Stalk combine harvester

A combine harvester and straw technology, which is applied to harvesters, crop processors, agricultural machinery and implements, etc., can solve the problems of straw crushing and deep processing, unsatisfactory available energy, waste of manpower and material resources, etc. Environmental protection, improvement of operating efficiency, and environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

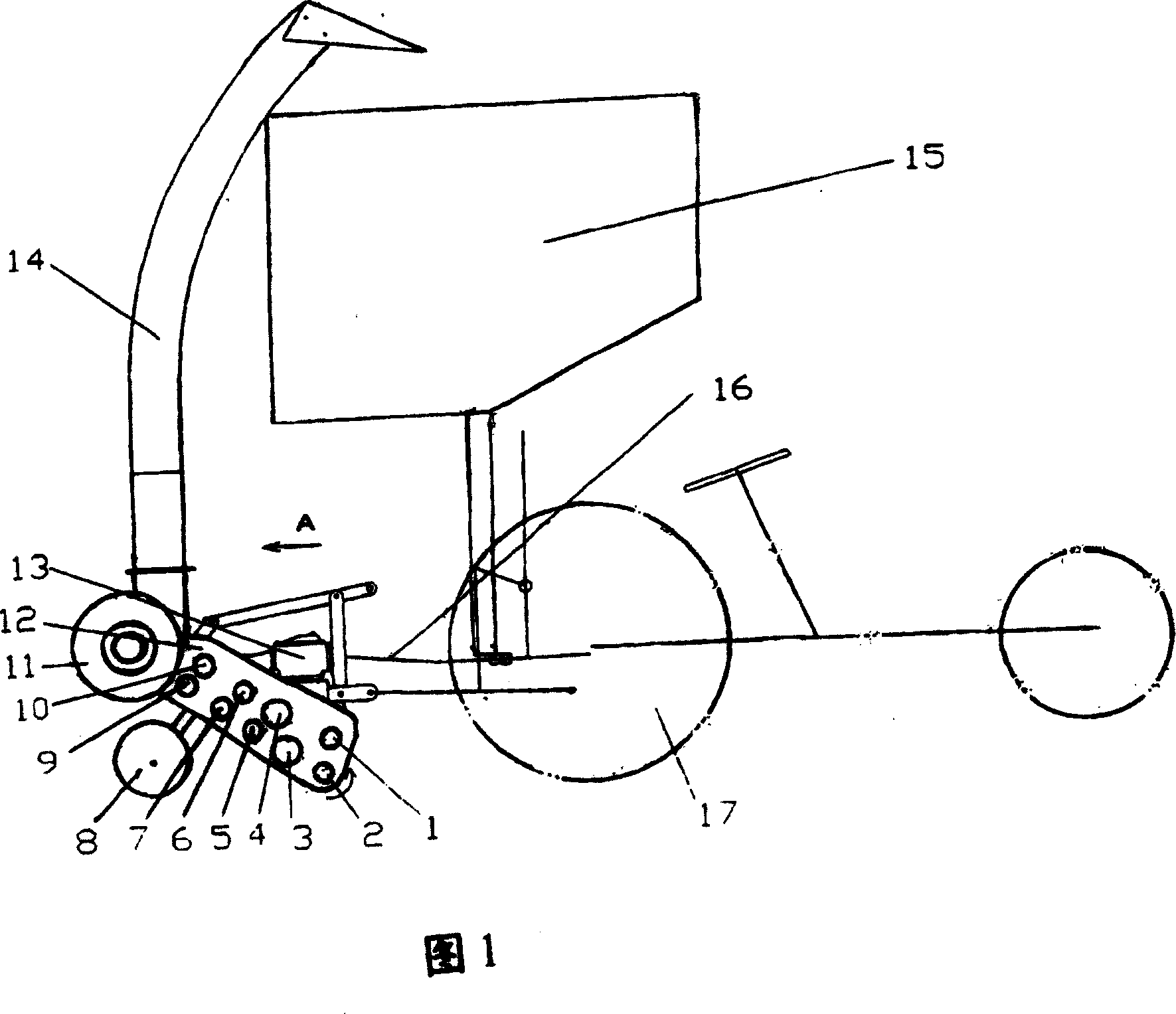

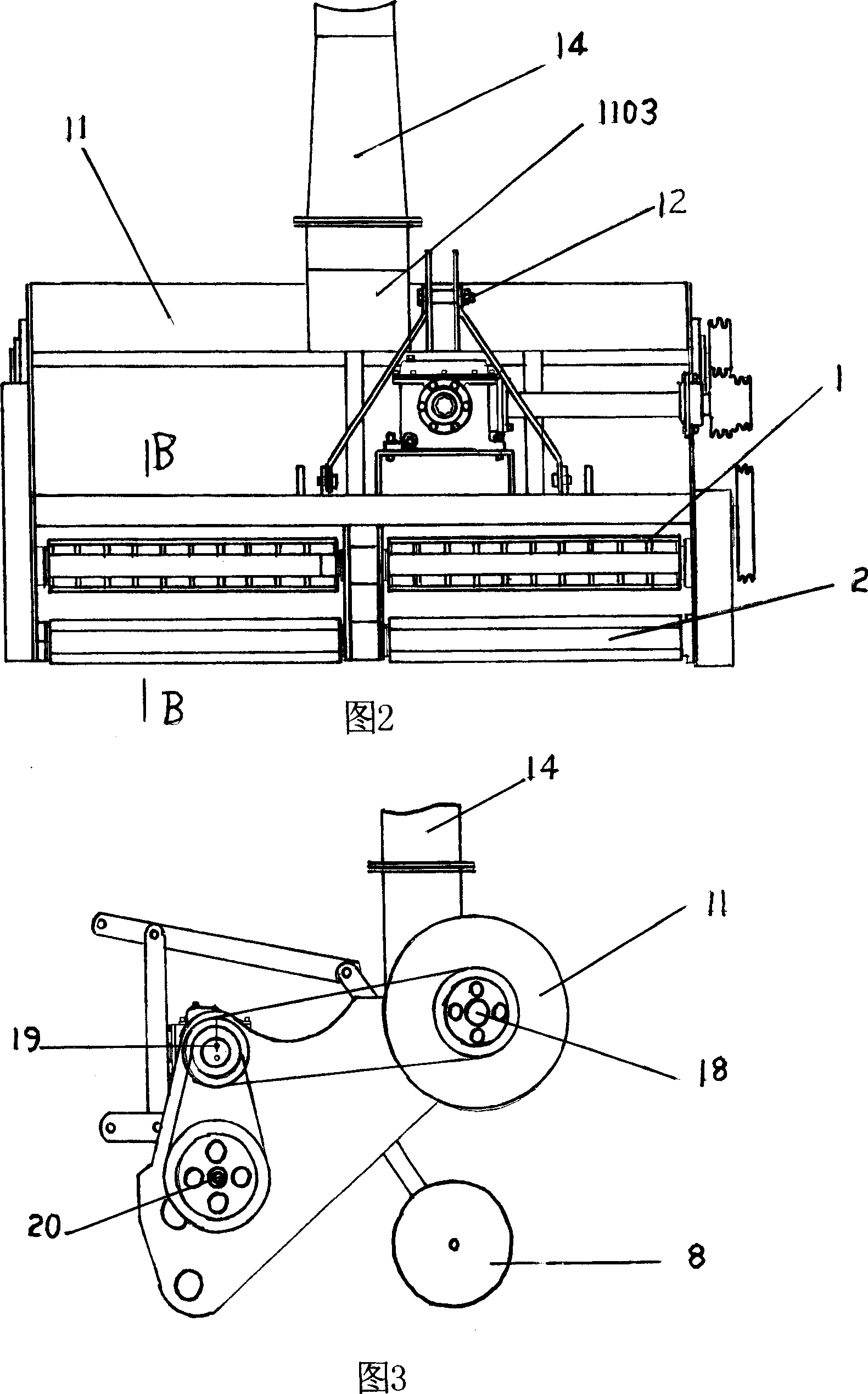

