Patents

Literature

2460results about "External frames" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

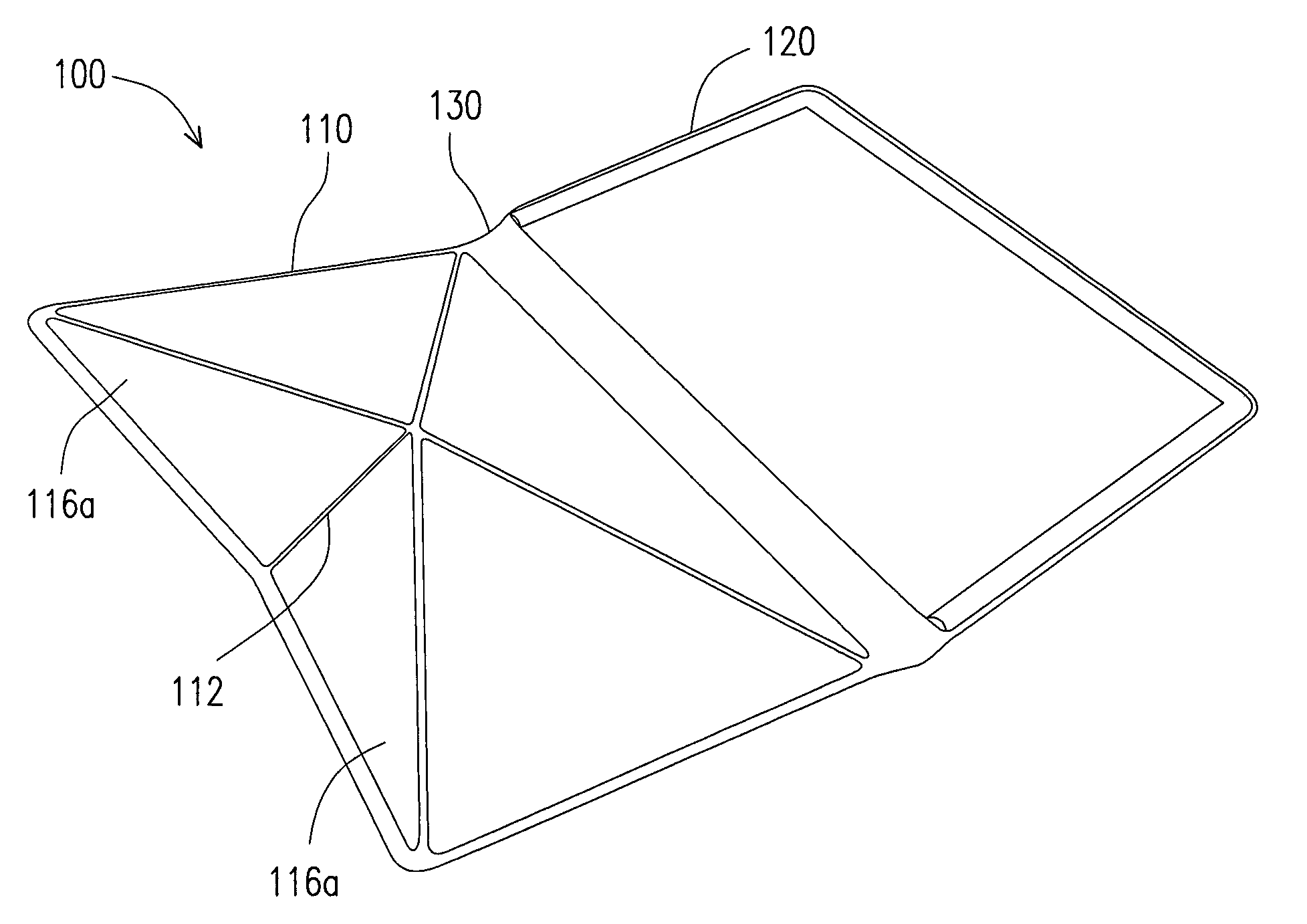

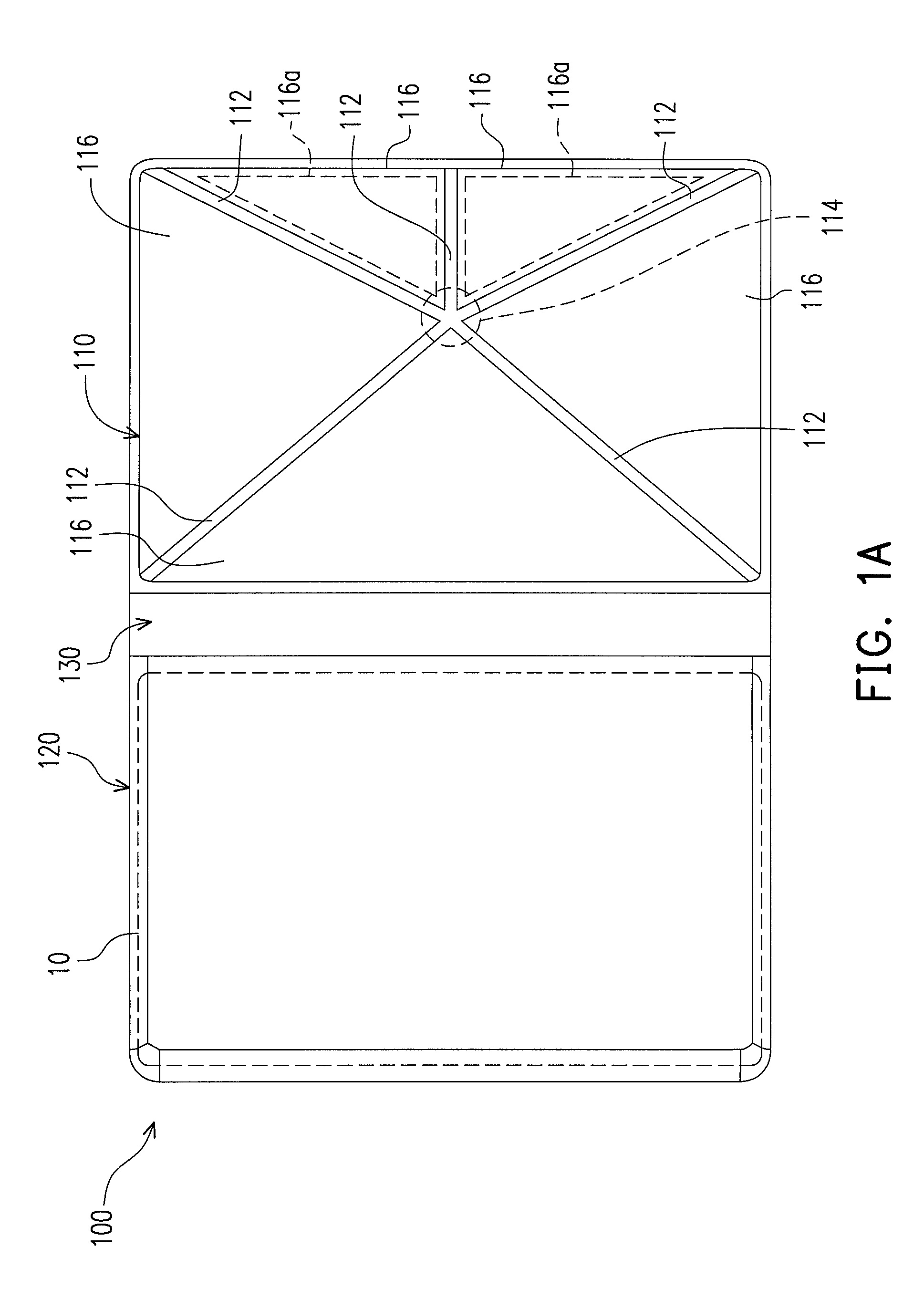

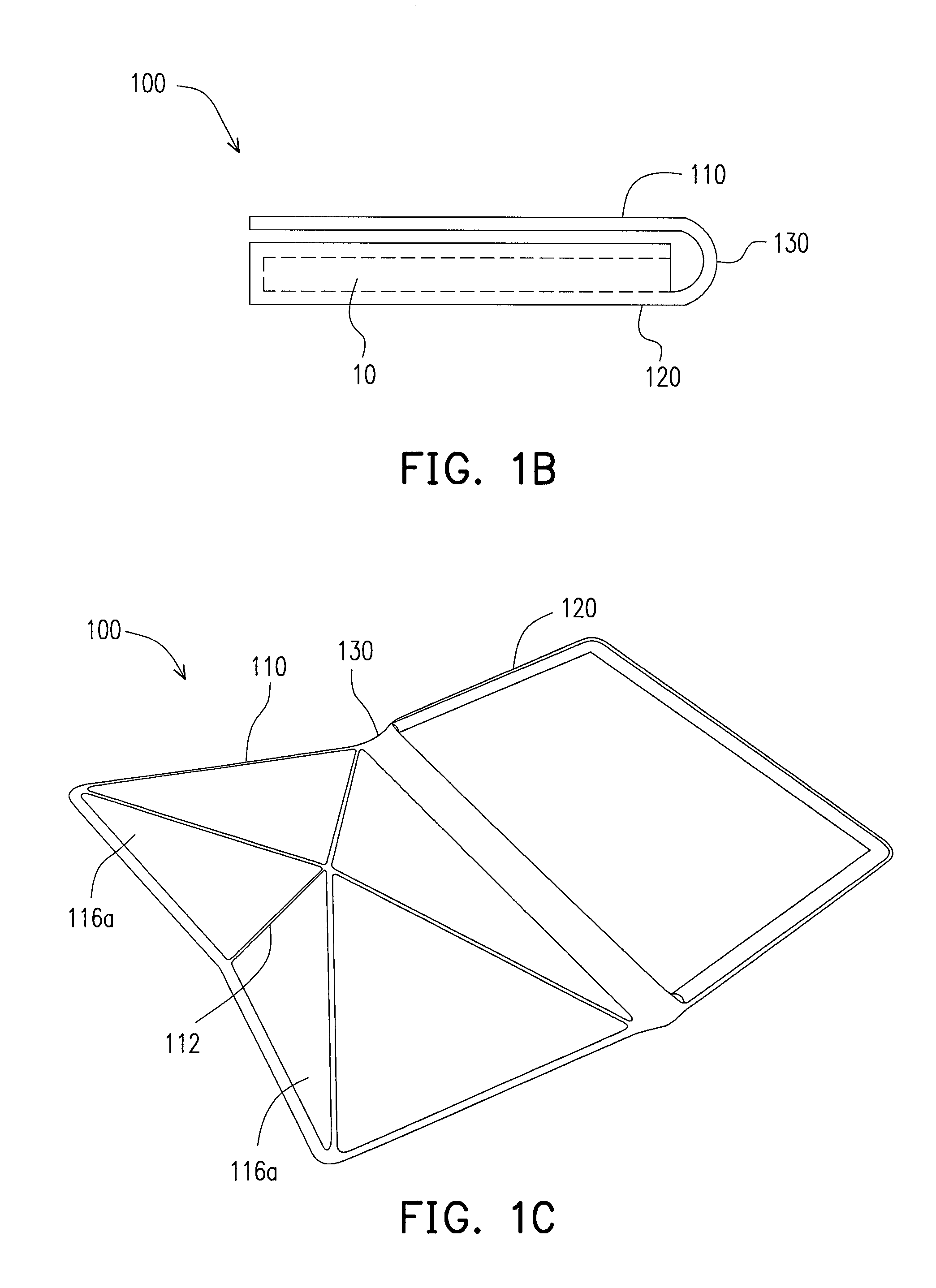

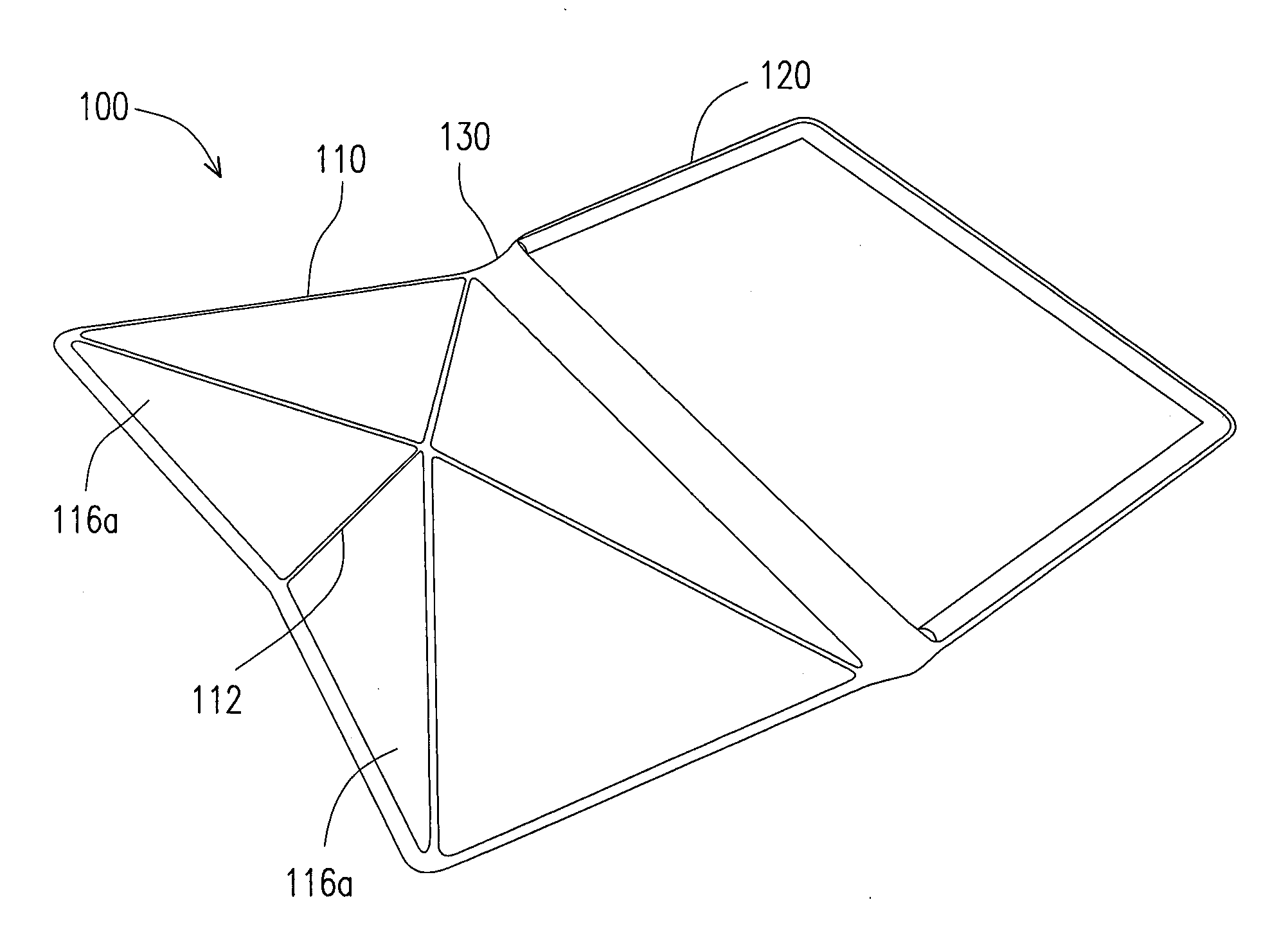

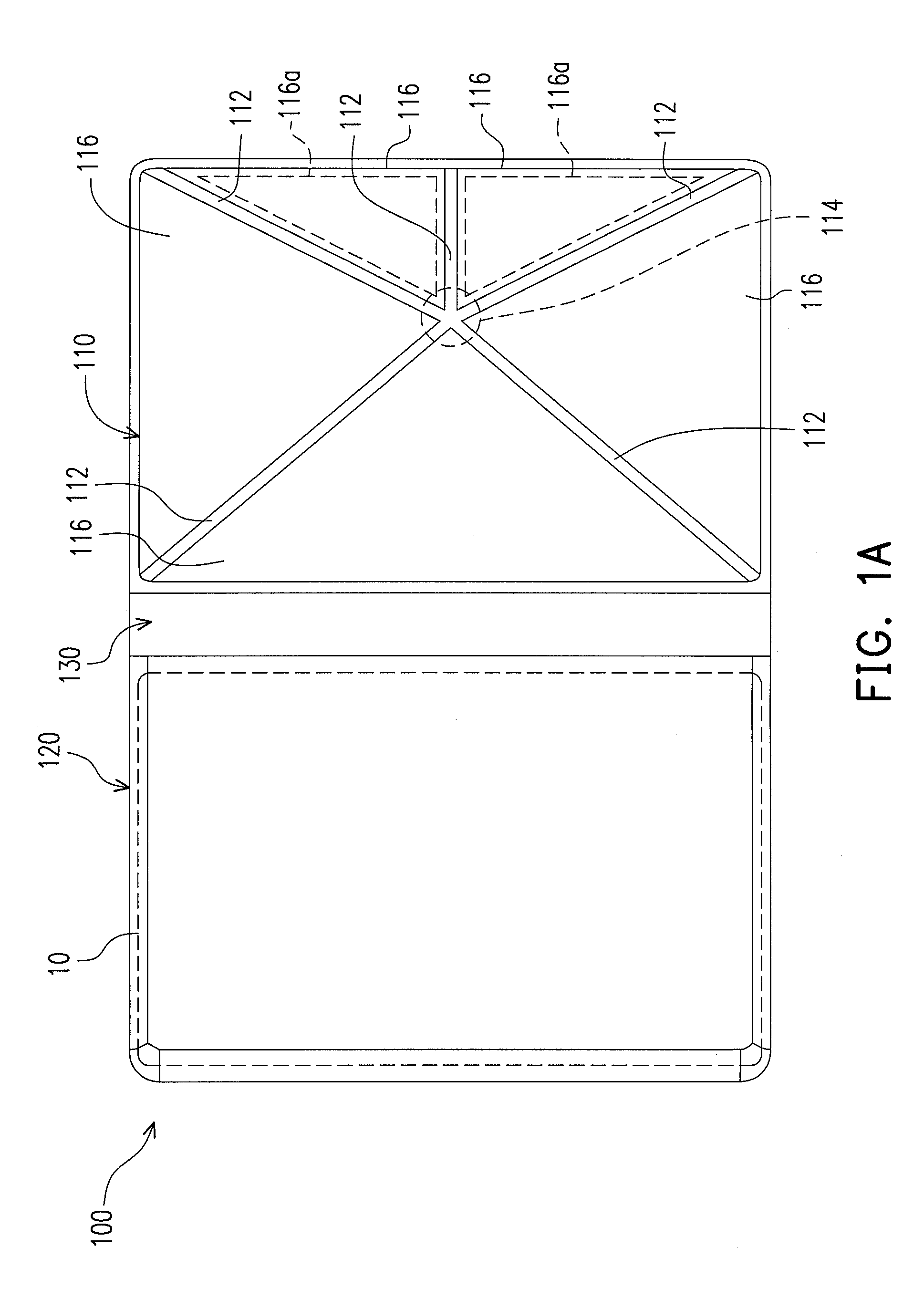

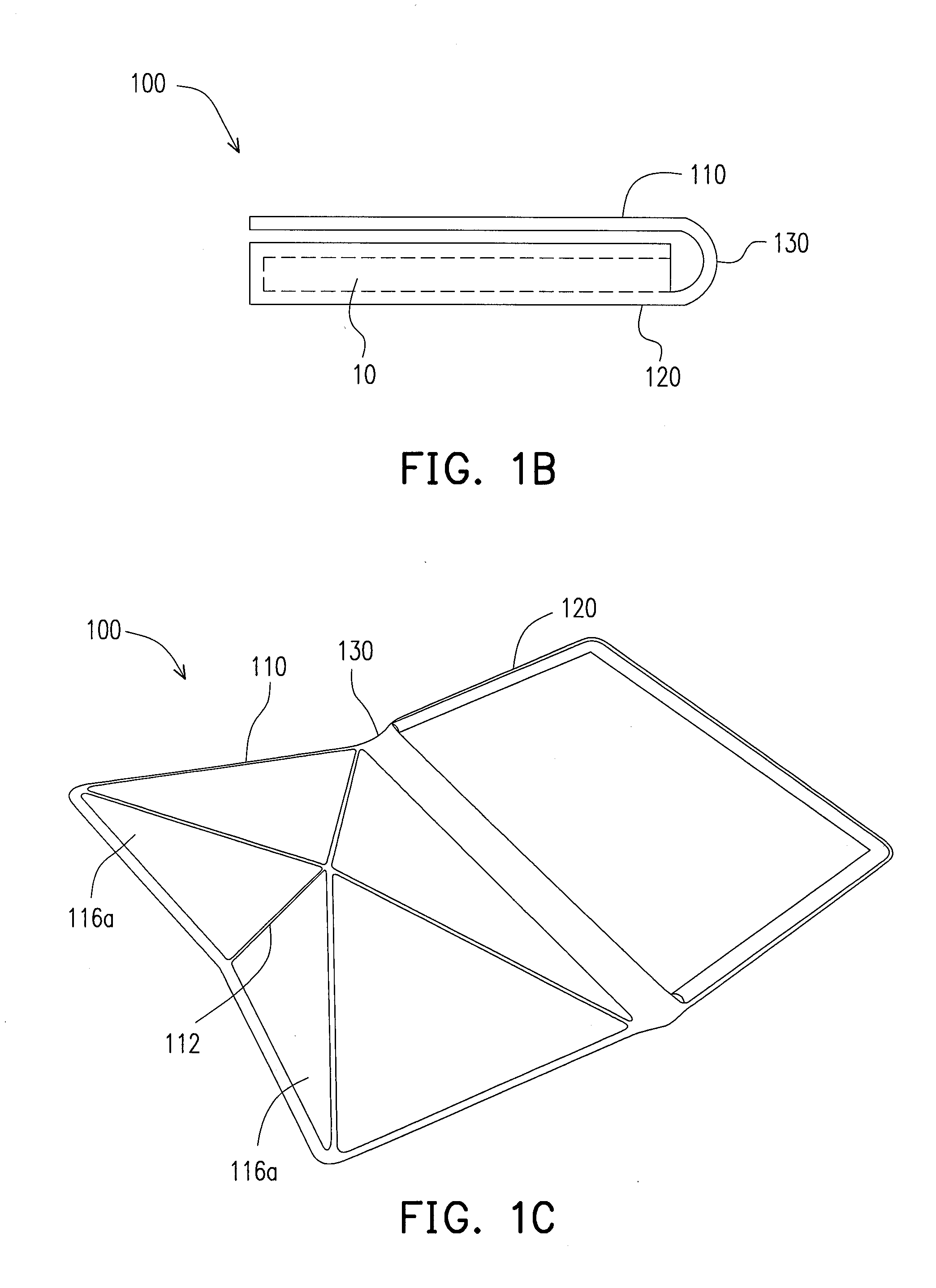

Foldable cover

InactiveUS8640864B2Conveniently turnedPicture framesDigital data processing detailsEngineeringElectrical and Electronics engineering

Owner:ASUSTEK COMPUTER INC

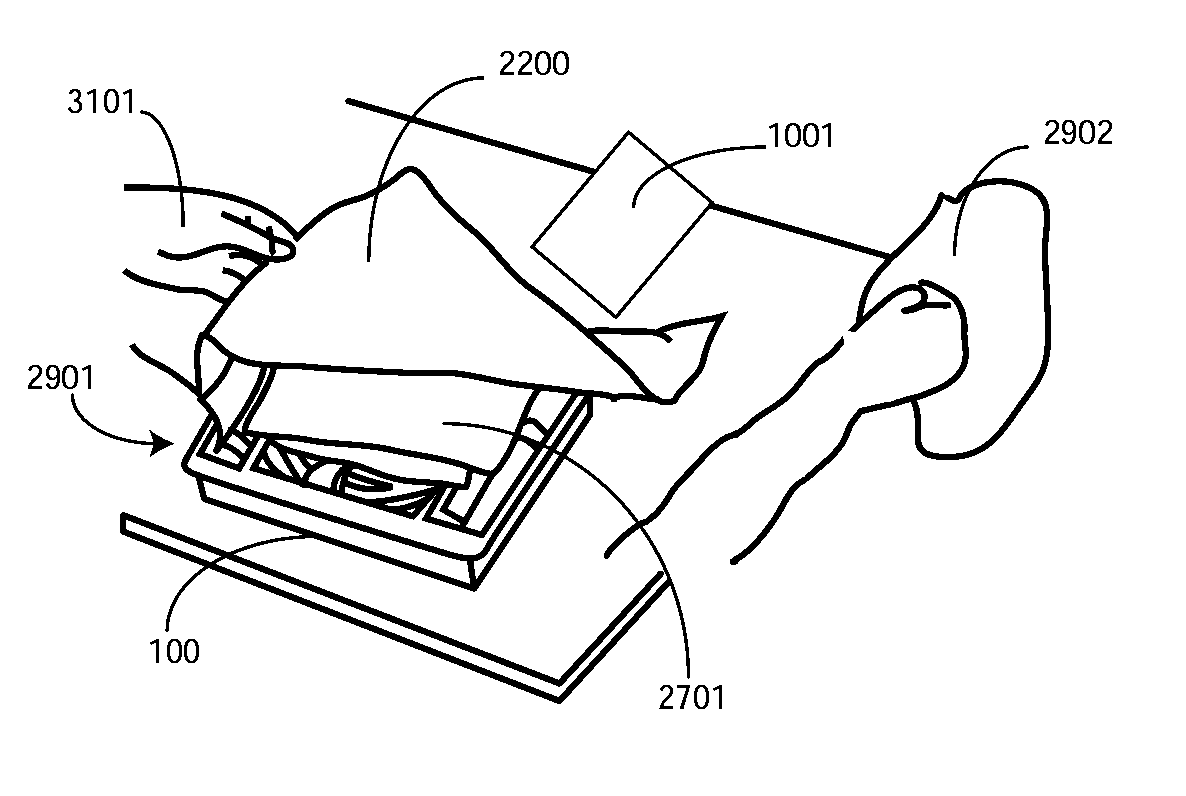

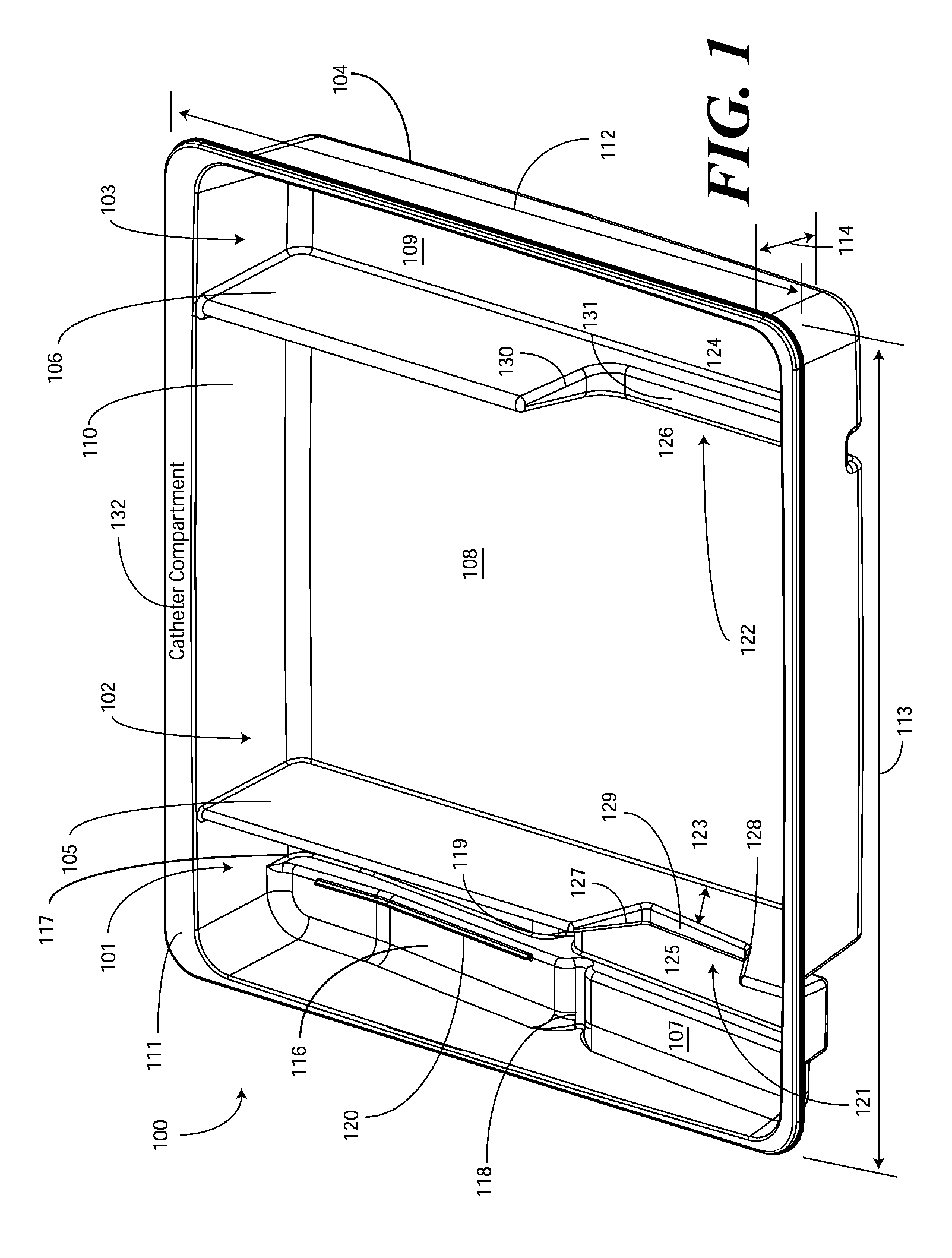

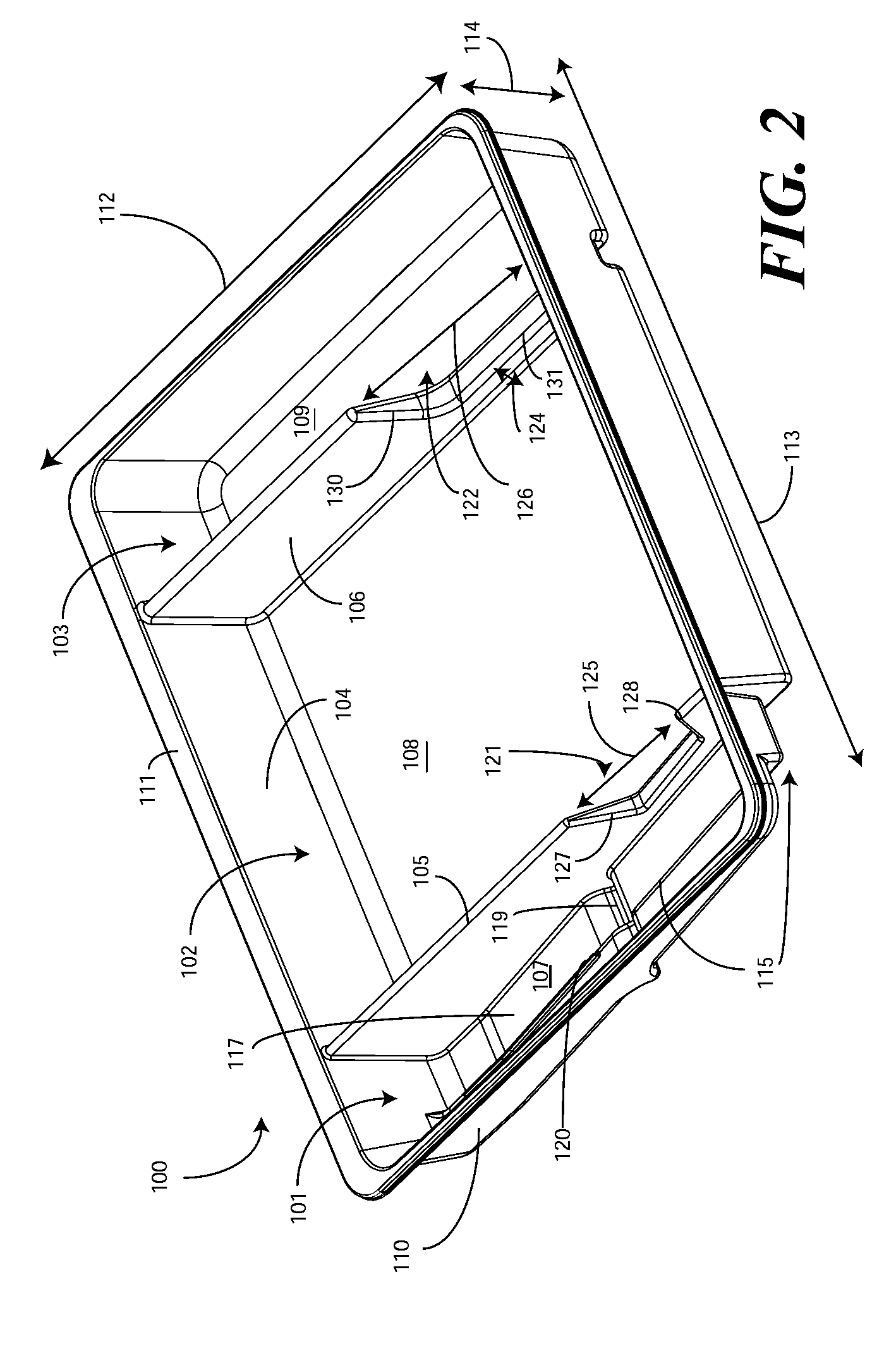

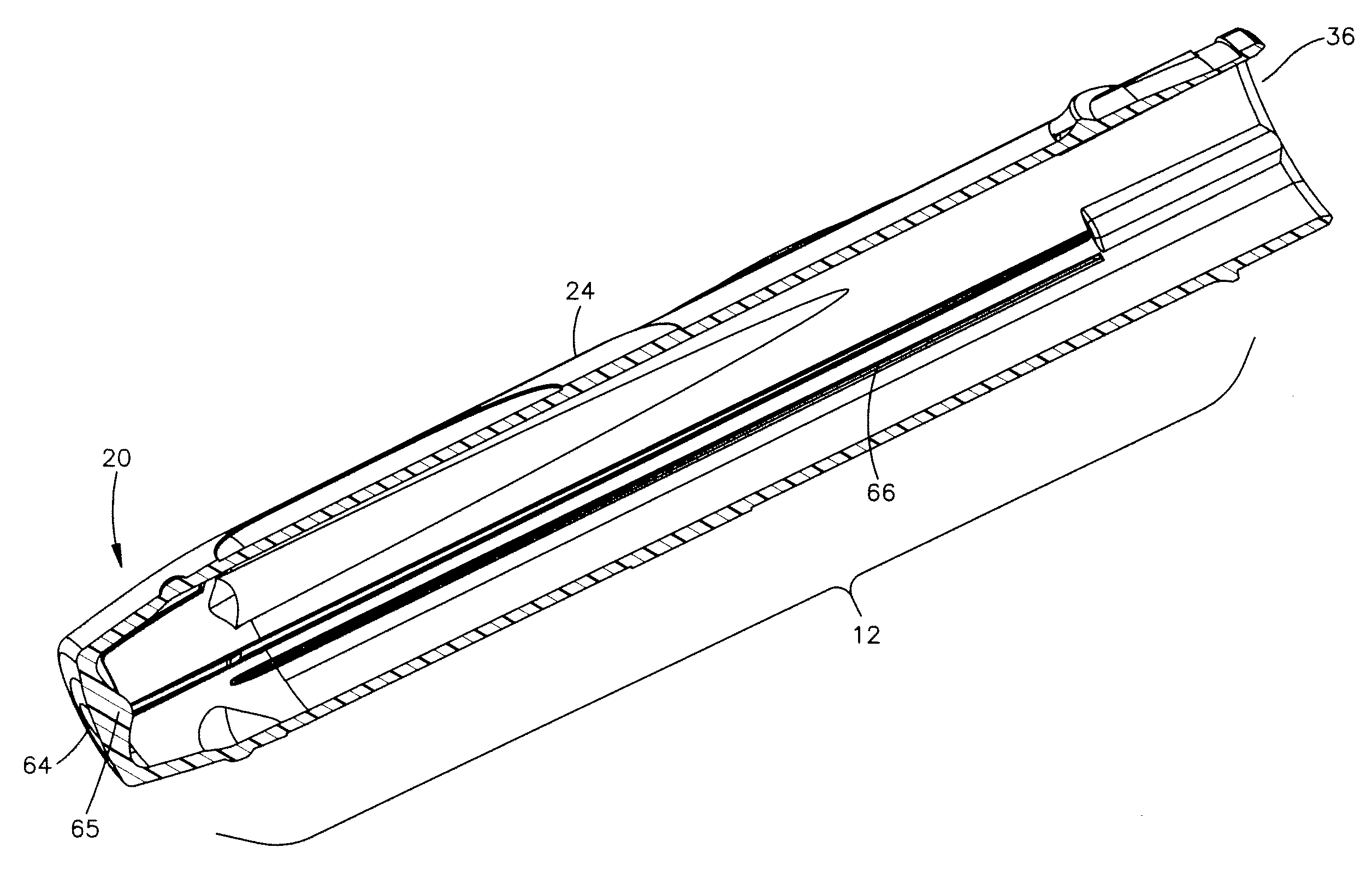

Catheter tray, packaging system, instruction insert, and associated methods

A tray (100) for accommodating a coiled medical device, such as a catheter assembly (700), includes a first compartment (101), a second compartment (102), and a third compartment (103). The catheter assembly (700) and devices associated with a catheterization procedure, such as syringes (701,702) containing sterile water and lubricating jelly and a specimen container (703) can be disposed within the tray. Printed instructions (1001) can be included with the tray (100). One or more layers of wrap material (2200) can be folded about the tray (100) to enclose the tray (100) and other items, such as an additional layer of wrap material (2701), packaged liquid hand sanitizer (2401), and packaged gloves (2402). When a health care services provider (3101) unfolds the wrap material, the same can be used to create a sterile field beneath a patient (3201).

