Bracket for plate

A technology of trays and support boards, applied in the field of tools, can solve the problems of wood consumption, increased transportation costs, increased sealing costs and packaging man-hours, etc., to achieve the effect of reducing warehouse area and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

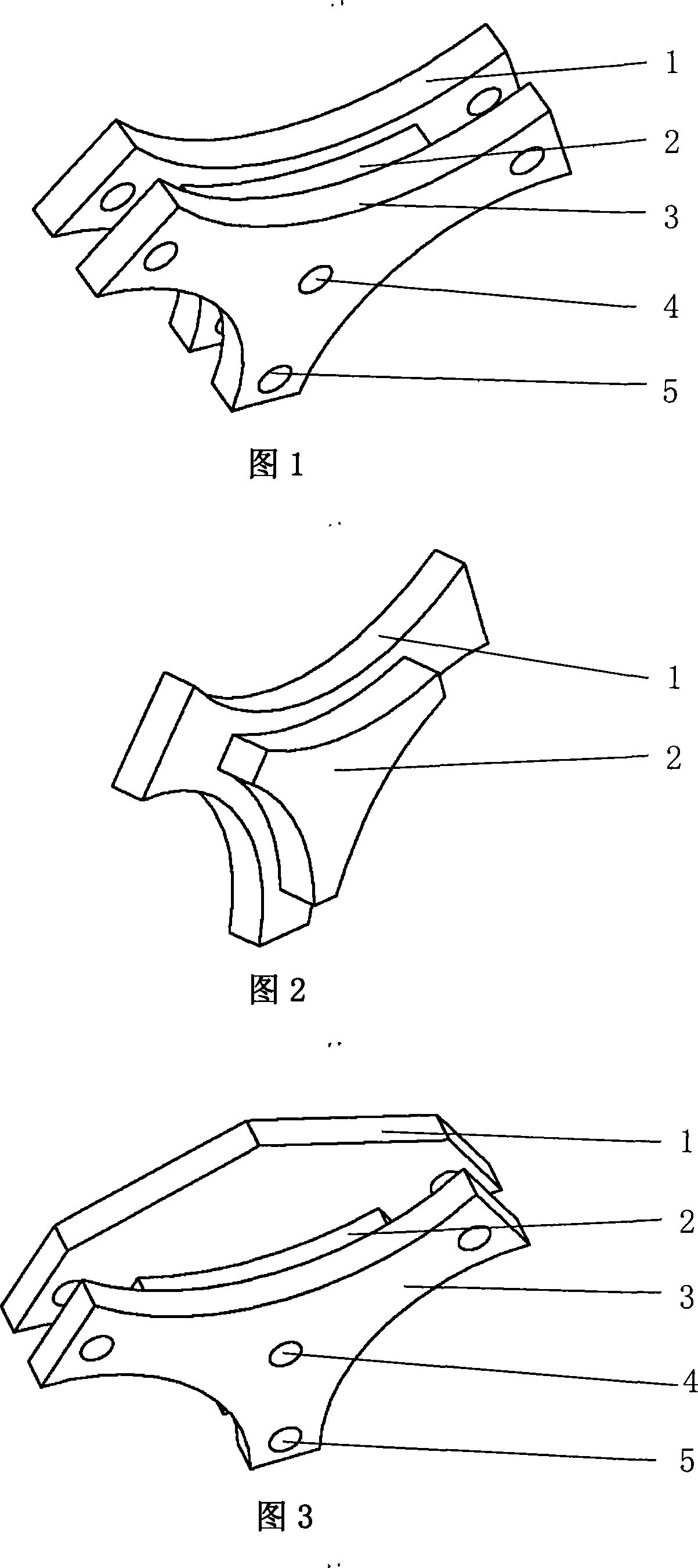

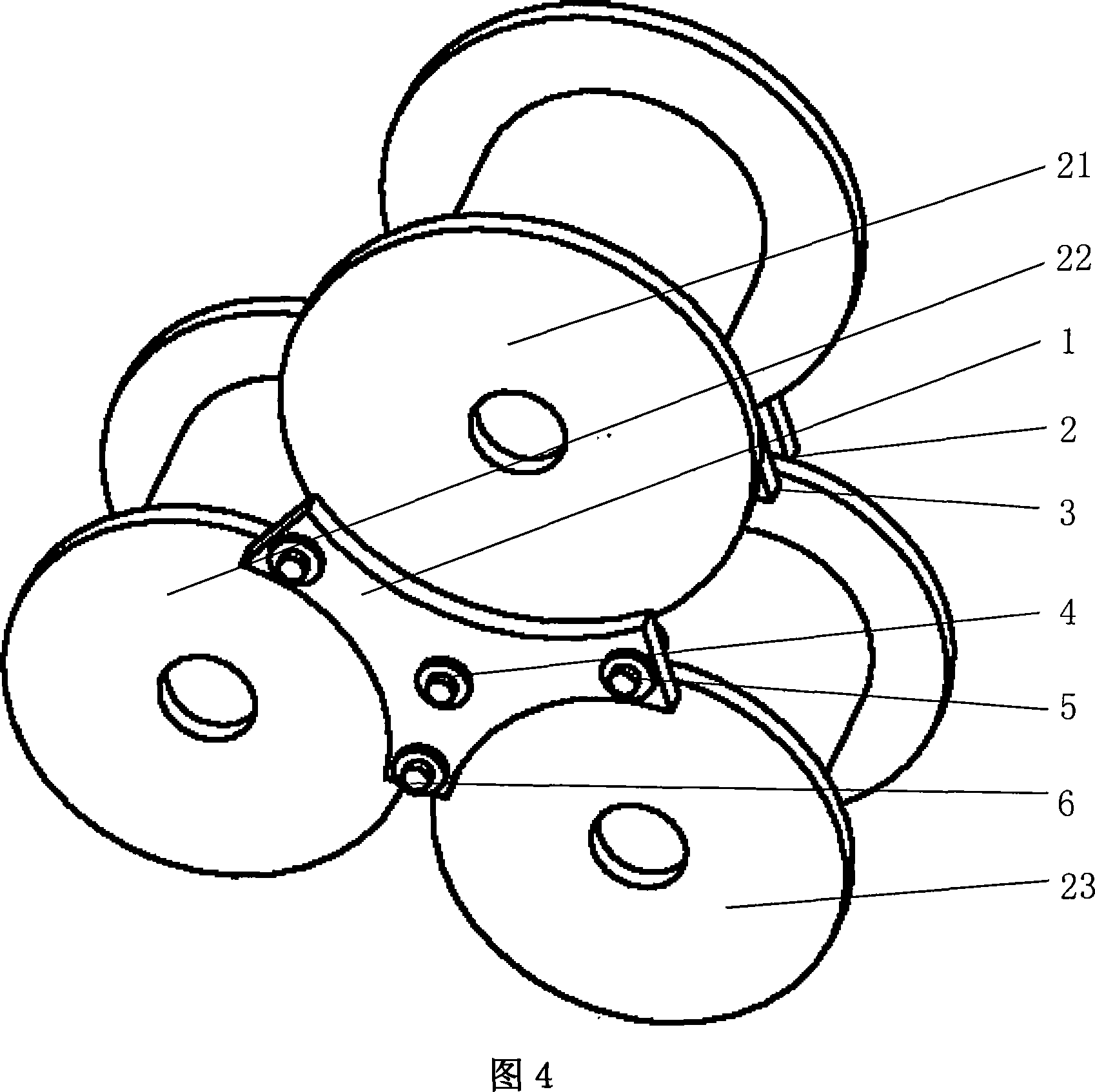

Embodiment 1

[0015] See Figure 1 and Figure 2 for details. The tray support is composed of a pair of outer plates (1, 3) and a supporting plate 2; a pair of outer plates and a supporting plate 2 together form three grooves, and the supporting plates are located in a pair of Between the outer plates, the area of the surface of the support plate in contact with the outer plate is smaller than the area of any outer plate surface in contact with it. The edge of the support plate 2 is in a circular arc shape and can be in good contact with the edge of the disk; a pair; The outer panels are of the same shape and the same size. The outer panels and the support panels are combined. They are made of hard wood. In order to make the bracket stronger, a central fixing hole 4 is set in the relative position of the outer panel and the support panel. And surrounding fixing holes 5, of course, the center fixing hole and surrounding fixing holes can be set as many as needed. For metal casting parts, the ce...

Embodiment 2

[0017] See Figure 3 for details. It is basically the same as Embodiment 1, except that it is an integral structure. The outer plate and the support plate are iron castings that are completed at one time. The shape and size of a pair of outer plates are not exactly the same. The height of one side plate is even greater. High, so that it can be placed on the outside of the reel, making the reel more neatly stacked.

[0018] Of course, in any of the above embodiments, the outer side plate and the support plate can also be made of the same material molded from engineering plastics; they can also be made of different materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com