Moxa extraction process and grinder therefor

An extraction process and grinding machine technology, applied in the field of moxa moxa extraction process and its grinding machine, can solve the problems of low separation rate, environmental pollution, low output, etc., to improve the separation and extraction rate, broaden the utilization prospect, and improve the crushing quality and the effect of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

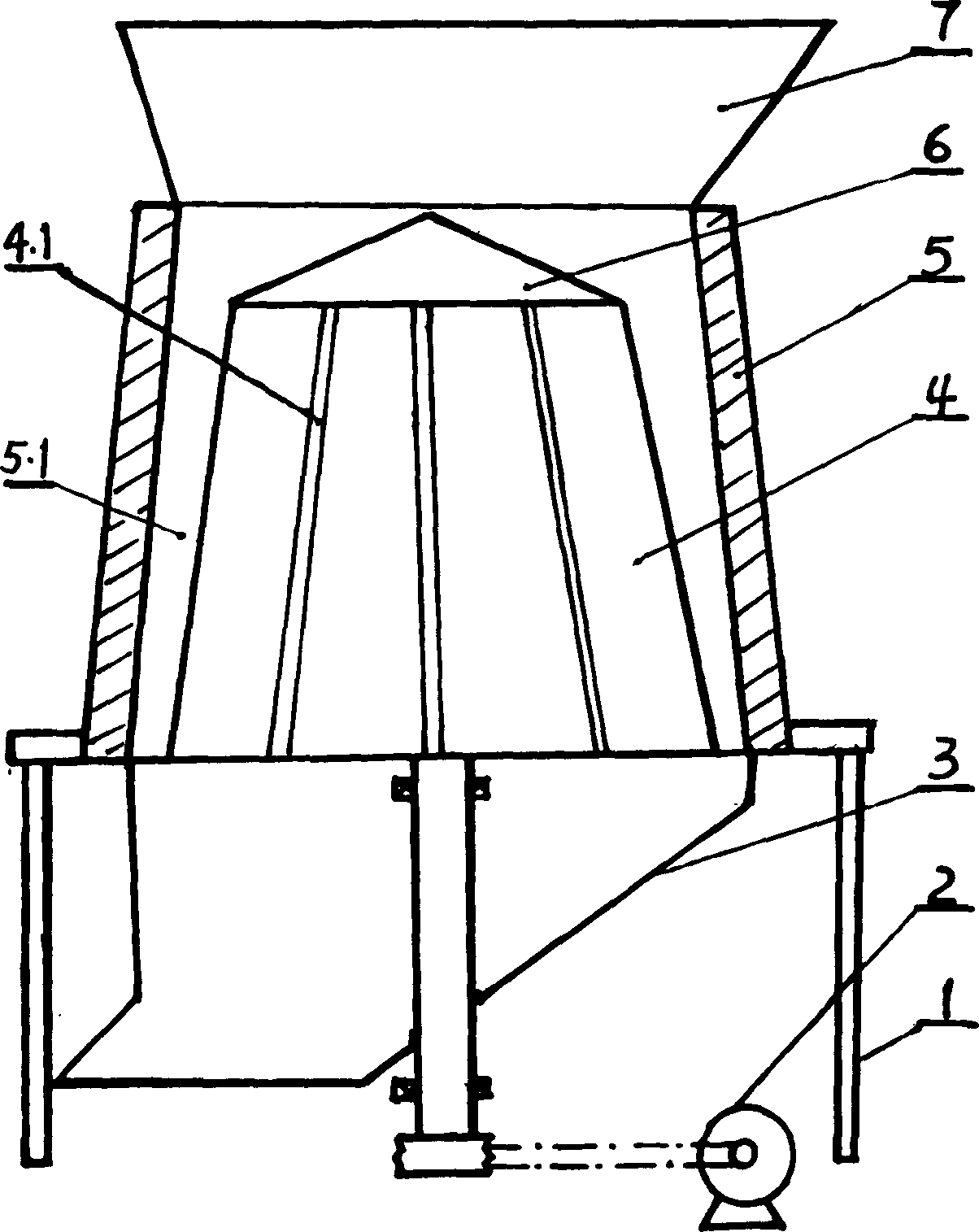

[0010] In conjunction with the accompanying drawings and examples, the specific steps of the moxa moxa extraction process of the present invention are further described, the technical effect of the process requirements and the specific structure of the conical grinder, and its characteristics and advantages will be clearer.

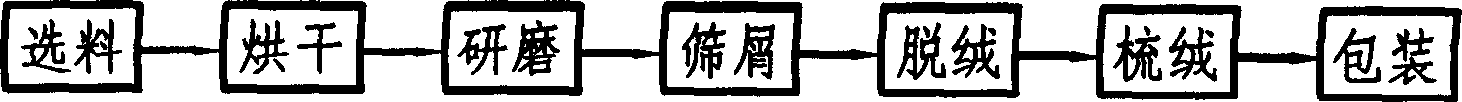

[0011] The embodiment of moxa moxa extraction process of the present invention, see figure 1 , the process flow is: material selection→drying→grinding→sieving dust→delinting→combing→packing. Among them, in the step of material selection, the leaves of mugwort are used as raw materials, regardless of dryness or wetness, and large leaves with a length of more than 40 mm are selected; in the drying step, the selected leaves of mugwort are sent to a commercially available W-type dryer to dry until the water content is not greater than 8%. In the grinding step, the dried Artemisia argyi is sent to a newly designed conical grinder for crushing and grinding at a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com