Patents

Literature

168 results about "Jet velocity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

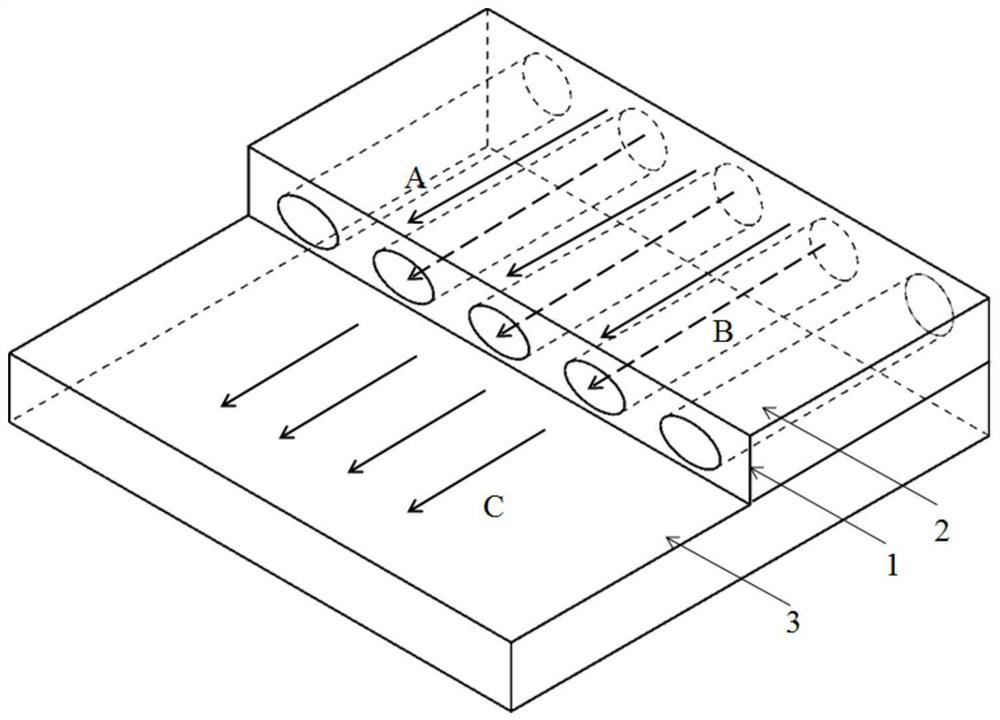

Method for preparing polymeric nano-micro fiber non-woven fabric

ActiveCN102071542AOvercoming demandsUniversally applicableNon-woven fabricsDry spinning methodsFiberPolymer dissolution

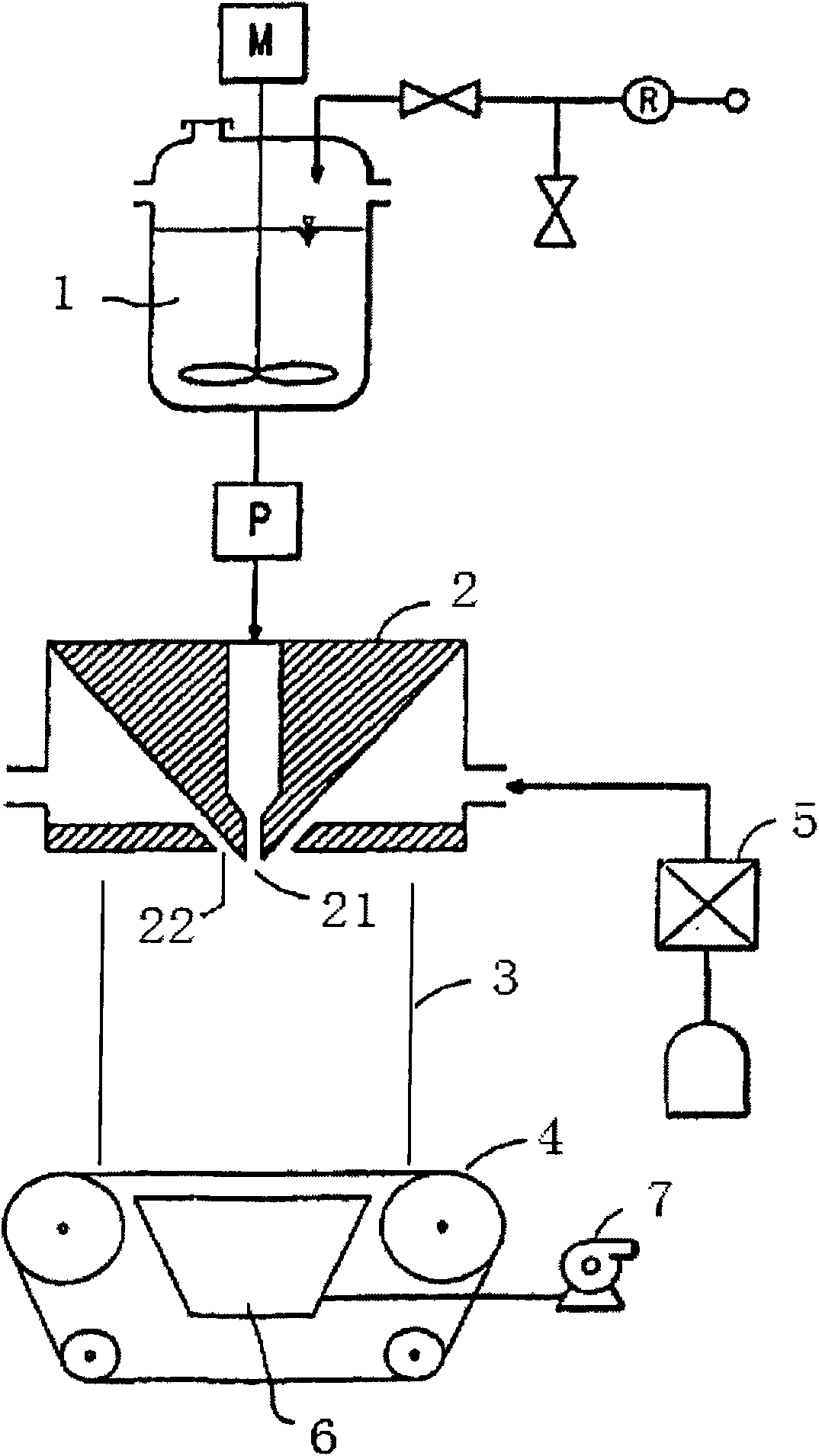

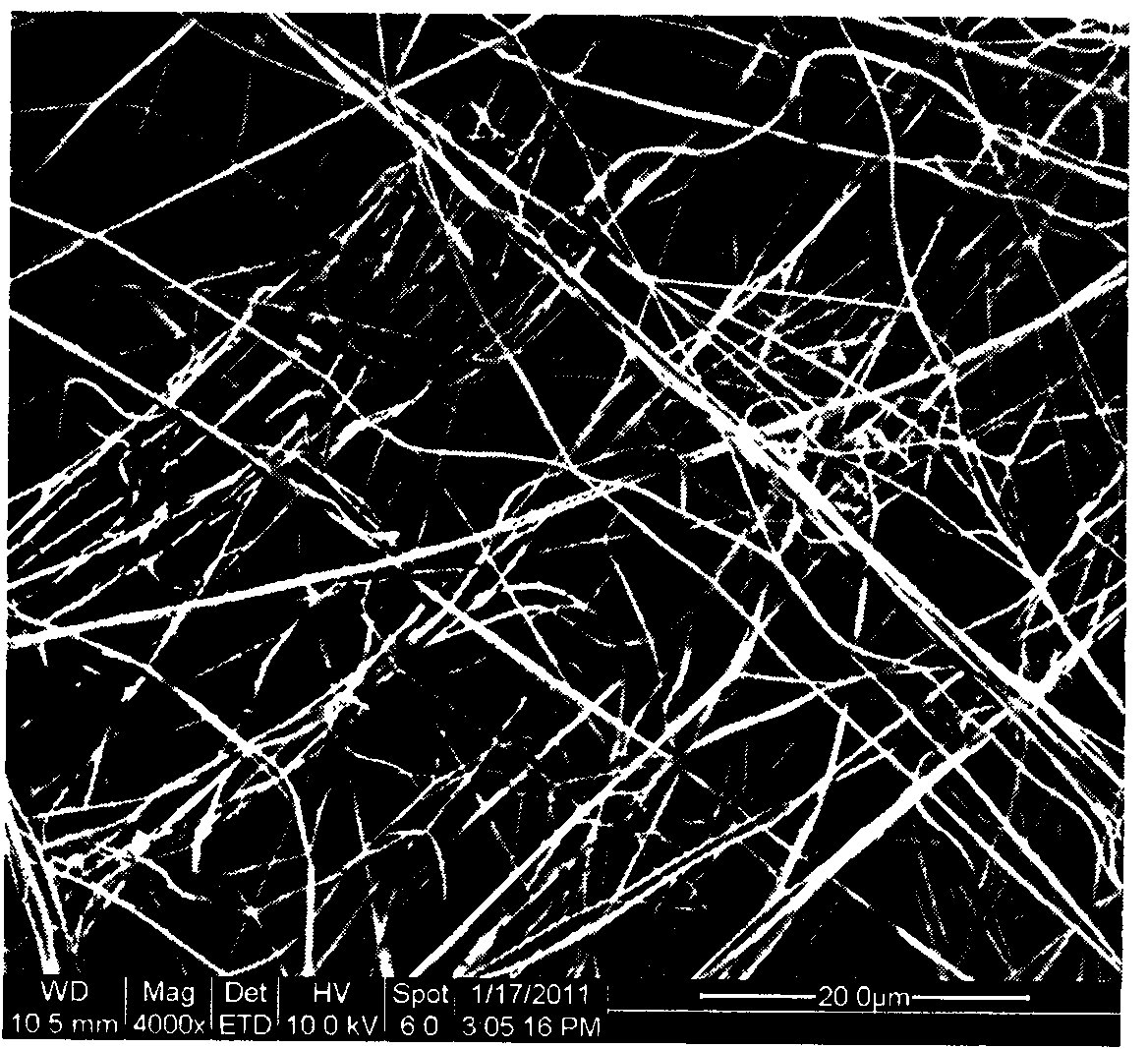

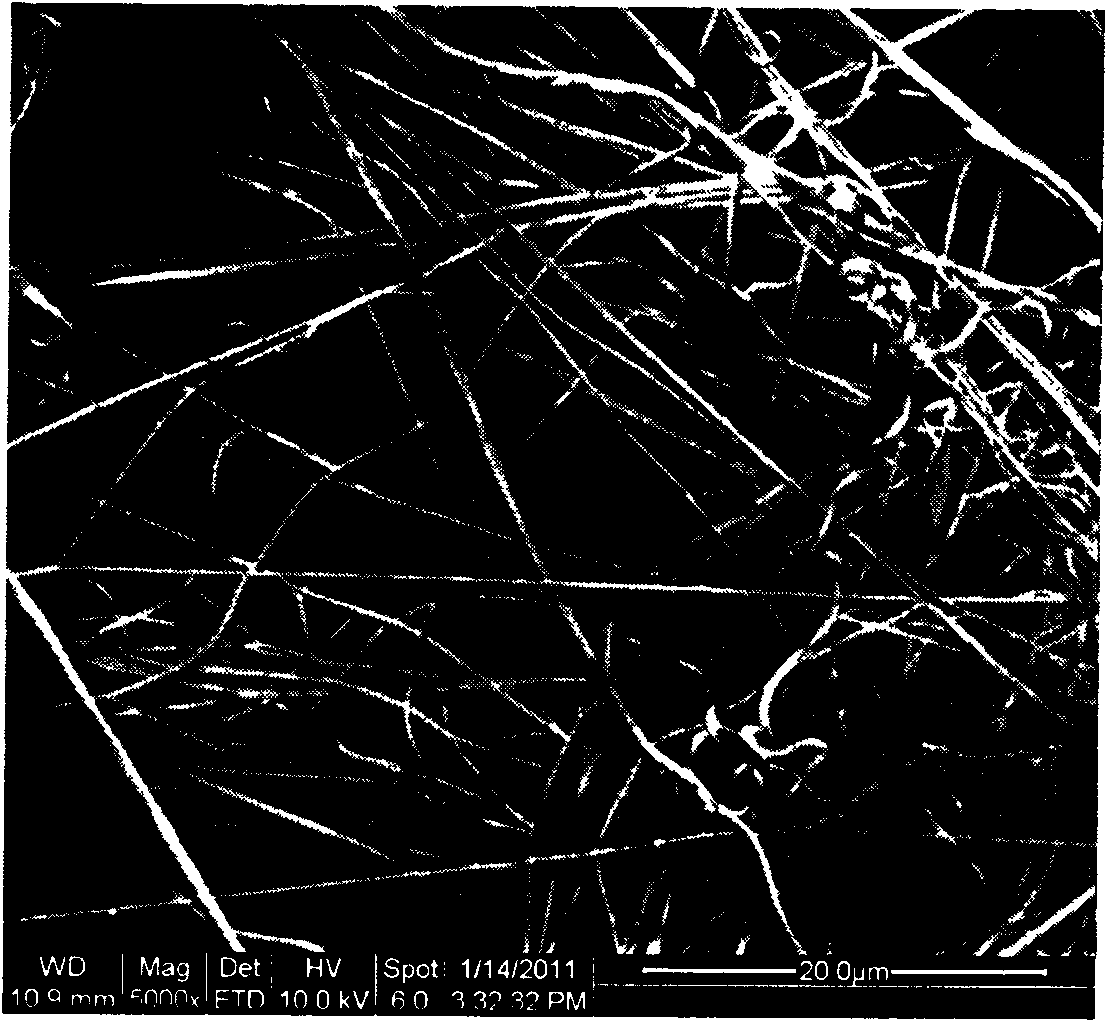

The invention discloses a method for preparing a polymeric nano-micro fiber non-woven fabric. The method comprises the following steps of: firstly, dissolving at least one polymer in at least one solvent to prepare spinning solution; then supplying the spinning solution to a spinneret plate with a series of spinneret orifices so as to make the spinning solution extruded from the spinneret orifices of the spinneret plate to form a trickle of the spinning solution; secondly, stretching and refining the trickle of the spinning solution by utilizing at least one high-speed jet airflow, and accelerating the volatilization of the solvent to form nano-micro fiber; and finally, collecting the nano-micro fiber on a web curtain by utilizing high-speed airflow and suction airflow. The polymer is a fiber-forming polymer; the solvent can dissolve the fiber-forming polymer and has the volatility; a jet angle of the high-speed airflow is between 15 and 60 degrees, and the jet velocity is at least 50 times higher than extrusion speed of the trickle of the spinning solution; the mass concentration of the polymer in the spinning solution is between 2 and 50 percent; and the viscosity of the spinning solution at a spinning temperature is between 10 and 100, 000mP.s.

Owner:上海榕融新材料技术有限公司

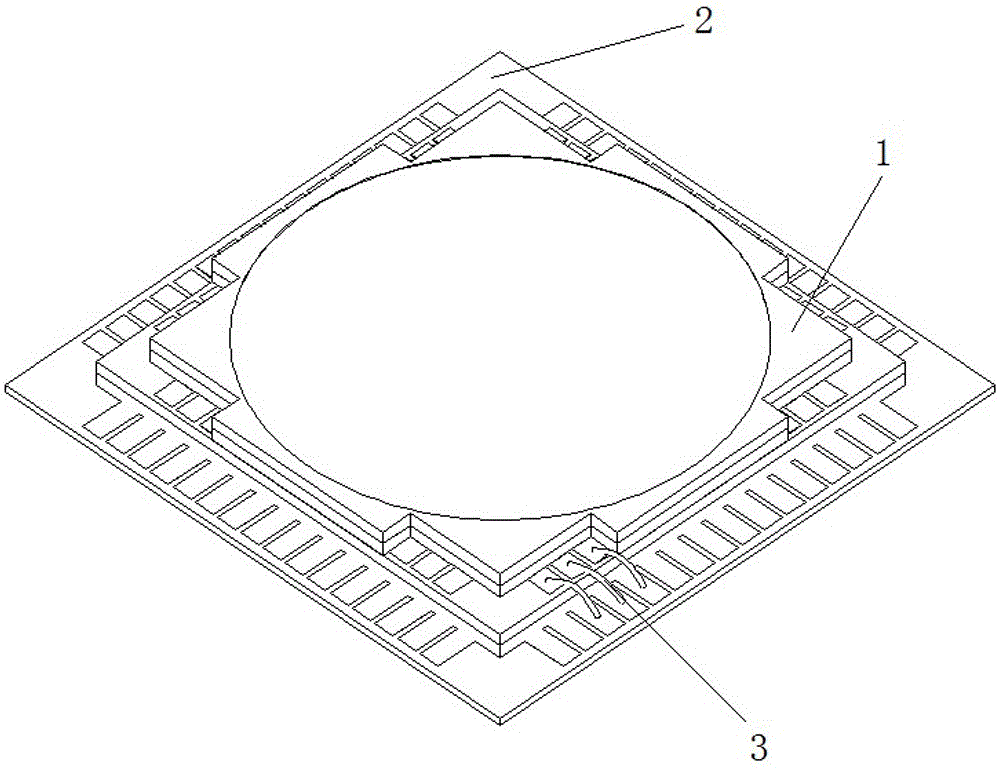

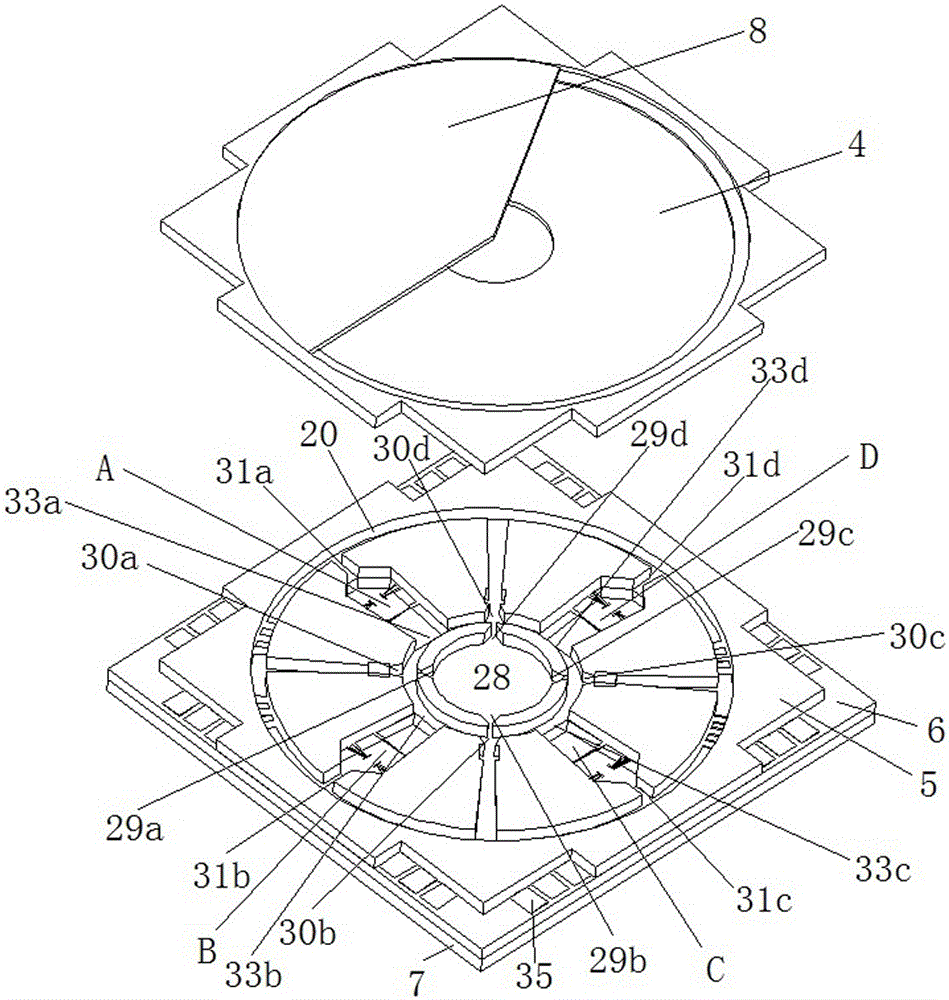

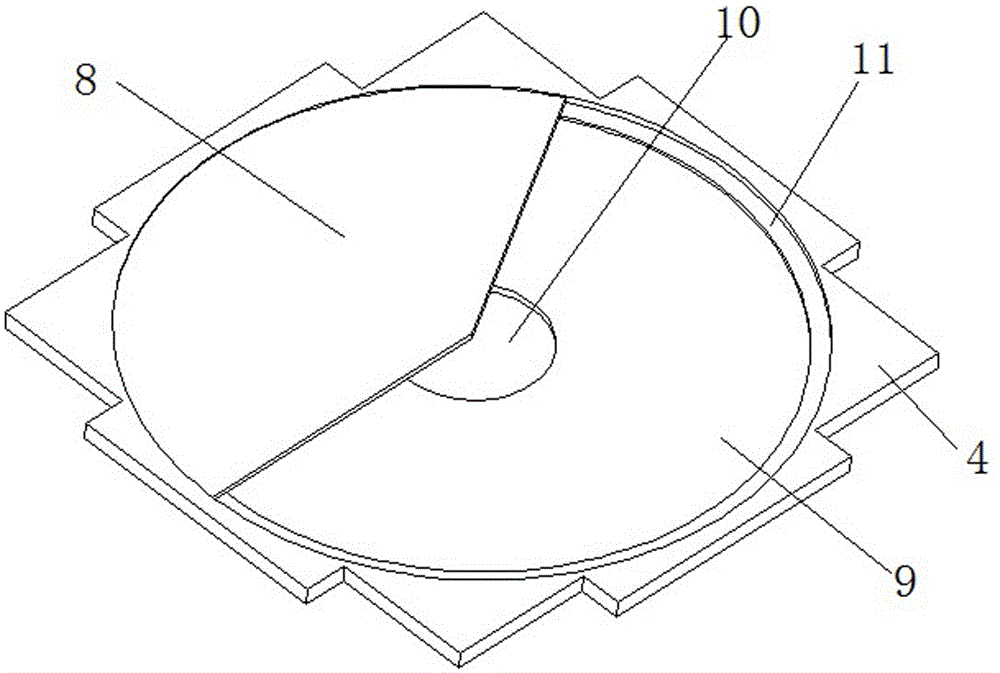

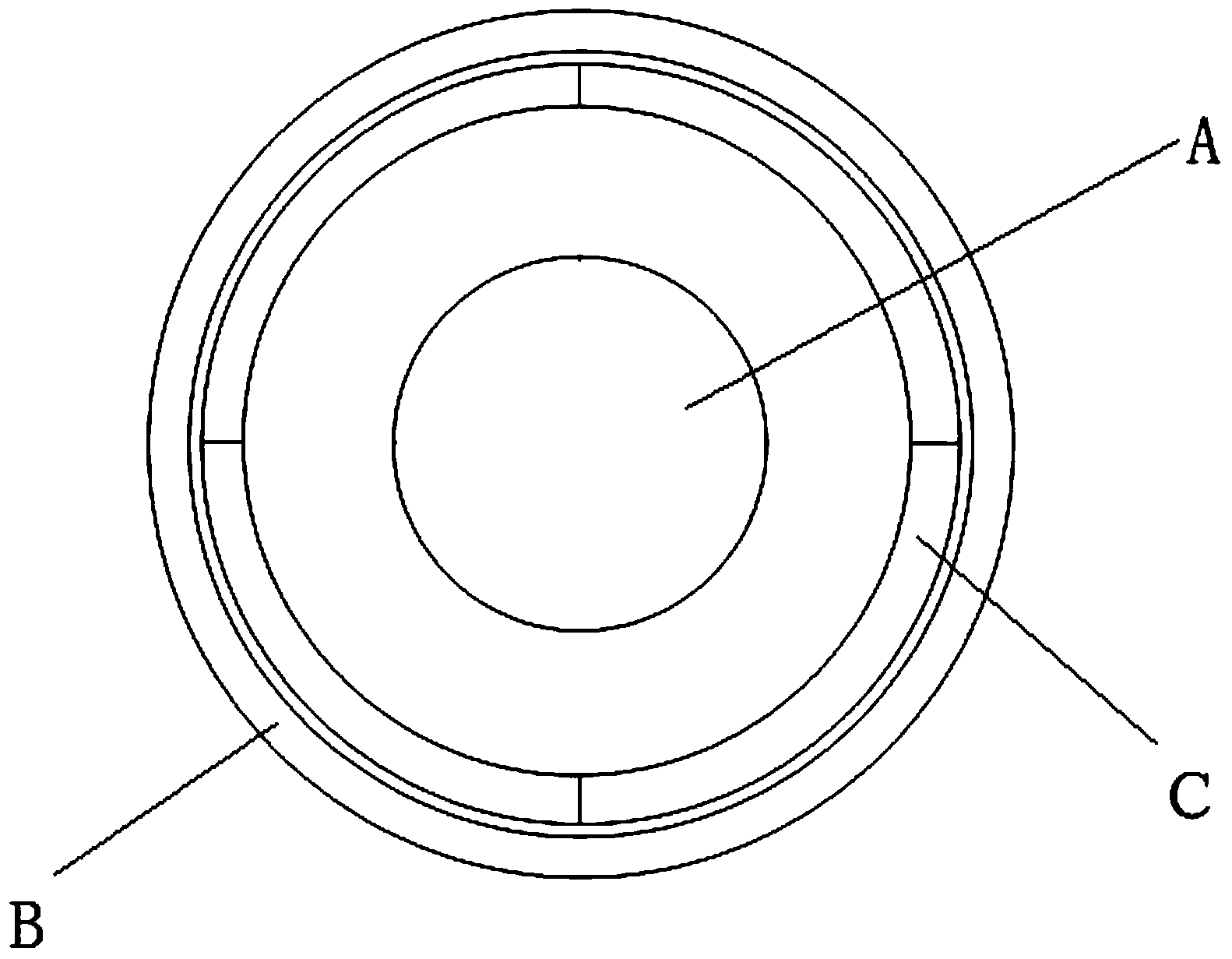

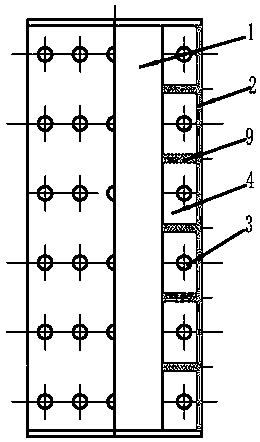

Miniature four-channel circular flow type triaxial silicon jet gyro

InactiveCN105091876AIncrease the areaImprove driving abilityTurn-sensitive devicesElectricityJet flow

The application exposes a miniature four-channel circular flow type triaxial silicon jet gyro; the jet gyro comprises a four-channel circular flow type triaxial angular velocity sensitive element and a PCB, and the sensitive element is electrically connected with the PCB, wherein the sensitive element comprises a PMMA upper cover, an upper silicon board, a lower silicon board, a PMMA bottom cover and a piezoelectric ceramic round oscillator; the piezoelectric ceramic round oscillator is embedded in the PMMA upper cover; the upper silicon board is provided with a jet network; the lower silicon board is provided with a jet network and a hot line; the PMMA upper cover, the upper silicon board, the lower silicon board and the PMMA bottom cover are successively bonded to form the sensitive element. The jet gyro adopts one piezoelectric ceramic round oscillator to drive four-channel circular flow, not only is simple in structure, long in life and low in power consumption, and implements deformation direction of the piezoelectric ceramic round oscillator and direction turning of jet flow network planes; the area of the piezoelectric ceramic round oscillator is large, the driving ability is strong, the jet velocity is high, and the jet gyro sensitivity is high; and angular velocities of three orthogonal directions can be sensitive at the same time, and multi-axis integration is achieved.

Owner:BEIJING INFORMATION SCI & TECH UNIV

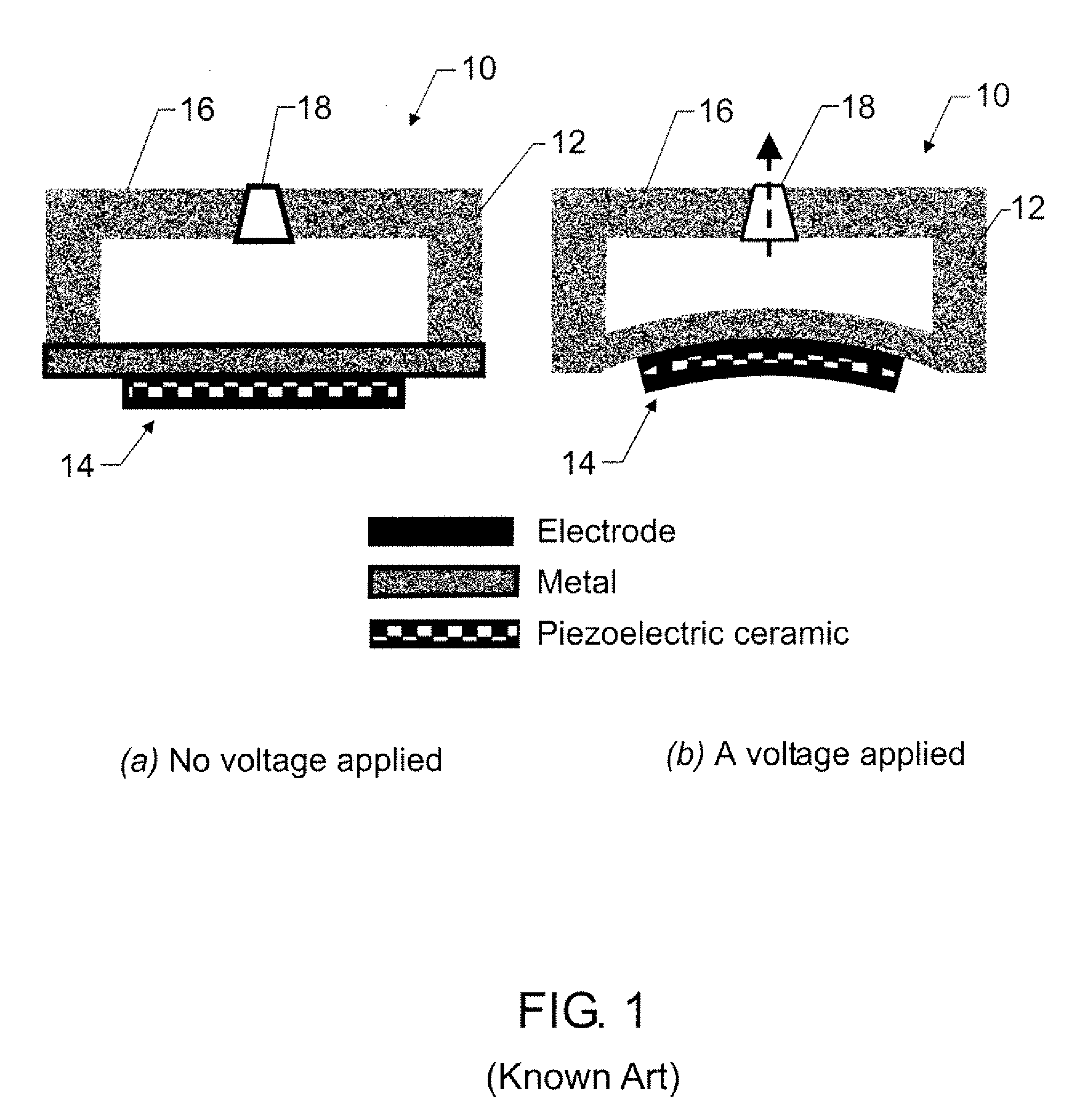

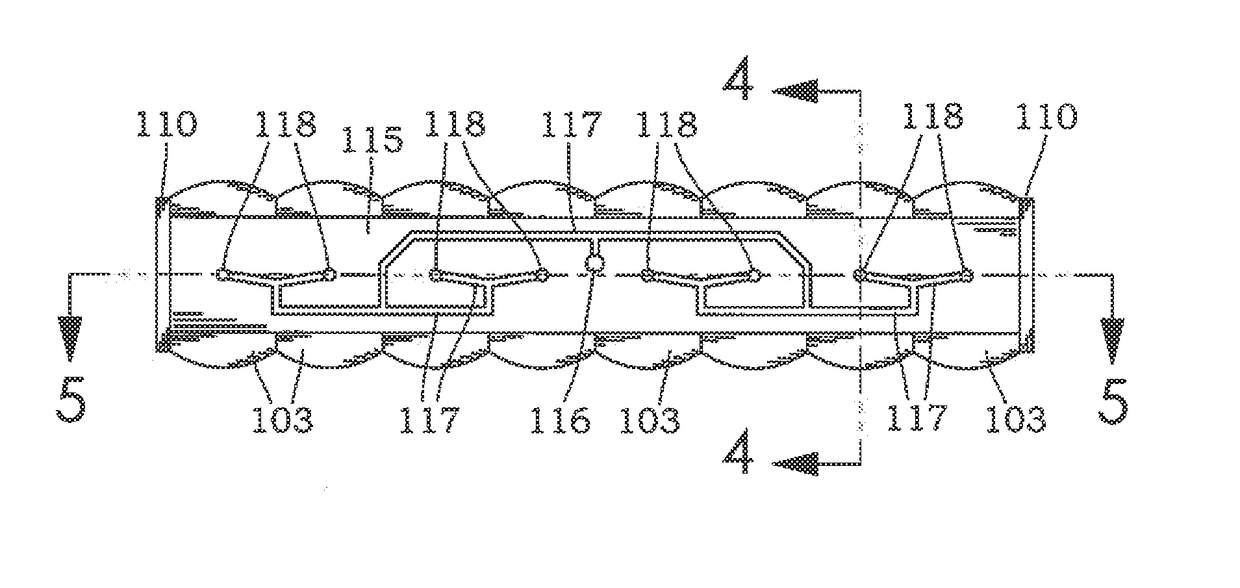

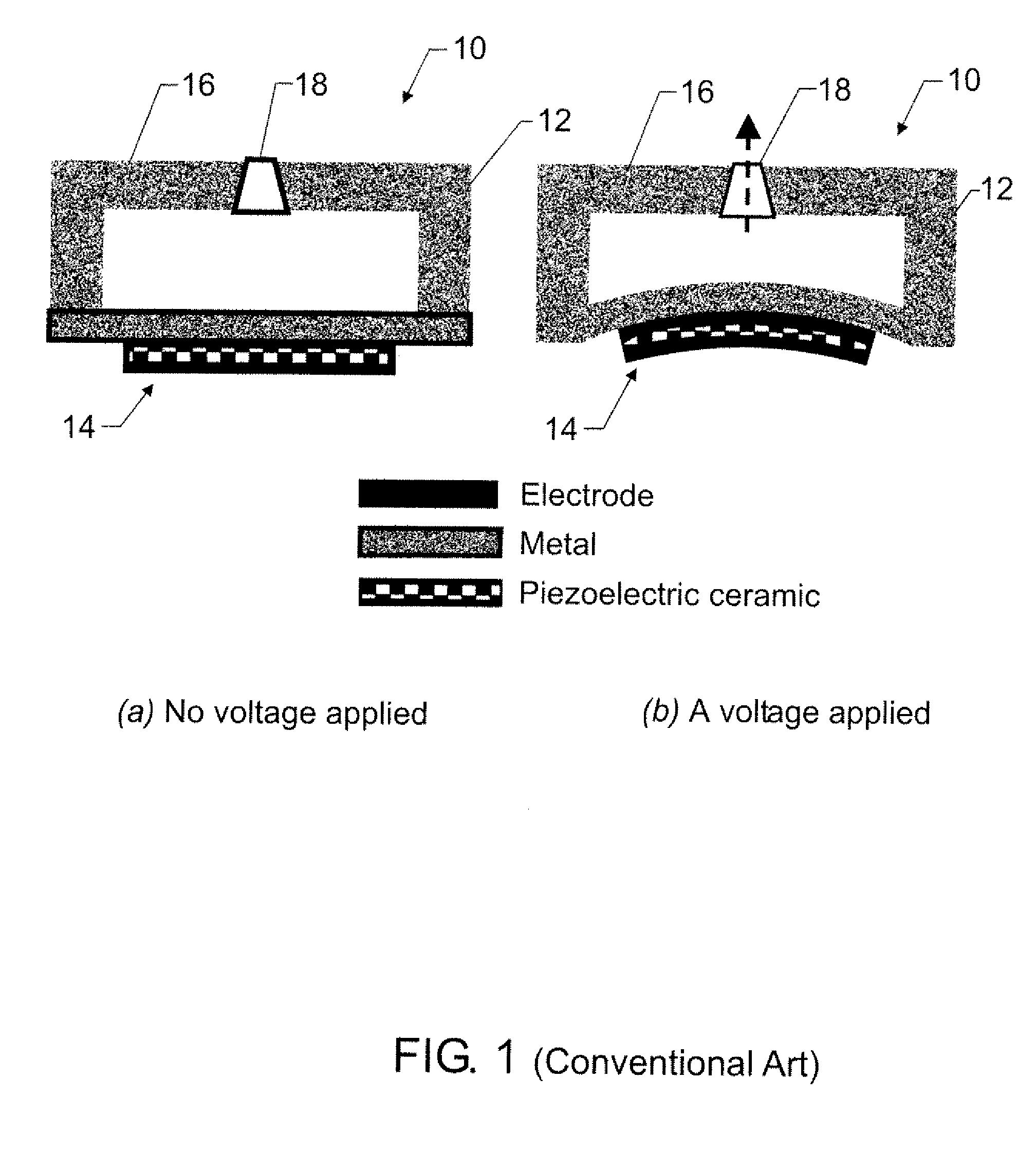

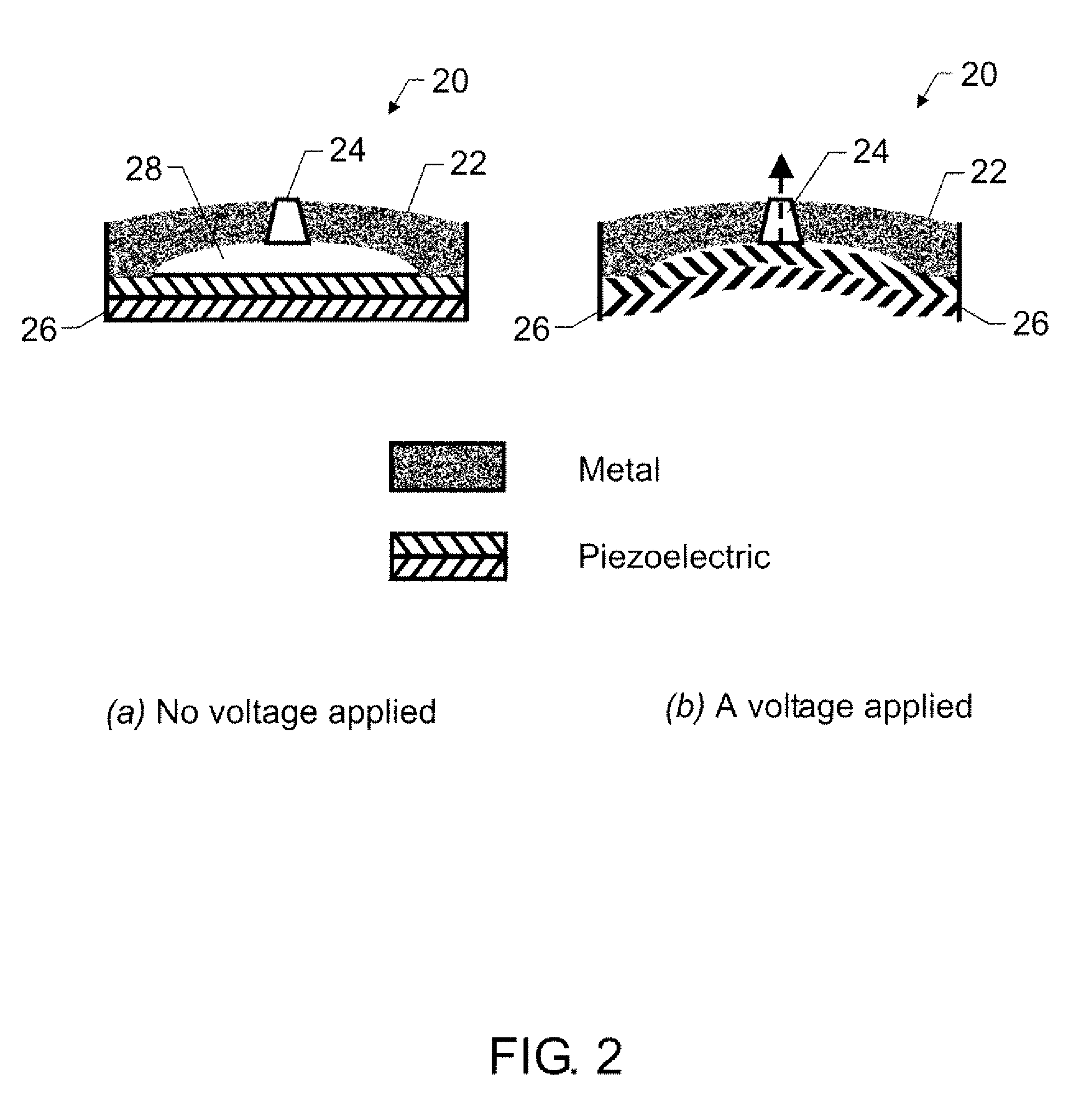

Advanced High Performance Vertical Hybrid Synthetic Jet Actuator

The present invention comprises a high performance, vertical, zero-net mass-flux, synthetic jet actuator for active control of viscous, separated flow on subsonic and supersonic vehicles. The present invention is a vertical piezoelectric hybrid zero-net mass-flux actuator, in which all the walls of the chamber are electrically controlled synergistically to reduce or enlarge the volume of the synthetic jet actuator chamber in three dimensions simultaneously and to reduce or enlarge the diameter of orifice of the synthetic jet actuator simultaneously with the reduction or enlargement of the volume of the chamber. The jet velocity and mass flow rate for the present invention will be several times higher than conventional piezoelectric synthetic jet actuators.

