Patents

Literature

92results about How to "Convenient crushing operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

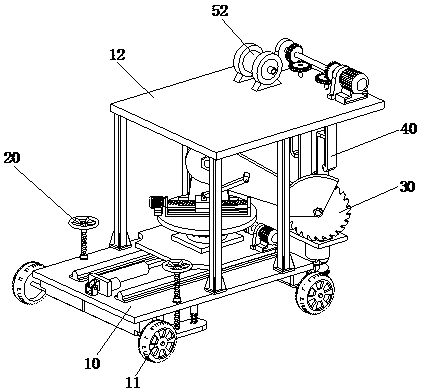

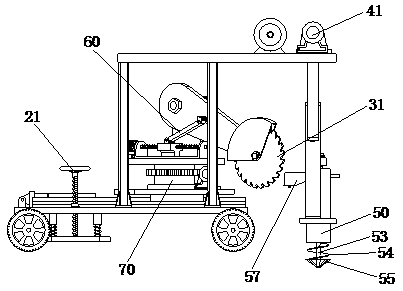

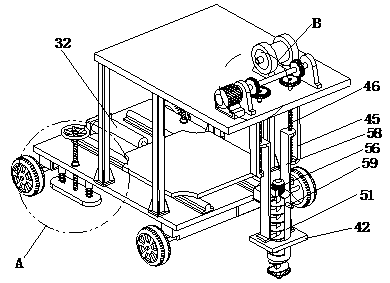

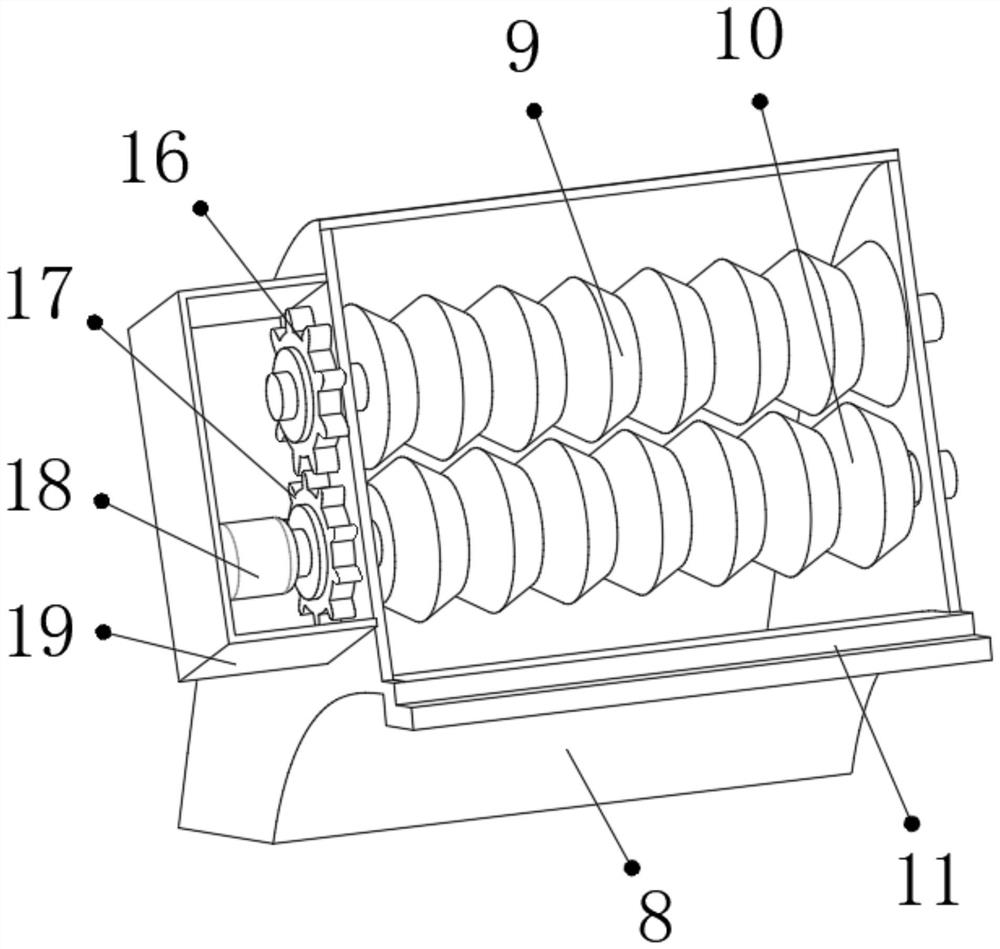

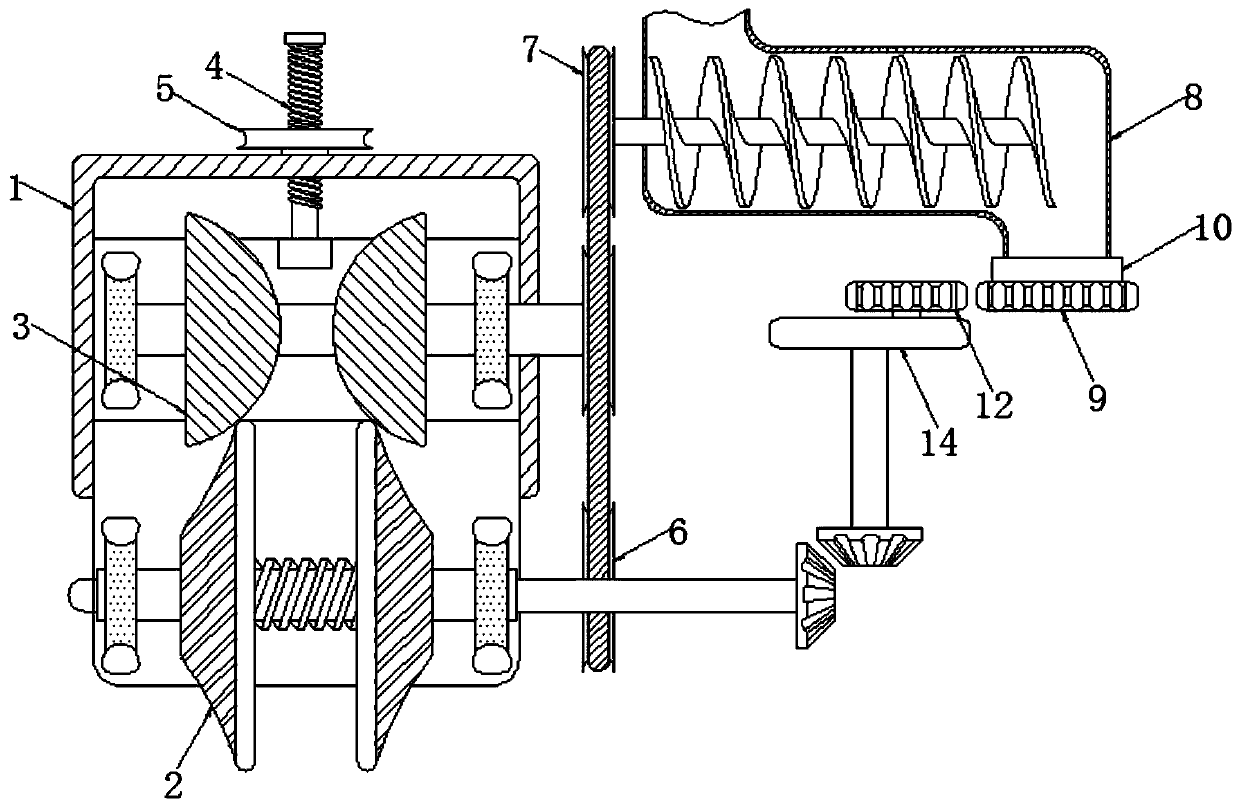

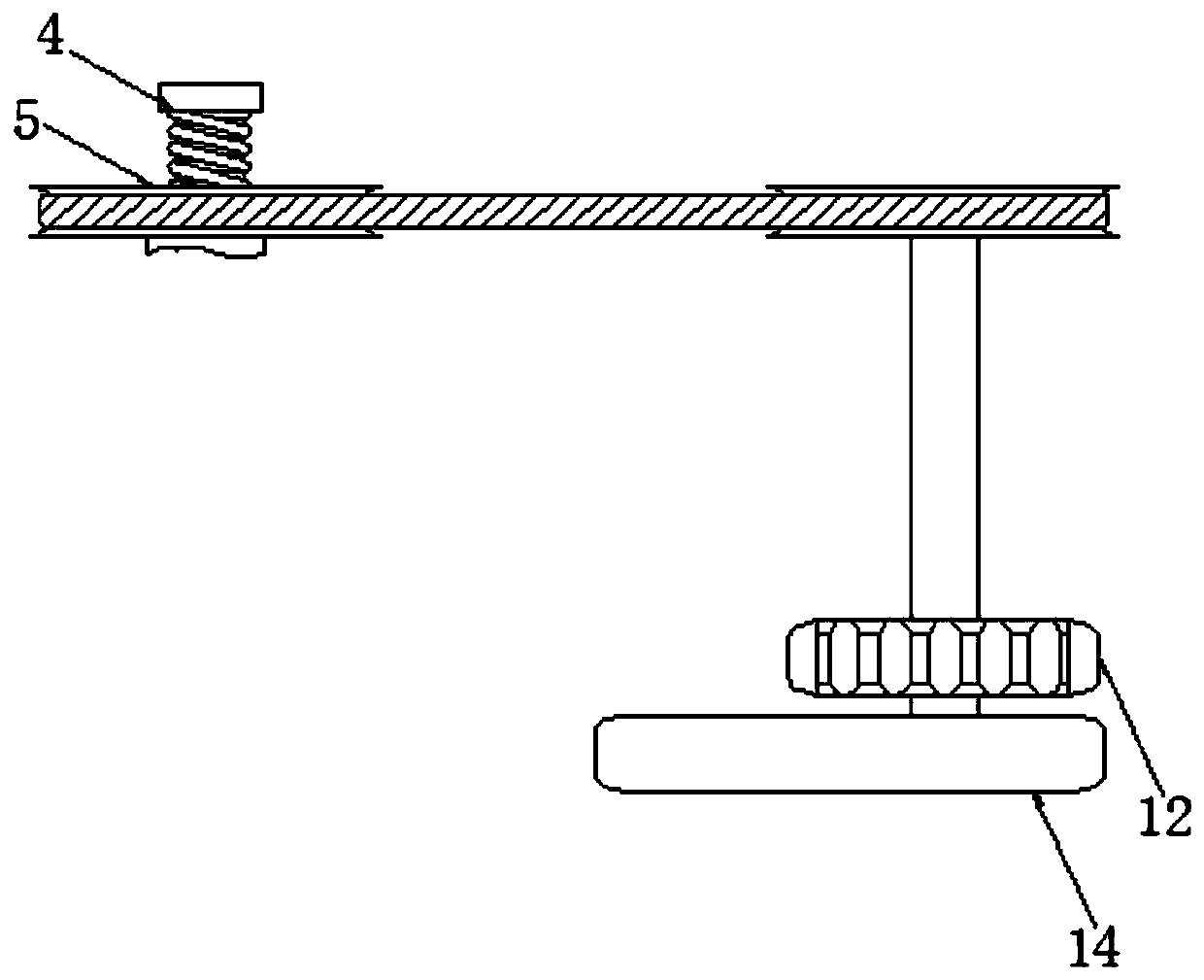

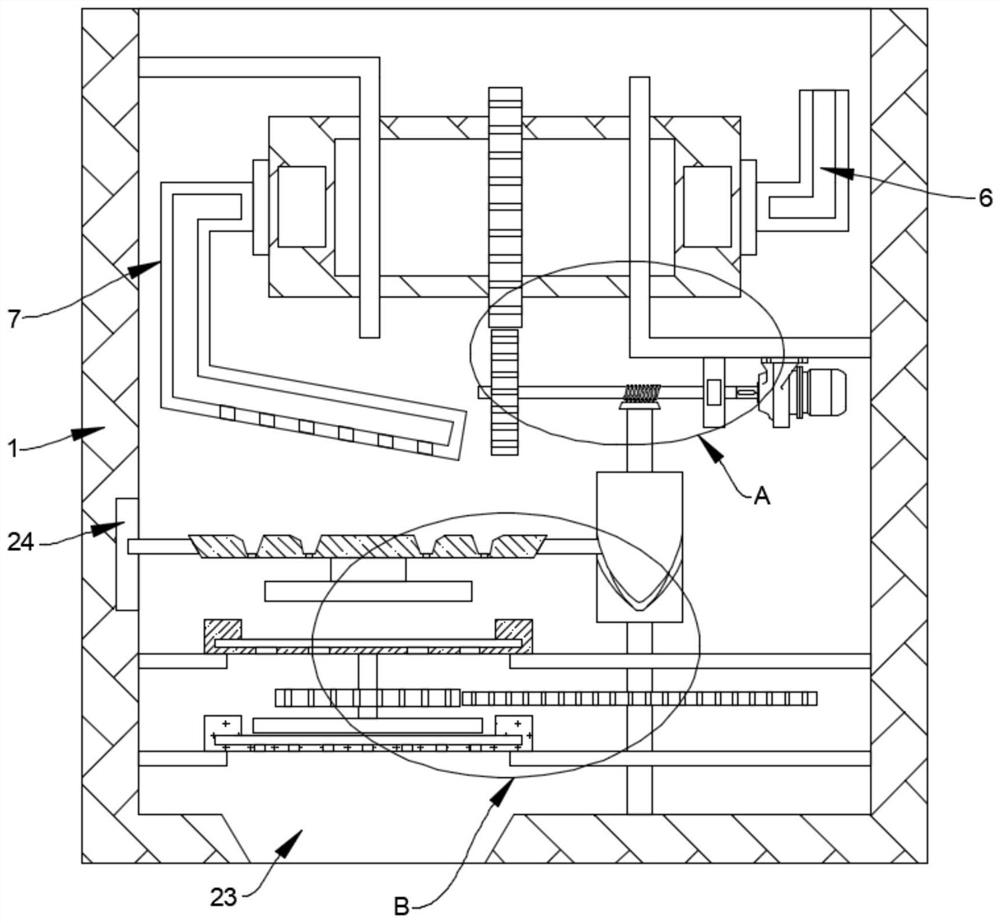

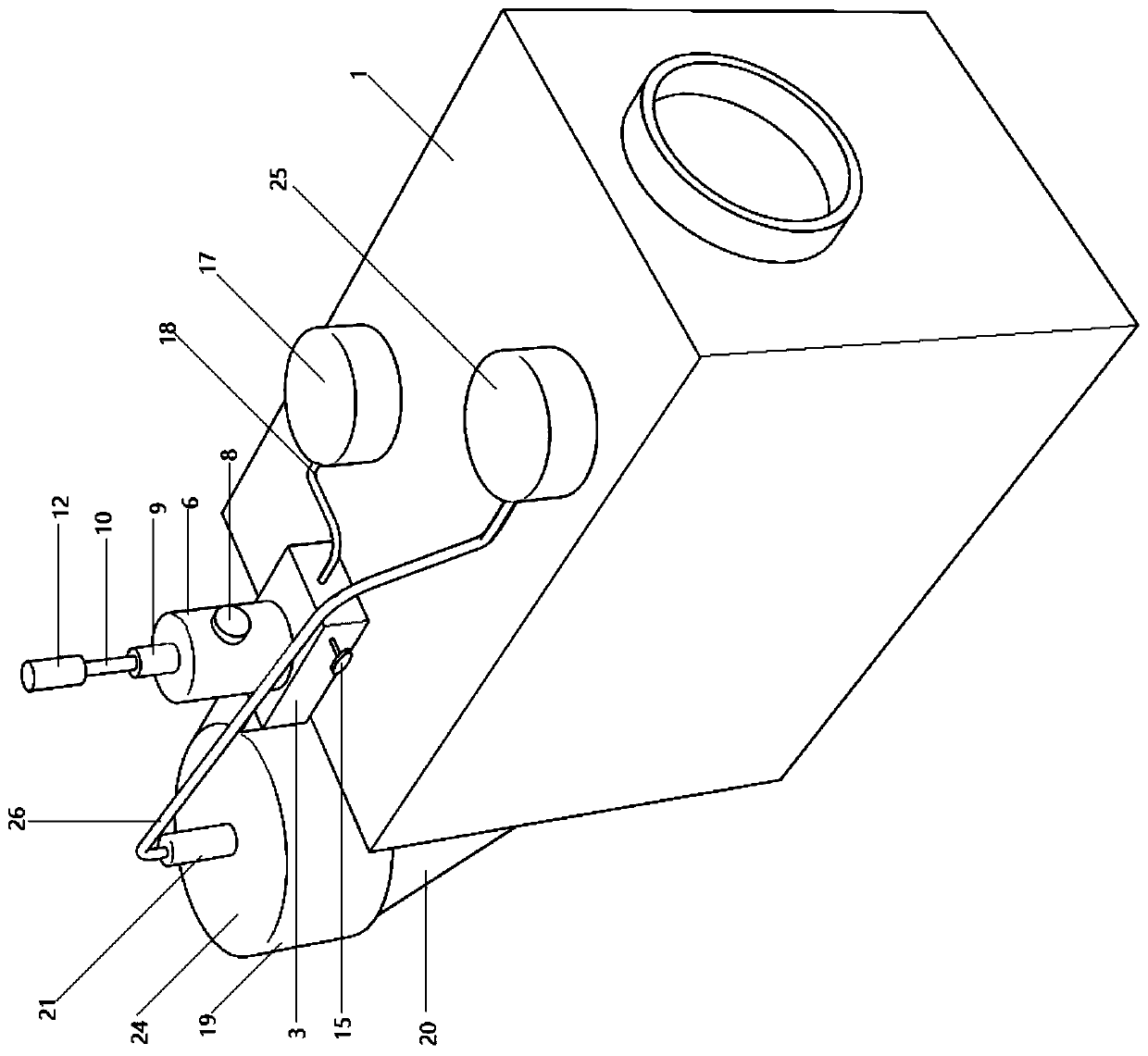

Sampling device for geotechnical exploration

InactiveCN110308010AAutomatic cuttingAutomatic crushing operationWithdrawing sample devicesDrive wheelSpiral blade

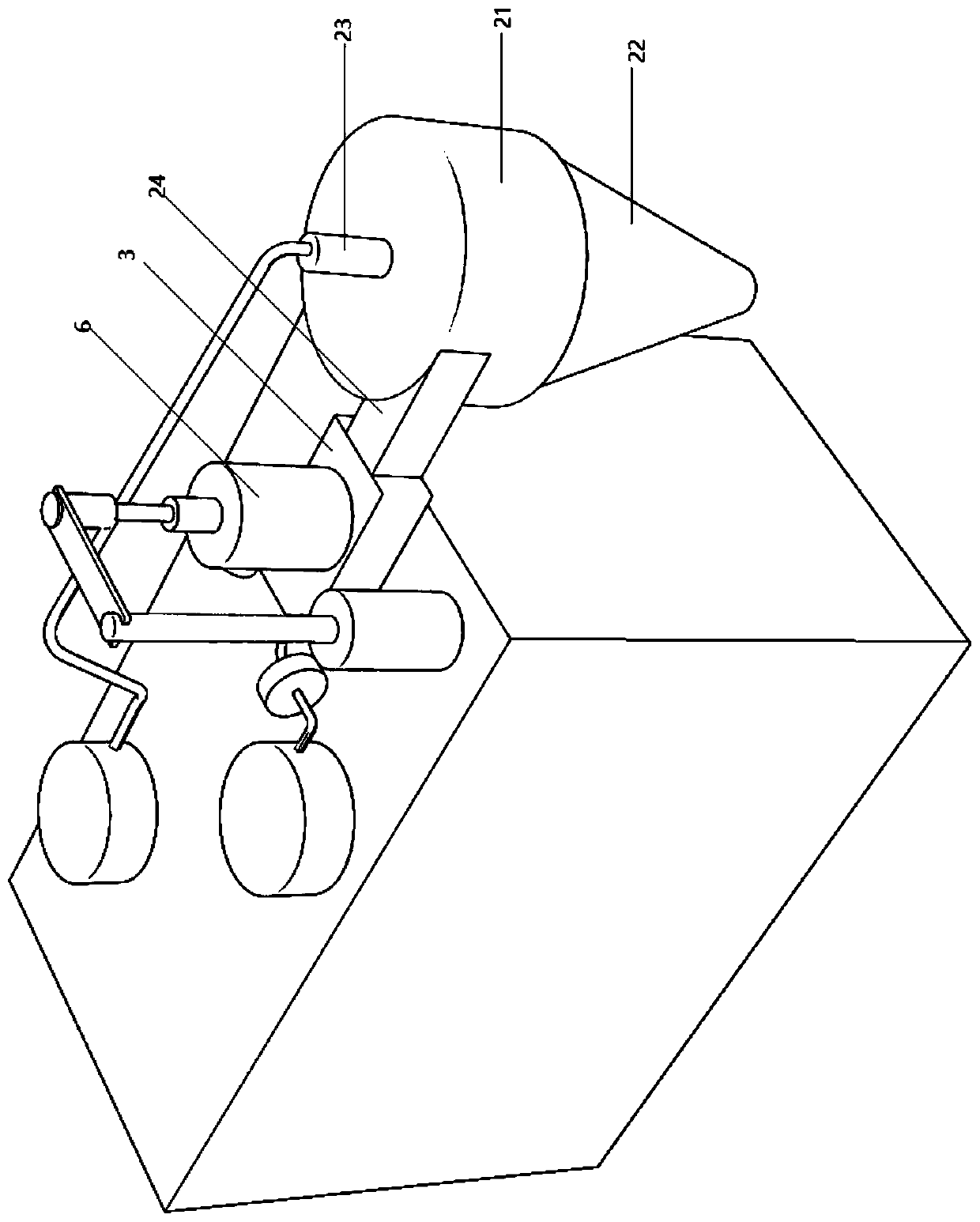

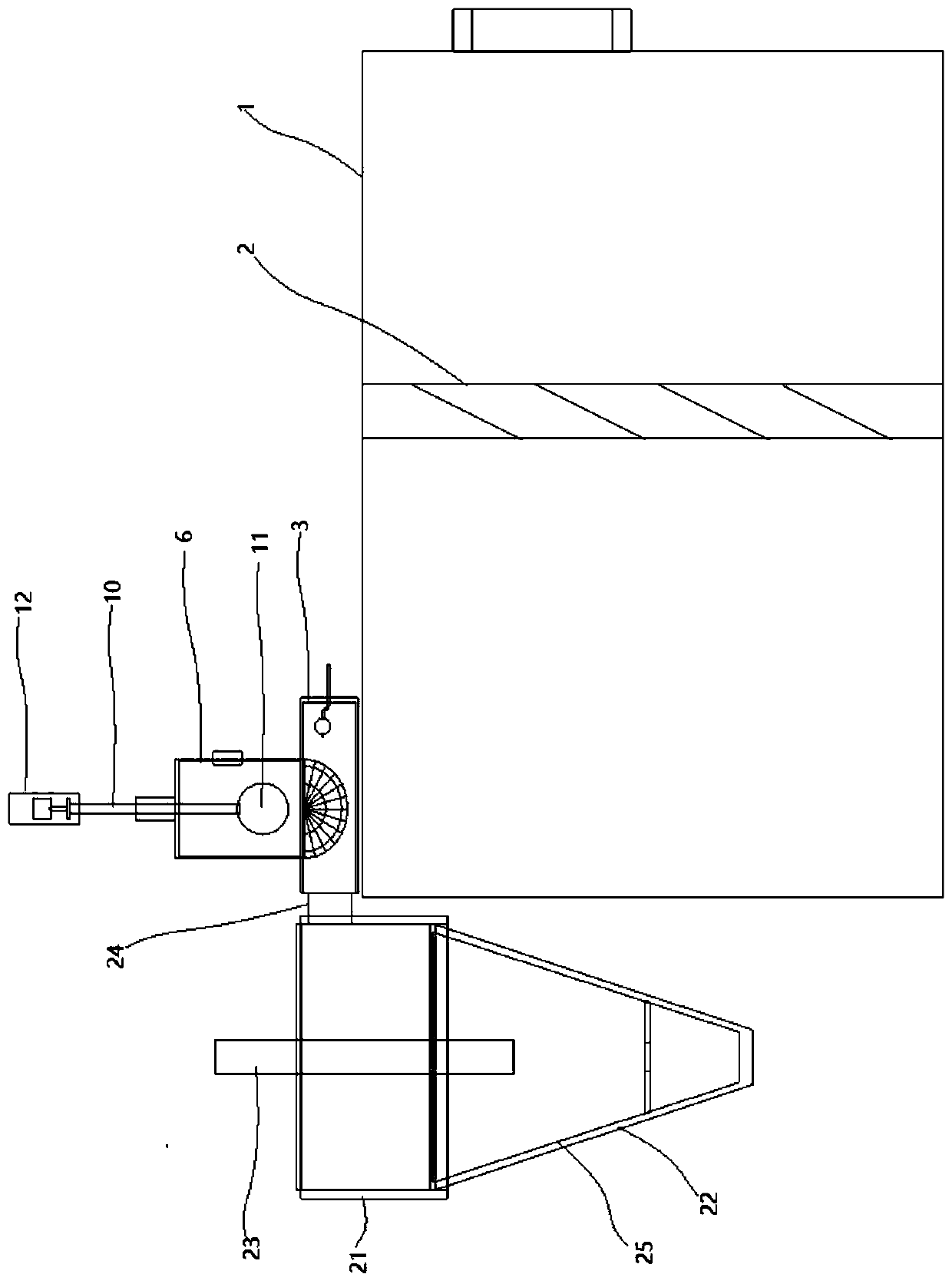

The invention discloses a sampling device for geotechnical exploration, and belongs to the technical field of geological exploration equipment. The sampling device comprises a base, a stabilizing mechanism, a rock cutting mechanism and a drilling and sampling mechanism; four driving wheels are arranged at the bottom of the base; a supporting frame is arranged on the top of the base; the drilling and sampling mechanism comprises a lifting assembly, a lifting plate and a drilling and sampling assembly; the drilling and sampling assembly comprises a sampling barrel and a connecting frame; a rotating shaft is arranged on the connecting frame; a spiral blade is arranged on the rotating shaft in a sleeved mode; and a drilling head is arranged at the bottom end of the rotating shaft in a sleevedmode. The sampling device has the beneficial effects that the lifting operation of the drilling and sampling assembly can be realized, and the sample can be conveyed to a material collecting hopper byvirtue of the drilling and sampling mechanism; the automatic cutting assembly can be used for cutting and crushing rock samples; and a rotary assembly can drive the automatic cutting assembly to rotate to a proper position, so that the interference of the automatic cutting assembly on the operation of the drilling and sampling mechanism is avoided.

