Patents

Literature

111results about How to "Large circulation capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

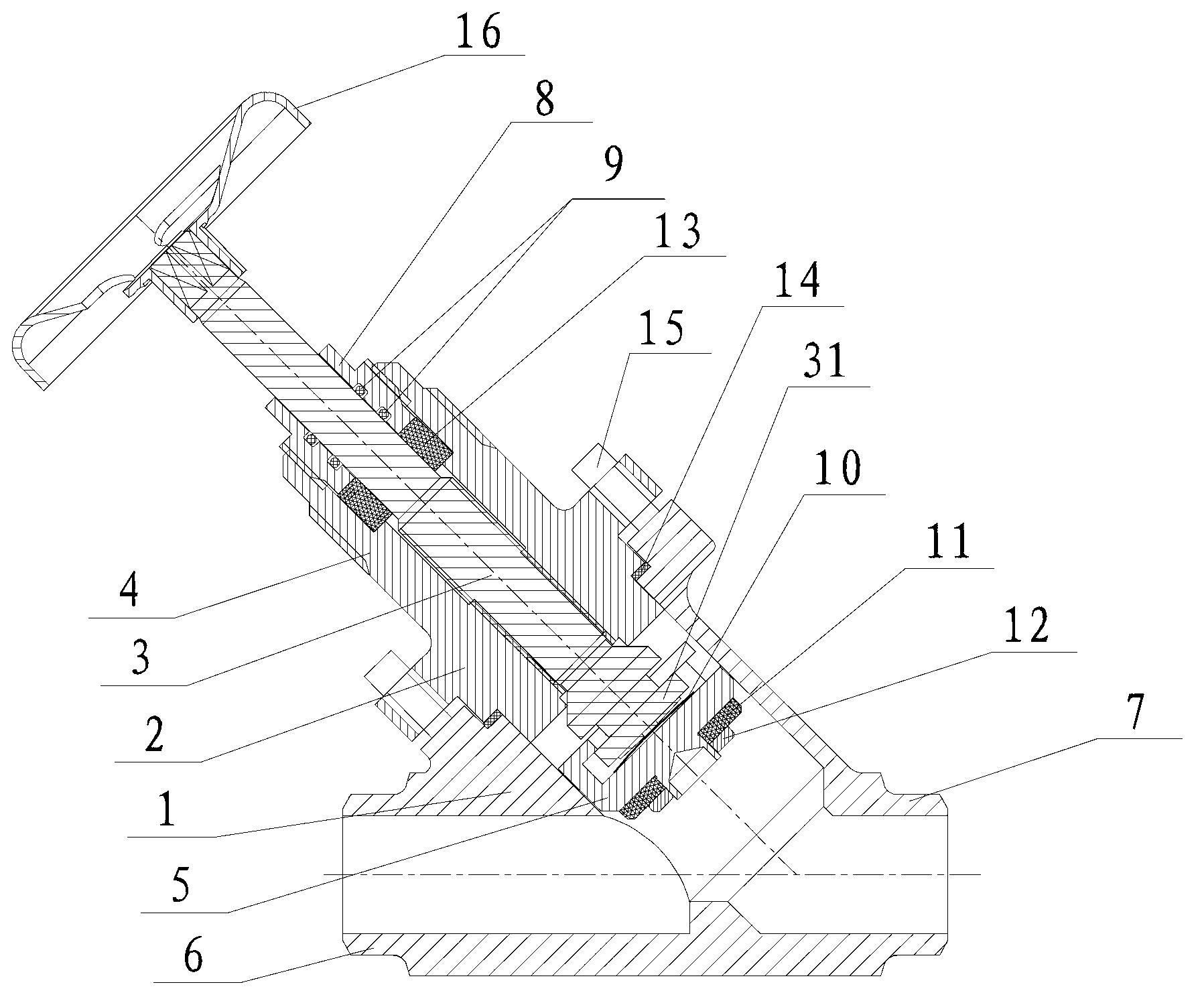

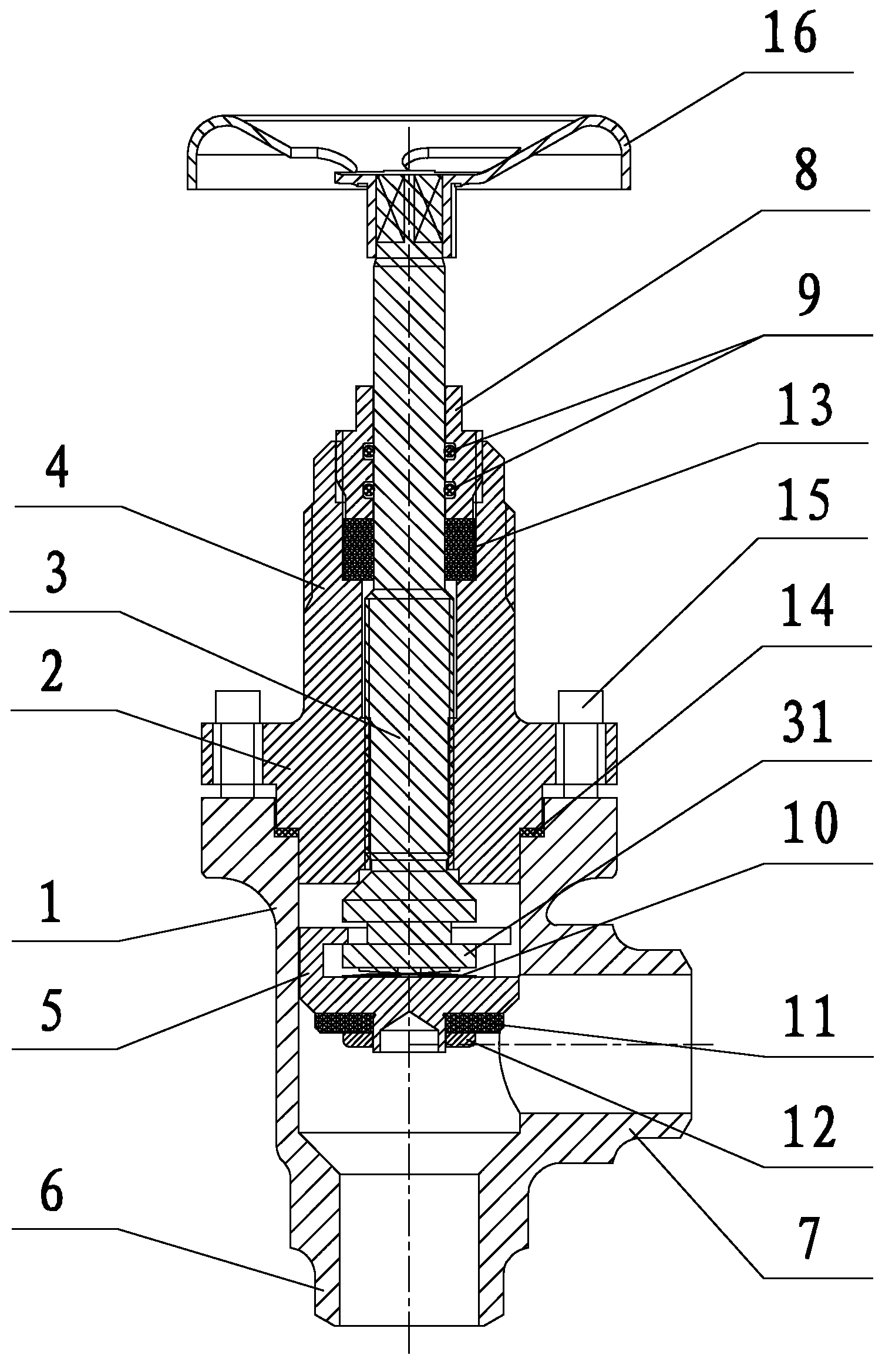

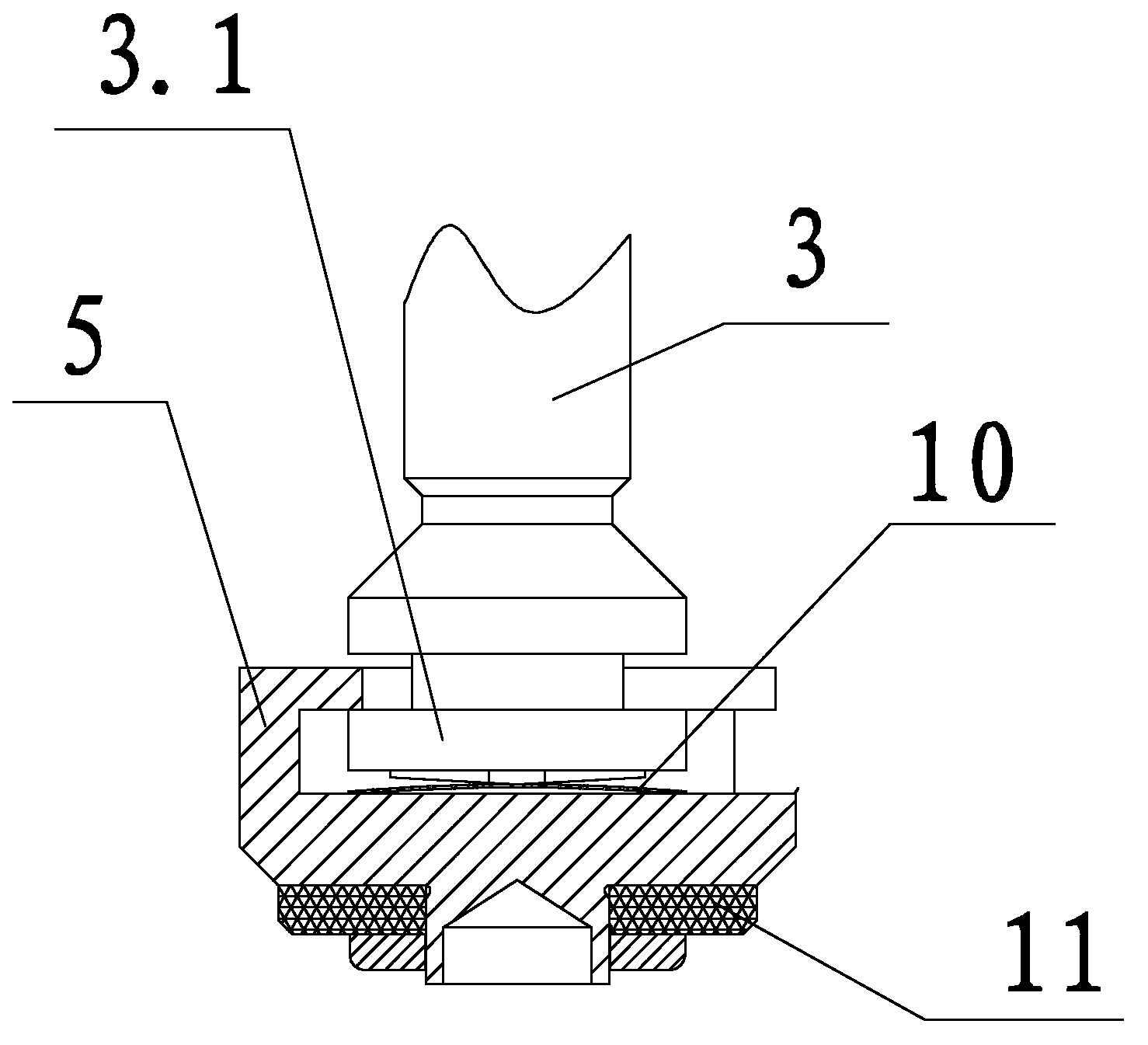

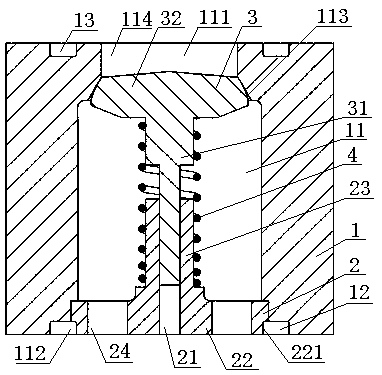

Steel forged refrigeration valve

InactiveCN103062419ACompact structureLarge circulation capacitySpindle sealingsLift valveRefrigerantValve stem

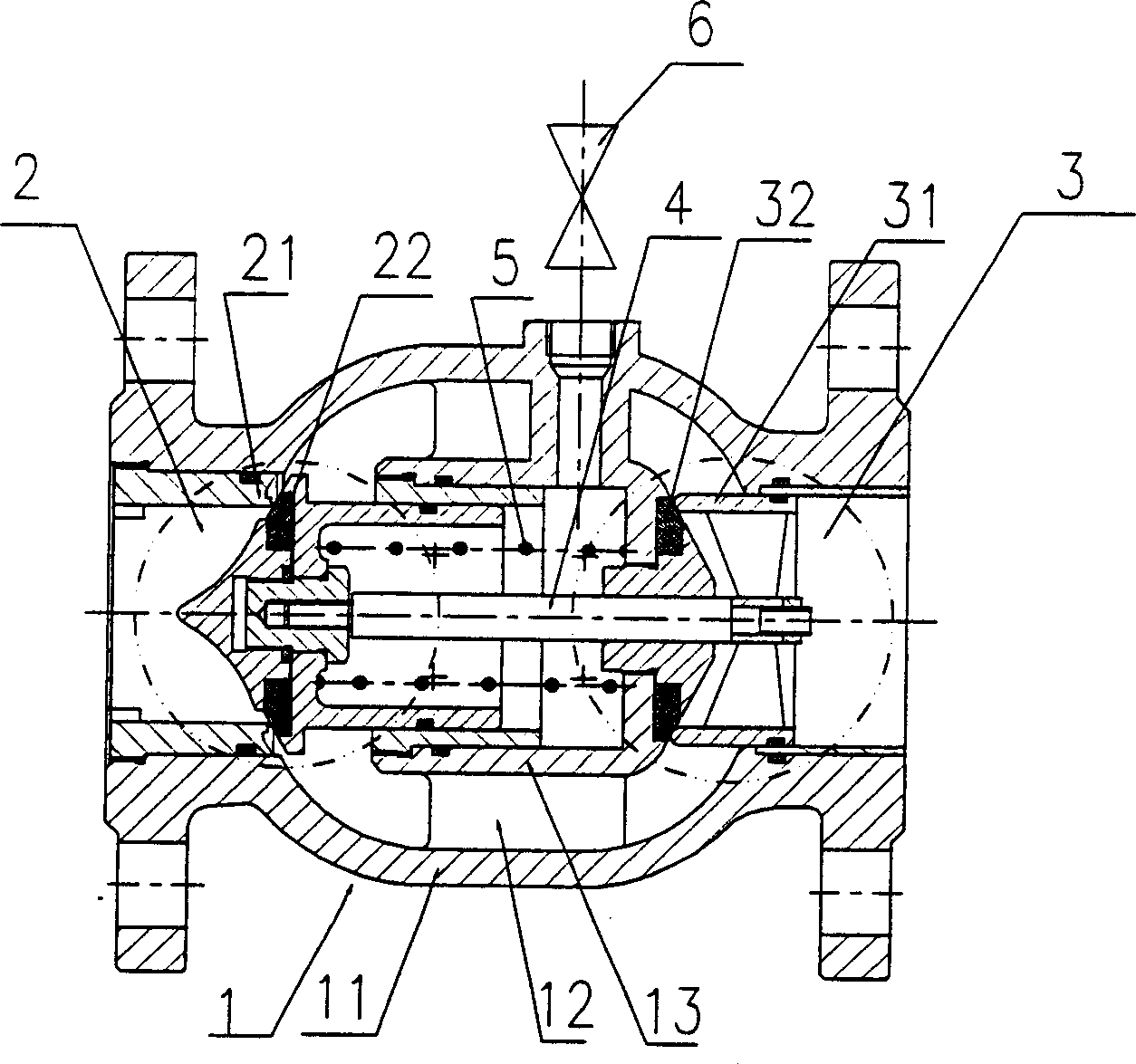

The invention relates to a valve, in particular to a steel forged valves including ammonia valves fluorine valves and the like which are applicable to all universal refrigerants, and mainly solves the problem that the refrigerant use for refrigeration utilizing a conventional valve is prone to leak since a bonnet mounted into a valve seat is eccentric and the conventional valve seat has multiple welding points. The steel forged refrigeration valve comprises a valve seat, a bonnet, a valve stem, a valve stem sleeve, a valve flap and a sealing cover, wherein the bonnet is in bolted connection with the valve seat, the valve stem sleeve is arranged on the bonnet, a clamp groove formed by an upper U-shaped chute and a lower U-shaped chute is arranged on the valve flap which is in clamping connection with the valve stem via the clamp groove, an elastic gasket is arranged between the valve stem and the valve flap, the valve flap and a valve body are enabled to be automatically adjusted concentrically, a valve flap gasket contacts with a sealing surface of the valve seat via a conical surface to form sealing, double O-shaped rubber sealing rings are arranged between the valve stem and the sealing cover for sealing, the valve stem sleeve is arranged on the valve bonnet, the sealing cover is arranged on the valve stem sleeve, and a bonded gasket seal is arranged between the sealing cover and the valve stem cover to improve sealing performance.

Owner:CHANGZHOU AMG REFRIGERATION EQUIP

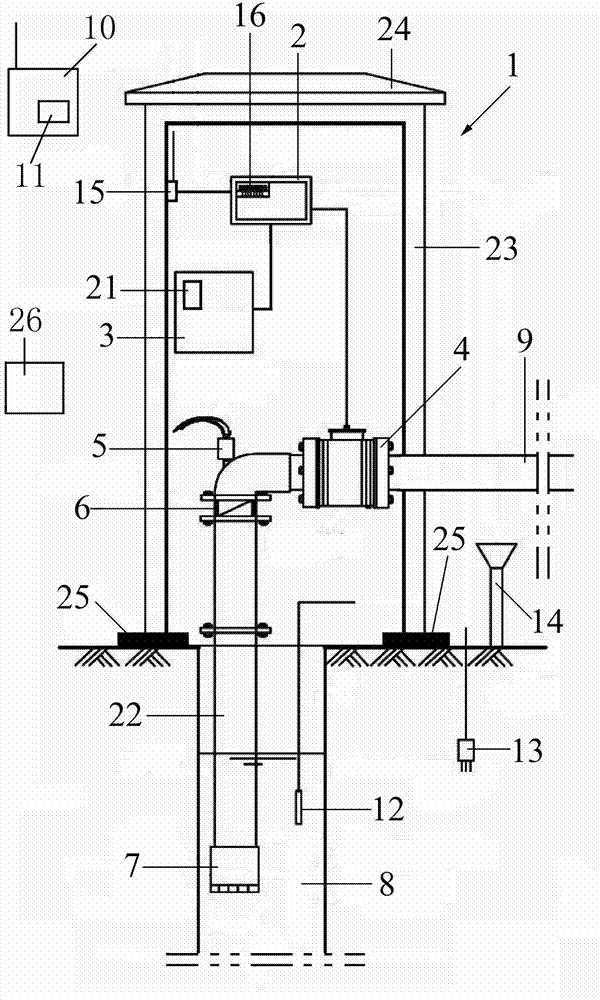

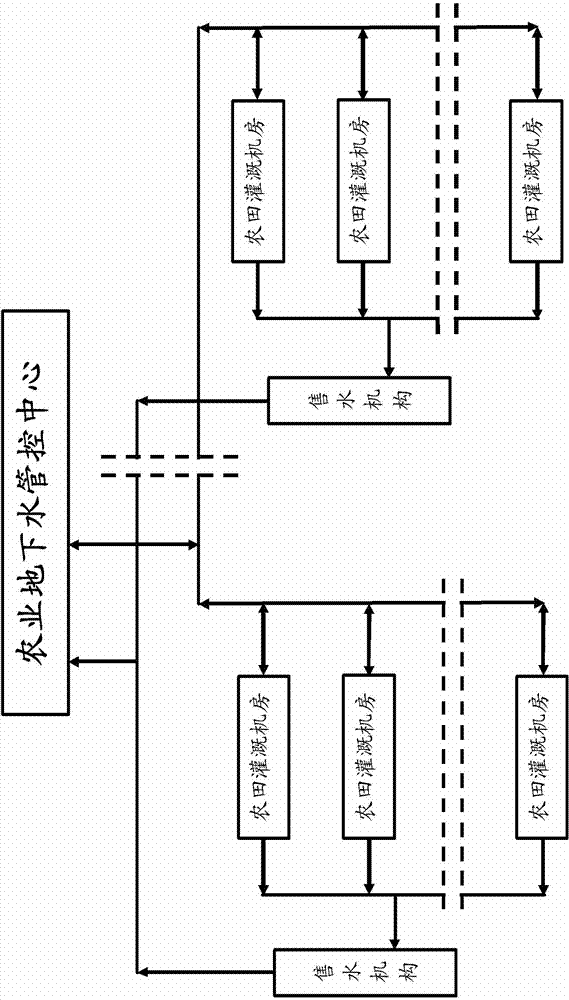

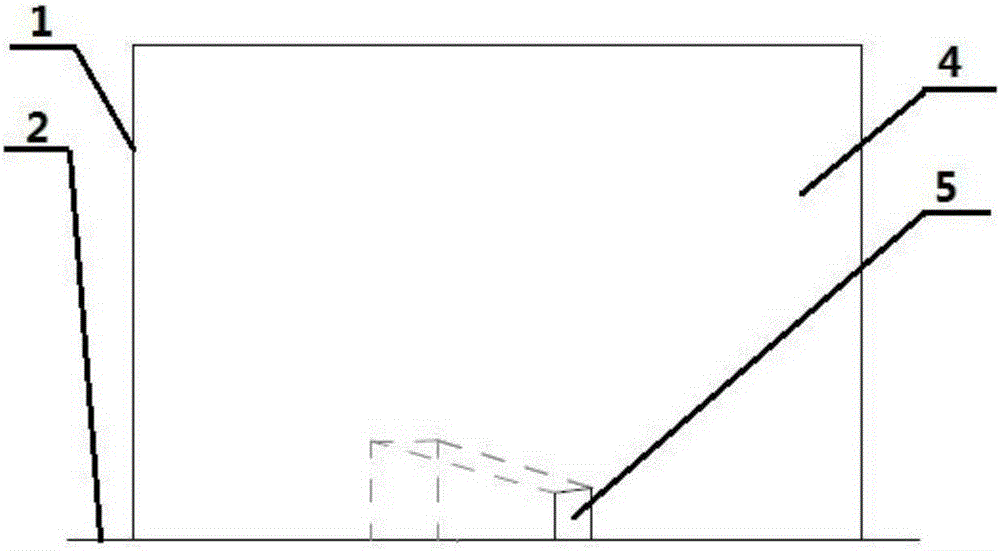

Agricultural underground water management and control system, manufacturing method and agricultural underground water management and control method

ActiveCN104299322ACorrosion resistantHas acid and alkali resistanceData processing applicationsWatering devicesExhaust valveEcological environment

The invention provides an agricultural underground water management and control system, a manufacturing method and an agricultural underground water management and control method. The system is composed of an agricultural water management and control center, water sale mechanisms and farm irrigation machine rooms. The agricultural water management and control center is built according to an agricultural irrigation plan of one region and used for managing and controlling the whole underground water resources of one region, only one water sale mechanism is arranged for every administrative village, the farm irrigation machine rooms are built according to the agricultural irrigation plan of one region, are set according to the farm irrigation area and are connected with the agricultural underground water management and control center through GPRS communication antennas. Each farm irrigation machine room is composed of a water resource controller, a distribution board, the GPRS communication antenna, a flow meter, an exhaust valve, a check valve, a submerged pump, an underground water source well, a water taking pipeline, a water conveying pipeline, a water level sensor, a soil moisture sensor and a rainfall sensor. The agricultural underground water management and control system is scientific in design, reasonable in structure, low in cost and easy to manufacture, water resources are saved, land subsidence is inhibited, the ecological environment is improved, the ability to withstand natural disasters is improved for the agriculture, and the agriculture comprehensive production capacity is improved.

