Blade root slotting gas compressor stator with gradual-contraction changes of slot span-wise height

A compressor and channel technology, which is used in mechanical equipment, non-variable capacity pumps, machines/engines, etc., can solve the problems of random connection arcs in the slotting scheme, difficult to optimize the design of the control scheme, and many control parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

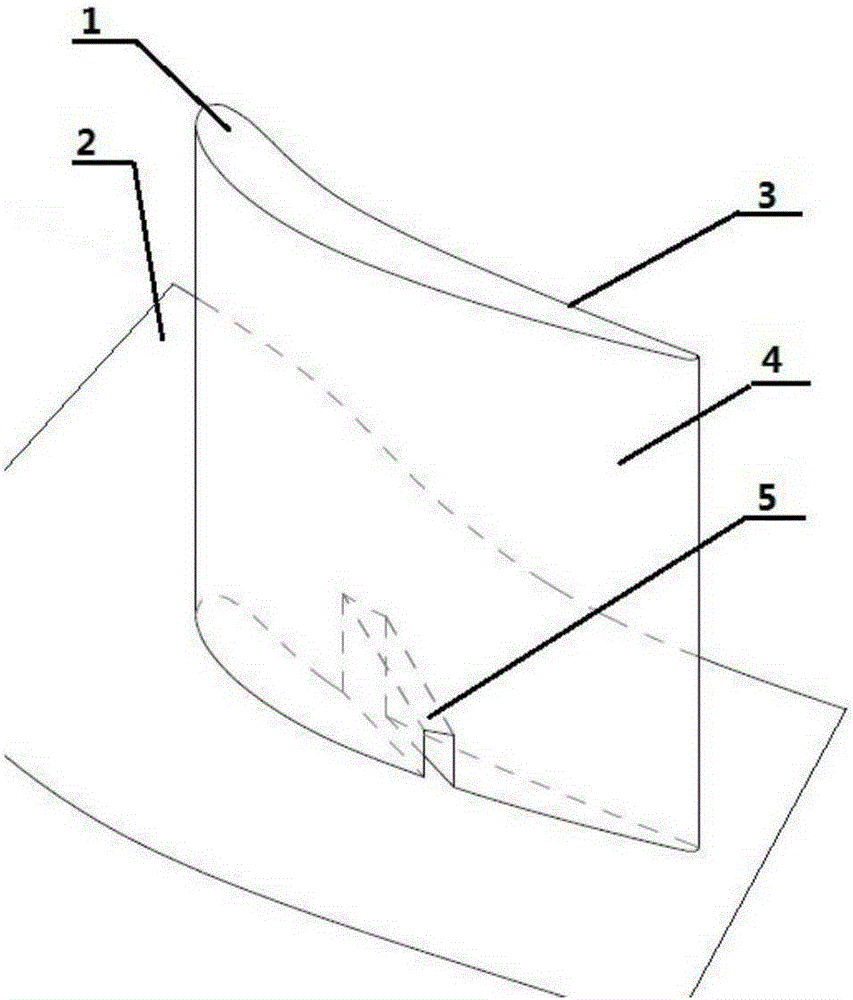

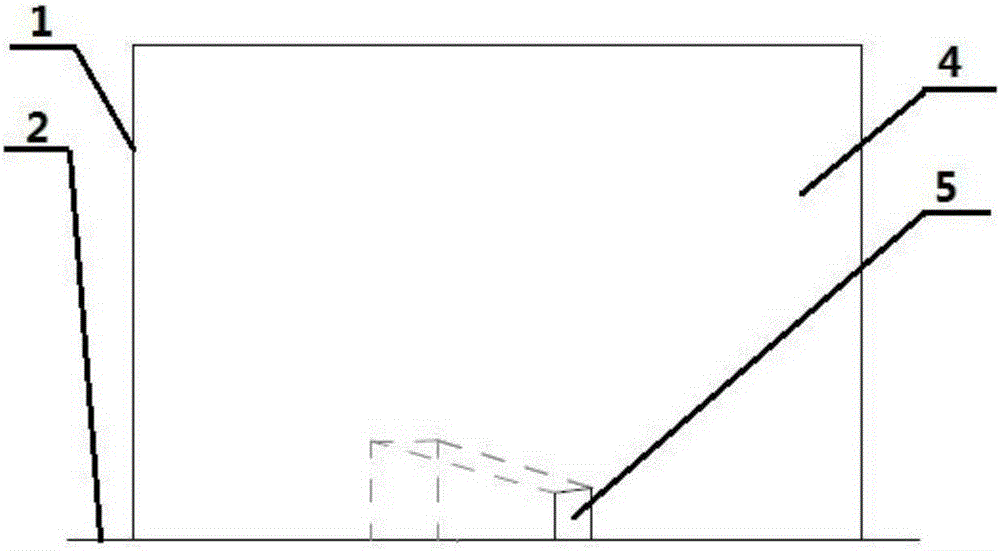

[0022] Such as figure 1 As shown in the figure, the slotted compressor stator with the slotted height of the slots changes gradually. At the end wall 2 of the root of the cascade 1, there is a channel that tapers in the spanwise height from the pressure surface 3 of the cascade 1 to the suction surface 4. Changing channel 5.

