Patents

Literature

198results about How to "Realize automatic transportation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

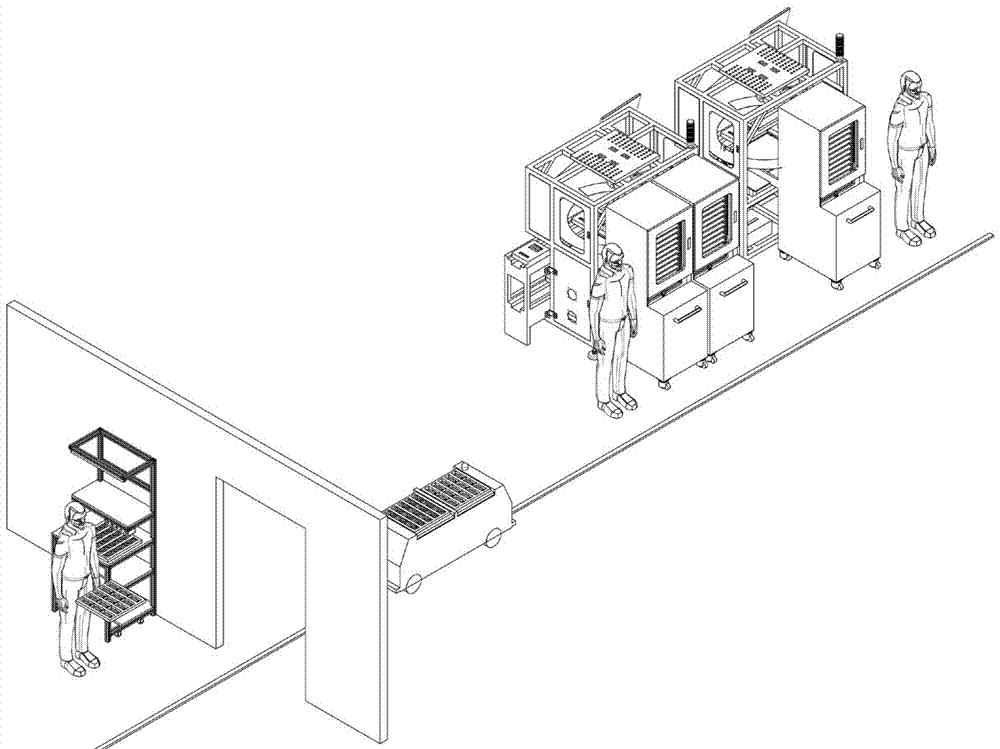

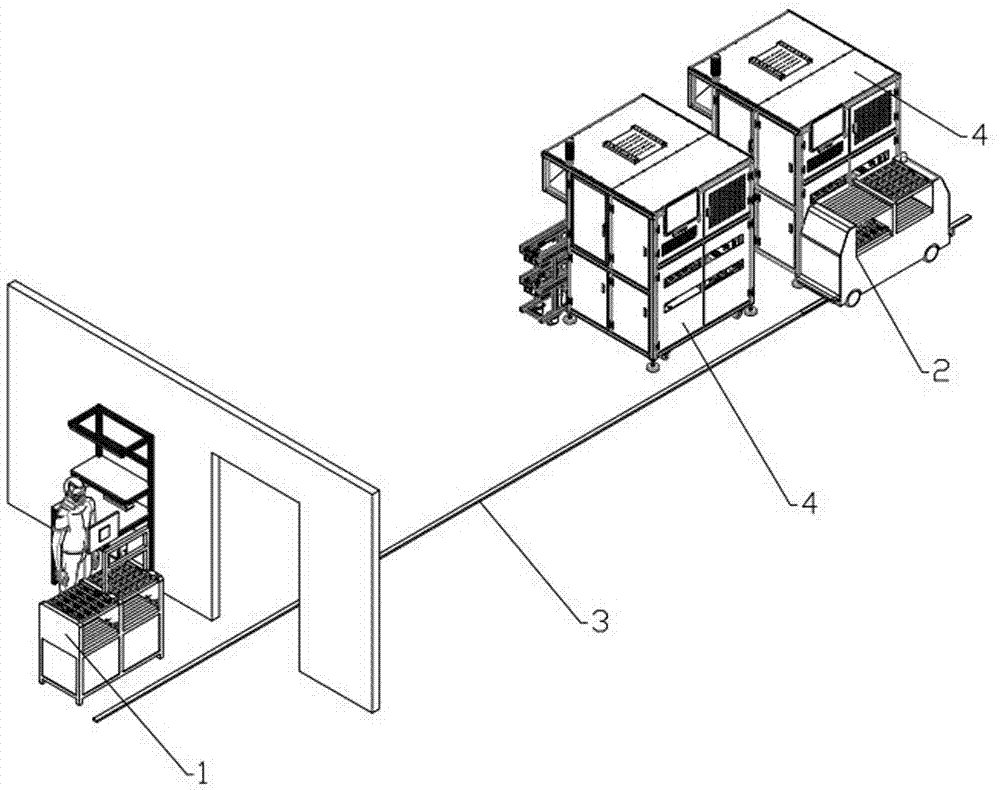

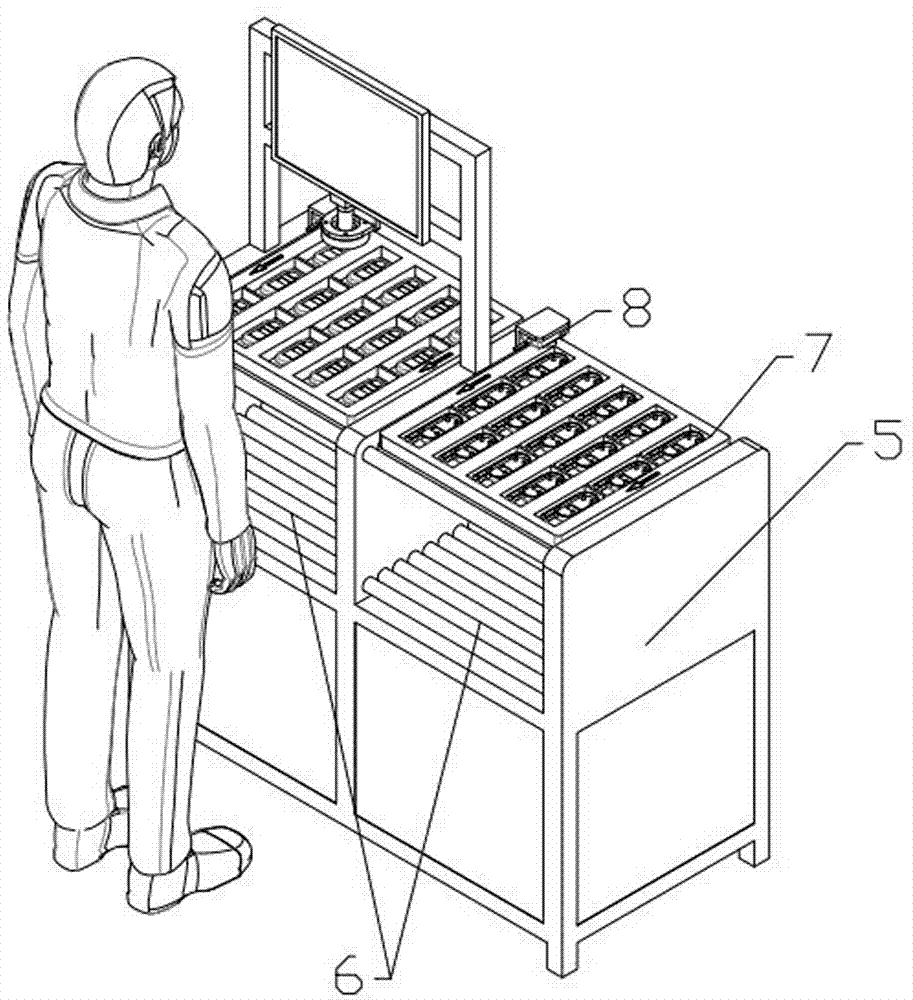

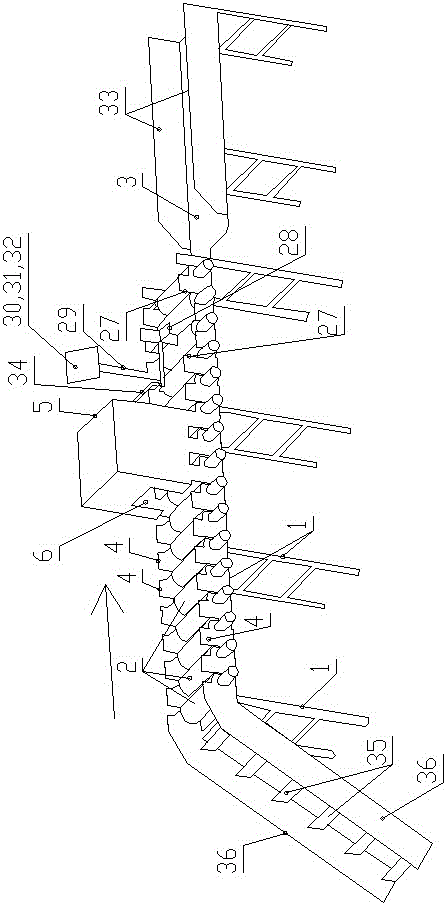

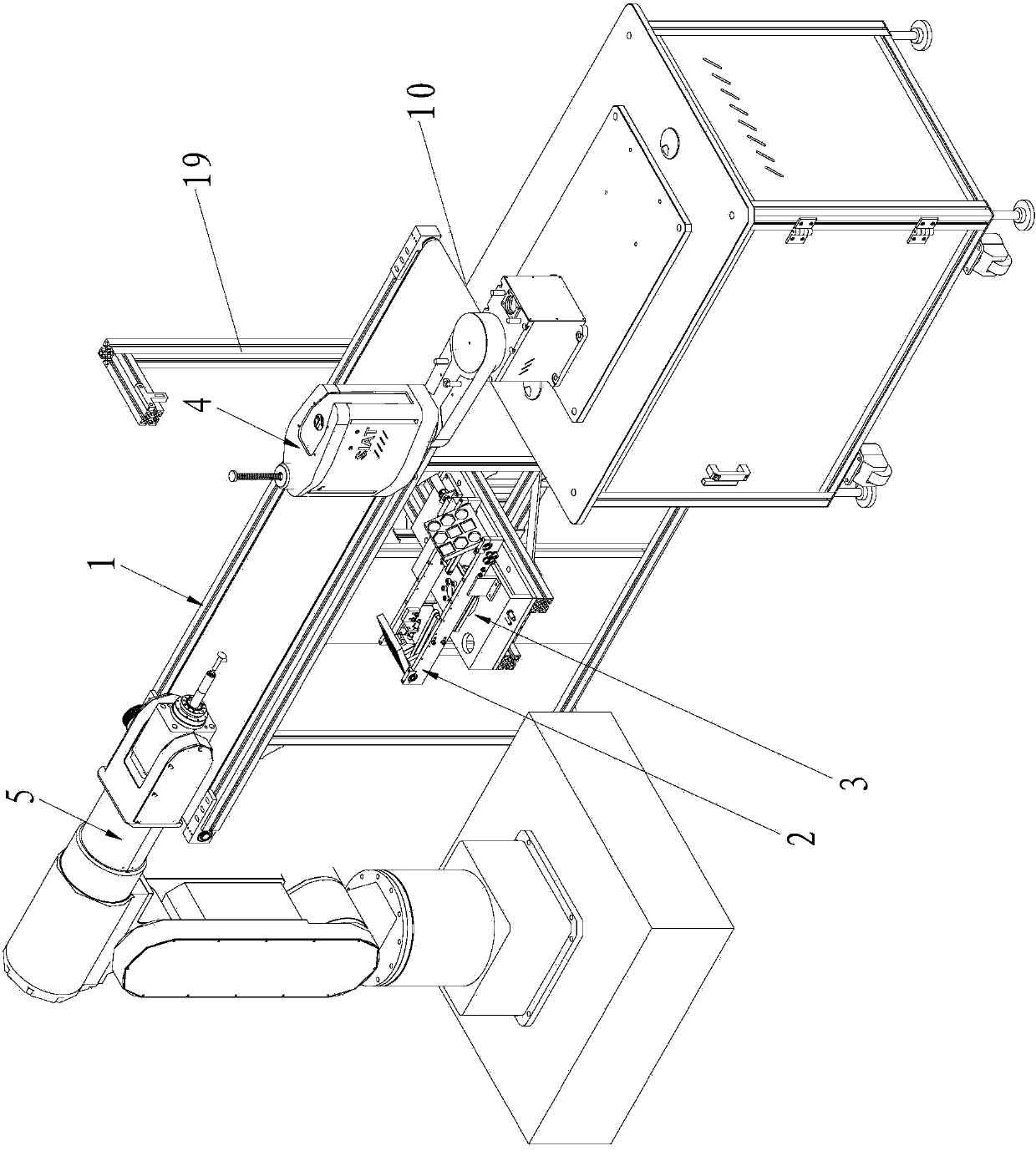

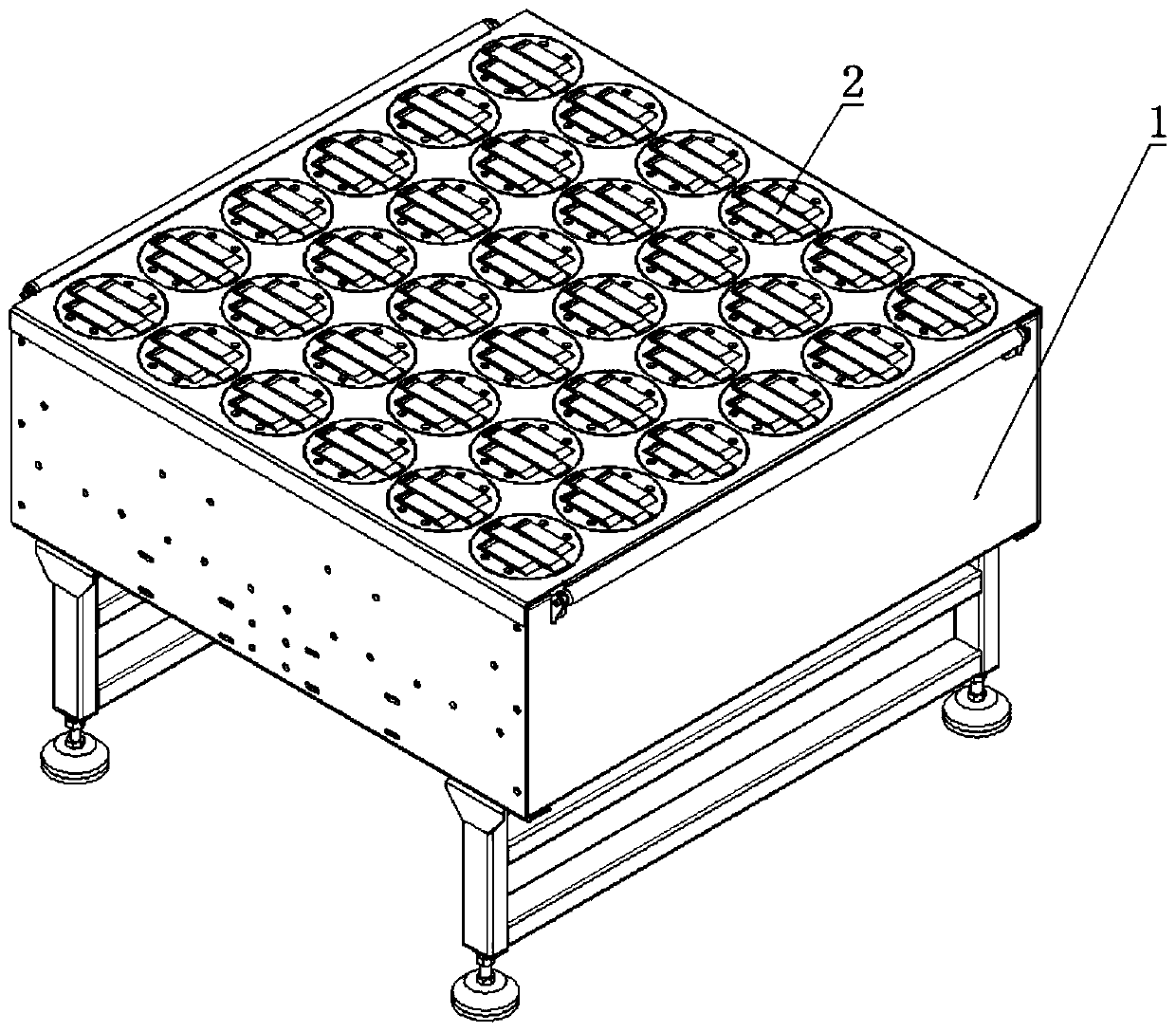

Automated material distributing system

PendingCN107336962ARealize automatic feeding processRealize blankingControl devices for conveyorsStorage devicesEngineeringMechanical engineering

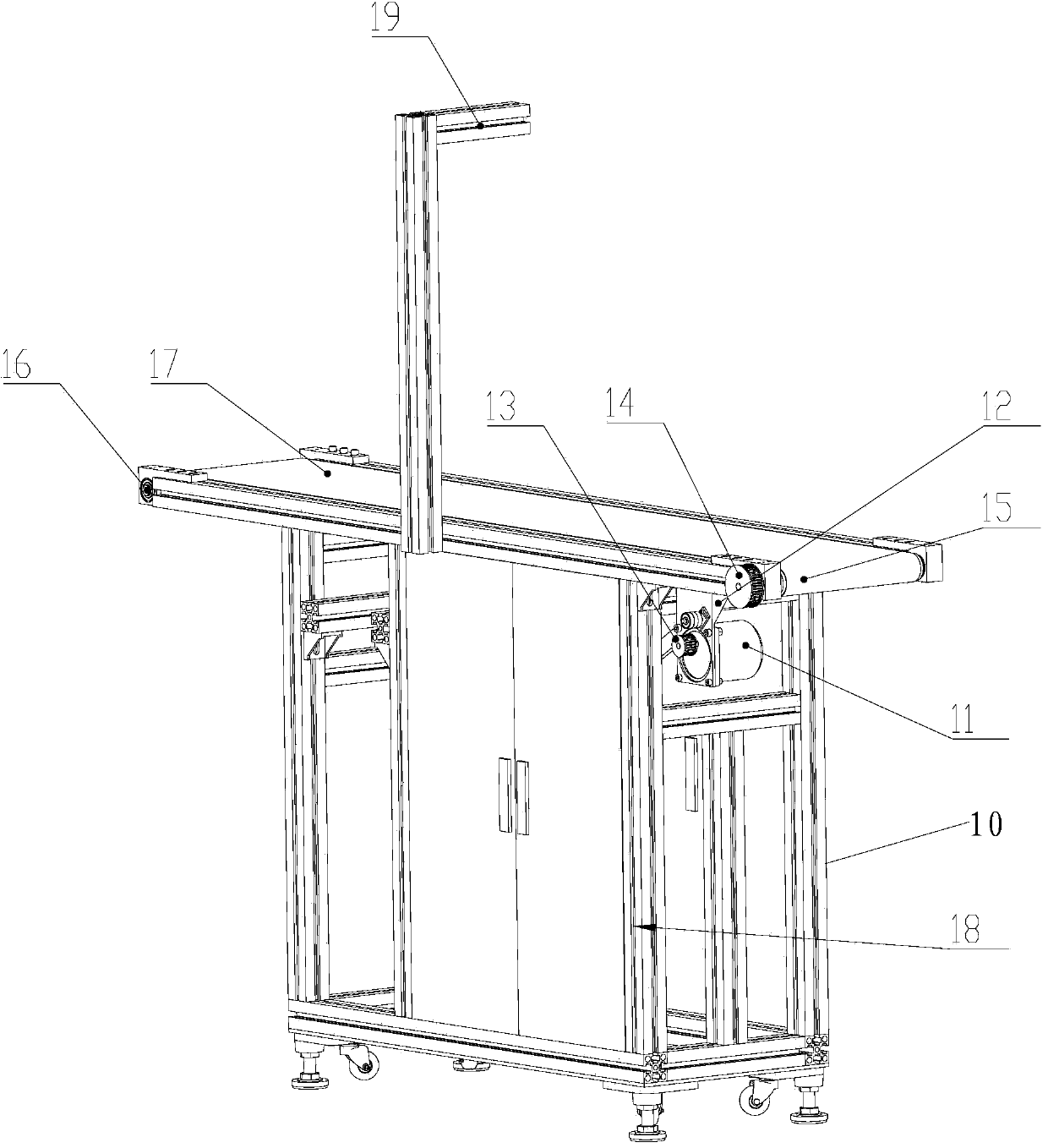

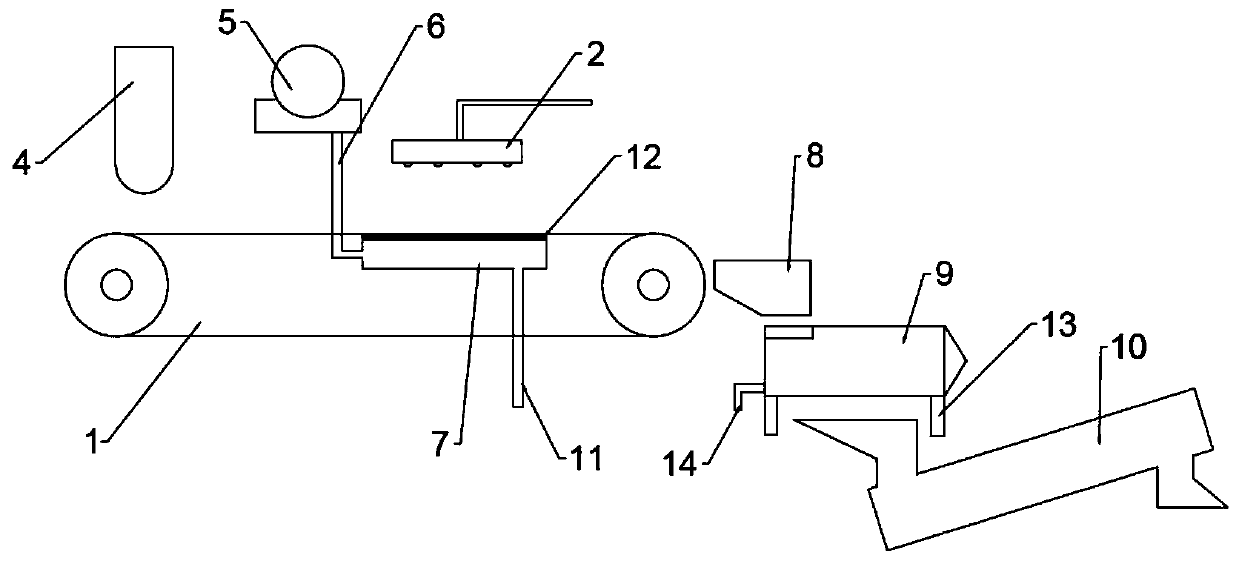

The invention provides an automated material distributing system. The automated material distributing system comprises an AGV inspection conveyor, an AGV trolley, an AGV trolley track, three-dimensional feeding mechanisms and a central controller, wherein the AGV inspection conveyor comprises multiple first horizontal conveying mechanisms, trays used for containing materials are arranged on the first horizontal conveying mechanisms, and the AGV trolley is provided with second horizontal conveying mechanisms which are connected with the first horizontal conveying mechanisms in a butted manner; and each three-dimensional feeding mechanism comprises a stock bin, a butting platform, a vertical lifting mechanism and a horizontal conveying mechanism, wherein the stock bin is used for enabling the trays to be stored in a stacked manner, the butting platform is fixed to the vertical lifting mechanism, the horizontal conveying mechanism is arranged at the bottom end of the butting platform, and the butting platform is driven by the vertical lifting mechanism and the horizontal conveying mechanism to enable the trays to move between the stock bin and the AGV trolley. According to the automated material distributing system, automatic feeding and discharging of materials can be achieved, and artificial burdening and material changing are reduced; and meanwhile, automatic conveying is achieved, artificial distribution is reduced, the tool efficiency can be effectively improved, and the labor cost is reduced.

Owner:SHENZHEN HYTERA COMM

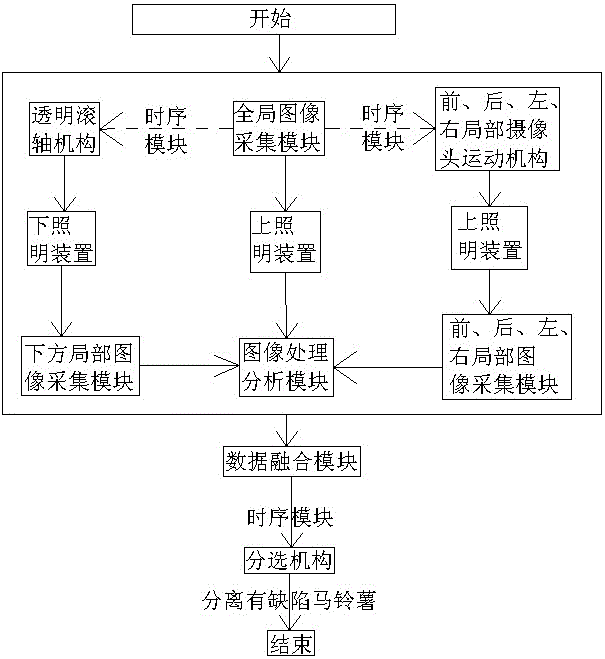

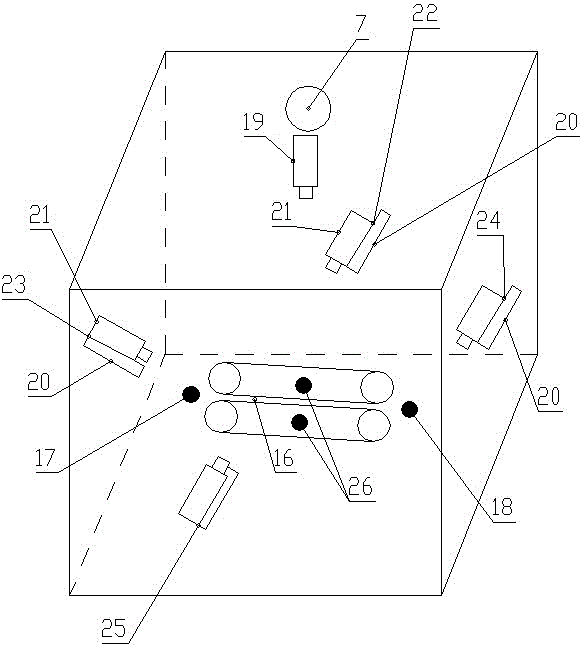

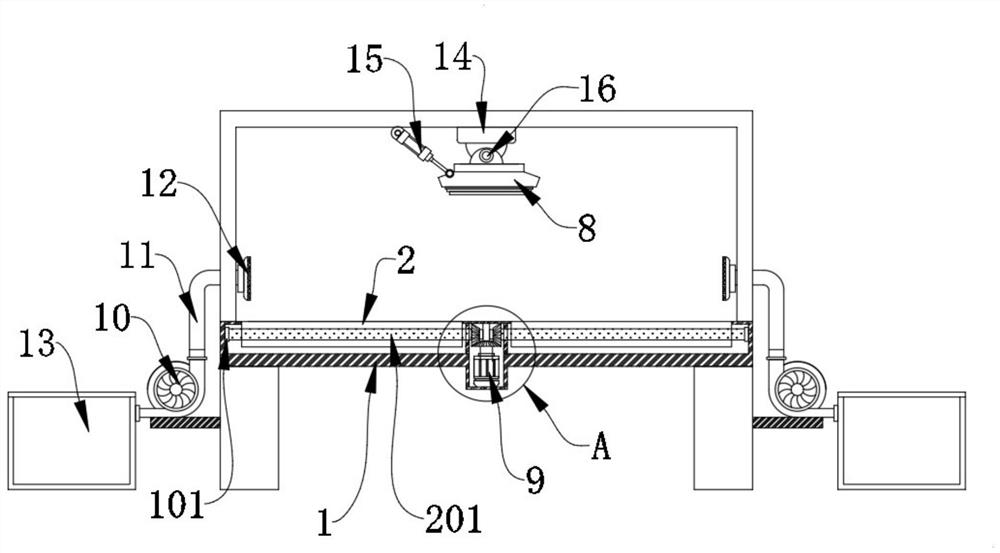

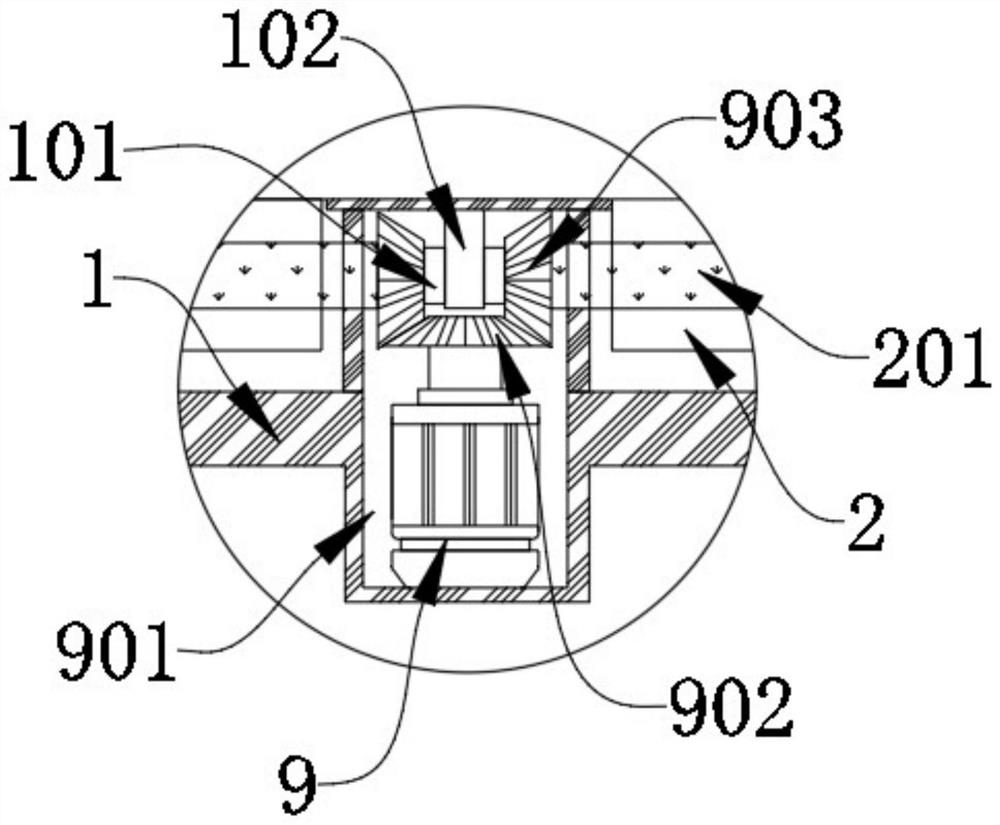

Panoramic-vision potato sorting and defect detection device as well as sorting detection method thereof

