Vector screening and duty cycle combined motor model prediction control system and method

A technology of motor model and predictive control, applied in vector control system, control system, motor generator control, etc., can solve the problems of torque ripple and flux linkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

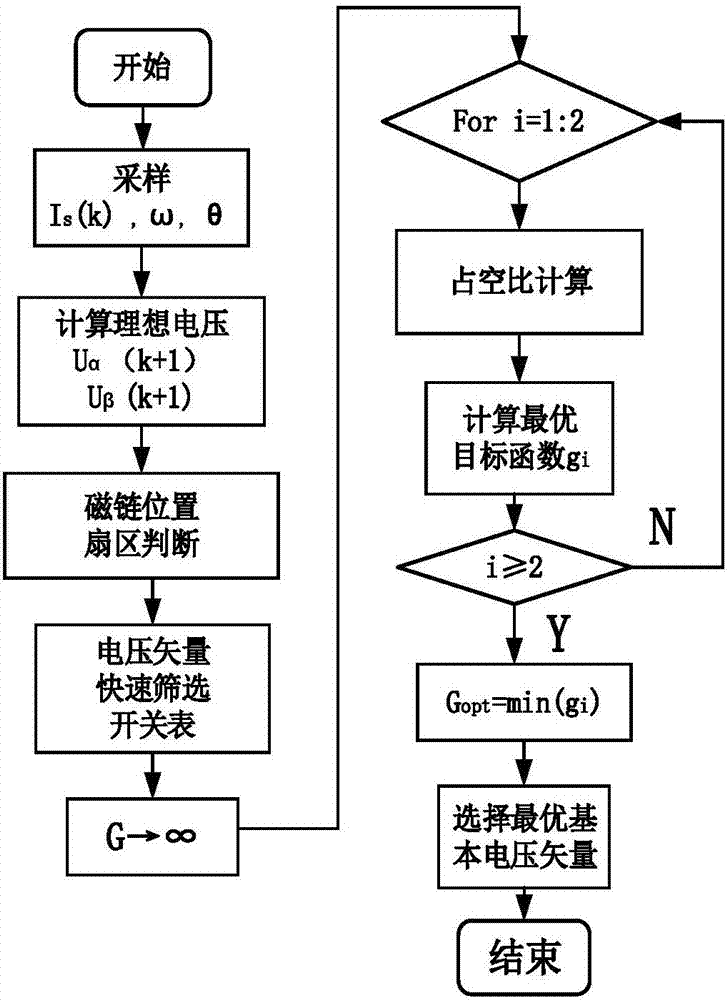

[0055] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

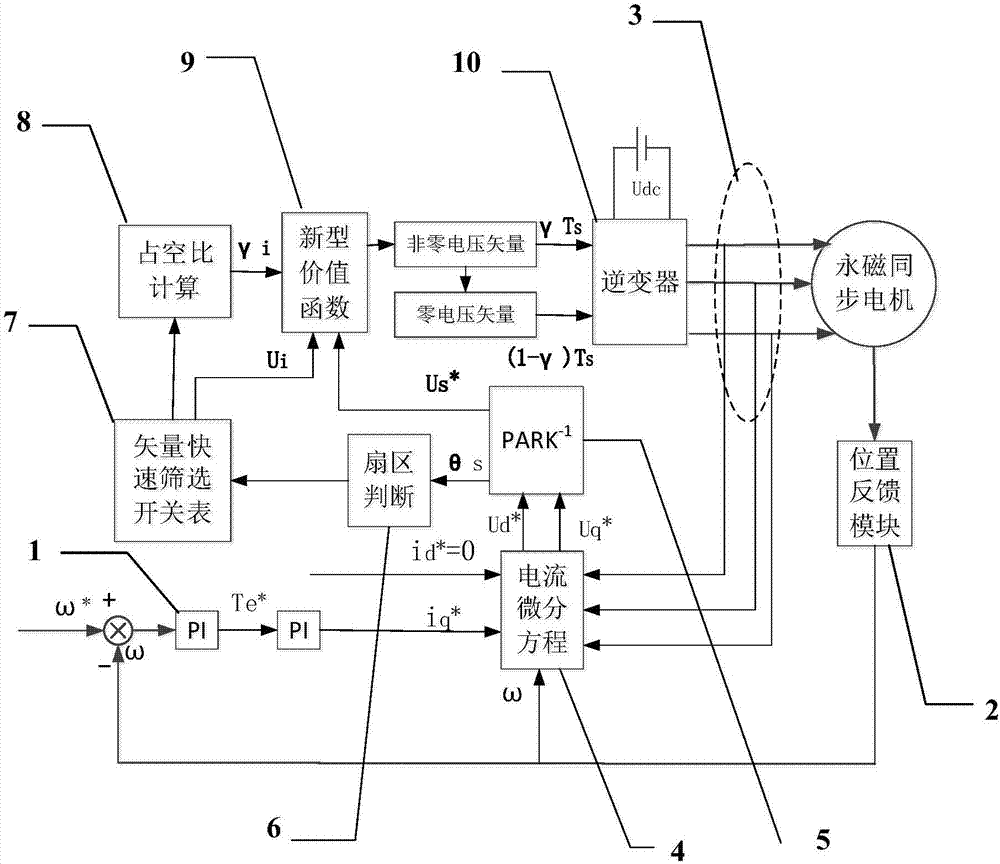

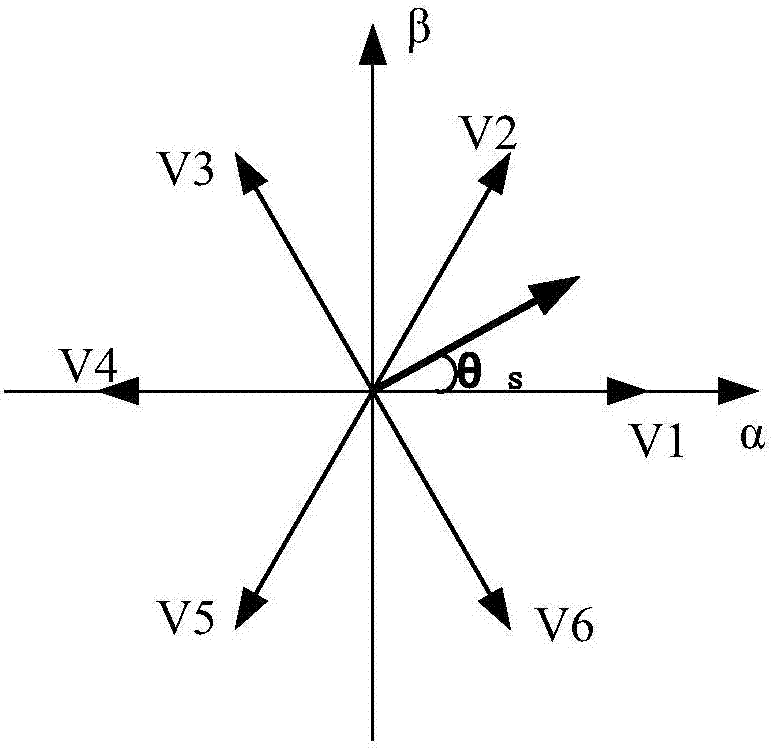

[0056] Such as figure 1 As shown, a permanent magnet synchronous motor model predictive control system based on the combination of vector fast screening and duty cycle control, including PI controller 1, position feedback module 2, stator current acquisition module 3, current differential equation calculation module 4, PARK inverse transformation module 5, sector judgment module 6, vector fast selection switch table 7, duty cycle calculation module 8, optimal value function module 9 and inverter 10;

[0057] The difference between the speed reference value and the speed feedback value obtained by the position feedback module 2 is made, and the difference is input to the speed PI controller 1; the reference torque value output by the speed PI controller 1 is obtained by the torque PI controller to obtain the quadrature axis reference current val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com