Novel flexible transposition platform shared by multiple plates

A plate and transposition technology, applied in the field of transposition table, can solve the problems of lack of versatility of material racks, low work efficiency, and inability of material racks to be stacked.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

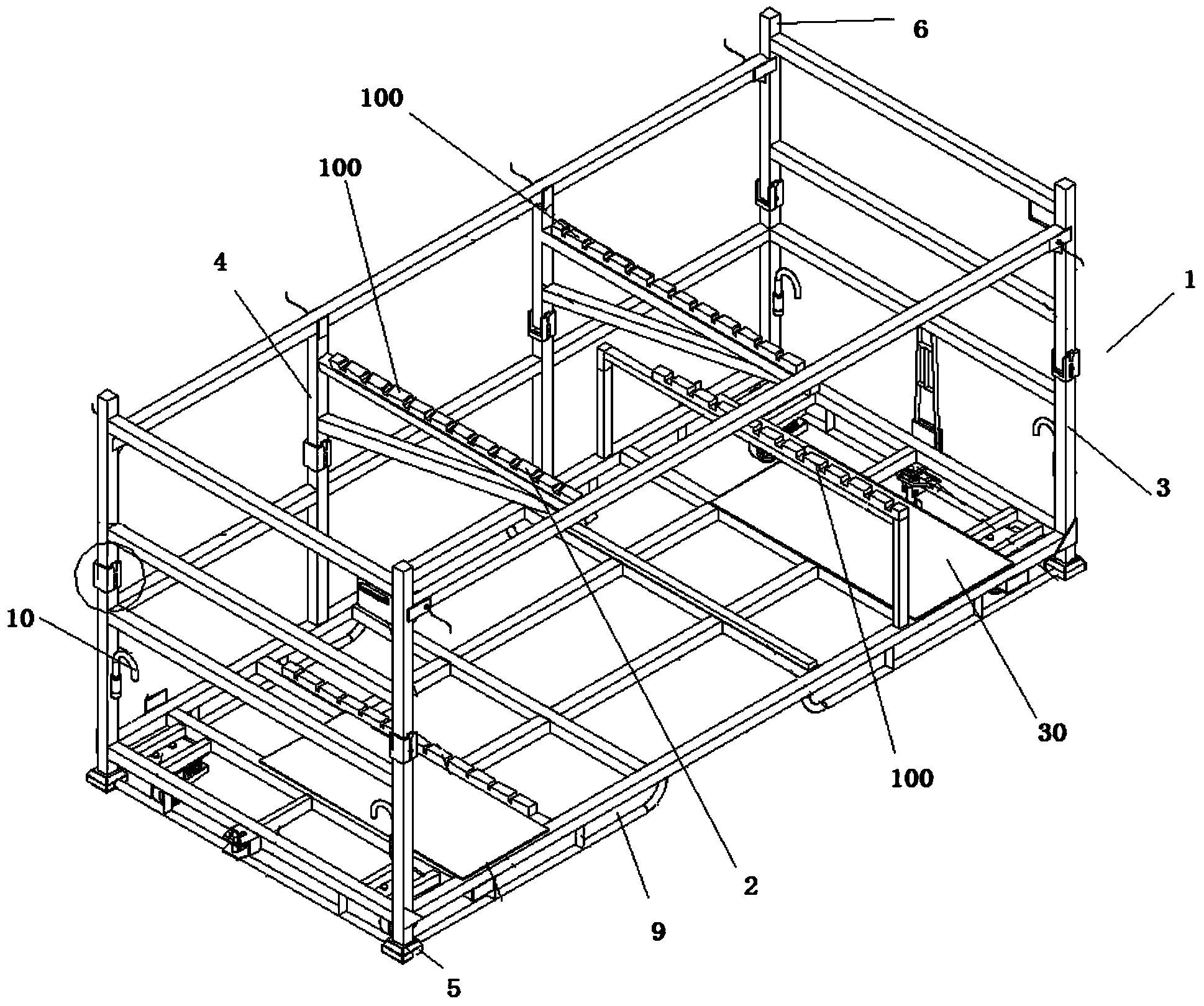

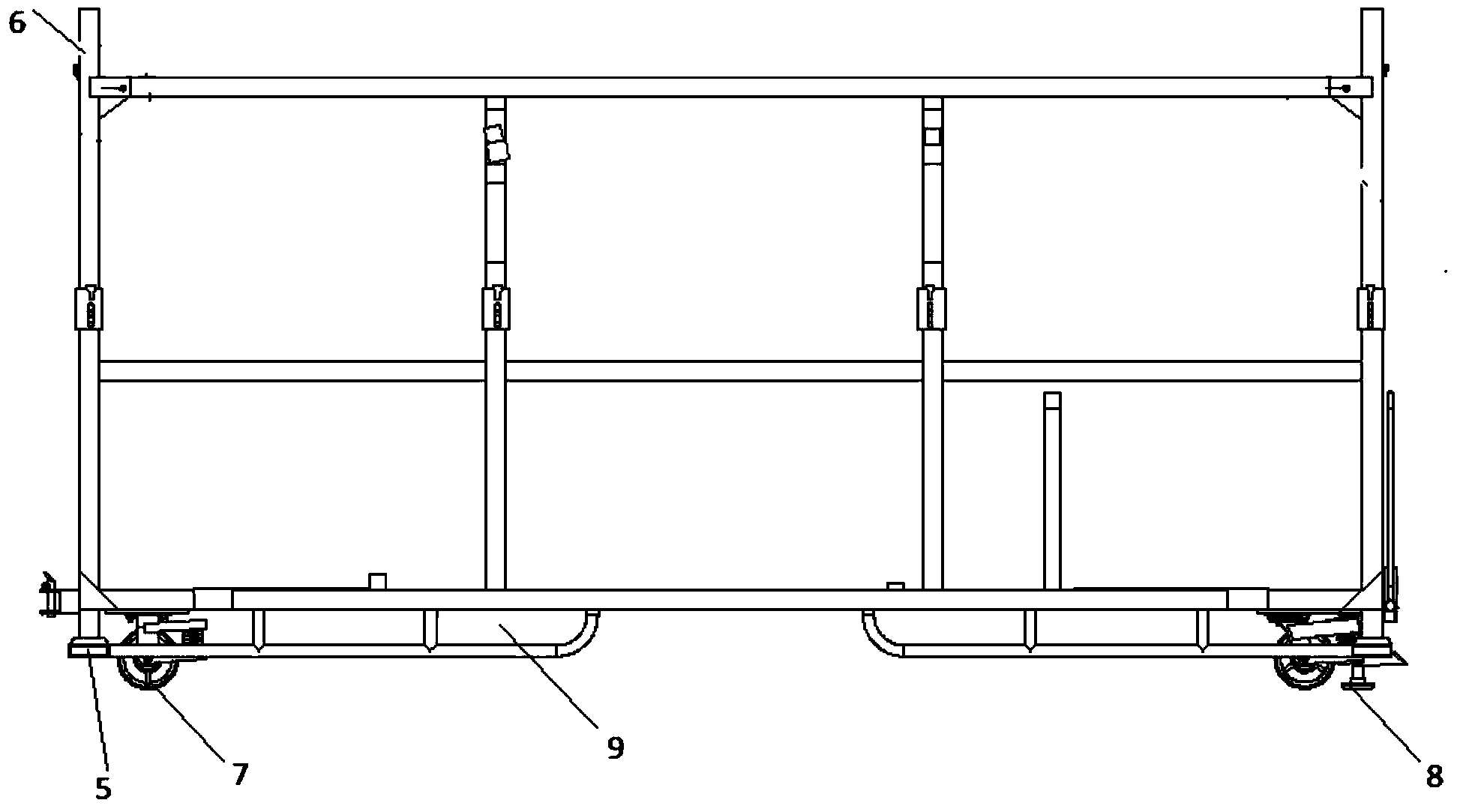

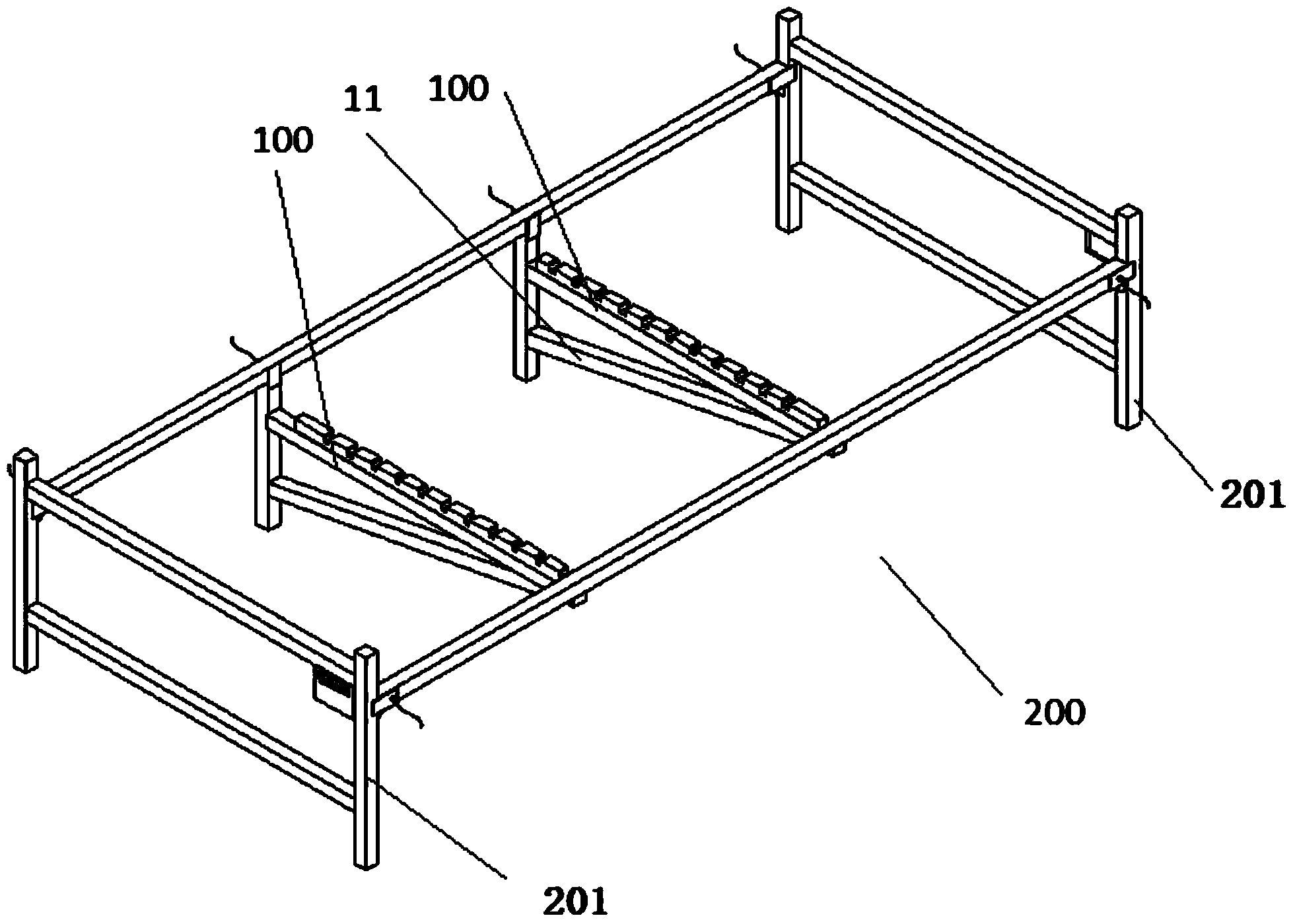

[0026] Such as Figures 1 to 5 As shown, the present invention provides a novel flexible transpose table 1 shared by multiple plates, the transpose table is a cuboid frame composed of columns, beams and longitudinal beams, and the plates are positioned in the cuboid frame, wherein : The transposition table also has a suspension arm 100, and the suspension arm supports the board so as to support and position the board in the cuboid frame.

[0027] In the present invention, a suspension arm device is adopted, which has a supporting effect on the boards to facilitate positioning and support of the boards, so that more types of boards can be placed in the transposition table. Realize the purpose of sharing the transposition table for multiple boards and improving the sharing rate of the transposition table.

[0028] As an optimization of the present invention, there are at least two types of boards, and at least one of the boards is supported and positioned by the suspension arm....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com