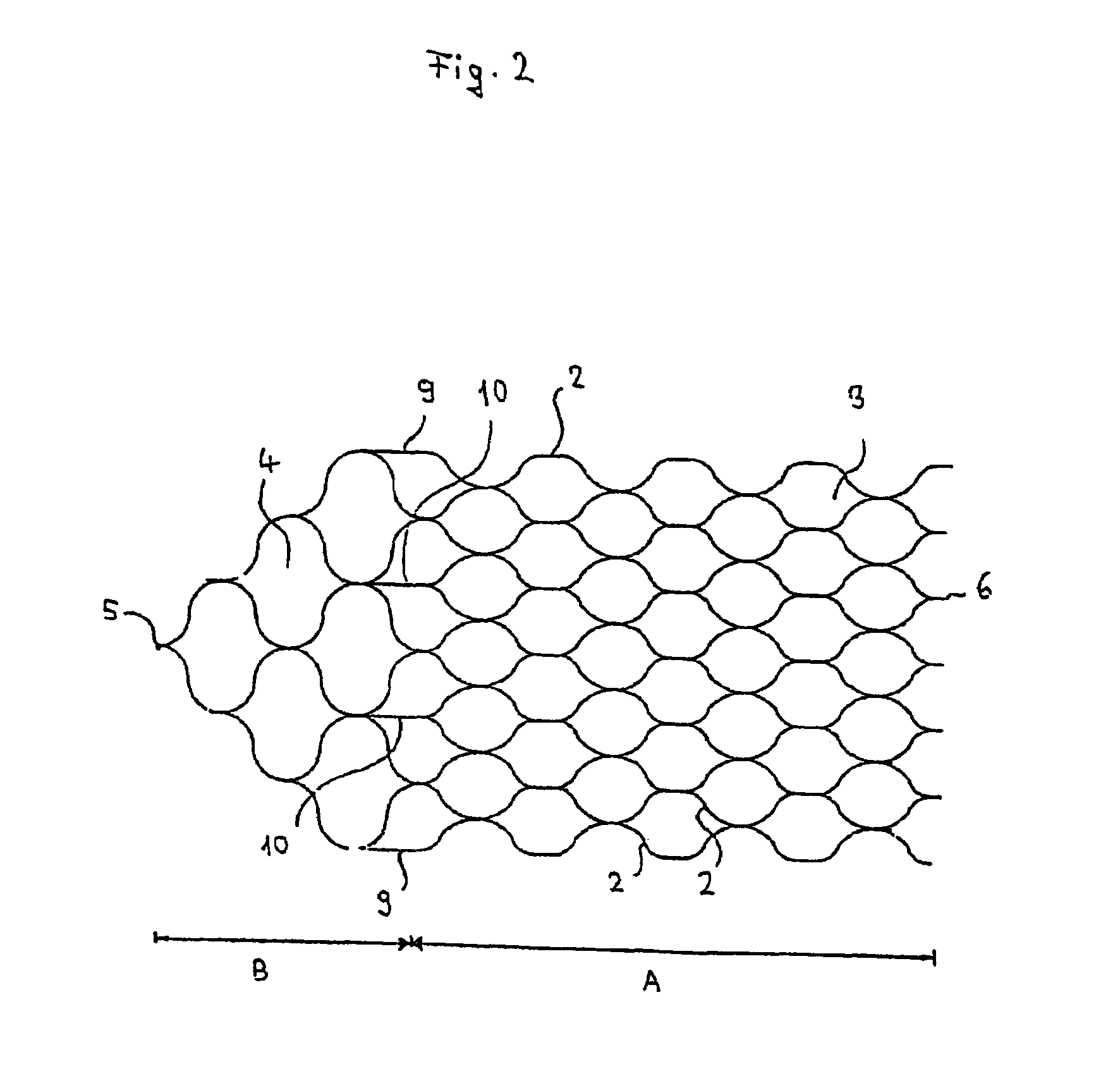

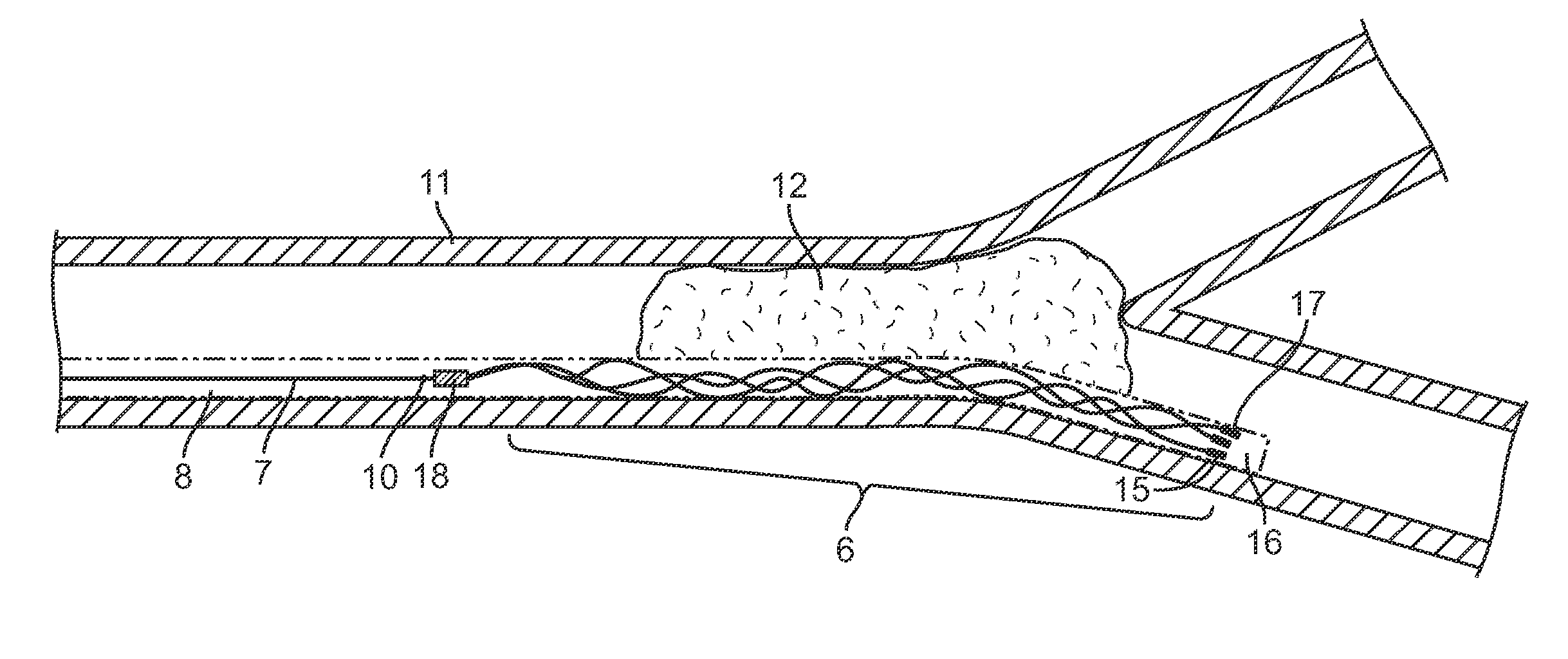

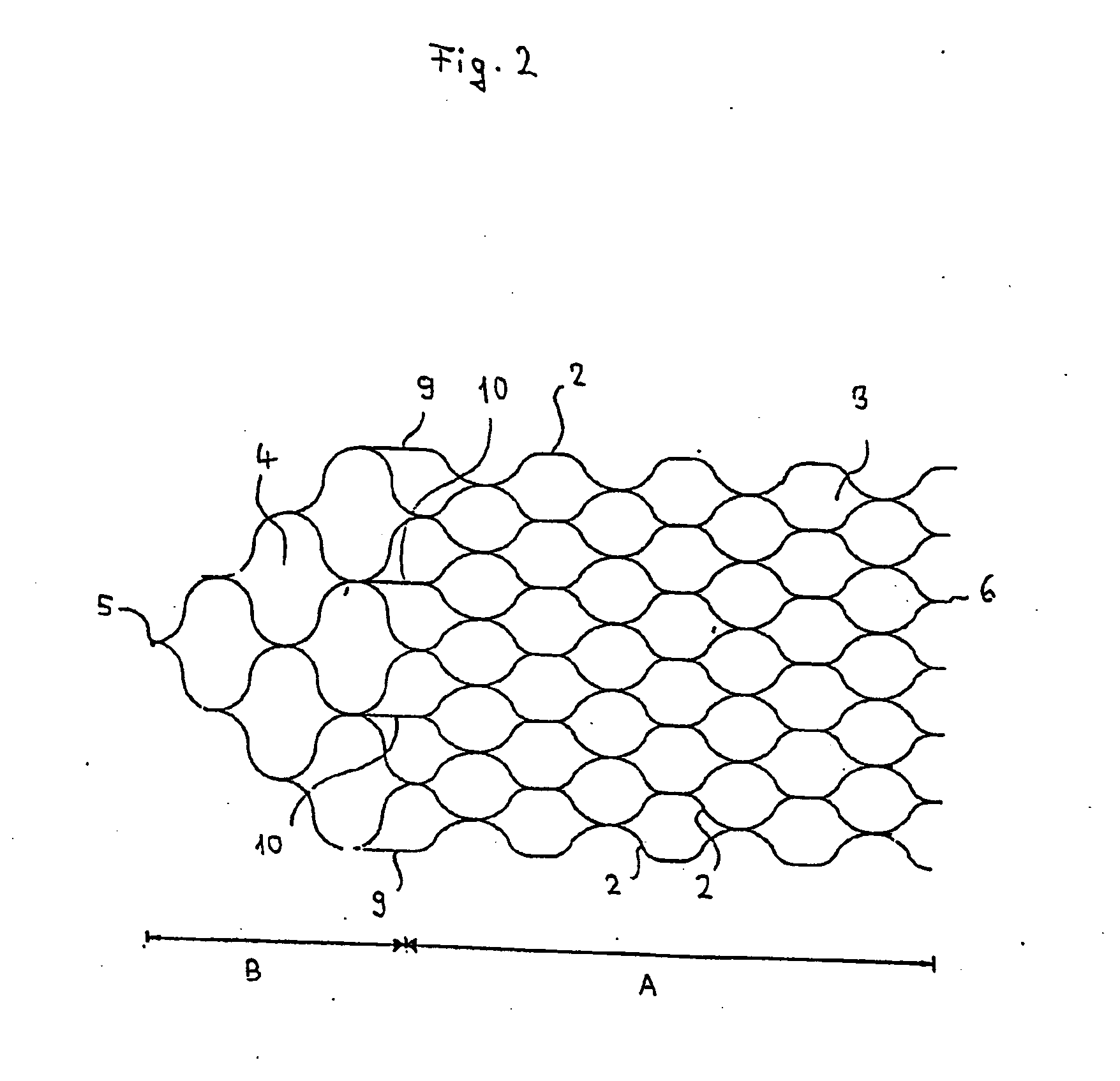

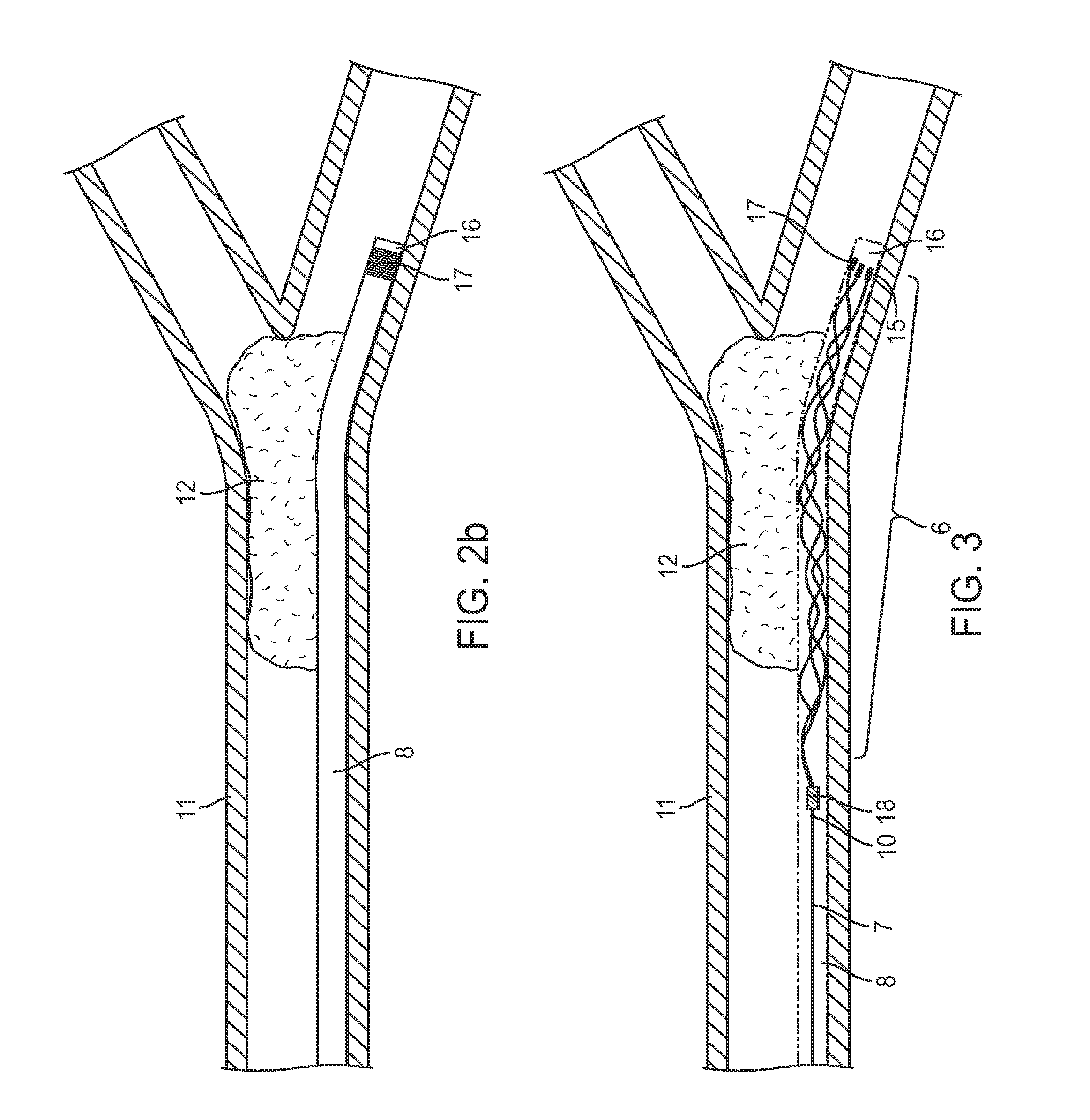

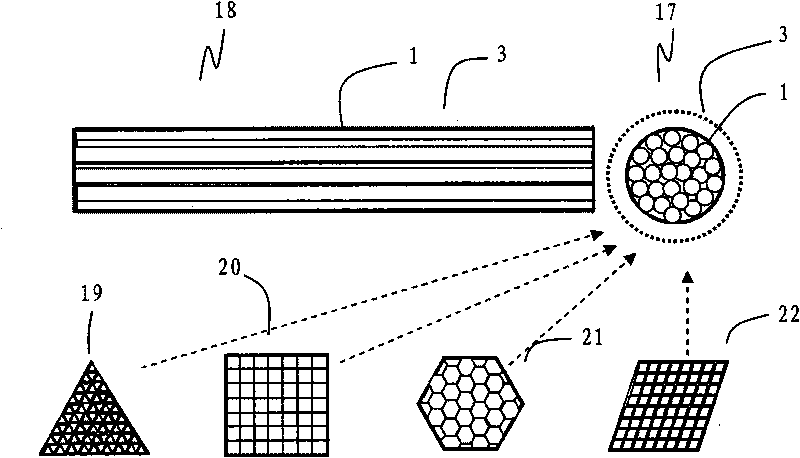

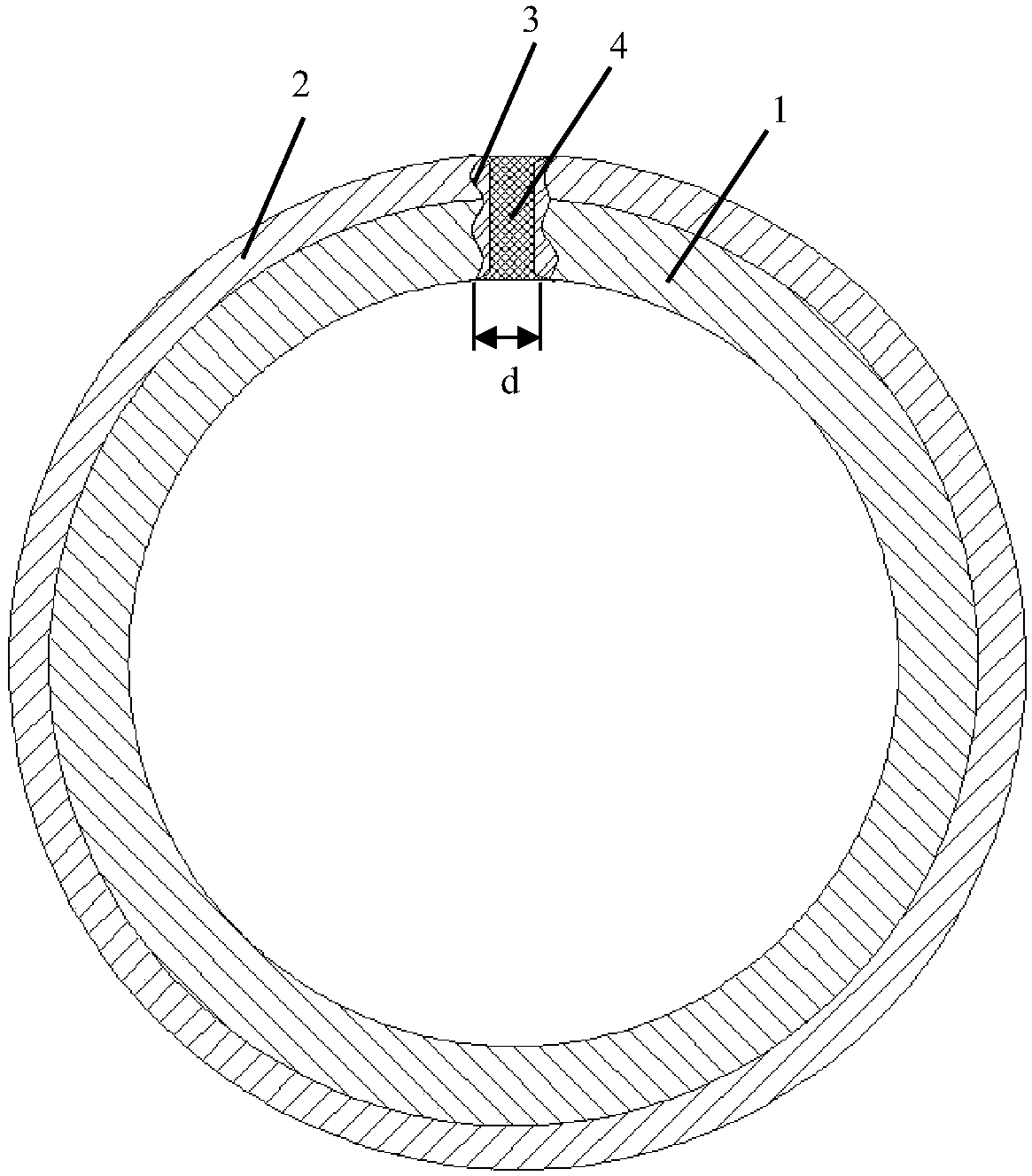

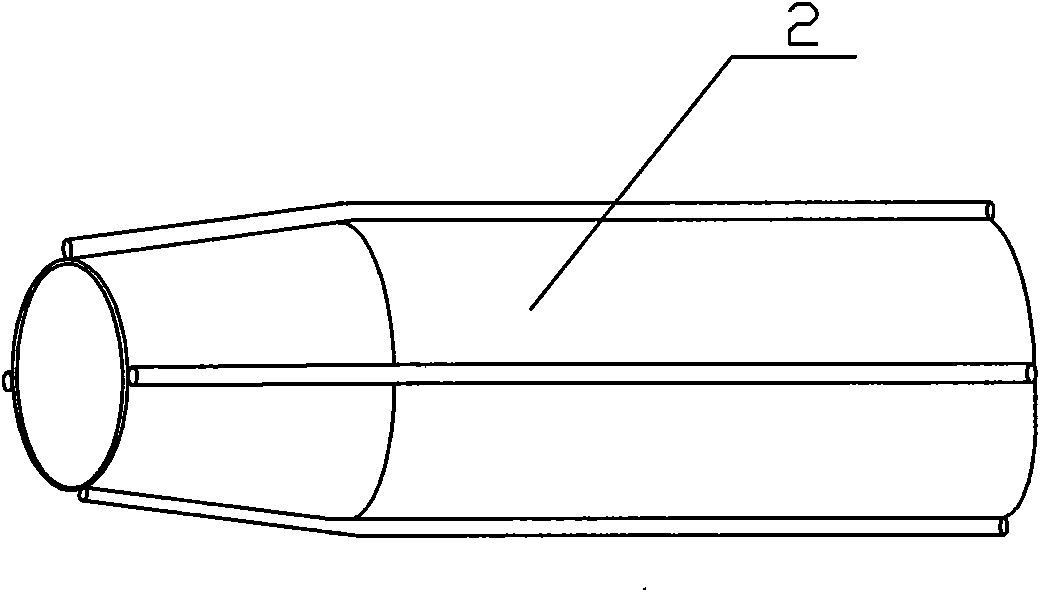

A medical implant, having a proximal and a distal end, that is preformed to assume a superimposed structure at an implantation site but can be made to take on a volume-reduced form making it possible to introduce it with a micro-catheter and a guide wire arranged at the proximal end, with the implant in its superimposed structure assuming the form of a longitudinally open tube and having a mesh structure of interconnected strings or filaments. The implant has a tapering structure at its proximal end where the strings or filaments converge at a connection point.

Owner:USSC MEDICAL GMBH

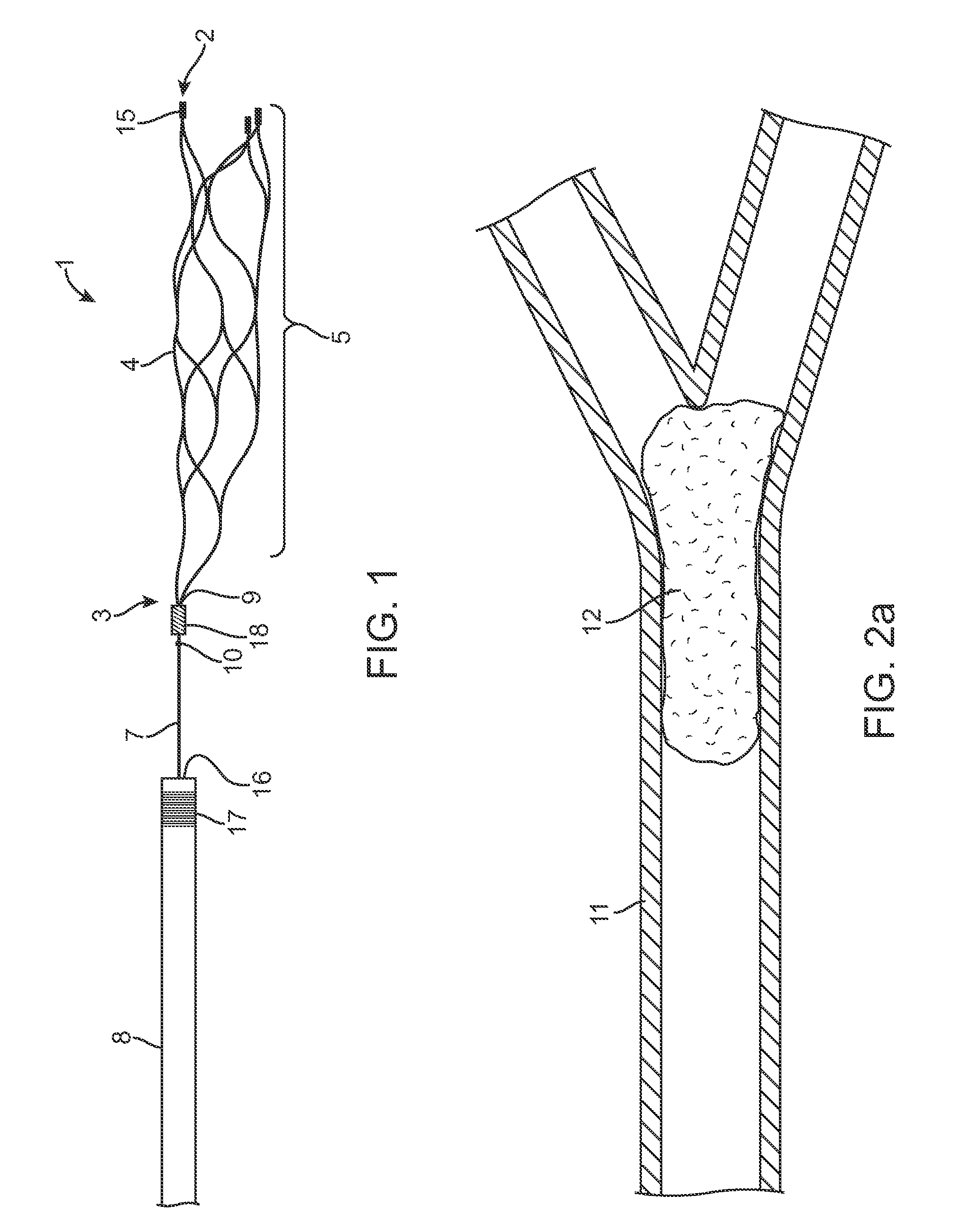

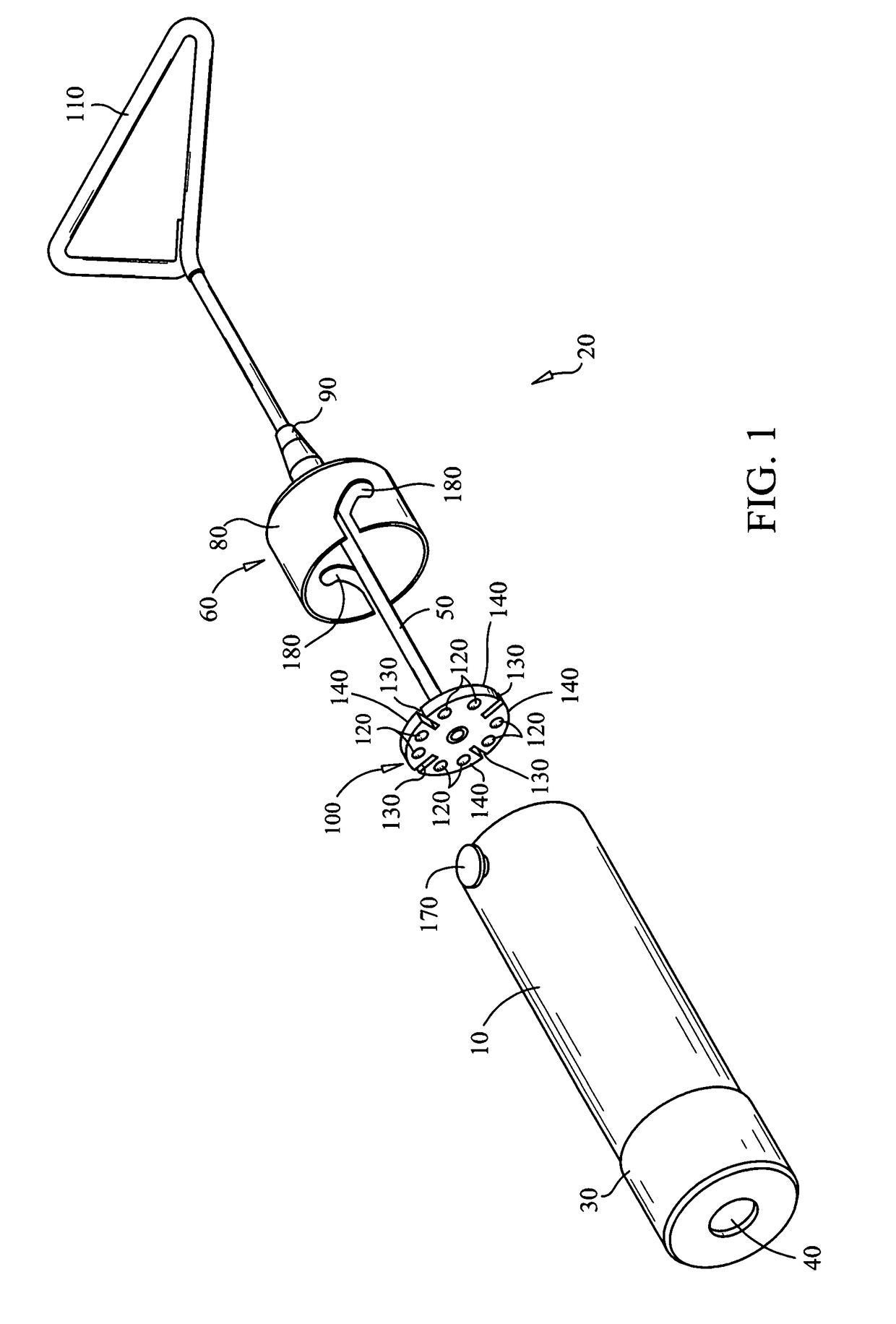

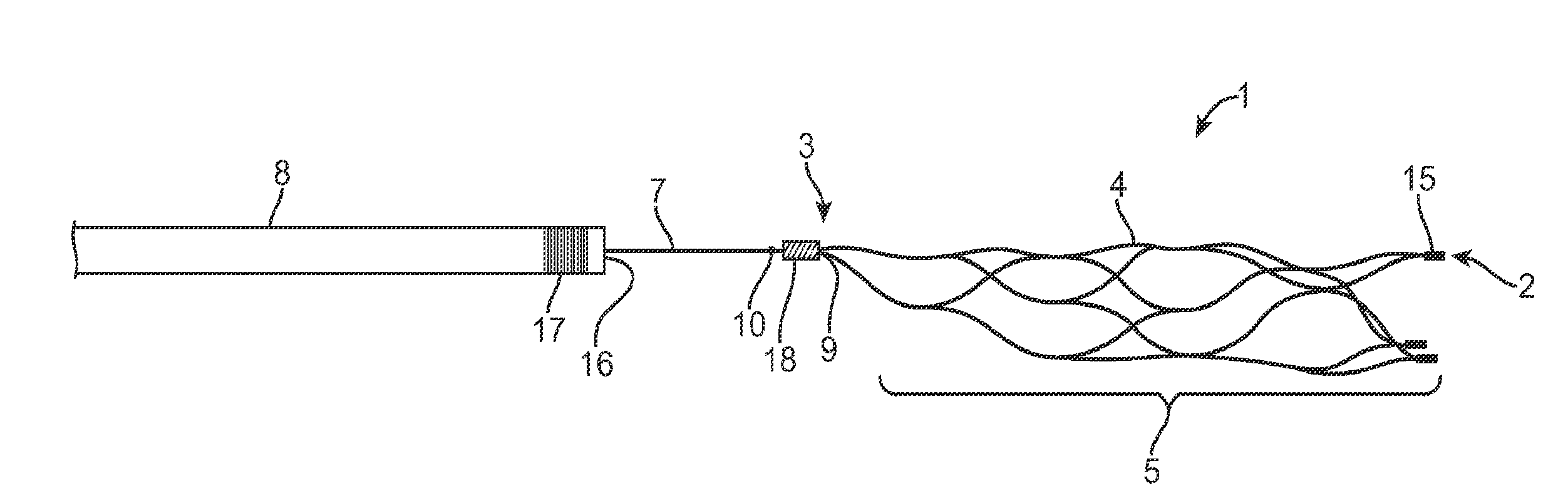

Methods and apparatus for flow restoration

Methods for restoring blood flow in occluded blood vessels using an apparatus having a self expandable distal segment that is pre-formed to assume a superimposed structure in an unconstrained condition but can be made to take on a volume-reduced form making it possible to introduce it with a microcatheter and a push wire arranged at the proximal end, with the distal segment in its superimposed structure assuming the form of a longitudinally open tube and having a mesh structure of interconnected strings or filaments or struts. In a preferred embodiment, the distal segment has a tapering structure at its proximal end where the strings or filaments or struts converge at a connection point.

Owner:TYCO HEALTHCARE GRP LP

Medical implant having a curlable matrix structure

A medical implant, having a proximal and a distal end, that is preformed to assume a superimposed structure at an implantation site but can be made to take on a volume-reduced form making it possible to introduce it by means of a micro-catheter and a guide wire arranged at the proximal end, with the implant in its superimposed structure assuming the form of a longitudinally open tube and having a mesh structure of interconnected strings or filaments. The implant has a tapering structure at its proximal end where the strings or filaments converge at a connection point.