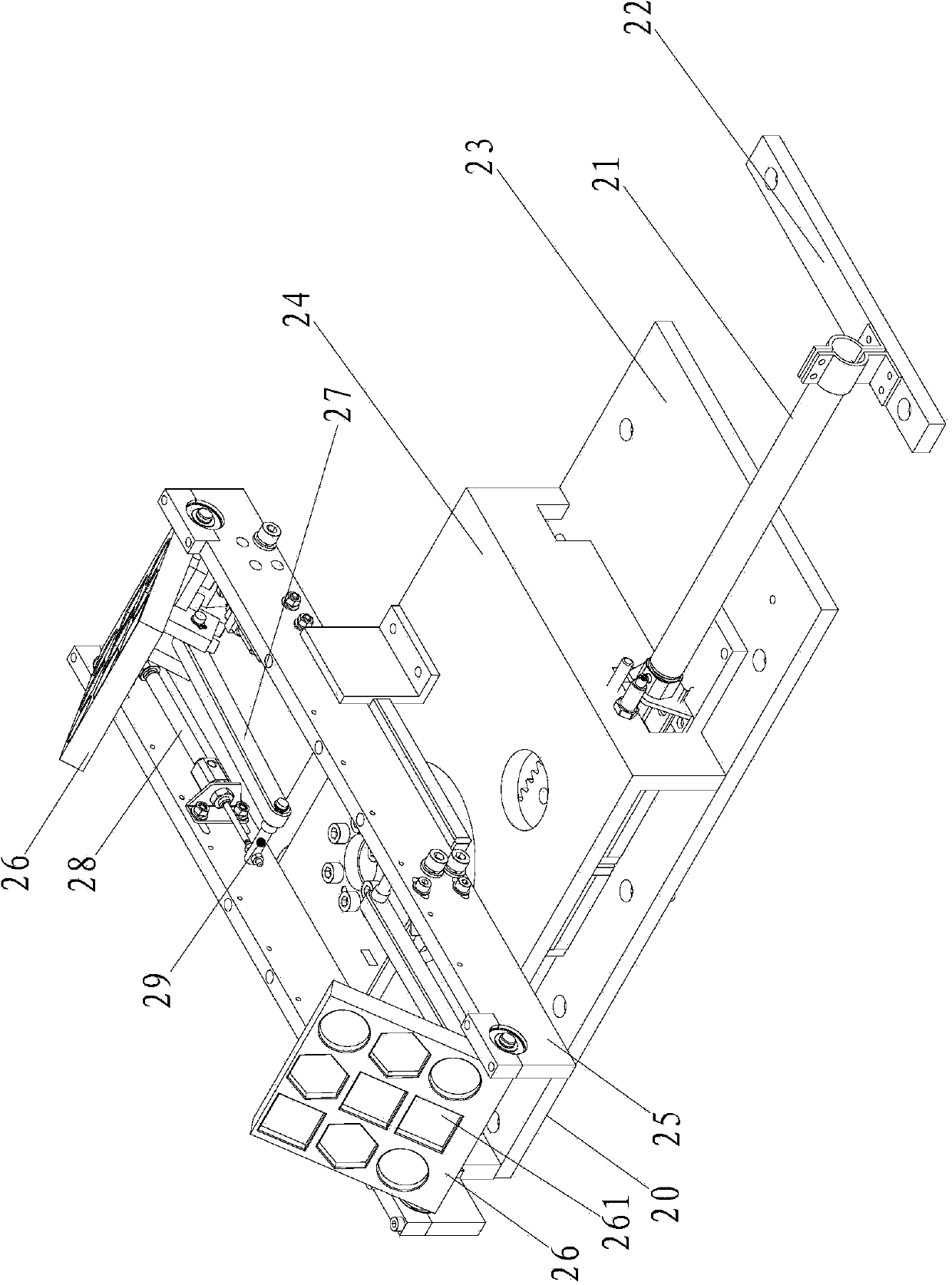

The invention discloses a panoramic-vision potato sorting and defect detection device which comprises a conveying device, a detection camera obscura, a sorting mechanism, an infrared sensor module, an image acquisition mechanism, an image processing-analyzing module, a data fusion module and a time sequence module, wherein a convolutional neural network and a support vector machine I (SVM I) are built in the image processing-analyzing module; an SVM II is built in the data fusion module; and the time sequence module is used for coordinating actions of all parts. The invention further discloses a potato sorting detection method using the above device. According to the device and the potato sorting detection method disclosed by the invention, all-around detection can be completed without turning over potatoes in a detection process. Accordingly, the potatoes can be protected from unnecessary damage on the one hand, and on the other hand, the instability during dynamic photo taking and detection can be avoided, and the image clarity and the detection accuracy can be improved. The device and the potato sorting detection method can be widely applied to real-time online detection of the external quality of potatoes, namely a kind of agricultural product, and has significance for promoting development of the Chinese potato industry.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

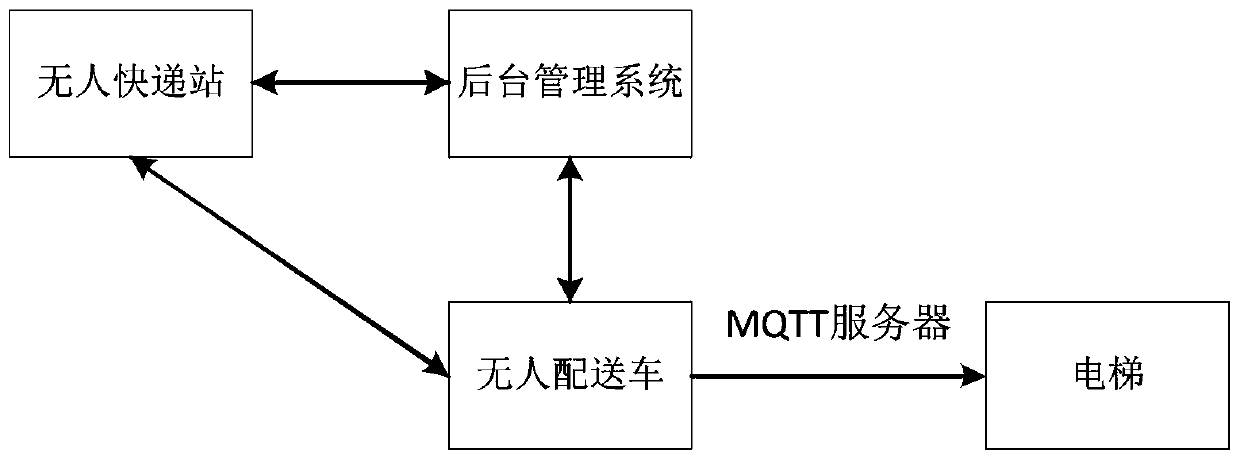

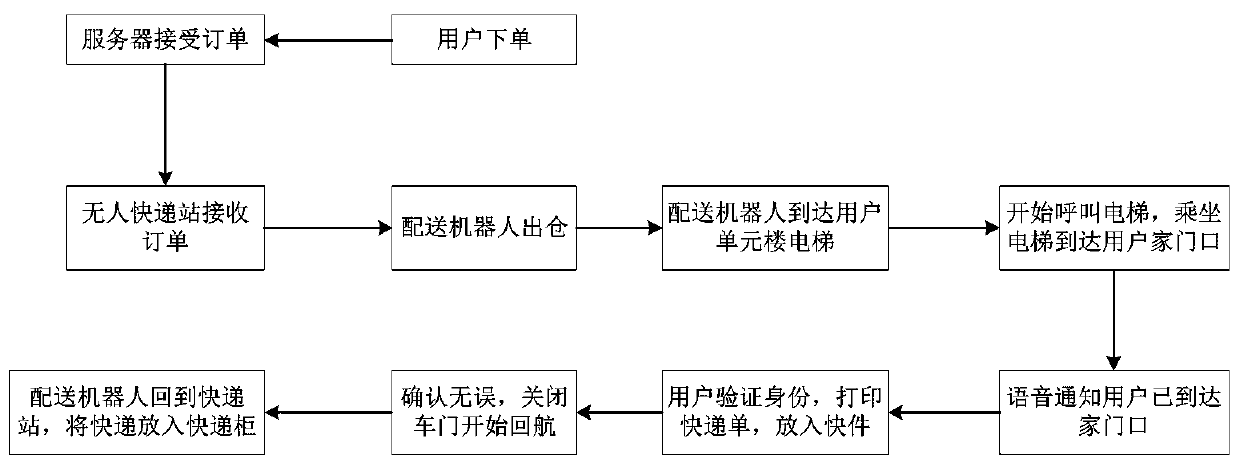

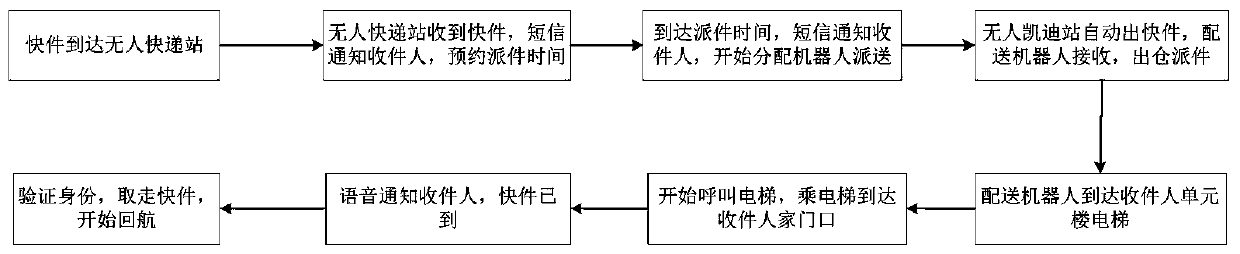

Unmanned express receiving and sending system and method

PendingCN110378647AConvenience for concentrated deliveryReduce labor intensityLogisticsAppointment timeComputer science

The invention discloses an express receiving and sending system and method, and aims to solve the technical problem of unreasonable distribution of unmanned distribution resources in the prior art. The express receiving and sending system comprises an unmanned express station, a background server and at least one distribution robot, wherein the distribution robot carries out automatic distributionbetween the unmanned express station and a user. The invention also designs a method for sending the express, and the distribution robot automatically navigates to the doorway of the user according to the user order, obtains the express to be sent and then automatically returns to the unmanned express station. The invention further designs a method for receiving the express delivery. The deliveryrobot transports the express delivery from the delivery station to the doorway of the user at the appointment time. The system has the beneficial effects of being high in working efficiency and convenient to use.

Owner:河南省吉立达机器人有限公司

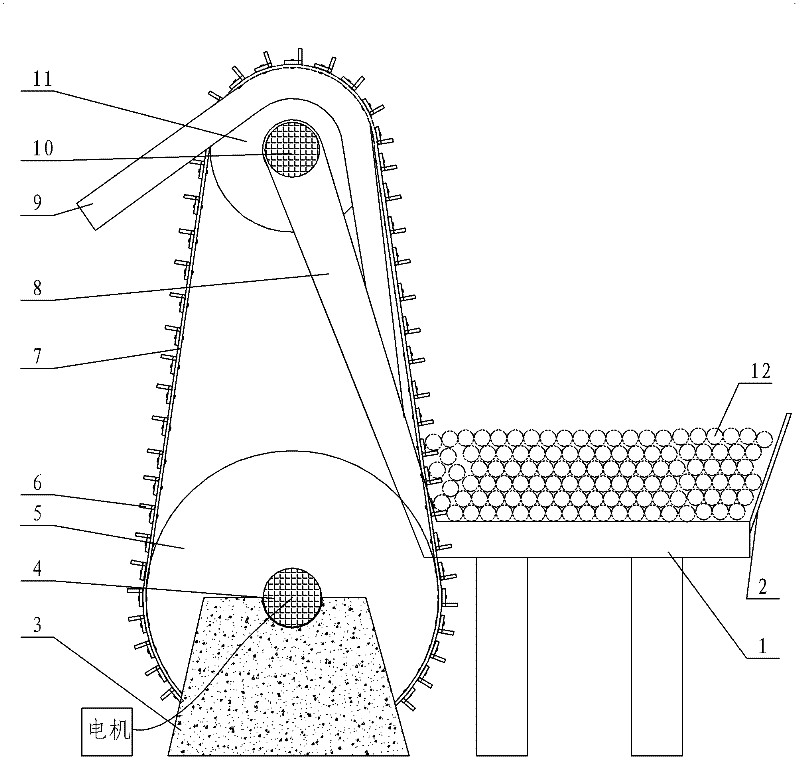

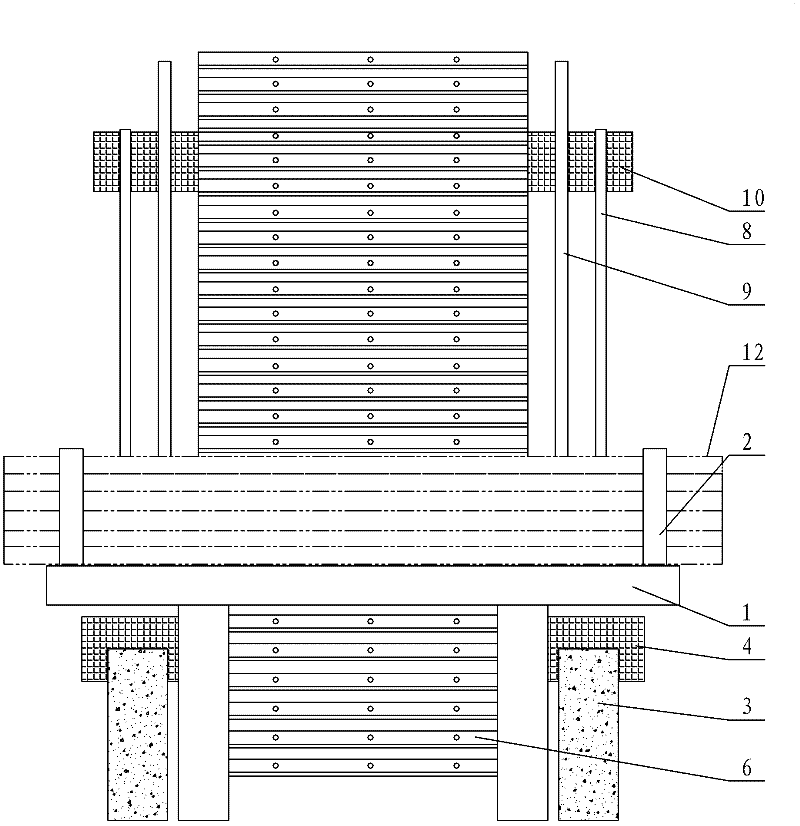

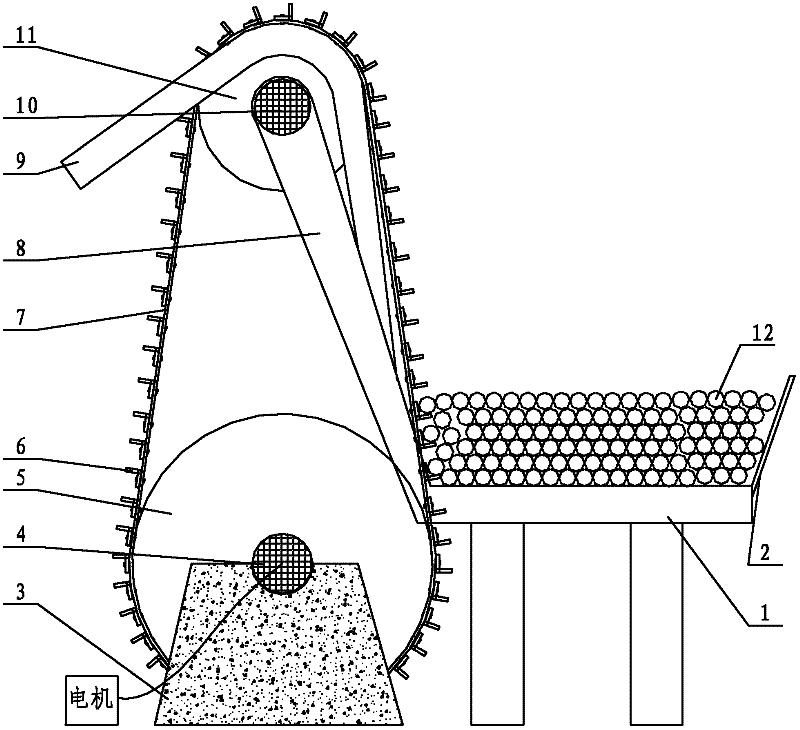

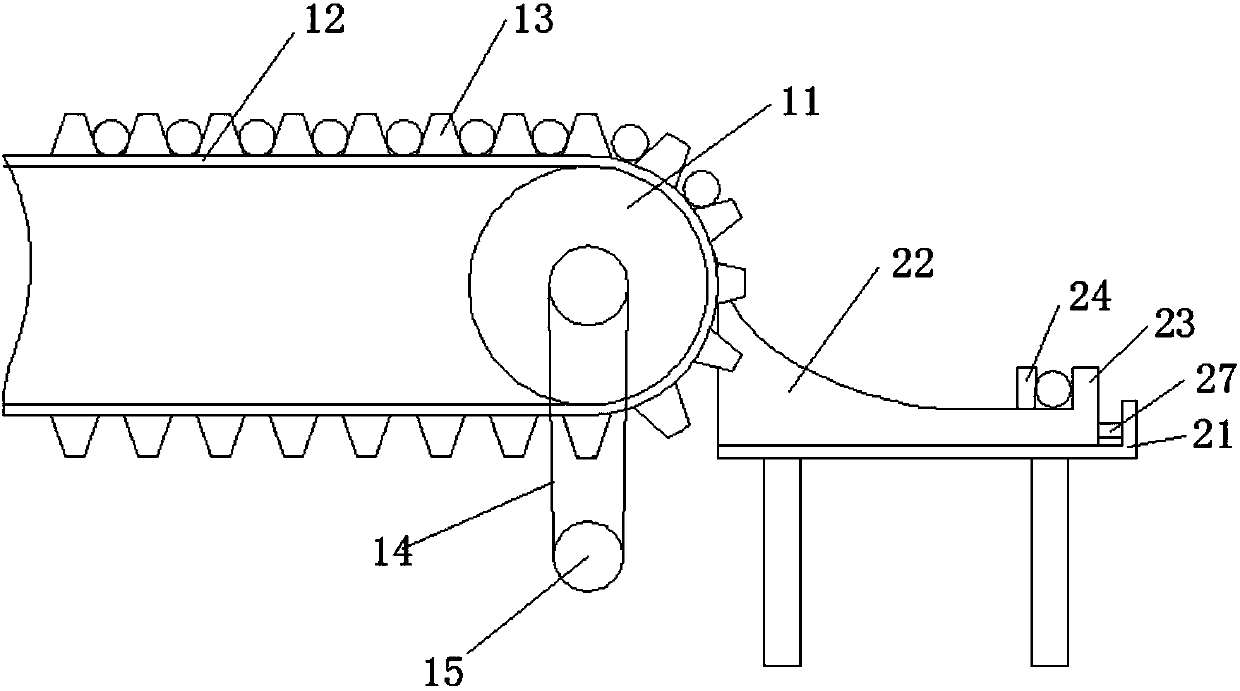

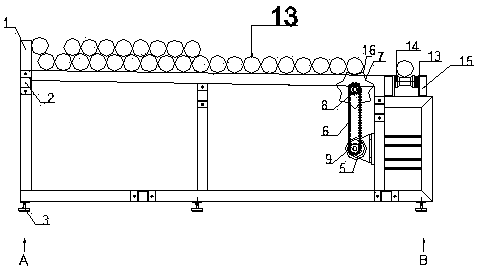

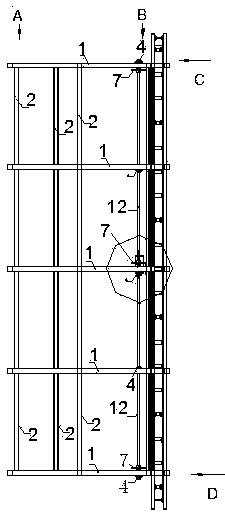

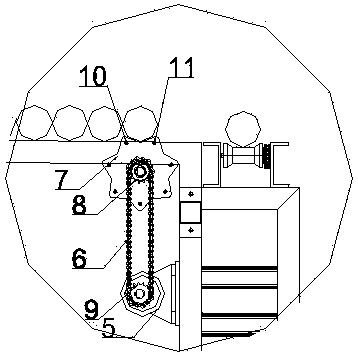

Glass tube automatic conveyer device of thermometer production line

InactiveCN102502174AReduce labor intensityAvoid breakingConveyorsConveyor partsProduction lineDrive wheel

The invention discloses a glass tube automatic conveyer device of a thermometer production line. The glass tube automatic conveyer device comprises an operating platform, wherein two support plates which are arranged in parallel are arranged at one side of the upper part of the operating platform, a driven wheel supported by a rotating shaft b is arranged between the two support plates, two bases which are arranged in parallel are arranged below the driven wheel, a driving wheel supported by a rotating shaft a is arranged between the two bases and a driving belt provided with a transportation plate with an L-shaped cross section is arranged on the driven wheel and the driving wheel. By arranging the L-shaped transportation plate, a glass tube can be hooked and can be conveyed by the driving belt, automatic transportation of a long glass tube can be realized, labour intensity of workers can be reduced, and the conveyor device disclosed by the invention has simple structure and high operability and can prevent the glass tube from being broken, reduce cost and guarantee personal safety of operators.