Owner:TIANJIN WATER RESOURCES RES INST

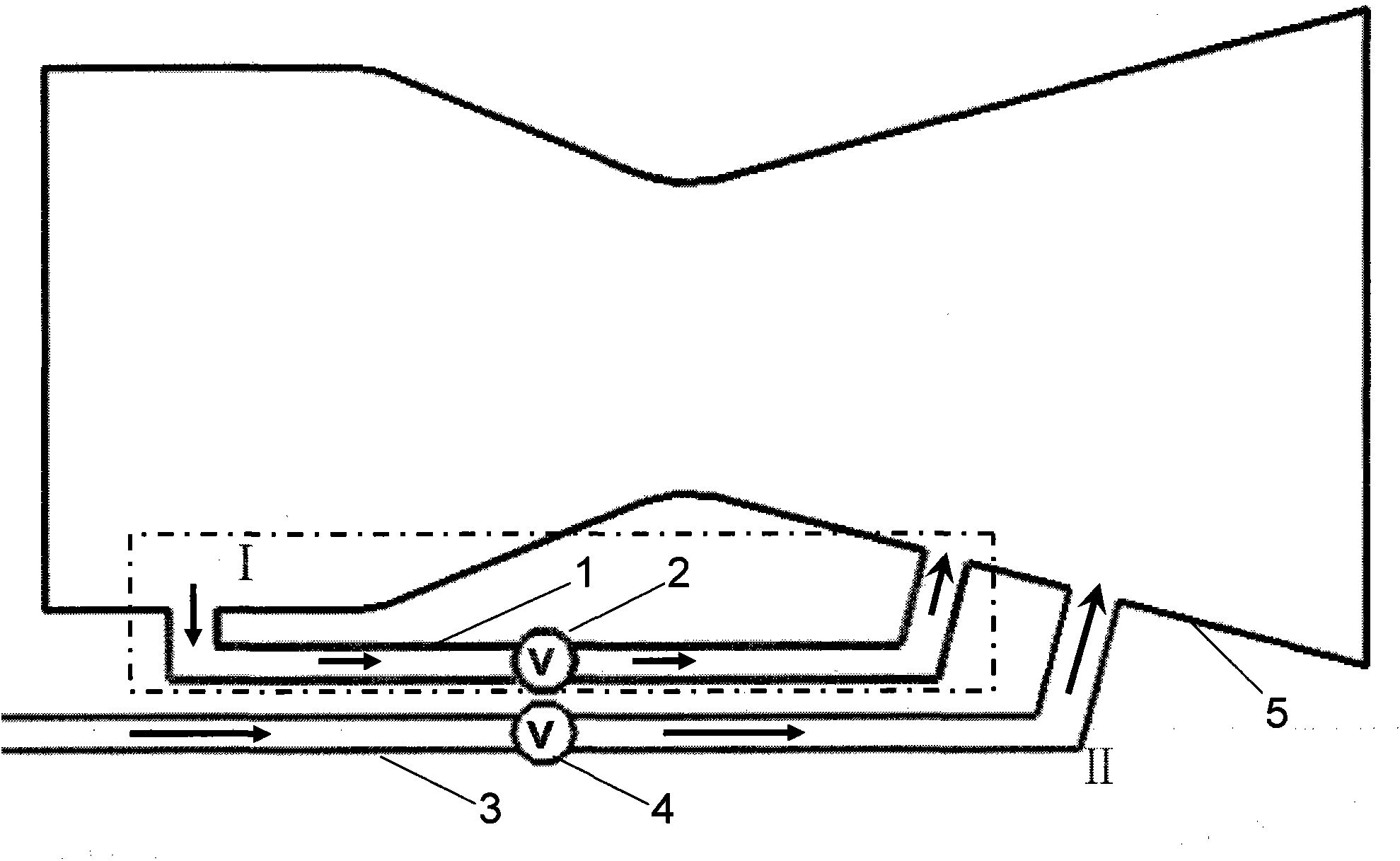

Improved pneumatic vectoring nozzle structure with function of injecting double secondary flow branches

InactiveCN103899432AIncreased throat areaLarge circulation capacityJet propulsion plantsAir entrainmentHigh pressure

The invention provides a pneumatic vectoring nozzle structure with a function of injecting double secondary flow branches. The pneumatic vectoring nozzle structure is characterized in that a pneumatic vectoring nozzle with the function of injecting the double secondary flow branches structurally comprises a secondary flow injection system I, a secondary flow injection system II and a closing and converging nozzle; the secondary flow injection system I comprises an air entrainment pipeline and a valve; the secondary flow injection system II comprises another air entrainment pipeline and another valve. The pneumatic vectoring nozzle structure has the advantage that shortcomings of decrease of flow of an engine and reduction of thrust due to the fact that air is entrained from a high-pressure component of the engine can be overcome.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

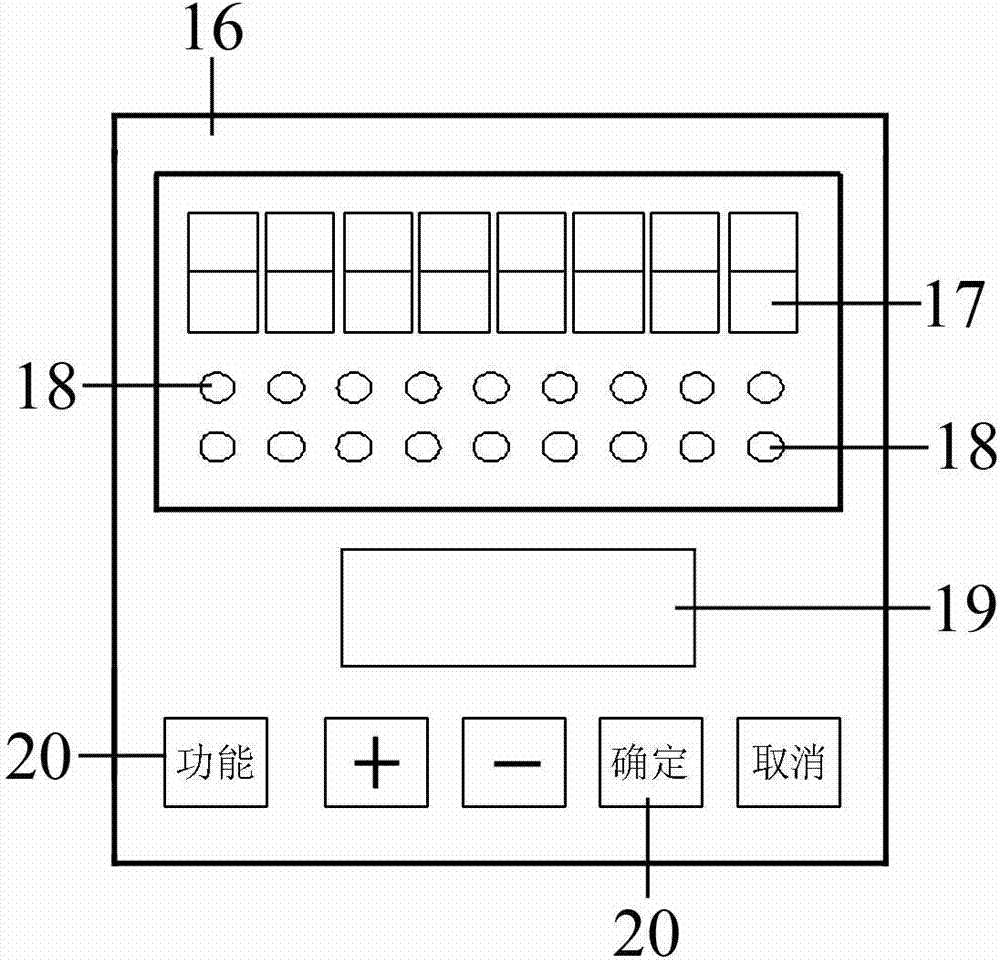

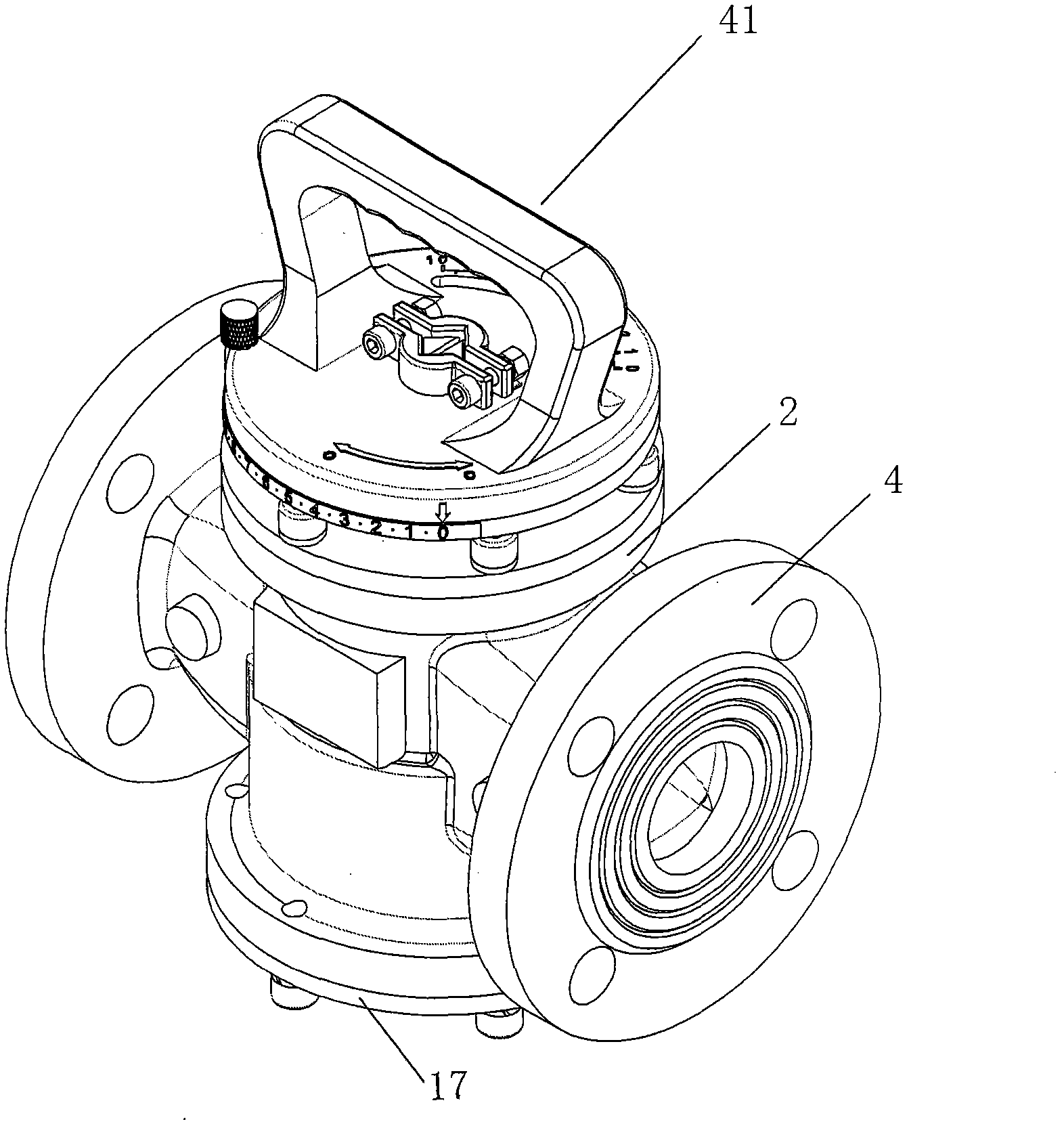

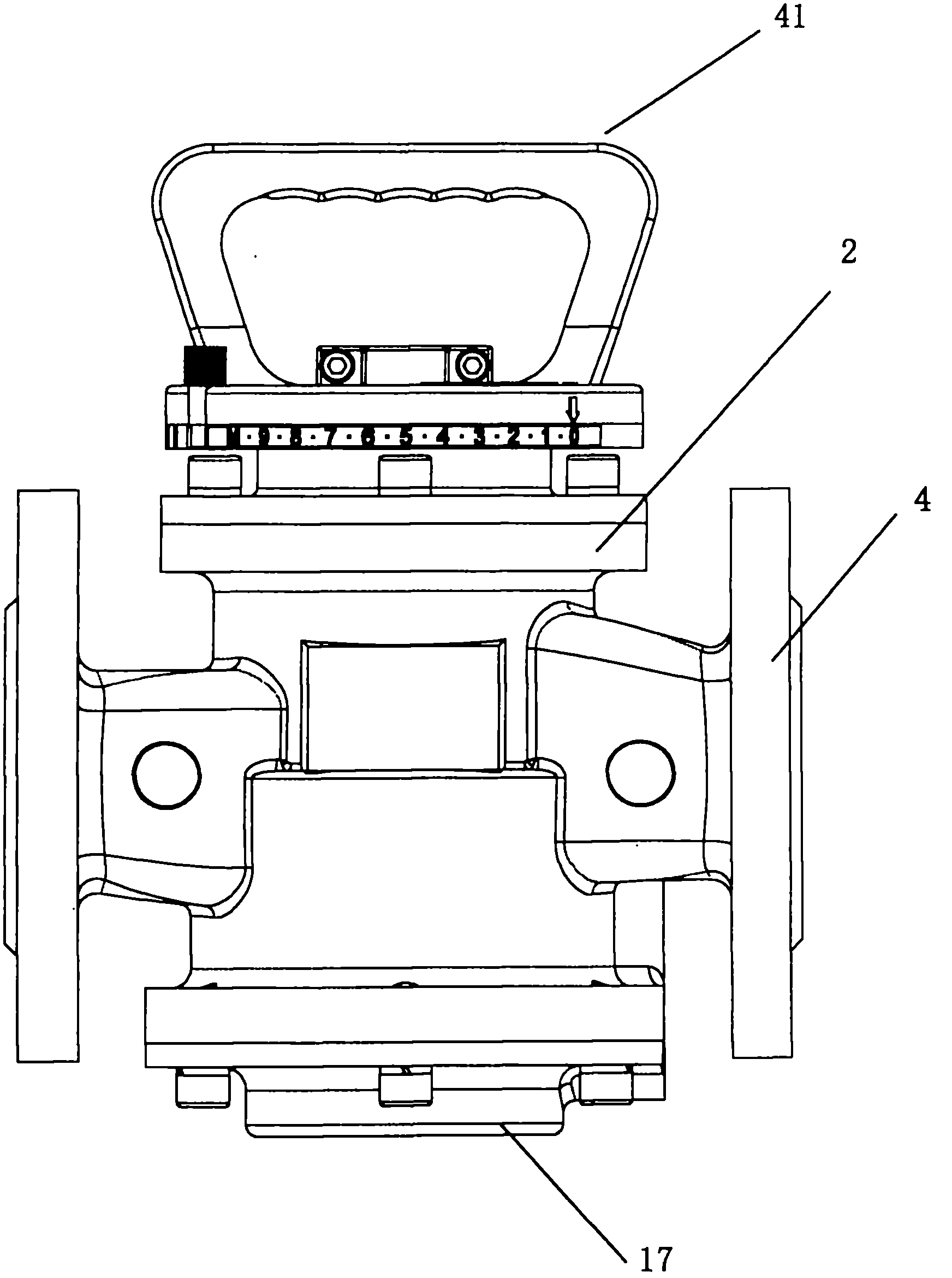

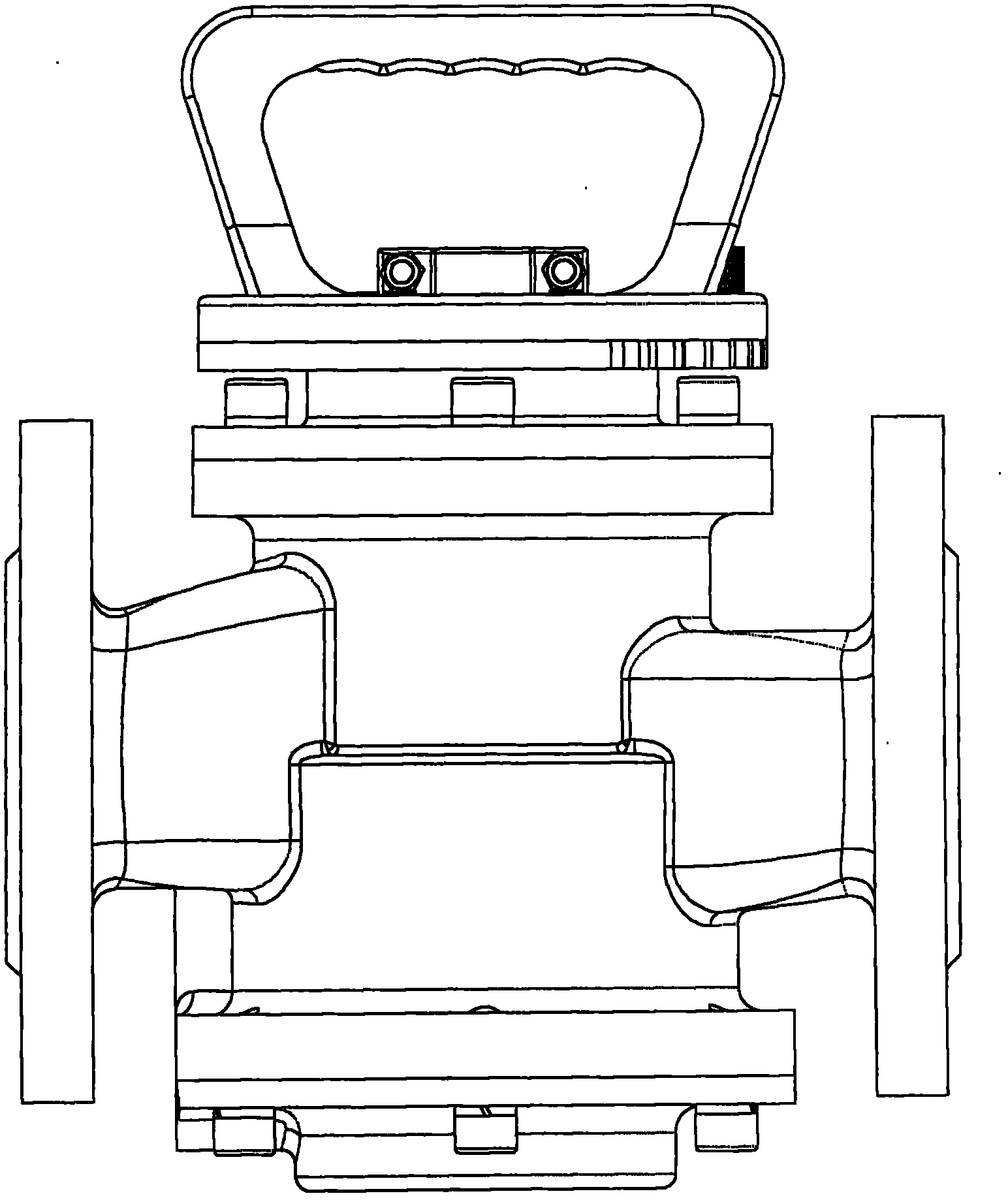

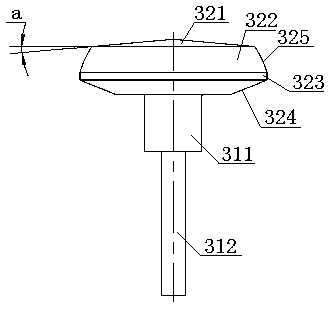

Membrane pressure type dynamic balance manual adjusting valve

InactiveCN102072346ASolve the imbalance of water conservancy flowAddressing DissonanceOperating means/releasing devices for valvesEqualizing valvesChemical industryDynamic balance

The invention provides a membrane pressure type dynamic balance manual adjusting valve. The adjusting valve comprises a handle component and an integrated valve which is positioned below the handle component and is fixedly connected with the handle component, wherein the adjusting valve is uniquely and integrally designed, so the dynamic flow balance of the valve is integrally combined with flow adjustment; the flow adjustment is realized through a low-torque small-angle travel turn-off structure; a valve body and an automatic flow balance component structure are optimally designed, so flow resistance and noise are reduced; the design of the handle component is suitable for the operation environment of a pipeline well; the adjusting valve has the advantages of high flow capacity, accuracy and convenience of operating control, wide working pressure difference range, convenience of assembly and maintenance, long life and low cost; a manual setting state can be controlled in real time through the flow of the valve; the adjusting valve is mainly applied to building heating, ventilating and air conditioning systems, industrial or residential fluid pipe network transmission and distribution systems and industries such as petroleum, chemical industry and the like; thus, the misadjustment phenomenon of water conservancy flow of a client pipe network system can be substantially eliminated and the valve is adjusted in real time to fulfill the aim of guaranteeing dynamic flow balance of a pipe network and energy conservation.

