Concrete wet-spraying self-walking shotcrete support robot

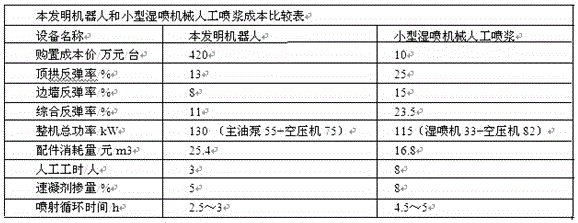

A self-propelled, concrete technology, used in earth-moving drilling, wellbore lining, tunnel lining, etc., can solve the problems of poor reliability and adaptability, low automation level, difficult maintenance of accessories, etc., to achieve convenient movement, reduce labor intensity, spray fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

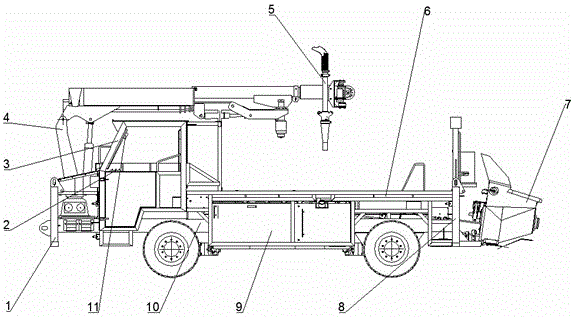

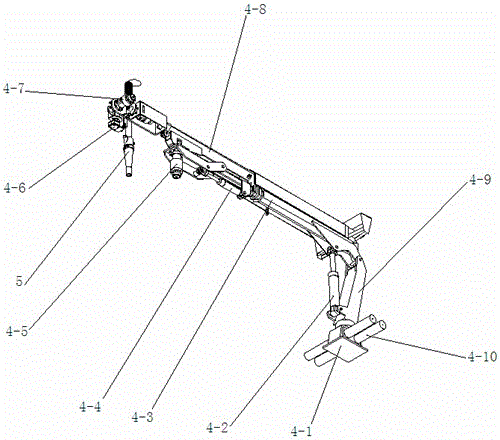

[0028] Example 1, see figure 1 , 2 , according to the design needs to select the appropriate wet spray car body 6, the wet spray car body 6 is diesel power, hydraulic transmission, four-wheel steering structure; the wet spray car body 6 is composed of a walking chassis 10 and a cab 3, the front end of the walking chassis 10 Above is the cab 3, the cab 3 is an anti-dumping cab, the power system 2 is installed under the cab 3, the front outrigger 1 is installed under the front end of the cab 3, and the wireless remote control receiving device 11 is installed inside the cab 3. The electric control part 9 is installed under the middle part of the chassis 10; the rear outrigger 8 is installed under the rear part of the walking chassis 10, and the concrete pumping device 7 is installed at the rear end of the walking chassis 10; the manipulator 4 is installed above the front end of the cab 3, and the manipulator 4 includes The manipulator base 4-1, the manipulator column 4-9 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com