Patents

Literature

57results about How to "Realize automatic bagging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

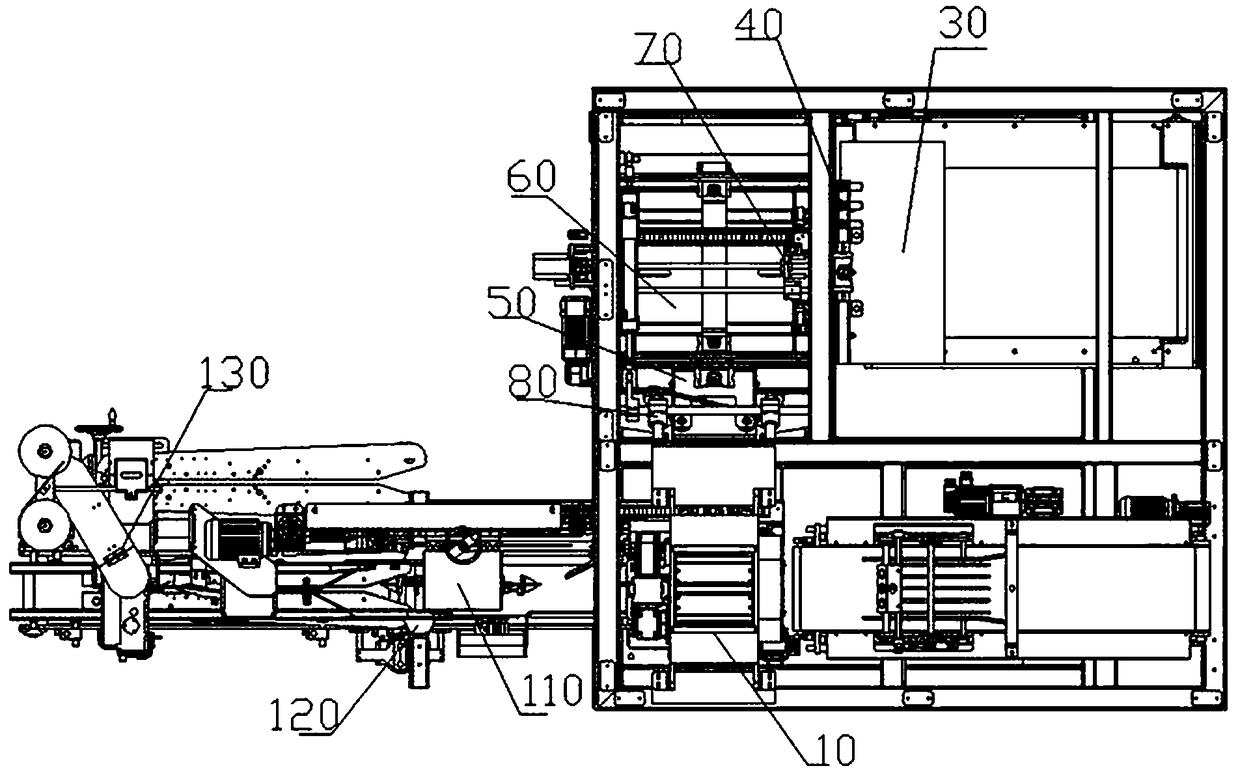

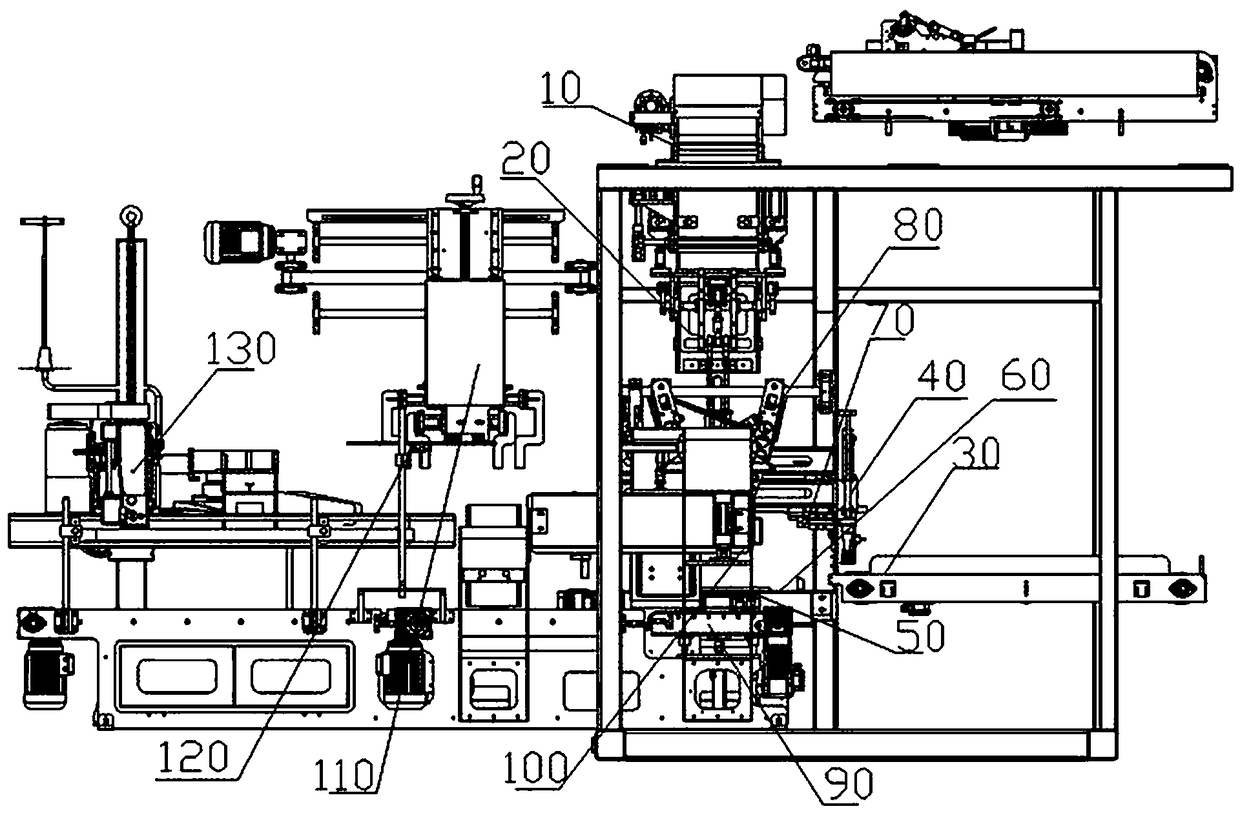

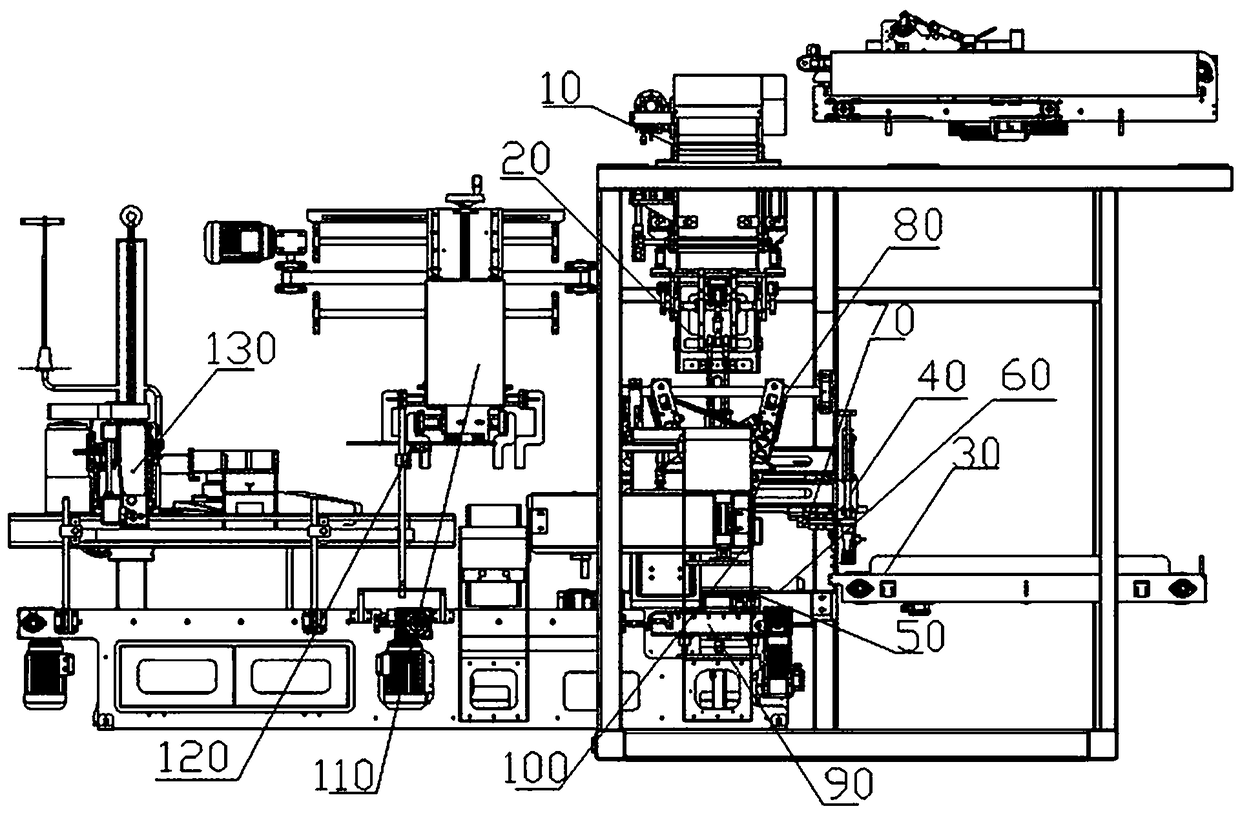

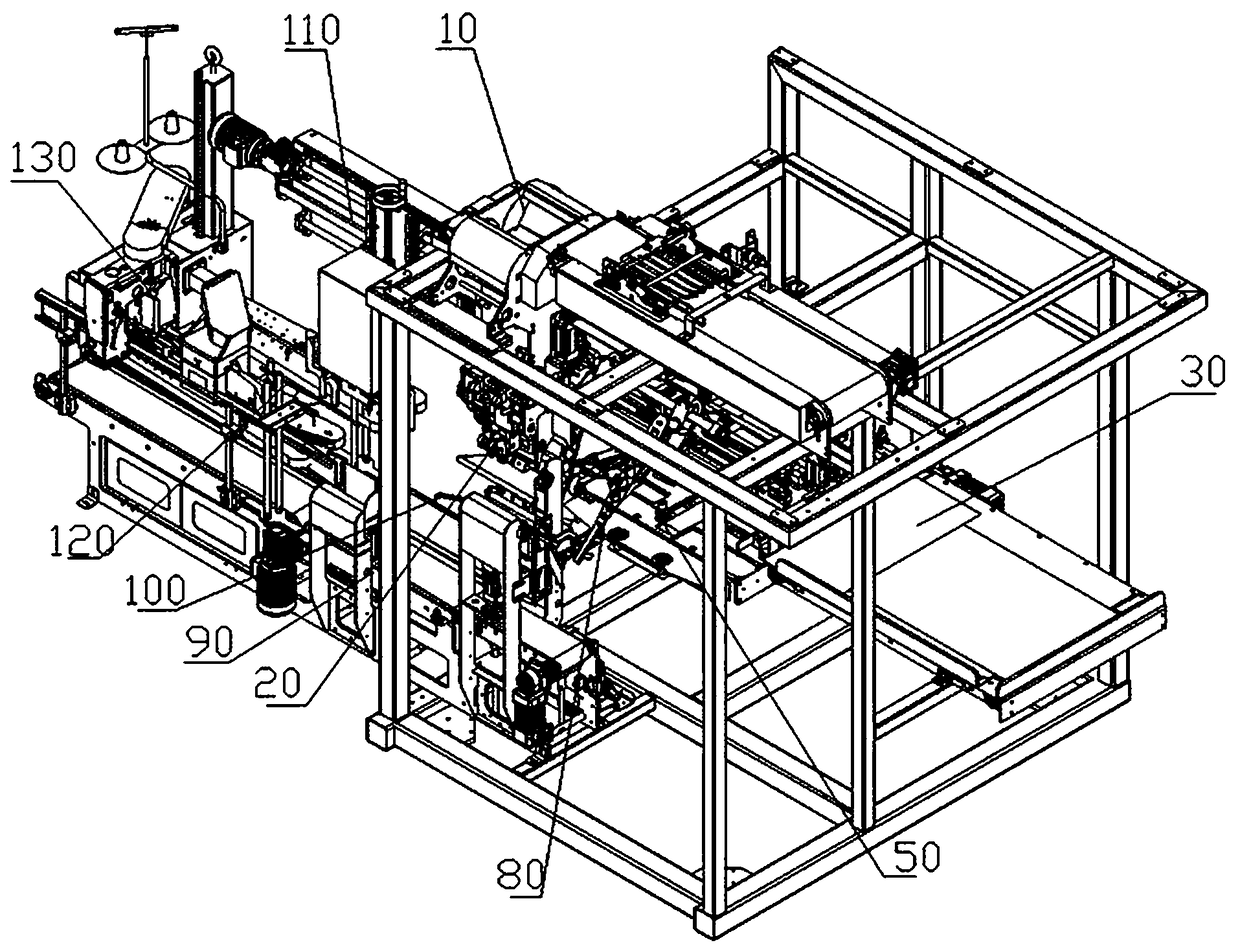

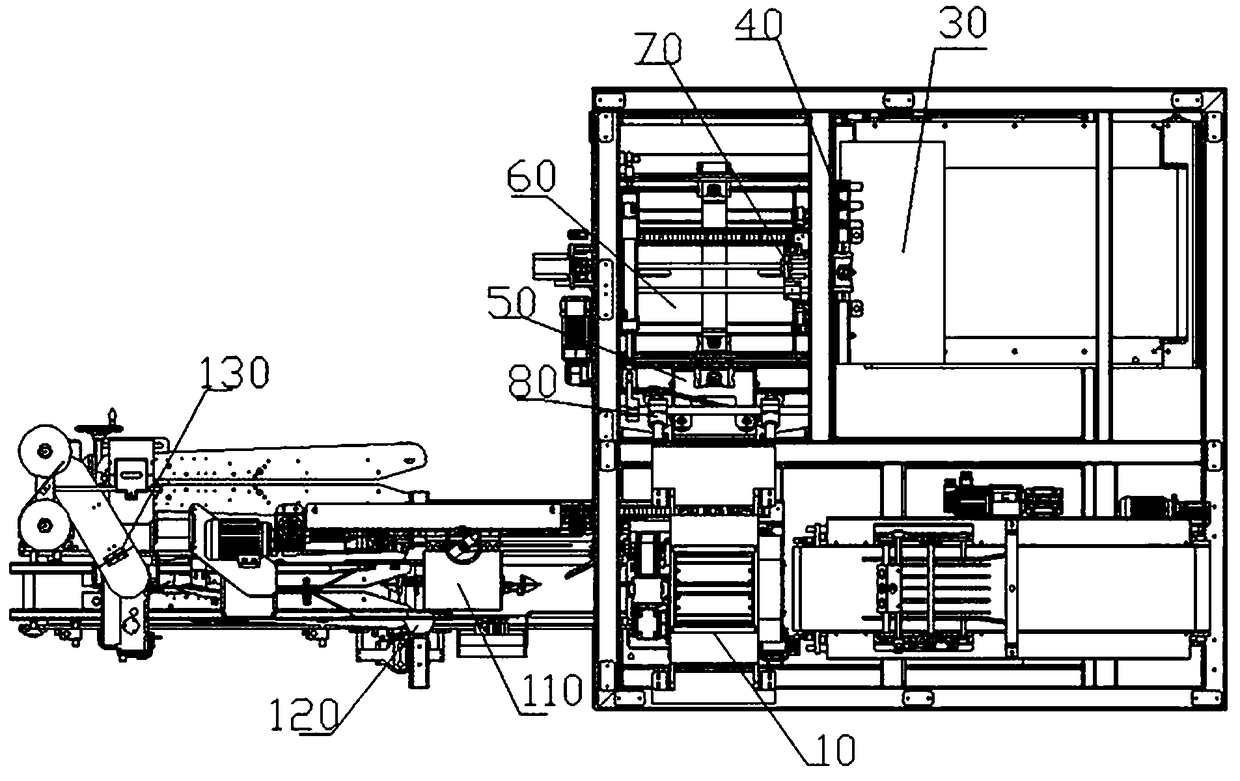

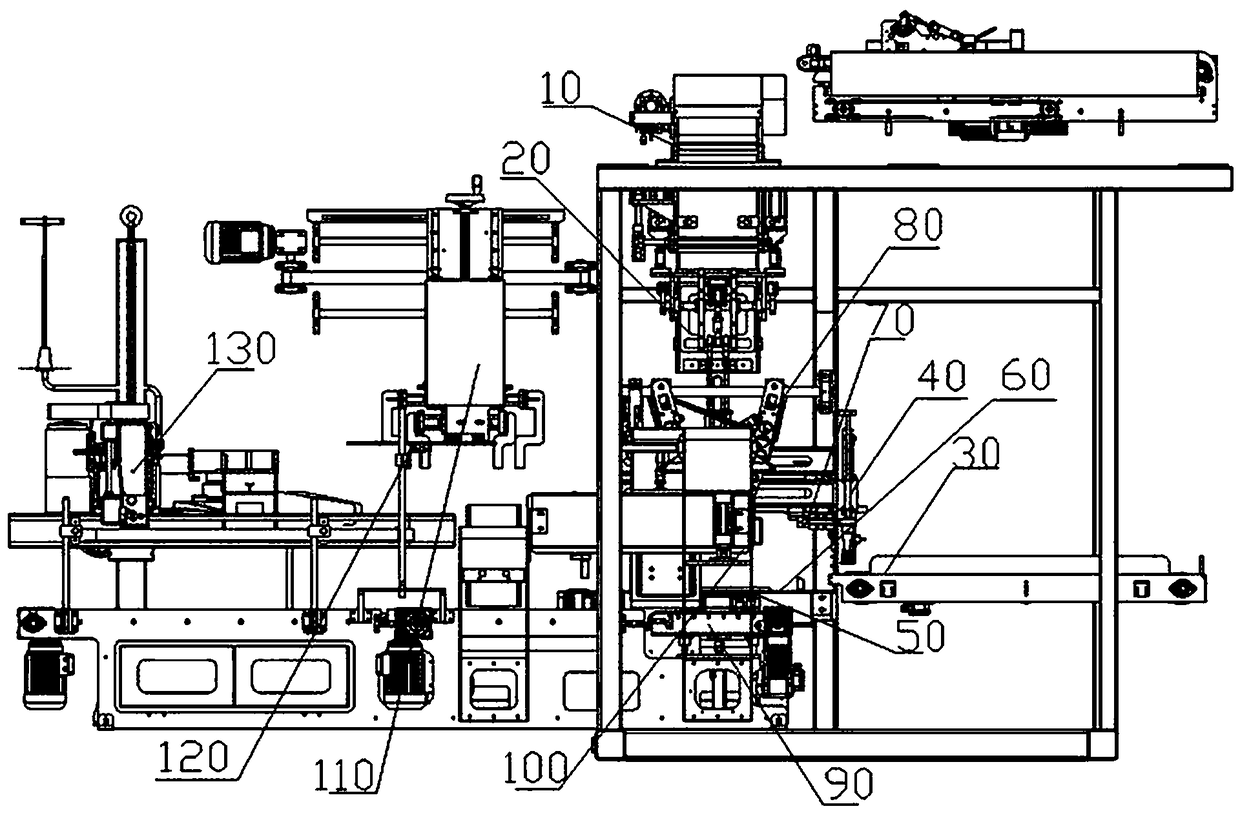

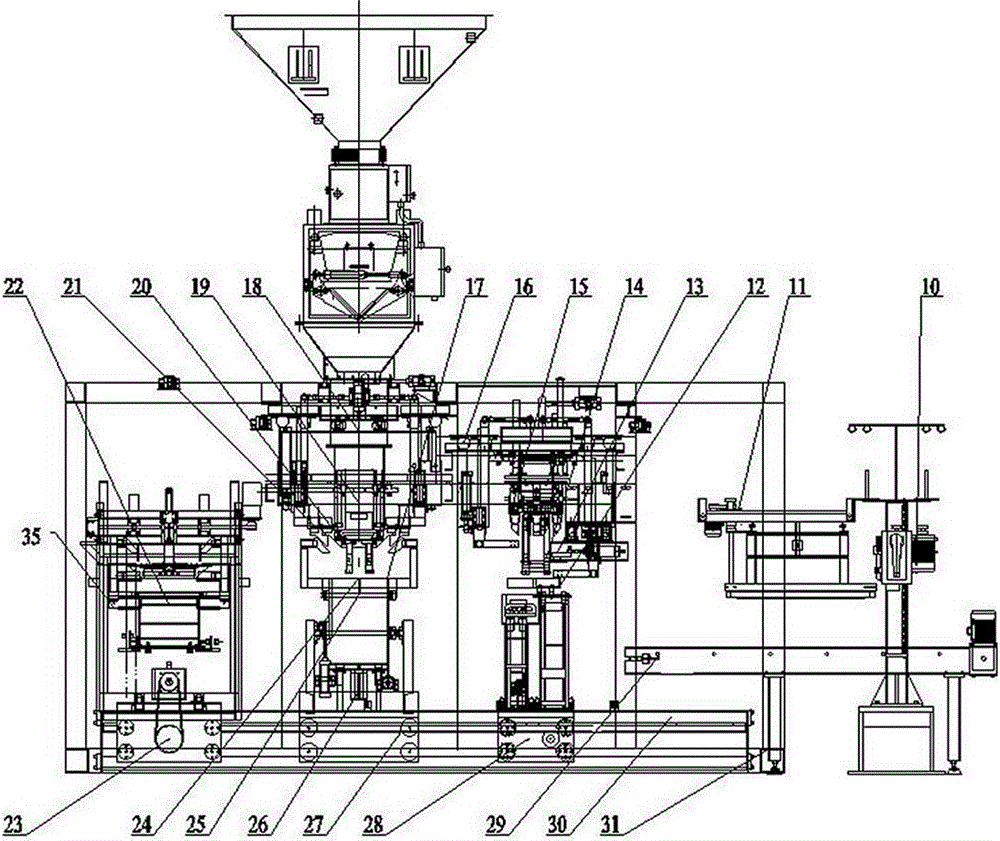

Full-automatic double-layer bag packaging machine

ActiveCN104648703AReduce labor intensityFast productionWrapper twisting/gatheringSolid materialEngineeringUltimate tensile strength

