Patents

Literature

64results about How to "Jet speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

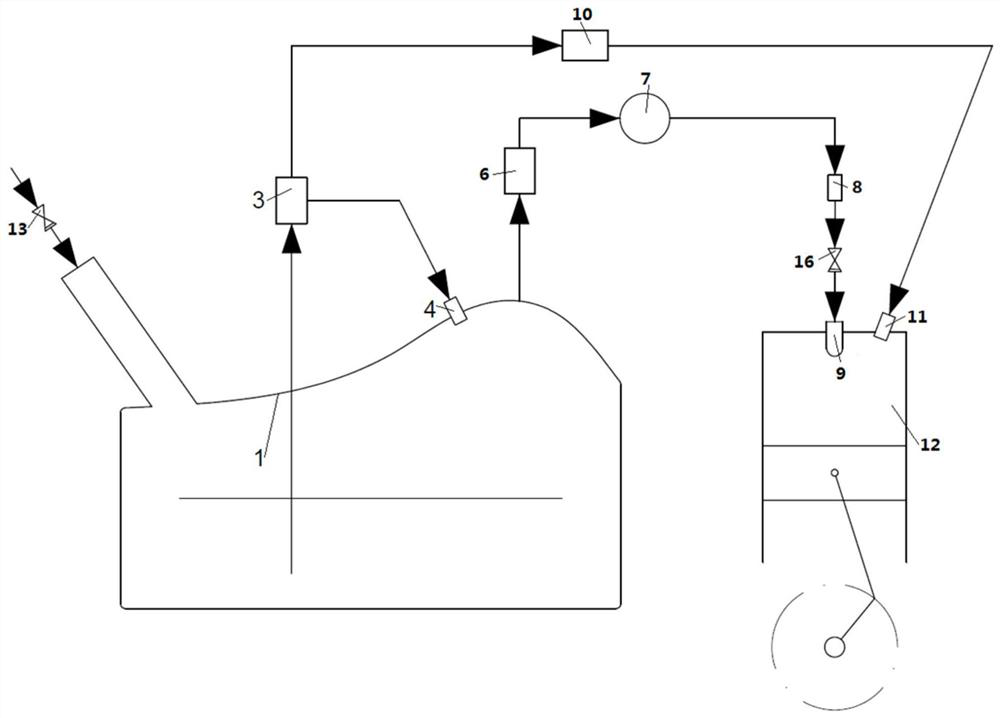

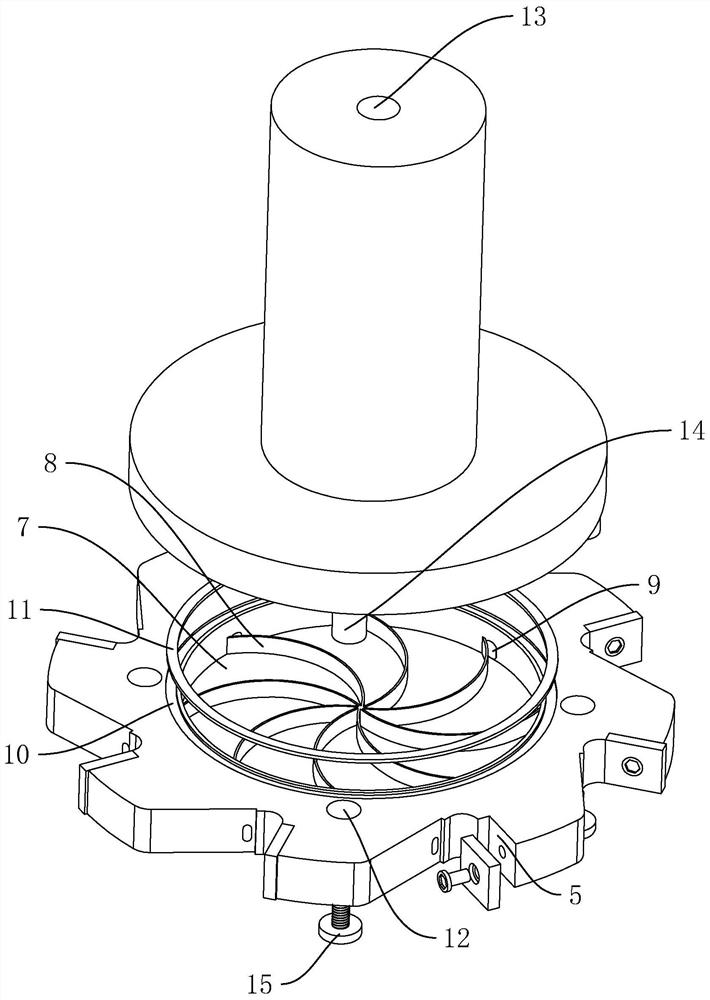

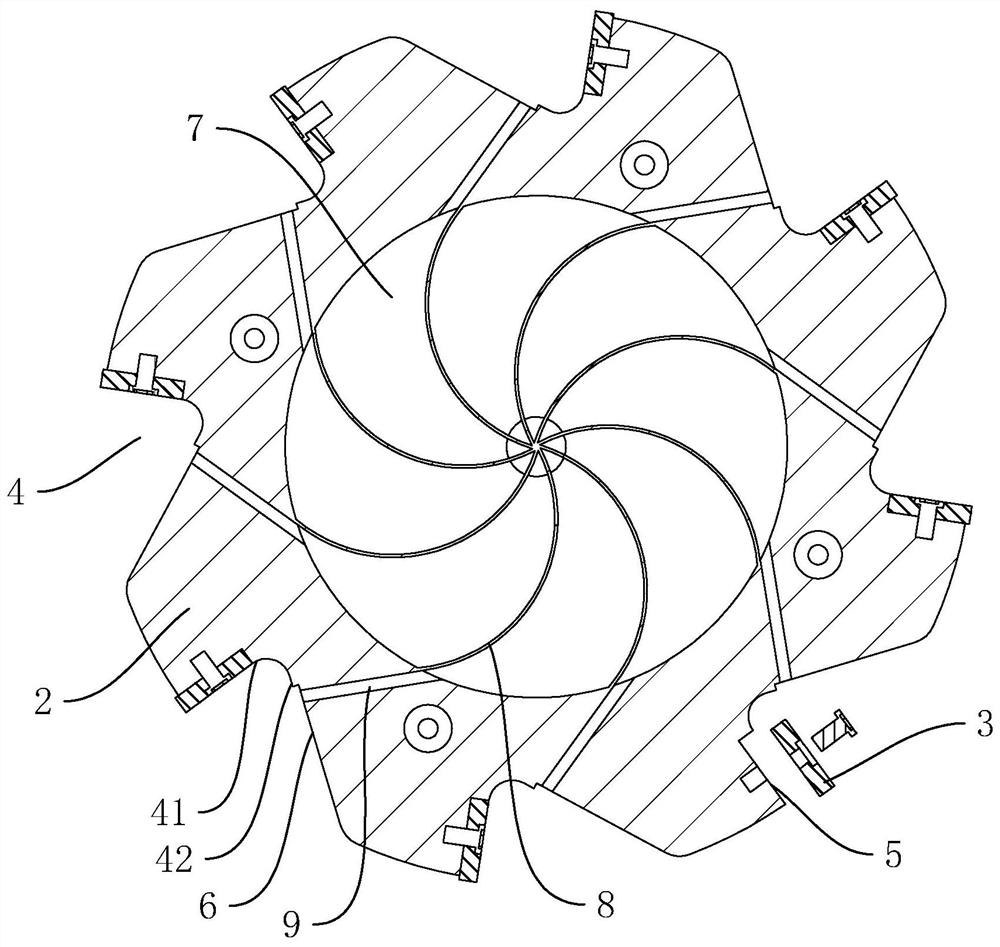

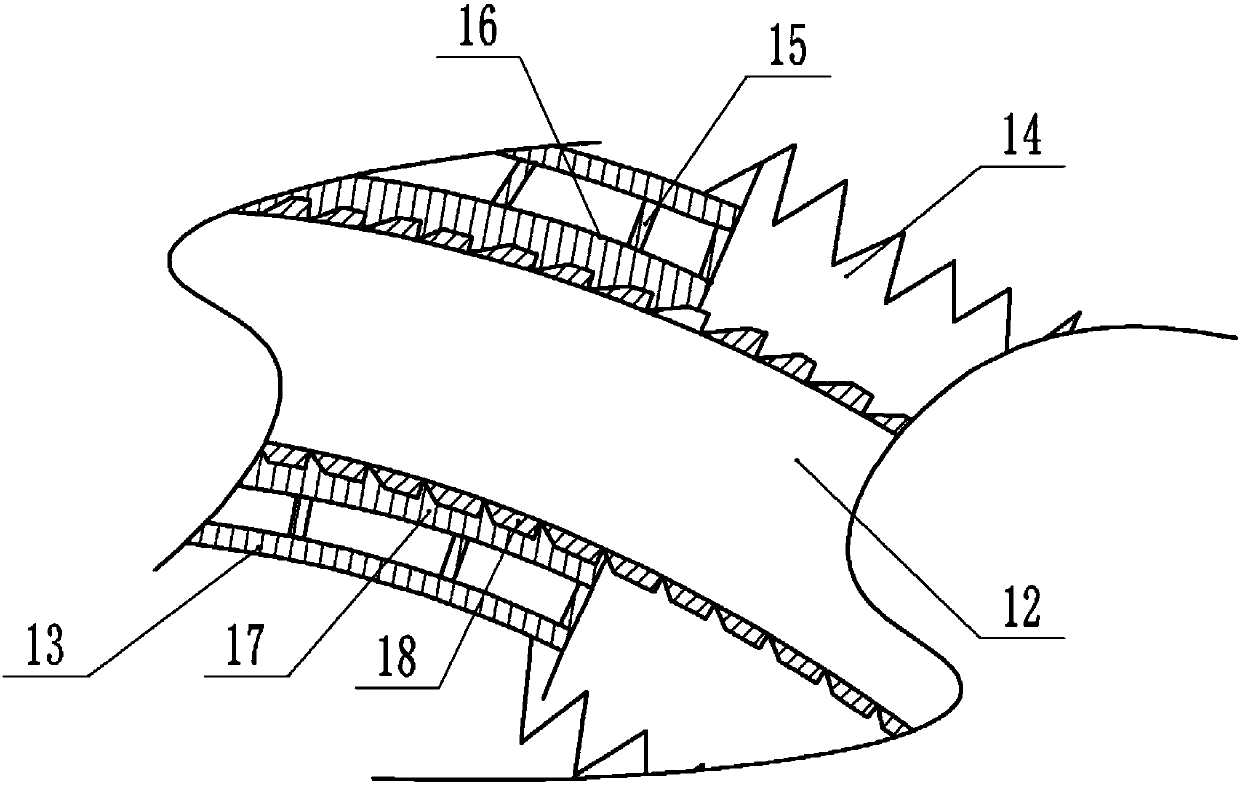

Gear burr removing technology

ActiveCN108746898AJet speedGood deburring effectElectrochemical machining apparatusTraffic volumeCorrosion