Owner:NASA

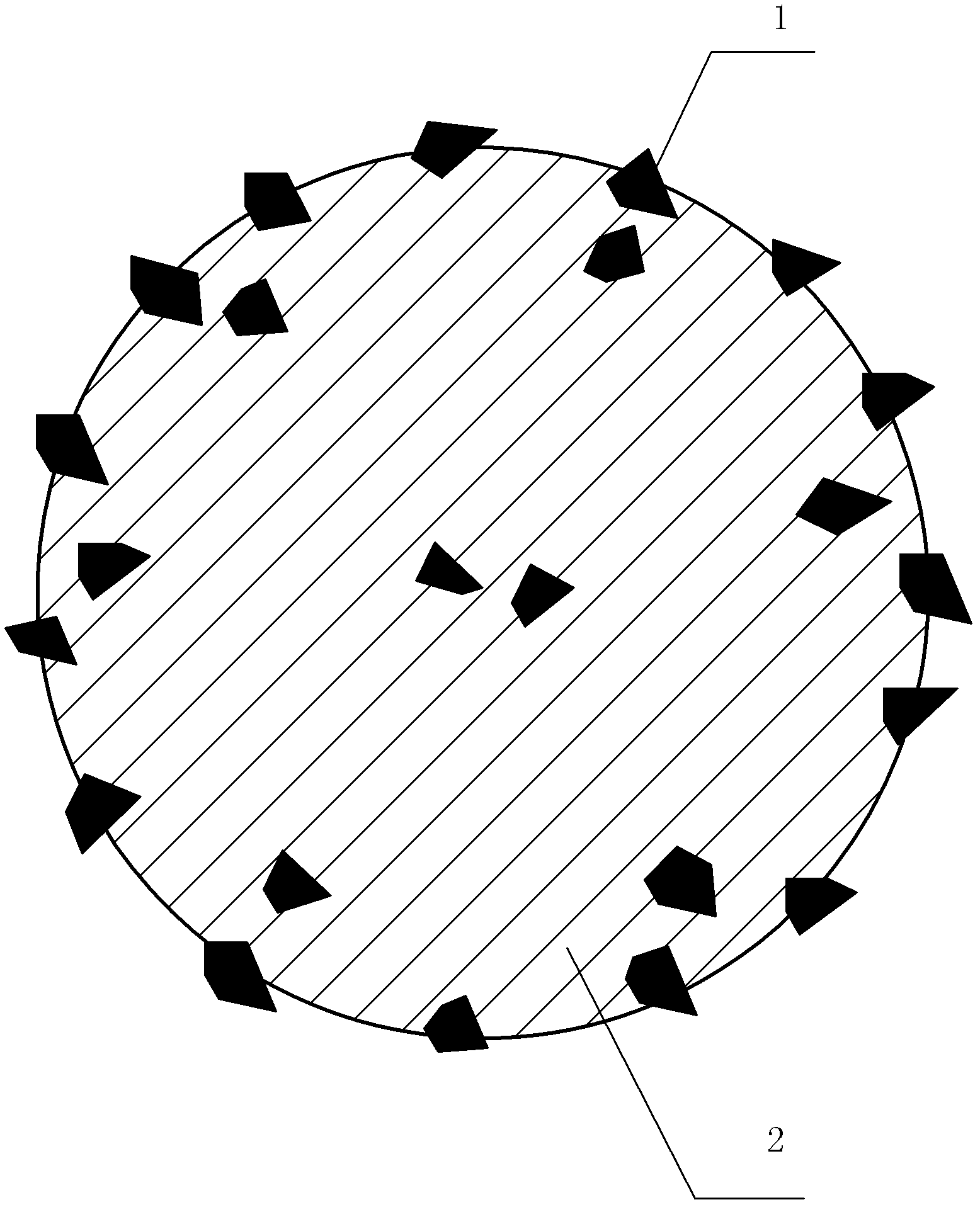

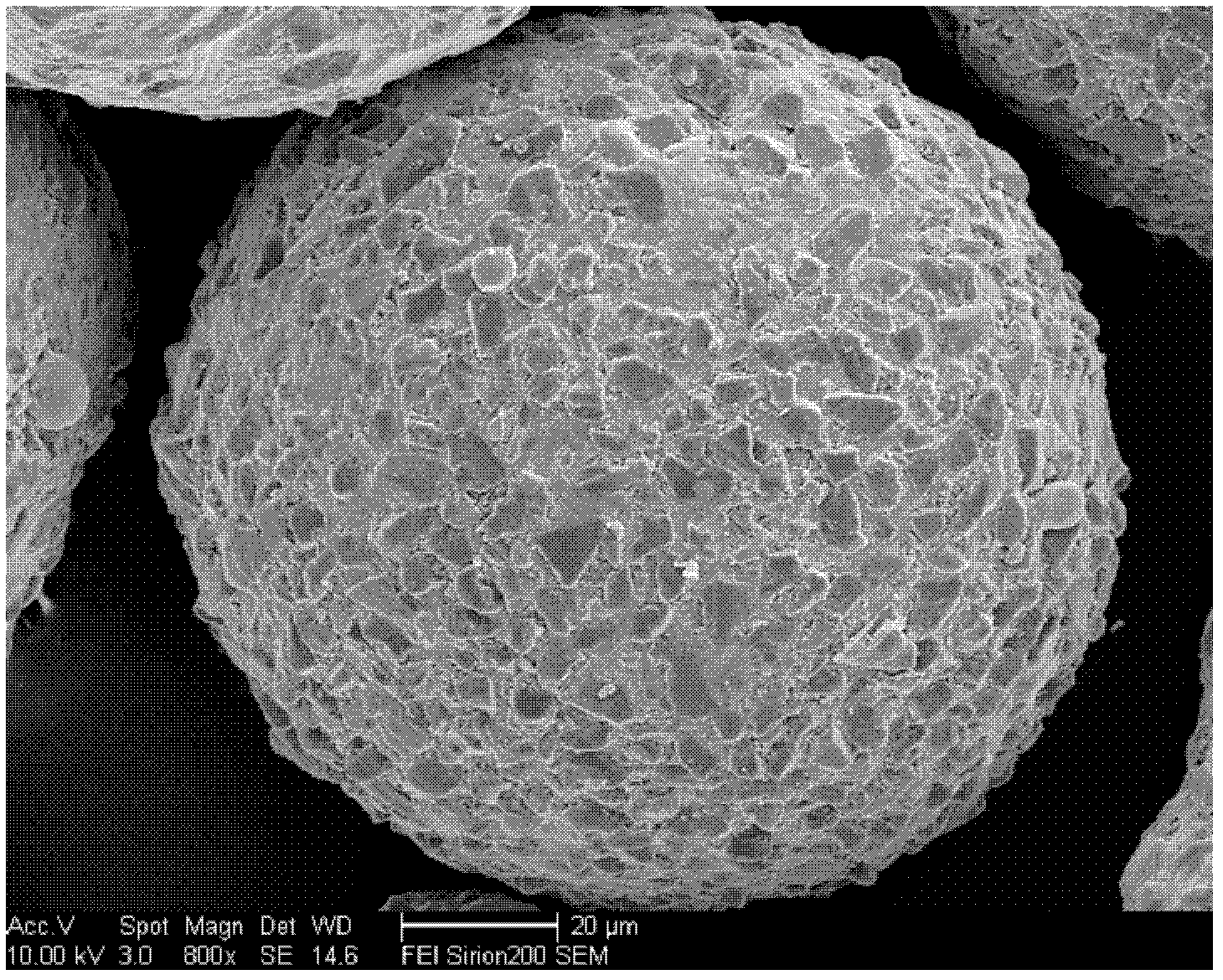

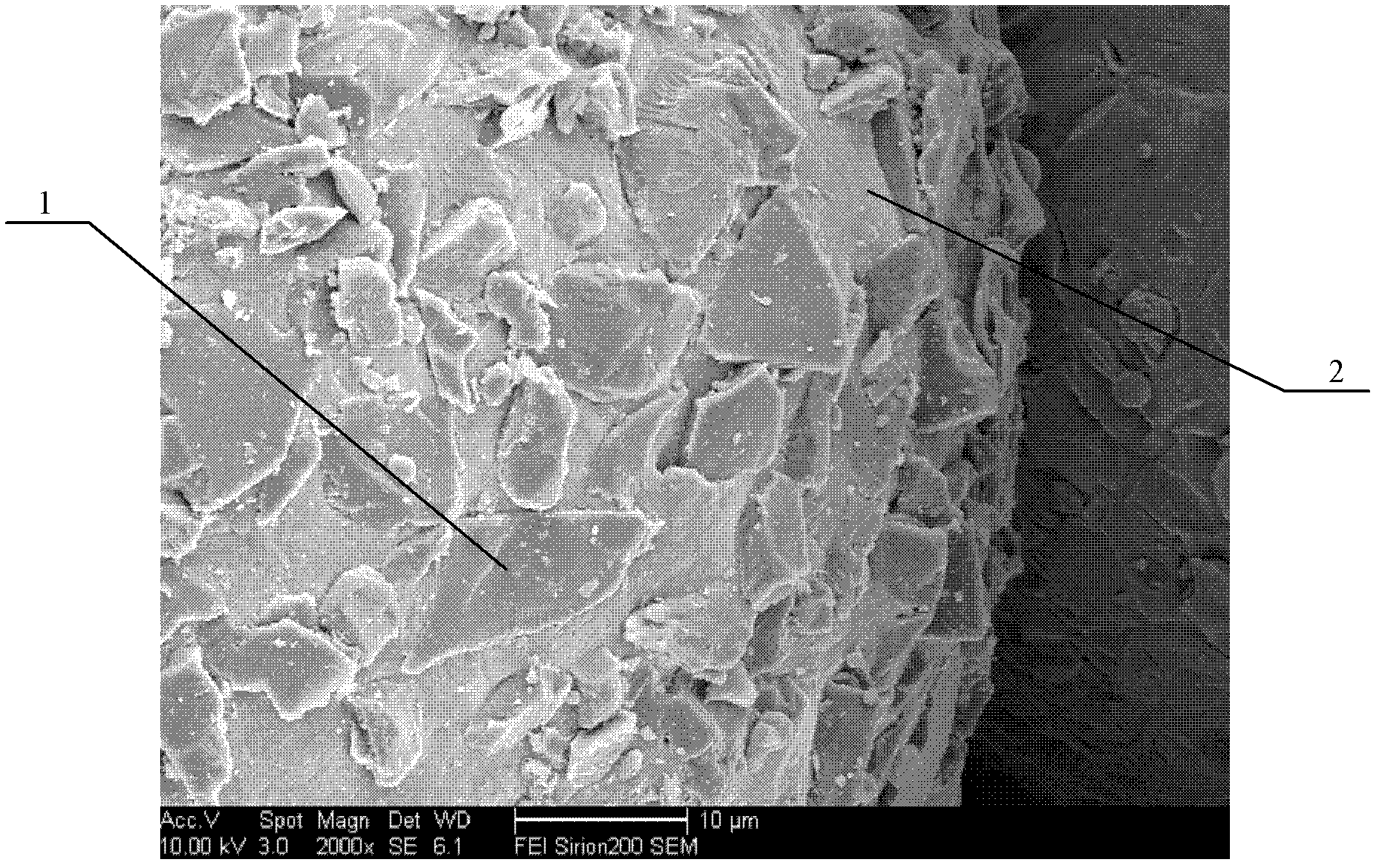

Structural and Morphological Control Method of Magnetic Abrasives Prepared by Gas Atomization Rapid Solidification

InactiveCN102277132AImprove bindingExtended service lifeOther chemical processesHard metalSpherical shaped

The invention relates to a method for controlling the structure and shape of magnetic abrasives prepared by a gas atomization quick-setting method. By controlling the melting temperature of the ferromagnetic metal at 50-280° C. above the melting point of the corresponding ferromagnetic metal and controlling the injection velocity of the powder-mixing airflow at 0.7-3.0 MPa, the obtained magnetic abrasive has a regular spherical structure. Its hard abrasive is evenly distributed on the superficial layer of the metal body and is firmly combined with the metal body for a longer service life. Hard abrasive particles are mainly distributed in the superficial layer of the ferromagnetic metal body, only a small amount is distributed in the center of the metal body, and almost not distributed in the middle layer between the superficial layer and the center. The cutting edge of the hard abrasive protrudes outside, and the outermost cutting edge is of equal height to the surface of the metal body; it has a strong ability to grind the workpiece to be processed, and can also significantly improve the processing quality of the surface of the workpiece to be processed; guide The high magnetic rate significantly enhances the grinding ability of the processed workpiece and improves the processing efficiency.

Owner:SHANDONG UNIV OF TECH

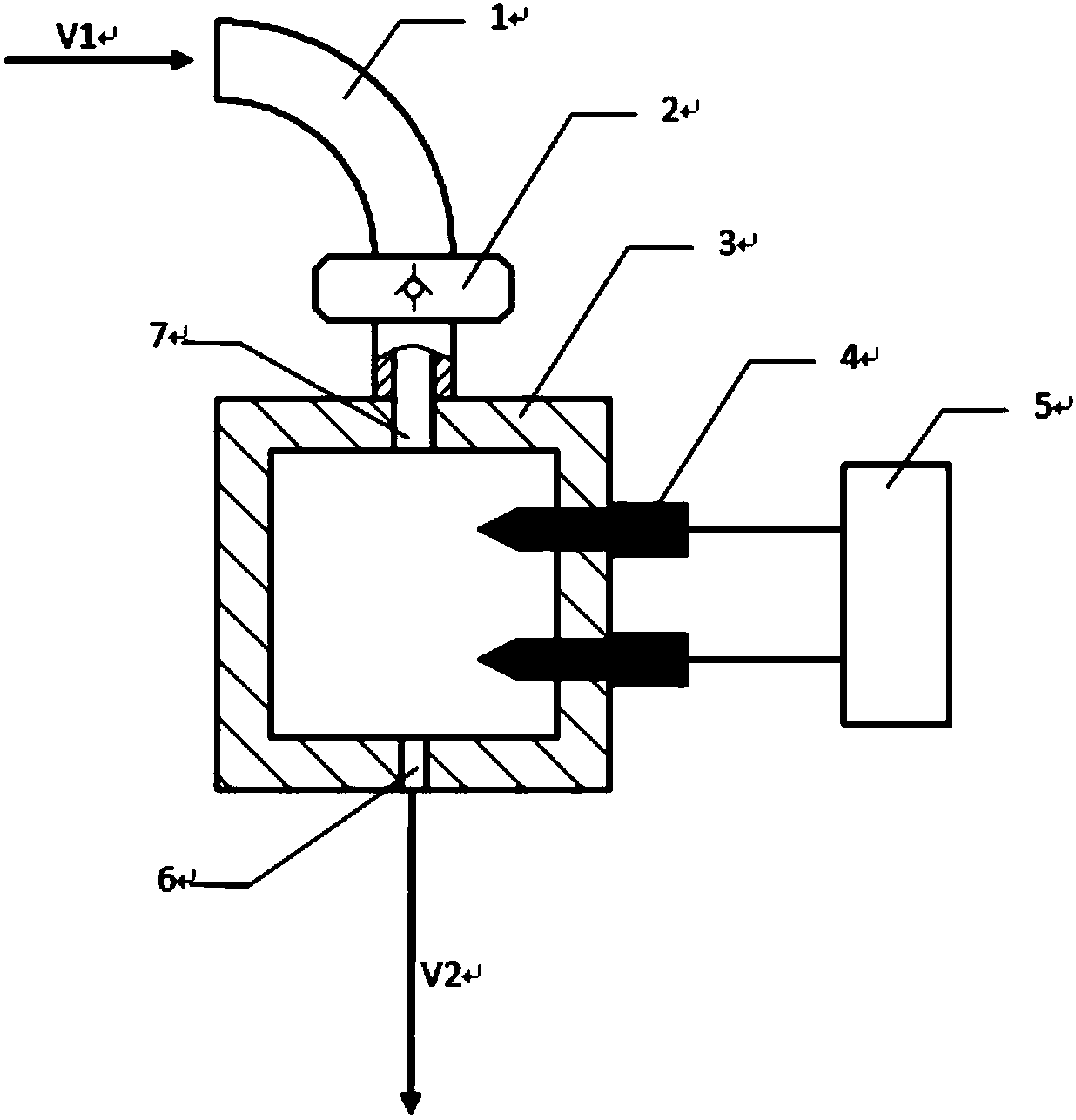

Water spray discharge air plasma jet processing device and high-voltage power source thereof

ActiveCN103482735AIncrease the rate of chemical reactionsGood application prospectWater/sewage treatment by magnetic/electric fieldsAc-ac conversionParameter controlCollision frequency

The invention discloses a water spray discharge air plasma jet processing device and a high-voltage power source thereof. Water to be treated is atomized into a fine mixture of water drops and air at first; consequently, the collision frequency of active particles generated by discharge with toxic and harmful species in water is effectively improved in the discharge reaction processing process, the chemical reaction rate can be effectively increased, the water-air mixing ratio of the water spray jet and the flow velocity of the water spray jet can be adjusted, the chemical reaction kinetics of the water spray jet generated in an atomization reactor are adjusted, the highest efficiency and the most energy-saving state of running of the water processing system are realized, and the processed water is subjected to circulating treatment a plurality of times so that the requirement of emission can be met at last; a voltage and current detection circuit for the input end and the output end of the high-voltage power source is capable of effectively determining whether the system runs normally; therefore, the optimal running parameter control of the water processing system between physical parameters such as the discharge power of the output end, the water spray jet speed and the water-air mixing ratio, and the water processing effect is realized.

Owner:HOHAI UNIV CHANGZHOU

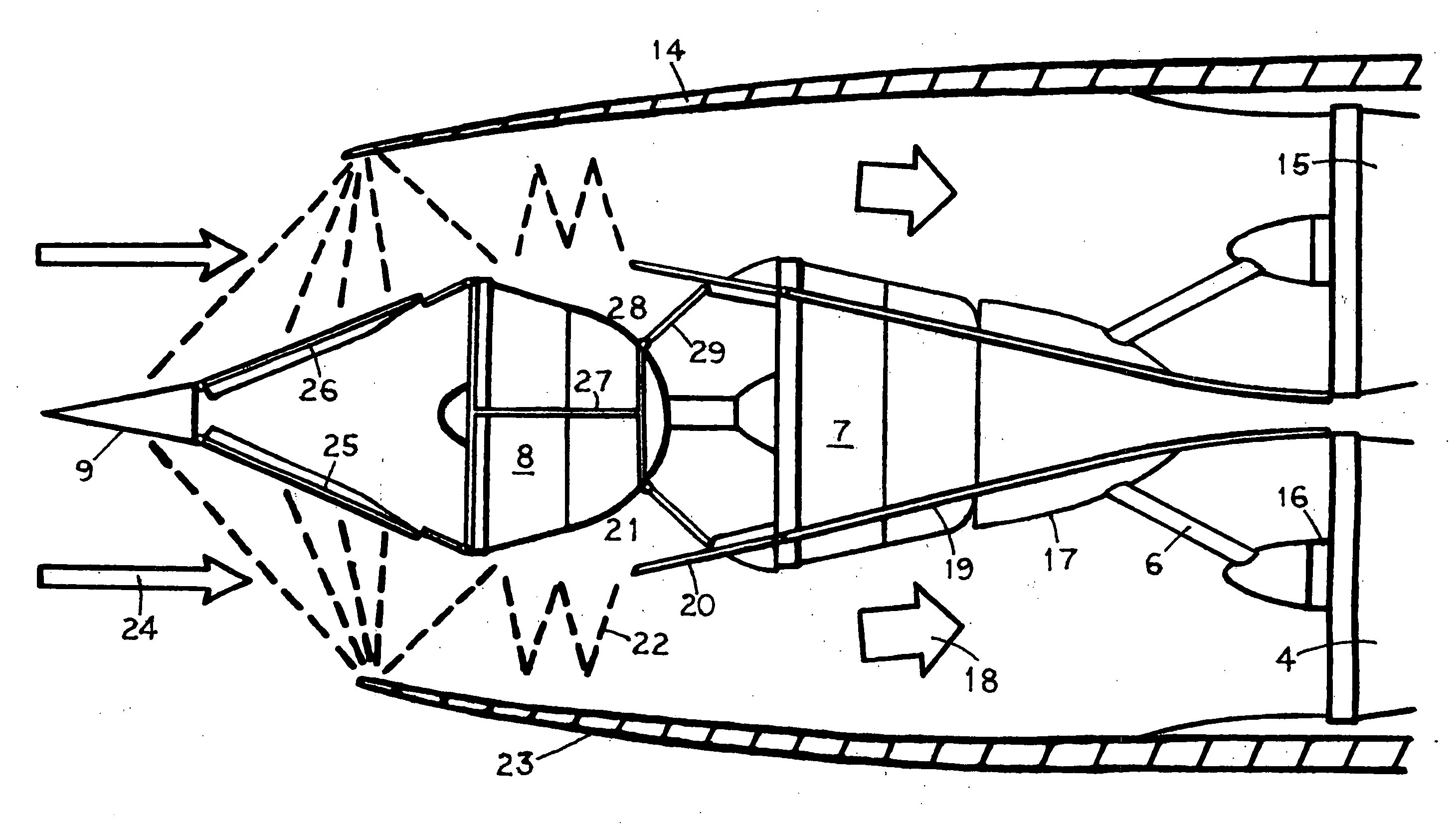

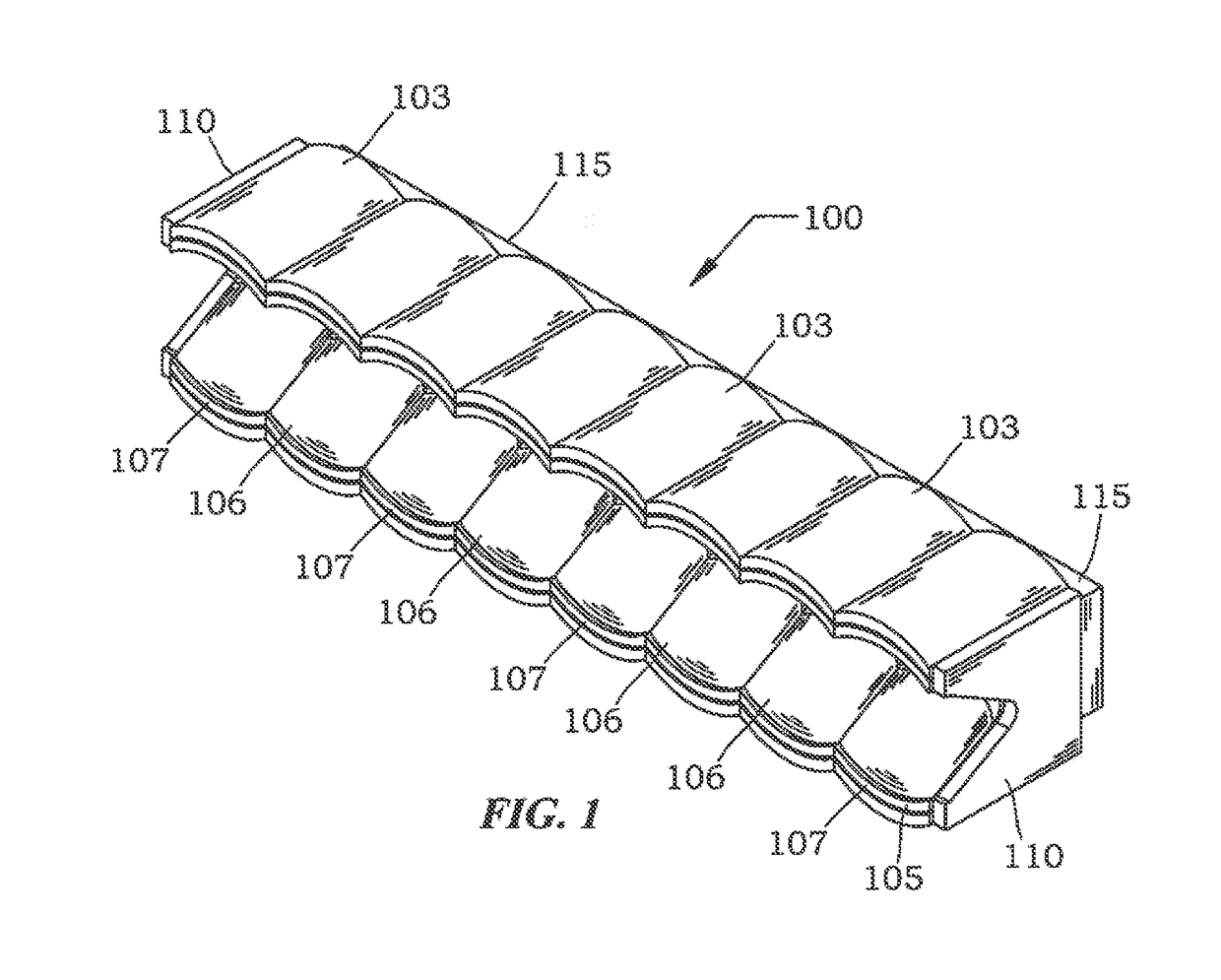

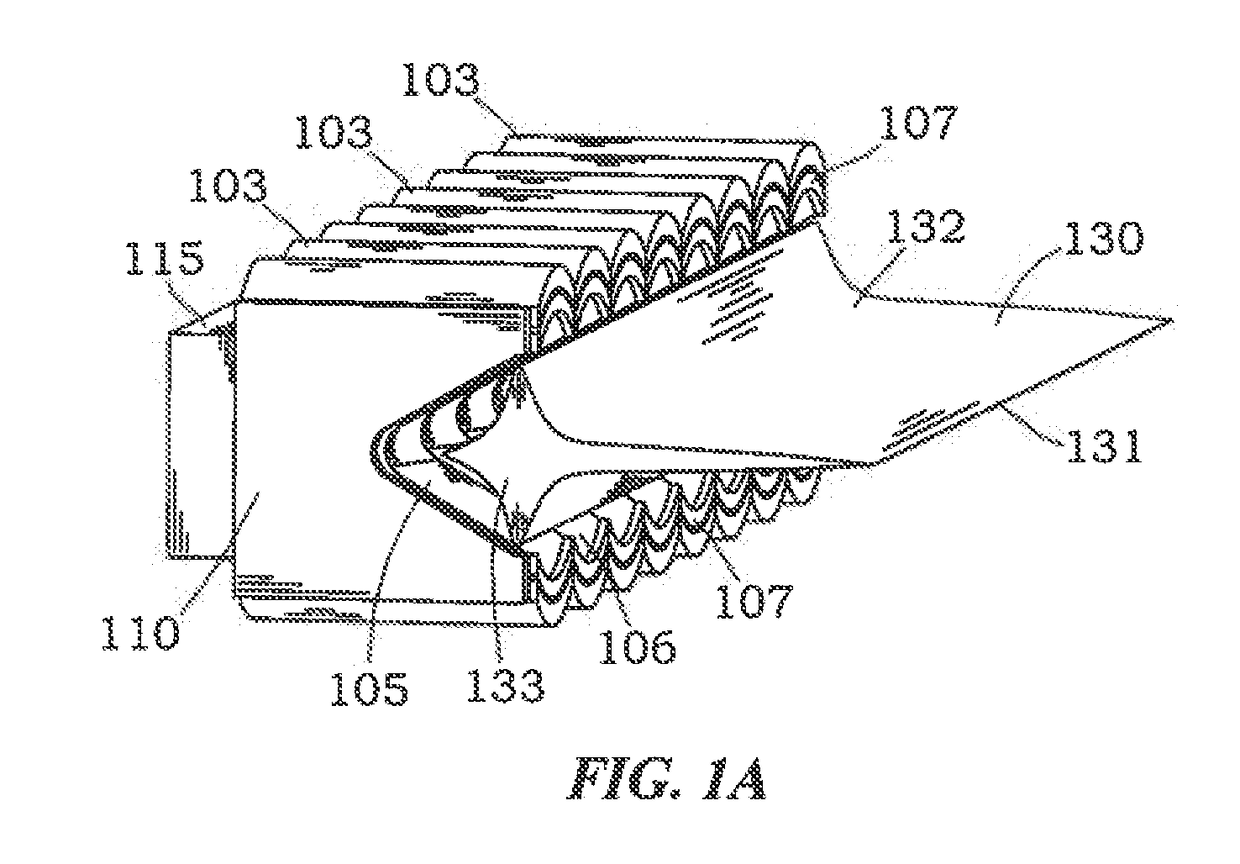

Ejector/Mixer Nozzle for Noise Reduction

InactiveUS20110162383A1Shorten speedReduce noisePump componentsBlade accessoriesEngineeringNoise reduction