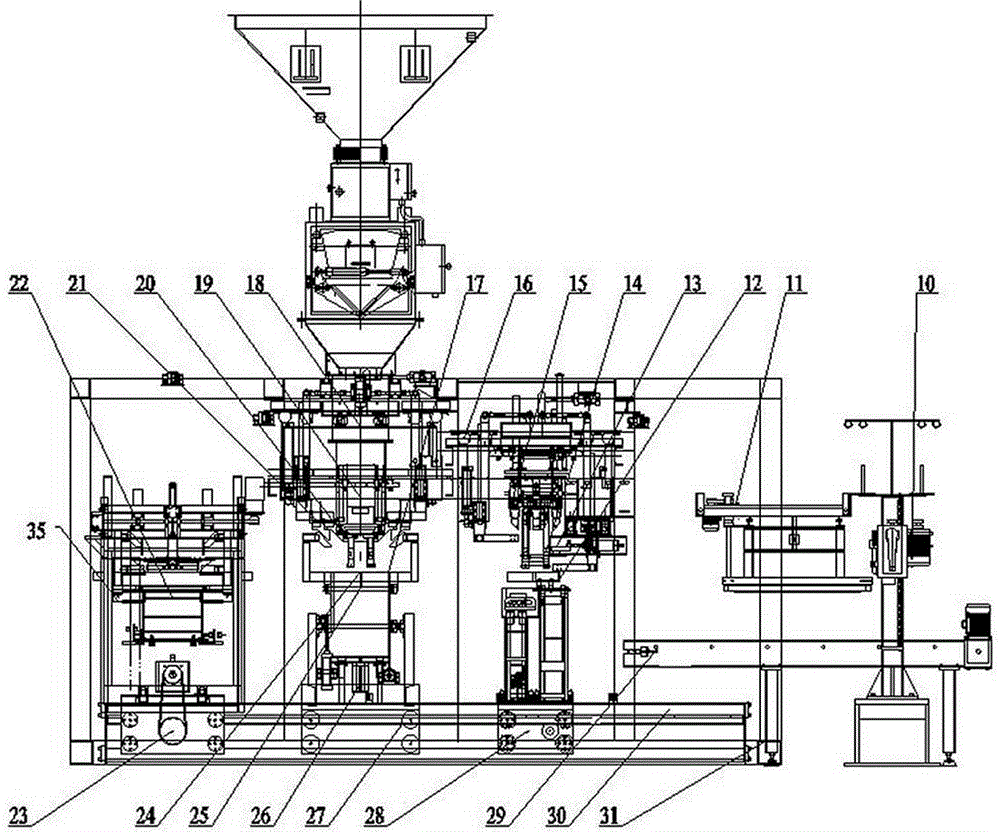

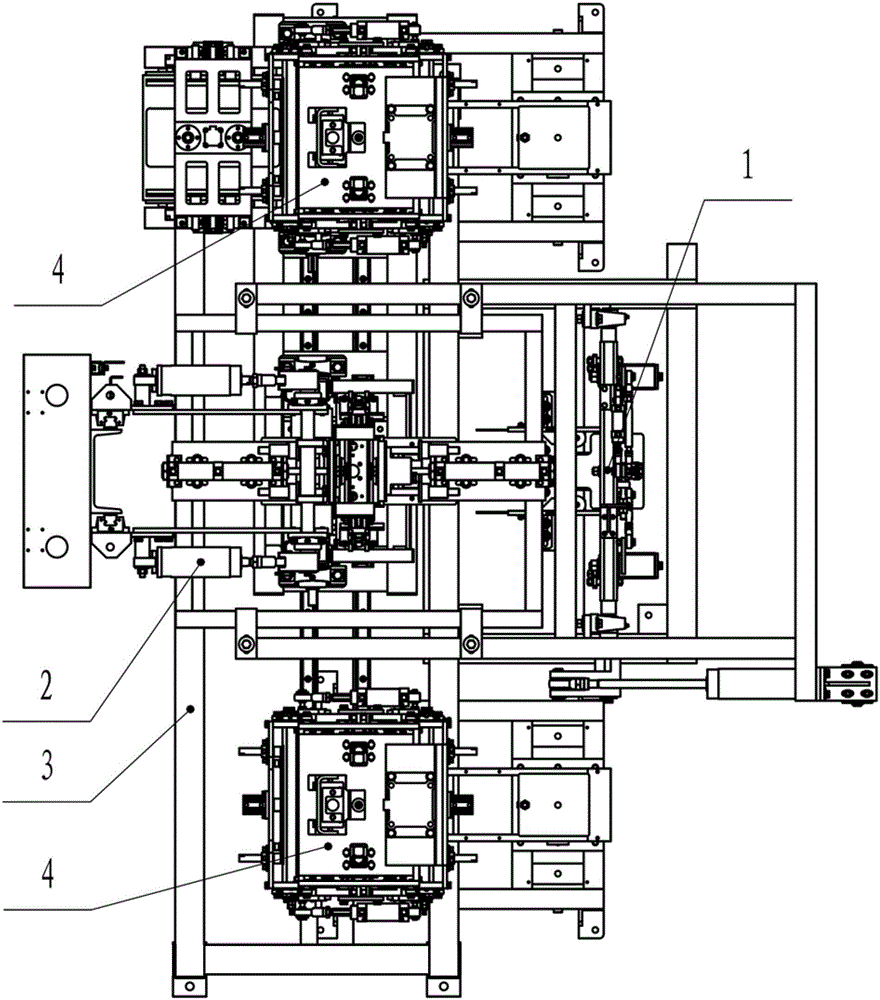

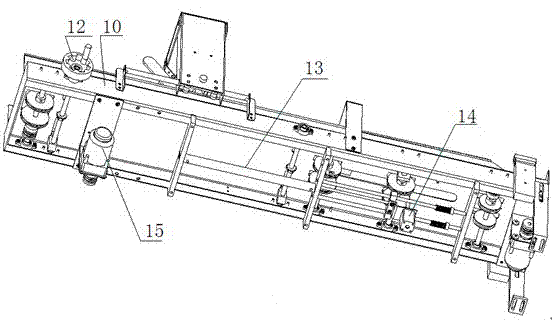

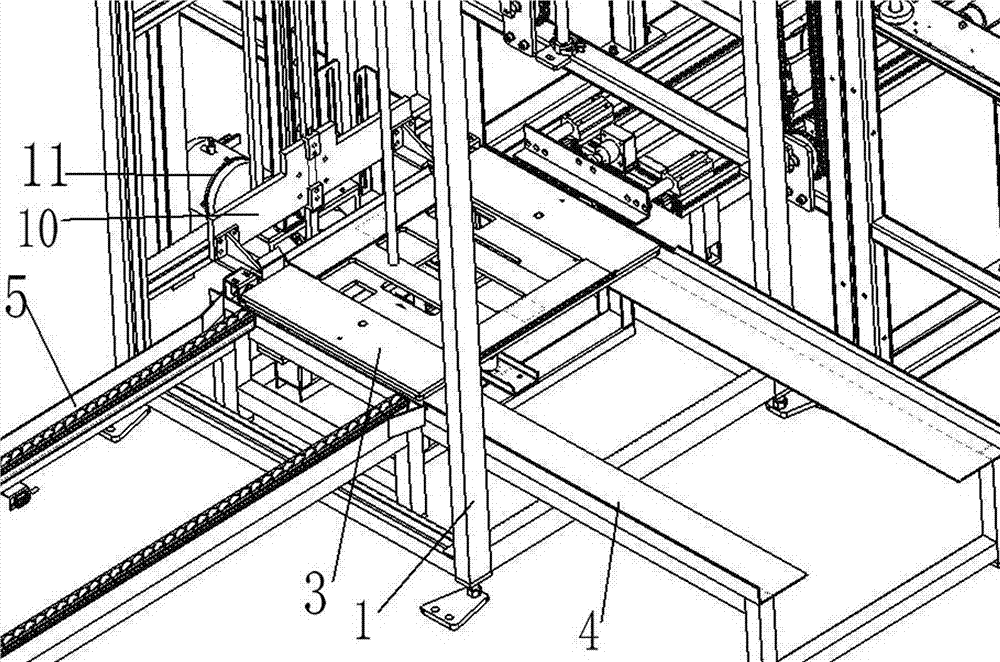

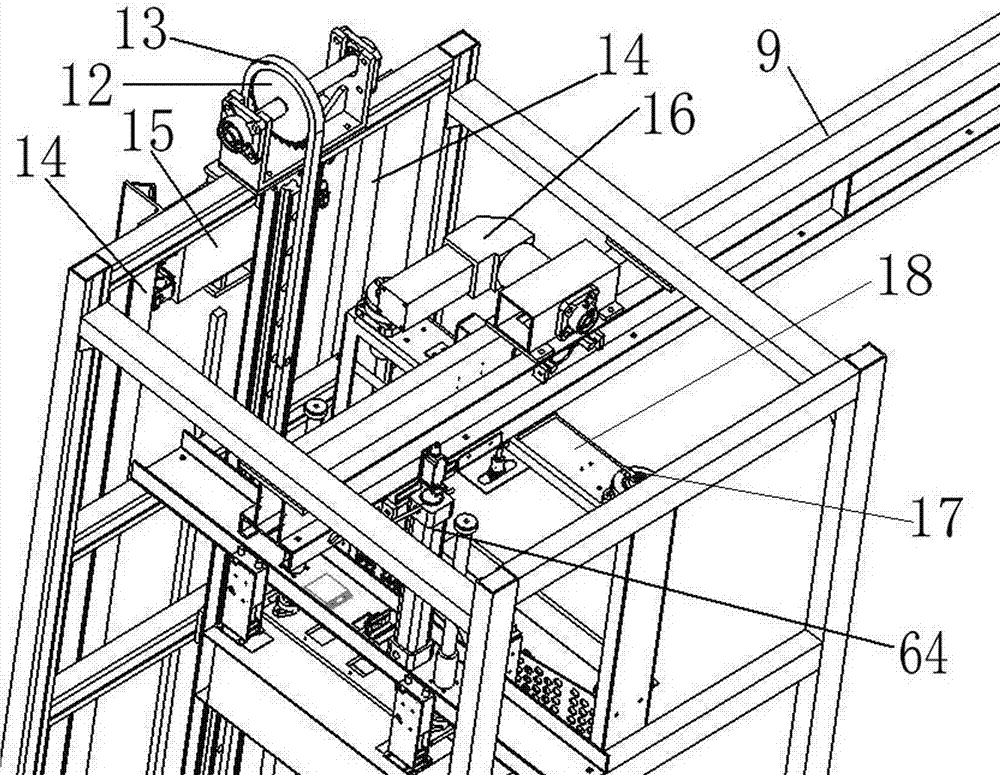

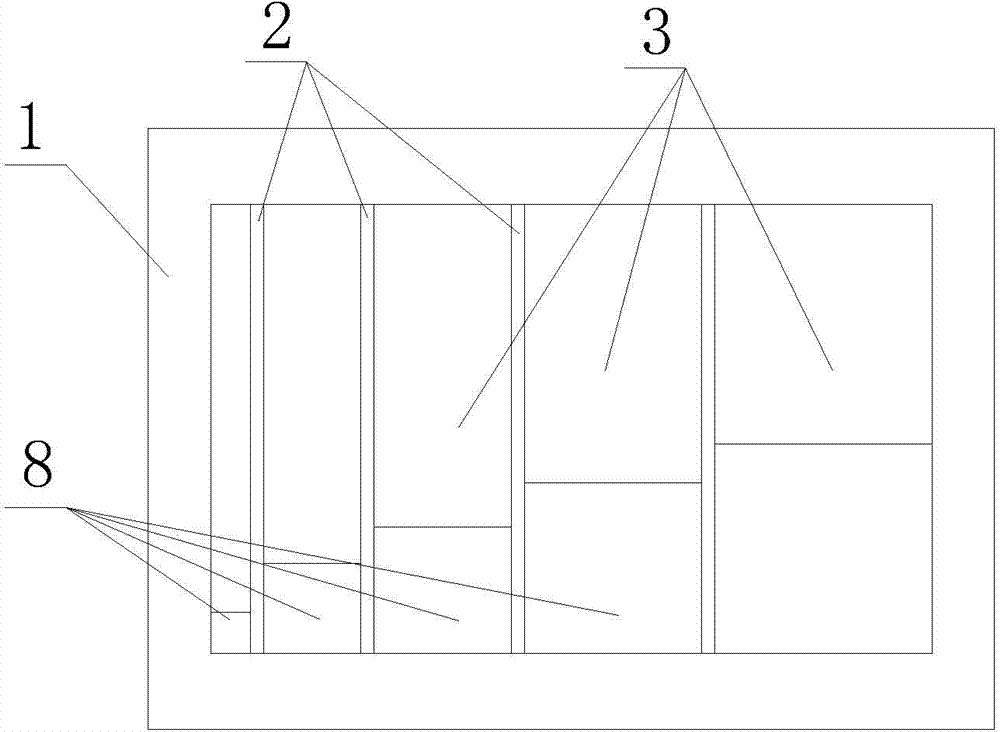

The invention provides a full-automatic double-layer bag packaging machine which comprises a machine frame. A track is arranged on the machine frame and is used for a front trolley, a middle trolley and a rear trolley, a bag feeding station, an inner bag arrangement station, a centering station, a filling station, a twisting opening-binding station and a sewing station are arranged on the machine frame, the bag feeding station is located in front of the inner bag arrangement station, the inner bag arrangement station is located in front of the centering station, the centering station is located in front of the filling station, the filling station is located in front of the twisting opening-binding station, and the twisting opening-binding station is located in front of the sewing station. The full-automatic double-layer bag packaging machine changes original manual operation, achieves automatic bag feeding, inner bag arrangement, bag centering, filling and binding, twisting and opening binding and the like and is low in labor intensity of workers, high in production speed and good in quality.

Owner:JIANGSU WANLE COMPOSITE MATERIAL

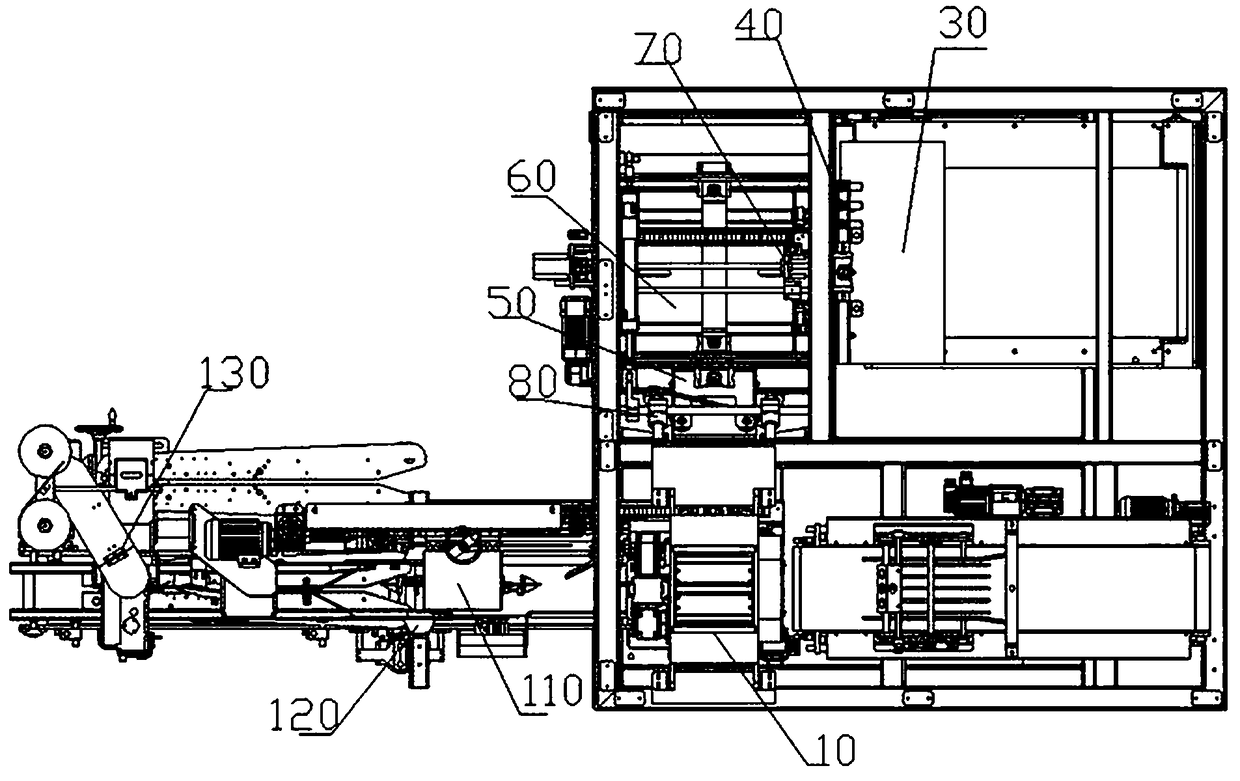

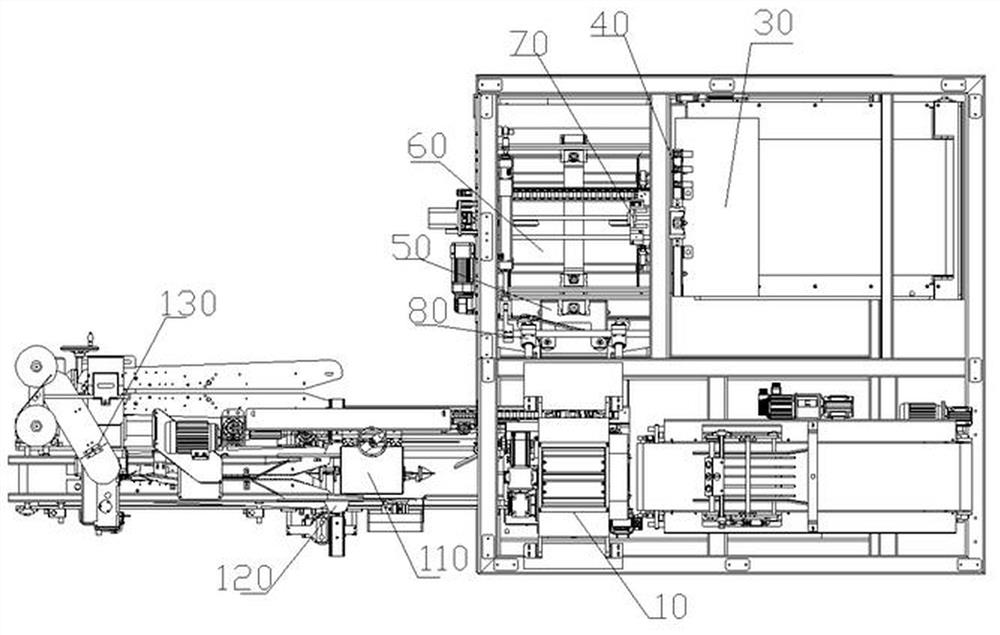

Automatic bagging machine

PendingCN108820273APrevent the bag from fallingEasy to stackWrapper twisting/gatheringSolid materialEngineeringMechanical engineering

The invention discloses an automatic bagging machine, and relates to the technical field of packaging machinery. The automatic bagging machine comprises a bag receiving bin mechanism, a bag clamping mechanism, a bag storage, a bag taking mechanism, a bag opening mechanism, a bagging mechanism, a bag shaking mechanism, a bag holding mechanism, a bag opening arranging mechanism, a bag opening guidemechanism and a bag sewing mechanism, wherein the bag shaking mechanism comprise a bag shaking platform which moves up and down in a reciprocating manner and flaps the bottoms of packaging bags sleeving on the bag clamping mechanism, the bag holding mechanism is arranged on one side of the bag shaking mechanism, the bag opening arranging mechanism is used for sorting the bag opening of each packaging bag, and the bag opening of each packaging bag enters the bag sewing mechanism under the guide of the bag opening guide mechanism to be sealed. According to the automatic bagging machine, in the bagging process, bag pouring of the packaging bags can be effectively prevented, the bag opening of each packaging bag is folded into an M shape through the bag opening arranging mechanism when the packaging bag is sealed, so that the opening of the sealing bag forms an end surface, and therefore material loosening of salt bags in the packaging bags cannot be caused in the transportation process.