Owner:胡立宇

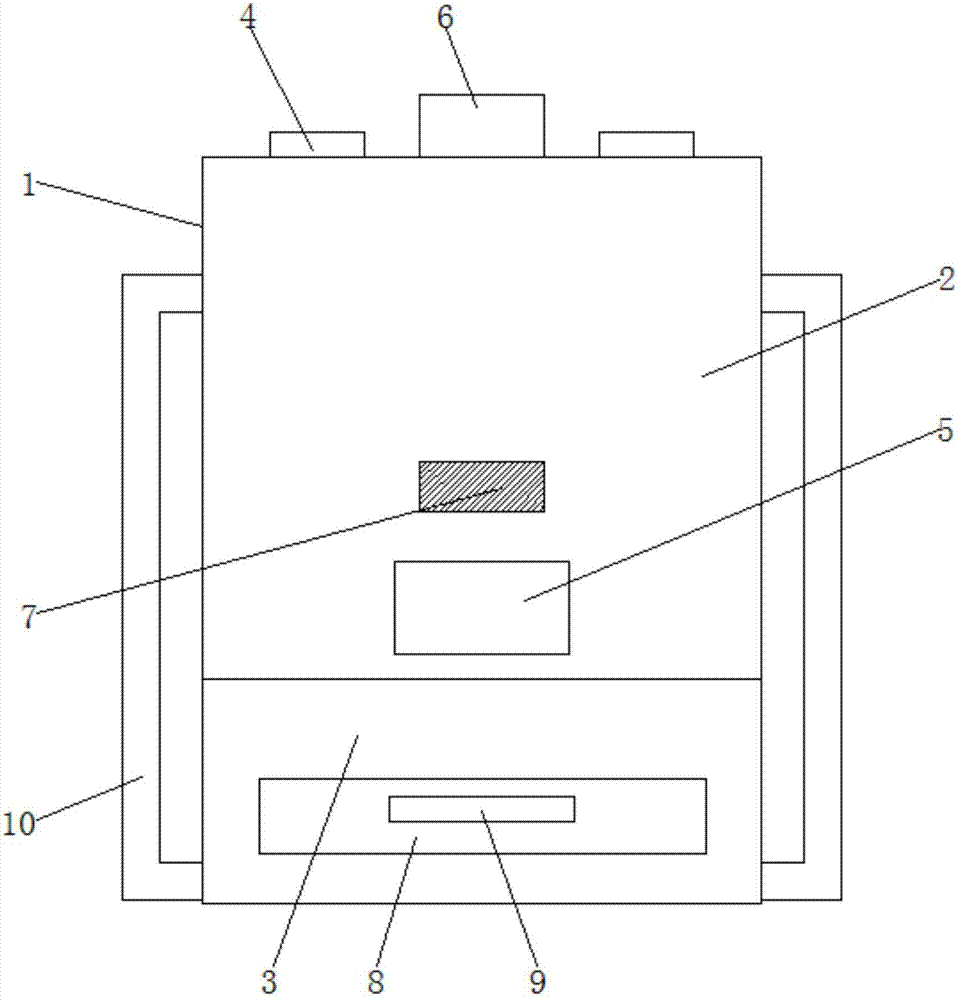

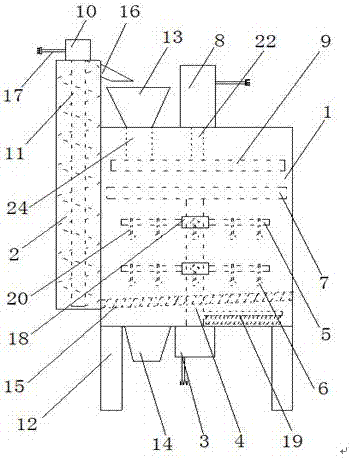

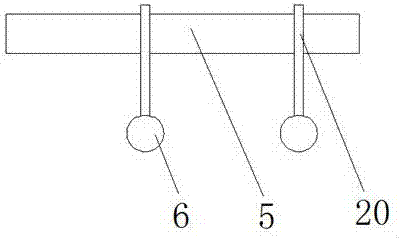

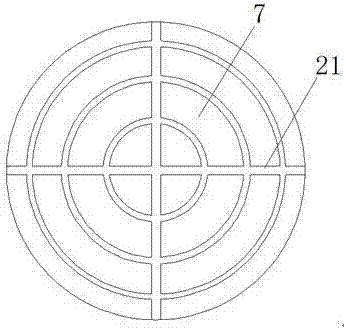

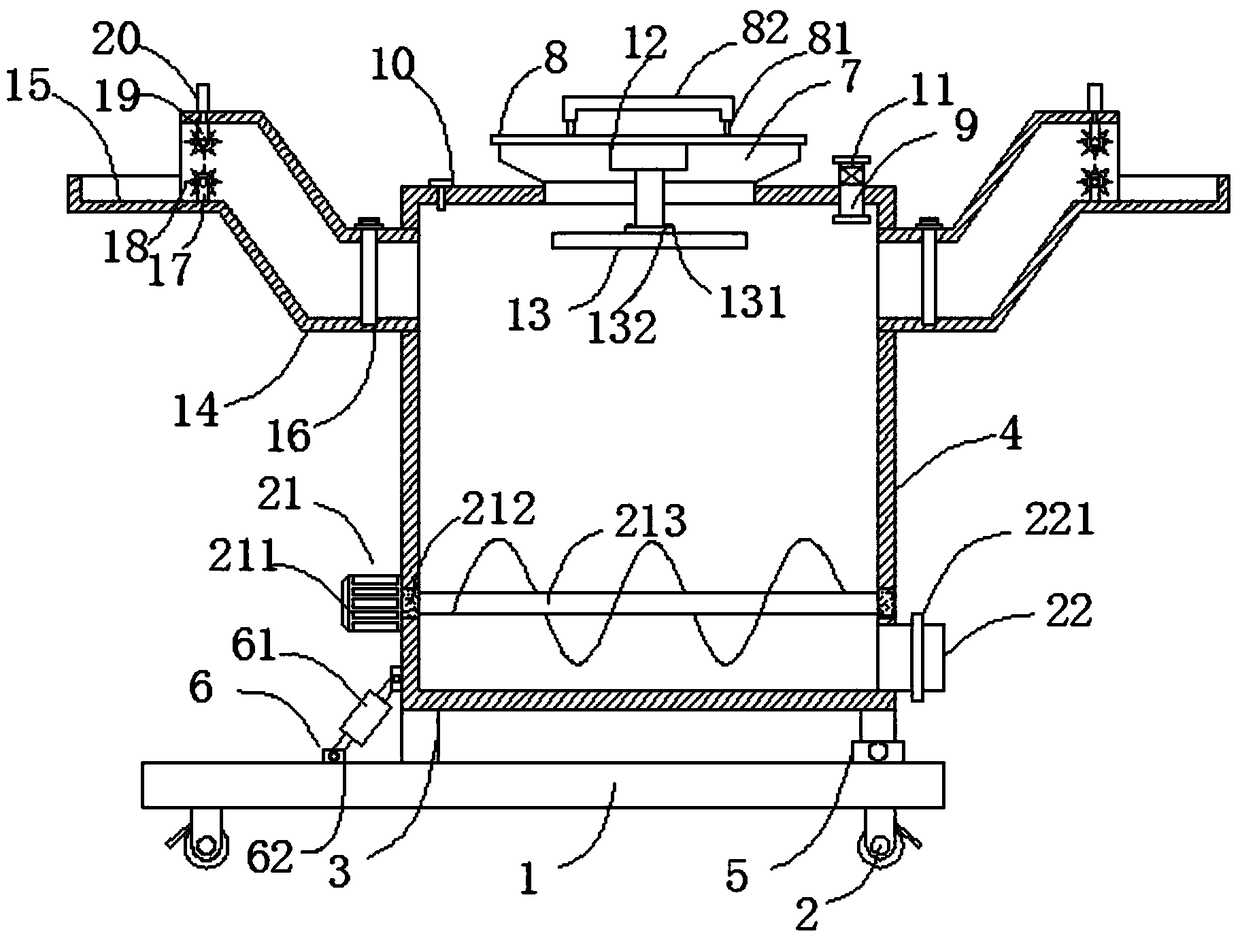

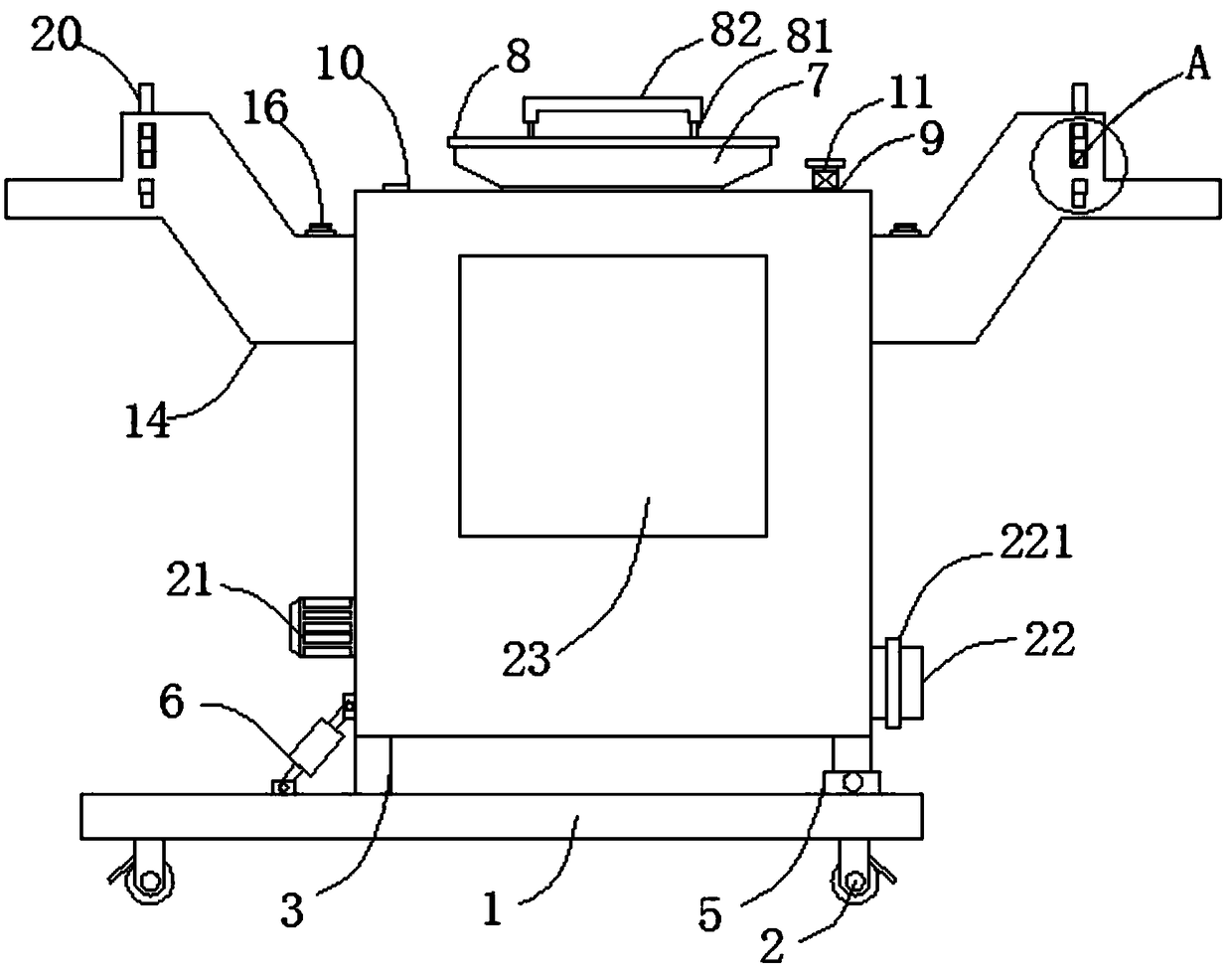

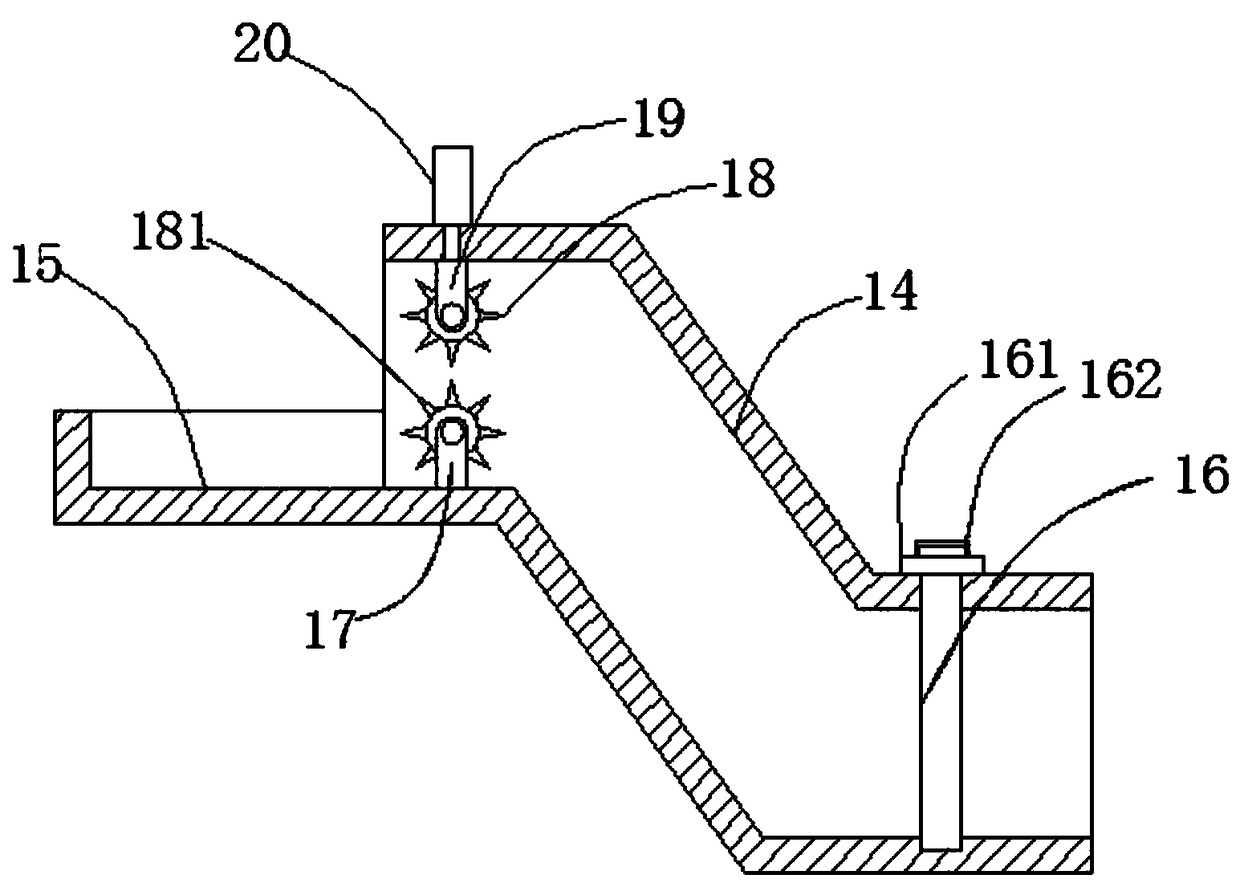

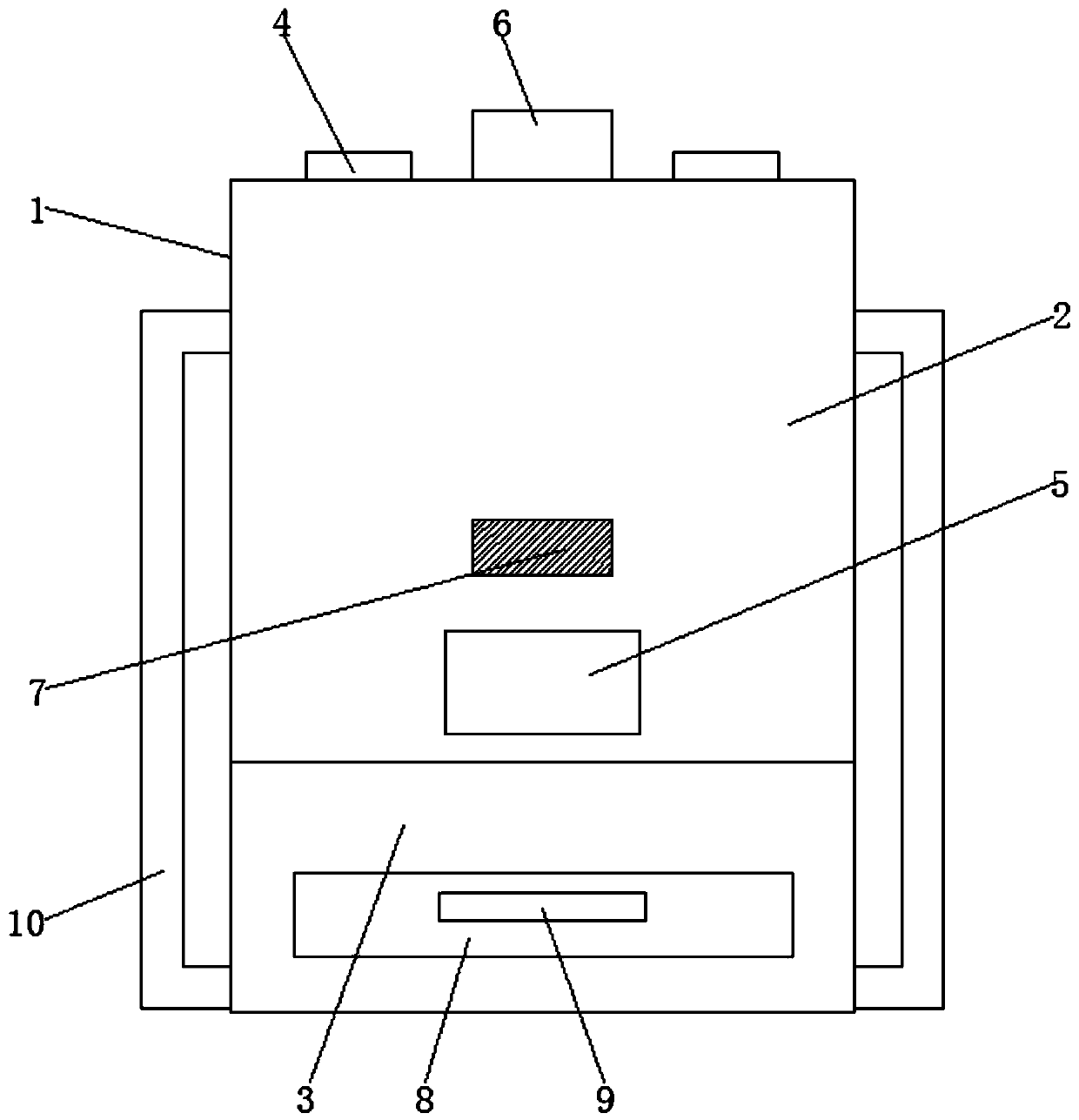

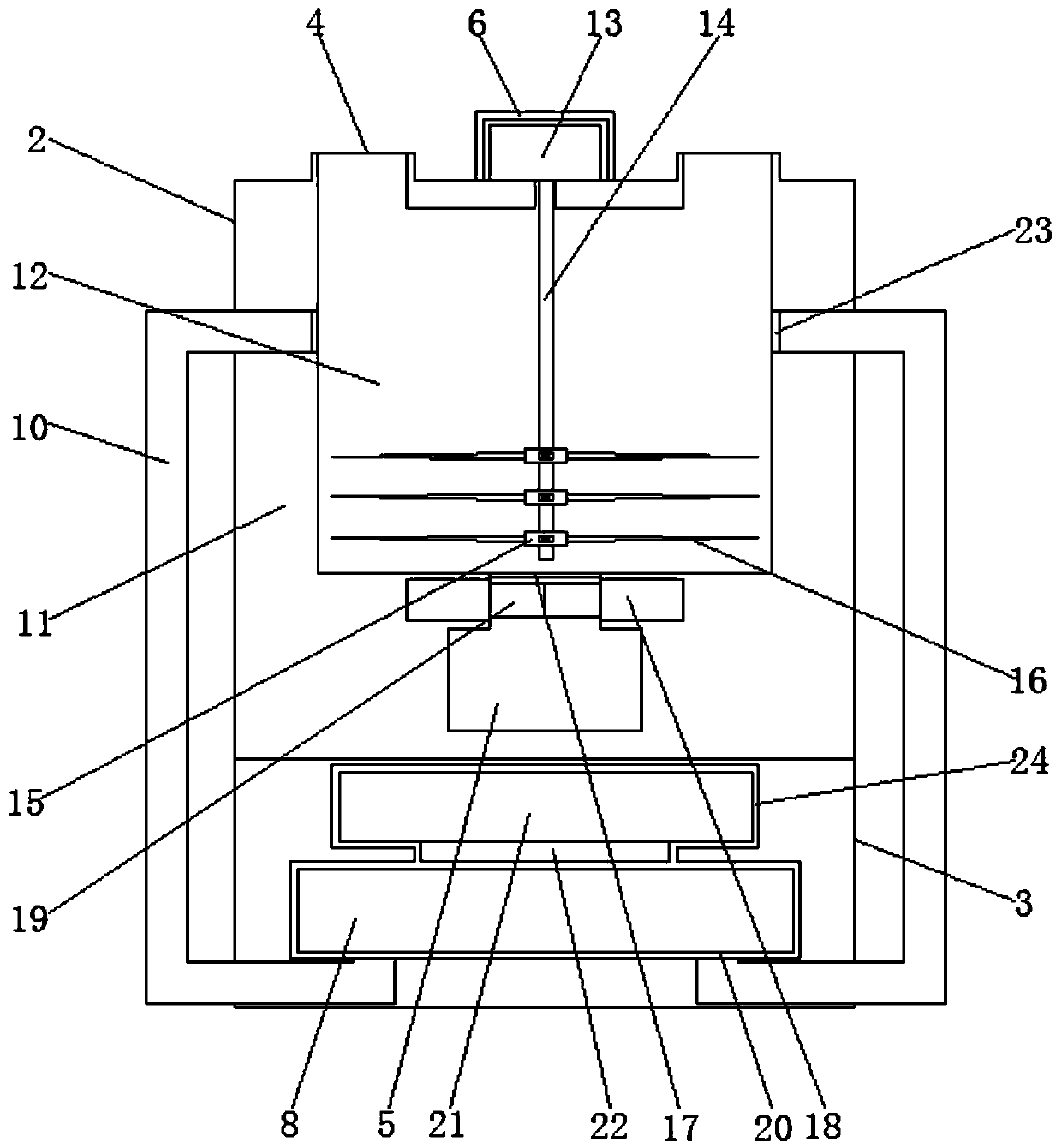

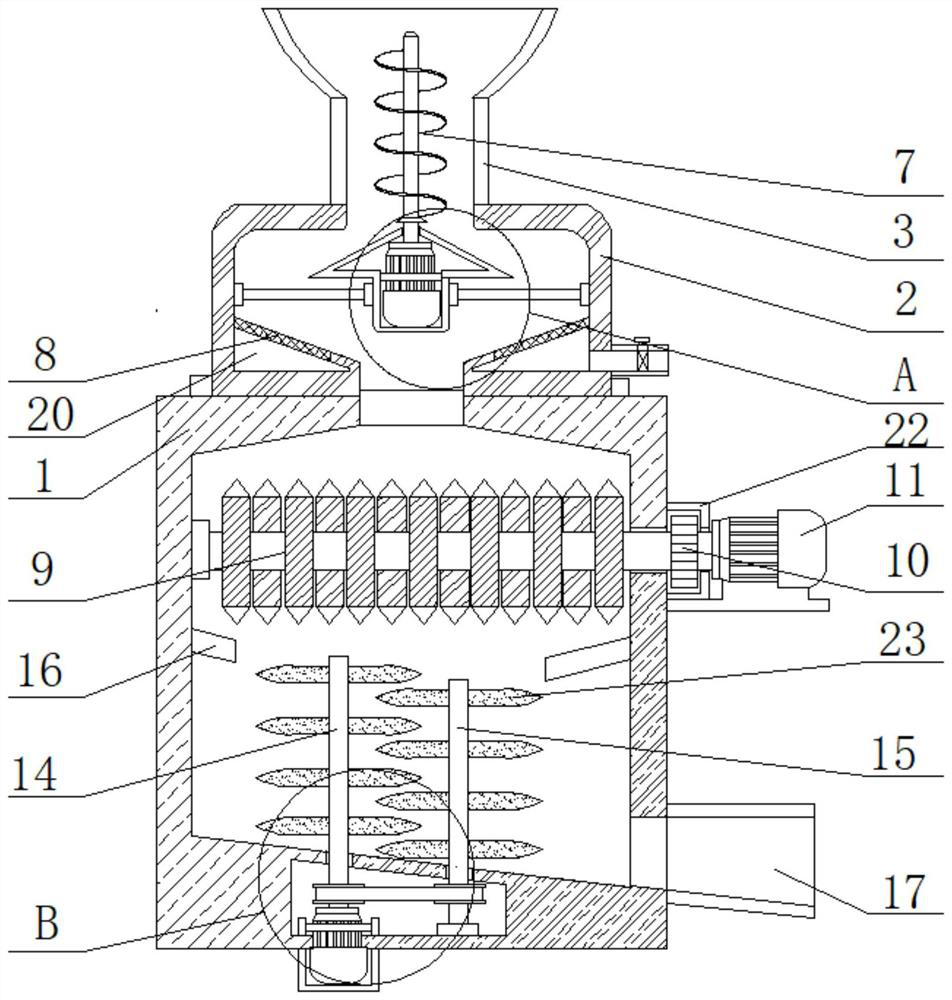

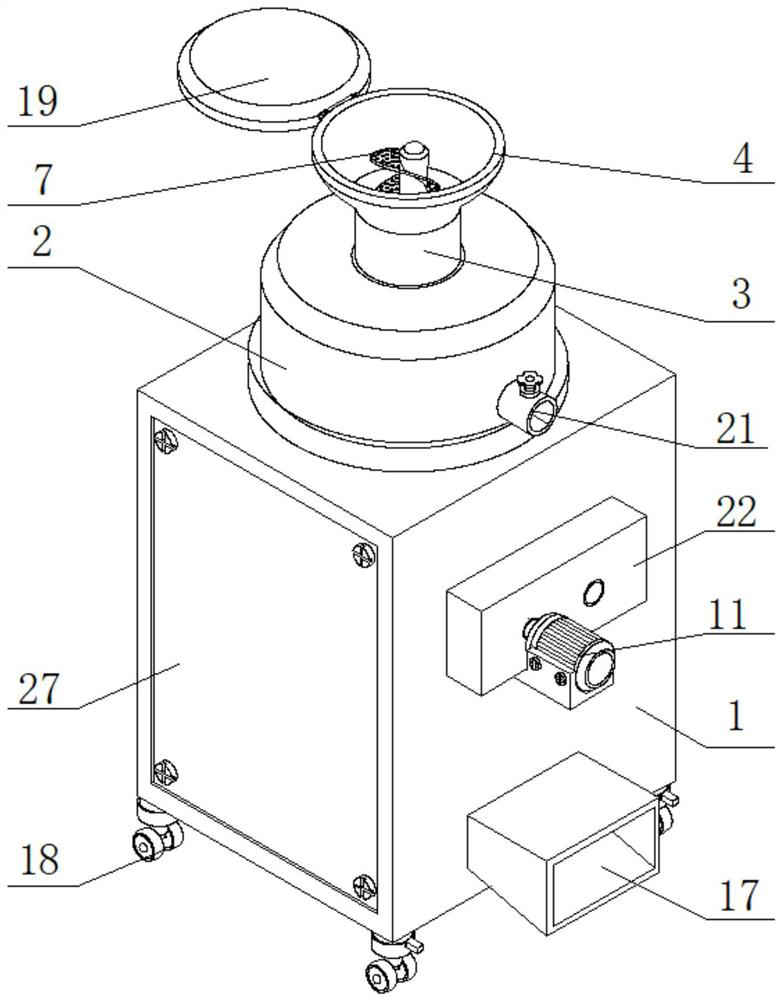

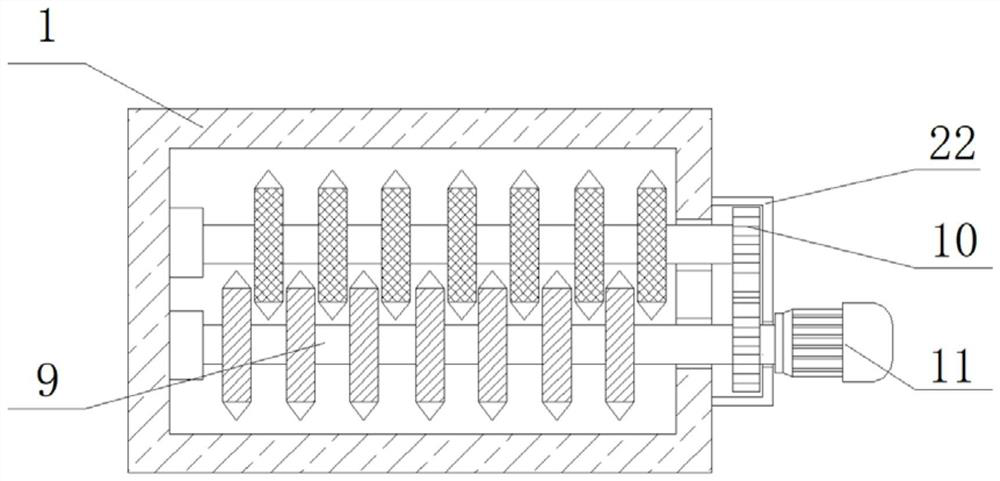

