Bag feeding device of ton bag packaging machine

A ton charter machine and packaging bag technology, which is applied in the field of bag loading devices on ton charter machines, can solve the problems of dragging material bags, difficulty in implementing mechanical devices, and low degree of automation, and achieve the effect of increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

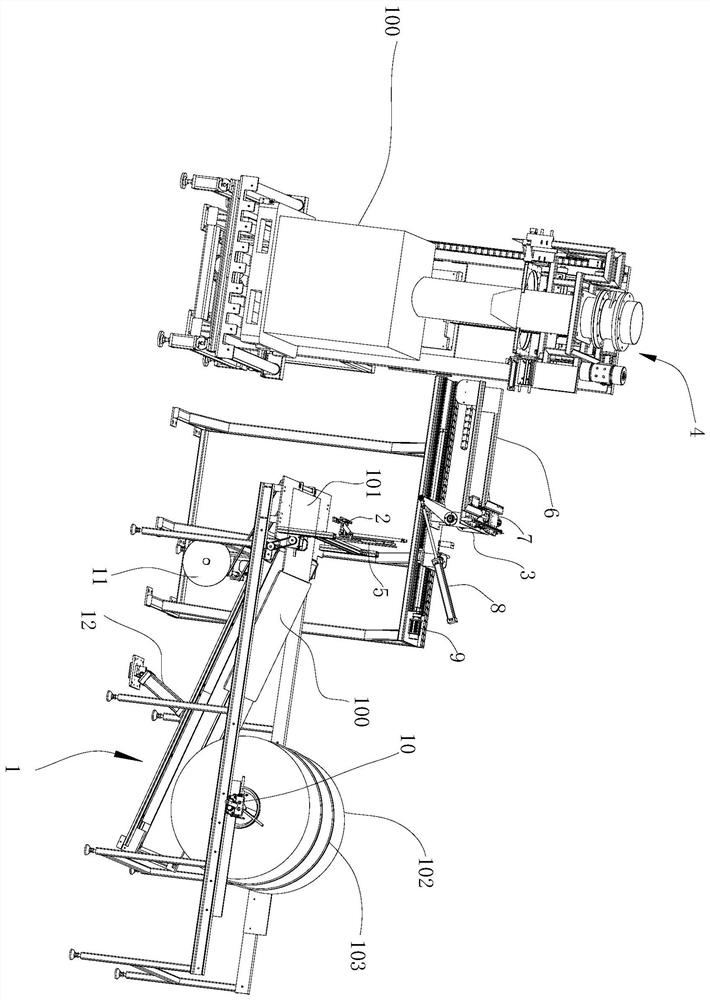

[0027] This embodiment provides a bag loading device for a ton charter machine, such as figure 1 As shown, it includes a packaging bag conveying mechanism 1, a film sensor (not shown in the figure), a suction cup device 2, a bag-loading manipulator 3 and an unloading barrel mechanism 4; the film sensor is located at the outlet of the packaging bag conveying mechanism 1 side, used to sense whether there is a packaging bag 100 arriving at the outlet side of the packaging bag conveying mechanism 1; a suction cup device 2 is also provided above the outlet side of the packaging bag conveying mechanism 1, and the suction cup device 2 is connected to the lifting device 5. The lifting device 5 is used to drive the suction cup device 2 to descend to absorb the pocket 101 of the packaging bag 100 and to drive the suction cup device 2 to rise to open the pocket 101 of the packaging bag 100; There is an opening and closing arm 6, and the opening and closing arm 6 is connected with an open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com