Owner:SHANGHAI SOONTRUE MACHINERY EQUIP

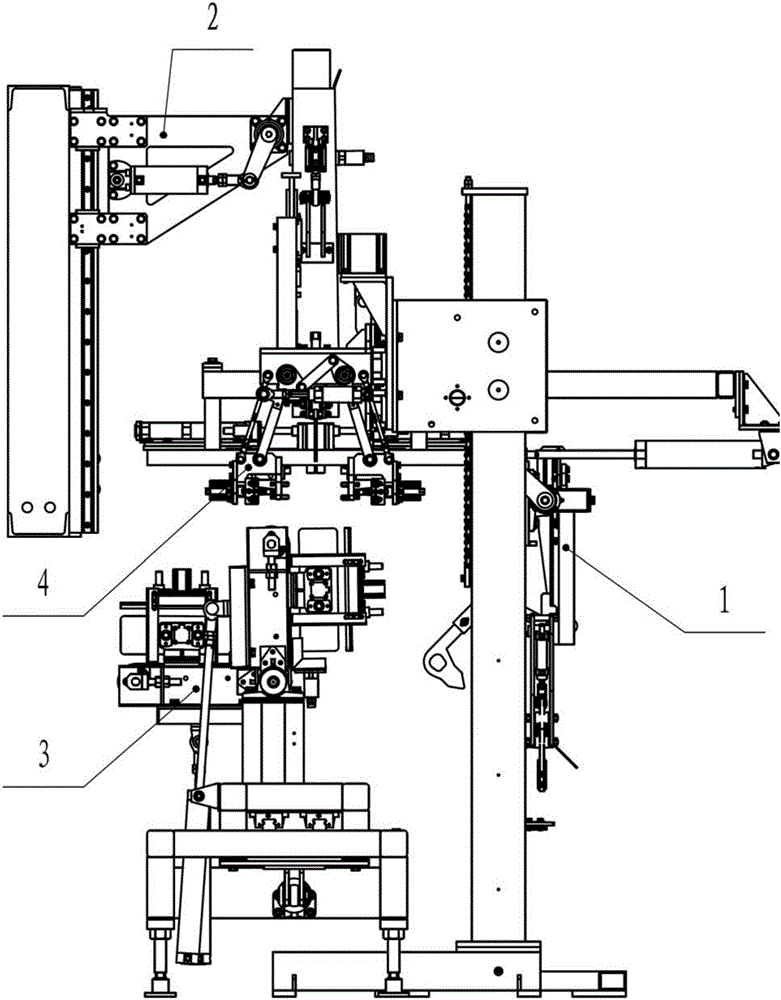

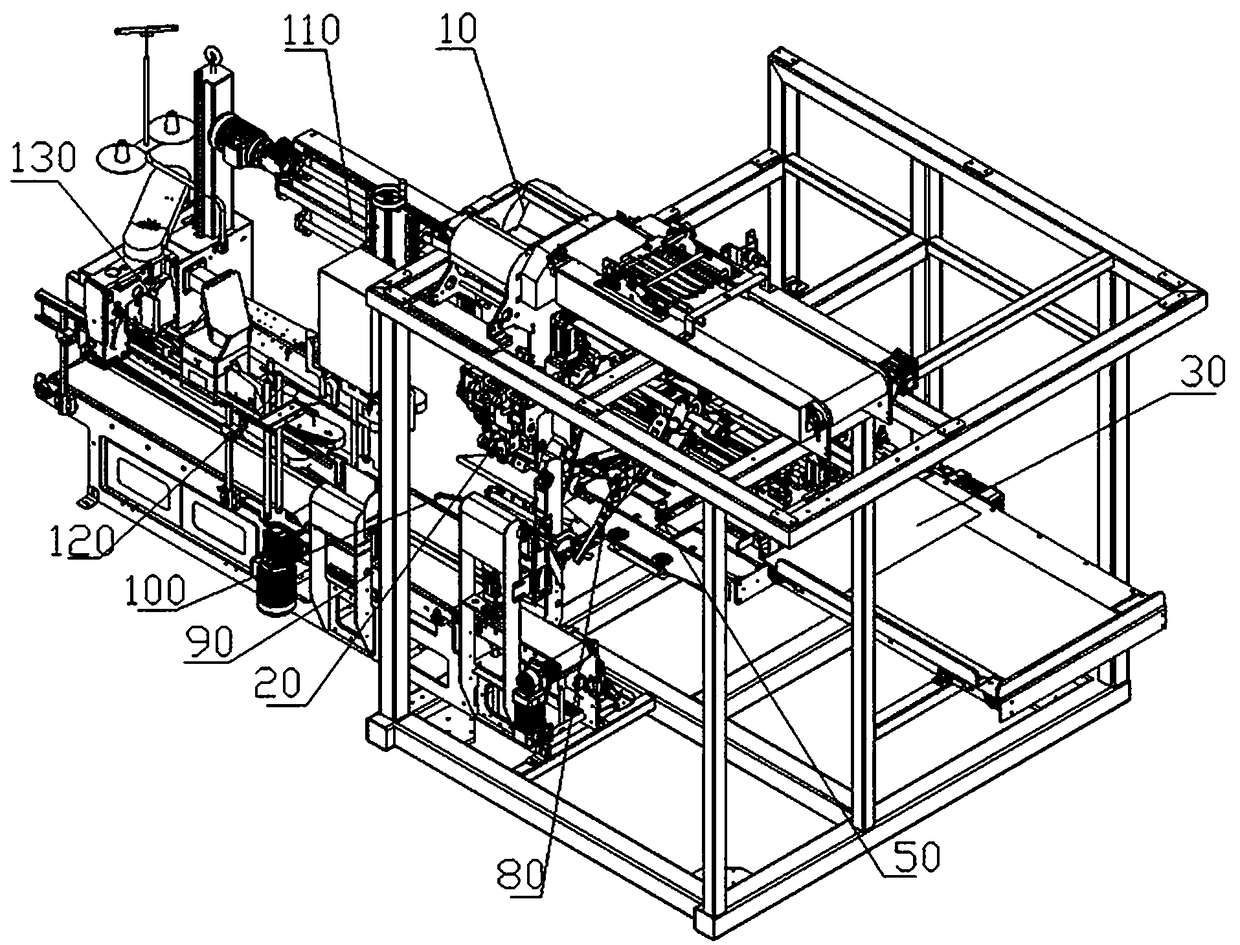

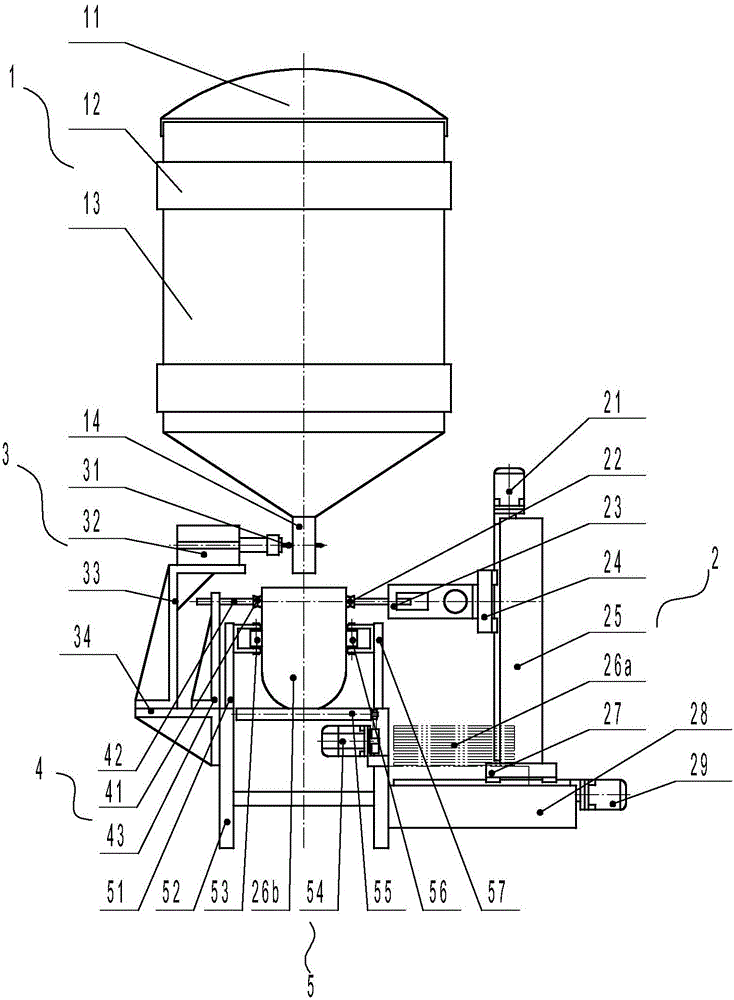

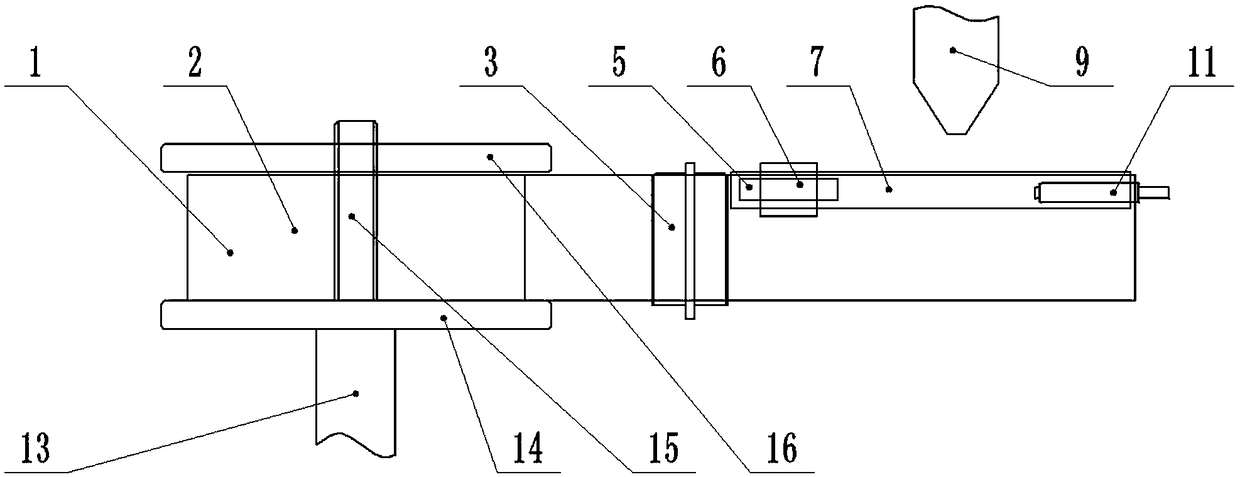

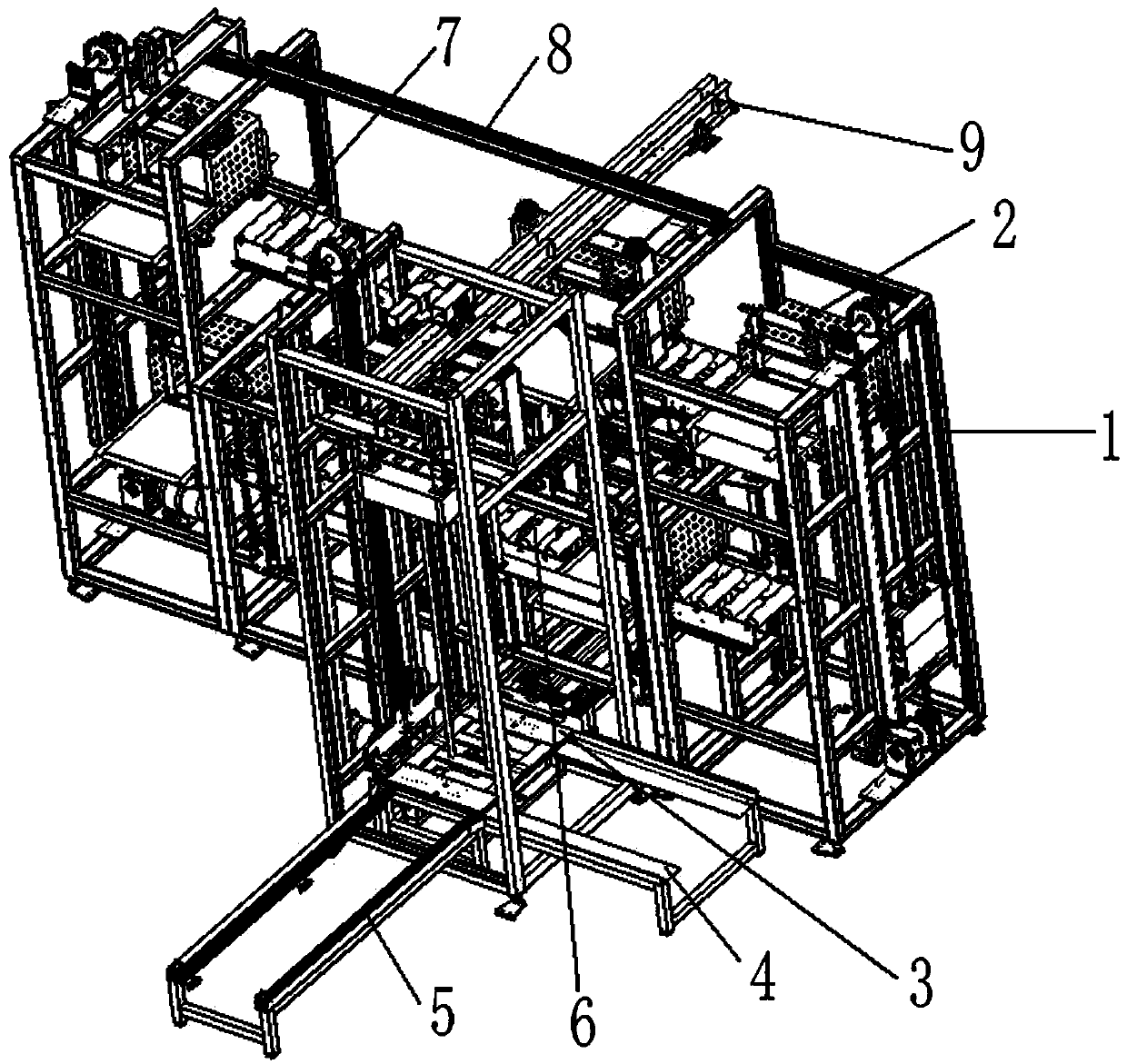

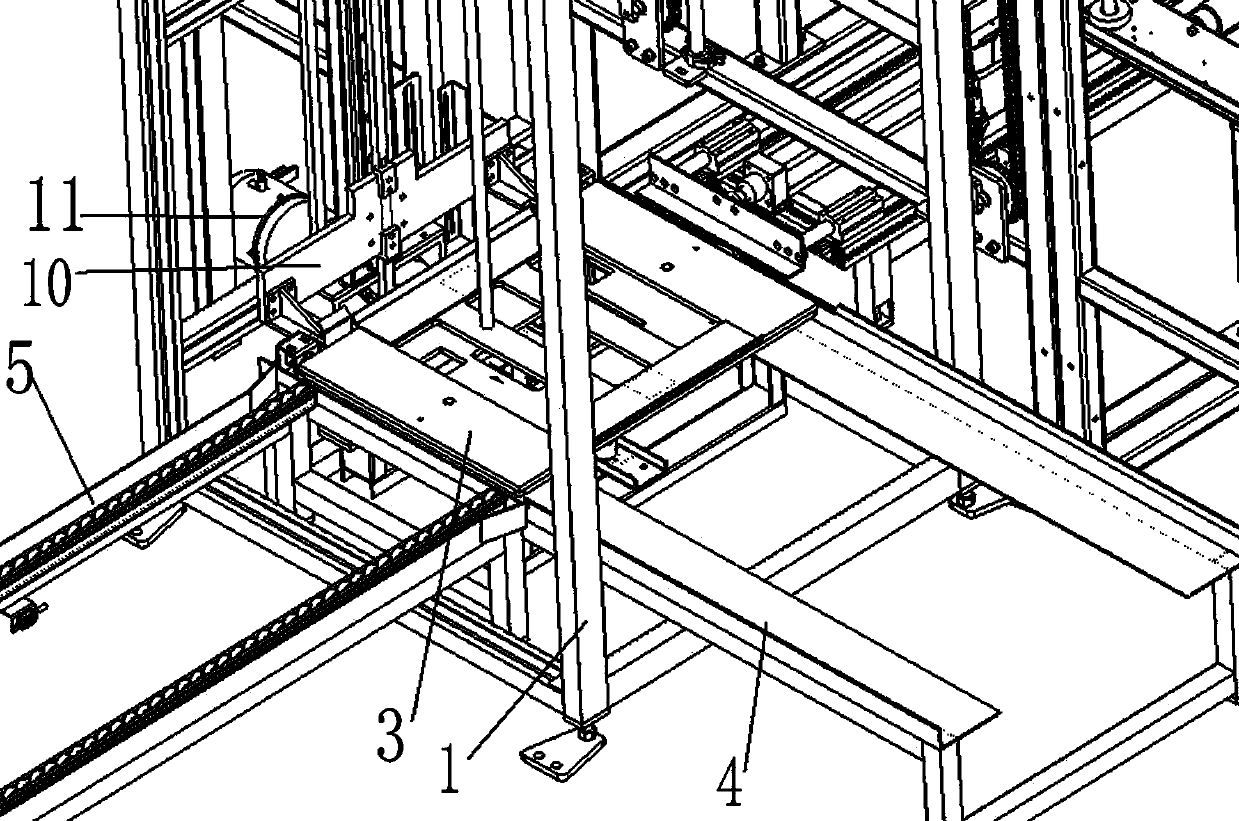

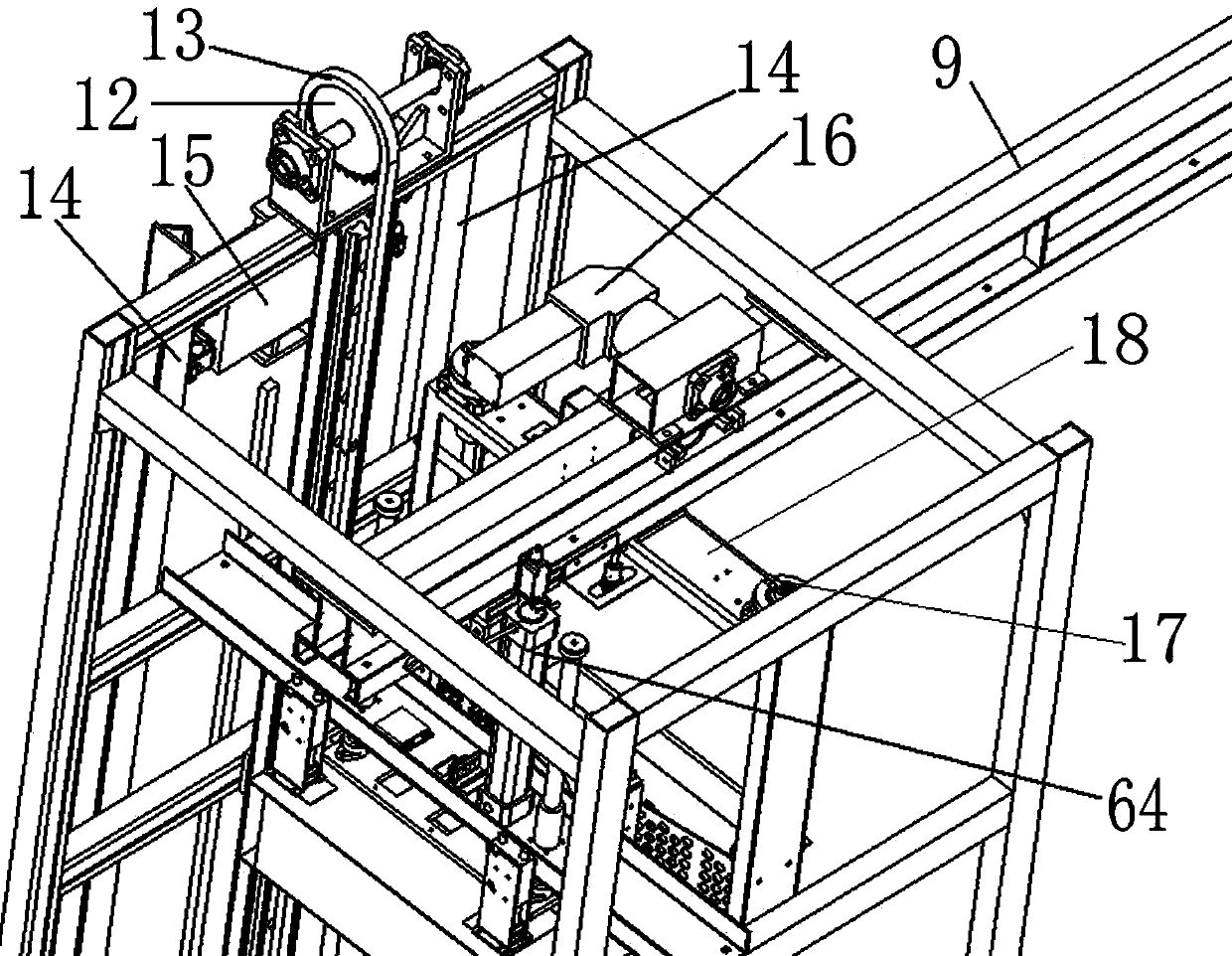

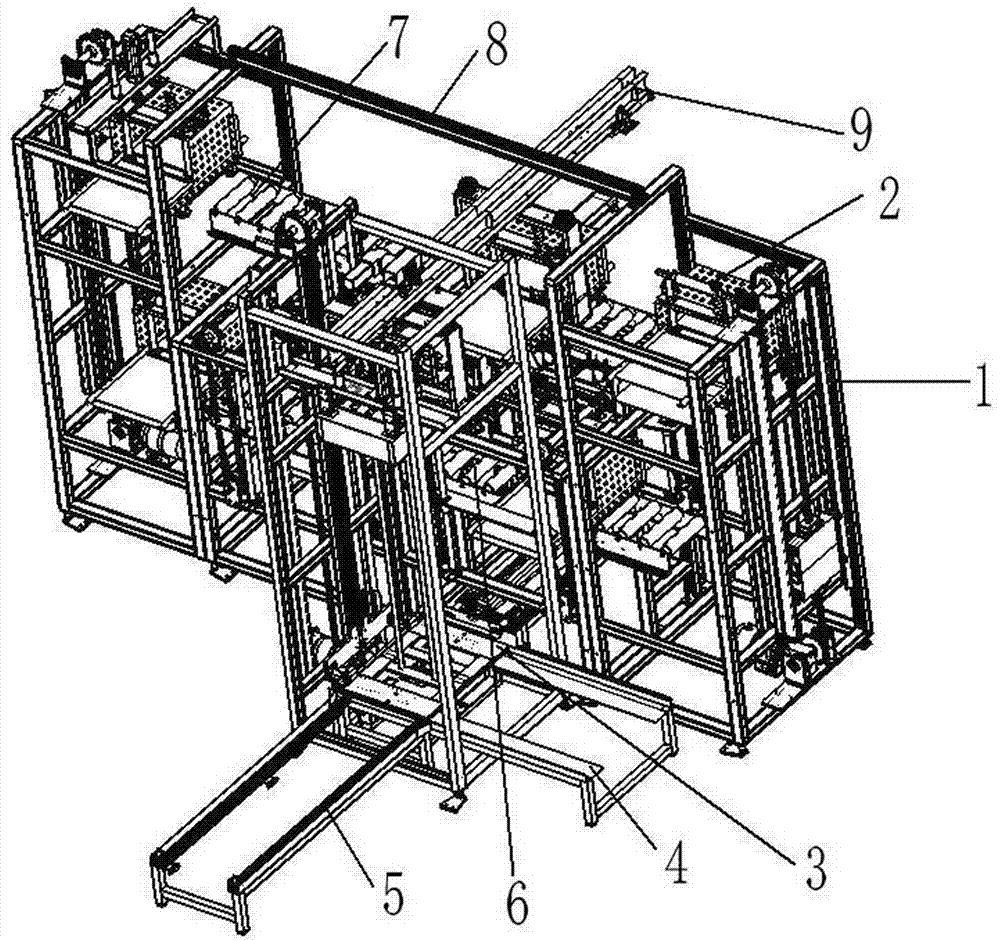

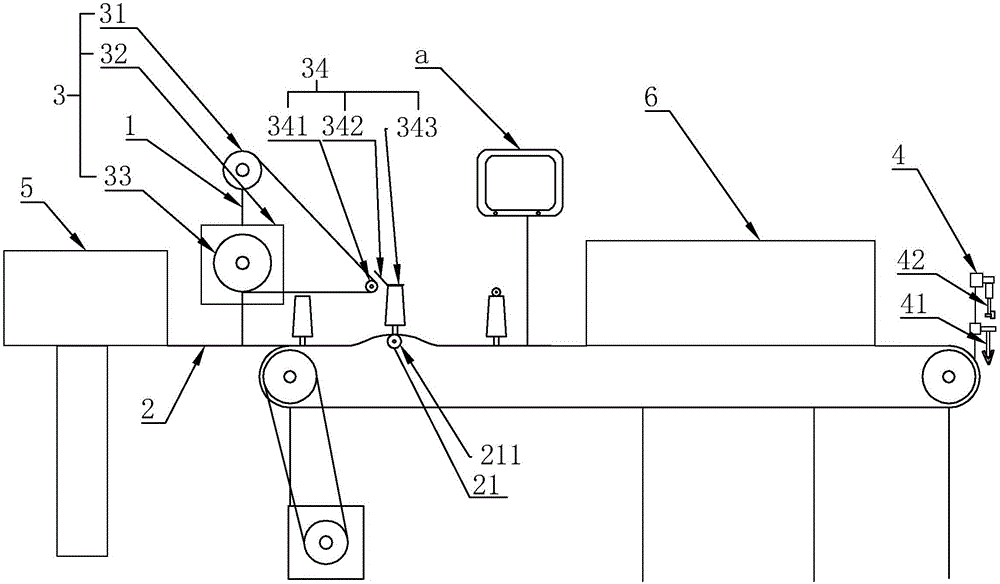

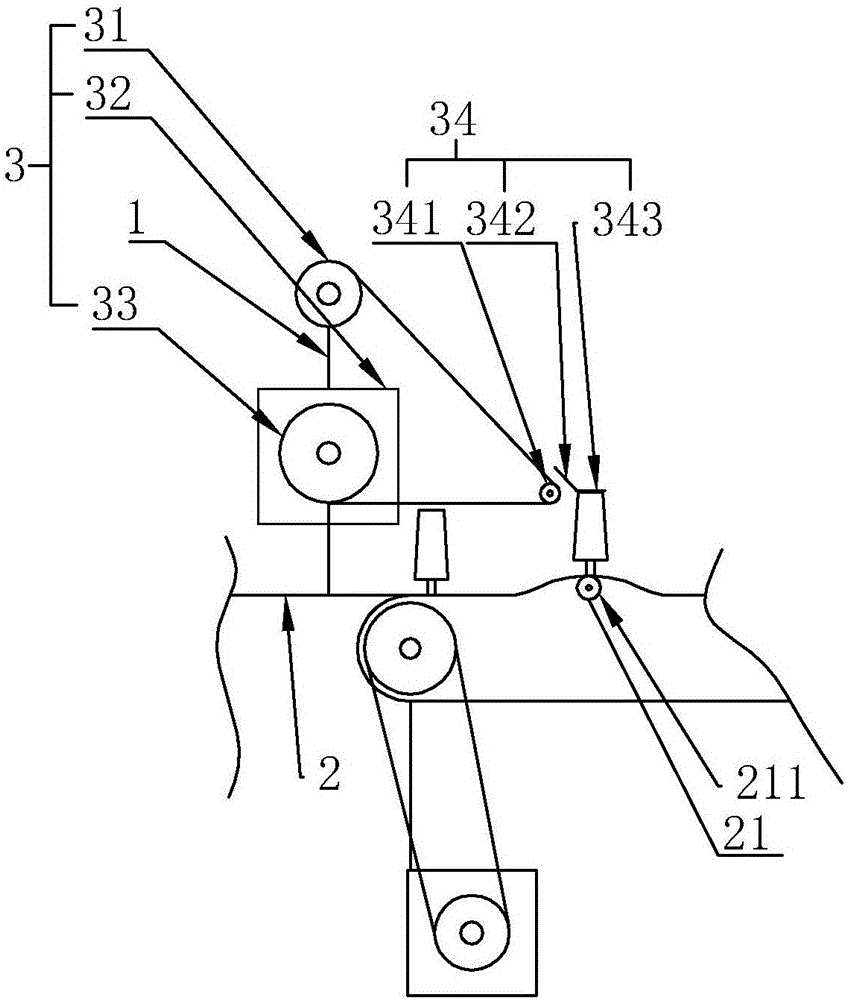

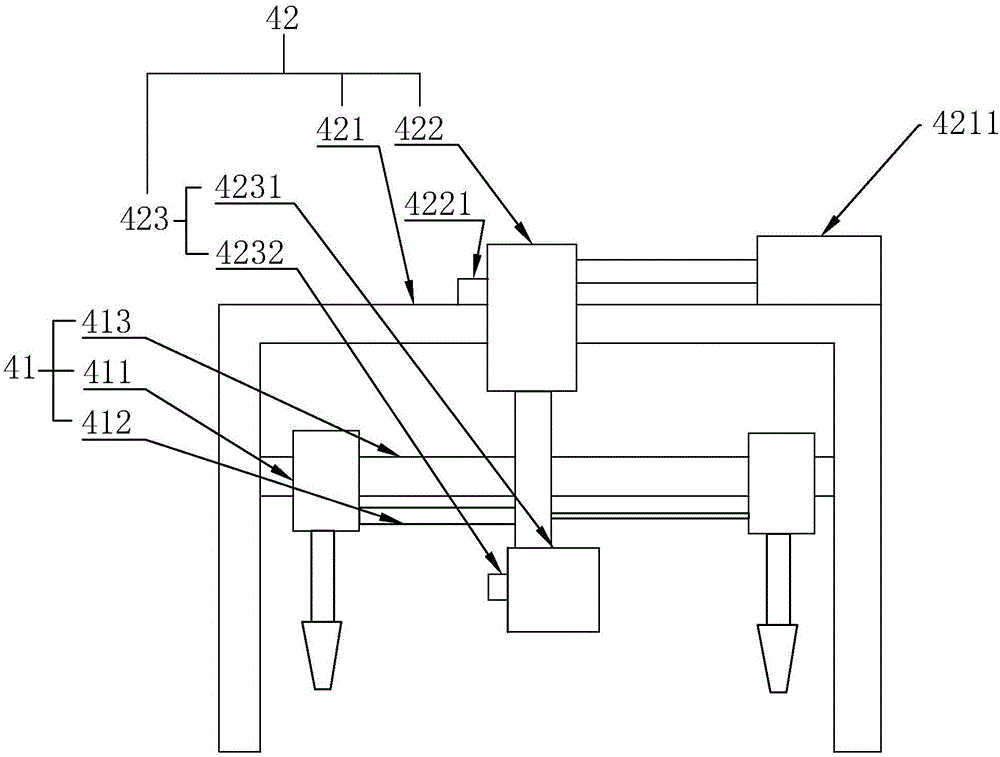

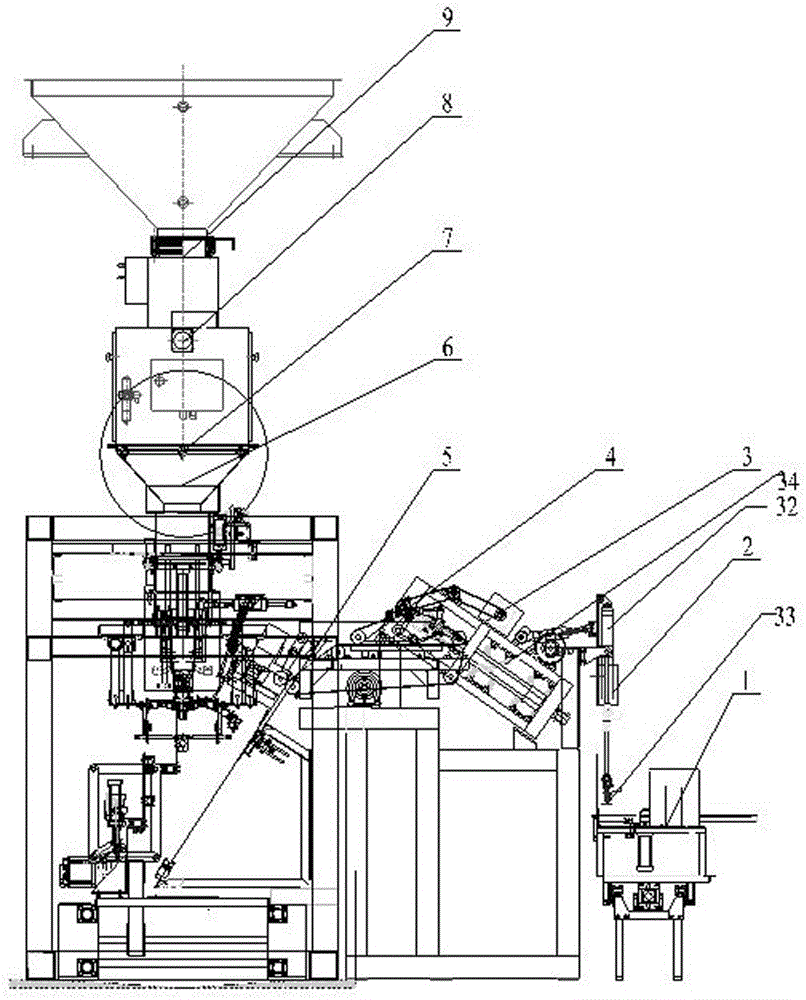

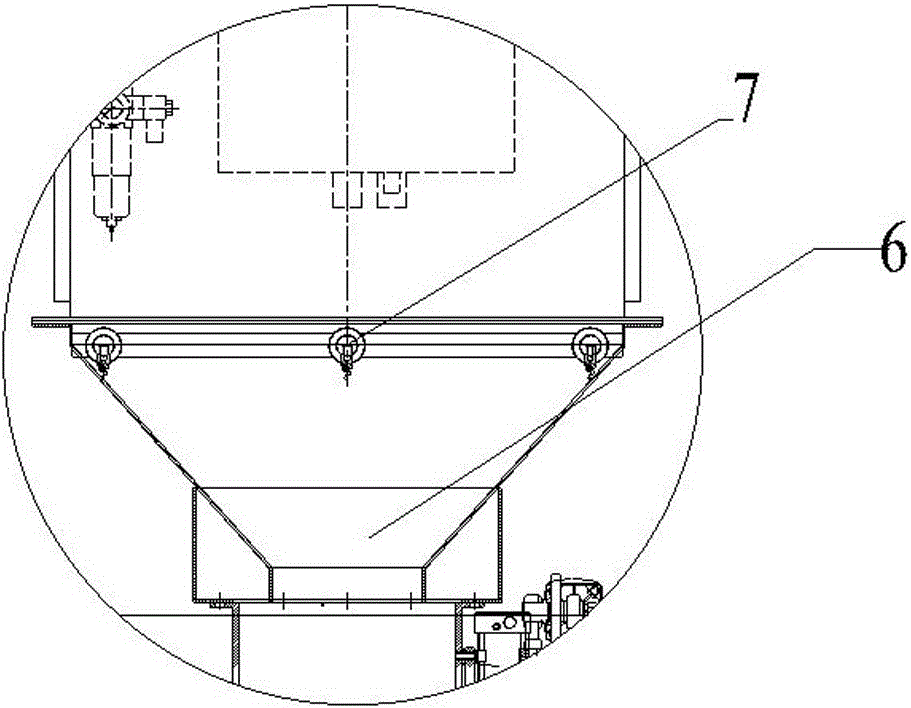

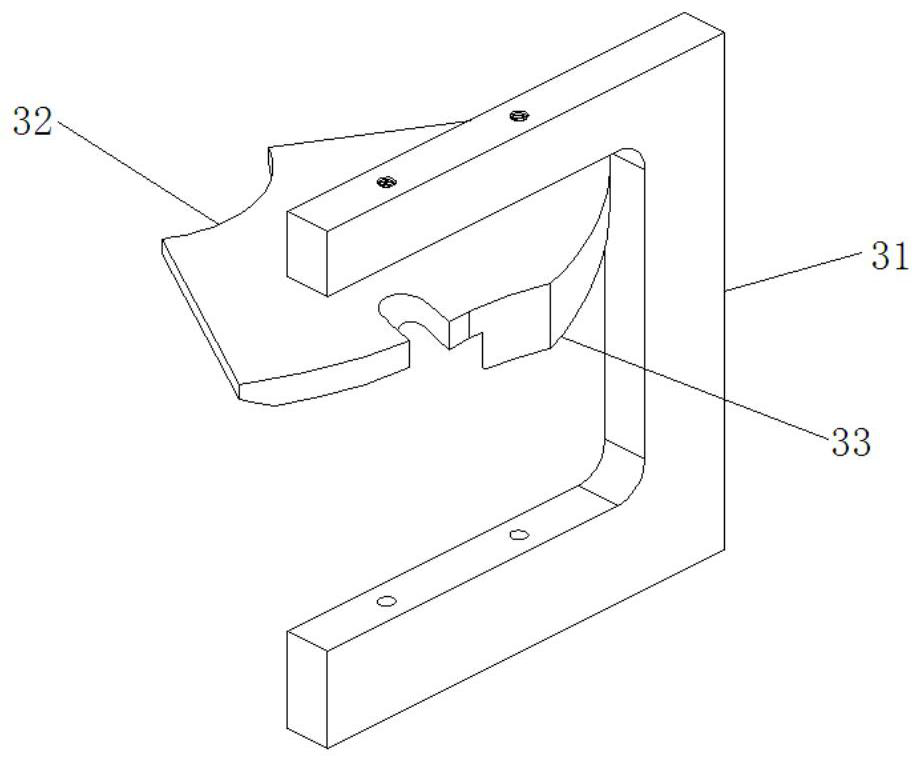

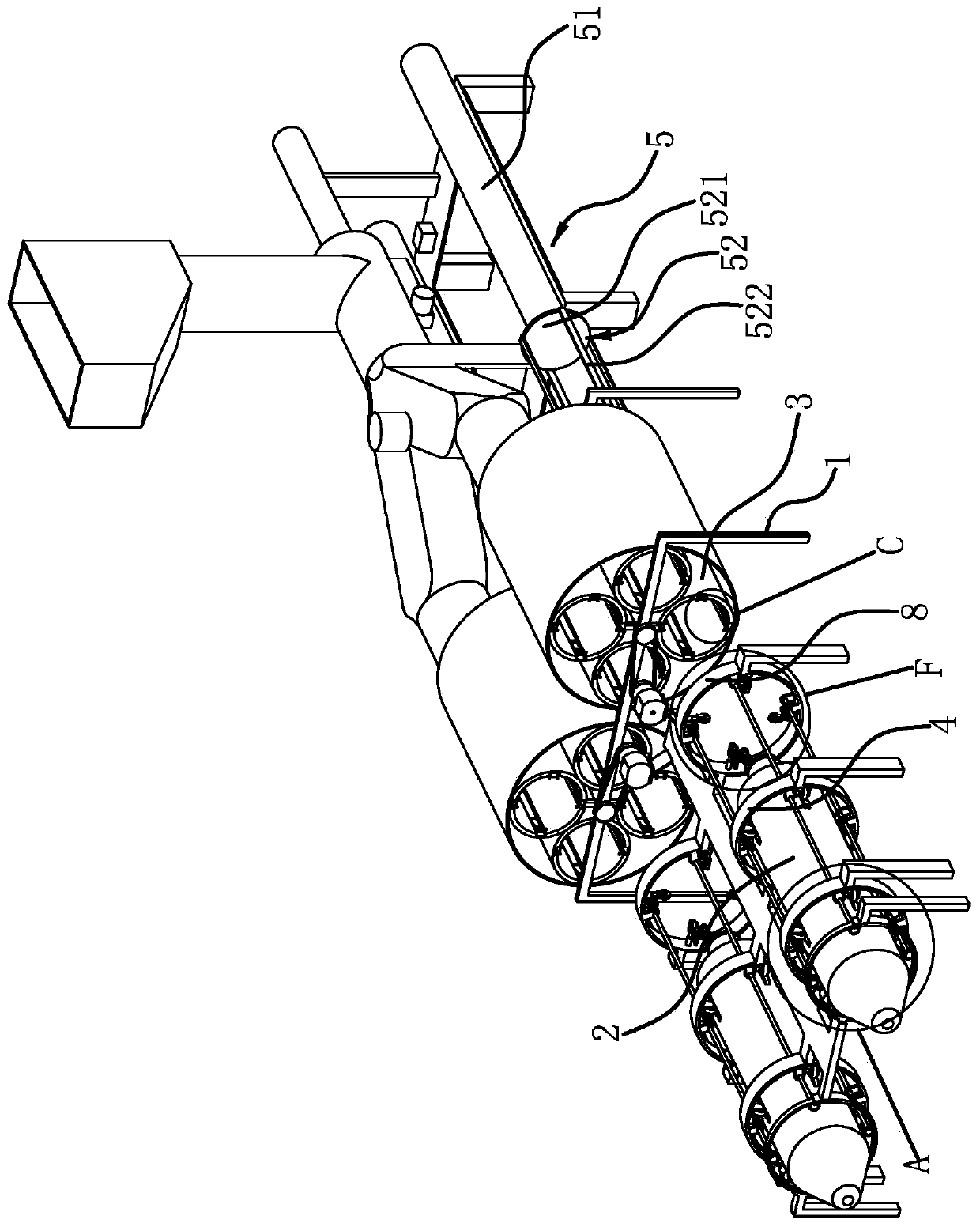

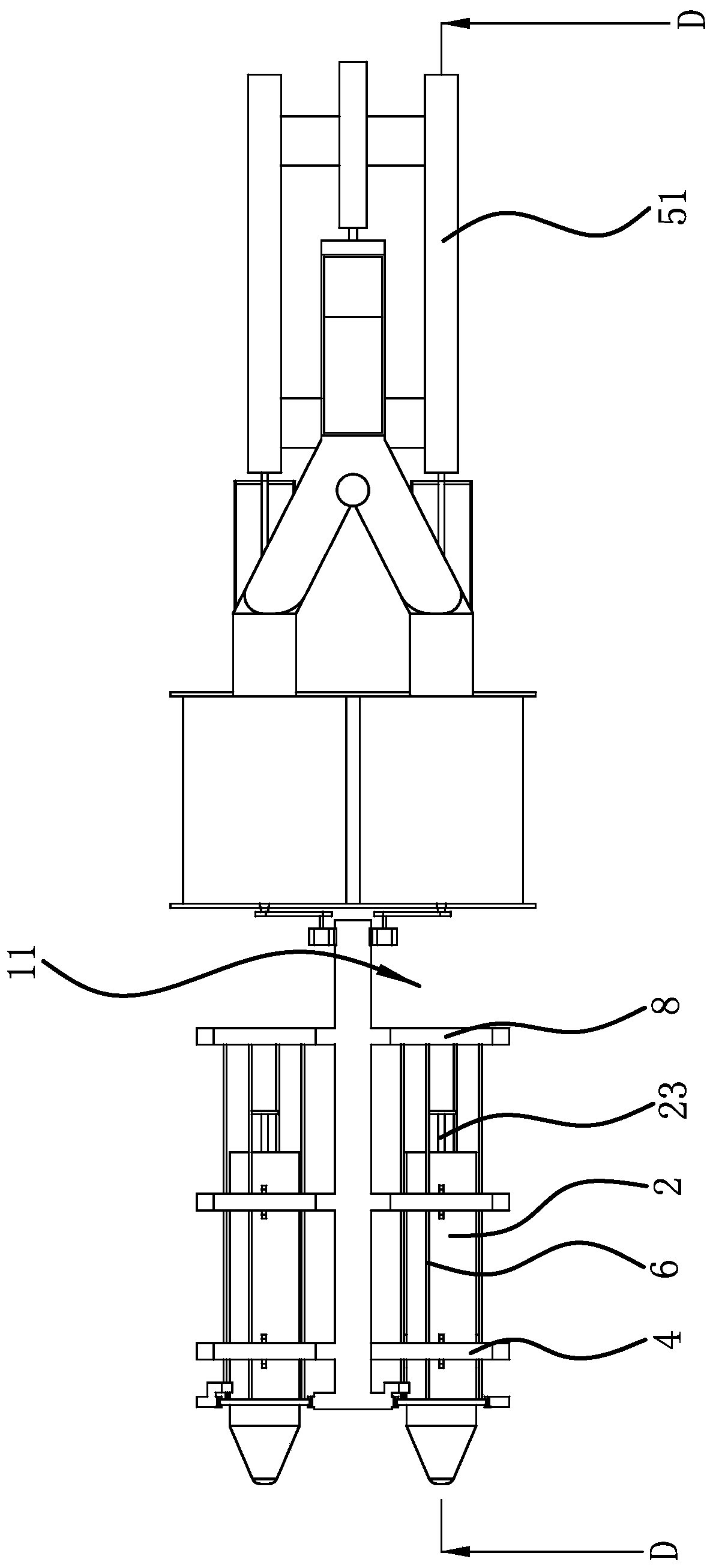

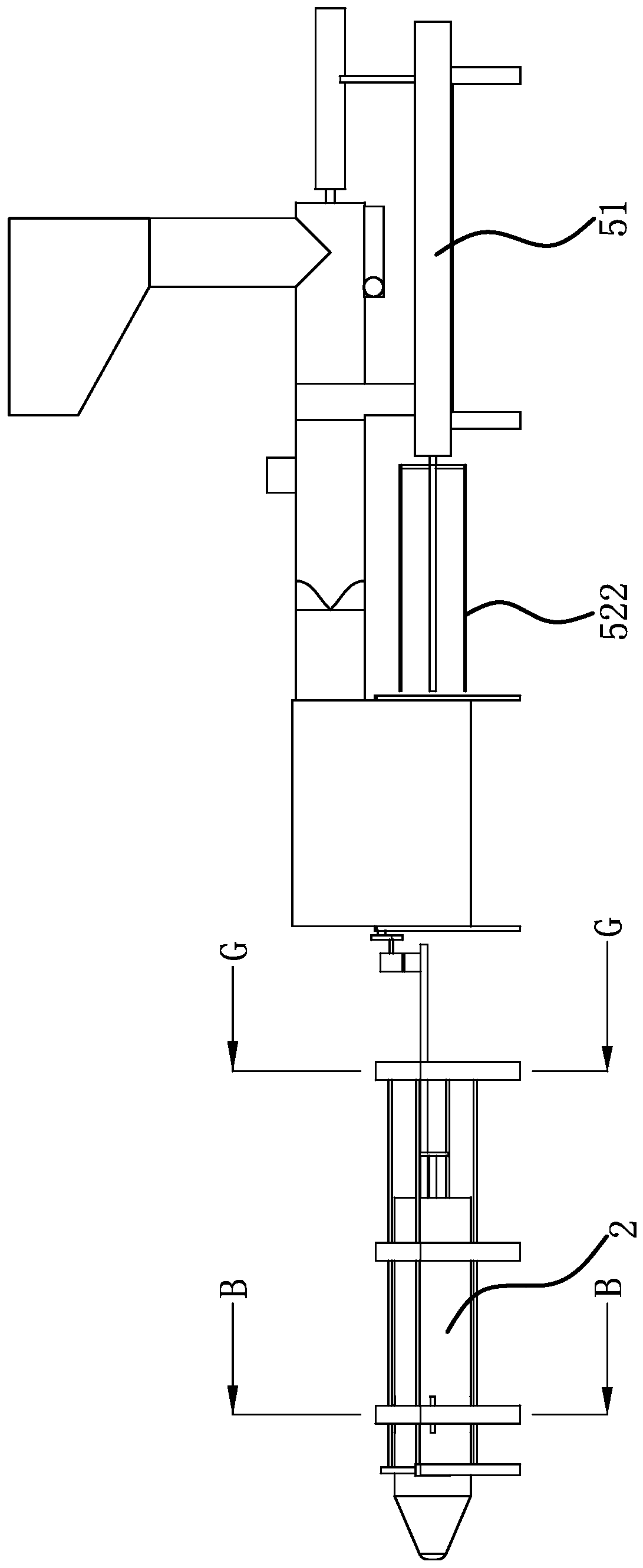

Automatic packing machine for polycrystalline silicon blocky bulk materials

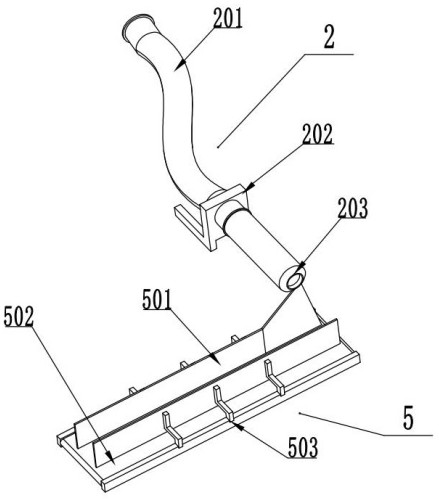

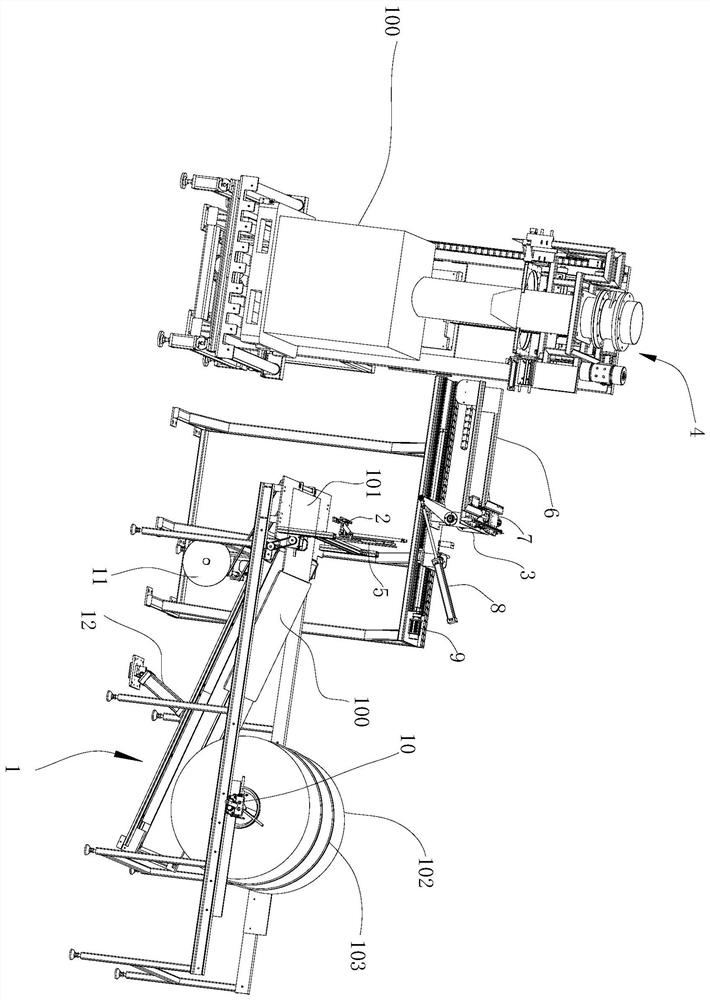

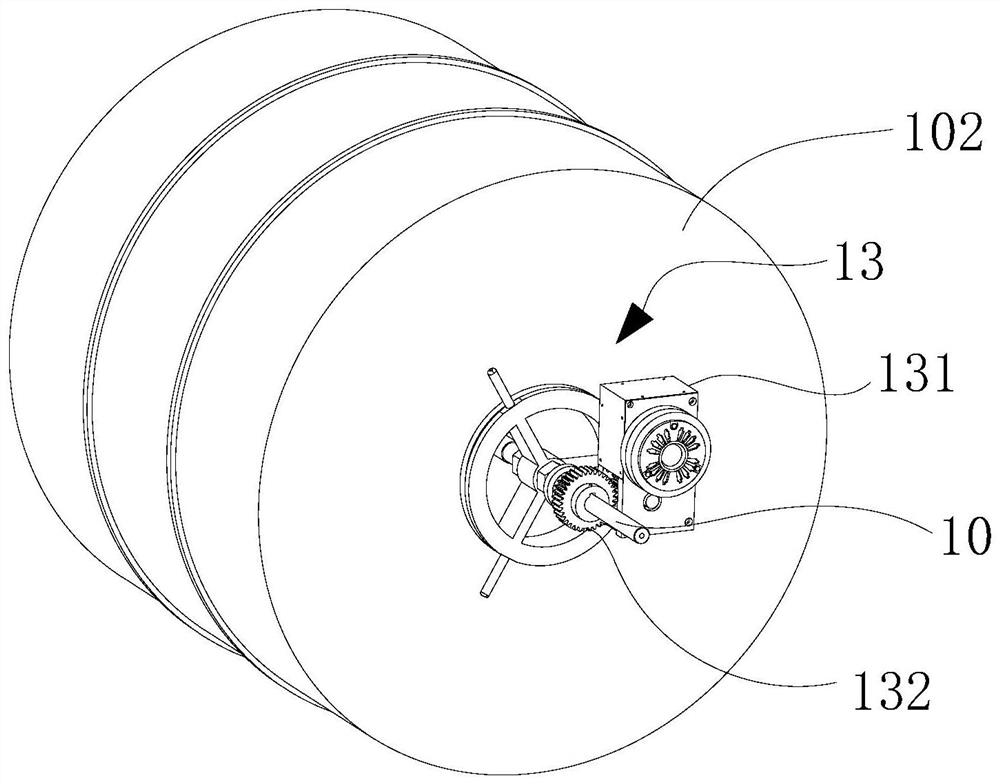

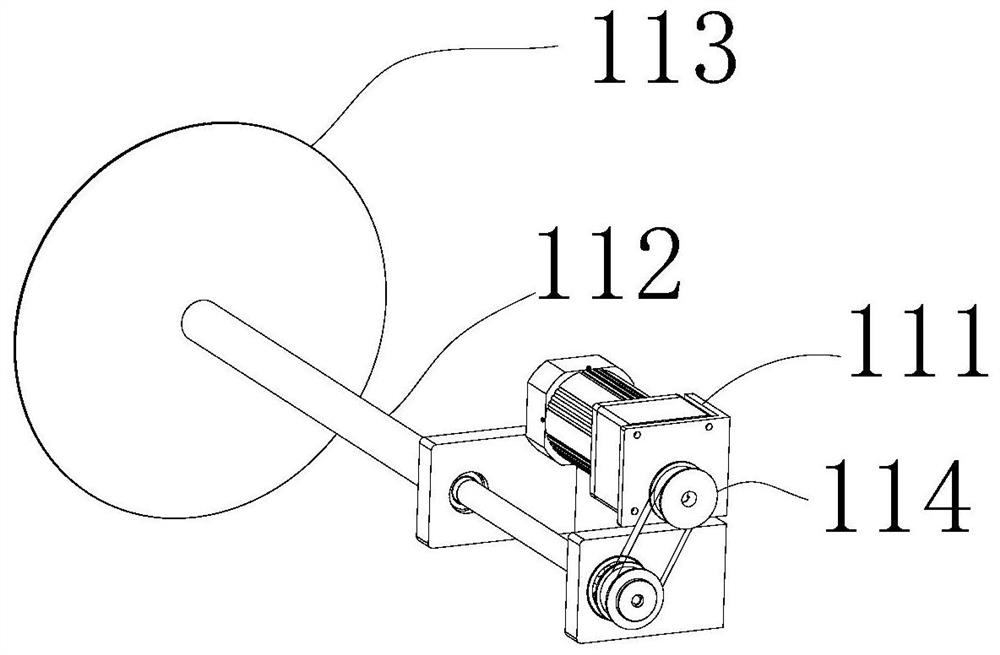

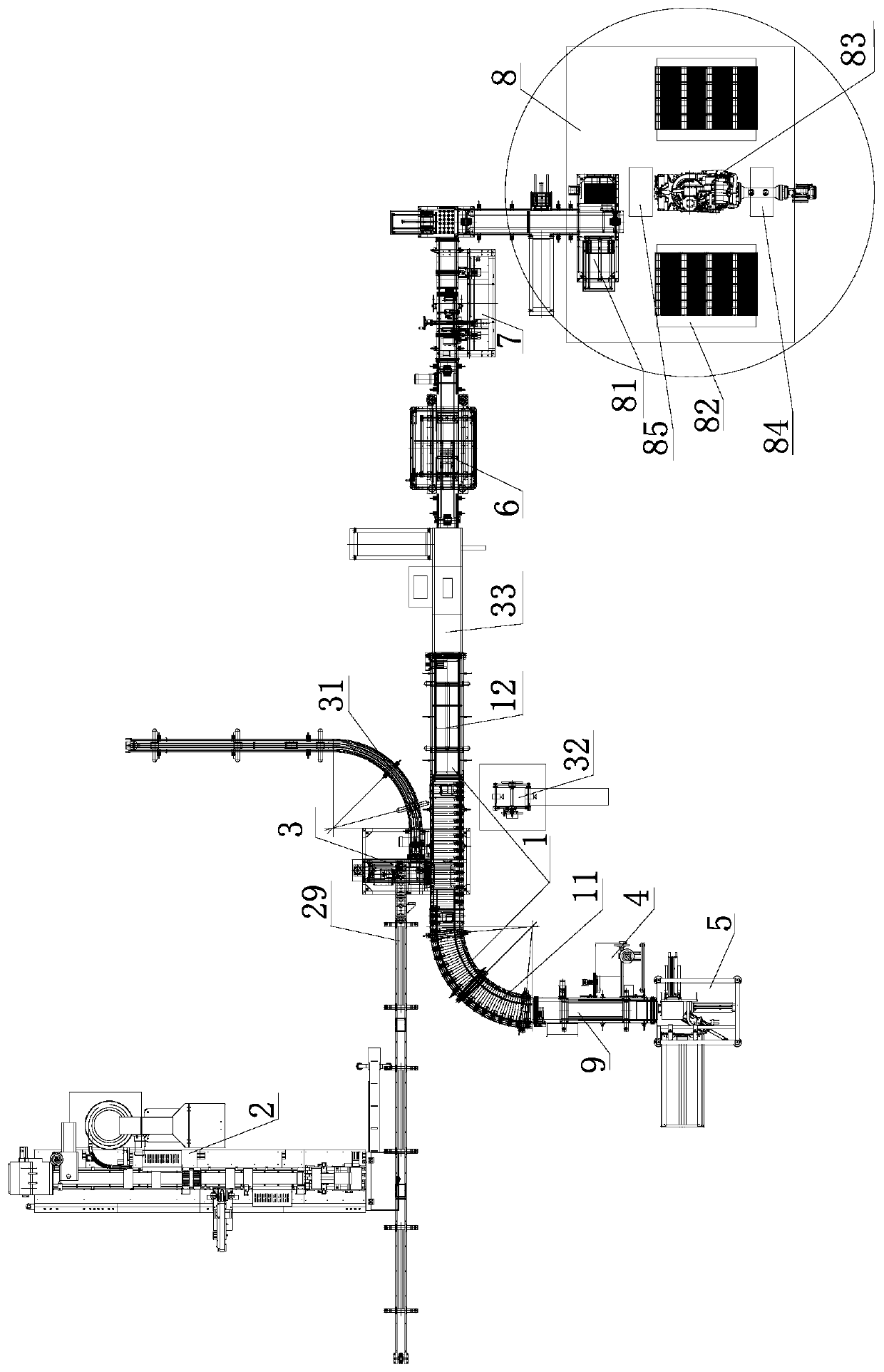

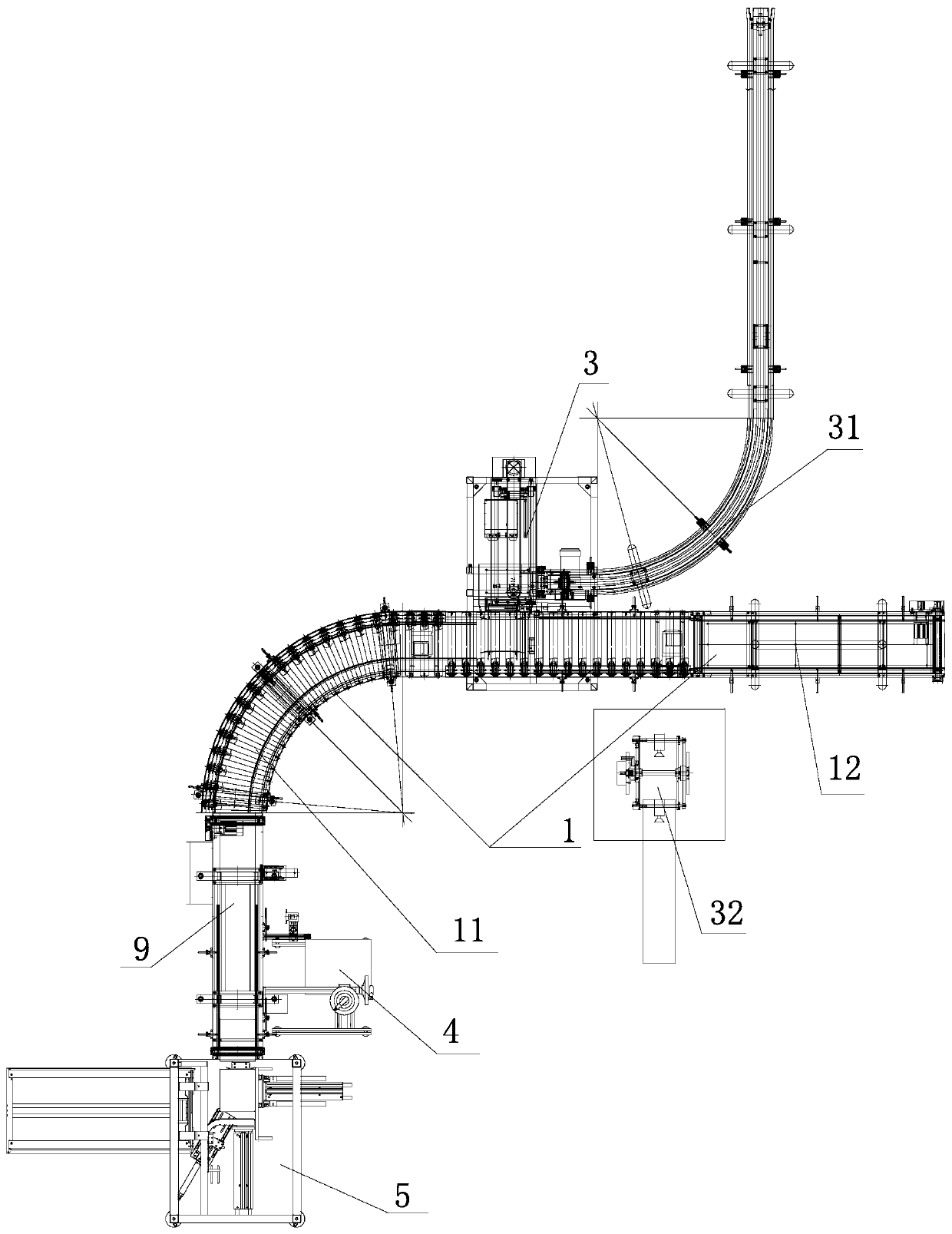

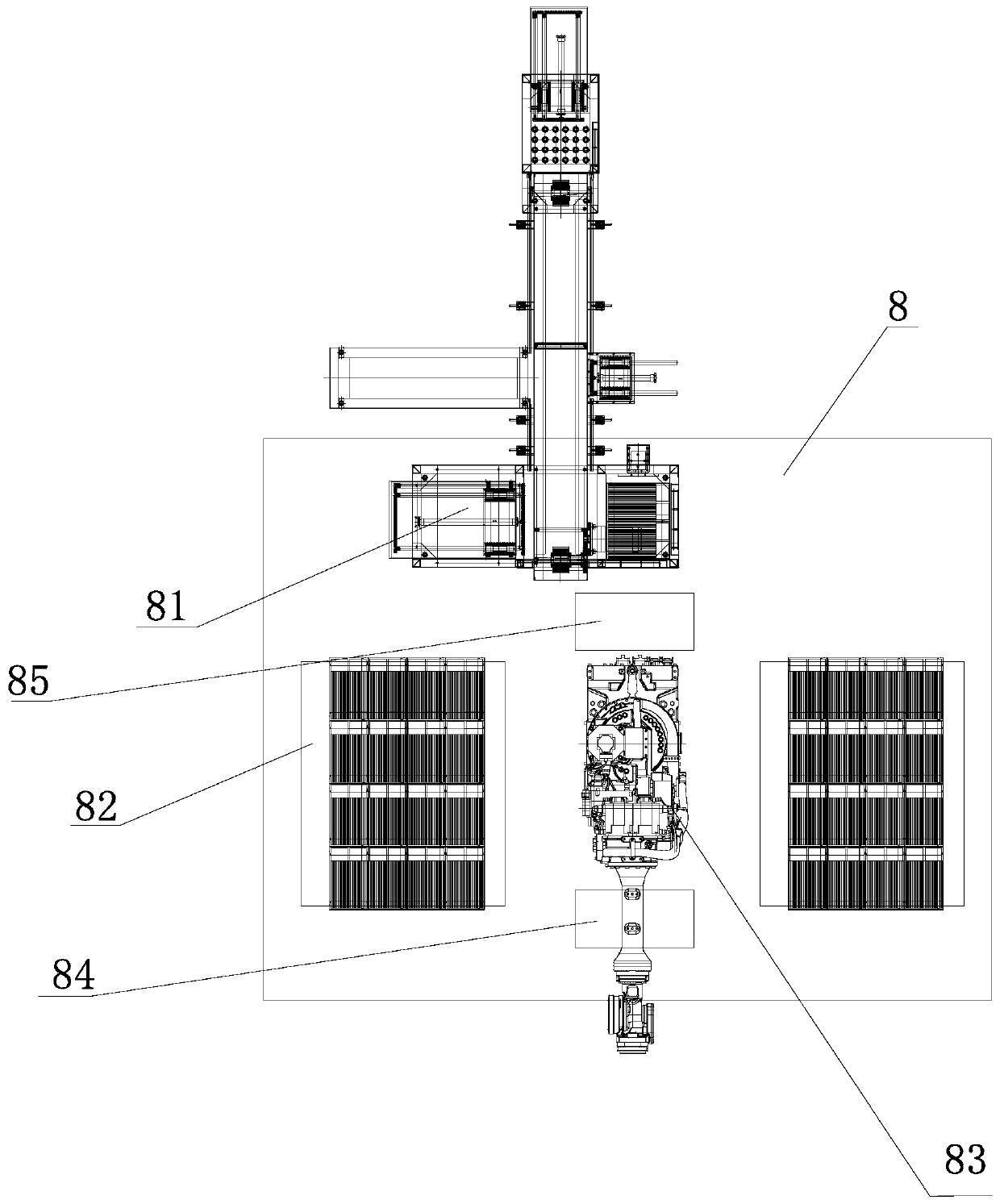

ActiveCN106742119AEasy to operateRealize automatic baggingPackaging by pressurising/gasifyingWrapper twisting/gatheringEngineeringVertical axis

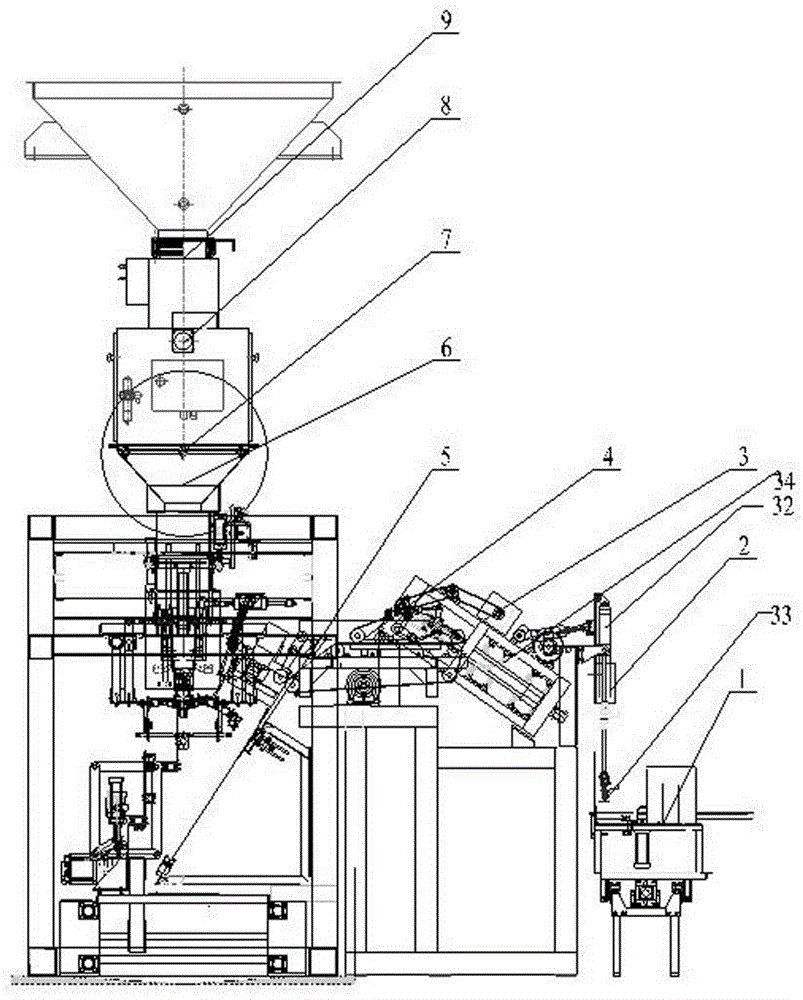

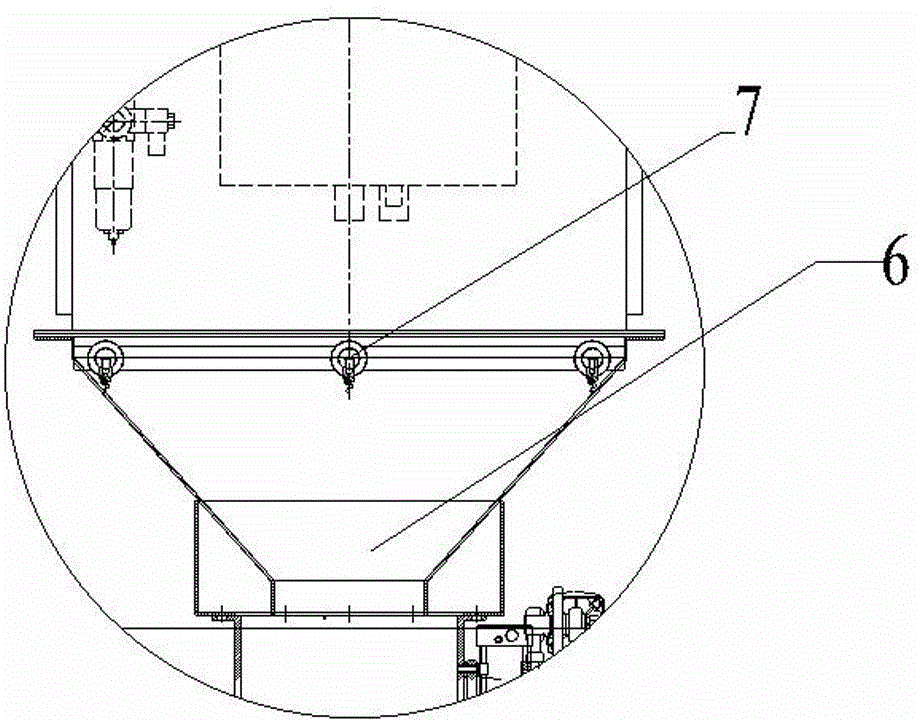

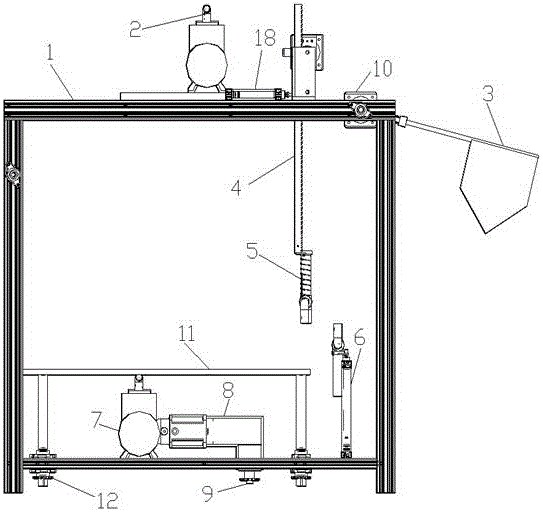

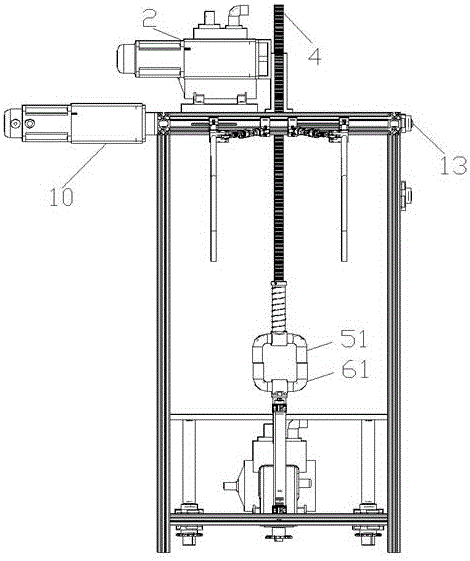

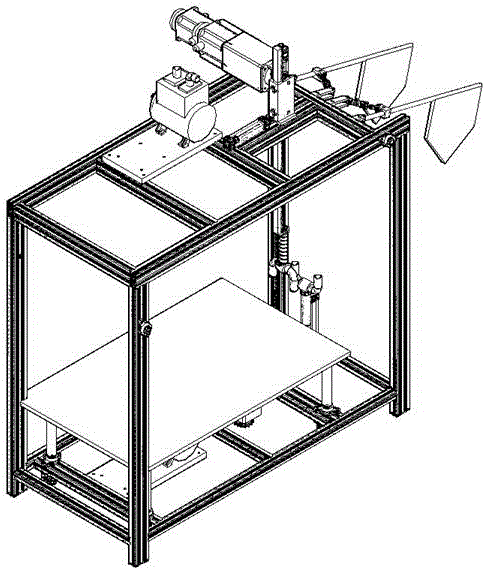

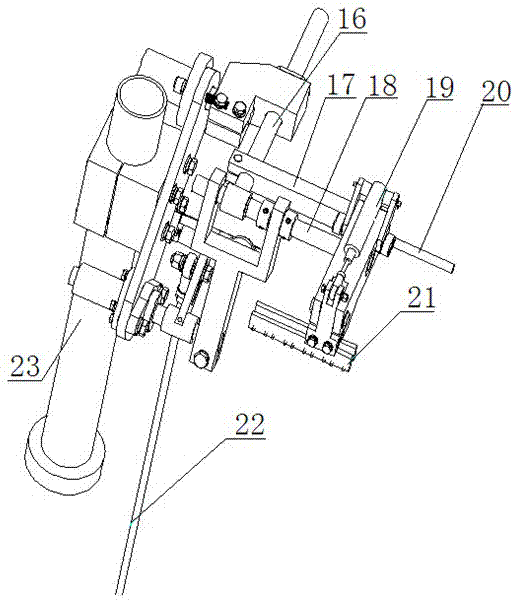

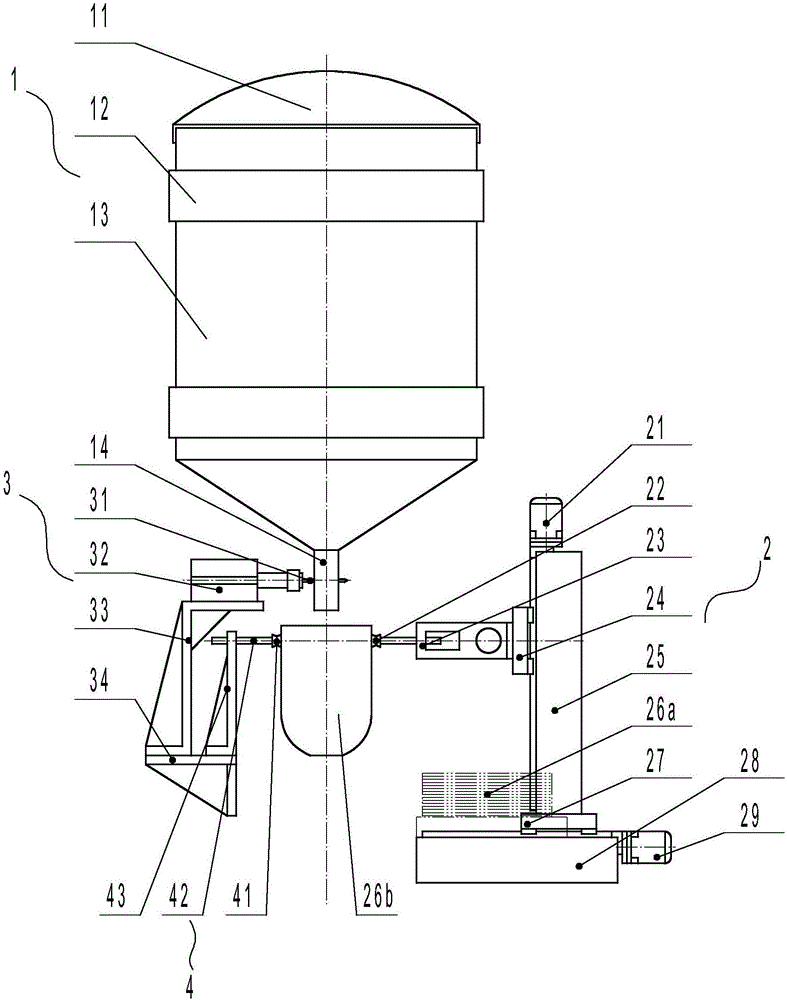

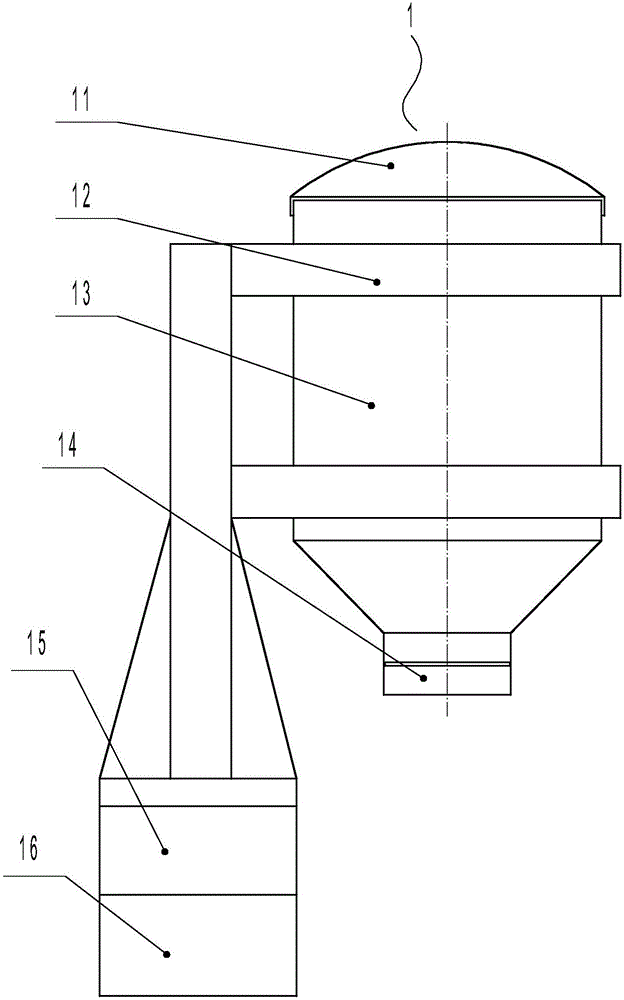