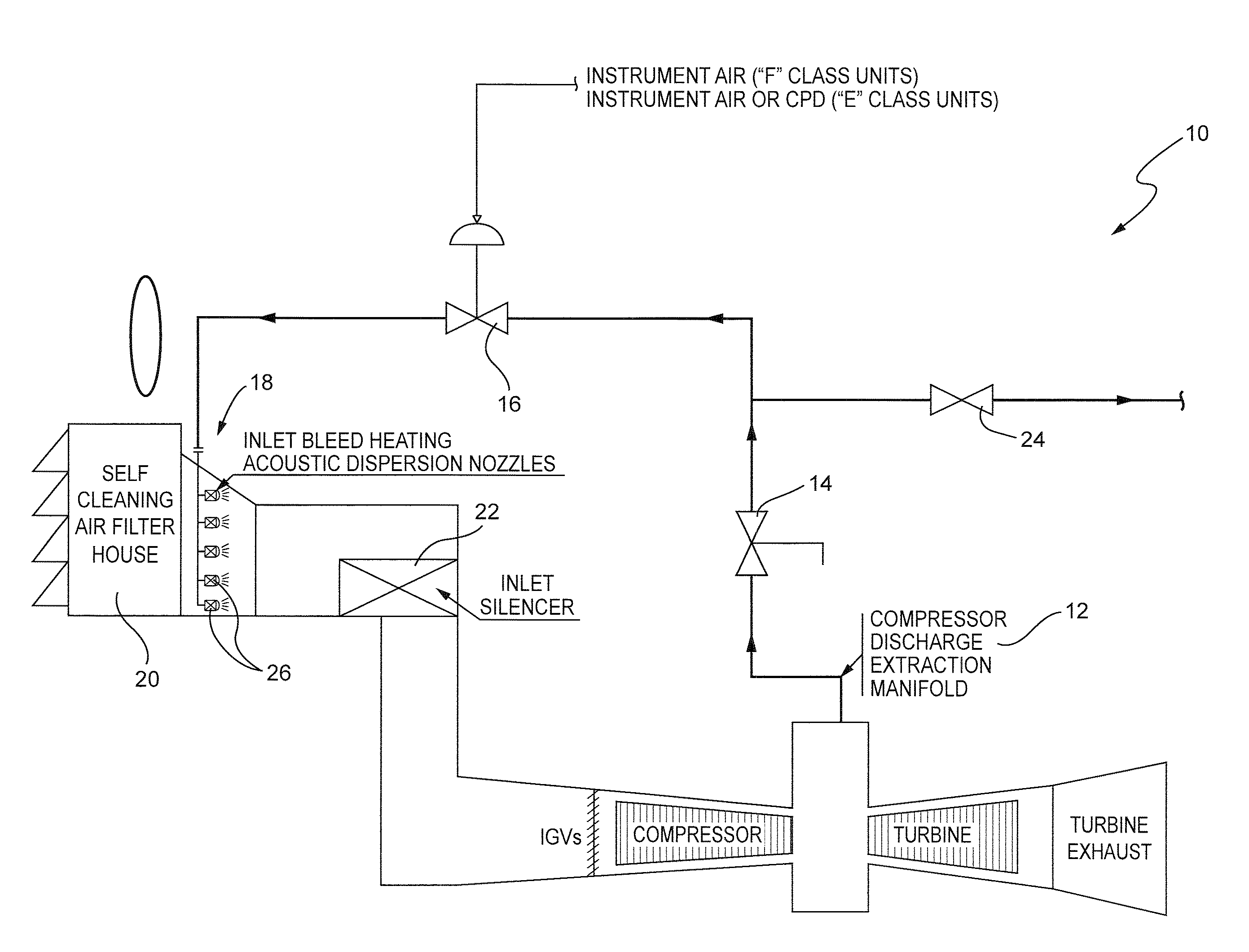

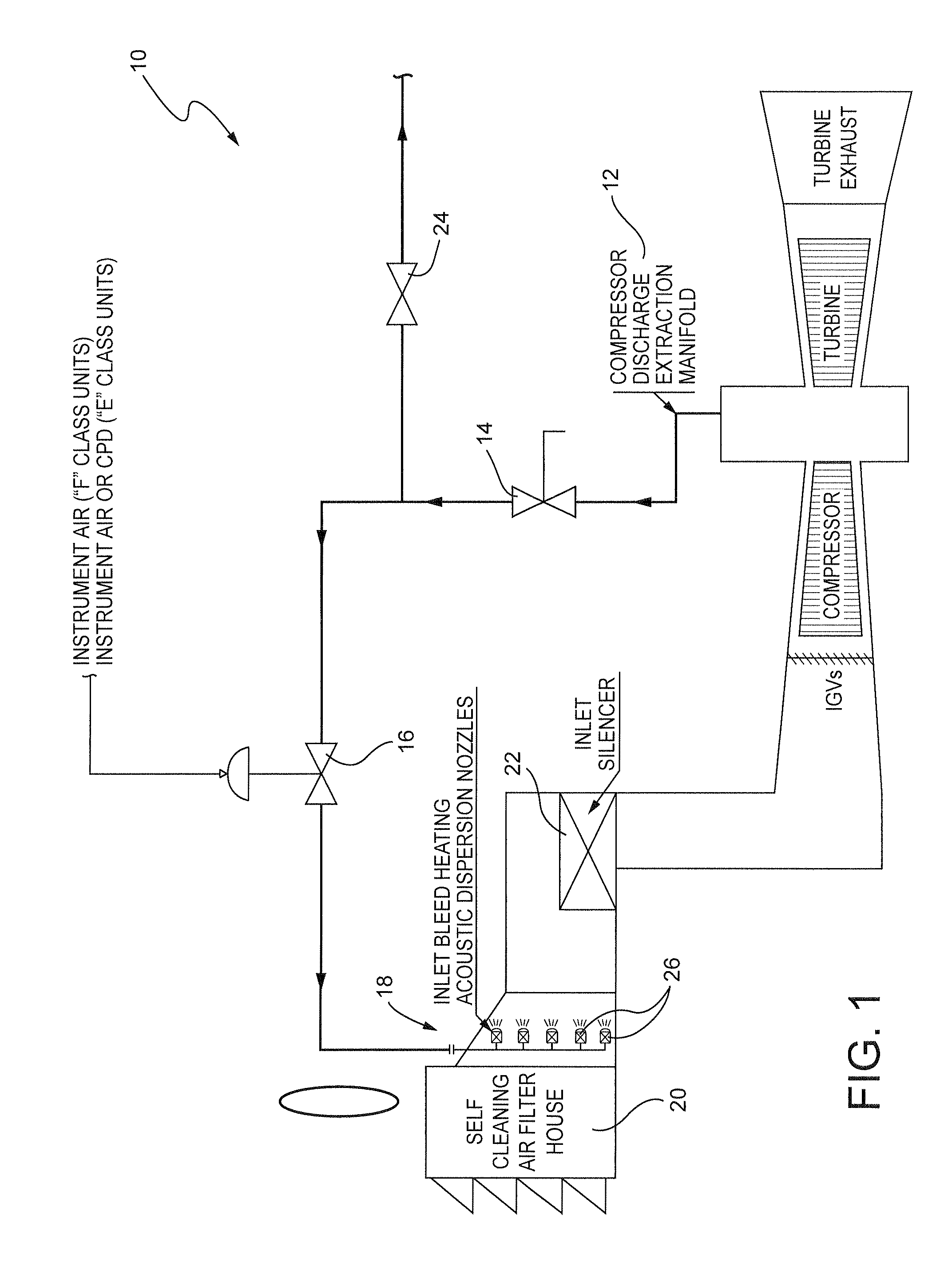

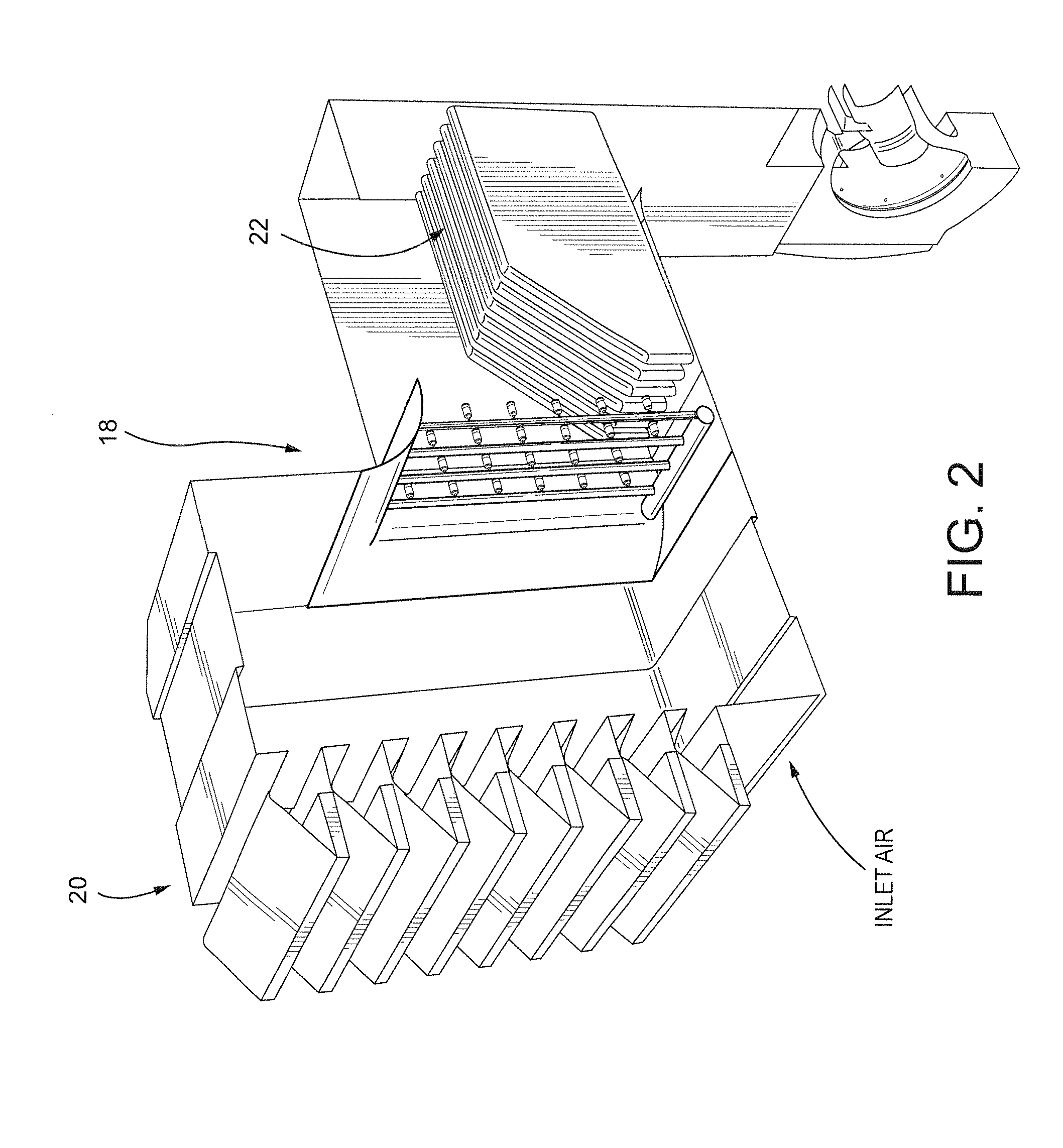

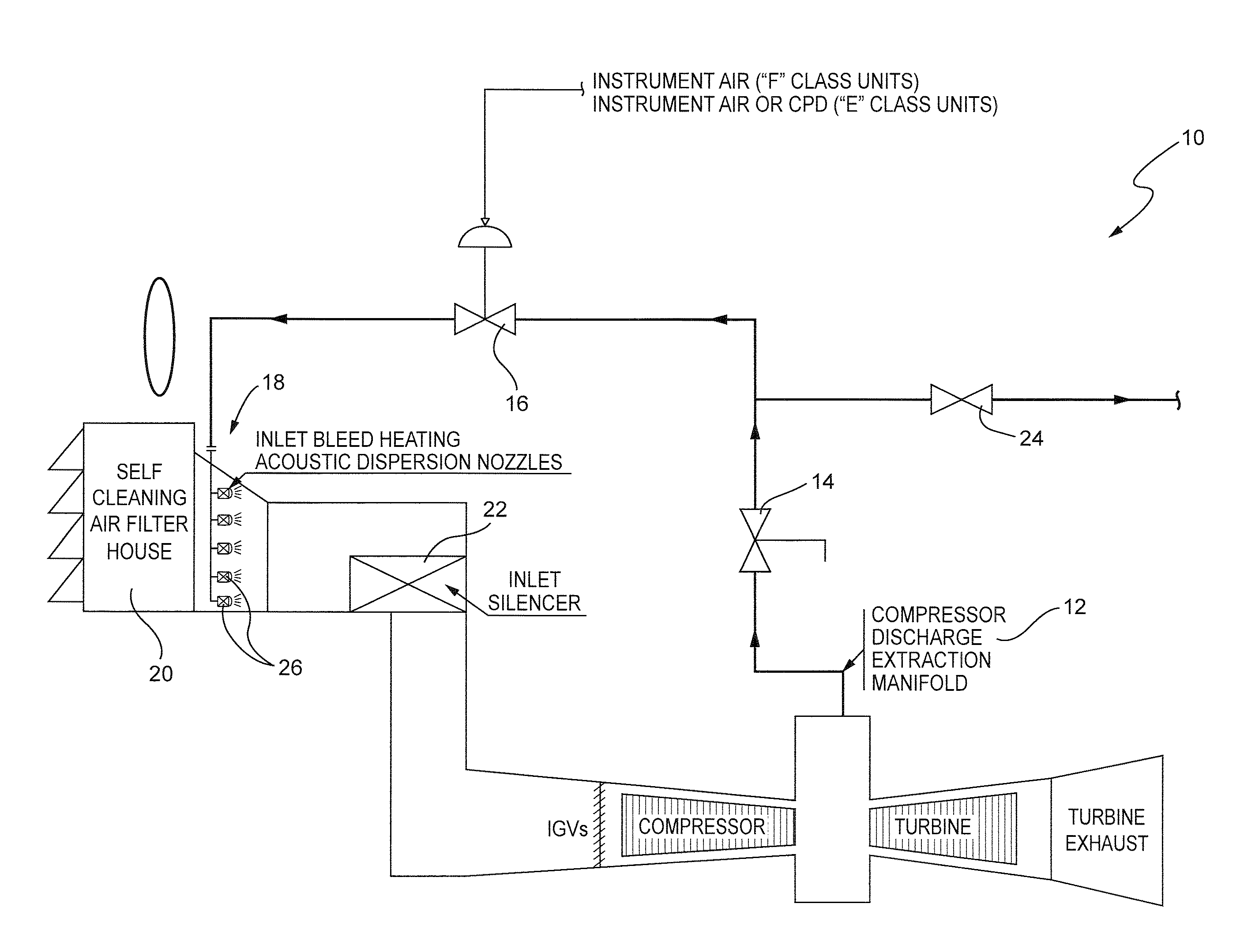

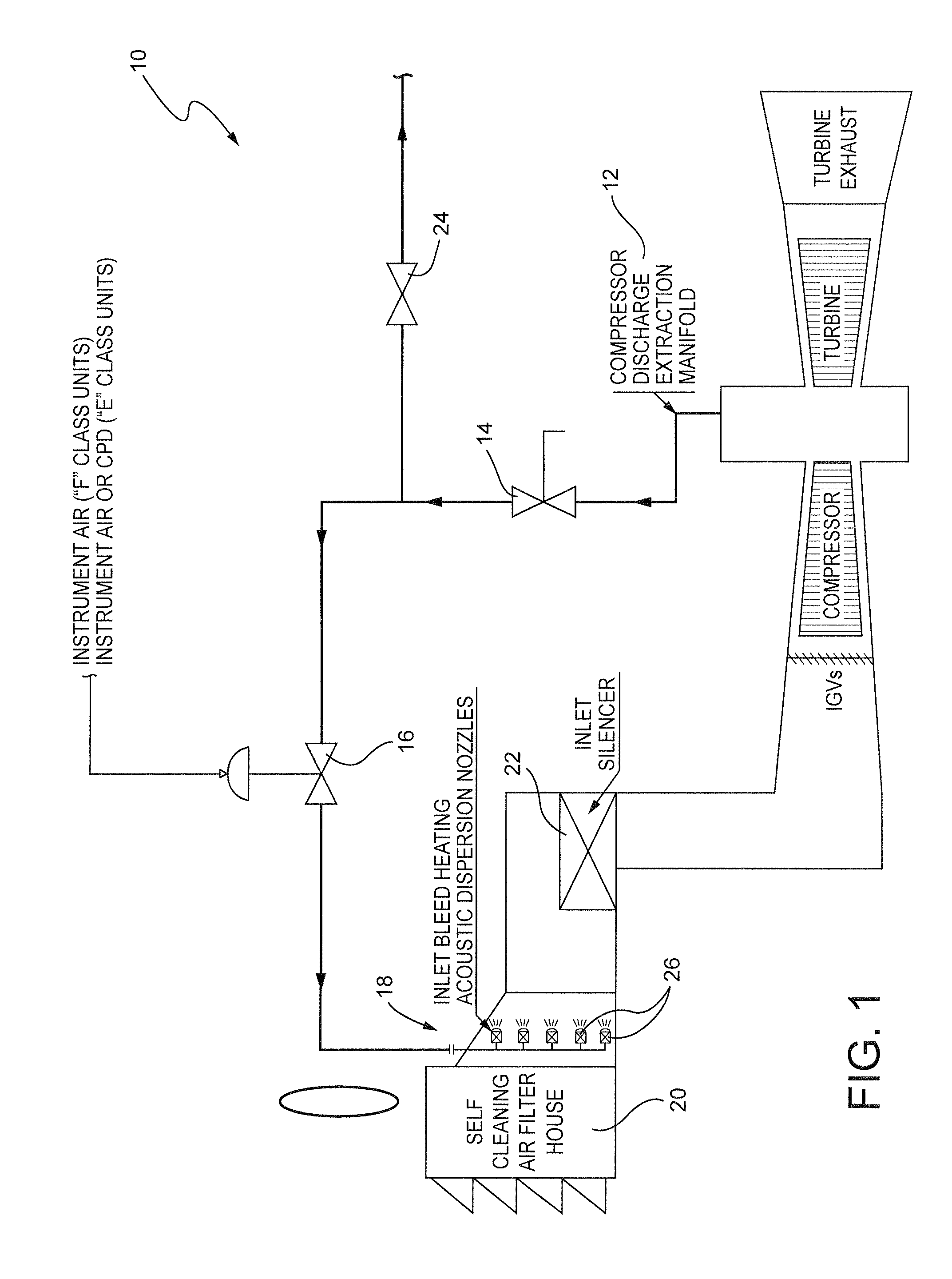

An inlet bleed heat system in a gas turbine includes a compressor discharge extraction manifold that extracts compressor discharge air, an inlet bleed heat manifold receiving the compressor discharge air, and a plurality of acoustic dispersion nozzles disposed at an output end of the inlet bleed heat manifold that reduce a velocity of the compressor discharge air in the inlet bleed heat manifold. Noise is generated from the shearing action between the surrounding atmosphere and air jets from orifices. When the air jet velocity is slowed using, for example, a multi-stage ejector / mixer, noise can be abated.

Owner:GENERAL ELECTRIC CO

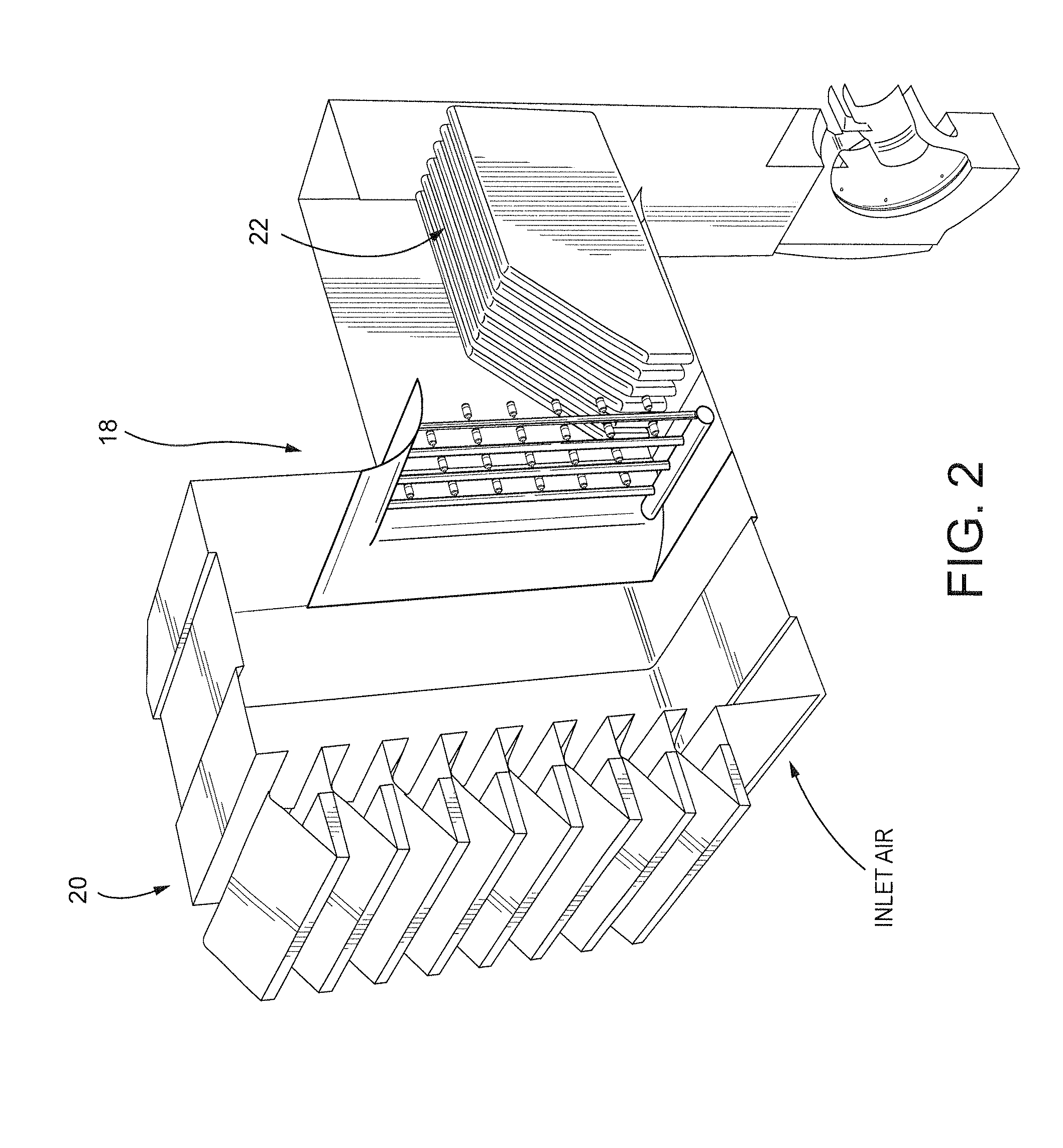

Inlet bleed heat system with ejector/mixer nozzles for noise reduction

InactiveUS8272222B2Shorten speedReduce noisePump componentsBlade accessoriesEngineeringNoise reduction

An inlet bleed heat system in a gas turbine includes a compressor discharge extraction manifold that extracts compressor discharge air, an inlet bleed heat manifold receiving the compressor discharge air, and a plurality of acoustic dispersion nozzles disposed at an output end of the inlet bleed heat manifold that reduce a velocity of the compressor discharge air in the inlet bleed heat manifold. Noise is generated from the shearing action between the surrounding atmosphere and air jets from orifices. When the air jet velocity is slowed using, for example, a multi-stage ejector / mixer, noise can be abated.

Owner:GENERAL ELECTRIC CO

Water mist discharge and ultrasound synergetic degradation wastewater treatment device and running method thereof

ActiveCN103523856AEasy to handleDegradabilityWater/sewage treatment by irradiationWater/sewage treatment with mechanical oscillationsDischarge rateHigh voltage pulse

Owner:HOHAI UNIV CHANGZHOU

Jet type stress-erosion corrosion test device

PendingCN109975153AWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesMaterial ErosionAir pump

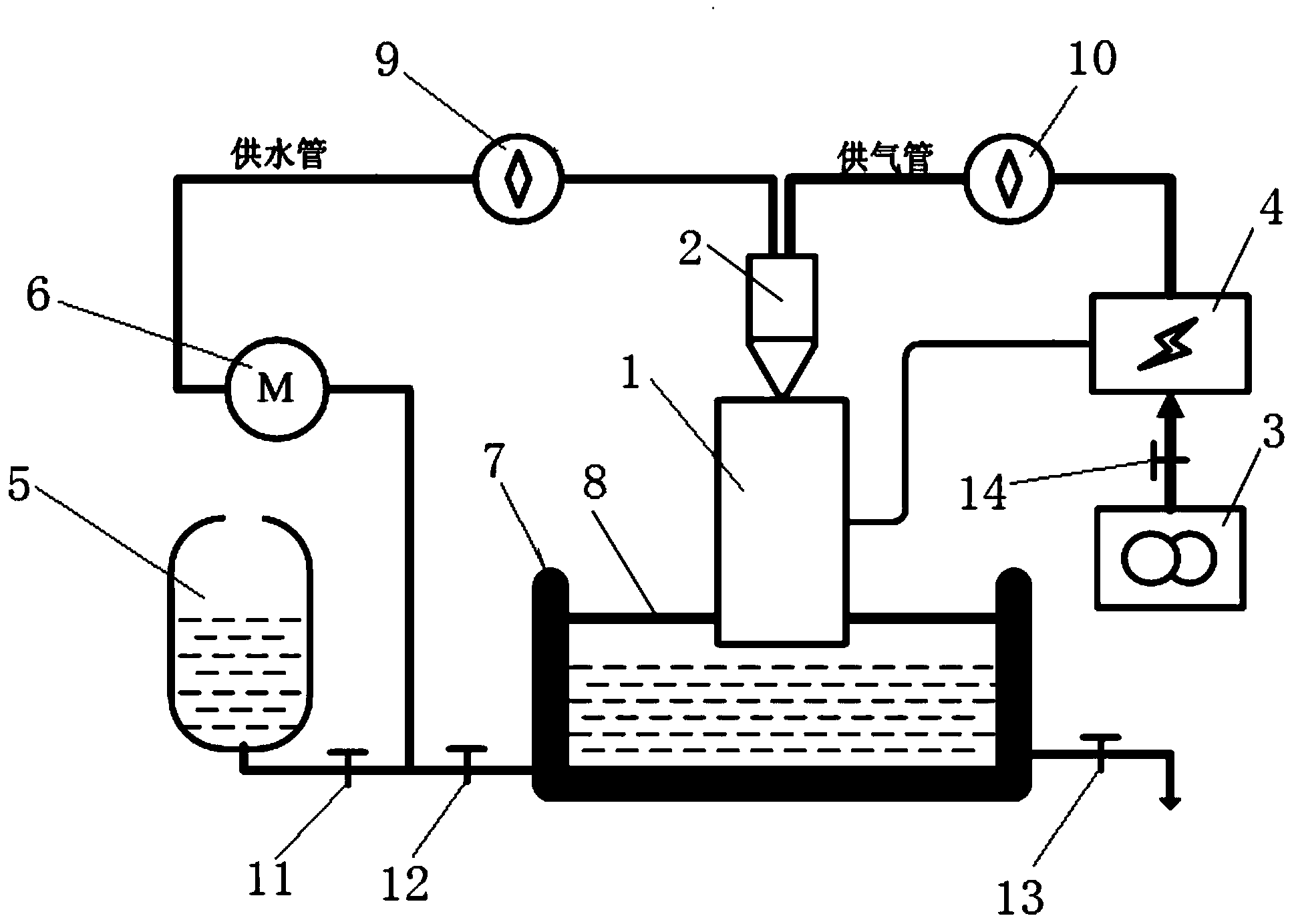

The invention relates to a jet type stress-erosion corrosion test device. The device comprises a liquid storage tank, a circulating system, a test piece mounting and stress loading mechanism; the testdevice is characterized in that a heater is arranged in the liquid storage tank and used for heating a test solution in the tank; the circulating system is provided with a water pump, an air pump andan air-liquid mixer; the water pump is used for sucking the test solution in the tank into the air-liquid mixer, the air pump is connected to the air-liquid mixer, the air-liquid mixer communicates with a nozzle through a pipeline, a sand storage tank is arranged on the pipeline at the front end of the nozzle, and the particle content entering the pipeline is controlled through an adjusting valve; a temperature sensor and a flowmeter for measuring the temperature and flow of a transmission medium input into the pipeline from the air-liquid mixer are arranged at an upstream of a sand storage tank mounting place; the heater power is adjusted according to the reading of the temperature sensor, the rotating speeds of the water pump and the air pump are controlled according to the reading of the flowmeter, thereby controlling the jet velocity. The evaluation research on the stress-erosion corrosion performance test and the corrosion mechanism of the metal material, the nonmetallic material, the composite material and the stress erosion corrosion resistant coating can be performed.

Owner:TIANJIN UNIV

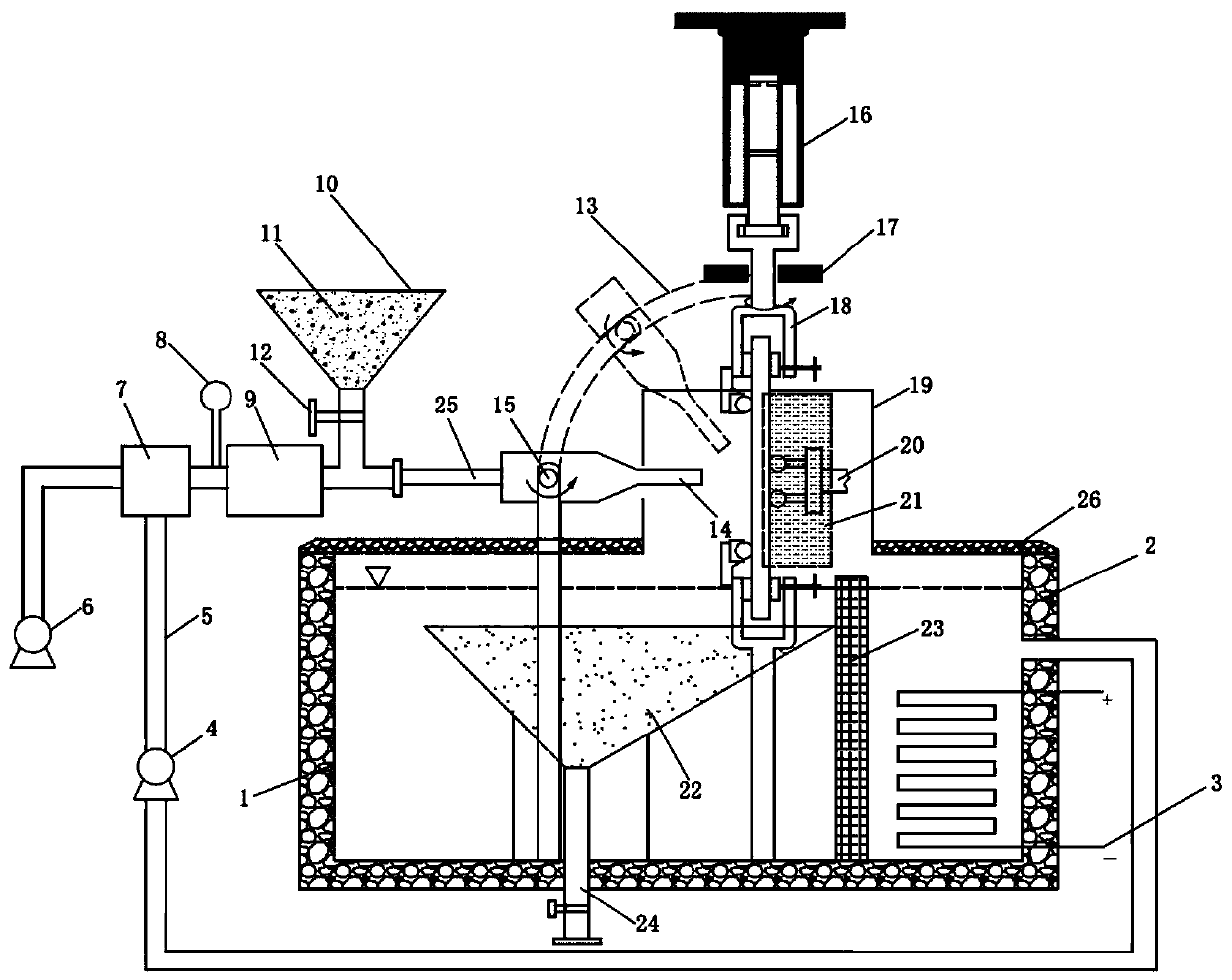

Mass flow increase at takeoff in supersonic airliner

InactiveUS20120292440A1Reduce noiseReduce jet velocityEngine fuctionsEfficient propulsion technologiesJet aeroplaneNacelle

In a supersonic aircraft, turbojet engine nacelles each containing two remote fans in the front half of the nacelle, for noise reduction at takeoff. During supersonic flight, a front wedge at the nacelle nose achieves external compression of intake air. The wedge is vertical, sending the airflow left and right inside the nacelle along its side walls. The two flows follow mirror image curved paths on their way to a turbojet, leaving unused space between them to house the fans in tandem. For takeoff, clutches connected to the turbojets's compressors are engaged. Driveshafts turn pinions against a gear on the same shaft as the remote fans. The fan output is discharged backward under the nacelle to produce thrust. The energy to turn the fans is taken from the turbojet cycle. The reduced exhaust jet velocity decreases its noise. Supercharging produces the extra power to turn the remote fans if multistage.