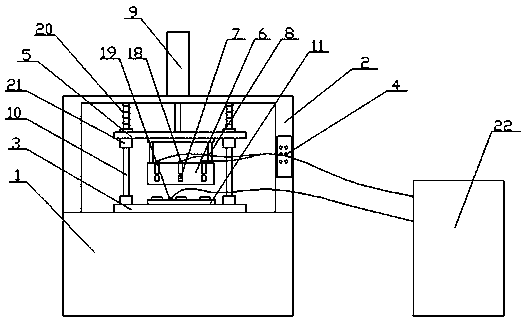

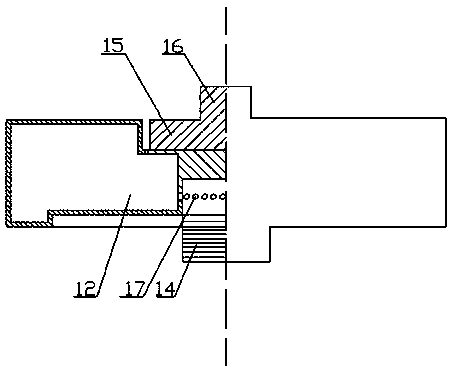

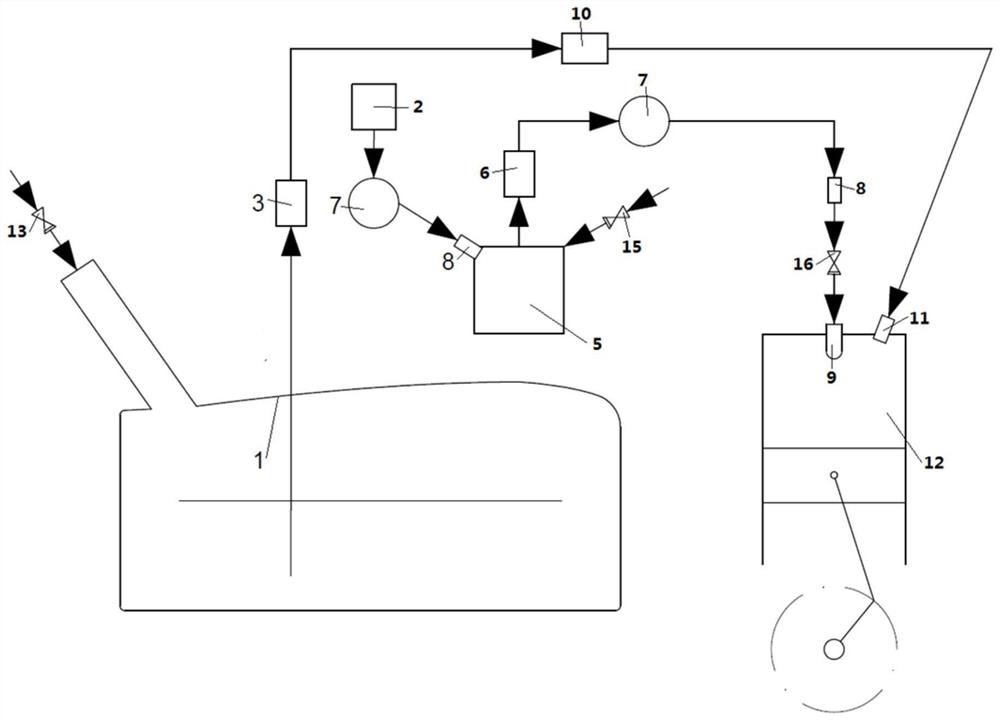

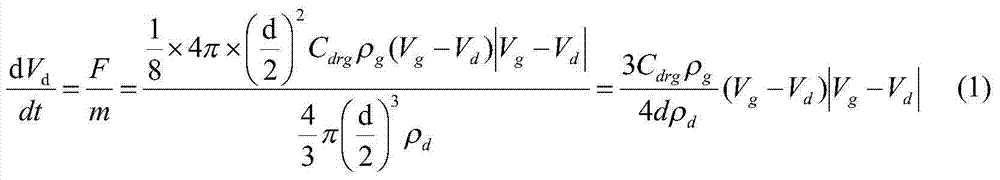

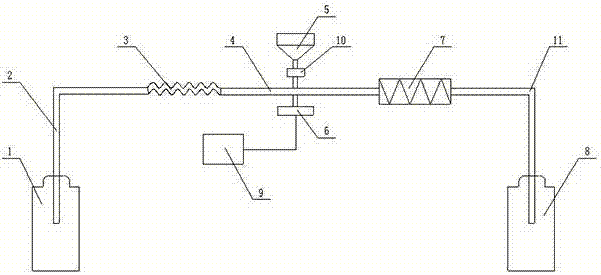

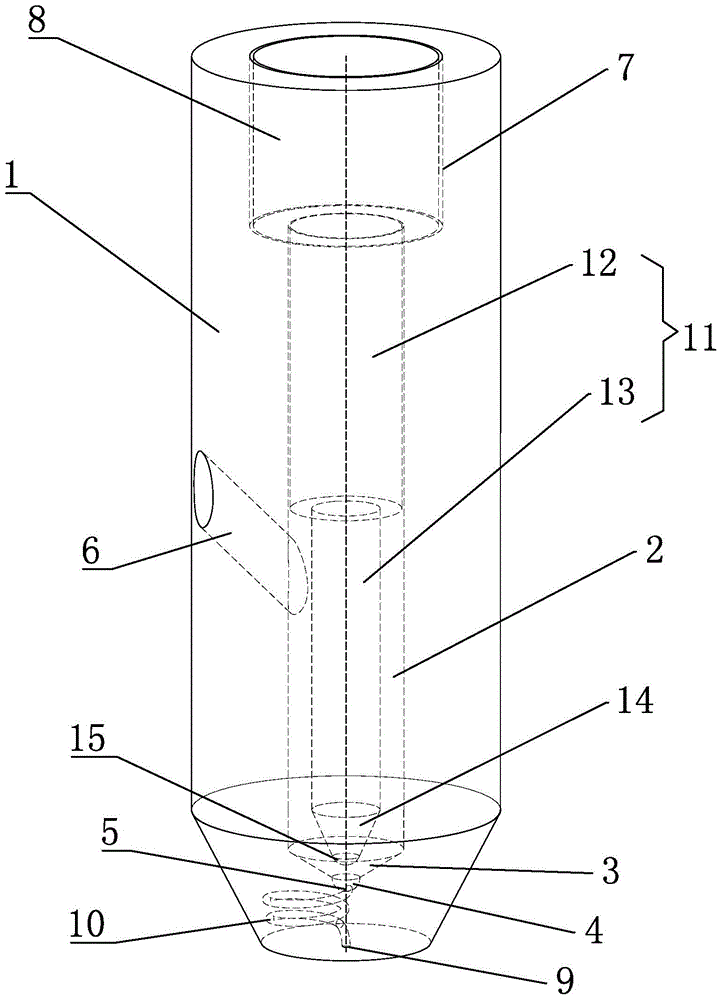

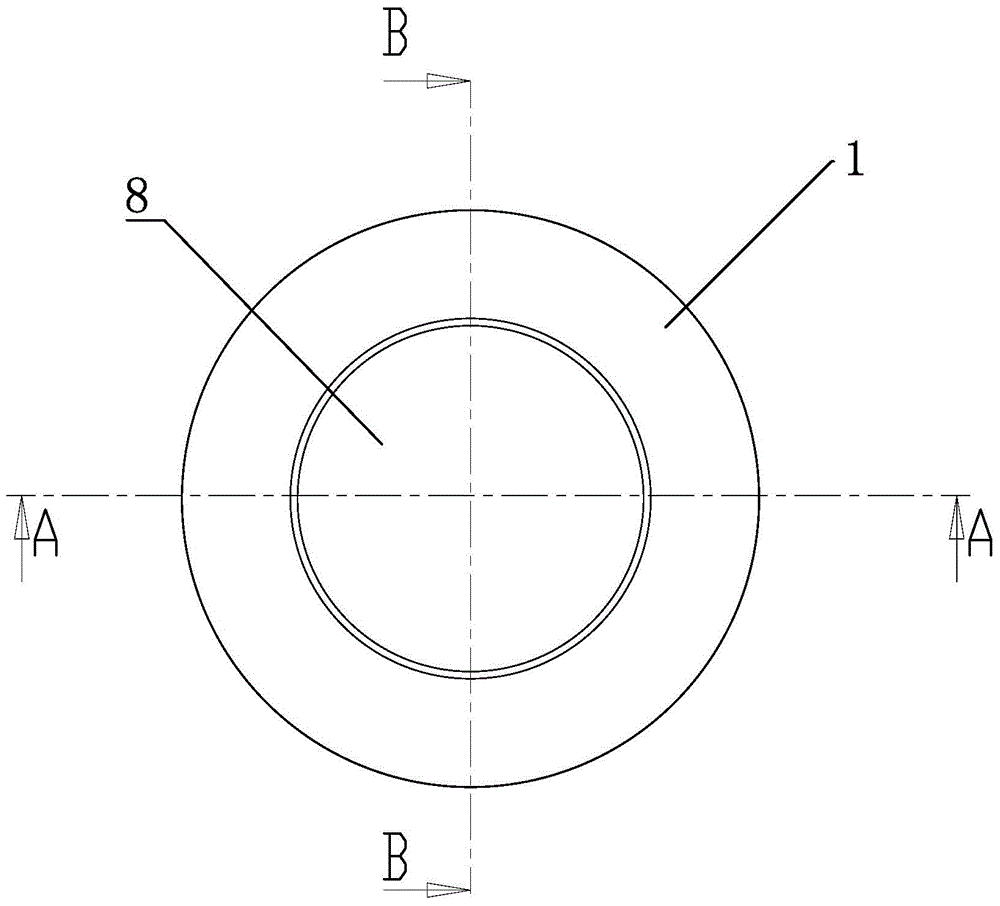

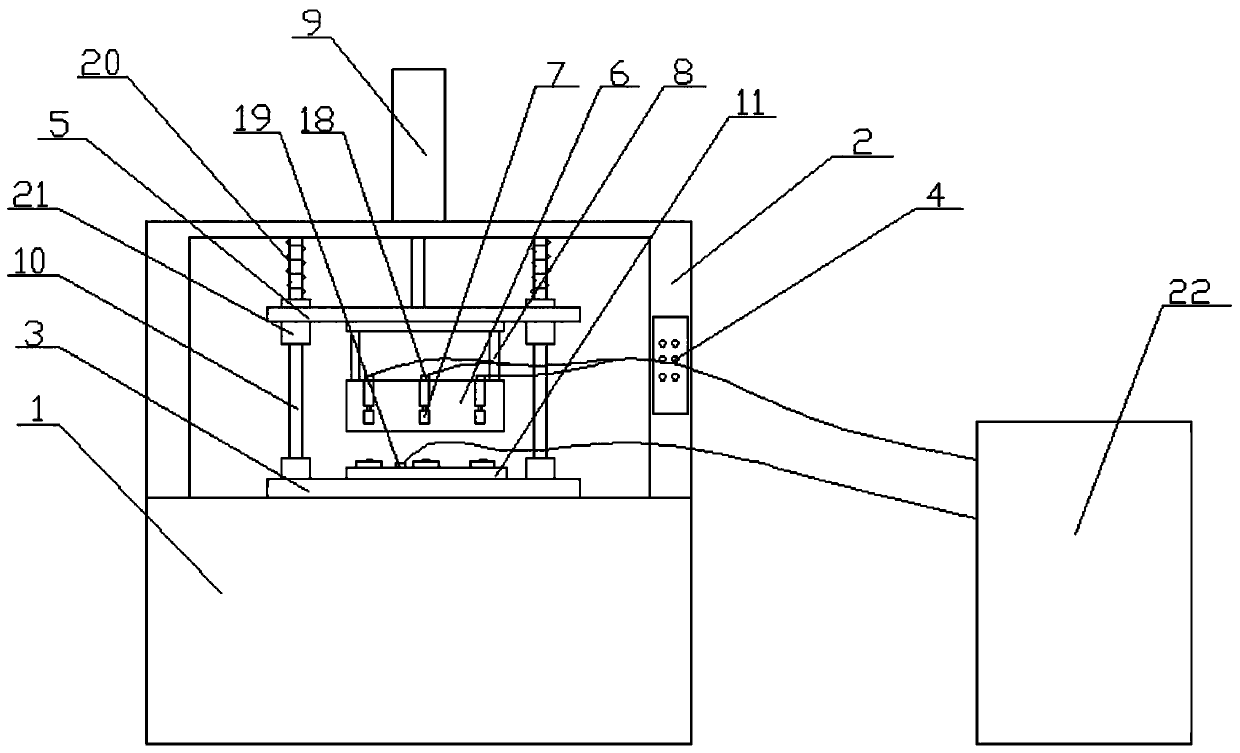

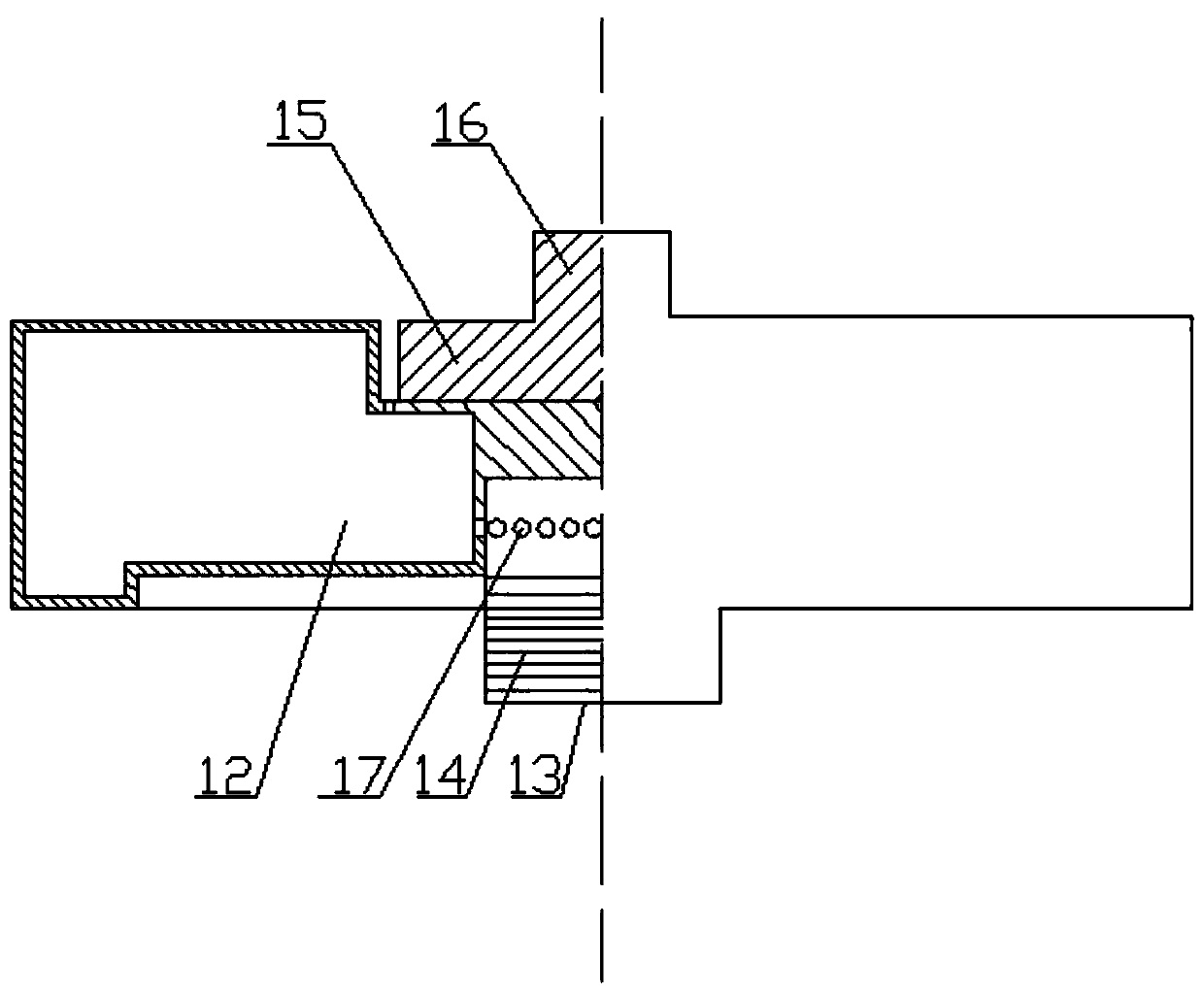

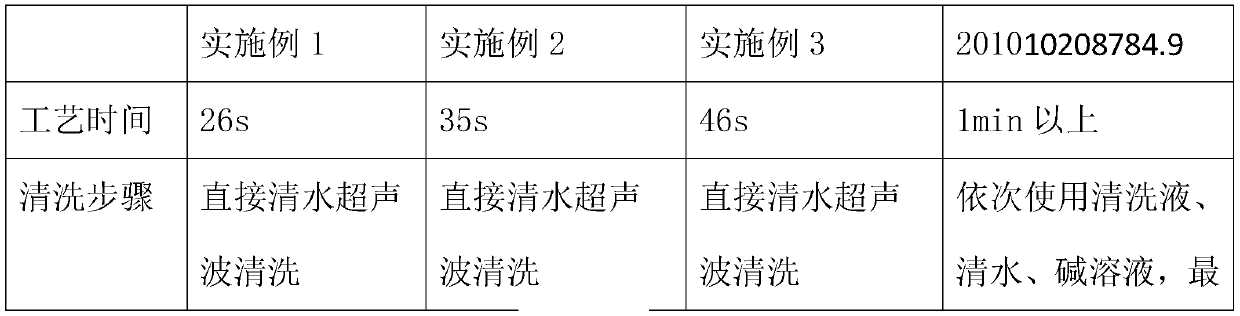

The invention relates to a gear burr removing technology. The technology comprises the following specific steps that 1, a burr removing device is constructed; 2, a gear is placed; 3, conducting and discharging are carried out; 4, an electrolyte is sprayed; 5, the gear is washed ultrasonically; 6, antirust treatment is carried out; and 7, the gear is naturally dried in air and delivered from storage. The technology has the following advantages that an anode terminal and a cathode terminal are utilized for conducting and discharging, the electrolyte is sprayed to the gear fast from bottom to top, the spraying speed is high, the electrolyte is sprayed in a centralized manner, and the burr removing effect is achieved; meanwhile, the burr removing effect is remarkable, the risk that the gear isbroken down is avoided, time for burr removing is short, and efficiency is high; the concentration of sodium nitrate is low, harm to the human body is avoided, corrosion to the surface of the gear isavoided, and meanwhile, the good burr removing effect can be ensured; and as the electrolyte spraying speed is high and the flow amount is large, the complex washing step in the later period is omitted, the gear only needs to be washed with clear water, the gear is washed ultrasonically, and thus greasy dirt on the surface of the gear can be decomposed and emulsified.

Owner:NANTONG ZHONGLV GEAR CO LTD

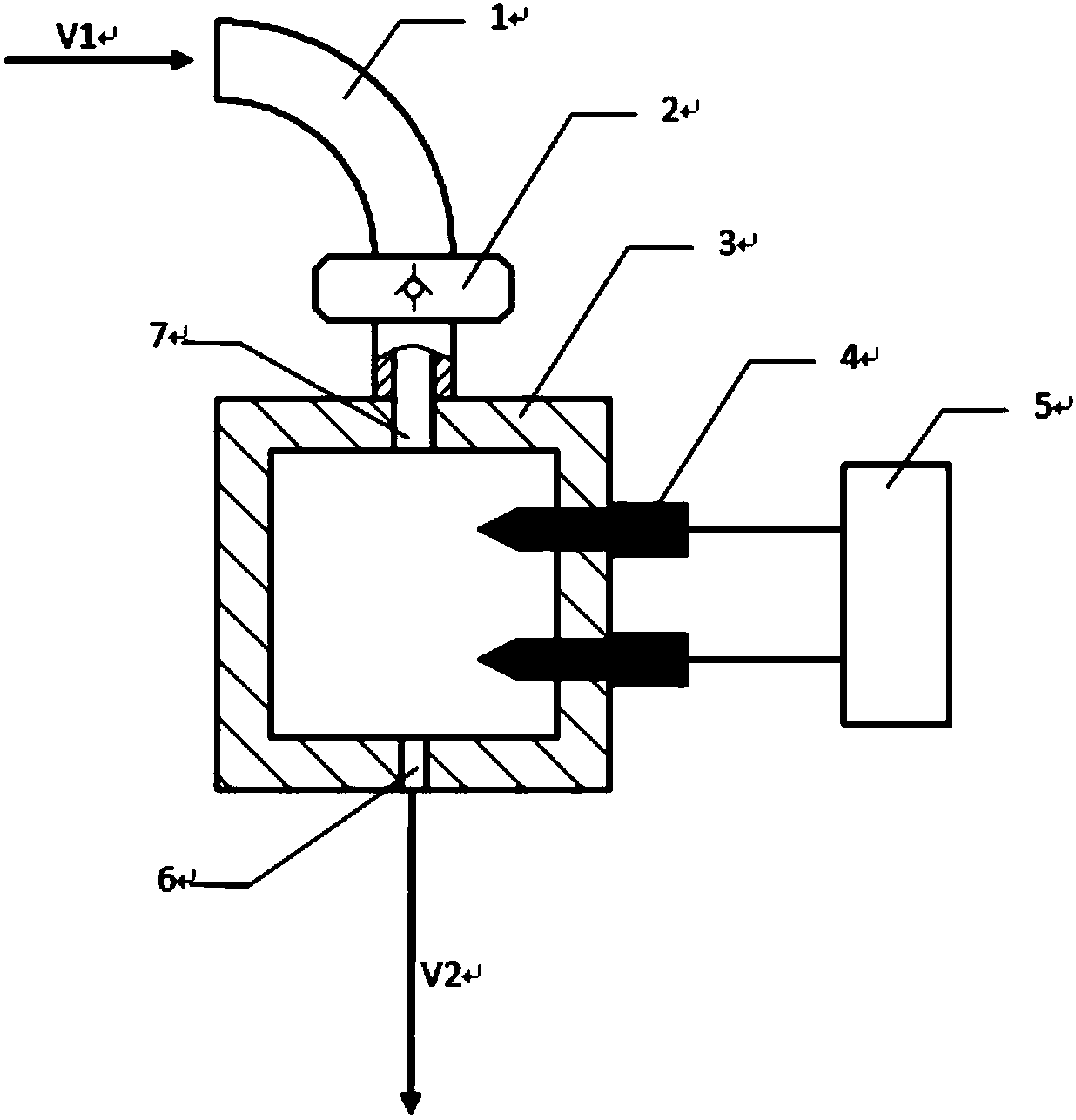

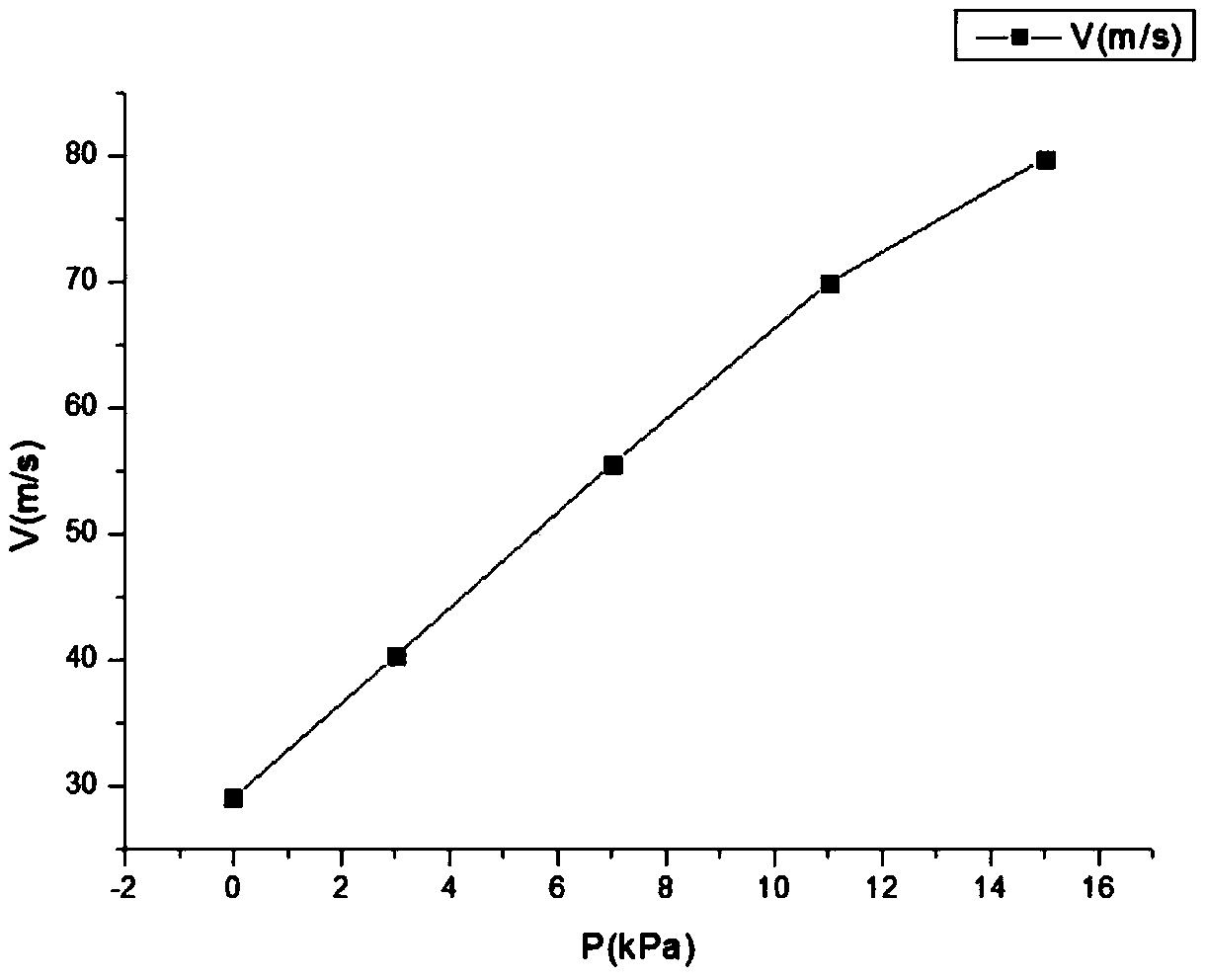

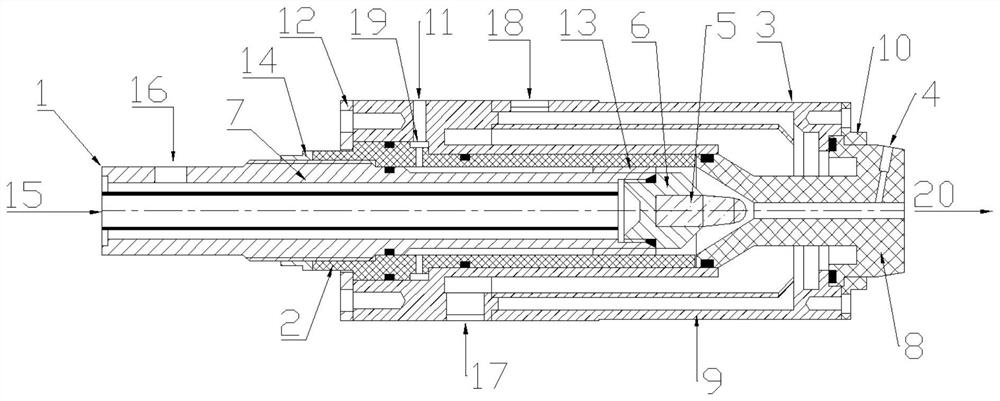

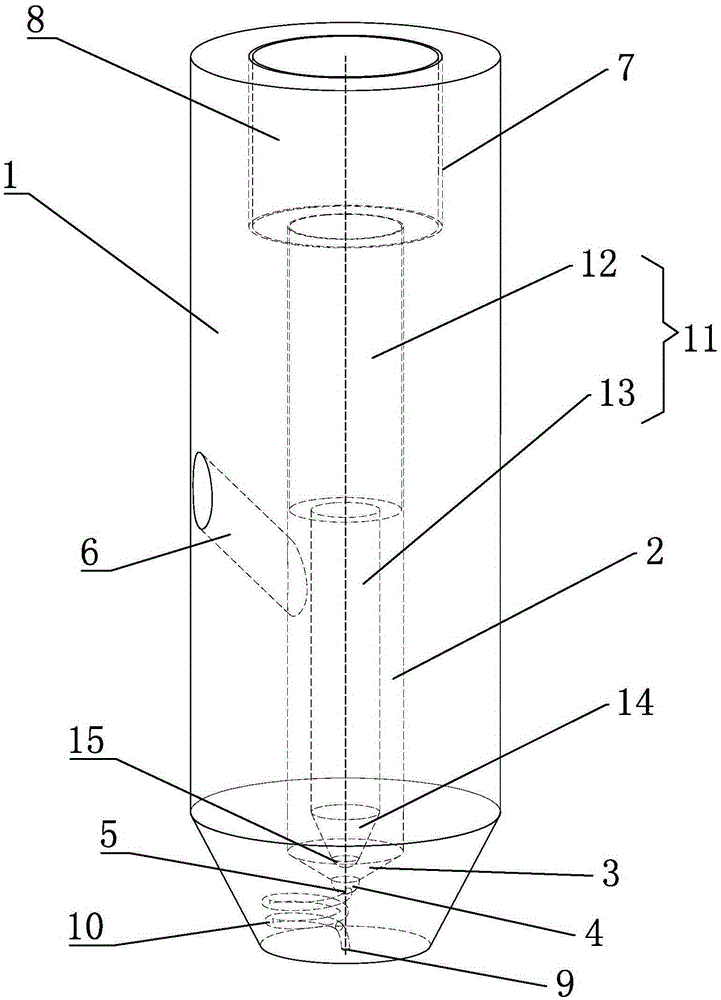

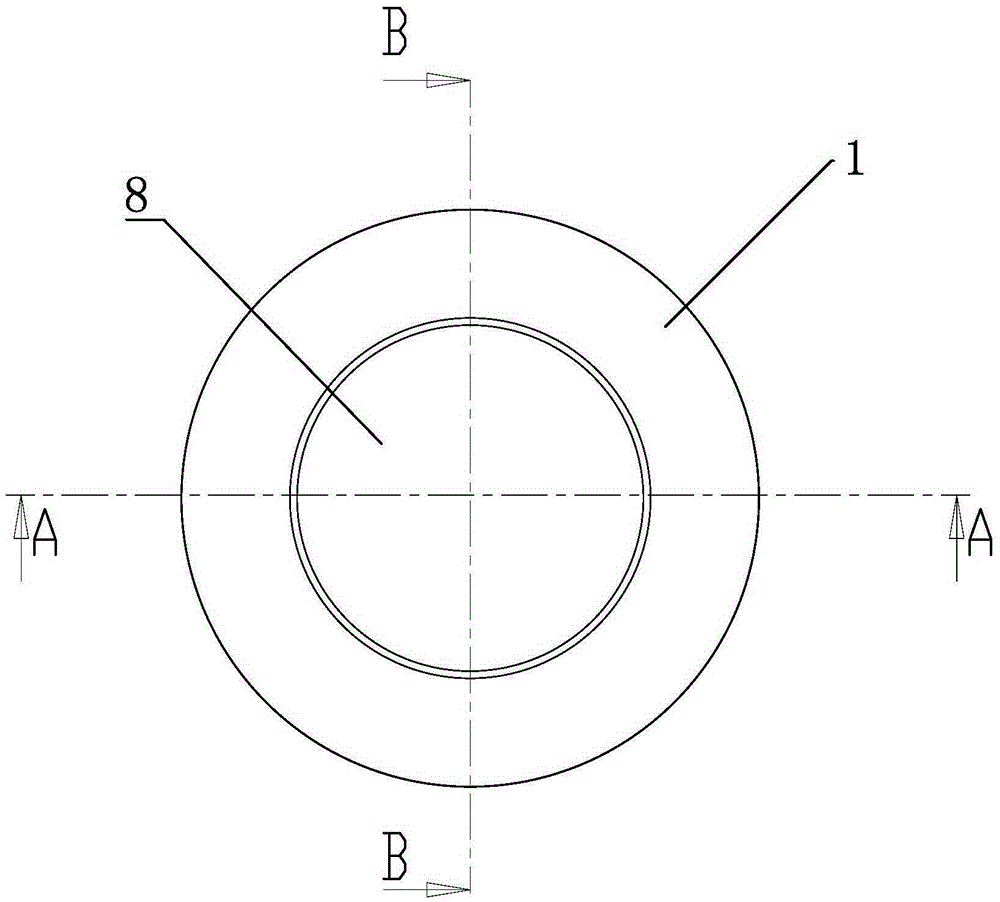

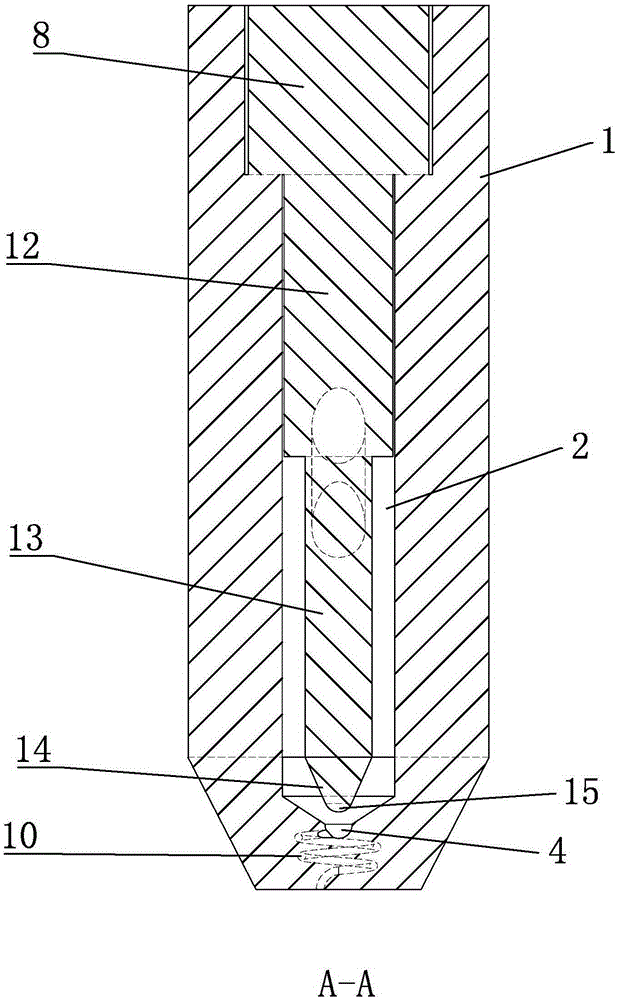

Dynamic pressure plasma synthesis jet generator

A dynamic pressure plasma synthesis jet generator relates to a jet generating device. The device uses the dynamic pressure of the forward incoming flow to introduce a high-speed incoming flow into a plasma generator cavity through an air bleed pipeline and a one-way valve, the pressure inside the cavity is increased, and meanwhile, a high-temperature plasma is generated in the cavity through high-voltage discharge, so that the air in the cavity is subjected to thermal expansion, and a high-speed jet is generated at a jet outlet. The device is provided with a plasma generator, the air bleed pipeline, the one-way valve and a high-voltage pulse power supply, wherein the plasma generator is composed of a negative electrode, a positive electrode and a generator cavity, and the generator cavityis provided with an incoming flow inlet, the jet outlet and electrode insertion holes. The device has the advantages of simple structure, light weight, low cost, almost no influence on the aerodynamicshape of an aircraft while generating the high-speed jet, and the like. In addition, the device can also control the jet velocity within a certain range by changing the loaded electrical parameters.