Owner:USSC MEDICAL GMBH

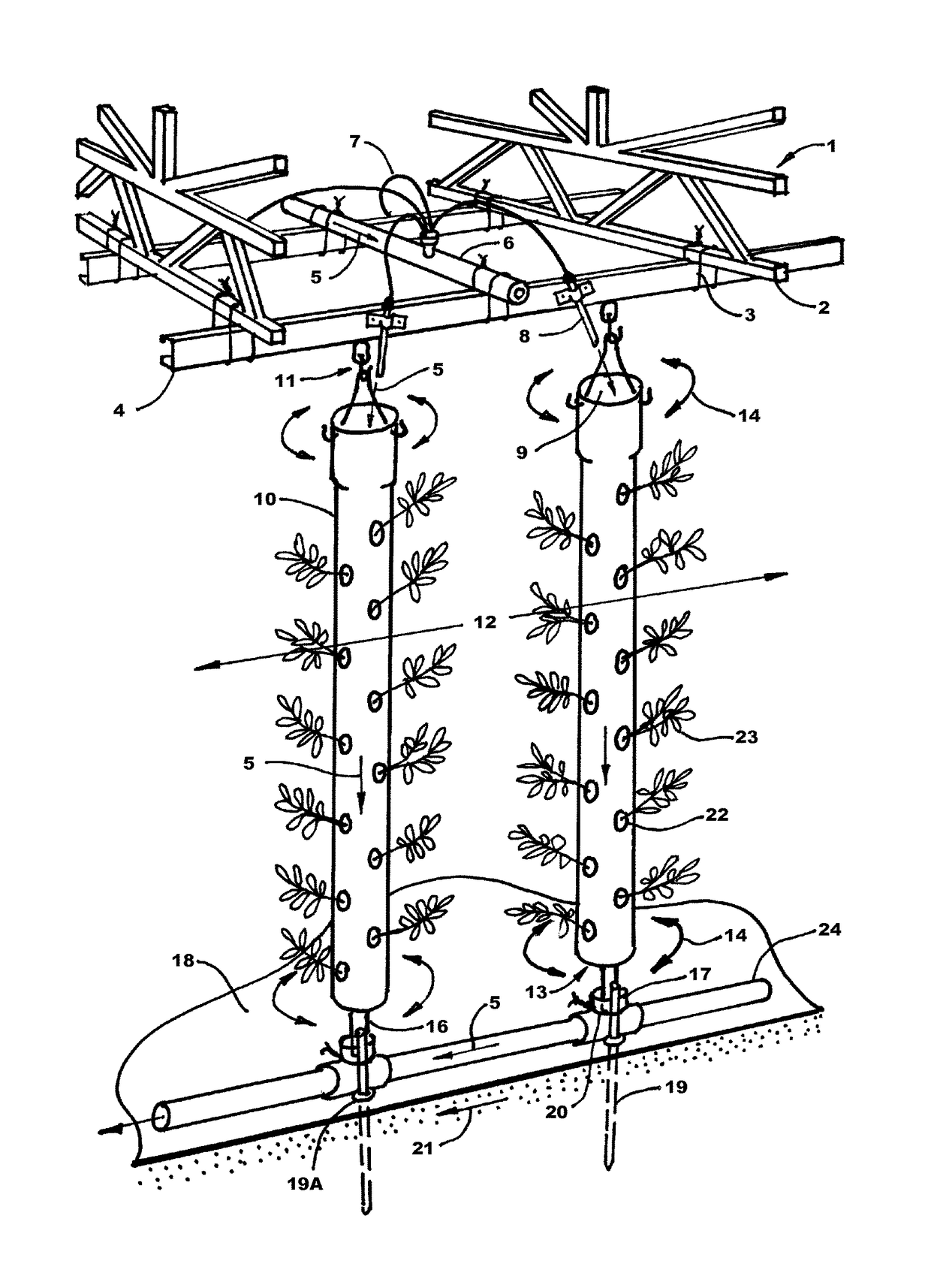

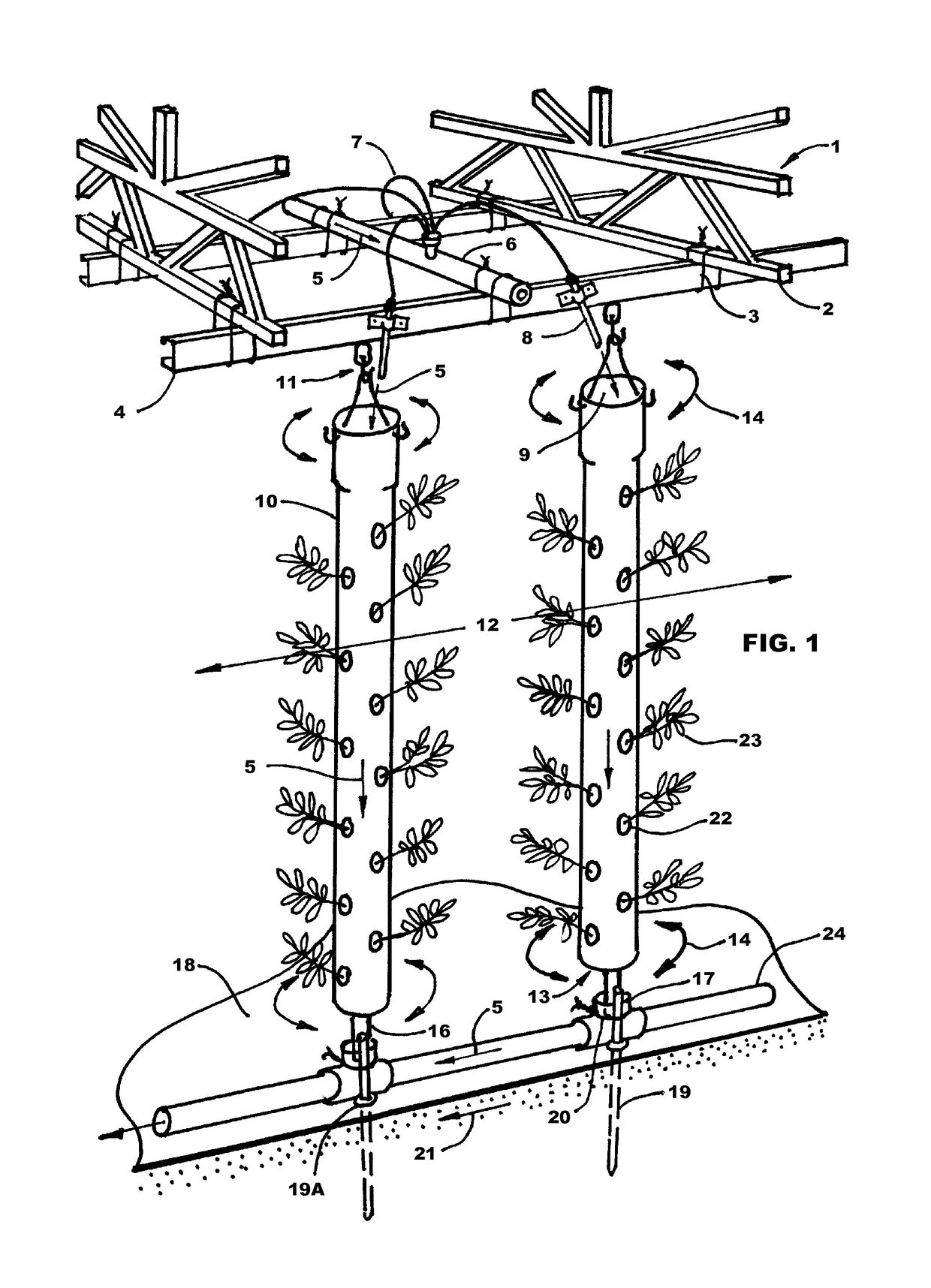

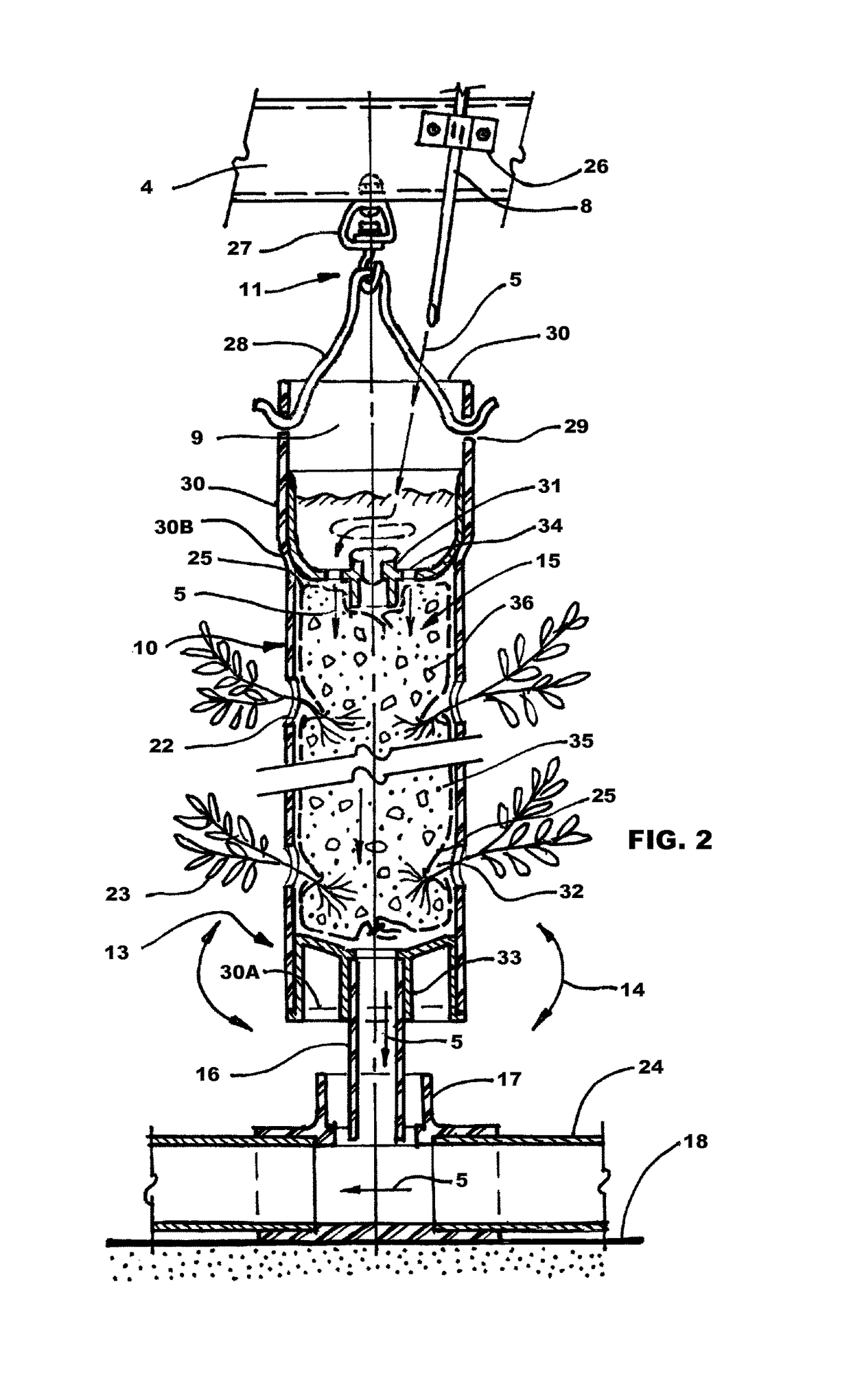

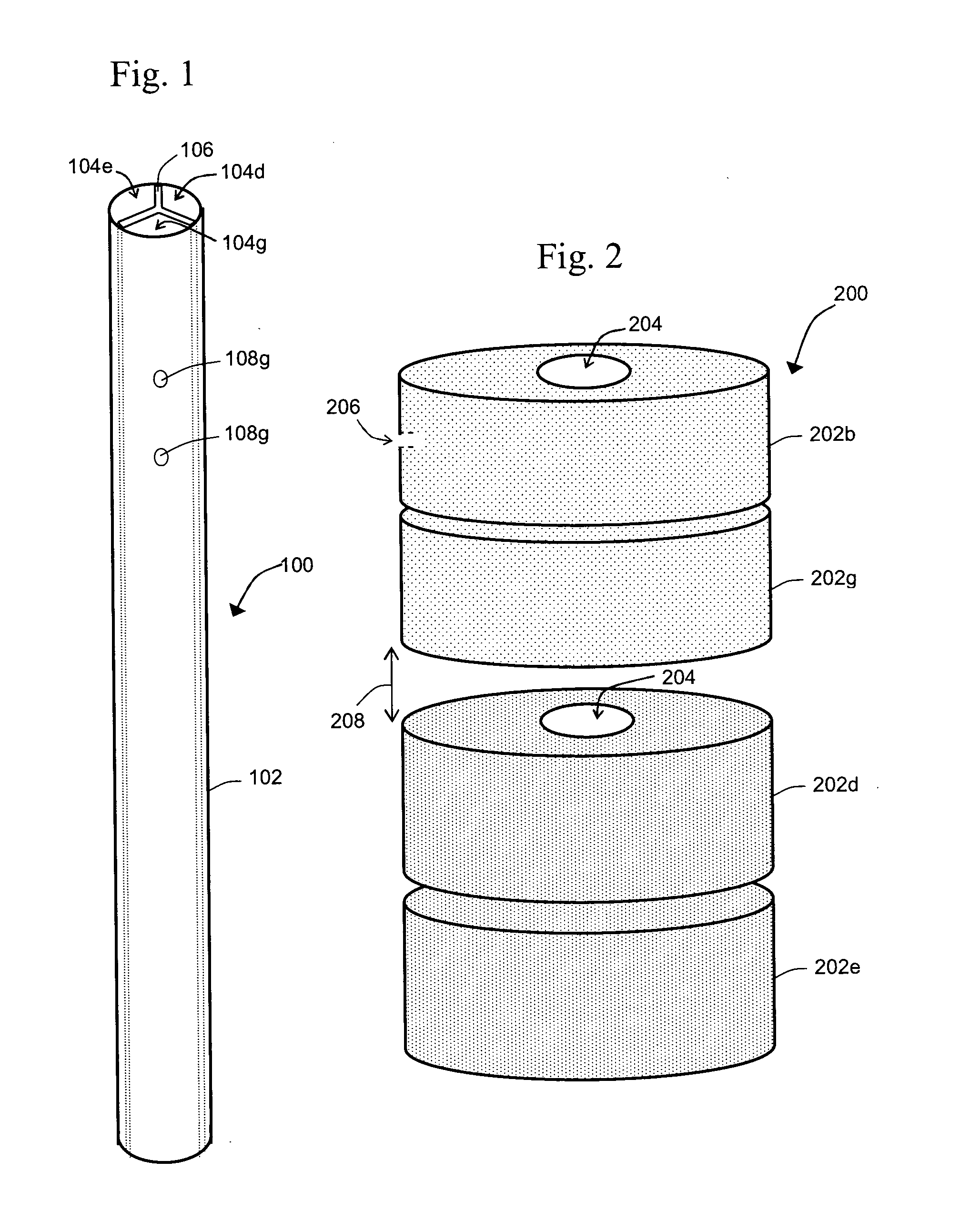

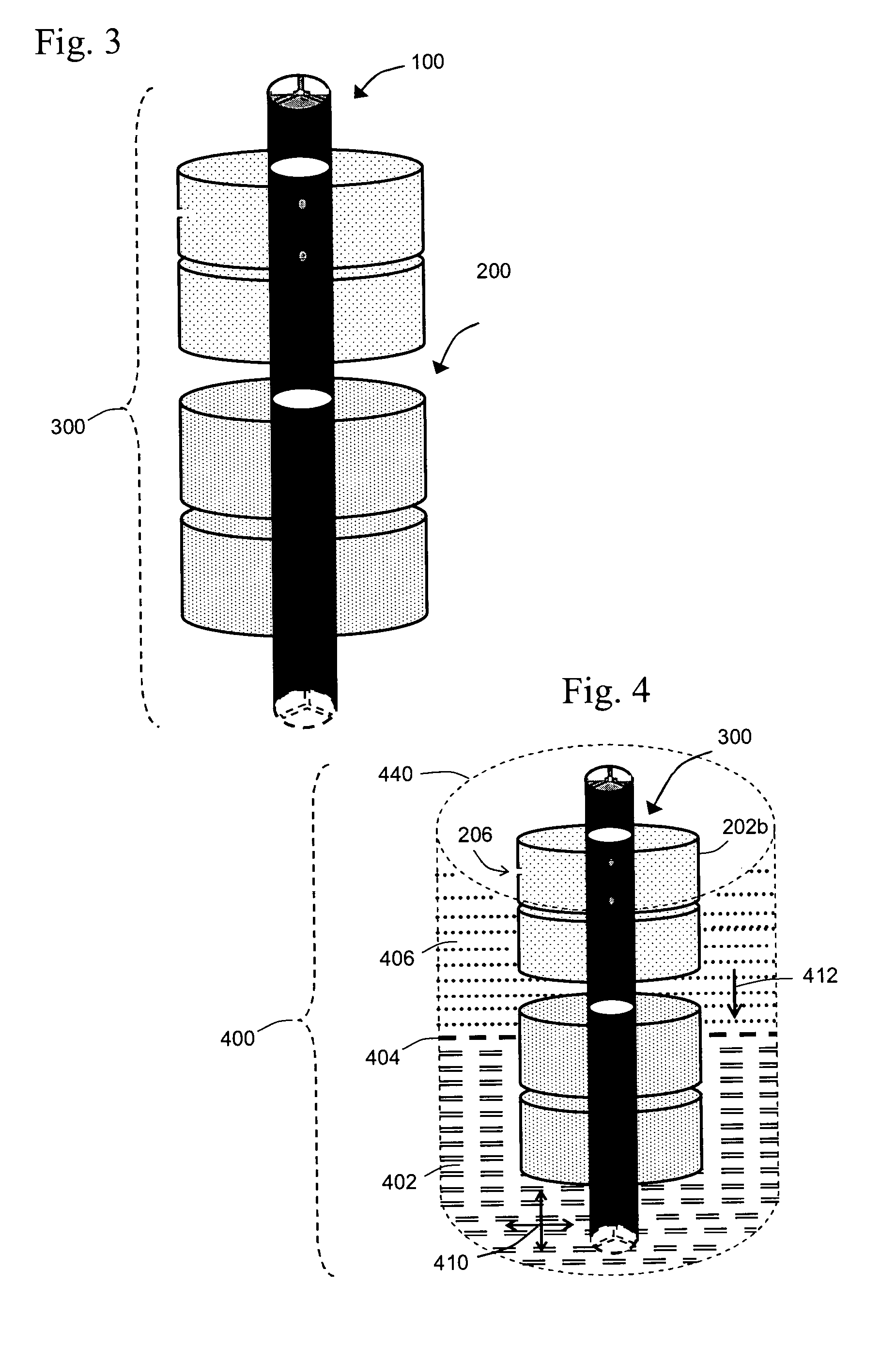

Light-weight modular adjustable vertical hydroponic growing system and method

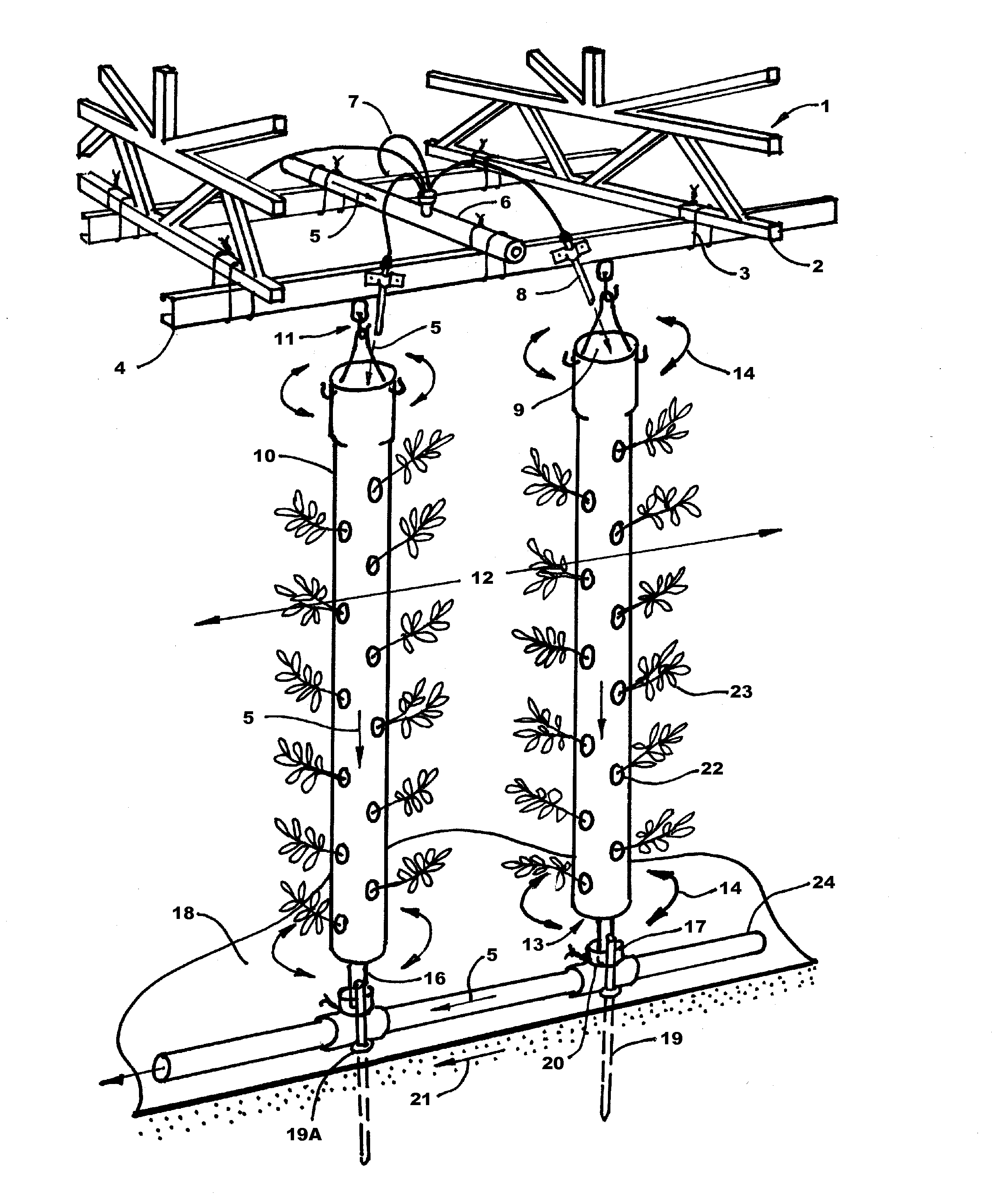

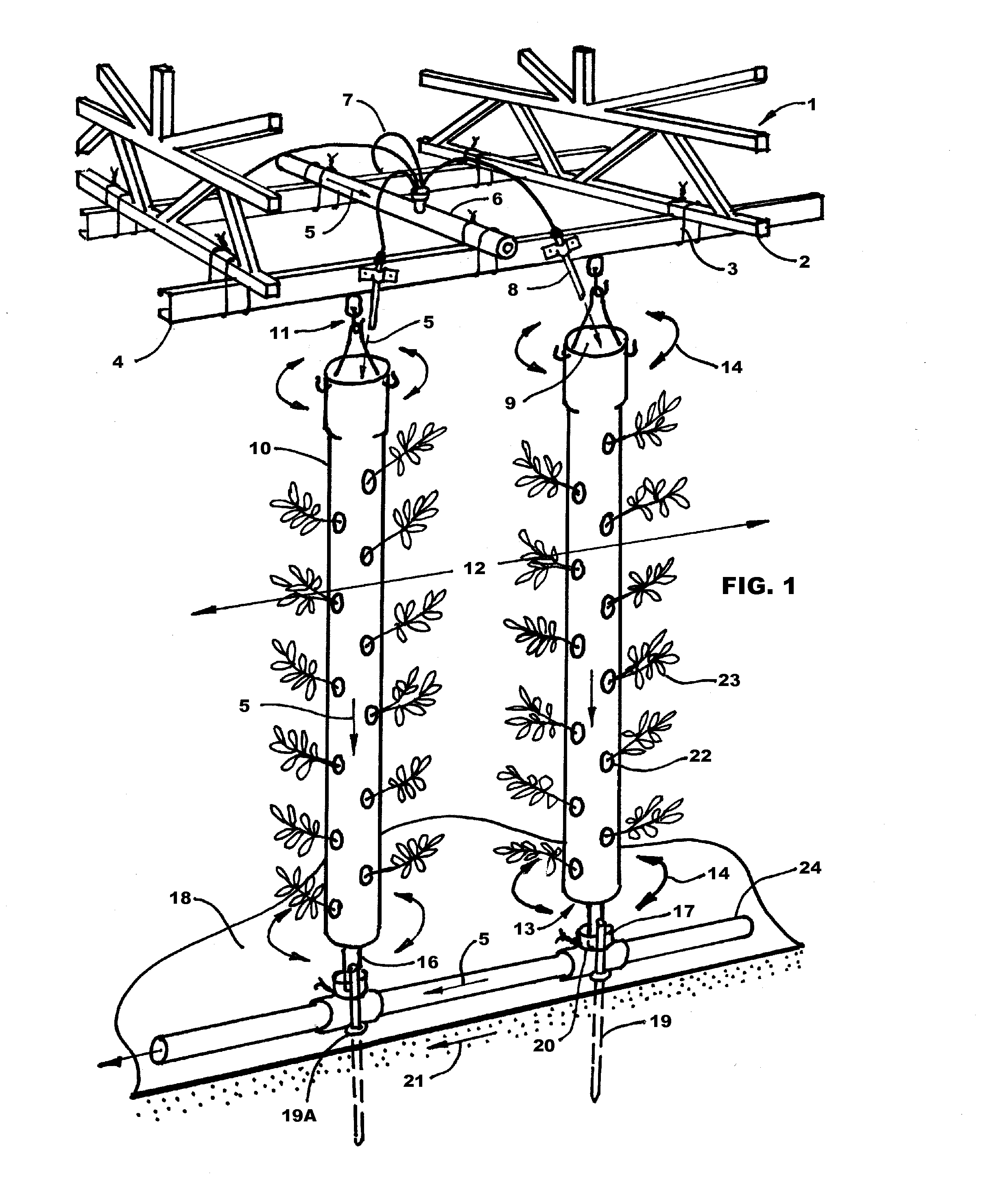

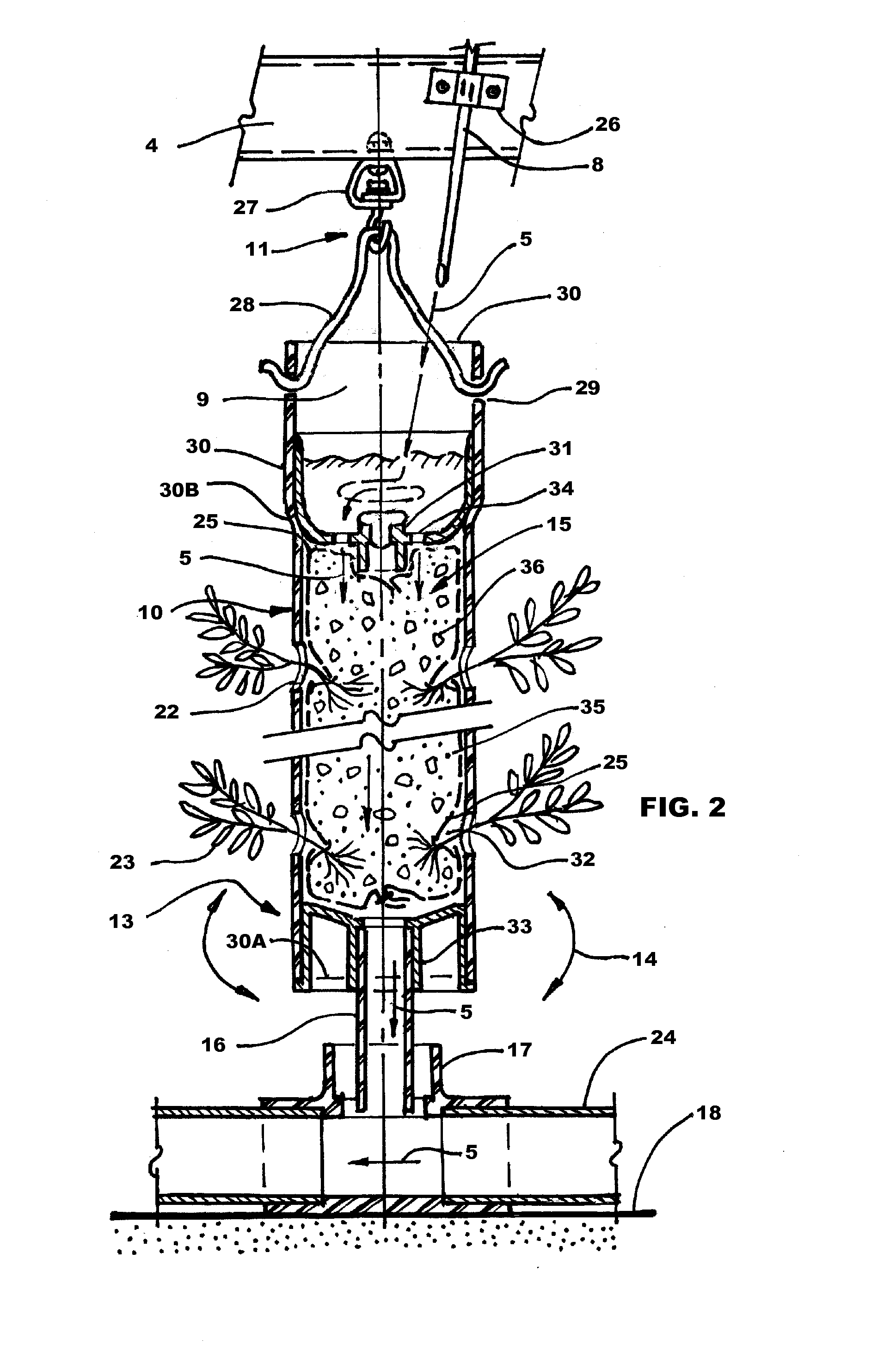

A light-weight, modular, adjustable vertical hydroponic growing system and method of Native American design for cultivation plants and beneficial soil organisms (BSO's) in symbiotic combination. Forest-like arrays of fully rotatable and demountable grow tubes are suspended within climate-moderating greenhouses, optionally from conveyor tracks. The tubes are filled with light-weight, porous 100% in-organic grow media predominately comprised of expanded volcanic or recycled glass granules. The grow tube arrays are provided with an insulated, overhead-mounted fertigation distribution system delivering metered intermittent flows from insulated mixing and holding tanks. The flows are recycled via an insulated return piping system to maintain cool fertigation temperatures near those of natural ground water. Fertigation supply mains provided with vortex flow induction devices impart rotational momentum to flows for delivery of uniform aerated fertigation to plants and BSO's via a combination of open-tube emitters and gravity flows within grow tubes.

