Patents

Literature

479 results about "Motor model" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

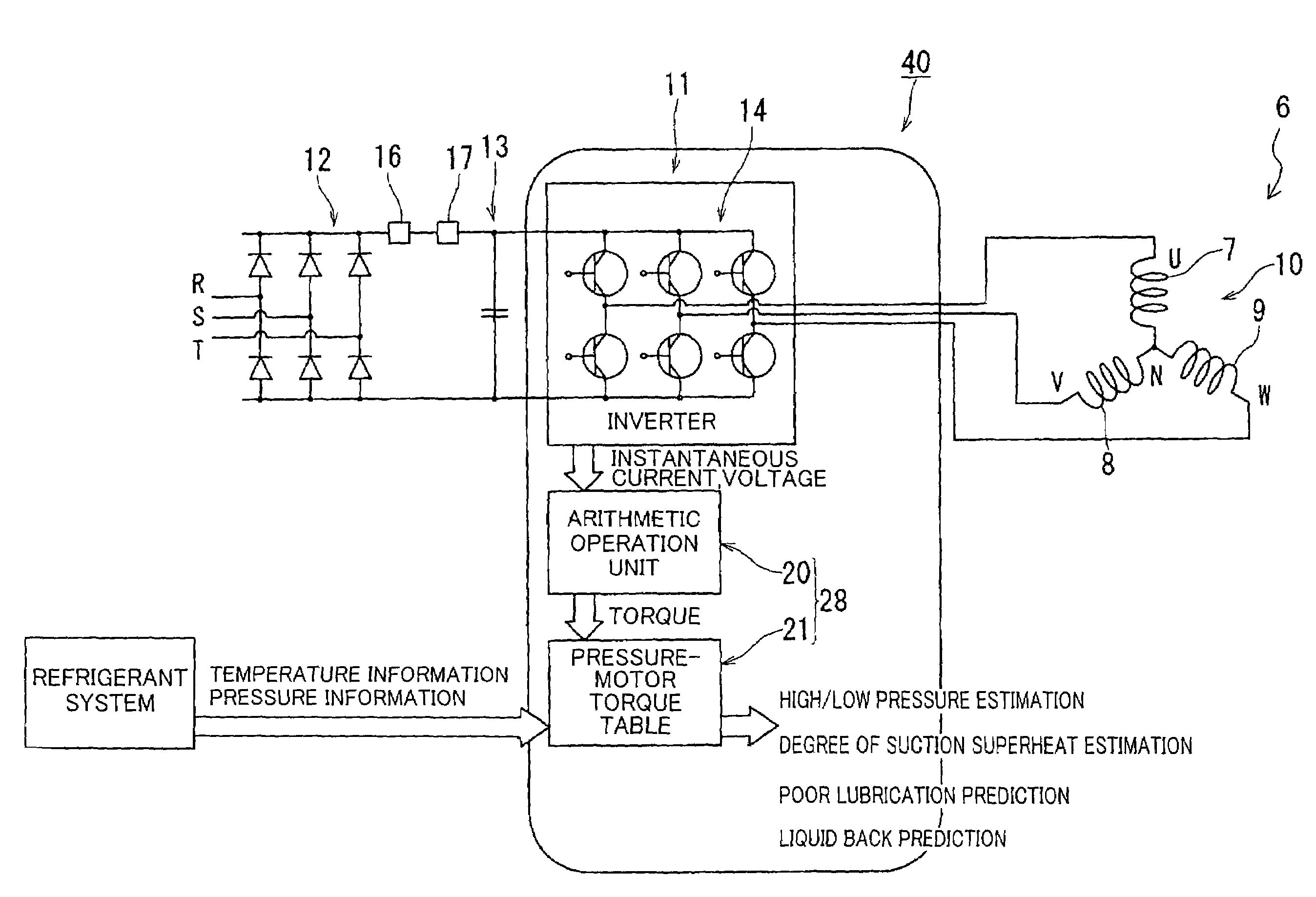

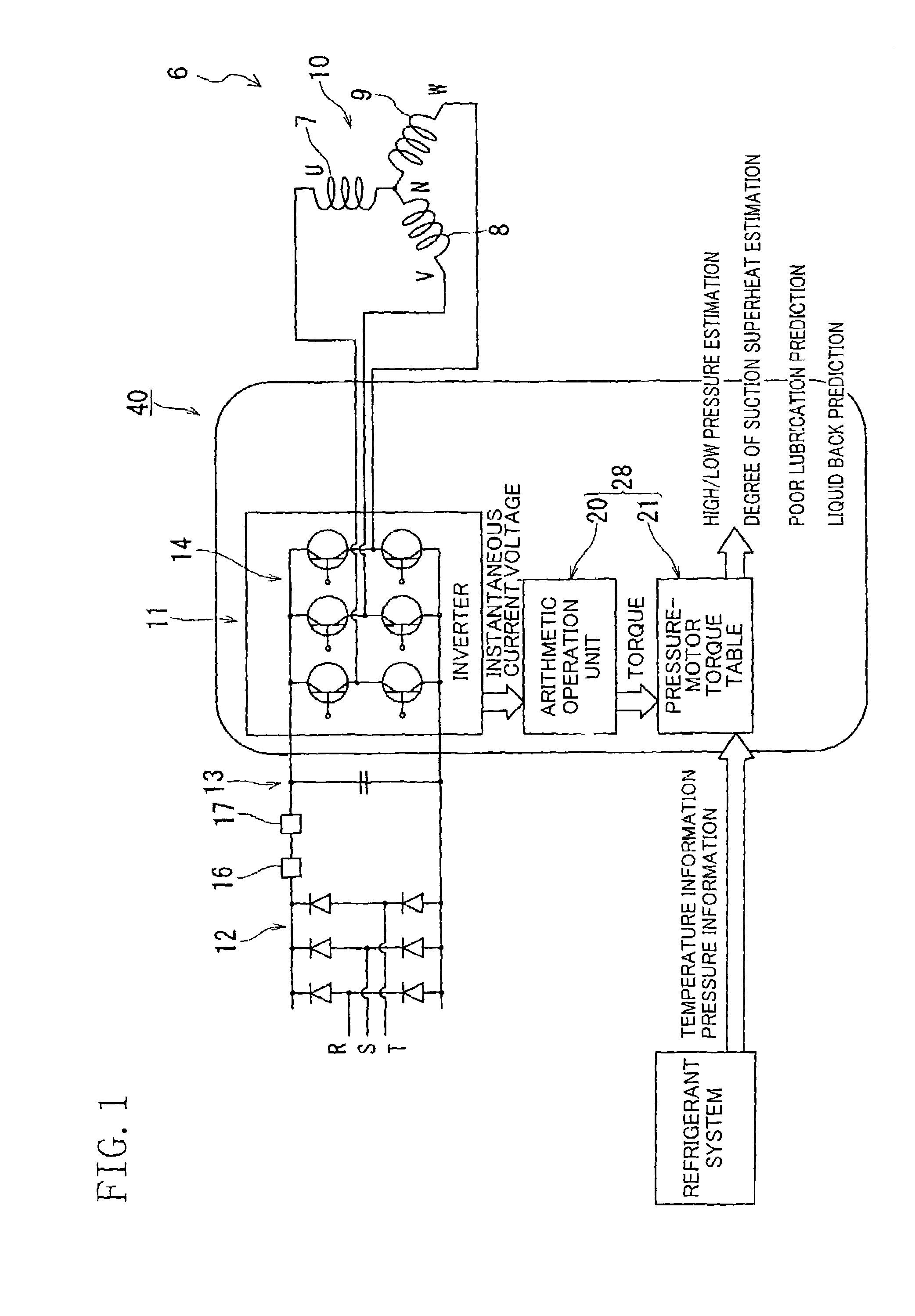

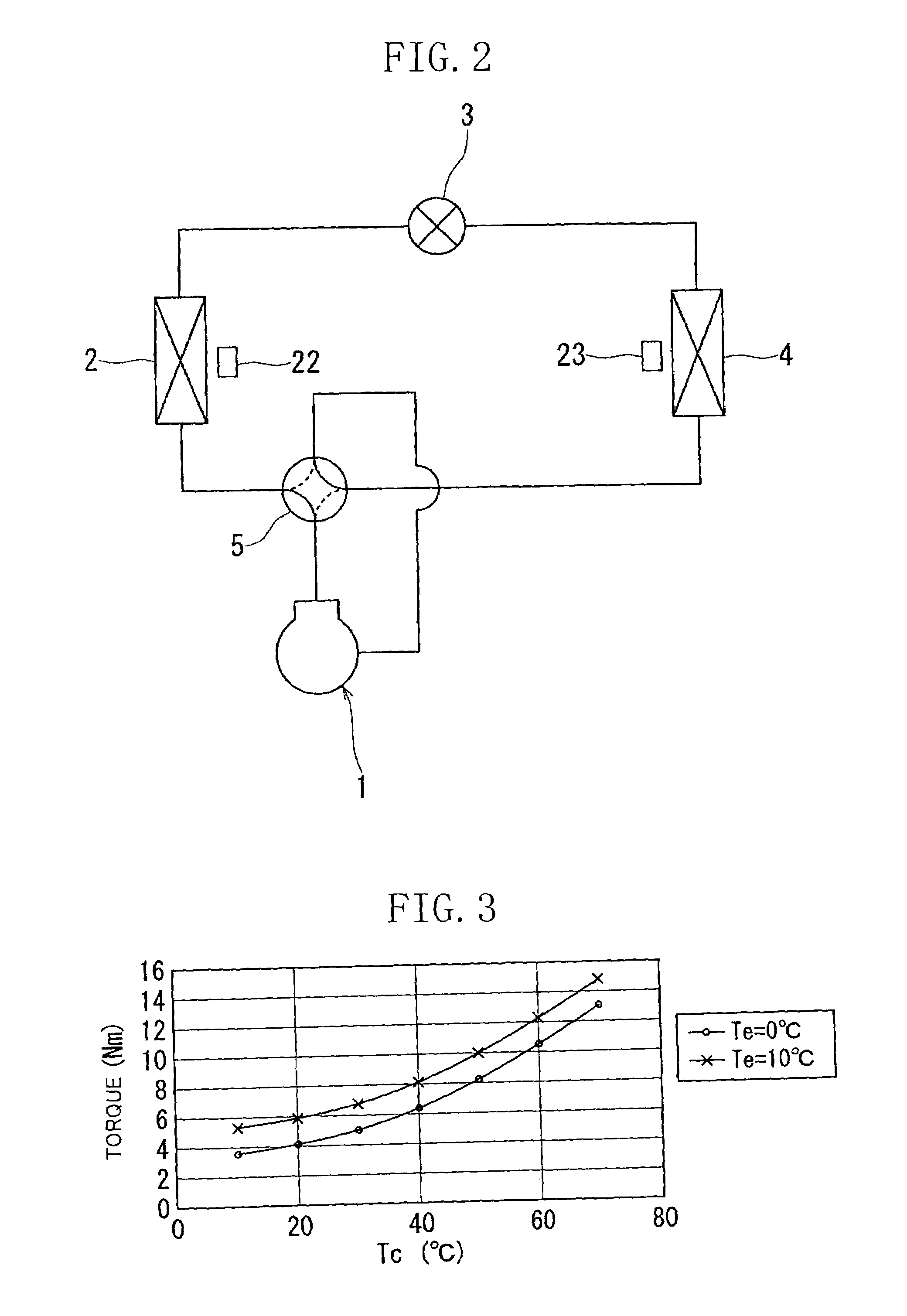

Driver of compressor and refrigerator

ActiveUS20050247073A1Easy to operateOperating frequency of the compressor <b>1Commutation monitoringSpace heating and ventilationPower flowMotor drive

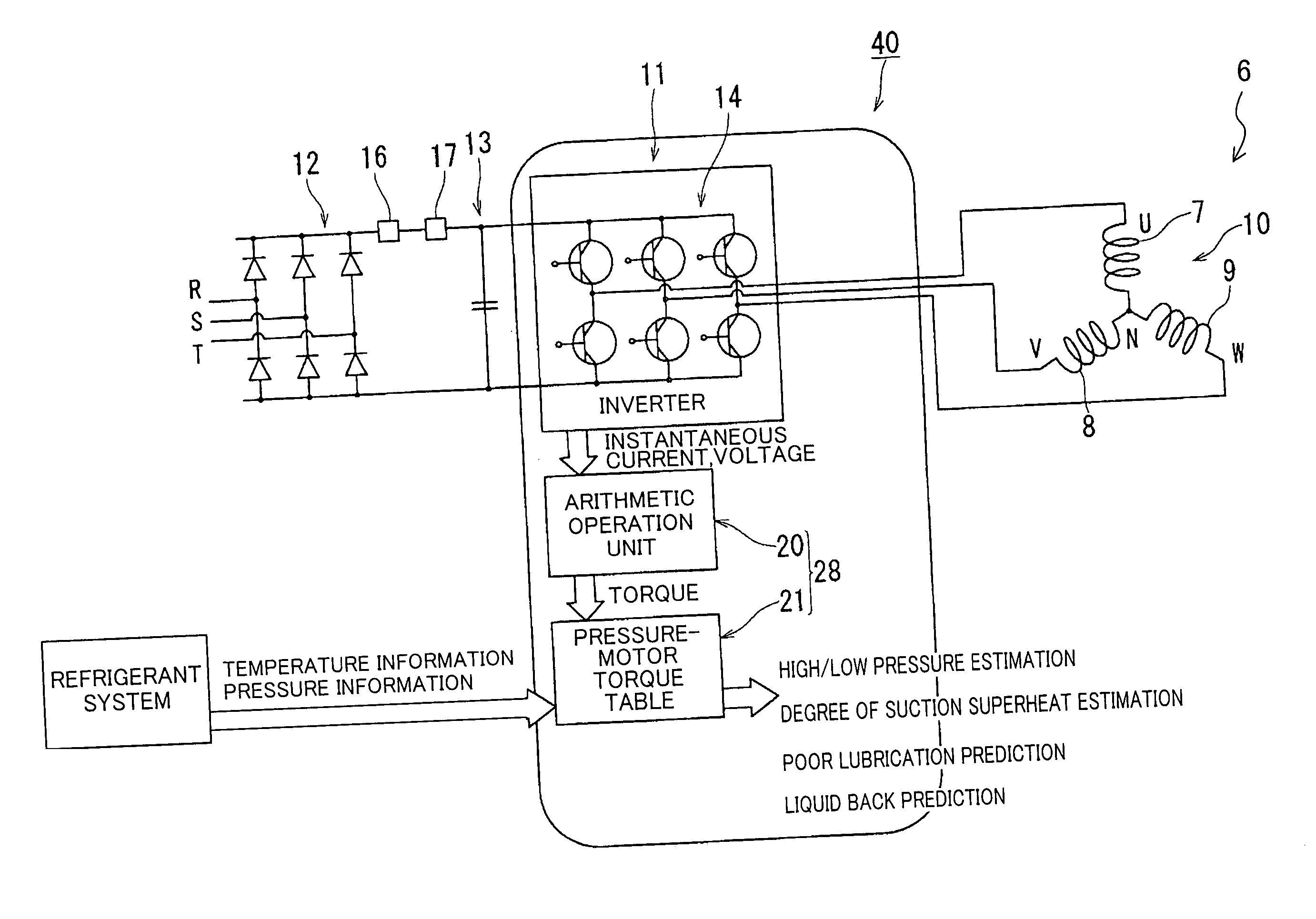

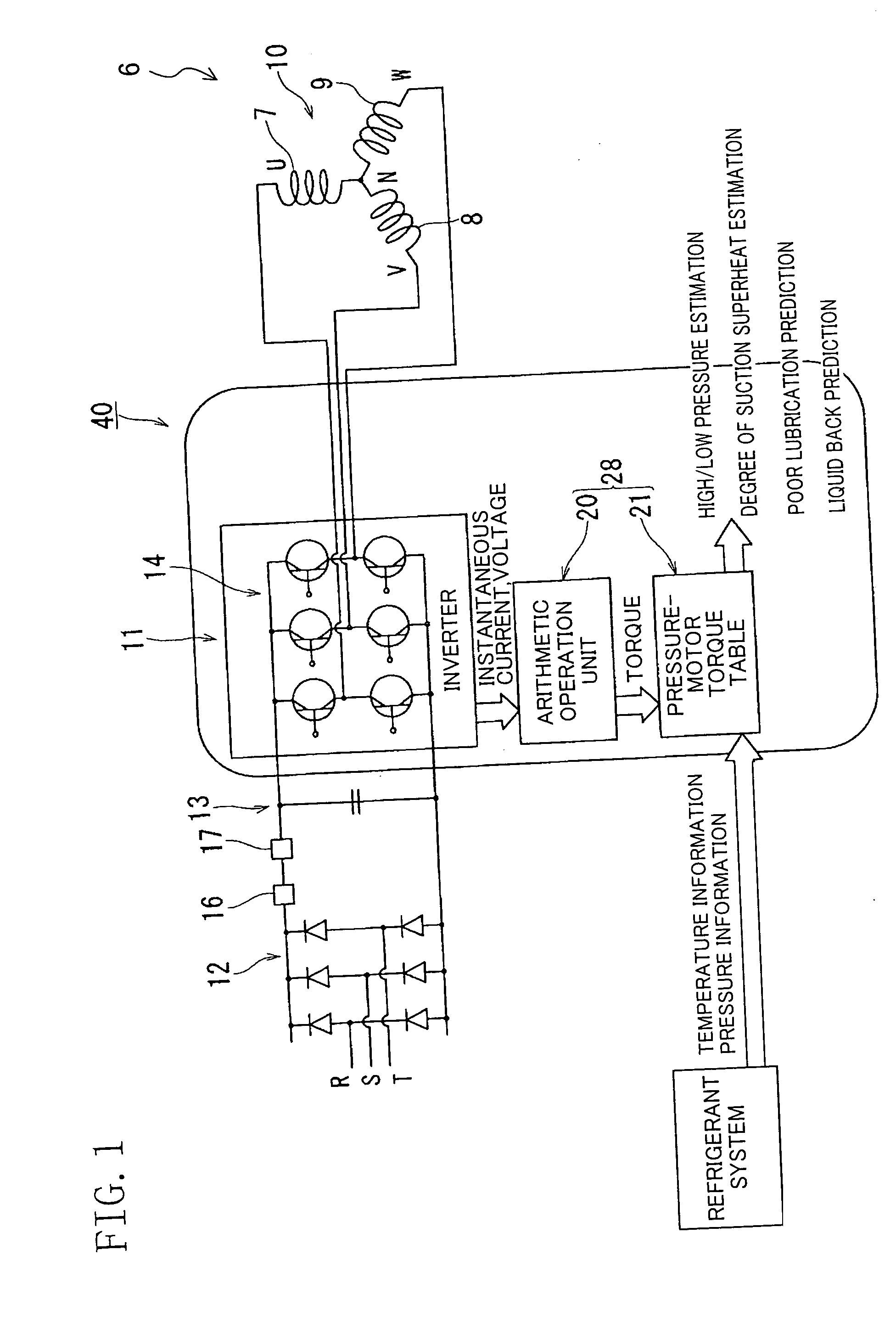

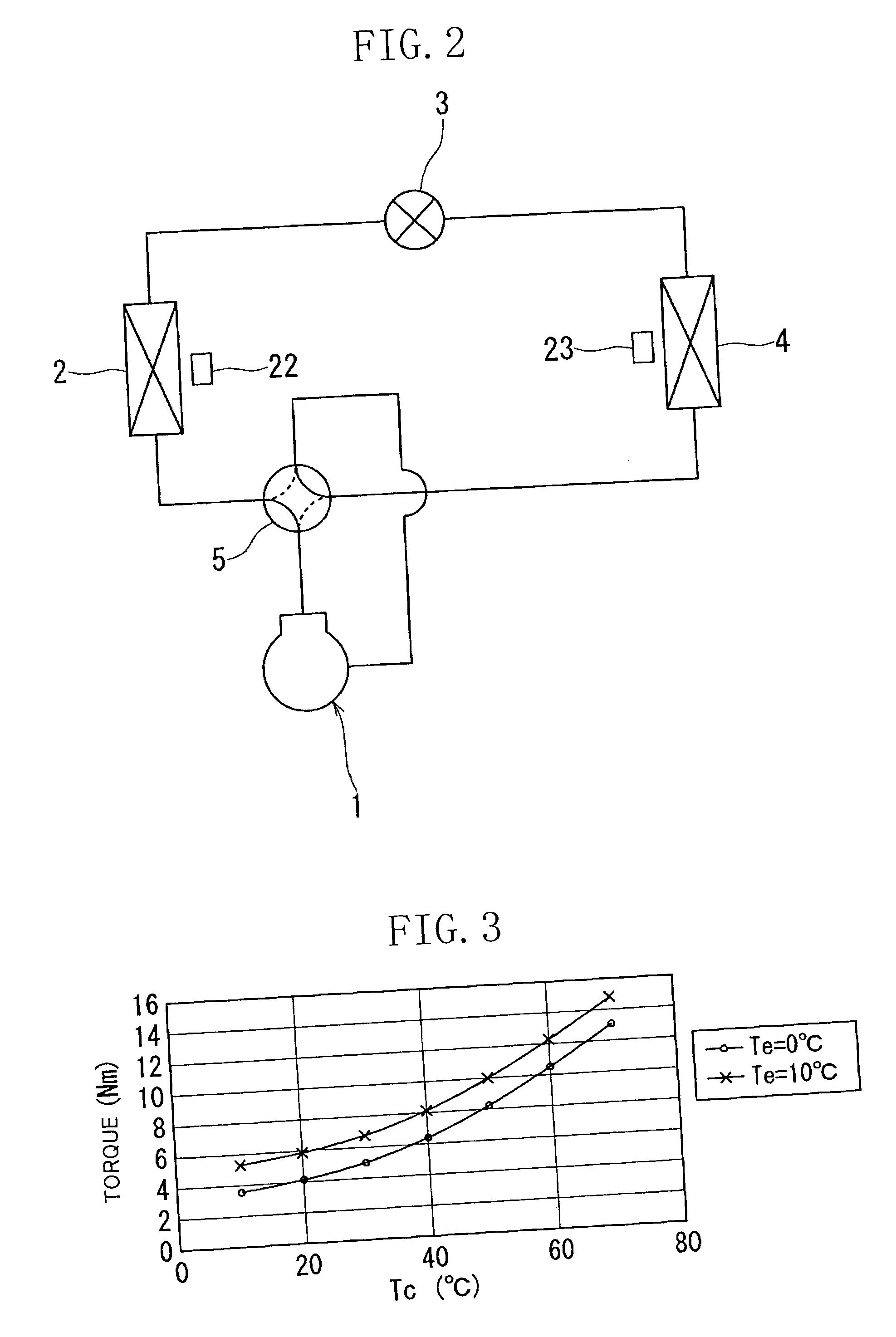

An instantaneous current and instantaneous voltage of a three-phase coil of a brushless DC motor are detected, and the internal condition of a compressor is predicted from these detection values. The prediction about the internal condition of the compressor is made in such a way that motor driving torque which is a parameter of a motor model is identified and poor lubrication, liquid compression or the like is predicted from this identified motor driving torque. This enables it to make, in real time, a failure forecast, failure diagnosis etc. on the compressor.

Owner:DAIKIN IND LTD

Status estimating method for dynamic process of electrical power system

ActiveCN101291061AStable and reliableRealize dynamic monitoringElectrical testingSystems intergating technologiesPower stationLoad model

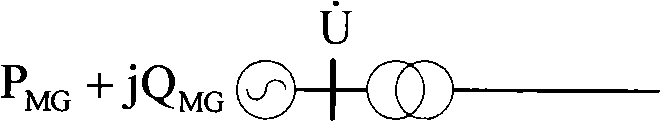

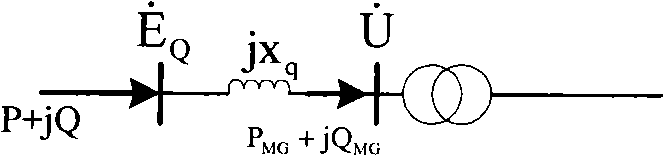

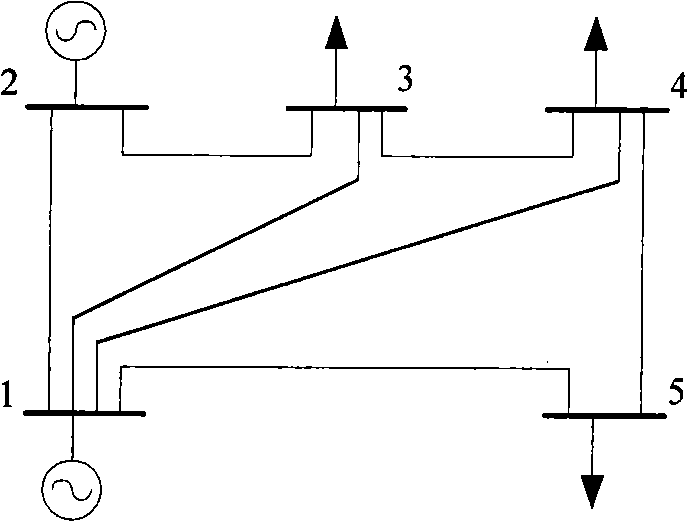

The invention provides a method for estimating a state of dynamic process of a power system. The method takes an estimated result of the static state before the electric grid disturbance as a basic section and introduces a load model and a motor model to perform the equivalent treatment to the electric grid; in the process of the electric grid disturbance, a synchronous phasor measuring unit(PMU) is used to measure and obtain data of a motor, and according to the active power and the reactive power zero injection pseudo-measurement equations of all nodes of the original electric grid, states of all nodes of the electric grid are estimated, and the state of dynamic process of the electric grid is acquired only by the PMU measurement of a power plant. Because the state of the electric grid before disturbance is taken as a basis and only the PMU distribution of the power plant is required, the method effectively resolves the problem of state monitoring under the condition of the electric grid disturbance; on the same disturbance, for continuous PMU measurement sections, PMU measurement data can be directly put in iterative computations, thereby the continuous sections in the process of electric grid disturbance are provided for stable control and analysis; moreover, the method is fast in speed, so that the method meets the requirement for monitoring the dynamic process in real time.

Owner:NR ELECTRIC CO LTD +1

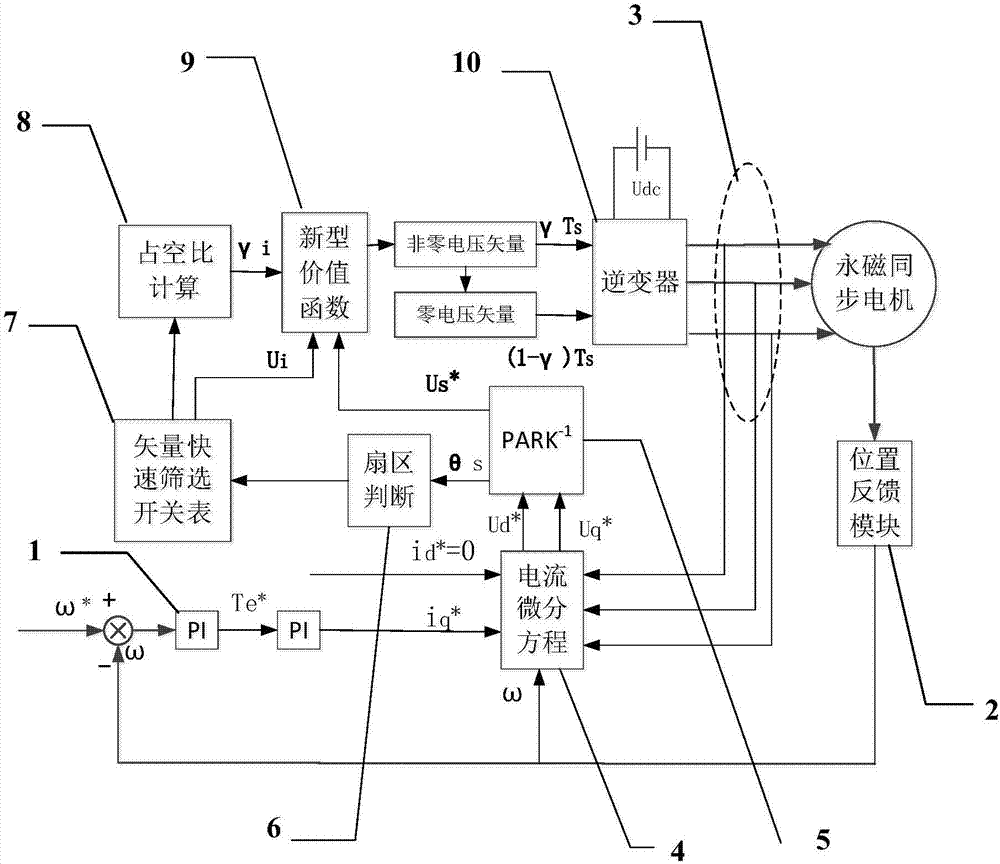

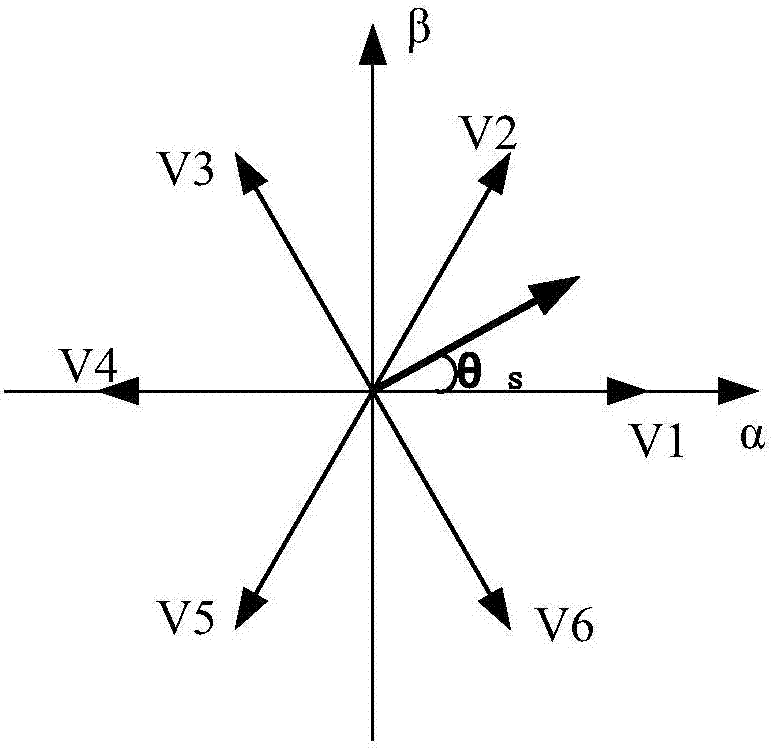

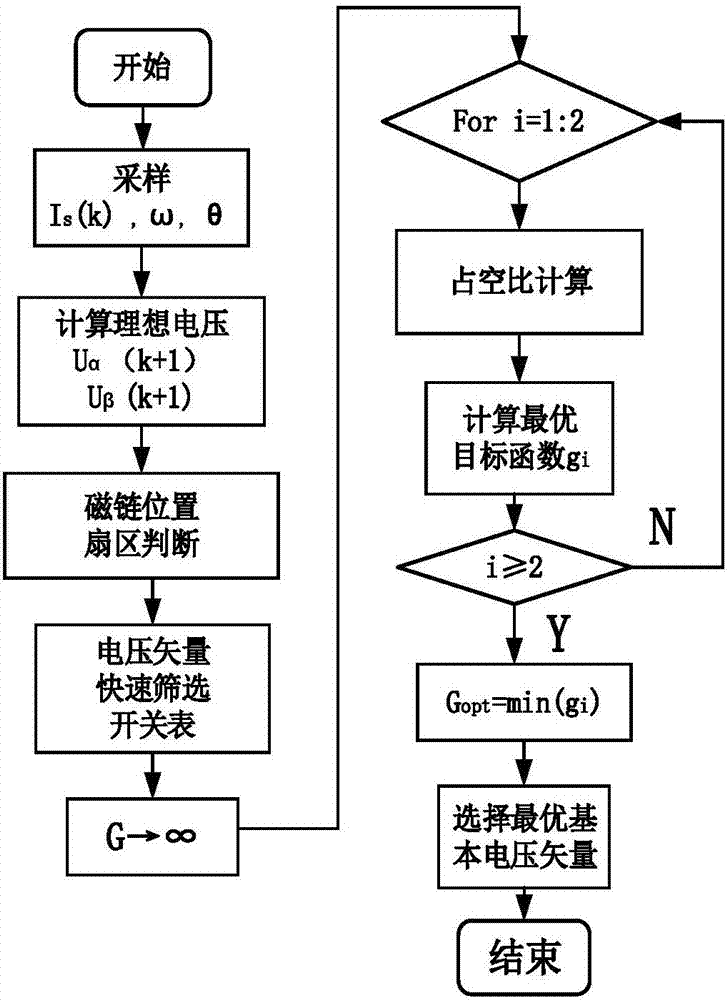

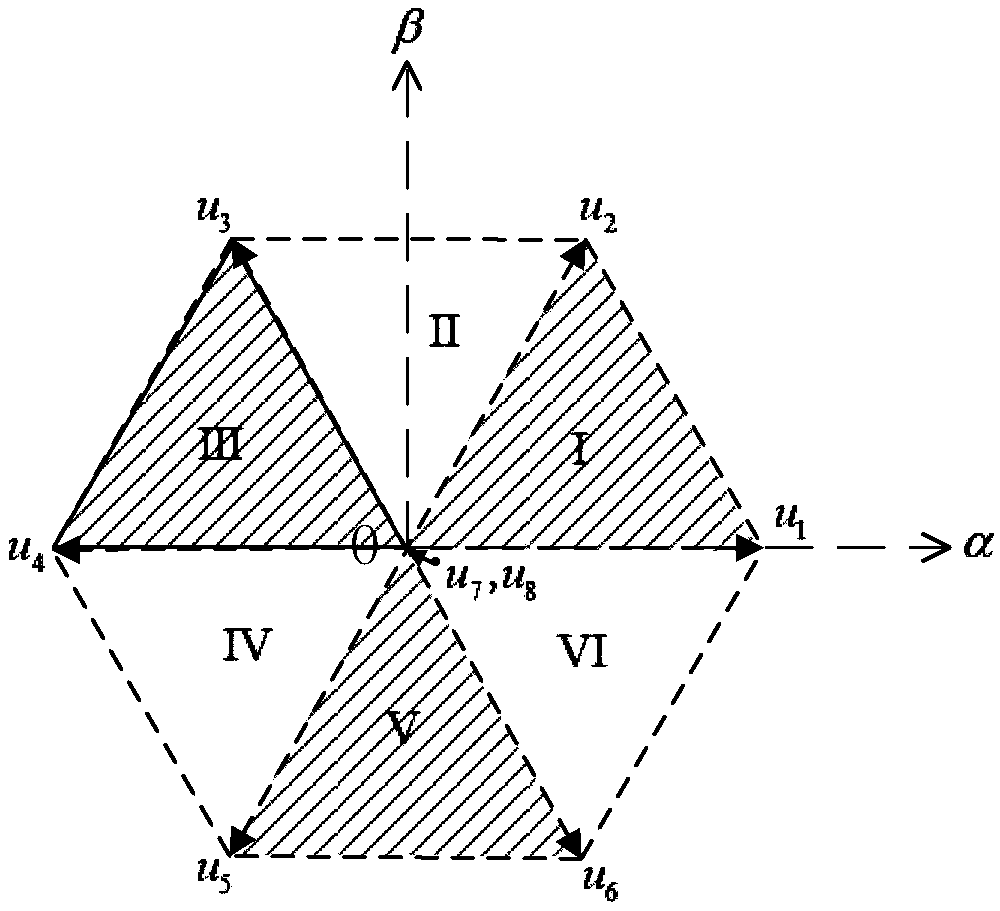

Vector screening and duty cycle combined motor model prediction control system and method

ActiveCN106936356AAvoid control performance impactReduce the burden onTorque ripple controlAC motor controlVoltage vectorPosition angle

The invention discloses a vector screening and duty cycle combined motor model prediction control system and method. The method comprises the steps that a reference voltage vector is acquired according to the idea of no-beat control; the sector of the reference voltage vector is judged through the position angle of the reference voltage vector, and at the same time two effective non-zero voltage vectors are quickly selected; the comparison between the reference voltage vector and two quickly selected effective non-zero voltage vectors is used as a value function; a new value function is provided, and a duty cycle control method is used to calculate the action time of the non-zero voltage vectors; and based on the principle of switching loss minimization, the appropriate zero voltage vector is selected according to the non-zero voltage vectors, and the action time of the zero voltage vector is calculated. The switching state and action time of the non-zero voltage vectors and the switching state and action time of the zero voltage vector are applied on an inverter in turn. The inverter converts the switching state into voltage and outputs the voltage to a permanent magnet synchronous motor to drive a motor to run.

