Epitaxial wafer carrier of etching and baking equipment

A technology of baking equipment and epitaxial wafers, which is applied in the direction of discharge tubes, electrical components, and post-processing details, etc., can solve the problems of high etching cost and low output, and achieve space saving, increase in quantity, and save etching and baking cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to make the objectives, technical solutions and advantages of the present disclosure clearer, the embodiments of the present disclosure will be further described in detail below with reference to the accompanying drawings.

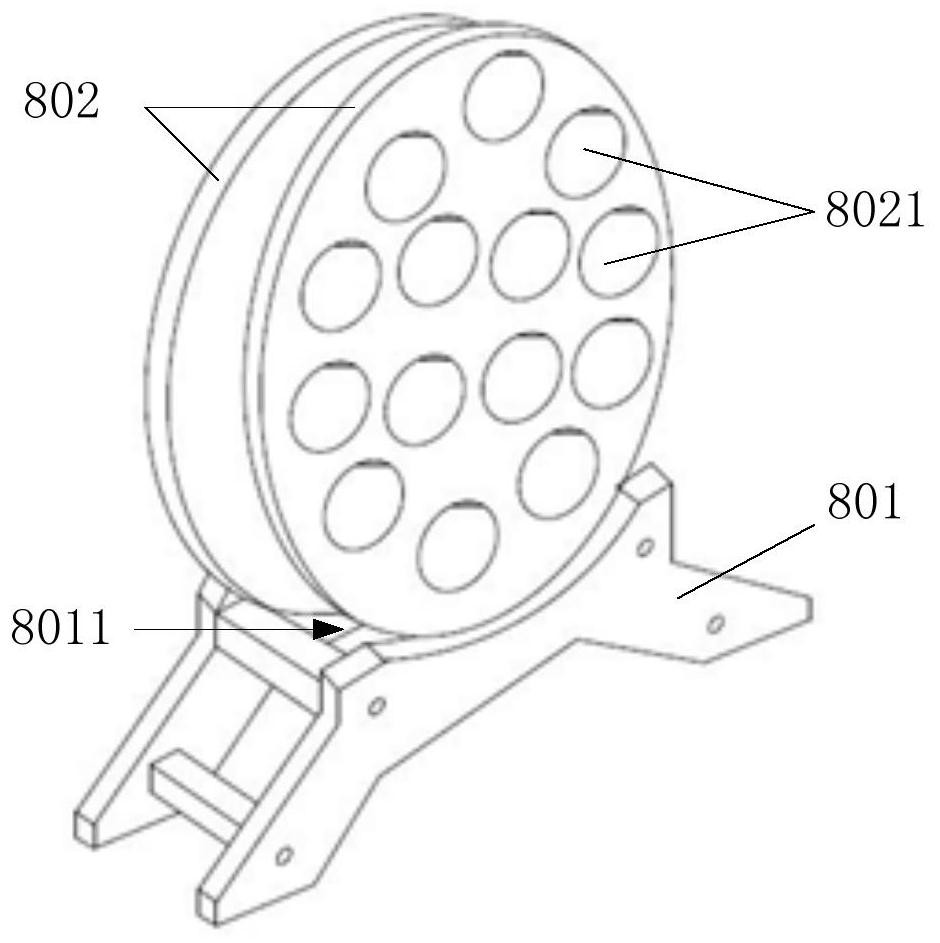

[0054] figure 1It is a schematic structural diagram of an etching wafer carrier in the related art provided by the embodiment of the present disclosure. see figure 1 , the etching wafer carrier includes a base 801 and a graphite disk 802 . The base 801 is provided with a groove 8011, and two graphite discs 802 can be placed in the groove 8011. There are 14 sheet grooves 8021 evenly distributed on the disk surface of the graphite disk 802 on the same horizontal plane, and each sheet groove 8021 can accommodate one sheet of 4-inch PSS. like figure 1 As shown, two graphite disks 802 are placed on the groove 8011 in a vertical position opposite to each other. The PSSs placed on the graphite disk 802 are all facing outward to fully contact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com