Owner:COLLINS FRED +1

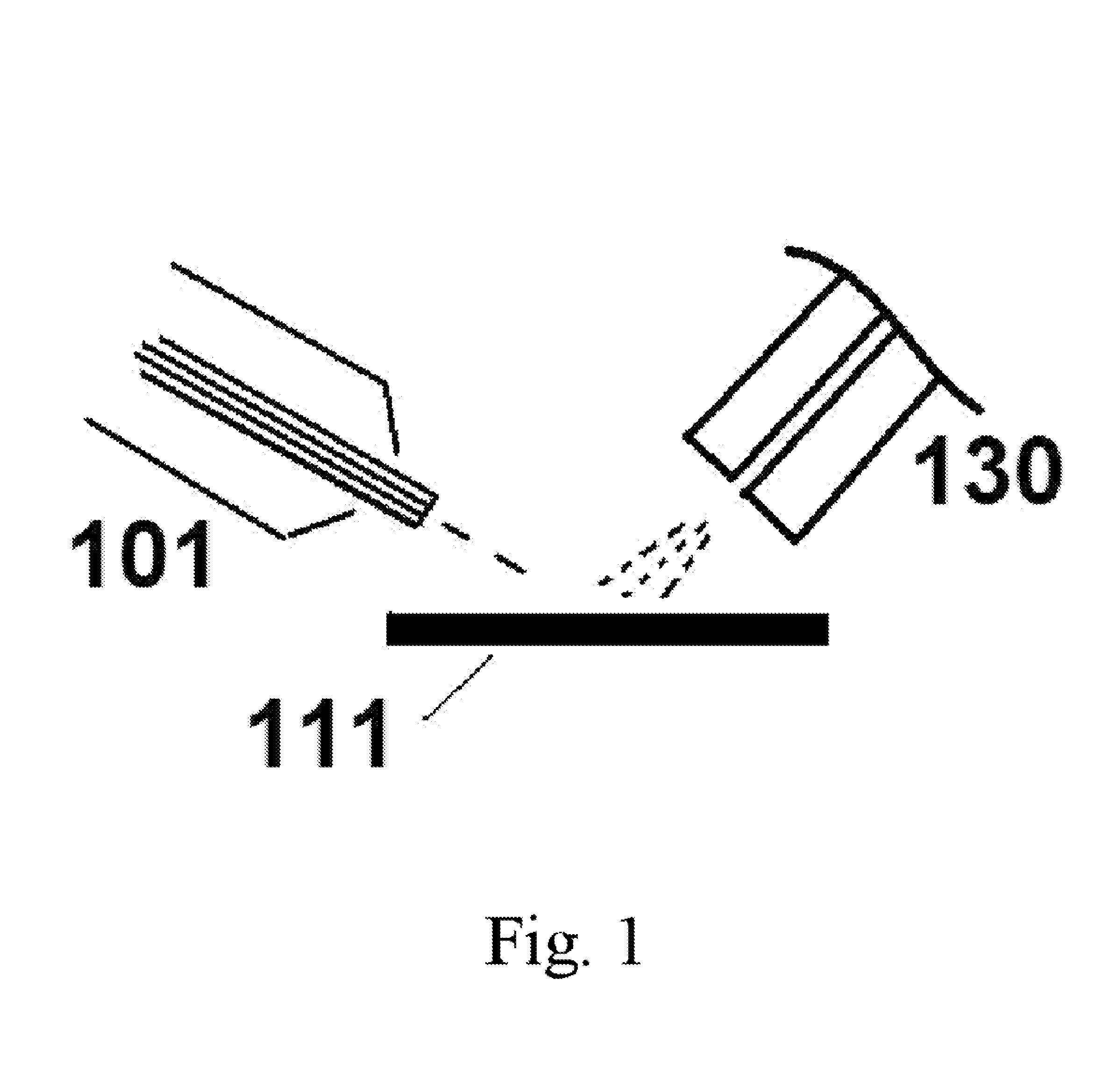

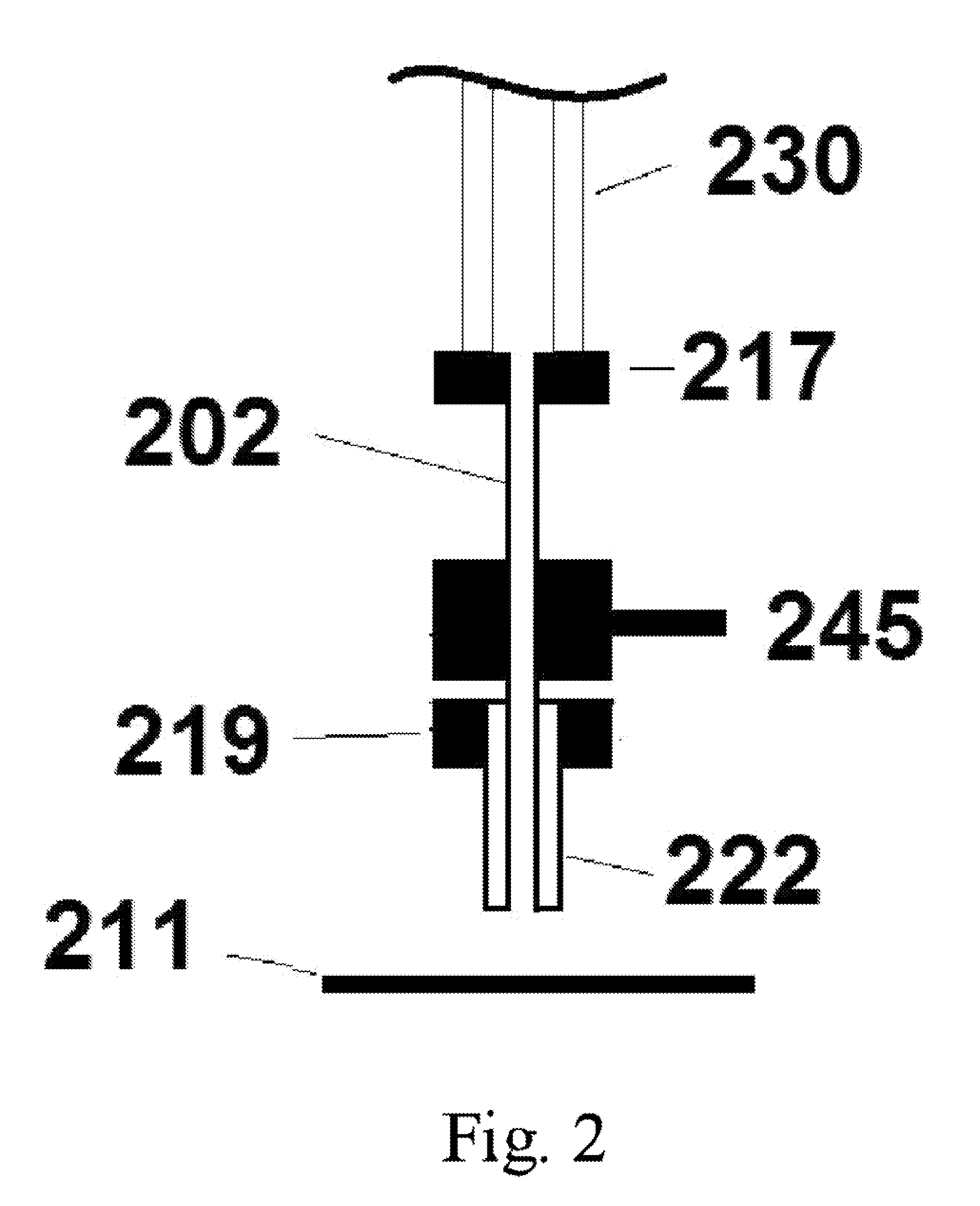

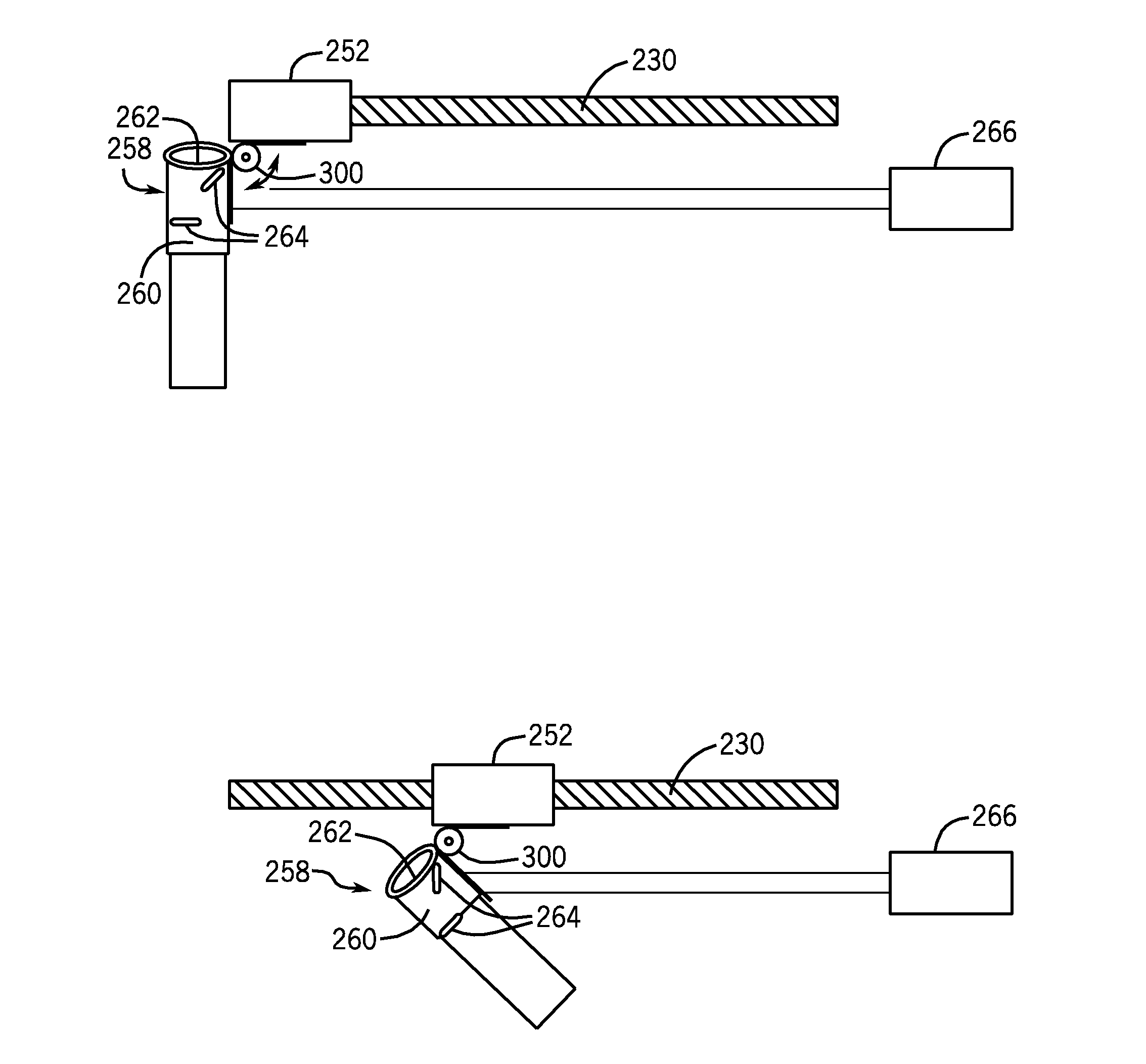

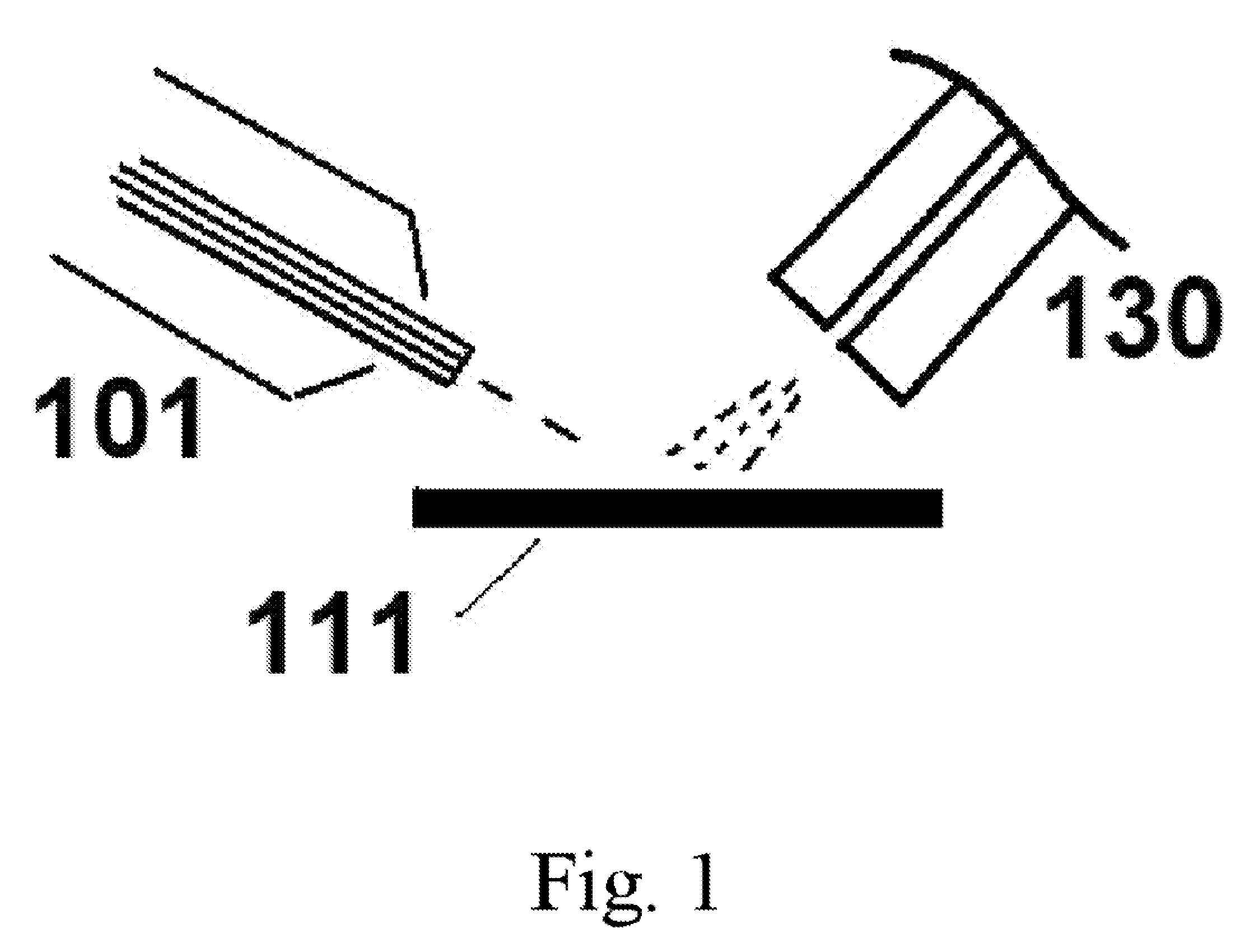

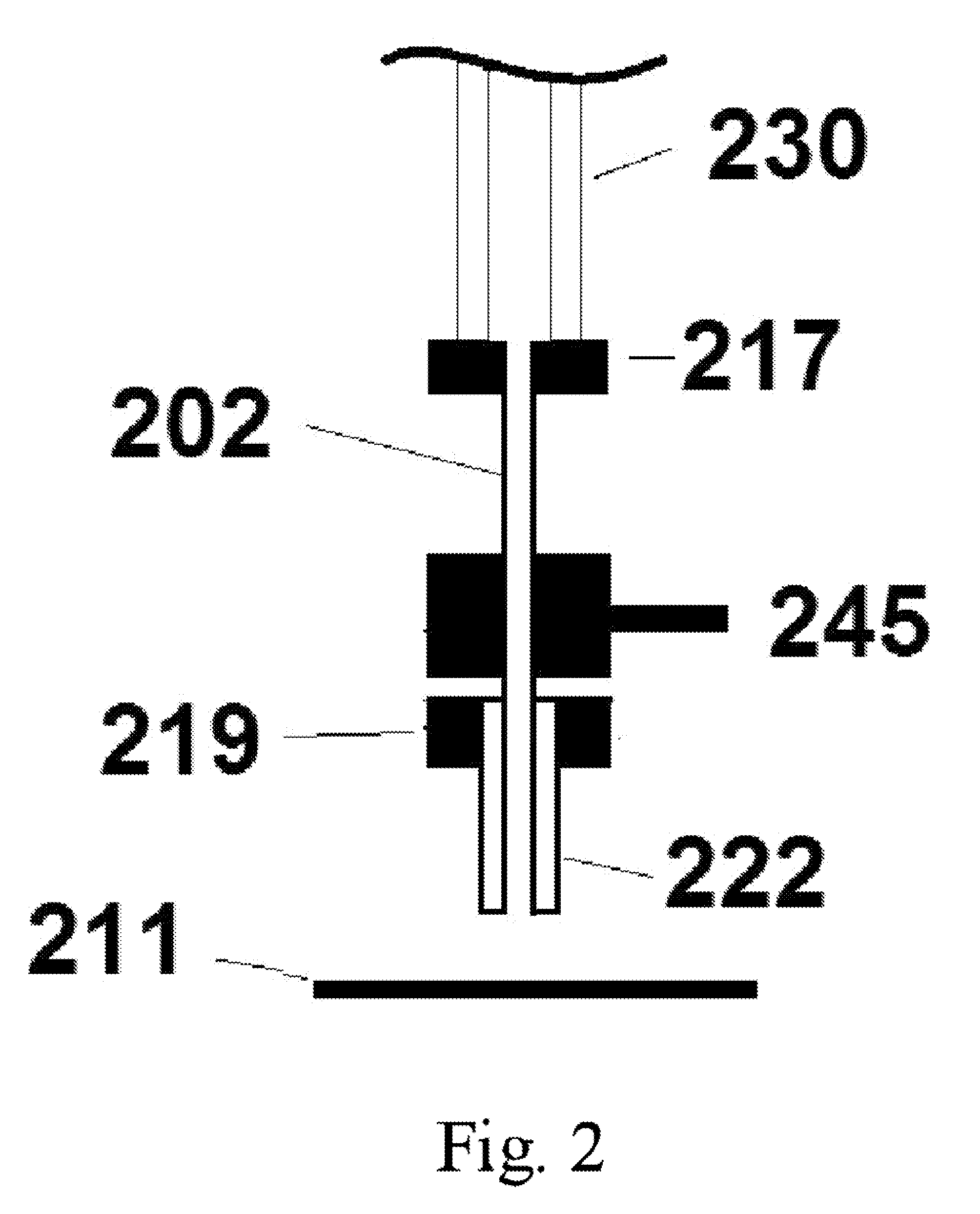

Flexible open tube sampling system for use with surface ionization technology

ActiveUS7705297B2Improve efficiencyStability-of-path spectrometersTime-of-flight spectrometersWide diameterSpectrometer

The present invention is a device to restrict the sampling of analyte ions and neutral molecules from surfaces with mass spectrometry and thereby sample from a defined area or volume. In various embodiments of the present invention, a tube is used to sample ions formed with a defined spatial resolution from desorption ionization at or near atmospheric pressures. In an embodiment of the present invention, electrostatic fields are used to direct ions to either individual tubes or a plurality of tubes positioned in close proximity to the surface of the sample being analyzed. In an embodiment of the present invention, wide diameter sampling tubes can be used in combination with a vacuum inlet to draw ions and neutrals into the spectrometer for analysis. In an embodiment of the present invention, wide diameter sampling tubes in combination with electrostatic fields improve the efficiency of ion collection.

Owner:BRUKER SCI LLC

Light-weight modular adjustable vertical hydroponic growing system and method

A light-weight, modular, adjustable vertical hydroponic growing system and method of Native American design for cultivation plants and beneficial soil organisms (BSO's) in symbiotic combination. Forest-like arrays of fully rotatable and demountable grow tubes are suspended within climate-moderating greenhouses, optionally from conveyor tracks. The tubes are filled with light-weight, porous 100% in-organic grow media predominately comprised of expanded volcanic or recycled glass granules. The grow tube arrays are provided with an insulated, overhead-mounted fertigation distribution system delivering metered intermittent flows from insulated mixing and holding tanks. The flows are recycled via an insulated return piping system to maintain cool fertigation temperatures near those of natural ground water. Fertigation supply mains provided with vortex flow induction devices impart rotational momentum to flows for delivery of uniform aerated fertigation to plants and BSO's via a combination of open-tube emitters and gravity flows within grow tubes.

Owner:COLLINS FRED +1

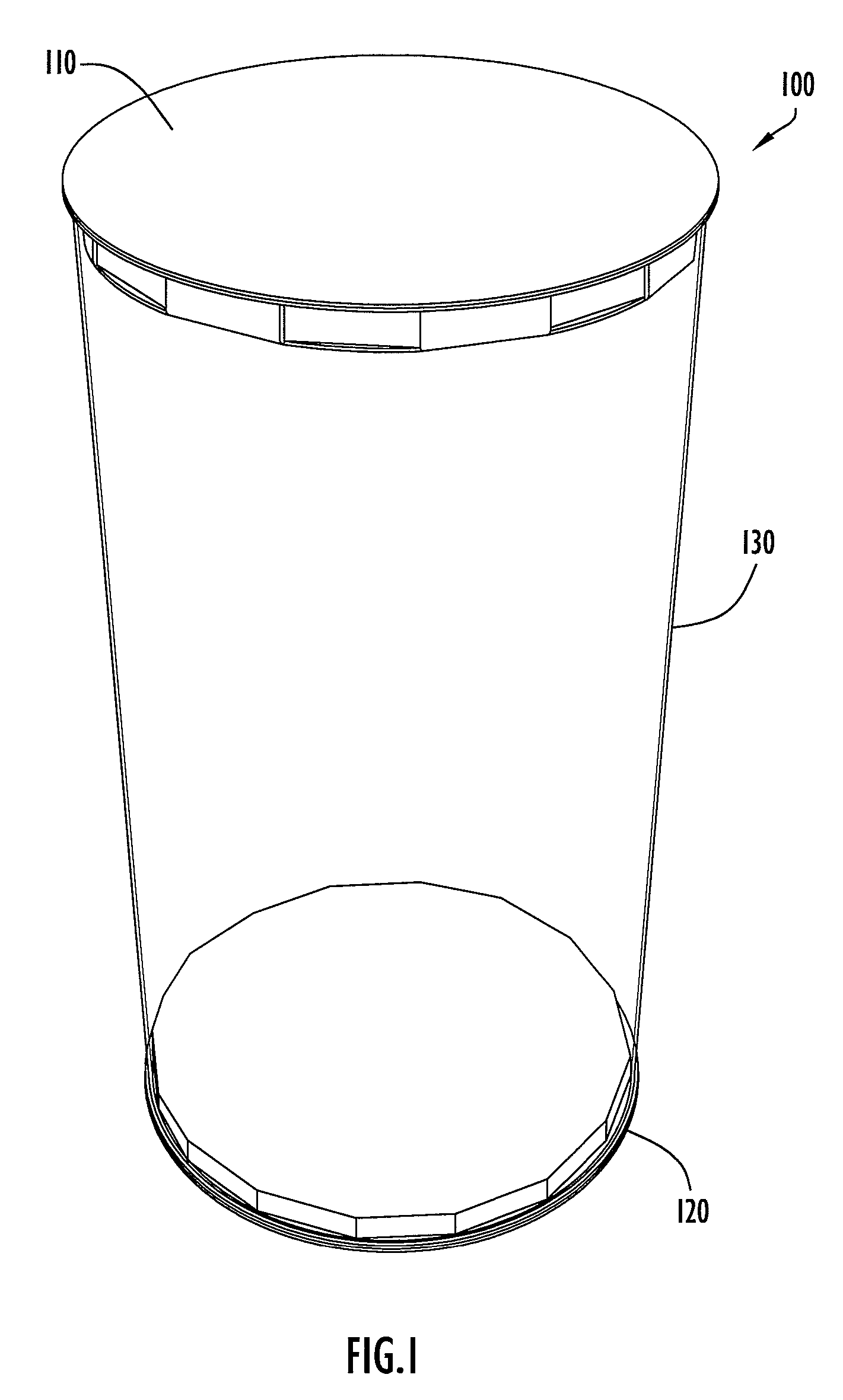

System, apparatus, and method for closed tube sampling and open tube sampling for automated clinical analyzers

InactiveUS20120308435A1Reduce riskReducing throughputComponent separationDispersed particle separationCentrifugationEngineering

A centrifuge to which sample tubes can be introduced while the centrifuge is in motion. The centrifuge comprises a carousel having an upper portion and a lower portion. The upper portion of the carousel has a plurality of positions for sample tubes for a centrifugation operation, a plurality of drive mechanisms attached to the upper portion of the carousel, a movable element mounted upon each drive mechanism, the movable element capable of traversing the length of the drive mechanism when the drive mechanism is actuated, a sample tube-holding assembly comprising a sample tube holder and a bearing attached to each movable element, and at least one balancing element capable of contributing to a force vector that cancels an imbalance vector generated by rotation of the centrifuge.

Owner:ABBOTT LAB INC

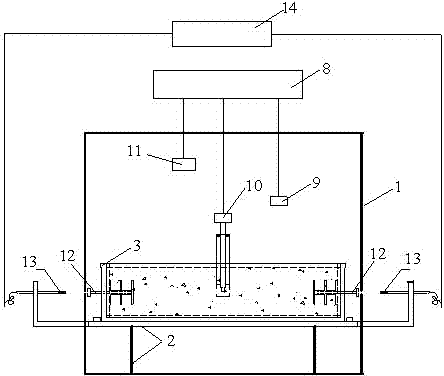

Method and apparatus for measuring early-stage autogenous shrinkage of cement-based material

InactiveCN103837670AAvoid errorsAutomatic adjustment of curing temperaturePreparing sample for investigationMaterial testing goodsEngineeringThreaded rod

The invention discloses an apparatus for measuring early-stage autogenous shrinkage of a cement-based material. The apparatus comprises a test piece die, a pre-embedded target and a displacement measurement system, wherein the test piece die comprises an outer die and an inner die, the outer die is a box-like cuboid with an open upper end, the inner die is a rectangular frame which can be accommodated in the outer die, corresponding positions of two opposite end faces of the outer die and two opposite end faces of the inner die are respectively provided with a circular through hole, the pre-embedded target comprises an internal thread open tube and a threaded rod mutually fitting, the threaded rod can pass through the circular through holes in the inner die and the outer die, the displacement measurement system is a non-contact displacement measurement system and comprises a displacement sensor and a displacement signal acquisition and processing unit, and the displacement sensor can monitor displacement of the pre-embedded target and transmits monitored displacement information to the displacement signal acquisition and processing unit for processing. The invention further discloses a method for measuring early-stage autogenous shrinkage of the cement-based material. According to the invention, testing can be carried before prehardening, and the apparatus has the advantages of a simple structure and low cost.

Owner:HOHAI UNIV

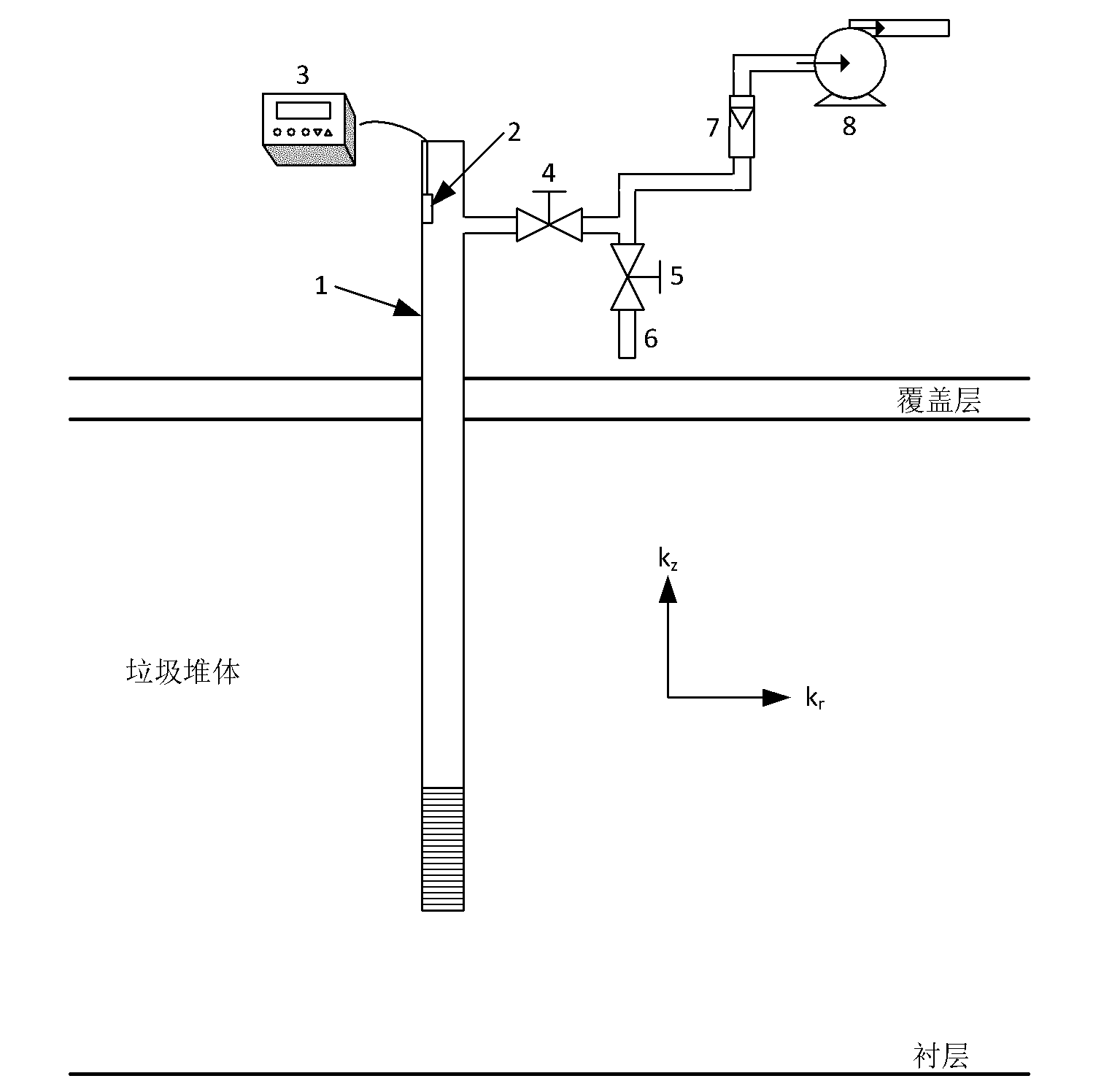

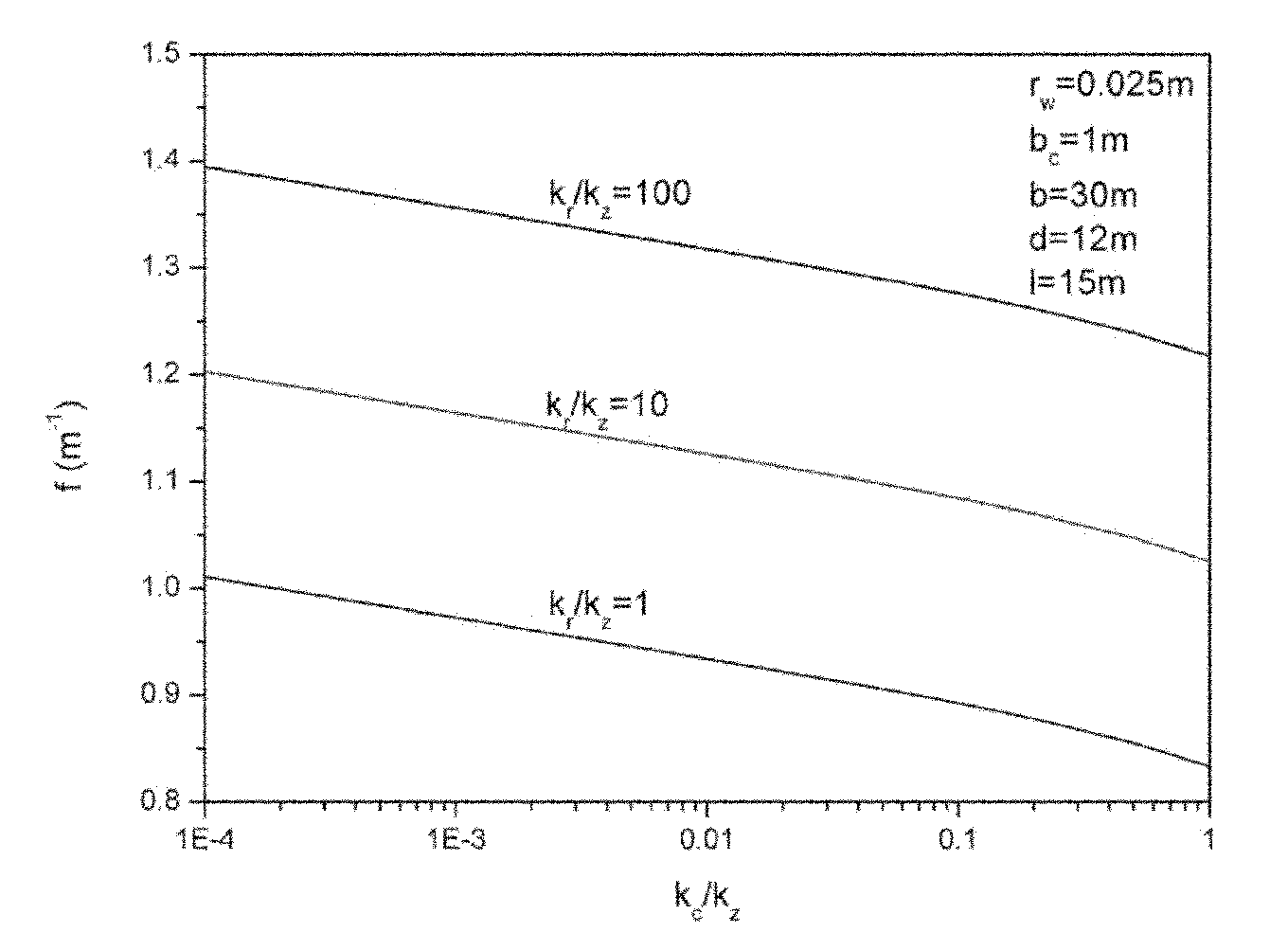

Method for on-site measuring permeability coefficient of landfill gas

InactiveCN102053054AExplosion proneOvercoming dangerPermeability/surface area analysisStationary modelPermeability coefficient

A method for on-site measuring permeability coefficient of landfill gas adopts a measurement system comprising a lower opened tube well, a gas pressure sensor, a gas pressure display recording instrument, an extraction pipeline valve, a leachate emptying valve, a leachate emptying pipe, a gas measuring apparatus and a centrifugal fan. The method adopting extraction mode comprises the following step tube well internal pressure and extraction flow rate are recorded after the gas is stable; and the permeability coefficient of landfill gas is obtained after the substitution to a stationary model. In the method, not only are the conventional extraction pipeline and equipment in a landfill utilized, but also the defects of easy explosion and high hazards which are caused after air and methane are mixed when gas injection mode is adopted are overcome, further the characteristics of landfill covering permeability and permeability coefficient difference in horizontal direction and vertical direction of the landfill caused by layered landfilling and compaction are fully considered. Therefore, the method provided by the invention has the advantages of high measurement accuracy, simple system, and convenience in operation; in addition, key parameters are provided for the pollution control and the recycling of the landfill gas, so that the method has a promised application prospect.