Owner:SOUTHEAST UNIV

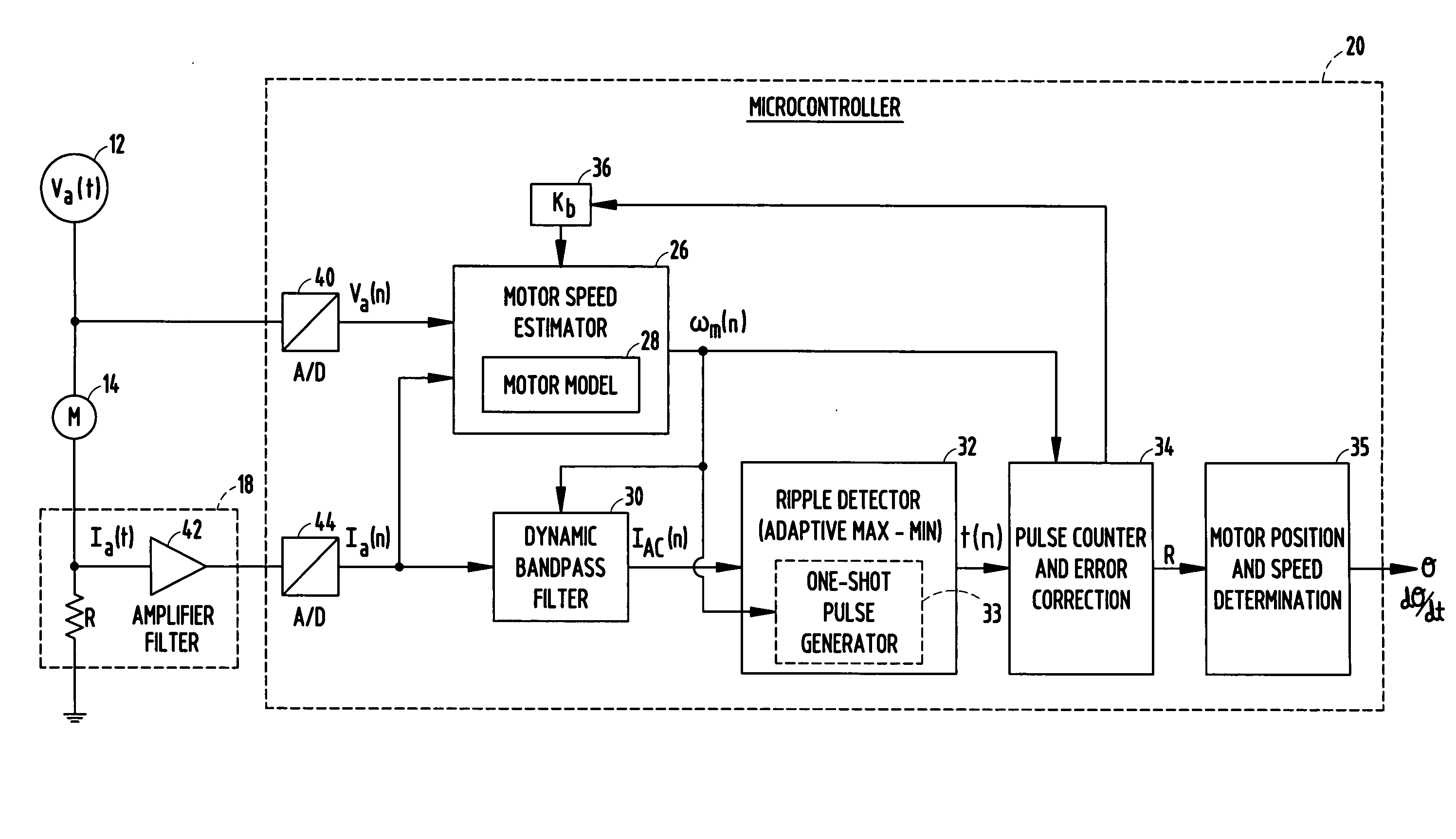

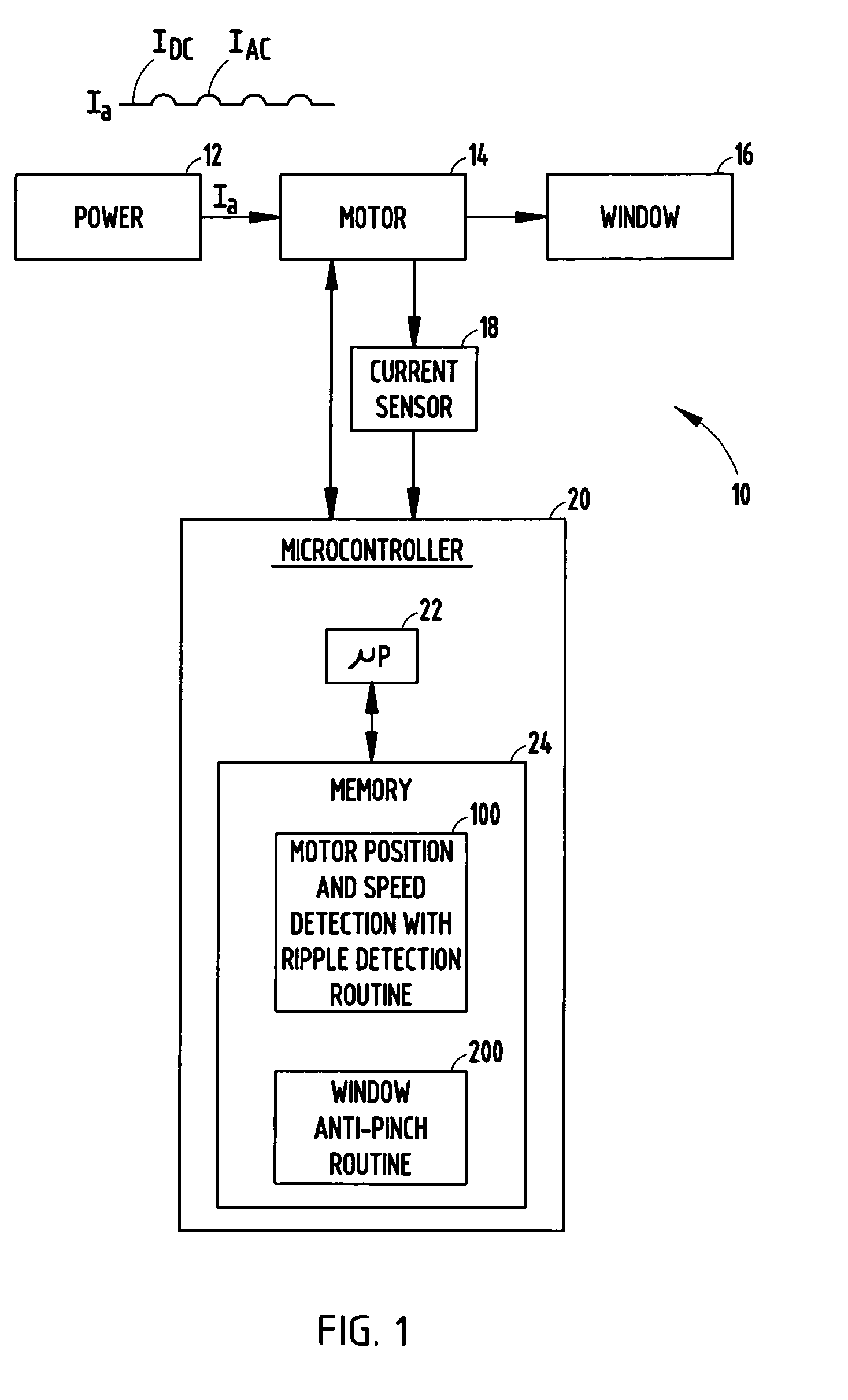

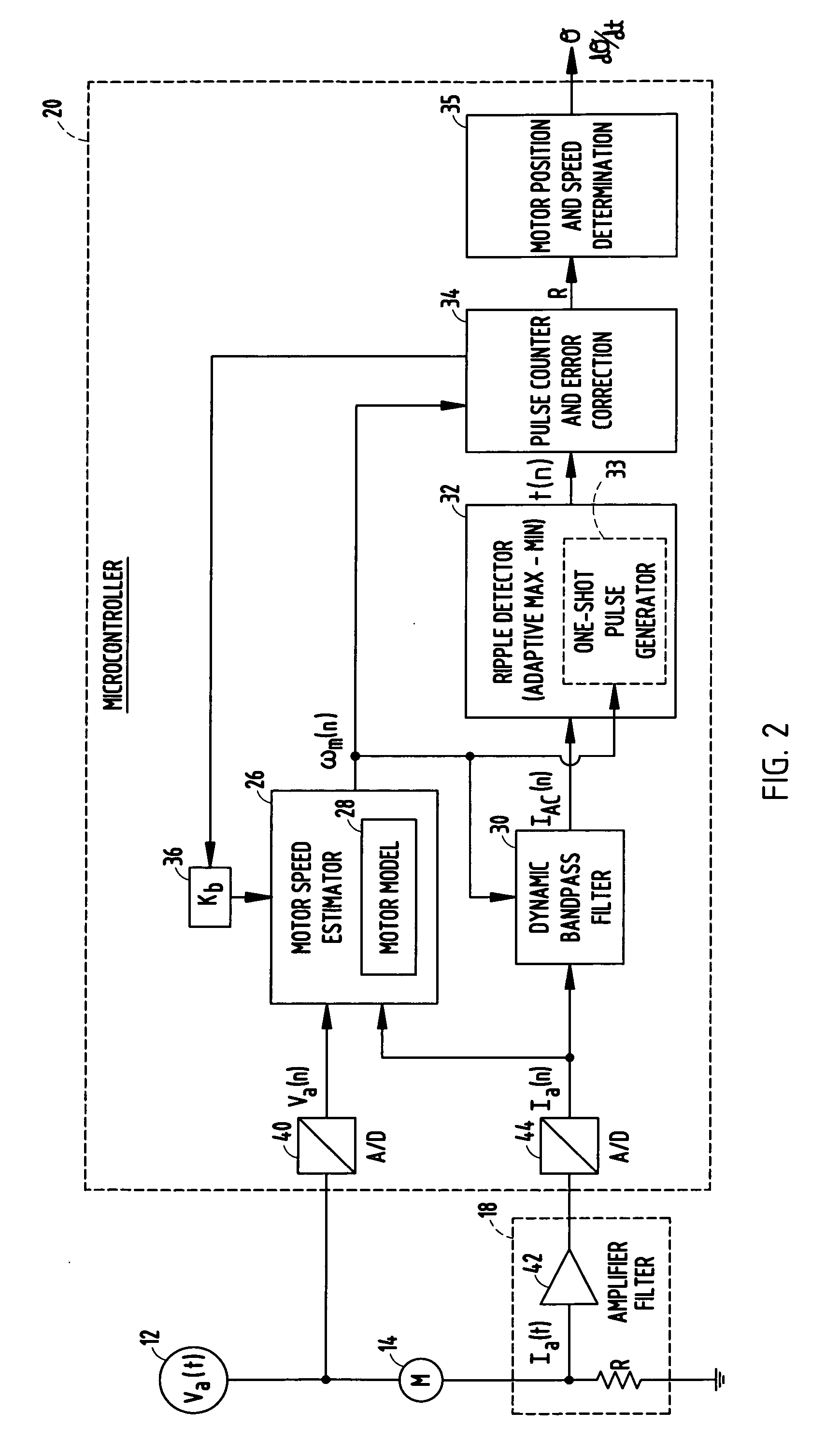

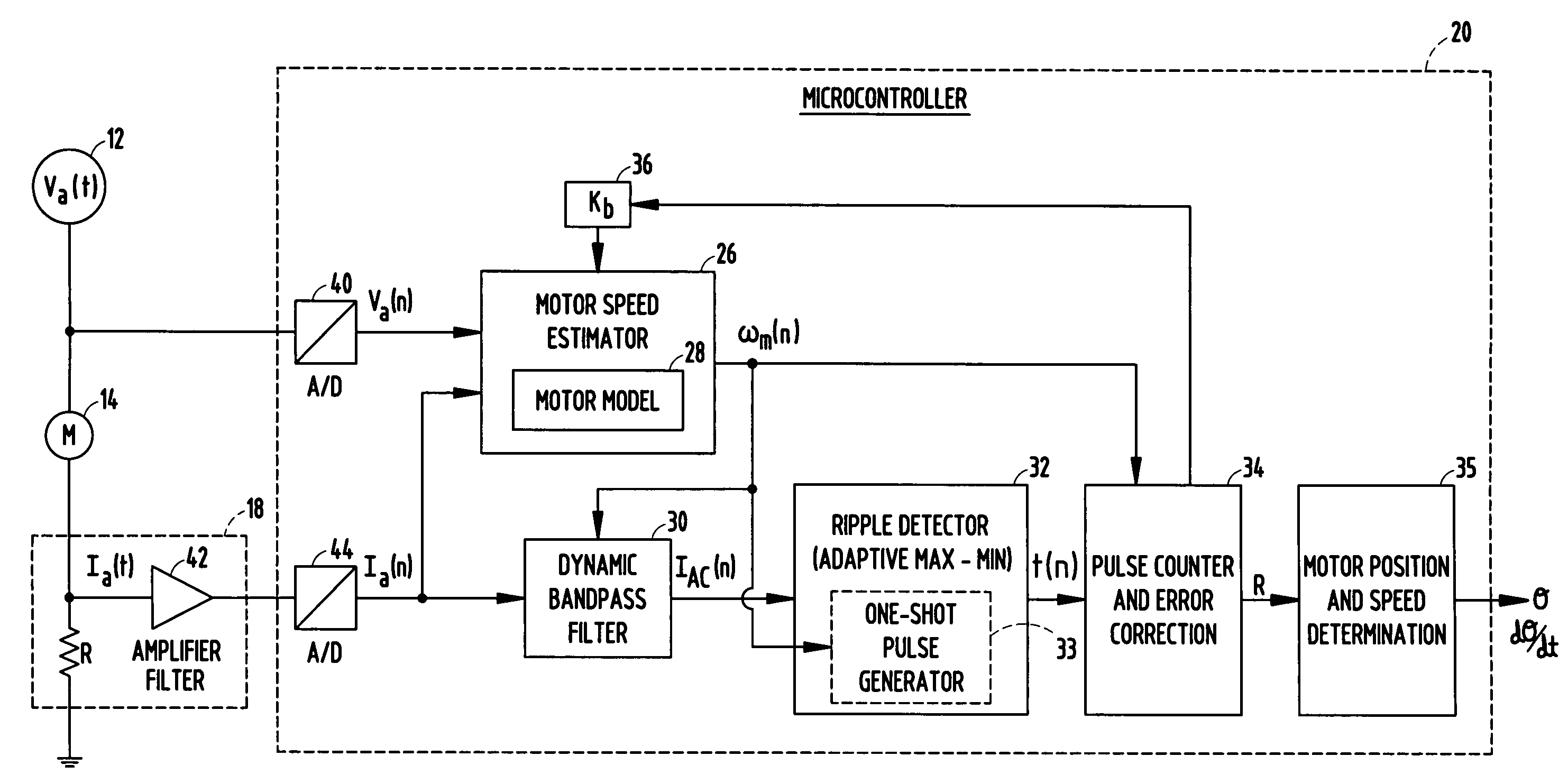

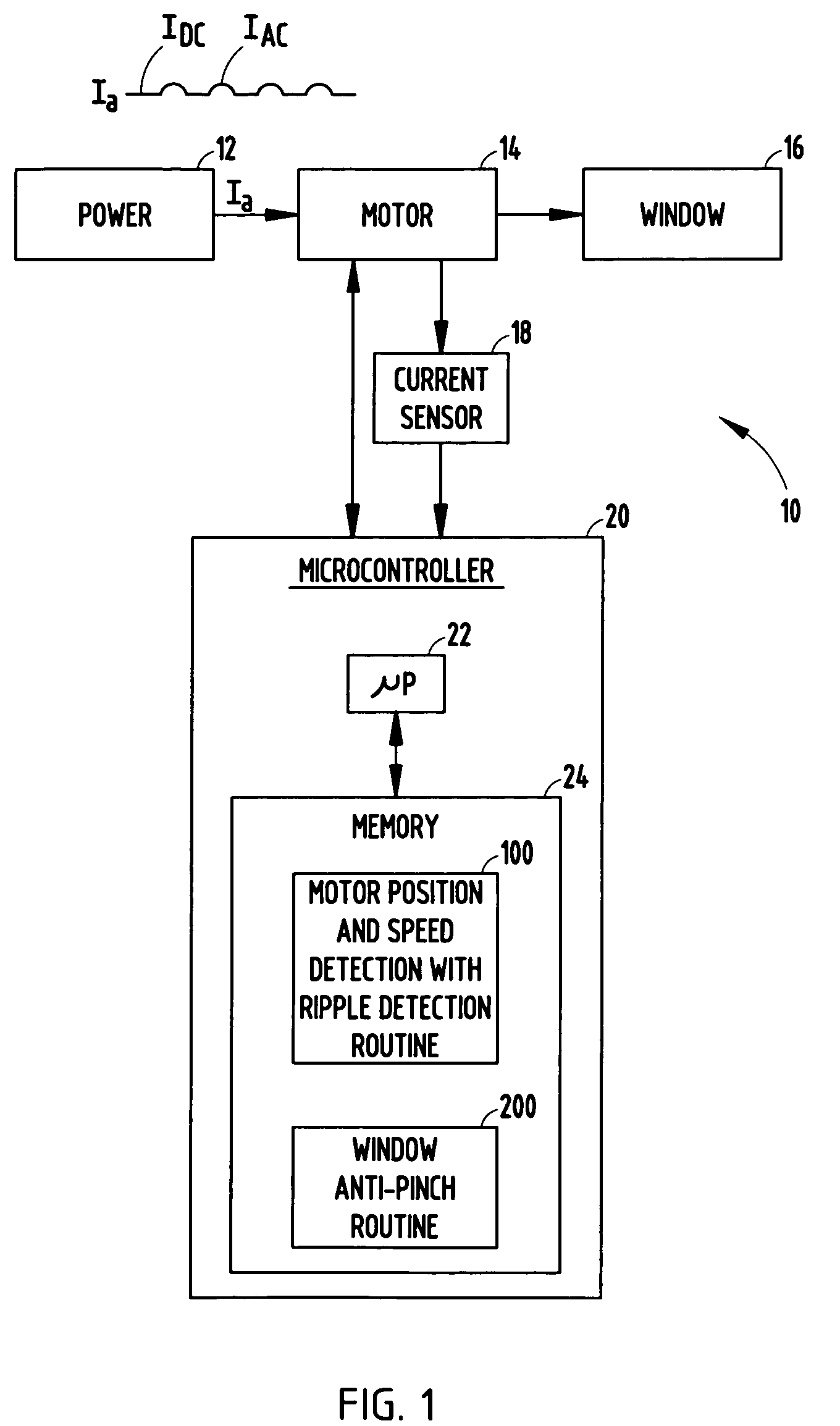

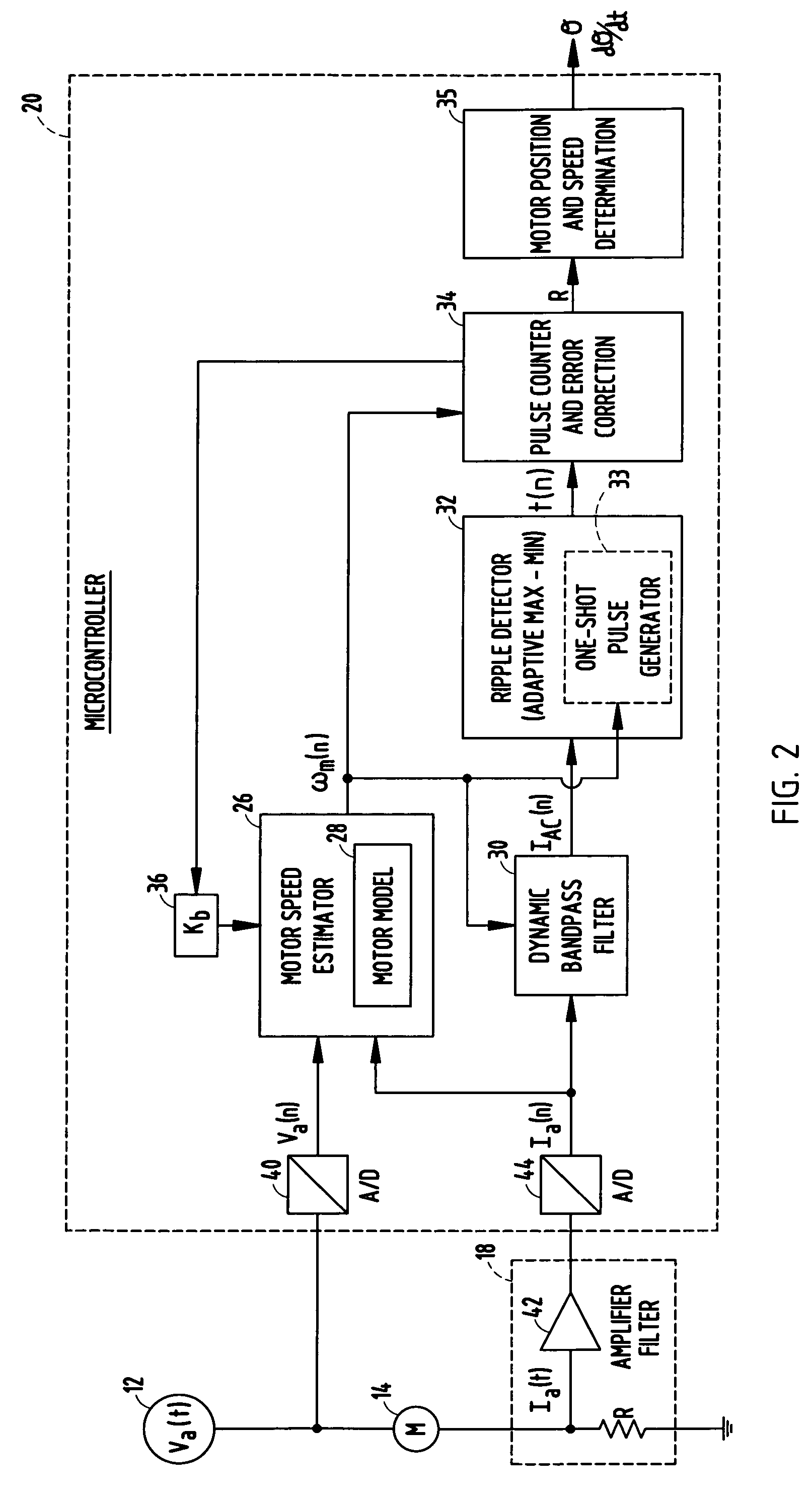

System and method for determining position or speed of a commutated DC motor with error correction

ActiveUS20090254300A1Torque ripple controlEmergency protective circuit arrangementsMotor speedControl system

A motor control system and method are provided for detecting current ripple in a commutated DC motor and further determining position and speed of the motor based on the detected ripple current. Ripples in the motor current are detected and a ripple frequency is calculated based on the time between successive ripples. A ripple count between successive frequencies is determined and the ripple count is compared to a threshold value, and an estimated ripple frequency is determined from a motor model when the ripple count exceeds the threshold value. A corrected ripple count is calculated from a ratio of the calculated ripple frequency and the estimated ripple frequency, and motor position and motor speed are determined based on the corrected ripple count.

Owner:APTIV TECH LTD

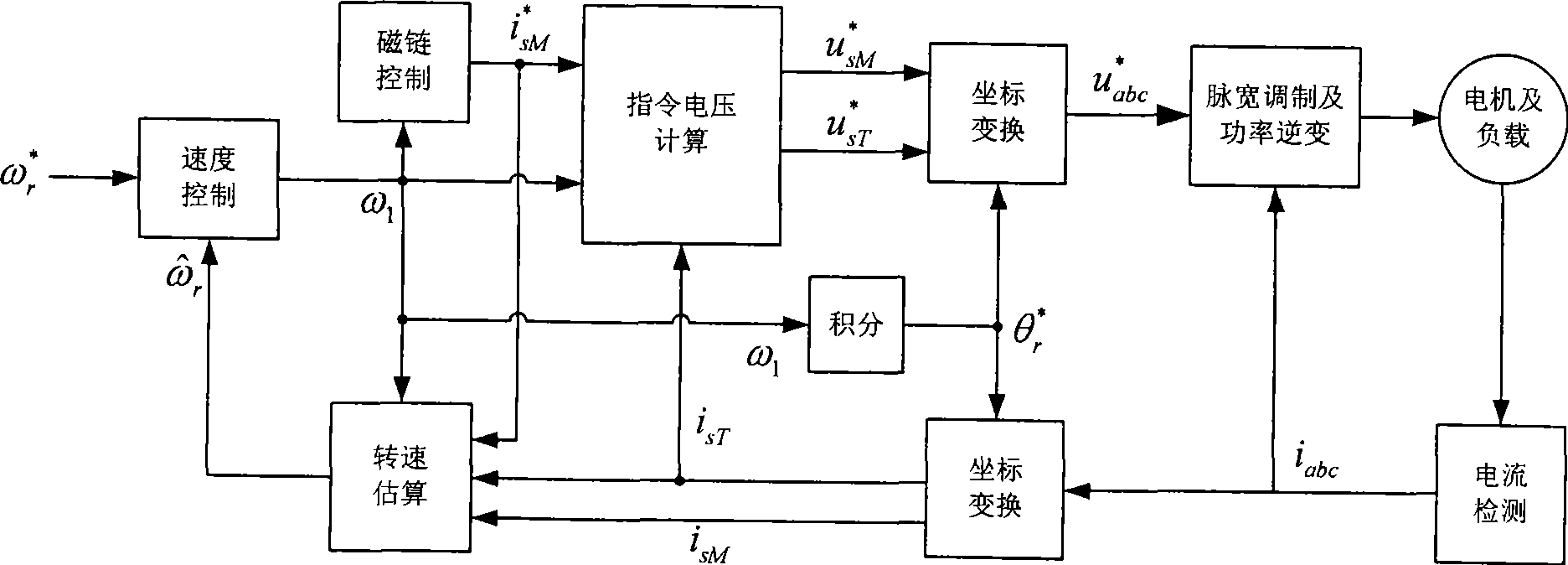

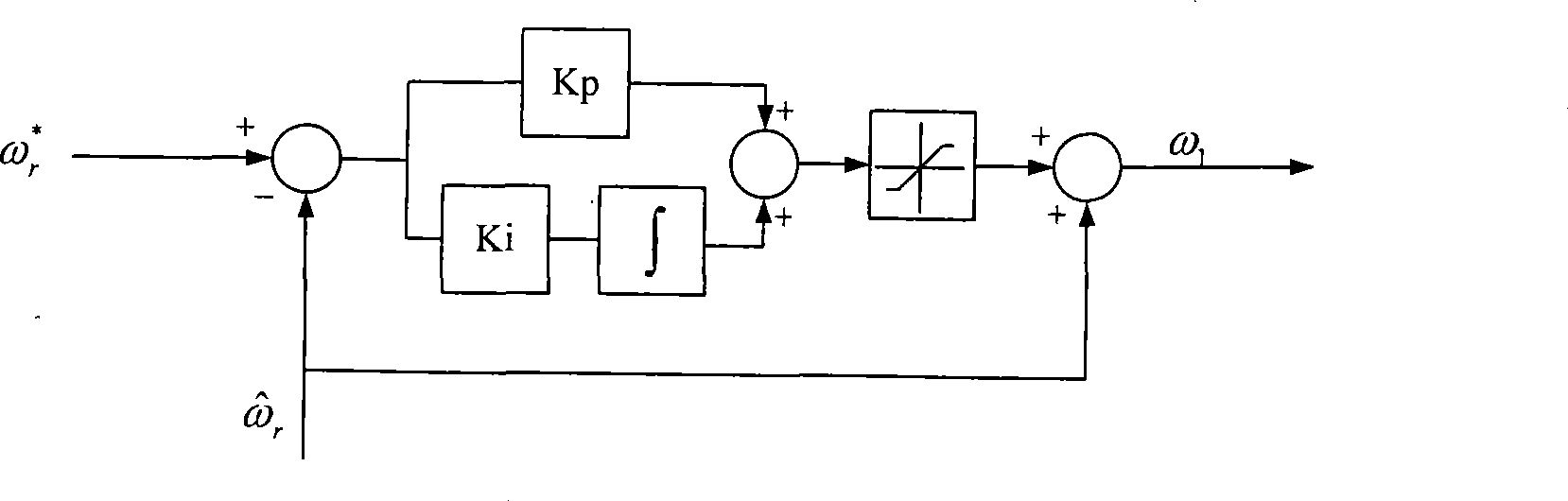

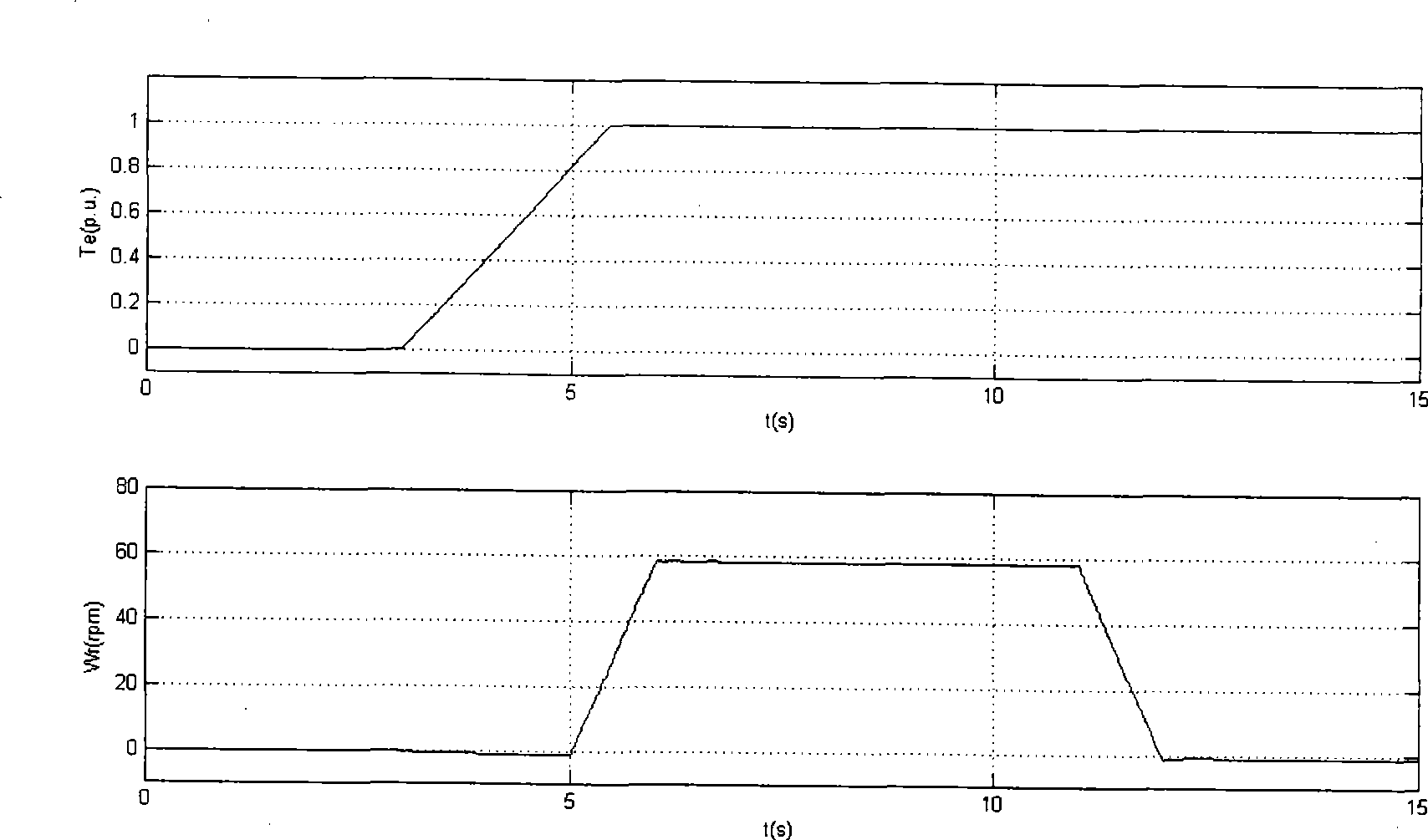

Non-speed sensor vector control method for AC asynchronous motor

InactiveCN101383585AImprove robustnessEasy to chooseElectronic commutation motor controlVector control systemsControl vectorExcitation current

