Patents

Literature

535results about How to "Improve crushing quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

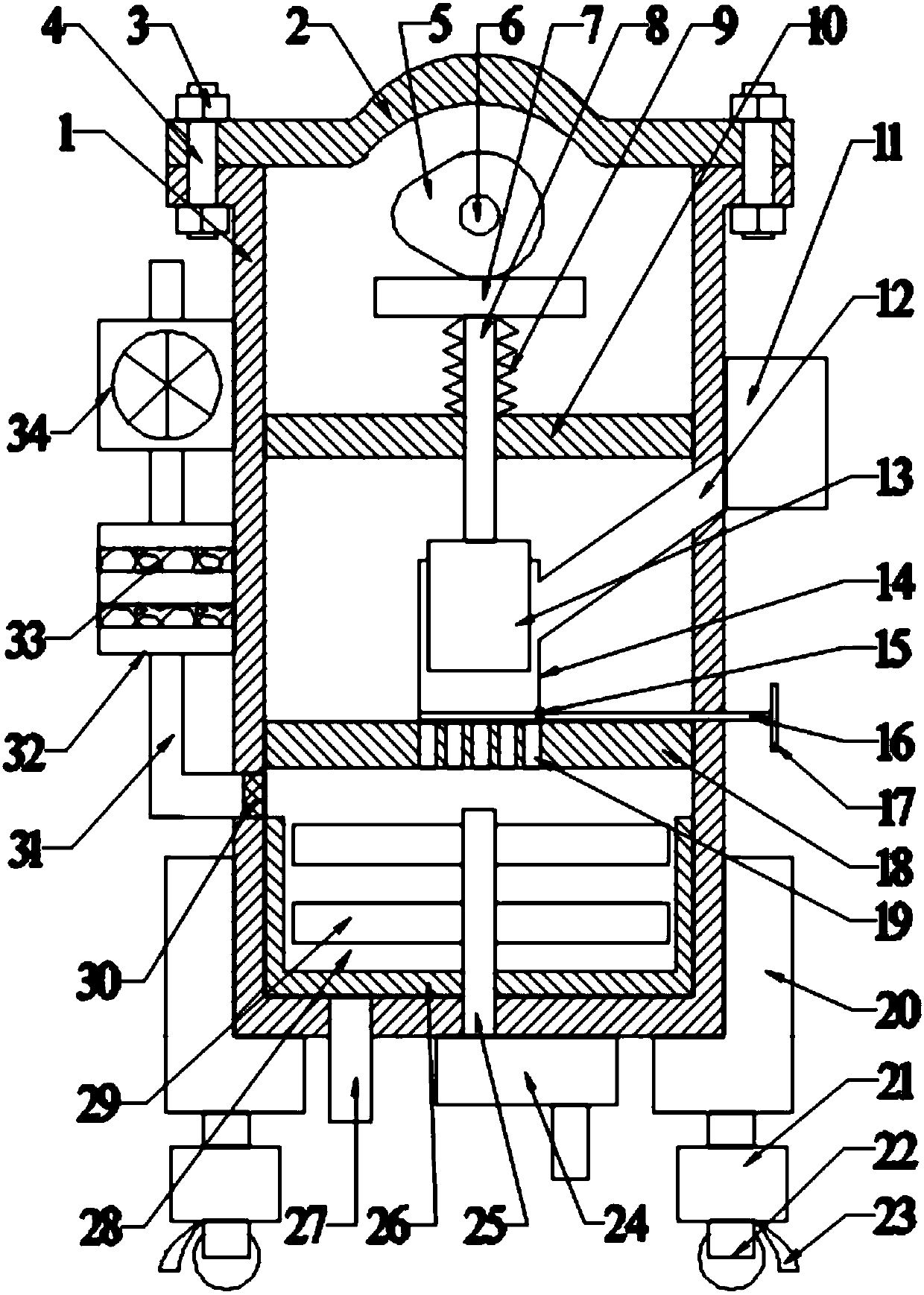

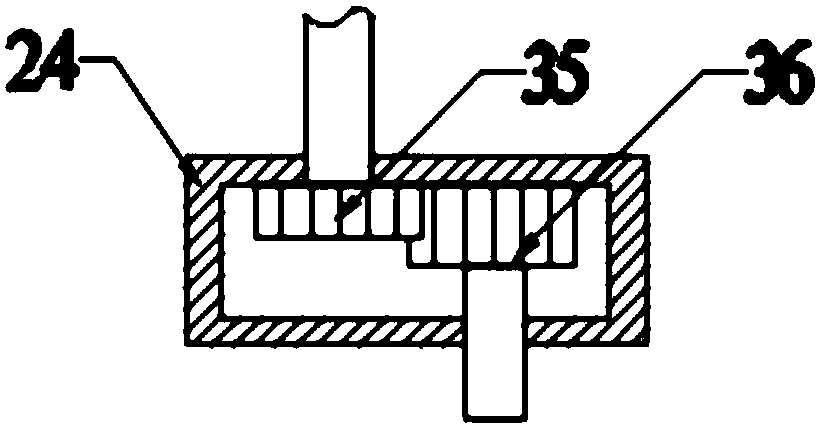

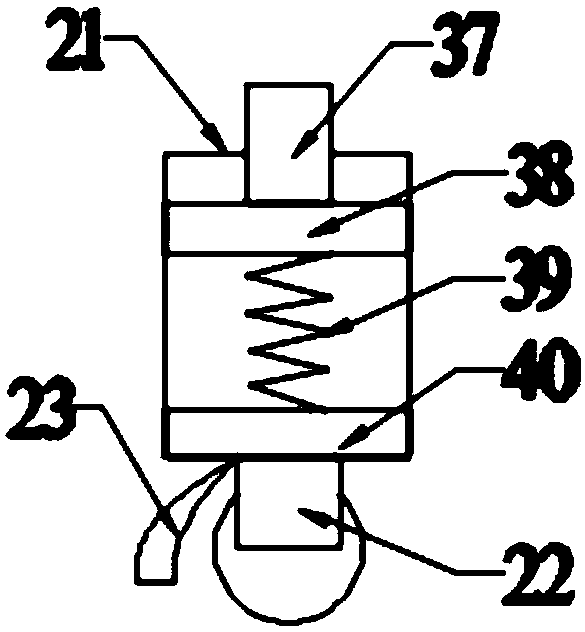

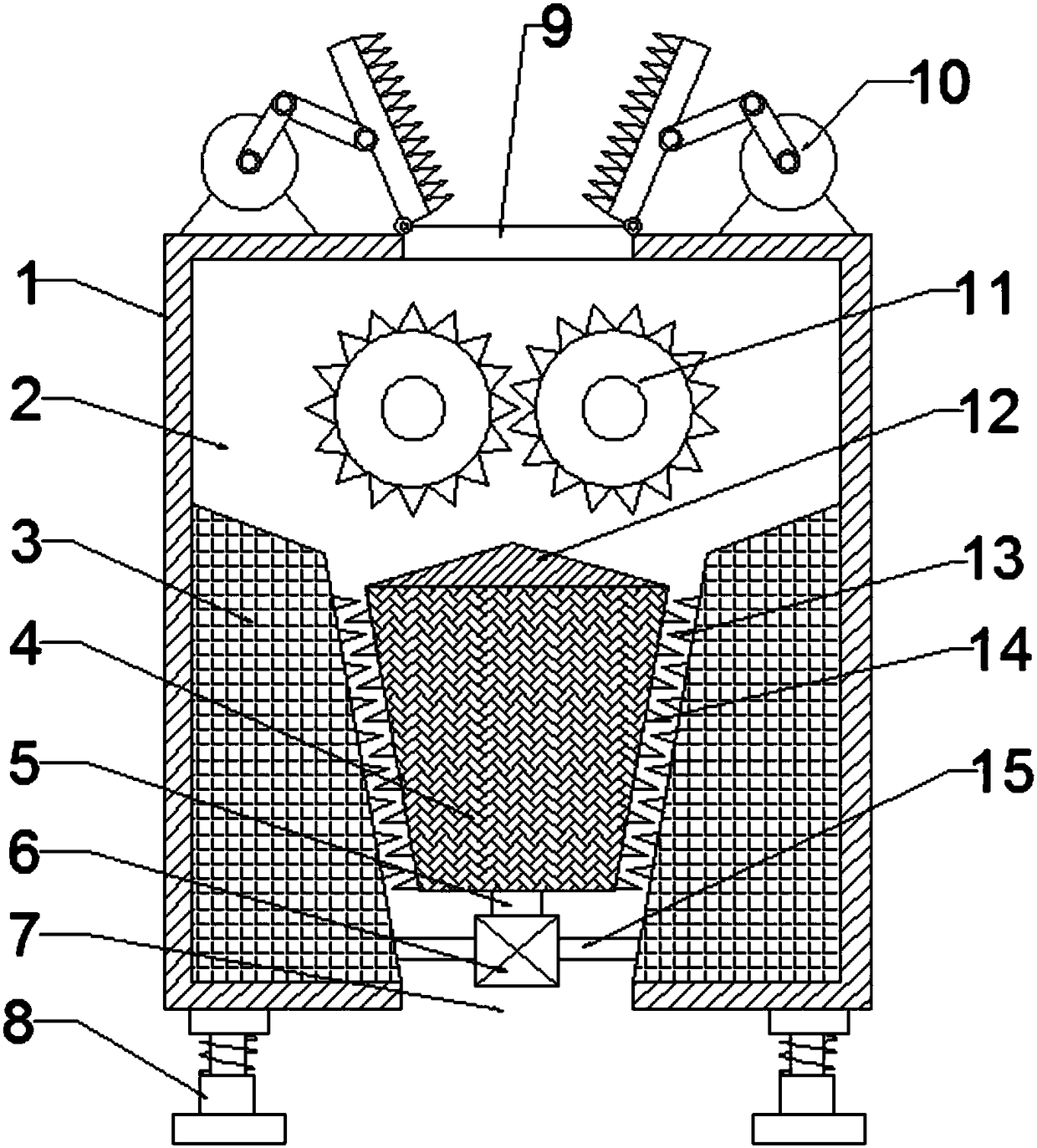

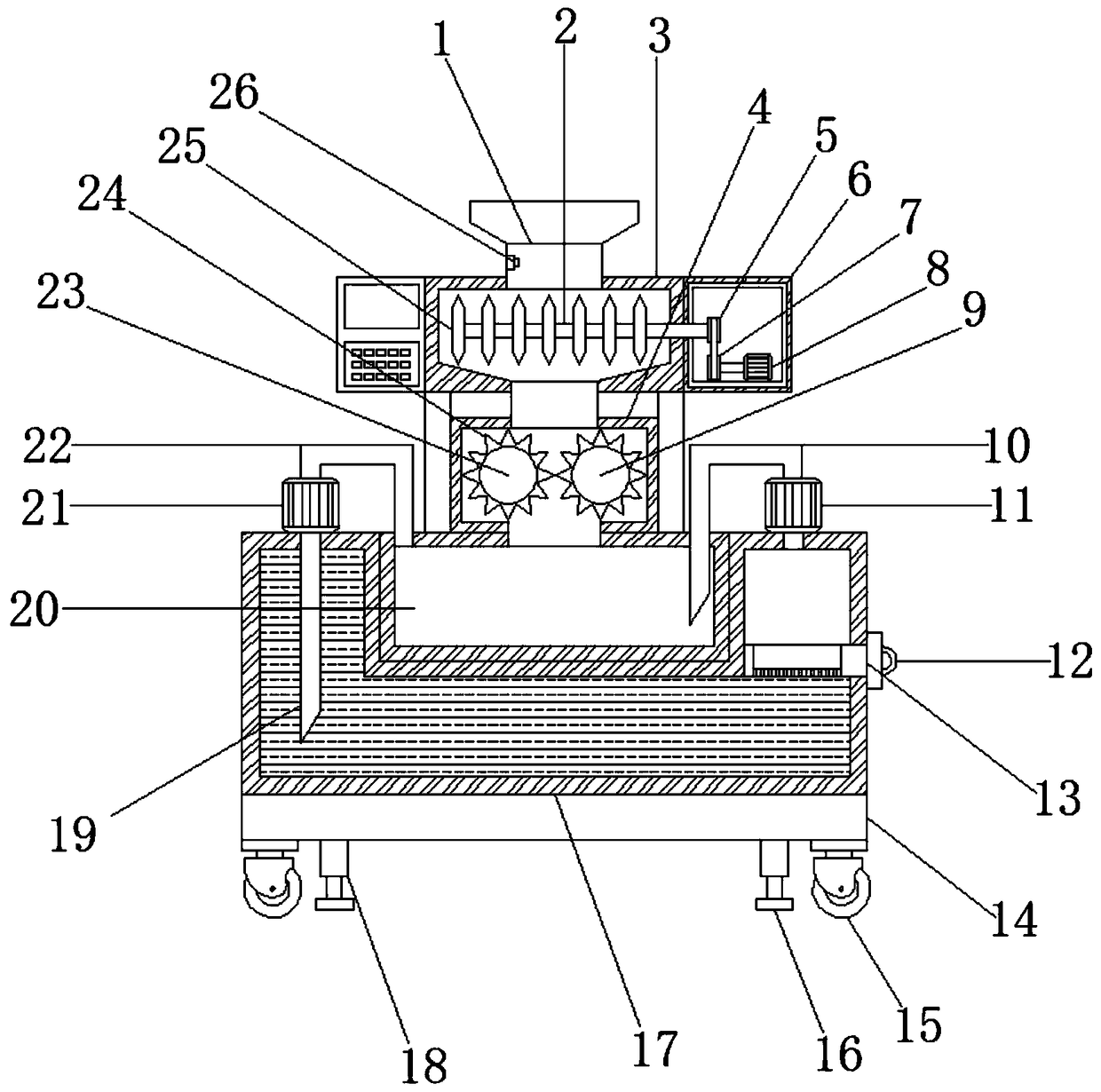

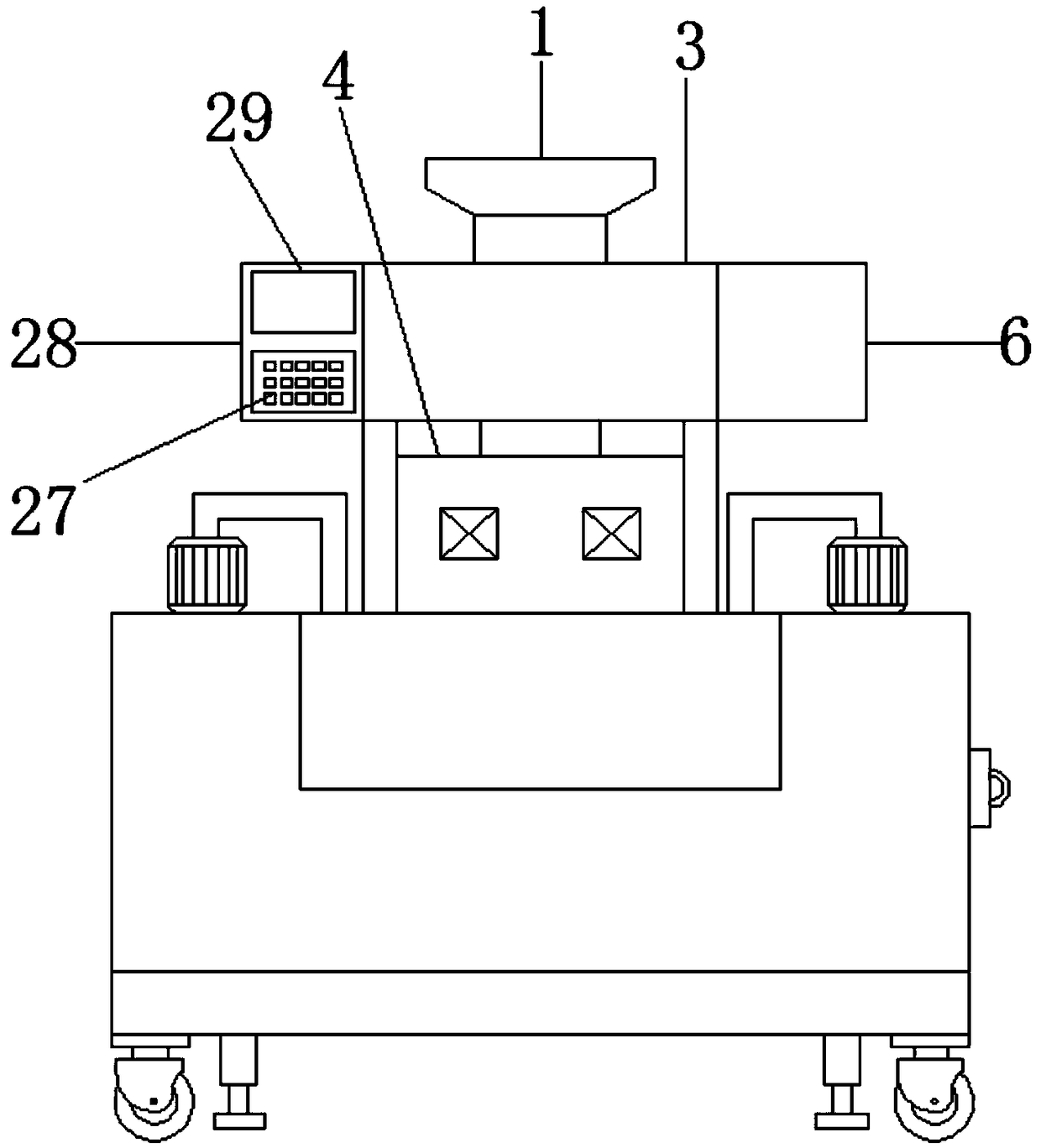

Construction cement production material crushing, stirring and drying device

InactiveCN107597259ARealize back-and-forth movementAvoid damageDrying solid materials without heatMixing operation control apparatusReciprocating motionBarrier effect

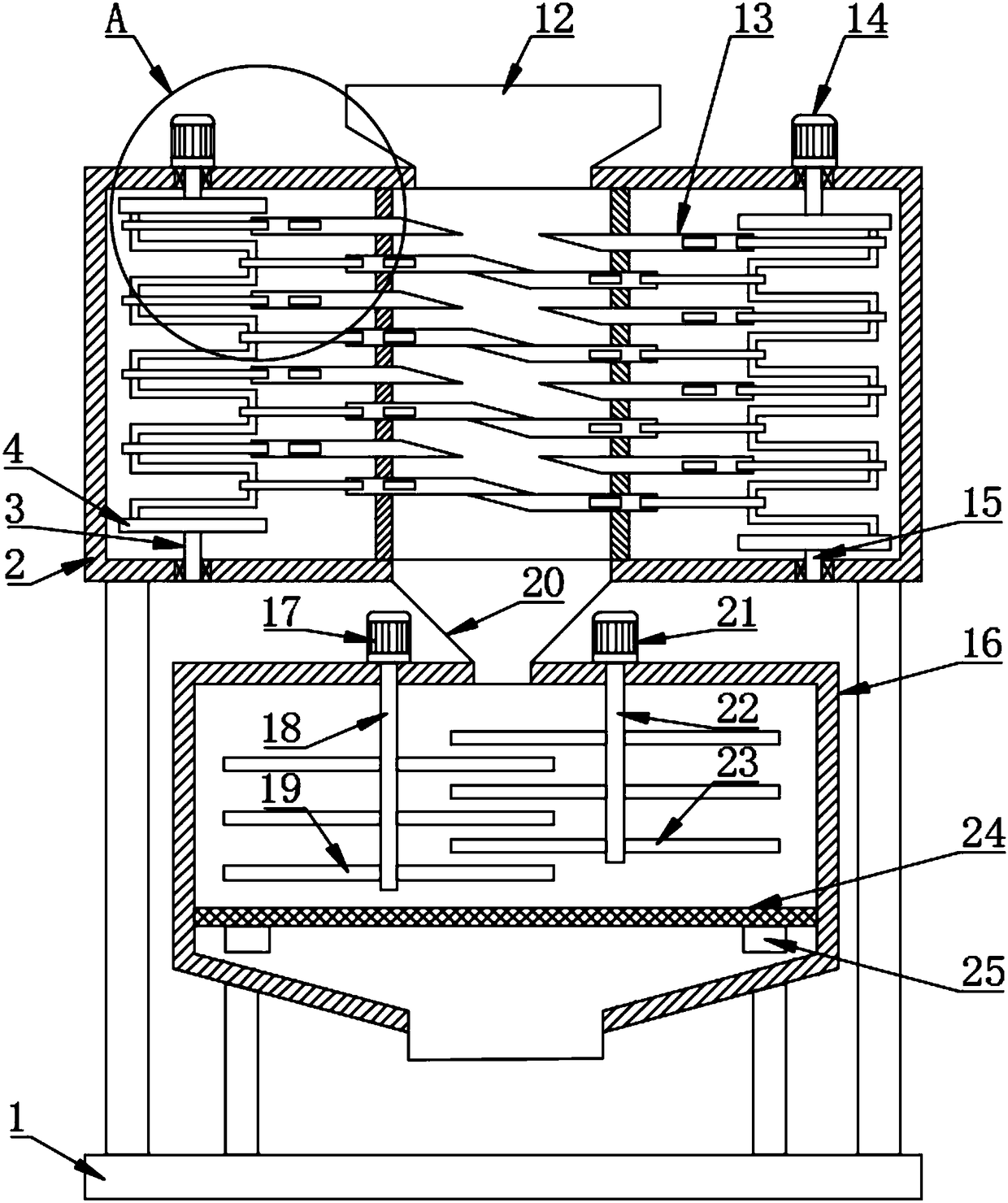

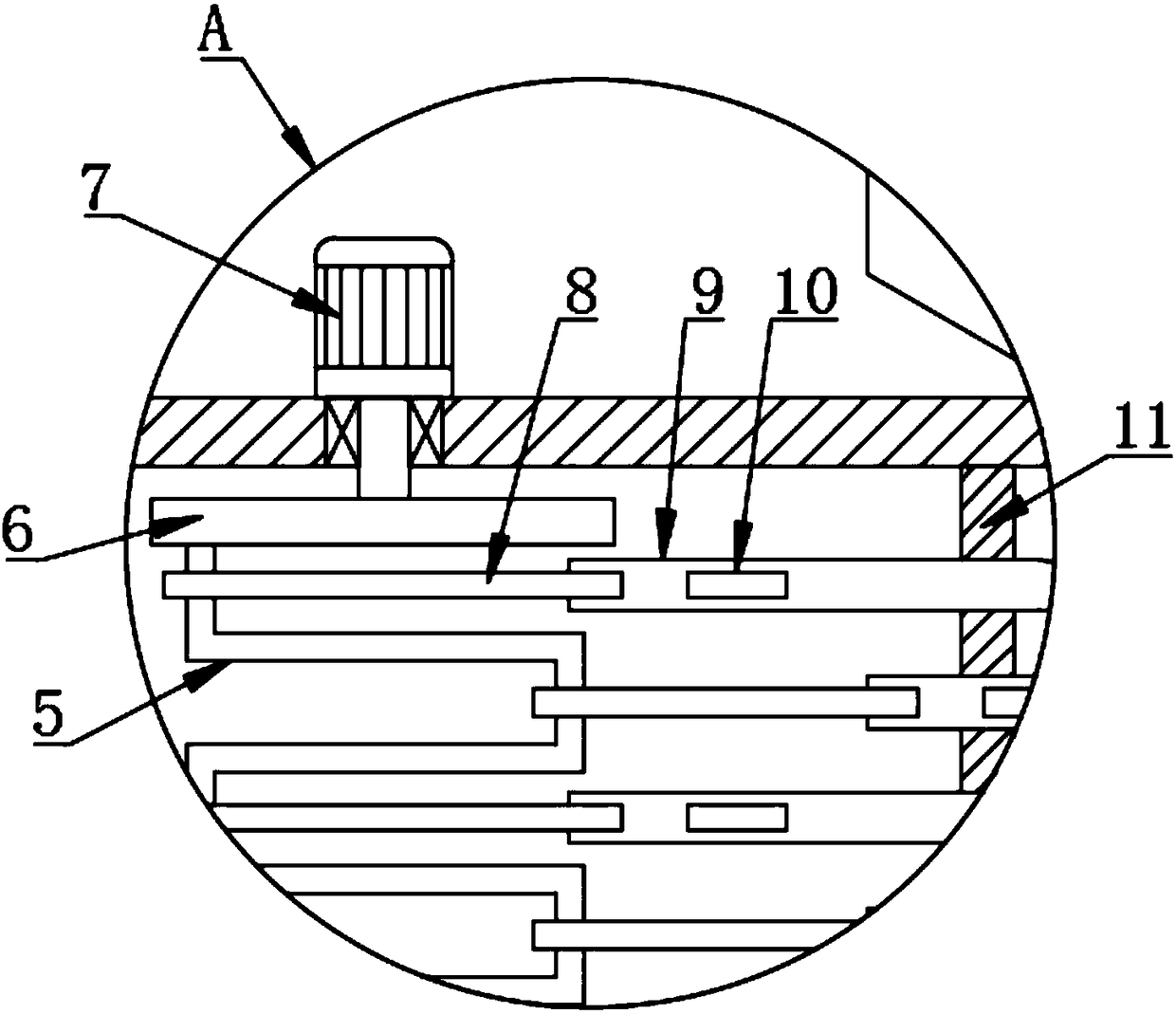

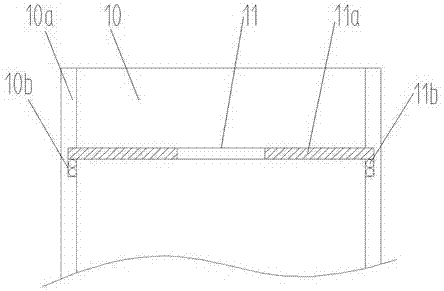

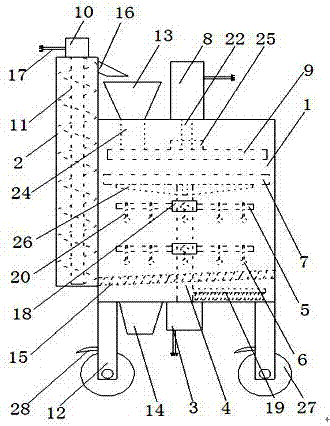

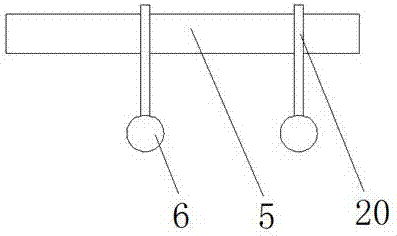

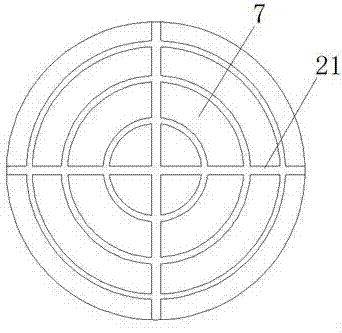

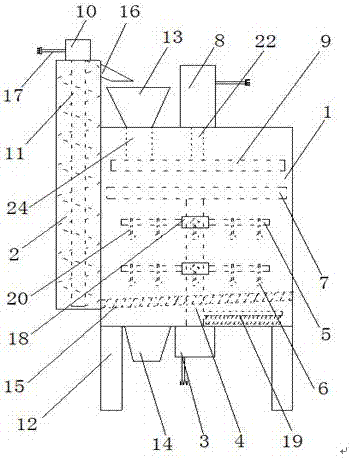

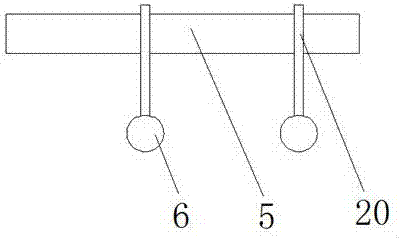

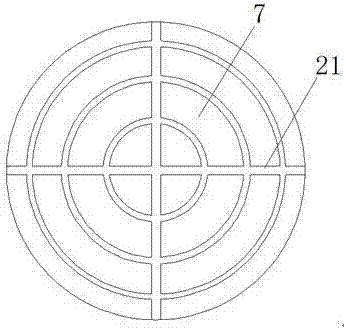

The invention provides a construction cement production material crushing, stirring and drying device, and belongs to the technical field of construction machinery. The device comprises a box, an upper cover, a storage box, a base, a vibration reducing device, universal wheels, an absorbing device and a dehumidifier; the upper cover is arranged above the box; the upper cover and the box are detachably connected through a hexagonal nut and a stud; a cam is arranged on the upper side in the box; a rotating shaft is fixedly connected to the middle of the cam; and a push plate is arranged below the cam. A reciprocating motion of a crushing column is realized by using cooperation of the cam, the push plate, a return spring and a push rod, so that the crushing efficiency and the crushing qualityare improved; an insertion plate achieves a temporary barrier effect on materials in a crushing chamber; after the materials are thoroughly crushed, the insertion plate is pulled out; the materials in the crushing chamber fall down from through holes in the separation plate to enter a mixing chamber; and the dehumidifier is arranged on the left side of the mixing chamber for drying the materialsto effectively inhibit damage of the materials due to moisture.

