Patents

Literature

53results about How to "Improve current control accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

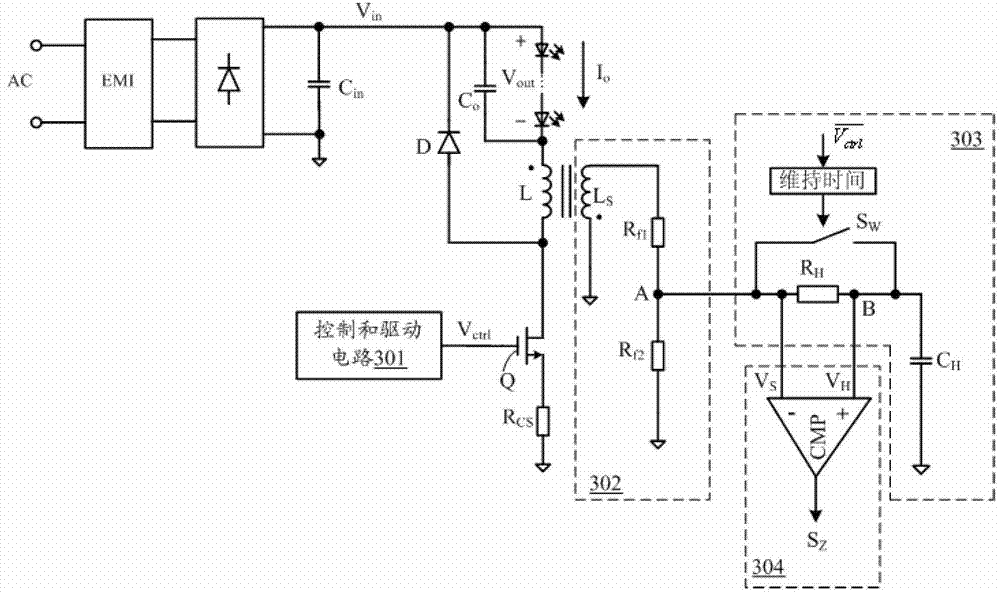

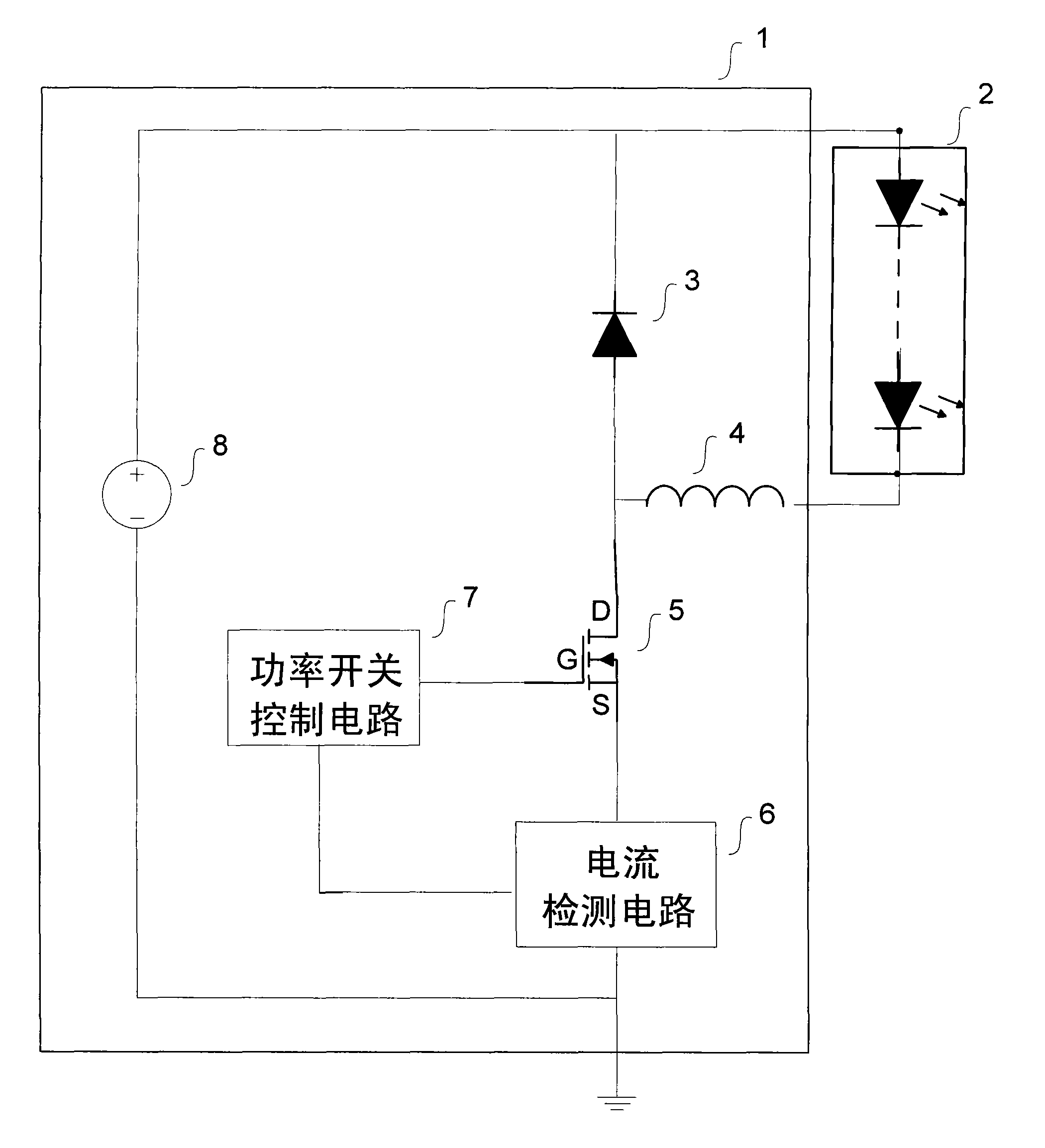

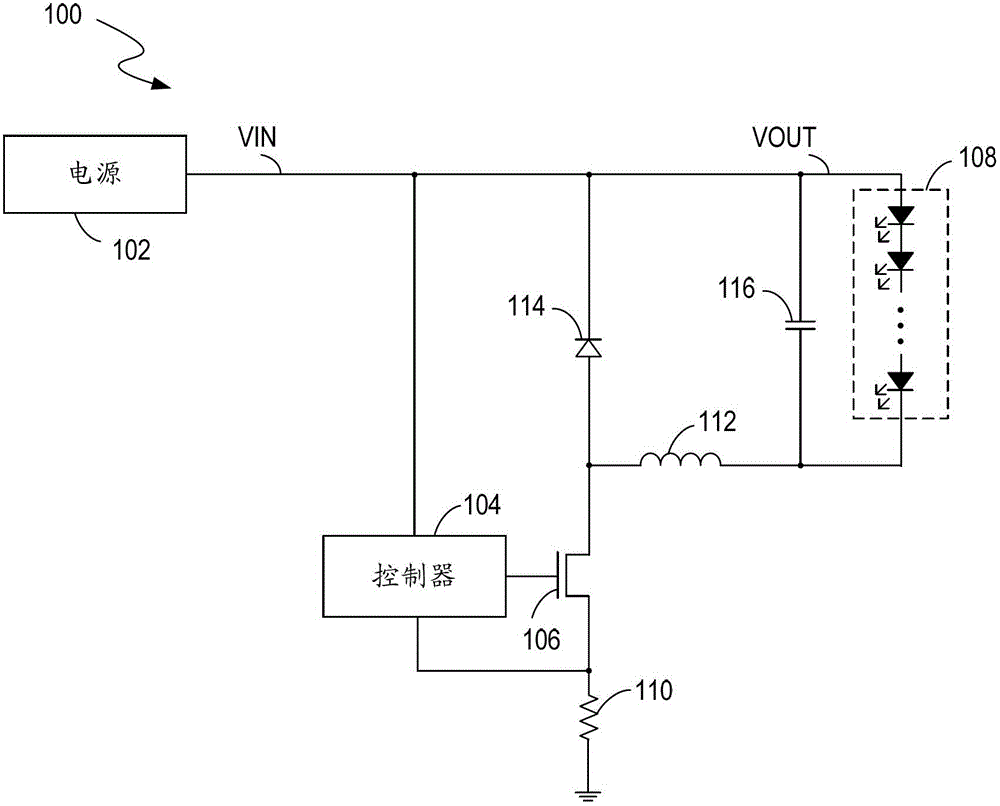

Inductive current detecting circuit and LED (light emitting diode) driving circuit using inductive current detecting circuit

ActiveCN102735906ADetection end timeHigh control precisionAc-dc conversion without reversalCurrent/voltage measurementEngineeringLED circuit

The invention relates to an inductive current detecting circuit in a switch power supply and an LED (light emitting diode) driving circuit using the inductive current detecting circuit. According to the inductive current detecting circuit provided by the embodiment of the invention, an inductive current ending time in an interrupted working mode of the inductive current can be detected precisely through a voltage sampling and holding circuit so that inductive current duration time can be obtained precisely. According to the LED driving circuit provided by the embodiment of the invention, with the adoption of the inductive current detecting circuit, an inductive current average value can be obtained precisely, i.e. output current information of the LED driving circuit can be obtained precisely, so that the current control precision is improved; furthermore, the power factor calibration is realized; and a higher power factor is obtained.

Owner:SILERGY SEMICON TECH (HANGZHOU) CO LTD

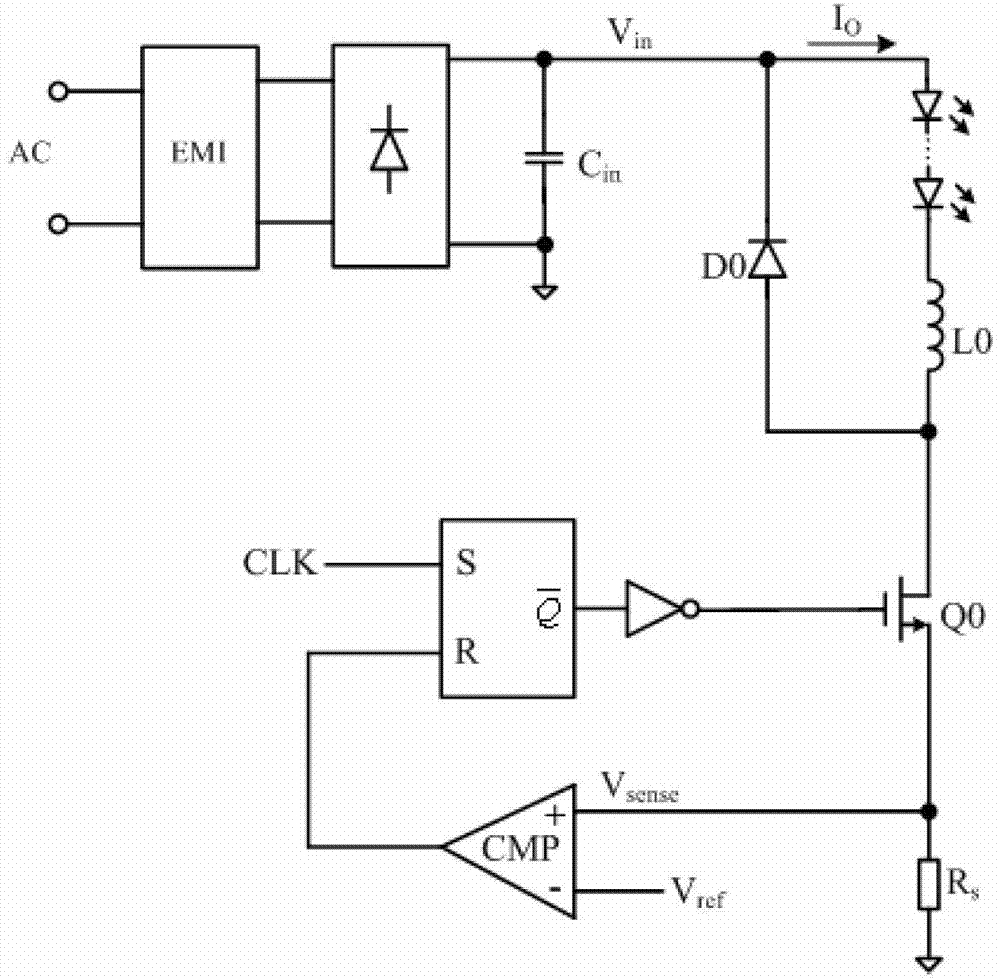

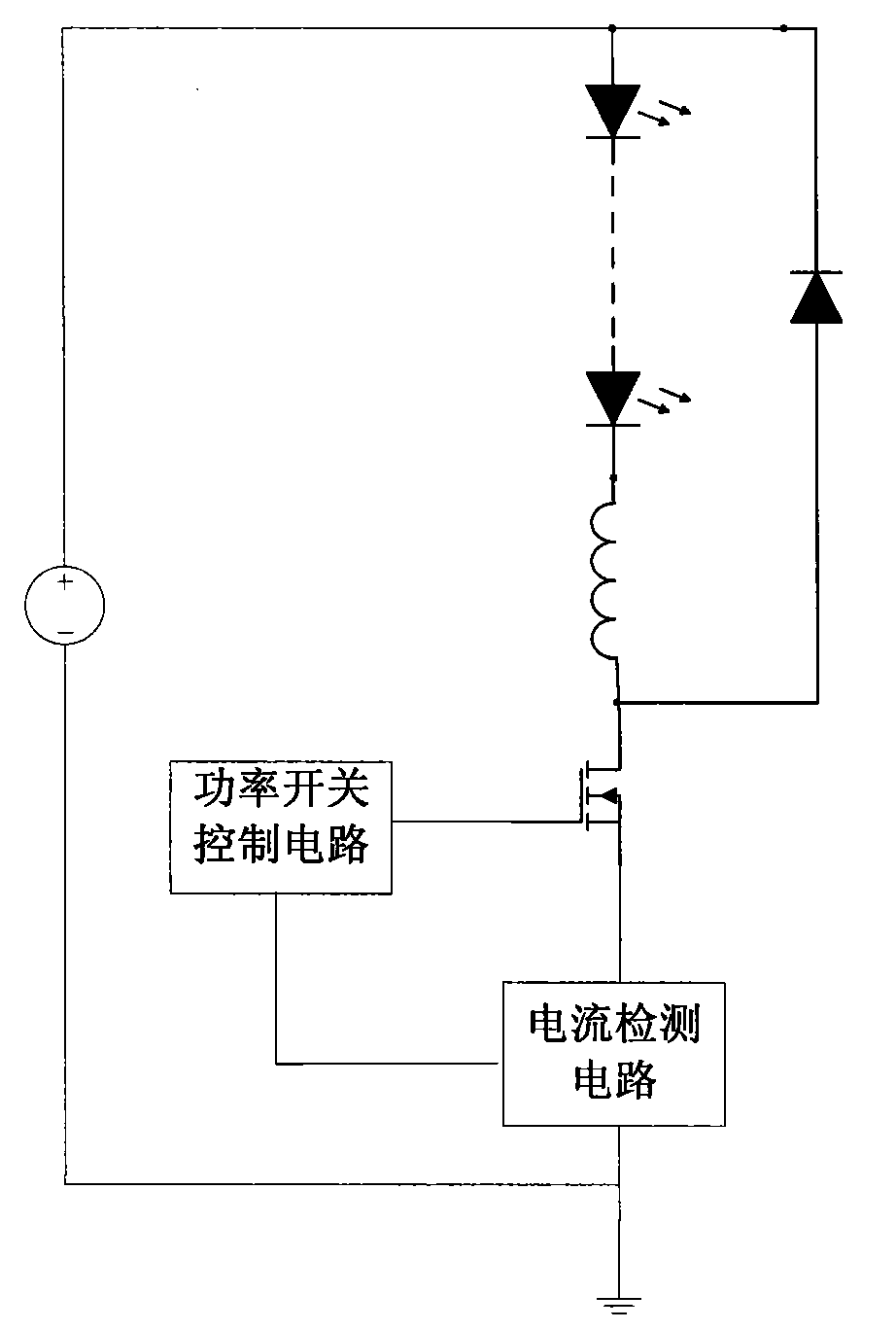

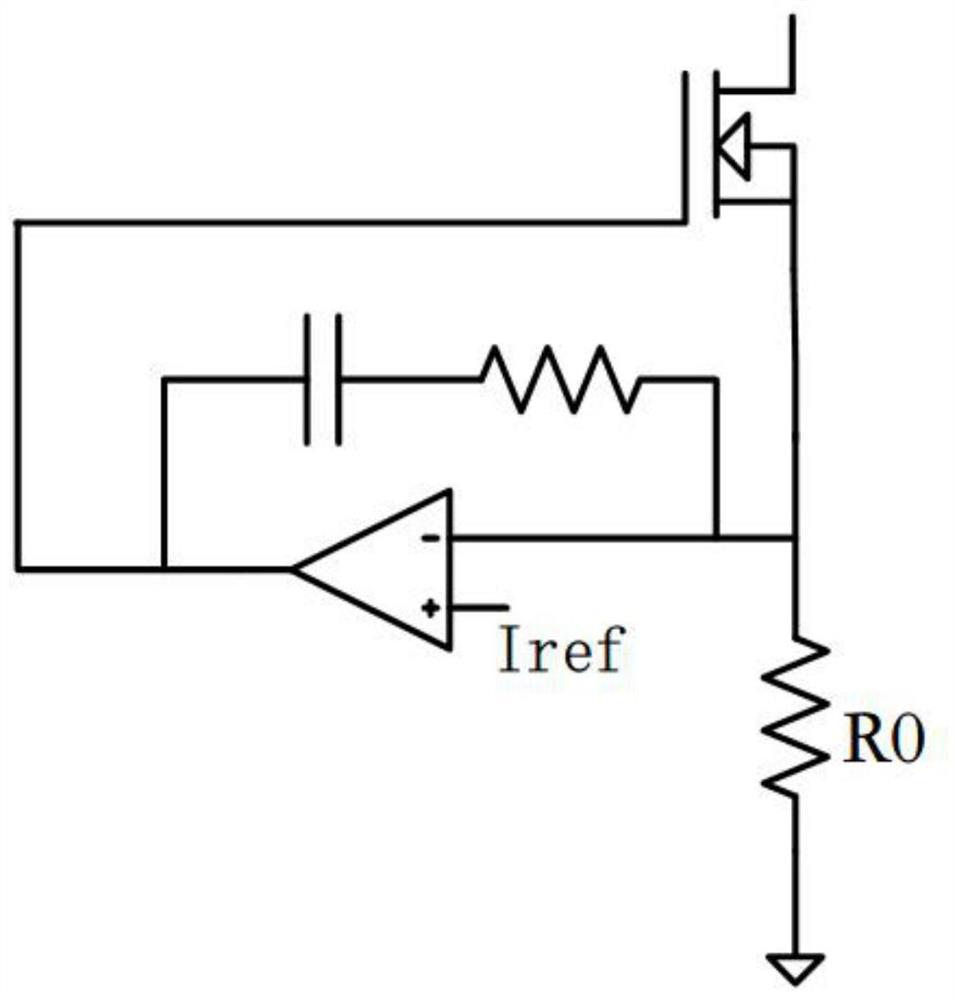

Constant-current control method of power switch type LED (Light-Emitting Diode) drive circuit and circuit thereof

InactiveCN101808444AImprove current control accuracyGood load regulationElectric light circuit arrangementEnergy saving control techniquesTurn off timeDirect control

The invention relates to a constant-current control method of a power switch type LED drive circuit and a circuit thereof. The method comprises the following steps of: setting a reference voltage value corresponding to the constant average current value of an LED lamp group and the sustainable turn-off time T2 of a power switch; opening the power switch to acquire an induced voltage corresponding to the working current of the LED lamp group, and comparing the induced voltage and the reference voltage value; accumulating the sustainable opening time Ta of the power switch since the power switch is opened until the induced voltage reaches the reference voltage value; accumulating the sustainable opening time Tb of the power switch since the induced voltage of the LED lamp group reaches the induced voltage value, when Tb is equal to Ta, turning off the power switch; and since the power switch is turned off, timing the sustainable turn-off time of the power switch, and after the set sustainable turn-off time T2 is reached, opening the power switch. The invention realizes the direct control on average current and improves the control precision on the current.

