Automatic bagging device for grains

A bagging device, grain technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of cumbersome operation, high labor intensity and low work efficiency for workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

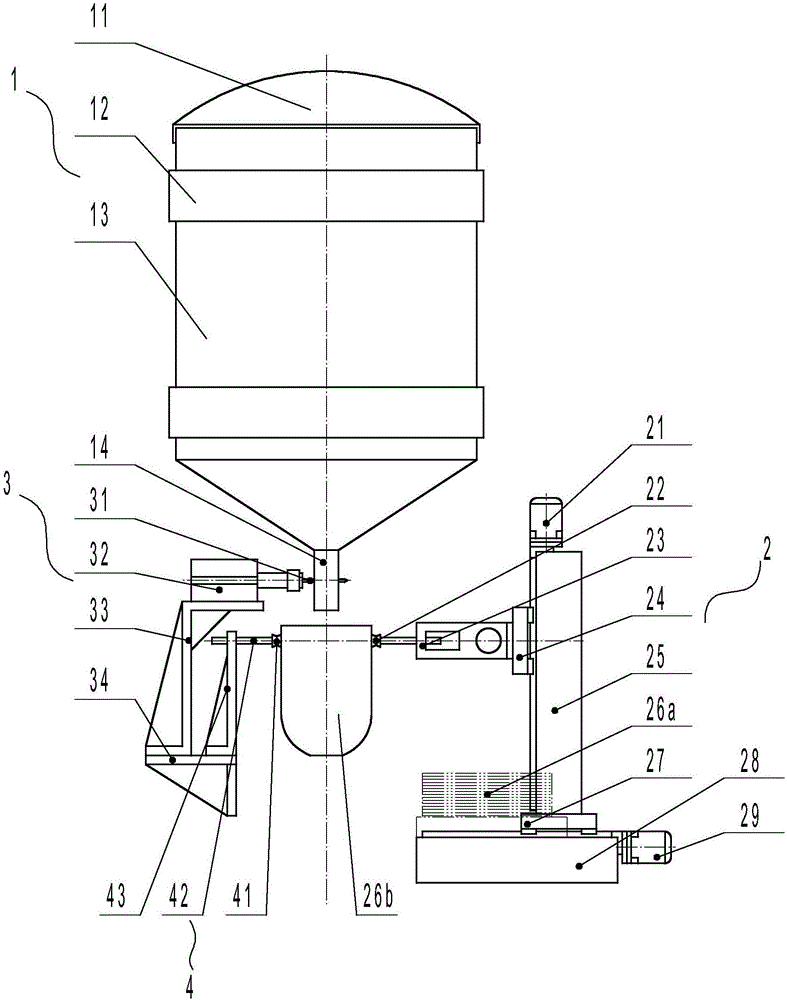

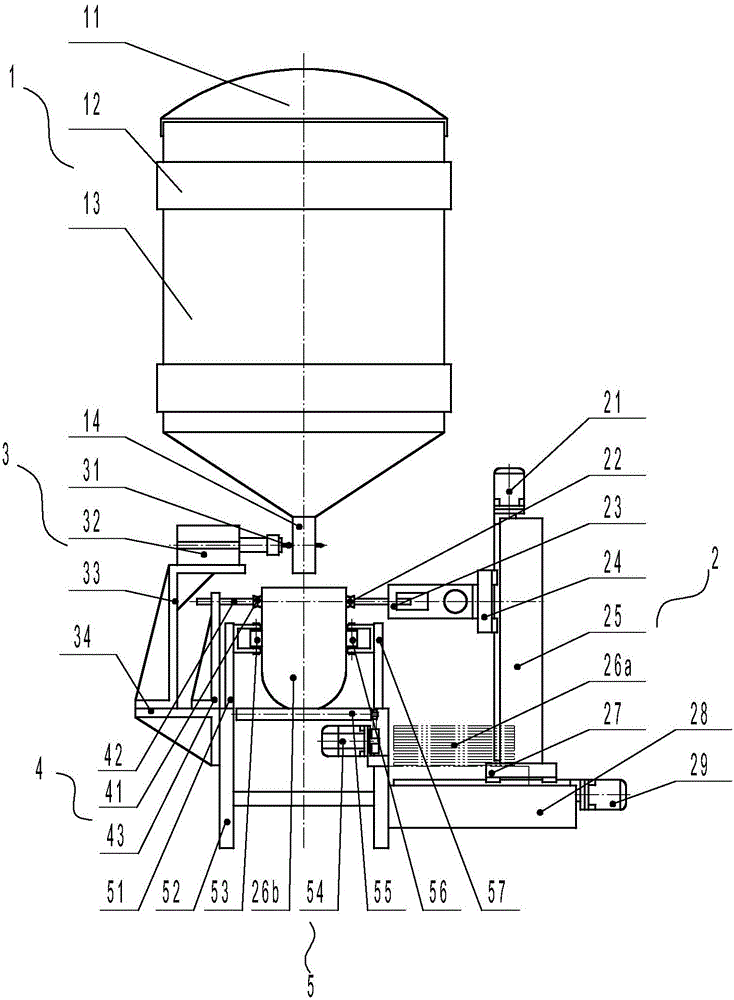

[0061] An automatic bagging device for grain, which includes a barn and weighing system 1, a bag taking and bagging mechanism 2, an automatic opening and closing mechanism for the barn 3, an auxiliary device for opening bags 4, and a control system; the barn and weighing system The input and output ends of the weighing system 1 are connected to the control system, and the output ends of the control system are respectively connected to the input ends of the bag taking and bagging mechanism 2, the automatic barn switch mechanism 3, and the bag opening auxiliary device 4.

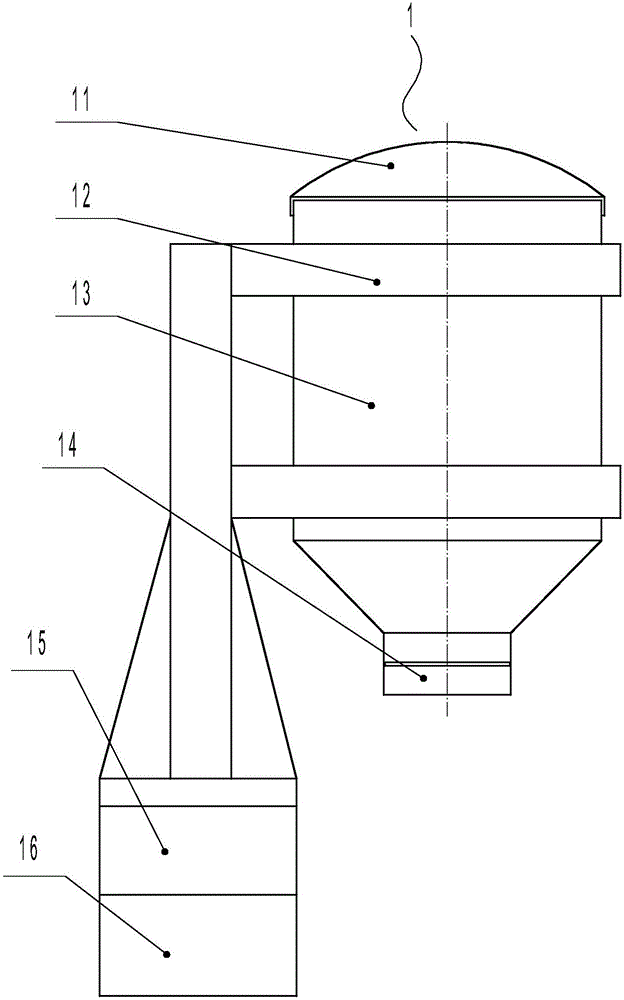

[0062] The barn and weighing system 1 includes a barn and a weighing system. The barn includes a barn cover 11, a barn support frame 12, and a barn body 13 containing grains. The barn cover 11 is connected to On the top of the barn body 13, the barn body 13 is installed on the barn support frame 12, the barn body 13 is an inverted V-shaped structure, and the bottom of the barn body 13 is provided with a barn mo...

Embodiment 2

[0068] An automatic bagging device for grain, the basic structure of which is the same as that of Embodiment 1, including a barn and a weighing system 1, a bag taking and bagging mechanism 2, an automatic opening and closing mechanism for the barn 3, an auxiliary device for opening bags 4 and a control system system; the difference