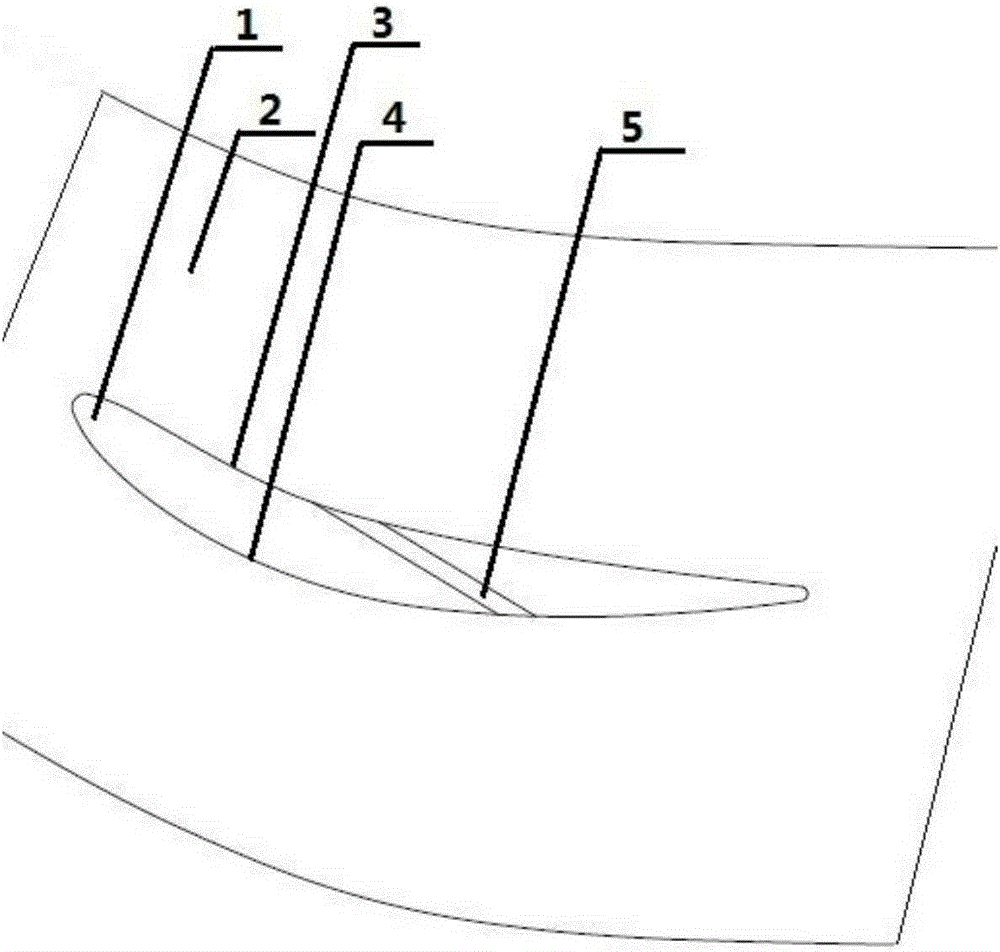

[0023] Such as figure 2 As shown, according to the PVD prototype stator cascade flow field, the position of the outlet of the channel 5 on the suction surface 4 is selected before the separation point; along the axial direction of the cascade, the position of the inlet of the channel 5 on the pressure surface 3 is located on the suction surface 4 Upstream of the outlet position; according to the pressure distribution on the surface of the PVD prototype stator cascade, the position of the inlet of the channel 5 on the pressure s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com