Method for on-site measuring permeability coefficient of landfill gas

A gas permeation and on-site measurement technology, applied in the field of resources and environment, can solve the problems of easy explosion, high risk, difficult to popularize, etc., and achieve the effects of convenient operation, high measurement accuracy and simple system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

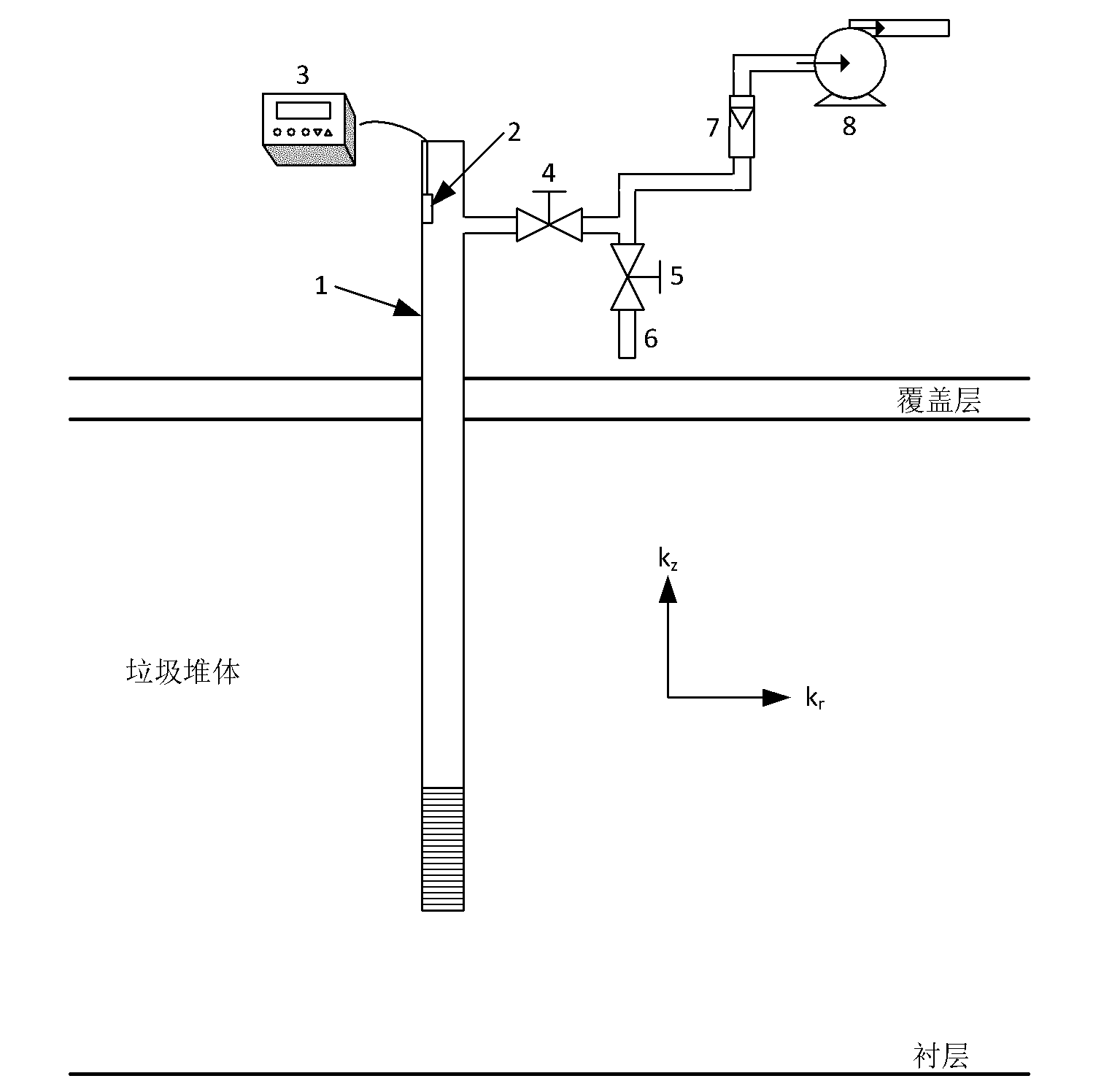

[0031] figure 1 It is a schematic structural diagram of a system for on-site measurement of landfill gas permeability coefficient provided by the present invention. The measuring system that this method adopts comprises lower opening tube well 1, gas pressure sensor 2, gas pressure display recorder 3, air extraction pipeline valve 4, gas flow meter 7 and centrifugal fan 8; Described gas pressure sensor 2 is installed in the tube well The upper part is connected with the gas pressure display recorder through the data line; the centrifugal fan is communicated with the upper end of the tube well through the gas pipeline, and the gas extraction pipeline valve and the gas flow meter are installed on the gas pipeline; A leachate venting pipe 6 and a leachate venting valve 5 are also installed on the gas pipeline between the exhaust pipe va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com