Preparation process of high-performance coating diaphragm having surface coated with organic layer

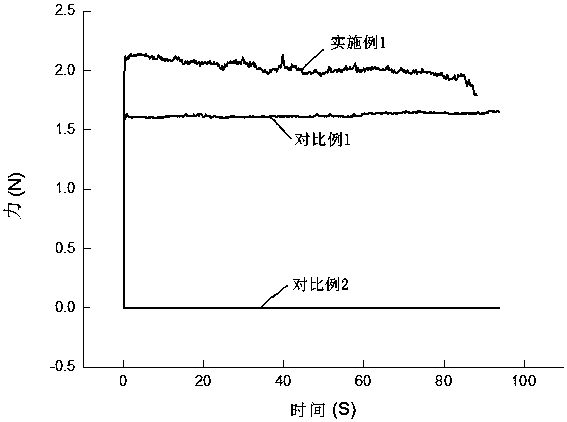

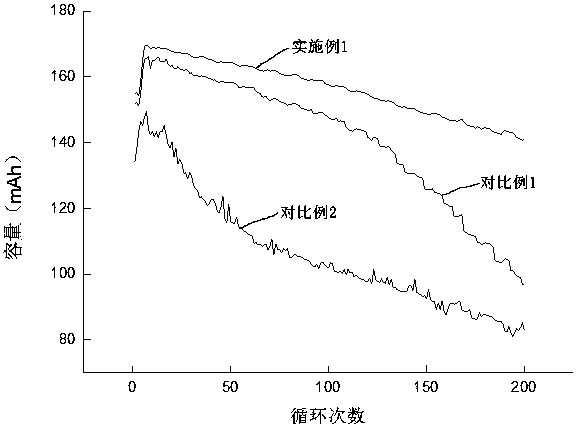

A technology of surface coating and preparation process, which is applied in the direction of separators/films/diaphragms/spacers, electrical components, electrochemical generators, etc., which can solve the problems of poor uniformity of holes, serious blocking of substrates, and uneven thickness of batteries. First-class problems, to achieve the effect of thin coating thickness, improved polarization, and uniform coating thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

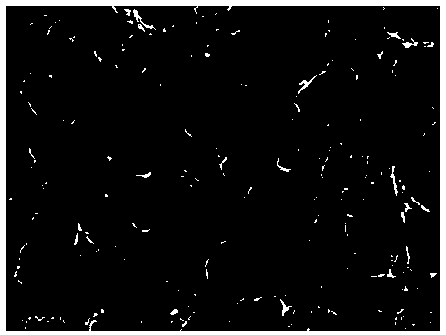

Embodiment 1

[0028] Weigh 4.2kg of polyvinylidene fluoride, 1.8kg of additives, and 194kg of acetone.

[0029] Mix acetone and additives into the mixing tank, stir for 10 minutes, add polyvinylidene fluoride gradually, heat and continue to stir until the polyvinylidene fluoride is completely dissolved, the temperature of the glue solution is controlled at 40-50°C during the stirring process, and the speed is 40r / min , the stirring time is greater than 90min, and the oil-based slurry-polymer solution is obtained.

[0030] The above-mentioned slurry is coated on both sides of the diaphragm substrate—polyethylene-based film by dip coating.

[0031] The specific method is: immerse the polyethylene-based membrane with a thickness of 12 μm, a porosity of about 40%, and an average pore diameter of 0.03 μm in the prepared slurry. The film is lifted away from the slurry, and the excess slurry is dropped back into the glue tank naturally or forcibly, and after being dried by hot air at a temperatur...

Embodiment 2

[0034] Weigh 4.2kg of polyvinylidene fluoride, 1.8kg of additives, and 194kg of acetone.

[0035] Mix acetone and additives into the mixing tank, stir for 10 minutes, add polyvinylidene fluoride gradually, heat and continue to stir until the polyvinylidene fluoride is completely dissolved, the temperature of the glue solution is controlled at 40-50°C during the stirring process, and the speed is 40r / min , the stirring time is greater than 90min, and the oil-based slurry-polymer solution is obtained.

[0036] The above slurry is coated on both sides of the polyethylene-based film by gravure coating,

[0037] The specific method is: pump the prepared slurry to the gravure roller, and then pass the gravure roller rotating at a speed of 10m / min to make the slurry with a thickness of 12μm, a porosity of about 40%, and an average pore diameter of 0.03 μm polyethylene-based film, the slurry can be coated on the surface of the polyethylene-based film, and then dried by hot air at a t...

Embodiment 3

[0039] Weigh 5.7kg of polyvinylidene fluoride, 2.3kg of additives, and 192kg of acetone.

[0040] Mix acetone and additives into the mixing tank, stir for 10 minutes, add polyvinylidene fluoride gradually, heat and continue to stir until the polyvinylidene fluoride is completely dissolved, the temperature of the glue solution is controlled at 40-50°C during the stirring process, and the speed is 40r / min , the stirring time is greater than 90min, and the oil-based slurry-polymer solution is obtained.

[0041] The above slurry is coated on both sides of the polyethylene single-sided ceramic base film by dip coating.

[0042] The specific method is: immerse the polyethylene single-sided ceramic base film in the prepared slurry. After all parts are covered with the slurry, lift the base film away from the slurry, and drop the excess slurry naturally or forcibly. Fall back into the glue tank, and get a PVDF-coated composite diaphragm after drying.

[0043] The above coating speed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com