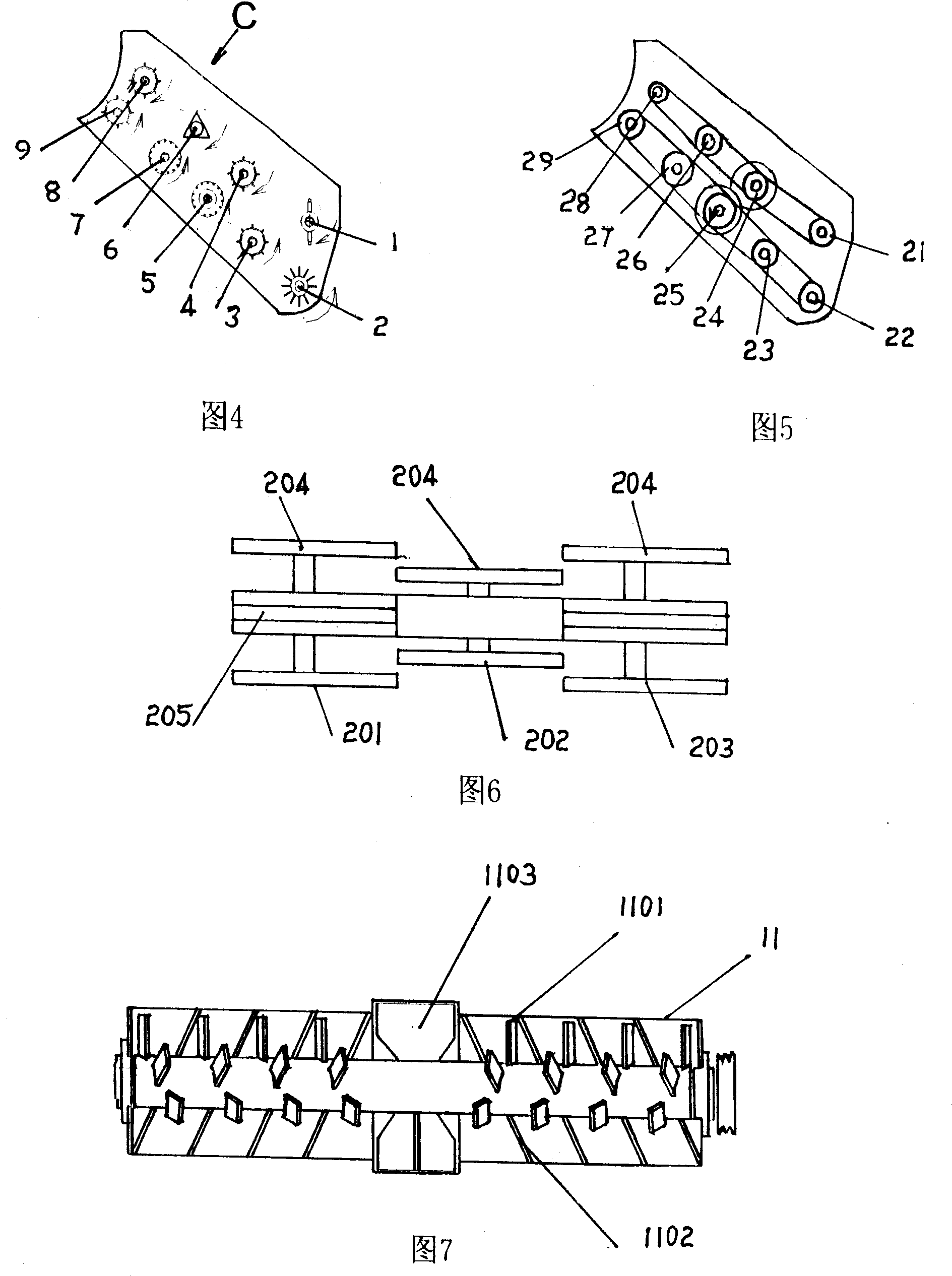

[0027] In Fig. 1 to Fig. 9, a straw conveying device is provided behind the straw harvesting mechanism, and a straw chopping device is provided behind the straw conveying device, and the straw chopping devices are connected. The structure of the straw harvesting mechanism is as follows: it has a counterclockwise-rotating horizontal axis-type clearing hob 2, and a clockwise-rotating reeling roller 1 above it. The horizontal axis type clearing hob 2 is a segmented misplaced multi-edge hob, and its structure is: it is divided into three sections 201, 202, 203 for dislocation discharge, each section is a group of clearing knives, and the discharge is a quadrangular shape with an angle Be 90 °, be respectively fixed on the hob frame 205, and each segment cutter dislocation angle is 45 °. The structure of the straw conveying device is as follows: it has a single lower conveying roller 3, and has 3 pairs of relatively rotating conveying rollers 4, 5, 6, 7, 10, 9. The conveying rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com