Owner:MEDLINE IND LP

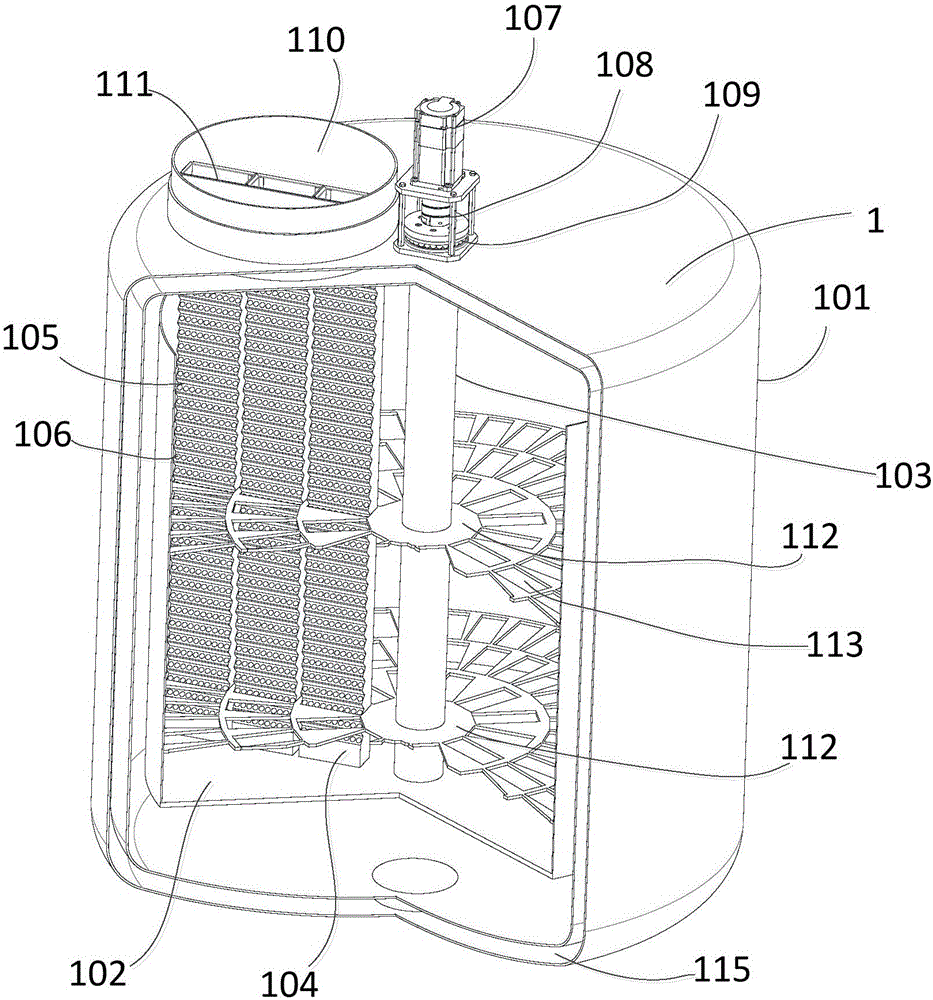

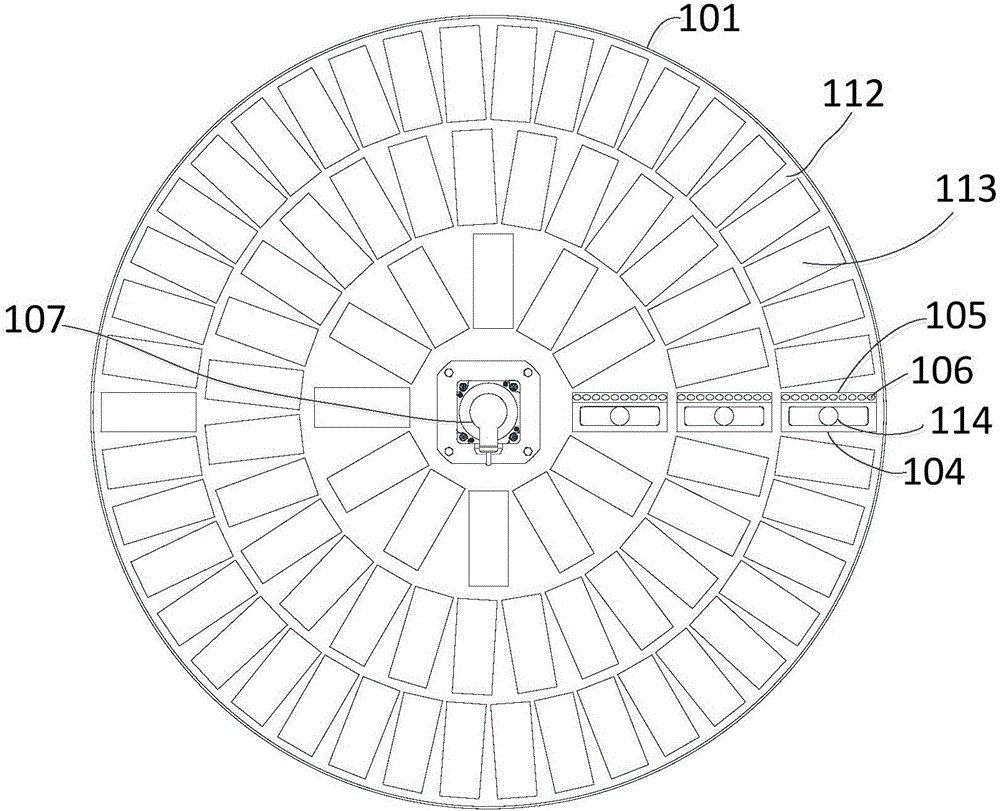

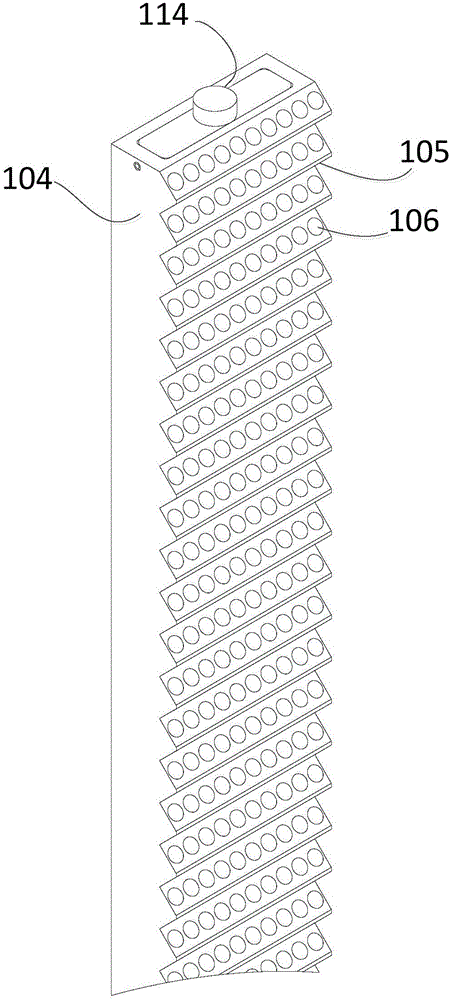

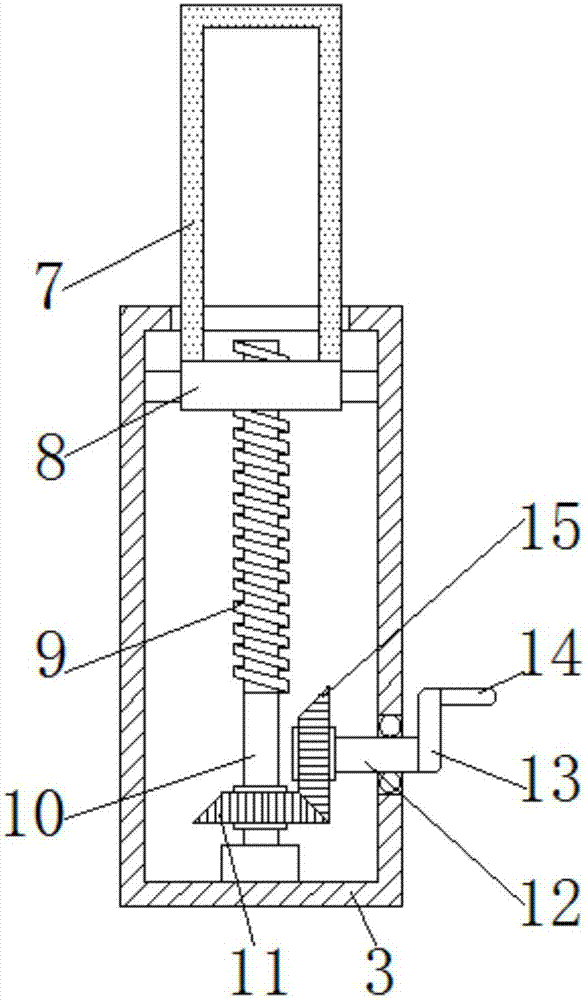

Liquid nitrogen container and cryogenic vial pick-and-place device

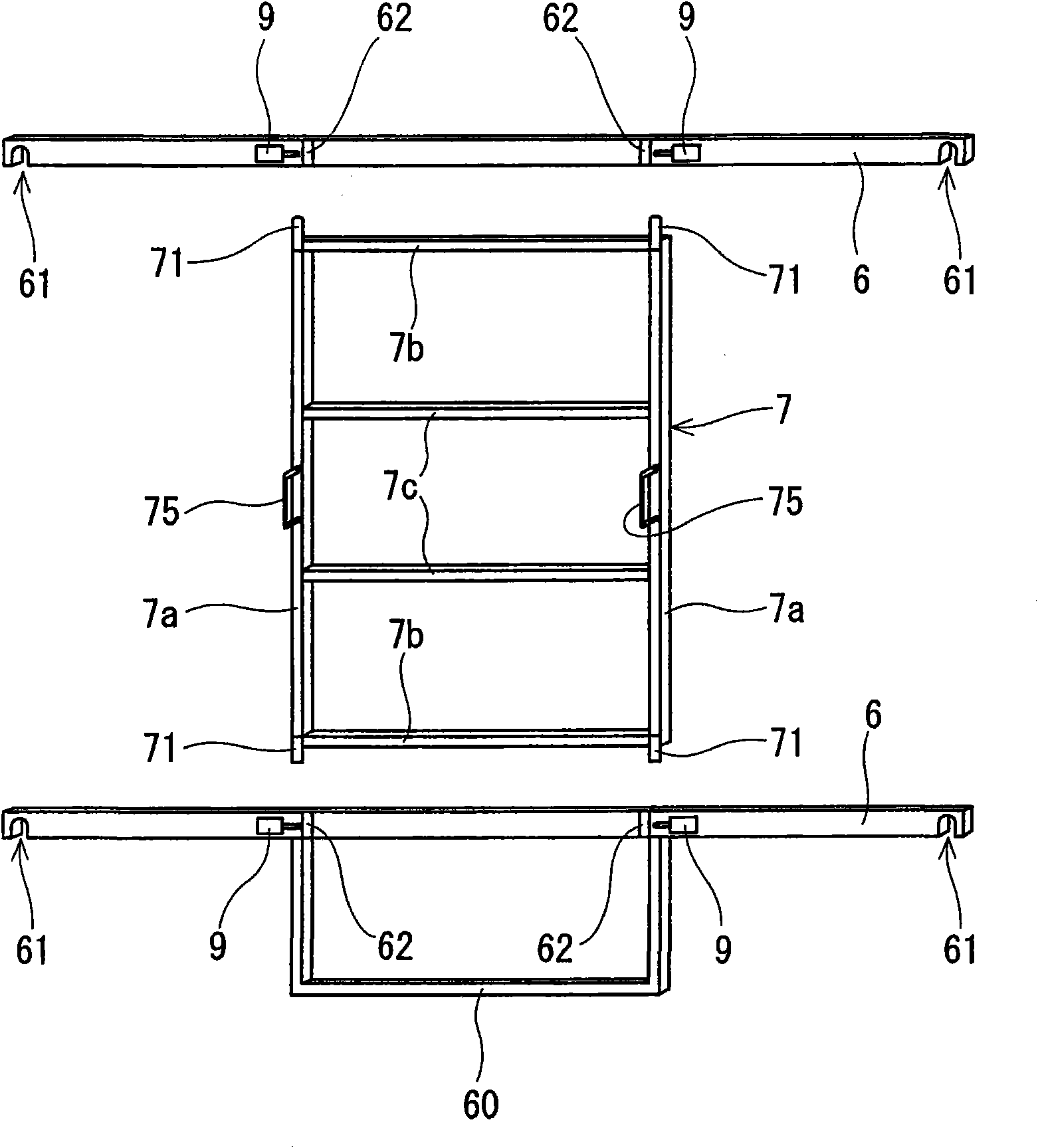

ActiveCN105857932AEasy to pick outGuaranteed biological performanceExternal framesShock-sensitive articlesLiquid nitrogen containerElectricity

The invention discloses a liquid nitrogen container and a cryogenic vial pick-and-place device. The liquid nitrogen container comprises a container body, and further comprises a rotary disc, a cryopreservation frame, a central shaft and a driving assembly, wherein an opening is formed in the container body; the rotary disc is arranged in the container body; the cryopreservation frame is supported by the rotary disc and comprises a plurality of layers of placement faces; the included angle between each placement face layer and the rotary disc is 40-60 degrees; the central shaft is perpendicularly arranged with and fixedly connected with the rotary disc; the driving assembly is electrically connected with the central shaft and used for driving the central shaft to rotate; and the central shaft is used for driving the cryopreservation frame to rotate through the rotary disc to reach the opening of the container body. By adoption of the liquid nitrogen container and the cryogenic vial pick-and-place device, the workload of operating personnel is reduced, the error rate of manual picking of cryogenic vials is lowered, and the potential safety hazard for the operating personnel is avoided. The liquid nitrogen container and the cryogenic vial pick-and-place device are particularly suitable for the work of picking cryogenic vials in a high-capacity biological sample bank, and meet the technical requirement for storage in the high-capacity biological sample bank.

Owner:SHANGHAI ORIGINCELL BIOLOGICAL CRYO EQUIP CO LTD

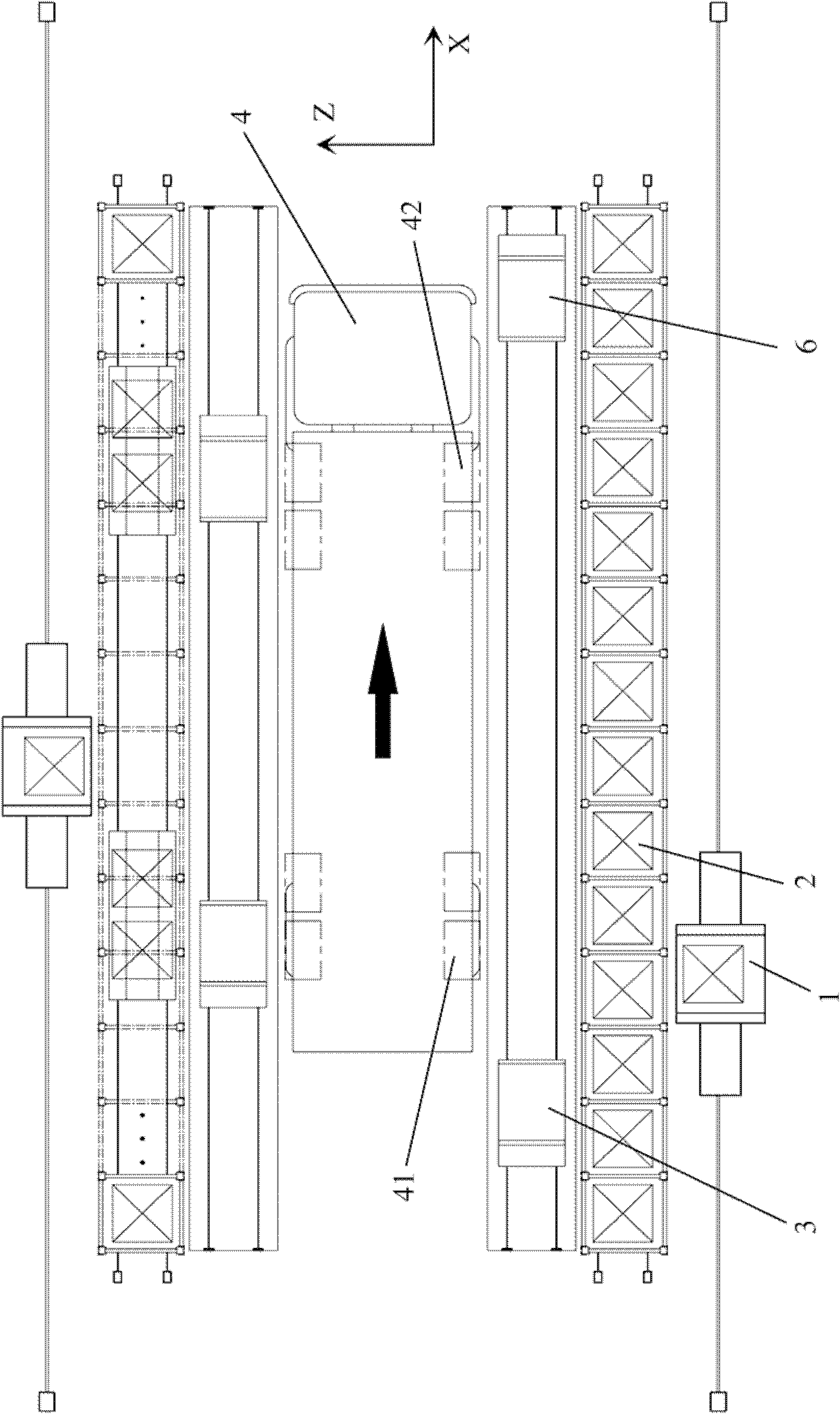

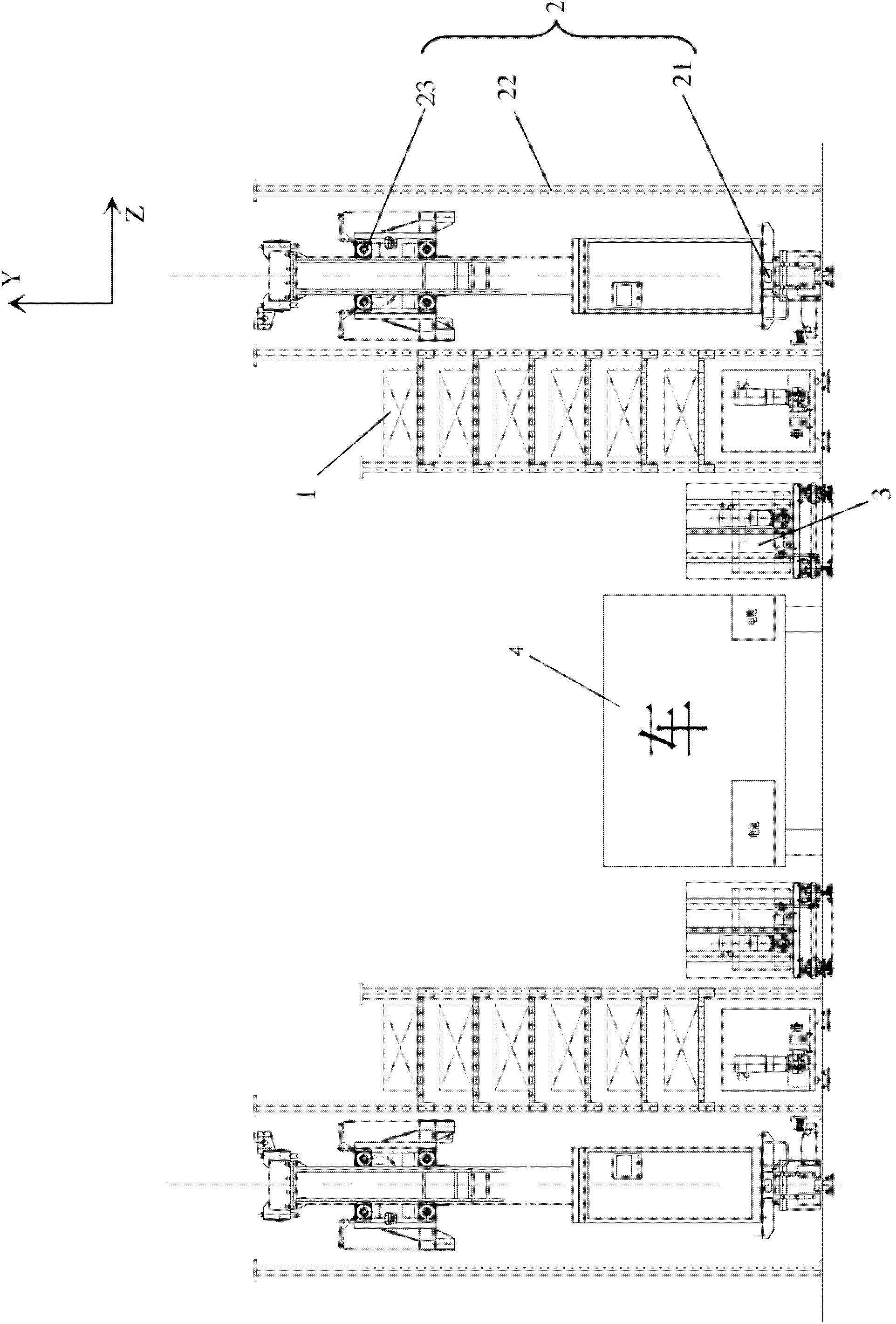

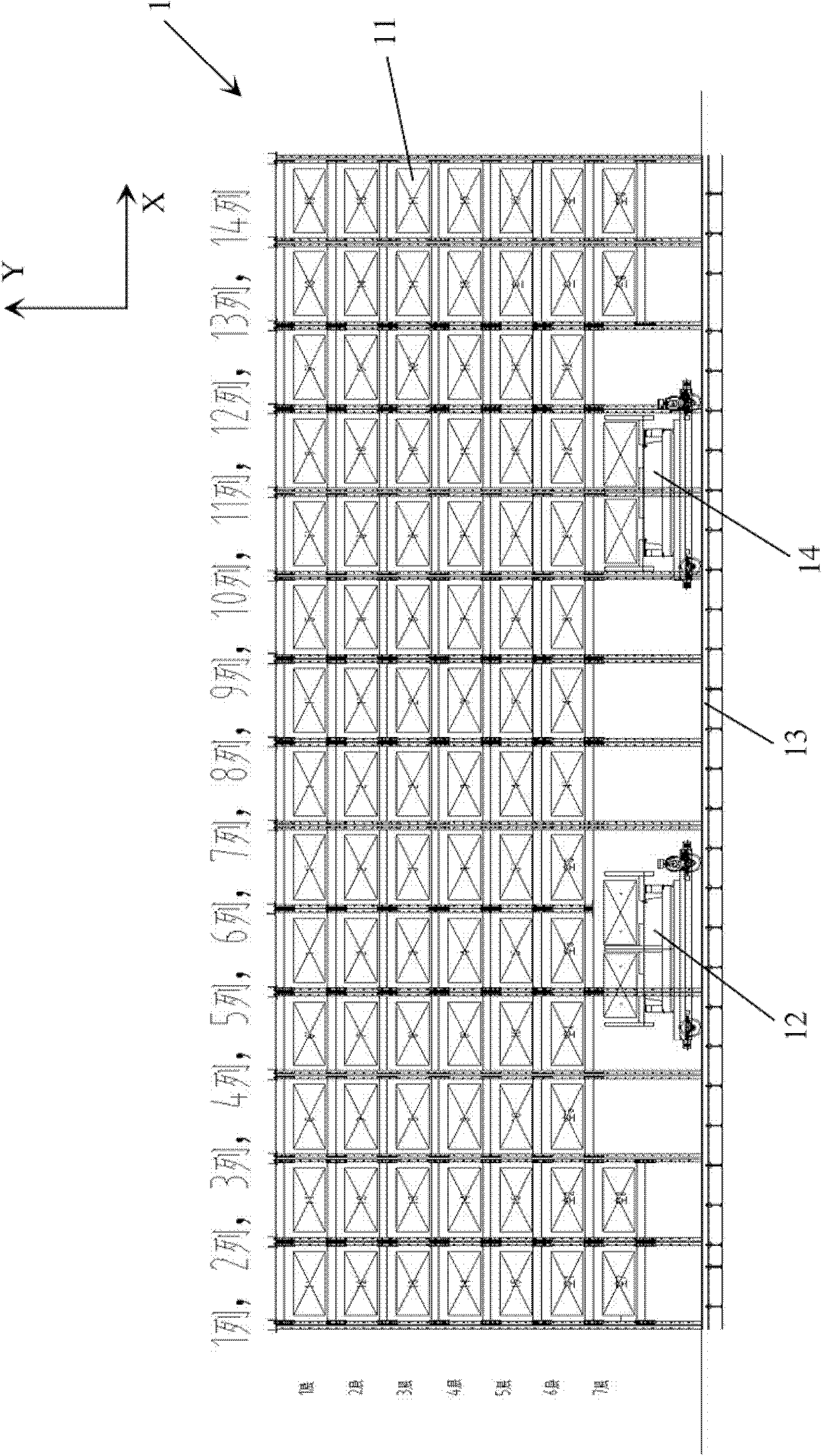

Battery replacing method, battery replacing system and battery rack of electric vehicle

ActiveCN102180143ASingle actionFit closelyElectric propulsion mountingExternal framesElectrical batteryEngineering

The invention discloses a battery replacing method, a battery replacing system and a battery rack of an electric vehicle. In the invention, the battery replacing system comprises the fixed battery rack, a ferry vehicle, a stocker and a manipulator, wherein the ferry vehicle is movably arranged in the battery rack, a battery temporary storing place is arranged on the ferry vehicle, and the stockeris movably arranged at one side of the batter rack and the manipulator is movably arranged at the other side of the battery rack. The replacing method comprises the steps of: taking out a charged battery, moving to the ferry vehicle and putting the charged battery on the ferry vehicle by utilizing the stocker; taking out an uncharged battery on the electric vehicle and putting on the ferry vehicle by utilizing the manipulator; shifting the charged battery and the uncharged battery which are loaded on the ferry vehicle, for one station, aligning to the manipulator and placing the charged battery on the ferry vehicle on the electric vehicle by utilizing the manipulator so as to complete a replacing motion. In addition, a universal ball capable of autorotation and guide rolls arranged shapedlike a horn are arranged in a unit grid on the battery rack so that the battery can be more conveniently and rapidly guided to be put in the battery rack.

Owner:亿源动力(北京)科技有限公司

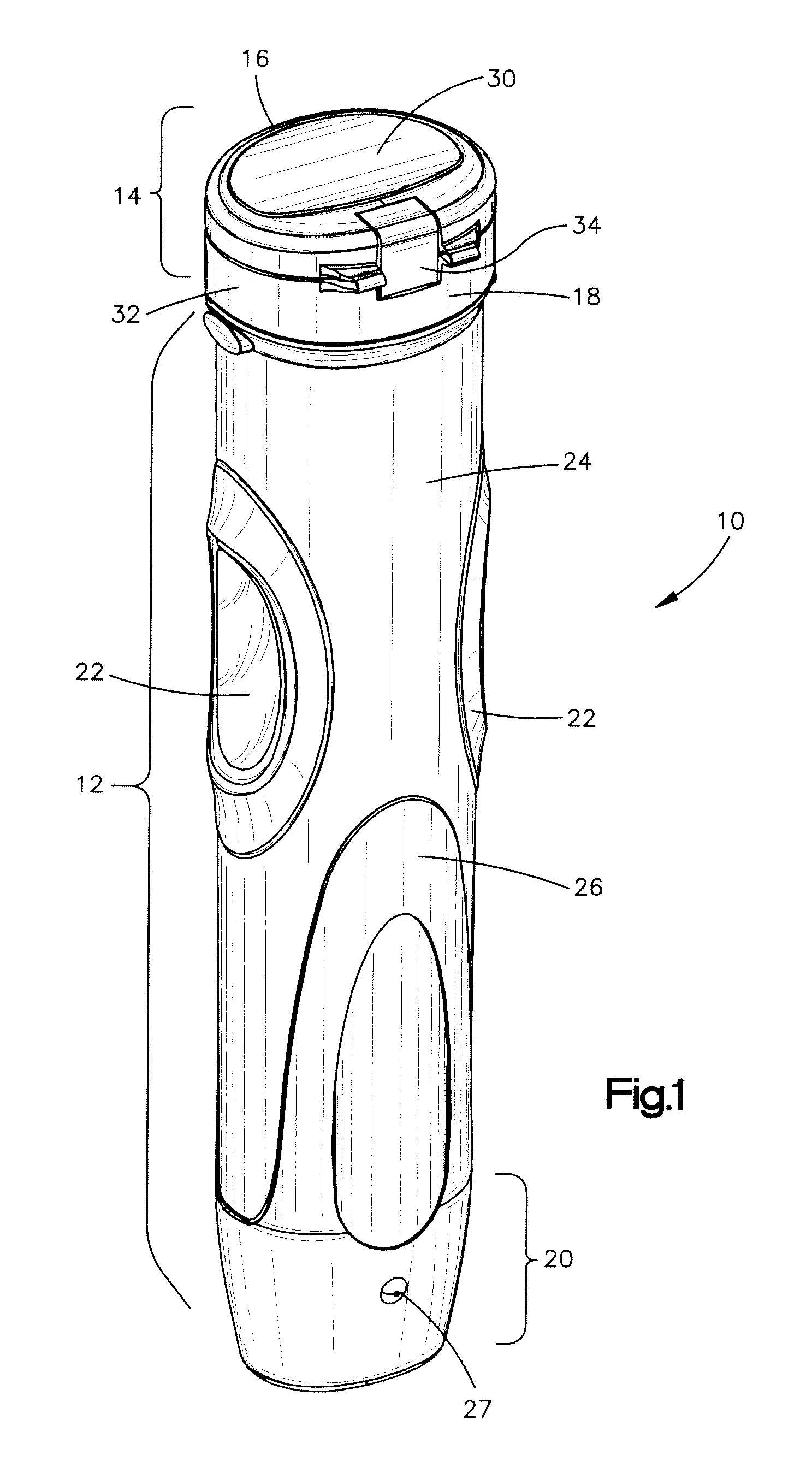

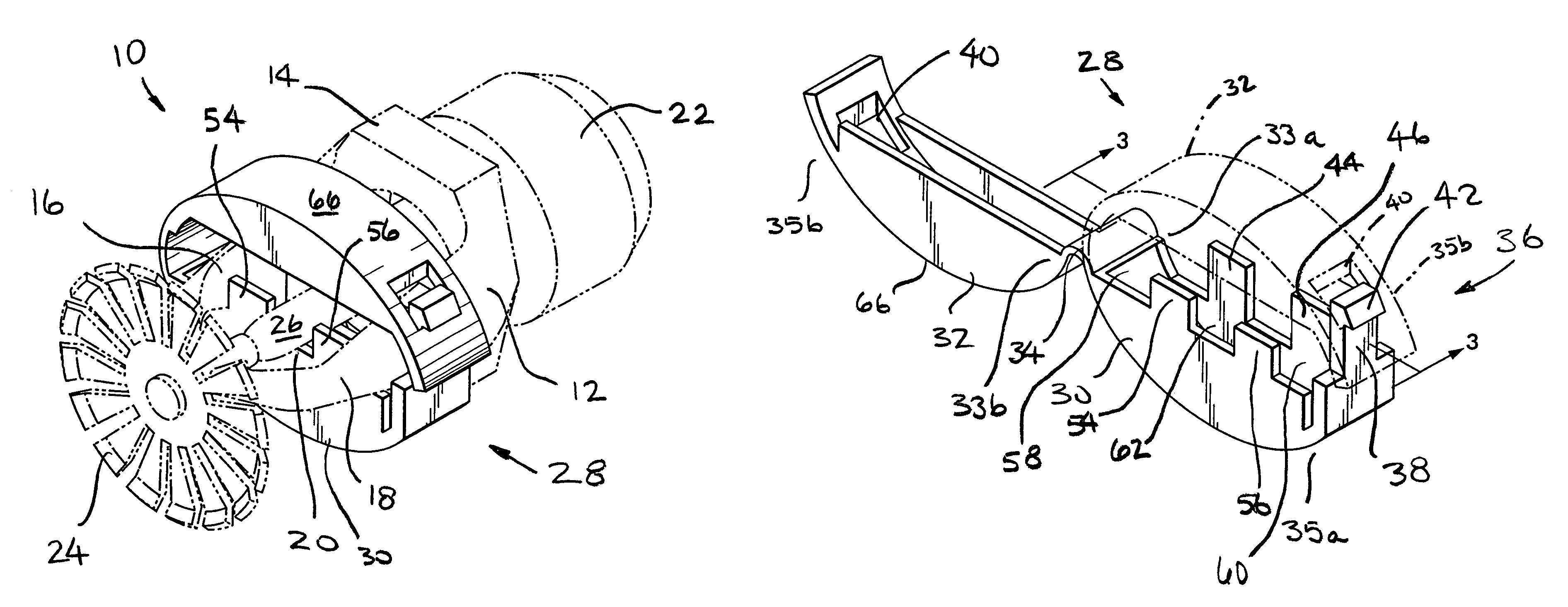

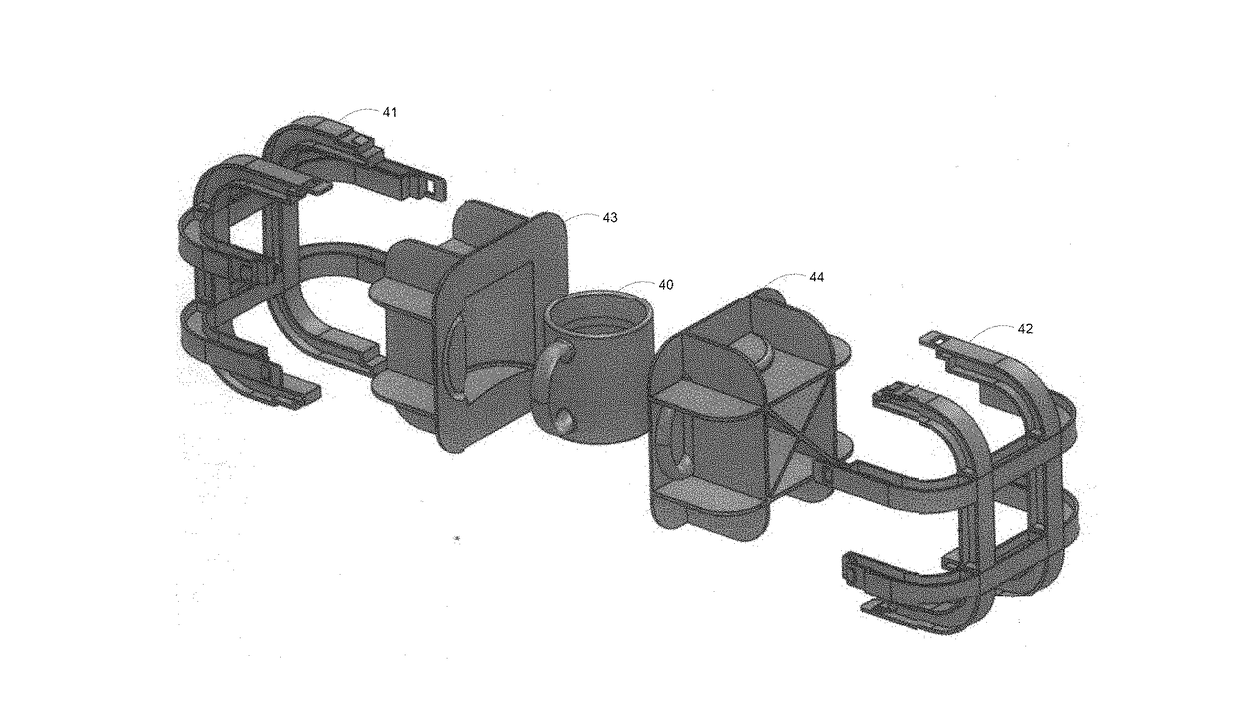

Container for an automatic injector

InactiveUS20080289984A1Open fastSafe storageDispensing apparatusContainer filling methodsSyringe needleSafe storage

A container for an automatic injector provides safe, quick, and easy access to an automatic injector stored therein. The container includes tactile features that allow a user to easily determine the orientation of the container by feel alone. A hinged cap with an automatic spring assist feature allows a user to single-handedly open the container quickly and easily to remove the injector from the container without interference from the cap. The container is structured to receive the automatic injector needle end first and has a puncture resistant bottom to prevent the needle of the injector from piercing through the body wall of the container. The container also provides safe storage of a discharged automatic injector, with the hinged cap spring assist feature automatically closing the cap enough to prevent the discharged injector from falling out of the container.