Owner:南安泰达农业科技有限公司

Chinese herbal medicine pulverizer

The invention discloses a Chinese herbal medicine pulverizer. The Chinese herbal medicine pulverizer comprises a container. A feeding pipe is arranged at the upper end of the container and connected with a hopper. A pulverizing cutter is arranged in the feeding pipe. A collecting tank is arranged at the bottom of the container. A screen is arranged above the collecting tank. A suction fan is arranged at the upper end of the container. An air suction pipe of the suction fan leads into the container, and the other end of the air suction pipe leads to the pulverizer. Pulverizing machining is conducted by arranging the pulverizer capable of achieving automatic filling, and large materials can be extracted to be secondarily pulverized in the pulverizing process. The Chinese herbal medicine pulverizer is simple in structure and convenient to operate, and the pulverizing efficiency and quality of the Chinese herbal medicine are improved.

Owner:WUHU YANGYAN PHARMA

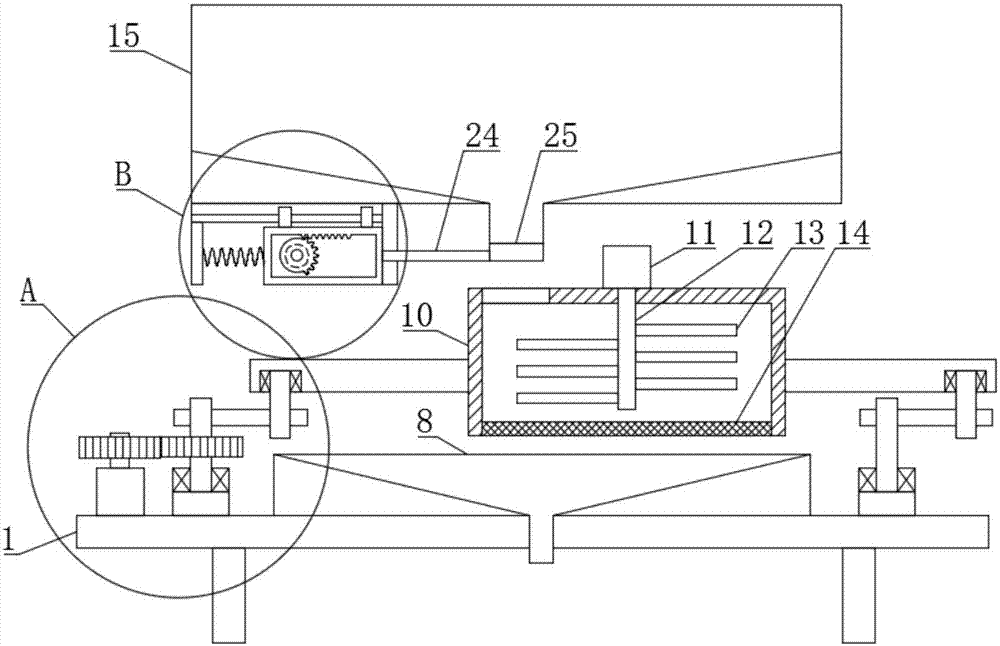

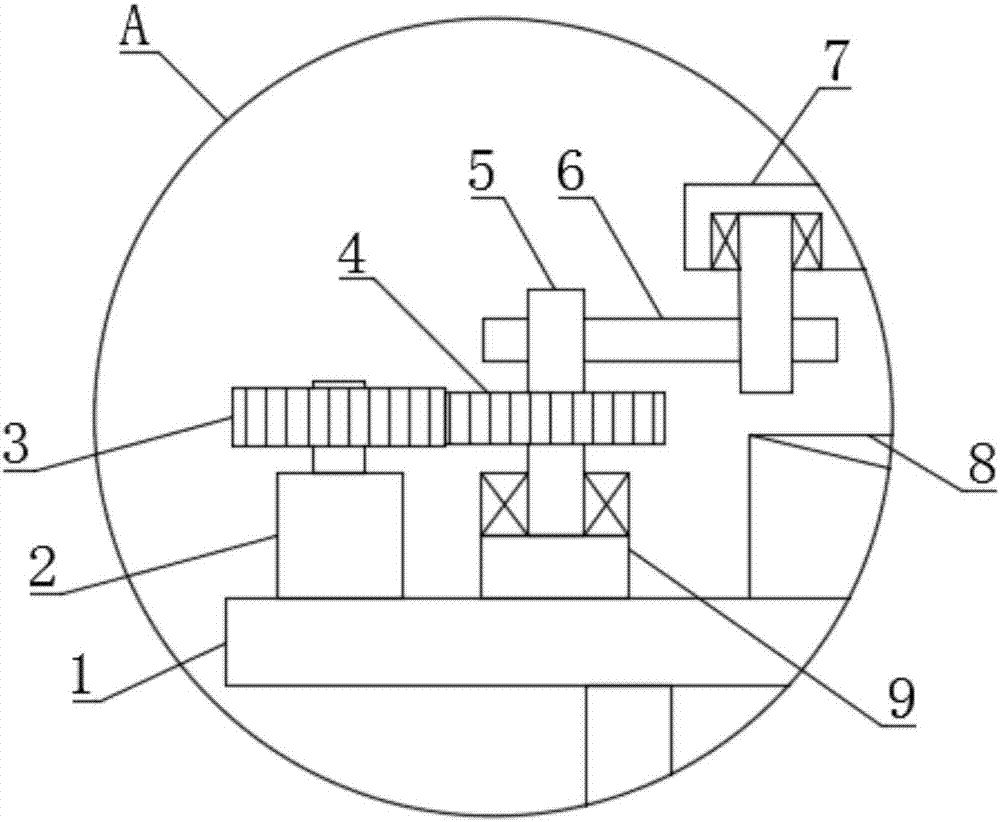

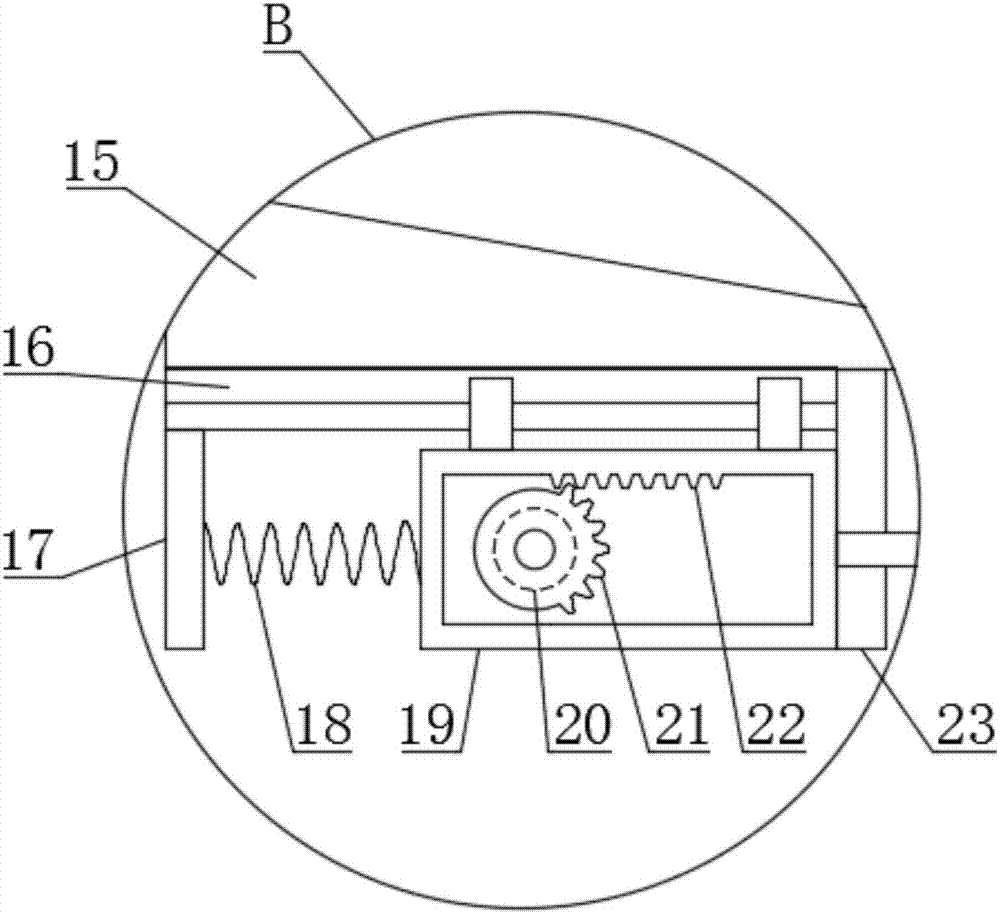

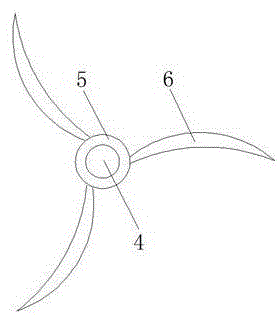

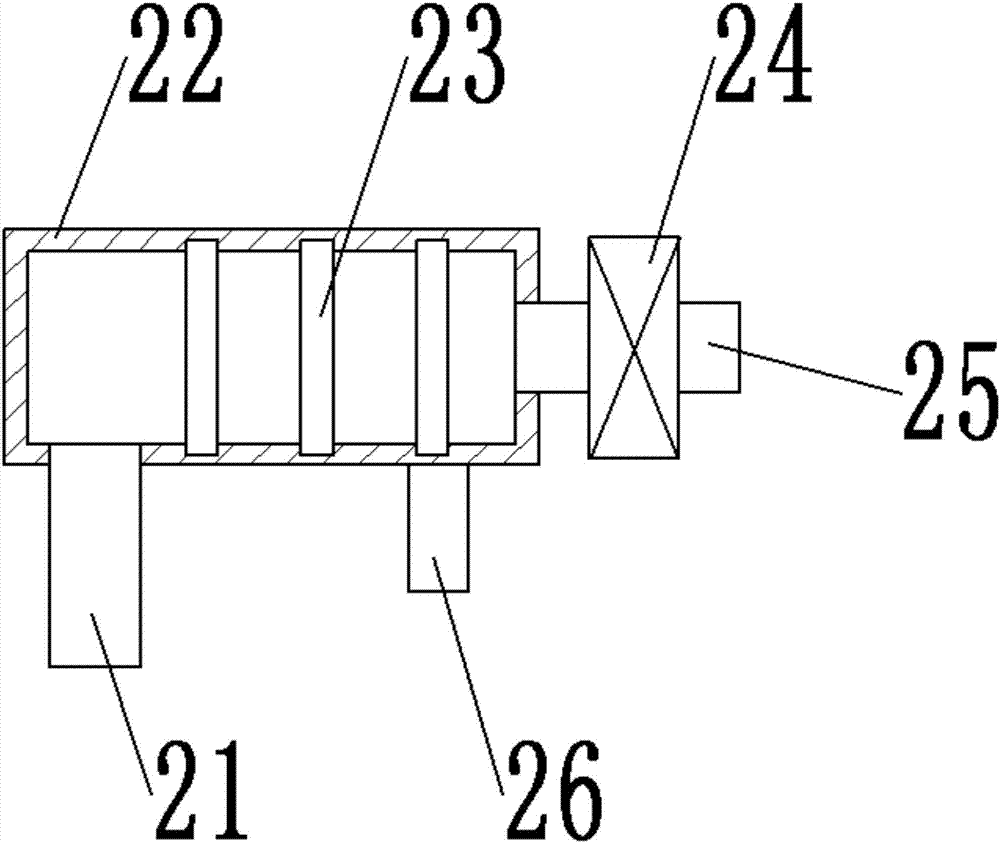

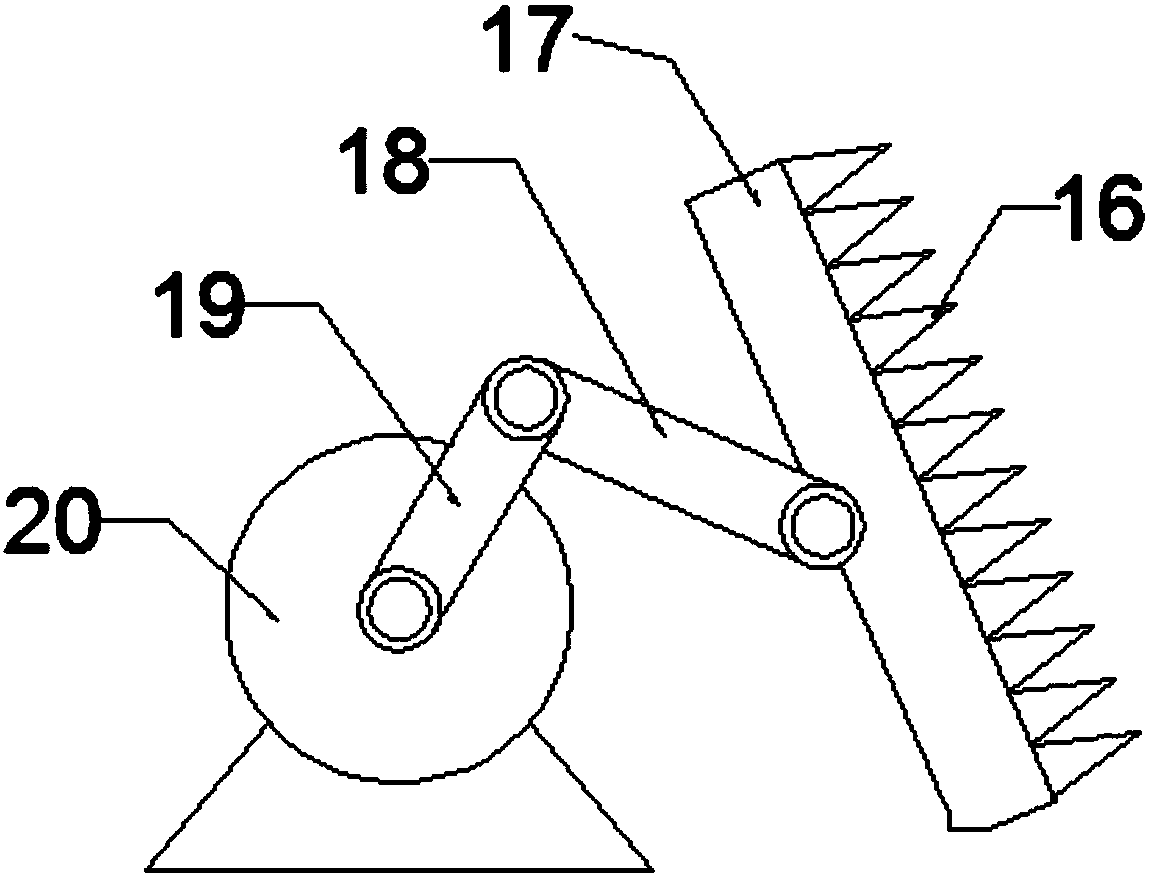

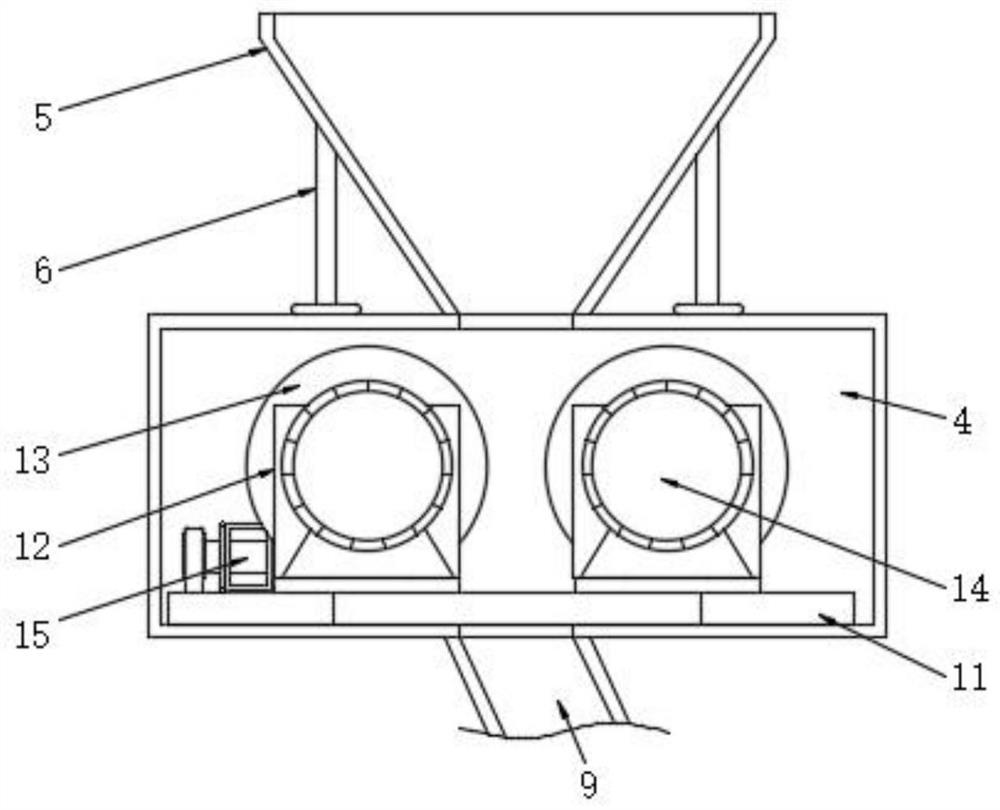

Rapid stone breaking-screening device for building

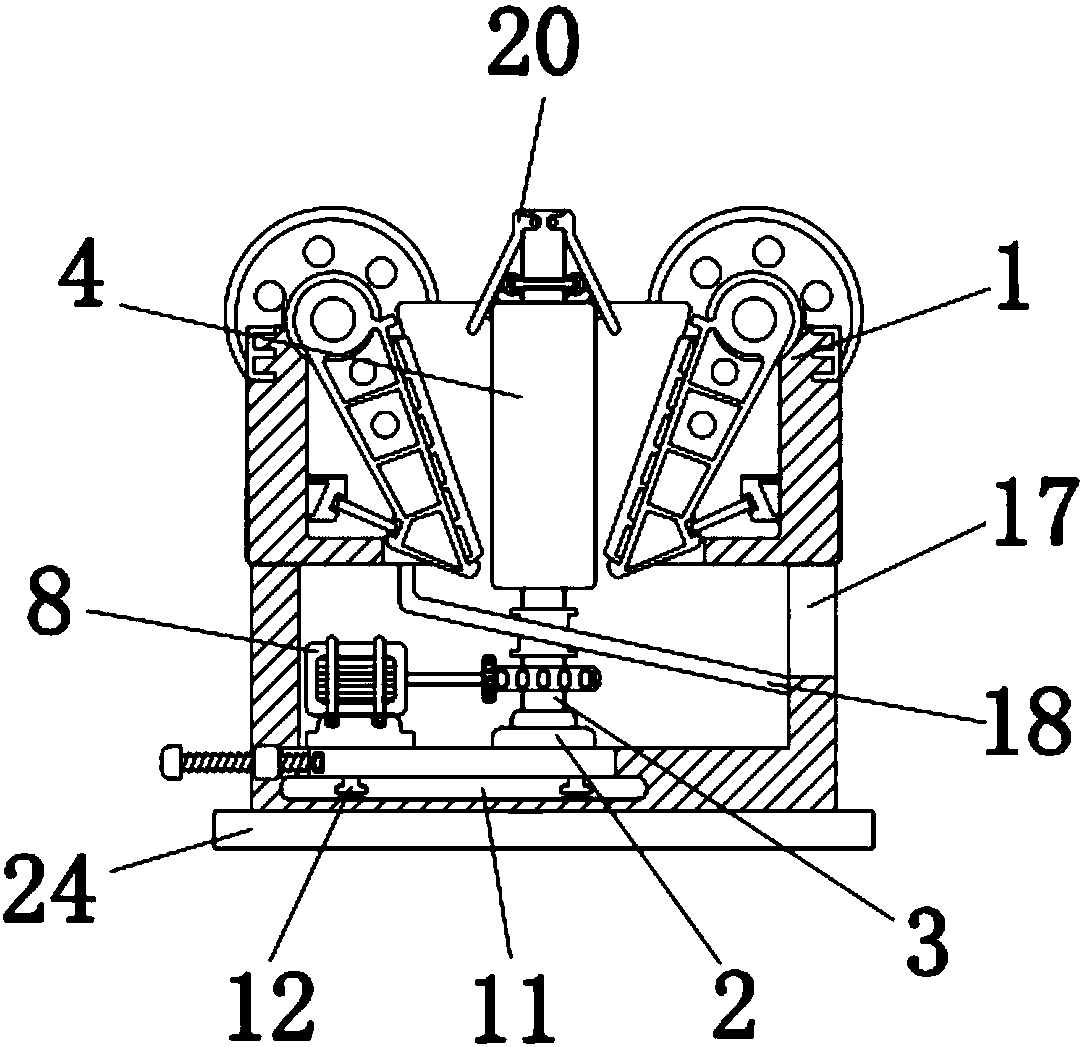

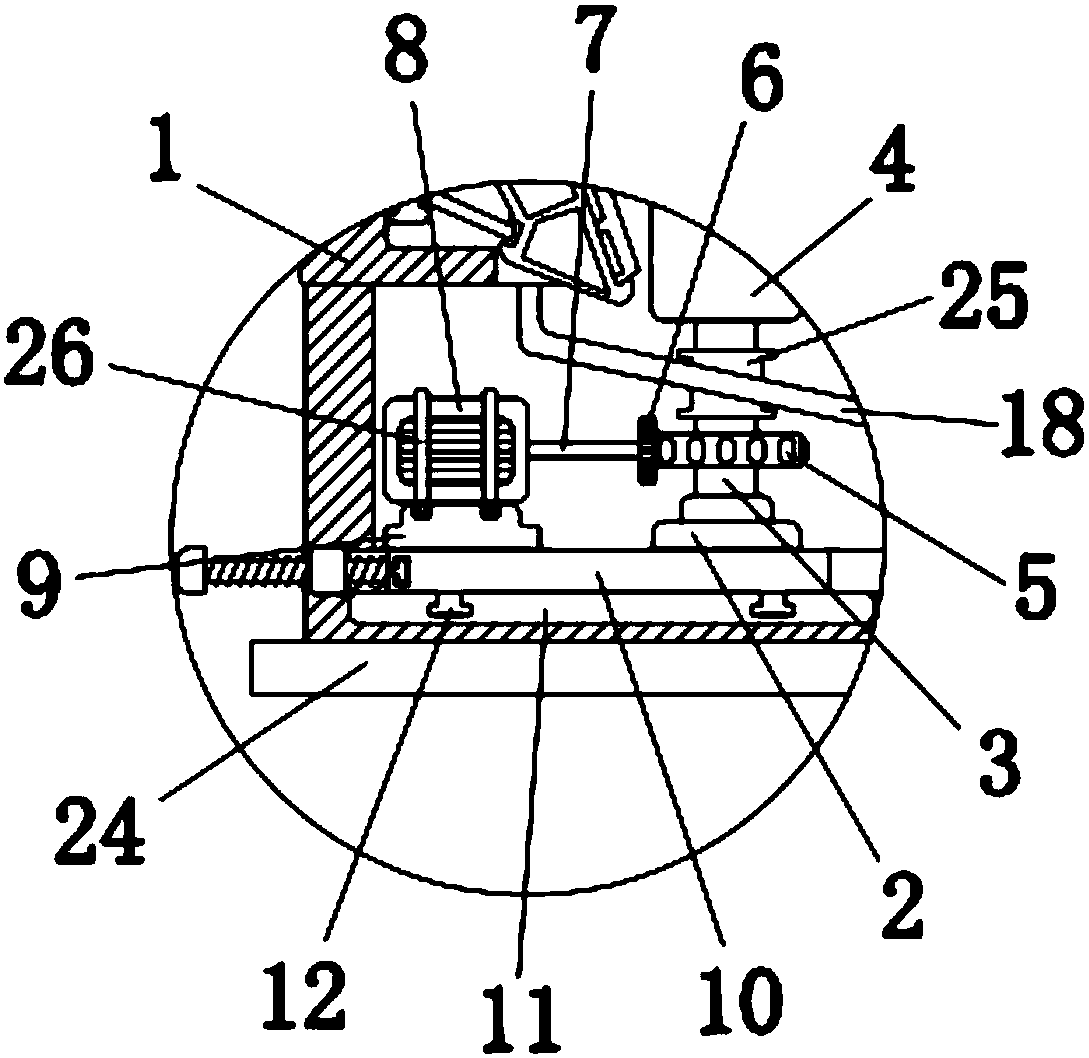

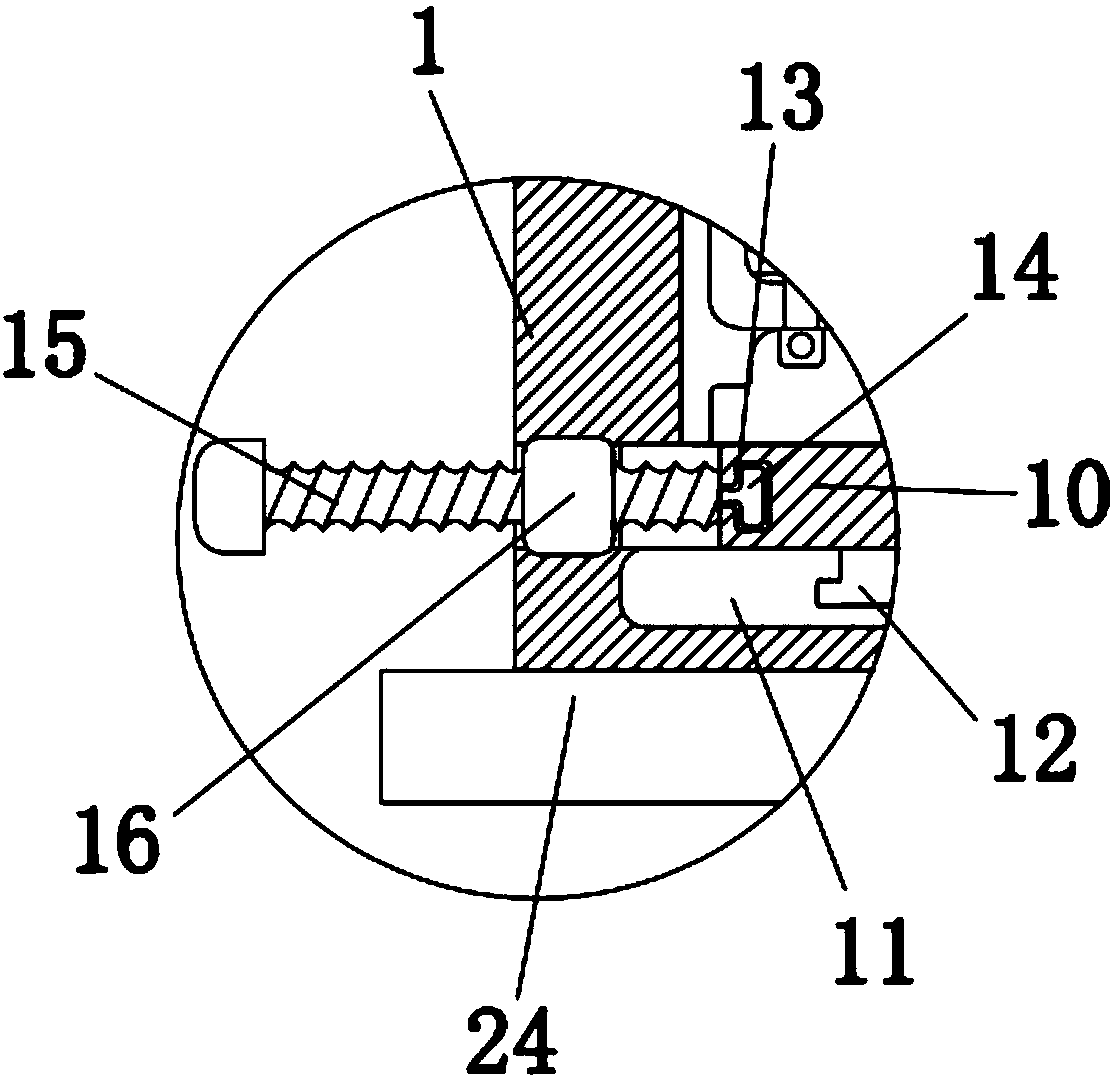

InactiveCN107377118AExpedited screeningImprove crushing qualityGrain treatmentsEngineeringMotor shaft

