Anti-splattering device for breaking hammer

A breaking hammer and anti-splash technology, which is applied in the field of anti-splash devices, can solve the problems of easily deflected gravel and dust, unsatisfactory anti-splash effects, unstable heating, etc., and achieve the effect of facilitating crushing operations and preventing dust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

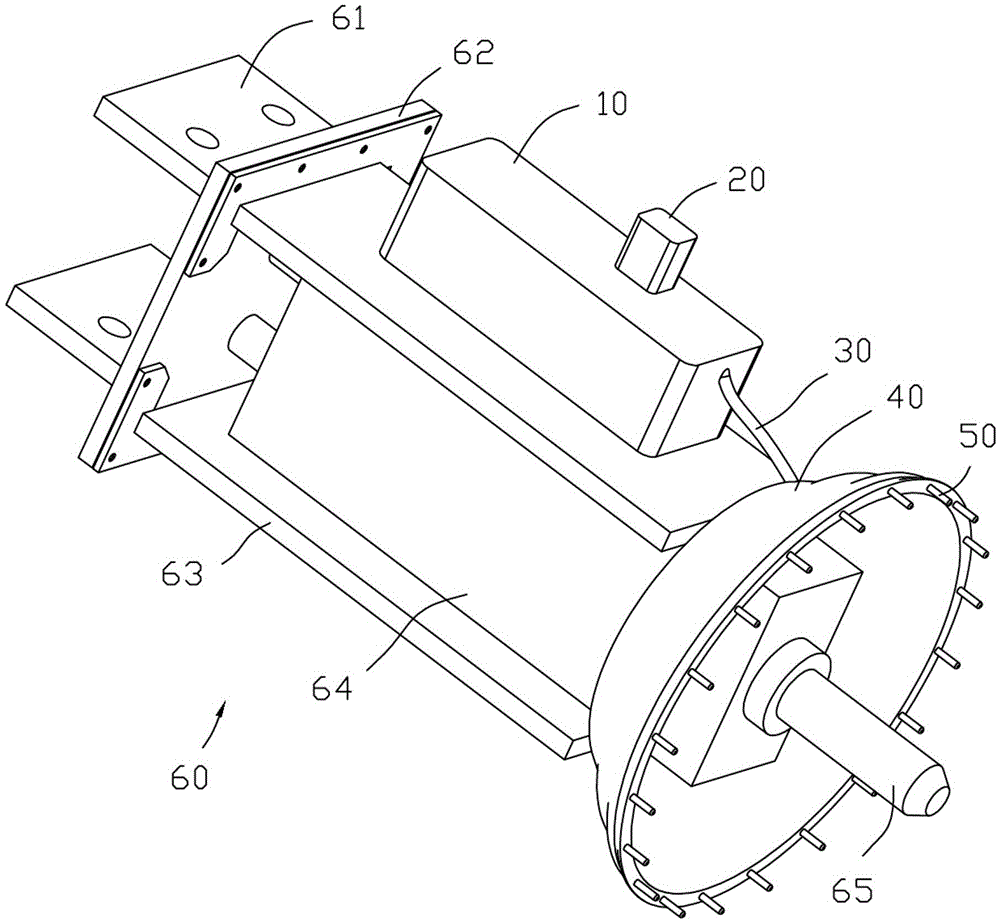

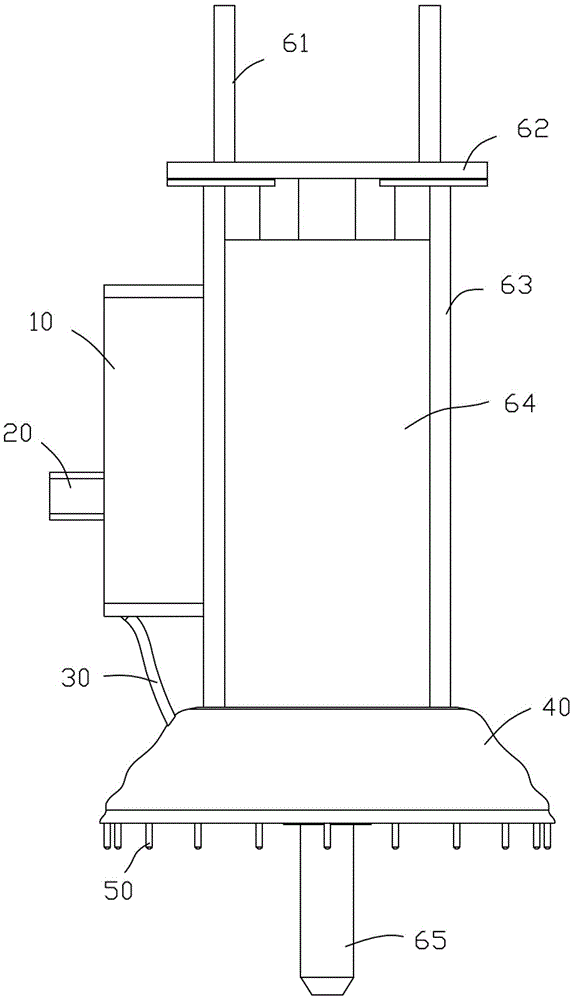

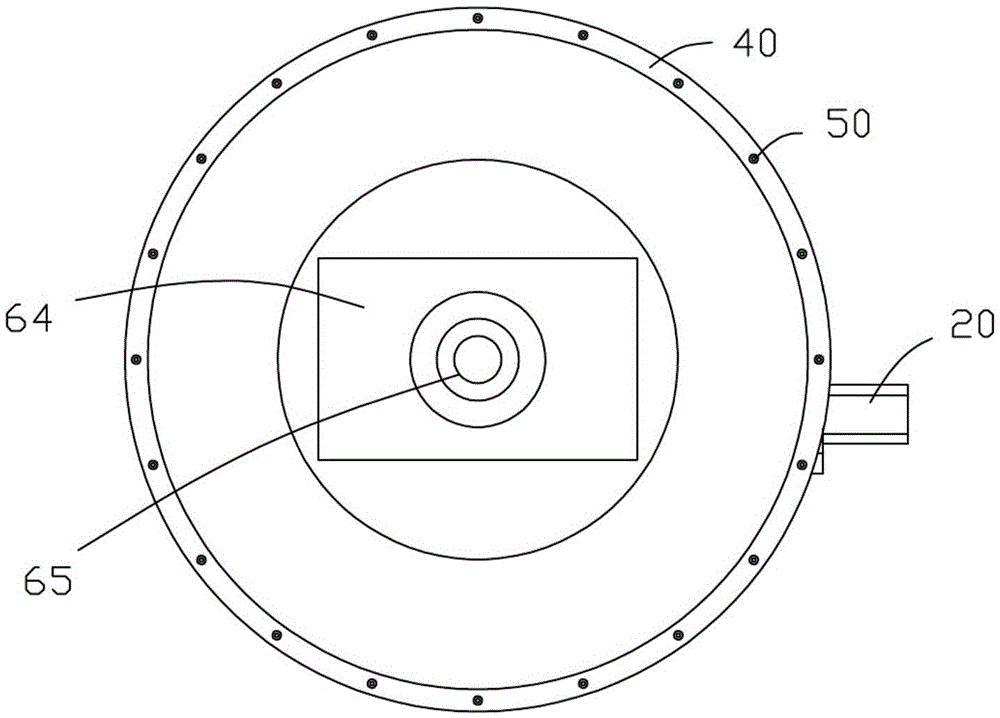

[0013] combine Figure 1 to Figure 3 , an anti-splash device for a breaker, comprising a breaker 60, a water tank 10, a motor 20, a water pipe 30, a dust cover 40 and a nozzle 50; the side of the breaker 60 is provided with a side plate 63, and the water tank 10 Installed on the side plate 63, the side of the water tank 10 is provided with a motor 20, a breaker body 64 is provided between the two side plates 63 of the breaker 60, and a dust cover is installed at the end of the breaker body 64 40, the dust cover 40 is fixed to the end of the side plate 63, one end of the water pipe 30 is connected to the water tank 10, and the other end is connected to the dust cover 40, the dust cover 40 is a bowl-shaped cover body, the Several nozzles 50 are provided on the bottom of the dustproof cover 40 , and the several nozzles 50 are circumferentially arranged at the end of the dustproof cover 40 .

[0014] combine figure 1 and figure 2 , the bottom of the breaking hammer body 64 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com