Owner:TSINGHUA UNIV

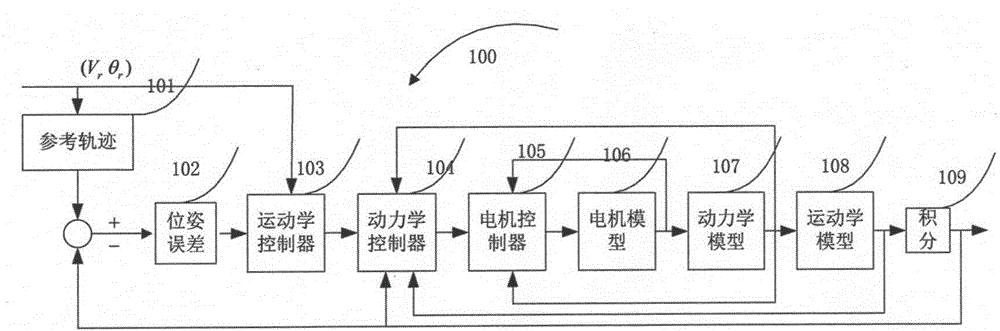

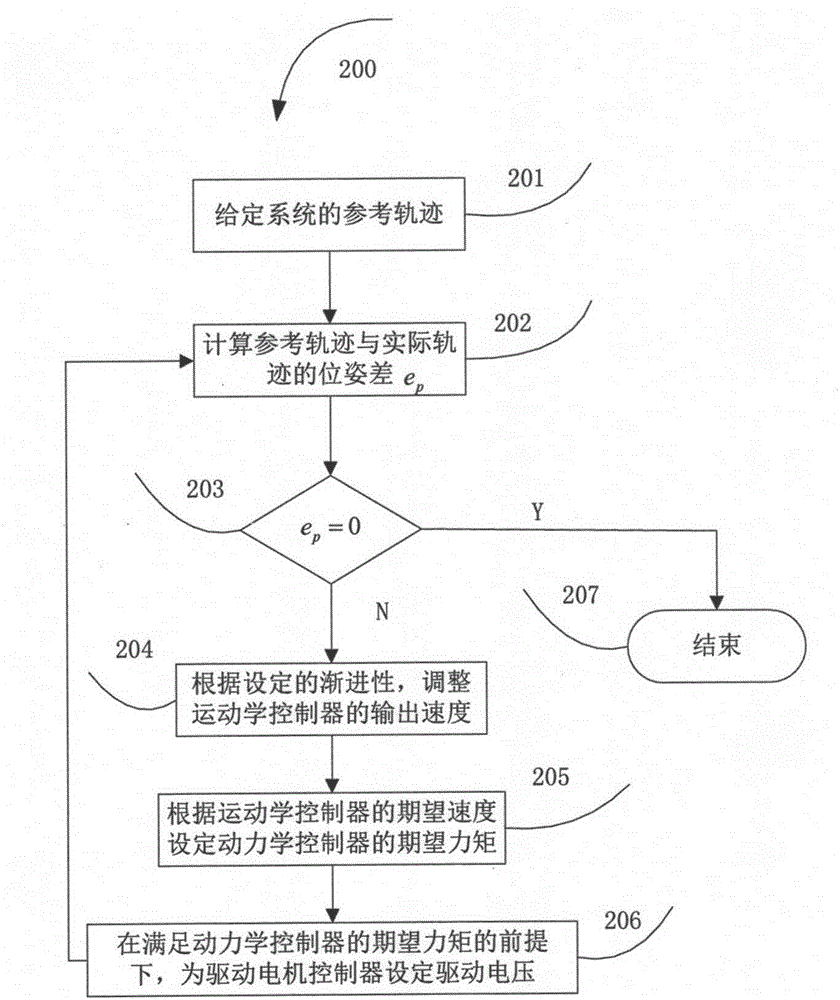

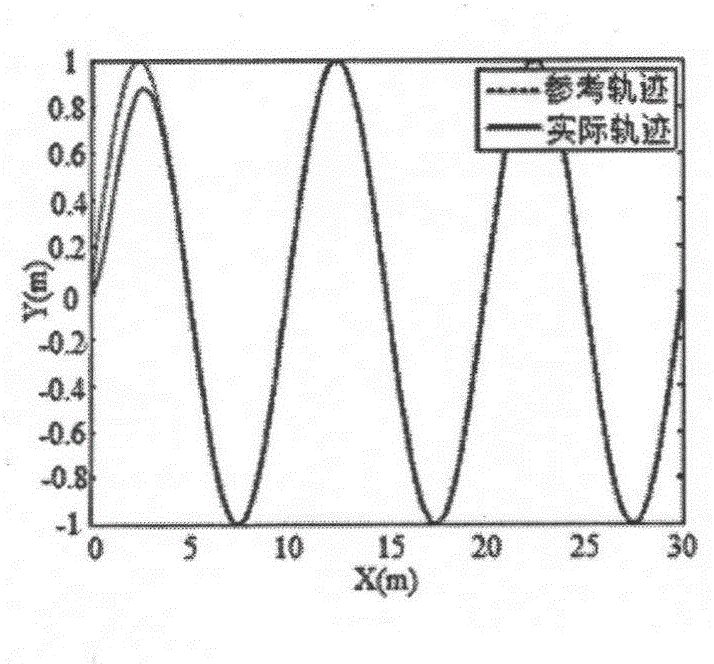

Trajectory tracking control method for four-wheel-driven wheeled mobile robot

ActiveCN106125728AImprove stabilityImprove effectivenessAdaptive controlPosition/course control in two dimensionsKinematic controllerBackstepping

The invention provides a trajectory tracking method for a four-wheel-driven wheeled mobile robot. The method comprises the steps of firstly establishing a kinematic model, a dynamic model and a driving motor model of a system; then designing a kinematic controller for adjusting speed of the system according to a given reference trajectory based on the kinematic model; operating the kinematic controller for obtaining the anticipated torque of a motor according to the speed of a to-be-adjusted system based on the kinematic model; designing a driving motor controller for designing an appropriate driving voltage of the system for satisfying the anticipated torque of the motor based on the driving motor model; and finally performing trajectory tracking control on the four-wheel-driven wheeled mobile robot according to a backstepping robustness trajectory tracking control method. The trajectory tracking method according to the invention realizes a purpose of improving stability of a four-wheel-driven wheeled mobile robot control system in a complicated uncertain environment and furthermore improves system controlling effectiveness on the condition with uncertain factors.

Owner:SHANGHAI DIANJI UNIV

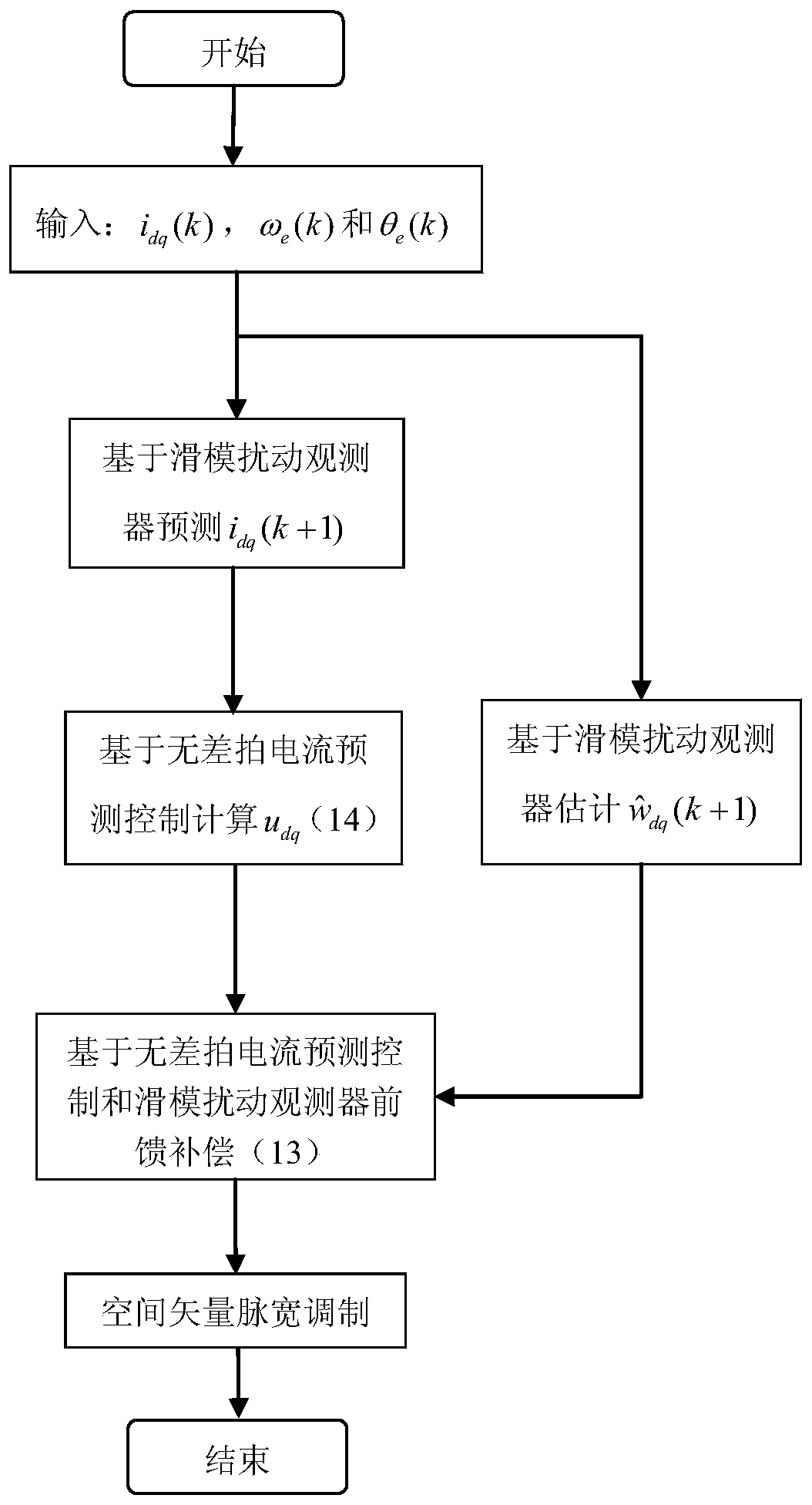

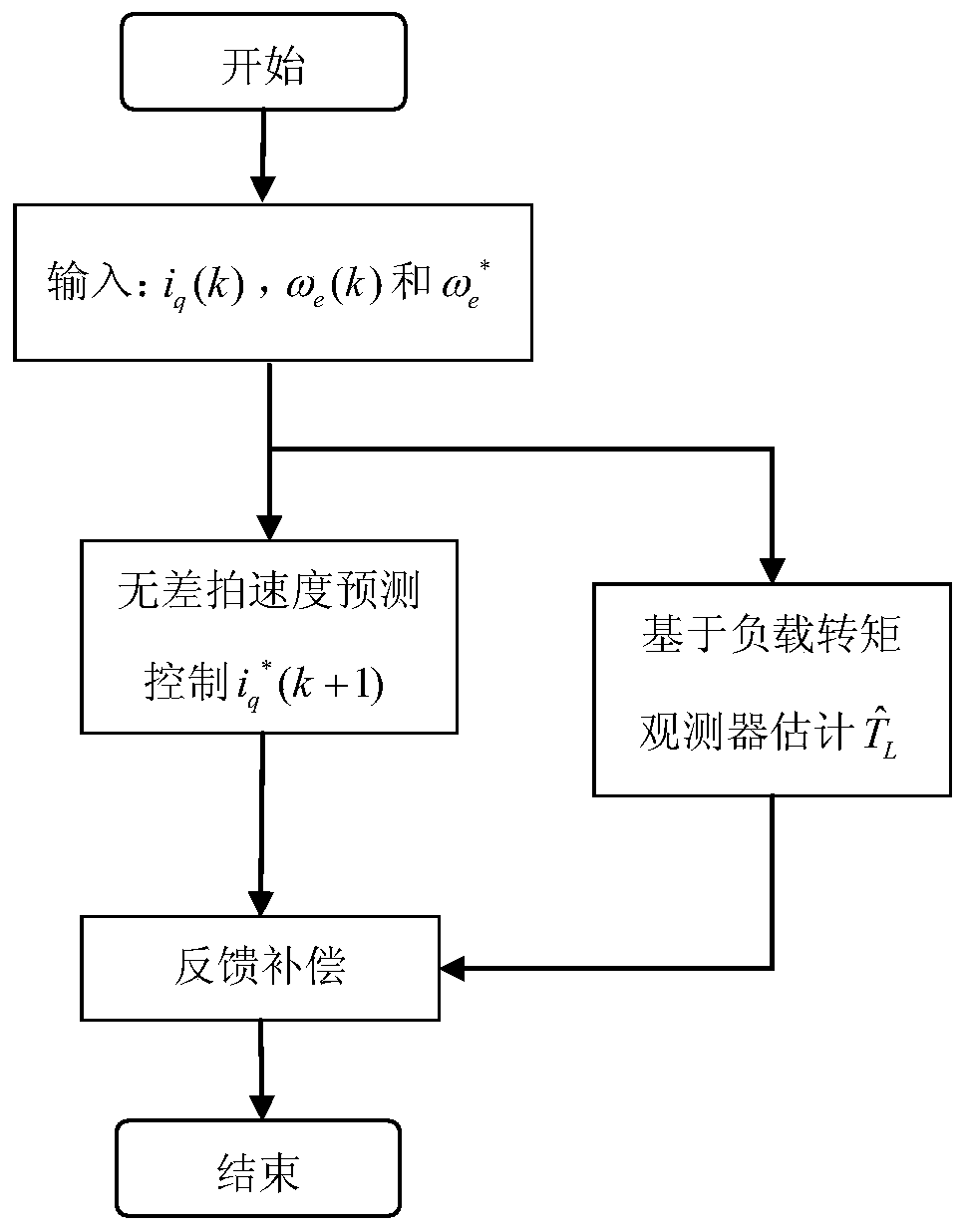

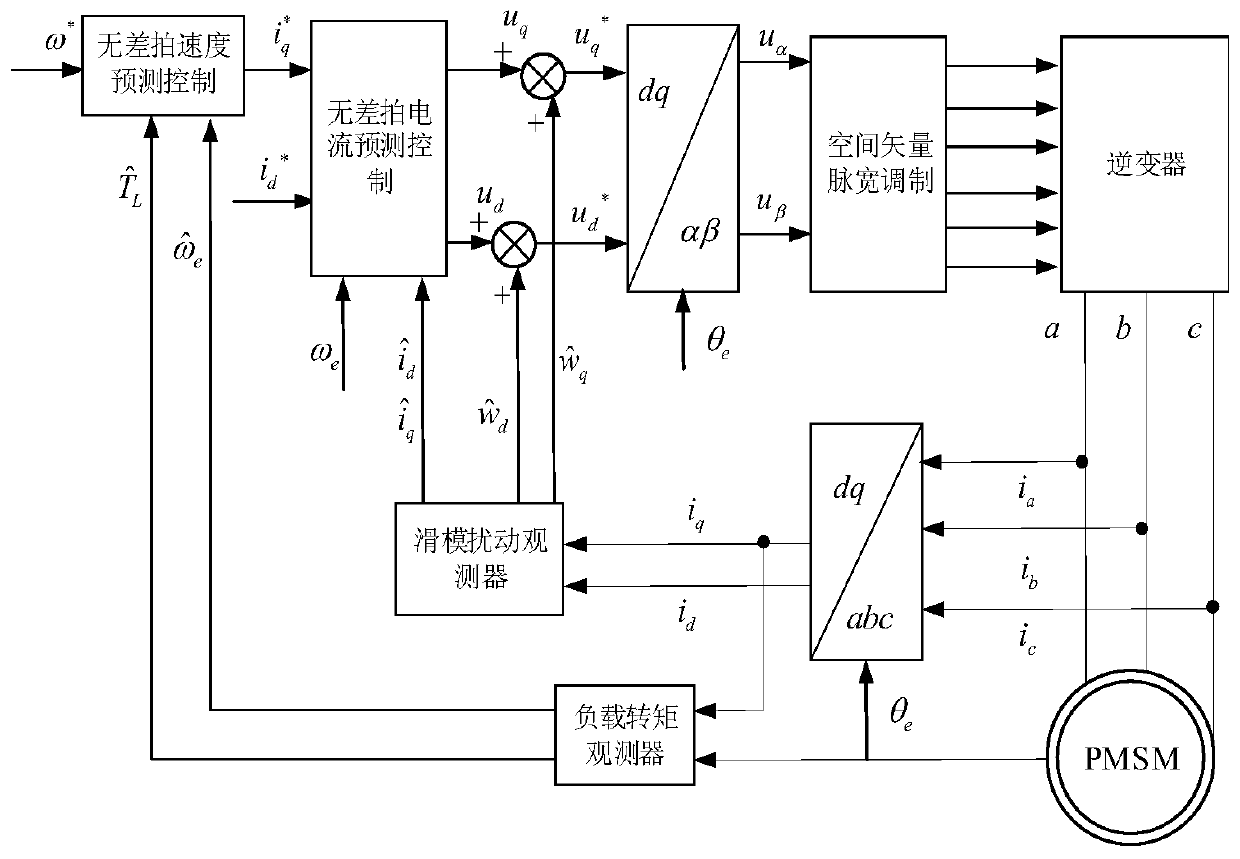

Double-ring dead-beat prediction control method for permanent magnet synchronous motor based on disturbance estimation compensation

ActiveCN110165951AFeatures to improve robustnessSmall steady state errorElectronic commutation motor controlElectric motor controlPower flowLoad torque

A double-ring dead-beat prediction control method for a permanent magnet synchronous motor based on disturbance estimation compensation comprises the following steps: establishing a discrete current prediction model of the permanent magnet synchronous motor, and designing a dead-beat current prediction controller; designing a sliding mode disturbance observer to estimate stator current and parameter disturbance; designing a dead-beat speed prediction controller; and designing a sliding mode disturbance observer to observe and compensate the load torque. According to the invention, under the condition that motor model parameters are not matched, the method achieve the accurate current control; under the condition that the dead-beat speed prediction controller is sensitive to load change, the method achieves the improvement of the dynamic and static performance and the anti-disturbance performance of the speed outer ring through load torque observation and compensation.

Owner:杭州领芯微电子有限公司

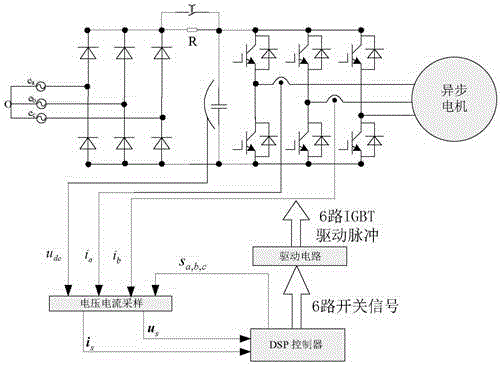

Finite state set asynchronous motor model prediction flux linkage control method and device

ActiveCN104092422ARobustAvoiding Weight Factor Design ProblemsElectronic commutation motor controlVector control systemsVoltage vectorWeight coefficient

The invention discloses a finite state set asynchronous motor model prediction flux linkage control method. The method includes the steps that a torque instruction is obtained through a speed external loop PI adjustor, and a flux linkage amplitude instruction is set to be at a rated value; an equivalent stator flux linkage vector instruction is obtained; duty ratios corresponding to three voltage vectors are calculated; a stator flux linkage vector instruction at the next moment is predicted; the three voltage vectors making the target function value be minimum and the corresponding duty ratios are selected to serve as the optimal output information of a prediction controller; according to the optimal output information of the prediction controller, driving signals of all switch tubes of an inverter are constructed. The invention discloses a finite state set asynchronous motor model prediction flux linkage control device. According to the finite state set asynchronous motor model prediction flux linkage control method and device, the problems that according to a traditional model prediction control scheme, complicated weight coefficient debugging is needed, steady state torque and current ripples are large, the requirement for sampling frequency is high, and switching frequency is not fixed are solved.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