The invention discloses a rapid stone breaking-screening device for a building. The rapid stone breaking-screening device comprises a bottom plate and a breaking bucket, wherein a support is arranged at a bottom of the bottom plate, a plurality of support arms are connected to a sidewall of the breaking bucket, a crank mechanism is rotationally connected to a bottom of each support arm through a bearing, and a mounted bearing is connected to each crank mechanism through a first rotary shaft and arranged on the bottom plate; a driven gear is installed on a first rotary shaft at a left side, a first motor is arranged on the bottom plate, and a drive gear is installed on a motor shaft at a top end of the first motor and engaged with the driven gear; and a second motor is arranged at the centre of a top of the crushing bucket, a second rotary shaft is connected to a motor shaft at a bottom end of the second motor, a crushing blade is installed on the second rotary shaft, and a filter screen is further arranged at a bottom of the breaking bucket. According to the rapid stone breaking-screening device disclosed by the invention, the broken stone is screened through the arrangement of the filter screen; and the stone in the breaking bucket can be driven to swing to increase breaking efficiency, and stone screening can also be accelerated to prevent the filter screen from being blocked through crank structures.

Owner:泉州森泸玩具有限公司

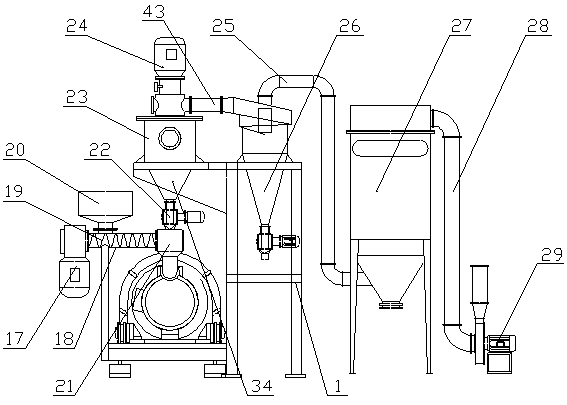

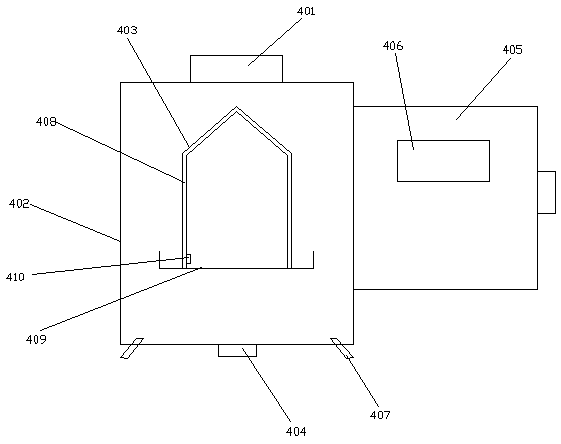

Biomass fuel crusher

The invention discloses a biomass fuel crusher. The biomass fuel crusher comprises a supporting base, wherein a rack is arranged on the supporting base, a feeding bin is arranged at the front part of the rack, a crawler-type feeding conveyer is horizontally distributed in the feeding bin, a forced feeding roll is arranged at the top part of the rear end of the crawler-type feeding conveyer, a crushing compartment is arranged on the rack at the rear part of the forced feeding roll, a crushing roll is arranged in the crushing compartment, a crushing cutter bit is arranged on the surface of the crushing roll, a crushing separating screen is coaxially sheathed at the periphery of the crushing roll, a crushing feeding hole matched with the forced feeding roll is formed at the front part of the crushing separating screen, a discharging compartment communicated with the crushing compartment is arranged at the bottom of the crushing compartment, a discharging hole is formed at the bottom of the discharging compartment, and a discharging conveyer is arranged under the discharging hole. According to the biomass fuel crusher, the universality of the crusher is improved, various biomass fuels in wastes in the fields of agriculture, forest industry, industry, construction industry and the like can be subjected to crushing processing, the operating efficiency and the crushing quality of the crusher are improved, the service life of the crusher is prolonged, the power consumption is reduced, and the using cost and the operating expense are reduced.

Owner:格薪源生物质燃料有限公司

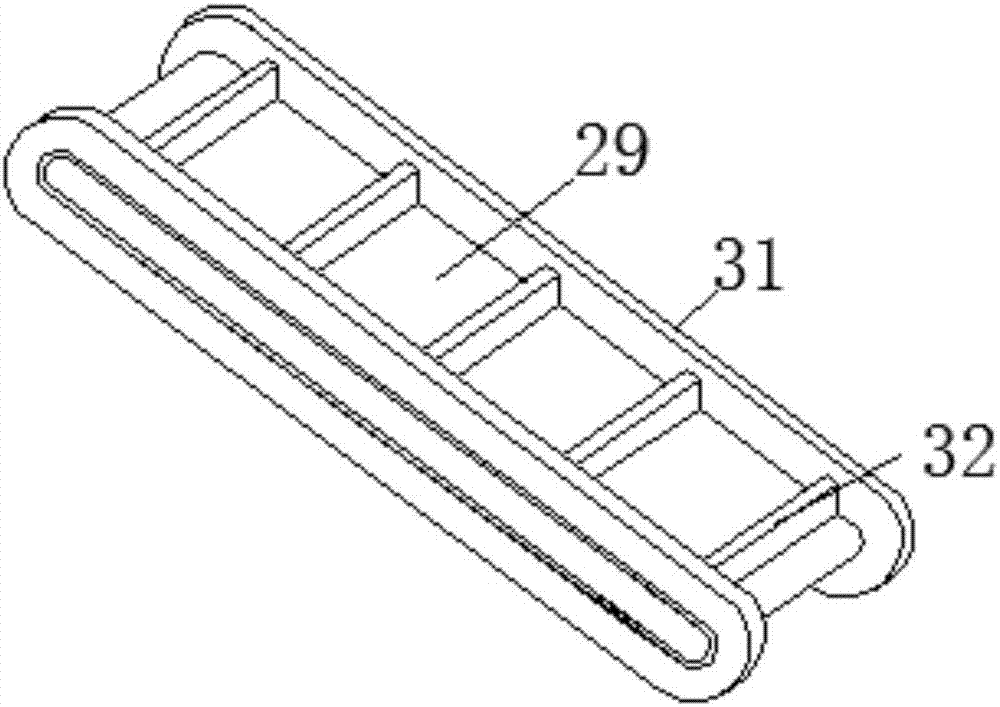

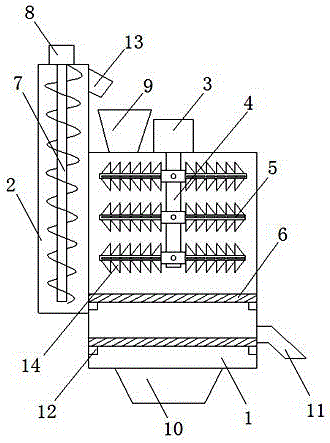

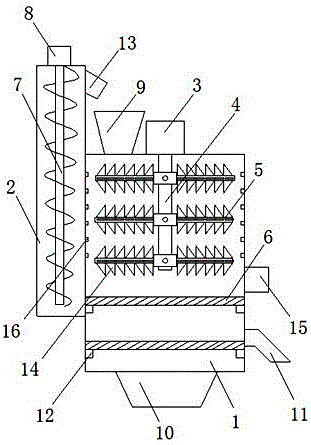

Cutting and smashing all-in-one machine for agricultural straw and use method of cutting and smashing all-in-one machine

InactiveCN106391231AFacilitate post-sequence crushingImprove crushing qualityGrain treatmentsAgricultural engineeringRaw material

The invention discloses a cutting and smashing all-in-one machine for agricultural straw. The cutting and smashing all-in-one machine for agricultural straw comprises a smashing box, a lifting drum, a motor I, a transmission shaft, connection blocks, cutter knives, agitating rods, smashing knives and filter sieves, and is characterized in that the smashing box is arranged on a support; a feed bin, discharge pipes and an impurity discharge opening are arranged on the smashing box; a workbin is arranged at one end of the lifting drum, and a motor II and a blowdown pipe are arranged at the other end of the lifting drum; and an auger is arranged in the lifting drum. According to the cutting and smashing all-in-one machine for the agricultural straw, the connection blocks and the agitating rods are arranged on the transmission shaft, the cutter knives and the smashing knives are arranged on the connection blocks and the agitating rods, and the raw material of agricultural straw entering the smashing box can be cut into broken sections by the cutter knives, so that follow-up smashing treatment of the agricultural straw is facilitated, and the smashing quality and the smashing efficiency of the agricultural straw are improved; and the plurality of cutter knives are arranged on the agitating rods, the crushing quality is further improved.

Owner:芜湖瑞德机械科技有限公司

Lump lime smashing equipment for building construction

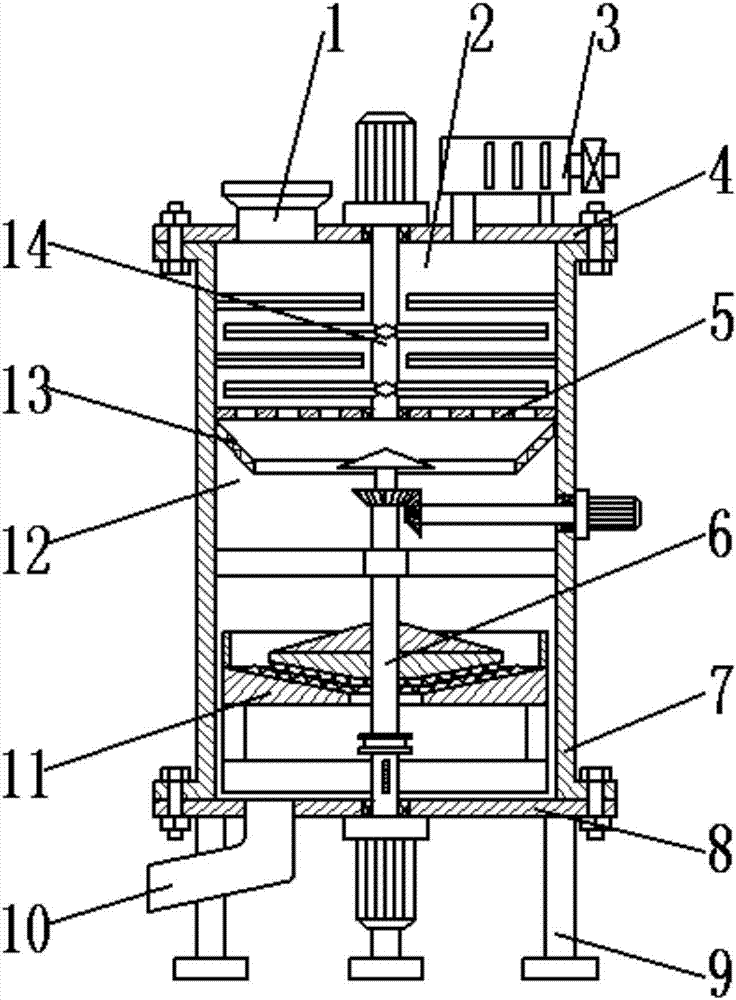

InactiveCN107199092AEfficient crushingFully brokenDispersed particle filtrationCocoaArchitectural engineeringComminution

The invention provides lump lime smashing equipment for building construction. The lump lime smashing equipment comprises a tank body; the tank body is arranged to be a hollow cylinder with two ends communicated, an upper cover is arranged at an opening in the top of the tank body, and a bottom cover is arranged at an opening in the bottom of the tank body; a feeding pipe is fixedly welded to the left side of the surface of the upper cover, and a dust absorption device is arranged on the right side of the surface of the upper cover; the interior of the tank body is divided by a separating plate into a breaking cavity and a smashing cavity; a material guide disc is fixedly welded to the lower surface of the separating plate; a breaking device is arranged in the breaking cavity; and an upper smashing device and a lower smashing device are arranged in the smashing cavity. According to the lump lime smashing equipment, blocky limb is shorn and smashed through the smashing device; the upper smashing device and the lower smashing device are arranged, relative rotation of a lower smashing disc and an upper smashing disc is used, an upper smashing block and a lower smashing block are used for grinding and smashing the smashed lime, the lime is firstly broken and secondly smashed, sufficient smashing of the lime is facilitated, and the smashing quality and the smashing uniformity are improved.

Owner:合肥多智科技开发有限公司

Crushing device used before rolling construction of sludge solidified soil

The invention discloses a crushing device used before rolling construction of sludge solidified soil, and belongs to the technical field of environmental protection. The crushing device comprises a housing, a crushing cavity, crushing rollers, crushing blades, connecting rods, a crushing motor, a mesh screen, a rotary motor, shock-absorbing bases, a feed hopper, a first rotating shaft, a vibration generator, a screw blade, a second rotating shaft and a discharge opening, wherein the housing is arranged at the tops of the shock-absorbing bases; the crushing cavity is arranged in the housing; the feed hopper is arranged at the center of the top end of the housing; the feed hopper communicates with the crushing cavity; the first rotating shaft is horizontally arranged below the crushing rollers; the crushing blades are arranged on the first rotating shaft through the connecting rods; the crushing motor is fixedly arranged at the middle of the left side of the housing; and the output shaft of the crushing motor is connected with the first rotating shaft. The crushing device used before rolling construction of sludge solidified soil is simple in structure, reasonable in design and time-saving and labor-saving, can be better used for quick and uniform crushing of solidified soil, and can further ensure the compactness and uniformity of the soil body after subsequent rolling and compacting construction.