Owner:XIAMEN UNIV

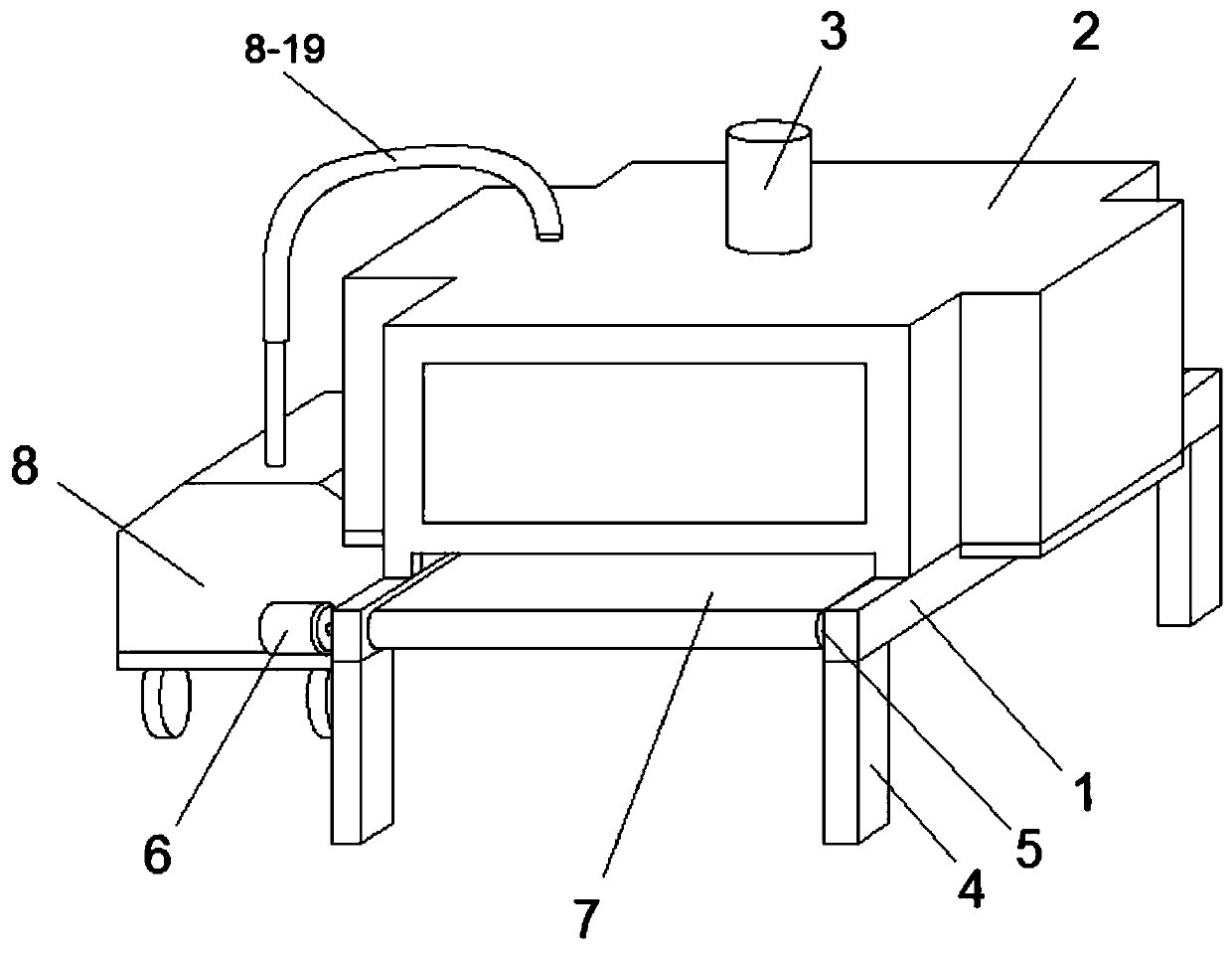

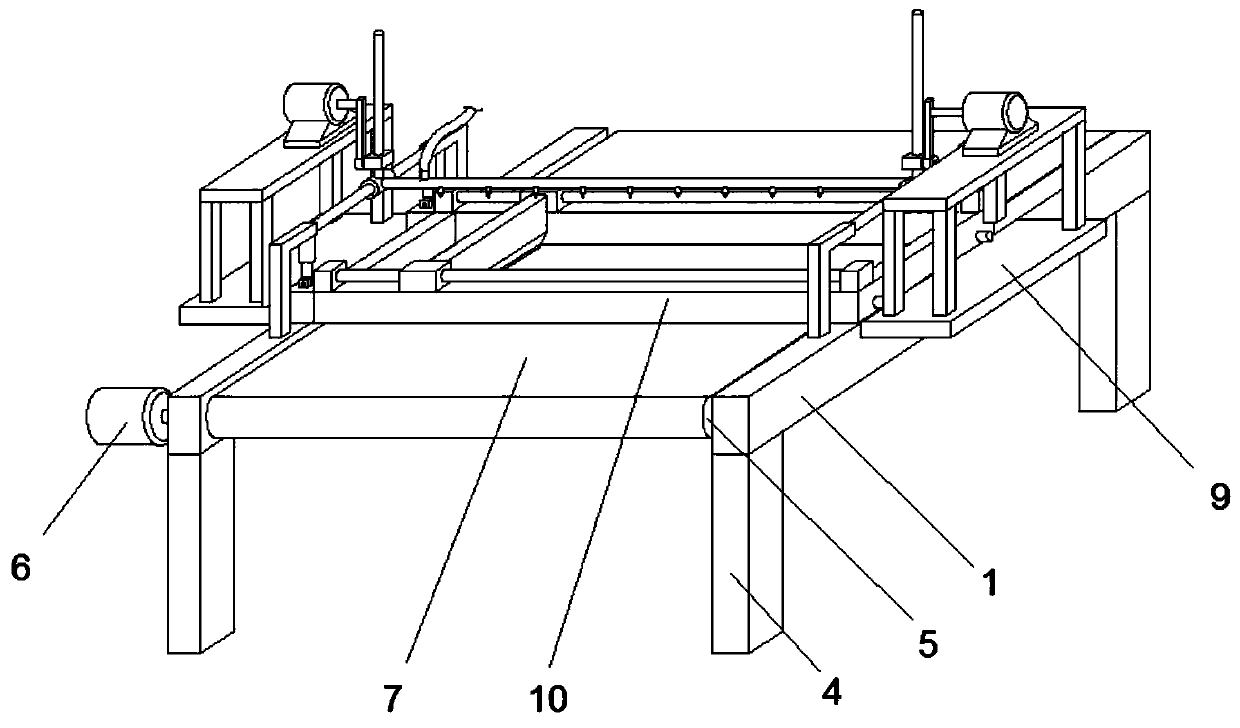

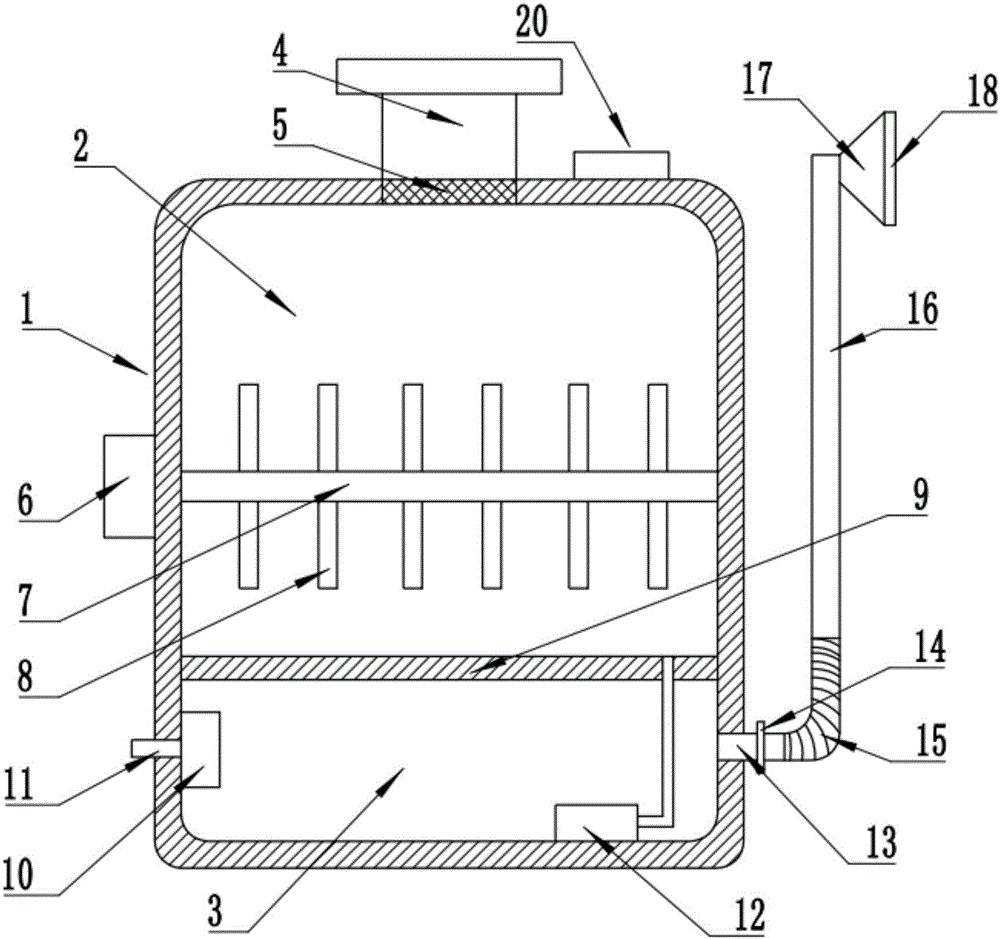

Coating device used for special coating glass fiber cloth preparation

ActiveCN110013930AImprove cleanlinessIncreased flexibility of useSpraying apparatusEngineeringCoating

A coating device used for special coating glass fiber cloth preparation comprises bottom frames, a shell, an exhaust pipe, column feet, a conveying roller, a transmission motor, a conveyor belt, a paint filling device, a spraying tool and a blade coating tool. The bottom frames are symmetrically arranged. The shell is arranged on the top faces of the bottom frames. Each column foot is arranged onthe lower surface of the bottom frame on the corresponding side. The conveying roller is arranged between the bottom frames on the two sides. The conveyor belt is arranged outside the conveying rollerin a wrapping manner. The paint filling device is arranged on one side of the bottom frames. The spraying tool is arranged above the bottom frames. The blade coating tool is arranged above the conveyor belt. The paint filling device is flexible to use and can clean the inner portion of a liquid storage cavity; and the device is stable in system operation, uniform in blade coating and high in coating efficiency.

Owner:镇江安之盾高温纤维制品有限公司

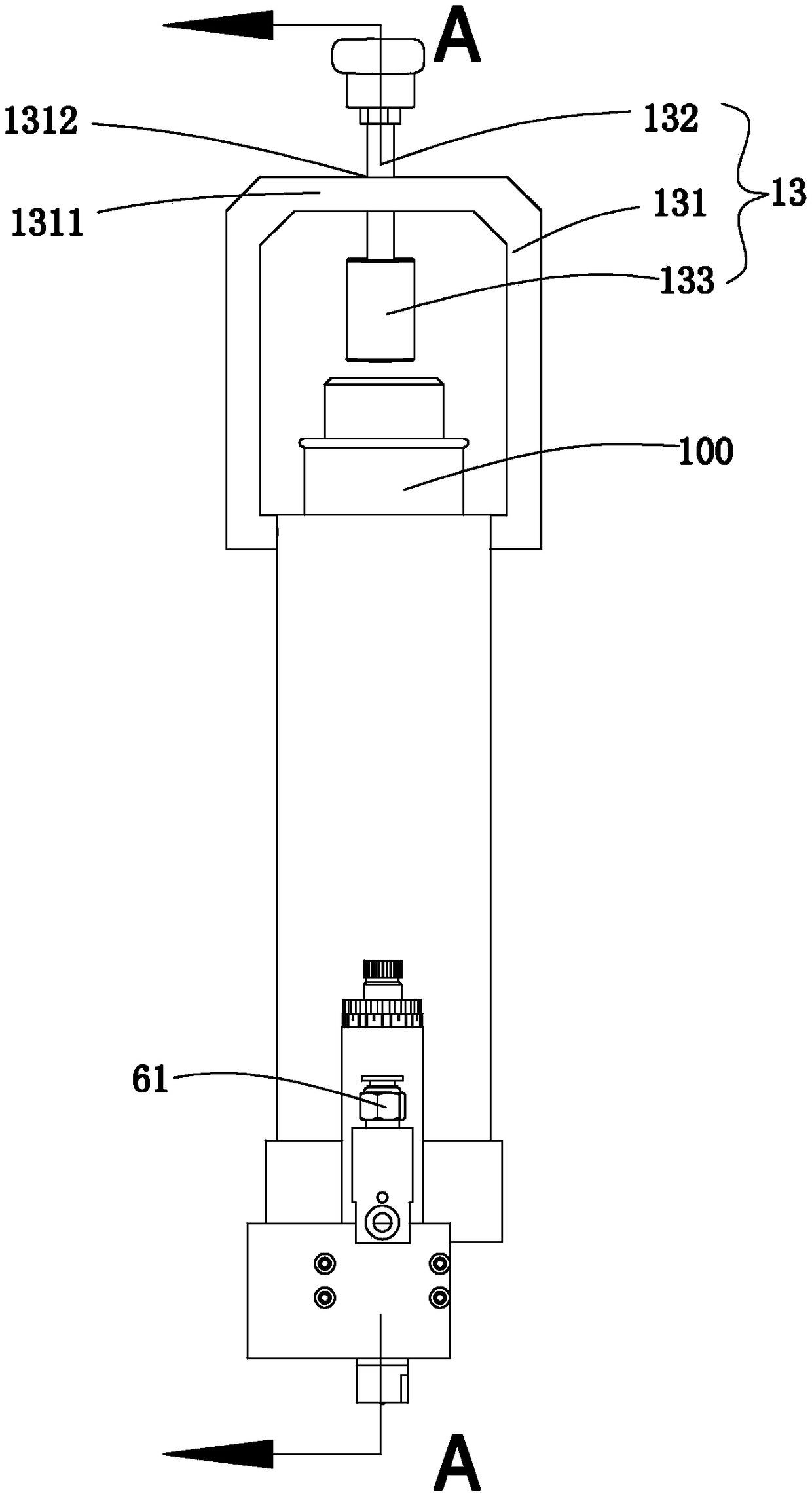

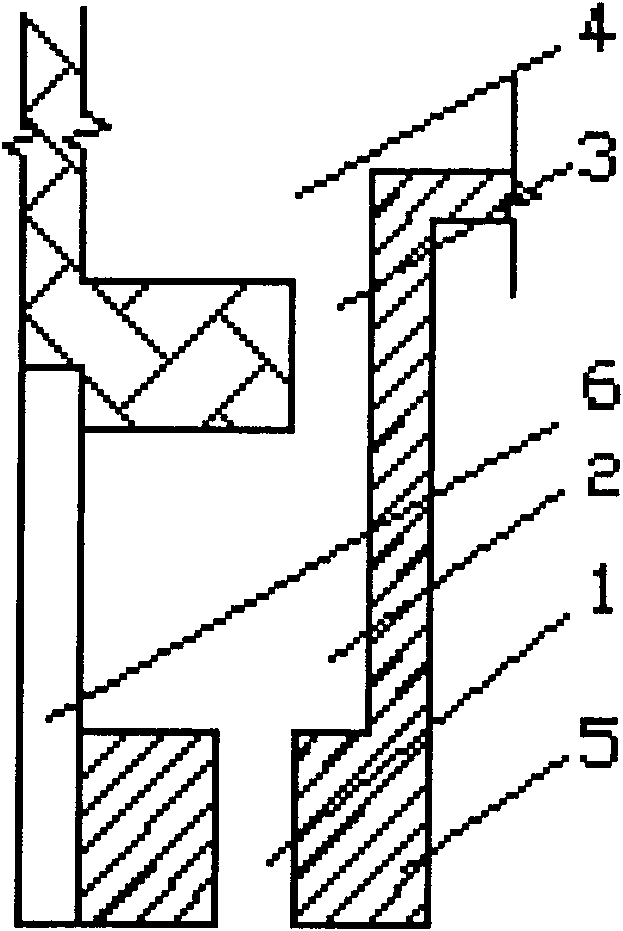

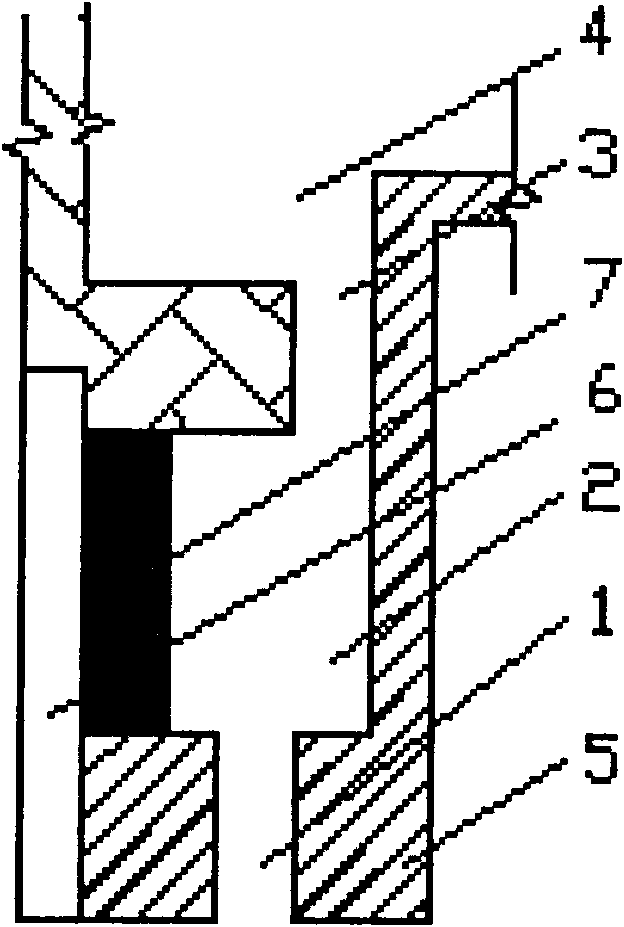

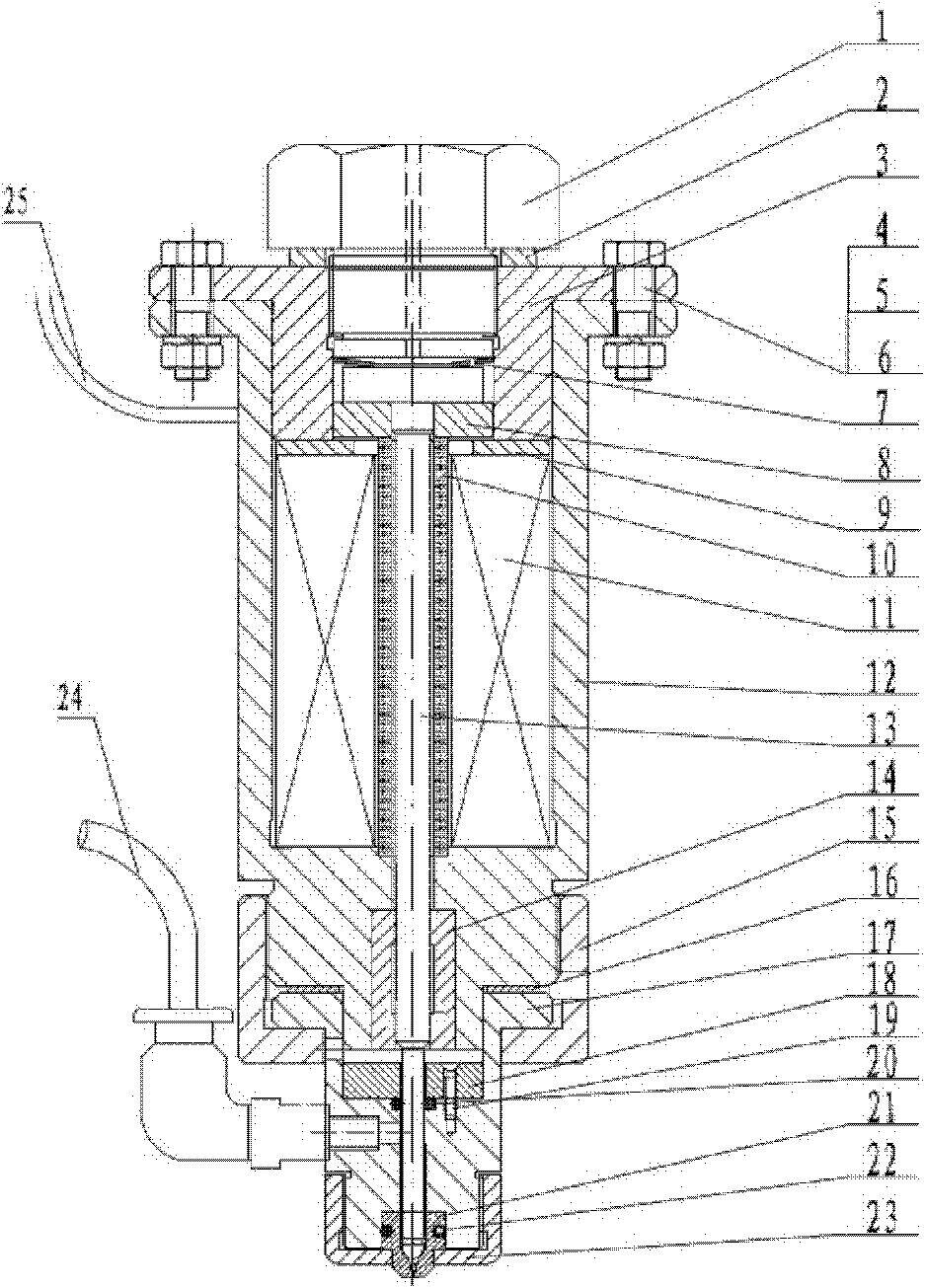

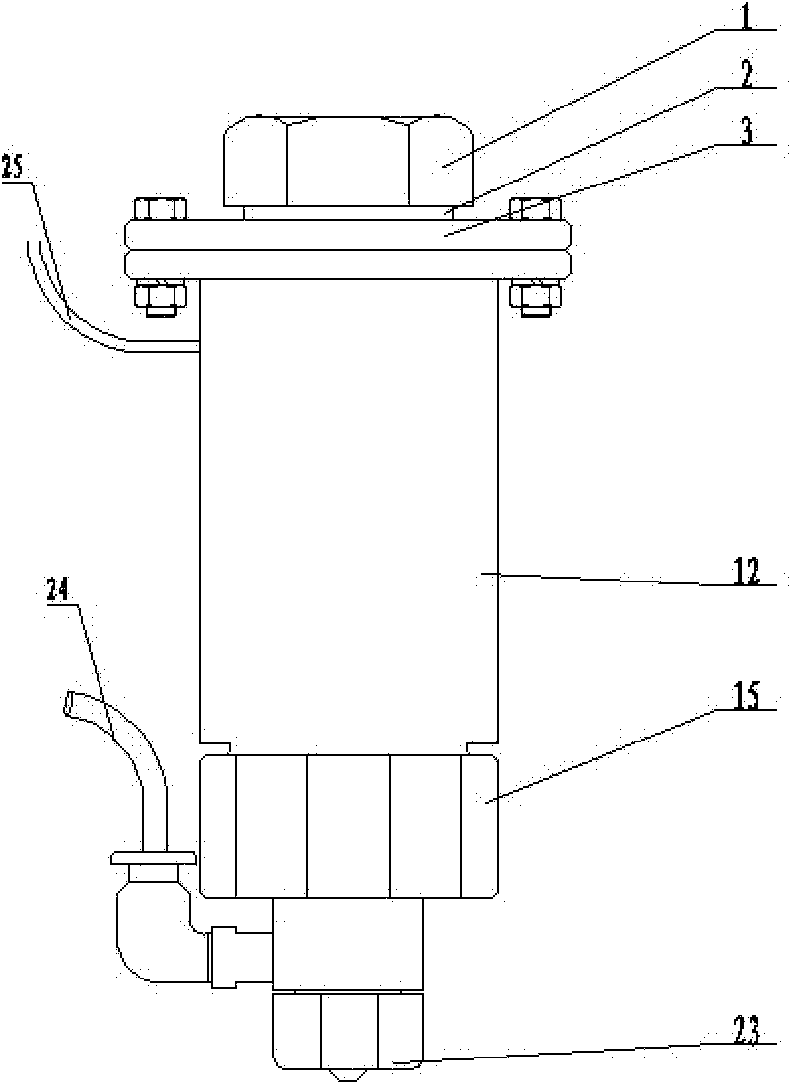

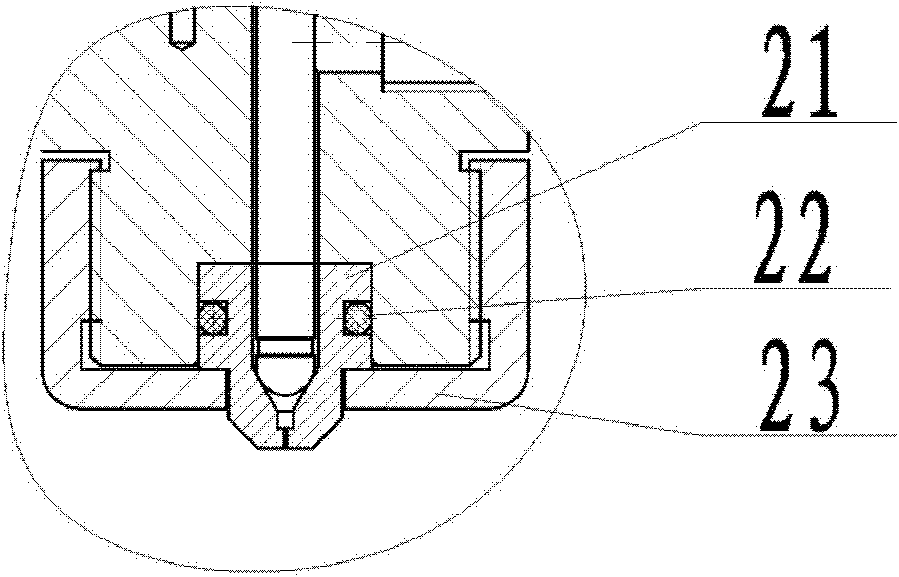

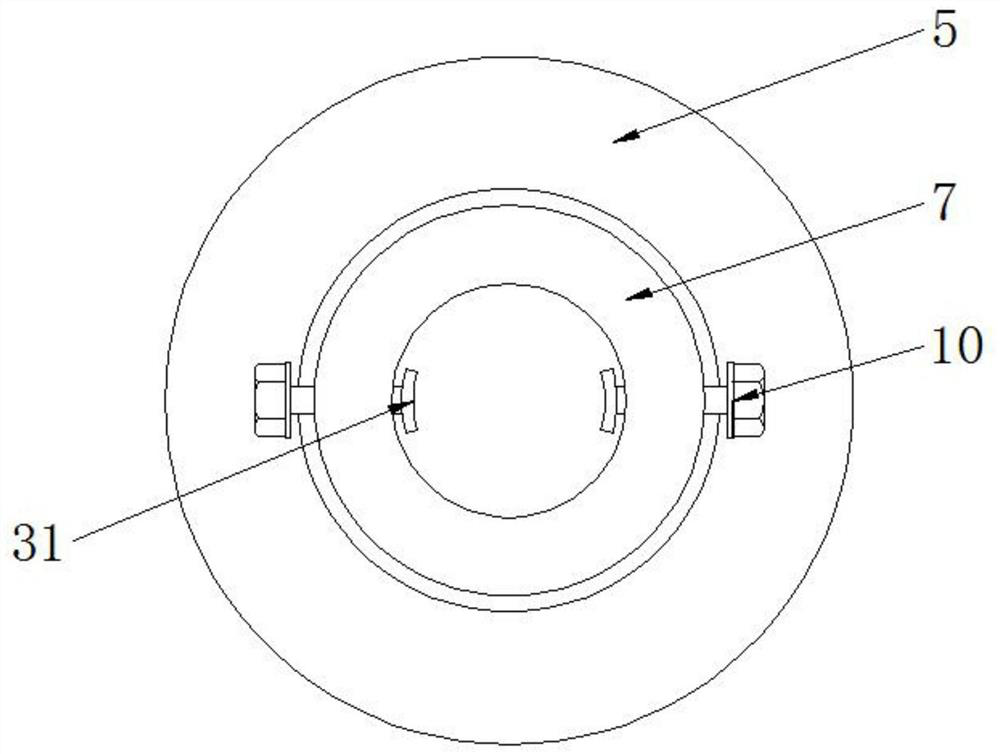

Hot melt adhesive spray valve

ActiveCN108906492AJet speedSpray evenlyLiquid surface applicatorsCoatingsElastic componentInlet channel

The invention relates to a hot melt adhesive spray valve. The hot melt adhesive spray valve can comprise a hot melt adhesive heating device, a valve body, a valve element and a striker. Heat transferof the hot melt adhesive heating device acts on a hot melt adhesive tank and a flow channel, wherein the flow channel communicates with an outlet of the hot melt adhesive tank. The valve body comprises a first cavity and a second cavity, wherein the first cavity and the second cavity are spaced from each other in a sealed manner. The first cavity is provided with an air inlet. On and off switchingof an air inlet channel communicating with the air inlet is achieved through a high-frequency air inlet and outlet switch. The air inlet end of the high-frequency air inlet and outlet switch is connected with high-pressure air. The second cavity is provided with an adhesive inlet and a spray orifice, wherein the adhesive inlet communicates with the flow channel, and the spray orifice is formed inthe lower end. The valve element is jointed into the first cavity in a sealed manner and connected with an elastic component. The upper end of the striker is fixed to the valve element and extends tothe second cavity. The lower end of the striker can plug the spray orifice. The valve element can perform reciprocation motion in the first cavity under the effect of the high-pressure air and the elastic component, and furthermore, the striker is driven to perform reciprocating motion so that hot melt adhesive entering the second cavity through the flow channel can be sprayed out of the spray orifice.