Owner:WUXI MEDICAL INSTR FACTORY

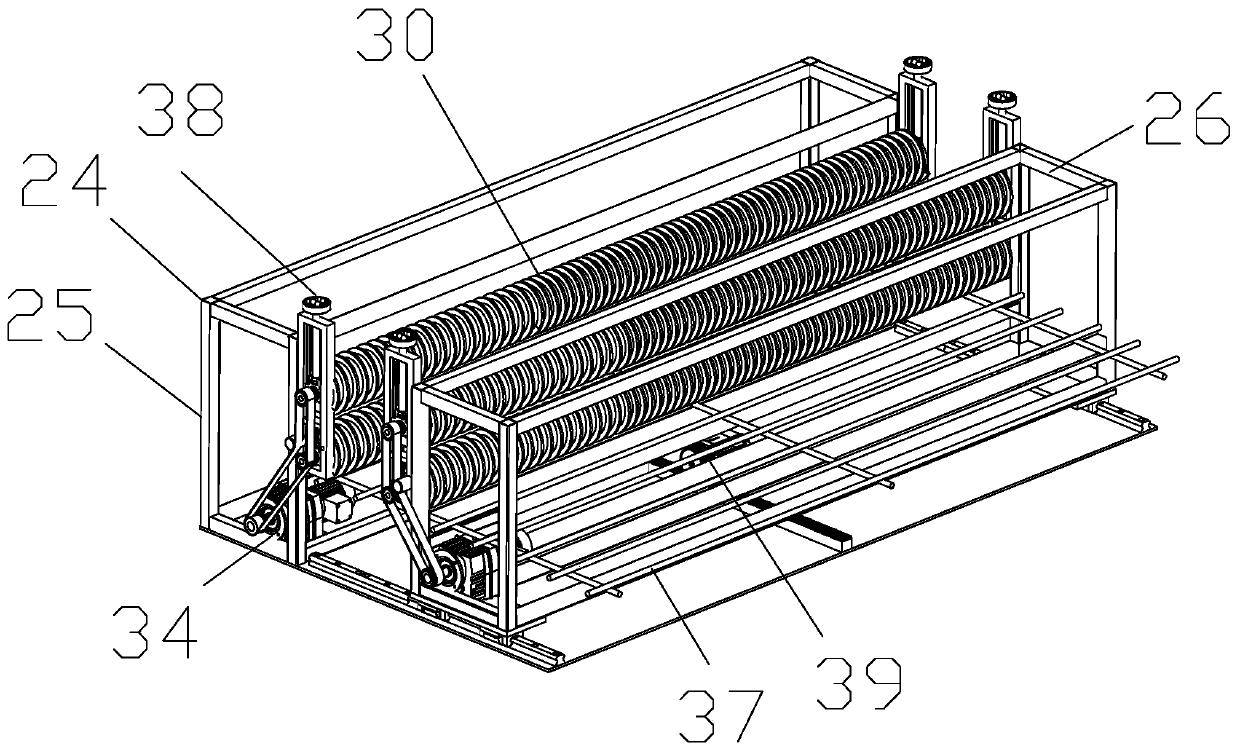

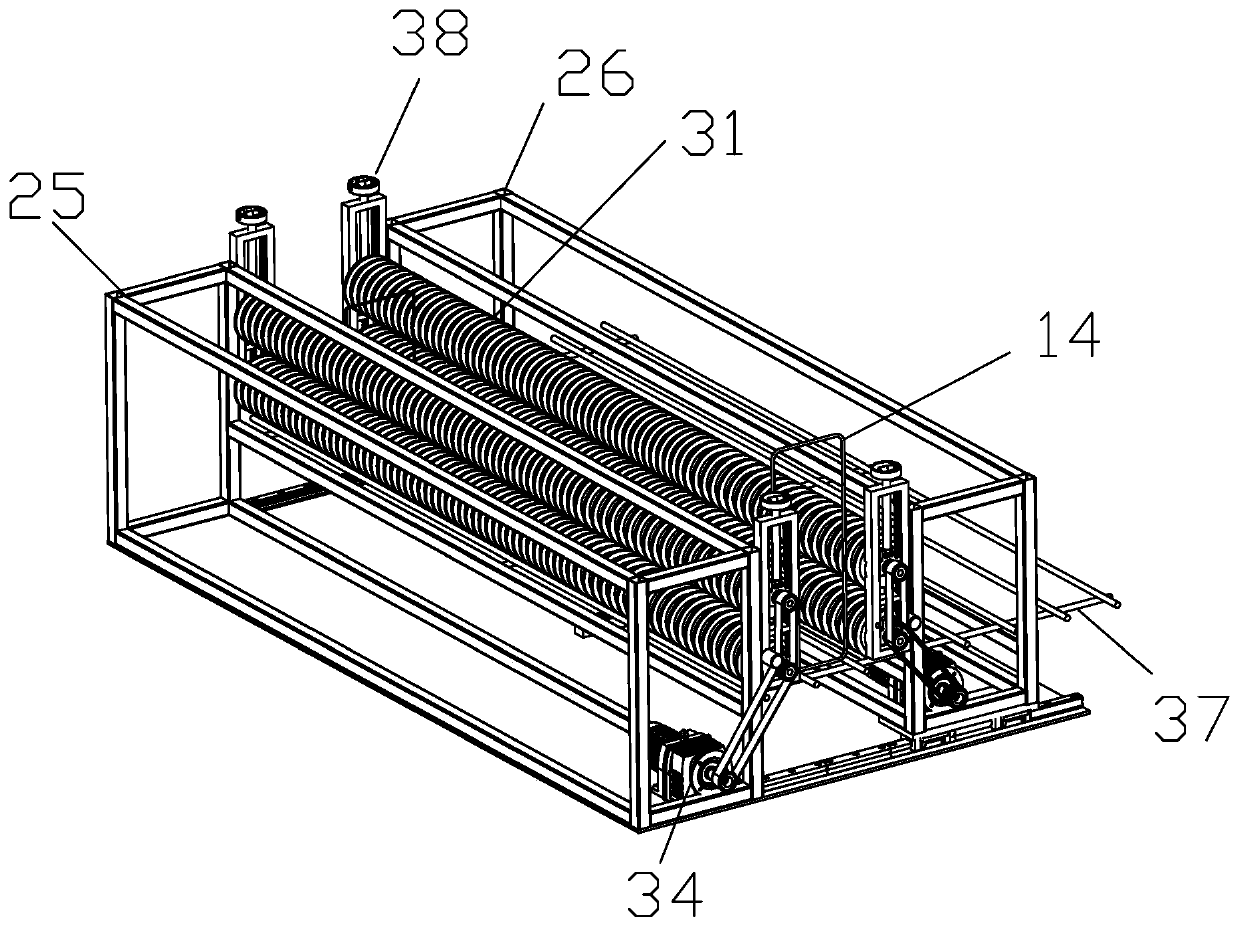

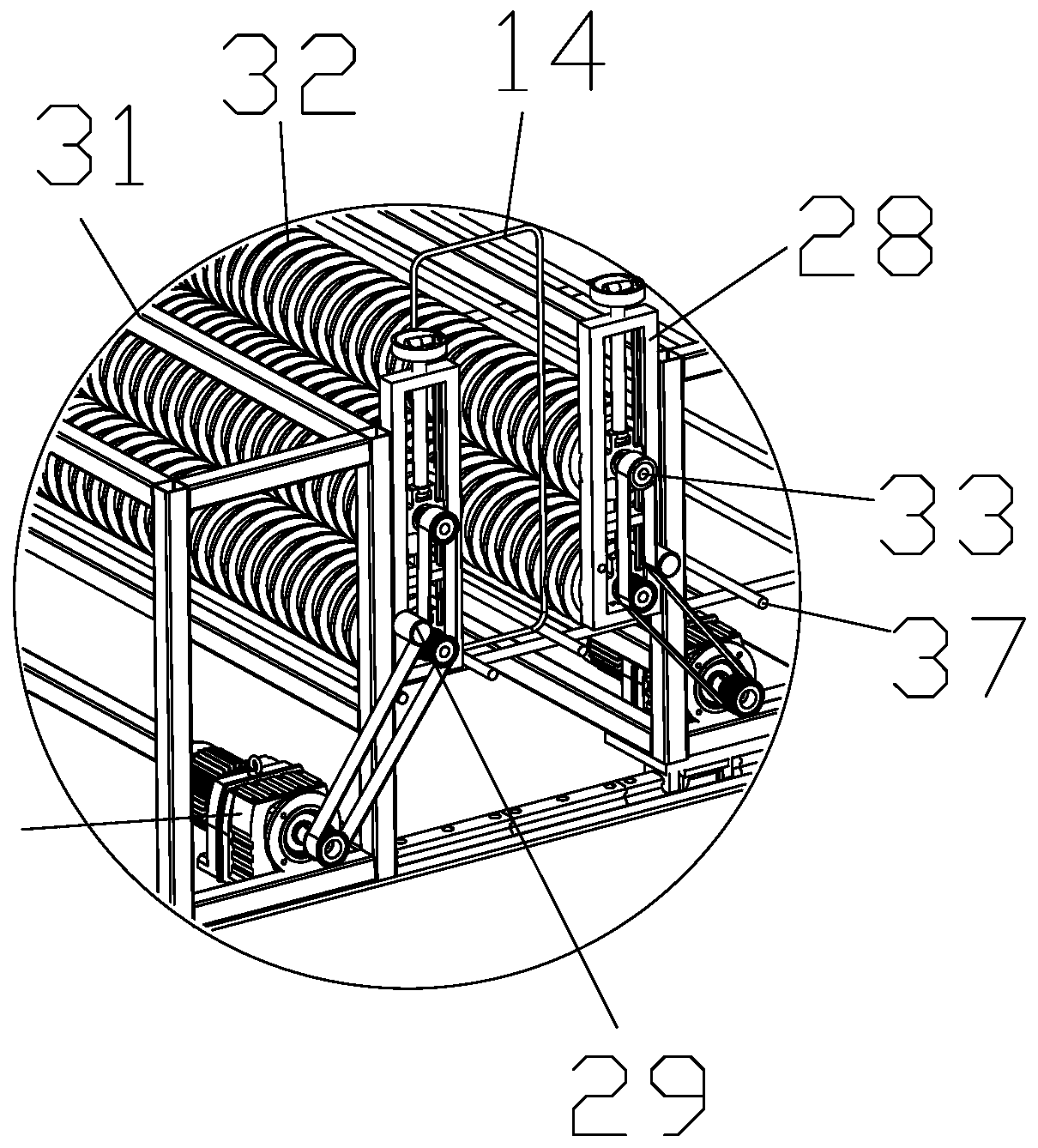

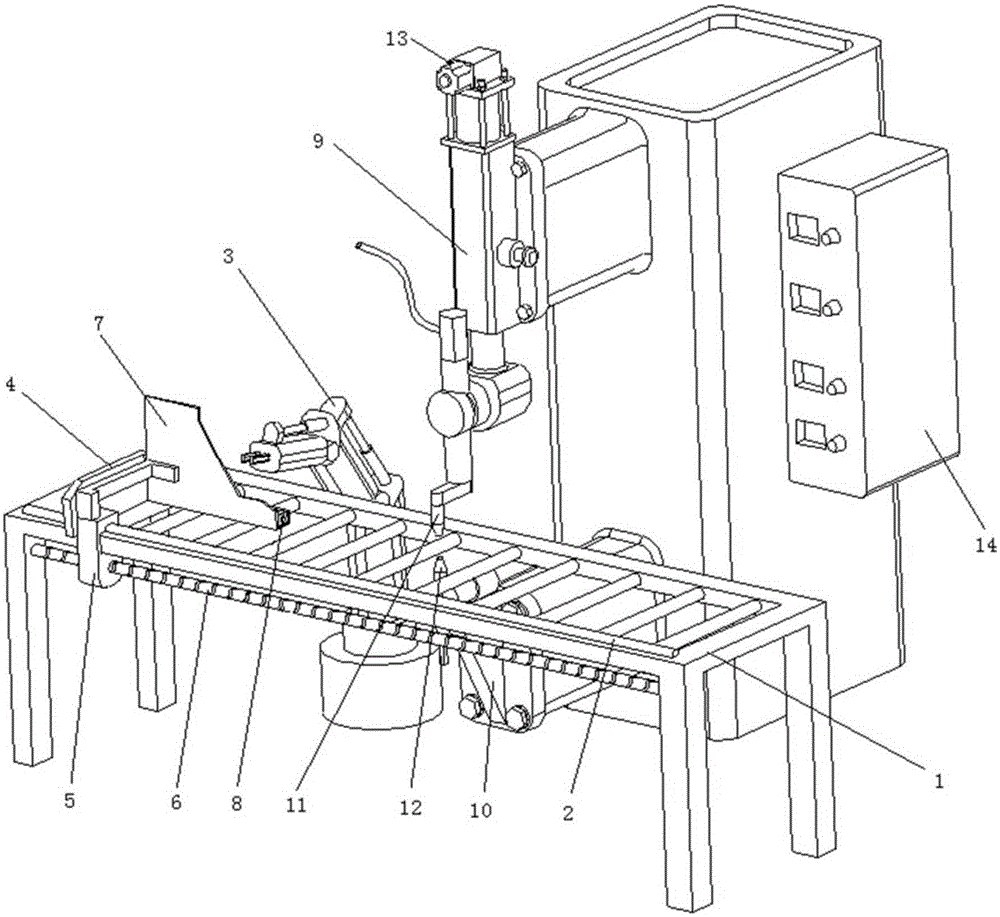

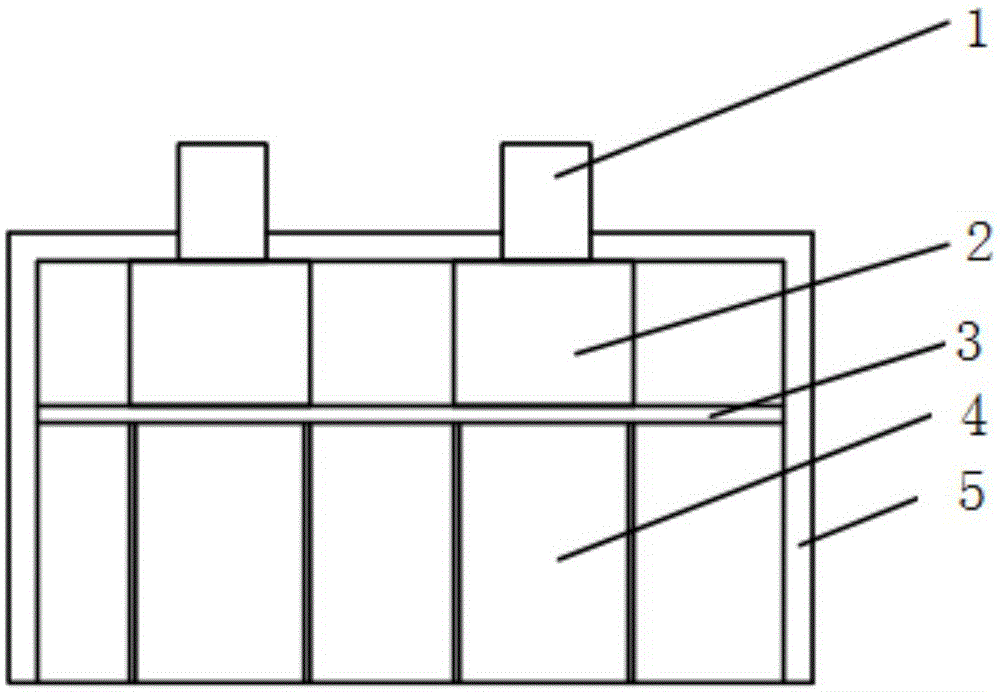

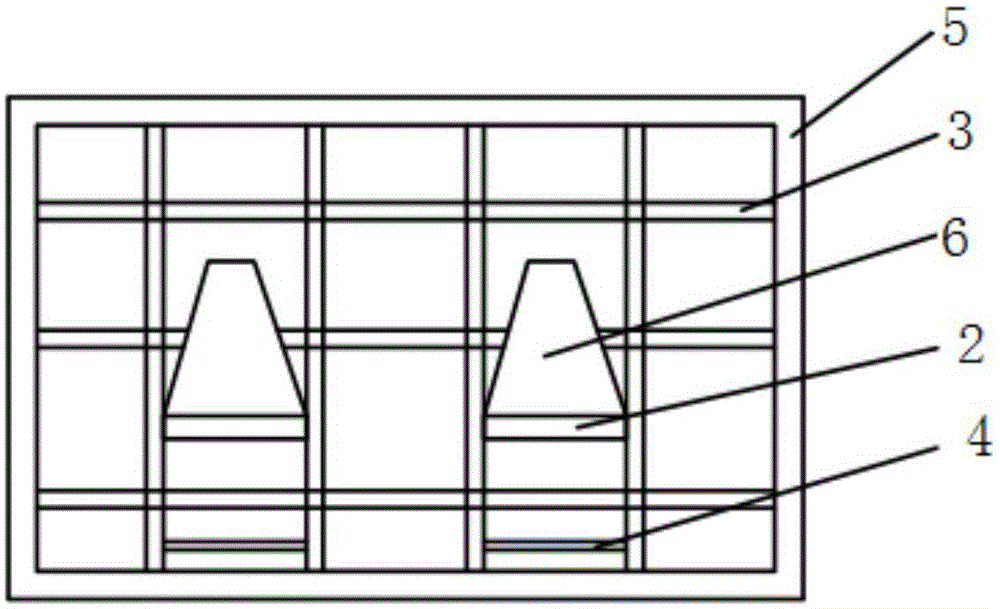

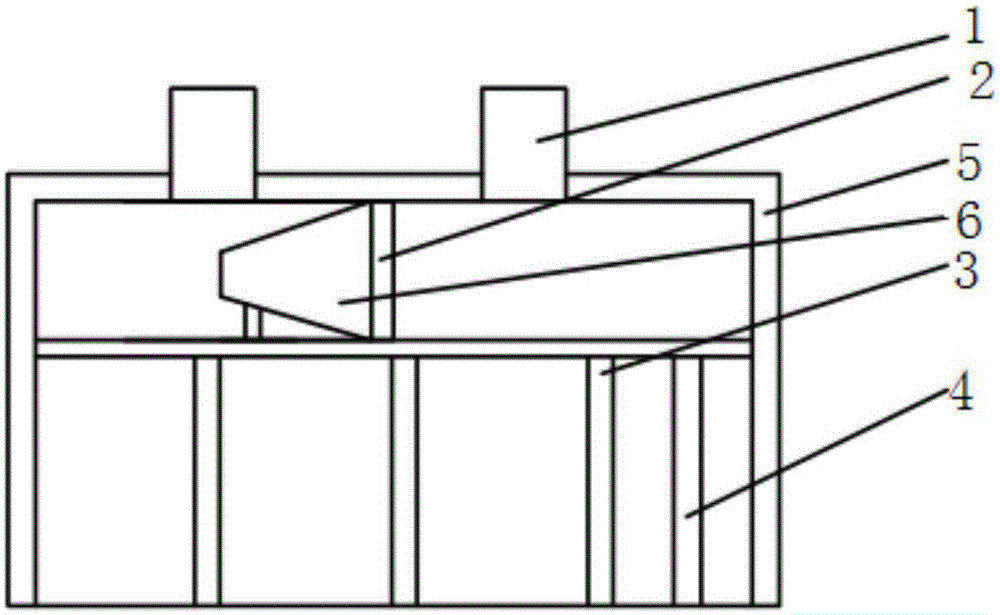

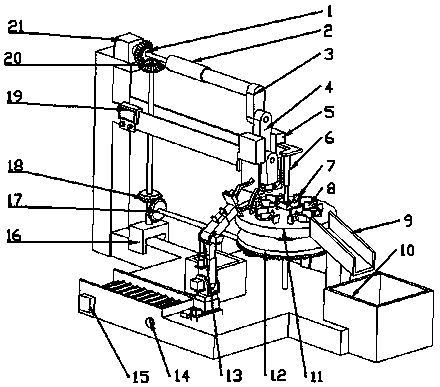

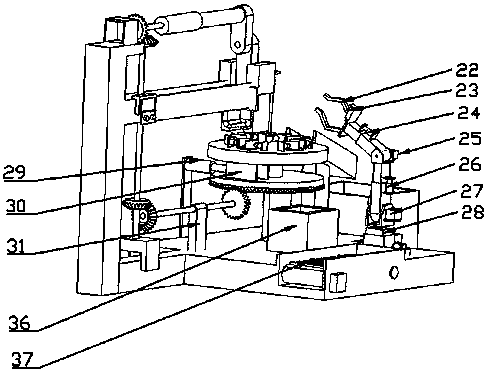

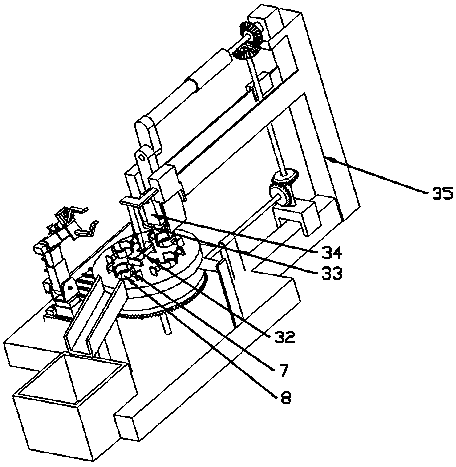

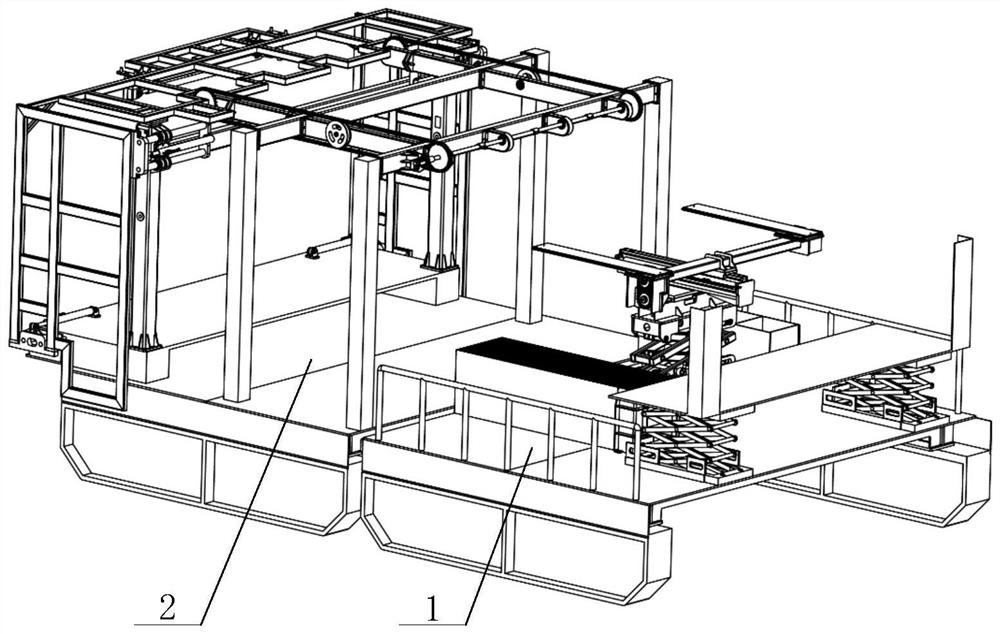

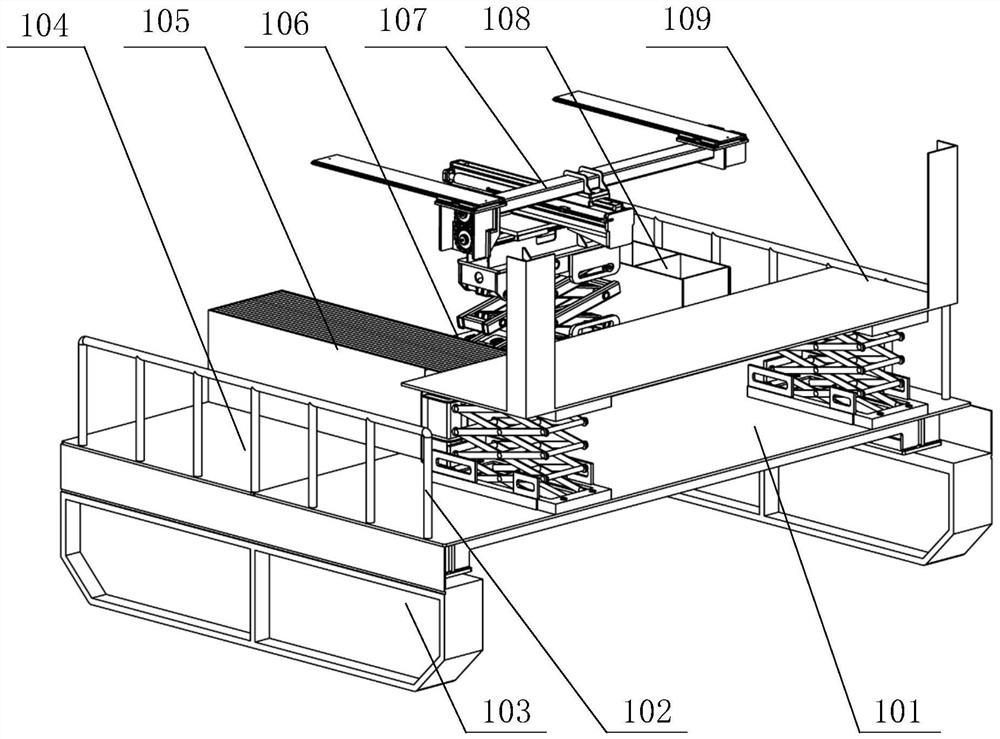

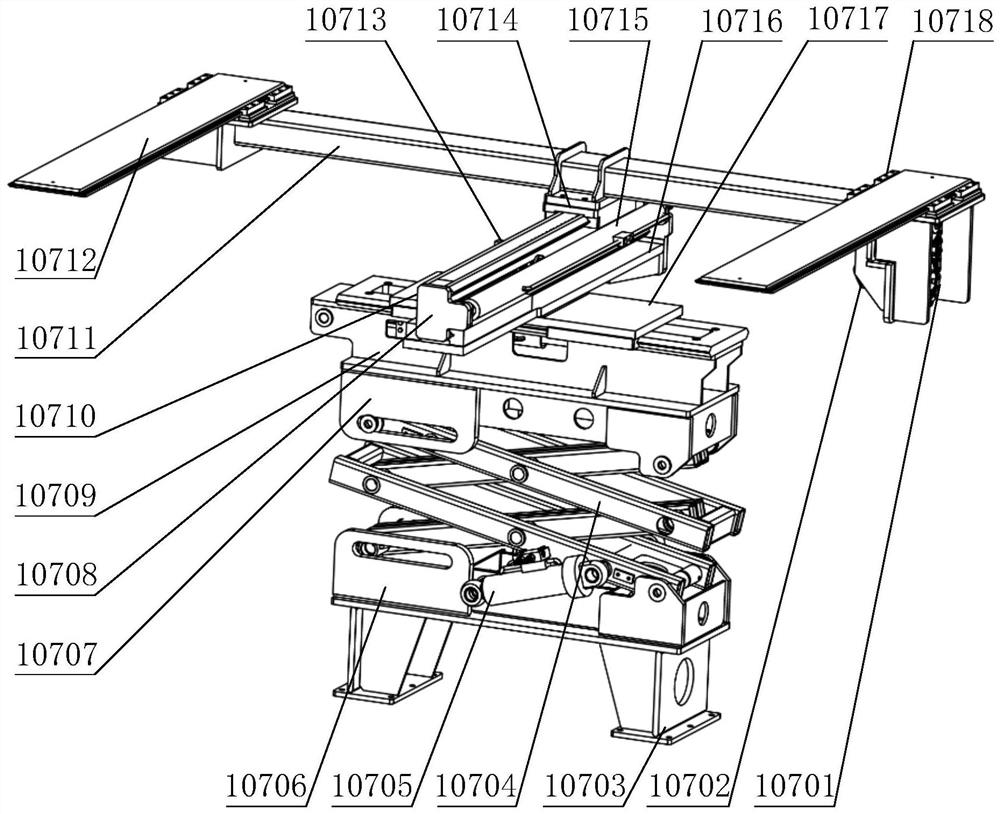

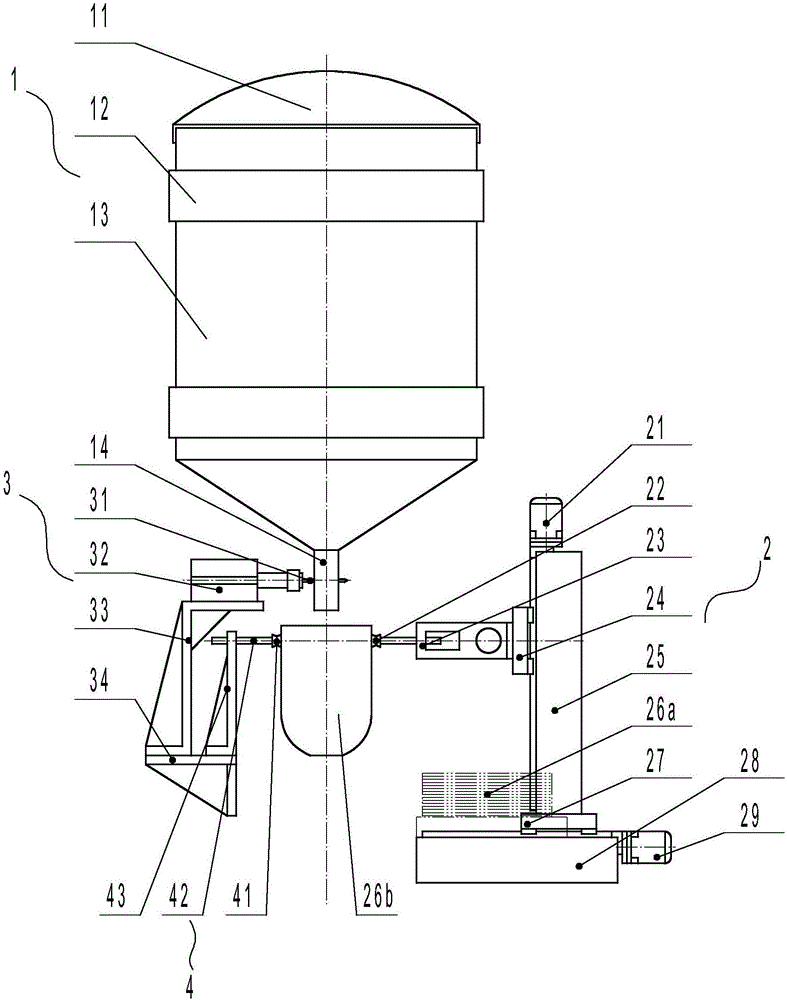

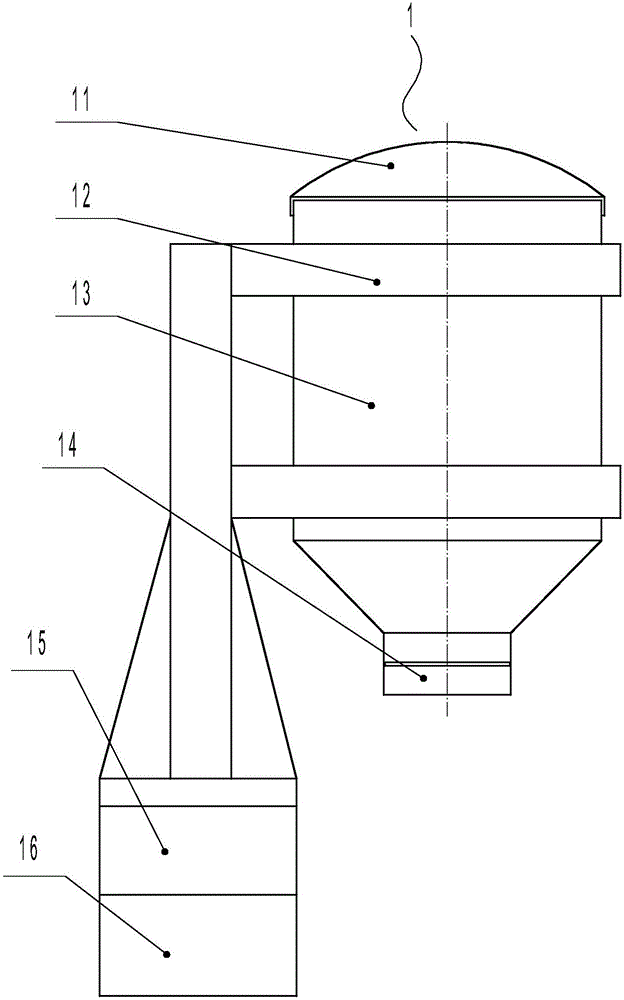

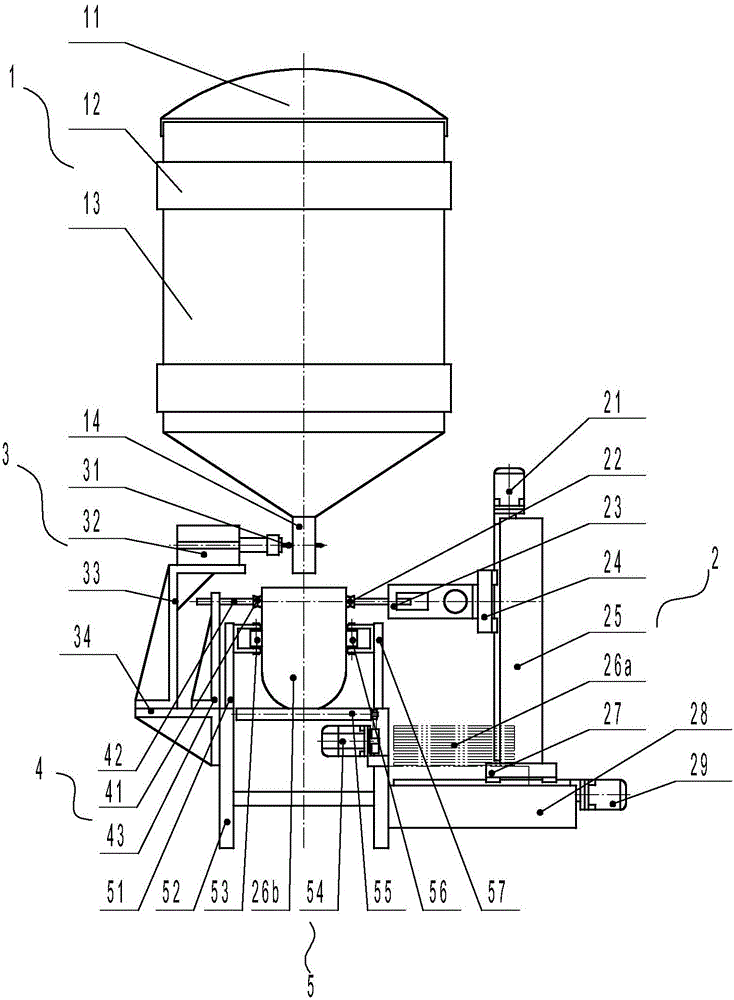

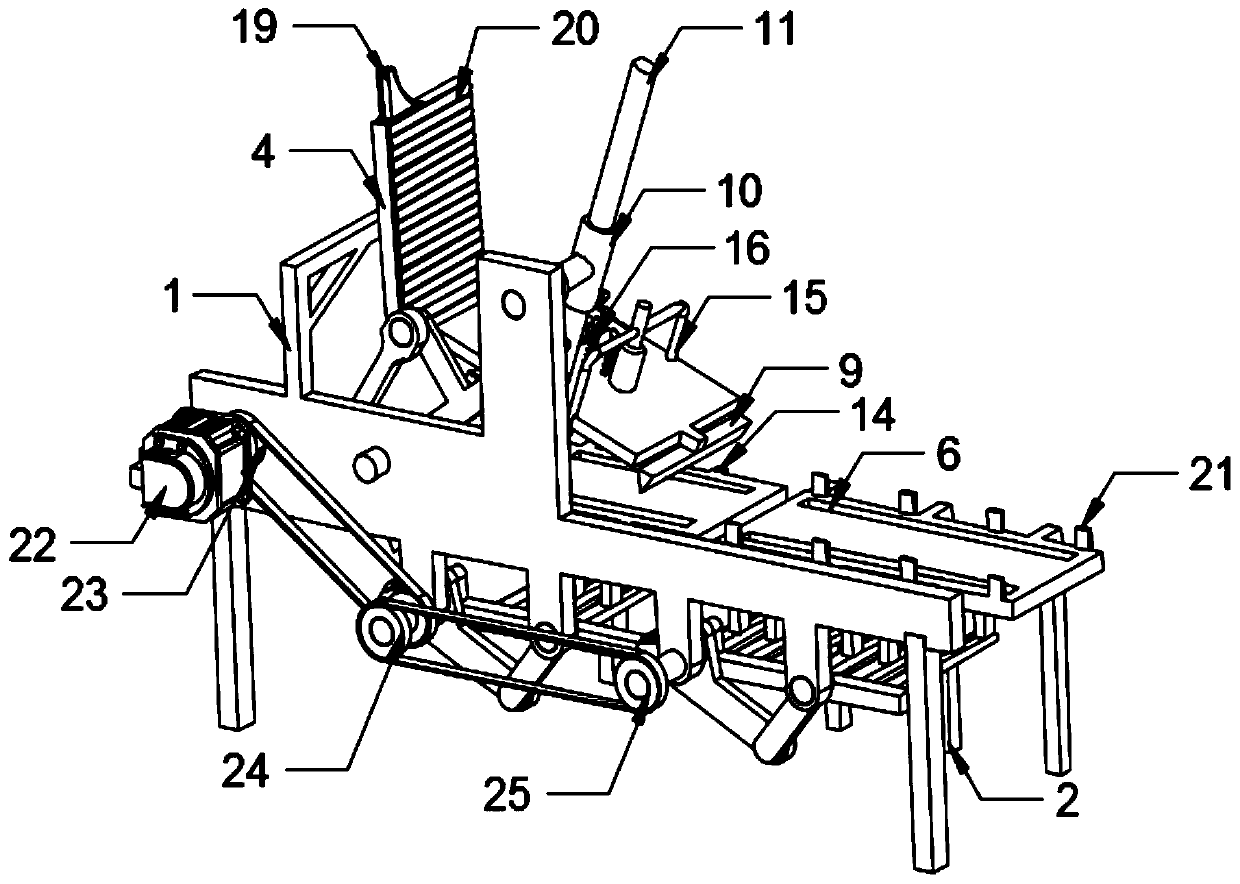

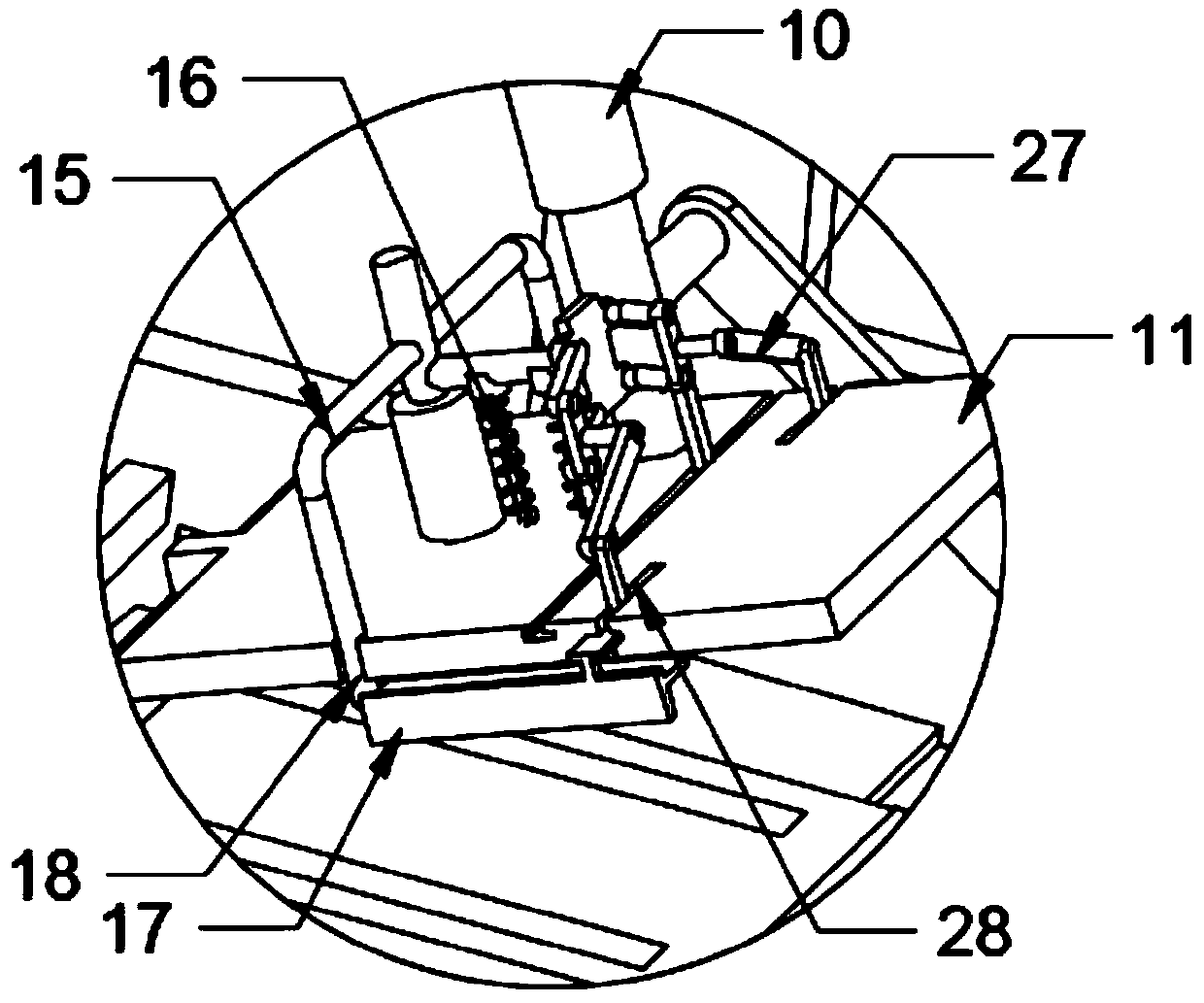

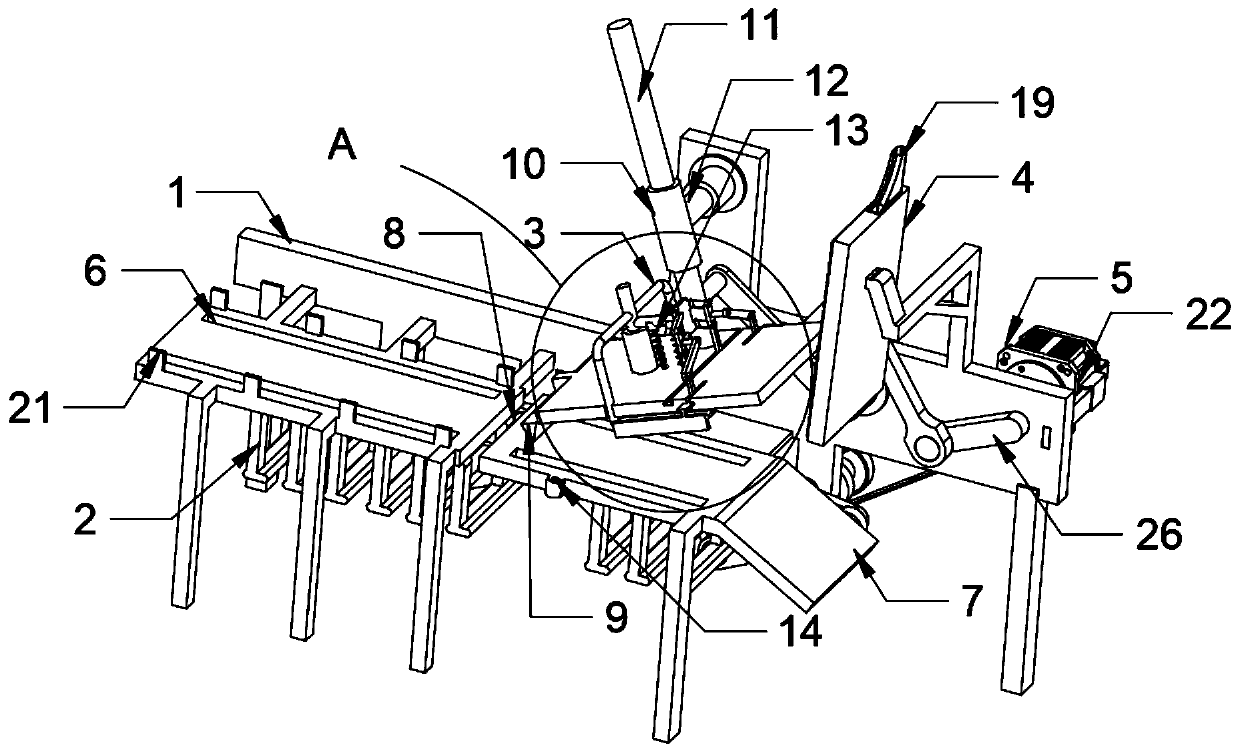

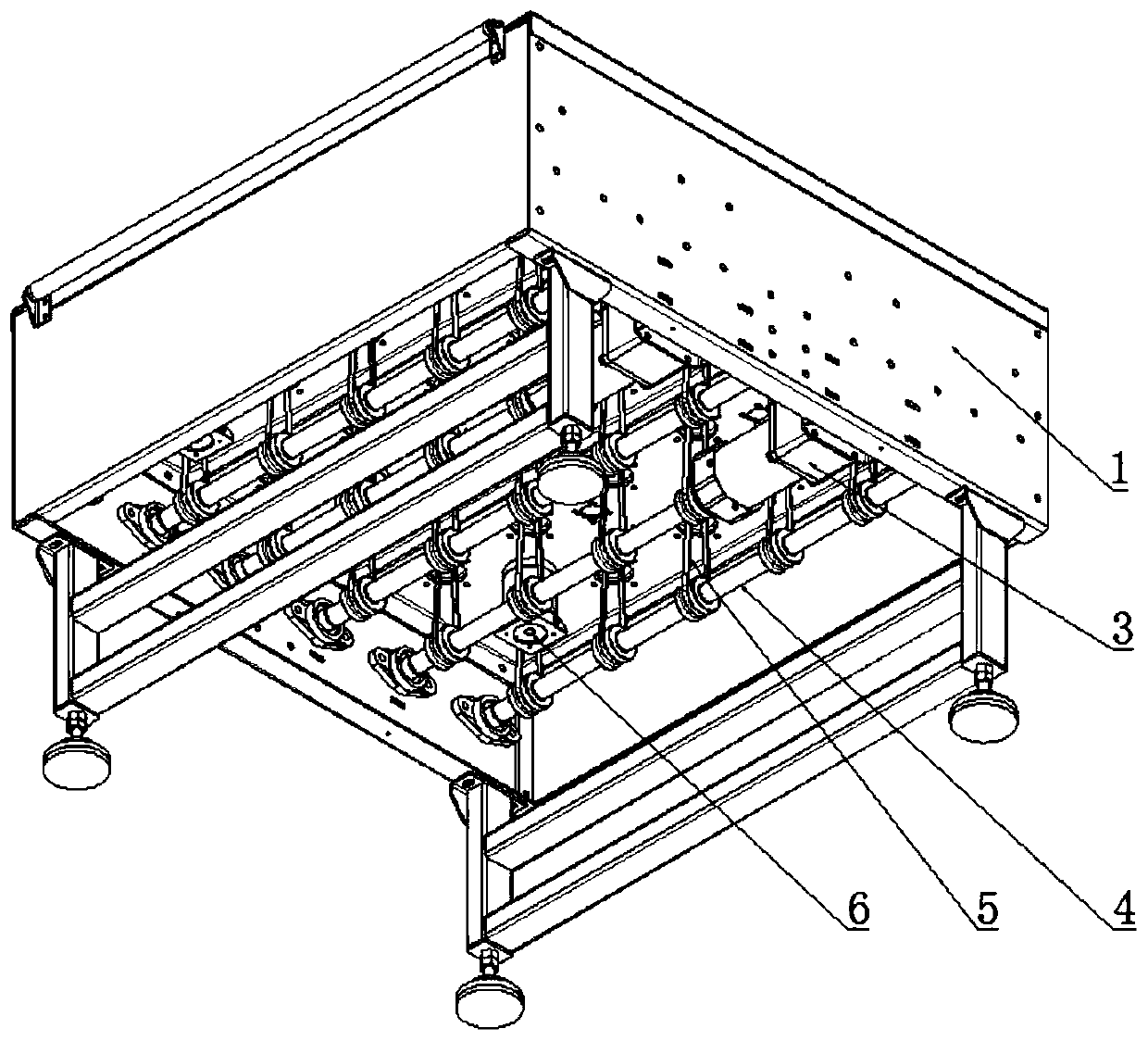

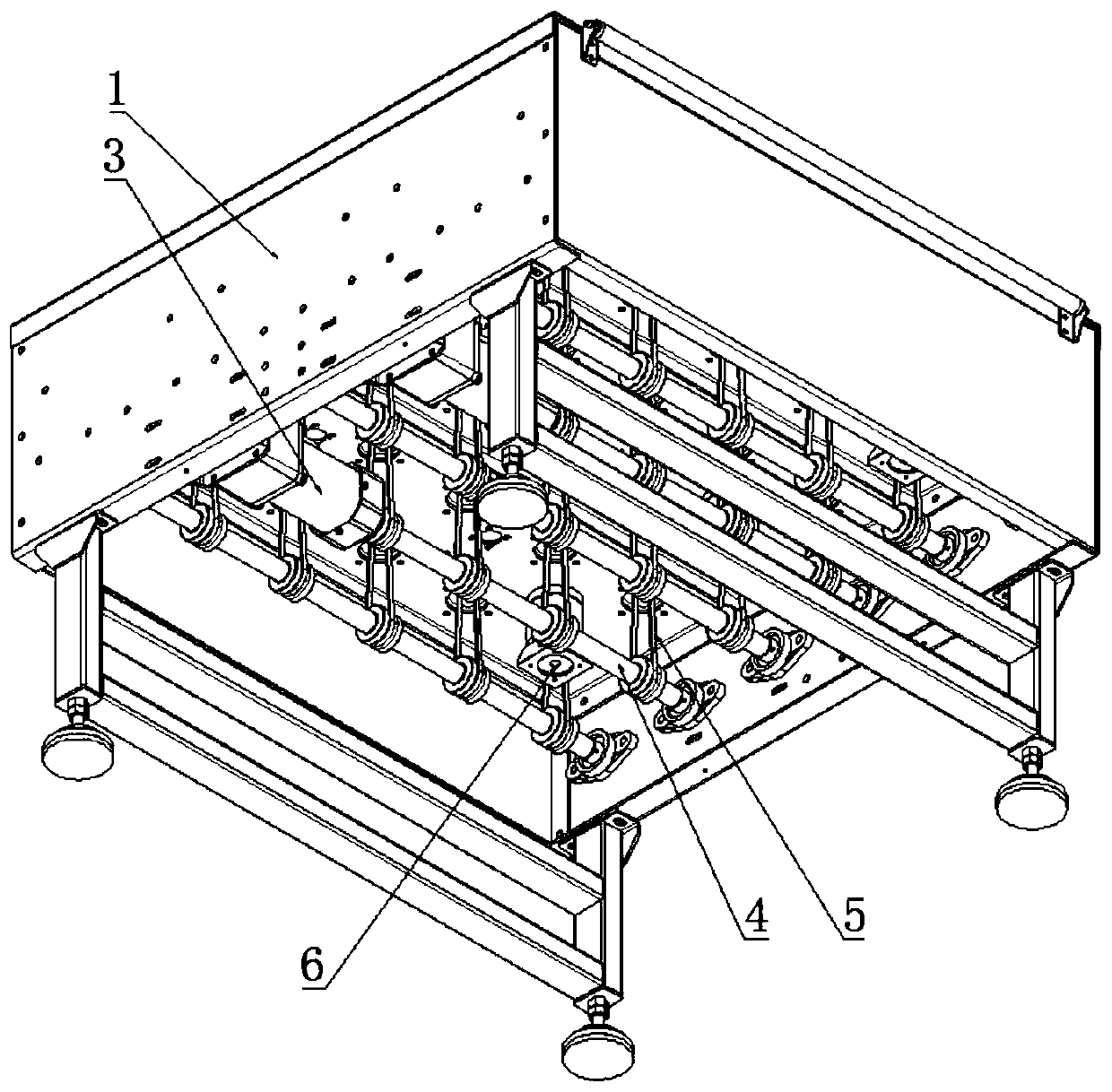

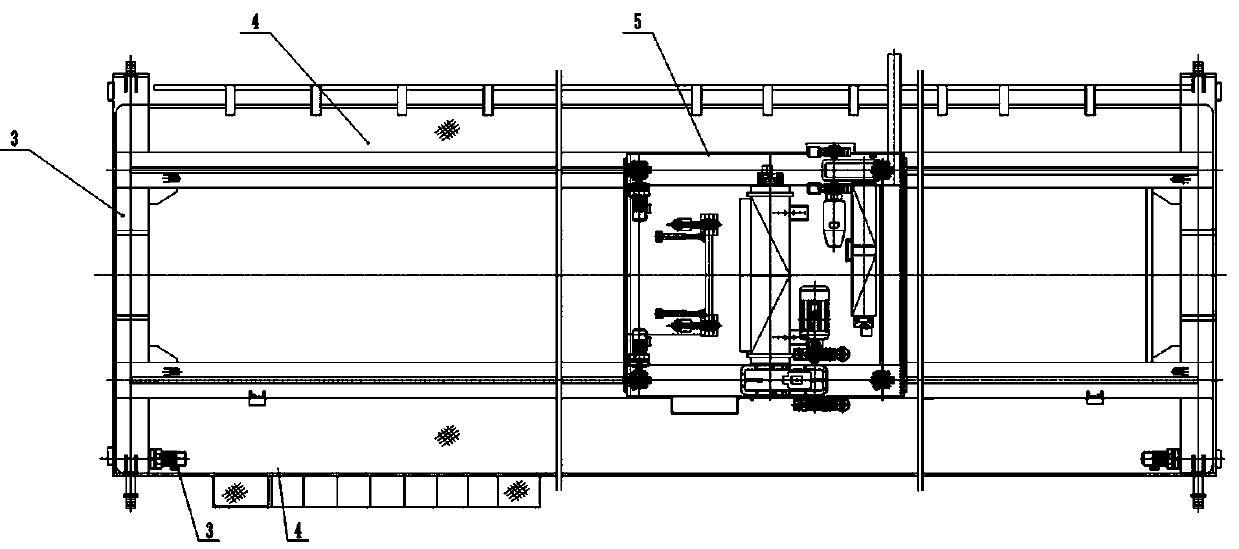

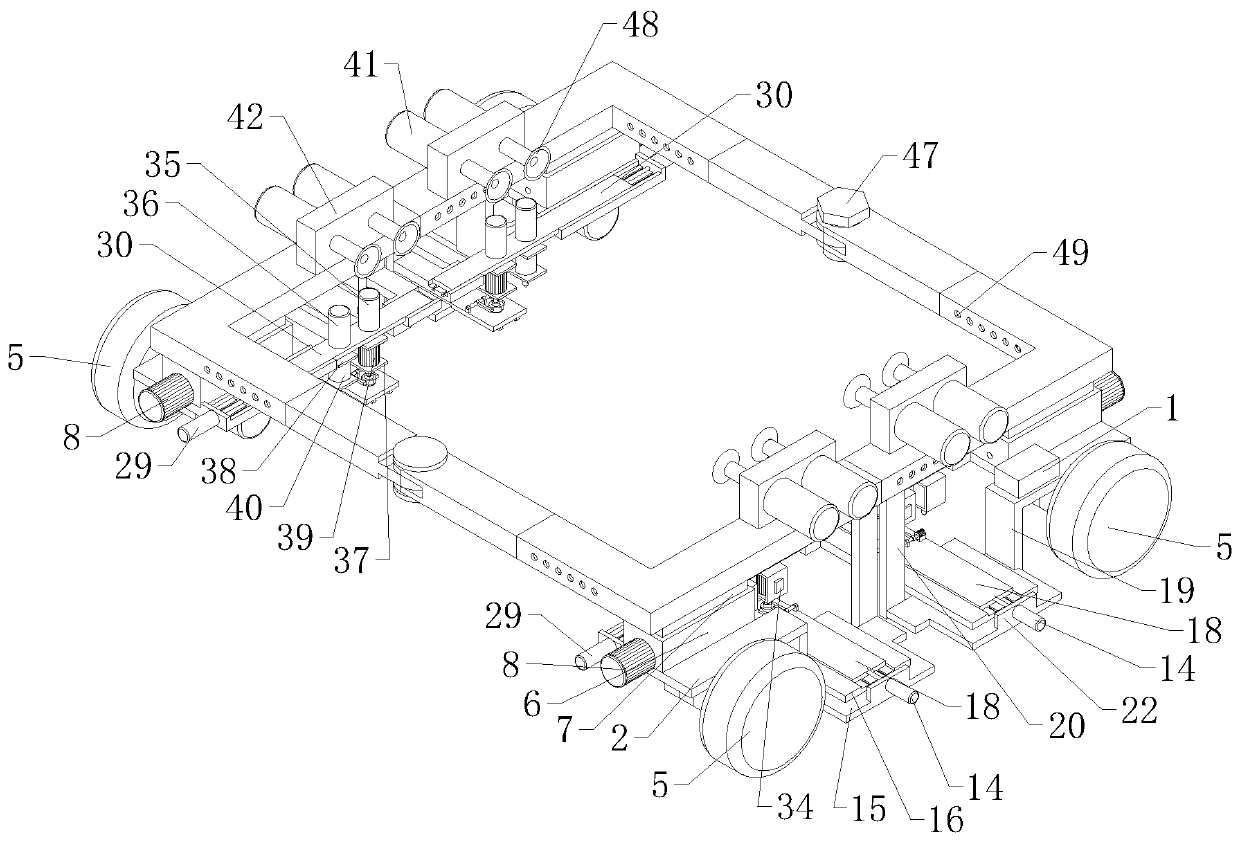

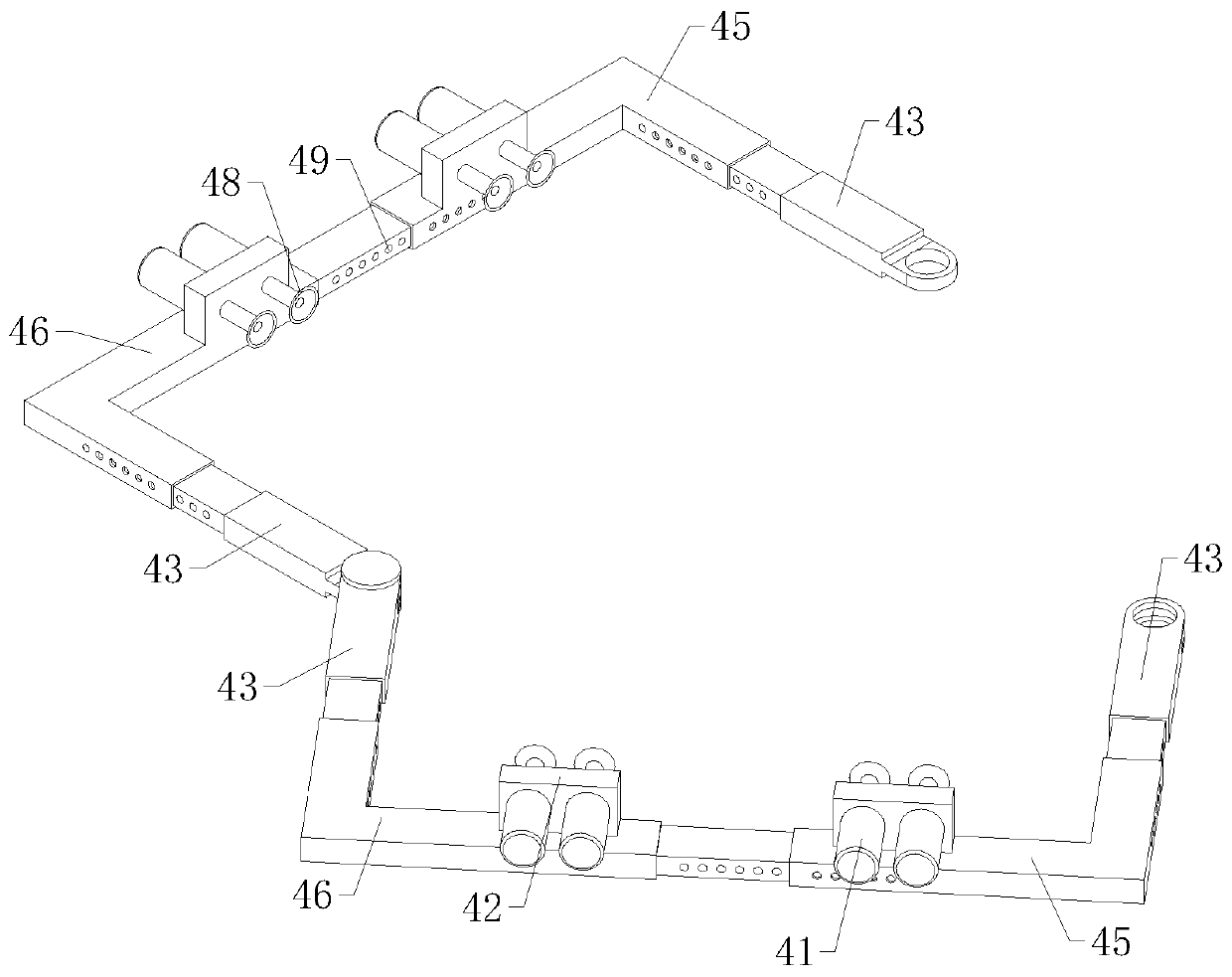

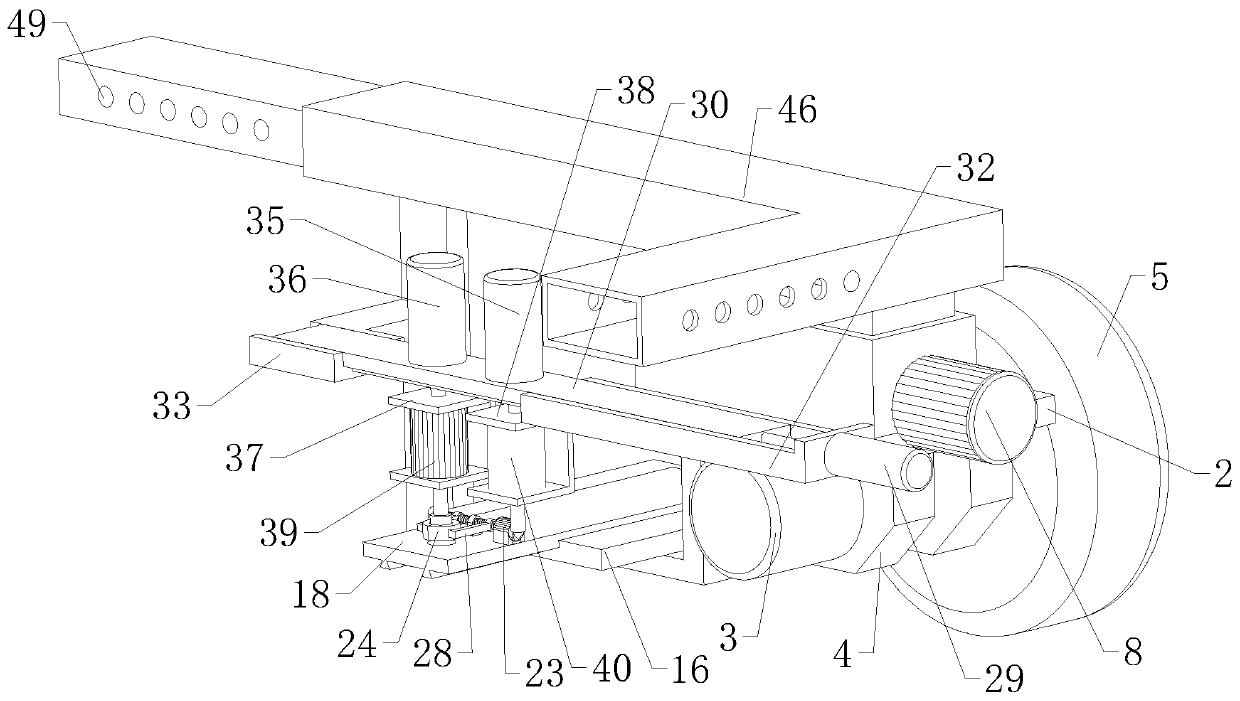

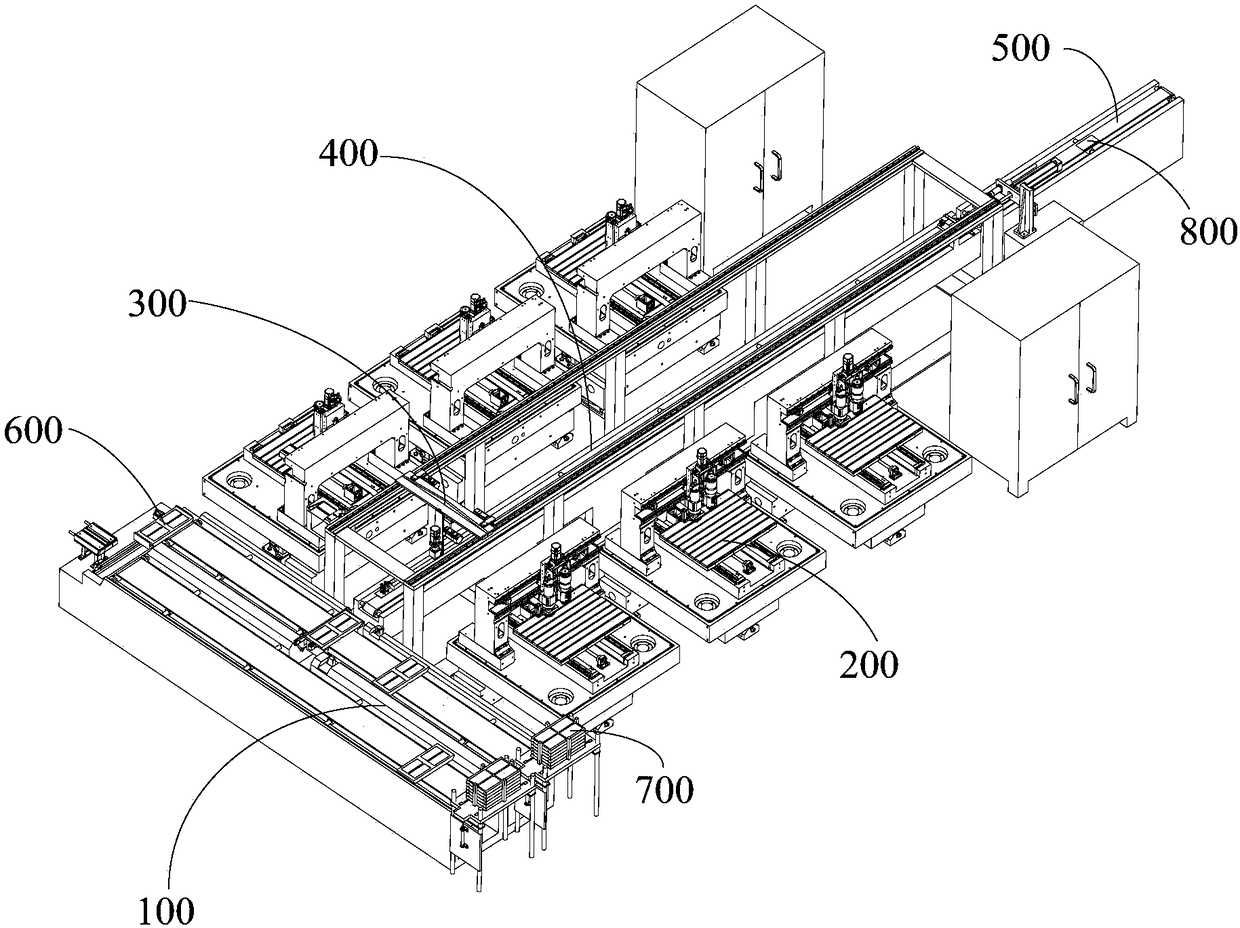

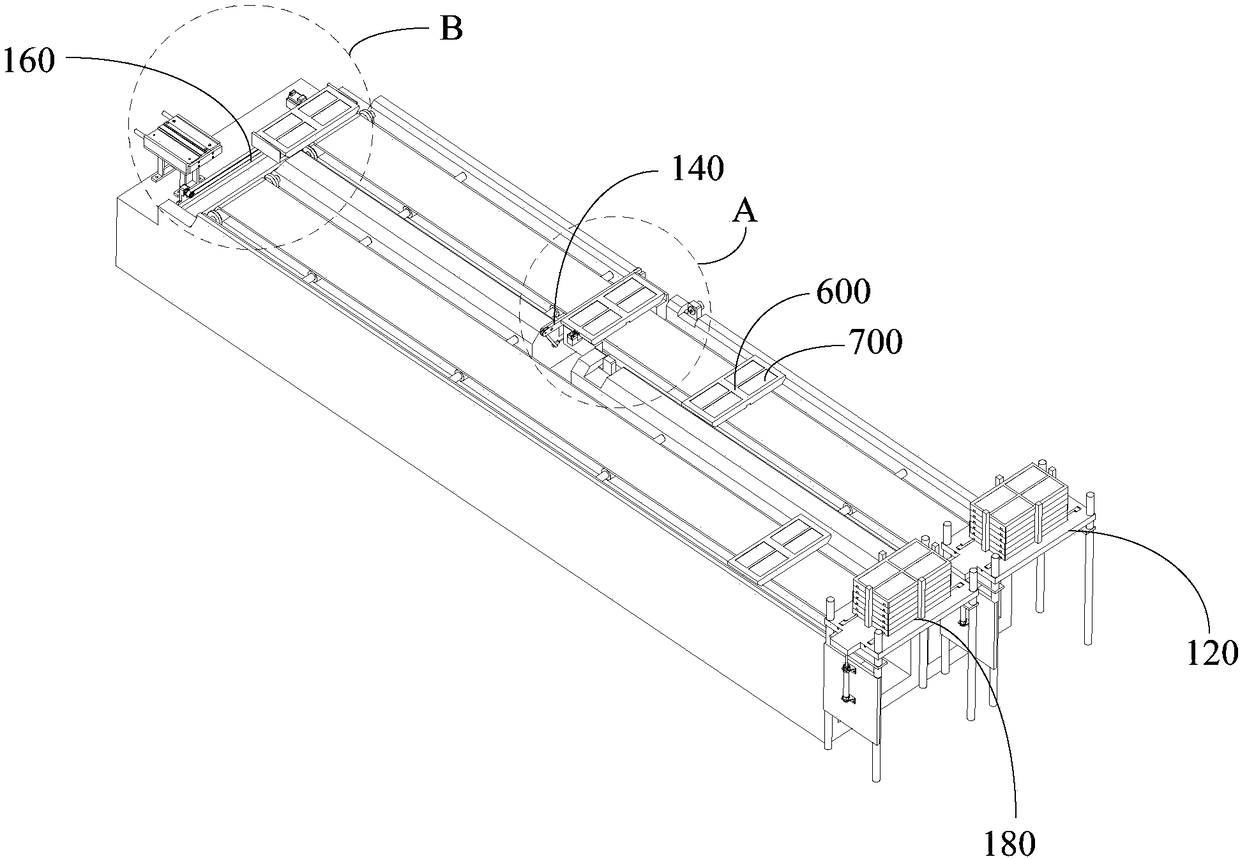

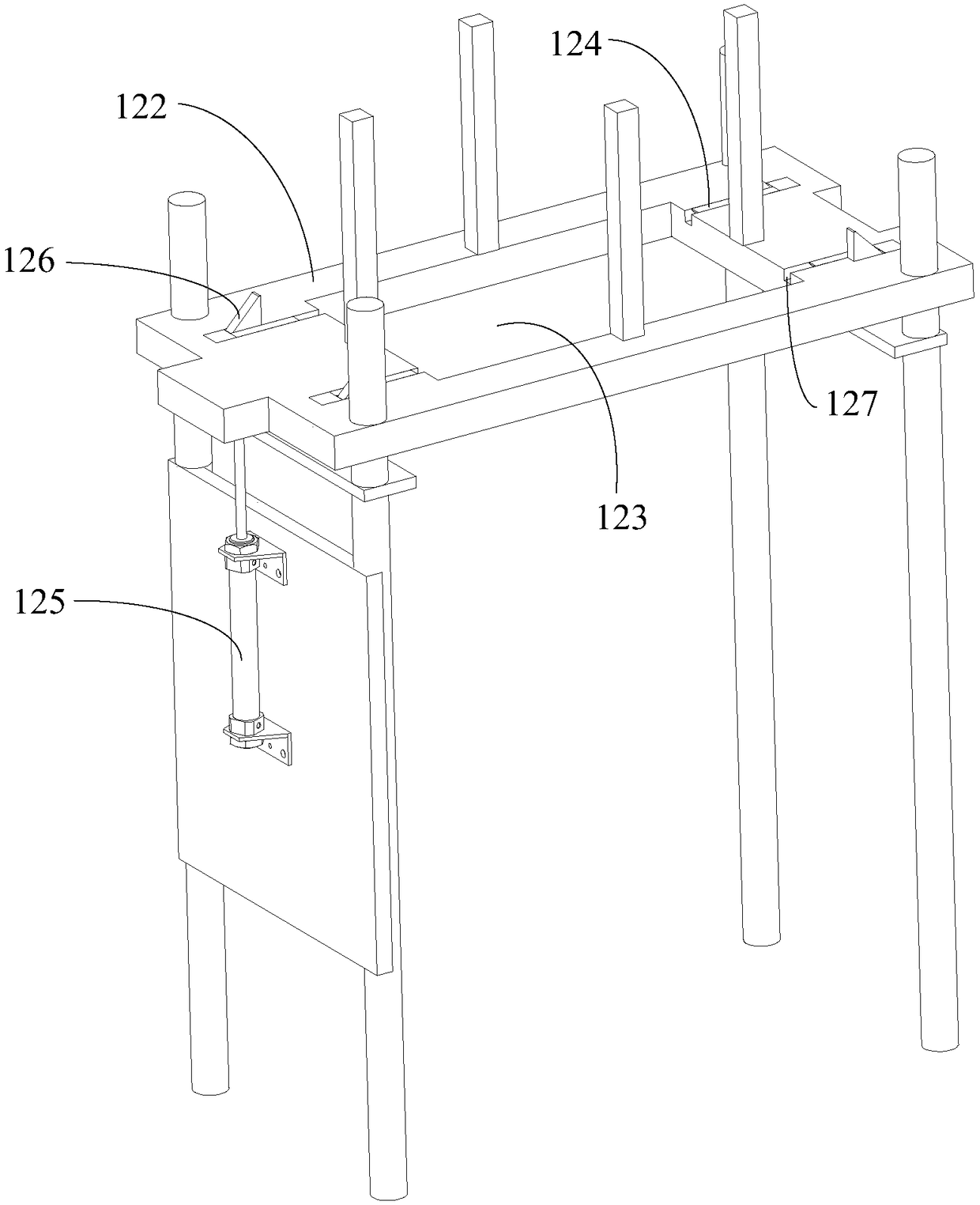

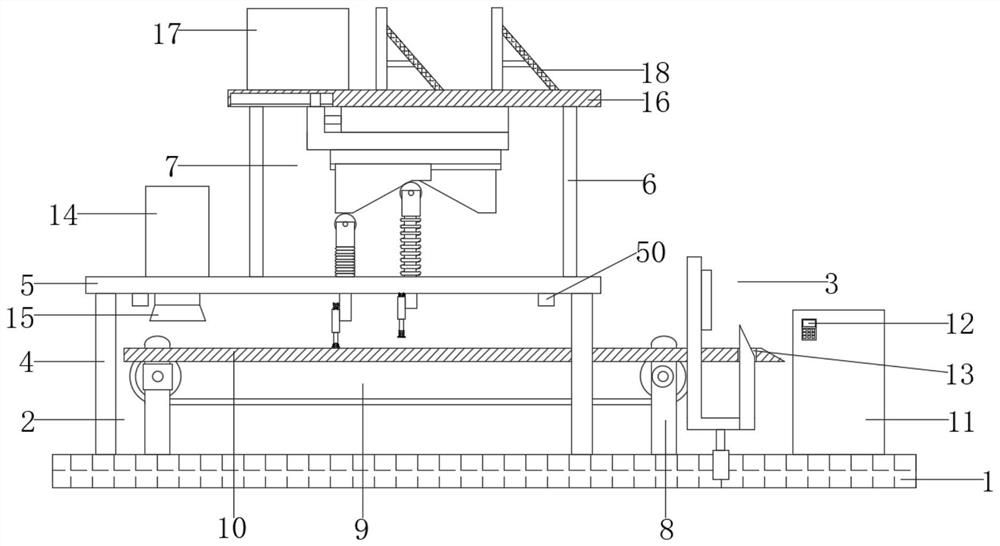

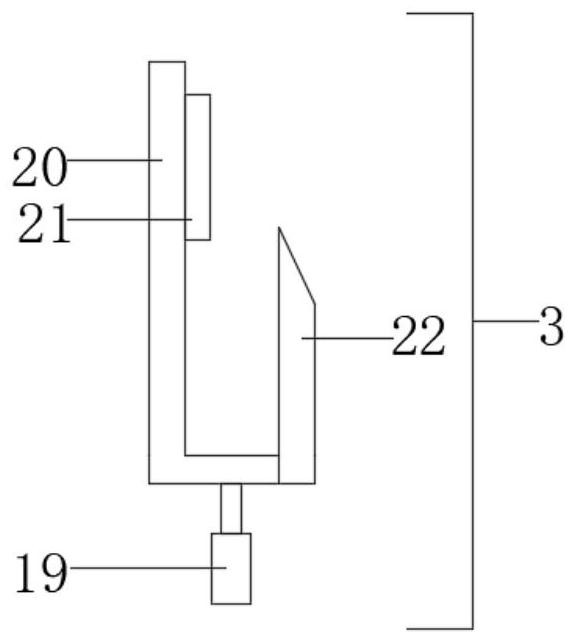

Complete equipment for welding beam or column reinforcement cage

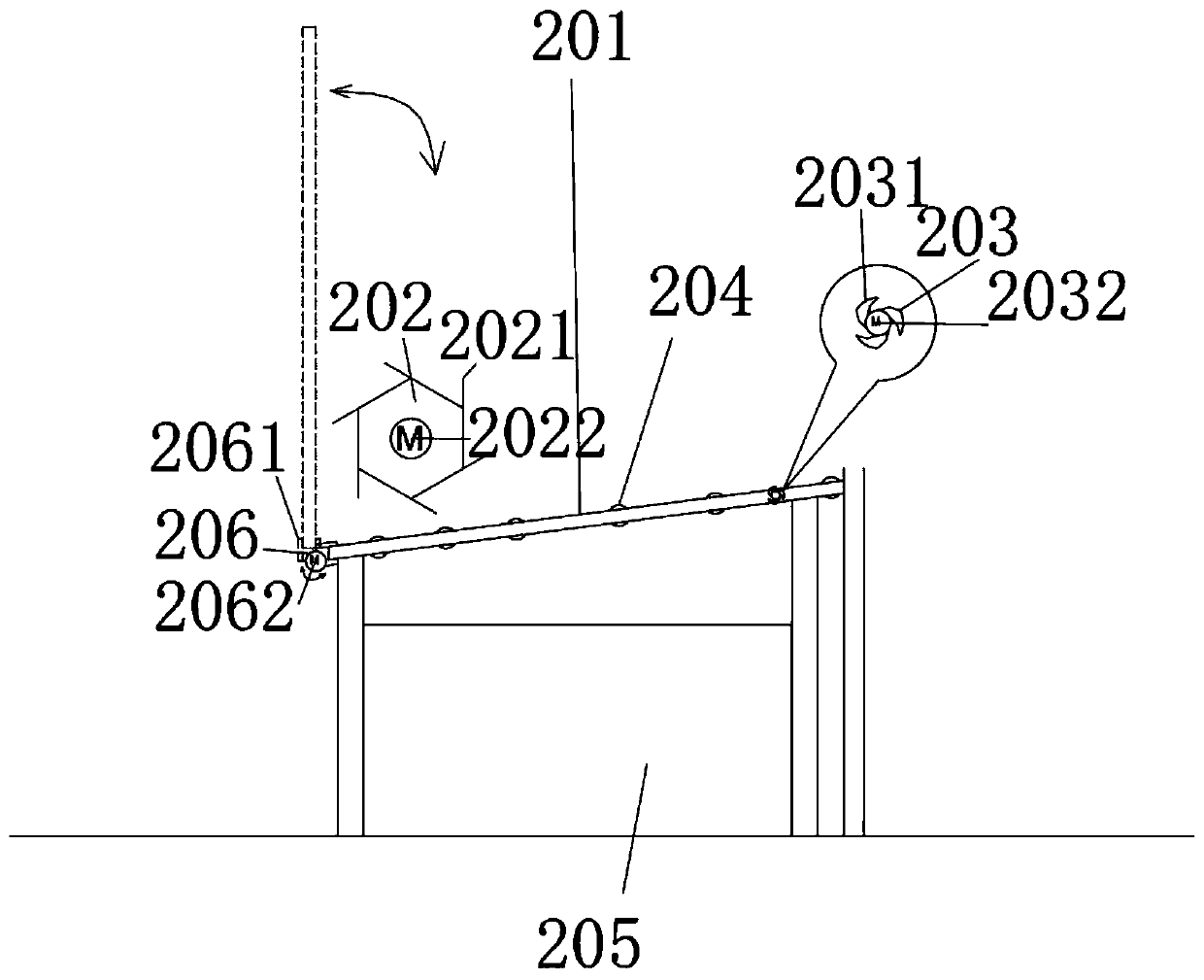

PendingCN109877481ARealize automatic transportationRealize feedingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringRebar

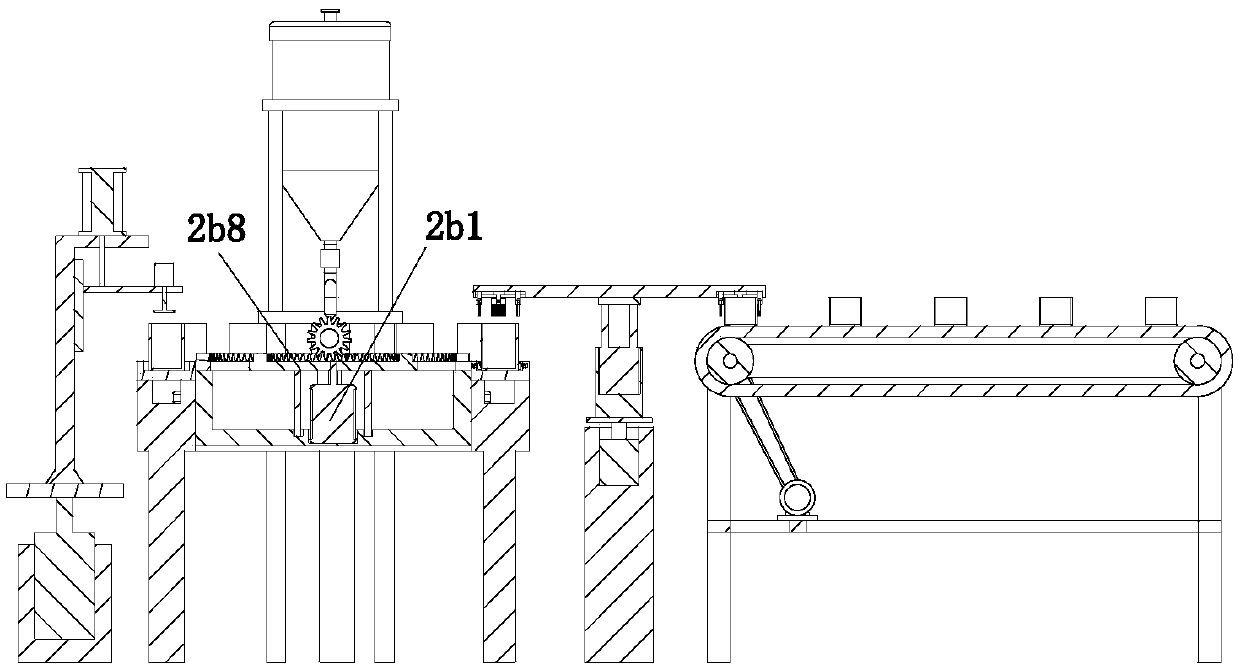

The invention provides complete equipment for welding a beam or column reinforcement cage. The equipment comprises a spiral hooping rib feeding device, a longitudinal rib feeding device and a weldingdevice, wherein the spiral hooping rib feeding device, the longitudinal rib feeding device and the welding device are sequentially arranged according to the production process, the