Owner:郑州莉迪亚医药科技有限公司

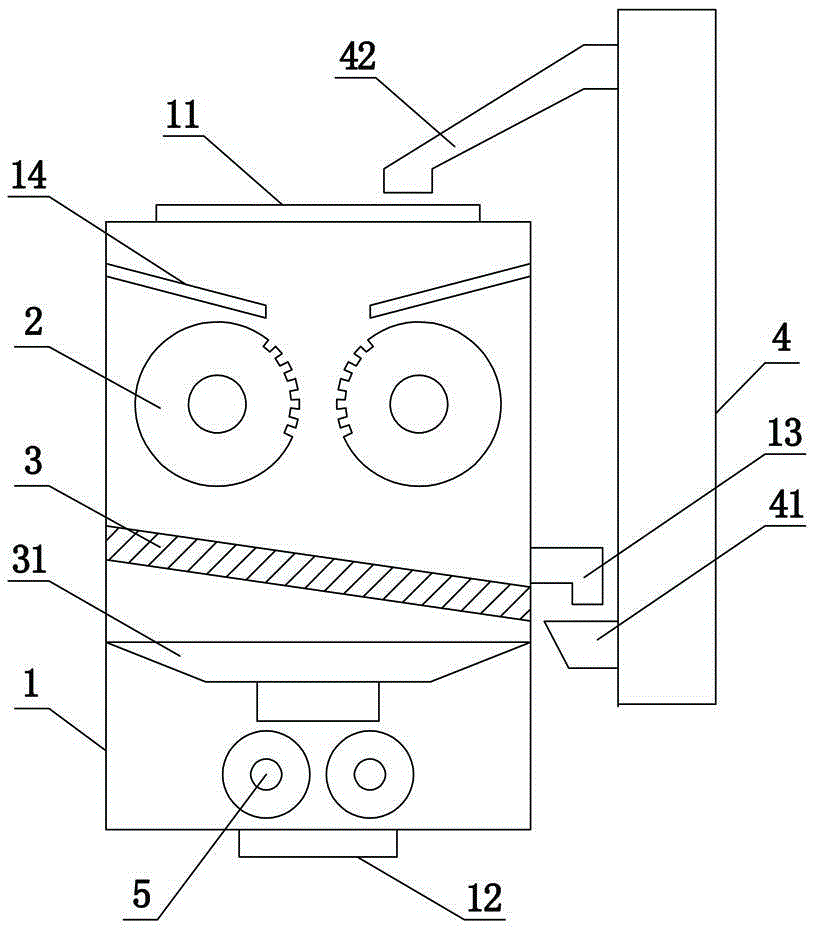

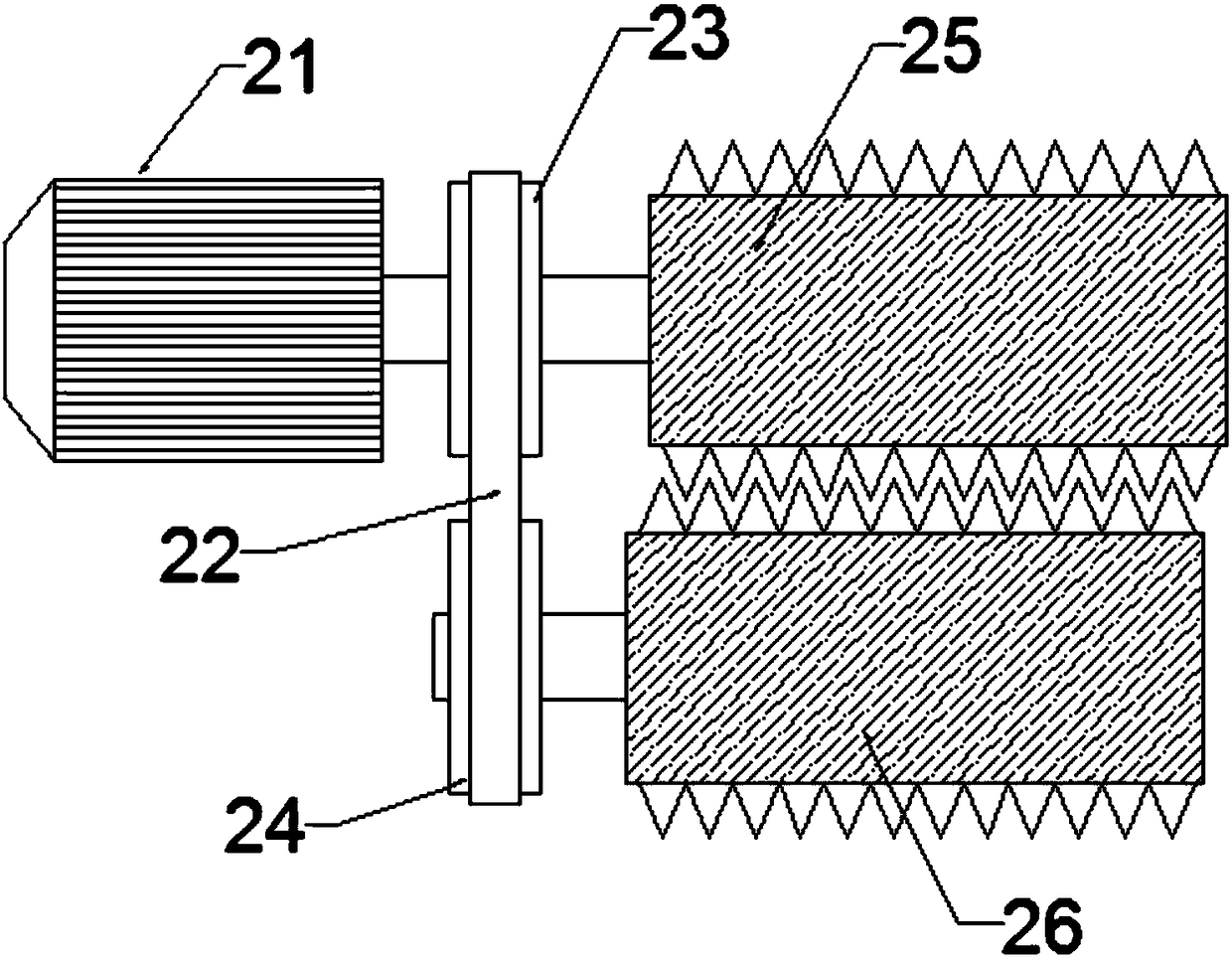

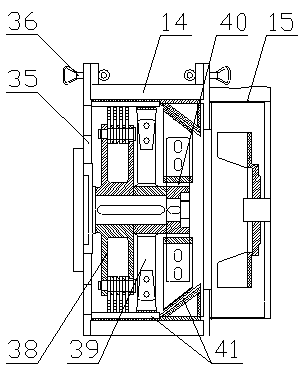

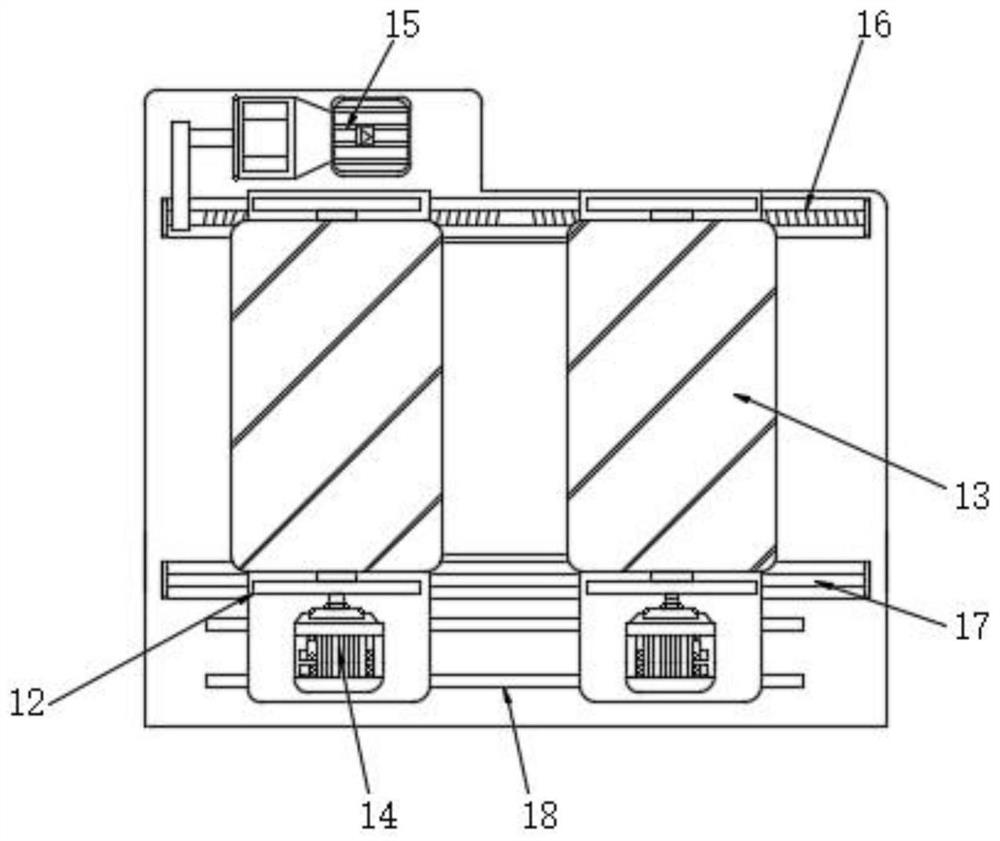

Biomass particle smashing device

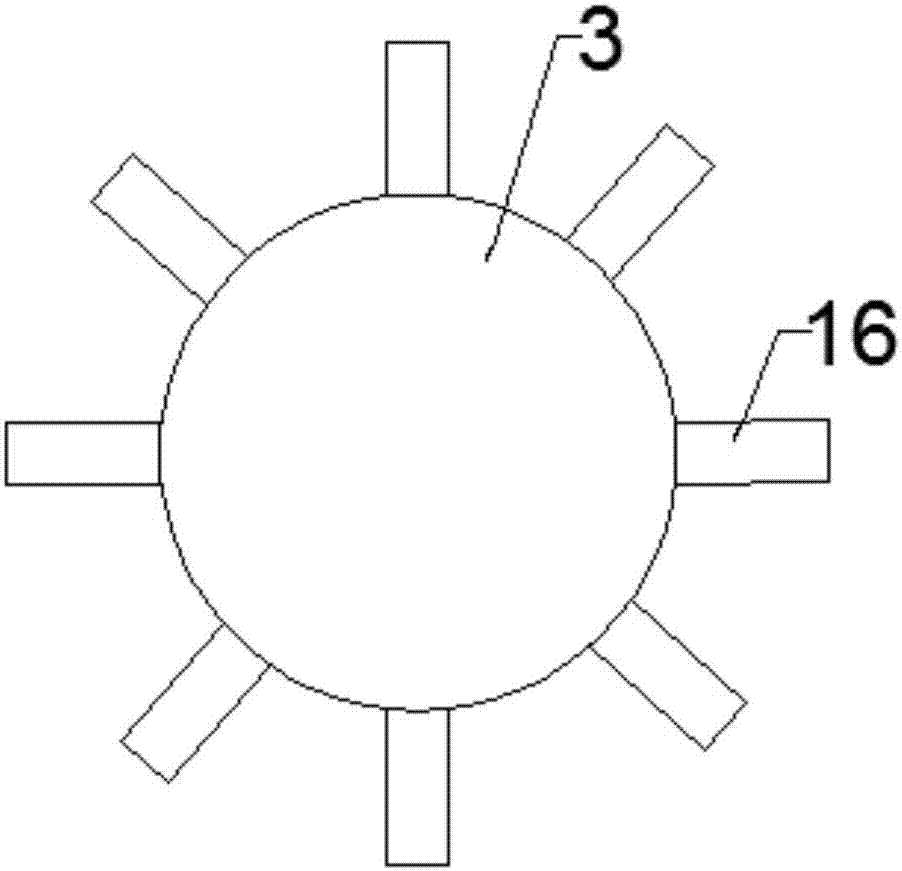

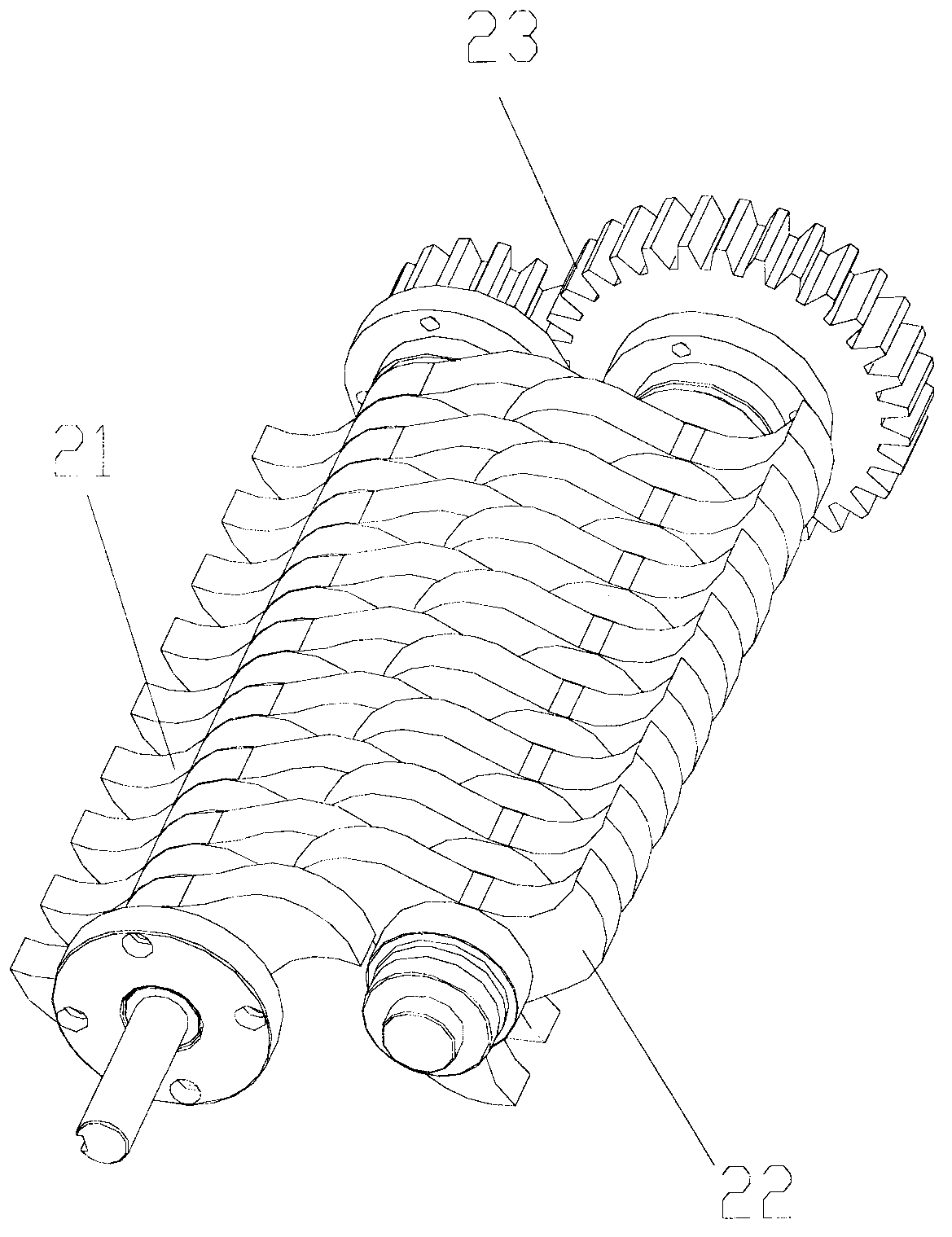

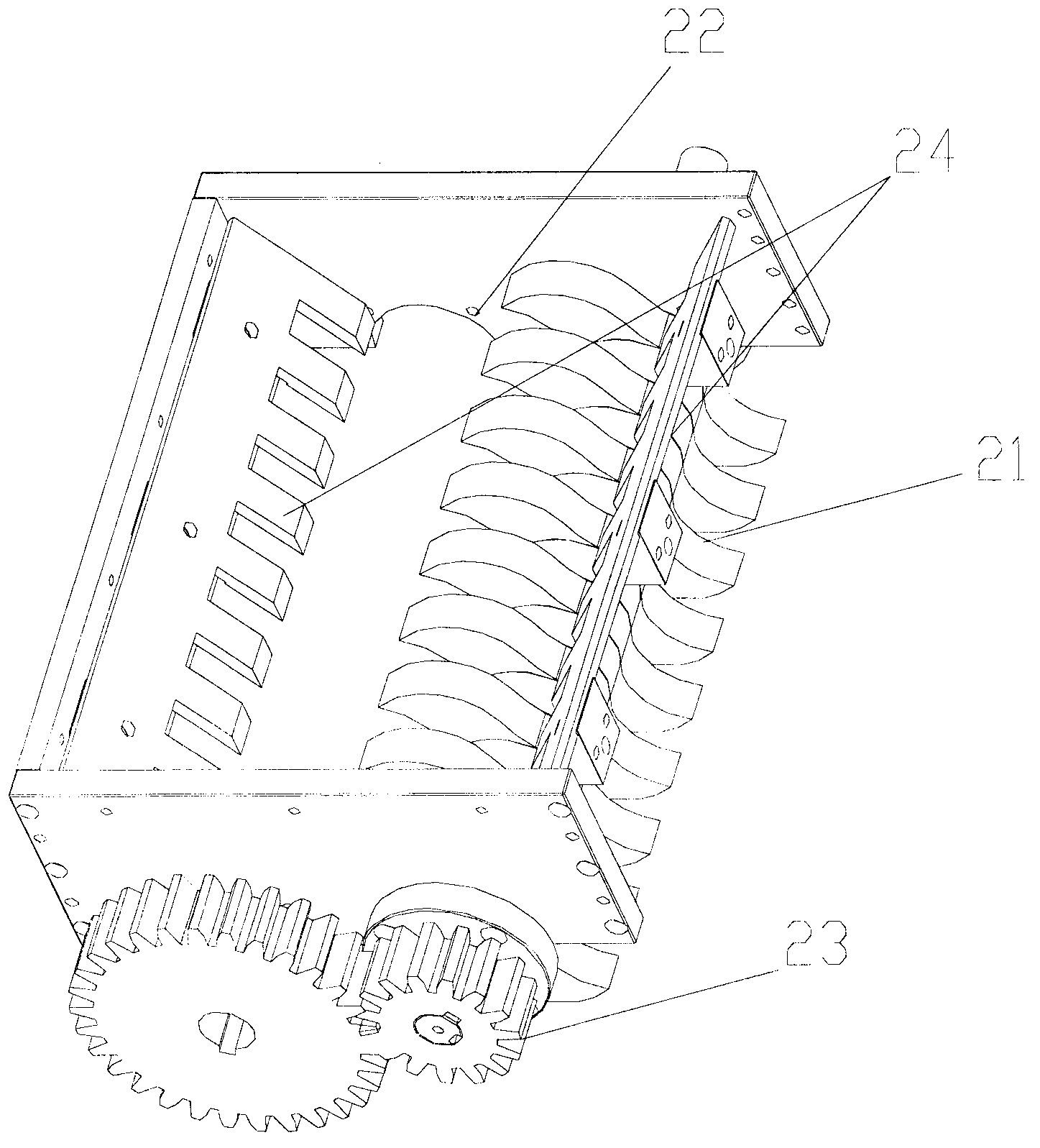

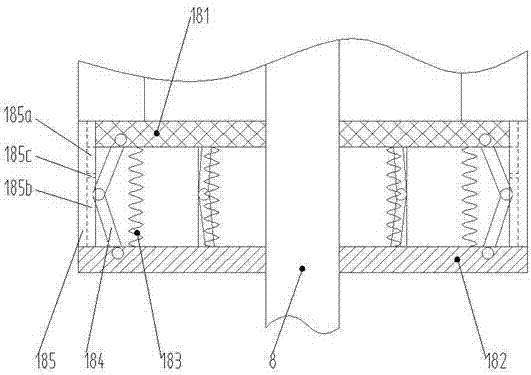

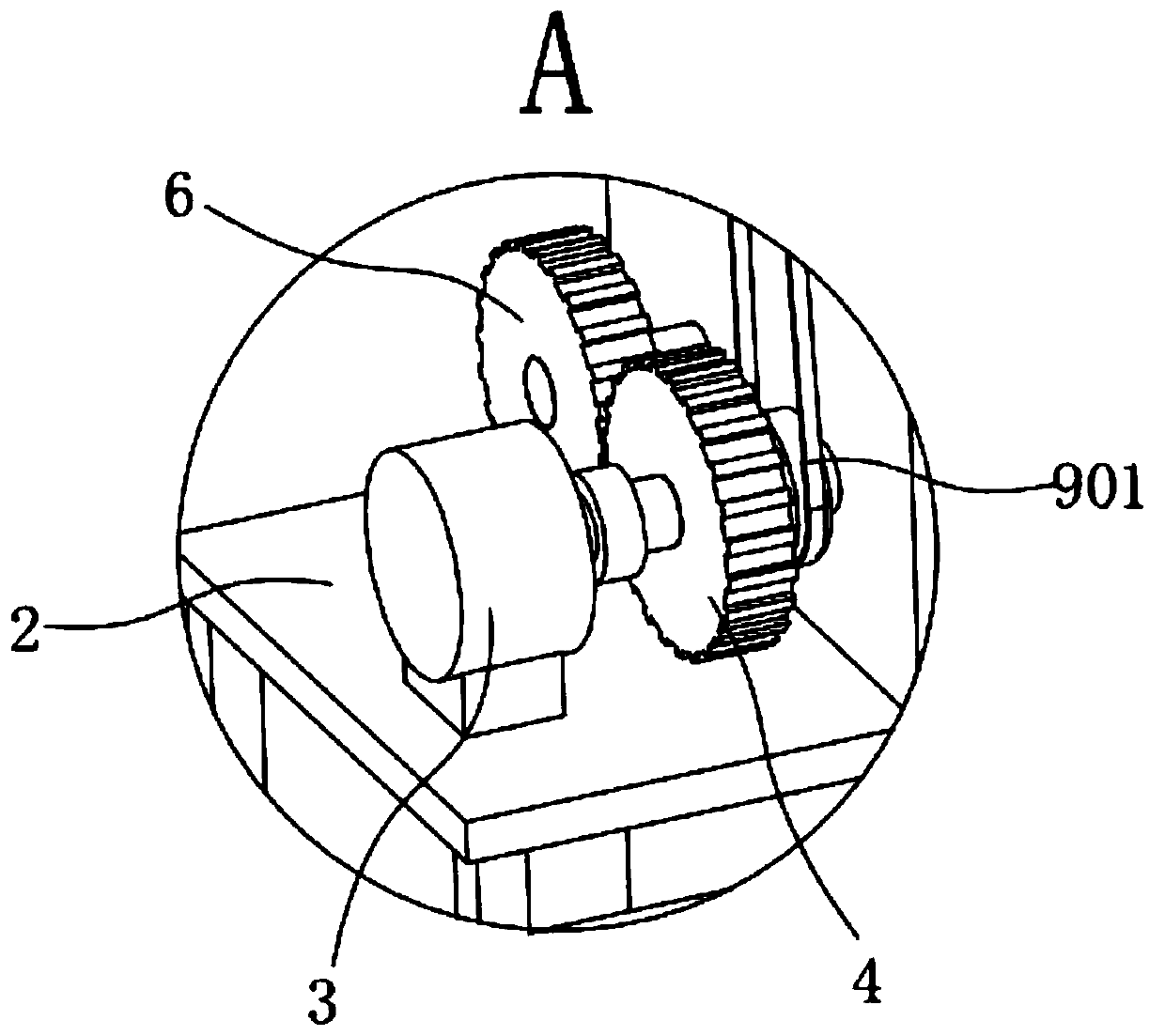

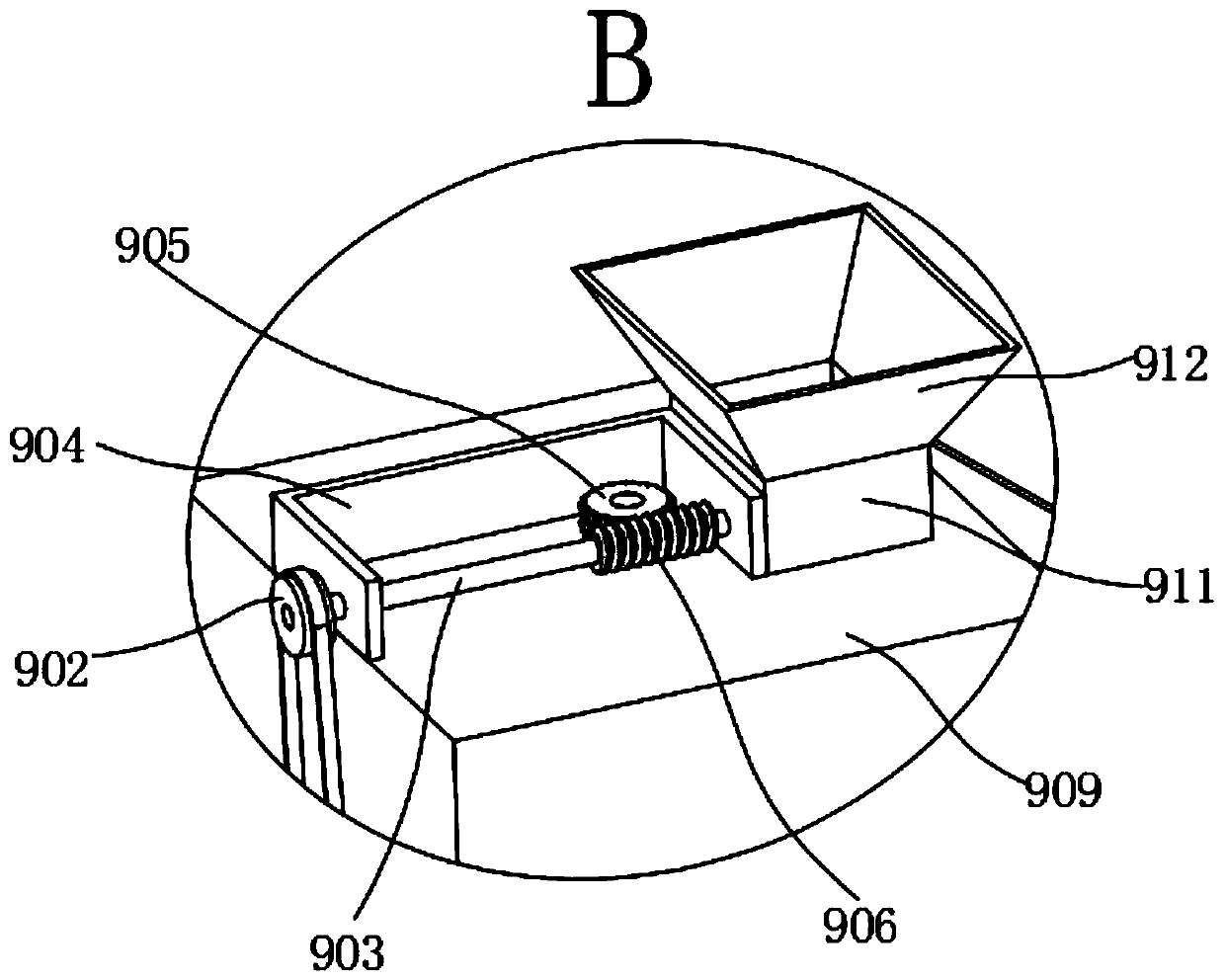

InactiveCN105413797AEasy to cleanGuaranteed crushing qualityGrain treatmentsGear wheelElectric machinery

The invention provides a biomass particle smashing device. The biomass particle smashing device comprises a rack, a smashing shell and a smashing motor, wherein the smashing shell and the smashing motor are arranged on the rack. A pair of smashing rollers is horizontally arranged in the smashing shell. Roller shafts of the pair of the smashing rollers are engaged through a gear. An output shaft of the smashing motor is connected with the roller shaft of one smashing roller. A feeding opening is formed in the upper portion of the smashing shell, and a discharging opening is formed in the lower portion of the smashing shell. The smashing shell is provided with a vibration screen obliquely located above the discharging opening. The smashing shell is provided with a circulating discharging opening corresponding to the vibration screen. A lifting auger is arranged at the circulating discharging opening. The biomass particle smashing device has the advantages of being scientific in design, high in practicality, reasonable in structure, high in production efficiency and good in smashing effect.

Owner:LUOYANG KAITUO NEW ENERGY DEV CO LTD

Automatic organic material crushing and dewatering machine and crushing and dewatering method

The invention discloses an automatic organic material crushing and dewatering machine which comprises a base frame, a feeding bucket, a hob crushing device, a driving chain wheel, a spiral feeding bin, an extruding dewatering bin, a spiral discharge bin, a discharge variable speed link group, a discharge port and a main motor, wherein the driving chain wheel, the spiral feeding bin, the extruding dewatering bin, the spiral discharge bin and the discharge variable speed link group are connected in sequence by screw rods; a water collecting bucket is arranged below the extruding dewatering bin; the hob crushing device is composed of a set of special crossed hobs with double blades and three blades and driven to operate by a pair of variable gears connected with the hobs; and screw rod structures are arranged in the spiral feeding bin and the spiral discharge bin, and spiral blade structures are arranged on screw rods to continuously push materials. The invention further discloses a crushing and dewatering method which uses the automatic organic material crushing and dewatering machine; different organic materials can be crushed and dewatered; the defects of the existing equipment available on the market are overcome; the automatic organic material crushing and dewatering machine has the advantages of simplicity and convenience in operation and maintenance; the service efficiency and the working efficiency of the equipment are improved; additionally, the operating environment is improved; and the wear of the equipment is reduced.

Owner:深圳市三盛环保科技有限公司

Device for quickly cutting and crushing forage of animal husbandry

PendingCN108093893AAvoid a direct fallConvenient for subsequent crushingCuttersEngineeringAnimal husbandry

The invention discloses a device for quickly cutting and crushing forage of animal husbandry. The device comprises a base; the top of the base is fixedly provided with a cutting box through a supportframe; the left side and the right side of the inner bottom of the cutting box are respectively rotatably connected with one lower round plate through a first rotating shaft and a second rotating shaft; the left side and the right side of the top of the cutting box are respectively fixedly provided with a first speed reduction motor and a second speed reduction motor; the motor shafts at the bottom ends of the first speed reduction motor and the second speed reduction motor pass through the top wall of the cutting box and are respectively fixedly connected with one upper round plate; a crankshaft is fixedly connected between the lower round plate and the upper round plate at the left side, and a crankshaft is fixedly connected between the lower round plate and the upper round plate at theright side; a plurality of connecting rods are respectively rotatably connected at the positions of the crankshaft journals; the right end of the connecting rods at the left side are hinge with a plurality of first cutting blades; the left ends of the connecting rods at the right side are hinged with a plurality of second cutting blades; and the first cutting blades are matched with the second cutting blades. According to the invention, forage is crushed by a plurality of cutting blades matched with each other, and vertically adjacent cutting blades move back and forth to cut the forage, so that the forage is prevented from falling directly after cutting for one time, so that the cutting effect is better and the efficiency is high.