Owner:MERIDIAN MEDICAL TECH

Foldable cover

InactiveUS20130043148A1Conveniently turnedDigital data processing detailsOther accessoriesStructural engineeringMechanical engineering

Owner:ASUSTEK COMPUTER INC

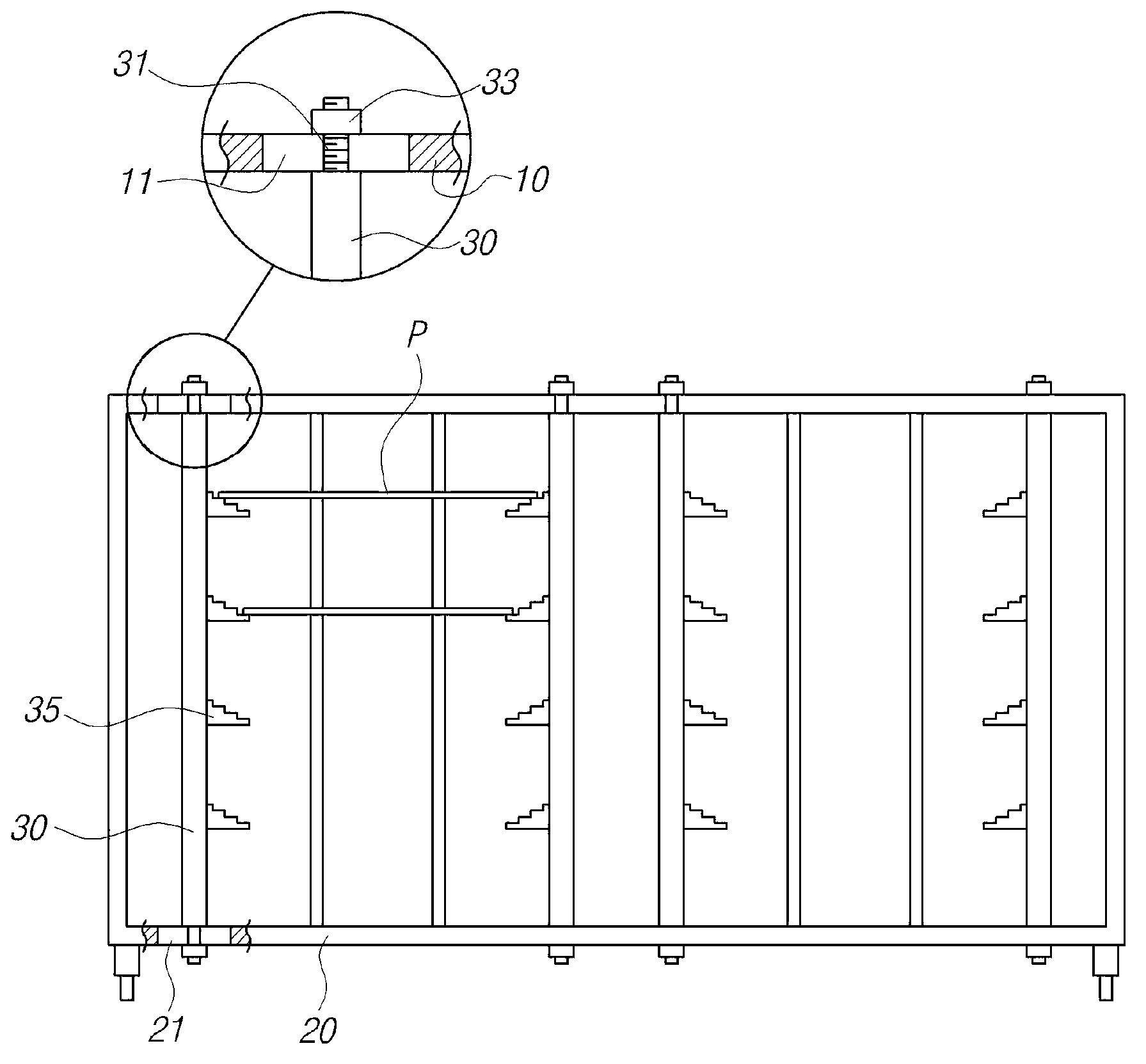

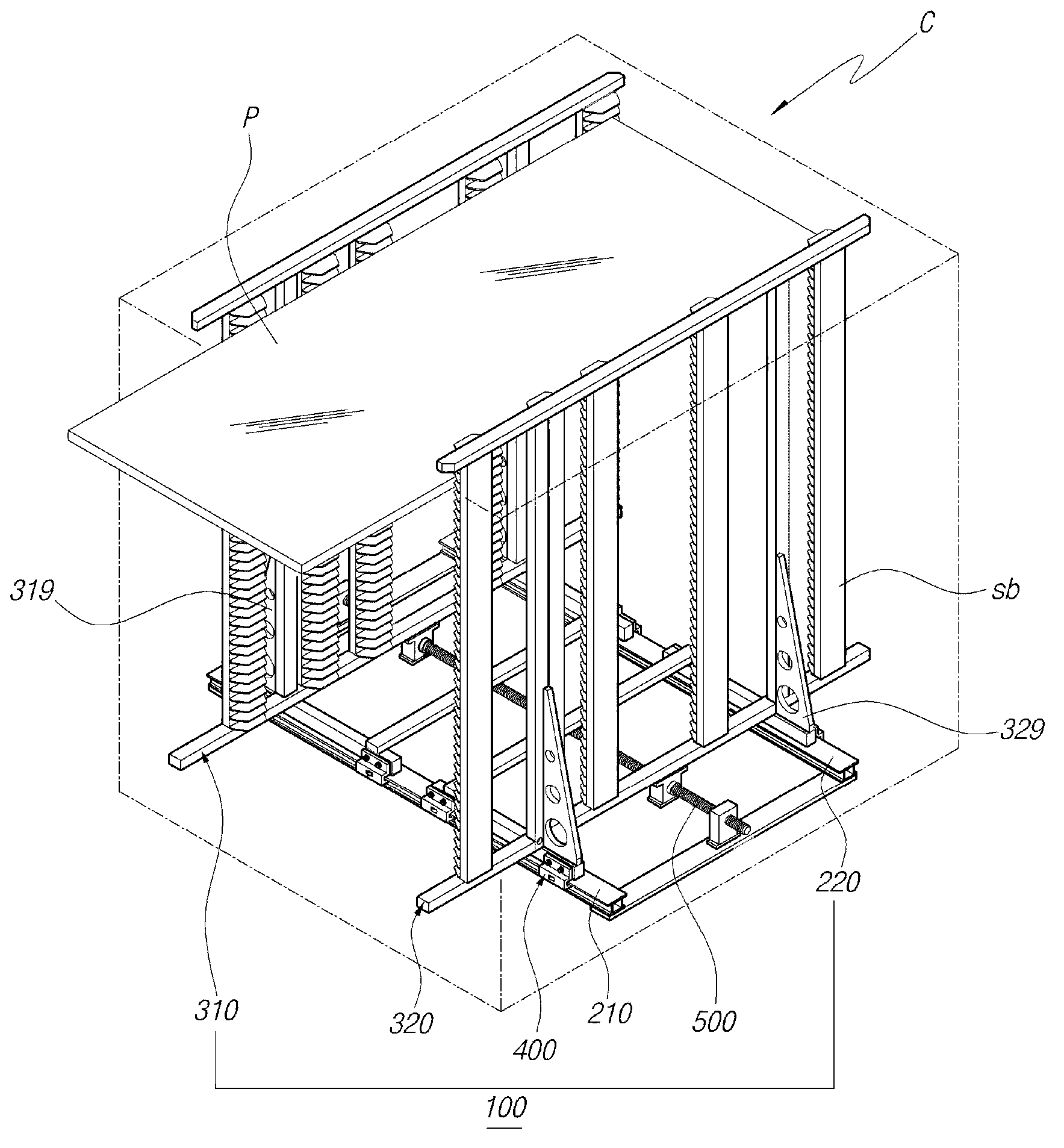

Glass substrate loading cassette for adjusting interval between slot bars

ActiveCN103183182ALarge size spanLarge adjustment rangeSemiconductor/solid-state device manufacturingExternal framesEngineeringMechanical engineering

Owner:SANG A FRONTEC

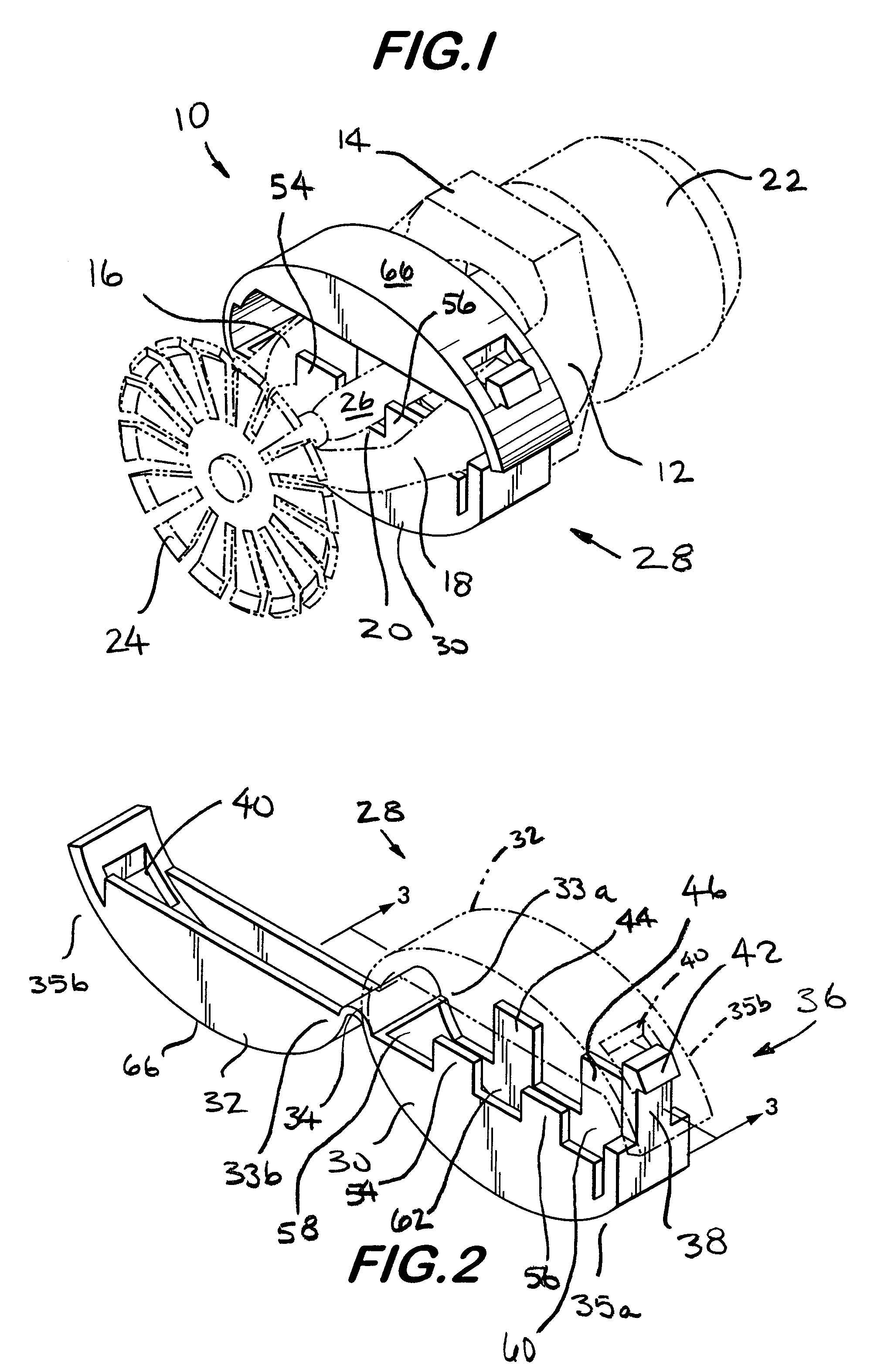

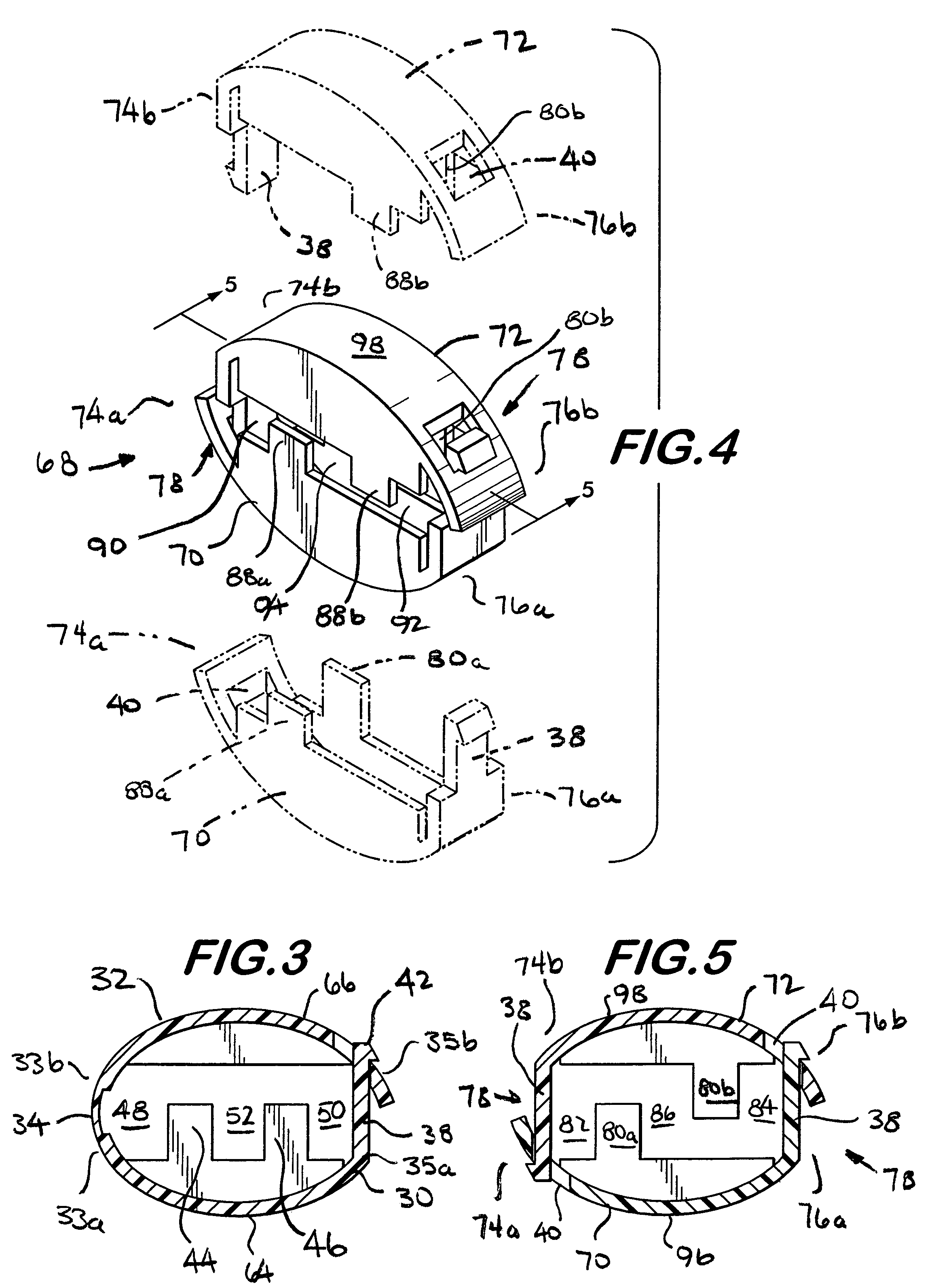

Protective cover for frangible bulb

A cover mountable on a support frame for protecting a frangible item mounted within the frame is disclosed. The cover has first and second cover portions engaging the frame on opposite sides of the item. A hinge connects first ends of the covers together and a releasable fastener connects the other ends. Fingers extend from one or both of the cover portions toward the opposite cover portion and are positioned in spaced relation to the ends of the cover portions. The fingers and the ends of the cover portions define spaces at opposite ends of the cover which receive and engage portions of the support frame. The fingers are in spaced relation to one another and define a space between them for receiving the frangible item. The fingers are sized and spaced so that they transfer any force on the cover to the frame exclusively. The covers have an arcuate shape to provide increased stiffness.

