Continuous color-changing fluorescent anti-counterfeiting material as well as preparation method and application thereof

A color-changing fluorescence and dye technology, applied in luminescent materials, applications, chemical instruments and methods, etc., can solve the problems of unable to provide color change and color change path, unable to meet the actual needs of anti-counterfeiting materials, and high equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

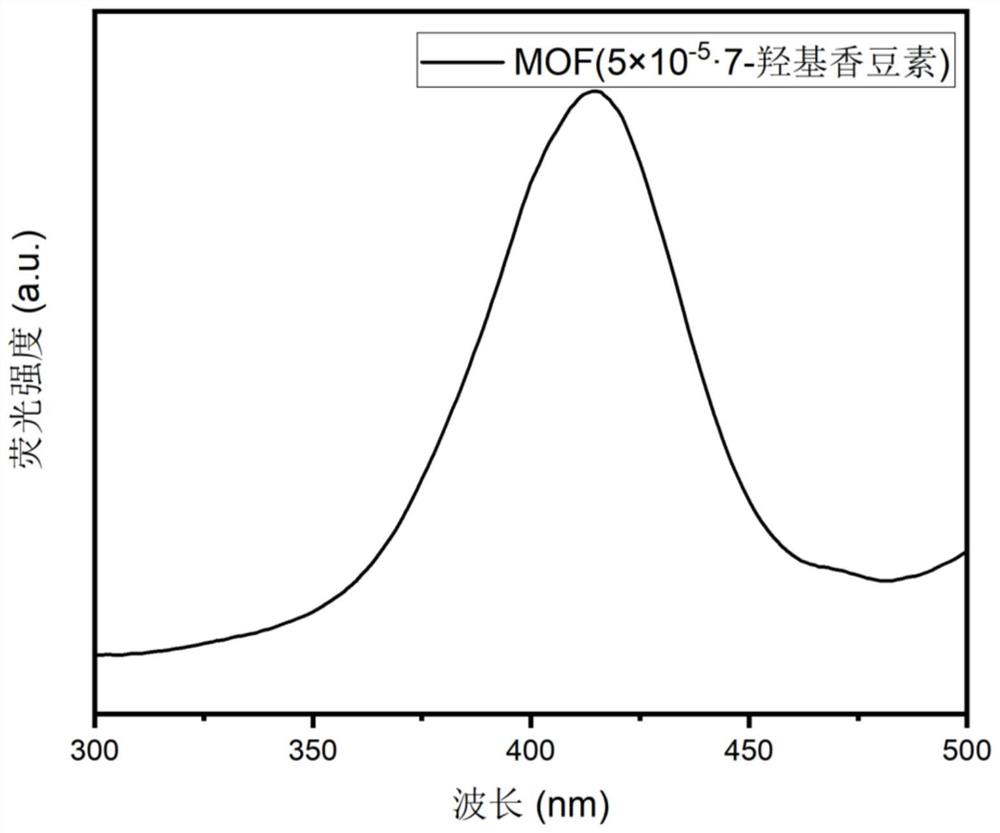

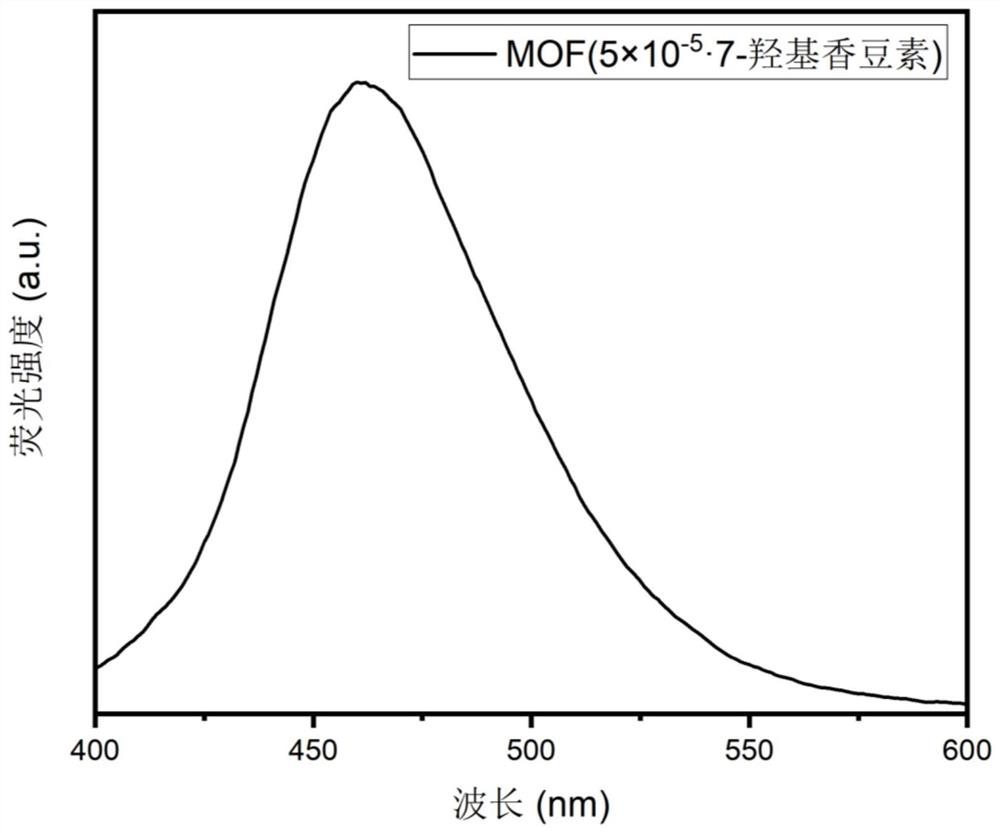

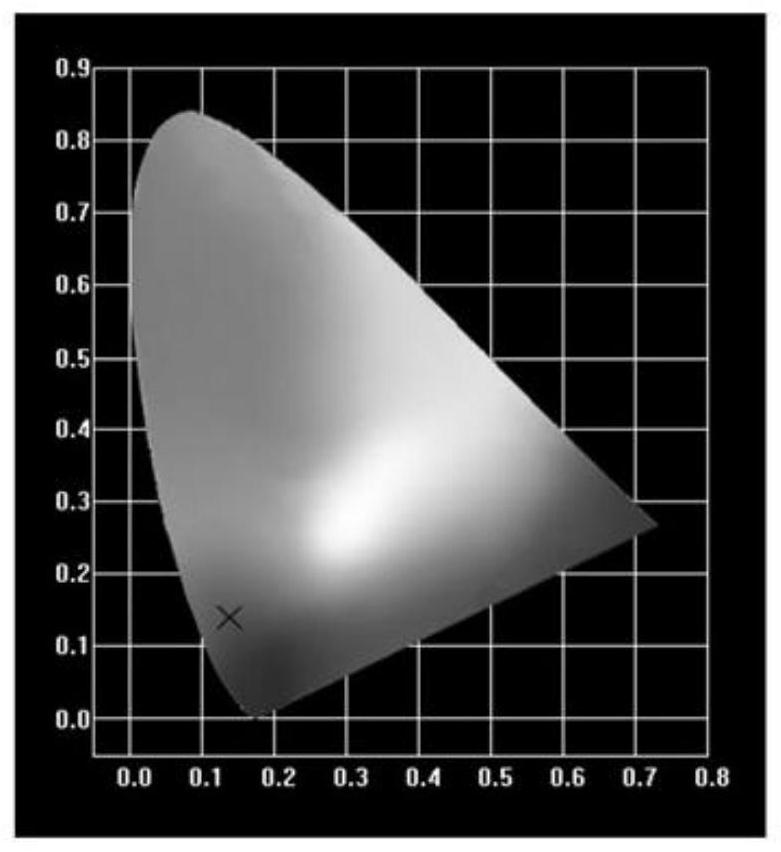

[0091] Preparation of MOF (5×10 -5 7-Hydroxycoumarin), Eu 3+ / MOF(5×10 -5 7-hydroxycoumarin) the steps are as follows:

[0092] Wherein, the structural formula of 7-hydroxycoumarin is:

[0093]

[0094] (1) MOF (5×10 -5 • Preparation of 7-hydroxycoumarin). Firstly, 0.0162g (0.1mmol) of 7-hydroxycoumarin was dissolved in 10mL of N,N-dimethylformamide (DMF) solution to prepare a DMF solution of 7-hydroxycoumarin. Then take 1.1672g (5.01mmol) of zirconium chloride (ZrCl 4 ), 0.6654g (4.01mmol) of terephthalic acid (TPA) and 0.1675g (1.01mmol) of 2,6-pyridinedicarboxylic acid (DPA) were successively dissolved in 30mL of DMF, and 5mL of 7-hydroxy The DMF solution of bean element was added to the above solution and stirred for 10 min, and about 1 mL of hydrochloric acid solution (mass concentration: 25%) was added to the above mixed solution after the stirring was completed. The resulting solution was transferred to a 50 mL round-bottomed flask, and the heating and reflux re...

Embodiment 2

[0106] Preparation of Tb 3+ / MOF(5×10 -5 7-hydroxycoumarin) the steps are as follows:

[0107] Step (1) is with embodiment 1;

[0108] (2)Tb 3+ / MOF(5×10 -5 • Preparation of 7-hydroxycoumarin). First weigh 1.8670g (5.00mmol) of TbCl 3 Sonicate dissolved in 50 mL of distilled water to prepare Tb 3+ solution. Then weigh 0.3000g of MOF (5×10 -5 7-Hydroxycoumarin) was put into a 50mL round bottom flask, and then 20mL of Tb 3+ The solution was added to the upper round bottom flask. This solution was refluxed at 80°C for 12h. Naturally cooled to room temperature, centrifuged to collect the precipitate, washed alternately with water and ethanol for 6 times, dried in a blast drying oven at 50° C. for 12 hours, and finally collected to obtain a solid powder product.

[0109] (3) Similarly, the Eu 3+ / MOF(5×10 -5 7-Hydroxycoumarin) material was changed to Tb 3+ / MOF(5×10 -5 7-hydroxycoumarin) material, other steps are with the step (3) of embodiment 1, prepare with Tb 3+...

Embodiment 3

[0115] Embodiment 3 prepares MOF (5 * 10 -5 ·5-Cl-HQ) material and Eu 3+ / MOF(5×10 -5 5-Cl-HQ) material steps are as follows:

[0116] Wherein the structural formula of 5-Cl-HQ is:

[0117]

[0118] (1) MOF (5×10 -5 • Preparation of 5-Cl-HQ). Other steps, MOF (5×10 -5 The preparation method of 5-Cl-HQ) and MOF (5×10 -5 · 7-hydroxycoumarin) was prepared in the same way. The difference is that 0.0162g (0.1mmol) of 7-hydroxycoumarin is replaced by 0.0180g (0.1mmol) of 5-chloro-8-hydroxyquinoline.

[0119] (2) Eu 3+ / MOF(5×10 -5 • Preparation of 5-Cl-HQ). Other steps, Eu 3+ / MOF(5×10 -5 The preparation method of 5-Cl-HQ) and Eu 3+ / MOF(5×10 -5 The preparation method of 7-hydroxycoumarin) is the same, the difference is that the MOF (5×10 -5 7-Hydroxycoumarin) was replaced by MOF (5×10 -5 · 5-Cl-HQ) is sufficient.

[0120] (3) Preparation of fluorescent anti-counterfeiting ink and anti-counterfeiting patterns. At 25°C, distilled water, Eu 3+ / MOF(5×10 -5 5-Cl-H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com