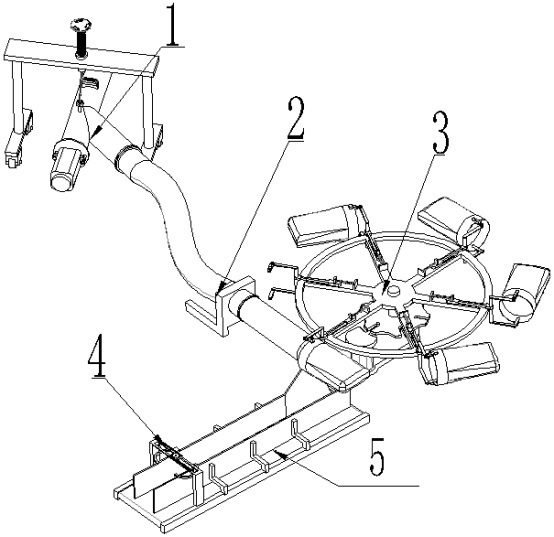

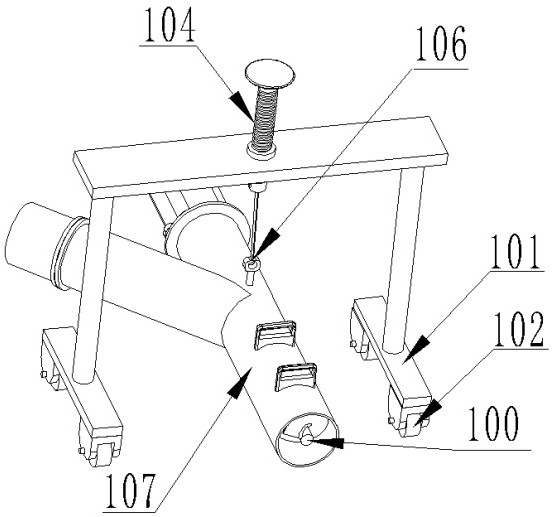

The invention discloses an automatic packing machine for polycrystalline silicon blocky bulk materials. The automatic packing machine comprises a bag feeding mechanism 1, a bagging mechanism 2, a material bag shaping mechanism 3 and a material bag sealing mechanism 4. The bagging mechanism 2 comprises a material falling cylinder 26 with a vertically lifting and dropping function. The bag feeding mechanism 1 comprises a bag clamping mechanism 13, the bag clamping mechanism 13 is located under the vertical axis of the material falling cylinder 26, the bag clamping mechanism 13 can support an opening of an empty bag to be a bag opening shape similar to the shape of the cross section of the material falling cylinder 26, and the material falling cylinder 26 can drop and be inserted in the bottom of the empty bag with the bag opening being supported. The material bag shaping mechanism 3 is located on the lower portion of the bag clamping mechanism 13 and comprises a horizontal moving frame 33; and a shaping mechanism 35 enabling the material bag to keep a preset shape is arranged on the horizontal moving frame 33. The material bag sealing mechanism 4 is located on the side of the bag clamping mechanism 13. The horizontal moving frame 33 can move the shaping mechanism 35 to be under the material bag sealing mechanism 4. Automatic bagging of the polycrystalline silicon blocky bulk materials is realized, and material pollution caused in the bagging process is avoided.