is: the automatic bagging device for grains also includes an automatic transmission mechanism 5, which includes a left auxiliary guide wheel support frame 51, a transmission support base 52, a plurality of left auxiliary guide wheels 53, transmission motor 54, several transmission drums 55 for transmitting the grain bag 26b that grain is housed, a plurality of right auxiliary guide wheels 56 and right auxiliary guide wheel support frame 57; described transmission motor 55 is fixed on the transmission support base On the seat 52, several transmission rollers 55 are installed side by side on the transmission support base 52, the roller shaft of each tr...

Embodiment 3

[0070] An automatic bagging device for grain, the basic structure of which is the same as that of Embodiment 2, including a barn and a weighing system 1, a bag taking and bagging mechanism 2, an automatic opening and closing mechanism for the barn 3, an auxiliary device for opening bags 4, an automatic Transmission mechanism 5 and control system; the difference is: the automatic bagging device for grain also includes an automatic sealing device 6 for sealing the grain bag, a sliding platform 7 for the grain bag, and the automatic sealing device 6 is installed on the transmission On the support base 52, the automatic sealing device 6 mainly realizes the sealing function of the grain bag filled with grain; the described grain bag sliding platform 7 is connected with the end of the transmission support base 52, and the grain bag sliding platform 7 It mainly realizes the sliding function of the sealed grain bag.

[0071] That is, the specific structure of the third embodiment is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com