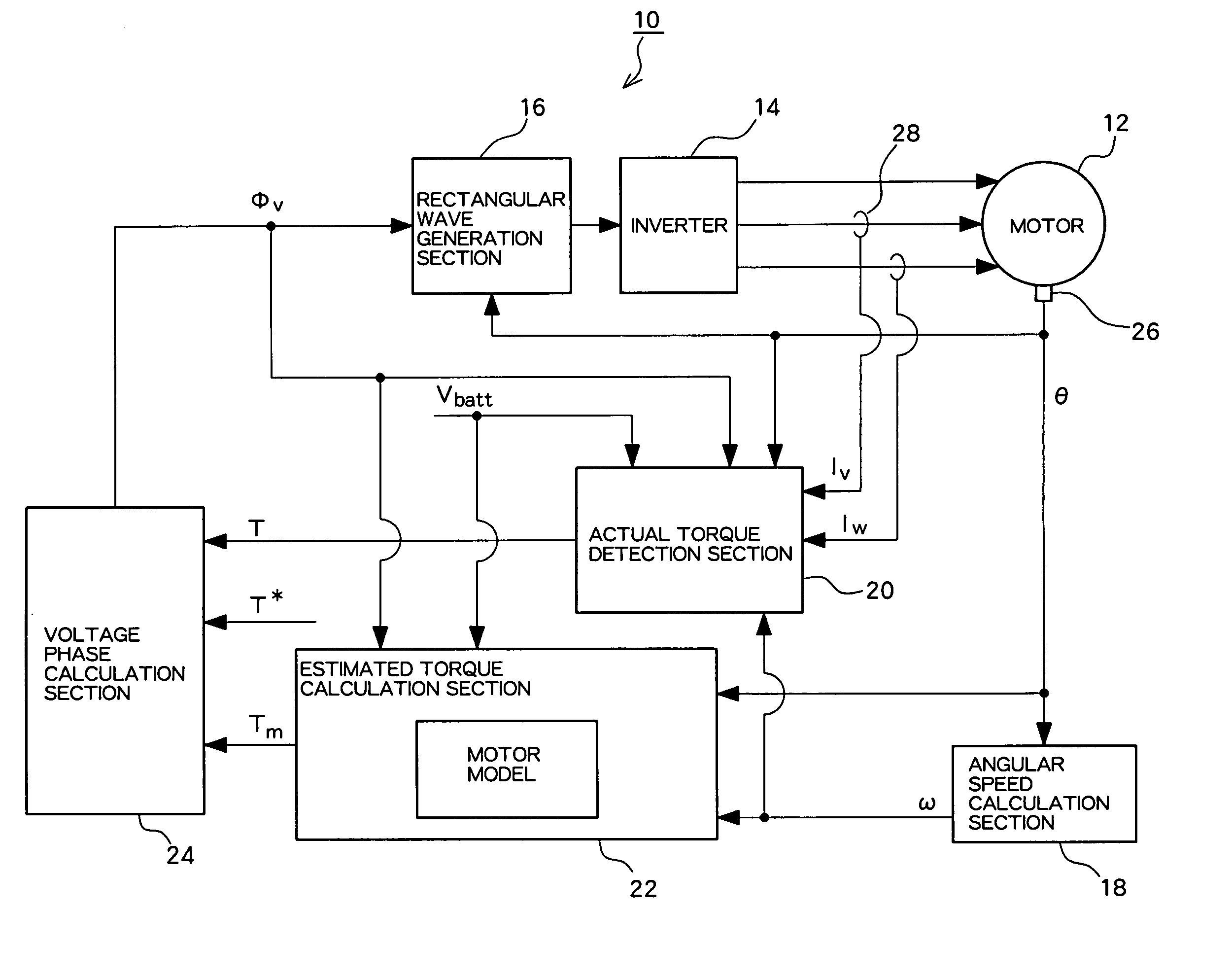

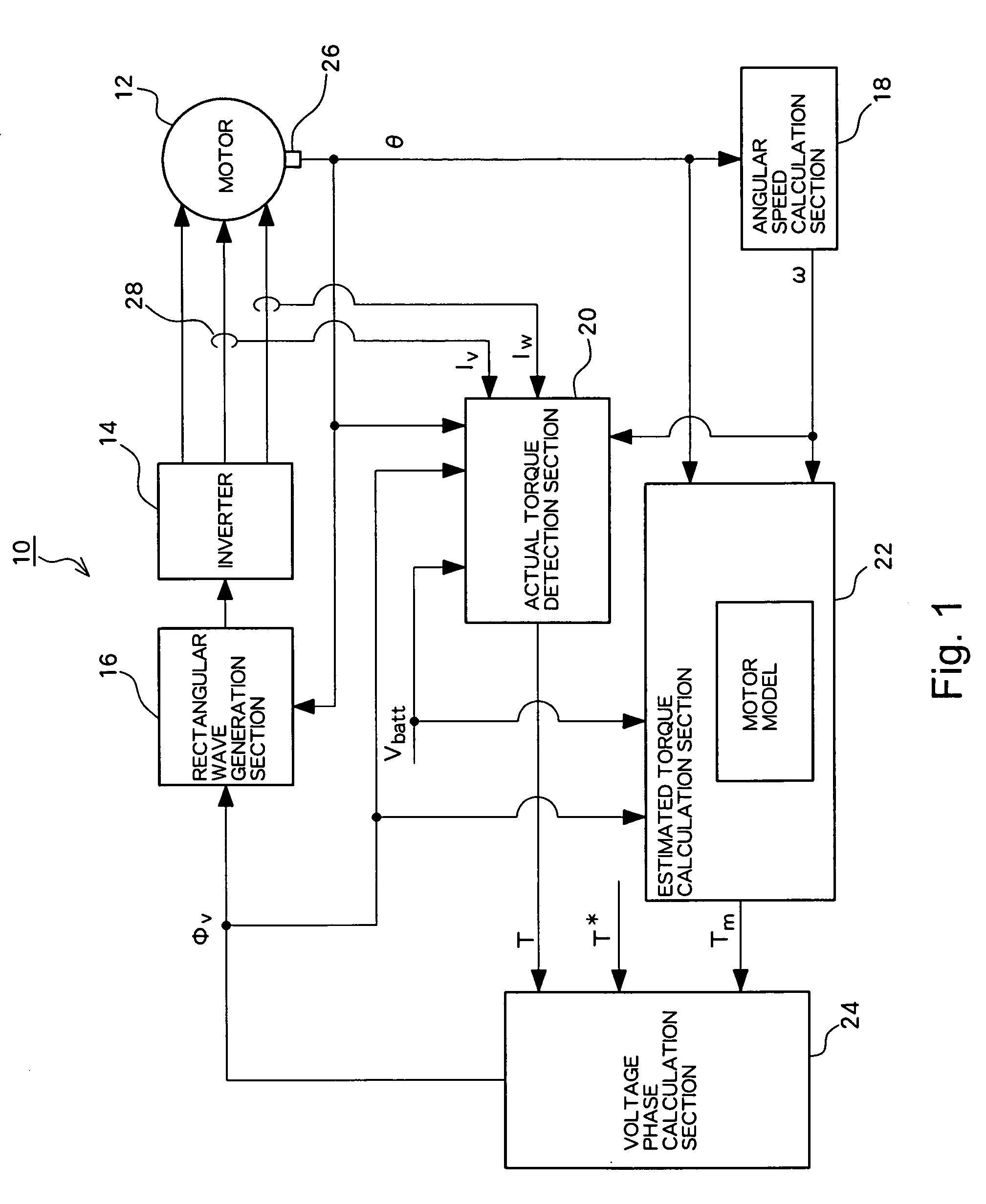

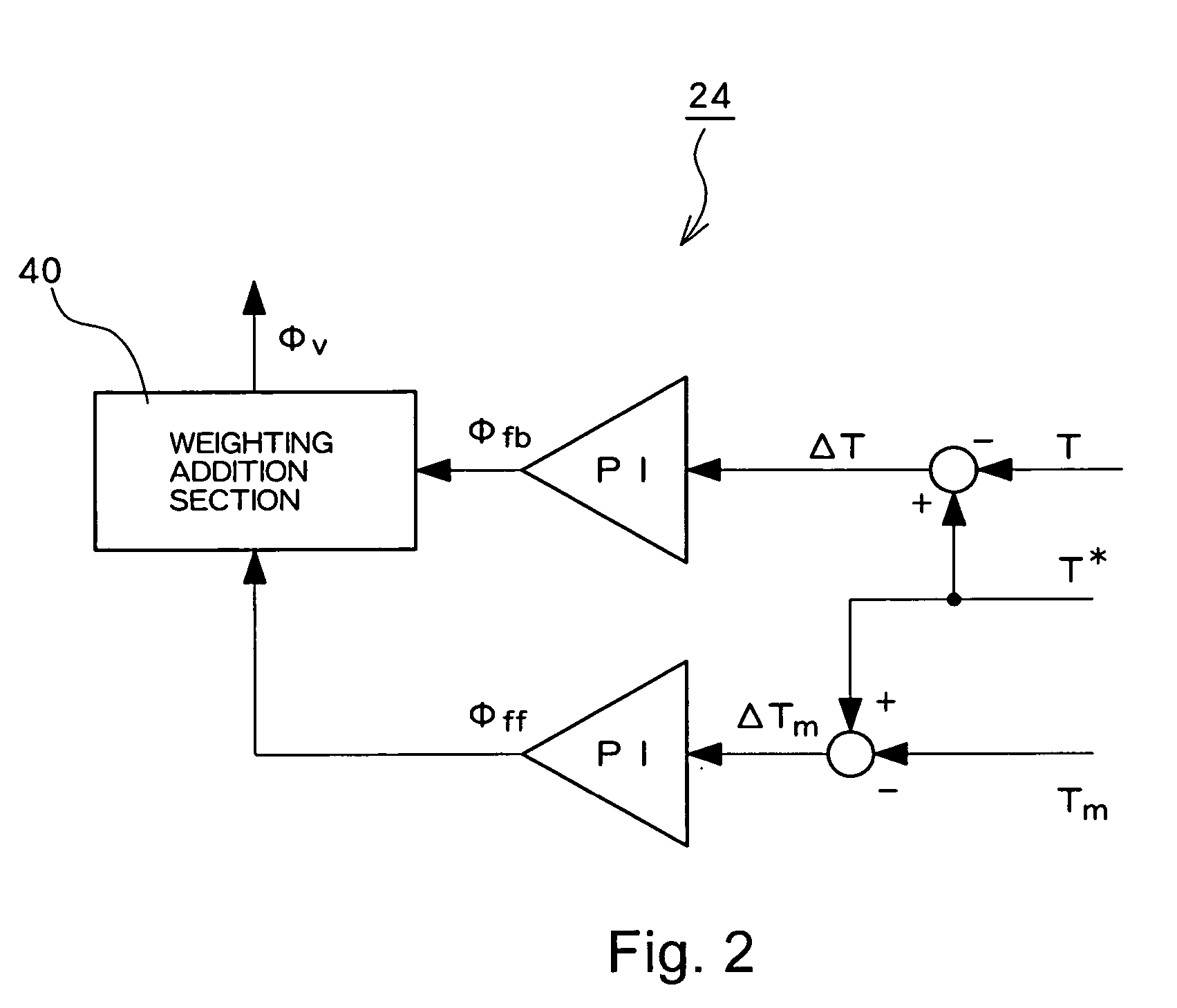

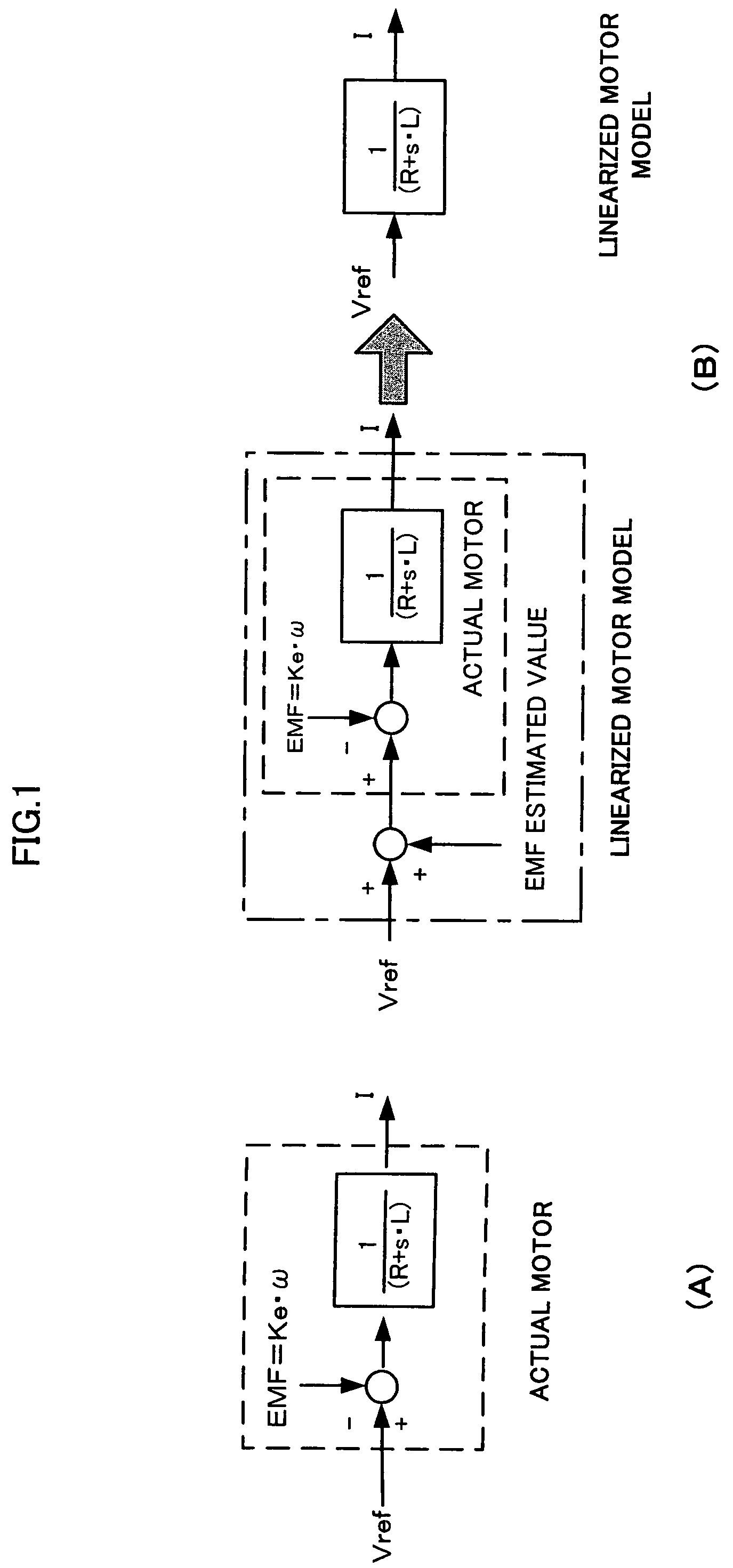

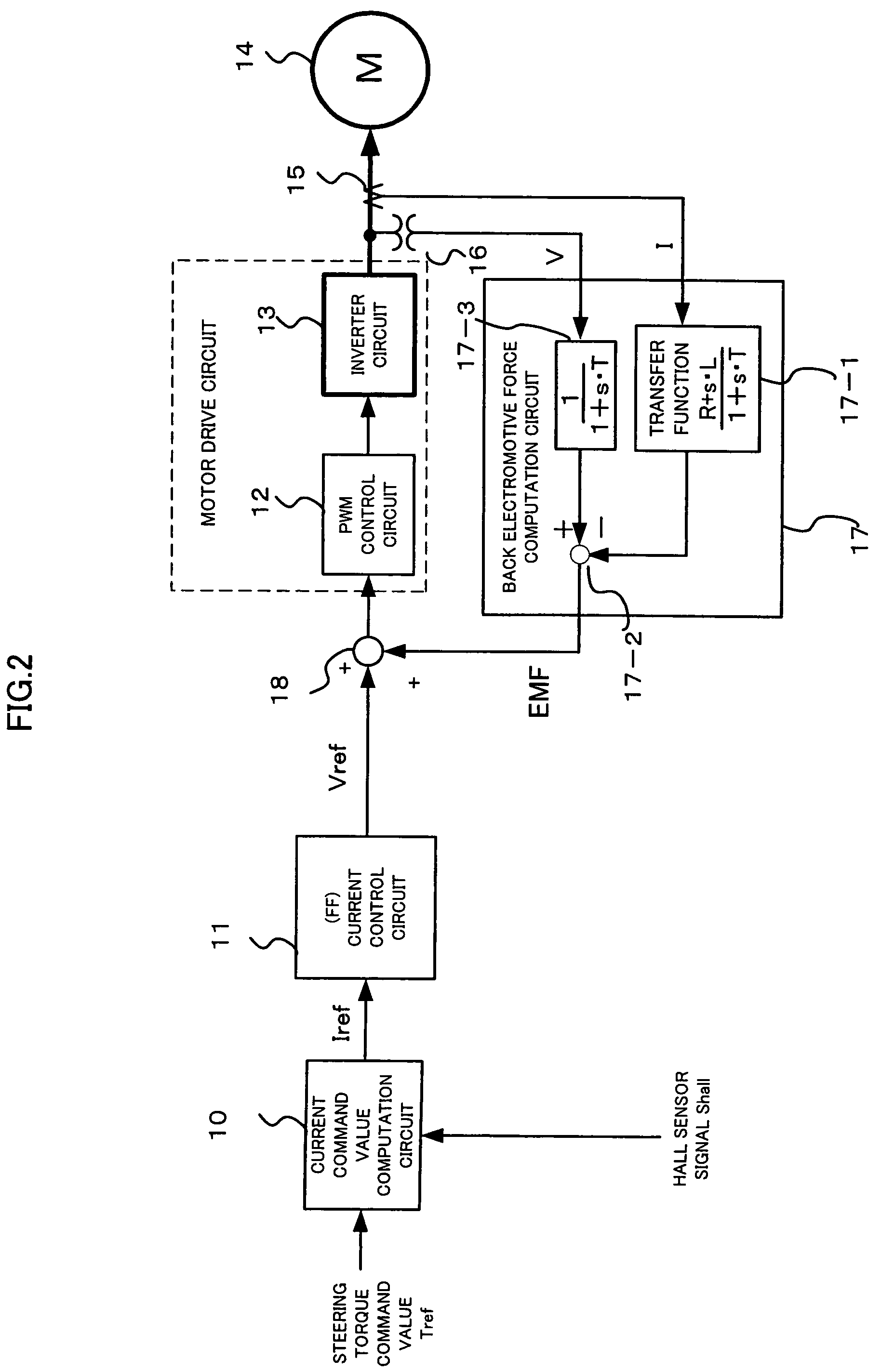

Drive control apparatus and method of alternating current motor

ActiveUS20060006825A1Solve precise controlSingle-phase induction motor startersSynchronous motors startersSimulation basedEngineering

A drive control apparatus, which controls an AC motor subjected to rotational drive by applying a rectangular wave voltage thereto, comprising: an actual torque detection section for detecting an actual torque value T outputted from the AC motor; an estimated torque calculation section for calculating an estimated torque value Tm based on a motor model with the AC motor in a simulated state; and a voltage phase calculation section wherein the voltage phase calculation section calculates a first voltage phase φfb based on the actual torque value T and a command torque value T*, and a second voltage phase φff based on the estimated torque value Tm and the command torque value T* respectively, and outputs a value obtained by making the voltage phase subjected to weighting addition, as a voltage phase φv.

Owner:TOYOTA JIDOSHA KK +1

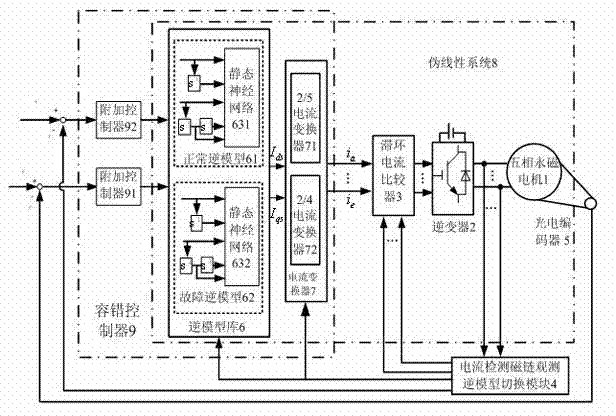

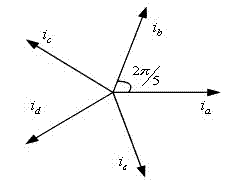

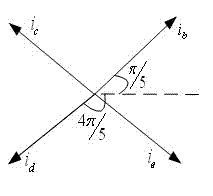

Polyphase motor fault-tolerant control method and system based on multi-neural-network inverse model

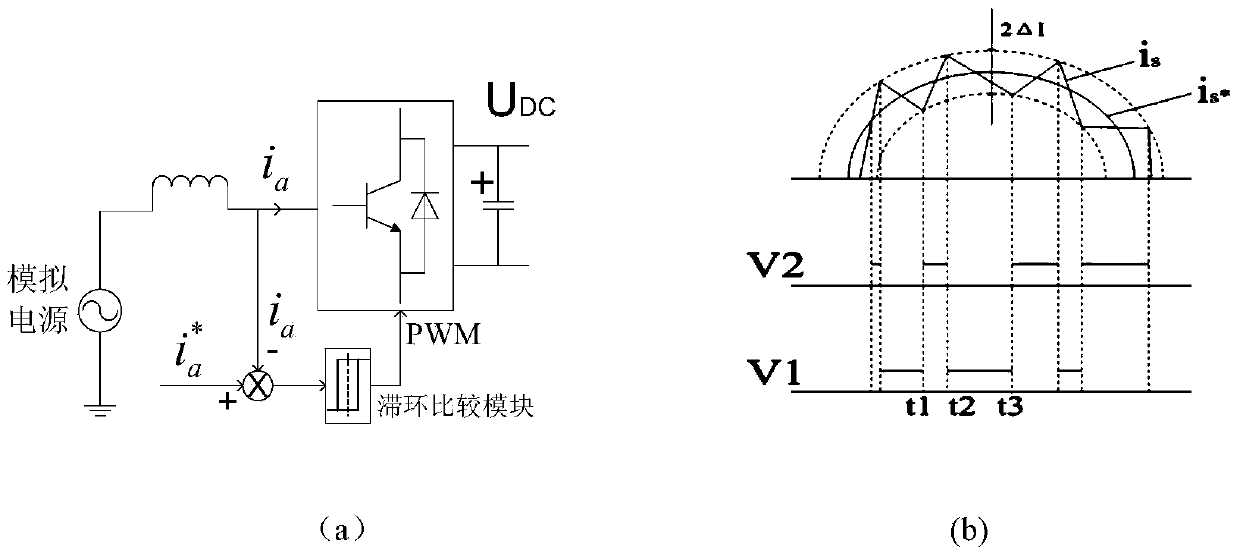

ActiveCN102522945ALow costLower requirementElectronic commutation motor controlVector control systemsHysteresisNerve network

The invention discloses a polyphase motor fault-tolerant control method and system based on a multi-neural-network inverse model in the field of motor control. The polyphase motor fault-tolerant control method comprises the following steps of: respectively acquiring a normal state inverse model and a fault state inverse module of a motor by adopting a neural network inverse model; selecting a corresponding inverse module and a current converter to be serially connected in front of a hysteresis current comparer by a current detection magnetic-chain observation inverse model switching module under a normal state or a fault state to obtain a constant pseudo-linear system; only considering to convert current of d axis and q axis of a stator, inversely output by the neural network after circuit-opening into four phases of reference current, and only adjusting phase relationships of the rest four phases of current; and when motor model parameters changes because the motor has a fault, approaching to a motor inverse system still accurately without the need of correcting control parameters of additional controllers again. According to the polyphase motor fault-tolerant control method and system disclosed by the invention, the adaptability of a fault-tolerant controller to the winding fault of the motor is improved, and the requirements and the circuit cost of an inverter power device are reduced; and the polyphase motor fault-tolerant control method and system have stronger fault tolerance and robustness.

Owner:UONONE GRP JIANGSU ELECTRICAL CO LTD

Drive unit for compressor and refrigerator

ActiveUS7392158B2Operating frequency of the compressor <b>1Easily damagedCommutation monitoringSpace heating and ventilationPower flowMotor drive

An instantaneous current and instantaneous voltage of a three-phase coil of a brushless DC motor are detected, and the internal condition of a compressor is predicted from these detection values. The prediction about the internal condition of the compressor is made in such a way that motor driving torque which is a parameter of a motor model is identified and poor lubrication, liquid compression or the like is predicted from this identified motor driving torque. This enables it to make, in real time, a failure forecast, failure diagnosis etc. on the compressor.

Owner:DAIKIN IND LTD

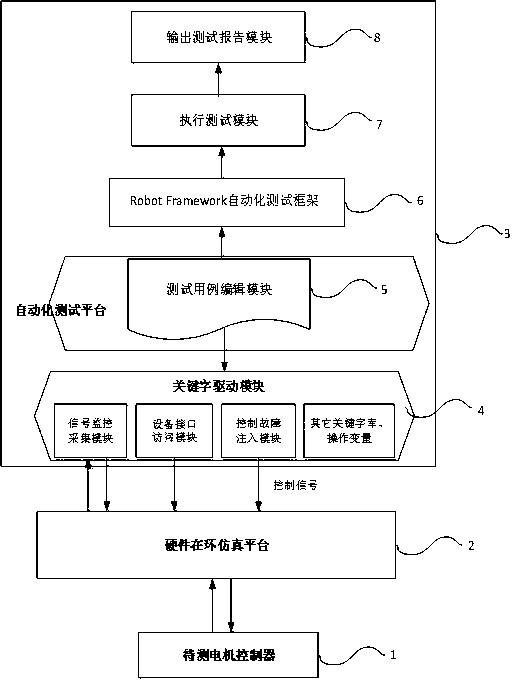

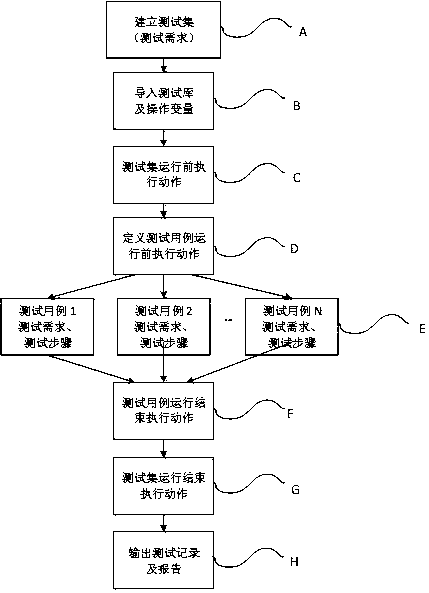

DSPACE-based motor control hardware-in-the-loop automated test system and method

ActiveCN107831757AEasy to integrateImprove the testing processProgramme controlElectric testing/monitoringTest platformTest execution

The invention discloses a dSPACE-based motor control hardware-in-the-loop automatic test system and method. The system includes a to-be-tested object motor controller, a hardware-in-the-loop simulation platform and an automatic test system platform; the hardware-in-loop simulation platform includes a real-time processor, an IO board card, test management software, and the like, wherein the real-time processor is connected with the to-be-tested motor controller through the IO board card and operates a virtual motor model to simulate the operating state of a motor; and the automatic test platform includes a keyword driving module, a test case editing module, a Robot Framework automatic test framework, a test execution module, and a test report output module. With the dSPACE-based motor control hardware-in-the-loop automatic test system and method of the invention adopted, the logic function of the to-be-tested motor controller can be tested automatically; the strategy response of fault injection can be verified; the startup of the automatic test system can be controlled through command line statements; a test report can be automatically generated; automatic testing can be realized ina real sense; and a sound test process of an enterprise can be established. The automatic test system can be conveniently integrated with an existing open-source Jenkins regression test system.

Owner:HEFEI JUYI POWER SYST CO LTD

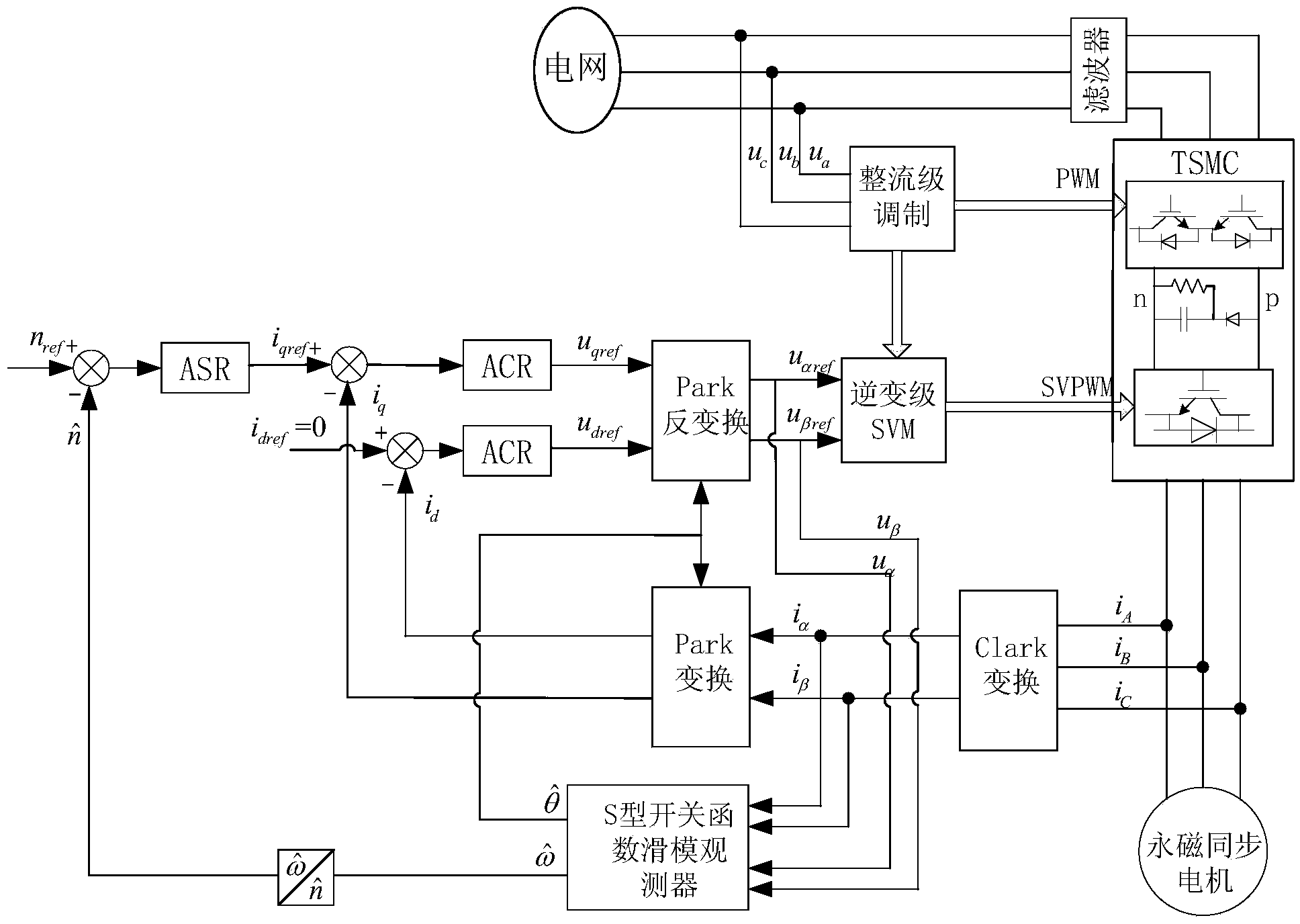

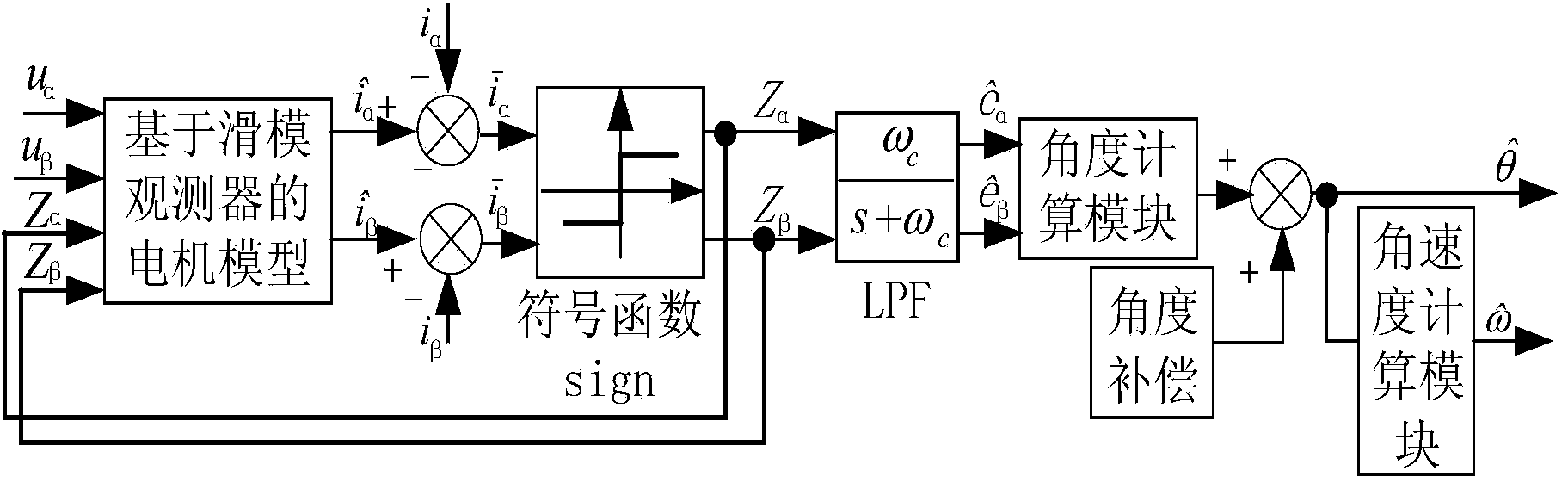

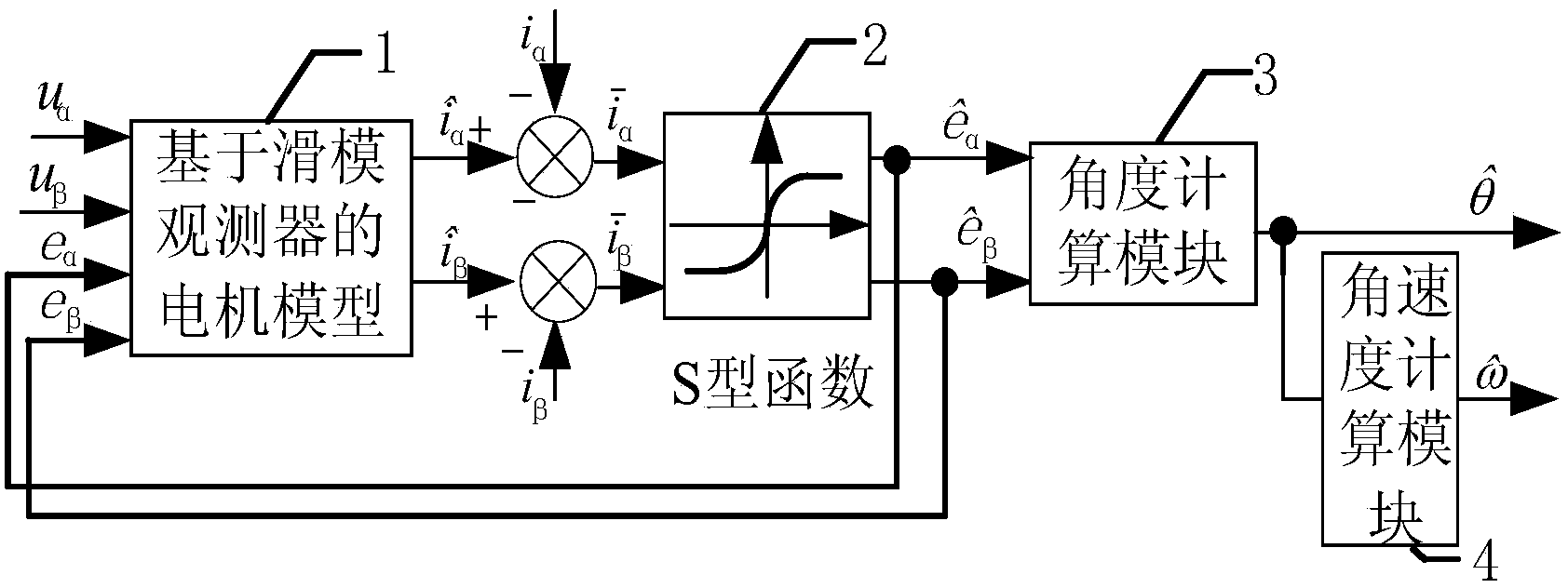

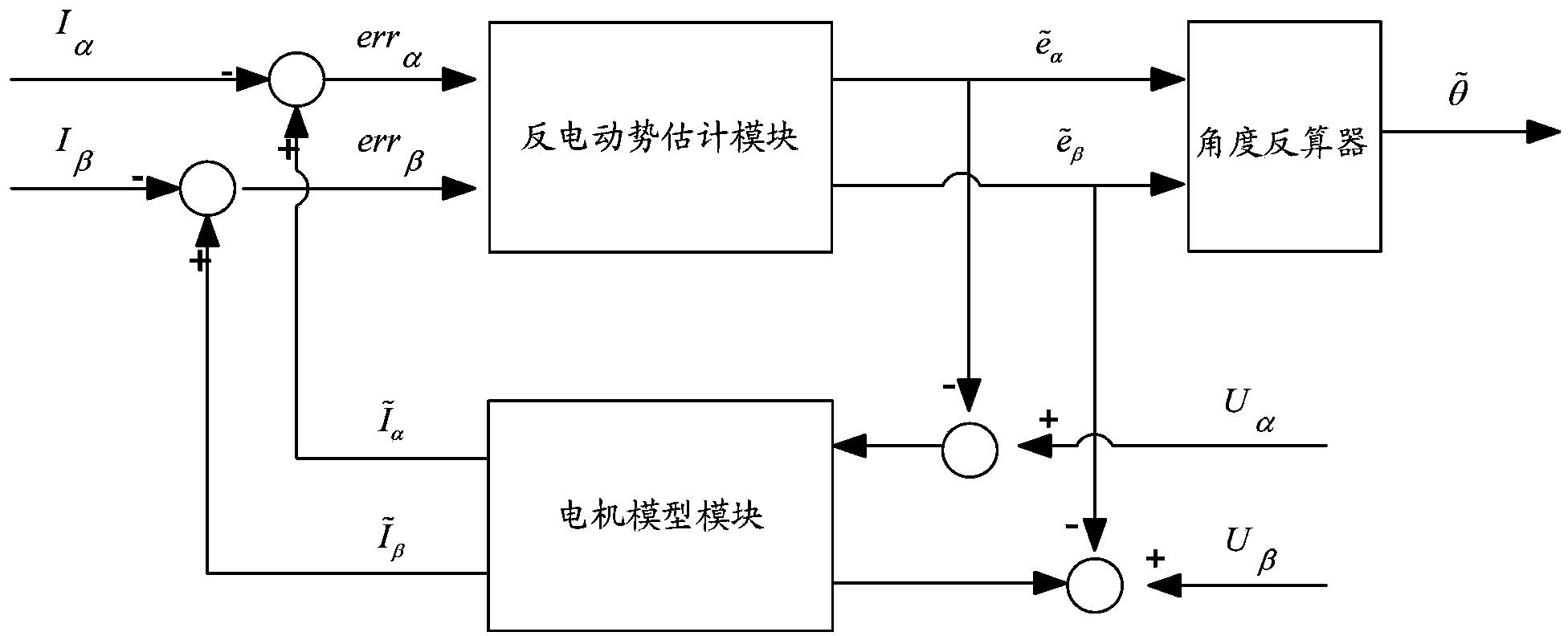

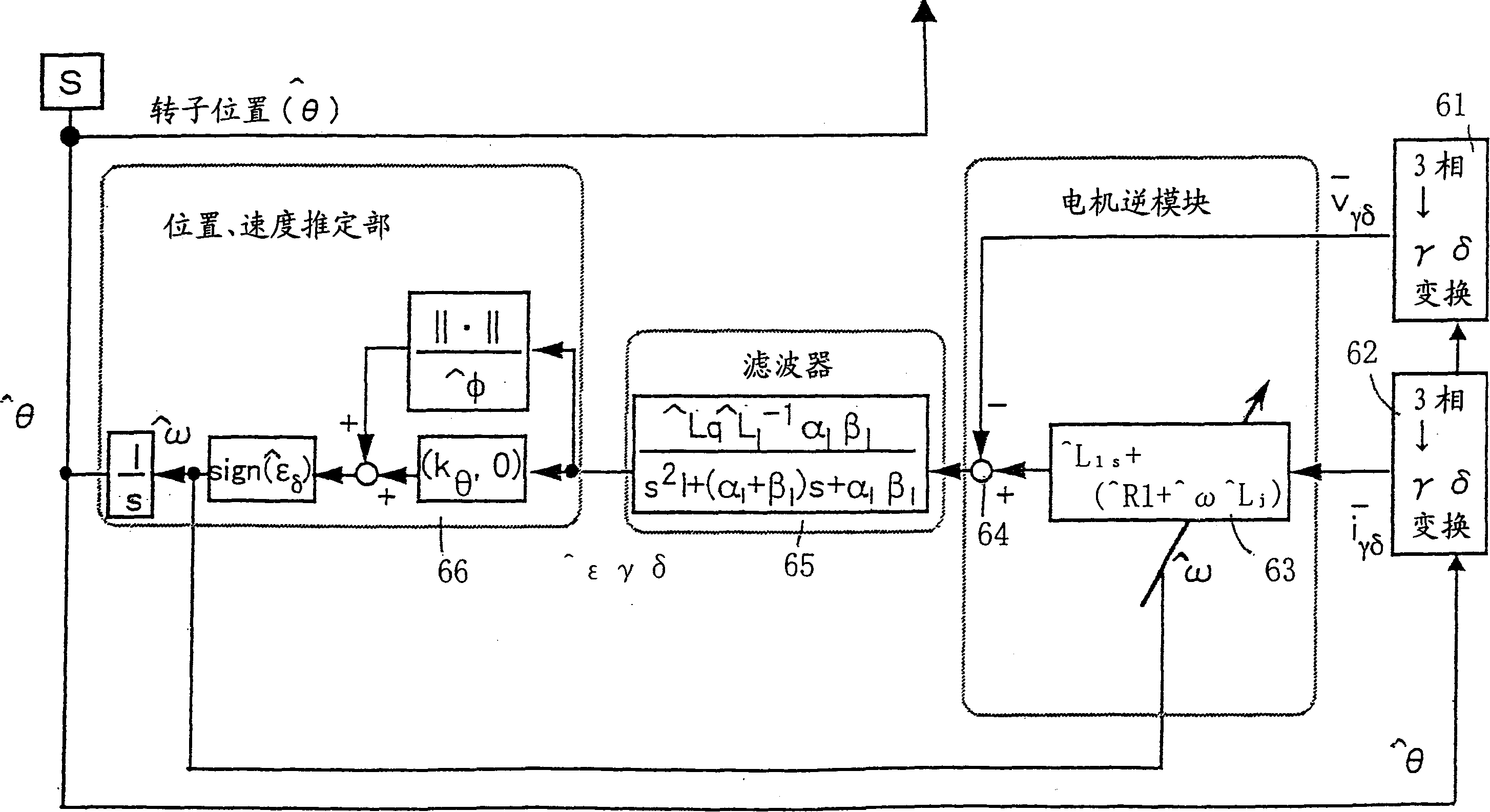

Permanent magnet synchronous motor sliding-mode speed observer driven by two-stage matrix converter

InactiveCN103715962AFix jitterResolve delayElectronic commutation motor controlVector control systemsMatrix convertersStator voltage

A permanent magnet synchronous motor sliding-mode speed observer driven by a two-stage matrix converter comprises a motor model based on the sliding-mode observer, an S-shaped switch function, an angle calculation module and an angular speed calculation module. Ualpha and Ubeta, obtained through the voltage reconstitution method, of stator voltages in a two-phase static coordinate system of a permanent magnet synchronous motor and the two S-shaped switch function output values (see the specification) serve as the motor model input based on the sliding-mode observer, the stator actual current values including ialpha and ibeta are subtracted from the four motor model output stator current observing values (see the specification) based on the sliding-mode speed observer, the two difference values serve as the S-shaped switch function input, the difference values are processed through the permanent magnet synchronous motor sliding-mode speed observer, then the two counter EMF estimated values in the two-phase static coordinate system are output, the rotor position is obtained through the angle calculation module, and the angular speed is obtained through the angular speed calculation module.