Owner:OVENTROP VALVES & SYST BEIJING

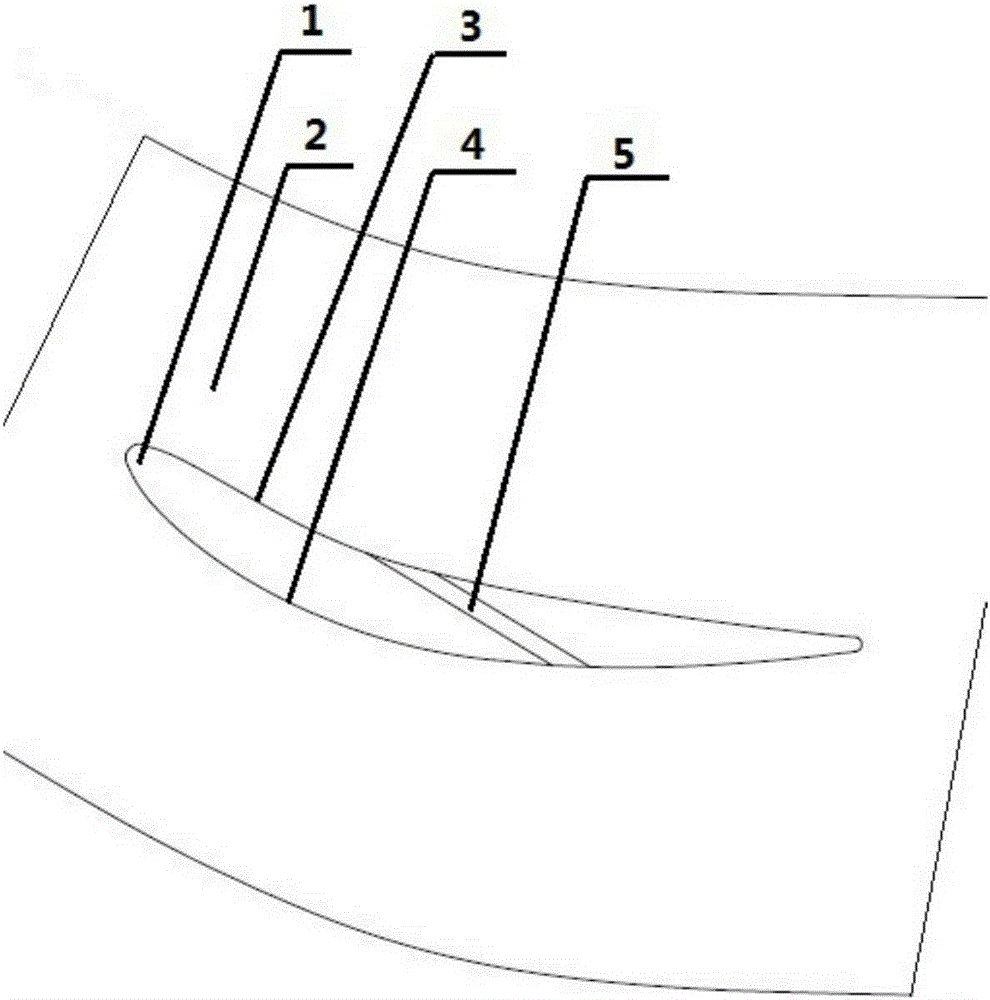

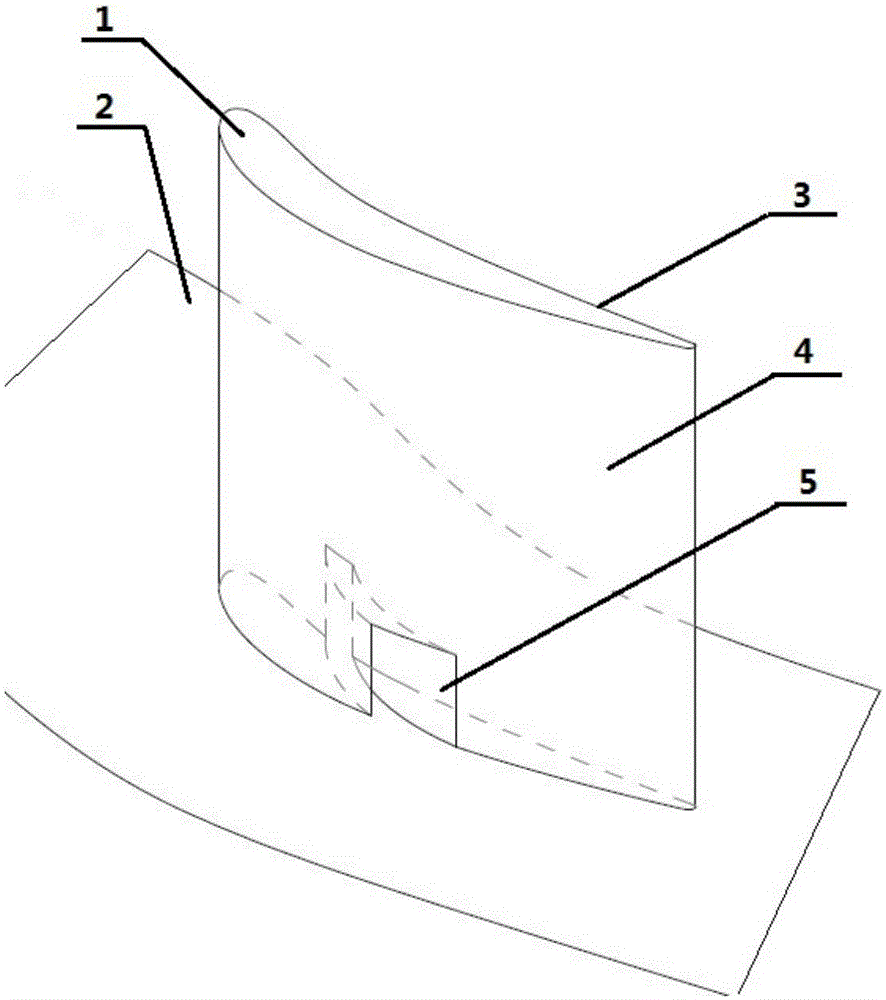

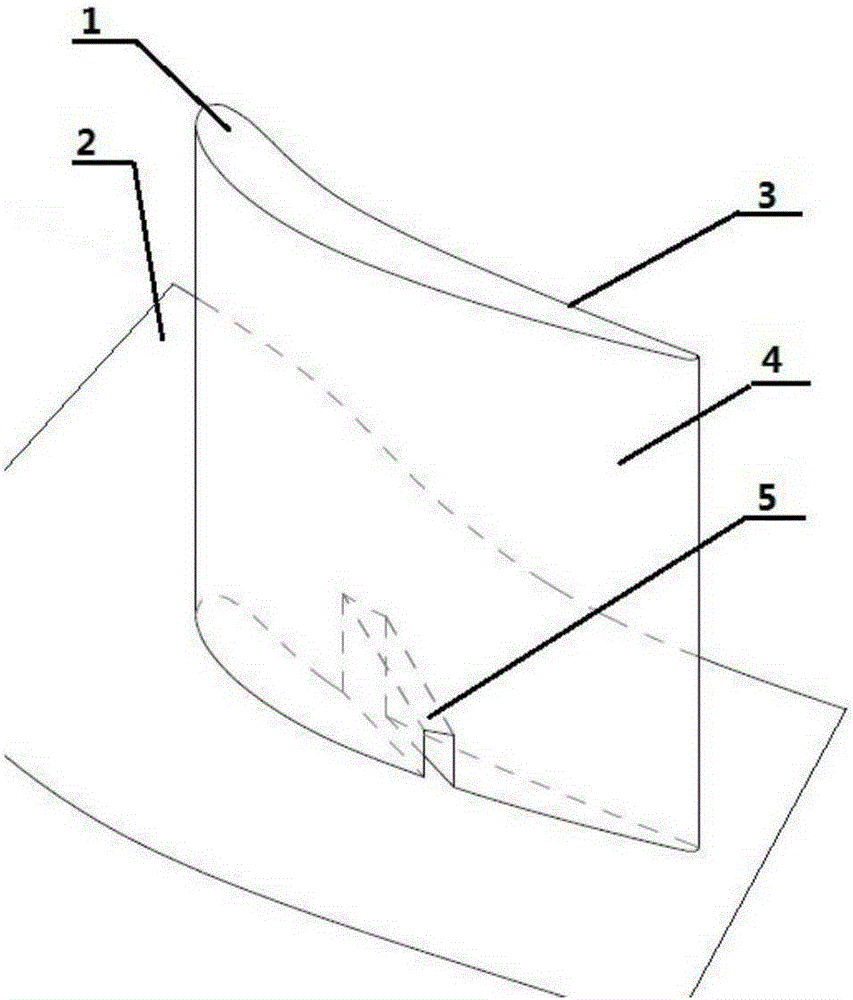

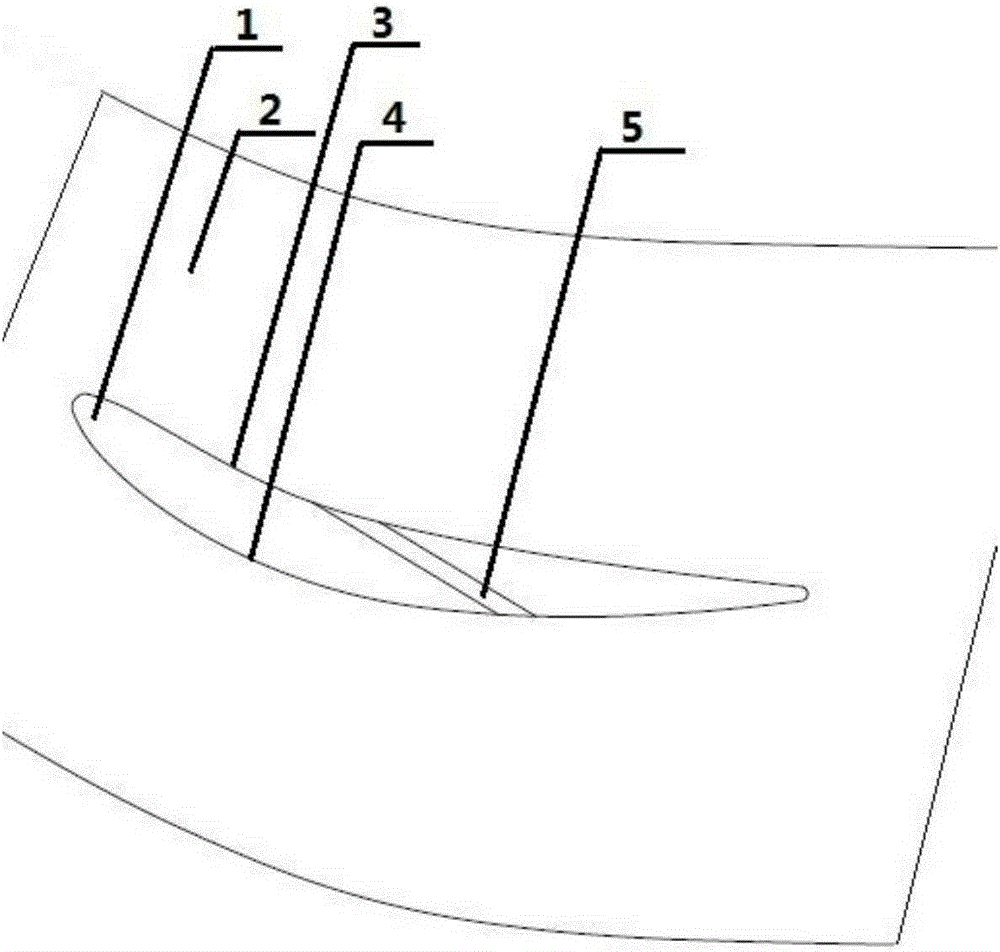

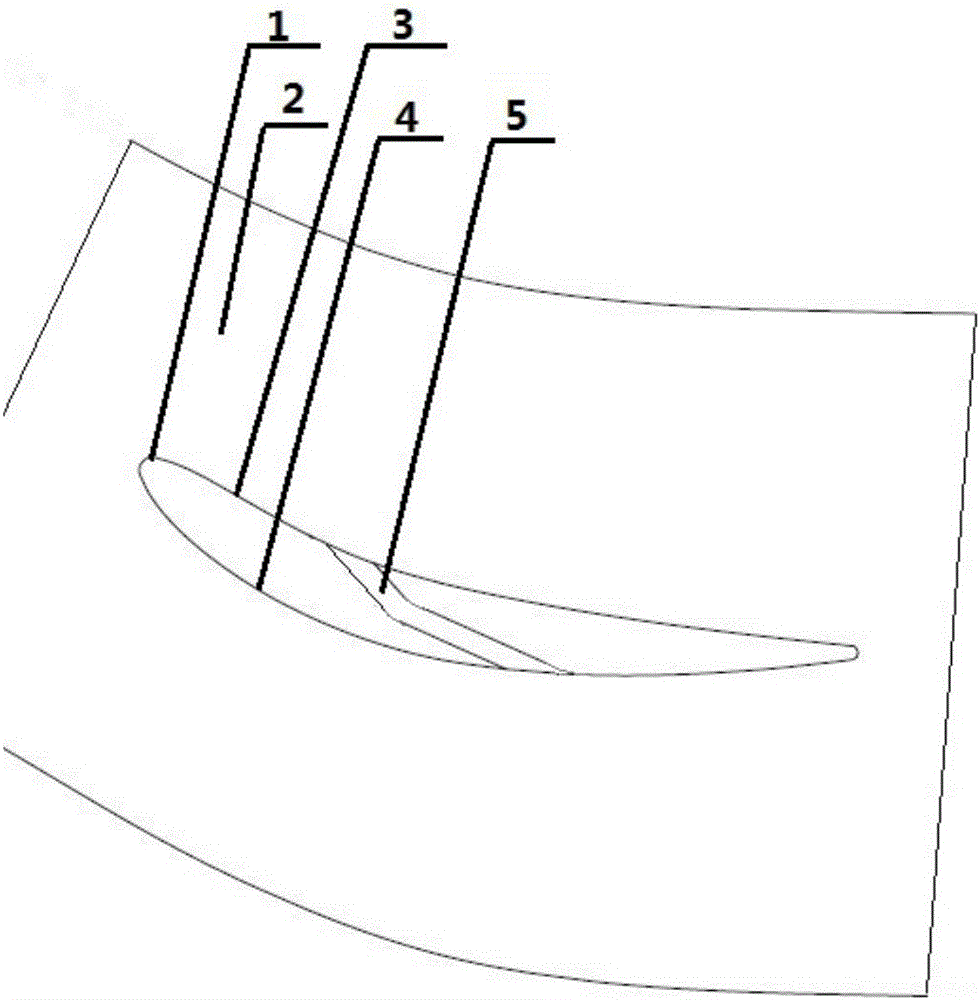

Gas compressor stationary blade cascade with equal-width linear groove formed in blade root

ActiveCN105179322AStrong ability to resist reverse pressure gradientInhibition of flow separationPump componentsPumpsEngineeringGas compressor

The invention provides a gas compressor stationary blade cascade with an equal-width linear groove formed in a blade root and relates to the passive flow control technology in the technical field of turbomachinery. By means of the gas compressor stationary blade cascade, the equal-width linear groove is formed in the blade root end wall of the gas compressor stationary blade cascade from the pressure face to suction face, and jet flow is formed through detour flow pressure differentials of a blade, so that flow separation is restrained and delayed. The groove is located in the blade root end wall of the gas compressor stationary blade cascade. The spanwise height is a constant value. The inlet of the groove is located in the pressure face of the stationary blade cascade. The outlet of the groove is located in the suction face of the blade cascade. The center line of the groove is a straight line and equidistant from the two side walls of the groove. The gas compressor stationary blade cascade has the beneficial effects that corner separation is restrained; the flow capacity of the blade cascade is increased; the total pressure loss is reduced; the diffusion capacity is improved.

Owner:BEIHANG UNIV

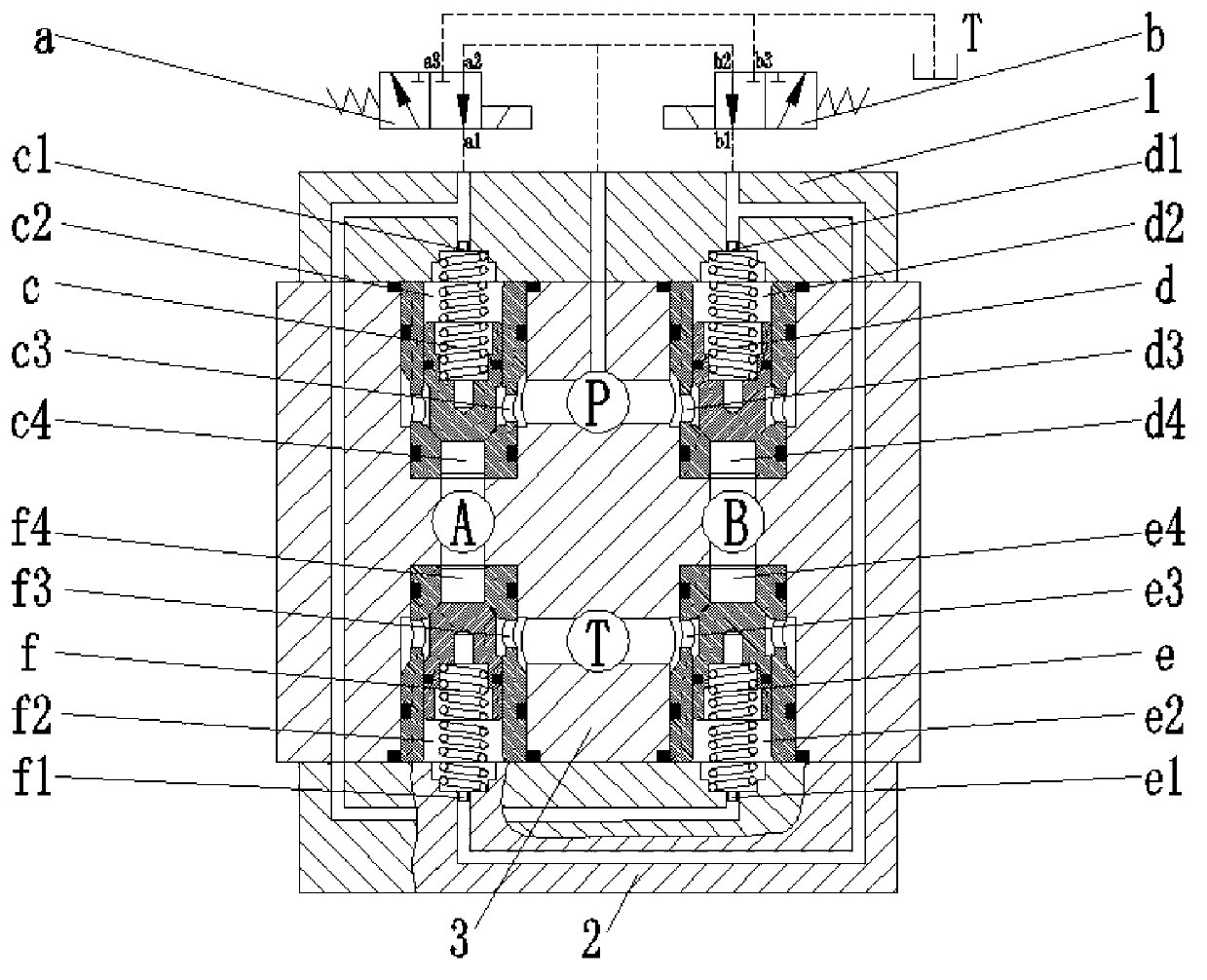

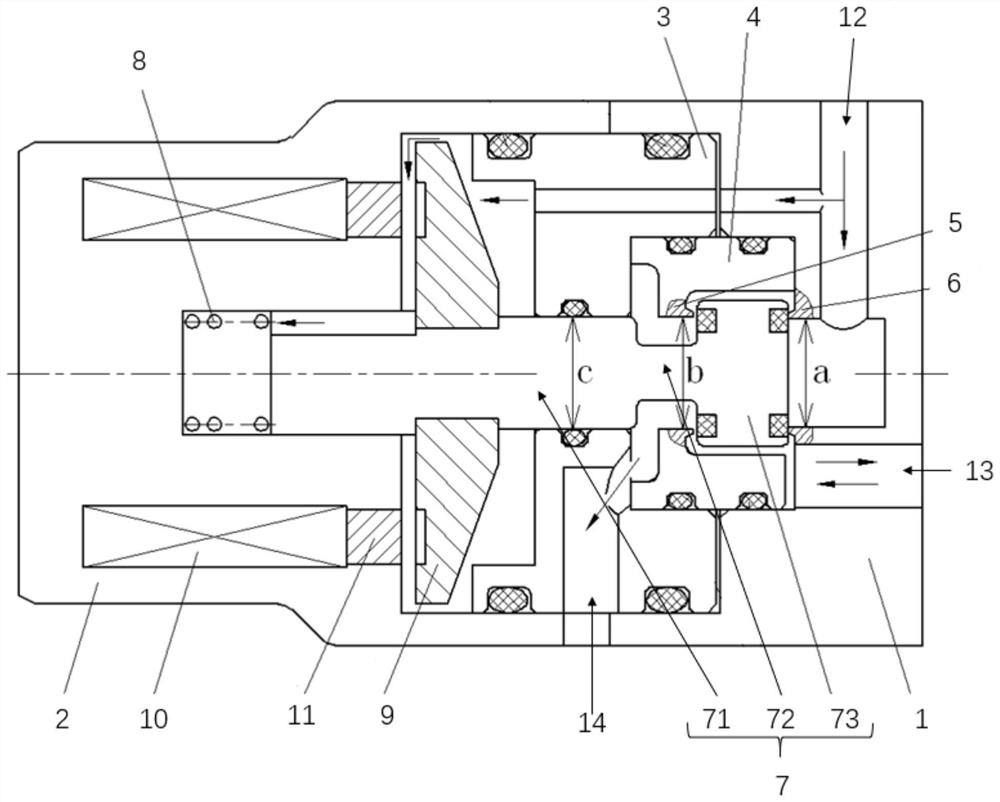

Three-position four-way water pressure magnetic exchange valve used in deep sea

ActiveCN103104569AReduce corrosionOvercome the problem that the effective positioning of the actuator cannot be completedServomotor componentsMagnetic exchangeEngineering

The invention provides a three-position four-way water pressure magnetic exchange valve used in a deep sea and relates to a component which controls a liquid flow direction in a hydraulic system. The three-position four-way water pressure magnetic exchange valve used in the deep sea is composed of two guide control valves, four sets of insertion components, two control cover plates and an insertion block. Each set of insertion component comprises a valve core, a valve sleeve, a spring and a sealing piece combination. Four sets of cone-valve-shaped two-way insertion components which are in the same structure are mutually communicated through ducts which are formed in the inner portion of a valve body by utilizing a method of plug-in mounting plus cover plates. The guide control valves control the opening or closing of each valve opening of each insertion component, and therefore a communication mode of four valve openings including a P valve opening, an A valve opening, a B valve opening and a T valve opening of the three-position four-way magnetic exchange valve is changed, and reversing function is achieved. The three-position four-way water pressure magnetic exchange valve used in the deep sea is suitable for a liquid flow direction control situation of middle and high pressure aqueous media (fresh sea water, seawater base and the like) and is particularly suitable for being used in a deep-sea mass-flow water hydraulic transmission system.

Owner:BEIJING UNIV OF TECH

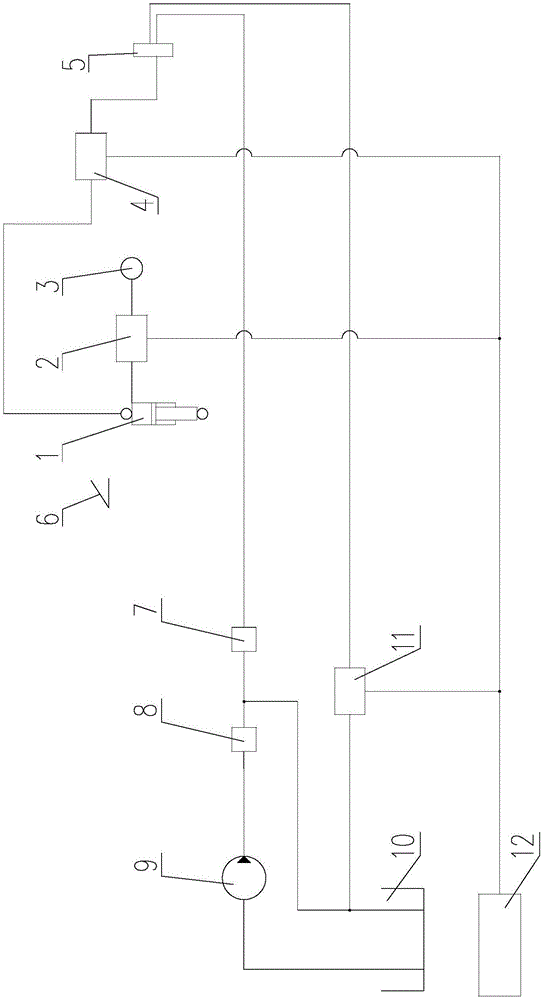

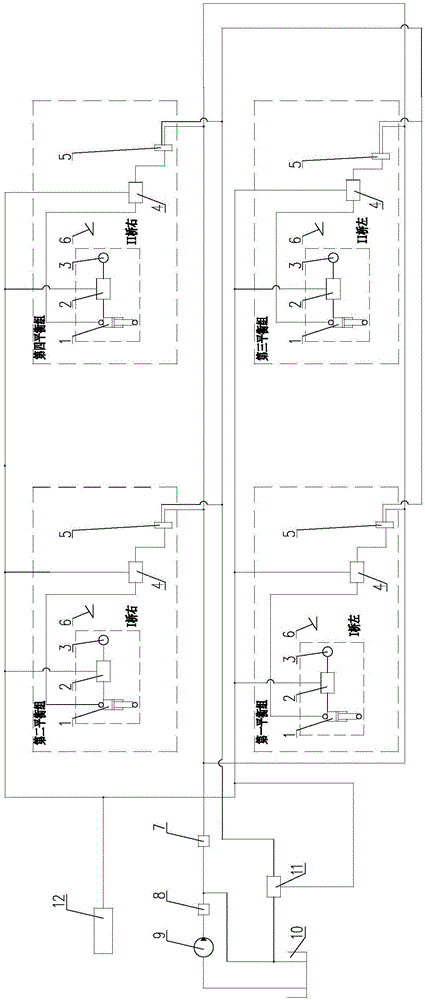

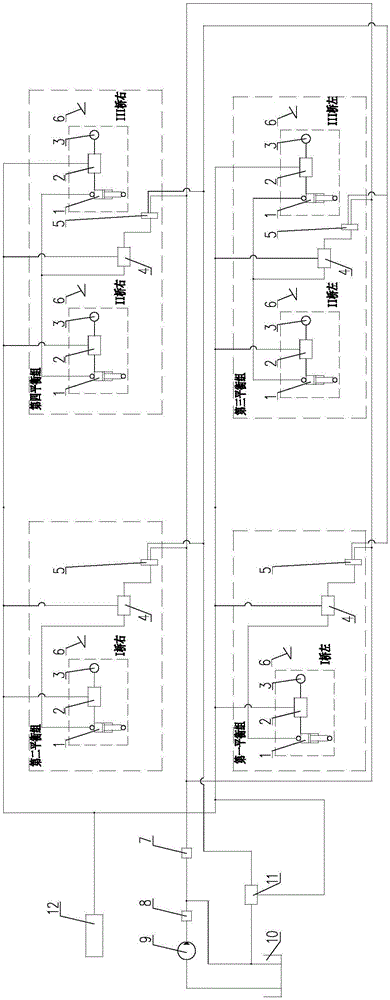

Lifting hydro-pneumatic suspension hydraulic system

ActiveCN106567904AMeet the automation level requirementsImprove reliabilityVibration dampersServomotor componentsHydropneumatic suspensionFuel tank

The invention discloses a lifting hydro-pneumatic suspension hydraulic system and relates to a hydraulic system applied to an automobile hydro-pneumatic suspension. According to the lifting hydro-pneumatic suspension hydraulic system, the automation level requirements of the lifting hydro-pneumatic suspension hydraulic system are met, and meanwhile the reliability is improved. The lifting hydro-pneumatic suspension hydraulic system comprises an oil tank (10), an oil supply pump (9), a safety valve (8), a one-way valve (7), an electromagnetic reversing valve (5), a grouping oil returning stopping valve (4), a rigidity stopping valve (2), an oil gas spring (1), an energy accumulator (3), a gas storage cylinder (12), an angle transducer (6), a pneumatic pipeline and a hydraulic pipeline. The oil conveying end of the electromagnetic reversing valve is connected with one oil end of the grouping oil returning stopping valve, and the other oil end of the grouping oil returning stopping valve is connected with the hydraulic oil opening of the oil gas spring. The rigidity stopping valve is arranged between the oil gas spring and the energy accumulator communicating with the oil gas spring. The grouping oil returning stopping valve and the rigidity stopping valve both are pneumatic ball valves.

Owner:SPECIAL VEHICLE TECH CENT OF HUBEI AEROSPACE TECH RES INST

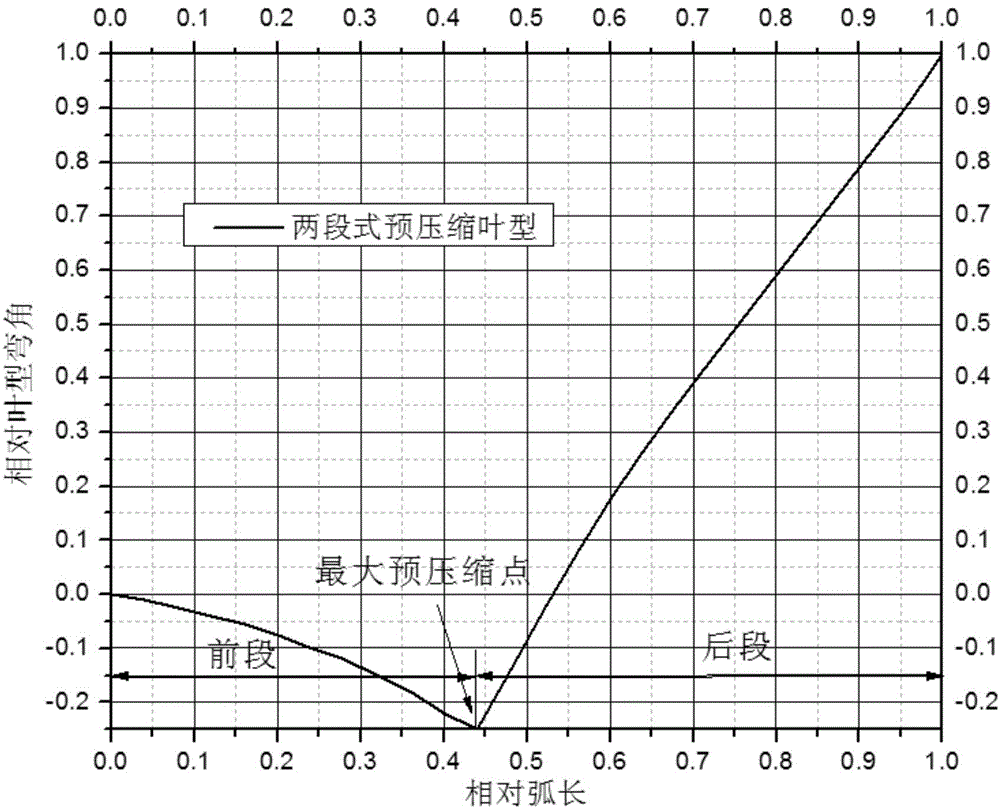

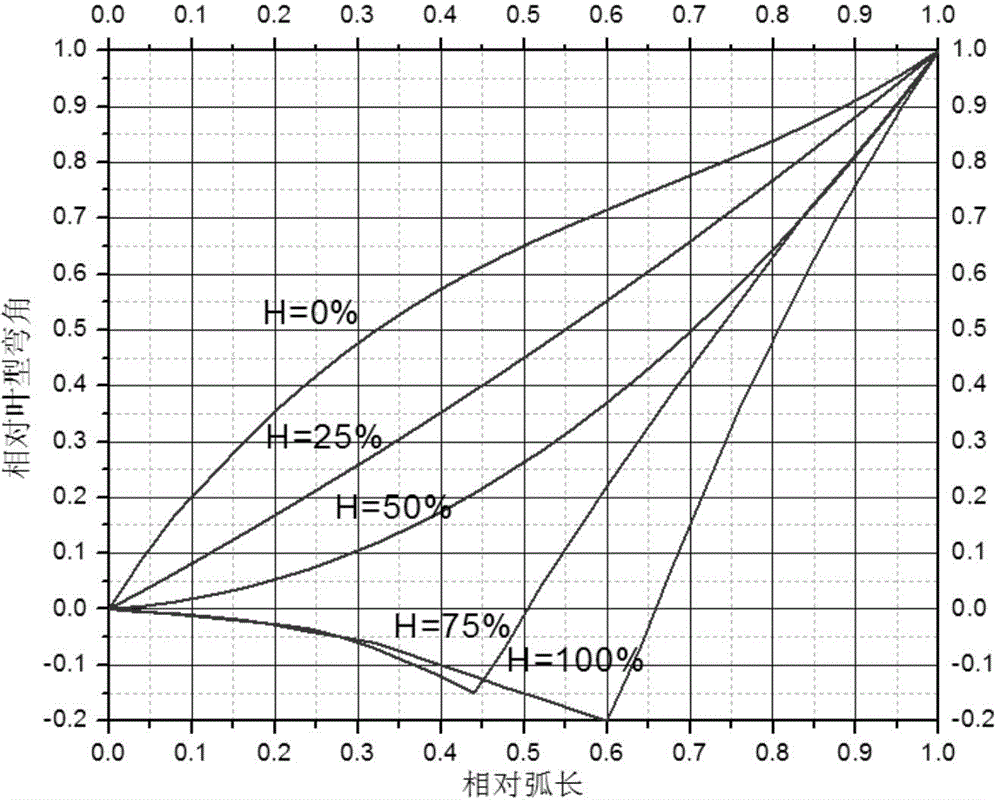

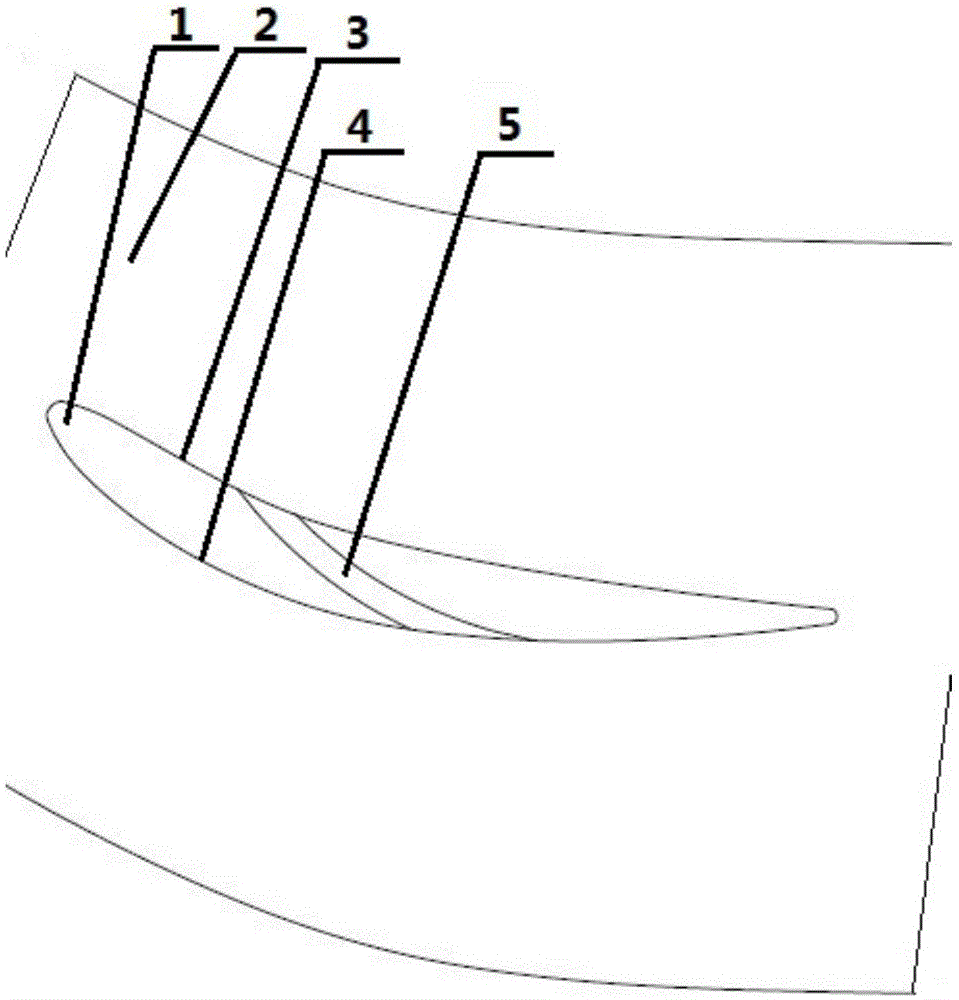

Two-section type pre-compression central arced curve blade profile structure

ActiveCN105465040AStrong supercharging abilityLarge circulation capacitySupersonic fluid pumpsPump componentsShock waveDemarcation point

Provided is a two-section type pre-compression central arced curve blade profile structure. Central arced curve blade profiles have multiple types according to different inlet Mach numbers, the dual-arc blade profile is adopted in a transonic region with the Ma being equal to 0.8-1.2, and a whole arc serves as the central line; the multi-arc blade profile is adopted in a supersonic region with the Ma being equal to 1.2-1.4, the central line is composed of two arcs, and the slopes of the two arcs are identical at a transition point. When the Mach number is larger than 1.4, shock wave loss increases, the front section of the blade back is concave so as to reduce the wave-front Mach number, the shock wave strength is controlled, and the shock wave loss is reduced, namely the pre-compression blade profile is adopted. The central arced curve is divided into a front section and a rear section with the maximum pre-compression point of a blade profile relative bend as the demarcation point, and different relative bend changing laws are adopted by the front section and the rear section respectively. The two-section type pre-compression central arced curve blade profile structure has the advantages that the pressurizing capacity is high, the flow capacity is high, the deviation angle is small, the higher pre-compression quantity and the larger pre-compression section length are selected, and the two-section type pre-compression central arced curve blade profile structure is suitable for the design of hypersonic-speed rotors.

