Automatic bagging machine

A bagging machine, automatic technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of false sealing effect, poor, reverse bagging and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0091] The technical solutions of the present application will be described in detail below in conjunction with the accompanying drawings.

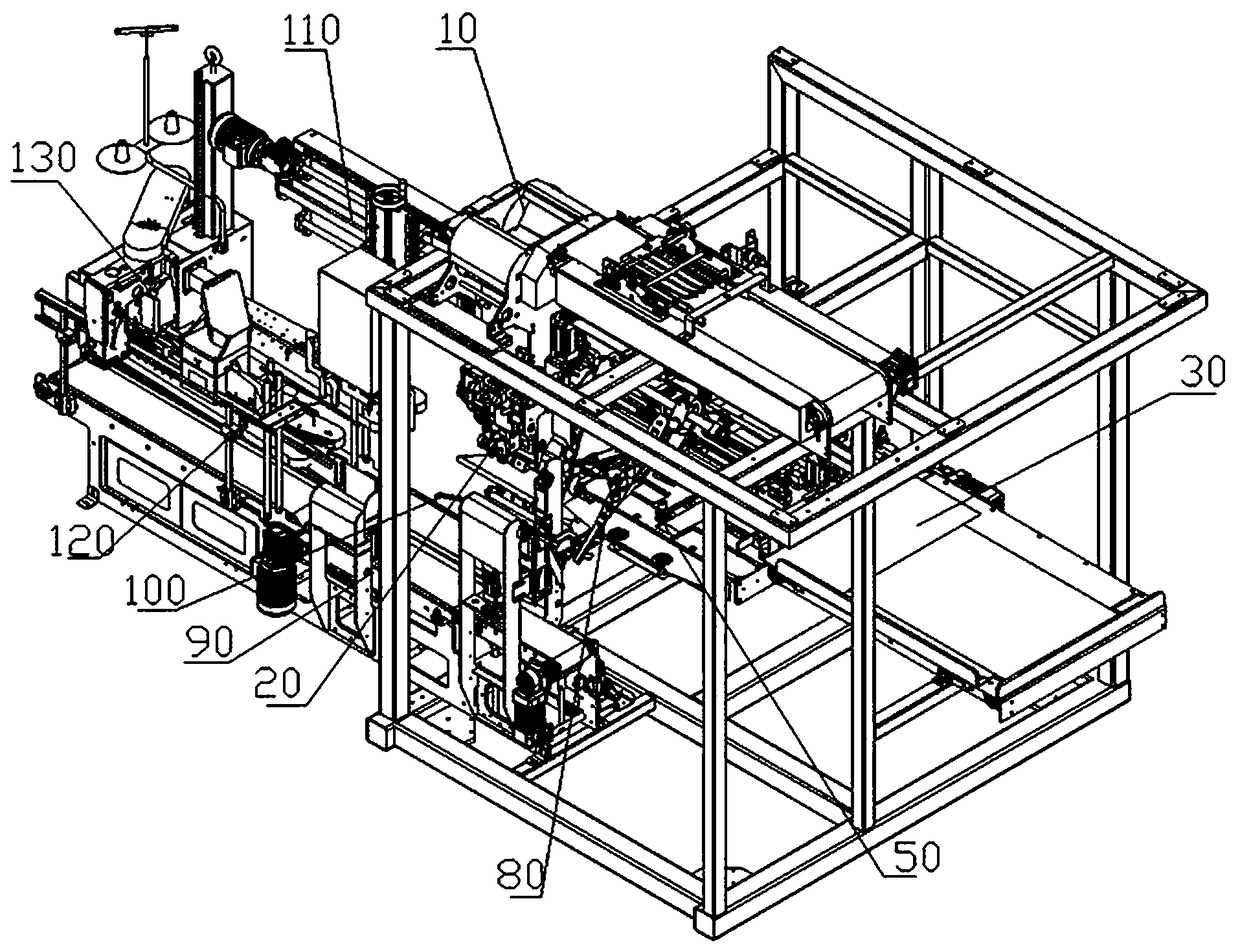

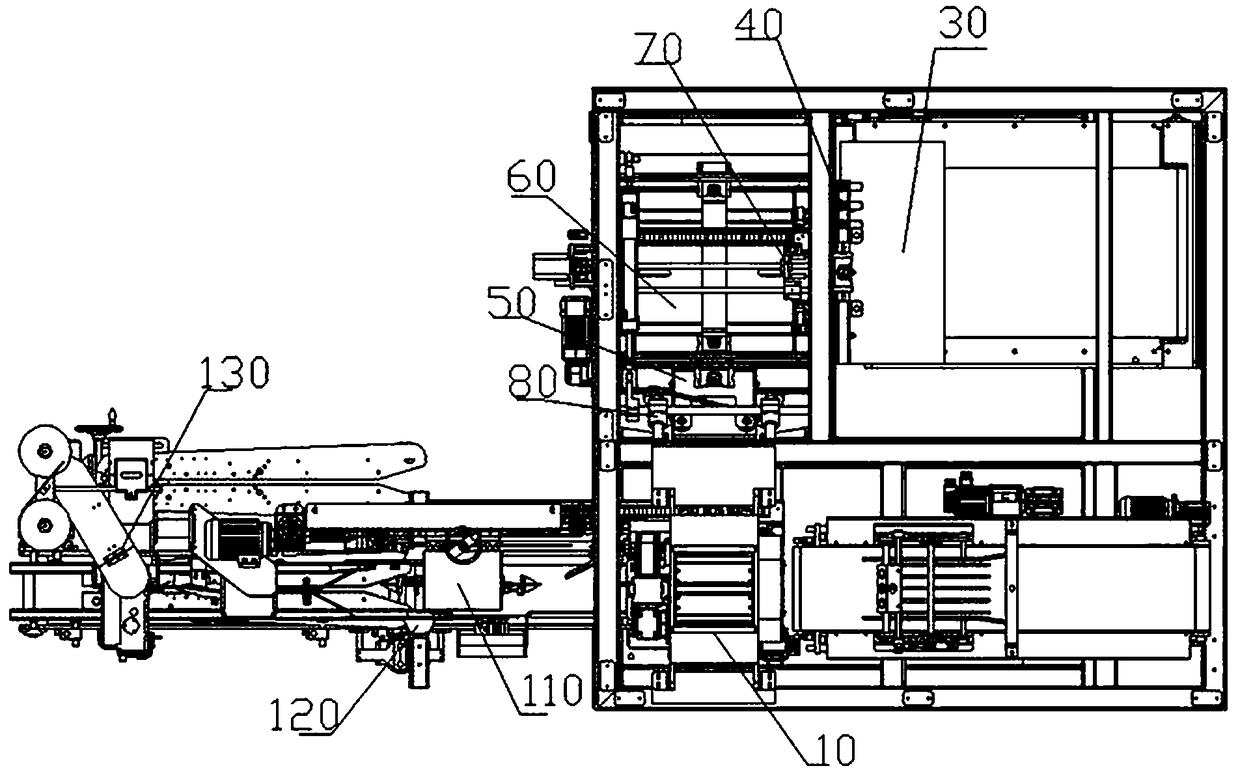

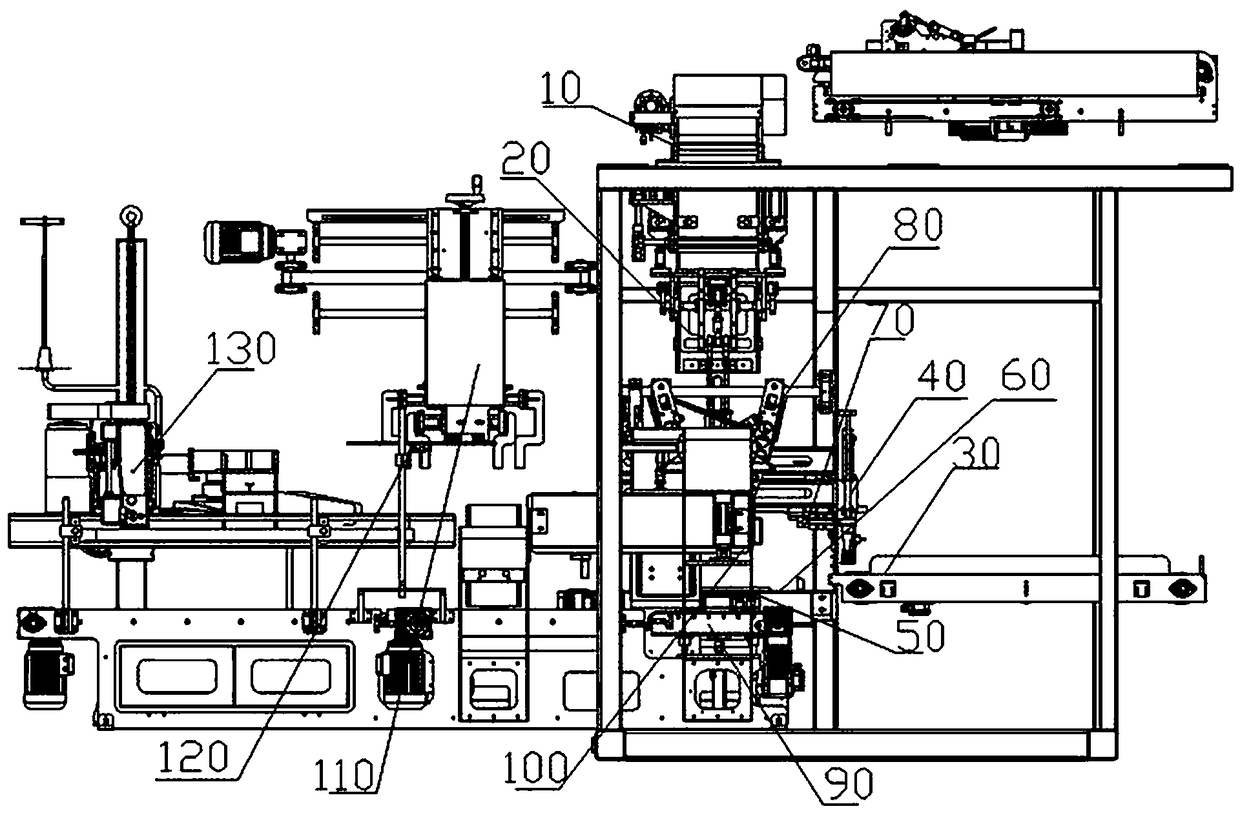

[0092] An automatic bagging machine, comprising a bag receiving bin mechanism 10, a bag clamping mechanism 20, a bag storehouse 30, a bag taking mechanism 40, a bag opening mechanism 50, a bagging mechanism 80, a bag shaking mechanism 90, a bag holding mechanism 100, Pocket finishing mechanism 110, pocket guiding mechanism 120 and bag sewing mechanism 130, described bag clamping mechanism 20 is provided with the bottom of receiving bag bin mechanism 10 and is connected with the bottom outlet of bag receiving bin mechanism 10; Bag taking mechanism 40 It is arranged on one side of the bag warehouse 30; the bag taking mechanism 40 includes a bag taking suction cup 4.1, and the bag taking suction cup 4.1 sucks the long side of the packaging bag to take out the packaging bag from the bag warehouse 30, and the bag opening mechanism 50 is located...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com