Owner:XIAN UNIV OF TECH

System and method for determining position or speed of a commutated DC motor with error correction

ActiveUS7668690B2Torque ripple controlEmergency protective circuit arrangementsMotor speedControl system

Owner:APTIV TECH LTD

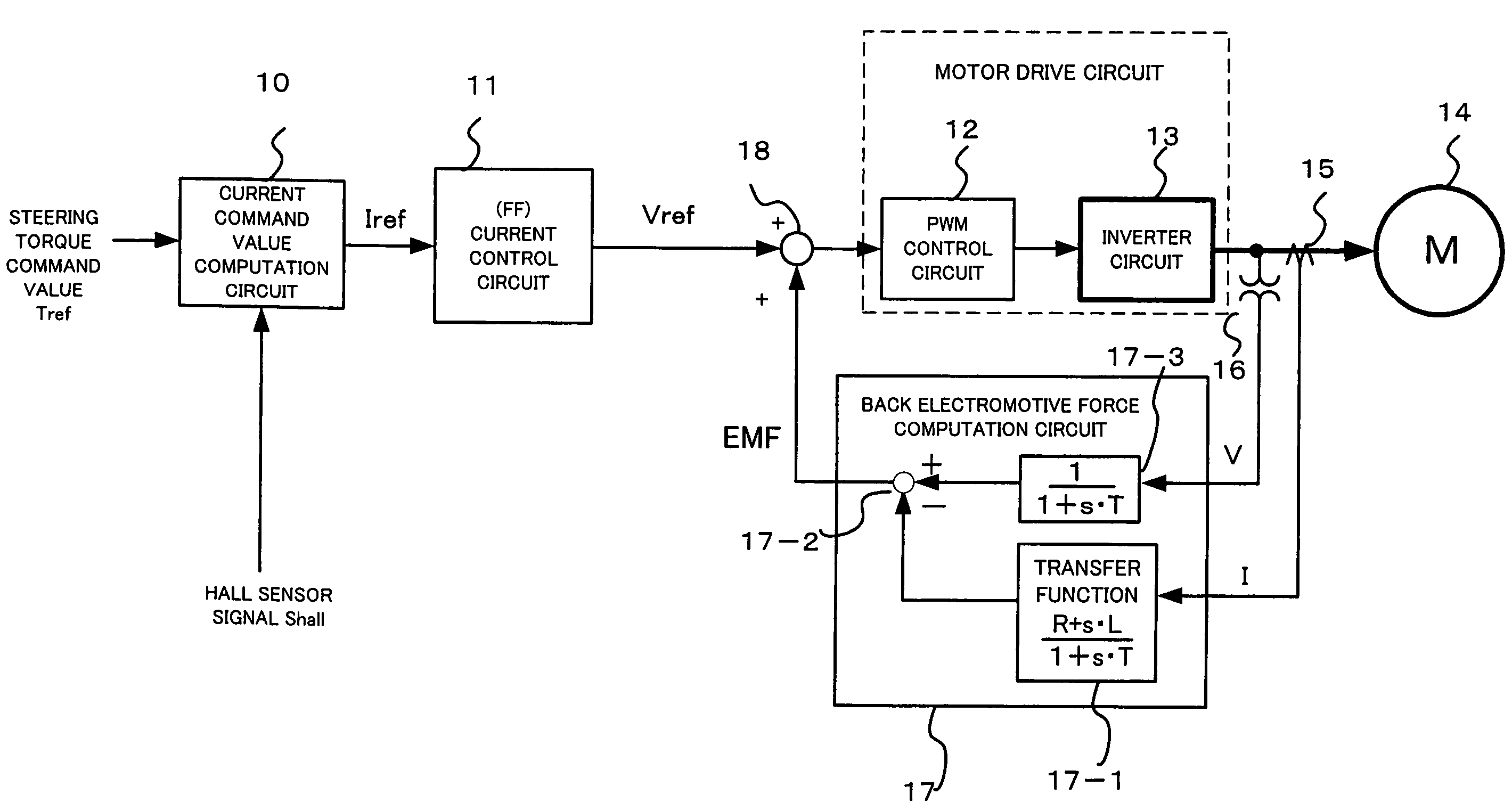

Controller for electric power steering device

InactiveUS7574294B2Digital data processing detailsSingle motor speed/torque controlElectric power steeringEngineering

Owner:NSK LTD +1

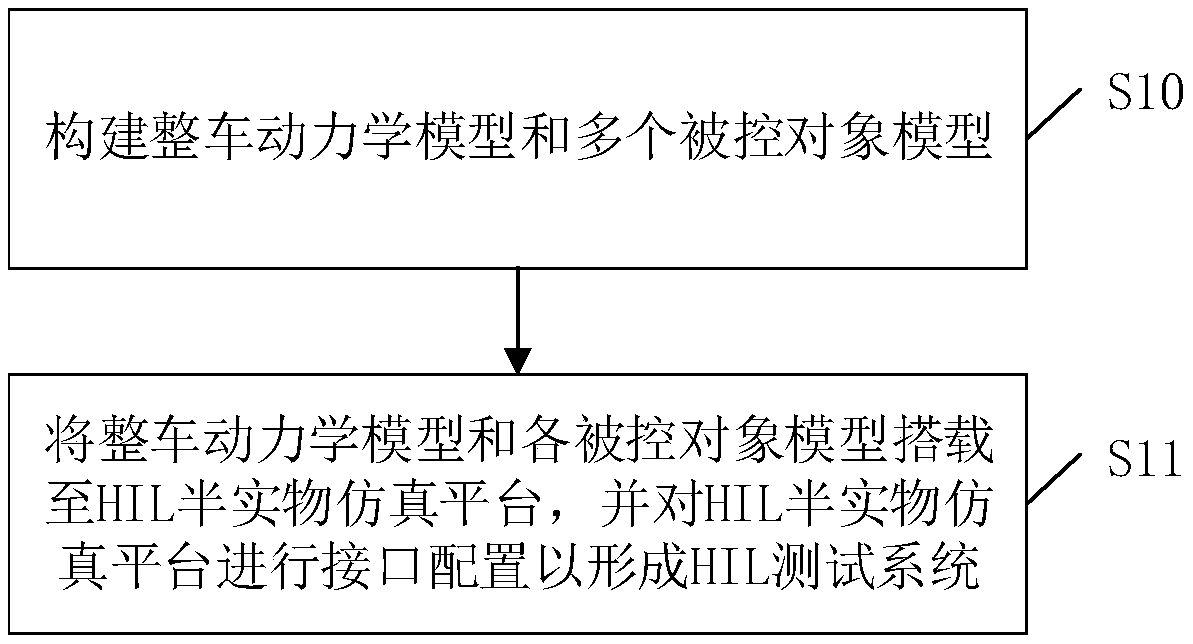

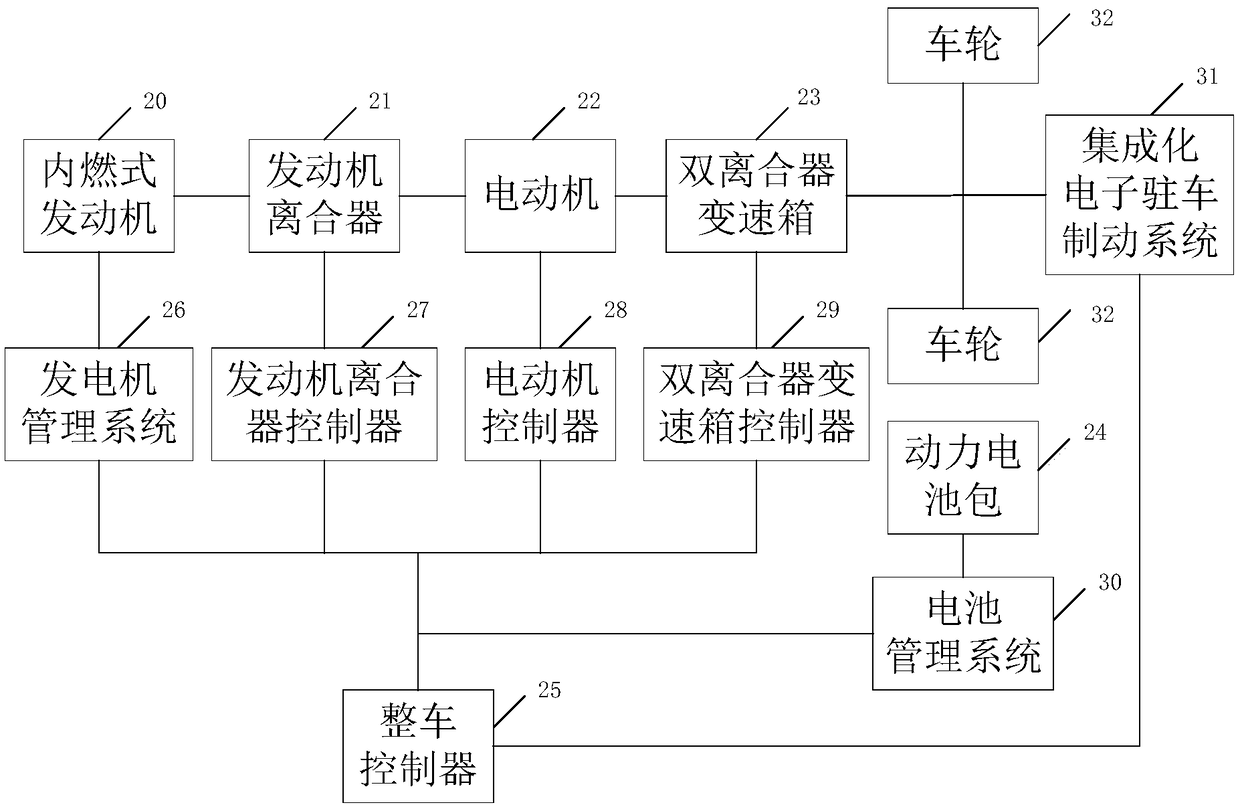

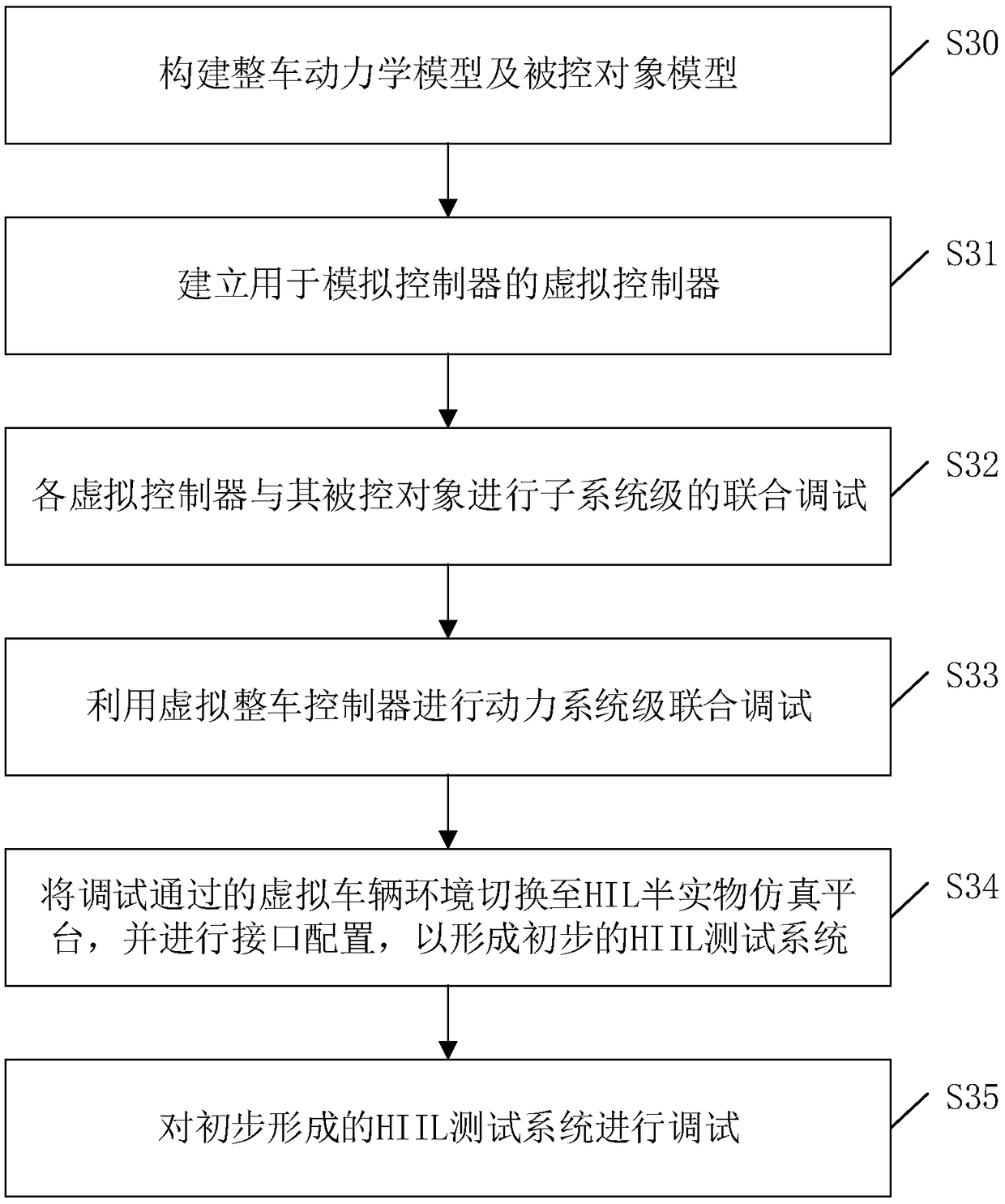

Design method for HIL test system, and HIL test system

The invention discloses a design method for an HIL test system. The design method comprises the steps of building a complete vehicle dynamics model and a plurality of controlled object models at leastincluding an engine model, a power coupling mechanism model, a motor model and a battery model; carrying the complete vehicle dynamics model and the controlled object models on an HIL semi-physical simulation platform; performing interface configuration on the HIL semi-physical simulation platform, so that the finally formed HIL test system can be matched with cooperative work of an engine controller, a coupling mechanism controller, a motor controller and a battery management system in a power system of a hybrid power new energy automobile; and switching a pure-electric, pure-maneuver or engine and motor hybrid drive working mode of a virtual vehicle, so that the HIL test of the power system of the hybrid power new energy automobile is completed. In addition, the invention discloses theHIL test system, which has the abovementioned effects.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

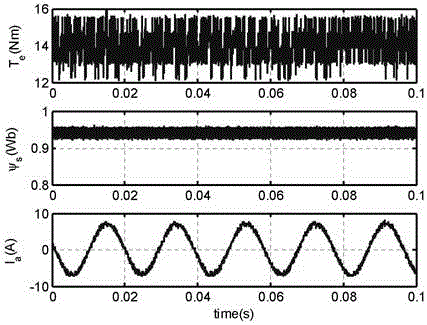

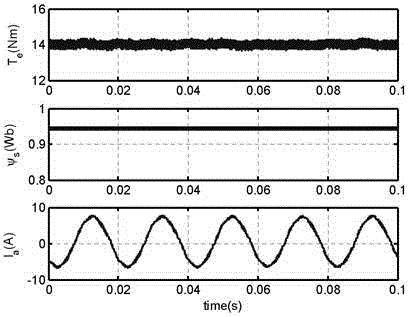

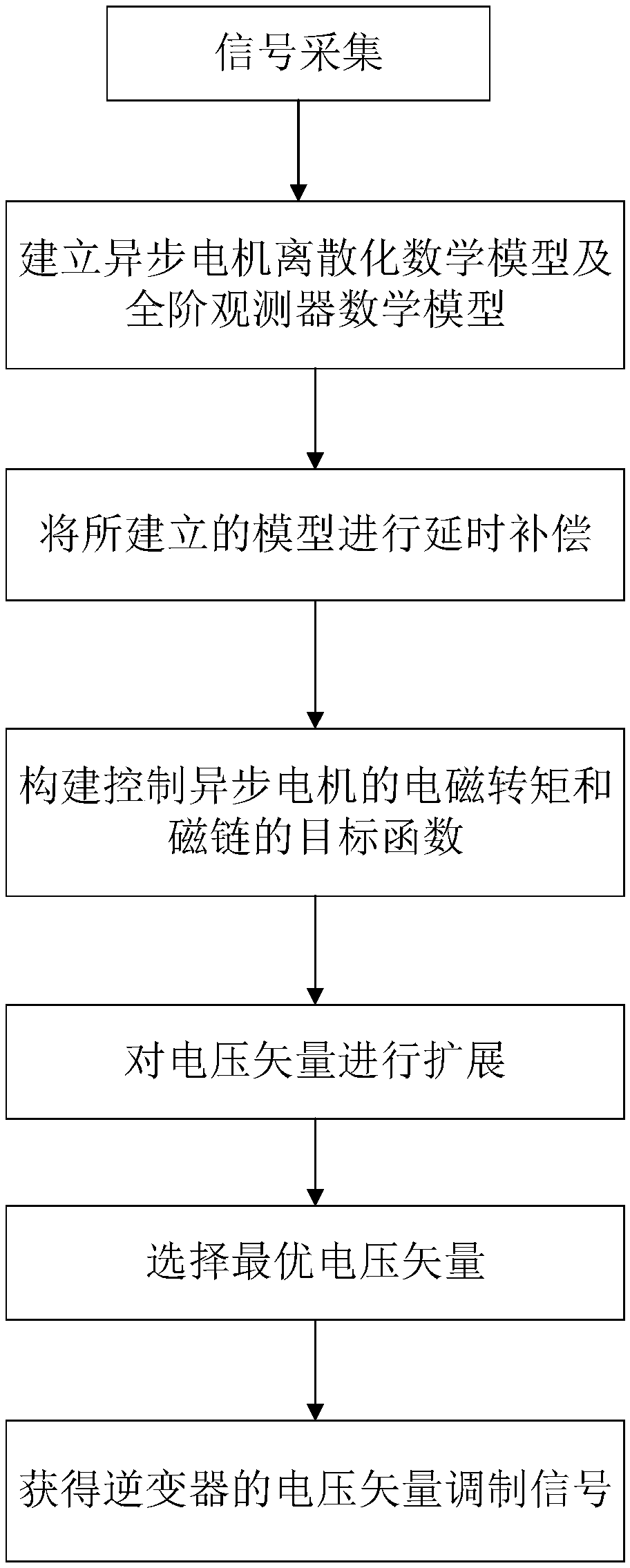

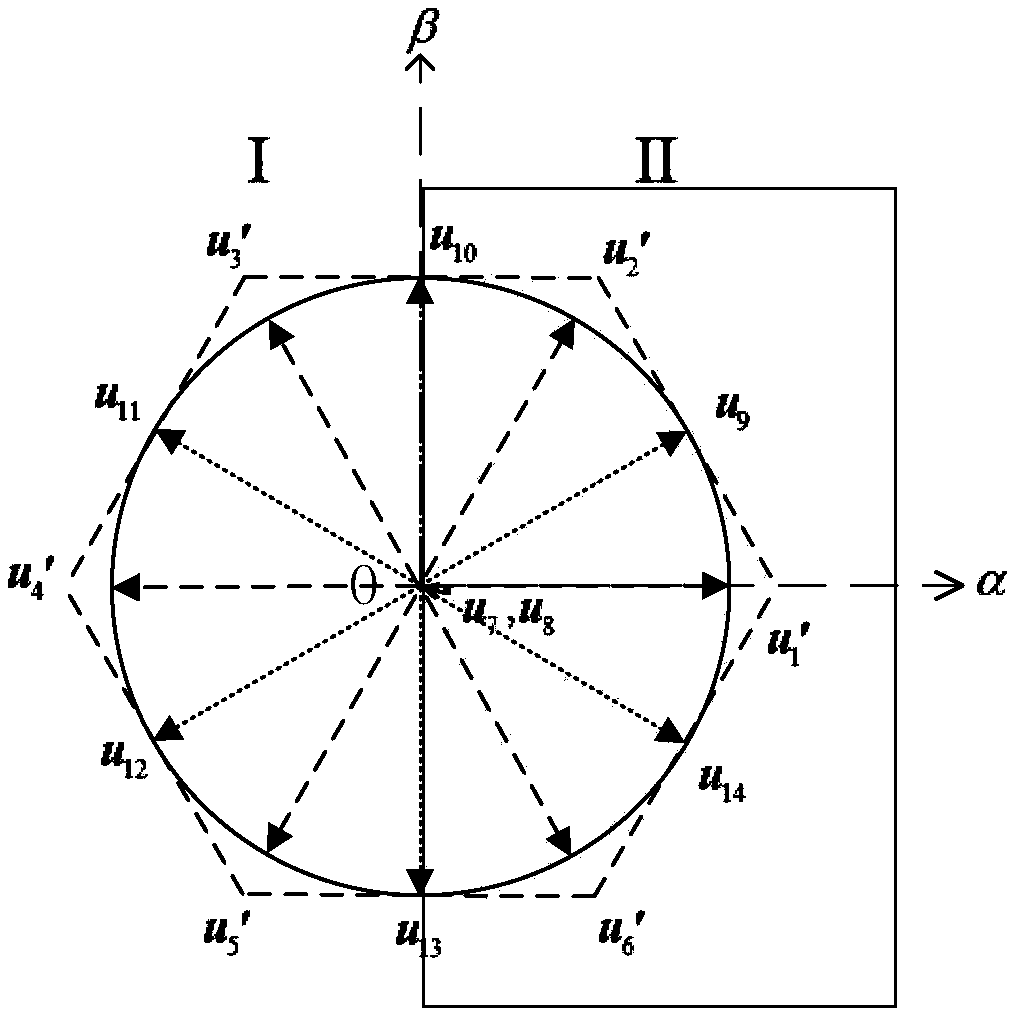

A model predictive control method for induction motor based on extended control set

ActiveCN109274303ASolve the problem of large torque rippleImprove stabilityElectronic commutation motor controlVector control systemsDigital signal processingVoltage vector

The invention discloses an asynchronous motor model predictive control method based on an extended control set, which relates to the technical field of asynchronous motor. The discretization mathematical model and full-order observer mathematical model of asynchronous motor are established, and the collected signals are substituted into the model. The model is compensated for the time delay. The objective function of electromagnetic torque and flux linkage of induction motor is constructed. Expanding the voltage vector; Selection of optimal voltage vector; According to the switching state andduty cycle of the switching transistor corresponding to the selected optimal voltage vector, the on-time of the switching transistor is obtained, the value of the comparison register is updated, and the switching signal of the inverter is generated by the digital signal processor to complete the generation of the voltage vector modulation signal of the inverter. The advantages are that the controlset is extended, the problem of large torque ripple is solved, and the stability of steady-state operation of the system is improved.

Owner:HEFEI UNIV OF TECH

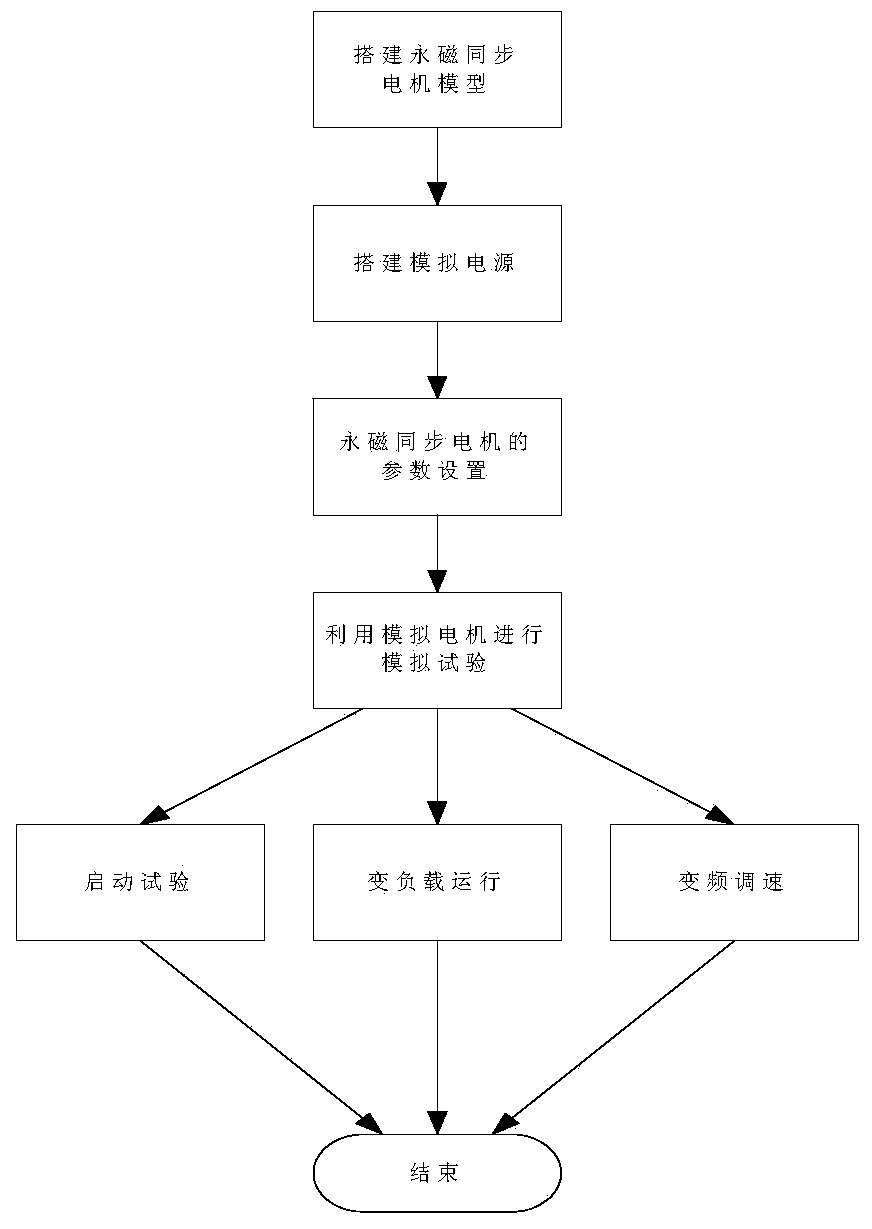

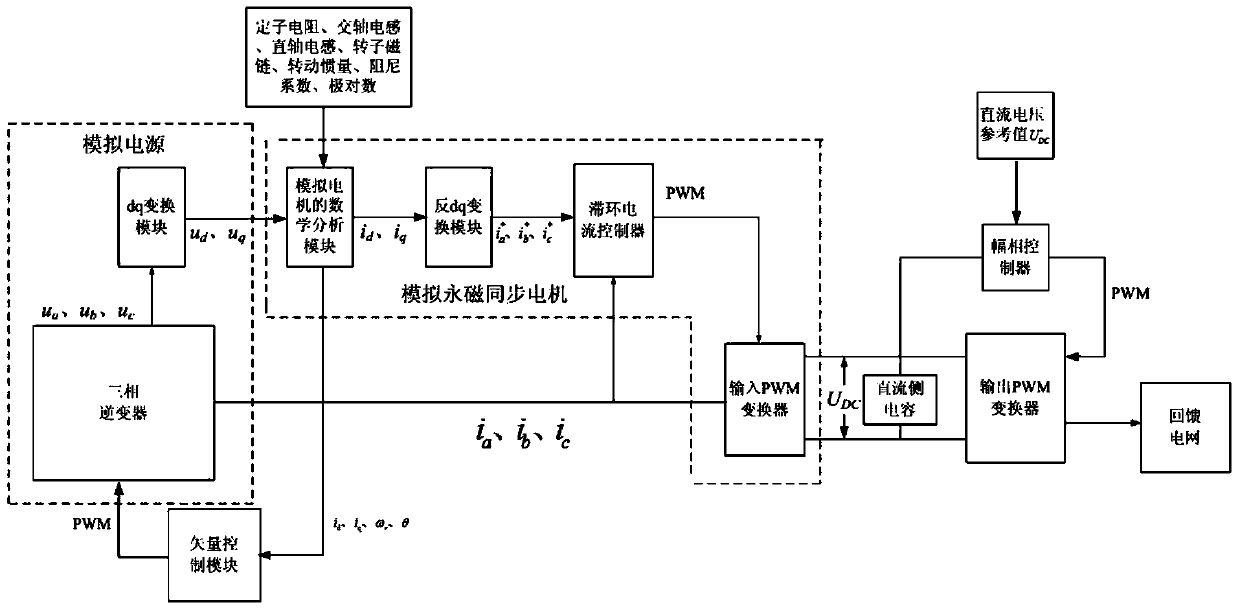

Power simulation method of permanent magnet synchronous motor

ActiveCN103472391ASimulation is accurateAdaptableDynamo-electric machine testingElectronic loadElectric power system

The invention belongs to the application field of a power electronic technology in a power system, in particular relates to a power simulation method of a permanent magnet synchronous motor, and provides a novel method for power simulation of the permanent magnet synchronous motor. A simulated motor model capable of accurately simulating the permanent magnet synchronous motor is designed by adopting double PWM (Pulse-Width Modulation) converter structures according to the basic characteristics of the permanent magnet synchronous motor, wherein the converters at a rectifier side of the simulated motor model are controlled according to the characteristics of the permanent magnet synchronous motor, so that the external interface characteristic voltage, the current, the rotating speed and other information of the simulated motor model are consistent with those of the actual motor; and the energy is fed back to a supply network by the inverter side. The simulated motor model is compact in whole structure design and is capable of accurately simulating the static characteristics and the dynamic characteristics of the actual permanent magnet synchronous motor. The simulated motor model is strong in adaptability, namely, the simulated motor model can be used for simulating various types of permanent magnet synchronous motors by only changing parameter setting in the simulated motor model. The electric energy during the testing is fed back to the supply network by the inverter side due to the adoption of an energy-feedback-type electronic load structure, so that the energy saving is realized.