Owner:AECC SHENYANG ENGINE RES INST

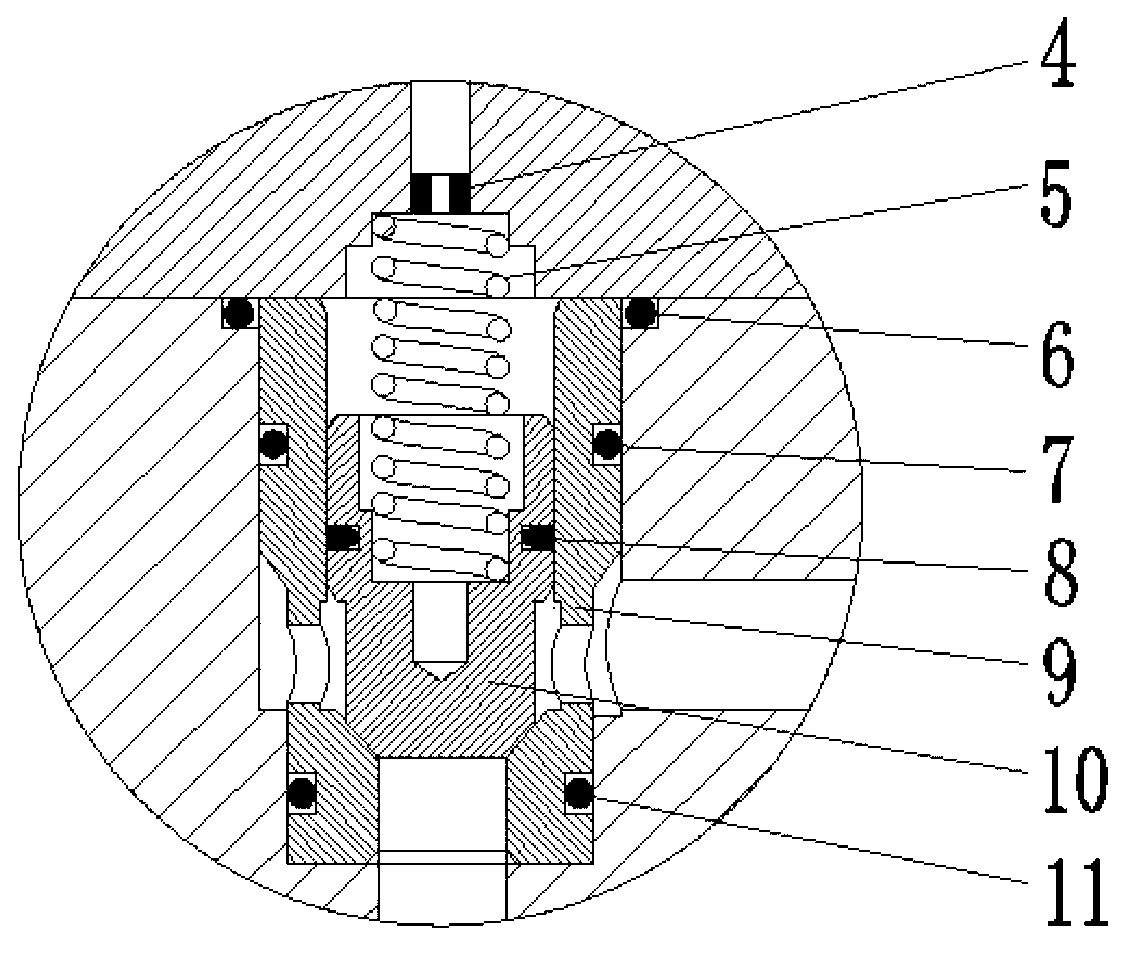

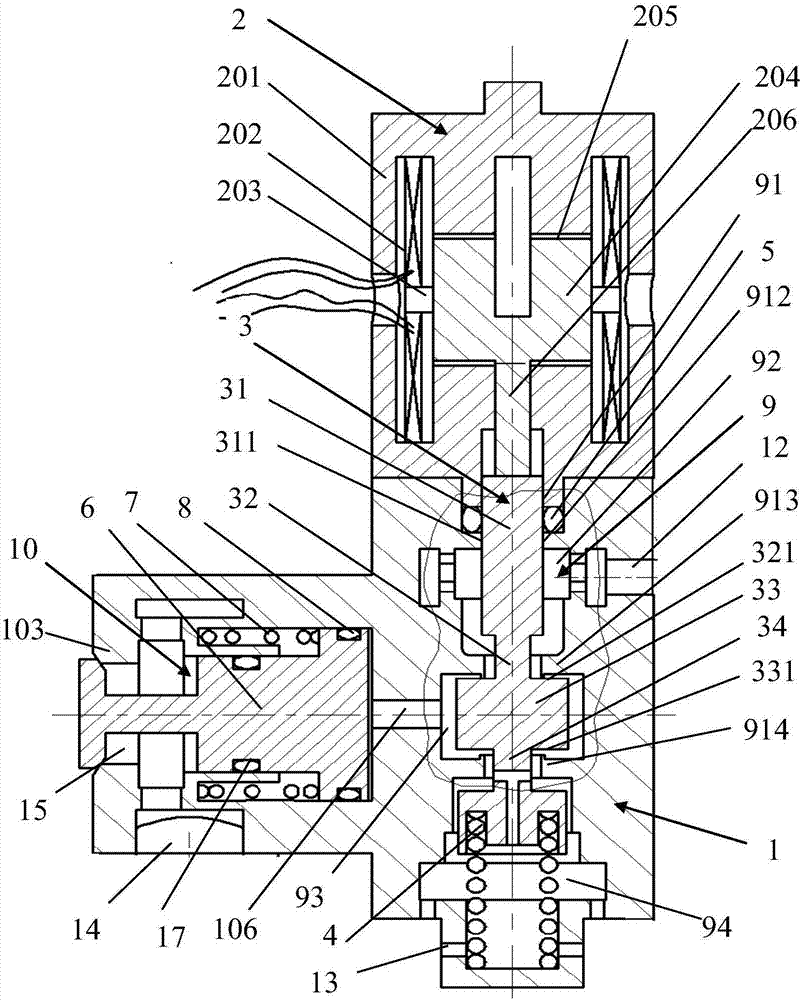

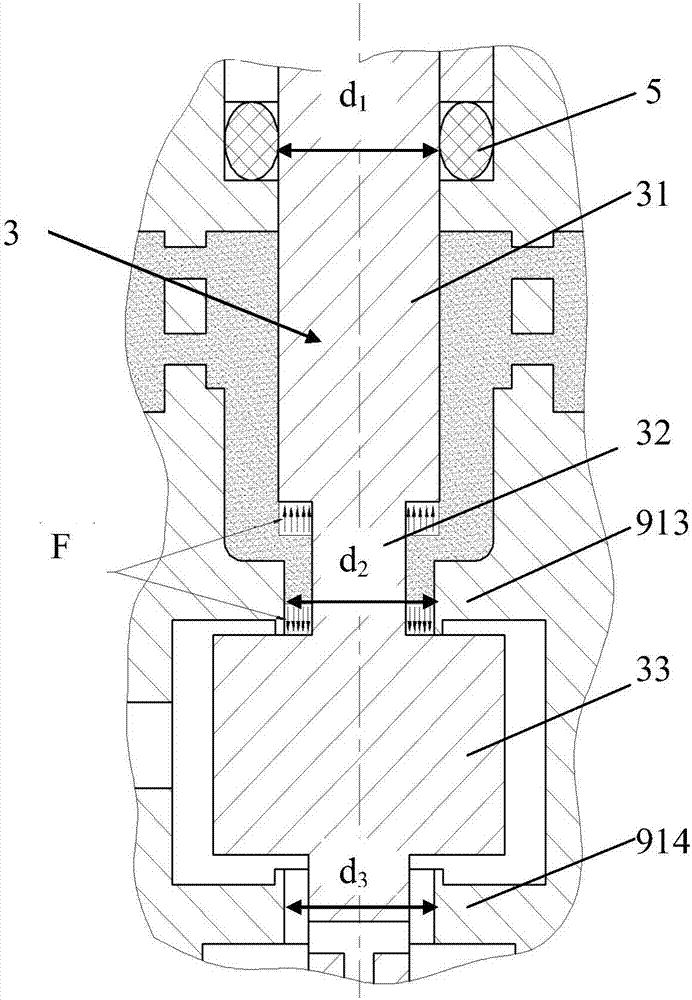

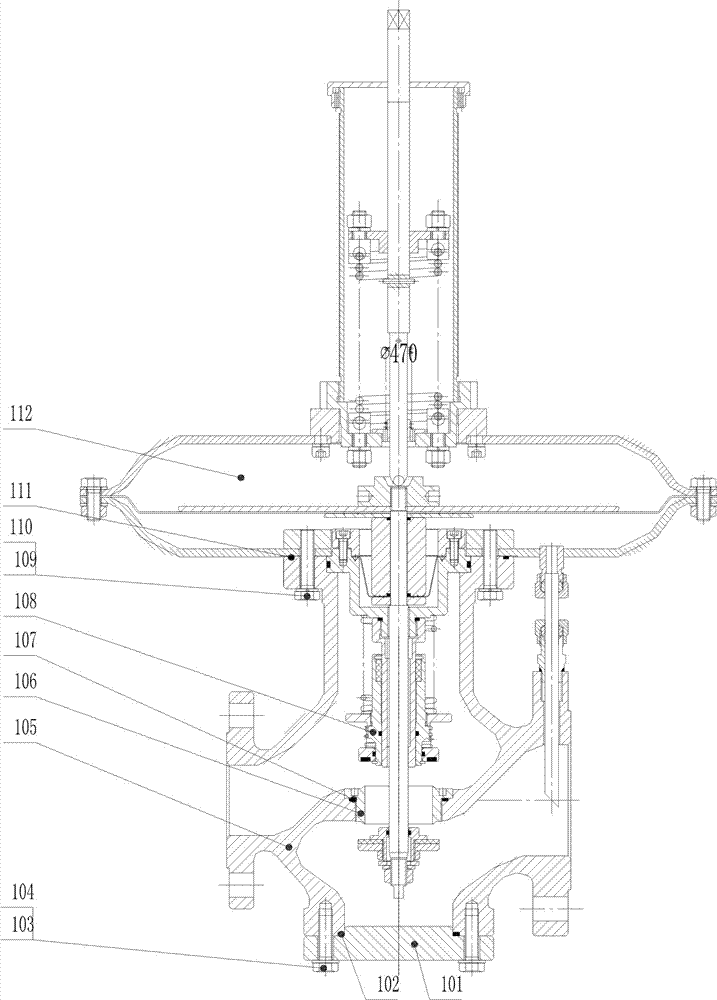

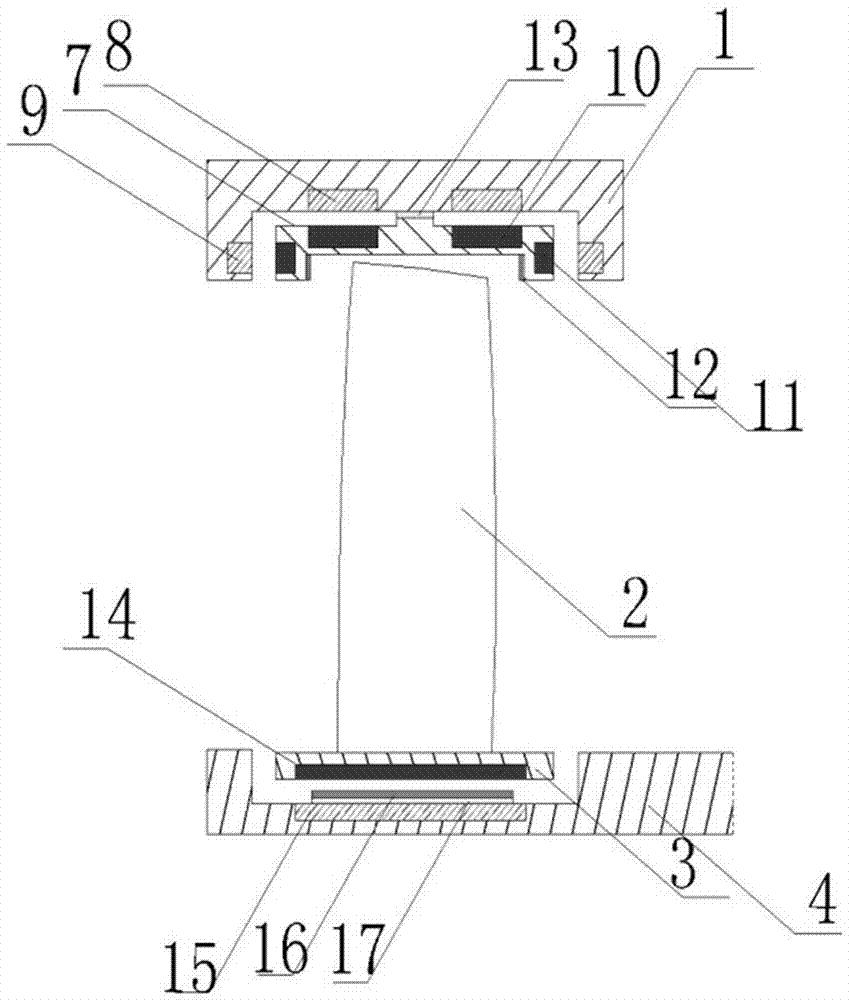

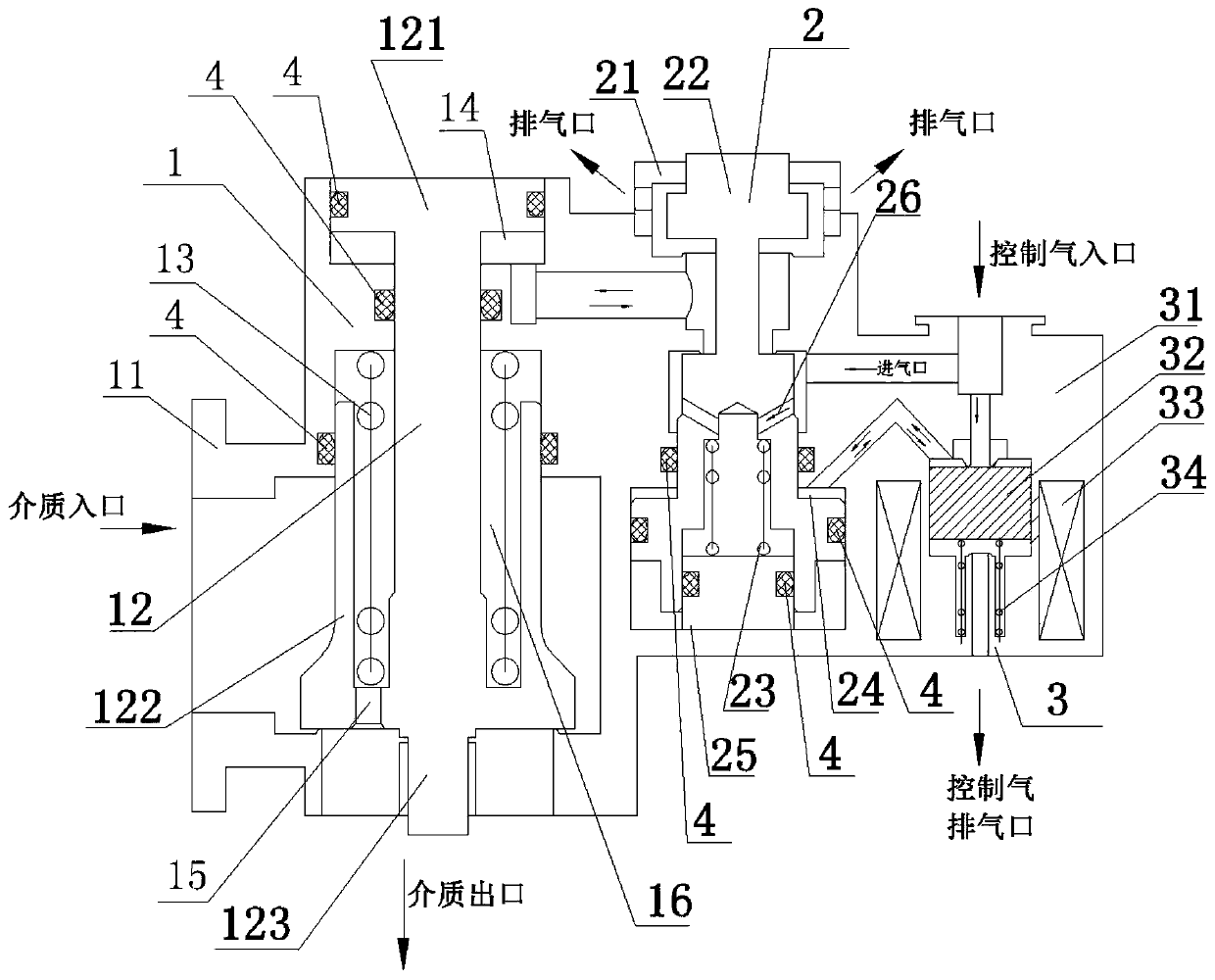

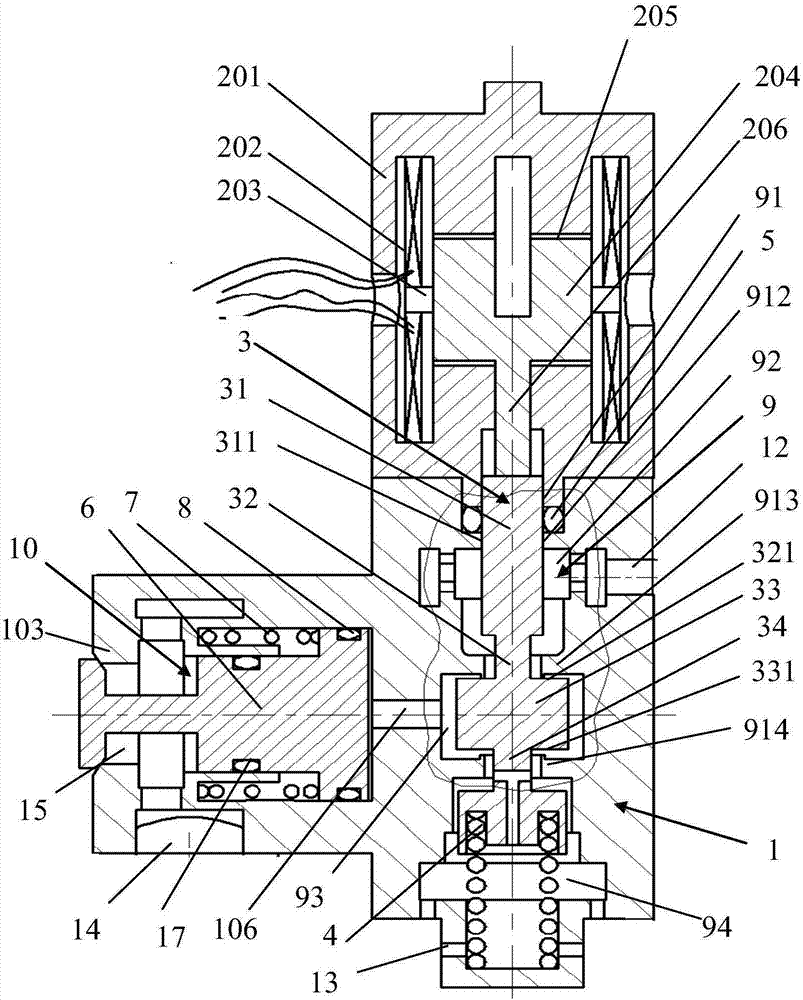

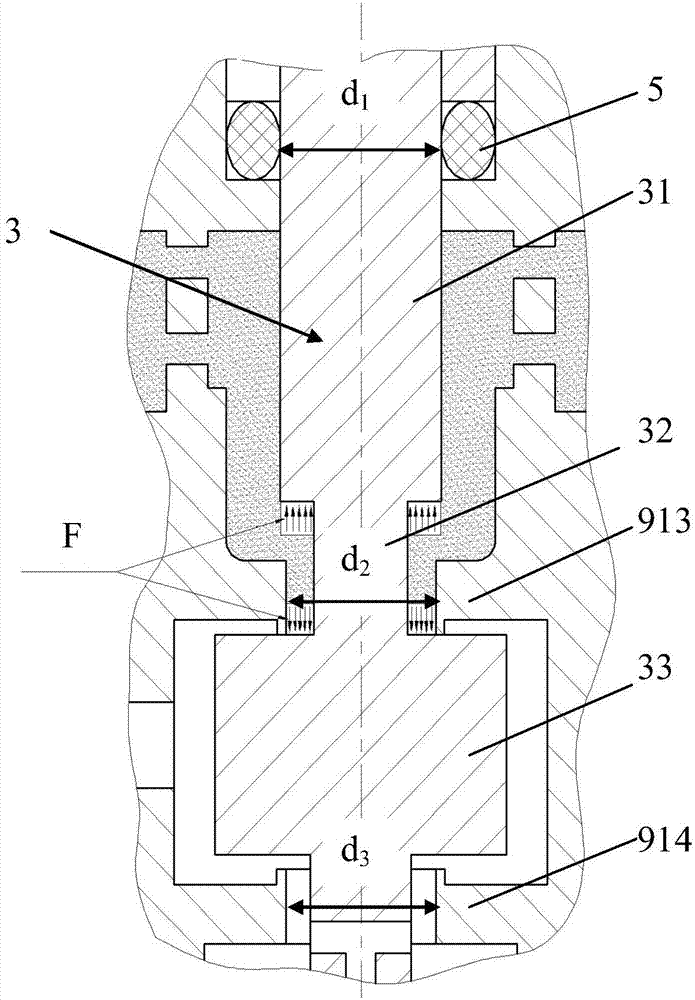

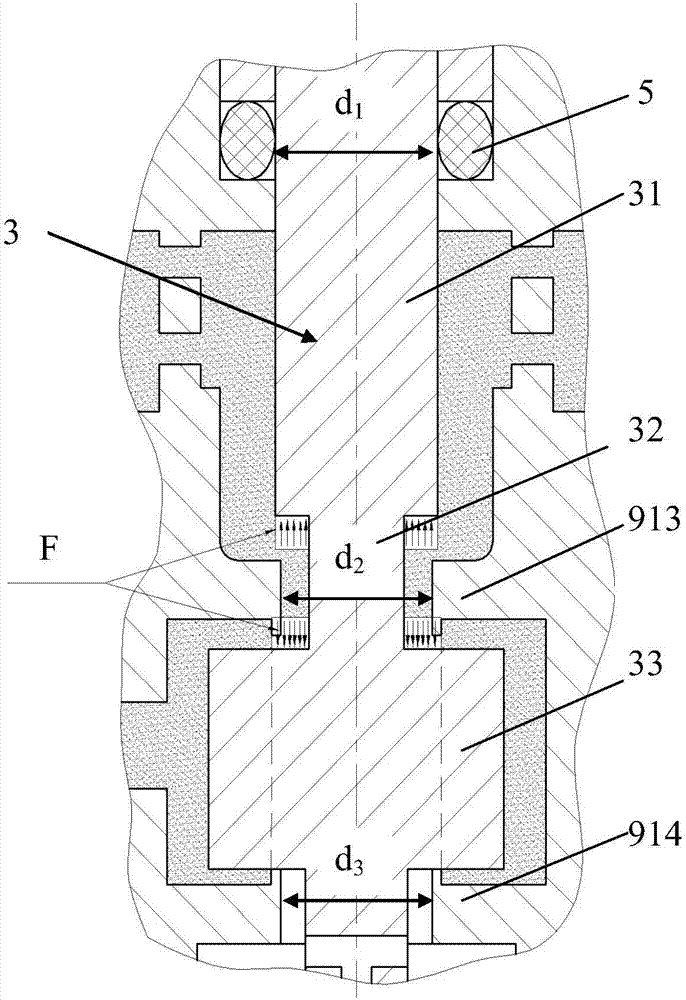

Pilot-operated type electromagnetic pneumatic valves and combined control valve

ActiveCN106989195AReduce load forceReduce drive loadOperating means/releasing devices for valvesLift valveEngineeringPneumatic valve

The invention belongs to the field of control valves and particularly relates to pilot-operated type electromagnetic pneumatic valves and a combined control valve. Each pilot-operated type electromagnetic pneumatic valve mainly comprises a valve body, a pilot-valve valve core component, a main-valve valve core assembly and an electromagnetic coil drive device. Each electromagnetic coil drive device is powered on to drive a pilot valve to be switched on and controls air to enter a pilot-valve core installation cavity, an exhaust opening is sealed, the air is controlled to establish pressure, then a main valve is driven to be switched on, and a medium flows out of a medium outlet from a medium inlet; and after each electromagnetic coil drive device is powered off, the pilot valve is switched off, the air is controlled to be exhausted out of the exhaust opening, the main valve is switched off, and the medium is prevented from flowing out of the medium outlet. The combined control valve is a combination of the multiple pilot-operated type electromagnetic pneumatic valves, the structure is optimized, and the combined control valve is suitable for occasions, such as a rocket with a high requirement for the radial size. The pilot-operated type electromagnetic pneumatic valves and the combined control valve are mainly used for occasions with a large flow and high pressure, such as, liquid rocket engines, satellite in-orbit execution systems, ground test systems and automated fluid pipe systems and have the advantages of being high in integrated degree and high in response speed.

Owner:XIAN AEROSPACE PROPULSION INST

Integrated cut-off type pressure regulator

InactiveCN103174858AEasy pressure settingHigh sensitivityOperating means/releasing devices for valvesEqualizing valvesStructural engineeringSteel ball

The invention discloses an integrated cut-off type pressure regulator. The integrated cut-off type pressure regulator is characterized in that the main structure of the integrated cut-off type pressure regulator comprises a regulating part, a balance valve core part, a cut-off part and a valve body. The integrated cut-off type pressure regulator provided by the invention has the advantages that the structure is simple, some module structures are divided, the size is compact, the space occupation is small, the online maintenance is convenient, an air inlet caliber of a product is DN50, an air outlet caliber is DN80, and the flow capacity is large; and a balance valve core structure is adopted, the pressure fluctuation is small, the applicable pressure range is wide, a steel ball affiliated cut-off structure is adopted, the sensitivity of cut-off movement is high, the replication property is good, the pressure setting of the cut-off movement is simple, and the range is wide.

