Energy-saving and consumption-reducing scrap steel preheating spray gun

A spray gun and steel scrap technology, which is applied in the field of iron and steel metallurgy, can solve the problems that it is difficult to meet the scrap steel preheating requirements of steel mills, difficult to meet production requirements, and small flame coverage, so as to achieve obvious effects of energy saving and consumption reduction, and ensure combustion rate and utilization rate , good preheating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

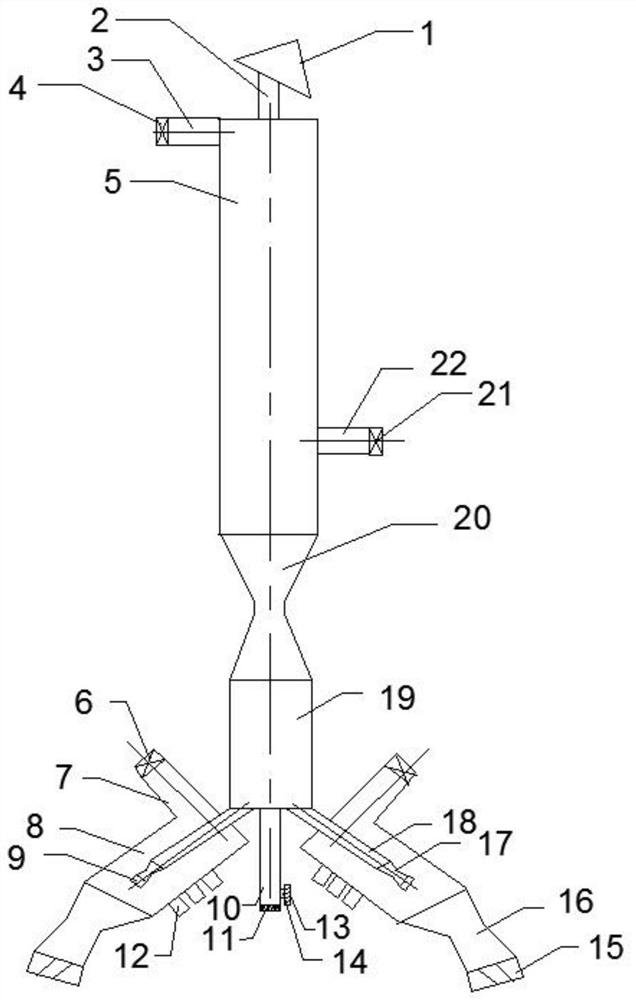

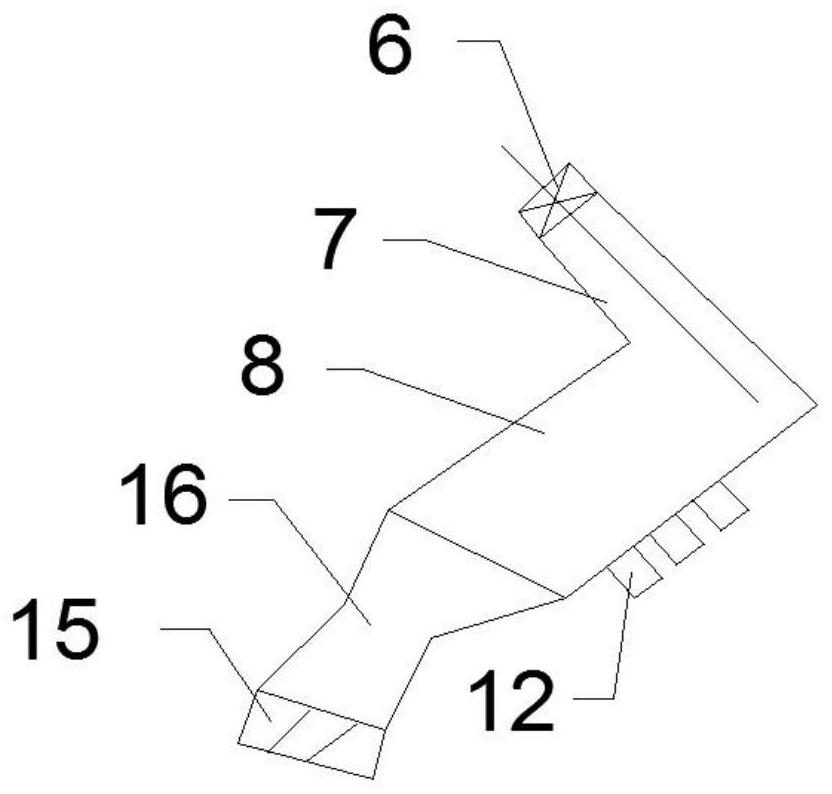

[0024] An energy-saving and consumption-reducing scrap steel preheating spray gun, comprising a gun body 5, the top of the gun body 5 is fixedly connected with a gun hanger bayonet 2, and the top of the gun hanger bayonet 2 