Owner:VISION XIAMEN AUTOMATION TECH CO LTD

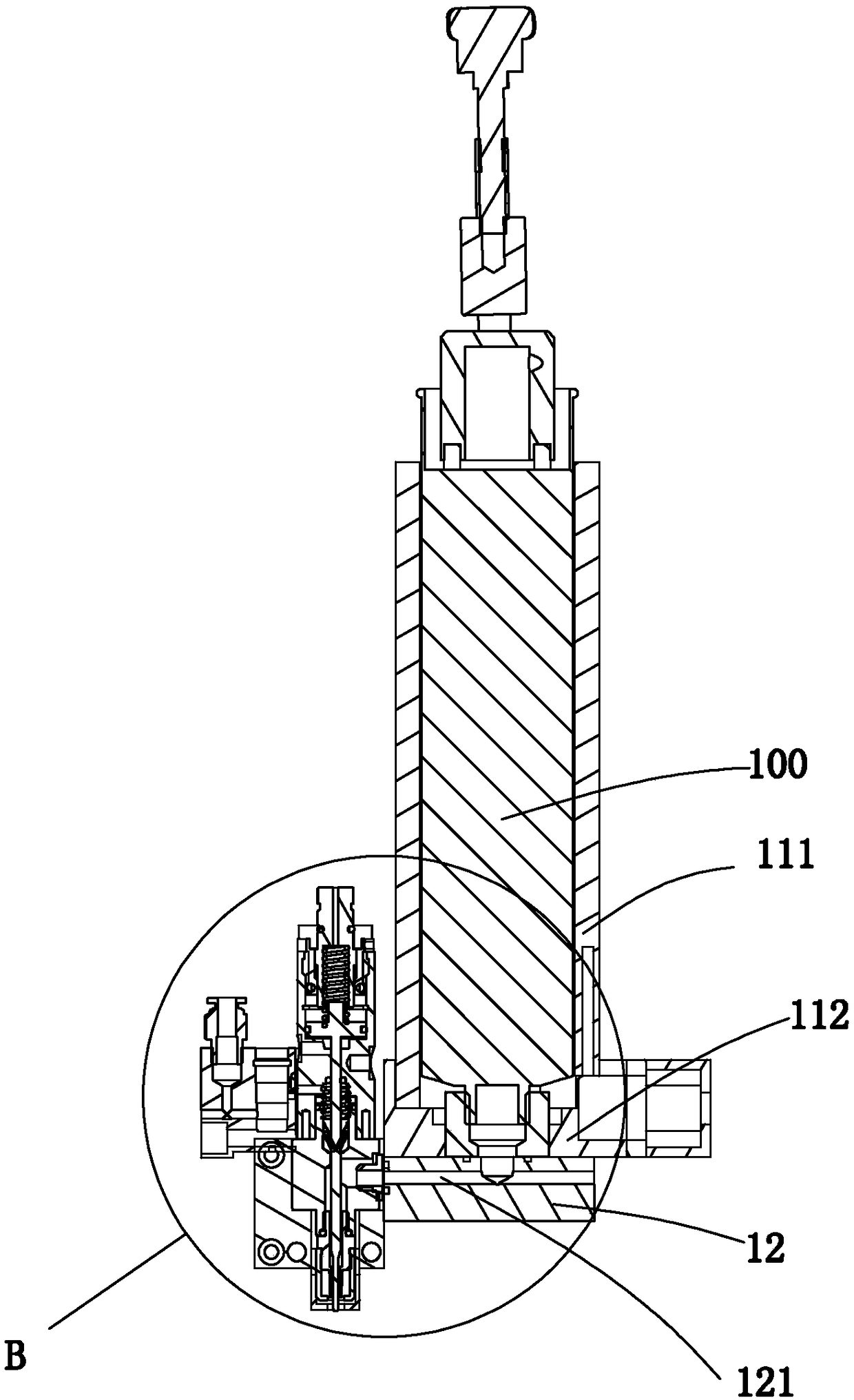

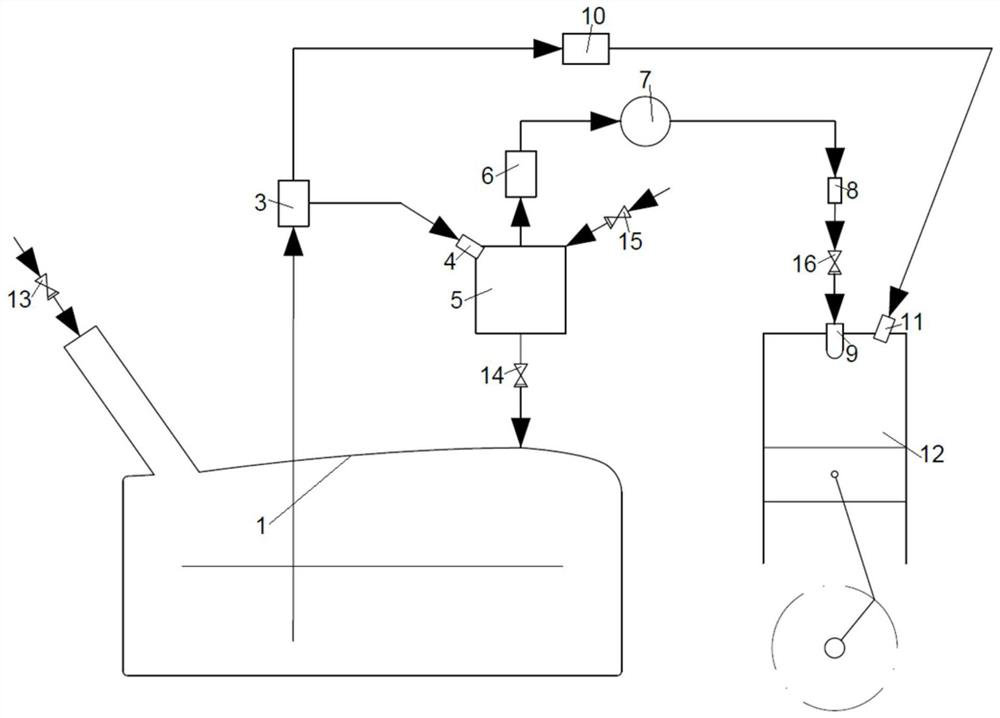

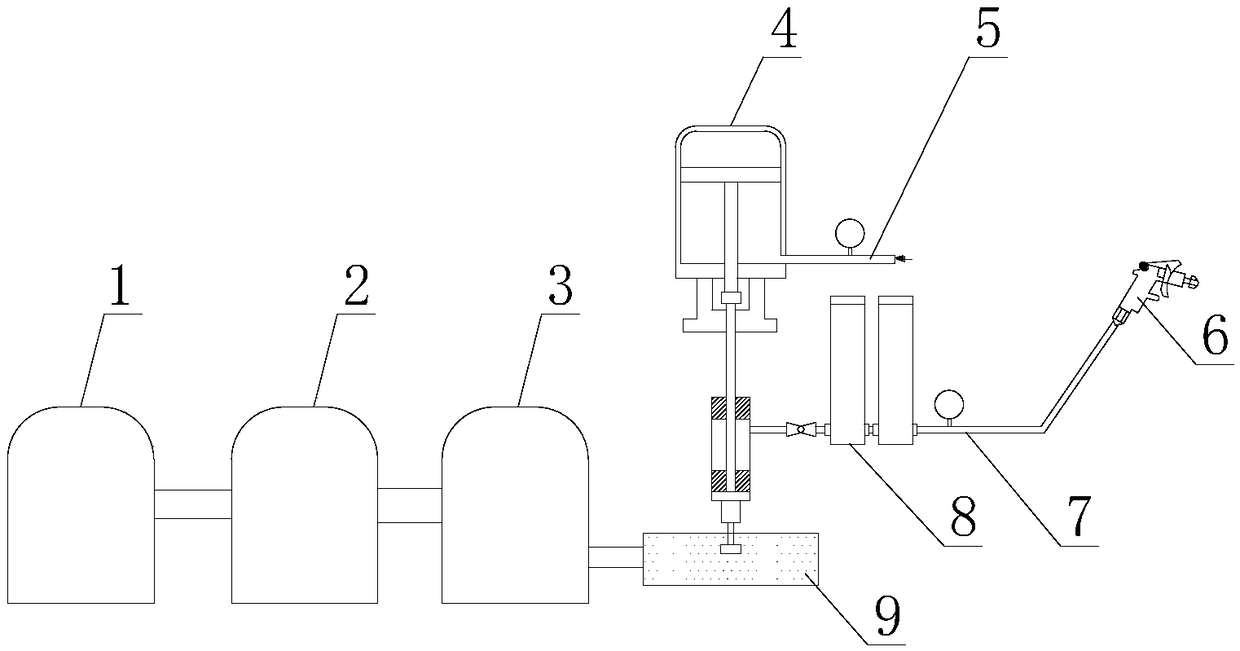

Fuel preparation and supply system and method for active pre-combustion chamber

PendingCN112145281ASimple structureSmall footprintInternal combustion piston enginesCombustion chamberInjector nozzle

The invention relates to a fuel preparation and supply system and method for an active pre-combustion chamber. The system mainly comprises a conventional fuel supply system and a fuel-air mixed gas preparation and supply system; the conventional fuel supply system comprises an oil tank, a fuel oil pipeline, a low-pressure oil pump, a high-pressure oil pump, an oil nozzle, a combustion chamber andan oil tank one-way valve; and the fuel-air mixed gas preparation and supply system comprises an oil tank, a fuel oil pipeline, a low-pressure oil pump, an oil nozzle, a premixing chamber, a gas pump,a pressure regulating valve, a fuel gas nozzle, a premixing chamber spark plug, a combustion chamber, a premixing chamber oil return one-way valve, a premixing chamber gas inlet one-way valve and a premixing chamber one-way valve. The invention further discloses a fuel preparation and supply method for the active pre-combustion chamber. The fuel preparation and supply system for the active pre-combustion chamber is simple in structure, and meanwhile the effects of optimizing combustion, improving emission, saving fuel and the like can be achieved.

Owner:TONGJI UNIV

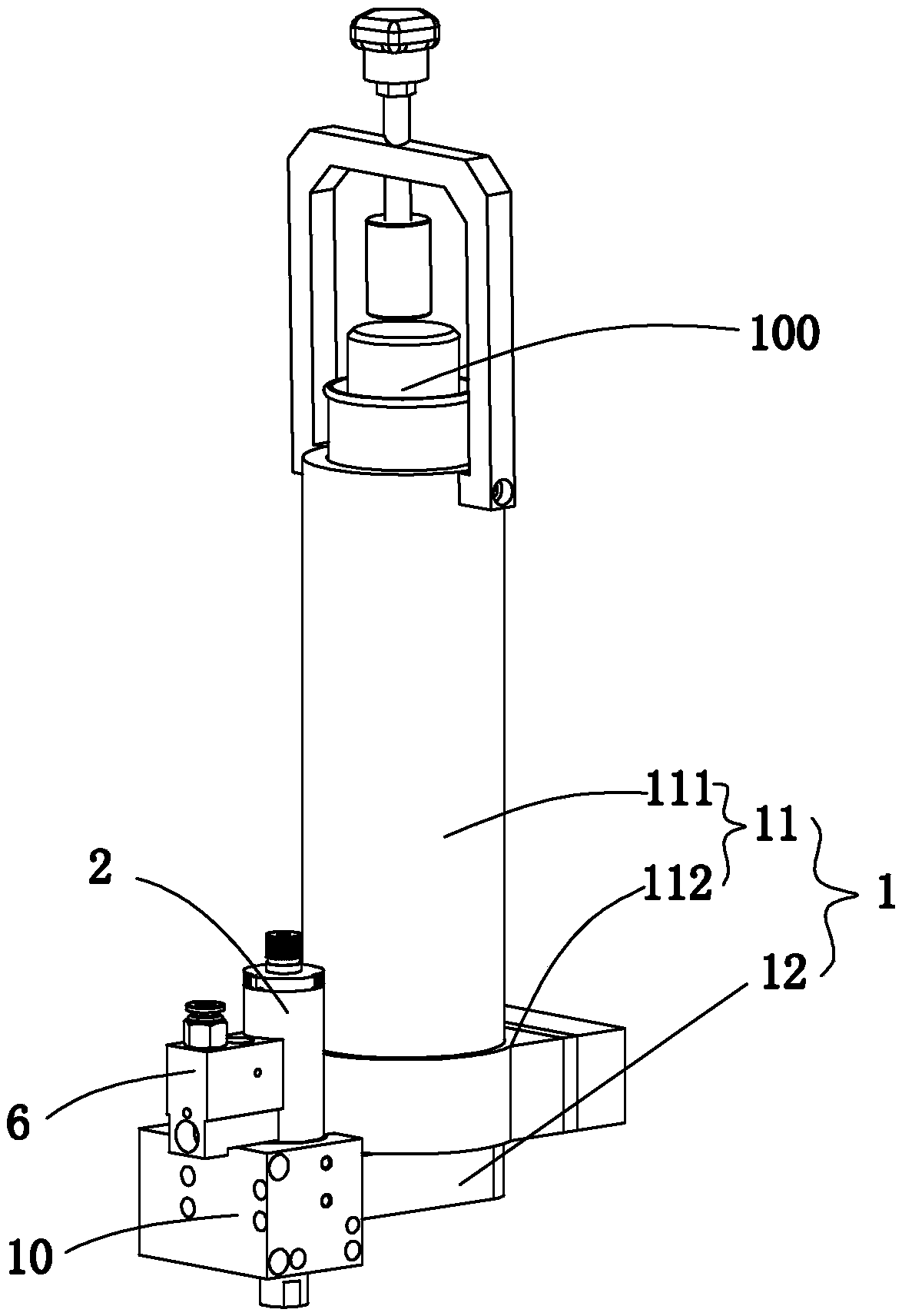

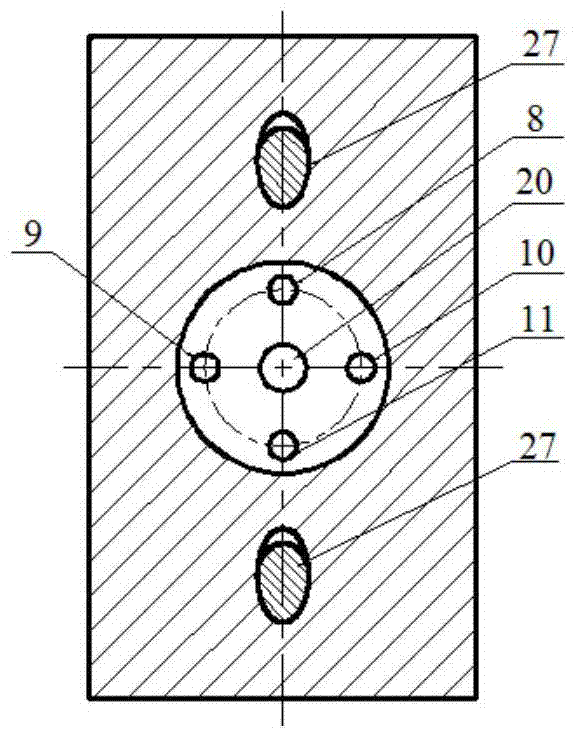

Plasma generator for powder spheroidizing or fine coating

PendingCN112911778AEasy to absorb heatImprove production efficiencyPlasma techniquePlasma jetPlasma technology

The invention relates to a thermal plasma technology, in particular to a plasma generator for powder spheroidizing or fine coating. The generator comprises a cathode assembly, an insulating sleeve and an anode assembly; the cathode assembly comprises a red copper seat, a cathode head and a cathode cooling sleeve, and the anode assembly comprises an anode and an anode cooling sleeve which are coaxially mounted. A spherical tungsten rod serves as a cathode head and is embedded in a red copper seat, electrode ablation is relieved, the service life of an electrode is prolonged, an anode is of a 2-5 mm hollow red copper structure, and working gas is converged in a channel between the cathode head and the anode to form high-speed plasma jet flow after forming higher atmospheric pressure and passing through an anode channel. The diameter of the plasma jet beam generated by the device ranges from 2 mm to 5 mm, energy is more concentrated, the jet speed is higher, powder can better absorb heat to be melted, and the spherical powder preparing or coating efficiency is improved.

Owner:SOUTHWESTERN INST OF PHYSICS

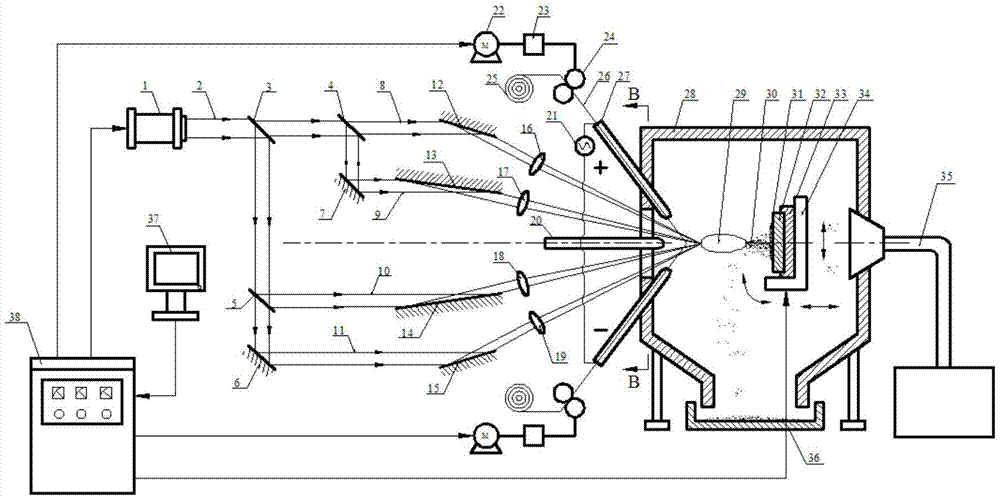

Directional ultrahigh-velocity spraying method and device based on laser induced shock wave technology

The invention discloses a directional ultrahigh-velocity spraying method and device based on a laser induced shock wave technology, belonging to the technical field of part processing and remanufacturing. According to the spraying method, a high-temperature electric arc generated by an electrode is firstly used for heating and melting spray wires of a coating material to form molten drops and the molten drops fall off and are atomized into a microdrop stream; then a laser pulse beam is used for irradiating the surface of the microdrop stream; a part of microdrops on the surface absorb laser energy and are instantly gasified and ionized into high-pressure plasma; the high-pressure plasma further absorbs laser energy and expands and blows up to form high-pressure shock waves at GPa grade; the high-pressure shock waves drive the corpuscular stream to jet onto the surface of a workpiece at a high velocity to form a coating. The spraying device comprises a laser generator, a beam guiding and splitting system, an electric arc liquid making system, a workpiece clamp system, a recycling system and a control system. The spraying device can be used for realizing high-velocity high-efficiency spraying; the combination strength of the coating and a substrate is good; the coating has high density and low void content and also has relatively high thermal fatigue resistance and mechanical fatigue resistance.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Laser ink-jetting head

InactiveCN102019753AReduce production processLow technical requirementsPrintingThermal bubbleEngineering

The invention relates to a laser ink-jetting printing head. The main parts of the laser ink-jetting printing head comprise a laser generator, a laser deflecting part, an ink-jetting part, and the like. Laser is sequentially projected in all small ink chambers of the ink-jetting part after being deflected by the laser deflecting part and generates thermal pressure or dynamic pressure, and ink is jetted out by pressure. Compared with a thermal bubble type and piezoelectric type ink-jetting head, laser ink-jetting printing head has low technical requirement for the manufacture process, simple circuit, high jetting speed and lower cost, can be easily manufactured into the ink-jetting head with page width and is easy to realize high-precision printing.

Owner:韦翔

Oil granule counter

ActiveCN107421876AImprove detection accuracySimple structureIndividual particle analysisWave shapeMechanical engineering

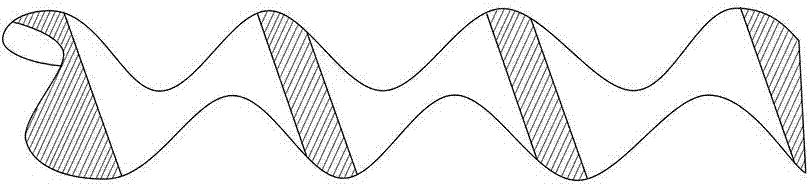

The invention relates to an oil granule counter which comprises an oil sample bottle, a liquid inlet tube, a sample pond, a liquid back tube, a plunger pump and a waste liquid collecting bottle, wherein one end of the liquid inlet tube is inserted into the oil sample bottle; the other end of the liquid inlet tube is connected with one end of the sample pond; the other end of the sample pond is connected with one end of the liquid back tube; the other end of the liquid back tube is inserted into the waste liquid collecting bottle; the plunger pump is arranged between the liquid back tube and the sample pond; a laser emitting device is arranged above the sample pond; a laser shaper is arranged between the laser emitting device and the sample pond; a light sensitive receiver is arranged below the sample pond; the light sensitive receiver is connected with a processor; a corrugated transverse tube is arranged between the liquid inlet tube and the sample pond; the corrugated transverse tube is of a hollow tube structure; wave-shaped bulges are arranged on both the upper surface and the lower surface of the corrugated transverse tube; and the bulges on the upper surface and the bulges on the lower surface are arranged in a staggered manner. The oil granule counter has the beneficial effects of being wide in application range, high in detection precision, simple in structure and convenient to operate, and the problem that a tube is blocked as the tube diameter is reduced to improve the precision is reduced.

Owner:PLA NO 5719 FACTORY

Dispersion-type efficient pesticide spraying machine

InactiveCN106489893AImprove spraying effectIncreased dispersionInsect catchers and killersAgricultural engineeringPesticide

The invention discloses a dispersion-type efficient pesticide spraying machine. The dispersion-type efficient pesticide spraying machine comprises a spraying machine body, a pesticide storing cavity, a pesticide spraying pipe and a spraying head. The inside of the spraying machine body is divided by a partition plate into the pesticide storing cavity and an air dissolving cavity; a stirring shaft is transversely arranged inside the pesticide storing cavity, stirring blades are perpendicularly arranged on the surface of the stirring shaft, and a driving motor is arranged outside the pesticide storing cavity; the air dissolving cavity is formed in the bottom of the spraying machine body, a micro-air pump is fixedly connected on the inner wall of the air dissolving cavity, and an air inlet is formed in the side wall of the left side of the spraying machine body; a water pump is fixedly connected to the bottom of the air dissolving cavity; a pesticide discharging opening is formed in the bottom of the right side of the spraying machine body; a stretchable flexible pipe is fixedly connected to the pesticide discharging opening in a hot-press mode; a pesticide spraying pipe is fixedly connected to the tail end of the stretchable flexible pipe, the spraying head is fixedly connected to the tail end of the pesticide spraying pipe, and a dispersion sheet is fixedly connected to the surface of the spraying head. The concentration of the pesticide liquid inside the pesticide spraying machine is even, the covering range when pesticide is sprayed is large, the atomization effect is good, the pesticide spraying effect is improved, the spraying speed of pesticide water is high when the pesticide is sprayed, the dispersion degree of the pesticide is high, and the pesticide spraying efficiency is improved.