Owner:TSINGHUA UNIV

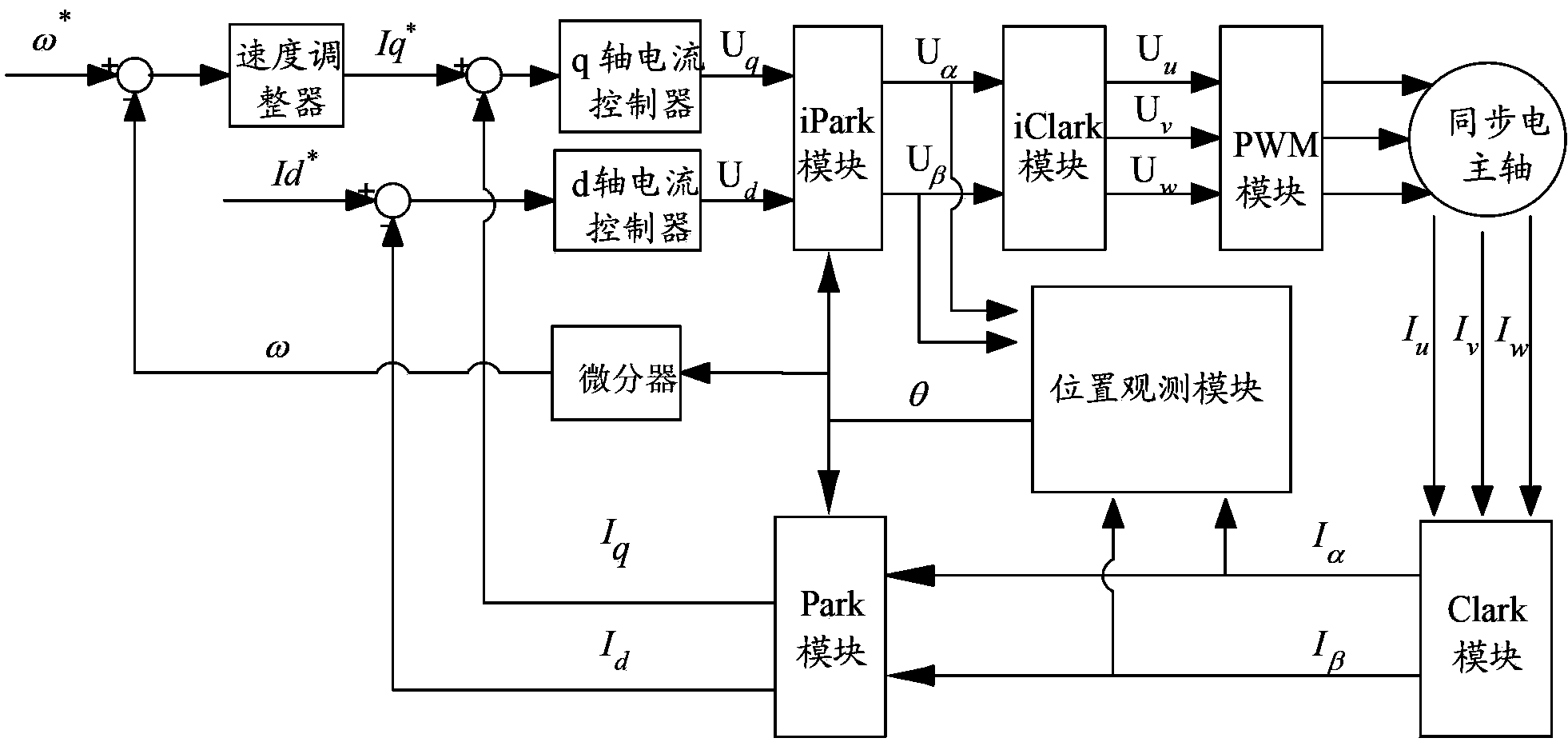

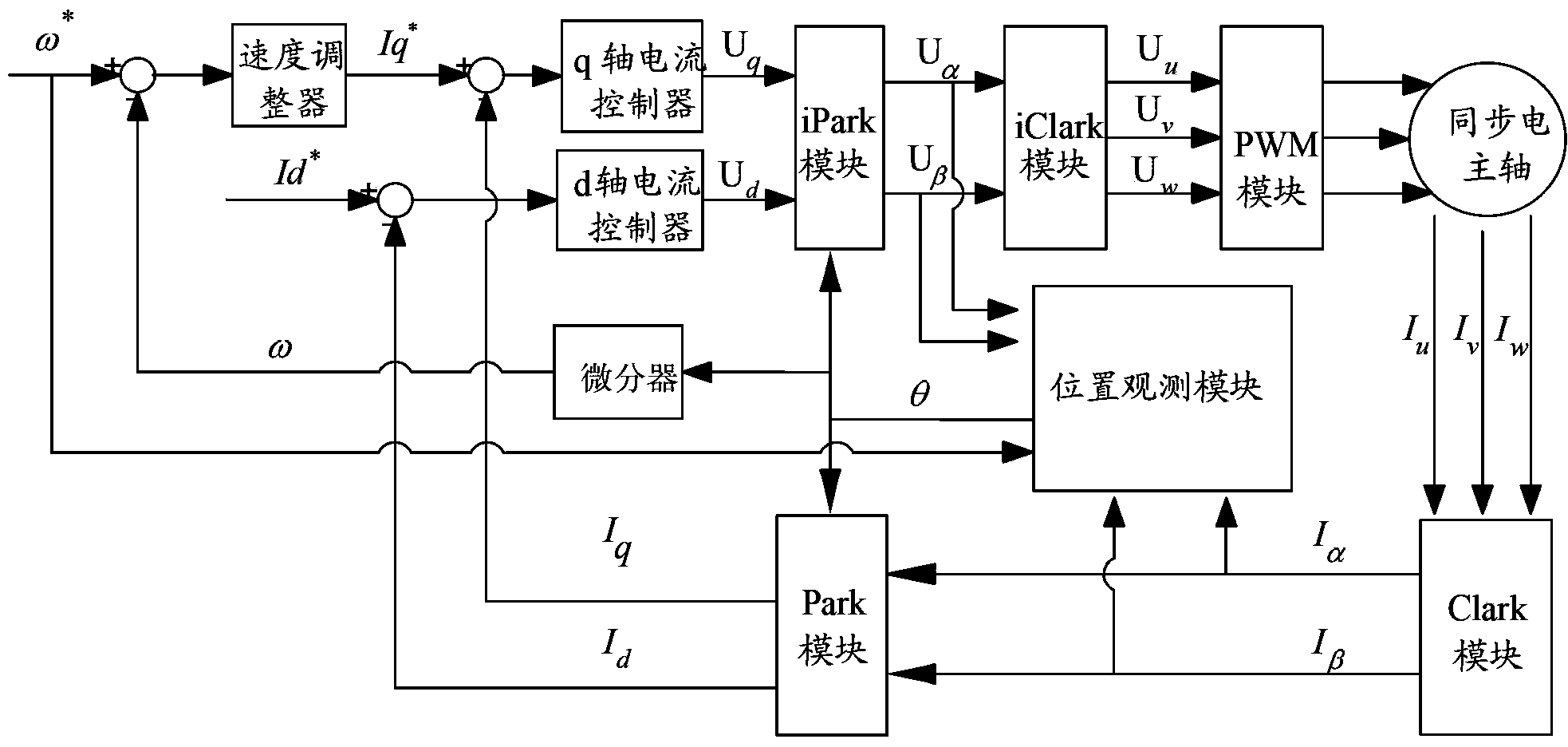

Control system and method for permanent magnet synchronous electric spindle driving

ActiveCN103401493AGuaranteed uptimeObserve the actual angleAC motor controlVector control systemsControl vectorElectric machine

The invention relates to a control system and method for permanent magnet synchronous electric spindle driving. The system carries out vector control to a sensor-less permanent magnet synchronous motor through the adoption of a position observation module. The position observation module comprises a motor model module, a counter electromotive force estimation module and an angle back calculation device, wherein the counter electromotive force estimation module is realized based on an internal model control principle comprising an electric angular velocity summit. The control system and method for the permanent magnet synchronous electric spindle driving can accurately observe the real angle of a rotor, so that the operation performance of the permanent magnet synchronous electric spindle can be improved.

Owner:GOOGOL TECH SHENZHEN LTD GUANGDONG

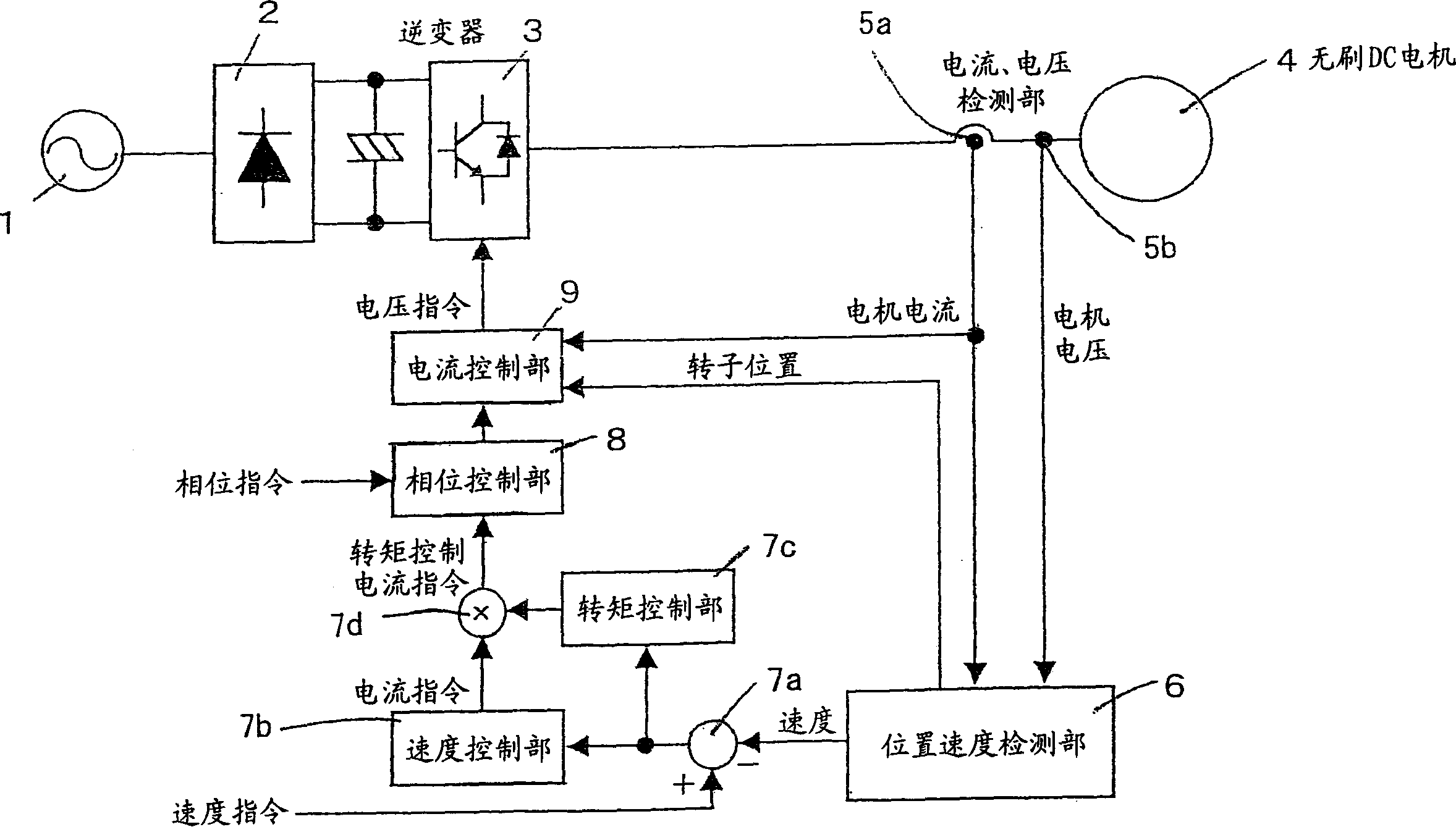

Synchronous motor control method and device thereof

InactiveCN1479965APrevent or significantly suppress speed fluctuationsImprove controllabilityTorque ripple controlAC motor controlSynchronous motorTerminal voltage

The invention provides a synchronous motor control device comprising a current detection unit for detecting current supplied to the synchronous motor, a voltage detection means for detecting a terminal voltage, a position / speed detection unit for computing the rotation speed and rotation position of a rotor from motor model-set current and voltage, a speed difference calculating unit for calculating the difference between the detected speed and an externally-given speed command, a speed control unit for computing a current command from the speed difference so that an average speed agrees with the speed command, a torque control unit for computing a current amplifying modulation signal from the speed difference so as to correct a current command, a multiplying unit for multiplying the current command by the current amplifying modulation signal to calculate a torque control current command, a phase control unit for computing a final current command from the torque control current command and an externally-given phase command, and a current control unit for computing a voltage command from the detected rotor position, motor current and final current command to supply it to an inverter.

Owner:DAIKIN IND LTD

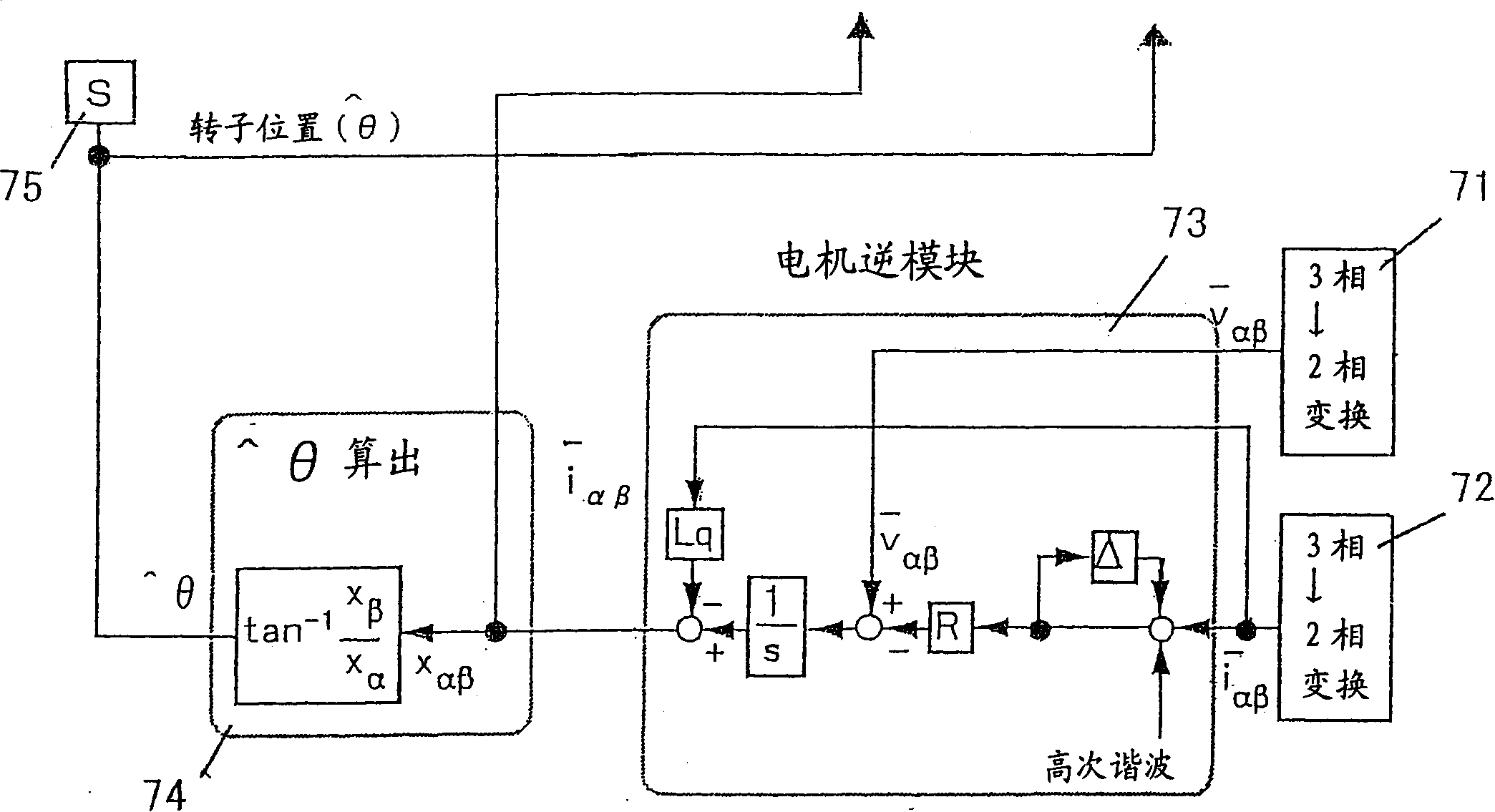

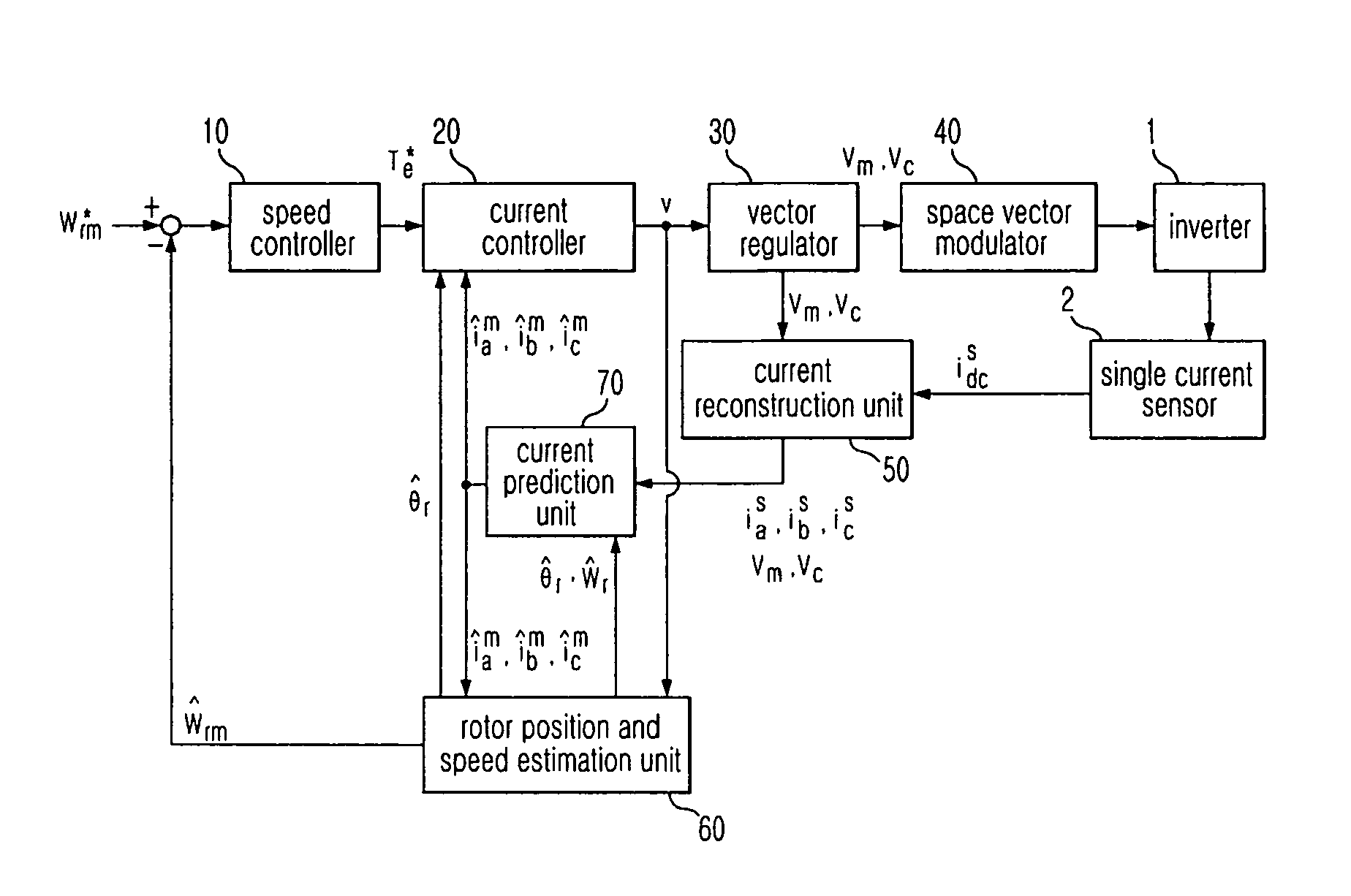

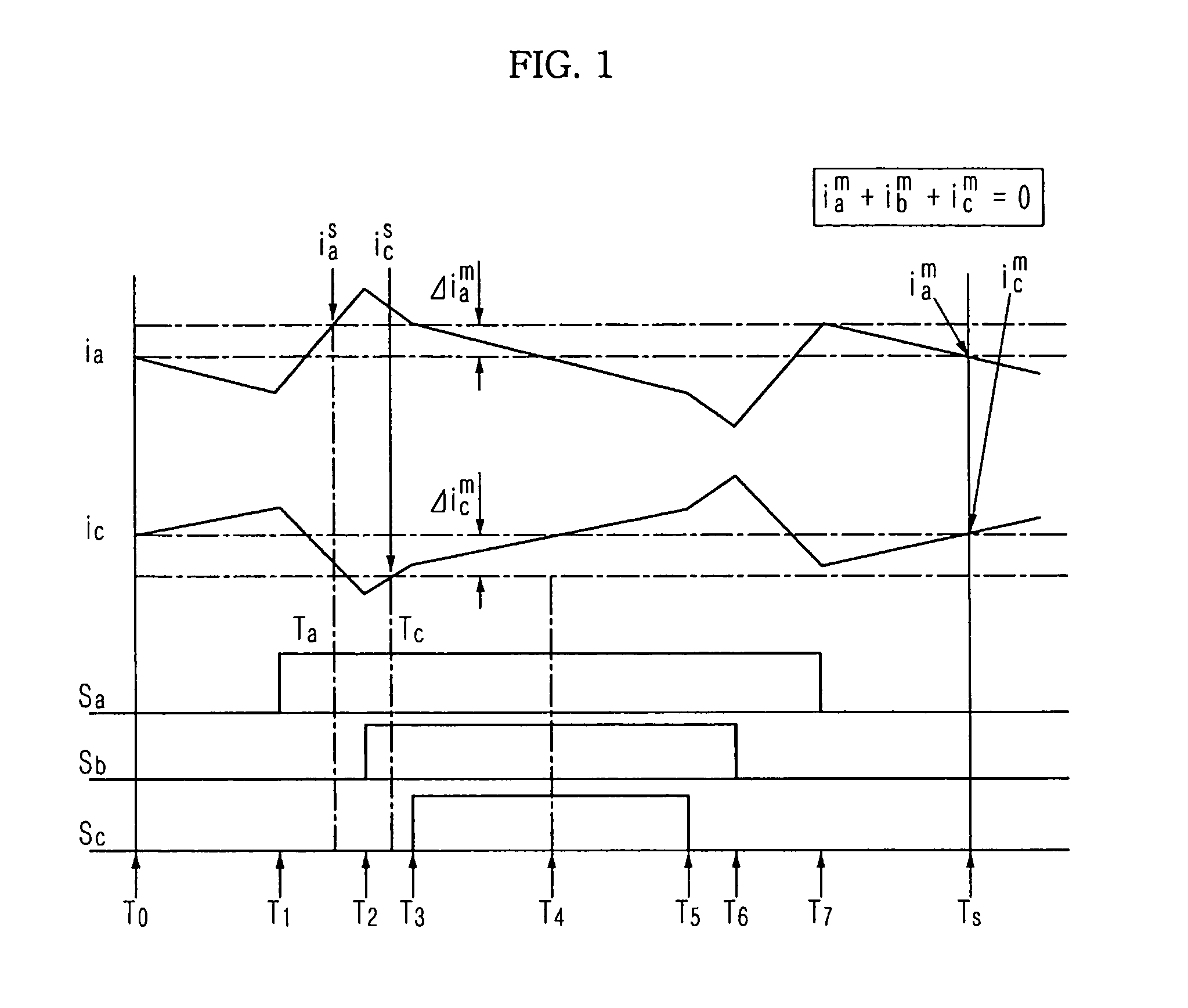

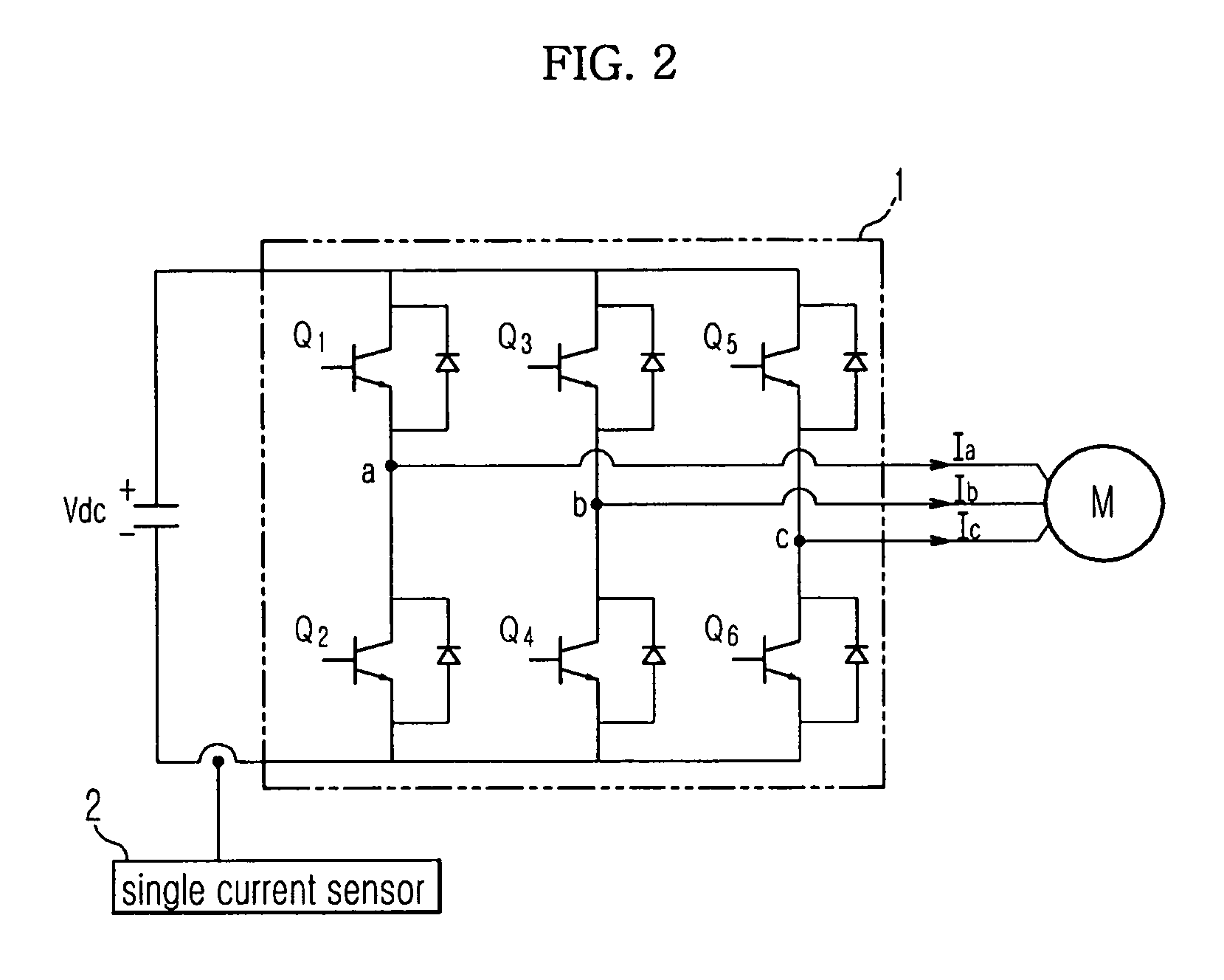

Method to predict phase current

ActiveUS8362759B2Total current dropSingle-phase induction motor startersAC motor controlPhase currentsCurrent sensor

A phase current prediction method is disclosed. The phase current prediction method predicts current representative of a PWM period using a motor model which receives current measured through a single current sensor as an input, instead of the measured current, and determines the predicted current to be phase current.

Owner:SAMSUNG ELECTRONICS CO LTD

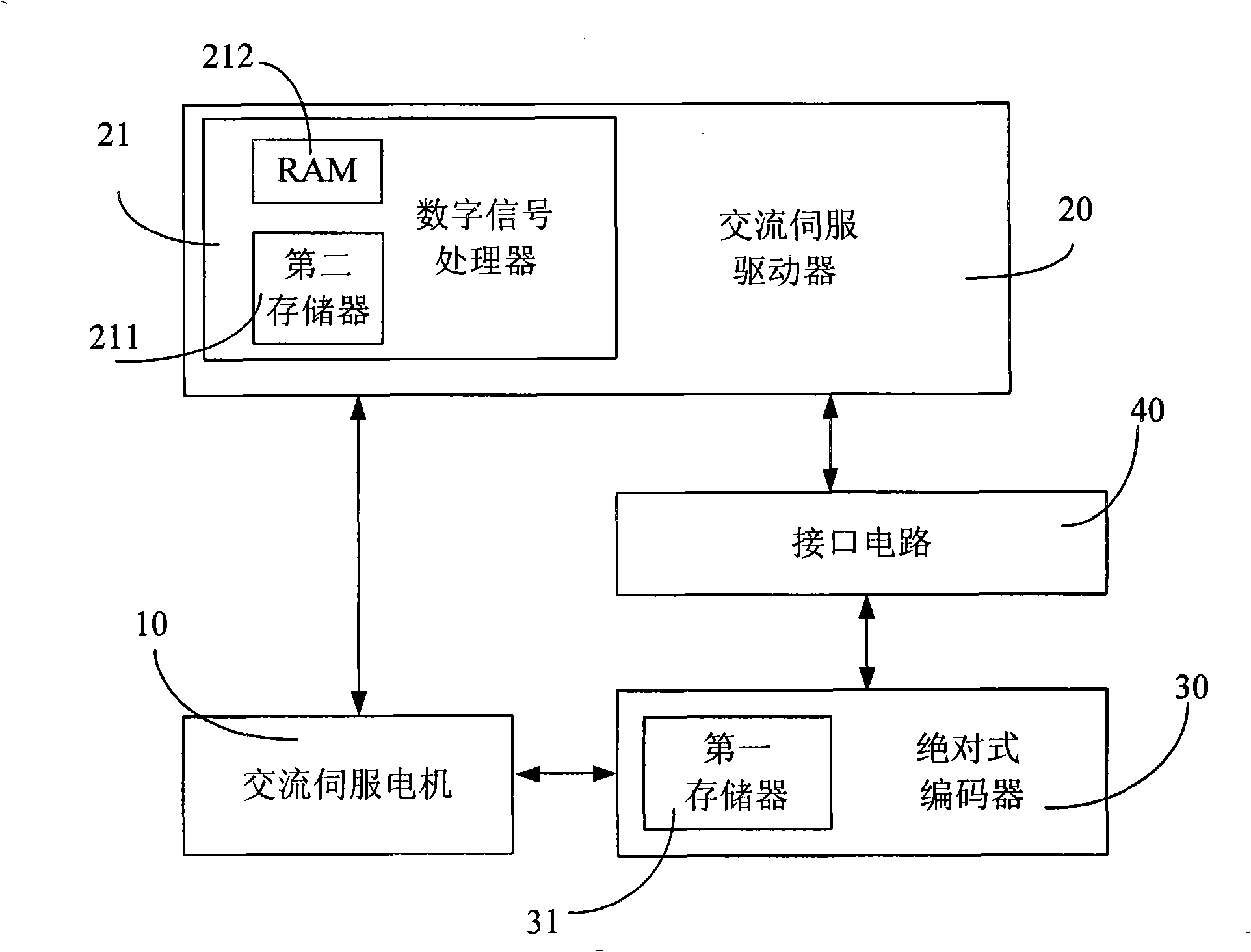

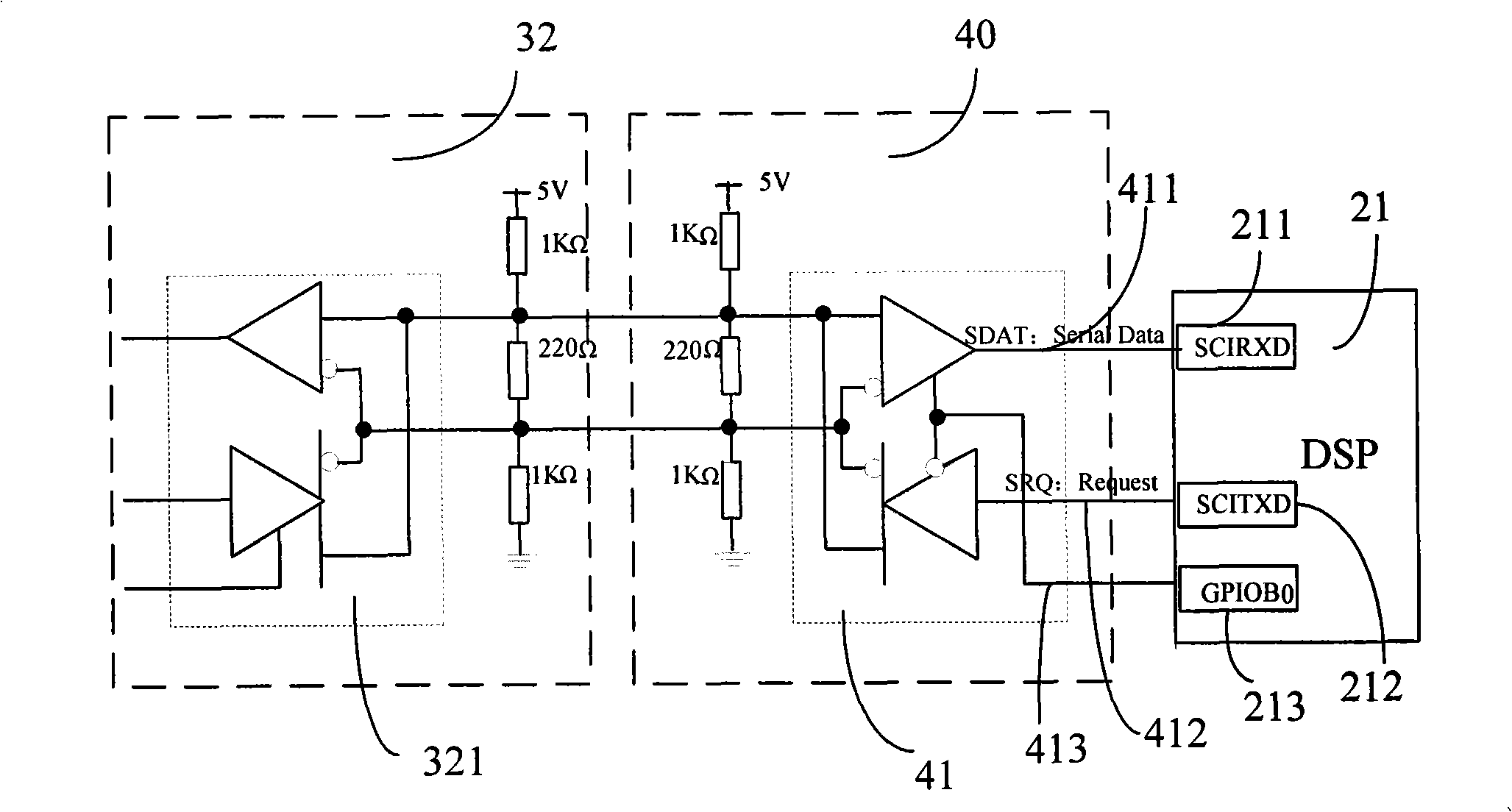

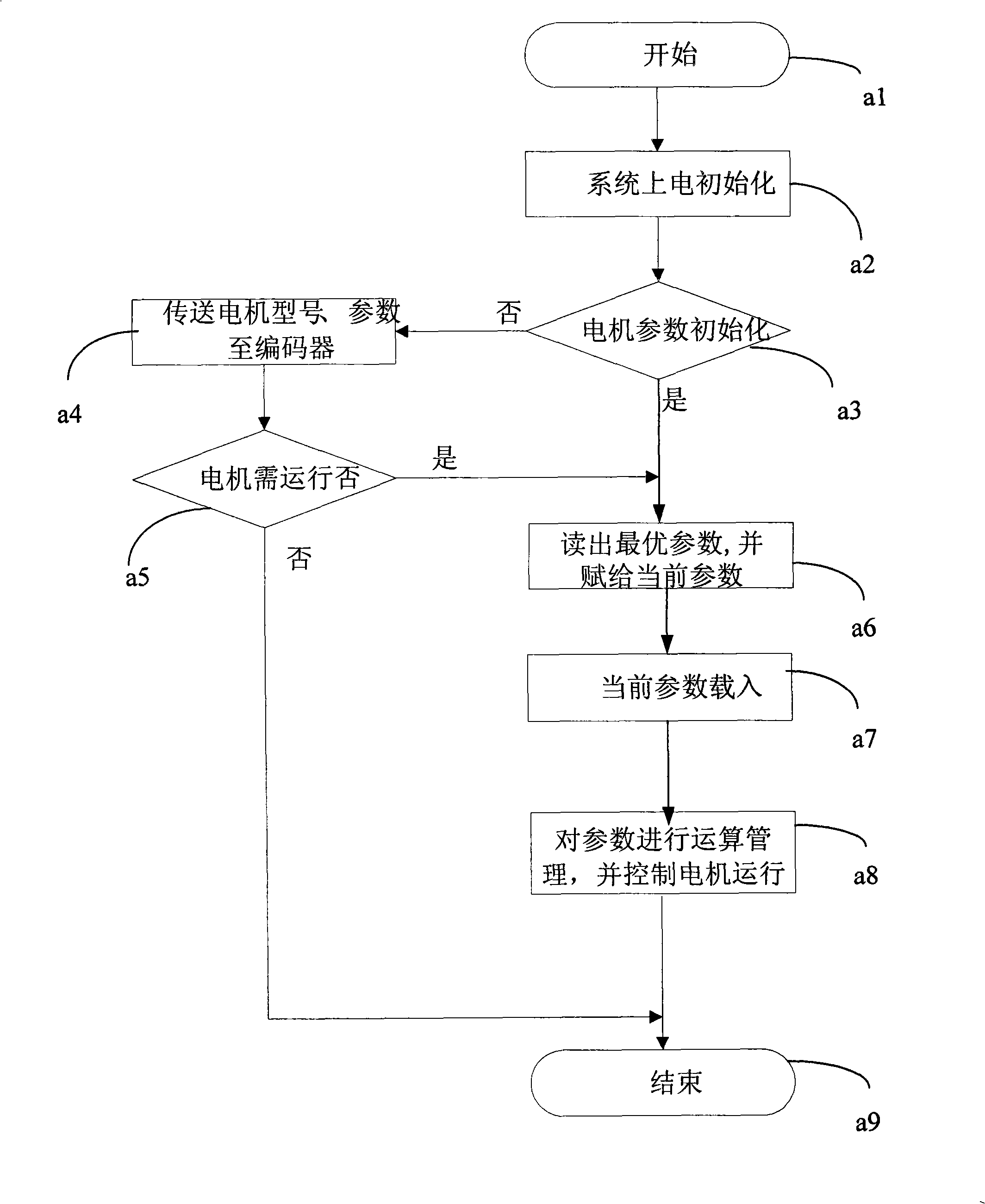

Apparatus and method for automatically recognizing AC servo motor model number and parameter