spiral hooping ribfeeding device is used for conveying hooping ribs to the welding device, the longitudinal bar feeding device is used for conveying the longitudinal bars to the welding device, the tail ends of the longitudinal bars are inserted into the hooping ribs, and the welding device is used for welding the hooping ribs on the peripheries of the plurality of longitudinal ribs to form the reinforcement cage.According to the equipment, automatic feeding of the hooping ribs and the longitudinal ribs and automatic welding of the reinforcement cage can be realized, manual participation is reduced, the working efficiency is improved, and the automatic and intelligent degree is high.

Owner:CHINA MINGSHENG DRAWIN TECH INVESTMENT CO LTD

Automatic workpiece conveying and assembling production system and method

ActiveCN103625920AAddress usability issuesAddressing Structural ComplexityManipulatorConveyor partsEngineeringMaterial storage

The invention discloses an automatic workpiece conveying and assembling production system and method suitable for the technical field of automatic production systems. The production system comprises a transmission device, a material accommodating device, a rotating drive device, a first industrial robot and a second industrial robot. The material accommodating device is provided with at least two material storage discs; an image recognition device is arranged above the transmission device and / or the material accommodating device. The production method includes the following steps that photos of different teaching workpieces are taken through the image recognition device, and then the workpieces are alternatively taken out of the material accommodating device and conveyed to the transmission device through the first industry robot; photos of the teaching workpieces on the transmission device are taken through the image recognition device, and then the workpieces are clamped into the material accommodating device from the transmission device through the second industrial robot. The automatic workpiece conveying and assembling production system and method are perfect in adaptability, high in production efficiency and convenient to adopt.