Owner:ZHENGZHOU TIANSHUN ELECTRONICS TECH CO LTD

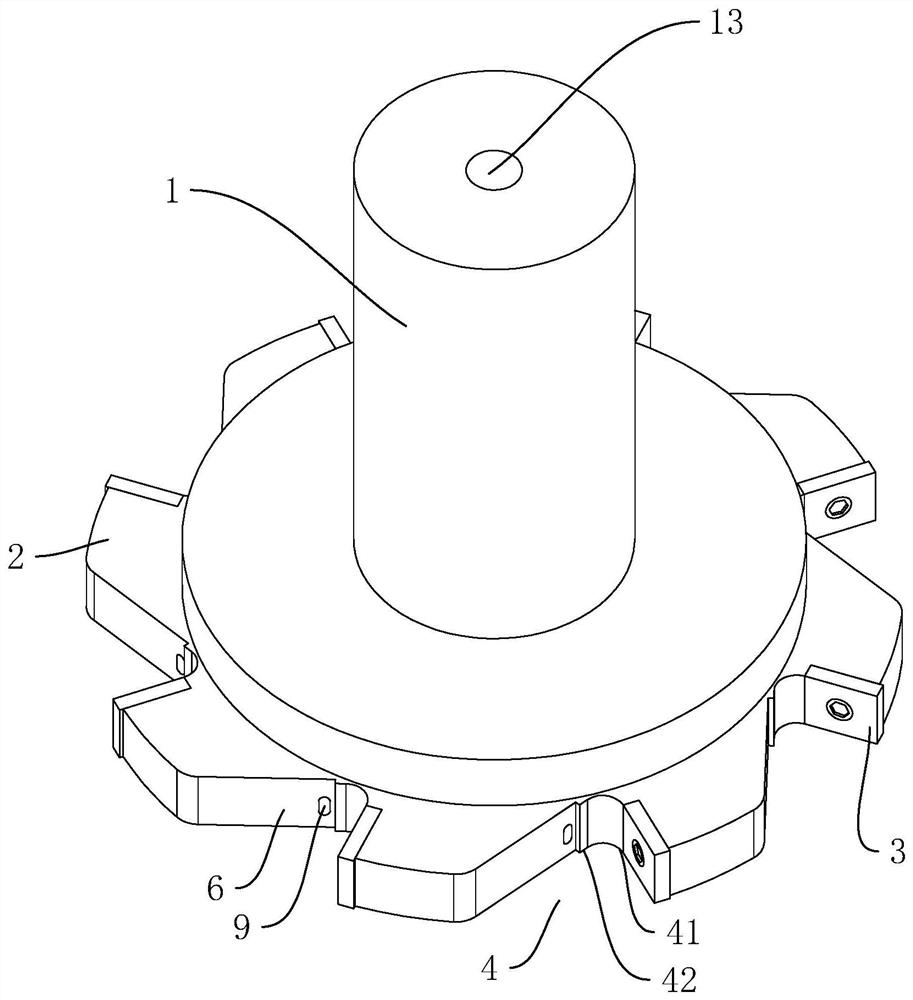

Groove milling cutter

The invention discloses a groove milling cutter, and relates to the technical field of milling cutters. The groove milling cutter comprises a cutter handle and a cutter head which is coaxially fixed at one axial end of the cutter handle, at least two blades are uniformly distributed in the circumferential direction of the cutter head, a containing groove is coaxially formed in one end, close to the cutter handle, of the cutter head, the cutter handle covers an opening of the containing groove, a liquid inlet hole which communicates with the containing groove is formed in the cutter handle in the axial direction; the cutter head is further provided with a plurality of liquid discharging holes, the liquid discharging holes correspondingly communicate with the circumferential inner wall of the containing groove, the number of the liquid discharging holes corresponds to the number of the blades, and the liquid discharging holes face the positions, away from the axis of the cutter head, ofthe blades. According to the groove milling cutter, the liquid inlet hole, the containing groove and the liquid discharging holes are formed, so that the blades make more sufficient contact with cooling liquid in the groove milling process of the groove milling cutter, and the cooling effect of the blades is better; and in addition, the cooling liquid sprayed out at a high speed can further carryout impact on cuttings, so that the situation that the cuttings are stuck to the cutter is reduced, and overall use is more stable.

Owner:台州市英络克工具有限公司

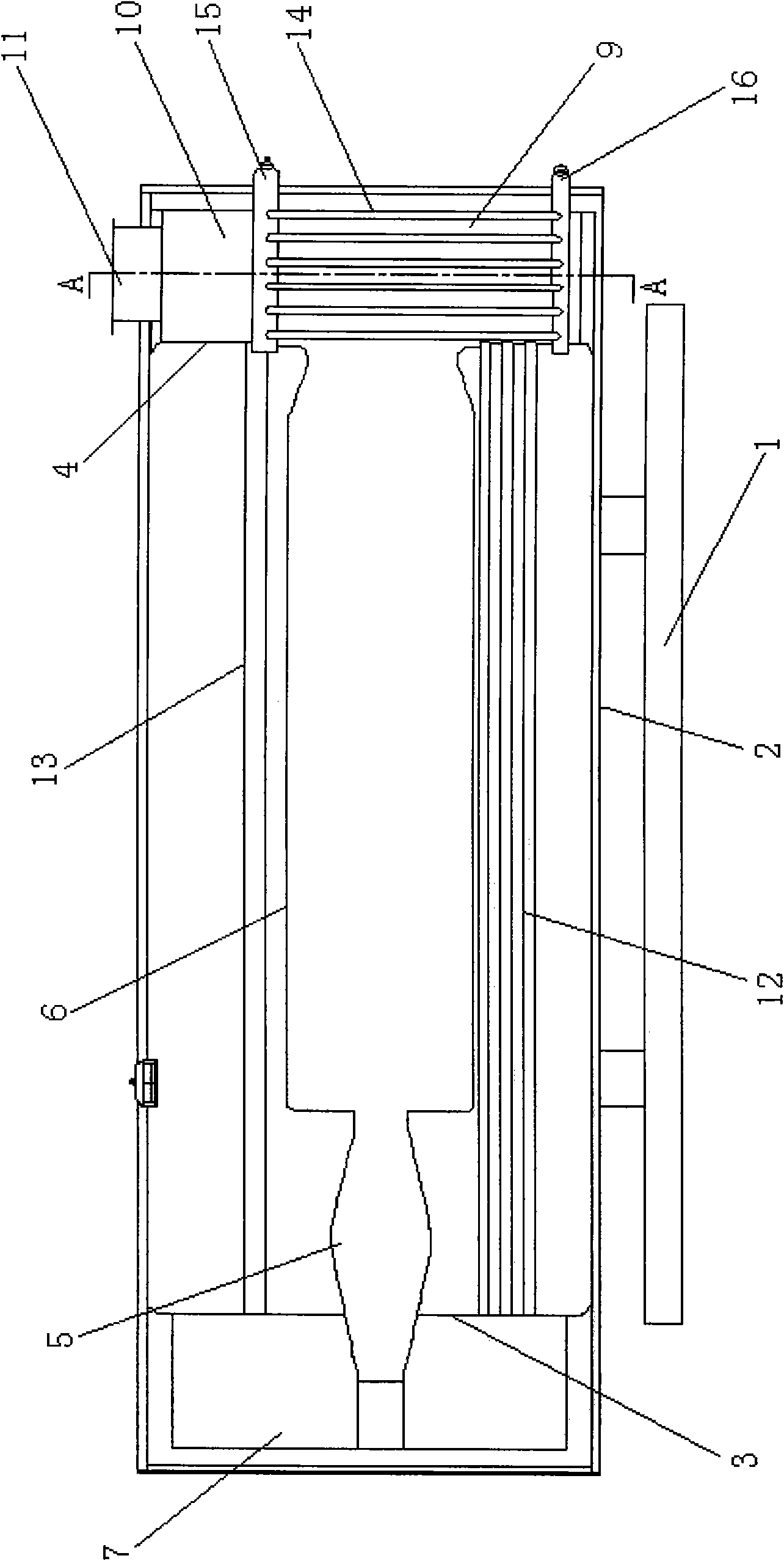

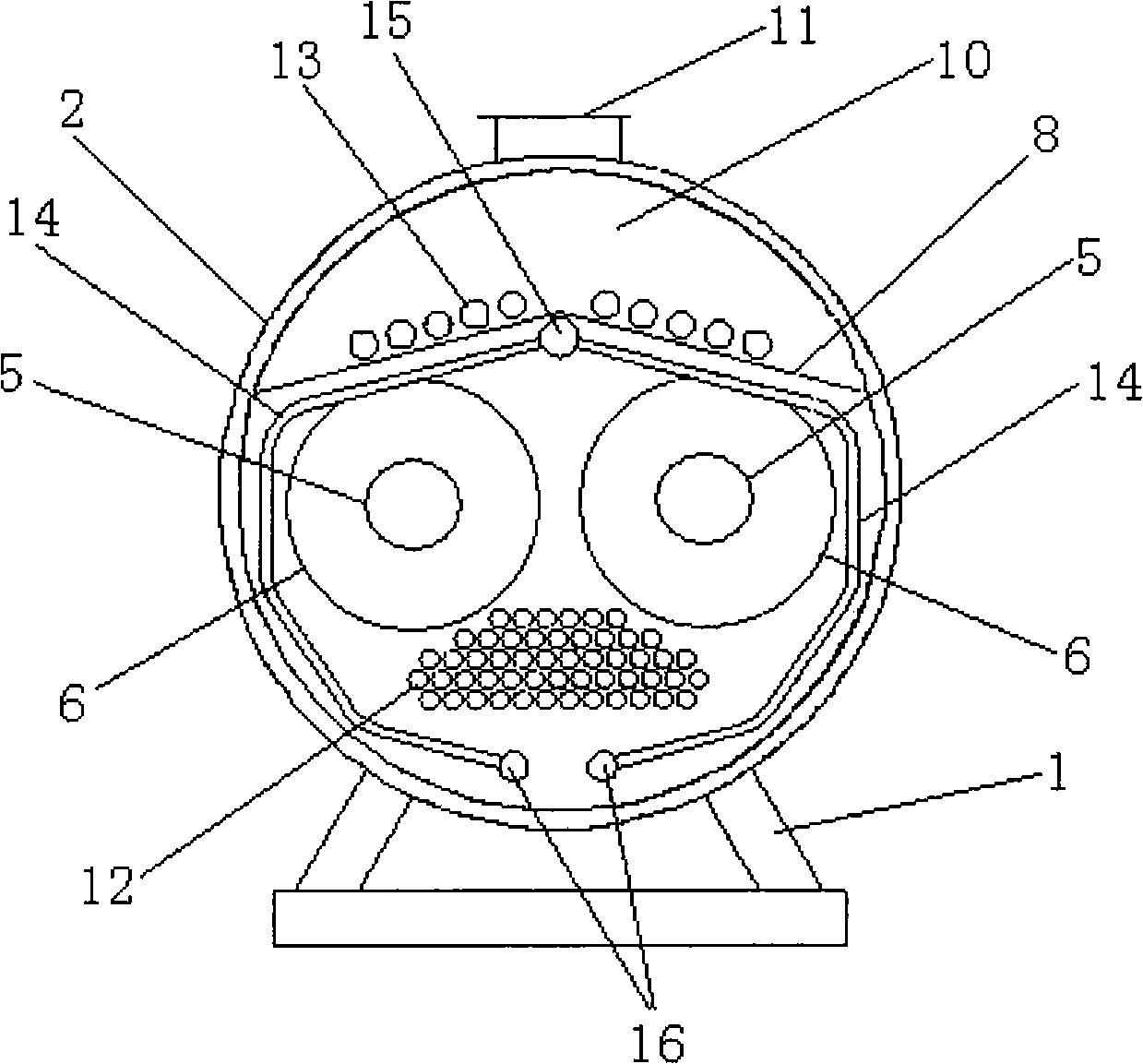

Horizontal type double-flue industrial coal powder boiler

The invention relates to an industrial coal powder boiler which is characterized by comprising a transversely arranged cylindrical boiler casing, wherein a front end plate and a back end plate are respectively arranged at the front part and the rear part in the boiler casing; two precombustion chambers abreast and axially penetrate the middle part of the front end plate, the outlet ends of the two precombustion chambers are respectively communicated with ends of two horizontal boiler flues abreast and transversely arranged in the boiler casing and other ends of the two boiler flues are respectively communicated with the back end plate; a front smokebox is formed between the front end of the boiler casing and the front end plate, the rear end of the boiler casing and the back end plate are divided into an upper part and a lower part through a partition board and a rear smokebox and a smoke collection chamber are respectively formed at the lower part and the upper part; a water wall circuit is vertically arranged in the rear smokebox and a chimney is communicated at the top of the smoke collection chamber; and a group of two-pass smoke pipes communicated with the front smokebox and the rear smokebox is axially arranged at the lower parts in the middles of the two boiler flues and a group of three-pass smoke pipes communicated with the front smokebox and the smoke collection chamber is axially arranged at the upper parts of the two boiler flues. The invention can be widely used in any situation where the small and medium-sized industrial coal powder boilers are required.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD

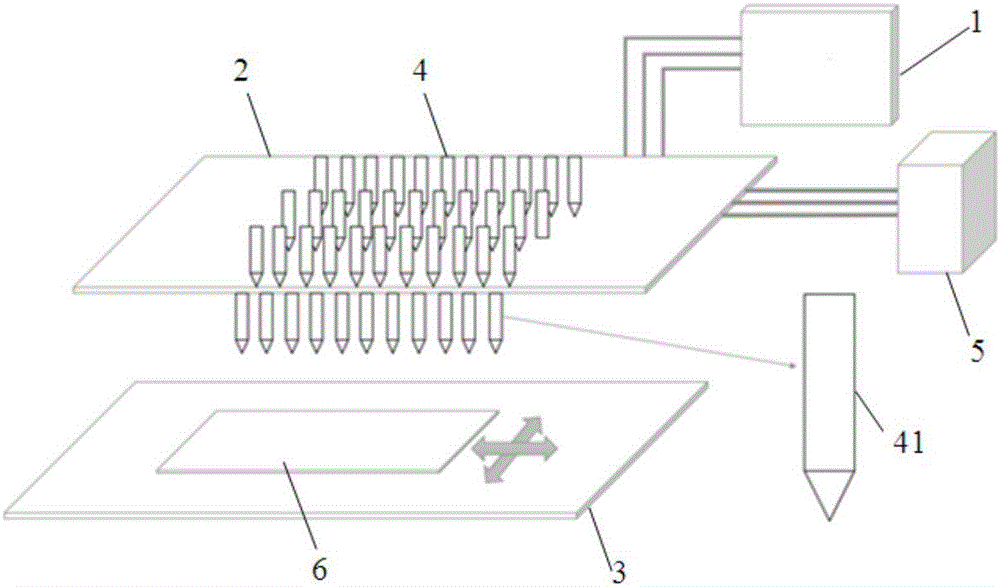

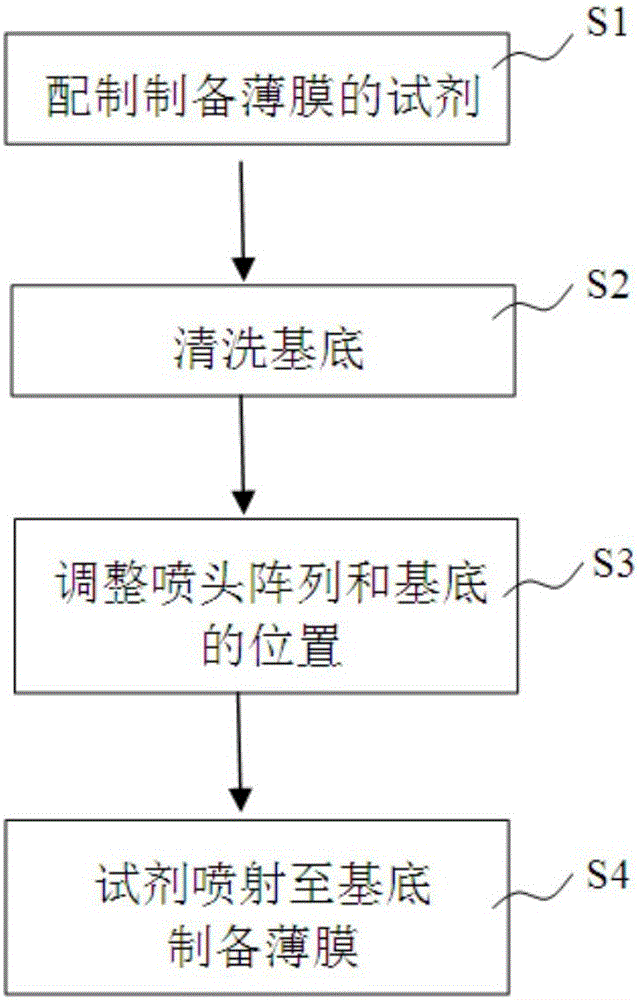

Film preparation device and preparation method based on ink-jet printing

InactiveCN106587041AGood adhesionSimple processAdditive manufacturing apparatusCarbon compoundsAgricultural engineeringReagent

The invention provides a film preparation device and preparation method based on ink-jet printing. A top plate and a bottom plate which are correspondingly arranged are adopted, nozzle arrays which face the bottom plate and are controlled by a control device are installed on the lower end face of the top plate and jet reagents to a substrate arranged on the upper end face of the bottom plate, and then film is prepared. The film preparation device is simple in structure, the film preparation method is simple in technological process and convenient to operate, and then the film preparation efficiency and quality can be effectively improved.

Owner:TSINGHUA UNIV

Machining equipment for automobile part mold

ActiveCN108044455AAvoid efficiencyVoid cleaningGrinding machinesGrinding work supportsEngineeringMachining

The invention relates to the field of automobile part machining and particularly discloses machining equipment for an automobile part mold. The machining equipment for the automobile part mold comprises a machine frame, a mold machining fixing base, a mold clamping device arranged on one side of the mold machining fixing base, a mold cleaning device and a mold polishing device adjacent to the moldclamping device. The mold machining fixing base comprises a machining base and a lateral stop block connected to one side of the machining base. Through the integral linkage arrangement, chippings generated after grinding can be directly removed while grinding is completed, and the problems that manual cleaning is low in efficiency and not thorough are solved.

Owner:重庆鑫盟精密模具有限公司

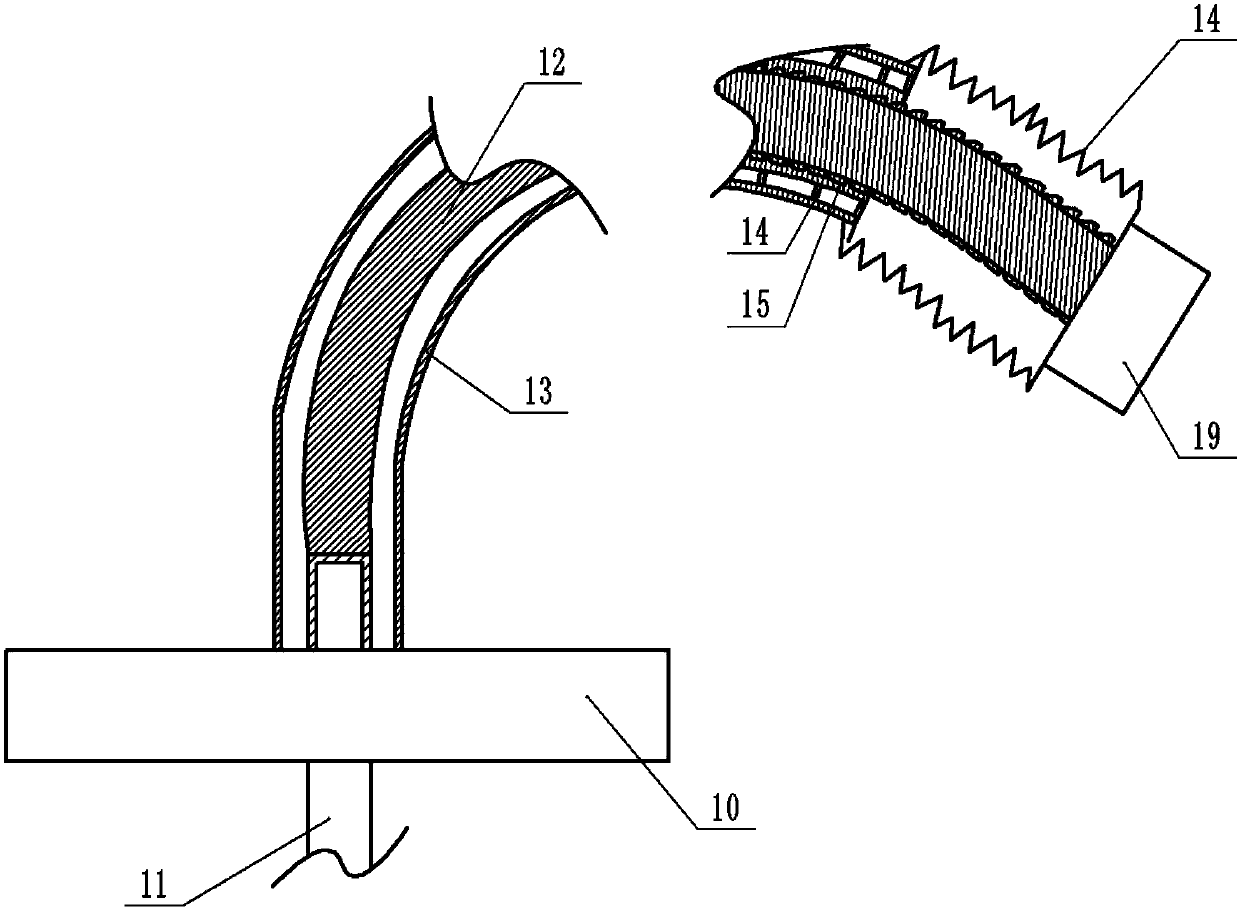

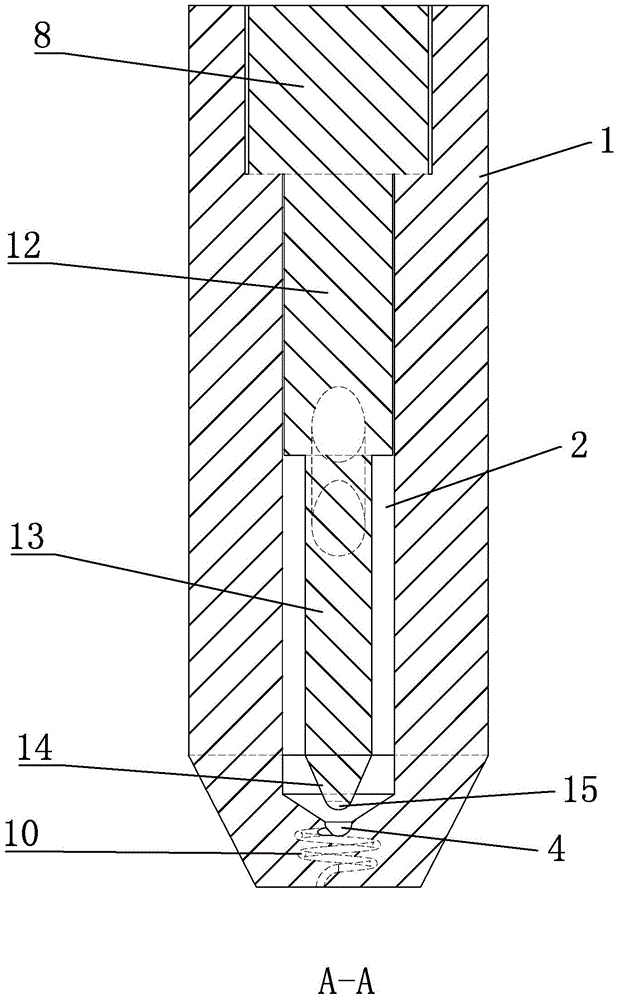

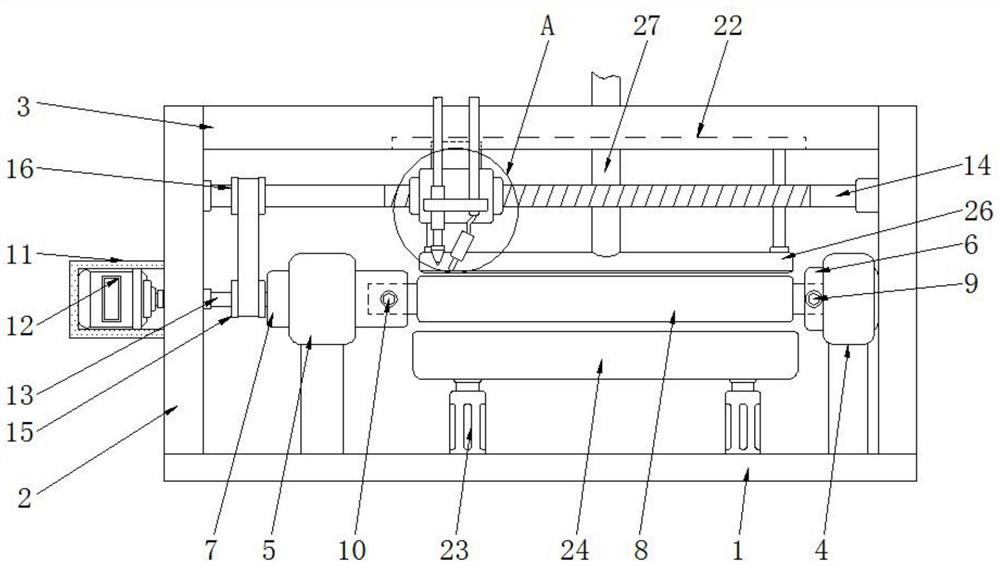

Spot gluing valve based on giant magnetostrictive rod drive

InactiveCN101786068AAvoid frequency doublingConsistent frequencyLiquid surface applicatorsCoatingsBiomedical engineeringExcitation coil

The invention discloses a spot gluing valve based on giant magnetostrictive rod drive, which comprises a spray needle (13) and a valve body. An end cover (3) is fixed on a shell (12), and an excitation coil (11) is fixed in the shell (12) through the end cover (3); an elastic pre-tightening device is arranged on the end cover (3); the upper end of the spray needle (13) is tightly pressed by the elastic pre-tightening device, and the lower end of the spray needle (13) enters the valve body through the shell (12); a giant magnetostrictive rod is arranged at the center of the excitation coil (11); one end of the giant magnetostrictive rod is tightly butted and fixed on the shell (12), and the other end of the giant magnetostrictive rod is butted on the spray needle (13) which is tightly pressed by the elastic pre-tightening device through a magnetic conduction sheet (8); the end cover (3), the magnetic conduction sheet (8) and the shell (12) are magnetic conduction materials; and the end cover (3), the magnetic conduction sheet (8), the shell (12) and the giant magnetostrictive rod form a closed magnetic circuit. In the invention, the spot gluing valve based on giant magnetostrictive rod drive has the advantages of simple structure, convenient use, high spraying frequency, high spraying accuracy and long service life.

