Driving circuit for plant illumination

A driving circuit, plant lighting technology, applied in the direction of electrical components, etc., can solve the problems of unable to work normally, unable to obtain accurate LED current, etc., to achieve the effect of being beneficial to photosynthesis and reducing the difficulty of design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

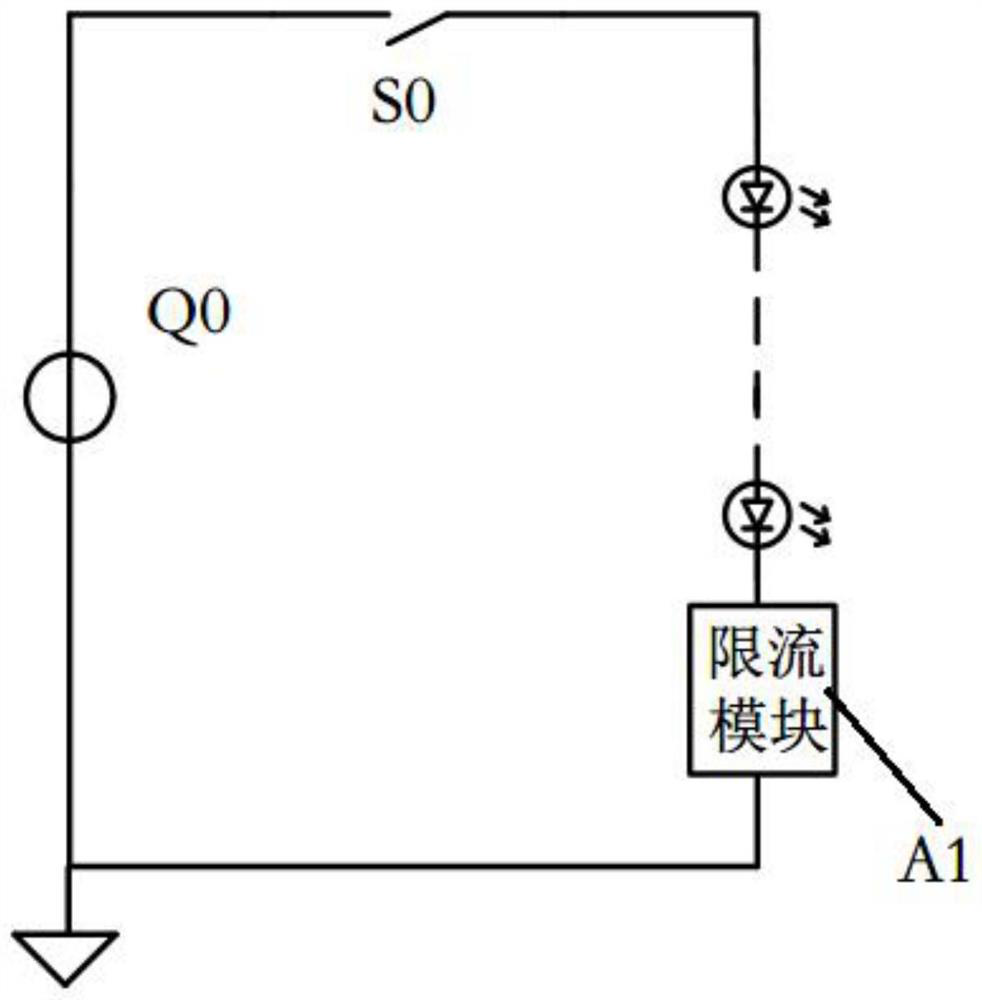

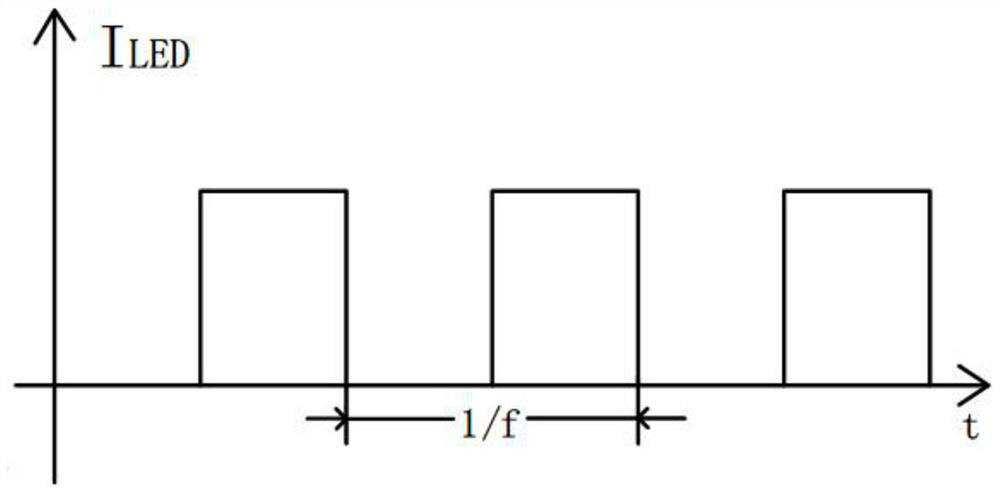

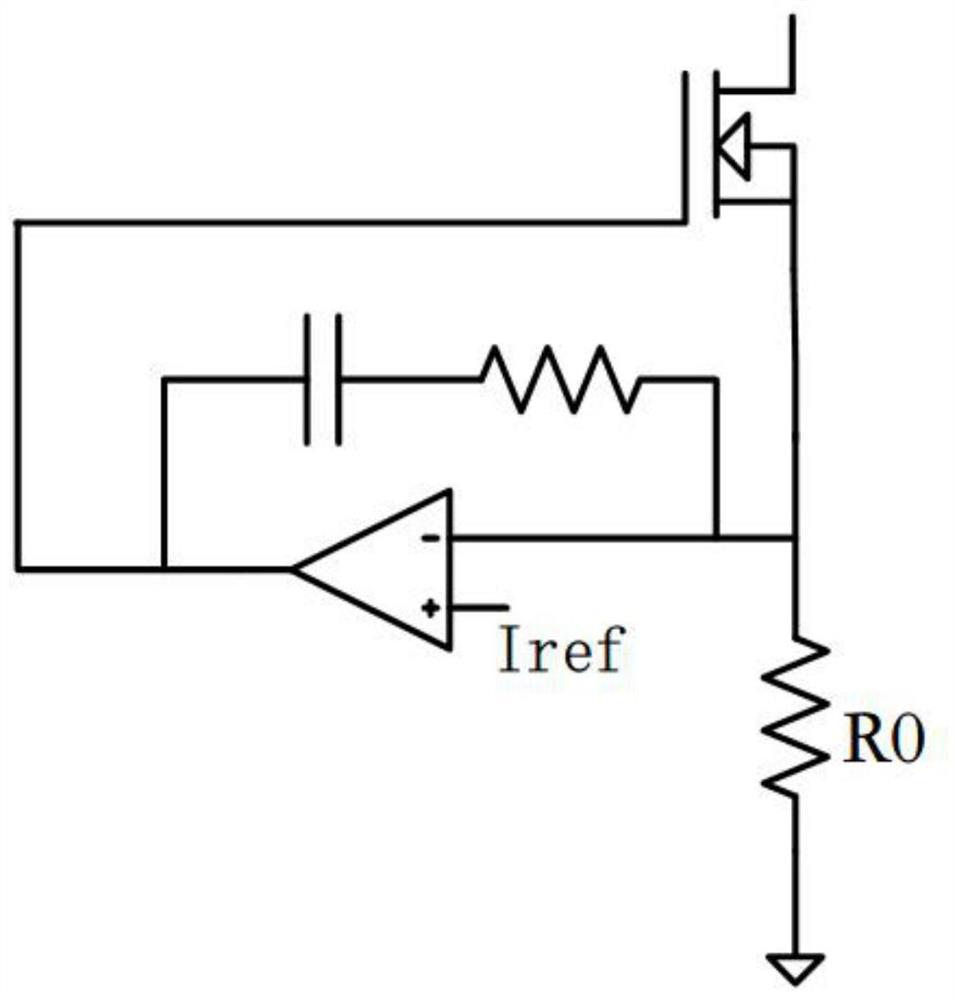

Method used

Image

Examples

Embodiment 2

[0057] In Embodiment 2, the drive circuit for plant lighting may include multiple adjustable circuits, and the multiple adjustable circuits are used to connect multiple groups of loads in one-to-one correspondence. Such as Figure 8 As shown, n adjustable circuits are used to connect n groups of loads one by one. When there are n LED lamp loads, each LED lamp load corresponds to a chopper switch and an adjustable voltage source. Multiple LED loads share A constant voltage source Qs. In the multi-output drive circuit, the voltage of each LED lamp is allowed to be different. Through the voltage adjustment at both ends of the adjustable voltage source in each branch, the voltage difference of the LED lamp of this road is made up, so that the voltage of each LED lamp can be adjusted. The sum of the voltage source and the LED lamp voltage is equal to the parameter voltage of the constant voltage source. Each group of LED loads may include multiple LED lamps connected in series. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com