Owner:四川嘉星燃气设备制造有限公司

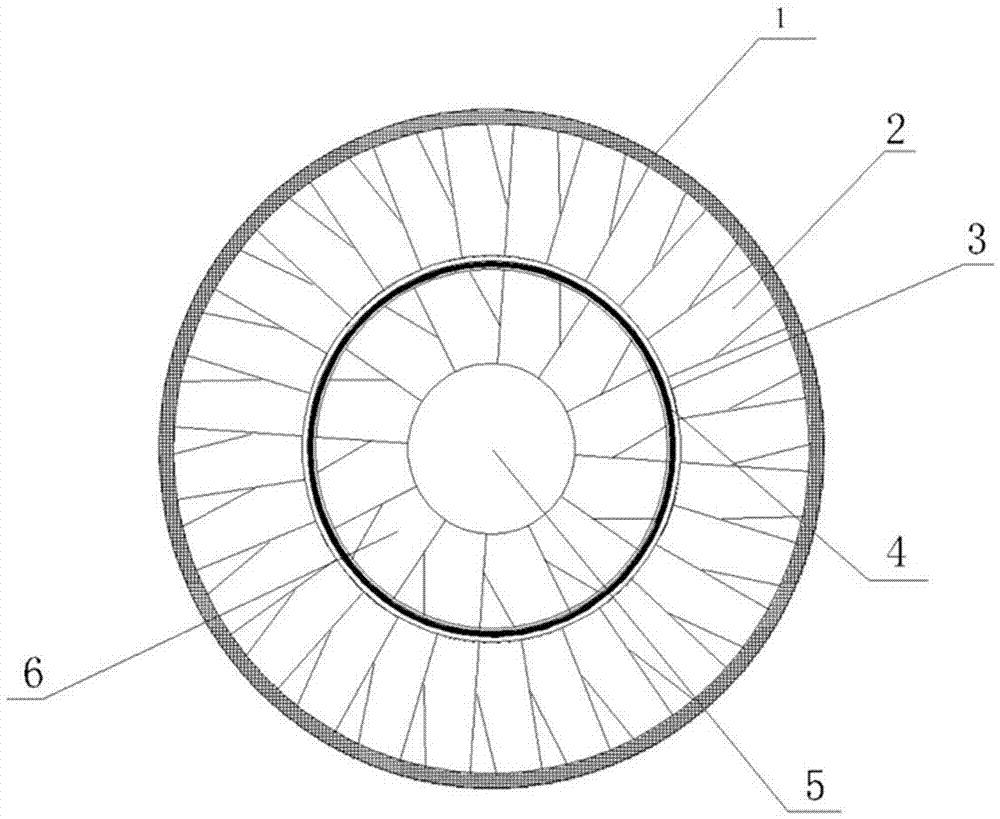

Magnetic suspension outer culvert fan used for aero-turbofan engine

ActiveCN107313876AImprove work efficiencyLight in massPump componentsPump controlAxial displacementAviation

The invention discloses a magnetic suspension outer culvert fan used for an aero-turbofan engine. The magnetic suspension outer culvert fan comprises an outer casing, a distribution casing, a hub, fan blades, blade tip magnetic rings and the like, wherein the outer casing comprises coils which are distributed on the outer casing body and have different winding directions, a controller and an axial displacement sensor. Each blade tip magnetic ring part comprises permanent magnets circumferentially arranged on the magnetic ring. The fan blades are mounted on the hub. The permanent magnets surround the hub circumferentially. The distribution casing comprises a coil surrounding the distribution casing body, a radial displacement sensor and a controller. The outer culvert fan has no mechanical relation with the internal turbojet engine, and thus the rotation speed of the fan can be adjusted in real time. The working efficiency of the aero-turbofan engine is greatly improved, the steps of a low-pressure gas compressor and a turbine are lowered, the engine mass is lowered, and the engine overall performance is improved. The design difficulty and the machining difficulty of the aero-turbofan engine are greatly lowered.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Large-flow high-pressure one-way valve for ship

A large-flow high-pressure one-way valve for a ship comprises a valve seat, a spring seat matched with the outlet end of an inner cavity of the valve seat, a valve core located in the inner cavity, and a spring located in the inner cavity; the valve core comprises a guide rod and a frustum valve core which are arranged coaxially; the frustum valve core comprises a valve core head, a sealing section, a cylindrical flow guide section and an inverted frustum flow guide section which are coaxially connected in sequence; the valve core head is of a conical structure, and the included angle betweenthe generatrix of the valve core head and the top face of the sealing section is smaller than or equal to 5 degrees; the sealing section is of a circular frustum structure, and the contour of the sideface of the sealing section is in sealing fit with a sealing conical face arranged at the inlet end of the inner cavity; the small-diameter end of the inverted frustum flow guide section is fixedly connected with one end of the guide rod, and the outer wall of the other end of the guide rod is in inserting fit with the inner wall of a guide channel formed in the spring seat; and the two ends of the spring sleeve the guide rod and the spring seat correspondingly. Through the design, the energy losses of flow media are effectively decreased, and in addition, the large flow capacity is achievedwith the small outline dimension.

Owner:WUHAN MARINE MACHINERY PLANT

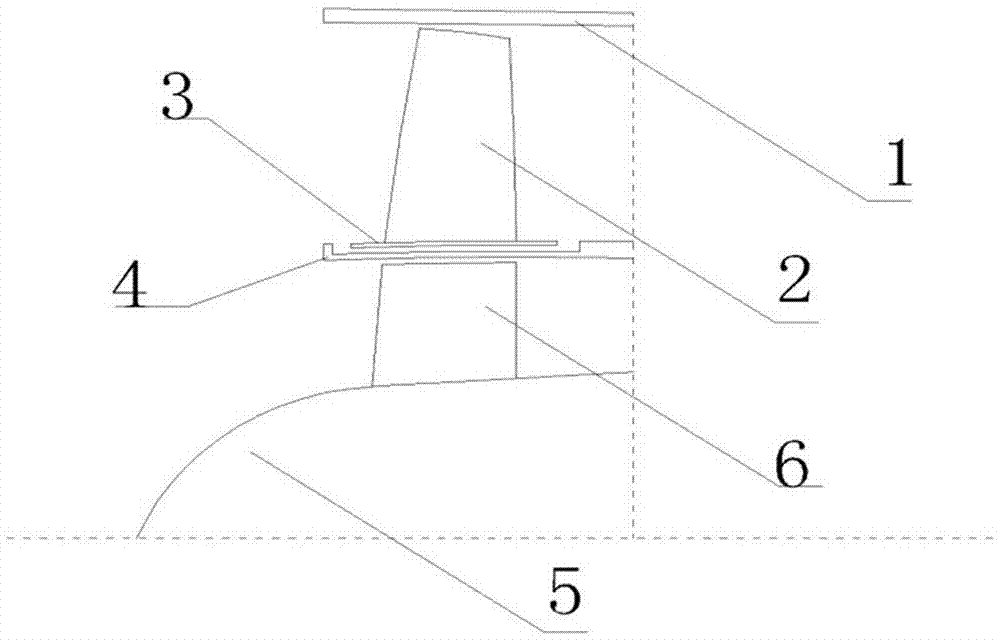

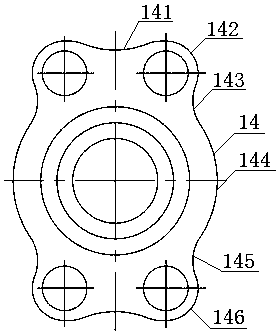

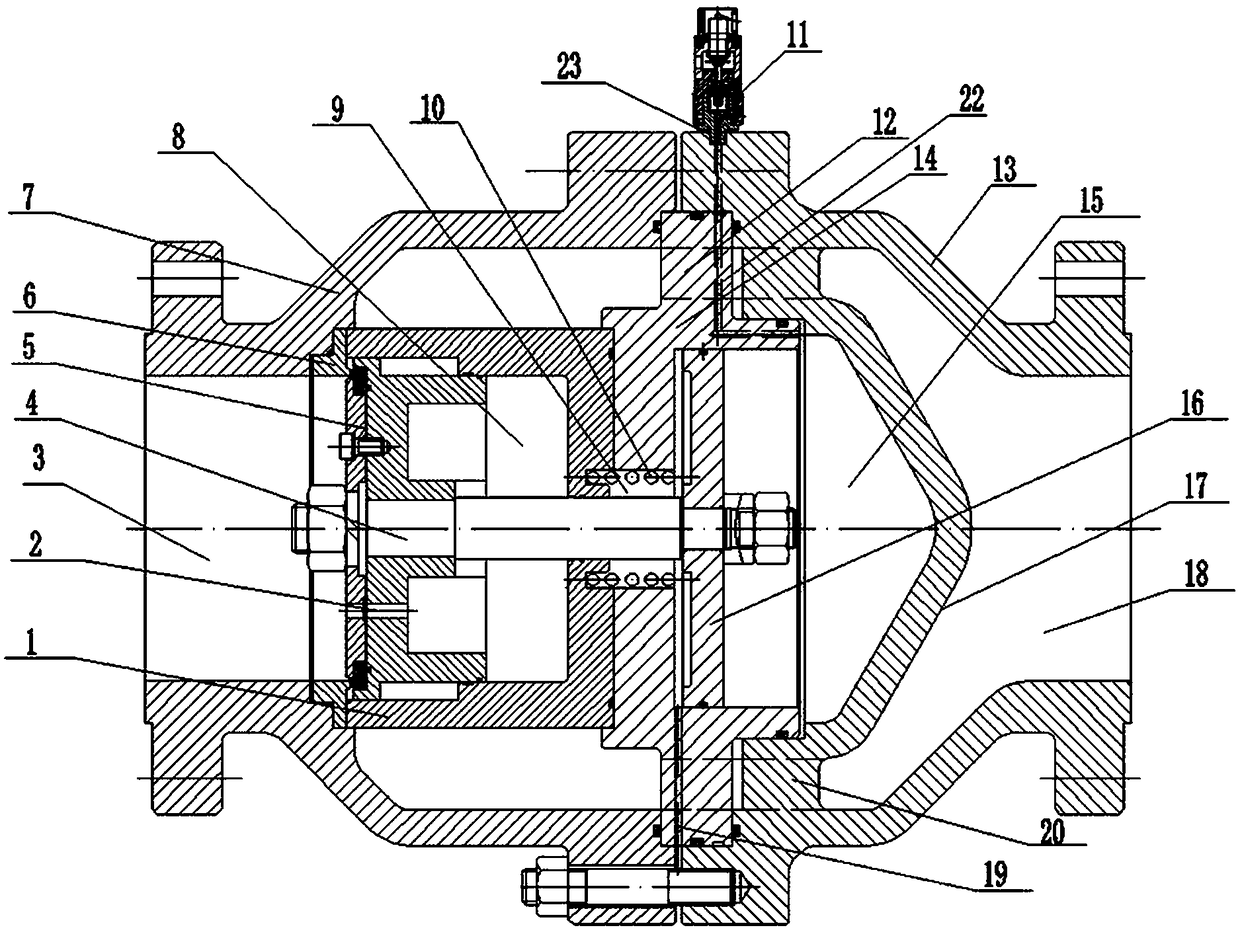

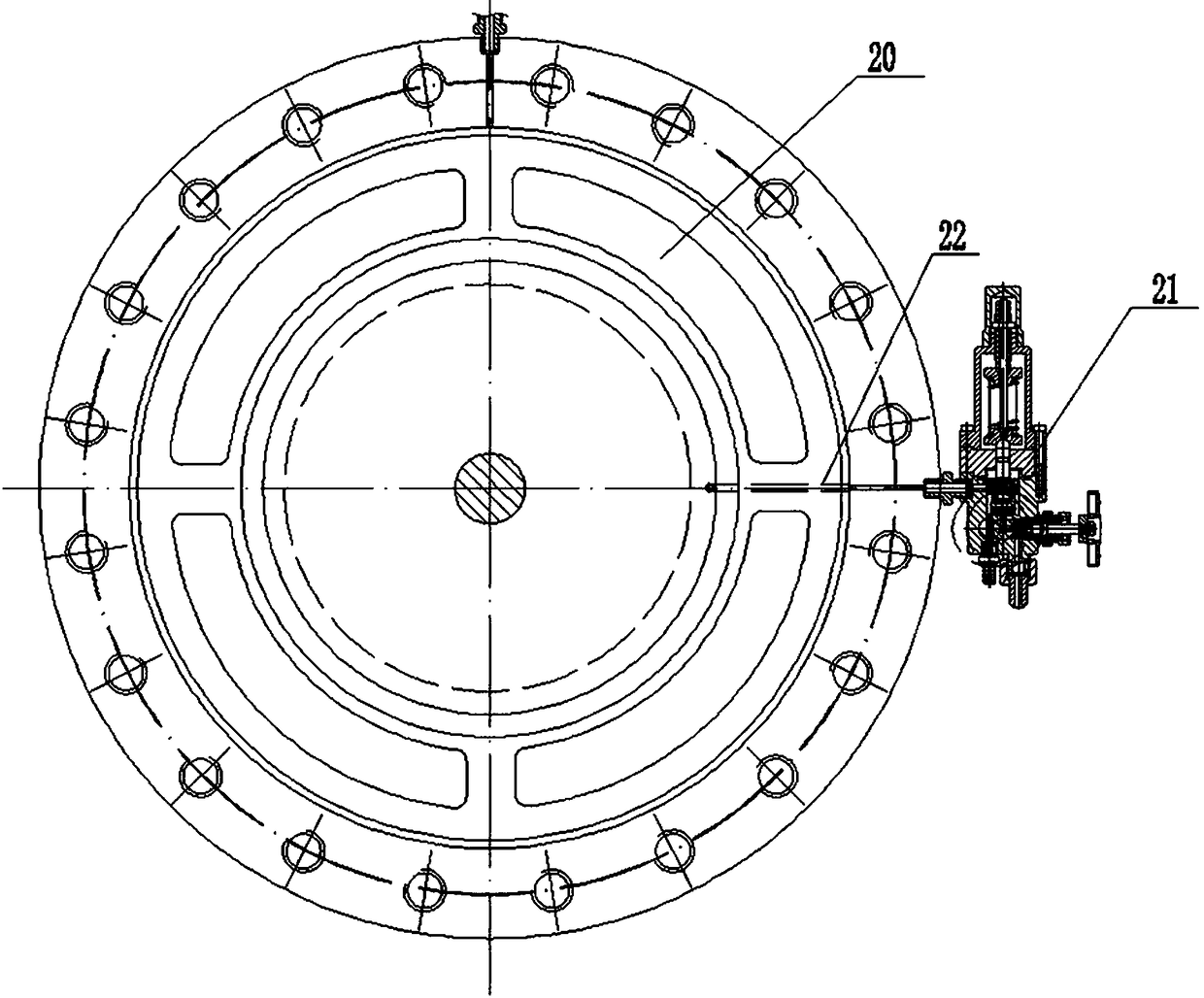

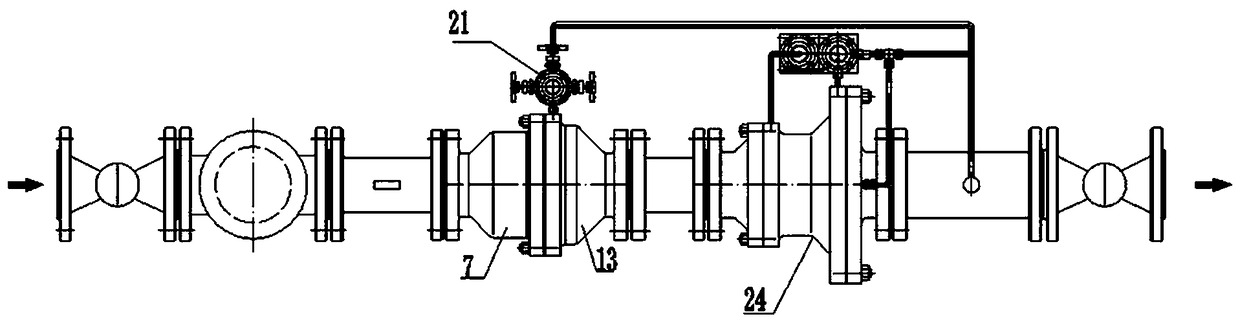

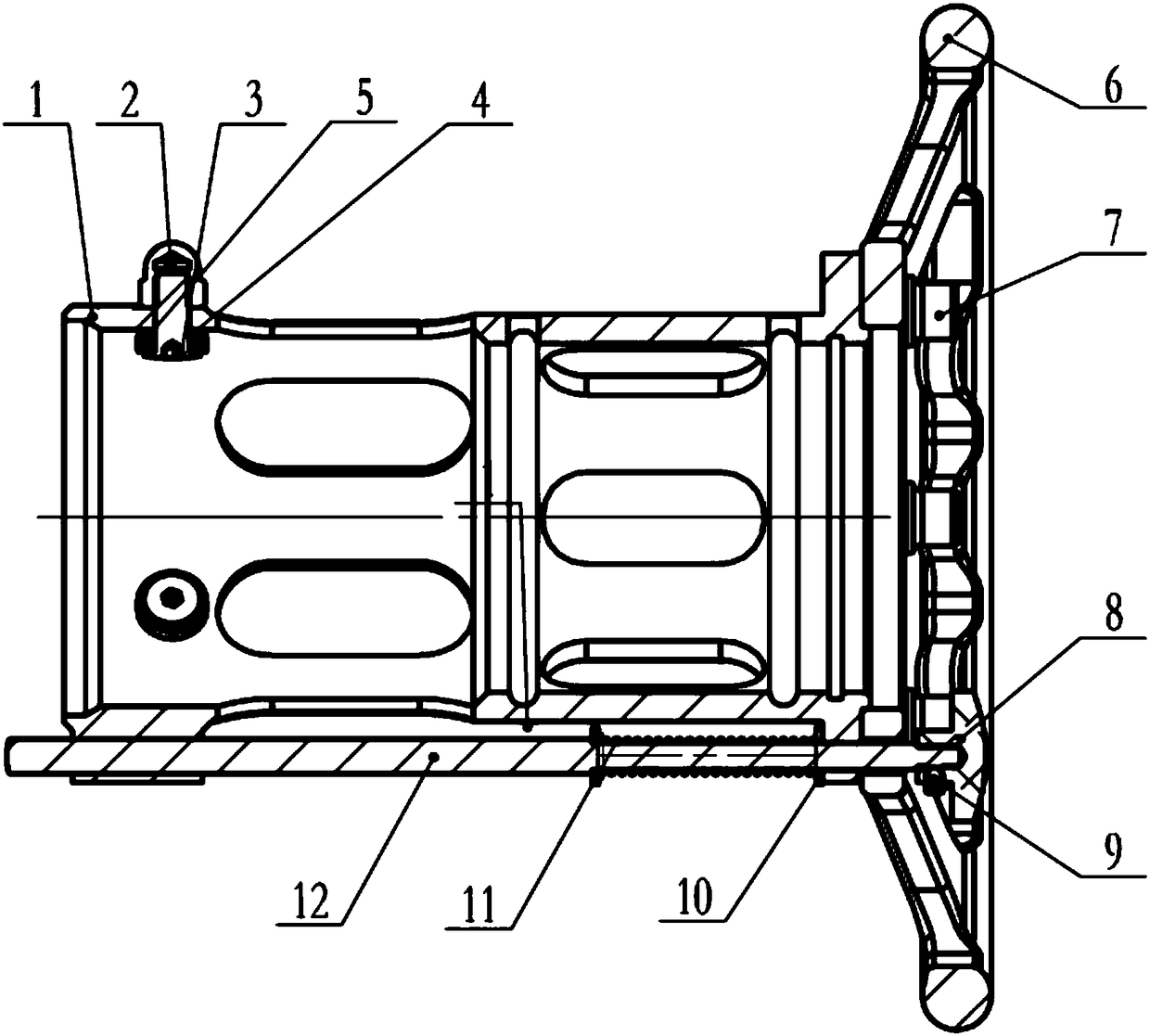

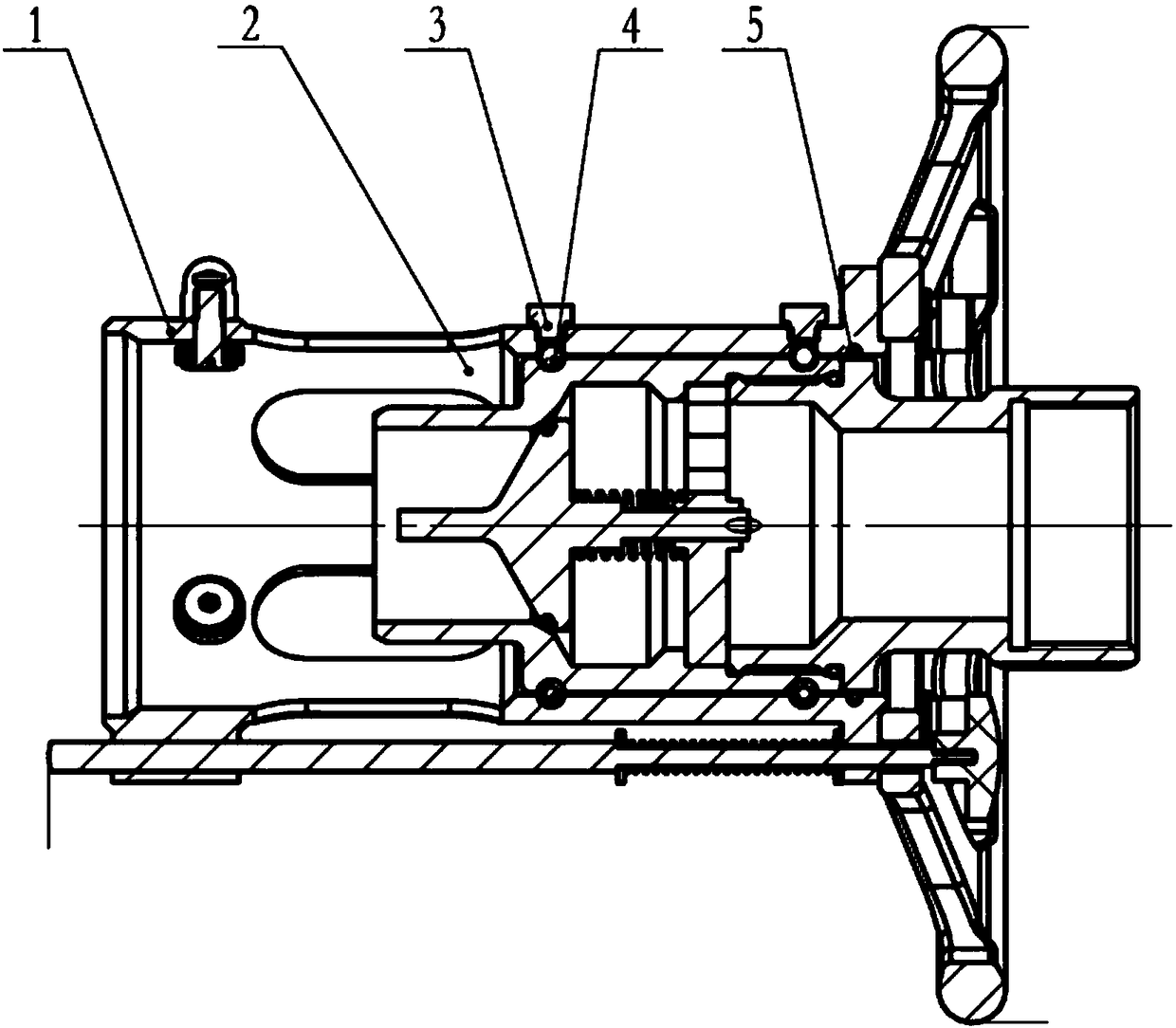

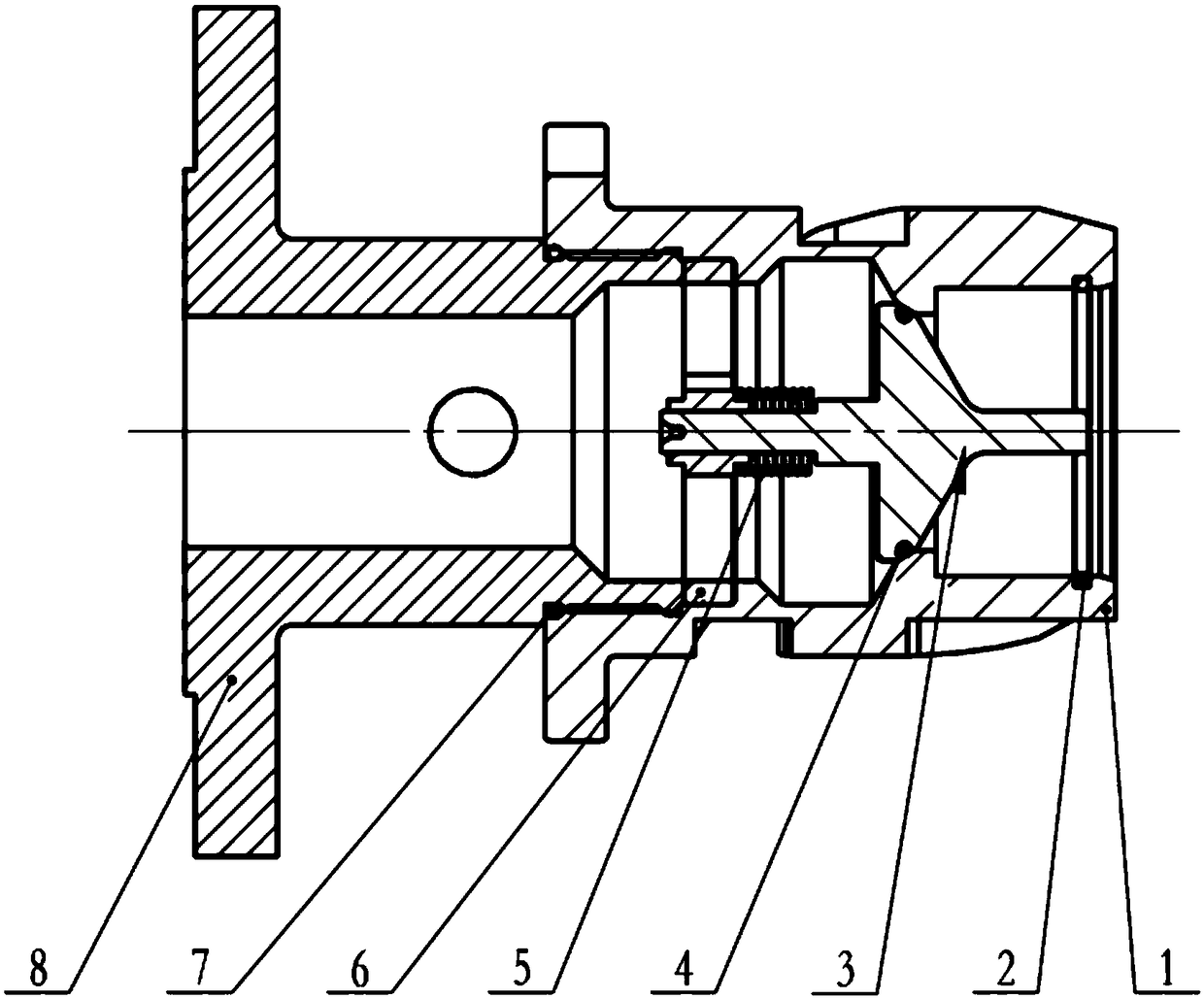

Axial-flow type safety block valve and overpressure cut-off control system thereof

PendingCN108716558ALarge circulation capacityReduce noiseEqualizing valvesSafety valvesTraffic capacityExternal energy

The invention discloses an axial-flow type safety block valve and an overpressure cut-off control system thereof. The axial-flow type safety block valve comprises a left valve body, a right valve body, a valve seat, a valve element, a valve rod, a valve element sleeve, a piston sleeve and a piston. Inlet space is formed by the left valve body, the valve seat and the valve element. The valve element is arranged in the valve element sleeve in a sliding connection manner. Left space is formed by the valve element and the inner side of the valve element sleeve. Damping space is formed by the rightside of the valve element sleeve, the inner side of the piston sleeve and the left side of the piston. A reset spring is arranged in the damping space. Right space is formed by the piston sleeve, thepiston and the left side of an inner sleeve of the right valve body. A signal medium hole is formed in the piston sleeve. The right space communicates with an outlet of an overpressure control valvethrough the signal medium hole. The axial-flow type safety block valve needs no external energy sources when in work, and carries out automatic cutting by utilizing the natural pressure energy of media. The axial-flow type safety block valve is low in pressure loss, high in flow capacity and low in noise when in work, has the functions of single overpressure cutting, multi-level overpressure cutting, remote control and the like, and is especially suitable for high-flow conveying occasions of natural gas long-distance transport pipelines, gas distributing stations and the like.