Owner:KOSHELEFF PATRICK A

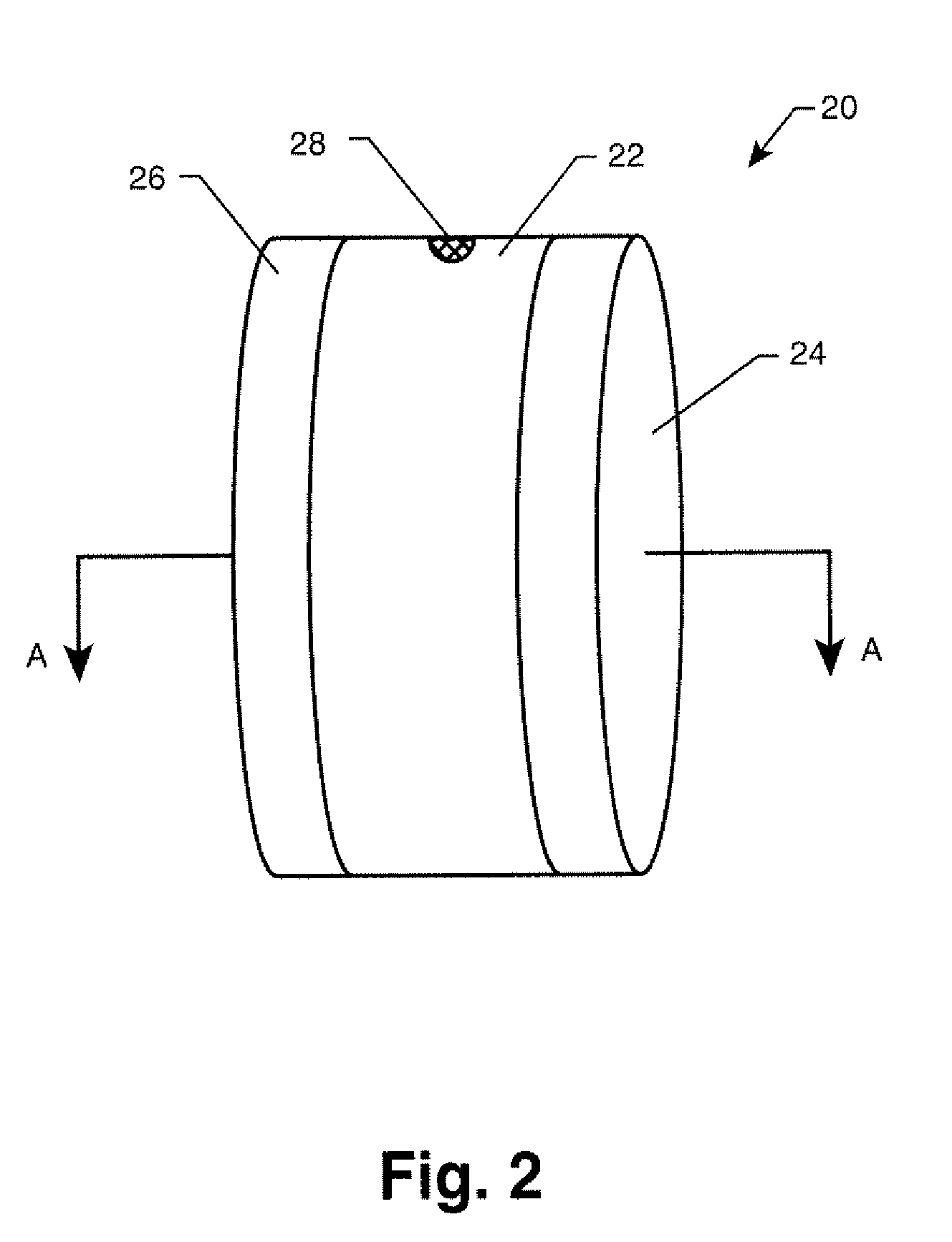

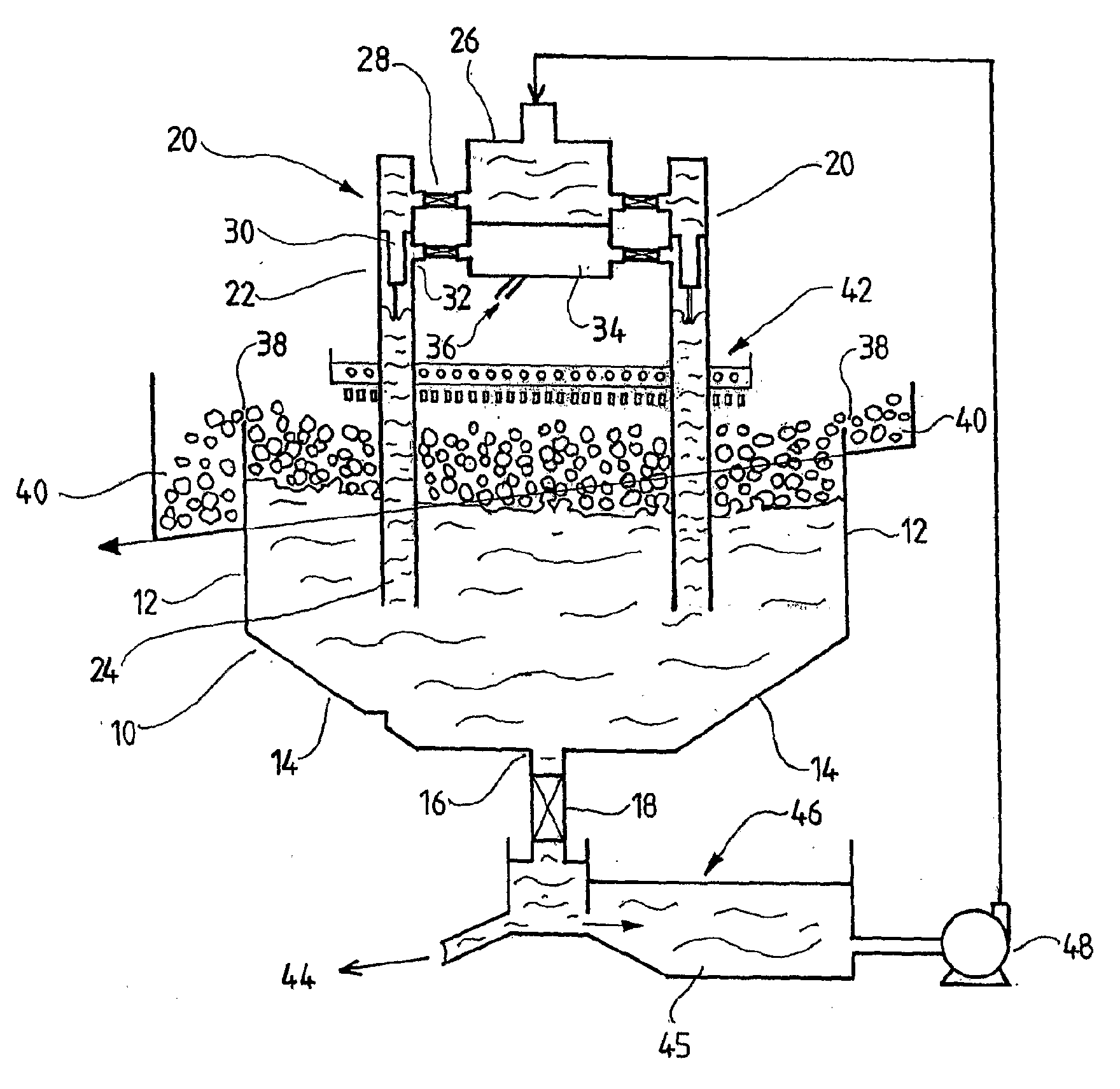

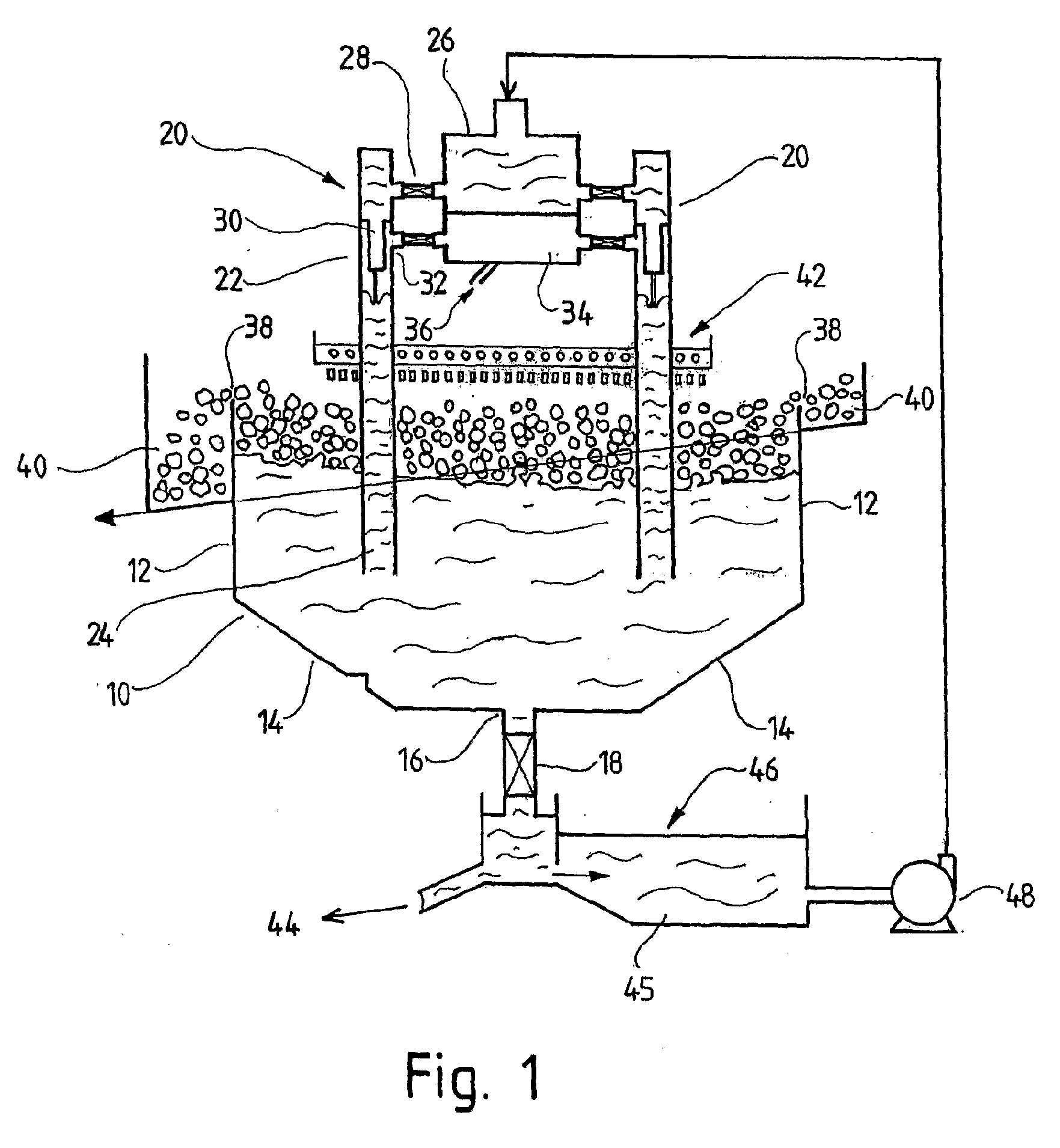

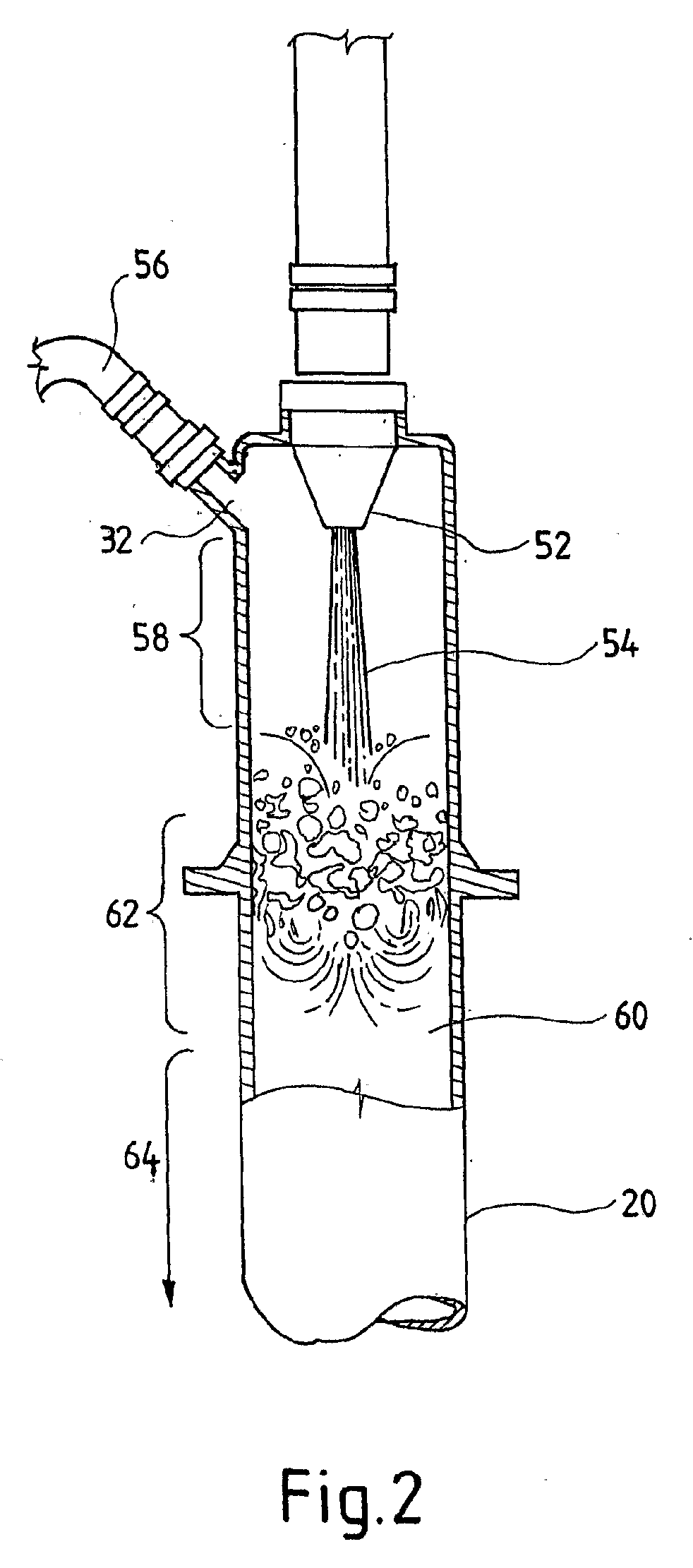

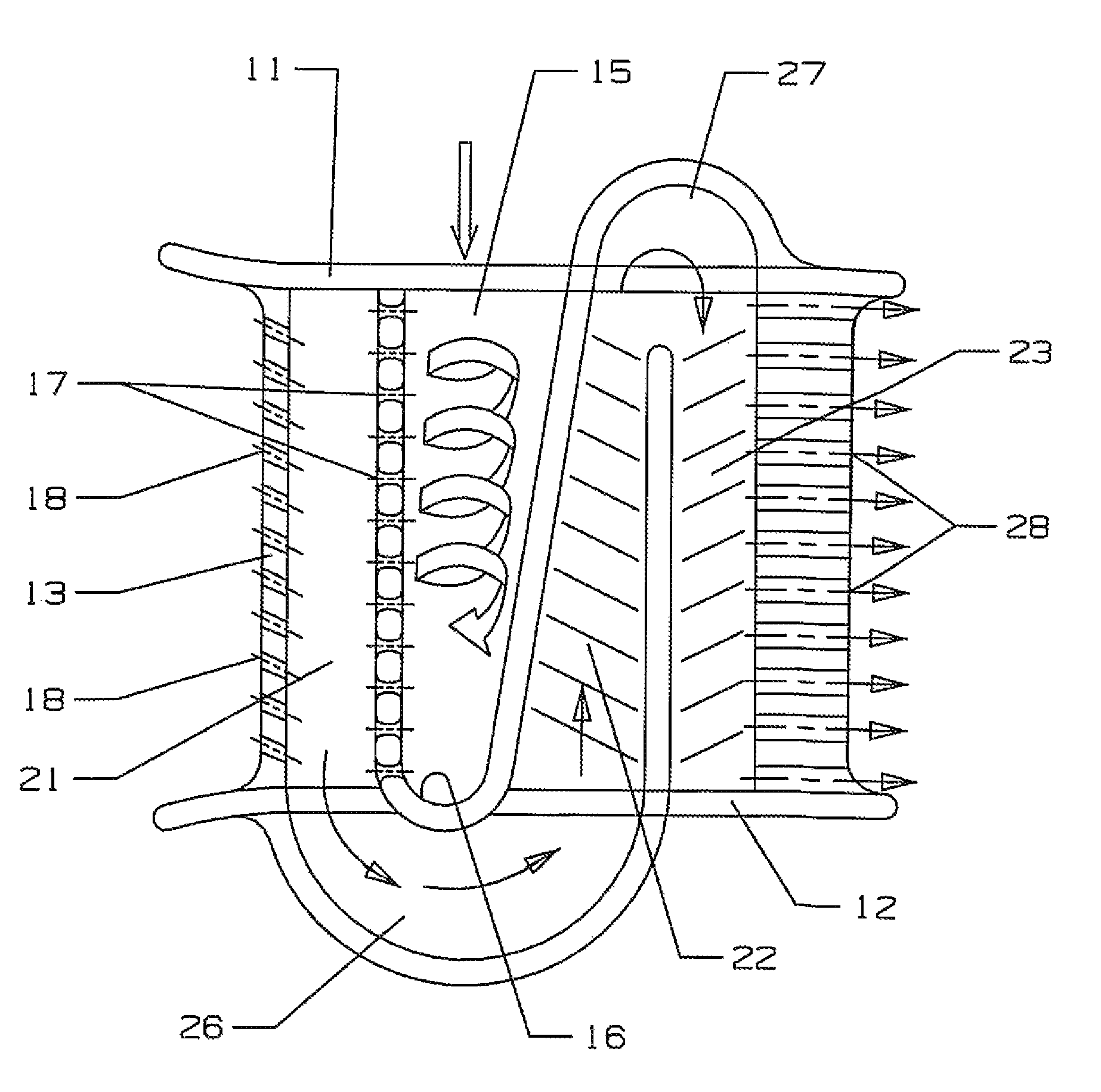

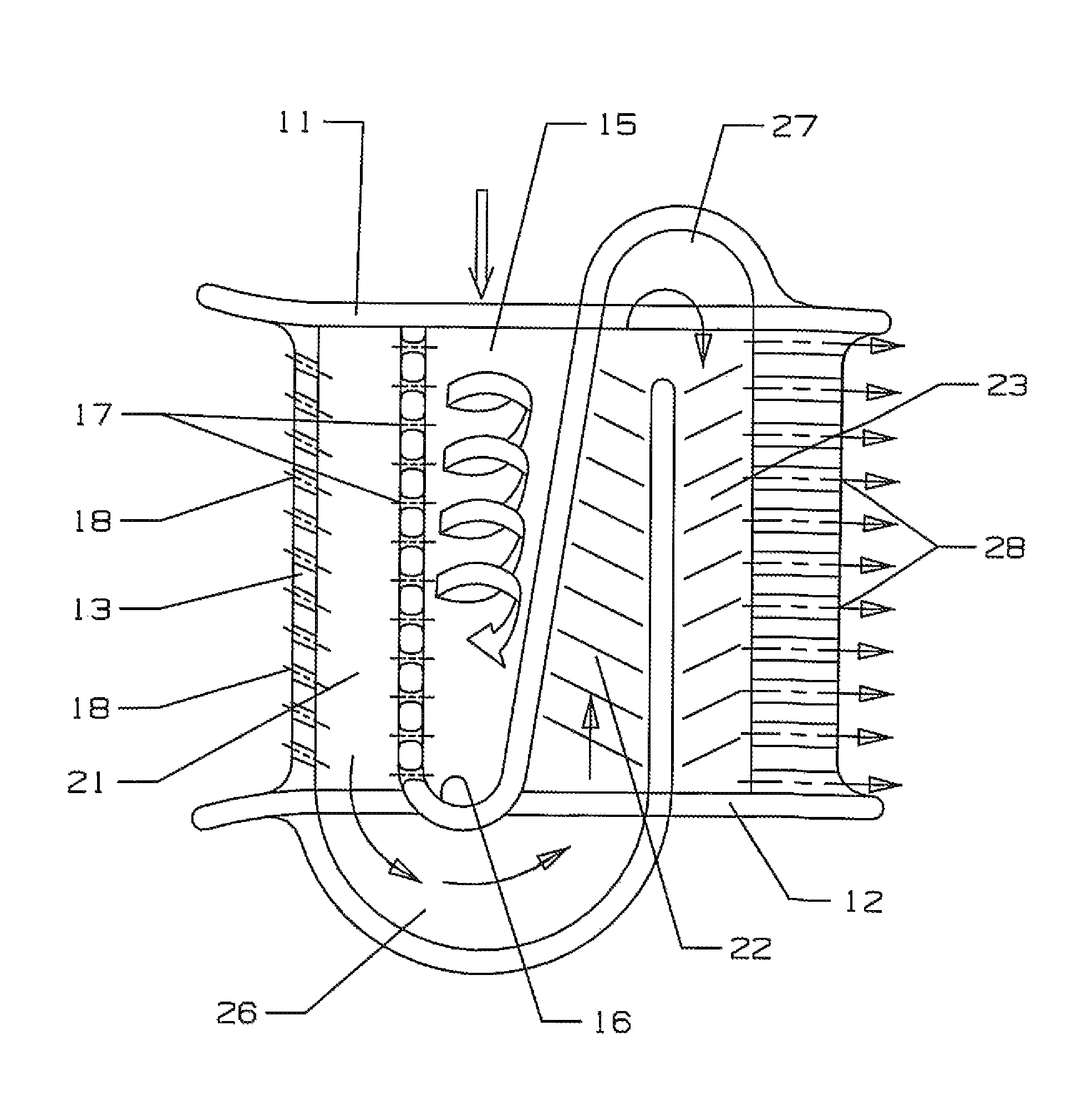

Flotation Method

A flotation method in which a liquid or slurry is fed to a downcomer (20) where it forms a region of high void fraction which moves out of the downcomer (20) into a vessel (10) in which a froth rises and liquid or slurry falls, characterized in that the liquid or slurry is fed to the downcomer (20) with a jet velocity as it exits an orifice and enters a free jet zone of less than 8 metres / second.

Owner:XSTRATA TECH PTY LTD

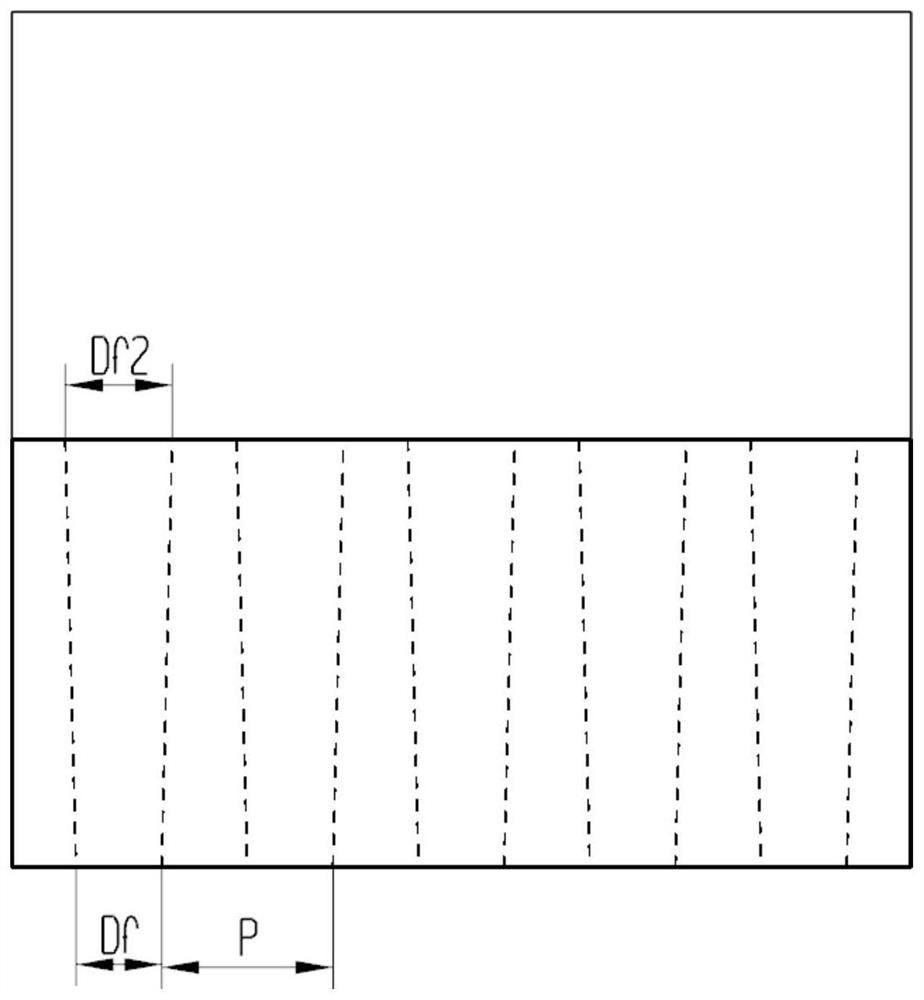

Slot jet flow gas film cooling structure for end wall of turbine

ActiveCN112049690AReduce normal velocityAvoid lostEngine fuctionsBlade accessoriesJet flowEngineering

The invention discloses a slot jet flow gas film cooling structure for the end wall of a turbine, and belongs to the field of cooling of turbine guide vane end walls of gas turbines. The cooling structure is formed by arranging jet flow gas film holes in the step surface of a backward step on the upstream of the end wall. The jet flow angle is parallel to the surface of the end wall and abuts against the surface of the end wall. In order to ensure the structural strength, the inlet diameter Df of the gas film holes is required to be smaller than two thirds of the height of the step. The slot jet flow holes parallel to the surface of the end wall only have a tangential jet flow speed, so that cold gas losses caused by direct injection of a large amount of cooling gas flow into main flow areavoided; and in addition, horseshoe vortexes at the front edges of blades are greatly weakened by the high-momentum slot jet flow cold gas, so that the jet flow is better attached to the wall surface. Meanwhile, the slot cold gas jet flow further breaks through a gas backflow dead zone formed on the downstream of the step, the downstream of the step is prevented from being located in a high-temperature area, and a gas film is formed to protect the surface of the end wall of the turbine.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