Owner:TSINGHUA UNIV

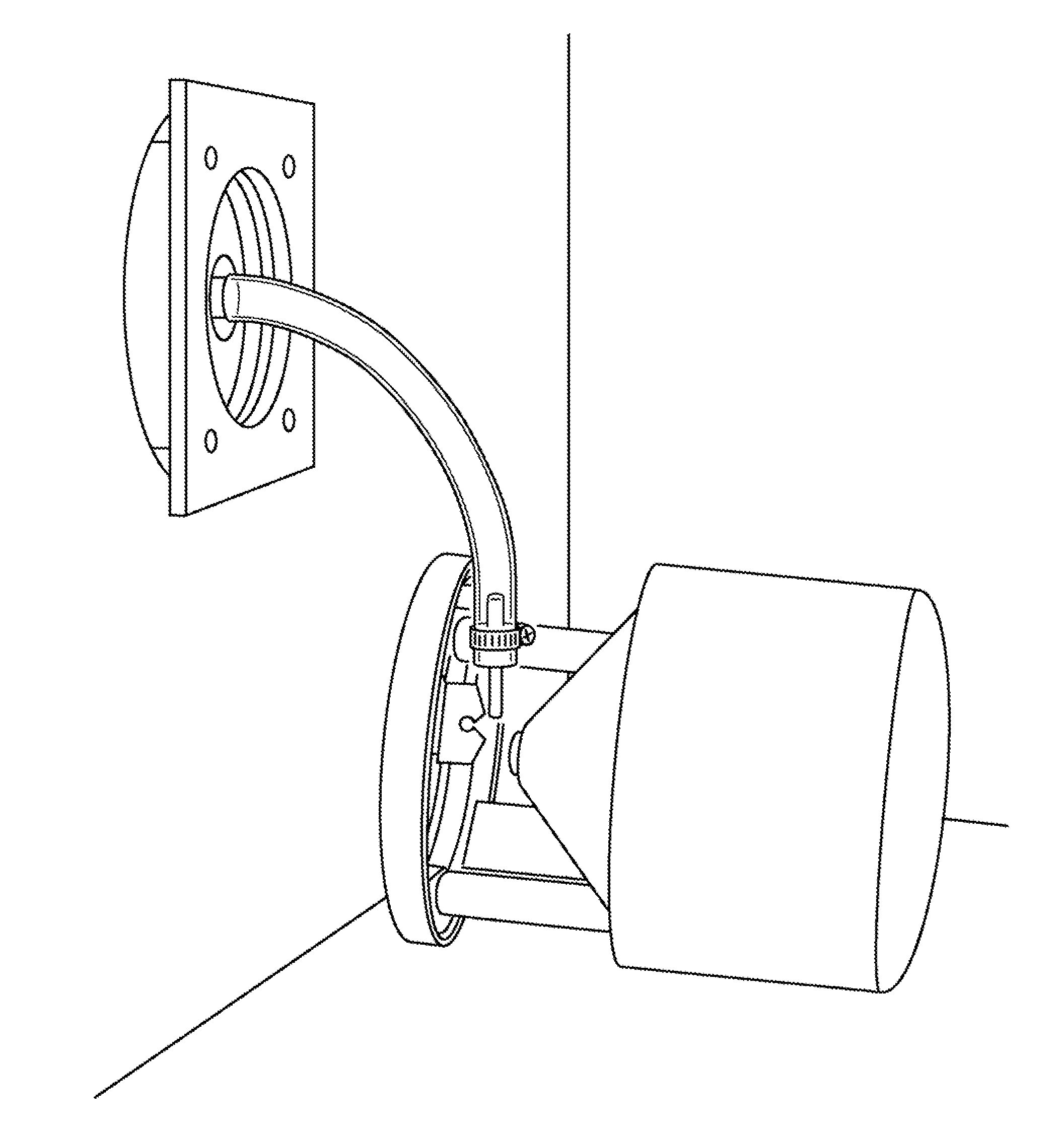

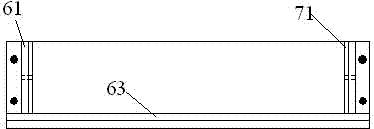

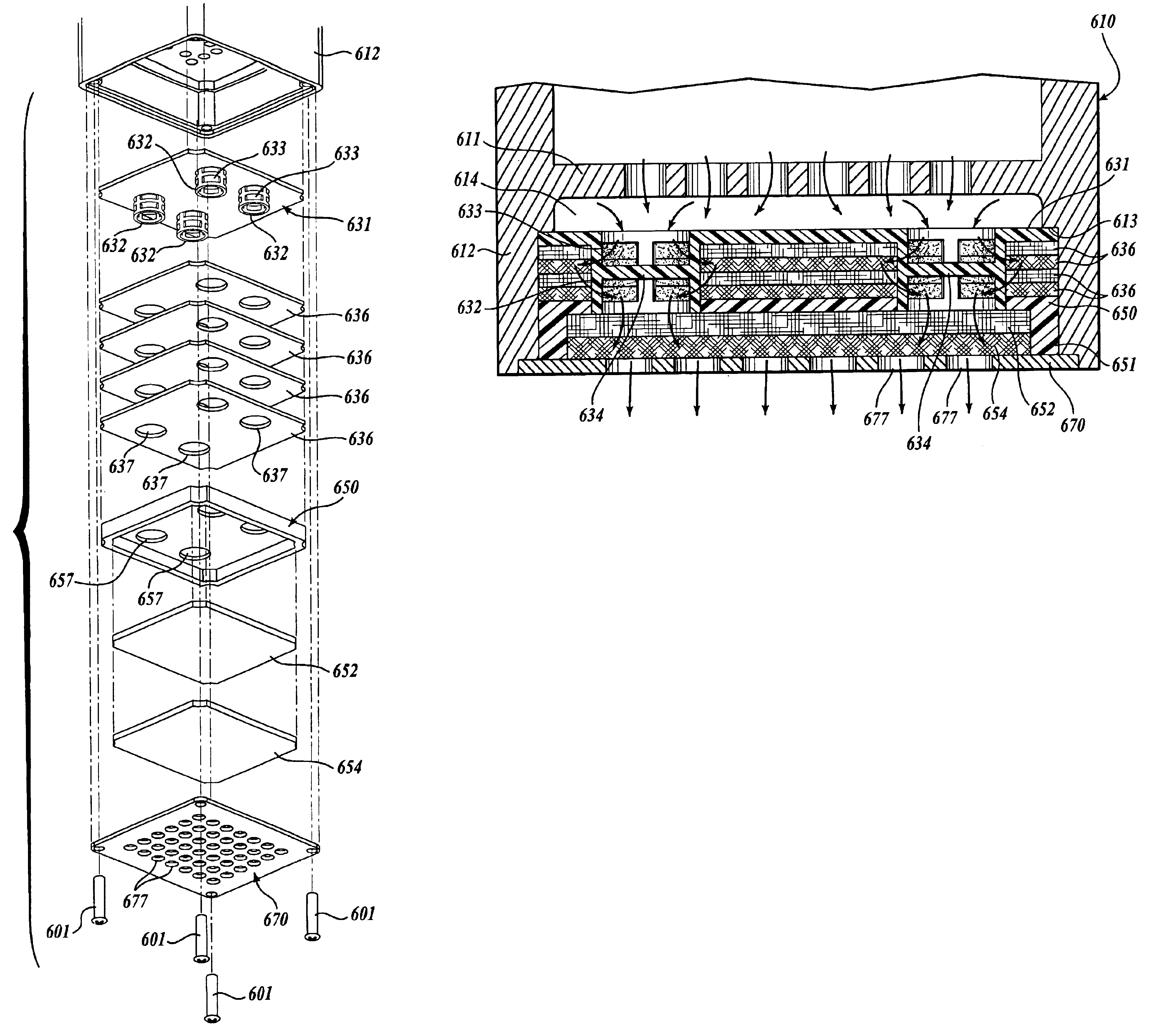

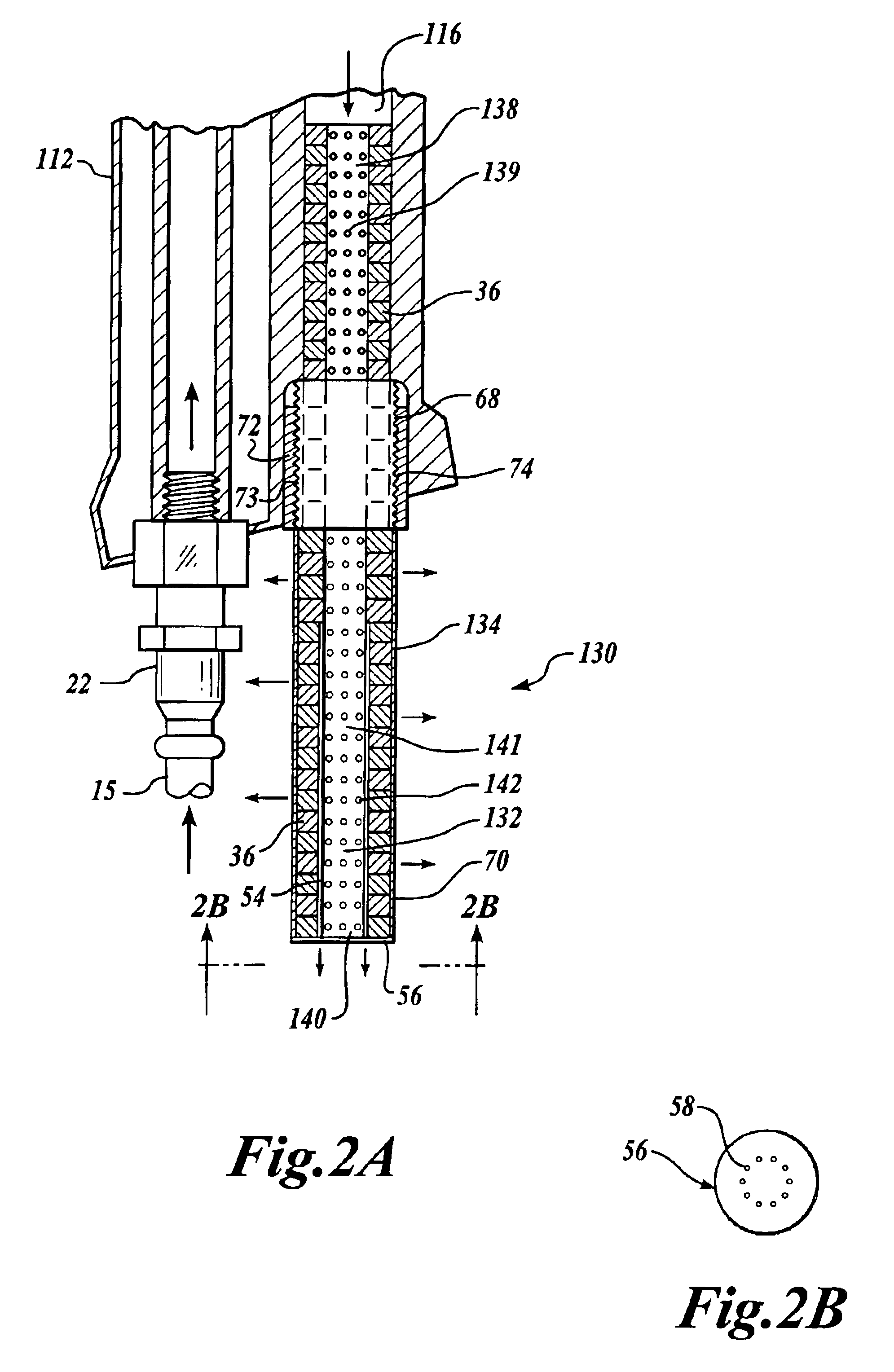

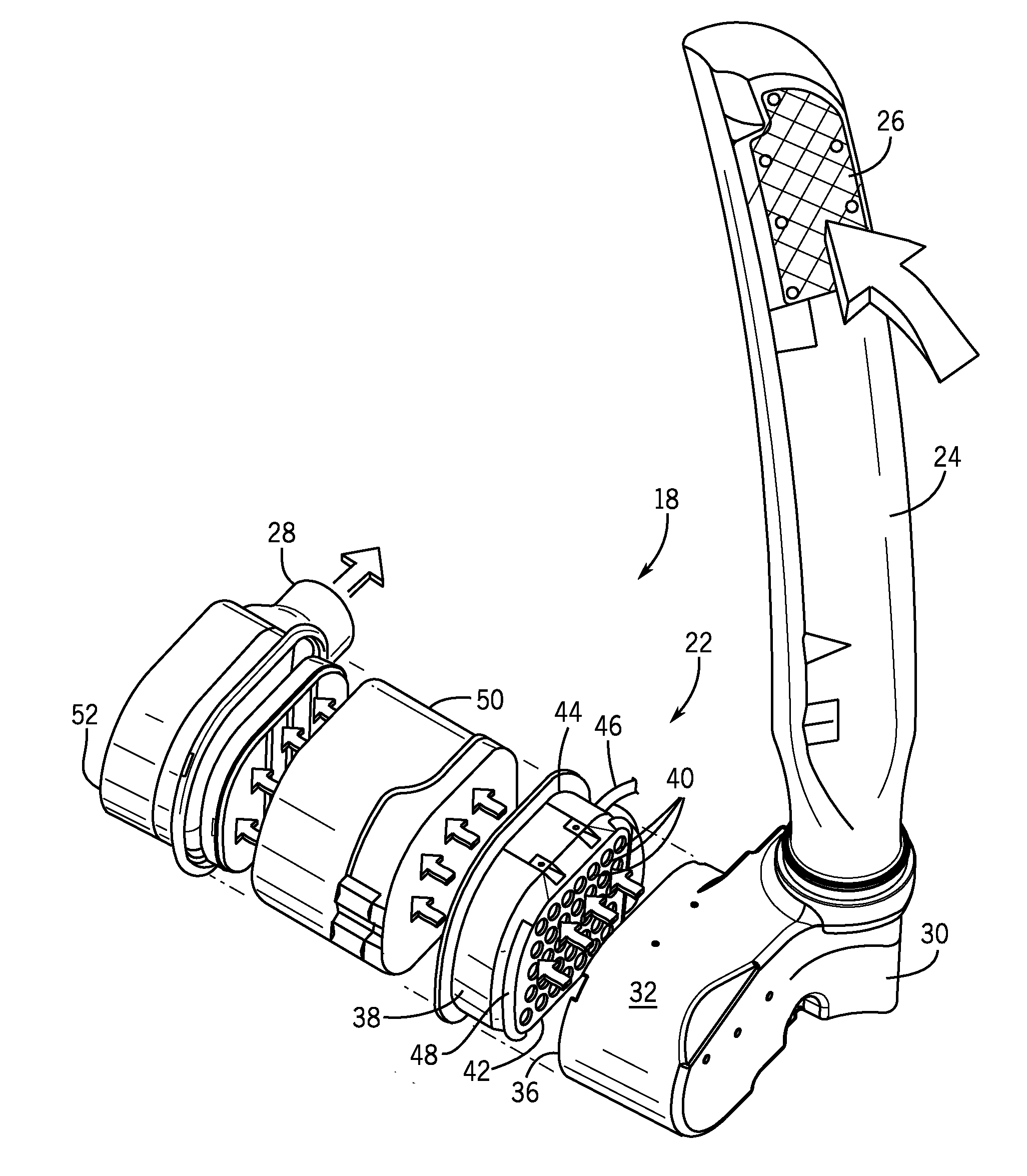

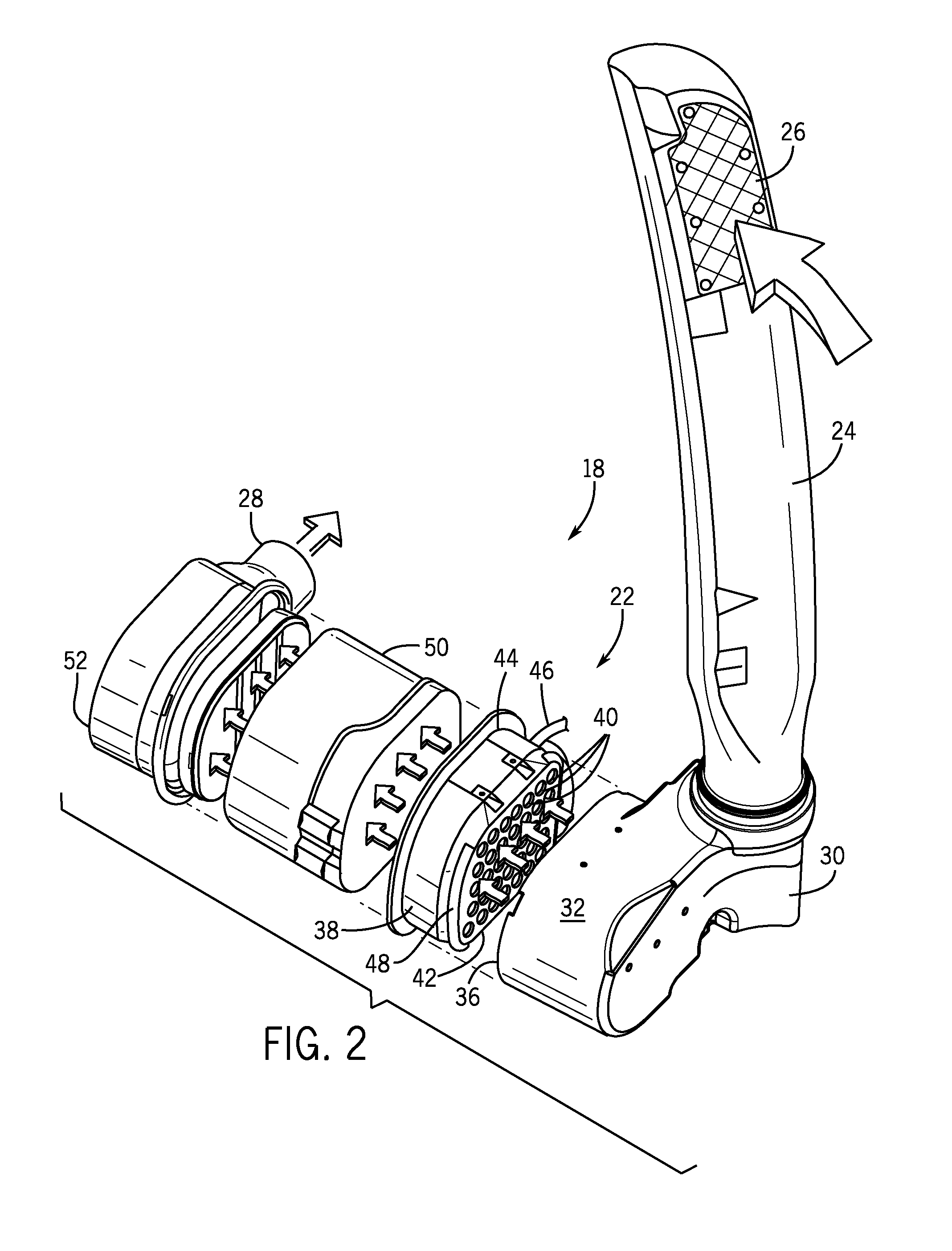

Muffler for pneumatic hand tool

InactiveUS6926117B2Reduce the soundSlows itExhaust apparatusCombustion-air/fuel-air treatmentPneumatic toolEngineering

A muffler for quieting the operation of a pneumatic tool. In one embodiment the muffler (630) is disposed within a volume defined by a peripheral wall (612) that receives an exhaust stream. An upper plate (631) having several open tubes (632) is disposed in the volume. Each tube is has an intermediate blocking plate (634). A plurality of sound-deadening panels (636) is disposed below the upper plate. The panels have apertures that slidably engage the tubes. A lower plate (650) is disposed below the tubes. The lower plate includes a plurality of apertures (657). One or more diffuser panels (652, 654) is disposed beneath the lower plate. An external exhaust vent (670) closes the volume. In operation, the exhaust enters the volume, is directed through the tubes, then into the sound-deadening panels, back into the tubes, and through the diffuser panels.

Owner:EXHAUST TECH

Flexible open tube sampling system for use with surface ionization technology

ActiveUS20080067359A1Improve efficiencyTime-of-flight spectrometersMaterial analysis by optical meansSpectrometerWide diameter

The present invention is a device to restrict the sampling of analyte ions and neutral molecules from surfaces with mass spectrometry and thereby sample from a defined area or volume. In various embodiments of the present invention, a tube is used to sample ions formed with a defined spatial resolution from desorption ionization at or near atmospheric pressures. In an embodiment of the present invention, electrostatic fields are used to direct ions to either individual tubes or a plurality of tubes positioned in close proximity to the surface of the sample being analyzed. In an embodiment of the present invention, wide diameter sampling tubes can be used in combination with a vacuum inlet to draw ions and neutrals into the spectrometer for analysis. In an embodiment of the present invention, wide diameter sampling tubes in combination with electrostatic fields improve the efficiency of ion collection.

Owner:BRUKER SCI LLC

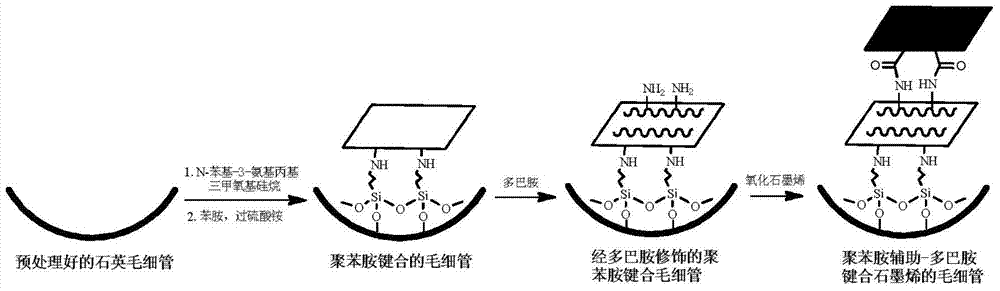

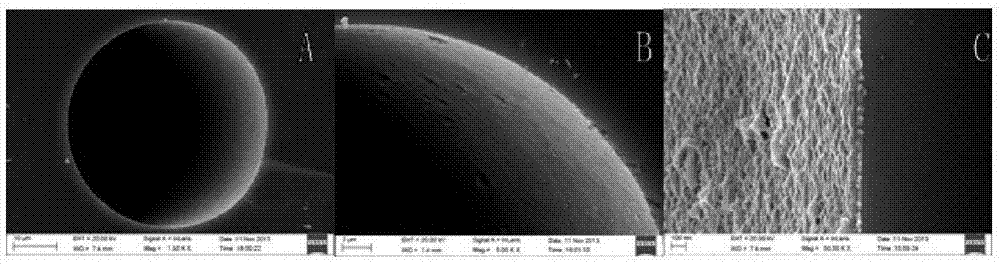

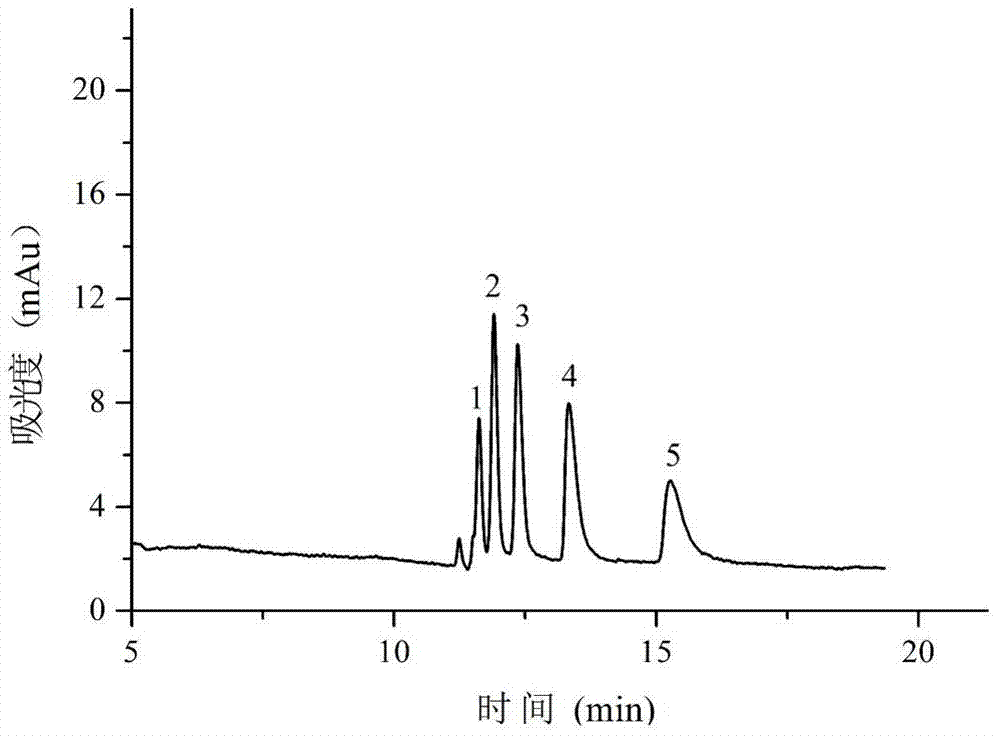

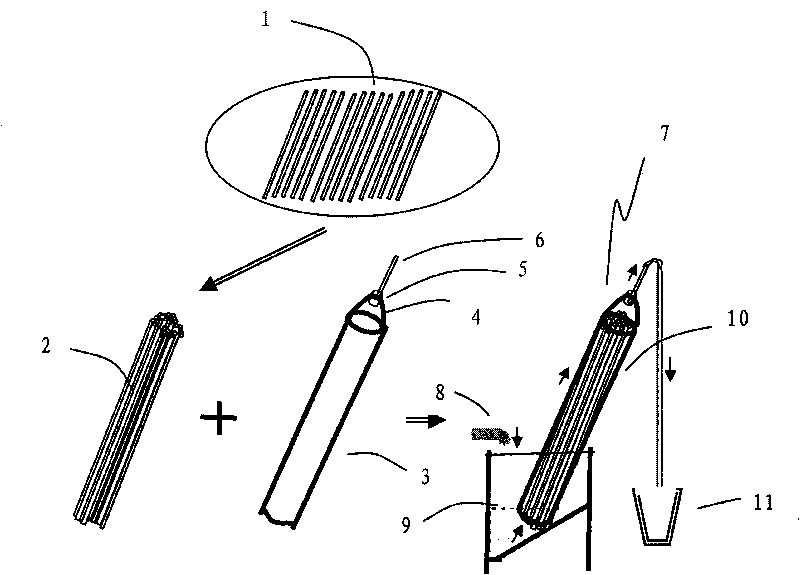

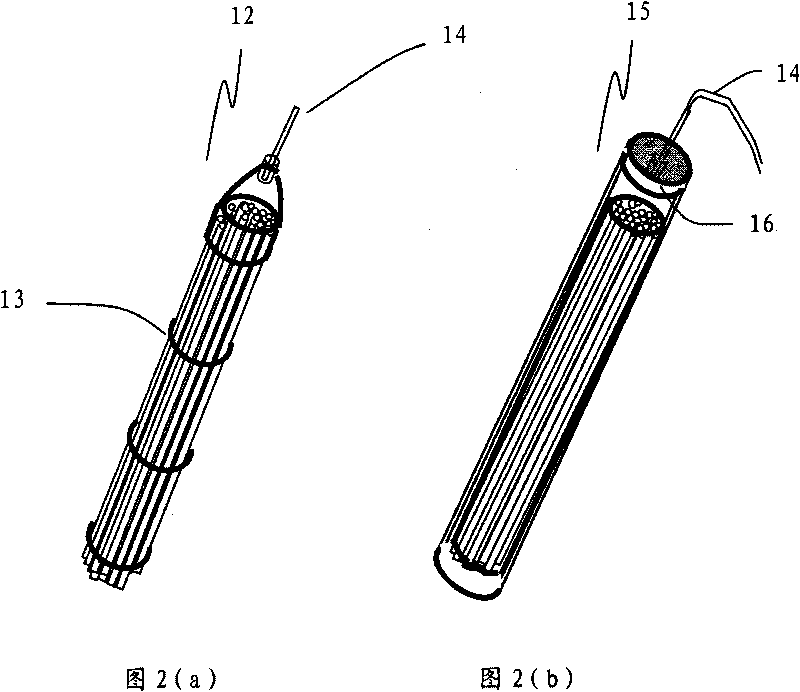

Preparation method for grapheme open-tube electric chromatographic column

ActiveCN103611511ANo pollution in the processImprove stabilityOther chemical processesAlkali metal oxides/hydroxidesConductive polymerCapillary column

The invention relates to a preparation method for a grapheme open-tube electric chromatographic column, and relates to the preparation method for a novel capillary electric chromatographic column. In the method, a conductive polymer polyaniline assisted polydopamine bonded graphite oxide is used as a fixed phase. The conductive polymer polyaniline is bonded to the inner wall of a capillary to serve as an underlying material, so that the specific surface area of the capillary is increased, the modification time and the modification frequency of dopamine are remarkably reduced, and the modification degree of the polydopamine is improved; and therefore, the reaction of the graphite oxide is facilitated. The preparation method is easy to operate and low in cost; the overall preparation process is performed in aqueous solution, and an organic solvent or a toxic reagent is not used; the environment is not polluted; each prepared coating has the high stability; the service life of the capillary column is long; according to the grapheme open-tube electric chromatographic column prepared by using the preparation method, the chromatographic performance of the grapheme open-tube column is remarkably improved, and the effect on separating the homologs of benzene is better compared with that of a polydopamine bonded graphite oxide open-tube.

