A large flow shaft distribution servo valve

A technology for axial flow distribution and servo valves, which is applied in servo motor components, valve devices, multi-way valves, etc., can solve the performance uncertainty of electro-hydraulic servo valves and electro-hydraulic proportional valves, increased testing and maintenance costs, high dynamic response, etc. problems, to reduce mechanical contact wear and eccentric wear hazards, ensure long-term effective work, and reduce the quality of the shaft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

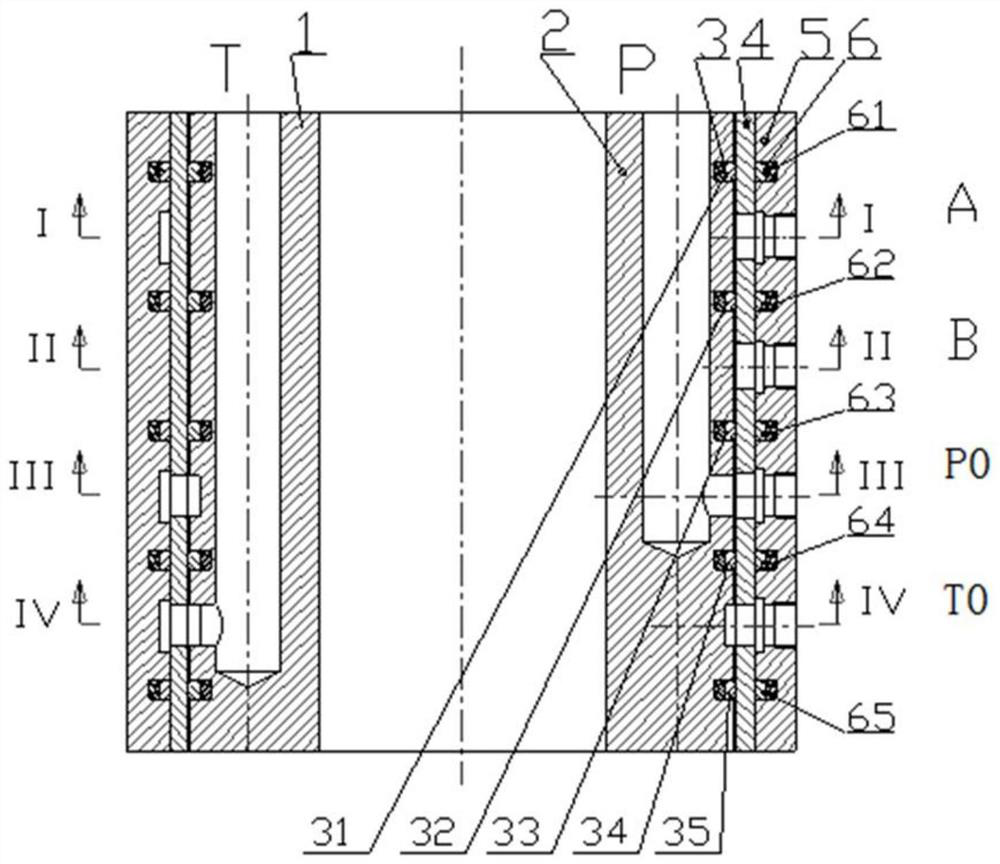

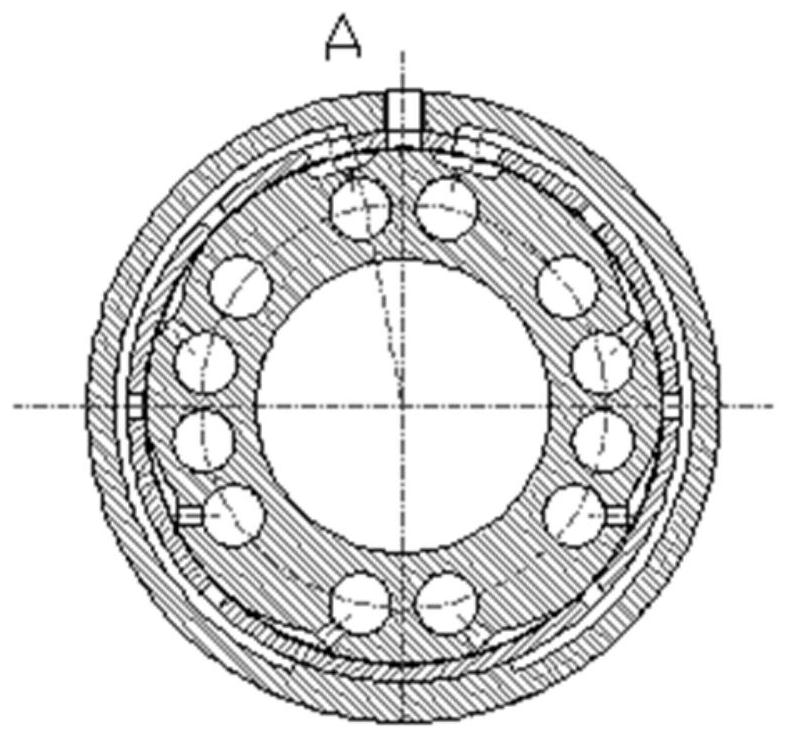

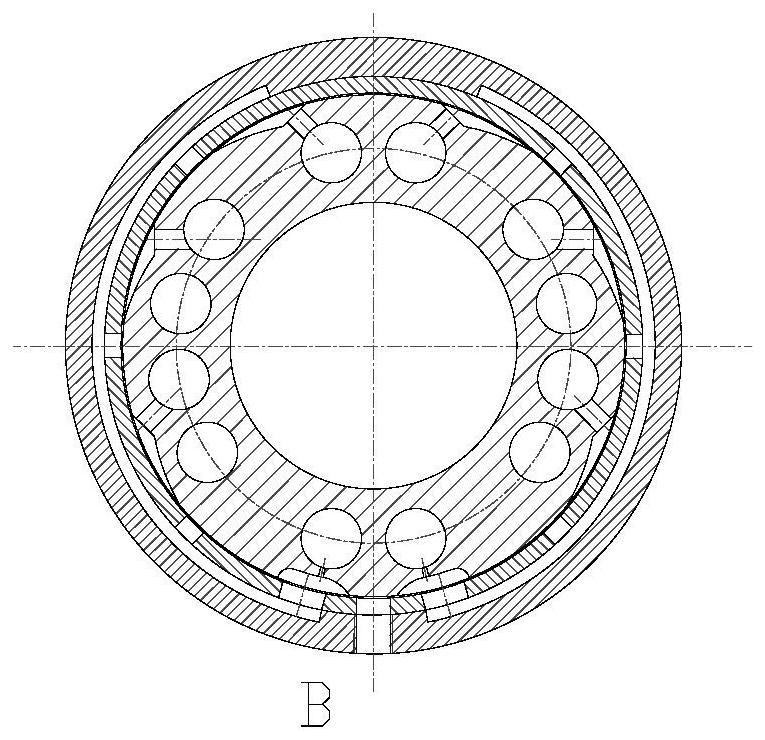

[0034] Such as Figure 1-5As shown, the present invention provides a large-flow axial distribution servo valve, including the internal axial distribution valve core rotor 2, the axial distribution valve sleeve 4, the external axial distribution valve body stator 5, and the corresponding rotor seal ring 3 and stator seal The ring 6, the shaft distribution valve sleeve 4 and the shaft distribution valve body stator 5 are cold assembled, and a through hole is opened at the center of the axis of the shaft distribution valve rotor 2 to reduce the mass of the shaft distribution valve rotor.

[0035] By adjusting the shaft distribution valve core rotor 2 to rotate to different angles, the continuous proportional communication between the working oil port, the oil supply port and the oil return port is realized, and the continuous different proportional speed control of the action of the actuator is realized within a specific rotation angle range. It can keep the state of the actuator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com