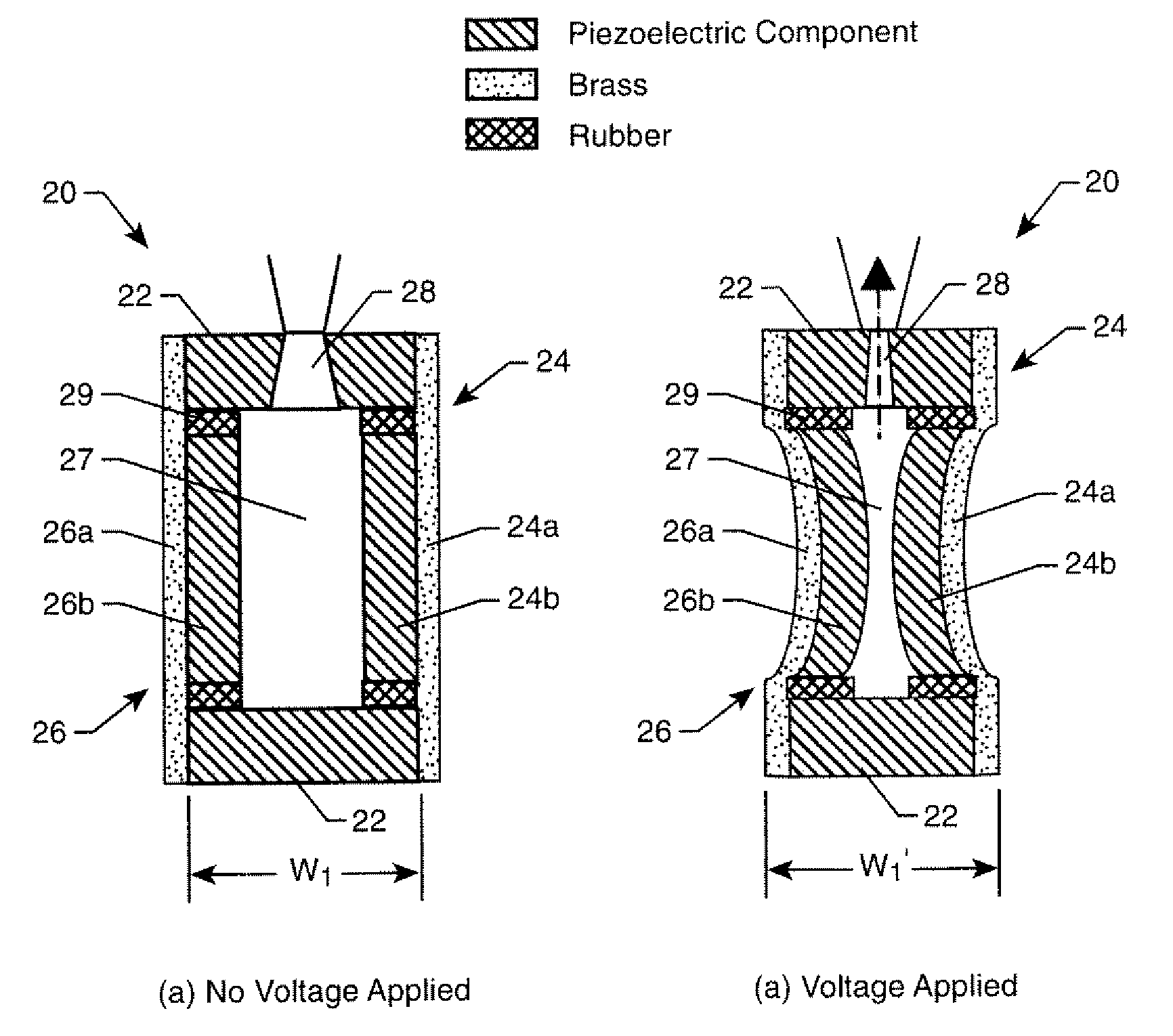

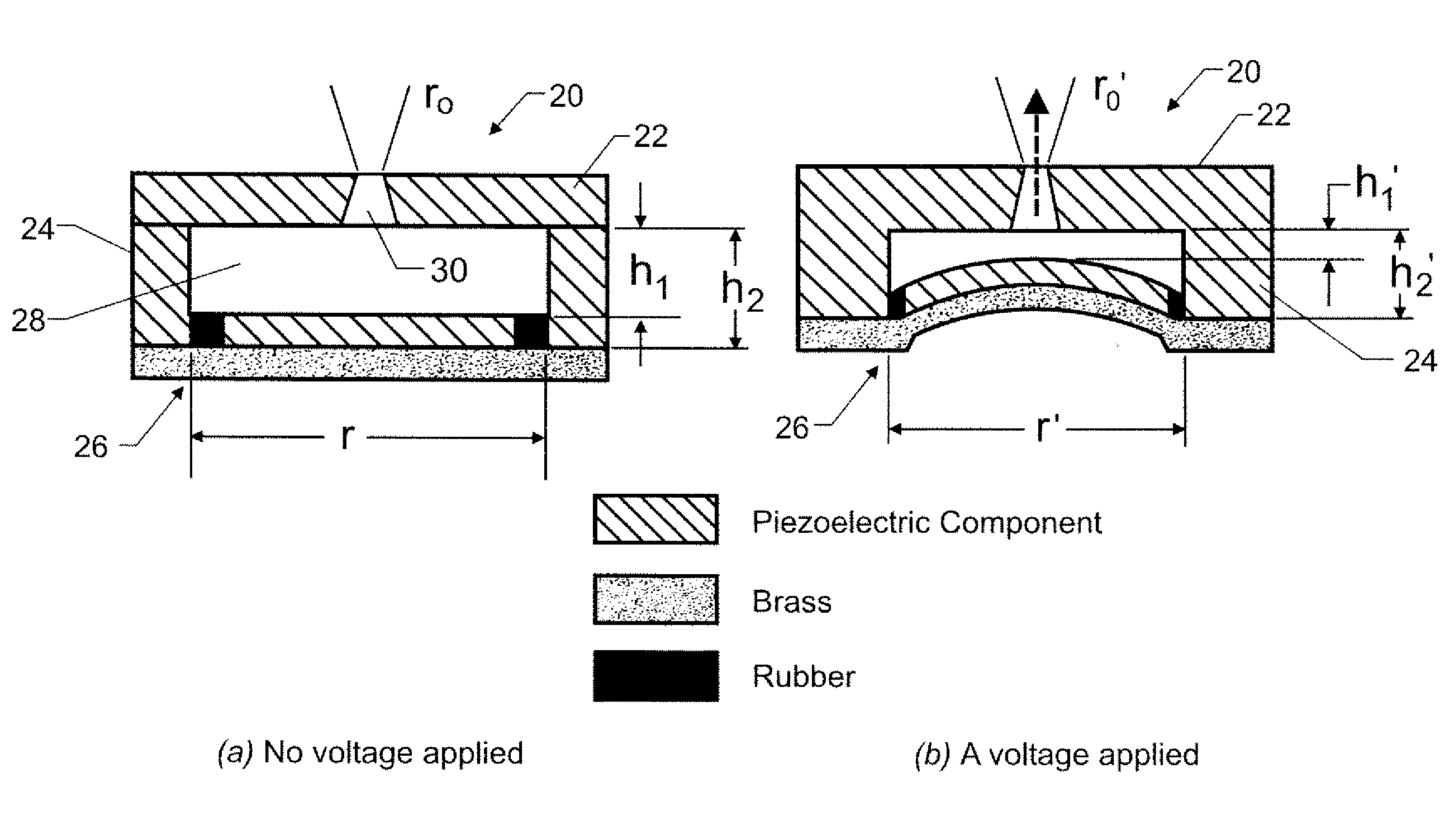

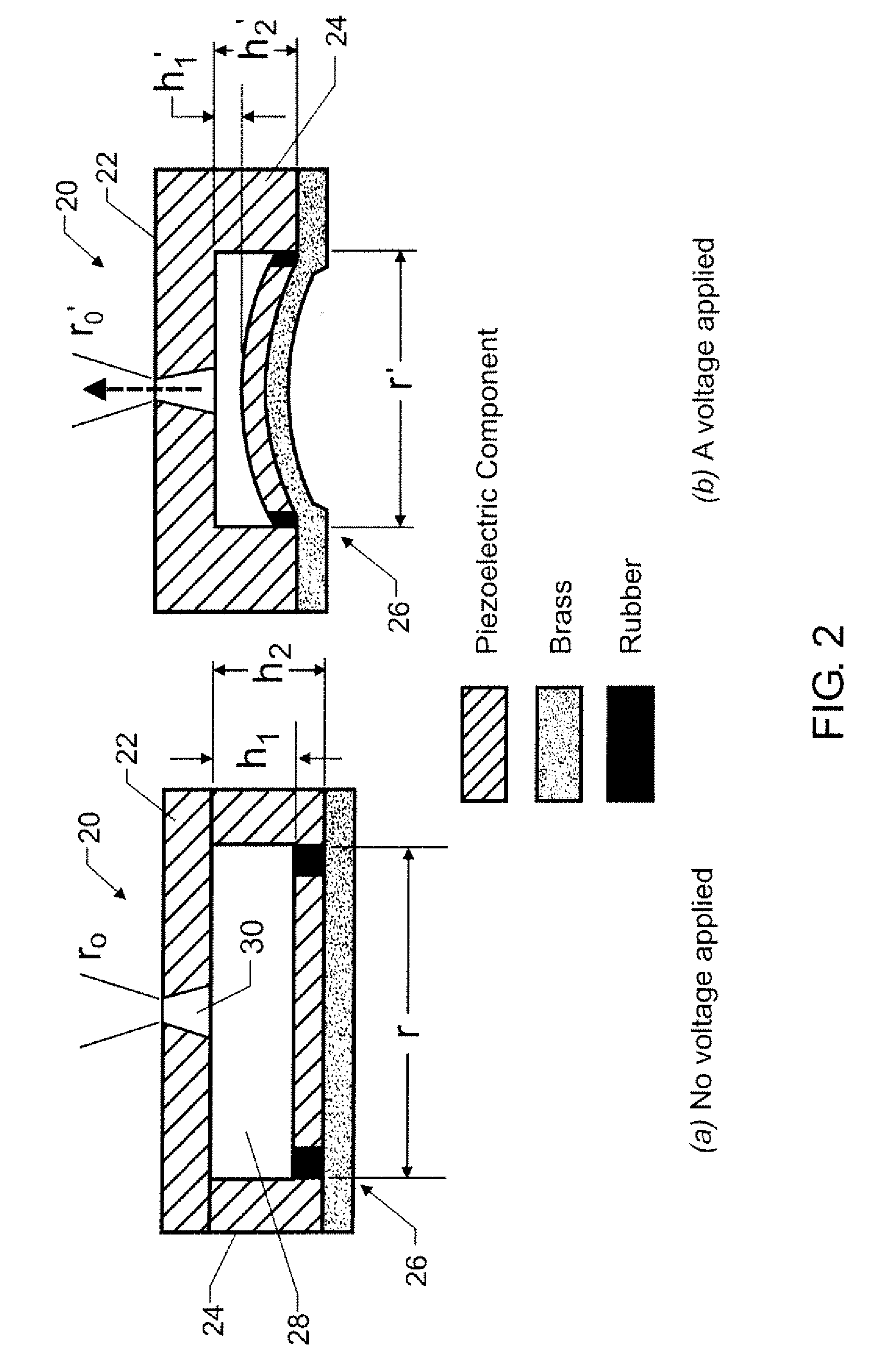

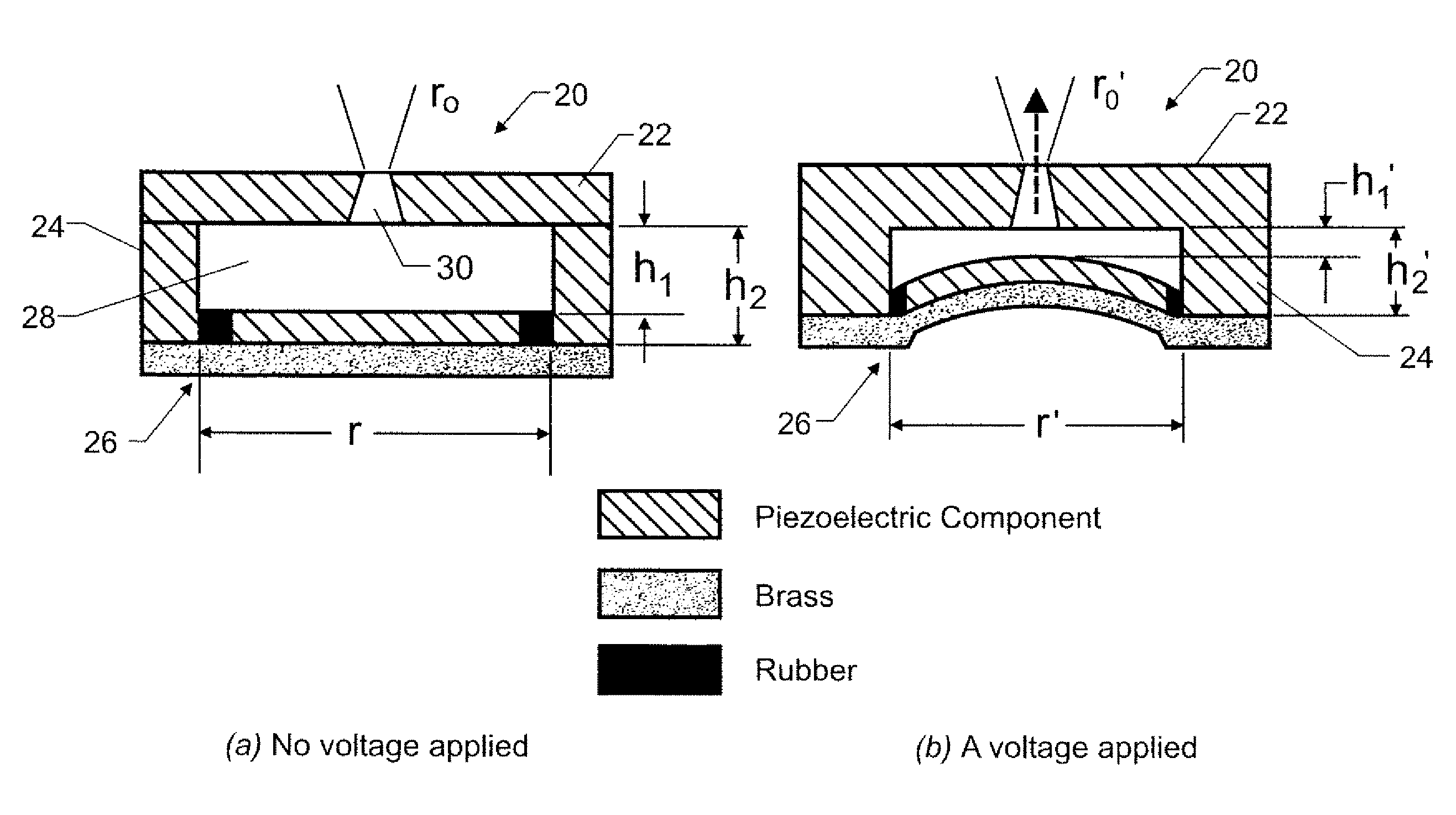

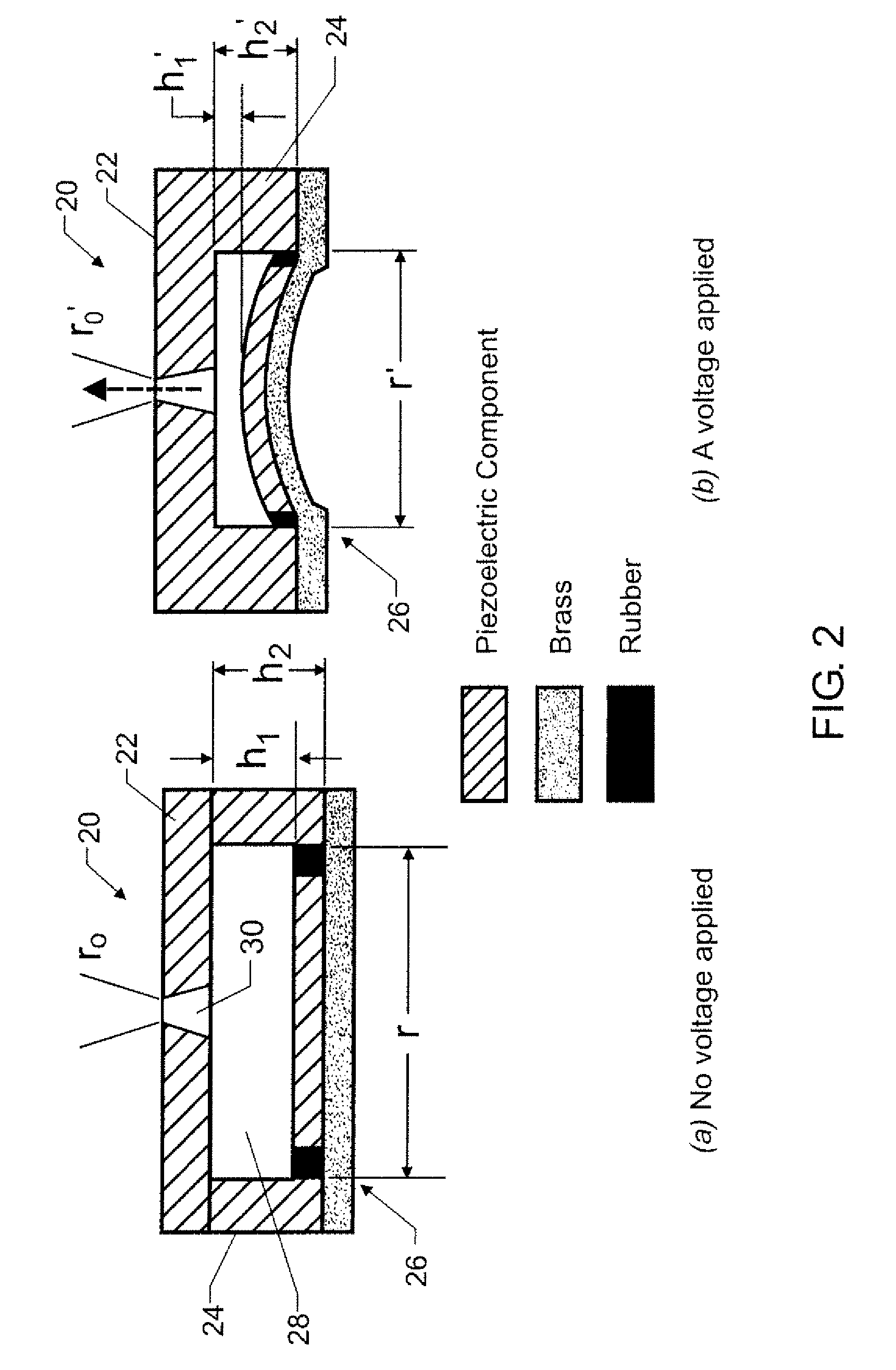

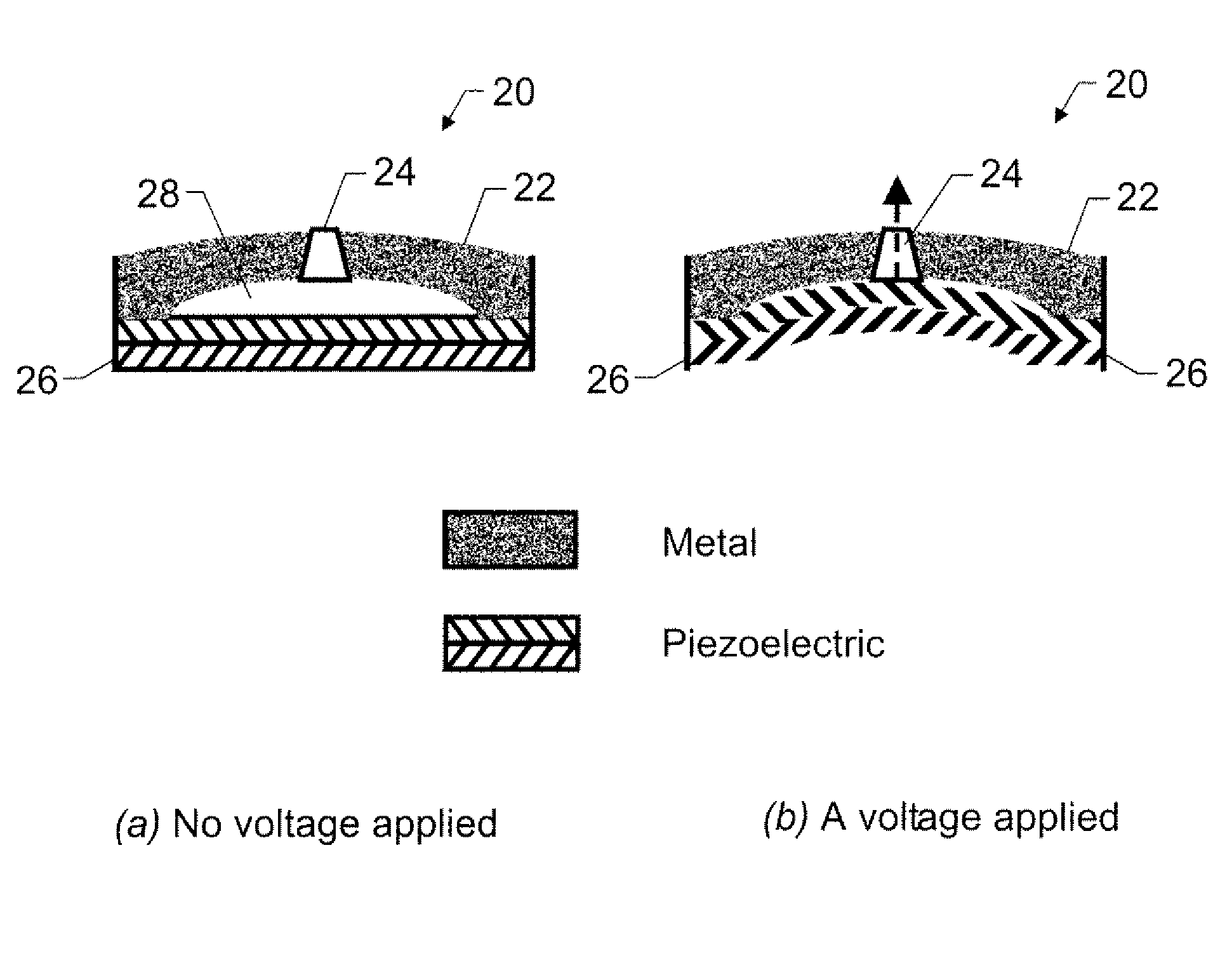

Advanced High Performance Horizontal Piezoelectric Hybrid Synthetic Jet Actuator

InactiveUS20100045752A1Increase the diameterPiezoelectric/electrostriction/magnetostriction machinesMovable spraying apparatusJet flowPiezoelectric actuators

The present invention comprises a high performance, horizontal, zero-net mass-flux, synthetic jet actuator for active control of viscous, separated flow on subsonic and supersonic vehicles. The present invention is a horizontal piezoelectric hybrid zero-net mass-flux actuator, in which all the walls of the chamber are electrically controlled synergistically to reduce or enlarge the volume of the synthetic jet actuator chamber in three dimensions simultaneously and to reduce or enlarge the diameter of orifice of the synthetic jet actuator simultaneously with the reduction or enlargement of the volume of the chamber. The present invention is capable of installation in the wing surface as well as embedding in the wetted surfaces of a supersonic inlet. The jet velocity and mass flow rate for the SJA-H will be several times higher than conventional piezoelectric actuators.

Owner:NASA

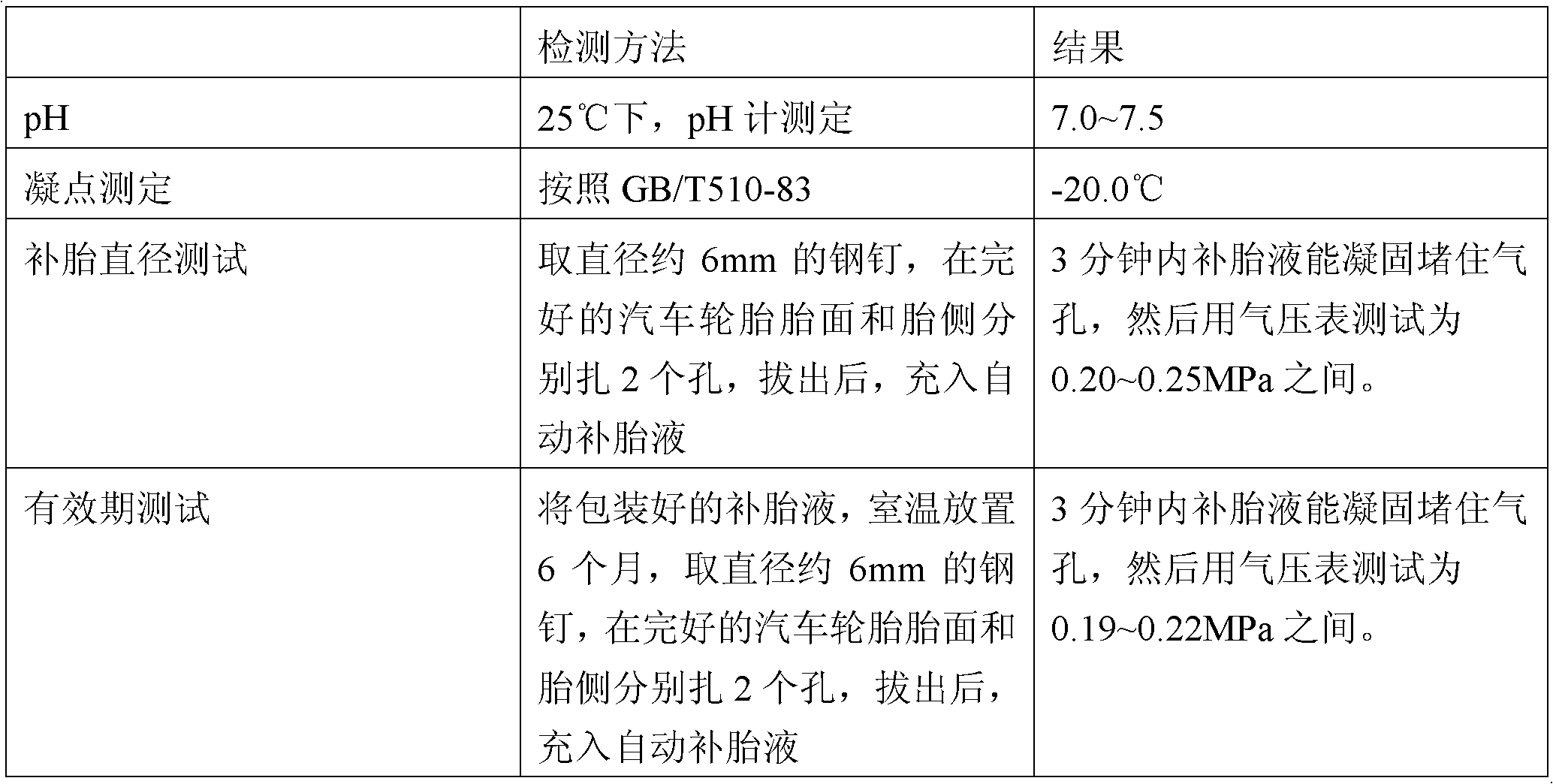

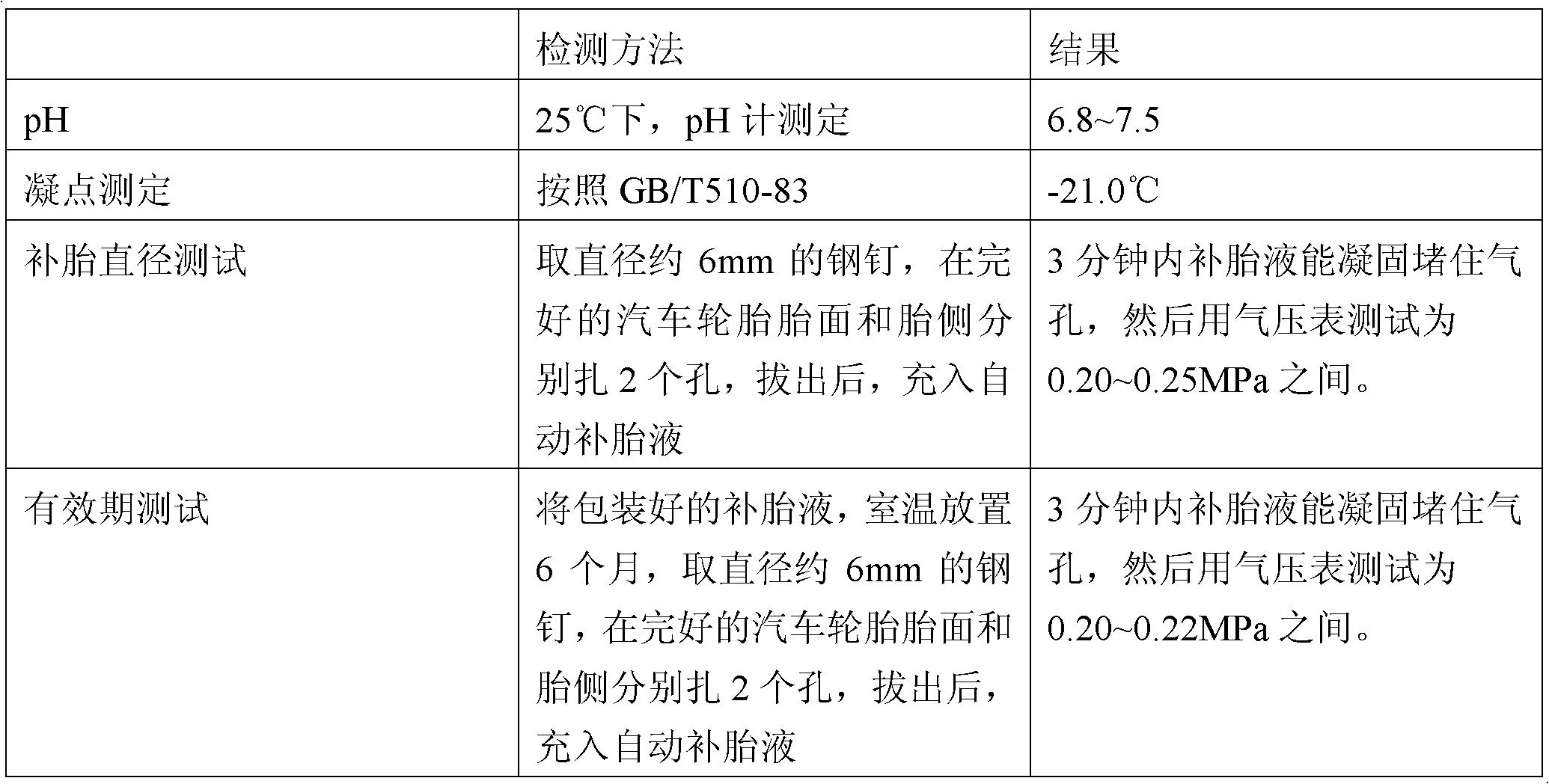

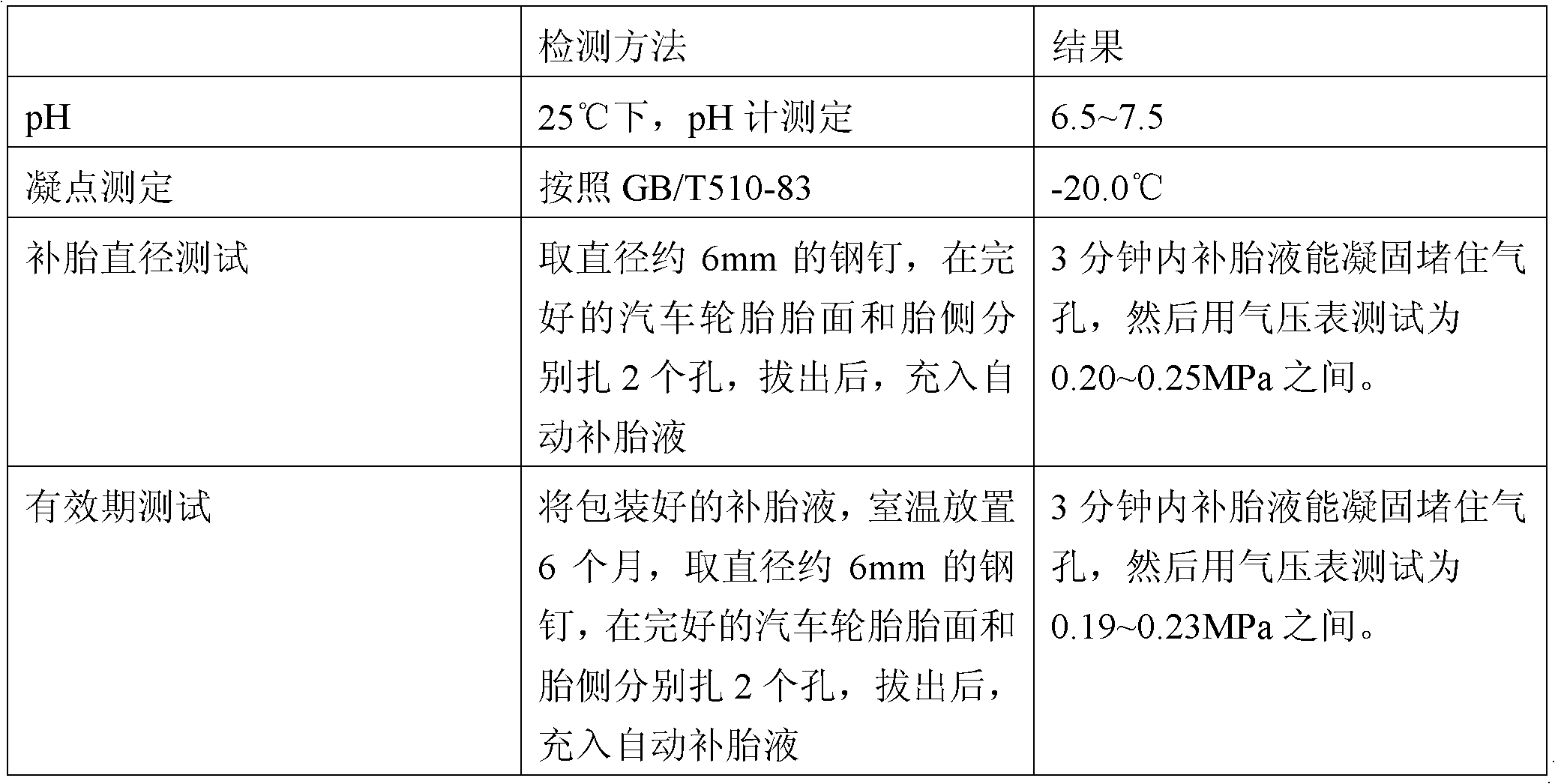

Automatic inflation tyre-repairing solution

InactiveCN102070998ATo achieve tire repair effectLow costOther chemical processesSocial benefitsFoaming agent

The invention relates to an automatic inflation tyre-repairing solution. The solution comprises the following raw material components in parts by weight: 50-70 parts of natural latex, 3-10 parts of emulsifier, 10-20 parts of antifreezing agent, 3-5 parts of surfactant, 0.3-1 part of stabilizer, 10-20 parts of distilled water and 100 parts of propellant. The automatic inflation tyre-repairing solution uses natural concentrated latex as main raw material and also uses various main agents such as antifreezing agent, foaming agent, stabilizer and polymerization inhibitor; the product cost is low, the shelf life is long, the period of validity is up to 6 months, the freezing resistance is good so that the solution can be used at -20 DEG C; and the jet velocity is high, the tyre-repairing effect is good, the preparation method is simple and the economic and social benefits are remarkable.

Owner:ZHEJIANG UNIV OF TECH

Advanced high performance horizontal piezoelectric hybrid synthetic jet actuator

InactiveUS8235309B2Piezoelectric/electrostriction/magnetostriction machinesMovable spraying apparatusJet flowPiezoelectric actuators

The present invention comprises a high performance, horizontal, zero-net mass-flux, synthetic jet actuator for active control of viscous, separated flow on subsonic and supersonic vehicles. The present invention is a horizontal piezoelectric hybrid zero-net mass-flux actuator, in which all the walls of the chamber are electrically controlled synergistically to reduce or enlarge the volume of the synthetic jet actuator chamber in three dimensions simultaneously and to reduce or enlarge the diameter of orifice of the synthetic jet actuator simultaneously with the reduction or enlargement of the volume of the chamber. The present invention is capable of installation in the wing surface as well as embedding in the wetted surfaces of a supersonic inlet. The jet velocity and mass flow rate for the SJA-H will be several times higher than conventional piezoelectric actuators.

Owner:NASA

Fluted linear shaped charge with simultaneous initiation

ActiveUS20180252507A1Well formedLow speed of soundExplosive chargesBlasting cartridgesDetonationShaped charge

This patent relates to lined shaped explosive devices, in particular it relates to linear Shaped Charges (SC), more particularly it relates to a Fluted or Scalloped Linear Shaped Charge. The fluted linear SC, unlike a standard linear SC produces hydrodynamic penetration, higher jet velocities, higher mass jets and deeper penetration. The fluted linear device disclosed herein produces greater compression and convergence of the liner material because of the partial radial collapse of the concave flutes. Further, the fluted linear SC is equipped with a simultaneous initiation of the full length of the explosive driving the liner, providing smooth detonation wave front along the full length of the fluted linear liner.