Owner:王桂兰

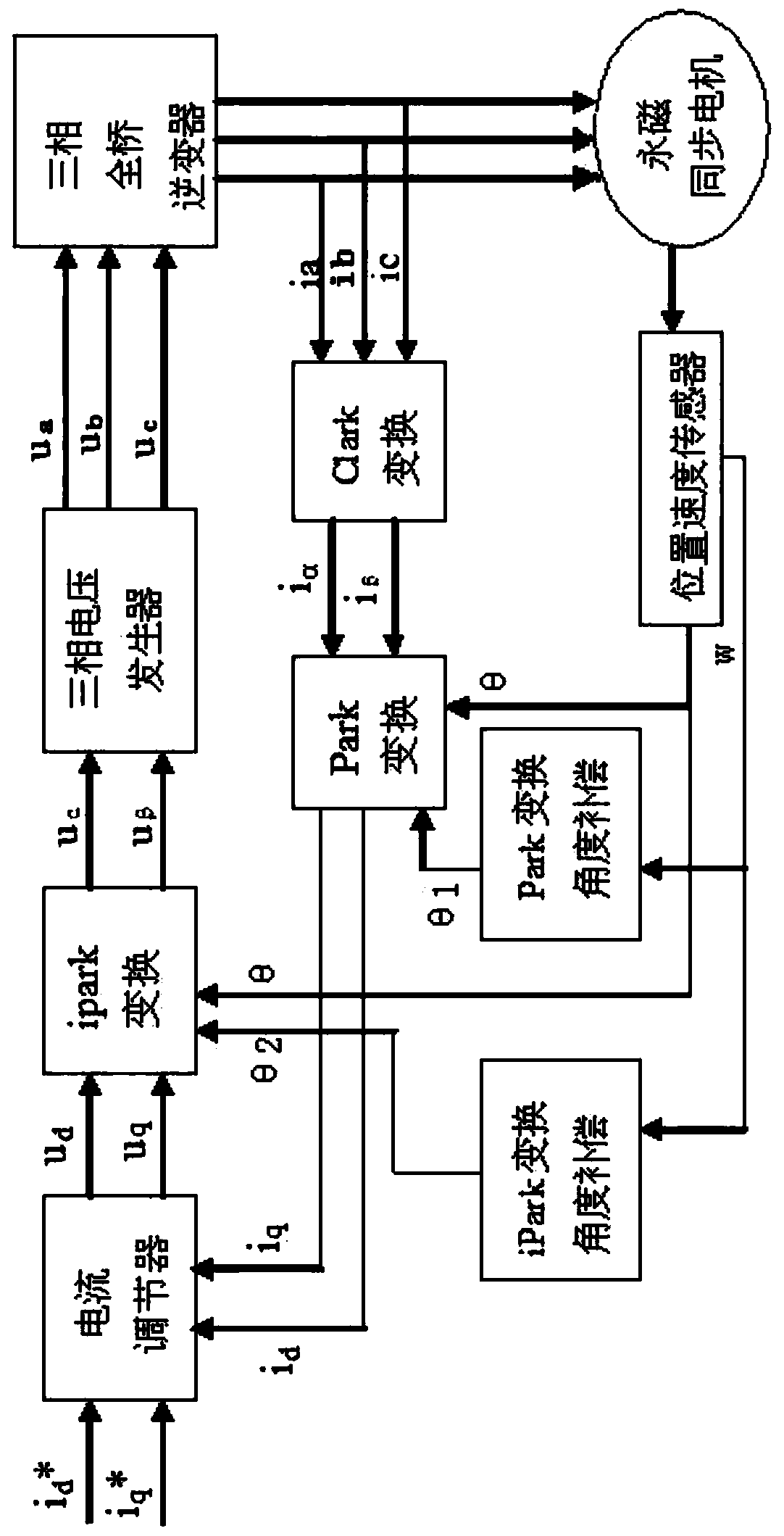

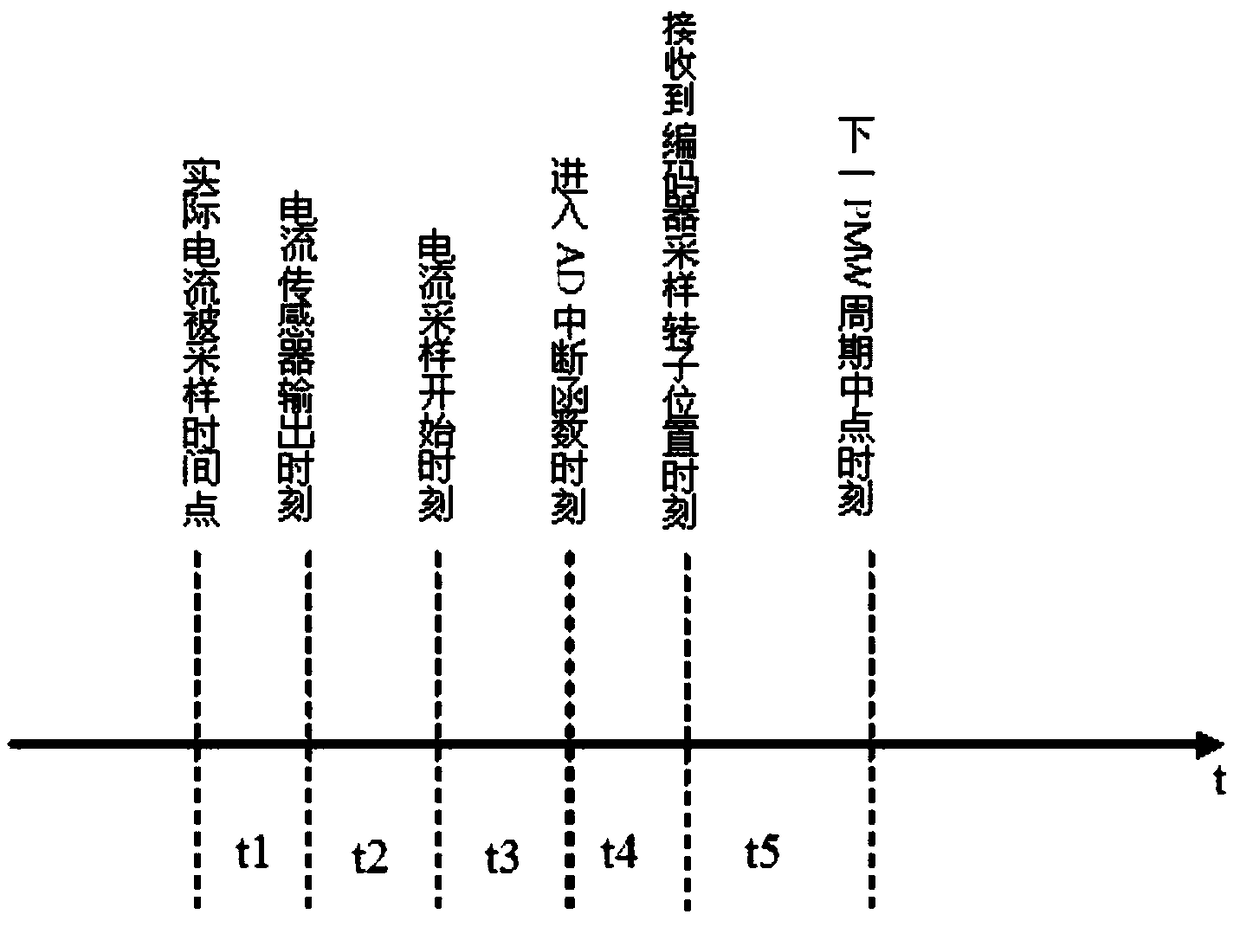

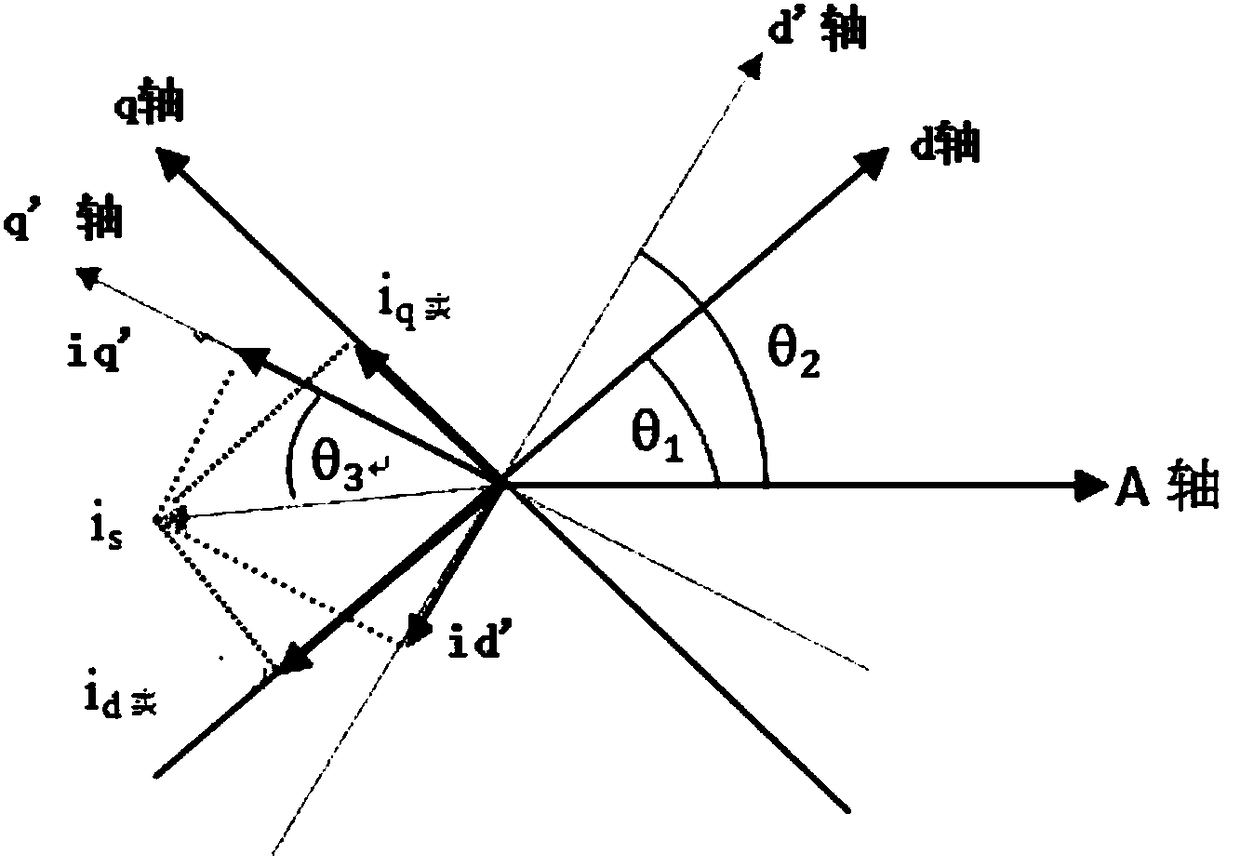

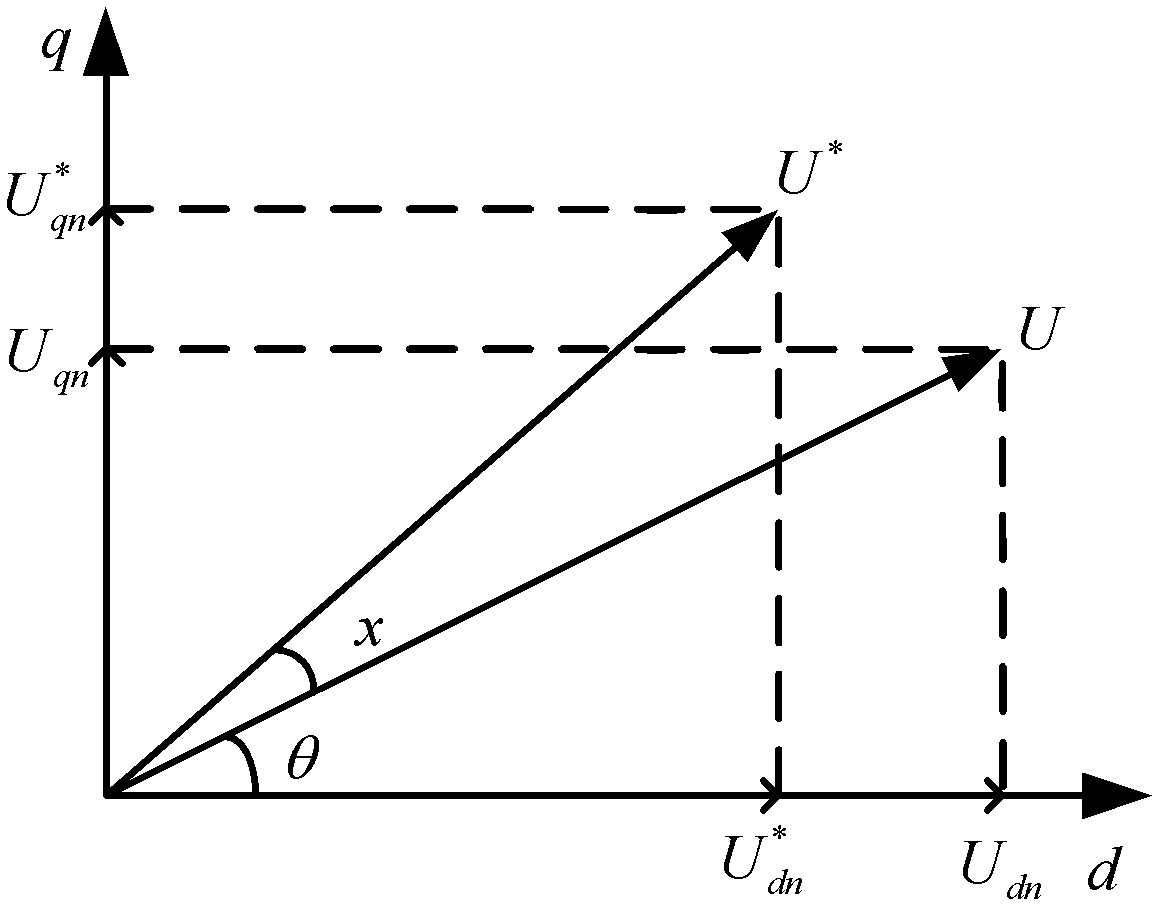

Rotor position angle compensation method of motor vector control

ActiveCN108282124AImprove current control accuracyImprove dynamic performanceElectronic commutation motor controlVector control systemsControl vectorPosition angle

The invention relates to a rotor position angle compensation method of motor vector control. A rotor position angle Theta obtained by sampling is compensated by a controller, Park conversion is performed on the compensated rotor position angle Theta', Theta'=Theta-Theta1, Theta1=w*(t1+t2+t3+t4), Theta1 is a Park conversion compensation angle, w is a running frequency of the motor, t1 is delay timeof a current sensor for sampling a stator current, t2 is delay time of a filtering circuit for filtering an output signal of the current sensor, t3 is time from an initial sampling moment of an AD external sampling module of the controller on the stator current to AD interrupt function moment, and t4 is time from the AD interrupt function moment to a moment when the rotor position angle Theta sampled by a rotor position detection device is received by the controller. By the rotor position angle compensation method, the current control accuracy of a vector control system under a high-speed working condition can be improved, and the dynamic performance of a motor control system is improved.

Owner:SHANGHAI SIGRINER STEP ELECTRIC

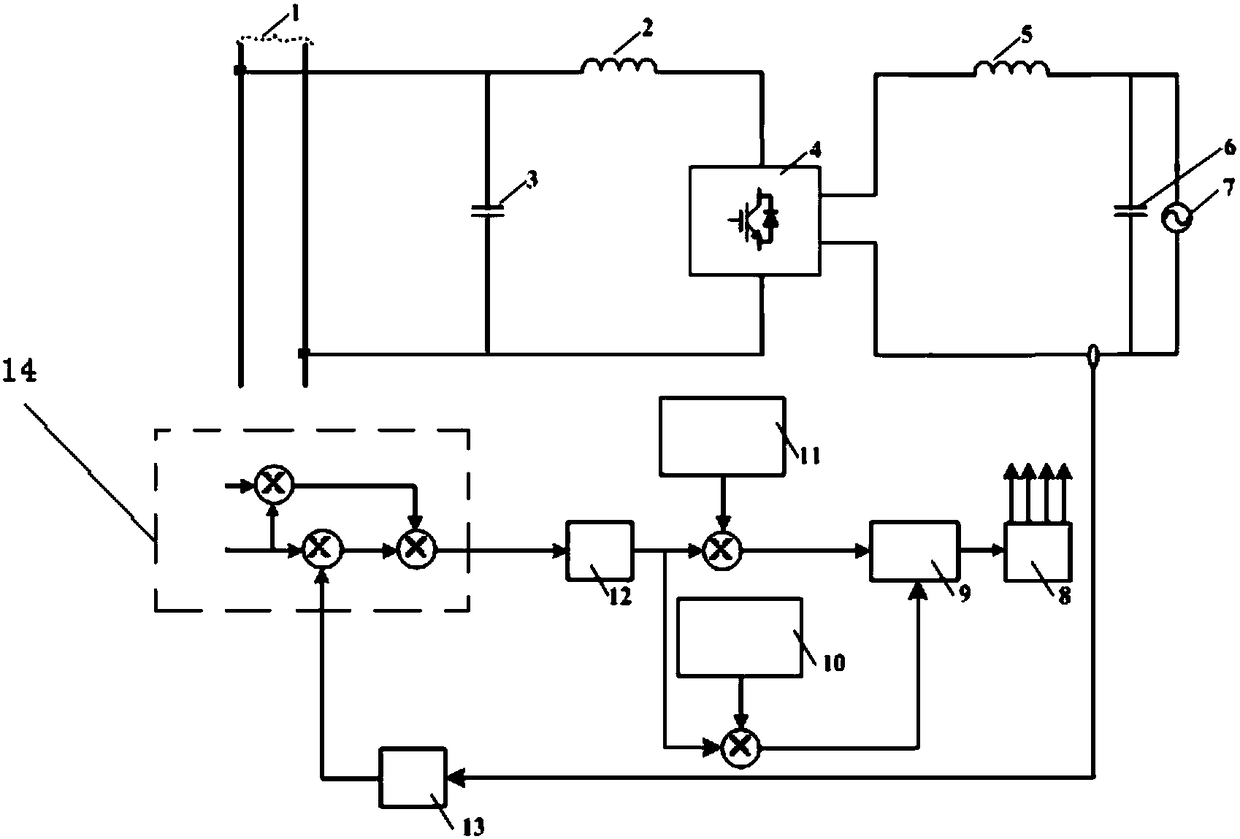

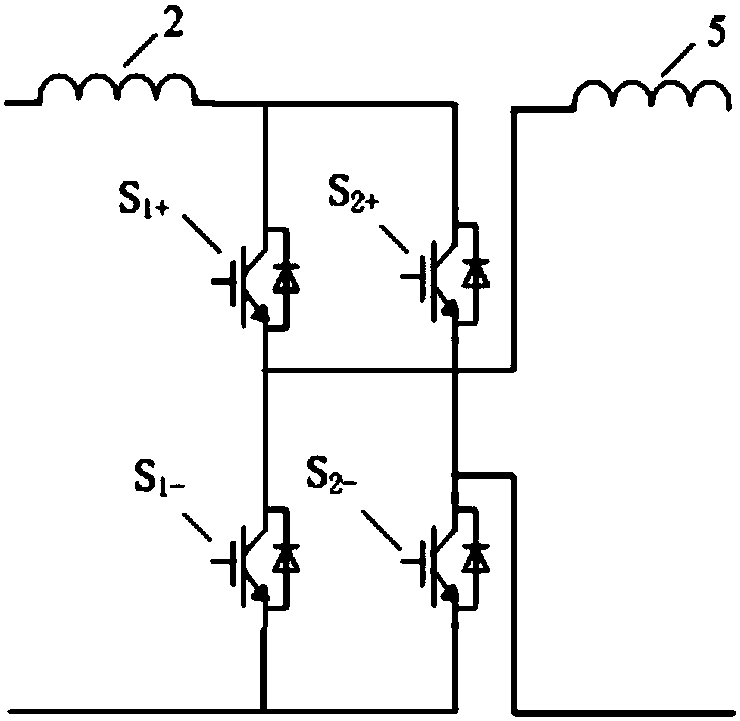

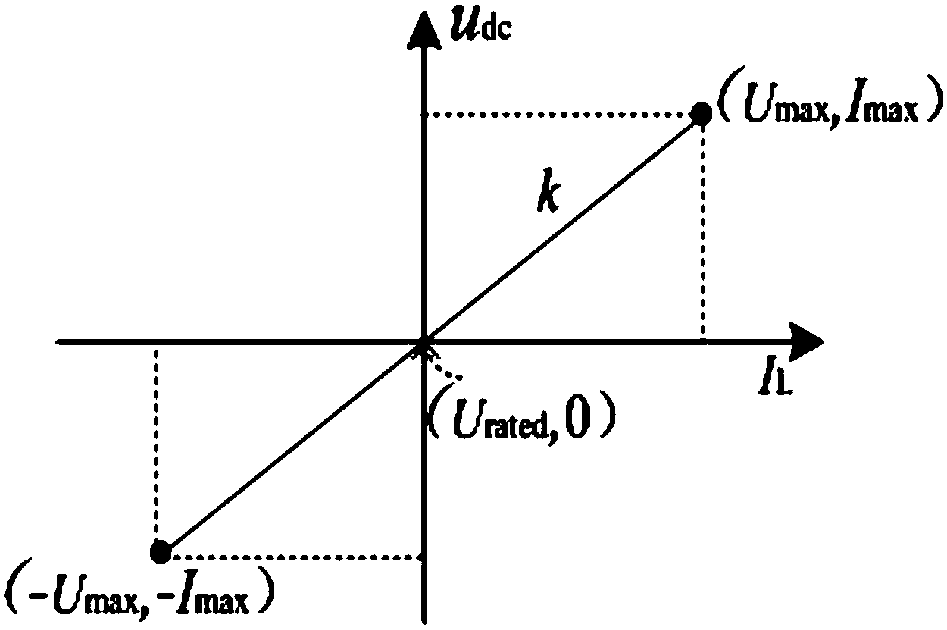

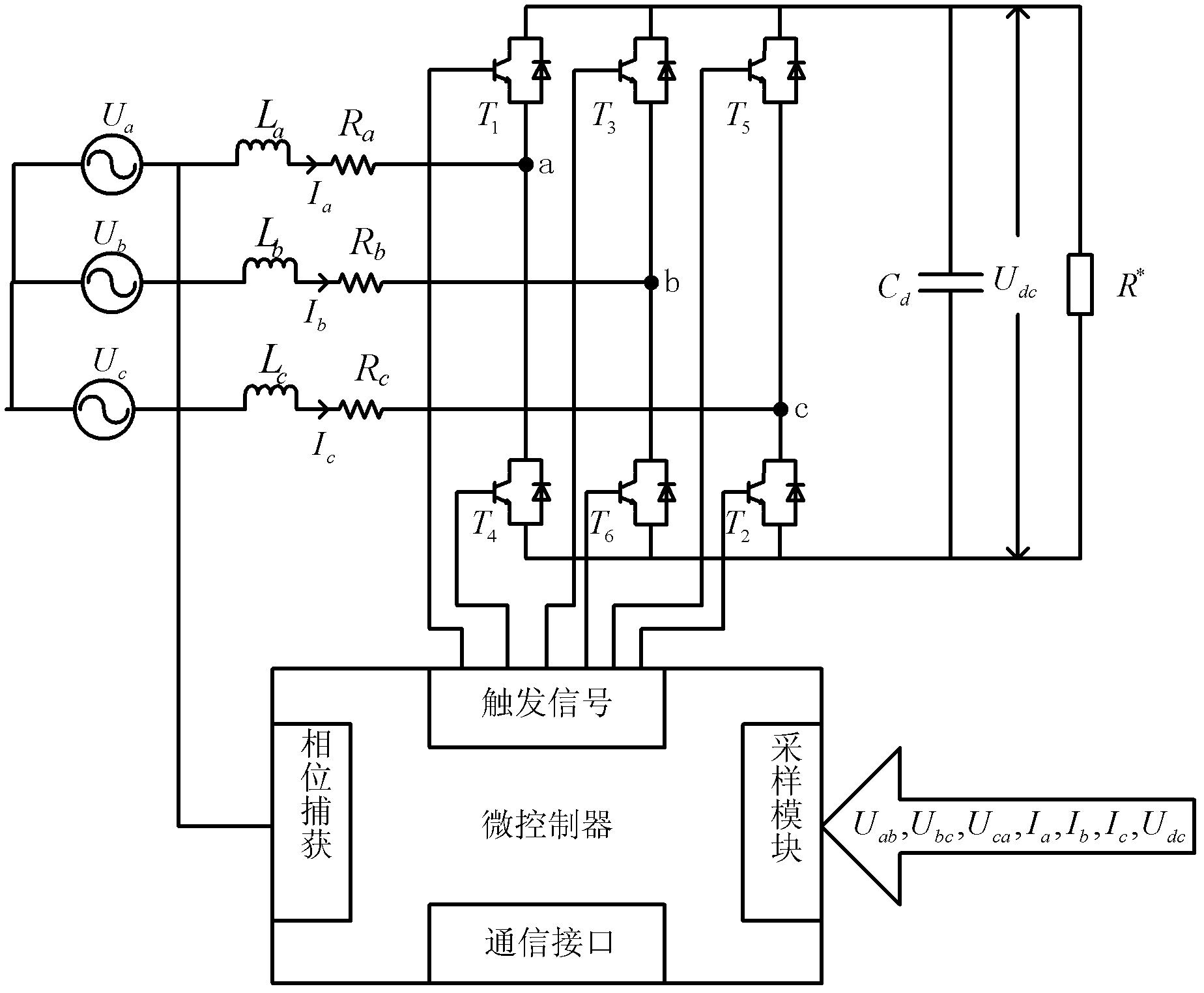

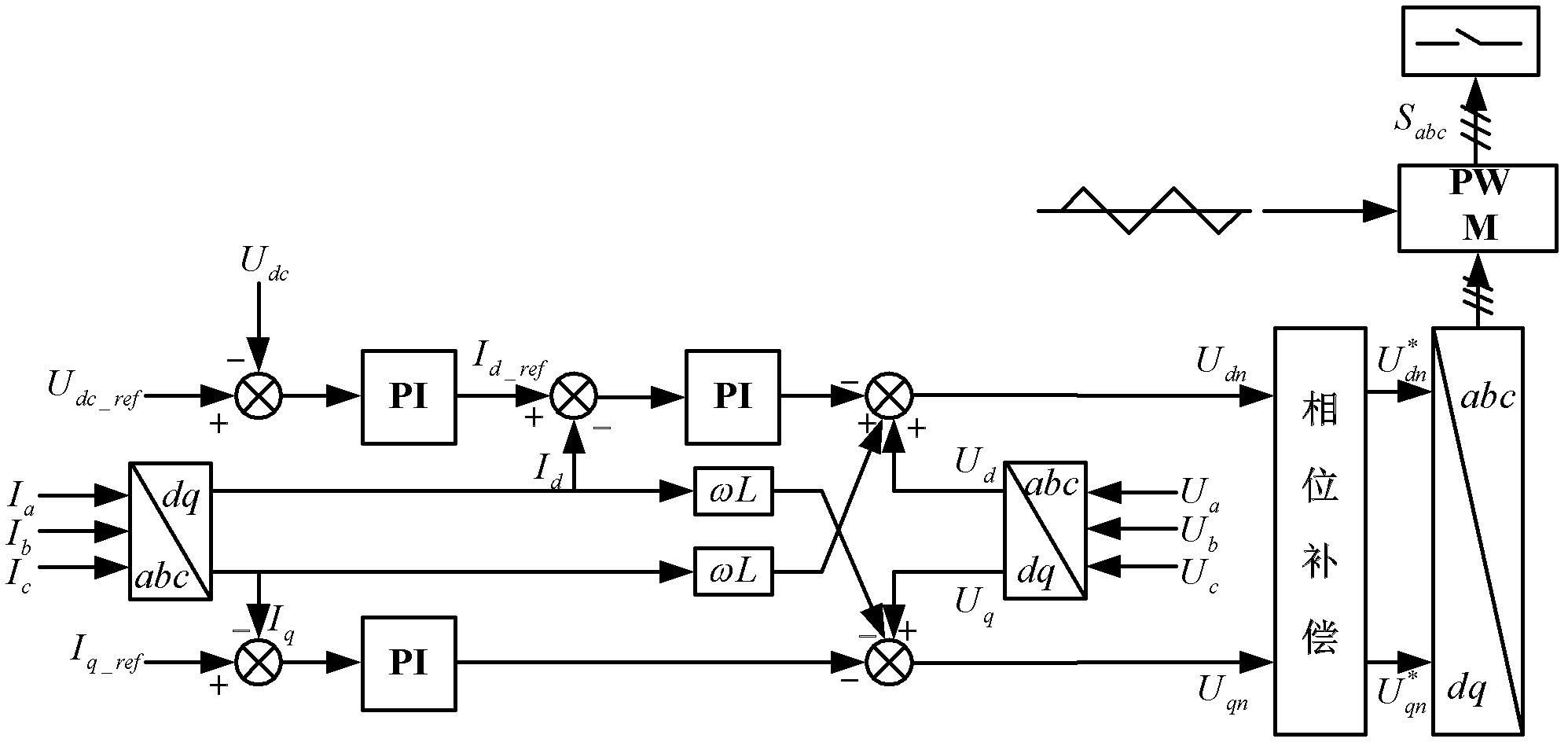

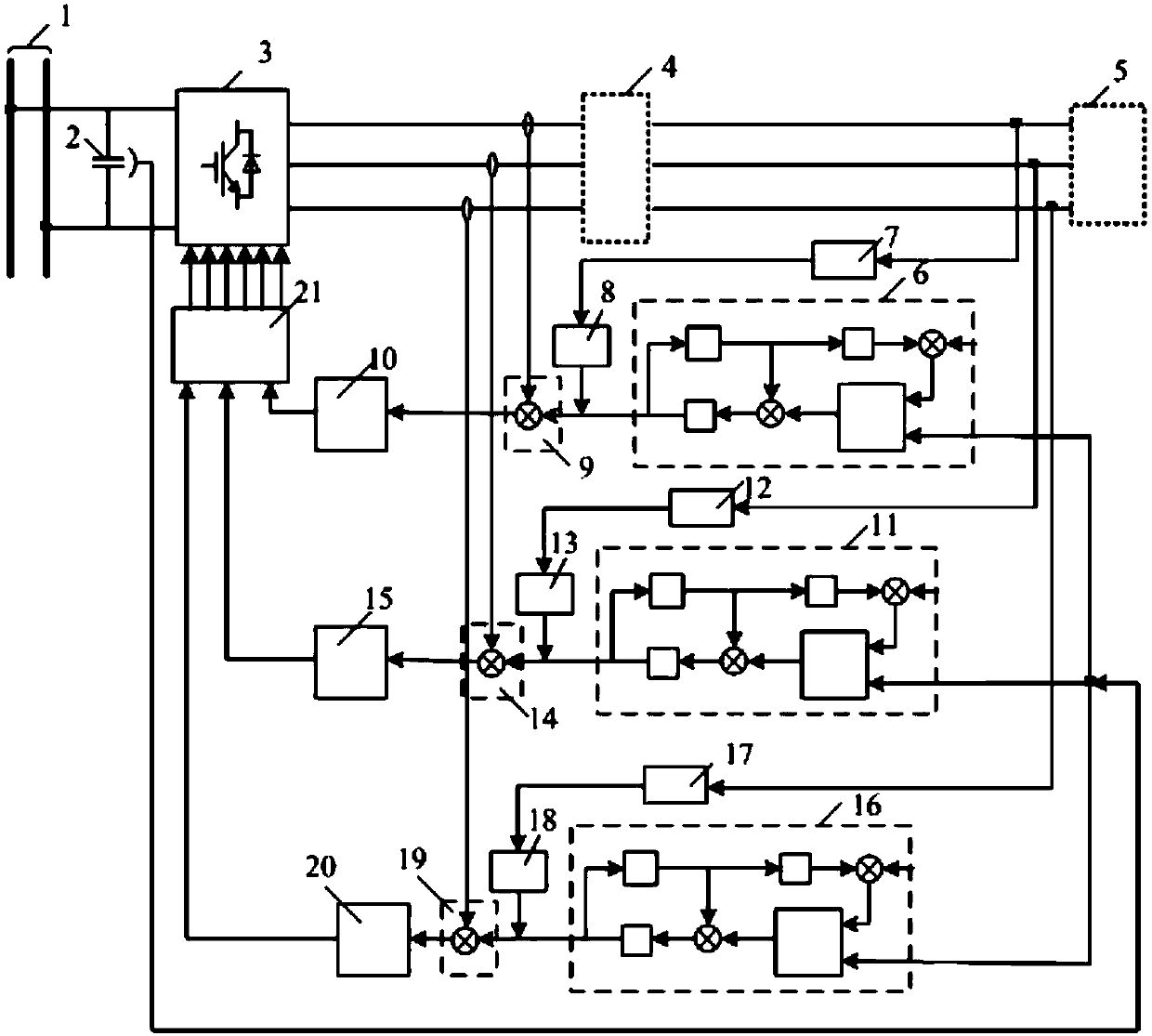

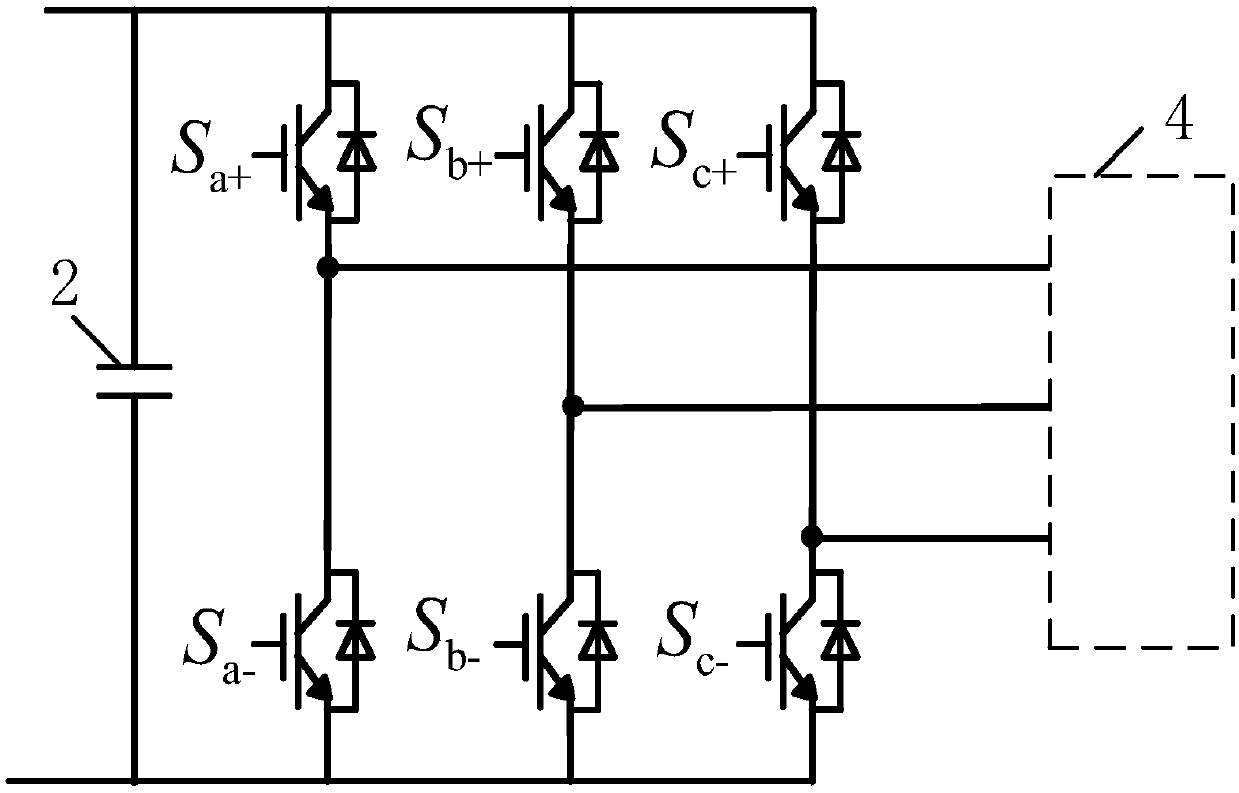

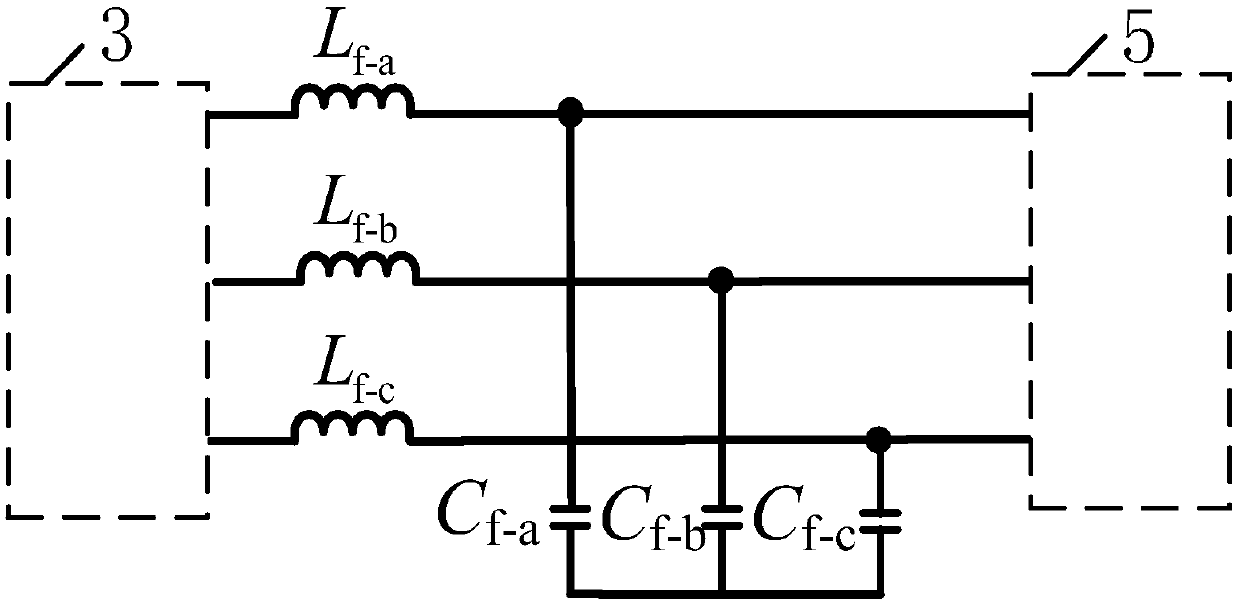

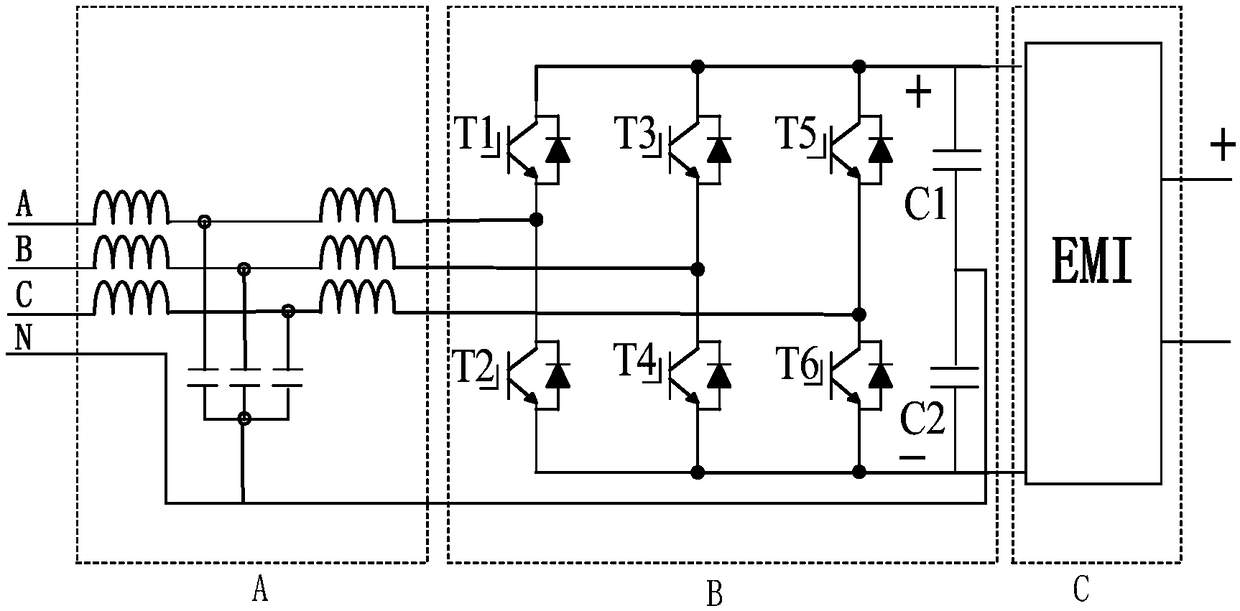

Current control system and method for grid-connected converter of DC micro-grid

InactiveCN108512452AImprove current control accuracyImprove robustnessAc-dc conversionSingle network parallel feeding arrangementsLinear controlPower flow

The invention discloses a current control system and method for the grid-connected converter of a DC micro-grid. The method comprises pre-estimating the power of the grid-connected converter by the change of DC bus voltage; calculating the steady-state value of the inductive current according to the change of the DC bus voltage; and establishing a linear control relationship between the DC bus voltage and the inductive current to predict directive current. The control strategy improves the current control accuracy of the grid-connected converter, increases response speed, and improves the dynamic and static performance of the grid-side current of the grid-connected converter, reduces the influence of system parameter changes on the grid-side current, and enhances the robustness of the DC micro-grid. The DC micro-grid grid-connected converter current control strategy and device include a bidirectional converter topology circuit and its control device, and solve the problem that the control of the grid-connected converter in the DC micro-grid in the prior art cannot realize bidirectional power flow and the grid-connected converter has line impedance.