Owner:周兰芝

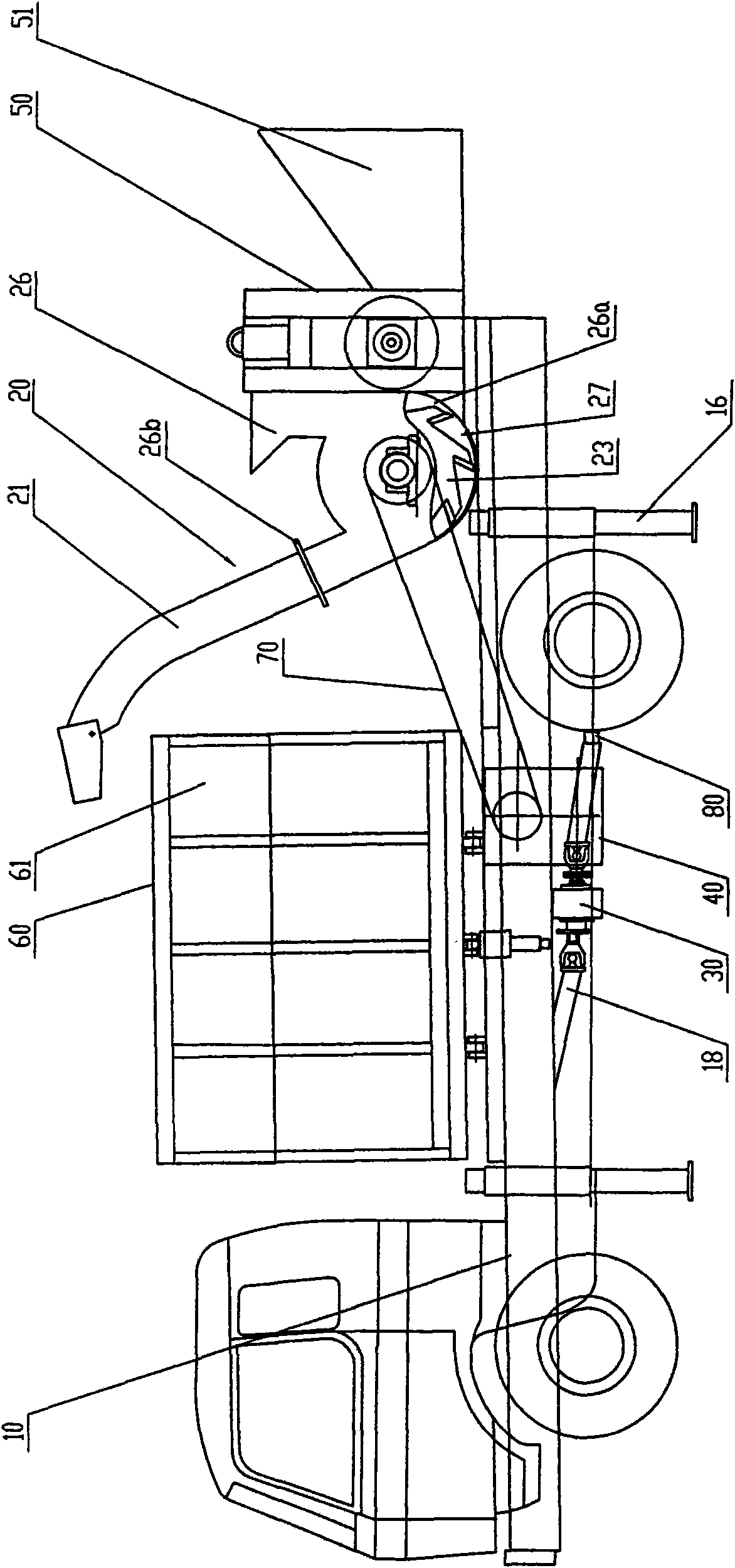

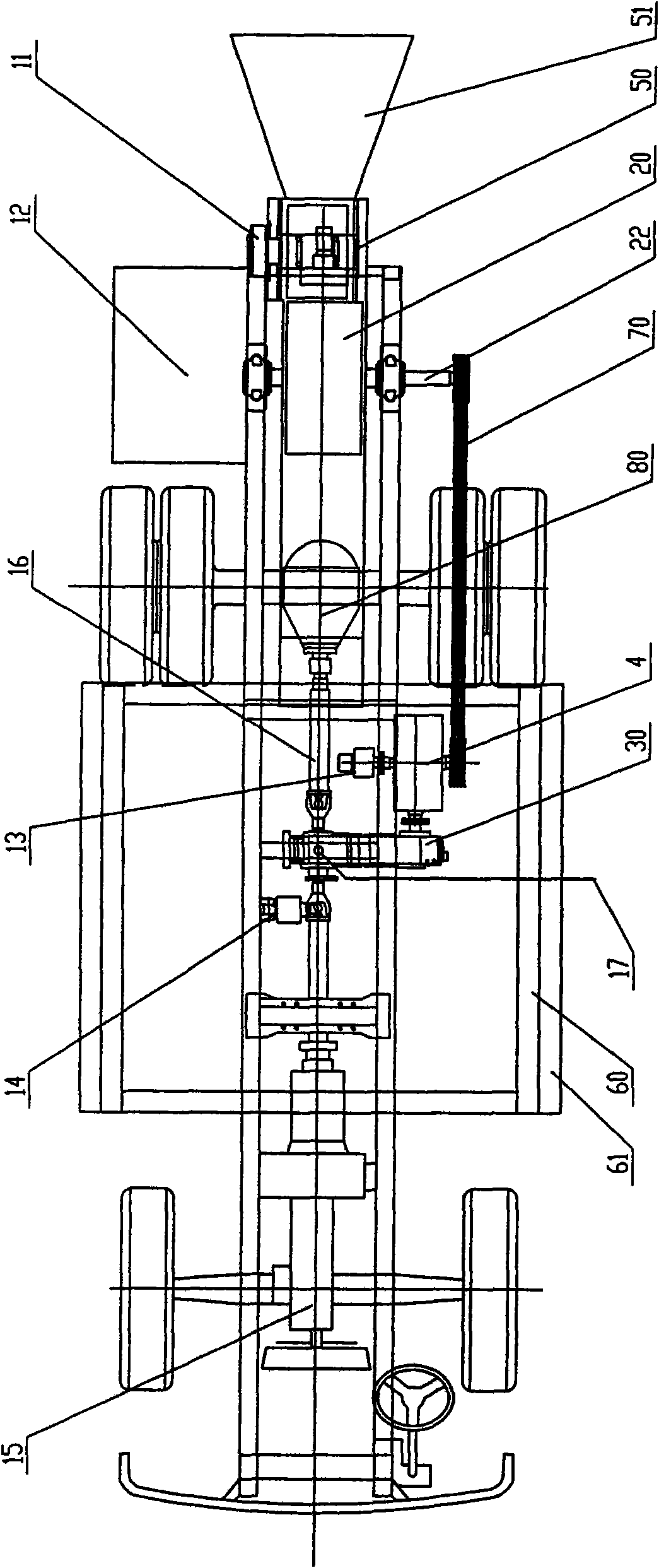

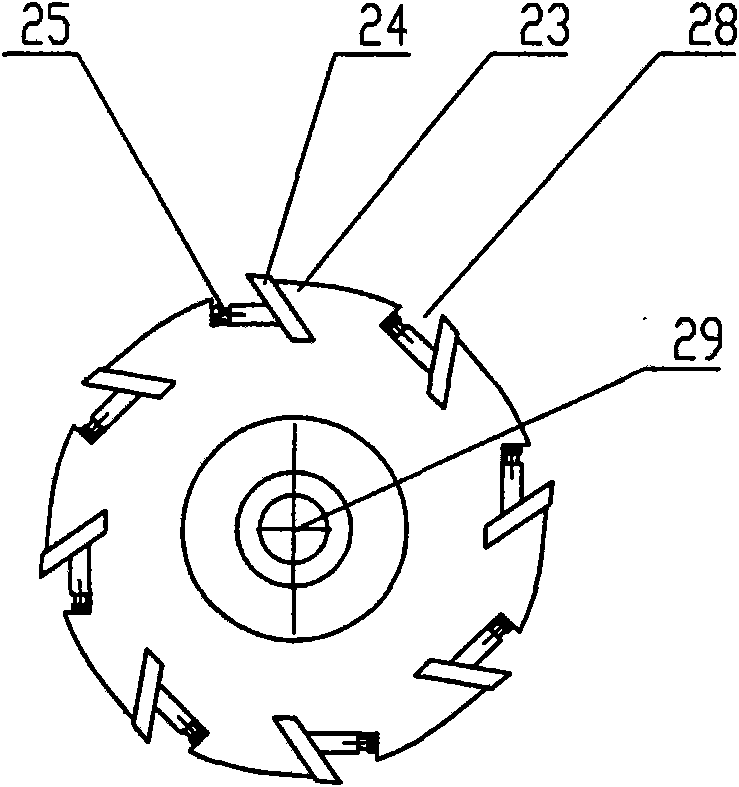

Branch crushing vehicle

The invention relates to a branch crushing vehicle. The vehicle comprises a chassis, a transmission shaft, a power distributor, a gear case, a material storage bin, a belt transmission mechanism, a crusher, a hydraulic valve, a hydraulic pump, a hydraulic motor, an engine, a rear axle and support legs, wherein the engine, the hydraulic pump, the power distributor, the gear case and the rear axle are fixed on the lower side of the chassis of the vehicle; the crusher and the material storage bin are arranged above the chassis of the vehicle; the transmission shaft is connected with an output shaft of a gear box of the engine and an input shaft of the power distributor, and a first output shaft of the power distributor is connected with a transmission input shaft of the gear case; and both ends of a transmission output shaft of the gear case are in transmission connection with the belt transmission mechanism and the hydraulic pump respectively, the belt transmission mechanism and the hydraulic pump are in transmission connection with a cutter head shaft and a feeding roller of the crusher respectively, and a second output shaft is connected with the rear axle. The vehicle has the advantages that: branches are crushed at any time and in any place, the conveying efficiency is improved, and the operating cost is lowered; because the milling mode is adopted for cutting, the crushing efficiency is high; and the occupied area is small, and the vehicle hardly affects traffic when working.

Owner:NANJING AGRICULTURAL UNIVERSITY

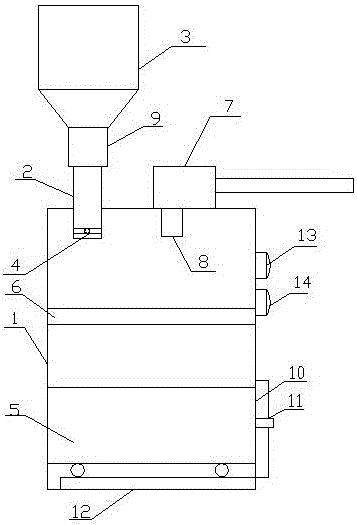

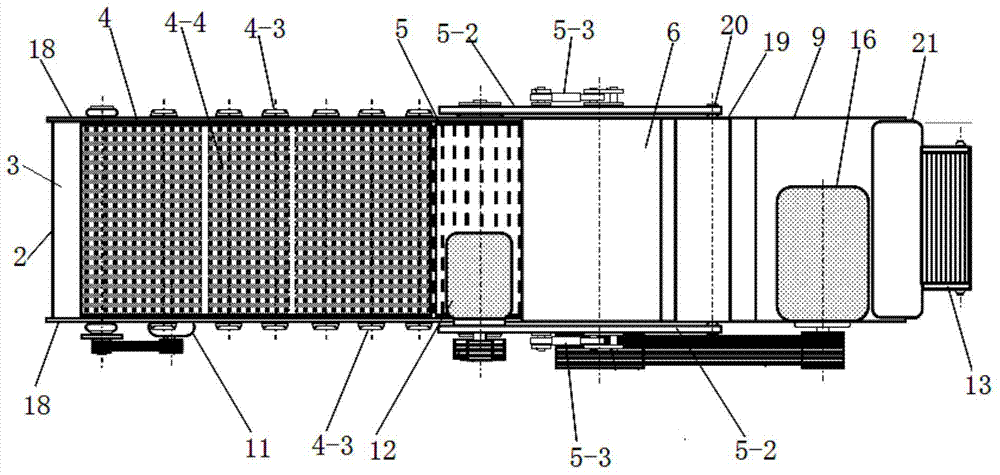

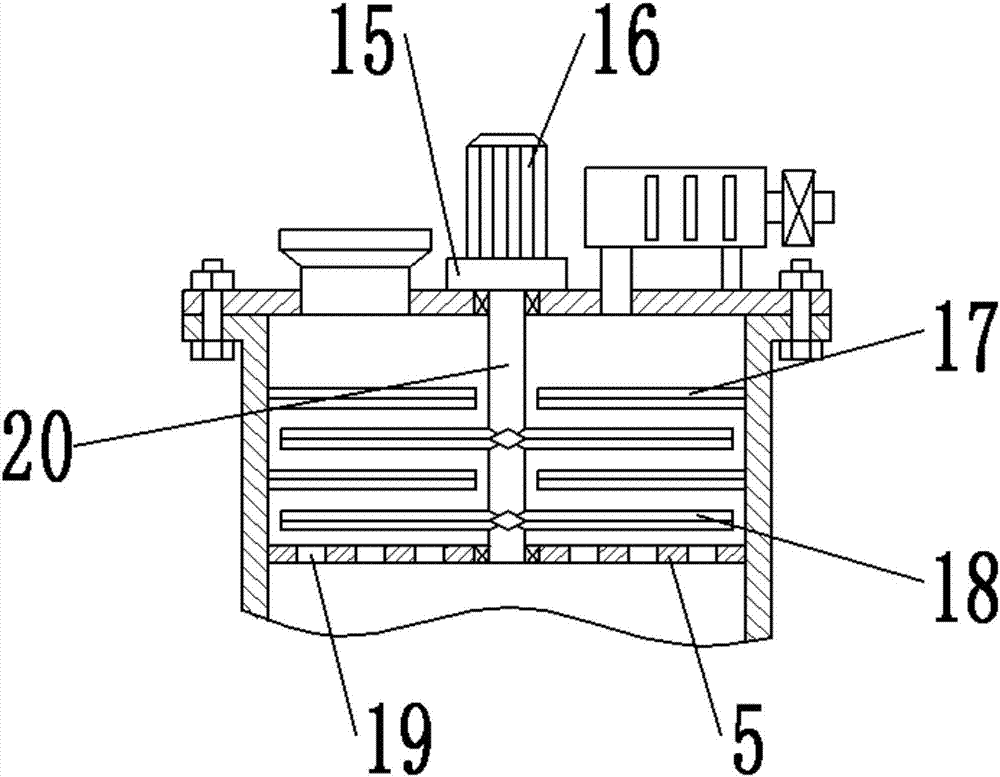

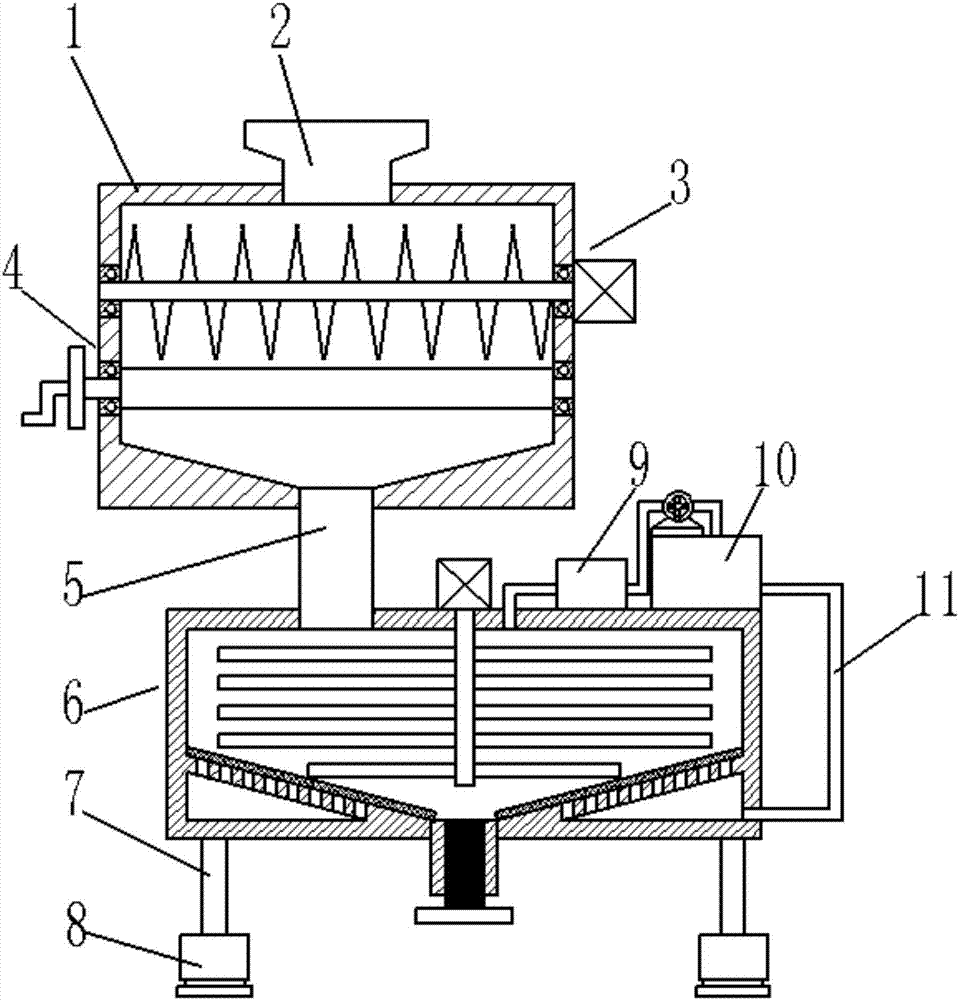

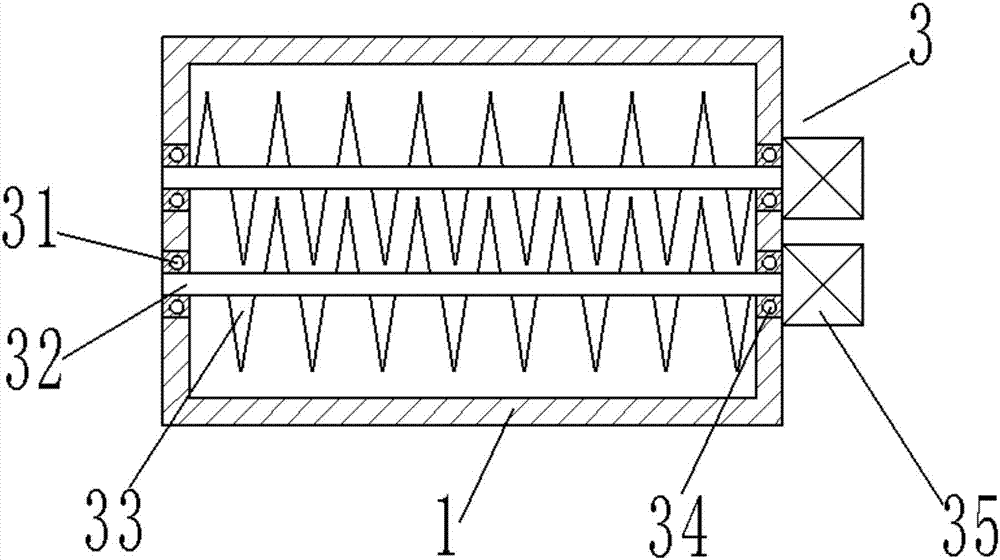

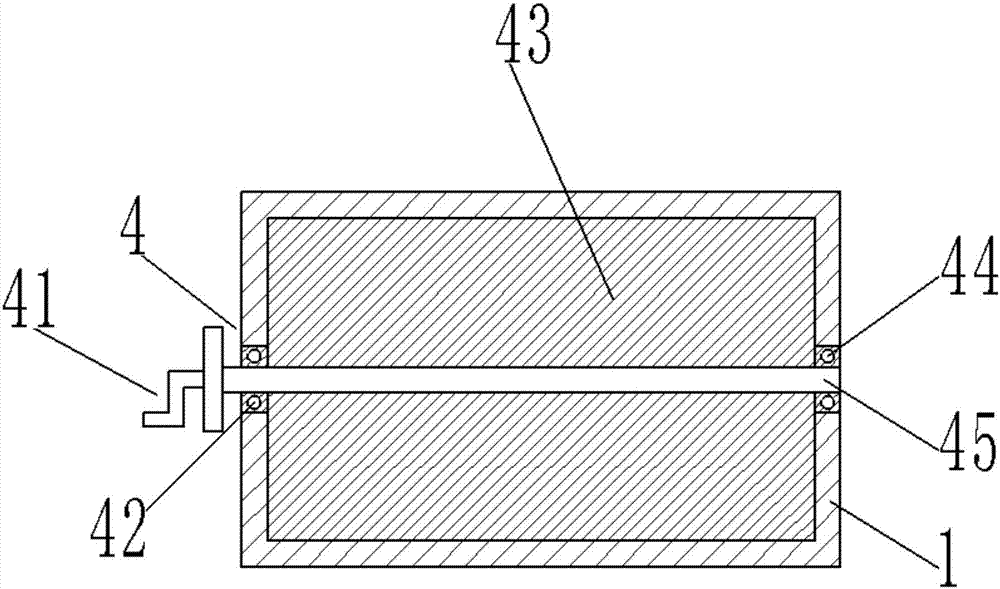

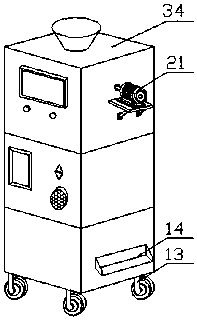

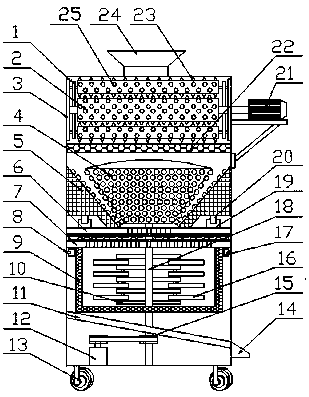

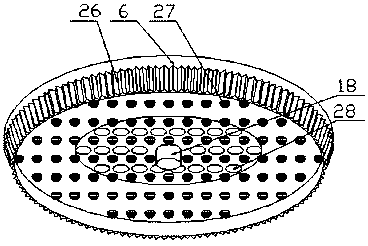

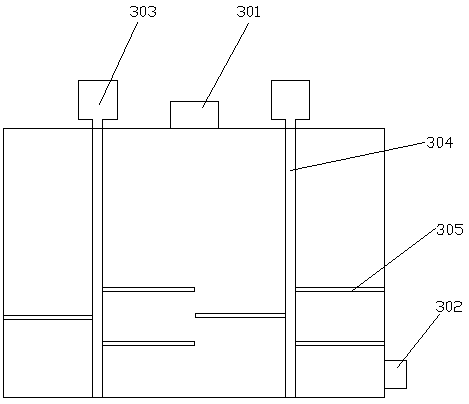

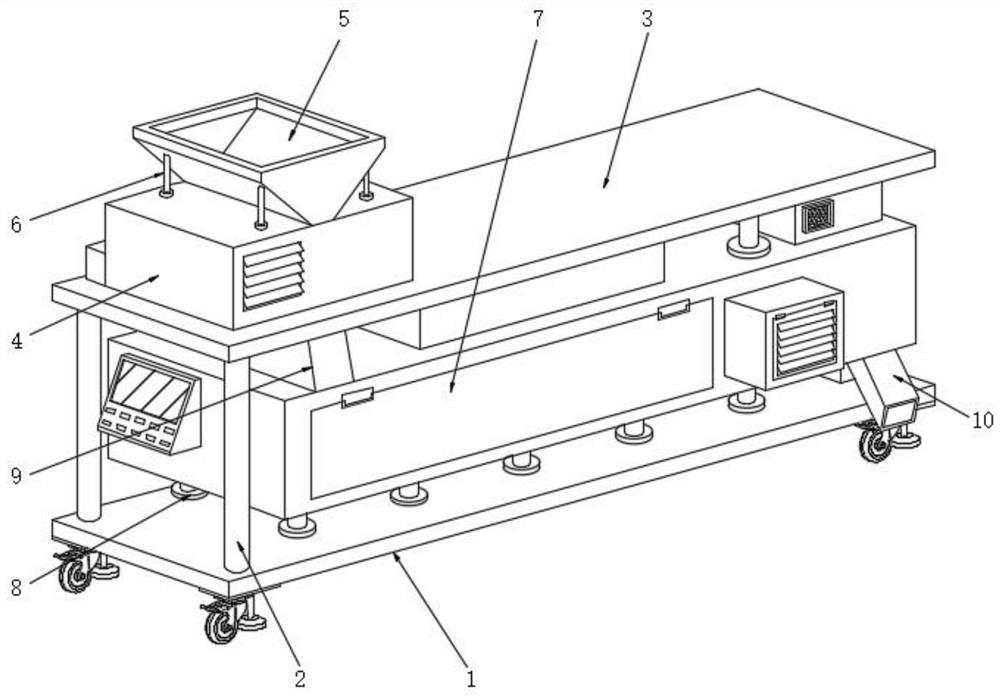

Straw grinding stirring drying device

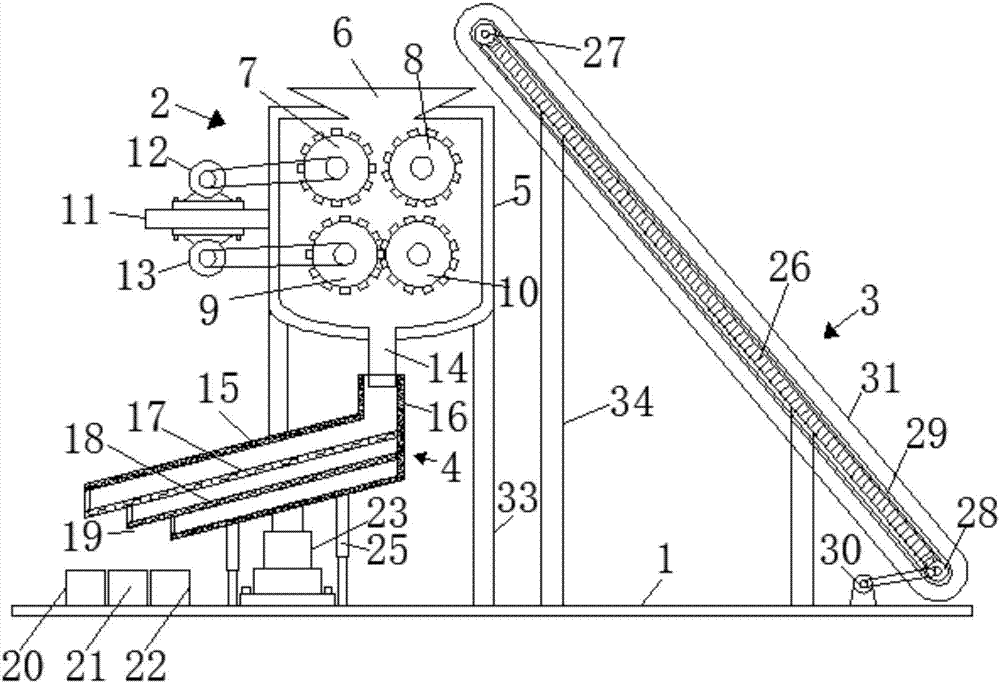

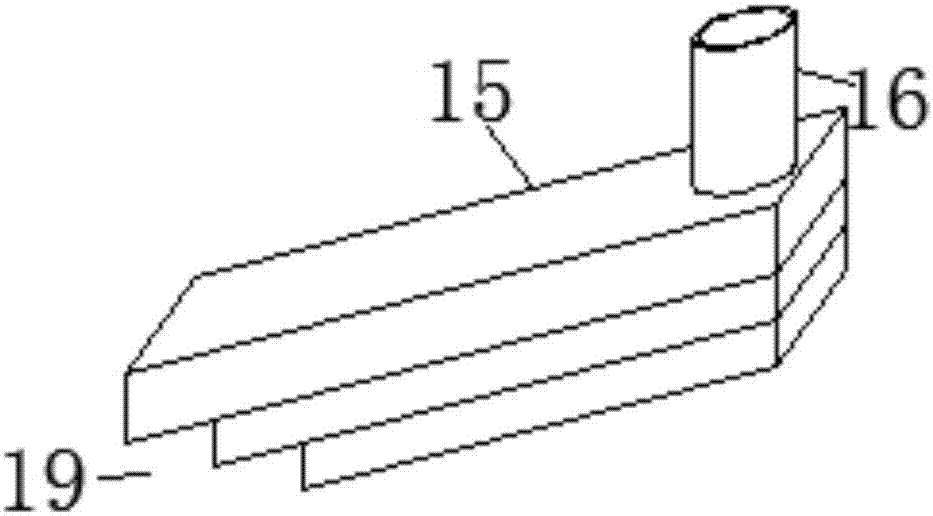

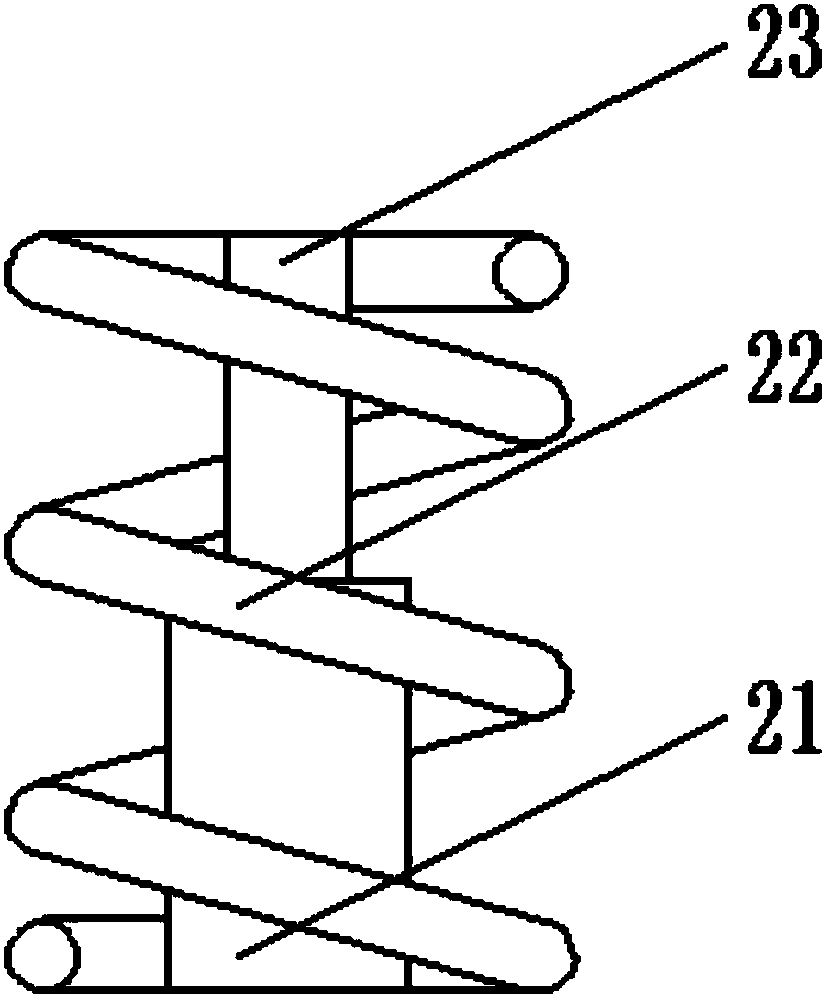

InactiveCN107211666ACrushed fullyImprove crushing qualityDrying gas arrangementsCuttersPulp and paper industryComminution

The invention provides a novel straw crushing, stirring and drying device, which belongs to the technical field of mechanical equipment. It includes a crushing device (3), a stirring and drying device (6), a dehumidification device (9) and an air heating device (10); the crushing device (3) is fixed above the inside of the crushing box (1); the stirring and drying device (6) Welded on the four supporting columns (7); the dehumidification device (9) is fixedly installed on the right side of the upper end of the stirring drying box (61) in the stirring drying device (6); the air heating device ( 10) Fixedly installed on the right side of the upper end of the stirring drying box (61) in the stirring drying device (6), on the right side of the dehumidification device (9). The novel device of the invention has high crushing quality of straw, and after crushing, the straw is stirred and dried, and the air in the stirring drying box is extracted to carry out circulating hot air drying, thereby ensuring the drying efficiency of the straw, and the dried straw is convenient for storage.