Owner:WUHAN UNIV

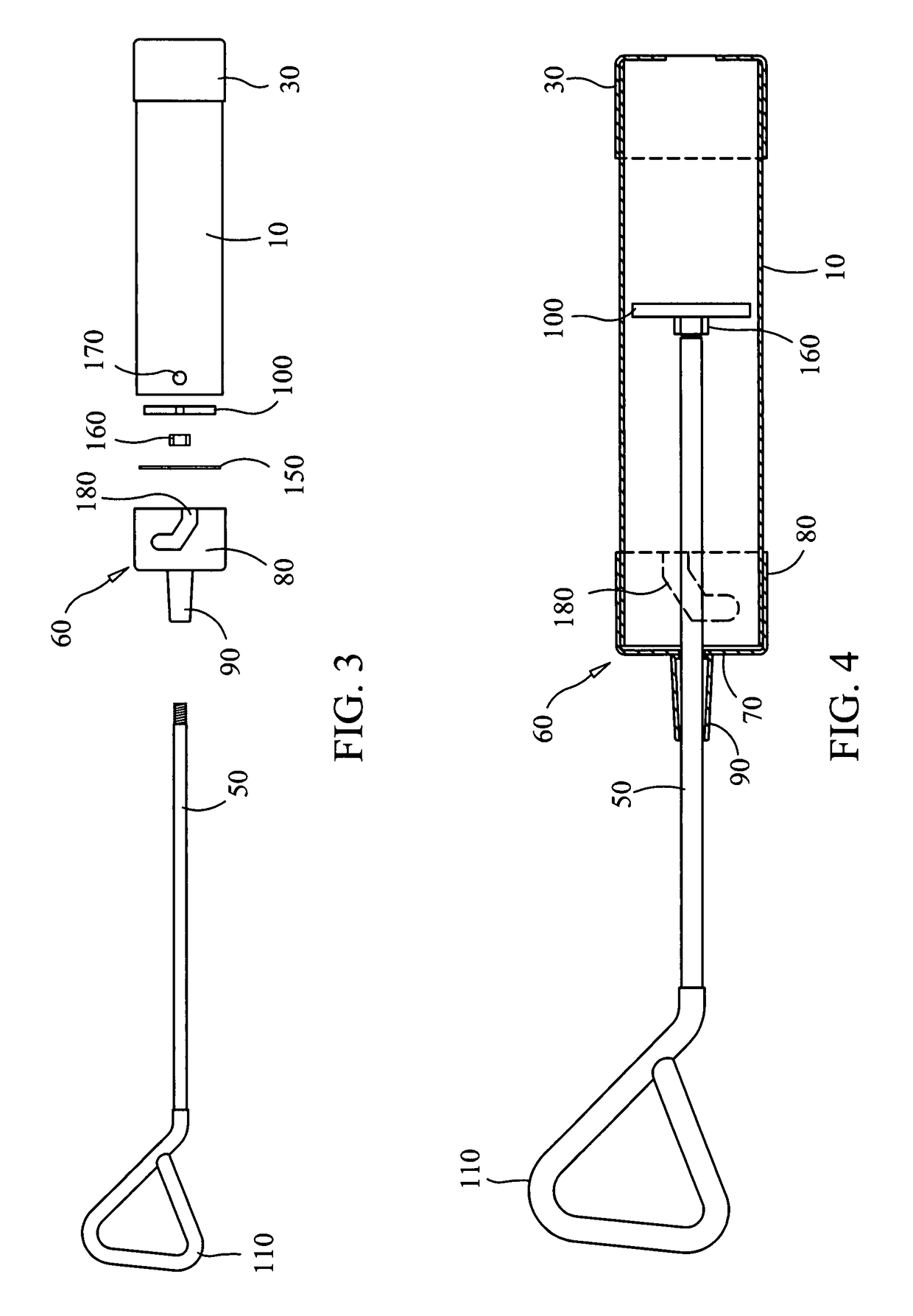

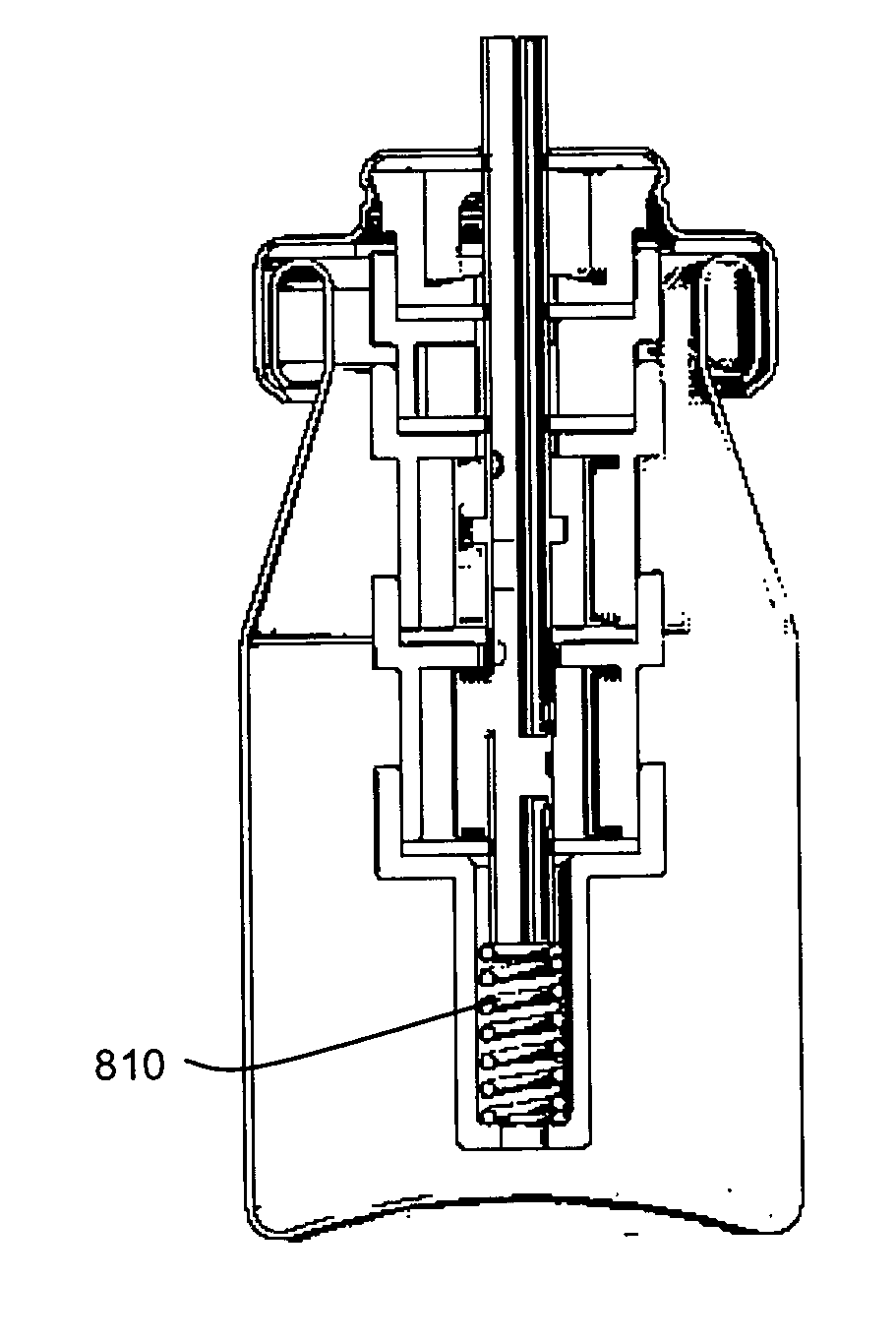

Hand held manually operated mixer

InactiveUS7905654B1Shaking/oscillating/vibrating mixersTransportation and packagingReciprocating motionHand held

A method using a mixer for disbursing an additive in a tube of compound. The mixer includes a rigid cylinder and a plunger assembly. The cylinder is configured for receiving an opened tube of compound, to which additive has been introduced. The plunger assembly includes a shaft on which a cap is slidably and rotatably mounted. A mixer blade is mounted on a first end of the shaft and a second end of the shaft is provided with a handle. The cap is provided with a pair of cutouts designed for receiving a pair of studs mounted on the outside surface of the cylinder, such that the cap may be fitted on the cylinder and turned to engage the studs with the cutouts and connect the cap and the cylinder. The handle may be rotated and reciprocated to move the mixer blade through the contents of the tube for mixing.

Owner:CORDERO LUIS

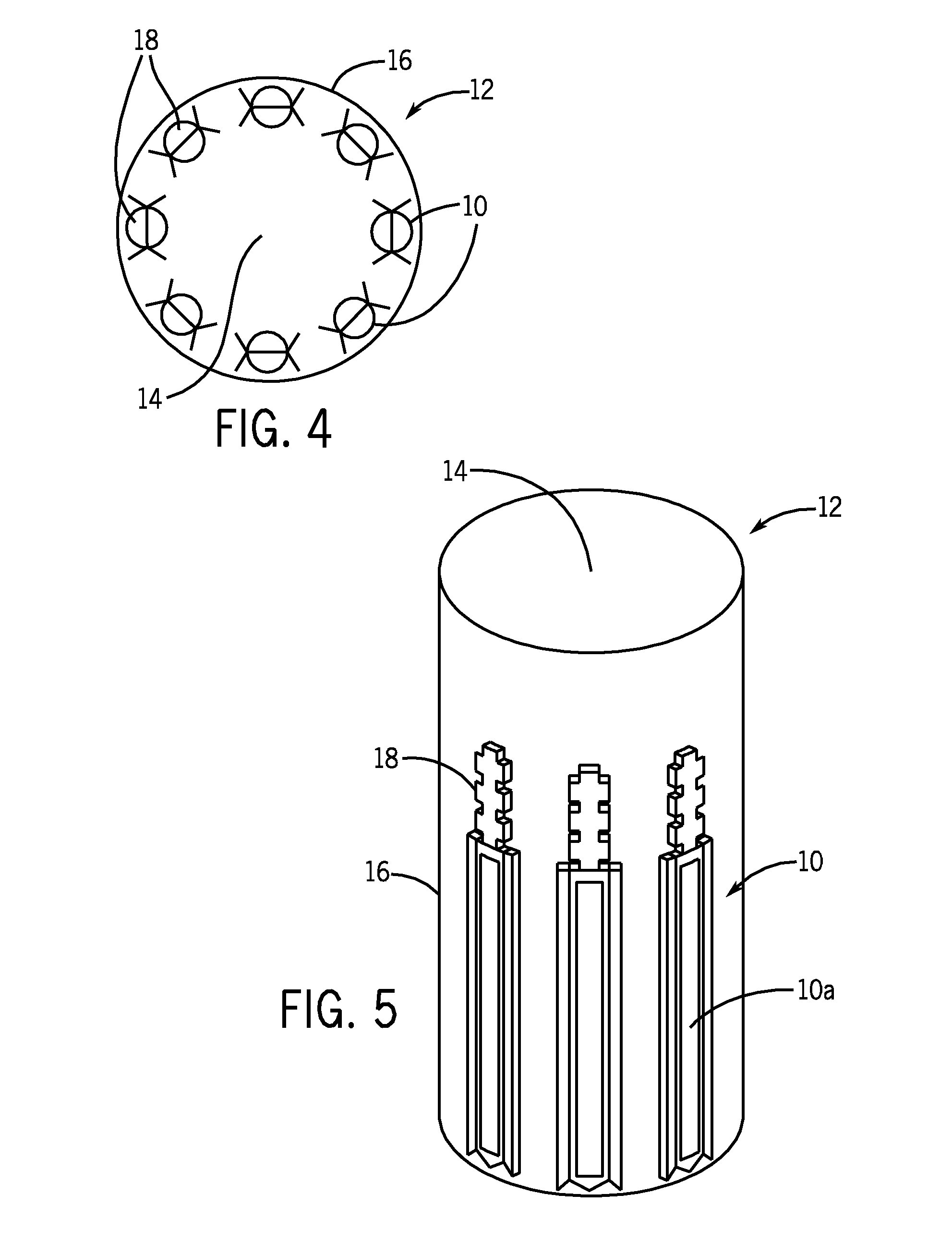

Methods and apparatus for flow restoration

ActiveUS20130079796A1Increase speedImprove effectivenessStentsSurgeryReticular formationDistal segment

Methods for restoring blood flow in occluded blood vessels using an apparatus having a self expandable distal segment that is pre-formed to assume a superimposed structure in an unconstrained condition but can be made to take on a volume-reduced form making it possible to introduce it with a microcatheter and a push wire arranged at the proximal end, with the distal segment in its superimposed structure assuming the form of a longitudinally open tube and having a mesh structure of interconnected strings or filaments or struts. In a preferred embodiment, the distal segment has a tapering structure at its proximal end where the strings or filaments or struts converge at a connection point.

Owner:COVIDIEN LP

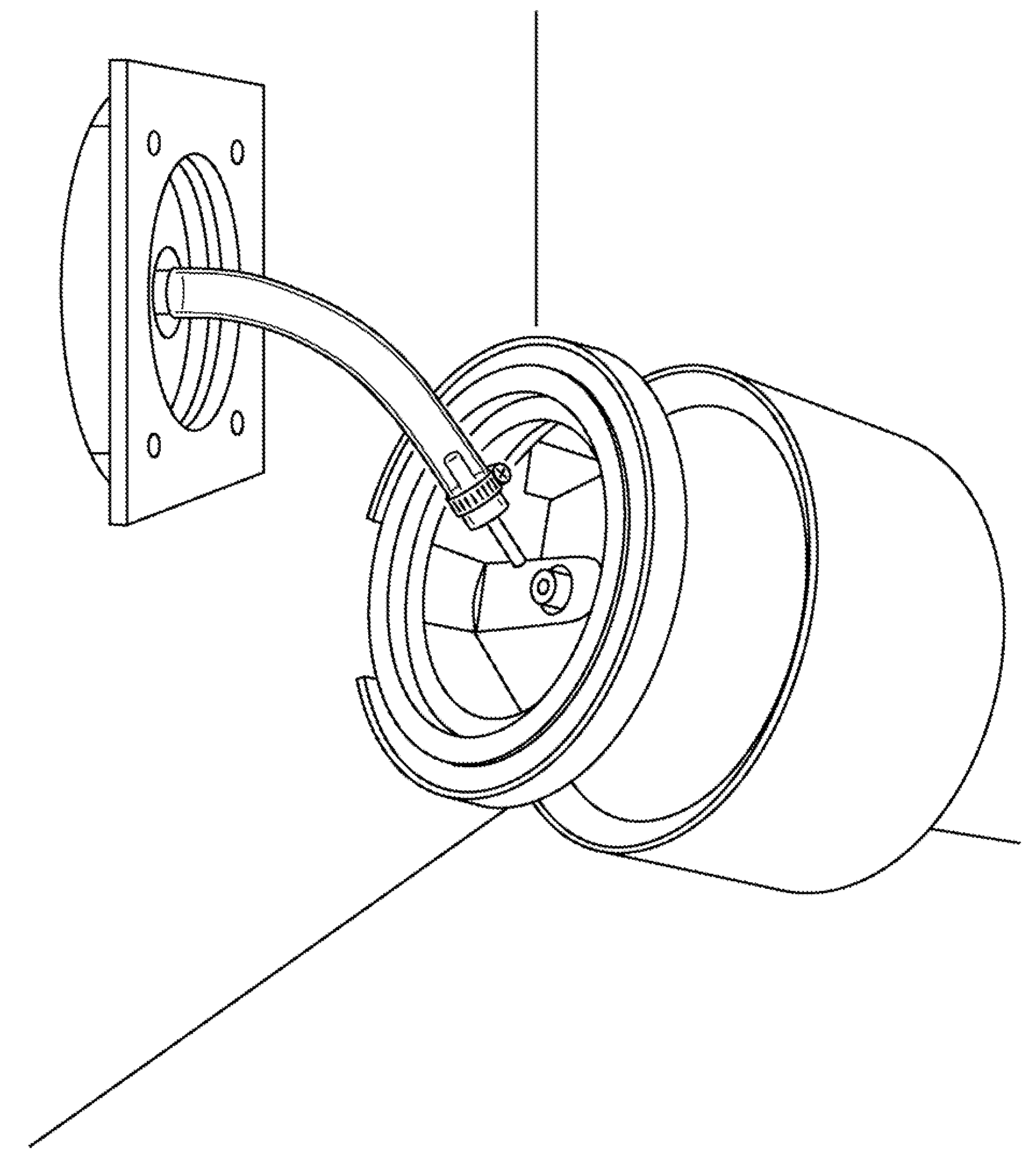

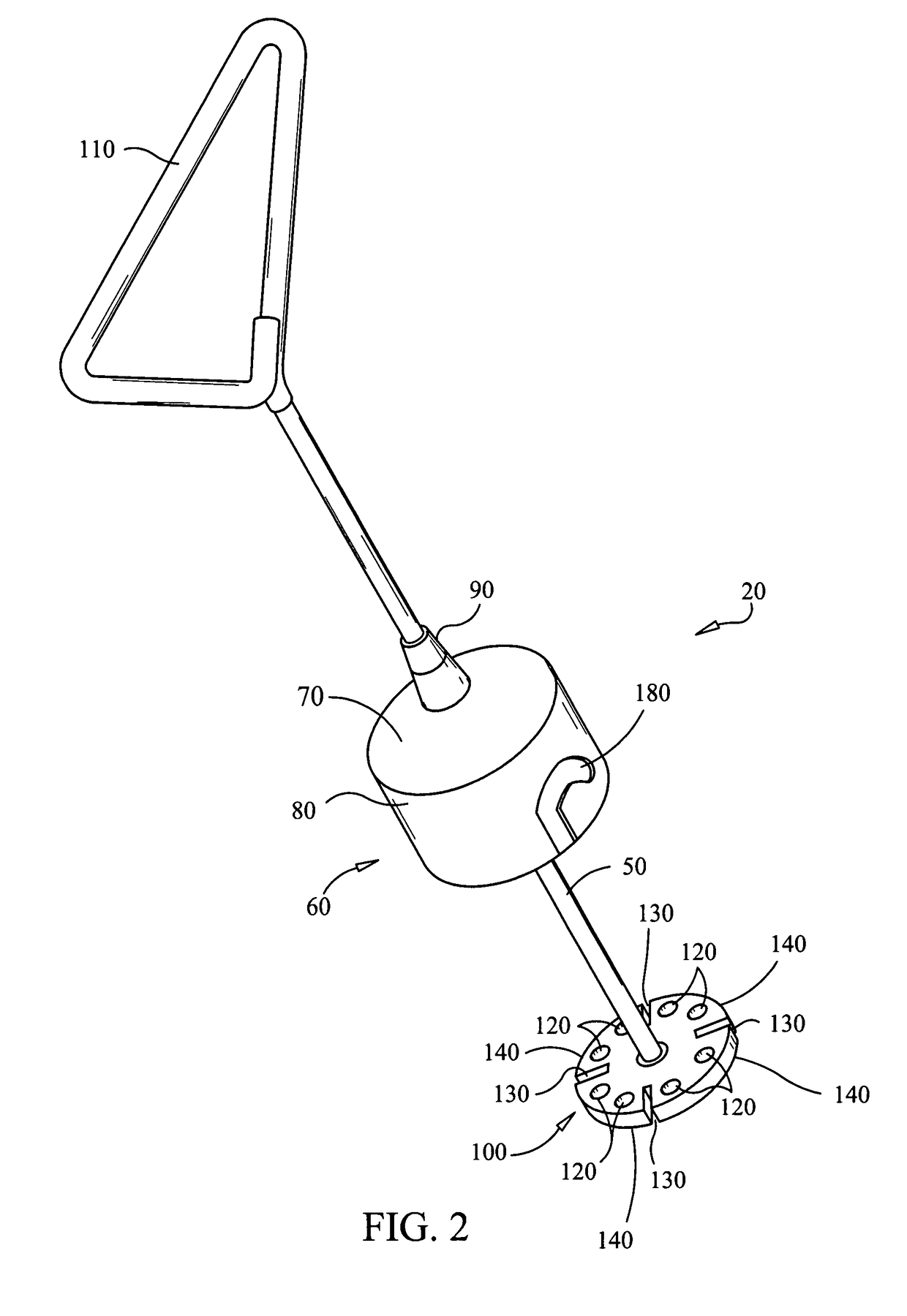

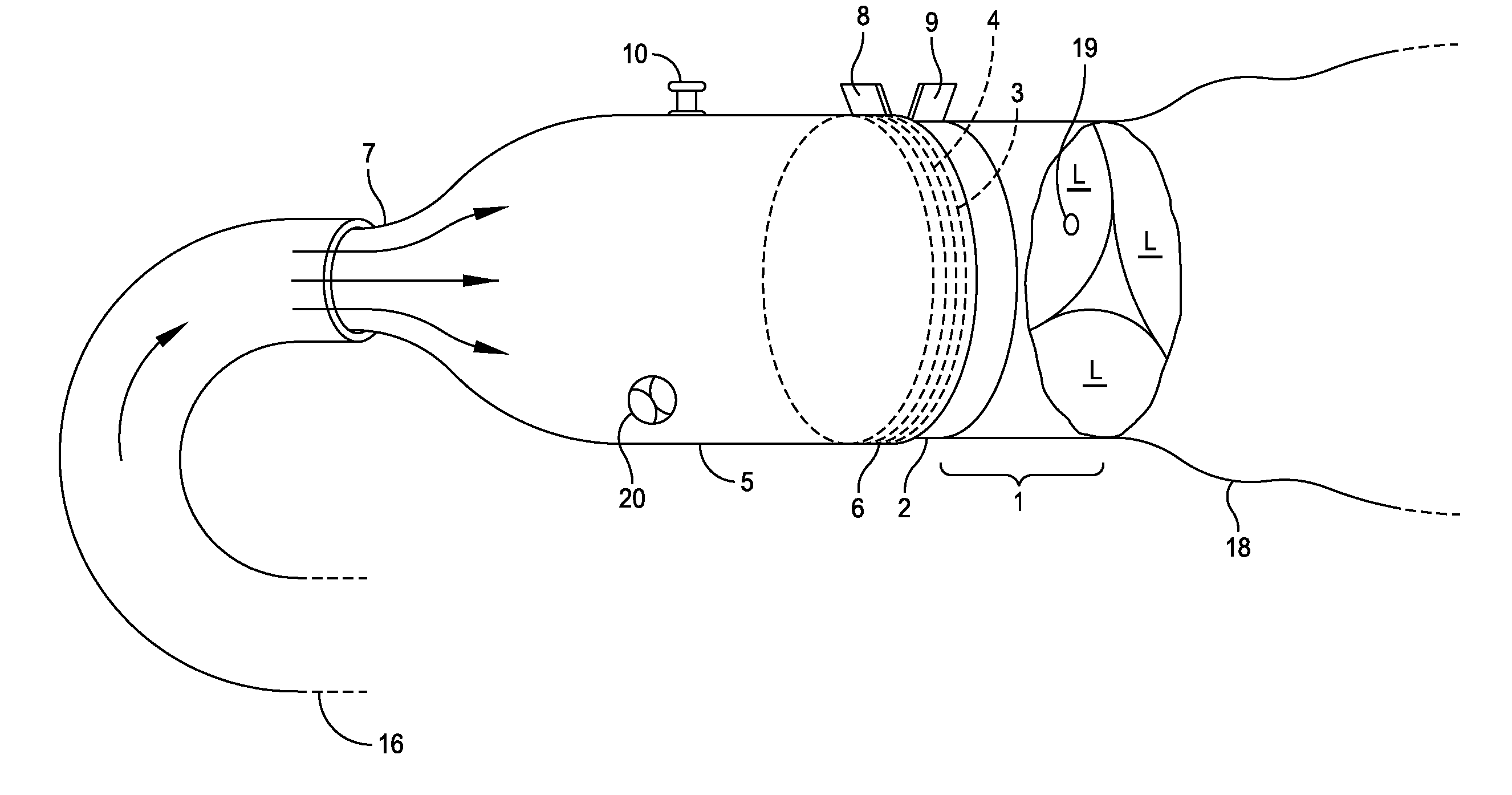

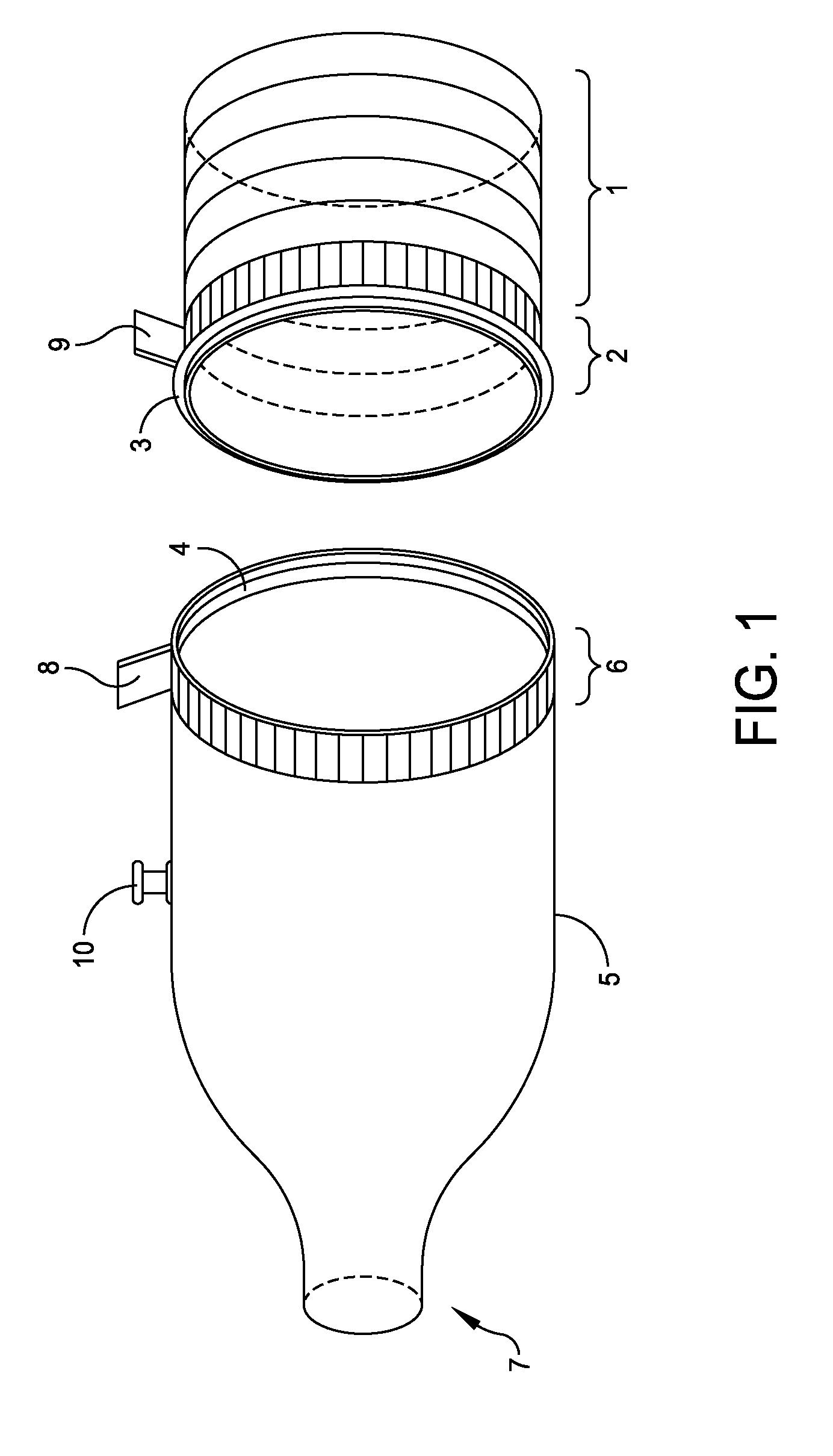

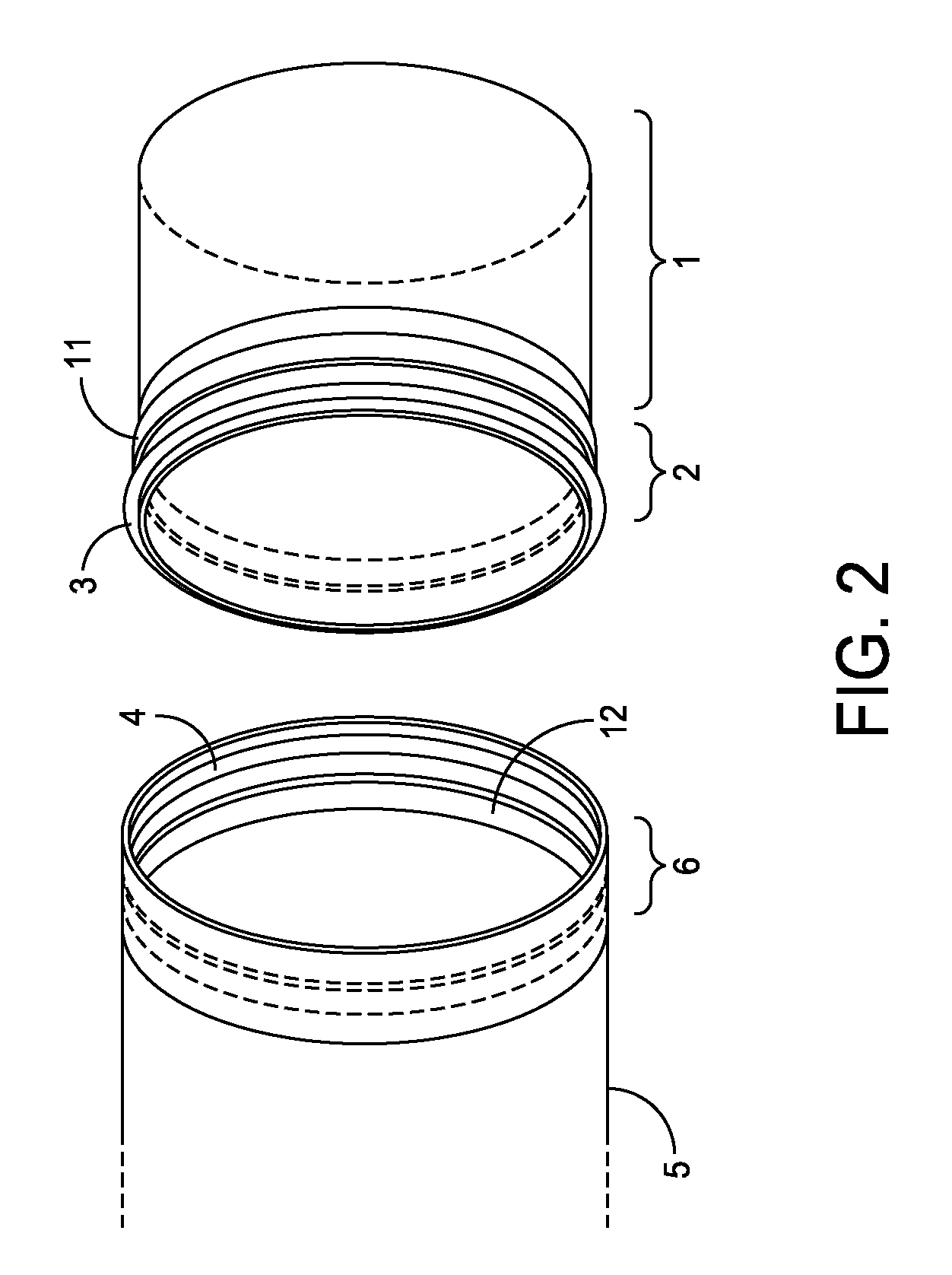

Apparatus and method for simulation of diastole and visualizing the diastolic state of an aortic valve and root during cardiac surgery

A device for evaluating an aortic valve after opening an aorta distal to the aortic valve includes a body defining a chamber. The body has a generally circular proximal open end and a distal end, the proximal open end being configured to be reversibly attachable to one of the aorta and a short open tube distal to the aortic valve in a generally water-tight fashion. At least a portion of the body is transparent to view the aortic valve. Other embodiments of the device and related methods are further disclosed.