Owner:CENT SOUTH UNIV

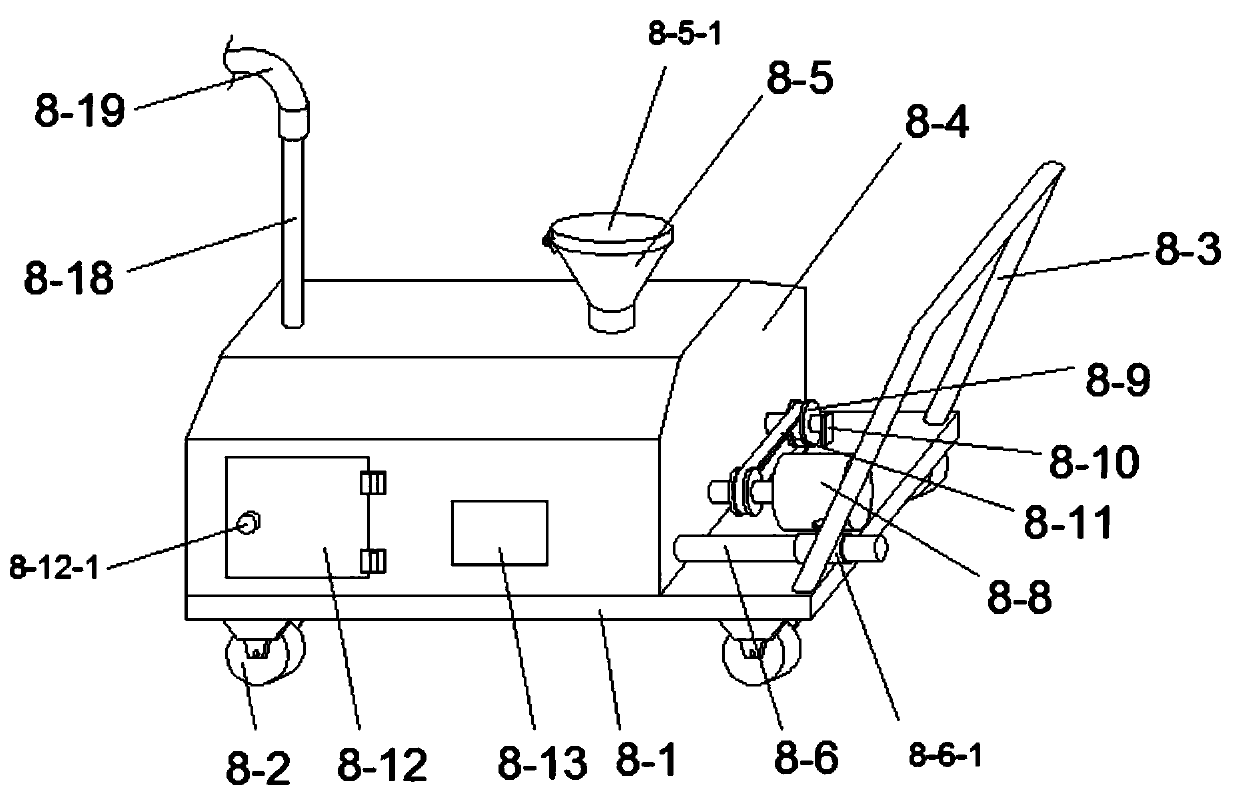

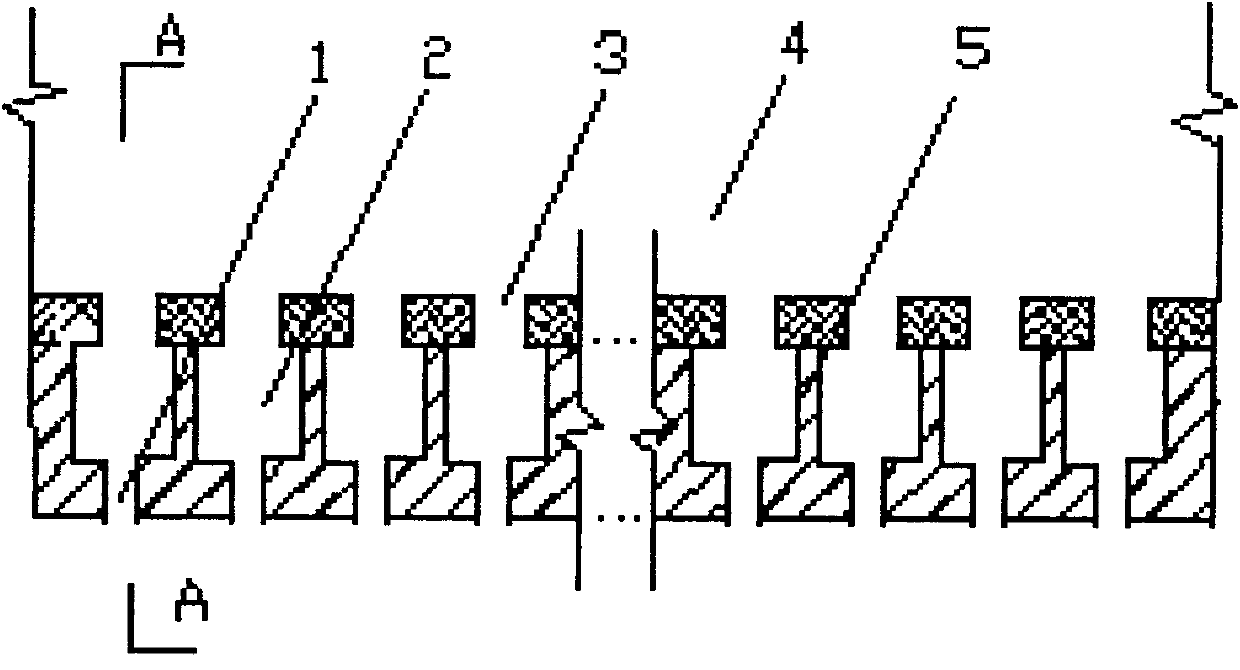

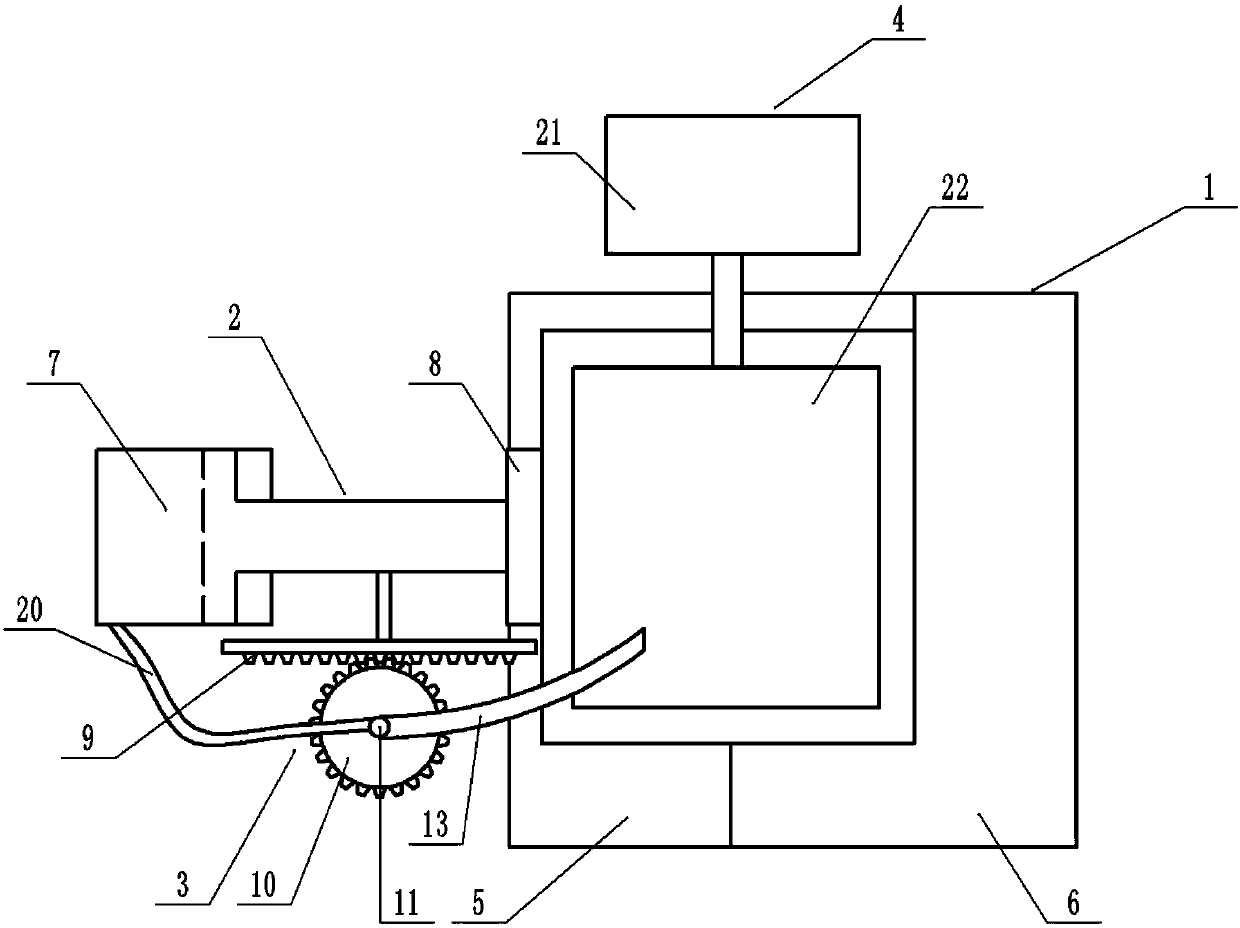

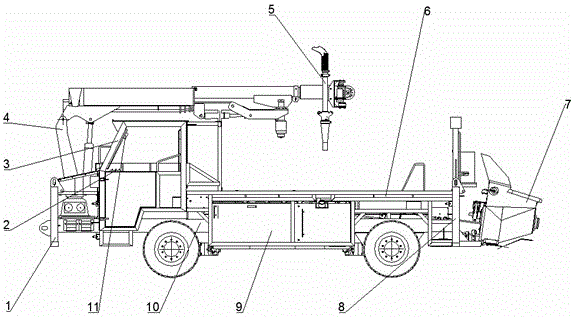

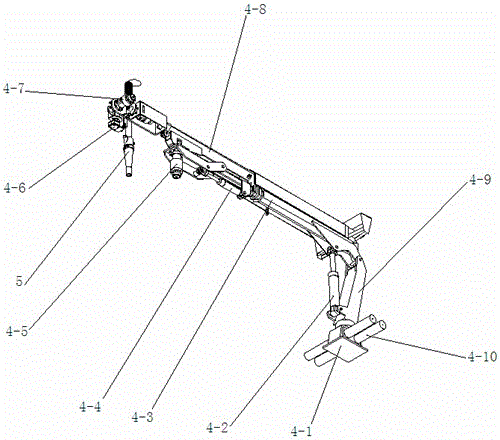

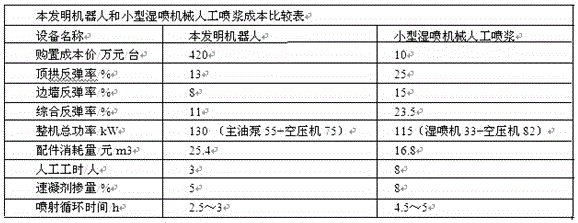

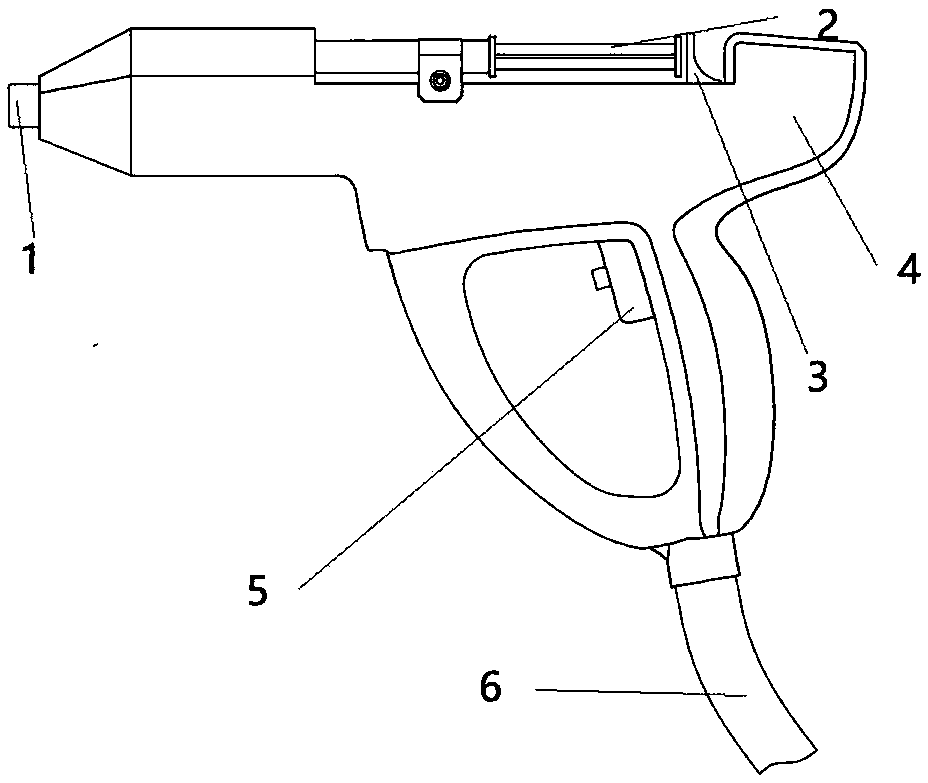

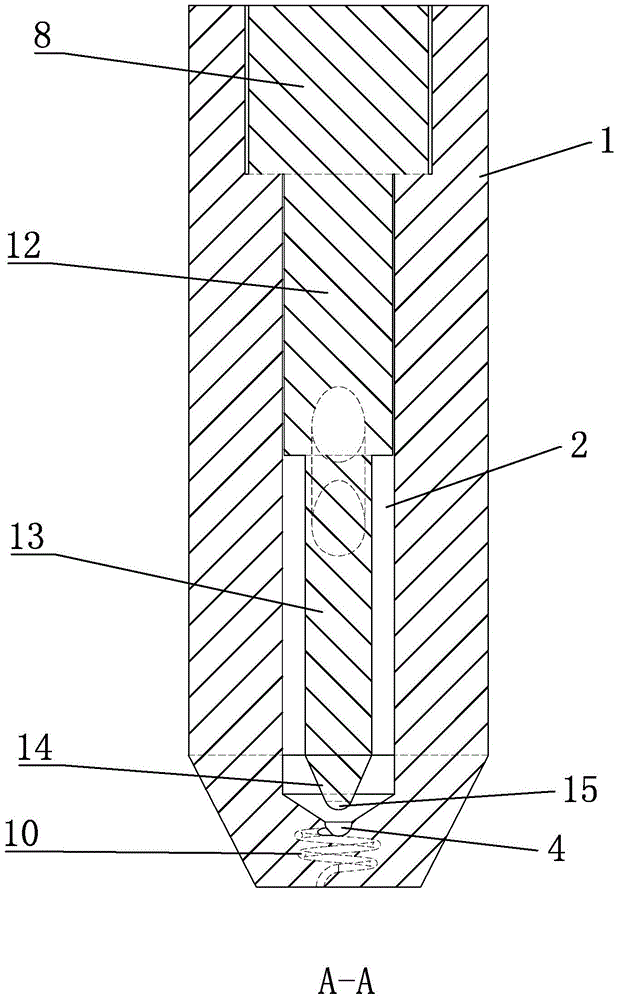

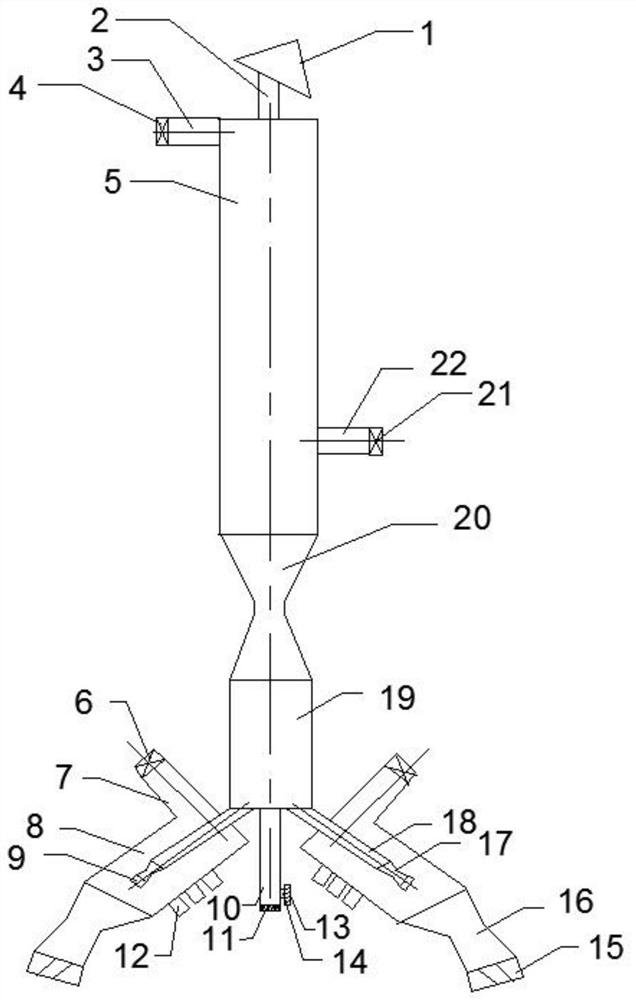

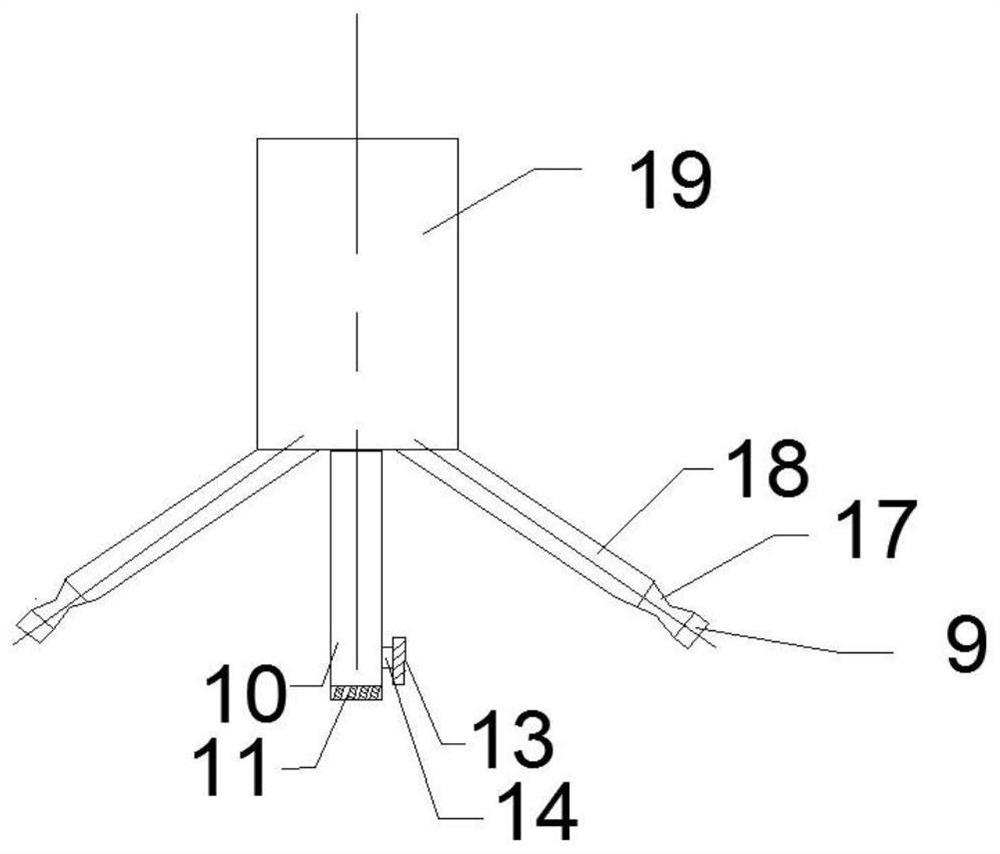

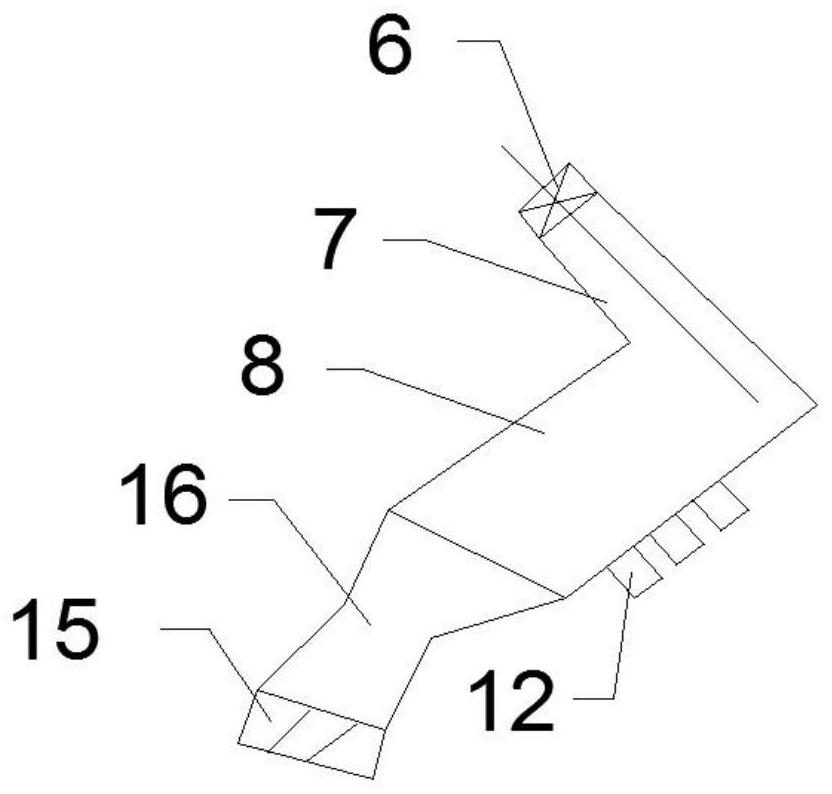

Concrete wet-spraying self-walking shotcrete support robot

InactiveCN105781584AJet speedImprove efficiencyUnderground chambersFoundation engineeringShotcreteElectric control

The invention discloses a concrete wet-spraying self-walking shotcrete support robot. The concrete wet-spraying self-walking shotcrete support robot comprises a wet spraying vehicle body consisting of a walking chassis (10) and a cab (3), wherein the cab (3) is arranged above a front end of the walking chassis (10), a power system (2) is arranged below the cab (3), front supporting legs (1) are arranged below the front end, a wireless remote receiving device (11) is arranged inside, an electric control part (9) is arranged below a middle part of the walking chassis (10), and rear supporting legs (8) are arranged below a rear part. The concrete wet-spraying self-walking shotcrete support robot is characterized in that a concrete pumping device (7) is arranged at a rear end of the walking chassis (10); a manipulator (4) is arranged above a front end of the cab (3) and the manipulator (4) is connected with a spray group (5); the concrete pumping device (7) is connected with the spray group (5) through a pipeline. The problems such as high sprayed concrete resilience rate, poor construction personnel safety, low production efficiency, long construction period and the like are better solved, and the mechanized matching technique and equipment levels of tunnel construction are improved.