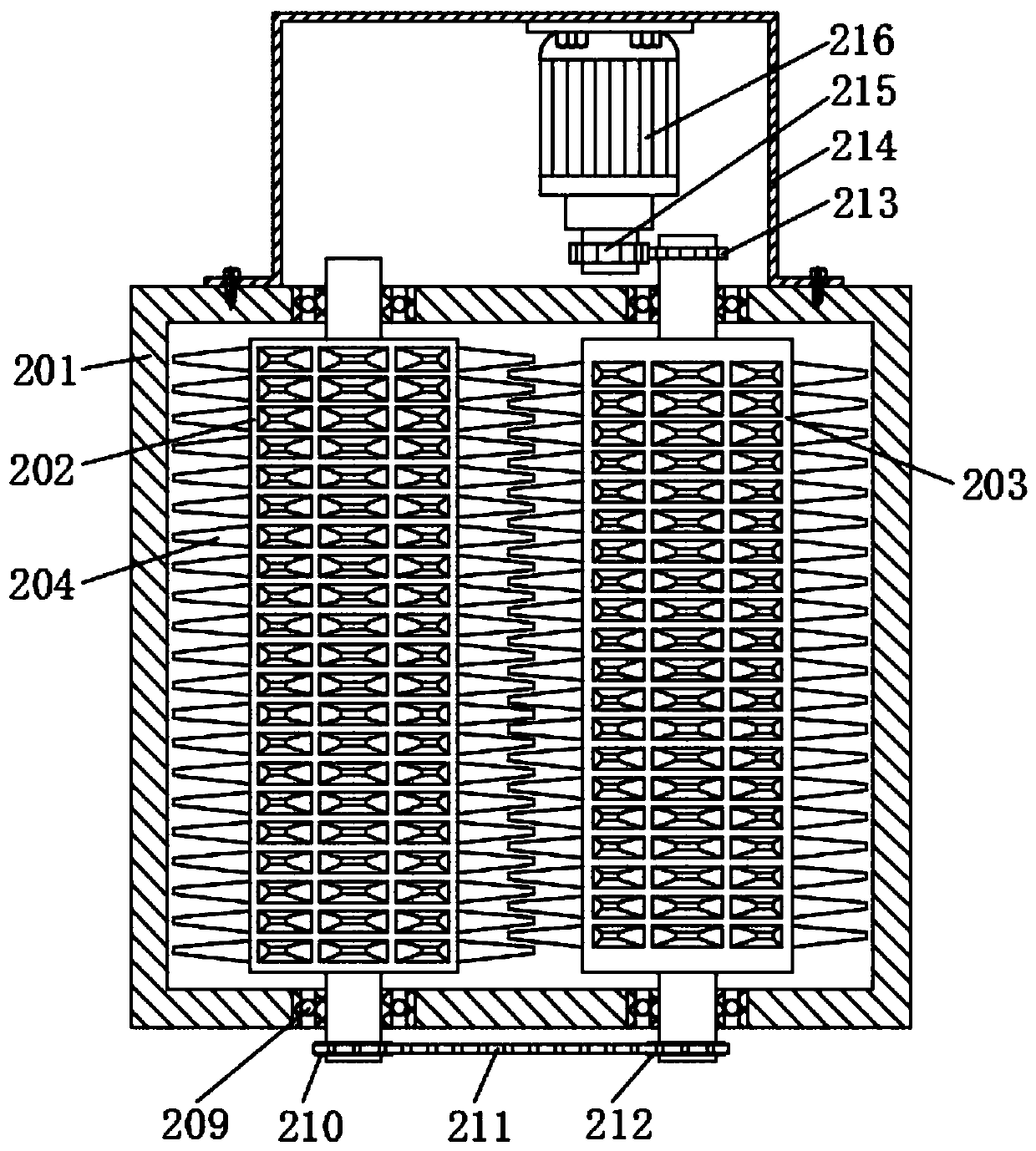

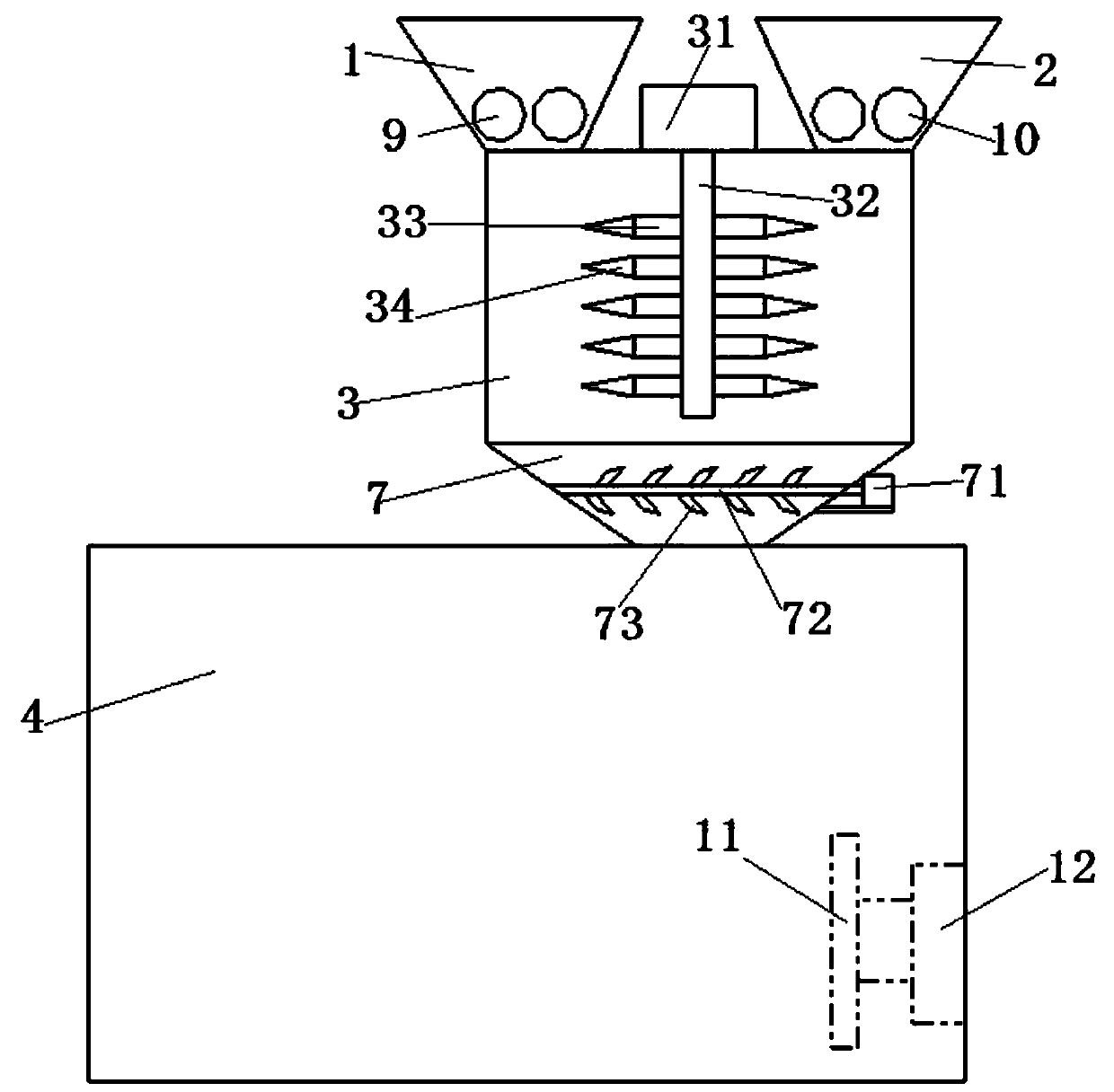

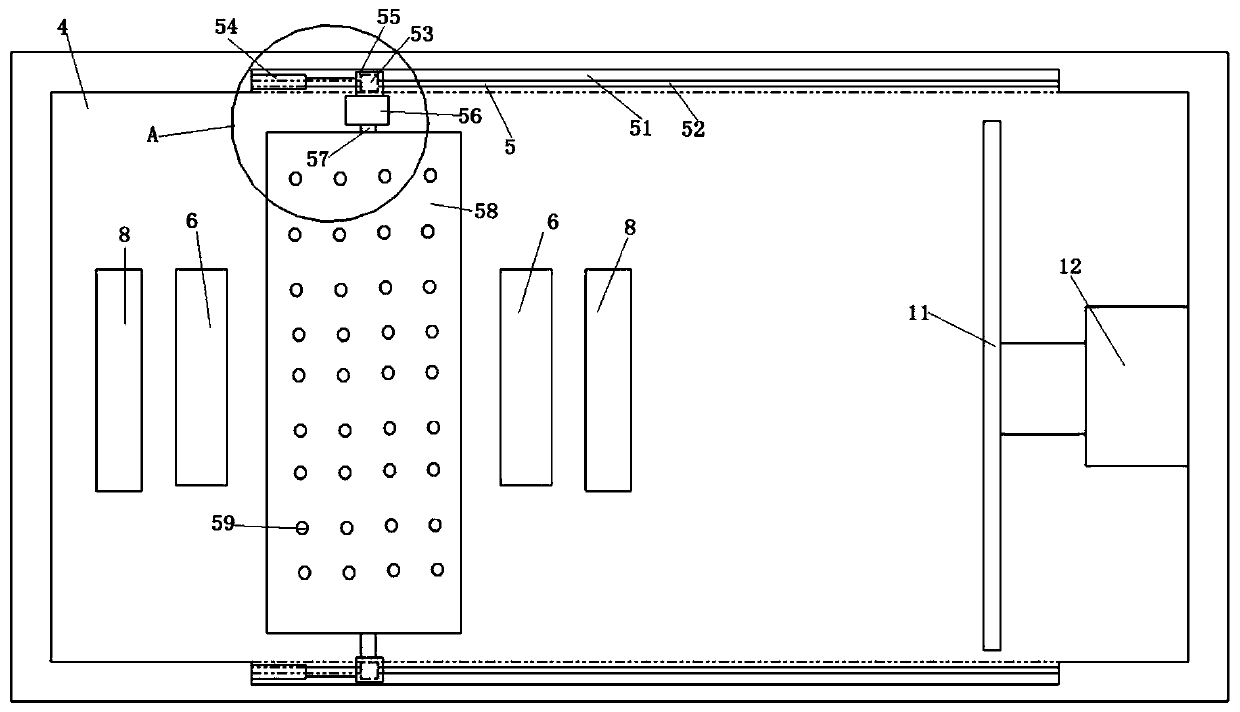

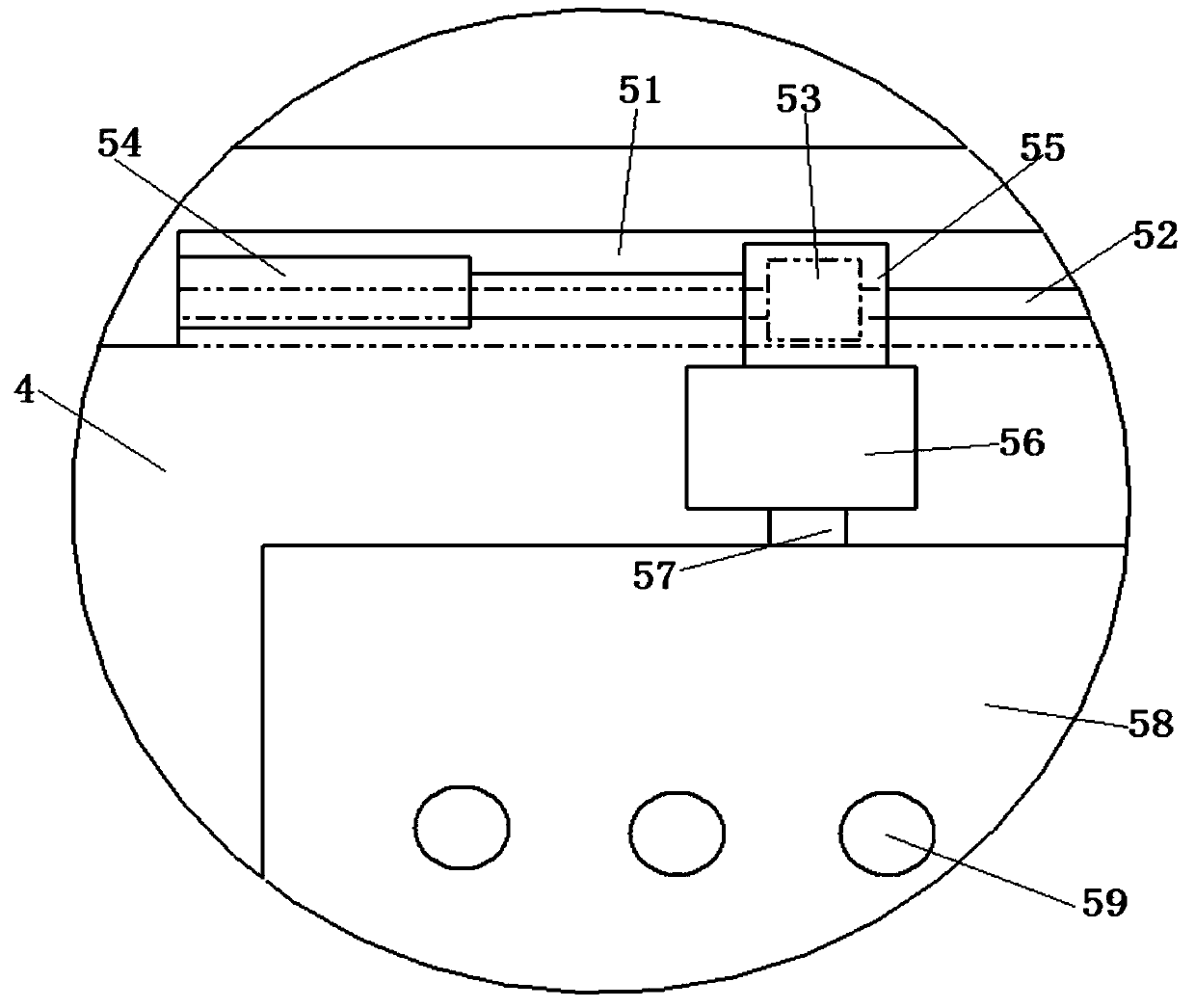

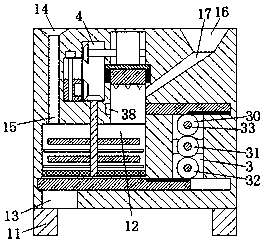

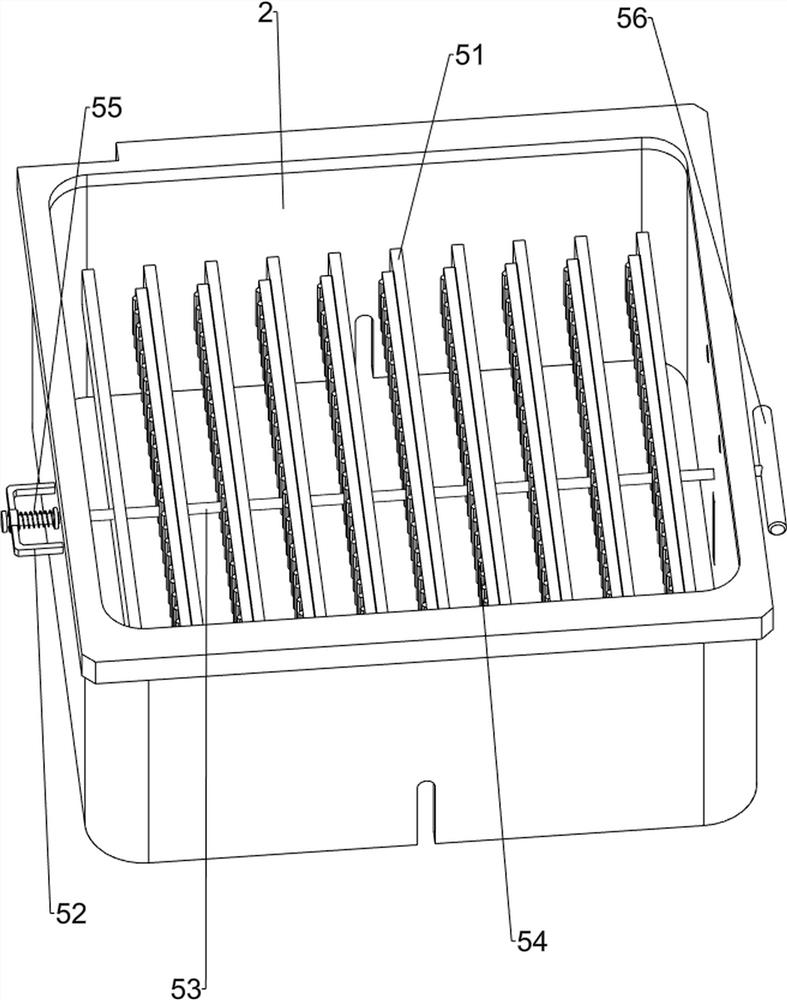

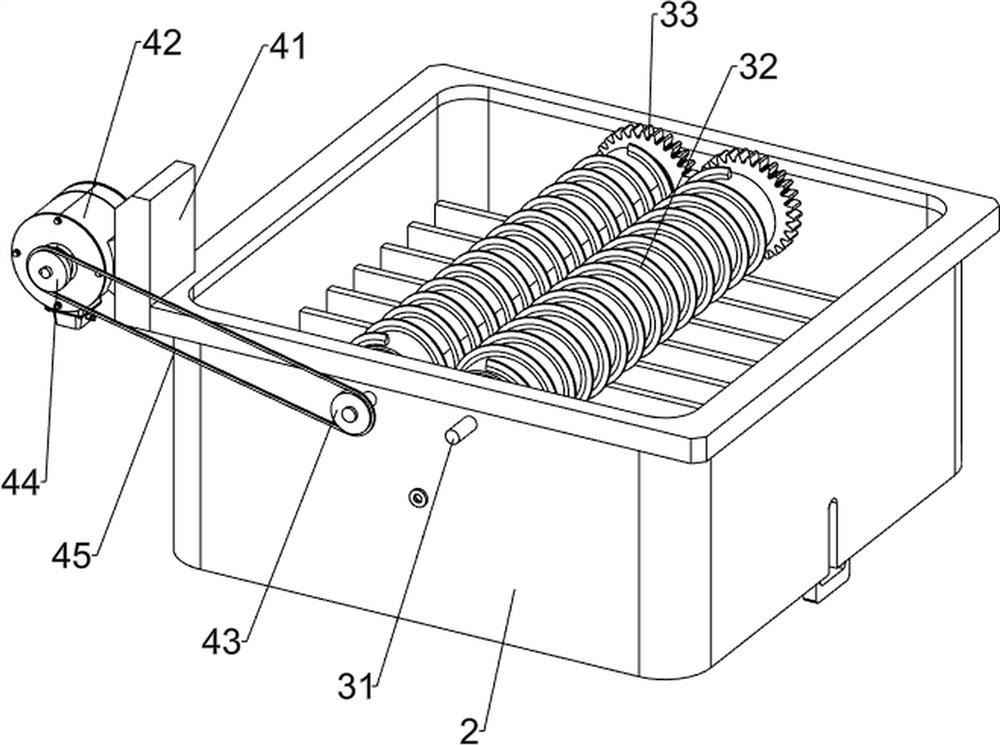

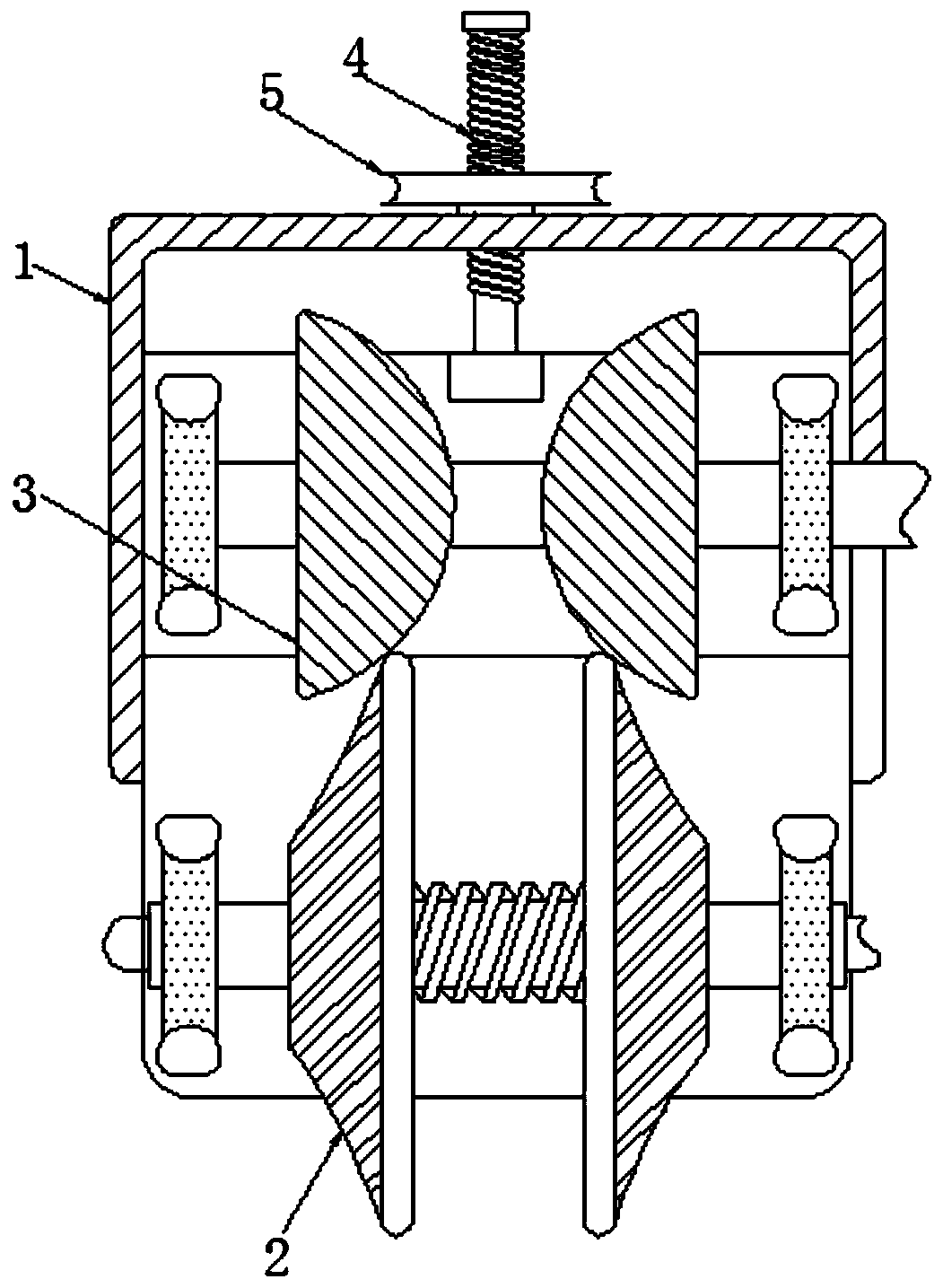

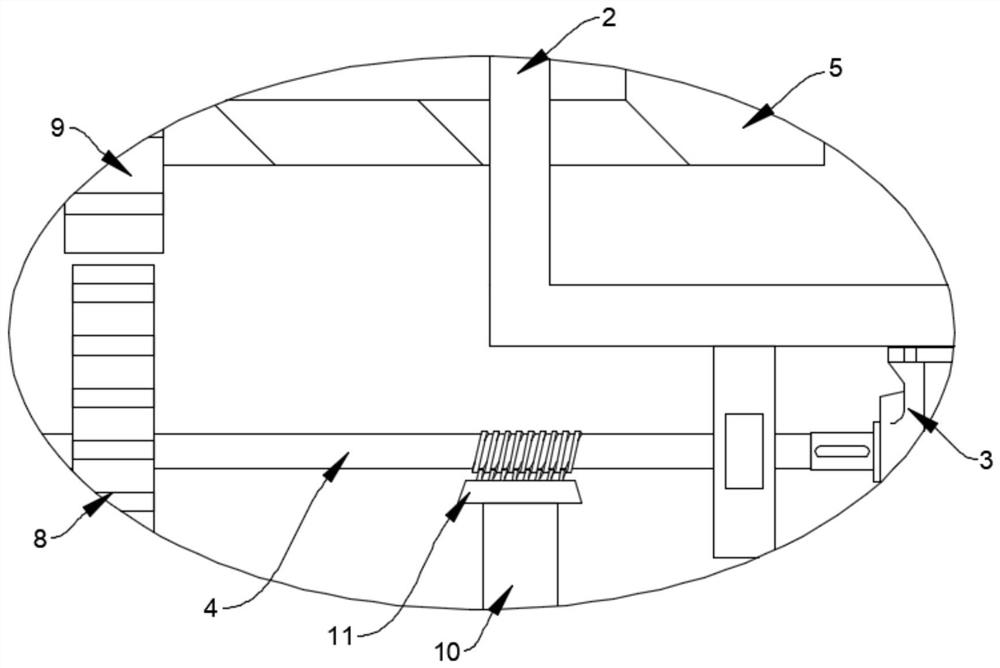

Traditional Chinese medicine crushing machine

ActiveCN107029841AEasy to controlConvenient crushing operationDrying gas arrangementsGrain treatmentsChinese drugMotor protection