Owner:CORFIGO INC

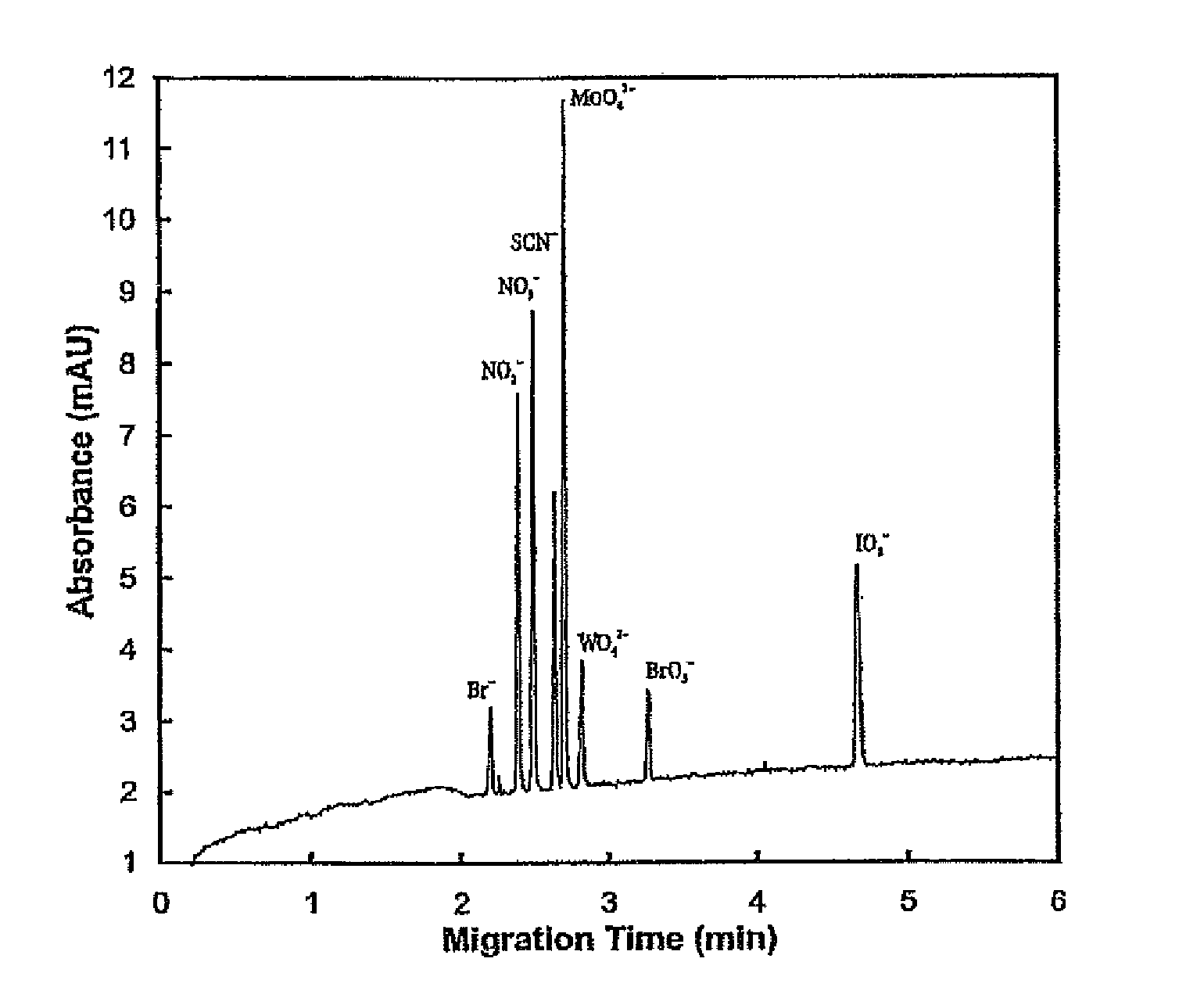

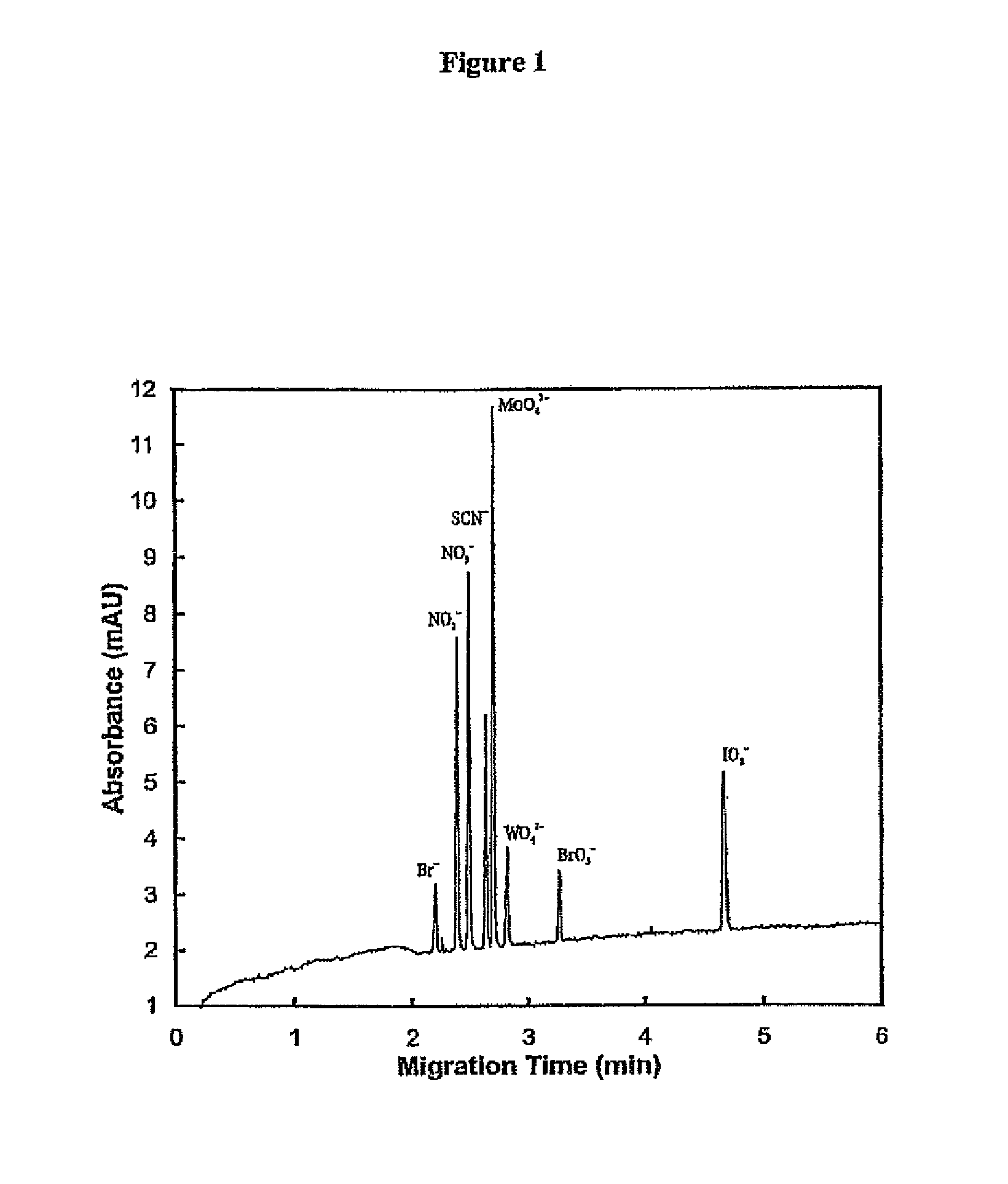

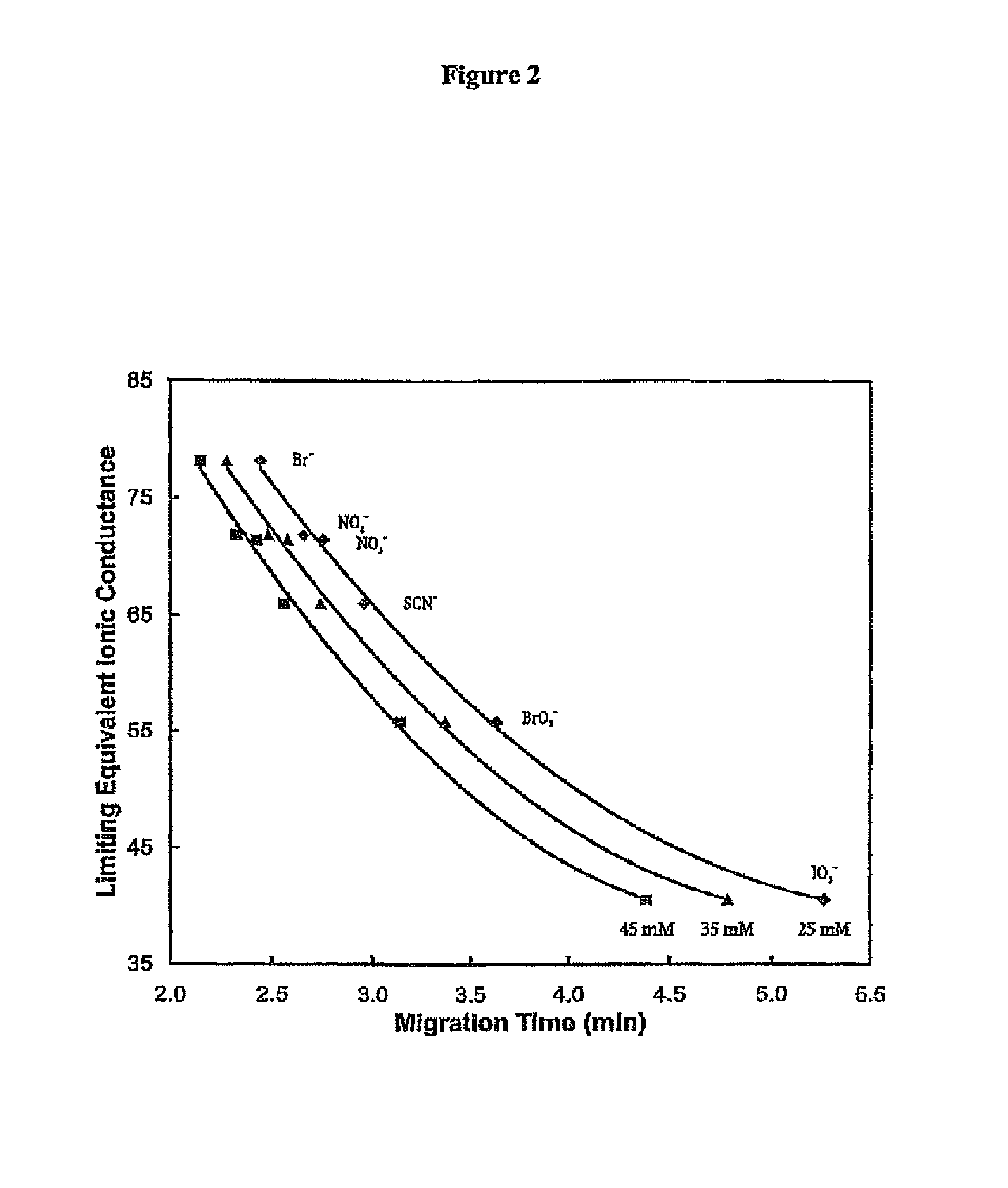

Open tube suitable for separation purposes comprising covalently bonded zwitterionic betaine groups

A novel open tube with a zwitterionic betaine polymer layer can be prepared by initiated grafting polymerization. This open tube can be used for separating inorganic anions, peptides and proteins. A capillary electrophoresis method and a capillary chromatography method use the novel open tube. There are methods for manufacturing the novel open tube.

Owner:MERCK PATENT GMBH

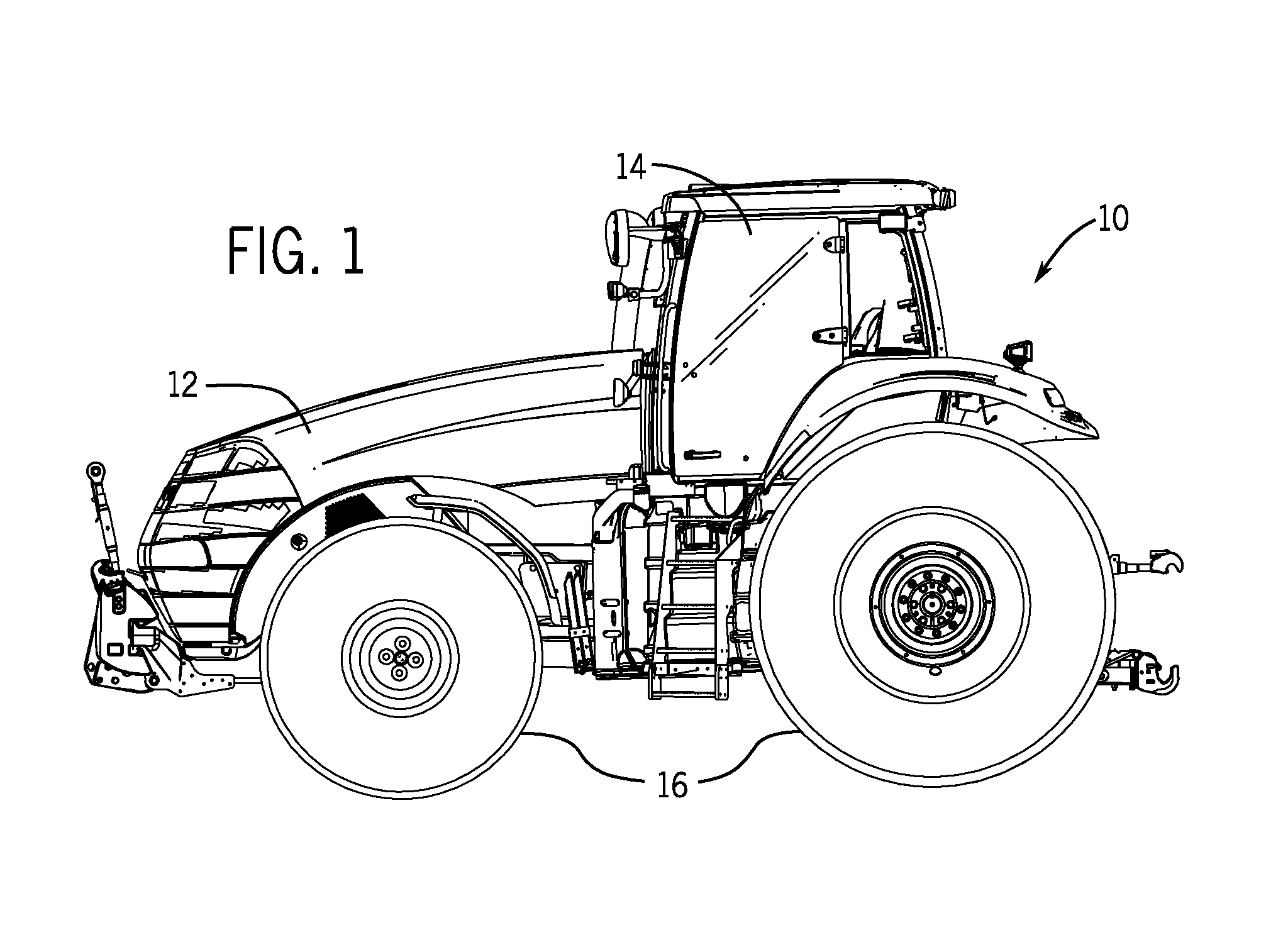

Air intake system for an off-road vehicle

An air intake system includes a pre-cleaner having a plurality of tubes configured to receive a flow of air, to filter particulate material from the flow of air, and to provide the flow of air to an engine of an off-road vehicle. The system also includes a controller configured to receive a first signal indicative of an air intake flow rate of the engine, to determine a target number of open tubes for the pre-cleaner based at least in part on the air intake flow rate and a desired air flow rate for each tube of the plurality of tubes, and to output a second signal to a component of the air intake system indicative of instructions to enable the flow of air to the target number of open tubes and to block the flow of air to the remainder of tubes of the plurality of tubes.

Owner:BLUE LEAF I P

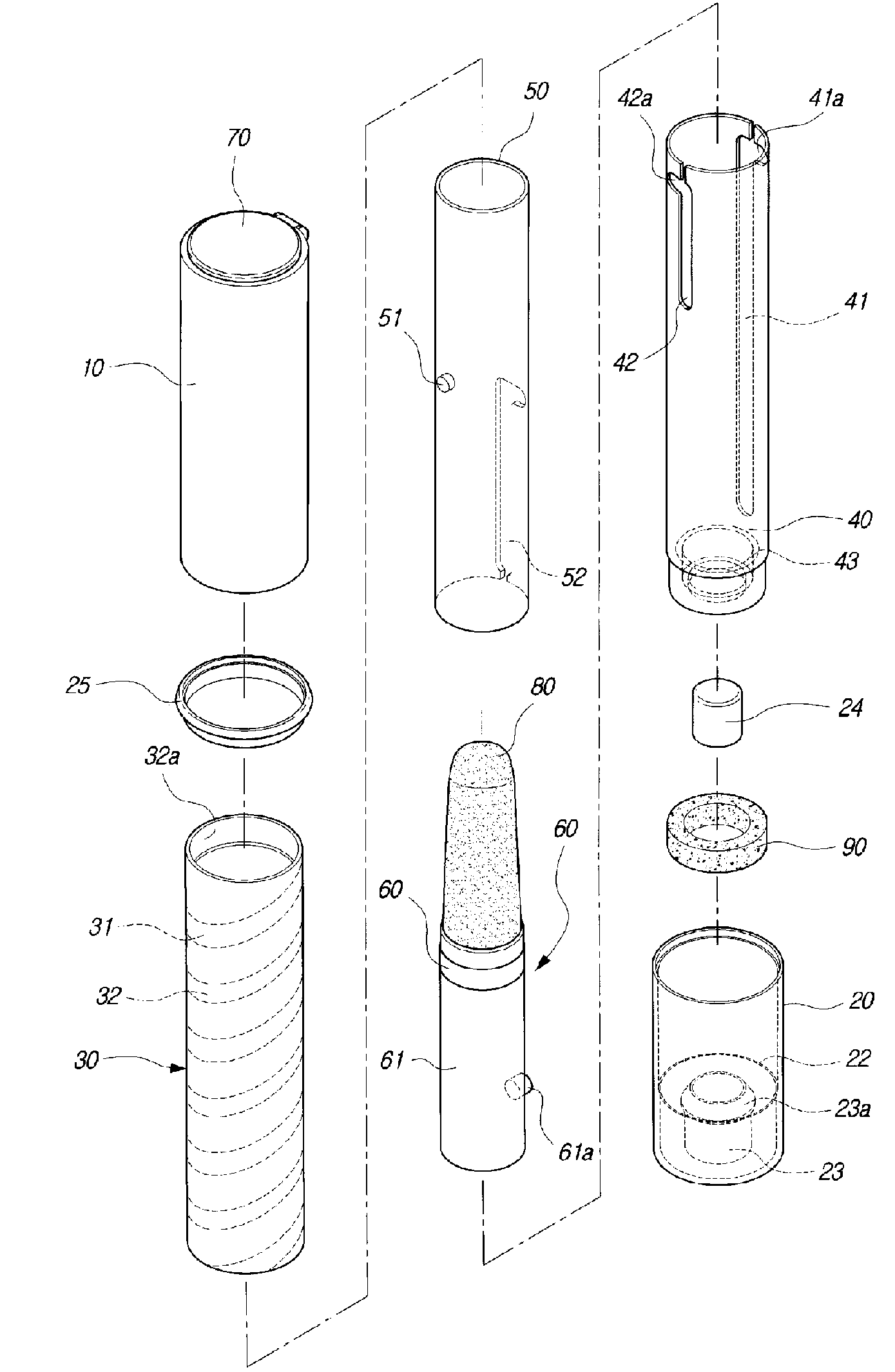

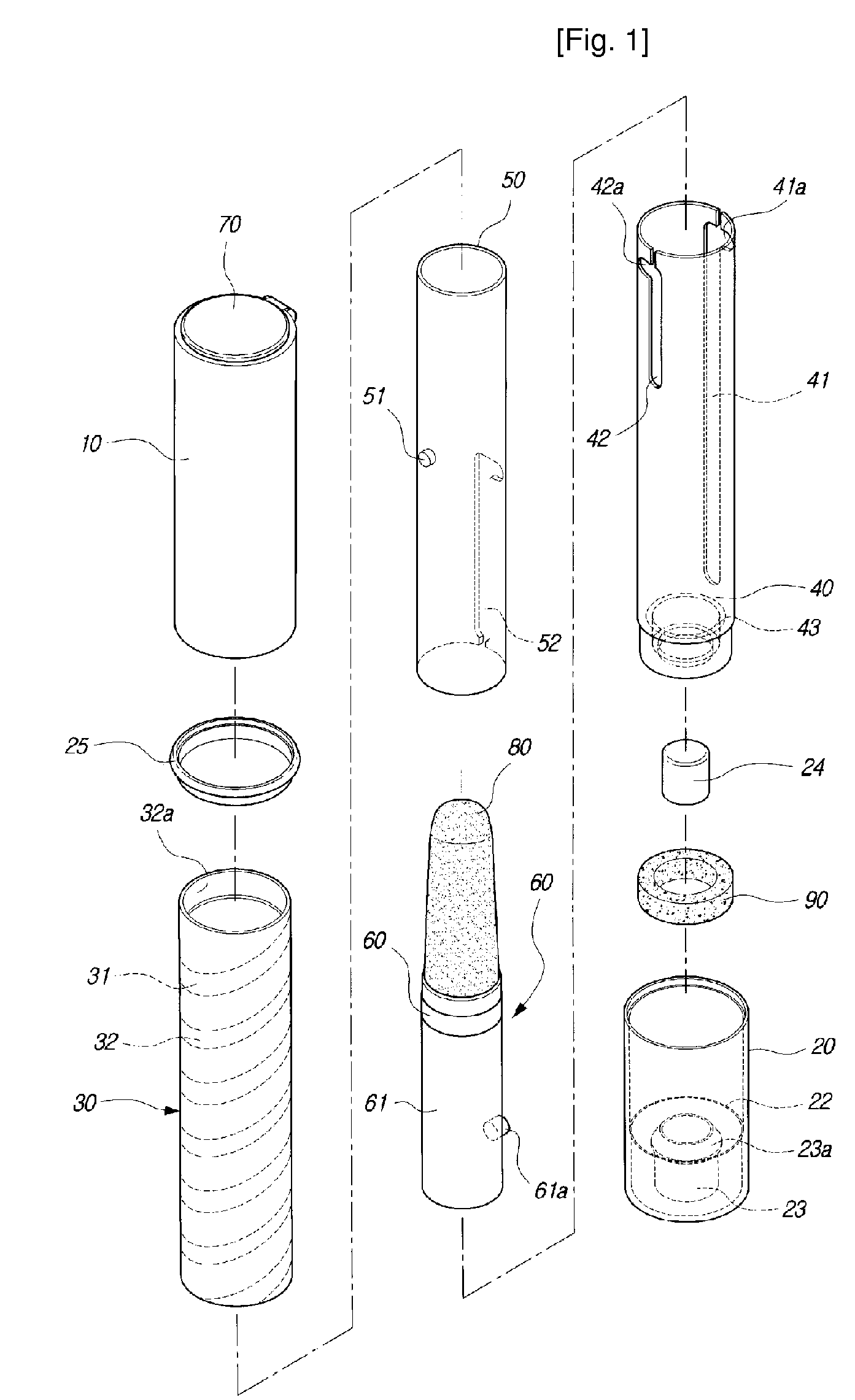

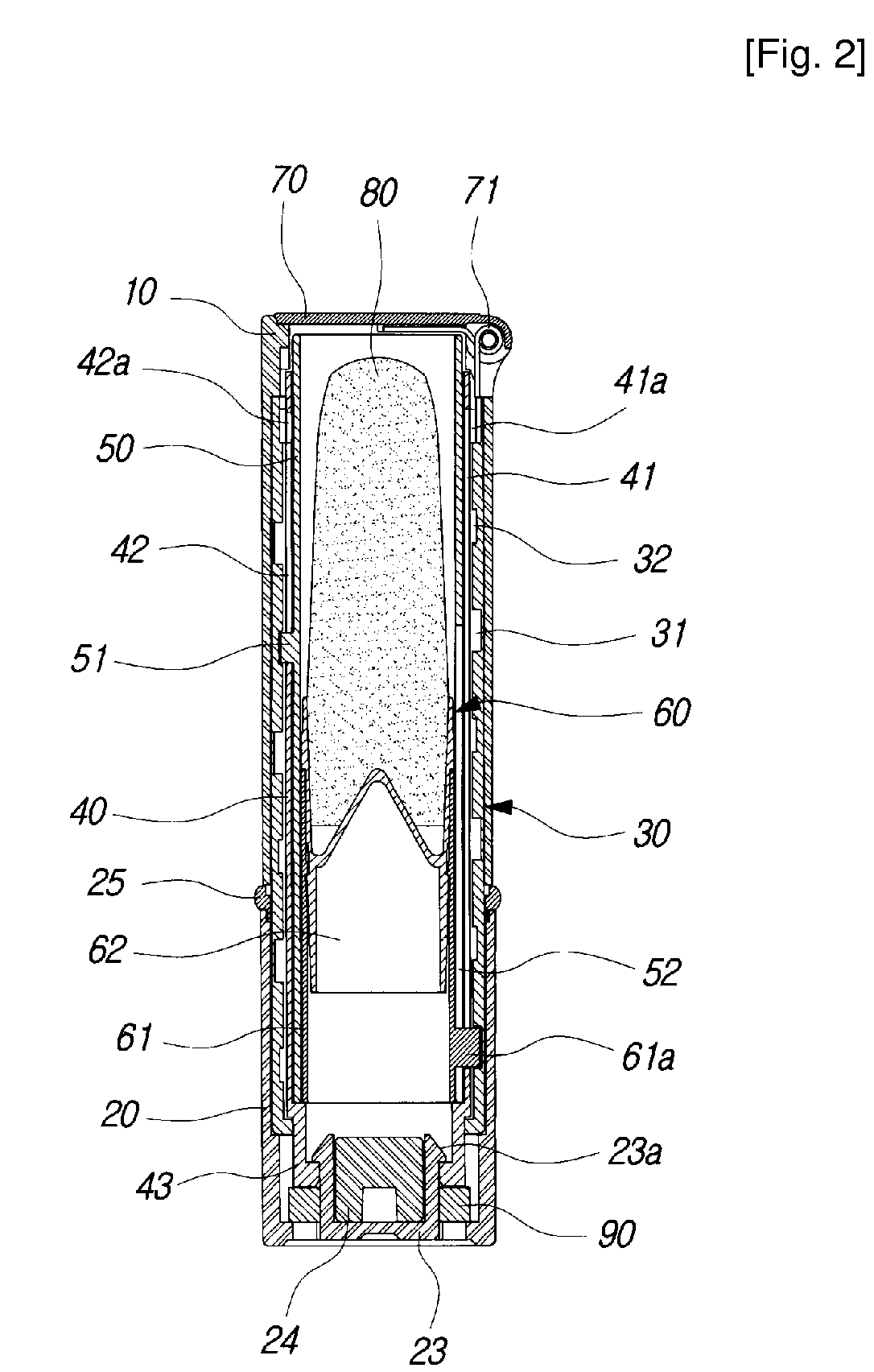

Lipstick case

Owner:KANG SUNGIL

Multiple-metered self-cleaning dispenser

InactiveUS20120000931A1Opening closed containersBottle/container closureBiomedical engineeringOpen tube

Owner:OTIC PHARMA

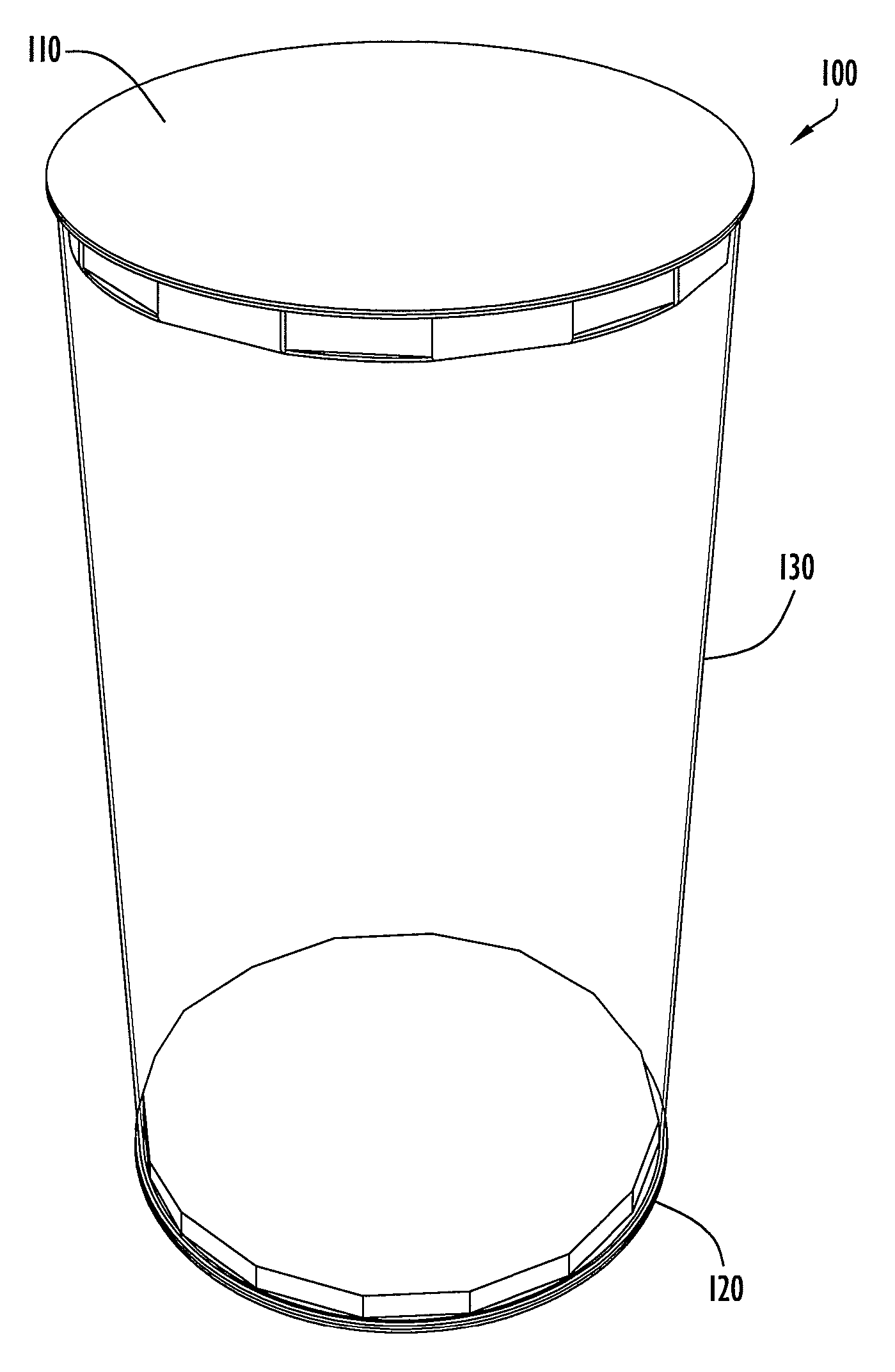

Product packaging end cap

InactiveUS7866536B2Easy to installEasily and cost-effectively assembledOther accessoriesContainer/bottle contructionEngineeringBiomedical engineering

The present invention relates to a packaging concept includes a tubular wall member and end caps. The packaging is constructed from a sheet of flexible material wrapped into a continuous wall and fastened at the ends of the sheet material leaving open tube ends. The open ends of the tube are then closed by an end cap. The end caps are each formed from a continuous blank of sheet material. The blank includes at least three aligned cap layers. The first and second cap layers are adjacent to each other and connected by a tab connector. Each of the first and second cap layers also includes a plurality of bendable support tabs and each of the first and second cap layers includes a plurality of spaces between adjacent respective bendable support tabs. The first cap layer is folded relative to the second cap layer such that the support tabs of the first cap layer enter the spaces of the second cap layer and the support tabs of the second cap layer enter the spaces of the first cap layer. The first and second cap layers are smaller than the open tube ends and the third and fourth cap layers are larger than the open tube ends. Therefore, the first and second cap layers enter the open tube ends and the third and fourth cap layers abut the open tube ends to provide cap that can be secured to the tubular wall member by an adhesive product.