Owner:烟台胜闻斯国际贸易有限公司

Work method of navigation system capable of preventing pileup

InactiveCN105180948AAvoid getting lostPrecise positioningInstruments for road network navigationMachines/enginesRear-end collisionControl signal

The invention discloses a work method of a navigation system capable of preventing pileup. The navigation system comprises a navigation device and a plurality of camera devices arranged on the periphery of a vehicle, where the navigation device is installed. The navigation device comprises a processor module, which is connected to the vehicle controller of the vehicle. When the processor module finds out that brake lamp of a vehicle (A), which is in front of the vehicle (B) in the same lane, lights; the processor module sends a brake lamp control signal to the vehicle controller; the vehicle controller controls the brake lamp of the vehicle (B) to light so as to indicate a vehicle (C) behind the vehicle (B) to carry out effective action in time so as to keep a safe distance, thus the vehicle rear-end collision is avoided, so the pileup will not happen, and the traveling safety is guaranteed.

Owner:谢保全

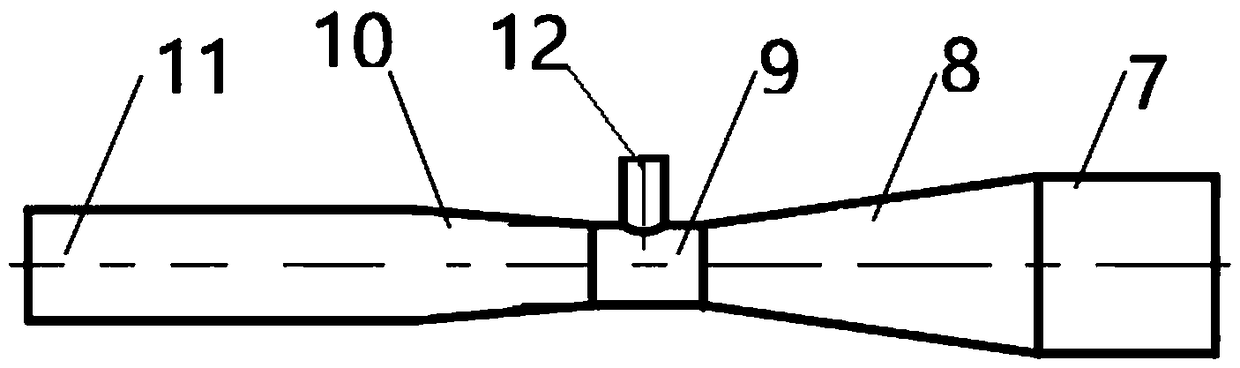

Device for accelerating permeation

InactiveCN108744163ASame initial velocityIncrease flow rateMedical devicesIntravenous devicesEngineeringPermeation

A device for accelerating permeation comprises a spraying pipe, a push plate, a syringe placing groove and a spraying device body; the spraying pipe is arranged in the spraying device body, and the syringe placing groove is formed in the portion, above the spraying pipe, of the spraying device body; a communicating pipe is arranged at the end, close to the spraying pipe, of the syringe placing groove; the communicating pipe is connected to the spraying pipe; the other end of the syringe placing groove is provided with the push plate; one end of the spraying pipe is provided with a spraying outlet, and the other end of the spraying pipe is connected with an external air pump; the spraying pipe is a Venturi tube, a spraying liquid inlet is formed in the middle of the spraying pipe, and the communicating pipe is connected with the spraying liquid inlet. According to the device, the spraying speed is high, particles are small, the atomization effect is good, the beautifying effect is remarkably improved, the utilization rate of beautifying liquid is extremely high, and waste is greatly reduced.

Owner:XIAN EMANTY ELECTRONICS TECH CO LTD

Plastering method of concrete base capable of preventing generation of empty drums

InactiveCN104805973AAvoid hollowingOvercome the problem of easy hollowingCovering/liningsMaterials science

The invention relates to a plastering method of a concrete base capable of preventing the generation of empty drums. The plastering method comprises the following steps: construction preparation: preparing plastering as well as tools and a reagent for plastering; surface treatment of concrete: wetting a concrete surface with water, and washing powder and other impurities on the concrete surface; mixing an adhesion agent to paste with water, and fully and uniformly mixing, wherein the adhesion agent is thick after the pasty adhesion agent is placed for 5-10 min; adding water into the adhesion agent, and uniformly mixing for further use, wherein the mixed adhesion agent must be used out during 5-6 hours; adhering the uniformly mixed adhesion agent on the concrete base through a smearing method or a spraying and texturing method; plastering after the adhesion agent is condensed. According to the plastering method provided by the invention, the plastering is carried out after a layer of adhesion agent is adhered to the concrete base through the smearing method or the spraying and texturing method, therefore the empty drums generated by directly plastering on the concrete base can be prevented.

Owner:SICHUAN YAHAO REAL ESTATE DEV

Navigation system working method capable of avoiding serial rear-ends

InactiveCN105241462AAvoid tailgatingAvoid driving intoInstruments for road network navigationMachines/enginesControl signalNavigation system

The invention discloses a navigation system working method being capable of avoiding serial rear-ends, wherein the navigation system includes a navigation device and a plurality of camera devices arranged around a vehicle (2). The navigation device includes a processor module being connected to a vehicle controller in the vehicle. When the processor module finds that a brake light of a vehicle (1) ahead the vehicle (2) in the lane is lighted on through the camera devices, the processor module sends a brake light control signal to the vehicle controller, so that the vehicle controller controls the brake light of the vehicle (2) to light on to reminding a vehicle (3) behind the vehicle (2) to take effective measures timely and keep enough distance from the vehicle (2). The method can avoid rear-end caused by the vehicle (3) and further avoid the serial rear-ends, thereby ensuring driving safety.

Owner:吴红平

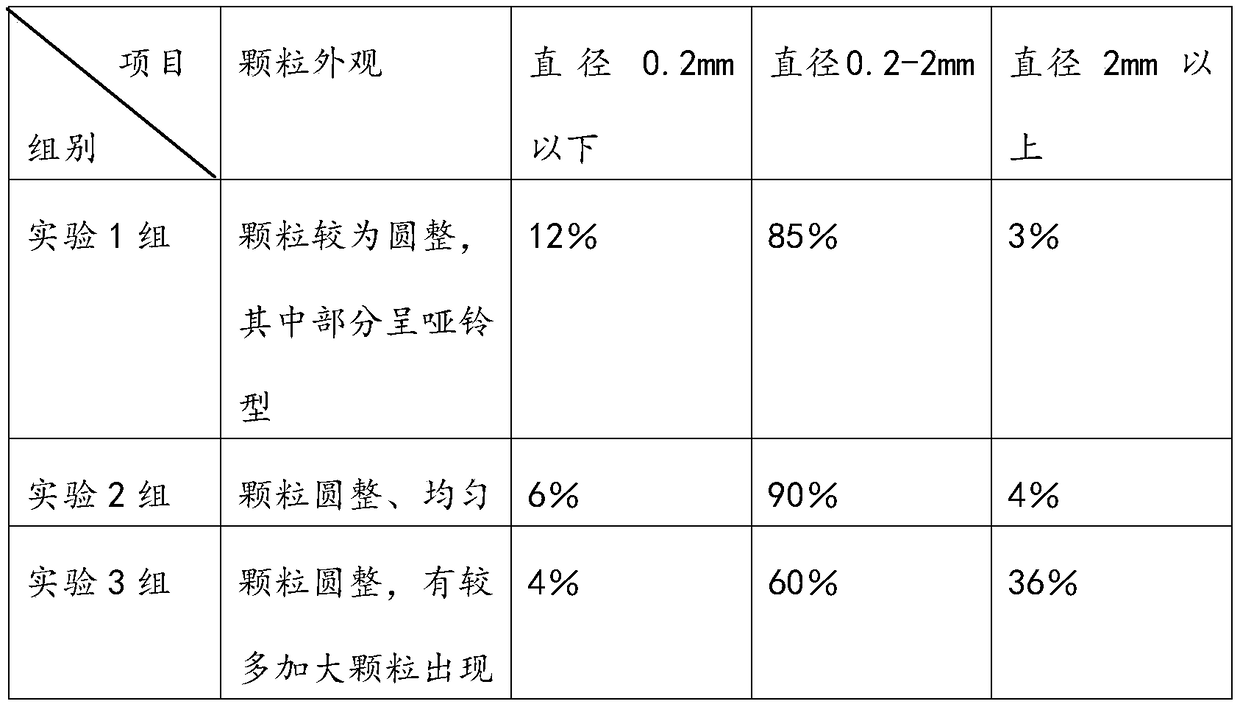

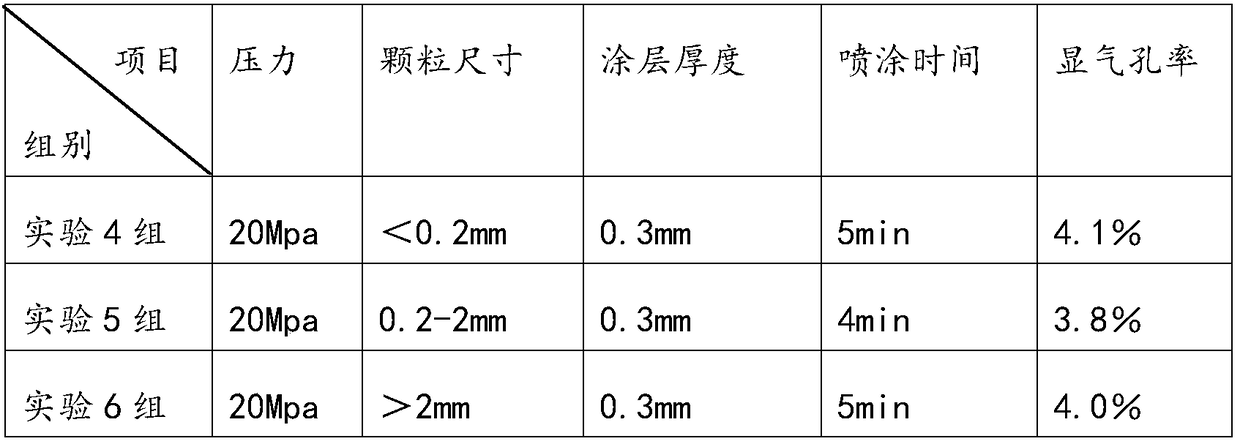

Silicon nitride coating of crucible for polycrystalline silicon ingot and preparation method thereof

ActiveCN109020626AReduce energy costsReduce manufacturing costPolycrystalline material growthSingle crystal growth detailsPorosityHigh pressure

The invention relates to a silicon nitride coating of a crucible for a polycrystalline silicon ingot and a preparation method thereof, and belongs to the technical field of silicon nitride coating preparation. The silicon nitride coating is prepared from the following components in percentage by mass: 35 to 50 percent of silicon nitride powder, 20 to 30 percent of microcrystalline cellulose, 5 to10 percent of silica sol, 0.5 to 1 percent of aceramic bonding agent and 20 to 40 percent of water. The preparation method comprises the following steps: (1) wet material preparation: mixing the silicon nitride powder, water, microcrystalline cellulose, silica sol and theceramic bonding agent according to a certain proportion, and stirring the mixture with a stirrer to obtain a material A; (2) granulation: extruding the material A with an extruder to form a cylindrical stripped extrudate, then rounding the extrudate with a rounder to form spherical particles serving as a material B, and storing the material B in a particle storage tank; (3) high-pressure cold spraying: flattening silicon nitride particles on the surface of the crucible by using a high-pressure cold spraying technology without heating the crucible in order that the silicon nitride particles are subjected to plastic deformation and adhere firmly. The silicon nitride coating has the advantages of low porosity, high density and high product yield, and the production cost is lowered.

Owner:YANTAI HEJING CERAMIC NEW MATERIALS

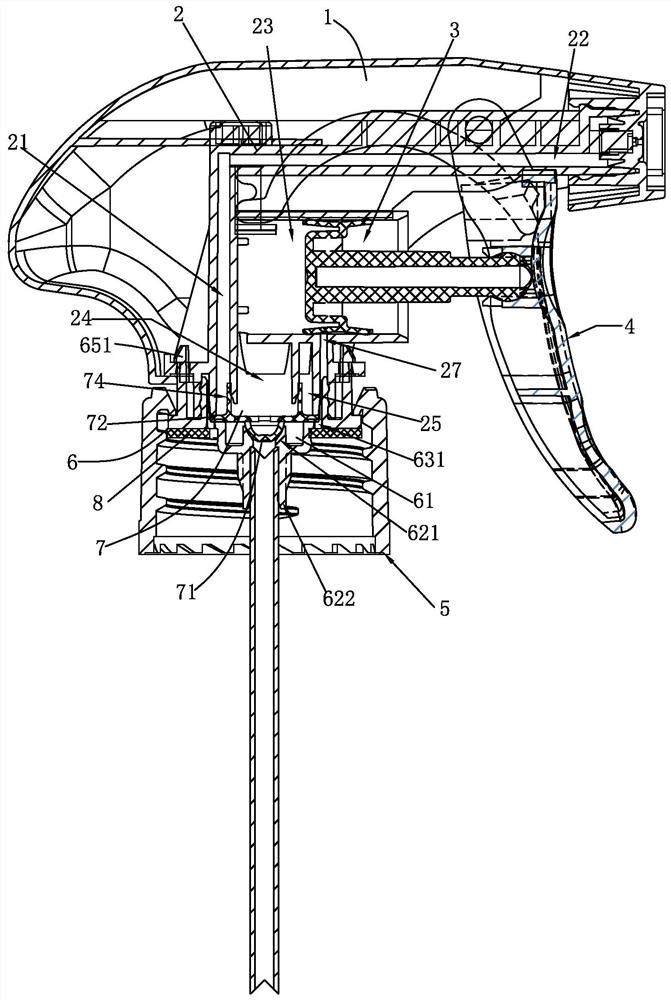

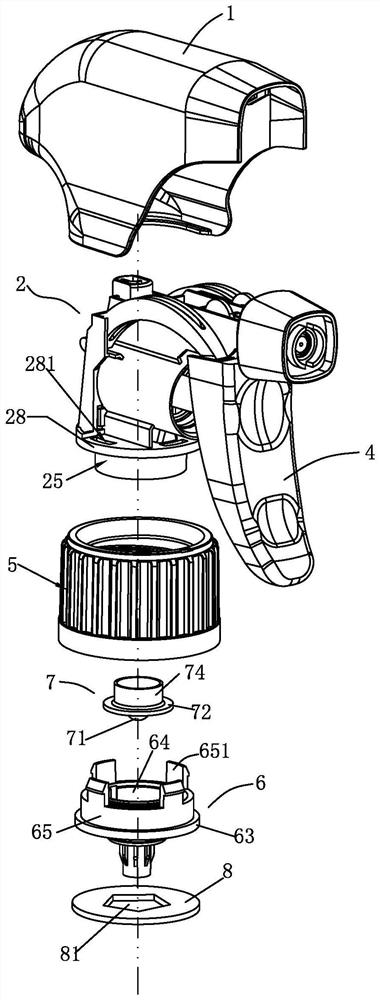

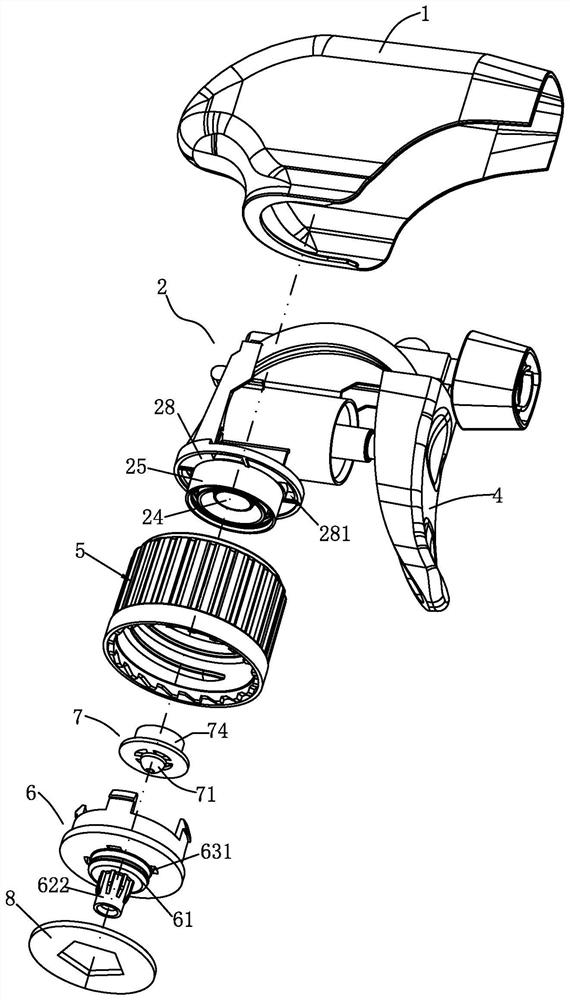

Spray gun with one-way valve cooperating with air supply

The invention provides a spray gun with a one-way valve cooperating with air supply, which comprises a shell, a base frame, a piston, a wrench and a thread and further comprises a valve body, a valve element and a sealing gasket, a valve element body of the valve element is matched with a valve element base, and a circular base plate supports a circular base plate; an air outlet connector is inserted into a cylindrical sleeve core to form a liquid outlet valve, an inserting sleeve is inserted into an annular inserting groove, a liquid outlet cavity is inserted into a connecting base, the valve element penetrates through a through hole on the thread, the circular base plate on the radial outer side of the connecting base is attached to a top plate of the thread, and the connecting base is connected with the base frame; and the valve element cavity is sleeved with the sealing gasket, the sealing gasket is attached to the circular base plate, and a center hole of the sealing gasket is communicated with an air guide hole. Due to the adoption of the structure, air supply and liquid outlet are coordinated, the sealing performance is good, and the spraying speed is high.

Owner:ZHONGSHAN LEUNCHEONG DISPENSING PUMP

A hot melt glue injection valve

ActiveCN108906492BJet speedSpray evenlyLiquid surface applicatorsCoatingsInlet channelReciprocating motion

The invention relates to a hot melt adhesive spray valve. The hot melt adhesive spray valve can comprise a hot melt adhesive heating device, a valve body, a valve element and a striker. Heat transferof the hot melt adhesive heating device acts on a hot melt adhesive tank and a flow channel, wherein the flow channel communicates with an outlet of the hot melt adhesive tank. The valve body comprises a first cavity and a second cavity, wherein the first cavity and the second cavity are spaced from each other in a sealed manner. The first cavity is provided with an air inlet. On and off switchingof an air inlet channel communicating with the air inlet is achieved through a high-frequency air inlet and outlet switch. The air inlet end of the high-frequency air inlet and outlet switch is connected with high-pressure air. The second cavity is provided with an adhesive inlet and a spray orifice, wherein the adhesive inlet communicates with the flow channel, and the spray orifice is formed inthe lower end. The valve element is jointed into the first cavity in a sealed manner and connected with an elastic component. The upper end of the striker is fixed to the valve element and extends tothe second cavity. The lower end of the striker can plug the spray orifice. The valve element can perform reciprocation motion in the first cavity under the effect of the high-pressure air and the elastic component, and furthermore, the striker is driven to perform reciprocating motion so that hot melt adhesive entering the second cavity through the flow channel can be sprayed out of the spray orifice.

Owner:VISION XIAMEN AUTOMATION TECH CO LTD

An automatic powder-spraying explosion suppressor for coal mine fire-fighting

An automatic powder-spraying explosion suppressor for fire-fighting in a coal mine relates to a fire-fighting explosion suppressor. A sheath is fixed at the lower end of a powder storage steel cylinder, and the sheath and a connecting flange are sealed and fixed, and a power connector is fixed on the sheath. The connecting flange and sealing ring are installed on the gas pipeline, the spout body is set on the fastening flange, the spout body is equipped with an explosion-proof device, and the flange plate is fixed at the lower end of the powder storage cylinder; the filling valve and pressure switch are installed on the rear side of the flange plate Installed on the front of the flange, the starter is fixed on the right side of the fastening flange; the electric squib is installed in the starter housing, and the front end is equipped with a push rod with a sealing ring, which is fixed and compressed by a compression nut; fastening method A horizontal lever is set in the blue inner hole. The powder spraying explosion suppressor has the advantages of simple structure, safety and reliability, fast starting and spraying speed, and conforms to environmental protection requirements.

Owner:沈阳险峰机械厂

Carbondeposition prevention oil sprayer

InactiveCN106150814AAvoid blockingInjection efficiency decayElectrical controlFuel injection apparatusCombustion chamberSprayer

The invention relates to a carbondeposition prevention oil sprayer which comprises a valve body and a plunger arranged in the valve body in a sliding fit mode. The plunger is controlled by a controller at the top end of the plunger. A valve needle is arranged at the bottom end of the plunger. The outer wall of the valve needle is suitable for being in sealed fit with the inner wall of a valve seat in the valve body. A liquid outlet is formed in the inner wall of the valve seat. The valve body is provided with a liquid intake hole for conveying gasoline to the valve seat, and a drainage channel is formed in the valve body. One end of the drainage channel communicates with the liquid outlet, and the other end of the drainage channel communicates with a liquid spray nozzle in the bottom of the valve body. The drainage channel isolates the precise valve needle and the precise valve seat from a combustion chamber in an air cylinder. When gasoline in the air cylinder burns, the valve needle and the valve seat are in a sealed state, carbon particles generated after combustion of the gasoline in the combustion chamber and colloidal materials formed by insufficient combustion are not likely to enter the drainage channel with the sealed upper end, accordingly, the carbon particles and the colloidal materials are prevented from adhering to the portions, at the liquid outlet, of the outer wall of the valve needle or the inner wall of the valve seat, and the situation that deposited carbon blocks a circulation gap between the valve needle and the valve seat after the valve needle is opened is avoided.

Owner:朱海燕

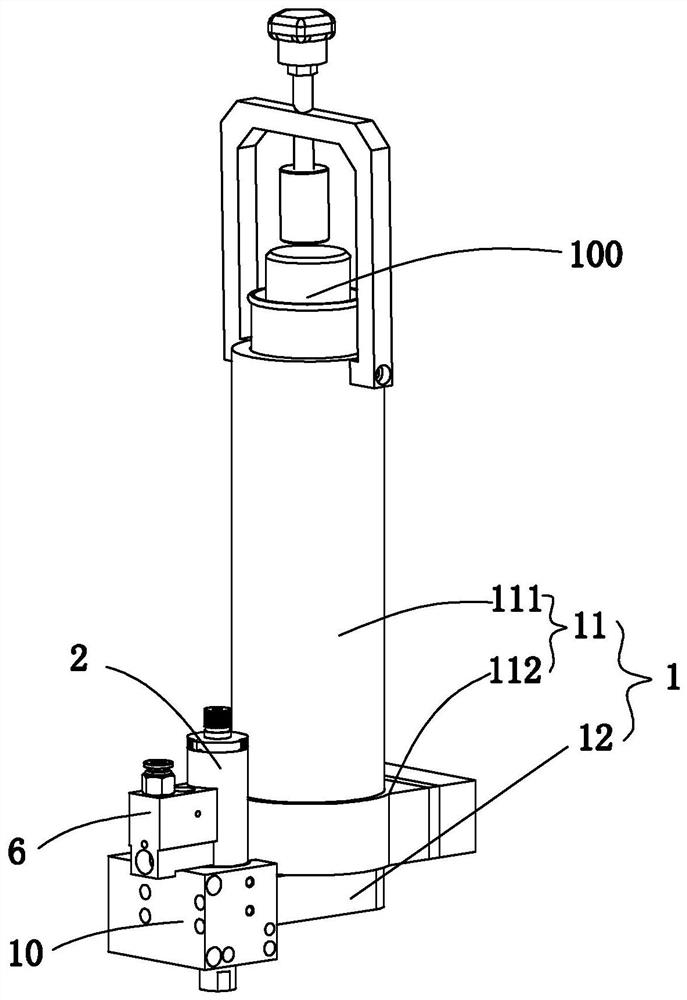

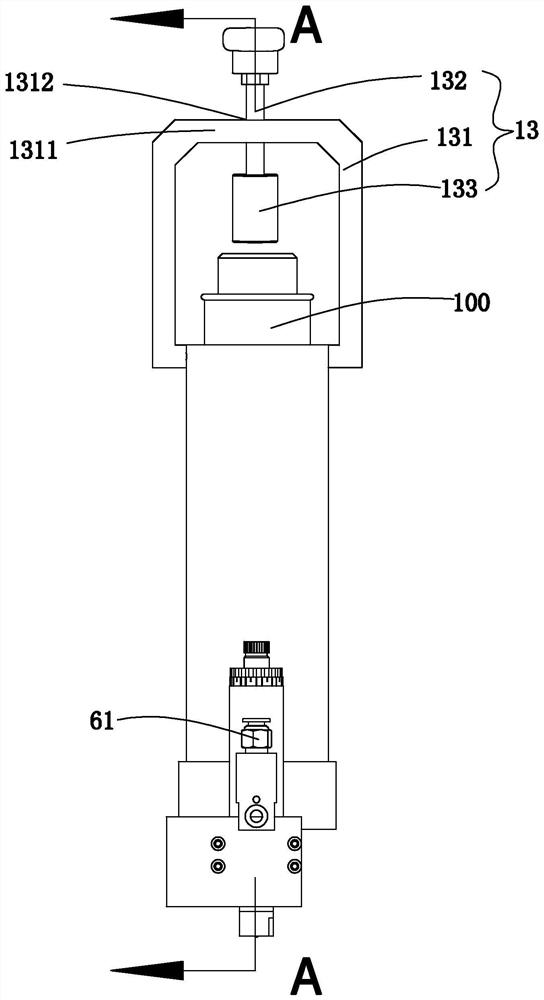

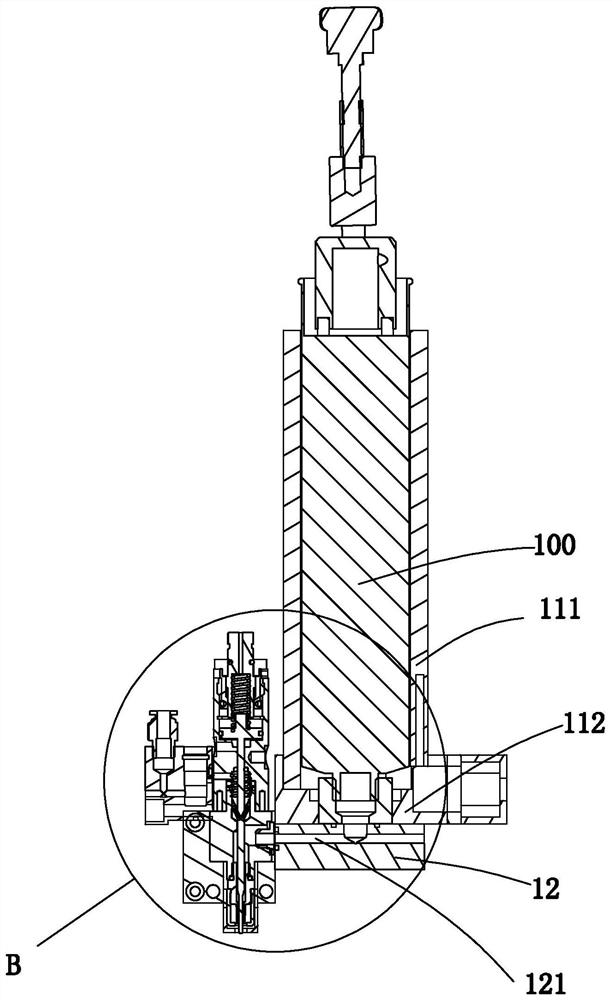

Cement clinker crushing roller surface heating repair device

InactiveCN112439968AShorten the timeImprove repair efficiencyGas flame welding apparatusDrive shaftElectric machinery

The invention discloses a cement clinker crushing roller surface heating repair device comprising a base. Supporting frames are fixedly connected to the two sides of the top of the base; and a top plate is fixedly connected to the tops of the two supporting frames. The cement clinker crushing roller surface heating repair device relates to the technical field of cement processing. According to thecement clinker crushing roller surface heating repair device, when a damaged crushing roller is repaired, the two ends of the crushing roller are inserted into a first rotating cylinder and a secondrotating cylinder correspondingly and fixed through a first locking bolt and a second locking bolt correspondingly, a driving motor is started to drive the first rotating cylinder to rotate and drivethe crushing roller to rotate, and a driving shaft rotates and drives a threaded rod to rotate at the same time, so that when the crushing roller rotates and is heated, a surfacing welding gun and a surfacing welding powder spraying pipe on a fixed plate move rightwards slowly to perform surfacing operation on the surface of the crushing roller, surfacing is performed while heating is performed, the surfacing quality is good, excessive convex points are not generated, and the surface of the crushing roller can be subjected to uniform surfacing.