Owner:合肥多智科技开发有限公司

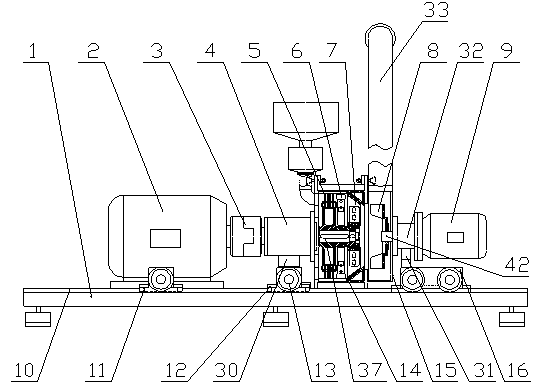

Combined type vibrating sand making machine

The invention discloses a composite vibrating sand making machine, which comprises an upper machine case, a lower machine case, a discharge box and a frame, which respectively correspond to a material inlet, a crushing cavity and a material discharge port, and the three are in the order of axes from top to bottom connection, the connection is connected with the lower frame as a whole; the drive motor is connected to the frame, and the drive motor is connected to the rotating main shaft inside the sand making machine through the transmission mechanism, and the upper end is connected to the impeller; the main shaft of the rotating shaft is also connected with The vibrating mechanism cooperates with the impeller; the vibrating screening is combined with the crushing structure of the sand making machine, which can screen the materials with uneven particle size to a certain extent and perform corresponding crushing. There is also a material distribution component. It can realize the switching of various crushing forms and has a wide range of applications. Through the above structure, the problems of unsmooth discharge, low crushing efficiency of sand making machine and insufficient crushing of materials in the prior art can be effectively solved, and the crushing efficiency of materials is greatly improved. The quality and beneficiation efficiency of the beneficiation process.

Owner:尹国祥

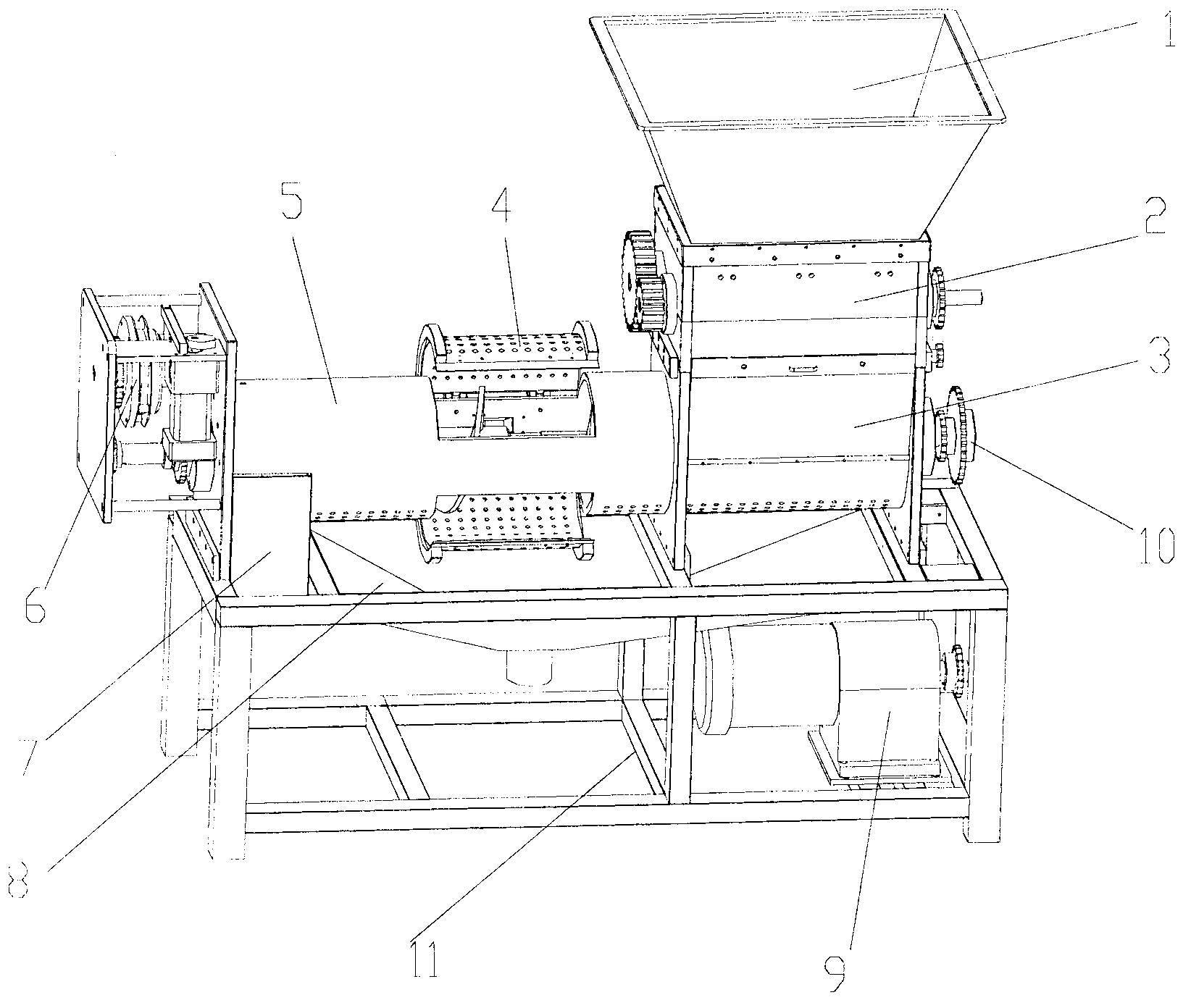

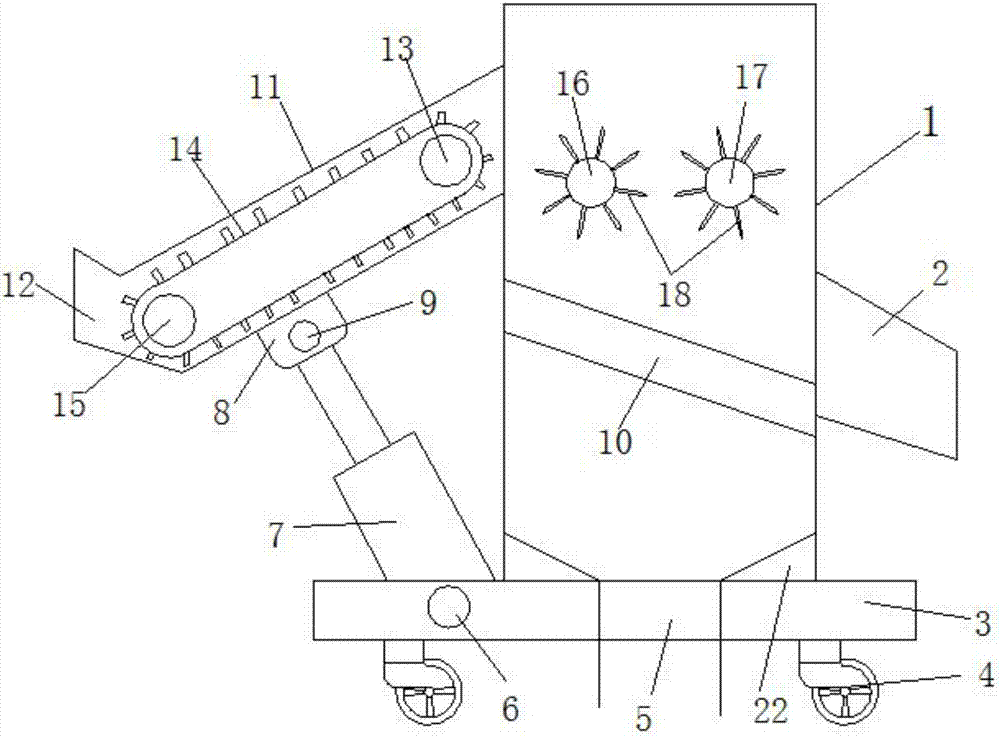

Mud-wrapped ore crushing machine facilitating feeding and screening

ActiveCN107971067AEasy to sort and filterConvenient classification and screening, convenient classification of oreSievingScreeningEngineeringCrusher

The invention discloses a mud-wrapped ore crushing machine facilitating feeding and screening. A crushing mechanism and a conveying device are fixedly installed above a base plate from left to right in sequence, a screening device is arranged below the crushing mechanism, a first driving crushing shaft and a first driven crushing shaft are rotationally installed on the top of the interior of a crushing box from left to right in sequence, a second driving crushing shaft and a second driven crushing shaft are rotationally installed on the bottom of the interior of the crushing box from left to right in sequence, a belt wheel of a first motor is in transmission connection with a belt wheel of the first driving crushing shaft through a belt, and a belt wheel of a second motor is in transmission connection with a belt wheel of the second driving crushing shaft through a belt. The mud-wrapped ore crushing machine having the good crushing effect and facilitating feeding and screening is convenient to feed, high in crushing efficiency, good in crushing quality, capable of classifying and screening ore, capable of facilitating sorting treatment of the ore, capable of avoiding pollution caused by dust to the environment, and further capable of guaranteeing the human body health.

Owner:内蒙古维拉斯托矿业有限公司

Efficient coal ternary pulverization apparatus

InactiveCN108160283AImprove crushing qualityReduce vibrationNon-rotating vibration suppressionGrain treatmentsPower stationEngineering

The invention discloses an efficient coal ternary pulverization apparatus, and belongs to the field of auxiliary equipment for a power plant. The apparatus includes a housing, which is internally provided with a pulverization chamber; the pulverization chamber is internally provided with feeding inclined blocks, a pulverization disc, a rotating shaft, a first motor, a pulverization roller apparatus, a feeding cone, first pulverization teeth, second pulverization teeth and a bracing frame; a feed inlet is formed at the center of the top of the housing; squeezing devices are fixedly arranged atthe top end of the housing; the feeding inclined blocks are arranged below the pulverization roller apparatus at the inner walls of the housing and are in fixed connection to the housing; and the first motor is connected to the pulverization disc via the rotating shaft and is in fixed connection to the feeding inclined blocks via the bracing frame. The apparatus is reasonable in structural designand convenient to use. The squeezing devices are used for primary pulverization on coal raw materials, and the pulverization roller apparatus and the pulverization disc are used for further pulverization. The ternary pulverization apparatus is used for pulverization, thereby greatly improving the coal pulverization efficiency.

Owner:长沙双合盛企业管理有限公司

Classification type efficient ultrafine grinder

The invention relates to a classification type efficient ultrafine grinder comprising a rack (1), wherein a feeding chamber (18), a grinding chamber (14) and a discharging chamber (15) are arranged on the rack (1); a grading chamber (23) is arranged at the top of the rack (1) and is located above the discharging chamber (15); the discharging chamber (15) is connected with the grading chamber (23) through a conveying pipeline I (33); a coarse material discharging opening (34) is formed in the bottom of the grading chamber (23); a coarse material air seal machine (22) is arranged below the coarse material discharging opening (34) in a connected manner; and the lower end of the coarse material air seal machine (22) is connected with a feeding opening (21) of the grinding chamber (14). According to the classification type efficient ultrafine grinder provided by the invention, a material enters the grinding chamber for three grinding processes; the grinded material is fed into the grading chamber; the material with a required fineness enters a cyclone discharging process; and a coarse material falls back to the grinding chamber for secondary grinding, so that the heat of a machine cavity is effectively reduced, and the production efficiency is improved.

Owner:JIANGYIN LONGCHANG MACHINERY MFG

Crushing and packaging integrated machine for garbage treatment

InactiveCN110653241AReduce volumeReduce work intensitySolid waste disposalGrain treatmentsGear wheelRefuse Disposals

The invention discloses a crushing and packaging integrated machine for garbage treatment. The crushing and packaging integrated machine for garbage treatment comprises a first mounting plate, whereina crushing box is fixed on the first mounting plate; a second mounting plate is fixed on one side of the crushing box; a first servo motor is fixed on the second mounting plate; a first crushing roller is fixed on an output shaft of the first servo motor; the first crushing roller is in key connection with a first gear; the first gear is engaged with a second gear; the second gear is in key connection with an end of a second crushing roller; teeth are arranged on the outer cylindrical surfaces of the first crushing roller and the second crushing roller; a scattering mechanism is arranged at the upper end of the crushing box; a conveying mechanism is arranged at the lower end of the crushing box; a third mounting plate is fixed on one side of the upper end of the crushing box; and a pressing mechanism is arranged on the third mounting plate. Automatic scattering, crushing, compacting and packaging of garbage are realized on one piece of equipment, the cost is low and the working efficiency is high.

Owner:林冬

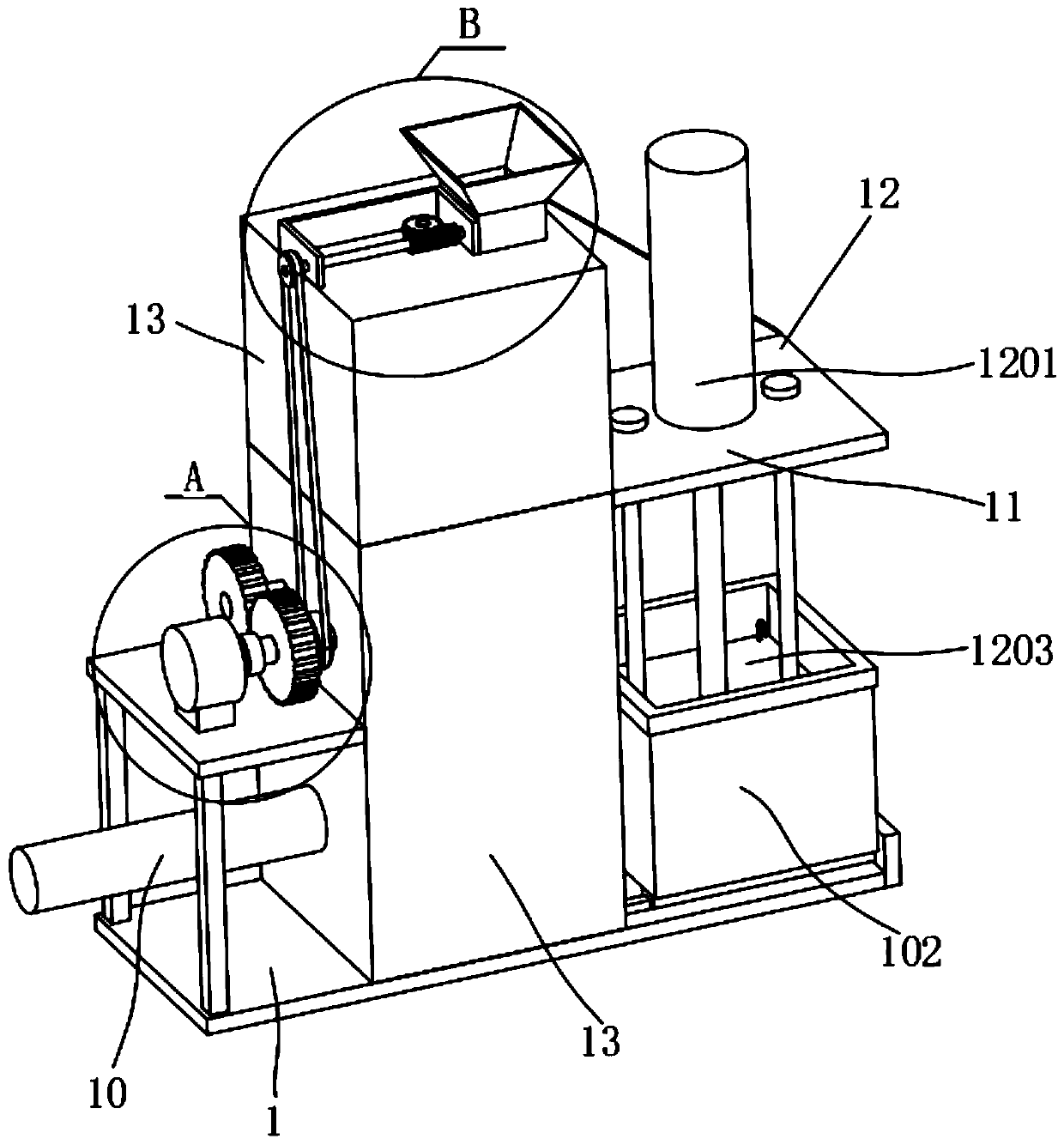

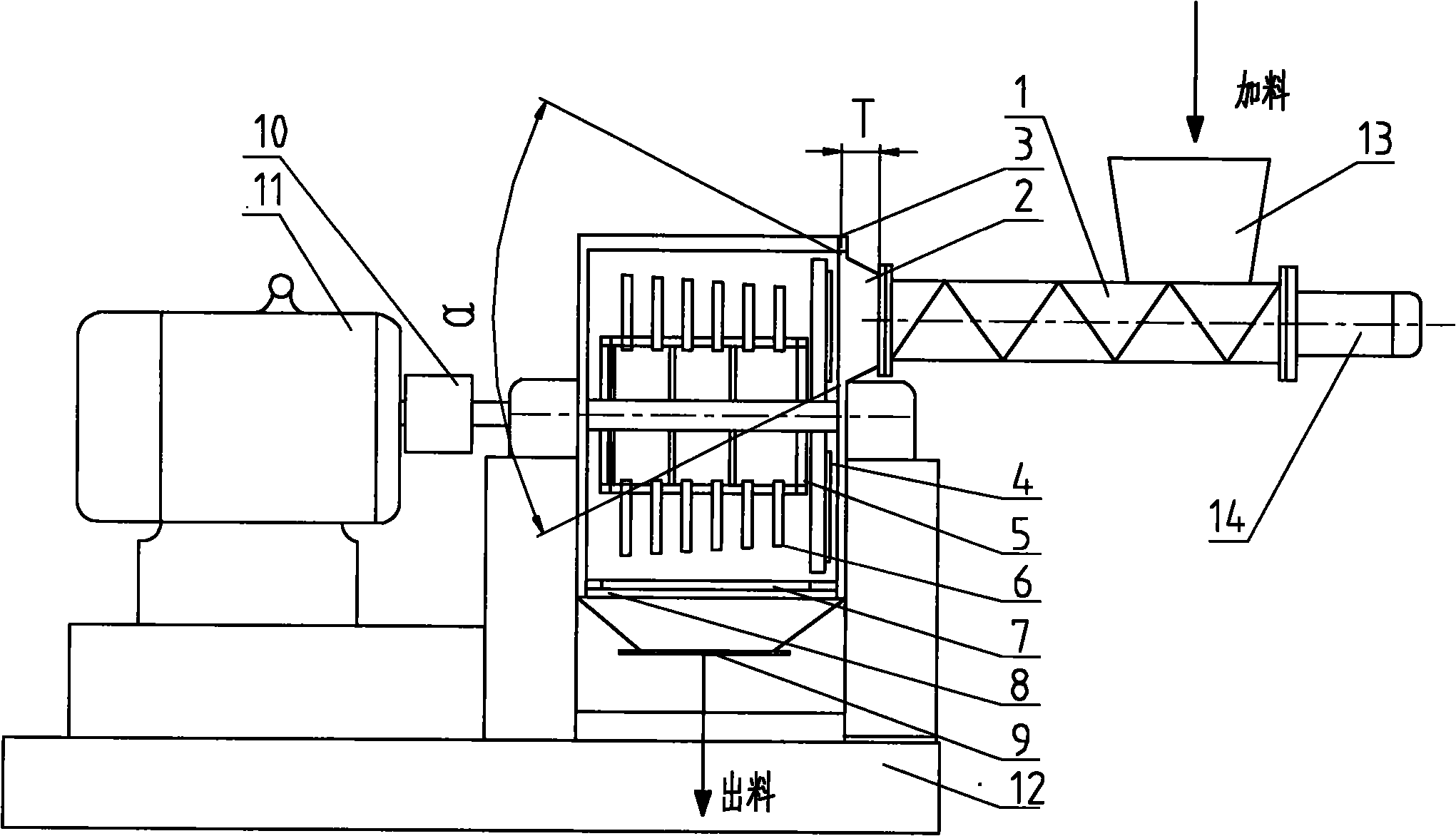

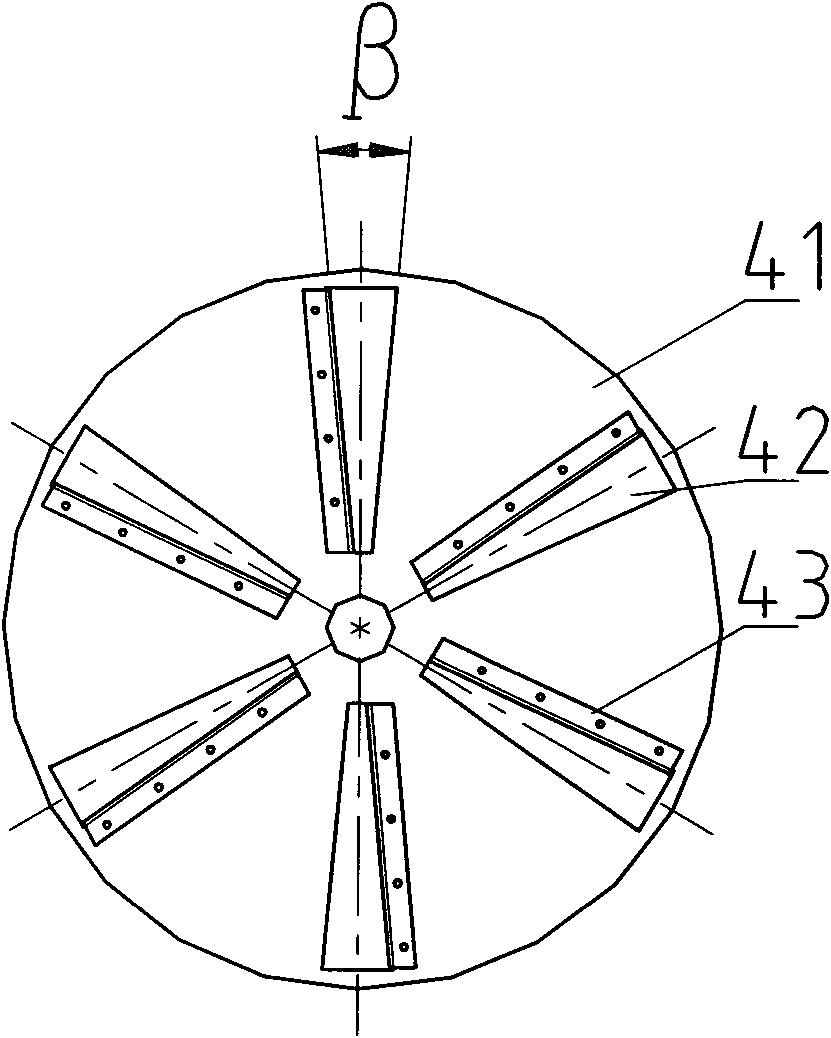

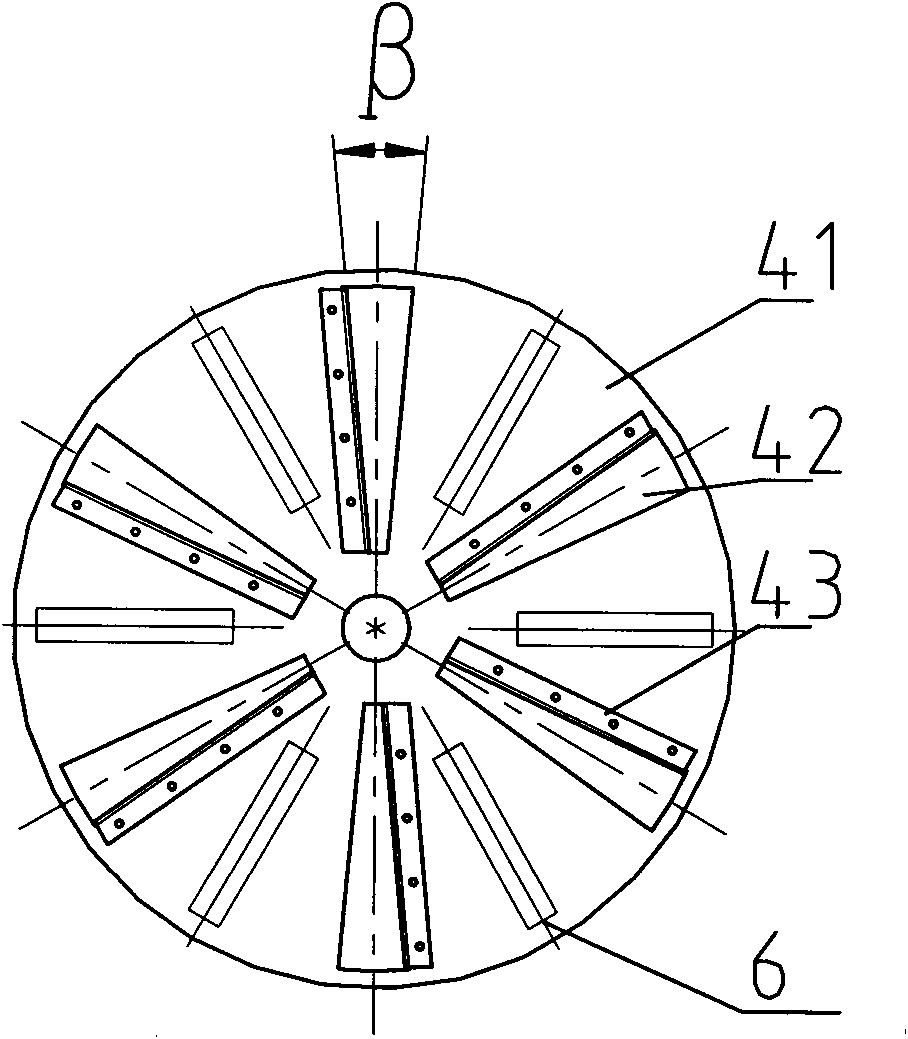

Special cut-off pulverizer for enteromorpha

The invention relates to a special pulverizer structure for enteromorpha for pulverizing long-fiber connected materials, in particular to a special cut-off pulverizer for enteromorpha. In the invention, a power shaft of a stand (12), provided with a motor (11), extends into a shell (3), a cylindrical rotor (5) is fixedly arranged on the power shaft, and a plurality of rows of hammer pieces (6) are fixed on the outer surface along the shaft; the upper part at the other side of the shell (3) is provided with a feed hole, a cylindrical feed drum is outwards extended through a diffusion type feedsection (2) which is big inside and small outside, and a forced material supply auger (1) is also arranged; the starting end of the feed drum is provided with a charging hole (13); the power shaft isprovided with a cut up mechanism (4) close to the feed hole; the lower part of the shell (3) is pressed by a screen pressing frame (8) to be provided with a screen net (7), and a discharge hole (9) is arranged below the shell; a plurality of slit cutting holes (42) are uniformly arranged on a cut up disk (41); and a protuberant cutter (43) is arranged at a side edge along the radial direction of the cutting holes (42). The invention changes the form of the traditional pulverizer, is additionally provided with the cutting mechanism, improves the pulverizing efficiency and has quite strong adaptability and high efficiency on long-fiber materials.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