Owner:MATTEL INC

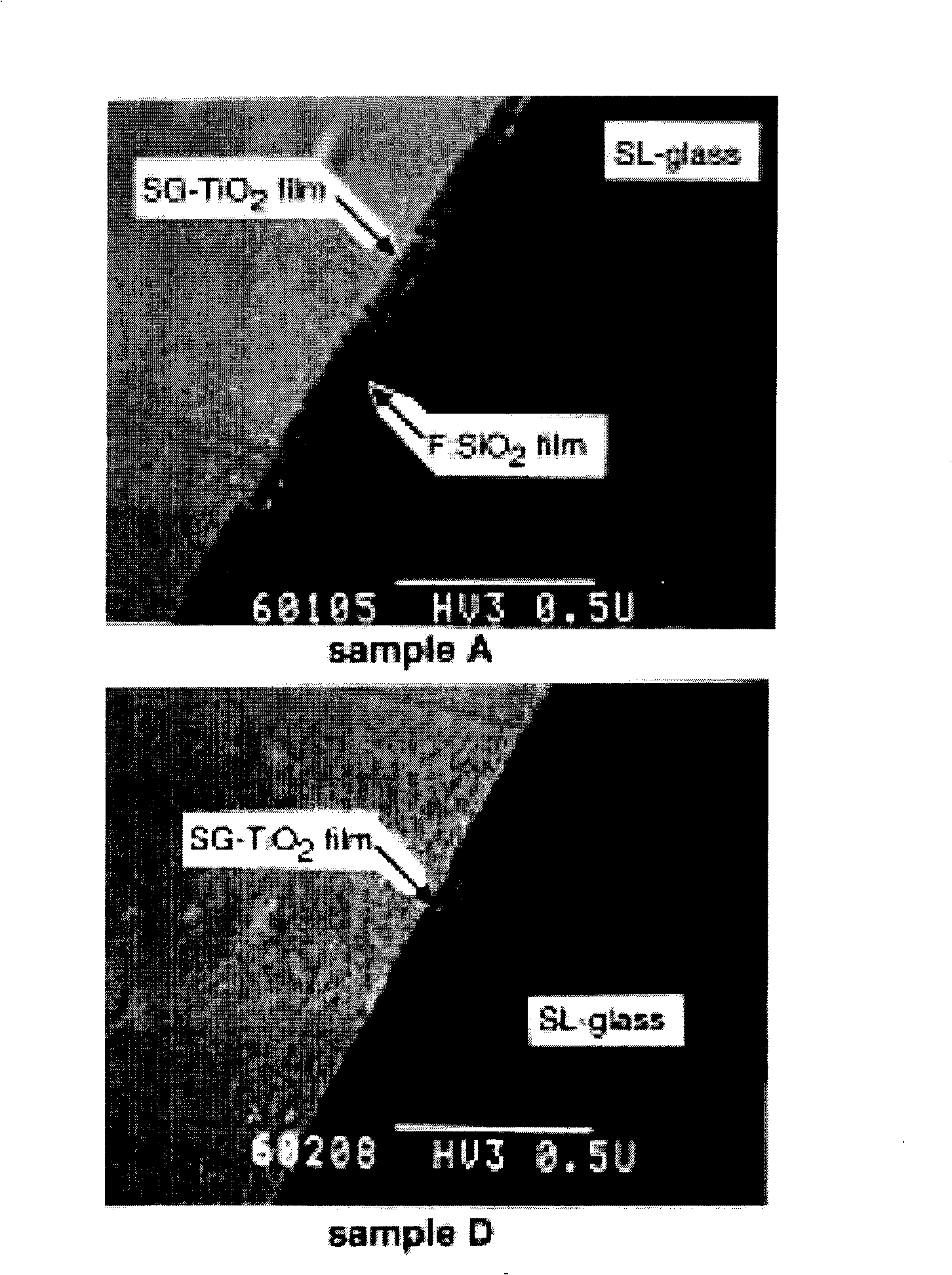

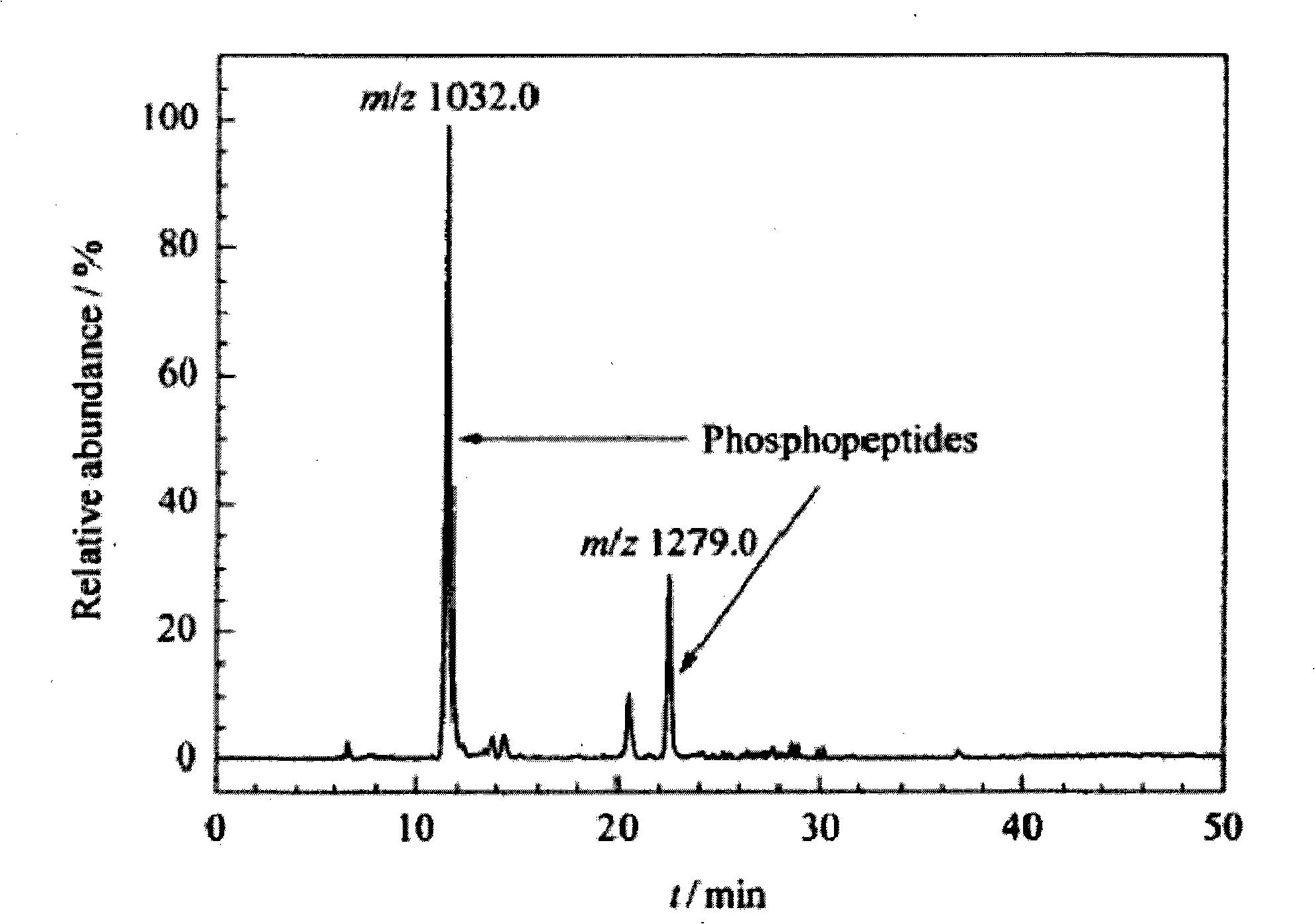

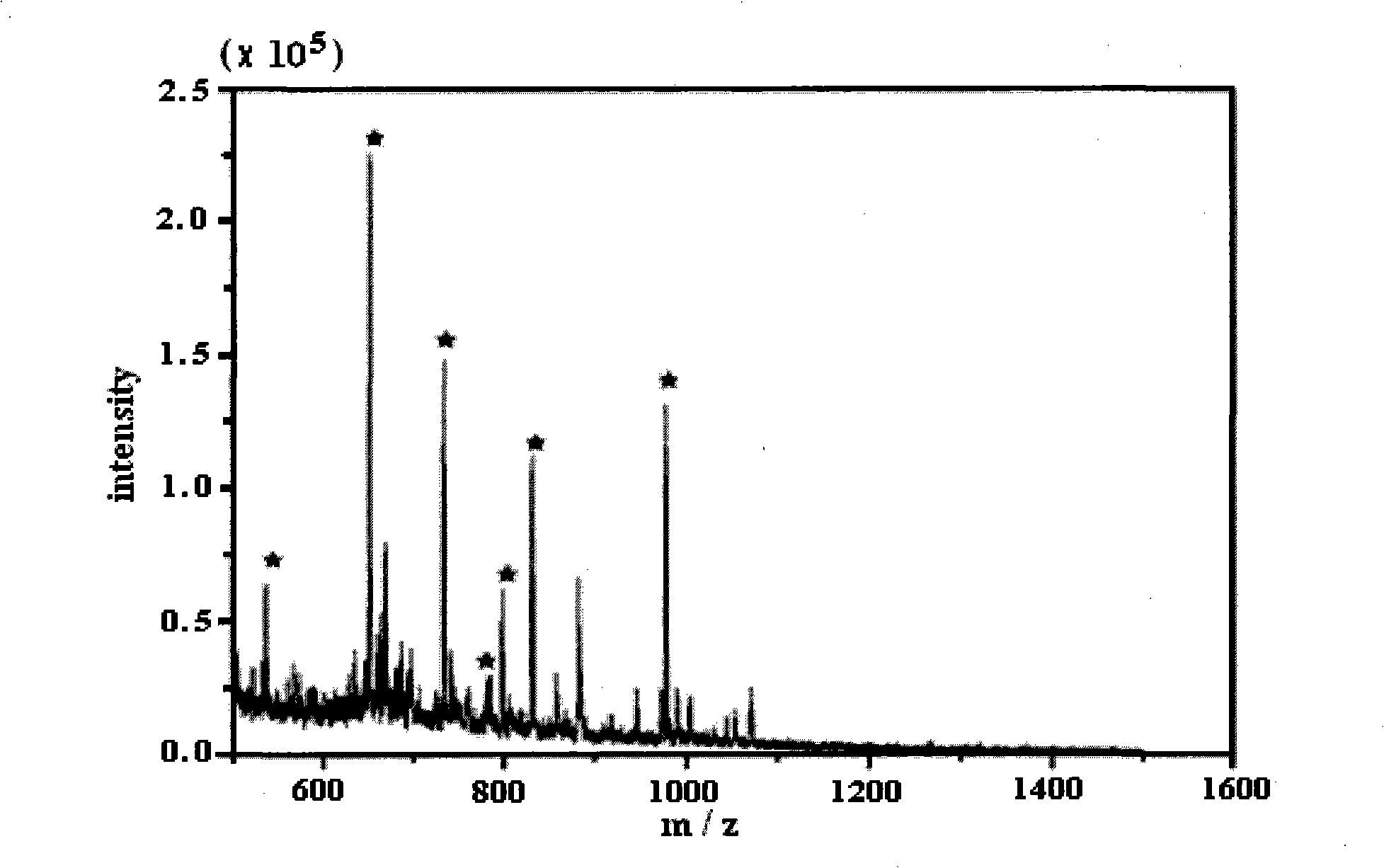

Method for producing open tubular electrophoresis column coating with nano titanic oxide and uses thereof

InactiveCN101406828AAchieve separationAchieve enrichmentComponent separationOther chemical processesMicroparticleSolvent

The invention discloses a method for preparing an open-tube electrophoretic column coated with nanometer titanium dioxide, as well as application thereof. In an etched capillary column, an open-tube capillary electrophoretic column coated with the nanometer titanium dioxide is prepared by a water (solvent) thermal method. The preparation method is characterized in simplicity, coatings insusceptible to fall off, and the like, and is suitable for the selective enrichment and separation of functionalized phosphorylated polypeptide and protein in complex biological samples. Titanium dioxide molecules are combined with silicon hydroxyl on the surface of the inner wall of a capillary through chemical bonds, and nanometer titanium dioxide particles are uniform in grain, complete in coatings and capable of effectively reducing the nonspecific adsorption effect to the protein and other macromolecule samples. The surface properties and micropore structures of the coatings can be conveniently controlled by changing the categories and proportion of middle pore-forming agents in hydrothermal mixtures, so as to obtain a phosphorylated polypeptide capillary column with adjustable pore diameter and specific surface area.

Owner:QIQIHAR UNIVERSITY

Slim tube sedimentation unit and separation system and separation method of suspended particles

InactiveCN101693152AReduce failureReduce lossSedimentation settling tanksSuspended particlesSolid particle

The invention discloses a slim tube sedimentation unit and separation system and separation method of suspended particles. The slim tube sedimentation unit comprises a tube bundle formed by fixing a plurality of slim sedimentation tubes into a whole, wherein one end of each slim sedimentation tube is an opening used as a liquid inlet, while the other end is connected with a liquid collecting cabin; the liquid collecting cabin is connected with a liquid outlet; and sewage inflows from the liquid inlet and outflows from the liquid outlet through the slim sedimentation tubes. In the separation system and the separation method of suspended particles, the slim tube sedimentation unit inclines a certain angle and inserts in open tube water or tube water (close tube water), and an inlet at the lower end of the slim tube sedimentation unit is below the water level to ensure that water inflows from the bottom of the slim tube sedimentation unit; suspended particles in the sewage are separated by the slim tube sedimentation unit; and treated clear water or outlet water containing micron-sized particles outflows from the upper part of the slim tube sedimentation unit. The invention can separate and treat the particles in the sewage by grading, achieve the effect of efficiently removing the suspended particles in the water and can be applied to various fields.

Owner:UNIV OF SCI & TECH BEIJING

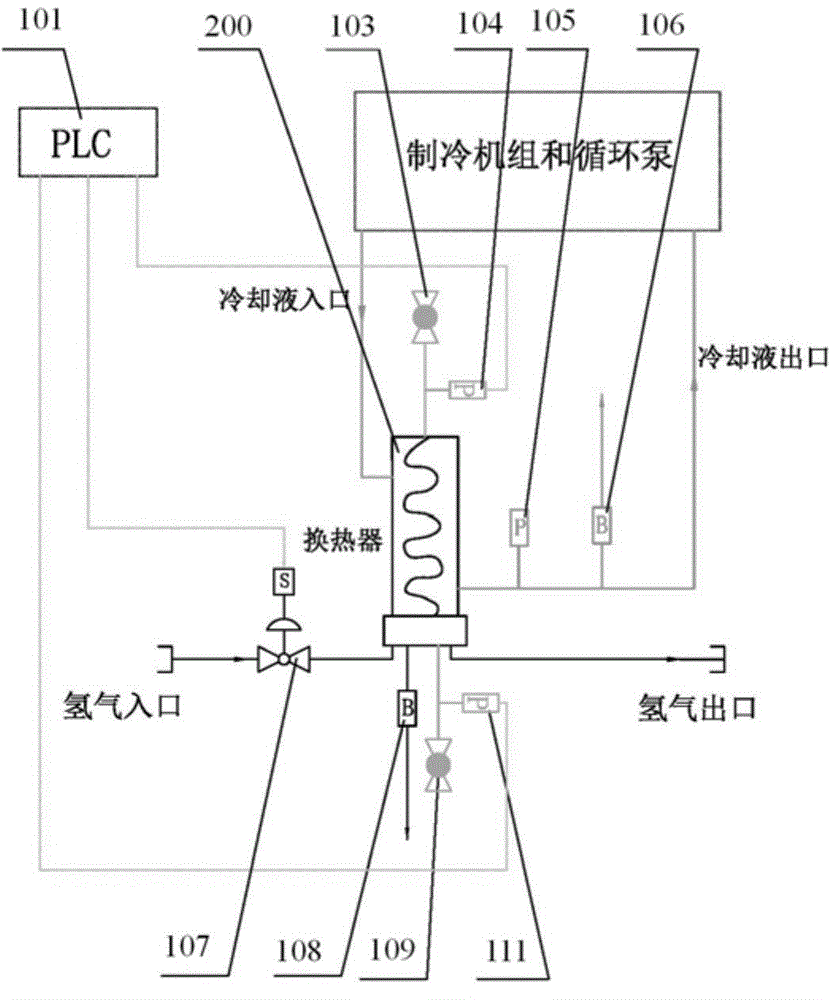

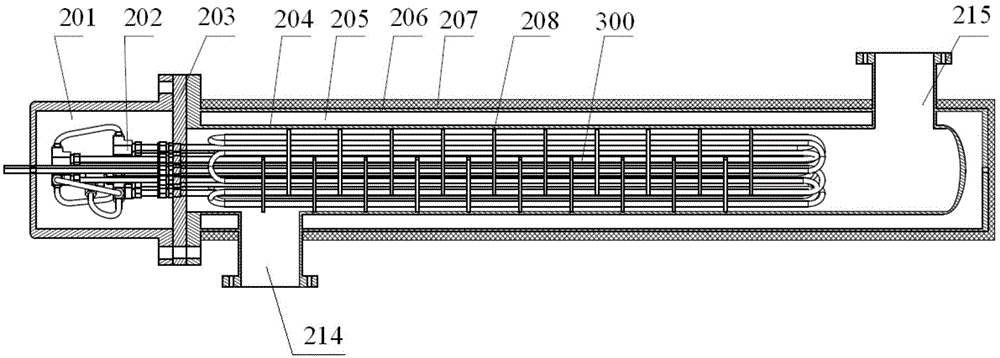

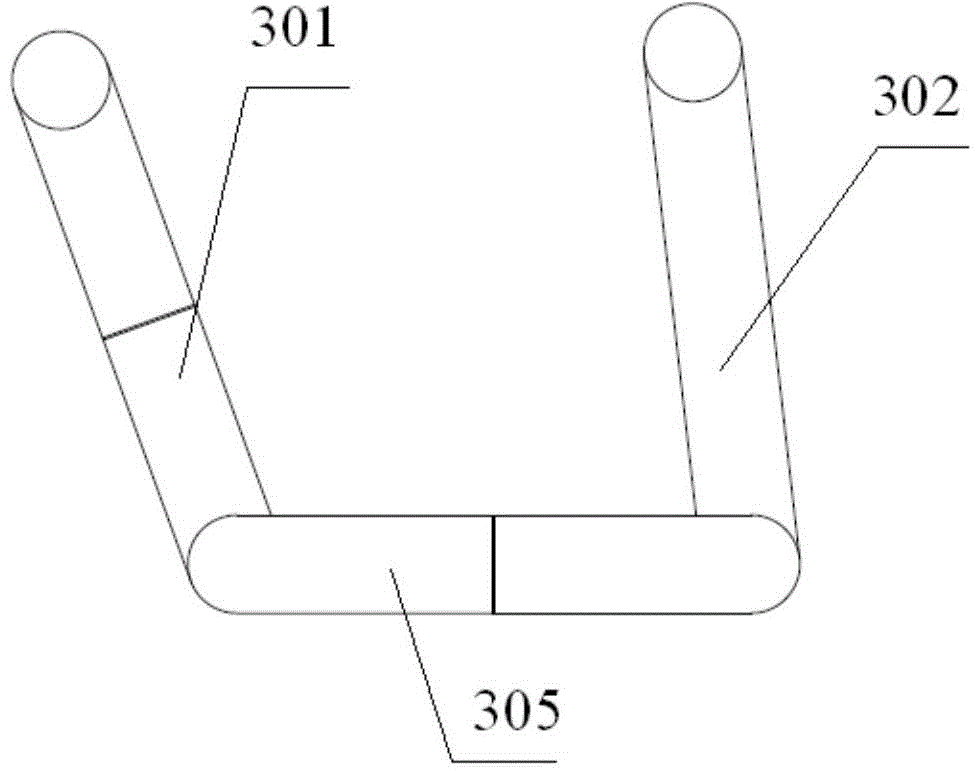

Tube case heat exchange system and heat exchanger

ActiveCN104101245AHigh densityImprove compactnessEvaporators/condensersStationary tubular conduit assembliesPlate heat exchangerStraight tube

A tube case heat exchanger comprises a drum body and a sealing cover positioned at one end of the drum body, wherein a liner is arranged in the drum body; a cooling liquid inlet and a cooling liquid outlet are formed in upper and lower sides of the liner; the liner and the drum are sealed by a liner cover plate; the sealing cover and the cover plate are arranged at the same side; the liner is internally provided with a heat exchange tube bundle structure comprising at least one irregular W-shaped heat exchange tube; each irregular W-shaped heat exchange tube is formed by bending the same straight tube and comprises a first U-shaped tube and a second U-shaped tube which are positioned at different planes and provided with openings in the same direction; respective straight tubes of each first U-shaped tube and the corresponding second U-shaped tube are connected by a bent tube to form a third U-shaped tube with the opening in the opposite direction; the irregular W-shaped heat exchange tubes are uniformly arrayed and arranged along the radial direction of the heat exchanger in a staggering mode; the other straight tubes of the first U-shaped tubes and the second U-shaped tubes penetrate through the cover plate of the liner of the heat exchanger as opening tubes; the opening tubes among different irregular W-shaped heat exchange tubes are serially connected by tube fittings. The tube case heat exchanger is compact in structure, and safe and efficient in use.