Owner:湖北宜飞复合新材料有限公司

Automatic powder spraying explosion suppressor for coal mine fire protection

The invention discloses an automatic powder spraying explosion suppressor for coal mine fire protection, and relates to a fire protection explosion suppressor. A sheath is fixed at the lower end of a steel powder storage bottle and is fixedly butted with a connection flange in a sealing manner; a power supply connector is fixed on the sheath and is mounted on a gas pipeline through the connection flange and sealing rings; a nozzle body is arranged on a fastening flange; an anti-explosion device is arranged on the nozzle body; a flange disk is fixed at the lower end of the steel powder storage bottle; a filling valve is mounted on the rear side of the flange disk; a pressure switch is mounted on the front surface of the flange disk; a starter is fixed on the right side of the fastening flange; an electric detonator is mounted in a starter shell; a mandril with sealing rings is mounted at the front end and is fixedly pressed by a pressing nut; a transverse lever is arranged in an inner hole of the fastening flange. The automatic powder spraying explosion suppressor is simple in structure, safe and reliable, is high in starting speed and jetting speed and can meet the requirement on environment friendliness.

Owner:沈阳险峰机械厂

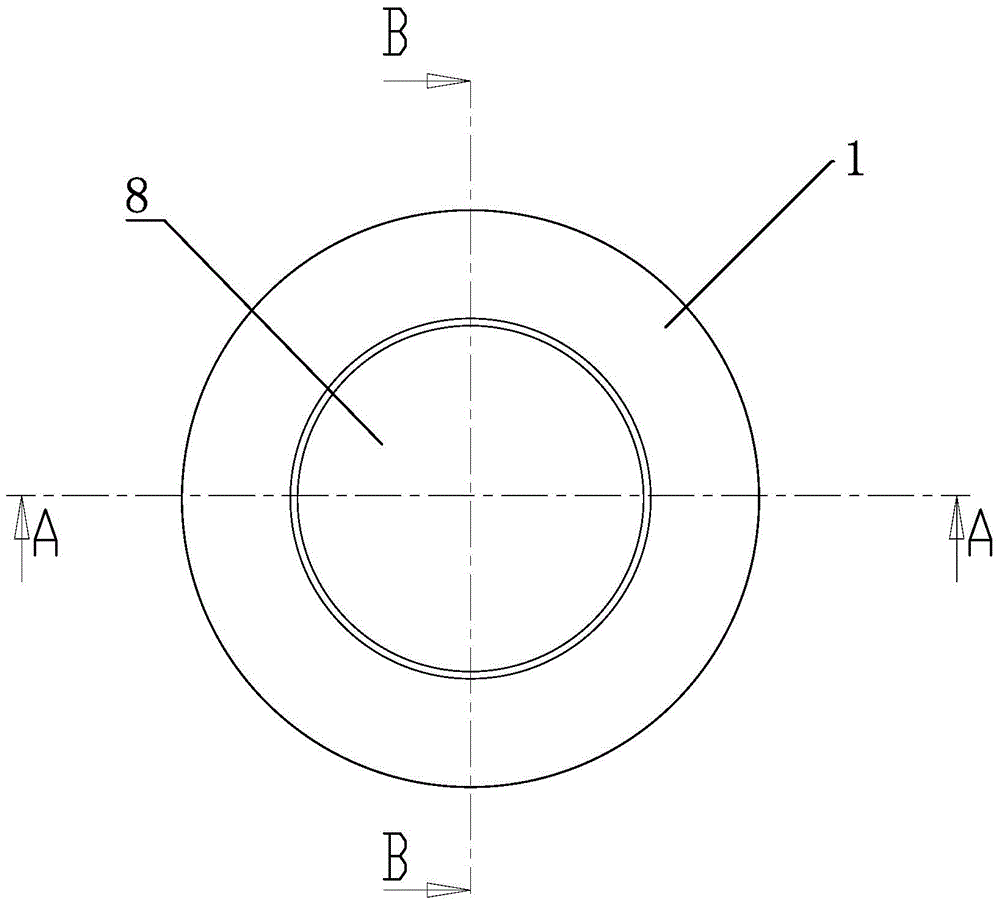

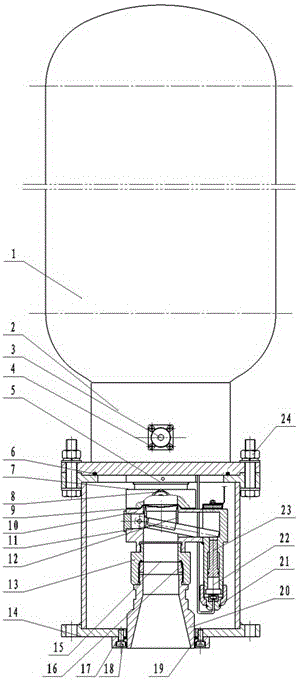

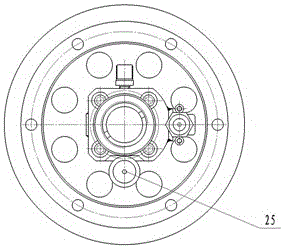

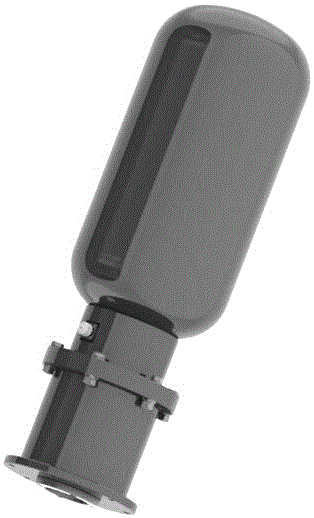

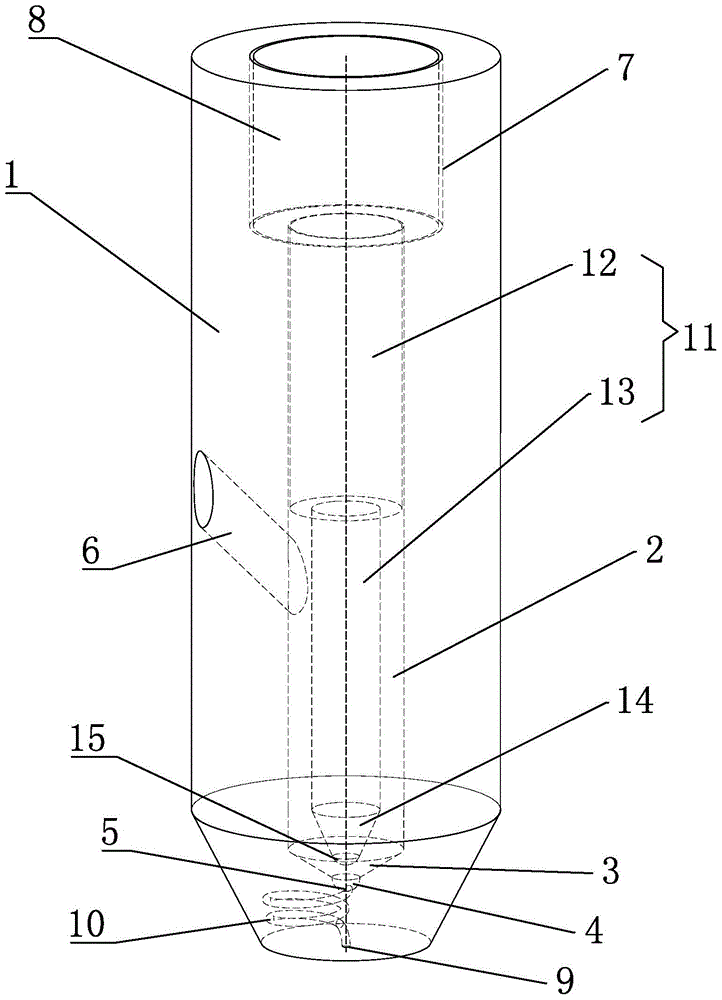

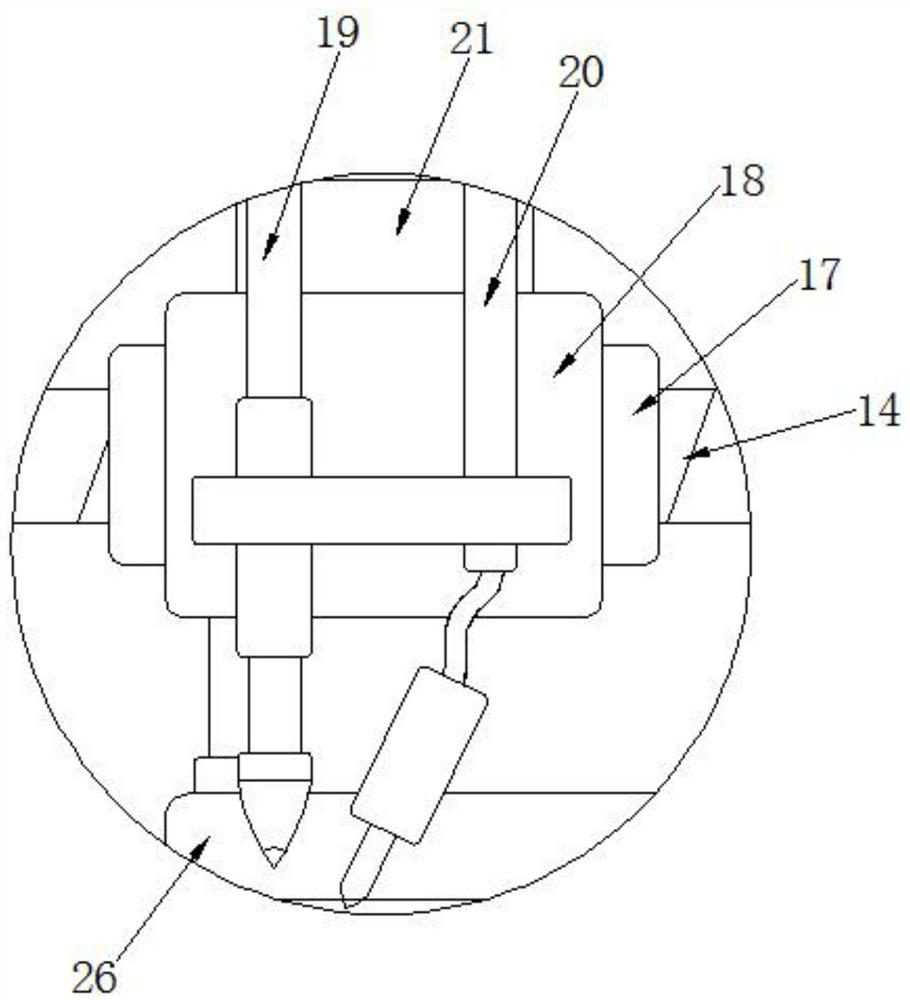

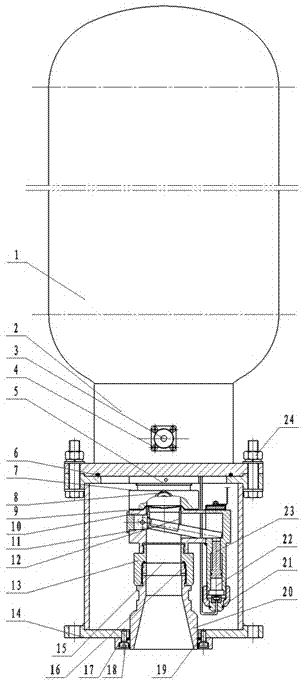

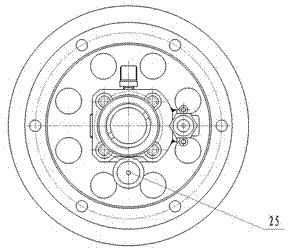

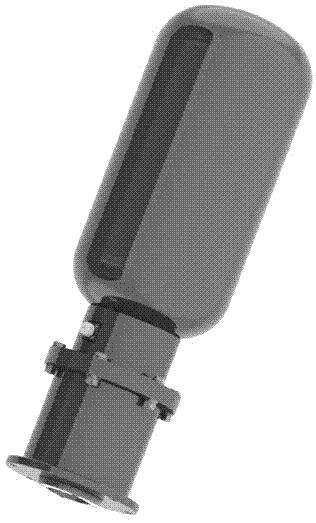

A gear deburring process

ActiveCN108746898BJet speedAvoid the risk of breakdownElectrochemical machining apparatusElectrolytic agentGear wheel

The invention relates to a gear burr removing technology. The technology comprises the following specific steps that 1, a burr removing device is constructed; 2, a gear is placed; 3, conducting and discharging are carried out; 4, an electrolyte is sprayed; 5, the gear is washed ultrasonically; 6, antirust treatment is carried out; and 7, the gear is naturally dried in air and delivered from storage. The technology has the following advantages that an anode terminal and a cathode terminal are utilized for conducting and discharging, the electrolyte is sprayed to the gear fast from bottom to top, the spraying speed is high, the electrolyte is sprayed in a centralized manner, and the burr removing effect is achieved; meanwhile, the burr removing effect is remarkable, the risk that the gear isbroken down is avoided, time for burr removing is short, and efficiency is high; the concentration of sodium nitrate is low, harm to the human body is avoided, corrosion to the surface of the gear isavoided, and meanwhile, the good burr removing effect can be ensured; and as the electrolyte spraying speed is high and the flow amount is large, the complex washing step in the later period is omitted, the gear only needs to be washed with clear water, the gear is washed ultrasonically, and thus greasy dirt on the surface of the gear can be decomposed and emulsified.

Owner:NANTONG ZHONGLV GEAR CO LTD

Energy-saving and consumption-reducing scrap steel preheating spray gun

PendingCN111964457AGuaranteed burn rateGuaranteed utilizationPreheating chargesGaseous fuel burnerProcess engineeringDistributor

The invention discloses an energy-saving and consumption-reducing scrap steel preheating spray gun, and relates to the technical field of ferrous metallurgy. The energy-saving and consumption-reducingscrap steel preheating spray gun comprises a gun body, one side of the gun body is fixedly connected with a fuel gas inlet pipeline communicating with the gun body, the bottom end of the gun body isfixedly connected with a fuel gas accelerator a, the bottom end of the fuel gas accelerator a is connected with a fuel gas distributor, the bottom end of the fuel gas distributor is connected with a fuel gas injection mechanism a and a fuel gas injection mechanism b, and the fuel gas injection mechanism b is fixedly connected with a mixed gas injection mechanism. According to the energy-saving andconsumption-reducing scrap steel preheating spray gun, the preheating effect is enhanced, the covering range is large, preheating is uniform, the combustion rate and the utilization rate of fuel gasare guaranteed, the preheating speed is high, fuel gas is saved, and the energy-saving and consumption-reducing effects are obvious.

Owner:大连新瑞晨环保科技有限公司

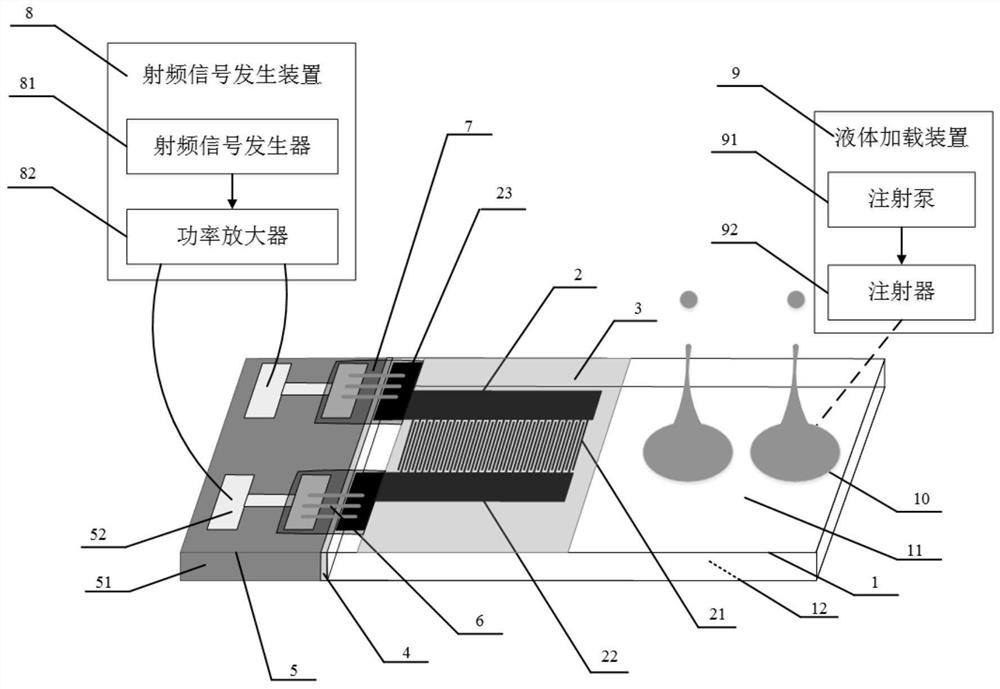

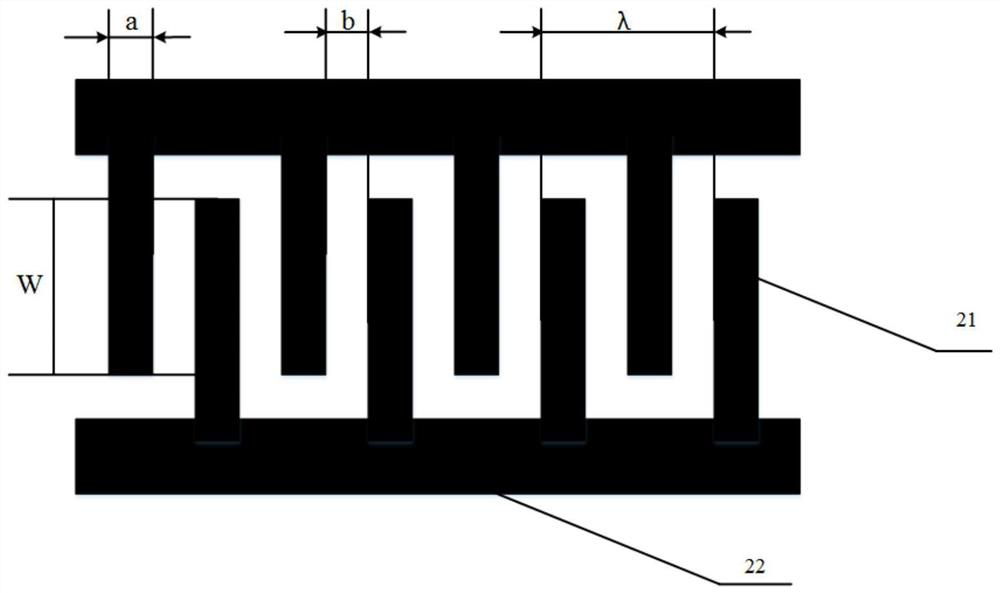

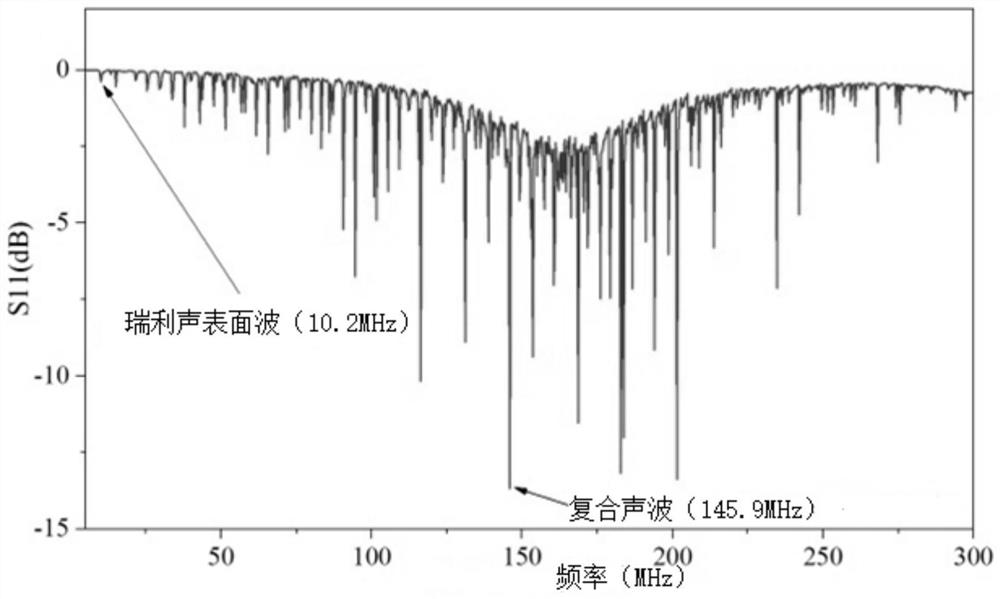

Droplet jetting device and related method

ActiveCN112916286AJet stabilityEasy to useLiquid spraying apparatusRadio frequency signalMechanical engineering

The invention provides a droplet jetting device and a related method. The droplet jetting device comprises a piezoelectric chip and an interdigital transducer arranged on the upper surface of the piezoelectric chip, the ratio of the thickness of the piezoelectric chip to the period of the interdigital transducer is 1-3, the interdigital transducer is driven by a radio frequency signal to excite surface acoustic waves and bulk acoustic waves in the piezoelectric chip, and the surface acoustic waves and the bulk acoustic waves are reflected on the upper surface and the lower surface of the piezoelectric chip to generate composite acoustic waves so as to drive to-be-driven liquid on a liquid attachment area to stretch in the direction perpendicular to the surface of the piezoelectric chip to form a liquid column, so that the liquid column generates a liquid drop pinch-off effect at the end part, and a single liquid drop is ejected, the liquid attachment area is located on the upper surface and / or the lower surface of the piezoelectric chip and corresponds to the area covered by the surface acoustic wave generated by the interdigital transducer propagating along the surface of the piezoelectric chip. The problems that a device is complex in structure, high in cost, low in efficiency and inconvenient to achieve on-demand jetting are solved.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com