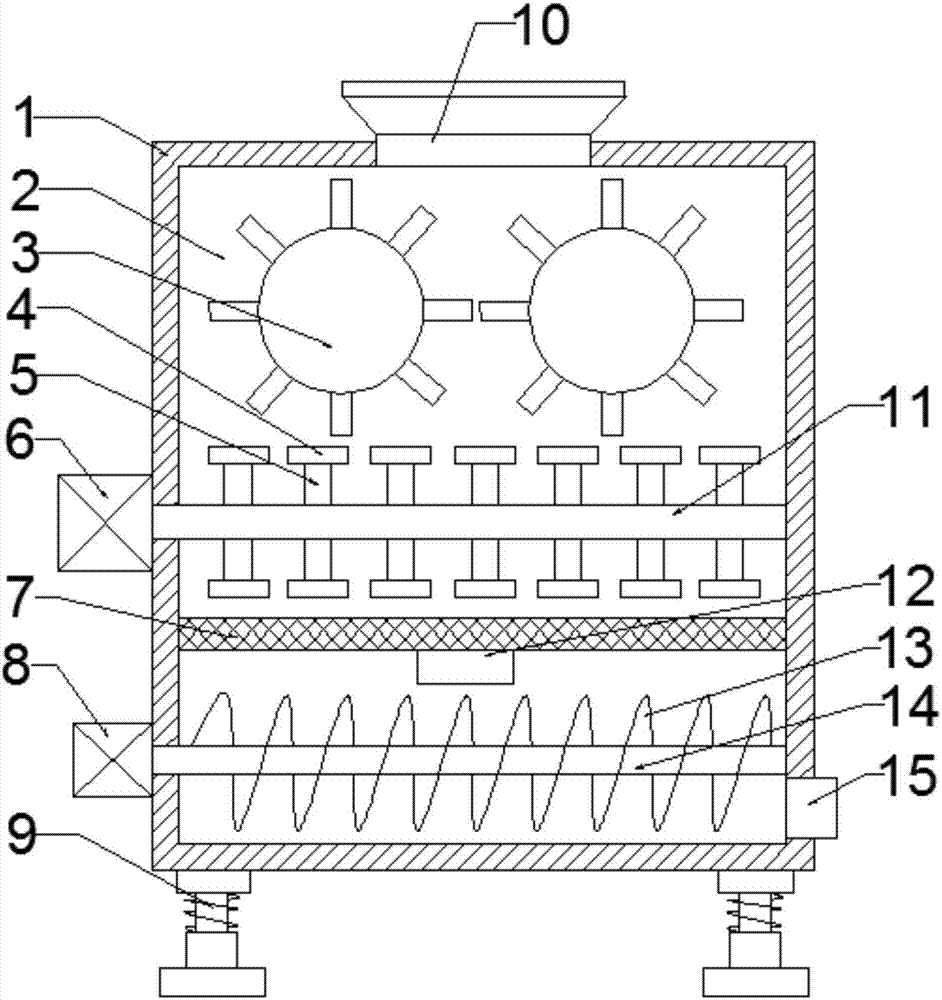

Lithium battery natural graphite multistage crushing device

InactiveCN109967214AImprove crushing qualityImprove crushing efficiencyGrain treatmentsEngineeringGraphite particle

The invention discloses a lithium battery natural graphite multistage crushing device. The lithium battery natural graphite multistage crushing device comprises a primary crushing barrel, a rotary shaft, a lower grinding plate and a crushing device body, a plurality of universal wheels are arranged at the lower end of the crushing device body, a feeding port is formed in the upper end of the crushing device body, the primary crushing barrel is arranged at the lower end of the feeding port, and gear rails are arranged on the surfaces of the two sides of the interior of the primary crushing barrel. The primary crushing barrel is arranged, a graphite raw material is directly placed into the primary crushing barrel through the feeding port, in the primary crushing barrel, a second rotary motordrives a driving crushing roller to rotate, the driving crushing roller drives auxiliary crushing rollers to rotate through shaft moving connecting rods at the two ends, meanwhile, the auxiliary crushing rollers move on the inner side surfaces of the gear rails through gears at the two ends so as to drive a secondary crushing barrel to rotate to cooperate with the driving crushing roller to actively crush the graphite back and forth, so that the graphite raw material is crushed into graphite particles which are uniform particles, and the crushing quality is improved.

Owner:陈宏尤

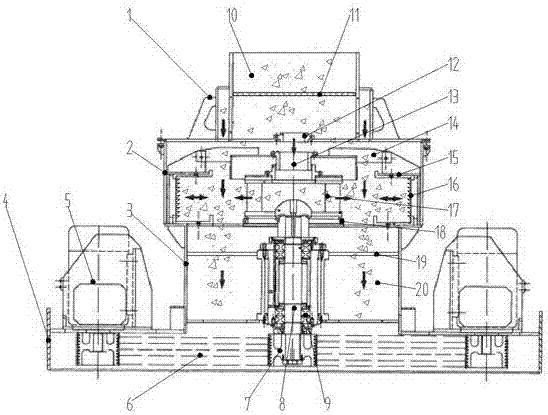

Double-cavity compound pendulum jaw crusher

PendingCN108160161AImprove crushing qualityReduce distanceGrain treatmentsEngineeringCompound pendulum

The invention discloses a double-cavity compound pendulum jaw crusher comprising a main body. A base is mounted at the bottom end of the interior of the main body, a supporting rod is mounted at the top end of the base, and a roller is arranged on the outer wall of the supporting rod. A first gear is mounted on the outer wall of the bottom end of the supporting rod, a second gear is arranged on the left side of the first gear, and the second gear is connected with the first gear in an engaged mode. According to the double-cavity compound pendulum jaw crusher, through cooperation of the supporting rod and the roller, cooperation of the first gear and the second gear, and cooperation of a motor and a rotating rod, the roller rotates in the main body to enable raw materials on the two sides to be evenly scattered, and the main body is assisted to crush the raw materials while the roller rotates at a high speed; and through cooperation of a sliding groove and a sliding block and cooperation of a bolt and a nut, the distance between the supporting rod and the inner wall of the main body is adjusted, the raw materials are more finely crushed while the distance is shortened, the crushingquality of the crusher is improved, and the work efficiency is high.

Owner:湖州志平矿山机械制造厂

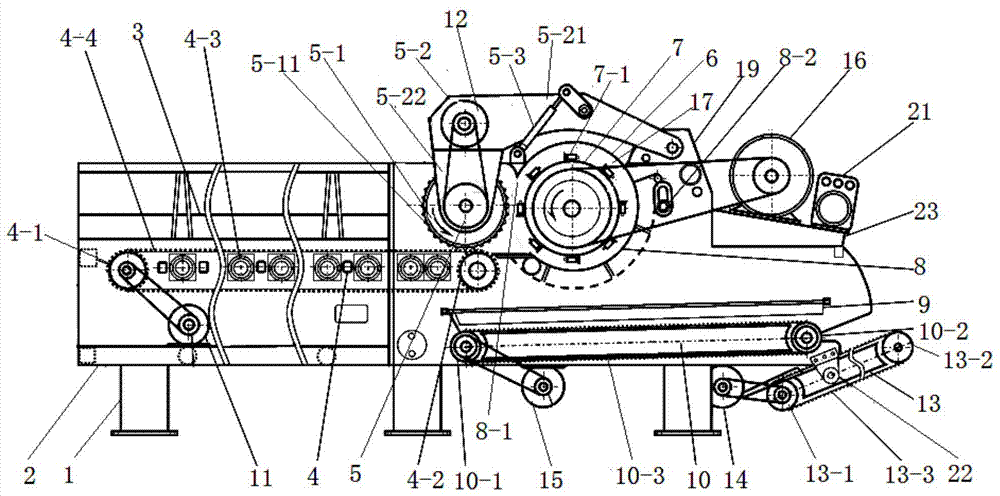

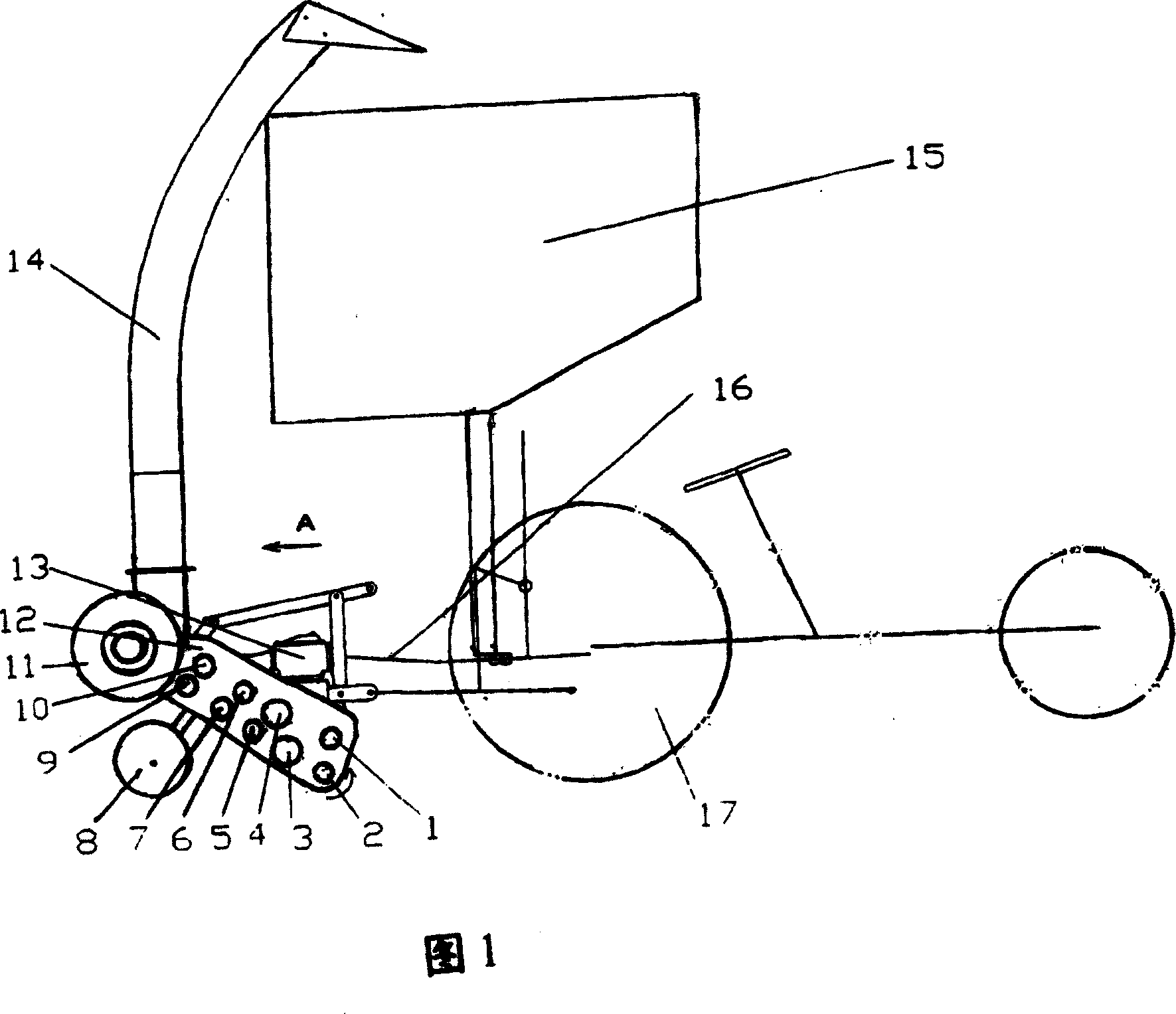

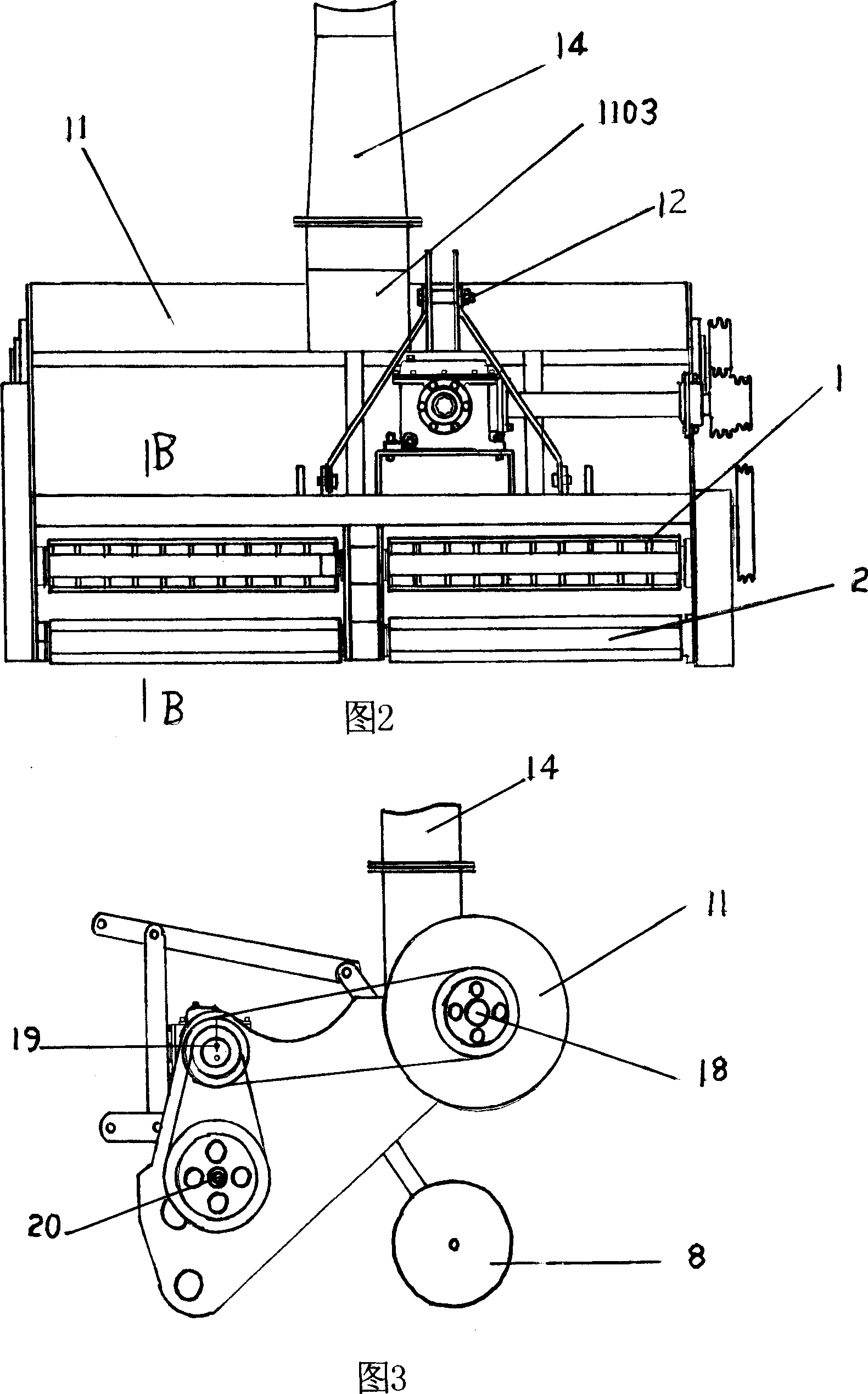

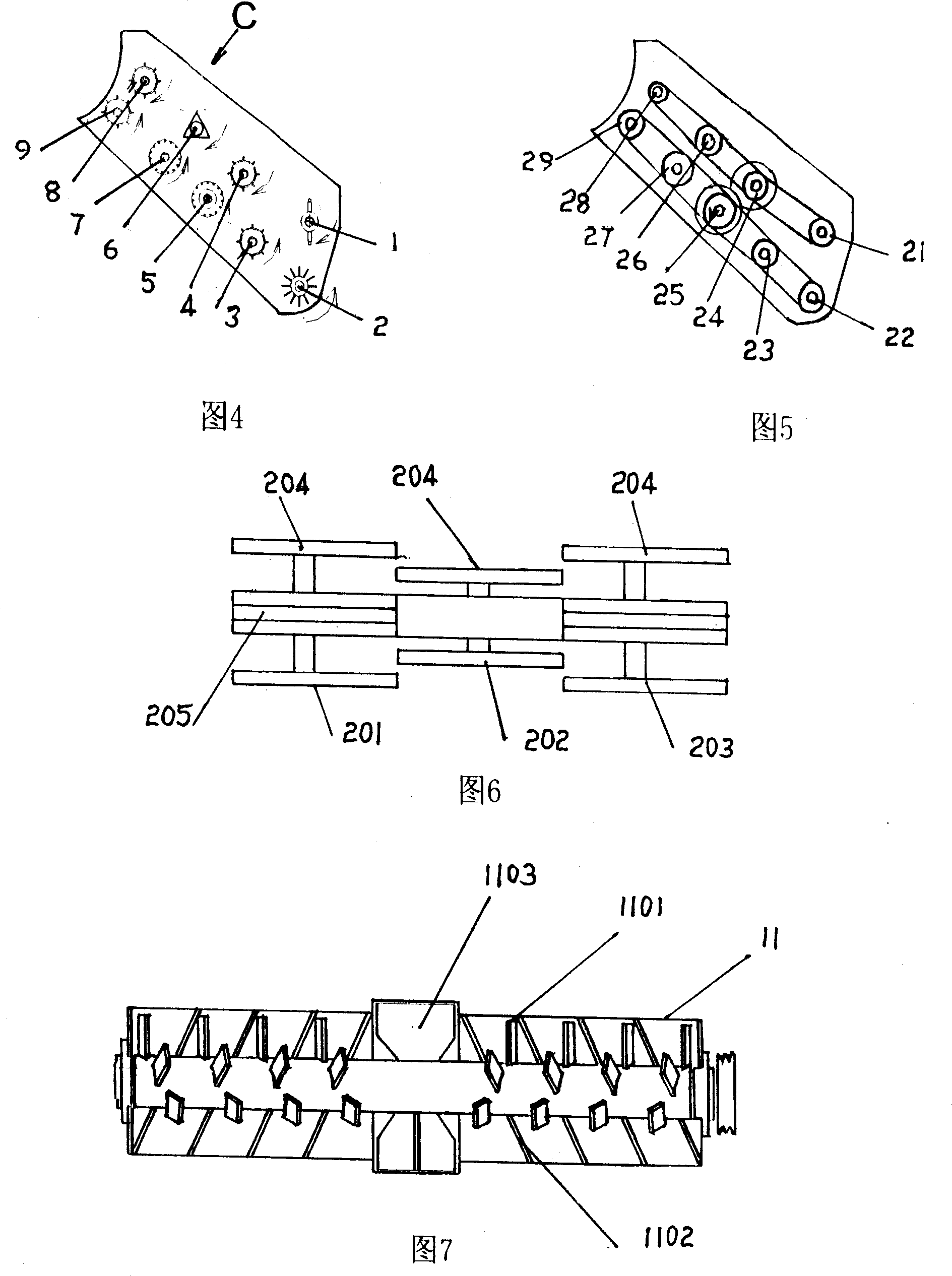

Stalk combine harvester

InactiveCN101099425AImprove protectionGood for lower protectionCrop conditionersMowersUltimate tensile strengthCombine harvester

The present invention provides stalk combine harvester. It includes the following several portions: stalk harvesting mechanism, stalk conveying device, stalk cutting device, machine frame, mechanical transmission device, traveling mechanism and power machine with power output shaft. Said invention also provides its working principle and its concrete operation method.

Owner:王风武

Paper shredder with good safety performance and for artistic pattern designing

InactiveCN108855480AImprove crushing efficiencyImprove crushing qualityGrain treatmentsConfidentialityPulp and paper industry

The invention belongs to the technical field of paper shredders, and particularly relates to a paper shredder with good safety performance and for artistic pattern designing. By adoption of the papershredder with the good safety performance and for artistic pattern designing, the problems that an existing paper shredder is simple in design structure, simplex in function, poor in paper shredding effect and low in safety performance are solved. According to the scheme, the paper shredder with the good safety performance and for artistic pattern designing comprises a base. Universal wheels are fixed to the four corners of the outer wall of the bottom of the base through screws, and a water tank of a concave structure is fixed to the outer wall of the top of the base through screws. A shredder paper collection box is fixed to the outer wall of the top of the water tank through screws. A second crushing box is fixed to the outer wall of the top of the shredder paper collection box throughscrews, and a first servo motor and a second servo motor are fixed to the outer wall of one side of the second crushing box through screws. The paper shredder is good in shredding effect, high in automation degree, capable of remarkably improving the shredding efficiency and quality of waste paper, improving the confidentiality and saving water and high in safety performance, and the use requirements of people are met through the user-friendly design.

Owner:ZHENGZHOU YOUAI NETWORK TECH CO LTD

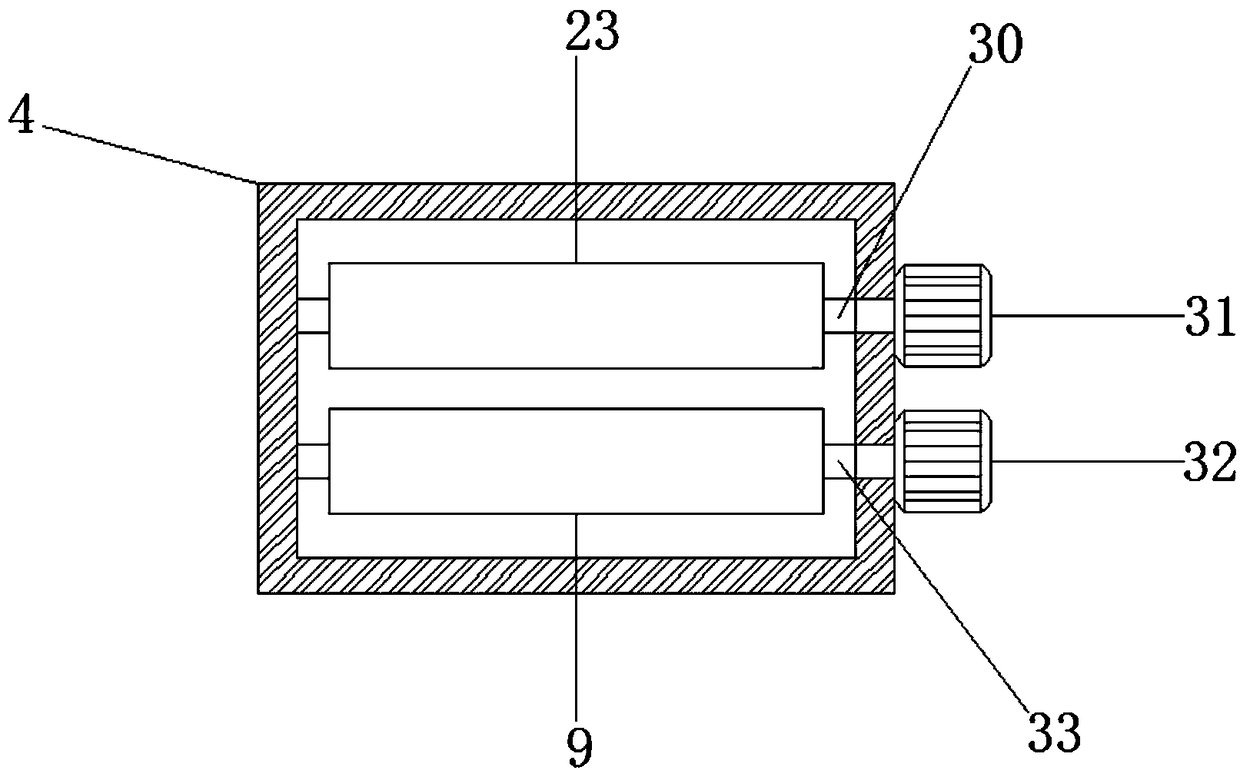

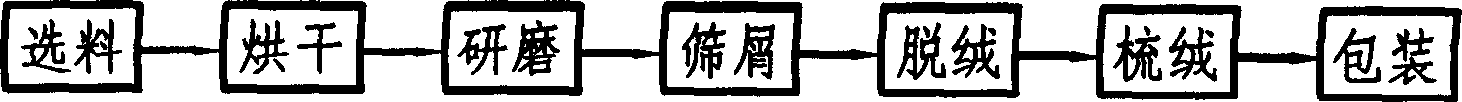

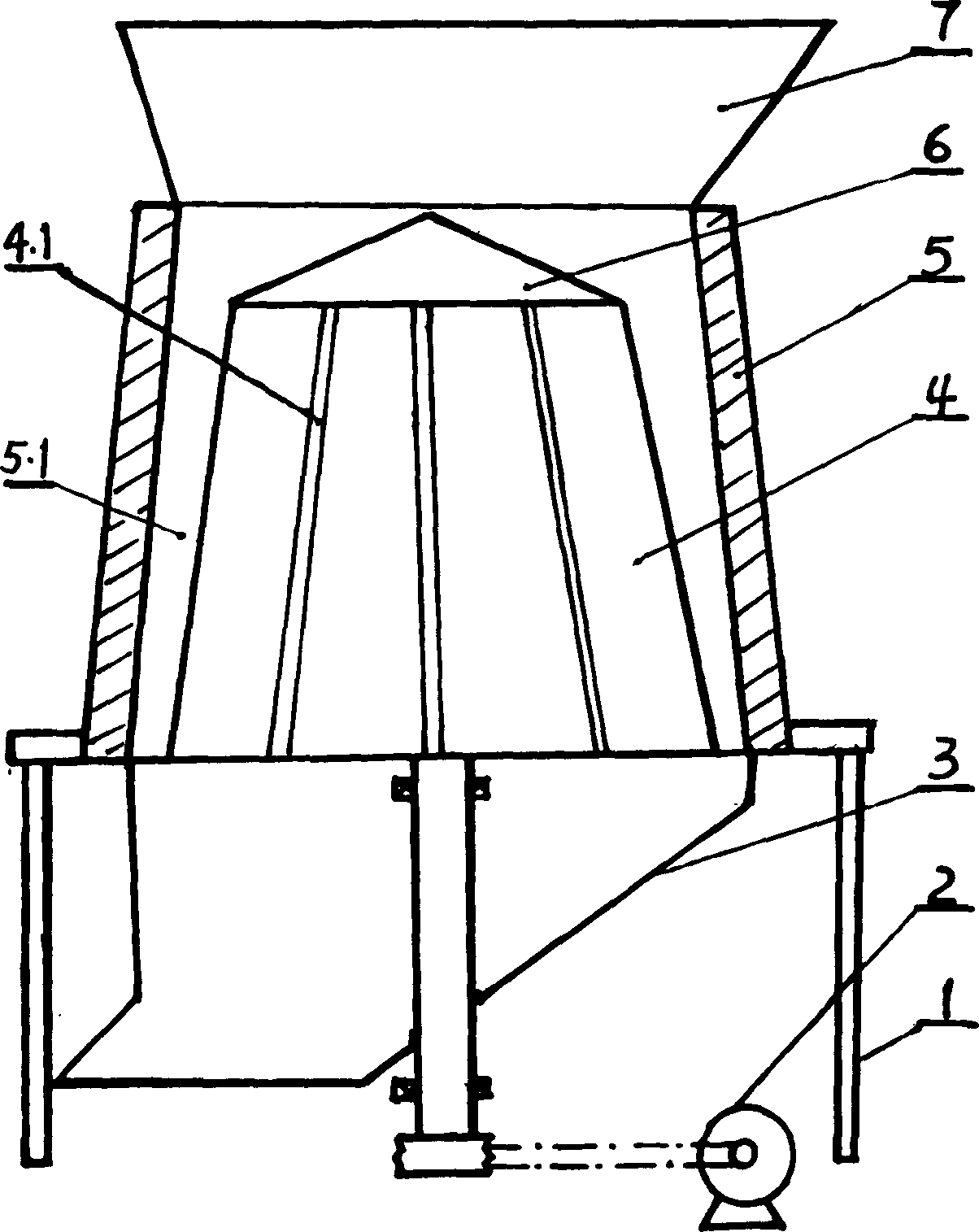

Moxa extraction process and grinder therefor

InactiveCN1864954AImprove crushing qualityImprove crushing effectVegetable fibres from other vegetable matterPlant material mechanical workingFiberEngineering

The invention relates to a method for extracting moxa from argyi leaf and relative grinder. It mainly comprises following steps that selecting material; drying; grinding; screening; removing hair; and combing moxa. Wherein. The invention uses taper grinder whose movable grinding element is a rotary table inside the cylinder fixed grinding element, while there is a grinding chamber between them; the upper end of movable grinding element is mounted with taper setting gauge. The invention can improve the quality of broken argyi leaf, to protect the natural length of moxa, improve the moxa extraction rate. And it uses eccentric moxa combing method, to improve the shape of moxa.