Owner:COLLIER NICHOLAS

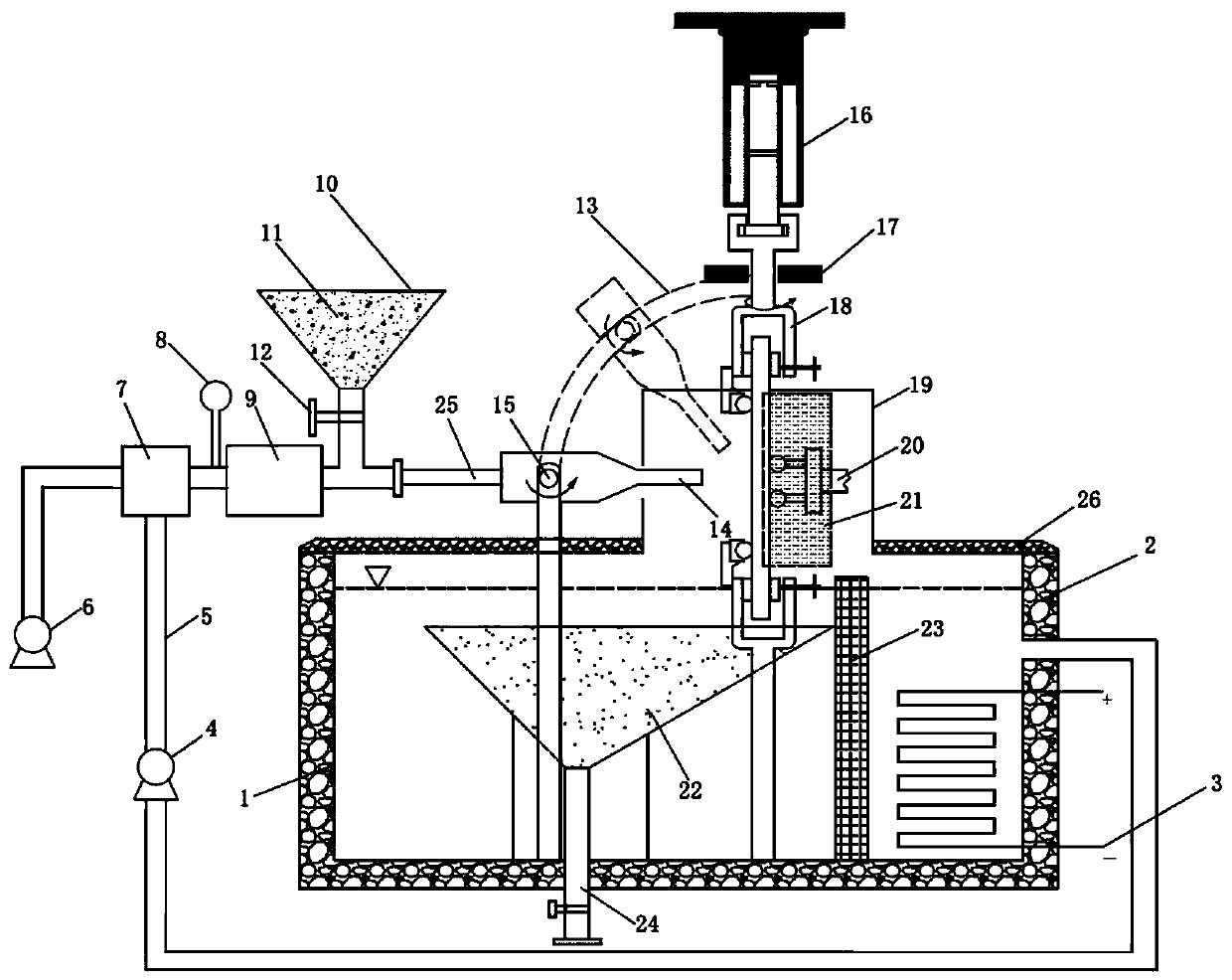

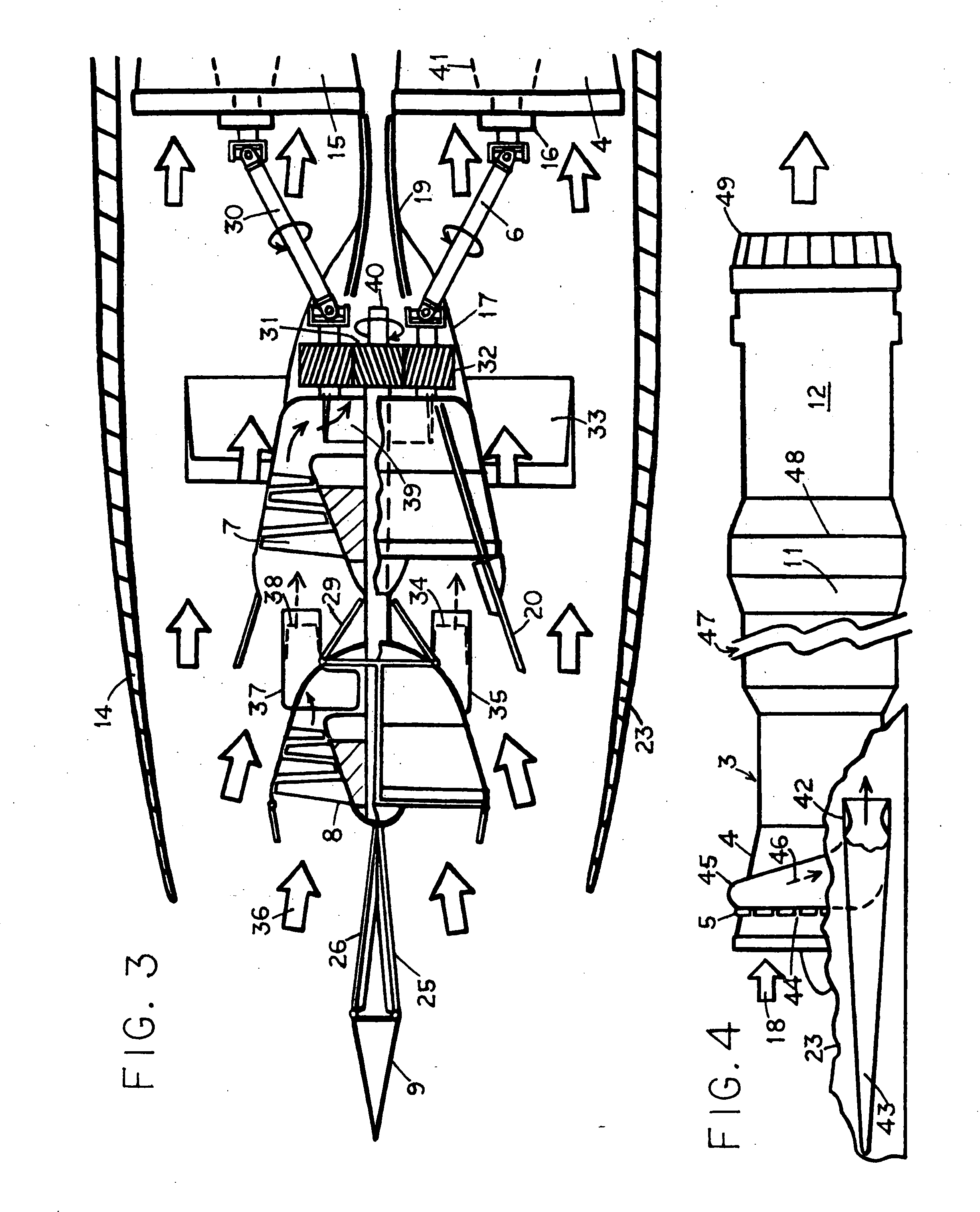

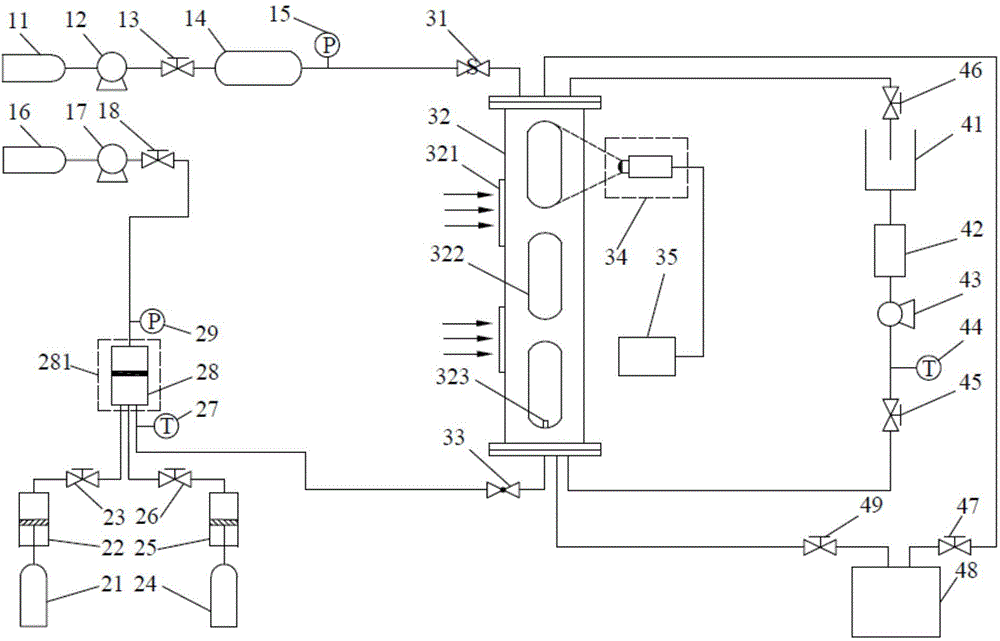

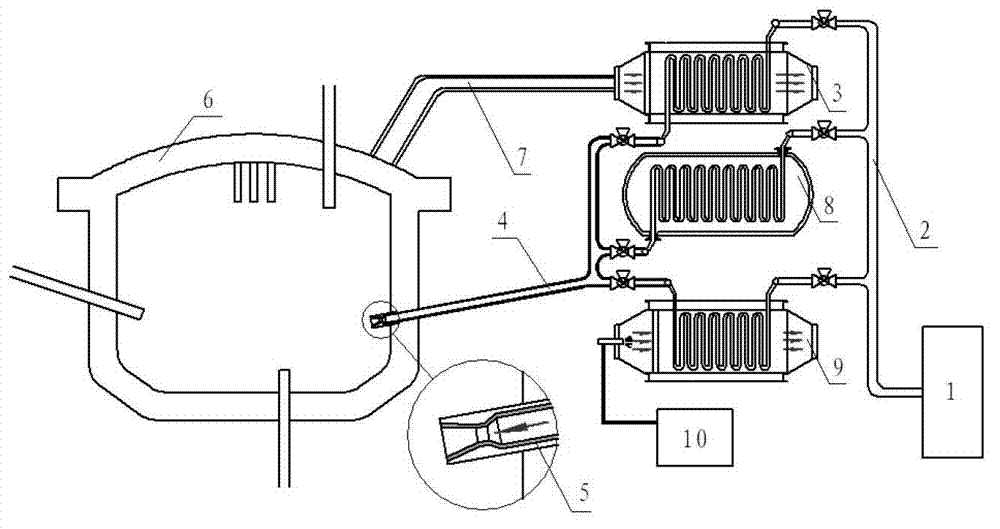

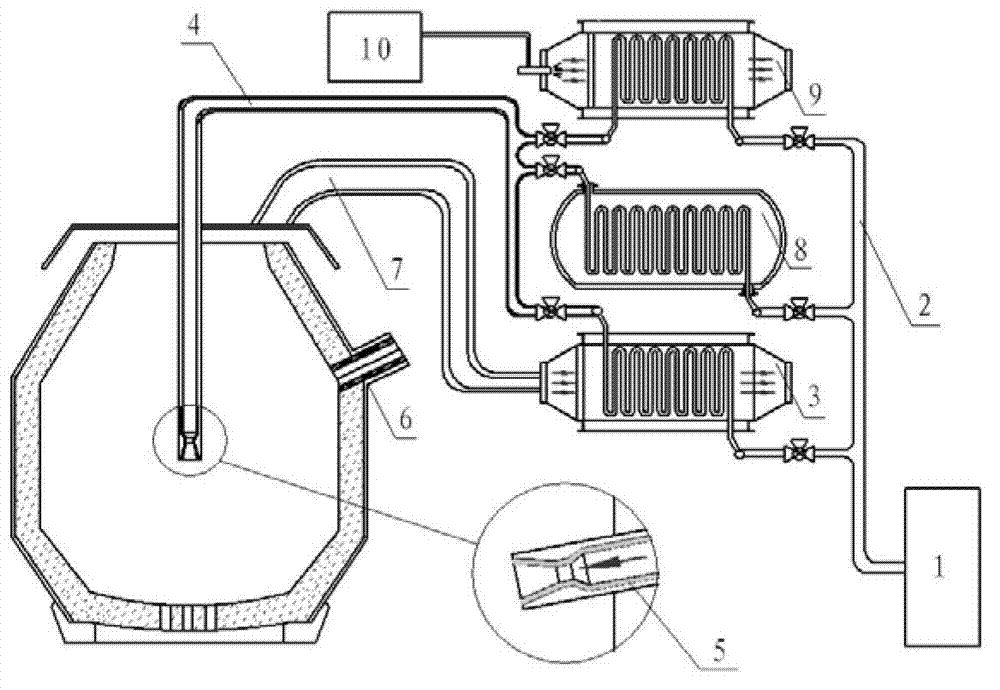

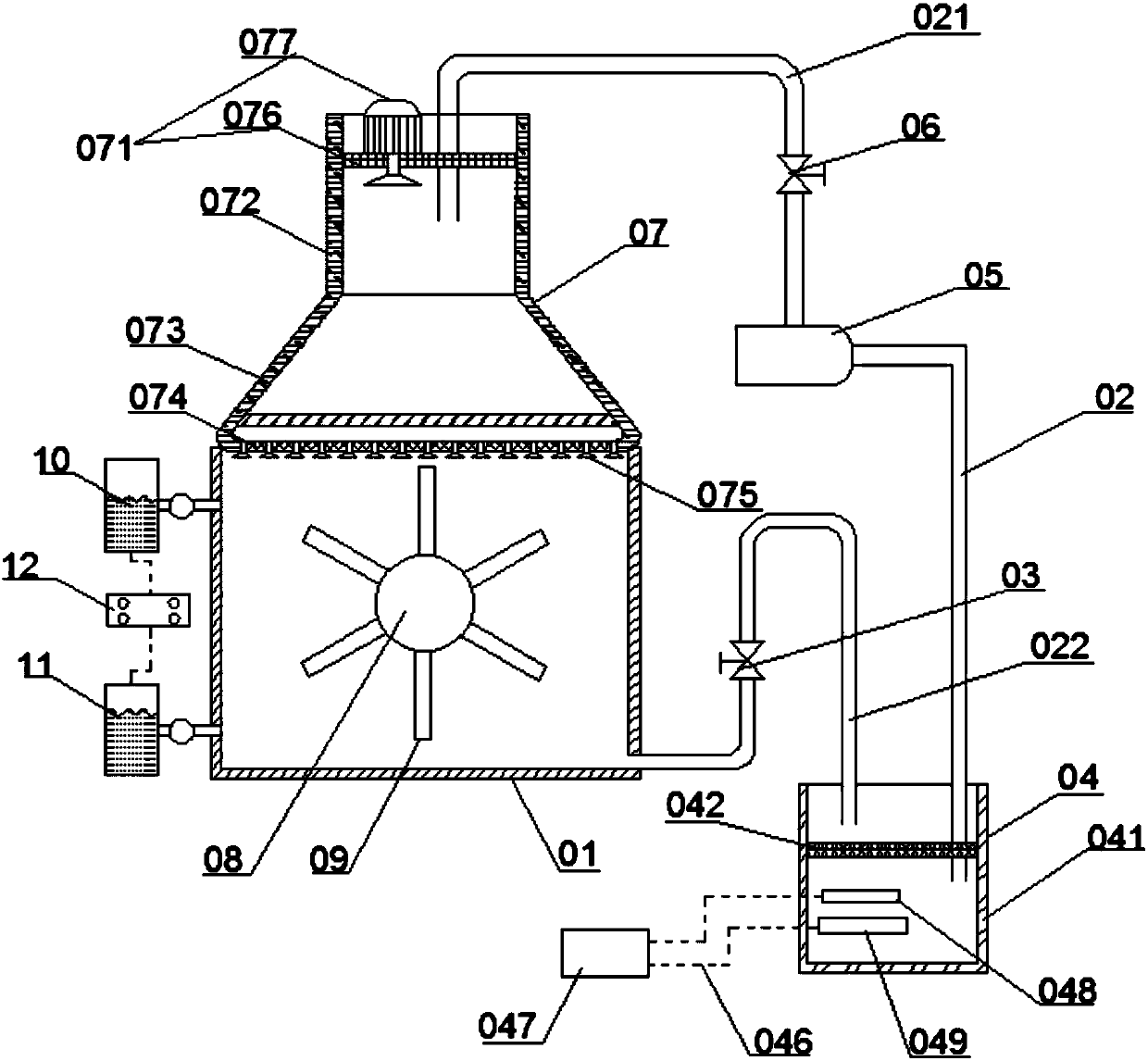

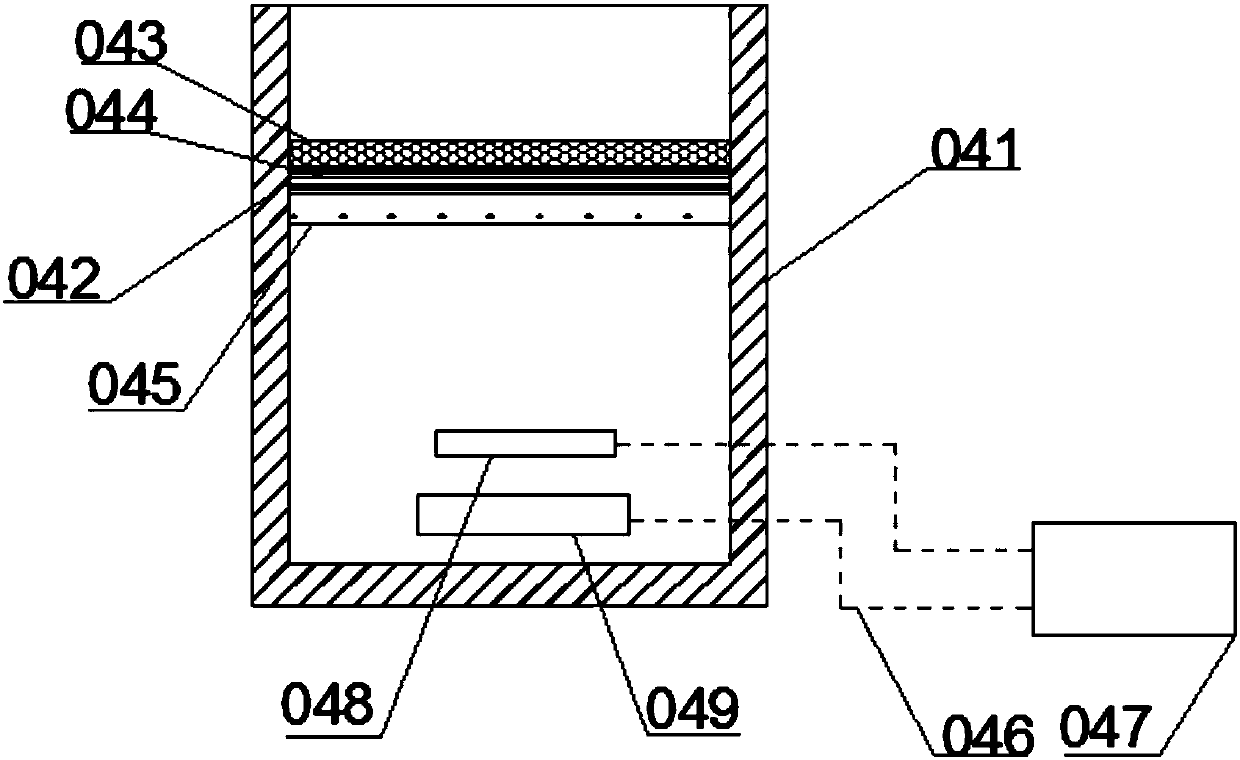

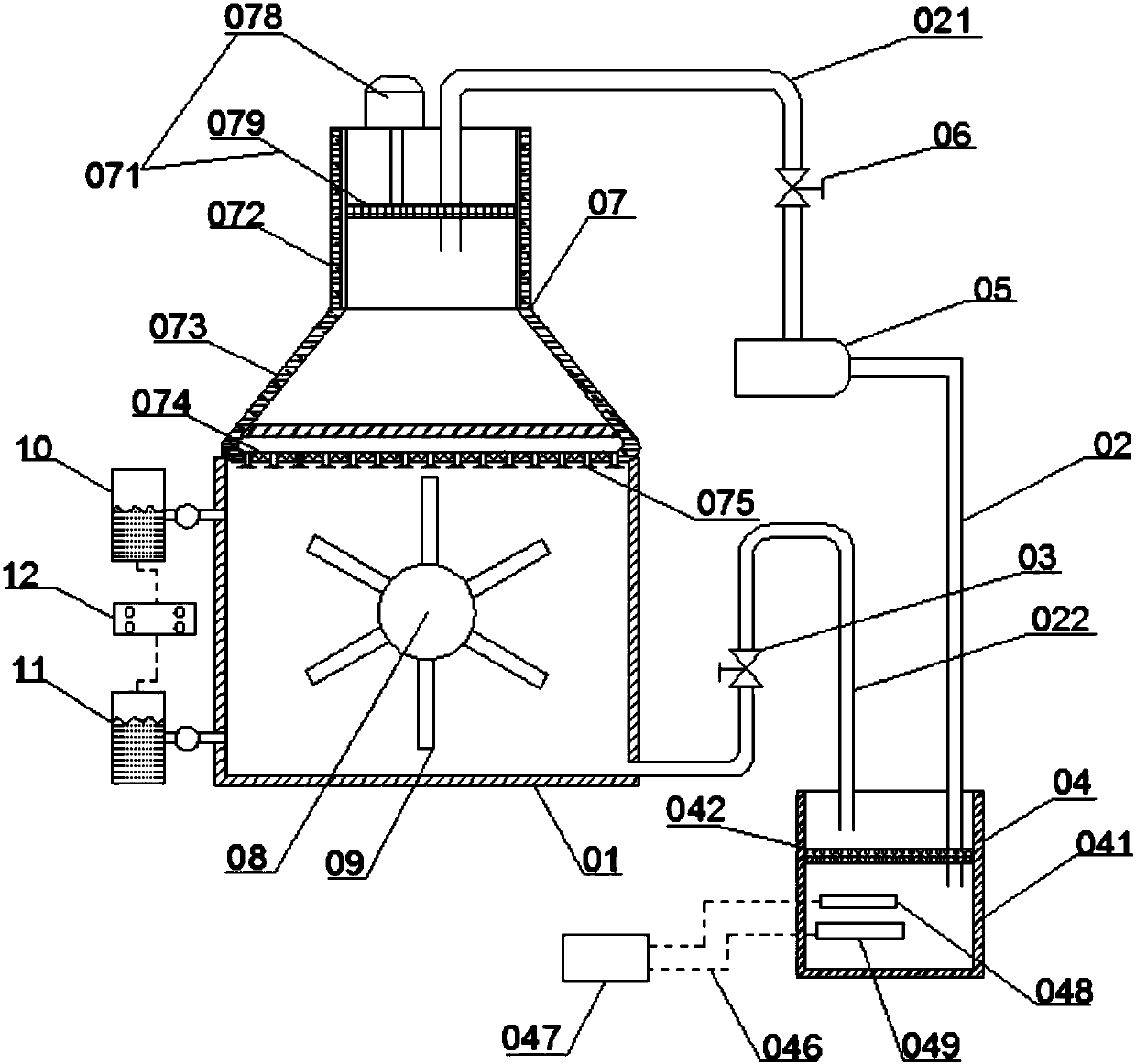

Device and method for simulating abyssal region underwater oil spillage

The invention belongs to the petroleum engineering field, and particularly relates to a device and a method for simulating abyssal region underwater oil spillage. The device for simulating the abyssal region underwater oil spillage comprises a pressure control system, a mixing injection system, an experimental model system and a water supply and drainage system, wherein the pressure control system supplies pressure for the experimental model system and the mixing injection system, the mixing injection system injects a mixture formed by mixing methane gas and crude oil according to a certain proportion into the experimental model system, the experimental model system supplies a high pressure and low temperature abyssal environment for an experiment, and the water supply and drainage system supplies a low temperature water source for the experiment and discharges sewage after the experiment is finished. The device and the method for simulating the abyssal region underwater oil spillage can simulate the abyssal oil spillage experiments under different pressure, different temperature and different jet velocity conditions and the like, provide accurate model parameters and effective data for an abyssal oil spillage model, and can confirm accuracy of the abyssal oil spillage model and simulate oil gas behavior fate under the abyssal environment. The device for simulating the abyssal region underwater oil spillage is simple to operate, and the method for simulating the abyssal region underwater oil spillage is easy to implement and high in feasibility. A measurement method used in the method for simulating the abyssal region underwater oil spillage is scientific, and can achieve high accuracy parameter measurement.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

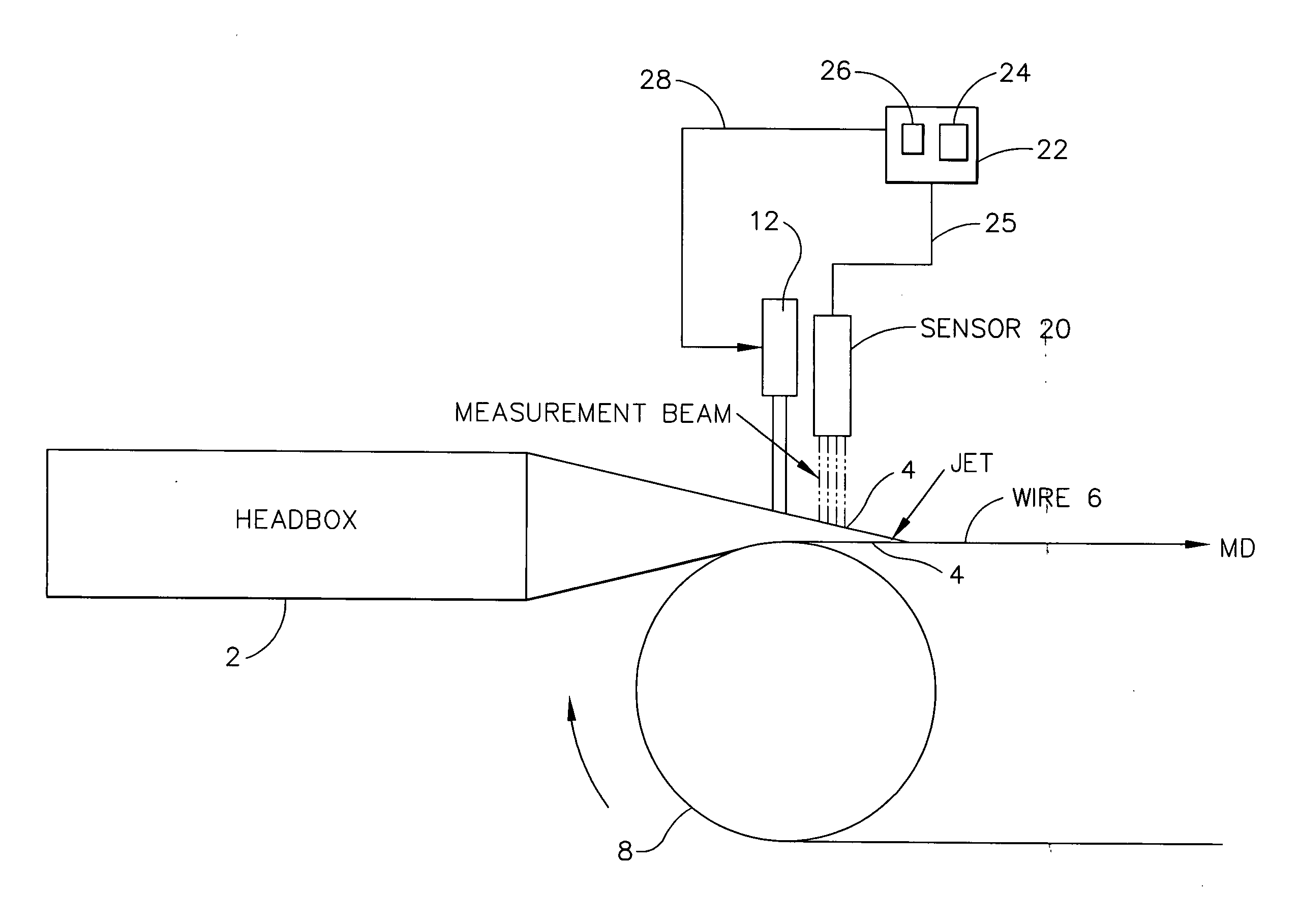

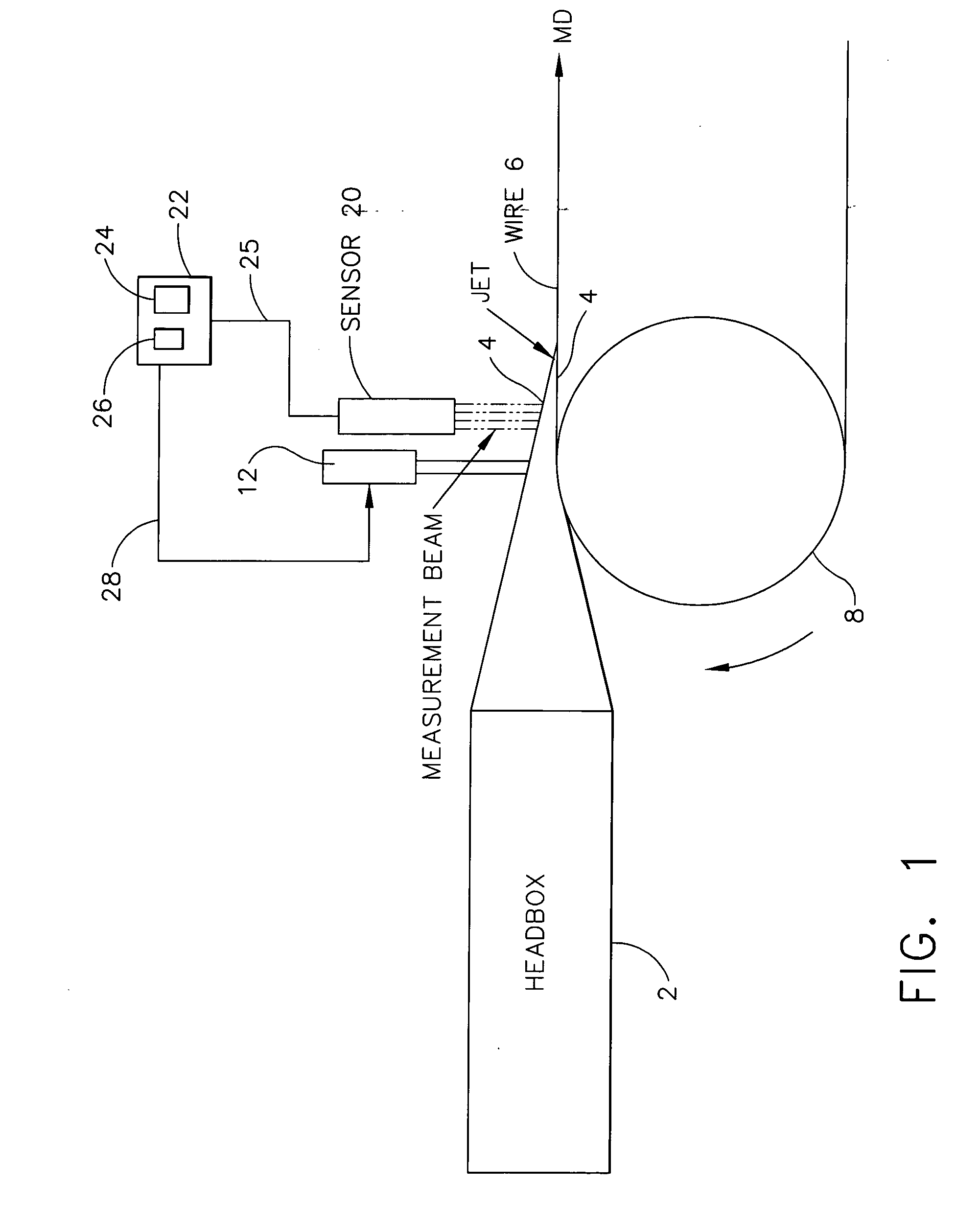

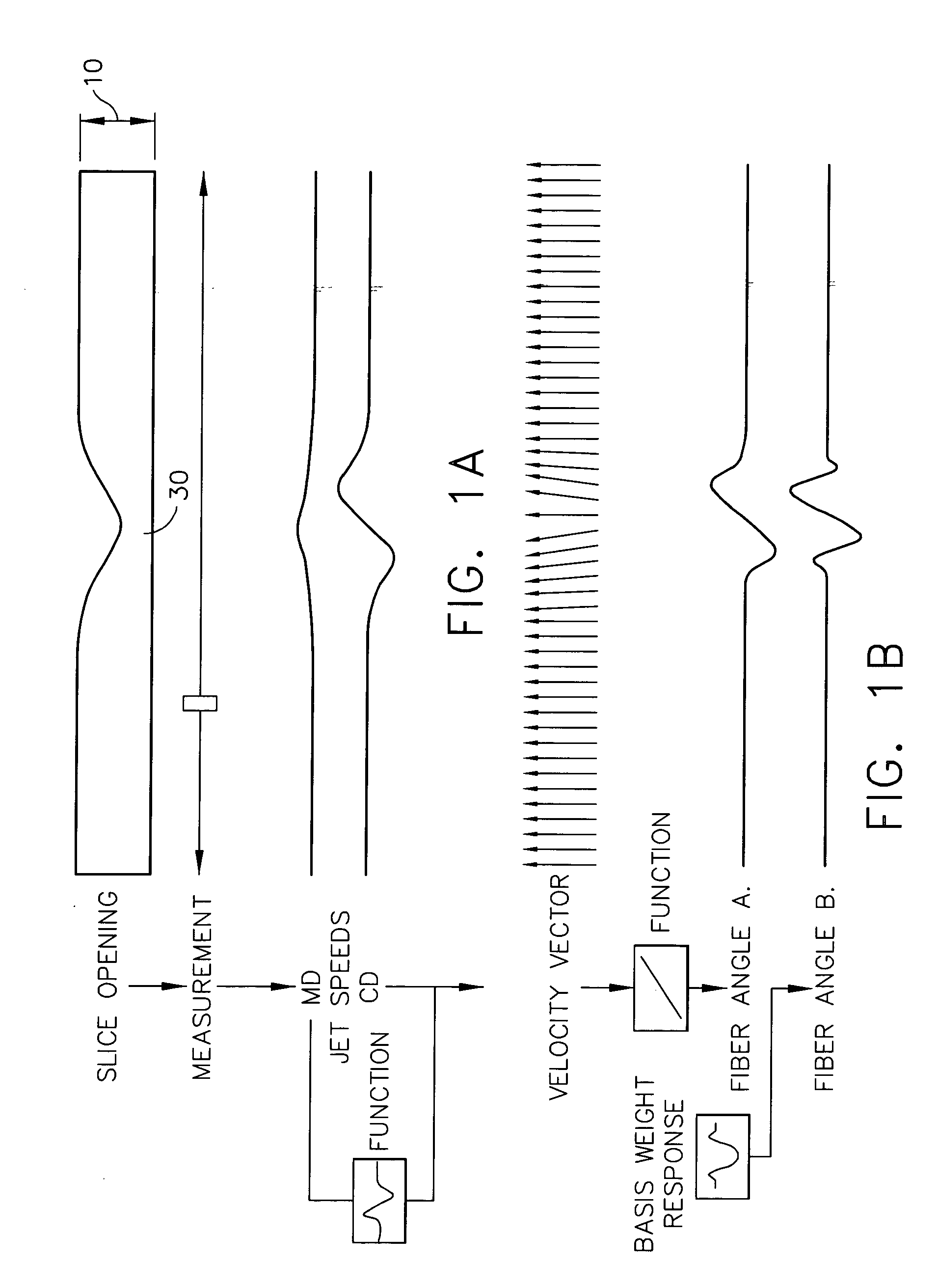

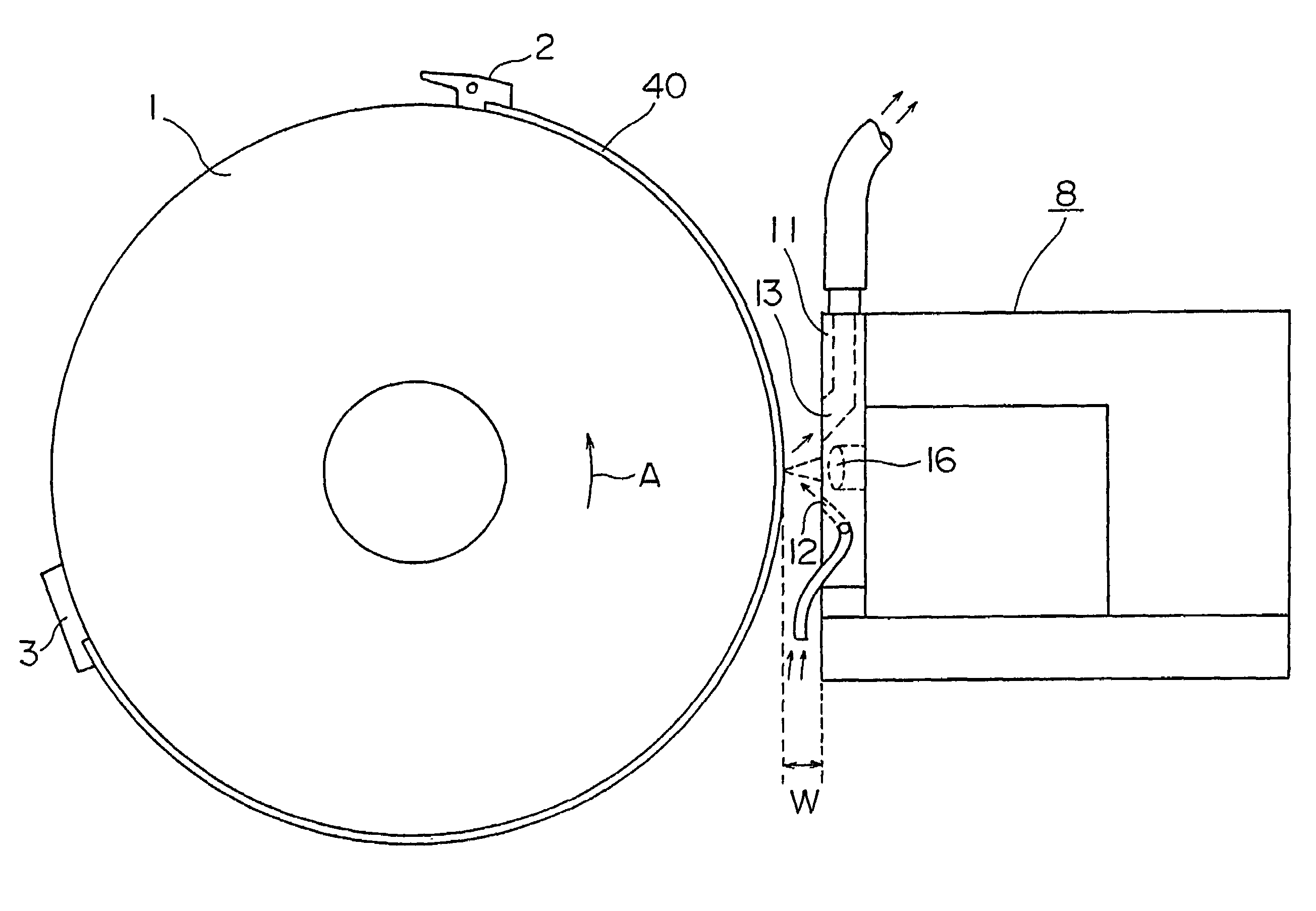

Jet velocity vector profile measurement and control

ActiveUS20060096727A1Quickly and accurately determineIncrease speed of resultMachine wet endPaper/cardboardJet flowEngineering

In a papermaking system having a headbox to dispense a jet of liquid and paper forming fibers, an improvement comprising at least one sensor arrangement for simultaneously or sequentially measuring in at least one location the jet velocity or jet flow correlation of the jet at plural known angles relative to the machine direction. The measured data is analyzed to generate a velocity vector profile or velocity direction profile of the jet, and hence to determine the profile of fiber orientation angles laid down in the sheet formed of the jet.

Owner:HONEYWELL INT INC

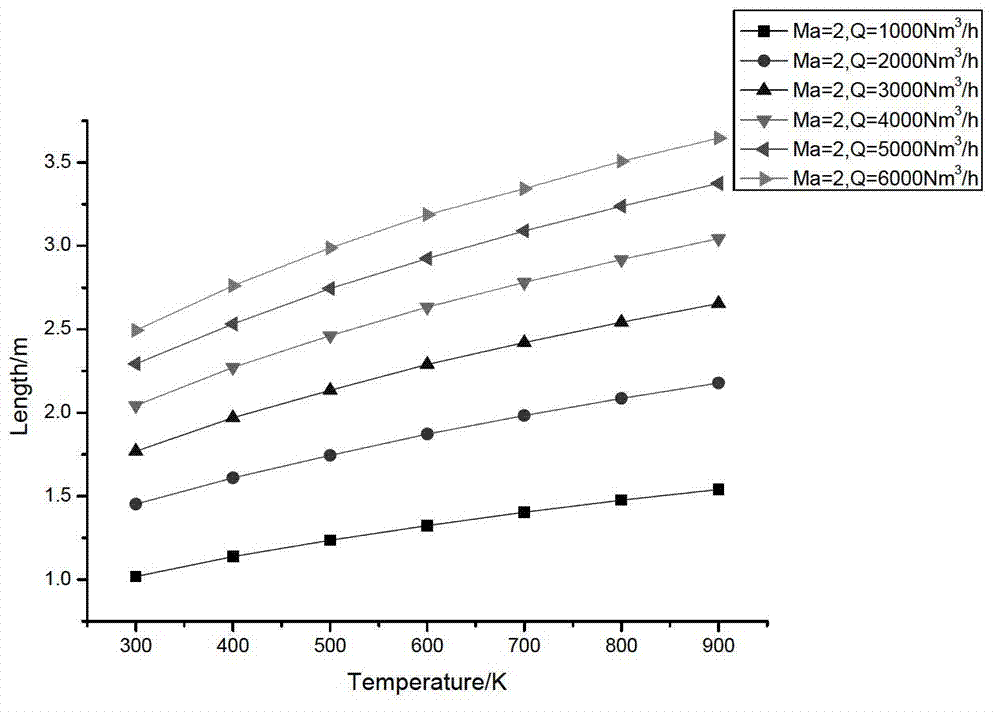

Oxygen furnace steel method capable of improving jet velocity through preheated oxygen

ActiveCN102732668AImprove the mixing effectMolecular mass transfer coefficient increasesManufacturing convertersProcess efficiency improvementCombustion systemElectric arc furnace

The invention belongs to the technical field of metallurgy, and relates to an oxygen furnace steel method capable of improving jet velocity through preheated oxygen. The method comprises the following steps: the oxygen flows into a preheating system from a normal temperature pipeline, the oxygen is preheated by high-temperature smoke for steel making or heat generated by electric heating or fuel combustion system, the oxygen temperature is controlled by adjusting heat input, and the preheated oxygen is subjected to blowing steel making by utilizing supersonic jet generated by an oxygen gun spray head. The method has the characteristics that the oxygen is preheated, and the preheated high-temperature oxygen is blown by the oxygen gun, so that the jet velocity of the oxygen is remarkably increased, the stirring effect is enhanced, the dynamics condition for reaction of a molten bath is improved, and the service life of the oxygen gun spray head is prolonged. The oxygen furnace steel method is suitable for steel-making processes of an electric arc furnace of 30-200 tons and a converter of 30-350 tons, in comparison with the conventional steel making process, the carbon removal speed and the phosphorus removal speed are remarkably improved, the smelting period is shortened by more than 2 minutes, the metal yield is improved by more than 1%, and the slag consumption is reduced by 10%.

Owner:UNIV OF SCI & TECH BEIJING

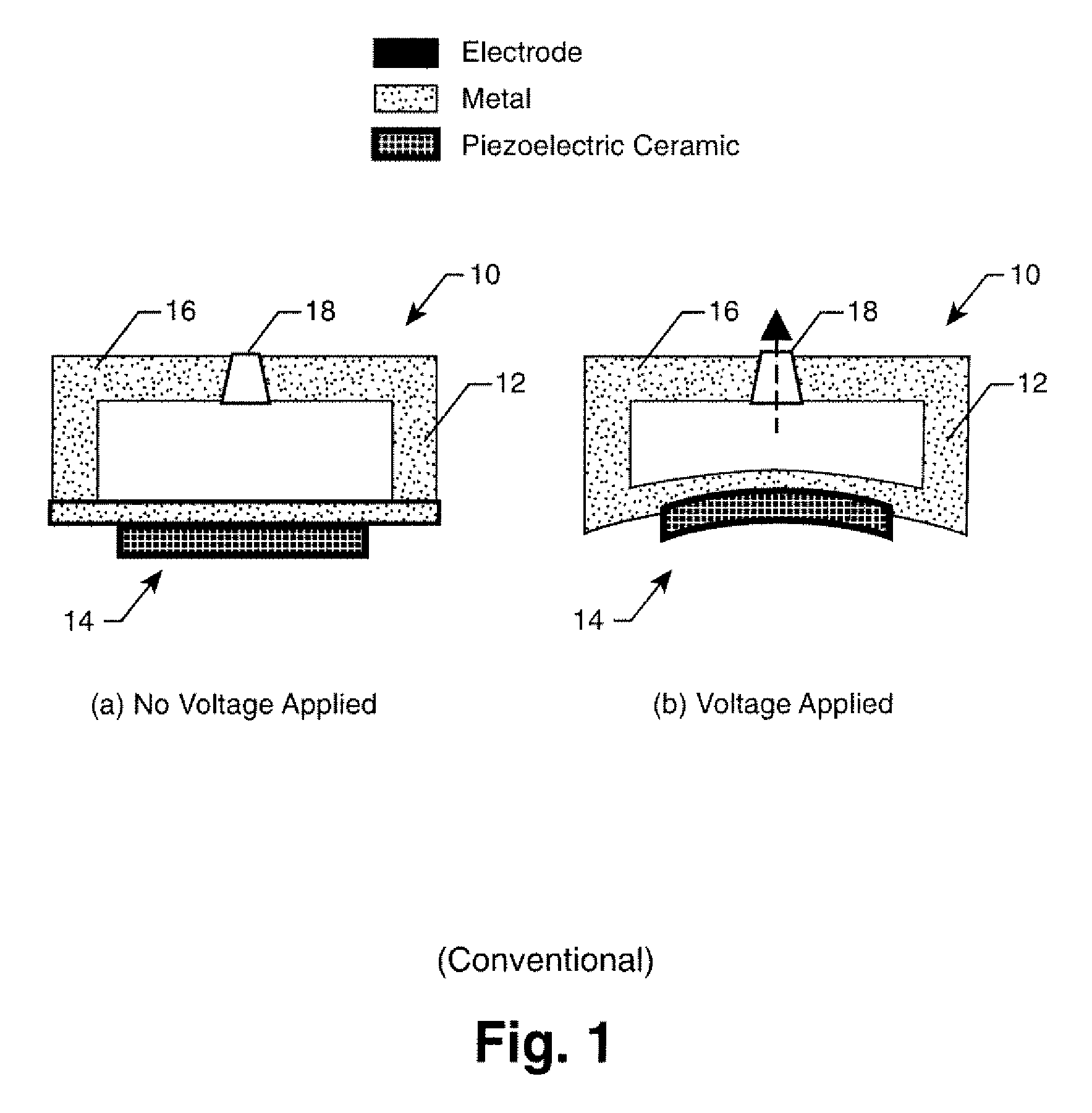

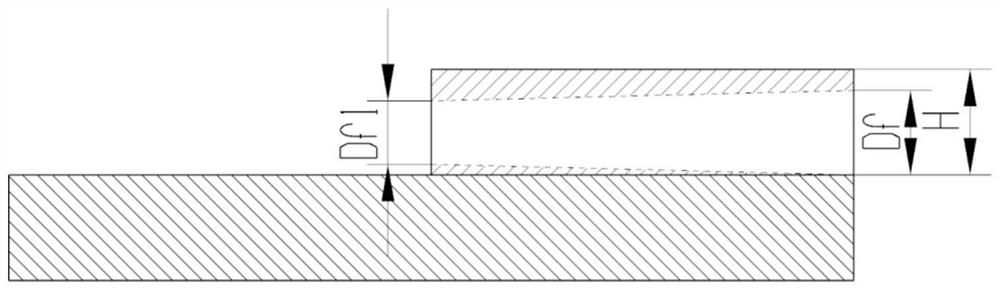

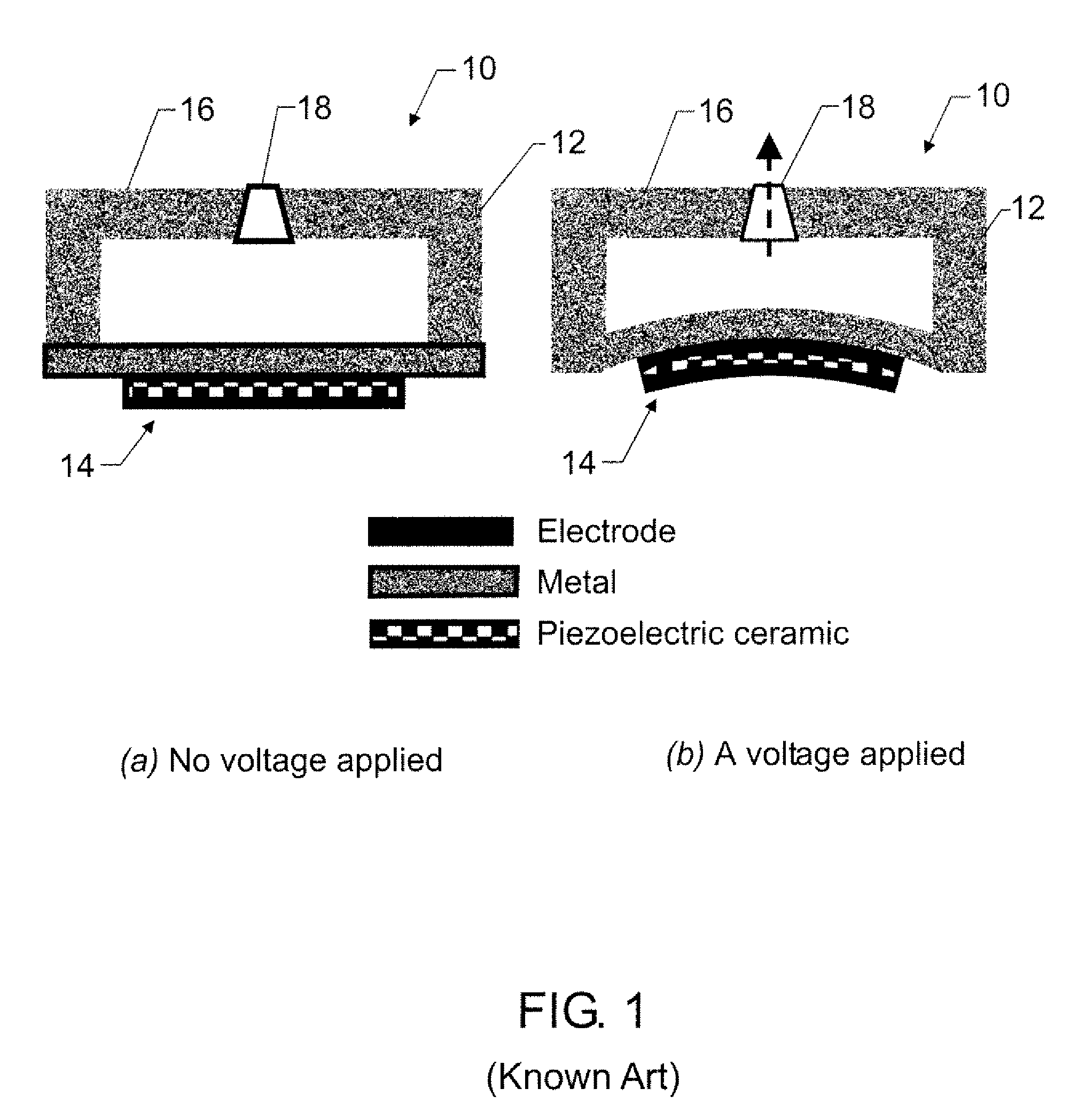

Advanced Modified High Performance Synthetic Jet Actuator With Curved Chamber

InactiveUS20100043900A1Increase the diameterCircuit elementsBoundary layer controlsElectricityDead volume

The advanced modified high performance synthetic jet actuator with optimized curvature shape chamber (ASJA-M) is a synthetic jet actuator (SJA) with a lower volume reservoir or chamber. A curved chamber is used, instead of the conventional cylinder chamber, to reduce the dead volume of the jet chamber and increase the efficiency of the synthetic jet actuator. The shape of the curvature corresponds to the maximum displacement (deformation) profile of the electroactive diaphragm. The jet velocity and mass flow rate for the ASJA-M will be several times higher than conventional piezoelectric actuators.