Owner:XIAN UNIV OF TECH

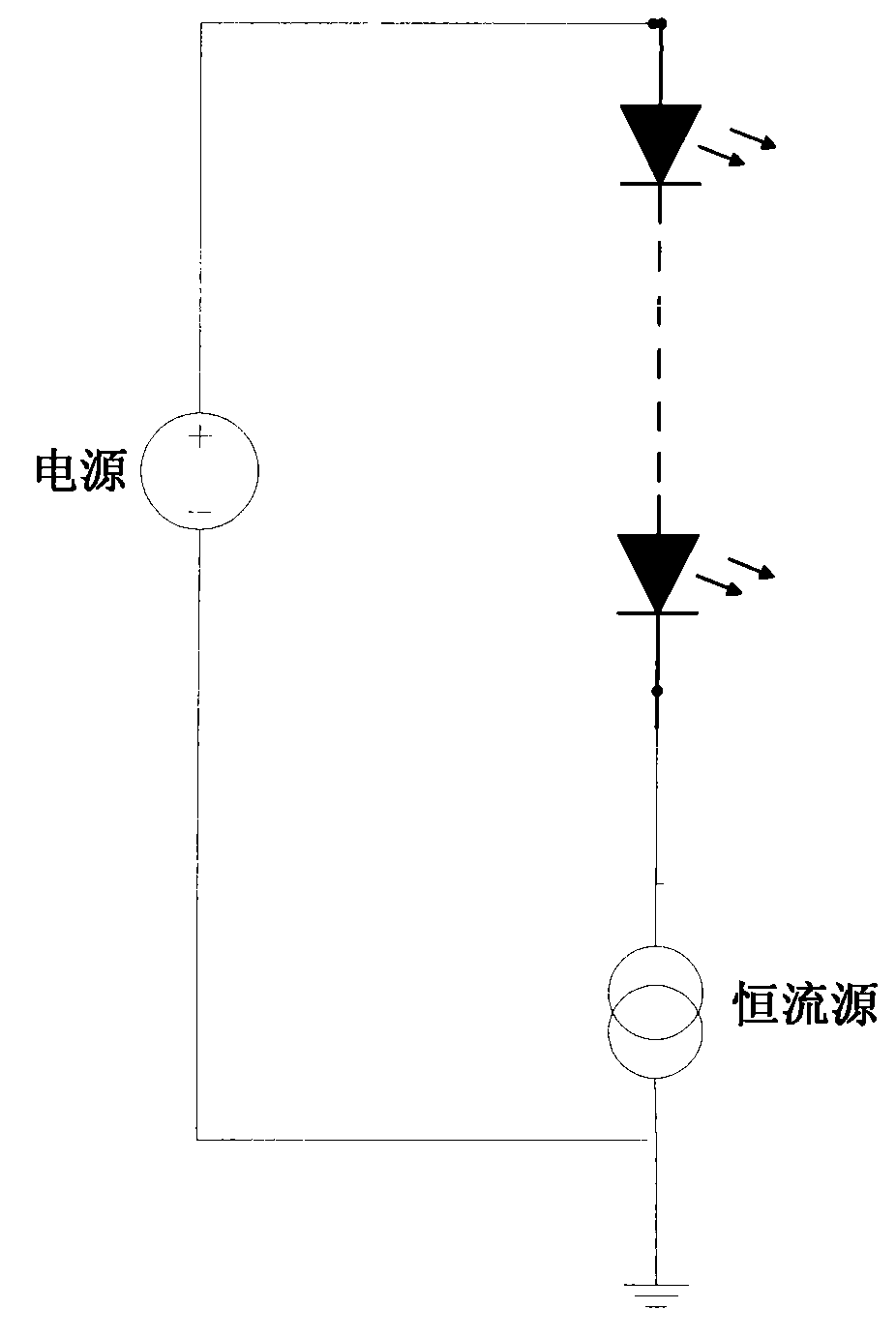

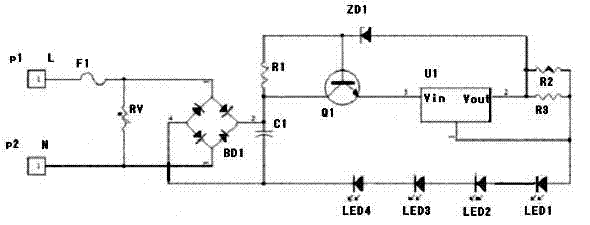

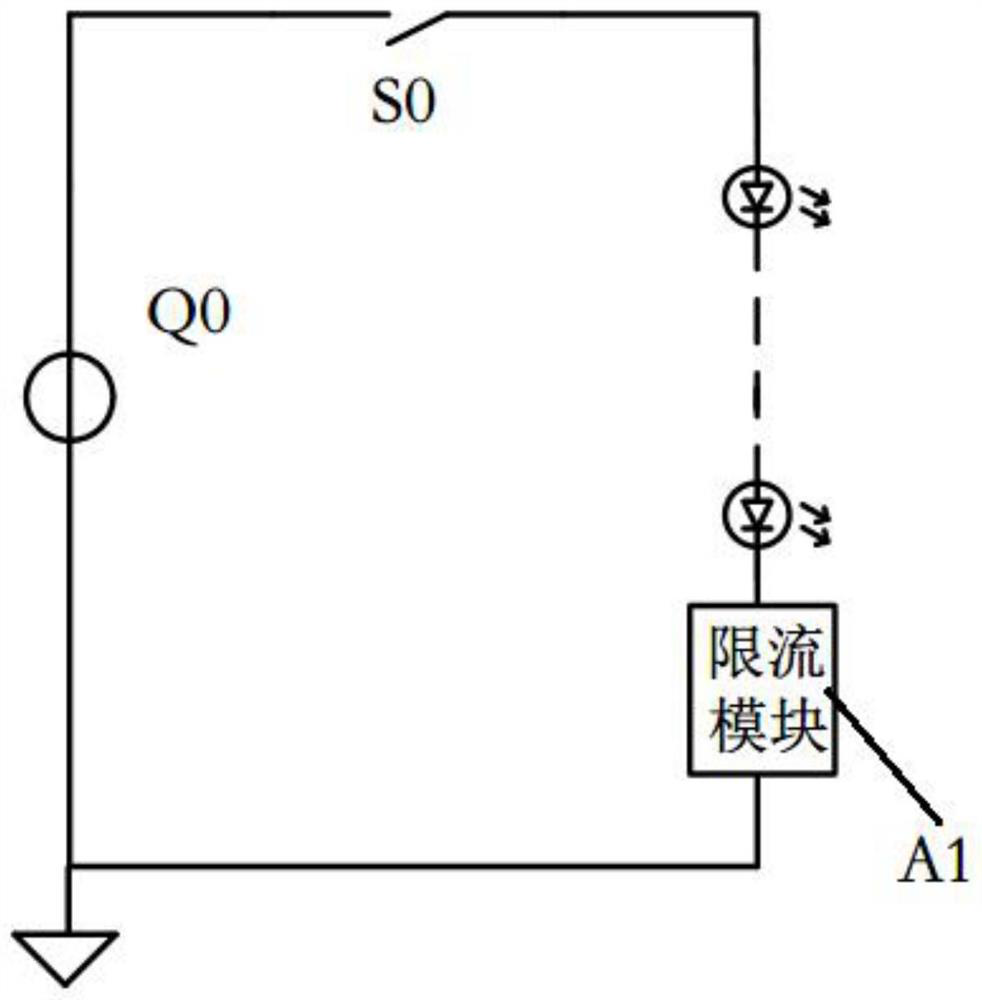

Circuit for LED constant current power supply

InactiveCN102933005ALow costImprove current control accuracyElectrical apparatusSemiconductor lamp usageCapacitanceDriver circuit

The invention discloses a circuit for an LED constant current power supply. The circuit is characterized in that in the circuit, an alternating current voltage is subjected to rectification by a rectifier bridge, and then is subjected to a filter to enable the waveform of an input voltage to be smooth; the input voltage is converted into a direct voltage after passing an electrolytic capacitor filter; the direct voltage is loaded on an LED after passing a constant-current IC chip; current range of the LED is adjusted by resistors R2 and R3, which are connected with the constant-current IC chip; and a constant-current IC chip protection circuit formed by a Zener diode ZD1, a triode Q1 and a resistor R1 is arranged between the electrolytic capacitor filter and the constant-current IC chip. The circuit is simple in line, low in cost and high in current control accuracy.

Owner:SHANGHAI DANGOO ELECTRONICS TARDING

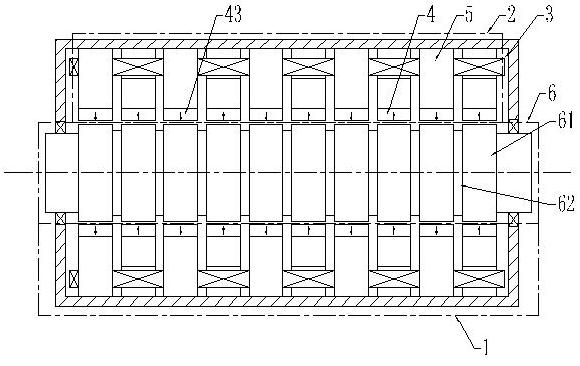

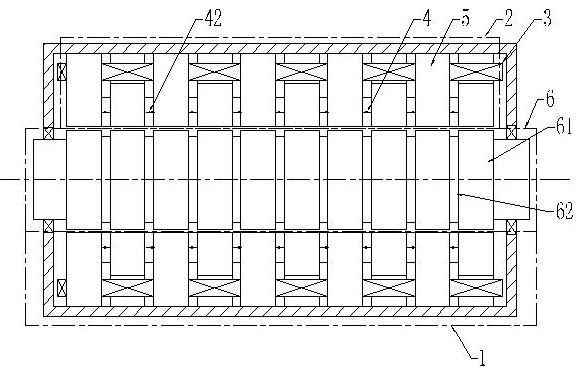

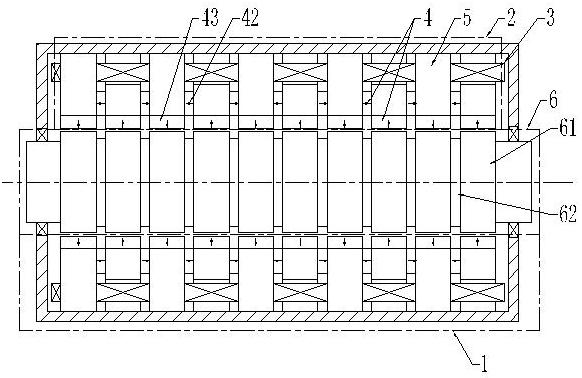

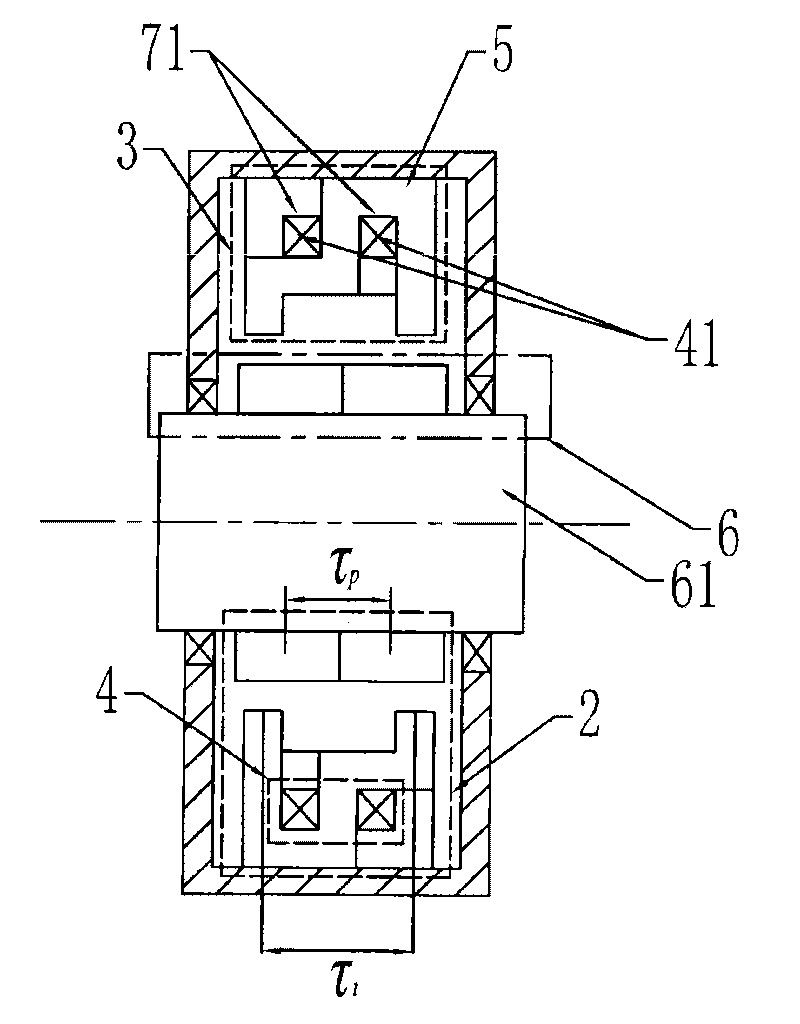

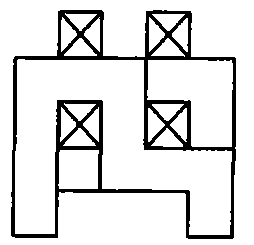

Transversal magnetic flux variable-reluctance permanent magnet motor

InactiveCN101807844AImprove reliabilityReduce eddy current lossPropulsion systemsPermanent magnet motorSprocket

The invention discloses a transversal magnetic flux variable-reluctance permanent magnet motor which relates to the field of a motor and solves the problems of complicated secondary structure and low reliability and current control accuracy. The secondary structure comprises a secondary iron core. The primary structure at least comprises a phase unit. Each phase unit consists of a phase unit iron core, a phase unit winding and a permanent magnet. The phase unit core consists of a plurality of iron core units and is provided with a sprocket hole. The sprocket hole is formed by stacking gear slots of the iron core units. A permanent magnet is arranged on the sprocket of each iron core units, and the magnetic field directions of the magnets on sprockets of adjacent iron core units are opposite to each other. A coil is wound into a one-phase phase unit winding through the gear hole of the phase unit core. The motor can be used as a motor and also can be used as a generator. The permanent magnet of the motor is arranged on the gear of the core unit, therefore the secondary structure has simple structure and high reliability. The vortex loss of the motor is reduced, the motor efficiency is enhanced, the control accuracy of the current is high, and the motor is easy to modularize.

Owner:HARBIN INST OF TECH

Current control method for three-phase rectifying device

InactiveCN102611339AImprove power factorReduce harmonic componentsAc-dc conversionAttenuation coefficientUltrasound attenuation

The invention provides a current control method for a three-phase rectifying device in order to solve the problems of low current precision control and current waveform distortions in the prior art and modify a PI (potential intensity) controller to subject each phase point of grid current to PI adjustment. An attenuation coefficient K is used for attenuation of error values to enable previous accumulated errors to be attenuated along with time. According to a test that the magnitude of errors nearby the current grid cycle plays a leading role and current electric current can better track expected current, the current control method has the advantages that defects in the traditional methods can be effectively overcome, current control precision is improved, and the power factor of the three-phase rectifying device can be further improved while harmonic component is reduced.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA +1

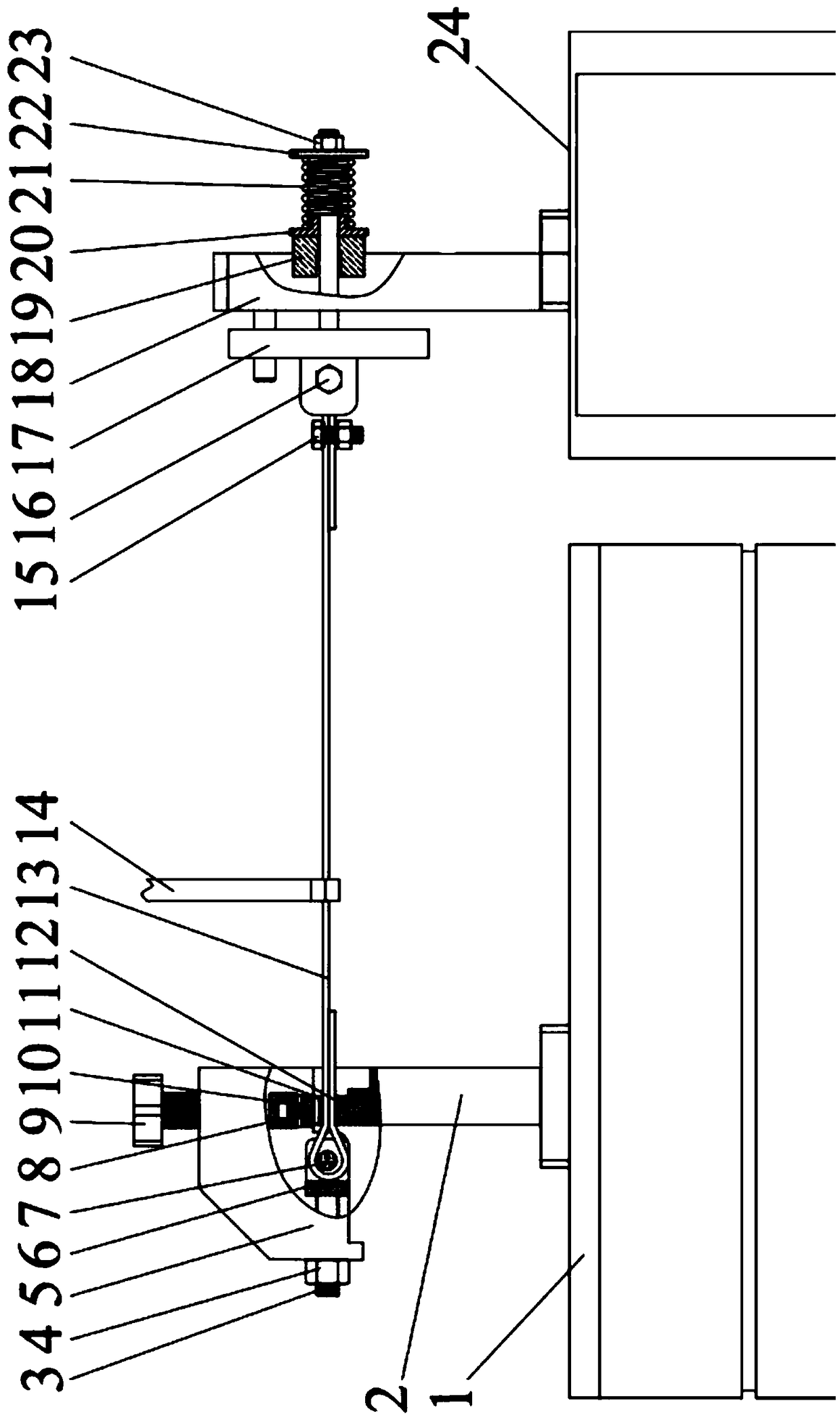

Bending fretting fatigue test device for dropper of high-speed railway catenary

PendingCN109357958AImprove current control accuracyGuaranteed reliabilityMaterial strength using repeated/pulsating forcesFrettingData acquisition

The invention discloses a bending fretting fatigue test device for a dropper of a high-speed railway catenary, which comprises a dropper fixing end, a force compensating end, a fatigue load loading part and a data acquisition and processing unit. One end of a dropper sample is fixed on a support of the fixing end, and the other end is fixed on a support of the force compensating end. A pre-tightening force is applied to the dropper by a force compensating spring. The middle part of the dropper is connected to a fatigue test machine through a loading rod. During the whole test, the bending fretting fatigue test of the dropper with variable parameters and multiple working conditions is carried out by controlling the fatigue test machine after the pressure of the fixing end and the pre-tightening force of the dropper are set.

Owner:SOUTHWEST JIAOTONG UNIV

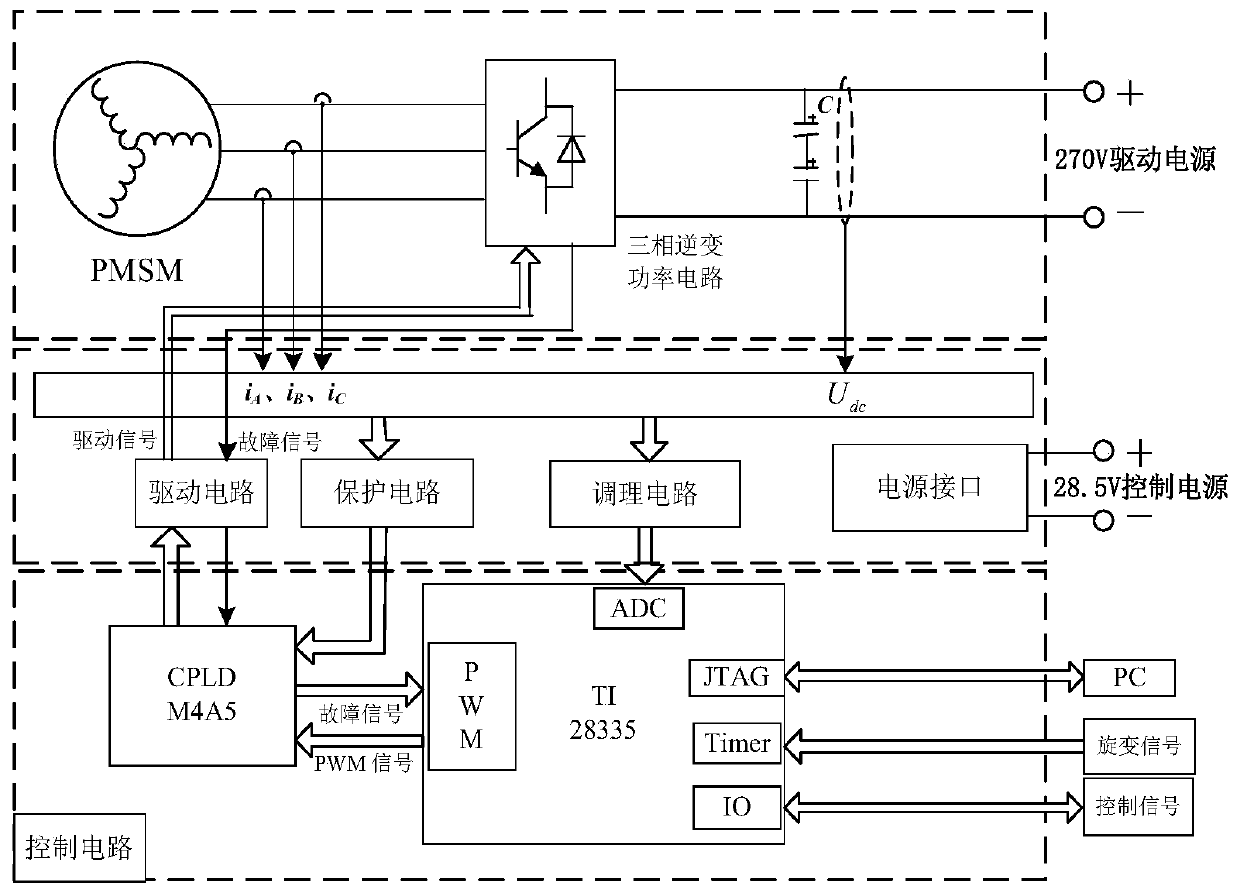

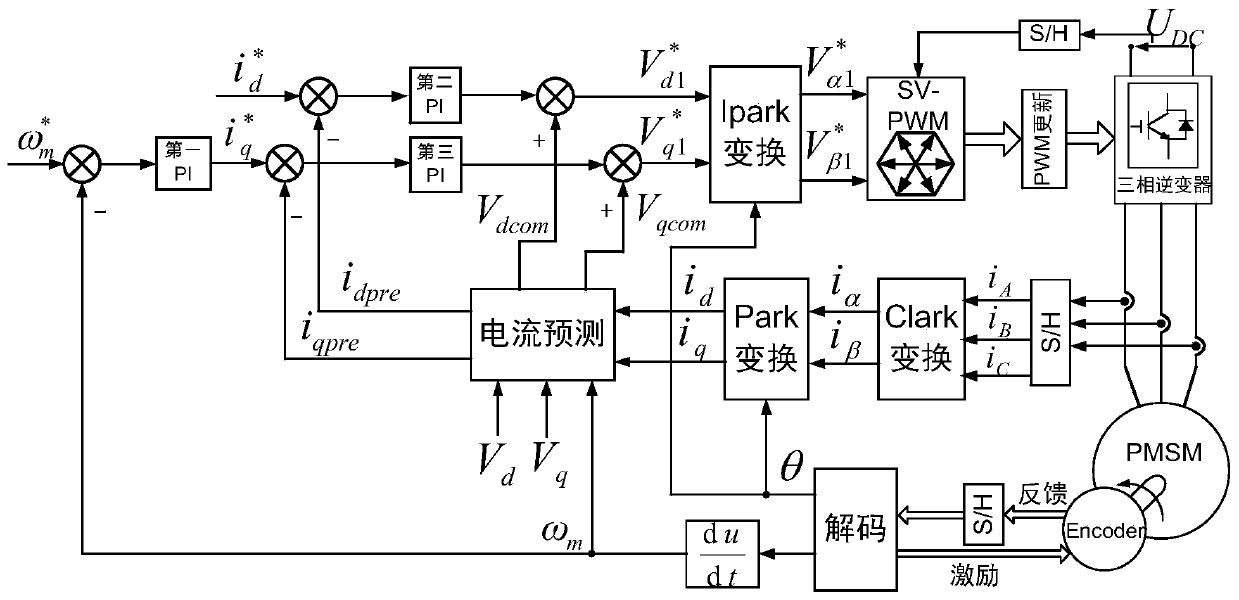

Current loop delay compensation method for three-phase permanent magnet synchronous motor driving system

ActiveCN111092583AWeaken the influence of dynamic characteristicsFast adjustmentElectronic commutation motor controlVector control systemsStator voltageElectric machine

The invention discloses a current loop delay compensation method for a three-phase permanent magnet synchronous motor driving system. The method comprises steps that a d-q axis stator current of a next period based on a motor model is predicted, and the d-q axis stator current is taken as a PI regulator feedback value for calculation to obtain a stator voltage reference value; aiming at the influence of motor parameter change on prediction precision, the prediction model is further corrected, when actual parameters are inconsistent with motor parameter nominal values, an error voltage item inthe model plays a role in correcting a current prediction value. The method is advantaged in that hardware configuration does not need to be changed or extra logic devices do not need to be added, themethod is simple in operation, low in cost, simple to implement and easy to expand, weakens the limitation of digital delay on the adjustment speed of the current loop, accelerates the current tracking characteristic, still ensures higher control precision even under the condition of larger motor parameter change, and is suitable for permanent magnet synchronous motor driving occasions with higher requirements on dynamic tracking and control precision.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Grid-connected converter forecast control system with voltage compensation and control method

ActiveCN108880316AImprove current control accuracyImprove robustnessAc-dc conversionCapacitanceLinear control

The invention discloses a grid-connected converter forecast control system with voltage compensation, and also discloses a grid-connected converter forecast control method having voltage compensation.The grid-connected converter forecast control method having voltage compensation comprises the steps of firstly, estimating a grid-connected converter power according to energy change of a capacitance electric field, calculating current changing quantity of an inductor according to the energy changing quantity of the capacitance electric field, and forecasting an instruction current; secondly, designing compensation virtual capacitance according to the energy change of the capacitance electric field, and compensating a DC bus voltage under disturbance; and finally, building a linear control relation between the DC bus voltage and the inductor current. By the grid-connected converter forecast control method, the problems that bidirectional flowing of power cannot be achieved, parameter adjustment exists and the system parameter influence is large due to low inertia and poor disturbance-resistant capability of a DC microgrid and control of a grid-connected converter in the prior art aresolved.