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Filling and sealing device for filling food

ActiveCN109573922AFilling operation realizedIncrease productivitySynchronising machinesLiquid bottlingEngineeringFood packaging

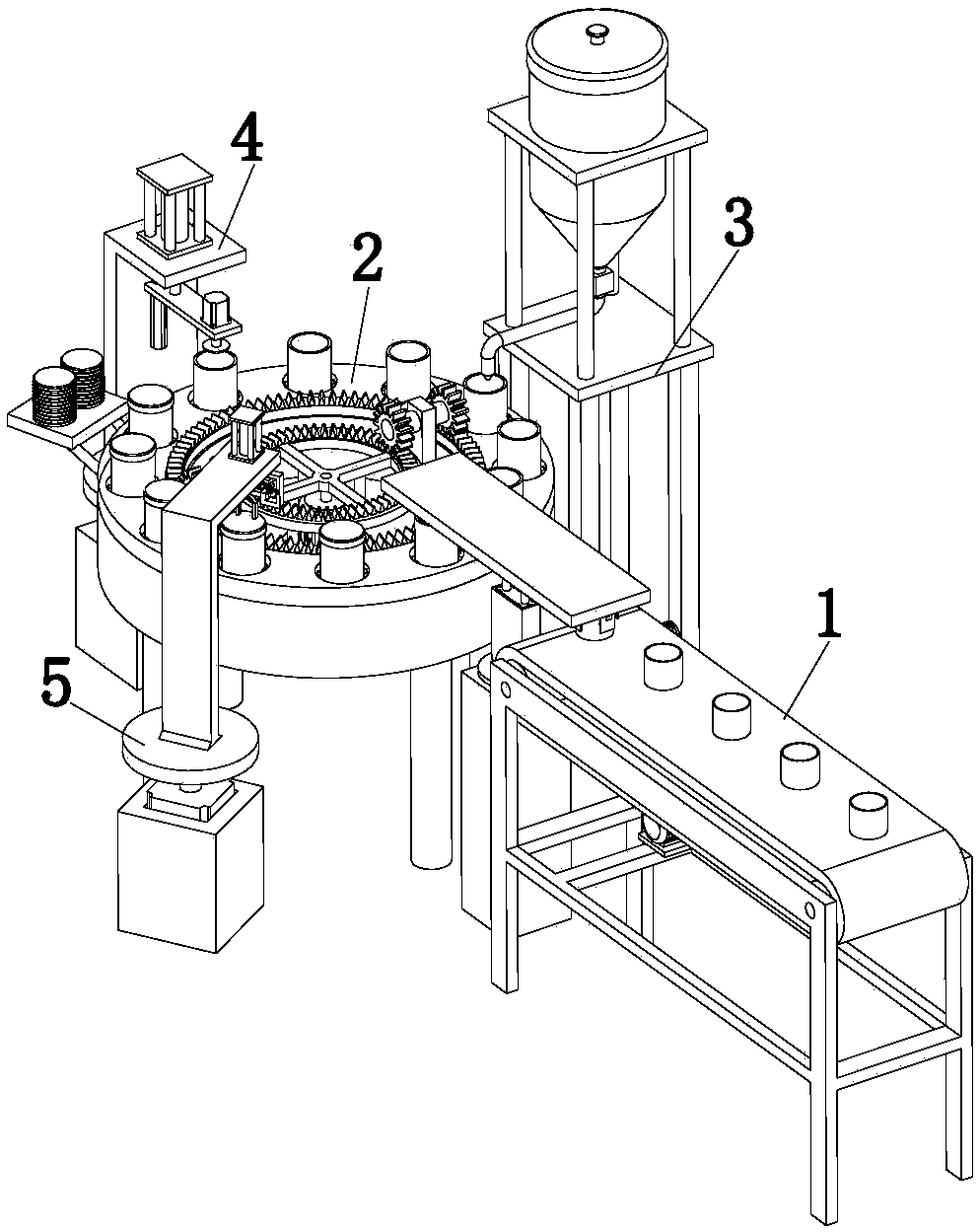

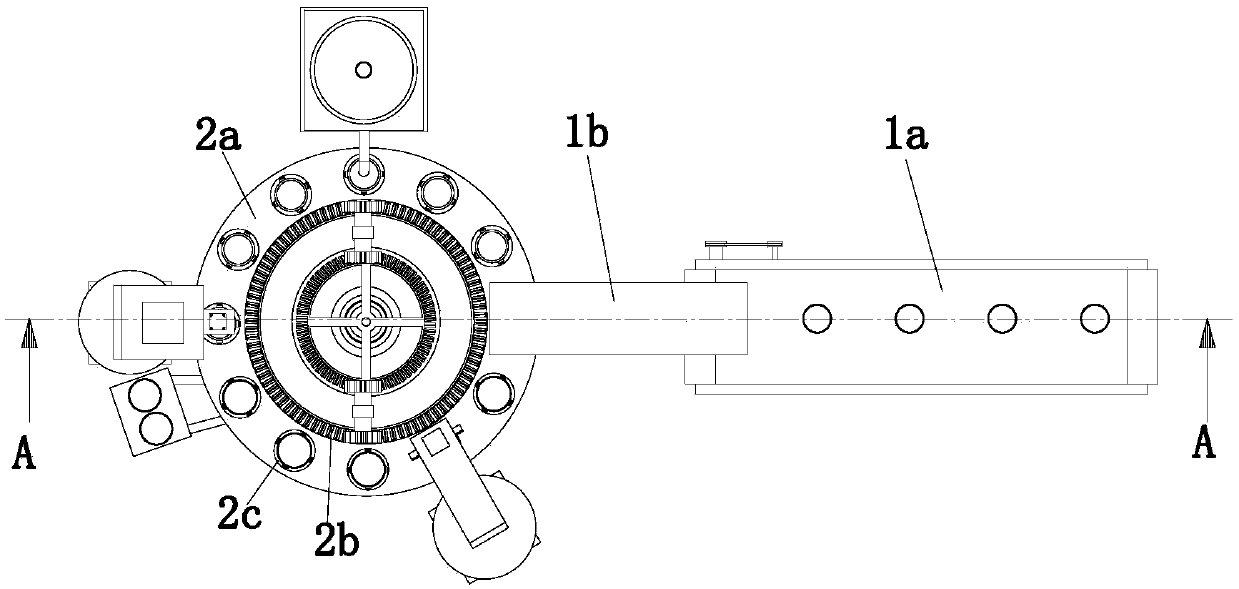

The invention discloses a filling and sealing device for filling food, and belongs to the technical field of food packaging machinery. The filling and sealing device comprises a feeding component, a rotating component, a filling component, a packaging component and a discharging component; the feeding component, the filling component, the packaging component and the discharging component are all arranged around the axis of the rotating component, and the feeding component comprises a conveying assembly and a transfer assembly; the conveying assembly is arranged at the discharging end of the transfer assembly, and the rotating component comprises a rotating assembly, a support assembly and a limit assembly; the rotating assembly is arranged on the support assembly, and the limit assembly isarranged on the rotating assembly; and in the working state, the transfer assembly, the filling component, the packaging component and the discharging component are all in but joint with the limit assembly. According to the filling and sealing device, filling bottles in different sizes can be clamped through movement of four pneumatic clamps, and the fixation of the filling bottles in different sizes can be achieved through movement of four springs and four stop blocks; and the sealing operation of the filling bottles in different sizes is achieved through the sealing device.