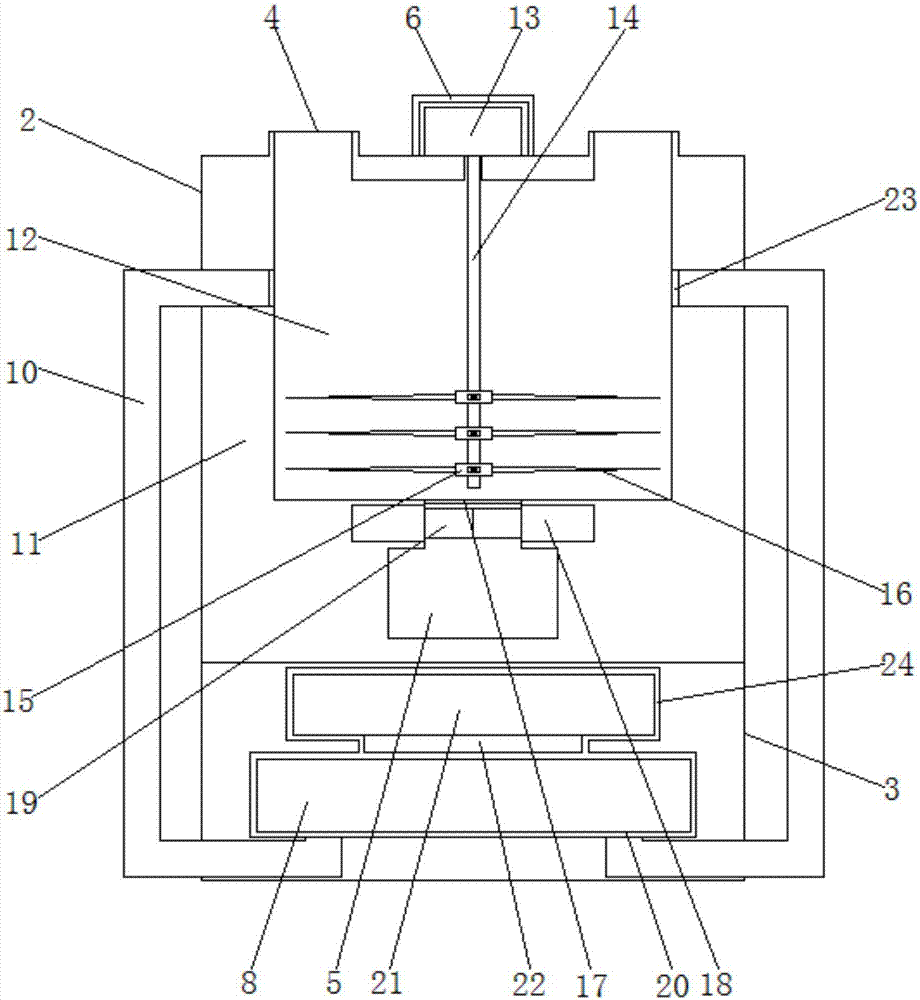

The invention discloses a traditional Chinese medicine crushing machine. The traditional Chinese medicine crushing machine comprises a traditional Chinese medicine crushing machine body, wherein the traditional Chinese medicine crushing machine body comprises a traditional Chinese medicine crushing device; a traditional Chinese medicine drying device is fixedly connected to the bottom of the traditional Chinese medicine crushing device; a traditional Chinese medicine charge pipe is fixedly communicated to the top of the traditional Chinese medicine crushing device; an inner shell is arranged in the traditional Chinese medicine crushing device; a traditional Chinese medicine crushing chamber is formed in the inner shell; the bottom of the traditional Chinese medicine charge pipe penetrates through the inner shell and communicates with the traditional Chinese medicine crushing chamber; and a motor protection cover is fixedly connected to the top of the traditional Chinese medicine crushing device. According to the traditional Chinese medicine crushing machine disclosed by the invention, traditional Chinese medicines in the traditional Chinese medicine crushing chamber are filtered through a filter plate, so that the crushing efficiency of the medicines is increased, only the crushed medicines can pass through the filter plate, the crushing force of the medicines is increased, uniform crushing for the traditional Chinese medicines is achieved, the crushing effect of the medicines is improved, the advantage of fine crushing is achieved, and then the problem of influence on a medicine manufacturing process due to the poor crushing effect of an existing traditional Chinese medicine crushing machine is effectively solved.

Owner:DAYA PHARMA HUIZHOU

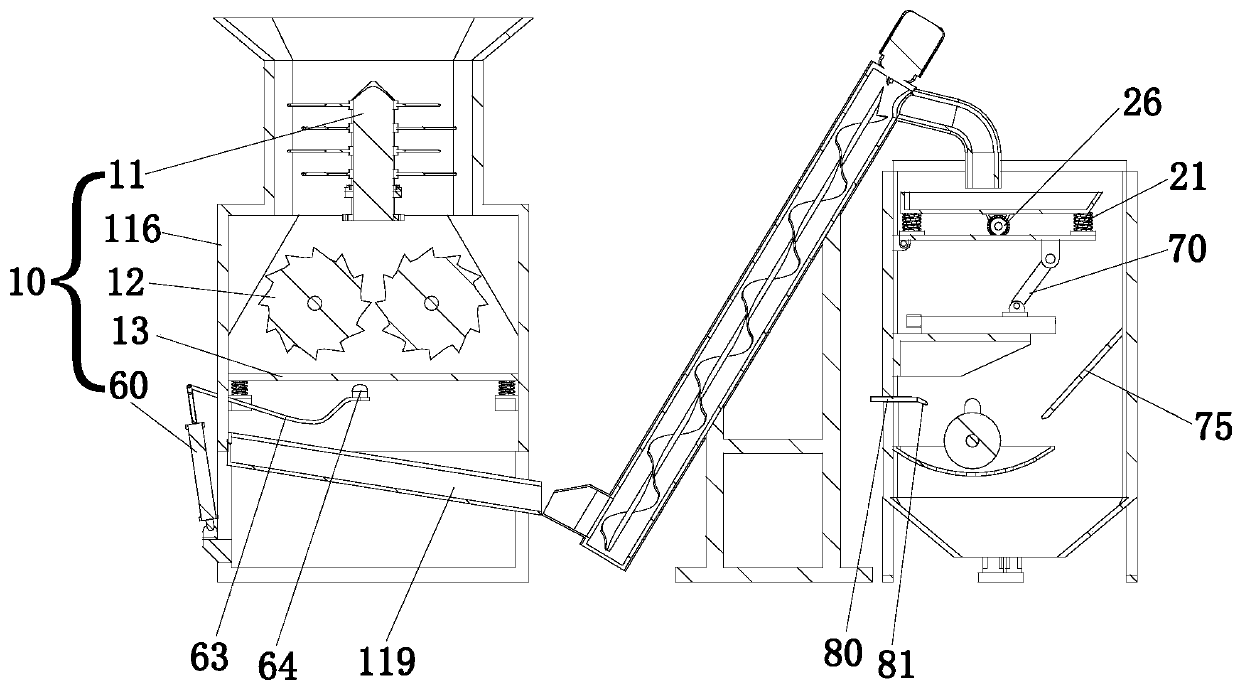

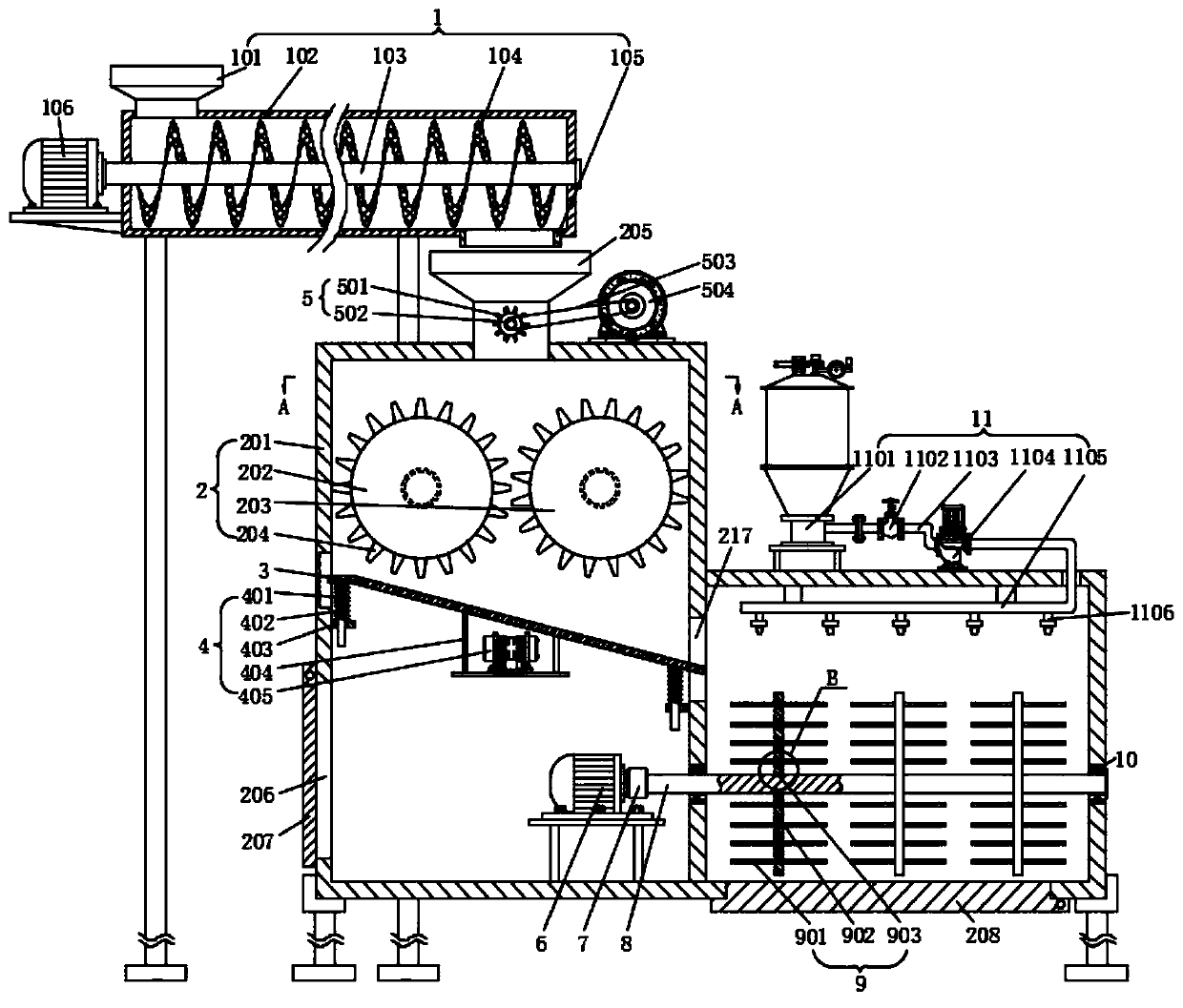

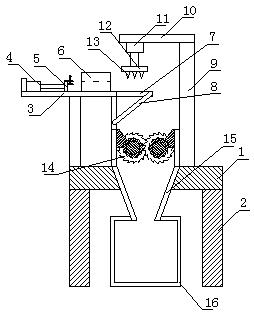

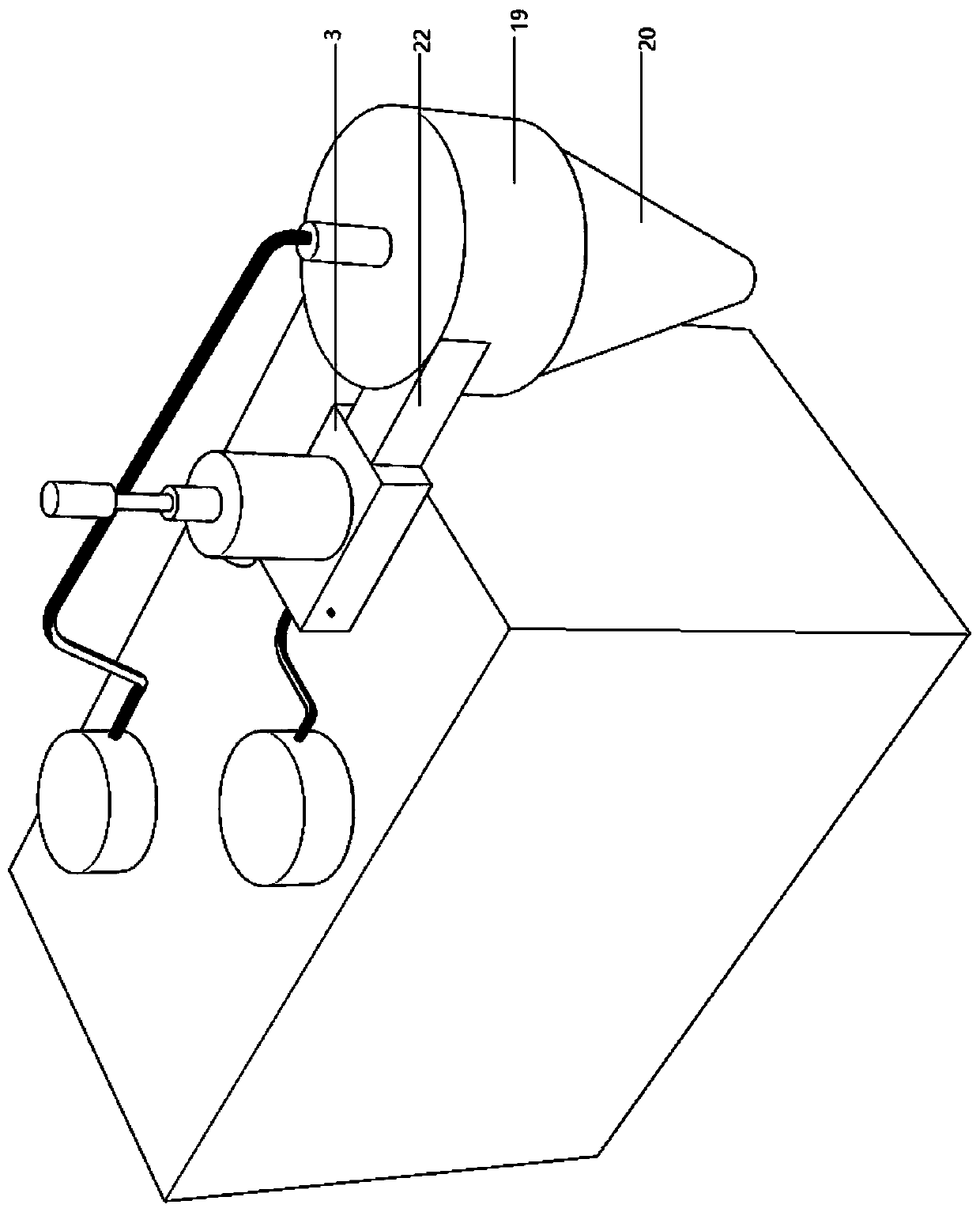

Organic fertilizer processing raw material efficient crushing equipment and application method thereof

InactiveCN107262207AConvenient crushing operationImprove crushing qualityCocoaGrain treatmentsDrive shaftEngineering

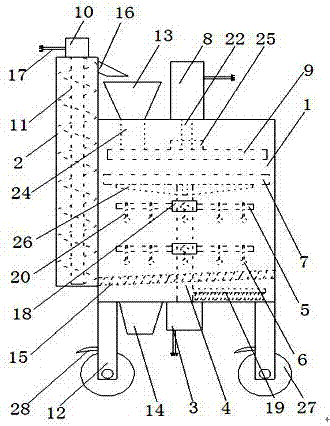

The invention discloses organic fertilizer processing raw material efficient crushing equipment which comprises a crushing chamber, a lifting barrel, a first motor, a transmission shaft, stirring rods, crushing blocks, a lower grinding disc, an air cylinder, an upper grinding disc, a second motor and a packing auger. The organic fertilizer processing raw material efficient crushing equipment is characterized in that the crushing chamber is arranged on supports; the lifting barrel is arranged on the outer wall of the crushing chamber; a discharging pipe is arranged at one end of the lifting barrel; the first motor is arranged on the crushing chamber; the transmission shaft is arranged in the crushing chamber; the stirring rods are arranged on connecting blocks; the lower grinding disc is arranged on the transmission shaft; the second motor is arranged at one end of the lifting barrel; and the packing auger is arranged in the lifting barrel. According to the organic fertilizer processing raw material efficient crushing equipment, the work efficiency is improved; the labor intensity of operators is reduced; the distance between the upper grinding disc and the lower grinding disc is adjusted, and therefore organic fertilizer raw materials can be crushed into particles of different sizes; the production needs of organic fertilizer of different types can be met; the application range of the crushing equipment is widened; and the crushing quality of the raw materials is further improved.

Owner:安徽乐农环保科技有限公司

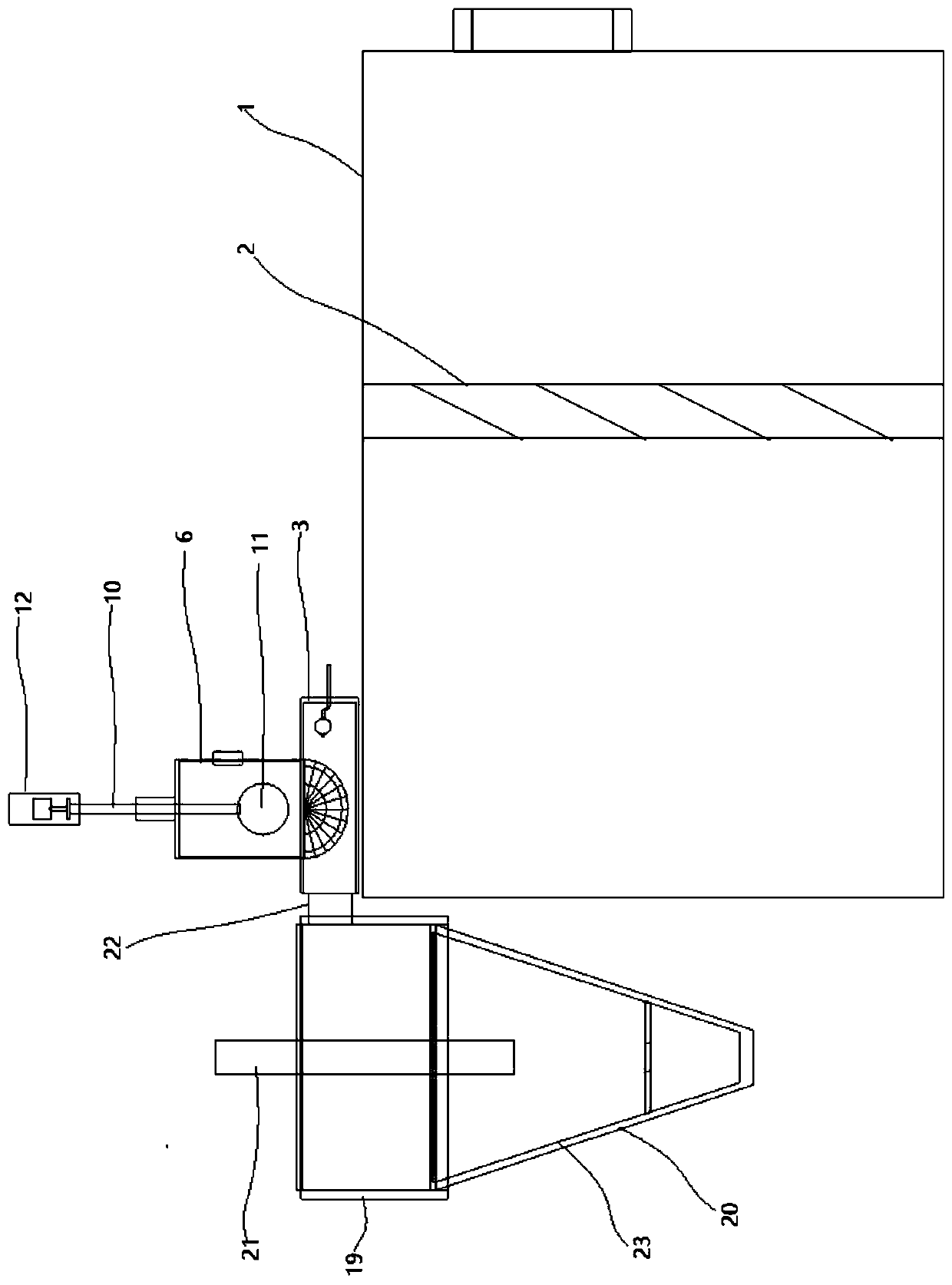

Organic fertilizer raw material crushing device and operation method thereof

InactiveCN107457043AImprove crushing qualityConvenient crushing operationCocoaGrain treatmentsElectric machineryEngineering

The invention provides a crushing device for organic fertilizer raw materials, comprising a crushing chamber, a feeding cylinder, a motor one, a transmission shaft, a stirring rod, a crushing block, a lower millstone, a cylinder, an upper millstone, a motor two and an auger, and is characterized in that: The crushing chamber is set on the bracket, the lifting cylinder is set on the wall of the crushing chamber, and a discharge pipe is arranged on one end of the lifting cylinder, the motor is set on the crushing chamber, and the The drive shaft is set in the crushing chamber, the stirring rod is set on the connecting block, the lower grinding disc is set on the drive shaft, the motor 2 is set at one end of the lifting cylinder, and the auger is set at the lifting Inside the barrel. In the present invention, an upper millstone is arranged on the piston rod of the cylinder, and a lower millstone is arranged on the transmission shaft of the motor one, and the organic fertilizer raw materials to be pulverized are transmitted to the upper millstone and the lower millstone through the feed bin, the feeding pipe, and the feed port. It is convenient to crush organic fertilizer raw materials and reduce labor intensity.