Owner:NASA

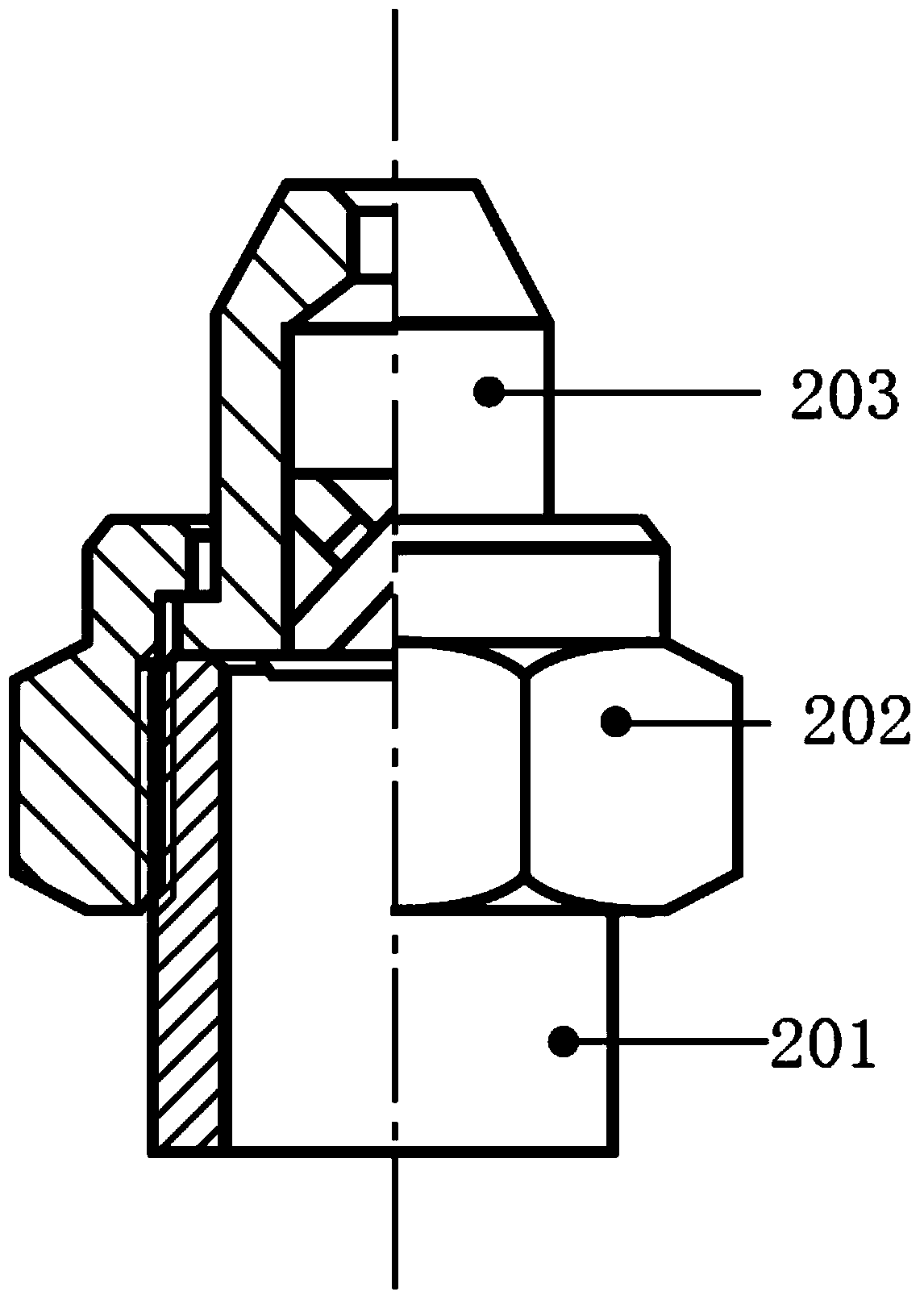

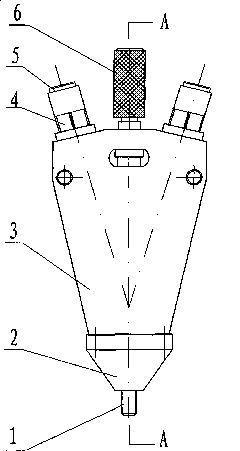

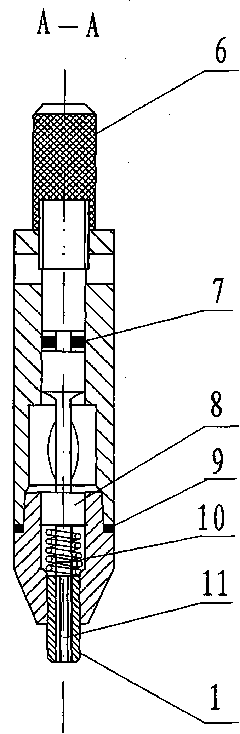

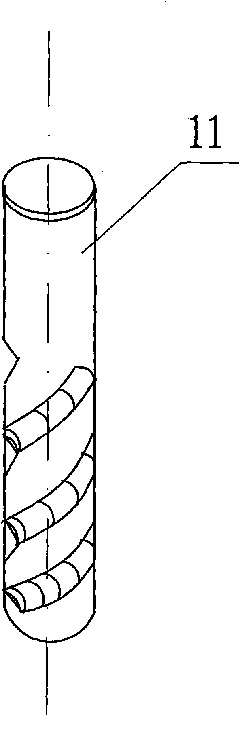

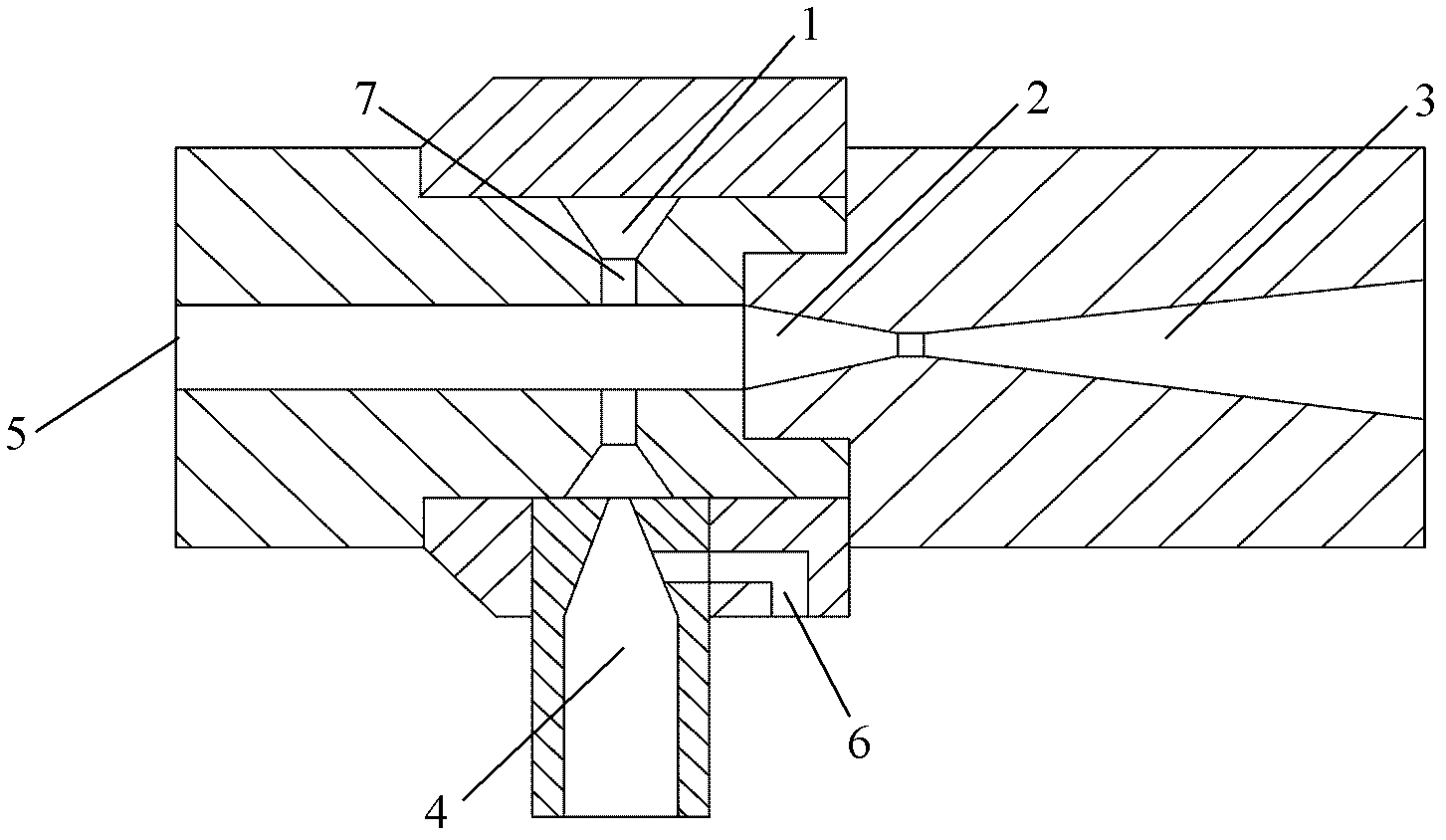

Nozzle device of spiral core control flow beam for micro-abrasive air jet machining

The invention discloses a nozzle device of a spiral core control flow beam for micro-abrasive air jet machining. The nozzle device comprises a nozzle body, a nozzle base, a nozzle, a spiral core, a spiral core base, a spiral core balance spring and a spiral micro-adjuster, wherein the nozzle is sleeved in the nozzle base; the nozzle base is arranged on the nozzle device body; the spiral core is connected with the spiral core base in the nozzle base; the spiral micro-adjuster is connected with the upper end of the nozzle device body through thread, and the lower end of the nozzle device body is connected with the upper end of the spiral core base; and the spiral core balance spring at the lower end of the spiral core base keeps the upper end of the spiral core acting on the spiral micro-adjuster all the time. Two compressed air input connectors are symmetrically arranged on the nozzle device body and connected with two air input passages. Gyroscopic motion effect is produced by two-phase flow air mixed with micro-fine abrasive and the abrasive through the position adjustment of the spiral core and the effect of the spiral groove of the spiral core, so that the external diffusion tread of the flow beam is limited to ensure uniform distribution of jet velocity in the flow beam, contribute to uniform removal of the grinded material of the part and improve the quality of the micro-abrasive jet machining.

Owner:SHENYANG LIGONG UNIV

Circular cleaning equipment for medical appliance

InactiveCN107716387AIncrease jet pressureEasy to rinseTreatment involving filtrationLavatory sanitoryLiquid tankCirculating pump

The invention provides a recyclable cleaning device for medical appliances, which includes a cleaning and disinfection tank and a cleaning liquid arranged in the cleaning and disinfection tank, and also includes a circulation pipeline, the circulation pipeline includes an input pipeline and an output pipeline, and the bottom of the cleaning tank passes through the circulation pipeline The first valve, liquid cleaning mechanism, circulation pump and second valve are connected in sequence. The cleaning liquid at the bottom of the cleaning tank is transported to the liquid cleaning mechanism through the output pipeline, and then purified and filtered by the liquid cleaning mechanism through the circulation pump and the input pipeline. It is connected to the cleaning and disinfection tank, and there is a spray mechanism between the cleaning and disinfection tank and the input pipeline, and a spray generator is installed in the spray mechanism; starting the spray generator can gradually compress the air or the purified cleaning solution into the cleaning and disinfection tank Inside. By implementing the technical scheme, the jet flow velocity of the filtered cleaning solution injected into the cleaning and disinfection tank can be increased, and the impurities and pollutants on the medical equipment can be directly washed to improve the cleaning effect.

Owner:弘毅天承知识产权股份有限公司

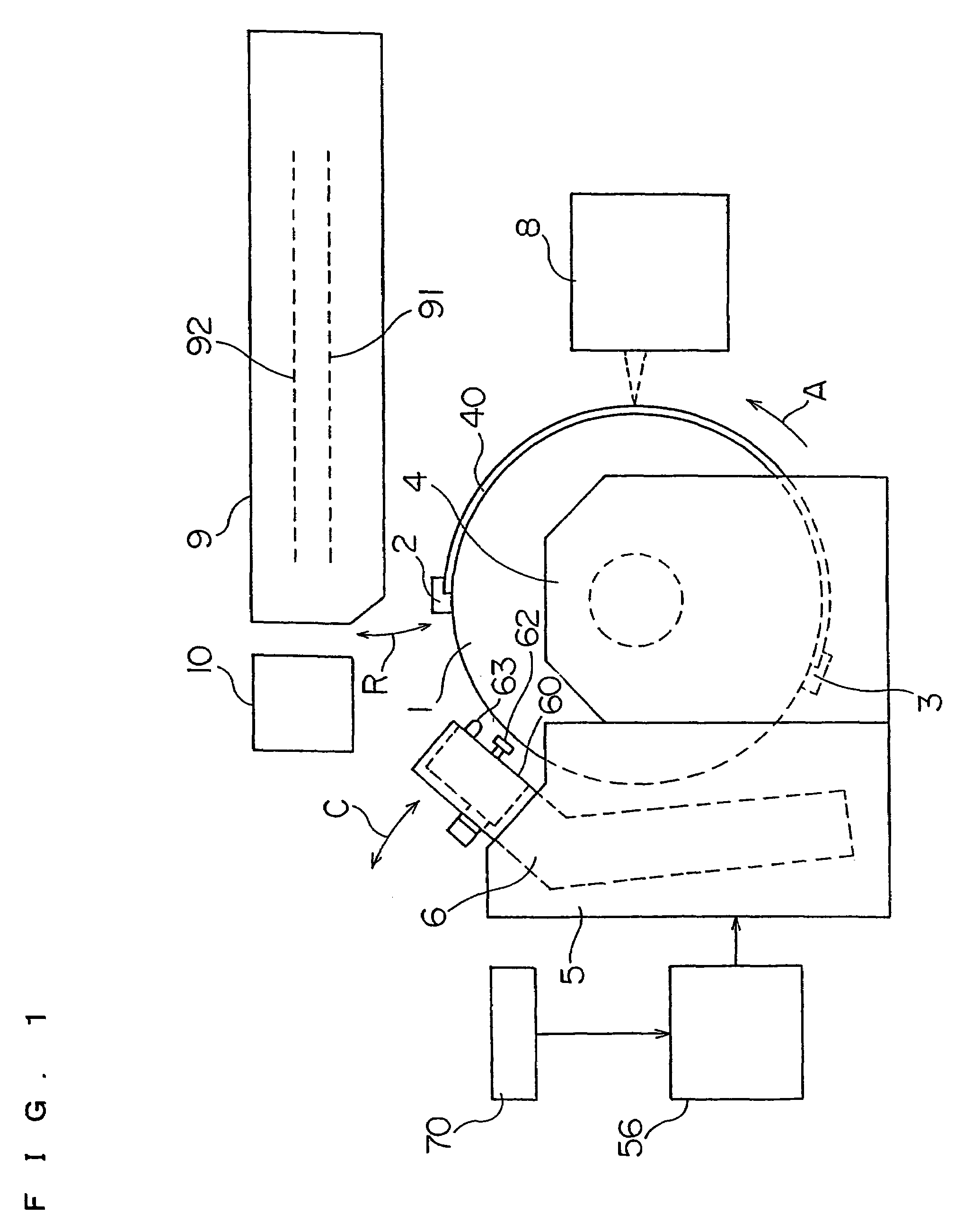

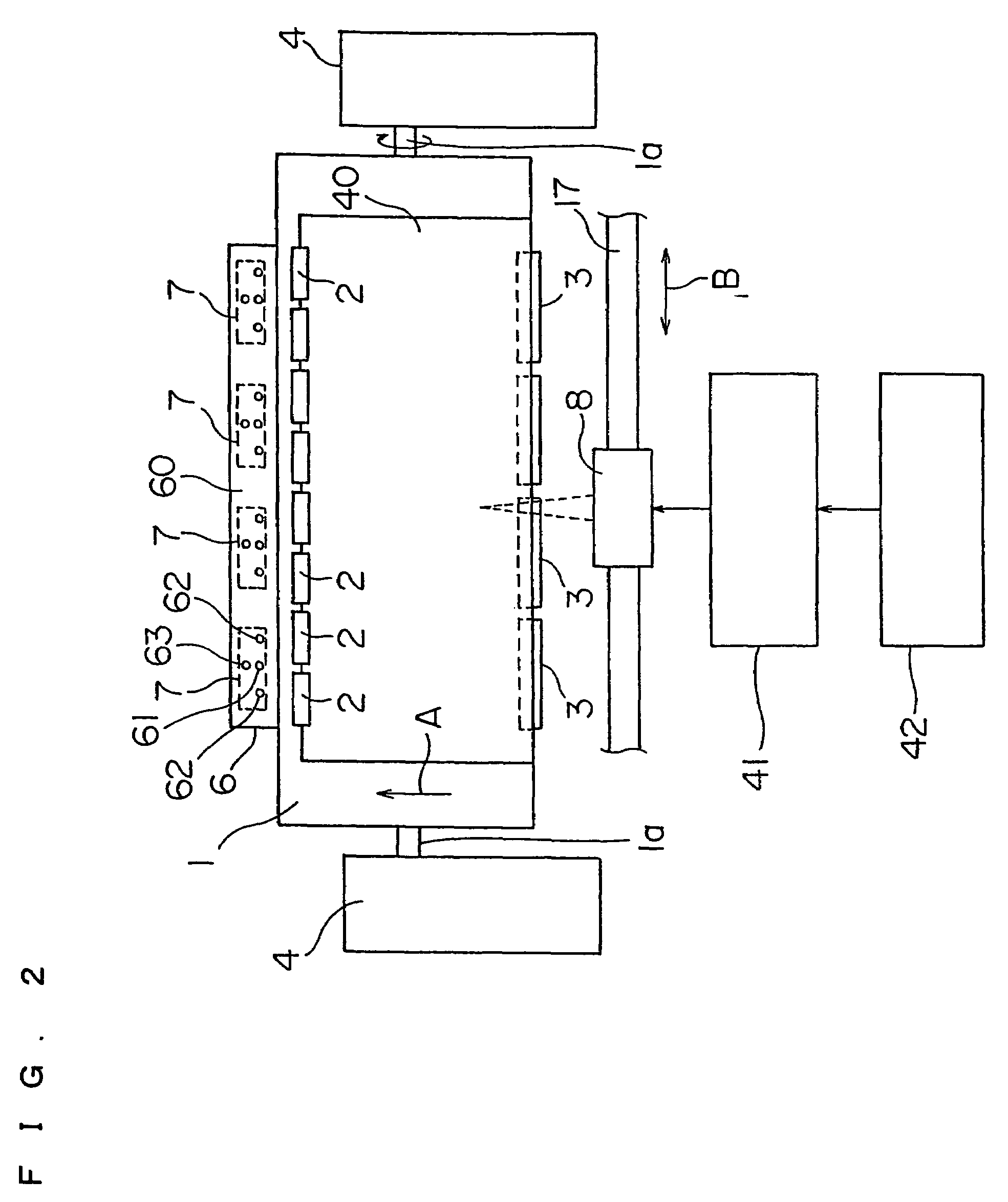

Image recording apparatus with jet and suction

InactiveUS7230636B2Minimize entryImprove efficiencyRecording apparatusElectrode and associated part arrangementsImage recordingLaser light

A gas is generated from a printing plate by exposure of the printing plate. A gas diffusing suction unit jets air from air jet ports to diffuse the gas generated from the printing plate by irradiation of laser light. The gas diffused by the air is sucked along with the air from a gas suction opening of the gas diffusing suction unit. At this time, a gas suction velocity is set to 1.2 or more times an air jet velocity to suck the gas / air efficiently. The gas / air may be sucked efficiently by setting a volume of suction to 30 or more times a volume of air jet.

Owner:DAINIPPON SCREEN MTG CO LTD

Turbine vane with dirt separator

InactiveUS8596966B1Increase speedIncrease chanceEngine manufacturePump componentsLeading edgeTurbine blade

A turbine stator vane with a cooling circuit that improves the cooling effectiveness of the airfoil as well as collects any dirt particles before passing the clean cooling air through the cooling circuit. The airfoil includes a 3-pass aft flowing serpentine circuit with a first leg located along the airfoil leading edge and connected to a showerhead arrangement for film cooling discharge. A cooling air supply channel is located between the first leg and the second leg of the serpentine flow circuit, and the cooling supply channel includes ribs arranged to produce a vortex flow within the cooling air that collects the dirt particles within a center of the vortex flow and deposits the dirt particles at the bottom of the channel. The vortex flow cooling air flows through impingement holes to produce impingement cooling on the backside wall of the leading edge with clean cooling air. The vortex flow pattern produces higher flow velocities at the outer periphery of the vortex which produces a higher impingement jet velocity of the cooling air to improve convection and impingement cooling capability.

Owner:FLORIDA TURBINE TECH

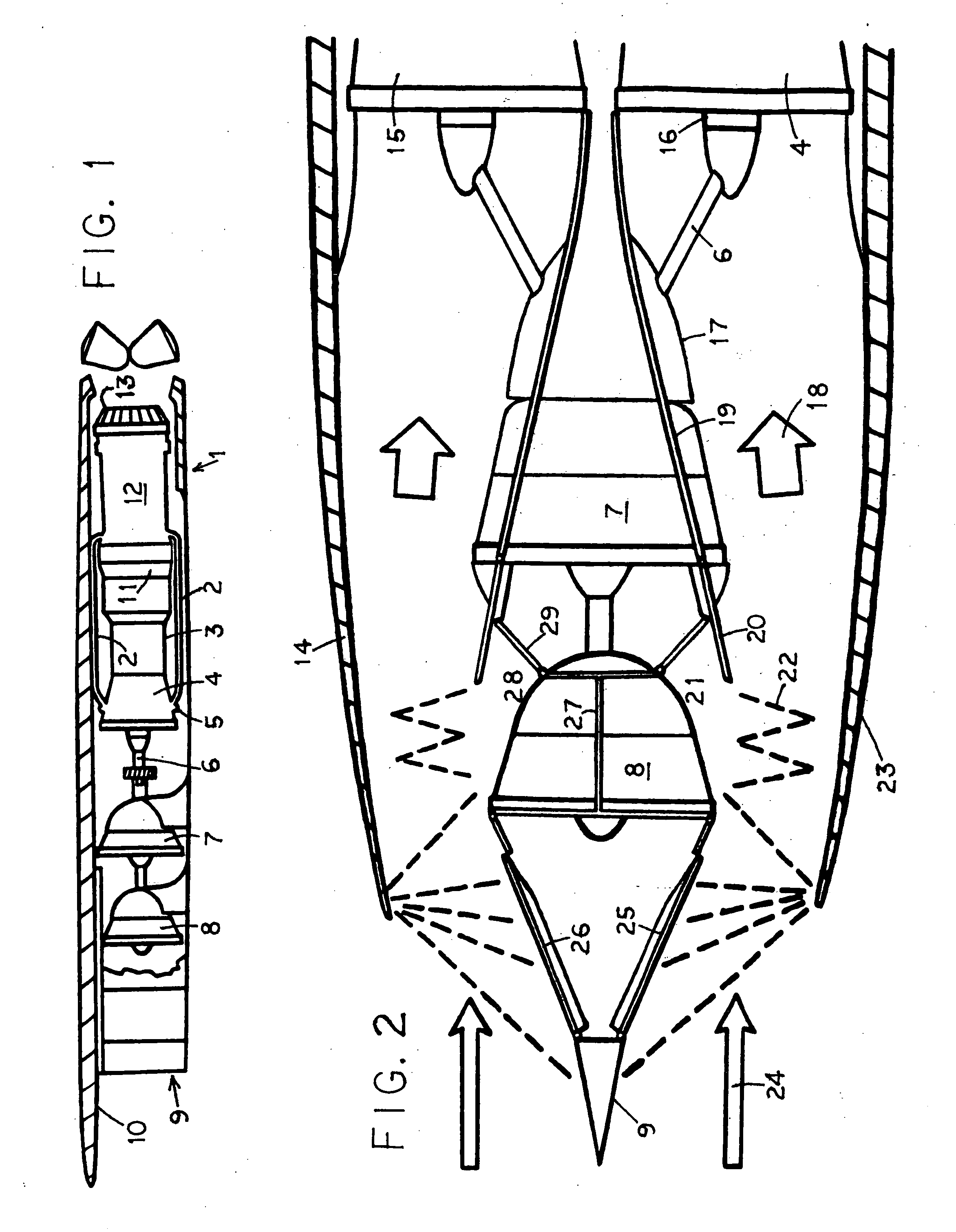

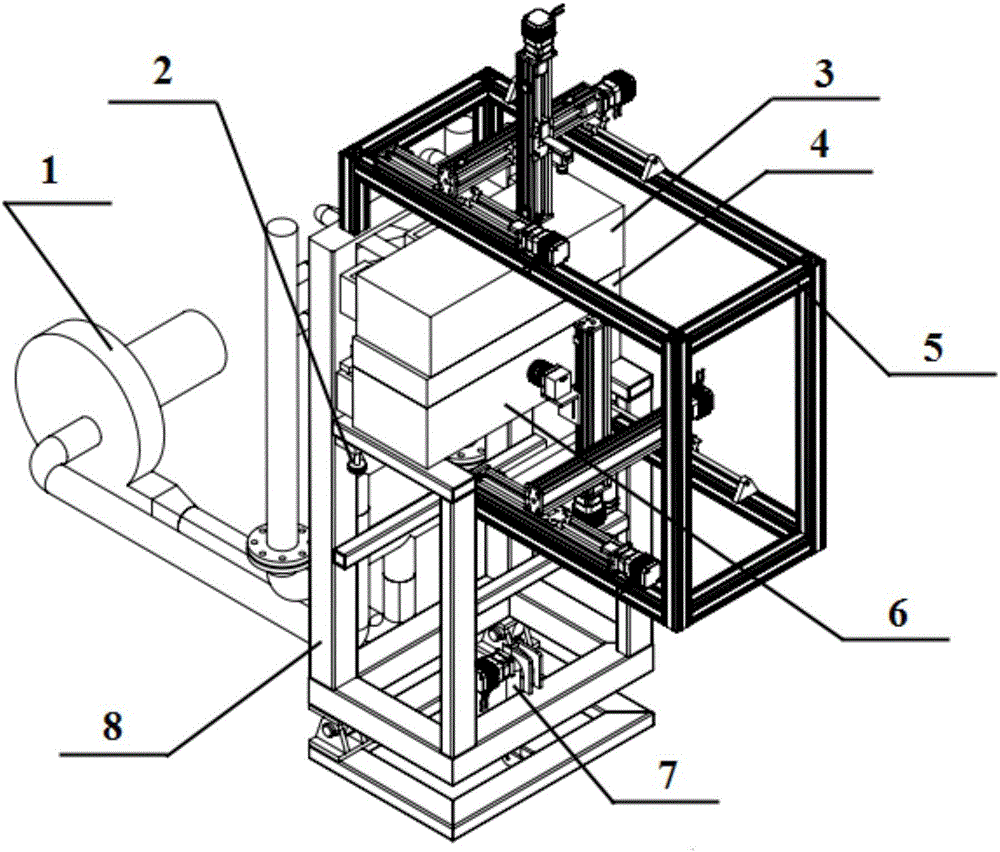

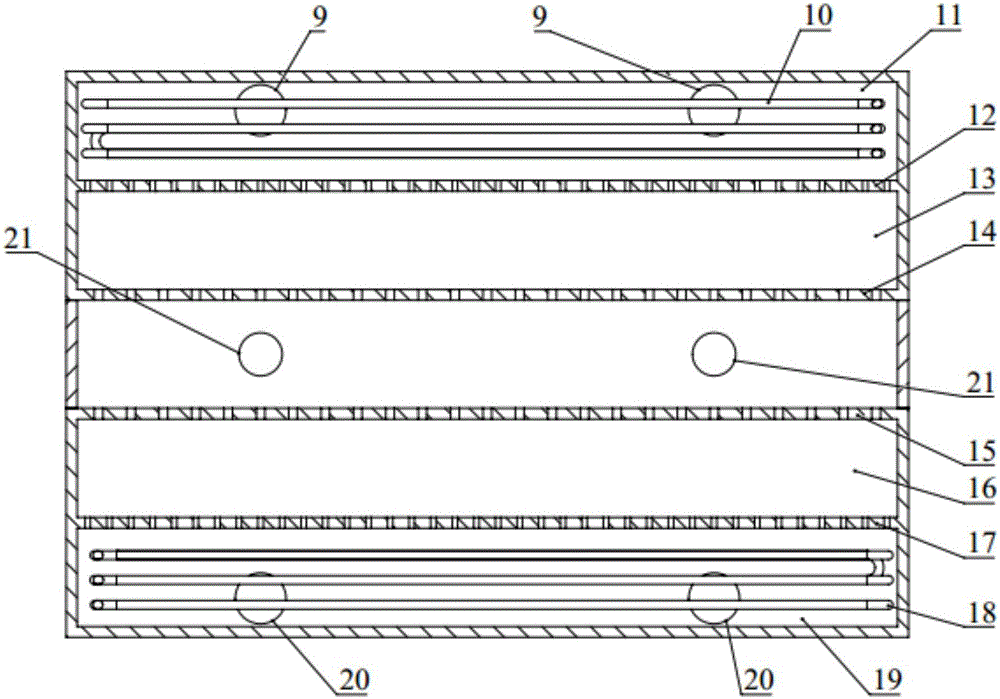

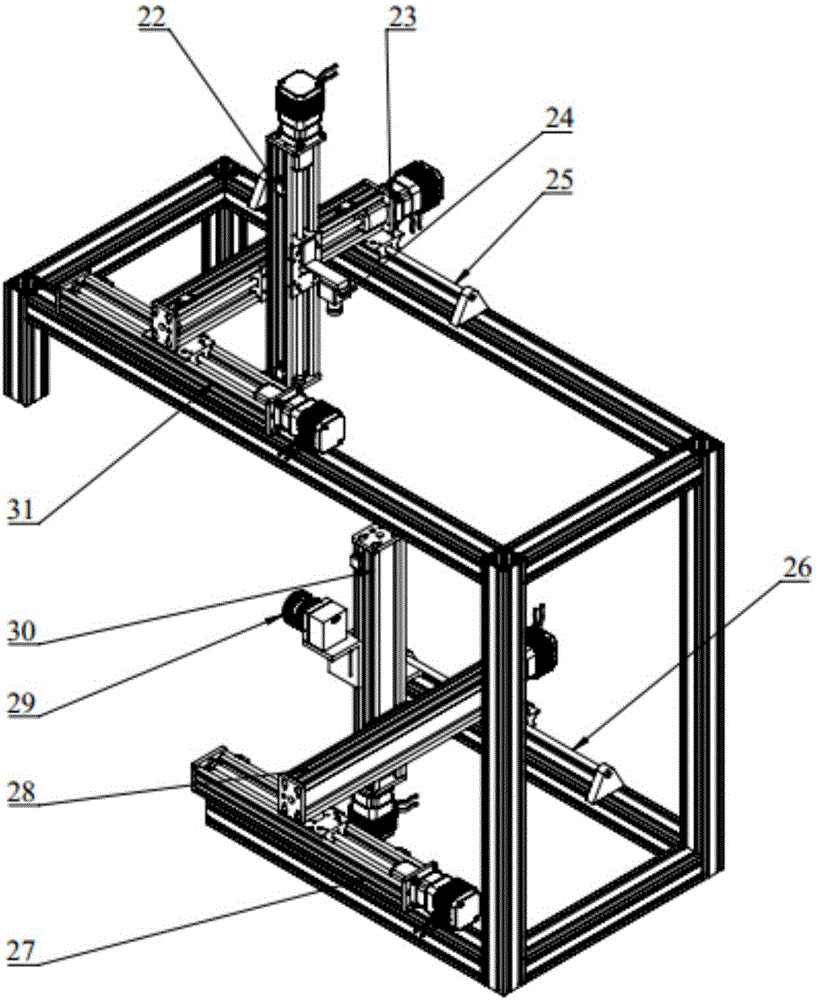

Orifice jet velocity measuring experimental device suitable for multi-field coupling condition

ActiveCN106645791AAchieve recyclingAccuracyHydrodynamic testingFluid speed measurementHeat flowMulti field

The invention relates to an orifice jet velocity measuring experimental device suitable for a multi-field coupling condition. The orifice jet velocity measuring experimental apparatus comprises a bracket, a high-temperature circulating fan, a PIV system and an angle adjusting system. Upper and lower chambers are disposed on the bracket and are arranged oppositely. An observation area is formed between an upper air hole plate and a lower air hole plate. A feed inlet and a feed outlet are formed at the left and right sides of the observation area respectively. The PIV system is located on the front side of the observation area and includes a digital camera capable of performing position adjustment in XYZ directions and a dual-pulse laser. The experimental device of the invention is simple and used for simulating orifice jet velocity measurement under the multi-field coupling condition in a plurality of industrial fields, recycles tracer particles in the fluid, and has an adjustable shooting area, experimental parameter diversity and shooting position accuracy.