Owner:XIAN UNIV OF TECH

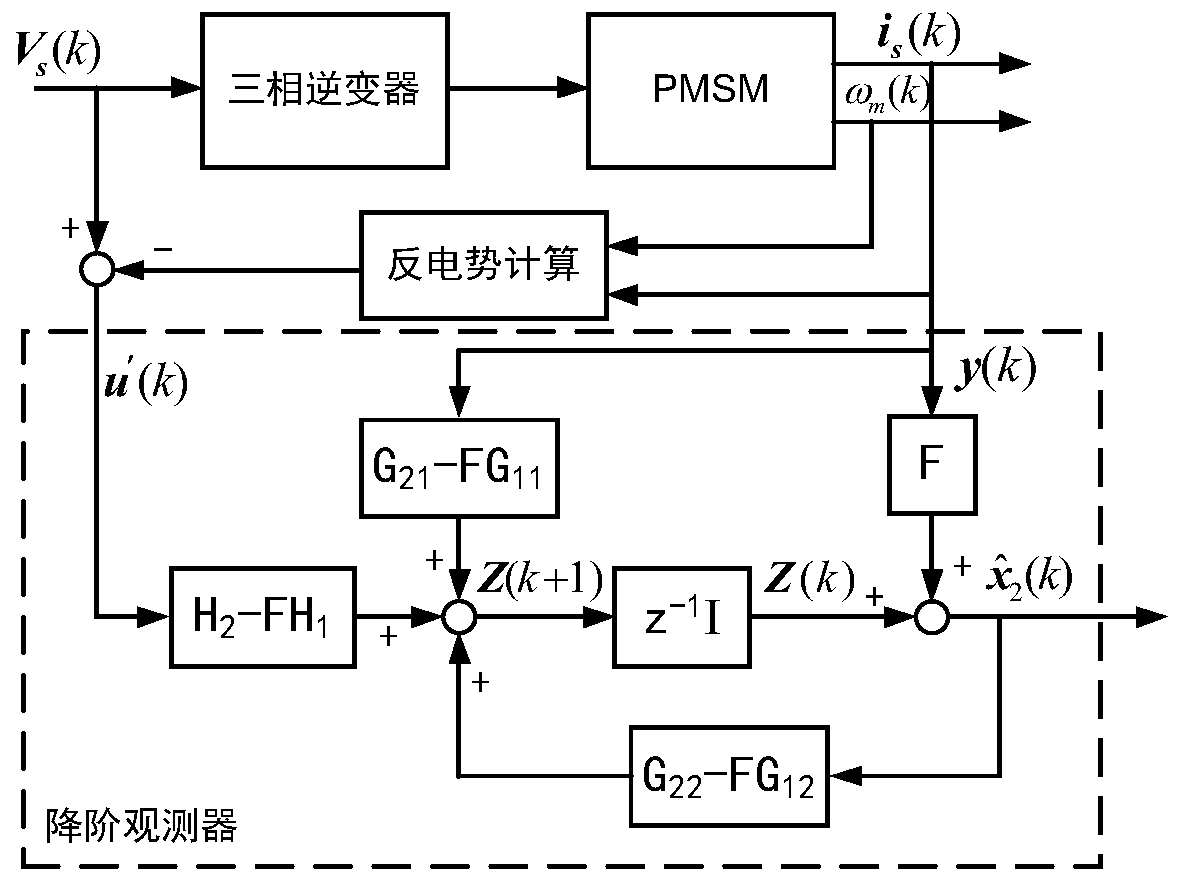

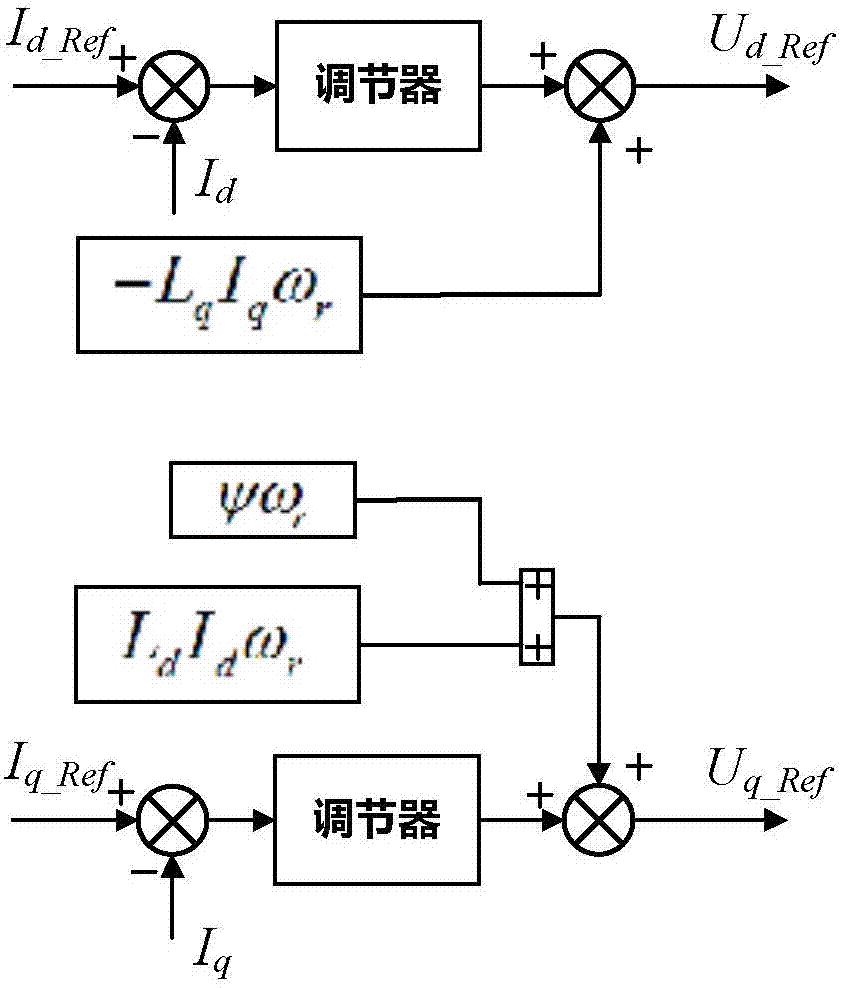

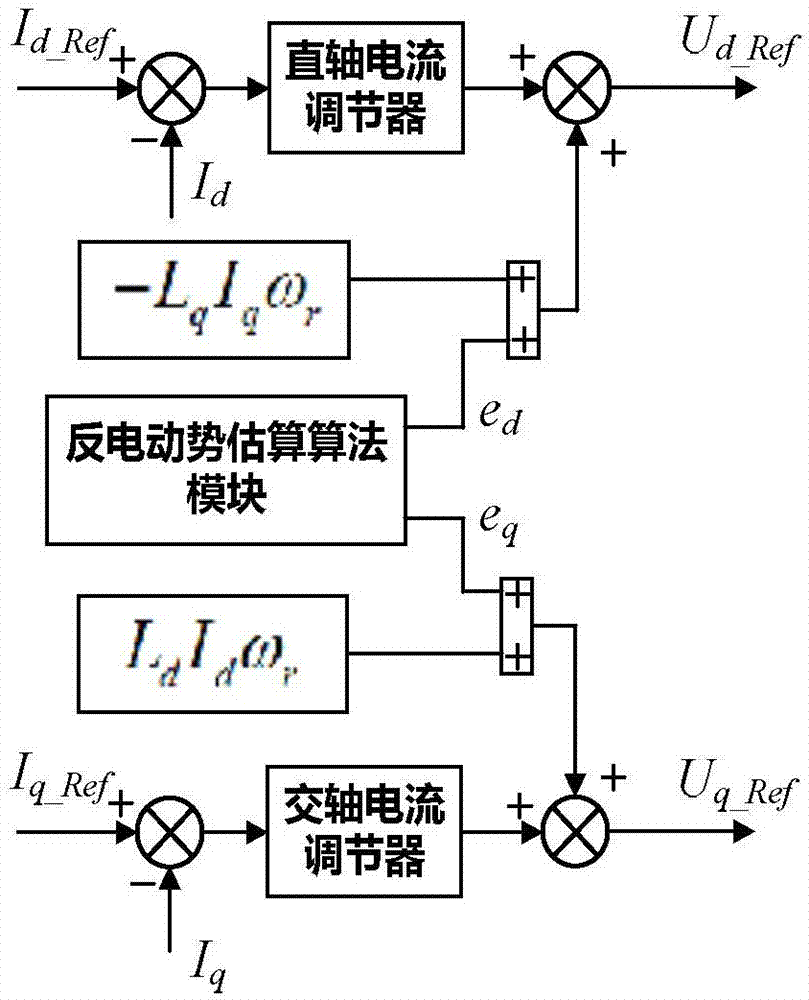

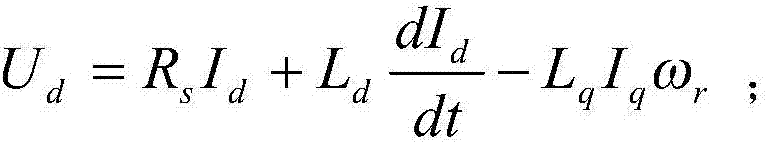

Current decoupling control method for permanent magnet synchronous motor

InactiveCN107404273AEasy to decoupleImprove current control accuracyElectronic commutation motor controlVector control systemsPermanent magnet synchronous motorPermanent magnet synchronous generator

The invention relates to a current decoupling control method for a permanent magnet synchronous motor. By taking influence of position detection or position estimation error into consideration, a direct current component and a quadrature-axis component of counter electromotive force in an error coordinate system are further used as decoupling items; the direct-axis current control expression is a formula which is as shown in the specification; and the quadrature-axis current control expression is a formula which is as shown in the specification. By virtue of the current decoupling control method for the permanent magnet synchronous motor, more accurate decoupling items can be obtained by calculation, and a better current decoupling effect for the permanent magnet synchronous motor and a better motor control effect can be achieved.

Owner:AUX AIR CONDITIONING LTD BY SHARE LTD

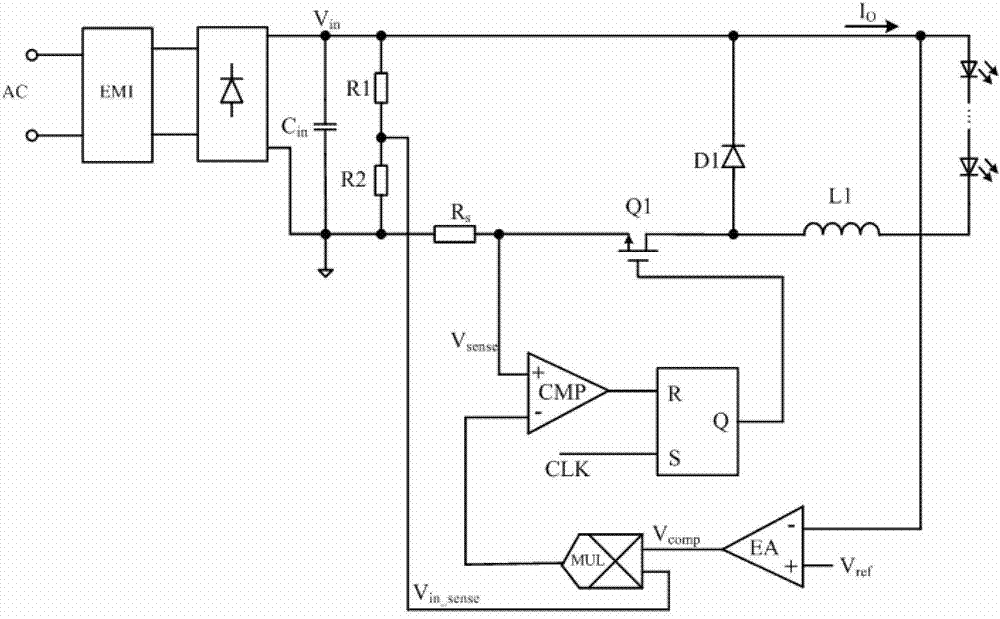

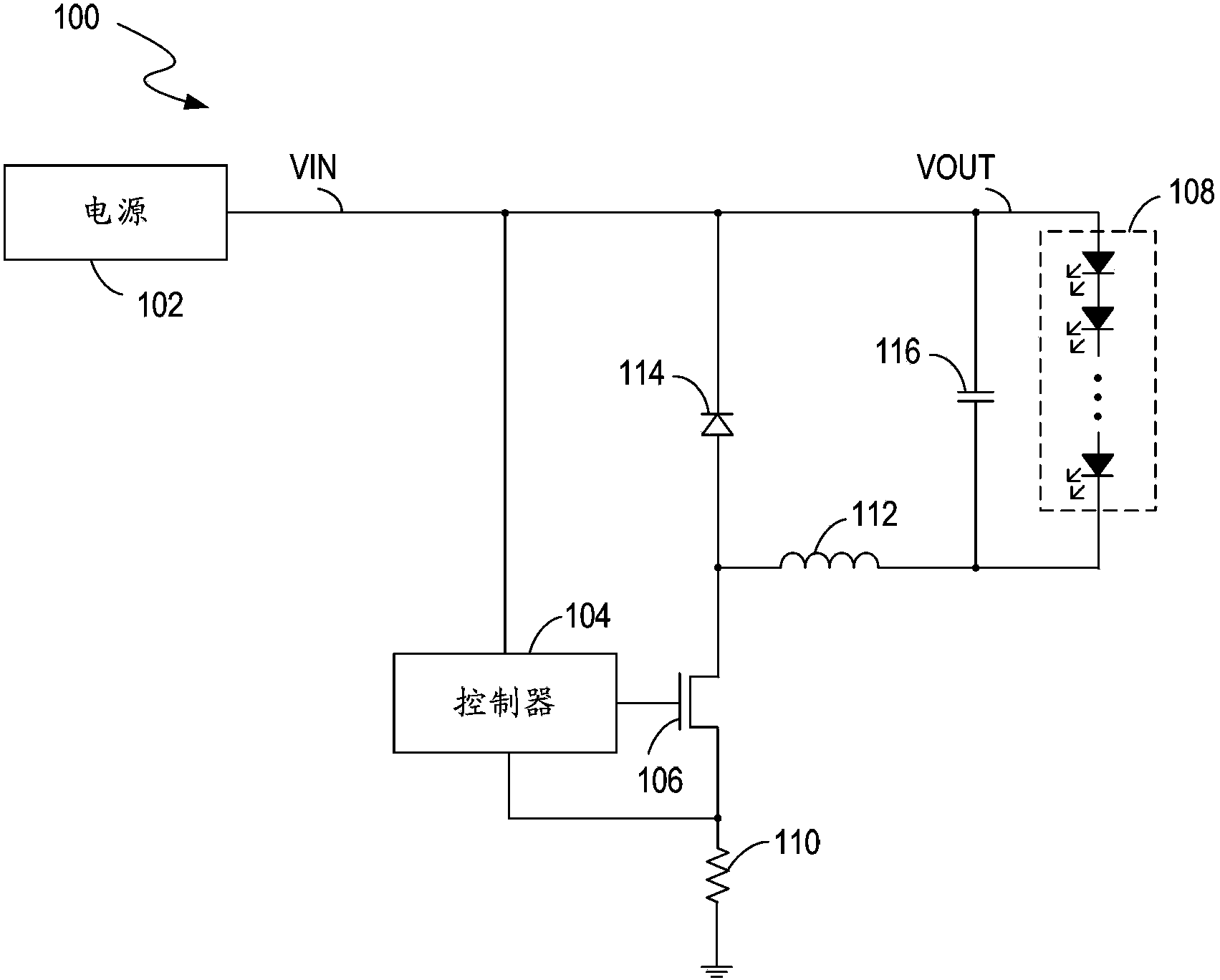

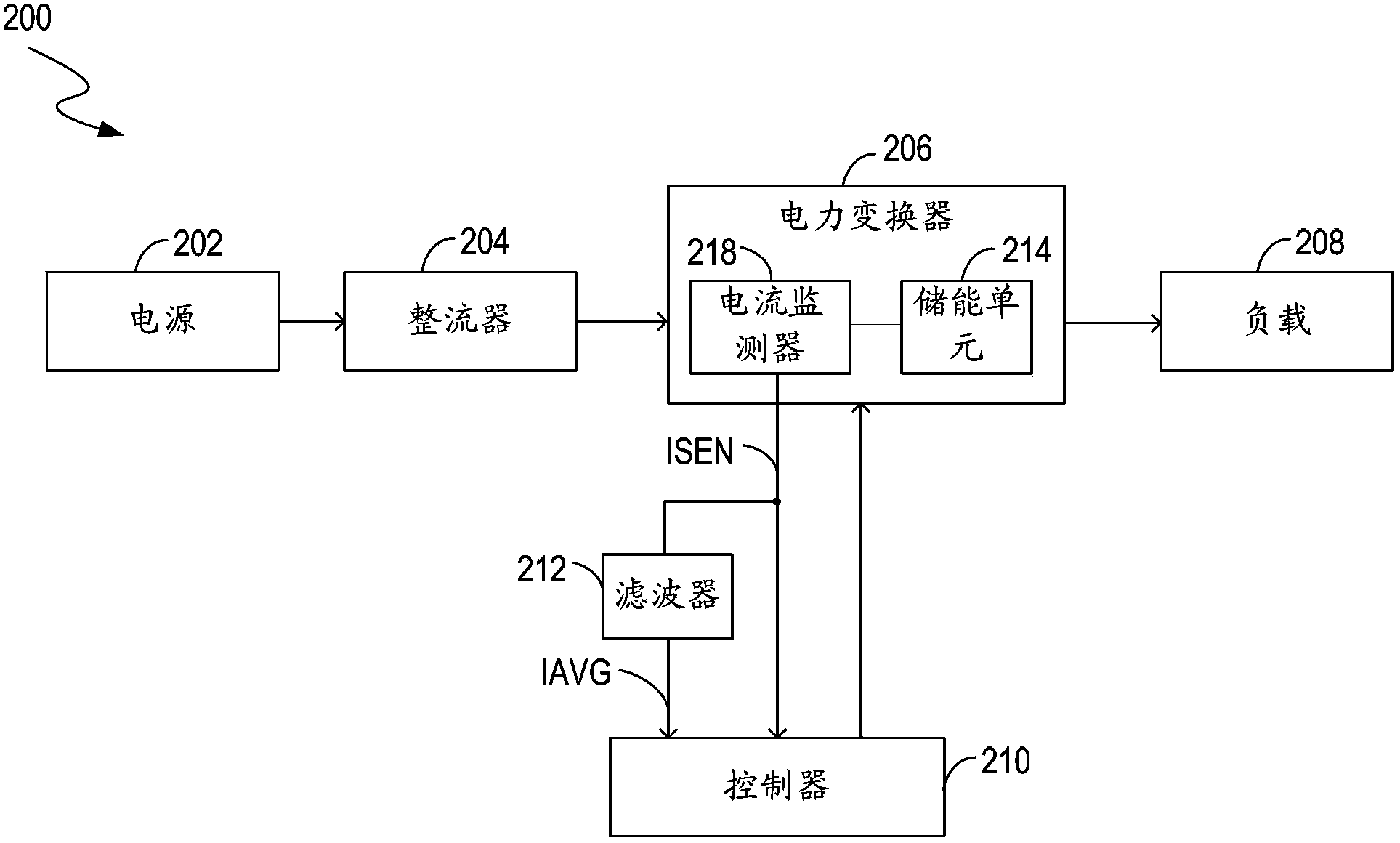

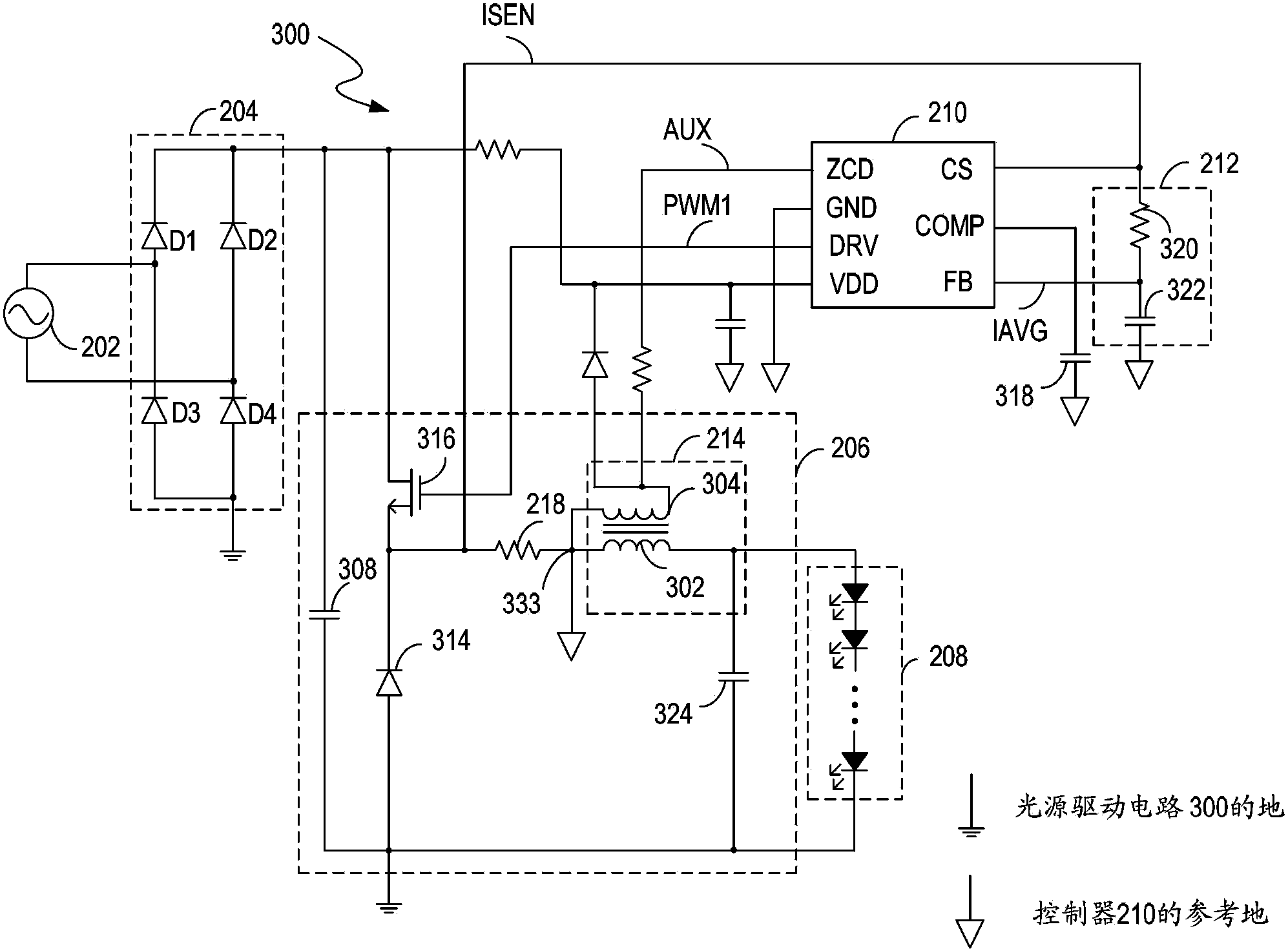

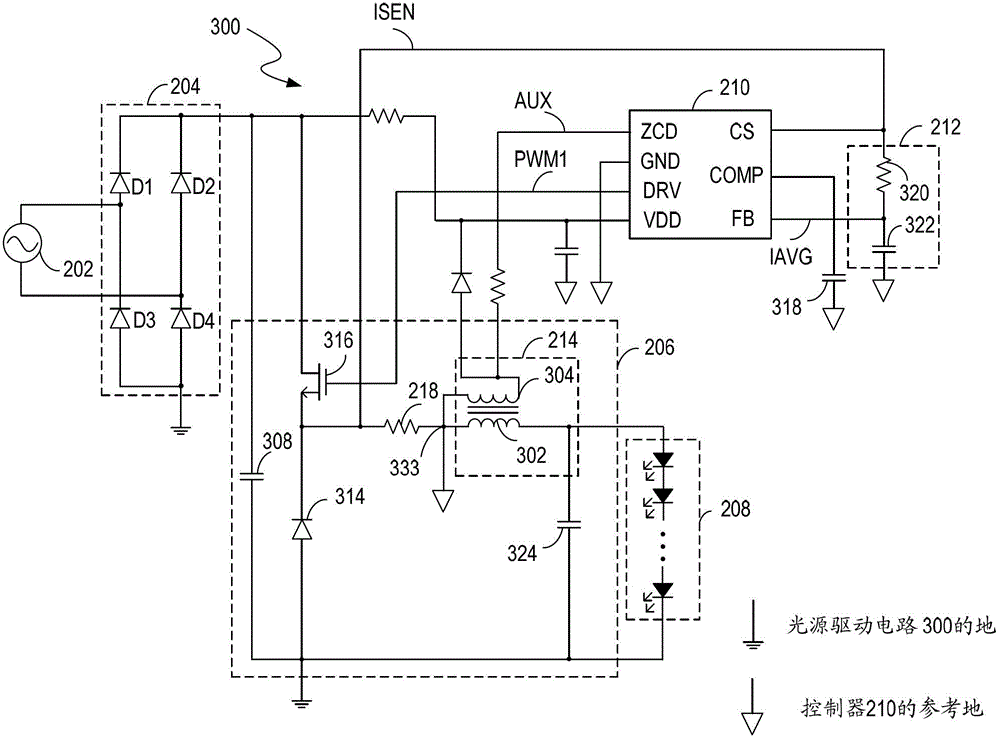

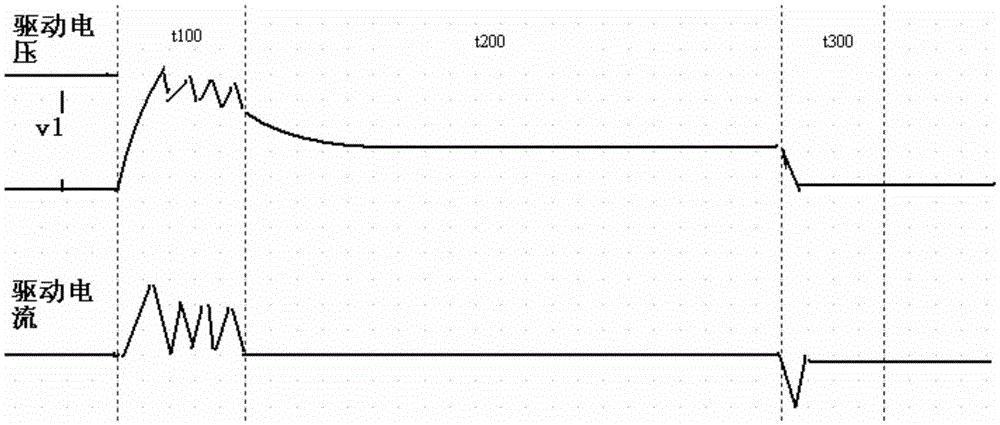

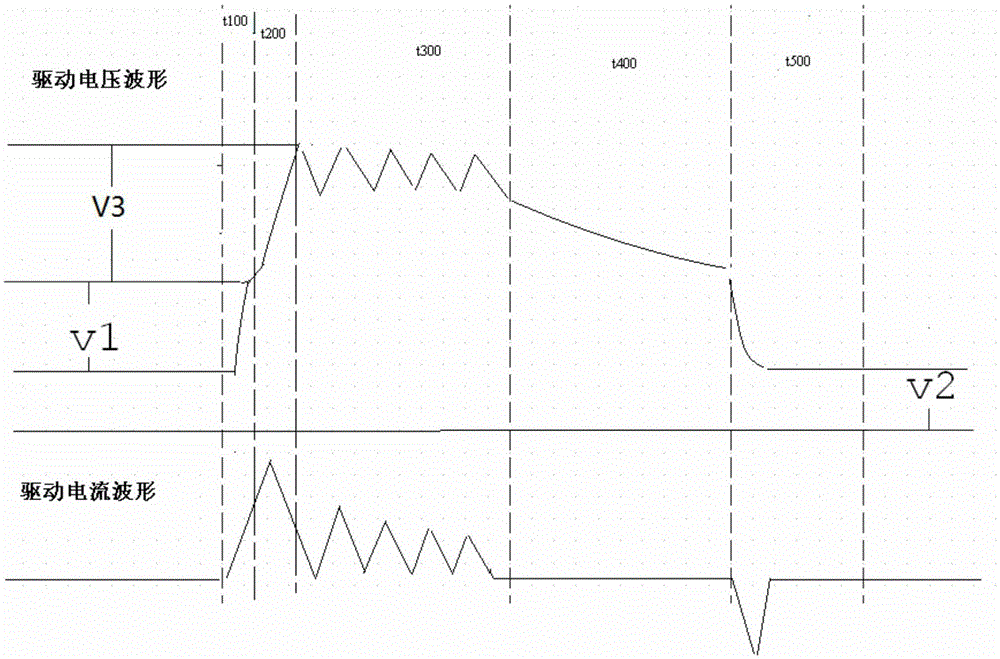

Driving circuit and method for providing power to led light source, and power converter

InactiveCN103517506AReduce line frequency interferenceCorrected power factorElectrical apparatusElectroluminescent light sourcesDriver circuitTransformer

The invention provides a driving circuit and method for providing power to an LED light source, and a power converter. The driving circuit comprises a voltage filter, a transformer and a controller. The voltage filter receives and filters an input voltage to provide a stable voltage. The transformer converts the stable voltage into an output voltage to provide power to a light source. The controller generates a driving signal to make a switch work alternatively between a first state and a second state. The controller controls time durations of the first state and the second state, such that an input current decreases to a predetermined level during the second state and increases to a peak level proportional to the input voltage during the first state. The controller controls the ratio of time in the first state to time in the second state to adjust an output current flowing through the light source to a target level. According to the invention, the current control precision is improved, power factors of the driving circuit are corrected, the quality of power supply is improved, and line frequency interference of lighting of the light source is minimized.

