Agricultural straw pulverizing device and using method thereof

A straw pulverizing and crop straw technology is applied in the field of agricultural straw pulverizing devices, which can solve the problems of insufficient mechanization, waste of human and material resources, and increased workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

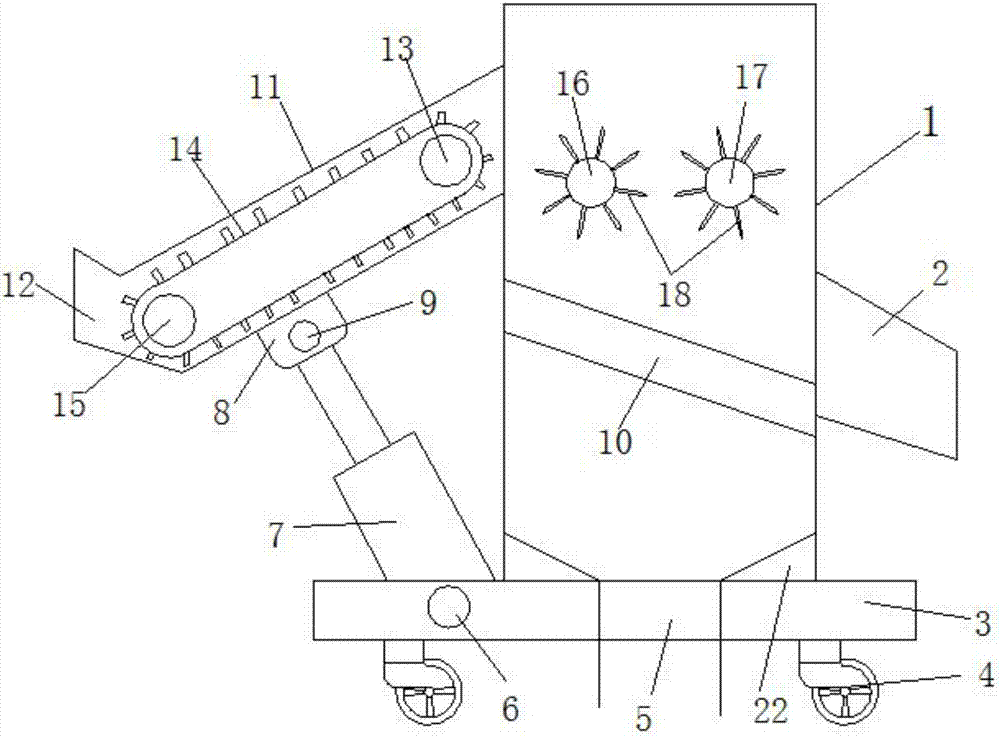

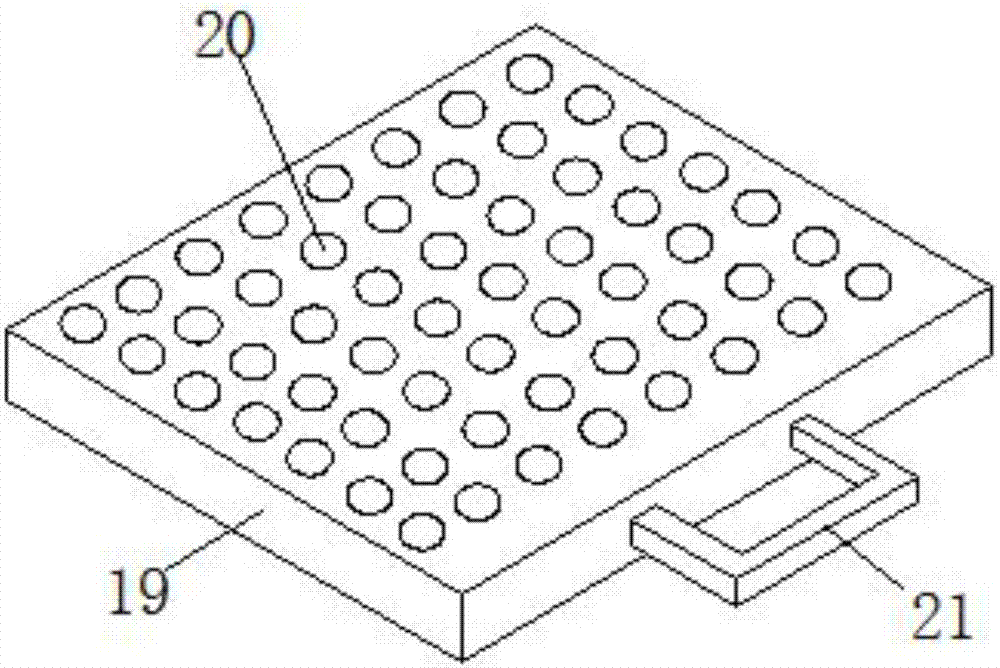

[0019] The present invention provides such Figure 1-2 An agricultural straw crushing device, comprising a base 3, moving wheels 4 are installed on both sides of the bottom of the base 3, an electric telescopic rod 7 is connected to the left side of the base 3 through a first pin shaft 6, and an electric telescopic rod 7 is installed on the right side of the upper end of the base 3 Crushing pot 1, the upper left side of the crushing pot 1 penetrates the front and rear walls of the crushing pot 1 to be provided with a first active shaft 16, and the upper right side of the crushing pot 1 runs through the front and rear walls of the crushing pot 1 to be provided with a second active shaft 17, the first The surfaces of the active rotating shaft 16 and the second active rotating shaft 17 are provided with crushing blades 18, and the middle part of the inner chamber of the crushing tank 1 is provided with a mounting groove 10, and the inside of the mounting groove 10 is inserted with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com