Owner:安徽乐农环保科技有限公司

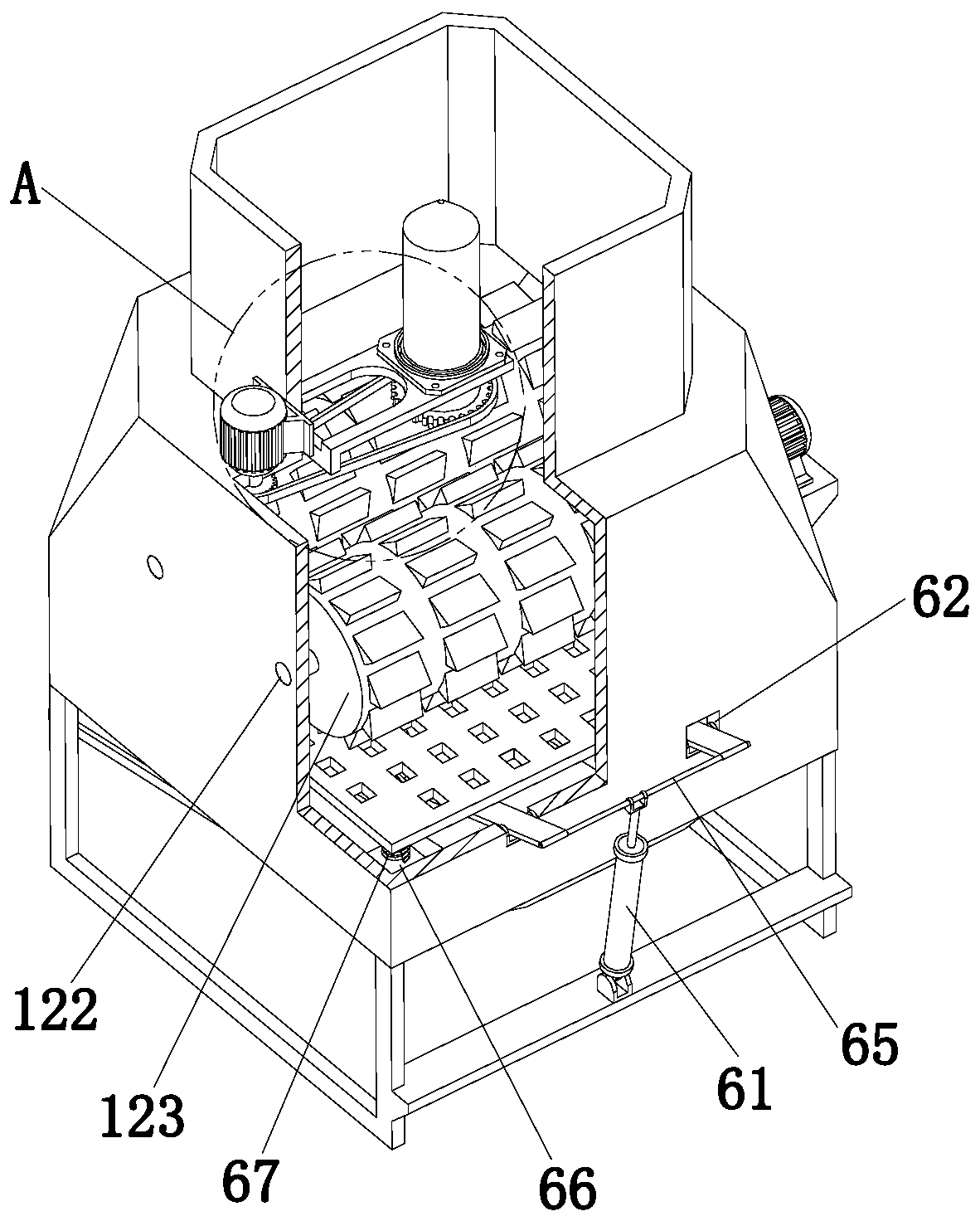

Fig fruit powder production device

The invention discloses a fig fruit powder production device, and belongs to the technical field of fig manufacturing. The fig fruit powder production device comprises a fruit crushing mechanism, a fruit particle drying mechanism, a feeding packing auger, a grinding cabinet and a fruit powdering and grinding mechanism, wherein the fruit crushing mechanism is provided with a cutting assembly, a crushing cabinet, a crushing assembly, a screening plate and a knocking vibration assembly; the top of the crushing cabinet is provided with a feeding hole and an anti-funnel; the bottom of the crushingcabinet is provided with a material conveying channel; the material conveying channel is provided with a water falling hole; the knocking vibration assembly comprises a driving air cylinder and two mounting grooves; a knocking rod is arranged in each mounting groove; a vibration hammer is arranged at the right end of each knocking rod; and a connecting rod is arranged between the left ends of thetwo knocking rods. According to the fig fruit powder production device, by knocking the vibration assembly, fig particles blocked in screening holes of a screening mesh can be vibrated out, the dryingoperation of figs can be realized through the fruit particle drying mechanism, and a drying box can be vibrated through a vibrating part, so that the figs positioned in the drying box are overturned.

Owner:义乌市昕闵日用品有限公司

Biomass fuel crushing device

InactiveCN111632672AImprove crushing effectConvenient crushing operationCrop conditionersMowersAcornAgricultural engineering

The invention discloses a biomass fuel crushing device. The biomass fuel crushing device comprises a crushing box. The crushing box is arranged in an acorn shape. The outer wall of one side of the crushing box is fixedly arranged with an air inlet pipe. A certain inclined angle is arranged between the air inlet pipe and the crushing box. A fan bracket is fixedly arranged on the inner wall of the air inlet pipe. A fan is fixedly arranged on one outer wall of the fan bracket. A first motor is fixed on the outer wall of the bottom of the crushing box, and one end of an output shaft of the first motor is fixedly provided with a crushing rod. The outer wall of the crushing rod is provided with a cutting blade, a crushing blade and a convoluted blade. The biomass fuel crushing device can repeatedly cut and crush agricultural and forestry wastes in an acorn-shaped crushing box, and use high-speed airflow to stir, so as to improve the crushing effect. The particles which meet the requirementsduring crushing can pass through a filter, while larger particles remain stay in the crushing box and continue to be crushed until the requirements are met. Compared with a traditional device, the crushing effect is better.

Owner:安徽华灿生物质燃料有限公司

Agricultural straw and weed smashing and fixed fermentation device

InactiveCN109089570AGood crushing effectImprove mixing efficiencyFeeding-stuffCuttersAgricultural engineeringAgriculture

The invention discloses an agricultural straw and weed smashing and fixed fermentation device, which comprises a supporting seat and universal wheels. The universal wheels are mounted on two sides ofthe bottom of the supporting seat through supporting rods respectively. A fermentation tank is mounted at the top of the supporting seat through supporting legs. One side of the supporting seat is movably connected to the fermentation tank through a movably-mounted pushing mechanism. The top of the fermentation tank is provided with a top port, a liquid inlet and a temperature gauge. A pressure plate is connected to the bottom of a seal cover plate through a piston rod at the end of a hydraulic cylinder. Two sides of the fermentation tank are provided with smashed material inlets respectively.Smashing rollers are mounted on one side of each guide chutes through a fixed support and a movable support. Each of the fixed supports and the movable supports is in transmission connection with a smashing motor corresponding to the penetration position of a corresponding smashing roller shaft, and a mixing mechanism is penetratingly arranged at the bottom of the fermentation tank. The device isgreat in smashing effect and thorough in material mixing, mixing efficiency is improved, material fermentation quality is guaranteed, convenience in feeding and discharging is achieved, and internalresidual waste is avoided.

Owner:李俊

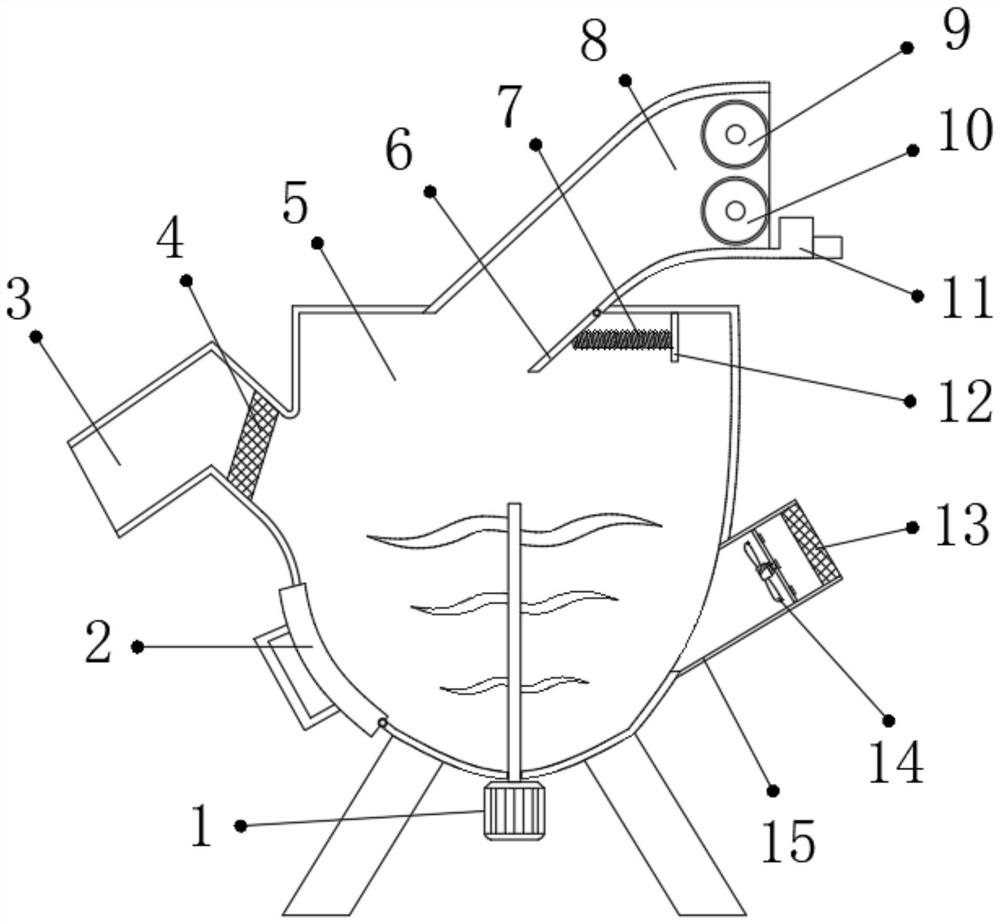

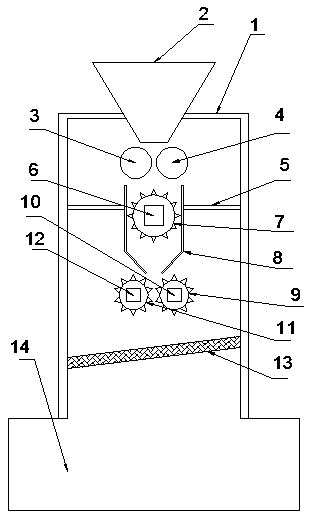

Garbage grading apparatus with rolling performance

The present invention relates to the field of garbage disposal. After the garbage is sent into the crushing box from the garbage inlet 2, the auxiliary motor in the box drives the left rolling cylinder 3 and the right rolling cylinder 4 to rotate, so as to realize the rolling treatment of garbage and reduce the volume of garbage. If the blockage device is too large, the crushed garbage will enter the cavity surrounded by the fixed vertical baffle 8, and the garbage will be crushed for the first time by the rotation of the main crushing roller 7, and the crushed garbage will go along the fixed vertical baffle. The formed inclined lower outlet is transported to the next crushing part. Due to the movement of the right crushing roller 9 and the left crushing roller 11, the second crushing operation of the garbage is completed, and the garbage that has completed a series of crushing operations falls into the lower garbage screen by gravity At 13 places, by the garbage screen 13, the required size of the garbage is sieved into the garbage collection box 14, and the garbage that does not meet the size is left in the screen to be taken out and crushed again to ensure that the collected garbage is the desired size.

Owner:CHENGDU ALI TECH CO LTD

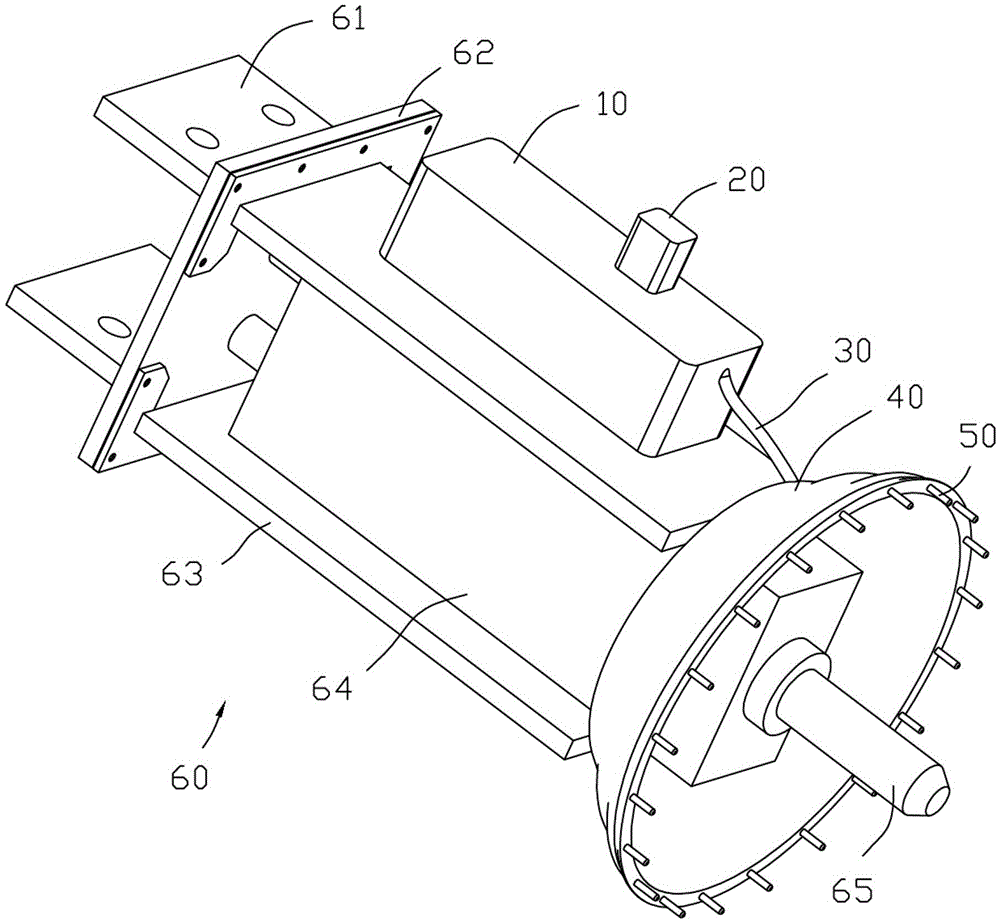

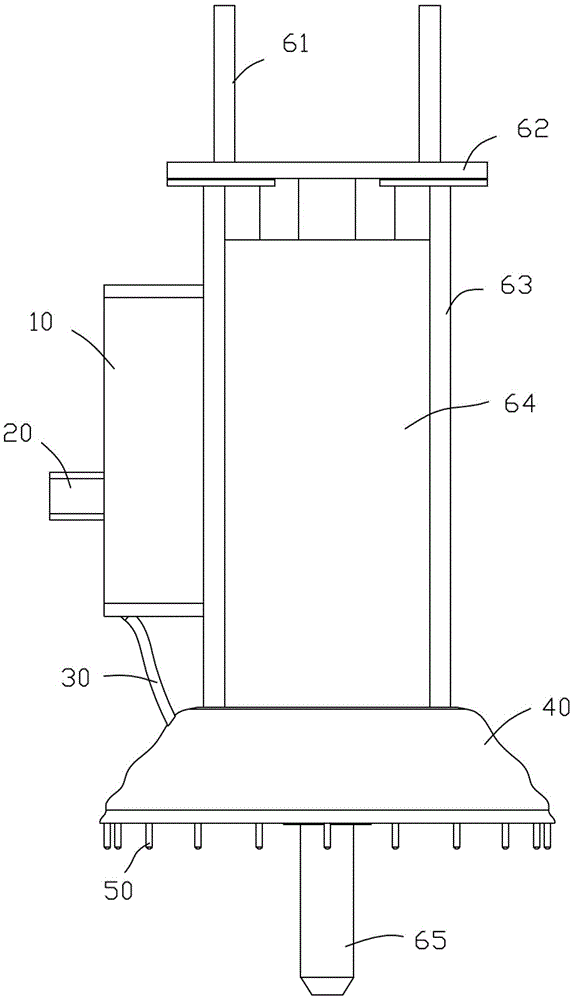

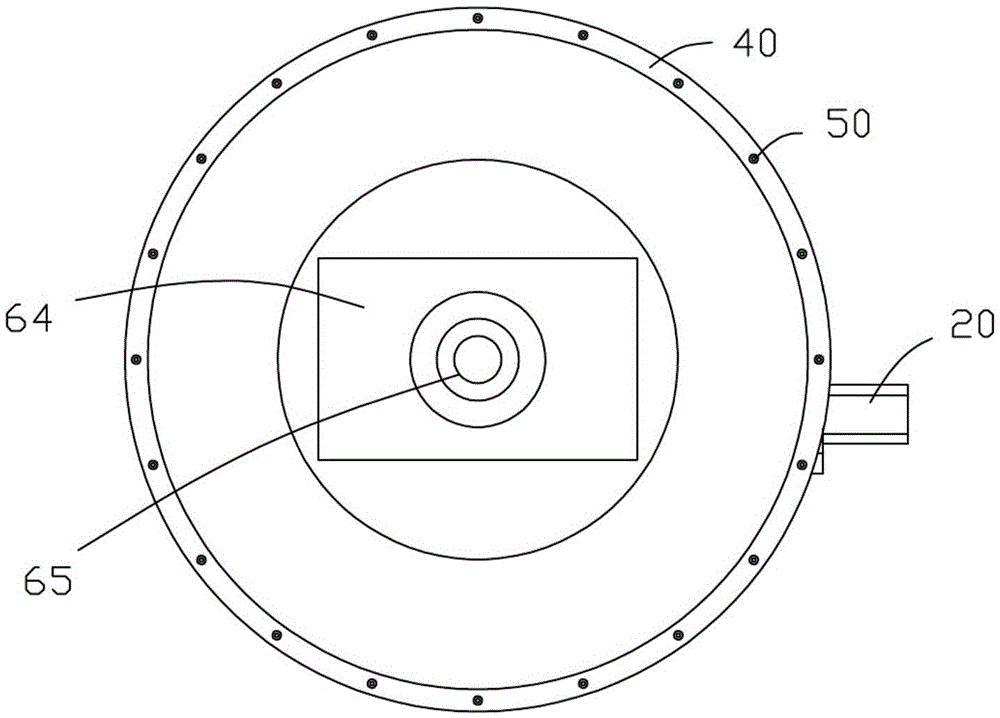

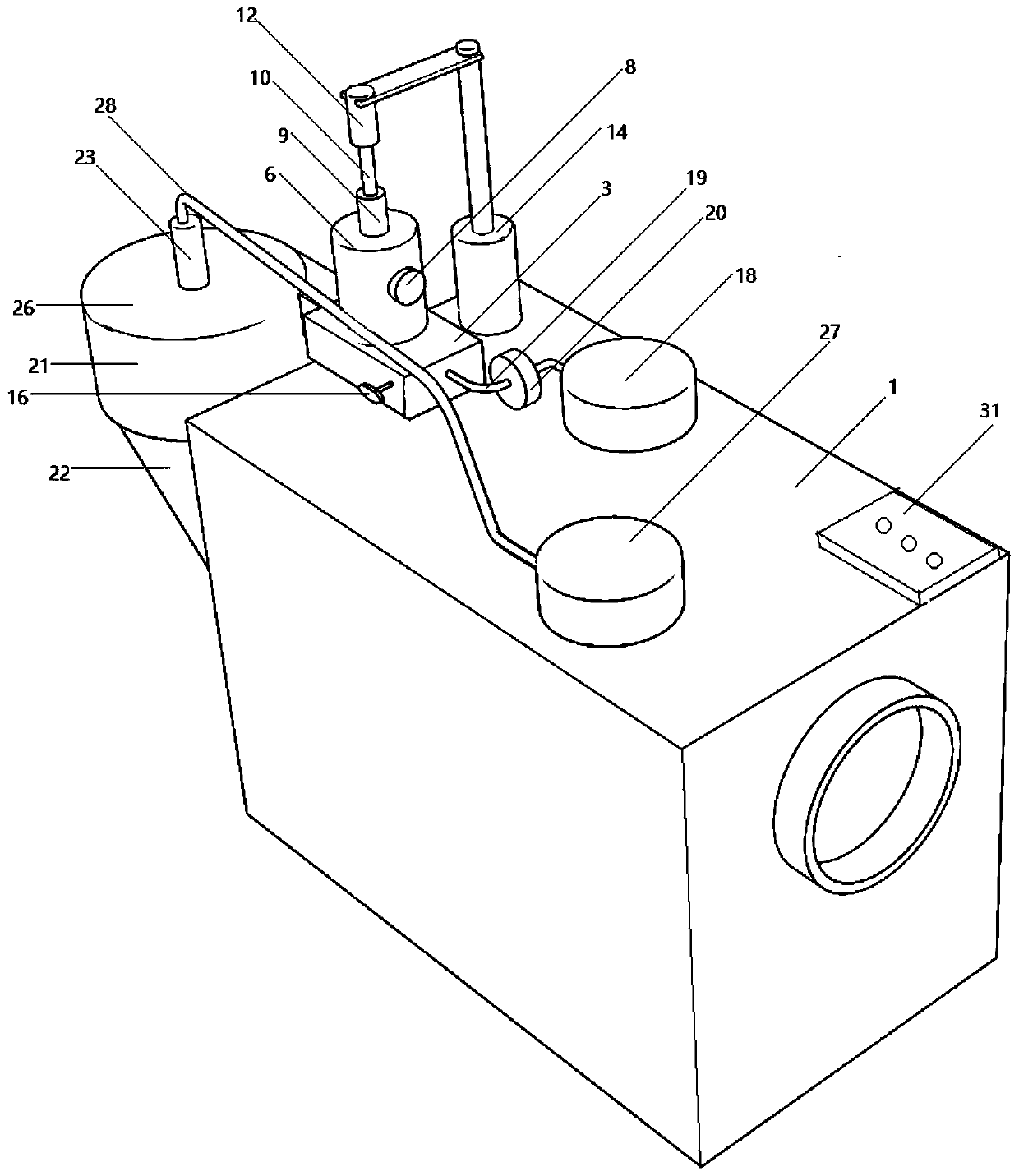

Anti-splattering device for breaking hammer

InactiveCN105625156AAvoid dustConvenient crushing operationBuilding repairsRoads maintainenceSpray nozzleWater pipe

The invention discloses an anti-splattering device for a breaking hammer. The anti-splattering device comprises the breaking hammer, a water tank, a motor, a water pipe, a dust cover and spray nozzles; side plates are arranged at the side of the breaking hammer, the water tank is mounted on the side plates, the motor is arranged at the side of the water tank, a breaking hammer body is arranged between the two side plates of the breaking hammer, the dust cover is mounted at the tail end of the breaking hammer body and fixed to the tail ends of the side plates, one end of the water pipe is connected with the water tank, the other end of the water pipe is connected with the dust cover, the dust cover is a bowl-shaped cover body, and multiple spray nozzles are arranged at the bottom of the dust cover and circumferentially arranged at the tail end of the dust cover. According to the anti-splattering device, a watering device is additionally mounted, through cooperation among the motor, the water tank, the bowl-shaped dust cover and the spray nozzles, water can be sprinkled to an object before the object is broken, raised dust and small broken stones are prevented, broken stones of large volume can also be blocked by the dust cover, and it is convenient to conduct breaking operation with the breaking hammer smoothly.