Owner:AOTU ELECTRONICS WUHAN

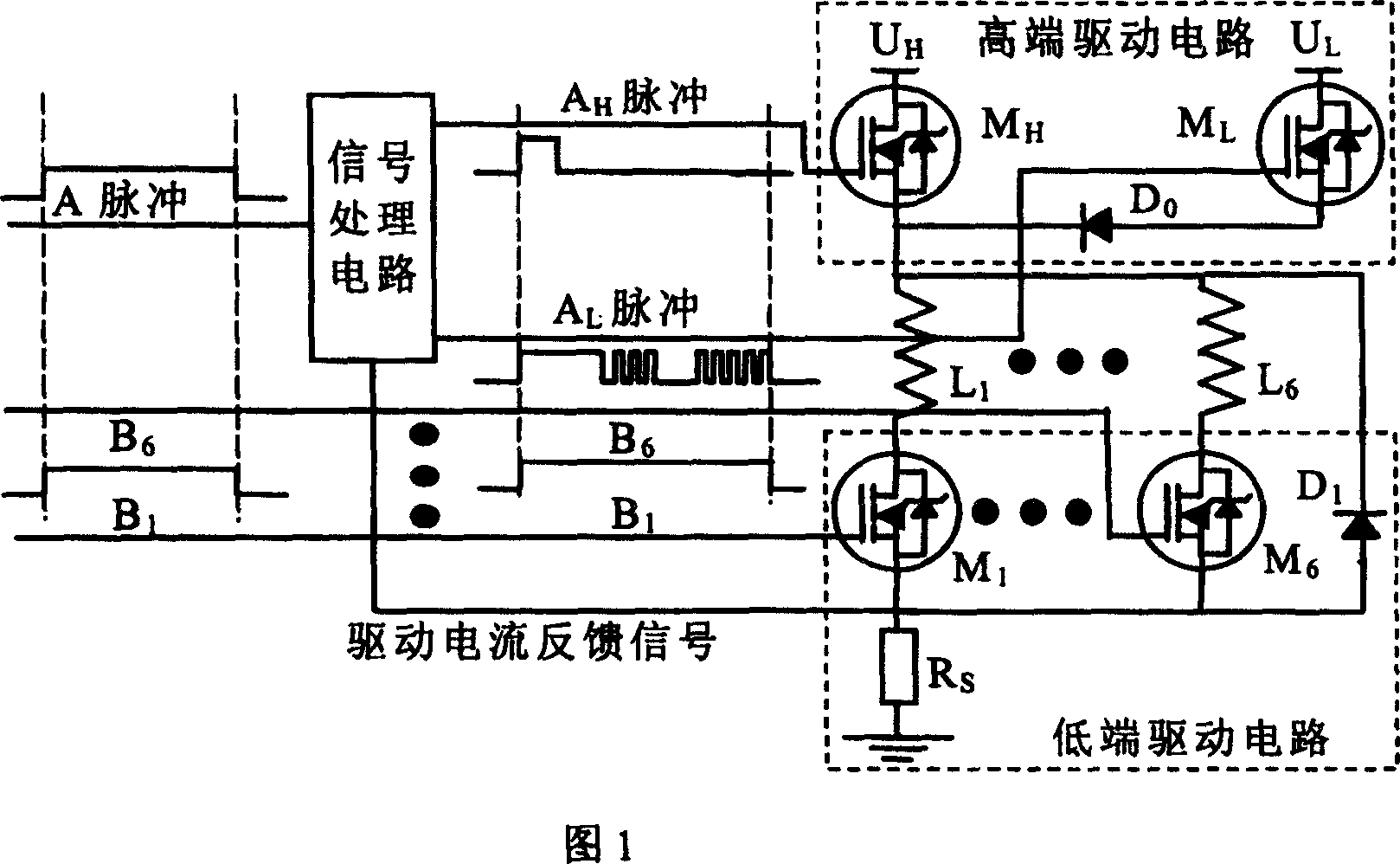

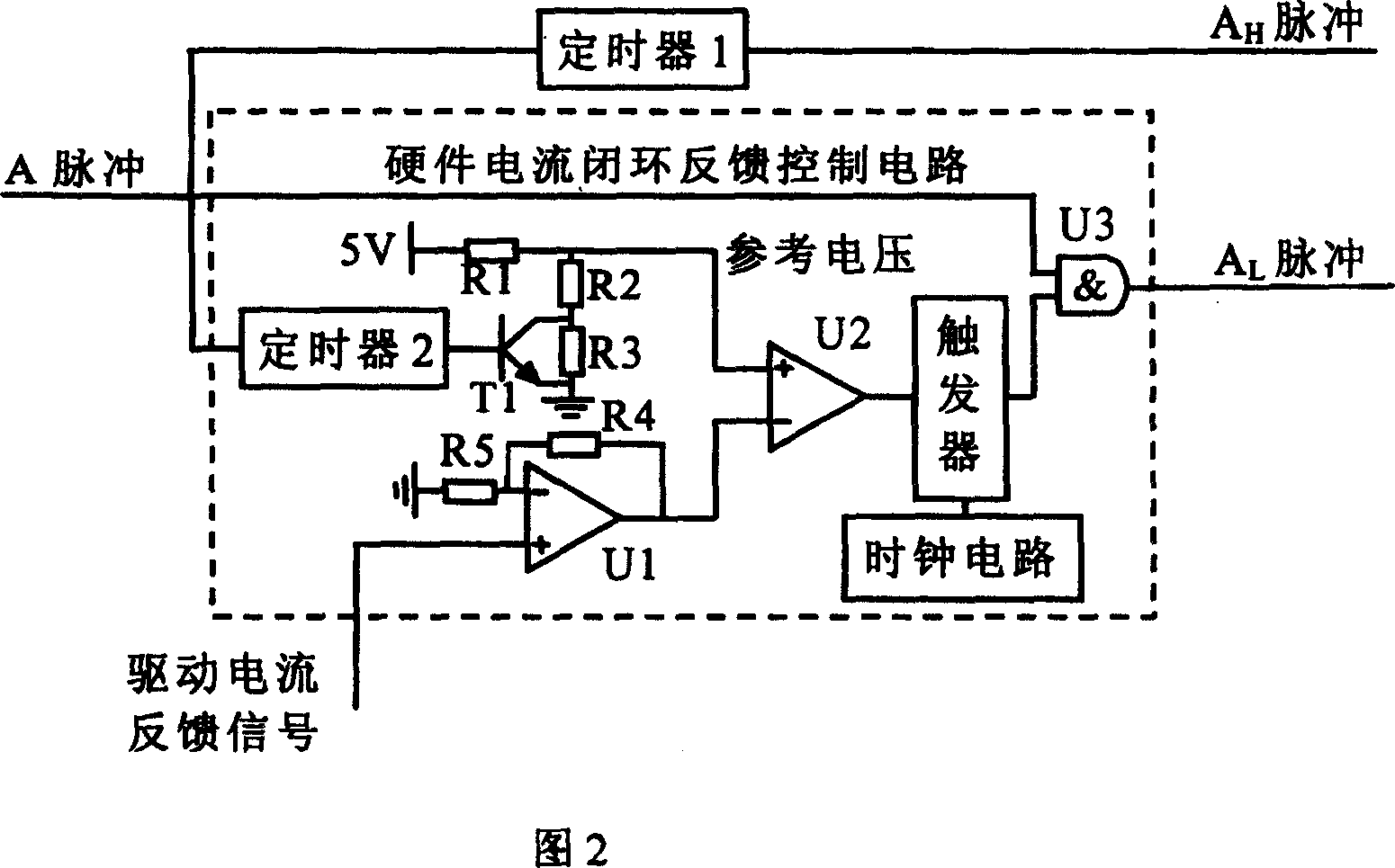

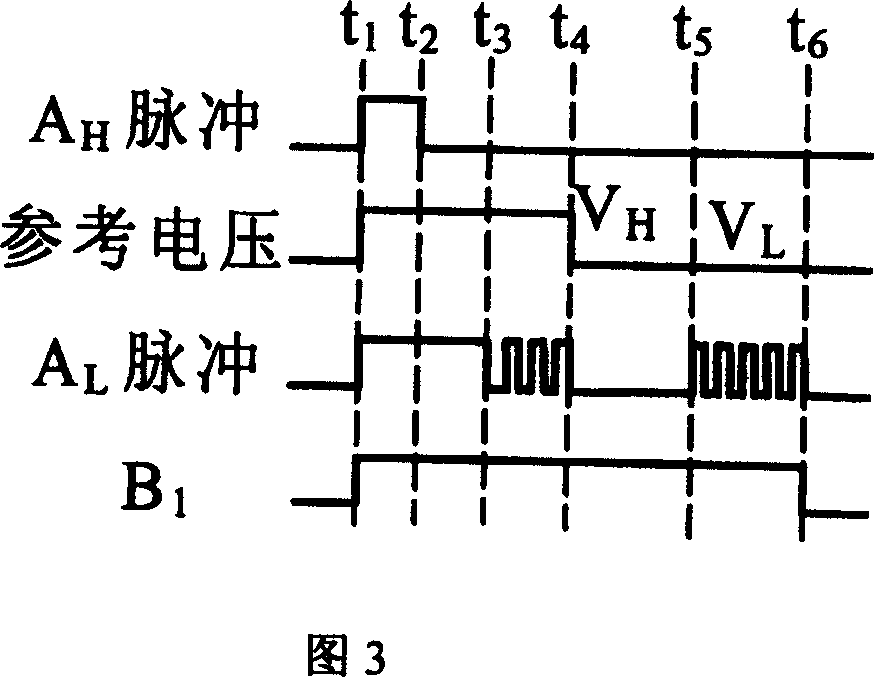

Electromagnetic valve drive circuit for engine

InactiveCN1317501CShorten closing timeHigh adjustment frequencyElectrical controlFuel-injection pumpsDriver circuitSignal processing circuits

Owner:TSINGHUA UNIV

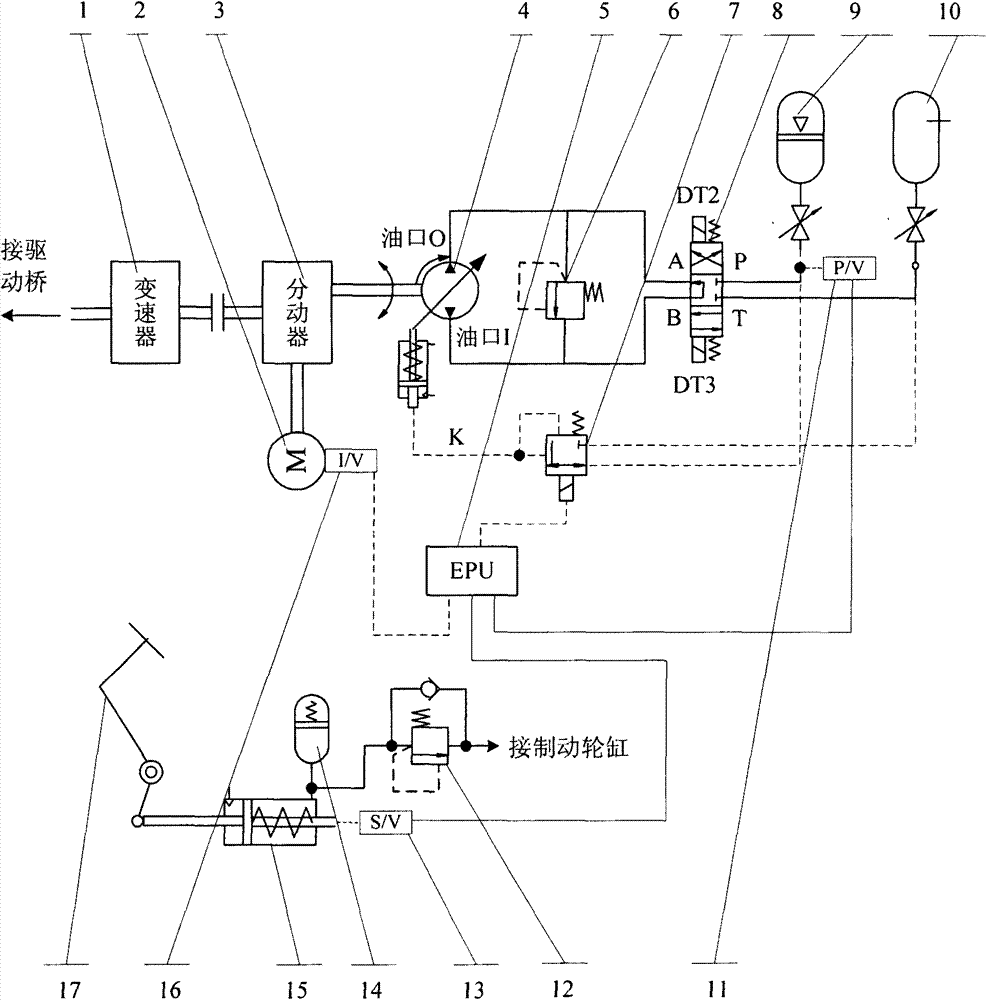

Electro-hydraulic proportional valve control pump/motor hydraulic power assisted system of electric automobile

InactiveCN103693034AImprove current control accuracyEasy to operateBraking action transmissionPropulsion unit arrangementsTransfer caseHydraulic pump

The invention discloses an electro-hydraulic proportional valve control pump / motor hydraulic power assisted system of an electric automobile, which comprises a hydraulic drive circuit, a compound brake system and an electric controller. The hydraulic drive circuit comprises a hydraulic pump / motor, a high-pressure accumulator, a low-pressure accumulator, an electromagnetic directional valve, an electric-hydraulic proportional pressure reducing valve and the like. The brake system comprises a brake pedal, a brake master cylinder, a direct-control sequence valve, a displacement sensor and the like. The hydraulic pump / motor is coupled with a power motor and a drive axle through a transfer case. When brake is performed, the hydraulic pump is driven by the inertia of the automobile to prefill the high-pressure accumulator, and a brake force is generated on the automobile by the drive torque of the pump. When emergency brake is performed, high-pressure oil is exported by the brake master cylinder to enter a brake cylinder, and the brake force is generated by the brake cylinder and the hydraulic pump together. When the automobile starts or is accelerated, if the current of the motor is out of limit, torque is output by the hydraulic motor to assist the motor in driving the automobile, the current of the motor is reduced, the discharge rate of a power battery is reduced, and the service life of the battery is prolonged.

Owner:NANJING INST OF TECH

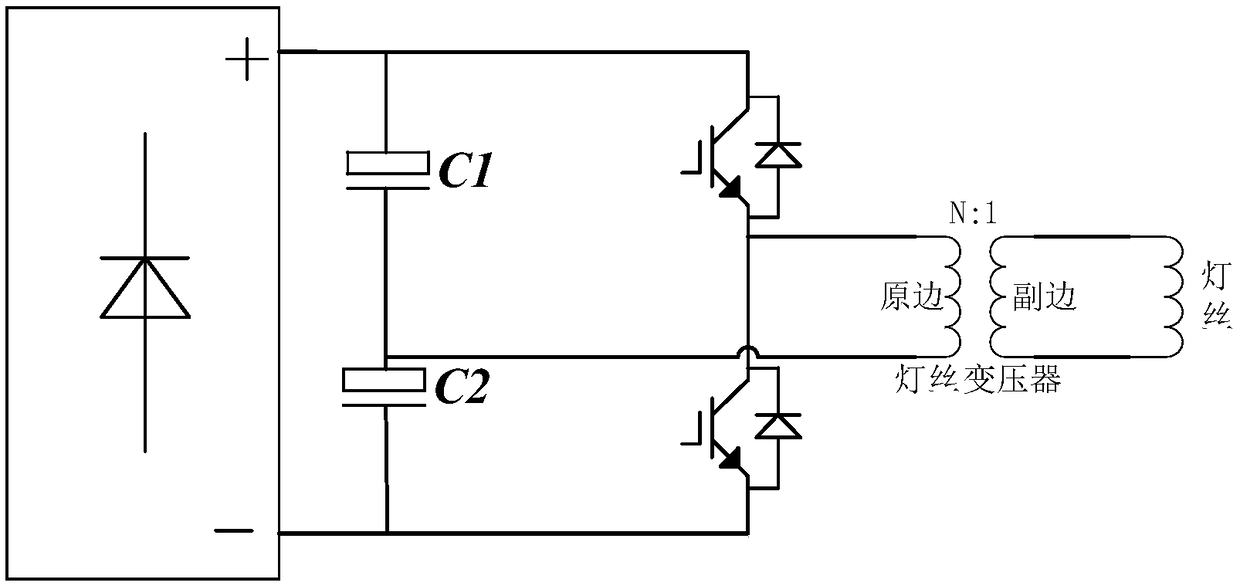

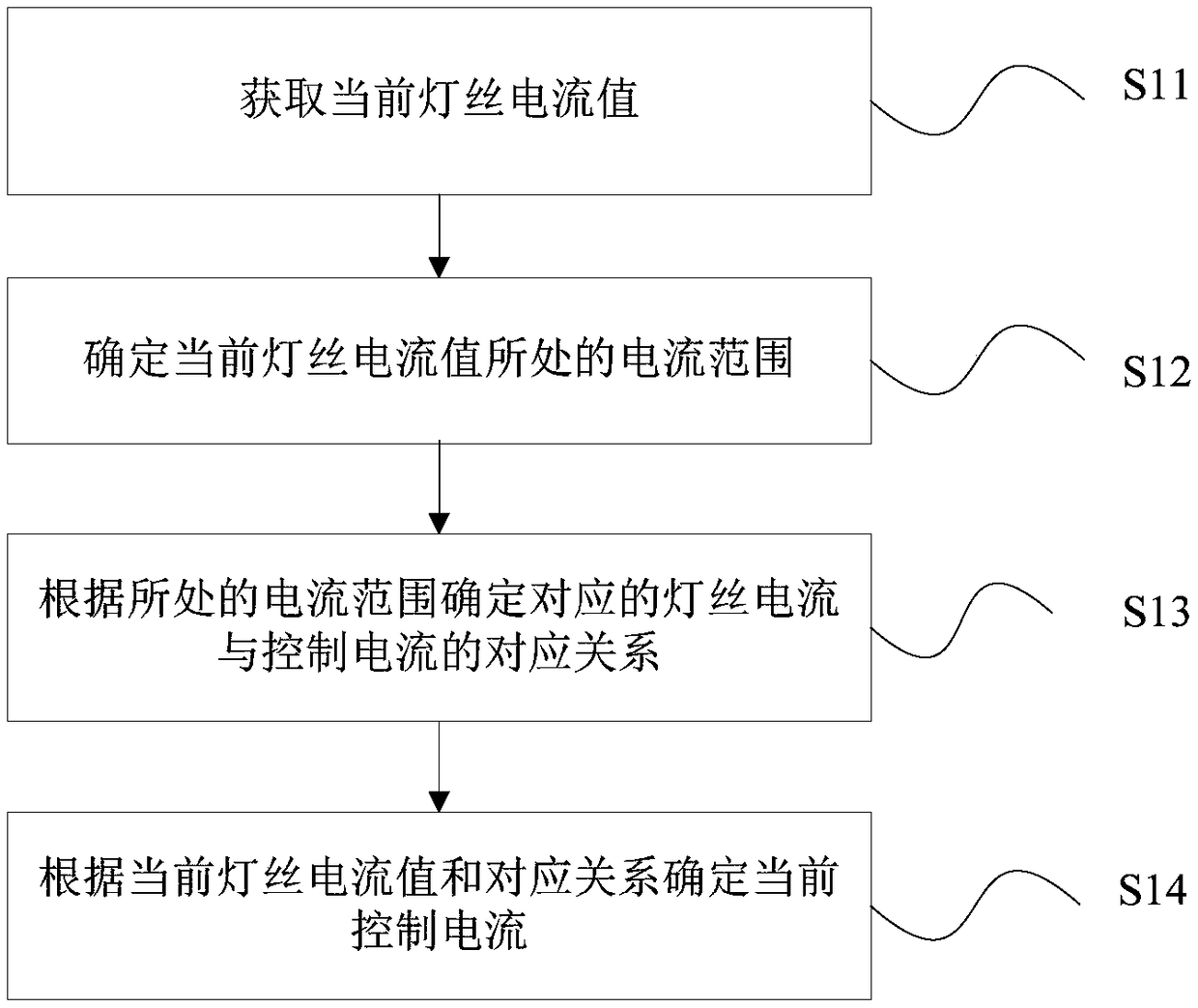

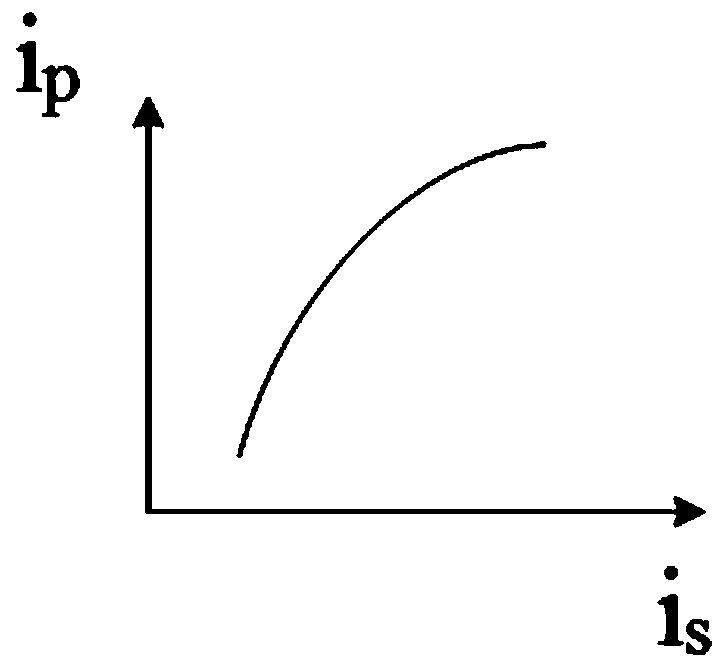

Filament current control method and device

ActiveCN108650768ASolve the problem of large control errorImprove current control accuracyX-ray apparatusTransformerCurrent range

The invention discloses a filament current control method and device. The method includes the following steps: acquiring a current filament current value; determining a current range in which the current filament current value is located; determining a corresponding relationship between the corresponding filament current and the control current according to the current range; and determining the current control current according to the current filament current value and the corresponding relationship. Thereby, the problem of large filament current control errors caused by the nonlinear characteristics of a filament transformer can be solved.

Owner:SUZHOU POWERSITE ELECTRIC CO LTD

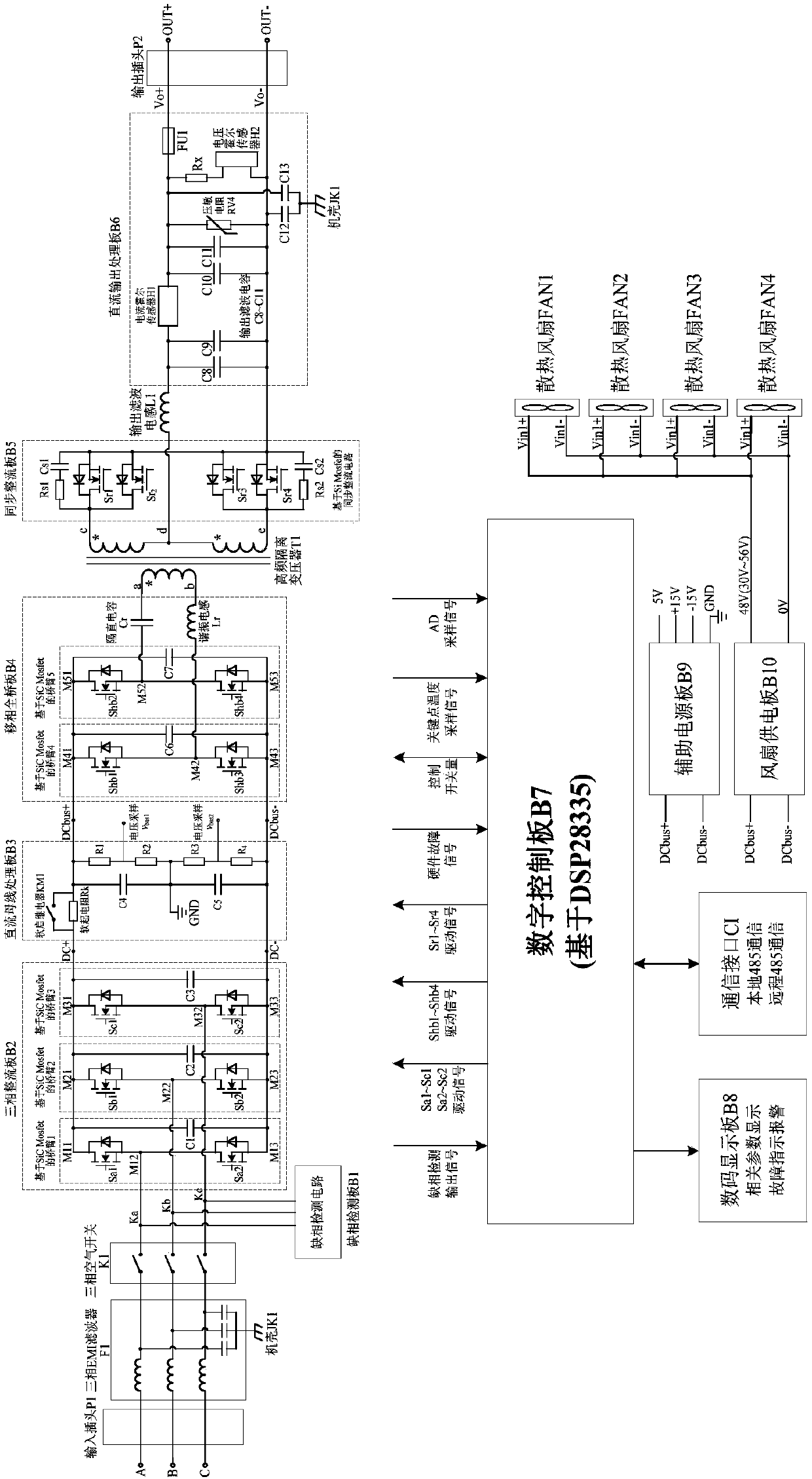

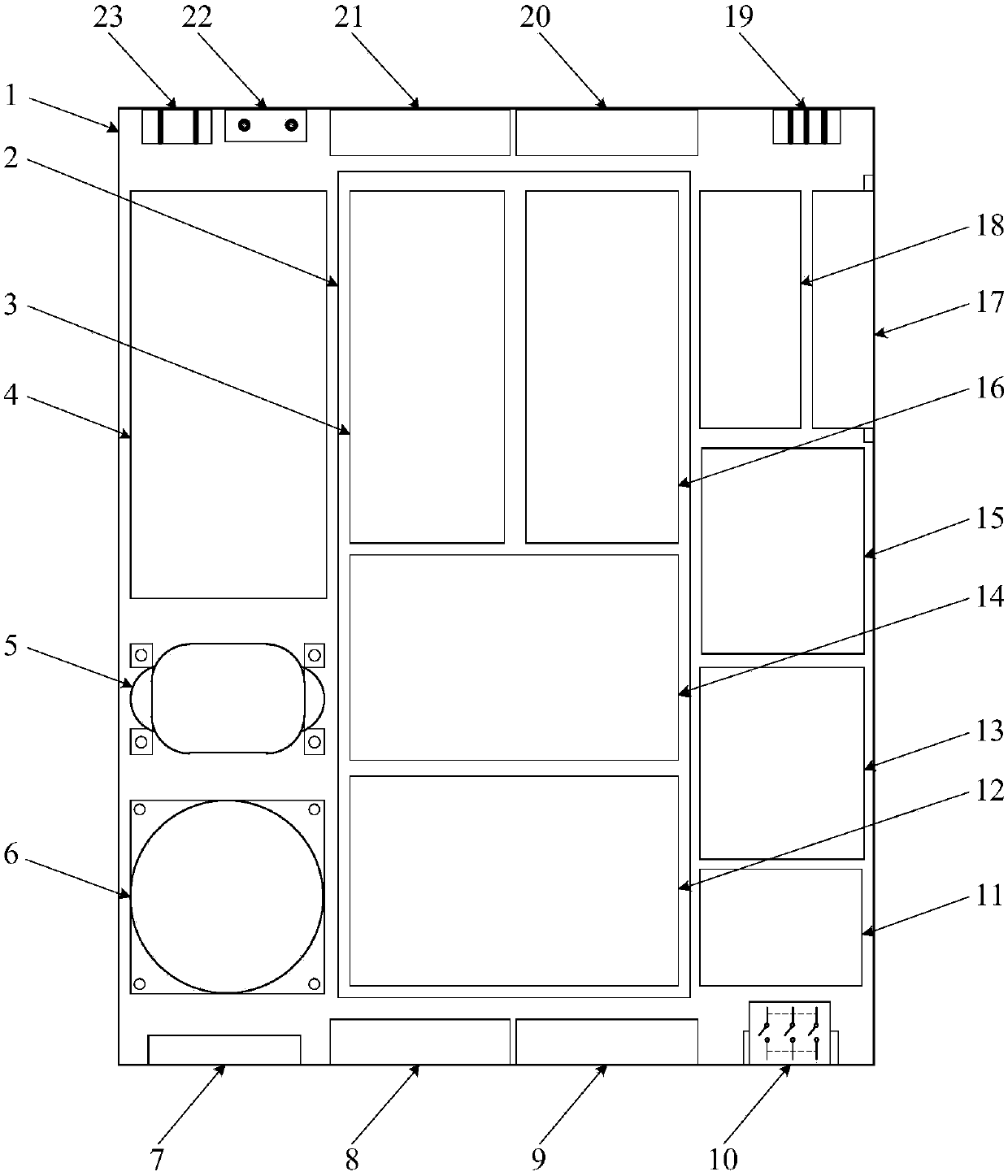

Silicon carbide based high-power low-voltage large-current-output direct-current power supply

ActiveCN107612366AReduce the amount of noiseIncrease the switching frequencyEfficient power electronics conversionAc-dc conversionBusbarFull bridge

The invention discloses a silicon carbide based high-power low-voltage large-current-output direct-current power supply which comprises an input plug P1, a three-phase EMI (electro-magnetic interference) filter F1, a three-phase air switch K1, a phase-loss detection board B1, a three-phase rectification board B2, a direct-current busbar processing board B3 and a phase-shifting full-bridge board B4. Silicon carbide devices of the power supply are high in switching frequency, low in switching loss, low in conduction resistance R and low in conduction loss, and system efficiency is greatly improved; power density of the power supply is greatly increased by the aid of the silicon carbide devices, a sampling current hall sensor is placed in the middle of four direct-current filter capacitors ina direct-current and output-current sampling circuit, interference value in current sampling can be greatly reduced, and current control accuracy is improved; in addition, in multi-module parallel application, a fuse protector is serially connected to the output side of the circuit so as to prevent the situation that a certain module is infused with large current by other modules when damaged.