InactiveCN101304232AEasy to operateEasy to useInput/output to record carriersMotor parameters estimation/adaptationData signalMotor model

The invention discloses a device for automatically recognizing the model and parameter of an AC servo motor and a method thereof. The device comprises an AC servo motor which is provided with an absolute type encoder and a servo driver which drives the AC servo motor; wherein, the absolute type encoder comprises a first memory which stores the model of the AC servo motor; the servo driver comprises a data signal processor which is provided with a second memory, the second memory stores a plurality of groups of models of AC servo motors and the default parameters corresponding to the models. The data signal processor reads out the default parameter which corresponds to the model of the AC servo motor from the second memory according to the model of the AC servo motor in the first memory. The device and method of the invention automatically recognizes the model and parameter of the AC servo motor without memorizes the models of different motors by human, thus has the advantages of conveniently operation and safety in use for the operators.

Owner:GSK CNC EQUIP

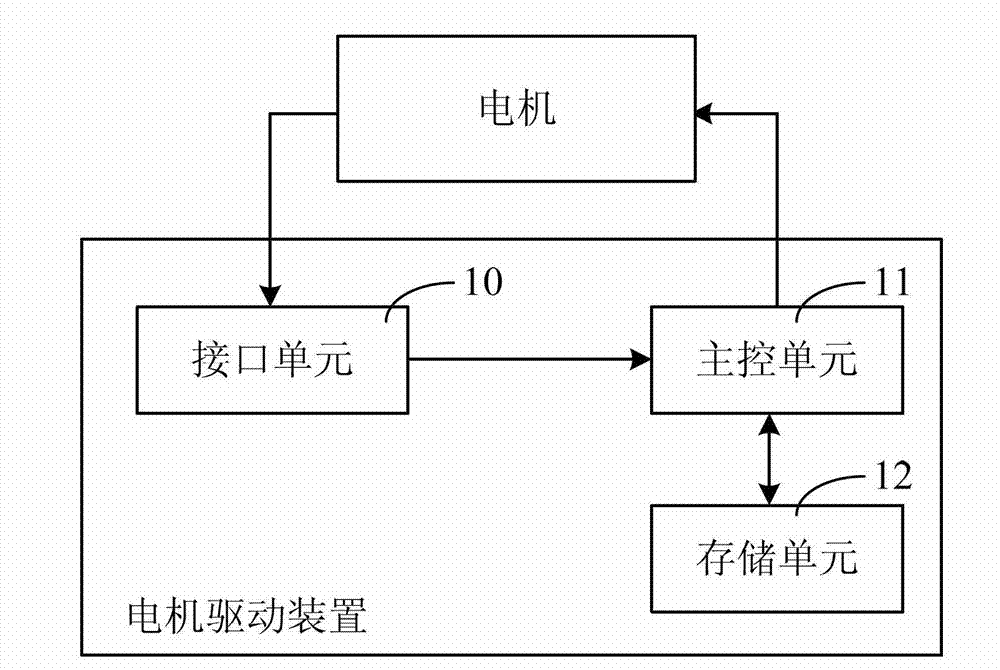

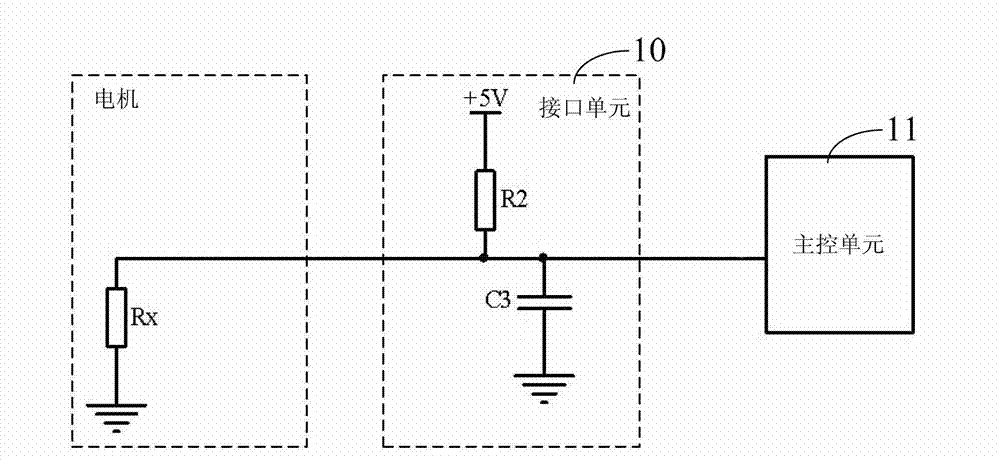

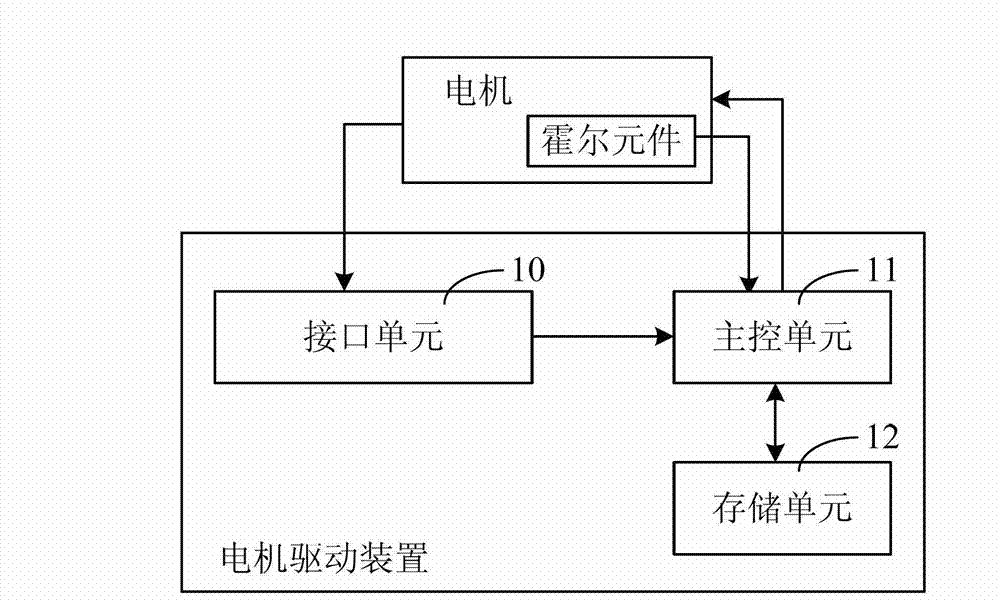

Motor driving device and driving method

The invention provides a motor driving device, which comprises an interface unit, a storage unit and a main control unit, wherein the interface unit is used for obtaining code information of the connected motors, the storage unit is used for storing the code information of each motor and the corresponding driving parameter of each motor, the main control unit is respectively connected with the interface unit and the storage unit, and the main control unit is used for calling the motor driving parameter corresponding to the code information from the storage unit according to the obtained code information, so as to drive the motor to run. The invention also discloses a motor driving method. The motor driving device has the advantage that the motor model can be automatically identified by a simple identification circuit, and then the motor is driven, so as to realize the self-adaptive performance of the motor.

Owner:FOSHAN SHUNDE HAIER INTELLIGENT ELECTRONICS CO LTD

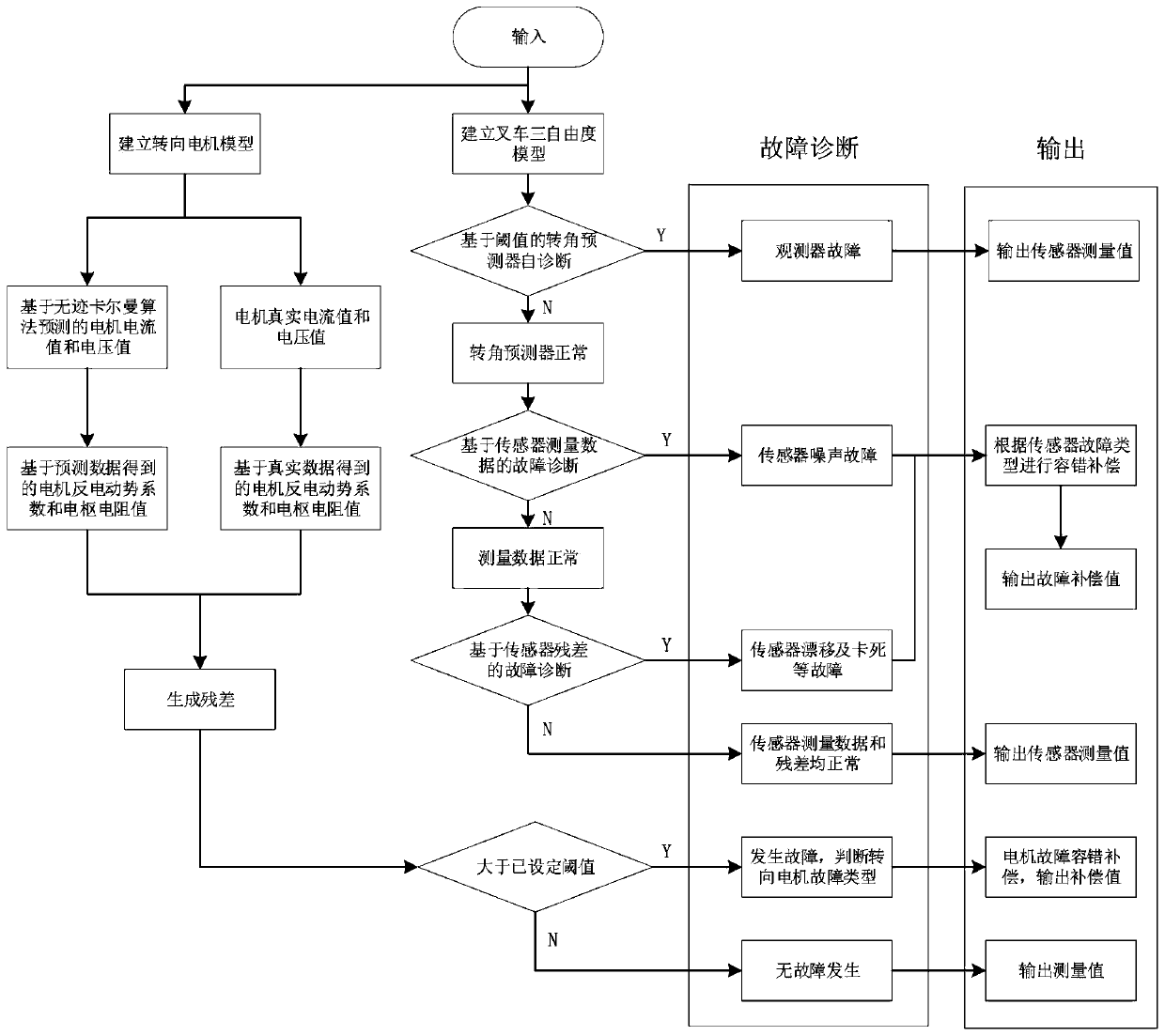

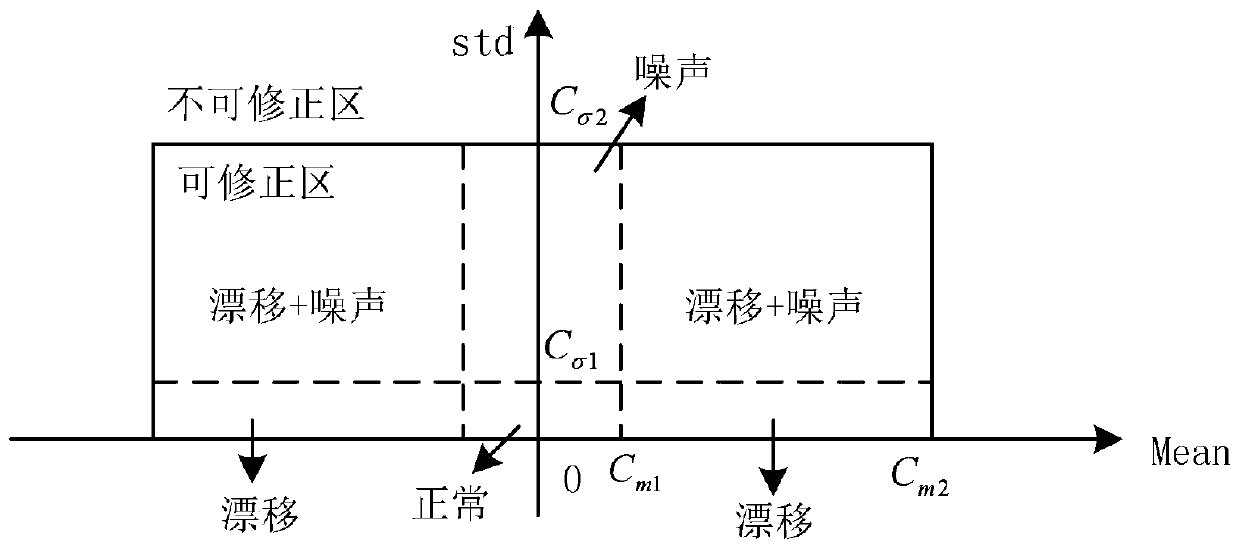

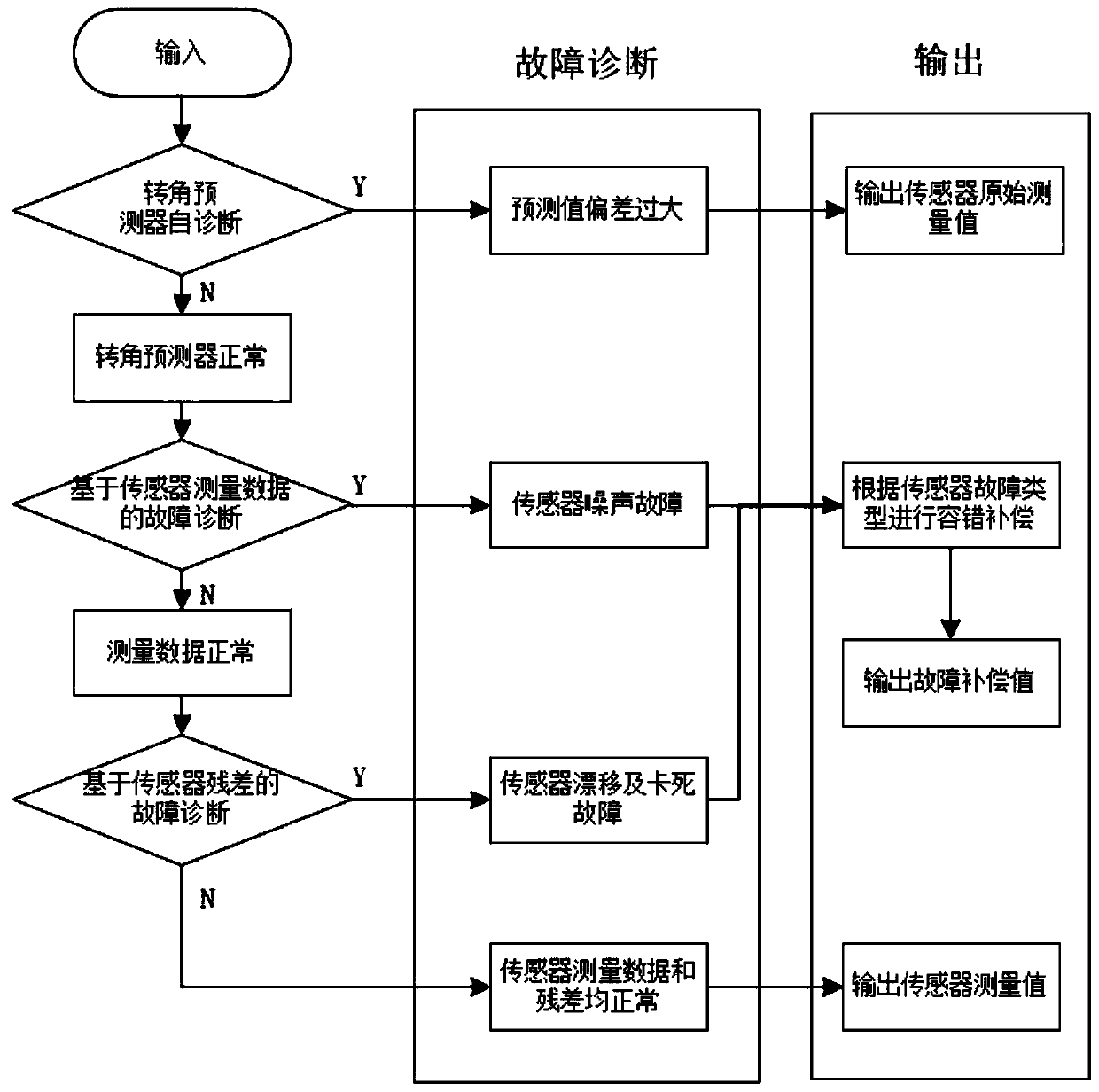

Fault diagnosis and fault-tolerant compensation algorithm for steer-by-wire motor and sensor

InactiveCN111422247AAvoid interferenceQuick distinctionElectrical steeringControl devicesFault toleranceElectric machinery

The invention relates to a fault diagnosis and fault-tolerant compensation algorithm for a steer-by-wire motor and a sensor. The algorithm comprises the steps of building a three-degree-of-freedom dynamic joint model of a steering mechanism and an electric forklift, and designing a traceless Kalman filtering algorithm to design a corner predictor, establishing a steering motor model, carrying outwheel rotation angle prediction and predictor self-diagnosis, analyzing fault type characteristics of the corner motor and the sensor and modeling various types of faults, designing a fault diagnosisalgorithm based on sensor measurement data, designing a fault diagnosis algorithm based on sensor data residual errors, using a corresponding fault tolerance compensation algorithm according to the sensor fault type, and designing a fault diagnosis method and a fault type judgment method of the steering motor. An error prediction value can be effectively prevented from entering a system fault diagnosis and fault-tolerant compensation module, and misjudgment of the system is avoided. And meanwhile, modeling is carried out for fault characteristics, the accuracy is higher than that of a traditional fault modeling method, and the fault types can be distinguished more effectively and quickly.

Owner:HEFEI UNIV OF TECH

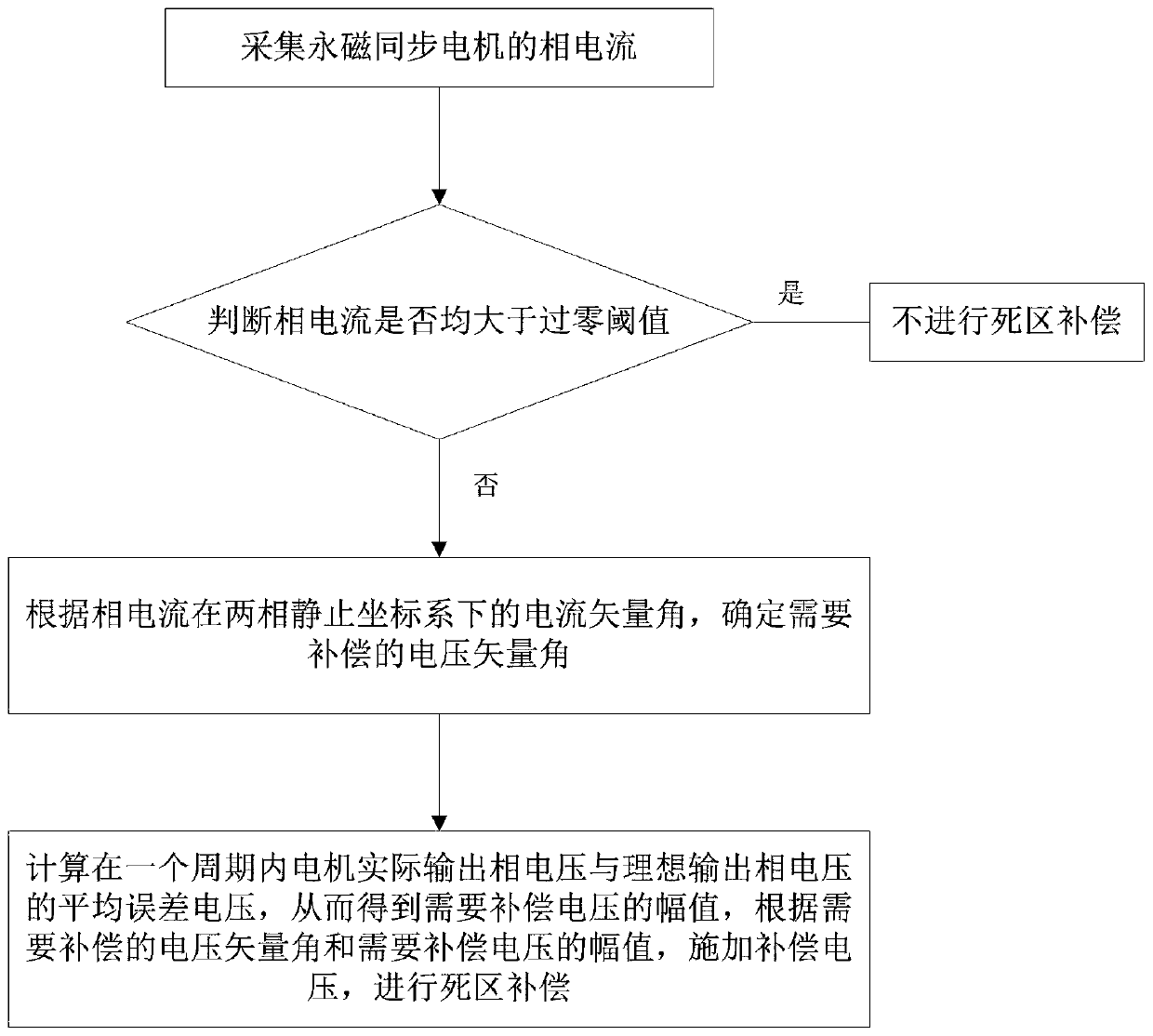

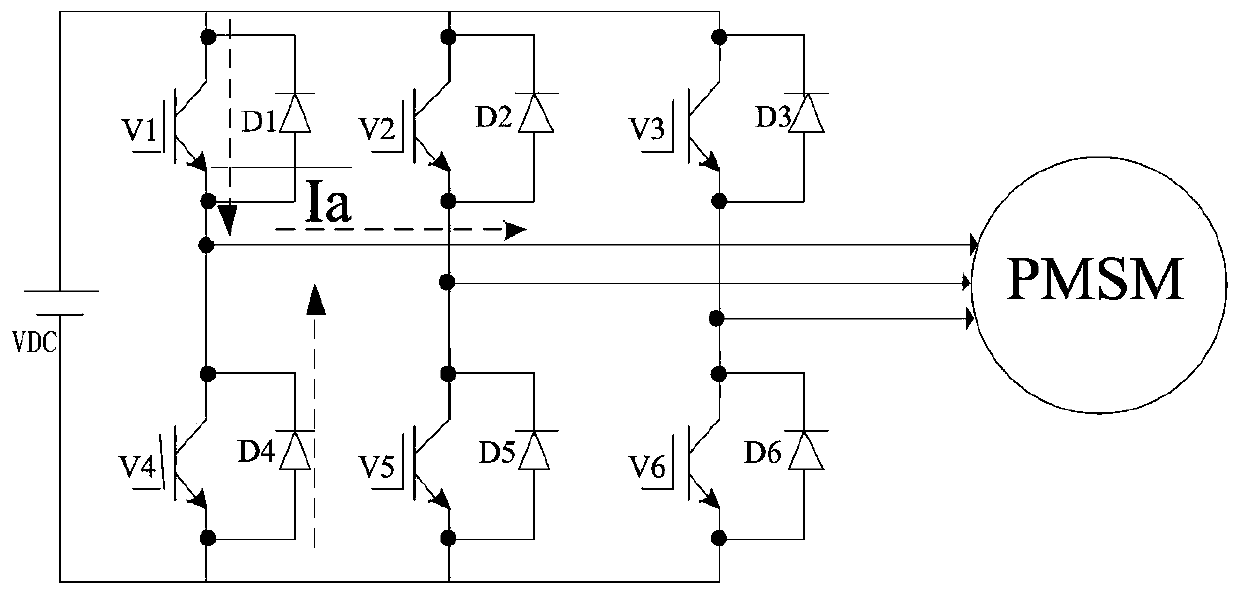

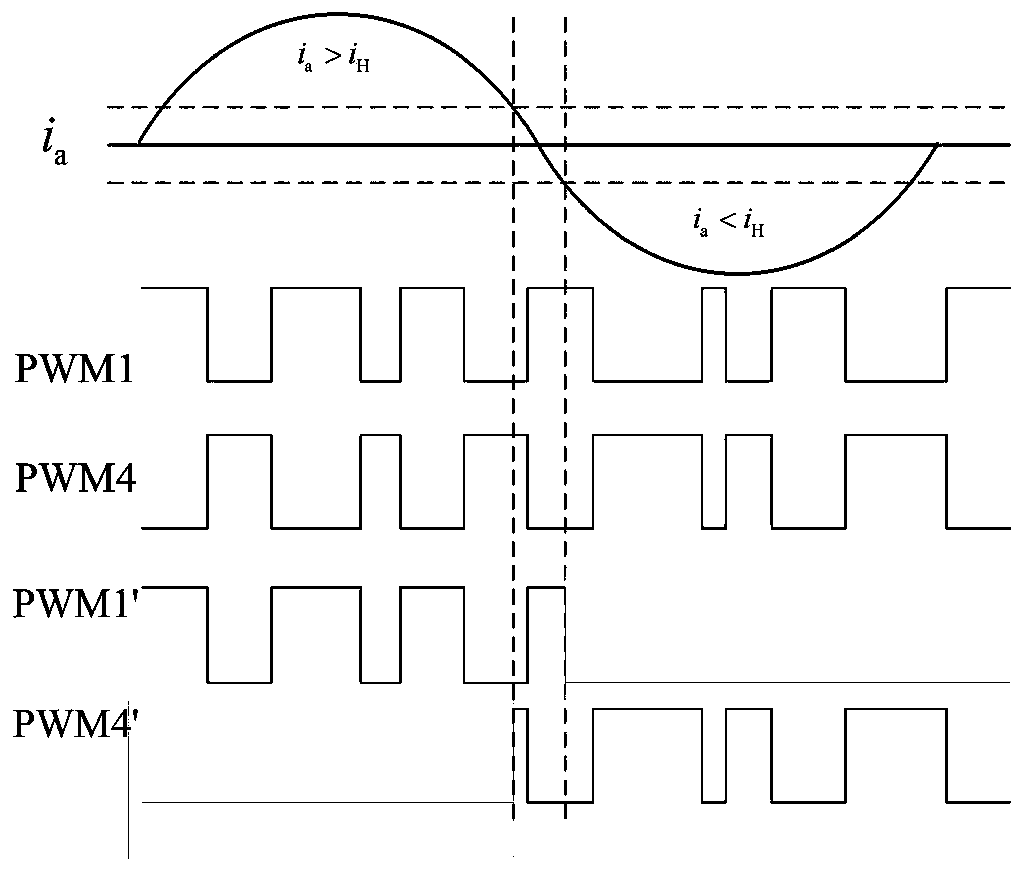

Vector controlled "dead-time effect" compensation method for permanent magnet synchronous motor

InactiveCN110071669ALow costPrevent false compensationElectronic commutation motor controlAC motor controlPhase currentsDead time

The invention relates to a vector controlled "dead-time effect" compensation method for a permanent magnet synchronous motor, and belongs to the technical field of permanent magnet synchronous motors,and solves the problems in the prior art such as compensation effect dependent on the accuracy of the motor model, need for additional hardware, complicated calculation and compensation by mistakes.The vector controlled "dead-time effect" compensation method for permanent magnet synchronous motor comprises the following steps: collecting phase currents ia, ib, ic of the permanent magnet synchronous motor; respectively comparing |ia|, |ib| or |ic| with a zero-cross threshold iH, if |ia|, |ib| or |ic| is less than or equal to the zero-cross threshold iH, performing the dead time compensation;otherwise, not performing the dead time compensation. The dead time compensation comprises steps of determining a voltage vector angle that needs to be compensated; calculating an average error voltage of the output phase voltages in a cycle, thereby obtaining the amplitude of the voltage to be compensated, applying a compensation voltage according to the voltage vector angle to be compensated andthe amplitude of the voltage to be compensated for performing a dead time compensation, so as to the accurate and fast dead time compensation.