Owner:HUZHOU ZHONGCHEN CONSTR

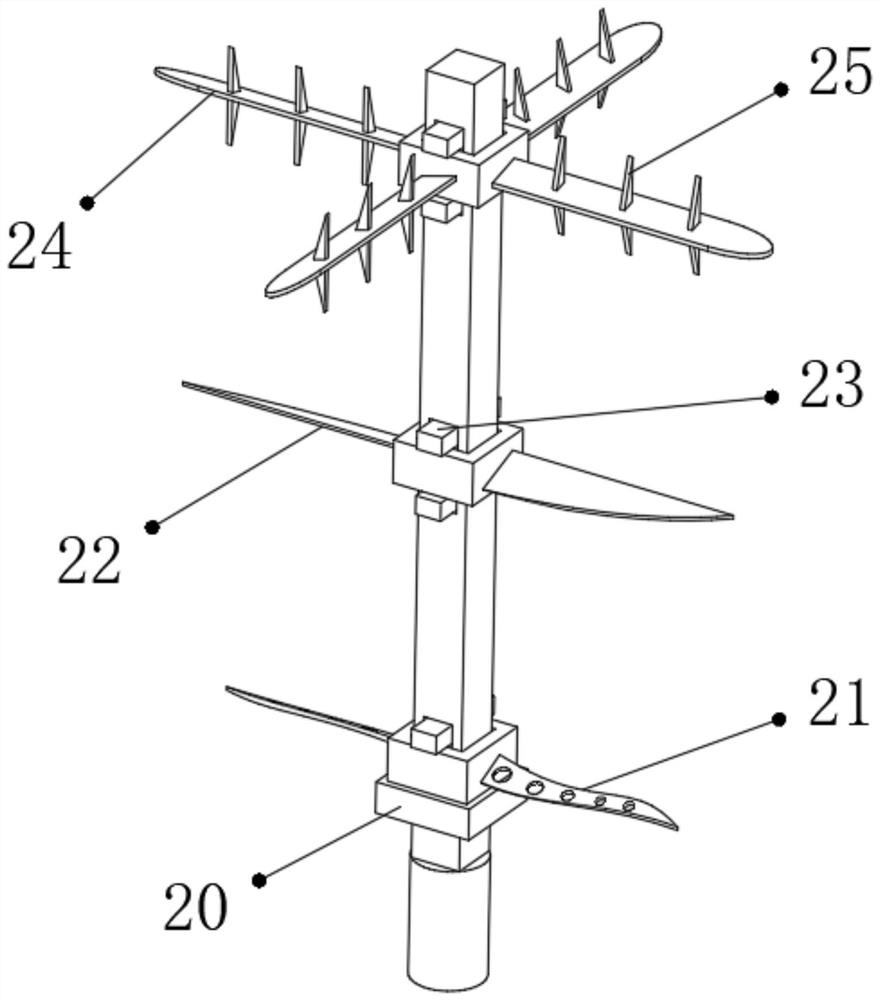

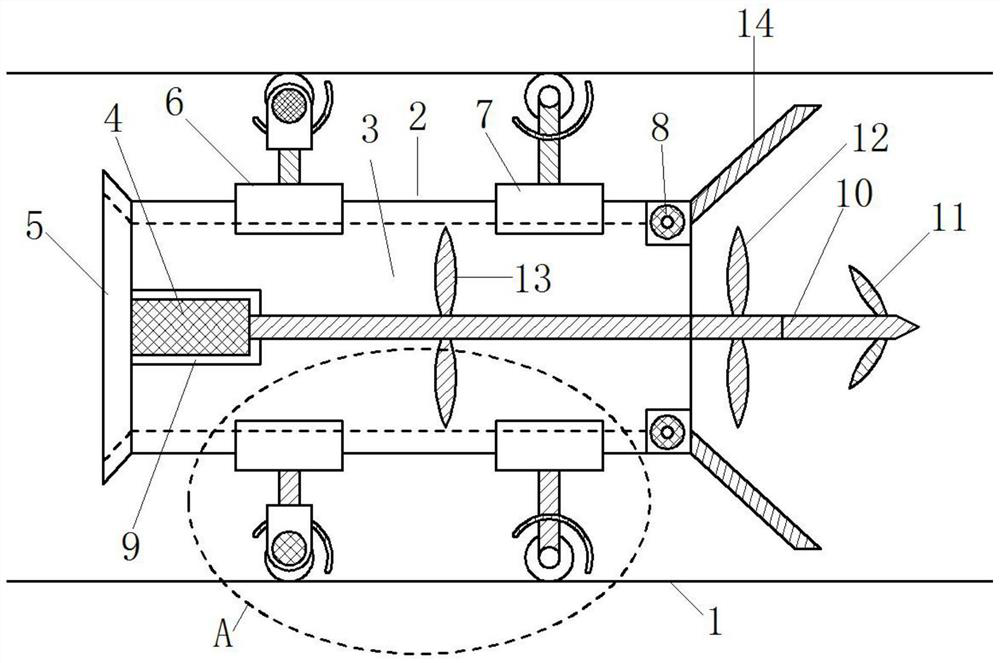

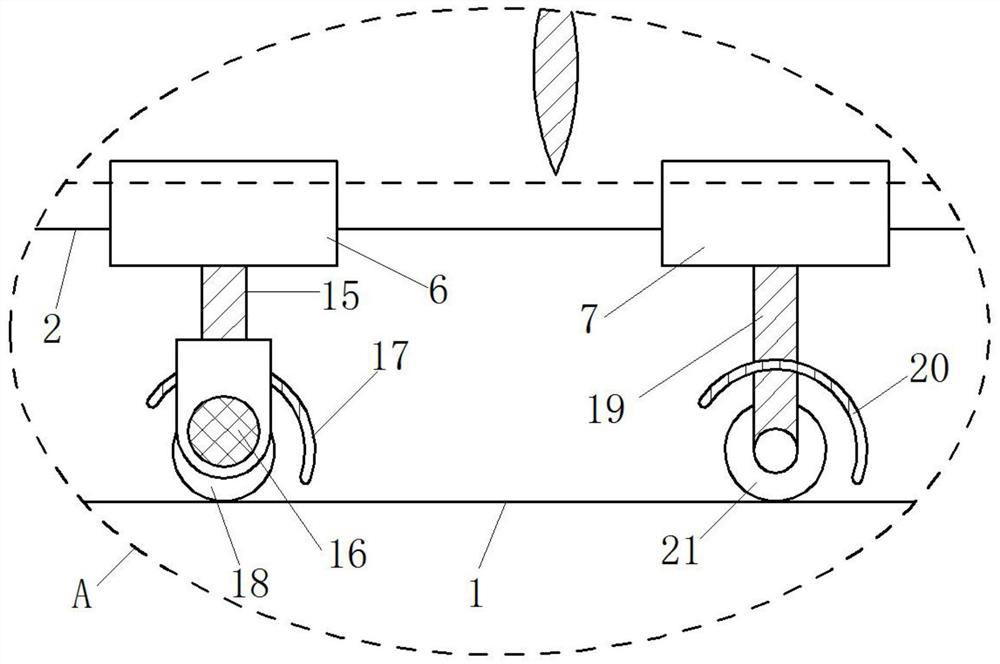

Walking and dredging mechanism device based on barrel-shaped pipeline dredging robot

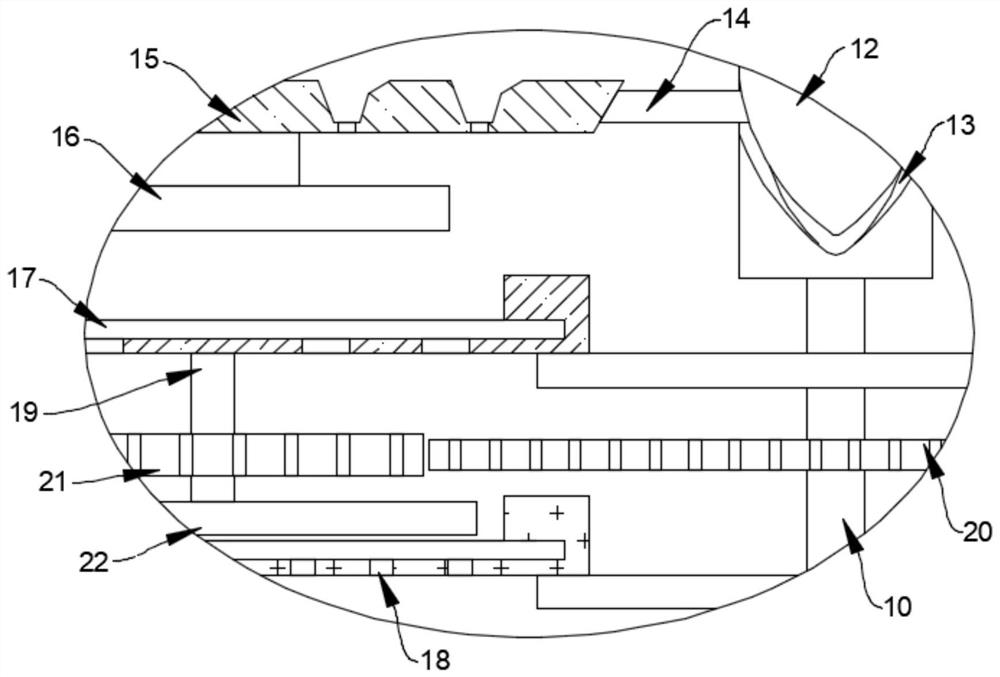

InactiveCN111705913AEfficient cleaning operationsConvenient crushing operationSewer cleaningDomestic plumbingDrive wheelControl engineering

The invention discloses a walking and dredging mechanism device based on a barrel-shaped pipeline dredging robot, and relates to the field of cleaning robot devices. In the walking and dredging mechanism device, a fifth drive power device is mounted on the end side of a second telescopic connecting rod mechanism; a drive wheel is mounted on the fifth drive power device; a walking wheel structure is mounted on the end side of a third telescopic connecting rod mechanism; multiple fourth rotating power devices are fixedly mounted at the open position of the end side of a crushing inner guide cavity; and an external connection flow baffle structure is connected to an output shaft of each fourth rotating power device. Multiple stirring blades are driven through a first rotating power device tocarry out sediment crushing operation from outside to inside, and clearing operation is efficiently carried out on blocked pipelines; and the drive wheel structure is arranged on the dredging robot, the corresponding walking wheel structure is arranged, and therefore drive and walking wheel supporting and adjusting operation can be carried out according to pipe diameters of pipelines, and power isprovided for advancing and retreating operation of the dredging robot.

Owner:泉州台商投资区钗旺机械设备设计室

A traditional Chinese medicine grinder

ActiveCN107029841BEasy to controlConvenient crushing operationDrying gas arrangementsGrain treatmentsCrusherTraditional medicine

The invention discloses a traditional Chinese medicine crushing machine. The traditional Chinese medicine crushing machine comprises a traditional Chinese medicine crushing machine body, wherein the traditional Chinese medicine crushing machine body comprises a traditional Chinese medicine crushing device; a traditional Chinese medicine drying device is fixedly connected to the bottom of the traditional Chinese medicine crushing device; a traditional Chinese medicine charge pipe is fixedly communicated to the top of the traditional Chinese medicine crushing device; an inner shell is arranged in the traditional Chinese medicine crushing device; a traditional Chinese medicine crushing chamber is formed in the inner shell; the bottom of the traditional Chinese medicine charge pipe penetrates through the inner shell and communicates with the traditional Chinese medicine crushing chamber; and a motor protection cover is fixedly connected to the top of the traditional Chinese medicine crushing device. According to the traditional Chinese medicine crushing machine disclosed by the invention, traditional Chinese medicines in the traditional Chinese medicine crushing chamber are filtered through a filter plate, so that the crushing efficiency of the medicines is increased, only the crushed medicines can pass through the filter plate, the crushing force of the medicines is increased, uniform crushing for the traditional Chinese medicines is achieved, the crushing effect of the medicines is improved, the advantage of fine crushing is achieved, and then the problem of influence on a medicine manufacturing process due to the poor crushing effect of an existing traditional Chinese medicine crushing machine is effectively solved.

Owner:DAYA PHARMA HUIZHOU

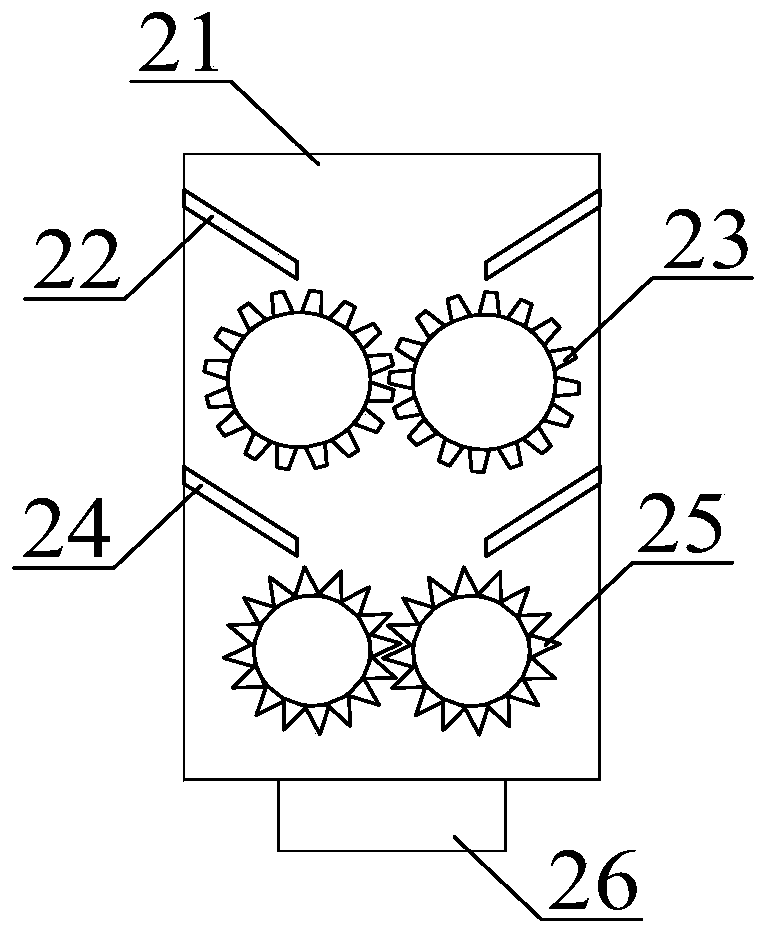

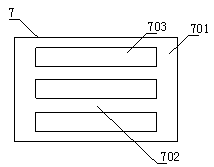

Industrial solid waste treatment device

The invention relates to the technical field of solid waste treatment, and discloses an industrial solid waste treatment device which comprises a box body. The upper surface of the box body is fixedlyconnected with a filter box, and the upper surface of the filter box is fixedly connected with a feeding pipe. According to the industrial solid waste treatment device, through the arrangement of structures such as the box body, a water storage cavity and feeding paddle, a first motor is started to drive the feeding paddle to rotate, so that waste in an arc-shaped funnel is conveyed into the boxbody, the feeding rate of the device is improved, and meanwhile the situation that the feeding pipe is blocked is avoided; through the arrangement of structures such as a filter plate, a drain pipe, the water storage cavity and a protective shell, waste can be effectively guided, and meanwhile part liquid in the waste is effectively filtered; through the arrangement of structures such as a secondmotor, a gear, smashing rollers and a rectangular shell, the second motor drives the gear to rotate, the gear drives the smashing rollers to rotate, and therefore the filtered waste can be further smashed through opposite rotation of the two smashing rollers.

Owner:ZHEJIANG QIANCHEN ECOLOGICAL ENVIRONMENTAL PROTECTION TECH CO LTD

Preparation method of enteromorpha health care beverage

InactiveCN106418076AGreat tasteRemove fishy smellNatural extract food ingredientsFood ingredient functionsYeastLycium barbarum fruit

The invention relates to a preparation method of an enteromorpha health care beverage. The preparation method comprises the following steps: (1) washing enteromorpha and drying and grinding enteromorpha, thus preparing enteromorpha powder; (2) weighing the enteromorpha powder, hawthorn fruit, gingers, dried yeast powder, distiller's grains, roses, flowers of kudzuvine, sweet osmanthus flowers, rock sugar, chamomile, forget me not, barbary wolfberry fruit, Pu'er tea, dwarf lilyturf tuber, dried tangerine peel, honey and sodium benzoate according to a ratio; (3) fermenting steamed enteromorpha, hawthorn fruit and gingers; (4) decocting the roses, the flowers of kudzuvine, the sweet osmanthus flowers and the rock sugar with slow fire until thick juice is obtained; (5) soaking chamomile, forget me not, barbary wolfberry fruit, Pu'er tea, dwarf lilyturf tuber and dried tangerine peel at 70-80 DEG C and collecting a soak solution; (6) carrying out filling and sealing. The preparation method has the advantages that not only can wastes be turned into wealth but also the prepared enteromorpha health care beverage has the health care effects of harmonizing blood and nourishing the stomach, soothing the liver and relieving depression, enriching and nourishing blood, strengthening muscles and bones, nourishing and enhancing the immunity.

Owner:NORTH CHINA SEA ENVIRONMENTAL MONITORING CENT OF STATE OCEANIC ADMINISTATION

Chemical dissolving device for reduction, recycling and harmless treatment of sludge

PendingCN111453952AHigh degree of mechanizationLow costShaking/oscillating/vibrating mixersSludge treatmentSludgeProcess engineering

The invention discloses a chemical dissolving device for reduction, recycling and harmless treatment of sludge, belonging to the technical field of sludge treatment. The chemical dissolving device comprises a crushing assembly and a conveying assembly, wherein the conveying assembly comprises a feeding shell; a feeding cylinder is arranged at the upper end of the feeding shell; a discharging cylinder is arranged at the bottom of the right side of the feeding shell; the discharging cylinder is positioned right above a hopper; the hopper is arranged at the center of the top of a case body; a material stirring assembly is arranged in the hopper; a driven crushing roller and a driving crushing roller are arranged in the case body; a material guiding plate is obliquely and movably arranged below the case body; the right end of the material guiding plate is located in a discharging port; a vibration assembly is arranged at the bottom of the material guiding plate; a stirring rotating shaft is arranged on the right side of the discharging port; a combined stirring assembly is arranged on the stirring rotating shaft; and a dosing assembly is arranged above the combined stirring assembly. According to the invention, automatic feeding operation of river sludge can be realized, crushed sludge and a sludge treatment chemical are fully mixed and uniformly stirred, the waste of the sludge treatment chemical is avoided, and sludge treatment cost is reduced.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

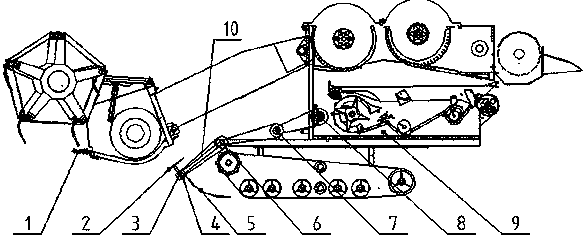

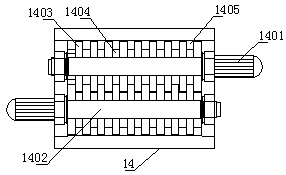

Secondary cutting and crushing device for combine harvester

The invention relates to the technical field of agricultural machines, in particular to a secondary cutting and crushing device for a combine harvester. A crushing blade is arranged in a gear box through a crushing cutter shaft; a first bevel gear, a second bevel gear, transmission gears, a first transition gear and a second transition gear are all positioned in the gear box; the bottom of the crushing cutter shaft is connected with the transmission gears, wherein a first transition gear and a second transition gear are arranged between every two adjacent transmission gears. Specifically, onetransmission gear is driven by the second bevel gear, the second bevel gear and the first bevel gear are engaged, and the first bevel gear is driven by a transmission sprocket. The secondary cutting and crushing device for the combine harvester realizes the opposite rotation direction of the adjacent crushing blades, the design is favorable for balancing the vibration of the cutter group, vibration is lowered and the service life of the crushing device is prolonged; at the same time, the two adjacent crushing blades form a pair of opposite rotations, which is beneficial to the crushing operation of the stem; the purpose of secondary cutting of the stem after the primary cutting of the plant can be completed, and meanwhile the purposes of pulverizing and field returning can be achieved.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

Rolling fineness pulverizer

The invention discloses a rolling fineness pulverizer, which includes a first crushing box. A first feeding hopper and a second feeding hopper are arranged on both sides of the upper end of the firstcrushing box in a communication mode correspondingly, a second crushing box is arranged at the lower end of the first crushing box in a communication mode through a first discharging hopper, the second crushing box is internally provided with a moving rolling assembly, and moving loose assemblies are distributed on the left side and the right side of the moving rolling assembly correspondingly; amoving shifting assembly is arranged between each moving loose assembly and the moving rolling assembly, the moving shifting assemblies and the moving loose assemblies are all connected with an uppertop plate of the second crushing box, and the moving rolling assembly is connected with a rolling barrel; and the moving rolling assembly is used for driving the roller barrel to roll and crush materials in the second crushing box, the moving loose assemblies are used for loosening the materials rolled by the roller barrel, and the moving shifting assemblies are used for shifting and paving the materials loosened by the moving loose assemblies. The rolling fineness pulverizer is not facilitated full crushing of different materials.

Owner:ANHUI FUYANG SHENGDA MACHINERY CO LTD

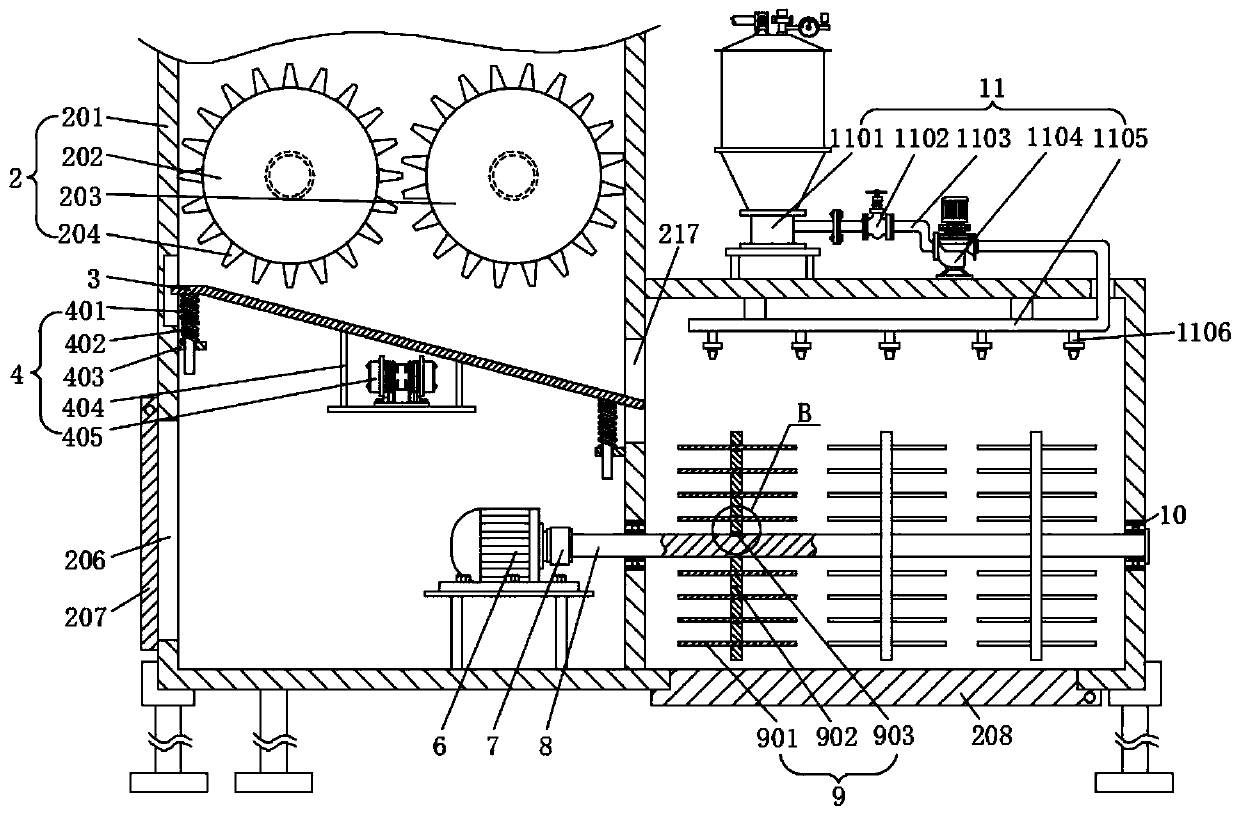

Equipment for water treatment materials

InactiveCN108499478AConvenient crushing operationSafe and convenient crushing operationRotary stirring mixersTransportation and packagingMixing chamberWater treatment

The invention discloses equipment for water treatment materials. The equipment comprises a seat body with supporting columns, a stirring mixing chamber is arranged in the seat body, the left side of the bottom end wall of the stirring mixing chamber is provided with a discharging tank extending downwards and communicating with the bottom of the seat body, the right side of the top end wall of thestirring mixing chamber is provided with a crushing tank extending upwards, the part, located on the left side of the crushing tank, of the interior of the seat body is provided with an adjusting tank, a driving tank is arranged in the left end wall of the adjusting tank, a first groove is arranged in the left side of the top end surface of the seat body, and a second groove is arranged in the right side of the top end surface of the seat body. The equipment disclosed by the invention has reasonable overall structural design, can automatically realize processing of a water treatment material mixture, greatly increases processing efficiency of the water treatment material mixture, increases processing quality of the water treatment material mixture, effectively improves the using effect ofthe water treatment material mixture, has simple and convenient processing operation, and greatly reduces labor costs.