Owner:VICTAULIC

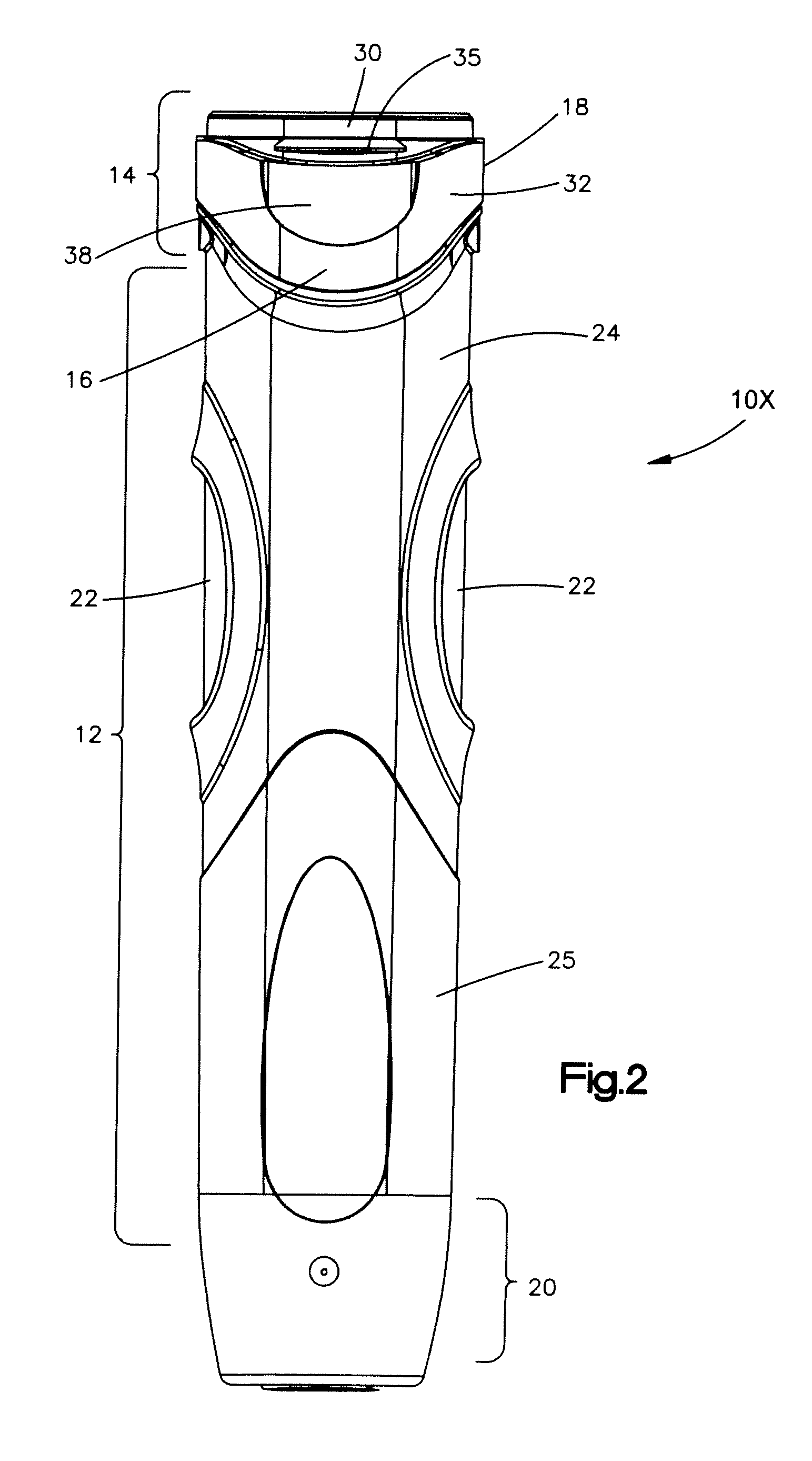

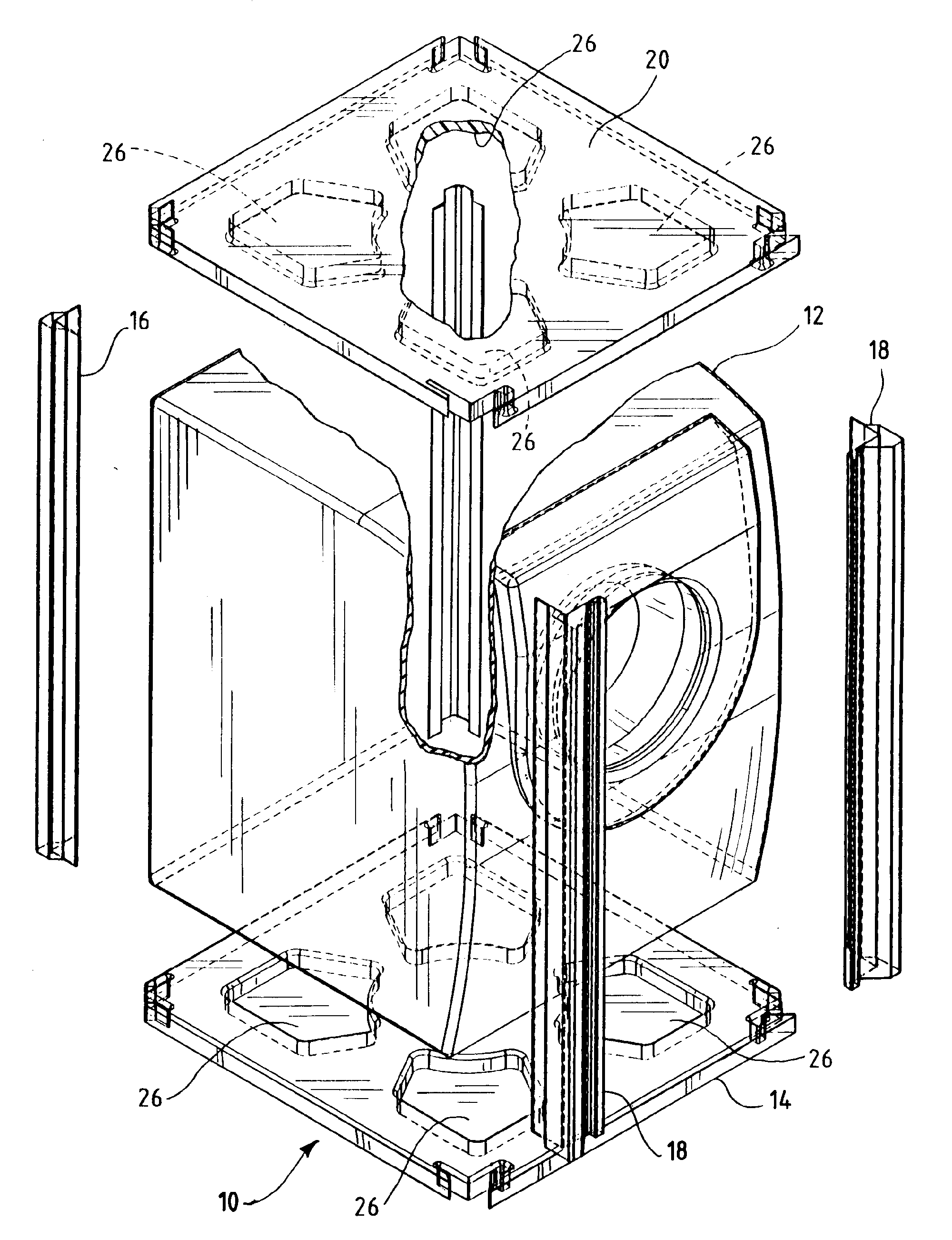

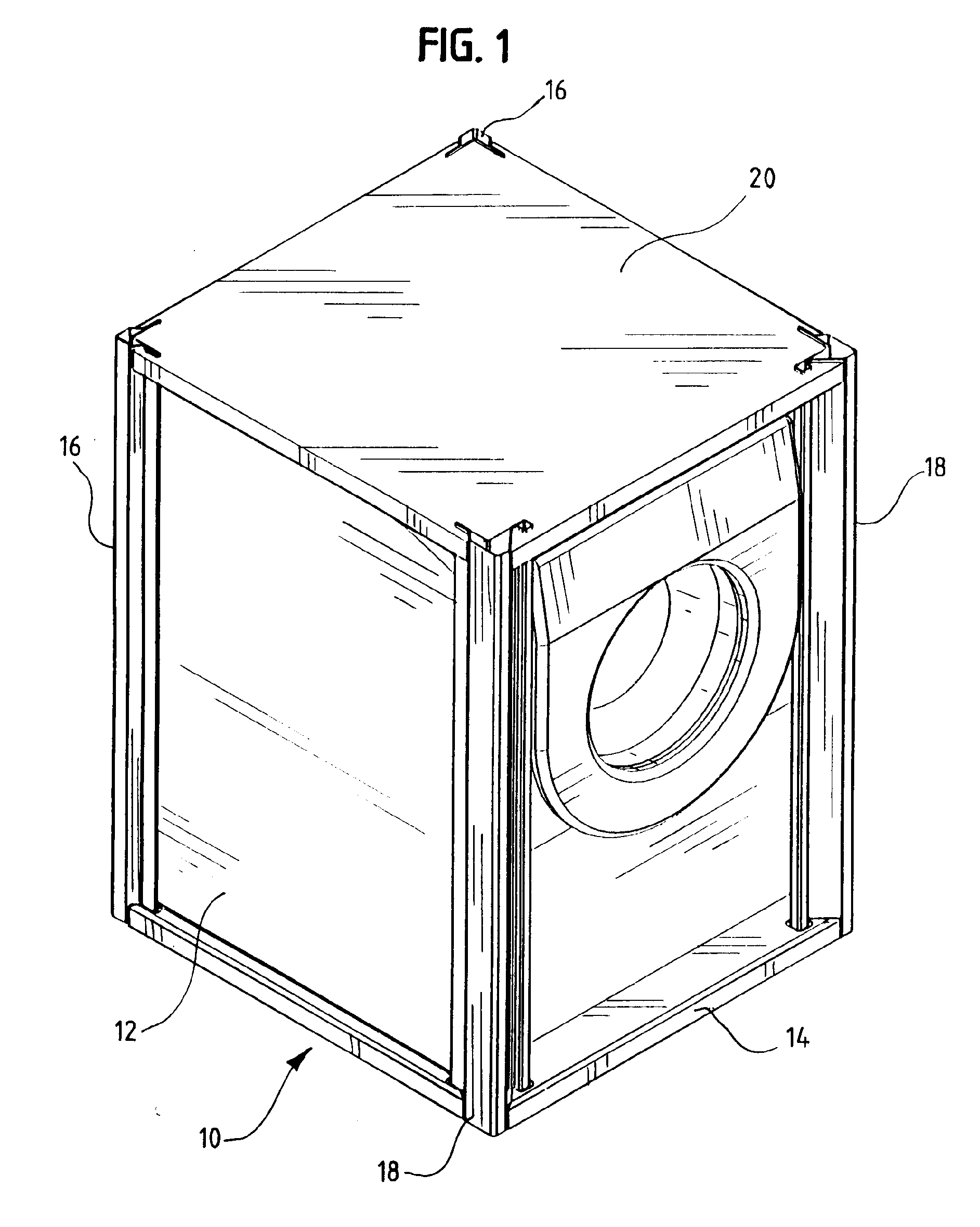

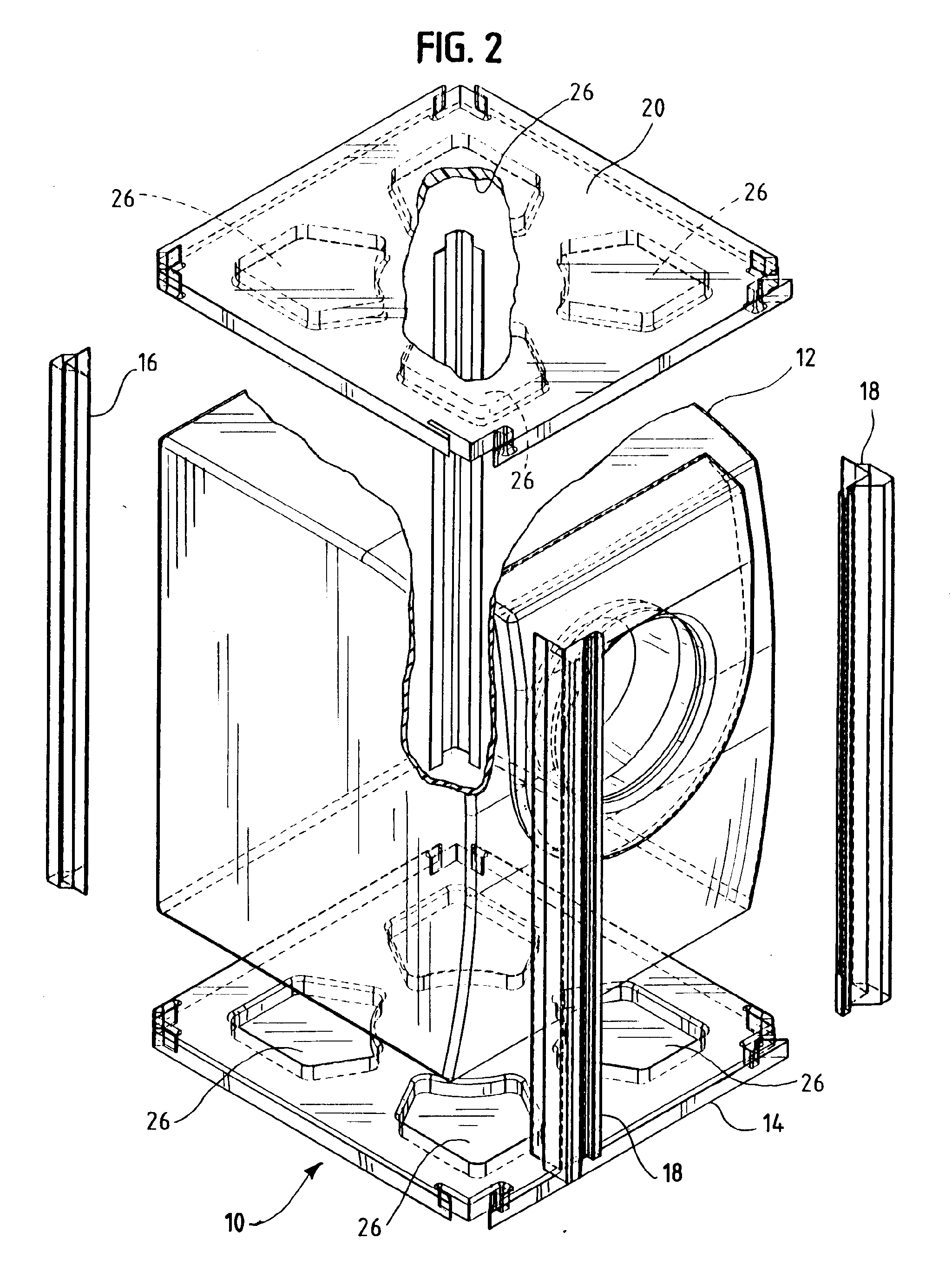

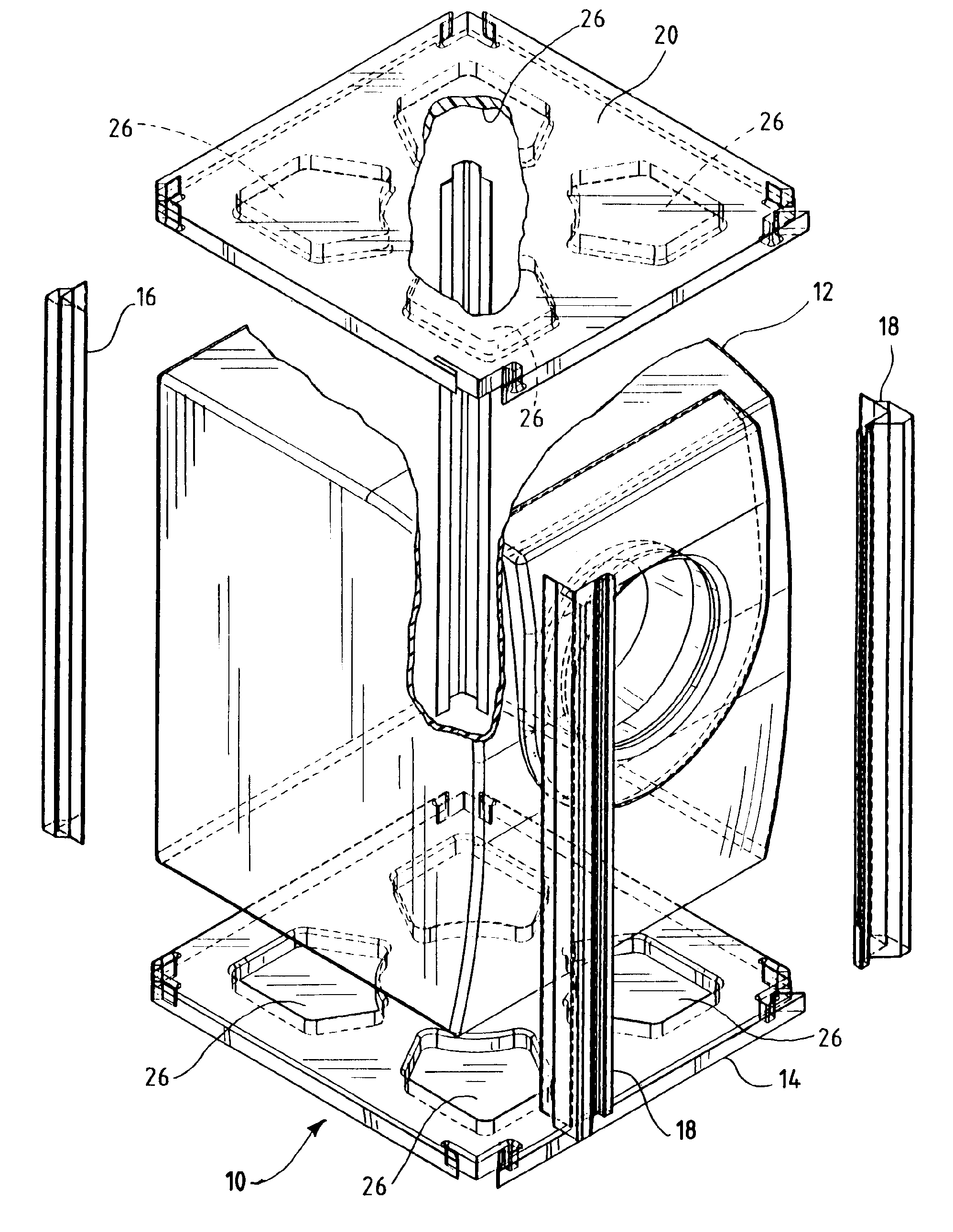

Support post with locking feature

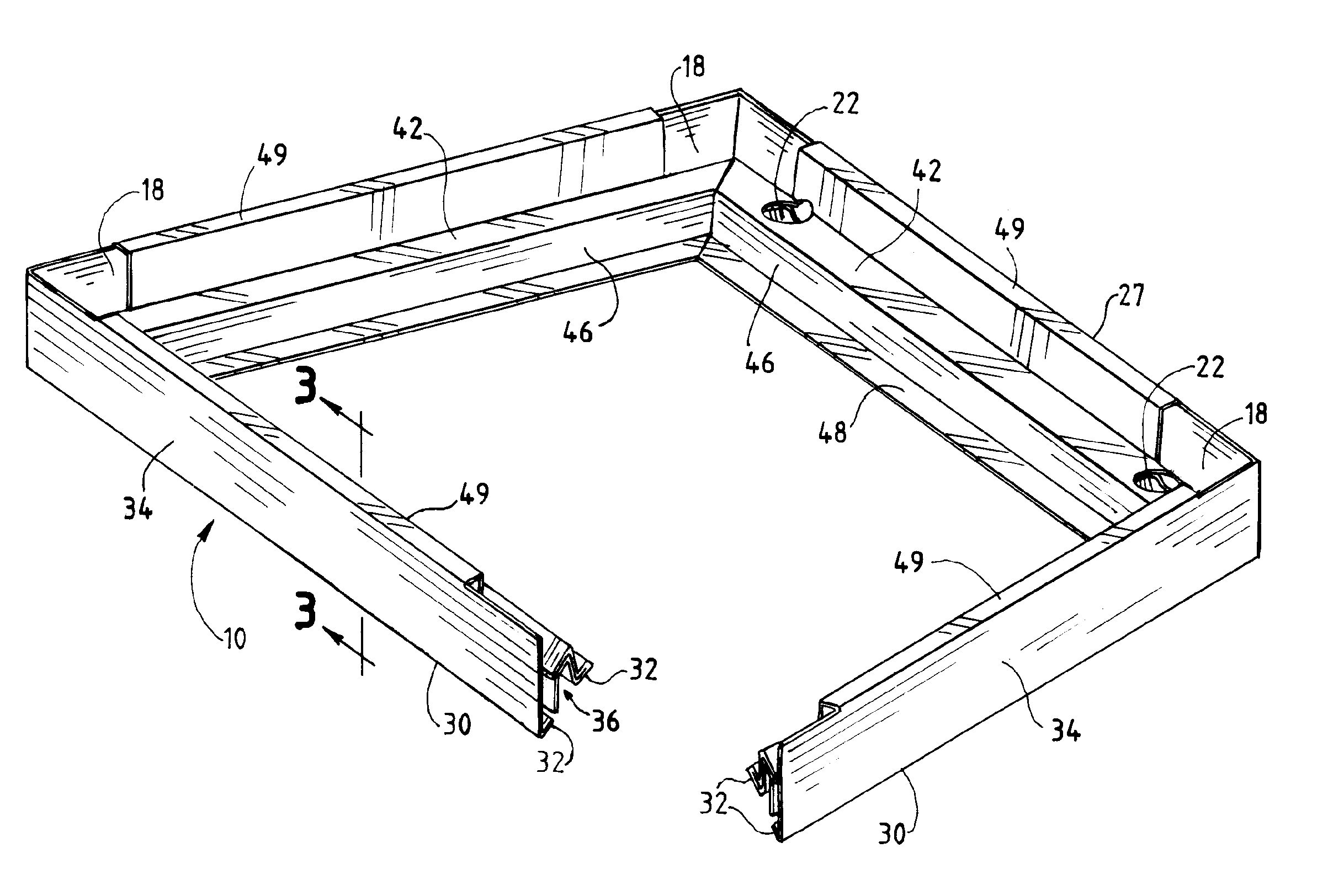

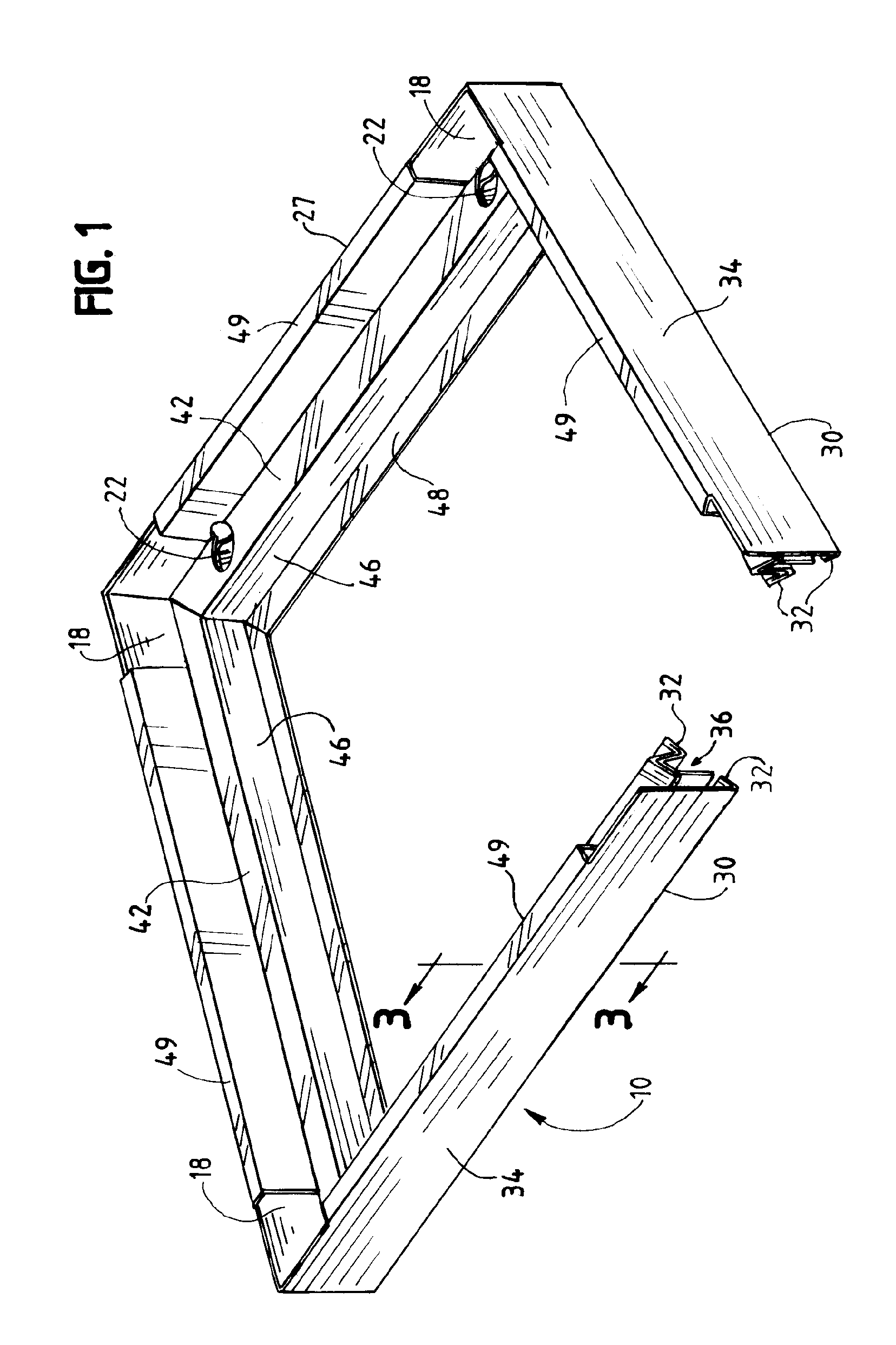

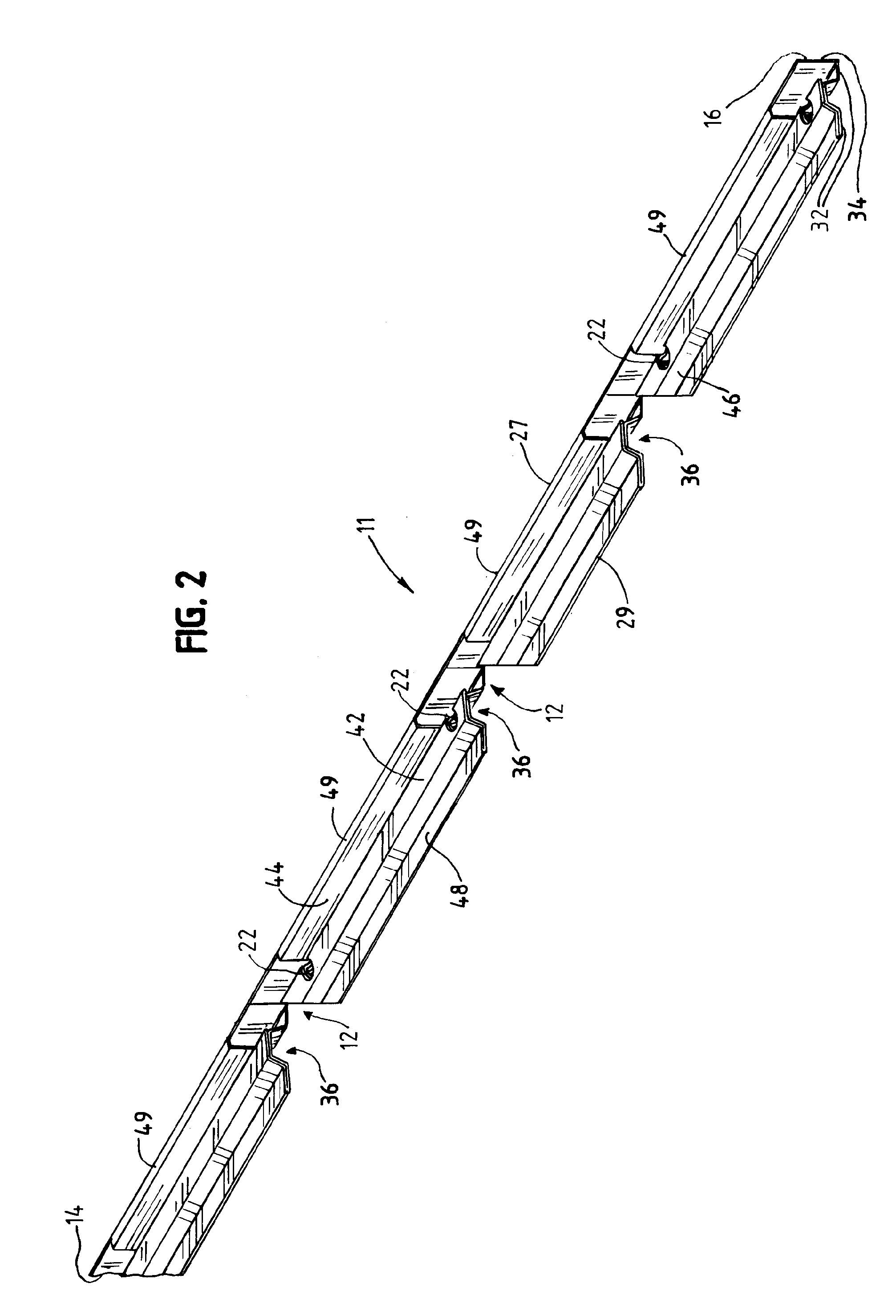

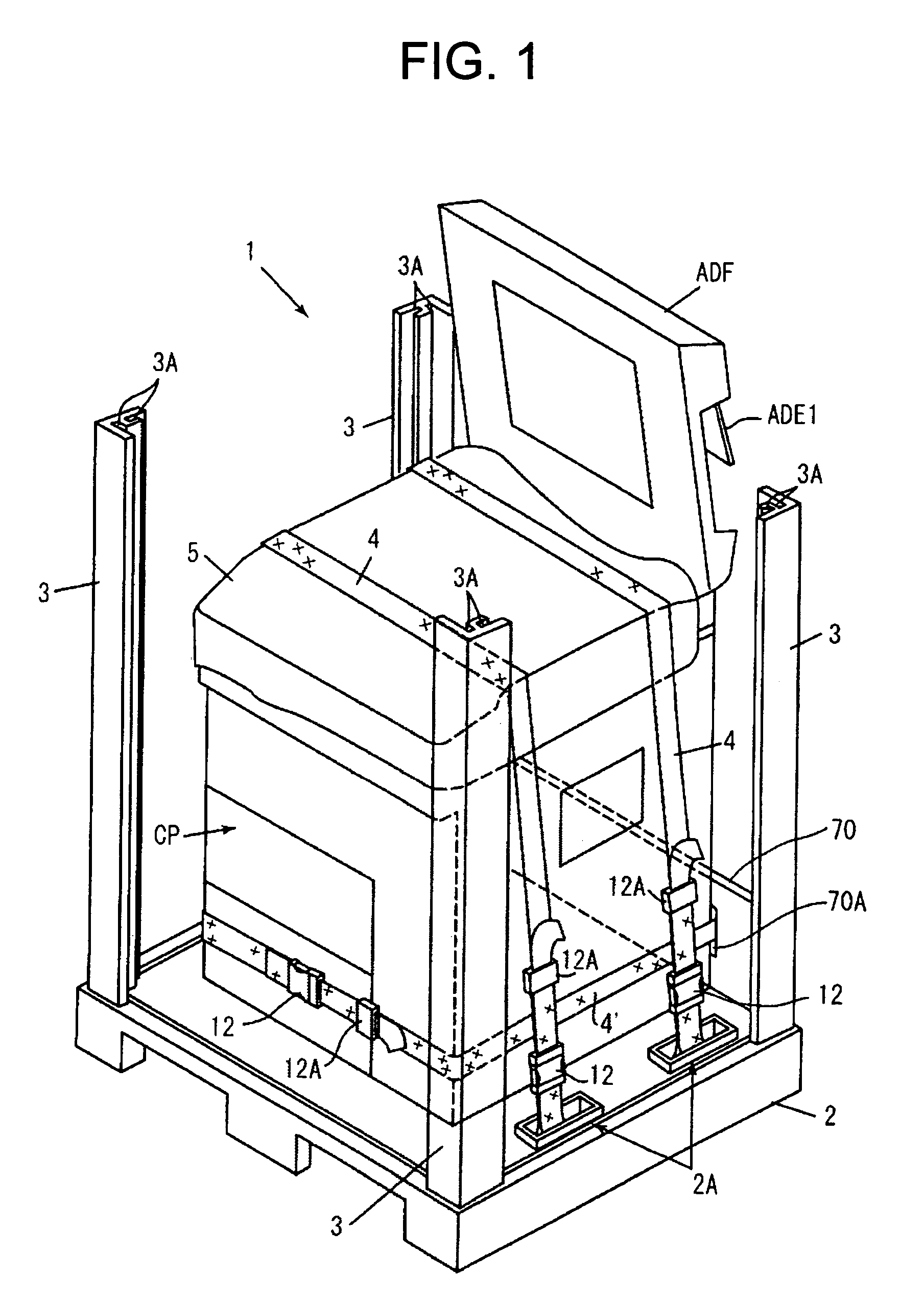

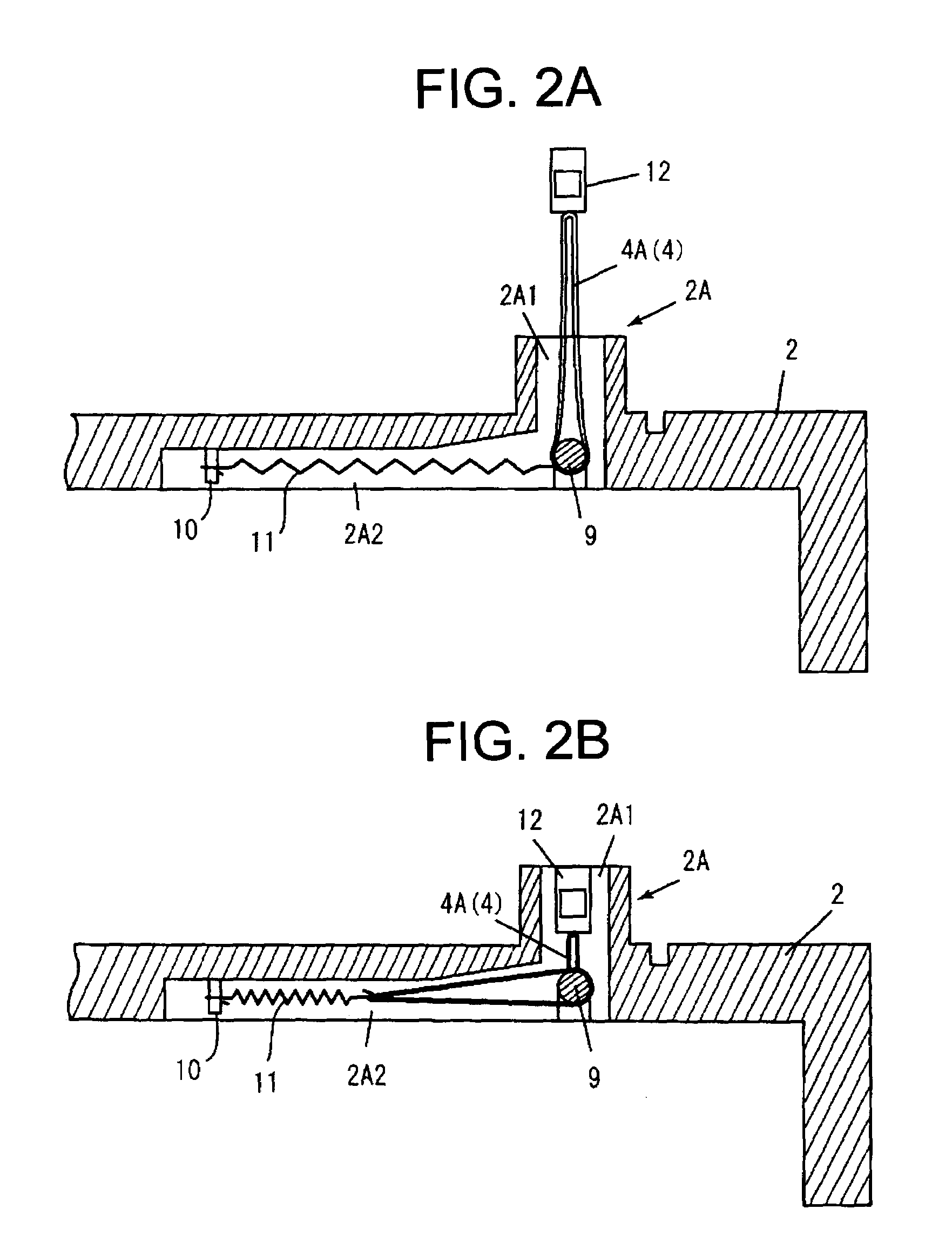

ActiveUS20050092633A1Prevent movementImprove stabilityOther accessoriesExternal framesEngineeringMechanical engineering

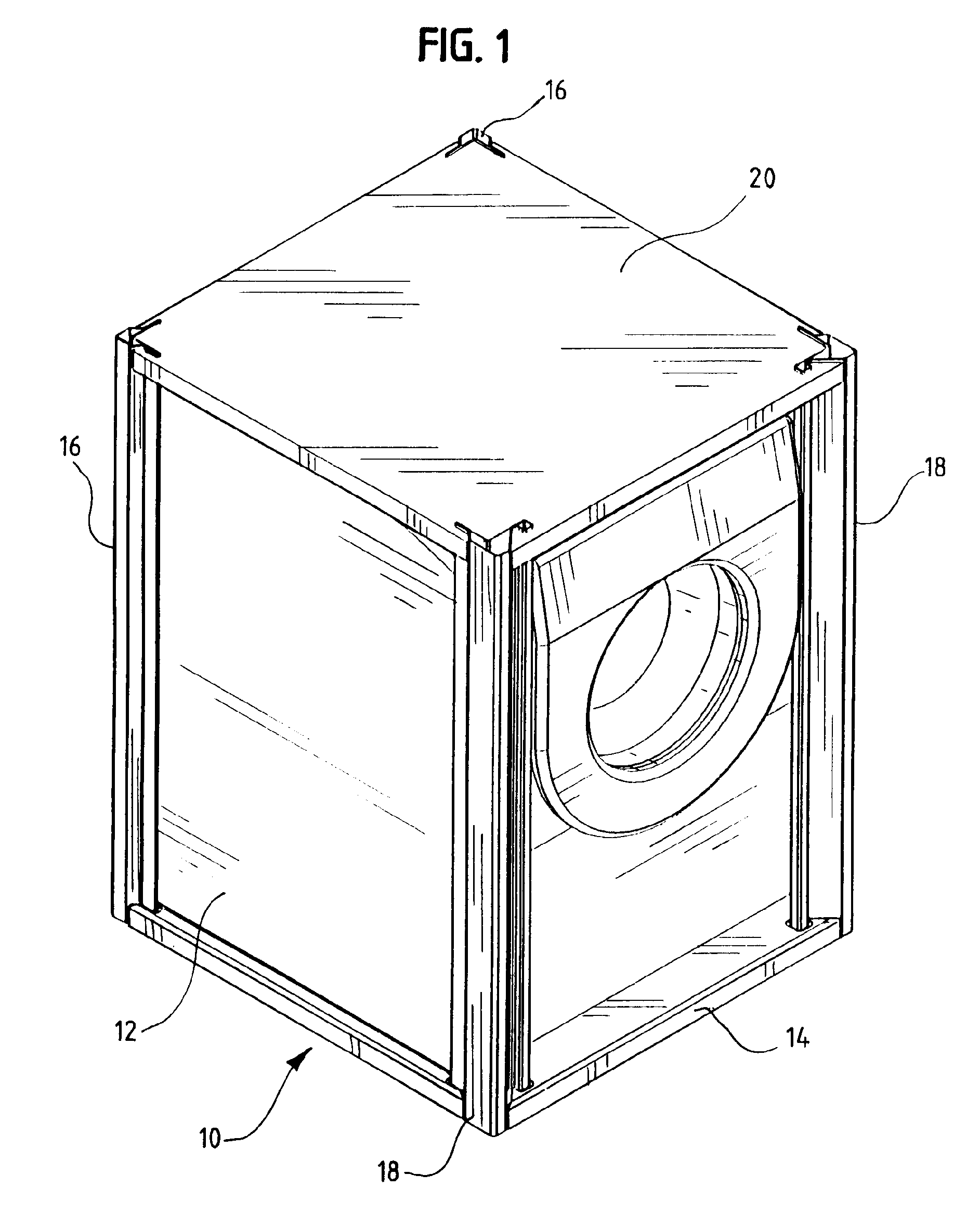

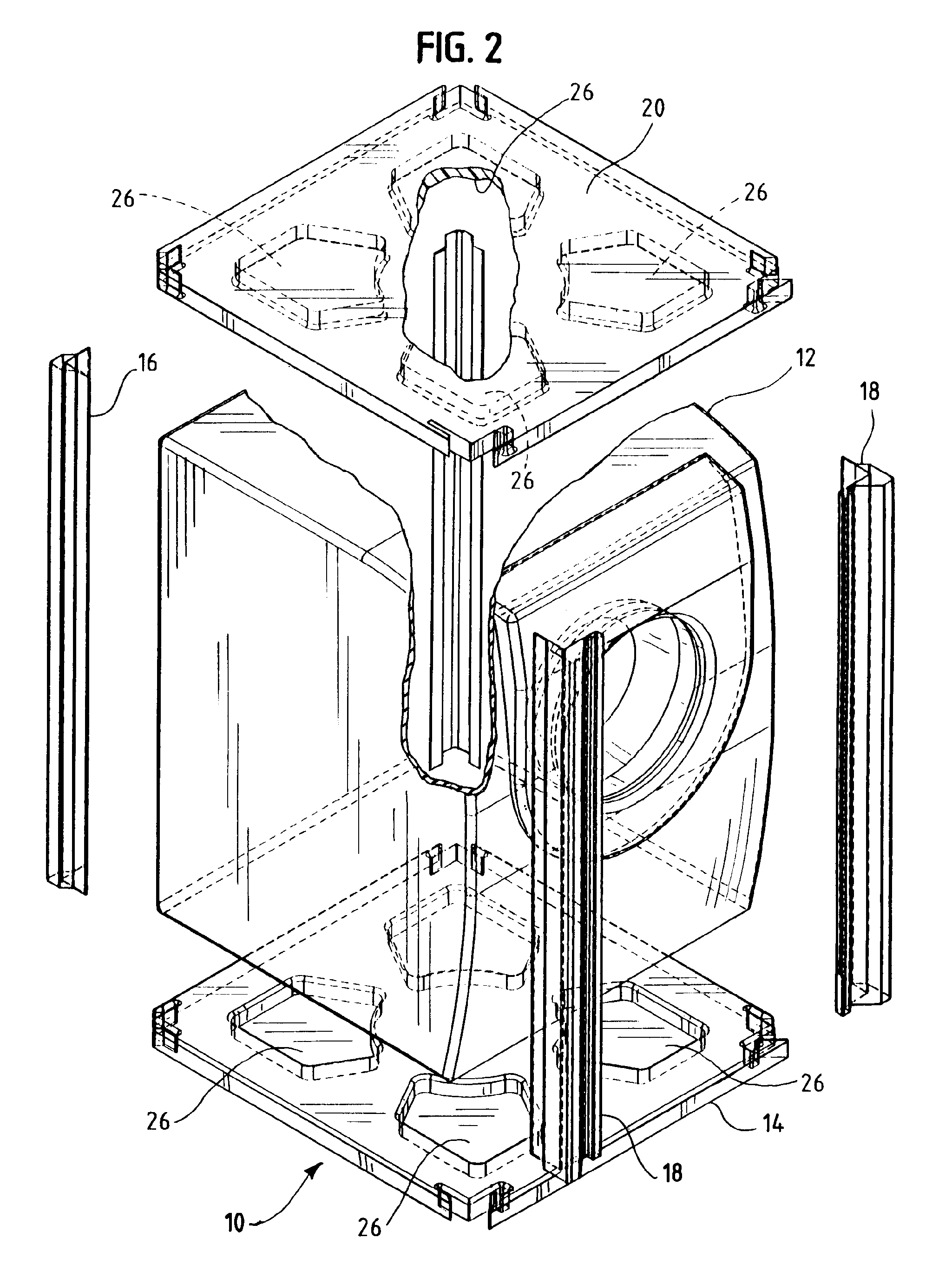

An improved open-sided package assembly for protecting and cushioning a product such as a large appliance, the assembly comprising a molded EPS base and top cap and four paper corner posts extending from the base to the top cap. The corner posts are shaped in such a way that when they are inserted into the base or top cap they do not fall out.

Owner:SONOCO DEV INC

Support post with locking feature

An improved open-sided package assembly 10 for protecting and cushioning a product 12 such as a large appliance, the assembly 10 comprising a molded EPS base 14 and top cap 20 and four support posts 16, 18 extending from the base 14 to the top cap 20. The support posts 16, 18 are shaped in such a way that when they are inserted into the base 14 or top cap 20 they do not fall out.

Owner:SONOCO DEV INC

Glass transportation container

ActiveCN105480565AImprove transportation safety factorReduce waste of resourcesExternal framesContainers to prevent mechanical damageEngineeringBinding time

The invention relates to a glass transportation container. The glass transportation container comprises a container body; chutes are symmetrically and horizontally formed in front and back two side surfaces of the container body; multiple baffle plates are horizontally arranged in the chutes in a manner of sliding left and right; an A-shaped bracket is detachably arranged in the container body; glass plates are aslant butted against front and back two side surfaces of the A-shaped bracket; tension devices are arranged between the baffle plates on the left rights and / or the right sides of the glass plates and a container body baseplate; and the tension devices tend to force the baffle plates on the left sides and / or the right sides of the glass plates to butt against the glass plates so as to fasten the glass plates from the left sides and / or the right sides. The glass transportation container effectively reduces the resource waste, reduces the binding times, improves the glass transportation safety coefficient, and improves the working efficiency.