Owner:BEIJING MECHANICAL EQUIP INST

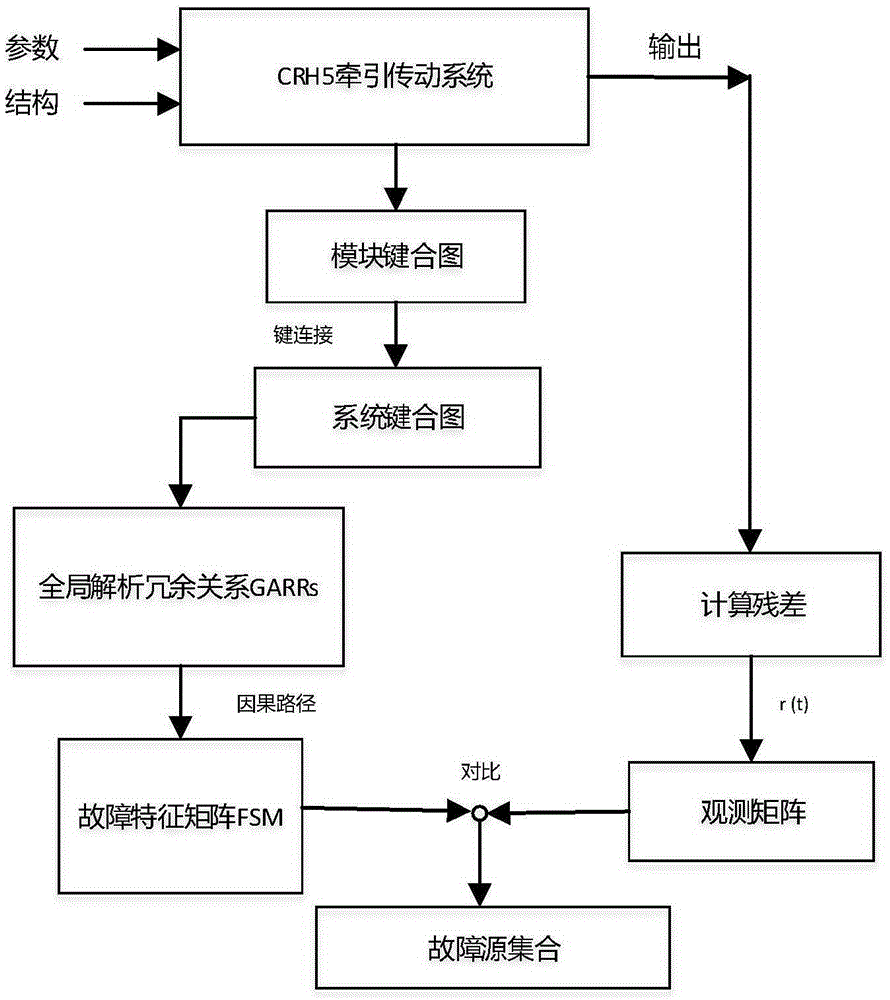

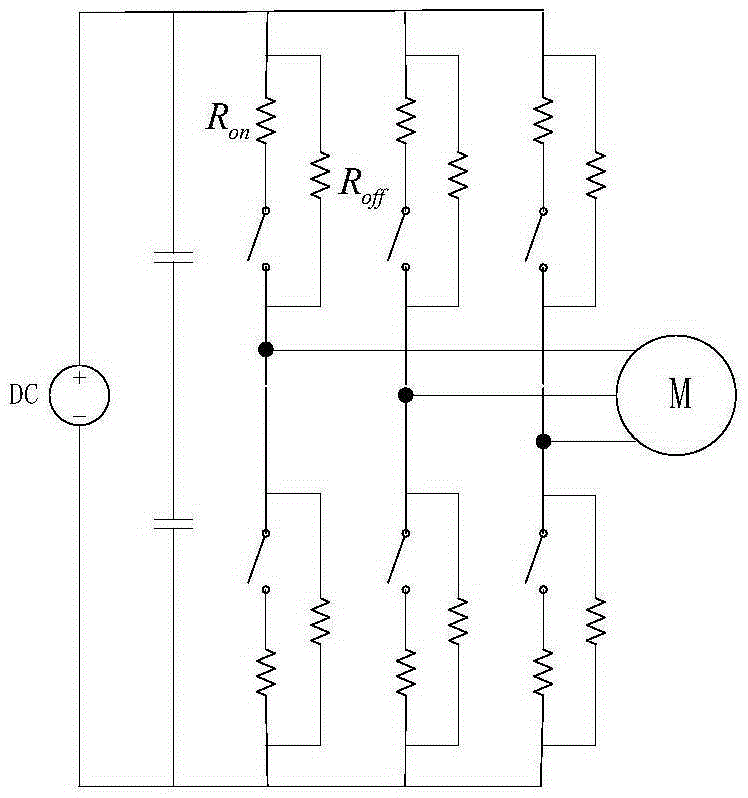

IGBT fault diagnosis method for traction drive system of CRH5 type high-speed train

ActiveCN105301470AGuaranteed uptimeFailure is timely and effectiveIndividual semiconductor device testingGraph modelBond graph

The invention discloses an IGBT fault diagnosis method for a traction drive system of a CRH5 type high-speed train, and the method comprises the steps: modeling a traction part bonding graph: respectively building a traction inverter model, a traction motor model, and a gearbox bonding graph model; carrying out system modeling: building a traction drive system model of a high-speed train, and simulating the operation states when the system is normal and an IGBT fault happens; building a global analysis redundancy relation: building a simplified system global analysis redundancy relation, obtaining a fault characteristic matrix, and analyzing a system fault propagation approach; carrying out fault diagnosis: enabling system output to be substituted into the global analysis redundancy relation, forming a residual error set and a consistency vector, comparing the residual error set and the consistency vector with the fault characteristic matrix, and detecting the health state of the system, and positioning an IGBT fault source. The method diagnoses the IGBT fault of the traction drive system of the high-speed train through employing a bonding graph method, builds the motor model through multiple bonding graphs, carries out the unified modeling of an electromechanical system, achieves the positioning of an IGBT element with a fault, and provides a solution for the modeling of the traction drive system of the CRH5 high-speed train and the diagnosis of the IGBT fault.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

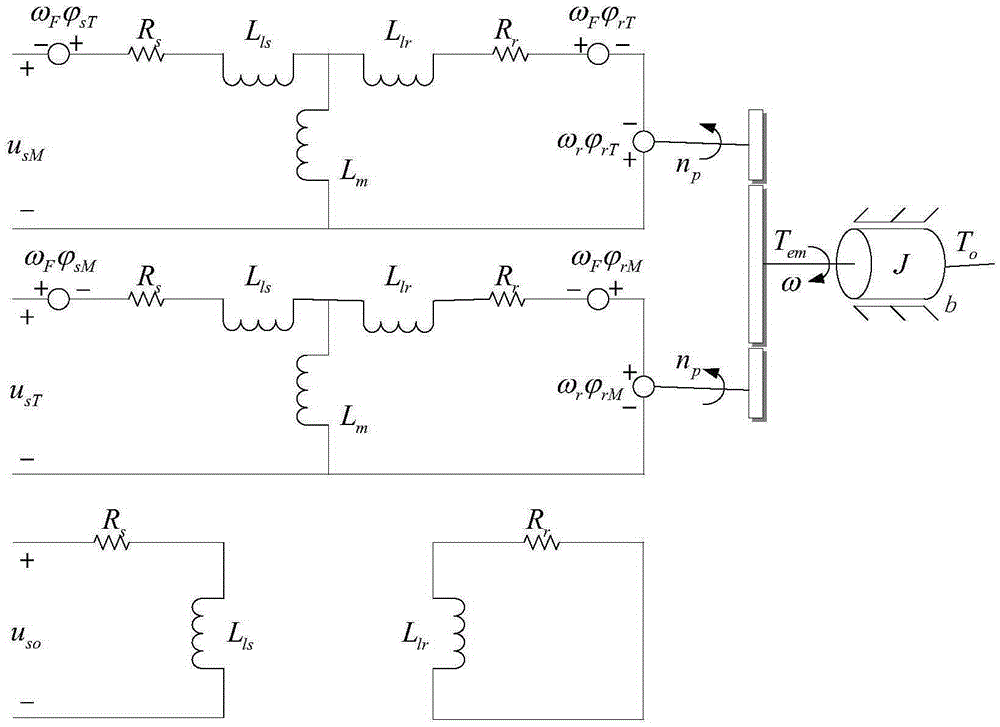

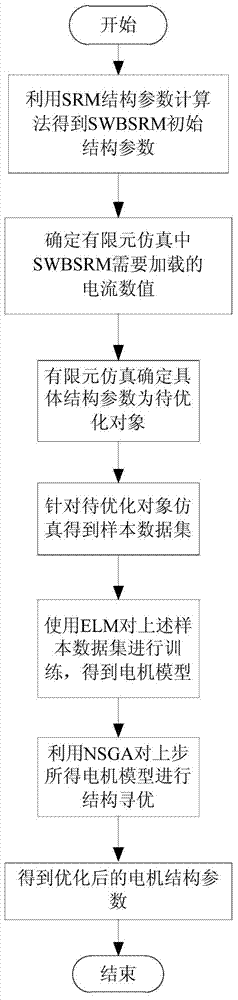

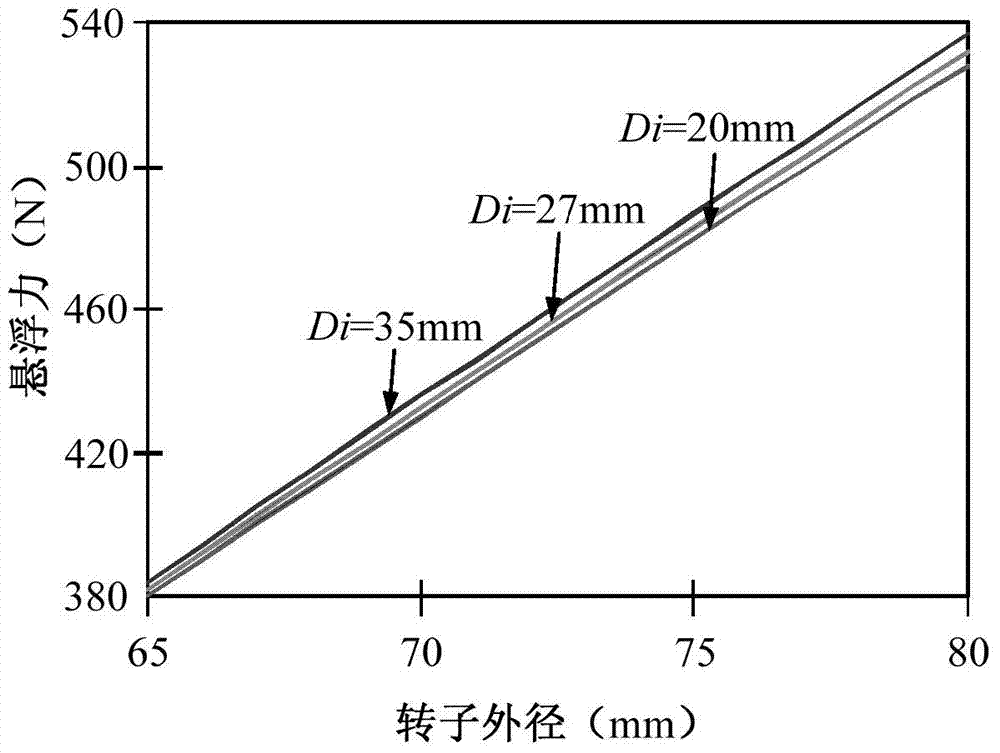

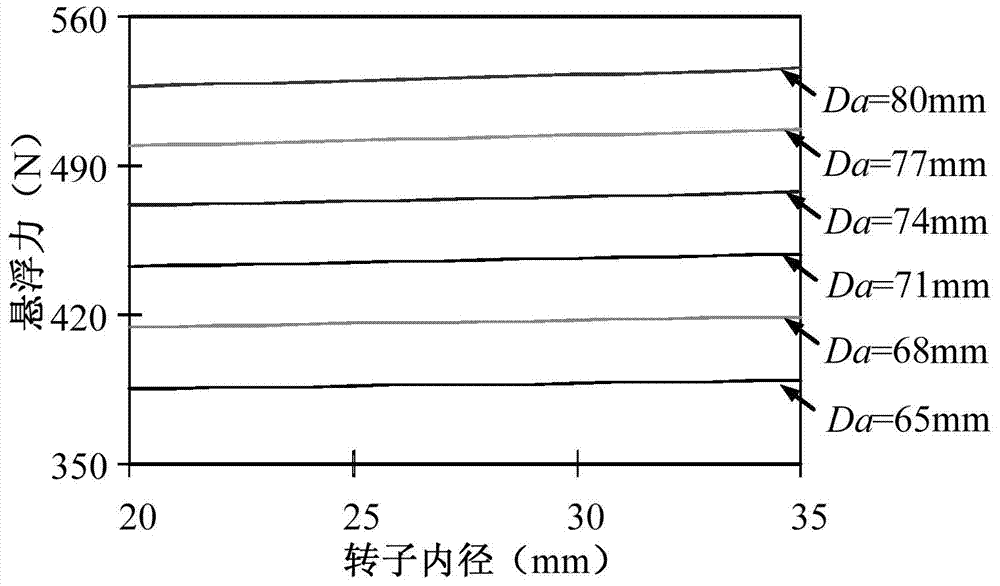

Method for optimizing structure parameter of single-winding magnetic suspension switch reluctance machine

ActiveCN104283393ANo need to iterateOptimal parameter designDesign optimisation/simulationDynamo-electric machinesLearning machineData set

The invention discloses a method for optimizing the structure parameter of a single-winding magnetic suspension switch reluctance machine, and belongs to the technical field of magnetic suspension switch reluctance machines. The method comprises the steps that the initial structure parameter of the single-winding magnetic suspension switch reluctance machine is calculated; finite element simulation is conducted on a motor model, the structure parameter to be optimized is selected, and a sample data set is determined; an extreme learning machine algorithm is used for training the sample data set to establish the motor model; the parameter to be optimized is used as an optimized object, and suspension force and torque are used as an optimizing object for conducting parameter optimizing on the motor model. According to the method, an extreme learning machine of a single implicit strata feedforward neural network is used for conducting model identification, iteration is of no need, the motor model can be quickly trained in a high-precision mode, and the parameter design that collaboration of the suspension force and the torque is optimum is achieved by a multi-objective optimizing algorithm.

Owner:NANJING INST OF TECH

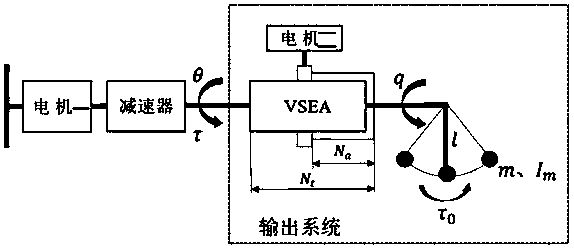

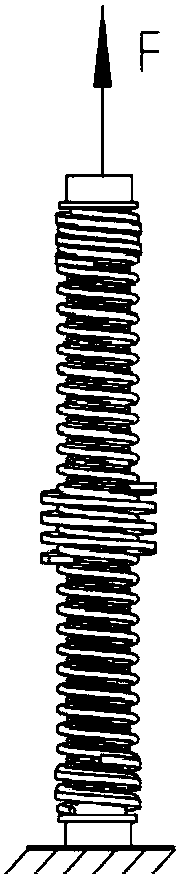

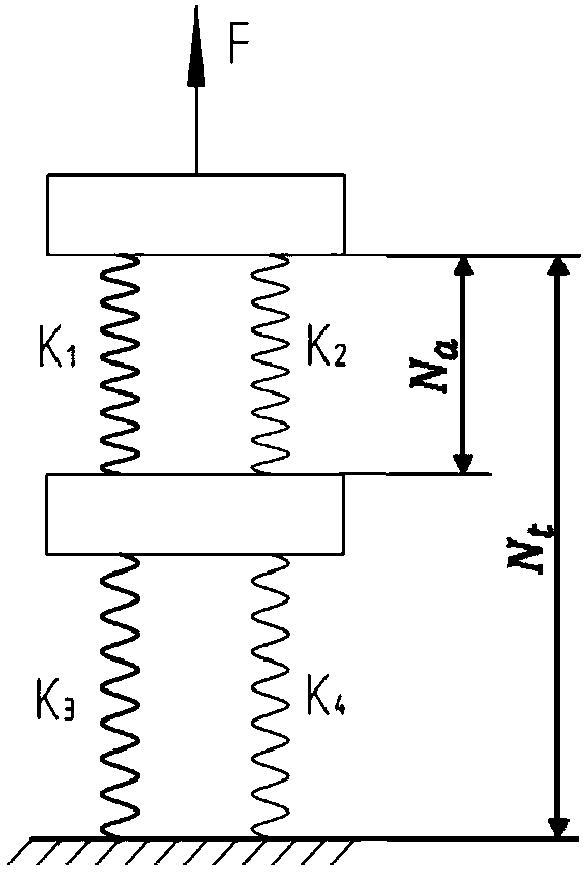

Robot joint self-adaption control method of variable-rigidity serial connection elastic driver

ActiveCN108527372AImprove utilization efficiencySolving Unresolvable Kinetic Parameter UncertaintiesProgramme-controlled manipulatorJointsKinematicsEngineering

The invention discloses a robot joint self-adaption control method of a variable-rigidity serial connection elastic driver; and based on the natural kinematics, and according to the energy consumptionsuboptimum rule under antiresonant frequency, the antiresonant frequency is calculated and the joint rigidity is adjusted to optimize the system energy consumption. On the basis of obtaining the optimal joint rigidity through optimization of the energy consumption, a motor model and a VSEA kinetics model are respectively built; a robot joint self-adaption control method based on VSEA is providedaccording to the kinetics model; and the approximation stability of the control method is proved. Compared with a traditional control method, the method can change controller parameters through changing self-adaption rules, so that uncertain items in the kinetics model are estimated and compensated in real time, the kinetics parameter uncertainty problem incapable of being solved by the traditional control method is effectively solved, the tracking error is reduced, the control precision and the stability are improved, the energy consumption can be greatly reduced, and the energy utilization efficiency is improved.

Owner:UNIV OF SCI & TECH OF CHINA

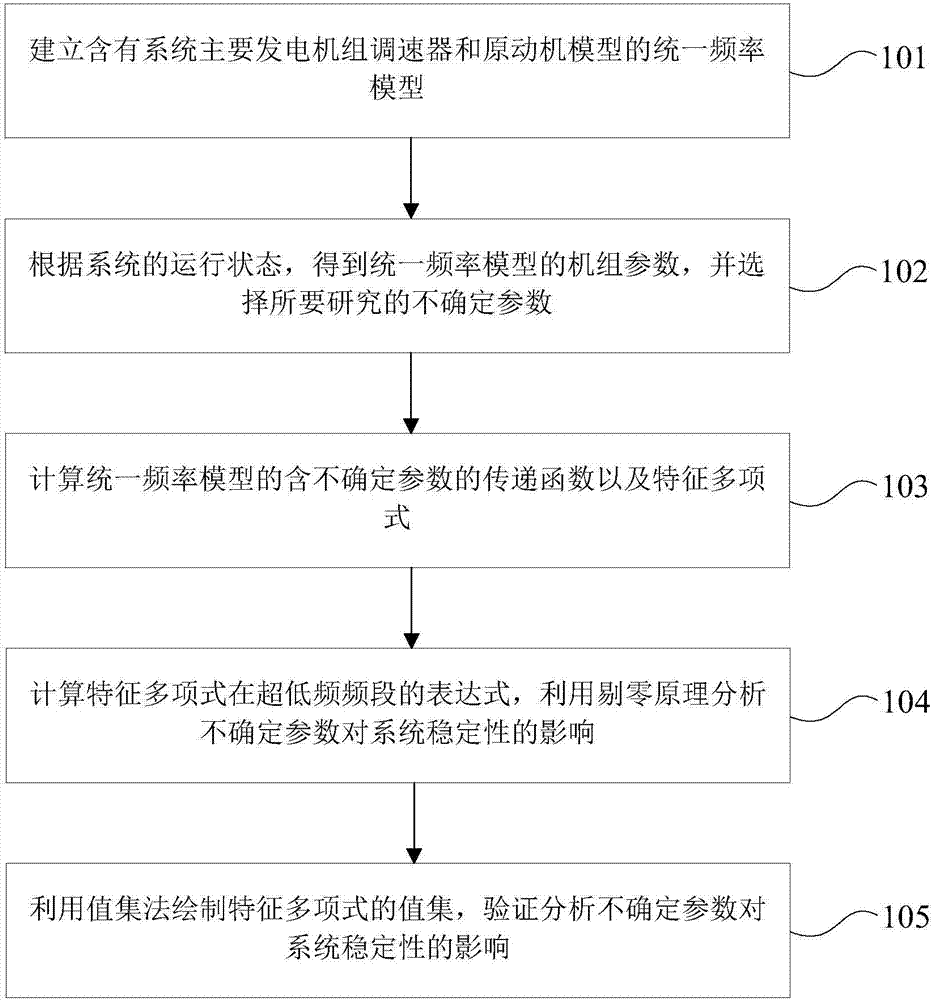

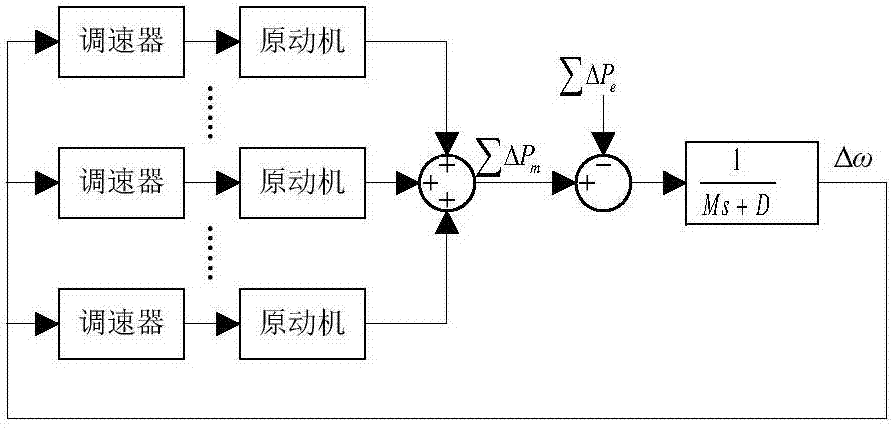

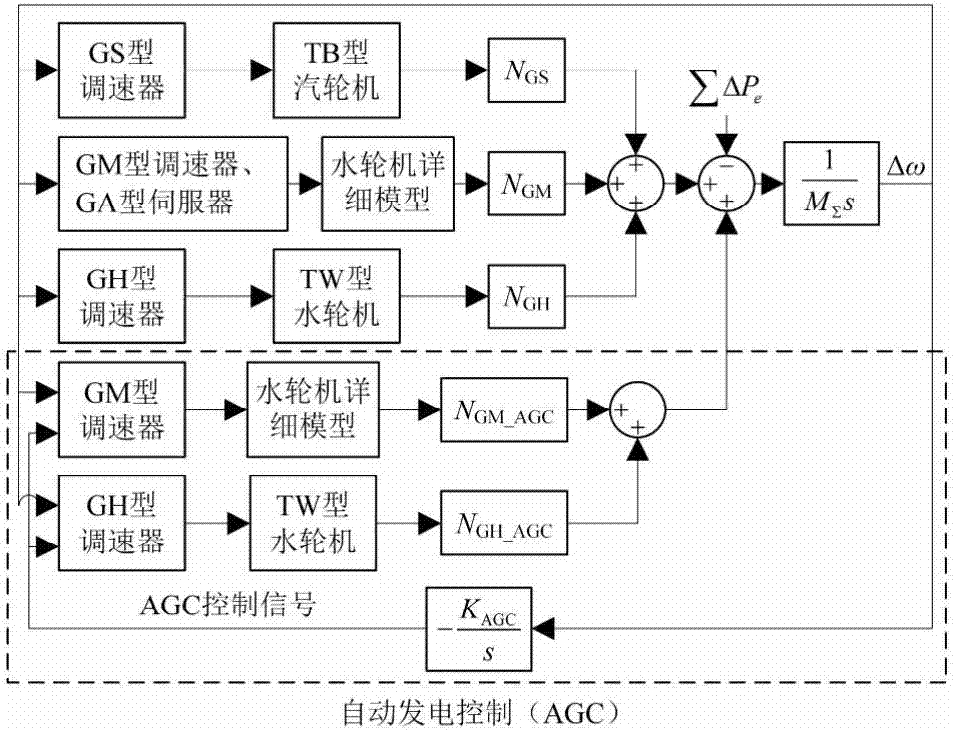

Method for analyzing impact on ultralow frequency oscillation of power system from uncertain parameters

ActiveCN107171345AReduce complexityRealize analysisPower oscillations reduction/preventionValue setEngineering

The invention relates to a method for analyzing the impact on the ultralow frequency oscillation of a power system from uncertain parameters, and belongs to the technical field of grid safety. The method comprises the steps: building a unified frequency model which comprises a main generator set speed regulator of a system and a prime motor model; obtaining set parameters of the unified frequency model according to the operation state of the system, and selecting the uncertain parameters to be researched; calculating a transfer function and a characteristic polynomial, comprising the uncertain parameters, of the unified frequency model; calculating the expression of the characteristic polynomial at the ultralow frequency, and analyzing the impact on the stability of the system through the zero exclusion principle; drawing the value set of the characteristic polynomial through a value set method, and verifying and analyzing the impact on the stability of the system from the uncertain parameters. The method achieves the mechanism analysis of the impact on the ultralow frequency oscillation from the parameters of the system, is simple, is effective, and can reflect the cause of the ultralow frequency oscillation so as to take corresponding measures to inhibit the ultralow frequency oscillation.

Owner:YUNNAN POWER GRID

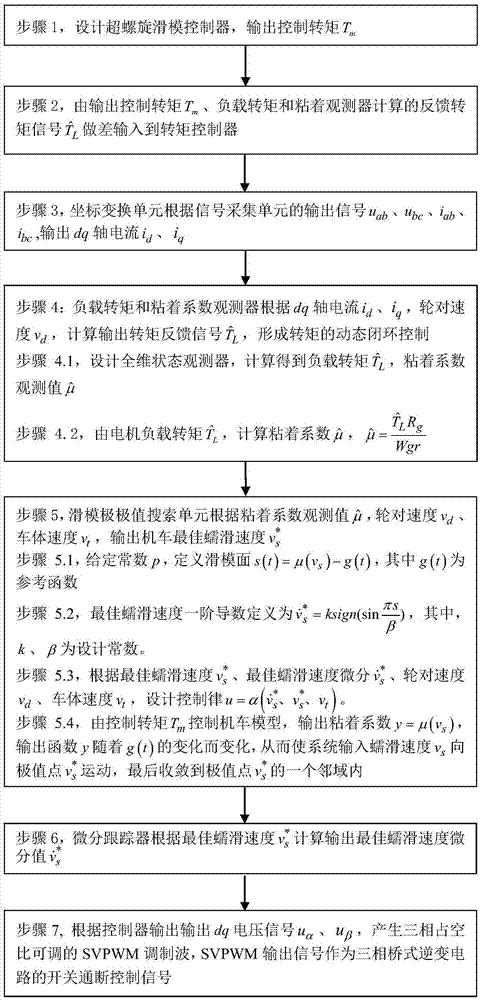

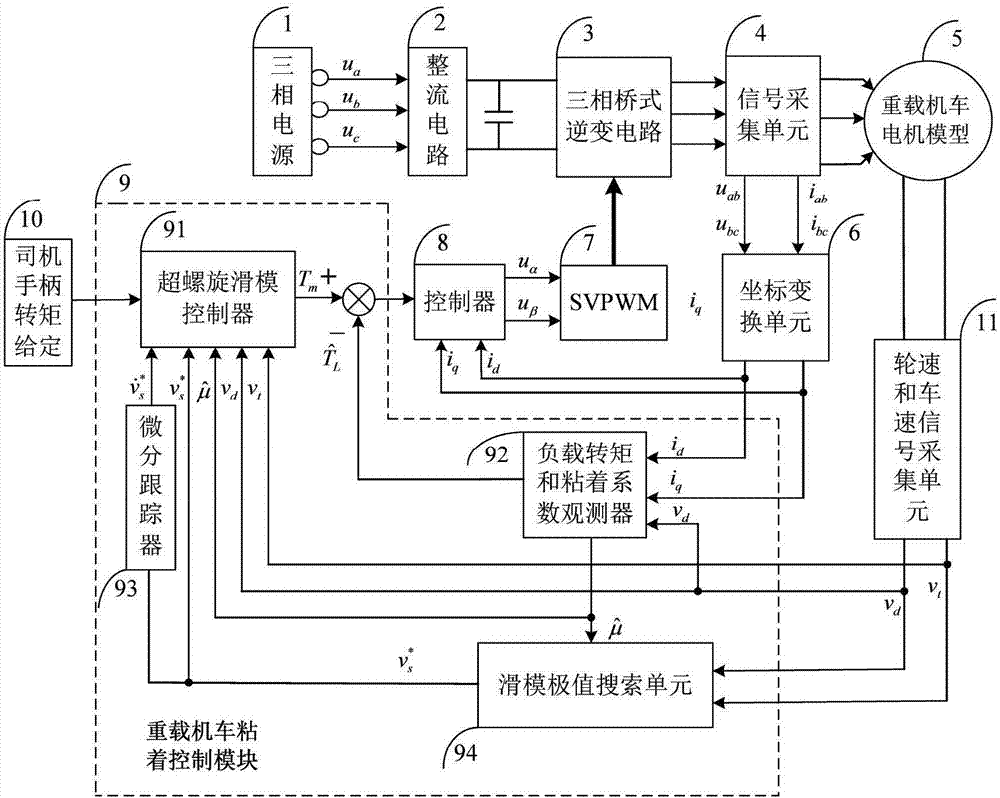

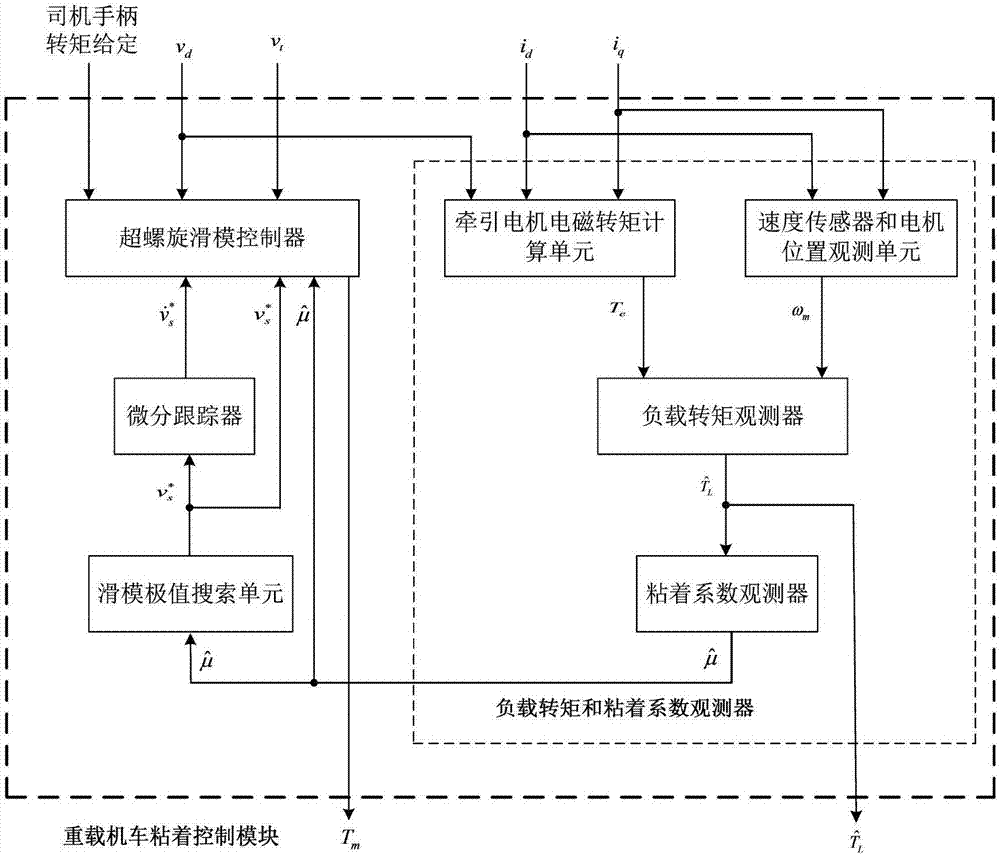

Heavy-load locomotive slip form extreme value search optimum adhesion control system and method

ActiveCN107395081AOptimum sticking controlReal-time estimation of adhesion coefficientElectronic commutation motor controlVector control systemsAdhesion coefficientControl vector

The invention discloses a heavy-load locomotive slip form extreme value search optimum adhesion control system and method. Heavy-load locomotive adhesion control can be achieved. A heavy-load locomotive adhesion control module comprises a superhelix slip form controller, a differential tracker, a load rotating torque and an adhesion coefficient observer and a slip form extreme value search unit so as to achieve dynamic closed-loop control over the rotating torque of a heavy-load locomotive traction motor. On the basis of locomotive motor model vector control, on the basis of the slip form extreme value search method, the adhesion coefficient observer is designed, a wheeltrack adhesion coefficient is estimated in real time, the locomotive is made to run near the best adhesion point under the external complex environment, the power of a traction motor is effectively brought into play, the optimum adhesion control over the heavy-load locomotive is achieved, and the heavy-load locomotive slip form extreme value search optimum adhesion control system and method can be widely applied to the best adhesion control occasion of the heavy-load locomotive.

Owner:HUNAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com