Owner:博实(苏州)智能科技有限公司

Automatic bag opening device for non-coated woven bags

The invention discloses an automatic bag opening device for a non-coated woven bag, which comprises a frame on which a lifting pallet is mounted to lift along the frame; the lifting pallet is driven by a first drive assembly Lifting, the first driving assembly includes a first motor; the frame is from left to right for the bag opening direction; the side of the lifting pallet is provided with a lower suction cup assembly driven by a cylinder; the lower suction cup assembly passes through The second air compressor installed on the frame provides air source power; on the frame, an upper suction cup assembly is installed at a position above the lifting pallet; Bag crank arm: one end of the bag opening crank arm is installed on the bag opening crank arm shaft, and the bag opening crank arm shaft is driven to rotate by a third motor.

Owner:QUANZHOU HUAZHONG UNIV OF SCI & TECH INST OF MFG

Method for bagging of materials

ActiveCN108839828AConvenient reverseInhibit sheddingWrapper twisting/gatheringSolid materialEngineering

Owner:SHANGHAI SOONTRUE MACHINERY EQUIP

Side suction nozzle packaging machine

The invention discloses a side suction nozzle packaging machine. The side suction nozzle packaging machine comprises a side suction nozzle horizontal bag feeding device, a bag opening fork device, a bag opening air blowing device, a charging device, a bag clamping device, a sealing device, a flat bag clip bag picking device and a rotating table, wherein the side suction nozzle horizontal bag feeding device, the flat bag clip bag picking device and the rotating table are arranged on the same line, the side suction nozzle horizontal bag feeding device is installed on a horizontal bag feeding support, the flat bag clip bag picking device is arranged at the right front of the side suction nozzle horizontal bag feeding device, the rotating table is arranged right ahead the side suction nozzle horizontal bag feeding device, and the bag opening fork device, the bag opening air blowing device, the charging device, the bag clamping device and the sealing device are arranged on the rotating table. Since the side suction nozzle horizontal bag feeding device and the flat bag clip bag picking device are arranged, the automatic feeding of side suction nozzle packaging bags is realized; through the improvement to the bag feeding device and in combination with the rotating table, the automatic bag opening, charging, sealing and output are realized, the packaging automation level is high and the production efficiency is high.

Owner:QINGDAO YILONG PACKAGING MACHINERY

Automatic bagging device for grains

PendingCN106742122ARealize automatic baggingRealize automatic transportationWrapper twisting/gatheringSolid materialAutomatic transmissionControl system

The invention provides an automatic bagging device for grains and relates to an automatic bagging device. The device comprises a grain bin and weighing system, a bag taking and bagging mechanism, an automatic grain bin opening and closing mechanism, a bag opening auxiliary device, an automatic transmission mechanism, an automatic sealing device, a grain bag sliding conveying platform and a control system, wherein the input end and the output end of the grain bin and weighing system are connected with the control system, and the output end of the control system is separately connected with the input ends of the bag taking and bagging mechanism, the automatic grain bin opening and closing mechanism, the bag opening auxiliary device, the automatic transmission mechanism and the automatic opening sealing device. The automatic bagging device not only can realize a function of automatically bagging grains, but also can realize automatic opening sealing and automatic transportation functions on the grains, so that a fully automatic production process is realized on the grains from bin discharging to packaging and transportation. The automatic bagging device not only greatly reduces labor force and increases the work efficiency, but also ensures bagging weight precision, thereby having wide popularization significance.

Owner:LUSHAN COLLEGE OF GUANGXI UNIV OF SCI & TECH

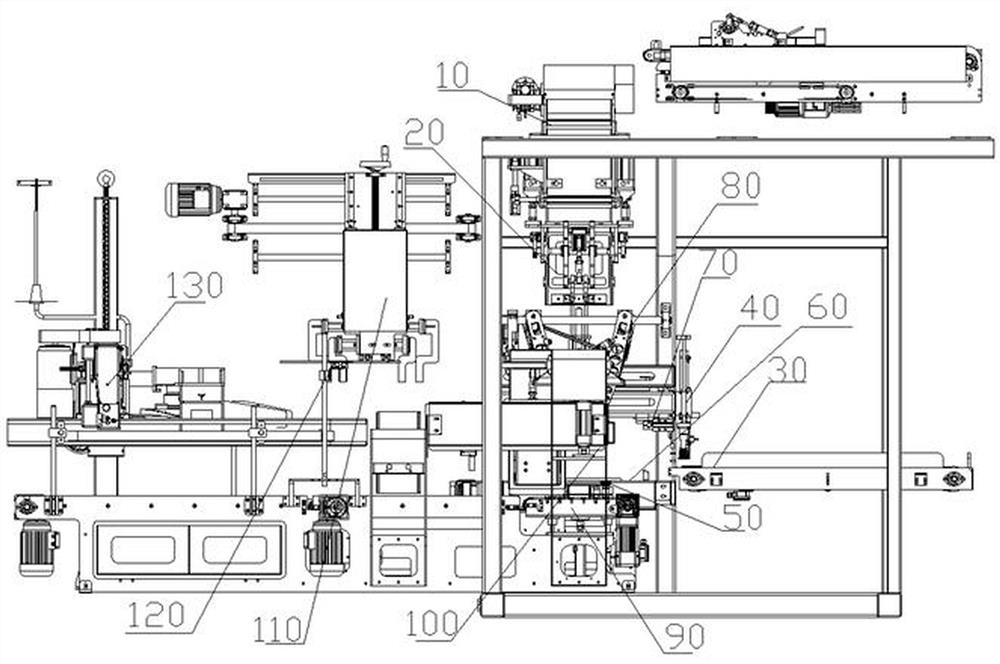

Bag feeding type packaging machine

PendingCN108820274AInhibit sheddingThe way it moves horizontally is stableWrapper twisting/gatheringSolid materialEngineeringPackaging machine

The invention discloses a bag feeding type packaging machine and relates to the technical field of packaging machines. The bag feeding type packaging machine comprises a material receiving station, abagging station, a bag preparing station, a bag fetching station, a bag opening station, a bag opening arranging station, a bag sewing station, a bag shaking mechanism and a bag holding mechanism. Thebag shaking mechanism comprises a bag shaking platform which moves up and down in a reciprocating manner to beat the bottom of a packaging bag arranged on the bagging station in a sleeving manner. The bag holding mechanism is arranged on one side of the bag shaking mechanism. The bag opening arranging station arranges a bag opening of the packaging bag located below the bag opening arranging station. The arranged packaging bag enters the bag sewing station to be sealed. According to the bag feeding type packaging machine, in the bagging process, the packaging bag can be effectively preventedfrom toppling, when the packaging bag is sealed, the bag opening arranging mechanism enables the bag opening of the packaging bag to be folded into one end face, one end face is formed at the positionof the bag opening of the sealed packaging bag, and scattering of salt packets in the packaging bag is avoided in the transportation process.

Owner:SHANGHAI SOONTRUE MACHINERY EQUIP

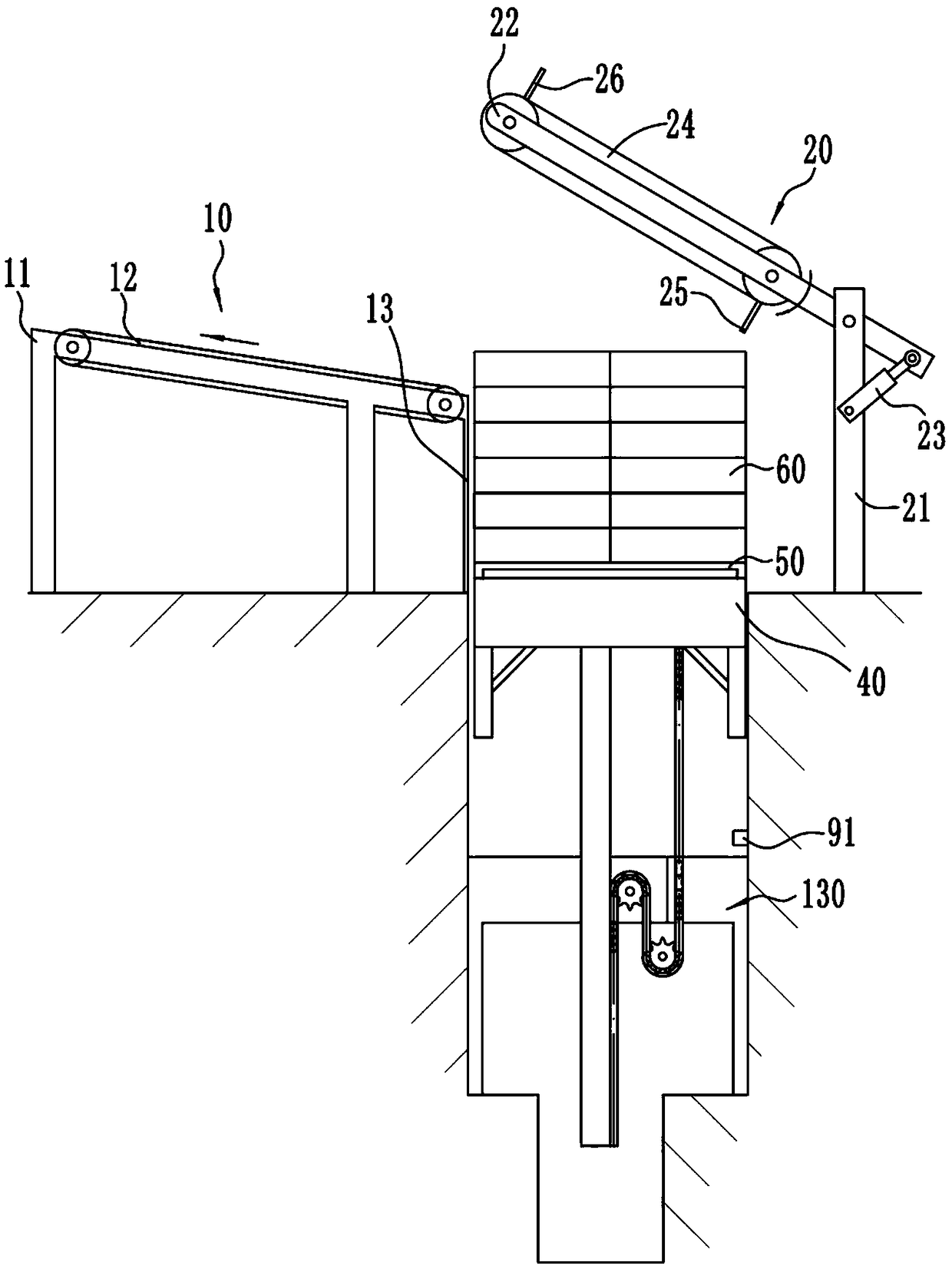

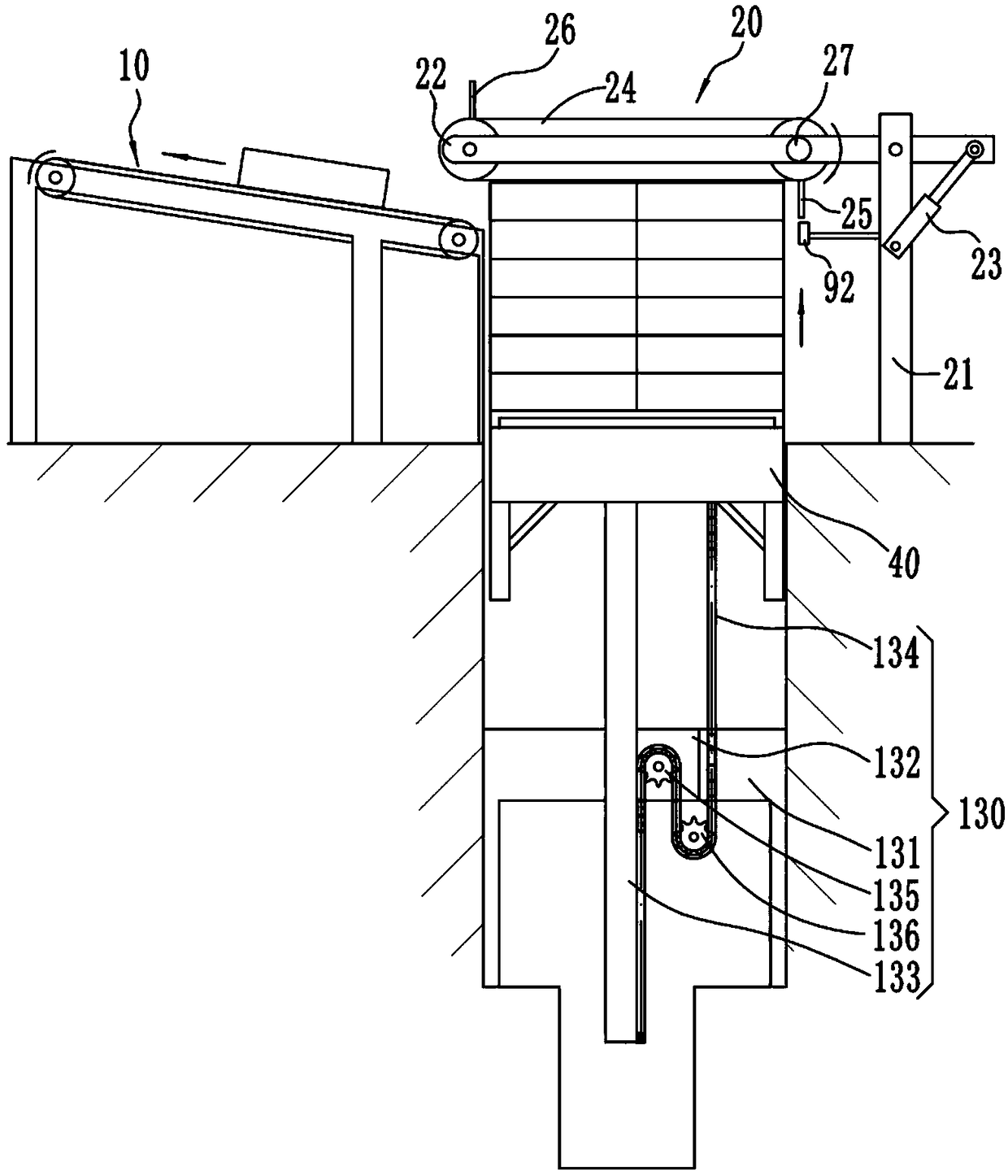

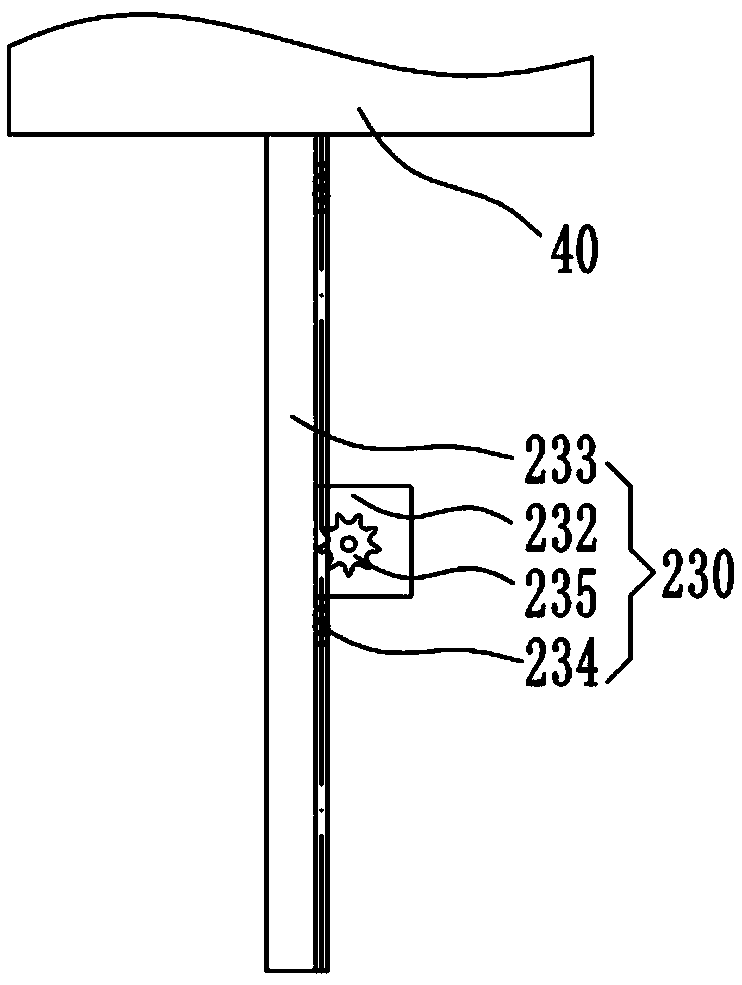

Automatic bag feeding machine

PendingCN108726192ASolve technical problems that are difficult to transfer to the conveyor beltRealize automatic baggingDe-stacking articlesConveyor partsEngineeringMechanical engineering

The invention provides an automatic bag feeding machine and relates to the technical field of feed bag conveying devices. The automatic bag feeding machine comprises a first conveying device, a lifting device and a second conveying device, wherein the first conveying device comprises a first bracket and a first conveyor belt; the first conveyor belt is arranged on the first bracket; a platform isarranged at the top of the lifting device; a tray can be placed on the platform; a feed bag is placed in the tray; the lifting device is set to ascend step by step; the second conveying device comprises a supporting beam, a second bracket, a lifting air cylinder and a second conveyor belt; the supporting beam is vertically and fixedly arranged; the upper end of the supporting beam is connected with the middle of the second bracket through a pivot; the second conveyor belt is arranged at one side of the second bracket; the lifting air cylinder is arranged at the other side of the second bracket; one end of the lifting air cylinder is connected with the supporting beam through a pivot; the other end of the lifting air cylinder is connected with the second bracket through a pivot; at least one push plate is arranged on the second conveyor belt; when the second conveyor belt rotates, the push plate is used for pushing the feed bag to the first conveyor belt.

Owner:德州支点机械科技有限公司

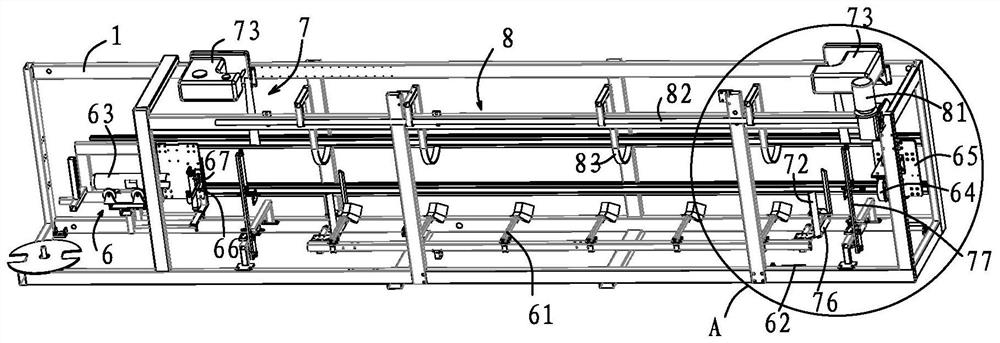

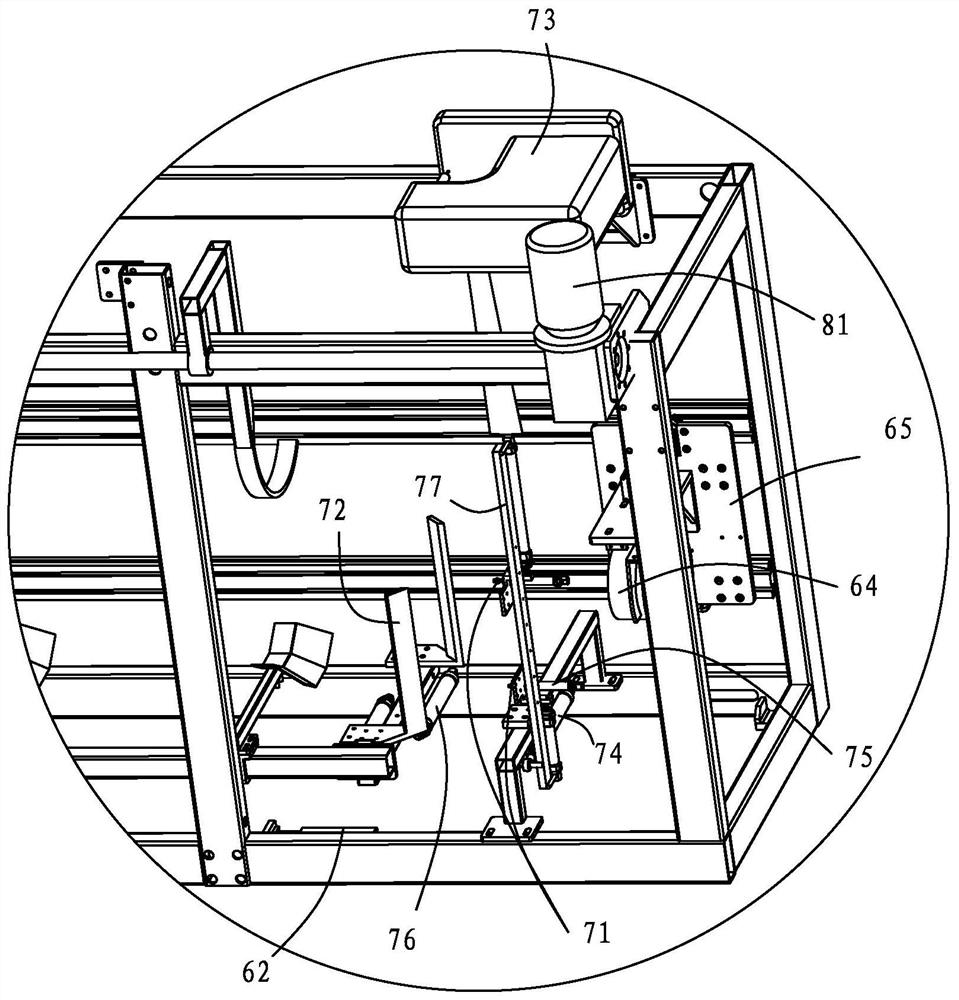

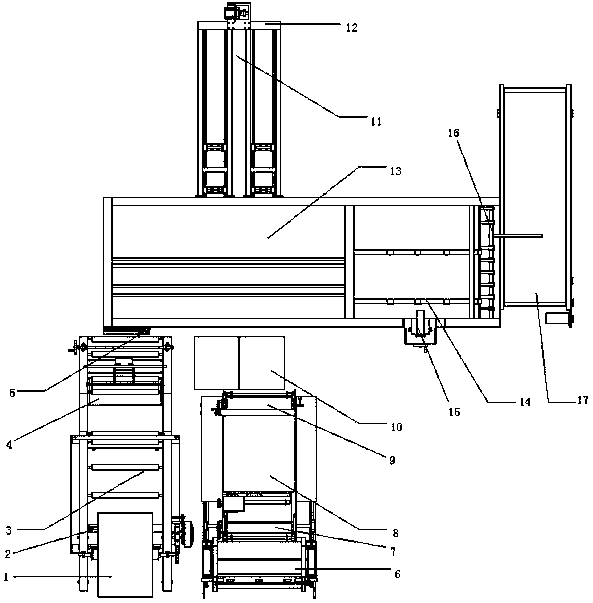

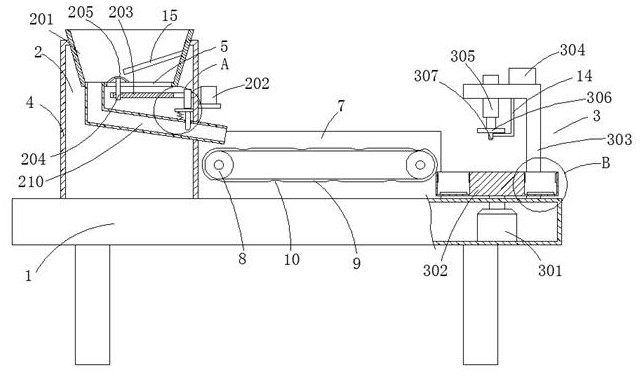

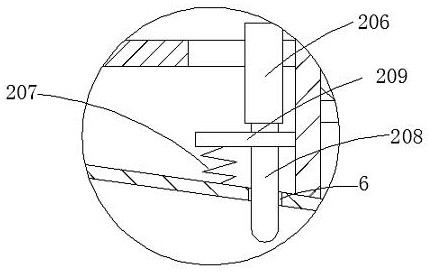

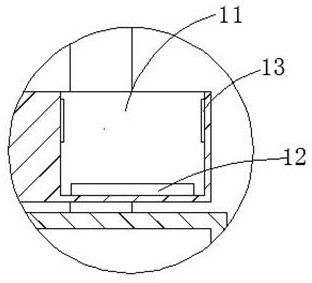

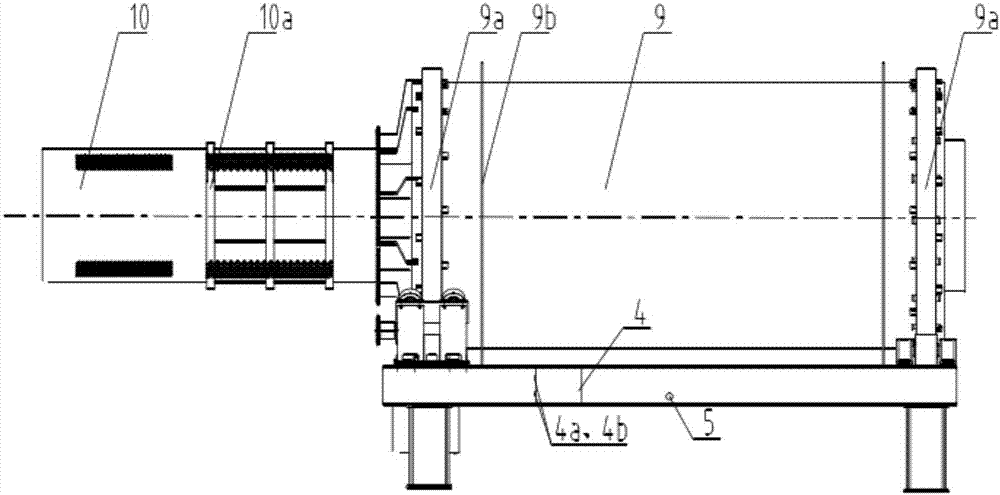

Automatic pipe packaging machine and packaging method thereof

ActiveCN111994356ARealize automatic baggingQuality improvementWrapper twisting/gatheringEngineeringPacking method

The invention discloses an automatic pipe packaging machine. The automatic pipe packaging machine comprises a rack, a pipe feeding device, a cap sealing device, a small bag sleeving device, a pipe pushing device, a large bag sleeving device, a bag sealing device and a pipe discharging device, wherein the pipe feeding device, the cap sealing device, the small bag sleeving device, the pipe pushing device, the large bag sleeving device, the bag sealing device and the pipe discharging device are arranged on the rack; the cap sealing device is arranged on one side of the pipe feeding device, the small bag sleeving device is arranged on one side below the cap sealing device, the pipe pushing device is arranged on one side of the small bag sleeving device, and the large bag sleeving device is arranged at one end of the pipe pushing device; and the bag sealing device is arranged above the large bag sleeving device, and the pipe discharging device is arranged on one side of the bag sealing device. The invention further provides a pipe packaging method of the automatic pipe packaging machine. Through the packaging method, automatic bag sleeving of pipes is achieved, and manual operation is not needed; and the outer sides of the plurality of small bag pipes are provided with large bags in a sleeved mode, overall transportation can be achieved, and the quality and cleanliness of the pipesin use can be improved.