Owner:中山市正友机械制造有限公司

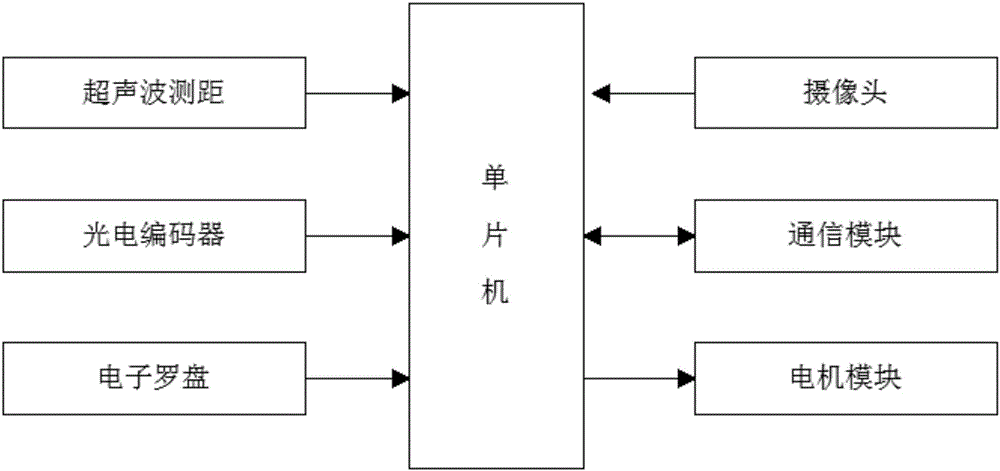

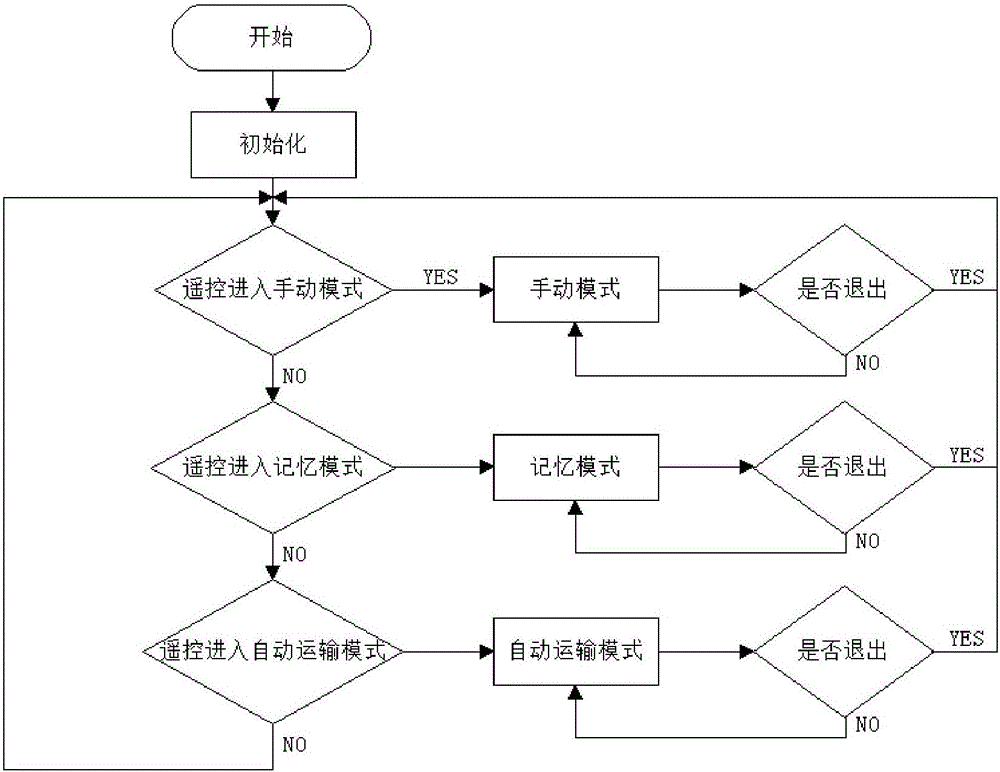

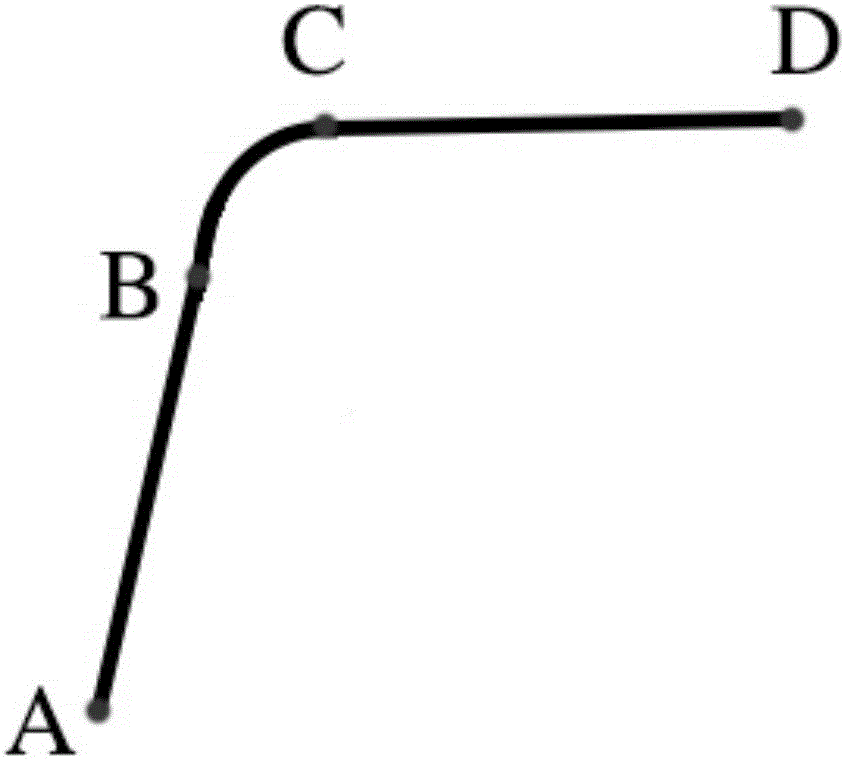

Intelligent transporting cart with track memory function

PendingCN106200648ARealize automatic transportationRealize remote operationPosition/course control in two dimensionsTransfer modeMemory module

The invention relates to an intelligent transporting cart with a track memory function. The intelligent transporting cart comprises a cart body capable of operating in a manual mode, memory mode or automatic transportation mode, and a remote control device capable of controlling starting and stopping, traveling direction and switching among the three operation modes of the cart body, wherein the cart body comprises two power wheels symmetrically arranged on the front side and a universal wheel arranged on the back side, a main control module, an ultrasonic ranging module, an optical-electricity encoder, an electronic compass, a camera and a motor module are arranged on the cart body, and the ultrasonic ranging module, the optical-electricity encoder, the electronic compass, the camera and the motor module are connected with the main control module. Remote operation of the cart can be achieved, cargos can be transferred to a destination from a starting point by the cart through automatic transportation without manual intervention by identifying a stored path, manual operation is not needed in the whole process, and automatic transportation of cargos can be achieved under the condition that no landmark or rail is arranged on the ground.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

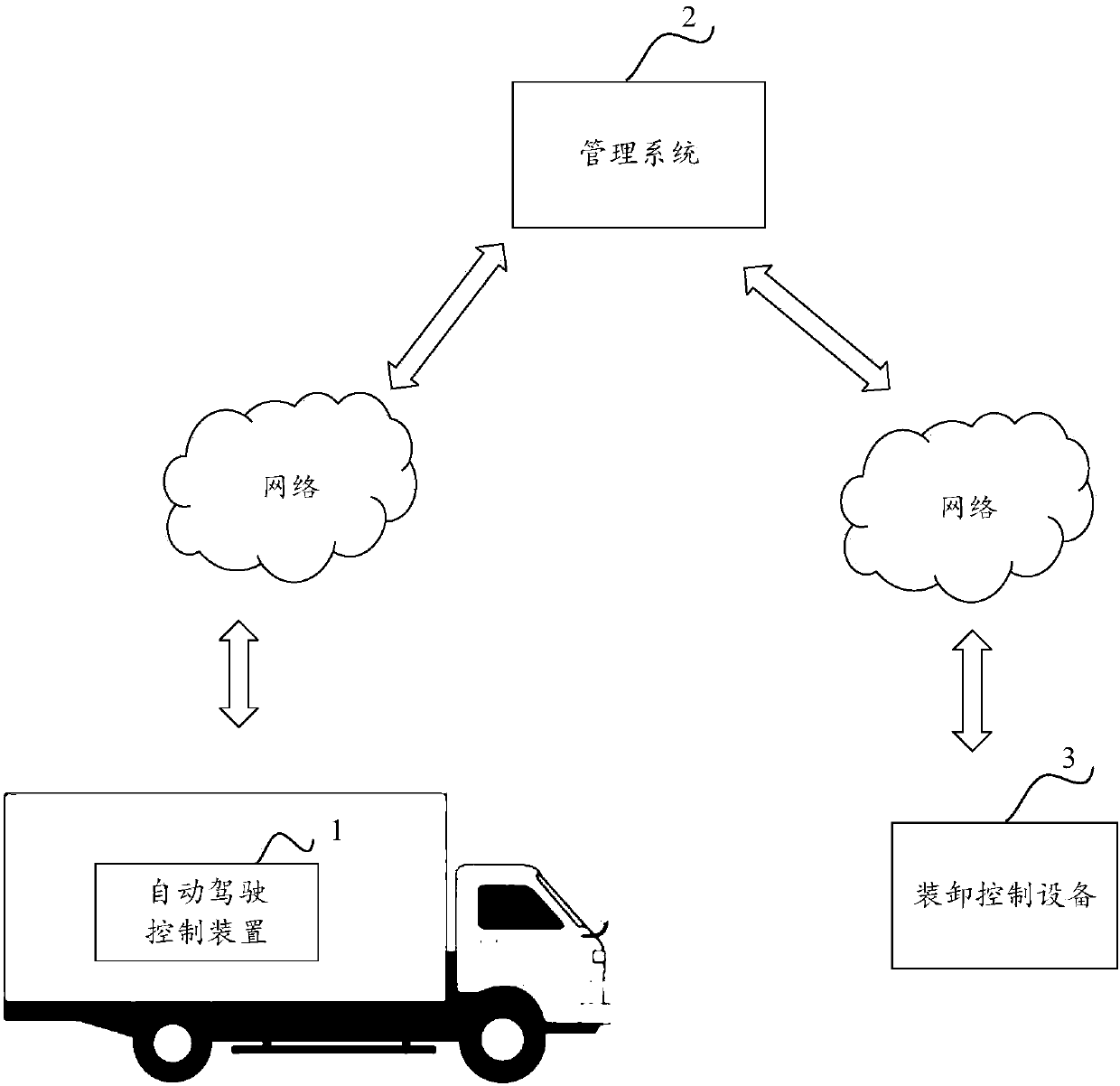

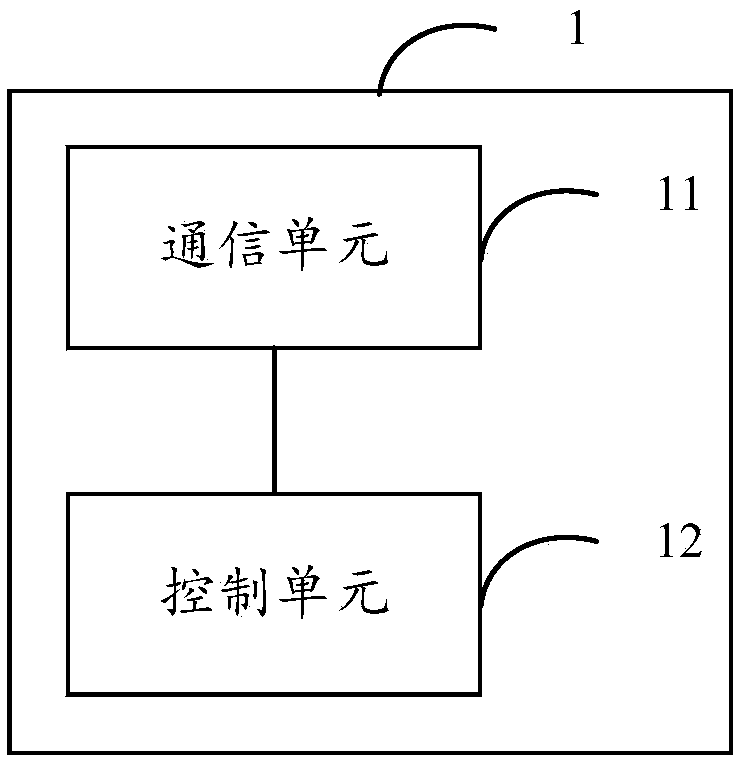

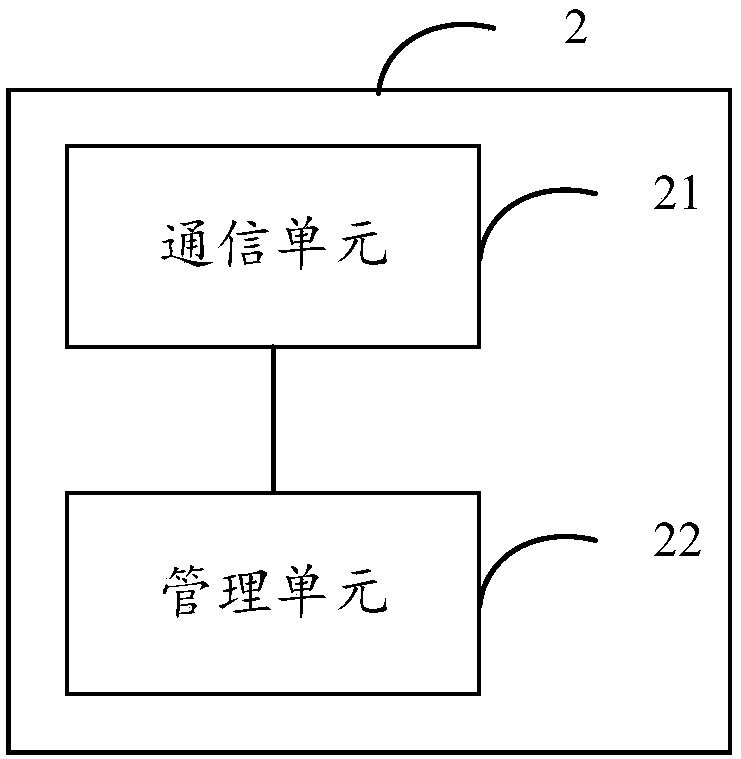

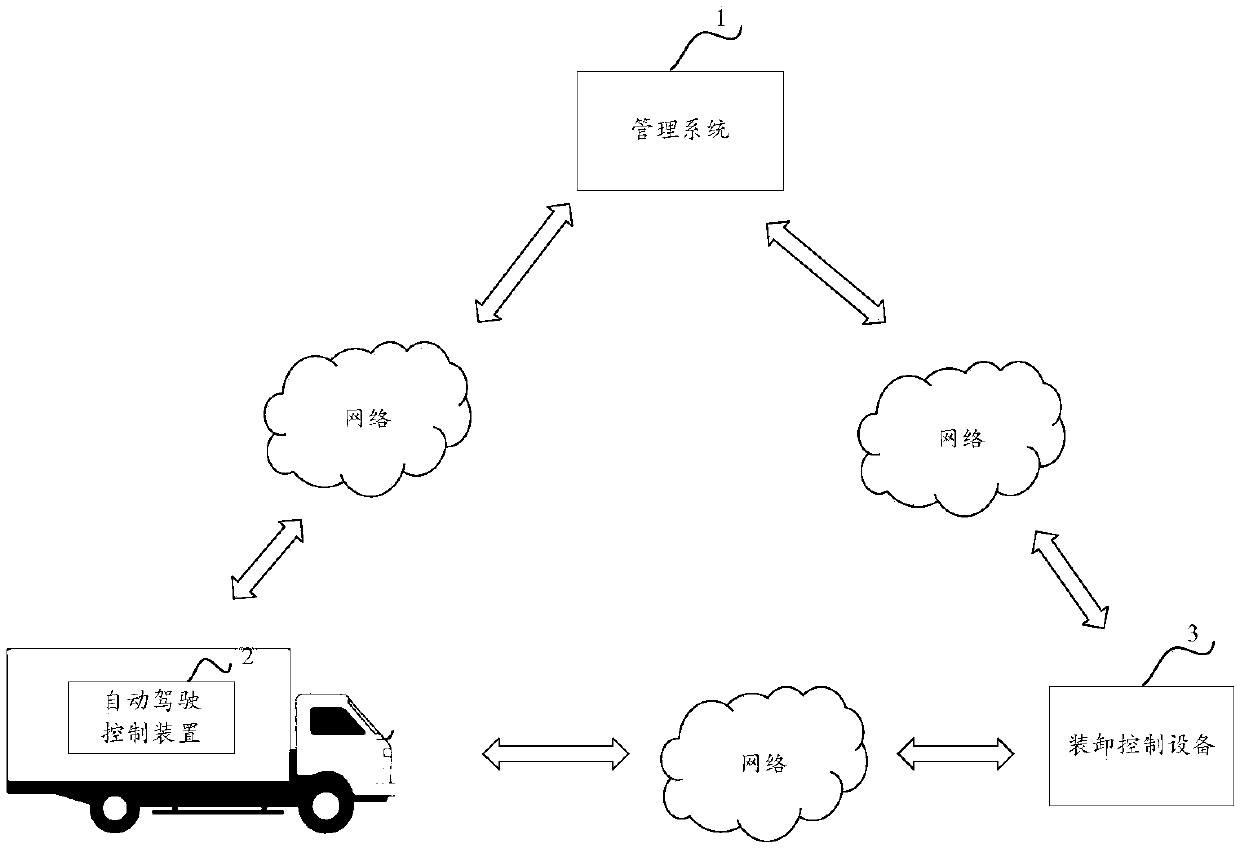

System for achieving automatic loading and unloading and related equipment

ActiveCN110197347ARealize automatic transportationFully automated transportationLifting devicesLogisticsEngineeringMechanical engineering

The invention discloses a system for achieving automatic loading and unloading and related equipment, and aims to achieve the purpose of full-automatic cargo transportation in a specific area. The system comprises: when an automatic driving control device receives a transportation instruction carrying a loading and unloading destination, controlling an automatic driving vehicle to automatically drive to the loading and unloading destination, and sending a standby message to a management system; and when a loading and unloading completion instruction is received, controlling the automatic driving vehicle to drive away from the loading and unloading destination, the management system sending a transportation instruction to the automatic driving control device and sending a loading and unloading instruction to corresponding loading and unloading control equipment when receiving the standby message; when a loading and unloading completion message sent by the loading and unloading control equipment is received, sending a loading and unloading completion instruction to the automatic driving control device; and the loading and unloading control equipment controlling the loading and unloading equipment to load and unload the automatic driving vehicle when receiving the loading and unloading instruction, and sending a loading and unloading completion message to the management system when loading and unloading are completed.

Owner:BEIJING TUSEN ZHITU TECH CO LTD

Full-automatic point welding machine

InactiveCN106552991ARealize automatic feeding processRealize automatic transportationResistance welding apparatusEngineeringManipulator

The invention relates to a full-automatic point welding machine. The full-automatic point welding machine is used for welding a piece to be welded to a thin plate piece. The full-automatic point welding machine comprises a welding platform, a transverse guide rail, a welding machine body and a controller. The point welding machine further comprises a manipulator arranged on one side of the welding platform, and a movable clamping mechanism arranged on the transverse guide rail. The manipulator and the clamping mechanism are connected with the controller. The manipulator puts the thin plate piece into the clamping mechanism, the controller controls the clamping mechanism to horizontally move to the position of the welding machine body along the transverse guide rail, and after the manipulator puts the piece to be welded onto the set position on the thin plate piece, the welding machine body carries out point welding on the piece to be welded and the thin plate piece. Compared with the prior art, the full-automatic point welding machine has the advantages of being high in welding precision and working efficiency and the like.

Owner:AURORA CHINA

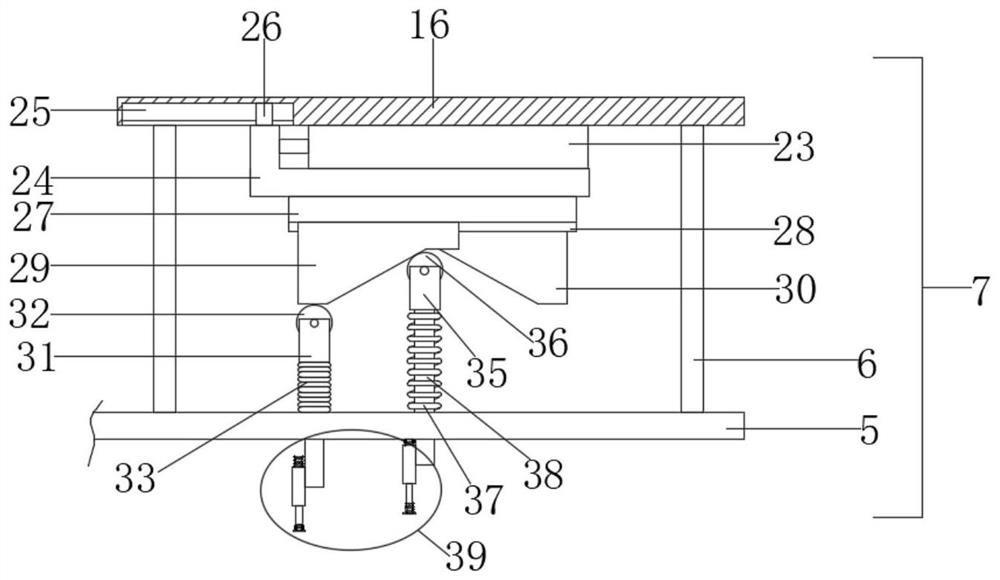

Secondary curing kiln of building material products

ActiveCN105150370ARealize automatic transportationStable maintenance spaceCeramic shaping apparatusProduction rateMeasurement device

The invention discloses a secondary curing kiln of building material products. The secondary curing kiln comprises a kiln body, a ventilation mechanism, a heat exchange device, a humidity measurement device, a temperature measurement device, a transporter, ground rails and a control device. Air in an air duct, driven by a fan, is heated or cooled by the heat exchange device and then delivered into the curing kiln. According to temperature and humidity information in the kiln body, the control device controls temperature and humidity in the kiln body through controlling the rotating speed of the fan, the opening angle of an air valve and the running of the heat exchange device. The control device drives wheels to rotate through a driving device and controls the transporter to transport materials to a target position. The secondary curing kiln can realize automation control over temperature and humidity in the kiln, is easy to realize, convenient to operate, high in automation degree, high in temperature and humidity control precision, and safe and reliable in work environment, provides a stable curing space for plate materials, can realize material automatic transporting, and can improve the production rate and quality of the products.

Owner:ZHUO DA NEW MATERIAL TECH GRP

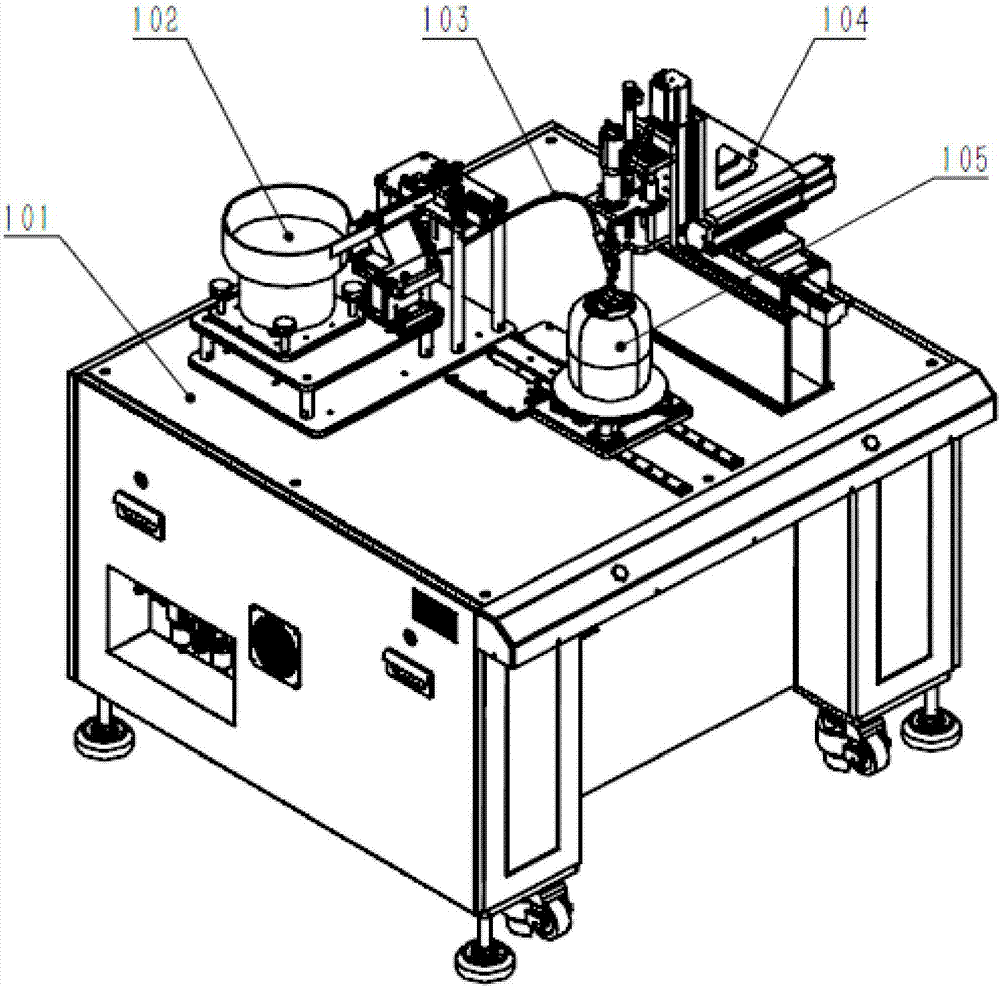

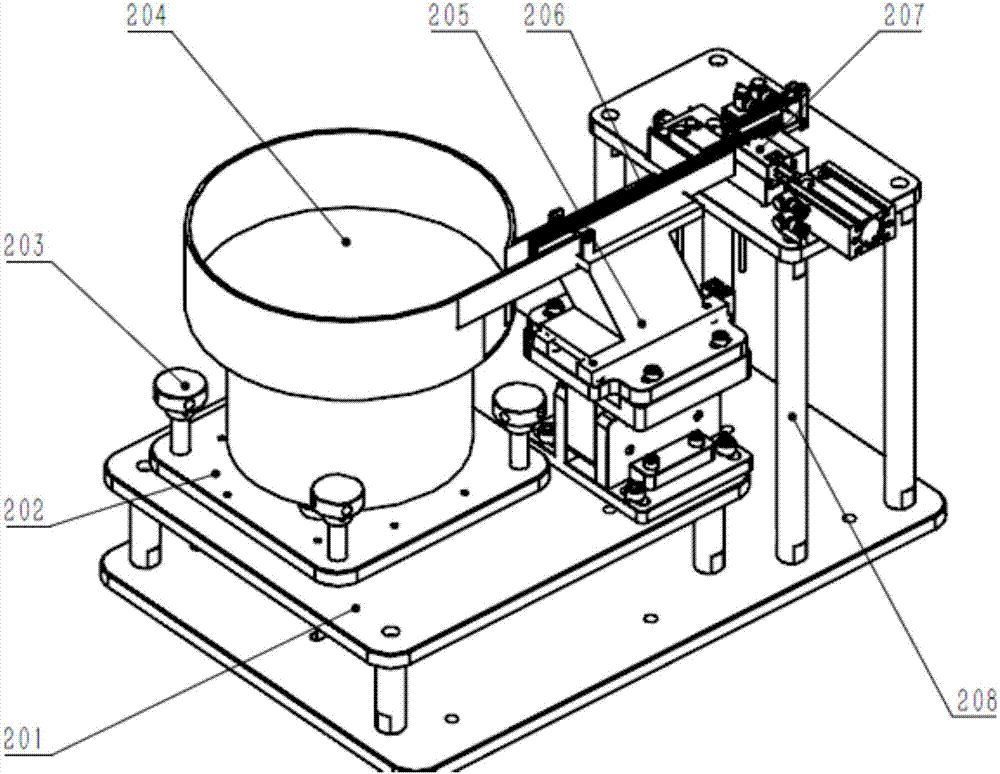

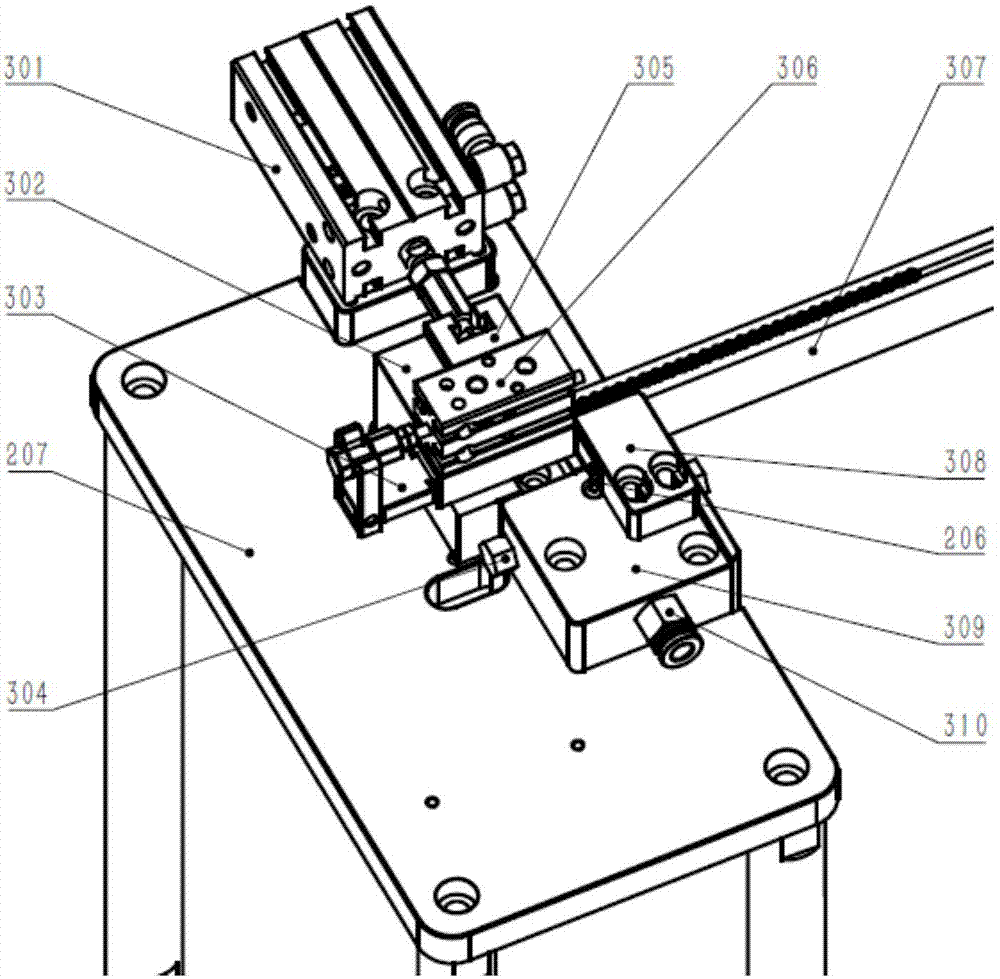

Automatic screw driving device

PendingCN107470898AEfficient delivery methodSimple structureMetal working apparatusEngineeringAutomation