Owner:四川长仪油气集输设备股份有限公司

Liquefied hydrocarbon tank car loading and unloading safety quick coupling

The invention relates to a liquefied hydrocarbon tank car loading and unloading safety quick coupling. The problems that in the prior art, a coupling is likely to be disengaged and prone to leakage, quick cutting cannot be achieved, and safety is poor are mainly solved. The liquefied hydrocarbon tank car loading and unloading safety quick coupling comprises a male end and a female end, the femaleend and the tank car are fixedly installed on the tank car through flanges, the tail of the female end is fixedly installed at the front end of a liquefied hydrocarbon crane pipe through threads of aconical pipe, the female end is provided with an ultra-short ball valve, a tapping ball valve and a flange base, spiral grooves are evenly distributed in the outer periphery of the male head, a stop valve is arranged inside, the female head of the quick coupling is provided with a locking mechanism, a roller is arranged at the head, a ball groove is formed in the middle section, a hand wheel is arranged at the tail, a ball groove is formed in the inner periphery of the female head, the stop valve is arranged inside through connection of the ball and the male head, and a universal joint is arranged at the tail, so that the problems are solved, and the quick coupling can be used for liquefied hydrocarbon tank car loading and unloading.

Owner:CHINA PETROLEUM & CHEM CORP +1

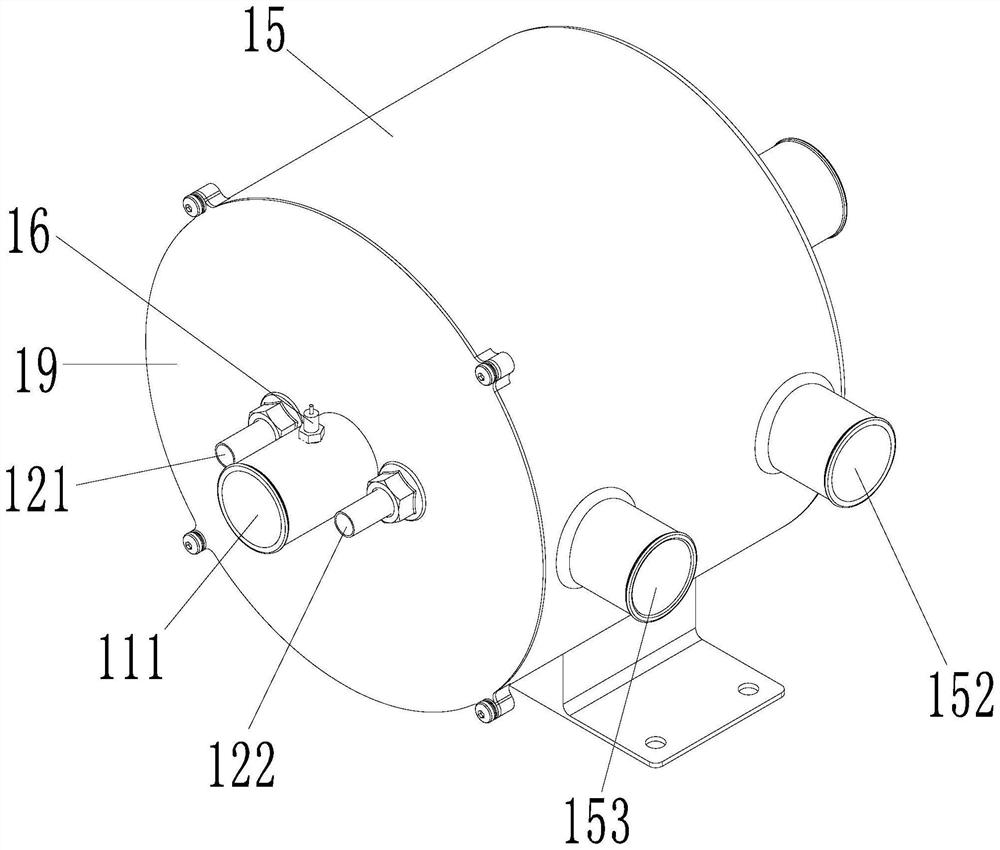

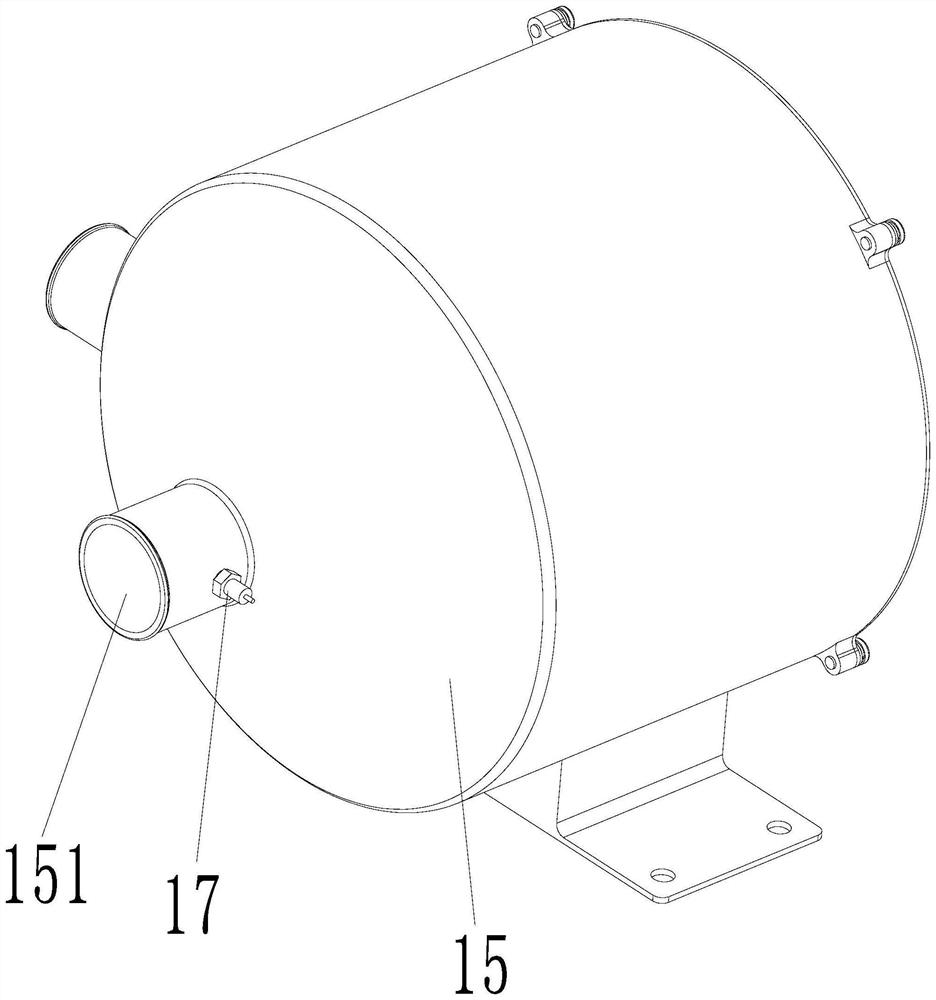

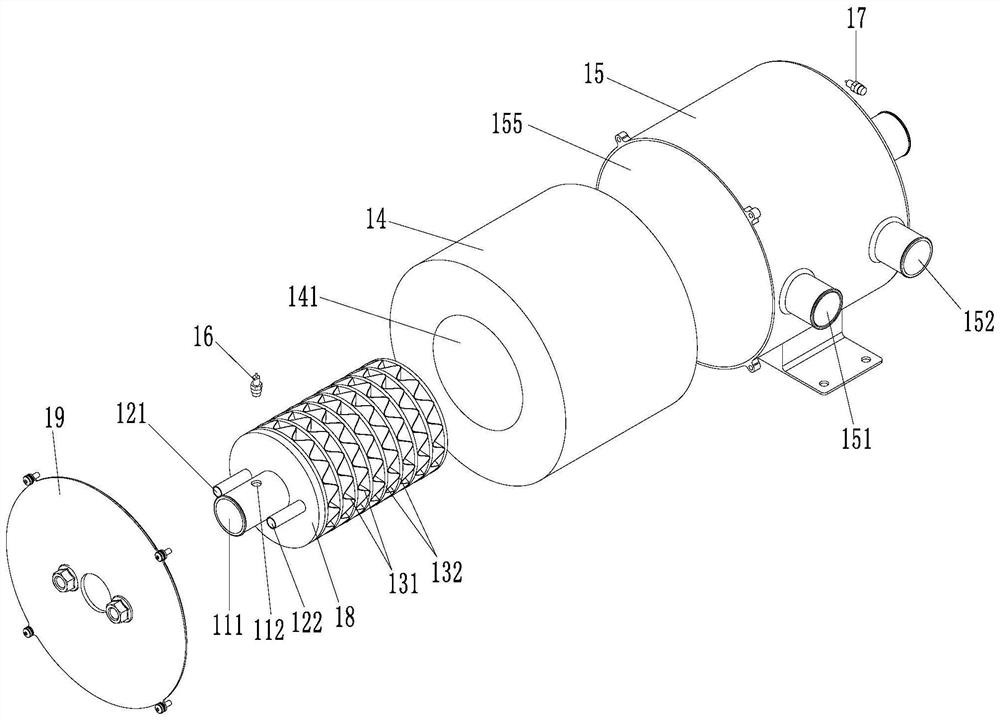

Intercooling humidifying device and fuel cell system applying same

PendingCN111725538AImprove efficiencyIncrease contact areaFuel cell heat exchangeThermodynamicsFuel cells

The invention discloses an intercooling humidifying device and a fuel cell system applying the same. The device comprises an air inlet pipeline, a heat exchange device, a humidifying module and a sleeve shell, the heat exchange device sleeves the air inlet pipeline; the humidifying module sleeves the heat exchange device; the humidifying module is sleeved with the sleeve shell; a first air outletis formed in one end of the sleeve shell; dry hot air enters from one end of the air inlet pipeline and flows out in the radial direction, the cooling treatment of the heat exchange device and the humidification treatment of the humidifying module are carried out, low-temperature humid air is formed, and the low-temperature humid air flows out of the first air outlet. The structure integrates thefunctions of intercooling and humidifying, the device is simple in structure, compact and small in occupied overall layout space of the fuel cell system, increases the mutual contact area of the heatexchange device and the humidifying module, increases the airflow circulation capacity, improves the overall efficiency of the fuel cell system, reduces parts and reduces the cost.

Owner:ZHONGSHAN BROAD OCEAN

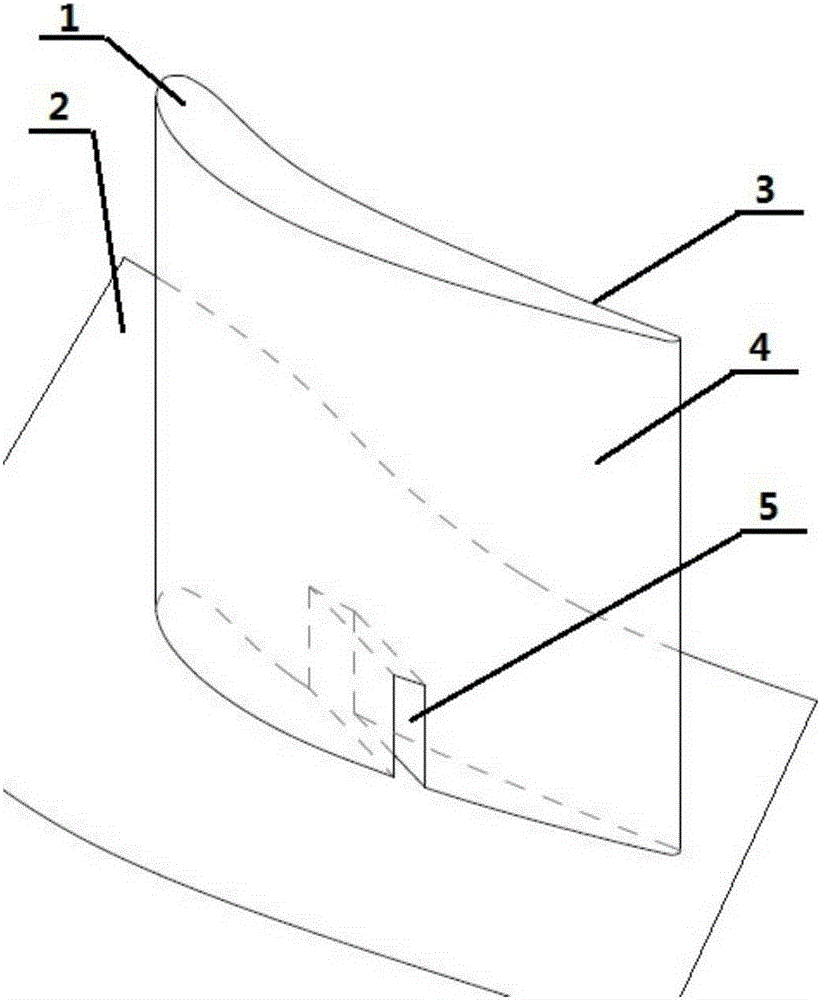

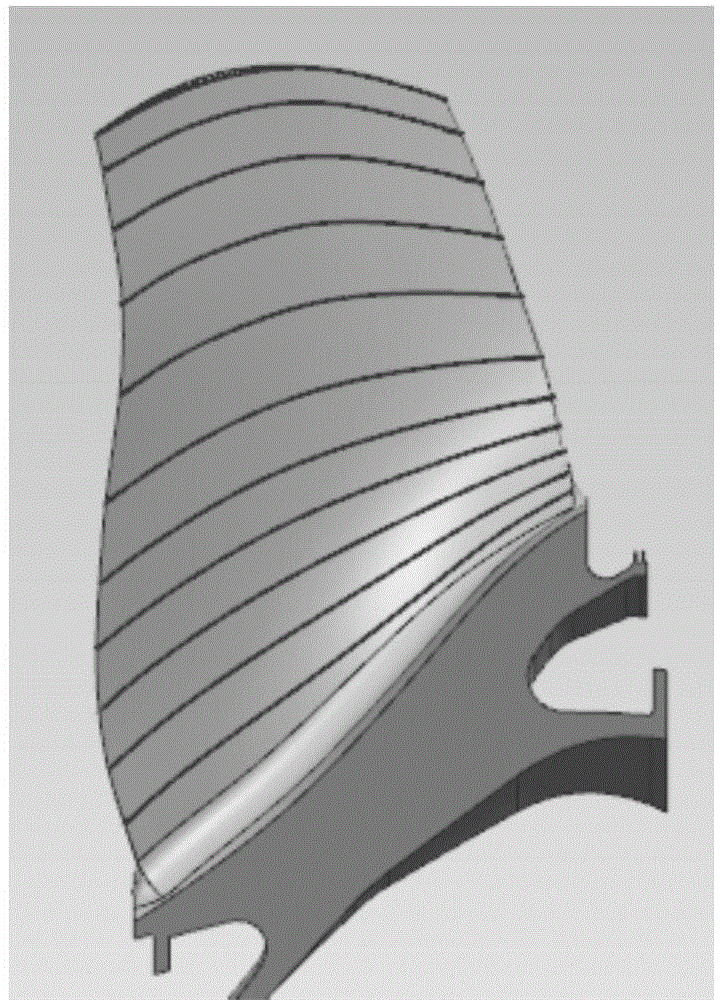

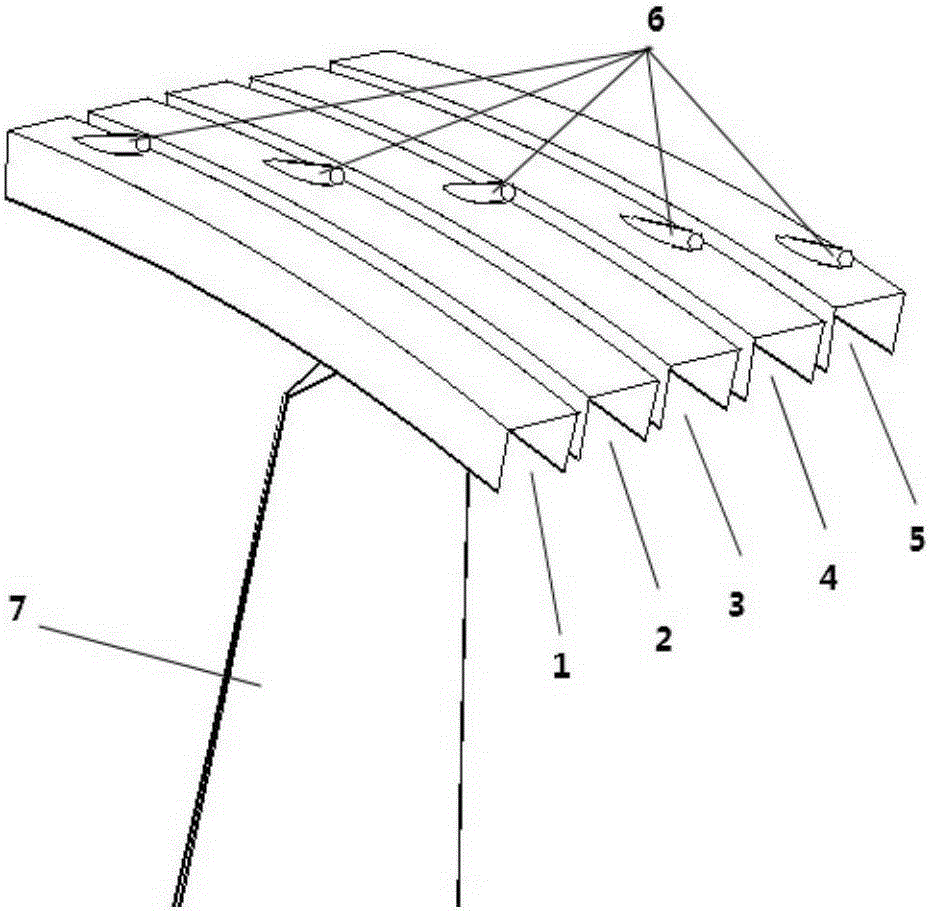

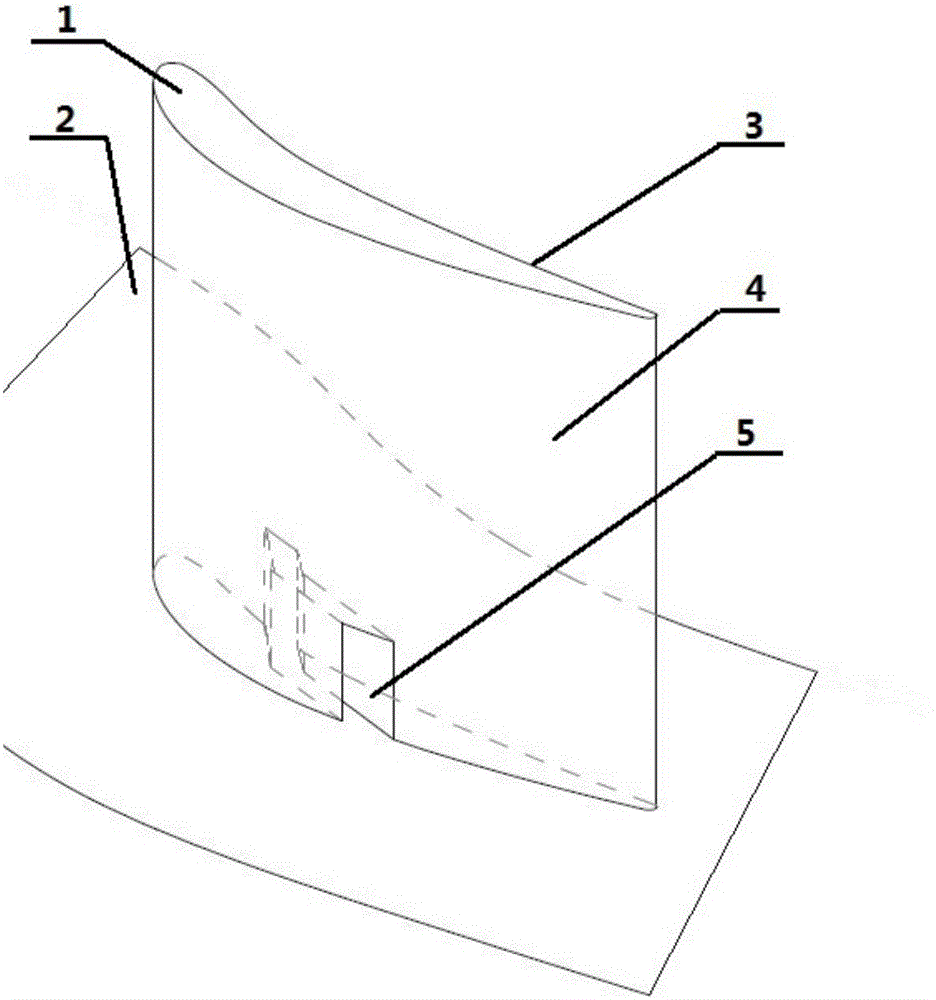

Compressor stator cascade with blade root provided with equal-width circular arc shaped channels

ActiveCN105156361ALarge circulation capacityIncrease kinetic energyPump componentsPumpsImpellerSuction stress

The invention provides a compressor stator cascade with a blade root provided with equal-width circular arc shaped channels, relating to passive flow control technology in the technical field of turbo-machinery. The adverse pressure gradient resistance is stronger, Coanda effects are additionally brought and corner separation is better inhibited by forming the equal-width circular arc shaped channels in an end wall of the blade root of the compressor stator cascade from a pressure surface to a suction surface, forming high-speed jet by utilizing self-differential pressure of blades, increasing the kinetic energy of low energy fluid at a corner and blowing down airflows on boundary layers of the suction surface and the end wall. The compressor stator cascade is characterized in that the channels are formed in the end wall of the blade root of the compressor stator cascade; the spanwise height is a constant value; the number of the channels can be one or multiple; inlets of the channels are formed in the pressure surface of the stator cascade and outlets are formed in the suction surface of the cascade; center lines of the channels are shaped like circular arcs; the two sides of the channels are equally distant from the center lines; and the outlets in the side walls of the channels are tangent to the downstream wall of the suction surface of the cascade. The compressor stator cascade has the beneficial effects of effectively inhibiting corner separation, increasing the cascade flow capacity, reducing the total pressure loss and increasing the pressure diffusion capacity.