Owner:TONGJI UNIV

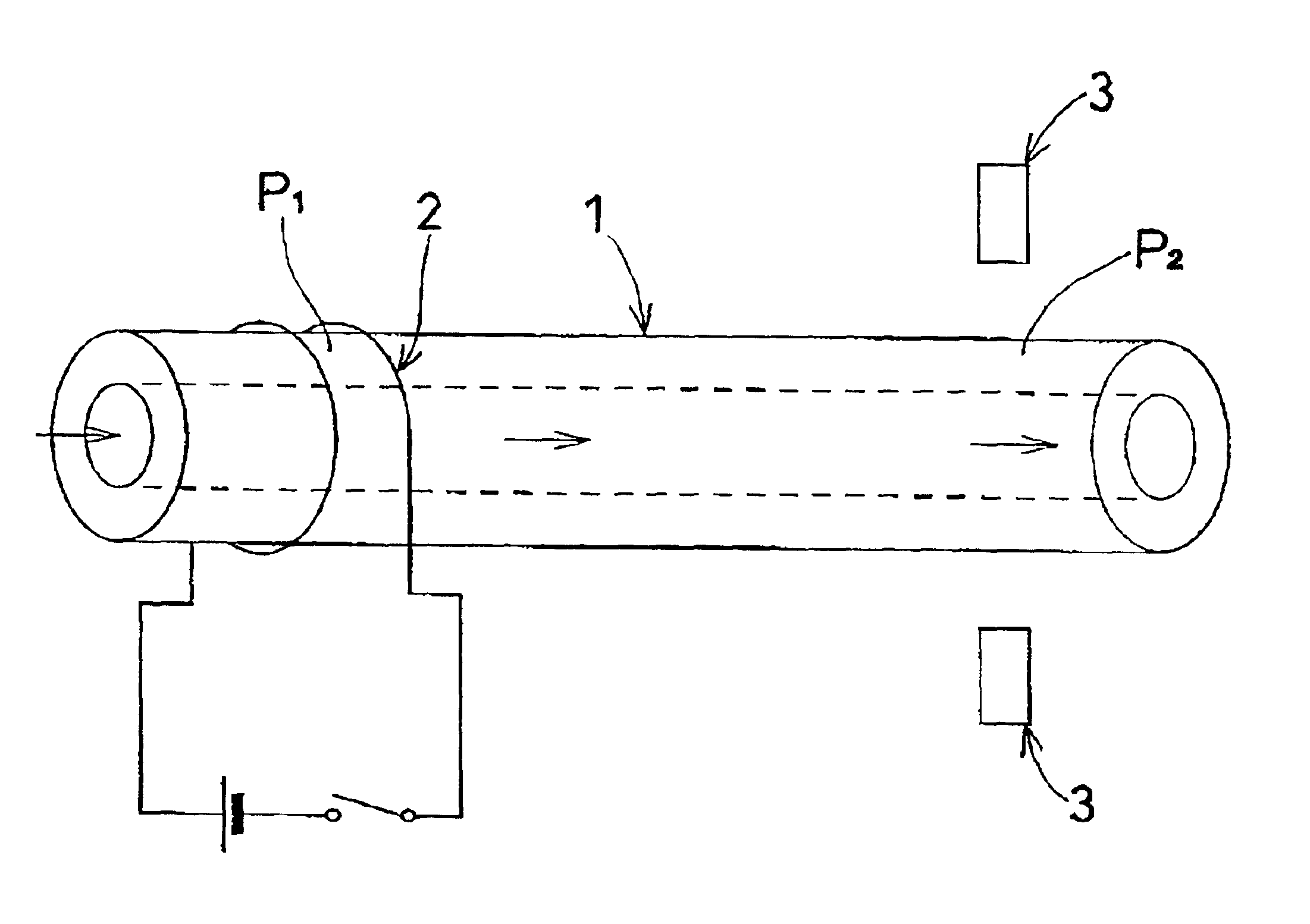

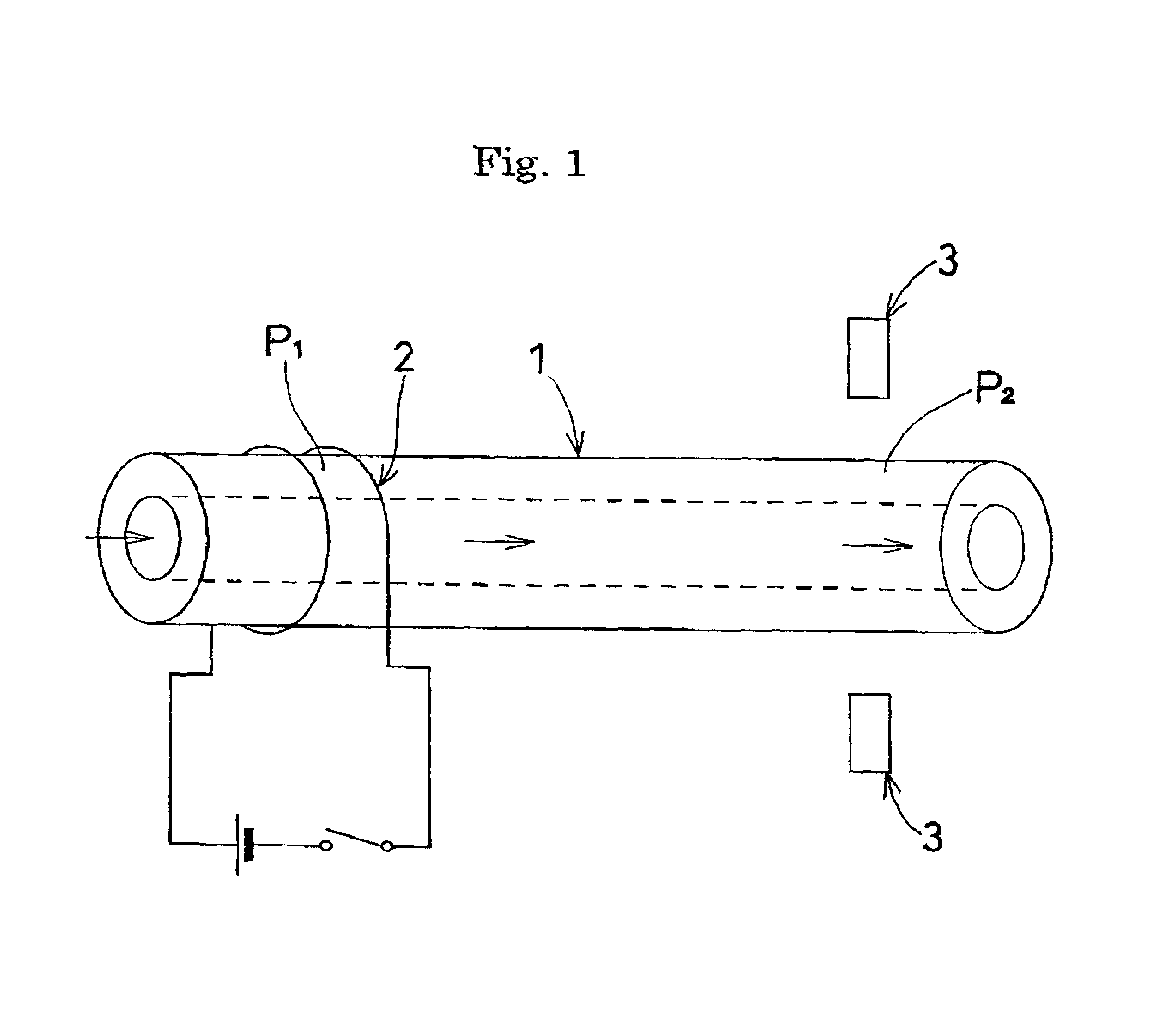

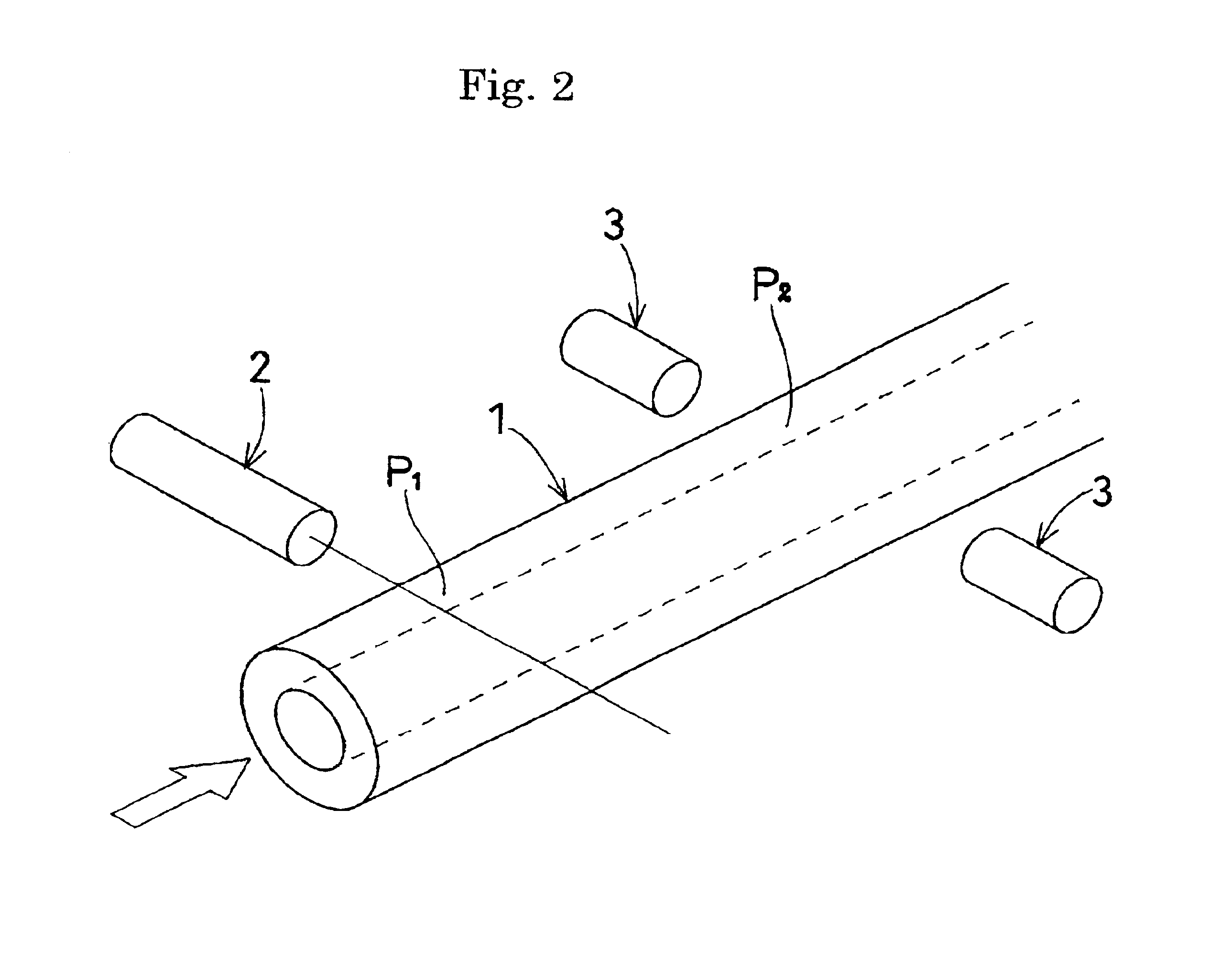

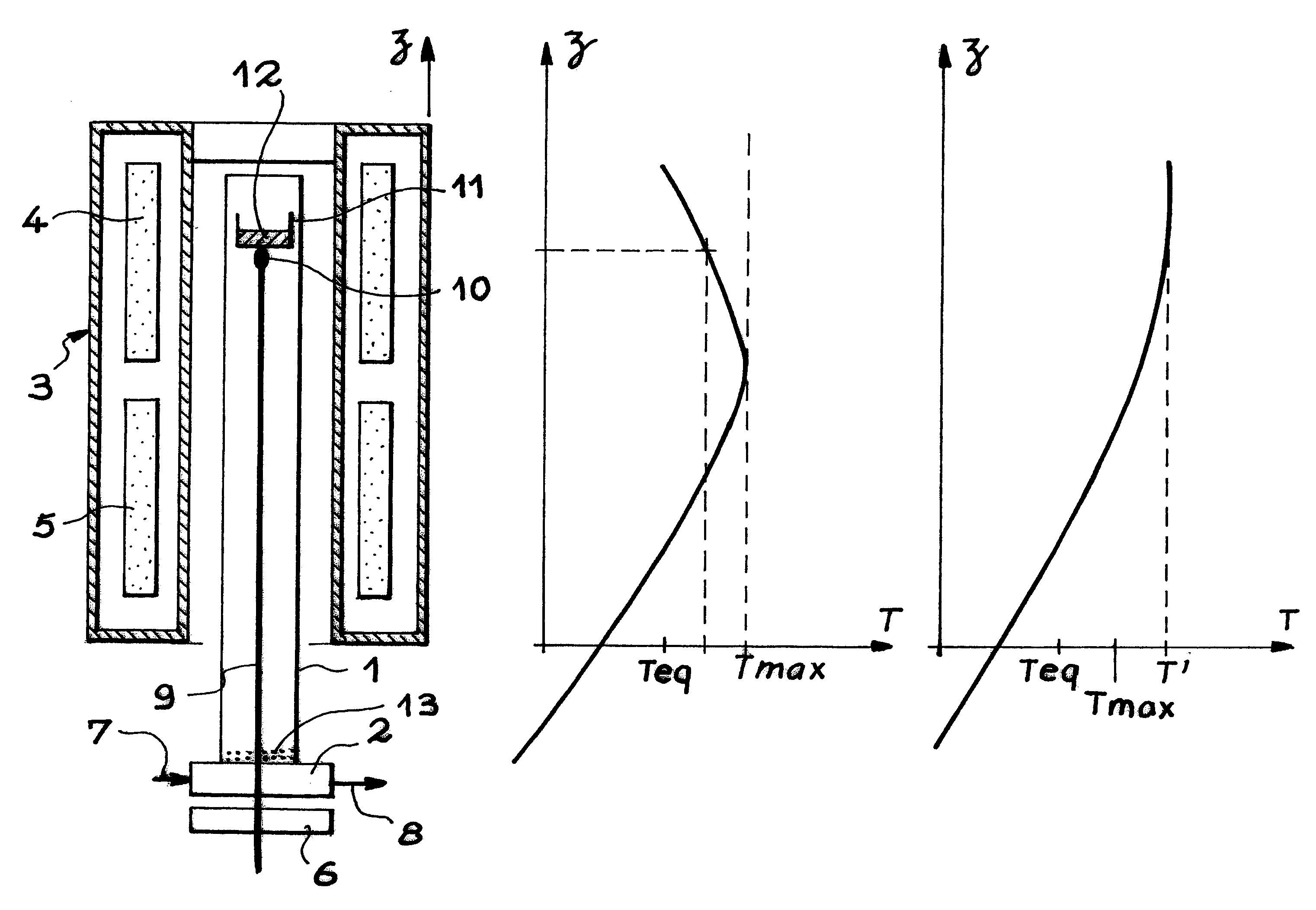

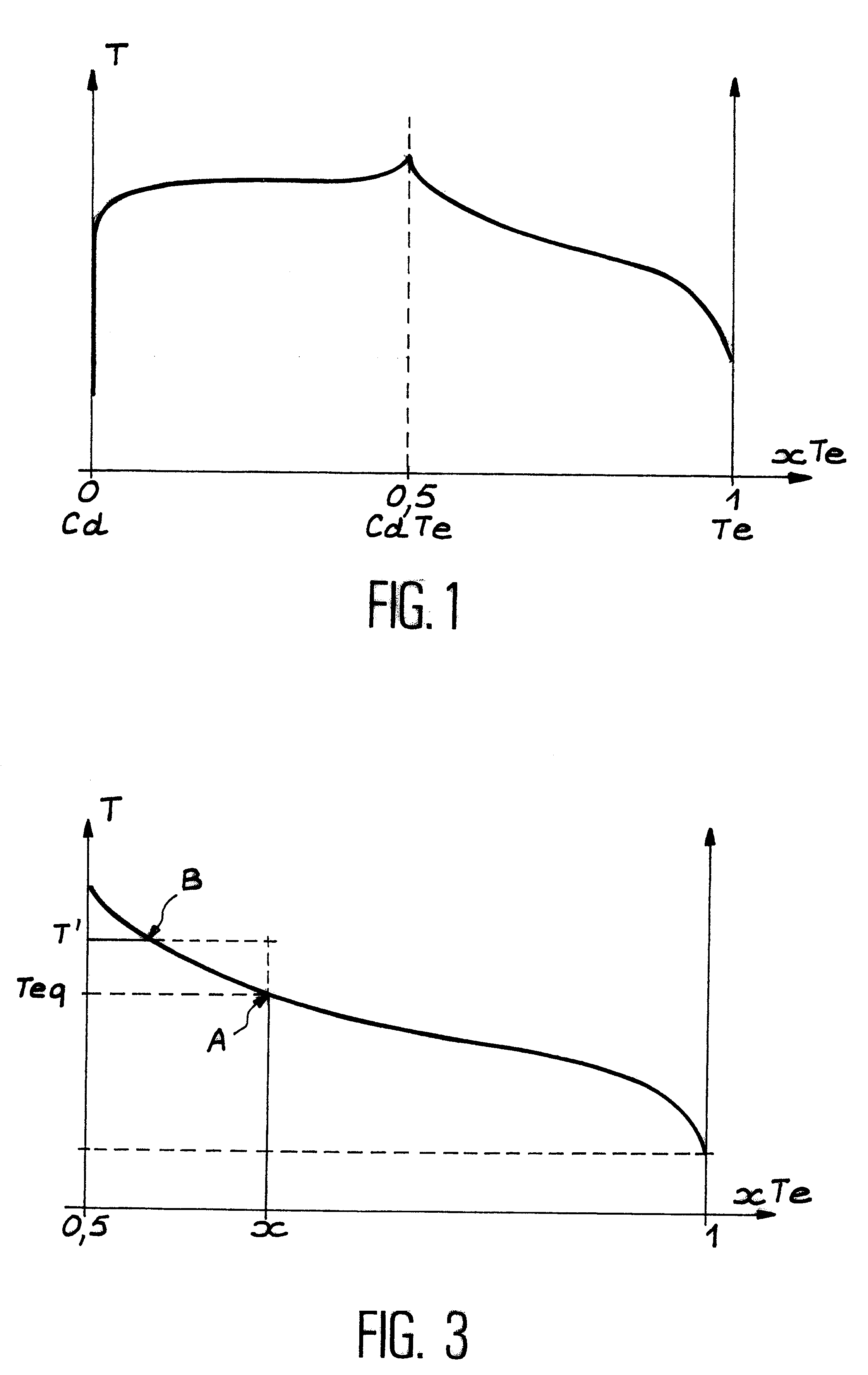

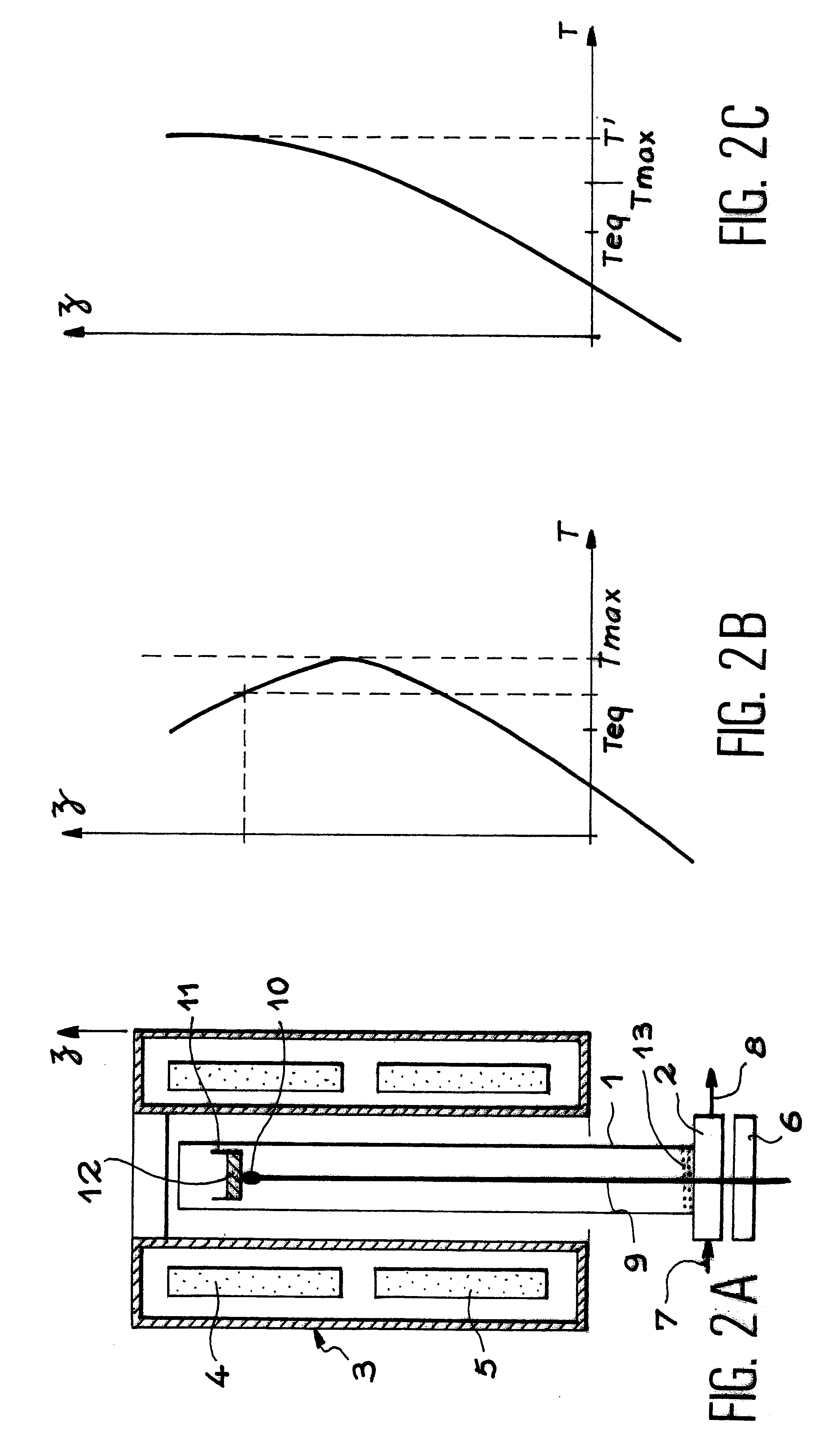

Method for measuring flow within an open tube

InactiveUS6779396B2Component separationVolume/mass flow by thermal effectsChemical synthesisEngineering

A change in physical properties of a fluid within an open tube which is caused by heating an arbitrary portion in the open tube by heating means is detected by using a detector disposed with a predetermined spacing from the arbitrary portion, thereby measuring the flow in the open tube. The present invention provides a method for measuring flow within an open tube, in which a mechanical error and contamination of a passage do not occur, as a method for measuring flow within an open tube having a very small diameter provided for the separation analysis field and chemosynthesis field.

Owner:TSUDA TAKAO +2

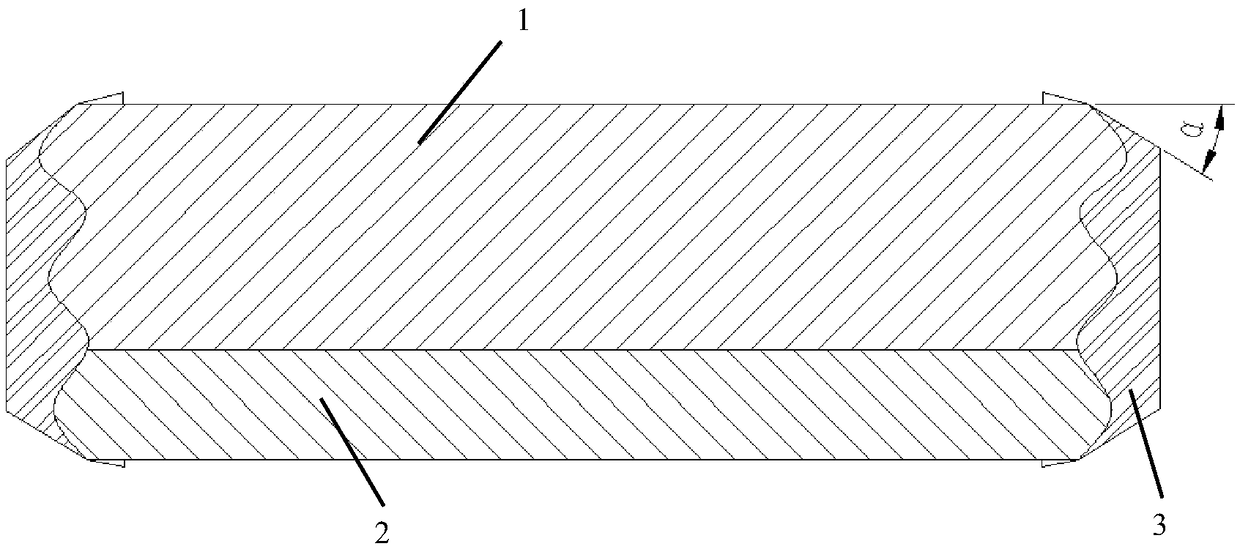

Preparation method for stainless steel and carbon steel composite tube liable to weld and coat edges

The invention discloses a method for rolling a stainless steel tube and a carbon steel tube into a composite tube, and belongs to the technical field of the metal composite tube manufacturing processes. The method is characterized by comprising the following steps of: (1) using a stainless steel composite plate manufactured in a manufacturing method for a stainless steel composite plate liable toweld and coat edges as blank; (2) milling out welding grooves in peripheral coated edges of the composite blank, and grinding by a grinding wheel to move impurities such as oxidized scale; (3) bendingthe stainless steel composite plate into the shape of an open tube by applying a JCO forming method on a bent tube forming machine; (4) adopting an argon-arc welding method for a stirring and friction-welding method along stainless steel coated edges of the bent stainless steel composite plate; (5) performing inclined-rolling thermal expanding on the welded stainless steel composite tube on an inclined-rolling expanding machine; and (6) performing follow-up thermal treatment and tube surface grinding. The method has the advantages that: the two-layer metal composite tube produced by the method is easily welded, production efficiency is improved, and welding seam bonding strength is improved.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for growing a solid type II-VI semiconductor material

InactiveUS6673647B2Polycrystalline material growthSemiconductor/solid-state device manufacturingSemiconductor materialsCrucible

A growth method for a bulk II-VI type semiconductor material, including at least a first component and a second component. The method supplies in a crucible a charge including the components, with proportions of the components being such that the first component is used as a solvent. The crucible is then laced in an open tube reactor. The reactor temperature is then raised to obtain a temperature profile in the reactor ensuring the melting of the charge in the crucible and with the evaporation of the first component beginning, with the pressure inside the reactor being adjusted by the circulation of a gas so that the atmospheric pressure, with the partial pressure of the first component being greater than the partial pressure of the second component.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

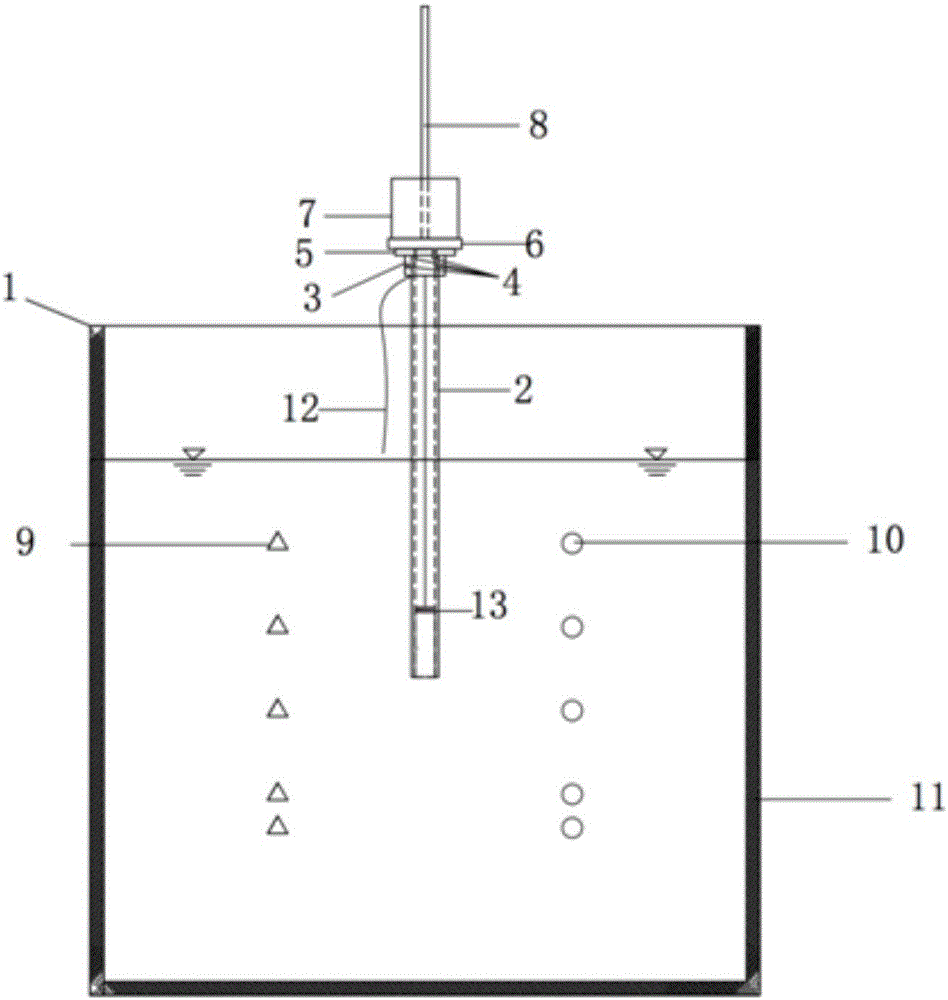

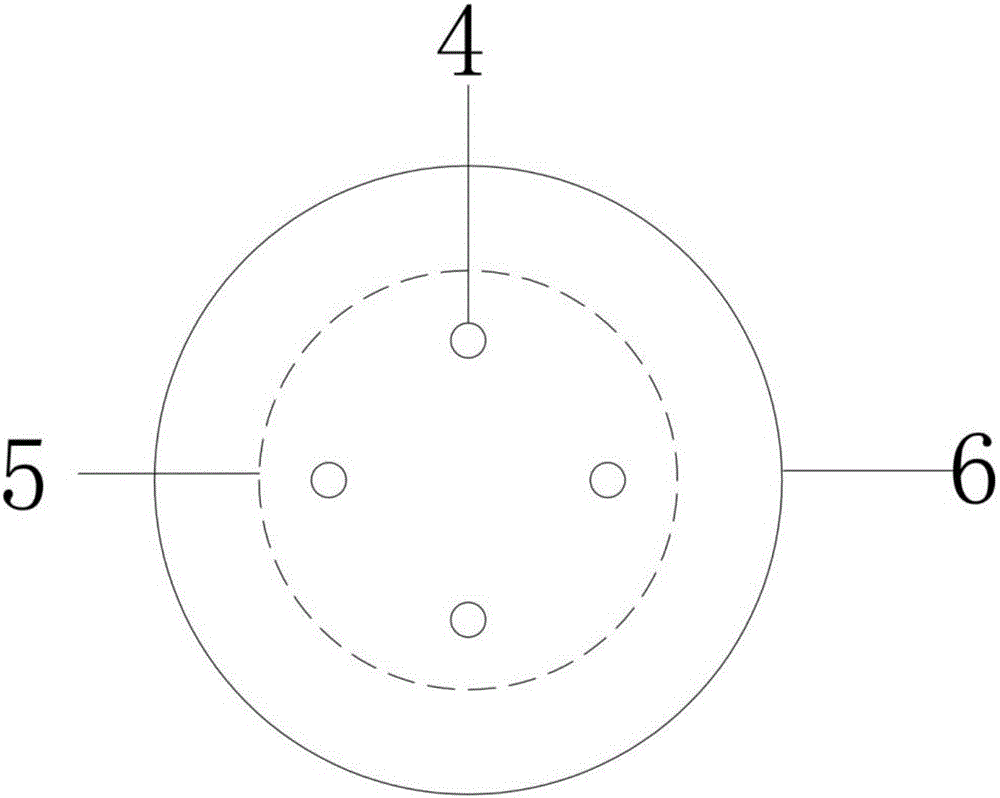

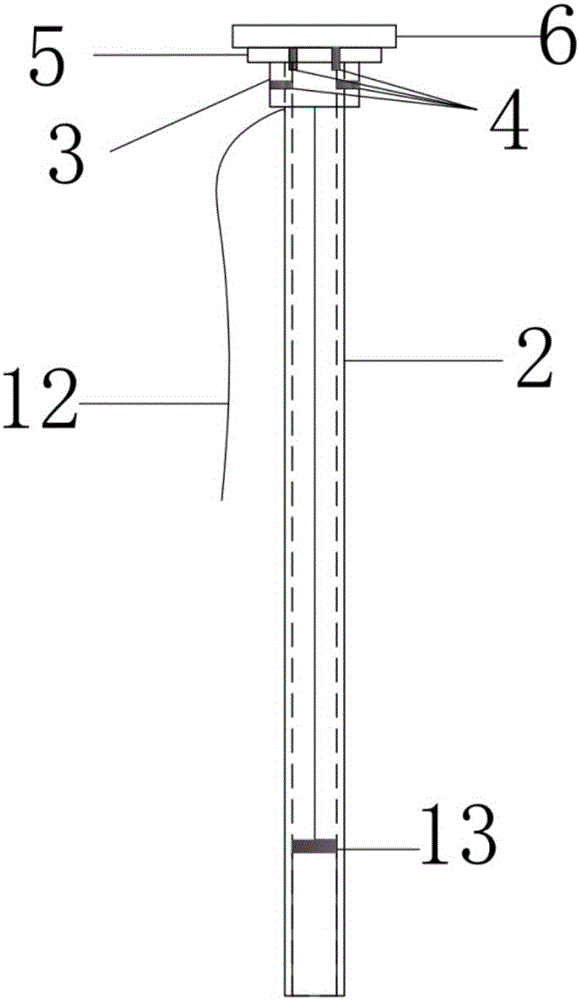

Pile driving model test device based on soil plugging effect and application of pile driving model test device

InactiveCN106836317AThe experimental results are accurateTest accurateFoundation testingUltrasound attenuationBoundary effects

The invention relates to a pile driving model test device based on a soil plugging effect and an application of the pile driving model test device. The pile driving model test device comprises a model box, an opening tube pile, a guide rod and a piecing hammer, wherein the model box is filled with sand samples; miniature earth pressure meters and acceleration sensors connected with a data acquisition instrument are embedded in the sand samples; the opening tube pile is vertically arranged in the center of the model box; the guide rod is vertically arranged at the upper end of the opening tube pile; the piecing hammer penetrates through the guide rod and is located at the upper part of the opening tube pile. Compared with the prior art, formation of soil plugs in a dynamic pile driving process of the tube pile can be simulated, height of the soil plugs is measured in real time, dynamic response around the pile in the dynamic pile driving process can be measured when the height of the soil plugs is fixed, boundary effect caused by model box walls is overcome, hammering power response of the opening tube pile under the soil plugging effect can be studied better, and soil compaction effect, vibration wave attenuation and load energy transmission rules caused by pile driving by the hammer are researched.

Owner:TONGJI UNIV

Method for butting buried cable steel tube on site during construction

InactiveCN101832435AReduce the occurrence of impenetrableGuarantee laying efficiencySleeve/socket jointsCable installations in underground tubesSlagRebar

The invention relates to the technical field of electric engineering construction, in particular to a method for butting a buried cable steel tube on site during construction. The method comprises the following steps of: (1) manufacturing a wedge-shaped chambering tube; (b) wedging the wedge-shaped chambering tube into a ring opening tube to expand the tube diameter of the ring opening tube, and welding fixed diameter steel bars to side walls on two sides of the opening of the ring opening tube to form a butting sleeve; (c) sleeving the tube ends of two polished cable steel tubes into the butting sleeve, and cutting off the fixed diameter steel bars on the butting sleeve; (d) totally fitting the tube orifices of the cable steel tubes, fixing the cable steel tubes by spot welding, and then tightly welding each connector; and (e) polishing the welding slag at the welded part, and coating anti-rusting paint on the cable steel tubes so as to finish butting the cable steel tubes. By using the method, materials are taken from the construction site, no extra material is needed, the manufacturing process is simple and practical, on-site construction is convenient, the construction cost is saved, the butting misalignment and burrs of the tube orifices can be reduced, and the efficiency and quality of paving cables are guaranteed.

Owner:CHINA FIRST METALLURGICAL GROUP

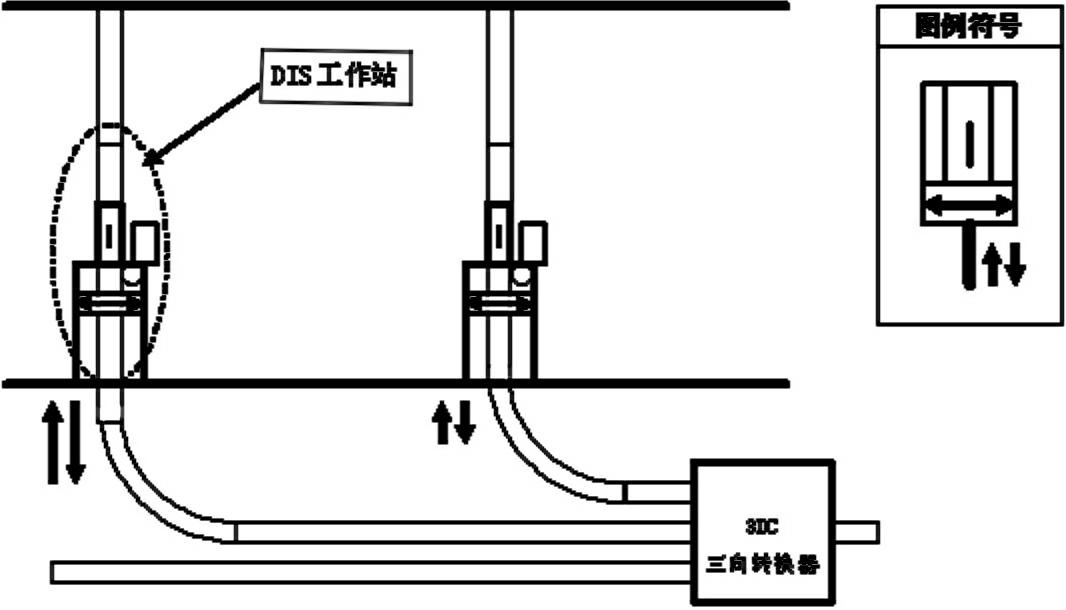

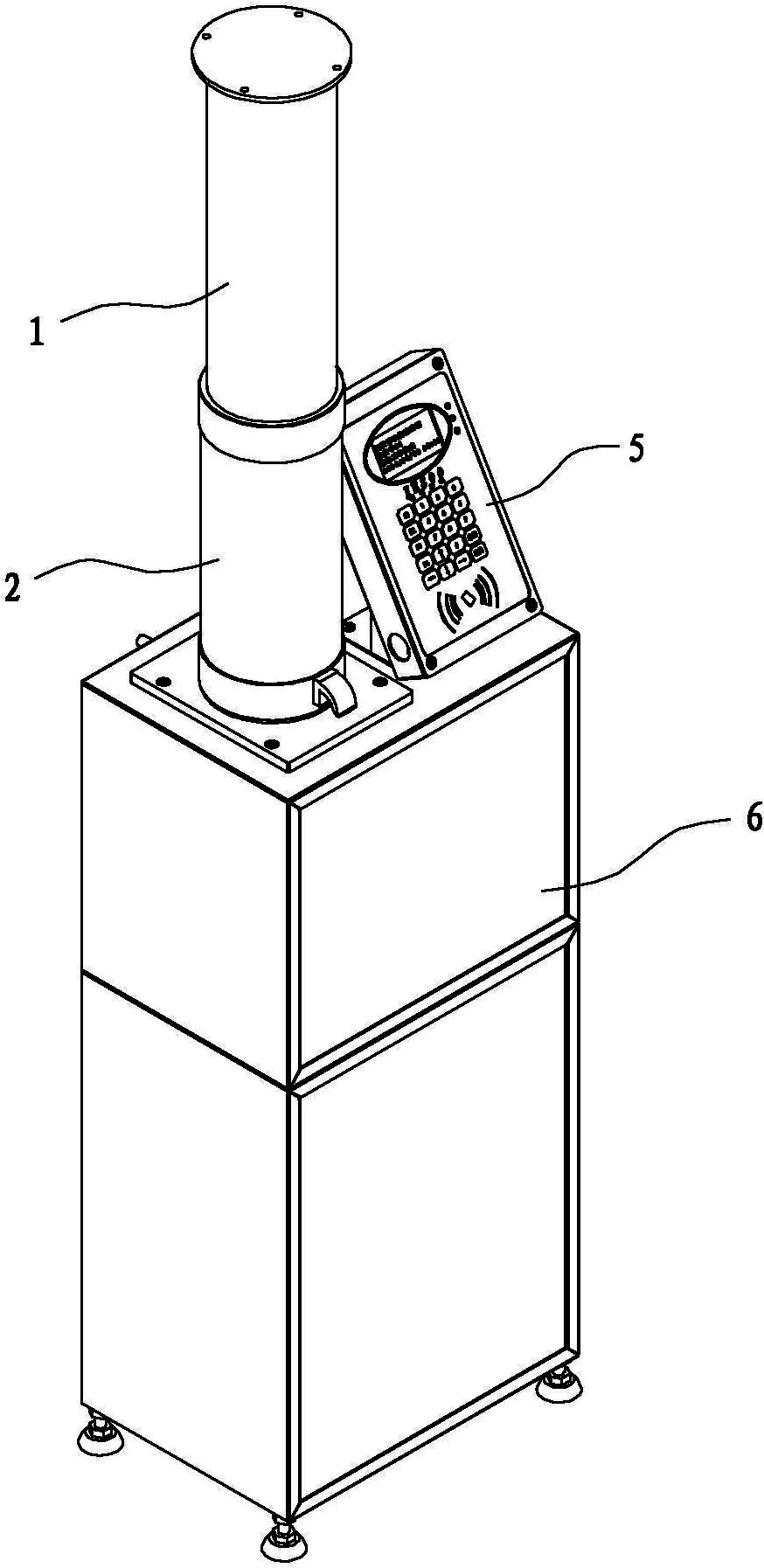

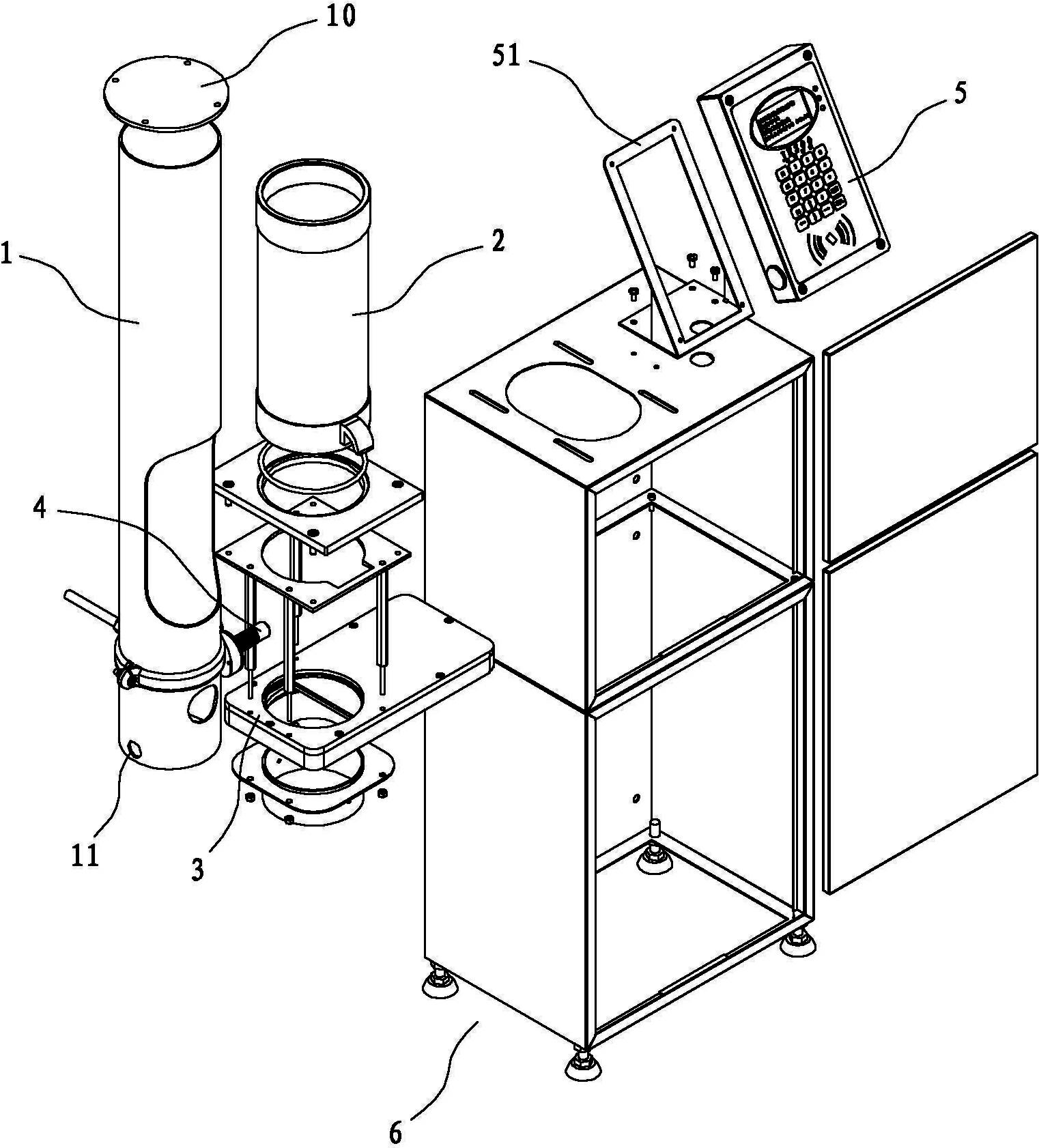

Pneumatic transmission downlink transceiving workstation device and transceiving method

The invention discloses a pneumatic transmission downlink transceiving workstation device and a transceiving method. The pneumatic transmission downlink transceiving workstation device comprises an open tube, a transparent sliding door, an electric sliding valve, a sensing detection device and a terminal controller, wherein the transparent sliding door is covered in the position of a side opening of the open tube, the sensing detection device is used for detecting whether a transmission carrier in a tube cavity passes through or not and exists or not, and the terminal controller is connected with the electric sliding valve and the sensing detection device and used for controlling a workstation to transmit and receive transmission bottles. As three working positions are arranged in the electric sliding valve and matched with the sensing detection device, the bottle clamping problem in a Y-shaped tube or an S-shaped elbow during downward movement can be solved by negative pressure generated by a pipeline during transmitting; and during receiving, an air cushion is used for cushioning, then the impact to the transmission bottles can be slowed down, and the pneumatic transmission downlink transceiving workstation device has the advantages of high transmission efficiency, safety, reliability and the like.

Owner:厦门赛摩积硕科技有限公司

Ionic liquid coated paper of thin-walled carbon nanotube and preparation method of ionic liquid coated paper

ActiveCN102677546AStrong dielectricOvercome van der Waals forcesSurface covering paperMaterial nanotechnologyElectrical resistance and conductanceAdhesive

The invention belongs to the technical field of conducting materials and discloses an ionic liquid coated paper of a thin-walled carbon nanotube and a preparation method of the ionic liquid coated paper. An ionic liquid in the paper of carbon nanotubes is evenly coated on the outer surfaces of the carbon nanotubes to form a coaxial structure, and then the carbon nanotubes are mutually lapped to form a net structure. The paper of the carbon nanotubes is prepared by the steps that firstly 15wt% to 30wt% of ionic liquid and the thin-walled carbon nanotube are subjected to dispersion mill, and then are compacted. The ionic liquid can have functions of dispersing the thin-walled carbon nanotube, opening tube bundles of the thin-walled carbon nanotube and serving as an adhesive. Compared with resistance of papers of thin-walled carbon nanotubes, which are directly compacted without using the ionic liquid, the resistance of the prepared paper of the thin-walled carbon nanotube is reduced by 20-40%, when the paper is used as an electrode material of a supercapacitor at a voltage of 4-6.5 volts, the performances of the supercapacitor are improved by 20-100%, and when the paper is used as a strength material, the tensile strength is improved by 20-100%. Besides, the preparation method has the advantages of being low in cost and easy to repeat and amplify.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com