Owner:FOSHAN HENGZHIDA TECH CO LTD

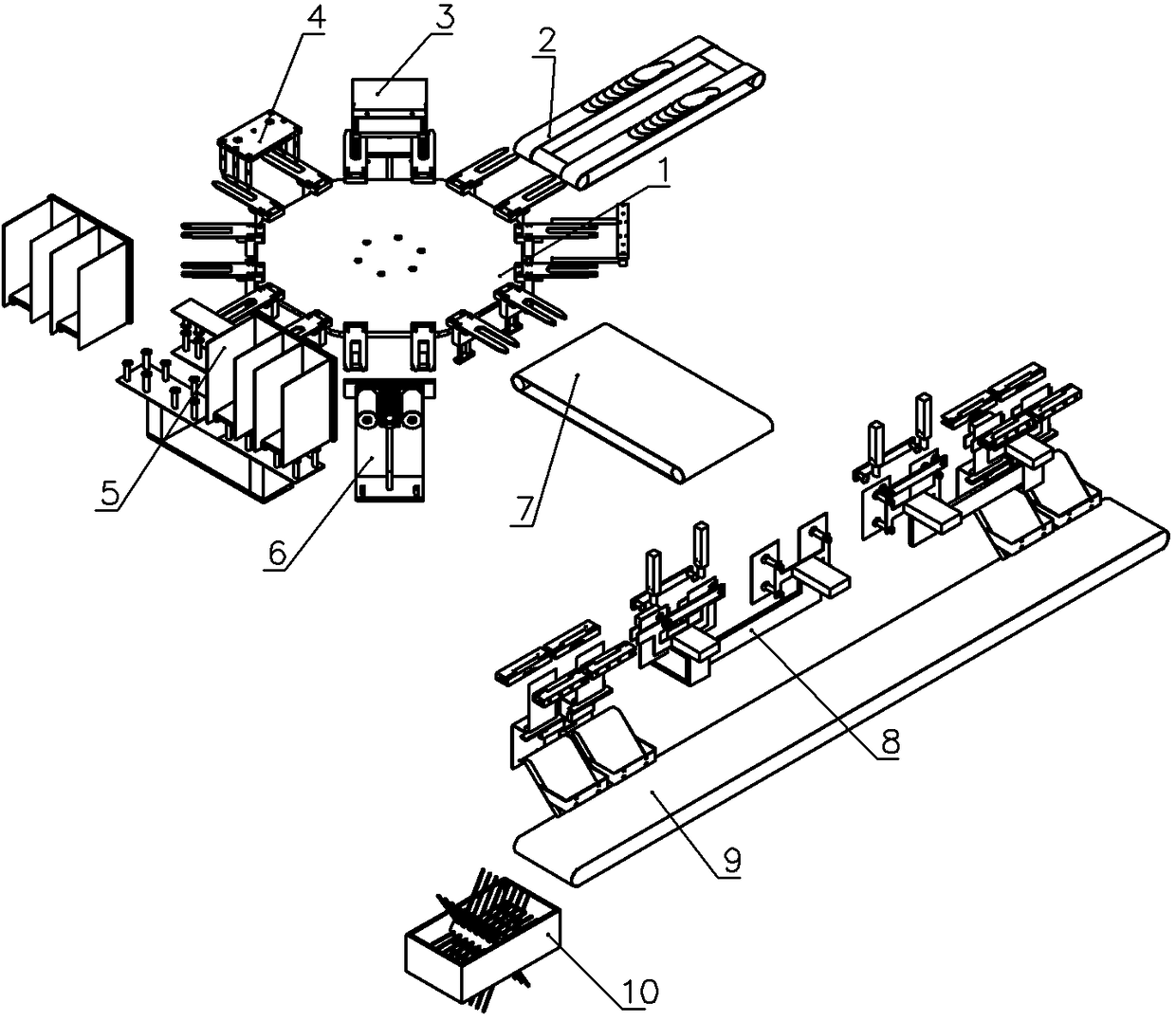

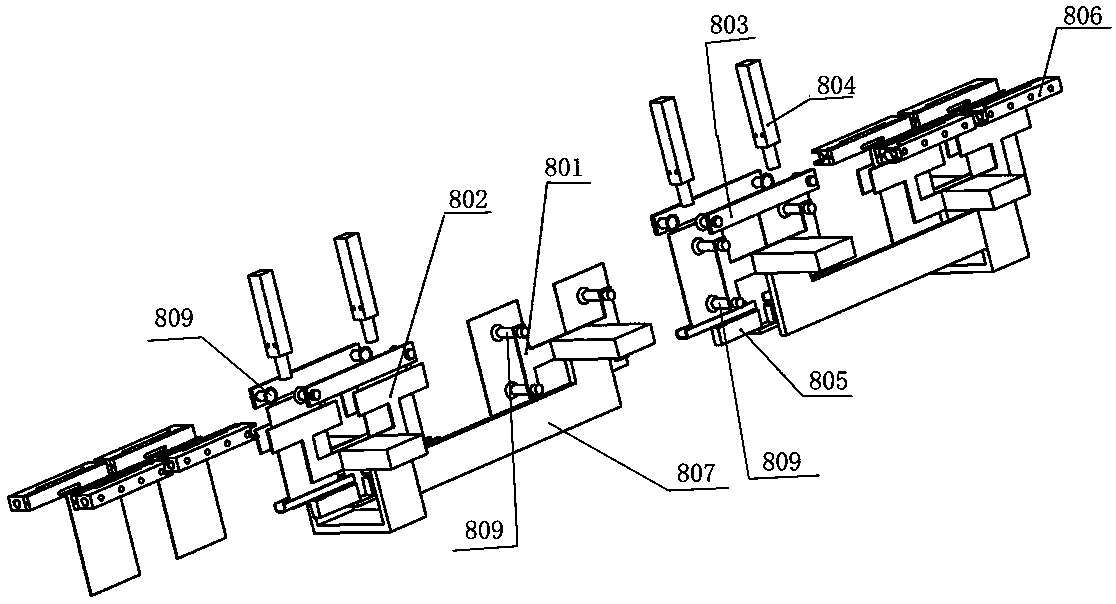

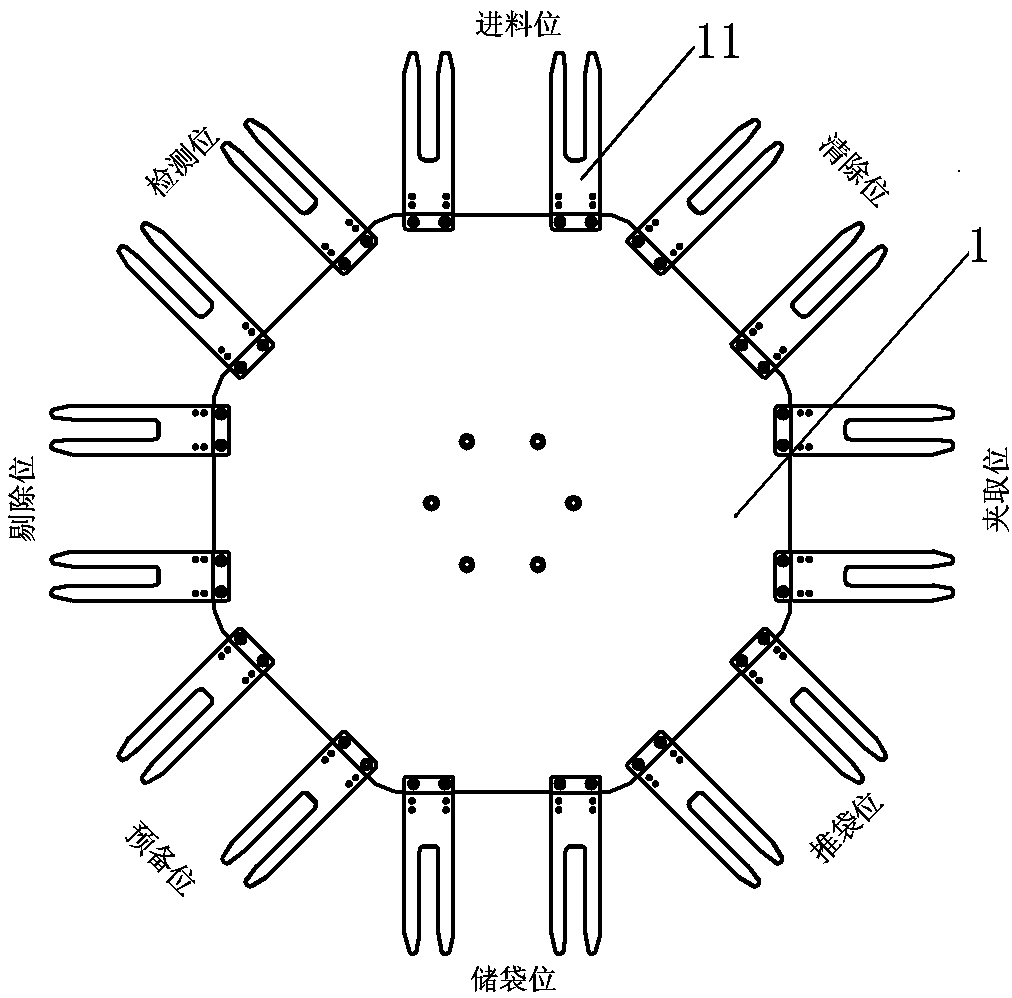

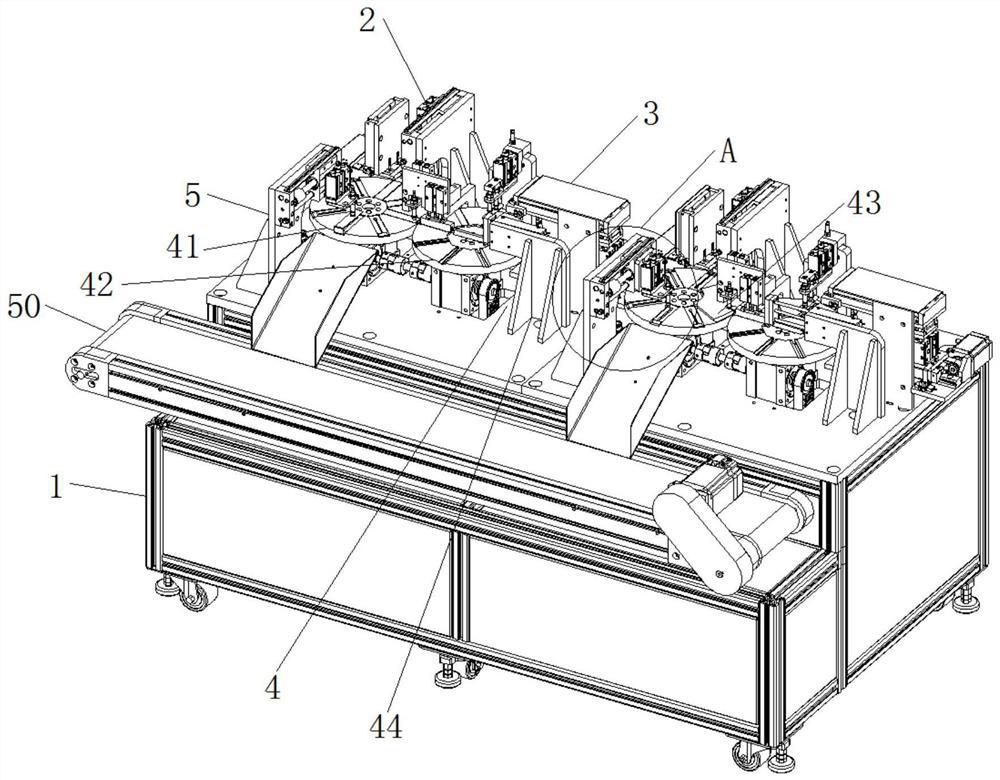

Automatic eye pad packaging equipment

ActiveCN108995868ARealize automatic baggingRealize drug fillingPackaging automatic controlPackaging machinesMechanical engineering

The invention discloses automatic eye pad packaging equipment which comprises a support and a rotary working table arranged on the support. Eight station zones are annularly arranged at the positions,on the periphery of the rotary working table, on the support, a clamping device is arranged at the position, corresponding to each station zone, on the rotary working table, each station zone is internally provided with a feeding mechanism, a detecting mechanism, a removing mechanism, a bag storage and containing mechanism, a bag pushing mechanism and a clamping and taking mechanism, the clampingdevices clamp eye pads sent out through the feeding mechanisms, the eye pads are rotated along with the rotary working table to sequentially pass through the eight station zones, eye pad bags containing the eye pads enter a dual-way transverse movement type filling mechanism under the effect of the clamping and taking mechanism to conduct filling and sealing operation, and then the sealed eye padbags are conveyed through a discharging conveying mechanism to a collecting mechanism to be counted and collected. According to the automatic eye pad packaging equipment, multiple operation equipmentcan be arranged on the periphery of the rotary working table, can be used in cooperation with the clamping devices arranged on the rotary working table to execute multiple processes at the same time,and can be combined with the dual-way transverse movement type filling mechanism to achieve automatic bagging, medicine filling and sealing operation of the eye pads, and efficiency is improved.

Owner:郑州乾正自动化科技有限公司

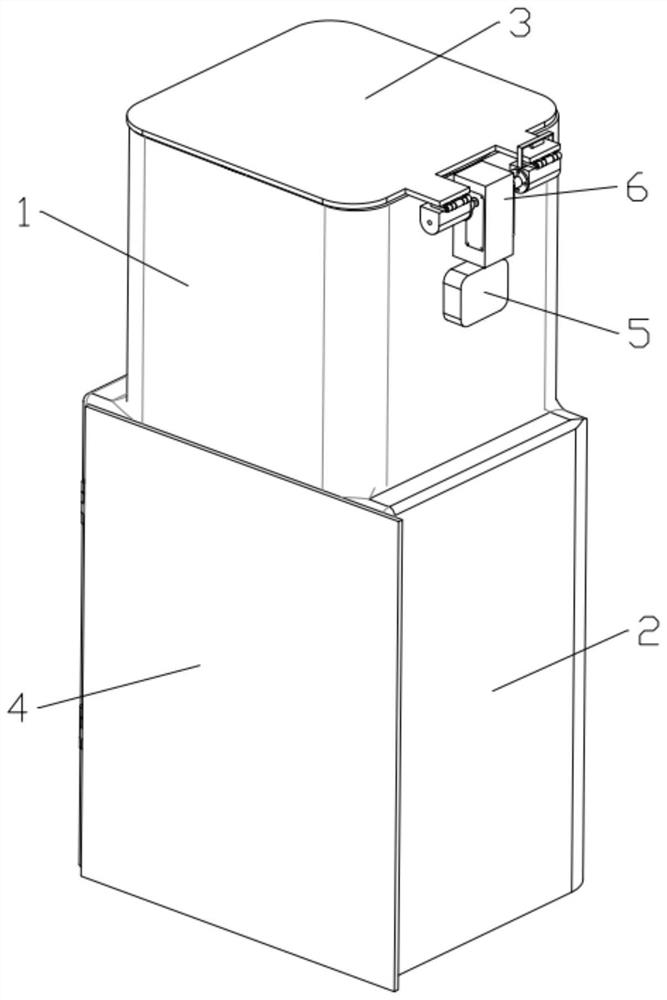

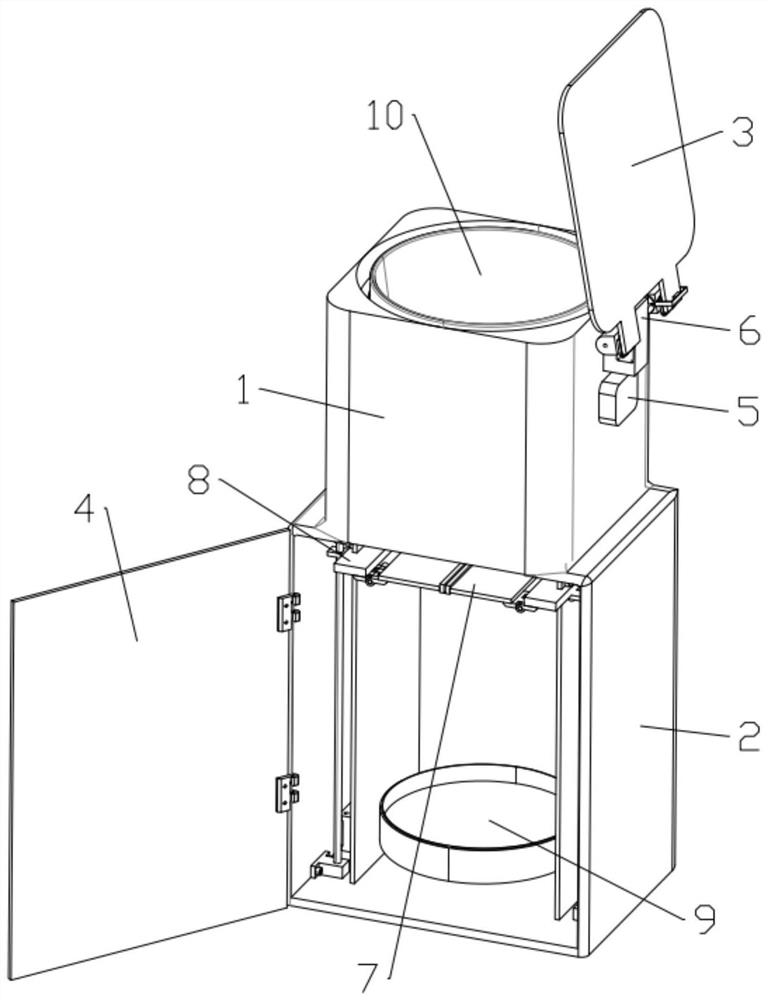

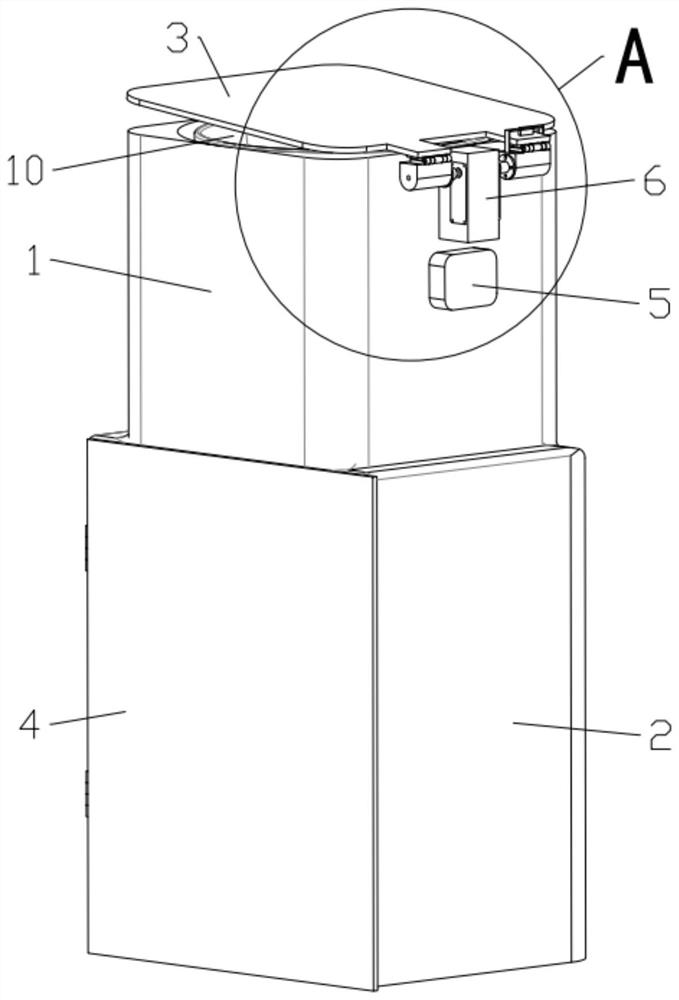

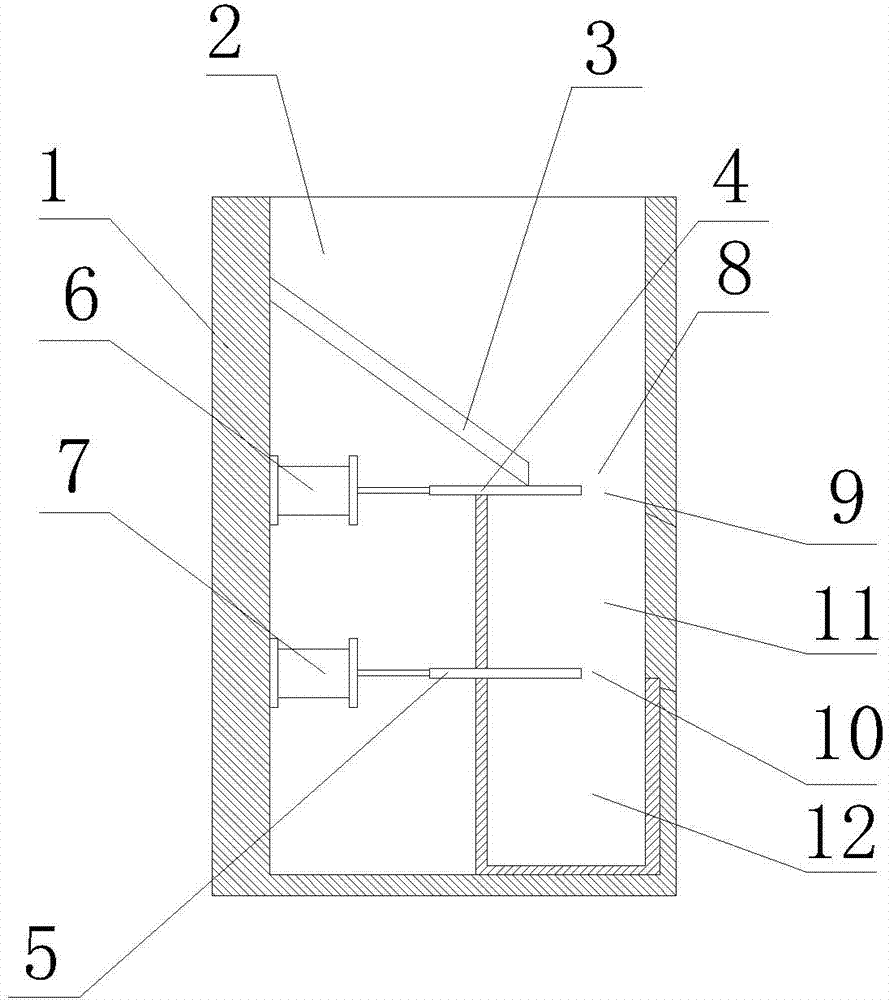

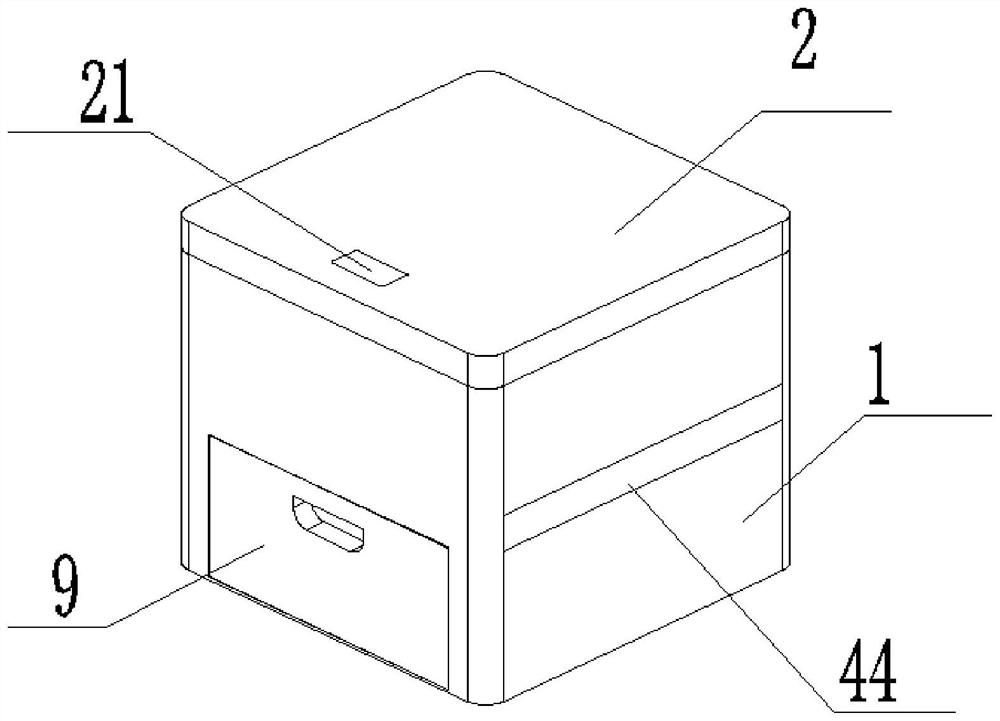

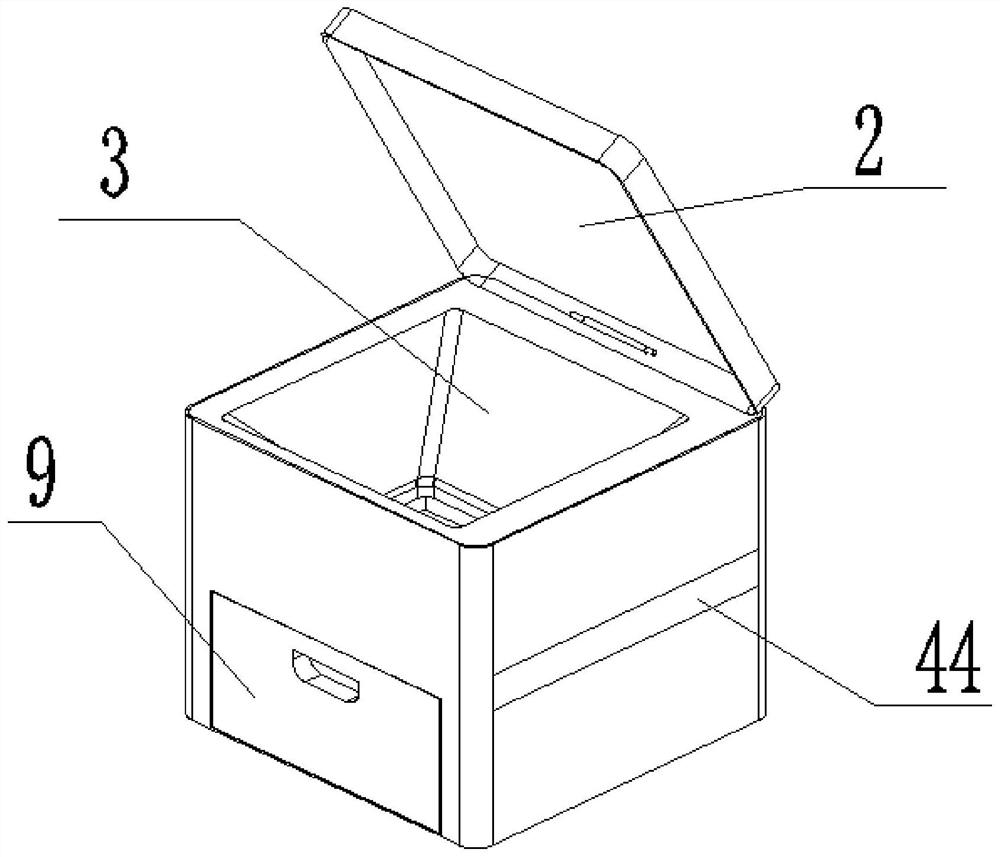

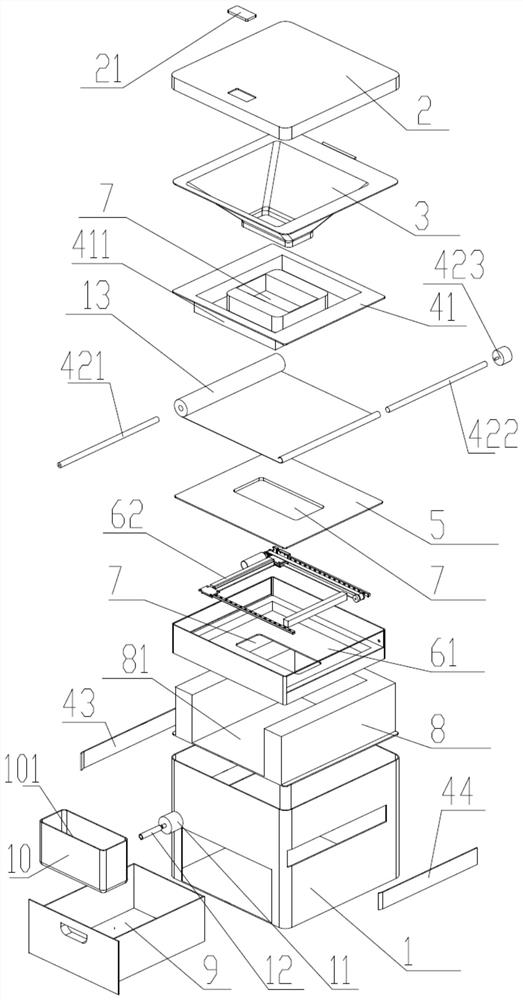

Intelligent garbage can

PendingCN113501235AIncrease storage spaceExtended time pointRefuse receptaclesWrapper twisting/gatheringComputer hardwareEngineering

The invention discloses an intelligent garbage can. The intelligent garbage can comprises a storage device, a controller, an overflow detection device and a seal cutting opening and closing assembly; the storage device comprises a lower can body and an upper can body arranged at the top of the lower can body, the top of the upper can body is covered with an upper can cover, the upper can cover is controlled by the overflow detection device to be opened and closed, and an inner can body is further arranged in the upper can body; the overflow detection device is mounted on one side of the upper can body; the seal cutting opening and closing assembly is arranged at the upper part in the lower can body; and when the garbage can is in an overflow state, the overflow detection device can be triggered when the upper can cover is closed, then the seal cutting opening and closing assembly can be opened to enable the garbage bag to fall into the lower can body, and after the seal cutting opening and closing assembly is reset, the non-breakpoint garbage bag can be subjected to double-position sealing, cutting and segmentation. The non-breakpoint garbage bag is used, garbage overflowing can be automatically detected, bagging, packaging and cutting are automatically conducted, the storage space of the garbage can is greatly enlarged, and use is more convenient.