The invention discloses an automatic screw driving device. A workbench is provided with an automatic screw feeding mechanism, a screw guiding tube, an automatic screw driving mechanism and a workpiece feeding mechanism, and the automatic screw feeding mechanism, the automatic screw driving mechanism and the workpiece feeding mechanism are fixed to the workbench by screws. The screw guiding tube is connected between the automatic screw feeding mechanism and the automatic screw driving mechanism, and the vibration disk of the automatic screw feeding mechanism is fixed to a vibration disk installation plate by screws. According to the automatic screw driving device, automatic screw driving is basically realized, the problems that screws are prone to loosing or gear smooth is caused by over high twisting force because the manner of manual screw driving is adopted in traditional assembly operation, the production efficiency is low, the labor cost is high, screw driving is inaccurate, and the twisting force for screw driving is over low are solved, and meanwhile, the defects of the existing screw driving machines in the market of being uncontrollable in pressure and low in safety and degree of automation are overcome.

Owner:上海莘翔自动化科技有限公司

Automatic kernel removal machine

ActiveCN110074421ARealize automatic transportationReduce labor intensityFruit stoningFleshEngineering

The invention provides an automatic kernel removal machine. The automatic kernel removal machine comprises a rack, wherein a control display, a transportation mechanism, a clamping mechanical arm, a fruit exchange and kernel removal mechanism and a flesh and kernel collection mechanism are arranged on the rack; the control display controls the whole machine to work; the transportation mechanism isinstalled in a groove of the rack to automatically transport fruit with kernels; the clamping mechanical arm clamps the fruit with the kernels on the transportation mechanism and transports the fruitto the fruit exchange and kernel removal mechanism; the fruit exchange and kernel removal mechanism comprises a rotary fruit exchange module and a kernel removal module; the rotary fruit exchange module and the kernel removal module provide power through a DC drive motor; a transmission shaft and a gear structure are connected, so that kernel removal and fruit exchange work is automatically completed through the difference between transmission ratios; the flesh and kernel collection mechanism comprises a flesh collection module and a kernel collection module; the flesh collection module automatically collects denucleated fruit; the kernel collection module automatically collects the kernels.

Owner:安徽铭凯食品有限公司

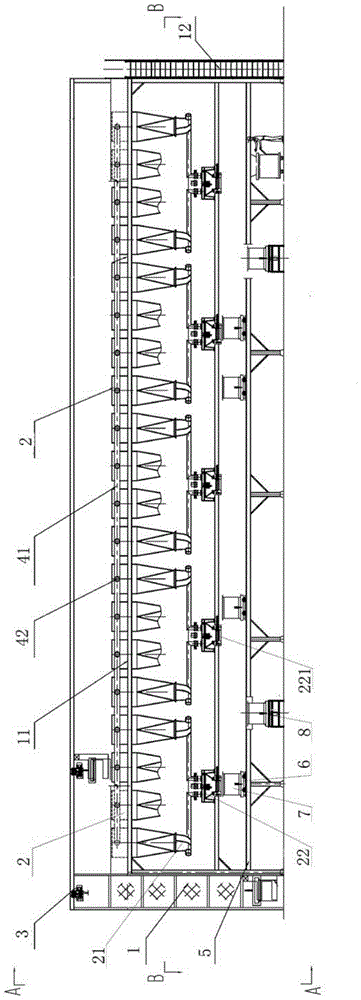

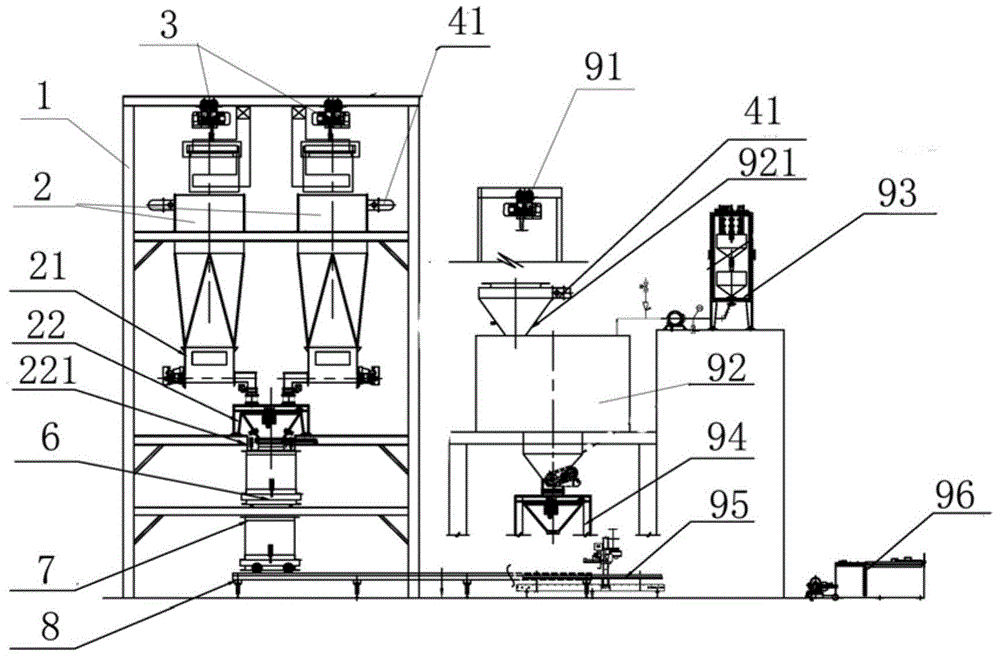

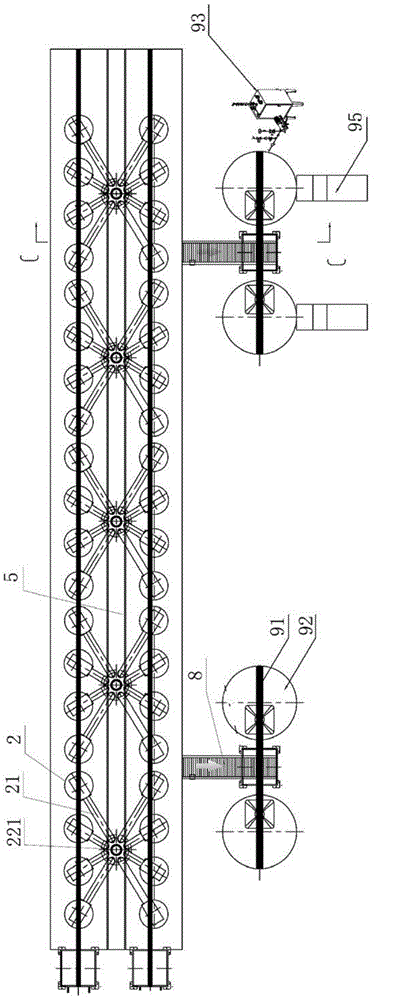

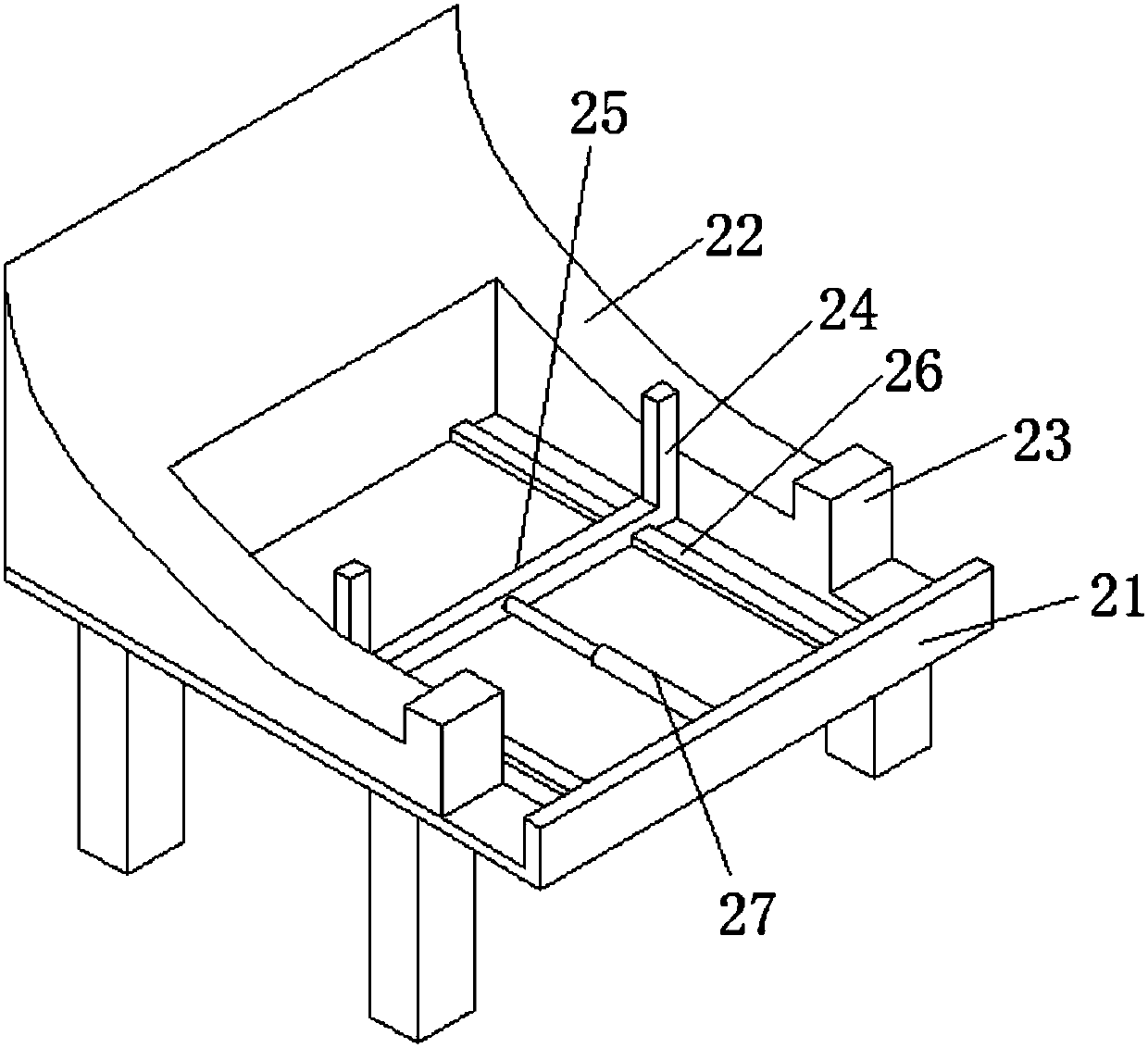

Automatic castable batching system

InactiveCN104085560ARealize automatic transportationReduce generationMixing methodsMixer accessoriesElectricityControl system

The invention provides an automatic castable batching system. The automatic castable batching system comprises a rack, powder storage hoppers, feeders and powder weighing devices. Feeding devices which can move in a reciprocating mode in the arrangement direction of the powder storage hoppers are mounted above the powder storage hoppers and located on the rack. Each feeding device is provided with a lifting device for lifting powder to the position above the corresponding the powder storage hopper. A dust remover is mounted at a feed port of each powder storage hopper and located on the rack. Each dust remover is provided with an air pipe and an air flow control valve arranged on the air pipe. A conveying track is arranged below the powder weighing devices and located on the rack. Powder transfer trolleys are arranged on the conveying track. Each powder transfer trolley is provided with a powder barrel. Conveying belts are arranged on one side of the conveying track. The output ends of the conveying belts are provided with powder processing systems. The feeders, the powder weighing devices, the feeding devices and the air flow control valves are all electrically connected with a control system. By the adoption of the automatic castable batching system, automatic conveying and batching of castable powder can be achieved, and manpower is saved; dust generated in the whole process is little, so the automatic castable batching system is friendly to the environment.

Owner:ZHEJIANG RUITAI REFRACTORY TECH

Sliding shoe type anchor net transportation robot

ActiveCN112012755ARealize automatic transportationReduce labor intensityUnderground chambersTunnel liningControl engineeringStructural engineering

The invention relates to the technical field of coal mine machinery, in particular to a sliding shoe type anchor net transportation robot. The sliding shoe type anchor net transportation robot comprises an anchor net transportation robot platform, a sliding shoe travelling mechanism installed at the bottom of the anchor net transportation robot platform, an anchor net transportation mechanism installed on a front platform, an anchor net storehouse installed on a rear platform, a chain type net feeding mechanism and a net laying mechanism. The chain type net feeding mechanism and the net layingmechanism are installed on an anchor drilling robot. The anchor net transportation mechanism has the functions of up-and-down movement, left-and-right movement and front-and-back movement and is usedfor taking out an anchor net from the anchor net storehouse and conveying the anchor net to the chain type net feeding mechanism. The chain type net feeding mechanism is located at the topmost end ofthe anchor drilling robot and used for conveying the anchor net to the shield net laying mechanism at the front end. The shield net laying mechanism is located on the front portion of the top end ofan anchor drilling robot frame and mainly comprises a net ejection mechanism, a left shield, a right shield and a net unfolding mechanism. According to the sliding shoe type anchor net transportationrobot, automatic transportation of the supporting anchor net and automation of net laying are achieved, the labor intensity of workers is reduced, and the reference basis is provided for the design ofa rapid tunneling system.

Owner:XIAN COAL MINING MACHINERY

Transporting and clamping device in column-shaped steel product machining

InactiveCN108033197ARealize automatic transportationAchieve positioningConveyorsConveyor partsEngineeringAutomation

The invention discloses a transporting and clamping device in column-shaped steel product machining. The transporting and clamping device in the column-shaped steel product machining comprises a conveying mechanism and a clamping mechanism; the conveying mechanism consists of a roller and a conveying belt; separating plates are arranged at the two sides of the conveying belt; the roller is drivenby a motor through a belt; the clamping mechanism comprises a supporting frame and two rails are arranged on the supporting frame in parallel; one ends of the rails are connected with a material discharging end of the conveying mechanism and blocking plates are arranged at the end parts of the rails; a clamping plate is arranged between the rails and the top end of the clamping plate is not higherthan the highest points of the rails; the clamping plate is controlled by a telescoping mechanism; the telescoping mechanism and the motor are controlled by a controlling center and work cooperatively. The device is capable of realizing the automatic transportation and clamping positioning in the steel product machining, low in cost, applicable to moderate and small scale machining enterprises, beneficial to the mechanization and automation in steel product machining and capable of improving the machining efficiency.

Owner:东莞市史雷帝三维数控科技有限公司

Automatic bagging device for grains

PendingCN106742122ARealize automatic baggingRealize automatic transportationWrapper twisting/gatheringSolid materialAutomatic transmissionControl system

The invention provides an automatic bagging device for grains and relates to an automatic bagging device. The device comprises a grain bin and weighing system, a bag taking and bagging mechanism, an automatic grain bin opening and closing mechanism, a bag opening auxiliary device, an automatic transmission mechanism, an automatic sealing device, a grain bag sliding conveying platform and a control system, wherein the input end and the output end of the grain bin and weighing system are connected with the control system, and the output end of the control system is separately connected with the input ends of the bag taking and bagging mechanism, the automatic grain bin opening and closing mechanism, the bag opening auxiliary device, the automatic transmission mechanism and the automatic opening sealing device. The automatic bagging device not only can realize a function of automatically bagging grains, but also can realize automatic opening sealing and automatic transportation functions on the grains, so that a fully automatic production process is realized on the grains from bin discharging to packaging and transportation. The automatic bagging device not only greatly reduces labor force and increases the work efficiency, but also ensures bagging weight precision, thereby having wide popularization significance.

Owner:LUSHAN COLLEGE OF GUANGXI UNIV OF SCI & TECH

Industrial steel plate printing machine

ActiveCN111300975AAchieve clampingRealize automatic transportationShearing machinesRotary pressesTextile printerMechanical engineering

The invention discloses an industrial steel plate printing machine. The industrial steel plate printing machine comprises a machine frame, two feeding mechanisms and a printing mechanism, the feedingmechanisms are installed at the bottom of the machine frame, and steel plate conveying openings are symmetrically formed in a conveying plate of the machine frame; the two feeding mechanisms are separately located on the lower parts of the steel plate conveying openings in two ends of the machine frame, the printing mechanism is installed at the top of the machine frame, a driving mechanism is installed on the side wall of the machine frame, and the driving mechanism is separately connected with the printing mechanism and the feeding mechanisms, and an ink cartridge is fixedly installed at theposition, located at the side edge of the printing mechanism, of the top of the machine frame; and an injection opening is formed in one end of the top of the ink cartridge, and an ink absorption sponge is fixedly installed at the position, located on one side of the printing mechanism, of the ink cartridge. The industrial steel plate printing machine is simple in the overall structure, the effects of automatic transportation, automatic clamping printing and automatic output of a steel plate are achieved, human labor is greatly saved, and meanwhile, the printing efficiency of the steel plateis improved, and convenient promotion is achieved.

Owner:瑞茂金泰(山东)智能设备制造有限责任公司

Belt sorting machine

InactiveCN109775289AIncrease contact areaGoods sorting is smoothConveyorsSupporting framesLeather beltLogistics management

Owner:郑州三格自动化设备有限公司

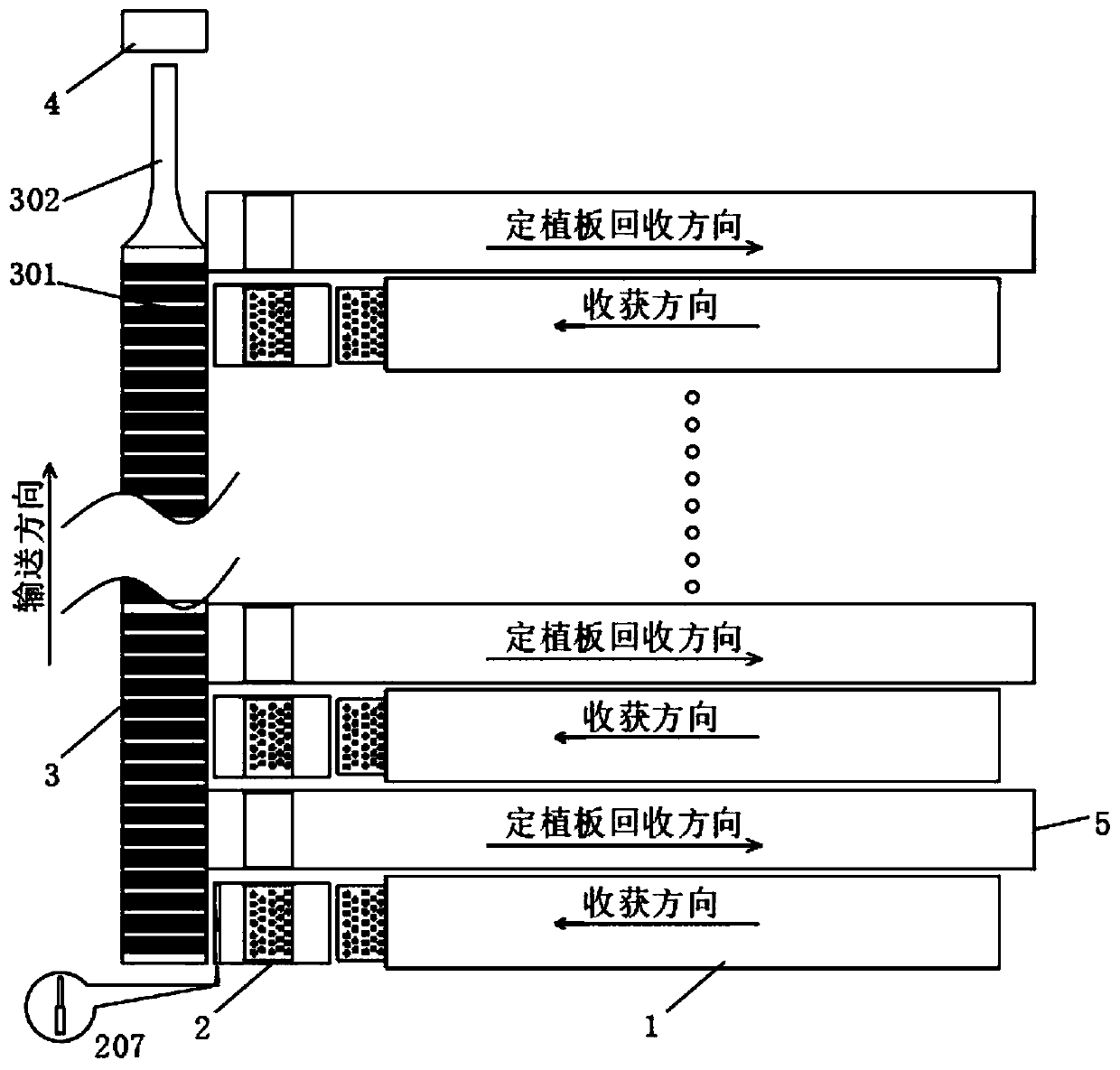

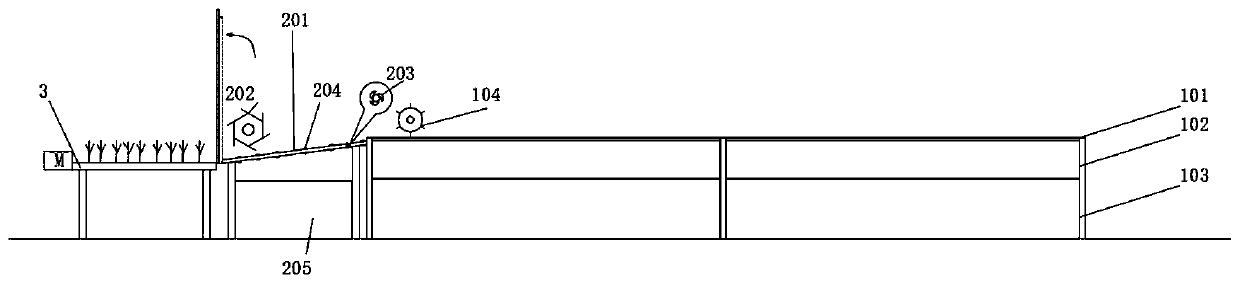

Full-automatic harvesting production line of hydroponic vegetables

PendingCN111406637ARealize automatic transportationImprove fluencyHarvestersAgriculture gas emission reductionDrive wheelAgricultural engineering

The invention discloses a full-automatic harvesting production line of hydroponic vegetables, and relates to the technical field of hydroponic vegetable production. In order to ensure a vegetable transportation capacity and facilitate maintenance, the device specifically comprises vegetable planting areas, cutting areas, a conveying area and a packaging area, wherein each cutting area is arrangedon one side of the corresponding vegetable planting area; each vegetable planting area comprises a planting plate, a cultivation groove, a cultivation frame and a driving wheel; the cultivation groovecomprises two first idler wheel groups and a nutrient solution tank, and the two first idler wheel groups are respectively fixed on a platform in the nutrient solution tank through pulley seats; andthe outer wall of the bottom of the planting plate is slidably connected to the outer circumferential walls of the first idler wheels, and the outer walls of two sides of the planting plate are slidably connected to the inner walls of two sides of the nutrient solution tank, and the outer wall of the bottom of the nutrient solution tank is fixed to the outer wall of the top of the cultivation frame by screws. According to the production line, via the arrangement of the structures such as driving holes and driving wheels, the hydroponic vegetables can be automatically transported; and via the arrangement of the first idler wheels, conveying smoothness of the planting plates can be improved.

Owner:INST OF URBAN AGRI CHINESE ACADEMY OF AGRI SCI

Automatic steel pipe feeding device

InactiveCN108706325ARealize automatic transportationSave human effortConveyor partsMetallurgyInductor

The invention relates to an automatic steel pipe feeding device. The automatic steel pipe feeding device can realize the automatic transportation of steel pipes without manpower to carry and shift steel pipes. The automatic steel pipe shifting and transportation are realized by an inductor. The steel pipes are stored and placed in a material storage system, the height, from the beginning to the end, of the material storage system gradually decreases, and the steel pipes can roll along the material storage system from the beginning to the end under the action of gravity. A material shifting system is connected to the tail end of the material storage system and shifts the steel pipes sliding to the tail end of the material storage system to a material conveying system, and the steel pipes are transported to a processing device by the material conveying system. Rotating shifting discs are arranged on the material shifting system, and the steel pipes are shifted to the material conveying system by rotating the shifting discs. A distance sensor is arranged on the material shifting system, and distance sensor stop dogs are arranged on the shifting discs. When the steel pipes on the material conveying system leave the material conveying system, the material shifting system is started, and the shifting discs rotate to shift the next steel pipes to the material conveying system; and meanwhile, the distance sensor stop dogs on the shifting discs block a sensor, the distance sensor feeds back a signal to the material shifting system, and the material shifting system stops shifting.

