Lead-acid storage battery grid automatic conveying device

A lead-acid battery, handling device technology, applied in the directions of transportation and packaging, conveyor objects, etc., can solve problems such as difficulty in automatic handling and increased weight of grids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further illustrate the technical means and functions adopted by the present invention to achieve the predetermined invention purpose, the structure and working process of the present invention are described in detail below in conjunction with the accompanying drawings and preferred embodiments.

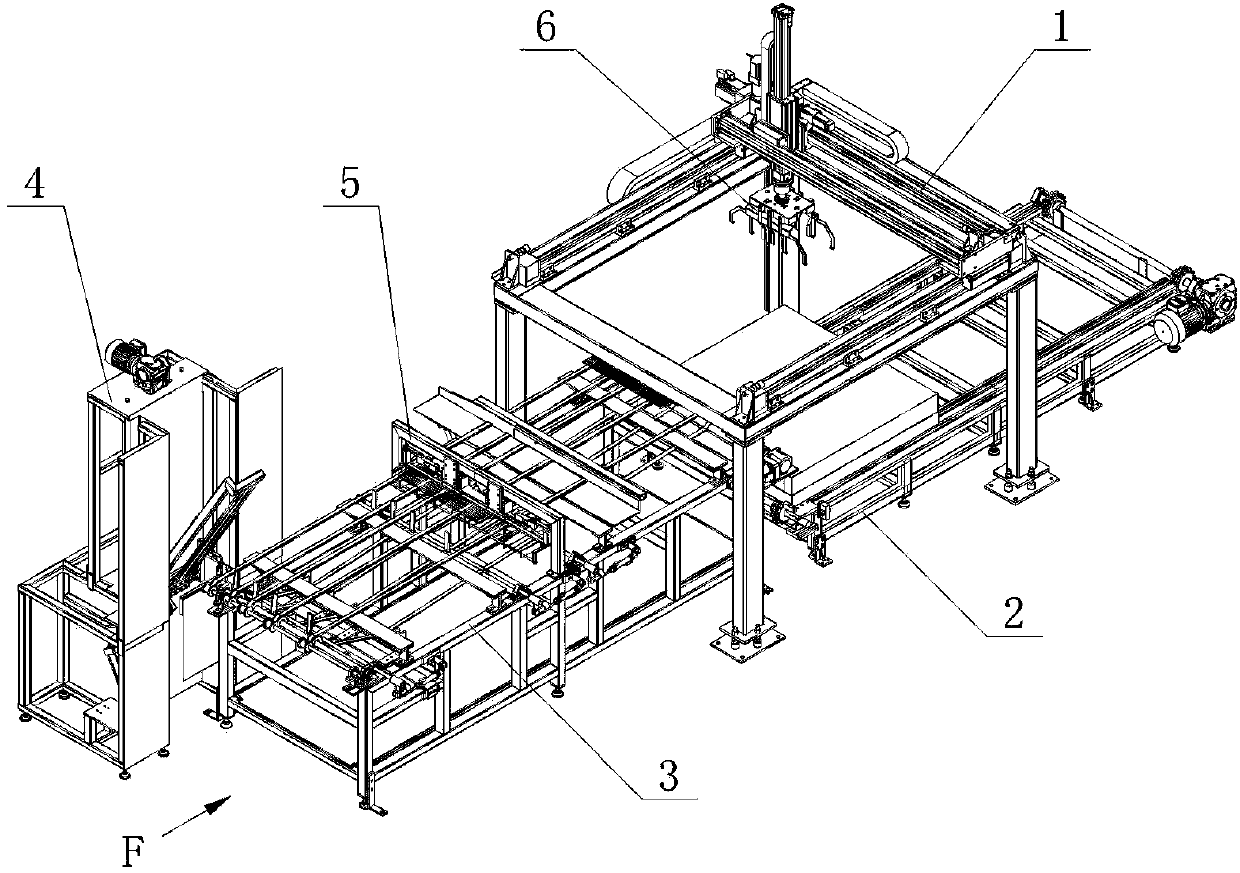

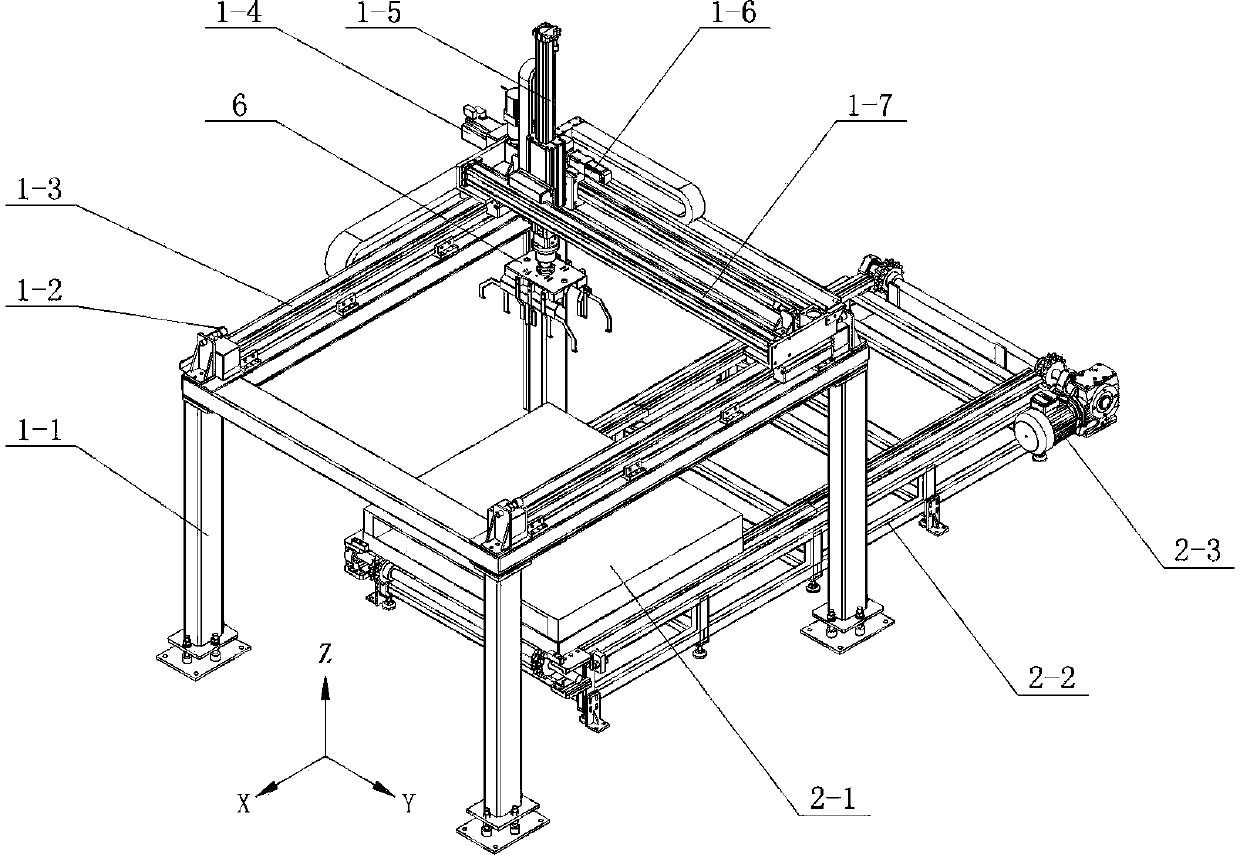

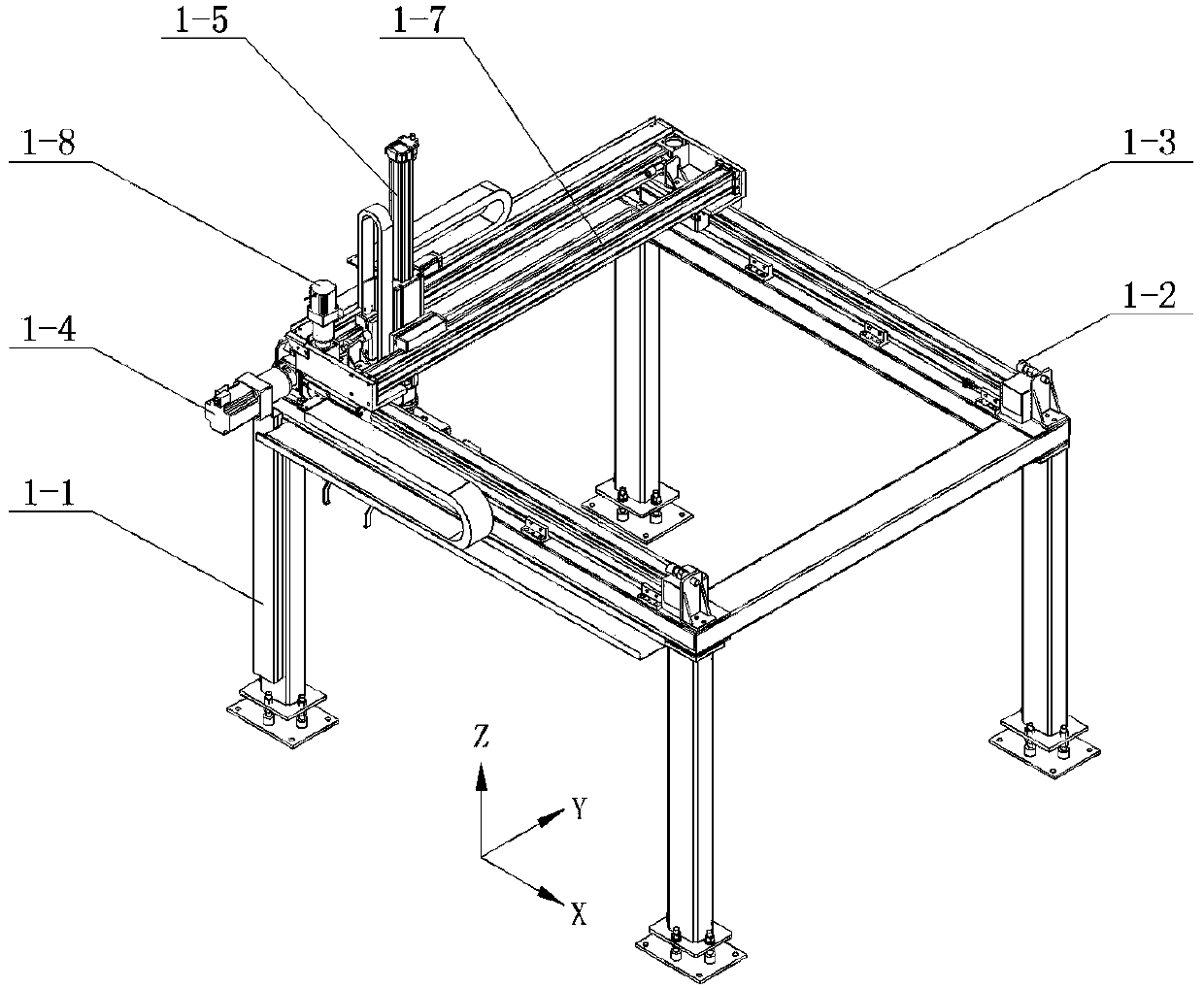

[0035] like figure 2 , image 3 , Figure 4 , Figure 5 Shown is one of the embodiments of the present invention, in this embodiment, the lead-acid storage battery grid automatic transfer device 1 is arranged at the end of the grid production line, as figure 1 At the end of the conveyor table 3, the automatic handling device 1 is provided with a main frame body 1-1, and the main frame body 1-1 is provided with three-axis direction guide rails, which can move in three-axis directions and can surround the Z axis through the guide rails. The manipulator 6 rotating in the direction, the manipulator 6 is provided with the openable mechanical claw that is adapted to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com