Owner:皖江工学院

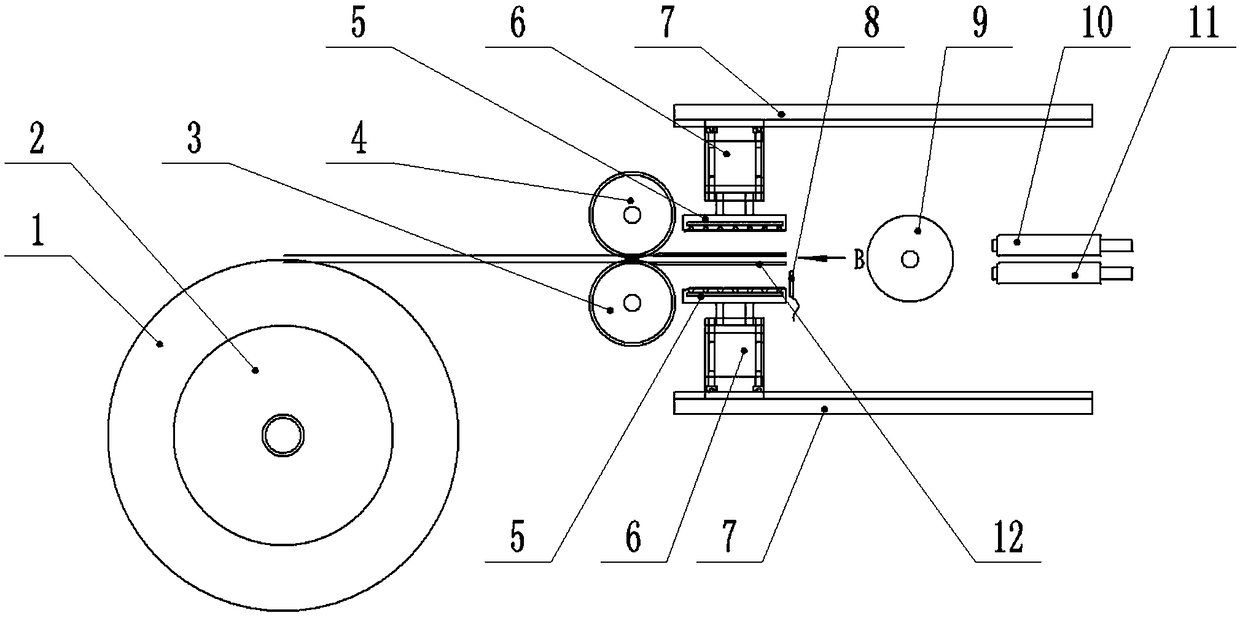

Food bagging device

The invention discloses a food bagging device. Rolled plastic bags are placed on a turntable mechanism; the plastic bags are conveyed to a sucker frame by a conveying driving wheel and a conveying driven wheel; a photoelectric inductor is used for detecting in place; the sucker frame moves to middle through a cylinder; meanwhile, a cutter cuts off nylon bags from tearing lines; the cylinder and the plastic bags are fed under a hopper by a linear guide rail; the sucker frame moves to two sides through the cylinder; meanwhile, the sucker works; and bag openings of the plastic bags are opened forfilling. The cylinder moves to middle; meanwhile, the plastic bags are conveyed to a rolling driving wheel and a rolling driven wheel by the linear guide rail; when the cylinder moves outwards, the sucker dose not work, and the plastic bags fall down through the gravity; and through extrusion by the rolling driving wheel and the rolling driven wheel, buckling bars of the plastic bags are pressedinto buckling grooves to finish bagging of food. The food bagging device is high in automation degree, and uses combination of multiple sets of mechanical actions to realize automatic food bagging soas to greatly improve the production efficiency.

Owner:舟山市敏瑞科技咨询有限公司

Multifunctional intelligent bag machining machine

PendingCN107745545ASmall footprintRealize automatic baggingBag making operationsPaper-makingSmall footprintEngineering

Owner:WENZHOU KEWANG MACHINERY

Bagging device for jelly orange packaging

ActiveCN112373787ASmooth entryRealize the material processingClimate change adaptationPackaging fruits/vegetablesControl engineeringProcess engineering

The invention provides a bagging device for jelly orange packaging, and relates to the field of jelly orange processing. The bagging device comprises a workbench, a distributing mechanism and a bagging mechanism, a servo motor is installed on the right side of a distributing box, a lead screw is connected to the output end of the servo motor, a connecting rod is in threaded connection to the leadscrew, a limiting groove is formed in the right end of the bottom of a feeding hopper, an arc-shaped plate is fixedly connected to the top of the connecting rod, a cam is installed on the lead screw,a through hole is further formed in the top of a discharging channel, a movable rod is inserted into a supporting plate, and the lower end of the movable rod is movably connected into the through hole. According to the bagging device, the arc-shaped plate is driven by the servo motor to move back and forth at the bottom of the feeding hopper, so that jelly oranges can smoothly enter the discharging channel from the upper end of the discharging channel; through the arranged movable rod, the jelly oranges can be sequentially discharged and fall into a groove of a transmission belt, and distribution treatment of the jelly oranges in batches is achieved, so that subsequent bagging operation is facilitated, and the production efficiency is improved.

Owner:荆门市懿华农业科技股份有限公司

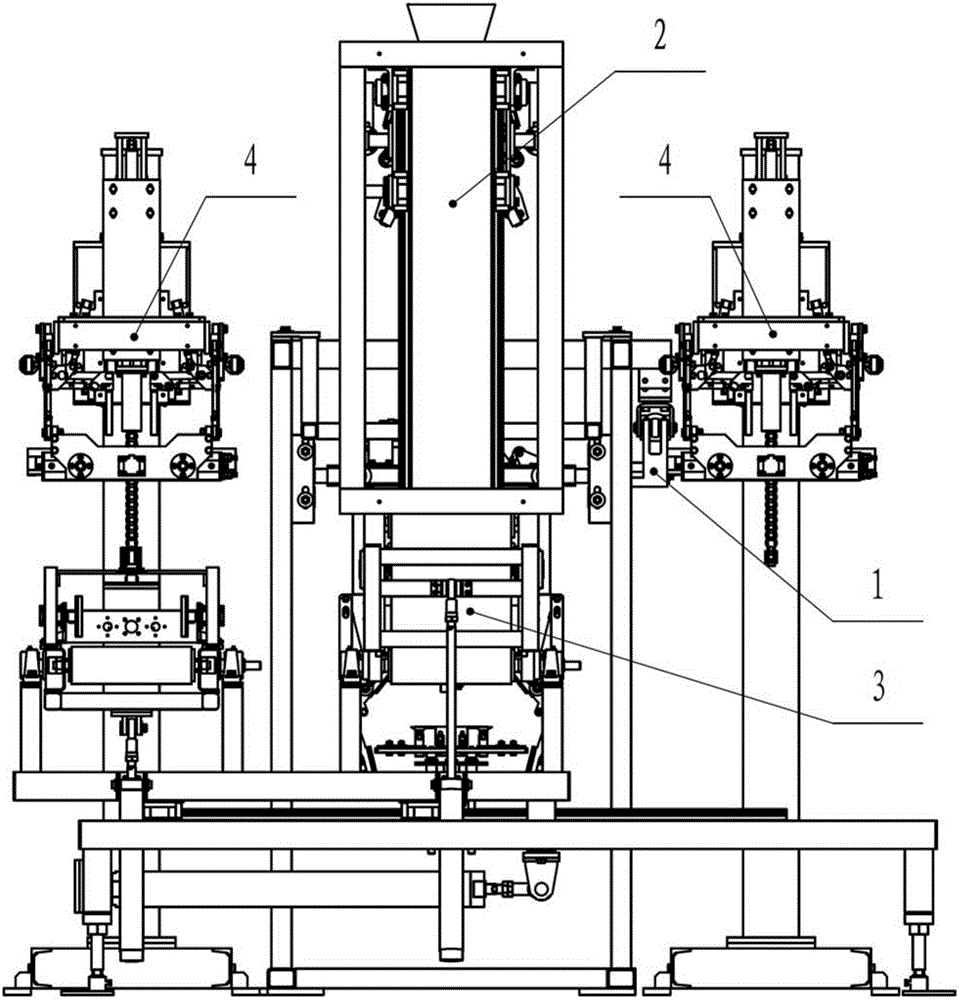

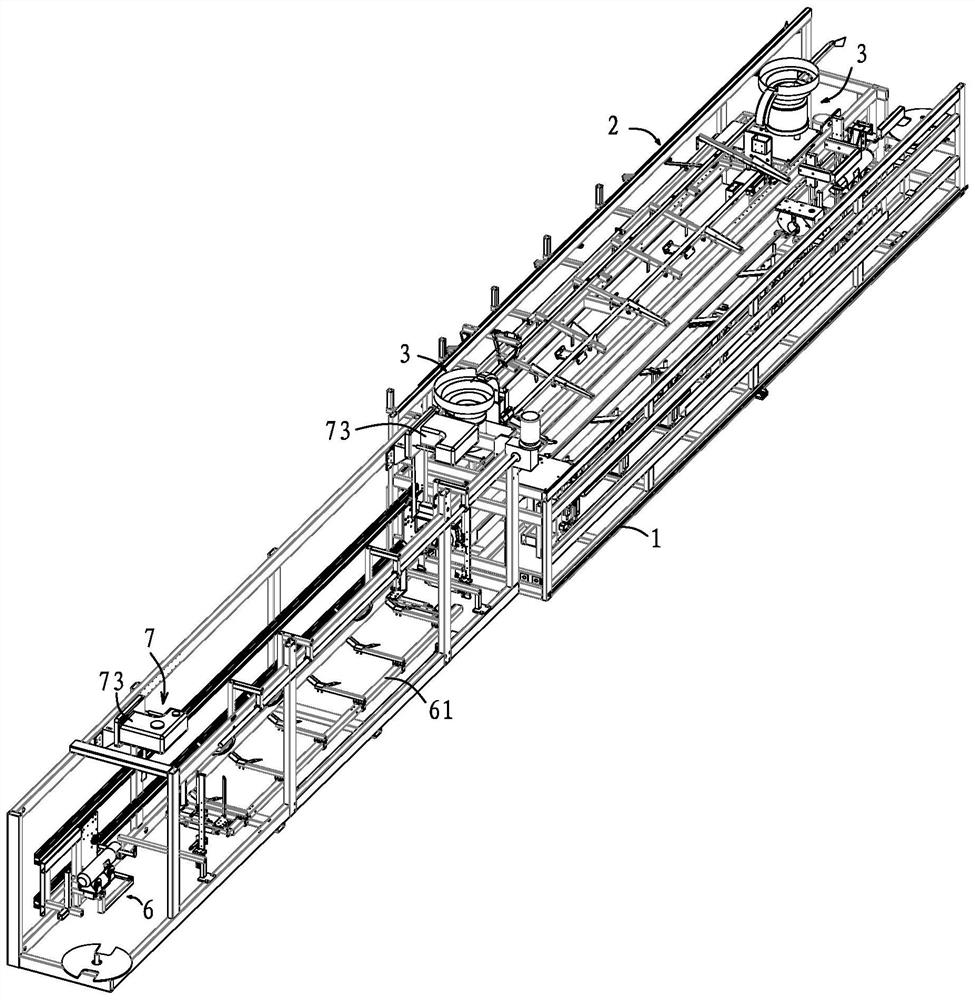

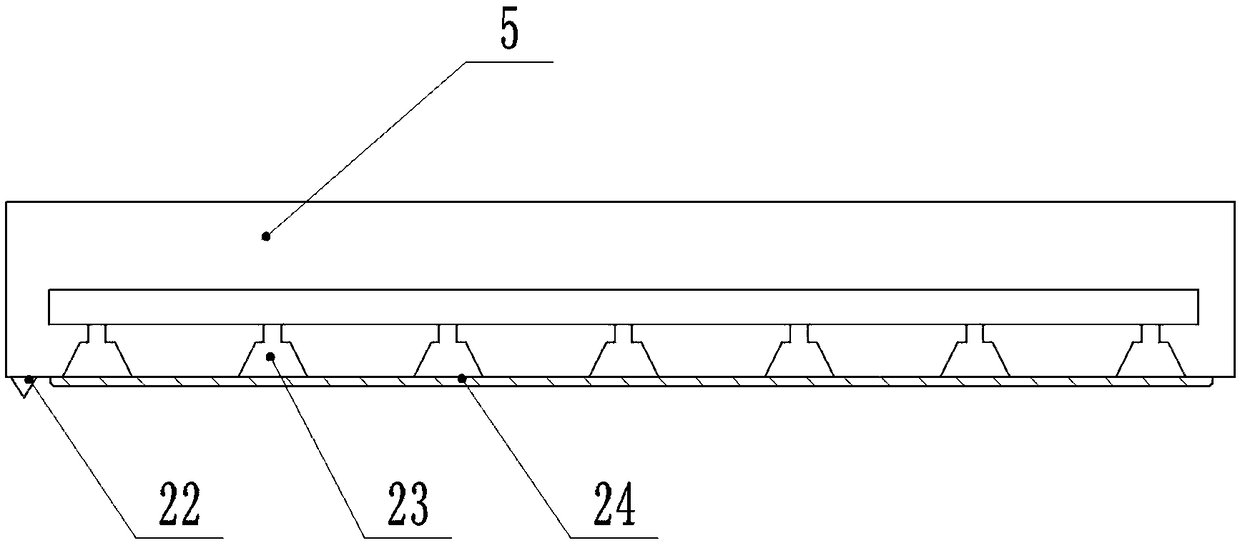

Novel cloth bag packing machine

ActiveCN105501537ARealize automatic baggingImprove packaging efficiencyPackagingEngineeringMechanical engineering

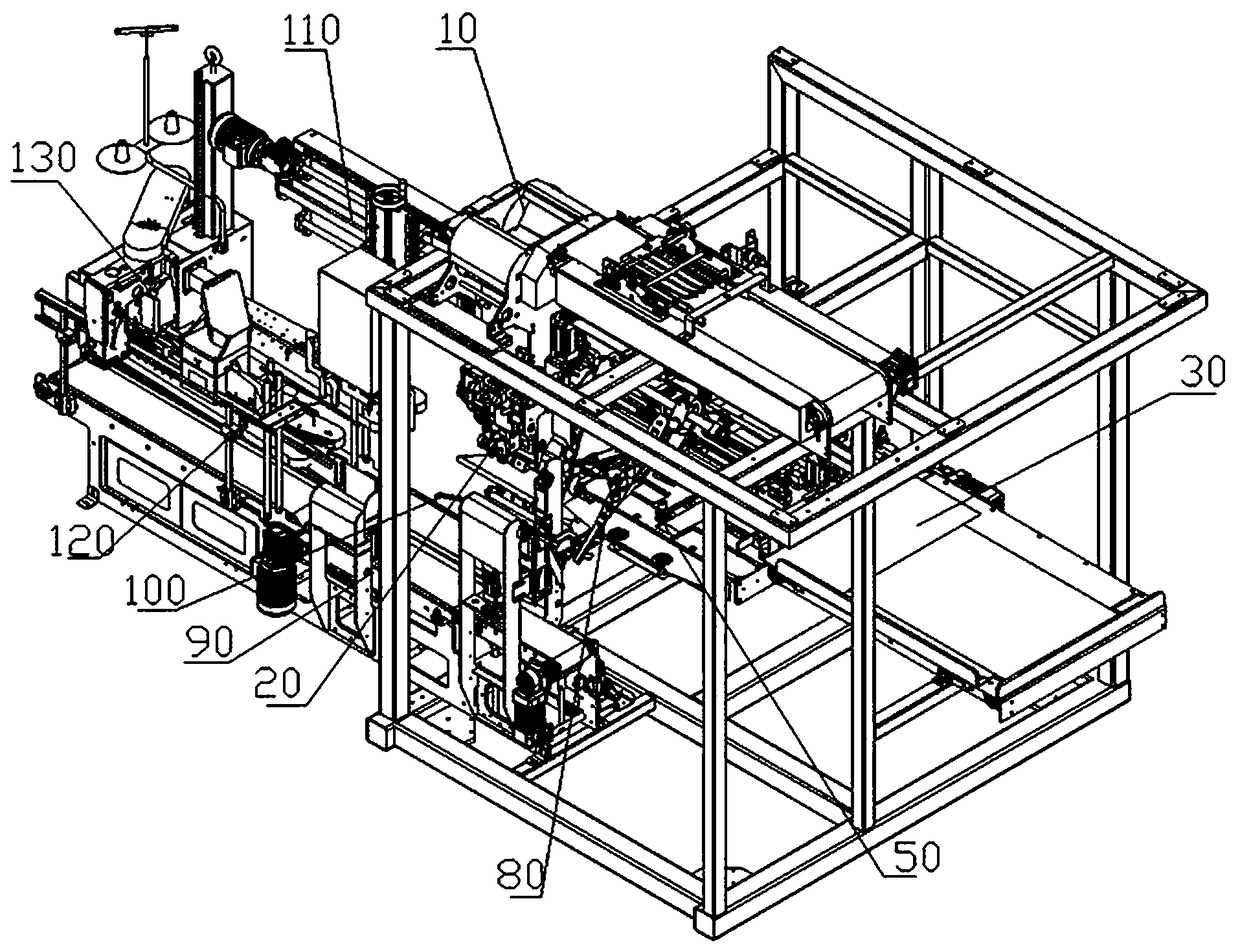

The invention discloses a novel cloth bag packing machine which comprises a rack, a tray, a tray lifting device, a bag lifting device, a transverse bag opening device, N longitudinal bag opening devices, a material pushing device and a longitudinal bag opening device circulating system, wherein after the tray lifting device lifts the tray to a certain height, the bag lifting device acts for lifting a cloth bag, so that the cloth bag is positioned in an opening state, then is opened to a designated width by the transverse bag opening device and is transported to the longitudinal bag opening devices; the cloth bag is longitudinally opened to a designated height on the premise of keeping transverse opening, and finally materials are pushed into the in-place opened cloth bag by the material pushing device, so that the working procedure of automatically bagging is realized. N recycled longitudinal bag lifting devices are arranged in the whole rack, so that the transverse bag opening device and the material pushing device can be continuously operated, all work stations are in a parallel working state and do not intervene one another, and the packing efficiency is greatly improved.

Owner:BLUESWORD INTELLIGENT TECH CO LTD

A cloth bag packaging machine

ActiveCN105501537BRealize automatic baggingImprove packaging efficiencyPackagingMechanical engineering

The invention discloses a novel cloth bag packing machine which comprises a rack, a tray, a tray lifting device, a bag lifting device, a transverse bag opening device, N longitudinal bag opening devices, a material pushing device and a longitudinal bag opening device circulating system, wherein after the tray lifting device lifts the tray to a certain height, the bag lifting device acts for lifting a cloth bag, so that the cloth bag is positioned in an opening state, then is opened to a designated width by the transverse bag opening device and is transported to the longitudinal bag opening devices; the cloth bag is longitudinally opened to a designated height on the premise of keeping transverse opening, and finally materials are pushed into the in-place opened cloth bag by the material pushing device, so that the working procedure of automatically bagging is realized. N recycled longitudinal bag lifting devices are arranged in the whole rack, so that the transverse bag opening device and the material pushing device can be continuously operated, all work stations are in a parallel working state and do not intervene one another, and the packing efficiency is greatly improved.

Owner:BLUESWORD INTELLIGENT TECH CO LTD

Sandbag filling device

The invention discloses a sandbag filling device which comprises a sand pumping system, a sand feeding mechanism, a bagging system, a sealing mechanism and a bag conveying mechanism. The sand pumping system comprises a movable support, a sand pumping assembly and a Y-shaped sand conveying cylinder; the Y-shaped sand conveying cylinder is installed on the movable support; a sand outlet is formed in the end of the Y-shaped sand conveying cylinder; the sand pumping assembly is arranged in the Y-shaped sand conveying cylinder so as to be used for carrying out sand pumping work; the sand feeding mechanism comprises a hose, a bag cylinder and a transmission seat; the hose is fixedly installed at the sand outlet; the bag cylinder is fixedly installed at the tail end of the hose through a supporting frame; the bag conveying mechanism is placed at a discharging opening of the bag cylinder and used for conveying sand bags filled with sand; the bagging system comprises a rotating disc, a clamping seat and an intermittent block; the intermittent block is rotationally installed in the middle of the base; the rotating disc is fixedly installed at the top of the intermittent block and used for assisting in sand loading and sand bag conveying; and the sealing mechanism is installed on the bag conveying mechanism and used for carrying out sealing work. According to the sandbag filling device provided by the invention, automatic sand bag loading can be directly carried out beside a sand pile, large carrying machines such as forklifts are not needed, and the sandbag filling device is convenient to use and easy to operate during use.

Owner:南通西田环保科技有限公司

Bag feeding device of ton bag packaging machine

PendingCN113800050AIncrease frictionGuaranteed dragPackaging automatic controlThin film sensorThin membrane

The invention discloses a bag feeding device of a ton bag packaging machine. A thin film sensor is arranged on the outlet side of a packaging bag conveying mechanism and used for sensing whether a packaging bag arrives at the outlet side of the packaging bag conveying mechanism or not; a suction cup device is further arranged above the outlet side of the packaging bag conveying mechanism and connected to a lifting device, and the lifting device is used for driving the suction cup device to descend so as to adsorb bag openings of packaging bags and driving the suction cup device to ascend so as to open the bag openings of the packaging bags, an opening and closing arm is arranged at one end of a bag feeding manipulator and connected to an opening and closing driving mechanism, the opening and closing driving mechanism is used for driving the opening and closing arm to be opened or closed, the bag feeding mechanical arm is connected to a rotation driving mechanism and a linear moving mechanism, and the linear moving mechanism is used for driving the bag feeding manipulator to move linearly so as to be close to a discharging material barrel mechanism or the packaging bag conveying mechanism, the rotation driving mechanism is used for driving the bag feeding manipulator to rotate up and down so as to be opposite to the outlet side of the packaging bag conveying mechanism or a material barrel of the discharging material barrel mechanism. According to the bag feeding device, automatic bag feeding can be achieved.

Owner:广州恒森智控科技有限公司

Full-automatic sewing thread packaging machine

ActiveCN106005609AAvoid inaccuraciesControl workPackaging automatic controlPackaging machinesControl systemEngineering

The invention discloses a full-automatic sewing thread packaging machine. The full-automatic sewing thread packaging machine comprises a control system, a machine frame, a conveying device, a contracting device, a conveying belt, a labeling device and a bagging device, wherein the conveying device, the contracting device and the conveying belt are all arranged on the machine frame, and the labeling device and the bagging device are sequentially arranged on the conveying belt. The control system comprises a main control circuit board, a first isolating circuit and a second isolating circuit, wherein the main control circuit board is coupled to an external manipulator and an external sensor to receive an induction signal output by the sensor and send out a driving signal to the manipulator so as to drive the manipulator to act; the first isolating circuit is coupled between the main control circuit board and the external manipulator to electrically isolate the communication between the main control circuit board and the external manipulator; and the second isolating circuit is coupled between the main control circuit board and the external sensor to electrically isolate the communication between the main control circuit board and the external sensor. According to the full-automatic sewing thread packaging machine, through the arrangement of the first isolating circuit and the second isolating circuit, the connection between the manipulator and the main control circuit board as well as between the sensor and the main control circuit board can be effectively isolated.

Owner:XINCHANG WANSHIFA TEXTILE MACHINERY

Quantitative steel ball packaging machine

ActiveCN104117422ARealize automatic baggingReduce labor intensityGrain treatmentsSteel ballPackaging machine

The invention discloses a quantitative steel ball packaging machine. The quantitative steel ball packaging machine comprises a rack, a screening device and multiple sub-packaging mechanisms, wherein the screening device and the sub-packaging mechanisms are arranged on the rack; the screening device comprises multiple vertical partition plates which are parallel to one another; a baffle plate perpendicular to the partition plates is aslant arranged at the lower parts of every two adjacent partition plates; a ball outlet is formed in the aslant downward end of each baffle plate; one sub-packaging mechanism is arranged below each ball outlet; each sub-packaging mechanism comprises a containing drum with a first opening and a second opening in two ends; each first opening is the same as the corresponding ball outlet in size and is communicated with the corresponding ball outlet; each second opening is communicated with a steel ball bag; a first valve plate is arranged at each first opening; a second valve plate is arranged at each second opening; both the first valve plates and the second valve plates are movably connected with the containing drums through chutes; the first valve plates and the second valve plates are connected with a first driving device and a second driving device, and are driven to move by the first driving device and the second driving device.

Owner:宁国东方碾磨材料股份有限公司

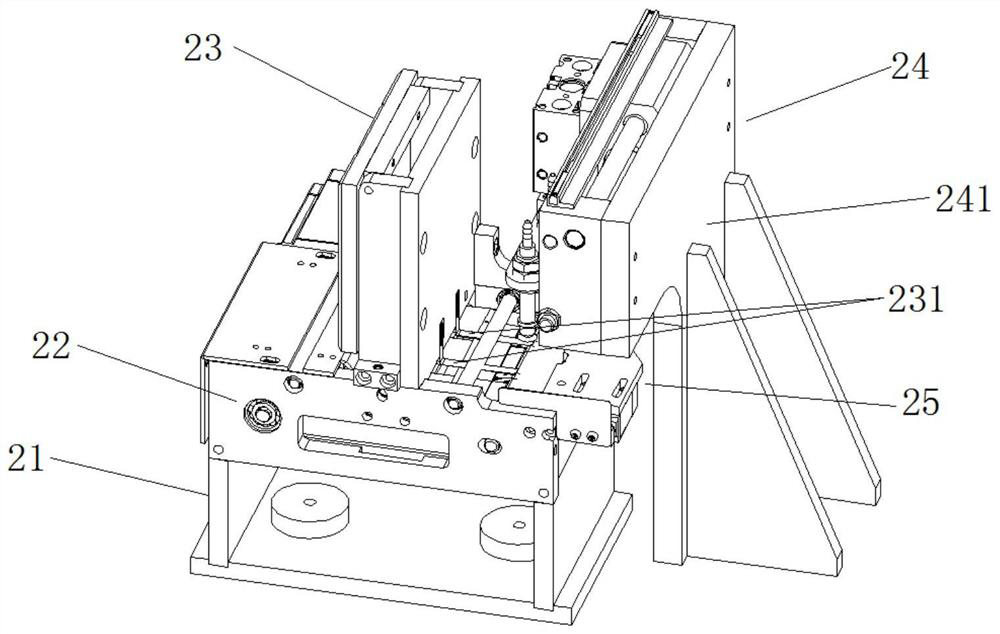

Device for automatically loading gas collection cards into aluminum foil bags

PendingCN111169753ARealize automatic baggingFully automatedPackaging automatic controlIndividual articlesEngineeringProcess engineering

The invention discloses a device for automatically loading gas collecting cards into aluminum foil bags, and relates to the device for automatically loading the gas collecting cards into the aluminumfoil bags. The device comprises a gas collecting card rack (21), wherein an aluminum foil bag material issuing machine (22) with a feeding belt, a gas collecting card coding machine (23) for coding the gas collecting cards, a bowing nozzle bagging machine (24) for placing blowing nozzles into the aluminum foil bags, a gas collecting card bagging machine (25) for placing the gas collecting cards into the aluminum foil bags, a second detecting and removing device (26) for unloading the aluminum foil bags with the blowing nozzles and the gas collecting cards and removing the unqualified aluminumfoil bags, and a dividually-pushing and collecting machine (27) with a material collecting belt are sequentially arranged at the upper end of the gas collecting card rack (21) in the flow direction ofa packaging line. According to the device for automatically loading the gas collecting cards into the aluminum foil bags, the production hours are reduced, the production efficiency is improved, andthe stability of the product quality is ensured.