Owner:福州市汇合兴机械设备有限公司

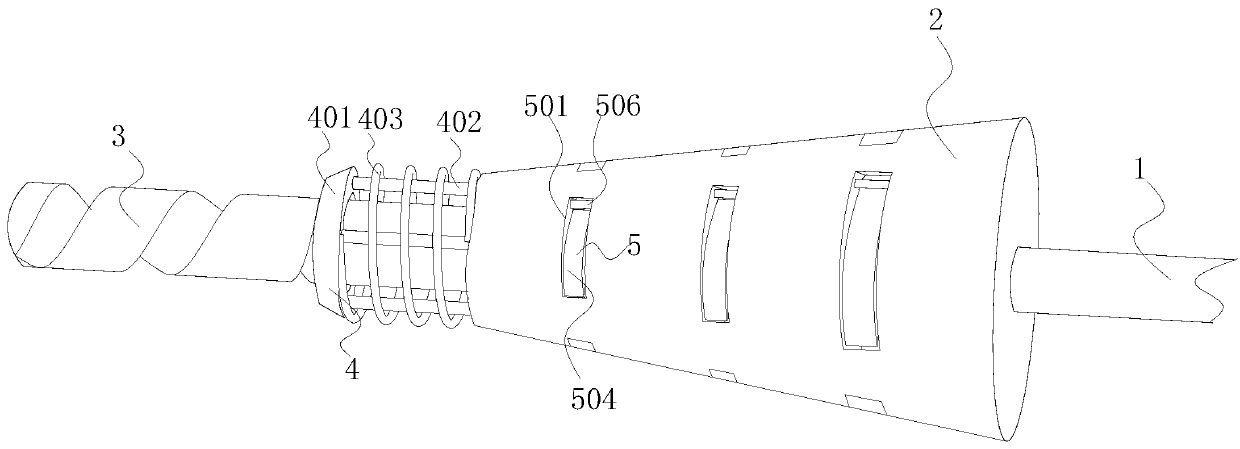

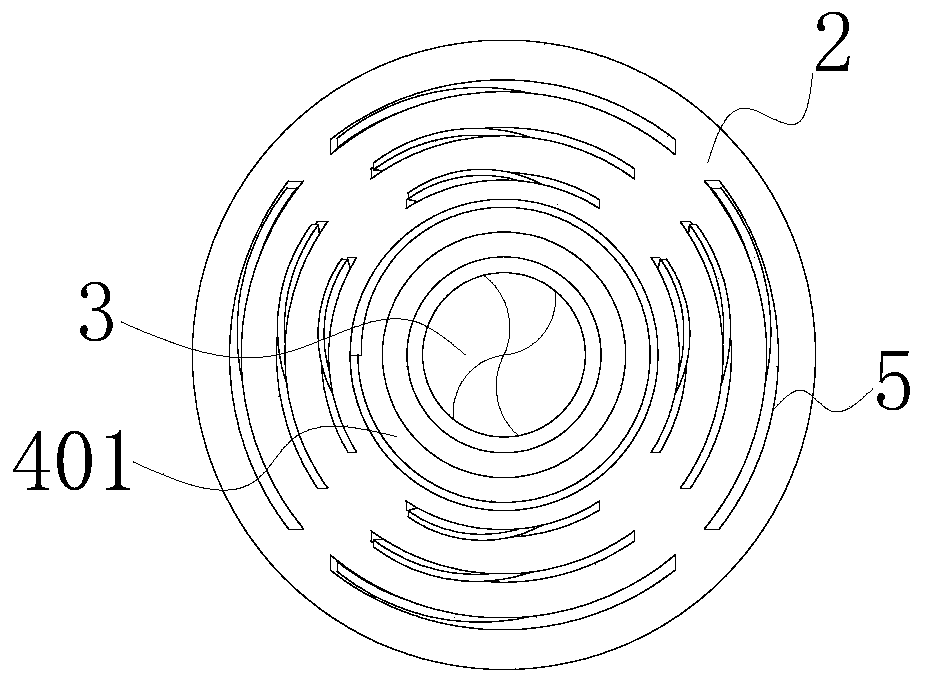

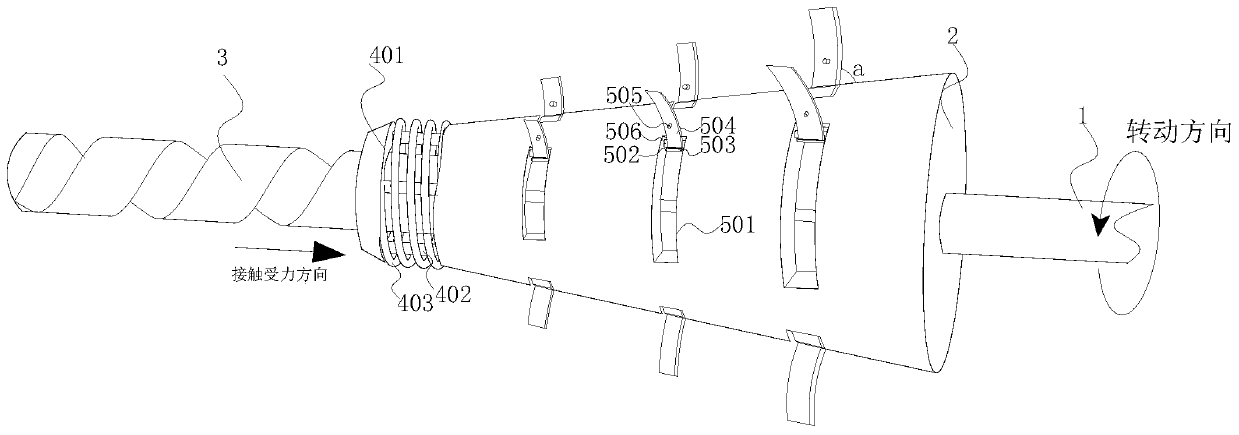

Drill bit for removing moso bamboo stems and roots

The invention provides a drill bit for removing moso bamboo stems and roots, and relates to the field of agricultural equipment. The drill bit for removing the moso bamboo stems and roots comprises atransmission connecting rod, a crushing head is fixedly welded to the end of the transmission connecting rod, a positioning drilling bit is fixedly welded to the end, away from the transmission connecting rod, of the crushing head, the outer surface of the positioning drilling bit is provided with a bottom contact linkage device, the outer surface of the crushing head is provided with bamboo stemand root crushing devices, and the bottom contact linkage device is provided with second permanent magnets and third permanent magnets separately. According to the drill bit for removing the moso bamboo stems and roots, bamboo stem and root crushing teeth can extend out of crushing grooves to increase the rotation radius of the bamboo stem and root crushing teeth, accordingly, the bamboo stem androot crushing teeth can be conveniently in contact with the inner walls of inner cavities of the bamboo stems and roots, after blade parts of the bamboo stem and root crushing teeth are in contact with the bamboo stems and roots, the bamboo stems and roots different in diameter can be conveniently crushed, and the efficiency of removing the bamboo stems and roots is effectively improved.

Owner:HANGZHOU MIAOSHOU INFORMATION TECH

Industrial waste residue crushing method

PendingCN112456839AAutomatic frictionConvenient crushing operationProcess engineeringToxic industrial waste

The invention discloses an industrial waste residue crushing method, which comprises the following operation steps: mixing various industrial waste residues with one another, and putting the mixture into a stirrer for preliminary stirring; heating and cooling circulation: carrying out primary crushing on the mixture obtained by primary stirring by adopting a hammer type crushing device, heating the mixture subjected to primary crushing to 700 DEG C or above, cooling the mixture to 300 DEG C or below at a cooling speed of 100 DEG C / min or above, heating the mixture to 700 DEG C or above at a heating speed of 20 DEG C / min or above, cooling the mixture to be below 300 DEG C at a cooling speed of 100 DEG C / min or above, and circulating for more than two times; and carrying out secondary crushing on the mixture by adopting a hammer type crushing device, cooling and sieving to obtain industrial waste residue powder. The industrial waste residue crushing method can effectively improve the crushing efficiency of industrial waste residues, reduce the crushing difficulty and improve the crushing fineness.

Owner:罗定市宏泰建材有限公司

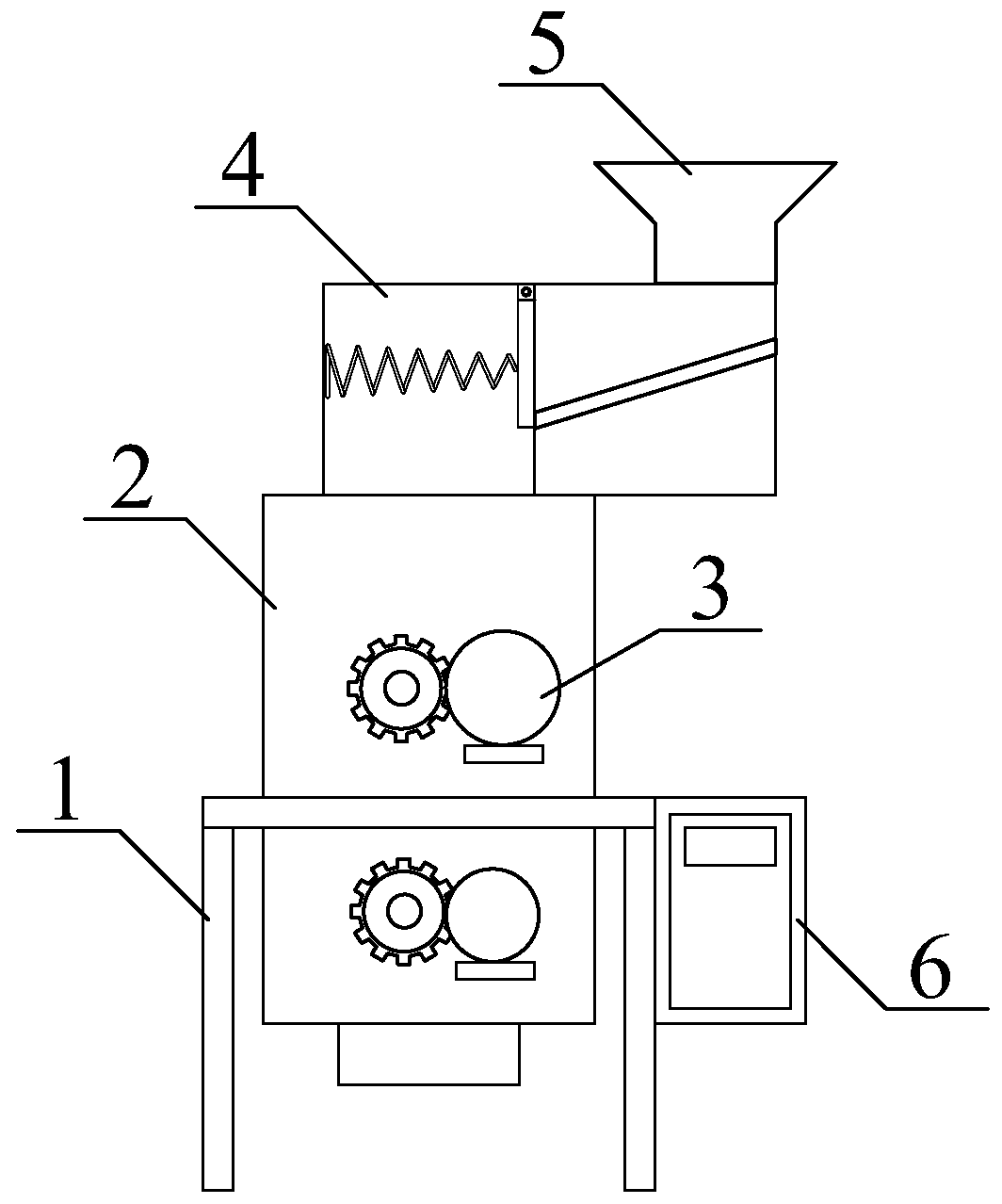

Radix puerariae crushing device

InactiveCN111250207AGuaranteed crushing effectSmall particlesSievingScreeningElectric machineryStructural engineering

The invention discloses a radix puerariae crushing device, which comprises a bracket, a crushing assembly, power assemblies, a purification assembly, a feeding pipe and an electric control cabinet. Byarranging the crushing assembly and the power assemblies, a driving motor drives first crushing rollers and second crushing rollers to rotate so as to crush radix puerariae, the radix puerariae is roughly crushed by the first crushing rollers and finely crushed by the second crushing rollers, and thus the crushing effect on the radix pueraria is ensured to facilitate subsequent pulping operation;by arranging the purification assembly, the radix pueraria enters a second conveying box from the feeding pipe, and impurities on the radix pueraria fall into the lower part of a second conveying boxthrough a filter screen, so that the purpose of purifying the radix pueraria is achieved, and the quality of radix pueraria powder obtained after crushing is ensured; and by arranging a spring and abaffle, the radix pueraria enters the first conveying box, and then the baffle blocks through holes of the first conveying box, so that the situation that dust in the crushing process enters the surrounding environment through the feeding pipe is avoided, the surrounding environment is prevented from being polluted, and it is ensured that the dust does not harm the health of operators.

Owner:赵菊兰

Acrylic plate processing leftover material crushing equipment

PendingCN112622105AAchieve opposite rotationSimple structurePlastic recyclingMechanical material recoveryStructural engineeringCrusher

The invention relates to crushing equipment, in particular to acrylic plate processing leftover material crushing equipment. The acrylic plate processing leftover material crushing equipment can perform secondary crushing and is uniform in crushing. The acrylic plate processing leftover material crushing equipment comprises footstands, a crushing mechanism and a driving mechanism, wherein the footstands are symmetrically arranged on the lower portion of a processing box; the crushing mechanism is arranged in the processing box; and the driving mechanism is arranged on the outer wall of the processing box, and the driving mechanism is in transmission connection with the crushing mechanism. The driving mechanism works, two crushing rollers can rotate oppositely, then poured acrylic plate leftover materials are crushed, and the equipment is simple in structure and convenient to operate.

Owner:李梦文

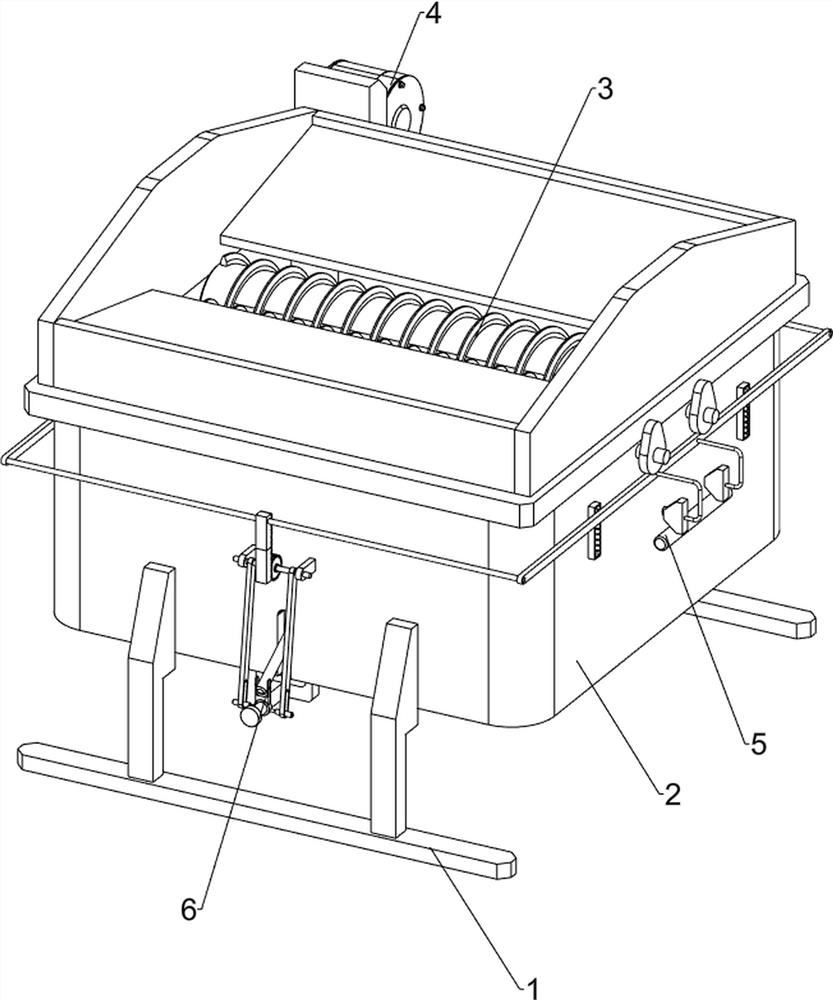

Straw discharging equipment capable of performing intermittent discharging and speed-change pushing, for electricity generation with agricultural garbage

InactiveCN111194628AIncrease linkageAchieve intermittent dropCuttersAgricultural engineeringAgriculture

The invention relates to the technical field of electricity generation with agricultural garbage, and discloses straw discharging equipment capable of performing intermittent discharging and speed-change pushing, for electricity generation with agricultural garbage. The straw discharging equipment comprises a frame plate, wherein cone disks are movably connected to the outer side of the frame plate. A gear rotates to enable baffles to be away from each other and then close to each other, so that intermittent falling down of materials can be realized, and the situation that too many materials are crushed in one time so that the crushing effect of the materials is influenced can be avoided; the cone disks drive arc disks to rotate, and then a material transmitting rod on the outer side of athird rotating disk rotates, so that the materials are pushed; besides, the gear enables an arc top region of each arc disk and a region away from the arc top region to be attached to the corresponding cone disk alternately, and the speed of the arc disks changes; when a discharge opening is opened, the material transmitting rod rotates at the largest speed, and the materials are quickly discharged; and when the discharge opening is in closed state, the material transmitting rod rotates at the smallest speed, the materials are pushed to a position above the discharge opening at a low speed, preparation is performed for subsequent discharging, and the situation that the materials are stacked and compressed due to large rotational speed and discharging is disadvantageous can be avoided.

Owner:简胜坚 +2

Crushing treatment device for plywood

InactiveCN109366665AConvenient crushing operationImprove crushing effectWood working apparatusEngineering

Owner:泗阳县翔宇包装材料厂

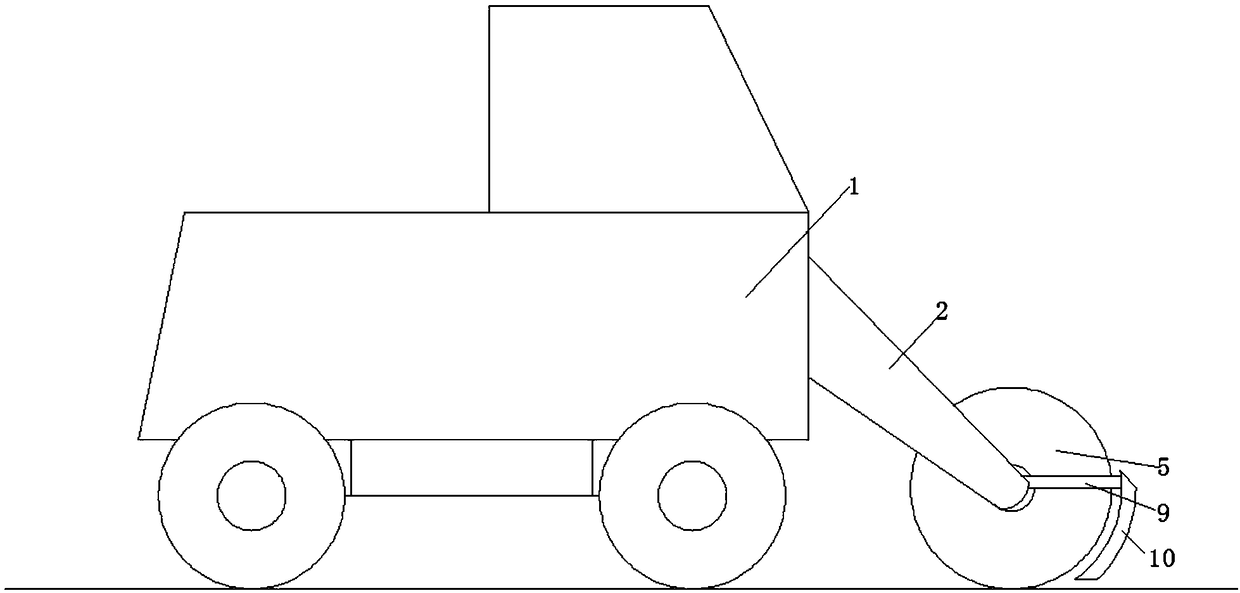

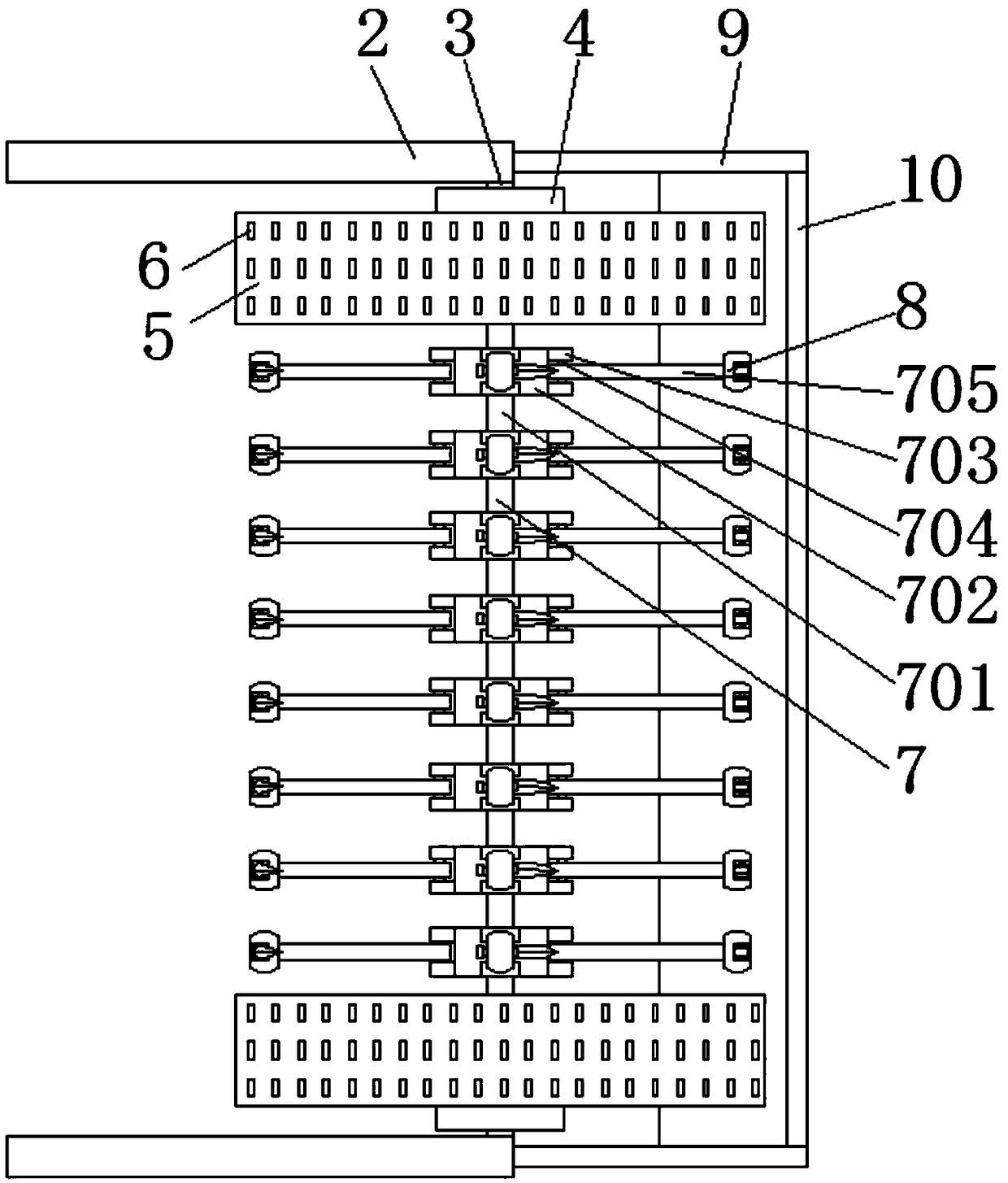

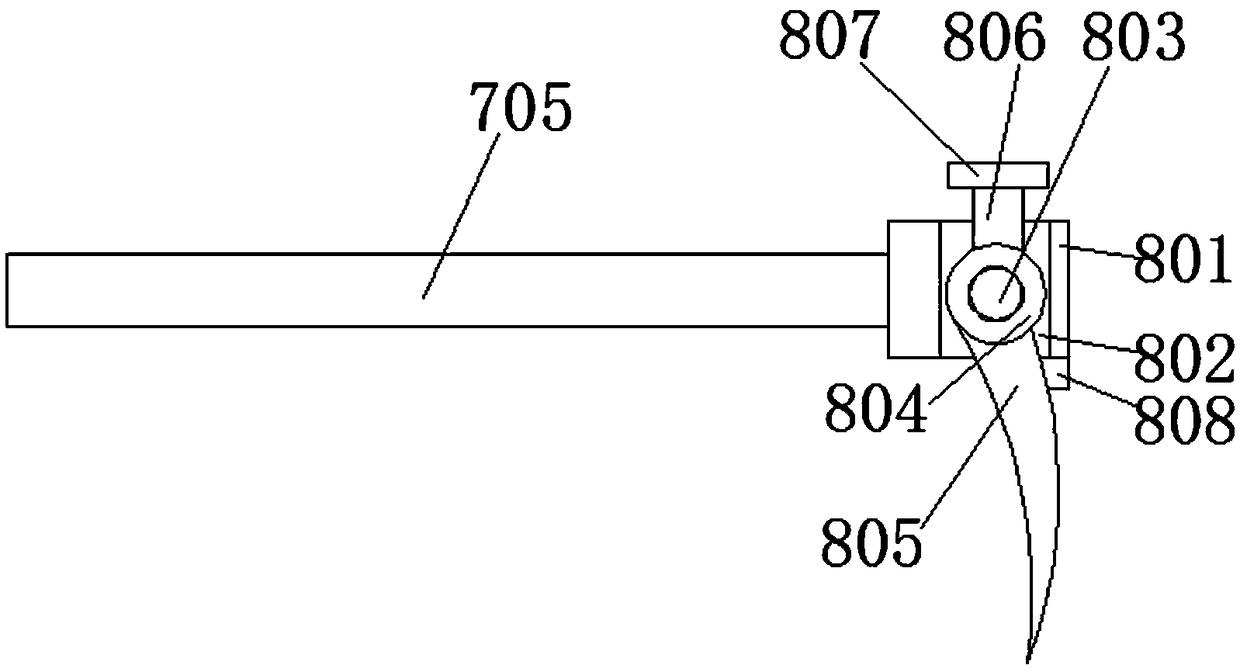

Icy pavement deicing vehicle

ActiveCN109281284AEasy crushing operationEasy to removeSnow cleaningMagnetic tension forceMagnetic poles

The invention provides an icy pavement deicing vehicle and relates to the field of special vehicles. The icy pavement deicing vehicle comprises a vehicle body; supporting arms are connected to the head of the vehicle body; the number of the supporting arms is two; wheel axles are fixed to one sides, close to each other, of the two supporting arms in a welded manner; bearings are fixedly inserted in one ends, far away from the supporting arms, of the wheel axles; the external rings of the two bearings are fixedly connected with rolling wheels; the surfaces of the external rings of the rolling wheels are fixedly connected with anti-skid teeth; and a connecting device is arranged between the two rolling wheels. According to the icy pavement deicing vehicle, as magnetic poles between an arc permanent magnet block and a permanent magnetic iron block are as same as each other, the permanent magnetic iron block can rotate anticlockwise along a connecting shaft and drive an ice-breaking cone to rotate anticlockwise along the connecting shaft under an effect of a magnetic force when a gravity hammer passes through the arc permanent magnet block; by enabling the ice-breaking cone to rotate anticlockwise along the connecting shaft, the external surface of the ice-breaking cone can be in contact with a limiting block; and therefore, the pointed end of the ice-breaking cone hits an ice surface, and the breaking effect of the ice surface can be made better.