Owner:BEIJING RUI LI HENG YI LOGISTICS TECH PLC

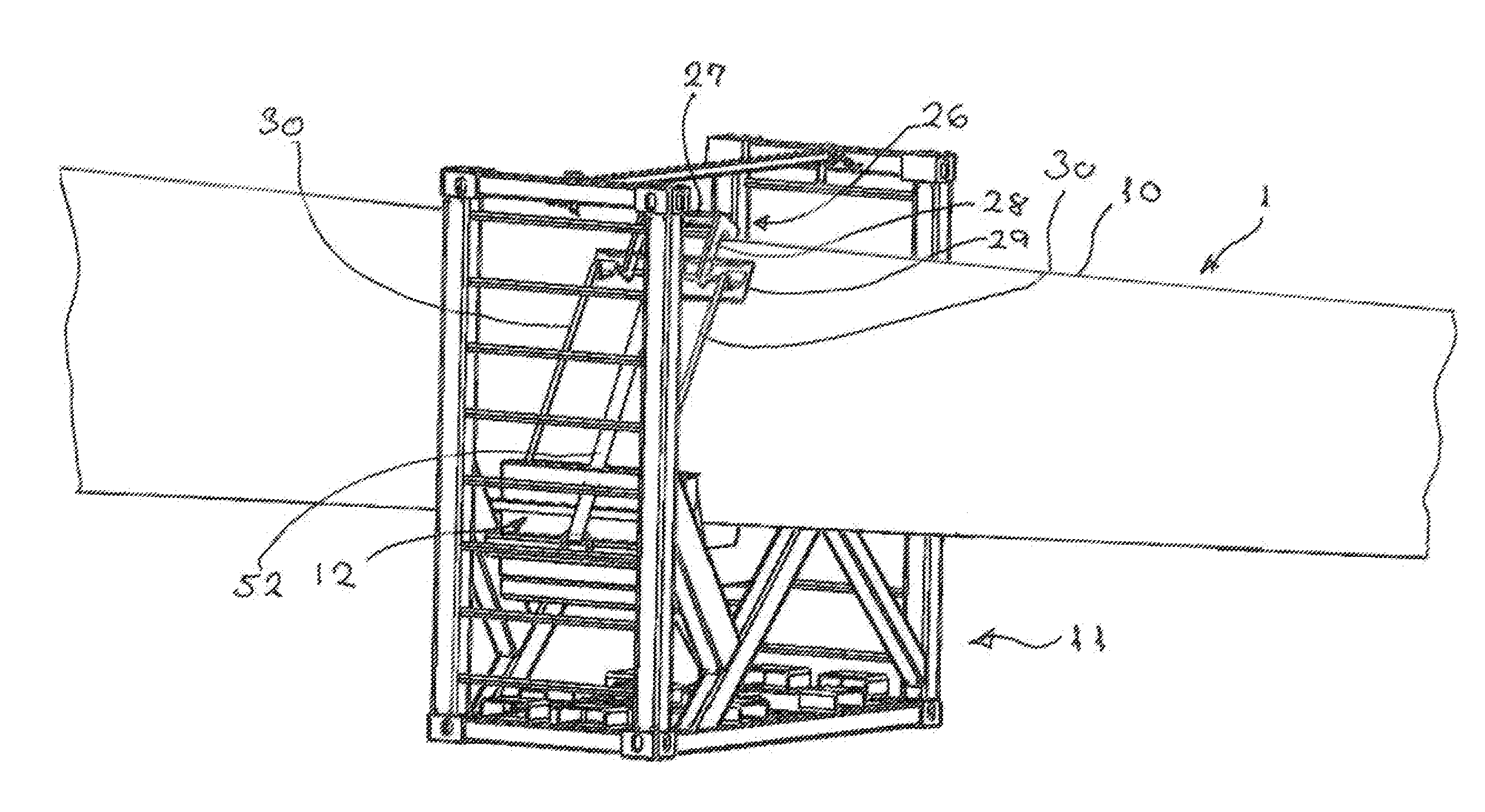

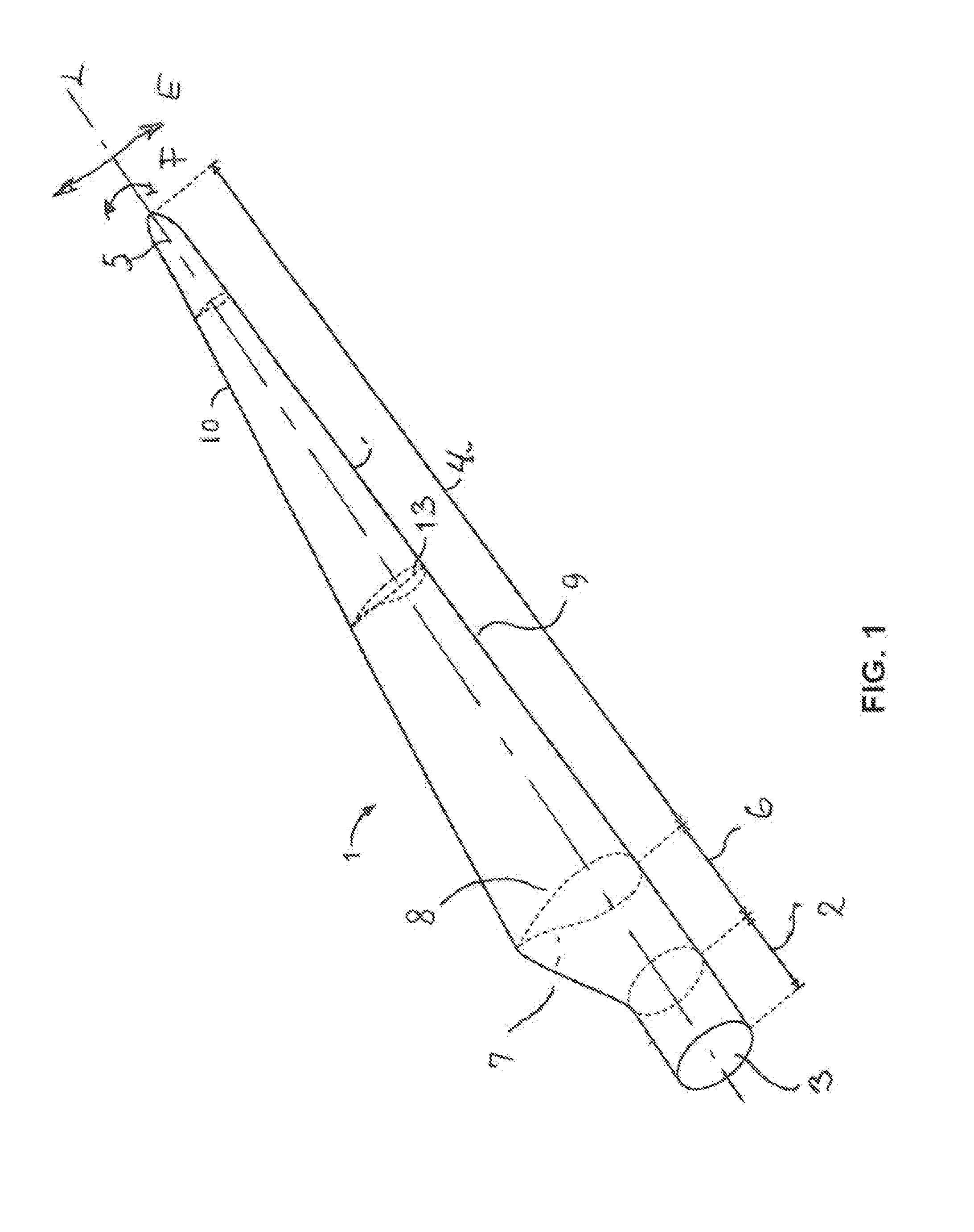

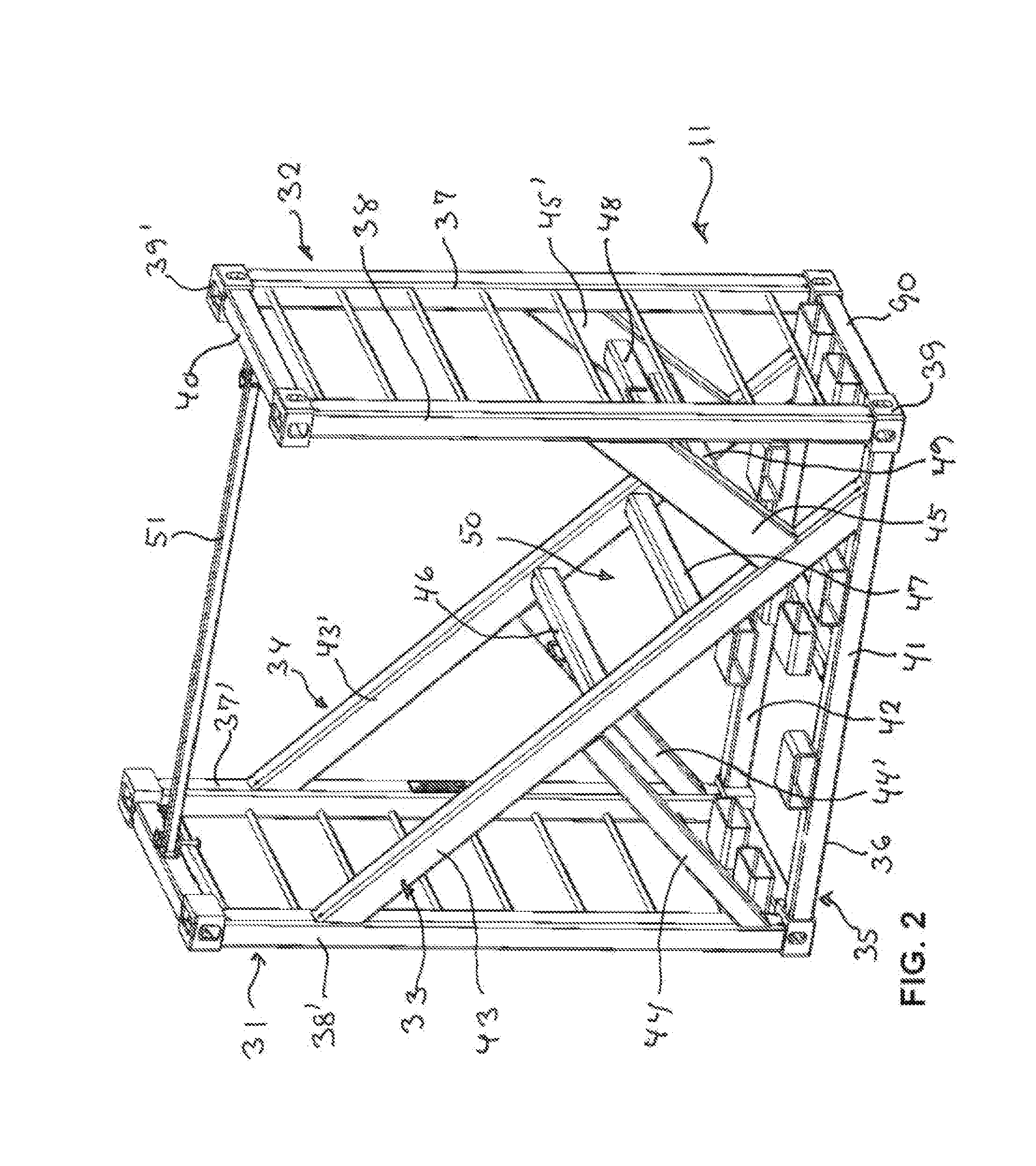

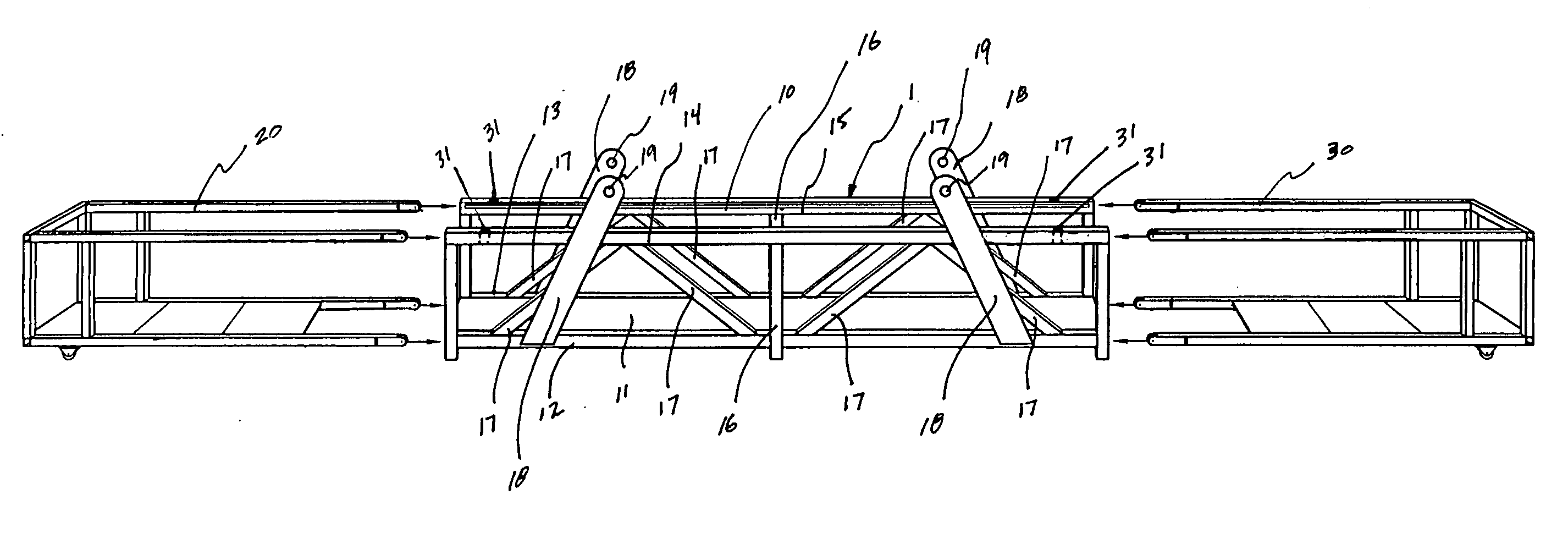

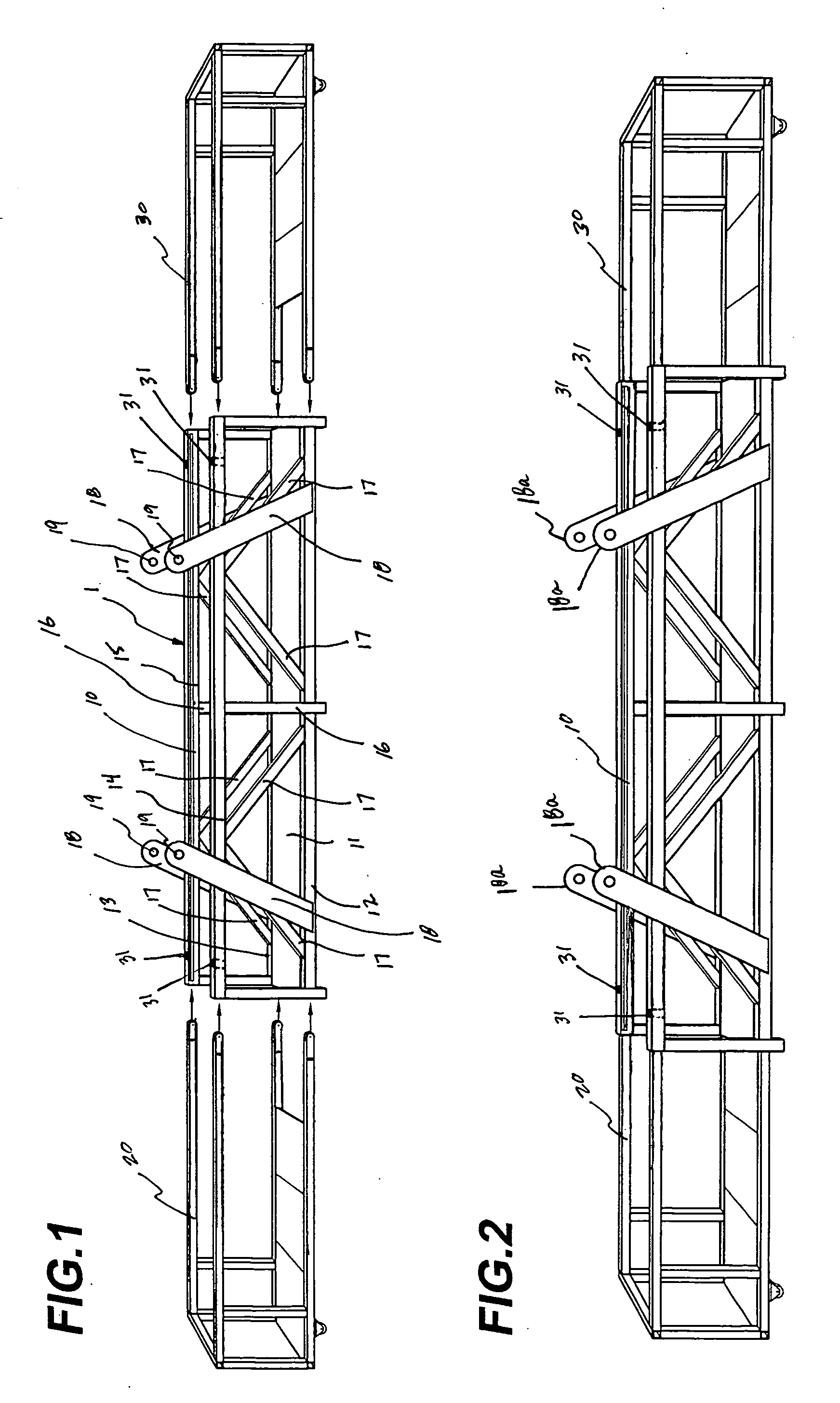

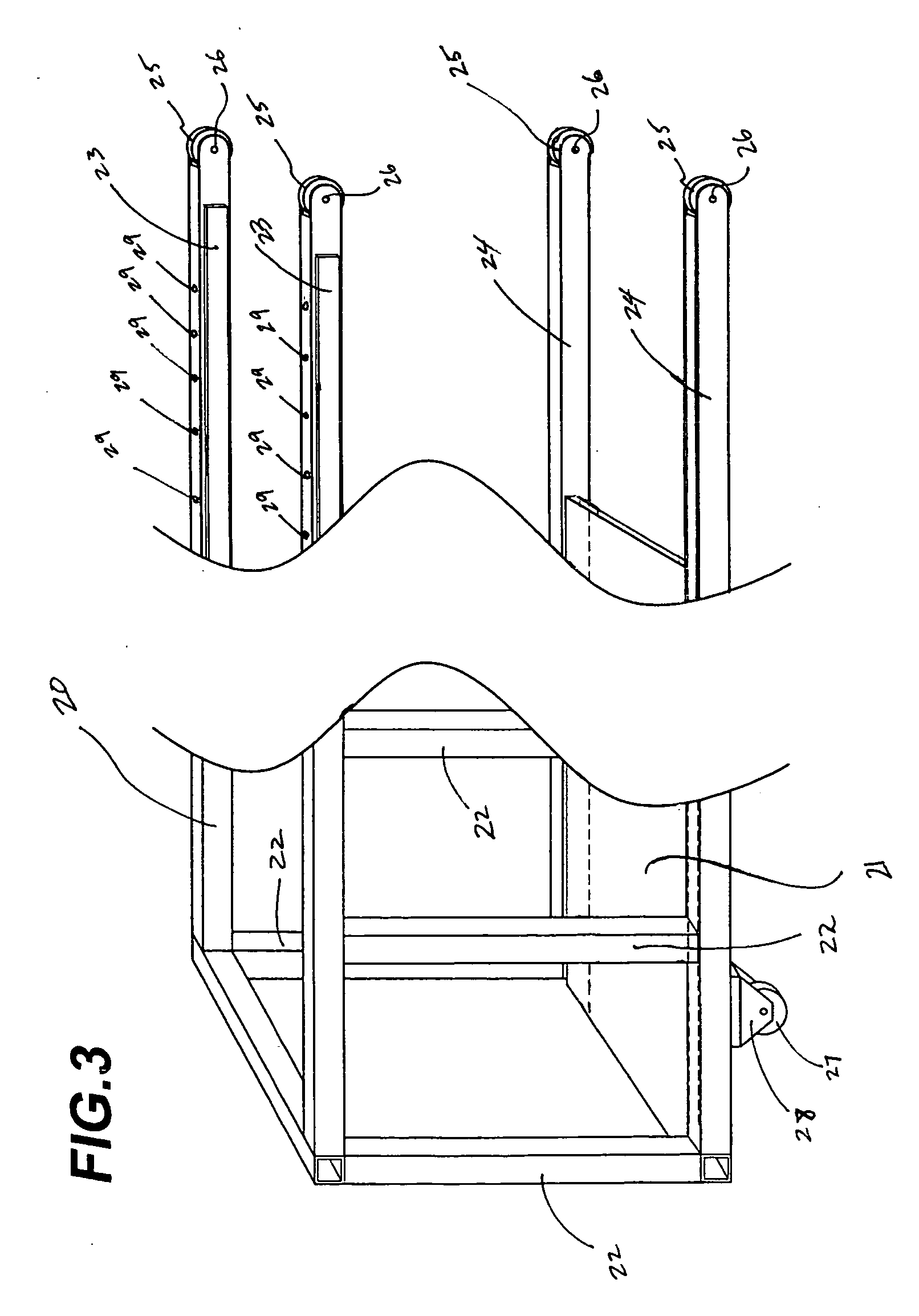

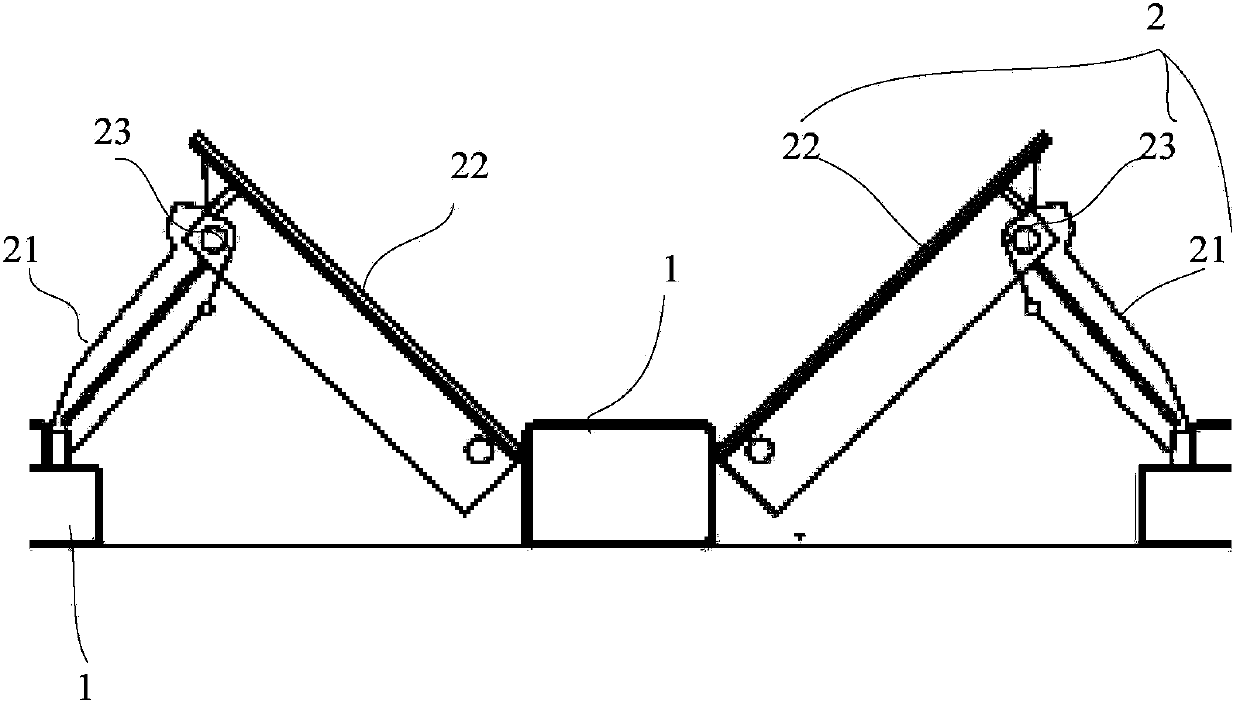

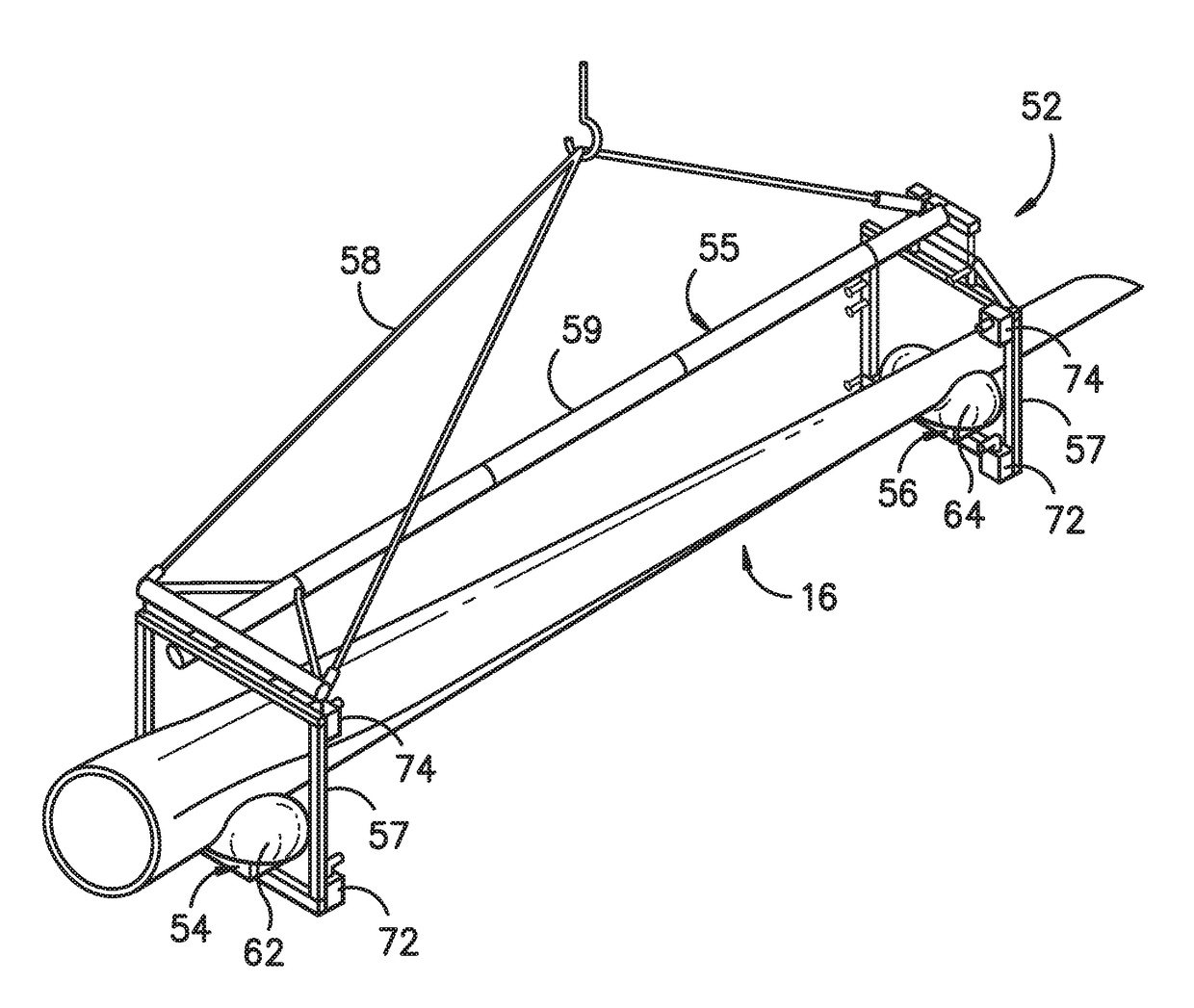

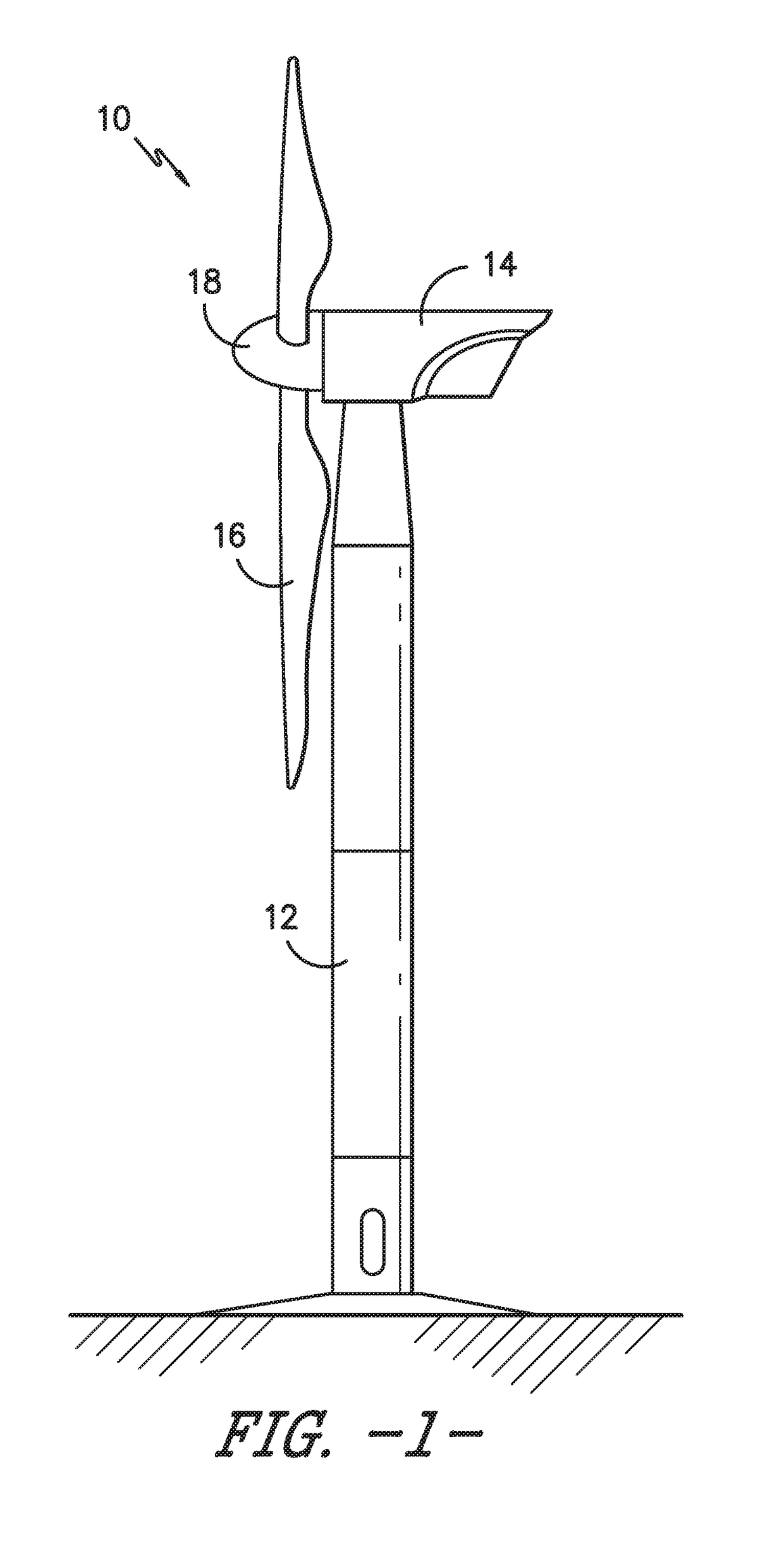

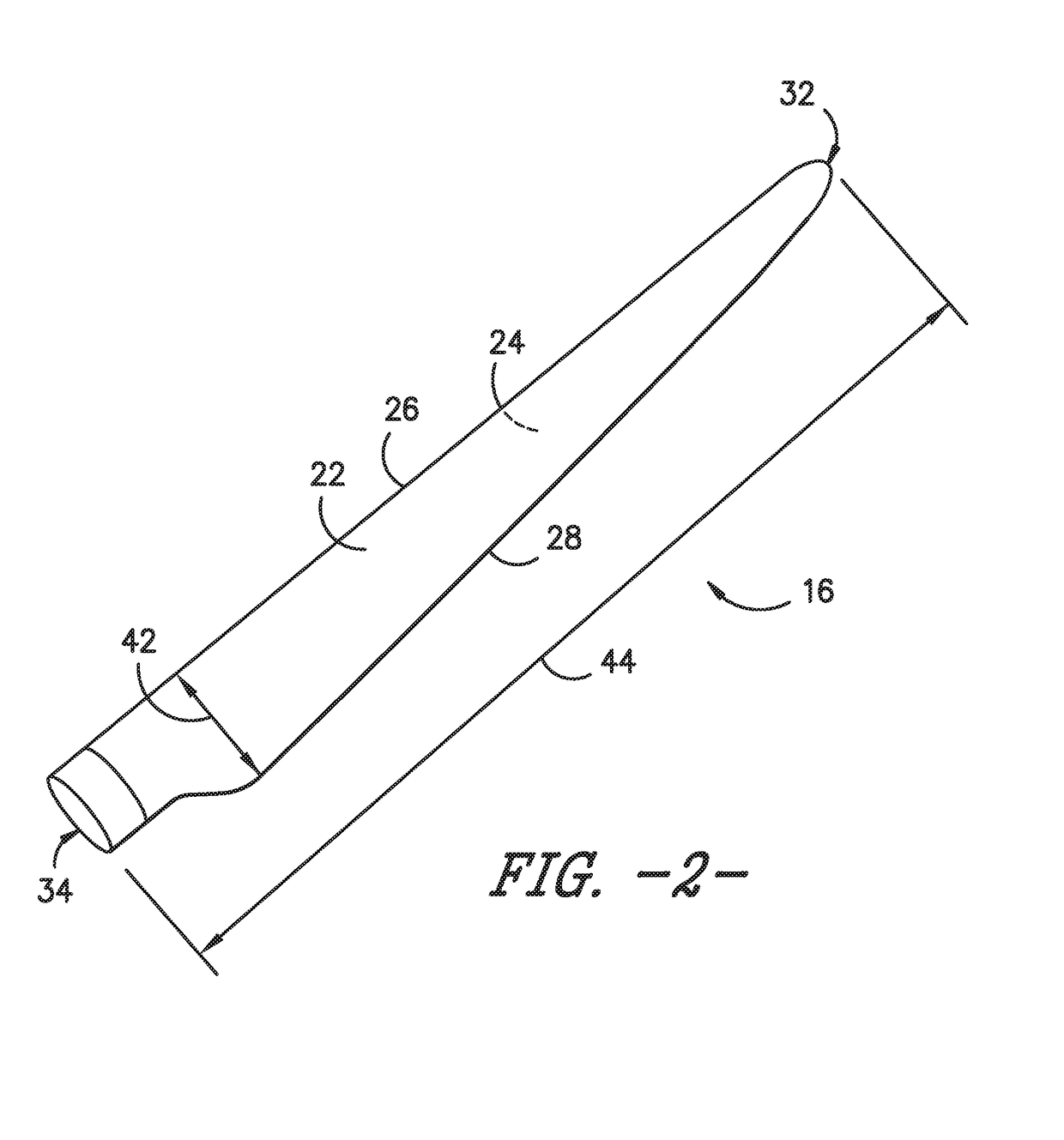

Transportation and storage system for wind turbine blades

ActiveUS20130119002A1Easy to carryLarge containersVehicle to carry long loadsTurbine bladeEngineering

A transportation and storage system for a wind turbine rotor blade comprises a tip end frame assembly comprising a tip end receptacle and a tip end frame. The tip end receptacle comprises an upwardly open tip end-receiving space for receiving a portion of the tip end of the blade and having a supporting surface for supporting the blade, a lower surface allowing the tip end receptacle to rest upright on a substantially horizontal surface, such as the ground, and releasable retaining means for releasably retaining the tip end of the blade in the receiving space of the tip end receptacle. The tip end frame comprises an upwardly open receptacle-receiving space for receiving the receptacle and provided with positioning means for positioning the receptacle in the tip end frame. A base part defines a bottom surface allowing the tip end frame to rest upright on the ground.

Owner:LM GLASSFIBER

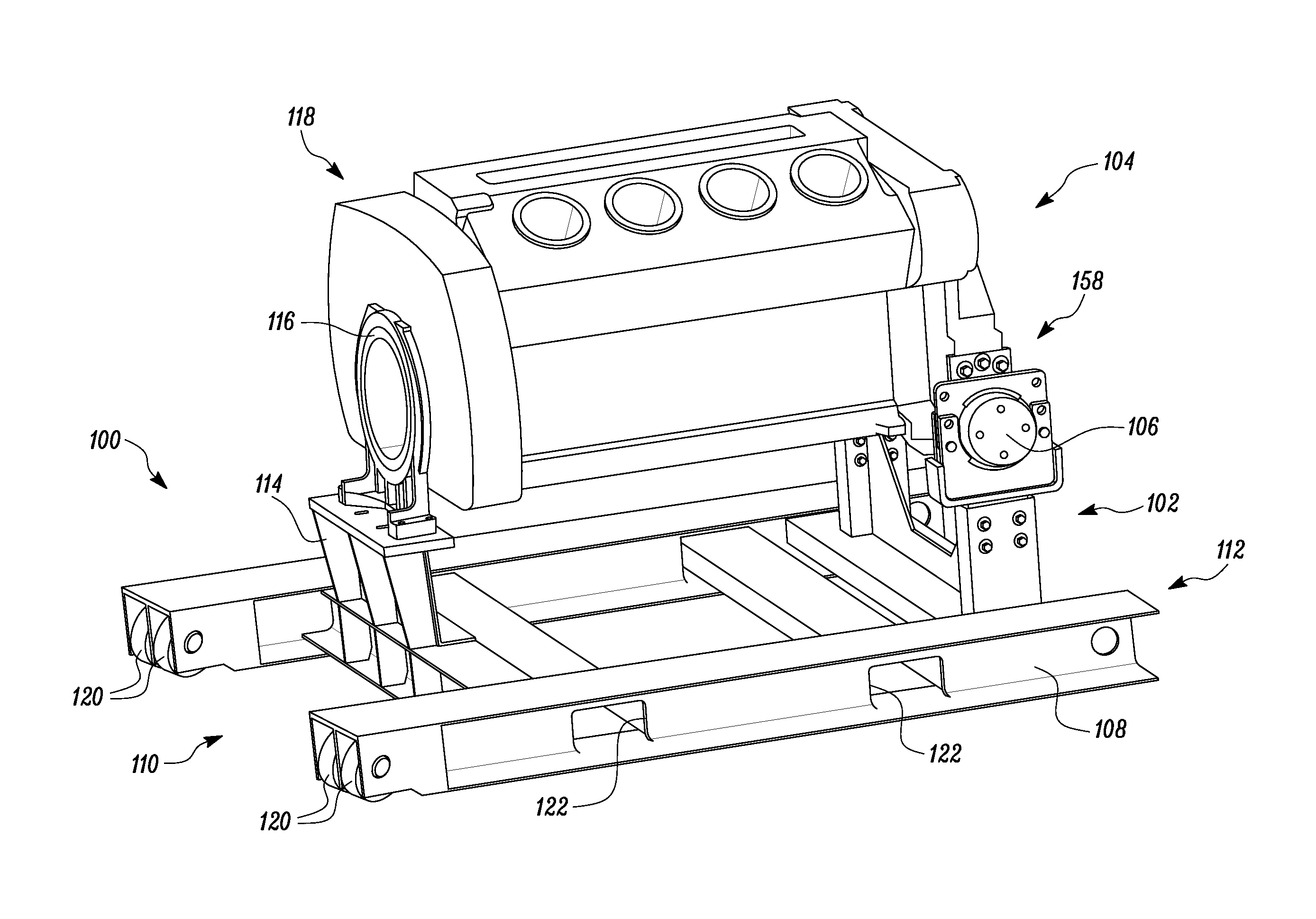

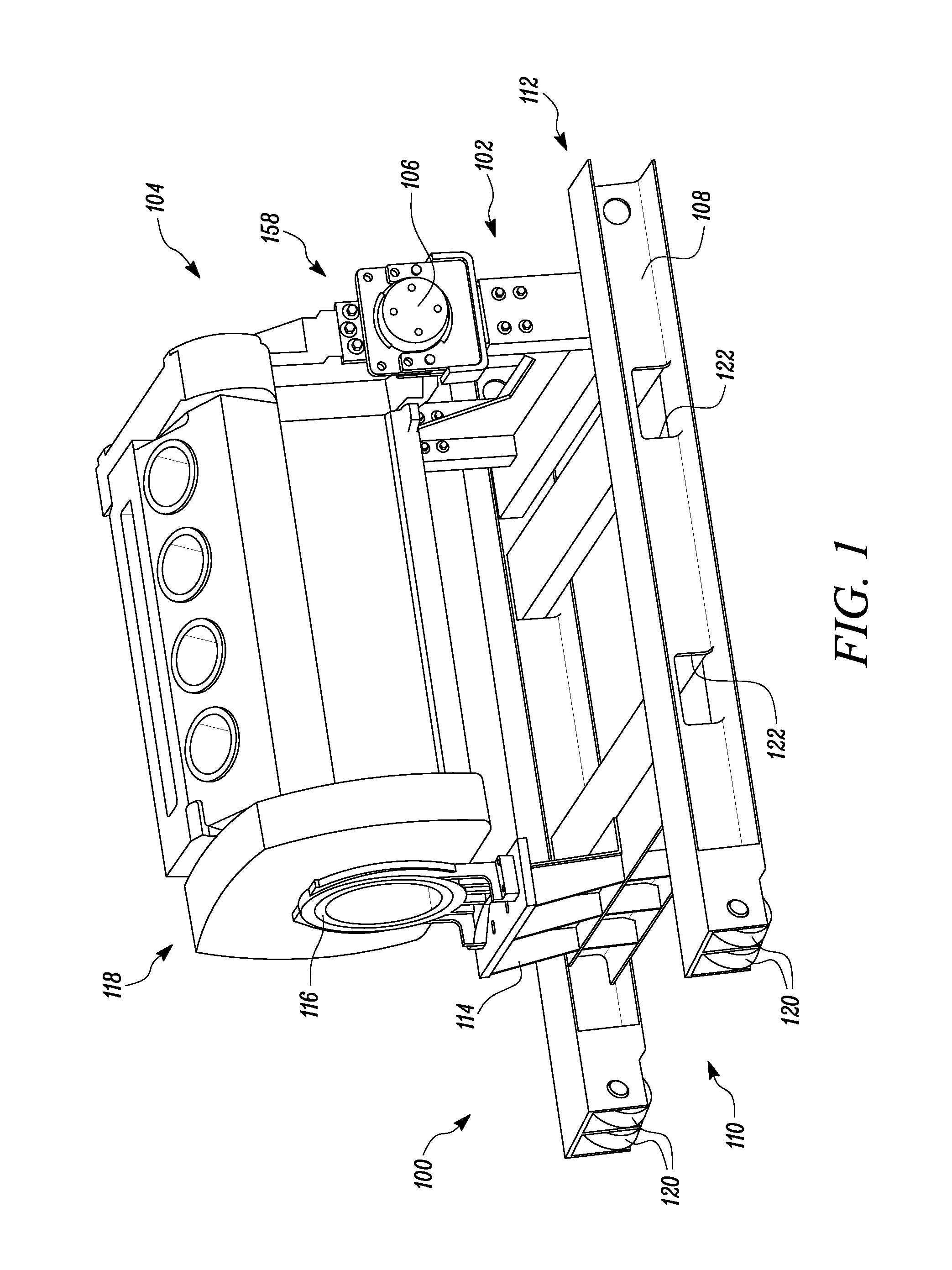

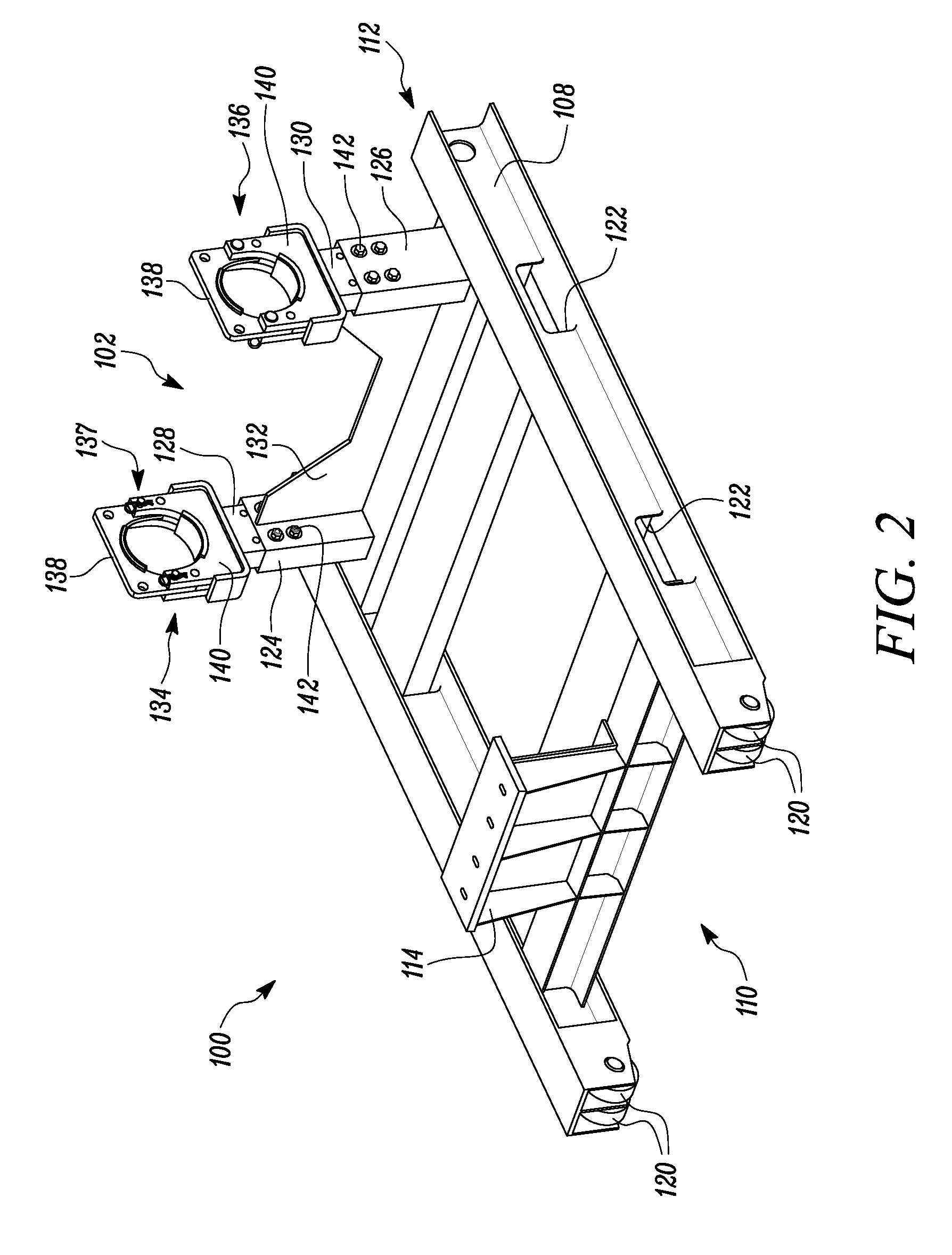

Engine stand with rear mount support

A stand for an engine is provided. The stand includes a base member having a first end and a second end. The base member also includes a front post fixedly connected to the base member at the first end. The base member further includes a rear support system fixedly connected to the base member at the second end. The rear support system includes two sleeve members and two rear posts, such that each rear post is slidably coupled to a sleeve member, and such that each rear post includes a clamp configured to hold a rear mount of the engine.