Owner:SHENZHEN ZHONGHE HEADWAY BIO SCI & TECH CO LTD

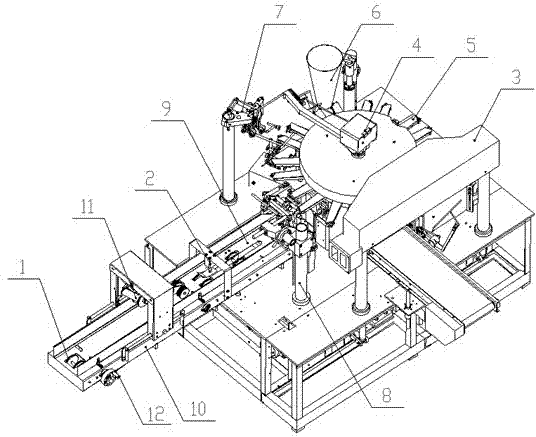

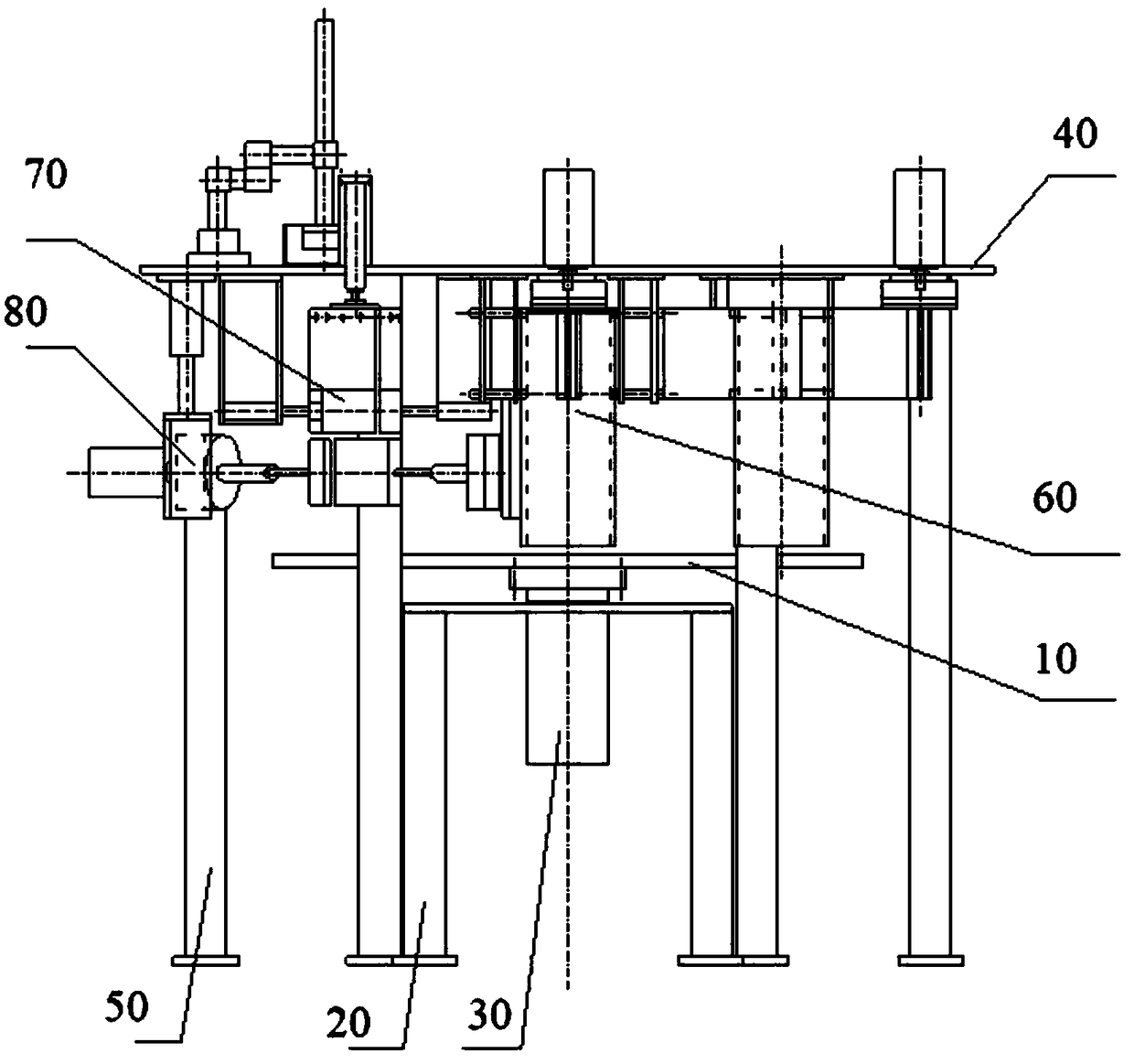

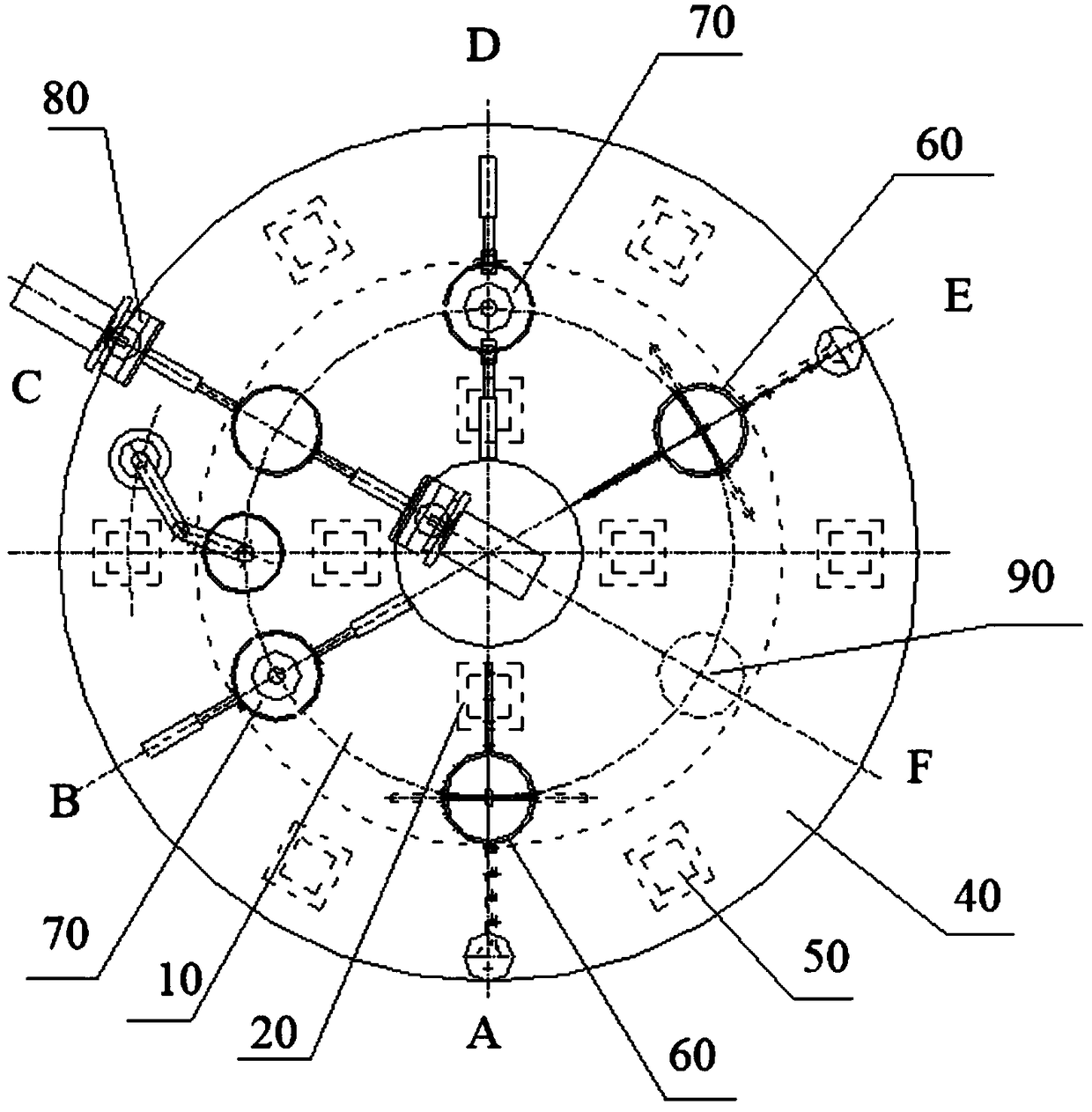

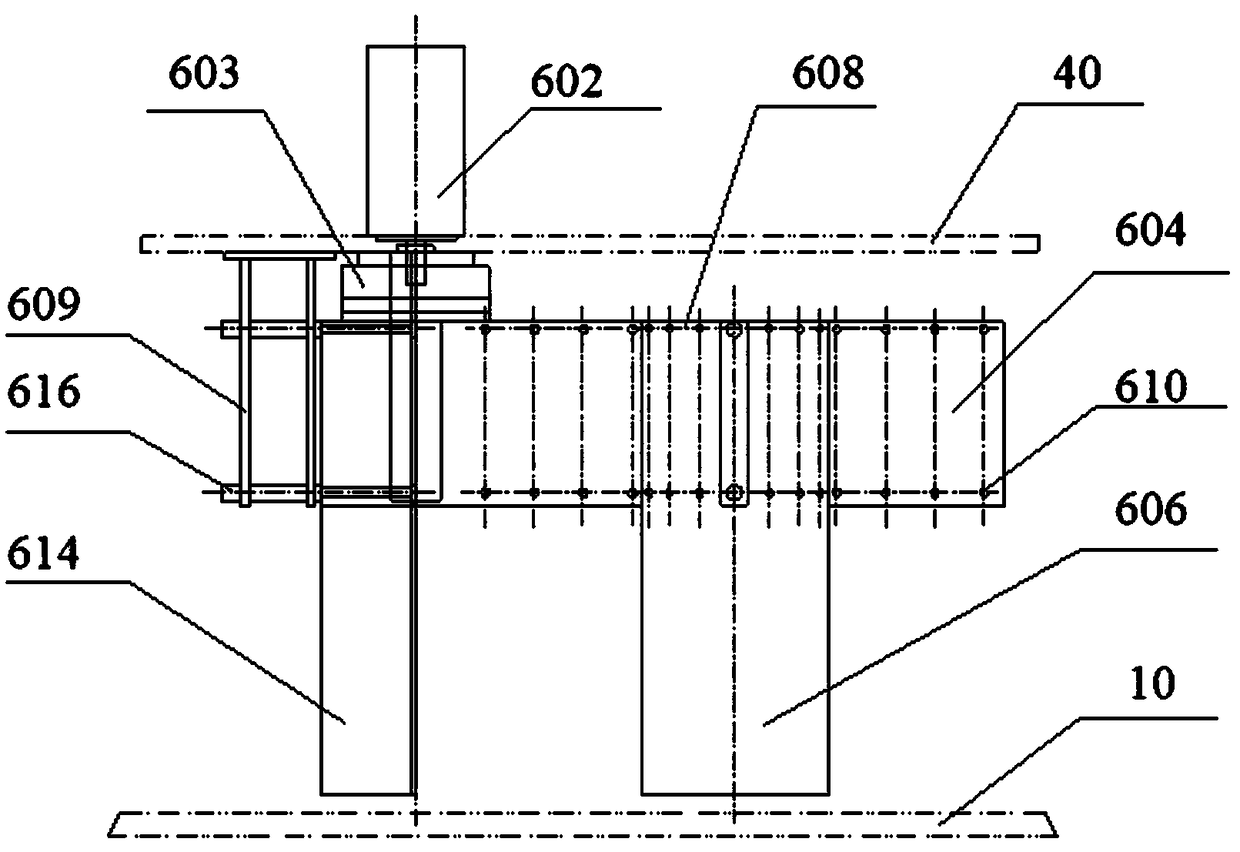

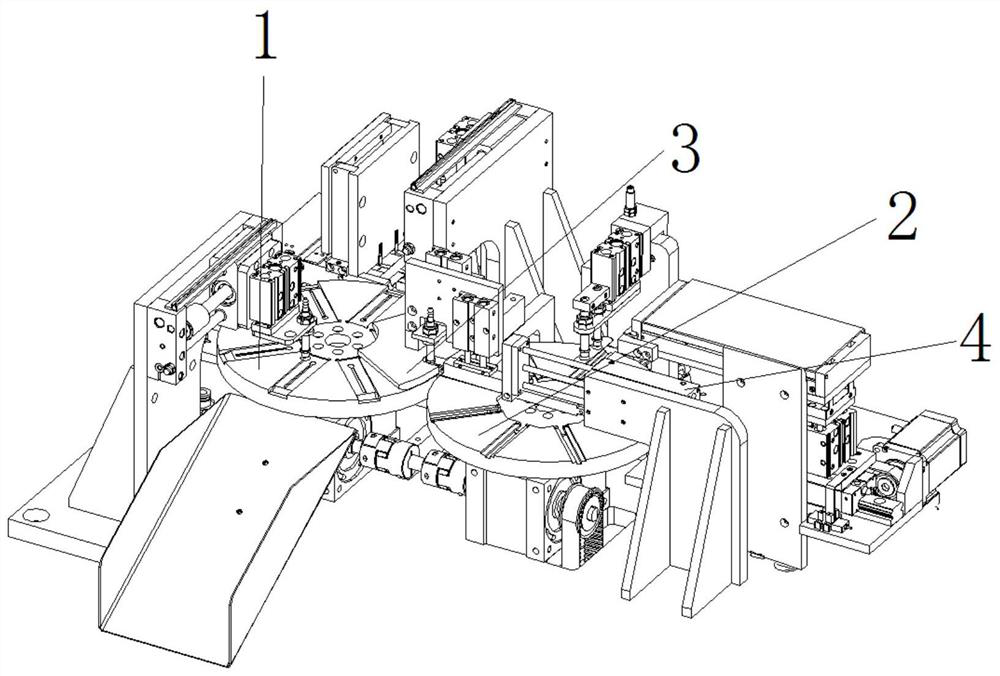

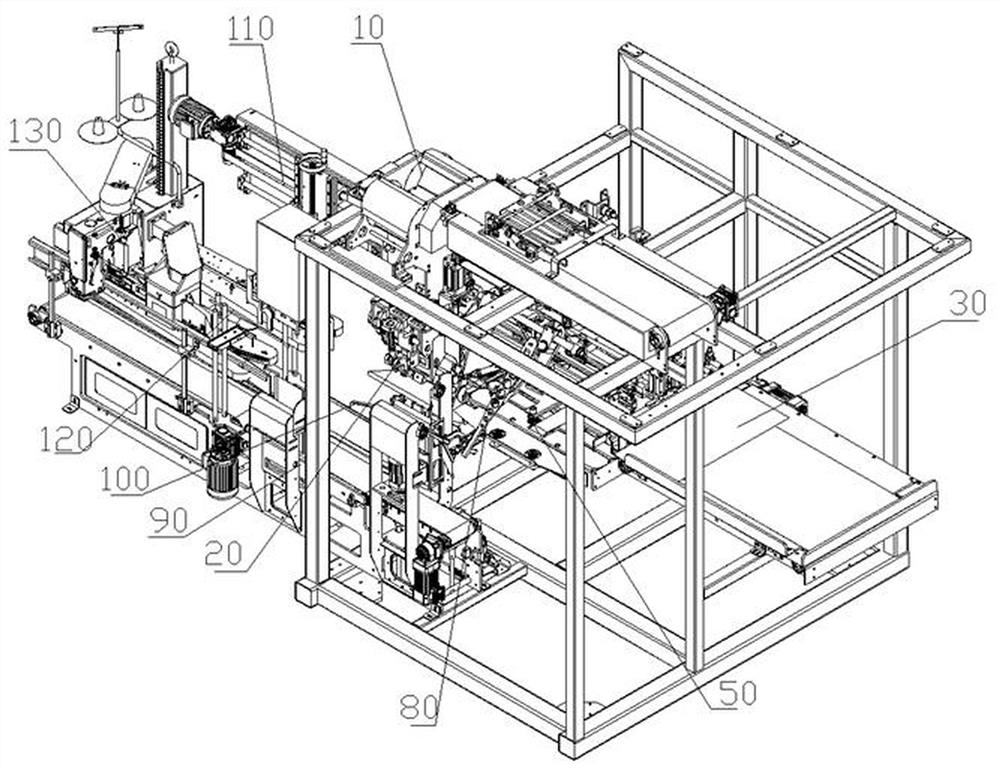

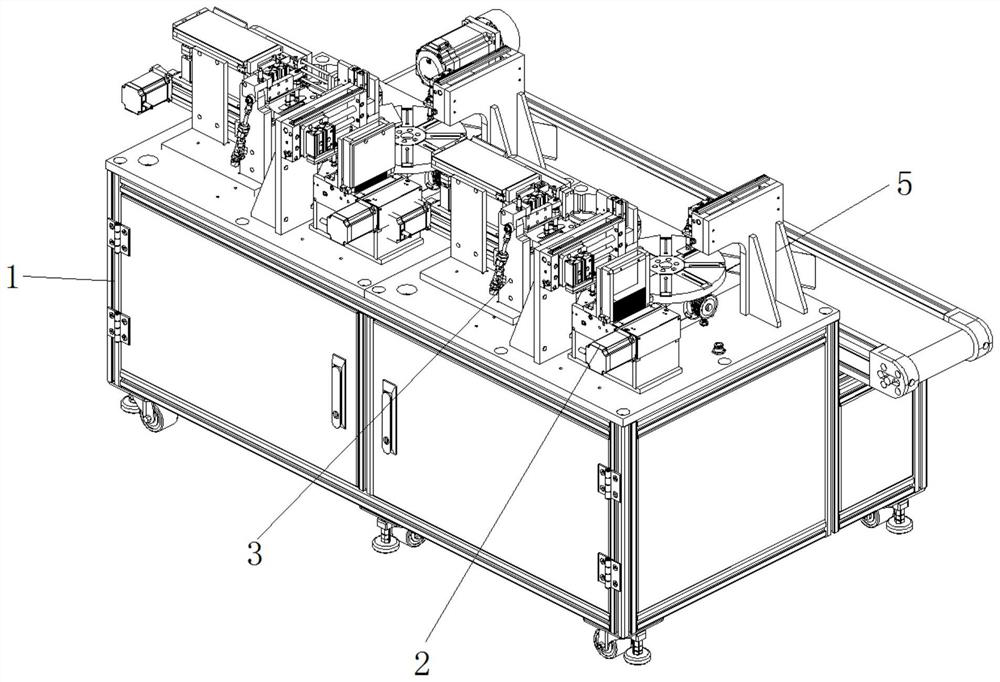

Piston wear-resistant inserted ring intelligent bagging machine and bagging method

PendingCN109279091AImprove automationImprove completenessWrapper twisting/gatheringSolid materialWear resistantEngineering

The invention provides a piston wear-resistant inserted ring intelligent bagging machine and bagging method. The piston wear-resistant inserted ring intelligent bagging machine comprises a rotating disc, a rotating disc support, a rotating disc motor, a top plate, a top plate support, bag opening and bagging mechanisms, opening closing and bag pressing mechanisms, a turnover mechanism, a bag unloading mechanism and a robot arm. The rotating disc, the rotating disc support and the rotating disc motor are arranged in a cooperation manner. The top plate is arranged above the top of the rotating disc. The top plate support is connected with the top plate and used for supporting the top plate. The bag opening and bagging mechanisms are arranged on the top plate and used in cooperation with therotating disc to form bag opening and bagging stations. The opening closing and bag pressing mechanisms are arranged on the top plate. The opening closing and bag pressing mechanisms and the bag opening and bagging mechanisms are arranged in an adjacent manner. The opening closing and bag pressing mechanisms and the rotating disc are used in cooperation to form opening closing and bag pressing stations. The turnover mechanism is arranged on the top plate. The turnover mechanism and the opening closing and bag pressing mechanisms are arranged in an adjacent manner. The turnover mechanism is used in cooperation with the rotating disc to form a turnover station. The bag unloading mechanism is arranged on the top plate. The bag unloading mechanism is used in cooperation with the rotating discto form a bag unloading station. The robot arm is arranged below the top plate. By means of the technical scheme of the piston wear-resistant inserted ring intelligent bagging machine and bagging method, the automation and intelligence degree of piston wear-resistant inserted ring bagging is increased, the bagging efficiency is improved, and therefore the production efficiency is improved.

Owner:BINZHOU YATAI ART POWER PARTS

A fully automatic double-layer bag packaging machine

ActiveCN104648703BReduce labor intensityFast productionWrapper twisting/gatheringSolid materialEngineeringFully automatic

The invention provides a full-automatic double-layer bag packaging machine which comprises a machine frame. A track is arranged on the machine frame and is used for a front trolley, a middle trolley and a rear trolley, a bag feeding station, an inner bag arrangement station, a centering station, a filling station, a twisting opening-binding station and a sewing station are arranged on the machine frame, the bag feeding station is located in front of the inner bag arrangement station, the inner bag arrangement station is located in front of the centering station, the centering station is located in front of the filling station, the filling station is located in front of the twisting opening-binding station, and the twisting opening-binding station is located in front of the sewing station. The full-automatic double-layer bag packaging machine changes original manual operation, achieves automatic bag feeding, inner bag arrangement, bag centering, filling and binding, twisting and opening binding and the like and is low in labor intensity of workers, high in production speed and good in quality.

Owner:JIANGSU WANLE COMPOSITE MATERIAL

a trash can

ActiveCN112722618BRealize automatic baggingHigh degree of intelligenceRefuse receptaclesEngineeringStructural engineering

A garbage bin provided by the present invention includes: an inner cylinder; a film covering structure, which is arranged at the mouth of the inner cylinder, and is suitable for installing a membrane structure covering the mouth of the cylinder; a first power part, which is arranged on the inner cylinder On the barrel, the membrane structure is adapted to be attached to the inner wall of the inner barrel driven by the first power member. By setting the coating structure at the mouth of the inner cylinder, a membrane structure that can cover the inner cylinder can be pre-set at the mouth of the cylinder, and the membrane structure at the mouth of the inner cylinder can be transported to the inner wall of the inner cylinder by the first power member on the inner cylinder , and adhere to the inner wall of the inner cylinder to form a bag body that can accommodate garbage. This setting can realize the automatic bagging of the dustbin, improve the intelligence of the dustbin, reduce the unhygienic and inconvenient handling methods of manual bagging and manual packing by users, and improve the user experience.

Owner:GREE ELECTRIC APPLIANCES INC

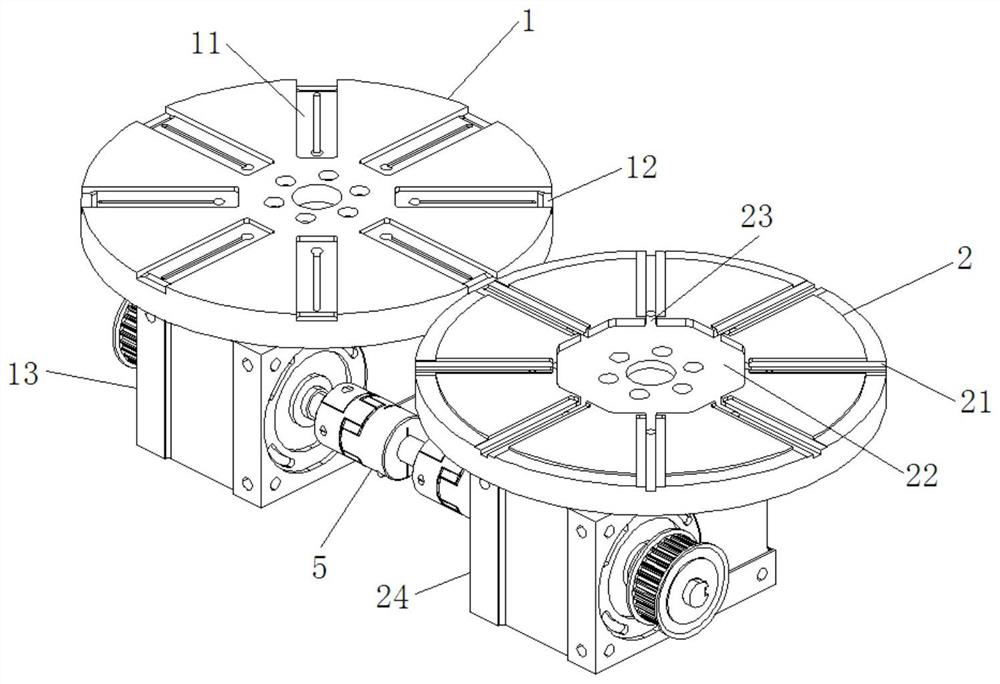

Rotary label bagging device

ActiveCN113291508ARealize automatic baggingHigh degree of automationIndividual articlesStructural engineeringMechanical engineering

The invention dislcoses a rotary label bagging device. The rotary label bagging device comprises a material bag index plate, a material core index plate and a bag opening and core pushing mechanism, the material bag index plate is used for containing material bags, the material core index plate is used for containing material cores, and the bag opening and core pushing mechanism is used for opening the material bags and pushing the material cores into the material bags, the bag opening and core pushing mechanism comprises a bag pressing mechanism, a bag opening mechanism and a core pushing mechanism, the bag pressing mechanism, the bag opening mechanism and the core pushing mechanism are located above the connecting line position of the circle center of the material bag index plate and the circle center of the material core index plate, the bag pressing mechanism is used for pressing the front ends of bag openings of the material bags, the bag opening mechanism is used for opening the bag openings of the material bags, and the core pushing mechanism is used for pushing the material cores into the material bags. According to the rotary label bagging device, the material bag index plate, the material core index plate, the bag opening and core pushing mechanism and the like are arranged, so that the material cores are loaded into material bags, automatic bagging of labels is realized, the automation degree is high, and the bagging efficiency is high.

Owner:GOLDEN PROSPERITY PRINTING & PACKAGING (HEYUAN) CO LTD

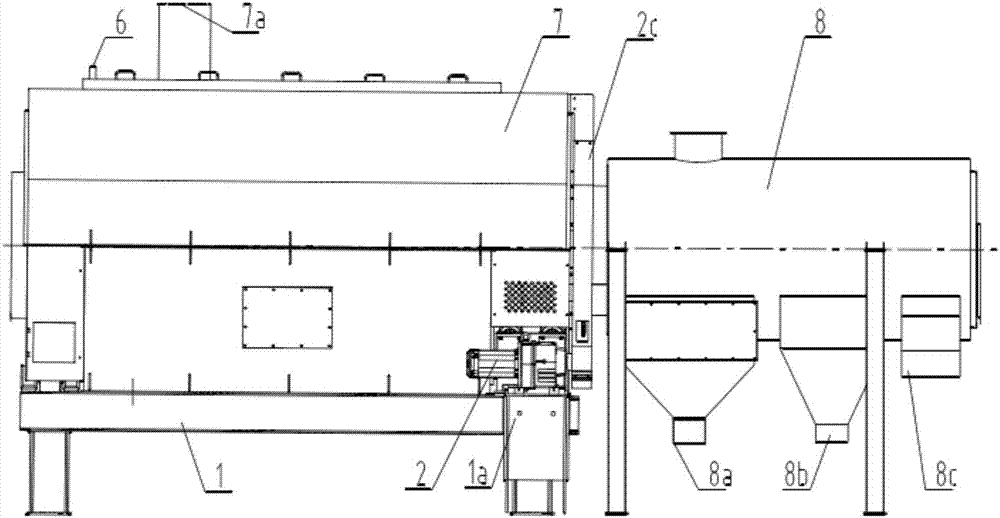

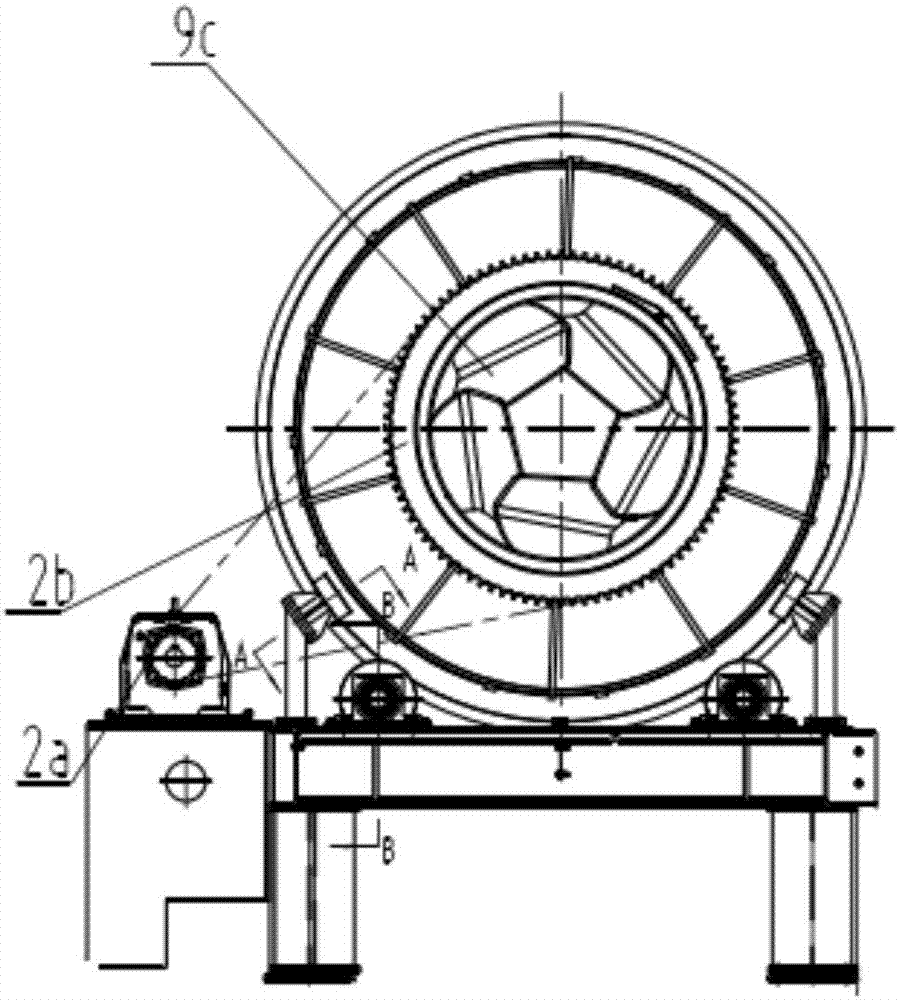

An automatic high temperature metal ash cooling and screening device

InactiveCN105537100BEnable recyclingRealize automatic baggingSievingLighting and heating apparatusStopped workMotor drive

Owner:SHANGHAI JIAOTONG UNIV +1

A kind of material packing method

ActiveCN108839828BConvenient reverseInhibit sheddingWrapper twisting/gatheringPackaging automatic controlMechanical engineeringIndustrial engineering

Owner:SHANGHAI SOONTRUE MACHINERY EQUIP

An automatic label bagging machine

ActiveCN113291509BRealize automatic baggingHigh degree of automationIndividual articlesEngineeringMechanical engineering

The invention discloses an automatic label bagging machine. Both the dial mechanism and the discharge mechanism are set on the frame, the bag feeding mechanism is used to transport the bag to the bagging index mechanism, and the material core feeding mechanism is used to transport the material core to the bagging index mechanism. The bag indexing plate mechanism is used to put the material core into the material bag. The bag indexing plate mechanism includes the material bag indexing plate, the material core indexing plate and the bag opening core pushing mechanism. The material bag indexing plate is used to place the material The bag and core indexing plate is used to place the material core, the bag opening mechanism is used to open the material bag and push the material core into the material bag, and the discharge mechanism is used to send out the bagged material bag and material core ; The automatic label bagging machine is used to put the material core into the material bag to realize the automatic bagging of the label, with a high degree of automation and high bagging efficiency.

Owner:GOLDEN PROSPERITY PRINTING & PACKAGING (HEYUAN) CO LTD

A bagging mechanism for packaging equipment

ActiveCN108609234BRealize automatic baggingImprove efficiencyIndividual articlesMechanical equipmentMachine

The invention provides a bagging mechanism of packaging equipment, and belongs to the technical field of mechanical equipment. The bagging mechanism solves the problem that in the prior art, the packaging efficiency of paper cups is low. The packaging equipment comprises a machine frame and the bagging mechanism comprises bagging rods, wherein the machine frame is connected to material collectingpipes and a plurality of first supporting rings, the plurality of first supporting rings are in axial alignment with the material collecting pipes, and the bagging rods are horizontally arranged in the plurality of first supporting rings in a penetrating mode; a plurality of first bag pushing wheels are rotationally connected to the inner peripheral surfaces of the first supporting rings, the plurality of first bag pushing wheels are abutted against the bagging rods, the ends, far away from the material collecting pipes, of the bagging rods are used for allowing packaging bags to be sleeved, and bagging stations are arranged between the other ends of the bagging rods and the discharging ends of the material collecting pipes; and the machine frame is provided with a material pushing piece,and the machine frame is provided with a driving piece capable of driving the plurality of first bag pushing wheels to rotate synchronously. According to the bagging mechanism of the packaging equipment, the paper cups can be automatically bagged and packaged, and the efficiency is high.

Owner:平邑经发科技服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com