Owner:绍兴神峰建材有限公司

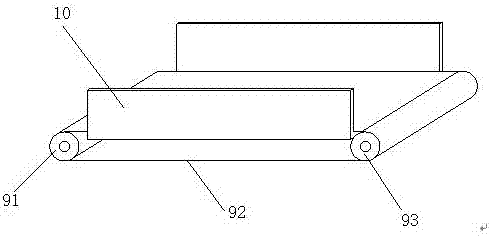

Waste tea recovery device

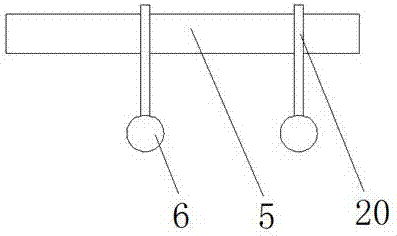

InactiveCN107307116AEasy crushing operationAchieving the purpose of double crushingPre-extraction tea treatmentTransmission beltEngineering

The invention relates to a waste tea recovery device, which includes a recovery box, a belt conveyor, a cam, a feeding plate, a mounting plate, a hinge, a motor, a baffle, a first cylinder, a second cylinder, a second pressure roller group, a first pressure roller The roller set and the limit plate, the belt conveyor is set at the bottom right inside the recovery box, the motor is set at the left side inside the recovery box, the cam is fixedly connected with the output end of the motor, the installation plate is fixed inside the recovery box, and the feeding plate rotates through the hinge Connected to the mounting plate, this design can disperse the waste tea, which is convenient for the subsequent crushing operation. The baffle is set in the middle of the recovery box. Both the first cylinder and the second cylinder are fixed on the right end of the baffle through the support seat. The second The air cylinder is arranged on the right side of the first air cylinder, the first pressure roller is connected with the output shaft of the first air cylinder, the second pressure roller is connected with the output shaft of the second air cylinder, and the limit plate is arranged on the inner lower end surface of the transmission belt of the belt conveyor. The design achieves the purpose of double crushing and improves the crushing effect.

Owner:安吉鸿丰机械厂

Glass production raw material deep processing device

PendingCN112718192AConvenient crushing operationRealize automatic transportationCocoaGrain treatmentsRatchetDrive shaft

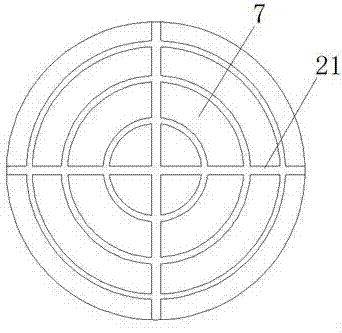

The invention discloses a glass production raw material deep processing device. The glass production raw material deep processing device comprises a machine frame with a discharge opening formed in the lower end, and a crushing mechanism and a grinding mechanism are arranged in the machine frame. A first-stage gear and a second-stage gear on a screw are used for driving a crushing roller to rotate, so that glass production raw materials entering the crushing roller are subjected to an efficient crushing operation. A transmission shaft is arranged in the machine frame, the screw and a ratchet wheel which are connected in a meshed mode are used for achieving rotating motion of a driving roller, a lifting table and a pressurizing plate block move up and down through a driving sliding groove in the driving roller so as to repeatedly apply pressure to glass raw materials which are crushed and then move to an upper crushing table, and therefore secondary pressurizing crushing is achieved. A third-stage gear and a fourth-stage gear which are connected in a meshed mode are used for achieving the rotating motion of a grinding turntable on a lower grinding table through the transmission shaft, so that the glass production raw materials subjected to secondary crushing are evenly ground, and therefore the glass production raw materials are recycled.

Owner:赖国强

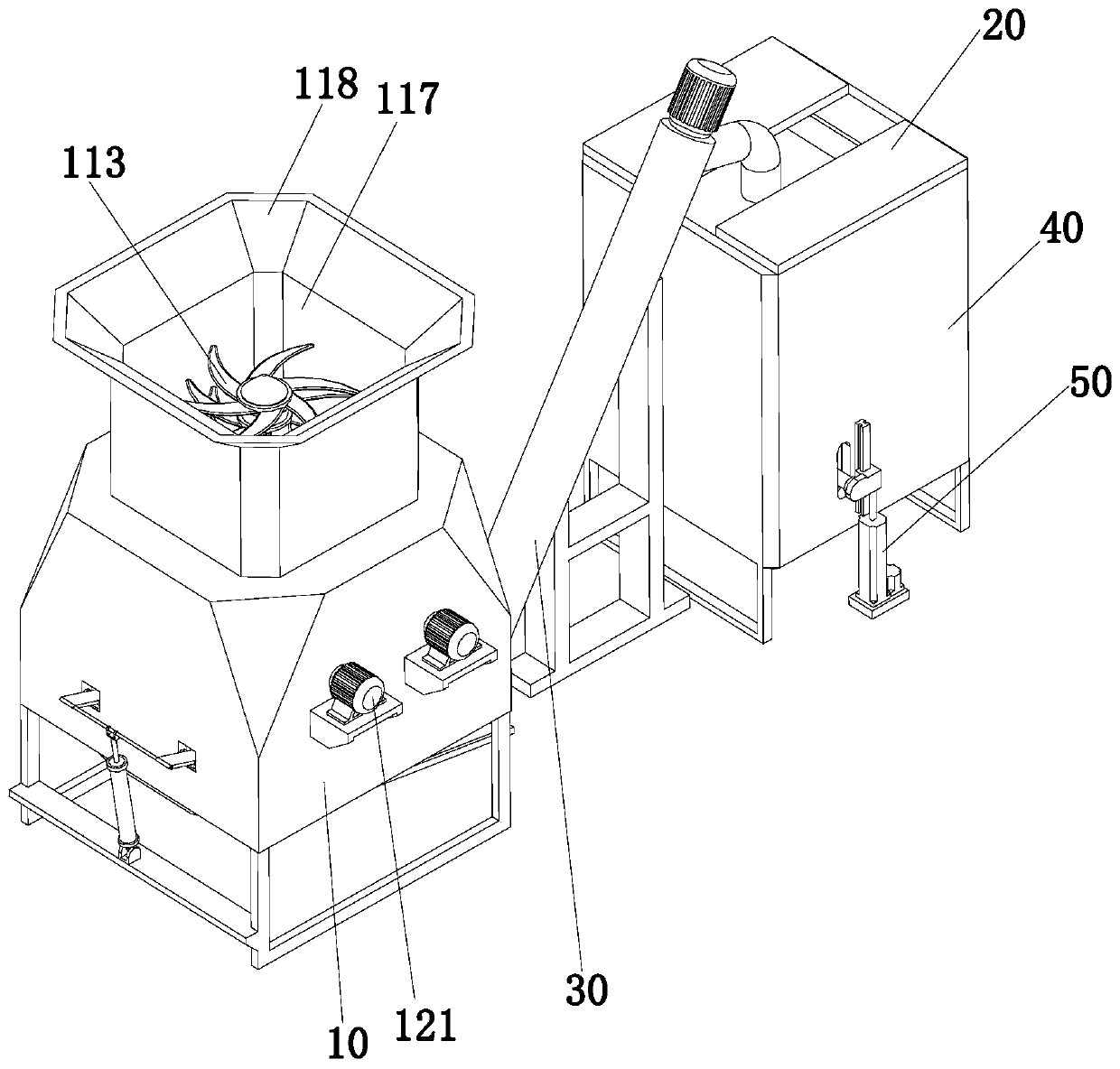

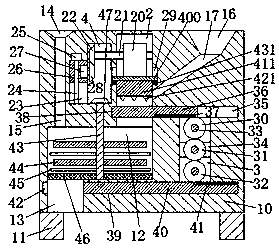

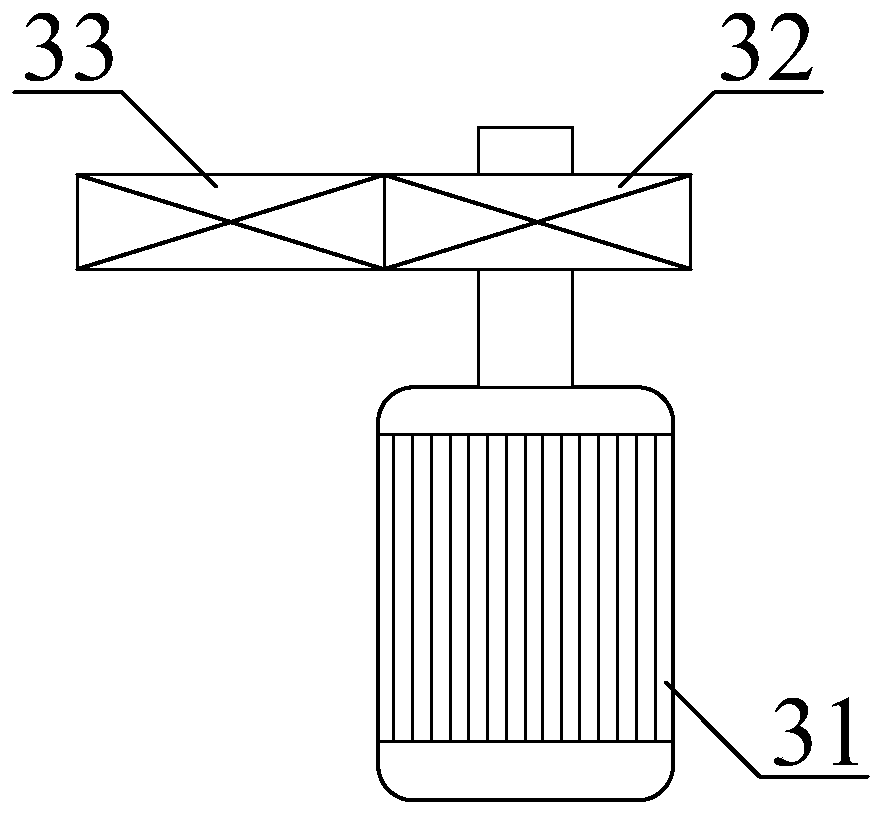

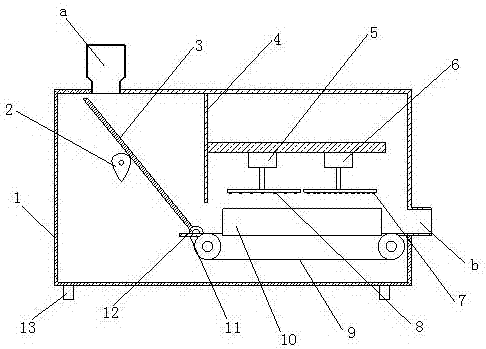

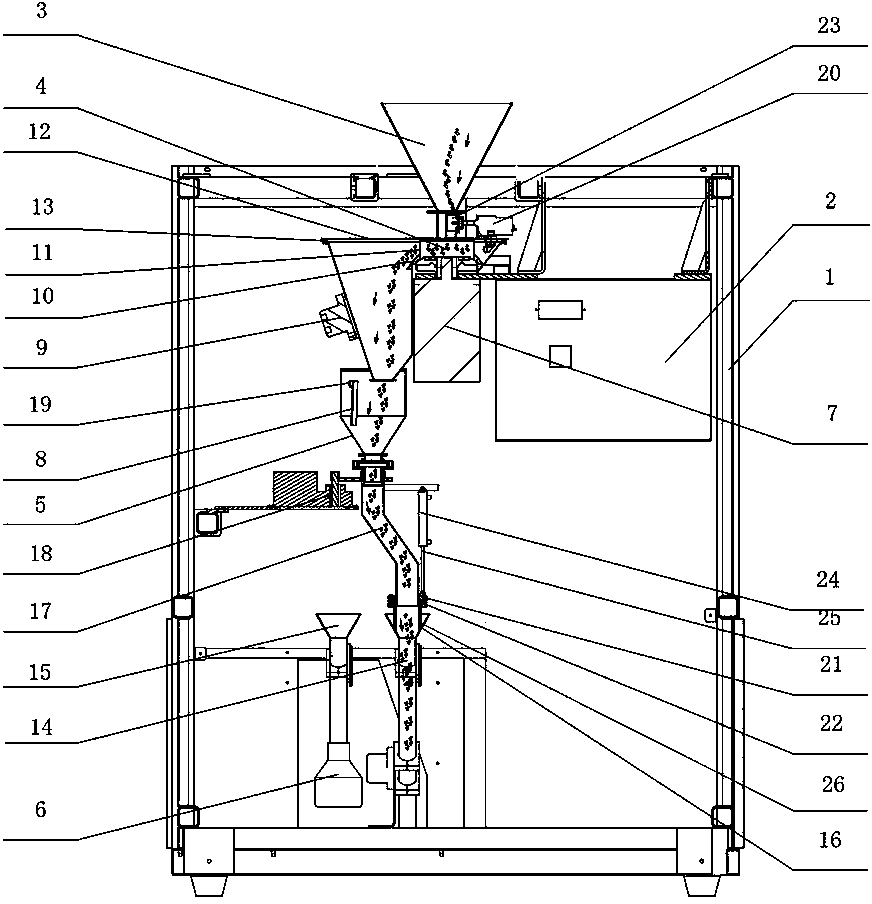

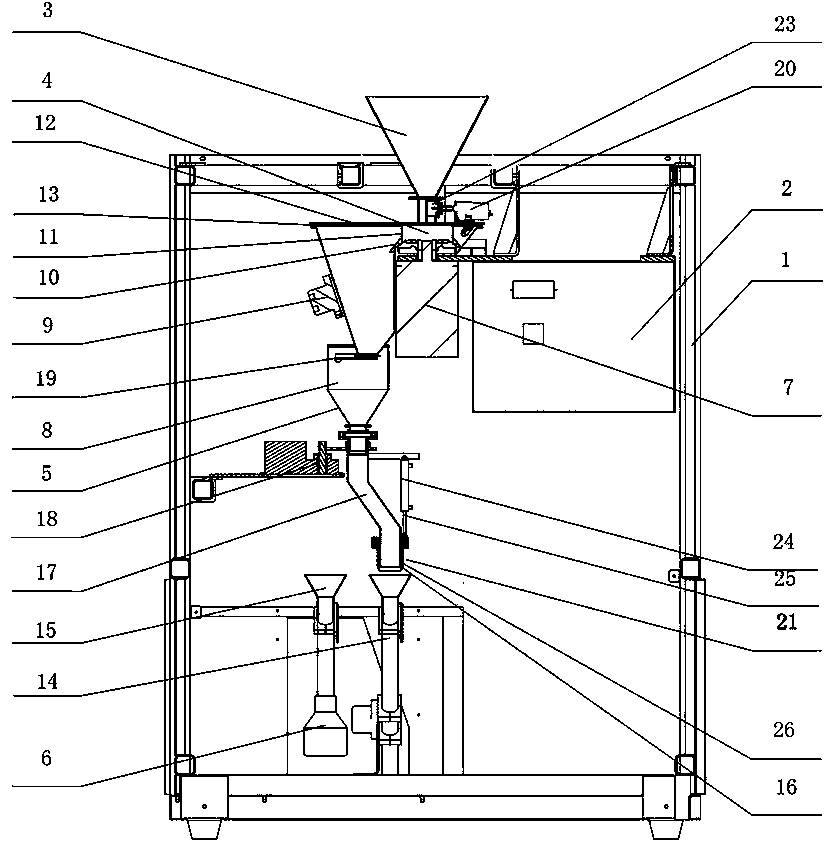

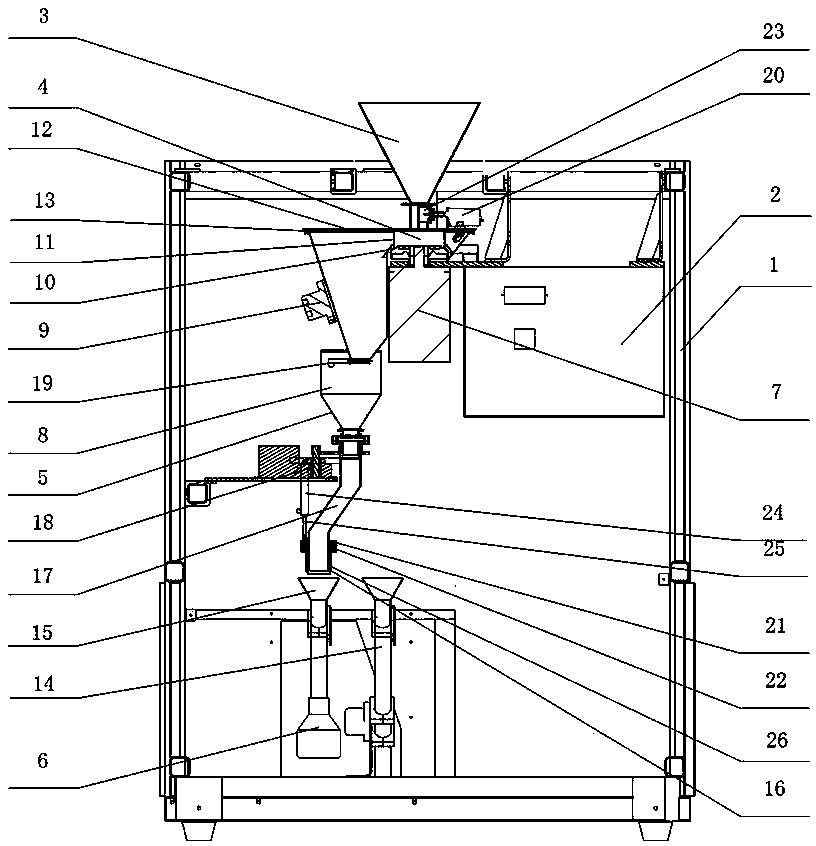

Automatic sample crusher

ActiveCN104209164AAvoid influenceImprove sealingPreparing sample for investigationGrain treatmentsCrusherDust pollution

The invention discloses an automatic sample crusher. The automatic sample crusher comprises a frame, a control component, a powder making component, a feed hopper, a collecting channel, a discarding channel and a remaining channel, wherein the feed hopper is positioned at the feed end of the powder making component; the collecting channel is communicated with the discharge end of the powder making component; the discarding channel and the remaining channel are positioned at the discharge end of the collecting channel; a discharge pipe is arranged at the discharge end of the collecting channel, is positioned on a sample channel switching mechanism, and is driven by the sample channel switching mechanism to rotate to be communicated with the discarding channel or the remaining channel; a sealing component fitting the discarding channel or the remaining channel covers the discharge end of the discharge pipe; and the sealing component is connected with a sealing driving component, and is driven by the sealing driving component to move in the axial direction of the discharge pipe. The automatic sample crusher has such advantages as simple and compact structure, further improved sample crushing precision and reduced dust pollution.

Owner:HUNAN SUNDY SCI & TECH DEV

Drug crushing device for pediatric nursing

InactiveCN110013906APrevents adhesive residueFaster and better separated collectionGrain treatmentsPediatric nursingCyclone

The invention discloses a drug crushing device for pediatric nursing, and relates to the technical field of ceramic medical treatment apparatuses. The device comprises an air handling box, wherein a grinding device is mounted at the front side of the upper end of the air handling box; a pneumatic cyclone separating device is connected to the front side of the grinding device; the grinding device comprises a guide housing which is fixed to the front side of the upper end of the air handling box; a semispherical filtering net is mounted at a through hole in a fitting manner; a grinding ball is fixed to the lower end of a connecting rod; an air outlet tube is rotatably mounted at the inner rear side of the guide housing; the pneumatic cyclone separating device comprises a pneumatic cyclone barrel, a tapered barrel and an air exhausting tube; and tapered edible sweet wrapper is arranged close to the inner sidewall of the tapered barrel. The device has the beneficial effects that air is blown through high pressure in order to remove the surface, so that the waste is reduced, and the next drug crushing operation is conveniently carried out; and meanwhile, the device is matched with the pneumatic cyclone separating device, so that drug particles can be quickly greatly separated and collected; and the edible sweet wrapper is damaged a little and achieves drug collection.

Owner:THE FIRST AFFILIATED HOSPITAL OF HENAN UNIV OF SCI & TECH

Medicine breaking device for pediatric nursing

ActiveCN110013439APrevents adhesive residueFaster and better separated collectionOral administration devicePediatric nursingAir treatment

The present invention discloses a medicine breaking device for pediatric nursing and relates to the technical field of porcelain medical devices. The medicine breaking device comprises an air treatment box; a grinding device is arranged on a front side of an upper end of the air treatment box; a cyclone separation device is connected to a front side of the grinding device; the grinding device comprises a guiding shell fixed on the front side of the upper end of the air treatment box; a hemispherical filter mesh is arranged on a through-hole; a grinding ball is fixed at a lower end of a connecting rod; an air outlet pipe is rotatably arrange an inner rear side of the guiding shell; a pulse valve is arranged on an air guiding pipe; the cyclone separation device comprises a cyclone cylinder,a cone cylinder and an air exhaust pipe; and an inner side wall of the cone cylinder is fitted with cone edible sugar paper. Beneficial effects are as follows: high pressure is used for air blowing toclean surface, waste is reduced, a next medicine breaking operation is facilitated, at the same time the cyclone separation device is cooperated to separate and collect medicine particles faster andbetter, and the medicine breaking device is very small on destroy of the edible sugar paper and realizes use of the edible sugar paper for drug collection.

Owner:周静

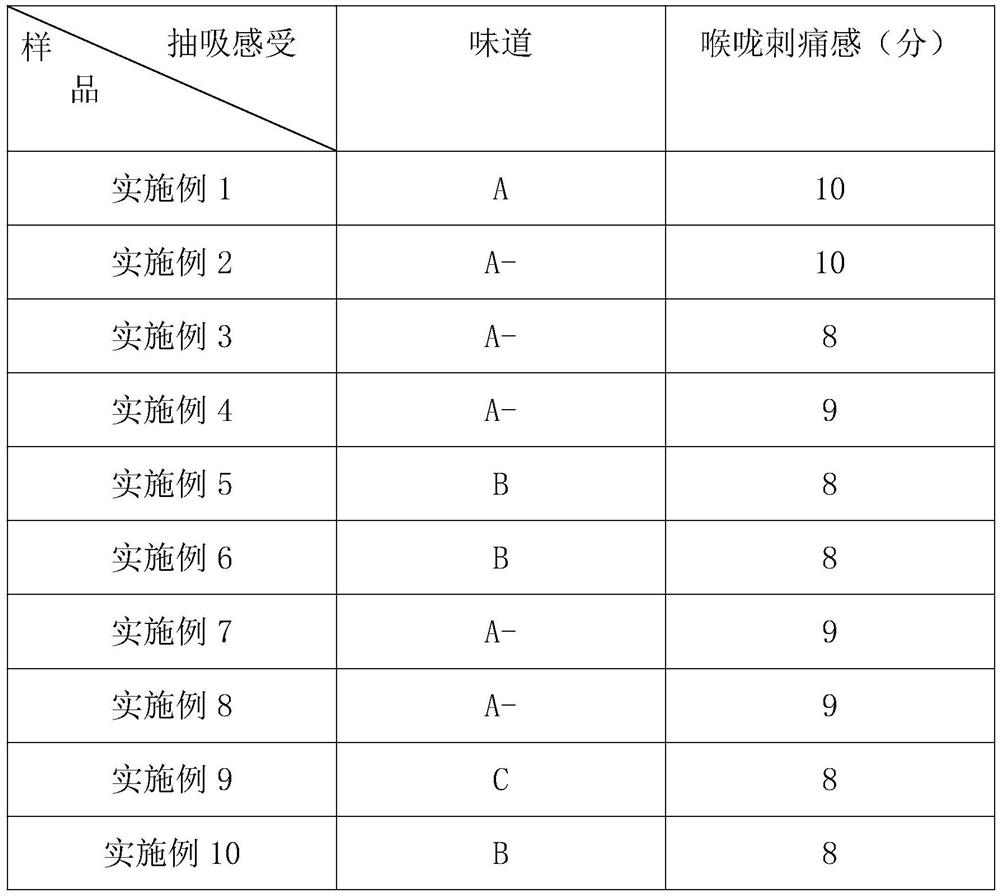

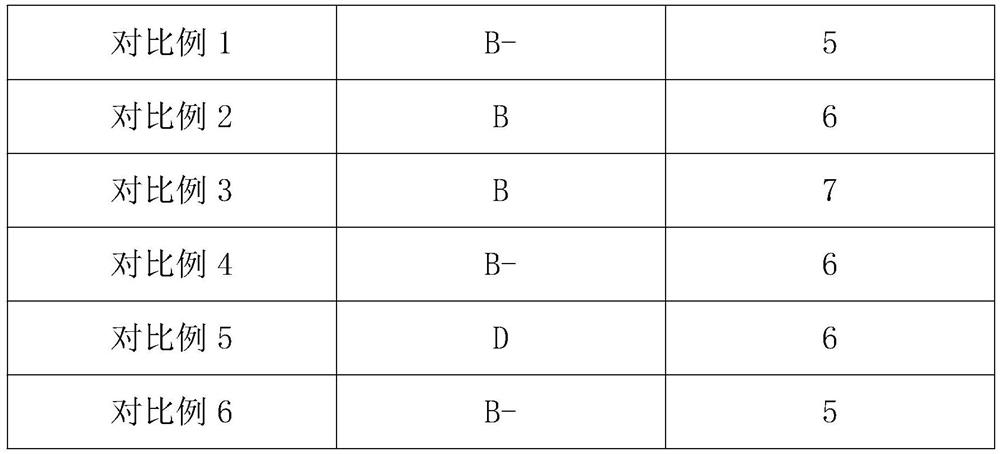

Preparation method of apple extract for cigarettes

ActiveCN113907394AReduce stimulationLow impurity contentTobacco treatmentAgainst vector-borne diseasesBiotechnologyPolyol

The invention relates to the technical field of tobacco flavors and fragrances, and particularly discloses a preparation method of an apple extract for cigarettes, which comprises the following steps: adding water into an apple raw material for hot reflux extraction, then filtering, and retaining a first filtrate; concentrating the first filtrate to obtain primary paste; re-dissolving the primary paste by using ethanol, uniformly stirring, freezing and standing for a period of time, extracting supernatant liquid, adding ethanol into the supernatant liquid, freezing and standing again, and repeating the operation until the supernatant liquid is in a red light-transmitting state; then filtering the supernatant liquid in the red light-transmitting state to obtain a second filtrate; and concentrating the second filtrate to obtain a primary concentrated solution, adding polyhydric alcohols, uniformly mixing, continuously concentrating until the relative density of the paste is 1.2920 + / -0.0080 to 1.3000 + / -0.0080, and discharging to obtain a product. The preparation method has the advantage of reducing the content of impurities in the apple extract.

Owner:SHENZHEN ZINWI BIO-TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com