Owner:CATERPILLAR INC

Glass plate packing pallet

InactiveCN101920821AAvoid breakingExternal framesRigid containersStatic friction coefficientEngineering

Provided is a glass plate packing pallet, which is used for packing large-scale glass plate, and comprises a body and a load-bearing part. The body comprises a bearing part which is stacked and loaded when the glass plate stands up, a back plate which supports the stacked glass plate from the back side, and a lower end surface whose load-bearing part is disposed on the bearing part and supports the glass plate. The load-bearing part consists of a buffer unit and a stress dispersion plate stacked on the buffer unit. The static friction coefficient of the surface of the load-bearing part which contacts with the lower end surface of the glass plate to the glass is no less than 0.50 and no more than 0.90.

Owner:AVANSTRATE INC

Tubular structure for supporting a product

A base pad for supporting and cushioning a product such as a major home appliance. The base pad is made from a tube formed into a desired cross-sectional shape (profile) and folded into a square or rectangular frame-like configuration. V-shaped sections are cut out of the tube to facilitate the folding. The tube may have pockets located at the corners to hold vertical support posts.

Owner:SONOCO DEV INC

Adjustable basket for storing and transporting cargo

InactiveUS20060032850A1Efficient transportAdjustable lengthLarge containersExternal framesEngineeringMechanical engineering

Owner:THERIOT RONALD J +1

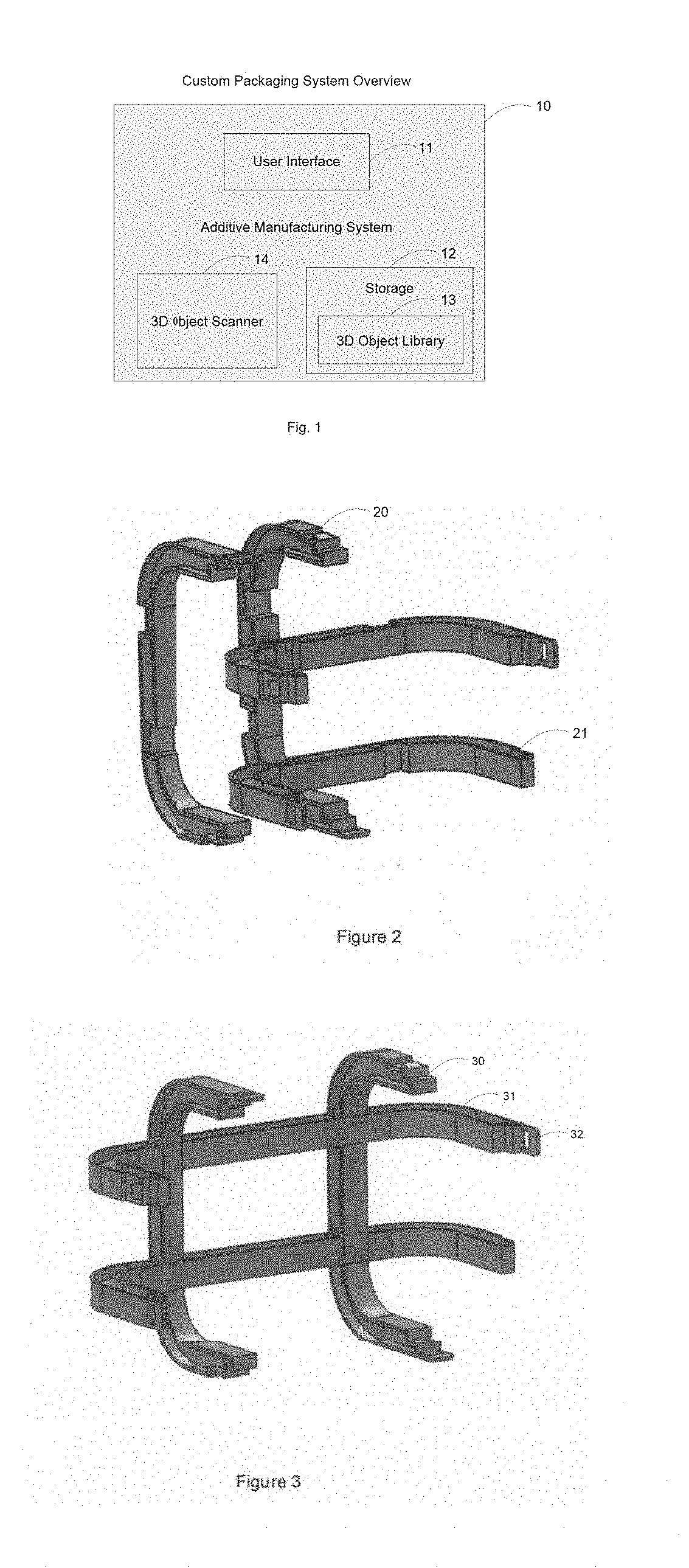

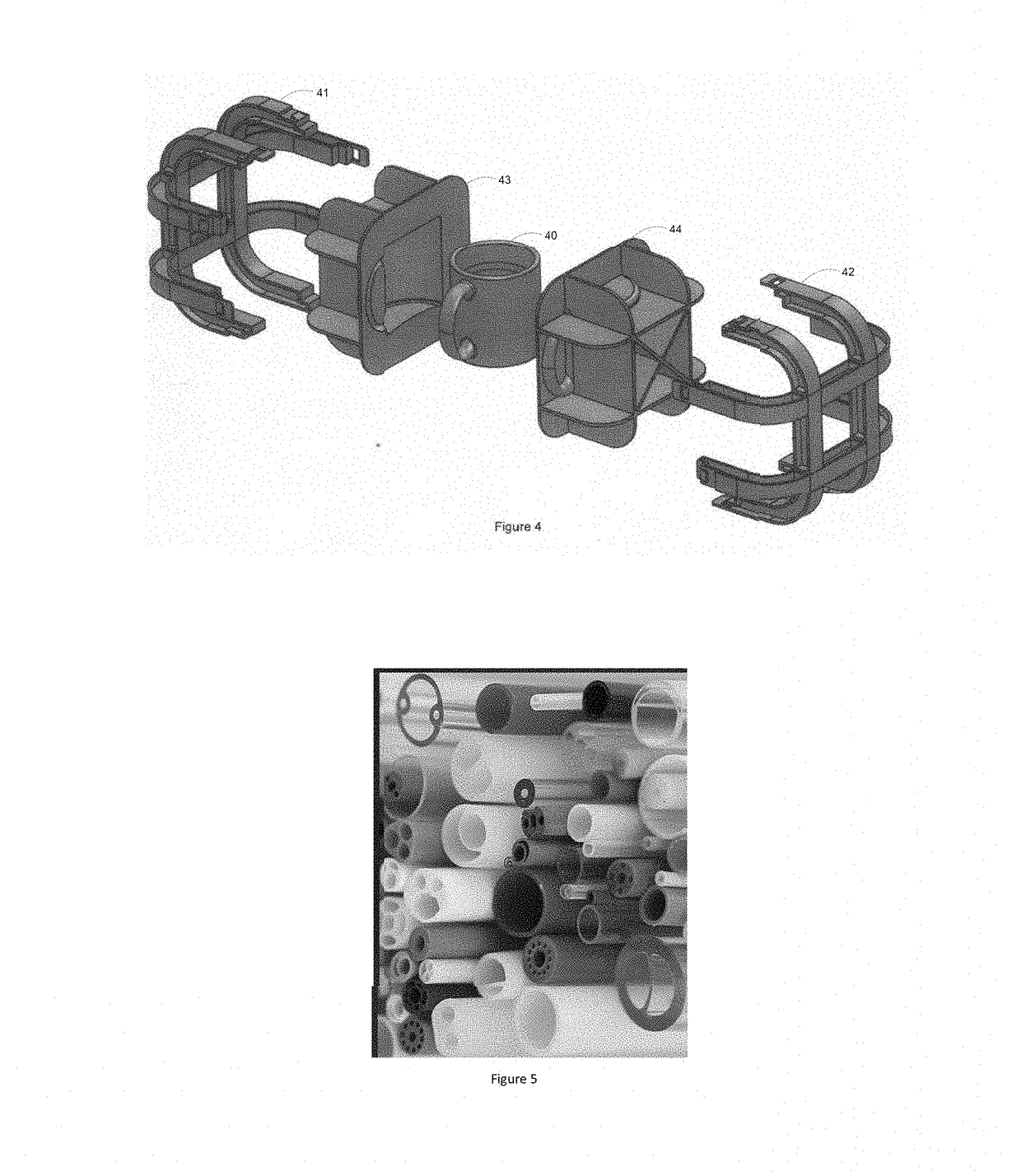

System and method for packaging items for shipping using additive manufacturing

InactiveUS20170253401A1Optimize quantityCost efficient pricingWrappersTotal factory controlManufacturing technologyPallet

The method for packaging objects for shipping, which may be configured as a single all-in-one device, is carried out by scanning or selecting an item to be packaged from a catalogue and then using that information to generate a custom shipping enclosure using additive manufacturing techniques. Additive manufacturing techniques to create these custom shipping packages may include 3D printing, extrusion and sintering based processes as well as other techniques obvious to those skilled in the art. This method has an additional benefit of allowing greater quantities of items to fit on pallets, in shipping containers, and even in warehouses and on retail shelves.

Owner:DESIGN NET TECHN PRODS

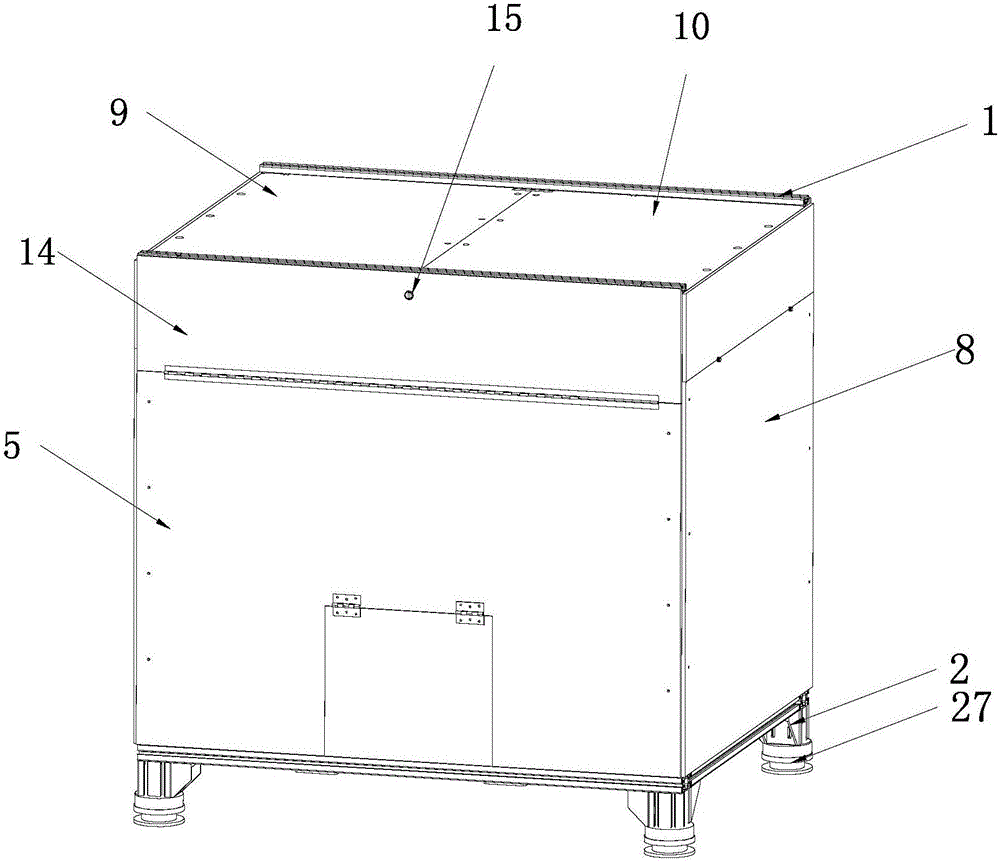

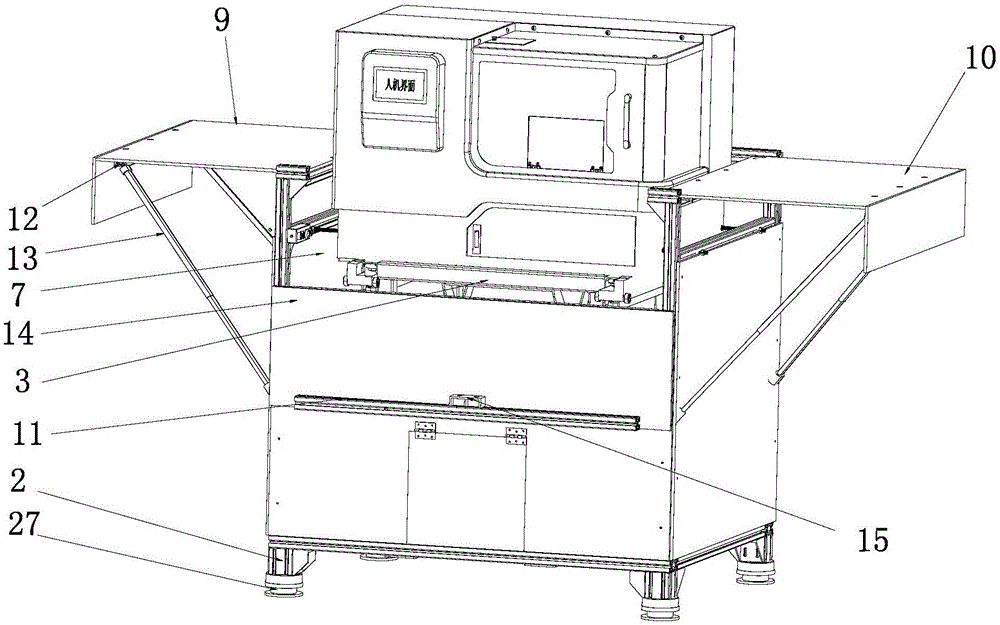

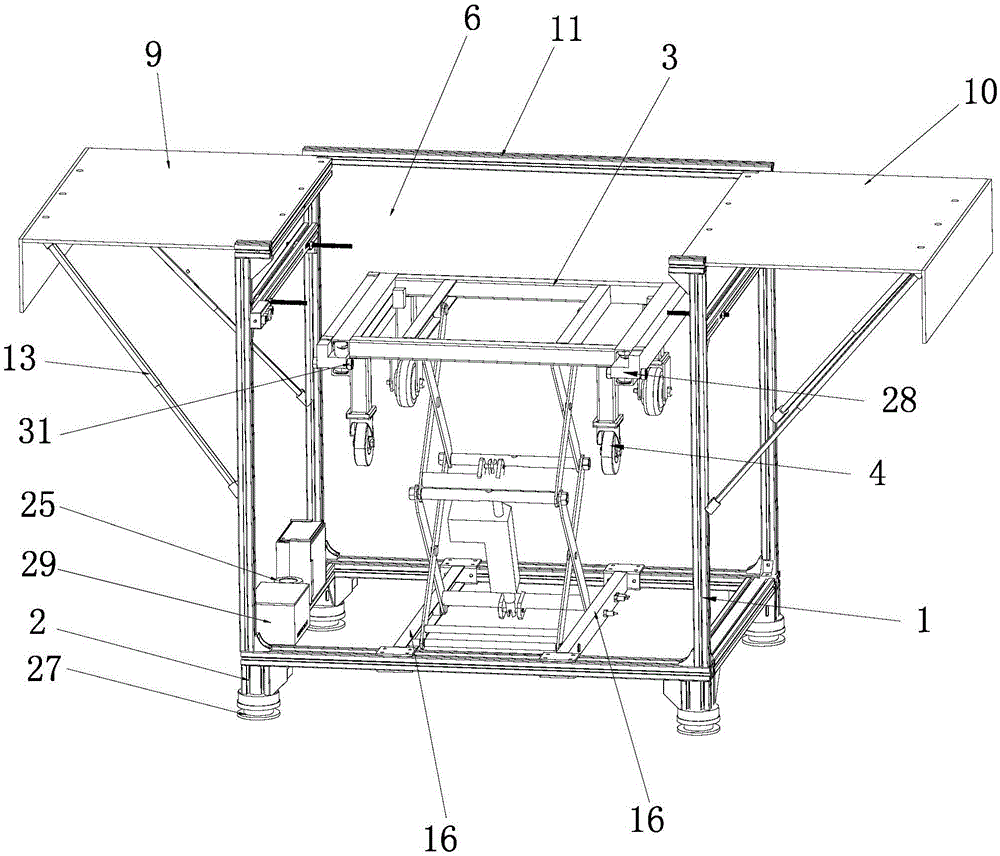

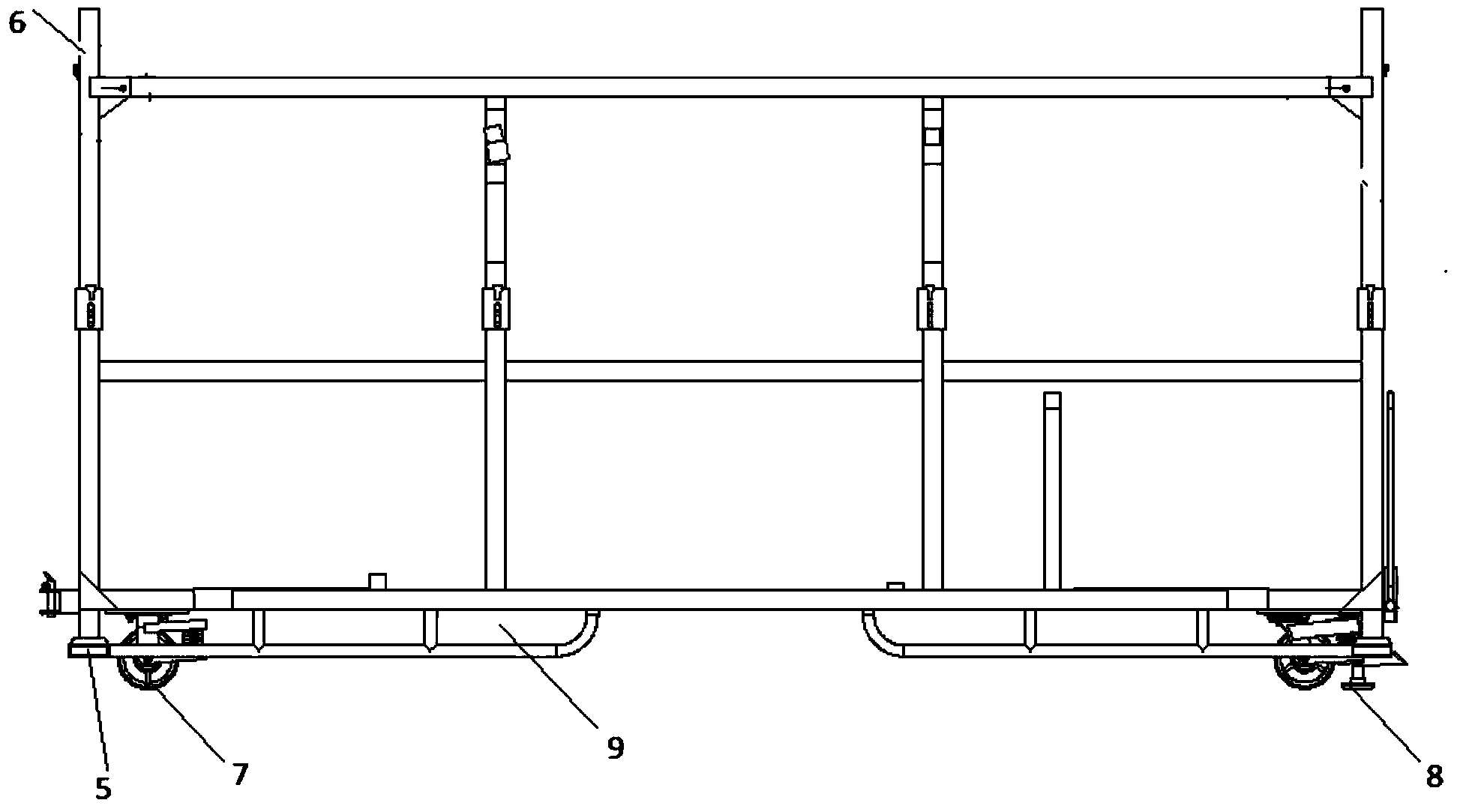

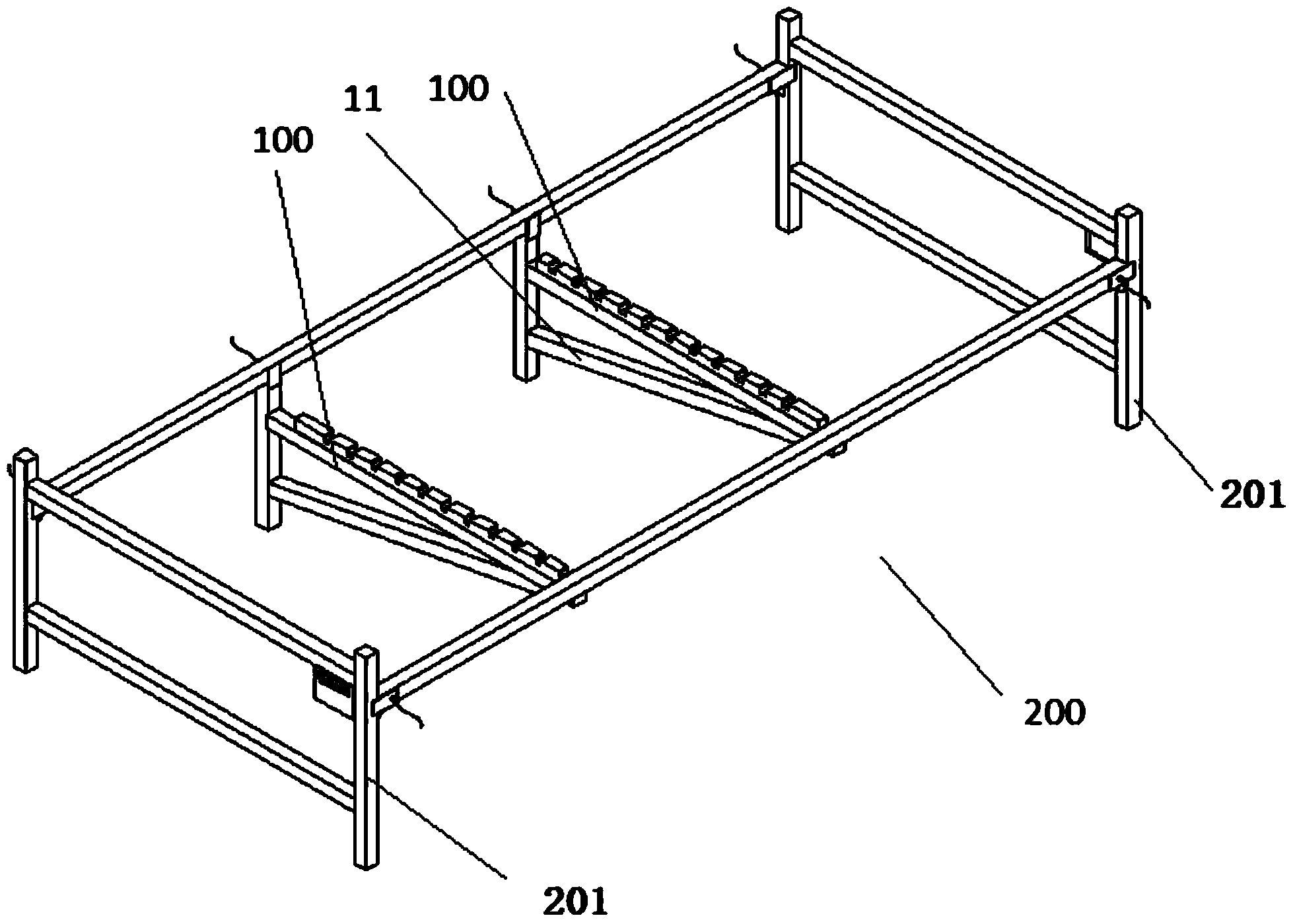

Packing container capable of moving and lifting to unload

ActiveCN106742590ARealize unloading functionEasy to operateExternal framesExternal fittingsFixed frameReducer

The invention discloses a packing container capable of moving and lifting to unload. The packing container comprises a fixed frame; a lifting mechanism is arranged in the fixed frame, and is connected with an object placing table; multiple trundles are fixed on the lower surface of the object placing table; the lifting mechanism drives the object placing table to descend to enable the trundles to support the fixed frame and to drive the whole packing container to move, so that the trundles and stand columns can be freely switched under heavy loads; the packing container can be freely switched between a landing mode and a moving mode to save both time and labors; the lifting mechanism drives the object placing table to ascend; an upper panel slides away to fix through support rods, the object placing table can show goods as a showing platform; guide rods on two sides of the object placing table extend out to place on the platform surface; the goods are flatly pushed to slide onto the platform surface through the guide rods; objects can be conveniently carried and unloaded; vibration reducers at the bottoms of the stand columns can protect carrying of the goods to improve the safety; and the whole multifunctional integral packing container satisfies the requirements of safe and quick goods conveying and time and labor saving in goods unloading.