Owner:张家港水云新能源科技有限公司

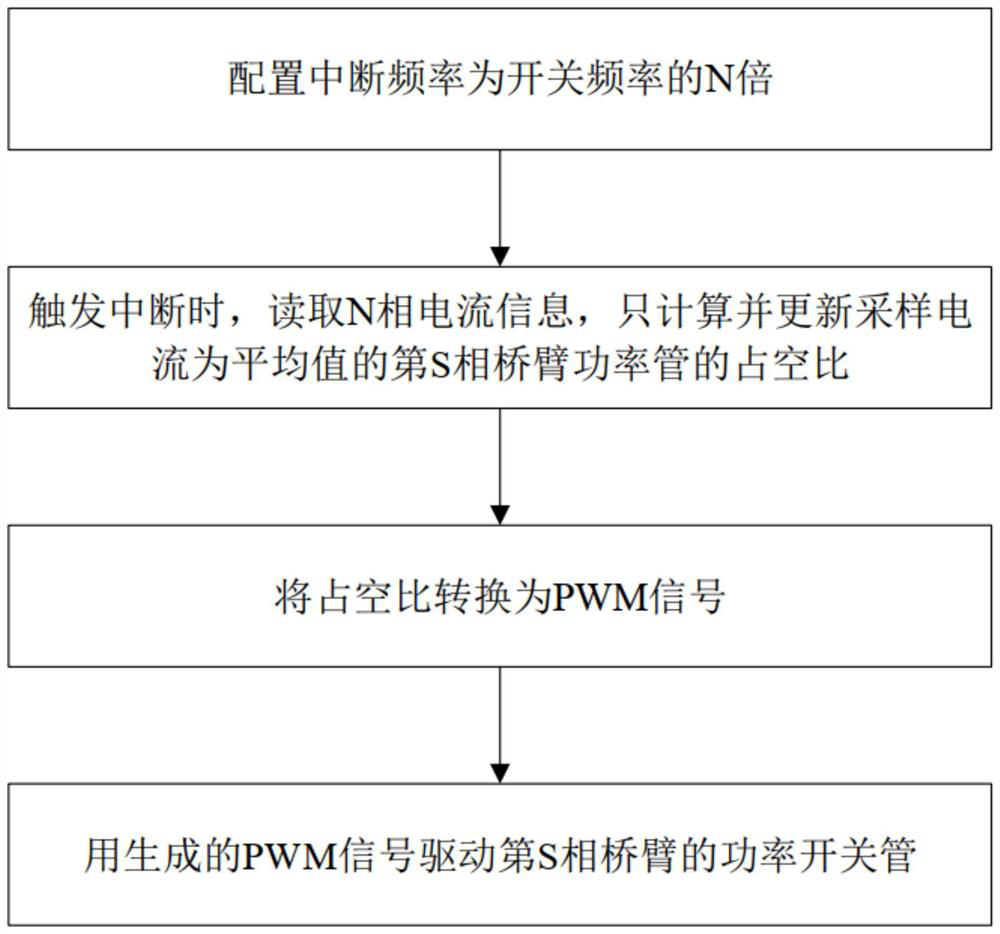

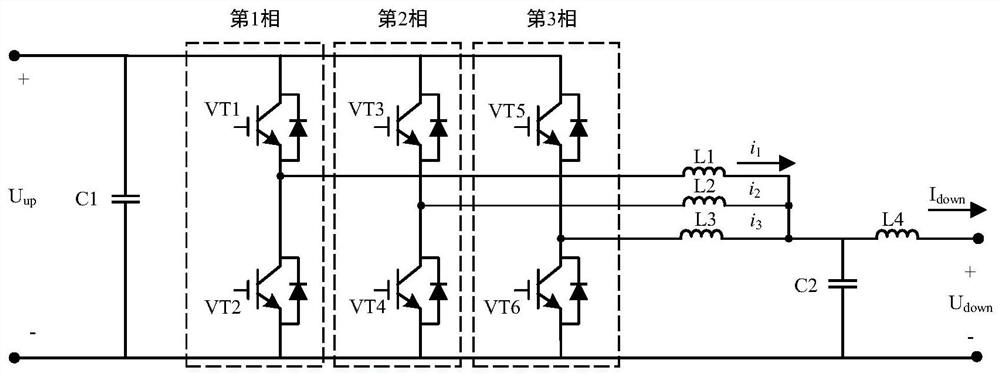

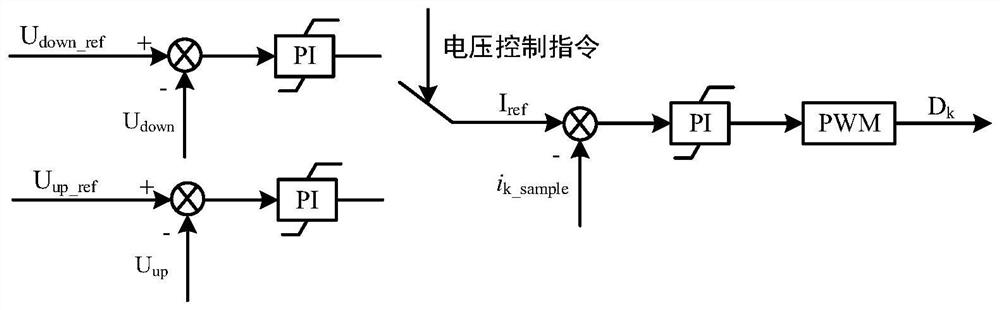

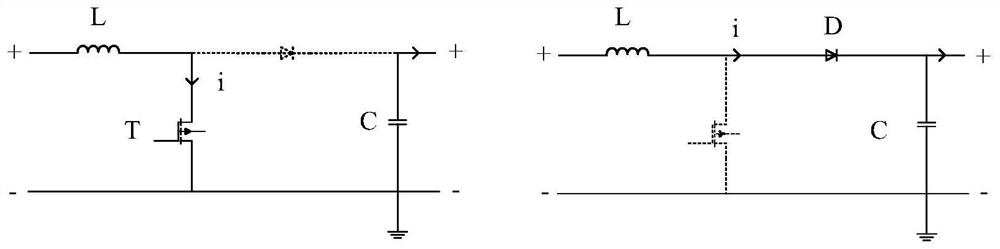

Multi-phase interleaving parallel DC-DC converter output current control method and system

ActiveCN112769335AGuaranteed uptimeSolve the problem of poor current control effectEfficient power electronics conversionDc-dc conversionCarrier signalControl engineering

The invention discloses a multi-phase interleaving parallel DC-DC converter output current control method and system. The method comprises the steps of: setting interruption frequency fi=N*fs, wherein fs is the switching frequency; setting the triangular carrier frequency of a pulse width modulation register PWM to be fs, employing a counting mode adopting increase and decrease counting, and setting triangular carrier phases to be sequentially lagged by 360 degrees / N. The method further comprises the following steps of: S1, when triggering interruption occurs, reading current information of N-phase bridge arms, and calculating a duty ratio of a power switch tube of an Sth-phase bridge arm when the current of the Sth-phase bridge arm is just the average value current; S2, converting the duty ratio into a PWM signal; and S3, driving a power switch tube of the Sth-phase bridge arm by using the generated PWM signal. The system comprises a calculation module, a digital control module and a driving module, wherein the driving module is used for generating PWM signals and sequentially driving the power switch tubes of the N-phase bridge arms. According to the multi-phase interleaving parallel DC-DC converter output current control method, the problem of poor current control effect caused by relatively large current ripples of a multi-phase interleaving parallel DC-DC converter can be solved, meanwhile, good current sharing among phases can be realized, and the current control precision is improved.

Owner:XJ POWER CO LTD +2

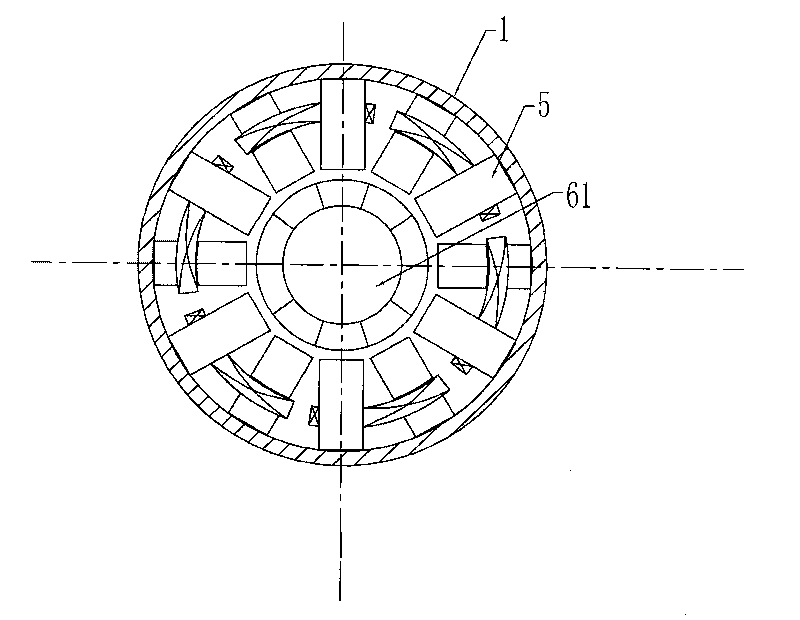

Permanent magnet synchronous motor with interphase uncoupled structure

InactiveCN101741195ASimple structureIncrease currentMagnetic circuit rotating partsSynchronous machine detailsCouplingElectric machine

The invention discloses a permanent magnet synchronous motor with an interphase uncoupled structure, relating to the field of motors and solving the problem that the control precision of current is influenced because magnetic coupling exists between phases and the defect that stator iron loss is larger because a magnetic circuit passed by magnetic flow generated by electrifying each group of windings is longer. The phase unit of a stator comprises a plurality of phase armature iron cores and a plurality of phase armature windings, wherein each phase armature iron core comprises 2k iron core units; each phase armature iron core is a phase armature iron core with comprises 2k iron core units and has a tooth hole; the tooth hole is formed by superposing tooth slots; the two teeth of each iron core unit are arranged along the axial direction; a magnet yoke section is connected between the two teeth; 2k iron core units are sequentially arranged in a housing case at equal intervals along the peripheral direction; and coils are wounded into single-phase armature windings by tooth holes. The motor has im phase units when being an m-phase motor, and the included angle between the axes of two adjacent phase armature windings is an electrical angle of [(j-1)+(1 / m)]*180 degrees. The permanent magnet synchronous motor not only can be used as an electromotor but also can be used as a generator.

Owner:HARBIN INST OF TECH

Application method of wireless discharging device of accumulator cell

InactiveCN101673960AImprove current control accuracyContinuously adjustable discharge currentBatteries circuit arrangementsElectric powerOperation modeEngineering

The invention discloses an application method of a wireless discharging device of an accumulator cell, which is realized by the following steps: (1) merging a temporary accumulator cell group into a running direct current (DC) loop, retreating an accumulator cell group in an original DC loop from running and using the accumulator cell group in an original DC loop as an accumulator cell group to bedetected; (2) accessing the wireless discharging device to the accumulator cell group to be detected; (3) setting discharging parameters of the wireless discharging device, detecting wire connectionsand patrolling data; (4) discharging and charging the accumulator cell group to be detected for a circle; (5) judging whether the accumulator cell group to be detected is qualified or not according to a discharging result obtained in step (4); if the accumulator cell group to be detected is qualified, turning to step (6); if not, turning to step (4); and (6) recovering original wire connection manner. The invention has the advantages of high accuracy of current control, continuously adjustable discharging current of accumulator cells, error within the range of 0.5 A, simple wire connection, small size for carrying conveniently, diverse operation modes, and clearer discharging data for comparing data conveniently.

Owner:BAOJI POWER SUPPLY BUREAU

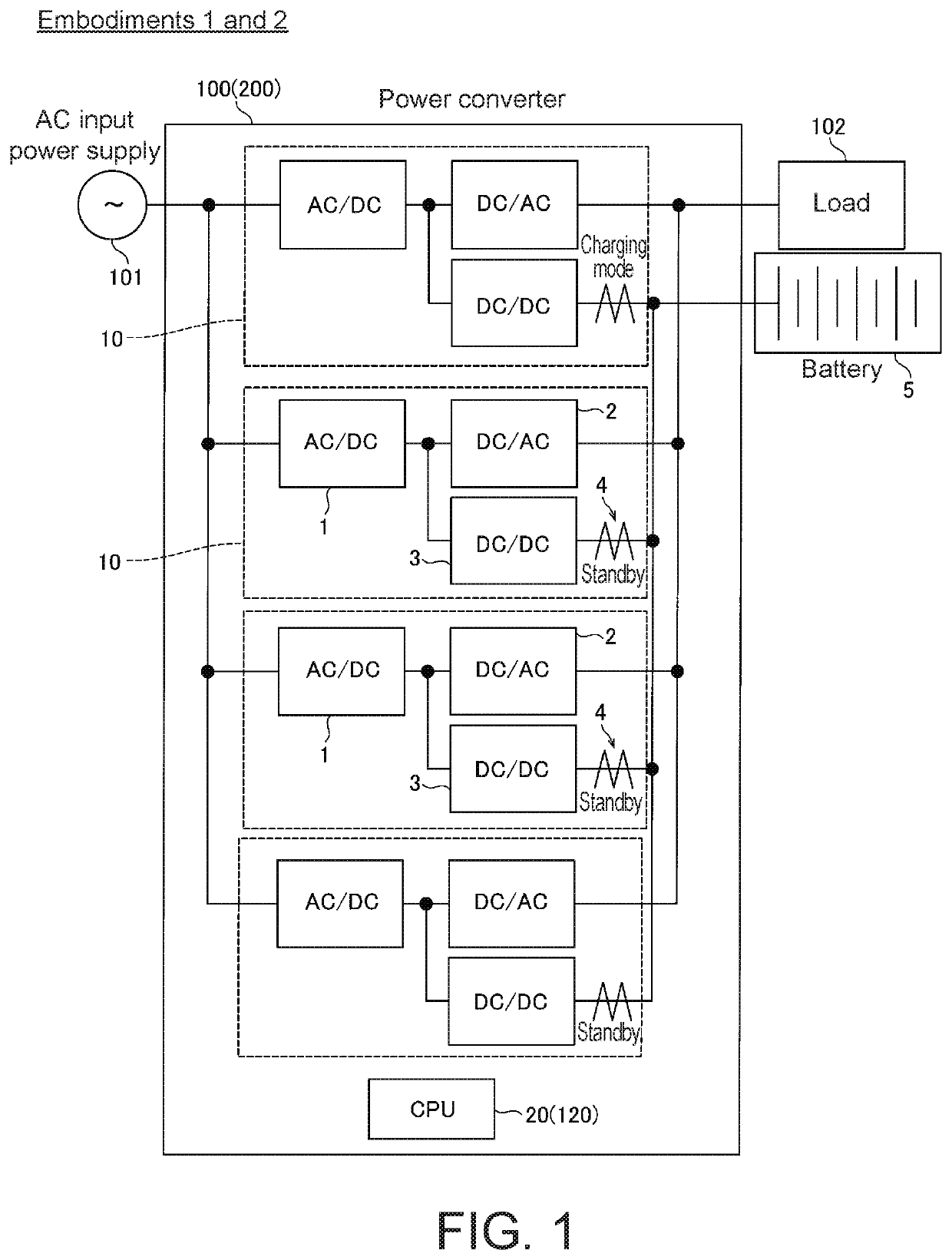

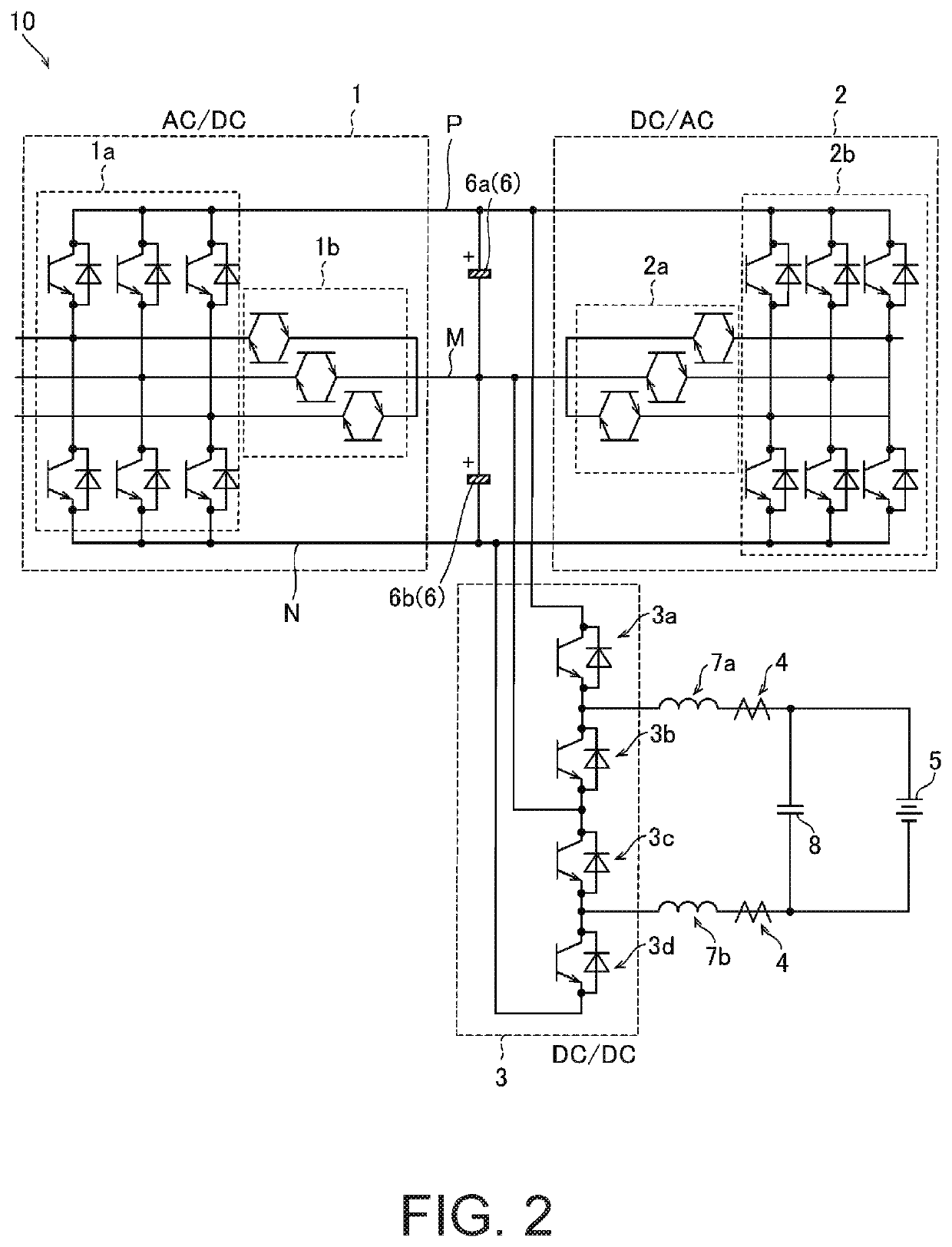

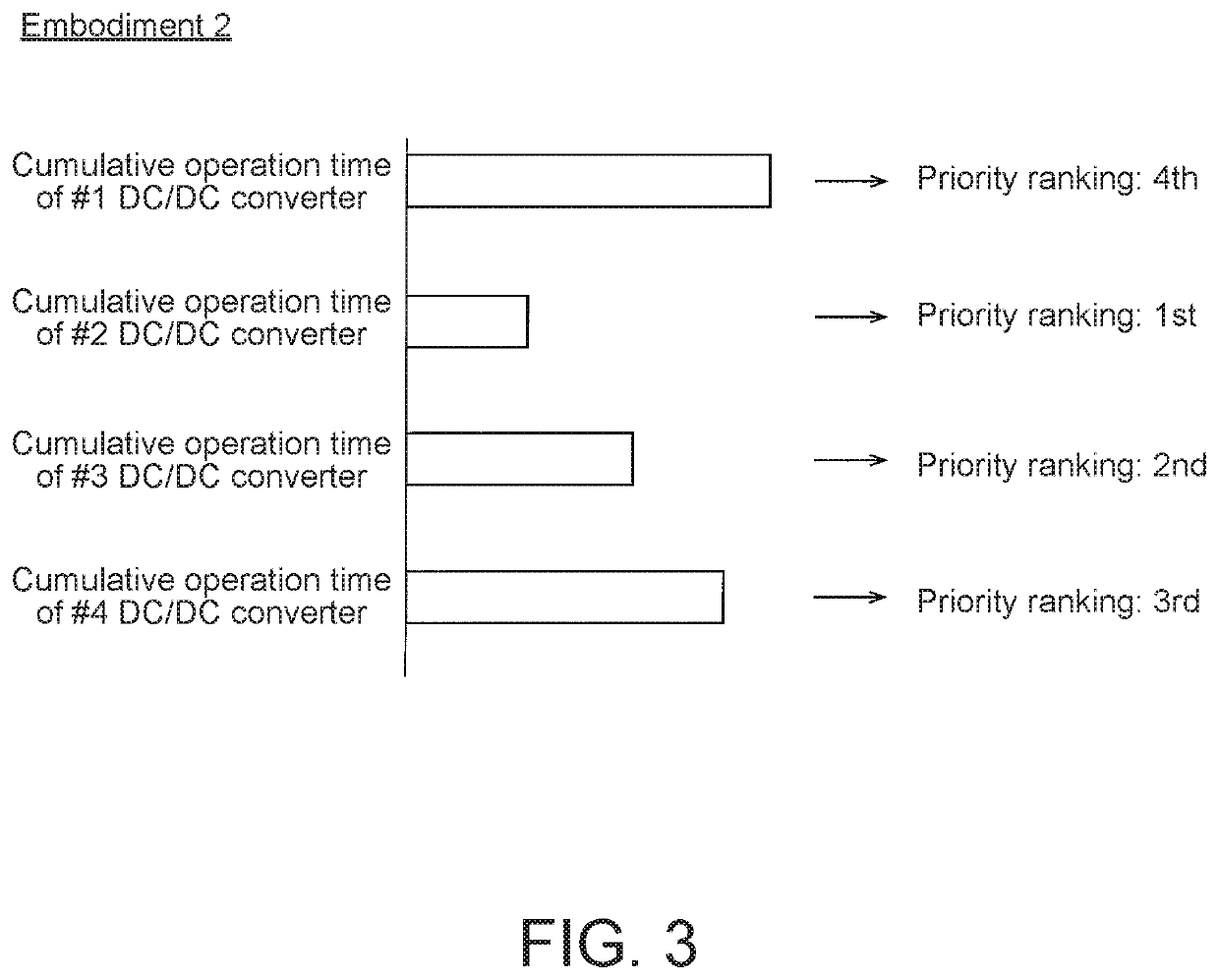

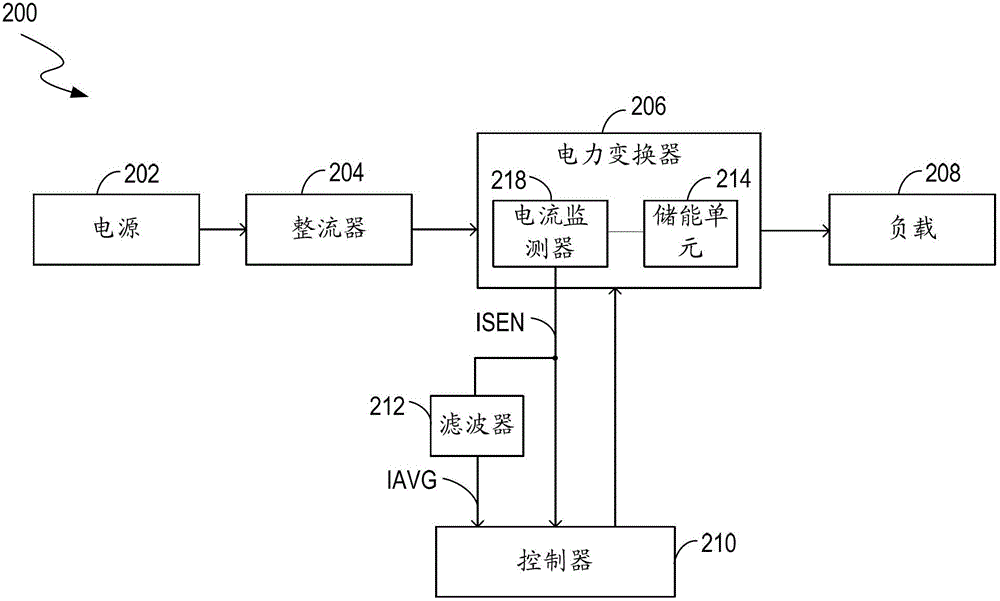

Power converter

ActiveUS11114882B2Improve current control accuracyAc-dc conversion without reversalDc-dc conversionConvertersElectrical battery

A power converter includes a plurality of power conversion units connected to one another in parallel, each including an AC / DC converter (rectifier) that converts AC power from an AC input power supply (commercial power supply) into DC power, a DC / DC converter (DC power converter) that converts the DC power from the AC / DC converter, and a current detector that detects charge current flowing from the DC / DC converter as well as discharge current flowing to the DC / DC converter. The power converter further includes a battery (electrical storage unit) that is charged by a subset of DC / DC converters among the DC / DC converters of the plurality of power conversion units, as well as a CPU (controller) that controls the DC / DC converters of the plurality of power conversion units.