Owner:刘志宏

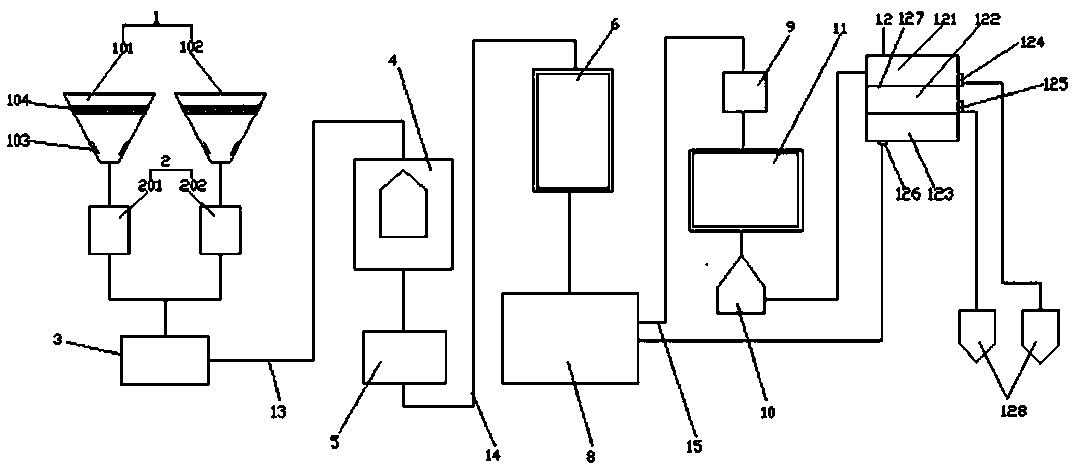

Granulated feed producing and processing equipment and method

PendingCN109480319AMessy layoutHigh energy consumptionFeeding-stuffProcess equipmentProcess engineering

The invention relates to granulated feed producing and processing equipment and method. The granulated feed producing and processing equipment comprises a raw material receiving system, a crushing system, a mixing machine, a granulating system and a quantitative packaging system, wherein the raw material receiving system comprises a feeding device, a dosing device, a stirring barrel, an impurity removing device and a dust removing device; the crushing system comprises a crusher and an ozone generating device; the granulating system comprises a conditioning device, a granulator and a cooler; and the quantitative packaging system comprises a sorting machine and a quantitative packaging mechanism. Through adoption of the granulated feed producing and processing equipment disclosed by the invention, the defects that in the prior art, a set of perfect feed producing and processing equipment does not exist, most conventional equipment has single equipment working procedure, the equipment layout is in disorder, the energy consumption is high, the production process is complex, the production efficiency is low, and the product quality cannot be guaranteed, are solved; and the granulated feed producing and processing equipment disclosed by the invention is high in automation degree, simple in structure, high in production efficiency and low in cost, and can produce multi-grade products,and the grade quality is high.

Owner:韶关正邦农牧科技有限公司

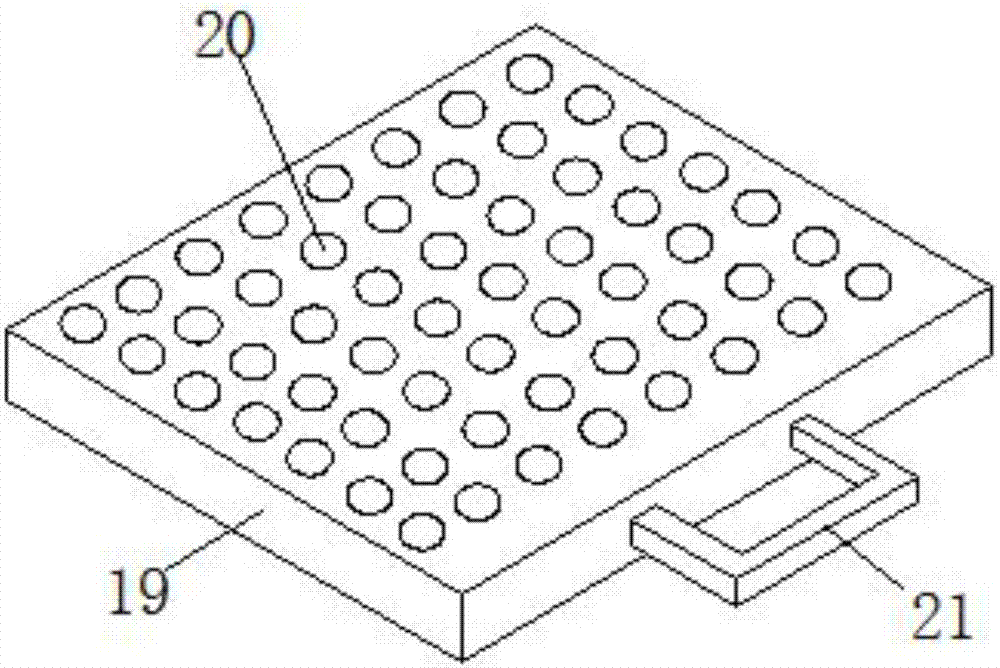

Agricultural straw pulverizing device and using method thereof

The invention discloses an agricultural straw crushing device, which includes a base, moving wheels are installed on both sides of the bottom of the base, an electric telescopic rod is connected to the left side of the base through a first pin shaft, and a crushing tank is installed on the right side of the upper end of the base. The surfaces of the first active shaft and the second active shaft are provided with crushing blades, and the middle part of the inner cavity of the crushing tank is provided with a mounting groove, and a dregs filter plate is inserted into the inside of the mounting groove, and the surface of the dregs filter plate is equidistantly arranged. Filter holes, the invention uses the rotation of the first and second active shafts to crush the crop stalks with the crushing blades, and the setting of the double shafts improves the crushing quality, and the crushed crop straws fall to the upper end of the dregs filter plate, and the crops The slag mixed in the straw can fall to the bottom of the inner cavity of the crushing tank through the filter hole, and be discharged through the slag discharge pipe.

Owner:合肥朝霞机械科技有限公司

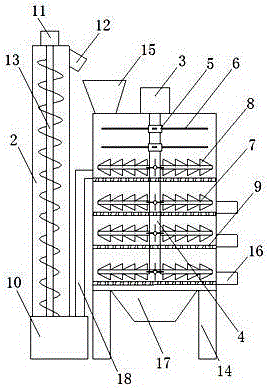

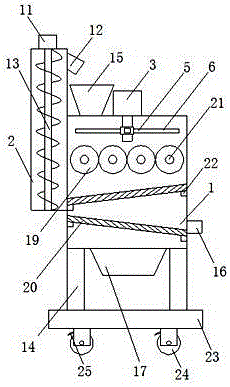

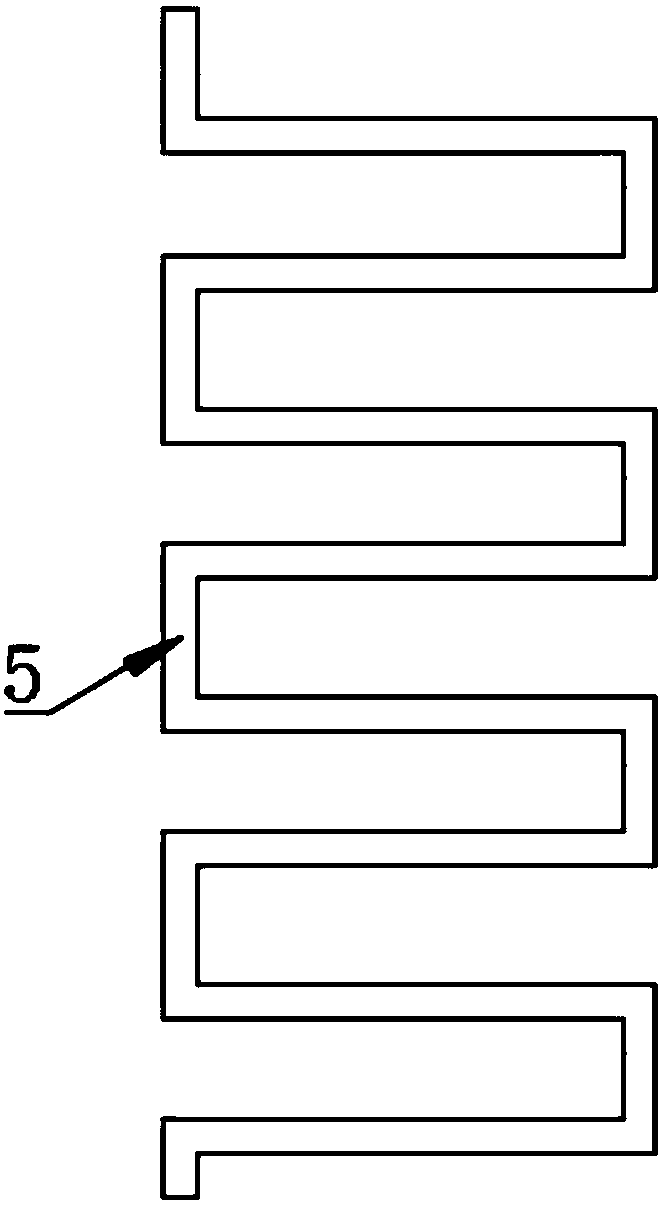

Smashing device for leftover material of automotive spoiler and operation method thereof

InactiveCN106000573AReduce wasteImprove crushing efficiencyGrain treatmentsMechanical engineeringSpoiler

The invention discloses a smashing device for a leftover material of an automotive spoiler. The smashing device comprises a smashing box, a material lifting cylinder, a motor I, a rotating shaft, stirring rods, vibrating screens and a screw conveyer, and is characterized in that a feed inlet, a discharge hole I and a discharge hole II are formed in the smashing box; vibration motors are arranged on the inner wall of the smashing box; one end of the material lifting cylinder is arranged on the outer wall of the smashing box; a motor II and a material return pipe are arranged at the other end of the material lifting cylinder; the motor I is arranged on the smashing box; the rotating shaft is arranged inside the smashing box; and one end of the rotating shaft is connected with the motor I. According to the smashing device, a plurality of layers of vibration screens are arranged inside the smashing box, the smashed leftover material of the automotive spoiler can be screened through the vibration screens, and the leftover material, which is not fully smashed, of the automotive spoiler enters the material lifting cylinder, and enters the smashing box again through the screw conveyer, the material return pipe and the feed inlet to be smashed, so that the waste of the leftover material of the automotive spoiler is reduced, and the smashing efficiency and smashing quality of the leftover material of the automotive spoiler are improved.

Owner:柴德维

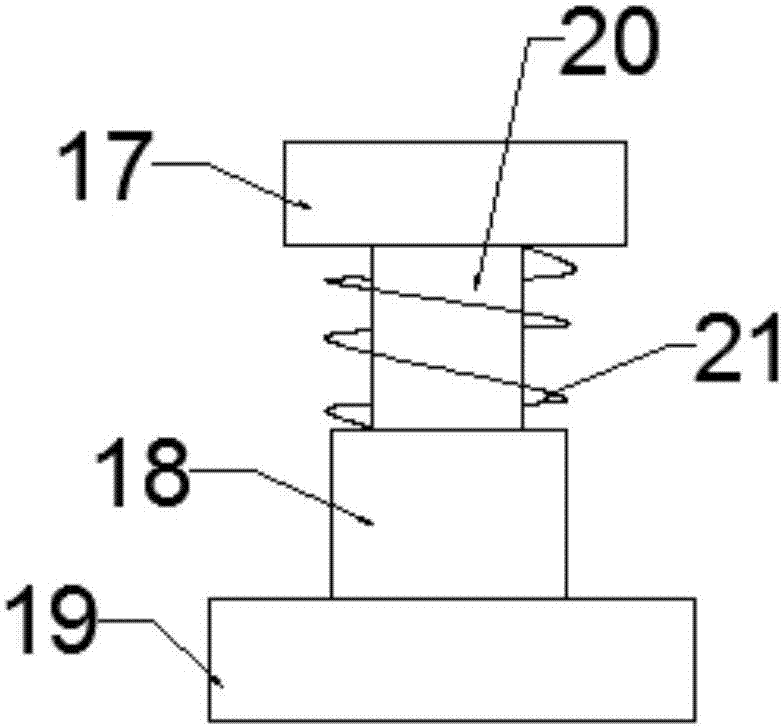

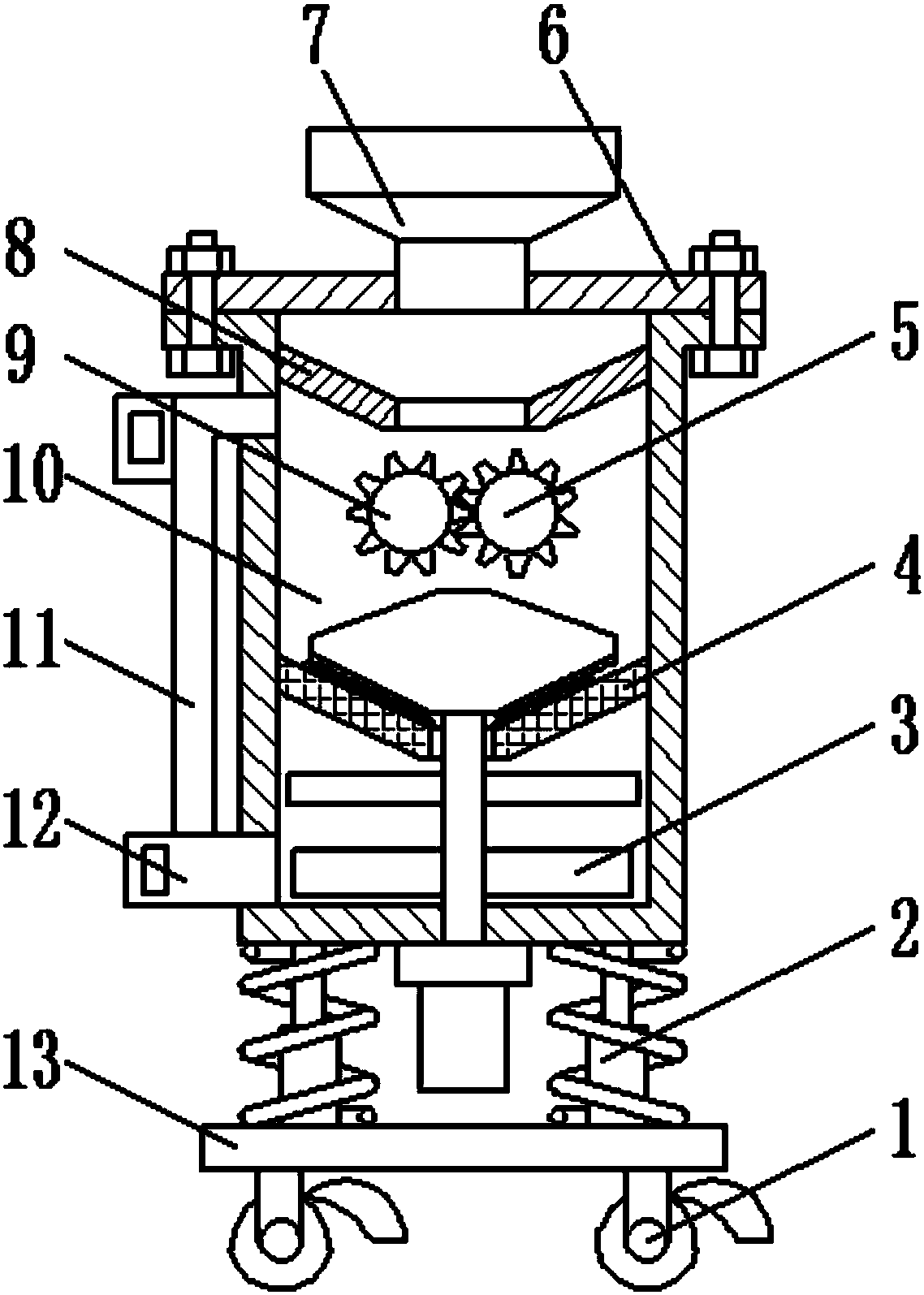

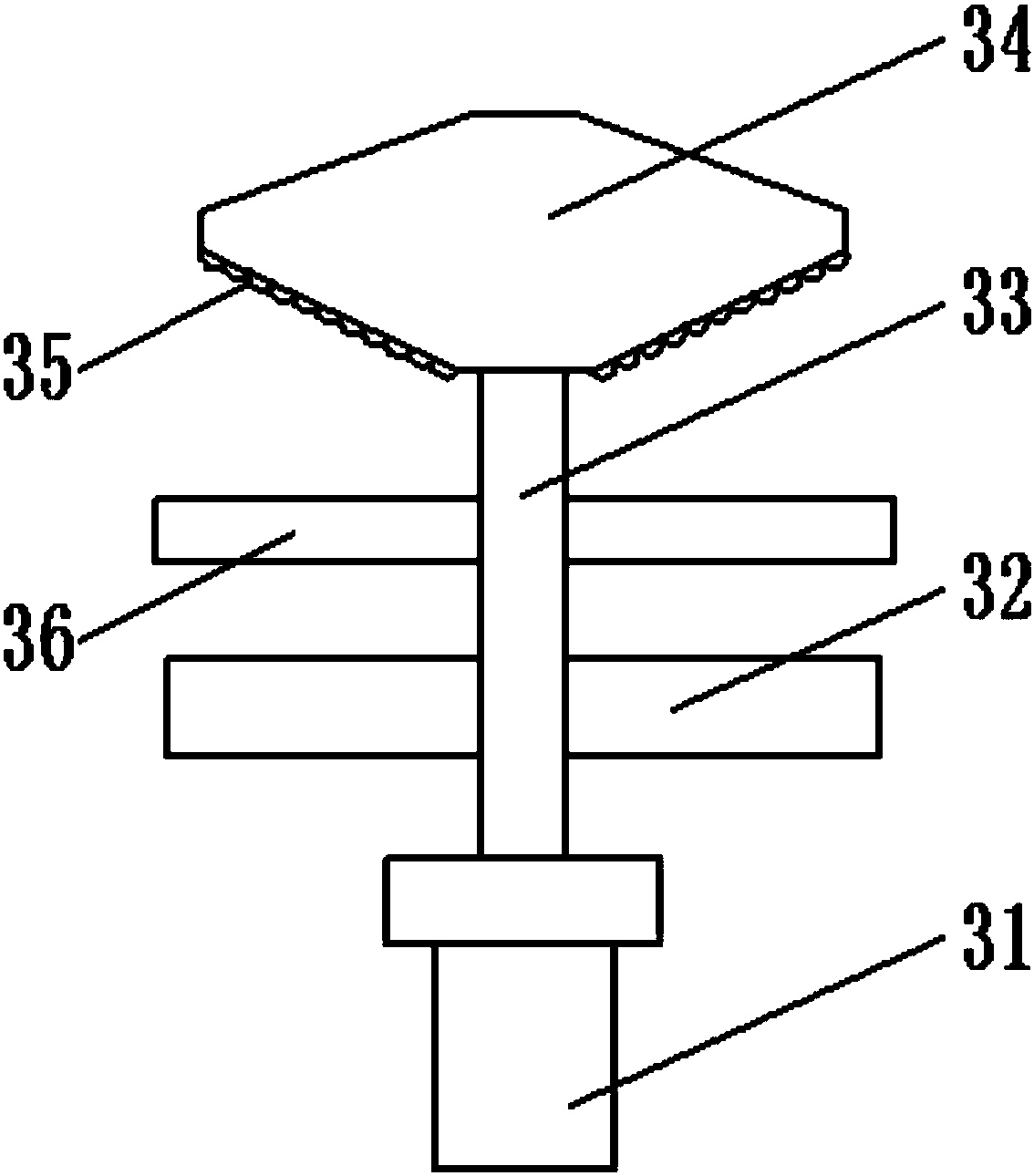

Vibration reduction type carbon block production wood powder breaking device convenient to move

InactiveCN108176448AImprove grinding and crushing qualityImprove crushing qualityRotary stirring mixersTransportation and packagingEngineeringMechanical engineering

The invention provides a vibration reduction type carbon block production wood powder breaking device convenient to move, and belongs to the technical field of material breaking. The device comprisesuniversal wheels, a bottom plate is arranged on the tops of the universal wheels, a vibration reduction base is arranged on the top of the bottom plate, a stirring device, a lower grinding block, a first breaking roller, a second breaking roller and a flow guide plate are arranged in the breaking chamber, and the device is simple in structure, reasonable in design and convenient to use; due to arrangement of the stirring device, under the action of a stirring motor, an upper grinding block is driven to move, in cooperation with the action of a lower grinding block, the material is subject to grinding and breaking, the material grinding and breaking quality is greatly improved, due to arrangement of the first breaking roller and the second breaking roller, a material can be primarily broken, the material breaking rate is improved, the material breaking quality is improved, due to arrangement of a dust suction pipe, dust generated in the grinding process is absorbed, and the dust is discharged along with the ground material, and the material use rate is greatly improved.

Owner:ZHENGZHOU HAOEN ELECTRONICS INFORMATION TECH CO LTD

Organic fertilizer processing raw material efficient crushing equipment and application method thereof

InactiveCN107262207AConvenient crushing operationImprove crushing qualityCocoaGrain treatmentsDrive shaftEngineering

The invention discloses organic fertilizer processing raw material efficient crushing equipment which comprises a crushing chamber, a lifting barrel, a first motor, a transmission shaft, stirring rods, crushing blocks, a lower grinding disc, an air cylinder, an upper grinding disc, a second motor and a packing auger. The organic fertilizer processing raw material efficient crushing equipment is characterized in that the crushing chamber is arranged on supports; the lifting barrel is arranged on the outer wall of the crushing chamber; a discharging pipe is arranged at one end of the lifting barrel; the first motor is arranged on the crushing chamber; the transmission shaft is arranged in the crushing chamber; the stirring rods are arranged on connecting blocks; the lower grinding disc is arranged on the transmission shaft; the second motor is arranged at one end of the lifting barrel; and the packing auger is arranged in the lifting barrel. According to the organic fertilizer processing raw material efficient crushing equipment, the work efficiency is improved; the labor intensity of operators is reduced; the distance between the upper grinding disc and the lower grinding disc is adjusted, and therefore organic fertilizer raw materials can be crushed into particles of different sizes; the production needs of organic fertilizer of different types can be met; the application range of the crushing equipment is widened; and the crushing quality of the raw materials is further improved.

Owner:安徽乐农环保科技有限公司

Organic fertilizer raw material crushing device and operation method thereof

InactiveCN107457043AImprove crushing qualityConvenient crushing operationCocoaGrain treatmentsElectric machineryEngineering

The invention provides a crushing device for organic fertilizer raw materials, comprising a crushing chamber, a feeding cylinder, a motor one, a transmission shaft, a stirring rod, a crushing block, a lower millstone, a cylinder, an upper millstone, a motor two and an auger, and is characterized in that: The crushing chamber is set on the bracket, the lifting cylinder is set on the wall of the crushing chamber, and a discharge pipe is arranged on one end of the lifting cylinder, the motor is set on the crushing chamber, and the The drive shaft is set in the crushing chamber, the stirring rod is set on the connecting block, the lower grinding disc is set on the drive shaft, the motor 2 is set at one end of the lifting cylinder, and the auger is set at the lifting Inside the barrel. In the present invention, an upper millstone is arranged on the piston rod of the cylinder, and a lower millstone is arranged on the transmission shaft of the motor one, and the organic fertilizer raw materials to be pulverized are transmitted to the upper millstone and the lower millstone through the feed bin, the feeding pipe, and the feed port. It is convenient to crush organic fertilizer raw materials and reduce labor intensity.

Owner:安徽乐农环保科技有限公司

Processing method for recycling waste packaging paper

InactiveCN112111984AImprove detachment efficiencySpread outWashing/displacing pulp-treating liquorsPaper recyclingFiberWarm water

The invention discloses a processing method for recycling waste packaging paper, and relates to the technical field of waste paper recycling. The processing method comprises the following steps of: 1,conveying waste paper into a cutting machine, and sequentially carrying out twice flattening treatment, cutting treatment and crushing treatment on the waste paper in the cutting machine, 2, pouringa waste paper raw material into a magnetic suction rolling cylinder, rotating the magnetic suction rolling cylinder, supplying power for electromagnet in the magnetic suction rolling cylinder to adsorb metal impurities in the waste paper raw material; and 3, pouring the waste paper raw material into a pulping machine, pouring warm water into the pulping machine, conducting stirring to obtain pulp,pouring a deinking agent, a defoaming agent and a dispersing agent into the pulp, and starting an ultrasonic cleaner in the pulping machine to physically clean the pulp. When paper pulp is stirred, the surfaces of fibers in the paper pulp can be physically cleaned through ultrasonic waves, so that the separation efficiency of the fibers in the paper pulp and ink is improved, ultrasonic cleaning and stirring are mixed and used for 2-3 times, and the deinking quality can be improved.

Owner:界首市鑫华装璜彩印有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com