Owner:BEIHANG UNIV

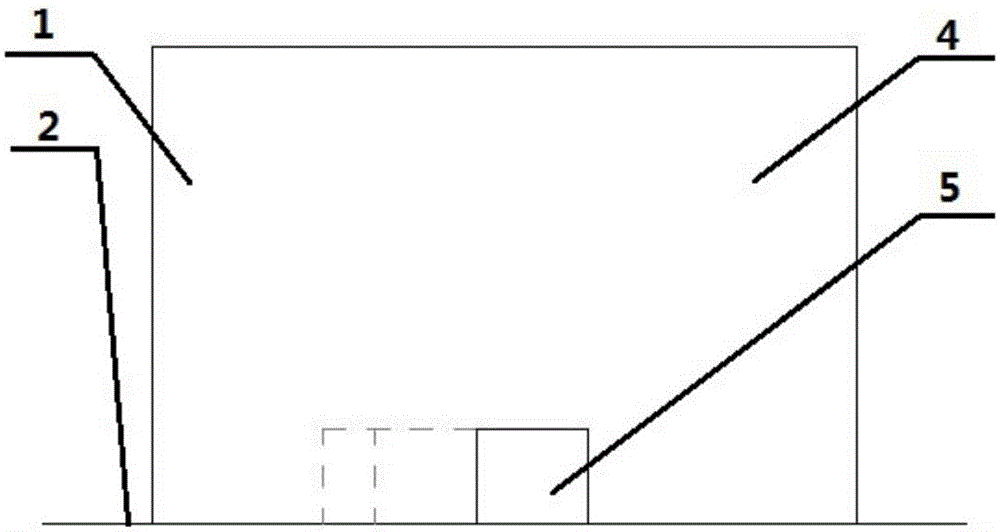

Axial flow compressor blowing-type circumferential groove casing treatment method

InactiveCN105179321AImprove stabilityImprove efficiencyPump componentsPumpsEngineeringStability margin

The invention discloses an axial flow compressor blowing-type circumferential groove casing treatment method to solve the technical problem that the stability margin of a compressor treated by the conventional axial flow compressor casing treatment method is poor. The method is characterized in that based on a circumferential groove type treatment casing, tangentially blown air is added to circumferential grooves of the treatment casing, and through experimental measures, the best blowing groove design scheme which obviously improves the stability margin and the efficiency of the compressor is sought. An experimental result shows that with the adoption of the axial flow compressor blowing-type circumferential groove casing treatment method, the flow capacity of an blade top area of an axial flow compressor is improved, the separation of a boundary layer is retarded, the loss of the boundary layer is reduced, a blocking situation of a blade top end wall area is improved, the stable working range of the axial flow compressor is enlarged effectively, and the efficiency of the axial flow compressor is improved to some extent.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

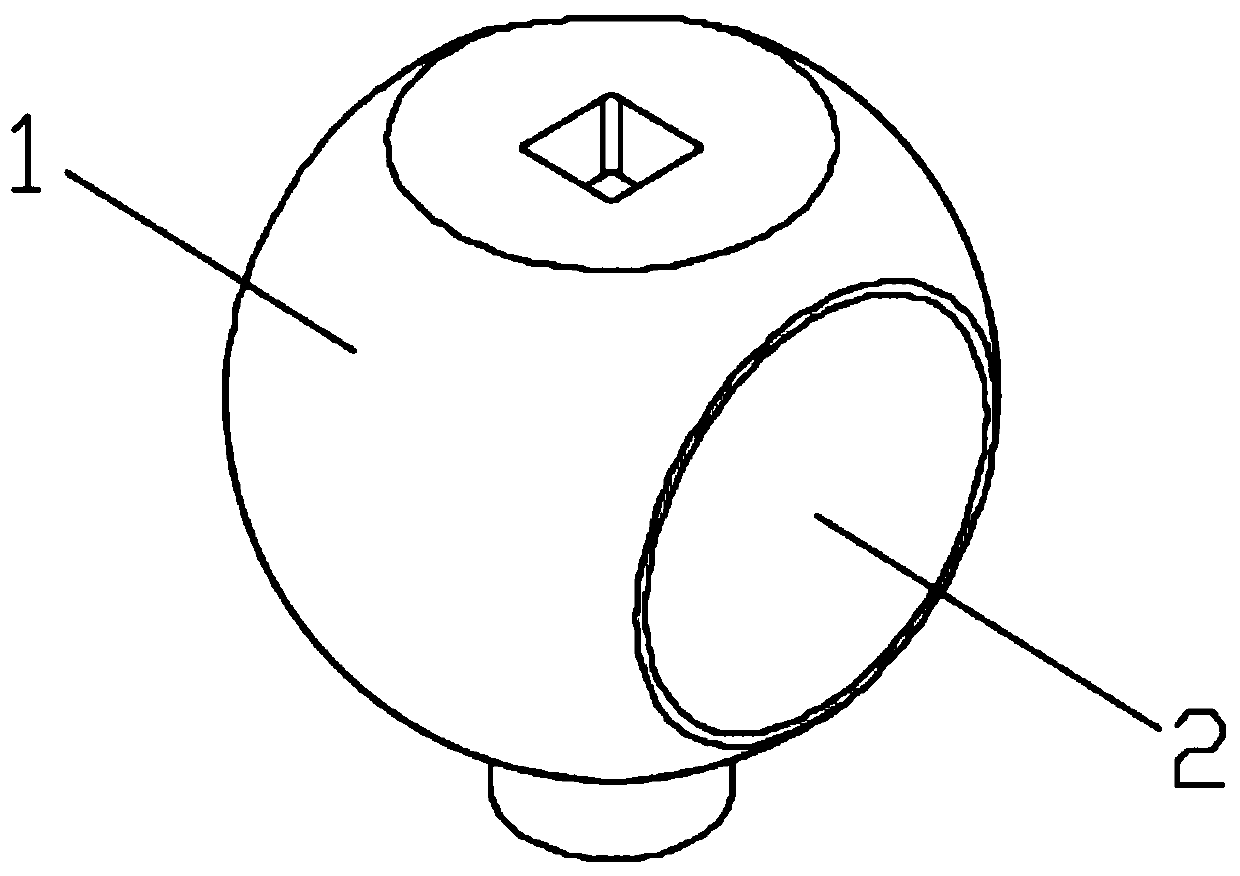

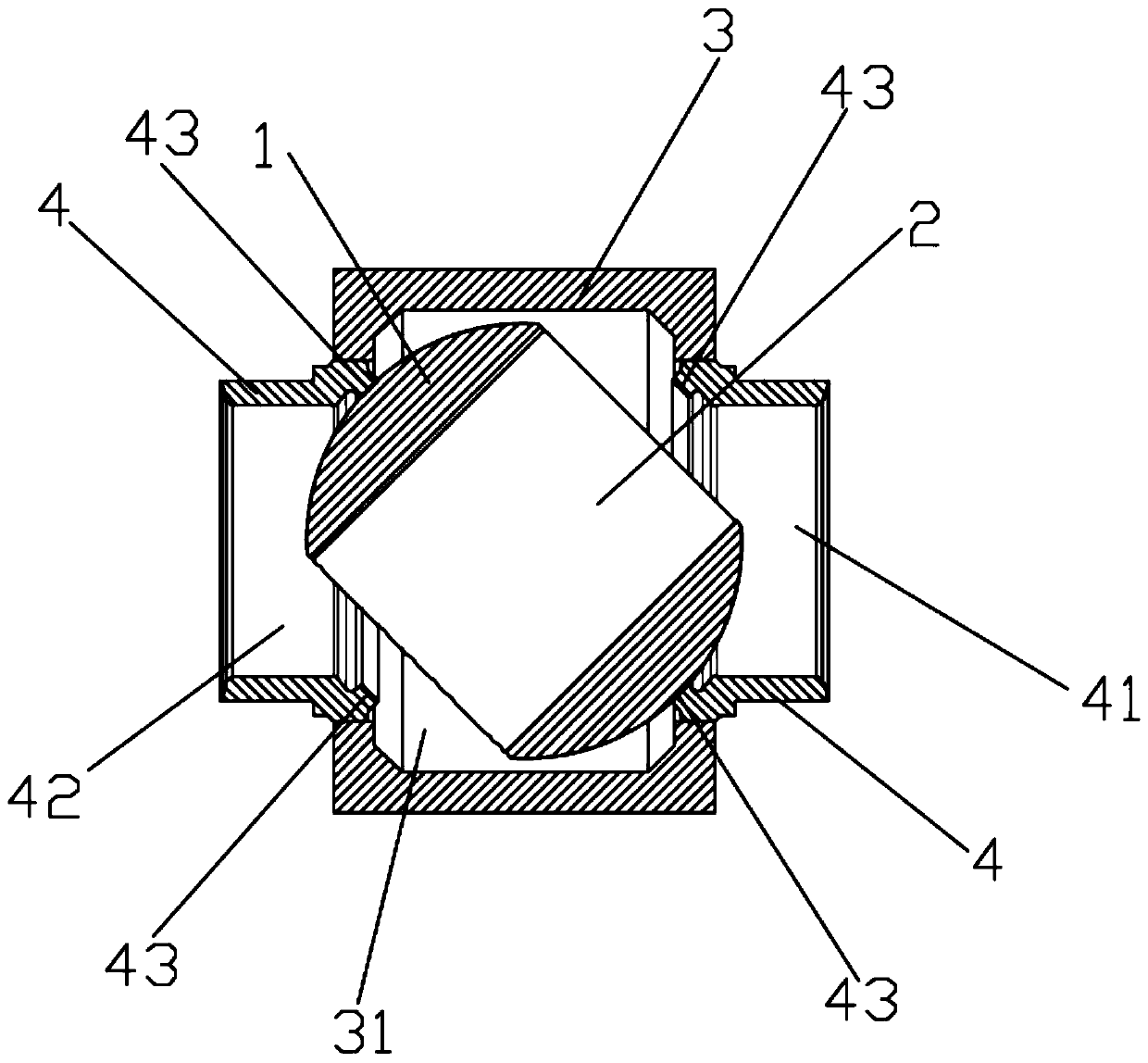

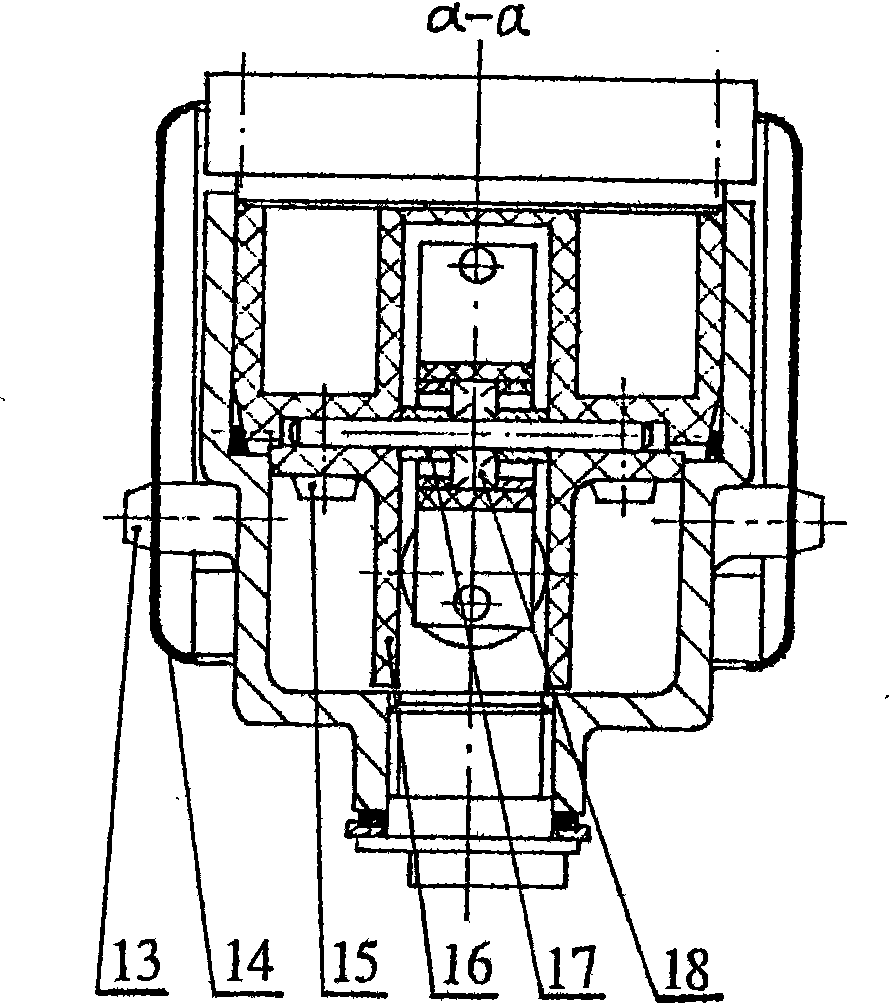

Double-scraper toroidal valve core and ball valve

The invention discloses a double-scraper toroidal valve core. The double-scraper toroidal valve core comprises a ball core body, a fully open seal ring, a fully closed seal ring and supporting shafts,the ball core body has a penetrating material channel, each of the fully open seal ring and the fully closed seal ring is externally convex to the surface of the ball core body, the fully open seal ring is arranged at the channel port and the channel port is arranged in the fully open seal ring, the axis of the fully closed seal ring is perpendicular and intersect the axis of the fully open sealring, the fully closed seal ring is arranged to be a partition surface, the sealing surface of the fully open seal ring and the sealing surface of the fully closed seal ring are arranged on the same spherical surface, each of the outer wall surface of the full open seal ring, the inner wall surface of the fully open seal ring, the outer wall surface of the fully closed seal ring and the inner wallsurface of the fully closed seal ring takes the spherical surface and a spherical center as the truncated conical surface of a vertex, the two opposite sides of the ball core body are provided with the supporting shafts, and one supporting shaft is provided with a valve rod connecting groove. The invention further discloses a ball valve adopting the double-scraper toroidal valve core, the double-scraper toroidal valve core and the ball valve are long in service life.

Owner:石森林

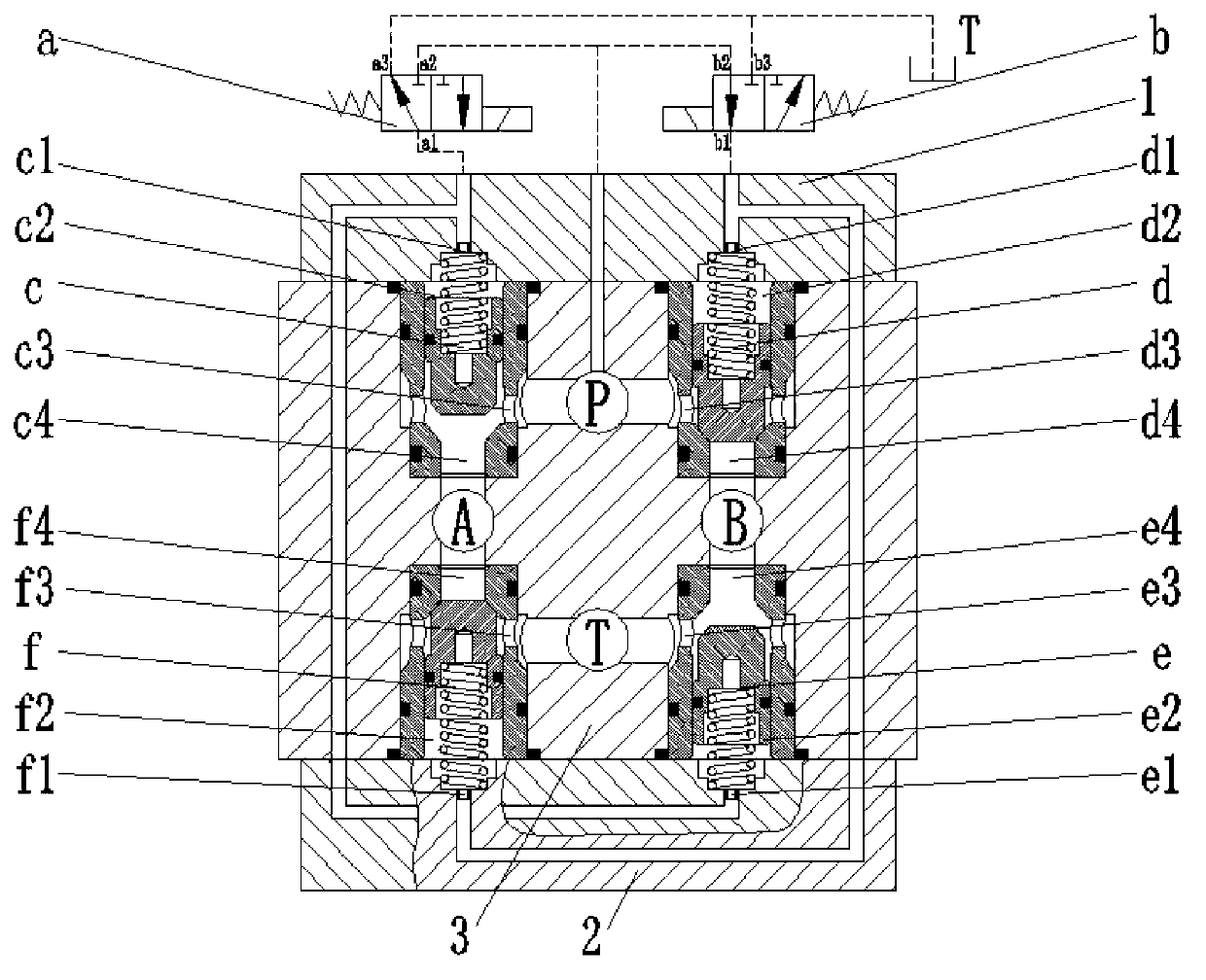

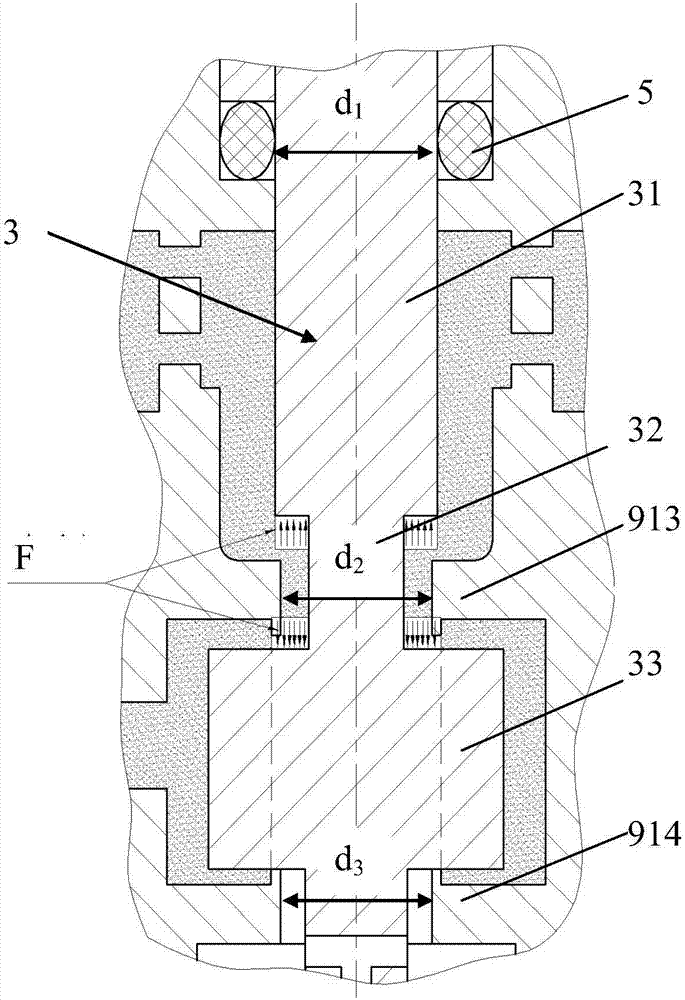

Large-flow three-stage pilot type electromagnetic valve

ActiveCN110486479AIncreased inflation and exhaust speedsFacilitates rapid filling and pressure build-upOperating means/releasing devices for valvesLift valvePressure loadEngineering

The invention provides a large-flow three-stage pilot type electromagnetic valve which solves the problems that the pressure load is too large, the response speed is slow and the system index requirement cannot be met under the conditions of large flow and small flow resistance of an existing valve. The high-flow three-stage pilot type electromagnetic valve comprises a first-stage electromagneticpilot valve, a second-stage pneumatic control pilot valve and a third-stage control main valve; the third-stage control main valve comprises a main valve body, a main valve core and a main valve spring; the main valve core is hermetically arranged in the main valve body, and two independent air cavities, namely an air opening cavity and a main valve spring mounting cavity are formed between in main valve body; the main valve body is provided with a medium inlet and a medium outlet; the main valve spring is arranged in the spring mounting cavity and provides closing force for the main valve core, so that the medium inlet and the medium outlet are blocked; the first-stage electromagnetic pilot valve controls the on-off of a gas path of the second-stage pneumatic control pilot valve through on-off of power, and the second-stage pneumatic control pilot valve is used for controlling inflation and exhaust of the air opening cavity and providing opening force for the main valve core.

Owner:XIAN AEROSPACE PROPULSION INST

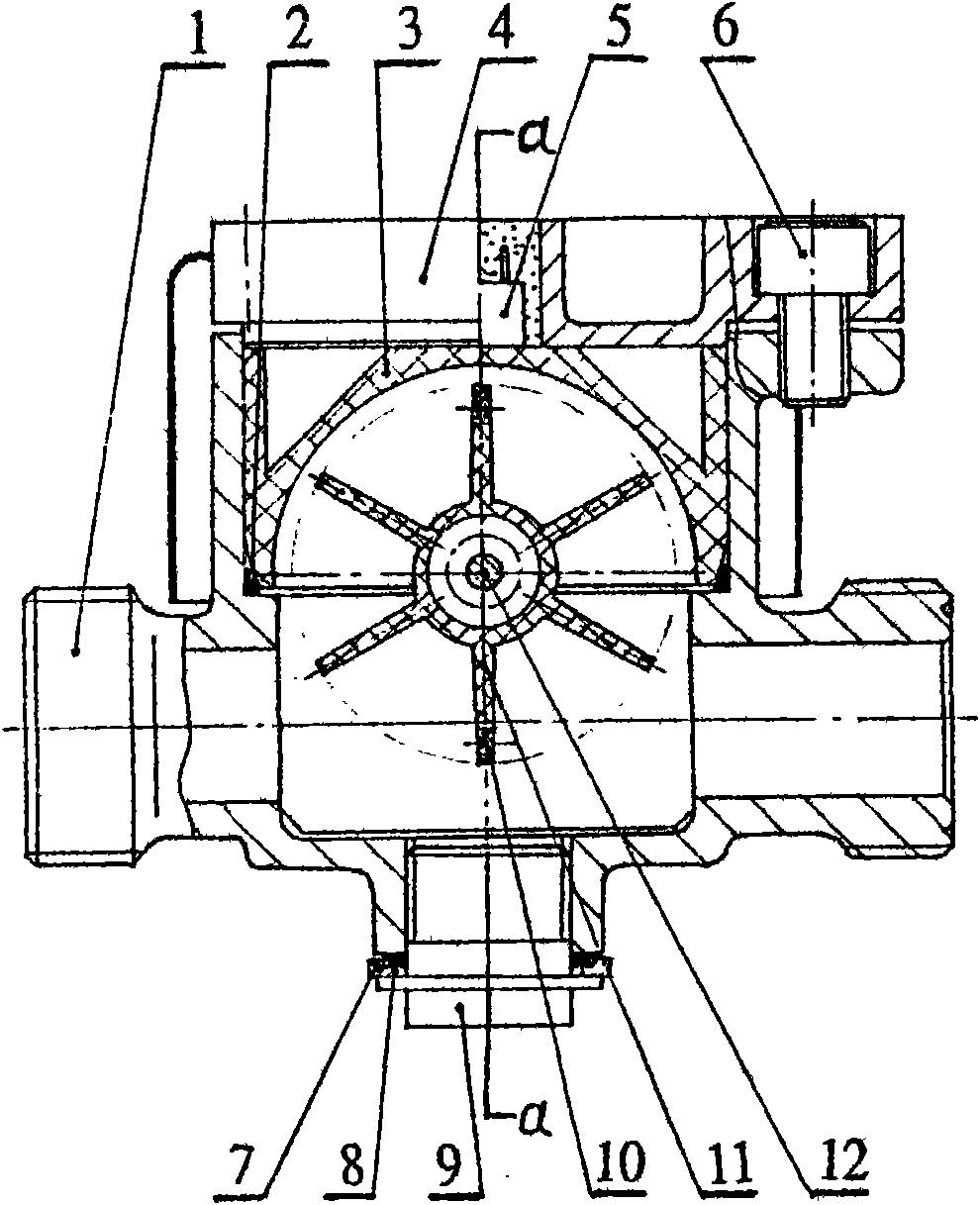

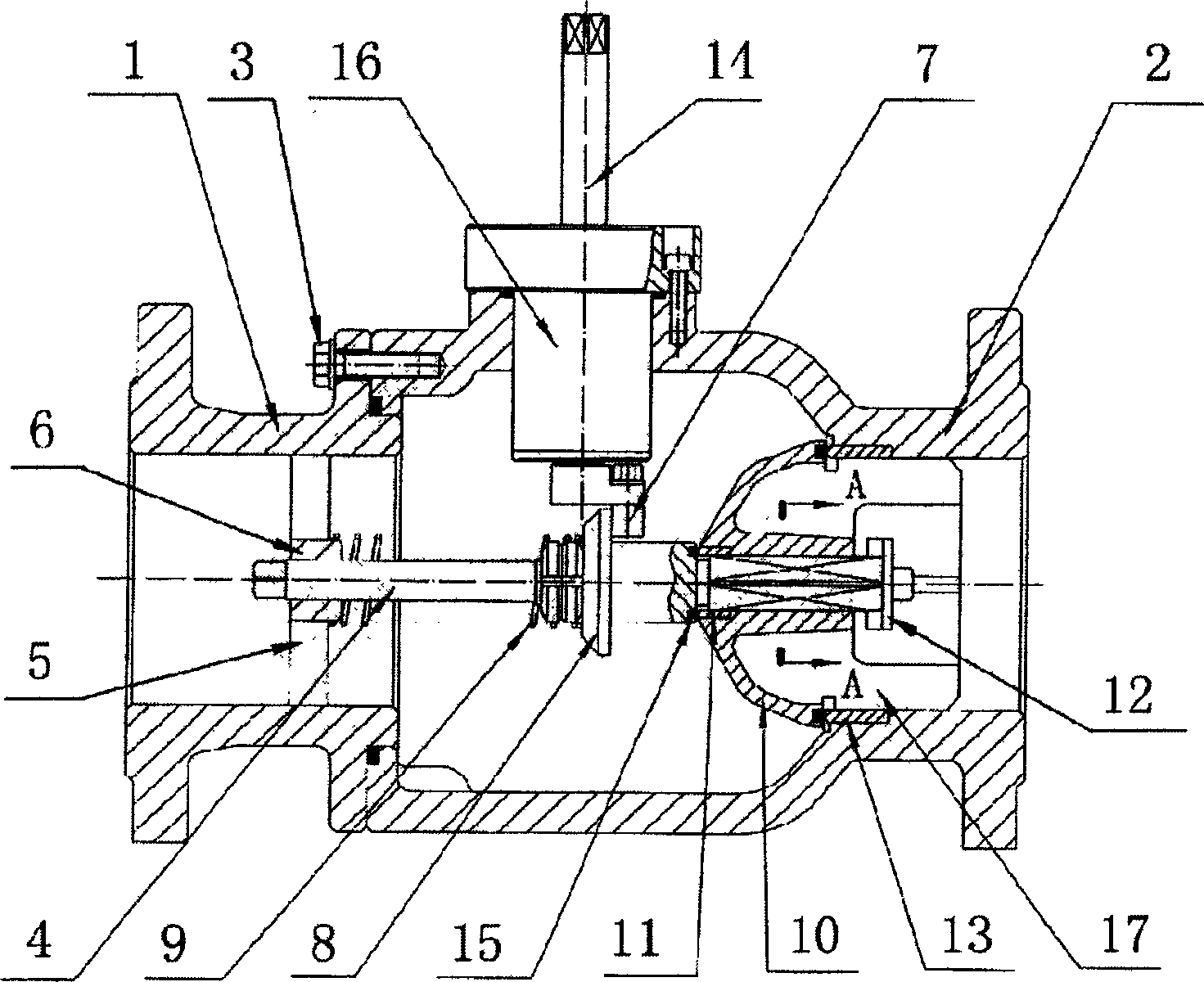

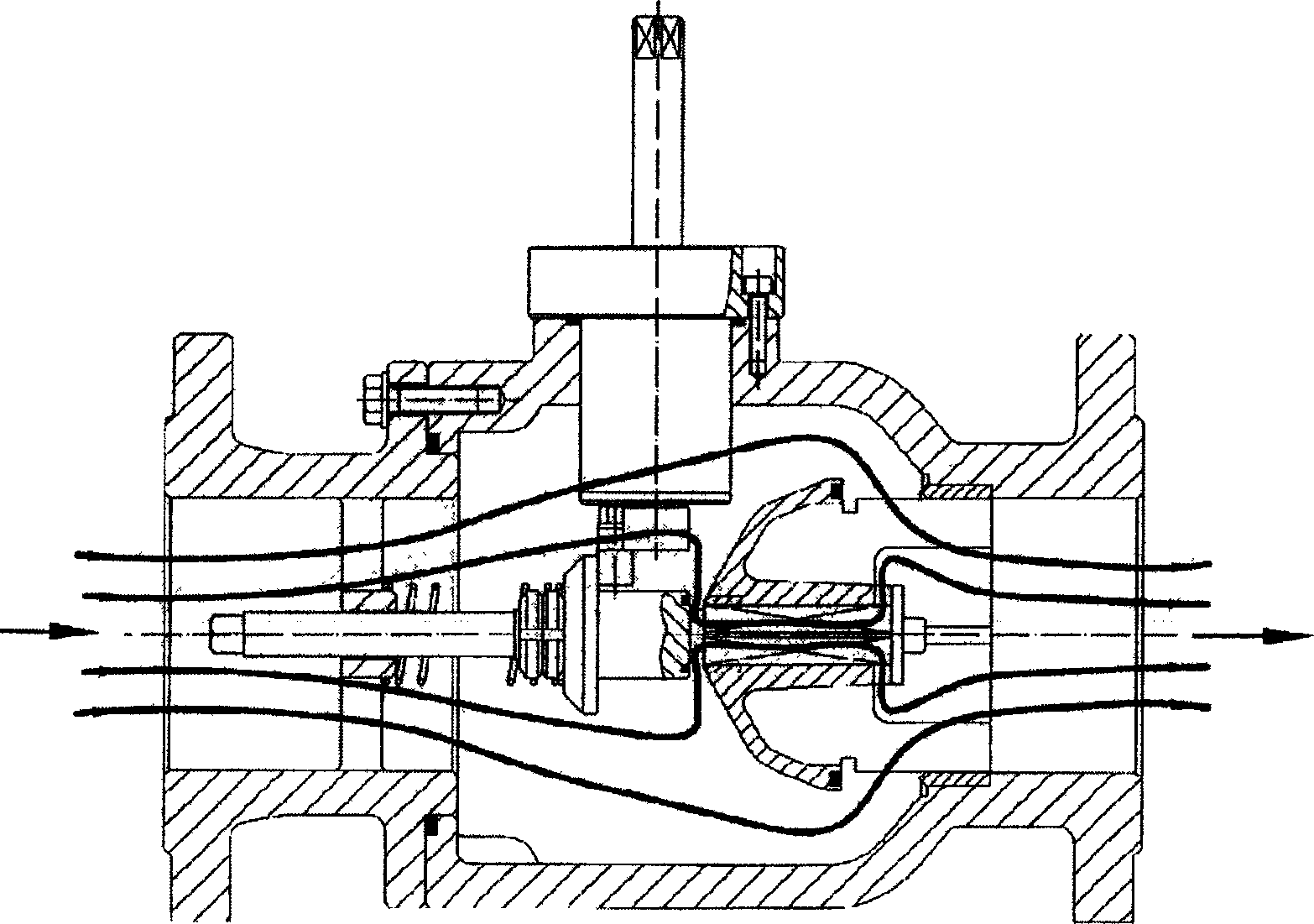

Flow sensor of heat energy meter

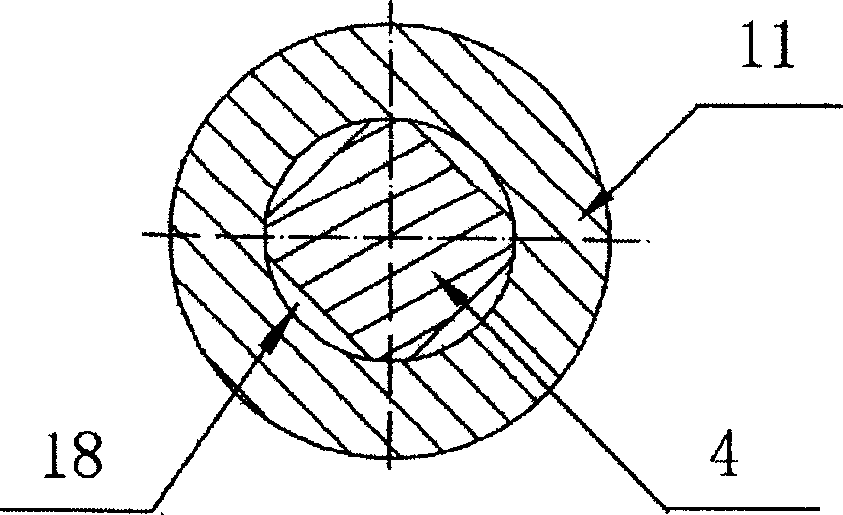

InactiveCN101619991AExtended service lifeImprove performanceVolume/mass flow by mechanical effectsCalorimeterImpellerRolling-element bearing