Owner:FUJI ELECTRIC CO LTD

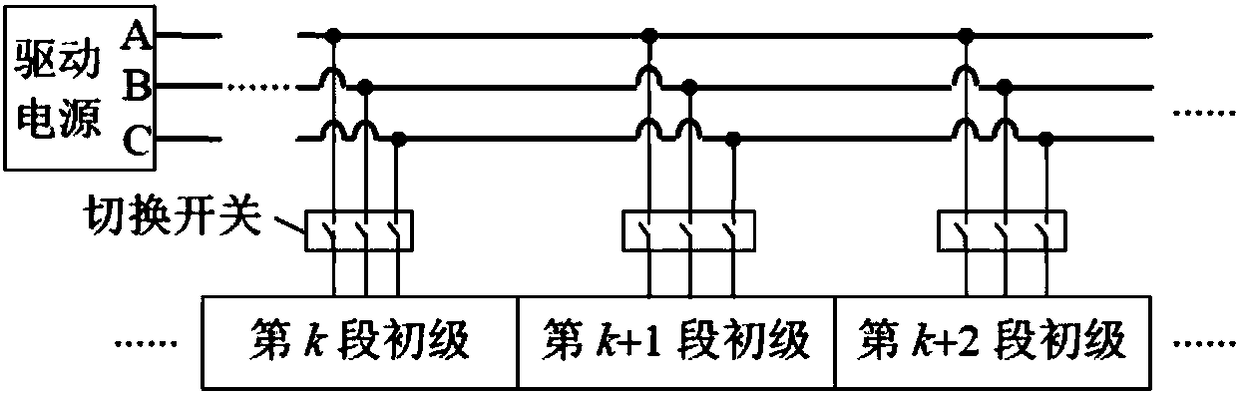

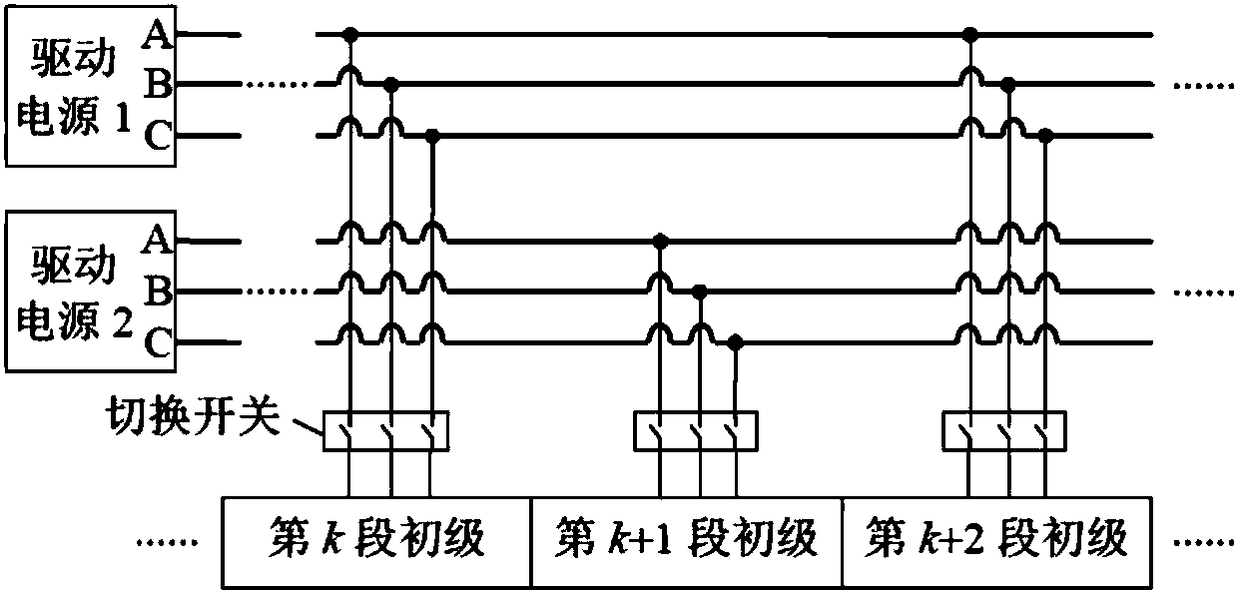

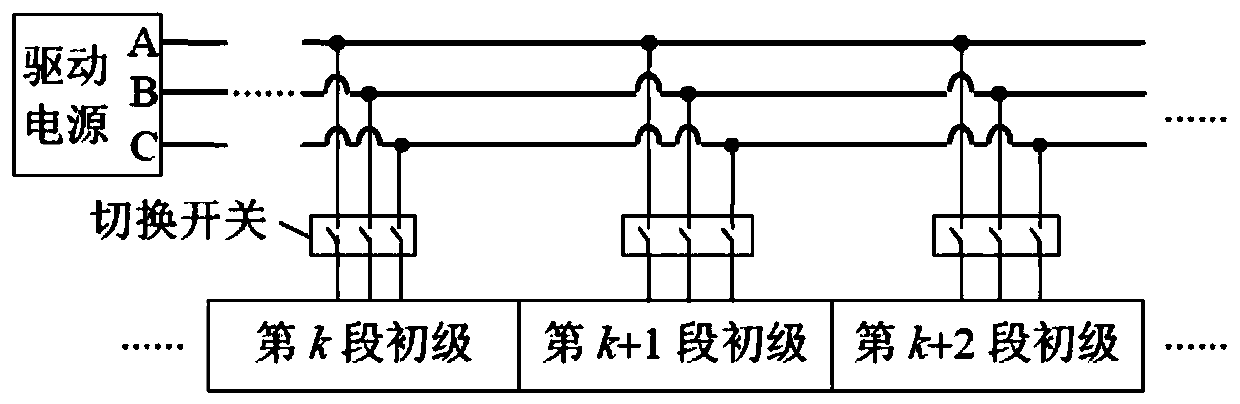

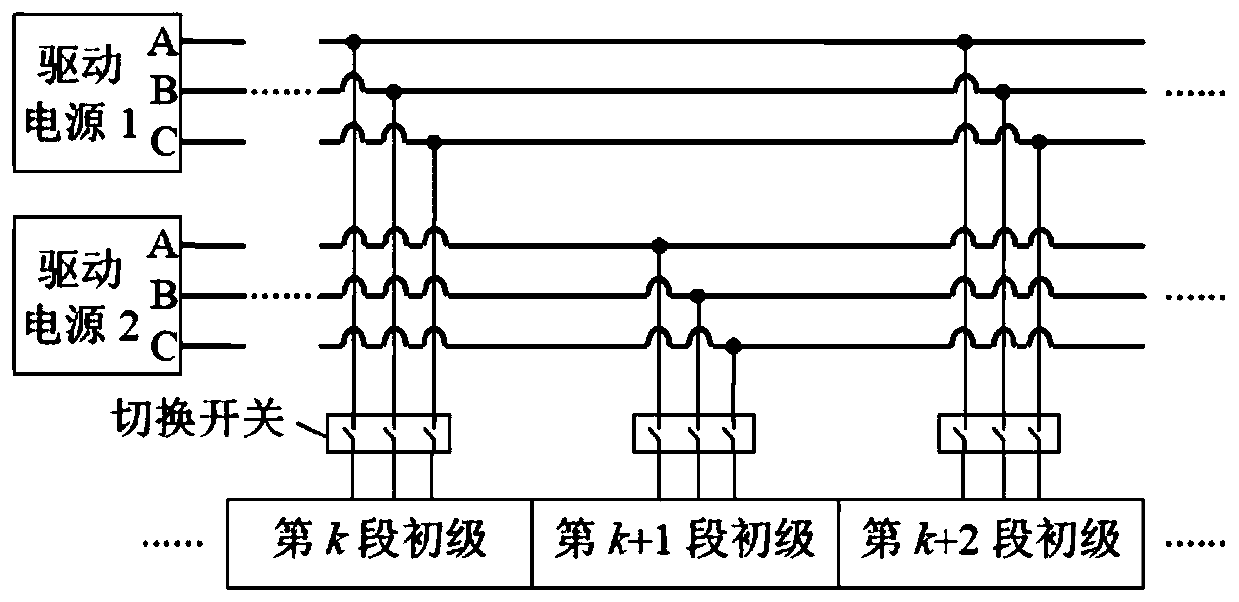

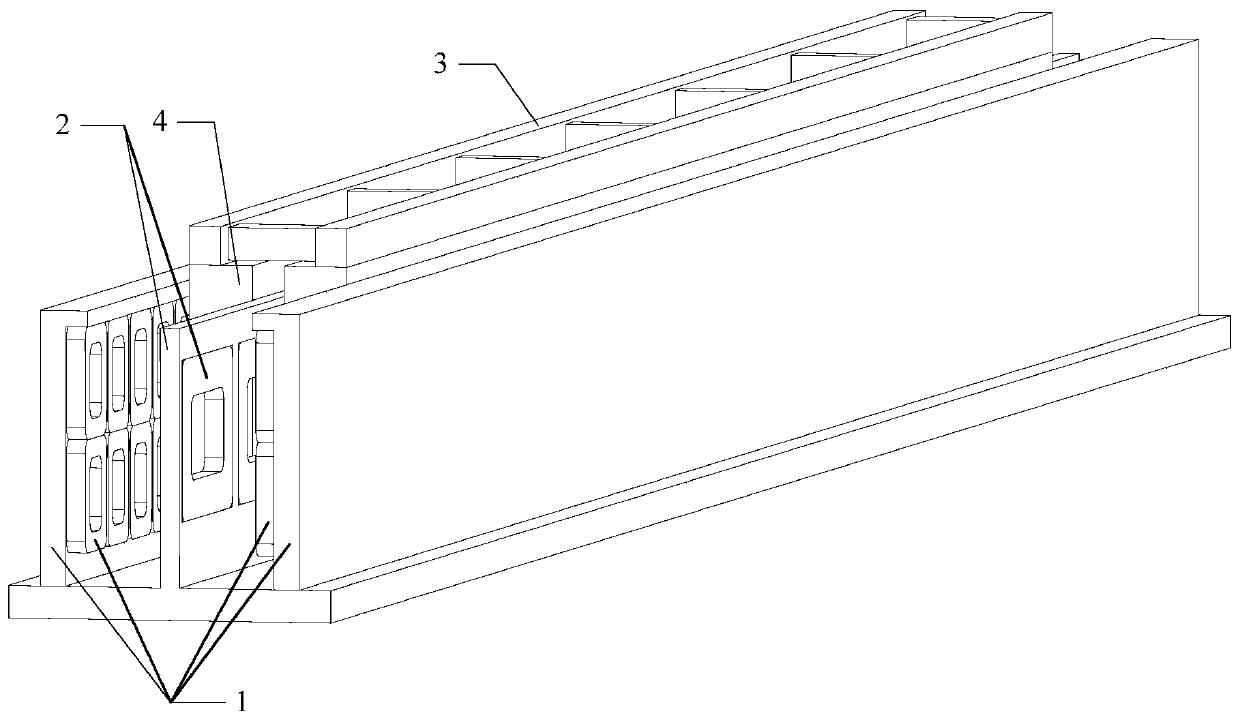

High-power linear electromagnetic acceleration system

ActiveCN108418386AMany turns in seriesSmall number of turns in seriesAc-dc conversionPropulsion systemsFault toleranceLow speed

The invention relates to a high-power linear electromagnetic acceleration system and belongs to the field of motors. The driving system of a conventional high-power linear electromagnetic accelerationsystem has a great difficulty in dynamic current-sharing control and does not have a fault-tolerant function. The high-power linear electromagnetic acceleration system is characterized in that coilsin a primary starting region has a large number of series turns, a coil driver has a small output current, a purpose of driving the low-speed section of a linear motor by using a driver with a small current and a high chopping frequency is achieved; coils in a primary terminal region has a small number of series turns and the coil driver has a large output current. When the high-speed section is driven, multiple parallel unit coils are connected in parallel, and each parallel unit coil is driven separately, thereby realizing a purpose of driving a high-power motor in parallel by using small and medium power drivers, avoiding the great difficulty in dynamic current-sharing control caused by parallel connection of multiple power switching devices and achieving the fault tolerance of the driving system.