Owner:CHANGZHOU UNIV +1

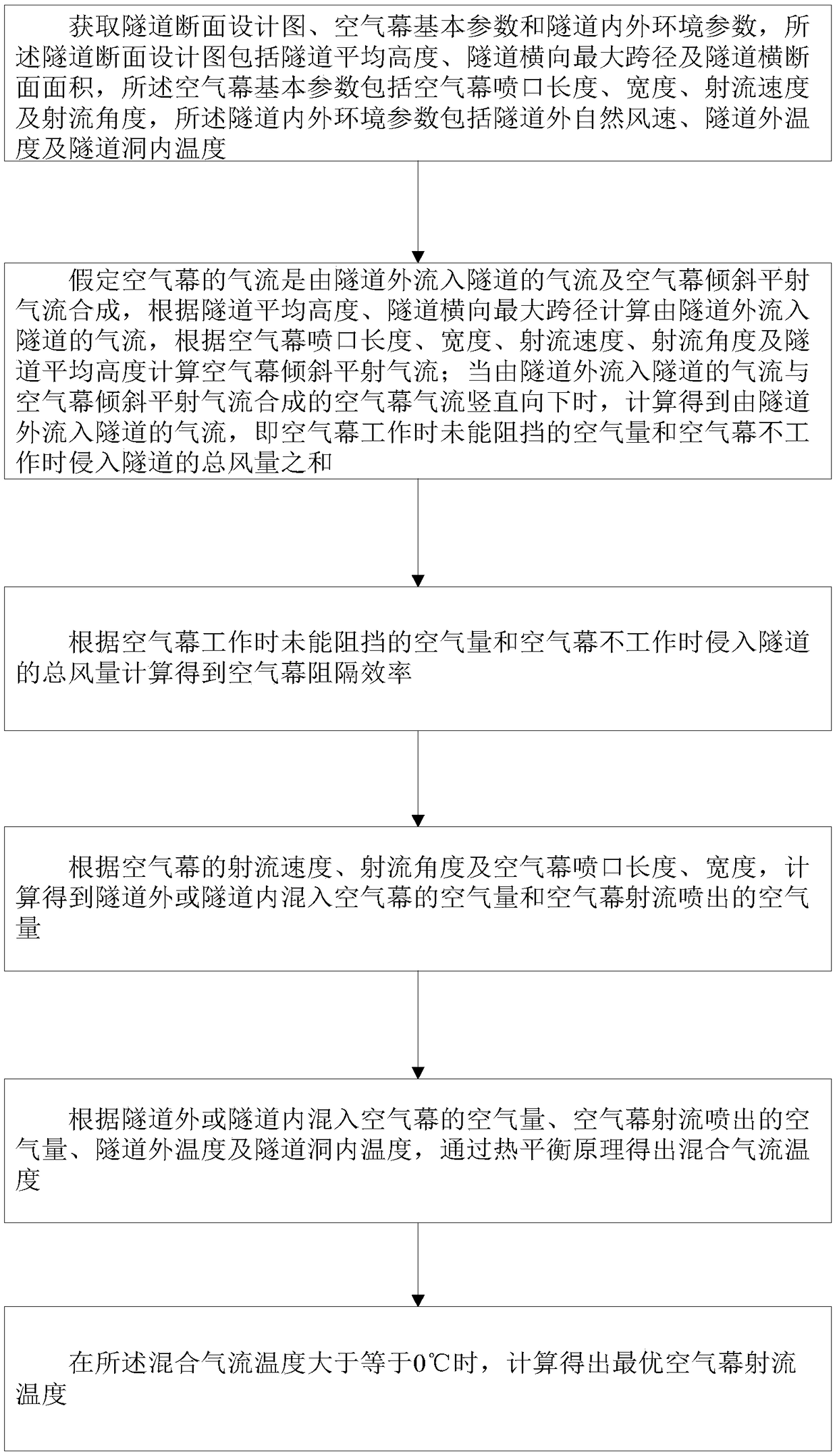

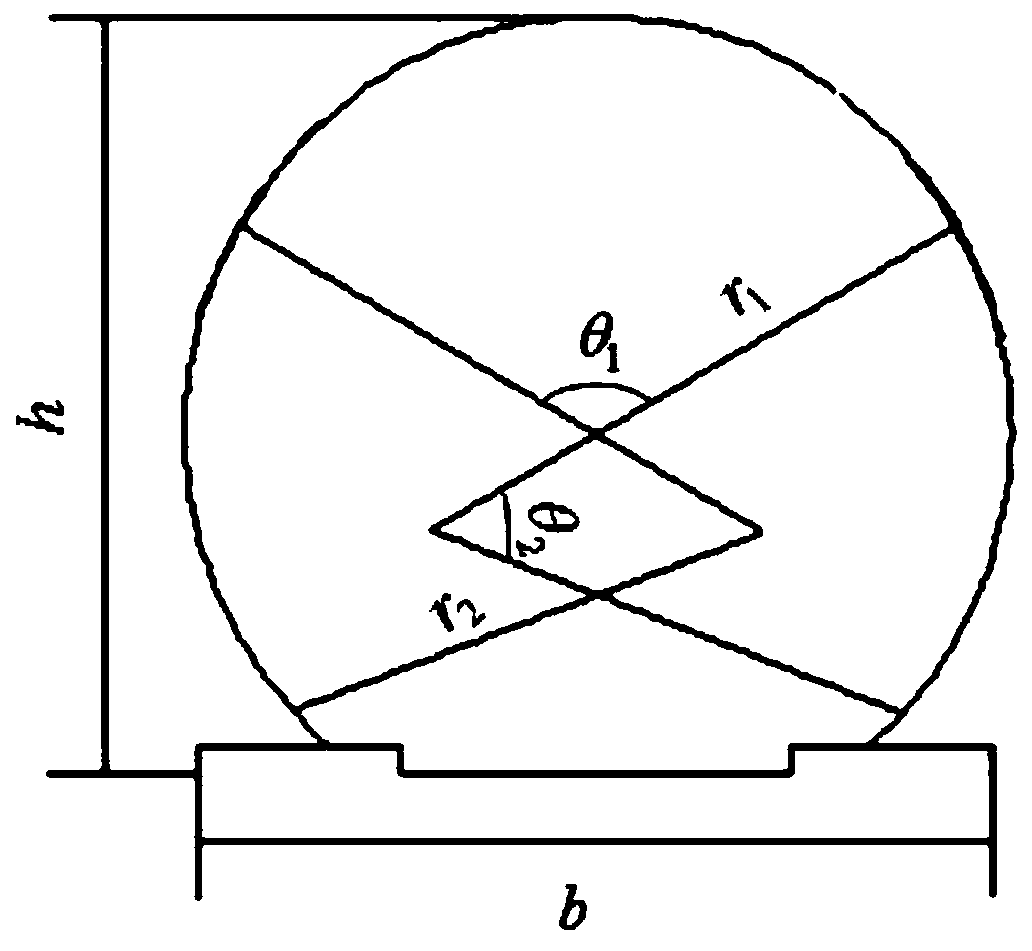

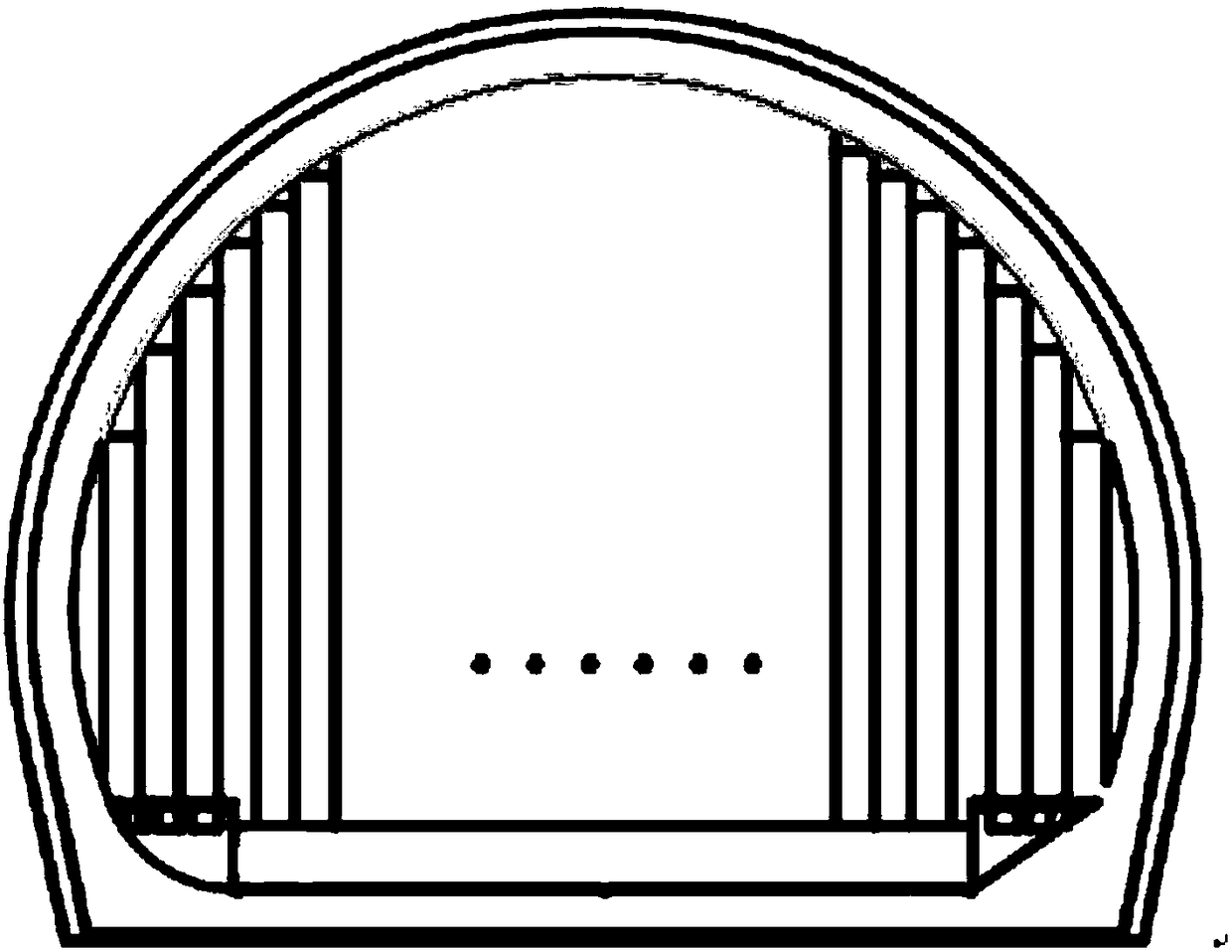

A calculation method of an air curtain heat preservation theory of a railway tunnel in a cold region

ActiveCN109190246AGuaranteed temperaturePrevent frost heaveGeometric CADUnderground chambersRailway tunnelHeat balance

The invention discloses a calculation method of an air curtain heat preservation theory of a railway tunnel in a cold region, which comprises the following steps: obtaining tunnel section design drawing, air curtain basic parameters and tunnel internal and external environment parameters; calculating the barrier efficiency of air curtain; according to the temperature inside and outside the tunnel,the quantity of air ejected from the air curtain jet and the quantity of air mixed into the air curtain inside and outside the tunnel, the optimum temperature of the air curtain jet is obtained by the heat balance principle. This method is mainly used to calculate the barrier efficiency of air curtain and the temperature of mixed gas flow in tunnel; the method is suitable for the design of air curtain size, or for the calculation of jet velocity, jet angle and jet temperature during the operation of air curtain, so as to achieve the purpose of blocking the air flow inside the tunnel and maintaining the temperature inside the tunnel in the cold region by multiple vertical air curtains, and prevent the frost heave in the tunnel in the cold region.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

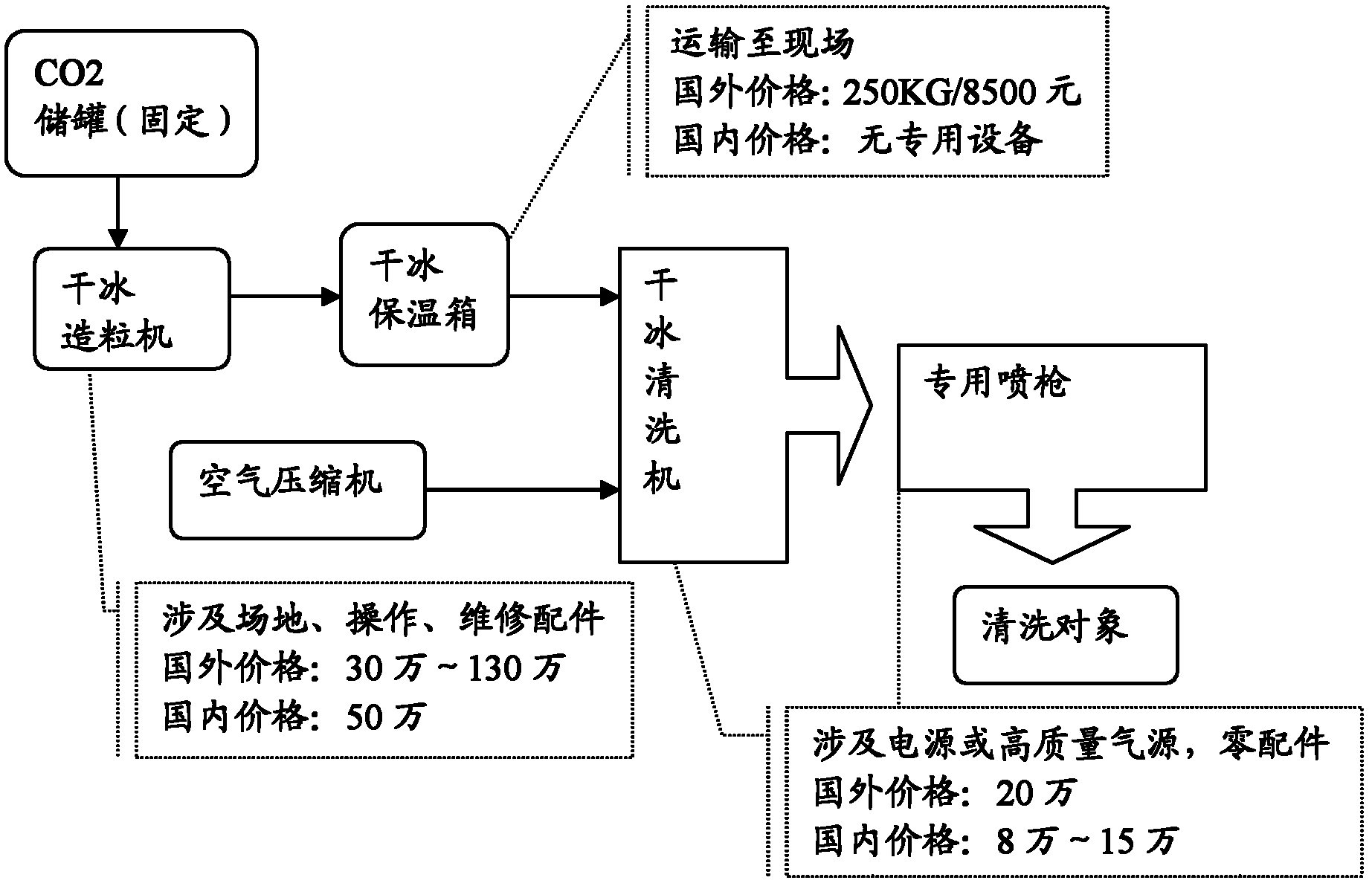

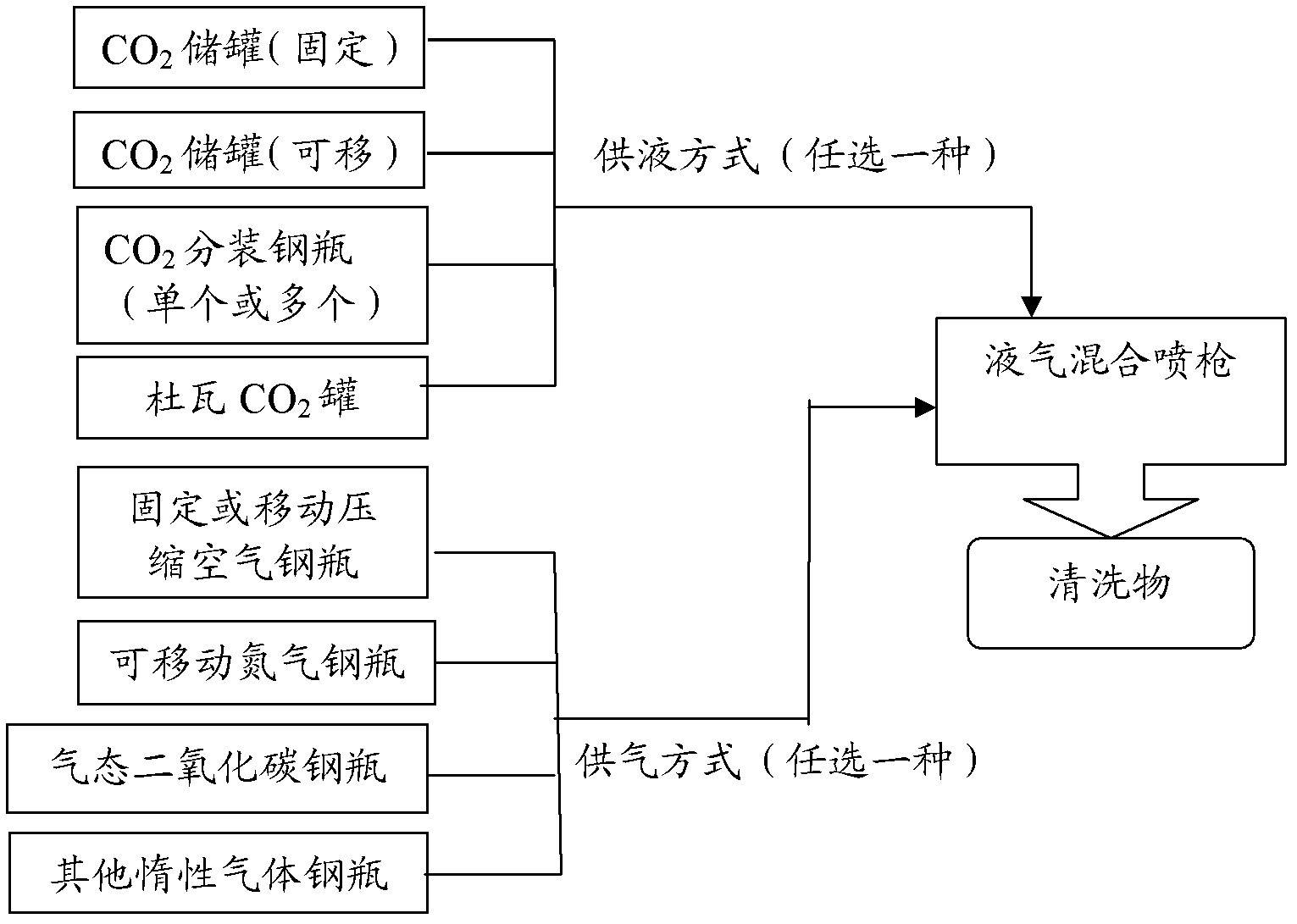

Cleaning method using uniformly and stably jet cleaning agent formed by separately using liquid carbon dioxide or mixing liquid carbon dioxide and compressed gas

InactiveCN102527660AUniform and stable sprayIngenious designCleaning using gasesCleaning using liquidsLiquid carbonCleaning methods

The invention relates to a cleaning method using a uniformly and stably jet cleaning agent formed by separately using liquid carbon dioxide or mixing liquid carbon dioxide and compressed gas. By the method, after at least one part of the liquid carbon dioxide produces solid-gas phase change, the liquid carbon dioxide is separately used as the cleaning agent and uniformly and stably jet to an object required to be cleaned or uniformly and stably mixed with the compressed gas to form the cleaning agent which is jet to the object required to be cleaned. Preferably, the liquid carbon dioxide is decompressed to 5Bar, so that at least one part of the liquid carbon dioxide produces the solid-gas phase change; the jet velocity is over 320 meters per second, the jet flow is 0.2 to 1.0 liter of liquid carbon dioxide per minute or 0.2 to 1.0 liter of liquid carbon dioxide and 4 cubes of compressed gas per minute; after at least one part of the liquid carbon dioxide produces the solid-gas phase change, the liquid carbon dioxide enters along the circumference of the compressed gas uniformly at intervals, so that the liquid carbon dioxide is uniformly and stably mixed with the compressed gas; and the cleaning method is implemented by adopting a jet gun. The method is skilful in design, easy to operate, low in cost and uniform and stable in jet, has a good cleaning effect, and is suitable for large-scale popularization and application.

Owner:上海鸣华化工科技有限公司

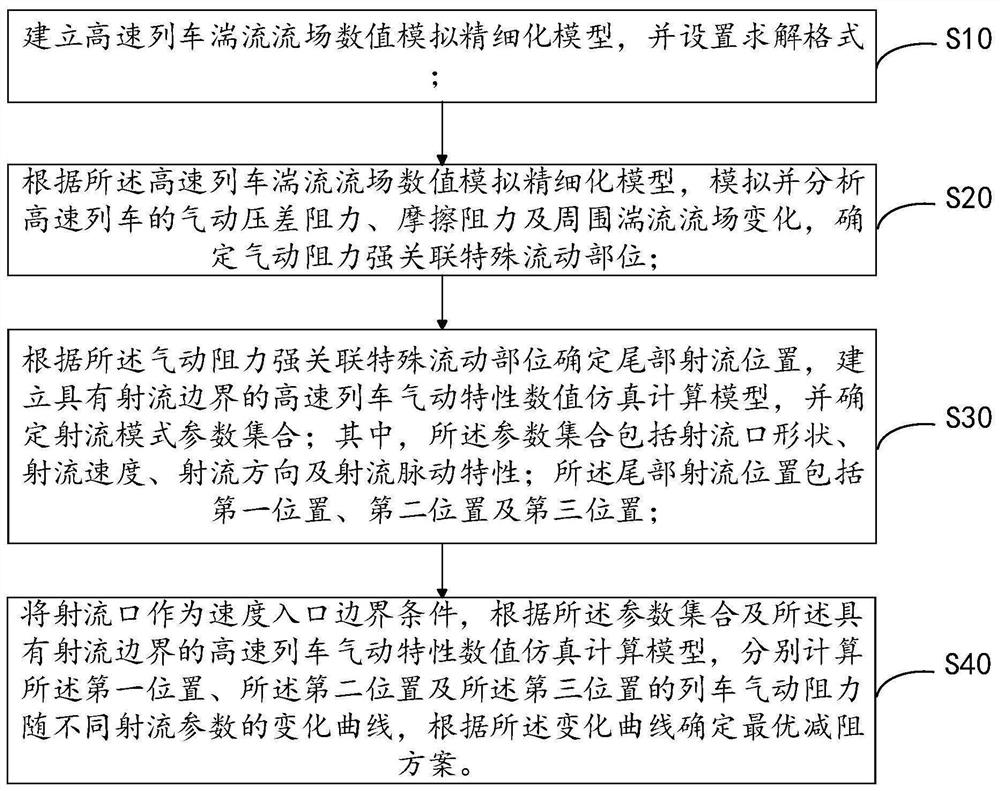

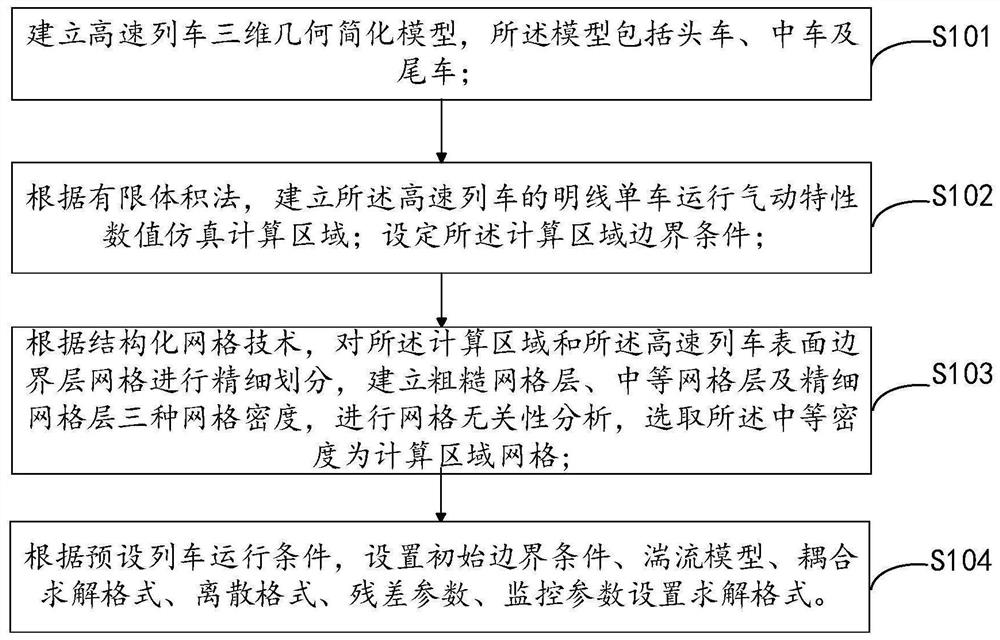

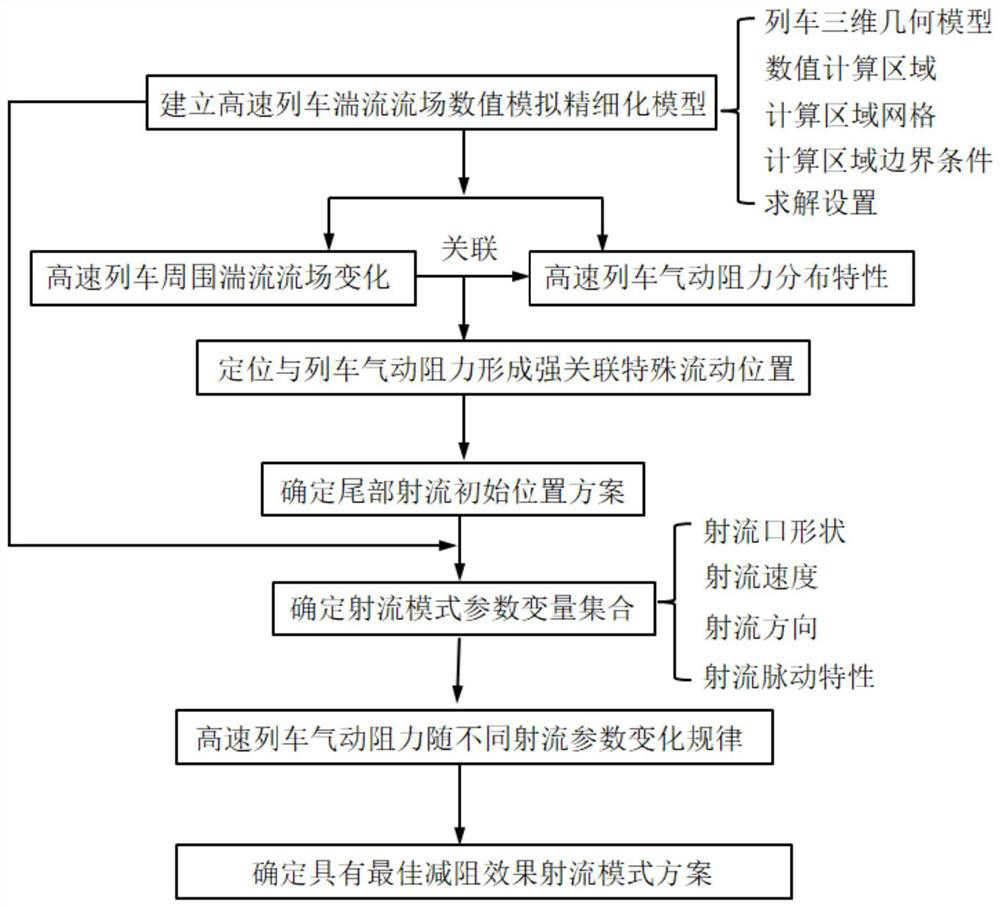

High-speed train tail jet pneumatic drag reduction numerical simulation analysis method and device

PendingCN112597583AEffective flow changeImprove applicabilityGeometric CADSustainable transportationAerodynamic dragJet flow

The invention discloses a high-speed train tail jet aerodynamic drag reduction numerical simulation analysis method and device, and the method comprises the steps: building a high-speed train turbulence flow field numerical simulation fine model, and setting a solving format; determining an aerodynamic resistance strong correlation special flow part and a tail jet flow position, establishing a high-speed train aerodynamic characteristic numerical simulation calculation model with a jet flow boundary, and determining a jet flow mode parameter set, wherein the parameter set comprises a jet orifice shape, a jet speed, a jet direction and a jet pulsation characteristic; and finally, taking the jet flow port as a speed inlet boundary condition, and according to the parameter set and a high-speed train aerodynamic characteristic numerical simulation calculation model with a jet flow boundary, respectively calculating change curves of aerodynamic resistances of trains at different jet flow port positions along with different jet flow parameters so as to determine an optimal drag reduction scheme. According to the high-speed train tail jet pneumatic drag reduction numerical simulation analysis method, the research period is shortened, the cost is reduced, and the accuracy of a simulation result is improved.

Owner:WUYI UNIV

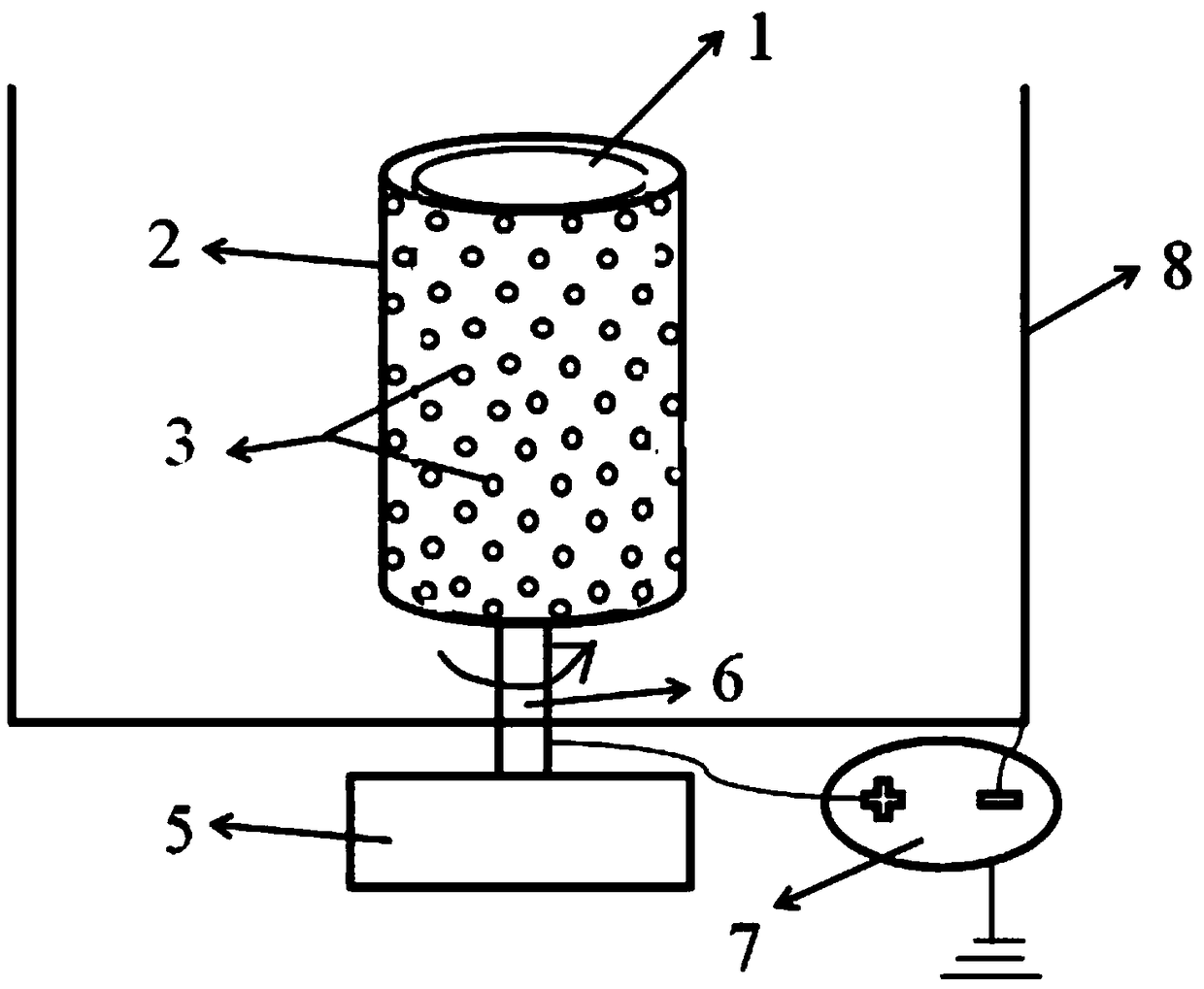

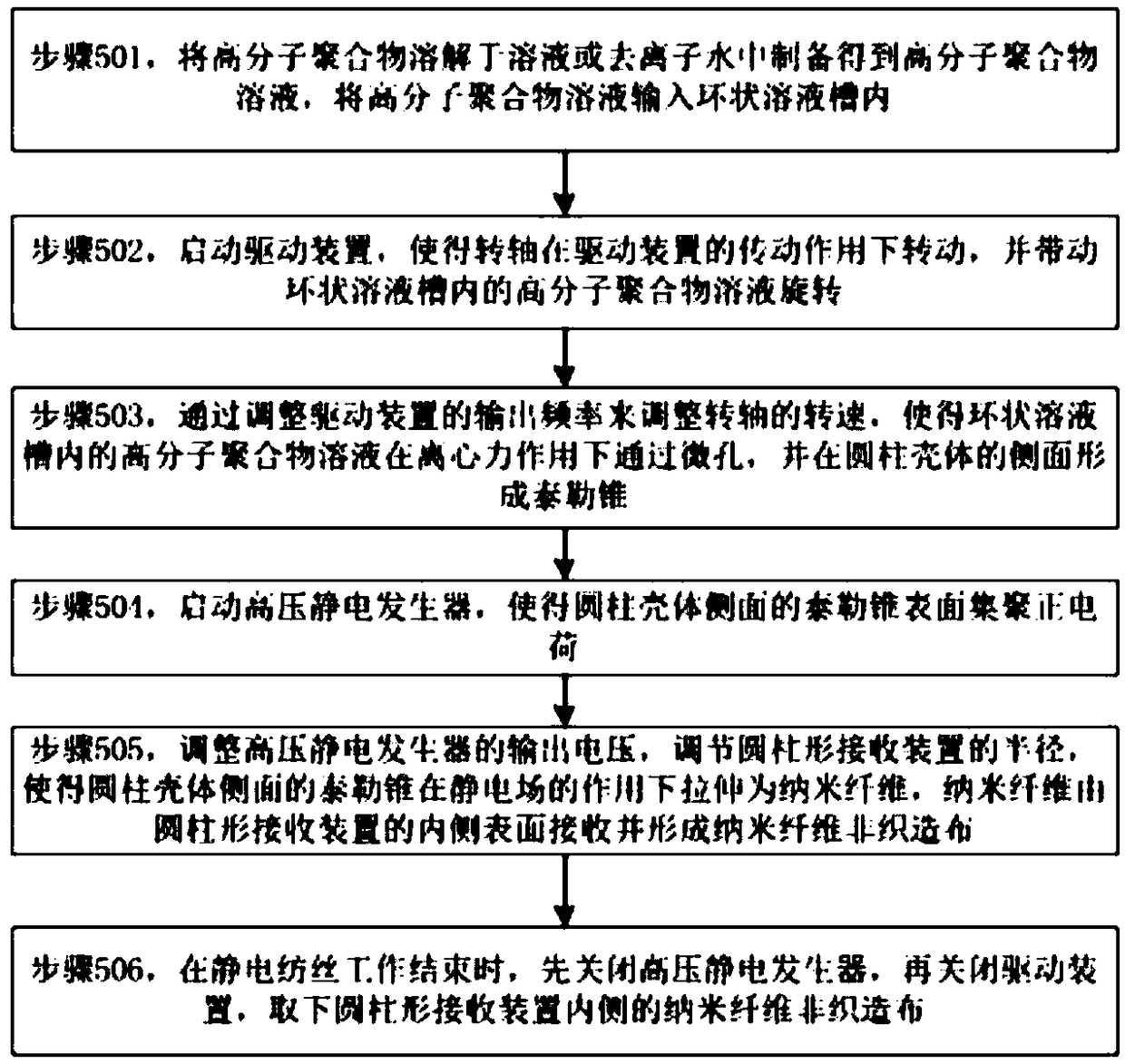

Multi-cavity drum-type electrostatic spinning device and using method thereof

InactiveCN109457394AAdvantages of usingEliminate distractionsFilament/thread formingNon-woven fabricsFiberSolid structure

The invention discloses a multi-cavity drum-type electrostatic spinning device and a using method thereof, and relates to the technical field of electrostatic spinning. The device comprises cylindrical core, a cylindrical shell, partitioning plates, a rotating shaft, a cylindrical receiving device, a driving device and a high-voltage static generator. The cylindrical core is of a solid structure,the cylindrical shell is of a hollow structure, an annular solution groove is formed by the side face of the cylindrical core, the bottom faces of the partitioning plates and the side face of the cylindrical shell, and miniature holes are uniformly formed in the side face of the cylindrical shell; the partitioning plates are circular-ring flat plates and are installed between the cylindrical coreand the cylindrical shell and distributed at equal intervals; the upper portion of the rotating shaft is fixedly connected with the bottom of the cylindrical shell, and the lower portion of the rotating shaft can be in drive connection with the driving device; a positive electrode of the high voltage static generator is connected with the bottom of the cylindrical shell, and a negative electrode of the high voltage static generator is connected with the cylindrical receiving device. The device has the advantages that the uniformity of a jet velocity and spinning is good, electrostatic spinningefficiency is high, and the thickness of a produced nanometer fiber membrane is uniform.

Owner:李瑞锋

Dynamic pressure plasma synthesis jet generator

A dynamic pressure plasma synthesis jet generator relates to a jet generating device. The device uses the dynamic pressure of the forward incoming flow to introduce a high-speed incoming flow into a plasma generator cavity through an air bleed pipeline and a one-way valve, the pressure inside the cavity is increased, and meanwhile, a high-temperature plasma is generated in the cavity through high-voltage discharge, so that the air in the cavity is subjected to thermal expansion, and a high-speed jet is generated at a jet outlet. The device is provided with a plasma generator, the air bleed pipeline, the one-way valve and a high-voltage pulse power supply, wherein the plasma generator is composed of a negative electrode, a positive electrode and a generator cavity, and the generator cavityis provided with an incoming flow inlet, the jet outlet and electrode insertion holes. The device has the advantages of simple structure, light weight, low cost, almost no influence on the aerodynamicshape of an aircraft while generating the high-speed jet, and the like. In addition, the device can also control the jet velocity within a certain range by changing the loaded electrical parameters.

Owner:XIAMEN UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com