Owner:梅木精密工业(珠海)有限公司

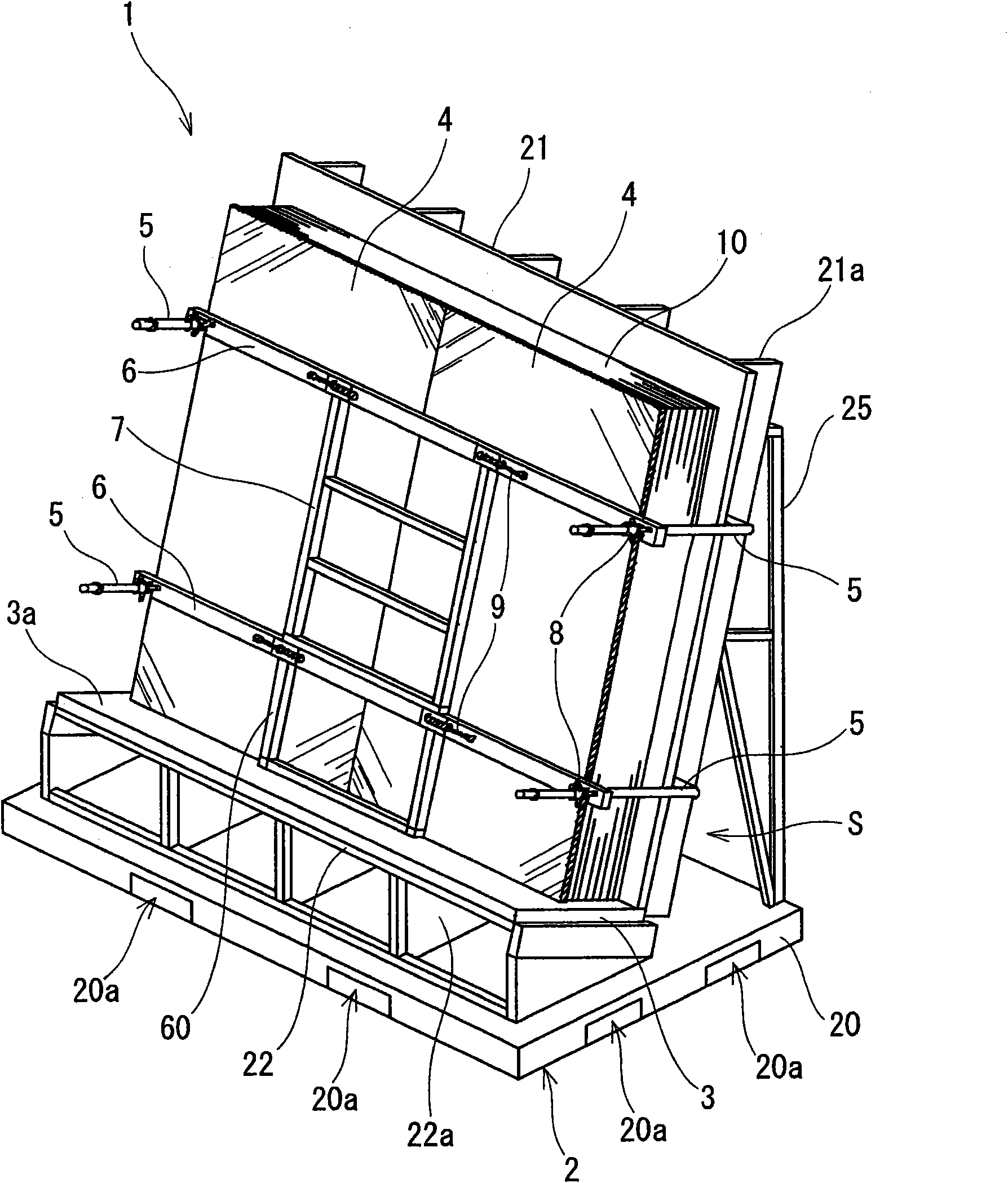

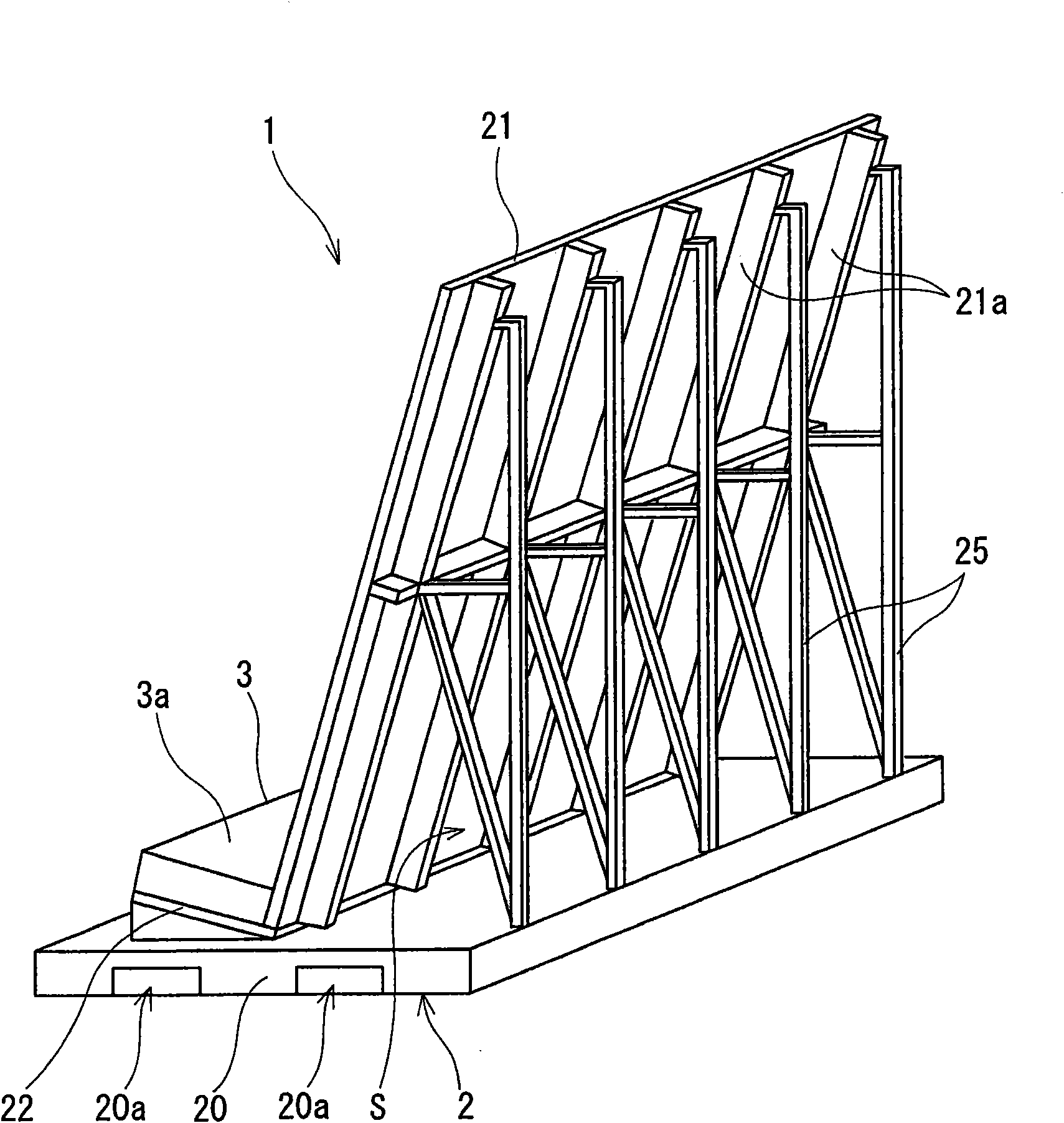

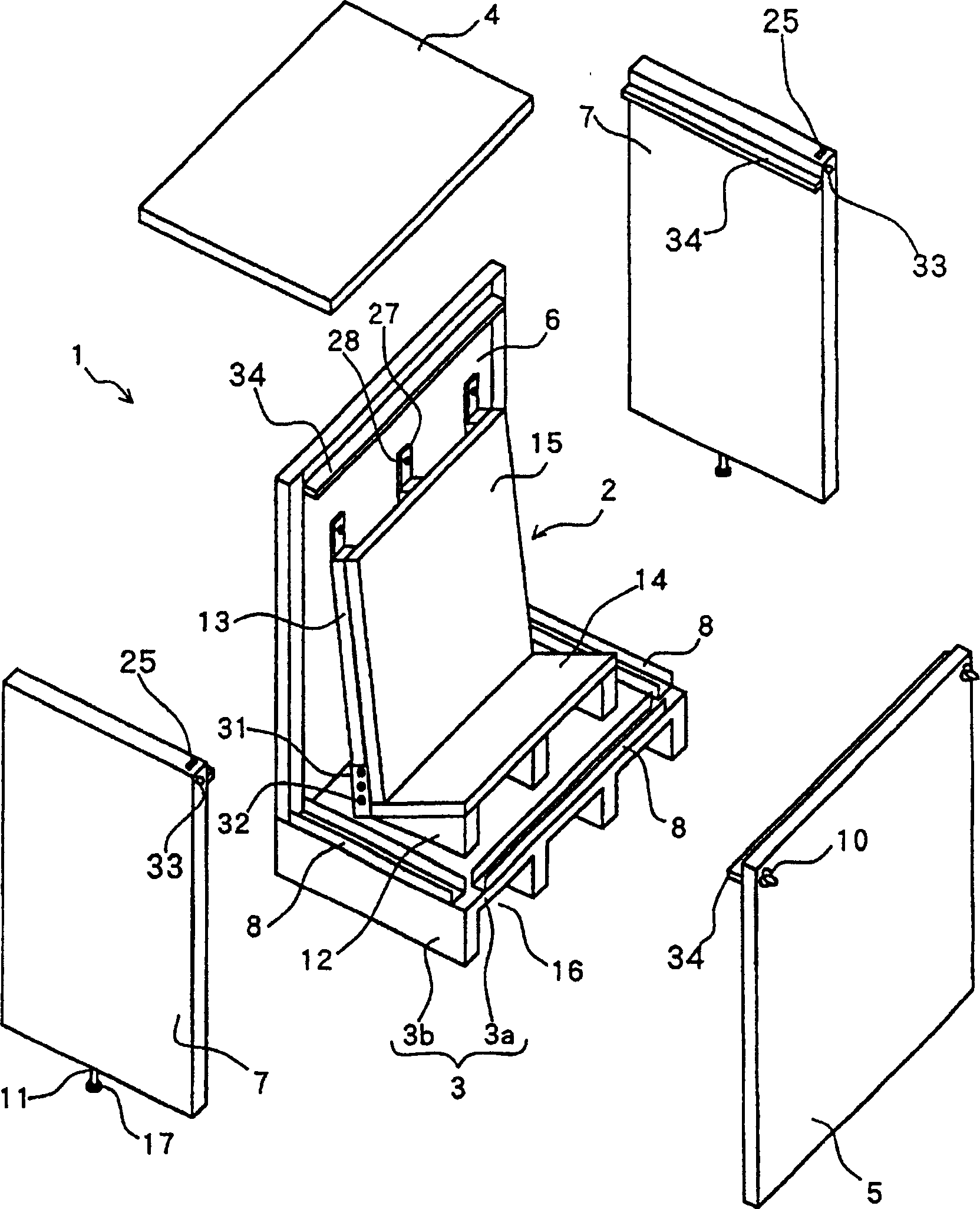

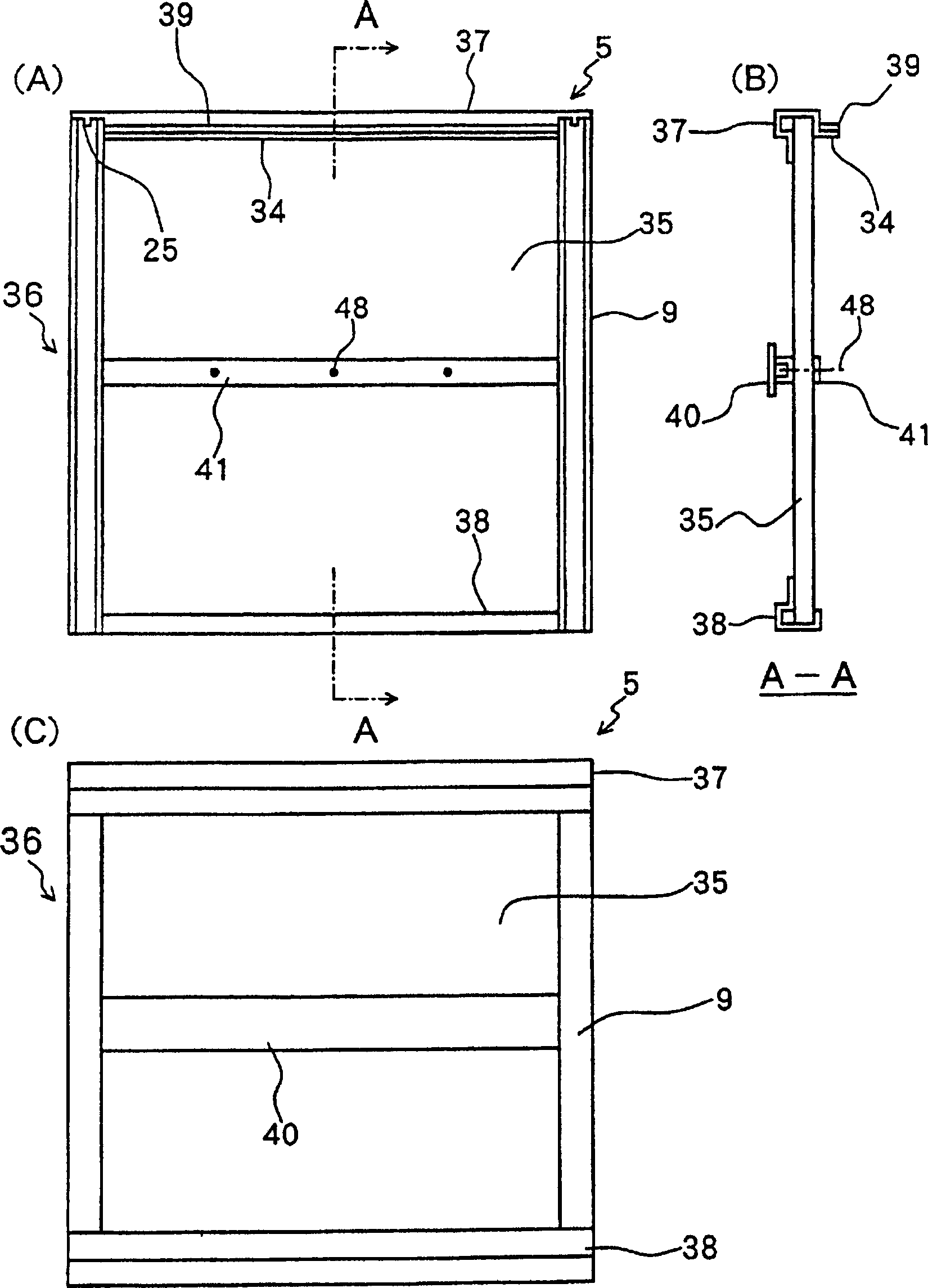

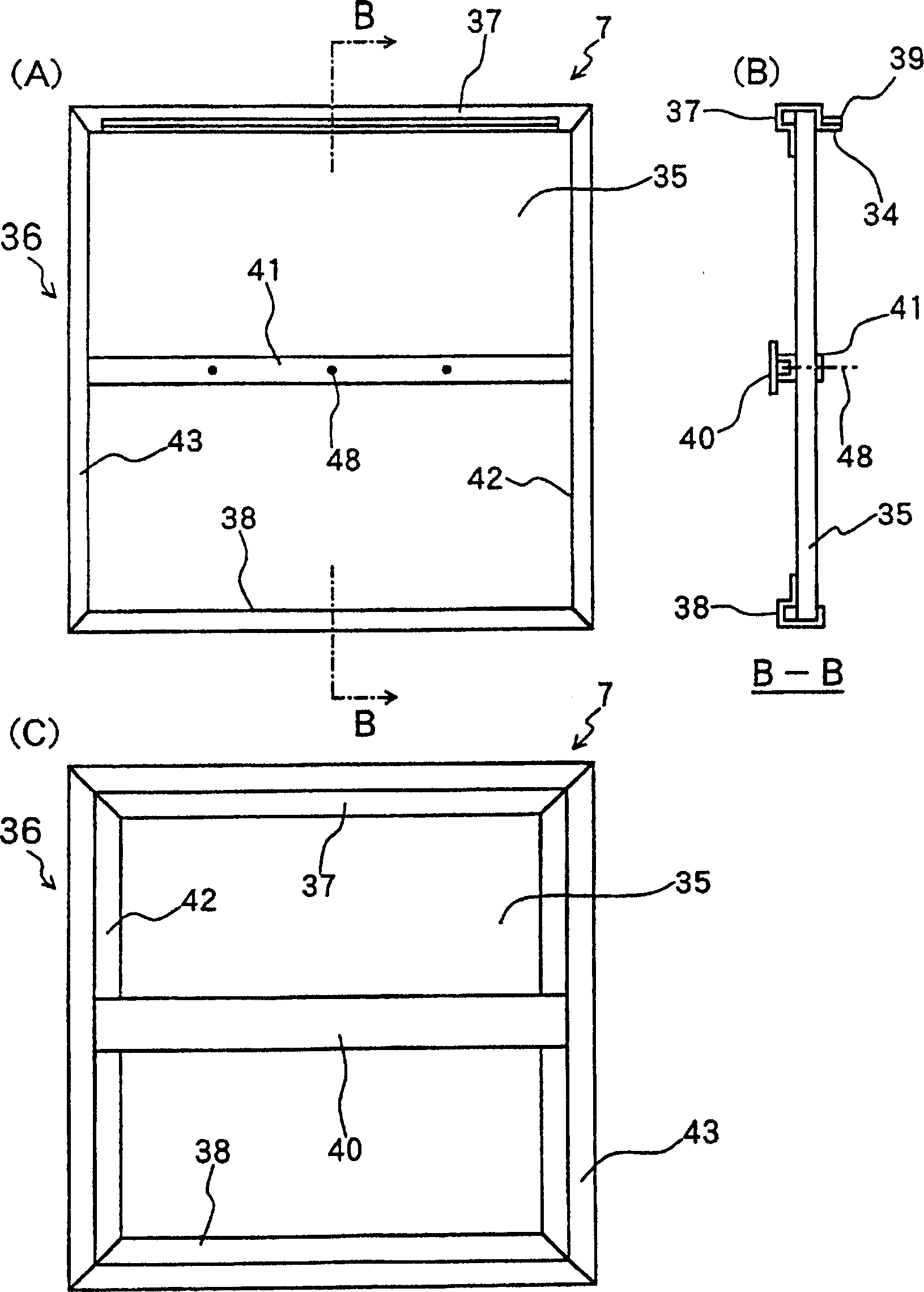

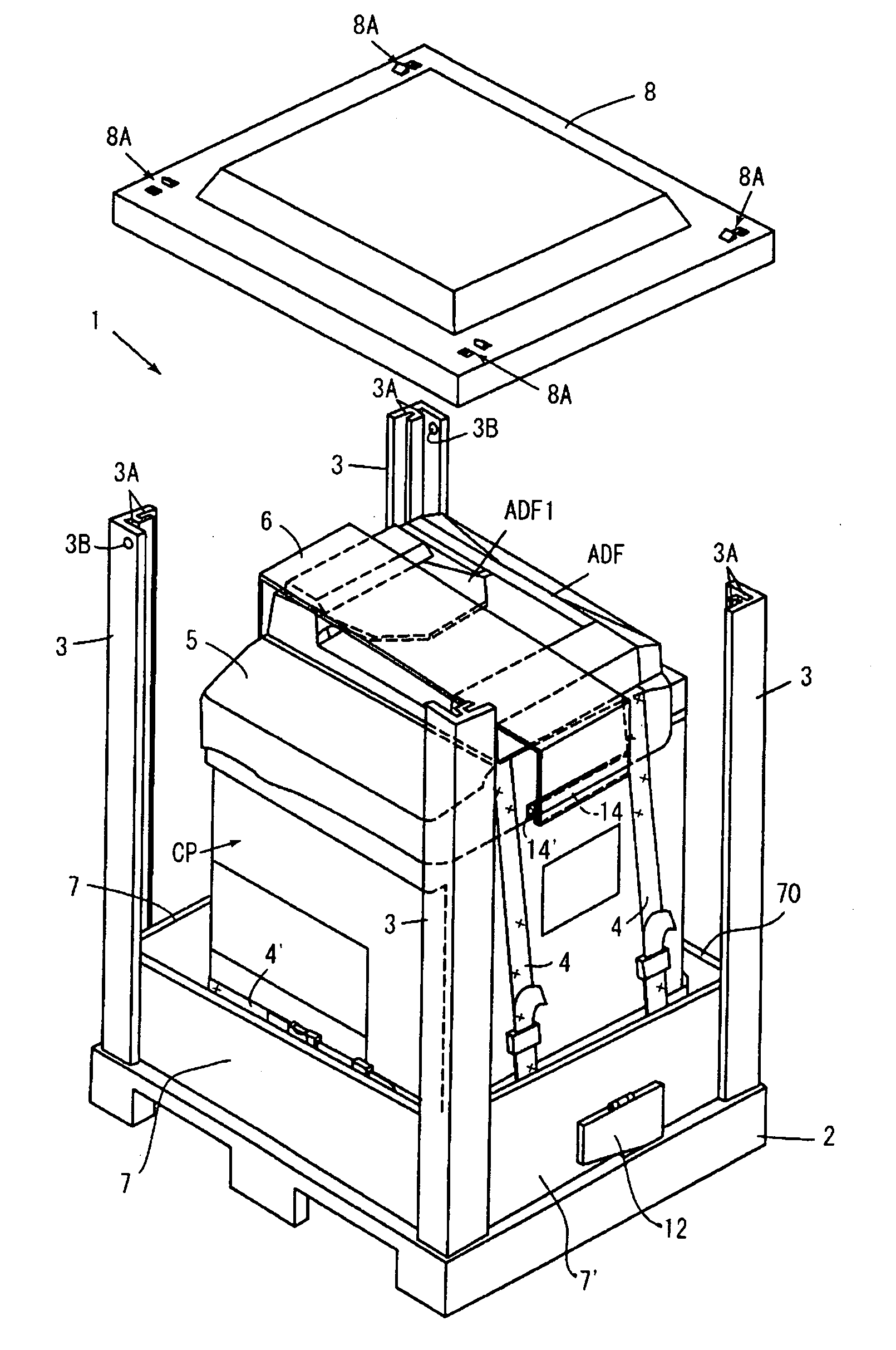

Box for packing glass plate and packing and unpacking method

A glass plate packaging box capable of transferring large-sized glass plates for flat panel displays (liquid crystal displays, plasma display panels, etc.) highly efficiently and with stabilized quality without scratching or soiling their surfaces and capable of efficiently performing packaging operation. A glass plate packaging box includes a box body which includes therein a mount (2) for placing glass plates thereon and which receives a plurality of glass plates on the mount (2) with a sheet inserted between adjacent glass plates. The surface (14) of the mount (2) for placing glass plates thereon is inclined. A top plate (4), front plate (5) and opposite plates (7) which constitute the box body can be mutually attached and removed, and the front plate (5) and opposite plate (7) can be attached and removed with respect to a bottom plate (3).

Owner:ASAHI GLASS CO LTD

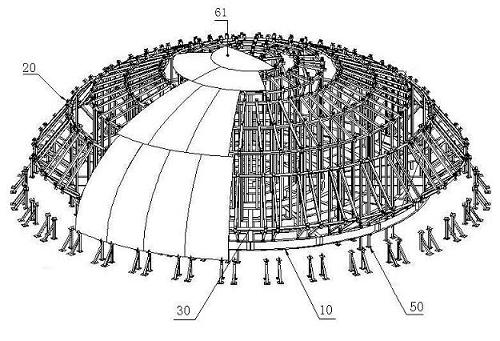

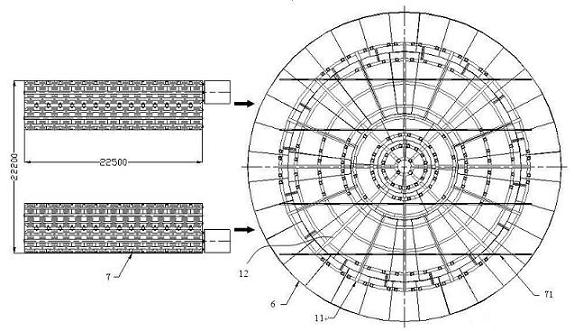

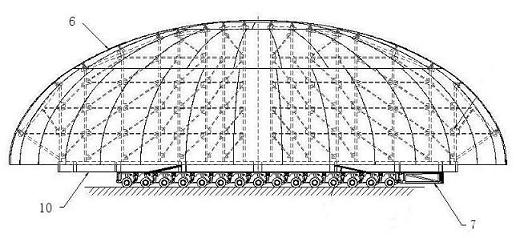

Special supporting device of cover head of nuclear island containment vessel made of steel and transportation method

ActiveCN102689736AControl deformationSave manpower and material resourcesExternal framesLoading/unloadingConcentric ringWork period

The invention relates to a special supporting device of large-scale equipment and a transportation method, in particular to a special supporting device of a cover head of a nuclear island containment vessel made of steel and a transportation method. The special supporting device comprises a platform, a support and edge fixing rods, the support and the edge fixing rods are fixed on the platform, the platform is a plane formed by a plurality of concentric rings radially connecting with connecting rods, the support is of an integral structure formed by a group of supporting structures mounted on the concentric rings, a circular ring beam is arranged at the top end of each supporting structure, adjusters are arranged on each circular ring beam, each adjuster butts against the inner wall of the cover head, and the edge fixing rods encircle the periphery of the platform. The transportation method includes: disposing the cover head on the platform and the support before transportation and checking and fastening the adjusters on the support to ensure the adjusters to contact with the cover head; and integrally transporting the platform and the support back to an assembly workshop and resetting short upright columns after finishing hoisting of the cover head. Deformation of the cover head can be controlled. Additionally, labor power and material resources are saved while working period is shortened effectively by the aid of the transportation way of integral transportation and integral resetting.

Owner:CHINA NUCLEAR IND FIFTH CONSTR CO LTD

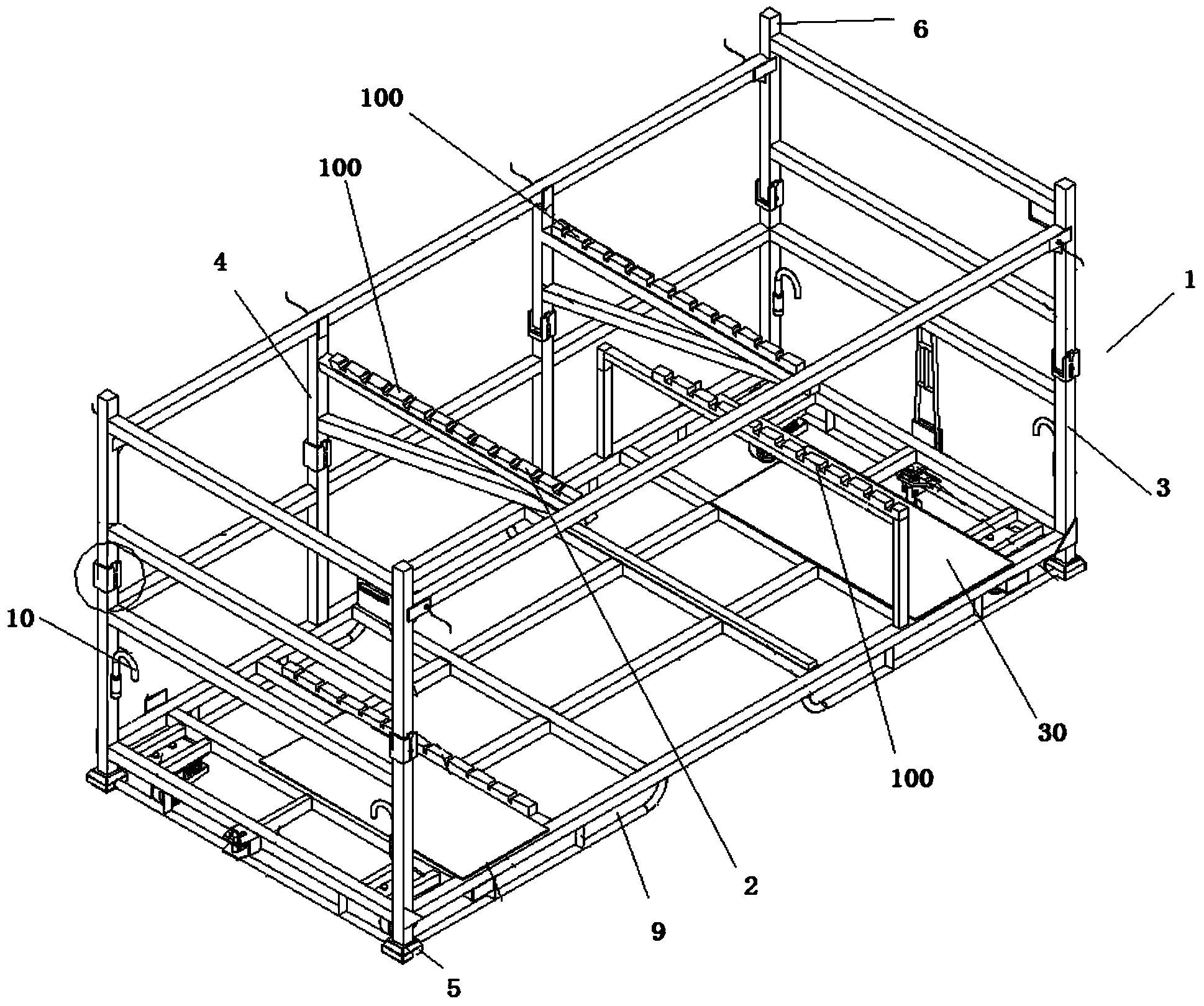

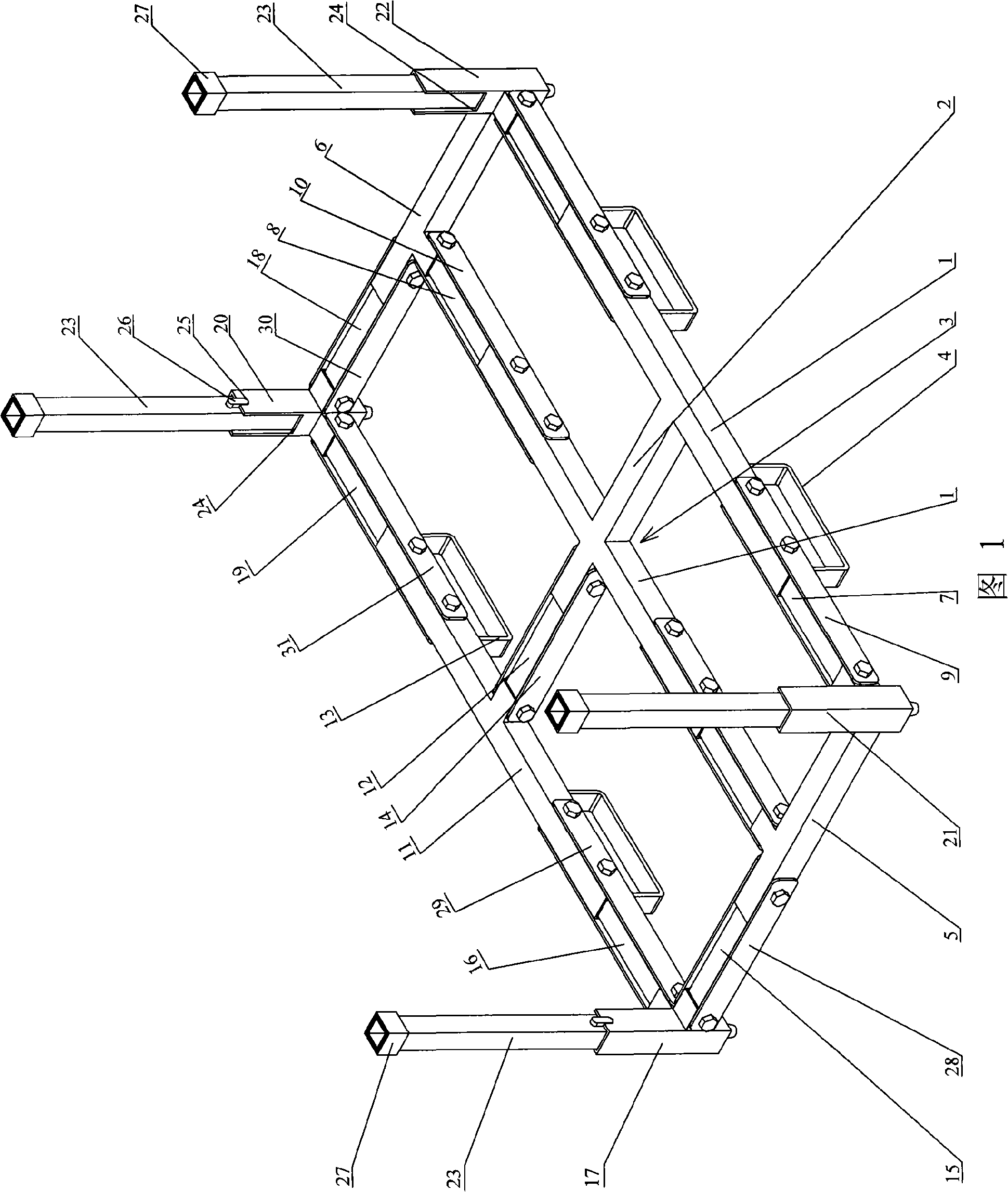

Novel flexible transposition platform shared by multiple plates

ActiveCN103723370APlace morePrecise positioningPackaging vehiclesContainers for machinesEngineeringMechanical engineering

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

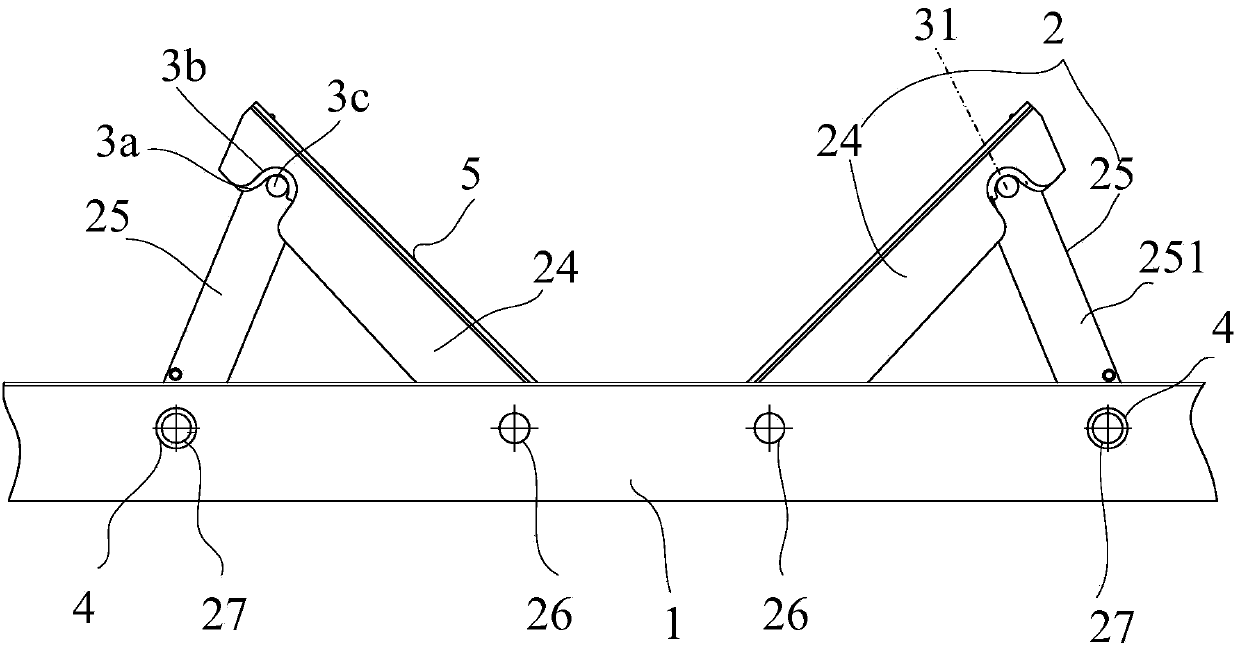

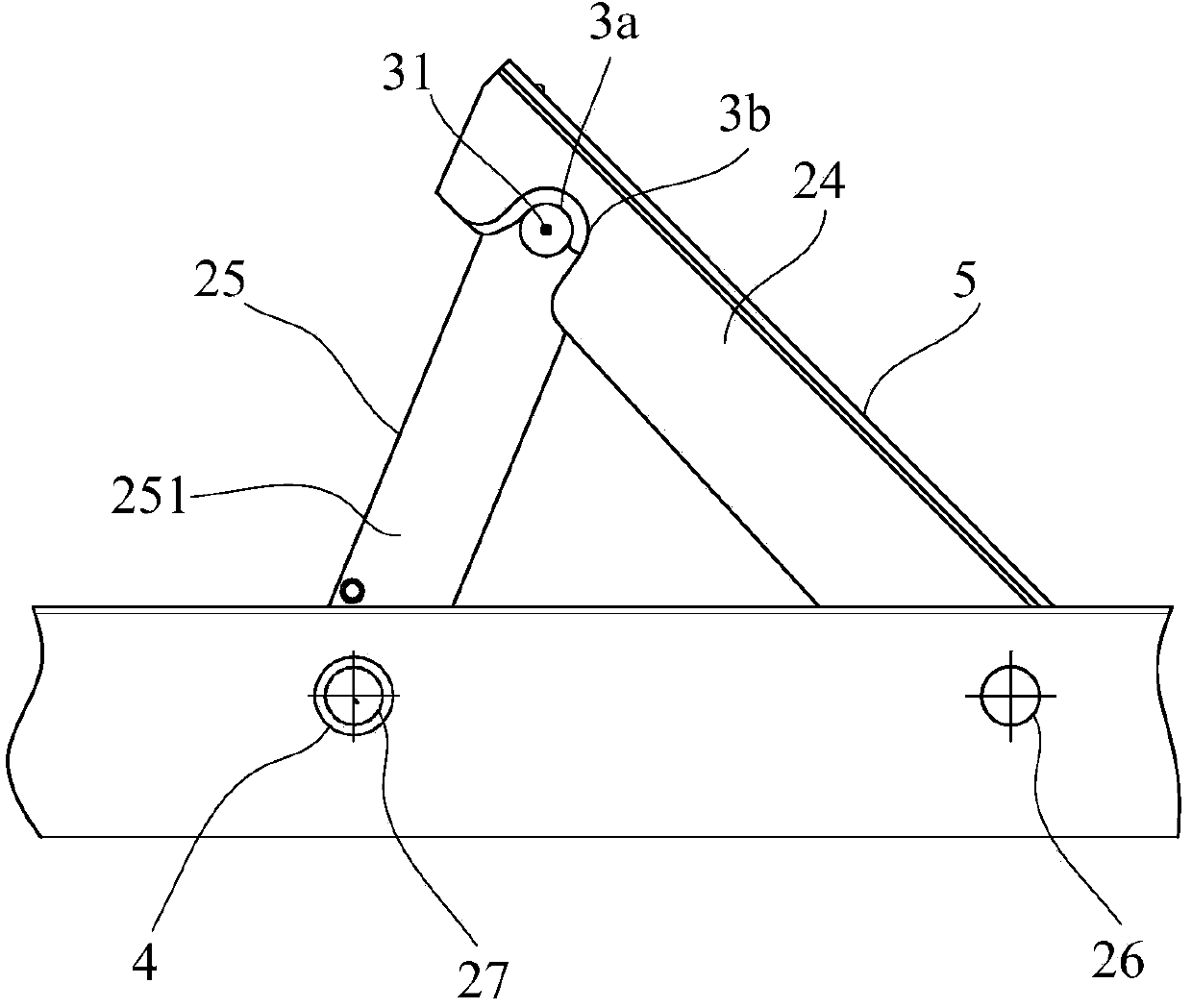

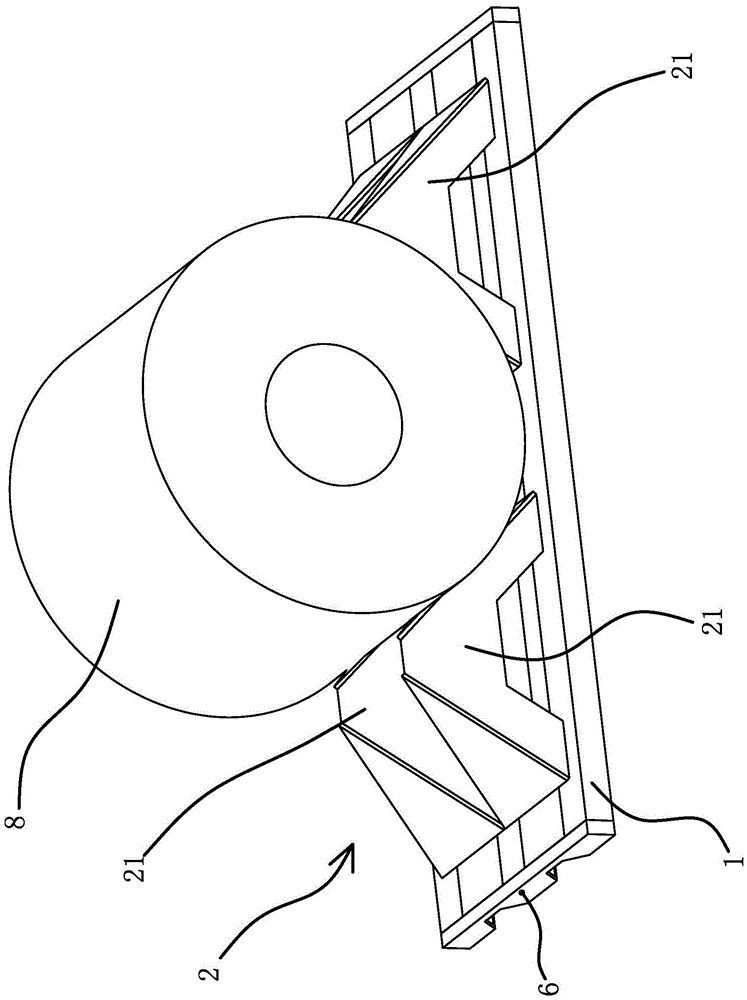

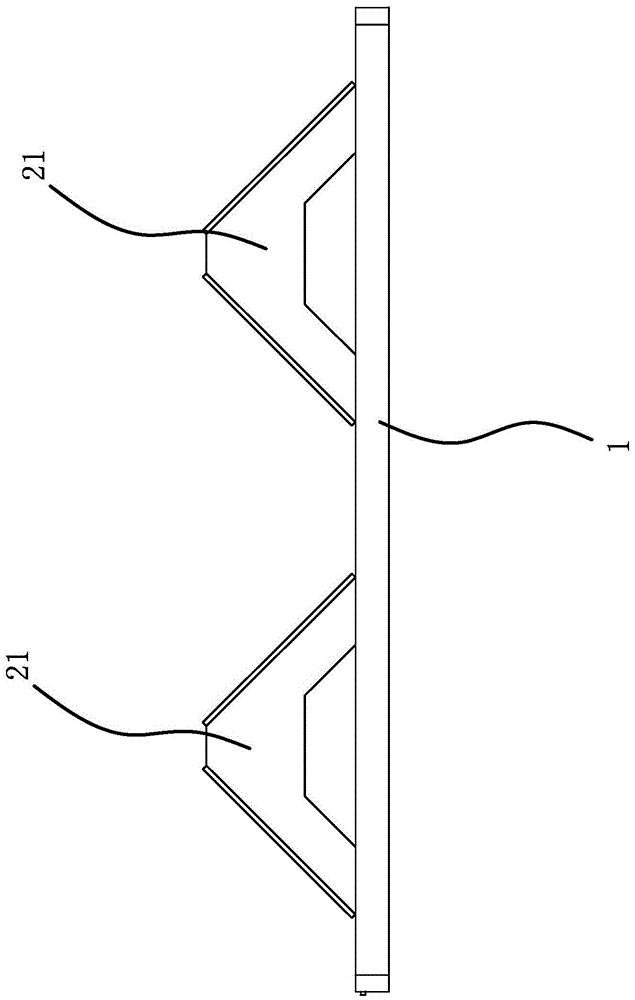

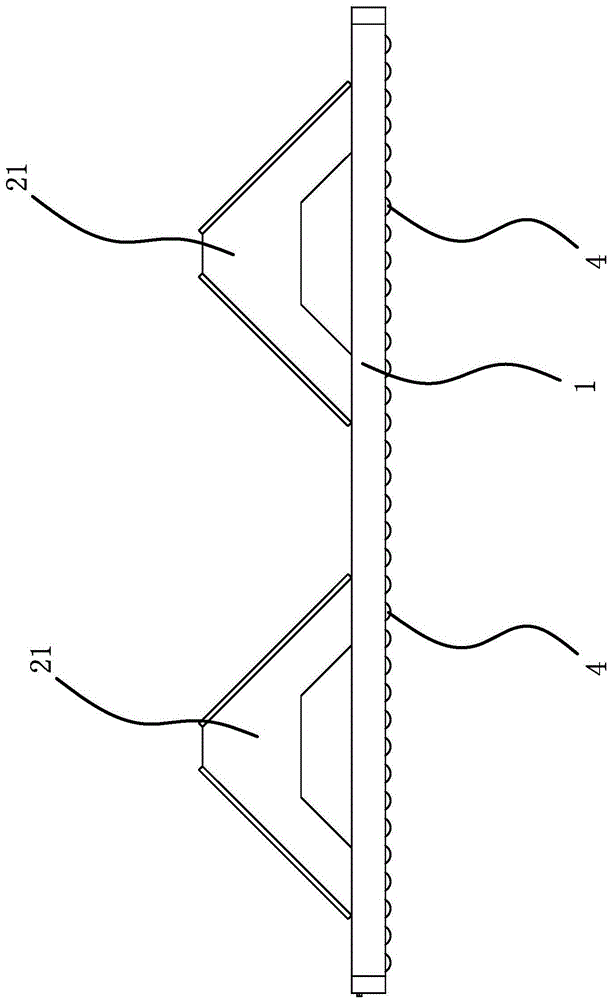

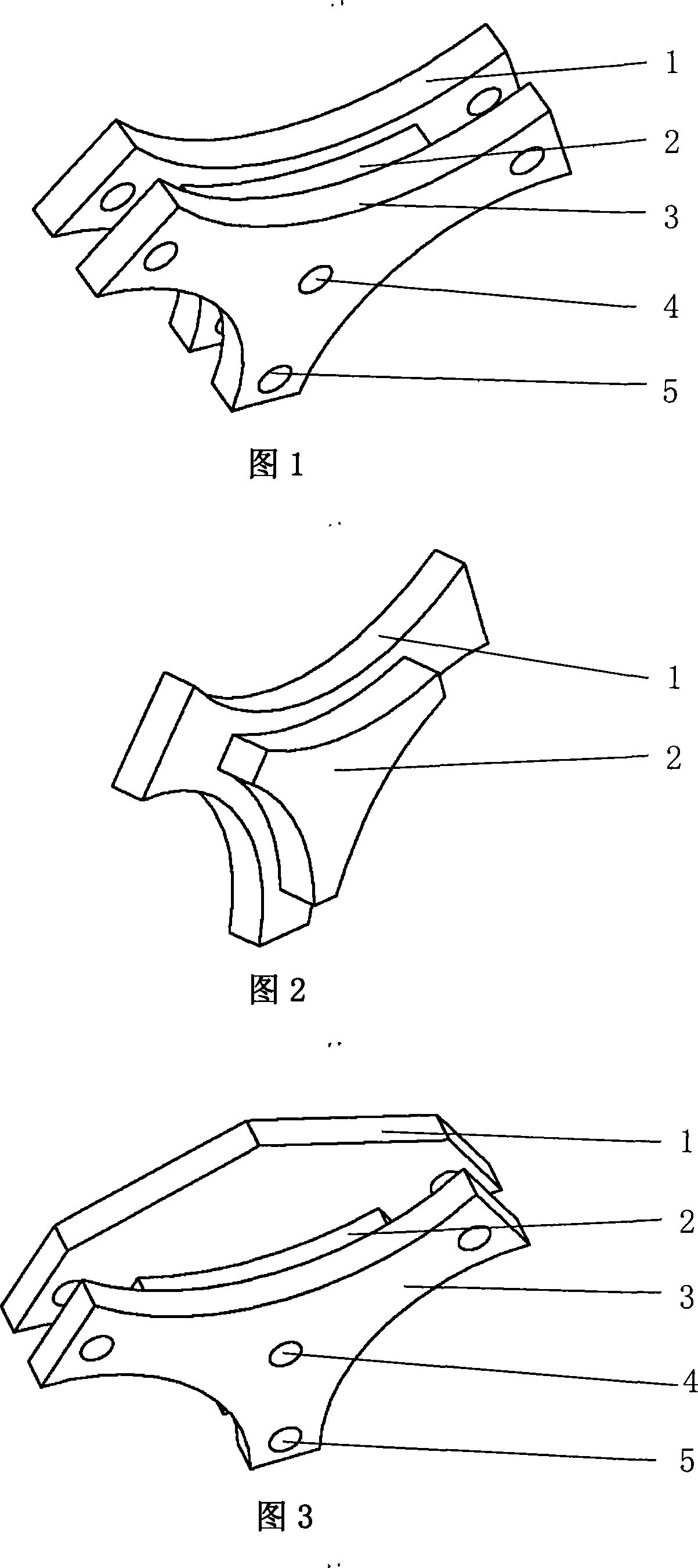

Foldable bearing saddle of steel coil transportation container

InactiveCN103662384AMeet shipping requirementsEasy flipExternal framesStructural engineeringEngineering

The invention provides a foldable bearing saddle of a steel coil transportation container. The foldable bearing saddle comprises a supporting seat and at least one pair of V-shaped brackets arranged on the supporting seat, each V-shaped bracket comprises a bearing beam and a supporting beam, first rotating shafts and second rotating shafts are arranged on the supporting seat, the bottom end of each bearing beam is hinged to the supporting seat through the corresponding first rotating shaft, and the bottom end of the supporting beam is hinged to the supporting seat through the corresponding second rotating shaft. The top end of each supporting beam is matched with the top end of the corresponding bearing beam in an inserted connection manner, and each bearing beam and the corresponding supporting beam are in the shape of an inverted V. The bearing beams of each pair of V-shaped brackets are arranged oppositely to form a V-shaped clamping bracket. The V-shaped clamping brackets can play a role in limit on rolling of columnar cargos, when ordinary dry cargos such as briquettes, bagged bulk cargos and the like are transported, the bearing beams are rotated clockwise to enable the supporting beams to retreat from bearing beam insertion grooves, then the supporting beams are rotated clockwise to horizontal positions, the bearing beams are rotated anticlockwise to the horizontal positions, the upper plane of each bearing beam is flush with the upper plane of the supporting seat, and transportation requirements of ordinary dry bulk cargos are met; the foldable bearing saddle is easy to turn over and operate, less prone to separation and high in reliability.