The invention relates to a flow sensor of a heat energy meter, which is characterized in that a rolling bearing is fixed in an impeller hole to form an impeller component together with the middle part of a shaft; two sleeves are arranged on two sides of the shaft of the impeller component and the rolling bearing, the impeller component is arranged in a groove of an impeller seat, and two eddy plates and bolts compact the shaft of the impeller component to form a machine core; a sealing ring and the machine core are arranged in a shell hole, and the machine core is compacted by a gland bush and bolts; and a magneto-electric converter is arranged in an upper hole of the gland bush, a magnetic shield is fixed outside the shell by using bolts, and the bottom of the shell is provided with a sewage outlet. By using the flow sensor of the heat energy meter, the hot water stream acts on an impeller vane in the tangential direction, the impeller generates revolution to perform flow measurement, and a permanent magnet material magnetic element is used for indicating the flow, the magnetic shield and the sewage outlet are arranged outside the shell, and the hot water flows through the shell directly, thus the low sensor of the heat energy meter has the characteristics of long service life, convenient pollution discharge, reliable performance, small hot water pressure loss, good flow capacity, wide flow range ratio, small appearance volume, low manufacturing cost and the like.

Owner:周文庆

Method for preparing oil soluble crude oil drag reducing powder

InactiveCN101386665ALarge circulation capacityReduce transportation energy consumptionPipeline systemsDiamineNitrogen gas

A method for preparing oil soluble drag reduction powder is characterized in that the method comprises the following steps: in the nitrogen gas atmosphere, carrying out the copolymerization reaction of long chain alpha-olefin with the carbon number of between 4 and 20 and cyclopentadiene according to certain proportion at a temperature of between 5 DEG C below and 20 DEG C with a catalysis system formed by a diamine metal compound added with pyridine and an ethyl chloride, and obtaining a polymer with high molecular weight. The inherent viscosity is between 10 and 20, and the weight ratio of alpha-olefin to cyclopentadiene is between 1 to 99 and 20 to 80; and the alpha- olefin polymer is frozen to a glass state by freezing air of 100 DEG C below through an air turbine expansion refrigeration method, simultaneously a stearate insulating agent is added, and crushing treatment is carried out in a low-temperature crusher so as to obtain the drag reduction copolymer powder product.

Owner:CHINA NAT OFFSHORE OIL CORP +2

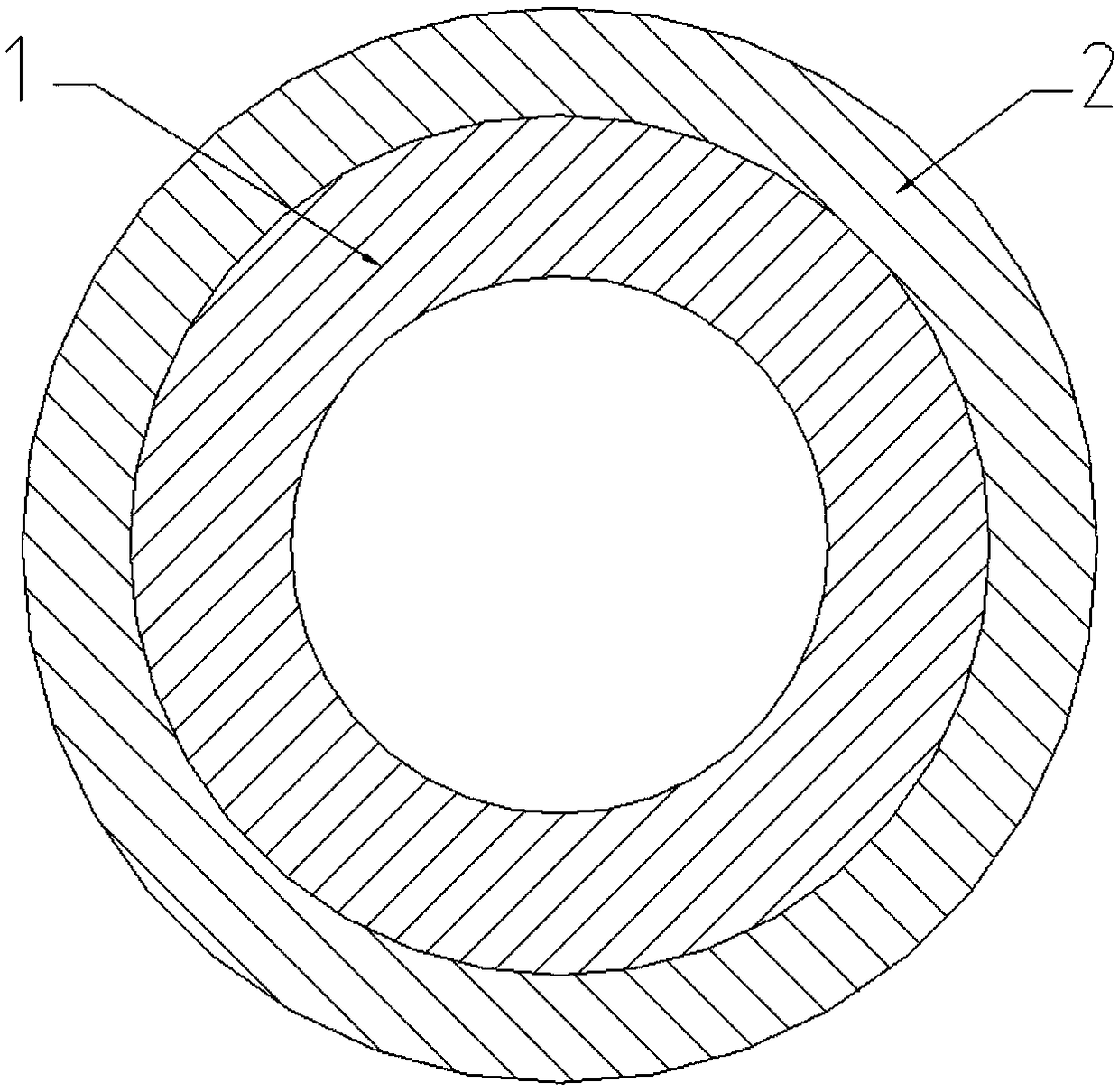

Scratch-resistant low-speed cracking PE fuel gas pipe and preparation method thereof

The invention provides a scratch-resistant low-speed cracking PE fuel gas pipe and a preparation method thereof, and belongs to the technical field of conveying pipes. The scratch-resistant low-speedcracking PE fuel gas pipe comprises a main body structure layer and a protecting layer. The main body structure layer is a PE material, and the protecting layer is a crosslinking material. A thicknessof the main body structure layer is greater than a thickness of the protecting layer. The scratch-resistant low-speed cracking PE fuel gas pipe is capable of increasing properties of wear resistance,scratch resistance, low-speed cracking and the like of the PE fuel gas pipe, keeping all advantages of the original PE fuel gas pipe, prolonging the service life of the PE fuel gas pipe, and avoidinga safety accident.

Owner:KANGTAI PLASTIC SCI & TECH GRP

Valve of sealing arrangement in two stages

A valve with double stages of seal device is composed of valve body, connection unit, spring and flow guide unit. It is featured as setting the first seal device at inlet section of valve body and the second seal device at outlet section of valve body, connecting valve clack of the first seal device to valve clack of the second seal device by connection unit. The said valve can not only be used on pressure control, flow rate control and flow direction control but also can be used on water level control, temperature control, multiloop control, electromagnetic ¿C automatic control, etc.

Owner:SHANGHAI SHANGLONG VALVE FACTORY

Pilot operated axial flow valve

InactiveCN1811236ALow costAdjustment appliesOperating means/releasing devices for valvesPressure relieving devices on sealing facesEngineeringVALVE PORT

The pilot operated axial flow valve has a valve body comprising a small half valve body in the inlet end and a large half valve body in the outlet end screw connected; a valve rod through the guide hole in the inside cavity of the small half valve body; a catch plate connected to the middle section of the valve rod and matched with eccentric shaft, a repositioning spring between the catch plate and the guide hole; the eccentric shaft below the main shaft, the eccentric main shaft with axis perpendicular to that of the valve body; a main valve seat inside a through hole of the large half valve body and coaxial with the valve body; and a pilot operated valve with seat in the axis of the main valve clack and clack embedded to the reduced end of the valve rod. The pilot operated axial flow valve has simple structure, small resistance coefficient, great flow capacity and wide application.

Owner:北京市燕山工业燃气设备有限公司 +1

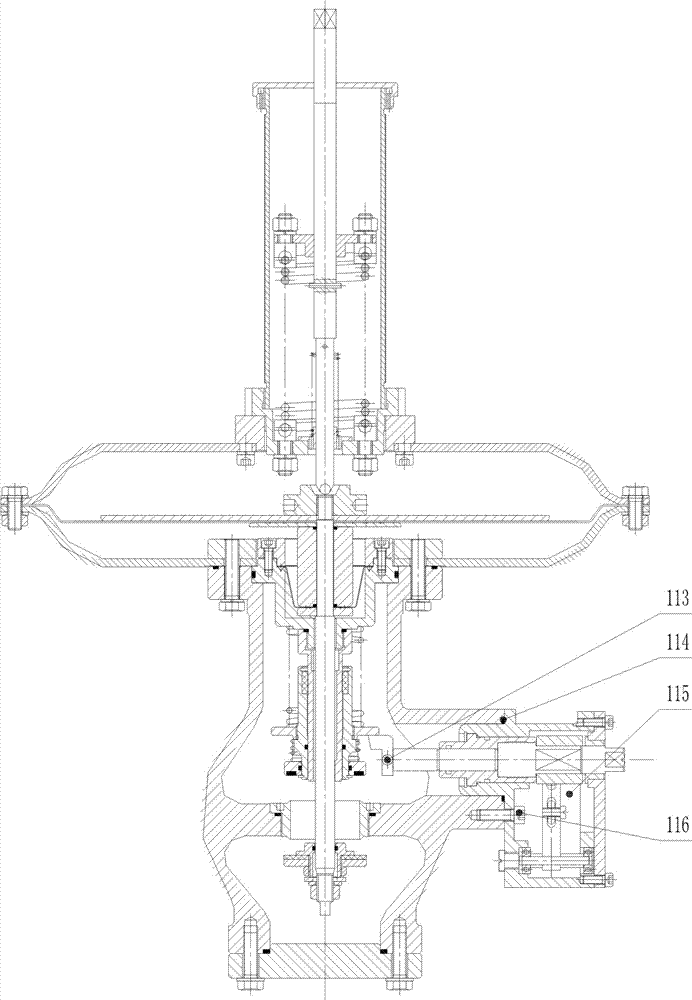

Electromagnetic drive device and pilot-operated type electromagnetic pneumatic valve

PendingCN106989196AImprove responsivenessGuaranteed driving abilityOperating means/releasing devices for valvesEngineeringPneumatic valve

The invention belongs to the field of control valves and particularly relates to an electromagnetic drive device and a pilot-operated type electromagnetic pneumatic valve. The electromagnetic drive device comprises a shell, an electromagnetic coil, a magnetism isolation pad, a permanent magnet and an armature. The pilot-operated type electromagnetic pneumatic valve comprises the above electromagnetic drive device and furthermore comprises a valve body, a pilot valve unit and a main valve unit. The electromagnetic drive device is subjected to optimized design, the armature is subjected to differential magnetic energy distribution, adverse influences of self-locking force of the permanent magnet are overcome, and it is effectively guaranteed that the required response performance can be achieved reliably. The electromagnetic drive device and the pilot-operated type electromagnetic pneumatic valve are mainly used for occasions with a large flow and high pressure, such as, liquid rocket engines, satellite in-orbit execution systems, ground test systems and automated fluid pipe systems and have the advantage of being high in response speed.

Owner:XIAN AEROSPACE PROPULSION INST

Blade root slotting gas compressor stator with gradual-contraction changes of slot span-wise height

The invention discloses a blade root slotting gas compressor stator with gradual-contraction changes of the slot span-wise height, and relates to the driven flowing control technology in the technical field of turbo machines. A slot of the equivalent-width span-wise height gradual-contraction type is formed from a pressure face to a suction face at the blade root of a blade grid of the gas compressor stator, and the streaming pressure difference of a blade is utilized for forming jet flow to restrain and delay flow separation. One or more slots are formed in the blade root of the blade grid of the gas compressor stator. A slot inlet is formed in the pressure face of the blade grid of the stator, and a slot outlet is formed in the suction face of the blade grid. The widths of the slots are equivalent, the slot inlet is higher than the slot outlet, the contraction slot is formed in the slot height direction, and the distance between the upper wall face and the end wall of each slot is in smooth transition. The blade root slotting gas compressor stator has the beneficial effects that kinetic energy of low-energy fluid of boundary layers at the end wall and the suction face outlet of the slot is supplemented through the jet flow of the slot, airflow of the boundary layer of the suction face of the blade grid and the boundary layer of the end wall are blown away, and flowing separation is restrained and delayed, so that the pressure expansion capacity of the portion behind a blade grid channel is recovered.

Owner:BEIHANG UNIV

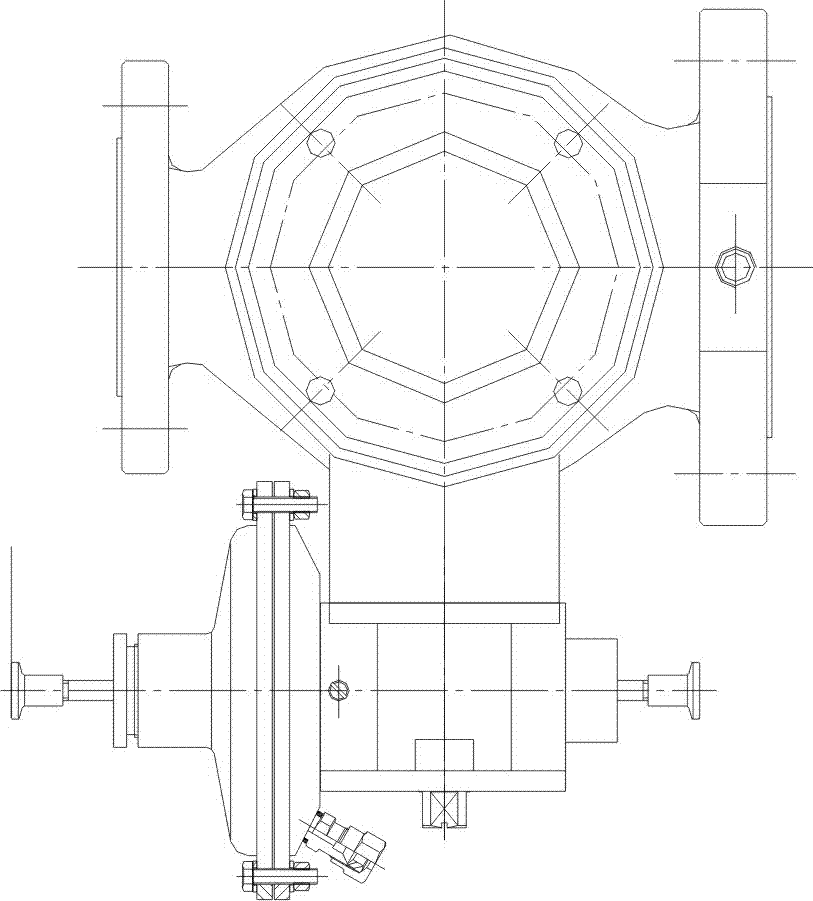

Full-unloading disc type magnetic pole large-drift-diameter two-position three-way electromagnetic valve

PendingCN113294553AEliminationRealization of compact and lightweight designOperating means/releasing devices for valvesMultiple way valvesExhaust valveMagnetic poles

The invention relates to a two-position three-way electromagnetic valve, in particular to a full-unloading disc type magnetic pole large-drift-diameter two-position three-way electromagnetic valve, which is used for solving the problems that when an existing two-position three-way electromagnetic valve is designed in a non-unloading large-drift-diameter mode, the opening and closing response is slow, the structural size and the weight are large, then the capacity of an air inlet channel and an air outlet channel is limited, and the response performance of a high-thrust engine of over 3000N is influenced. The full-unloading disc type magnetic pole large-drift-diameter two-position three-way electromagnetic valve comprises a valve body, an electromagnetic shell, an outer lining ring, an inner lining ring, an exhaust valve seat, an air inlet valve seat, a valve element rod, a reset spring, a magnetic disc and a coil.

Owner:XIAN AEROSPACE PROPULSION INST

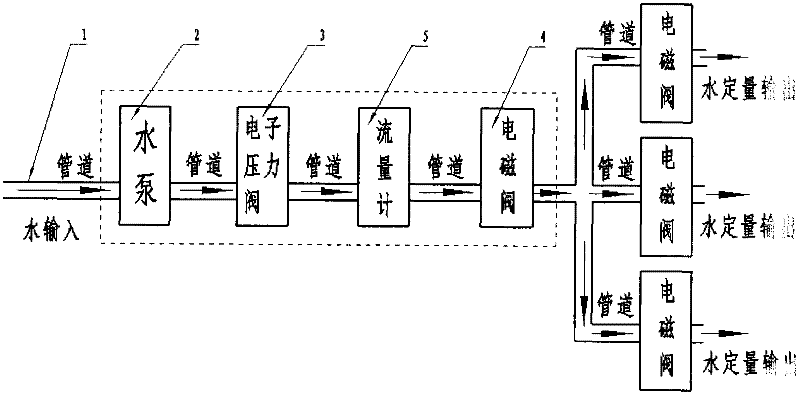

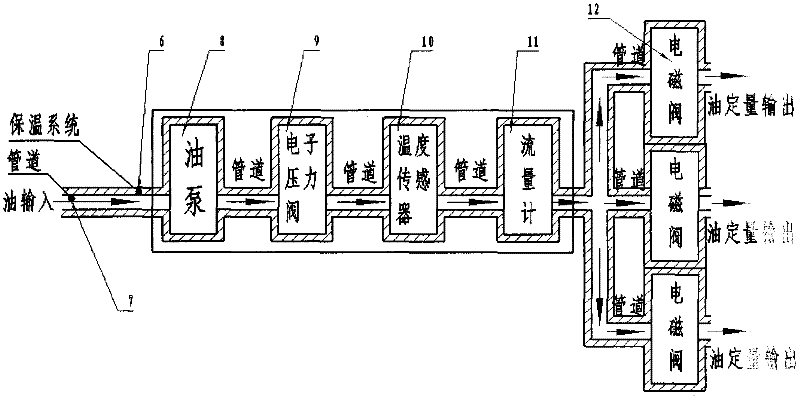

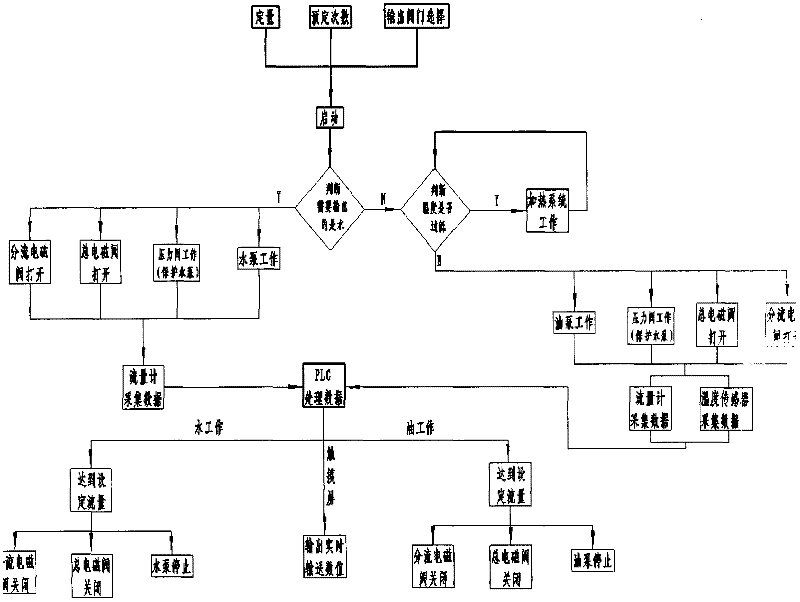

Water-oil fixed quantity automatic control system

InactiveCN102354230AHigh precisionGood repeatabilityControlling ratio of multiple fluid flowsWater storageAutomatic control

The invention belongs to a water-oil fixed quantity automatic control system. The water-oil fixed quantity automatic control system mainly comprises pipelines, a water pump, an electromagnetic valve, a flowmeter and the like, wherein the water pump takes water from a water-storage reservoir and supplies the water to a transportation measuring system; when the water flows through the flowmeter arranged on a conveying pipeline, the flowmeter acquires data and transmits the data to the control system; an interception mechanism is arranged on the conveying pipeline; and the quantitative supply of the control system is finished by controlling the interception mechanism after the data acquired by the flowmeter is received to ensure that the conveyed water quantity is appropriate. Finally, a certain number of electromagnetic valve shunting mechanisms are arranged on an output pipeline to facilitate quantitative water supply to different places.

Owner:蔡锡涛

Compressor stator cascade with blade root provided with equal-width broken line shaped channels

ActiveCN105156356ALarge circulation capacityIncrease the effective jet flowPump componentsPumpsImpellerDifferential pressure

The invention provides a compressor stator cascade with a blade root provided with equal-width broken line shaped channels, relating to passive flow control technology in the technical field of turbo-machinery. The adverse pressure gradient resistance is stronger, Coanda effects are additionally brought and corner separation is better inhibited by forming the equal-width broken line shaped channels in an end wall of the blade root of the compressor stator cascade from a pressure surface to a suction surface, forming high-speed jet by utilizing self-differential pressure of blades, increasing the kinetic energy of low energy fluid at a corner and blowing down airflows on boundary layers of the suction surface and the end wall. The compressor stator cascade is characterized in that the channels are formed in the end wall of the blade root of the compressor stator cascade; the spanwise height is a constant value; the number of the channels can be one or multiple; inlets of the channels are formed in the pressure surface of the cascade and outlets are formed in the suction surface of the cascade; center lines of the channels are multiple broken lines; the two sides of the channels are equally distant from the center lines; and the directions of airflows at the outlets of the channels are basically consistent with the directions of ideal non-separation flow lines. The compressor stator cascade has the beneficial effects of effectively inhibiting corner separation, increasing the cascade flow capacity, reducing the total pressure loss and increasing the pressure diffusion capacity.

Owner:BEIHANG UNIV

An acid fracturing process method for forming differential etching

ActiveCN109681179BImprove liquidityLarge circulation capacityFluid removalDrilling compositionAcid fracturingEtching

The invention relates to an acid fracturing technology method for forming differentiated etching. The method comprises the steps that 1, through an oil-gas well shaft, fracturing fluid is injected into a stratum to form artificial fractures in the stratum; 2, carrying fluid is injected into the artificial fractures, wherein oil-soluble resin particles which account for 5-20% of the amount of the carrying fluid are added into the carrying fluid; 3, the oil-soluble resin particles are made to be distributed in artificial fracture surfaces unevenly; 4, acid fluid is injected into the artificial fractures; 5, after acidic rock reaction is completed, the fracture surfaces form an uneven corrosion form, and the artificial fractures with the uneven corrosion form character cannot be completely closed under stratum pressure, so that a channel beneficial for oil-gas flowing is formed; 6, after acid fracturing construction is completed, with the increase in time, the oil-soluble resin particlesattached to rock surfaces are slowly degraded, and flow back to the ground along with oil-gas production. By means of the technology, an optimum uneven corrosion surface (with a best supporting effect) under the stratum pressure can be obtained, so that the flowing capability of the oil-gas in the stratum is improved furthest.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

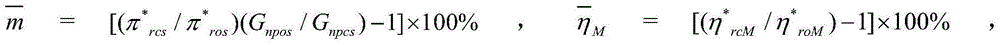

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com