An automatic high temperature metal ash cooling and screening device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

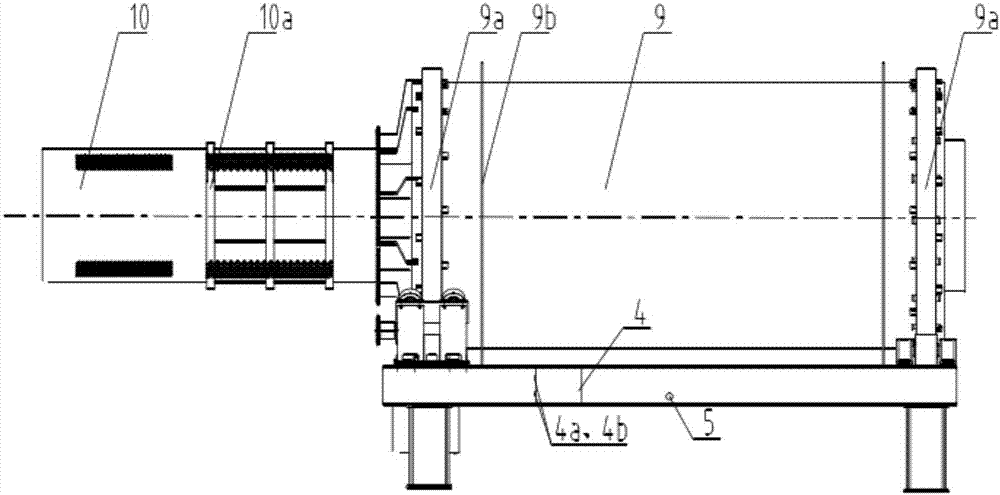

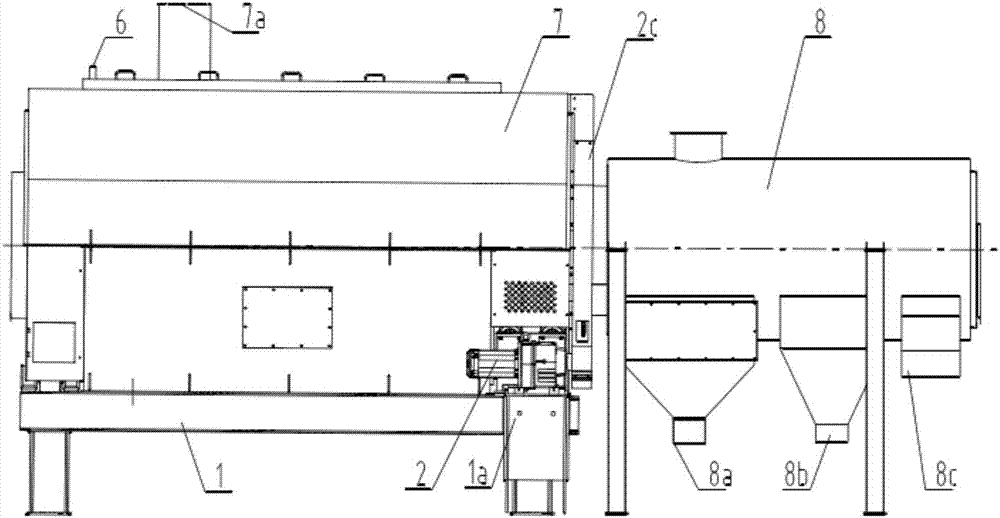

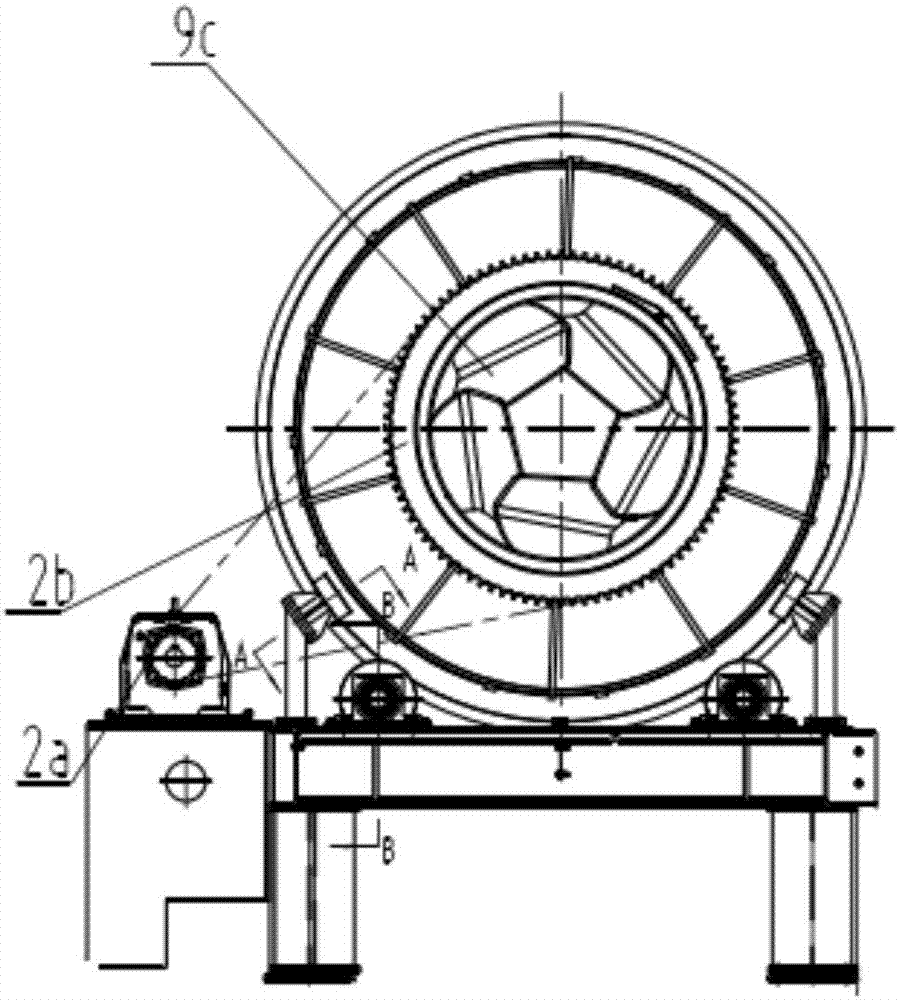

[0024] see Figure 1-6 , an automatic high-temperature metal ash cooling and screening device, characterized in that: it includes a cooling part and a screening part; the cooling part includes a frame 1, and the frame 1 is provided with at least four bearing roller assembly devices 3 , the bearing roller assembly 3 supports the cooling barrel 9; the edge position of the bearing roller assembly 3 is at least provided with a pair of limit bracket assembly 11, and the limit bracket assembly 11 is for cooling Bucket 9 carries out position-limiting; Described frame 1 is provided with deceleration motor 2, and described deceleration motor 2 drives described cooling bucket 9 to rotate through sprocket wheel, and the sieving bucket 10 of described screening part rotates synchronously together; The outside of the cooling barrel 9 is fixed with a coolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com