Owner:HARBIN INST OF TECH +1

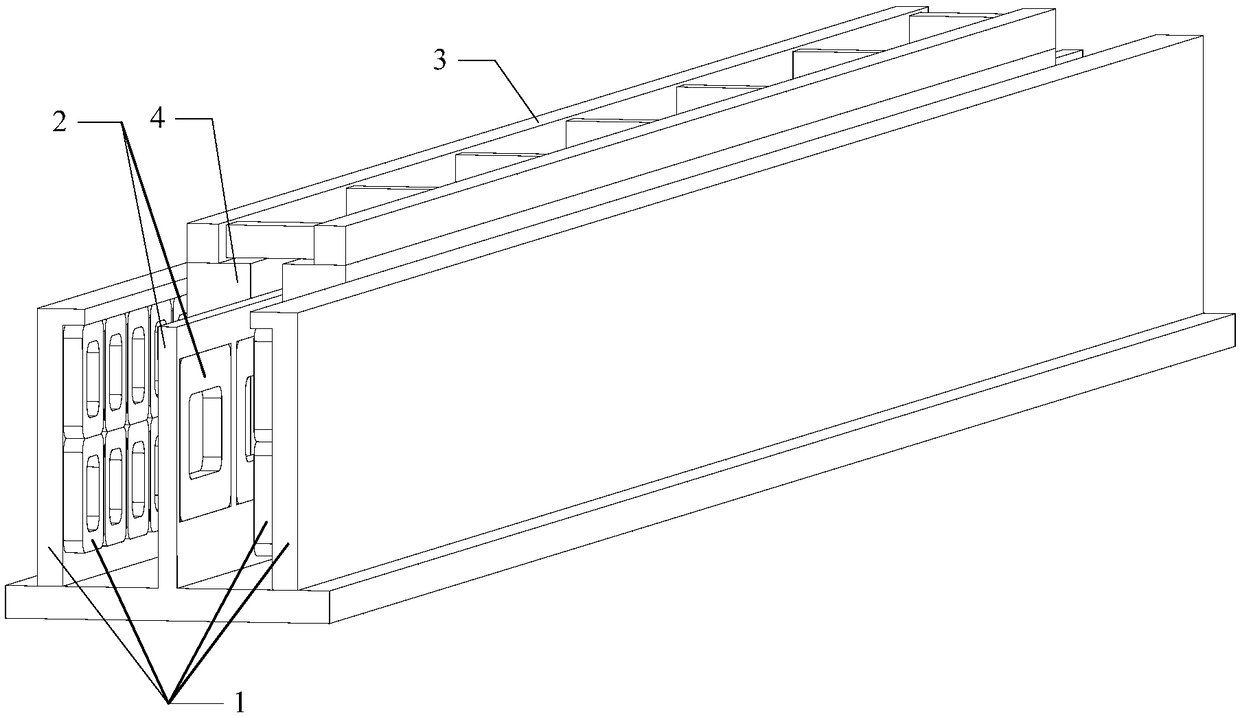

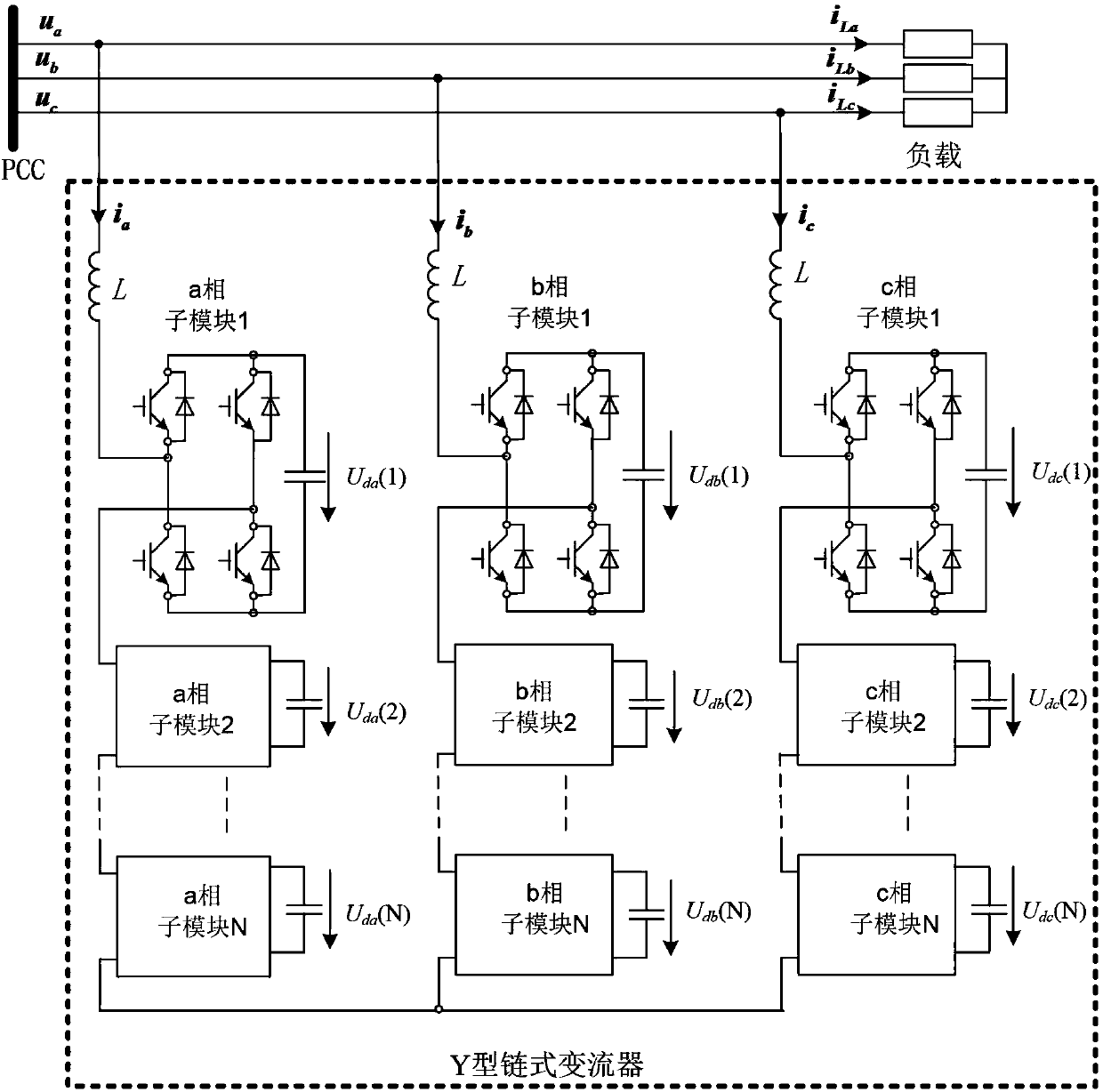

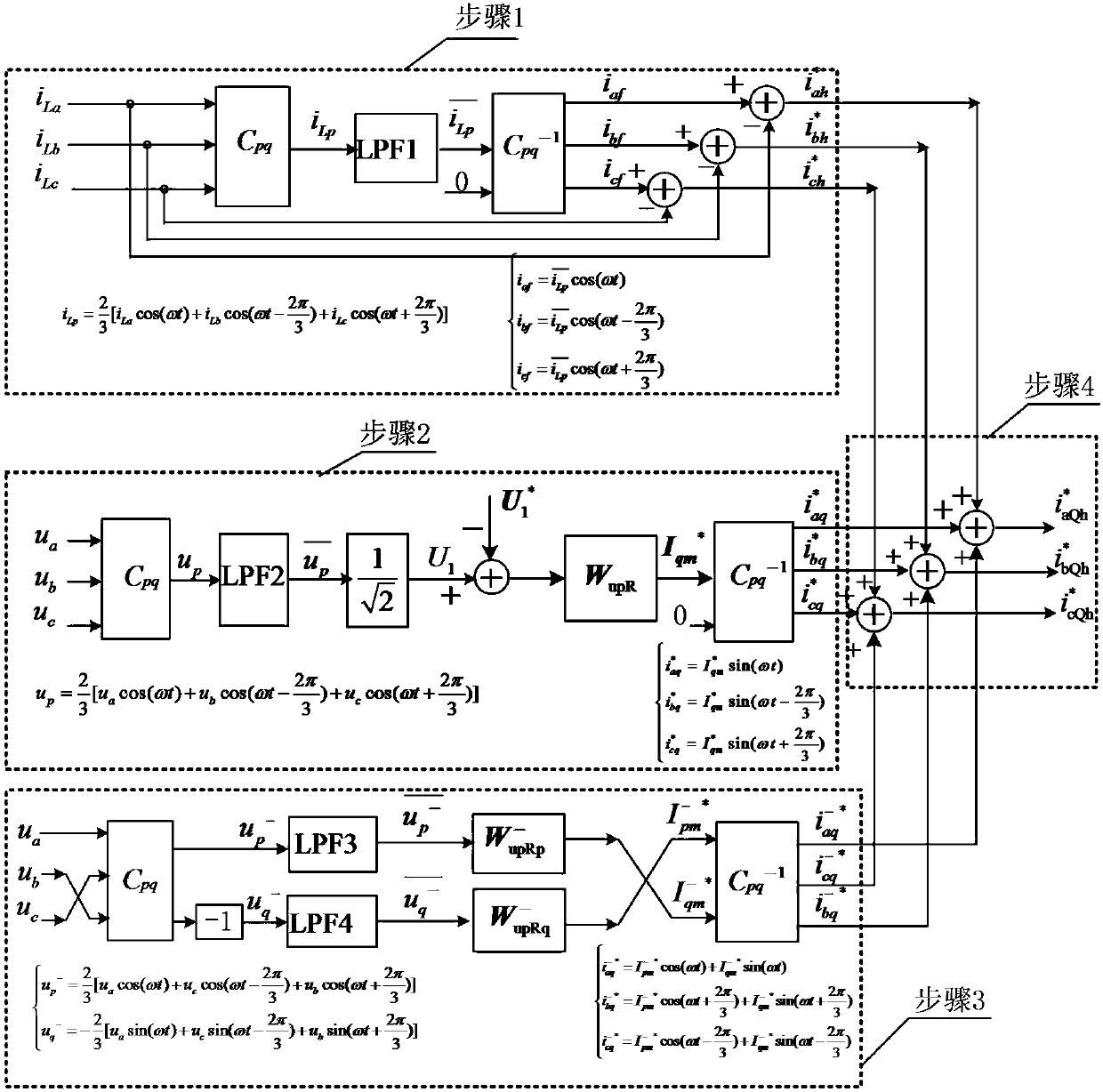

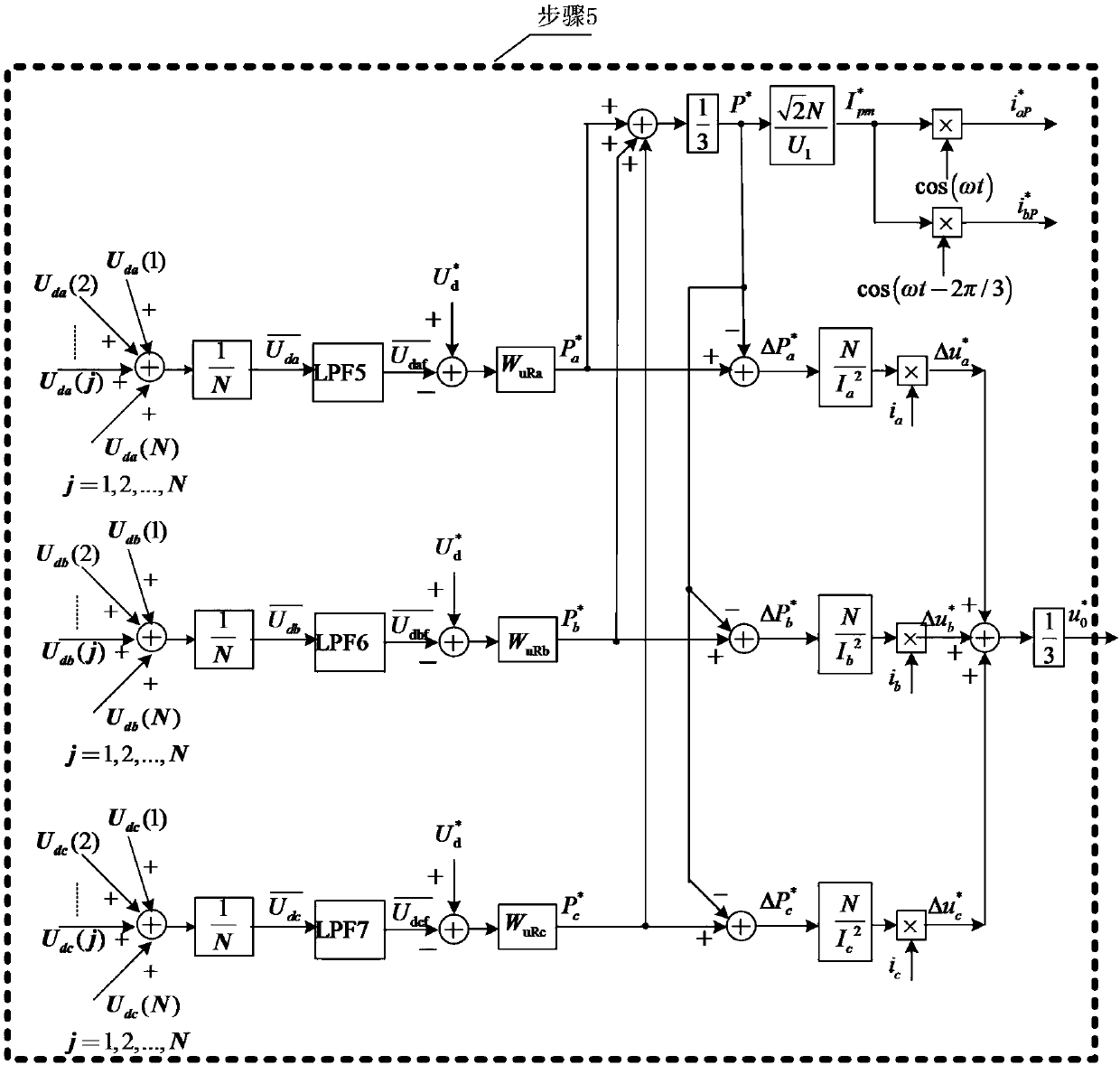

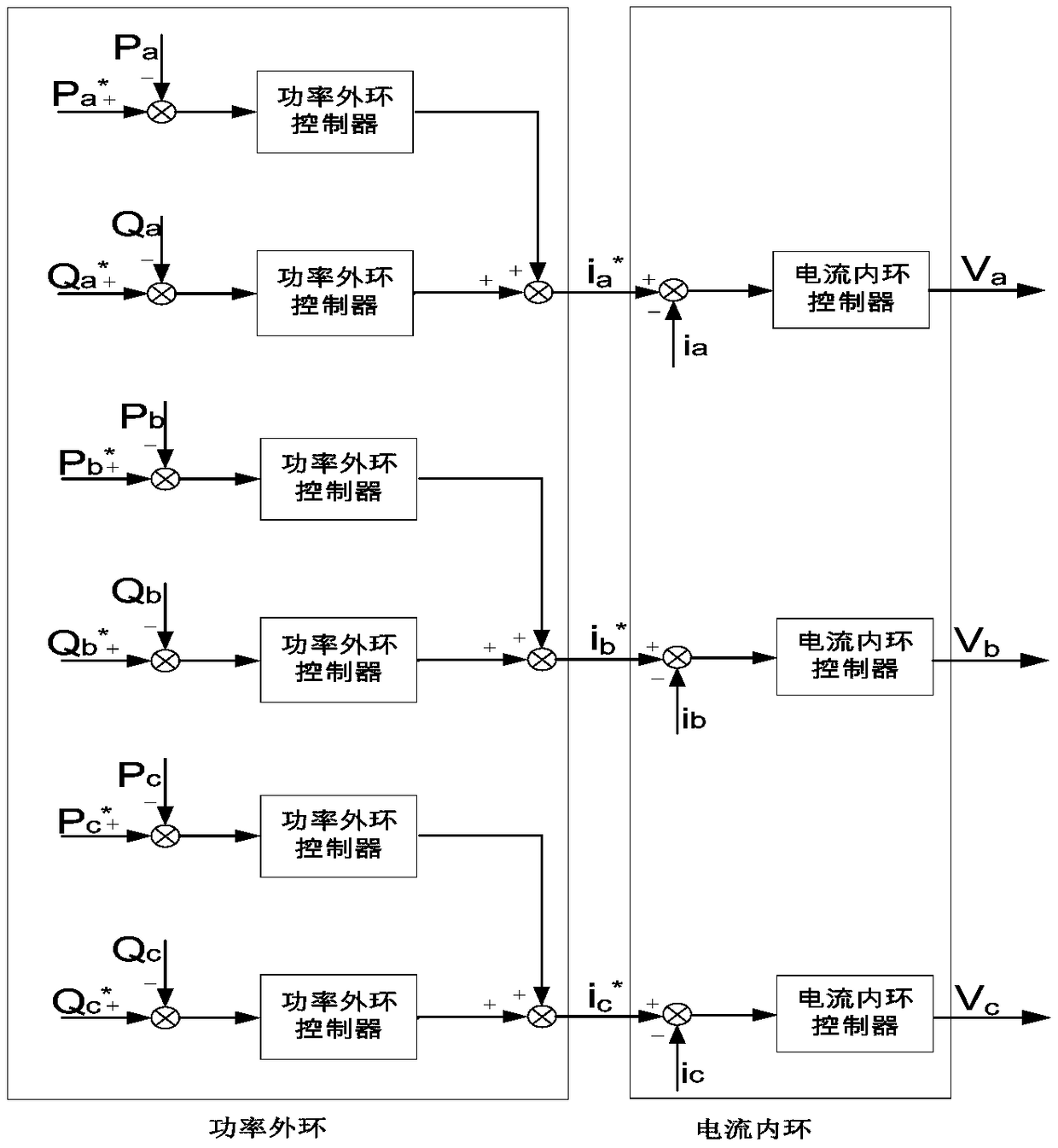

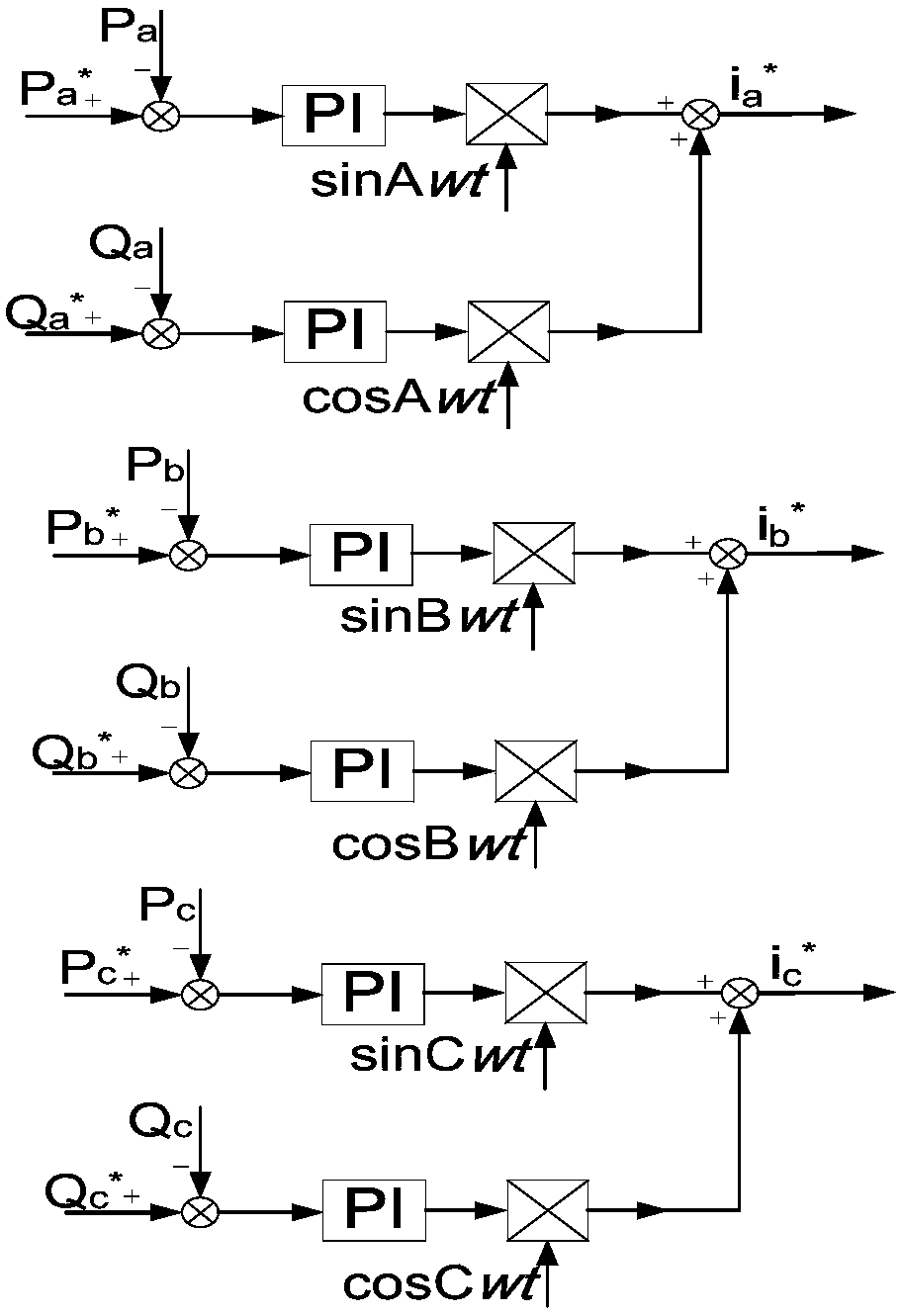

Chain type converter-based power distribution network electric energy quality comprehensive control method and system

ActiveCN107069725AImprove current control accuracyIncrease profitPolyphase network asymmetry elimination/reductionReactive power adjustment/elimination/compensationCapacitancePower quality

The present invention relates to a chain type converter-based power distribution network electric energy quality comprehensive control method and system. The method includes a system-level control strategy and a device-level control strategy, wherein the system-level control strategy realizes load reactive power, harmonic and unbalanced current detection, power distribution network PCC fundamental wave positive sequence voltage control, and power distribution network PCC fundamental wave negative sequence voltage control, and comprehensively generates chain type converter current control instruction signals, and the device-level control strategy realizes sub-module direct-current side capacitor voltage control of chain type converter control, realizes three-phase conversion chain current control of a chain type converter according to a current control instruction from the system level, and generates chain type converter switching tube duty cycle signals. With the method and system provided by the technical scheme provided by the invention adopted, electric energy quality problems such as harmonic, flicker and imbalance in a power distribution network can be comprehensively controlled.

Owner:CHINA EPRI SCIENCE & TECHNOLOGY CO LTD +4

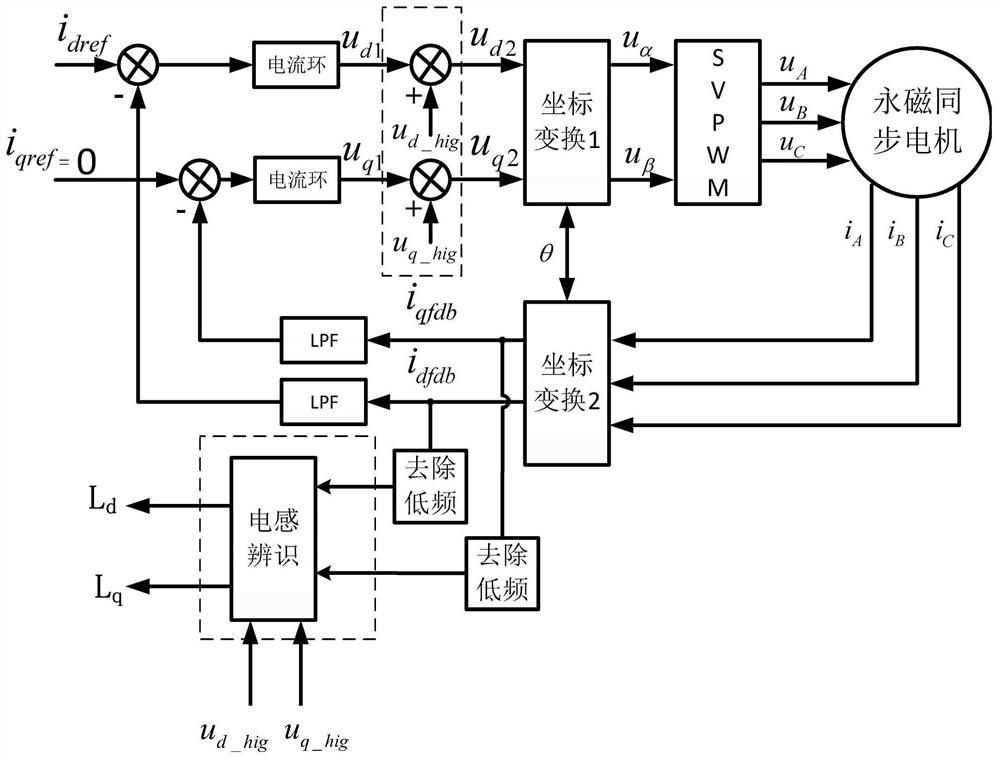

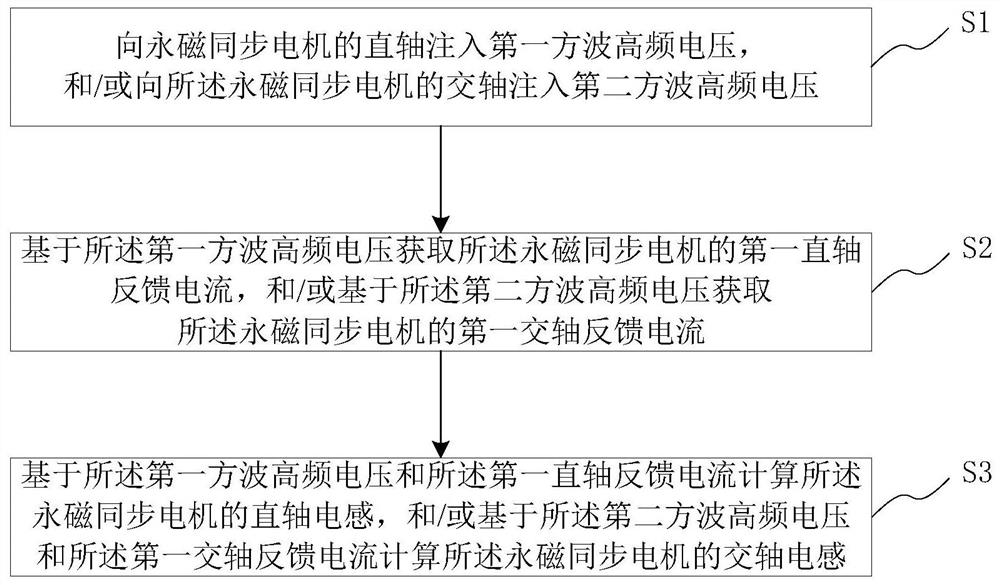

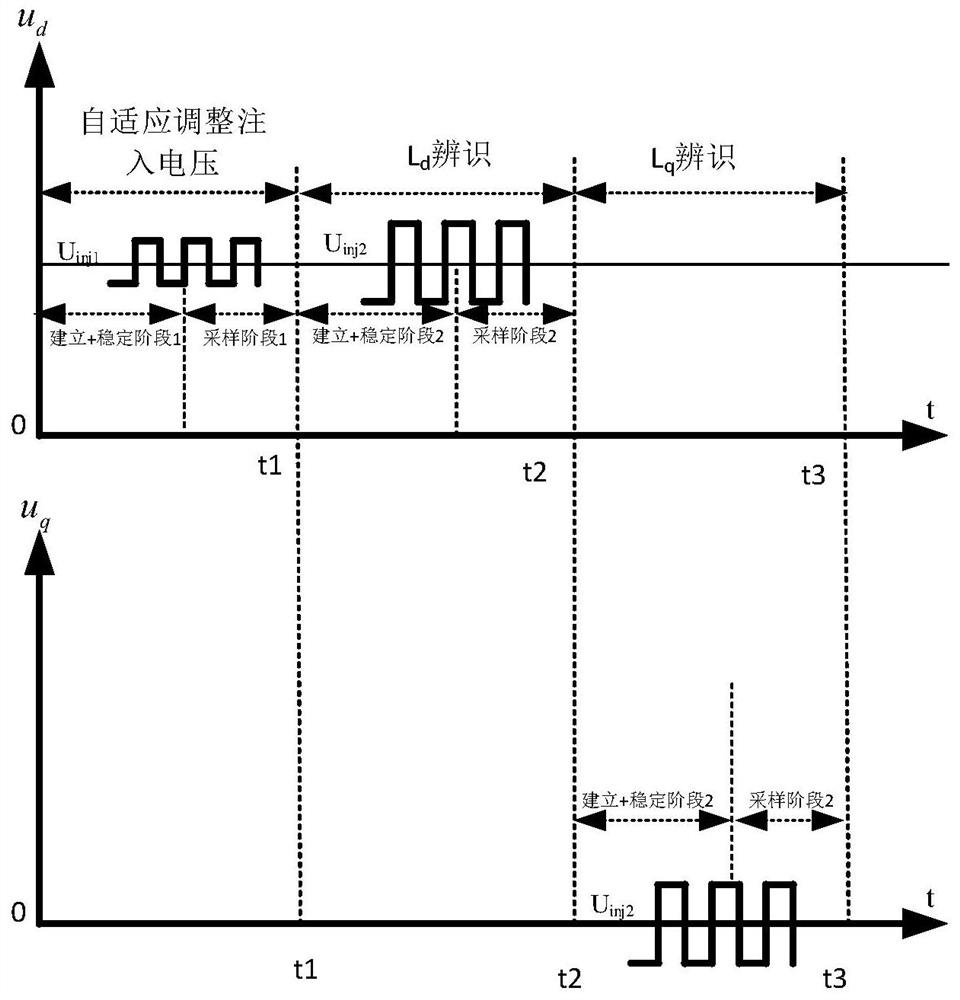

Inductance identification method and system of permanent magnet synchronous motor, medium and terminal

PendingCN113691183AImprove accuracy and reliabilityThe proportion is reducedElectronic commutation motor controlAC motor controlElectrical resistance and conductancePermanent magnet synchronous motor

The invention provides an inductance identification method and system of a permanent magnet synchronous motor, a medium and a terminal. The method comprises the following steps: injecting a first square-wave high-frequency voltage to a direct axis of the permanent magnet synchronous motor, and / or injecting a second square-wave high-frequency voltage to a quadrature axis of the permanent magnet synchronous motor; acquiring a first direct-axis feedback current based on the first square-wave high-frequency voltage, and / or acquiring a first quadrature-axis feedback current based on the second square-wave high-frequency voltage; and calculating the direct-axis inductance of the permanent magnet synchronous motor based on the first square wave high-frequency voltage and the first direct-axis feedback current, and / or calculating the quadrature-axis inductance of the permanent magnet synchronous motor based on the second square wave high-frequency voltage and the first quadrature-axis feedback current. The square-wave high-frequency voltage is injected into the direct axis and / or the quadrature axis of the permanent magnet synchronous motor, the injection frequency can reach the kilohertz level and even the switching frequency, the equivalent inductive reactance is large, the component occupied by the resistor is greatly reduced, the influence of the resistor can be further ignored, and then the accuracy and reliability of inductance identification of the permanent magnet synchronous motor are improved.

Owner:RUKING EMERSON CLIMATE TECH SHANGHAI CO LTD

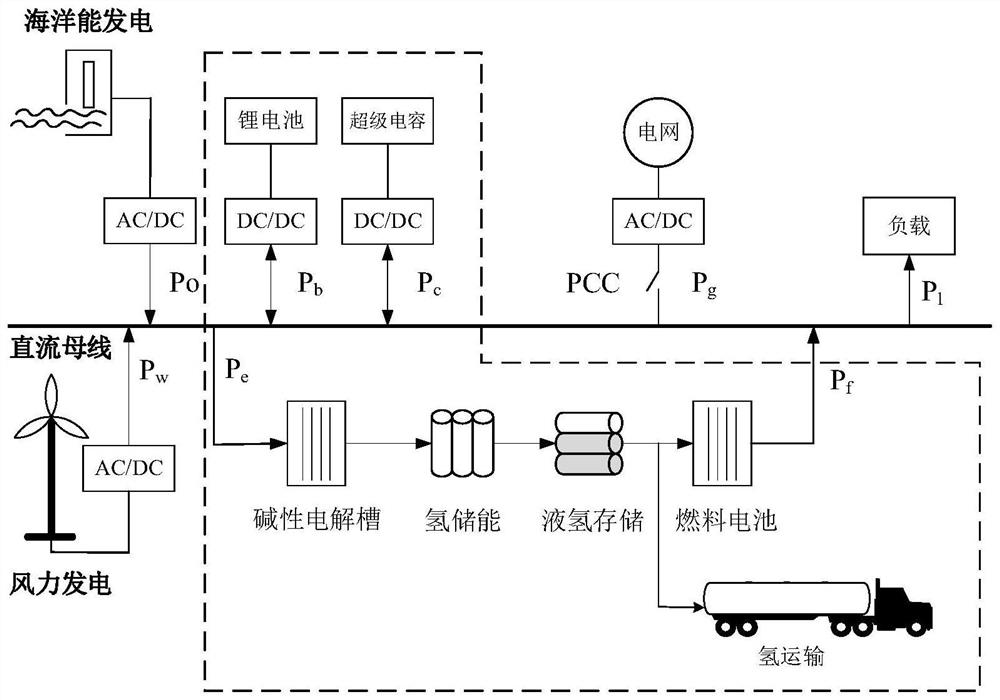

Fractional order model predictive control method for power of electricity-hydrogen hybrid energy storage system

InactiveCN114709866AImprove current control accuracyGuaranteed dynamic responsivenessDc network circuit arrangementsBatteries circuit arrangementsLoop controlCapacitor voltage

The invention discloses a fractional order model prediction control method for the power of an electricity-hydrogen hybrid energy storage system, and the method comprises the eight steps: respectively giving equivalent circuit diagrams when a switching tube is switched on and switched off in two working modes of a BOOST circuit and a BUCK circuit, and monitoring an inductive current change process and a capacitor voltage change process. A fractional order calculus algorithm and model prediction control are combined for power control of an electricity-hydrogen combined hybrid energy storage system and device, a fractional order type voltage and current prediction model is obtained, double-loop control is adopted, the switching state of an energy storage converter is selected through prediction output, the output current of the converter relative to a bus is accurately controlled, and the energy storage efficiency is improved. The power fluctuation of distributed power generation is stabilized more finely, and the defects that the response speed of current common double-loop PI control is low, deviation possibly occurs during prediction of existing integer order model prediction control, and the current control precision is low are overcome.

Owner:SHENZHEN JINGQUANHUA ELECTRONICS

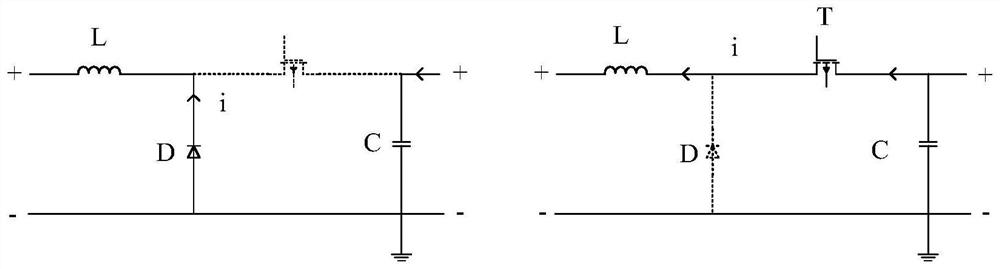

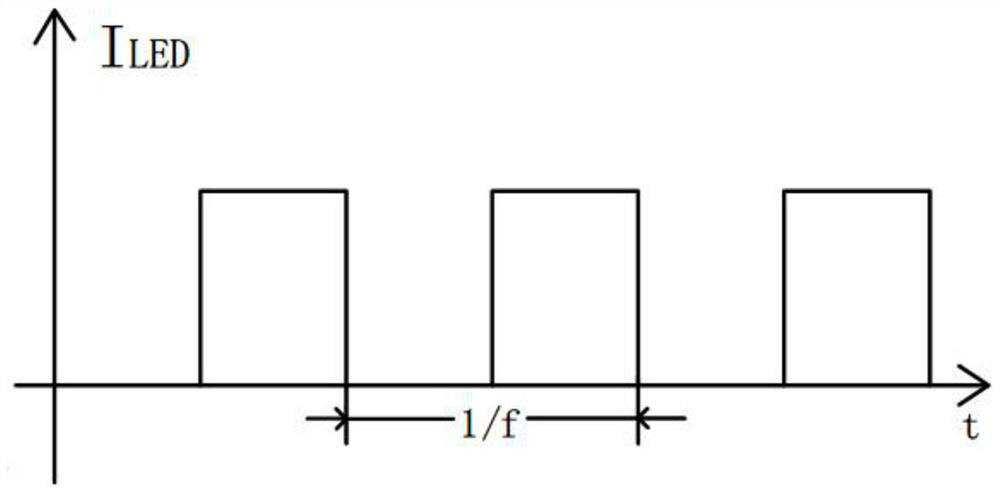

Impulse type linear constant current drive LED circuit

ActiveCN103917025AImprove efficiencySolve the problem of overheatingElectric light circuit arrangementVoltage dropControl circuit

The invention discloses an impulse type linear constant current drive LED circuit and relates to the technical field of LEDs. A half-wave sine wave signal is formed by a bridge rectifier circuit under the control of an alternating-current voltage; a linear constant-current circuit is connected between a positive electrode of the bridge rectifier circuit and a negative electrode of the bridge rectifier circuit and used for outputting constant current according to the half-wave sine wave signal; an LED circuit is connected between an output end of the linear constant-current circuit and the negative electrode of the bridge rectifier circuit; an impulse control circuit is connected with the bridge rectifier circuit and the linear constant-current circuit and used for forming an impulse voltage signal according to the half-wave sine wave signal and outputting the impulse voltage signal to the LED circuit. The LED circuit will be opened when alternating-current sine voltage increases to be higher than the forwarding voltage of the LED circuit and will be closed when the alternating-current sine voltage drops to be approximate to the forwarding voltage of the LED circuit, loss of the part by which sine voltage is higher than the forwarding voltage of the LED circuit is avoided, efficiency of the linear constant-current circuit is improved, the temperature of a power supply is prevented from being too high, and the impulse type linear constant current drive LED circuit has the advantages that the number of devices is small and the circuit is simple.

Owner:吴光敏

Driving circuit for plant illumination

In order to solve the technical problem that an existing driving scheme cannot work normally in a high-frequency chopping occasion or cannot obtain high-precision LED current, the invention provides adriving circuit for plant illumination. The driving circuit comprises a constant voltage source and an adjustable circuit, and the first end of the constant voltage source is used for being connectedwith the first end of a load. The adjustable circuit comprises: an adjustable voltage source, wherein the first end of the adjustable voltage source is connected with the second end of the constant voltage source; a chopper switch, wherein the first end of the chopper switch is connected with the second end of the adjustable voltage source, and the second end of the chopper switch is used for being connected with the second end of the load; and a control circuit, wherein the first end of the control circuit is used for being connected with the first end of the load, the second end of the control circuit is connected with the third end of the chopper switch, the third end of the control circuit is connected with the third end of the adjustable voltage source, and the control circuit is used for controlling the chopper switch and controlling the voltage of the adjustable voltage source according to a load current signal in order to match the sum of the voltage of the adjustable voltagesource and the voltage of the constant voltage source with a target voltage.

Owner:4D BIOS INC

Microgrid energy storage PCS control system and method

ActiveCN109378847AImprove current control accuracySolve instabilityAc network load balancingMicrogridEngineering

The invention discloses a microgrid energy storage PCS control system and method. An input end of a three-phase bridge inverter circuit is connected to a storage battery through a direct current EMI filter circuit, and an output end is connected to a three-phase power grid through an LCL filter circuit; a current sensors and a voltage sensor are separately disposed on a three phase line of the output end of the three-phase bridge inverter circuit, and output ends of current transformers and the voltage sensor are separately connected to a control module; the control module receives an externalthree-phase command signal, and according to the received command signals corresponding to each of phases, and a voltage or a current feedback value input by a corresponding phase voltage sensor andcurrent sensor, turn-on or turn-off of each of switching devices in the three-phase bridge inverter circuit is controlled. The control module of the system and the method can achieve phase splitting control of microgrid energy storage, and the power control precision can be improved.

Owner:NANJING GUODIAN NANZI POWER GRID AUTOMATION CO LTD

Driving circuit and method for powering light emitting diode light source, power converter

InactiveCN103517506BReduce line frequency interferenceCorrected power factorElectrical apparatusElectroluminescent light sourcesDriver circuitTransformer

The invention provides a driving circuit, a method and a power converter for powering a light emitting diode light source. The driving circuit includes: a voltage filter, a transformer and a controller. The voltage filter receives and filters the input voltage to provide a stable voltage; the transformer converts the stable voltage into an output voltage to supply power to the light source; the controller generates a driving signal to make the switch work alternately in the first state and the second state, and the controller controls the the duration of the first state and the duration of the second state such that the input current decreases to a preset value in the second state and increases from the preset value to a peak value proportional to the input voltage in the first state, The controller controls the ratio between the duration of the first state and the duration of the second state to adjust the output current flowing through the light source to a target value. The invention improves the current control accuracy, corrects the power factor of the driving circuit, improves the power supply quality, and reduces the horizontal frequency interference of the light source.

Owner:AOTU ELECTRONICS WUHAN

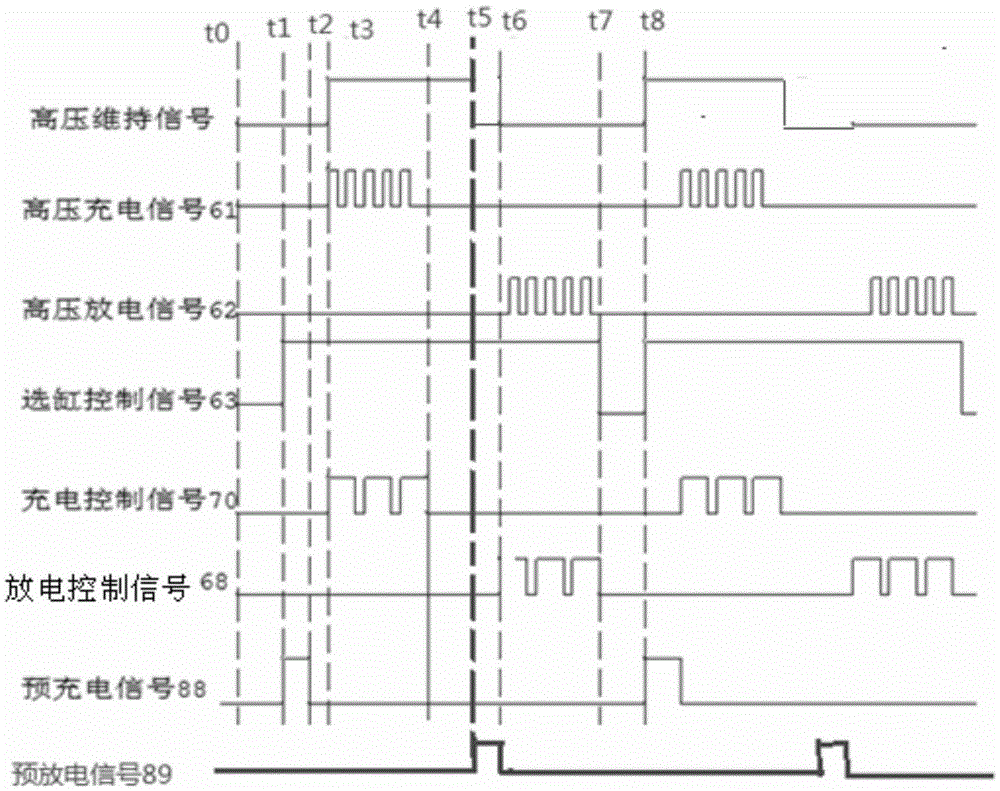

Drive piezo injector unit

ActiveCN104037880BCompact structureImprove stabilityBatteries circuit arrangementsElectric powerCapacitanceOvervoltage

The invention relates to a driving piezoelectric injector device. A current feedback module monitors the current of a piezoelectric actuator in charging and discharging; a voltage feedback module monitors the voltage of the piezoelectric actuator in charging and is capable of regulating and controlling the high charging voltage and the discharging voltage of the piezoelectric actuator; an actuator medium consumption feedback control circuit regulates a charging threshold voltage; a capacitance gating compensation circuit compensates the capacitance of the piezoelectric actuator to prevent the medium consumption of the piezoelectric actuator influencing the work of the injector; an energy recycling circuit module recycles voltage from the voltage of the piezoelectric actuator and the transient high-voltage electric potential of an oil pump and is capable of pre-charging the piezoelectric actuator. The driving piezoelectric injector device is compact in structure, high in current control precision and capable of lowering the system consumption and improving the working stability and reliability of the injector under a complex working condition.

Owner:CHINA FAW LIMITED WUXI FUEL INJECTIONEQUIP RES INST +1

High Power Linear Electromagnetic Acceleration System

ActiveCN108418386BMany turns in seriesSmall number of turns in seriesAc-dc conversionPropulsion systemsFault toleranceElectric machine

The invention relates to a high-power linear electromagnetic acceleration system and belongs to the field of motors. The driving system of a conventional high-power linear electromagnetic accelerationsystem has a great difficulty in dynamic current-sharing control and does not have a fault-tolerant function. The high-power linear electromagnetic acceleration system is characterized in that coilsin a primary starting region has a large number of series turns, a coil driver has a small output current, a purpose of driving the low-speed section of a linear motor by using a driver with a small current and a high chopping frequency is achieved; coils in a primary terminal region has a small number of series turns and the coil driver has a large output current. When the high-speed section is driven, multiple parallel unit coils are connected in parallel, and each parallel unit coil is driven separately, thereby realizing a purpose of driving a high-power motor in parallel by using small and medium power drivers, avoiding the great difficulty in dynamic current-sharing control caused by parallel connection of multiple power switching devices and achieving the fault tolerance of the driving system.

Owner:HARBIN INST OF TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com