Owner:山东三维重工有限公司

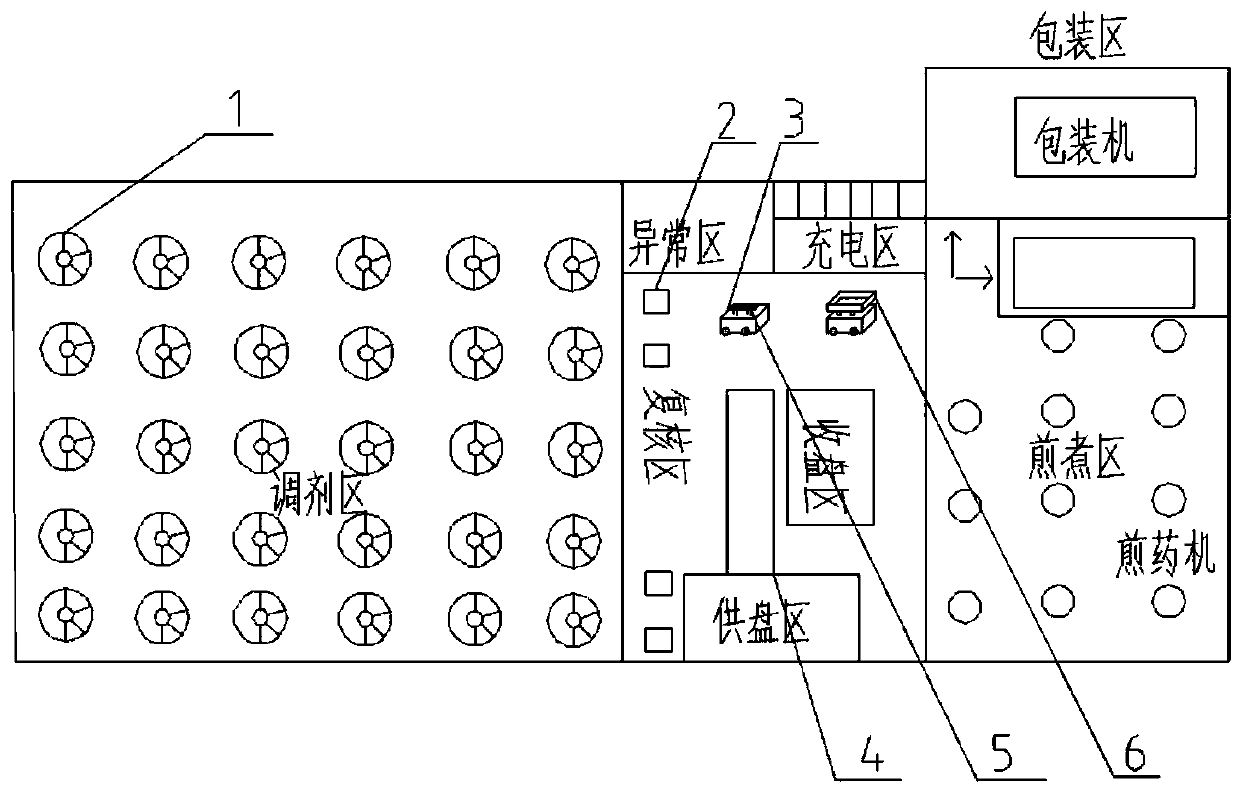

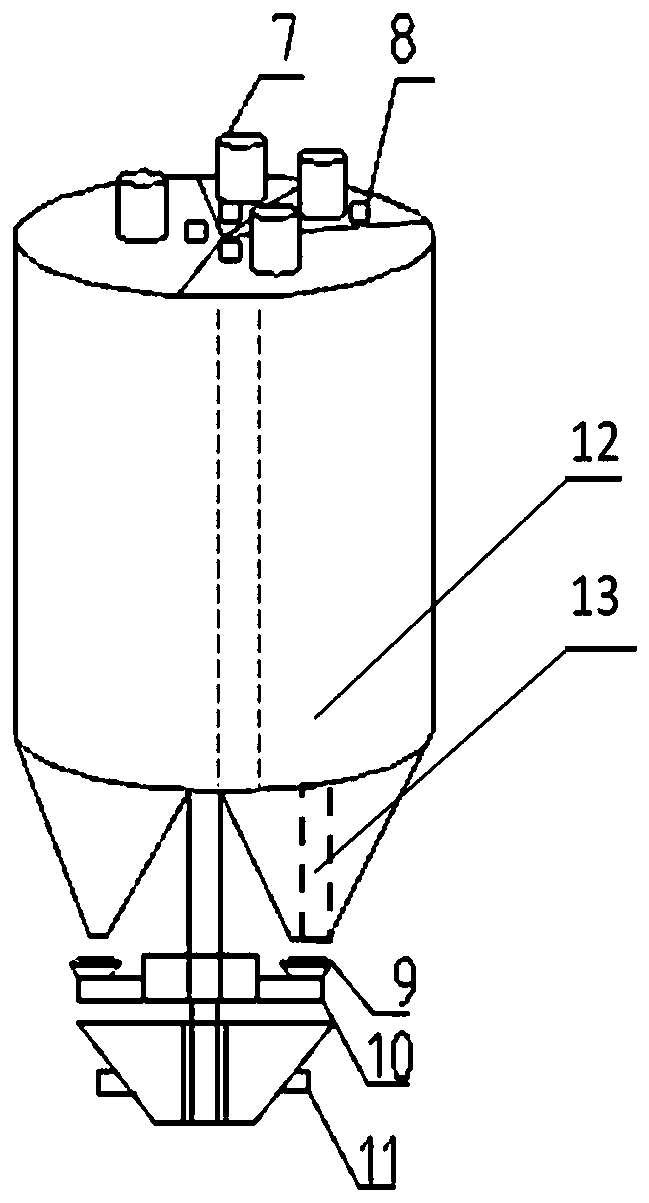

Automatic combination and intelligent conveying system for traditional Chinese medicine decoction pieces and application of automatic combination and intelligent conveying system

ActiveCN110723372AReduce waiting time for medicine collectionImprove work efficiency and intelligent levelAlternative medicinesPharmaceutical product form changeProcess engineeringTraditional Chinese medicine

The invention discloses an automatic combination and intelligent conveying complete equipment system for traditional Chinese medicine decoction pieces and application of the automatic combination andintelligent conveying complete equipment system. The system is divided into an adjustment region, a rechecking region, an abnormal region, a charging region, a tray supply region, a tray collection region, a decoction region and a packaging region, wherein the complete equipment consists of a combined type material supply device, a rechecking device, a logistics device, a washing machine, a tray rack, a material picking tray, a decocting machine, a control computer and so on. The complete equipment can implement the operation steps such as tray taking, material picking, rechecking, conveying,discharging and tray returning. The automatic combination and intelligent conveying complete equipment system disclosed by the invention realizes automatic combination and compounding of hundreds of traditional Chinese medicine decoction pieces according to a traditional Chinese medicine prescription and subsequently the traditional Chinese medicine decoction pieces are conveyed to the decocting machine or the packaging machine to make sure that the traditional Chinese medicines are centrally decocted or are allocated in a pharmacy. The automatic combination and intelligent conveying completeequipment system disclosed by the invention has the functions such as multi-point random material picking, multi-task collaborative operation, centralized supply and intelligent delivery and can realize full-automatic adjustment and delivery of the traditional Chinese medicine decoction pieces, thereby liberating strenuous work of a traditional Chinese medicine pharmacist, shortening the waiting time for a patient to get the medicine, improving the work efficiency of a traditional Chinese medicine pharmacy and increasing the intelligentization level of the traditional Chinese medicine pharmacy.

Owner:杭州智徽医药科技有限公司

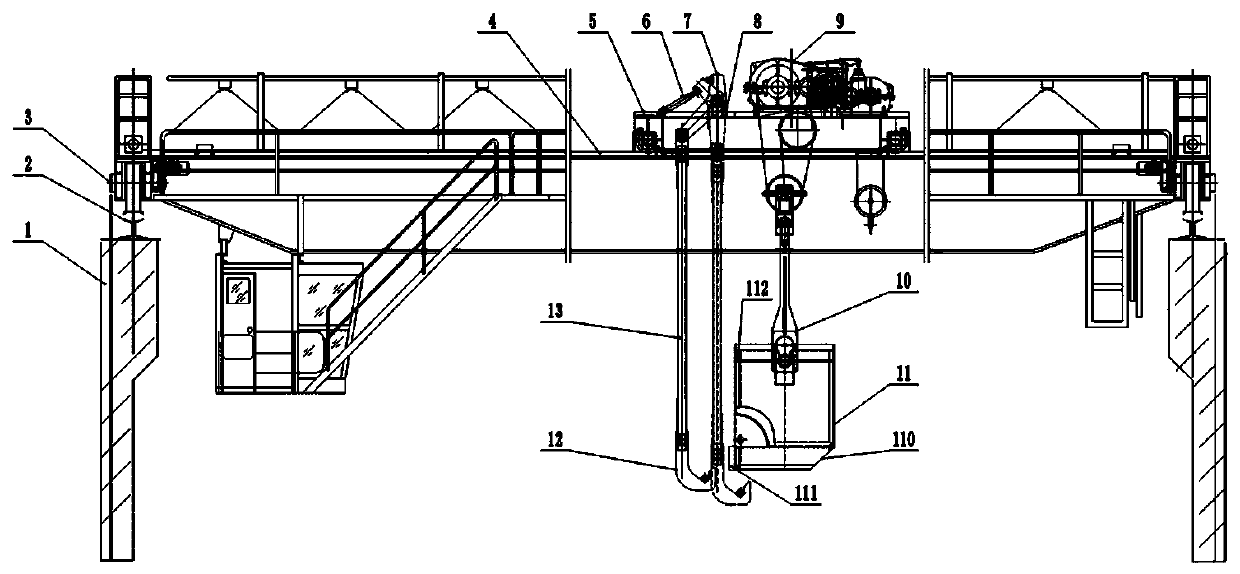

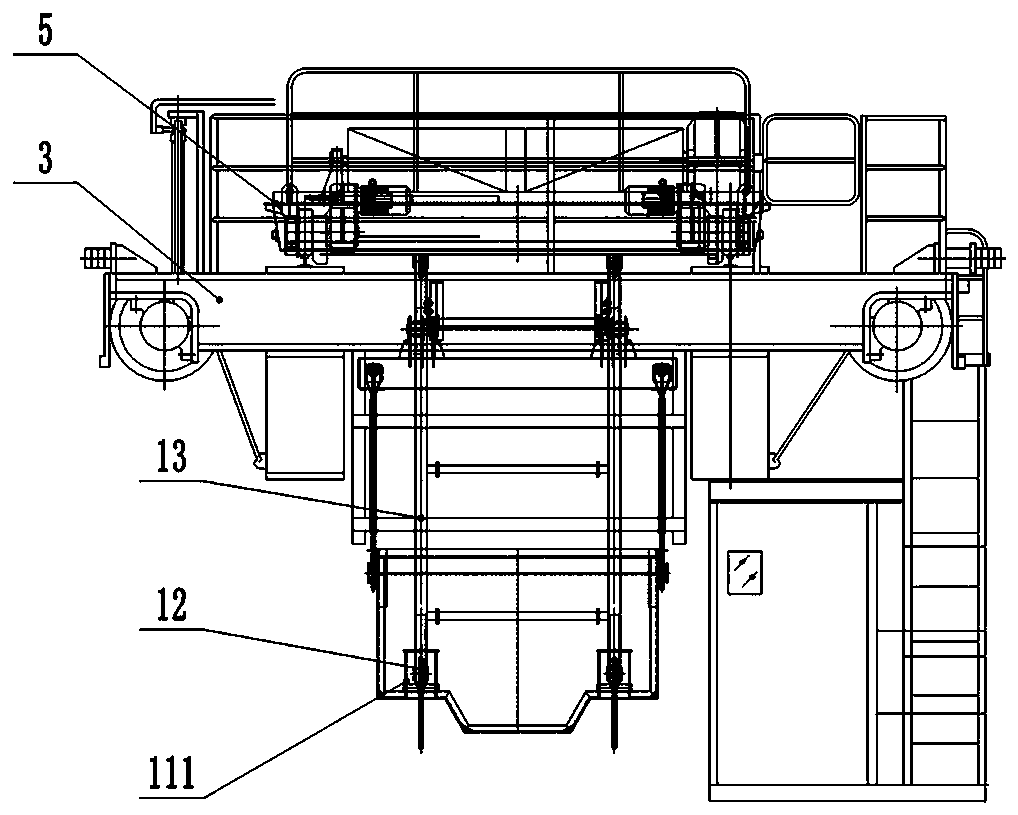

Slag extractor used for subway construction

The invention discloses a slag extractor used for subway construction. The slag extractor comprises a crane span structure, carts are arranged on the bottoms of the two ends of the crane span structure, a trolley is arranged on the crane span structure, an electric hoist is arranged is arranged on the trolley, a hopper is hung on a lifting hook of the electric hoist, a tipping device used for tipping the hopper is arranged on the trolley and comprises a first telescopic rod, an L-shaped connecting rod, a supporting device, a vertical connecting rod and a hook, the first telescopic rod is arranged in an inclined manner, the L-shaped connecting rod is hinged to the supporting device, the supporting device is fixedly connected with the trolley, the first telescopic rod is connected with the vertical connecting rod through the L-shaped connecting rod, the vertical connecting rod is fixedly connected with the hook, and the face, close to the tipping device, of the hopper is provided with ahanging lug hooked by the hook. Slag soil is loaded into the hopper, the electric hoist on the trolley elevates the hopper to the designated height, the carts carry out conveying, the slag soil is conveyed to the designated position, the tipping device tips the hopper, the slag soil is poured out, the slag soil can be automatically conveyed and tipped, manpower and material resources are saved, and work efficiency is improved.

Owner:HENAN DONGFENG CRANE CO LTD

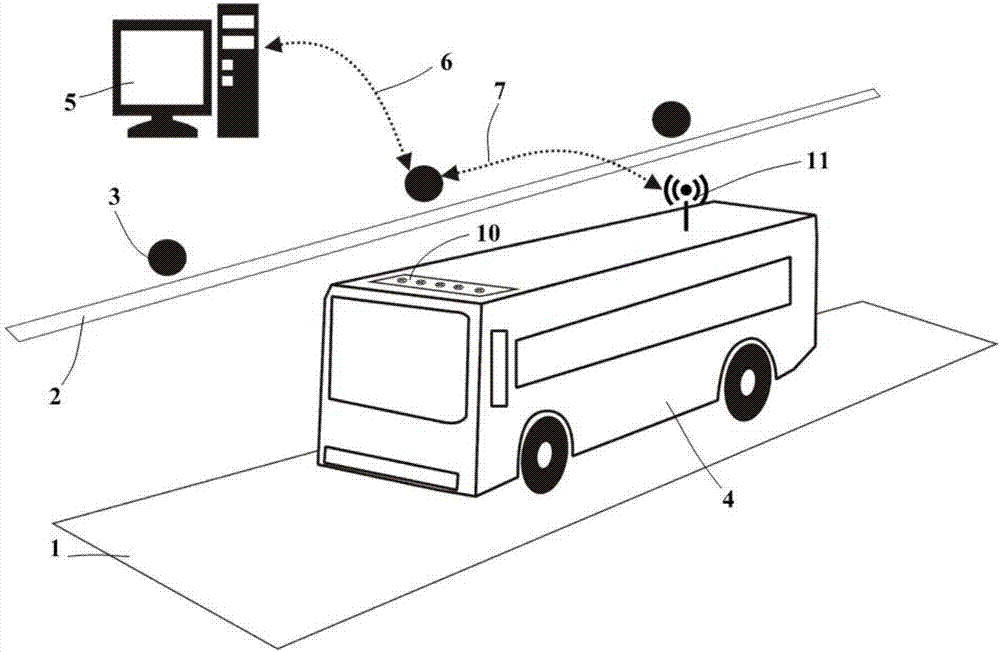

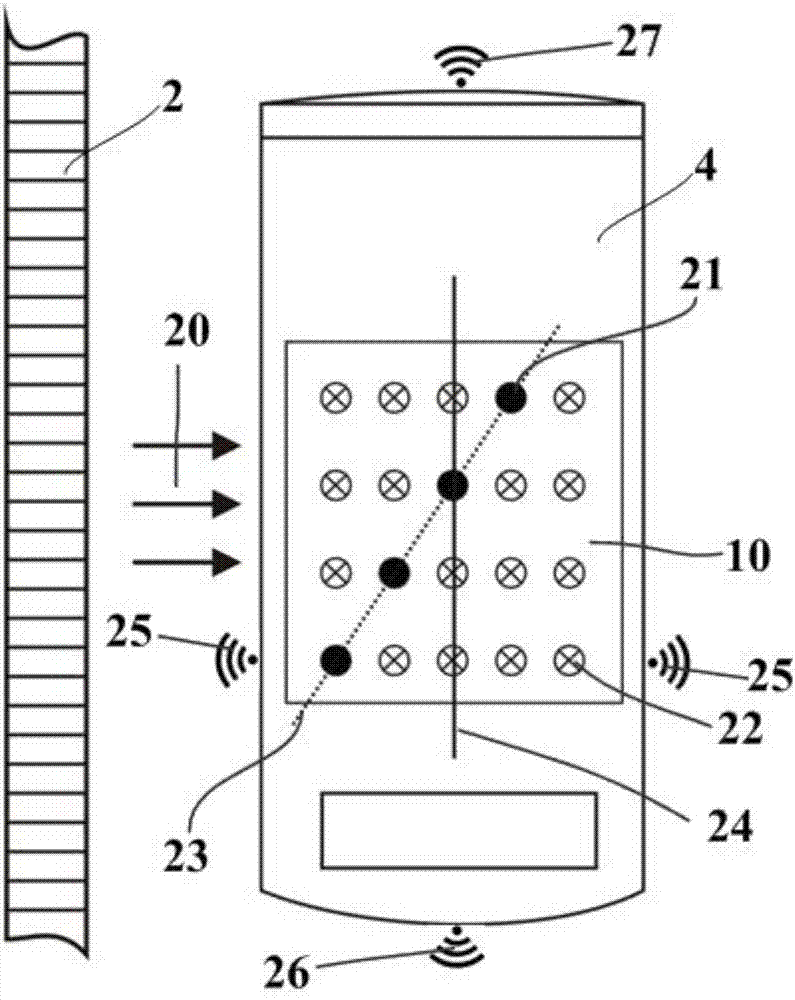

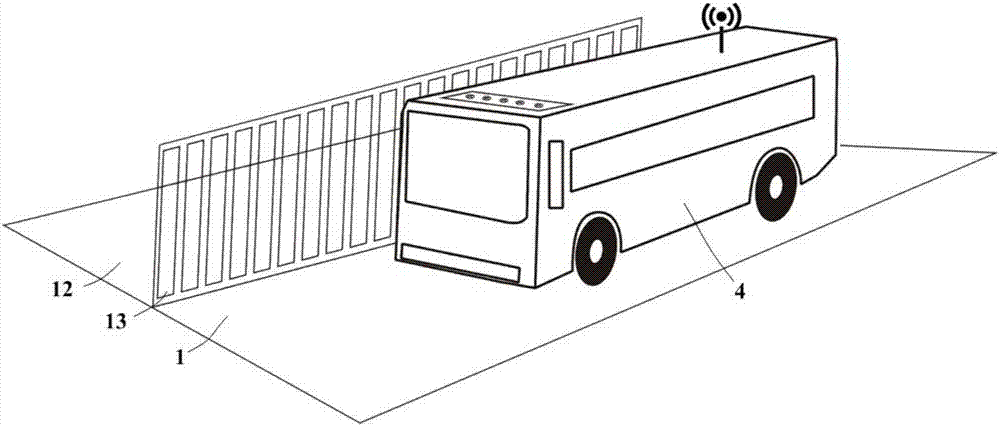

Rail vehicle control system, rail vehicle, rail system and transport system

InactiveCN107168326ASimple structureReduce in quantityPosition/course control in two dimensionsTransport systemControl system

The invention provides a rail vehicle control system, a rail vehicle, a rail system and a transport system. The rail vehicle control system is based on a rail sensor, an information transmit-receive device and a mobile control device to realize positioning based on the guide rail zone and receive the movement requirement transmitted by a central computer so as to control the rail vehicle to move along the guide rail zone according to the movement requirement. The rail vehicle control system is simple in structure and is installed on the existing vehicle and then the rail vehicle can be obtained through modification so that the rail vehicle control system is applied to the transport system, the utilization rate of the roads and the vehicles can be greatly enhanced, the number of the vehicles can be reduced, and the problems of traffic congestion and parking difficulty can be solved and the vehicle exhaust pollution can be reduced.

Owner:杨国强

Auxiliary equipment for installation of power distribution cabinet

The invention relates to the technical field of power grids, and specifically relates to auxiliary equipment for the installation of a power distribution cabinet. The equipment comprises a bracket, four walking mechanisms, four clamping mechanisms and four mounting devices. The bracket is of a rectangular frame structure, and is horizontally arranged. The four clamping mechanisms are symmetricallyarranged at the middles of the top ends of a left side bracket and a right side bracket. The output ends of the clamping mechanism are oppositely arranged; the four mounting devices are symmetricallyarranged at the middles of the bottom ends of the left side bracket and the right side bracket respectively. According to the invention, the automatic transportation of the power distribution cabinet, punching, bolt installation and screw cap fastening can be achieved through the telescopic bracket and the walking mechanisms, clamping mechanisms and mounting devices arranged on the bracket. The equipment can greatly reduce the inaccuracy of manual installation, greatly improves the installation efficiency of the power distribution cabinet, and is high in speed. Moreover, the equipment is suitable for the installation of power distribution cabinets in different sizes, greatly saves the installation cost, and increases the construction speed.

Owner:徐小梅

Glass engraving and milling machine based automatic production line

PendingCN108583112ARealize automatic supplyRealize automatic loading and unloadingCharge manipulationFlexible article cleaningProduction lineEngineering

The invention discloses a glass engraving and milling machine based automatic production line. The glass engraving and milling machine based automatic production line comprises a supplying device, glass engraving and milling machines, a fix-axis driving type manipulator, a finished product conveying device and a washing device, wherein the supplying device is arranged at one end of the finished product conveying device and is used for conveying and positioning a material tray; the glass engraving and milling machines are arranged at two sides of the finished product conveying device and are used for processing glass materials into glass products; the five-axis driving type manipulator is arranged above the finished product conveying device and is used for picking the glass materials from the material tray, positioning the glass materials on the corresponding glass engraving and milling machine, picking the glass product from the corresponding glass engraving and milling machines and positioning the glass product on the finished product conveying device; the finished product conveying device is used for conveying the glass product to the washing device; and the washing device is used for washing the glass product. According to the technical scheme, the glass engraving and milling machine based automatic production line has the advantages that the glass materials are prepared into the glass product in a complete automatic manner, so that the labor cost is effectively decreased while the production efficiency is effectively improved.

Owner:SHENZHEN CREATE CENTURY MACHINERY

Surface plastic spraying treatment and automatic welding production process for leisure chair

PendingCN113796685AImprove spraying effectAvoid spraying dead endsWelding/cutting auxillary devicesAuxillary welding devicesGear wheelElectric machinery

The invention discloses a surface plastic spraying treatment and automatic welding production process for a leisure chair, and relates to the field of leisure chair production. The process comprises a workbench and a supporting frame, a motor cavity is formed in the middle of the workbench, a second motor is installed in the motor cavity, and the output end of the second motor is connected with a main gear. According to the invention, the two conveying belts with opposite conveying directions are mounted on the workbench, when the workpiece is conveyed, a worker puts a cleaned workpiece on a conveying belt, a liquid pump is started to pump out paint in a paint box and convey the paint to a spraying base, spraying heads are installed at the bottom of the spraying base, the paint can be sprayed to the surface of the workpiece, the spraying heads are in a linear flat shape, the spraying effect of the workpiece can be improved, and spraying dead corners are completely eradicated. After the workpiece is conveyed to the other end, a worker at the other end turns over the workpiece and places the workpiece on the other conveying belt, the other face of the workpiece is sprayed, and the spraying effect is improved.

Owner:浙江旺达诗家具有限公司

Material distributing device for automatic bin separation of blast furnace crude fuel and using method of material distributing device

InactiveCN114410867ARealize automatic transportationEasy to transportBell-and-hopper arrangementProcess efficiency improvementEngineeringMaterial distribution

The invention discloses a material distributing device for automatic bin separation of blast furnace crude fuel and a using method of the material distributing device, and relates to the technical field of blast furnace material distribution.The material distributing device comprises a base, two first supporting columns are fixedly connected to the top of the base, and first transverse plates are fixedly connected to the tops of the first supporting columns correspondingly; the automatic plate conveying device has the beneficial effects that the automatic conveying assembly is arranged, automatic conveying of plates is achieved through operation of the conveying belt body, a second limiting and distributing mechanism is arranged, falling limiting of a first stop lever and rising of a second stop lever are achieved, and the plates are conveyed away; the first limiting and distributing mechanism is arranged, a second baffle of an inclined plane structure assists a first plate to fall into the storage box, and the storage box, an electricity storage box, a solar panel and an illuminating lamp are arranged, so that the cost is reduced; and the two illuminating lamps are installed for auxiliary illumination night operation.

Owner:CHENGYU VANADIUM TITANIUM TECH CO LTD

System and related equipment for realizing automatic goods transportation

PendingCN109669427ARealize automatic transportationFully automated transportationSensing record carriersLogisticsControl equipmentTransport engineering

The invention discloses a system and related equipment for realizing automatic goods transportation so as to achieve the aim of full-automatic goods transportation in a specific area. The system comprises a management system, loading and unloading control equipment and automatic driving control devices arranged on automatic driving vehicles, wherein the management system is used for managing goodsinformation and the transportation states of the automatic driving vehicles, and generating transportation tasks according to the goods information and the transportation states of all the automaticdriving vehicles and transmitting all the transportation tasks to the automatic driving control devices matched with the automatic driving vehicles; the automatic driving control devices are used forcontrolling the automatic driving vehicles to finish transportation according to the transportation tasks when the transportation tasks are received; and the loading and unloading control equipment isused for controlling loading and unloading equipment to automatically load and unload the automatic driving vehicles.

Owner:BEIJING TUSEN ZHITU TECH CO LTD

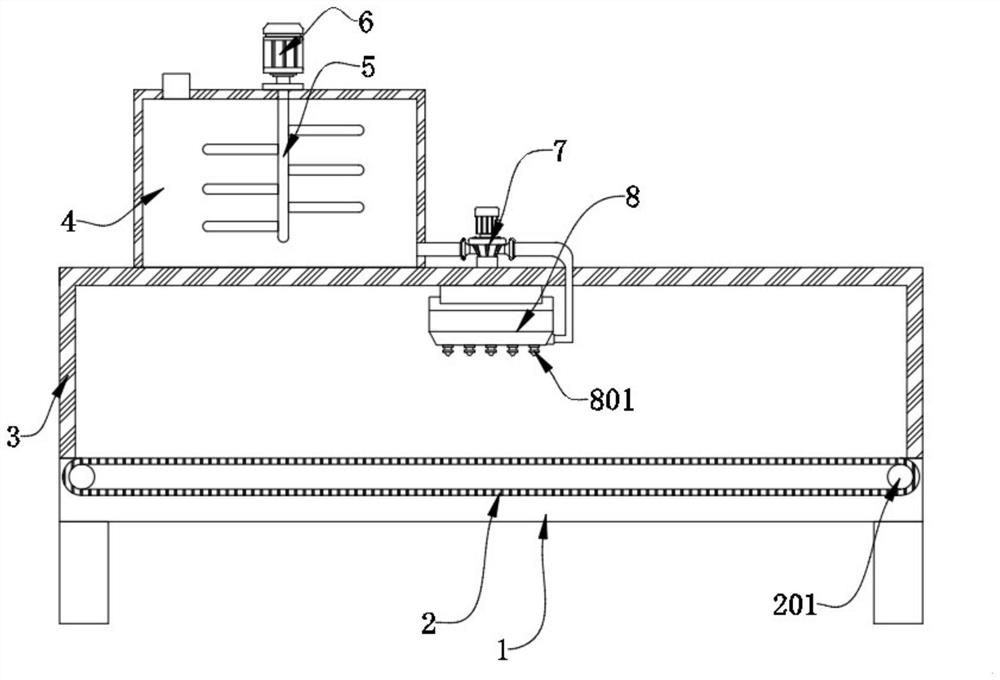

Supercapacitor carbon conveying and dehydrating system

InactiveCN109696036ASimple structureImprove dehydration efficiencyCarbon compoundsDrying solid materials without heatCapacitanceEngineering

The invention discloses a supercapacitor carbon conveying and dehydrating system. The supercapacitor carbon conveying and dehydrating system comprises a belt-type filter conveyor, a spray washing device, a dehydrating drum machine and a vacuum dehydrating device, a feeding tank is arranged above the front end of the belt-type filter conveyor, the spray washing device is arranged above the middle of the belt-type filter conveyor, the vacuum dehydrating device comprises a vacuum pump, a connecting pipe and a dehydrating box, the dehydrating box is arranged below a filter cloth of the belt-type filter conveyor, spray heads of the dehydrating box and spray heads of the spray washing device are arranged on the same vertical plane correspondingly, a material collecting hopper is arranged at thetail end of the belt-type filter conveyor, the dehydrating drum machine is arranged below the material collecting hopper, a spiral conveying pipe is arranged below the dehydrating drum machine, and adischarging outlet of the dehydrating drum machine corresponds to a feeding inlet of the spiral feeding pipe. Compared with the prior art, the supercapacitor carbon conveying and dehydrating system has the advantages of simple structure, high dehydration efficiency and low using cost, and automatic transportation can be achieved.

Owner:HUAXIAN DACHAOLIN BUSSAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com