is fixedly connected with a gun hanger joint 1, on the side wall of the gun body 5 A purge air intake pipeline 3 is connected vertically, and one end of the purge air intake pipeline 3 is fixedly connected with a purge air intake pipeline interface 4 .

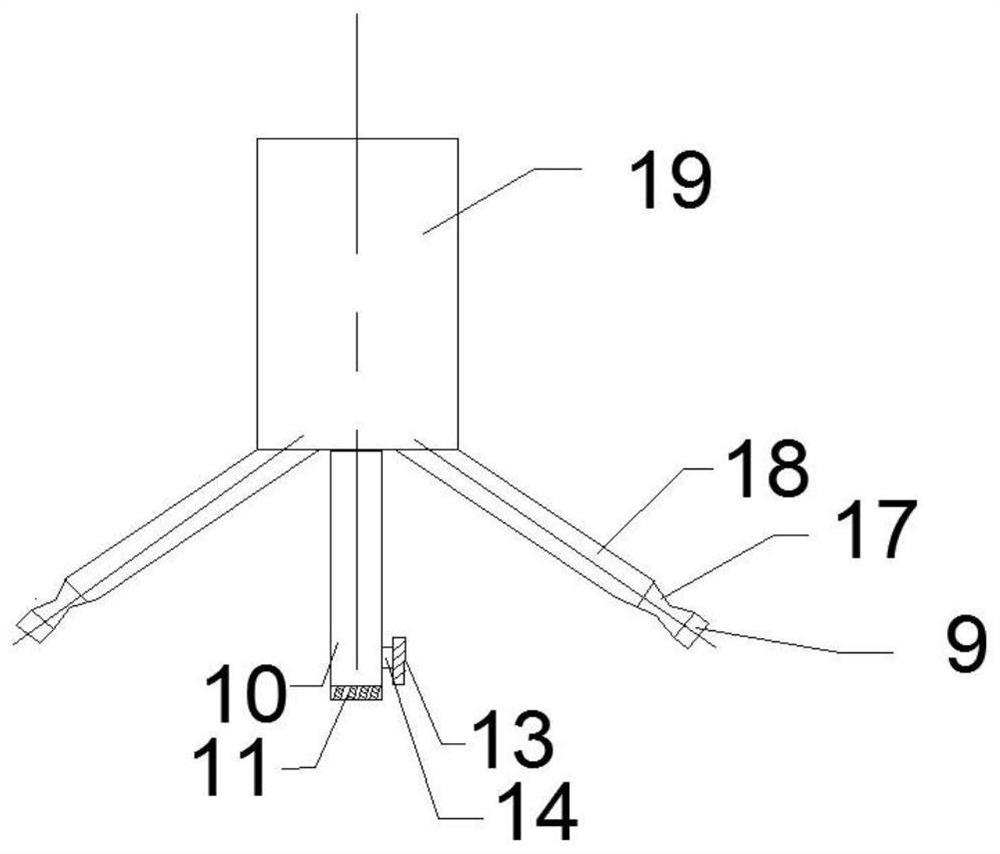

[0025] One side of the gun body 5 is vertically fixedly connected with a gas inlet pipeline 22 communicating therewith, and one end of the gas inlet pipeline 22 is welded with a gas inlet pipeline interface 21 . The bottom end of the gun body 5 is fixedly connected with a gas accelerator a20, and the bottom end of the gas accelerator a20 is connected with a gas distributor 19, and the bottom end of the gas distributor 19 is respectively connected with a gas injection mechanism a and a gas injection mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com