Robot for assembling and disassembling automobile wheel on braced chain coating line

A coating line and wheel technology, which is applied to manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of high labor intensity of loading and unloading workers, low loading and unloading efficiency, and difficult loading and unloading of automobile wheels, so as to achieve rapid loading and unloading, reliable grasping, location-accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

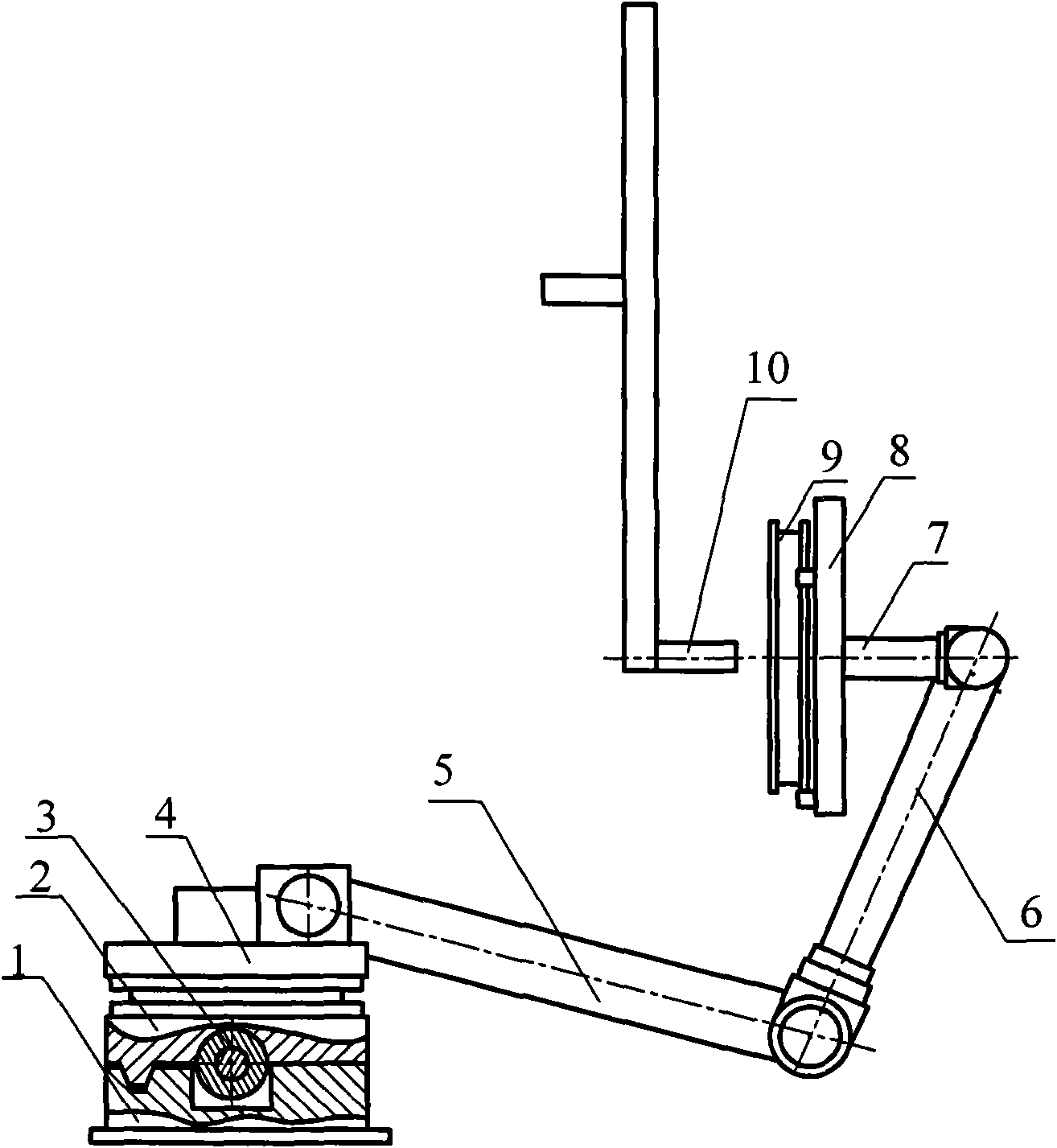

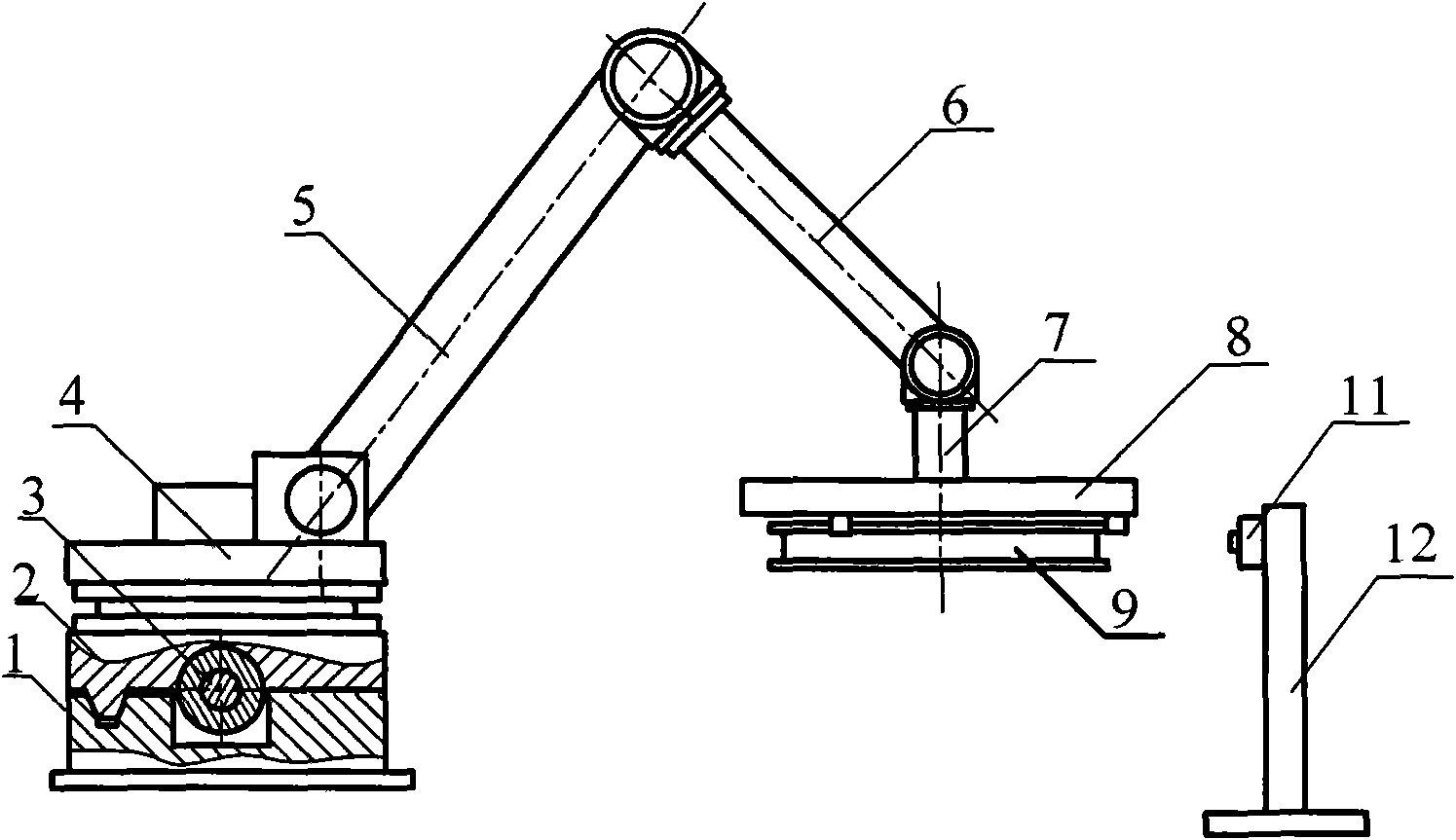

[0011] The working principle of the automobile wheel loading and unloading robot on the catenary coating line of the present invention:

[0012] When grabbing the automobile wheel 9, the cylinder in the wheel clamp 8 moves and clamps the automobile wheel 9, the waist 4 rotates relative to the moving seat 2, the lower arm 5 swings relative to the waist 4, the upper arm 6 swings relative to the lower arm 5, and the wrist 7 relatively The upper arm 6 swings, and when the car wheel 9 is lifted to the same height as the industrial camera 11, it stops rotating or swinging, and the wrist 7 starts to rotate around its own axis. When the industrial camera 11 captures the valve hole on the car wheel 9, the wrist 7 Stop rotating, then the waist 4 rotates, the lower arm 5 swings, the upper arm 6 swings and the wrist 7 swings. When the center of rotation of the automobile wheel 9 reaches the height of the catenary boom 10, and the automobile wheel 9 faces the catenary boom 10, The ball scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com