Owner:CRRC QIQIHAR ROLLING CO LTD

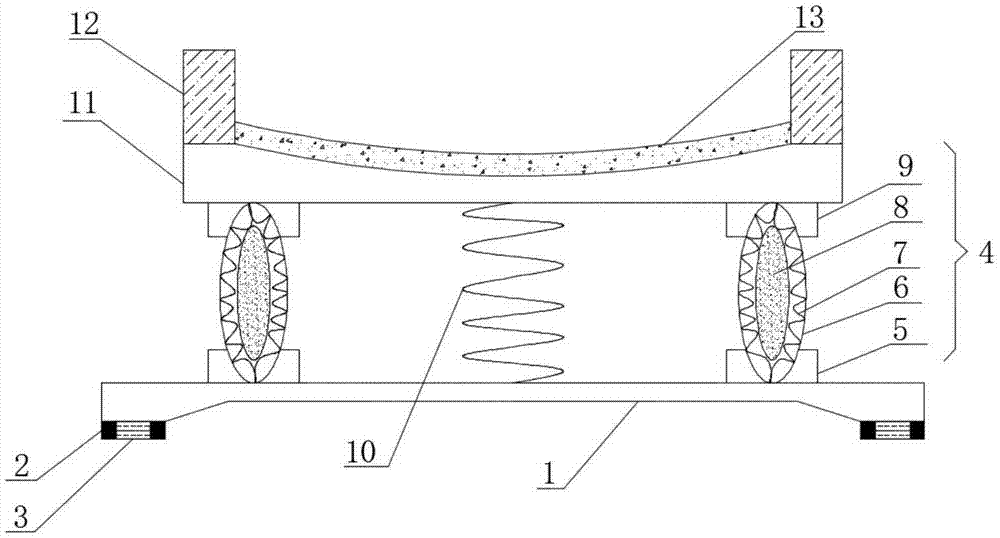

Glass transportation device

InactiveCN106864986AAvoid damageImprove protectionExternal framesContainers to prevent mechanical damageEngineeringAirbag

The invention discloses a glass transportation device, which comprises a base, a shock absorbing device and a placement plate. Both left and right sides of the upper part of the base are connected with a shock absorbing device. The shock absorbing device includes an air bag base, and the lower side of the air bag base It is fixedly connected with the upper part of the base, the upper part of the airbag base is fixedly connected with the airbag casing, the inner side of the airbag casing is provided with an airbag, the upper part of the airbag casing is fixedly connected with the top seat of the airbag, and the top part of the airbag top seat is placed The lower part of the board is fixedly connected, the base and the middle part of the placement board are fixedly connected with load-bearing springs, and the left and right sides of the upper end surface of the placement board are provided with limit blocks. Generally speaking, the present invention has a simple structure and can effectively reduce the Small vibration can protect the glass very well and is suitable for popularization.

Owner:CHONGQING CITY FULING DISTRICT XIONGXIANG PAPER PROD CO LTD

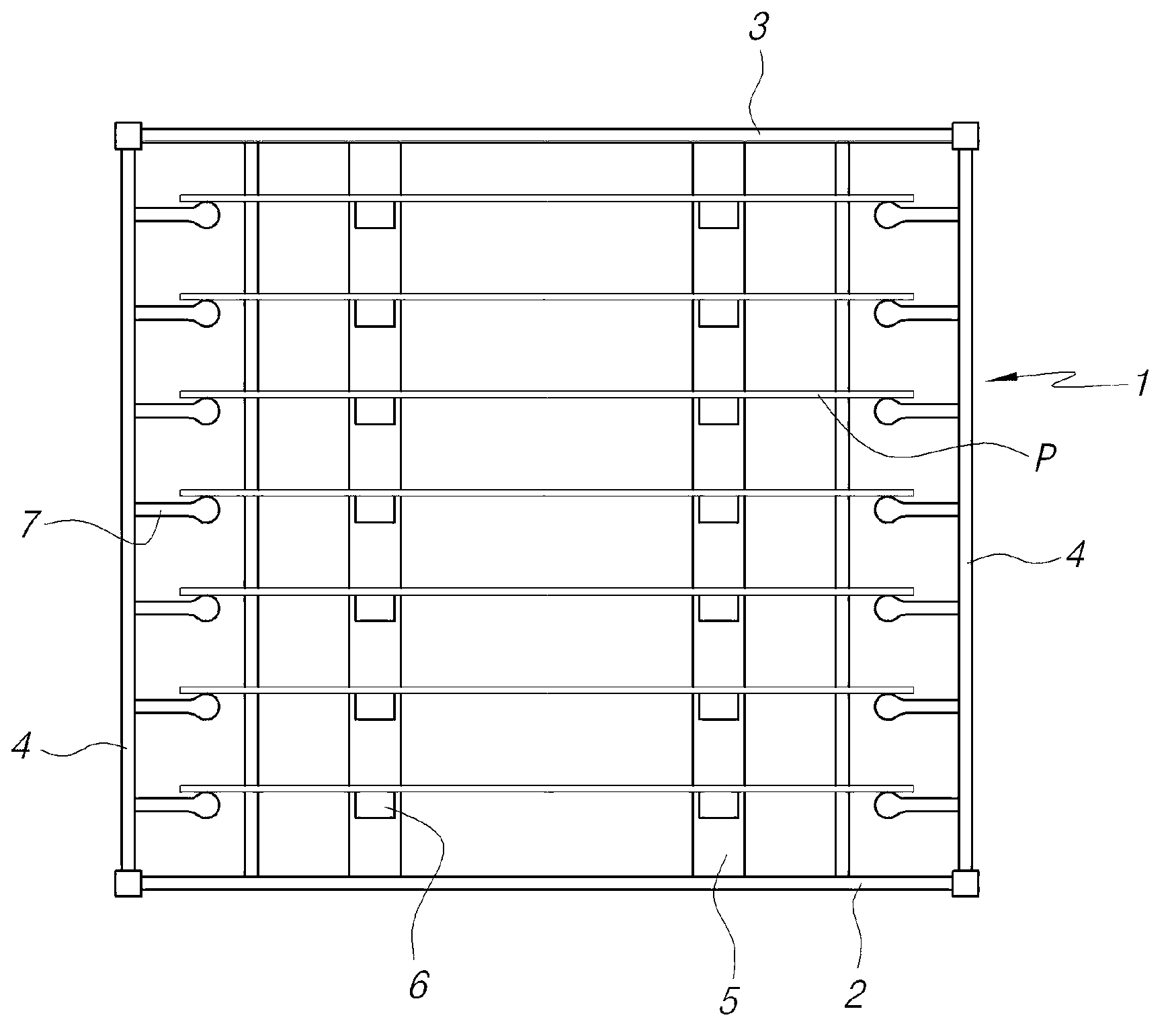

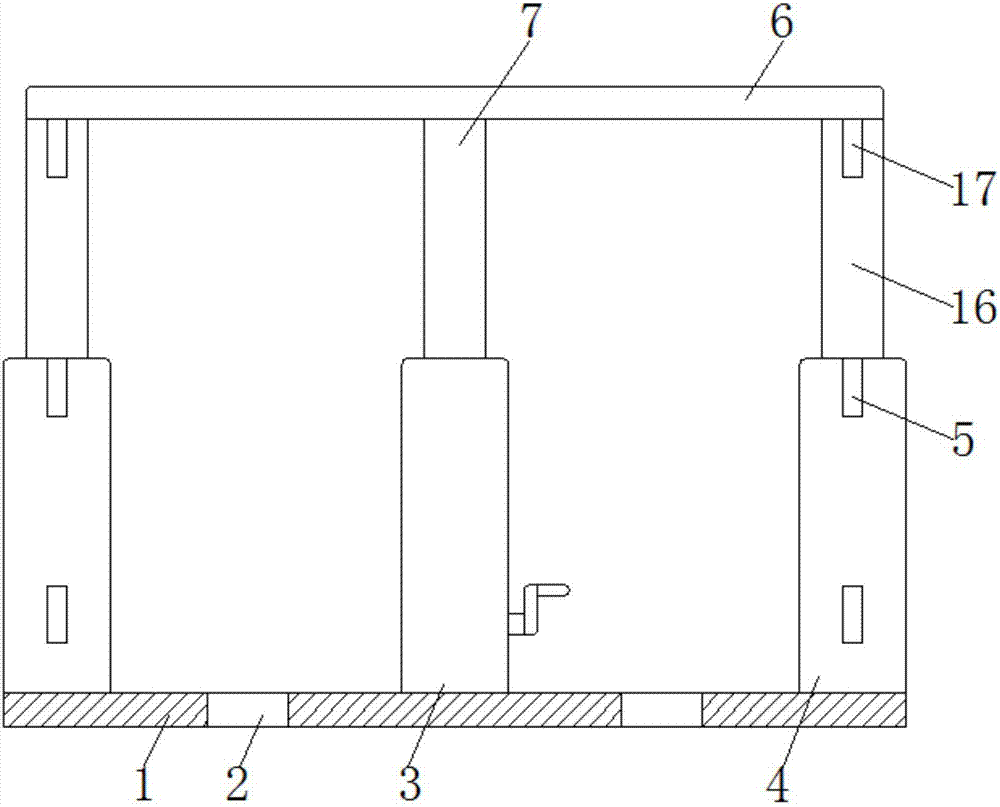

Combined type material rest

InactiveCN101327858AReduce labor intensityIncrease flexibilityExternal framesVariable capacity containersBody shapeChinese characters

Owner:刘明春

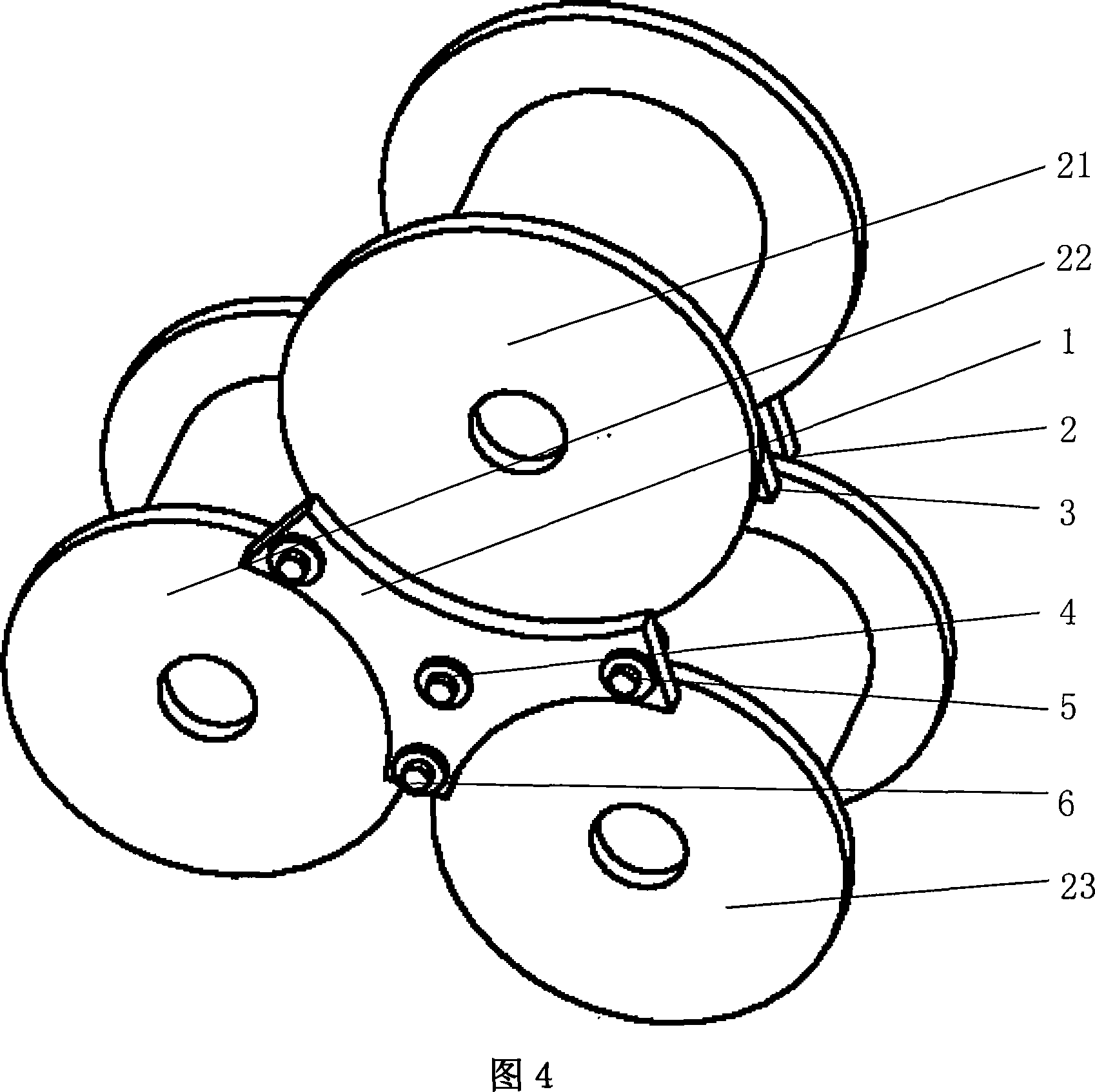

Placing rack for textile winding drum

InactiveCN107310844ASolve the problem of not having lifting functionImprove practicalityContainers for annular articlesExternal framesArchitectural engineeringThreaded rod

The invention discloses a placing frame for textile rolls, which comprises a base, and casings are fixedly connected to both sides of the top of the base, and a lifting rod is penetrated through the inner cavity of the casing, and the top of the lifting rod penetrates To the outer side of the casing, a fixing plate is fixedly connected between the tops of the two lifting rods, and first hooks are fixedly connected to the tops of the front side and the rear side of the lifting rods. The present invention is provided with base, installation hole, shell, casing, second hook, fixed plate, telescopic rod, threaded sleeve, threaded rod, rotating shaft, driven bevel gear, rotating rod, connecting rod, handle, driving bevel gear , sliding block, lifting rod and the first hook solve the problem that the existing rack for textile rolls does not have the lifting function. This kind of rack for textile rolls has the advantage of lifting function, which facilitates different The use of tall users improves the practicability of the existing rack for textile rolls and is worth popularizing.

Owner:SUZHOU YUANLING TEXTILE CO LTD

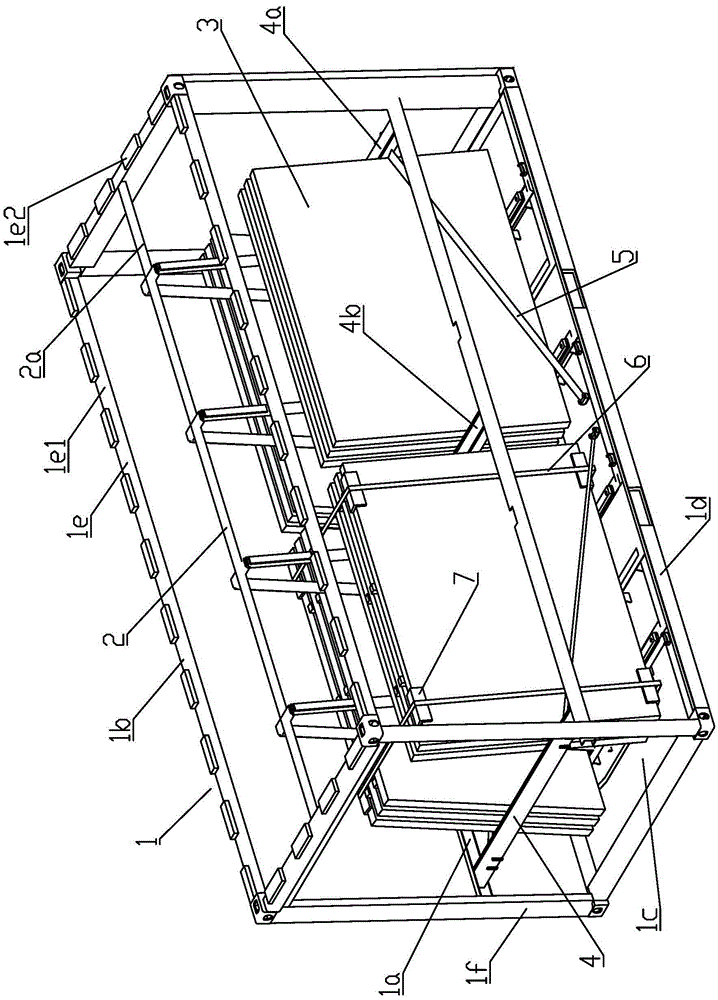

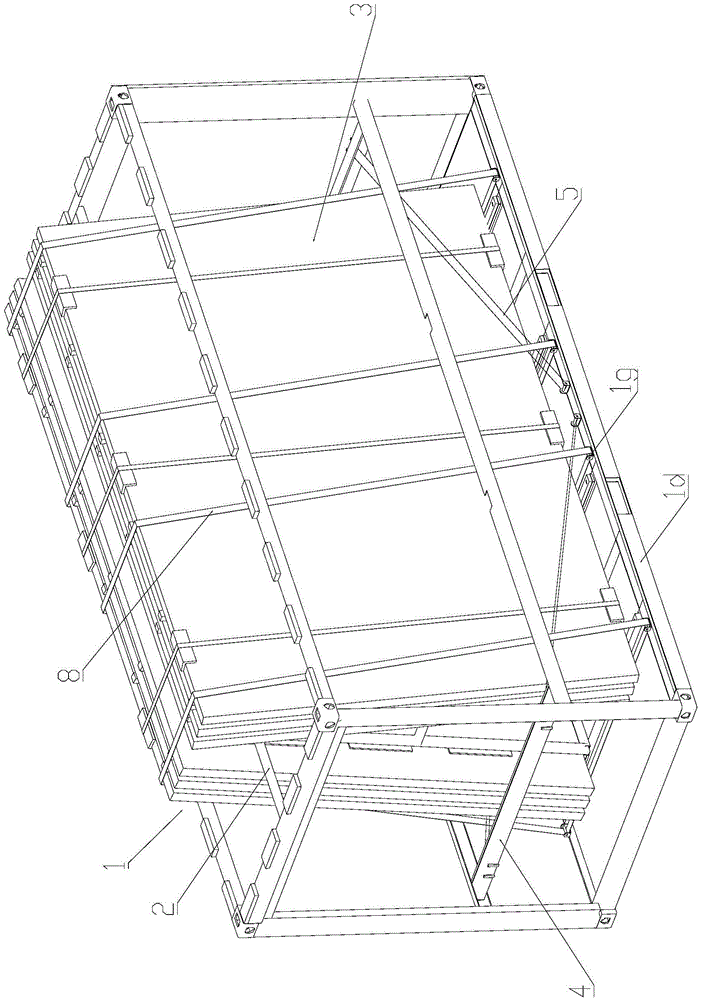

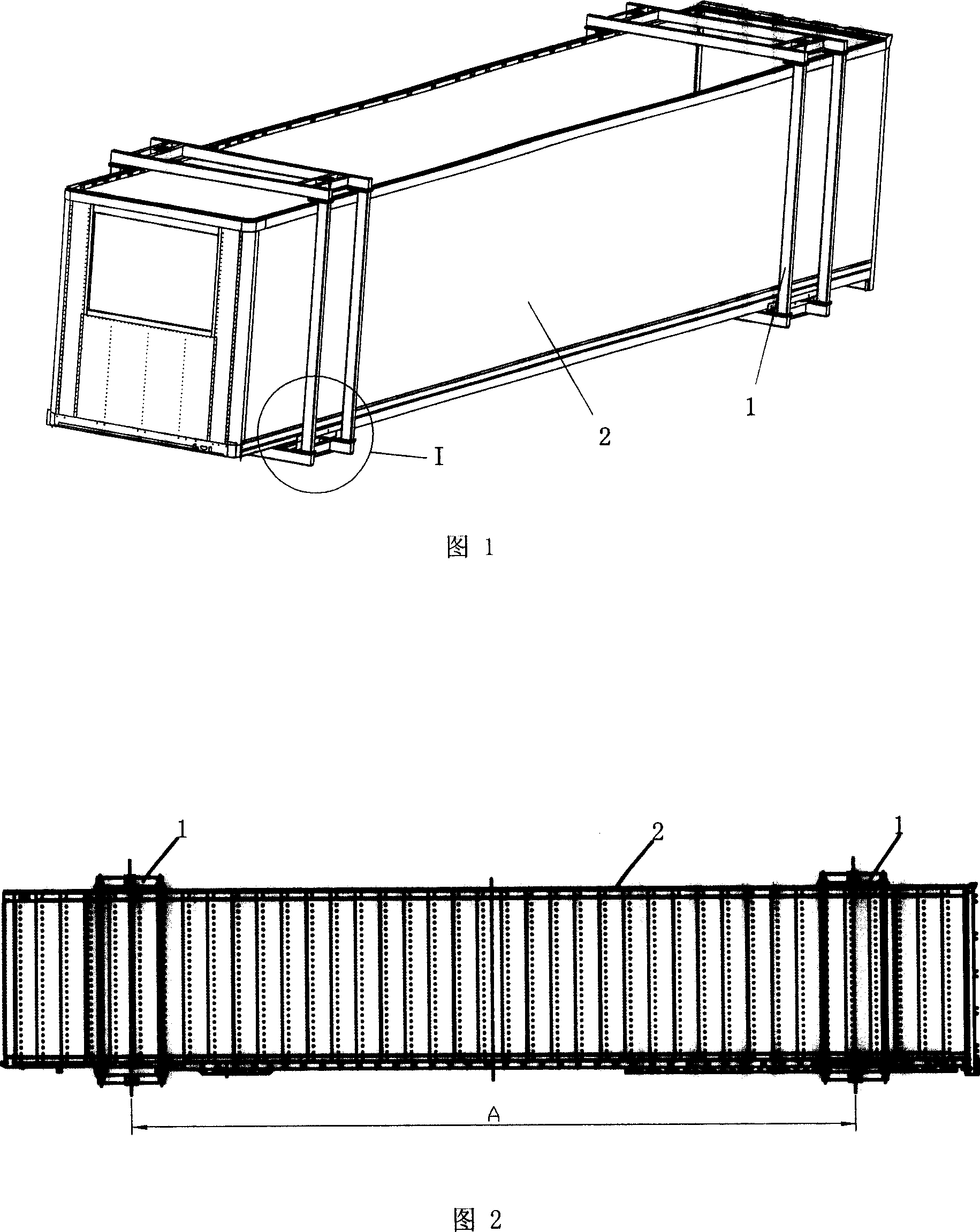

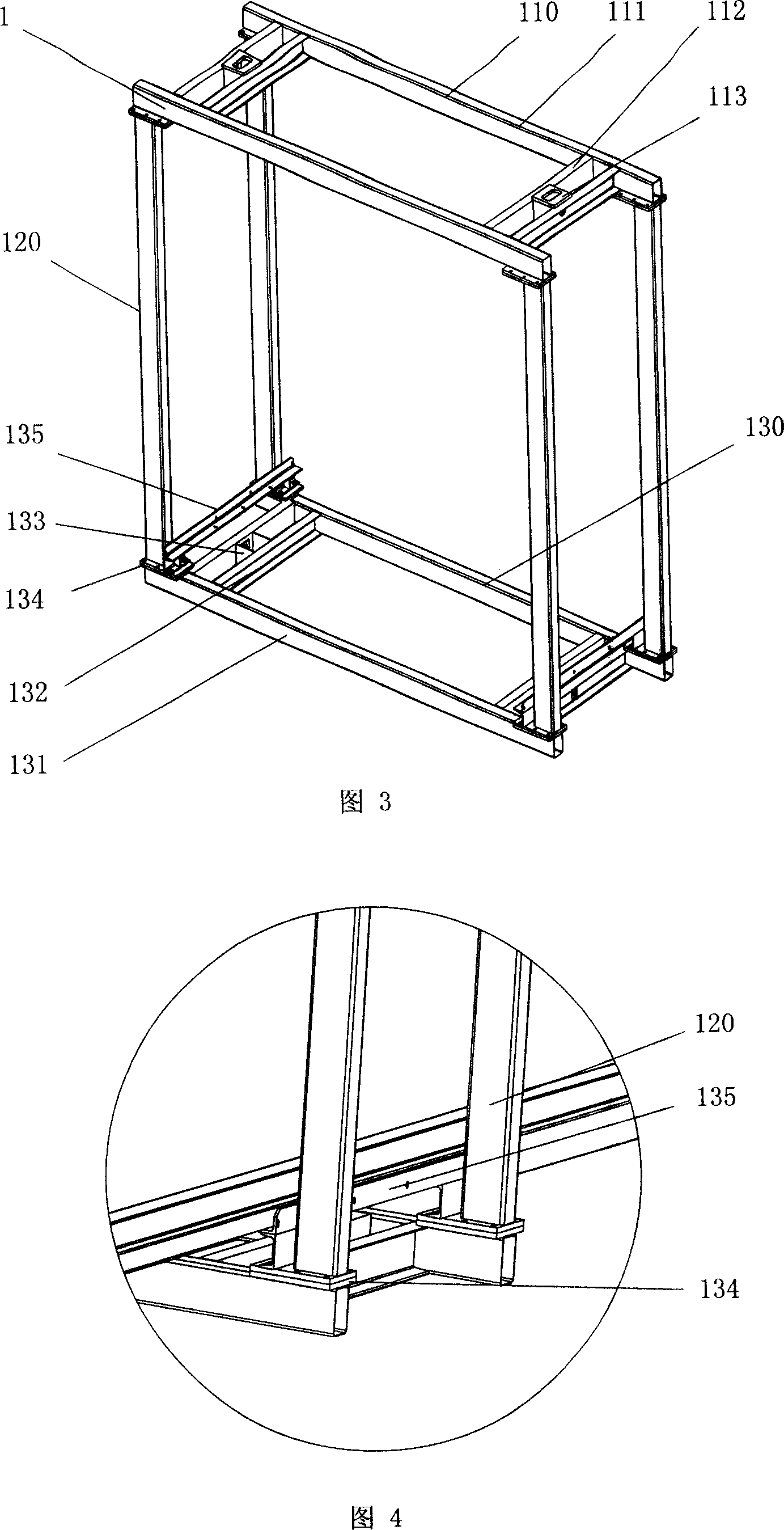

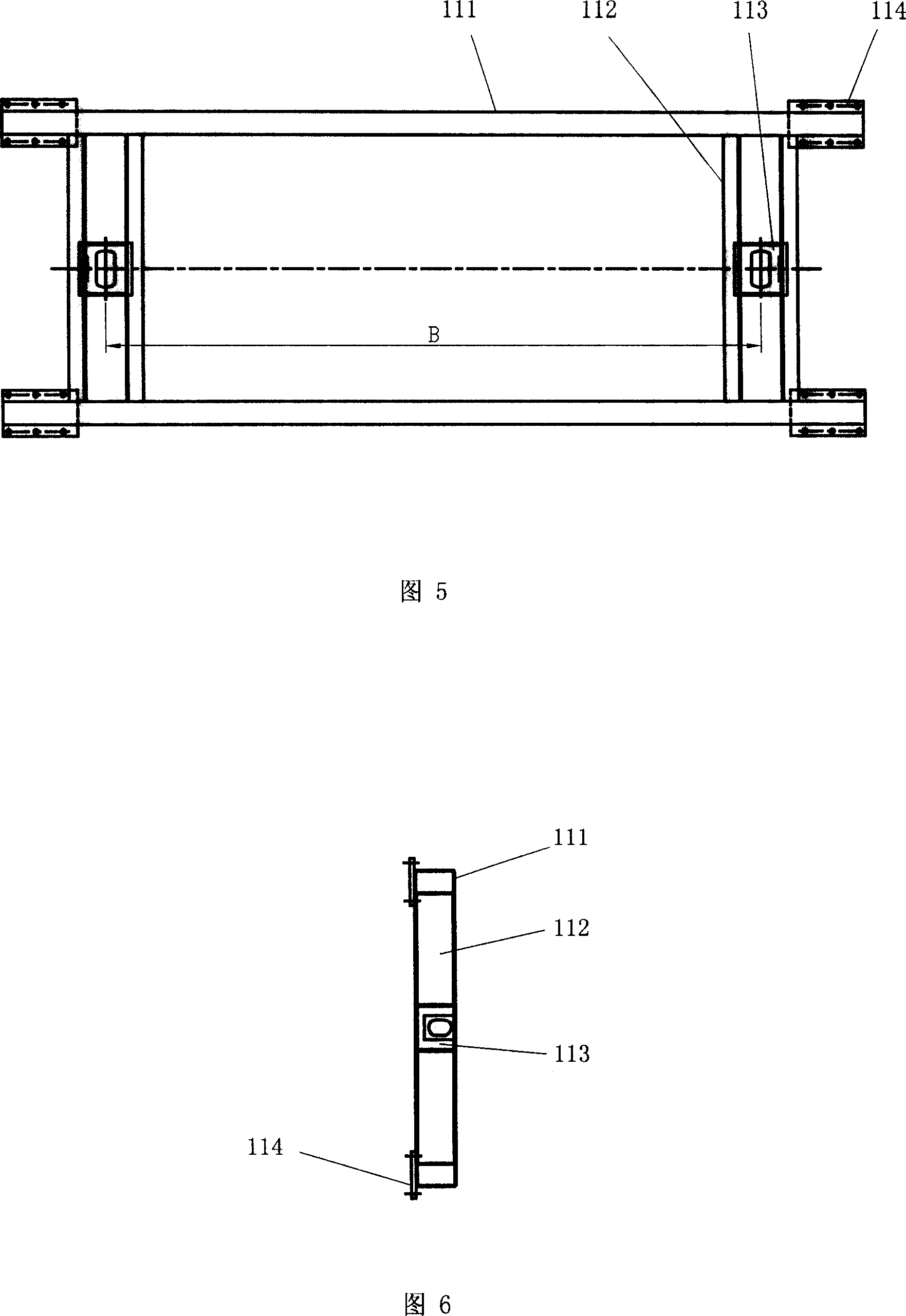

Transportation frame for big cabinet, and installation method

InactiveCN101092205AEasy to operateImprove transportation efficiencyPackage recyclingLarge containersTransit systemEngineering

Owner:CHINA INTERNATIONAL MARINE CONTAINERS (GROUP) CO LTD +1

Tray used for steel coil transportation

ActiveCN105600134AEasy to transfer and transportEasy to transportExternal framesRigid containersEngineeringMechanical engineering

The invention provides a tray used for steel coil transportation, and belongs to the technical field of transportation. The tray solves the technical problem that an existing movable tray is not suitable for bearing steel coils. The tray comprises a tray frame and a limiting frame arranged on the tray frame and used for positioning a steel coil. At least two long-strip-shaped installation grooves are formed in the bottom of the tray frame. Long-strip-shaped rolling wheel frames are arranged in the installation grooves. A plurality of rolling wheels are connected to the rolling wheel frames in the length direction of the rolling wheel frame. Guide structures capable of guiding the rolling wheel frames to move up and down relative to the tray frame and limiting structures capable of preventing the rolling wheel frames from being disengaged from the installation grooves are arranged on the portions, located in the installation grooves, on the tray frame. Gas bags are arranged in the installation grooves and located above the rolling wheel frames. The whole rolling wheels can be located in the installation grooves when the gas bags are not inflated. The gas bags can act on the rolling wheel frames to make the rolling wheels stretch out of the installation grooves when the gas bags are inflated and expanded. The tray has the advantage that the steel coil can be stably transported.

Owner:ZHEJIANG TOPSUN LOGISTIC CONTROL CO LTD

Handling device for a wind turbine rotor blade having a moldable support pad

A handling device for a rotor blade of a wind turbine e.g. that can be used for lifting, lowering, transporting, or storing the rotor blade includes at least one cradle for supporting the rotor blade and a moldable support pad secured to the cradle. The moldable support pad includes an outer covering filled with a plurality of granules that act as a fluid when the rotor blade is placed atop the support pad such that a shape of the support pad substantially matches a profile of at least one of the exterior surfaces of the rotor blade.

Owner:GENERAL ELECTRIC CO

Bracket for plate

The invention relates to a support rack for fixing dishes, which comprises a pair of outer side plates and a support plate. The outer side plates and the support plate jointly form three concave grooves used to fix dishes; the support plate is positioned between the pair of outer side plates, the area of the contact surface of the support plate and the outer side plate is less than the area of the plate surface of either of the outer side plates, the outer side plates and the support plate can be of an integral structure and also of a split structure, the support plate and the outer side plates are respectively of the same wood, the same metal casting piece, the same plastics, or the same composite material mouldings, or more than two kinds of material. The invention saves seal plates and the making cost of the seal plates, the packing time of the seal plates, and the transport cost, and reduces the warehouse area occupied by the dishes; the fixing of the contained goods can be more reliable; and the support rack can be recovered to be reused, and can be used in a plurality of fields of coiled materials such as cables, steel wires, glassfiber belts, and ropes, etc.

Owner:NINGBO RUITONG NEW MATERIAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com